Patents

Literature

40results about How to "Increase the speed of flame spread" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

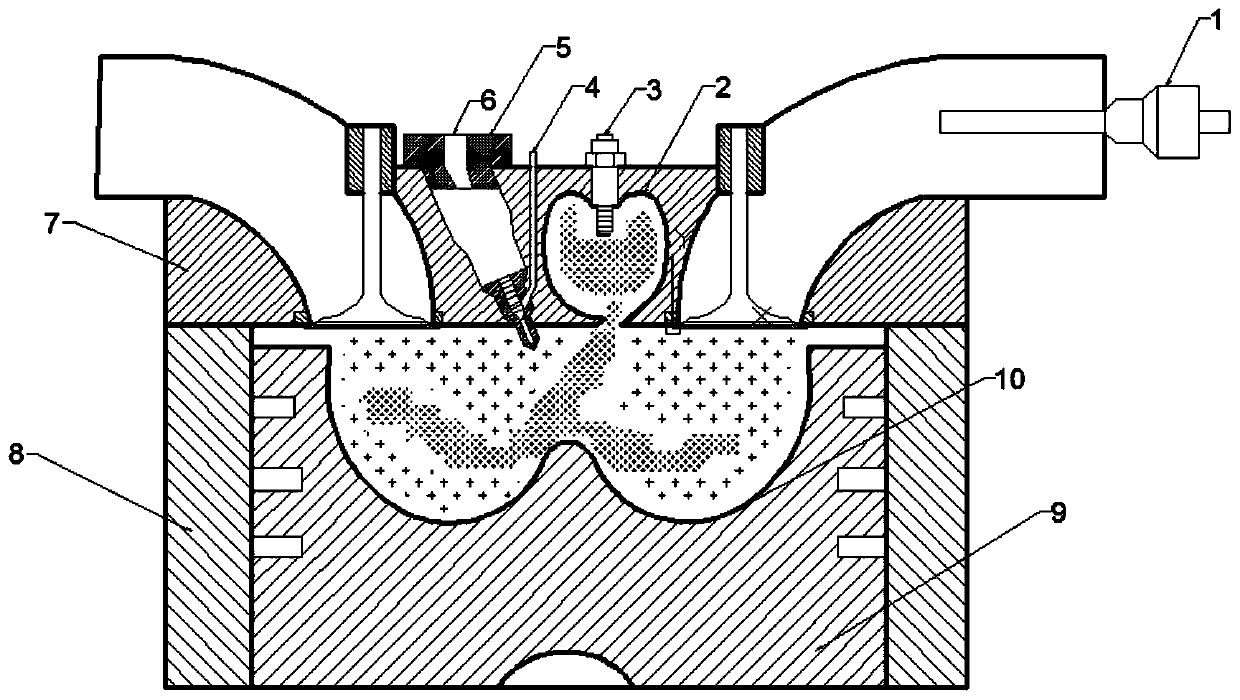

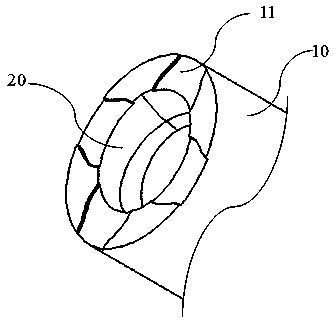

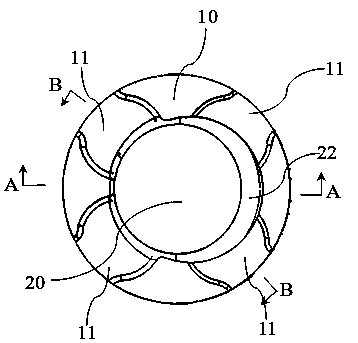

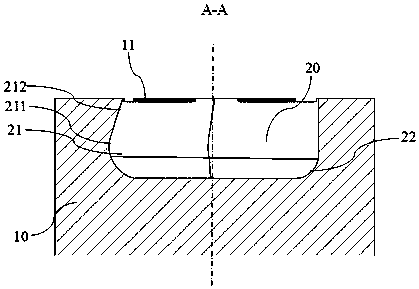

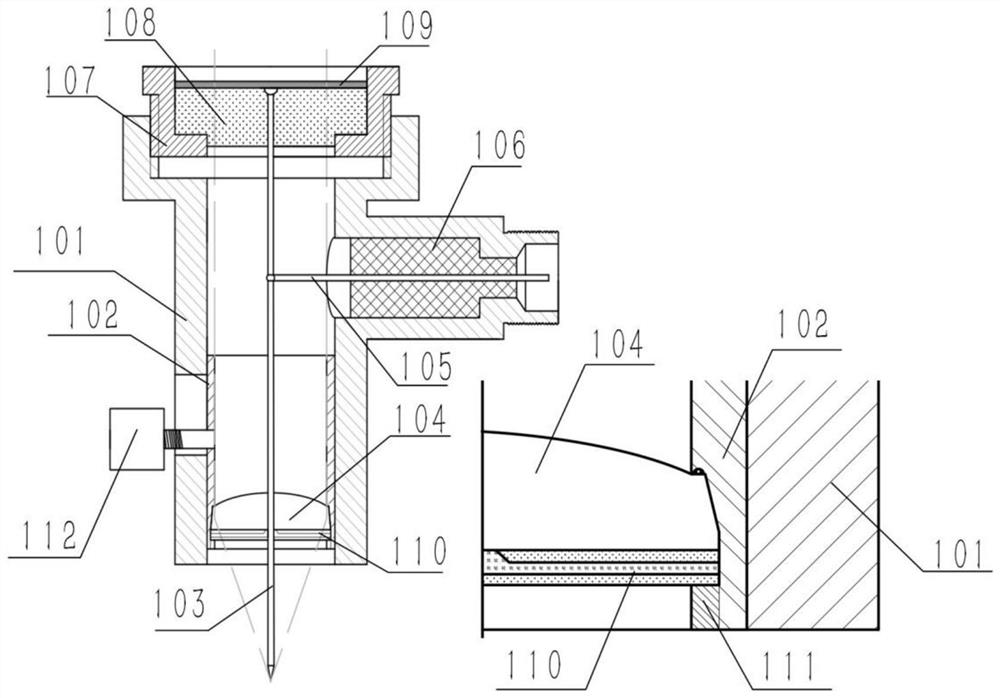

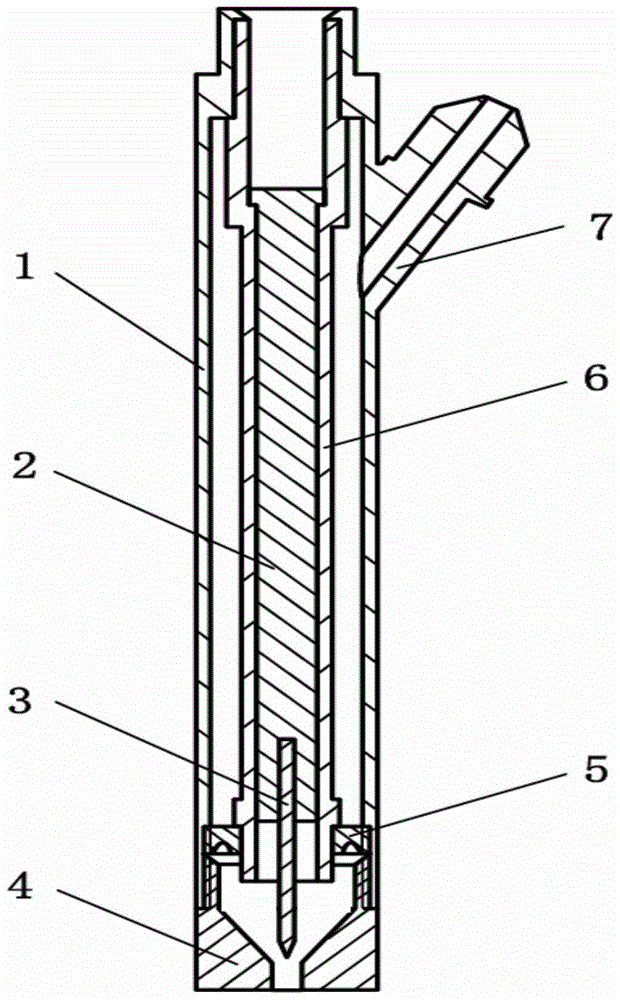

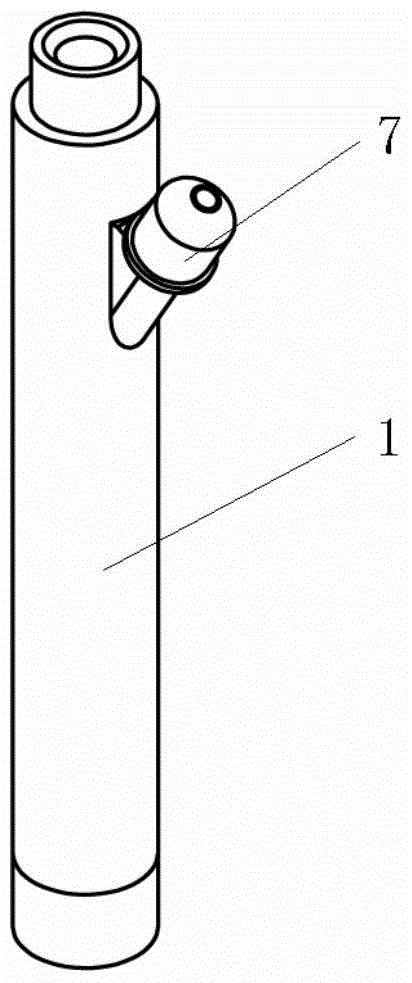

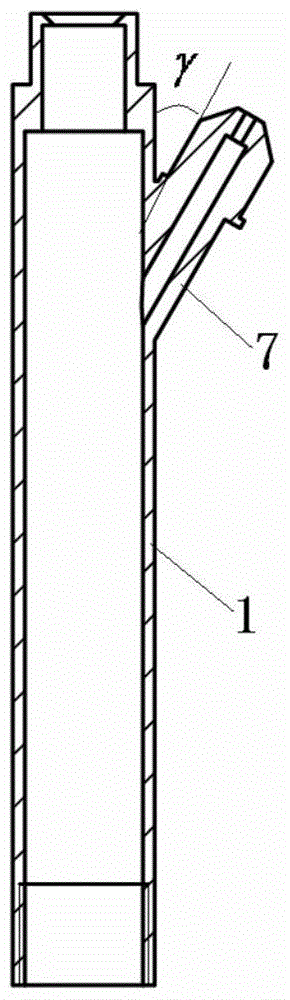

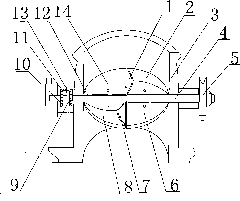

Elongating arc plasma jet ignition device

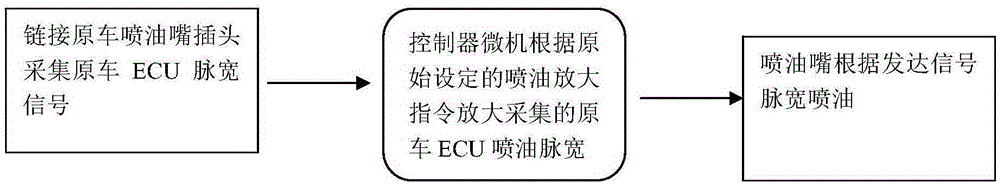

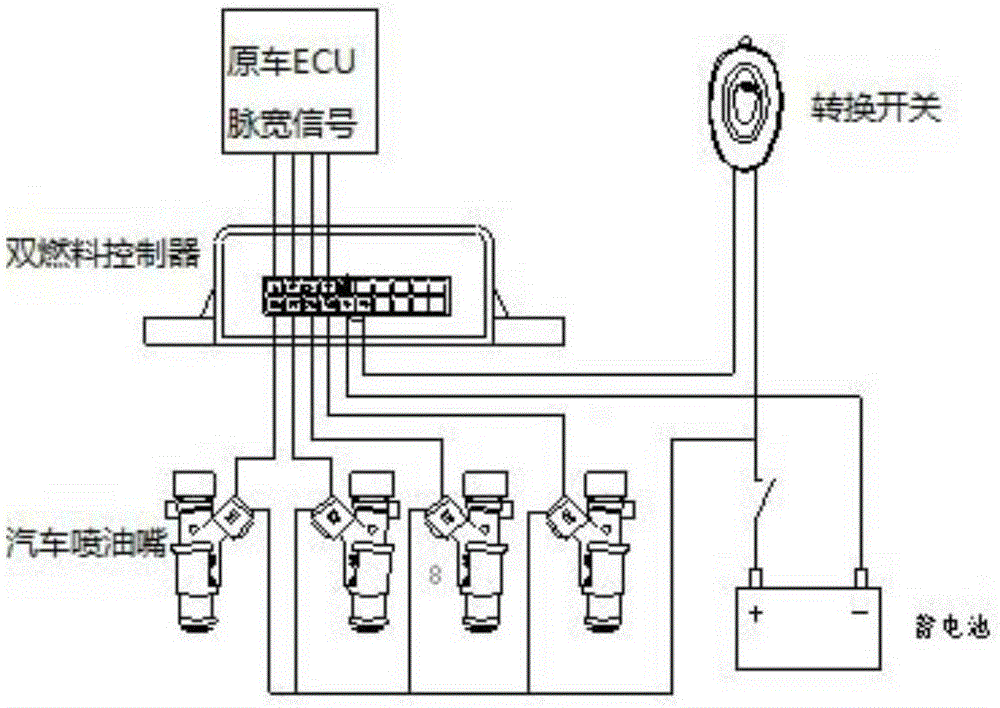

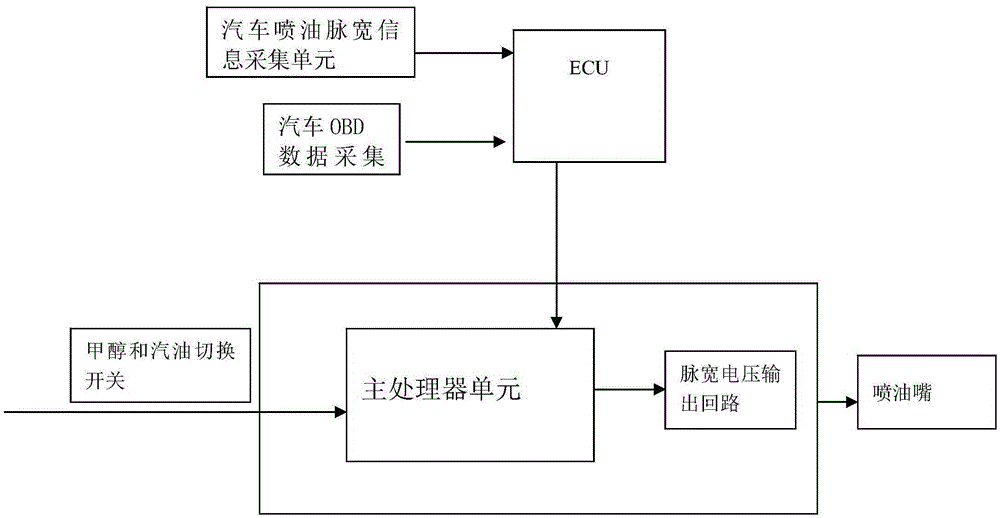

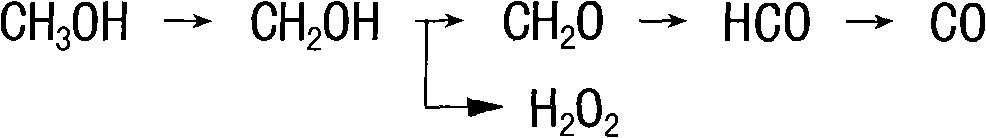

ActiveCN104454290AIncrease the speed of flame spreadStrong penetrating powerMachines/enginesEngine ignitionPlasma jetFlame spread

