Large two-phase flow cooling system and method for pump drive cavitation self-repairing

A cooling system, self-healing technology, applied in the direction of cooling/ventilation/heating renovation, etc., can solve the problems of inability to quickly and completely complete gas-liquid separation, standing for a long time, shutdown, etc., to eliminate the risk of over-temperature and shorten the start-up time , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

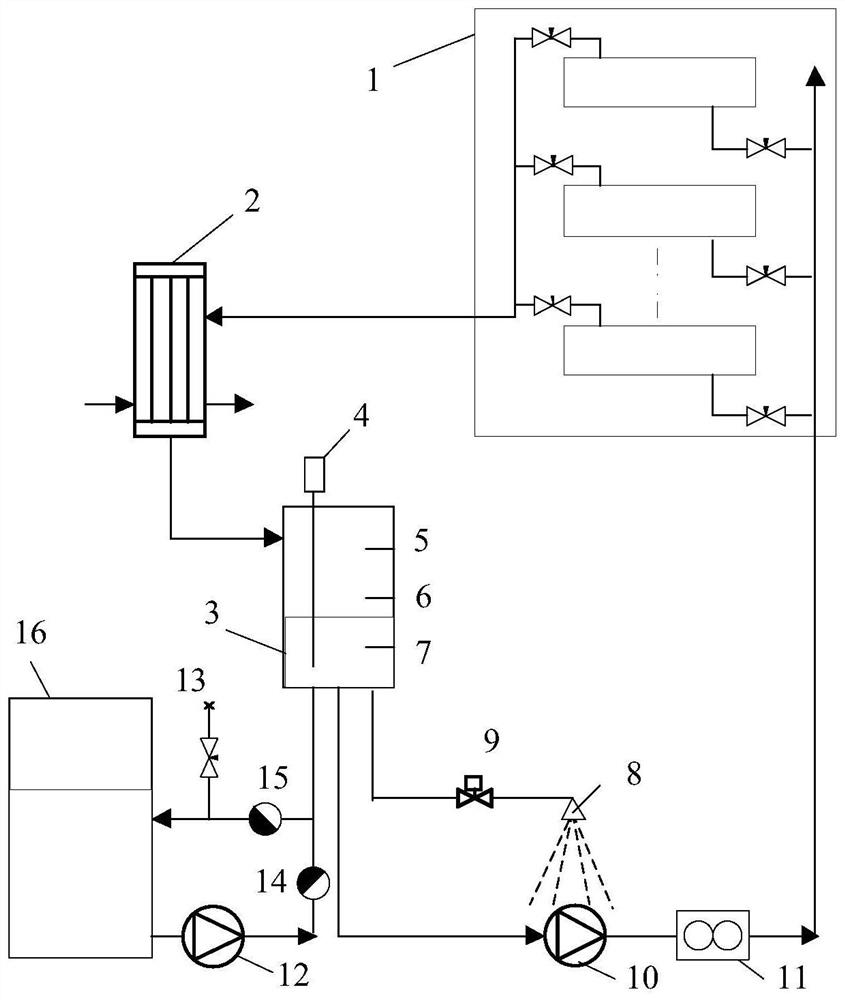

[0026] A large-scale two-phase flow cooling system with pump-driven cavitation self-healing, such as figure 1 The main components of the large-scale two-phase flow cooling system include the evaporative cold plate 1 of the electronic equipment, the condenser 2, the liquid storage tank 3, the liquid level sensor 4, the maximum liquid level mark of the liquid storage tank 5, and the intermediate liquid level of the liquid storage tank. Mark 6, minimum liquid level mark of liquid storage tank 7, nozzle 8, solenoid valve 9, liquid supply pump 10, flow meter 11, liquid replenishment pump 12, refrigerant charging port 13, liquid replenishment check valve 14, liquid return check valve 15. Rehydration tank 16. In this embodiment, the refrigerant in the cooling system is freon, the evaporative cold plate of the electronic device is connected to the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com