Rock debris filtering device

A filtering device and cuttings technology, which is applied in the field of cuttings filtering devices, can solve the problems of low working pressure of the separator, inability to separate specific gravity, etc., and achieve the effects of large internal space, reduction of flushing times, and large flow area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

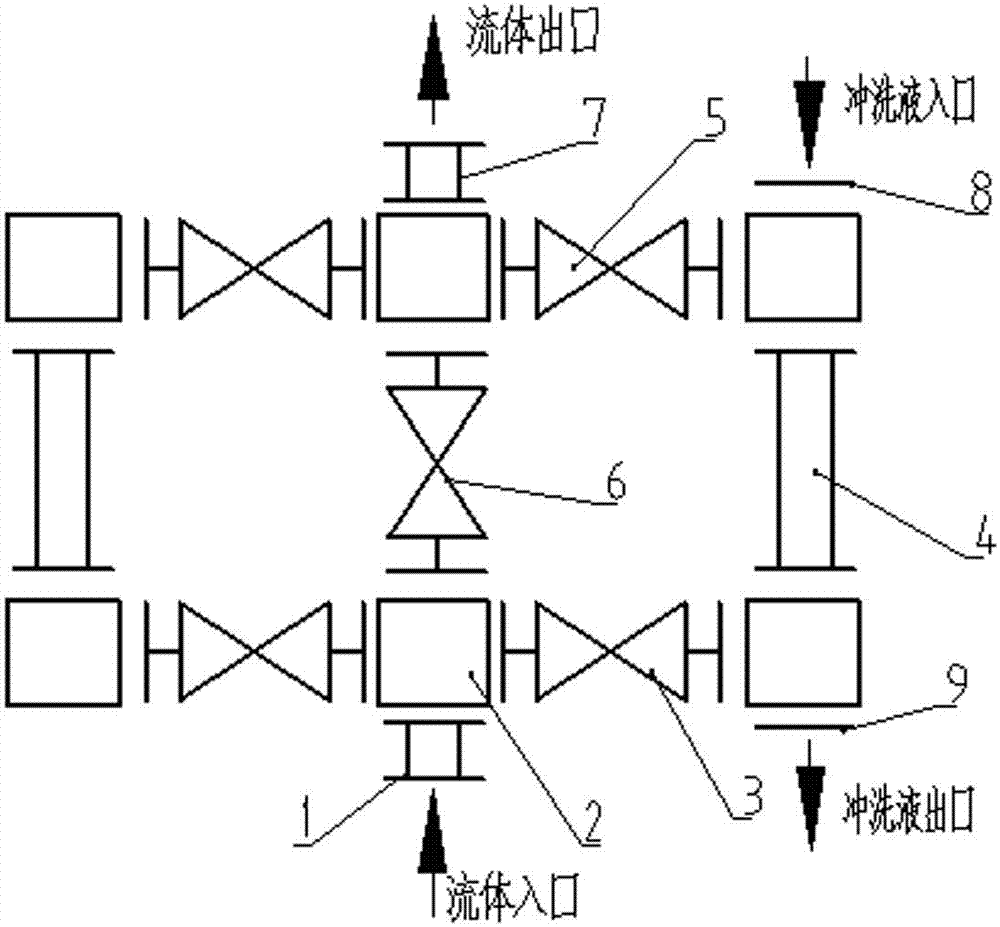

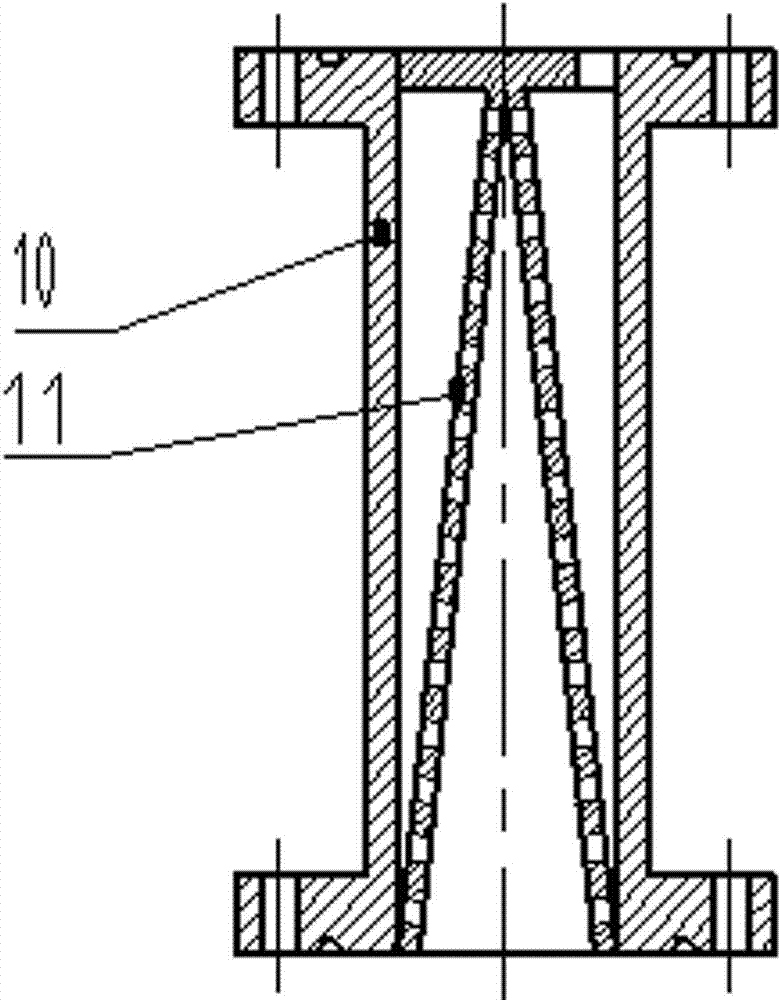

[0017] Embodiment 1, in conjunction with attached figure 1 And attached figure 2 .