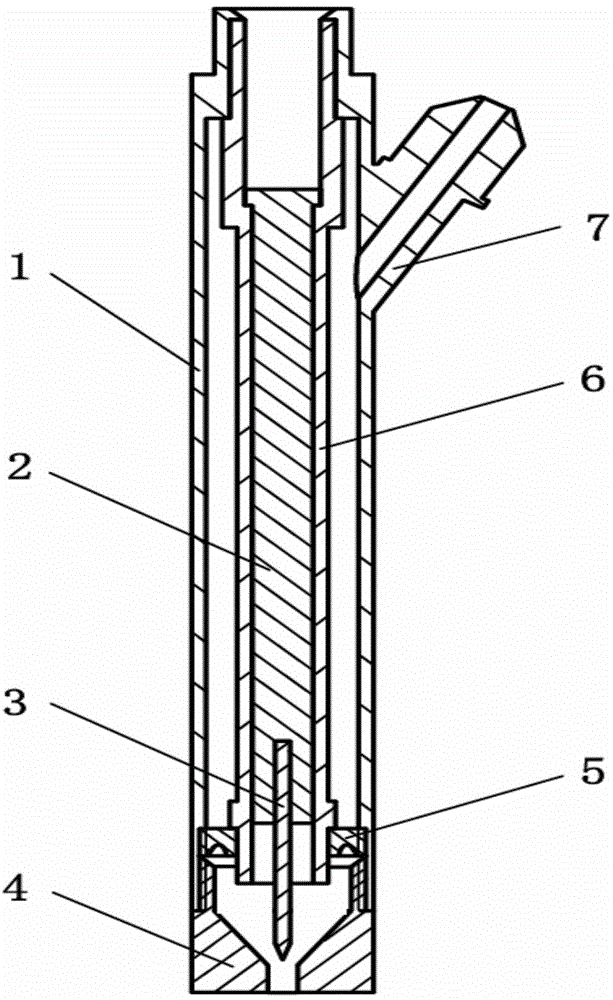

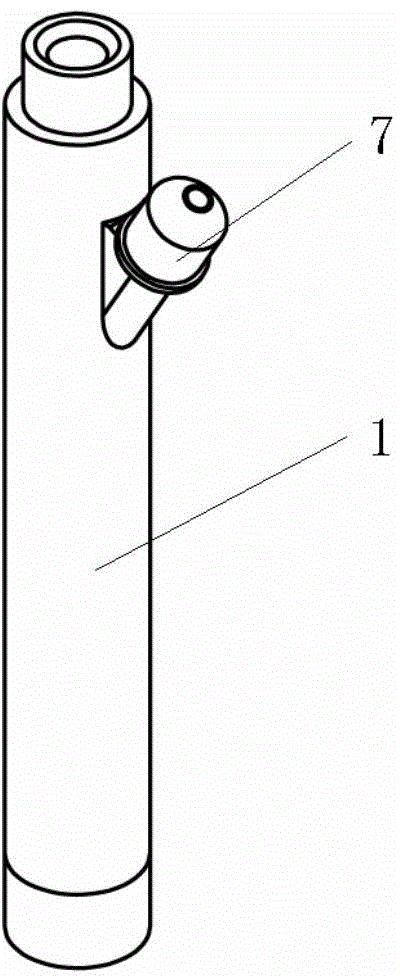

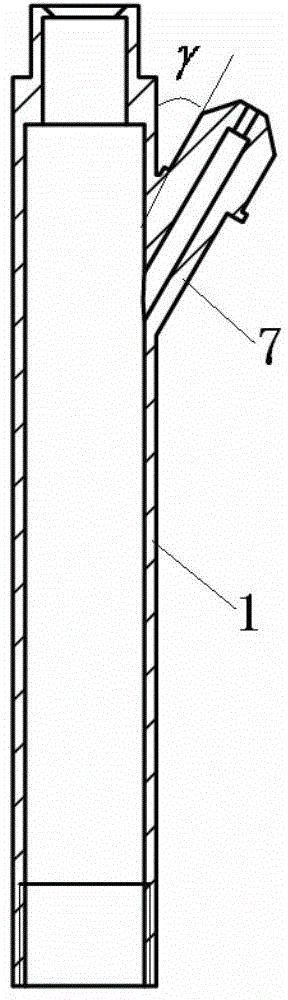

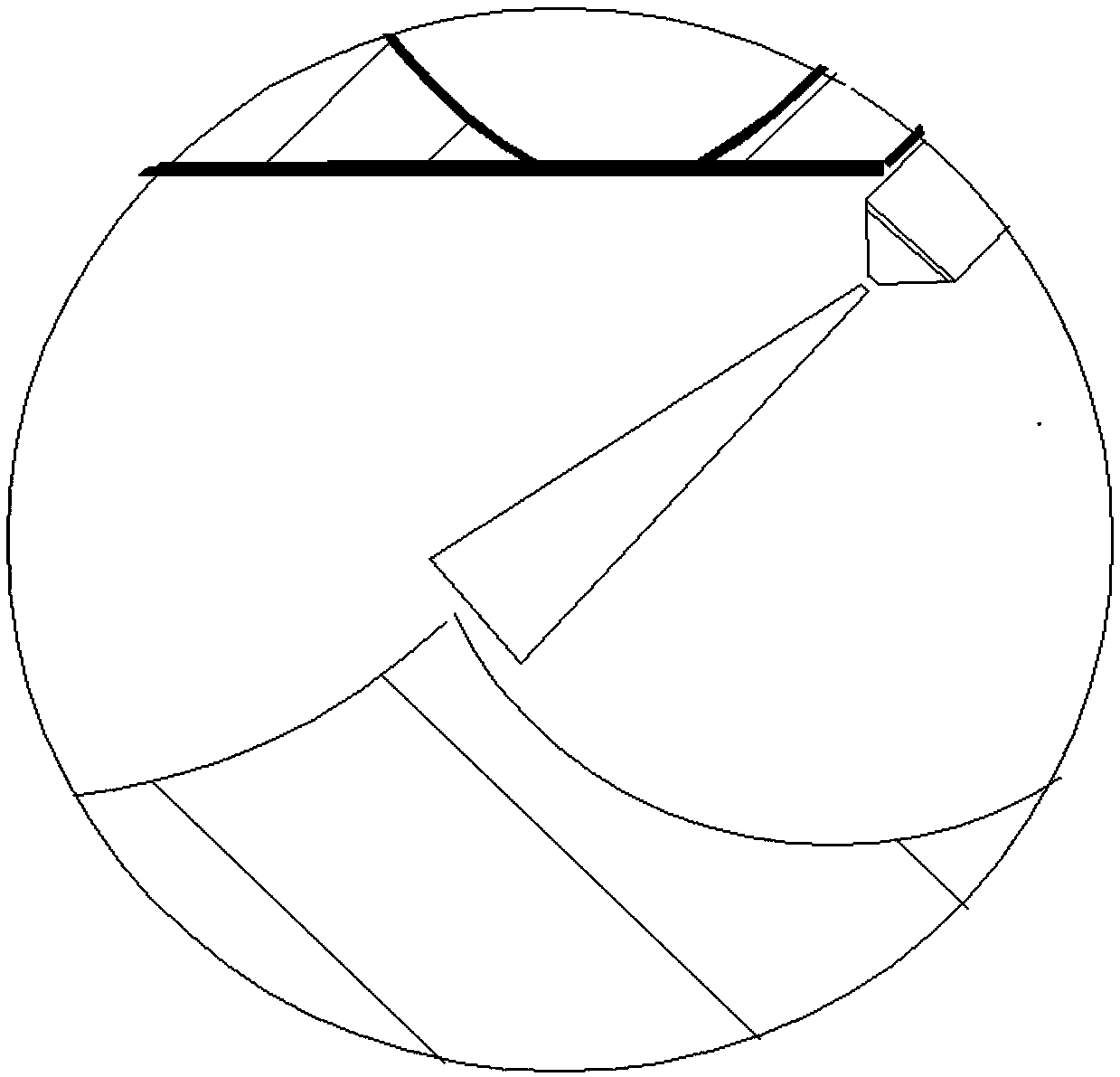

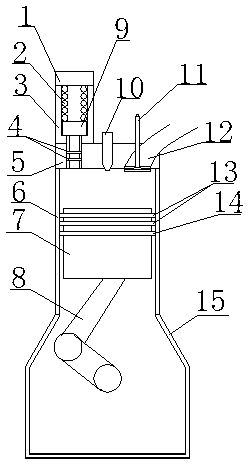

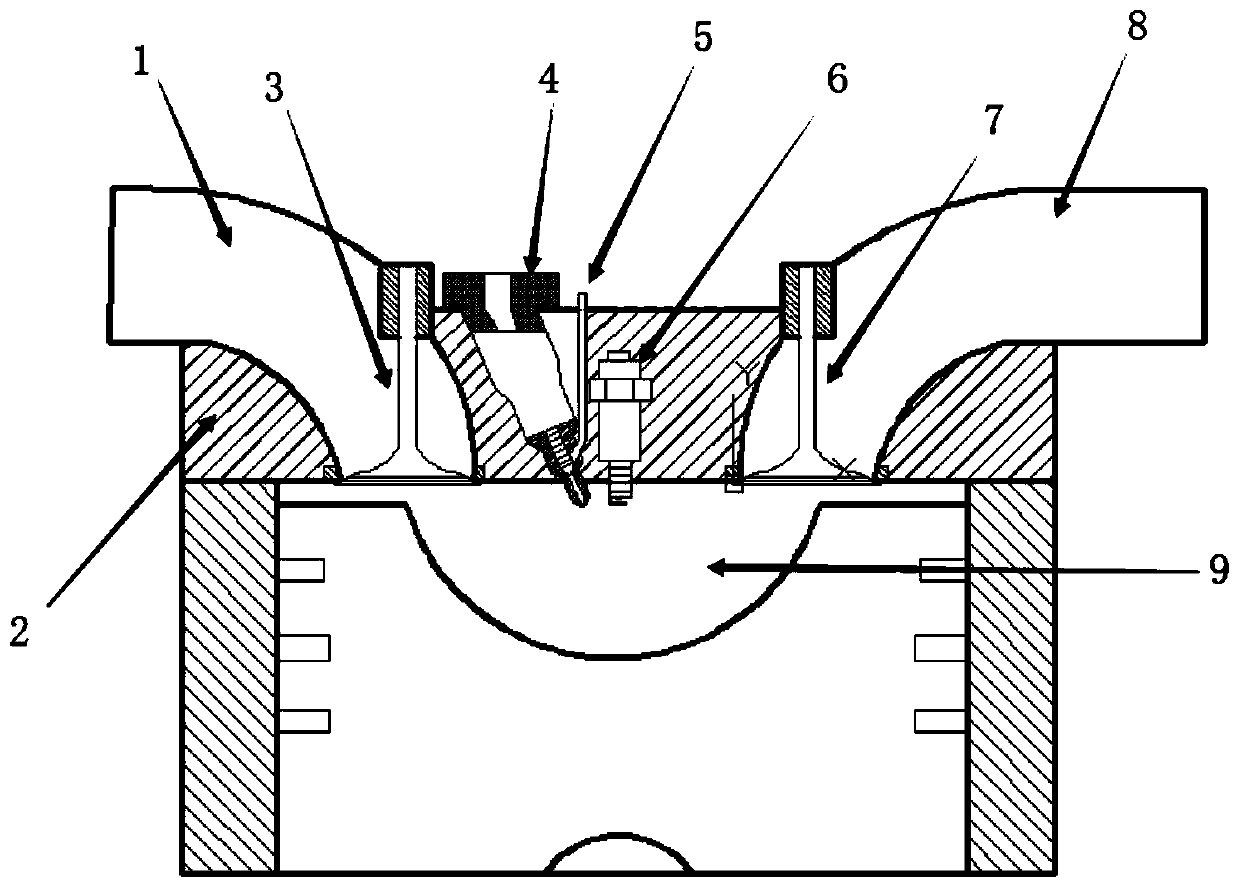

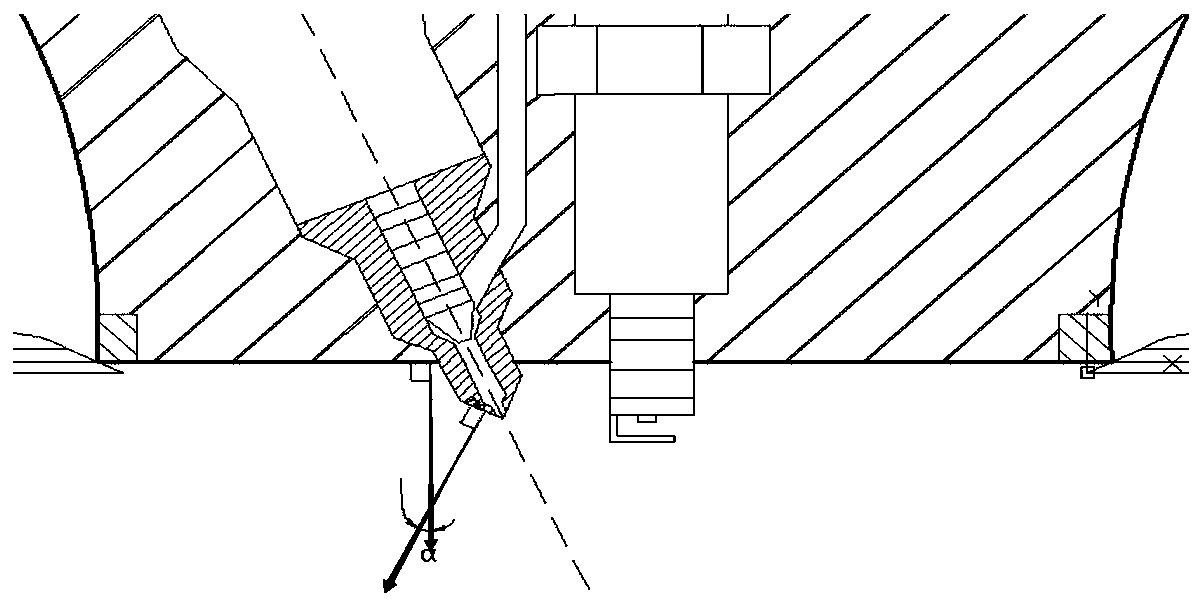

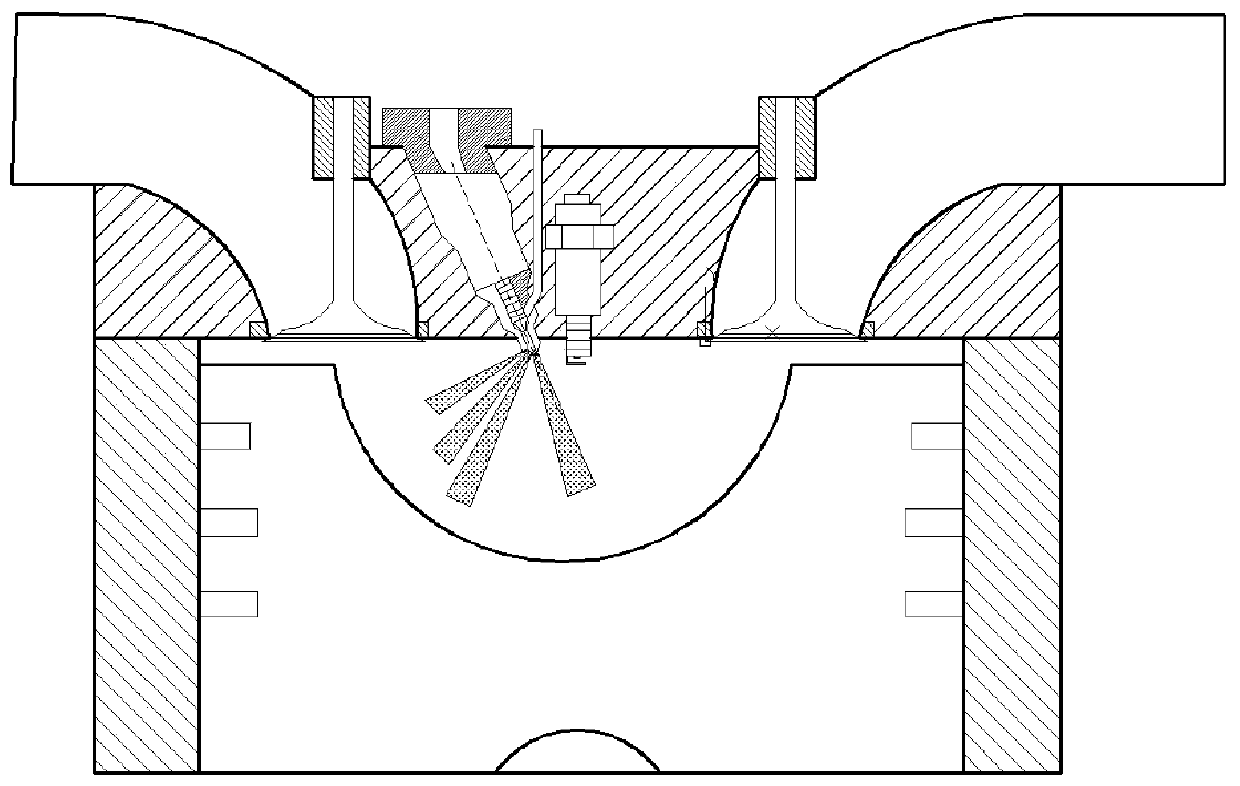

Disclosed is an elongating arc plasma jet ignition device. A swirler is fixed to the bottom of an inner cavity of a shell; a positive pole is located in the shell and fixedly connected with the swirler; the lower end of an insulation sleeve is installed in a central hole of the swirler, and an air chamber is formed in the gap between the outer peripheral surface of the middle of the insulation sleeve and the inner surface of the shell. A negative pole is embedded on a negative pole installation base, and the arc end of the negative pole extends out of the lower end of the insulation sleeve to be located in the positive pole. An arcing distance 2-8 mm long is kept between the arc end of the negative pole and a nozzle of the positive pole; an air inlet pipe is located at the upper end of the shell and communicated with the space of the air chamber formed between the insulation sleeve and the shell. The taper angle beta of the arc end of the negative pole is 40 degrees. The taper angle alpha of a contraction section of the positive pole is 60-90 degrees. Eight swirling holes with the spiral angle of 45 degrees are evenly distributed in an end surface of the swirler, and work media passing through the swirler generate swirling flow. The elongating arc plasma jet ignition device has the advantages of being high in flame spreading speed, high in penetrating power and rich in active air plasma.

Owner:AIR FORCE UNIV PLA

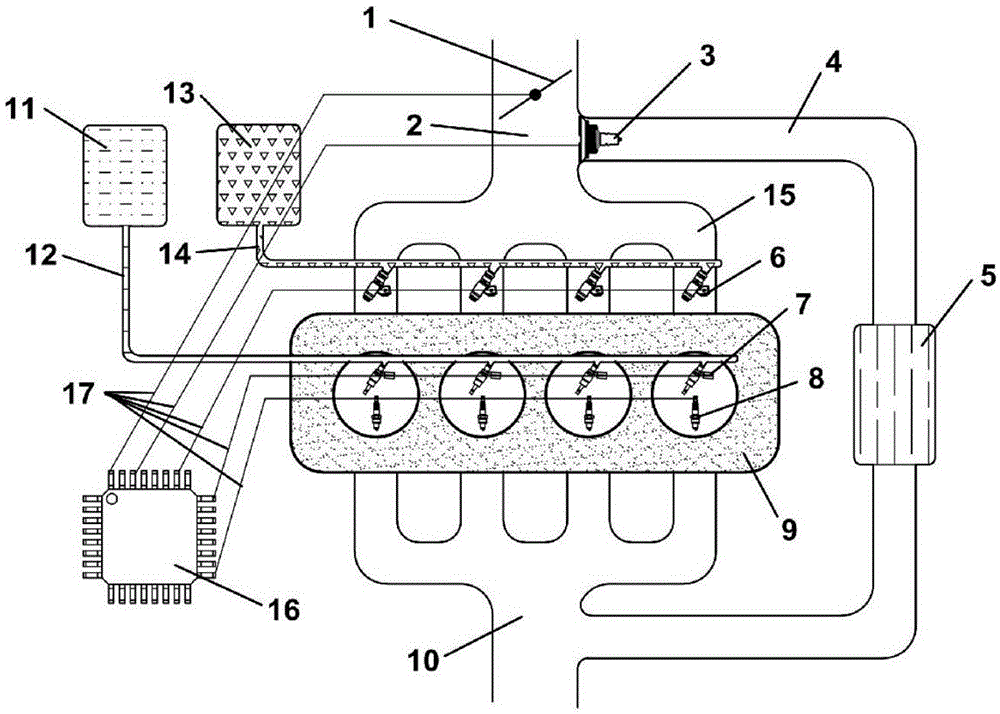

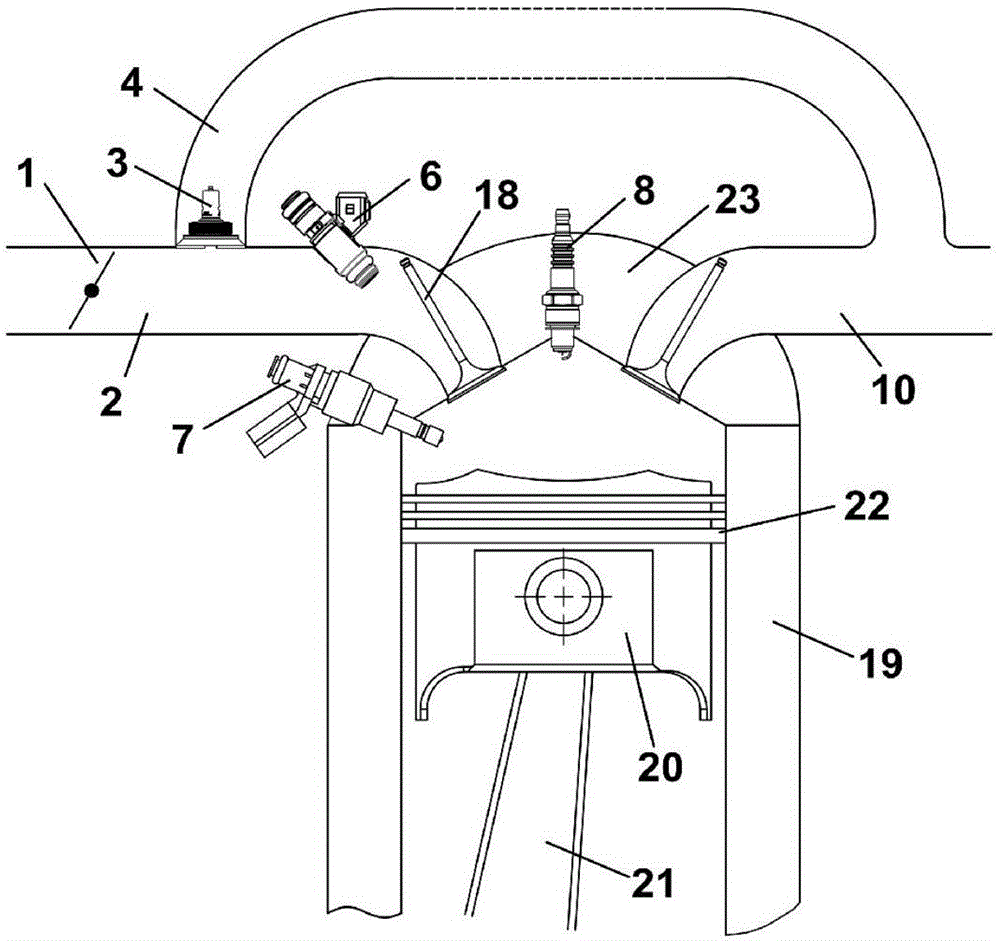

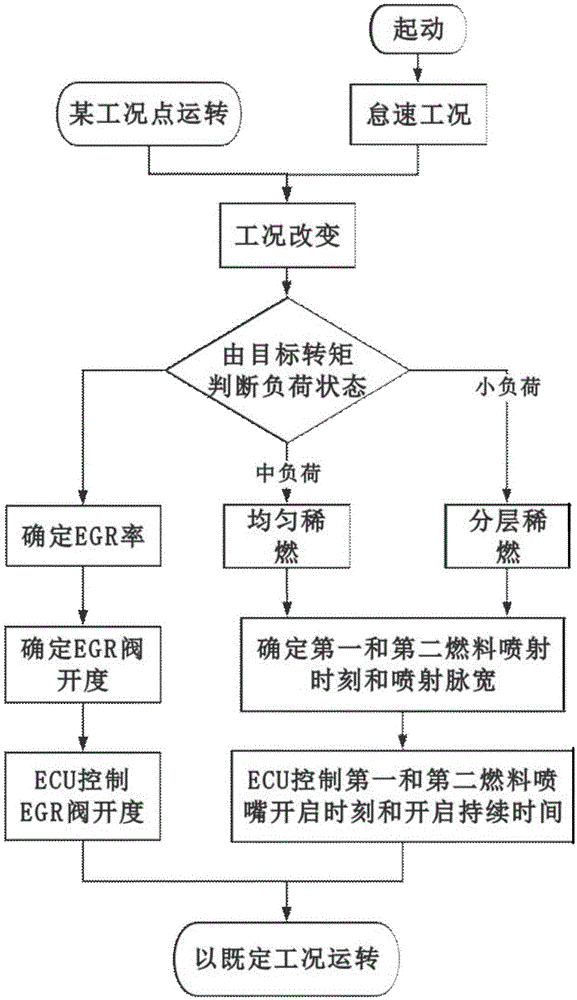

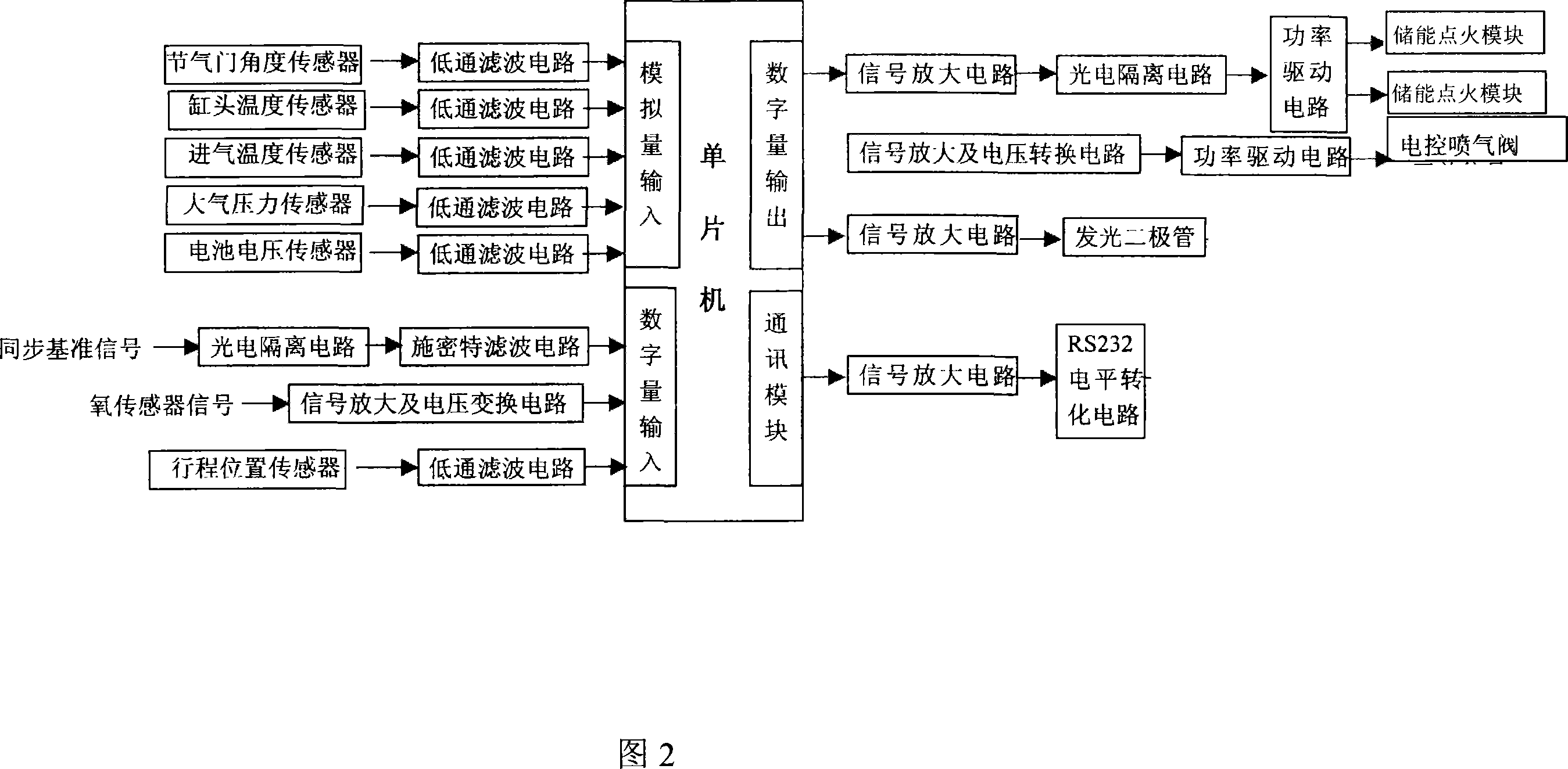

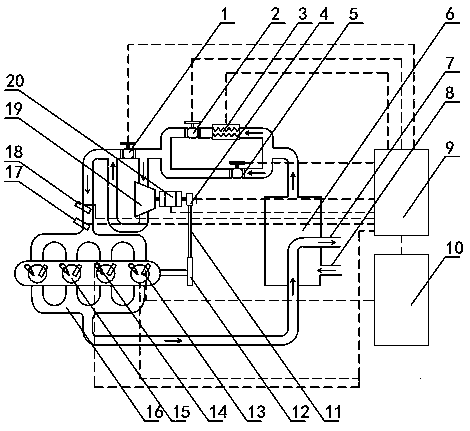

Lean-burn gas duel-fuel spark-ignition-type internal combustion engine based on EGR system and control method

InactiveCN105114174AReduce lossesCurb emissionsElectrical controlNon-fuel substance addition to fuelExternal combustion engineExhaust gas recirculation

The invention relates to a lean-burn gas duel-fuel spark-ignition-type internal combustion engine based on EGR (Exhaust Gas Recirculation) system and a control method, and can solve the problems of unstable combustion, high NOx emission and the like of a gas fuel spark-ignition-type internal combustion engine caused during lean burn. Based on the in-fuel-gas-cylinder direct injection and inlet duct spray combined duel-fuel spark-ignition-type internal combustion engine technology and the EGR technology, the internal combustion engine and the control method ensure that the duel-fuel spark-ignition-type internal combustion engine can realize stable and efficient lean burn and reduce the phenomena of cyclical variation and fire accident at a high compression ratio; meanwhile, part of exhaust gas is re-guided into the cylinder to participate in combustion, the EGR ratio is changed according to the requirements of working conditions, the in-cylinder combustion temperature is lowered, and the generation of NOx is inhibited; and besides, as lean burn and EGR co-exist, the opening degree of a throttle valve can be increased and the pumping loss is reduced. In conclusion, reduction of energy consumption and super-low emission of pollutants can be fundamentally realized.

