Patents

Literature

567results about How to "Large flow area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

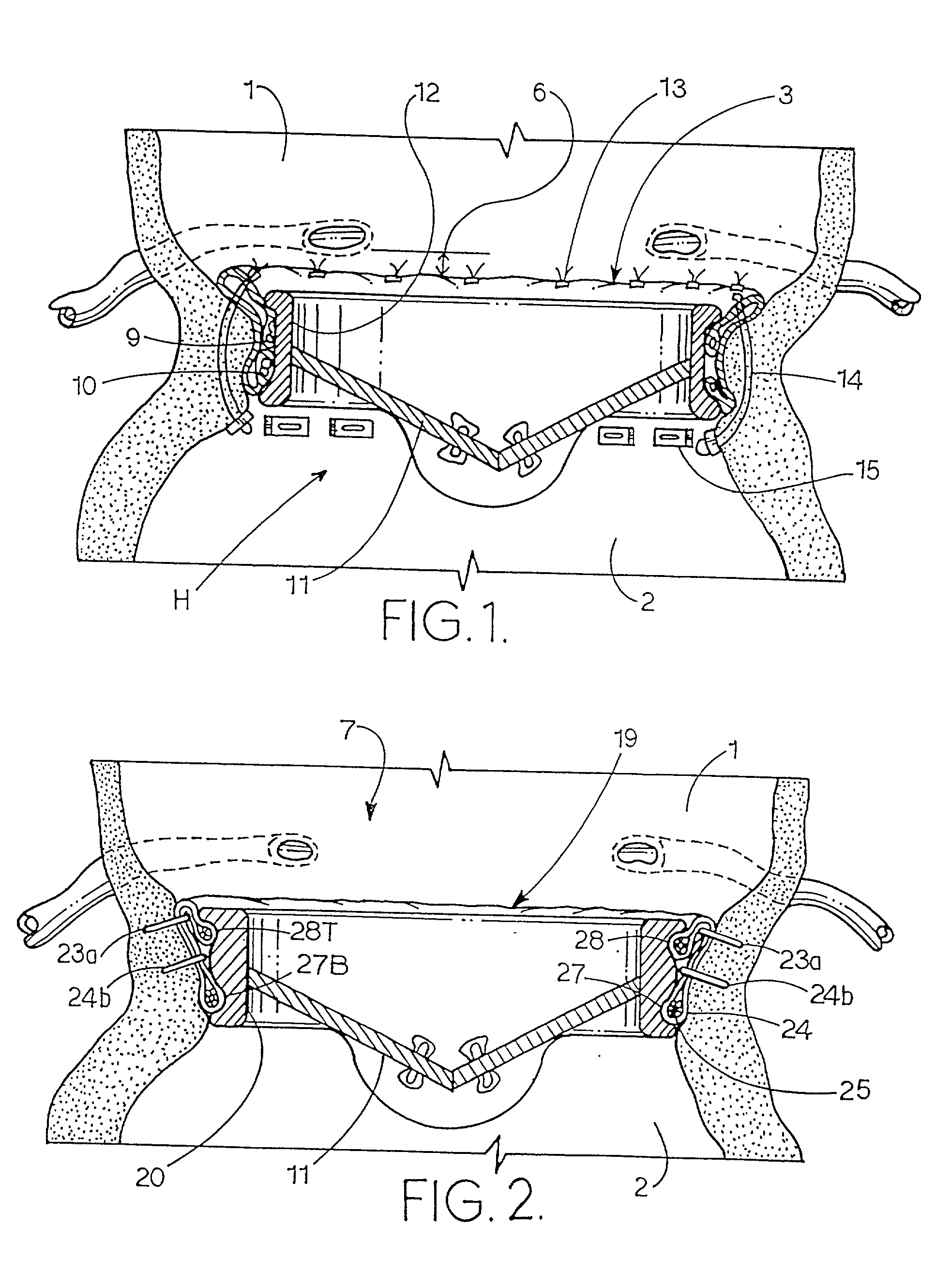

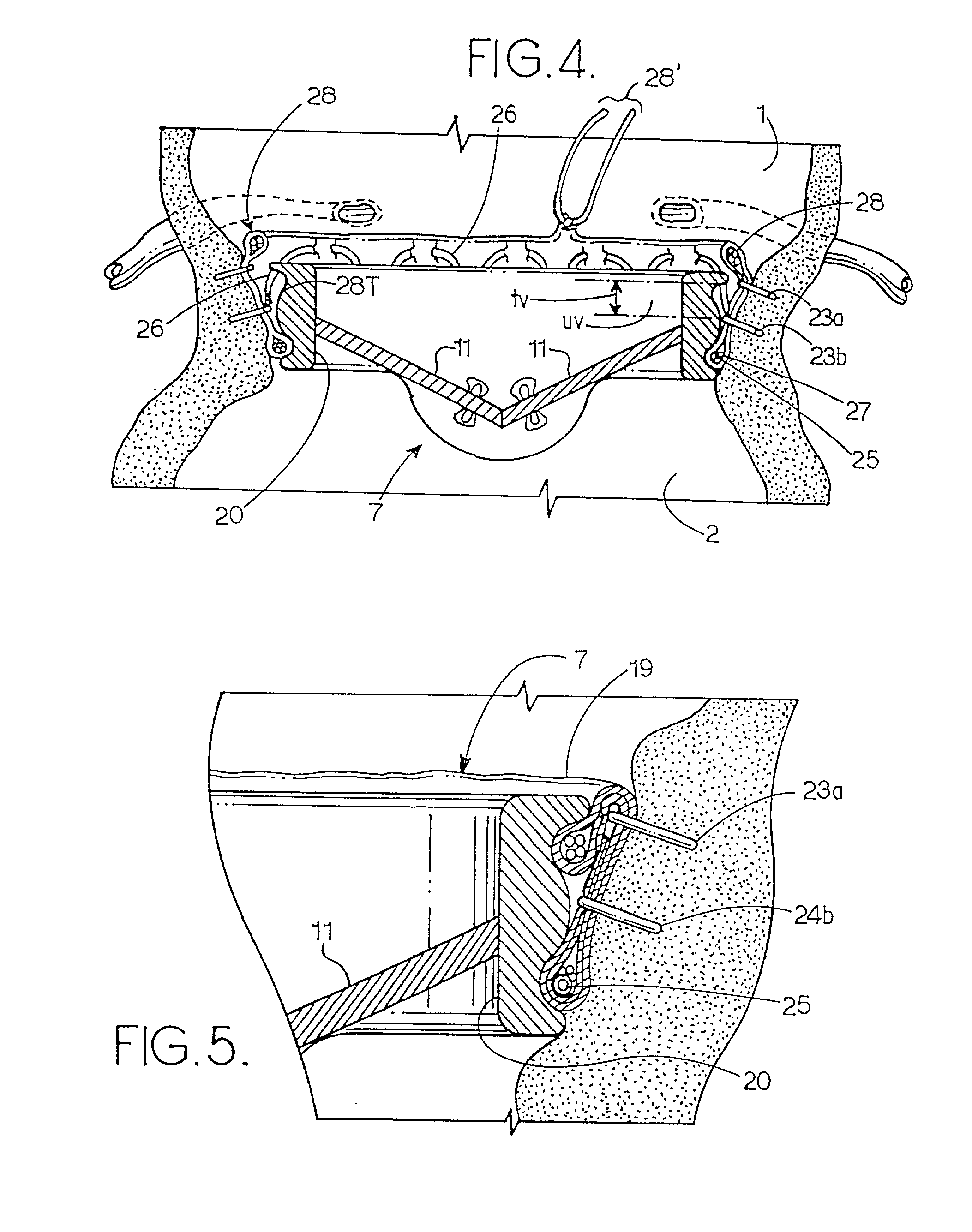

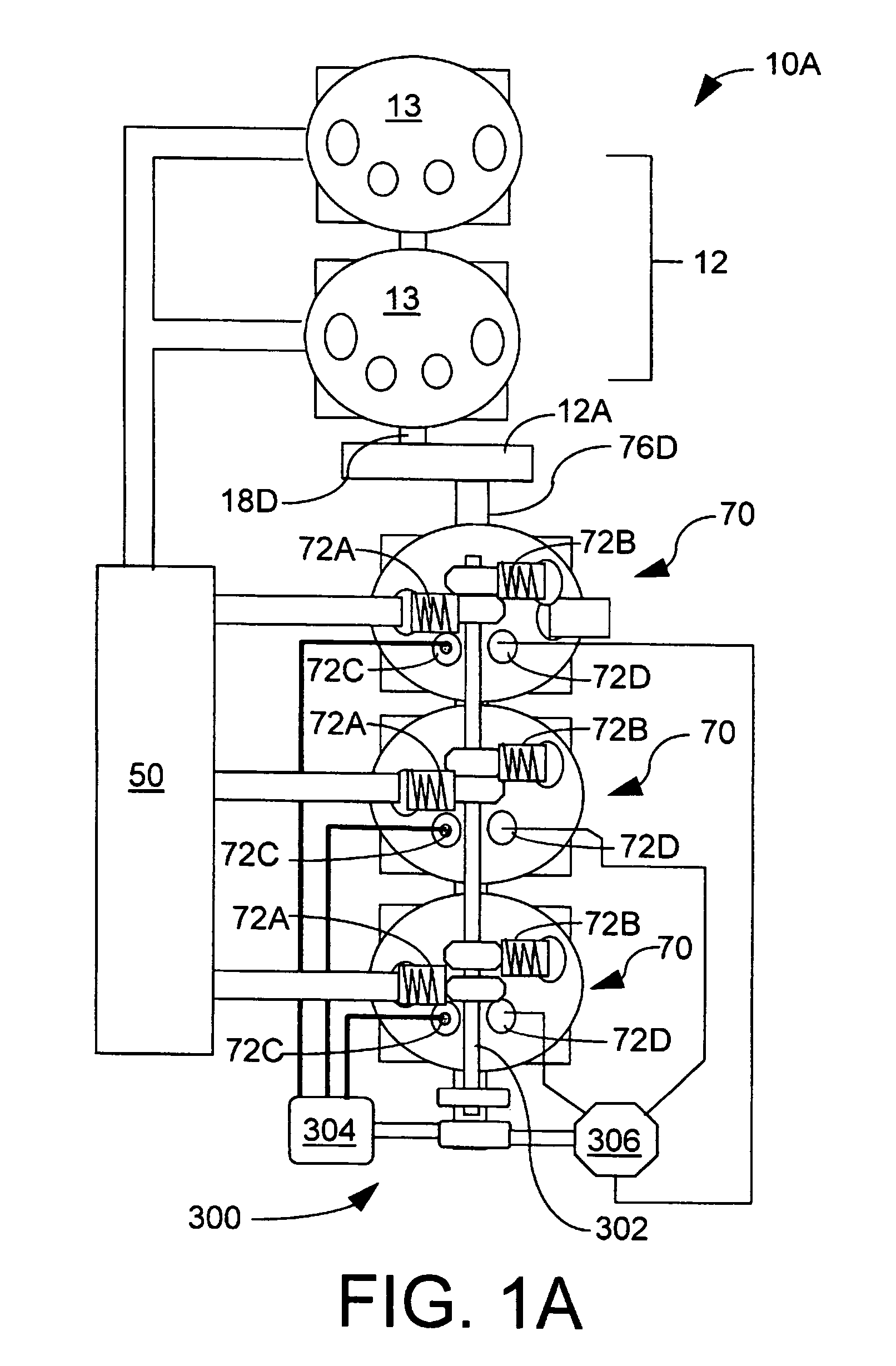

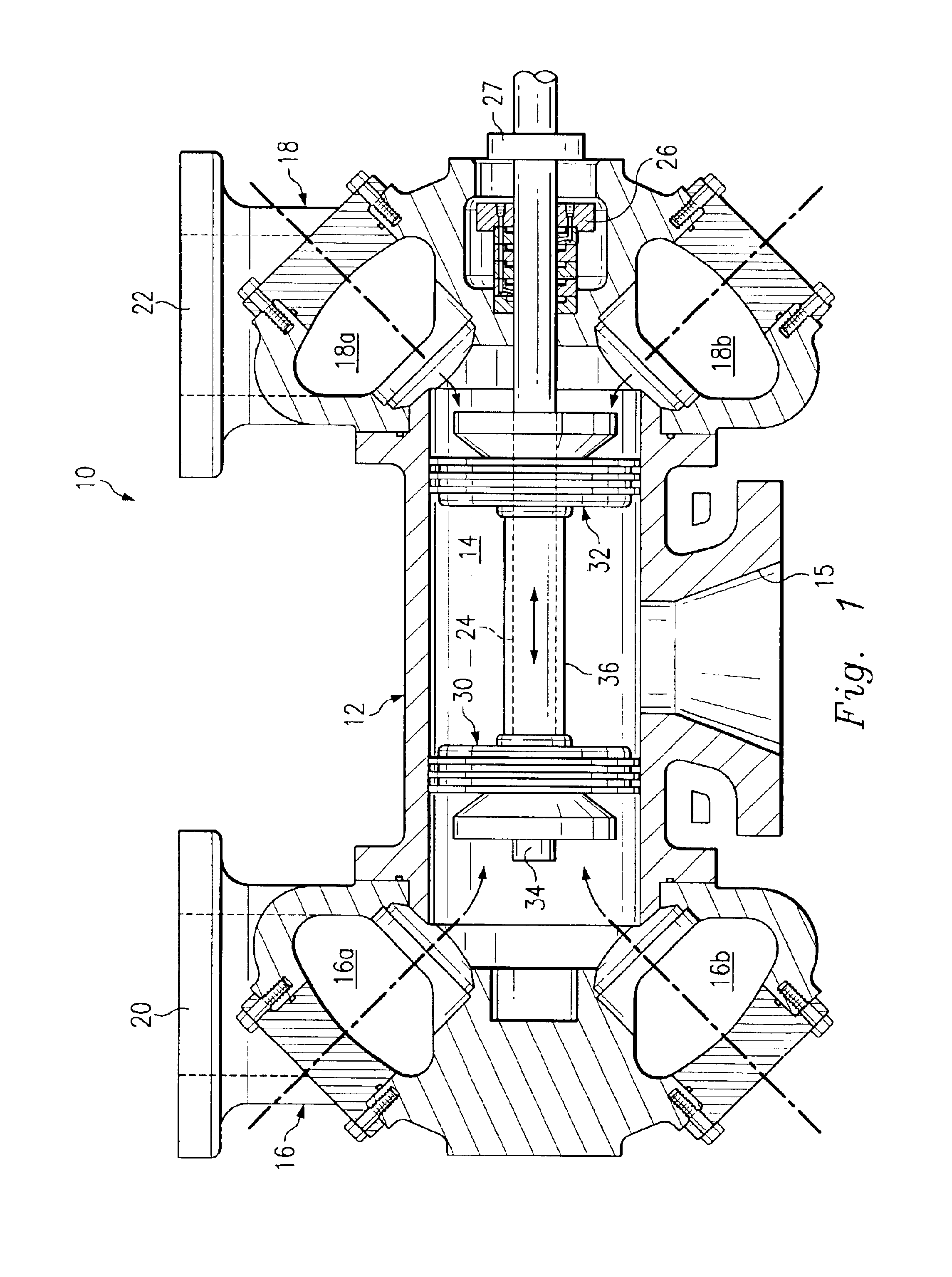

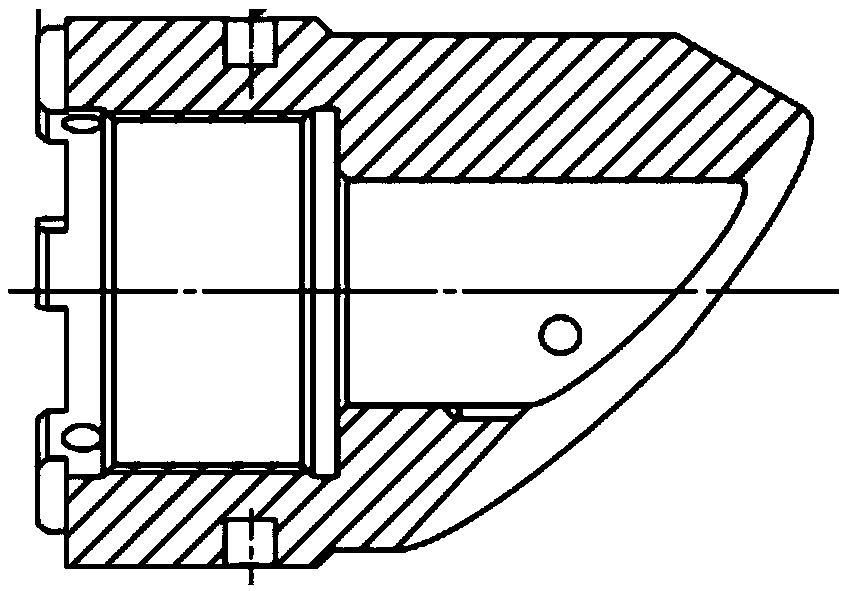

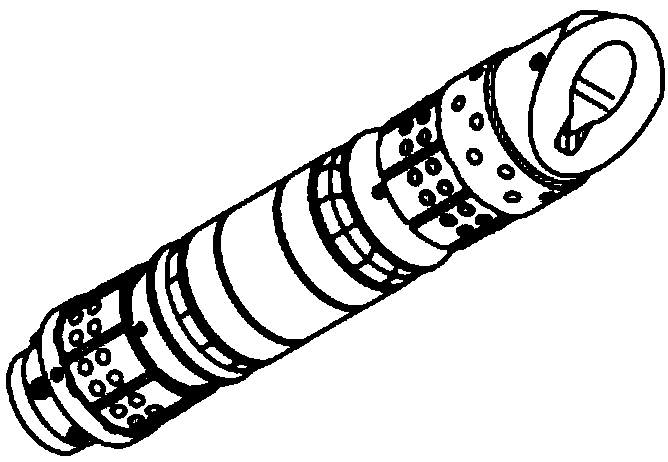

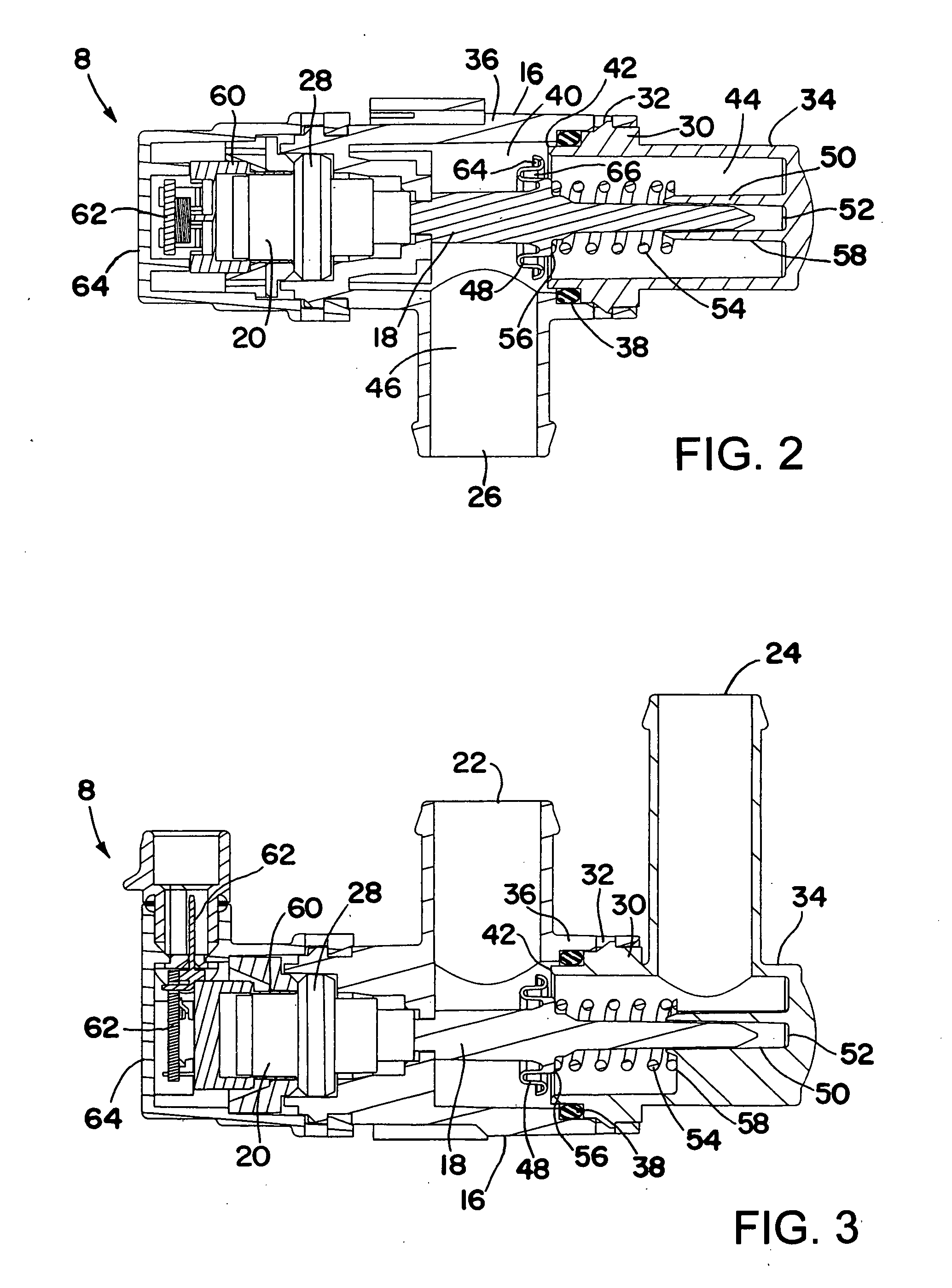

Means and method of replacing a heart valve in a minimally invasive manner

InactiveUS20010044656A1Minimally invasiveLarge flow areaSuture equipmentsStentsLess invasive surgerySelf forming

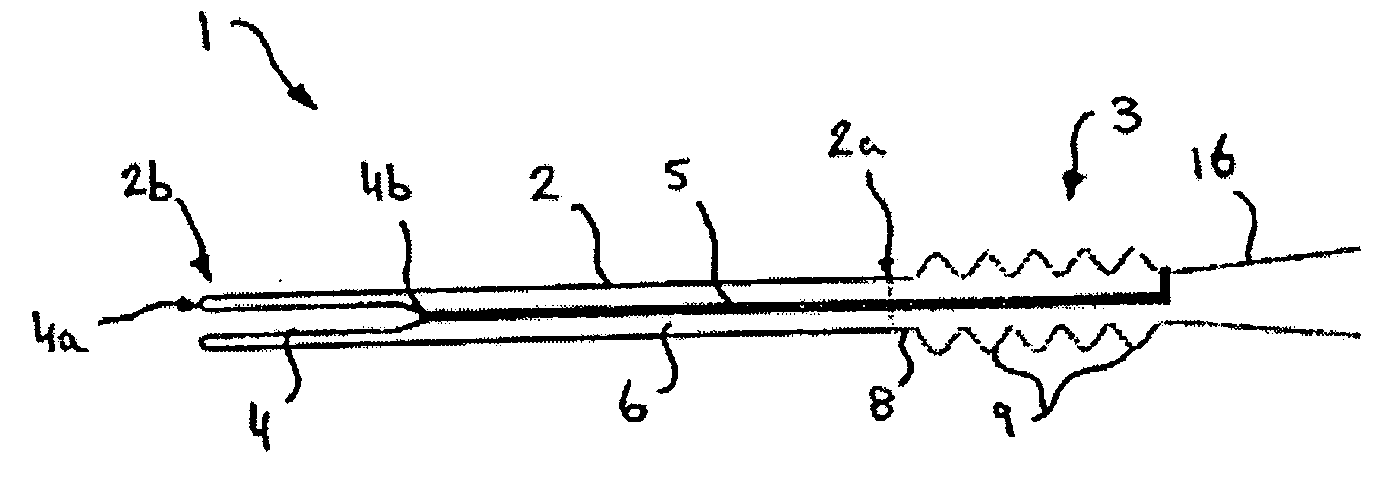

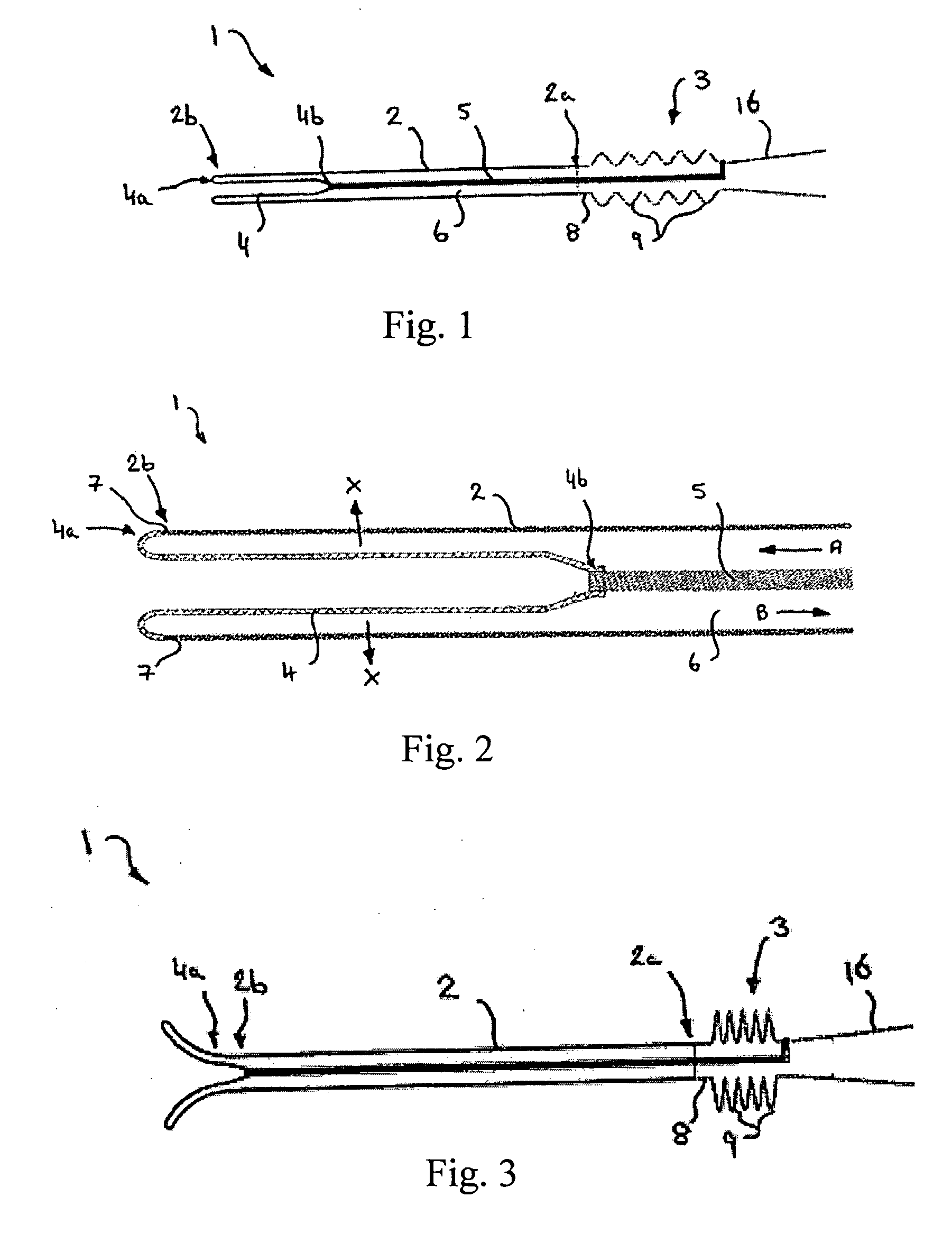

A heart valve can be replaced using minimally invasive methods which include a sutureless sewing cuff that and a fastener delivery tool that holds the cuff against the patient's tissue while delivering fasteners to attach the cuff to the tissue from the inside out. The tool stores a plurality of fasteners and is self-contained whereby a fastener is delivered and placed all from inside a vessel. The fasteners are self-forming whereby they do not need an anvil to be formed. Anchor elements are operated from outside the patient's body to cinch a prosthesis to an anchoring cuff of the valve body. The cuff is releasably mounted on the tool and the tool holds the cuff against tissue and drives the fastener through the cuff and the tissue before folding over the legs of the fastener whereby secure securement between the cuff and the tissue is assured. Fasteners are placed and formed whereby fasteners are located continuously throughout the entire circumference of the cuff. A minimally invasive surgical method is disclosed, and a method and tool are disclosed for repairing abdominal aortic aneurysms in a minimally invasive manner. Fasteners that are permanently deformed during the process of attaching the cuff are disclosed as are fasteners that are not permanently deformed during the attaching process.

