Patents

Literature

73results about How to "Eliminate cavitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

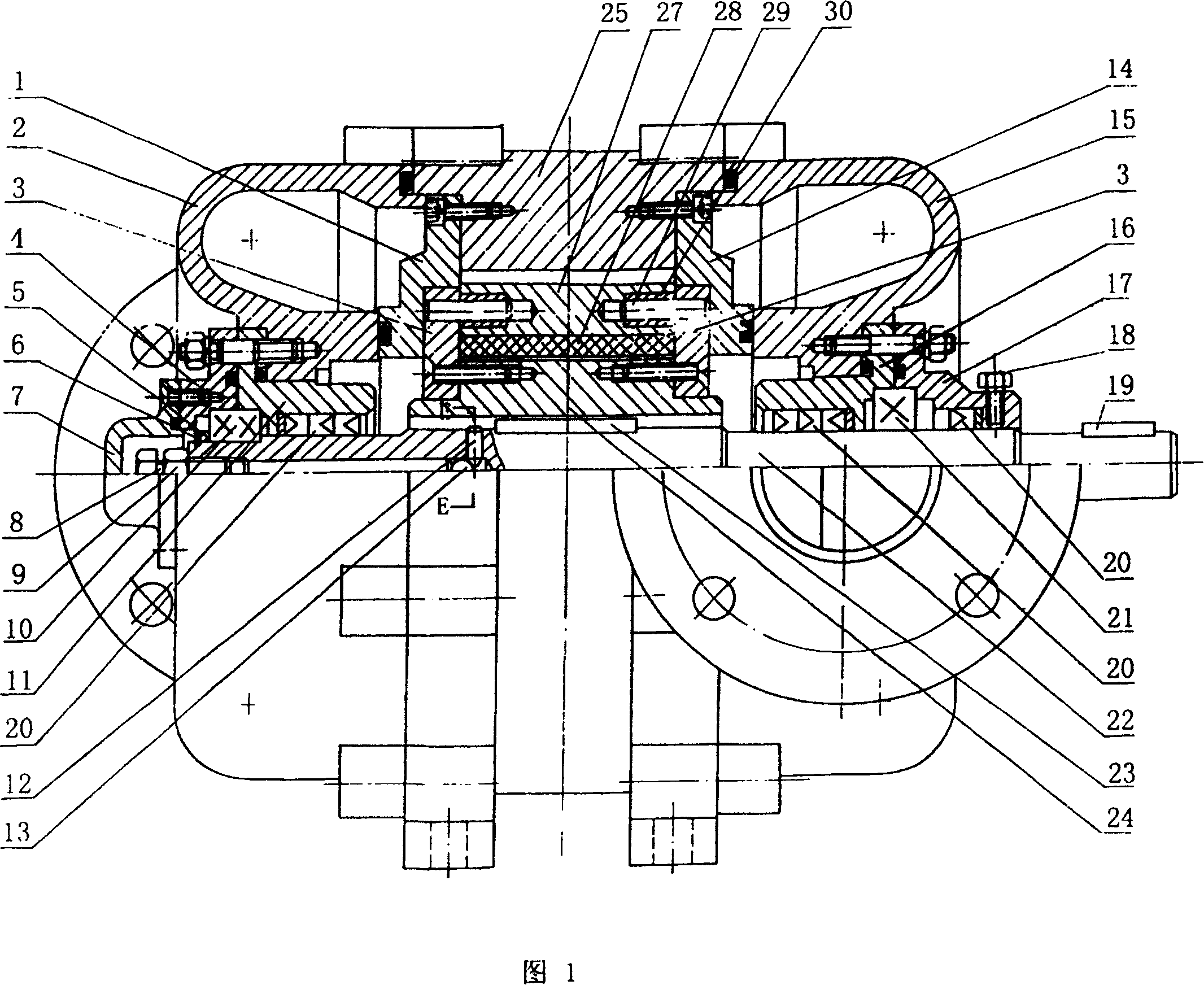

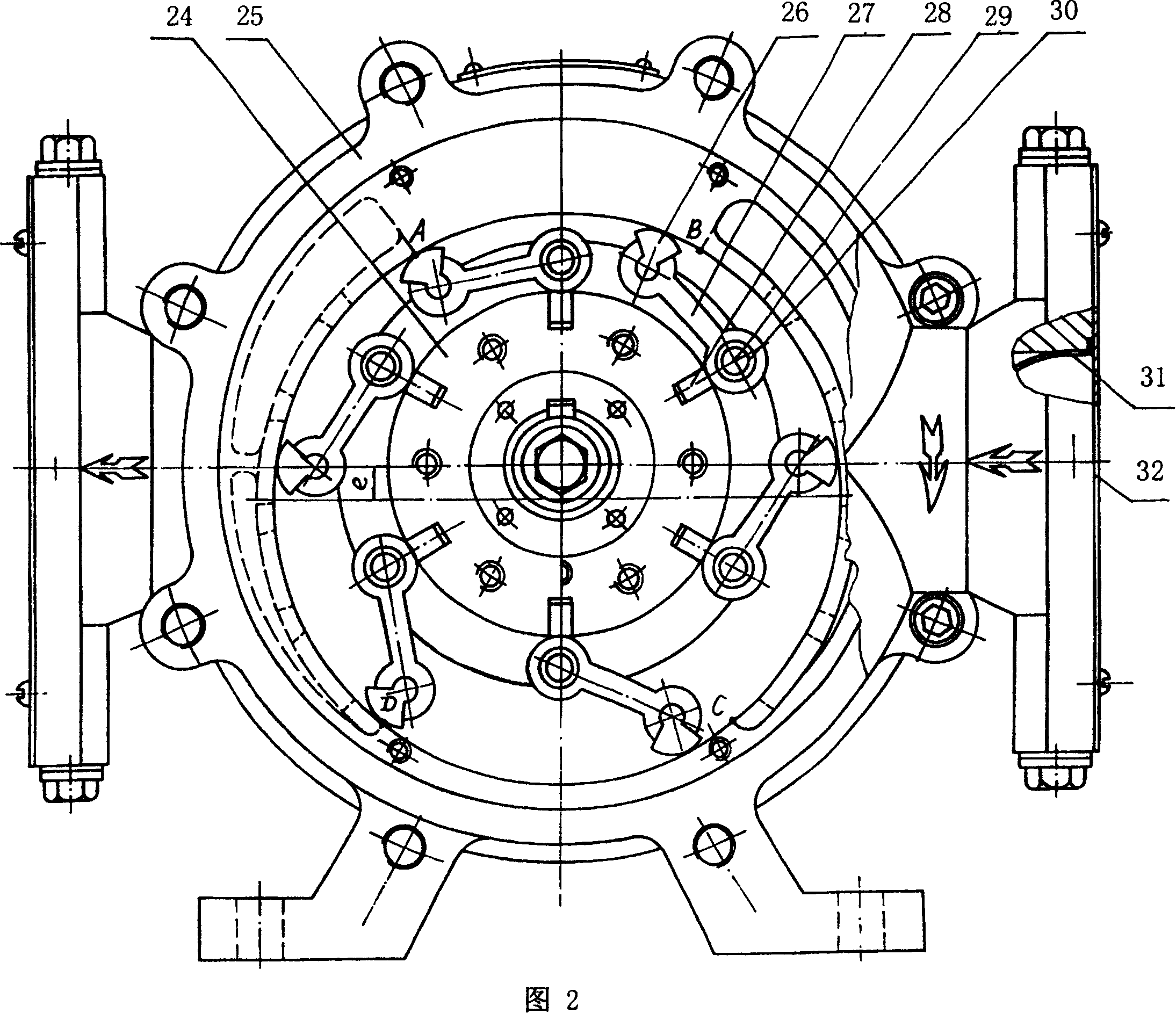

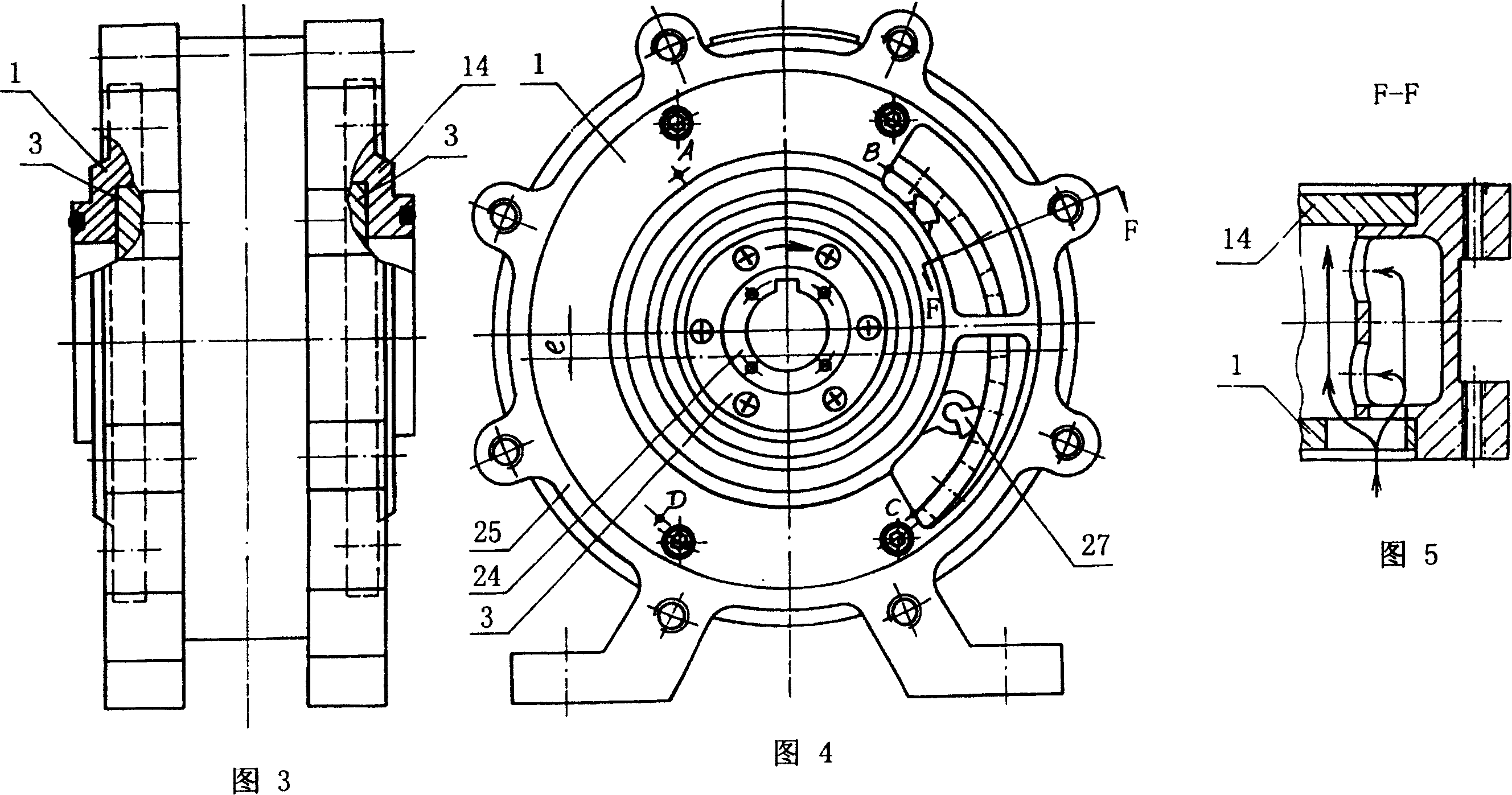

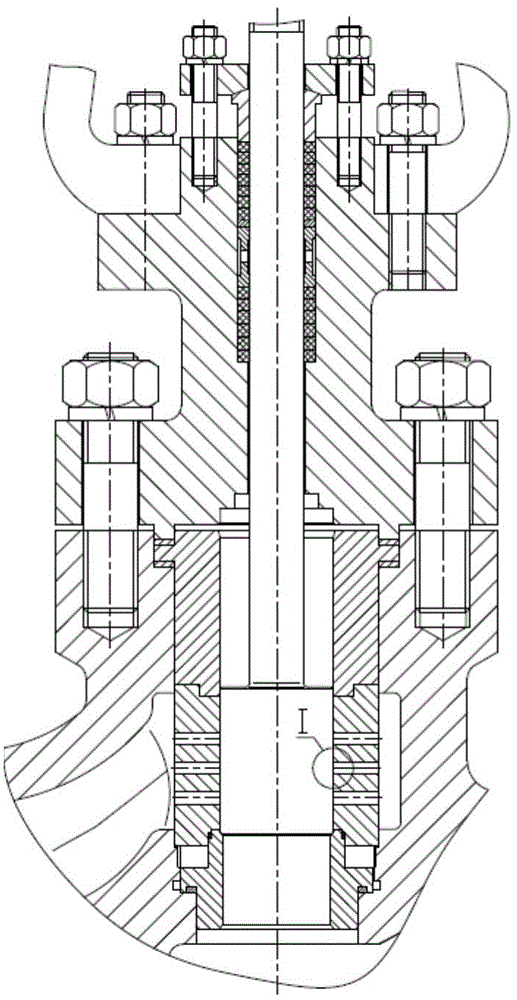

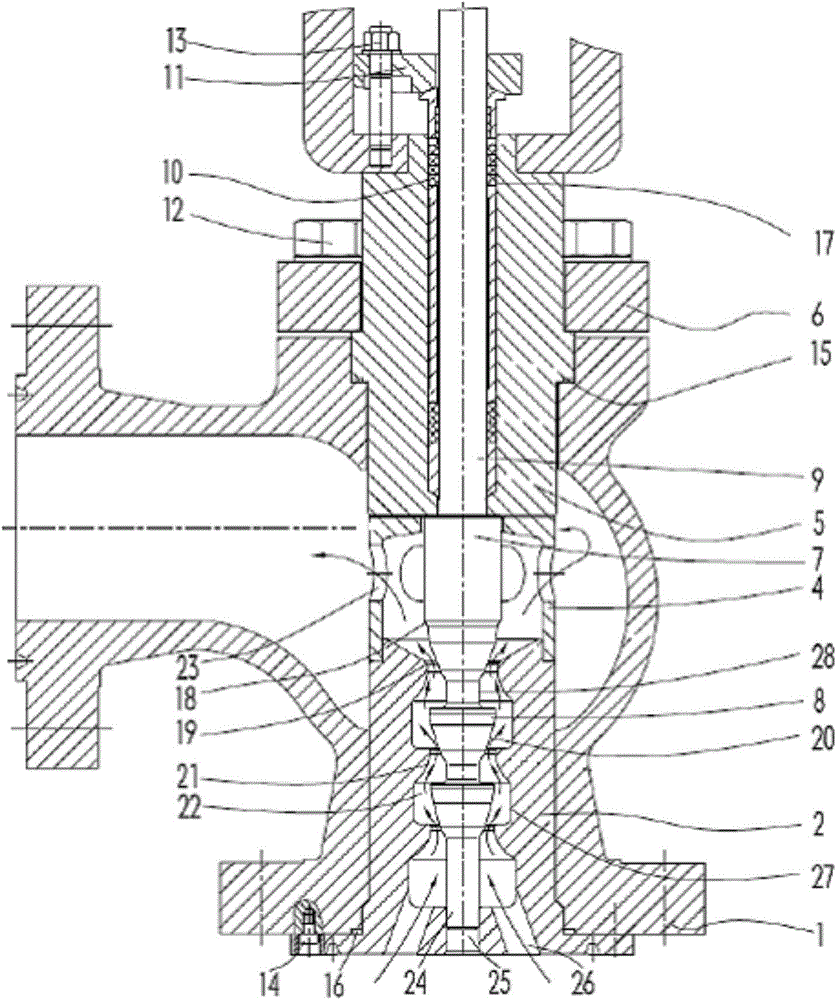

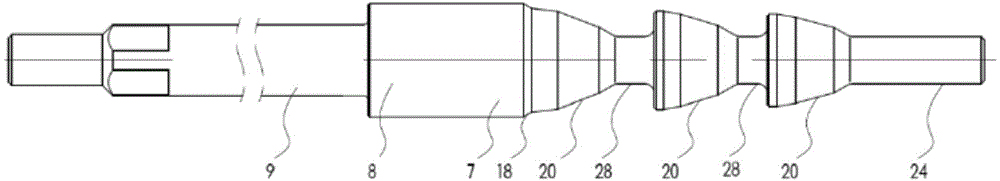

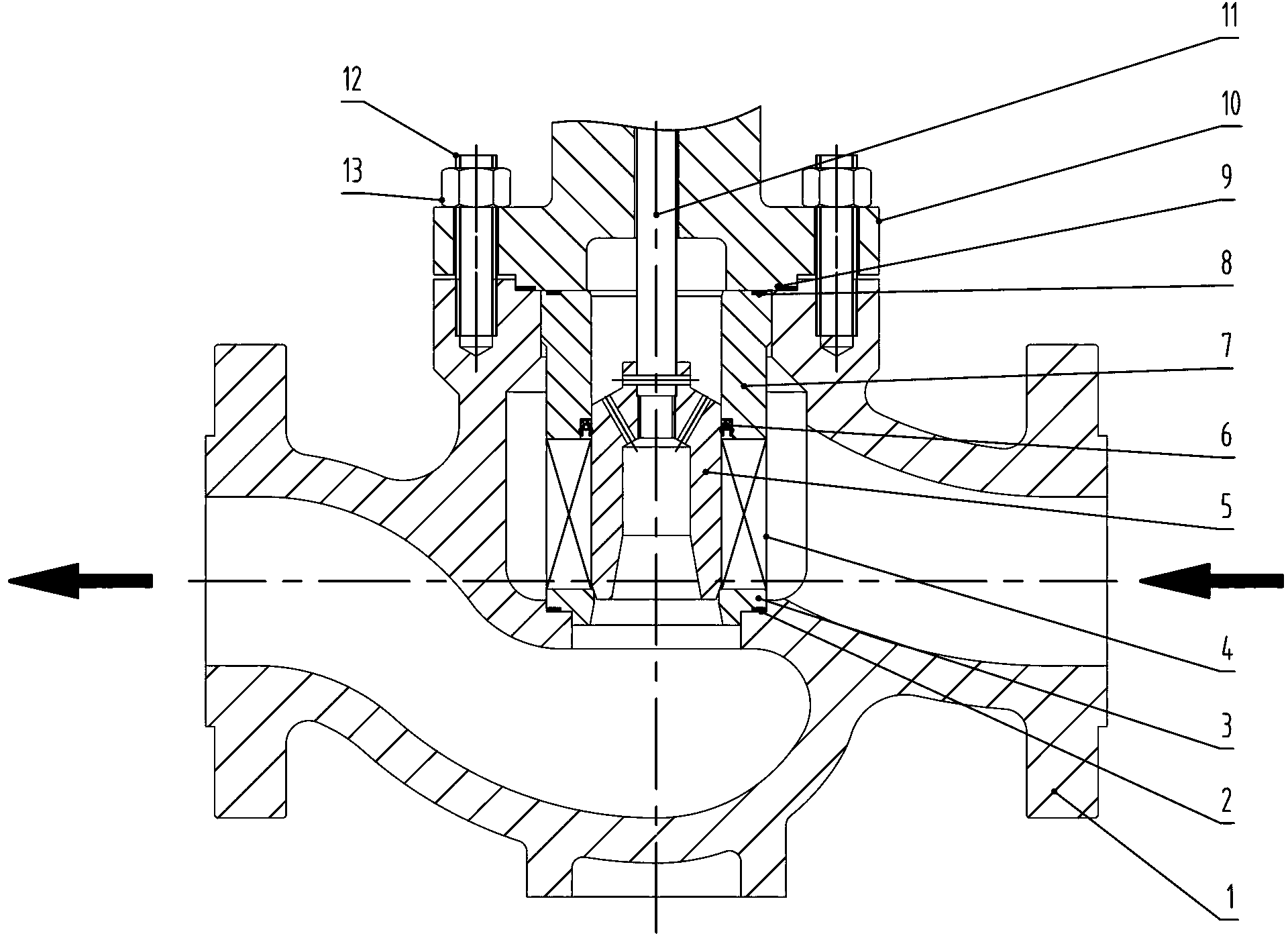

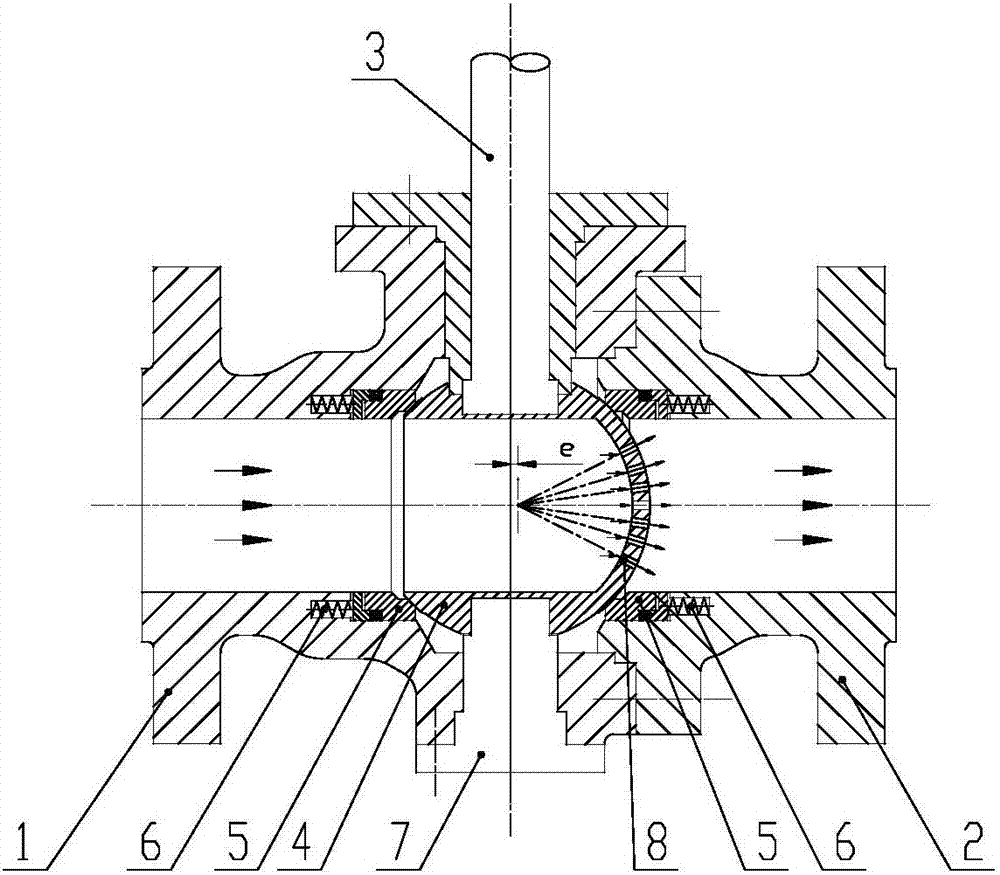

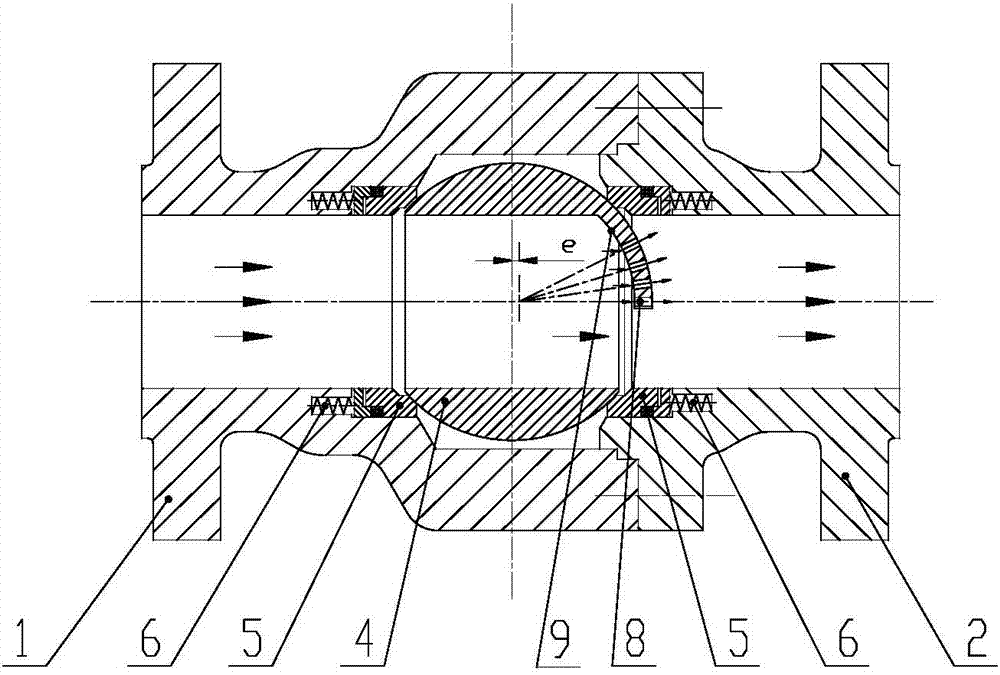

Rotary blade pump

InactiveCN100374725CReduce line speedEliminate cavitationRotary piston pumpsRotary piston liquid enginesClassical mechanicsEngineering

In the invention, an inlet-outlet oil flow plate is fixed at two ends of a pump case stator. A radial inlet-outlet runner is built-up on the pump case stator to realize axial and radial inlet and outlet oil at the same time. A rotor is mounted in the internal cavity of the pump case stator and there is an offsetting e between the rotor and the ID of the pump case stator. Rotary vanes are mounted on a rotating board fixed on the two end faces of the rotor. The rotor is mounted on the pump spindle via a rotor key. A rotor locking device is assembled on the front part of the pump spindle. The inlet-outlet oil pump covers are fixed at two ends of the pump stator separately. A ring inlet-outlet oil passageway is disposed in inlet-outlet oil pump. A bearing support and sealing device is assembled on the central of the inlet-outlet oil pump cover.

Owner:王振忠 +1

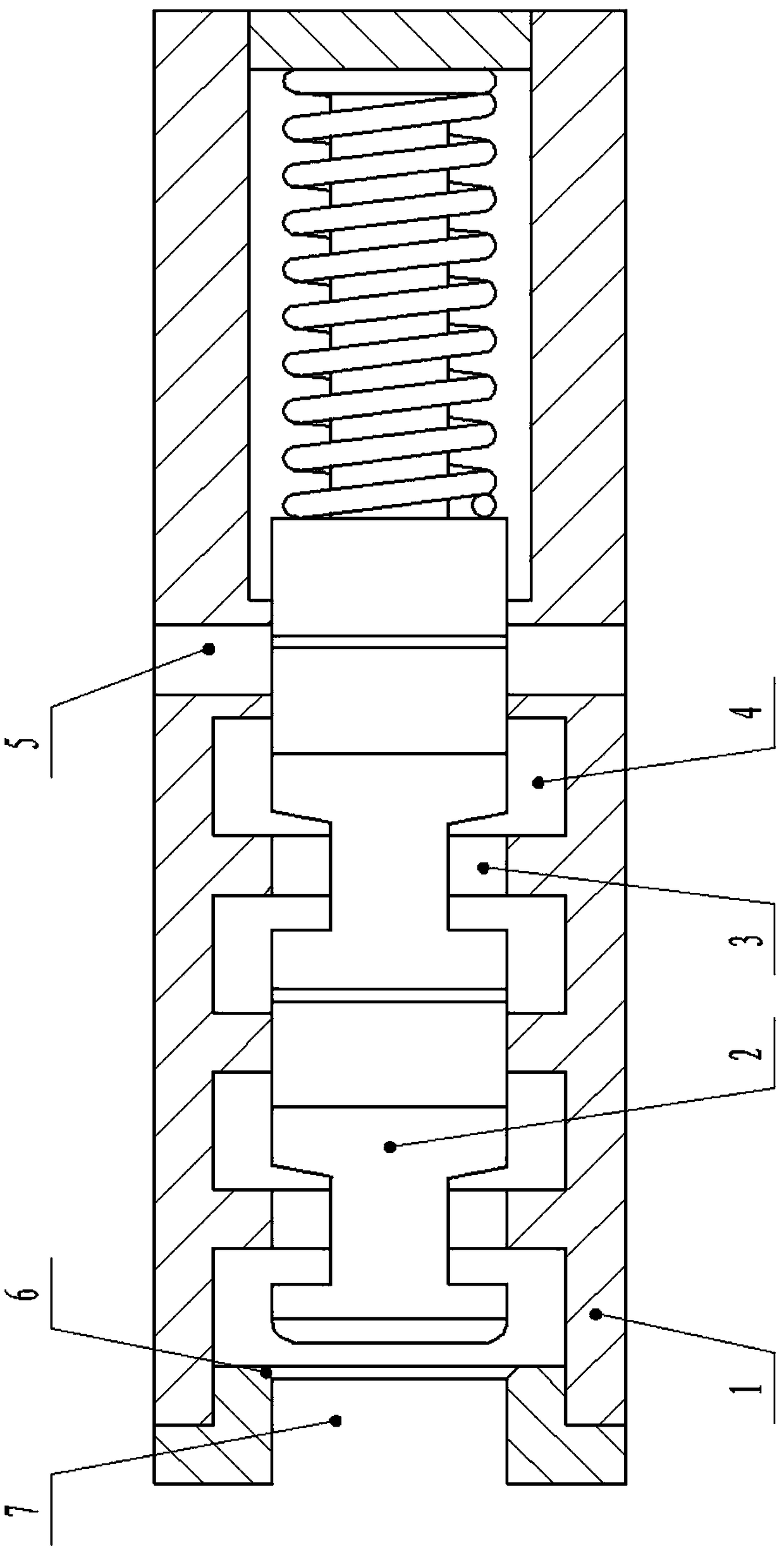

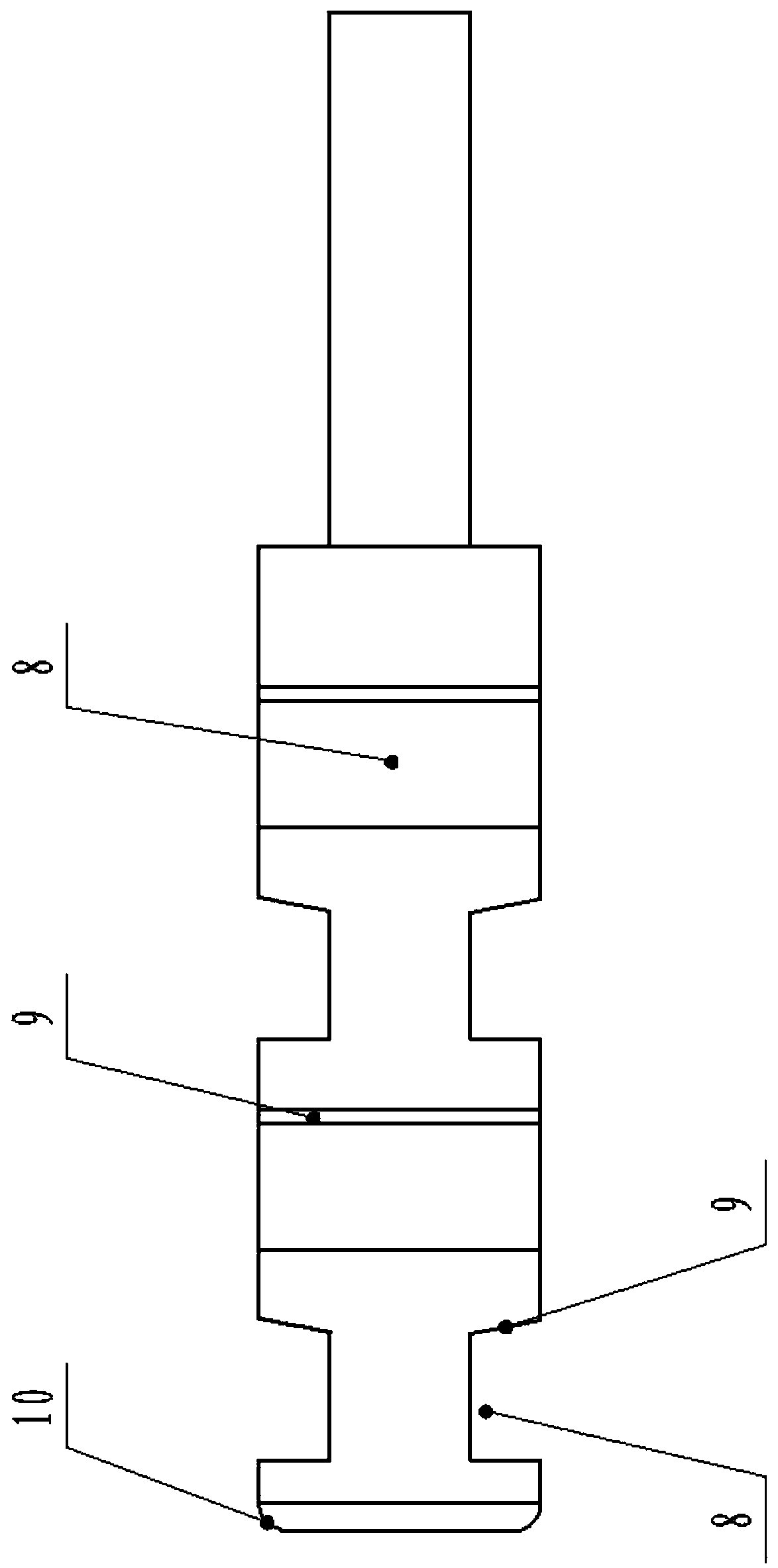

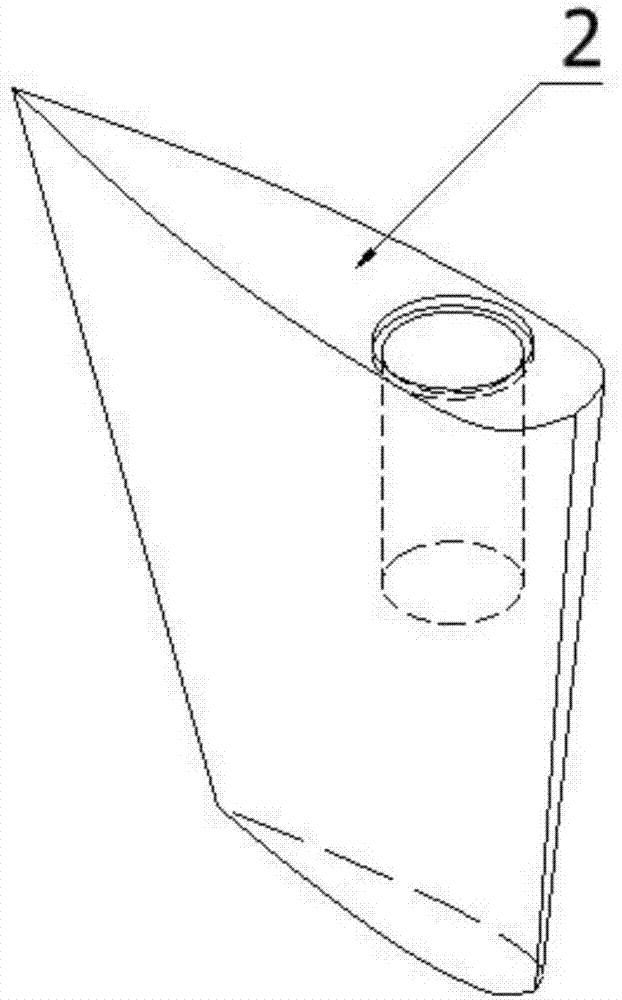

Buoyancy driving device of deep-sea underwater glider

InactiveCN102501955ARealize the development to the deep seaLarge oil flowUnderwater vesselsUnderwater equipmentGear pumpFuel tank

The invention discloses a buoyancy driving device of a deep-sea underwater glider, which comprises an oil tank, a high-pressure plunger pump, a gear pump and a normally closed electromagnetic valve. The oil tank is mounted in a pressure-resistant shell and consists of a shell fixedly connected with the pressure-resistant shell, a corrugated pipe type leather sac is mounted in the shell, one end of the corrugated tube type leather sac is hermetically fixedly connected with the bottom end of the shell, the other end of the corrugated tube type leather sac is hermetically fixedly connected with a movable end cover, the movable end cover is slidably connected into the shell, an end cover photoelectric sensor and a top end photoelectric sensor are mounted on the shell, an oil outlet of the oil tank is connected with an oil inlet of the gear pump, an oil outlet of the gear pump is connected with an oil inlet of the high-pressure plunger pump, an oil outlet of the high-pressure plunger pump is connected with an oil inlet of an outer oil sac, the oil outlet of the gear pump is connected with an oil inlet of the oil tank by a check valve communicated with the gear pump, and an oil outlet of the outer oil sac is connected with the oil inlet of the oil tank by the normally closed electromagnetic valve. By the aid of the buoyancy driving device, underwater gliders can run in the deep sea, and requirements on deep-sea operation for a long time and at high depth are met.