Owner:JILIN UNIV

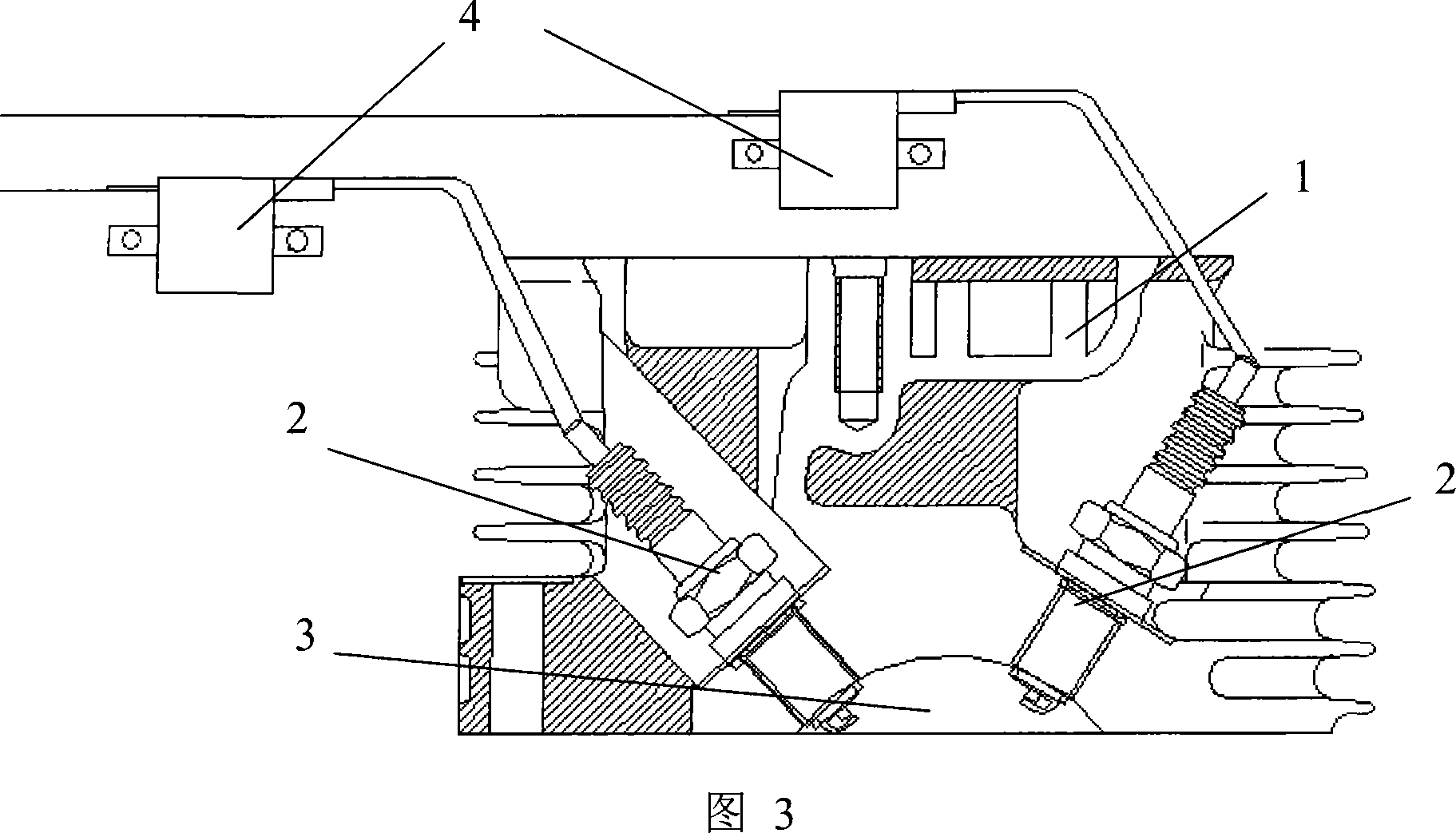

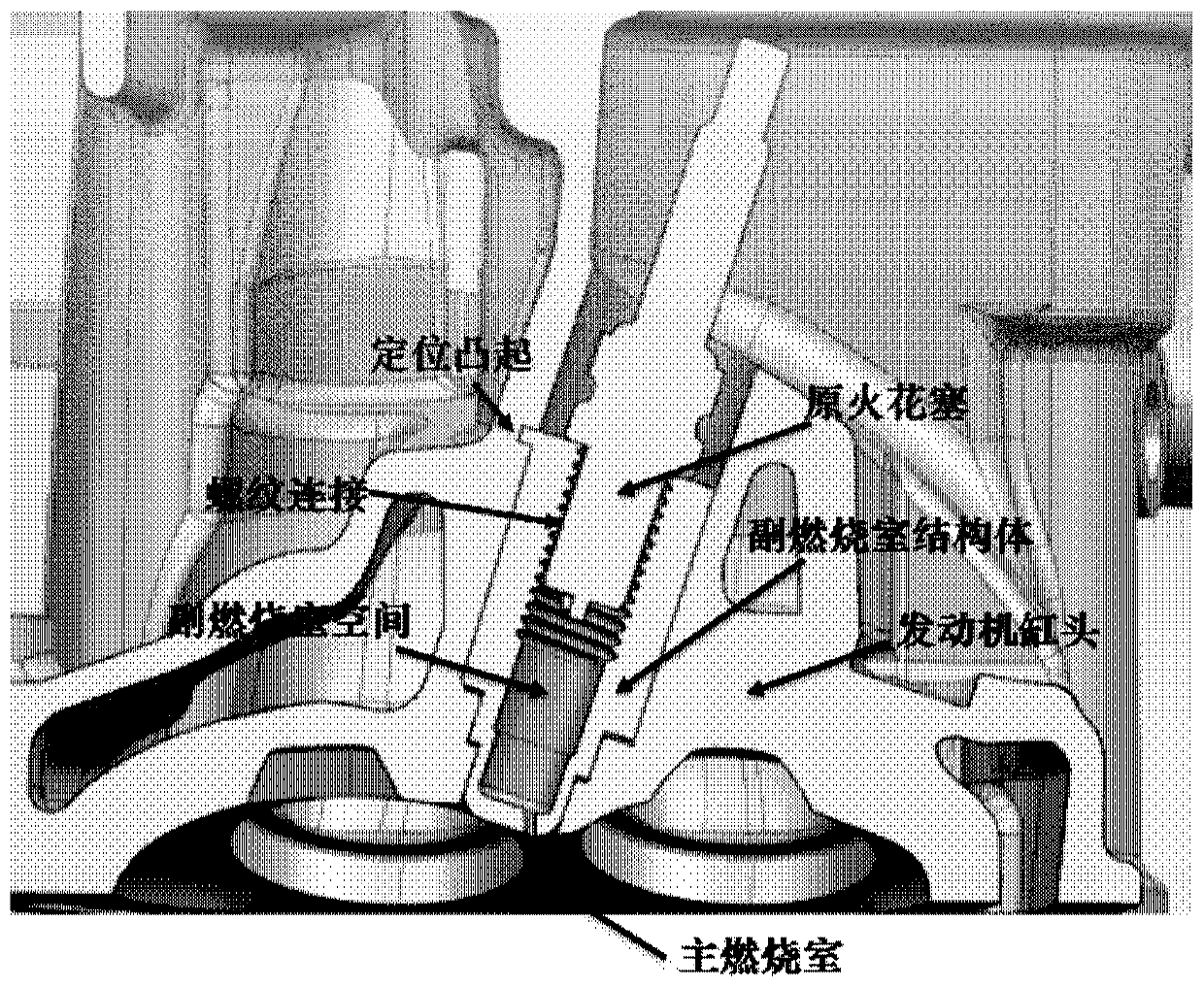

Natural gas engine combustion organization method with precombustion chamber low-pressure air supply and in-cylinder high-pressure direct injection functions

ActiveCN109098835AGuaranteed ignition stabilityIncrease the speed of flame spreadInternal combustion piston enginesGaseous engine fuelsAutomotive engineeringCombustion chamber

The invention aims to provide a natural gas engine combustion organization method with precombustion chamber low-pressure air supply and in-cylinder high-pressure direct injection functions. The natural gas engine combustion organization method is characterized in that a high-pressure gas injecting device is mounted on a cylinder cover, and gas injected at the tail end of compression stroke formsconcentration gradient distribution in a cylinder; a precombustion chamber is positioned right above a main combustion chamber, and a sparking plug is obliquely mounted on the left above the precombustion chamber; a low-pressure one-way air supply valve is mounted at the top of the precombustion chamber and is used for supplying air into the precombustion chamber during the intake stroke, such airand air pushed into the precombustion chamber during the compression stroke form a combustible gas mixture, the combustible gas mixture is ignited by the sparking plug, and flames enter a gas mixturein an ignition cylinder of the main combustion chamber; the air supply pressure of the one-way air supply valve is controlled at 4-6 bar during a low load and at 8-10 bar during a high load. The natural gas engine combustion organization method has the advantages that the ignition stability in different operation conditions can be guaranteed through adjustment of the air supply pressure in the one-way valve, and concentration stratification and rapid combustion of the thin gas mixture in the cylinder are achieved through in-cylinder direct injection, so that an engine is more economical and higher in exhaust performance.

Owner:HARBIN ENG UNIV

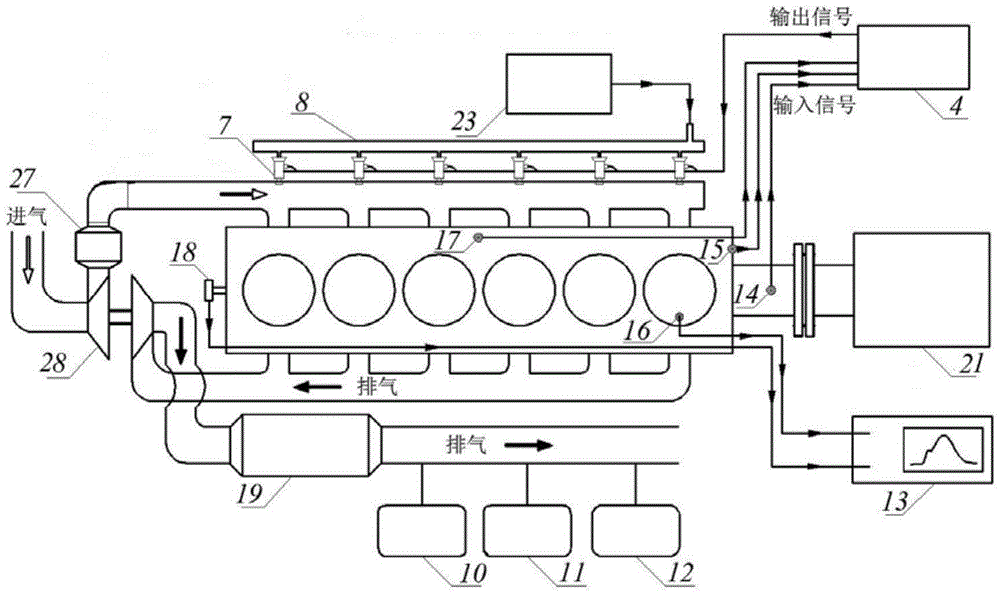

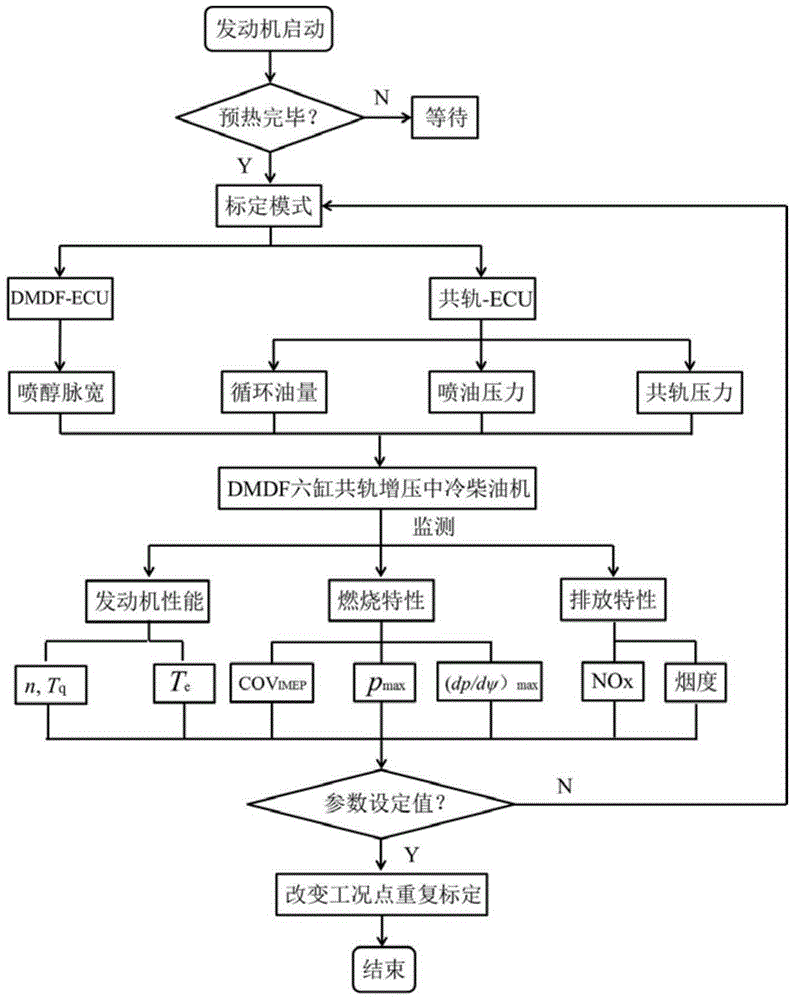

System and method for reducing NOx and particles in emitted pollutants of diesel engine

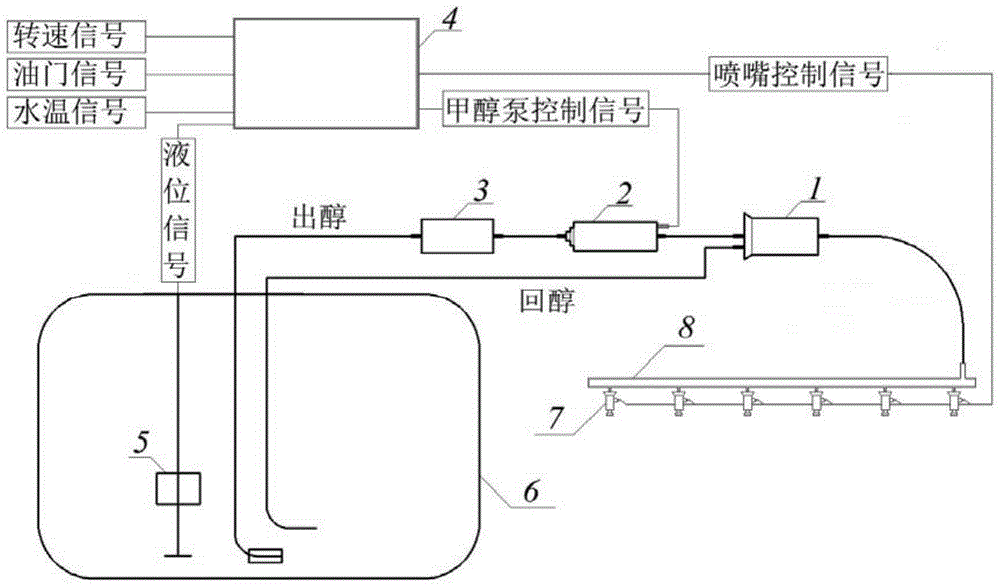

InactiveCN105179112AEmission reductionLarge latent heat of vaporizationElectrical controlInternal combustion piston enginesDiesel engineOil consumption

The invention relates to a technology for reducing emissions of a diesel engine, in particular to a system and method for reducing NOx and particles in emitted pollutants of the diesel engine. The system for reducing the NOx and the particles in the emitted pollutants of the diesel engine comprises an independent methanol injection system added to a gas inlet pipe of the engine and an oxidation catalytic converter (DOC)+particle oxidation catalytic converter (POC) integrated body special for methanol added to a gas discharge pipe of the engine. Compared with the prior art, the system and method have the advantages that in the method, the methanol takes part in combustion serving as both fuel and an emission improver, so that it is unlike that urea is only used for controlling emissions in the existing selective catalytic reduction (SCR) art; the general oil consumption is reduced; the cost of the fuel is lowered; users accept the system and method more easily.

Owner:TIANJIN UNIV

Method and equipment for improving heat efficiency of automobile fuel

ActiveCN105257437AHigh thermal efficiencyMake up for the disadvantage that the latent heat of vaporization cannot be directly used in gasoline enginesInternal combustion piston enginesFuel supply apparatusEngine powerMixed gas

The invention discloses a method and equipment for improving the heat efficiency of an automobile fuel. According to the method, the automobile fuel before entering a cylinder is heated, thus the heat efficiency of the fuel is improved; and in particular, an electromagnetic induction coil is used for heating, the operation is convenient, safe and reliable, and the electromagnetic induction heating efficiency is high. The equipment comprises a heating unit, wherein the heating unit comprises a heating control main board, a power supply acquisition module, a relay and a heating module; the power supply acquisition module, the relay and a heating control unit are sequentially connected, and the heating module is controlled by the heating control main board; the relay is connected with an automobile-mounted storage battery; and the heating module is arranged at an oil rail or an oil nozzle of an automobile oil supply system. The reaction speed and the flame propagation speed of a mixed gas in the cylinder are increased according to the detonation theory of the mixed gas, thus an engine power is improved; and more chemical energy of the fuel is converted to kinetic energy, thus the heat efficiency of the fuel is increased, and the effects of energy conservation and emission reduction are achieved.

Owner:杨记

Combustion system of spark-ignition engine

InactiveCN101196153ABurn fullyEnsuring successful cold start ignitionIgnition automatic controlAutomatic controlCombustion chamberHigh energy

A spark-igniting engine combustion system is provided, which comprises: an electric control unit ECU, a high energy spark coil, a spark plug, an engine cylinder head and a hemispherical combustion chamber. Wherein, the spark plug is matched with the engine cylinder head and is positioned on the latter; the electric control unit ECU controls the high energy spark coil to facilitate the spark plug producing electric spark, so as to realize ignition in the hemispherical combustion chamber; the engine cylinder head adopts double spark plug structure; the electric control unit ECU adopts two suites of independent energy storage and ignition modules being respectively connected with the high energy spark coil; the varied ignition control strategy is adopted to control the ignition by the double spark plug. The invention is able to ensure the cold start or successful ignition of engine, enhance the combustion velocity and the rate of flame spread, organize the movement of air flow in the combustion chamber and assure full combustion in the engine, thereby improving the thermal efficiency of the engine and reducing the emission of tail gas.