Owner:MEDTRONIC INC +1

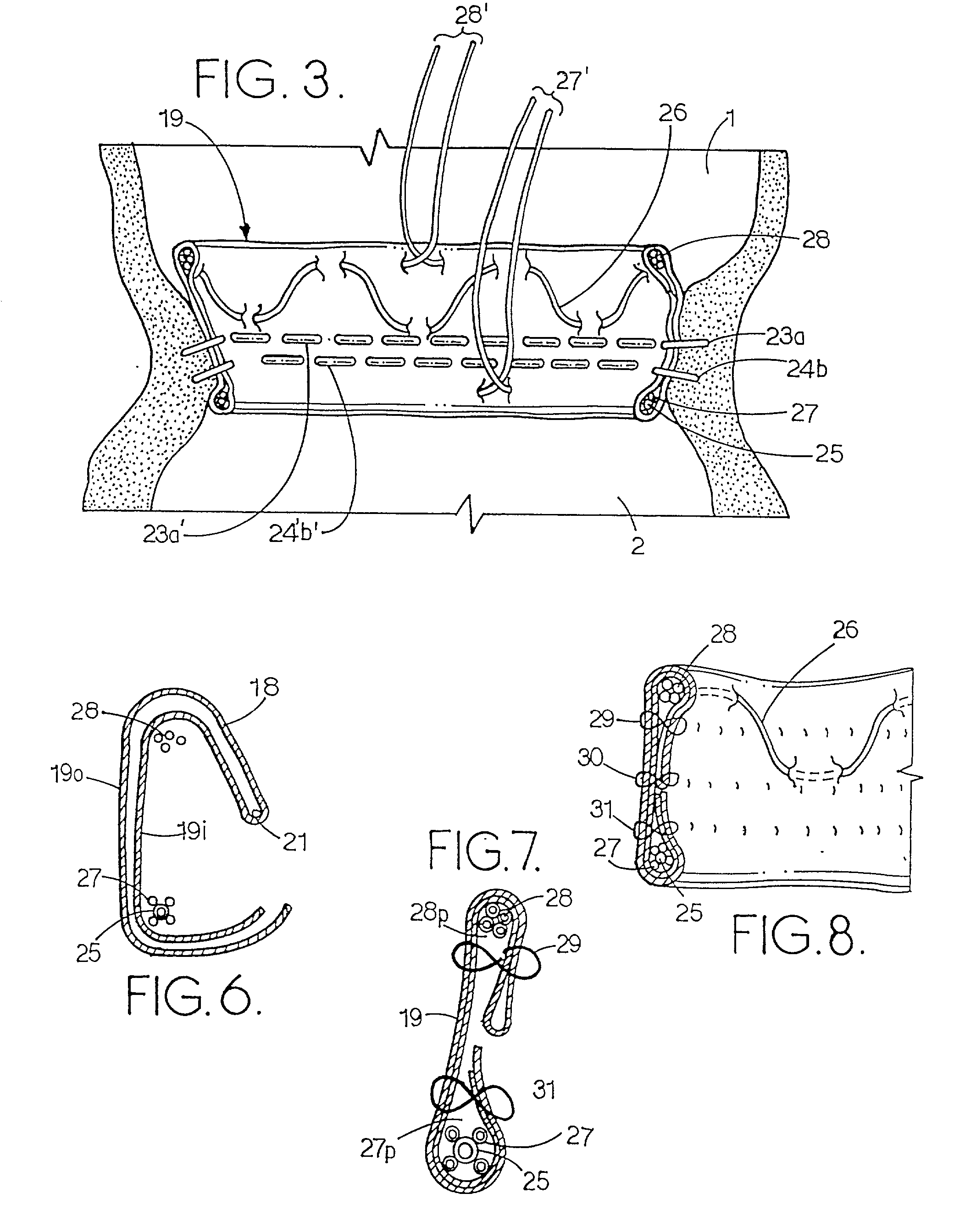

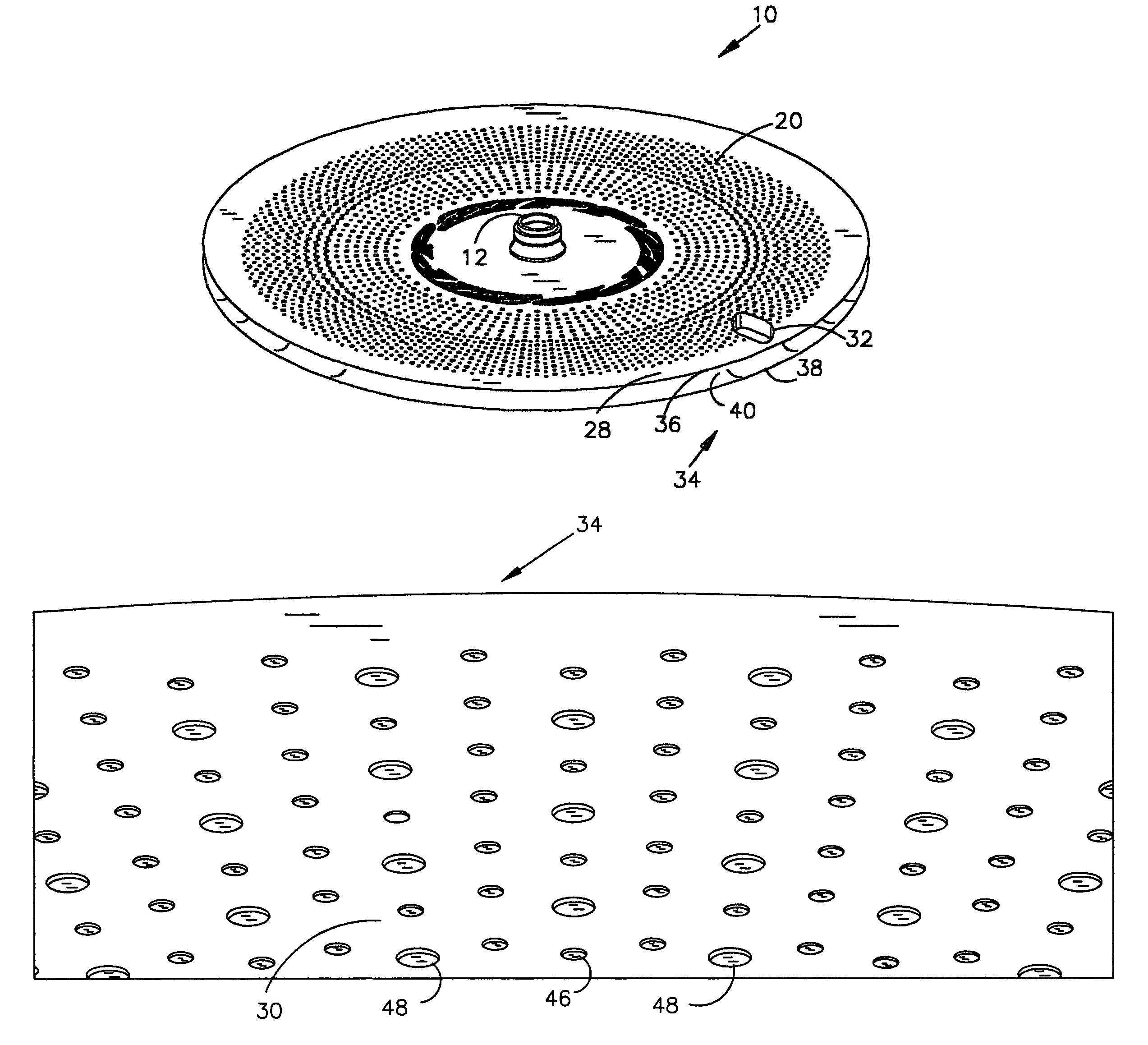

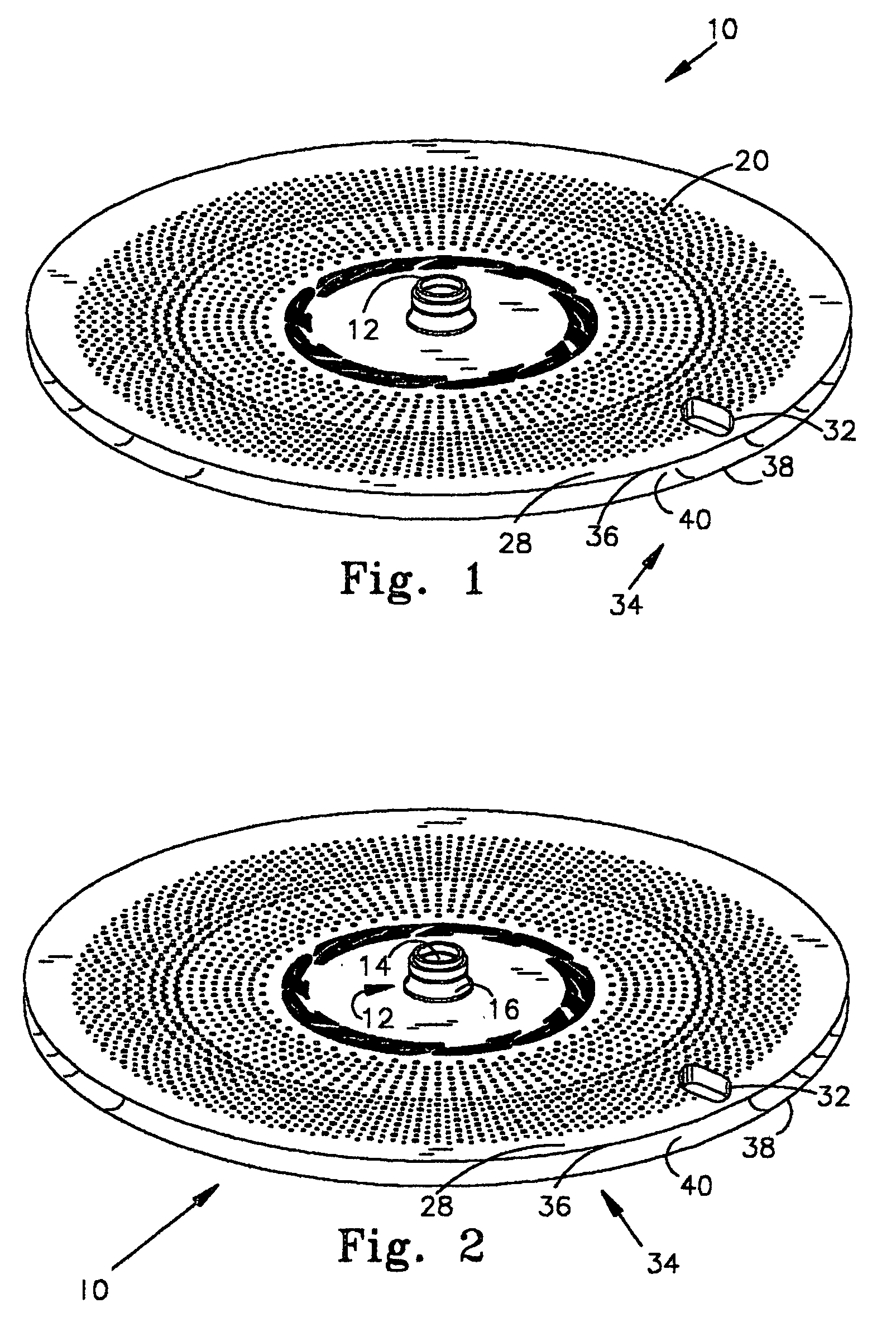

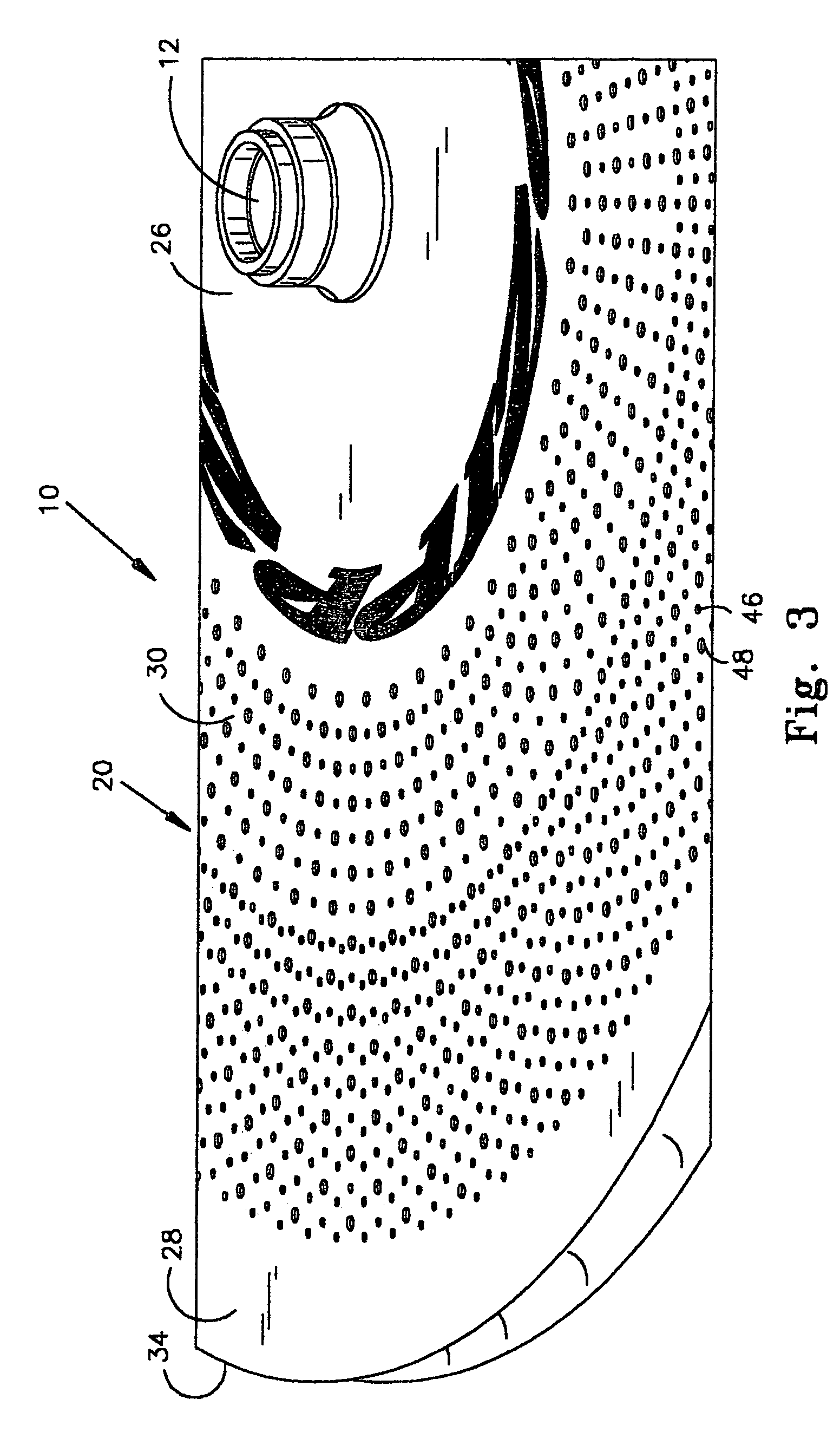

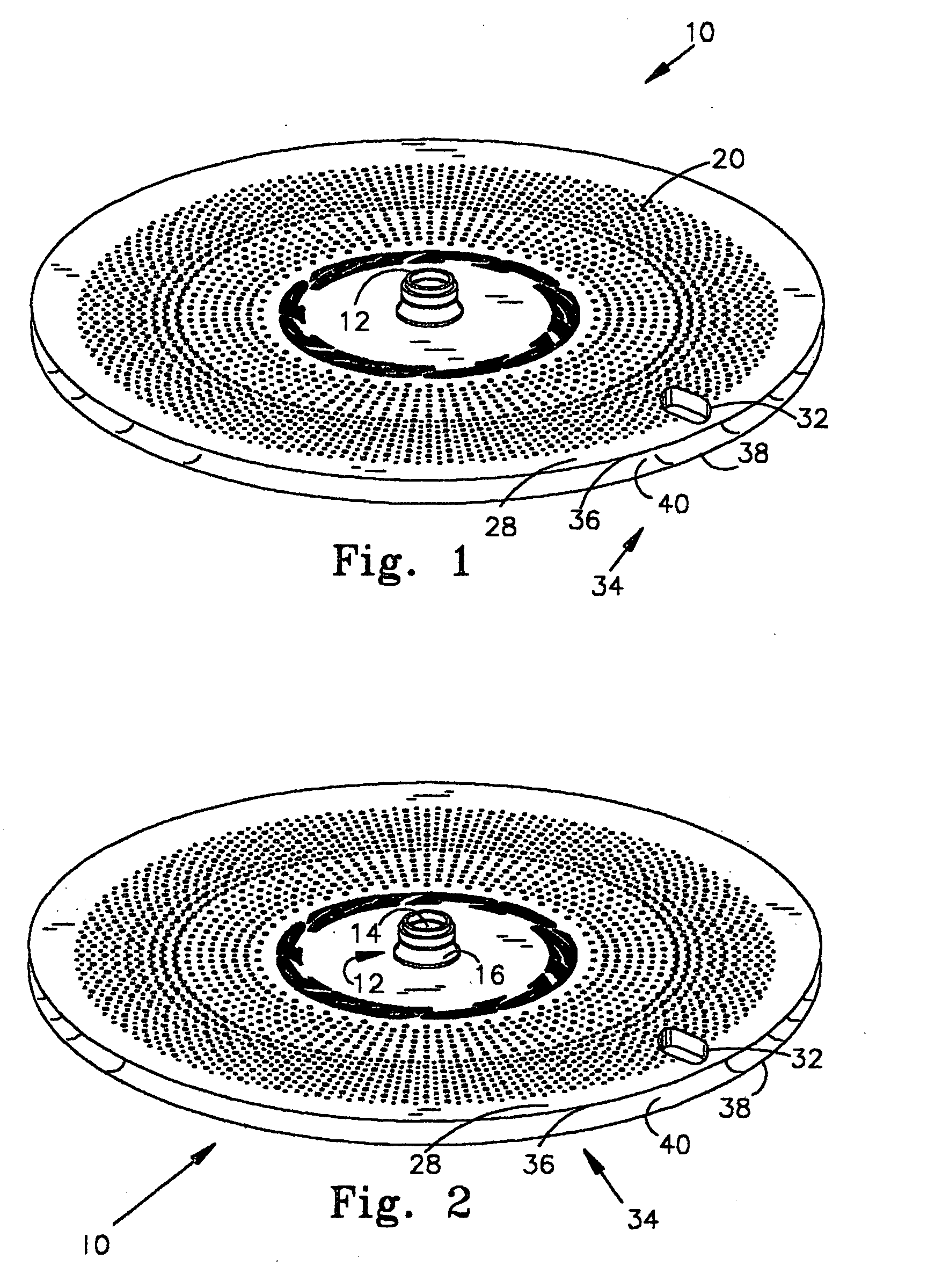

Aerodynamic surfaced bicycle wheel

InactiveUS7114785B2Reduce air resistanceHigh speedNon-metallic wheel bodyWheel protectionAerodynamic dragEngineering

A bicycle wheel includes a tire engaging portion located at the outward perimeter of the wheel, an inner portion located radially inward from the tire engaging portion A pair of air engaging side surfaces extend radially between the inner portion and the tire engaging portion forming the sides of the wheel. The air engaging side surfaces contain a plurality of surface features designed to create a turbulent boundary layer when the wheel travels through air to reduce aerodynamic drag on the wheel.

Owner:COMPOSITECH

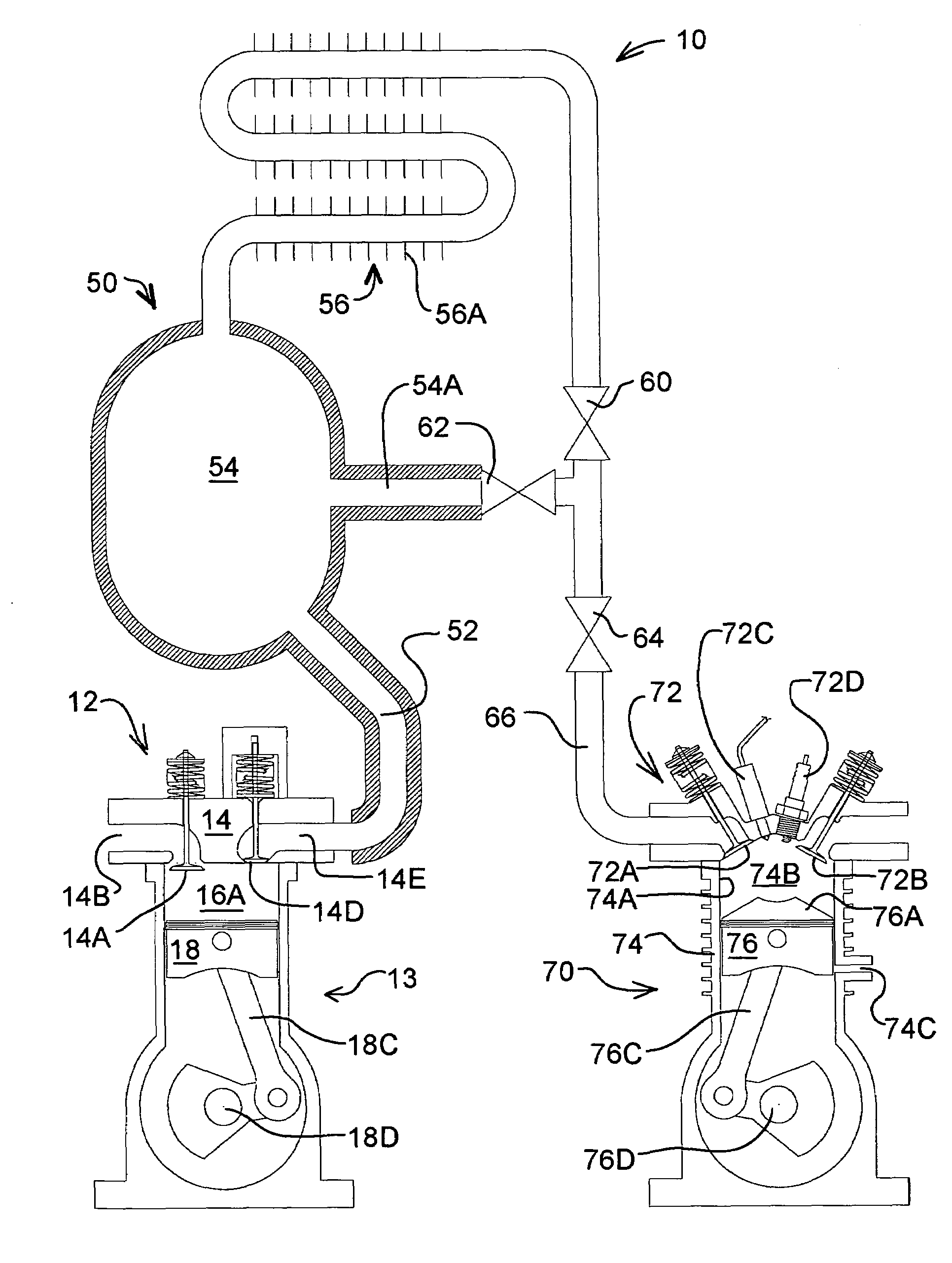

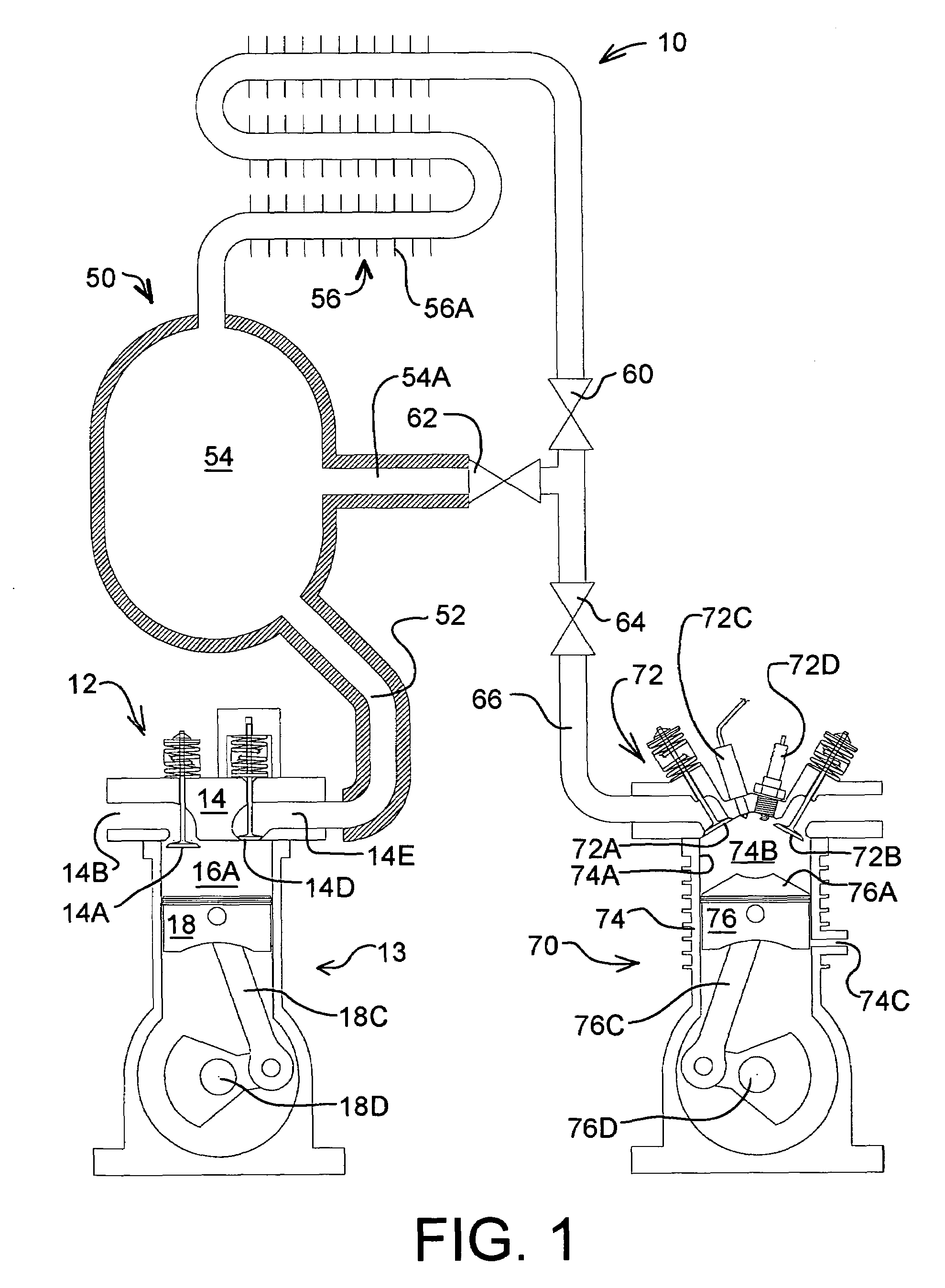

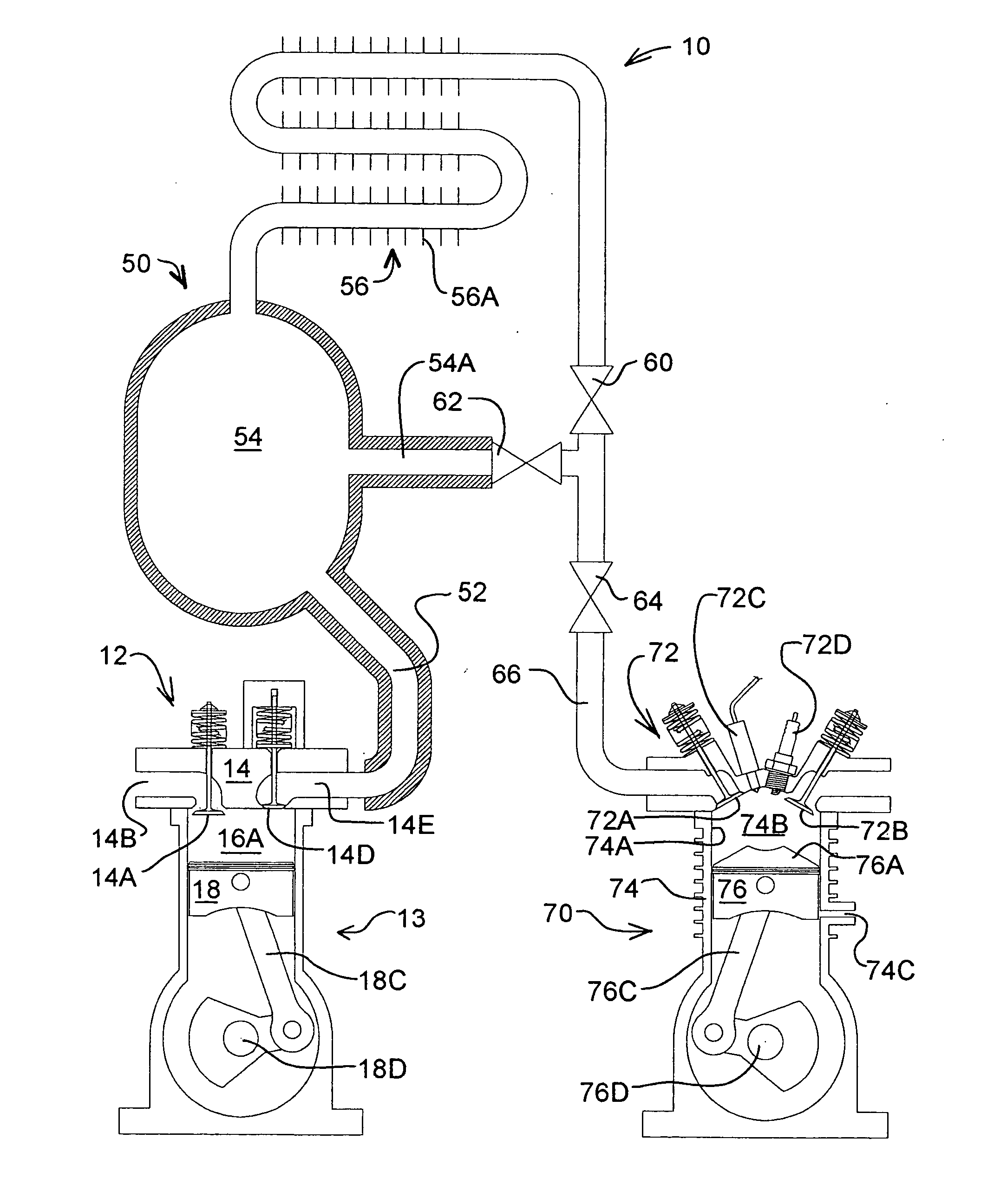

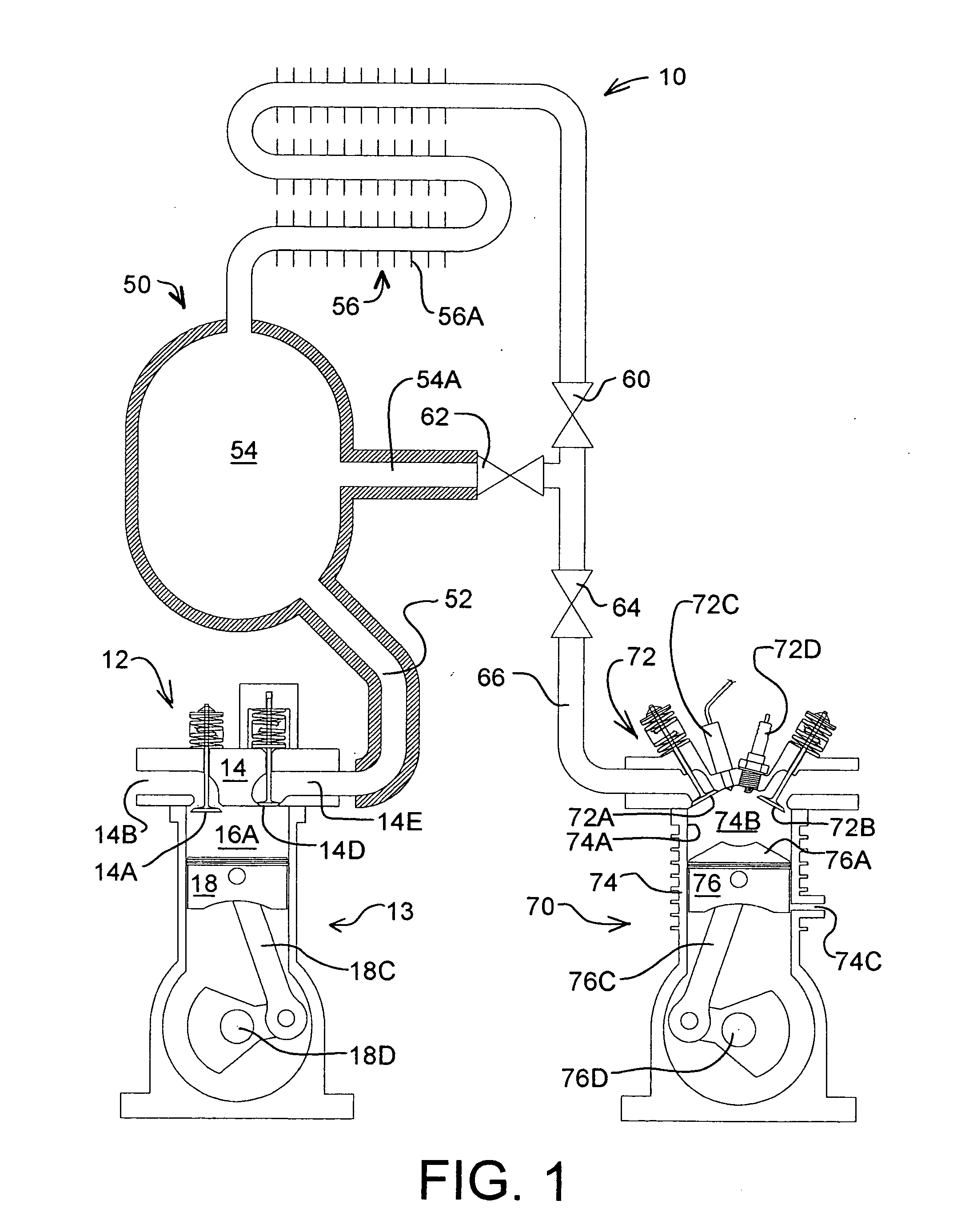

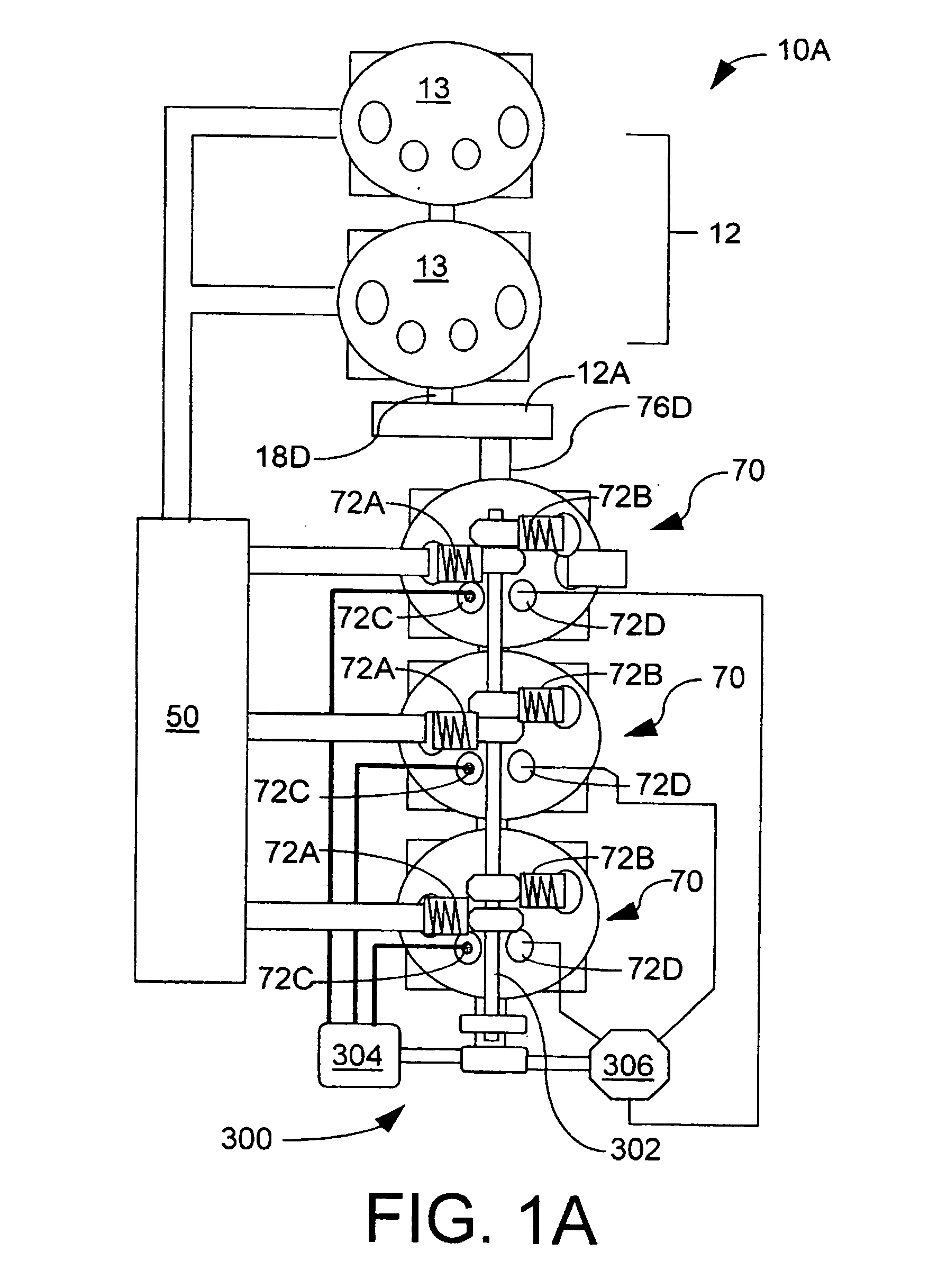

Air injection engine

InactiveUS7007639B1Improve power densityHigh expansion rateInternal combustion piston enginesOutput powerCombustionExternal combustion engine

An internal combustion engine of the present invention features separate compression and expansion cycles. The engine includes a separate compressor device which pressurizes air by a ratio greater than 15 to 1, at least one two stroke combustion cylinder and a compressed air conduit for transferring compressed air from the compressor to the at least one combustion cylinder. An air injection valve injects the compressed air into the combustion cylinder during the second half portion of the return stroke of the combustion cylinder. The compressed air is mixed with fuel and combusted for expansion during a power stroke. In this engine compression occurs only to a minor degree in the combustion cylinder. Accordingly, the compression ratio of the present engine may be significantly higher or lower than the volumetric expansion ratio of the combustion cylinder thus resulting in corresponding increases in either power density or thermodynamic efficiency respectively.