Owner:TIANJIN UNIV

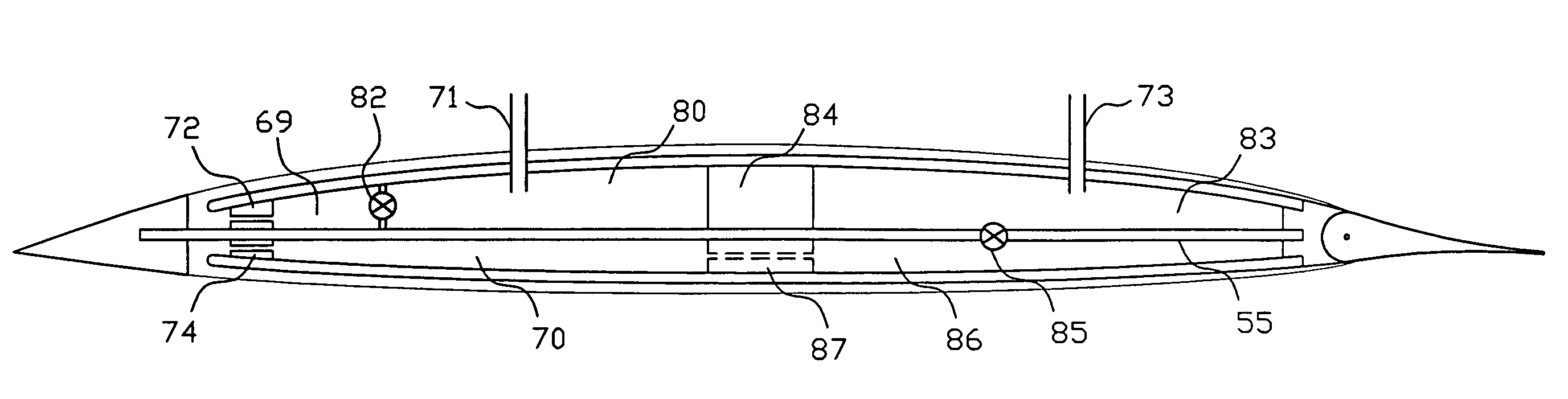

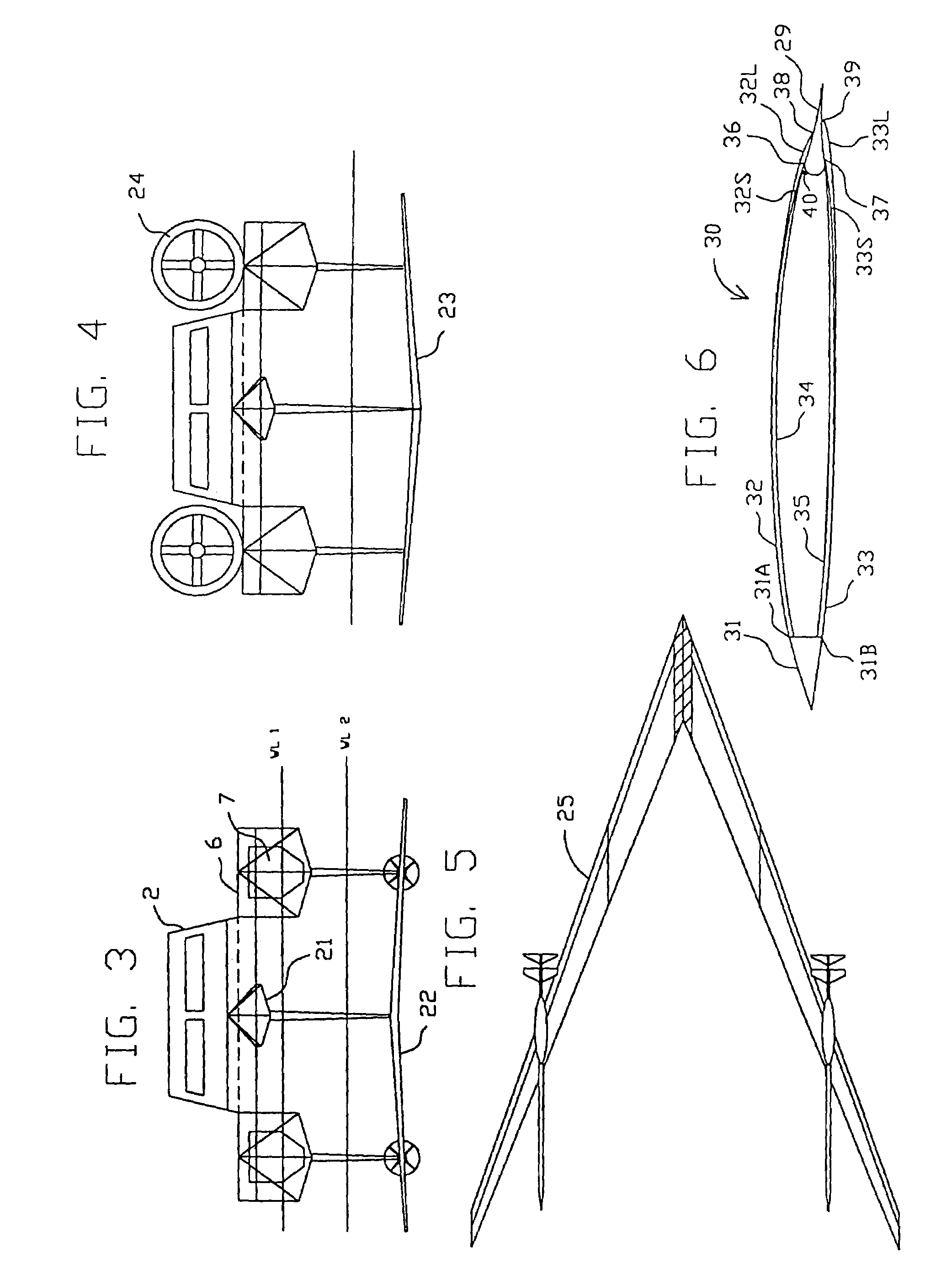

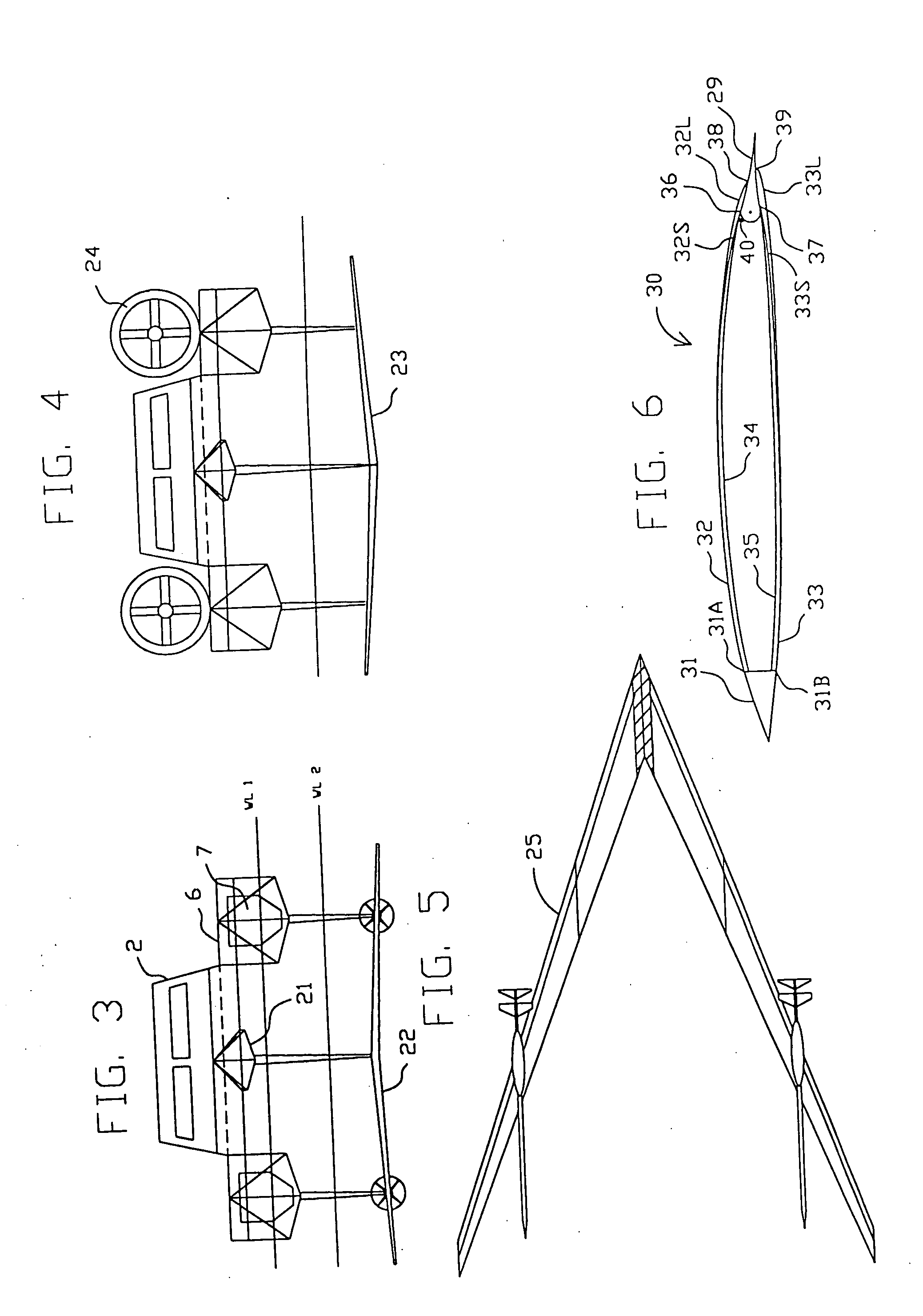

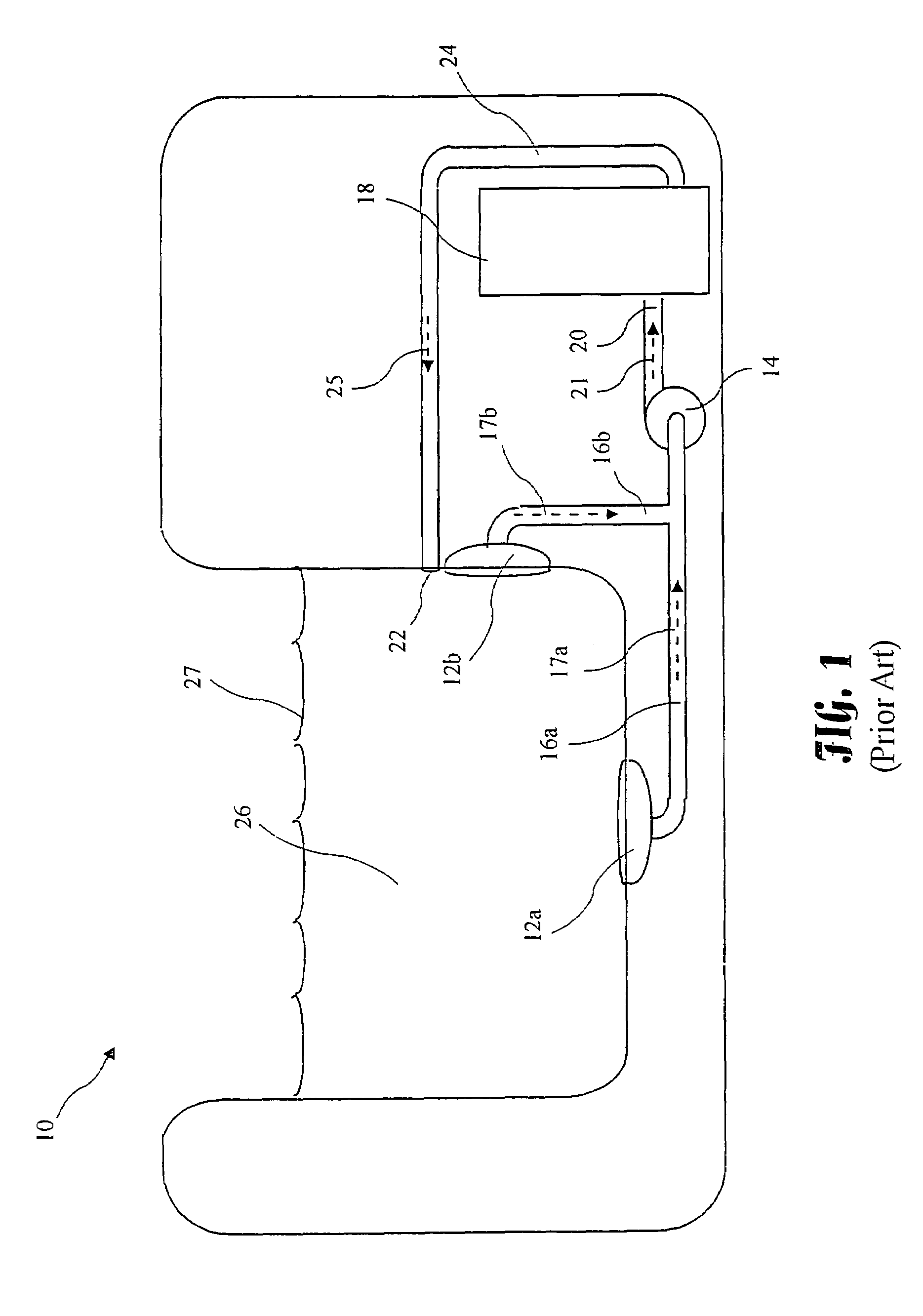

Low-drag hydrodynamic surfaces

InactiveUS6901873B1Reduce resistanceEliminate cavitationWatercraft hull designFloating buildingsKeelAtmospheric air

The invention relates to the use of gas cavities to reduce frictional drag on underwater surfaces such as hydrofoils, struts, fins, rudders, keels, propeller blades, ship hulls, underwater bodies, and wetted surfaces in general. Each gas-filled cavity is formed behind a discontinuity in the surface that causes the water boundary layer to separate from the surface. Gas is ejected into a region behind the discontinuity to fill the cavity; the gas can be air. If a cavity is open to the atmosphere, then air can typically fill the cavity naturally without air ejection. Cavities can either be closed or open. A low drag hydrofoil may have a closed cavity on one side, and an open cavity on the other side. For closed cavities, the underlying surface can be shaped to minimize cavity closure drag. Various ways to generate cavities, change hydrodynamic forces, and duct gas internally on hydrofoils and struts with cavities are covered. Different designs of hydrofoil boats, hydrofoil ships and ship hulls that are amenable to drag reduction are presented.

Owner:LANG THOMAS G +1

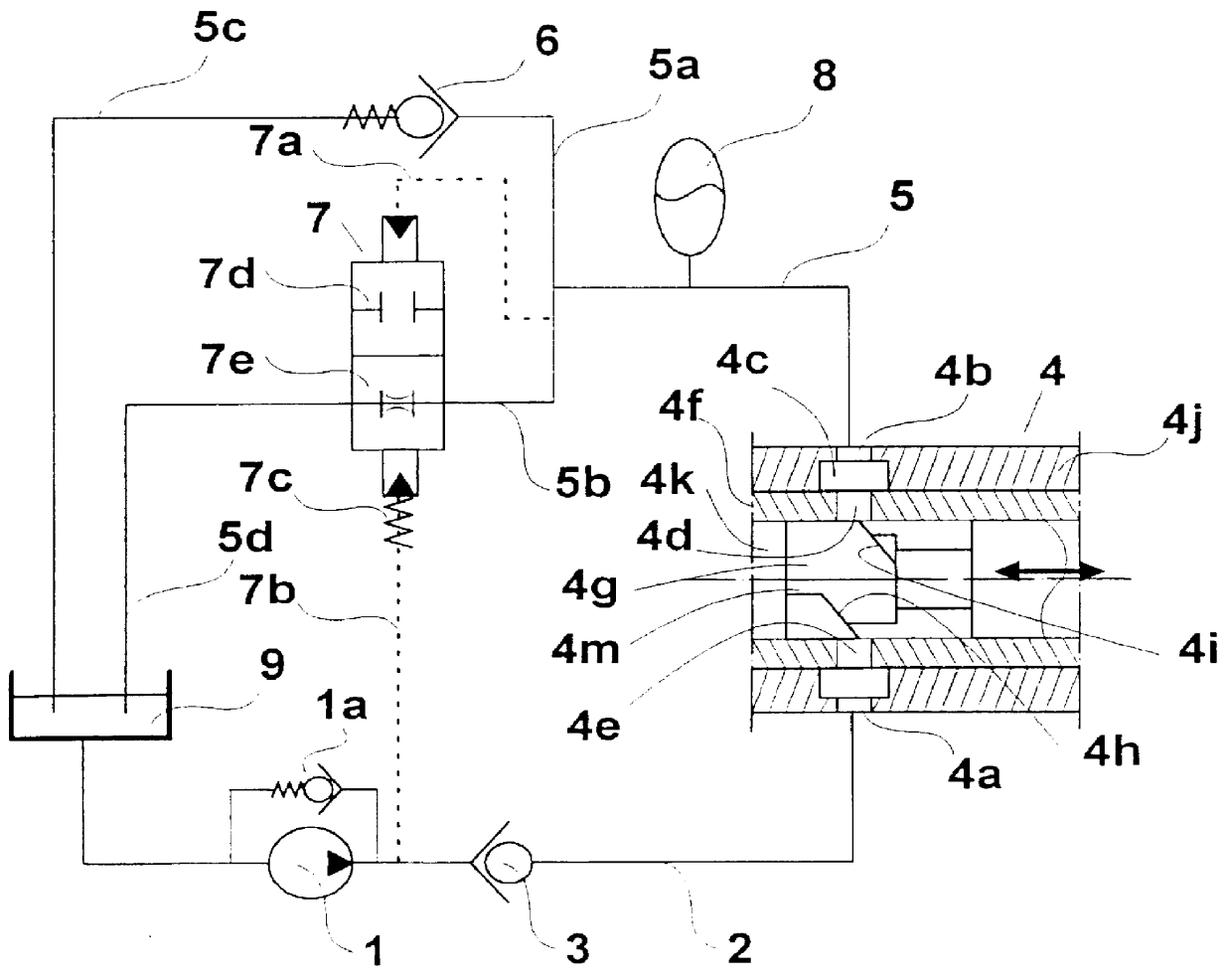

Device for avoiding cavitation in injection pumps

InactiveUS6065453AReduced component wearMinimize dispersionMachines/enginesFuel injecting pumpsCavitationInternal combustion engine

The invention provides a device for eliminating cavitation in the excess fuel return orifice(s) in the compression chamber of a fuel injection pump of an internal combustion engine after the end of the injection stage, said injection pump being connected firstly to a feed duct including a first check valve having low headloss enabling fuel to reach the compression chamber, and secondly to an excess fuel return duct, wherein the return duct comprises in parallel and close to the return orifice of the injection pump, a second check valve that is rated to cause the pressure in said return orifice of the injection pump to rise, and a two-port valve that is normally open and that is caused to close by the appearance of pressure in the return orifice greater than the pressure which obtains in the feed duct upstream from said first check valve.

Owner:SEMT PIELSTICK

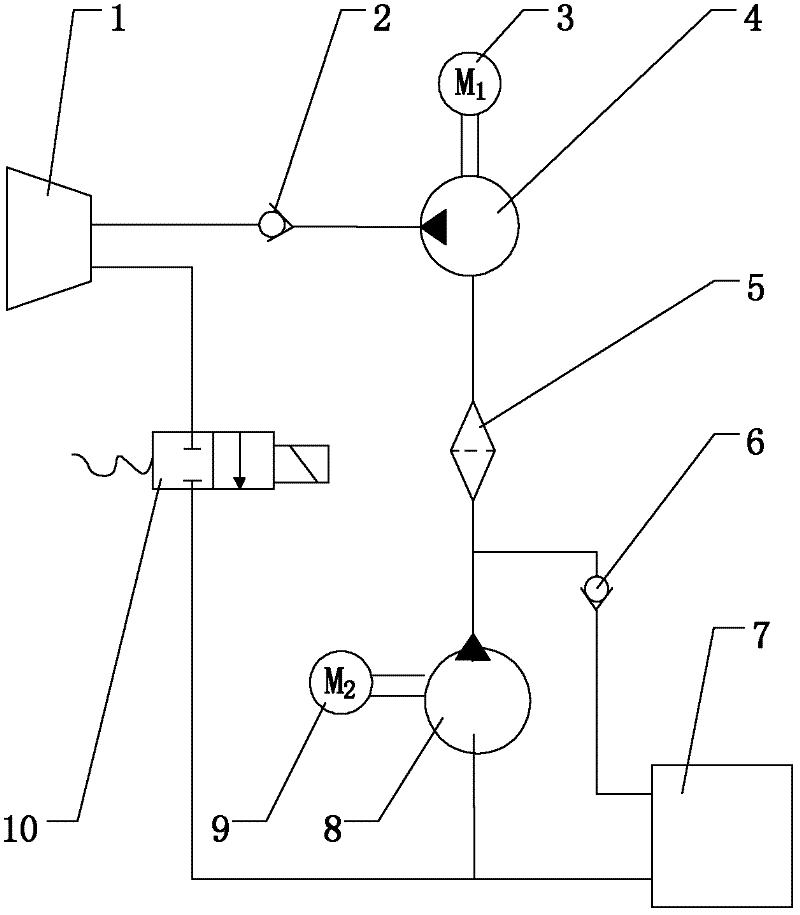

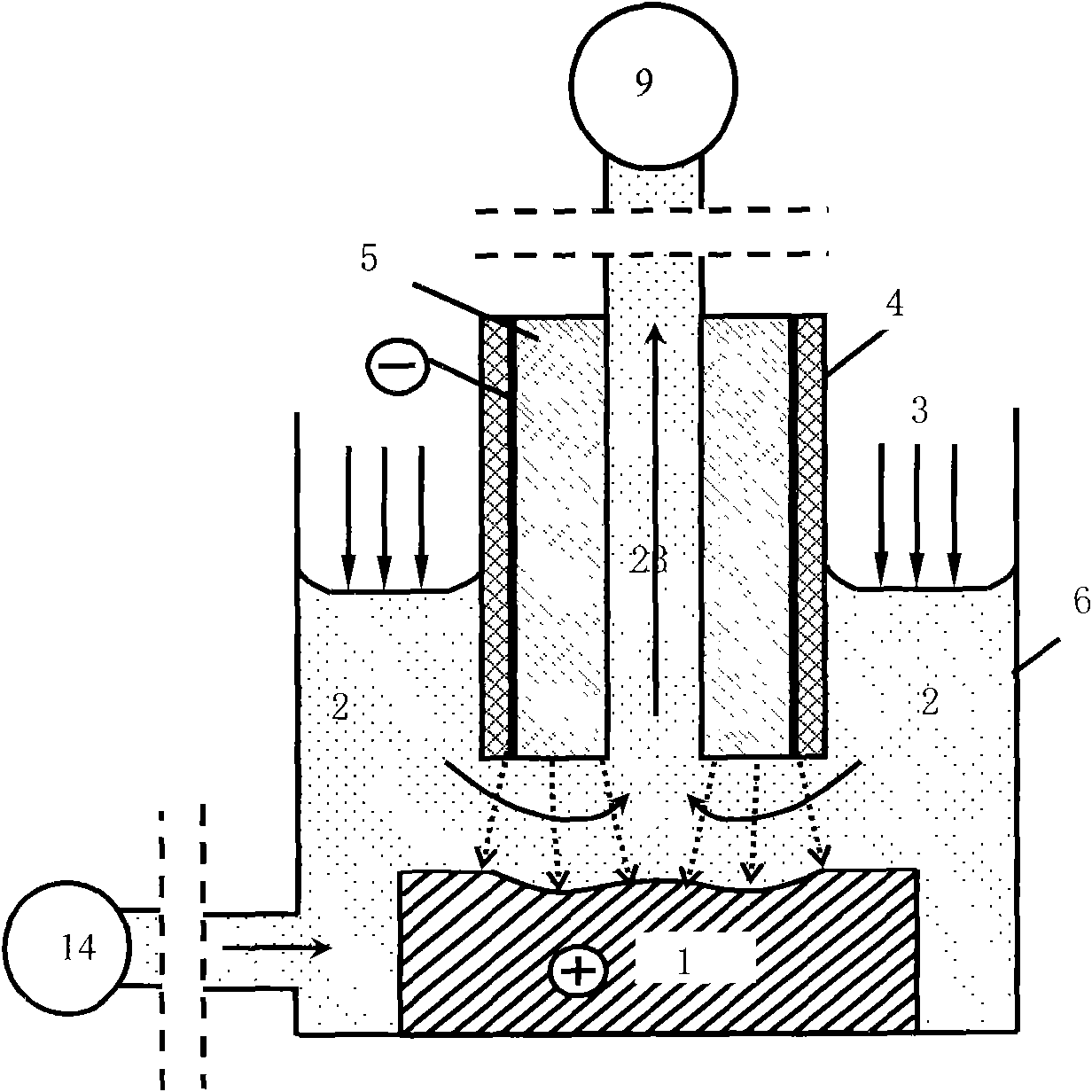

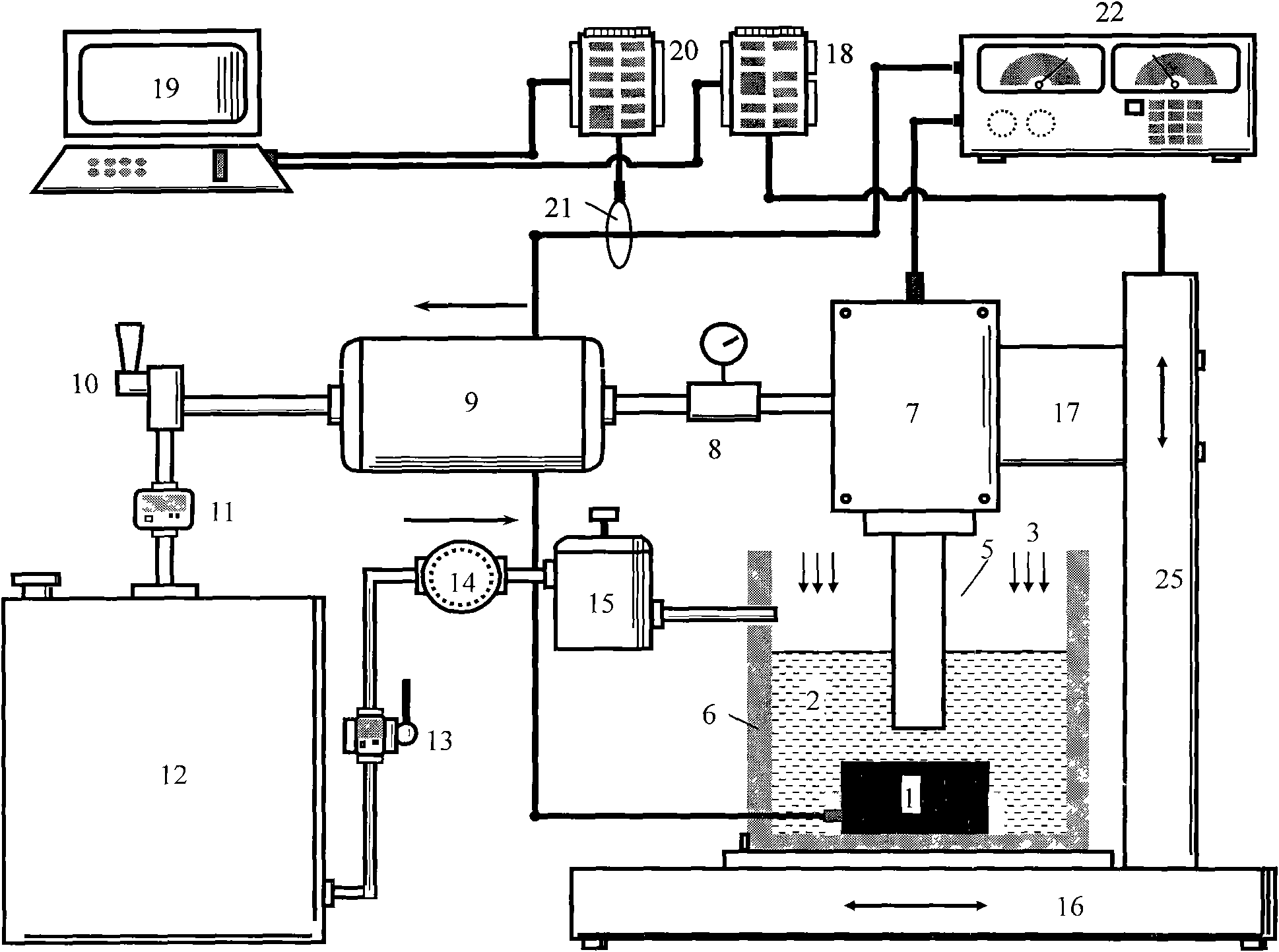

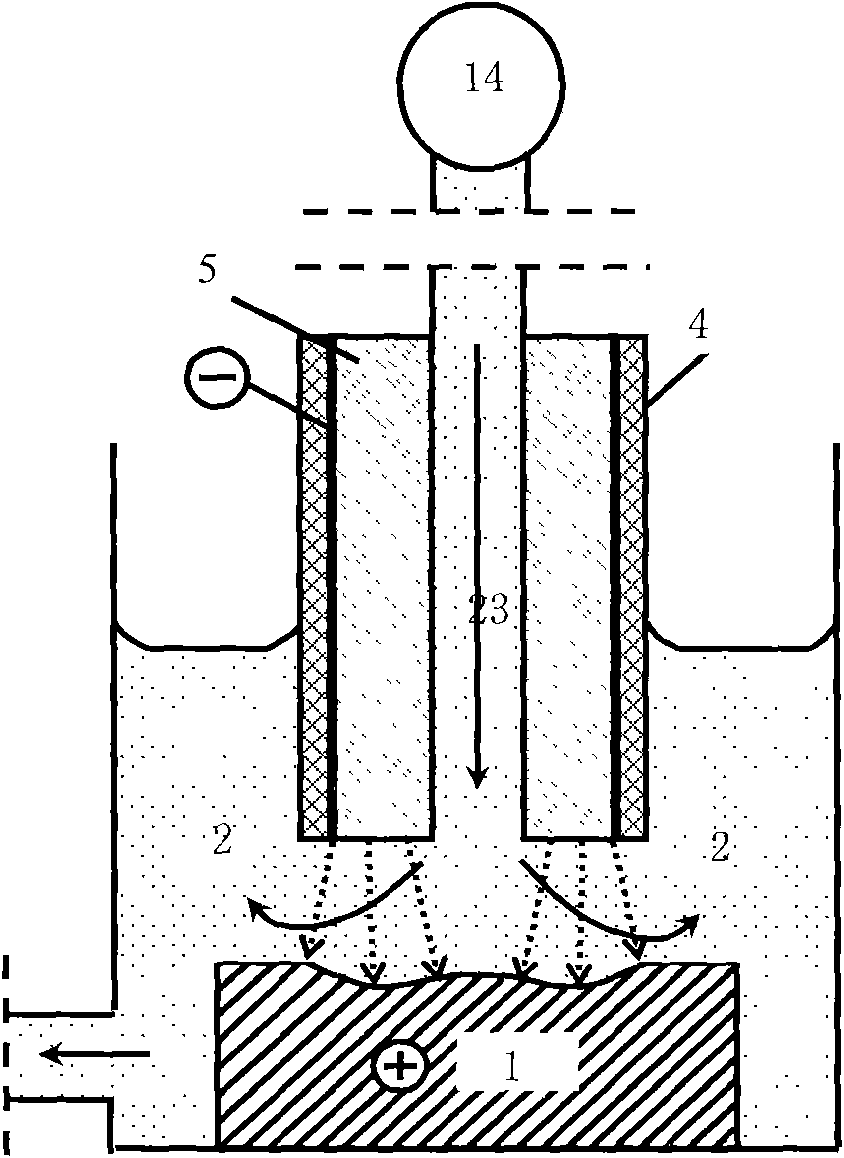

Vacuum backflow electrolysis processing method and vacuum backflow electrolysis processing device

