Installation head

A technology for installing heads and passages, applied in the direction of electrical components, electrical components, etc., can solve problems such as inconvenience and improve practicability, and achieve the effect of shortening time and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, as a mode for implementing the present invention, embodiments of the present invention will be described in detail with reference to the drawings.

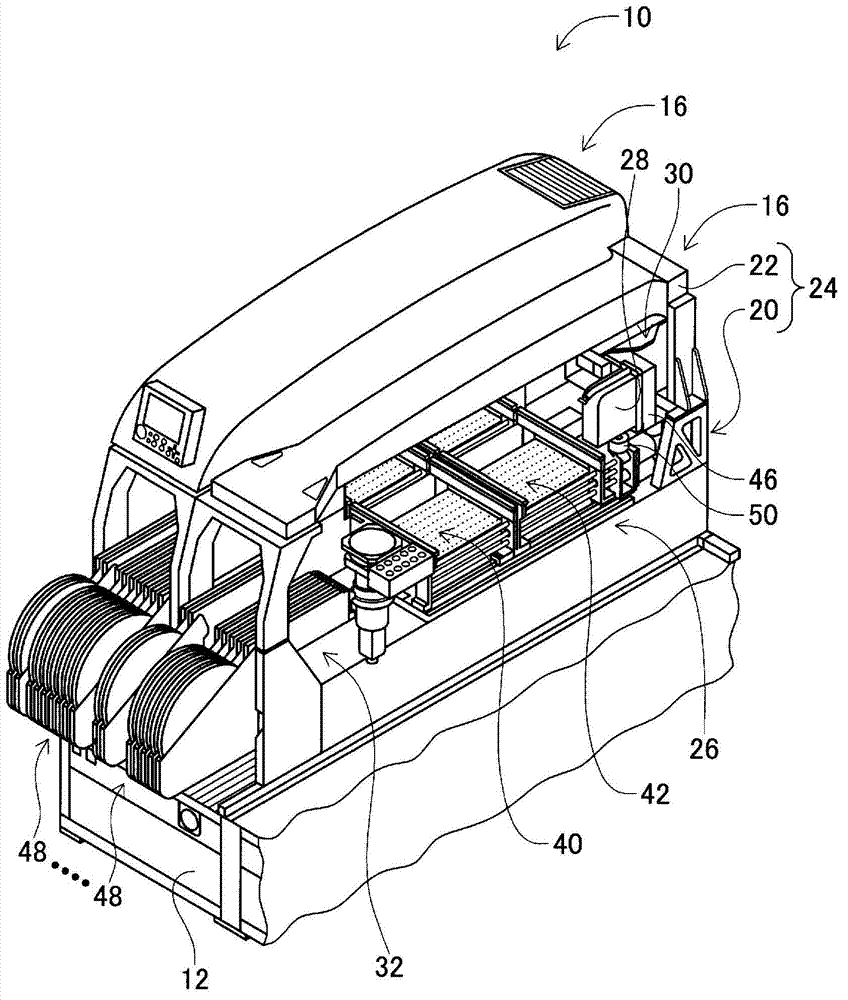

[0031] figure 1 An electronic component mounting device (hereinafter, sometimes simply referred to as a "mounting device") 10 is shown. This figure is a perspective view with part of the exterior components of the mounting device 10 removed. The mounting device 10 includes a system base 12 and two electronic component mounting machines (hereinafter, sometimes simply referred to as "mounting machines") 16 arranged side by side on the system base 12 to mount electronic components on the circuit board. Operation. In addition, in the following description, the direction in which the mounting machines 16 are arranged is called an X-axis direction, and the horizontal direction perpendicular|vertical to this direction is called a Y-axis direction.

[0032] The mounting machine 16 included in the mounting device 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com