Owner:TIANJIN UNIV

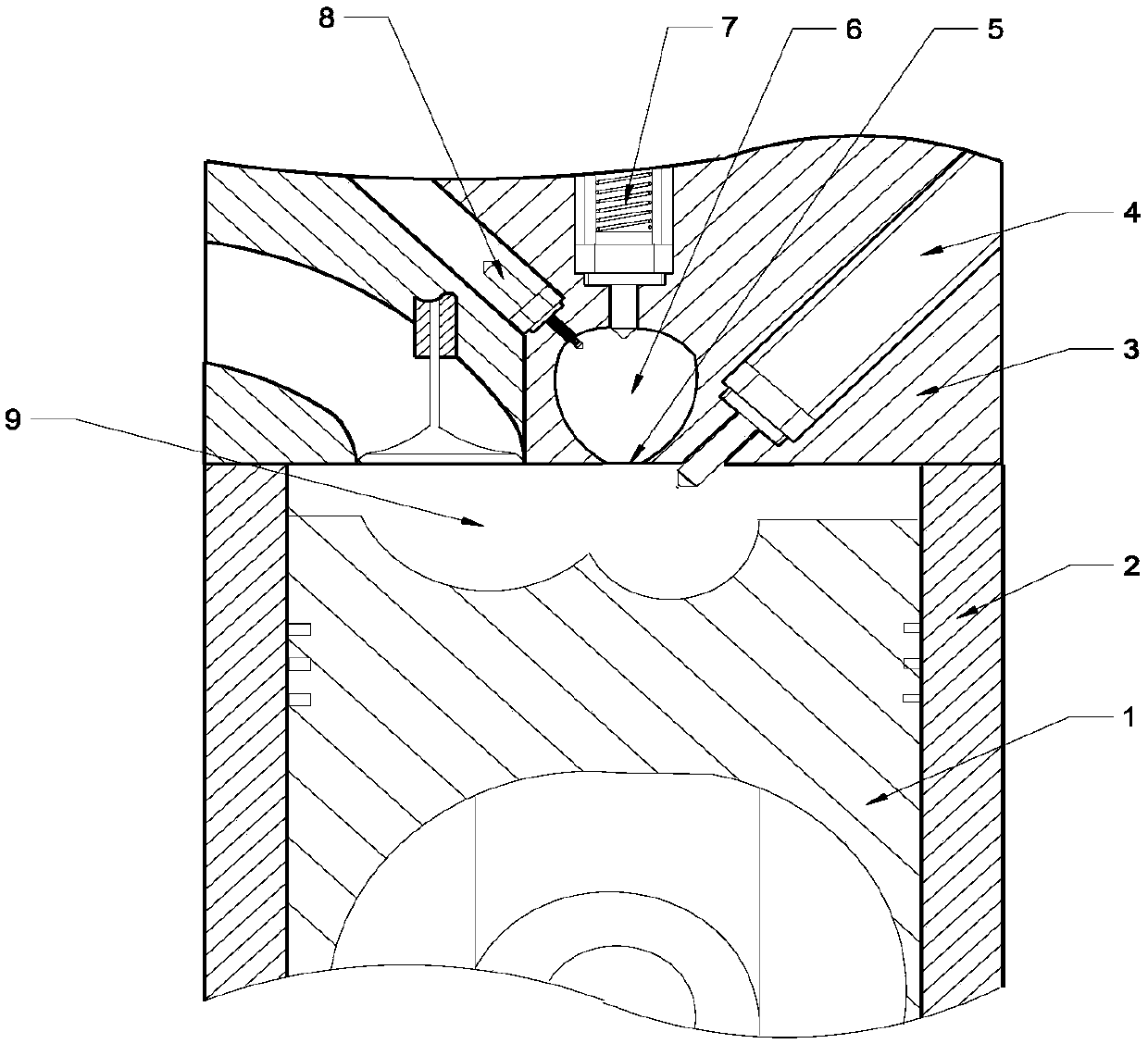

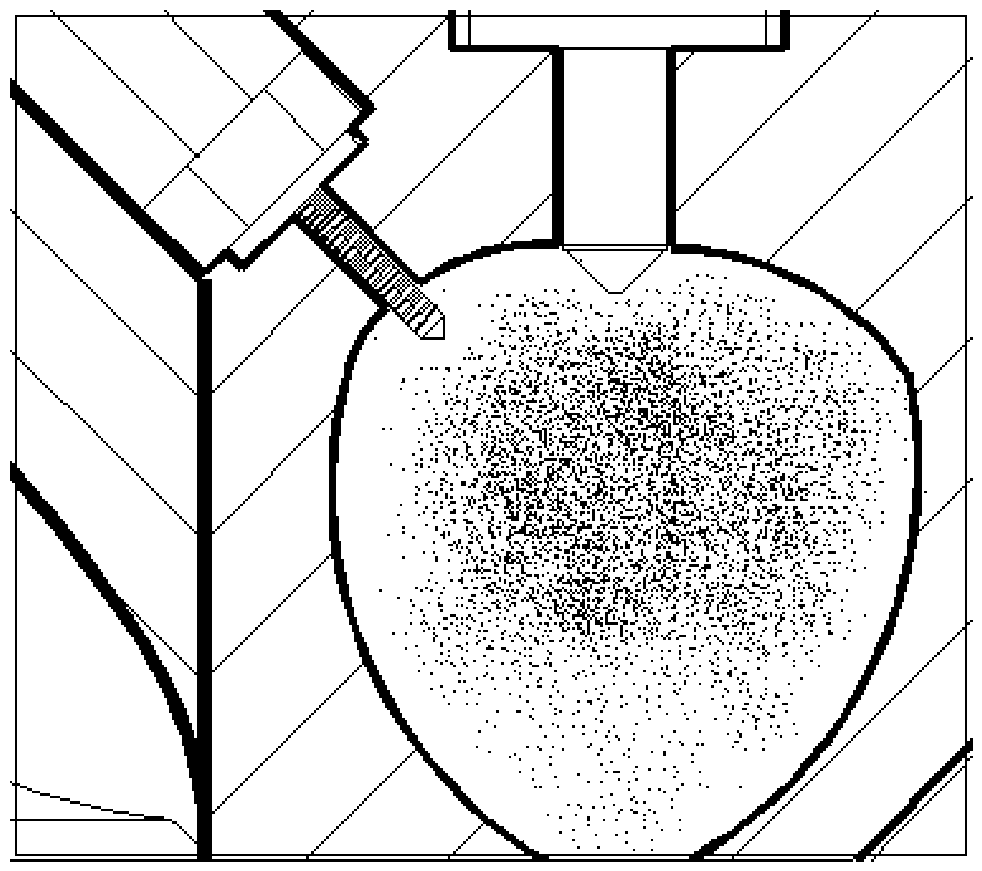

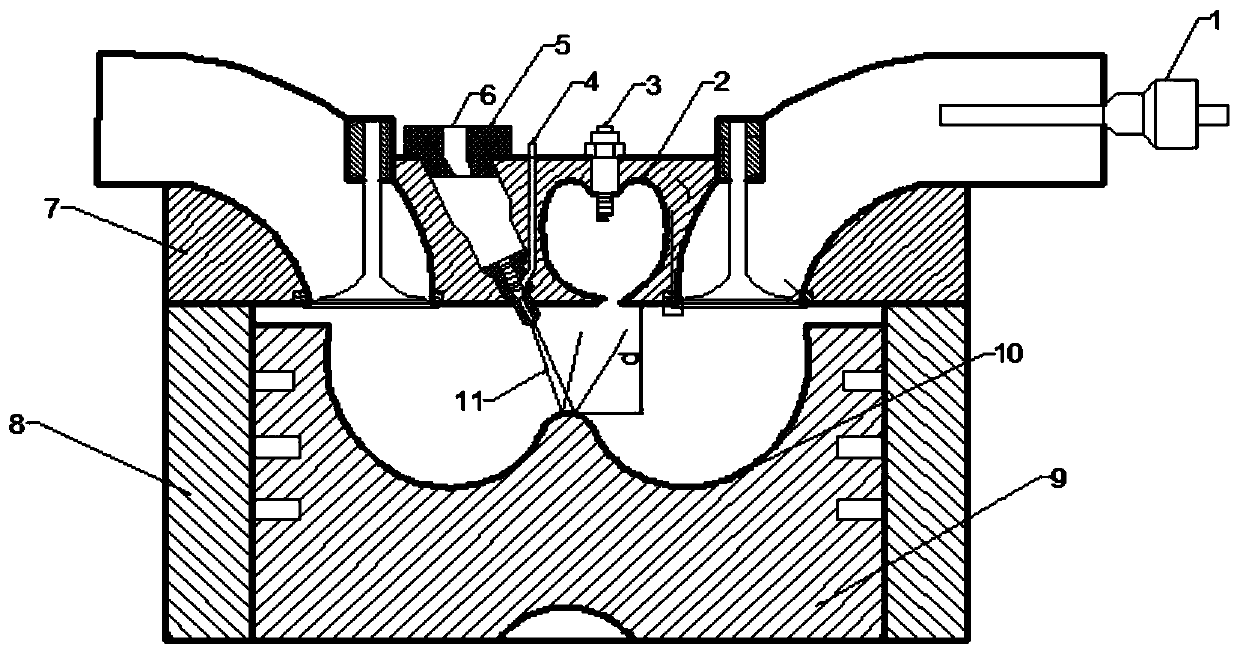

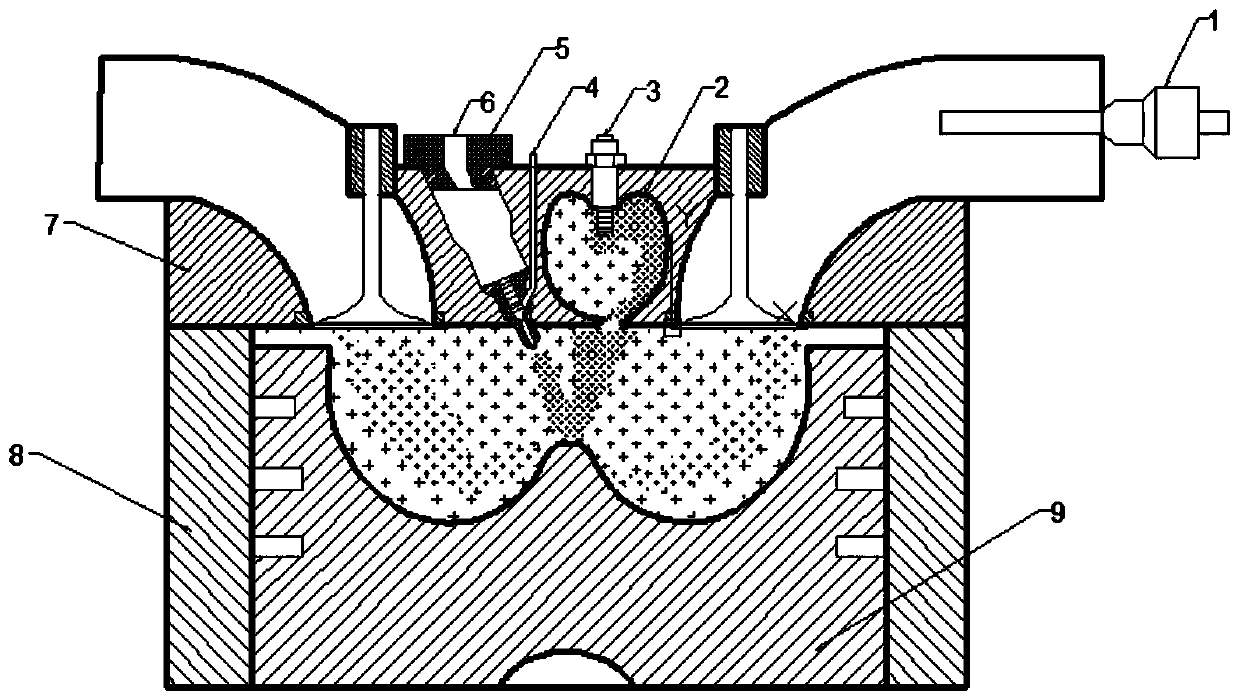

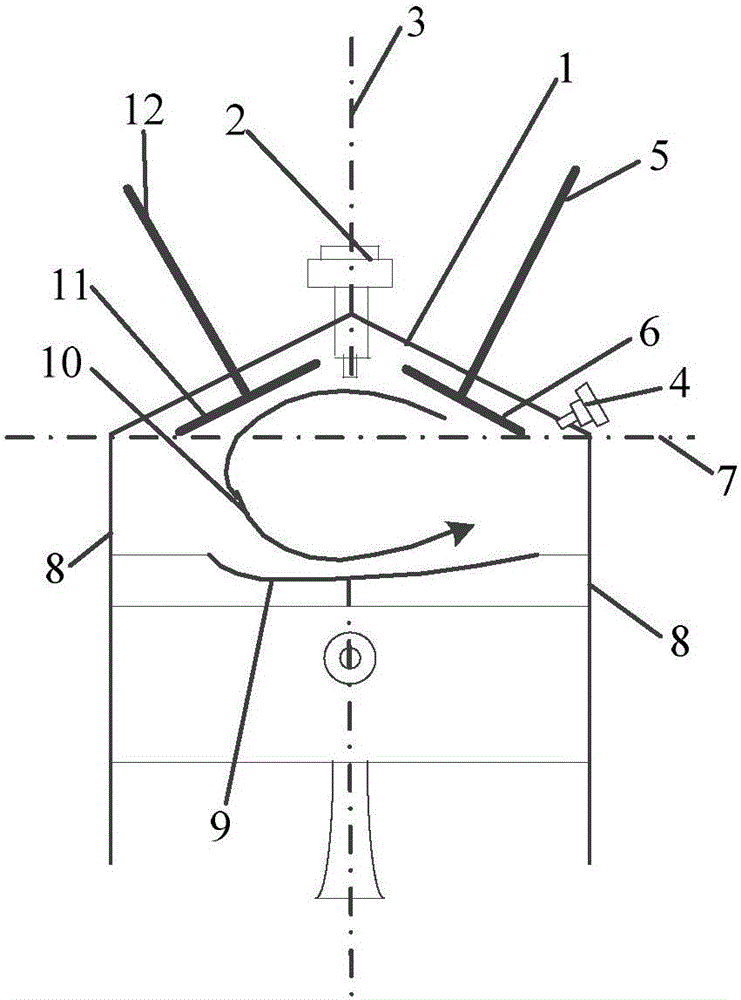

Engine layered rapid combustion method capable of achieving multi-time natural gas spraying

InactiveCN110318859AGuaranteed stable ignitionIncrease the speed of flame spreadElectrical controlInternal combustion piston enginesSingle holeCombustion chamber

The invention aims at providing an engine layered rapid combustion method capable of achieving multi-time natural gas spraying. A system comprises an air inlet way, an exhaust way, a low-pressure natural gas injection valve and a heart-shaped pre-combustion chamber with an inclined outlet (single hole), therefore, a rolling flow, a spark plug, an in-cylinder high-pressure direct injection air injection valve and a main combustion chamber are formed in the air flow, the manner of air inlet way low-pressure injection and in-cylinder high-pressure direct injection is adopted for supplying naturalgas, for different running conditions of an engine, the different proportions of the gas total quantity needed by each cycle in the air inlet way injection and high-pressure direct injection and theair injection rule of an in-cylinder high-pressure direct injection air injection valve are adjusted, the mixed gas concentration layering from thick to thin is formed in the cylinder from a pre-combustion chamber outlet to the exterior, the distribution of the mixed gas from thick to thin is formed nearby the spark plug, and natural gas engine layering rapid combustion is achieved. Natural gas engine ignition stability is ensured, the engine efficiency is improved, and the emissions are reduced.

Owner:HARBIN ENG UNIV

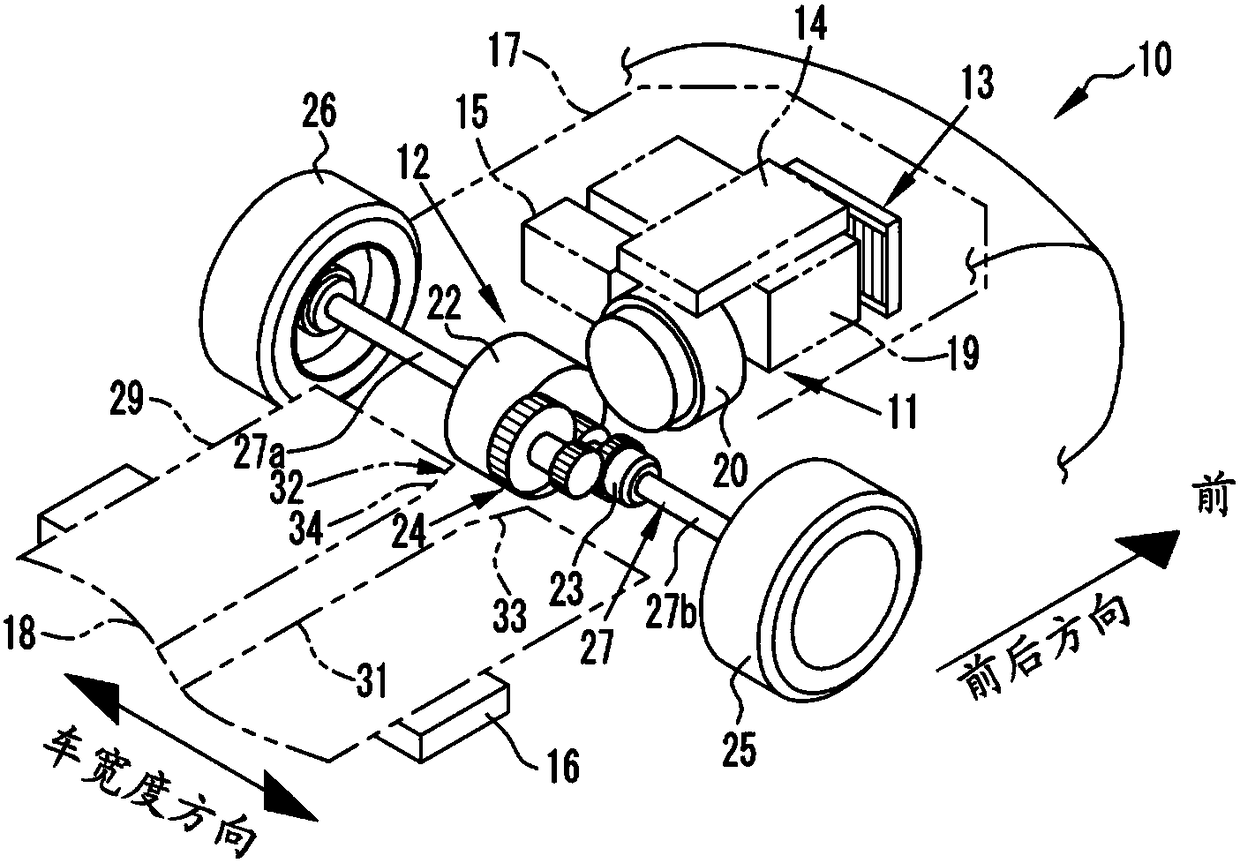

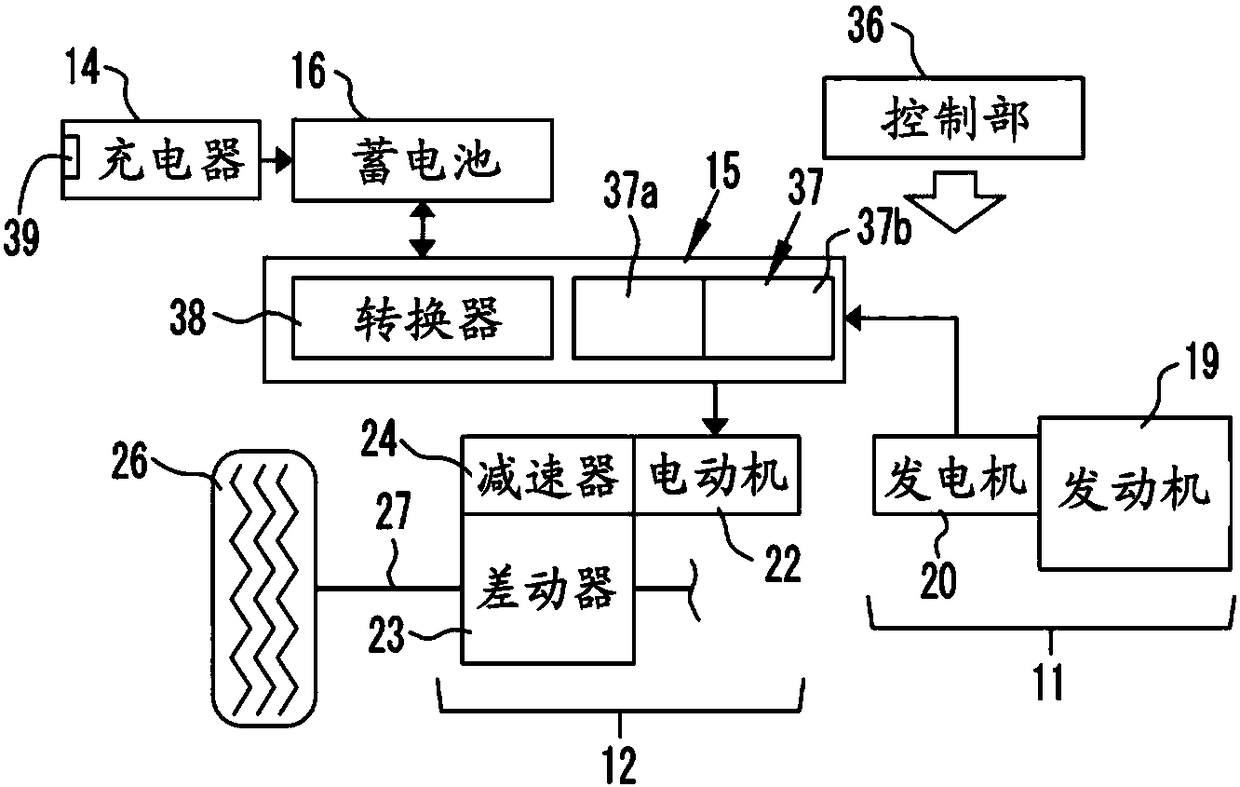

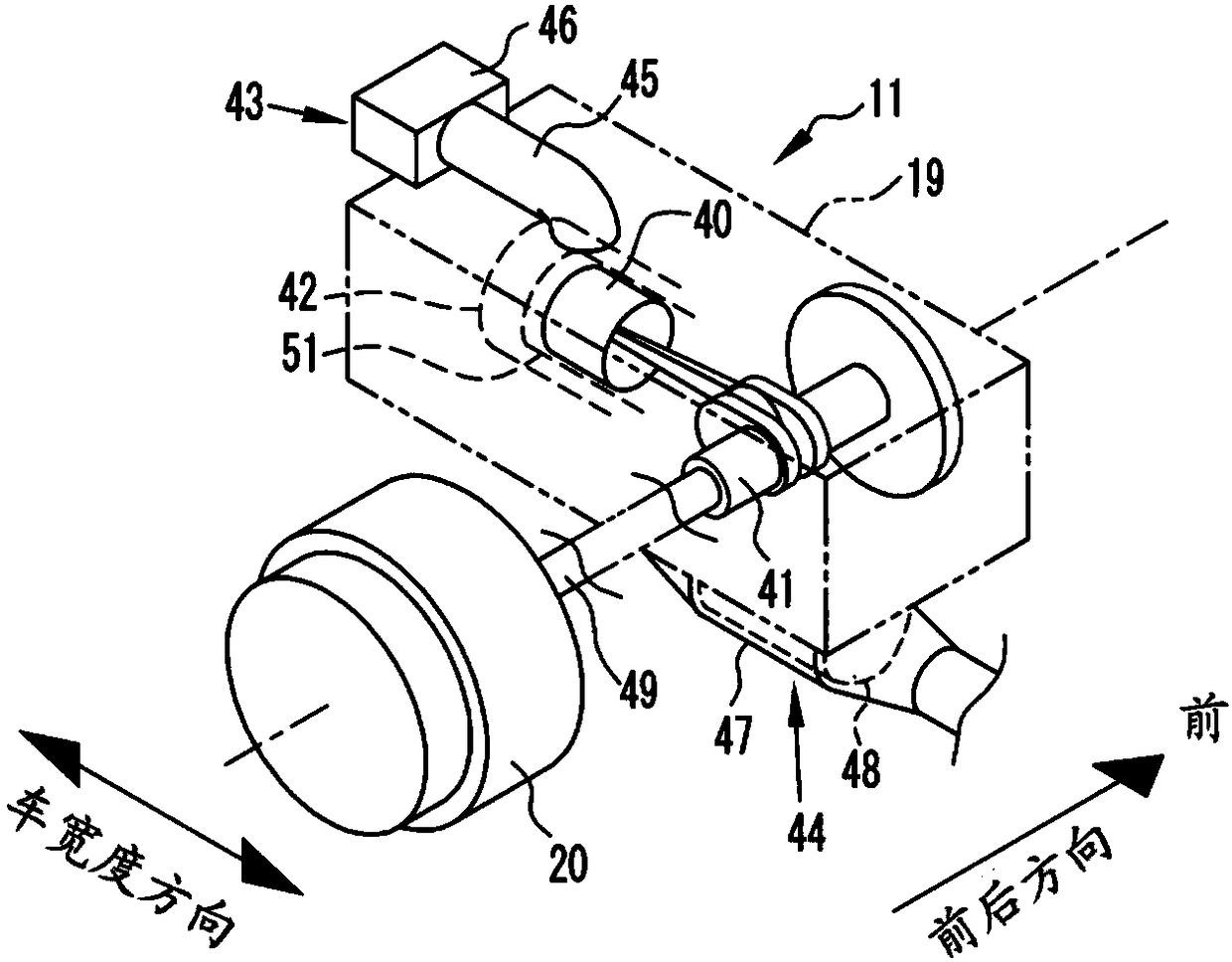

Vehicle

ActiveCN108407600ASmall sizeSeek lightweightHybrid vehiclesElectric propulsion mountingBattery chargeMiniaturization

The present invention provides a vehicle that can achieve miniaturization in the front-rear direction of the vehicle. A vehicle (10) includes an engine (19), a generator (20), and a motor (22). The engine (19) burns a gaseous mixture in a cylinder to output a drive force. The generator (20) generates electricity by being rotated by the drive force outputted from the engine (19). The motor (22) drives by utilizing electric power (20) generated by the generator or electric power that has accumulated in a battery charged with electric power generated by the generator, and the motor (20) thereby outputs a vehicle-running drive force. A case (61) covering the motor (22) is of larger diameter than a case (65) covering a differential. The motor (22) has an output shaft outputting the vehicle-running drive force, and has the output shaft disposed parallel to a vehicle width direction. The generator (20) is disposed such that part of the generator overlaps an upper section (65a) of the case covering the differential.

Owner:TOYOTA JIDOSHA KK

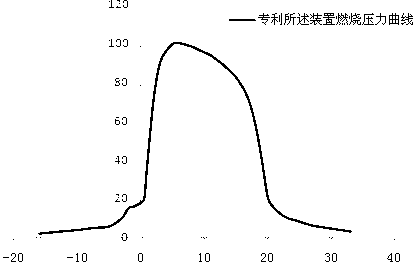

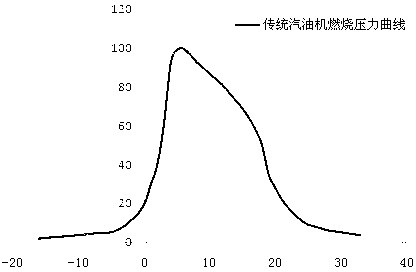

Diesel engine combustion device capable of changing clearance volume

InactiveCN103104339ACompensate for high stressReduced pressure rise rateMachines/enginesAdvancing/retarding ignitionCombustionGasoline

The invention discloses a diesel engine combustion device capable of changing clearance volume which comprises a shell body, a pre-loaded spring, a gas sealing ring, an automatic piston, a cylinder cover, a cylinder body, a piston, a connecting rod, a sparking plug, a valve rod, an intake manifold, a piston gas sealing ring, an oil sealing ring and a crank case. A through hole is formed in the top of the cylinder cover, the shell body is installed in the through hole, the automatic piston is arranged inside the through hole of the shell cylinder and also extends in the through hole of the top of the cylinder, and the pre-loaded spring maintains the piston under a down-pressing state. The diesel engine combustion device capable of changing the clearance volume can optimize combustion conditions of a gasoline engine, effectively solves the defects that when a spark advance angle is enlarged, pressure in a cylinder is too high, compression negative work is too large, and is favorable for stability increasing of parts of the gasoline engine. The diesel engine combustion device capable of changing the clearance volume is simple and stable.