Owner:D J ENG

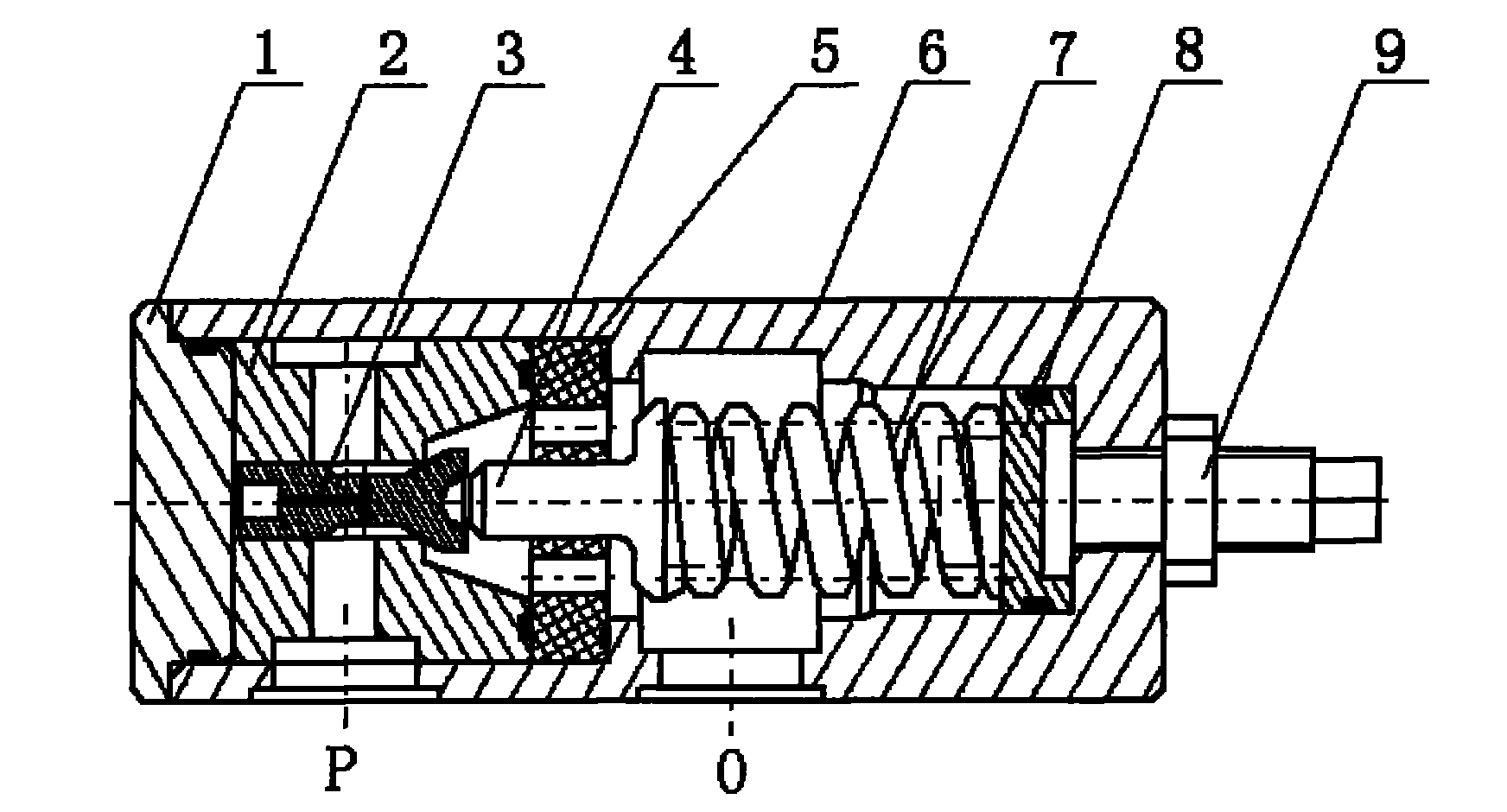

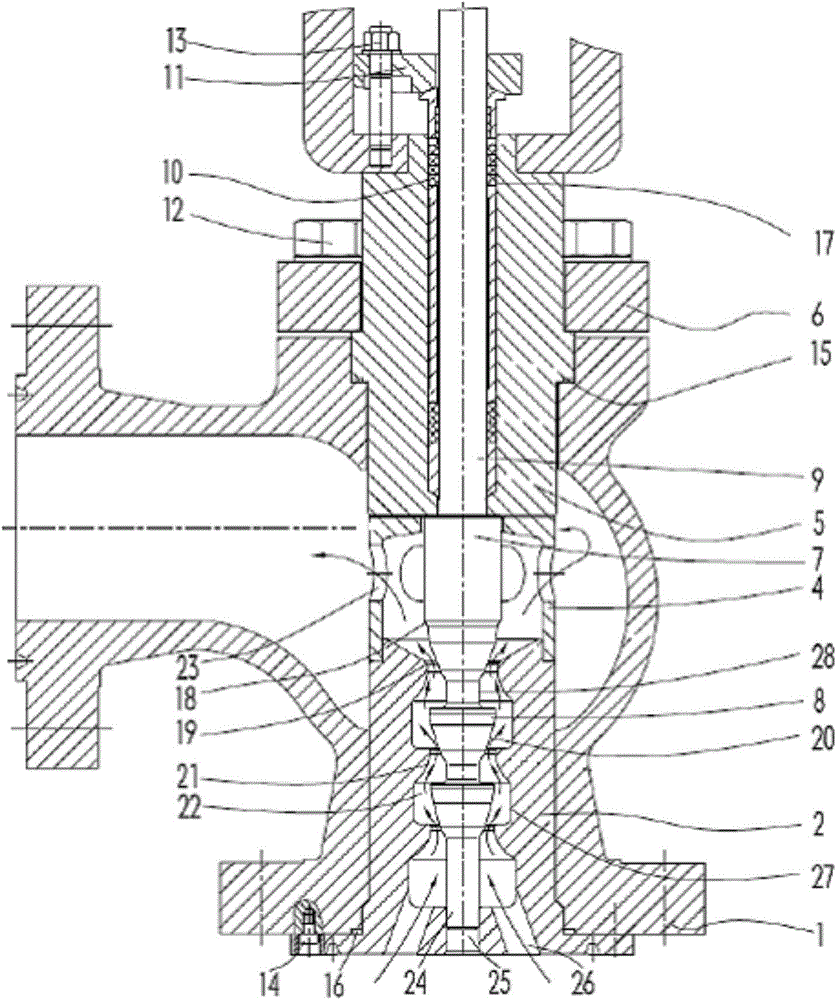

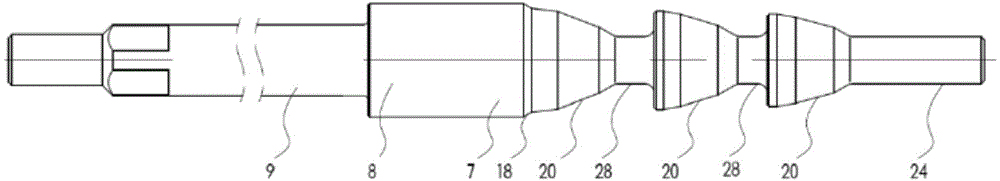

Direct-acting water pressure overflow valve with damping piston

InactiveCN102042432AReduce flow rateReduce noiseValve members for absorbing fluid energyEqualizing valvesLow noiseWater based

The invention relates to a direct-acting water pressure overflow valve with a damping piston. The overflow valve comprises an end cover, as well as a valve seat, a valve core, a left spring seat, a guide sleeve, a spring, a right spring seat and a pressure regulating screw which are arranged in a valve body sequentially; an annular groove and a cross through hole are arranged in the valve seat, the valve core is arranged in an axial through hole of the valve seat, the end part of the valve core is provided with a countersunk groove, a cylindrical surface at the tail part of the valve core and the axial through hole of the valve seat form a guide surface, and cylindrical surface at the tail part of the valve core and a valve port formed by the valve seat form a cone valve structure; the valve core is in contact fit with the left spring seat; the left spring seat is guided by the inner bore of the guide sleeve, the guide sleeve is provided with a small through-flow hole, and the right side of the guide sleeve is provided with the annular groove; the spring is positioned between the left spring seat and the right spring seat; and the pressure regulating screw is connected with the valve body by screw threads. The overflow valve is suitable for a pressure control element in a medium and high-pressure water hydraulic system using seawater, fresh water, a high water base or the like as a working medium. Compared with similar valves, the overflow valve has the advantages of simple structure, convenience for processing, low leakage, small vibration, low noise, good cavitation corrosion resistance and high working stability.

Owner:BEIJING UNIV OF TECH

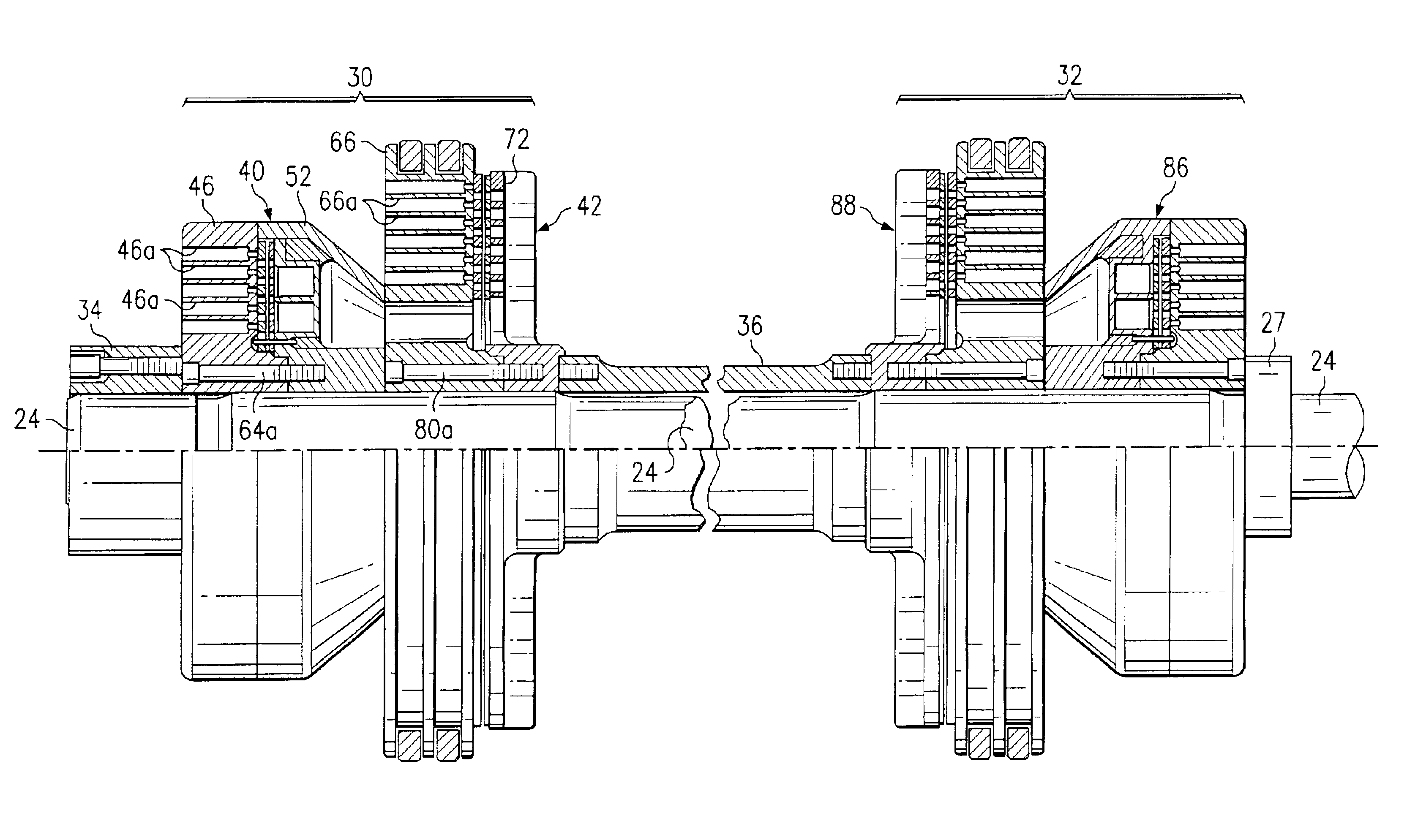

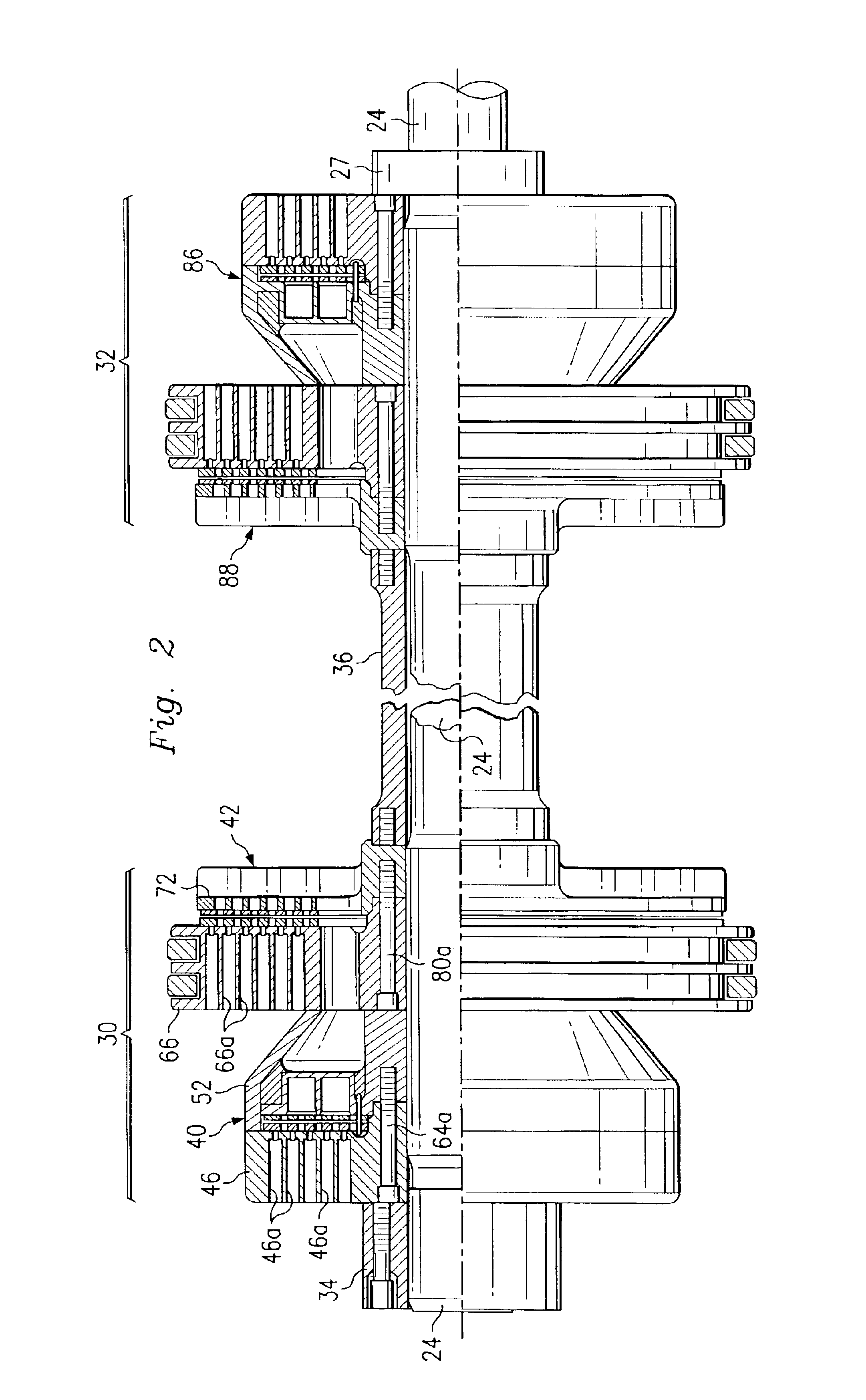

Gas compressor and method with improved valve assemblies

InactiveUS6817846B2Improve efficiencyLarge flow areaPositive displacement pump componentsCheck valvesPistonEngineering

A gas compressor and method according to which a piston assembly reciprocates in a bore to draw the fluid to be compressed into the bore during movement of the piston unit in one direction and to compress the fluid during movement of the piston unit in the other direction.

Owner:DRESSER RAND CO

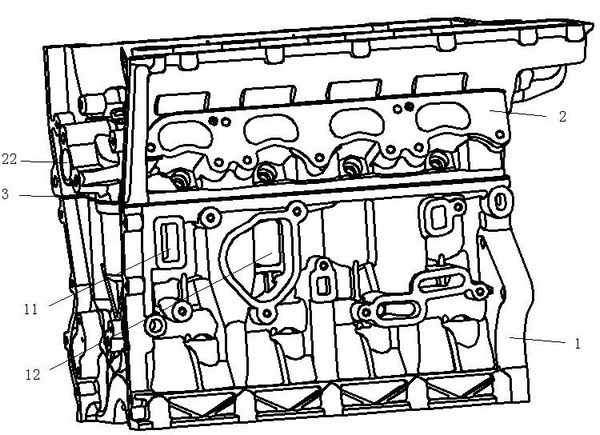

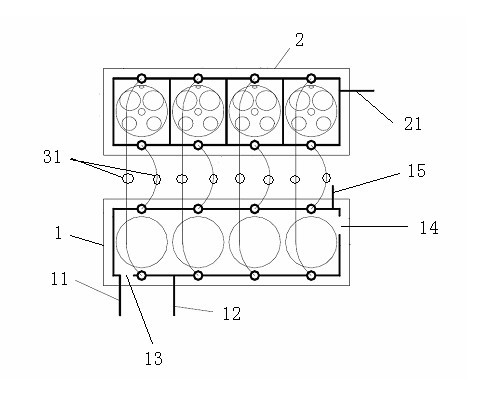

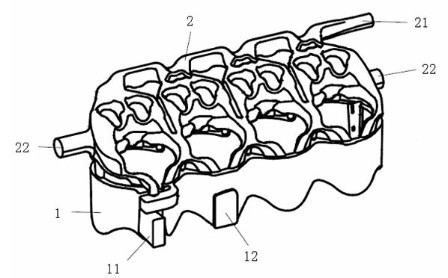

Engine cooling water jacket

InactiveCN102042116AImprove powerImprove performanceLiquid coolingCylinder headsThermal stateEngineering

The invention provides an engine cooling water jacket which has the advantages of simple structure, small volume, uniform flow rate and low pressure loss. The engine cooling water jacket comprises a cylinder body water jacket and a cylinder cover water jacket, wherein the cylinder body water jacket is separated by two baffle plates to form a first flow channel and a second flow channel, and the first flow channel and the second flow channel are communicated with the cylinder cover water jacket through water holes in a cylinder gasket; and coolant mainly flows into the first flow channel from a water inlet and flows through an air exhaust side, then flows into the cylinder cover water jacket through the water holes at one side of the cylinder gasket, subsequently flows into the second flow channel through the water holes at the other side of the cylinder gasket and flows through an air admission side, and finally flows out from a water outlet. Thus, the invention enables the flow rate of the coolant in the whole engine cooling water jacket to be more uniform, reduces the thermal-state deformation of the cylinder holes and improves the dynamic performance of the engine; and the water holes in the cylinder gasket can be arranged as required without being influenced by the design of traditional water jacket cylinder holes, thereby integrally increasing the flow areas of the water holes in the cylinder gasket, reducing the pressure loss of the whole water jacket and lowering the performance requirements for water pumps.