InactiveCN101633066AImprove processing stabilityEliminate cavitationElectrochemical machining apparatusMachining processBackflow

The invention relates to a vacuum backflow electrolysis processing method and a vacuum backflow electrolysis processing device which belong to the technical field of electrolysis processing. The method adopts a backflow liquid supply way in the process of electrolysis processing; and electrolyte enters a front gap from a side gap of a processing area to participate in reaction and is finally discharged from an electrolyte passage in a tool electrode. The vacuum backflow electrolysis processing method is characterized in that the backflow liquid supply way is realized by a pumping function of a vacuum generating device. The method and the device are significant for improving the stability and the processing efficiency of electrolysis processing.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

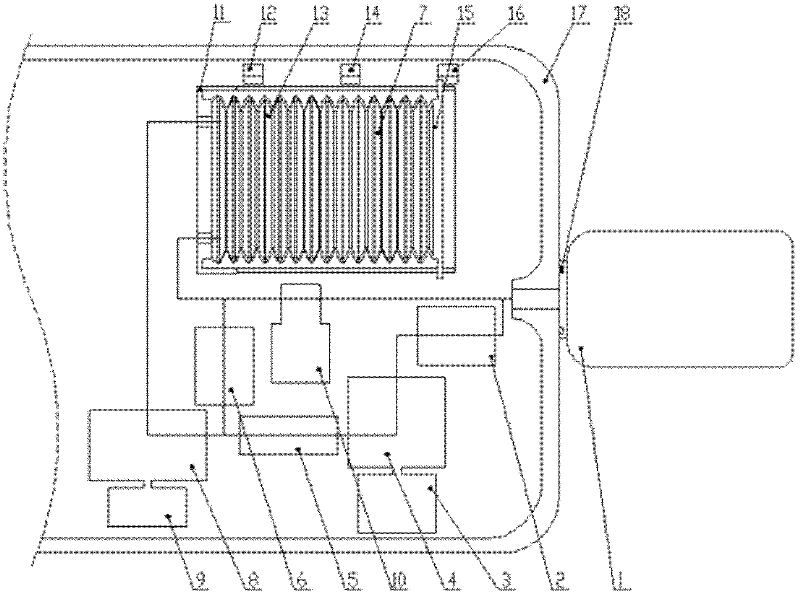

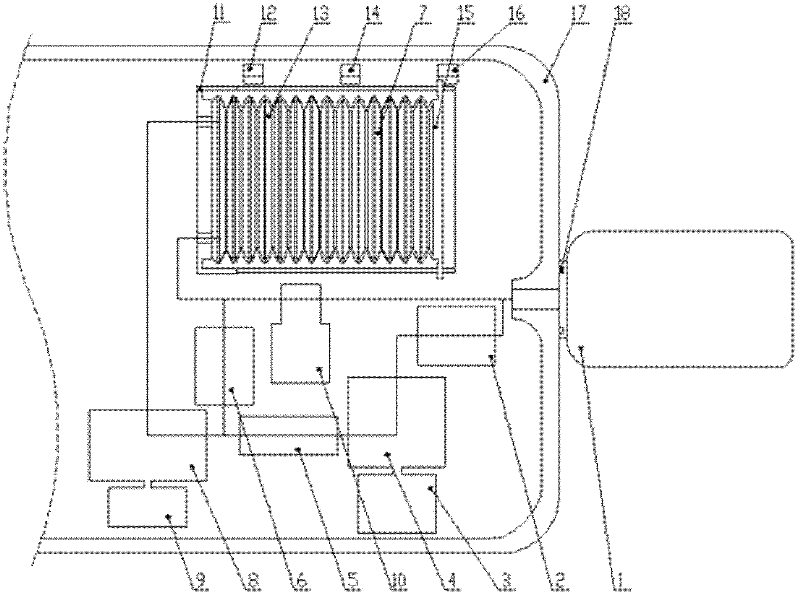

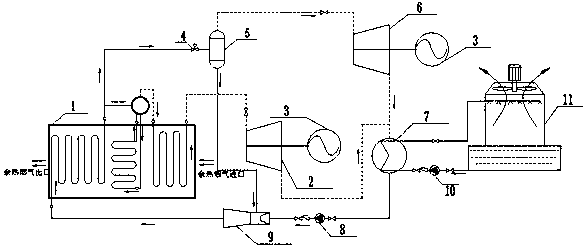

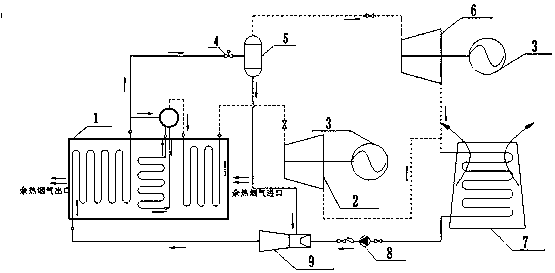

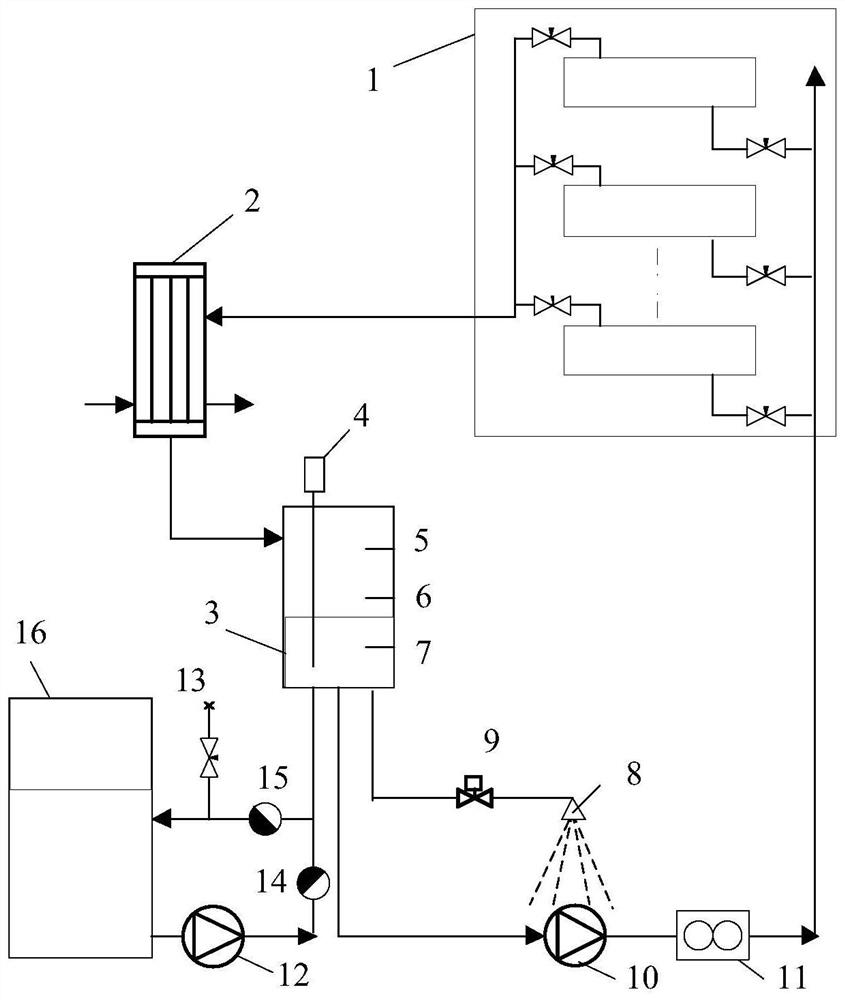

Dual-pressure expansion organic rankine cycle (ORC) mid-low-temperature waste heat recovery power generation system

ActiveCN108167040AEfficient cascade utilizationEliminate cavitationSteam engine plantsCavitationOrganic Rankine cycle

The invention relates to a dual-pressure expansion organic rankine cycle (ORC) mid-low-temperature waste heat recovery power generation system and belongs to the technical field of energy and environments. According to the system, mid-low-temperature waste heat flue gas with the temperature being 200-350 DEG C is utilized as the driving heat source, organic working medium feeding liquid is preheated to be in a saturated liquid state in an ORC waste heat boiler preheating segment, then part of a saturated liquid organic working medium enters an evaporation segment and an superheating segment ofa waste heat boiler, generated saturated (or superheated) steam enters a radial-inward-flow turbine, and a high-pressure stage ORC expansion work doing process is completed; and the other part of thesaturated liquid organic working medium enters a flash vessel after being subjected to throttling and pressure reducing, saturated steam separated from the flash vessel enters a low-pressure stage screw expander, and a low-pressure stage ORC expansion work doing process is completed. An ejection compressor recovers the liquid-phase working medium separated out of the flash vessel, utilization ofliquid conveying pumps is reduced, the system is simplified, and the possibility of pump cavitation is eliminated.

Owner:KUNMING UNIV OF SCI & TECH

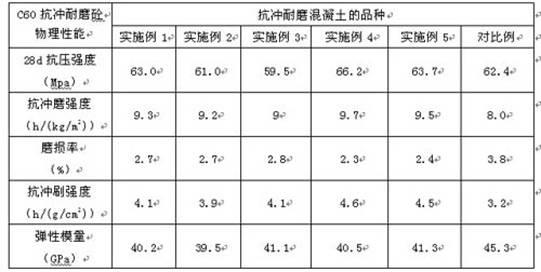

Impact-resistant anti-wear agent for hydraulic concrete

The invention provides an impact-resistant and anti-wear agent for hydraulic concrete, which mainly comprises a nano material, slag, latex powder, rubber powder, a water reducing agent, fibers, an exciting agent and a defoaming agent. The impact-resistant anti-wear agent is suitable for places such as water conservancy projects, roads and airport pavements requiring high impact-resistant and anti-wear concrete, has the functions of resisting crack, reducing water, reinforcing and reducing elasticity, and excellent mixing and constructing properties. The impact-resistant and anti-wear agent has the advantages of increasing concrete impact-resistant and anti-wear properties, prolonging maintenance period and reducing maintenance cost.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE +1

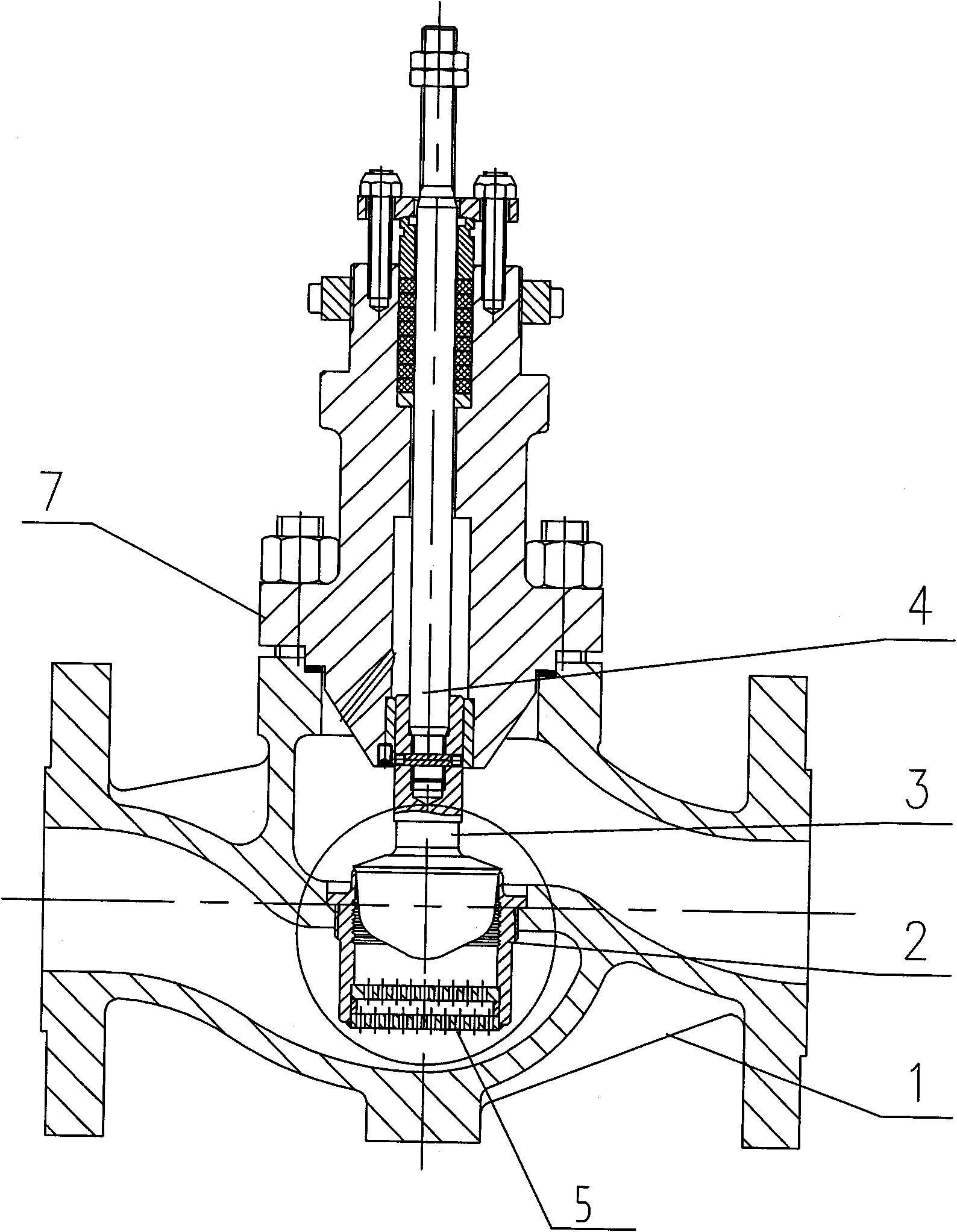

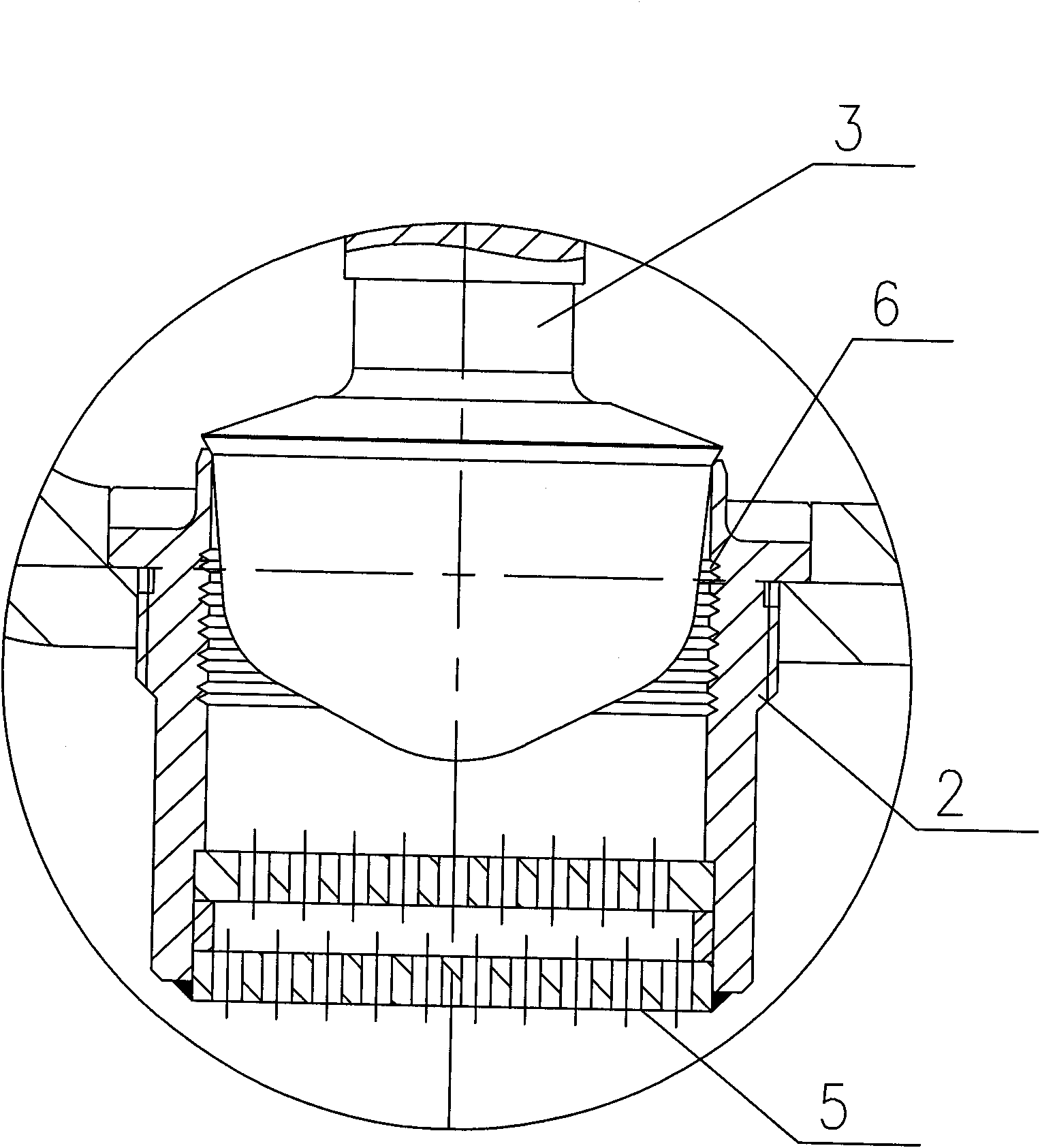

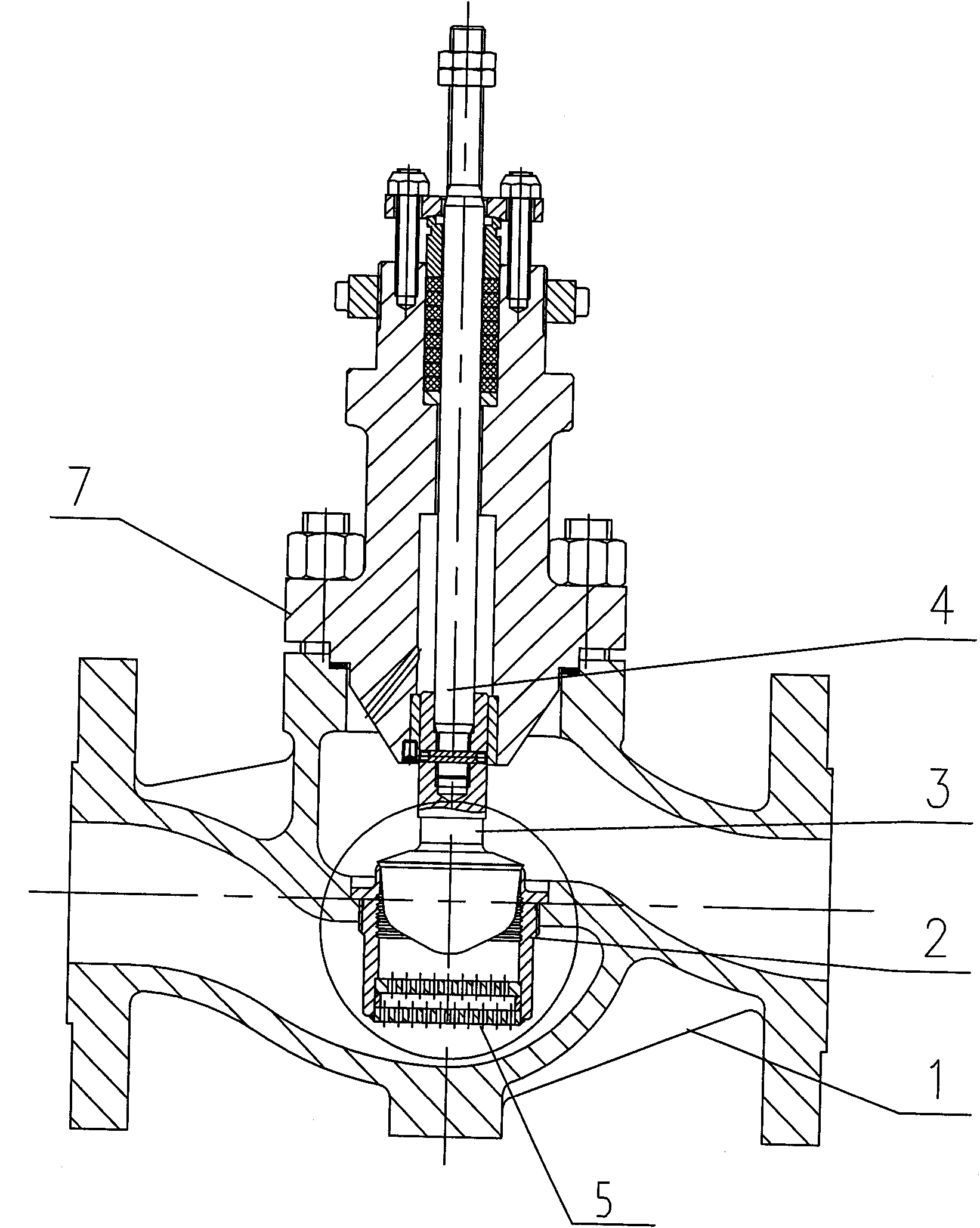

Anti-cavitation erosion adjusting valve capable of cutting

InactiveCN101865297AGuaranteed tightnessEliminate cavitationValve members for absorbing fluid energyLift valveEngineeringSmall hole

The invention relates to an anti-cavitation erosion adjusting valve capable of cutting, which comprises a valve body, a valve seat, a valve core and a valve rod. The invention is characterized in that the sealed face of the valve seat is provided with a cut, the upper side of the sealed face of the valve core is provided with the cut, the valve core sealed face tightly contacts with the valve seat sealed face and the lower part of the valve seat is provided with two or more than two layers of parallel restriction orifices which are provided with small holes. The inner wall at the lower part of the valve seat sealed face is provided with a zigzag groove so that a zigzag swirl chamber is formed between the valve seat and the valve core. The invention adopts the valve seat cutting technology and cuts air bubbles generated by flash evaporation through the sharp cut of the valve seat sealed face, consequently the cavitation erosion is avoided and the damage of the cavitation erosion on the interior components of the valve is eliminated thoroughly.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