Owner:ZHEJIANG UNIV

Light hydrocarbon fuel composition for vehicle

PendingCN112899044AImprove cleanlinessGood dispersionLiquid carbonaceous fuelsFuel additivesAnti oxidantTrimethylbenzenes

The invention discloses a light hydrocarbon fuel composition for a vehicle. The light hydrocarbon fuel composition comprises the following components in parts by weight: 500-600 parts of stable light hydrocarbon (octane site in a research method is greater than 92 #), 80-120 parts of isobutanol, 180-340 parts of aromatic hydrocarbon, 130-150 parts of xylene, 200-305 parts of isooctane, 0.25-0.5 part of lanthanum isooctanoate, 0.5-0.7 part of biphenyl, 0.1 part of a metal corrosion inhibitor and 0.1 part of an antioxidant. The stable light hydrocarbon is oil refinery downstream byproducts or methanol to olefin (MTO) and coal tar hydrogenation stable light hydrocarbons; the molecular formula of the isobutanol is C4H100; the aromatic hydrocarbon is a mixture of methylbenzene, dimethylbenzene and trimethylbenzene or one or two of methylbenzene, dimethylbenzene and trimethylbenzene for blending gasoline; the isooctane is alkylated oil and is also called isomer octane, and the research octane number is 98-100; and the metal corrosion inhibitor is benzotriazole. The light hydrocarbon fuel composition for the vehicle can improve power and reduce gasoline consumption; and emission of tail gas pollutants is reduced.

Owner:平湖市晨星科技实业有限公司

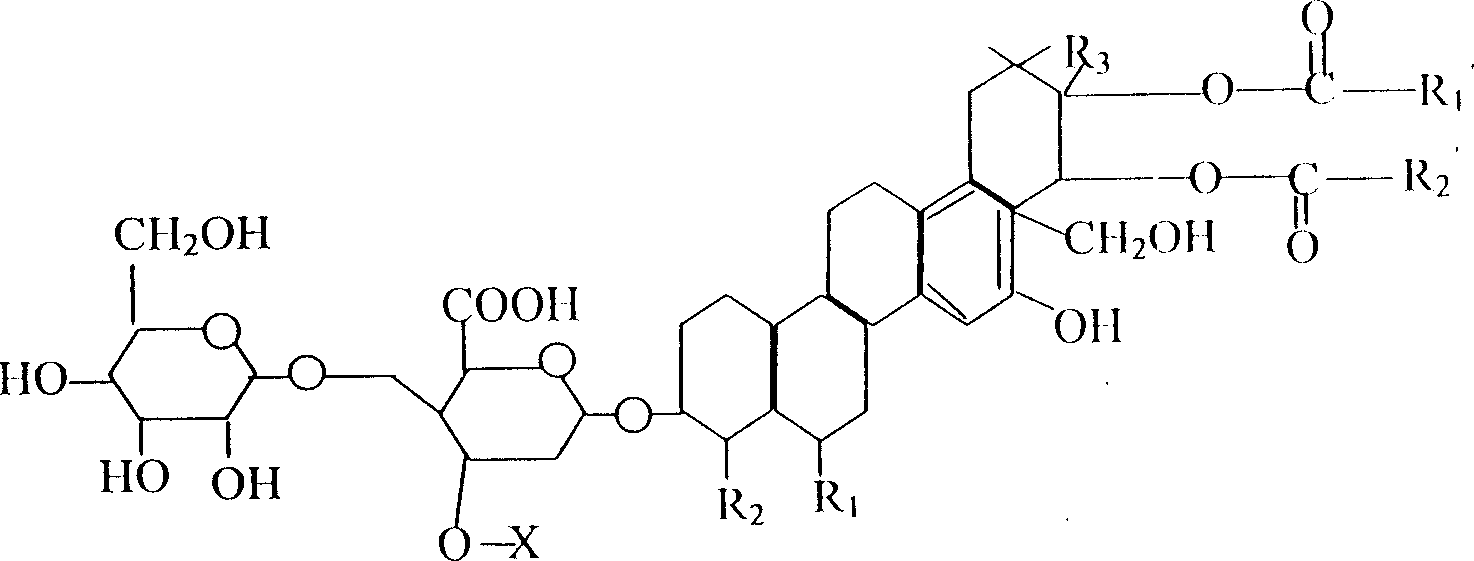

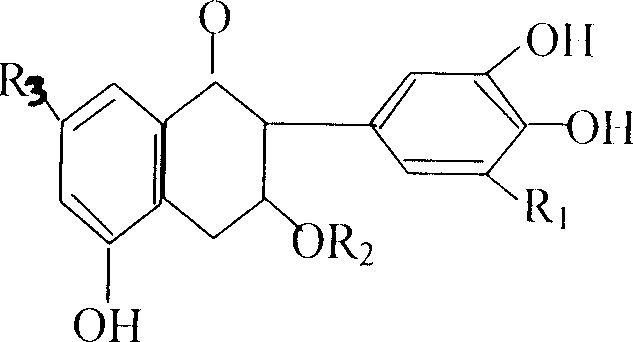

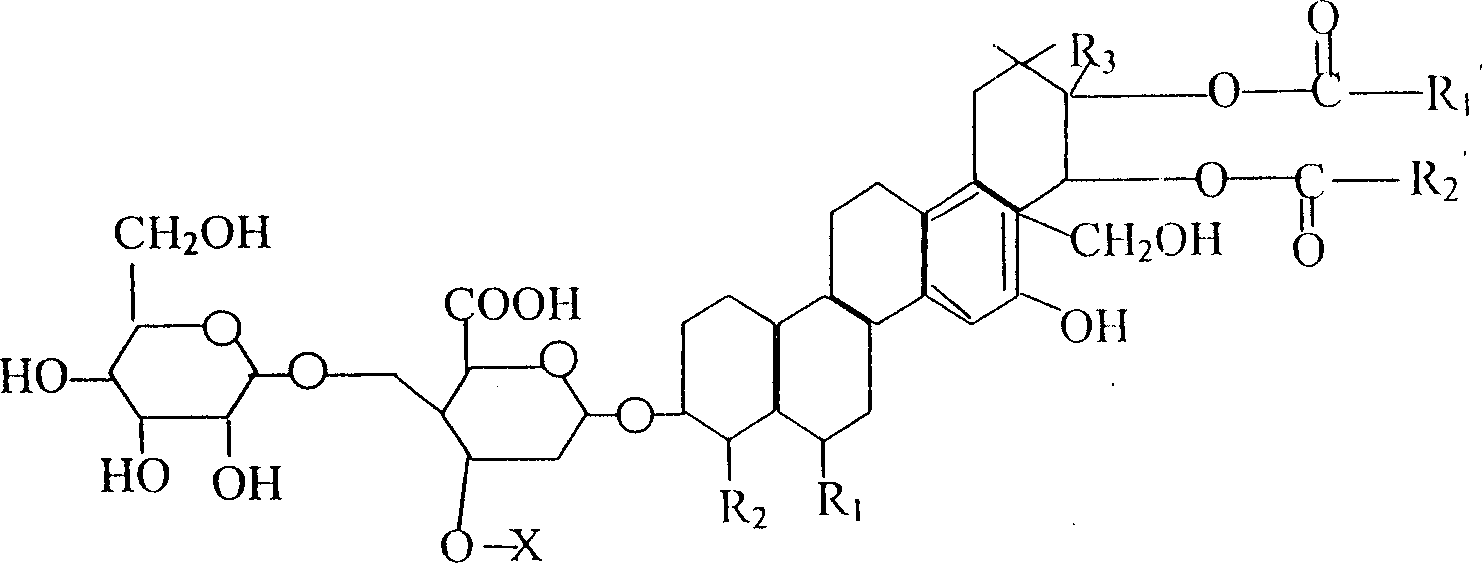

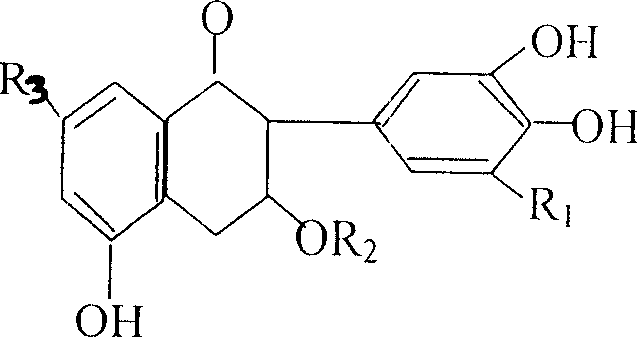

Heavy fuel oil additive containing benzopyran multi-hydroxy metal compound

InactiveCN1763158APromote combustionIncrease surface tensionLiquid carbonaceous fuelsBenzopyranOil additive

The heavy fuel oil additive containing benzopyran polyhydroxy metal compound is one kind of catalyst capable of promoting heavy petroleum part to burn completely and reducing the ablation and wear of heavy fuel oil on engine parts. It contains benzopyran polyhydroxy metal compound obtained with benzopyran polyhydroxy compounded from camellia plant and inorganic metal salt through reaction in 6-30 weight portions, macro molecular surfactant extracted from camellia plant 1-8 weight portions and solvent 62-95.2 weight portions. The additive of the present invention may be used for mixed oil with heavy oil components and mixed oil of petroleum oil and plant oil for burning in furnace, kiln and diesel enginge.

Owner:蔡可而

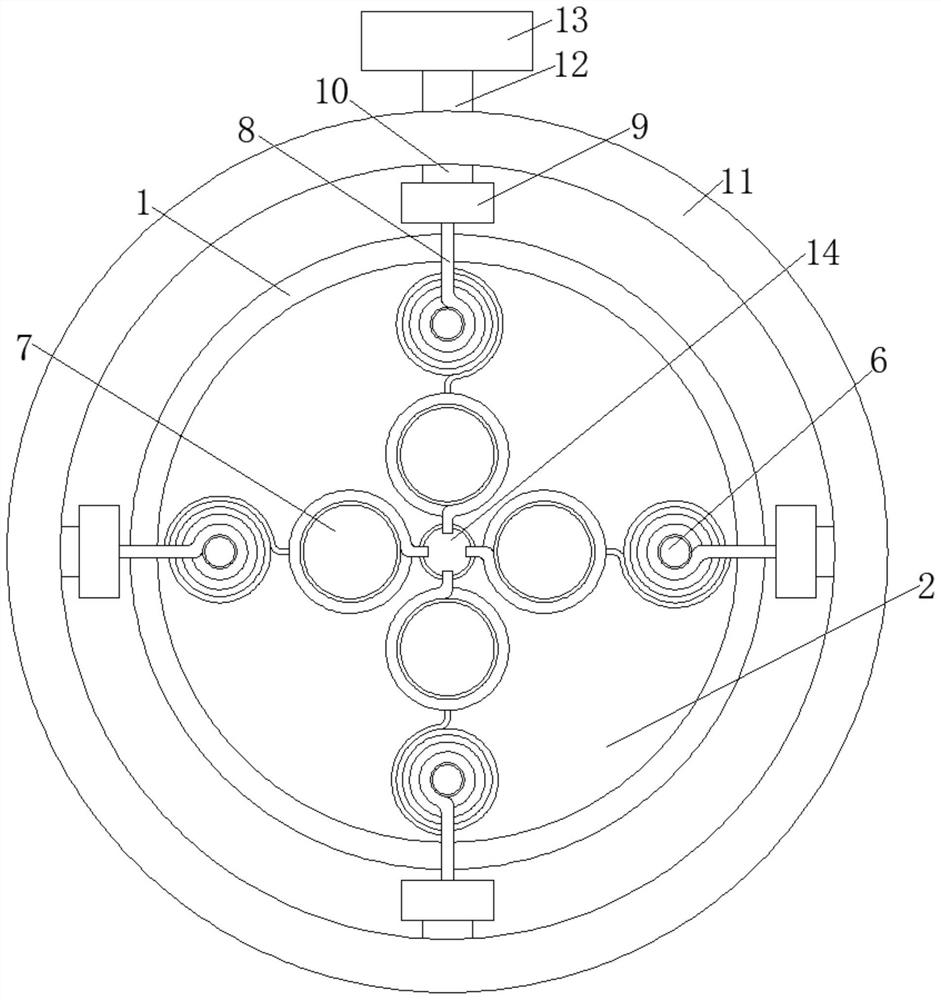

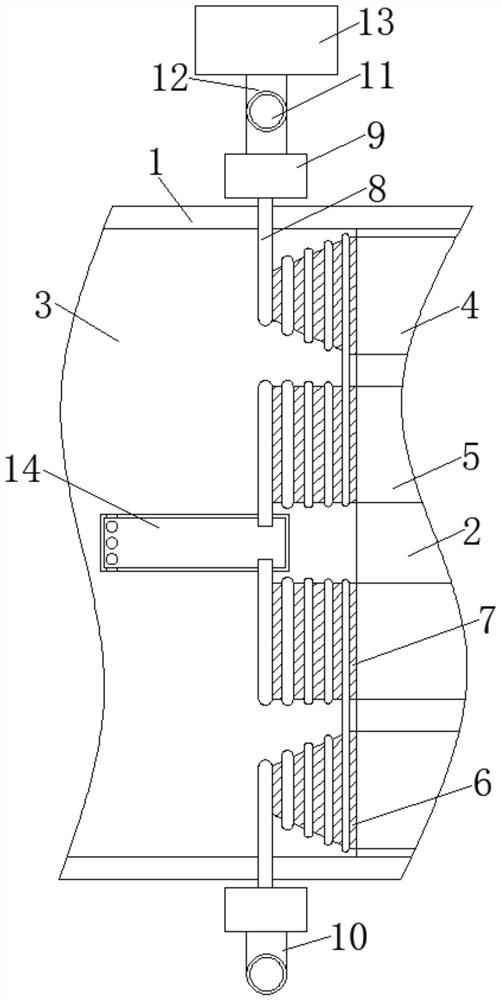

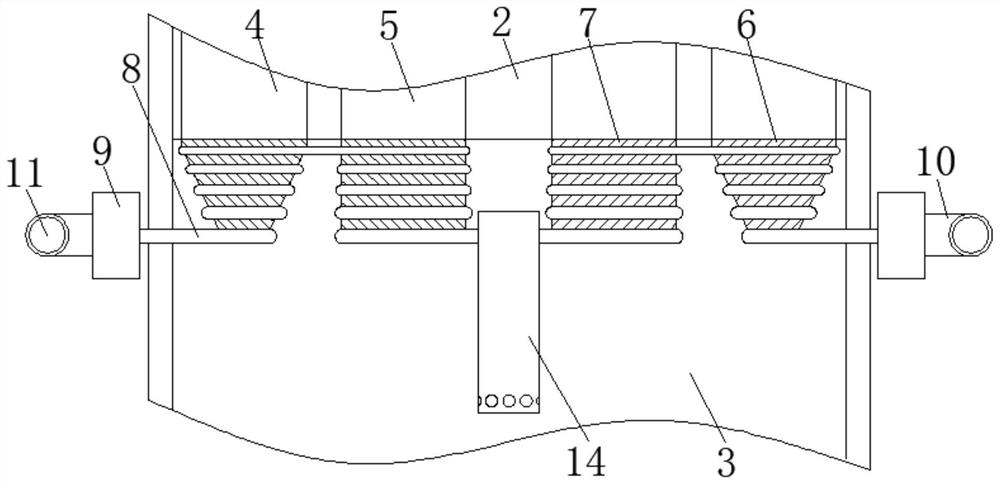

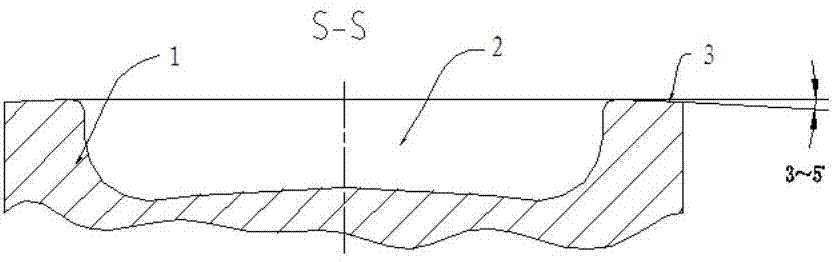

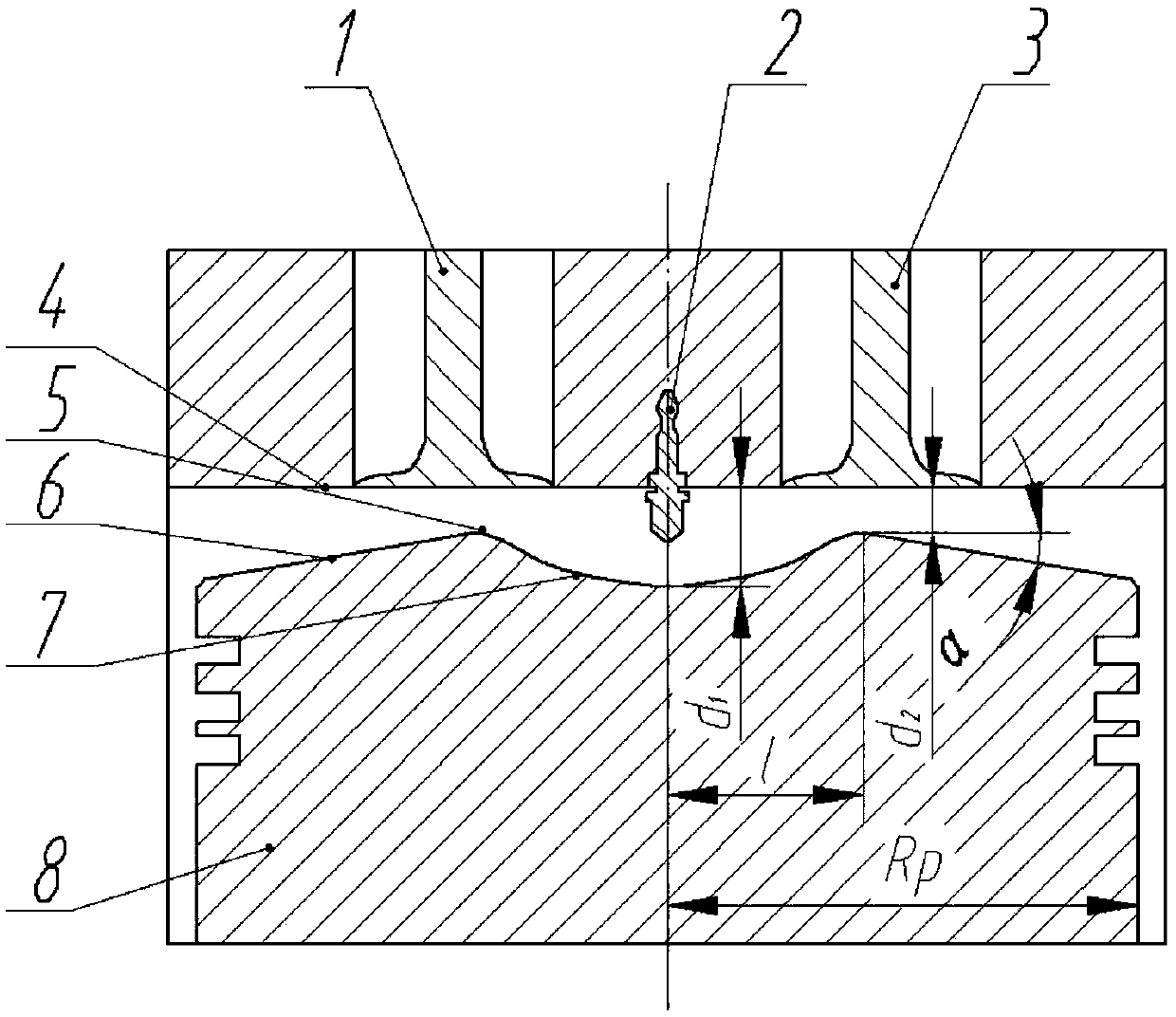

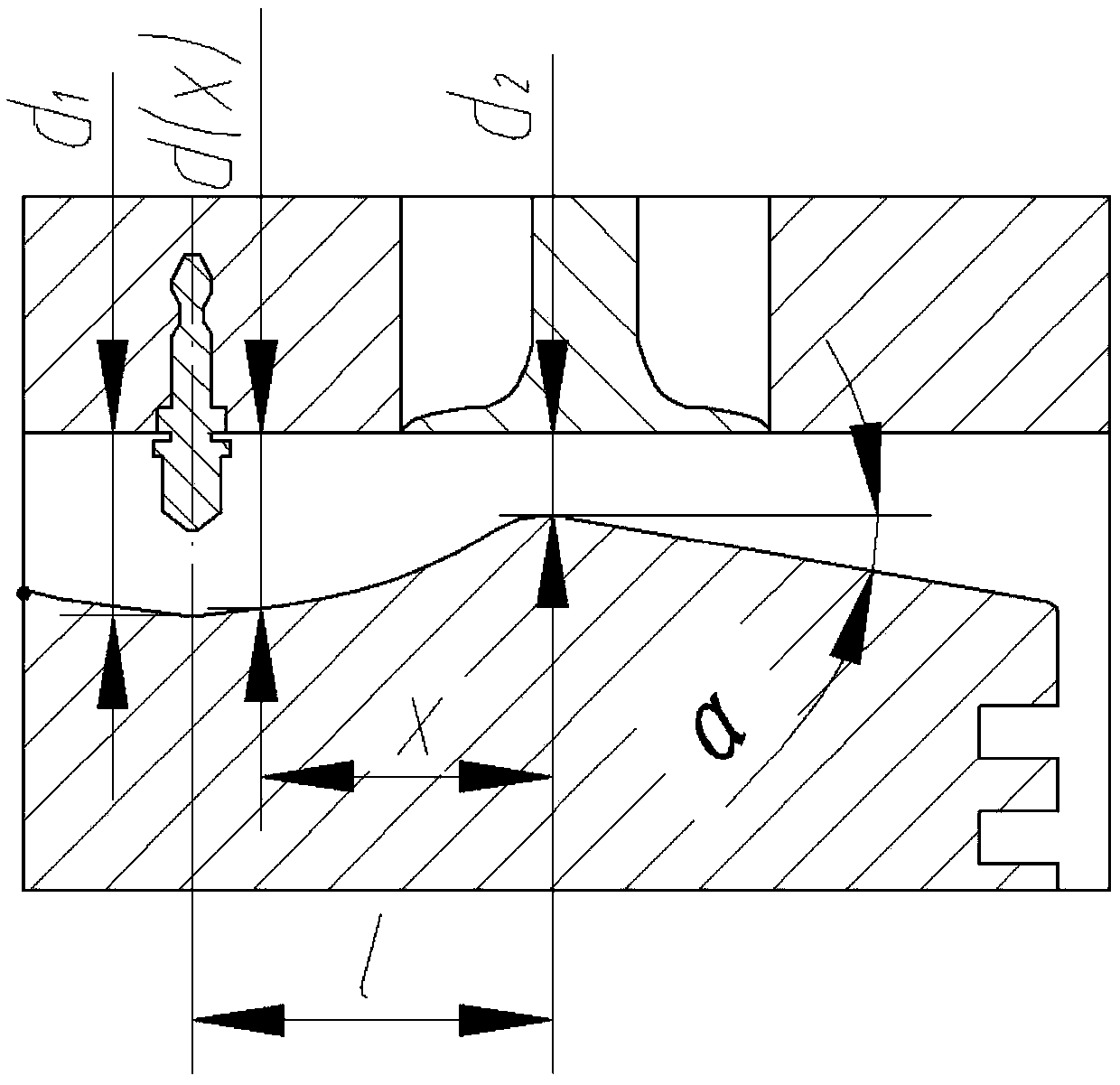

Piston for gas engine and gas engine with same

InactiveCN110630400AIncrease the speed of flame spreadImprove combustion performanceInternal combustion piston enginesPistonsPistonCombustion chamber

The invention belongs to the technical field of engines, and particularly relates to a piston for a gas engine and the gas engine with same. The piston comprises a combustion chamber arranged at the top of the piston, wherein the combustion chamber is of a cylindrical cavity shape structure, and the combustion chamber is provided with an inward concave portion extending in a direction away from the axis of the piston. According to the provided piston for the gas engine, the inward concave portion is additionally arranged inside the combustion chamber, so that airflow entering an air cylinder is guided, relatively strong turbulent flow is locally formed, the flame propagation speed is increased, the equivalent gas engine combustion performance is improved, meanwhile, extrusion flow is generated through an asymmetric structure, so that the influence of a part of tumble flow on the vicinity of a spark plug is counteracted, the airflow speed on the vicinity of the spark plug is reduced, and the misfire risk is reduced.

