Damping noise reduction valve plate for plunger hydraulic pump

A valve plate, hydraulic pump technology, applied in pump components, variable capacity pump components, liquid fuel engines, etc., can solve the problems of valve plate surface damage, cavitation, bubble generation, etc., to achieve good anti-pollution ability and reduce noise. , the effect of eliminating cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

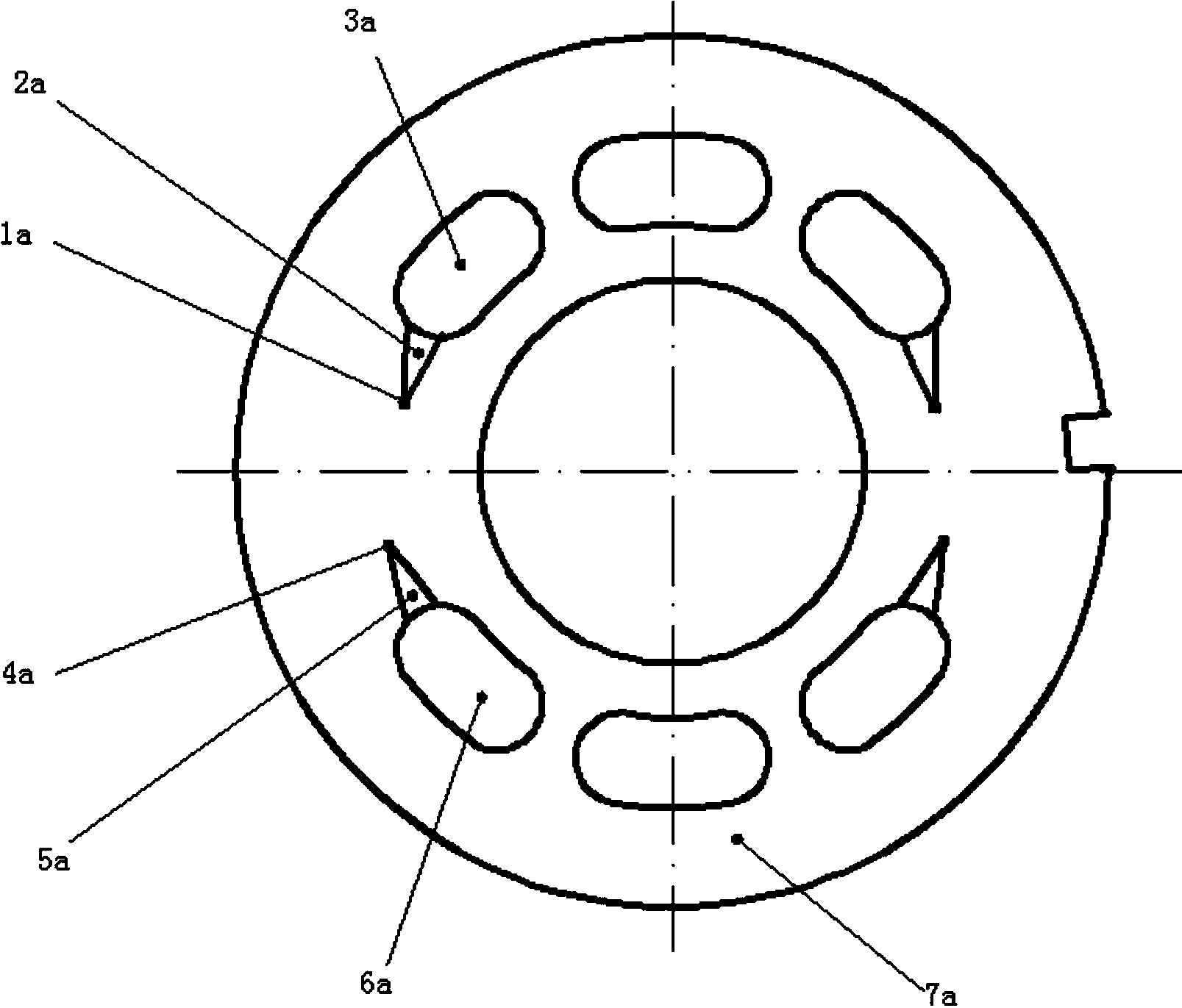

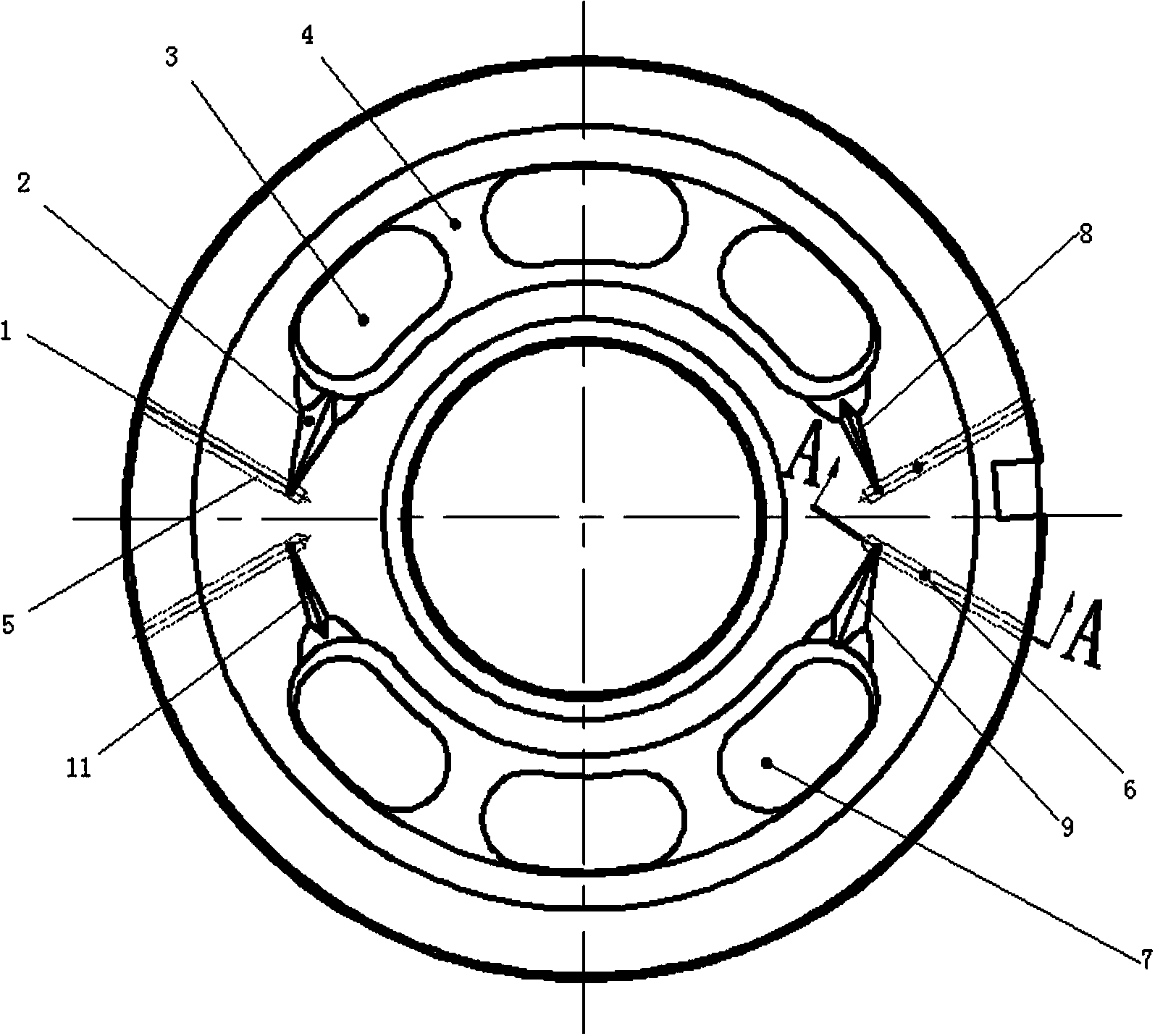

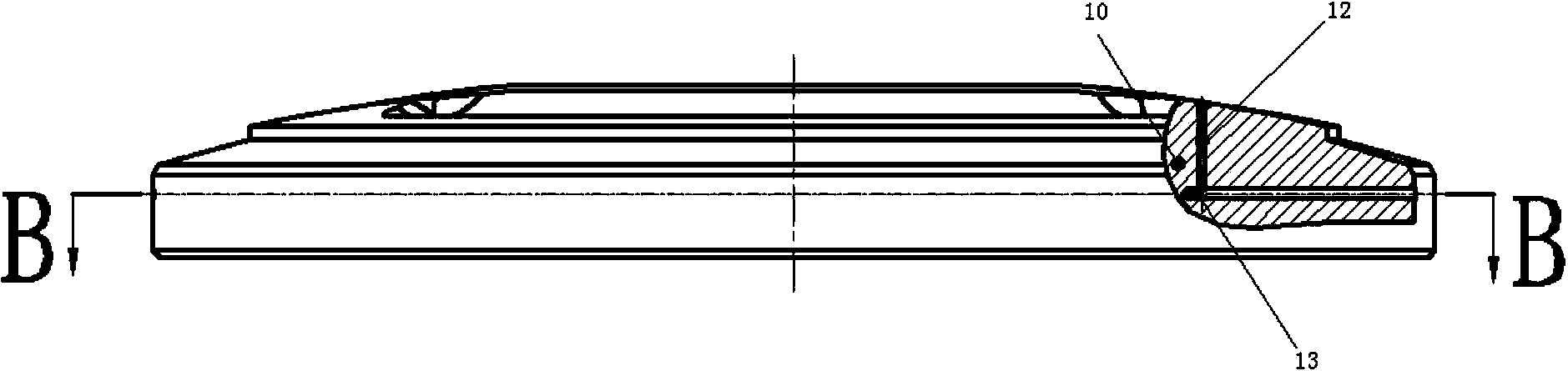

[0030] Such as Figure 2-4As shown, a shock-absorbing and noise-reducing valve plate for a plunger hydraulic pump includes a valve plate body 10, and the valve plate body 10 is provided with a low-pressure oil suction area that