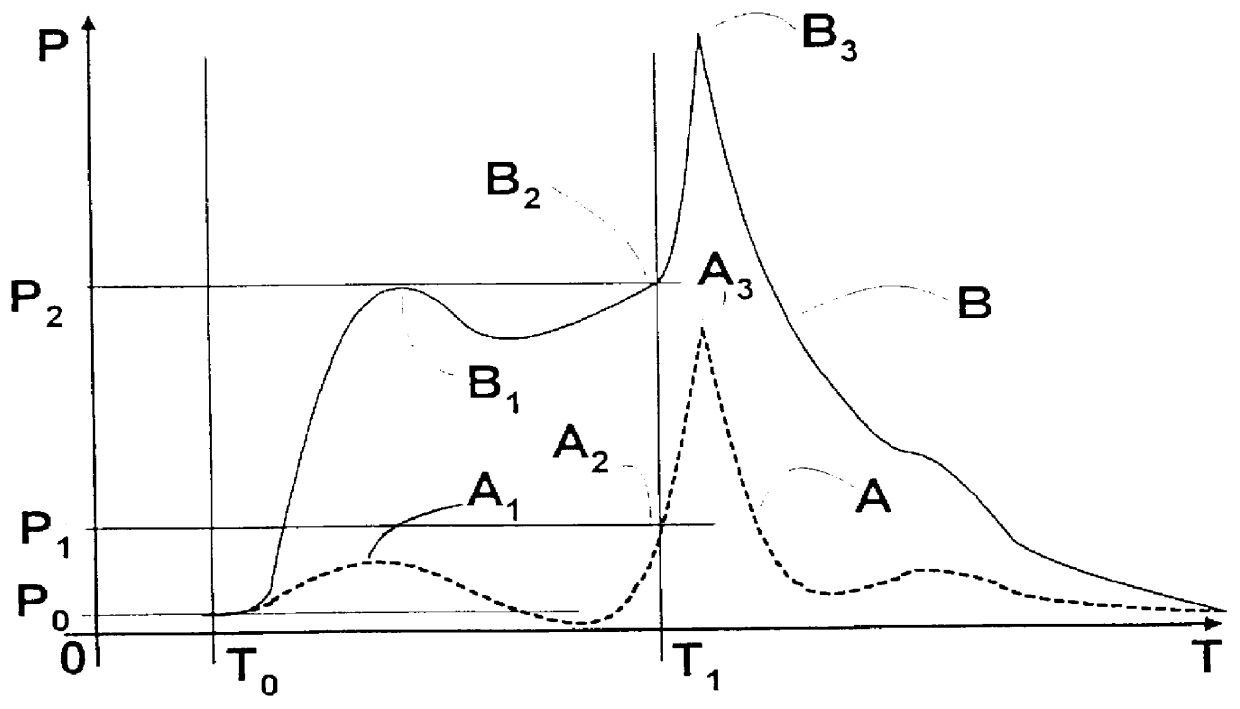

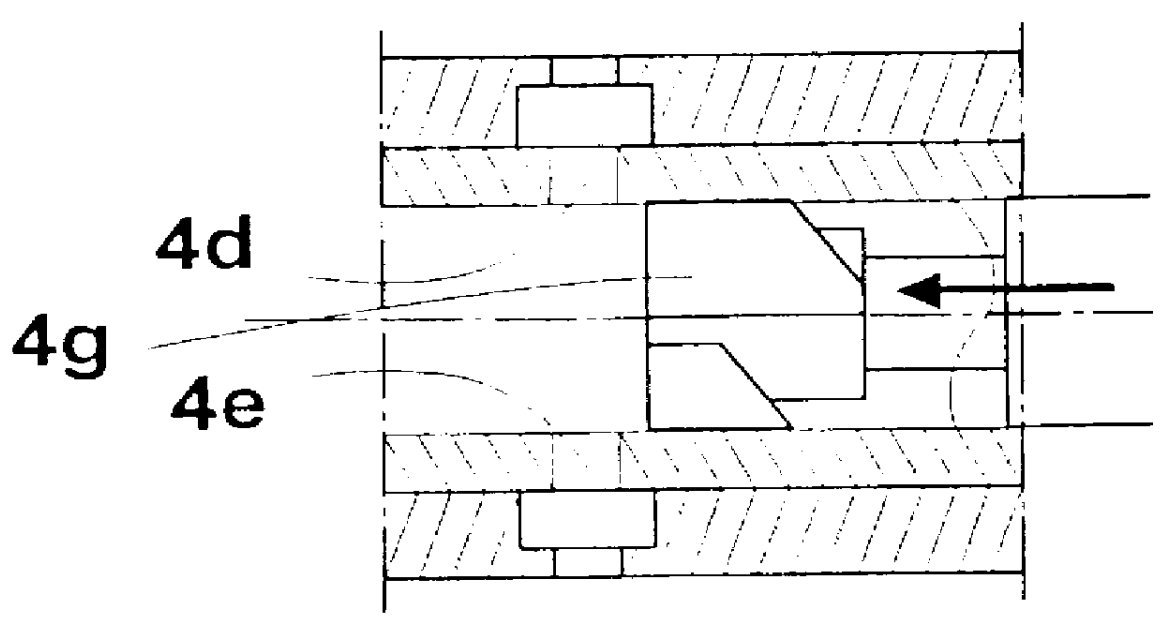

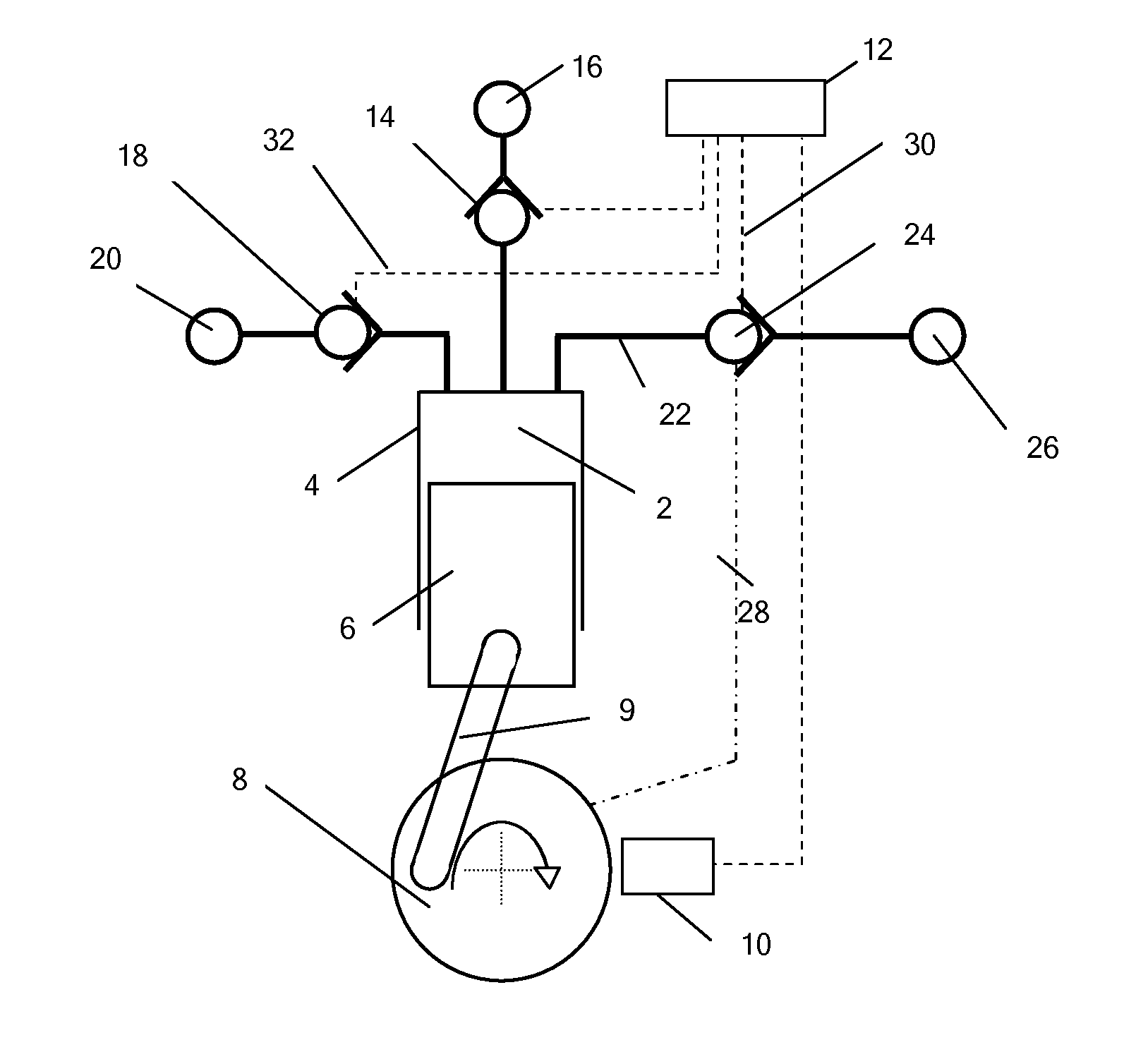

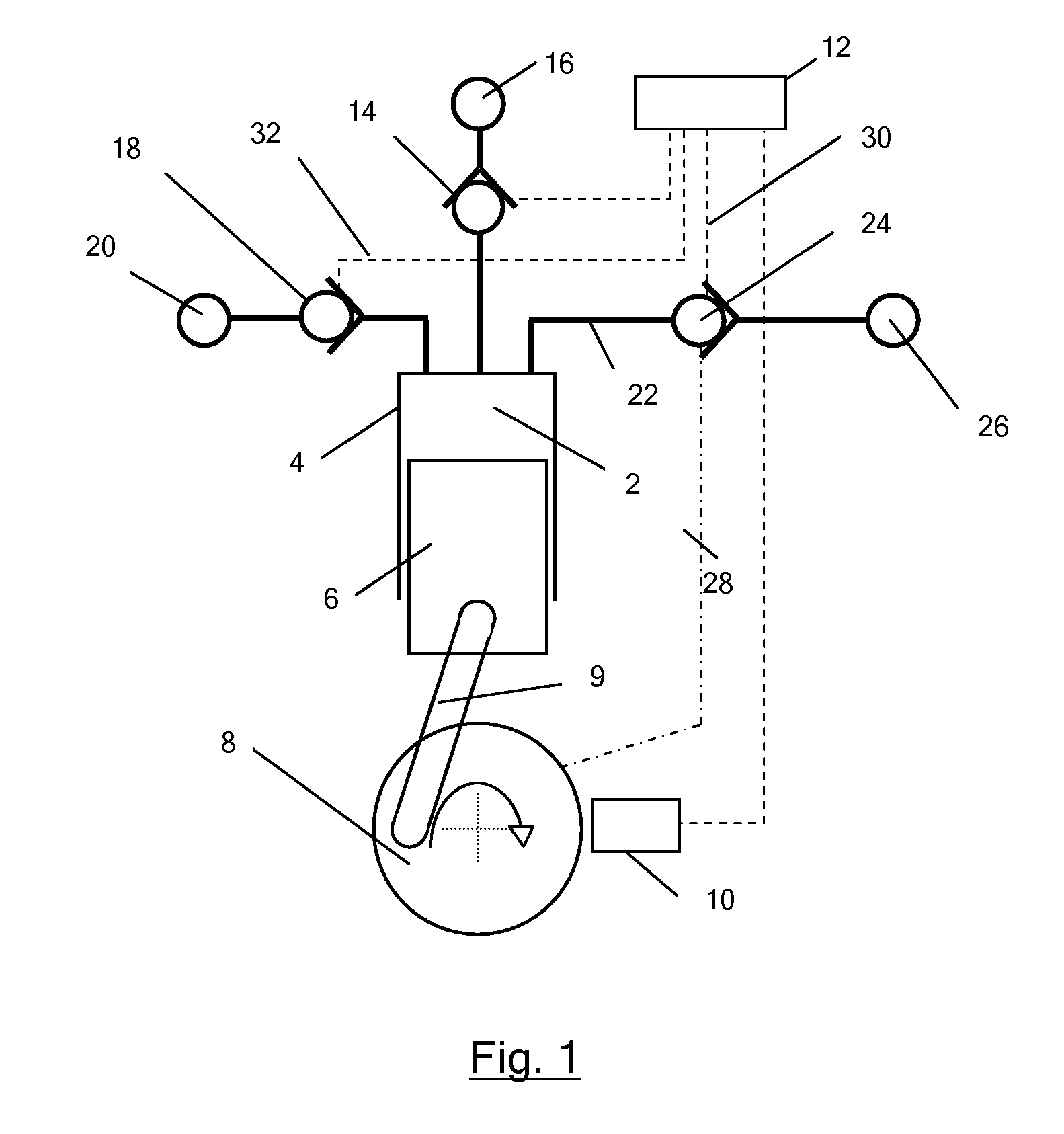

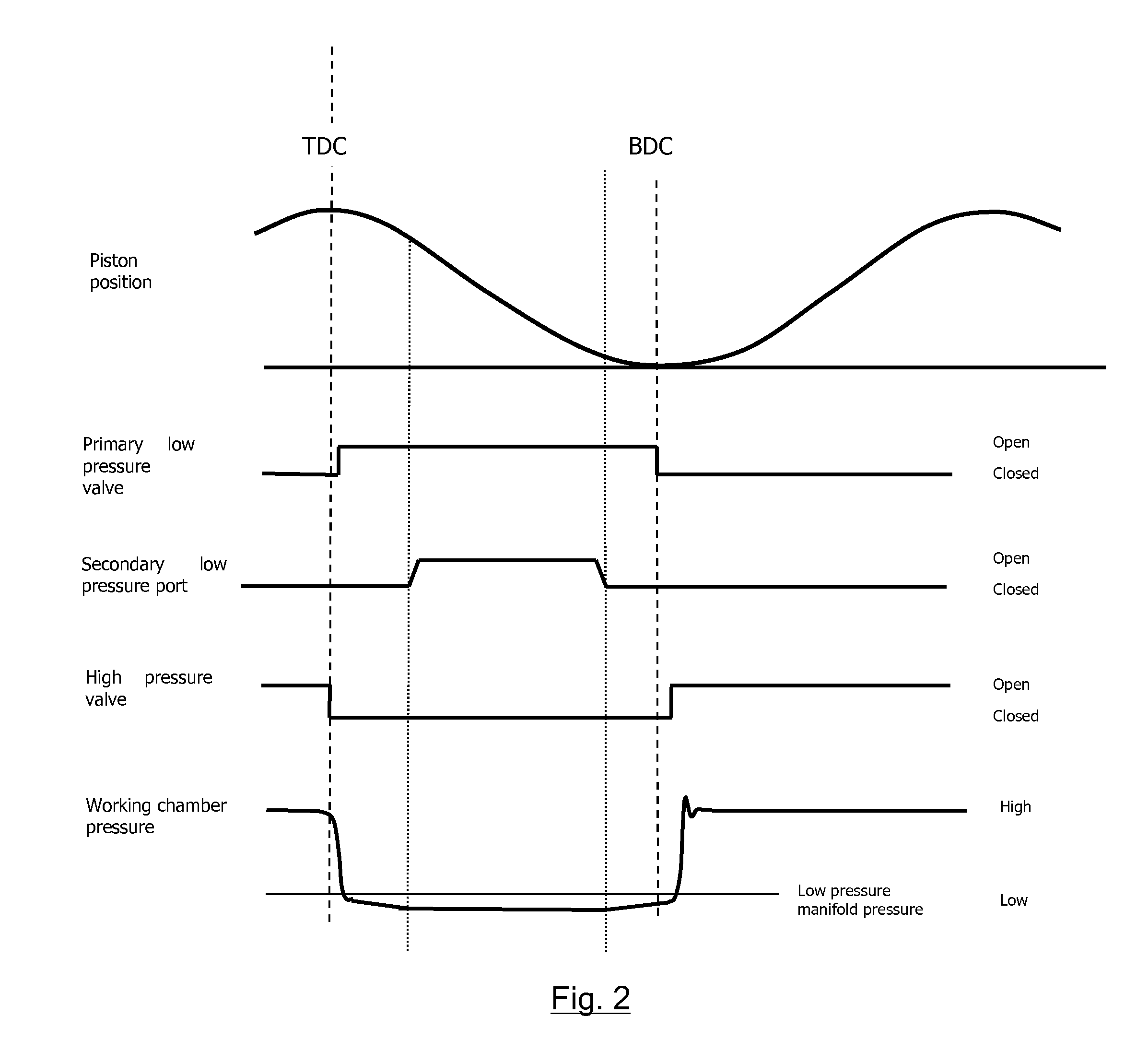

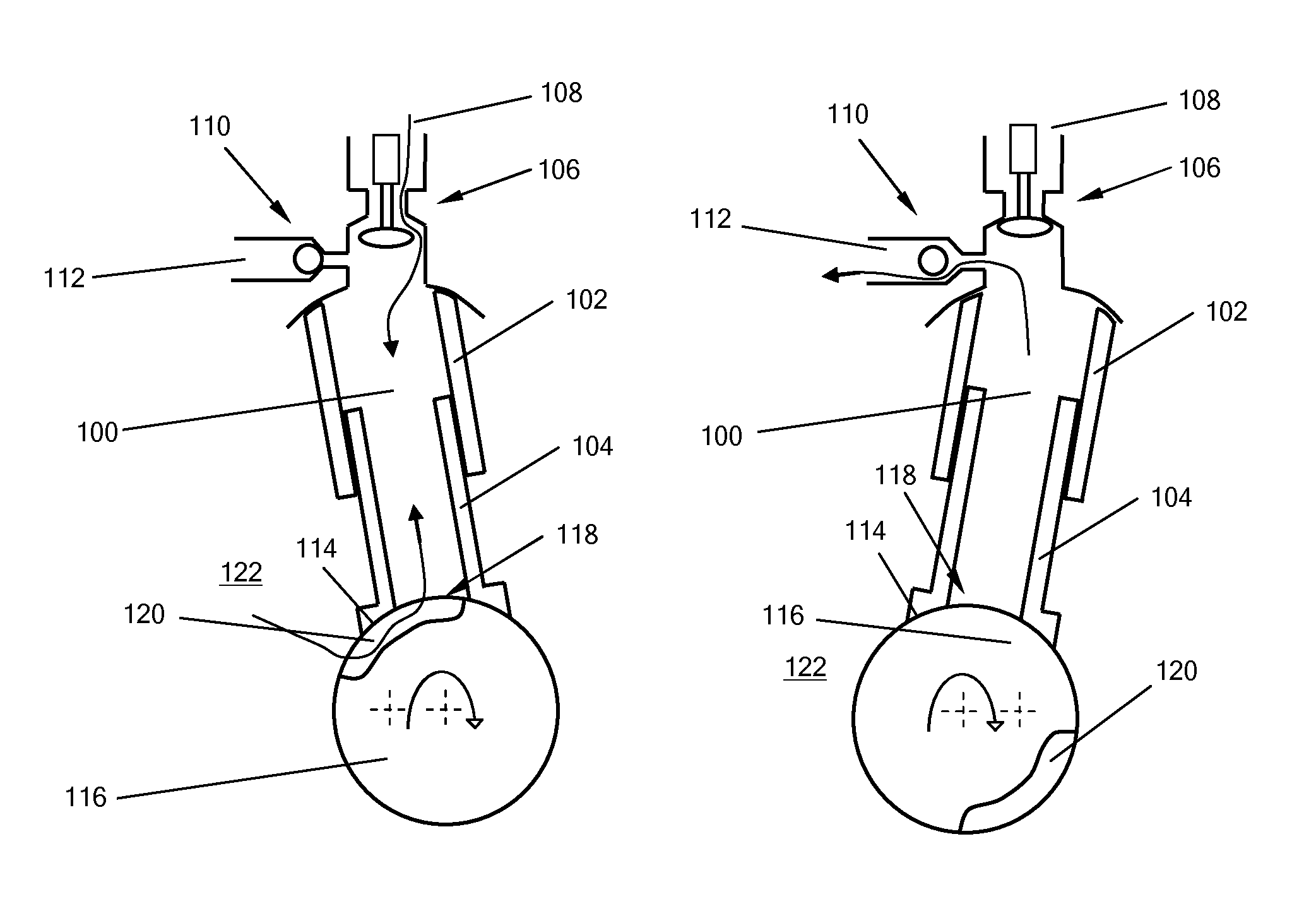

Fluid working machines and methods

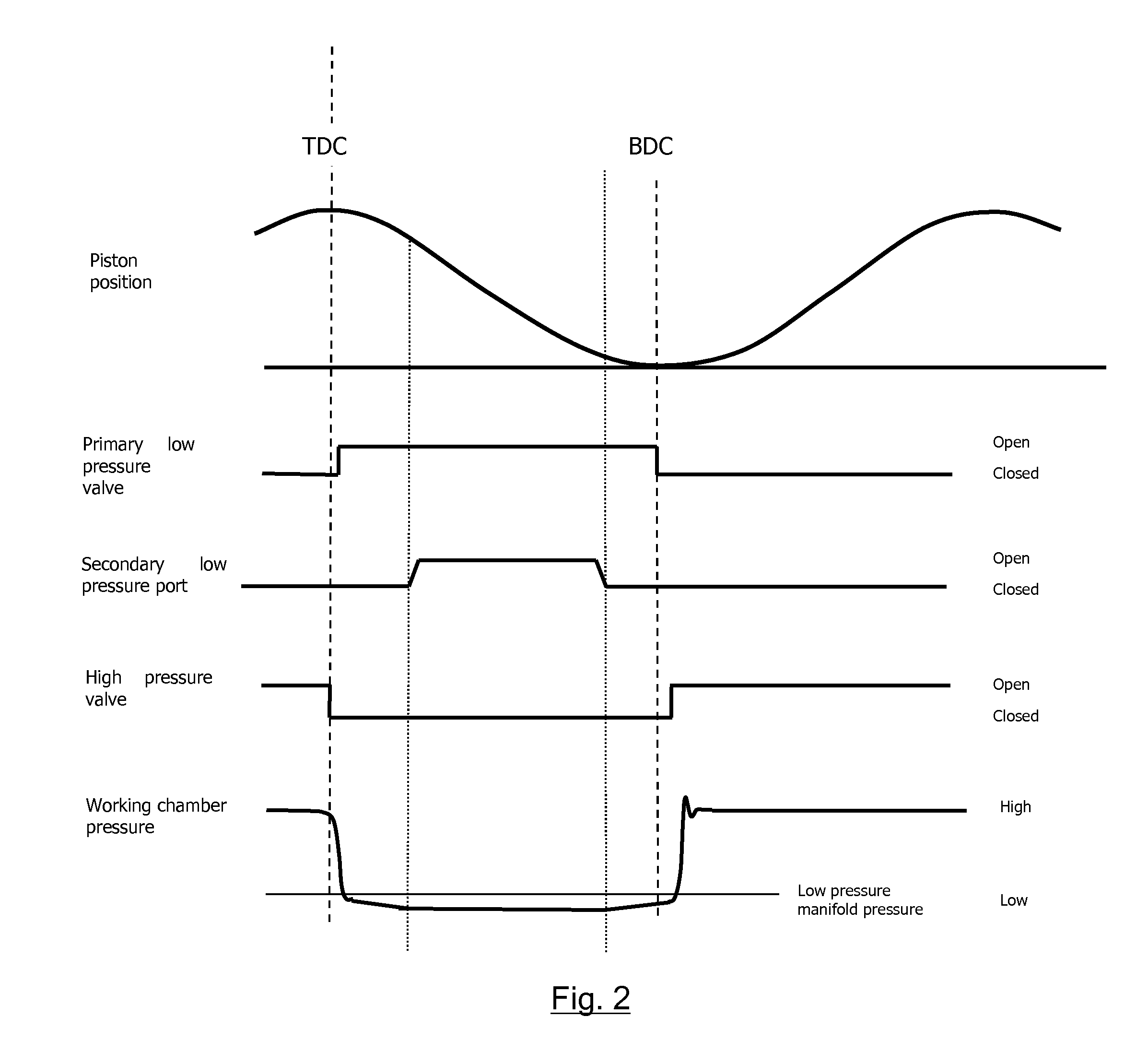

ActiveUS20110226342A1Reduce pressureAvoid hard activationPipeline systemsPump controlActive controlMechanical engineering

A fluid working machine comprises a controller (12) and a working chamber (2) of cyclically varying volume. The working, chamber has both an electronically controllable primary low pressure valve (14) and a secondary low pressure port (22) associated therewith, each of which is openable and closable in phased relation to cycles of working chamber volume to bring the working chamber into fluid communication with a low pressure manifold (16, 26). At least the primary low pressure valve is under the active control of the controller to enable the controller to determine the net displacement of fluid by the working chamber on a cycle by cycle basis. The primary low pressure valve and the secondary low pressure port are openable concurrently during a portion of at least some cycles of working chamber volume to enable fluid to flow into or out of the working chamber concurrently through both the primary low pressure valve and the secondary low pressure port. The primary low pressure valve may be closed under the active control of the controller a period of time after the secondary low pressure port closes.