Owner:WEICHAI POWER CO LTD

Large-proportion methanol catalytic combustion agent

InactiveCN101962583AIncrease burn rateIncrease motivationLiquid carbonaceous fuelsFuel additivesCombustion chamberBiodiesel

The invention relates to a large-proportion methanol catalytic combustion agent, which belongs to the field of alcohol ether fuel alternative oil additives, and comprises 3-50% of initiator, 4-90% of oxidizer, 1-20% of activating agent, 0.5-10% of cleaning agent, and 2-30% of friction-reducing agent. The large-proportion methanol catalytic combustion agent has the effects of overcoming the cold start of methanol and the difficult self-ignition, and improving the burning rate of the methanol, the power of an engine and the oil conservation. Due to the strong catalytic oxidation and decomposition capability of the catalytic combustion agent, the large-proportion methanol catalytic combustion agent can promote the fast and full combustion of the methanol, improve the carbon deposition of a combustion chamber, play roles of cleaning and lubricating the engine, reduce the abrasion of the engine caused by the combustion of the methanol and reduce the emission of combustion waste gas. The large-proportion methanol catalytic combustion agent has the comprehensive catalytic function and the synergy, and can effectively inhibit metal corrosion and rubber swelling, further enhance and improve the large-proportion methanol catalytic combustion effect, and open a new way of the large-proportion methanol catalytic combustion technology for popularization and application of large-proportion methanol fuels: methanol gasoline, microemulsion alcohol gasoline, methanol bio-gasoline, methanol diesel, microemulsion alcohol diesel, methanol bio-diesel and alcohol-based fuel.

Owner:占小玲

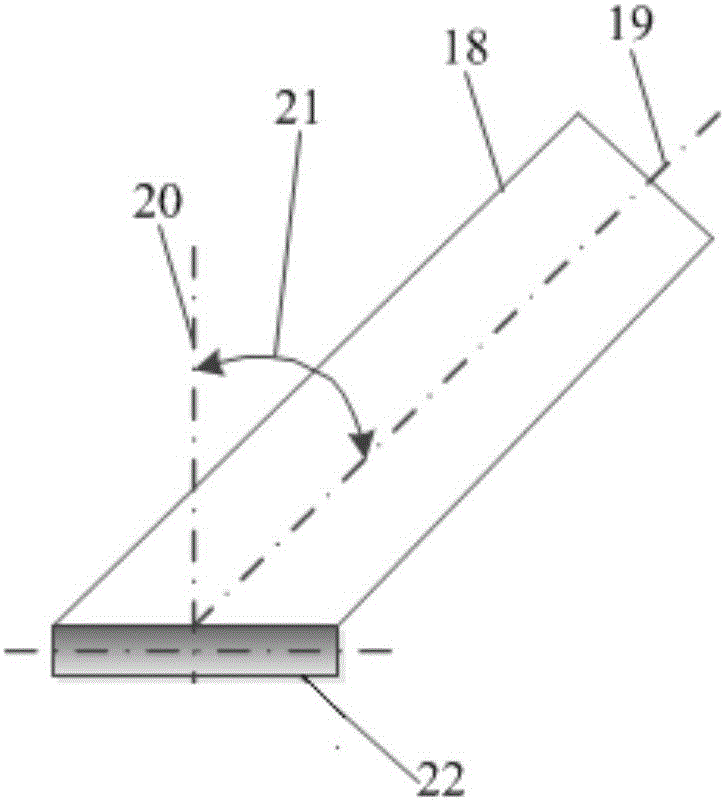

Engine capable of directly injecting natural gas for multiple times under high pressure in cylinder and layered rapid combustion method thereof

ActiveCN110905652AShorten the propagation distanceWell mixedElectrical controlInternal combustion piston enginesExhaust valveInlet valve

The invention aims to provide an engine capable of directly injecting natural gas for multiple times under high pressure in a cylinder and a layered rapid combustion method thereof. The engine comprises an air cylinder cover, an air cylinder wall, a piston, an air inlet channel, an air inlet valve, an exhaust channel, an exhaust valve, a high-pressure natural gas injection valve, a high-pressure natural gas supply pipeline and a spark plug, wherein the cylinder cover, the cylinder wall and the spark plug form a combustion chamber, the combustion chamber is hemispherical, the air inlet channel,the exhaust channel, the high-pressure natural gas injection valve, the high-pressure natural gas supply pipeline and the spark plug are arranged in the cylinder cover, the high-pressure natural gassupply pipeline is connected with the high-pressure natural gas injection valve, the air inlet valve is arranged in the air inlet channel, the exhaust valve is arranged in the exhaust channel, and thehigh-pressure natural gas injection valve is located between the air inlet channel and the spark plug. The engine is advantaged in that layered combustion of different gradients under different loadscan be achieved, the ignition stability of the natural gas engine is guaranteed, economical efficiency and dynamic property of the engine are effectively improved, and emission is reduced.

Owner:HARBIN ENG UNIV

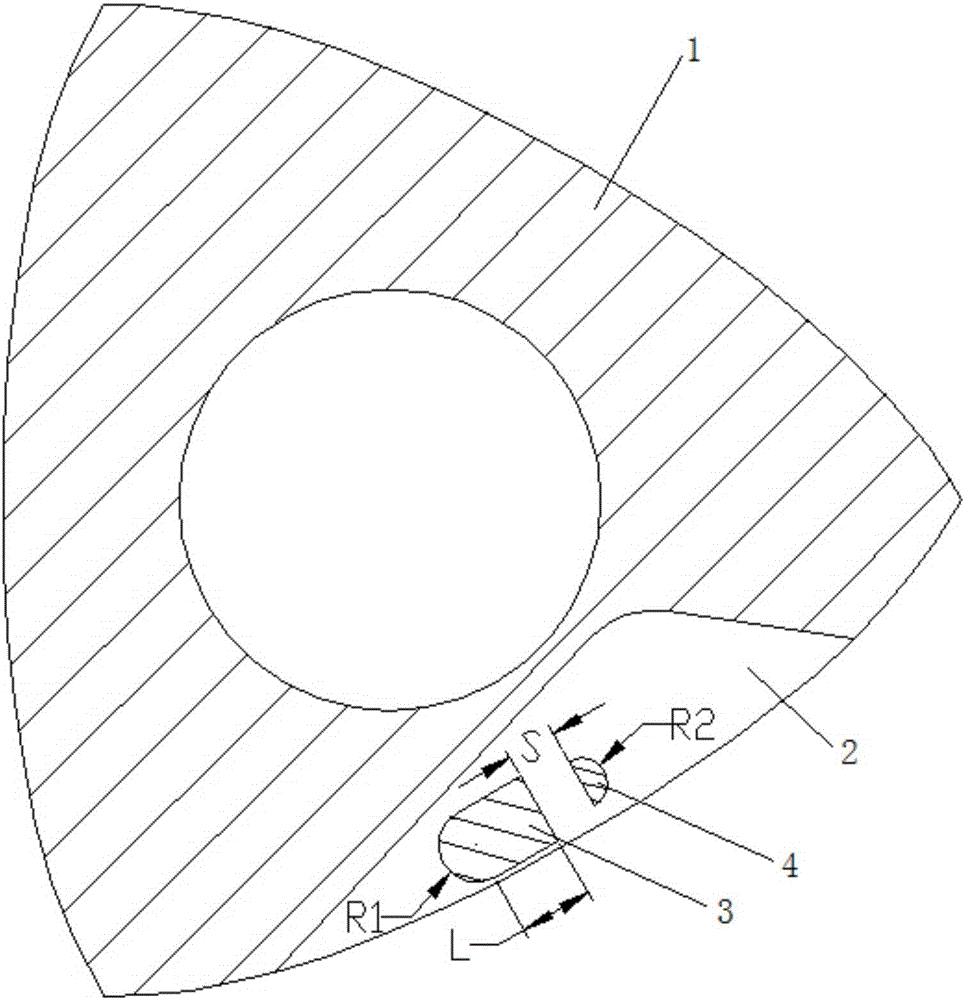

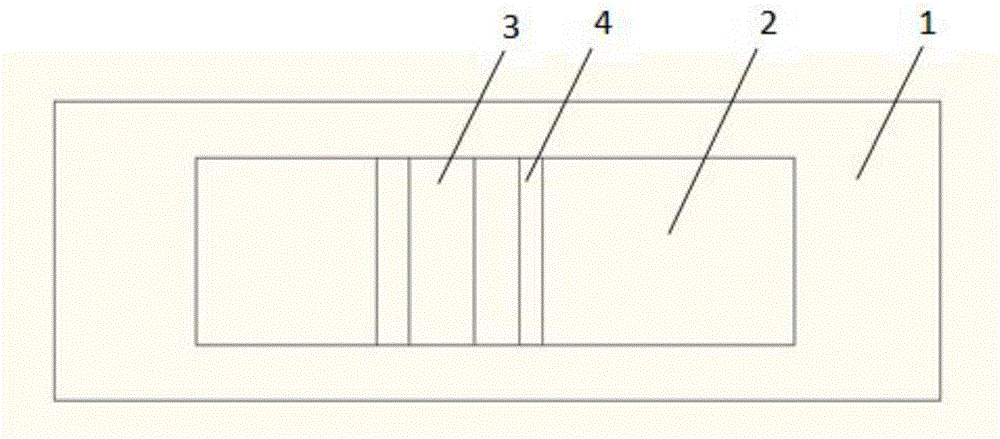

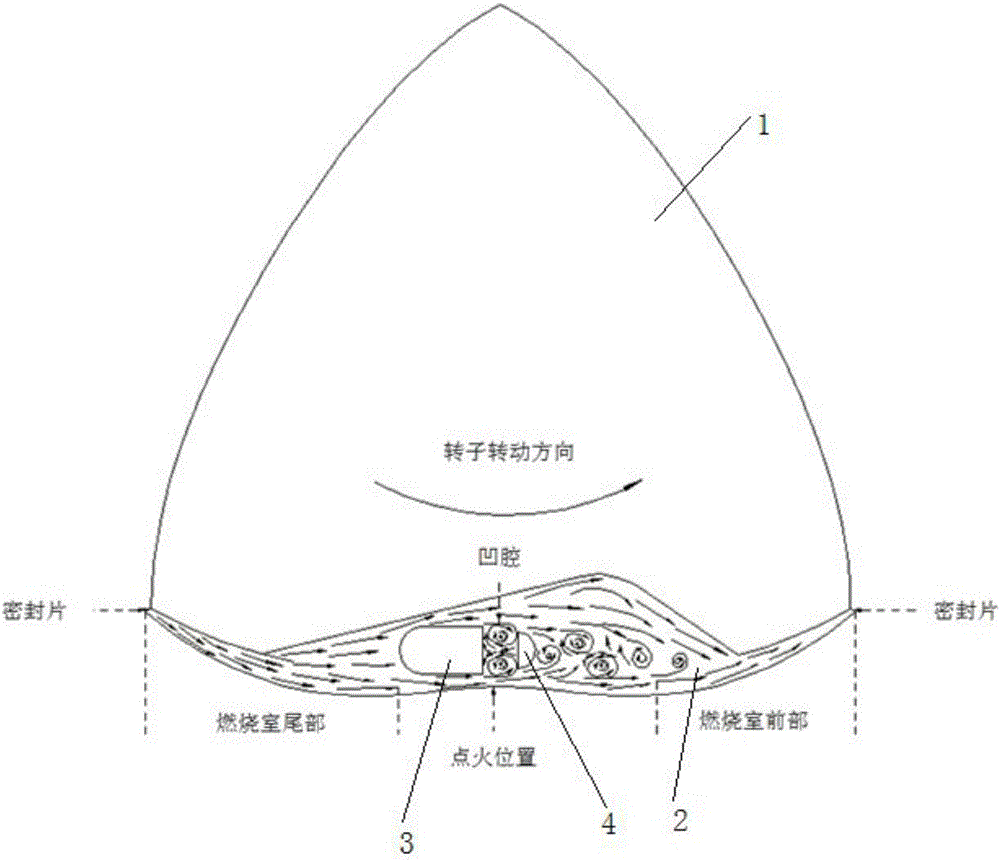

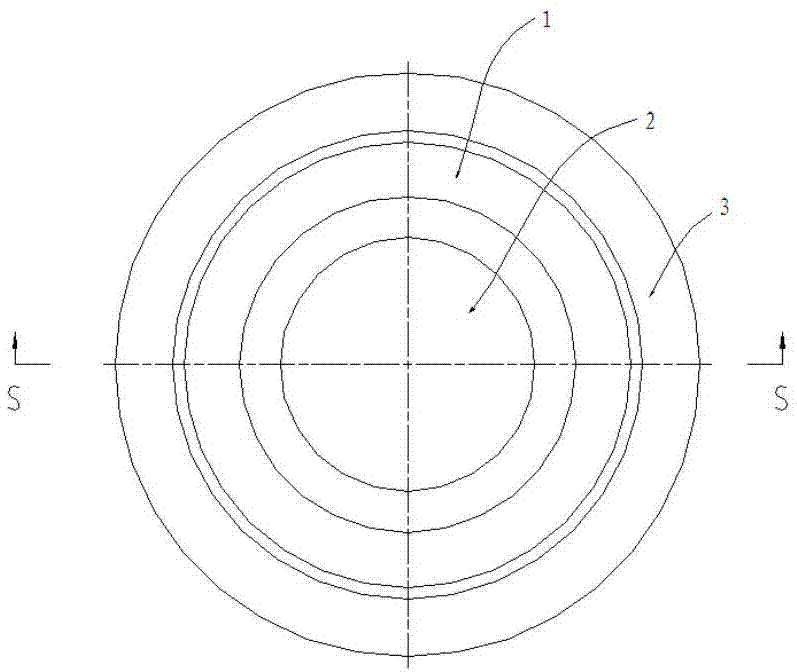

Swirl combustion chamber of rotor engine

InactiveCN106640360AWell mixedEnhance heat and mass transferInternal combustion piston enginesFlame propagationCombustion chamber

The invention provides a swirl combustion chamber of a rotor engine. Two blunt bodies perpendicular to the end face direction are arranged front and back in a concave pit of a wankel rotor in the motion direction of the rotor, the two ends of each blunt body are fixedly connected with the inner end face of the concave pit of the rotor, the section of the front blunt body is composed of a semicircle and a rectangle using the diameter of the semicircle as one edge, the section of the back blunt body is in a semicircle shape, the diameter of the back blunt body semicircle is parallel to one edge of the front blunt body rectangle, a cavity is formed between the diameter of the back blunt body semicircle and the edge of the front blunt body rectangle, and the radius of the front blunt body semicircle is larger than that of the back blunt body. By the additional arrangement of the blunt bodies in the concave pit of the rotor of the rotor engine, a backflow region is formed in a combustion chamber, the formation of gas mixture and flame propagation are accelerated, and the high combustion efficiency is achieved.

Owner:JIANGSU UNIV

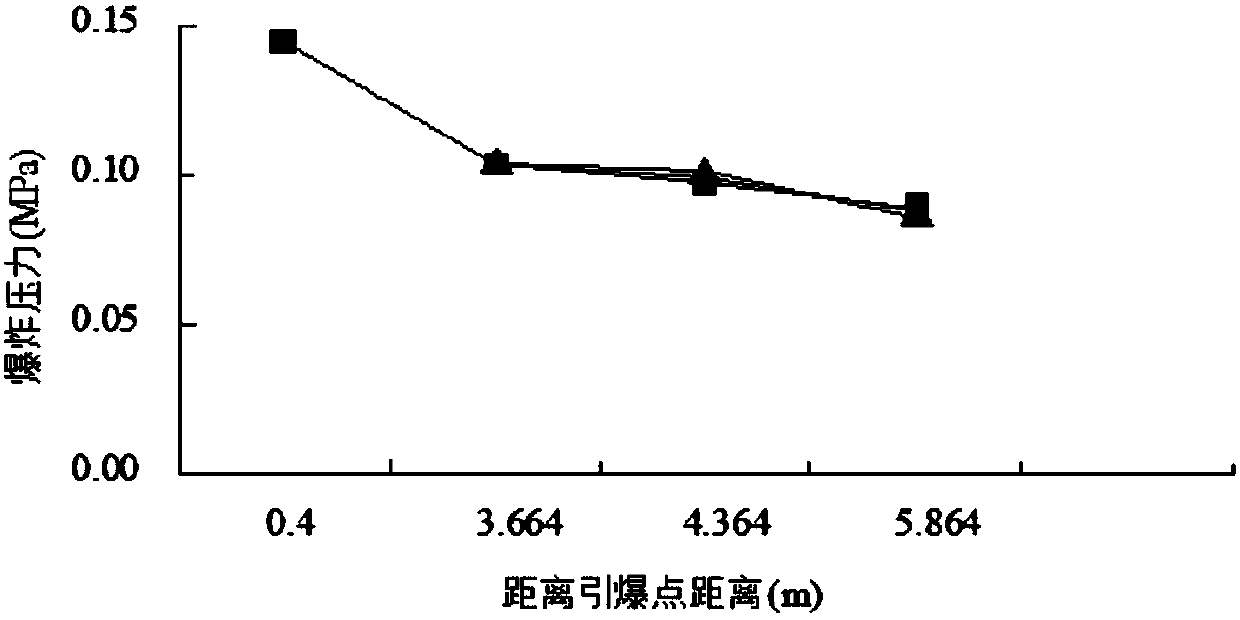

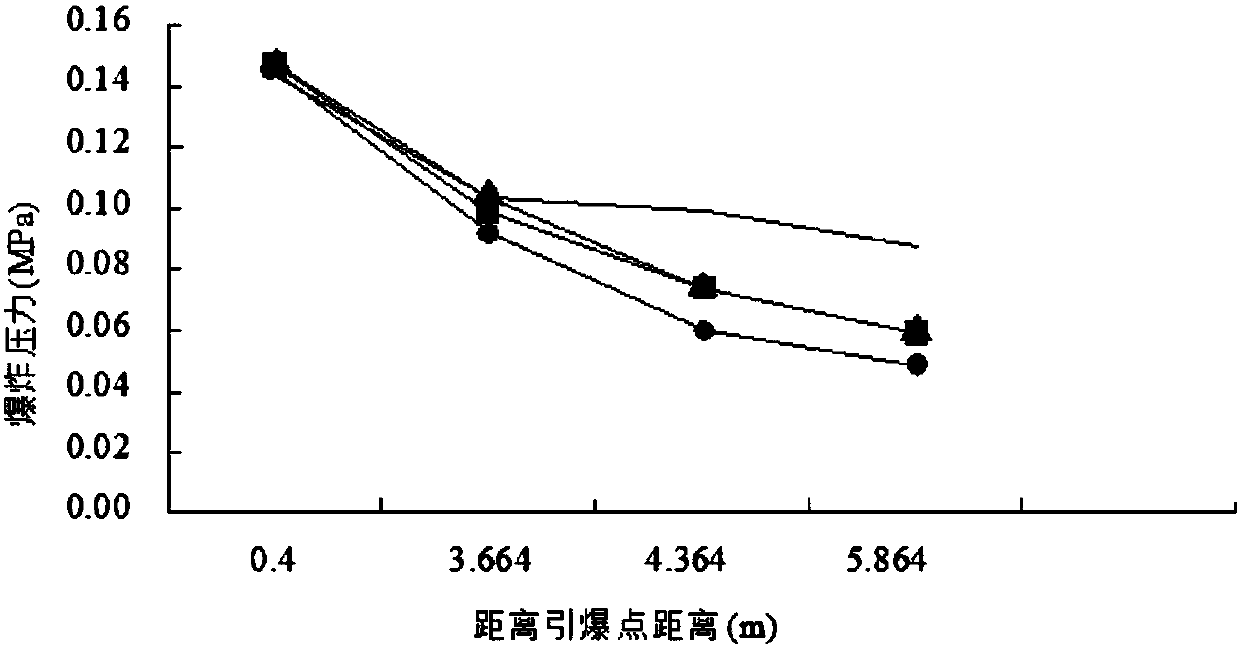

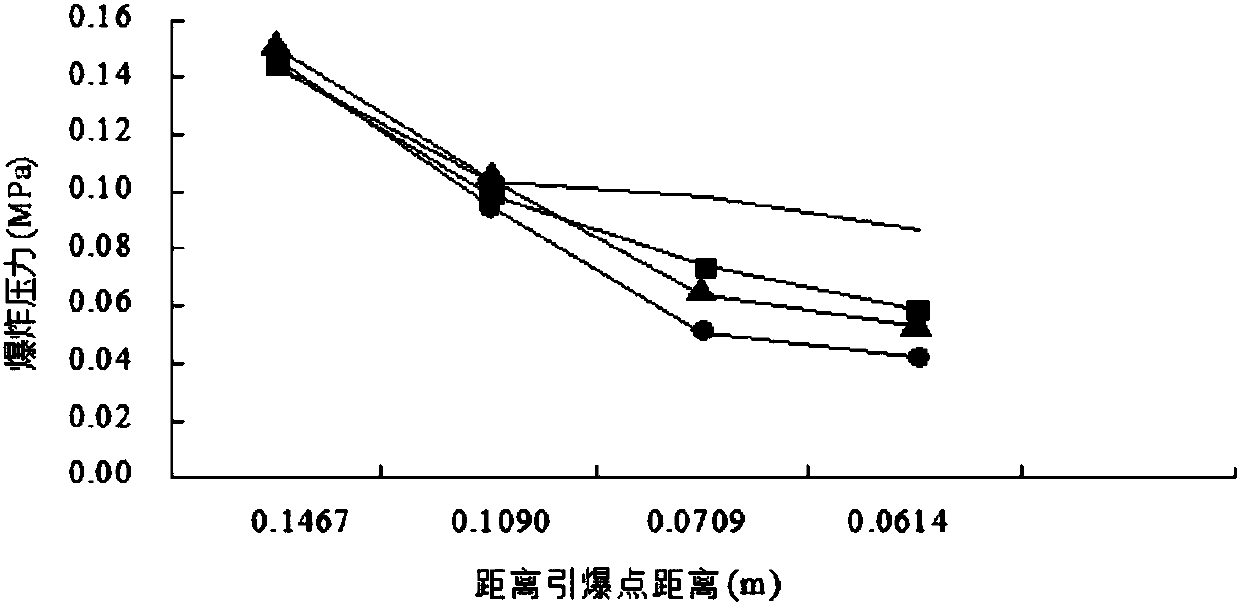

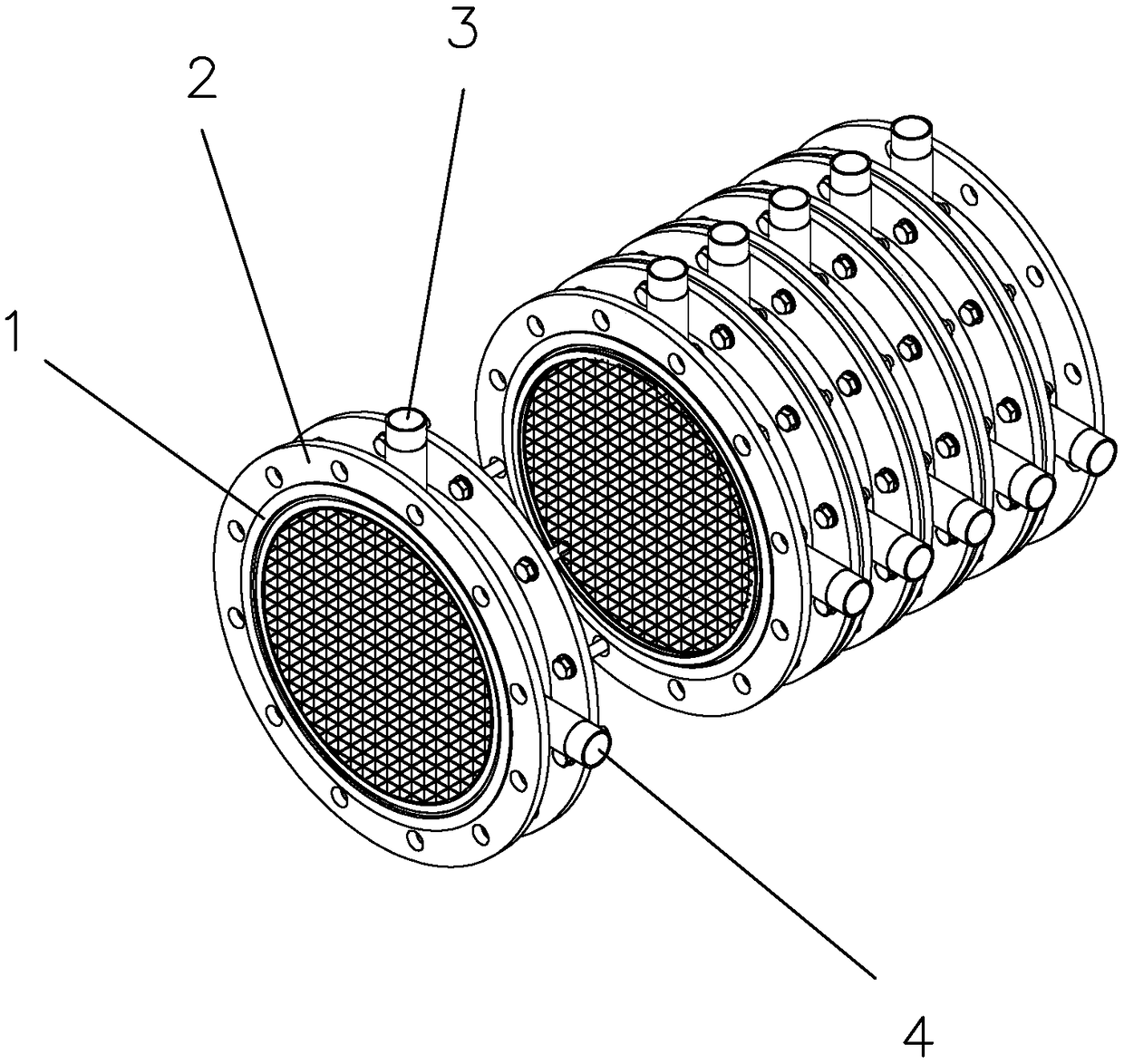

Application of multilayer foamed iron-nickel metal materials in isolation and suppression of gas explosion