Owner:CHERY AUTOMOBILE CO LTD

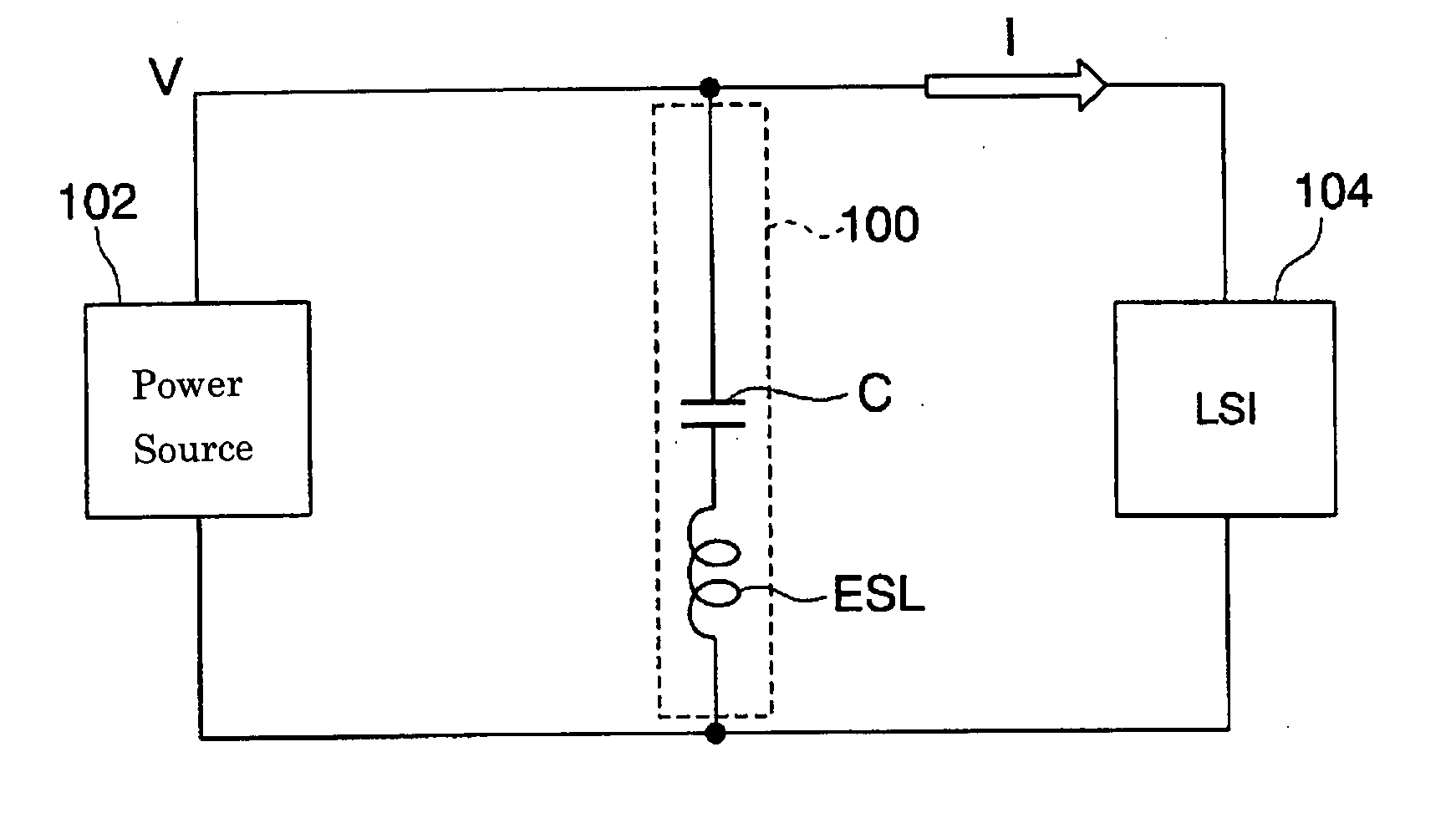

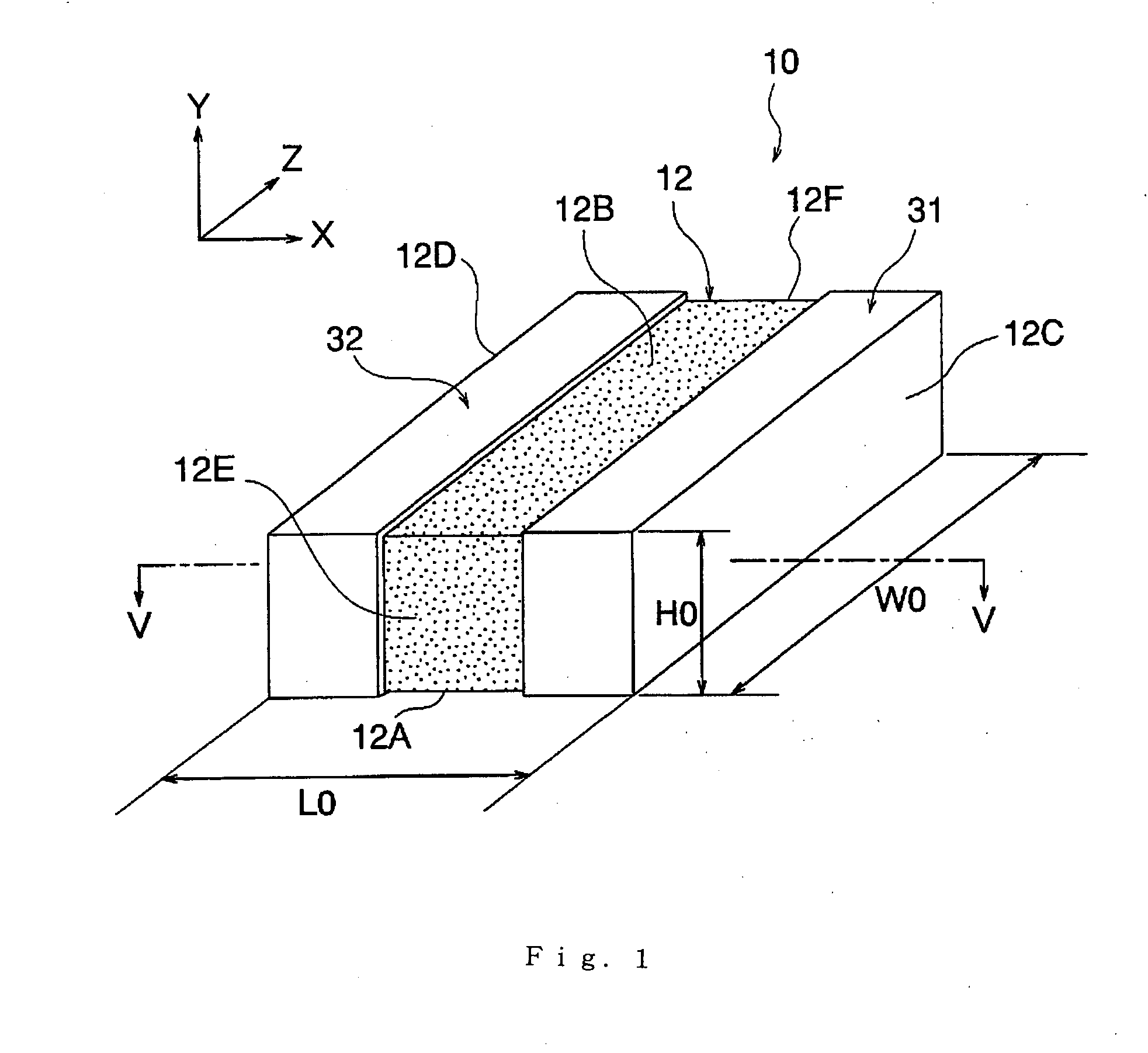

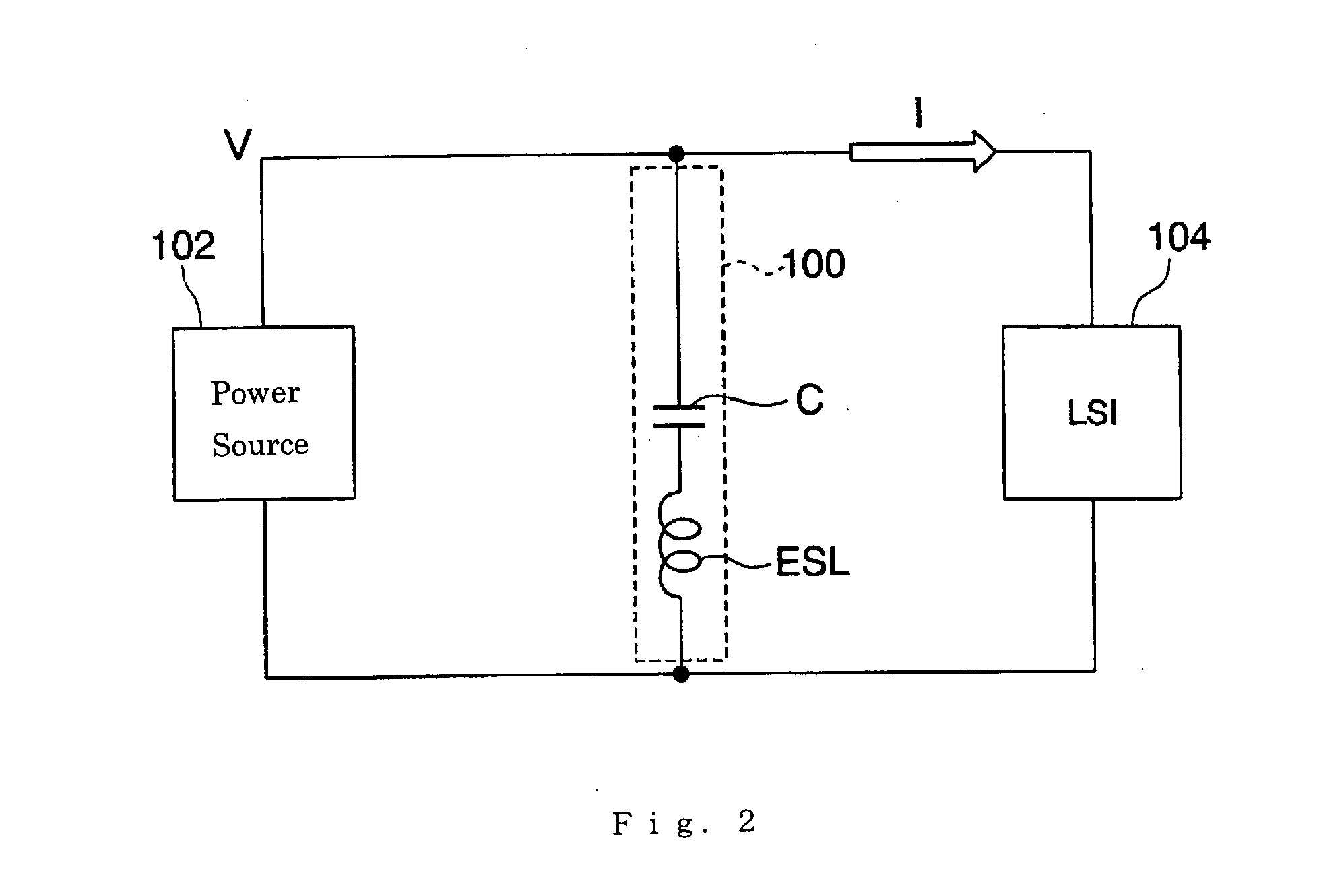

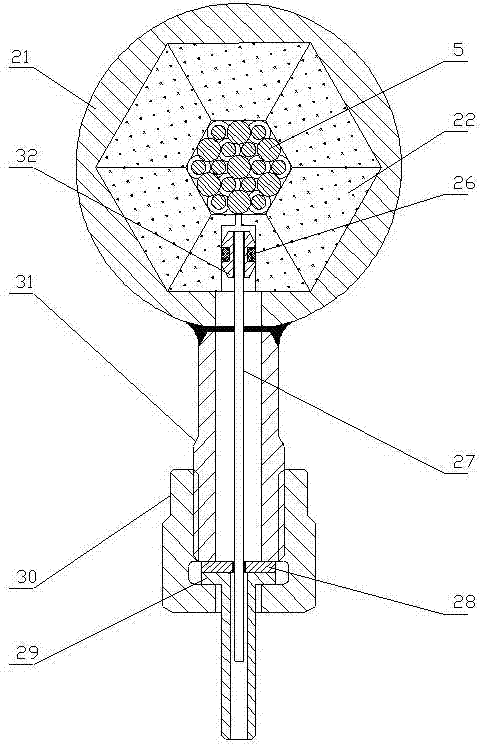

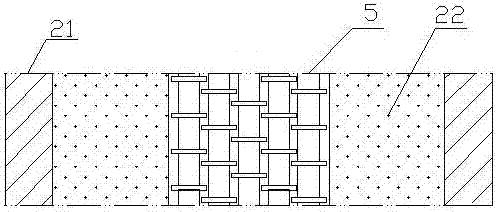

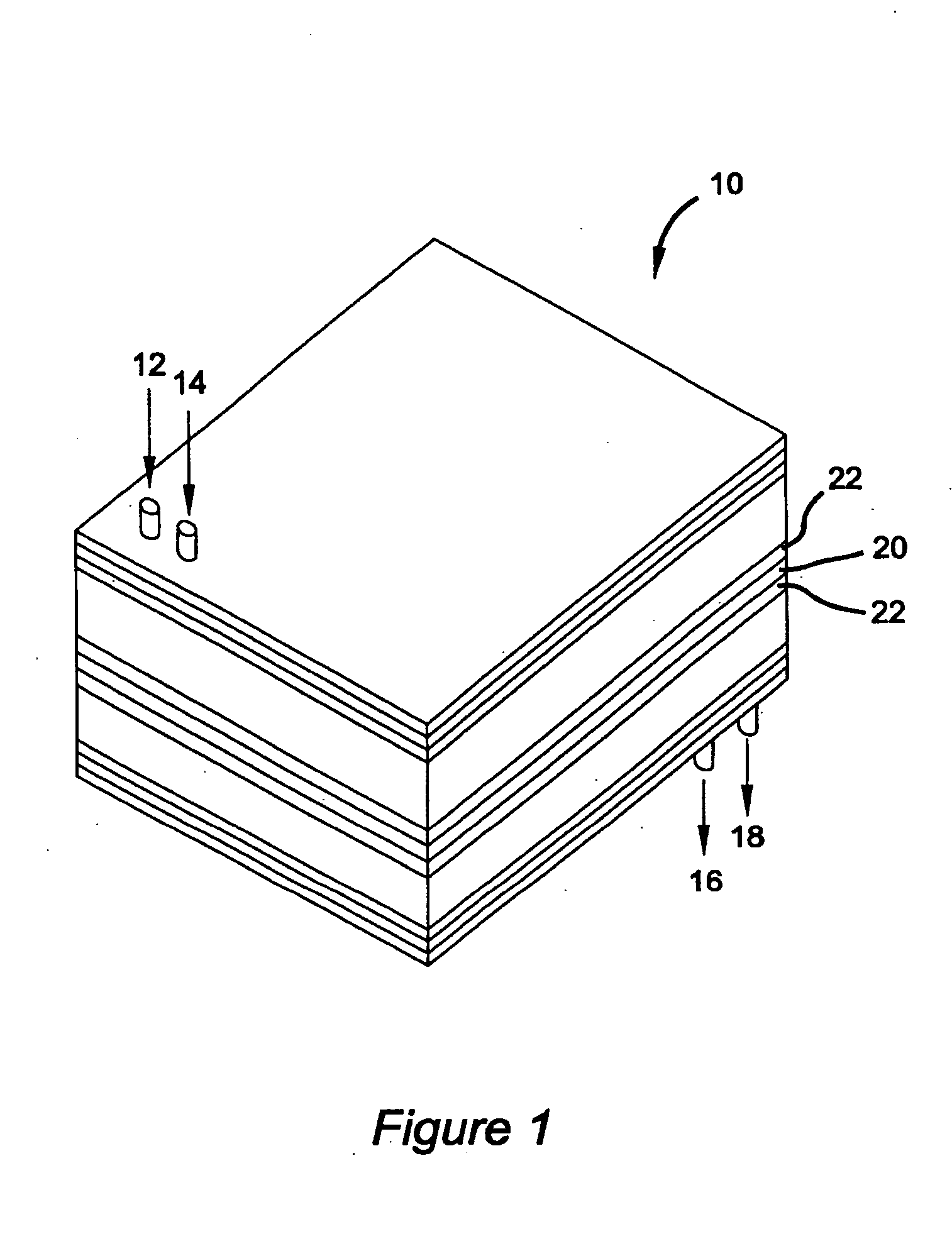

Multilayer capacitor

ActiveUS20080144253A1Reduce ESLLow manufacturing costFixed capacitor electrodesFixed capacitor dielectricElectrical conductorDielectric layer

A multilayer capacitor 10 comprising a dielectric body 12 having an approximately rectangular parallelepiped shape formed by alternately stacking a plurality of dielectric layer 12a, a first conductor layer 21, a second conductor layer 22, a first terminal electrode 31 and a second terminal electrode 32 formed on a first side face 12A of side faces 12 of the dielectric body in parallel to a stacking direction Z. The first conductor layer 21 comprises a first lead portion 21L connected to the first terminal electrode 31, the second conductor layer 22 comprises a second lead portion 22L connected to the second terminal electrode 32. Between a length “a” of the first lead portion 21L and the second lead portion 22L in vertical direction to the stacking direction Z, a length “b” of conductor layers positioned at both ends of the dielectric body 12 in the stacking direction, a space length “c” of the first side face 12A and the first conductor layer 21, a total number of the conductor layers 22, 22, (a+c) / (b×n)≦0.035 is consisted.

Owner:TDK CORPARATION

Air injection engine

InactiveUS20060124085A1Ratio of compression can be significantly higher or lowerHigh expansion rateInternal combustion piston enginesOutput powerInjection airCylinder (engine)

An internal combustion engine of the present invention features separate compression and expansion cycles. The engine includes a separate compressor device which pressurizes air by a ratio greater than 15 to 1, at least one two stroke combustion cylinder and a compressed air conduit for transferring compressed air from the compressor to the at least one combustion cylinder. An air injection valve injects the compressed air into the combustion cylinder during the second half portion of the return stroke of the combustion cylinder. The compressed air is mixed with fuel and combusted for expansion during a power stroke. In this engine compression occurs only to a minor degree in the combustion cylinder. Accordingly, the compression ratio of the present engine may be significantly higher or lower than the volumetric expansion ratio of the combustion cylinder thus resulting in corresponding increases in either power density or thermodynamic efficiency respectively.

Owner:D J ENG

Active water fracturing technology of coal-bed gas well

ActiveCN102094612AImprove diversion capacityLarge flow areaFluid removalFracturing fluidHydraulic fracturing

The invention relates to the coal-bed gas exploitation technology, and in particular relates to an active water fracturing technology of a coal-bed gas well, which is used for solving the problem that the yield of coal-bed gas can not be effectively improved by the existing hydraulic fracturing technology owing to a poor fracturing effect. The fracturing technology comprises the following steps: (1) circulation; (2) pressure test; (3) extrusion test; (4) fracturing; (5) support; and (6) pressure release, wherein, in steps (1), (3), (4) and (5), a fracturing fluid is prepared from clear water, a surfactant and a bactericide based on the volume ratio of 2000:1:1; in steps (4) and (5), the pumping delivery of a fracturing pump is 5-9m<3> / min; and the fracturing fluid is infused into the well via a sleeve by utilizing the fracturing pump. By utilizing the fracturing technology, the problem that the yield of coal-bed gas can not be effectively improved by the existing hydraulic fracturing technology owing to a poor fracturing effect is effectively solved, thus the technology is applicable to coal-bed gas exploitation.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

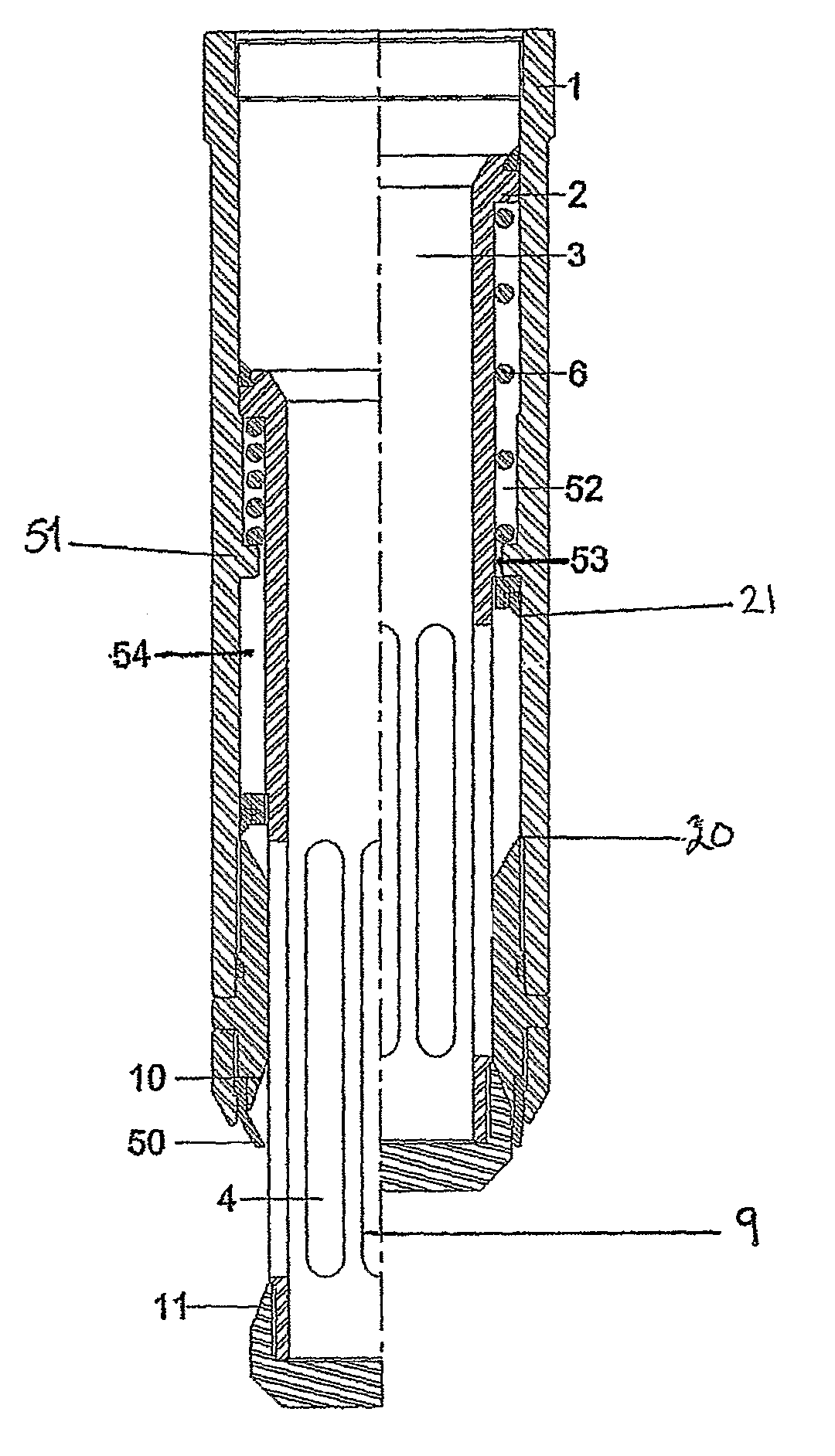

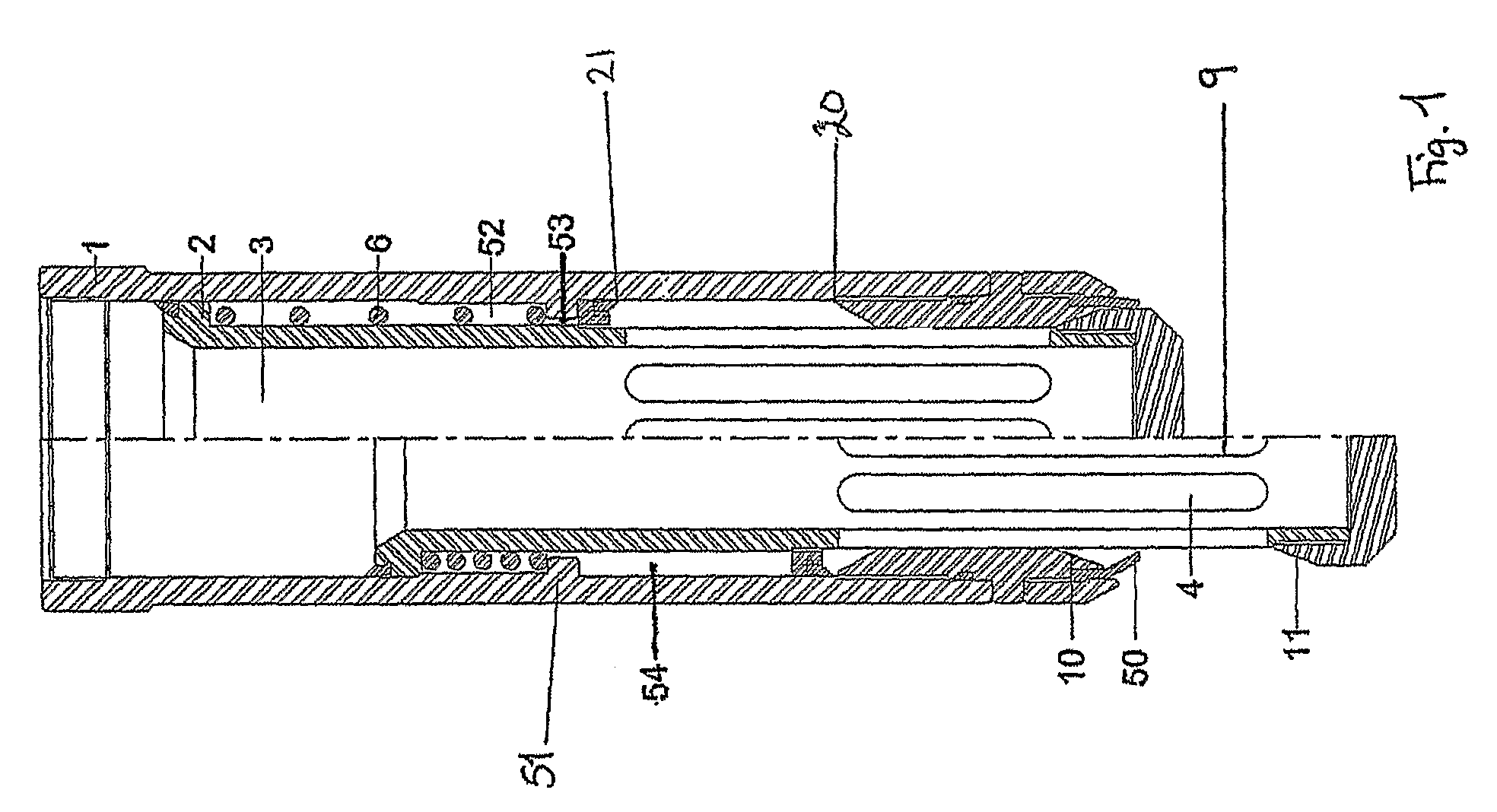

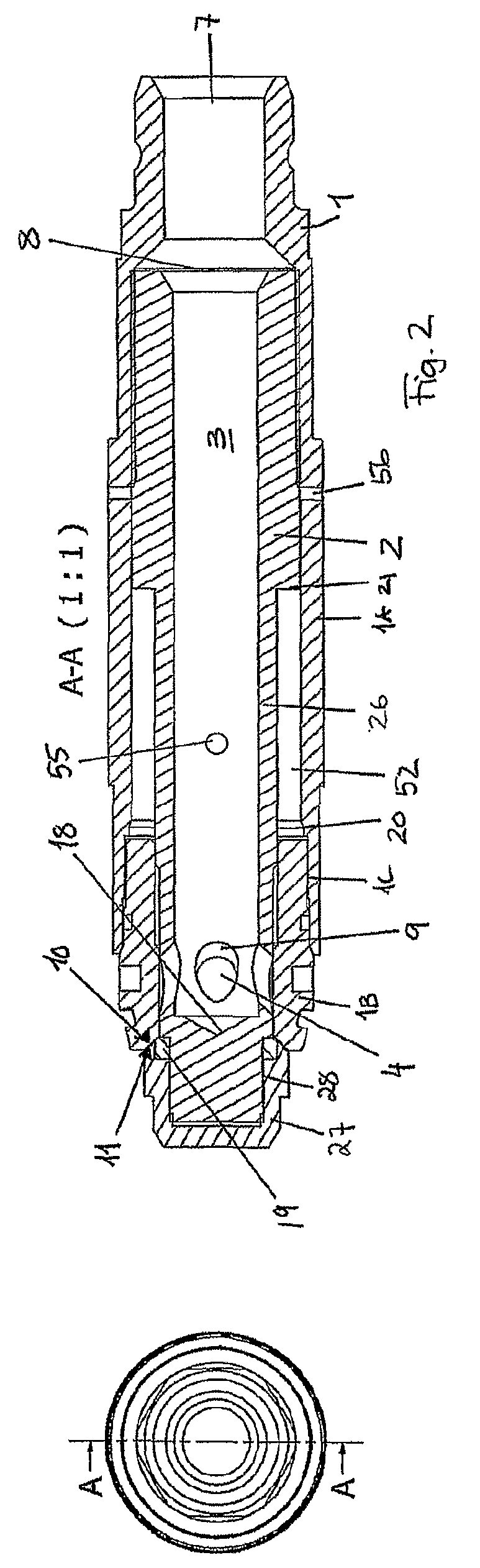

Medical device

1. A medical device with a proximal end for insertion into a body of a living being and an axially opposite distal end, the device comprising: a tip which in a first position forms the proximal end of the device, a drainage section forming a conduit extending in an axial direction of the device, and a retention section extending between the draining section and the tip, wherein the tip is operable between the first position and a second position so as to move the retention section between a first configuration and a second configuration, in which second configuration the retention section is expanded in a direction transverse to the axial direction. The conduit and the tip may be dimensioned to allow the tip to be received within the conduit. One advantage of such a system is that the retention system may be retracted entirely into the conduit so as to make insertion and retraction of the device more comfortable for the patient.

Owner:RANIER LIMITED

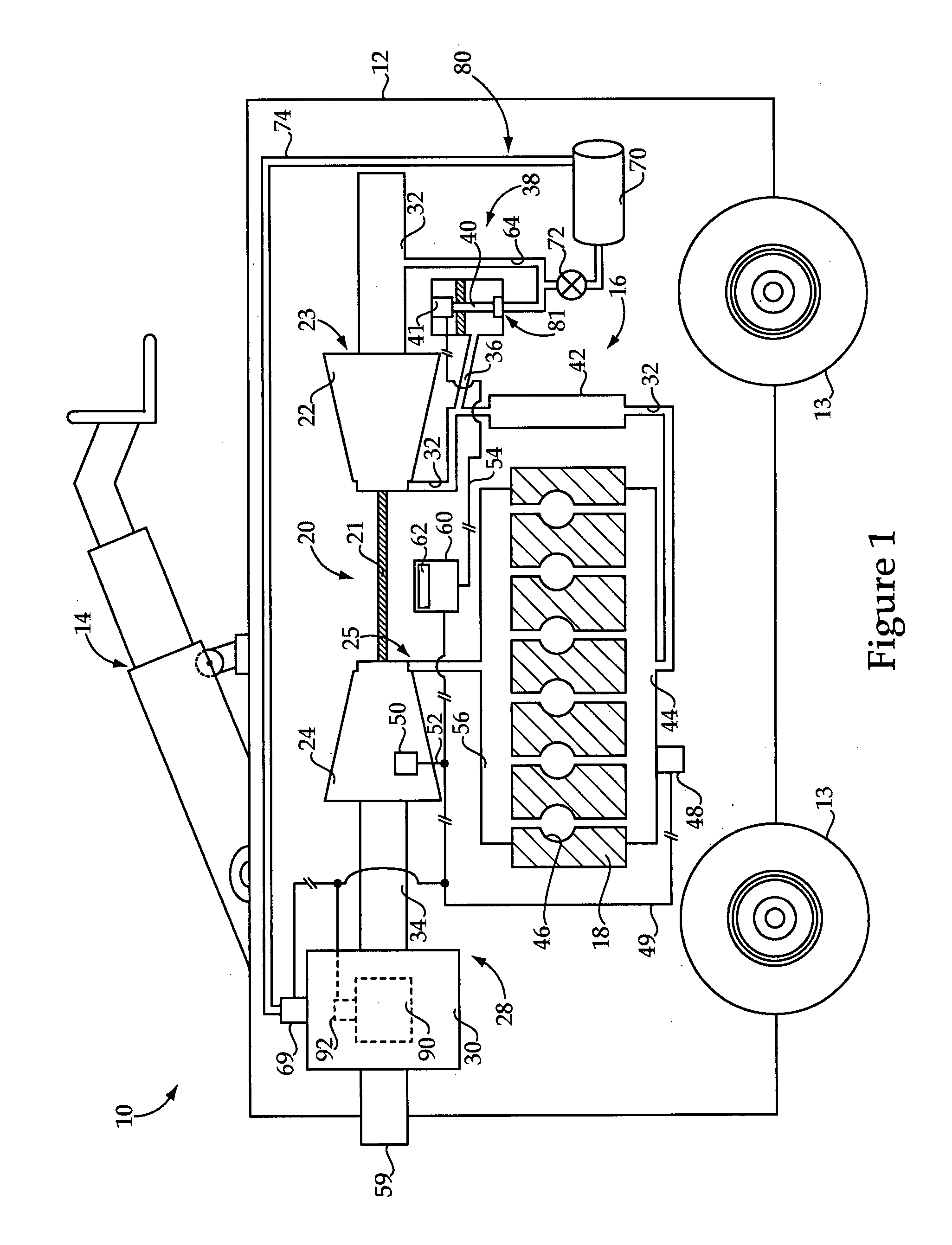

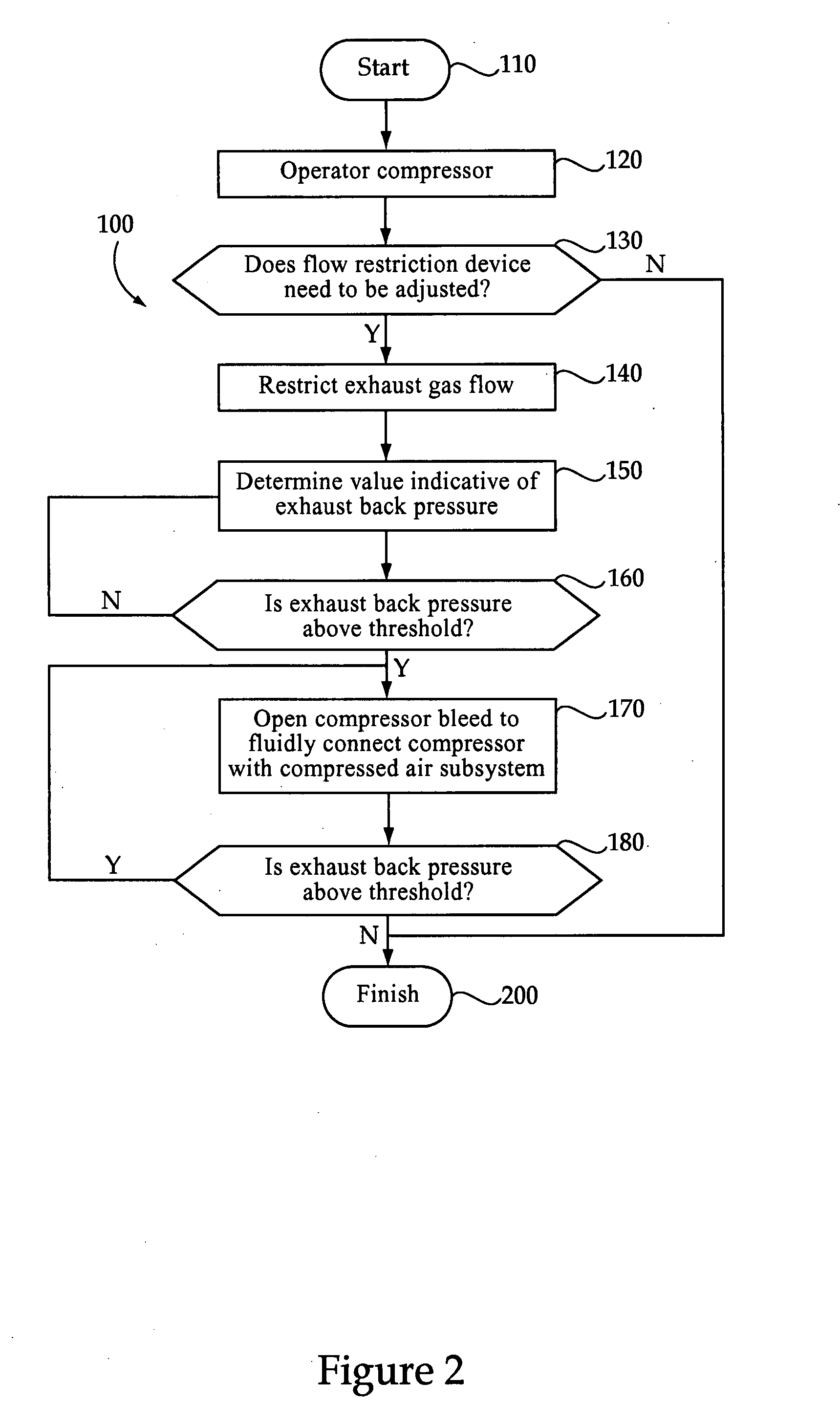

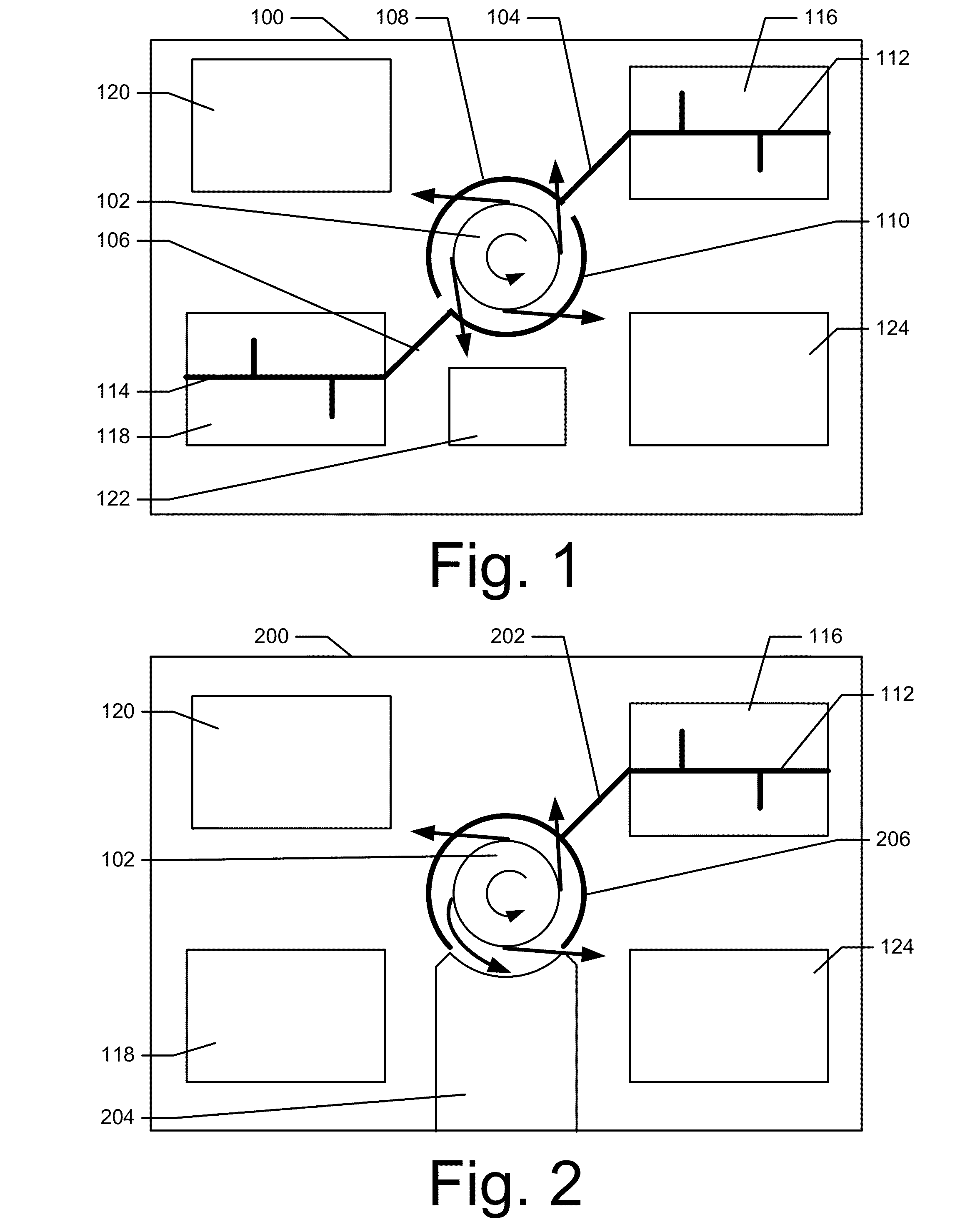

Machine, engine system and operating method

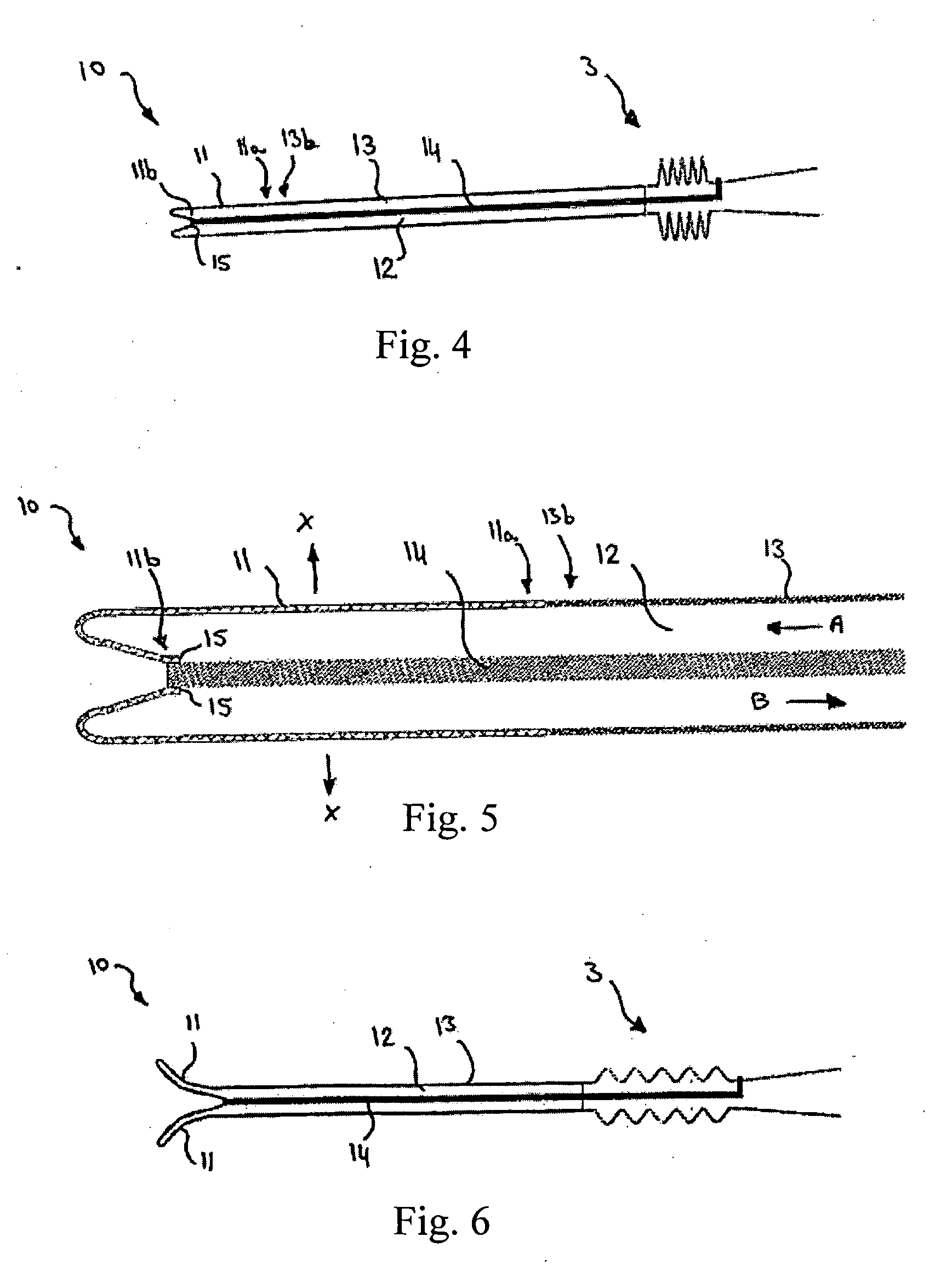

InactiveUS20090056311A1Large flow areaReduced flow areaInternal combustion piston enginesExhaust apparatusPressure controlTraffic volume