Owner:DANFOSS PAUER SOLYUSHENS APS

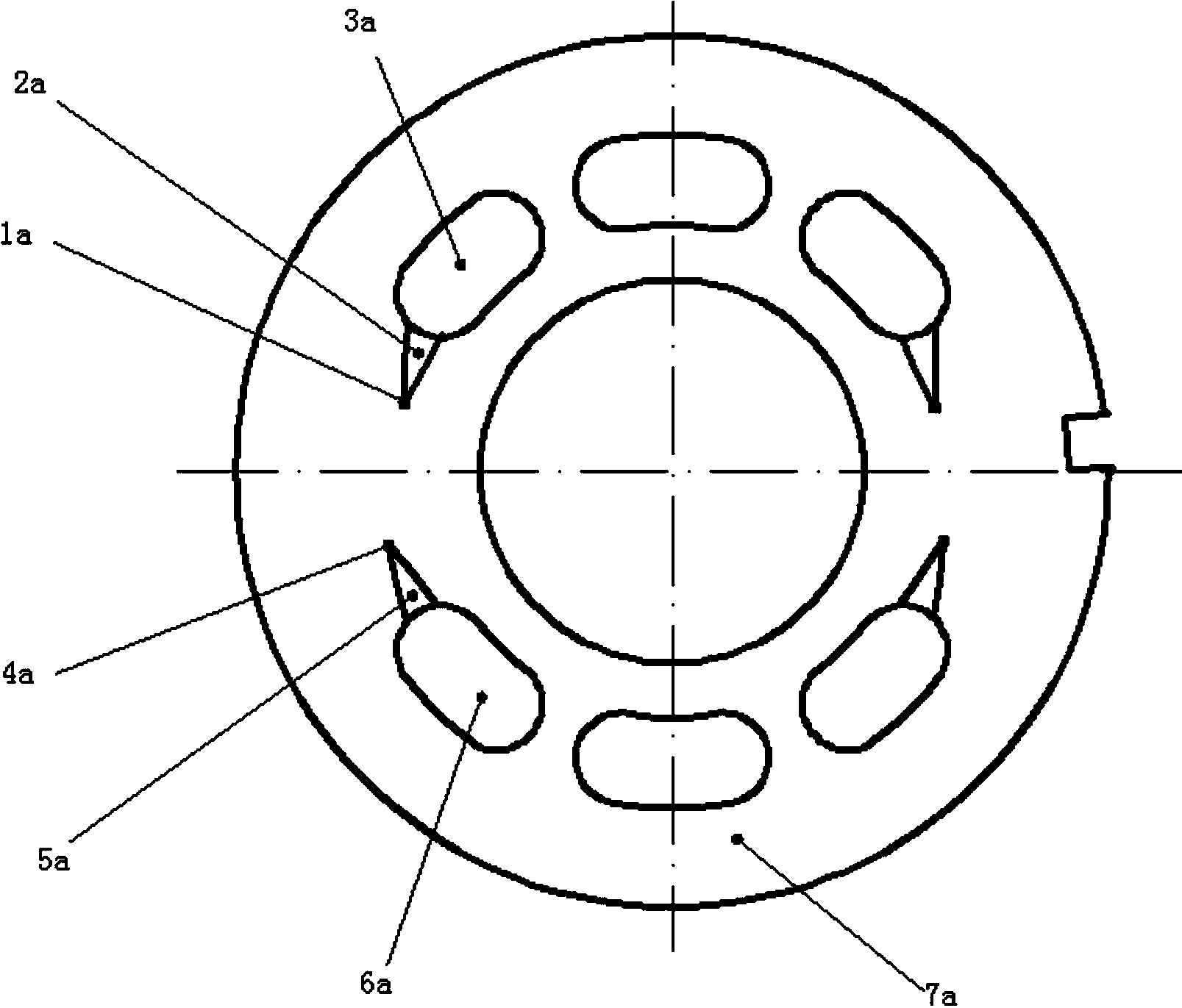

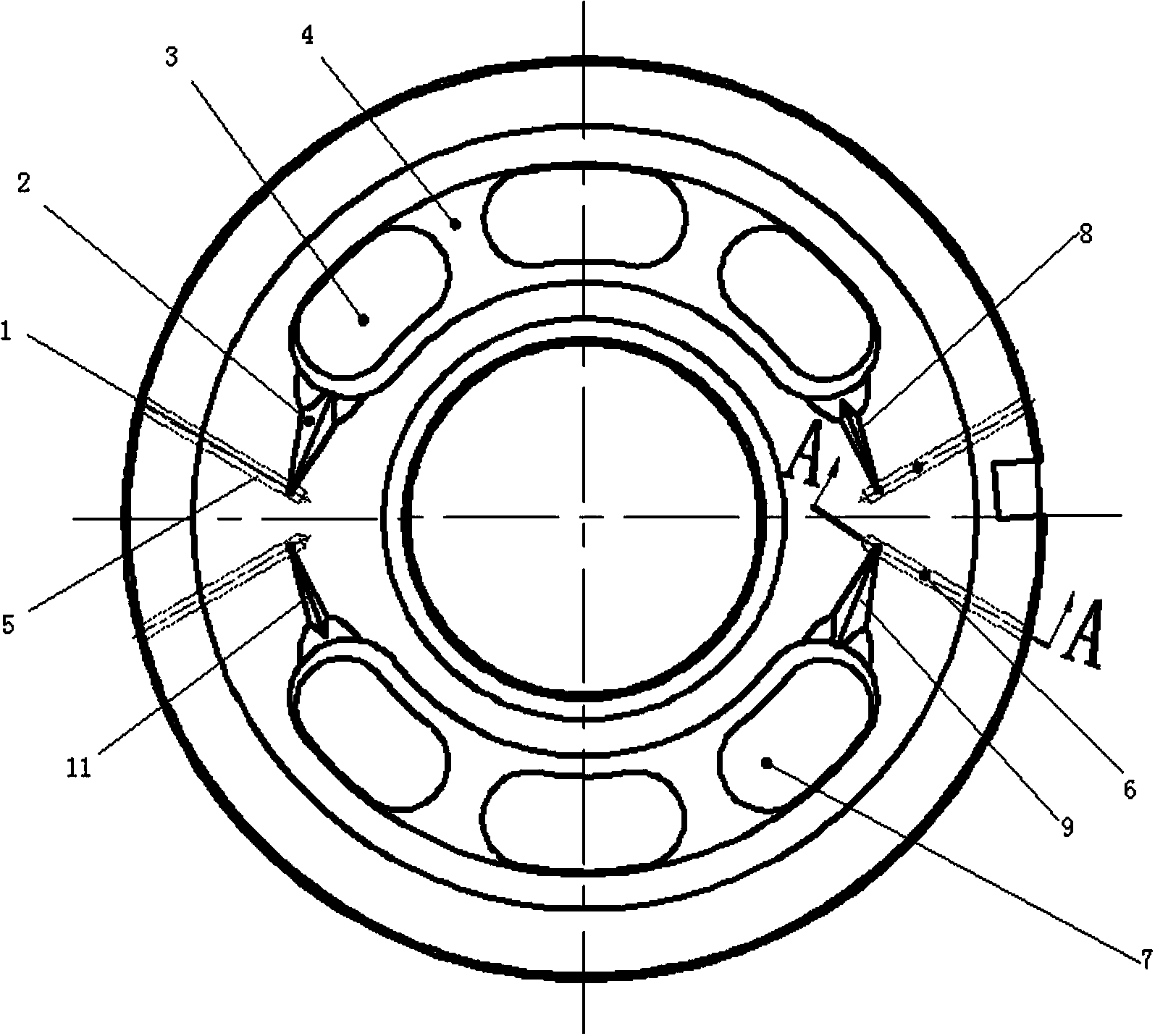

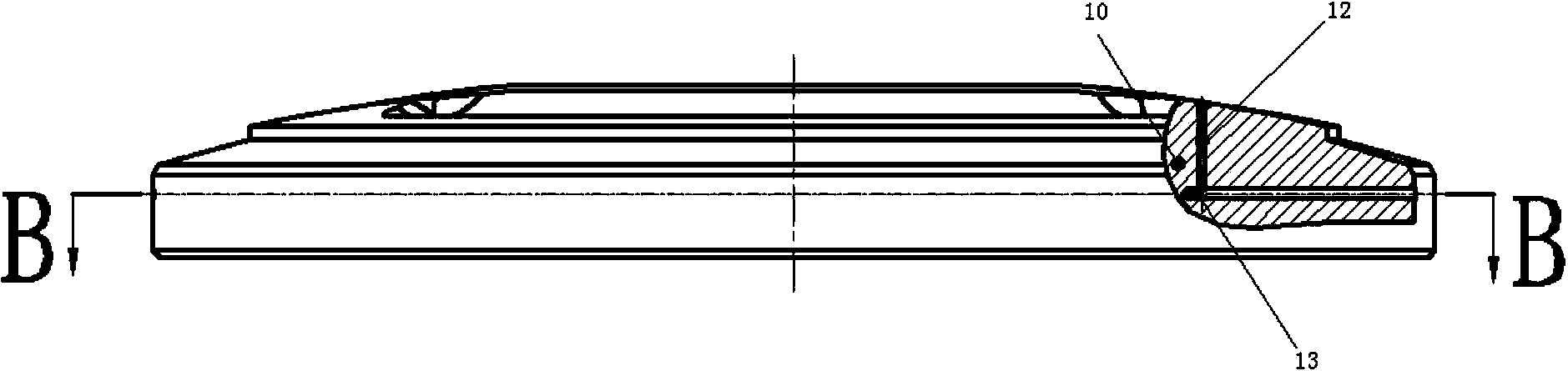

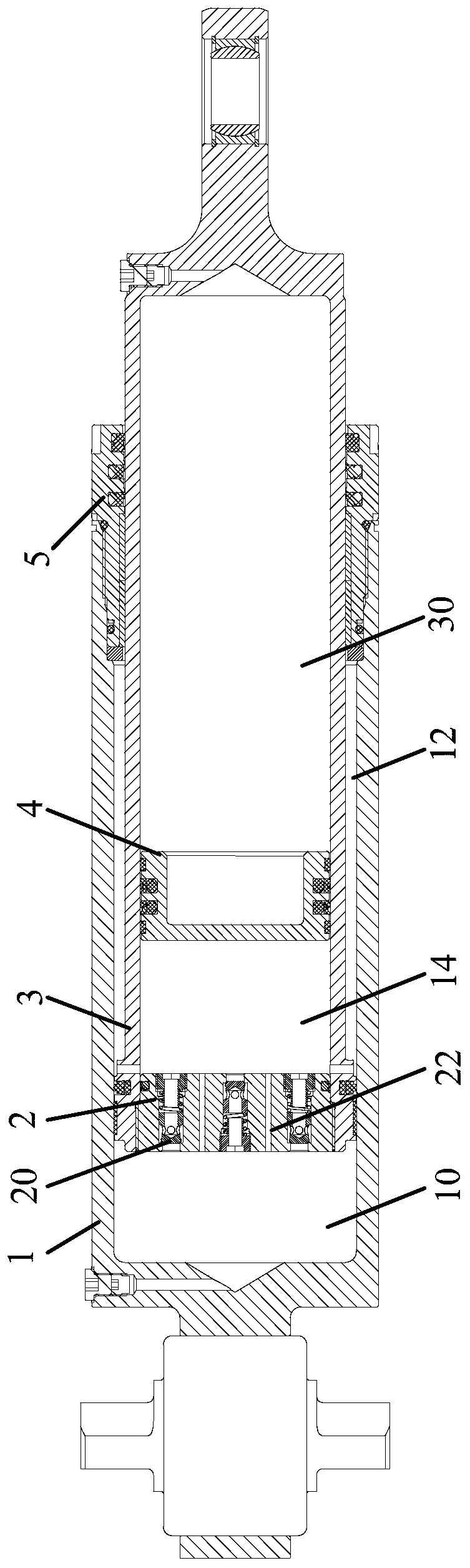

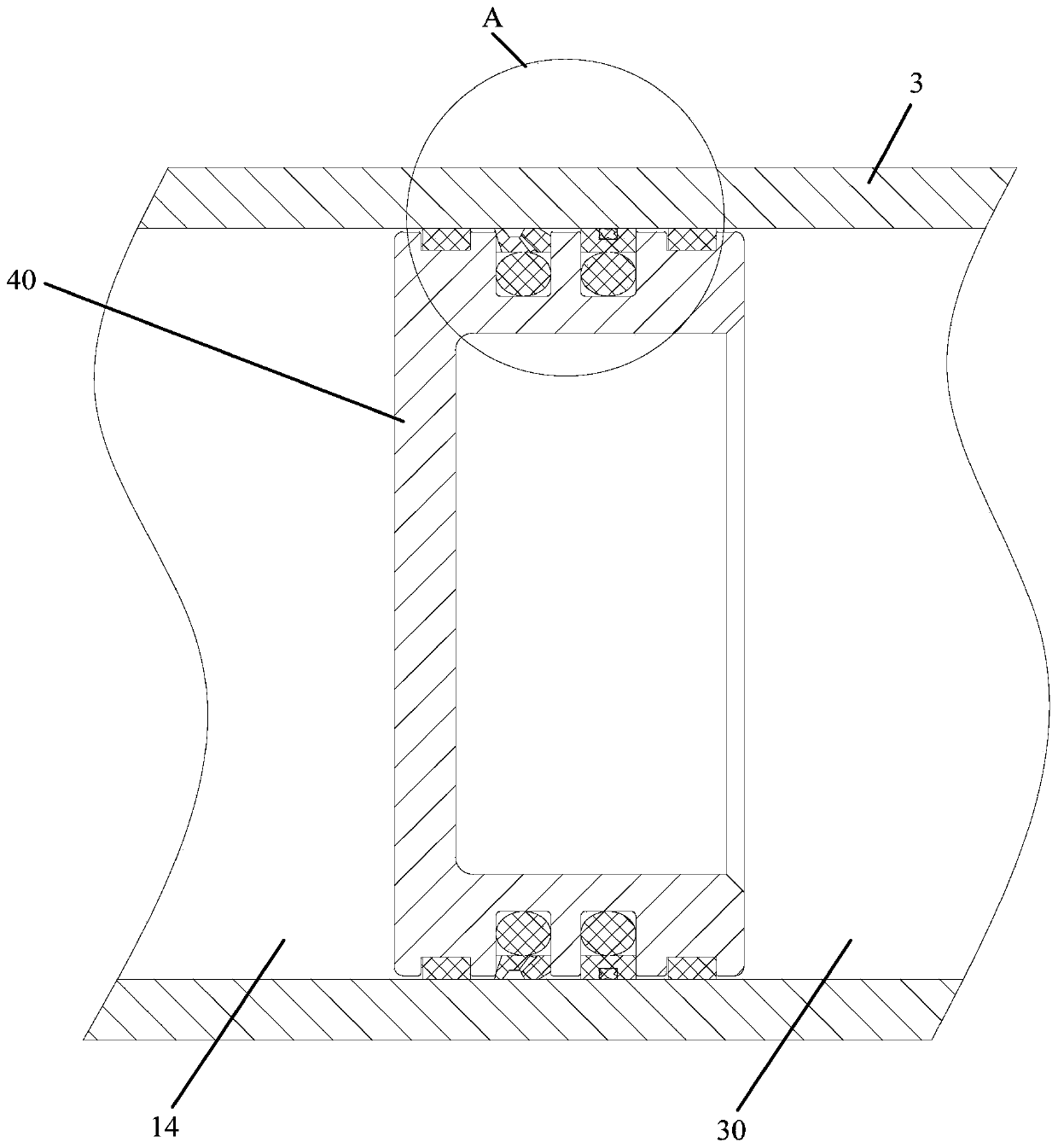

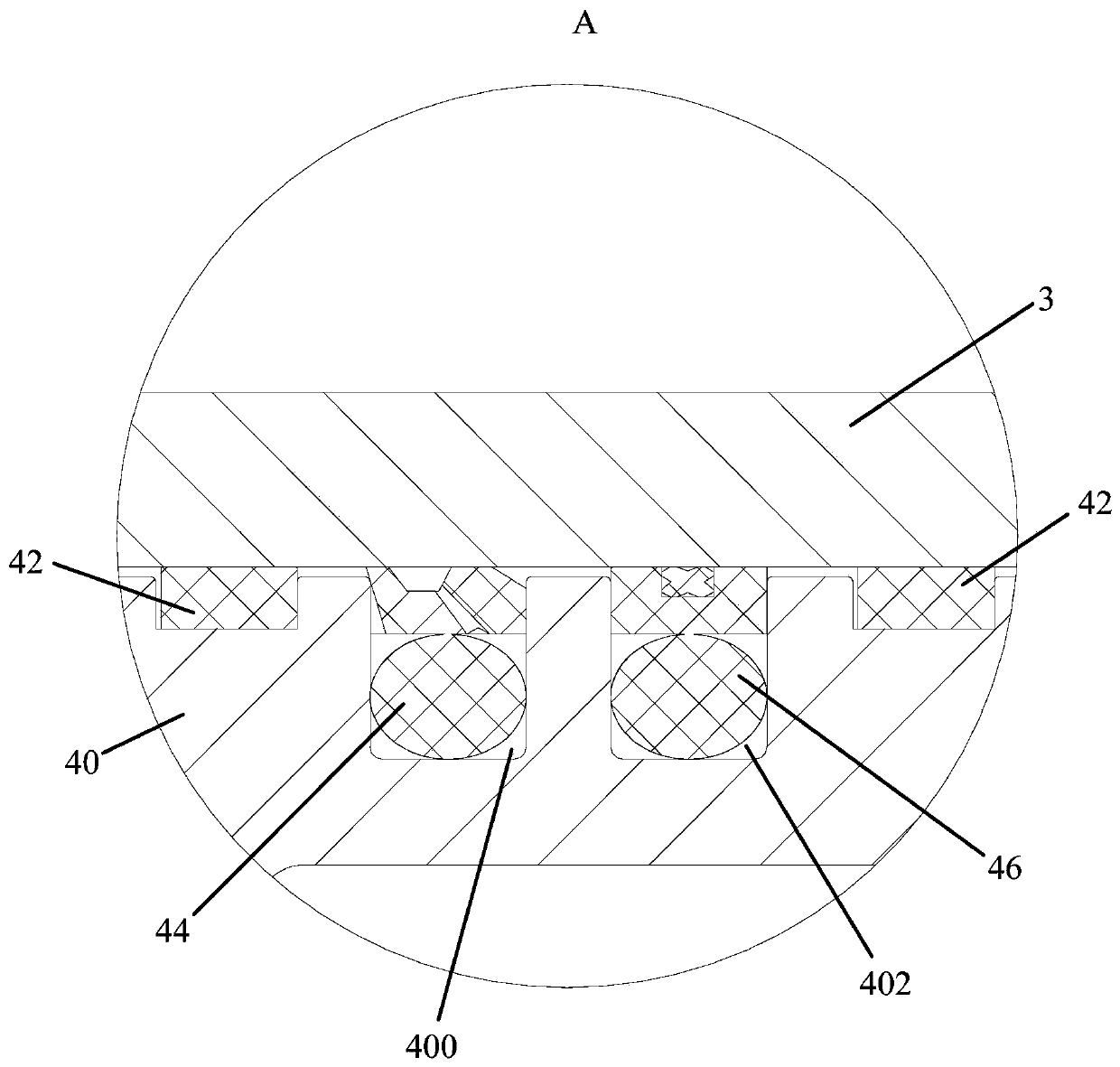

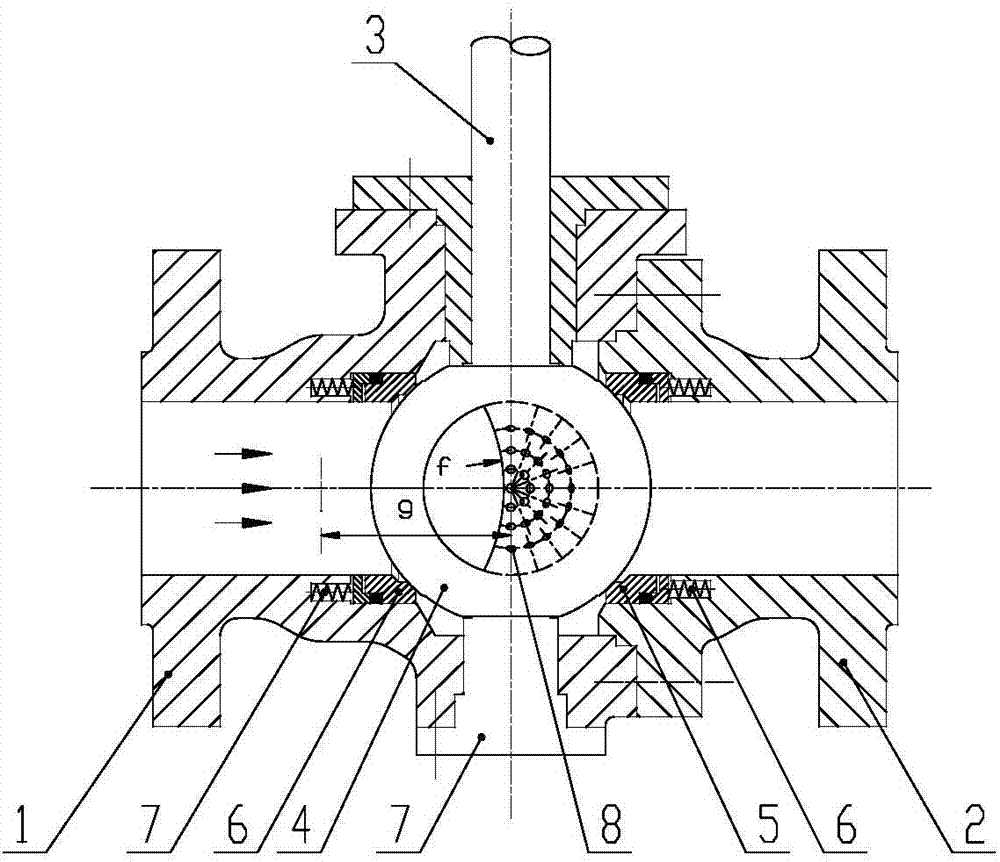

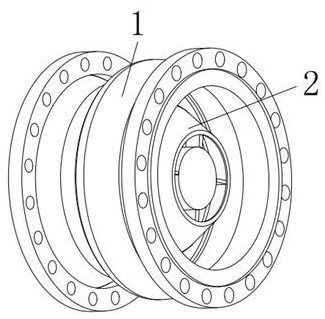

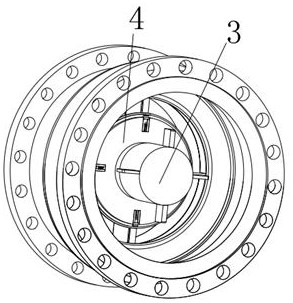

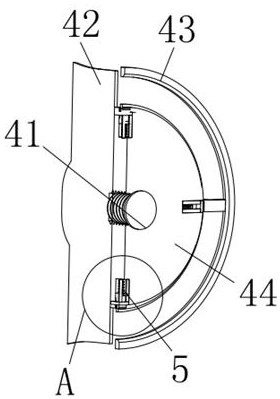

Damping noise reduction valve plate for plunger hydraulic pump

ActiveCN103939330AEliminate cavitationDrain oil thoroughlyPositive displacement pump componentsLiquid fuel engine componentsCavitationHydraulic pump

The invention relates to a damping noise reduction valve plate for a plunger hydraulic pump. The damping noise reduction valve plate for the plunger hydraulic pump comprises a valve plate body which is provided with a low pressure oil suction area and a high pressure oil discharging area, wherein the low pressure oil suction area and the high pressure oil discharging area are isolated from each other and are symmetric relative to a horizontal shaft of the valve plate body. The two ends of the low pressure oil suction area and the two ends of the high pressure oil discharging area are respectively communicated with a triangular groove. A damping hole is formed in the bottom of the top end of the triangular groove, an oil channel is formed in the bottom of the damping hole, and the oil channel is communicated with an inner cavity of a pump shell through the cylindrical side face of the valve plate body. The oil channel is composed of a vertical section oil channel and a horizontal section oil channel. Through the arranged oil channel, bubbles generated in the working process and bubbles sucked in can be timely discharged into the cavity of the pump shell, and therefore cavitation, noise and vibration caused by bubble breakage are lowered. The damping noise reduction valve plate for the plunger hydraulic pump obviously improves the cavitation resistance of the plunger pump, and has the advantages of being small in vibration, low in noise, good in working stability and the like.

Owner:TONGJI UNIV

Throttling serial type multistage pressure reduction and adjustment valve

InactiveCN104455469APrecise pressure/flow controlEliminate cavitationValve members for absorbing fluid energyLift valveSolid particlePressure difference

The invention provides a throttling serial type multistage pressure reduction and adjustment valve. A valve rod and a valve element assembly are arranged inside a valve body; a valve seat assembly is provided with multistage pressure reduction units, and each stage of pressure reduction unit of the valve seat assembly is composed of a cylindrical fluid expansion unit and a throttling unit, wherein the throttling unit is shaped like a circular truncated cone, and the area of the throttling unit decreases gradually; correspondingly, the pressure reduction units are arranged on corresponding positions of the valve element assembly, wherein the stage number of the pressure reduction units in the valve element assembly is equal to that of the pressure reduction units in the valve seat assembly; each stage of the pressure reduction unit of the valve element assembly is composed of a bowl-shaped molded surface for controlling flow and a cylindrical shrinkage unit; the upper portion of the valve element assembly is provided with valve elements, and the lower portion of the valve element assembly is provided with guide rods; valve bottom drainage holes are formed in the positions, located on the outer sides of valve seat guide holes, of the bottom of the valve seat assembly; a flow diversion sleeve is arranged on the top of the valve seat assembly, and a flow diversion hole is formed in one side of the flow diversion sleeve. According to the throttling serial type multistage pressure reduction and adjustment valve, the service life of the valve can be prolonged, vibration and noise of pipelines behind the valve can be eliminated, and it is guaranteed that the adjustment accuracy of the valve is high and operation is stable under the working condition that the pressure difference is large and solid particles exist in media in the Texaco process of coal chemical industries.

Owner:BEIJING AEROSPACE PROPULSION INST +3

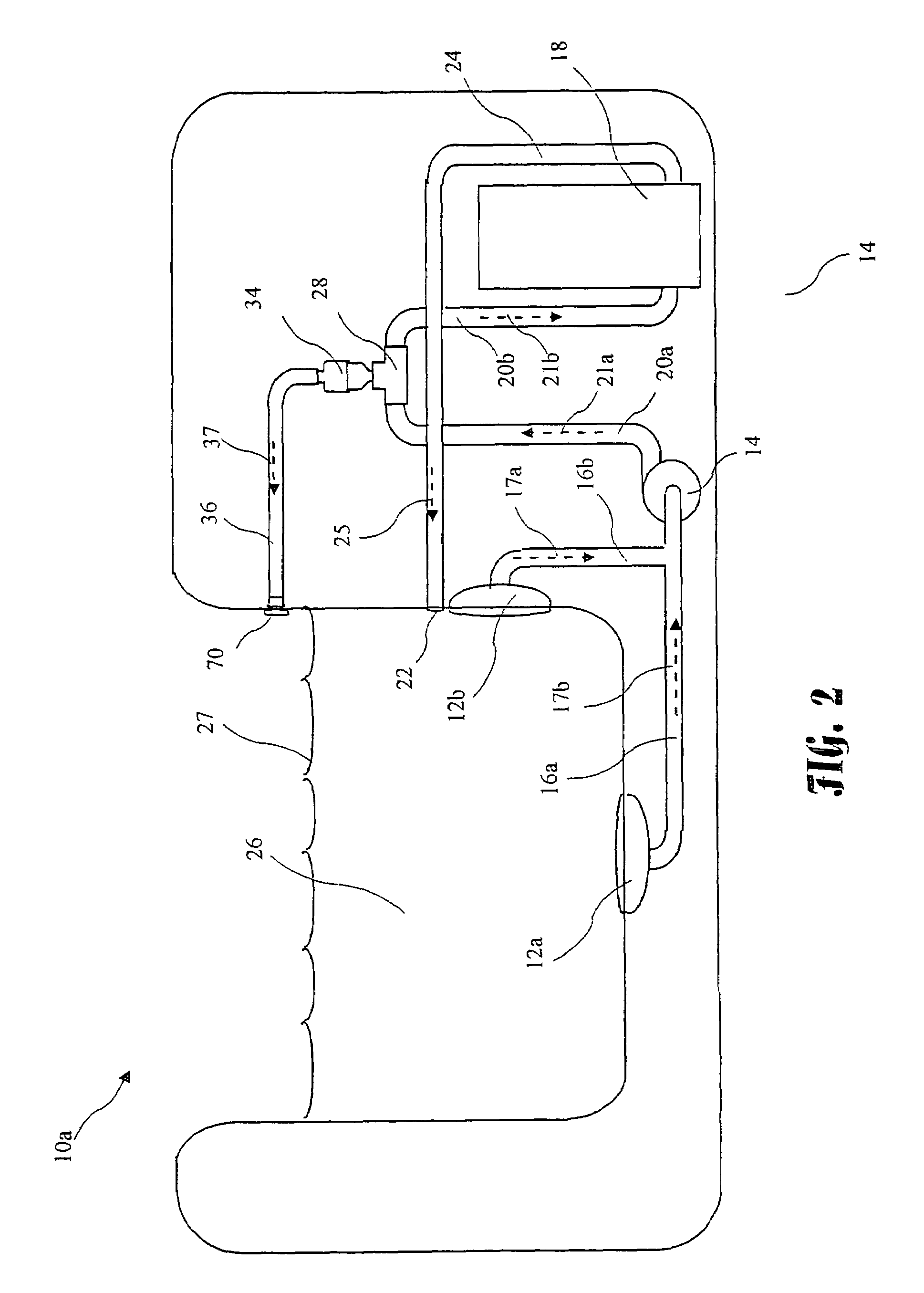

Low-drag hydrodynamic surfaces

InactiveUS20050109257A1Reduce resistanceEliminate cavitationWatercraft hull designFloating buildingsPropellerClosed cavity

The invention relates to the use of gas cavities to reduce frictional drag on underwater surfaces such as hydrofoils, struts, fins, rudders, keels, propeller blades, ship hulls, underwater bodies, and wetted surfaces in general. Each gas-filled cavity is formed behind a discontinuity in the surface that causes the water boundary layer to separate from the surface. Gas is ejected into a region behind the discontinuity to fill the cavity; the gas can be air. If a cavity is open to the atmosphere, then air can typically fill the cavity naturally without air ejection. Cavities can either be closed or open. A low drag hydrofoil may have a closed cavity on one side, and an open cavity on the other side. For closed cavities, the underlying surface can be shaped to minimize cavity closure drag. Various ways to generate cavities, change hydrodynamic forces, and duct gas internally on hydrofoils and struts with cavities are covered. Different designs of hydrofoil boats, hydrofoil ships and ship hulls that are amenable to drag reduction are presented.

Owner:LANG THOMAS G +1

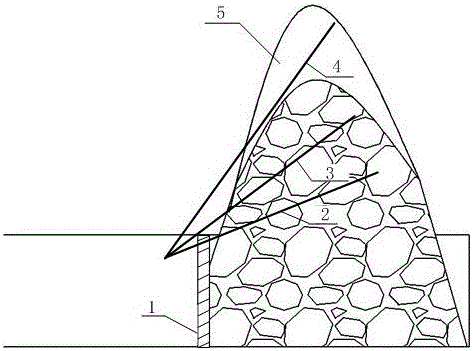

Grouting treatment method for top-caving area of driving face of coal mine

InactiveCN106121717AImprove reinforcement effectSpread evenlyMaterial fill-upMaterial consumptionEngineering

Coal mine excavation face often causes roof fall accidents due to changes in geological conditions, inadequate support measures, and poor management. For large-scale roof fall accidents, they often cannot be handled well. The usual method is to clear out the working passage in the roof-fall area, and the personnel go deep into the top of the roof-fall area to install anchor rods and anchor cables and erect wooden pile roofs. This approach requires a large amount of labor, difficult construction, poor safety, a large amount of gangue cleaning, and the hidden danger of gas accumulation in the roof fall area. Therefore, the present invention proposes a grouting treatment method for the high risk area of the excavation face. The method includes three technological processes of constructing a blocking wall, subarea grouting, and shed clearing. This method does not require workers to go deep into the roof fall area to operate, the amount of gangue cleaning is small, the cavity of the fall is eliminated, and the risk of gas accumulation is eliminated. It has a good reinforcement effect on gangue in the roof fall area, and the slurry spreads more evenly. Low material consumption and low cost.

Owner:HENAN POLYTECHNIC UNIV

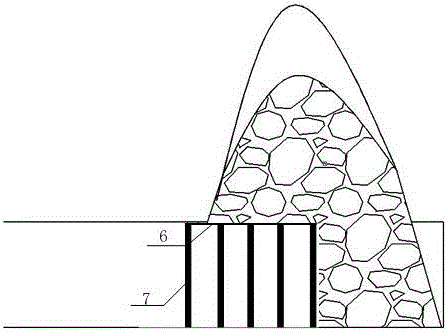

Oil-gas suspension cylinder and vehicle

The invention provides an oil-gas suspension cylinder and a vehicle. The oil-gas suspension cylinder comprises a cylinder barrel, a throttling piston, a piston rod and a pneumatic piston, wherein thethrottling piston is arranged in the cylinder barrel, and is used for partitioning the space in the cylinder barrel into a roded cavity and a rodless cavity; the piston rod is located in the roaded cavity, and connected with the throttling piston; a piston rod barrel cavity is formed in the piston rod; the pneumatic piston is arranged in the piston rod barrel cavity slidably; the piston rod barrelcavity is partitioned by the pneumatic piston into a throttling cavity and a gas cavity independent of each other; and the throttling cavity is adjacent with the rodless cavity and communicates withthe roded cavity. Due to the technical scheme of the oil-gas suspension cylinder, oil-gas separation in the oil-gas suspension cylinder is effectively achieved, so that damping force in two directionsin the oil-gas suspension cylinder is more balanced, and the driving stability of the vehicle can be kept easily; the oil-gas ratio can also be accurately controlled, inflating and deflating are moreconvenient and faster, and maintaining is convenient; and cavitation by mixed gas in oil liquid on sealing pieces and parts can also be eliminated, and the service life of the oil-gas suspension cylinder is prolonged.

Owner:LOUDI ZHONGXING HYDRAULIC COMPONENTS CO LTD

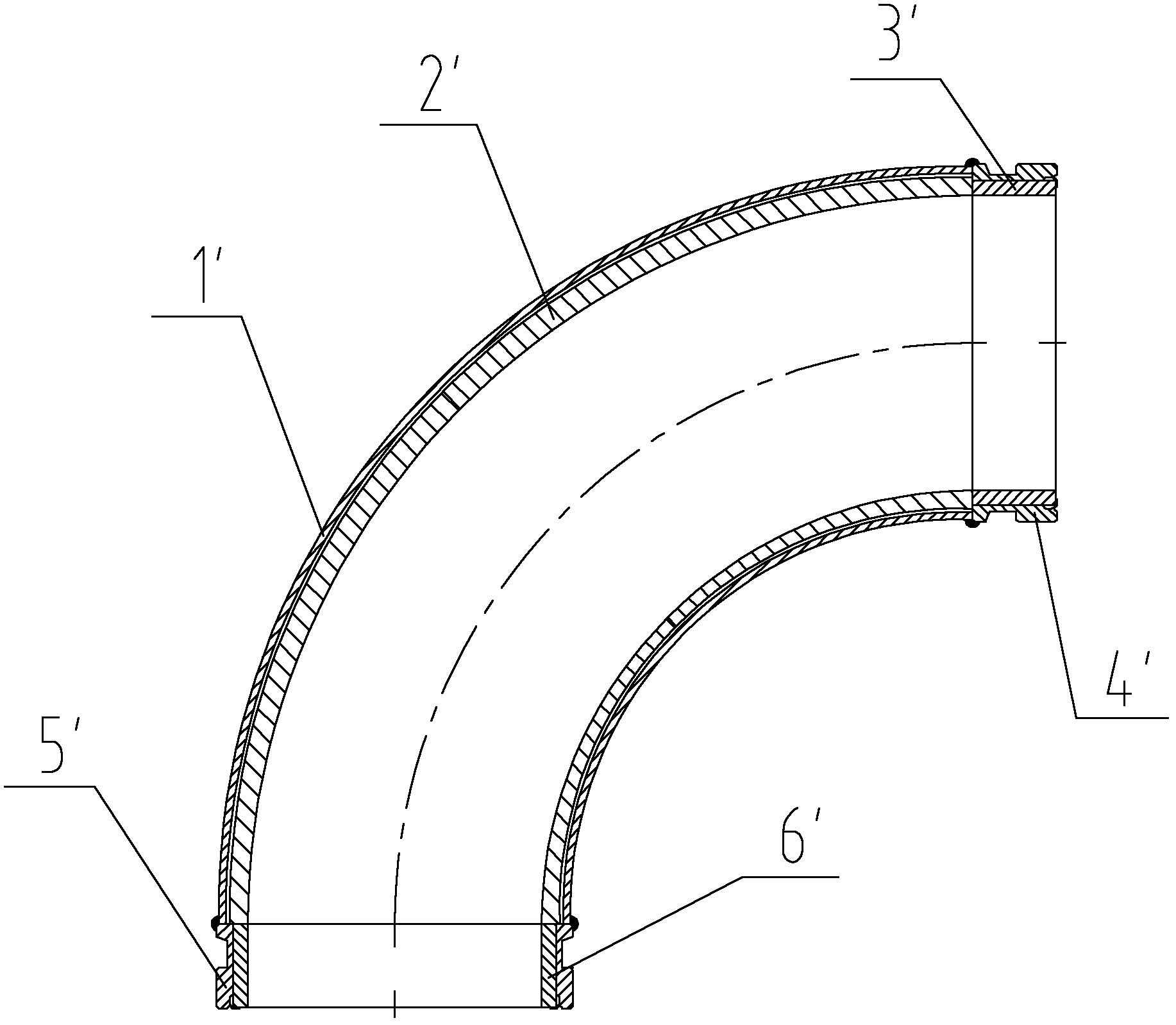

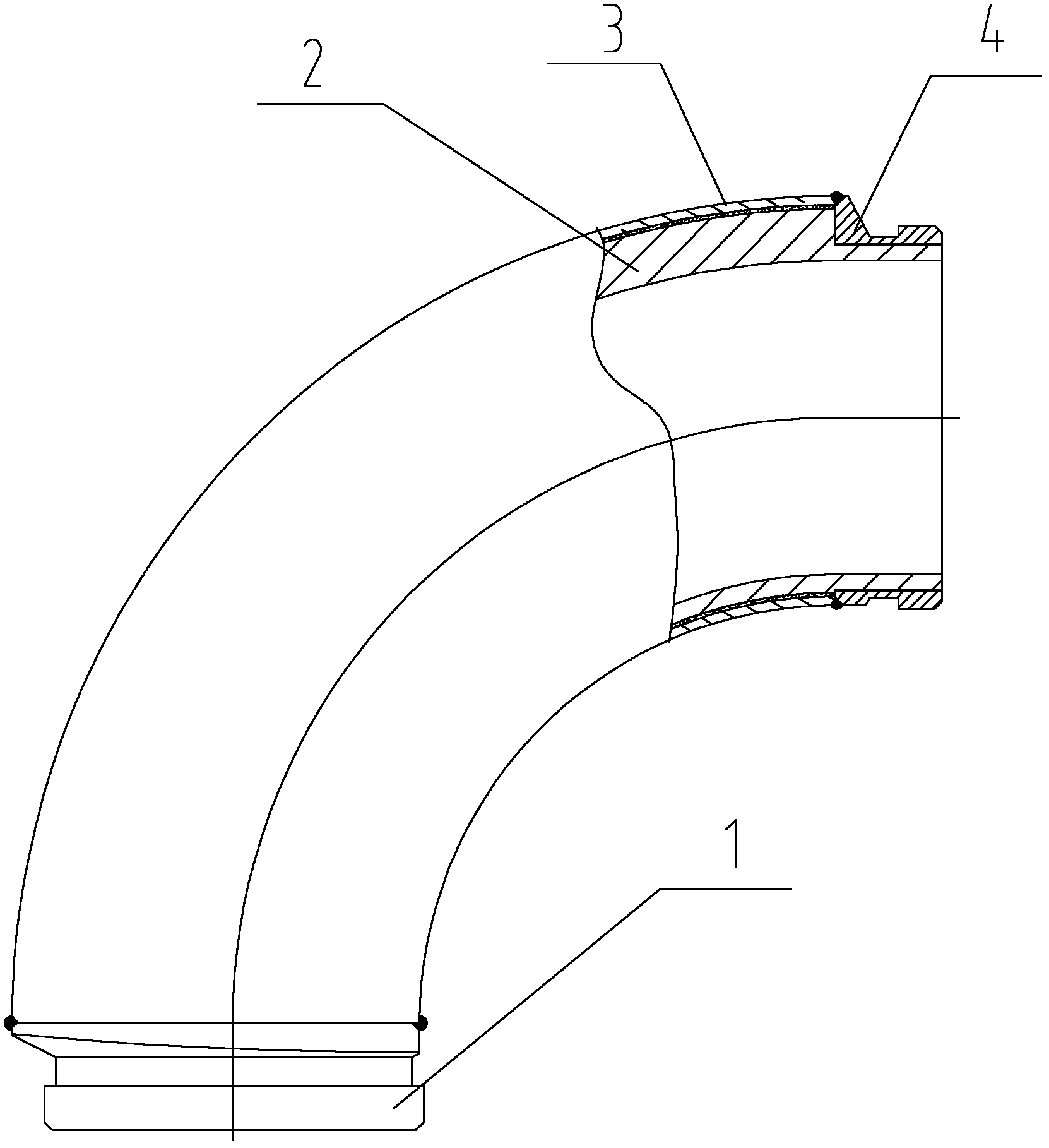

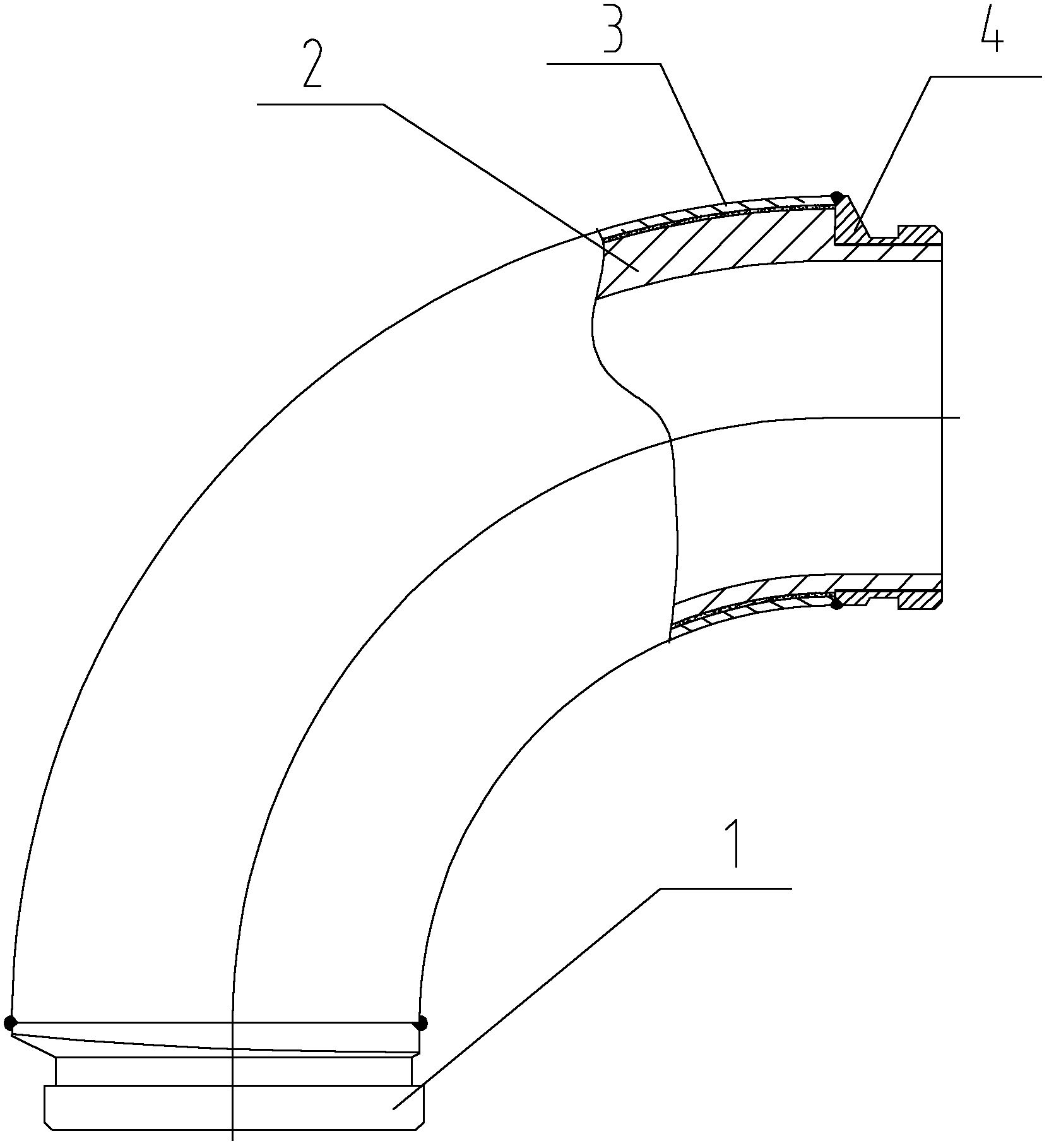

Delivery elbow pipe and production method thereof

InactiveCN102494218AReduce pressure sleeve processAvoid vortexPipe protection against damage/wearSiphonsCavitationEngineering

The invention provides a delivery elbow pipe and a production method thereof. The delivery elbow pipe comprises an outer elbow pipe (3), an inner elbow pipe (2) and a connecting flange, wherein the inner elbow pipe (2) is made of abrasion resisting materials and embedded inside the outer elbow pipe (3), at least one end of the inner elbow pipe (2) extends out of the outer elbow pipe (3) from the end portion of the outer elbow pipe (3), and the connecting flange is sleeved on the outer side of the end portion of the inner elbow pipe (2) and fixedly connected with the inner elbow pipe (2) and / or the outer elbow pipe (3). By means of the delivery elbow pipe, an abrasion resisting material layer integrally formed by the inner elbow pipe is free of seam, so that the delivery elbow pipe is capable of avoiding eddy caused in the position of the seam in the prior art and removing cavitation caused by the eddy accordingly.