InactiveCN107780967AIncreasing the thicknessHigh decay rateMining devicesDust removalGas explosionMetallic materials

The invention relates to an application of multilayer foamed iron-nickel metal materials and aims to provide an application of the multilayer foamed iron-nickel metal materials in isolation and suppression of gas explosion in order to explore the isolation and suppression conditions of the multilayer foamed iron-nickel metal materials in the aspect of the gas explosion. A method comprises steps asfollows: 2-3 layers of the foamed iron-nickel metal materials are arranged at intervals, the distance between every two adjacent foamed iron-nickel metal materials is 5-20 cm, the thickness of each layer of the foamed iron-nickel metal material is 2-3 cm, porosity of the foamed iron-nickel metal material close to the side of a detonating point is 20-30 PPI, and porosity of the other foamed iron-nickel metal materials is 10-30 PPI. The invention applies to the field of gas explosion suppression and isolation.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

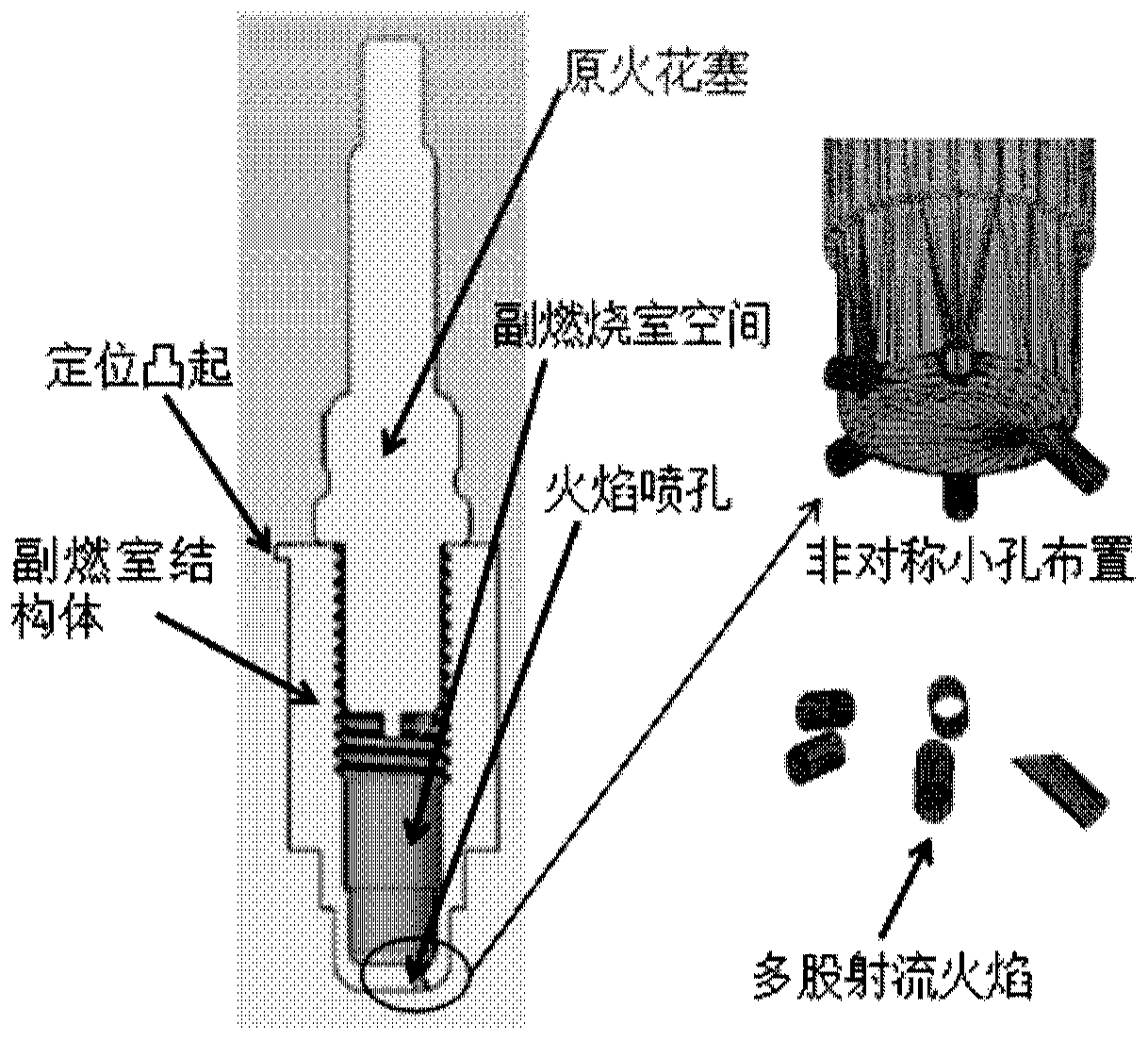

Engine rapid combustion device suitable for low-evaporation characteristic fuel

PendingCN111485992ABurn fasterFast ignitionInternal combustion piston enginesCombustion chamberMixed gas

The invention relates to an engine combustion device. The engine combustion device comprises a main combustion chamber, a spark plug, an auxiliary combustion chamber and flame spray holes, wherein initial flames are generated in the auxiliary combustion chamber through discharging of the spark plug, then the flames are generated in the auxiliary combustion chamber and develop rapidly, then multiple jet flames are generated through the plurality of spray holes used for connecting the auxiliary combustion chamber with the main combustion chamber, the multiple jet flames are jetted into the maincombustion chamber at the same time and are equivalent to a high-energy multi-core ignition source of the main combustion chamber, and mixed gas in the main combustion chamber is ignited by multiple large-area flames at the same time. According to the engine combustion device, the combustion speed of the mixed gas is increased, the ignition stability and reliability are improved, and the knockingphenomenon can be effectively restrained.

Owner:天津内燃机研究所(天津摩托车技术中心)

Anticlockwise-tumble-ratio combustion system for automotive engine

InactiveCN106640337AEasy to useBurn quicklyInternal combustion piston enginesCombustion systemExhaust valve

The invention relates to an anticlockwise-tumble-ratio combustion system for an automotive engine. The anticlockwise-tumble-ratio combustion system comprises a combustion chamber roof, a cylinder wall, an exhaust valve, a pit piston, an exhaust-side oil sprayer, an intake valve seat ring and a vertical intake channel, wherein the exhaust valve, the exhaust-side oil sprayer, an asymmetrical intake valve rod and an asymmetrical intake valve are arranged on the combustion chamber roof; the included angle between the central line of the vertical intake channel and the central line of the intake valve seat ring is 15-25 degrees; fresh air enters through the vertical intake channel, and more gases flow towards the right under the action of the asymmetrical intake valve, collide with the pit piston to be reflected, and form serious clockwise rotating tumble in a cylinder through the guide of the cylinder wall and the combustion chamber roof, for improving flowing at the exhaust side, reducing a detonation trend and accelerating combustion. The anticlockwise-tumble-ratio combustion system disclosed by the invention is capable of effectively reducing the detonation of a lateral direct-injection gasoline engine in the cylinder, improving the strength of the tumble in the cylinder, and accelerating the combustion.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

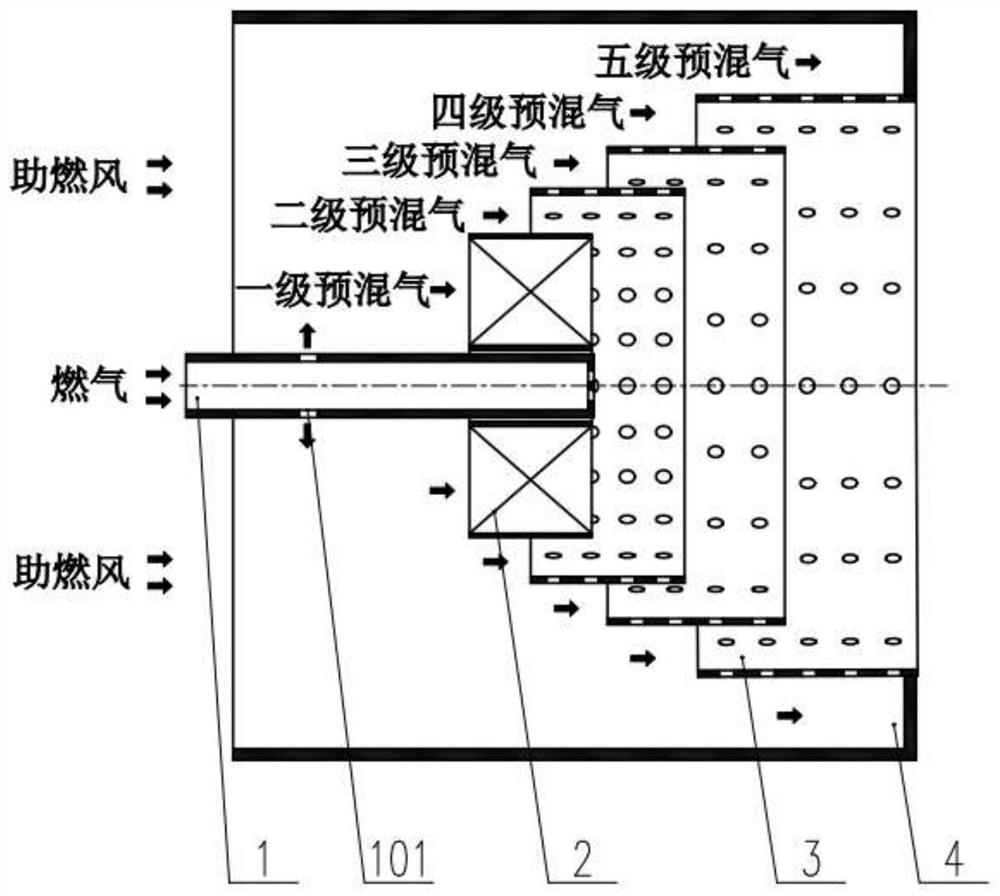

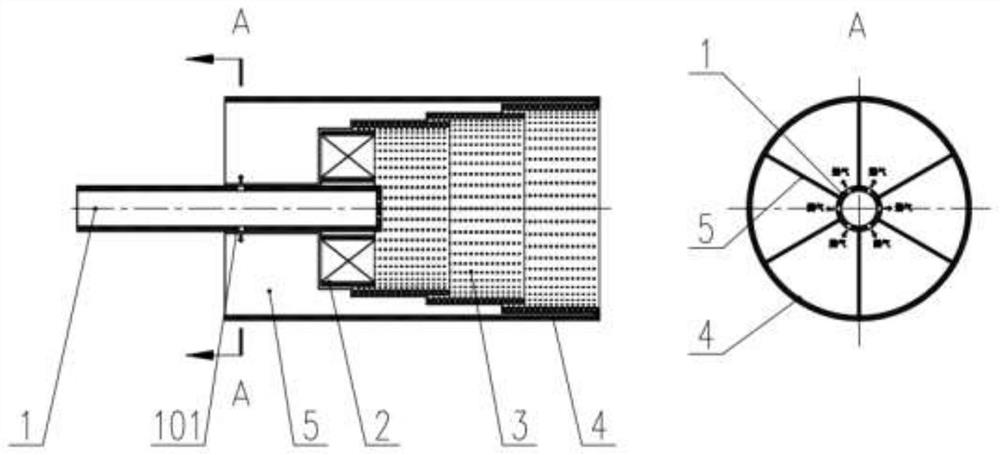

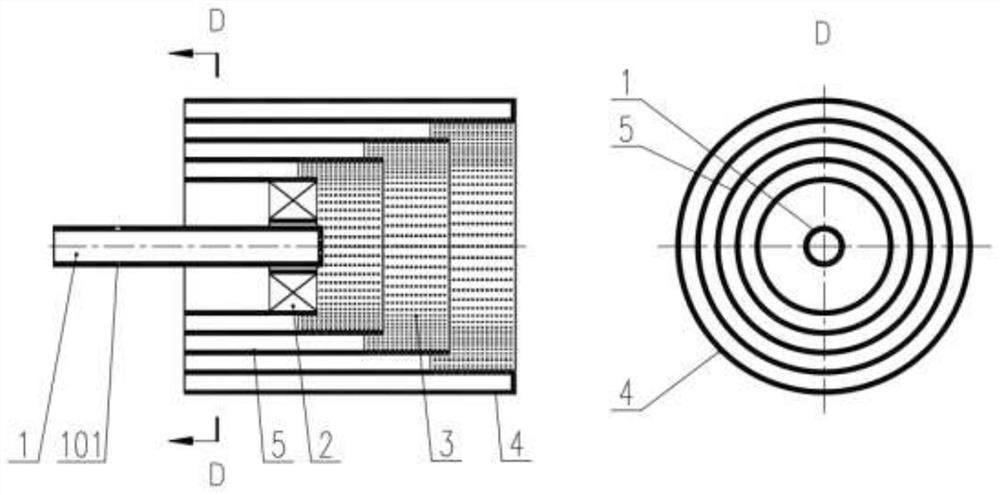

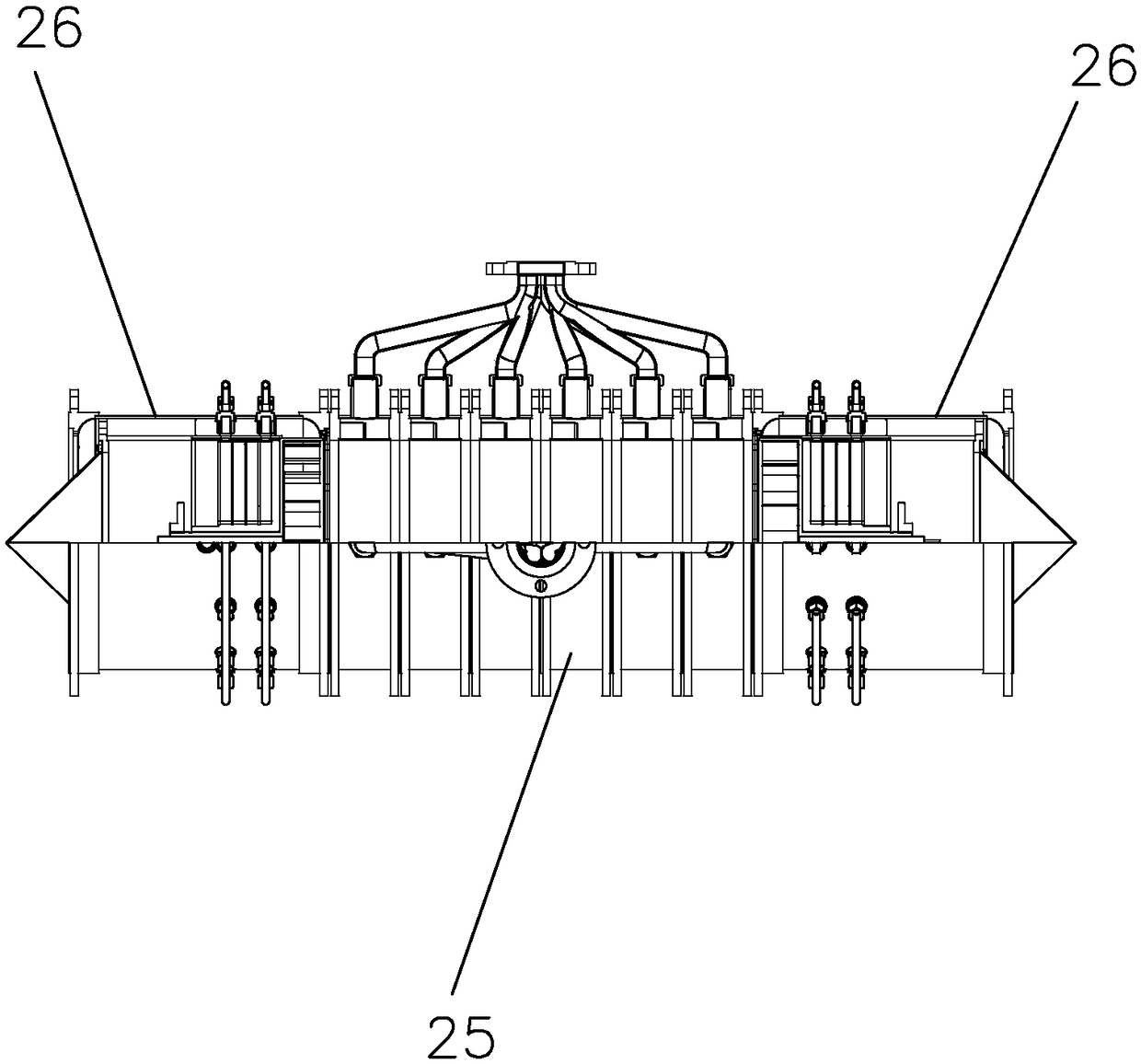

A flame tube, an industrial low-nitrogen burner, and a step-by-step amplification method for a gas flame

ActiveCN112344371BReduce generationReduces the possibility of flashback deflagrationContinuous combustion chamberGaseous fuel burnerThermodynamicsCombustor

The invention discloses a flame tube, an industrial low-nitrogen burner, and a gas flame step-by-step amplification method. The gas flame step-by-step amplification method is mainly embodied in the form of a flame tube, with stable flame and low NOx emission; high-speed smoke is ejected from the outlet of the flame tube. The flue gas in the injection furnace is recirculated to achieve low-nitrogen combustion with uniform temperature. In the absence of flue gas external circulation, the NOx emission can be controlled at 20 mg per standard square (3.5% O 2 )the following. The industrial low-nitrogen burner using the gas flame step-by-step amplification method, the flame tube is premixed combustion with an excess air coefficient greater than 1; the gas outside the flame tube is premixed and is ignited by the high-temperature flue gas ejected from the flame tube nozzle in the burner Combustion, the volume expansion of the ignited gas is accelerated and ejected from the burner outlet at high speed, and the flue gas in the ejector furnace is evenly mixed; the burner nozzle protrudes from the front wall of the furnace; part of the gas is injected into the leeward side of the burner to mix with the return flue gas Then it meets the burner nozzle flame to realize slow low-oxygen combustion.

Owner:徐州燃烧控制研究院有限公司

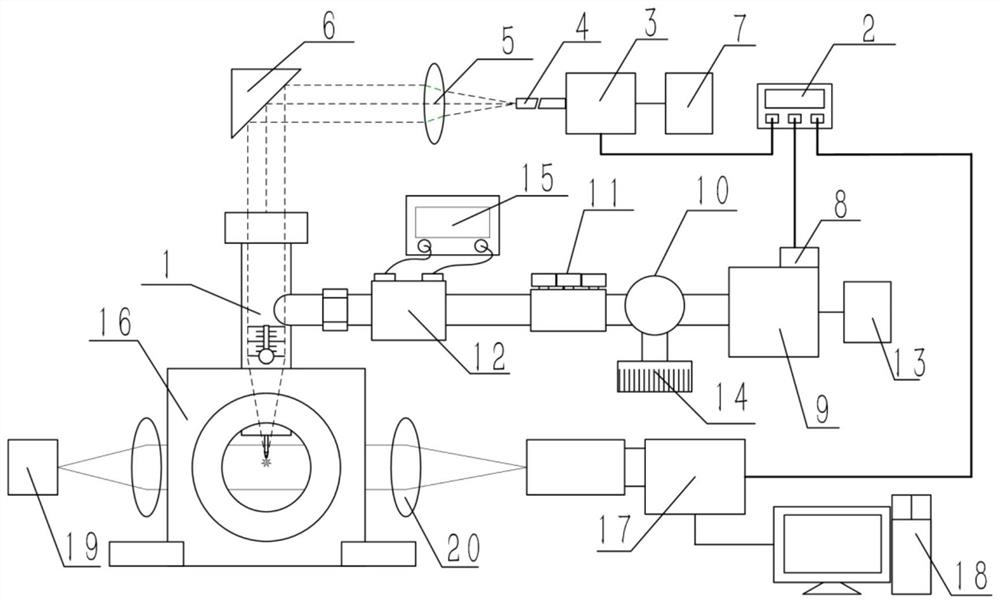

Integrated microwave enhanced laser plasma ignition experiment system

ActiveCN113916540AReduced Power RequirementsReduce cooling requirementsInternal-combustion engine testingChemical analysis using combustionEngineeringParticle physics

The invention belongs to the related technical field of laser ignition, and discloses an integrated microwave enhanced laser plasma ignition experiment system. The system comprises a laser emission unit, a microwave emission unit, an igniter and a constant volume combustion bomb, the laser emission unit is used for emitting laser, the microwave emission unit is used for generating microwaves, the igniter is used for receiving the laser emitted by the laser emission unit and the microwaves generated by the microwave emission unit, and performing ignition by using the laser and the microwaves. The constant-volume combustion bomb is arranged below the igniter, and an ignition head of the igniter is arranged in the constant-volume combustion bomb, so that the combustion process is isolated from the outside. According to the system, microwave ignition and laser ignition are coupled together, and a basic research means is provided for deep research on the microwave-enhanced laser ignition process, the plasma-enhanced combustion mechanism and potential application of microwave-enhanced laser ignition on a real machine.