A method of operating an engine system includes compressing intake air, restricting exhaust flow from the engine via a flow restriction device, and supplying compressor air to a compressed air subsystem of the engine during restricting exhaust flow. Supplying of compressor air may occur by selectively actuating a pressure control device to fluidly connect an inlet of a compressed air subsystem with the compressor. An associated machine and engine system include a compressor, a flow restriction device, a compressed air subsystem and a pressure control device to selectively fluidly connect the compressed air subsystem with the compressor when the flow restriction device is in a relatively more closed configuration.

Owner:CATERPILLAR INC

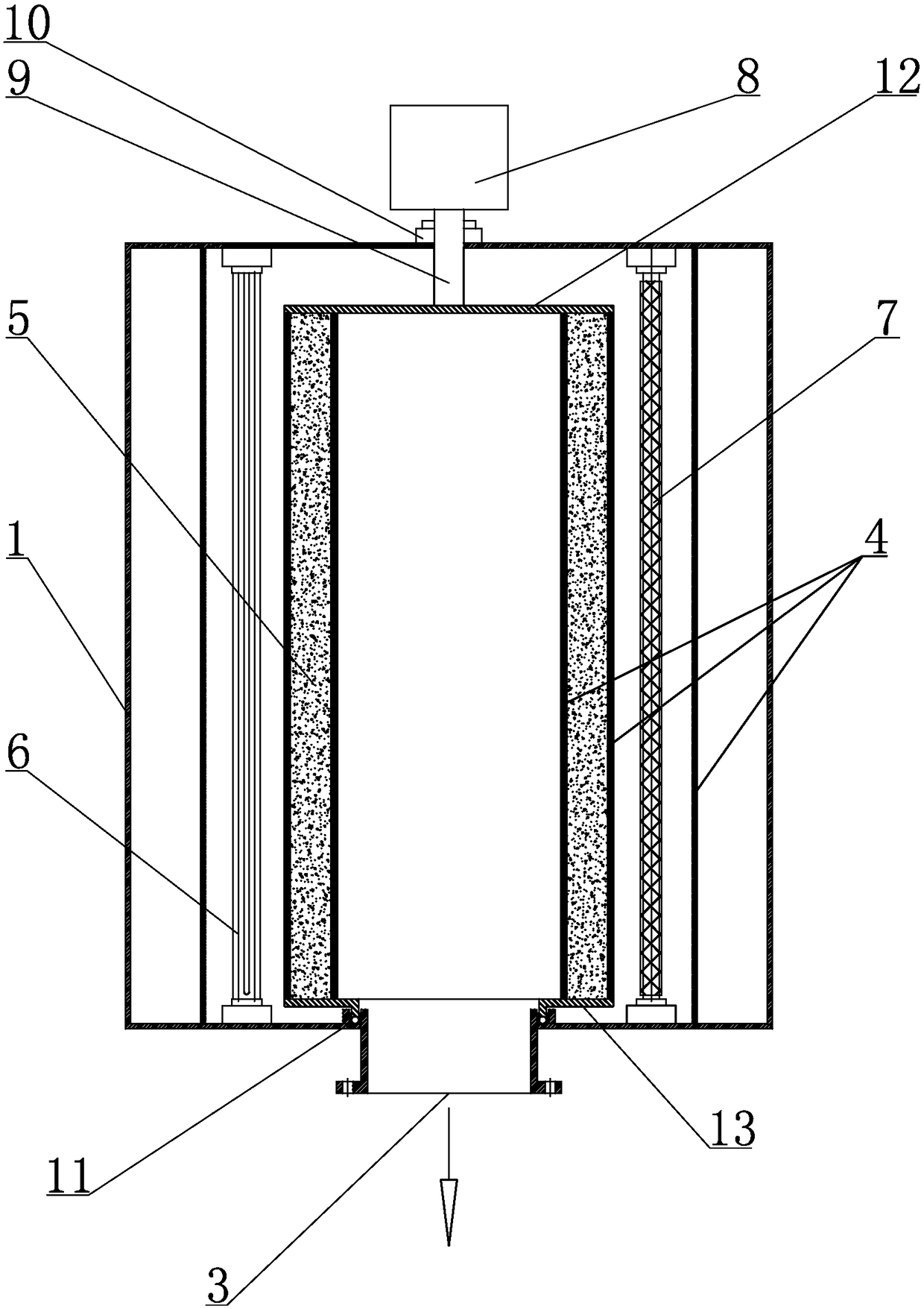

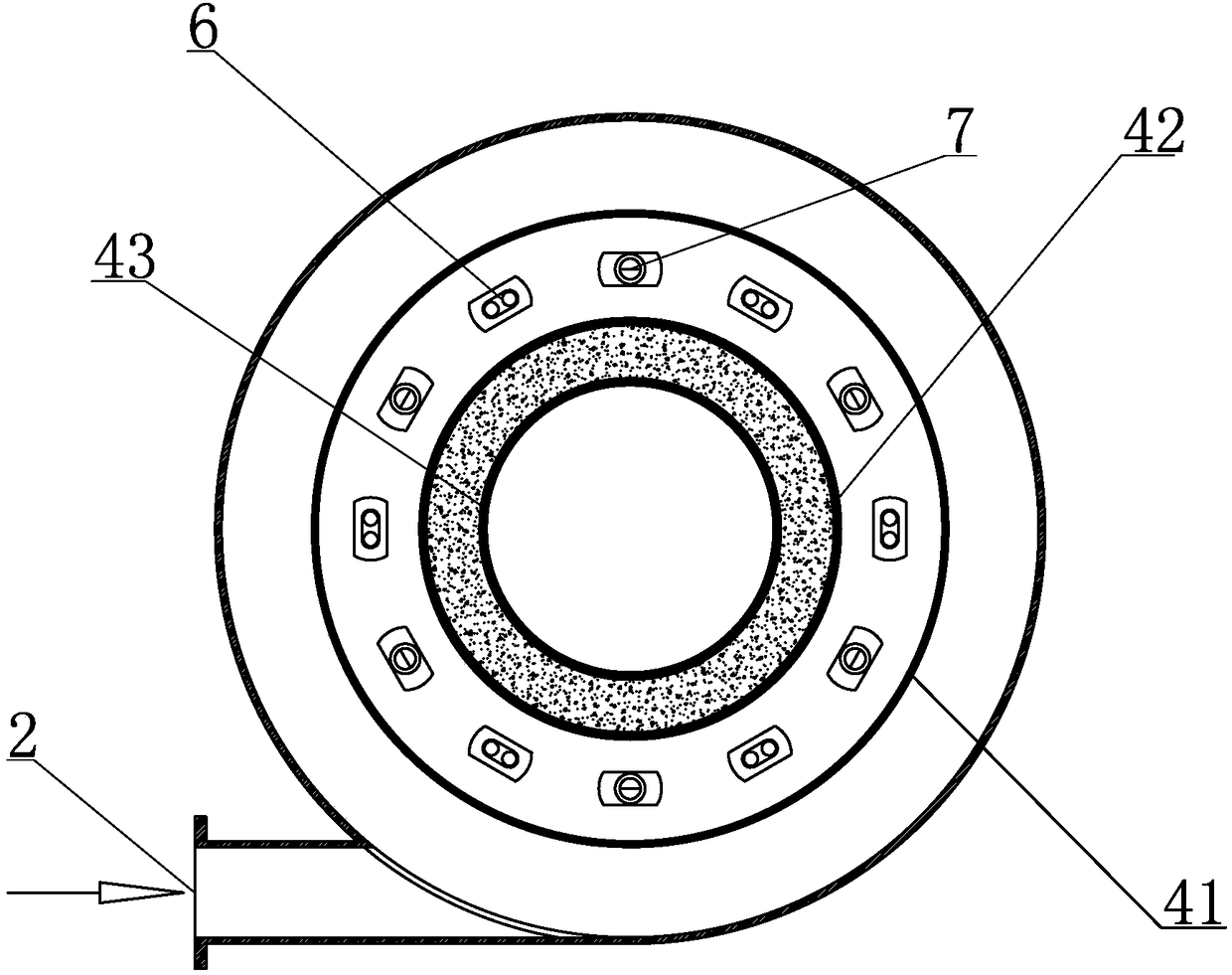

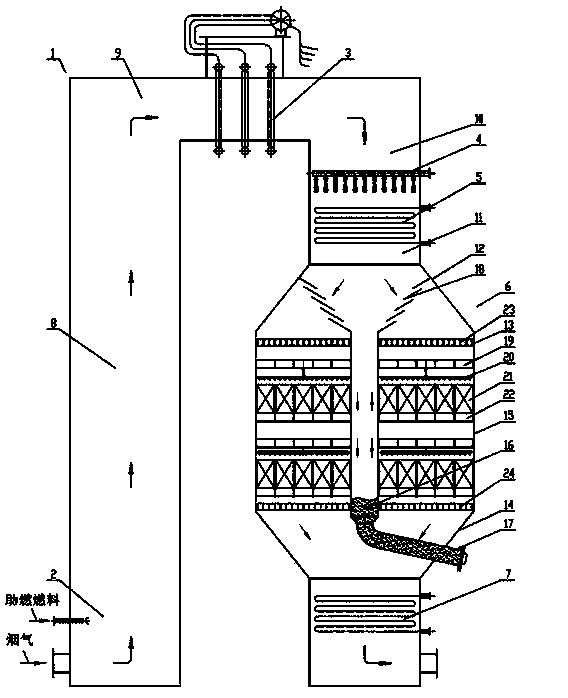

Integral type organic waste gas treatment device

PendingCN108273344AExtended service lifeImprove adsorption capacityCombination devicesGas treatmentActivated carbonEngineering

The invention discloses an integral type organic waste gas treatment device which comprises a shell, wherein an air inlet is formed in a side surface of the shell; an air outlet is formed in the upperend surface or the lower end surface of the shell; a rotating main shaft extending outside from inside is arranged inside the shell; a speed reduction motor is arranged at an end part, outside the shell, of the rotating main shaft; a first filtering cylinder, a second filtering cylinder and a third filtering cylinder are sequentially arranged inside the shell in a layer to layer manner; a plurality plasma bodies and ultraviolet lamp tubes which are distributed at annular intervals are arranged between the first filtering cylinder and the second filtering cylinder; an activated carbon layer isarranged between the second filtering cylinder and the third filtering cylinder; the upper end and the lower end of the first filtering cylinder are respectively connected with the interior of the shell; an upper sealing end cover and a lower sealing end cover are respectively arranged at two ends of the second filtering cylinder and the third filtering cylinder; the rotating main shaft penetrates through the shell, the upper end cover and the lower end cover. The integral type organic waste gas treatment device has the effects of being high in waste gas treatment efficiency, thorough in waste gas treatment, low in energy consumption and long in service life.

Owner:张世红

Water baffle mounted in inner container of water heater

The invention discloses a water baffle mounted in an inner container of a water heater. The water baffle covers an outlet of a water inlet pipe at the bottom of the inner container of the water heater and is provided with water flow guide passages. The water baffle is mounted at the bottom of the inner container of the electric water heater to enable the water outlet of the water inlet pipe in the inner container to be positioned below the water baffle, the guide passages of a certain quantity are distributed on the water baffle, and accordingly overflowing area is widened, water inlet speed is reduced, and pressure is reduced. Further, inflow water can be more uniform in distribution by adjusting open directions of guide holes and increasing water retaining ribs to form distribution grooves, water flow rebounding and disturbance layering caused by collision of water flow with the inner wall of the inner container can be reduced or avoided, hot water output efficiency is further improved, and energy is saved.

Owner:WUHAN HAIER WATER HEATER +2

Spherical flue element equivalent model thermotechnical waterpower experimental apparatus

ActiveCN102855802AReflect thermal hydraulic characteristicsRealize electric heatingEducational modelsThermal expansionEngineering

The invention discloses a spherical flue element equivalent model thermotechnical waterpower experimental apparatus comprising a pressure-bearing component, an electric heating component, an insulation component, a seal component, a pressure measurement component and the like, and field assembly and disassembly can be realized between the components. According to the spherical flue element equivalent model thermotechnical waterpower experimental apparatus, a banded fin thin rod bundle electric element is taken as an equivalent model structure of the spherical flue element, electrical heating method is realized, single-phase water flow and heat transfer experiment can be developed, and thermal-hydraulics of the spherical flue element can be reflected. The pressure measurement component can be assembled and disassembled on spot, consumables such as an O-shaped seal ring and a lead pressure pipe are convenient to replace, thereby reducing loss and cost. A grid spacer plays a role in transverse orientation for the banded fin thin rod bundle electric element, and a single-cone structure of the grid spacer can guide a plurality of the banded fin thin rod bundles to assemble, thereby reducing the difficulty of assembling and improving the efficiency of assembling. Copper braid is adopted to connect a lower conducting element and a lower conductive contact to realize flexible connection, so that the problem caused by electric component thermal expansion is effectively solved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

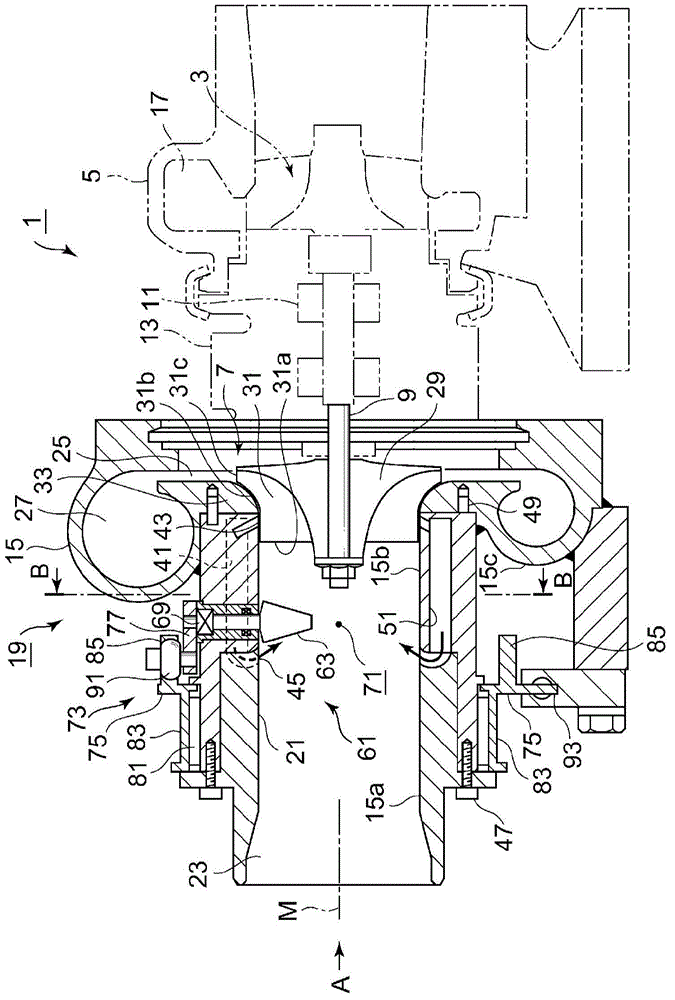

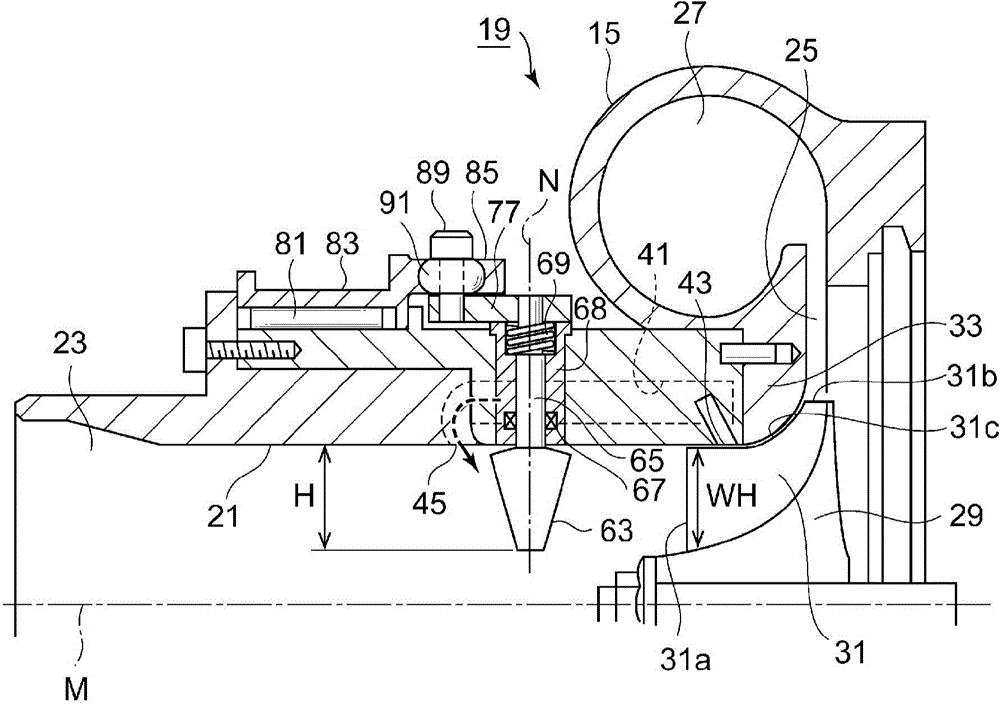

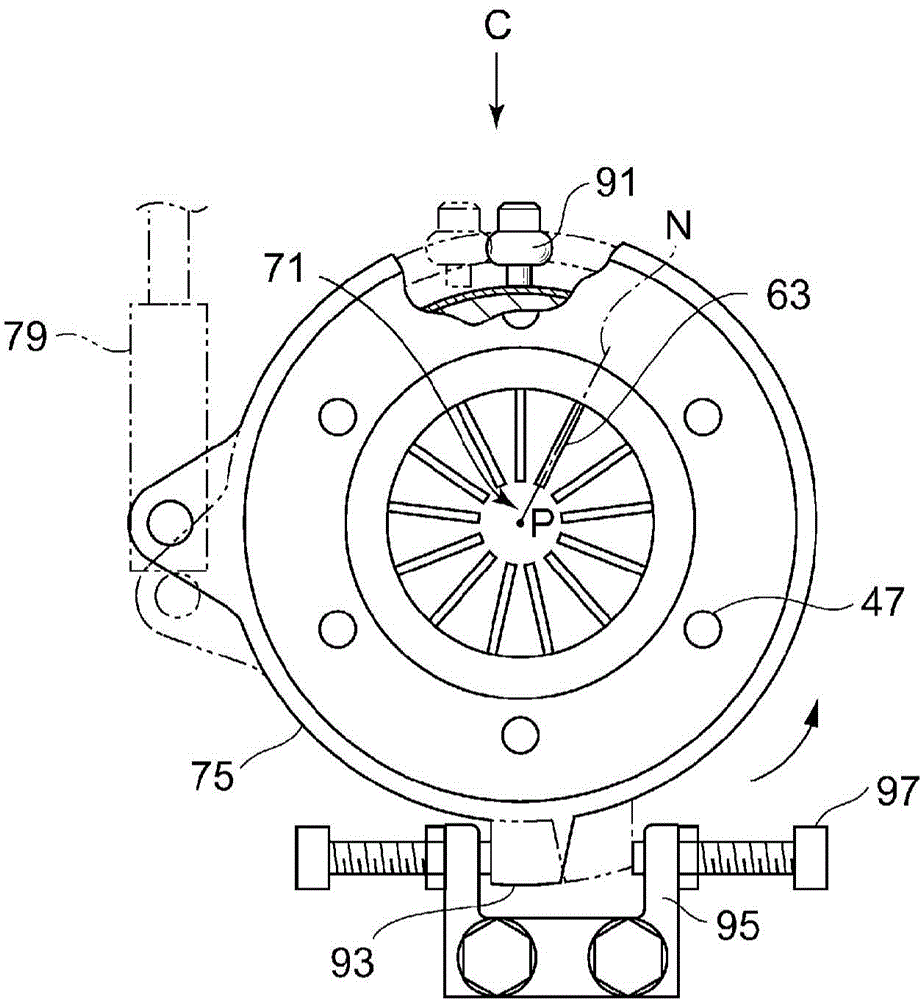

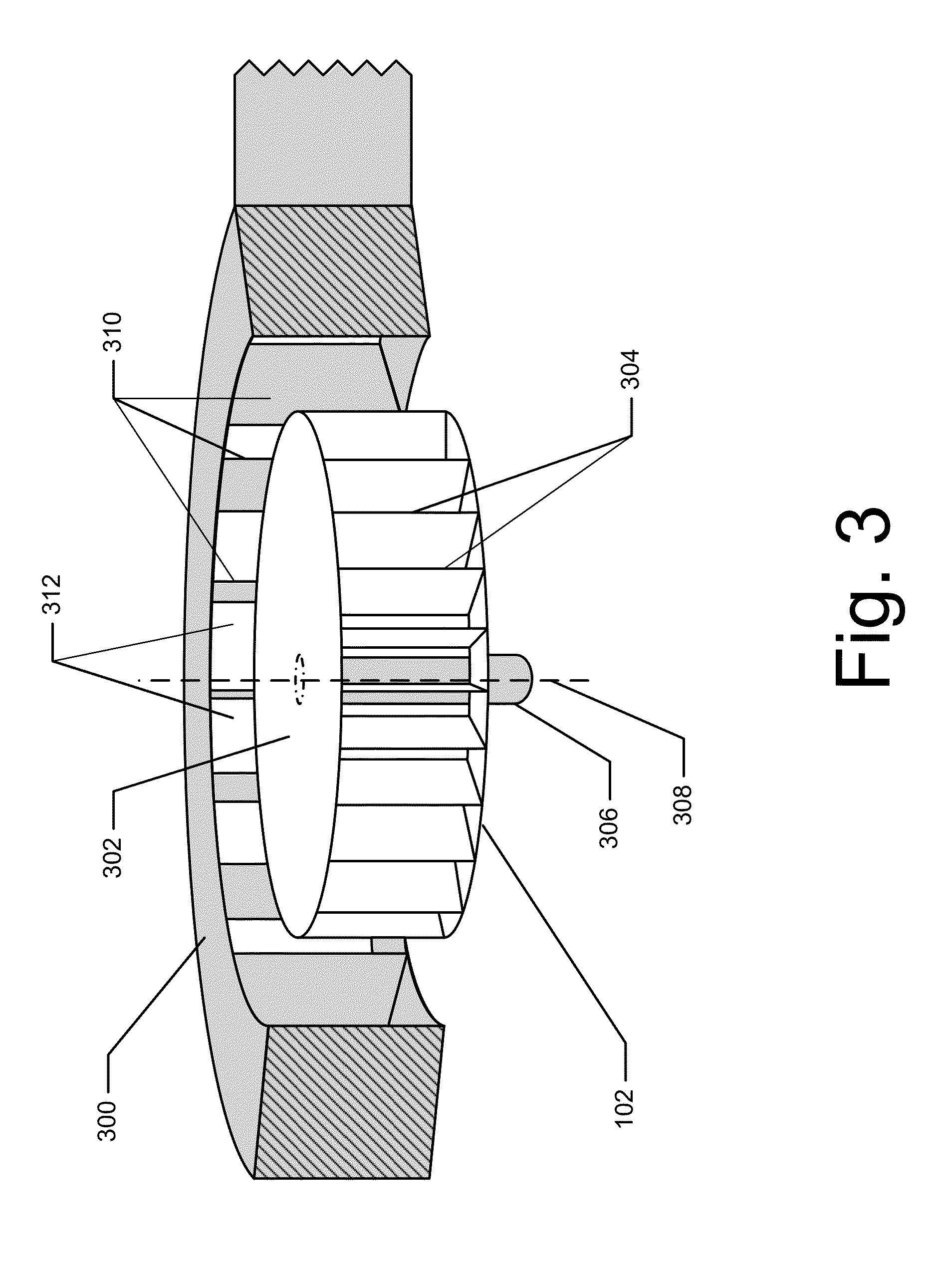

Centrifugal compressor

ActiveCN104428509ASmall inspiratory airflow resistanceReduce throttling flowInternal combustion piston enginesEngine manufactureRotational axisChoked flow

An object is to position guide vanes for generating swirl flow at a housing inner circumferential side in front of an impeller wheel to improve a surge margin and to restrict decrease in a choke flow rate, while making the inclination angle of the guide vanes variable. A centrifugal compressor 19 includes a compressor housing 15, an impeller wheel 7 which compresses intake gas from an intake-air inlet 23, a plurality of guide vanes 63 disposed circumferentially along an inner circumferential wall of the intake-air channel 21 between the intake-air inlet 23 and the impeller wheel 7 to swirl the intake gas around the rotational axis, a central intake-air flow path 71 formed at an inner side of the guide vanes 63 to allow the intake gas to flow to the impeller wheel without passing through the guide vanes 63, and a guide-vane moving mechanism 73 which simultaneously changes the inclination angle of the guide vanes 63.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

