Elongating arc plasma jet ignition device

A technology of arc plasma and jet point, which is applied in the direction of engine ignition, machine/engine, engine components, etc., can solve the problems of low ignition energy, electrode ablation, and low working environment pressure, and achieve high flame propagation speed and insulation performance Good, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

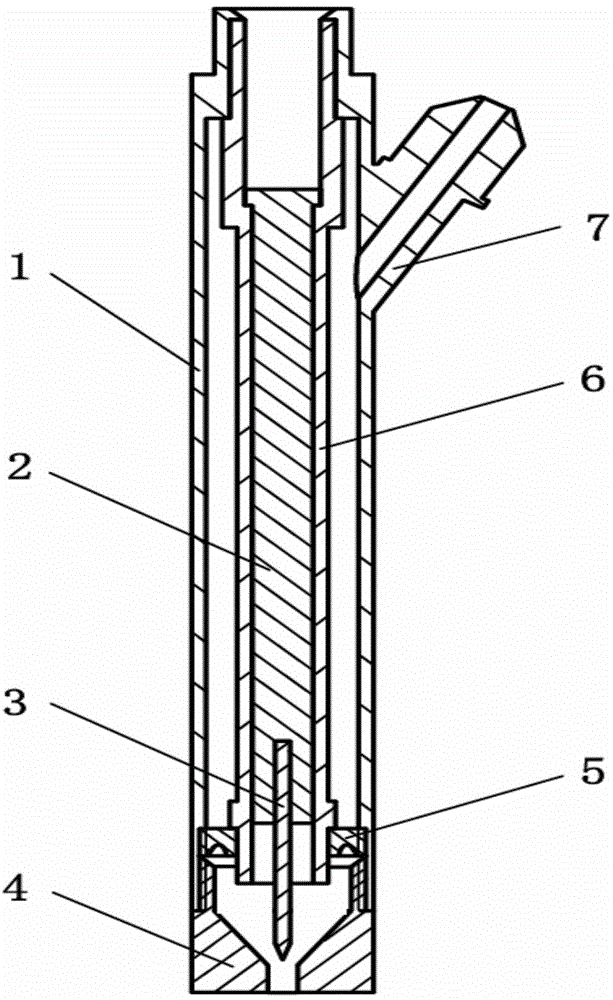

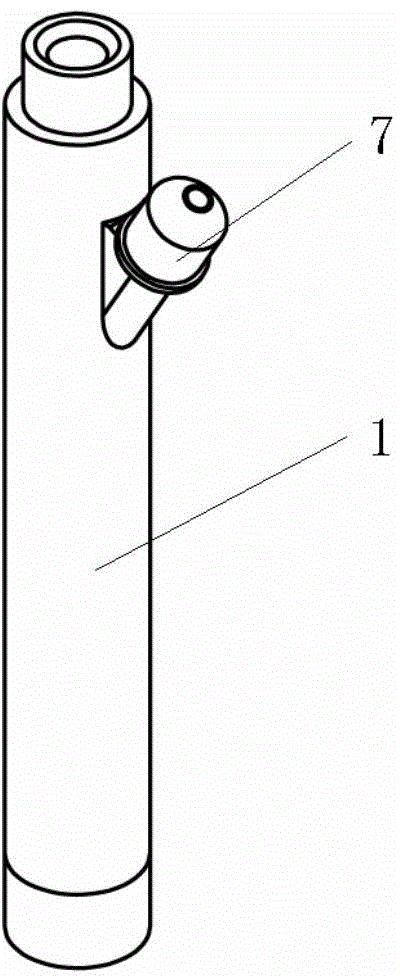

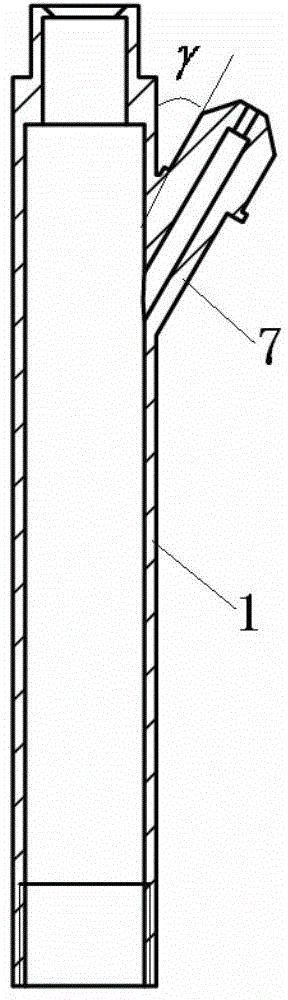

[0033] This embodiment is an elongated arc plasma jet igniter, which includes a casing 1 , a cathode mount 2 , a cathode 3 , an anode 4 , a swirler 5 , an insulating sleeve 6 and an air intake pipe 7 . Wherein, the cyclone 5 is fixed on the bottom of the inner cavity of the housing 1 through external threads, and the upper end surface of the cyclone is contacted with the boss end surface of the outer circumferential surface of the lower end of the cathode mounting seat 2; the threaded connection section of the anode Put it into the cyclone, screw the threaded connection section of the anode with the internal thread surface of the cyclone, so as to fix the anode 4 at the bottom of the casing 1 .

[0034] The insulating sleeve 6 is located in the casing, and the lower end of the insulating sleeve is fitted into the central hole of the cyclone. The outer circular surface of the upper end of the insulating sleeve 6 is in interference fit with the inner surface of the upper end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com