is isolated from each other and is symmetrical with respect to the horizontal axis of the valve plate body 10. High-pressure oil discharge area; the low-pressure oil-absorbing area includes an arc-shaped groove, an oil-absorbing waist-shaped window 3 and a reinforcing rib 4 arranged at the bottom of the arc-shaped groove, and the oil-absorbing waist-shaped window 3 is at least one; the described The high-pressure oil discharge area includes an arc groove, an oil discharge waist window 7 and a reinforcing rib arranged at the bottom of the arc groove, the oil discharge waist window 7 is at least one; the two ends of the low pressure oil suction area and Both ends of the high-pressure oil discharge area are provided with a triangular groove connected to it...

Embodiment 2

[0034] In this embodiment, four oil-absorbing waist-shaped windows 3 and four oil-discharging waist-shaped windows 7 are respectively provided. At the same time, the oil passages arranged at the bottom of the four damping holes have a diameter of 0.8 mm in the vertical section and 0.8 mm in diameter of the oil passage in the horizontal section. Diameter is 1.5mm, and all the other are with embodiment 1.

Embodiment 3

[0036] In this embodiment, five oil suction waist windows 3 and five oil discharge waist windows 7 are respectively provided. At the same time, the oil passages arranged at the bottom of the four damping holes have a diameter of 1mm in the vertical section and 1mm in the horizontal section. Be 2mm, all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com