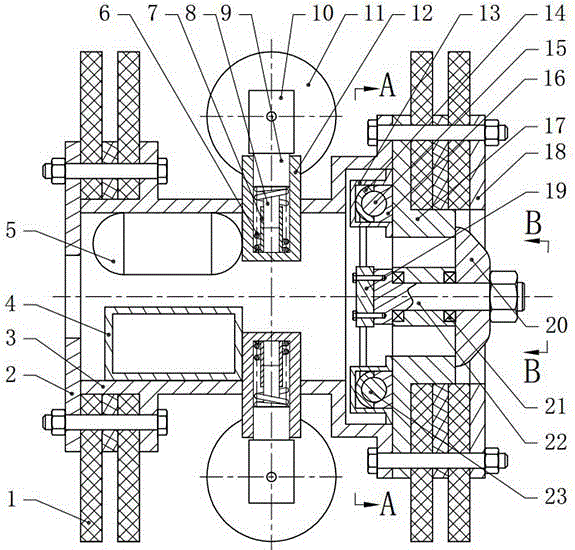

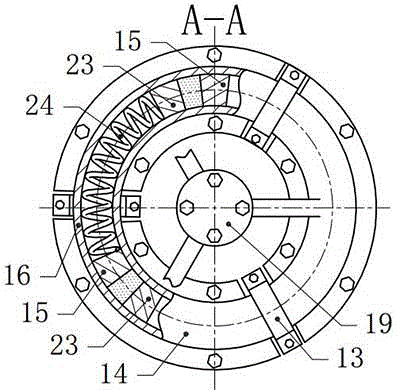

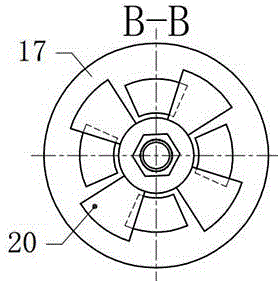

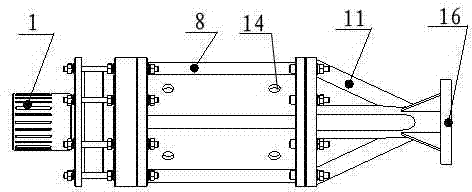

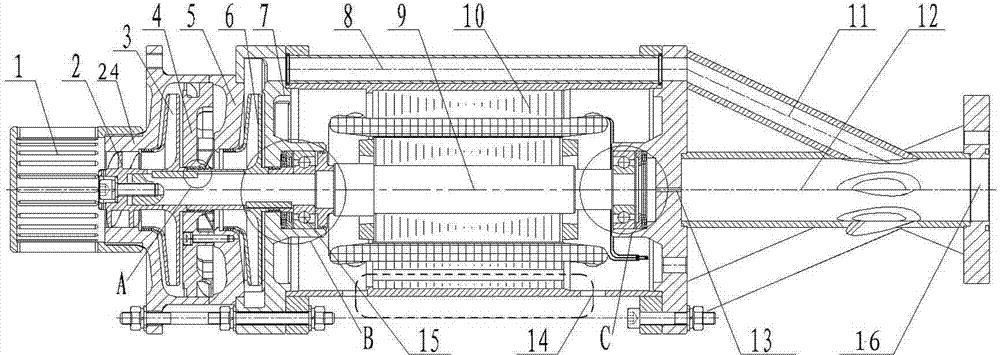

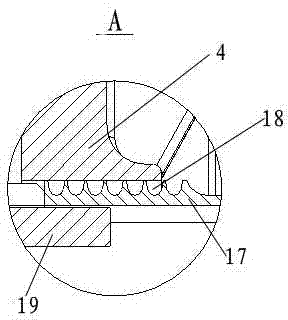

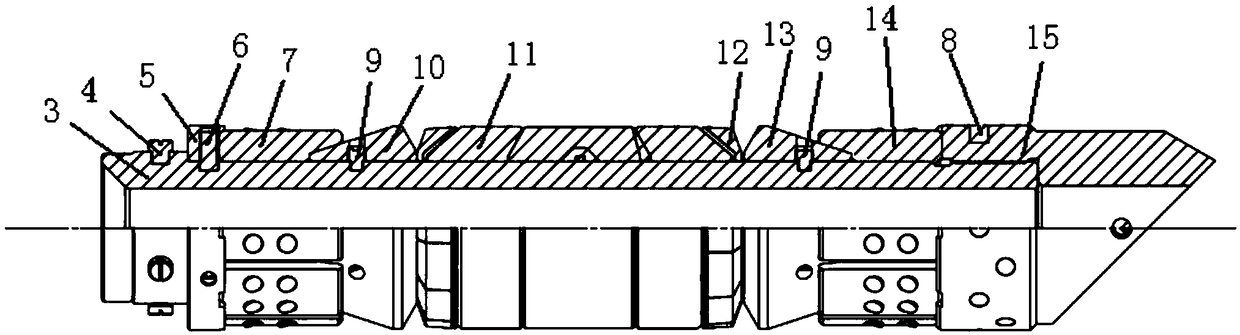

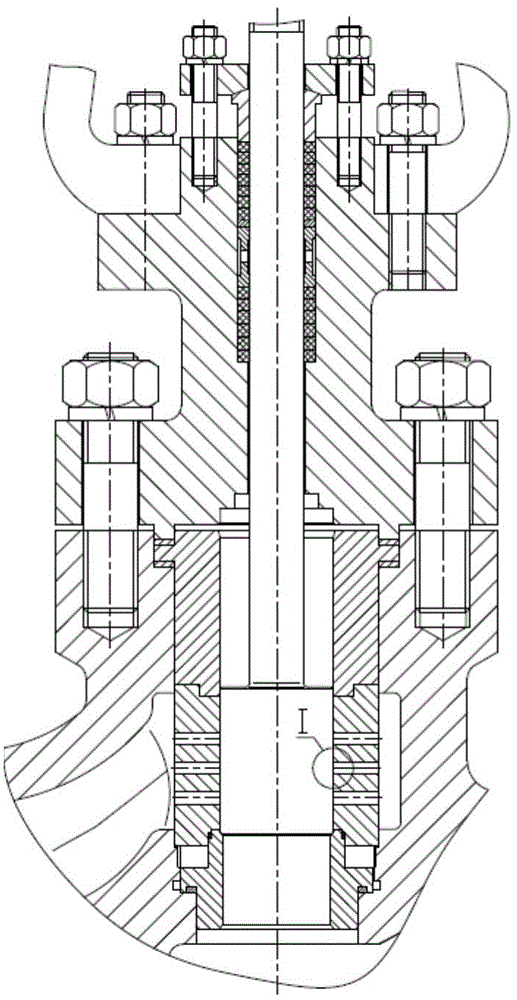

Speed-adjustable pig provided with rotary by-pass valve

InactiveCN105665382ALarge flow areaReduce the throttle pressure differenceHollow article cleaningVelocity controllerEngineering

The invention relates to a speed-adjustable pig provided with a rotary by-pass valve. The pig can overcome the defect about the control manner of electrically-controlled by-pass valves. According to the technical scheme, speed collecting wheels are pressed against the inner wall of a pipeline under the spring force and the hydraulic force and drive hydraulic pumps, the hydraulic pumps output high-pressure oil which flows back to an oil tank by the aid of a throttling valve, pressure at the front end of the throttling valve is introduced into an annular oil cylinder, and the annular oil cylinder drives a valve core to rotate and change the flow area. A speed controller of the pig comprises no electrical apparatus elements, the pig is safe and reliable and can be used for long-distance pipeline cleaning, and energy is not required to be stored in a storage battery; pipeline detection equipment can be carried, and pipeline detection and cleaning work can be completed.

Owner:SOUTHWEST PETROLEUM UNIV

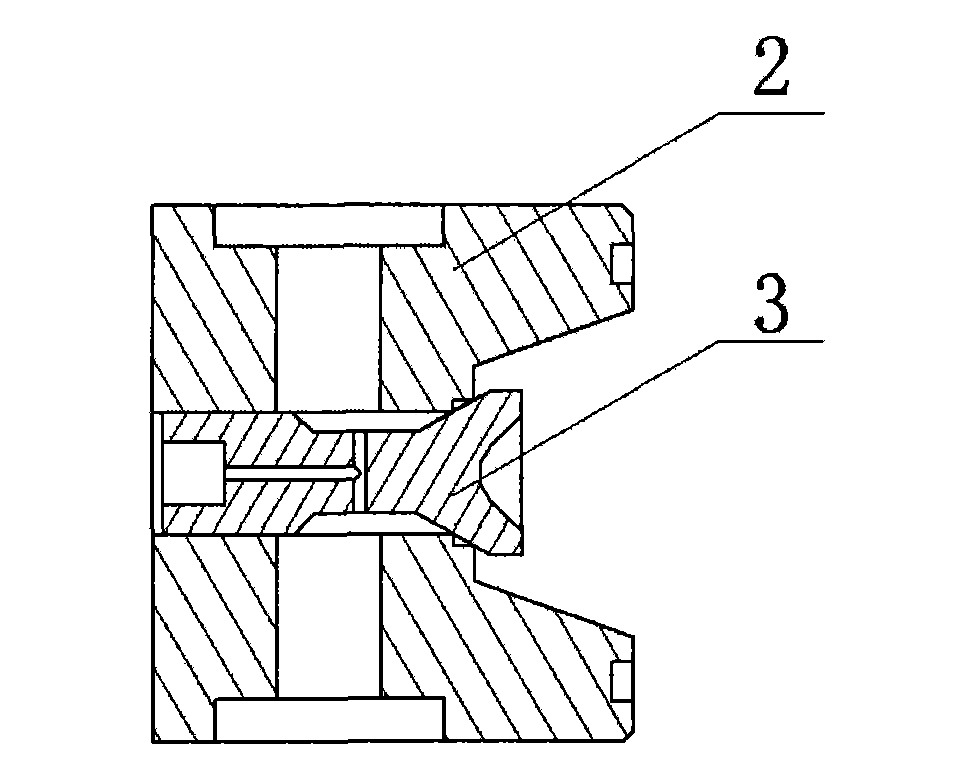

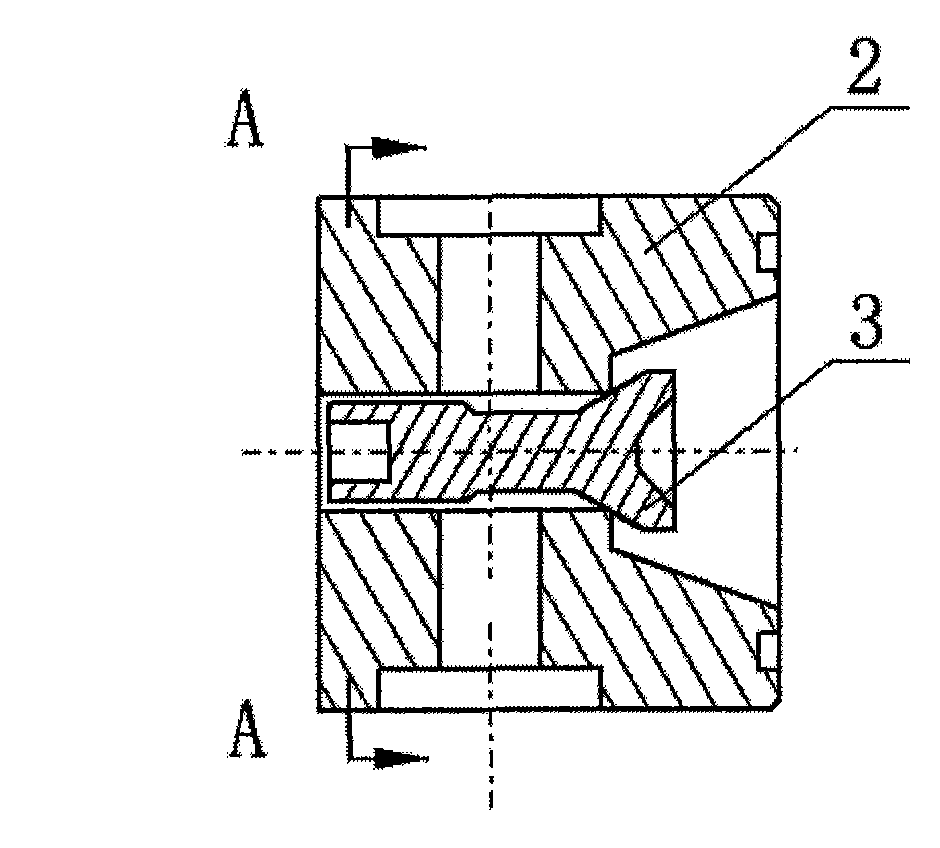

Fluid injection device

ActiveUS8186440B2Large flow areaLess pressure lossCheck valvesFluid removalEngineeringPressure difference

The present invention regards a device designed for injection of fluids in a well bore, typically an offshore well bore for petroleum production and gas injection / gas lift system for fluid injection. The device comprises a outer hollow housing (1) with an internal body (2) moveable within the outer housing (1) with an internal bore (3) which in a first closed position is closed with a metal to metal seal system between the outer housing (1) and the internal body (2), which internal body (2) is operated by pressure differential across the internal body (2), where the internal body (2) is designed with slots (4) forming outlets of the internal bore (3) which in an open position of the device is positioned outside of the outer housing (1).

Owner:GASOLINEEUM TECH

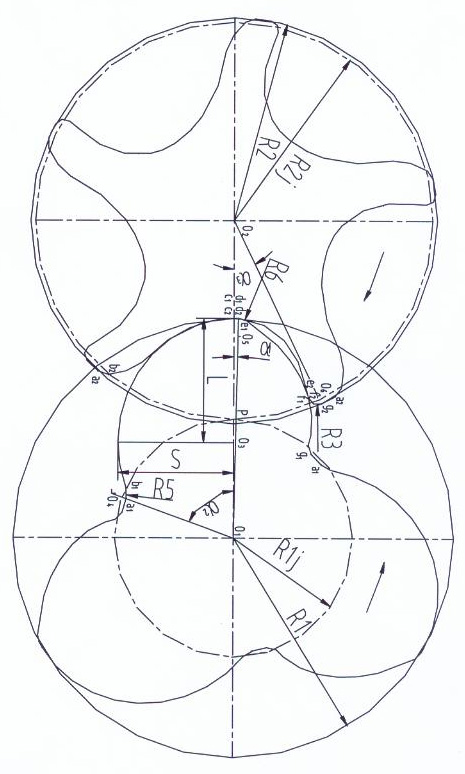

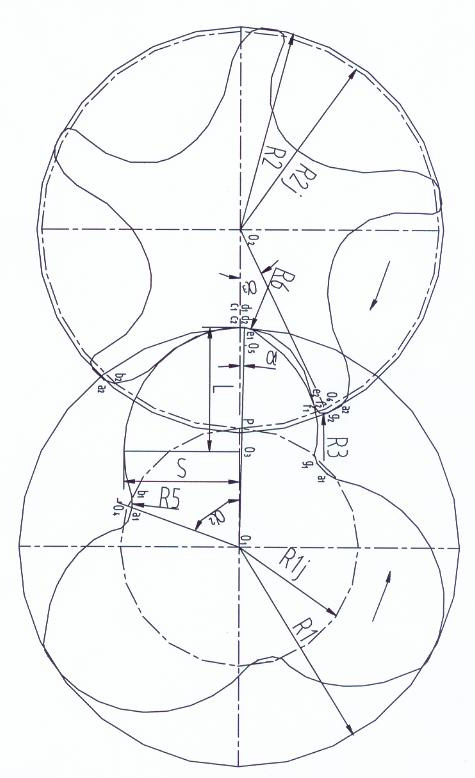

Twin-screw compressor rotor profile

InactiveCN102052322AContact wire shortLeaky triangle smallRotary piston pumpsRotary piston liquid enginesBilateral asymmetryEllipse

The invention relates to a twin-screw compressor rotor profile, wherein a two-side asymmetric profile is adopted, six sections of profiles are combined to form end face profiles of a female rotor and a male rotor, and the female rotor and the male rotor which are identical in central distance A and different in size are combined to a form a female / male rotor profile series of a screw compressor. An arc f2g2 with a certain radius and an arc envelope d2e2 at the addendum circle on the passive side of the female rotor end face profile are in smooth connection through taking a straight line e2f2 as a common tangent. The elliptic arc b1c1 on the male rotor end face profile is different from the ordinary arc pin tooth curve or the envelope and can enable the engagement and releasing of the male and female rotors to be more stable through properly adjusting the length ratio of the major and minor axes of the ellipse, so as to reduce noise and vibration. The included angle of the addendum arc c1d1 on the male rotor end face profile can be adjusted, and the addendum arc c1d1 is in tangent and smooth connection with both the elliptic arc b1c1 and an arc d1e1. The invention endows the rotors with the advantages of short contact line, small disclosed triangle, big flow passage area, streamlined rotor profile, reduced aerodynamic resistance and the like.

Owner:南通永力液压设备有限公司

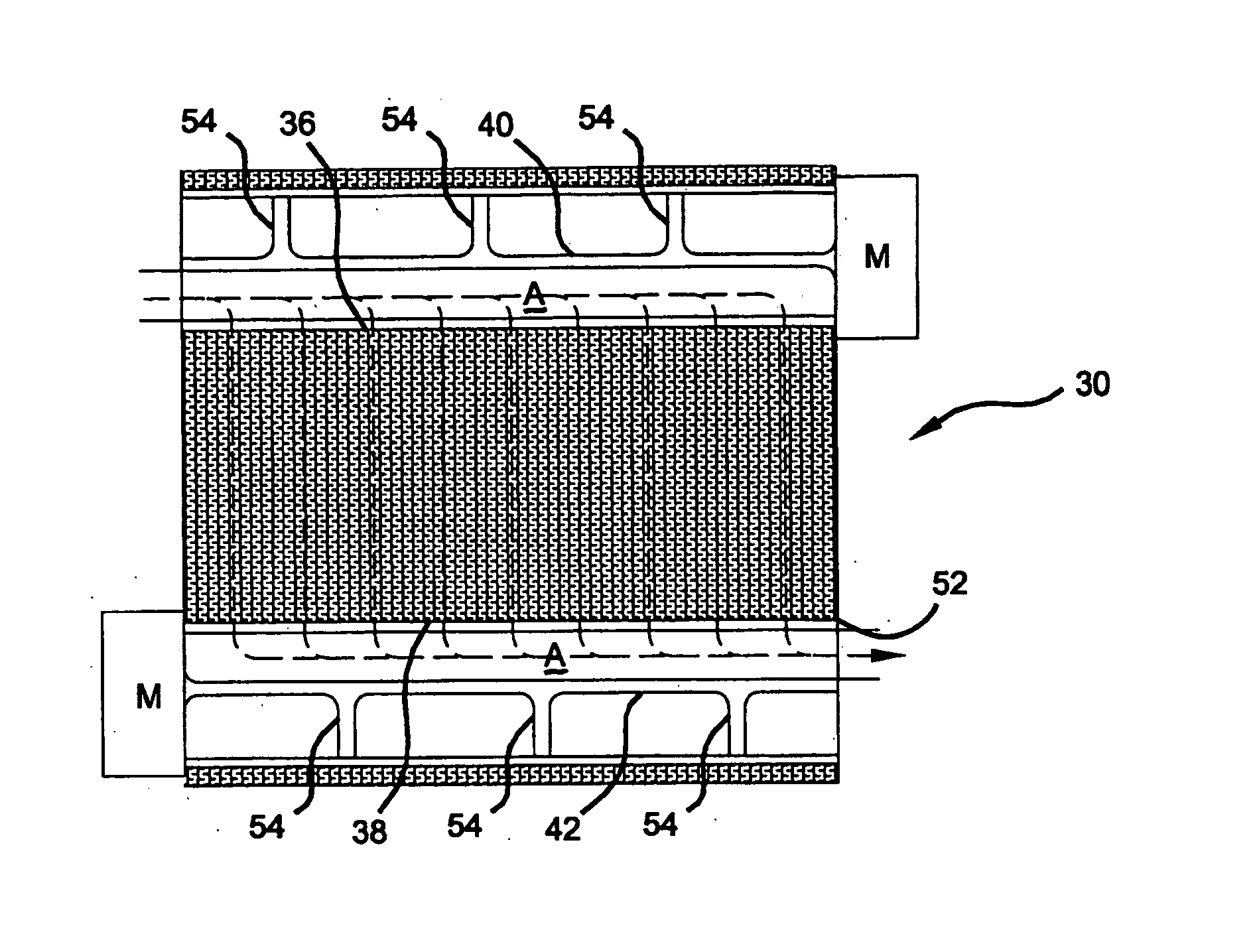

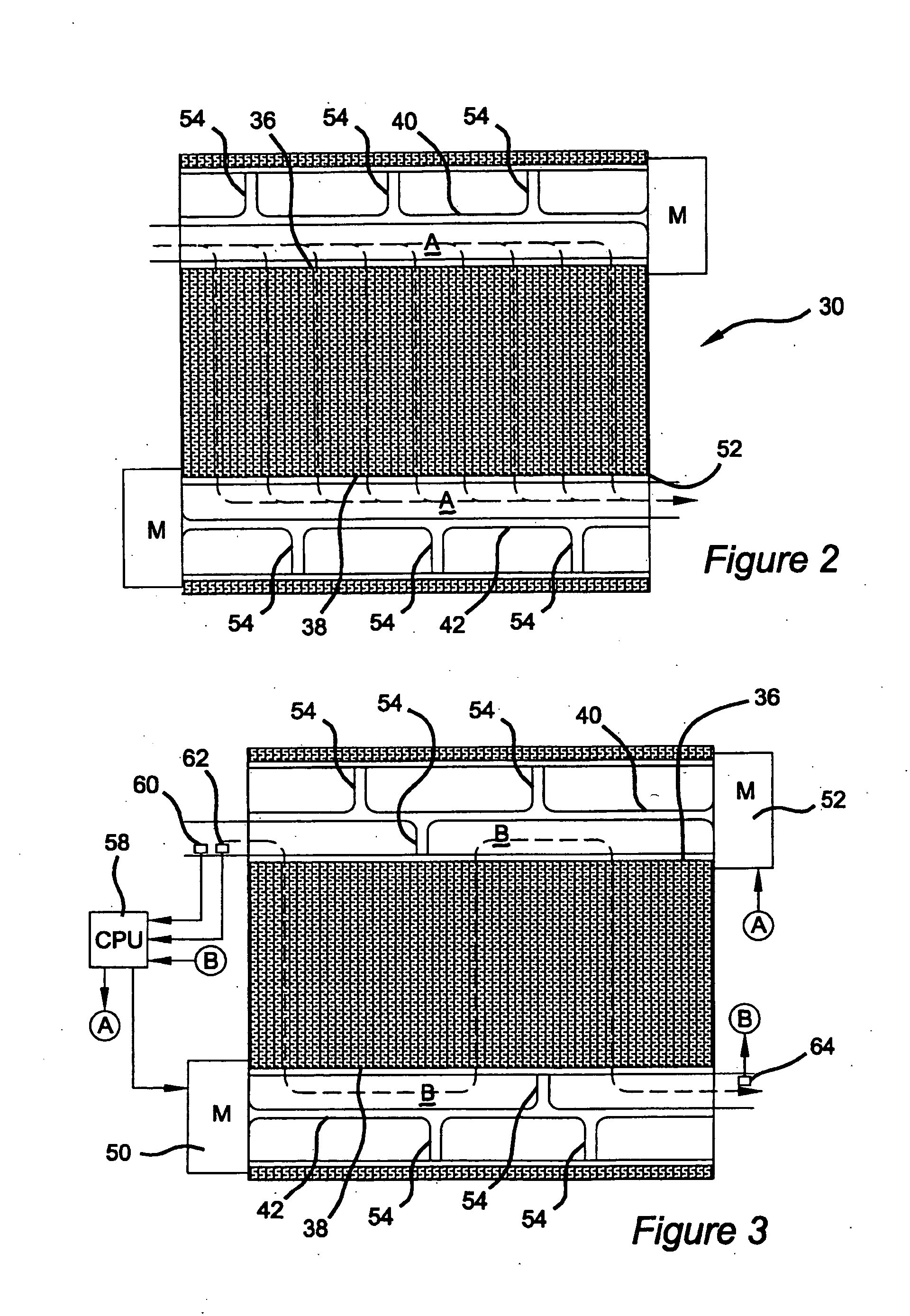

Device and method to expand operating range of a fuel cell stack

InactiveUS20050037254A1Expand the scope of operationHigh gas velocityFuel cells groupingFuel cell auxillariesFuel cellsEngineering

A device and method are provided to allow the flowpaths in a fuel cell stack to be reconfigured dependent on reactant gas throughput in order to maintain appropriate pressure drop, sufficient velocities, and reactant concentrations of each cell of a fuel cell stack.

Owner:GM GLOBAL TECH OPERATIONS LLC

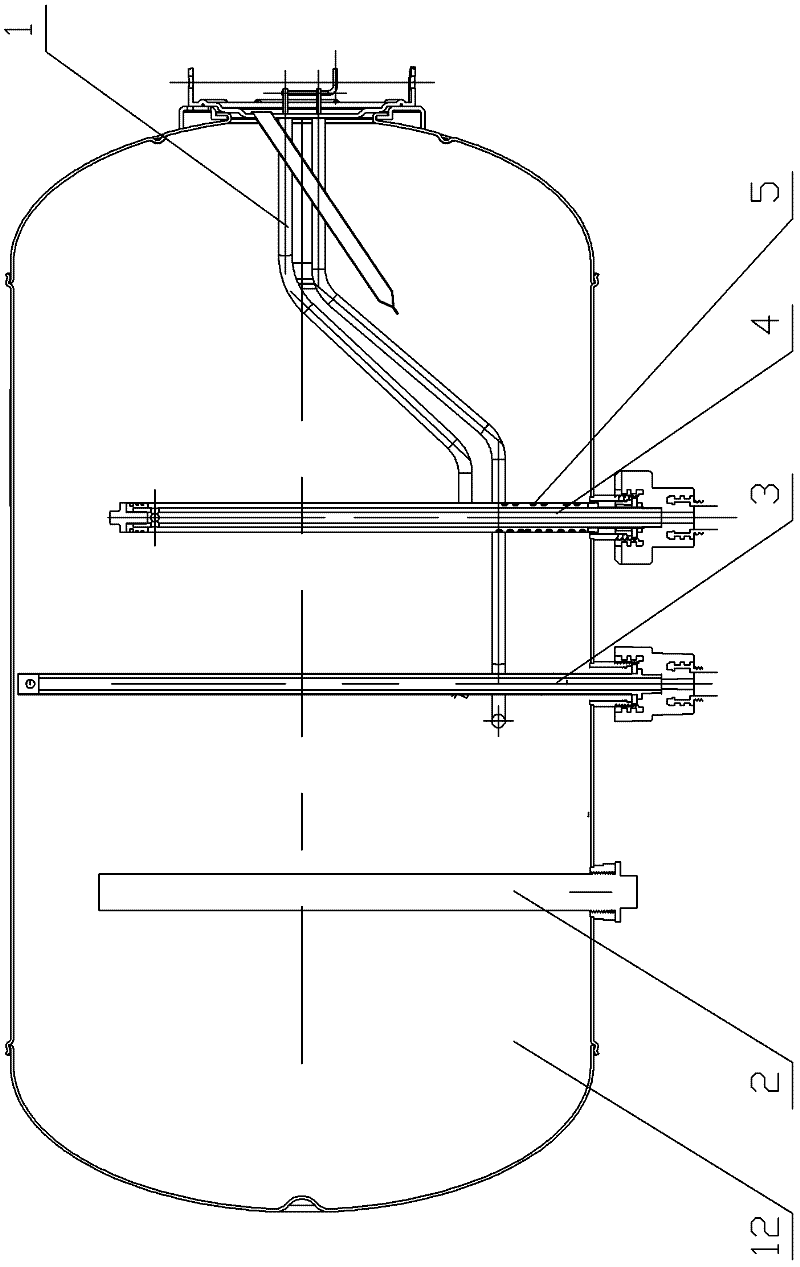

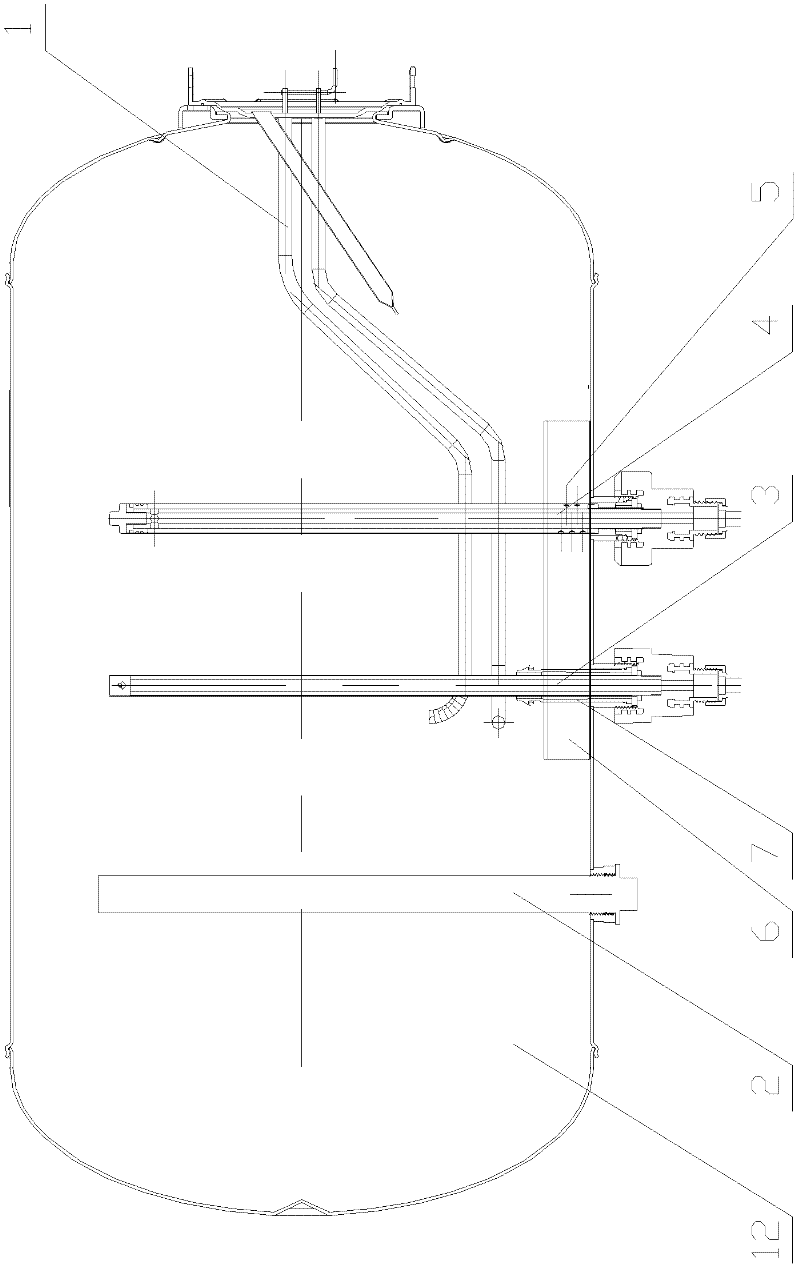

LNG immersed pump

The invention discloses an LNG immersed pump and belongs to the technical field of LNG. A stator and a rotor shaft are arranged in a motor cavity in the LNG immersed pump, and side wall channels are arranged in the side wall of a pump body; a motor upper cover is connected to the rear end of the pump body and provided with a plurality of liquid flowing channels communicated with the side wall channels, and the liquid flowing channels are arranged in an inclined mode and intersect with one another at a liquid outlet; a motor lower cover is connected to the front end of the pump body, liquid via holes communicated with the side wall channels are formed in the motor lower cover, a shell is connected to the motor lower cover to form a working cavity and provided with a first-stage flow guide disc to partition the working cavity into a front cavity and a rear cavity, a flow channel communicated with the front cavity and the rear cavity is arranged on the first-stage flow guide disc, a second-stage impeller is arranged in the rear cavity, a first impeller is arranged in the front cavity, a liquid inlet is formed in the front cavity in a connected mode, and an inducer is arranged in the liquid inlet; the rotor shaft penetrates through the motor lower cover and the working cavity and extends into the liquid inlet, and the first-stage impeller, the second-stage impeller and the inducer are all arranged on the rotor shaft in a sleeved mode. The LNG immersed pump is simple in structure and suitable for being popularized and used.

Owner:CHENGDU ANDERSON MEASUREMENT

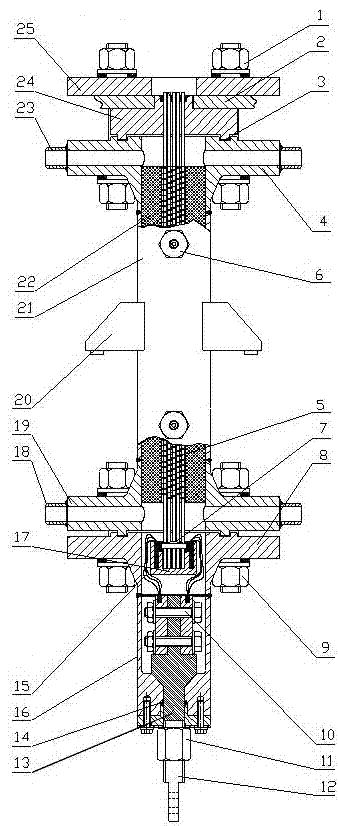

Magnesium-based metal-soluble bridge plug

InactiveCN109236230AGuaranteed anchoring effectGuaranteed anchoring forceSealing/packingMetallic materialsEngineering

The invention discloses a magnesium-based metal-soluble bridge plug. The magnesium-based metal-soluble bridge plug comprises a central tube, a releasing shear nail, a spacer ring, an upper slip, an upper conical body, a rubber cylinder, a protective ring, a lower conical body, a lower slip, a base and an anti-blocking pattern tube; the spacer ring, the upper slip, the upper conical body, the rubber cylinder, the protective ring, the lower conical body and the lower slip separately sleeve the central tube from top to bottom in sequence, and the base is connected with the central tube through anexternal thread of the lower end of the central tube; the upper end of an outer setting cylinder is connected with an ignition setting tool through a T-shaped thread. Compared with the prior art, themagnesium-based metal-soluble bridge plug has the advantages that a magnesium-based soluble metal material is adopted, and the dissolution performance is reliable; an upper-and-lower bidirectional integral slip structure is adopted, the integral slip junction is broken when the thrust reaches 2-3 t, and the slips are opened; slip teeth adopt combinations of ceramic particles and alloy particles to ensure an anchoring effect and an anchoring force; the base has an anti-rotation structure design, and the plug is drilled conveniently when plug drilling is needed in a short time due to sand blockage or complicated well bottom conditions.