Owner:ZOOMLION HEAVY IND CO LTD

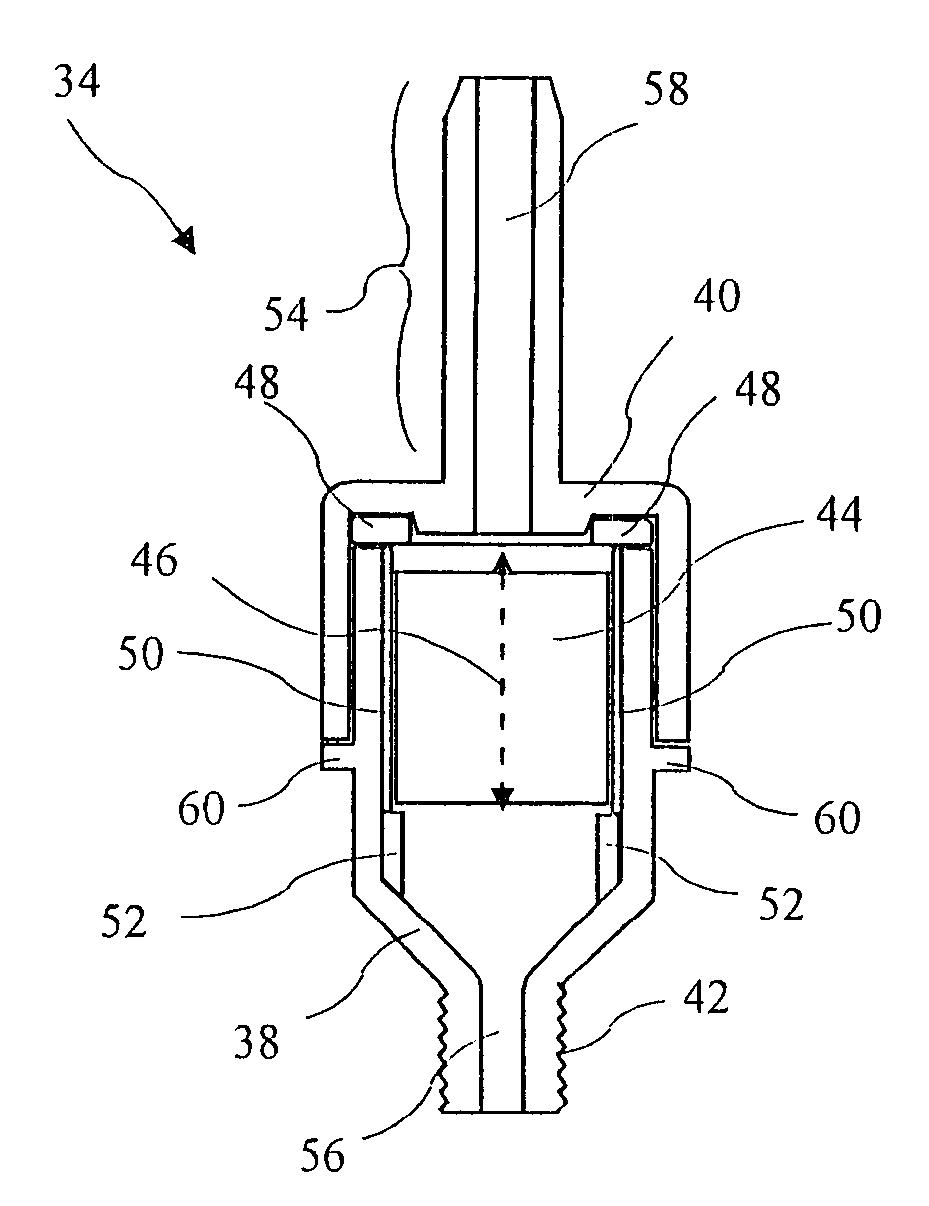

Air bleed-off valve

InactiveUS7025079B1Eliminate cavitationAvoid flowBathing devicesVenting valvesCavitationExhaust valve

An automatic air bleed valve which allows air to escape from water lines. Allowing air to thus escape, prevents pump cavitation and / or air in the heater. The air bleed valve is positioned between a pump and the heater, and is higher than the heater, and no higher than the water level in the spa. The air bleed valve comprises a vertically disposed cylinder containing a piston and having a valve bottom, a valve inlet proximal to the valve bottom, valve top, and a valve outlet proximal to the valve top. The piston moves vertically in the cylinder. While water is present in the cylinder, the piston raises and cooperates with a seal to prevent a flow of water through the valve. While air is present in the cylinder, the piston drops and allows the air to flow past the piston to the valve outlet.

Owner:ELNAR JOSEPH G

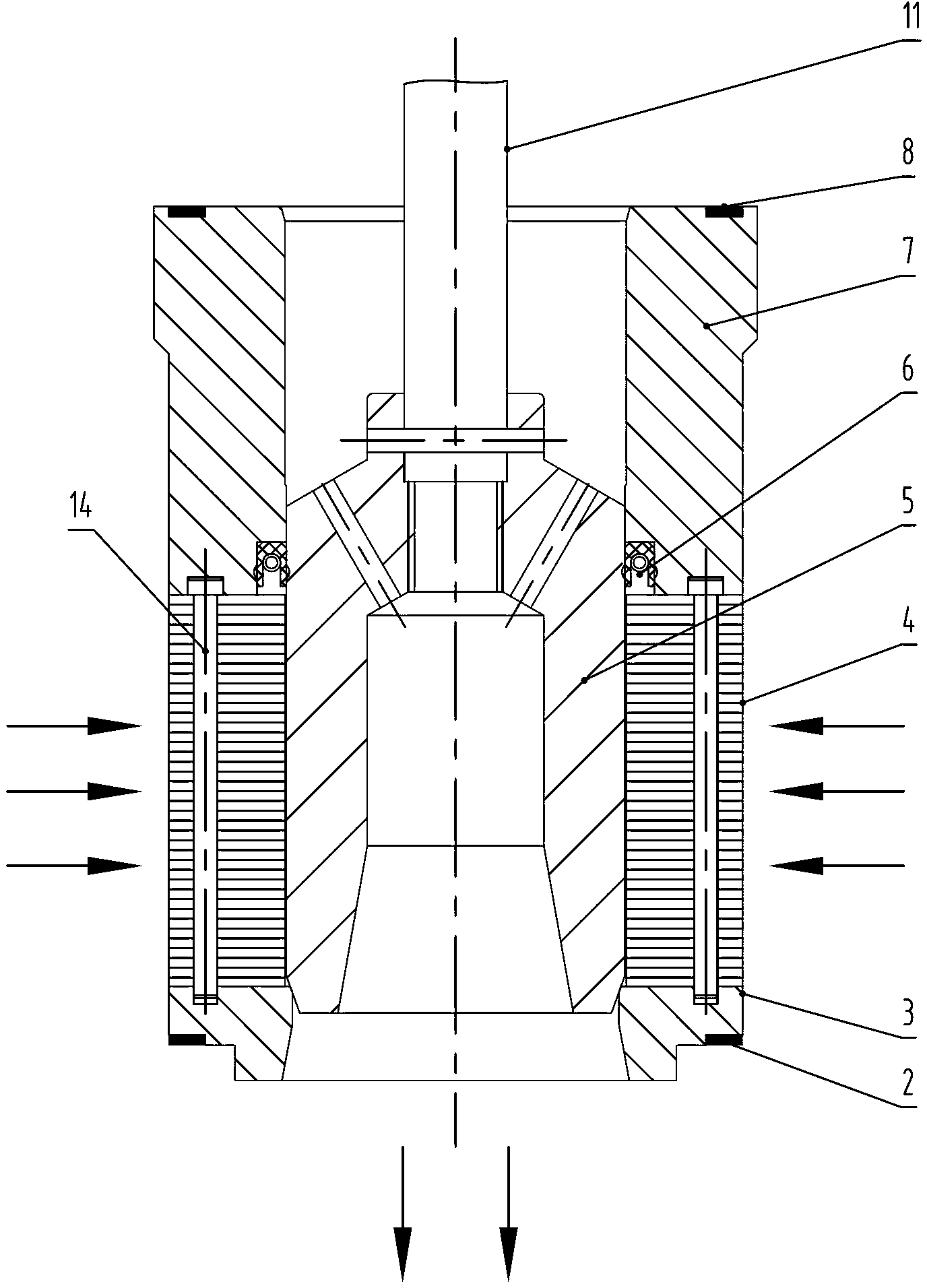

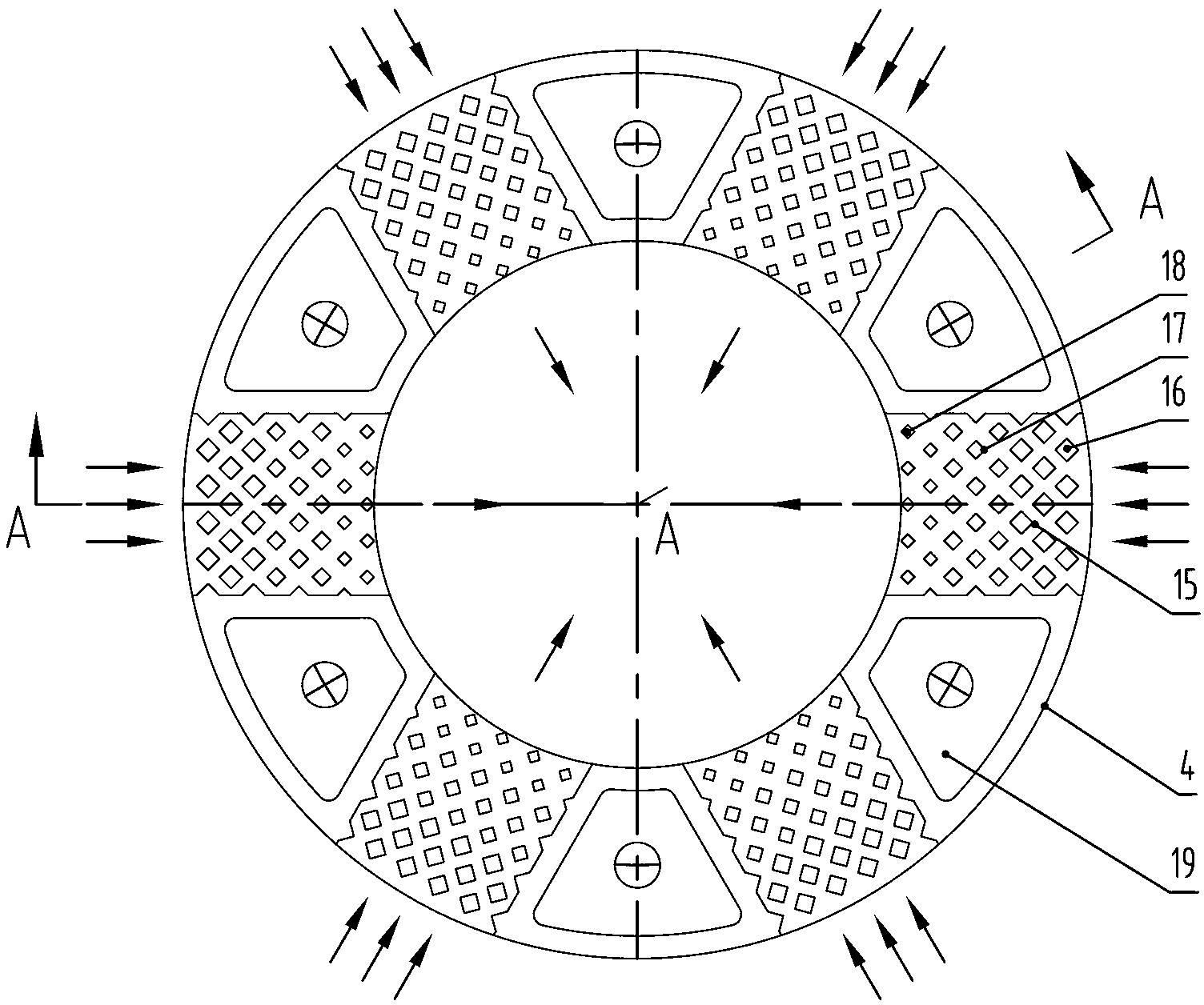

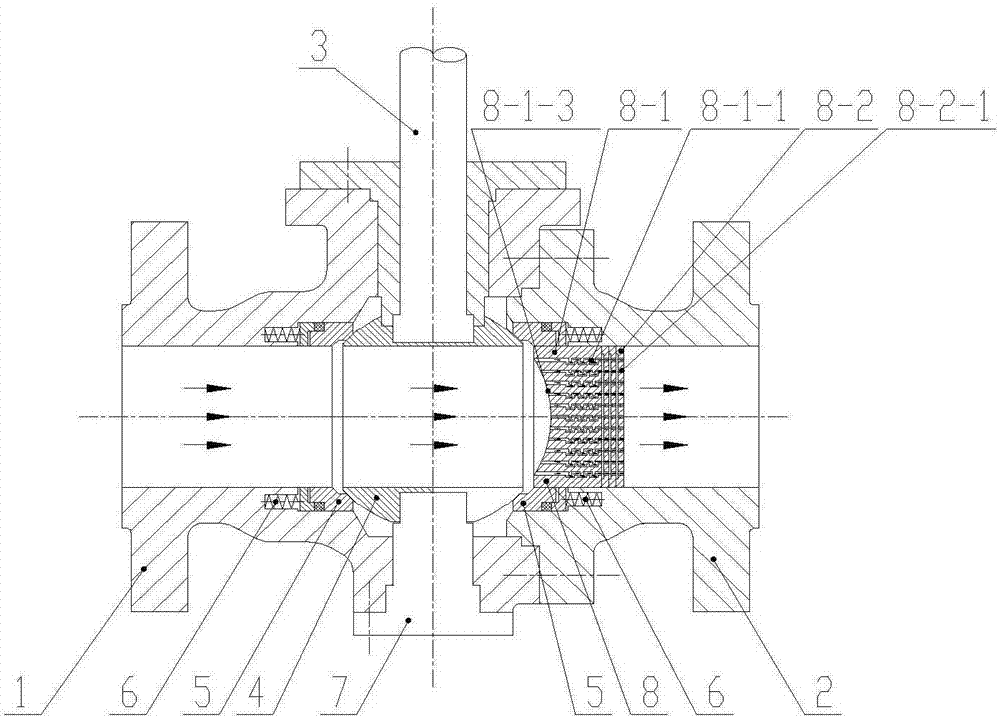

Array flow velocity control valve structure suitable for incompressible fluid

InactiveCN102937188AReduce kinetic energyImprove efficiencyValve members for absorbing fluid energyLift valveCavitationEngineering

The invention relates to an array flow velocity control valve structure suitable for incompressible fluid. The structure comprises a valve body, a valve base, valve cores, an upper cover and valve rods, wherein the base valve is arranged in the valve body, a plurality of throttle slices are arranged installed on the valve base, the throttle slices are positioned through positioning pins, each of the throttle slices comprises a parallel thin plate body and a rhombic pillar-shaped array structure, a guide base is installed on the throttle slices, balancing sealing rings are installed in the guide base, valve cores are installed in the throttle slices, the valve cores are connected with the valve rods, and the upper cover is installed on the valve body; and the upper cover is fixed on the valve body through a screw bolt and a nut. According to the structure, the fluid pressure is kept to be above the saturated vapor pressure, bubbles are avoided, and a cavitation phenomenon is eliminated; damages of inner parts of a valve, which are caused by energy blasting energy, are reduced; the valve is convenient to disassemble and clean, and on-line maintenance is facilitated; and the pressure is reduced step by step through flow rate control of high-speed incompressible fluid, the cavitation phenomenon is avoided, and the normal operation of the valve is guaranteed.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

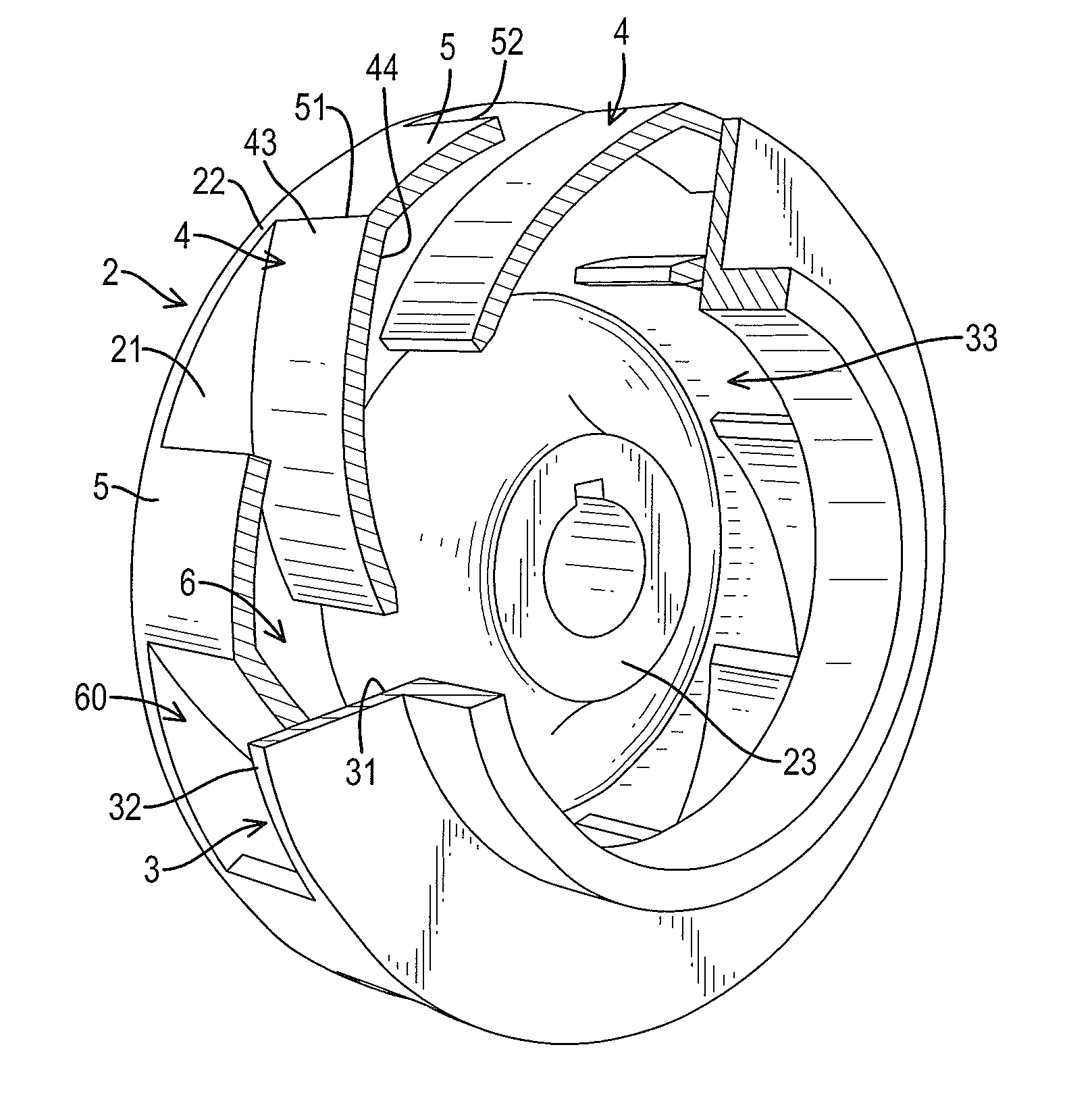

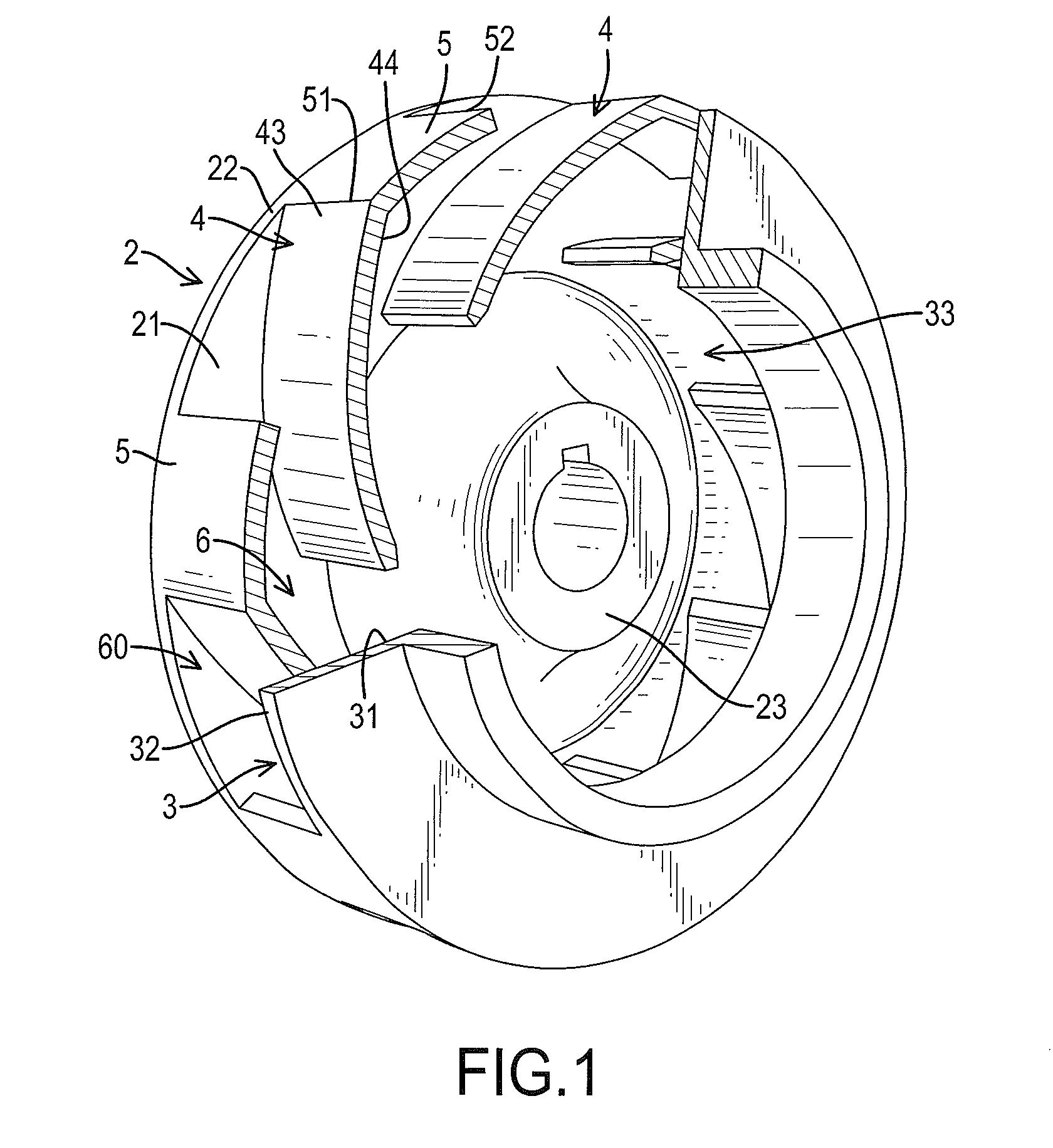

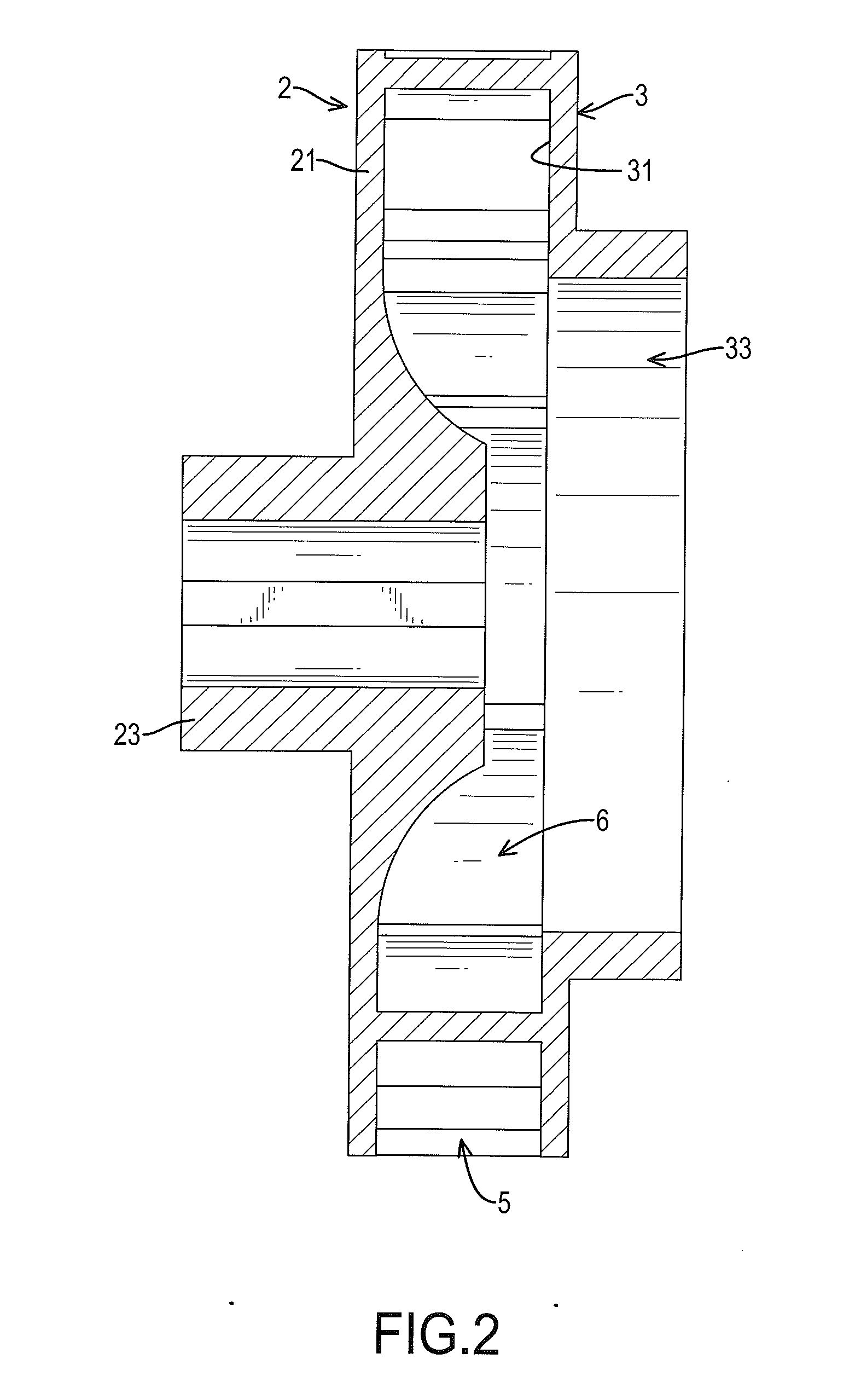

Low-Turbulence Impeller for a Fluid Pump

InactiveUS20150337665A1Eliminate cavitationReduce energy consumptionPump componentsBlade accessoriesImpellerCavitation

A low-turbulence impeller for a fluid pump comprises a first base wall, a second base wall, multiple guiding blades, multiple back-up plates, and multiple runners. The second base wall has an inlet formed through the second base wall. Each one of the runners is formed between two adjacent guiding blades. Each runner has an outlet formed between two adjacent back-up plates. Each runner has a laminar zone communicating with a corresponding outlet and a turbulent zone aligning with the corresponding back-up plate. The fluid can only be flowed out of the outlet from the laminar zone, such that the fluid through the outlet of each runner is in low-turbulence condition. The phenomenon of inverse flow caused by negative pressures and the cavitation corrosion is greatly reduced. The rotational velocity of the low-turbulence impeller is enhanced to promote the fluid-draining efficiency.

Owner:YANG YUNG SHO

Fluid working machines and methods

ActiveUS9091253B2Improve efficiencyExtended service lifePump controlPiston pumpsEngineeringActive control

A fluid working machine comprises a controller and a working chamber of cyclically varying volume having an electronically controllable primary low pressure valve and a secondary low pressure port associated therewith, each of which is openable and closable in phased relation to cycles of working chamber volume to bring the working chamber into fluid communication with a low pressure manifold. At least the primary low pressure valve is under the active control of the controller to enable the controller to determine the net displacement of fluid by the working chamber on a cycle by cycle basis. The primary low pressure valve and the secondary low pressure port are openable concurrently and in parallel during a portion of at least some cycles of working chamber volume, including at the point in the expansion or contraction stroke where the rate of change of volume of the working chamber is greatest.

Owner:DANFOSS PAUER SOLYUSHENS APS

Ultra-low temperature nitridation method for engine cylinder liner of large-scale watercraft

ActiveCN101492806AOvercoming the disadvantages of high temperature nitridingQuality assuranceSolid state diffusion coatingWatercraftPulp and paper industry

The invention discloses an ultra low temperature nitridizing method for a large ship engine cylinder sleeve, comprising the steps as follows: (1) towel is used to clean up the oil stain on a work piece; (2) the work piece is put into a clamping apparatus; (3) the work piece is put into a decontamination agent tank to carry out oil coating at the temperature of 75-95 DEG C for 5-8min; (4) the coated work piece is washed by running water; (5) the work piece is preheated at the temperature of 200-250 DEG C for 50-60min; (6) Na2SO4 with the weight of 8% is added into the nitridizing agent in the nitridizing furnace; the nitridizing temperature is 350 plus / minus 5 DEG C and the period is 2.5-3h; (7) the nitridized work piece is cooled in the air to below 150 DEG C; (8) the work piece is washed by running water; (9) the nitridized cylinder sleeve is checked; (10) the qualified cylinder sleeve is soaked into rust preventative oil; (11) the soaked cylinder sleeve is packaged and stored for transportation. The invention adopts low temperature nitrogen treatment, so that the nitridizing period is shortened, the production cost is lowered, and the product quality is improved, thus being suitable for industrialized mass production.

