Preparation method of perfluoropolyoxyalkylene peroxide and perfluoropolyether

A polyoxyalkylene and perfluoroolefin technology, which is applied in the preparation of peroxy compounds, the preparation of organic compounds, chemical instruments and methods, etc. Problems such as low preparation and reaction safety, to achieve the effect of improving yield, improving reaction selectivity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In view of the problems that the current preparation method cannot realize the efficient preparation of peroxidized perfluoropolyoxyalkylene compounds with high number-average molecular weight, the product yield is low, and the industrial safety and continuous production cannot be realized. In the preparation of perfluoropolyoxyalkylene peroxide, the microscopic mixing, mass transfer and heat transfer process of the reaction are greatly enhanced, the reaction time of the material in the high gravity reactor is greatly shortened, and the reaction selectivity and total yield are greatly improved , and there is no local overheating, avoiding production safety problems, and realizing continuous industrial production.

[0039] The embodiment of the present application provides a method for preparing perfluoropolyoxyalkylene peroxide and perfluoropolyether, which solves the problem that the high number average molecular weight of perfluoropolyoxyalkylene peroxide cannot be eff...

Embodiment 1

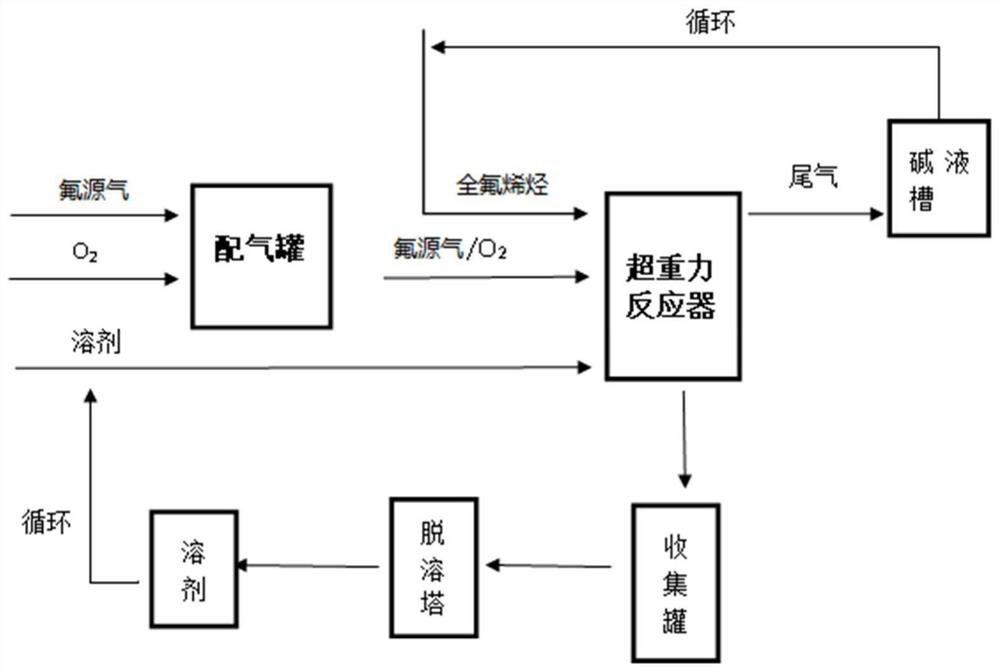

[0069] According to this embodiment figure 1 Operate as shown in the process flow chart.

[0070] f 2 / O 2 Mixed gas preparation: at room temperature, pass the fluorine-nitrogen mixed gas with a mass ratio of 20% of fluorine gas and oxygen into the gas distribution tank respectively according to the raw material ratio requirements shown in Table 1 through the respective Cortesian mass flow meters , get F 2 / O 2 mixed gas.

[0071] Peroxidized perfluoropolyoxyalkylene synthesis: tetrafluoroethylene (TFE), solvent, F 2 / O 2 The mixed gas is continuously fed into the high-gravity reactor of the self-rotating packed bed at the same time, and the tetrafluoroethylene, solvent, F 2 / O 2 The inlet flow rate of the mixed gas, and the maximum flow rate shall not exceed 1kg / h. Control the reaction pressure in the reactor to normal pressure, the reaction residence time is 30s~80s, and the supergravity level is 10g. After the tail gas flows out from the gas phase outlet above the ...

Embodiment 2-8

[0078] Embodiment 2-8 uses tetrafluoroethylene as raw material, adopts the operating procedure substantially identical with embodiment 1 to prepare peroxidized perfluoropolyoxyalkylene, and concrete reaction conditions and corresponding reaction result are shown in Table 1, wherein CF 3 When OF is the initiator, CF 3 OF / O 2 The mixed gas is prepared as follows: at room temperature, the CF 3 Fluorine-nitrogen mixed gas with a mass ratio of 20% of OF and oxygen are respectively passed into the gas distribution tank according to the raw material ratio requirements shown in Table 1 to obtain CF 3 OF / O 2 mixed gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com