Owner:CNPC BOHAI DRILLING ENG

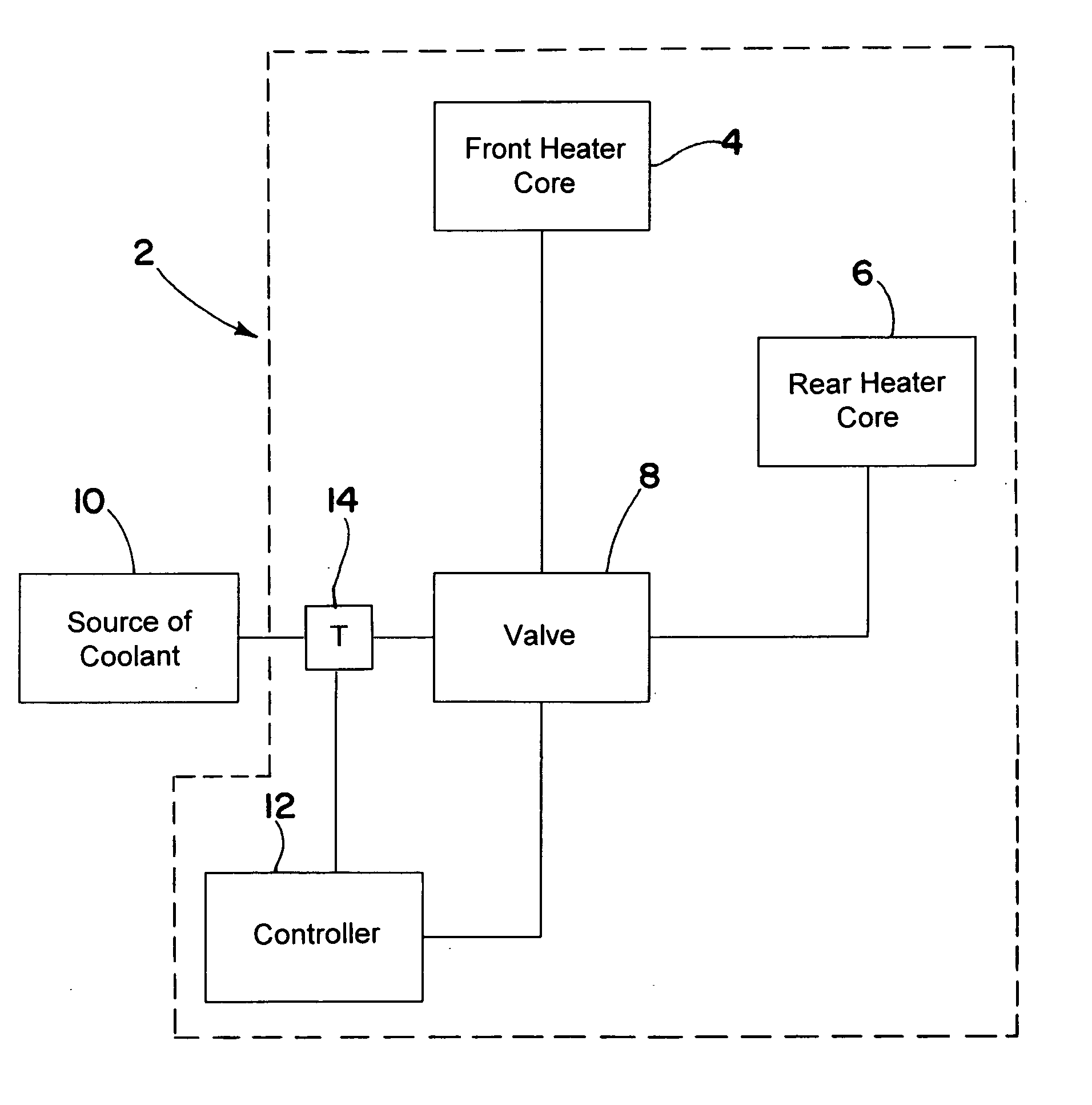

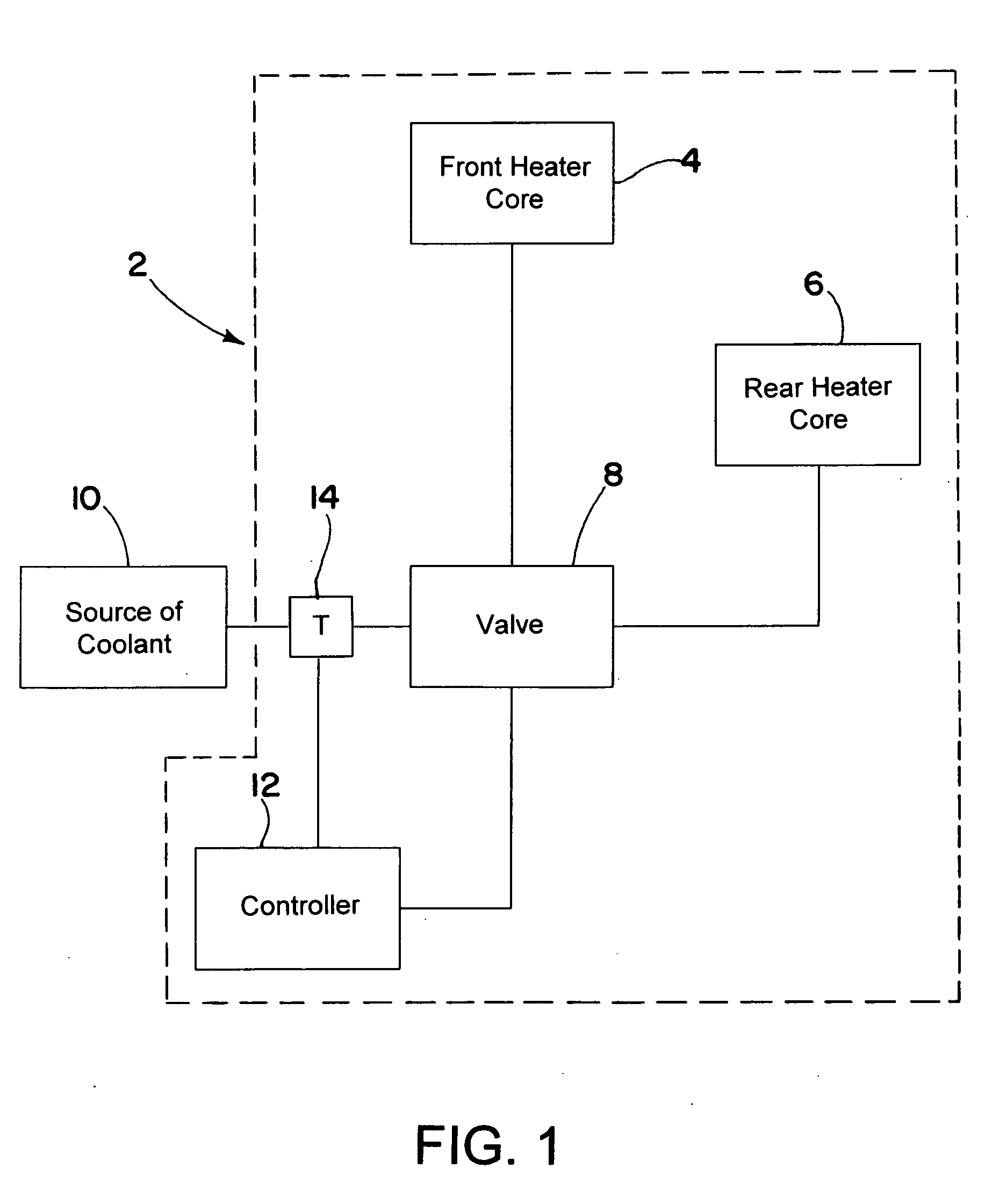

Vehicle cabin heating system with wax motor three-way valve

InactiveUS20050224031A1High strengthSimple moldingAir-treating devicesOperating means/releasing devices for valvesCoolant flowEngineering

The present invention provides a wax motor actuated valve assembly for controlling the flow of coolant to a heater core or cores until the coolant reaches a predetermined operating temperature. The wax motor actuated valve has particular application to vehicle cabin heating systems comprising front and rear heat exchangers (cores) over which air can pass for heating front and rear portions of the cabin, respectively. Initially, flow to the rear heat exchanger is shut off until the temperature of the coolant reaches a predetermined elevated temperature, whereby initial coolant flow is directed to the front heat exchanger for more rapid heating of the forward portion of the vehicle cabin. After the predetermined elevated temperature has been reached, the wax motor valve assembly is actuated to supply coolant to the rear heat exchanger for heating the rear portion of the vehicle cabin.

Owner:PARKER HANNIFIN CORP

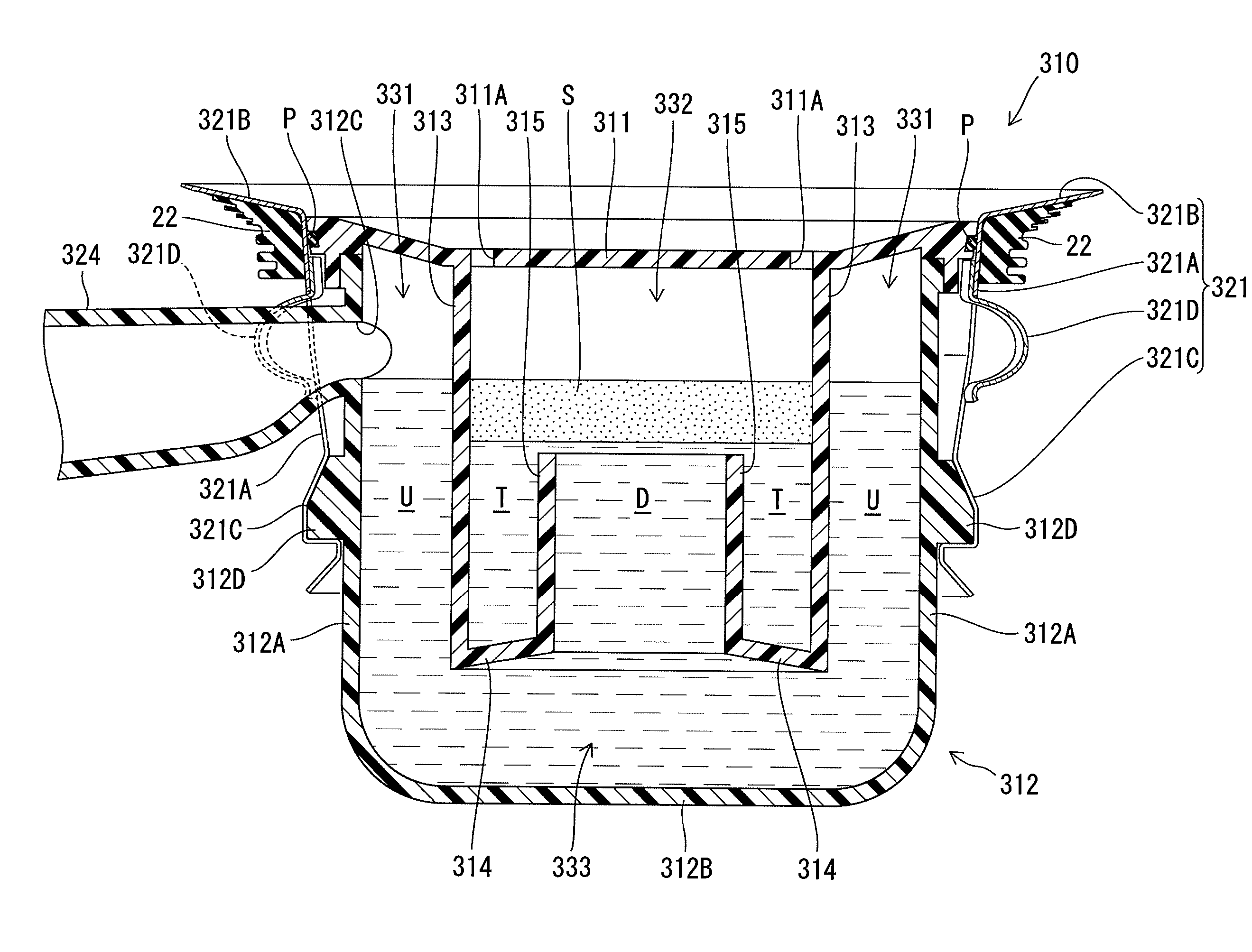

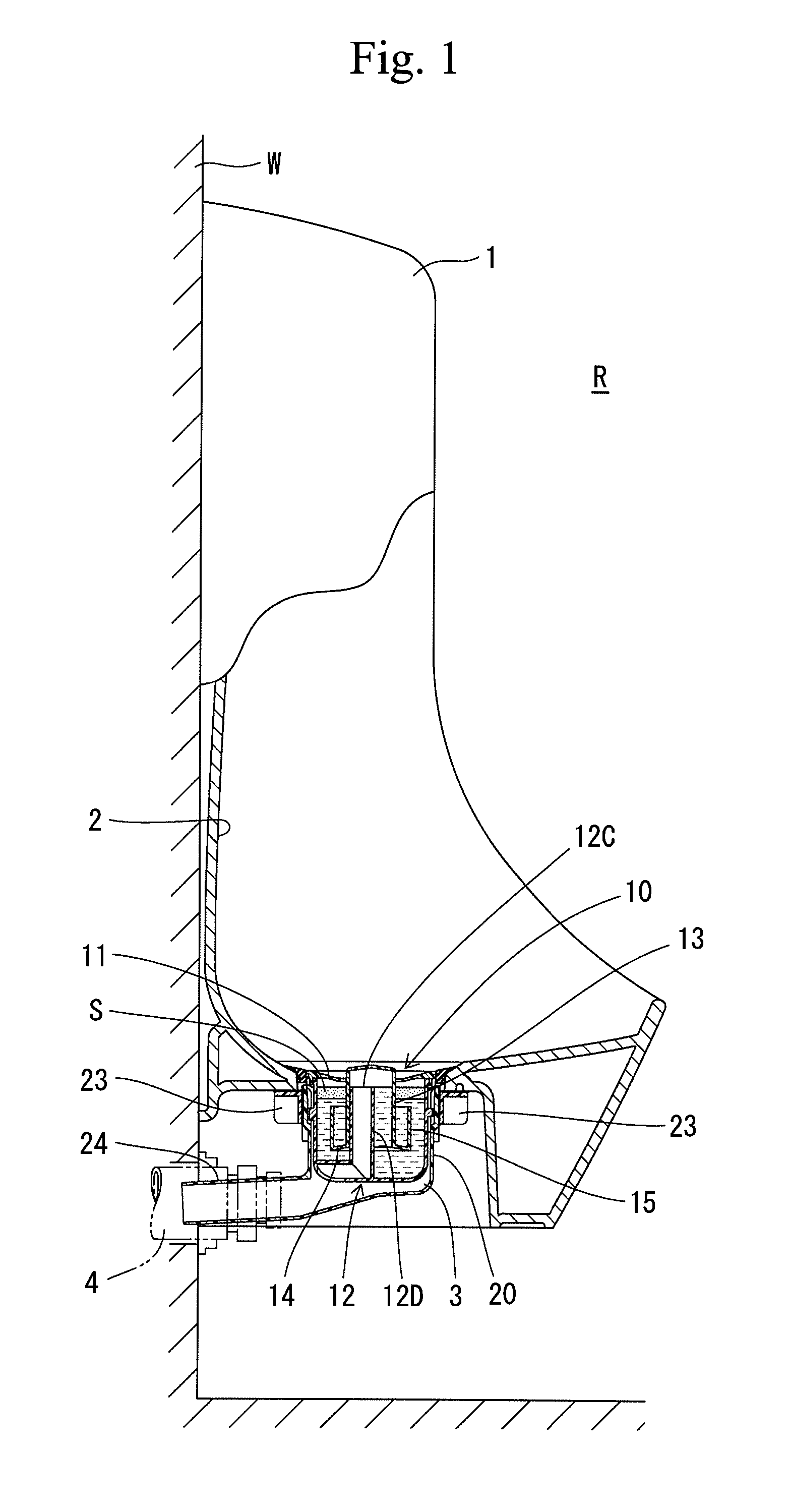

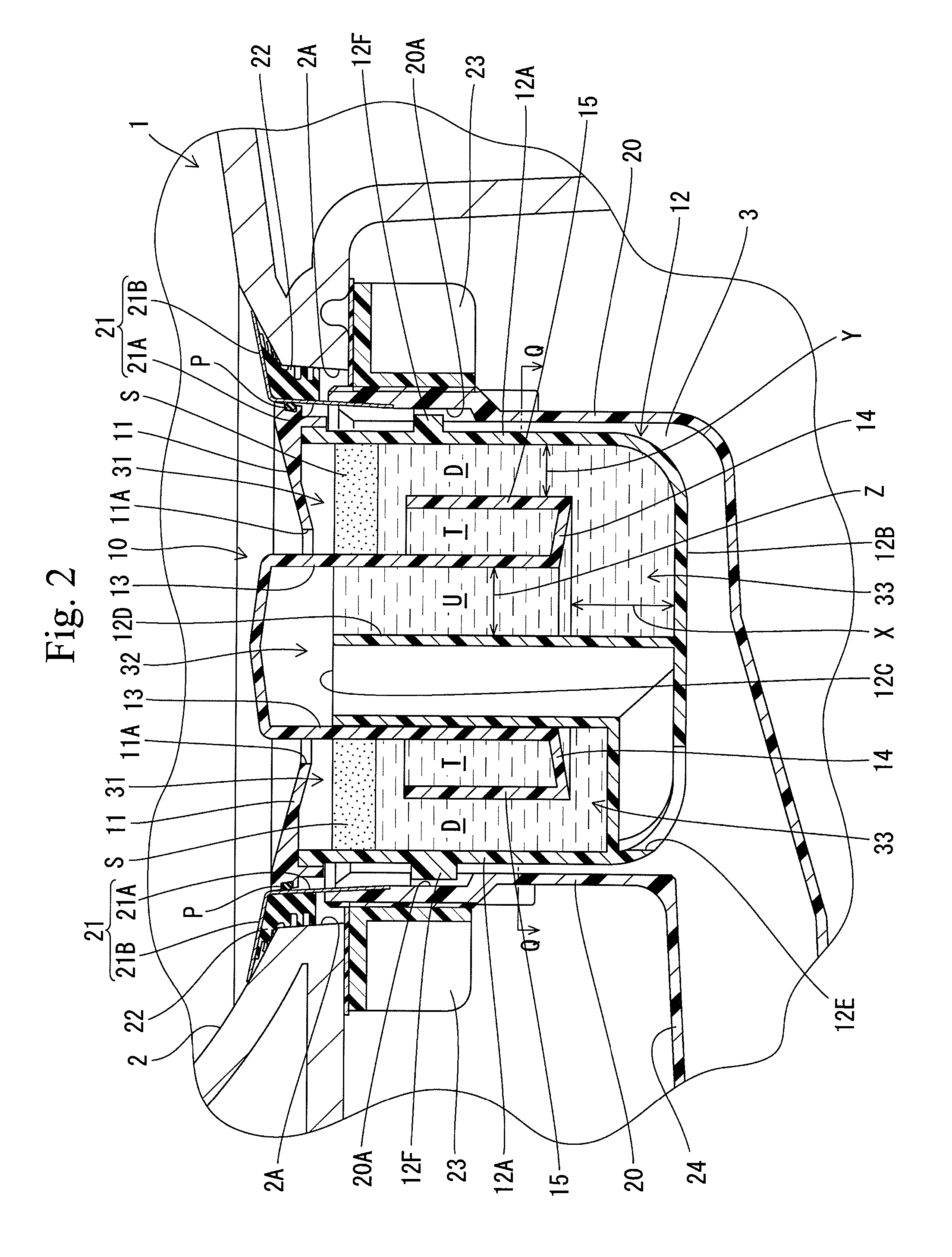

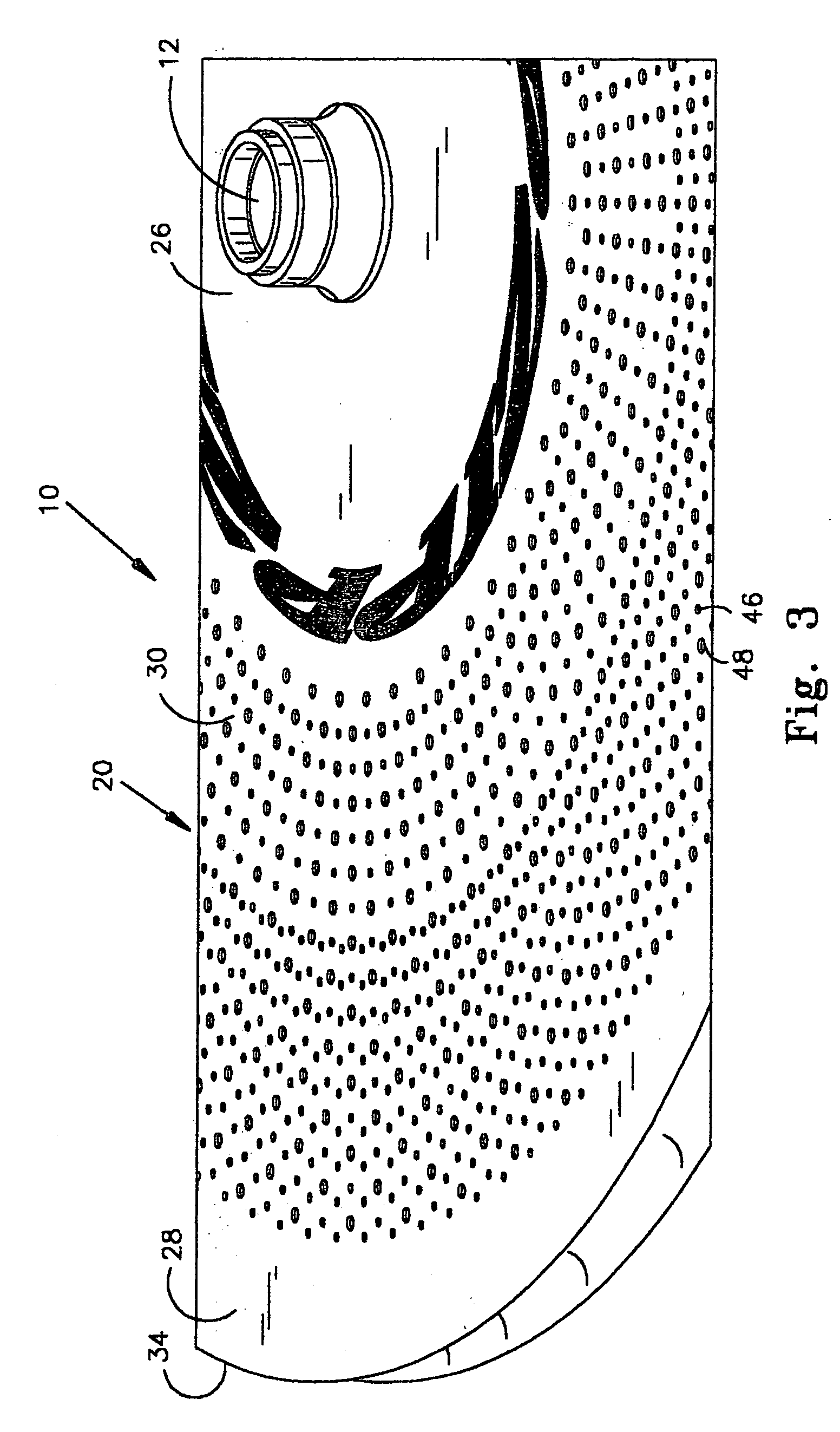

Urinal drain trap

InactiveUS20120167296A1Prevent siphon actionLarge flow areaUrinalsDomestic plumbingEngineeringMechanical engineering

Provided is a urinal drain trap which is capable of preventing diffusion of odor for a long period of time. The urinal drain trap (10) is equipped with a lid (11) having an inlet (11A); a body (12) having an outlet (12C); and a tubular partition wall (13). The interior of the body (12) is divided into a first region (31) and a second region (32). The first region (31) and the second region (32) are linked with each other by a third region (33). Sealing liquid is injected into the first region (31), this sealing liquid being non-water-soluble, having a lower specific gravity than urine, and forming a sealing layer (S) at an elevation above retained urine. In a peripheral area of the lower end of the partition wall (13), there is formed a connecting portion (14) which extends laterally. In a peripheral area of the tip of the connecting portion (14), there is formed a folded portion (15) which extends upward. Between the partition wall (13) and the folded portion (15), the inlet (11A) is provided, in such a way as to form a through opening, at a location where urine flows in from above. The outlet (12C) is located in the second region (32) and is open at an elevation above the upper end of the folded portion (15).

Owner:LIXIL CORP

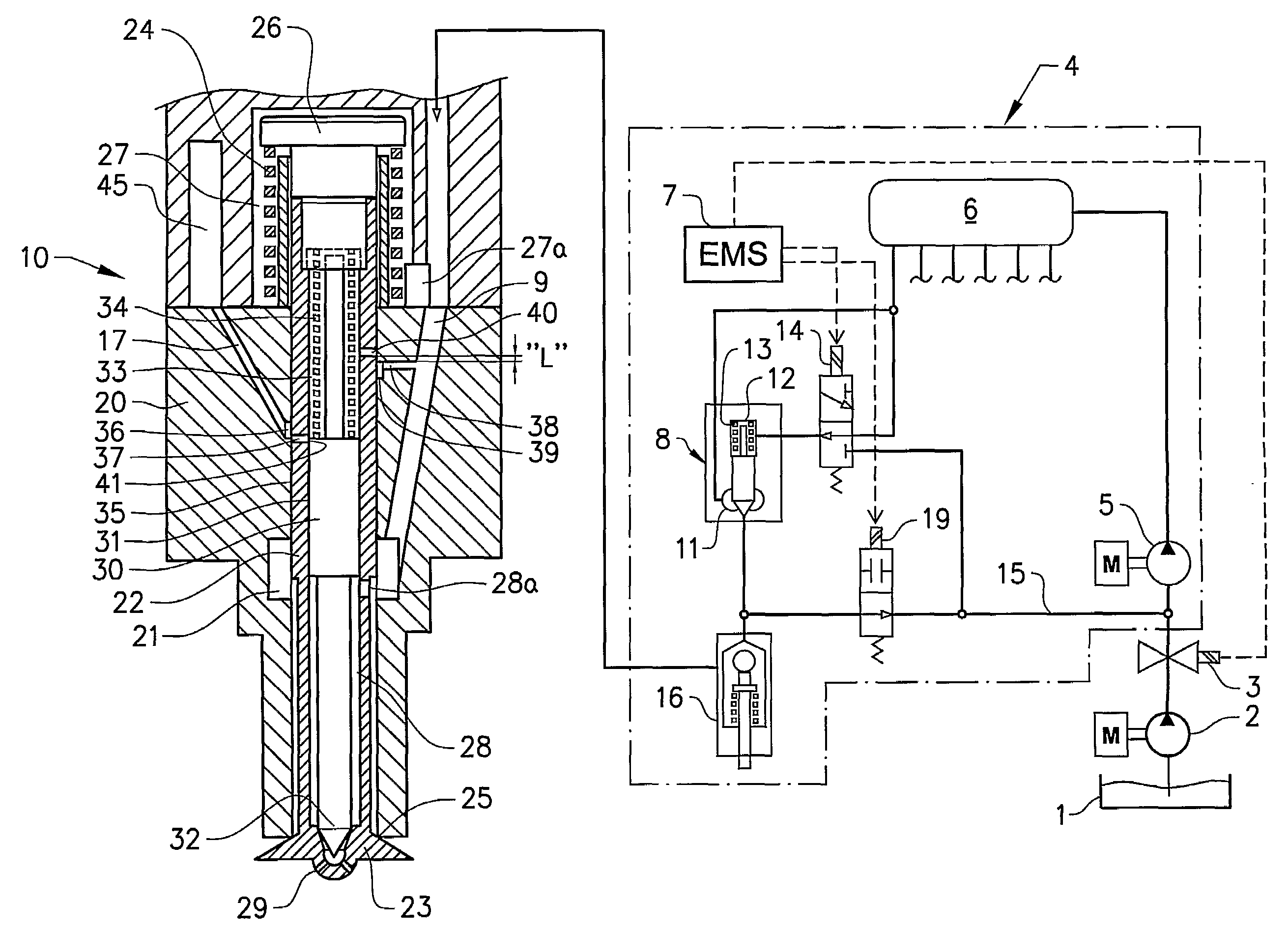

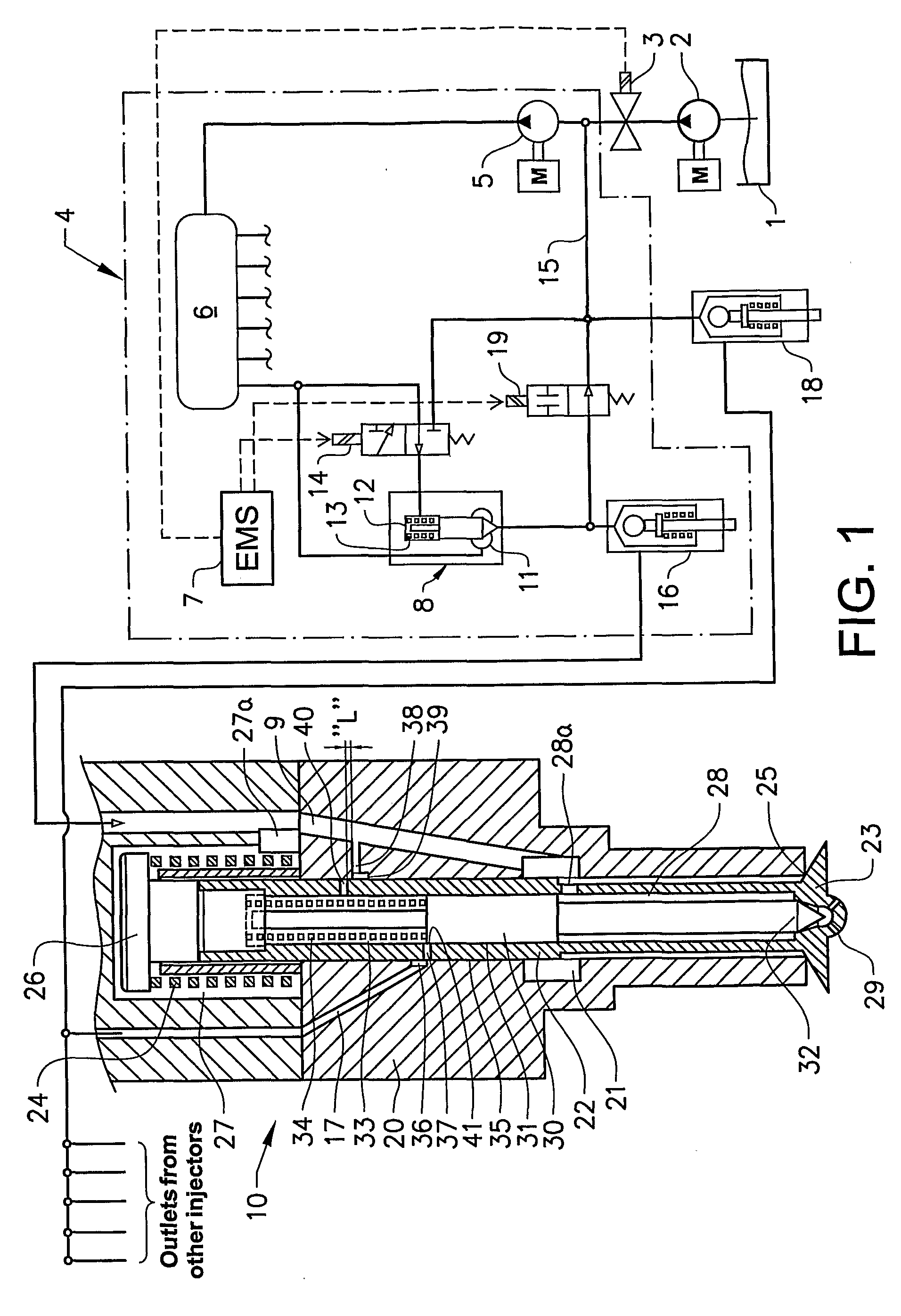

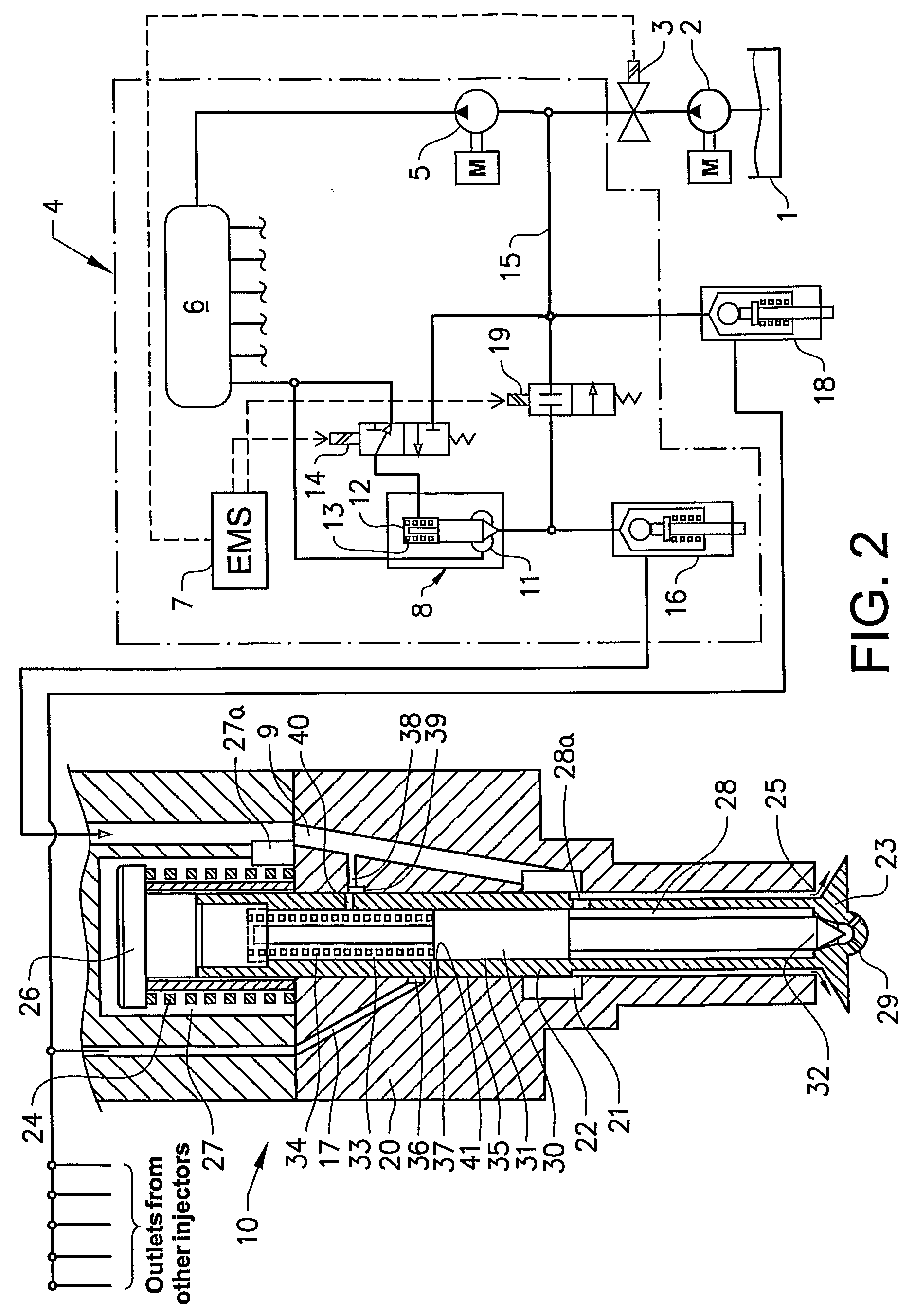

Fuel Injection System

InactiveUS20080308064A1Quick closeReduce pressureCombustion enginesSpecial fuel injection apparatusNeedle valveEngineering

A fuel injection system for an internal combustion engine is provided for providing an injection event including a first stage and a second stage via a single nozzle. The nozzle is connected by its inlet port to a source of variable fuel pressure and it includes a needle valve for performing the first stage of injection, and a poppet valve for performing the second stage of injection. The first and second stages of injection are selectable by controlling the fuel pressure in the inlet port which is common for both the needle valve and the poppet valve.