Owner:江苏华晨气缸套股份有限公司

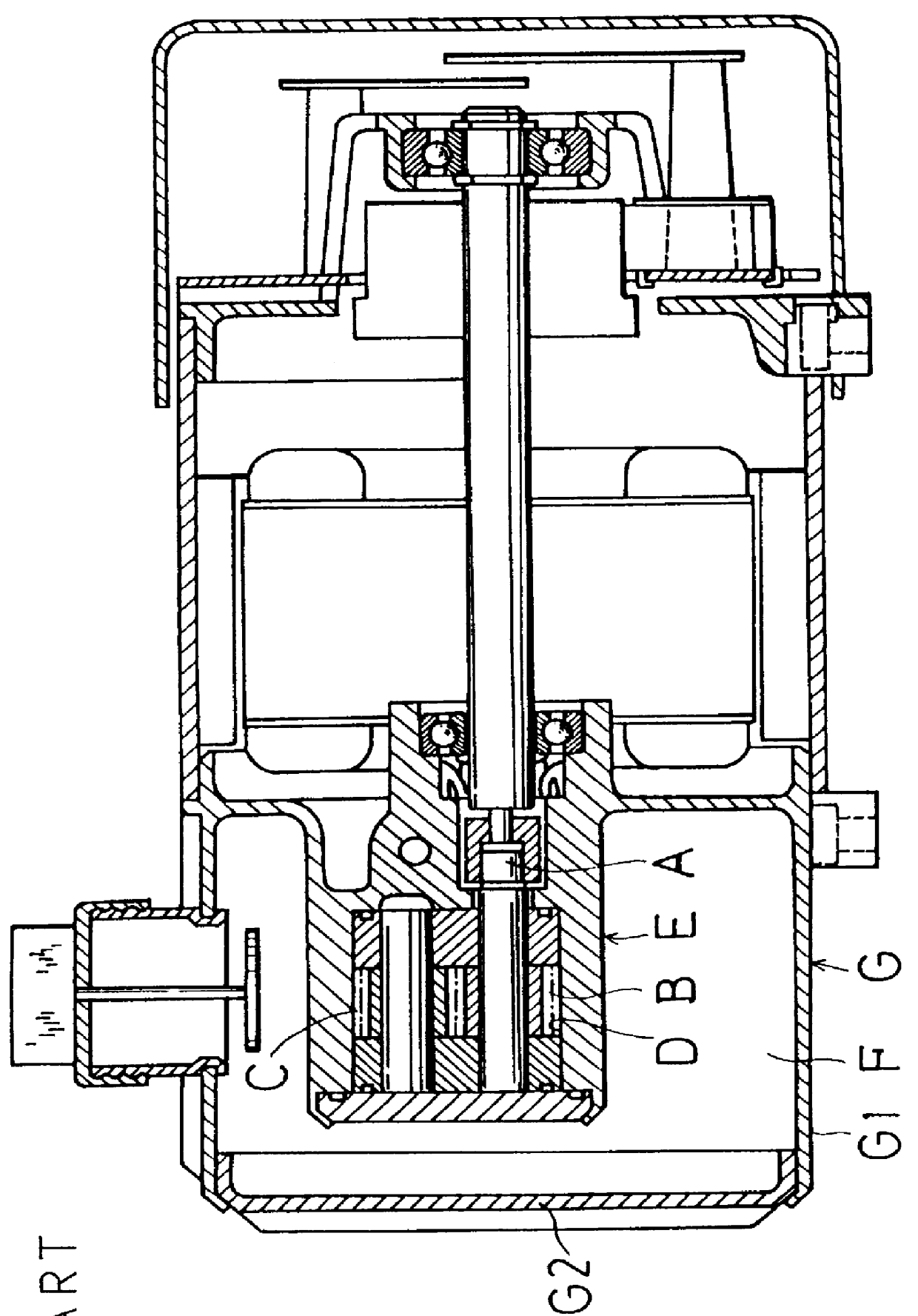

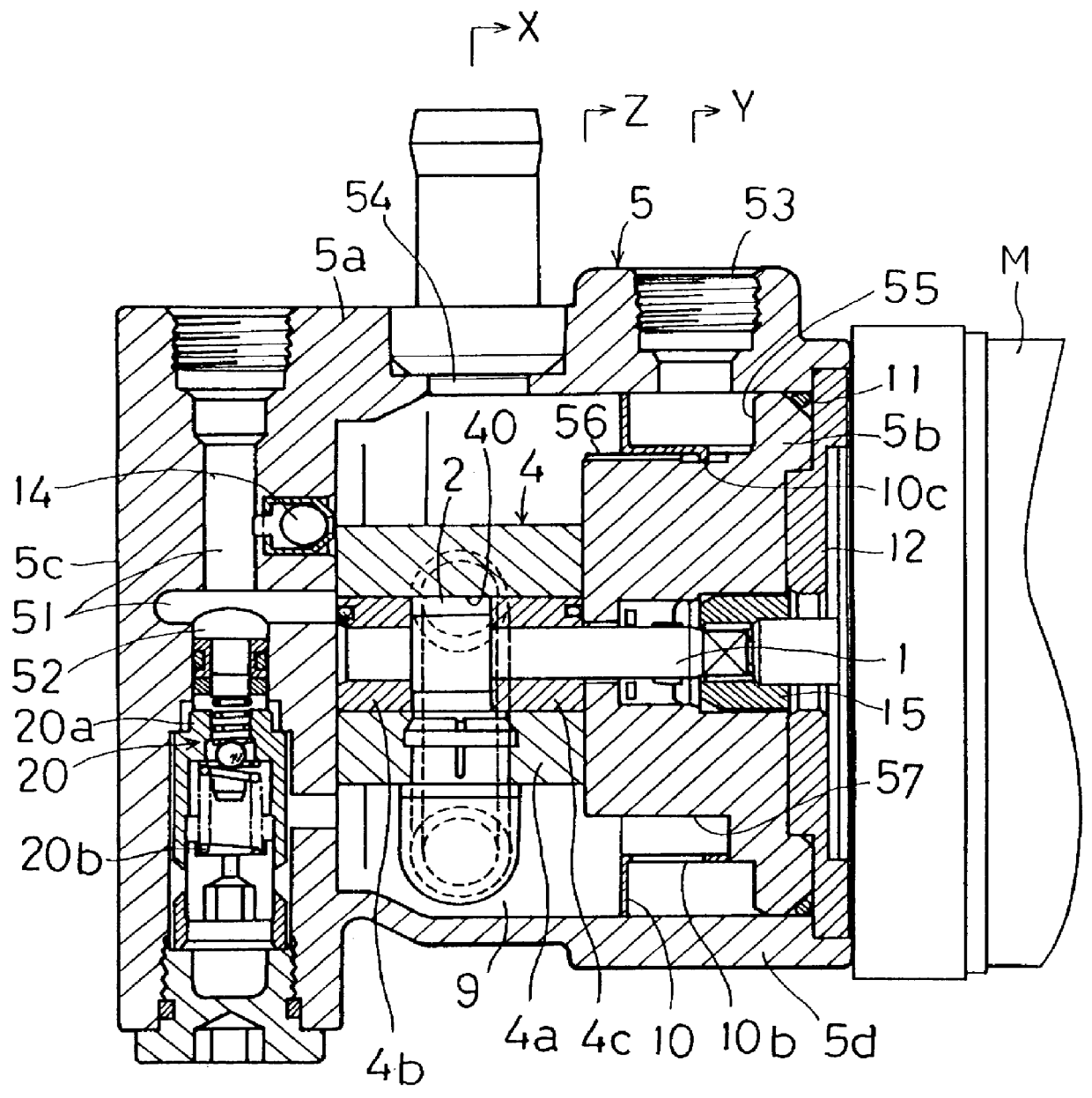

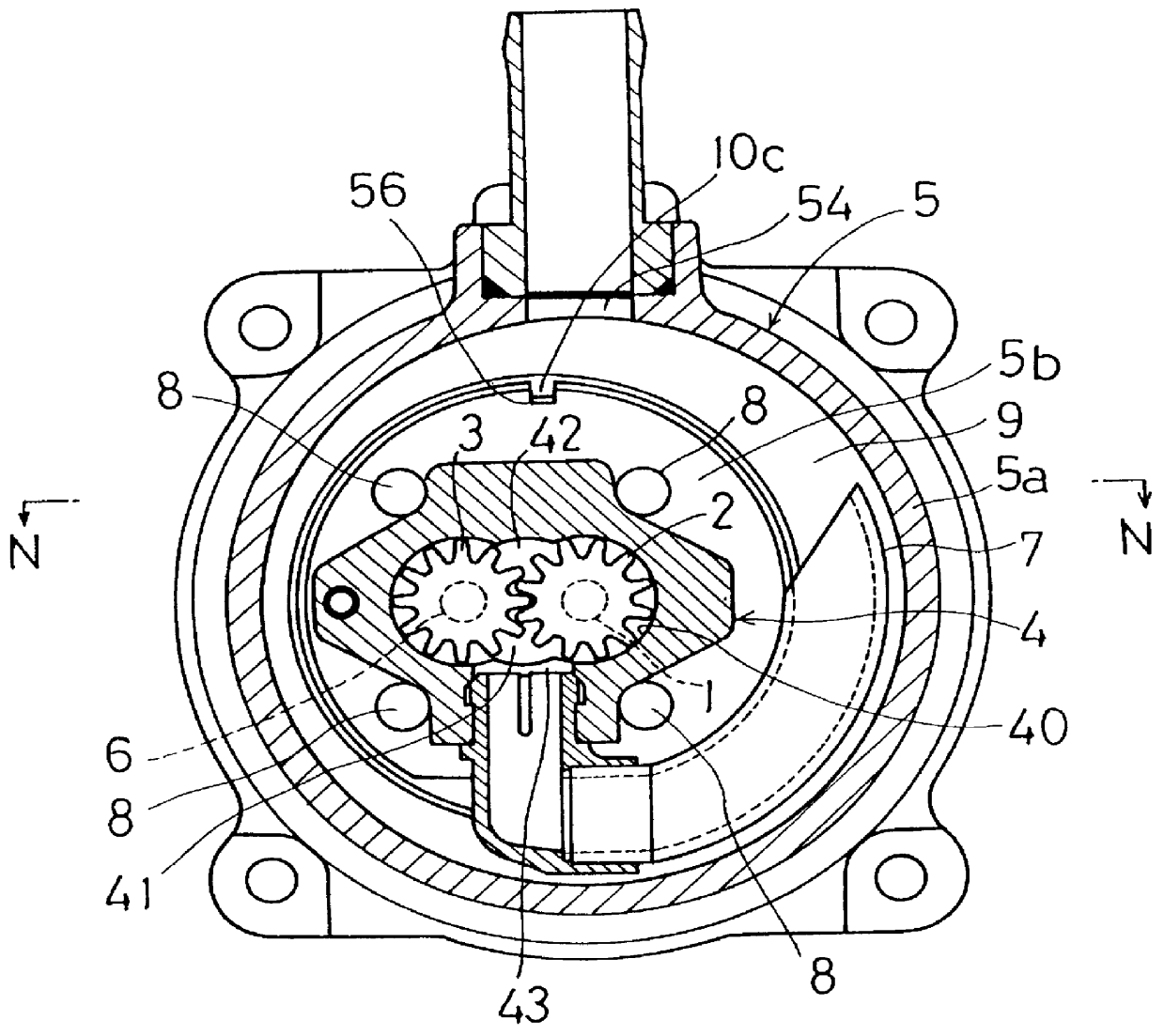

Gear pump

InactiveUS6048187ASmall sizeShorten speedEngine of counter-engagement typeEngine of intermeshing engagement typeCavitationGear pump

A gear pump is provided with a drive gear rotated via a drive shaft; a slave gear; a gear housing containing a gear chamber housing these gears therein; and a pump housing composed of a cylindrical housing main body with a bottom which contains the gear housing for serving as a low pressurized chamber, the inside of which communicates with the gear chamber, and an opening being defined thereon, and a covering member for closing the opening, wherein an eccentric pitted portion being eccentric with respect to the axis of the drive shaft is defined on the covering member, and the fluid return port is allowed to face to the eccentric pitted portion to function the eccentric pitted portion as a return fluid passage for return fluid, whereby it is possible to reduce a size of the gear pump without accompanying any cavitation.

Owner:KOYO SEIKO CO LTD

High-pressure multi-stage pressure reducing valve

PendingCN109505988AReduce power energyGuaranteed sealing effectivenessValve members for absorbing fluid energyLift valveRoundingHigh pressure

The invention discloses a high-pressure multi-stage pressure reducing valve. The high-pressure multi-stage pressure reducing valve comprises a shell, wherein a fluid inlet and a fluid outlet are arranged on the shell; a plurality of sealing bosses are arranged on the inner side of the shell; a groove is formed between every two sealing bosses; the multi-stage pressure reducing valve further comprises a valve core connected to the sealing bosses; a plurality of guiding grooves are formed in the valve core; the number of the guiding grooves is equal to the number of the grooves; the axially adjacent guiding grooves are arranged with an angle alpha, and of the angle alpha is greater than 0 DEG and less than or equal to 90 DEG; the guiding grooves are radially and symmetrically arranged with every two guiding grooves falling into one group; a flow guiding bevel is arranged on the surface, away from the fluid inlet, of each guiding groove; chamfers are arranged on the inner side of the sealing boss at the fluid inlet of the shell; and a rounding is arranged on the end, near to the fluid inlet, of the valve core. When the high-pressure multi-stage pressure reducing valve is connected tothe fluid, the distance between the chamfers and the rounding is larger than the distance between the flow guiding bevels to the sealing boss closest to the flow guiding bevels. The high-pressure multi-stage pressure reducing valve is suitable for high pressure fluid, and is also suitable for low pressure fluid.

Owner:华润电力(贺州)有限公司

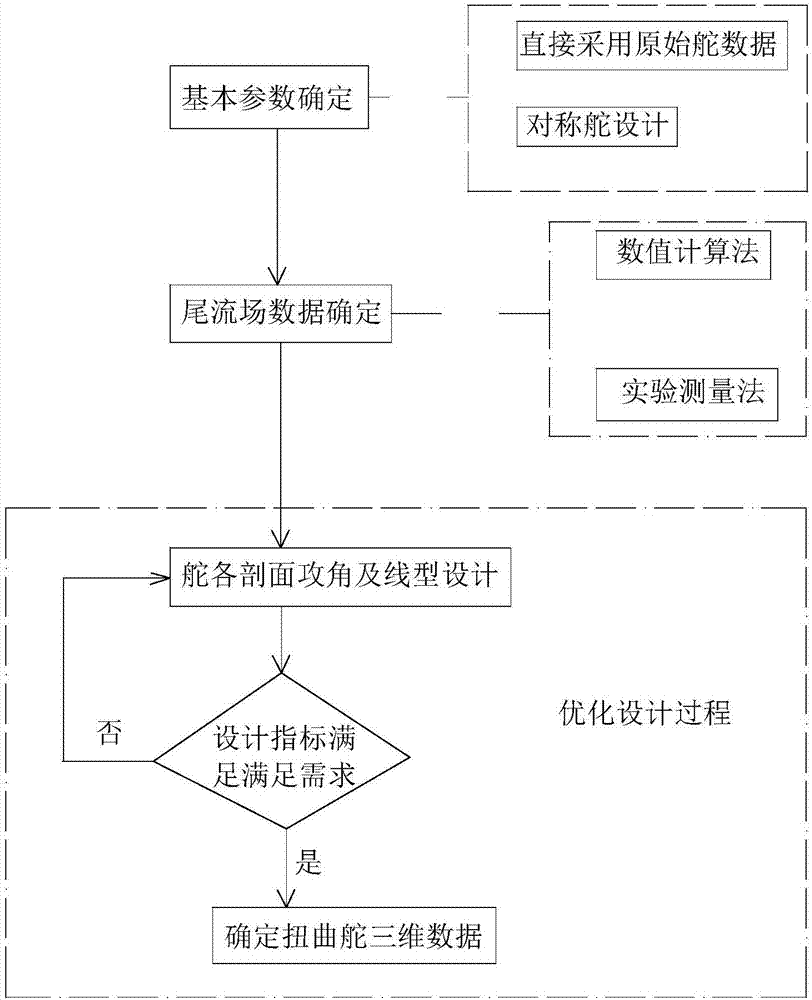

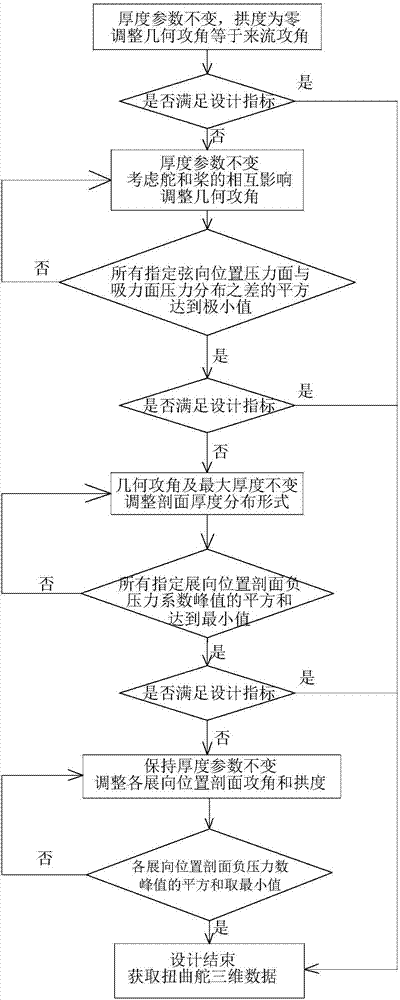

Anti-cavitation twisted rudder and design method thereof

ActiveCN107264763AImprove pressure distributionIncrease critical speedSteering ruddersVessel designingCavitationPropeller

The invention belongs to the field of ship or rudder design and particularly relates to an anti-cavitation twisted rudder and a design method thereof. On the basis that the influence of various factors such as the rotational speed in the ship propeller wake flow on the rudder is fully considered, the geometrical attack angles and line types of all the spanwise position sections are designed and determined through the distribution characteristic of a propeller rear wake flow field in direct sailing of a ship, so that the geometrical shape of the rudder is matched with that of the propeller wake flow field, and the purposes that the pressure distribution of the rudder surface is improved, the cavitation starting sailing speed of the rudder is increased, the time of rudder cavitation is shortened, the area of rudder cavitation is decreased, vibration and noise caused by the rudder are reduced, cavitation denudation of the rudder surface is restrained, the maintenance cost of the rudder is saved, the force state of rudder blades is improved, the rudder efficiency is improved, and the load of the rudder is reduced are achieved.

Owner:NAVAL UNIV OF ENG PLA

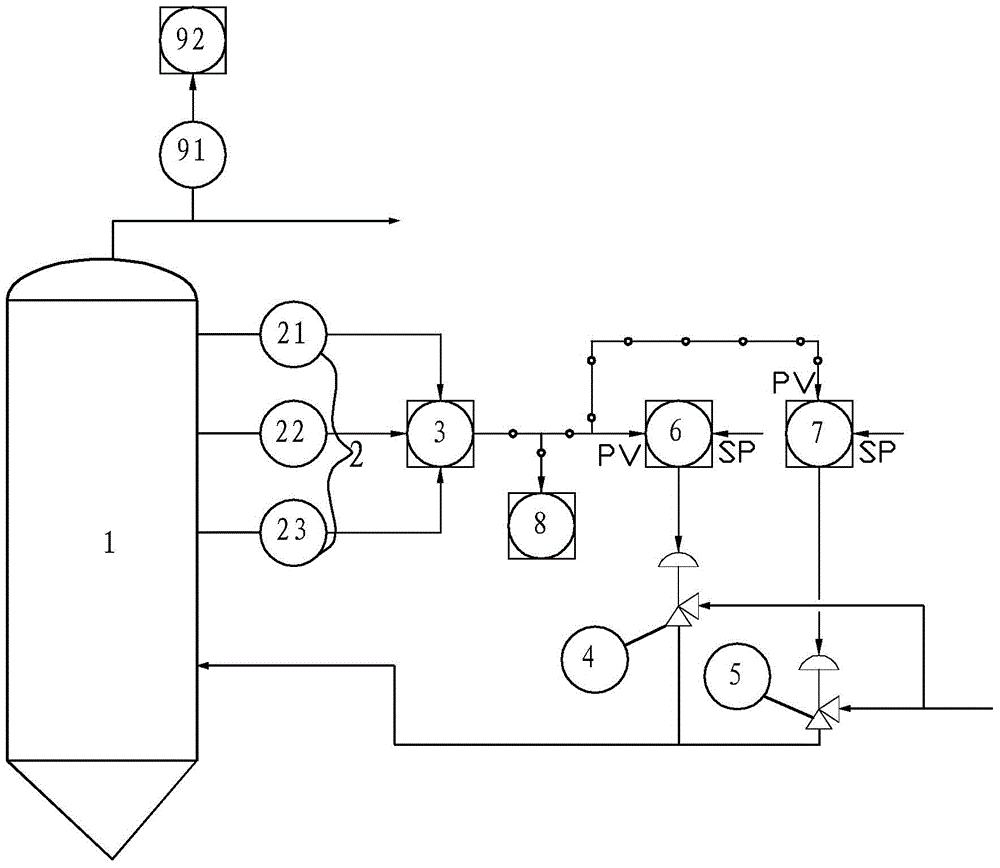

Synthetic gas washing tower liquid level control system and control method thereof

ActiveCN104932561AHigh liquid level automatic control commissioning rateReduce working pressure differenceLevel controlAutomatic controlControl system

The invention relates to a synthetic gas washing tower liquid level control system, comprising a liquid level transmitter, a liquid level operation module, a liquid level indication module, a first liquid level regulating valve, a first liquid level controller, a second liquid level regulating valve, and a second liquid level controller. The invention also relates to a control method of the synthetic gas washing tower liquid level control system, which can realize interlock switching between the first liquid level regulating valve and the second liquid level regulating valve under different pressure operating conditions, thereby substantially reducing the operating pressure difference of the first liquid level regulating valve, and eliminating cavitation erosion in operating processes. Meanwhile the liquid level automatic control commissioning rate of the synthetic gas washing tower liquid level control system is high, thereby effectively improving the stability and reliability of washing tower liquid level control, reducing apparatus non-planned parking, facilitating operation, and reducing operation cost and maintenance workload.

Owner:SINOPEC NINGBO ENG +2

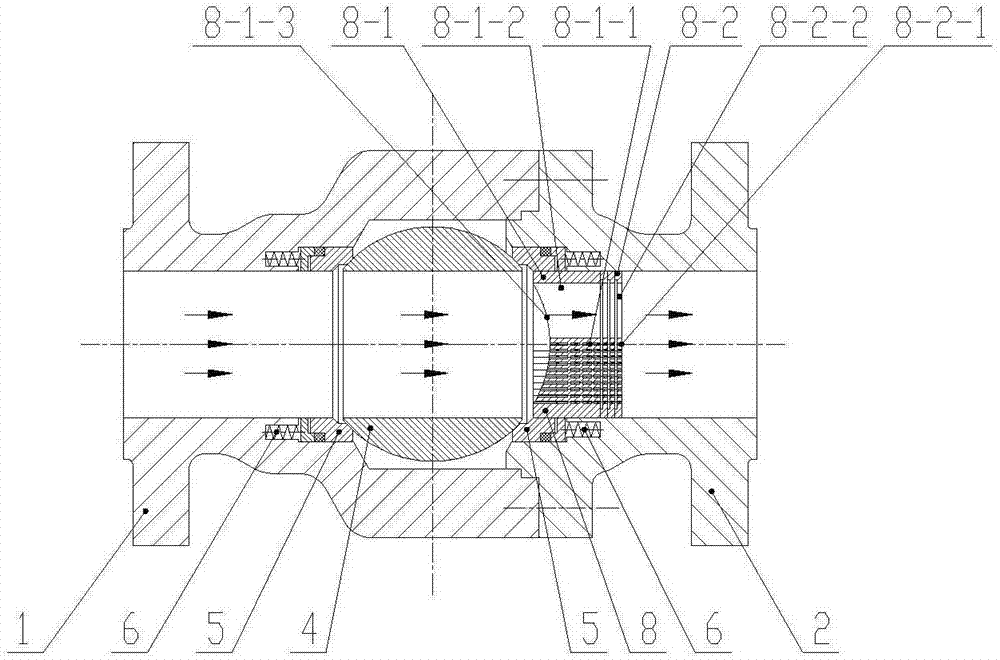

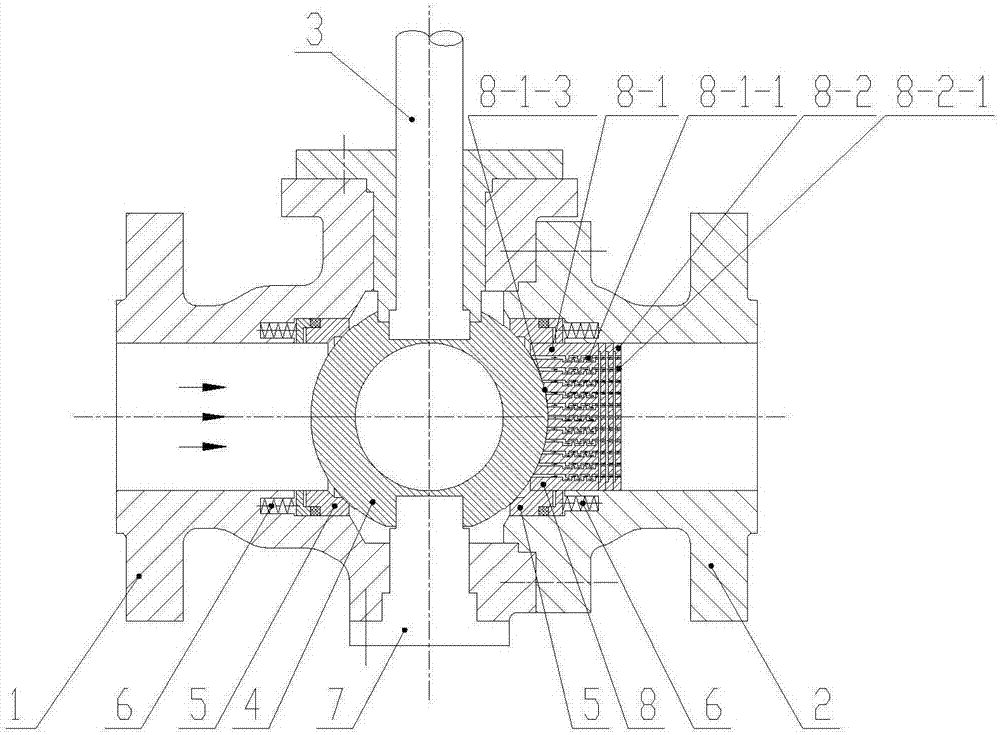

Ball valve capable of eliminating cavitation

PendingCN107120472AIncrease resistanceIncrease friction lossPlug valvesValve members for absorbing fluid energyCavitationEngineering

The invention provides a ball valve capable of eliminating cavitation and relates to the field of pipeline control valves. The problem that valve internals of an existing ball valve are damaged due to the cavitation phenomenon is solved. The ball valve capable of eliminating cavitation comprises a first valve body part, a second valve body part, a valve rod, a ball body, valve seats, springs and a fixing shaft and further comprises a spherical surface wall plate provided with through holes. An outlet runner of the ball body is covered by part of the spherical surface wall plate. The ball valve capable of eliminating cavitation can effectively eliminate cavitation when the opening degree is small, and can meet the requirement of the valve for higher flow when the opening degree is large and the cavitation phenomenon is unobvious, in addition, the structure is simple, machining is convenient, assembly is facilitated, and the ball valve has the characteristics of being capable of saving energy and efficient.

