Modified structure of S495 diesel engine air inlet pipe

A technology for diesel engines and intake pipes, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of large difference in the volume ratio of intake branch pipes, reduce the charge coefficient of diesel engines, affect the mixing of fuel and gas, etc., and achieve smooth flow , the effect of reducing the resistance and increasing the charge coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

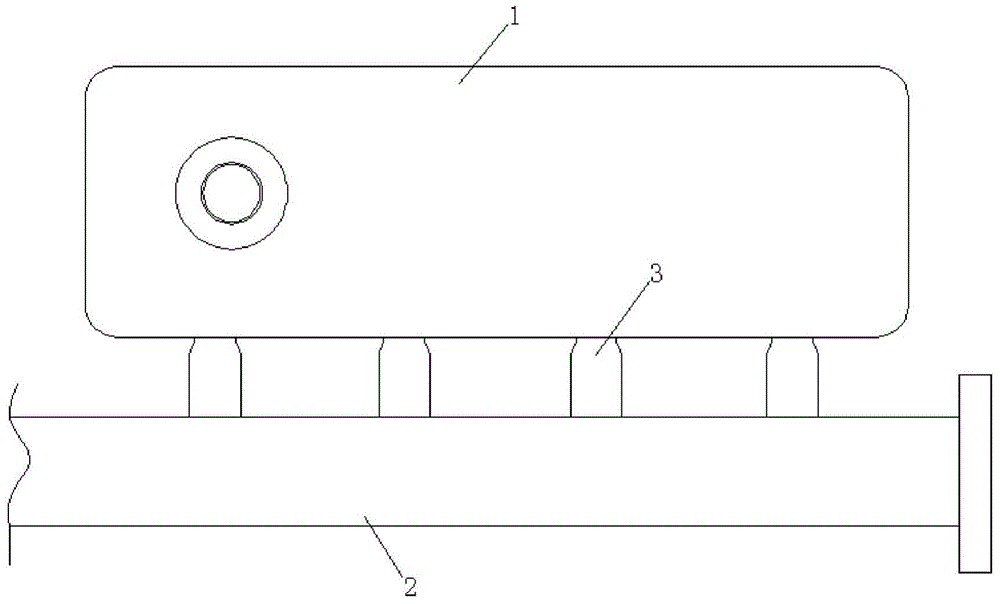

[0023] Such as figure 1 As shown, an improved structure of an S495 diesel engine intake pipe in this embodiment includes a diesel engine body 1, an intake manifold 2 and an intake manifold 3, and the intake manifold 2 communicates with the diesel engine body 1 through the intake manifold 3. Since the intake pipe has a great influence on the fuel consumption rate of the S495 diesel engine, and in the prior art, the intake pipe turns too sharply and has a region with a sudden change in cross-section, which causes a large flow resistance and reduces the charge coefficient of the intake port , the average pressure loss of the intake air increases. In order to solve the above problems, a new intake pipe structure is designed in this embodiment, in which the inner diameter of the intake manifold 3 is larger than that of the intake manifold 3 which is arranged on the diesel engine body 1 and is in phase with the intake manifold 3. Corresponding air inlet diameter. Specifically, the ...

Embodiment 2

[0025] A kind of S495 type diesel engine air intake pipe improvement structure of this embodiment, compared with embodiment 1, its difference is: in this embodiment, the inner aperture of intake manifold 3 is made to be smaller than the air intake caliber on diesel engine body 1 15mm larger, and the cross section of the intake manifold 3 is circular.

Embodiment 3

[0027] A kind of S495 type diesel engine air intake pipe improvement structure of this embodiment, compared with embodiment 1, its difference is: in this embodiment, the inner aperture of intake manifold 3 is made to be smaller than the air intake caliber on diesel engine body 1 20mm larger, and the cross-section of the intake manifold 3 is square.

[0028] The improved structure of the air intake pipe of the S495 diesel engine of the present invention simply improves the existing air intake pipe of the S495 diesel engine, and expands the flow area of the airflow without increasing the manufacturing cost, so that the gas enters the combustion chamber before entering the combustion chamber. The air pressure fluctuates less, the air intake is uniform, the flow loss is reduced, the work is reliable, the effect is remarkable, and it has strong practicability and economy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com