Optimized internal combustion engine piston top structure

An optimized structure and piston top technology, applied in the direction of pistons, mechanical equipment, engine components, etc., can solve problems such as poor squeeze flow strength and weak direction of flow field in the engine cylinder, and achieve increased mixing speed, shortened combustion time, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

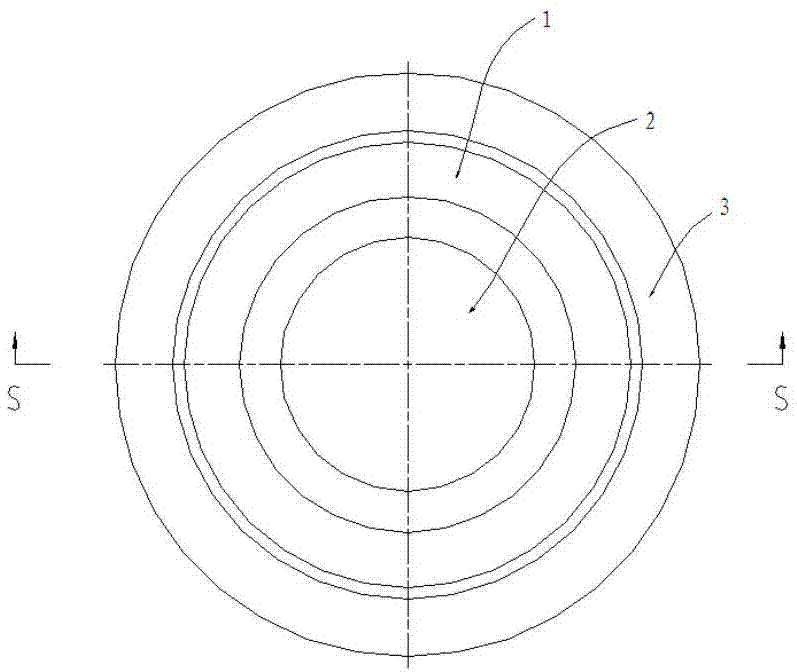

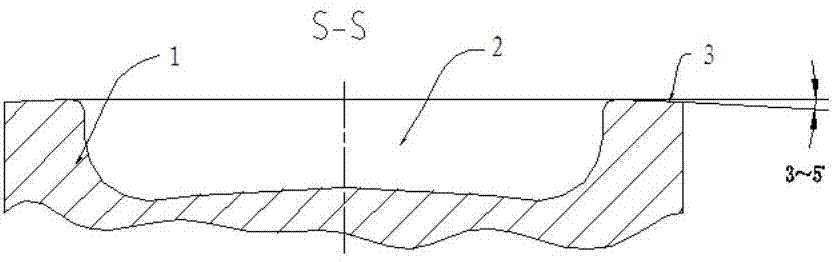

[0014] like figure 1 and figure 2 The shown optimization structure of a piston top surface of an internal combustion engine comprises a piston body 1, a combustion chamber 2 recessed into the piston body 1 is provided at the top of the piston body 1, and a ring guide is provided near the edge of the piston body 1 top surface. Flow surface 3, the flow guide surface 3 is arranged obliquely, and the outside is low and the inside is high, the inside of the flow guide surface 3 extends to the inner wall of the combustion chamber 2, and the outside of the flow guide surface 3 extends to the outside of the piston body 1 wall.

[0015] See figure 2 : The included angle between the diversion surface 3 and the horizontal plane is 3-5°.

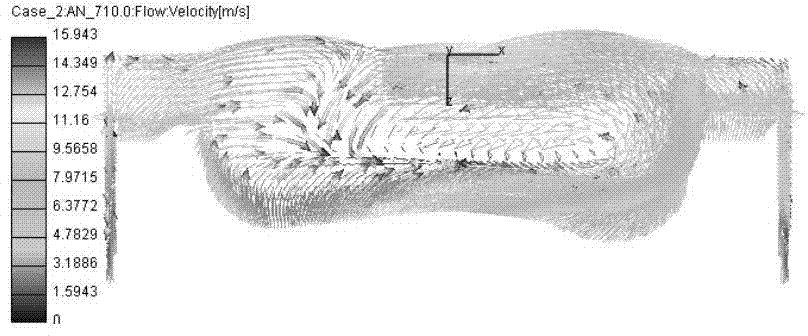

[0016] See image 3 and Figure 4 : Use the three-dimensional flow field combustion simulation software converge to sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com