[0018] A cuttings filtering device includes a stop valve, a connecting pipeline and a filter. The inlet pipe 1 of the debris filtering device is connected to the multi-pass block 2, and the downstream of the multi-pass block 2 is sequentially connected to the stop valve A3, the filter 4, the stop valve B5 and the outlet pipe 7 to form a debris filter channel; The downstream of the through block 2 is sequentially connected with the shut-off valve C6 and the outlet pipe 7 to form a non-filtering channel for cuttings; the upstream and downstream of the filter 4 are connected with the flushing pipeline outlet 9 and the flushing pipeline inlet 8 respectively. The downstream of the multi-pass block 2 is connected to a backup filter channel of a cuttings filter channel; the filter 4 on the filter channel and the backup filter channel is composed of an external filter housing 10 and an internal fil...

Embodiment 2

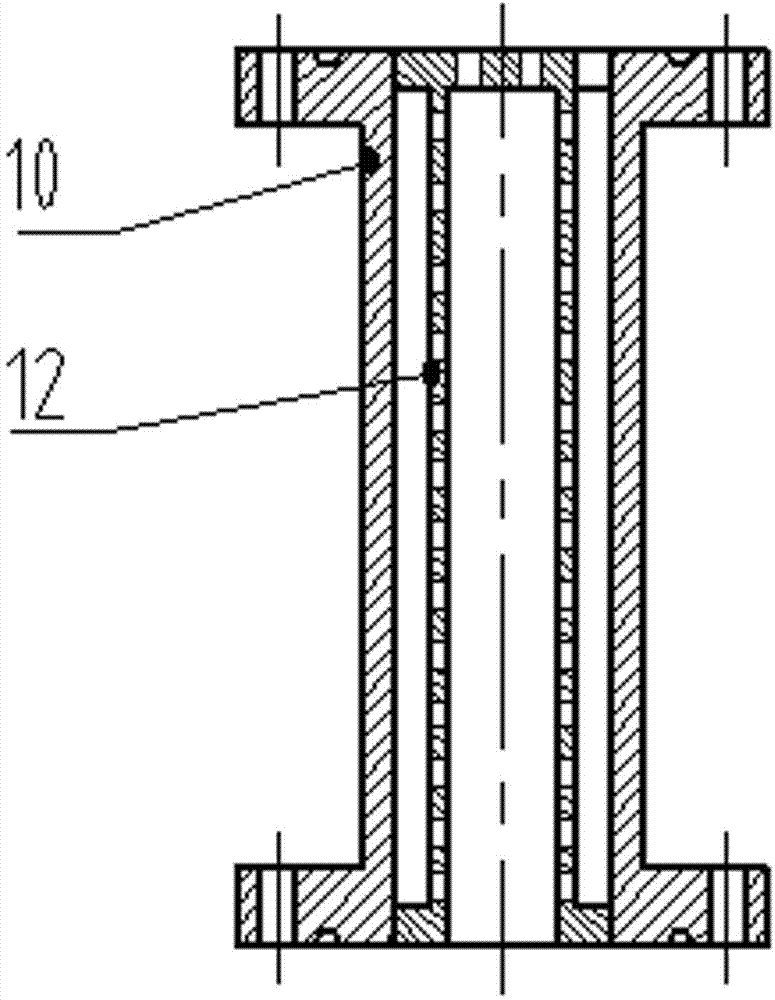

[0019] Embodiment 2, in conjunction with attached figure 1 and 3 .

[0020] A cuttings filtering device includes a stop valve, a connecting pipeline and a filter. The inlet pipe 1 of the debris filtering device is connected to the multi-pass block 2, and the downstream of the multi-pass block 2 is sequentially connected to the stop valve A3, the filter 4, the stop valve B5 and the outlet pipe 7 to form a debris filter channel; The downstream of the through block 2 is sequentially connected with the shut-off valve C6 and the outlet pipe 7 to form a non-filtering channel for cuttings; the upstream and downstream of the filter 4 are connected with the flushing pipeline outlet 9 and the flushing pipeline inlet 8 respectively. The downstream of the multi-pass block 2 is connected to a backup filter channel of a cuttings filter channel; the filter 4 on the filter channel and the backup filter channel is composed of an external filter housing 10 and an internal filter core 12, and ...

Embodiment 3

[0021] Embodiment 3, in conjunction with attached figure 1 And attached Figure 4 .

[0022] A cuttings filtering device includes a stop valve, a connecting pipeline and a filter. The inlet pipe 1 of the debris filtering device is connected to the multi-pass block 2, and the downstream of the multi-pass block 2 is sequentially connected to the stop valve A3, the filter 4, the stop valve B5 and the outlet pipe 7 to form a debris filter channel; The downstream of the through block 2 is sequentially connected with the shut-off valve C6 and the outlet pipe 7 to form a non-filtering channel for cuttings; the upstream and downstream of the filter 4 are connected with the flushing pipeline outlet 9 and the flushing pipeline inlet 8 respectively. The filter 4 of the filtering channel is composed of an external filter housing 10 and an internal filter core 13, and the filter core is processed with through holes; the filter core is in the shape of a truncated cone 13.

[0023] During...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com