Owner:CHANGZHENG ENG +1

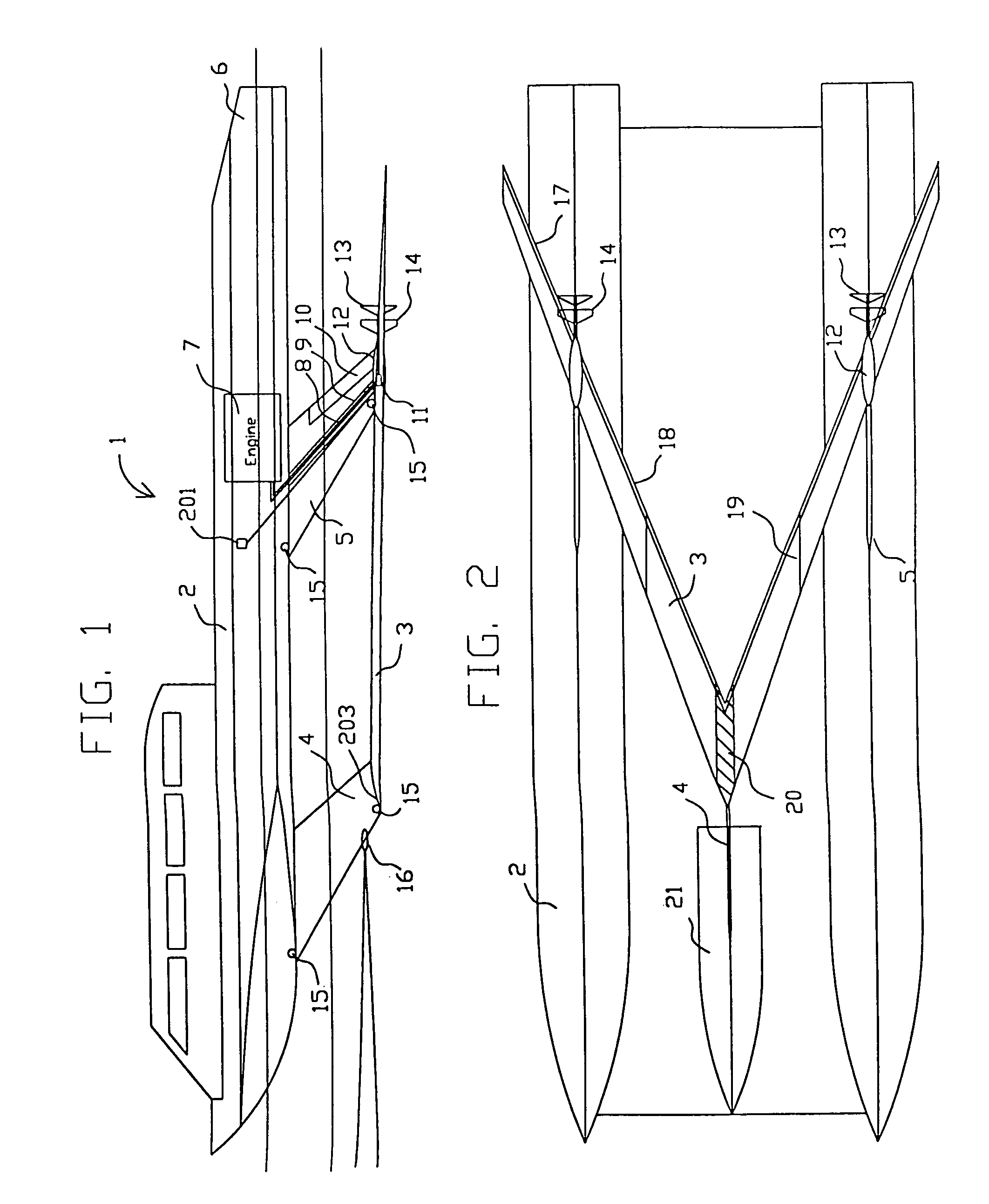

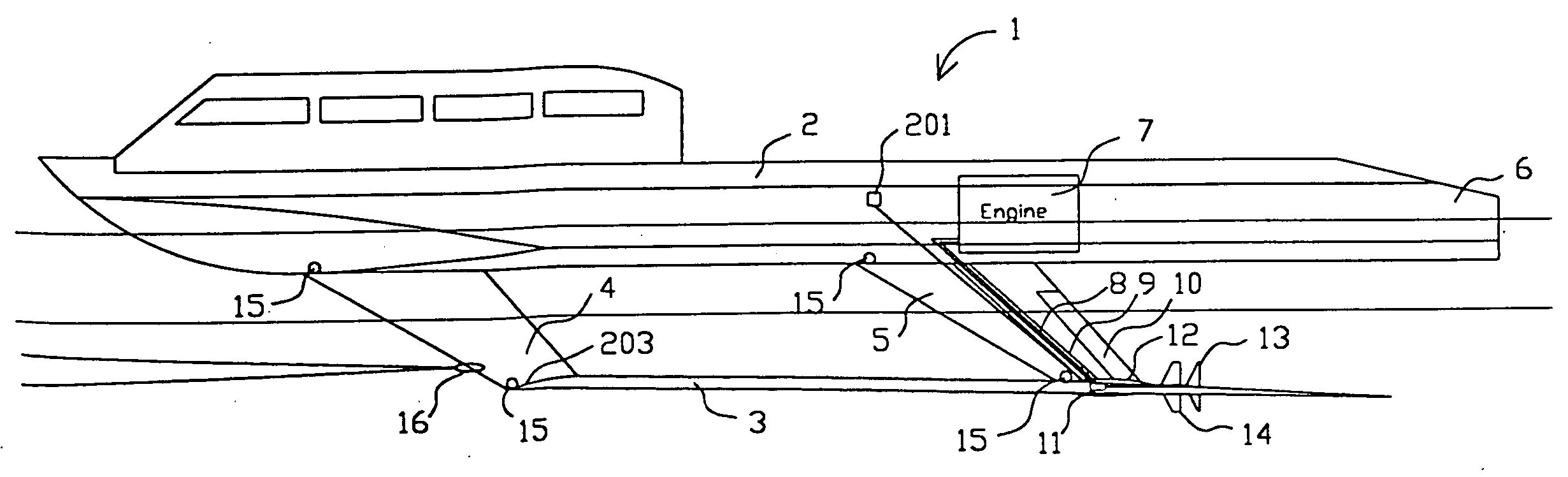

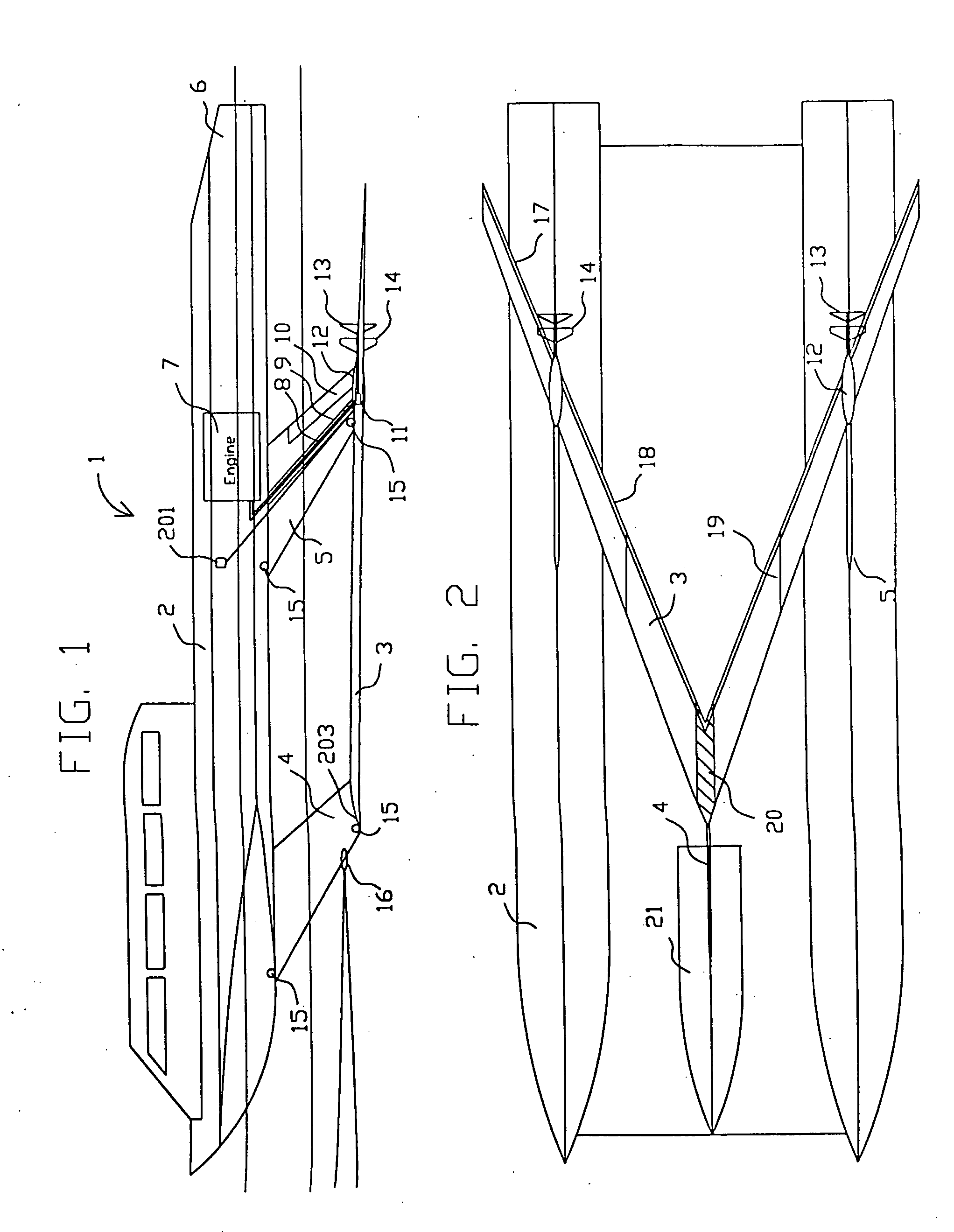

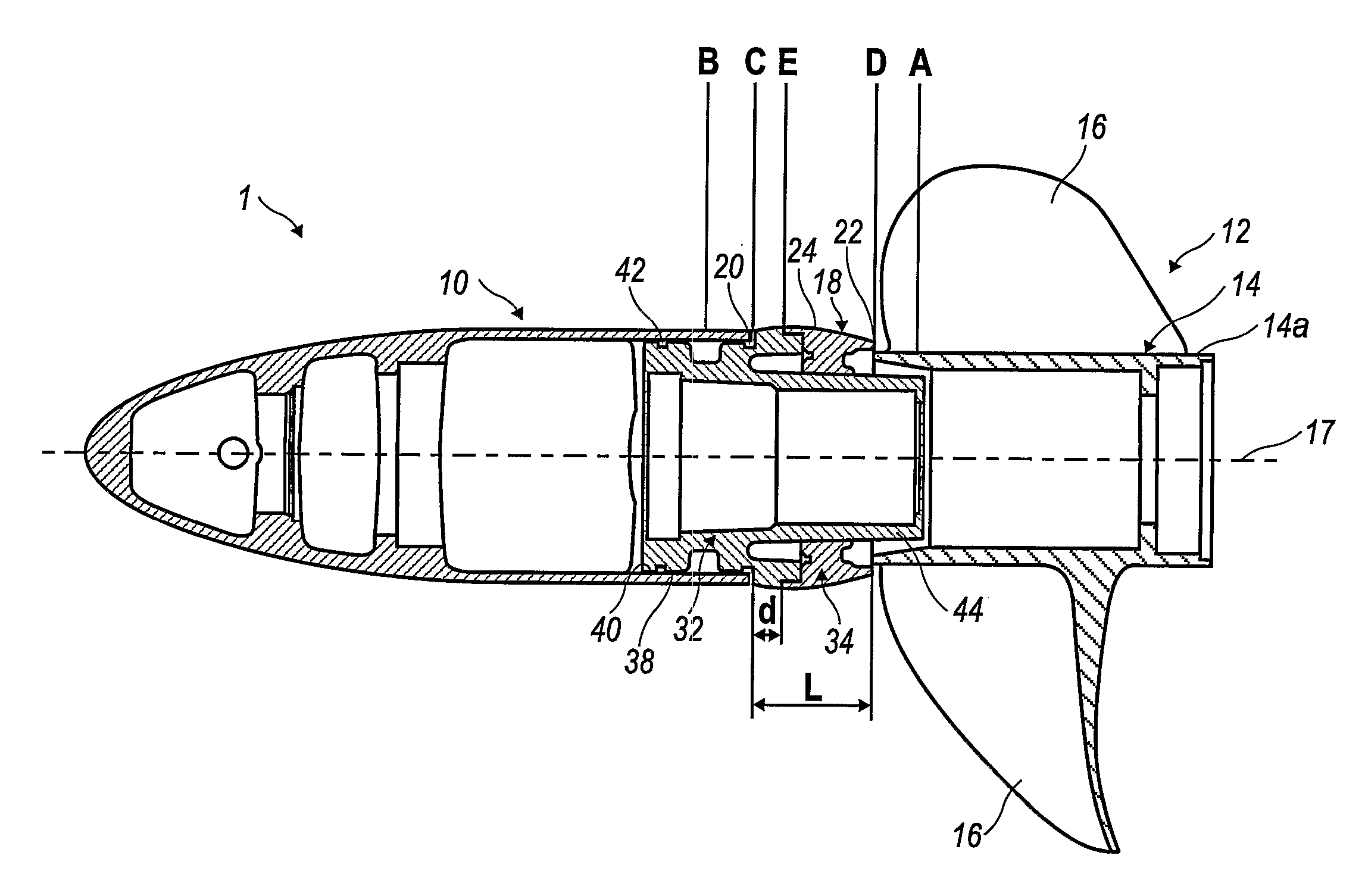

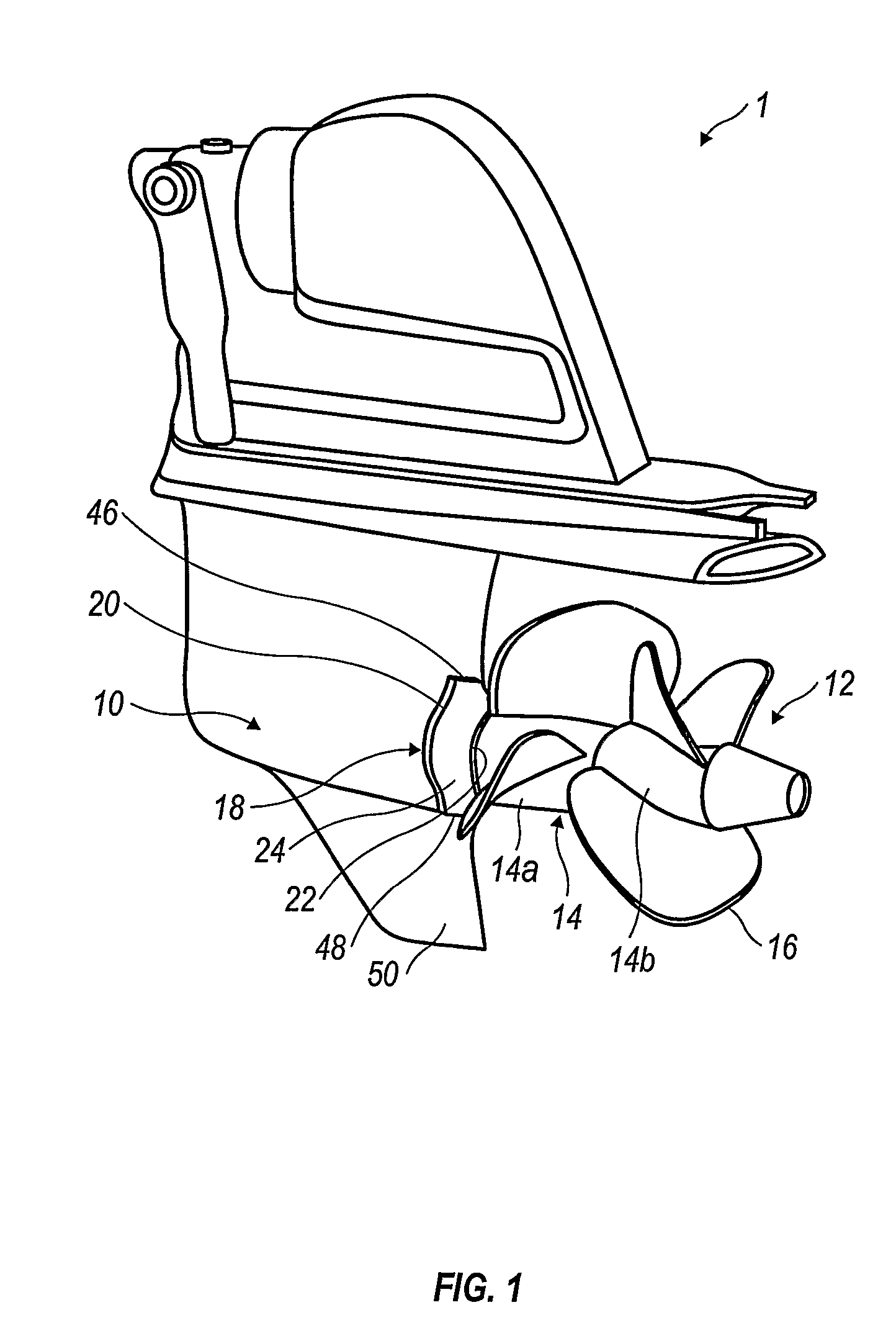

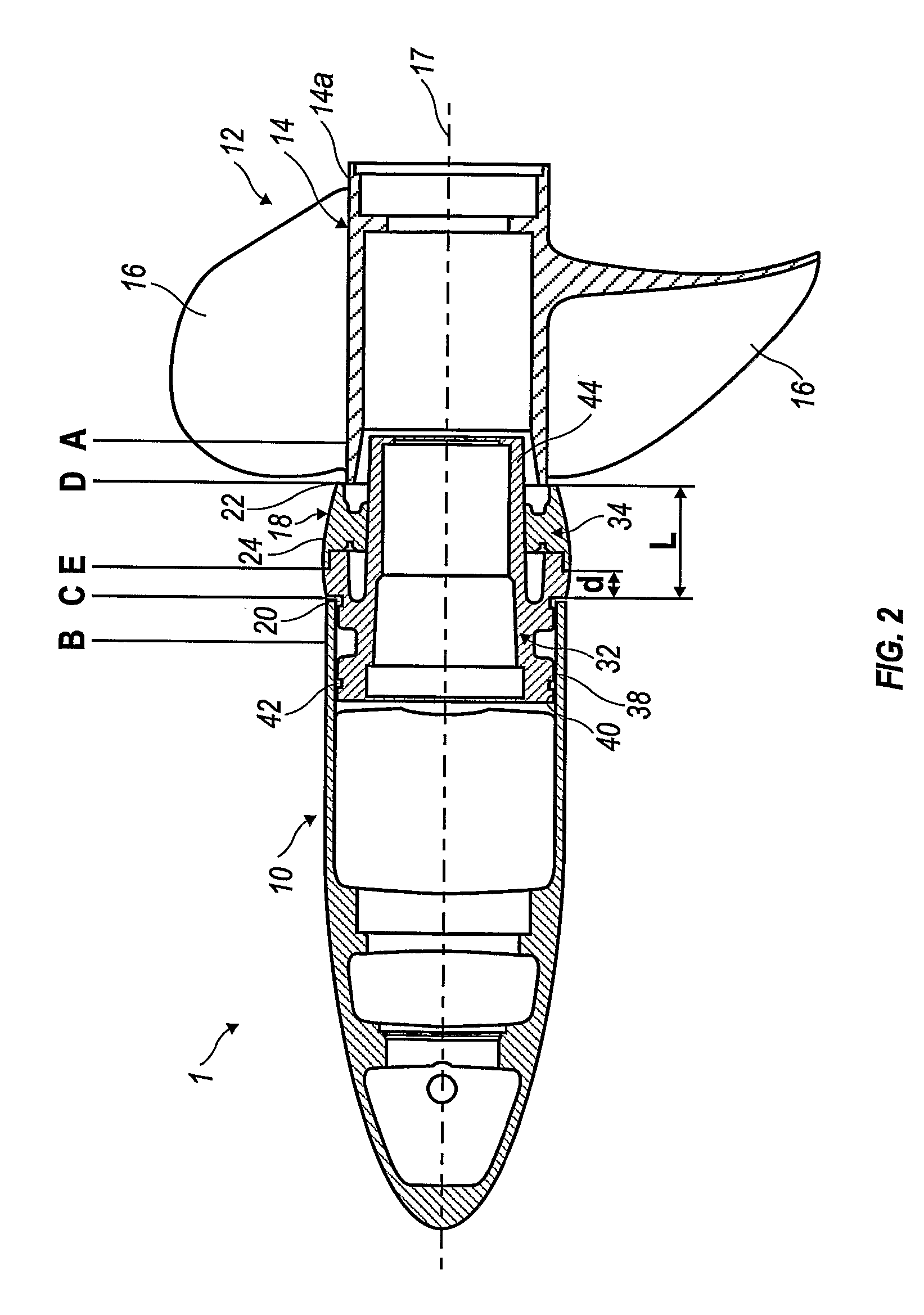

Marine propeller drive

ActiveUS8444391B2Risk minimizationEliminate cavitationRotary propellersPropulsion power plantsPropellerStructural engineering

A propeller drive for boats features a transition cone between the gearbox housing and the propeller hub(s). The propeller hub (that is closest to the gearbox housing) is smaller in cross-sectional dimension than the gearbox housing. The dimension of the front end of the transition cone corresponds to the cross-sectional dimension of the gearbox housing, and the dimension of the rear end of the transition cone corresponds to the cross-section dimension of the (closest) propeller hub. The transition cone has a bulging shoulder between the front and rear ends, the largest peripheral cross-sectional dimension of which is greater than the cross-sectional dimension of the front of the transition cone.

Owner:VOLVO PENTA AB

Shaft-free and sleeve-free suspension type double-seat metal hard sealing check valve

InactiveCN114484020AEffective protectionEliminate cavitationCheck valvesValve members for absorbing fluid energyStructural engineeringCheck valve

The invention discloses a shaft-free and sleeve-free suspension type double-seat metal hard sealing check valve, and relates to the technical field of check valves, the shaft-free and sleeve-free suspension type double-seat metal hard sealing check valve comprises a valve body, a first flow guide body and a valve clack, and further comprises a connecting mechanism, a second flow guide body, a limiting mechanism and a supporting mechanism, the first flow guide body is installed in the valve body, and the connecting mechanism is installed in the first flow guide body; the second flow guide body comprises a flow guide plate, a connecting bolt, a valve seat and a connecting plate, the flow guide plate is installed in the valve body, one side of the flow guide plate is connected with one side of the connecting plate, a threaded hole is formed outside the connecting plate, the connecting bolt is installed in the threaded hole, and the valve seat is installed outside the flow guide plate; and four mounting grooves are formed in the outer surface of the connecting plate. According to the shaft-free and sleeve-free suspension type double-seat metal hard sealing check valve, the valve clack can be dynamically opened and closed along with the flow state of water, water hammers can be eliminated, meanwhile, valve closing noise is not generated, and the mute effect is achieved.

Owner:宁波一机阀门制造有限公司

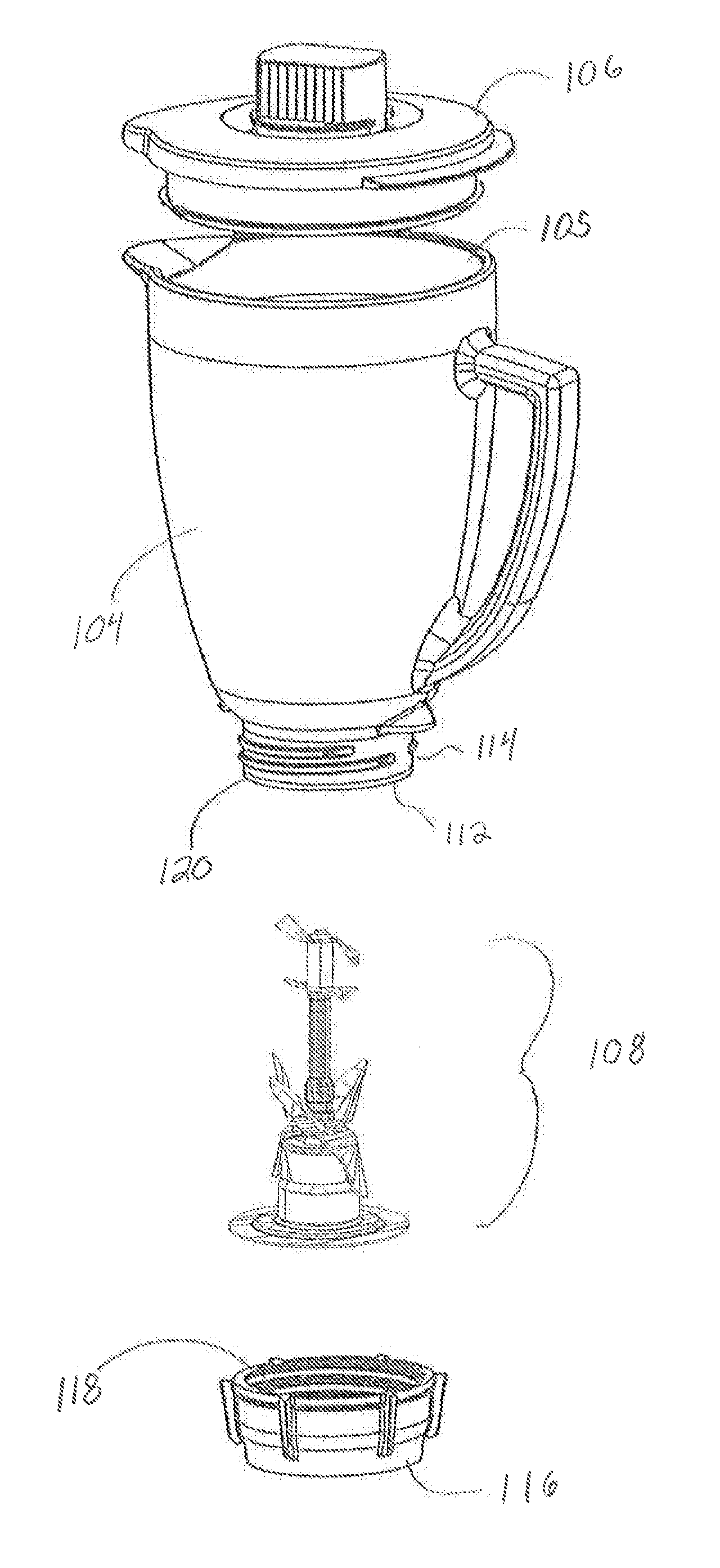

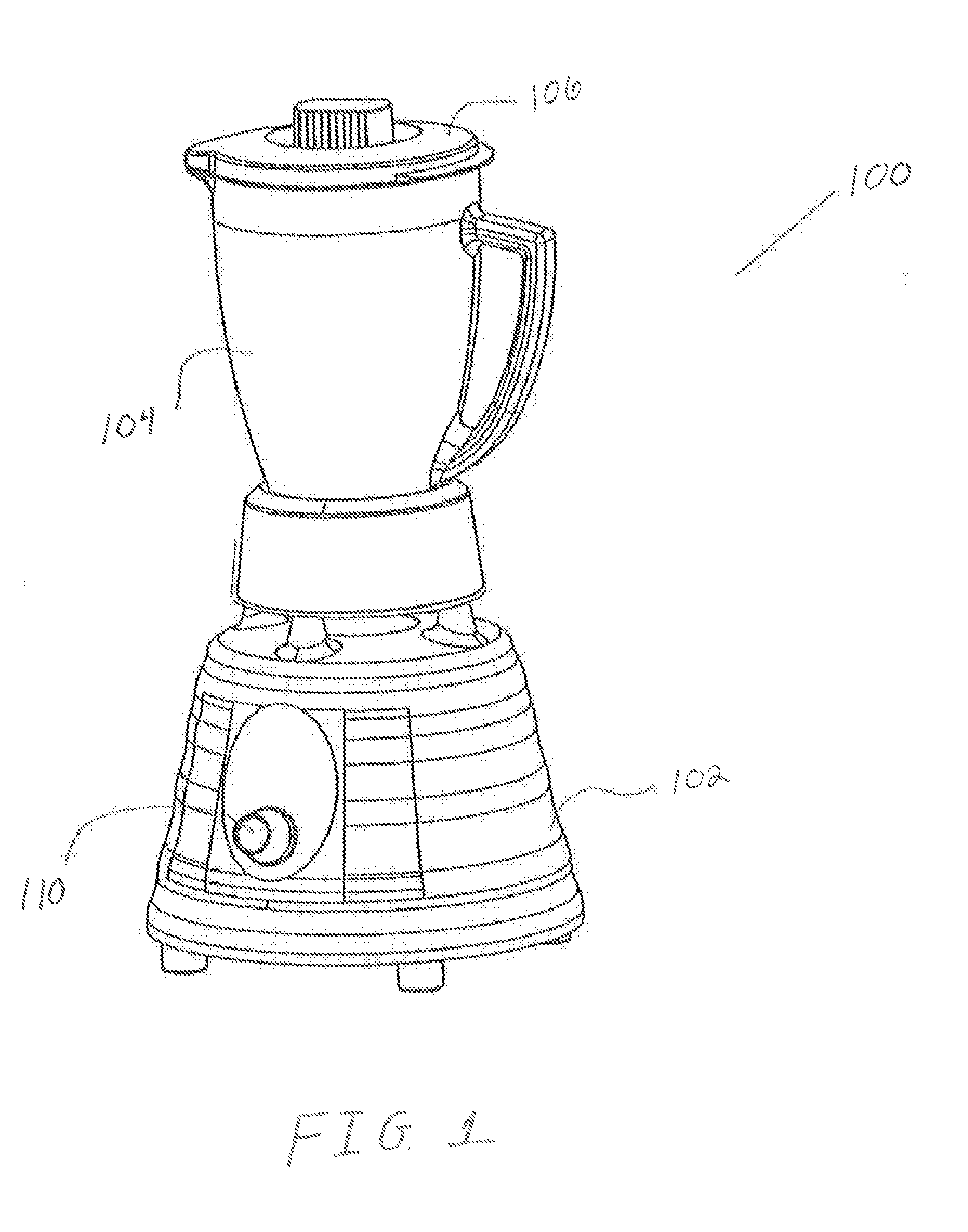

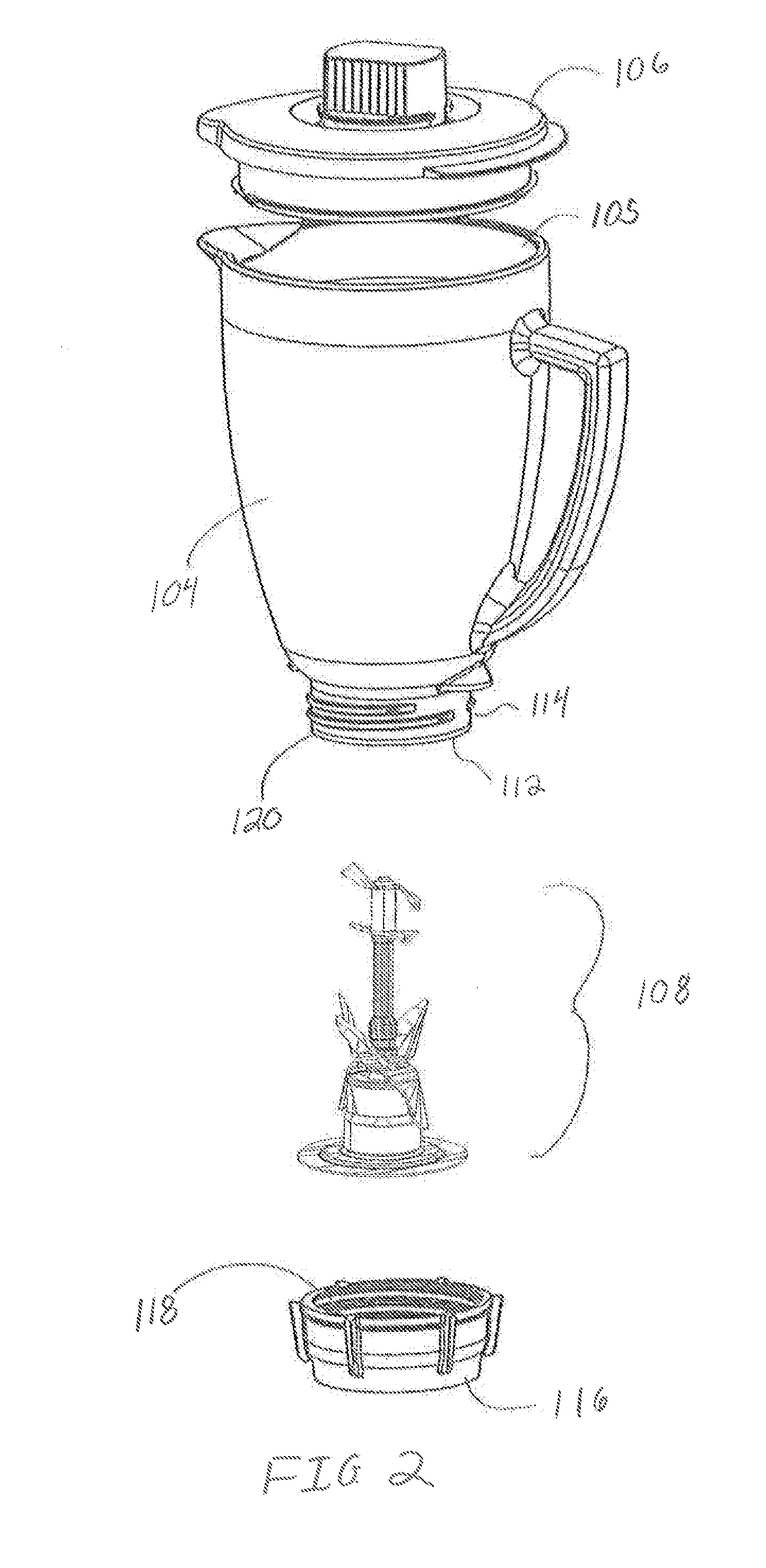

Blending Appliance with Paddle Blade

ActiveUS20160360927A1Avoid cavitationEliminate cavitationMixing methodsTransportation and packagingCavitationEngineering

A blending appliance is provided including a motorized base, a blending container, and a blade assembly fitted into an opening of the blending container and rotatably coupled to the motorized base when the blending container is mounted on the motorized base. The blade assembly includes a lower blade element disposed on a spindle performing blending operations on ingredients at a lower end of the blending container; and an upper working element disposed on a shaft spaced apart from the lower blade element, and including an upper working portion and a lower working portion spaced apart from the upper working portion. The upper working portion acting to reduce cavitation in the lower blades element during the blending process.

Owner:SUNBEAN PROD INC

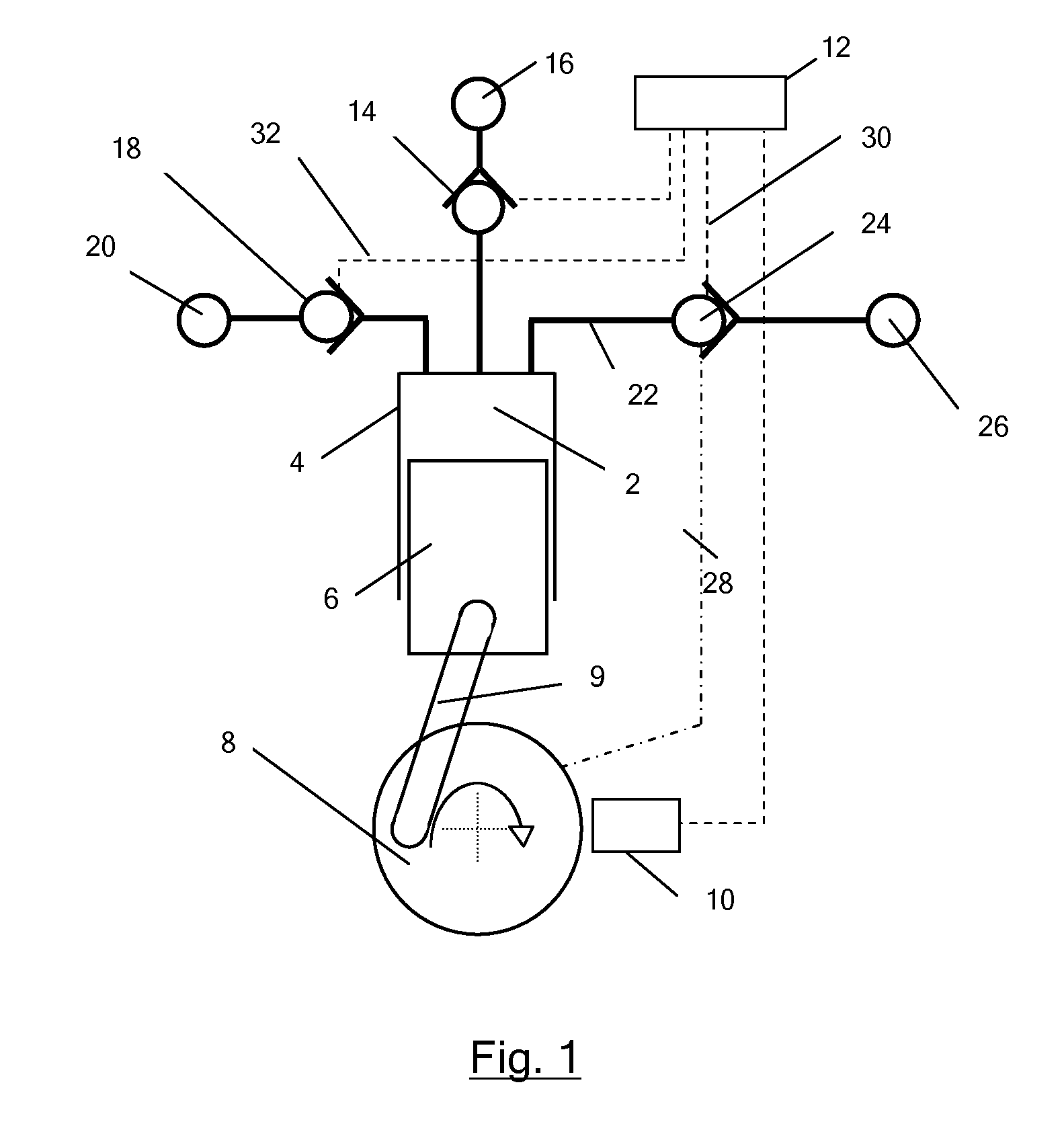

Large two-phase flow cooling system and method for pump drive cavitation self-repairing

PendingCN114786431AEliminate the risk of overheatingImprove reliabilityModifications using liquid coolingPhysicsRefrigerant

The invention discloses a pump drive cavitation self-repairing large-scale two-phase flow cooling system and a method thereof.The system comprises an evaporation cold plate of electronic equipment and a condenser, the evaporation cold plate of the electronic equipment is connected with the condenser, the condenser is connected with a liquid storage tank, a liquid level sensor is arranged in the liquid storage tank, and the liquid level sensor is connected with the evaporation cold plate of the electronic equipment; two pipelines are arranged at the bottom of the liquid storage tank and connected with a liquid supplementing tank, a liquid return one-way valve is arranged on one pipeline, a liquid supplementing one-way valve is arranged on the other pipeline, a refrigerant filling opening is formed between the liquid return one-way valve and the liquid supplementing tank, a liquid supplementing pump is arranged between the liquid supplementing one-way valve and the liquid supplementing tank, and a liquid supply pump is connected to the bottom of the liquid storage tank. And the liquid supply pump supplies liquid to an evaporation cold plate of the electronic equipment. Self-repairing and self-starting of the pump after cavitation are achieved, and the engineering applicability and reliability of a large two-phase flow cooling system are improved.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

Ball valve controlling cavitation

PendingCN107448637ASolve the problem of easy cavitationReduce noisePlug valvesValve members for absorbing fluid energyCavitationEngineering

The invention provides a ball valve controlling cavitation and belongs to the technical field of pipeline control. The ball valve controlling the cavitation is used for solving the problem that an existing ball valve is prone to generating the cavitation. The ball valve controlling the cavitation comprises a valve body composed of a first valve body portion and a second valve body portion, a sphere, a valve rod, valve seats, springs and a fixing shaft, wherein the sphere, the valve rod, the valve seats, the springs and the fixing shaft are located between the first valve body portion and the second valve body portion. The fixing shaft is located on the lower side of the sphere and used for supporting the sphere. The valve rod is connected with the sphere and used for driving the sphere to rotate. Spherical surface seal is formed by the sphere and the valve seats on the left and right sides. The springs are arranged on the outer sides of the valve seats and used for pressing the valve seats to the sphere. The ball valve further comprises a valve element which is arranged on an outlet flow channel of the sphere in a tightly attached manner. The valve element is provided with a channel extending in the direction of a ball valve flow channel. The ball valve controlling the cavitation can effectively restrain generation of the cavitation and is beneficial for lowering of noise and vibration generated by fluid.

Owner:CHANGZHENG ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com