Owner:VOLVO LASTVAGNAR AB

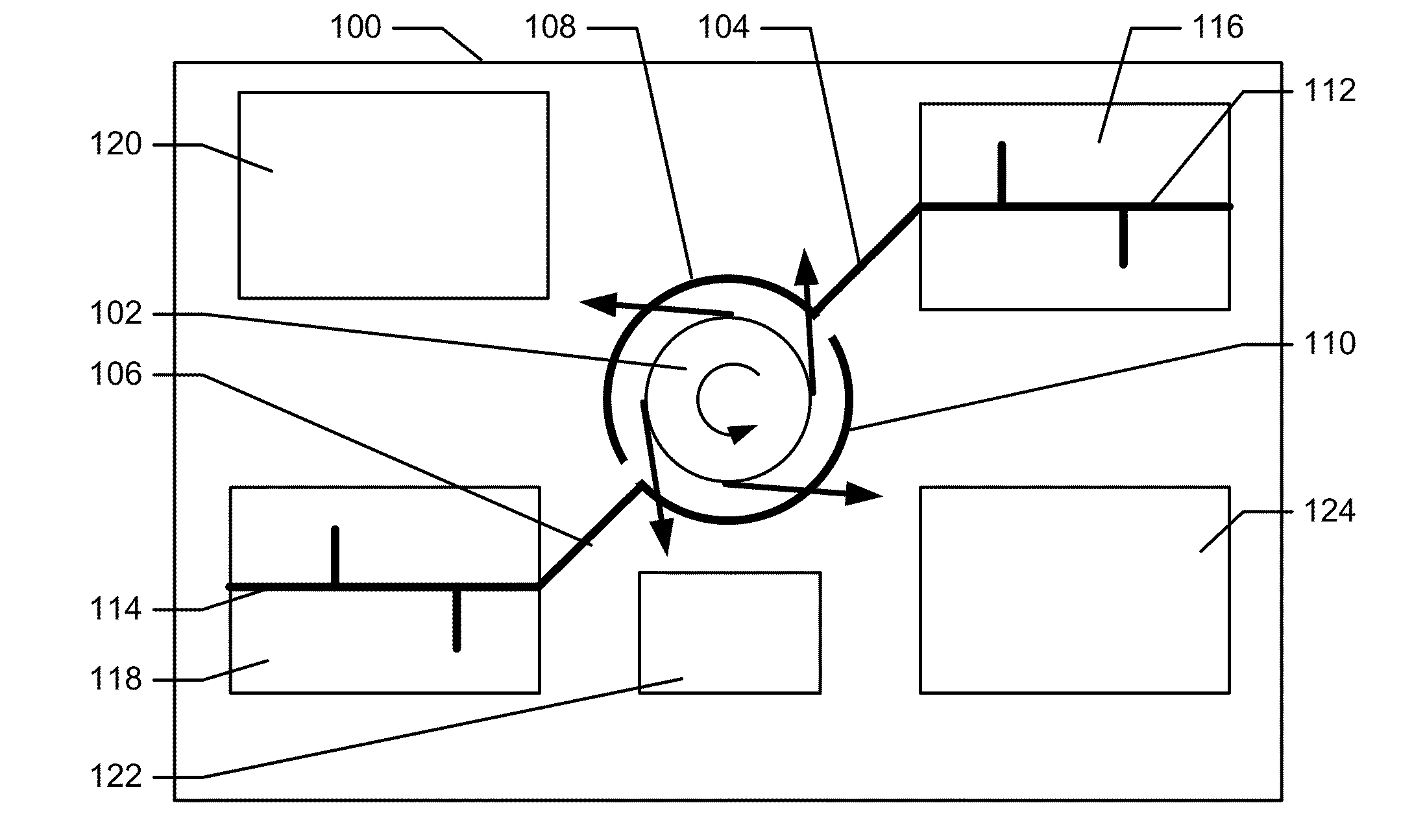

Centrifugal Fan with Integrated Thermal Transfer Unit

ActiveUS20150116928A1Reduce resistanceLarge cross-sectional flow areaPump componentsDigital data processing detailsEngineeringCentrifugal fan

Disclosed herein are computing devices, and methods of manufacturing computing devices, that have a cooling fan and integrated thermal transfer unit. A centrifugal fan unit includes a rotatable hub, a plurality of blades disposed on the rotatable hub, and a motor coupled to the rotatable hub. The motor causes the rotatable hub to rotate about an axis such that airflow proceeds outward from the centrifugal fan unit along trajectories that are perpendicular to the axis. One or more thermal transfer units have first portions that are coupled to the one or more heat sources and second portions that collectively at least partially surround the centrifugal fan unit.

Owner:MICROSOFT TECH LICENSING LLC

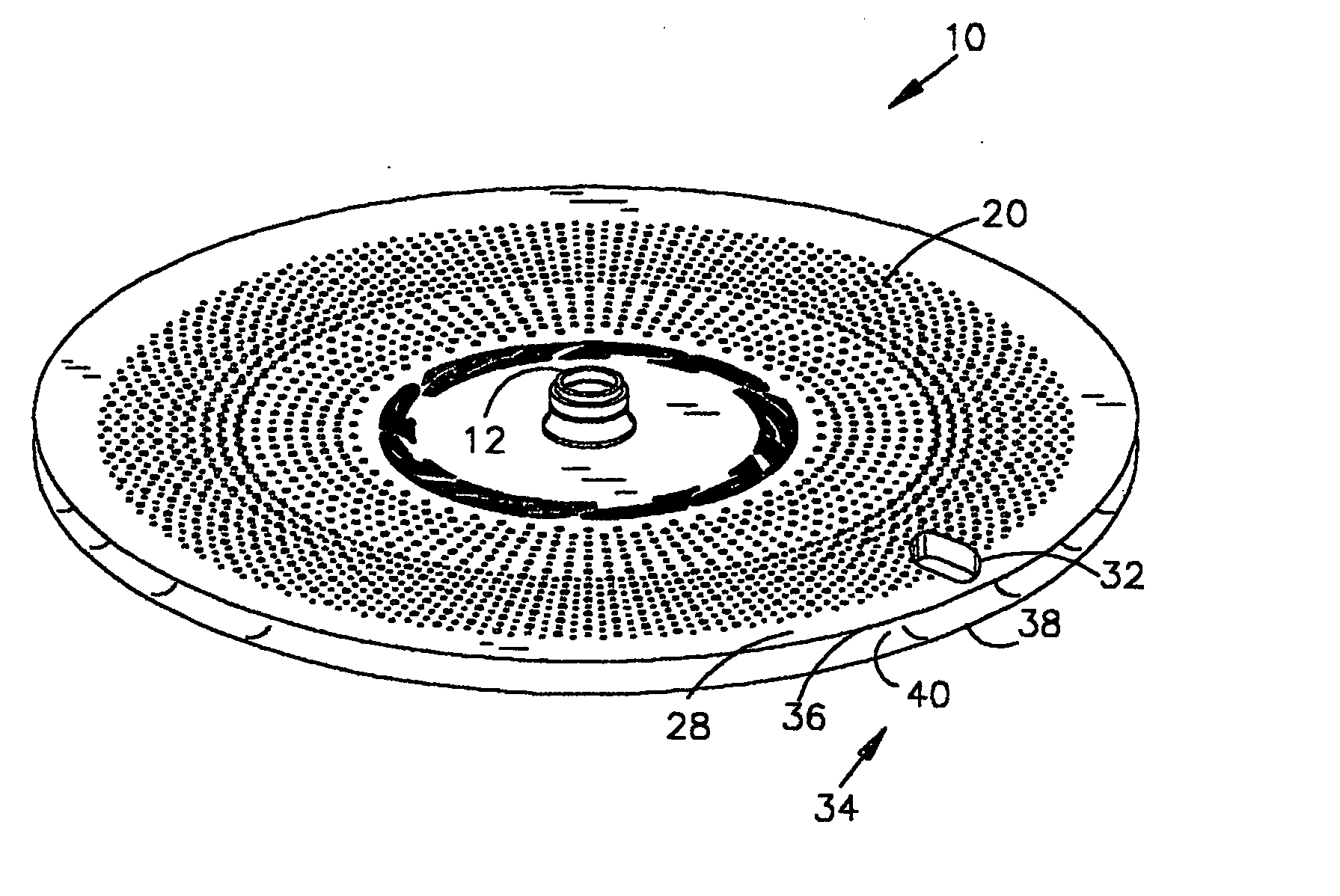

Aerodynamic surfaced bicycle wheel

ActiveUS20040135424A1Reduce air resistanceHigh speedNon-metallic wheel bodyWheel protectionAerodynamic dragMechanical engineering

A bicycle wheel includes a tire engaging portion located at the outward perimeter of the wheel, an inner portion located radially inward from the tire engaging portion A pair of air engaging side surfaces extend radially between the inner portion and the tire engaging portion forming the sides of the wheel. The air engaging side surfaces contain a plurality of surface features designed to create a turbulent boundary layer when the wheel travels through air to reduce aerodynamic drag on the wheel

Owner:COMPOSITECH

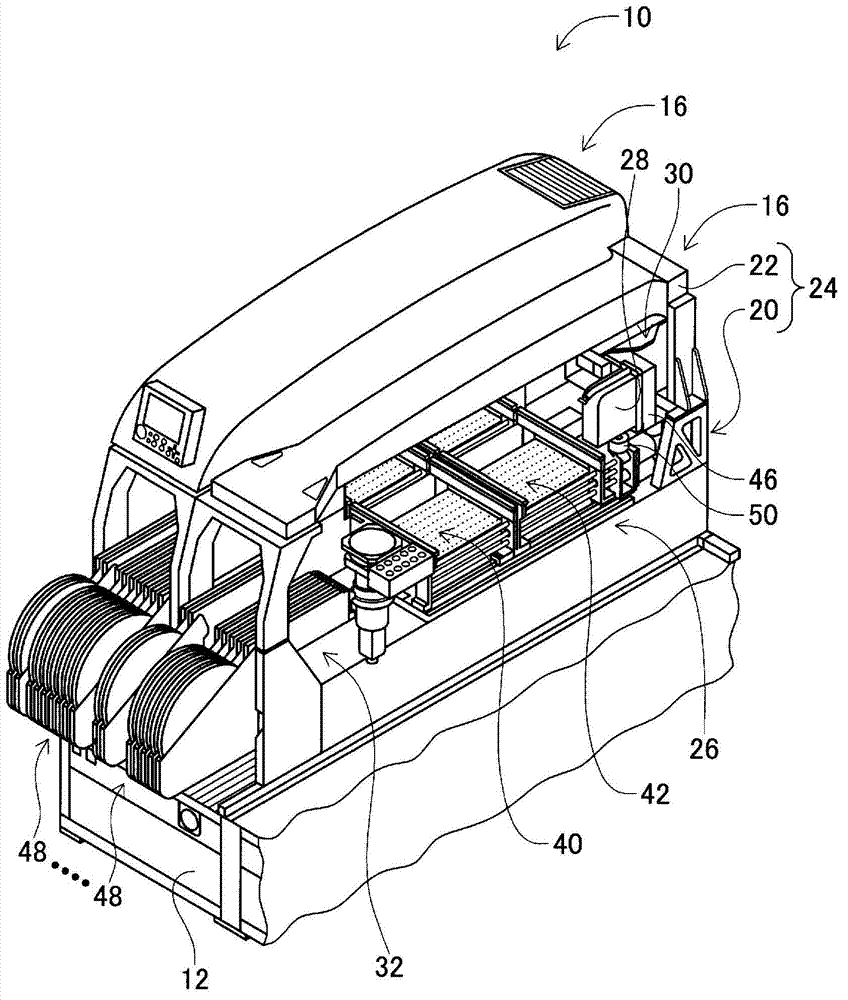

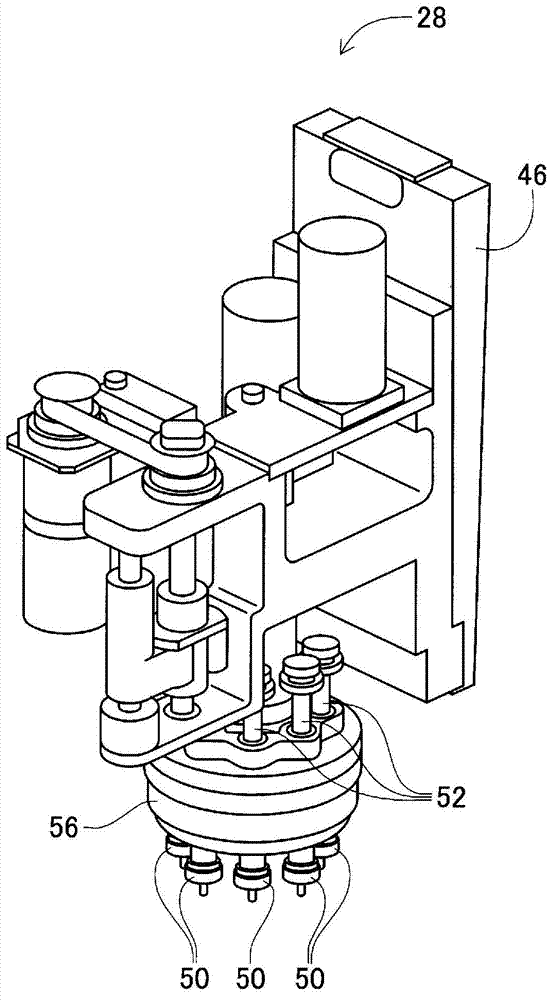

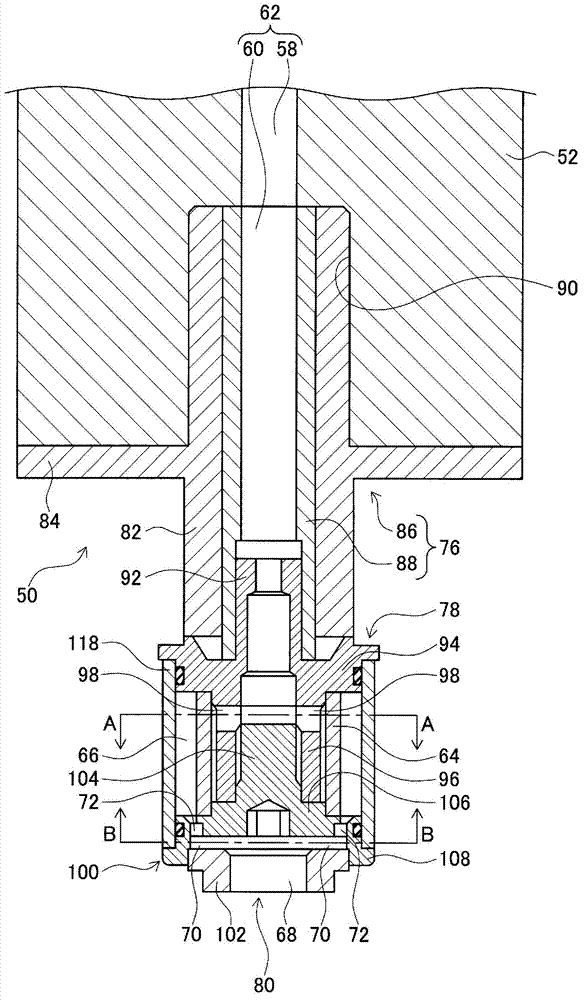

Installation head

The invention provides an installation head with high practicality. The installation head is used for absorbing and holding electronic elements so as to install the electronic elements on a circuit substrate. The installation head comprises an absorption passage way (62) connected with a negative pressure source and formed inside the installation head; a filter (64) arranged on the outer periphery of the absorption passage way; an absorption port (68) opened towards the lower end face of the installation head and applied for absorbing and holding electronic elements; and communicators (66, 70, 72) making the absorption port and the absorption passage way communicated. The communicators are opened towards the outer periphery of the installation head so that the filter can be noticed and identified through the opening. By adopting the above-mentioned structure, the outer periphery of the filter with dust attached thereon can be observed and identified from the outside of the installation head. Therefore, the pollution of the filter can be detected without taking the filter out of the installation head. The practicality of the installation head is thus increased.

Owner:FUJI KK

CO boiler having dustproof function and denitration function

ActiveCN103776042AImprove utilization efficiencyEfficient use ofCombination devicesLighting and heating apparatusFlueCoal

The invention relates to a CO boiler having the dustproof function and the denitration function. The CO boiler having the dustproof function and the denitration function comprises a flue, a combustion chamber, steam drums, an evaporation section and an economizer section. The CO boiler further comprises an ammonia spraying and mixing mechanism and a dustproof denitration reactor. The ammonia spraying and mixing mechanism is arranged above the evaporation section or between the evaporation section and the denitration reactor. The dustproof denitration reactor is arranged between the evaporation section and the economizer section and comprises a mixed-smoke inlet section, a denitration section and a purified-smoke discharging section, wherein an ash removal section is arranged between the mixed-smoke inlet section and the denitration section, ash baffles are arranged in the ash removal section, an ash bin is arranged in the denitration section, the center line of the ash bin and the center line of the reactor coincide, and the lower end of the ash bin is connected with an ash discharging pipeline. According to the CO boiler having the dustproof function and the denitration function, the denitration reactor is arranged in the CO boiler, so that the utilization rate of smoke heat is increased; due to the fact that the ash removal section is arranged in the reactor, smoke dust of mixed smoke can be removed before the mixed smoke enters denitration units, catalyst hole channels are prevented from being blocked, and the denitration efficiency and the denitration effect are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Throttling serial type multistage pressure reduction and adjustment valve

InactiveCN104455469APrecise pressure/flow controlEliminate cavitationValve members for absorbing fluid energyLift valveSolid particlePressure difference

The invention provides a throttling serial type multistage pressure reduction and adjustment valve. A valve rod and a valve element assembly are arranged inside a valve body; a valve seat assembly is provided with multistage pressure reduction units, and each stage of pressure reduction unit of the valve seat assembly is composed of a cylindrical fluid expansion unit and a throttling unit, wherein the throttling unit is shaped like a circular truncated cone, and the area of the throttling unit decreases gradually; correspondingly, the pressure reduction units are arranged on corresponding positions of the valve element assembly, wherein the stage number of the pressure reduction units in the valve element assembly is equal to that of the pressure reduction units in the valve seat assembly; each stage of the pressure reduction unit of the valve element assembly is composed of a bowl-shaped molded surface for controlling flow and a cylindrical shrinkage unit; the upper portion of the valve element assembly is provided with valve elements, and the lower portion of the valve element assembly is provided with guide rods; valve bottom drainage holes are formed in the positions, located on the outer sides of valve seat guide holes, of the bottom of the valve seat assembly; a flow diversion sleeve is arranged on the top of the valve seat assembly, and a flow diversion hole is formed in one side of the flow diversion sleeve. According to the throttling serial type multistage pressure reduction and adjustment valve, the service life of the valve can be prolonged, vibration and noise of pipelines behind the valve can be eliminated, and it is guaranteed that the adjustment accuracy of the valve is high and operation is stable under the working condition that the pressure difference is large and solid particles exist in media in the Texaco process of coal chemical industries.

Owner:BEIJING AEROSPACE PROPULSION INST +3

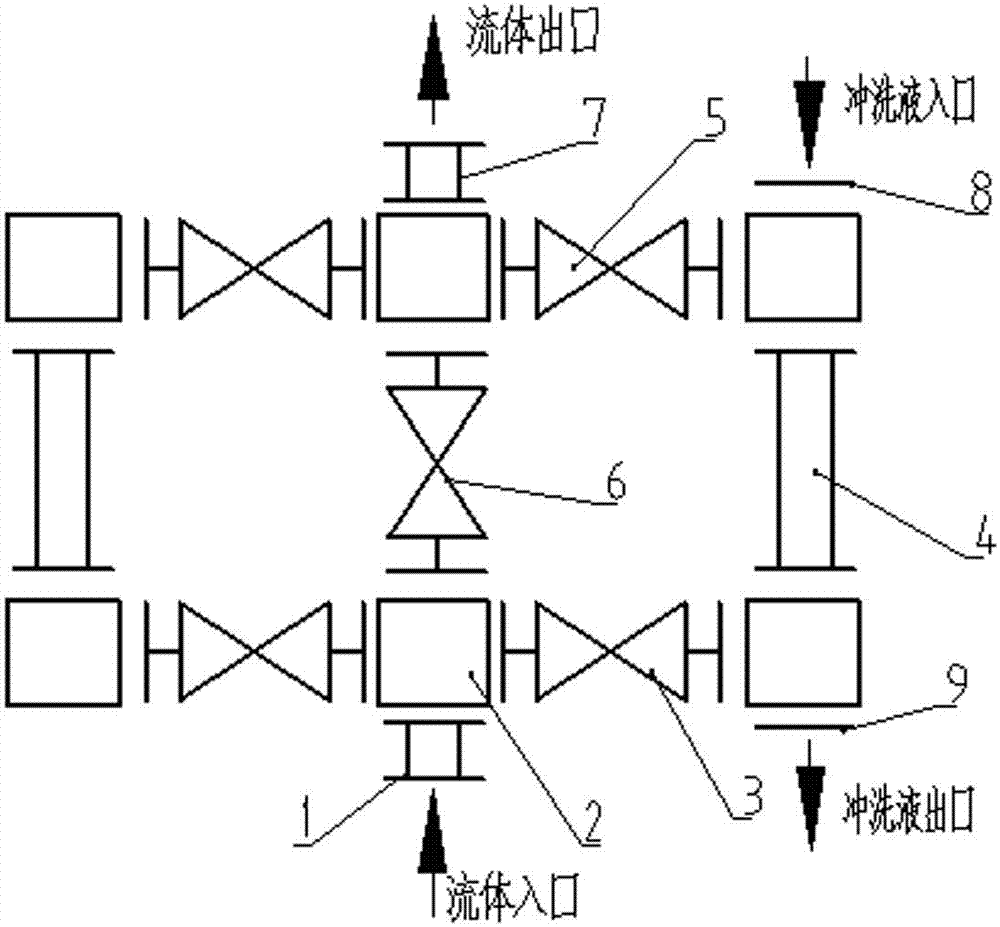

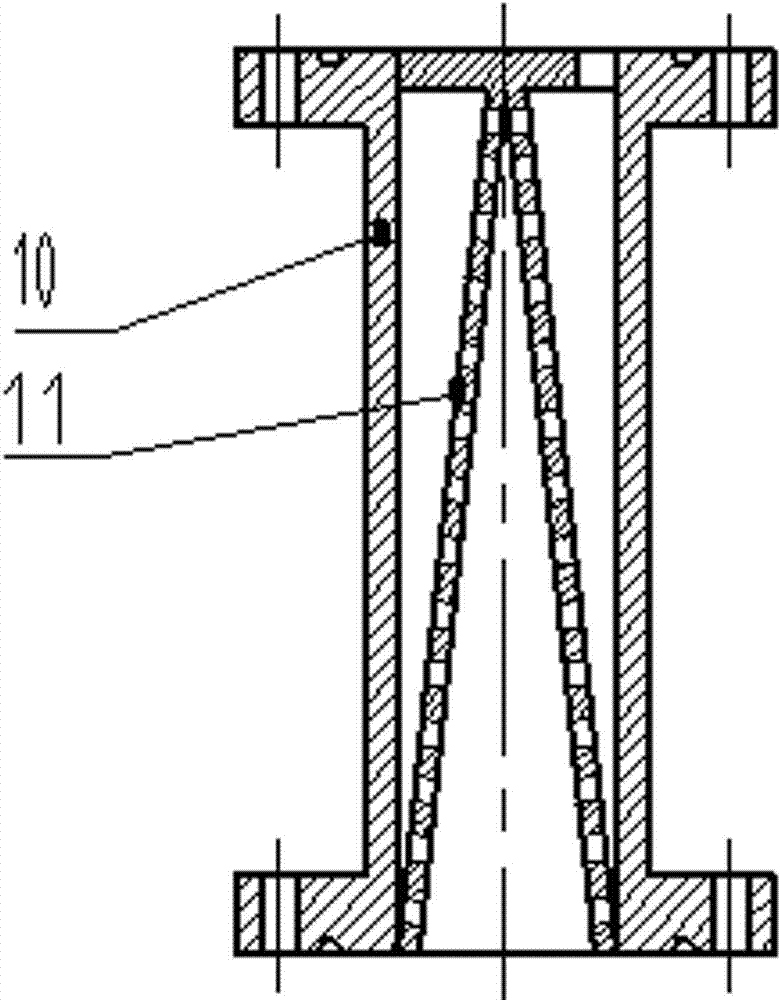

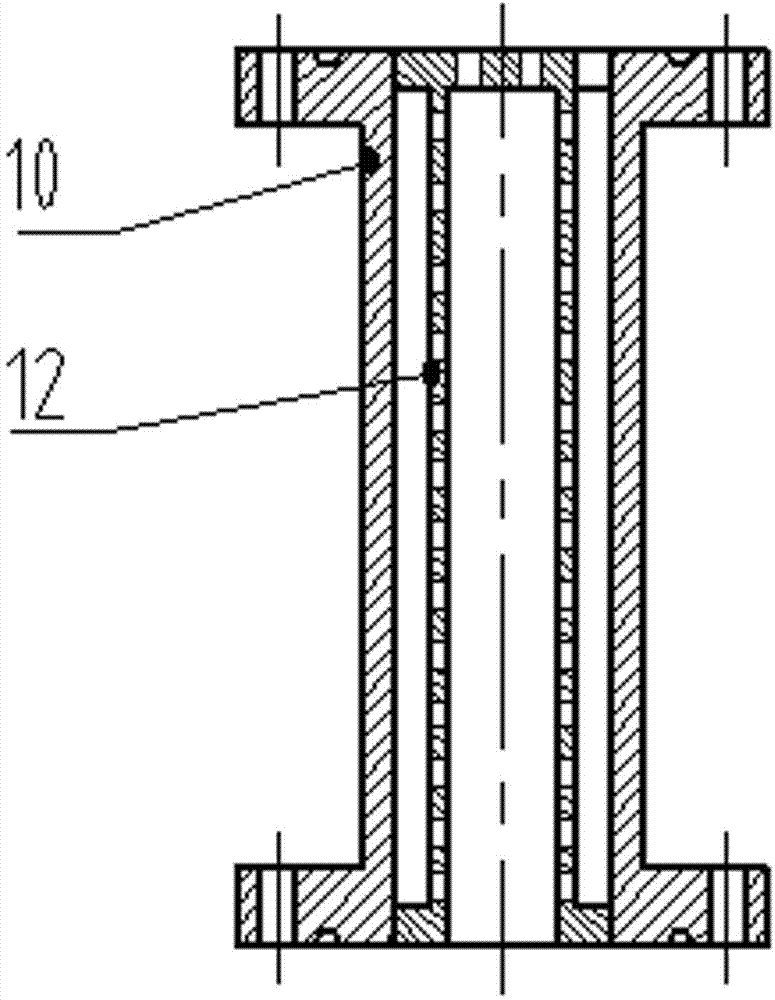

Rock debris filtering device

The invention discloses a rock debris filtering device. The rock debris filtering device comprises a stop valve, a connecting pipeline and a filter. The rock debris filtering device is provided with a rock debris filtering channel, a rock debris non-filtering channel and a standby filtering channel; a filter cartridge can be conical, cylindrical or in a round-table shape; an inlet and an outlet of the rock debris filtering device can be respectively installed with a pressure measuring device; and the upstream and the downstream of the filter are connected with an outlet of a flushing pipeline and an inlet of the flushing pipeline. The rock debris filtering device has the advantages of small pressure reduction, strong rock debris filtering capacity, a small number of flushing times for the filter cartridge and on-line cleaning.

Owner:CHINA PETROCHEMICAL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com