Owner:HUAZHONG UNIV OF SCI & TECH

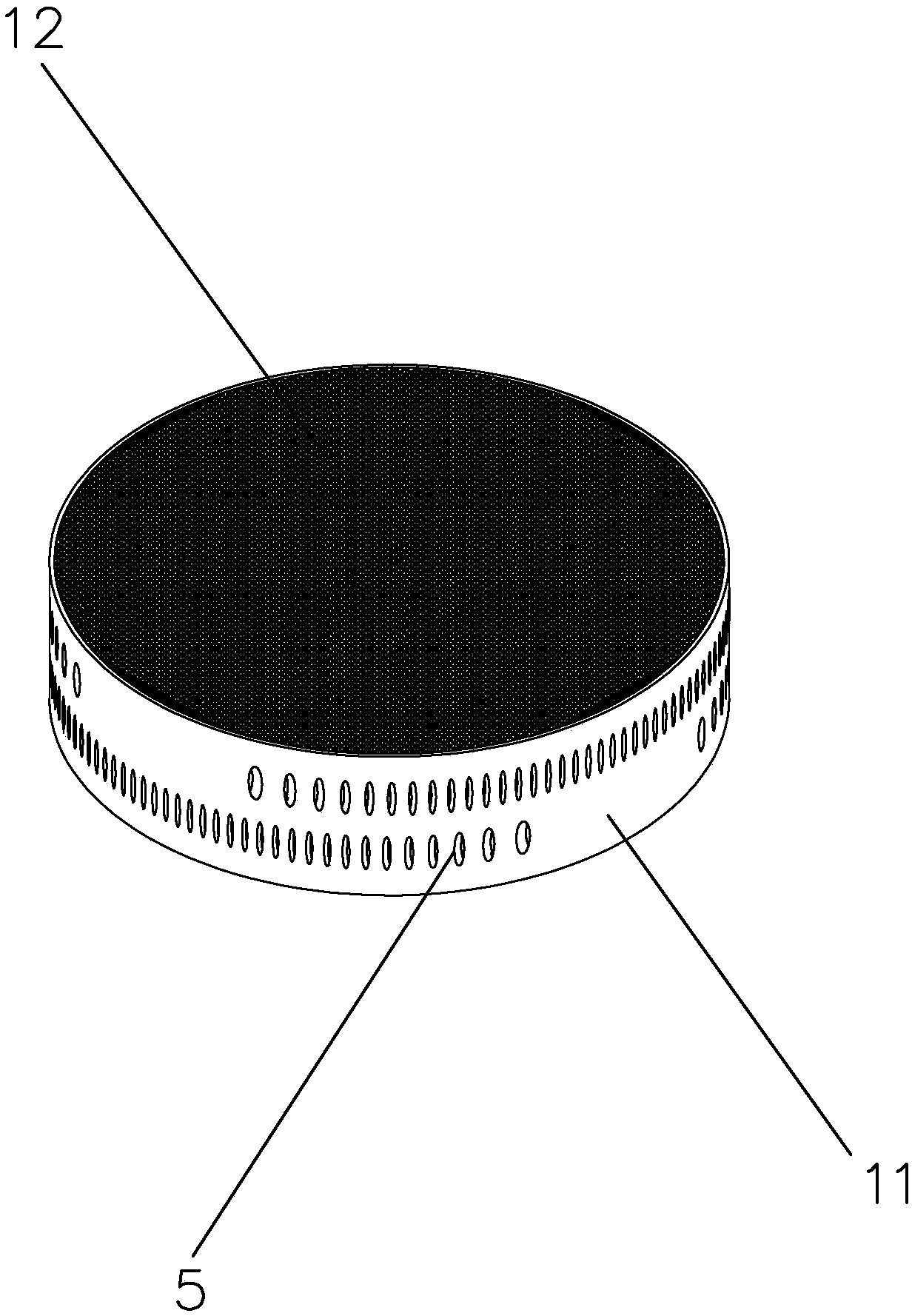

Anti-backfire device for gas mixing type combustor

PendingCN113898945AThe difference in flame propagation speed is reducedPrevent flashbackCombustion technology mitigationGaseous fuel burnerThermodynamicsCombustor

The invention relates to the technical field of heat energy engineering, and discloses an anti-backfire device for a gas mixing type combustor. The anti-backfire device comprises a shell, a mixing pipe cavity is fixedly formed in one end of an inner cavity of the shell, a combustion cavity located in the inner cavity of the shell is fixedly formed in one side of the mixing pipe cavity, and four hydrogen pipes are fixedly installed in the inner cavity of the mixing pipe cavity. According to the anti-backfire device, a first spray head is cooled through flowing of air, the flame propagation speed of hydrogen is decreased, meanwhile, the flame propagation speed of natural gas is increased, and the backfire phenomenon is effectively prevented; and by designing that the pipe body diameter value of a protection pipe set changes in a progressive manner, when air flows in a pipe body of the protection pipe set located on the outer surface of the first spray head, insufficient heat absorption caused by heat contained in the air is effectively offset, and when air flows in the pipe body of the protection pipe set located on the outer surface of a second spray head, the reverse heat conduction phenomenon at the position of the second spray head and the reverse cooling problem of an opening in the front end of the second spray head can be avoided.

Owner:王志海

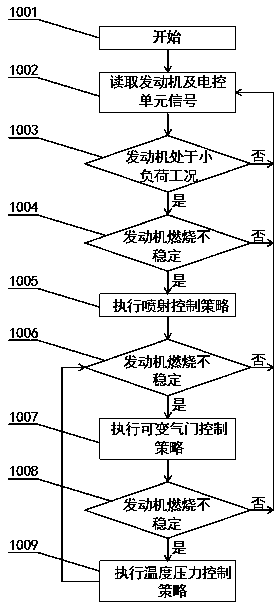

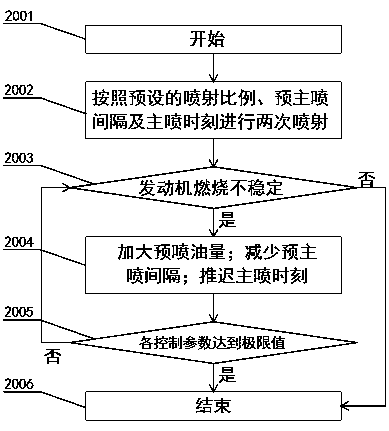

Control method and system for improving combustion stability of gasoline compression ignition in small-load working condition

ActiveCN111173635AImprove combustion stabilitySolve combustion instabilityElectrical controlInternal combustion piston enginesIn vehicleGasoline

The invention discloses a control method and system for improving combustion stability of gasoline compression ignition in a small-load working condition, and belongs to the technical field of engines. The system is characterized in that a main gas inlet pipe (8) is simultaneously connected with a gas inlet heater (3) and a gas inlet flow control valve (5), the gas inlet heater (3) is connected with a gas inlet heater flow control valve (2) in series, then the gas inlet heater (3) and the gas inlet flow control valve (5) are connected with an engine (16), an in-cylinder pressure sensor (13) and an in-cylinder direct injection oil injector (14) are installed in a variable valve (15), and the gas inlet heater flow control valve (2), the gas inlet heater (3), the gas inlet flow control valve(5), the in-cylinder direct injection oil injector (14) and the variable valve (15) are connected with a vehicle-mounted computer (9). Through the control method and system for improving the combustion stability of the gasoline compression ignition in the small-load working condition, the combustion stability of a gasoline compression ignition combustion mode in the small-load working condition isimproved, and the problem that at present, combustion of the gasoline compression ignition combustion mode in the small-load working condition is unstable is solved.

Owner:SHANDONG UNIV OF TECH

Heavy fuel oil additive containing benzopyran multi-hydroxy metal compound

InactiveCN100343371CPromote combustionIncrease surface tensionLiquid carbonaceous fuelsBenzopyranOil additive

The heavy fuel oil additive containing benzopyran polyhydroxy metal compound is one kind of catalyst capable of promoting heavy petroleum part to burn completely and reducing the ablation and wear of heavy fuel oil on engine parts. It contains benzopyran polyhydroxy metal compound obtained with benzopyran polyhydroxy compounded from camellia plant and inorganic metal salt through reaction in 6-30 weight portions, macro molecular surfactant extracted from camellia plant 1-8 weight portions and solvent 62-95.2 weight portions. The additive of the present invention may be used for mixed oil with heavy oil components and mixed oil of petroleum oil and plant oil for burning in furnace, kiln and diesel enginge.

Owner:蔡可而

Grinding waste perforated brick

InactiveCN106242607AHigh strengthImprove the authenticity rateCeramic materials productionCeramicwareBrickSlag

The invention discloses a grinding waste perforated brick. The grinding waste perforated brick comprises, by weight, 10-25 parts of grinding wastes, 5-10 parts of basalt, 35-50 parts of furnace slag, 2-6 parts of manganese dioxide, 1-2 parts of borax, 2-4 parts of perlite, 10-20 parts of river sands, 1-5 parts of wood chips and 80-100 parts of water. The perforated brick has the advantages of scientific production technology, convenience in manufacturing, realization of waste utilization, low production cost, compactness, high strength, high hardness, good binding property, good wear resistance, no desertification, no cracks caused by rapid change of the temperature, no porcelain formation, no fragmentation, strong water absorption property, small shrinkage, wear, pressure, acid-alkali and ageing resisting functions and long service life.

Owner:安徽琮玥工程项目管理有限公司

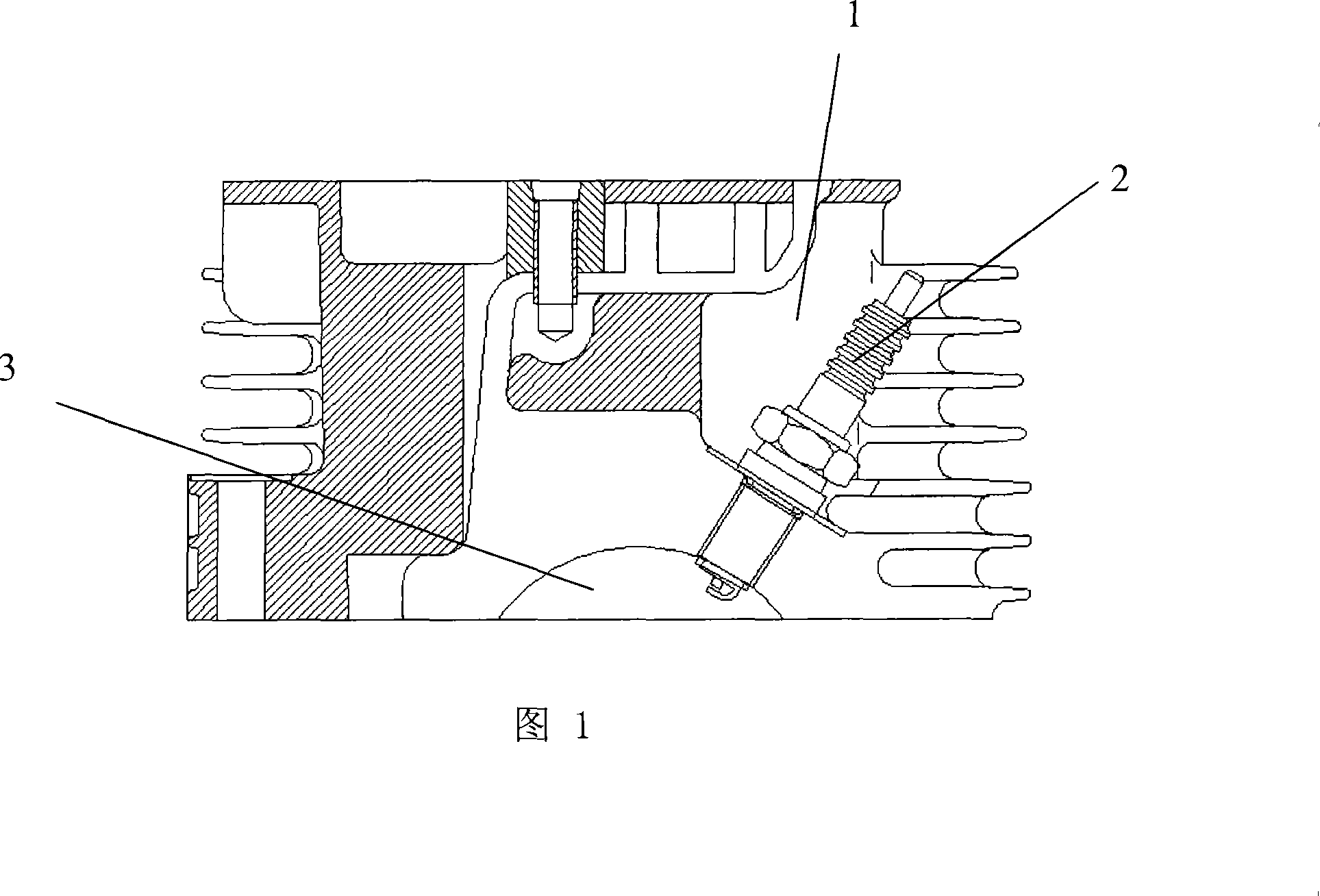

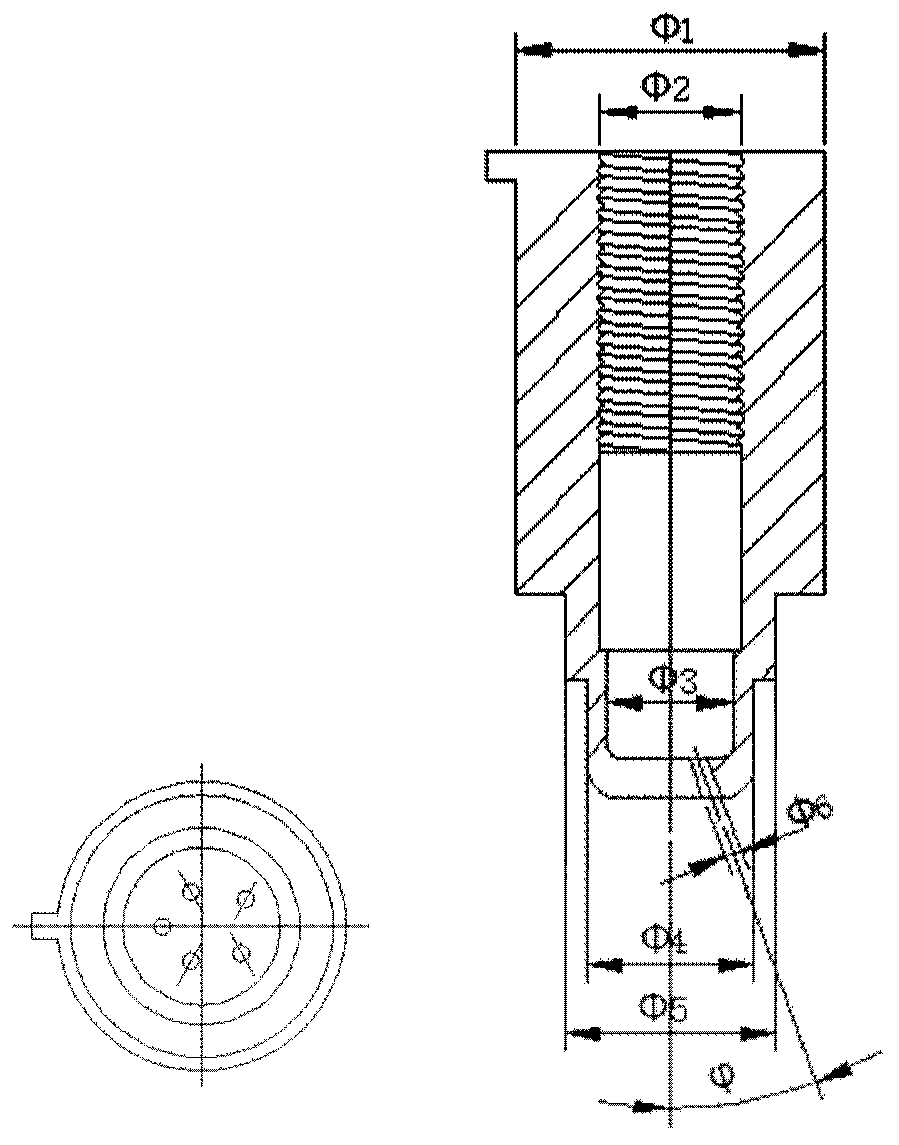

An Elongated Arc Plasma Jet Igniter

ActiveCN104454290BIncrease the speed of flame spreadStrong penetrating powerEngine ignitionMachines/enginesPlasma jetFlame spread

An elongated arc plasma jet igniter, the swirler is fixed at the bottom of the inner cavity of the casing; the anode is located in the casing and is fixedly connected with the swirler; the lower end of the insulating sleeve is installed in the center hole of the swirler, and insulated The gap between the outer peripheral surface of the middle part of the sleeve and the inner surface of the housing forms an air chamber. The cathode is embedded on the cathode mounting base, and the arc end of the cathode protrudes from the lower end of the insulating sleeve and is located in the anode; the arc end of the cathode is kept at a discharge distance of 2-8mm from the anode nozzle; the air intake pipe is located in the casing The upper end communicates with the air chamber space formed between the insulating casing shells. The cone angle β at the end of the cathode arc is 40°. The cone angle α of the anode shrinkage section is 60-90°. Eight swirl holes with a helix angle of 45° are evenly distributed on the end face of the cyclone, so that the working medium passing through the cyclone generates swirl. The invention has the characteristics of high flame propagation speed, strong penetrating power and rich active air plasma.

Owner:AIR FORCE UNIV PLA

Optimized internal combustion engine piston top structure

InactiveCN104500255AIncreased strength of the flow fieldImprove efficiencyMachines/enginesPistonsExternal combustion engineEngineering

The invention discloses an optimized internal combustion engine piston top structure comprising a piston. A concave combustion chamber is arranged on the piston top, and a circle of a flow guide surface is obliquely arranged on the piston top adjacent to the edge and is provided with the lower exterior and the high interior. Thus, the piston top is capable of guiding the flow and oblique as designed, the machining and manufacturing process is simple, the cylinder internal flow field strength can be increased by 8% around under the same compression ratio, the flame transmission or fuel and gas mixing speed of the internal combustion engine is increased significantly, the combustion time is shortened, the isopycnal level is raised, and the efficiency of the engine is improved.

Owner:CHONGQING PUSH MECHANISM

Gas mixed clean fuel

The invention discloses a gas mixed clean fuel, and belongs to the technical field of fuel combustion. The purpose of the invention is to provide the clean fuel containing multiple mixed gases and having a high combustion efficiency and a low production cost. The fuel comprises, by mass, 36-42% of natural gas, 24-32% of water gas, 2-6% of liquefied petroleum gas and 25-35% of methyl ether. The natural gas, water gas, liquefied petroleum gas and dimethyl ether are mixed according to a reasonable ratio, so the advantage complementation of all above fuels is well achieved, the combustion efficiency is obviously improved, and the gas mixed clean fuel also has the advantages of no environmental pollution during combustion, facilitation of atmospheric environmental protection, reduction of the overall cost, and significant commercial and economic benefits.

Owner:武威福民汇科技开发有限公司

Side-by-side sound wave throttle valve

InactiveCN101825020AIncrease the charge factorIncrease the speed of flame spreadEngine controllersMachines/enginesEngineeringCarburetor

The invention relates to a throttle valve of an automobile engine, in particular to a sound wave throttle valve. The side-by-side sound wave throttle valve of the invention consists of a carburetor base, a driving shaft and a throttle valve blade, wherein the driving shaft is connected with the carburetor base; the throttle valve blade is fixedly connected with the driving shaft; a sounding hole bearing device is arranged on the upside of the throttle valve blade; and a sounding hole is formed on the sounding hole bearing device. When the side-by-side sound wave throttle valve of the invention is used, the transmission speed of a flame in a combustion process is improved; explosive thrust is increased, the fuel consumption is reduced; the exhaust emission is greatly reduced; the engine power is enhanced; and thus, the aims of self-cleaning in the engine, saving oil and reducing emission are achieved.

Owner:张莉萍

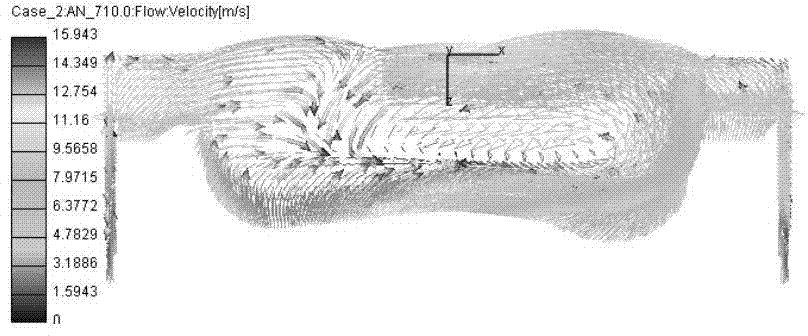

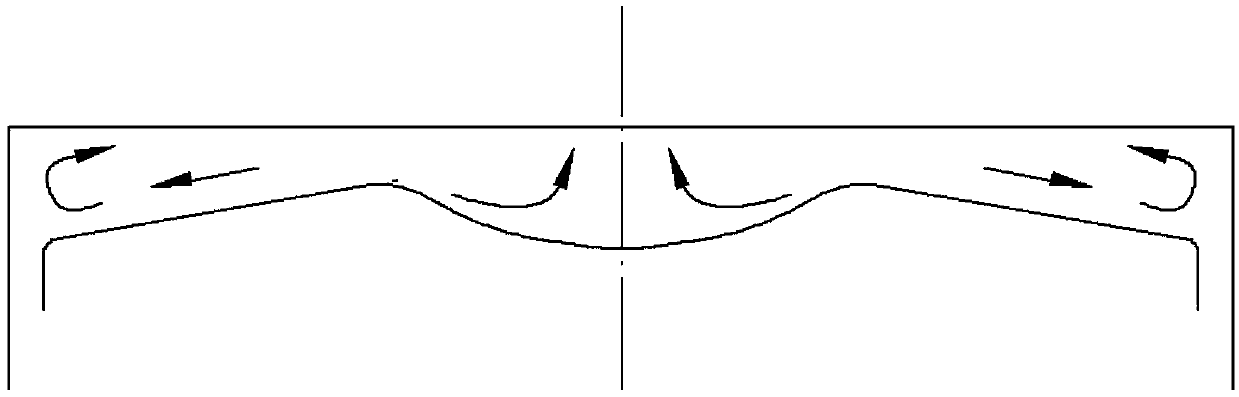

Combustion chamber for natural gas engine

InactiveCN109252972AIncrease profitEliminate dependenciesMachines/enginesPistonsCombustion chamberEngineering

The invention relates to a combustion chamber for a natural gas engine. The combustion chamber is a closed area composed of a cylinder sleeve, a piston and a cylinder cover, a spark plug is arranged at the position, in the middle of the combustion chamber, of the cylinder cover, and the bottom of the cylinder cover is flat. The combustion chamber is characterized in that the top of the piston hasan uneven shape and comprises a gradual contraction part, a throat part and an expansion pare from inside to outside with the center line of the piston as a symmetry axis; the gradual contraction partexpands outwards in the radial direction of the piston from the center line of the piston, the cross section area gradually decreases, and the gradual contraction ends at the throat part; the cross section area of the throat part is the smallest; the expansion part extends outwards in the radial direction of the piston, and the cross section area gradually increases; the cross section curve of the gradual contraction part is designed according to the Witoszynski formula.

Owner:TIANJIN UNIV

A water-regulated porous medium pulse isovolumic burner

ActiveCN106765082BDoes not have the conditions for temperingLow reaction temperatureGaseous fuel burnerCombustion chamberLiquid temperature

The invention discloses a water temperature adjustment porous medium pulse isometric burner. The burner is characterized by comprising a liquid temperature adjustment porous medium combustion chamber, and two pulse isometric gas burner driving heads arranged on two sides of the liquid temperature adjustment porous medium combustion chamber; and the three are fixedly connected. Compared with the prior art, the burner has the advantages of safety, stability, high efficiency and low nitrogen.

Owner:许华雄 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com