Side-by-side sound wave throttle valve

A throttle and sound wave technology, which is applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of insufficient air intake of the engine throttle, short service life of the engine, uneven air intake, etc., so as to save fuel and improve The effect of shortening the power and reflection distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

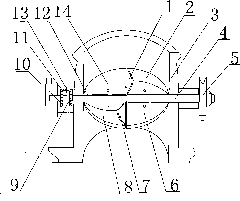

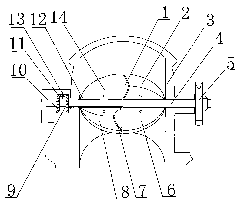

[0014] Such as figure 1 As shown, in the split sonic throttle, the throttle blade 6 is two pieces, and the driving shaft 4 is sleeved with a driven shaft 12, wherein one throttle blade 6 is fixedly connected with the driving shaft 4, and the other throttle blade 14 It is fixedly connected with the driven shaft 12 socketed on the driving shaft 4. There are sound hole bearing devices 2 and 8 respectively on the top of the two throttle blades. The sound hole bearing devices 2 and 8 are provided with sound holes 1 and 7. The driving shaft 12 is fixedly connected with the driving bevel gear 10, the driven shaft 12 is fixedly connected with the driven bevel gear 9, the driving bevel gear 10 meshes with the reverse bevel gear 11, and the reverse bevel gear 11 meshes with the driven bevel gear 9. The driven bevel gear 9 is fixed on the outside of the valve body by a pin 13 . The two throttle blades rotate 90 degrees apart.

Embodiment 2

[0016] The split sonic throttle valve of the present invention is composed of a carburetor base, a driving shaft, and a throttle blade. The driving shaft is connected to the carburetor base, and the throttle blade is fixedly connected to the driving shaft. The hole carrying device is provided with a sounding hole on the sounding hole carrying device. The throttle blade is one piece, and the bearing device of the sound hole is one of bosses or reeds.

Embodiment 3

[0018] In the split sonic throttle valve of the present invention, the throttle blade is one piece, and the throttle blade is fixedly connected with the drive shaft. There is a reed on the front of the throttle blade on one side of the drive shaft, and the opposite side of the throttle blade on the other side of the drive shaft. Bosses are arranged, and pronunciation holes are arranged on the bosses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com