Continuous annealing production method of cold-rolled sheet No.45 steel

A No. 45 steel and production method technology, applied in the field of metal material processing, can solve the problems of pearlite dispersion and spheroidization of No. 45 steel, and achieve the effect of improving product quality, high strength and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

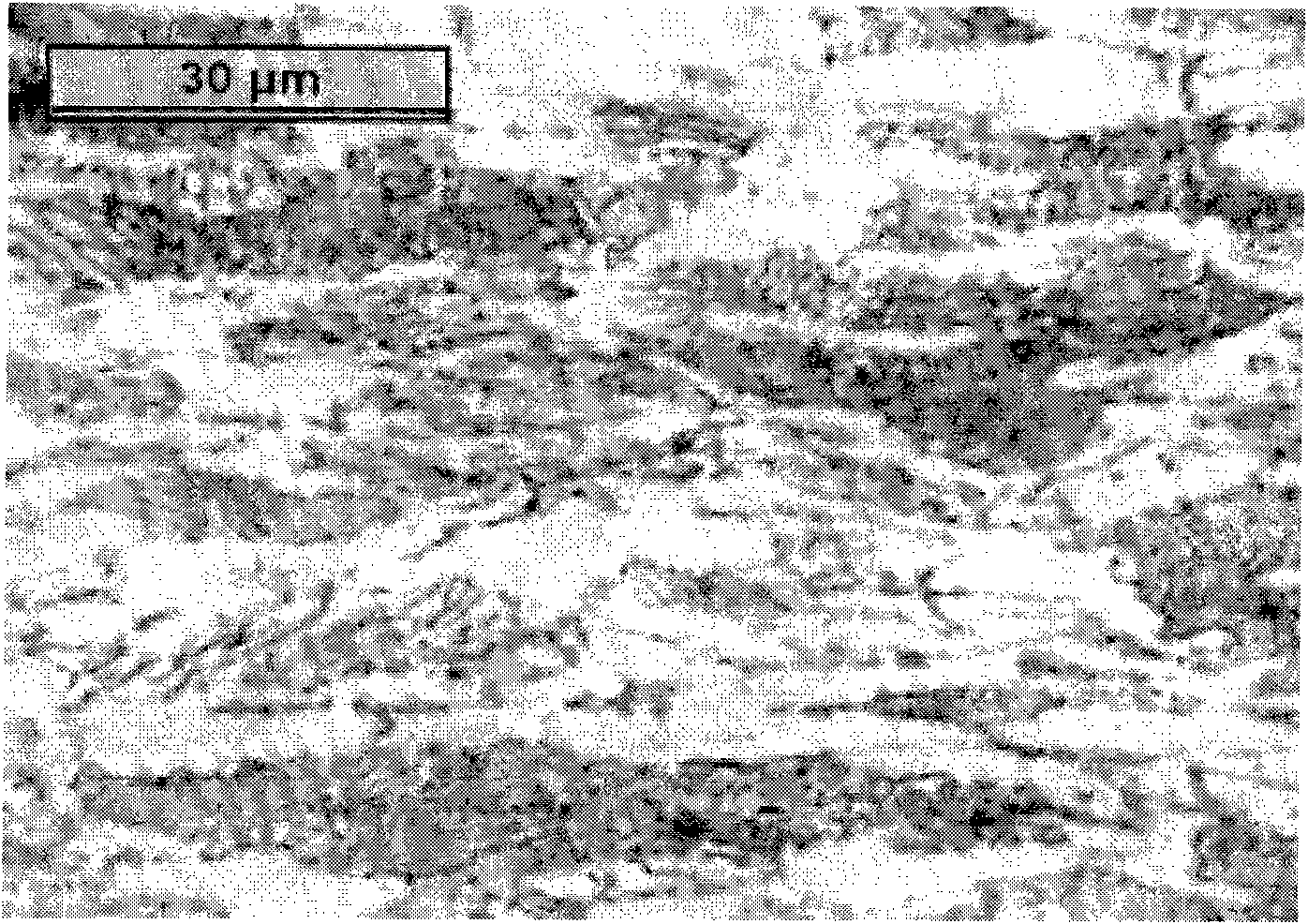

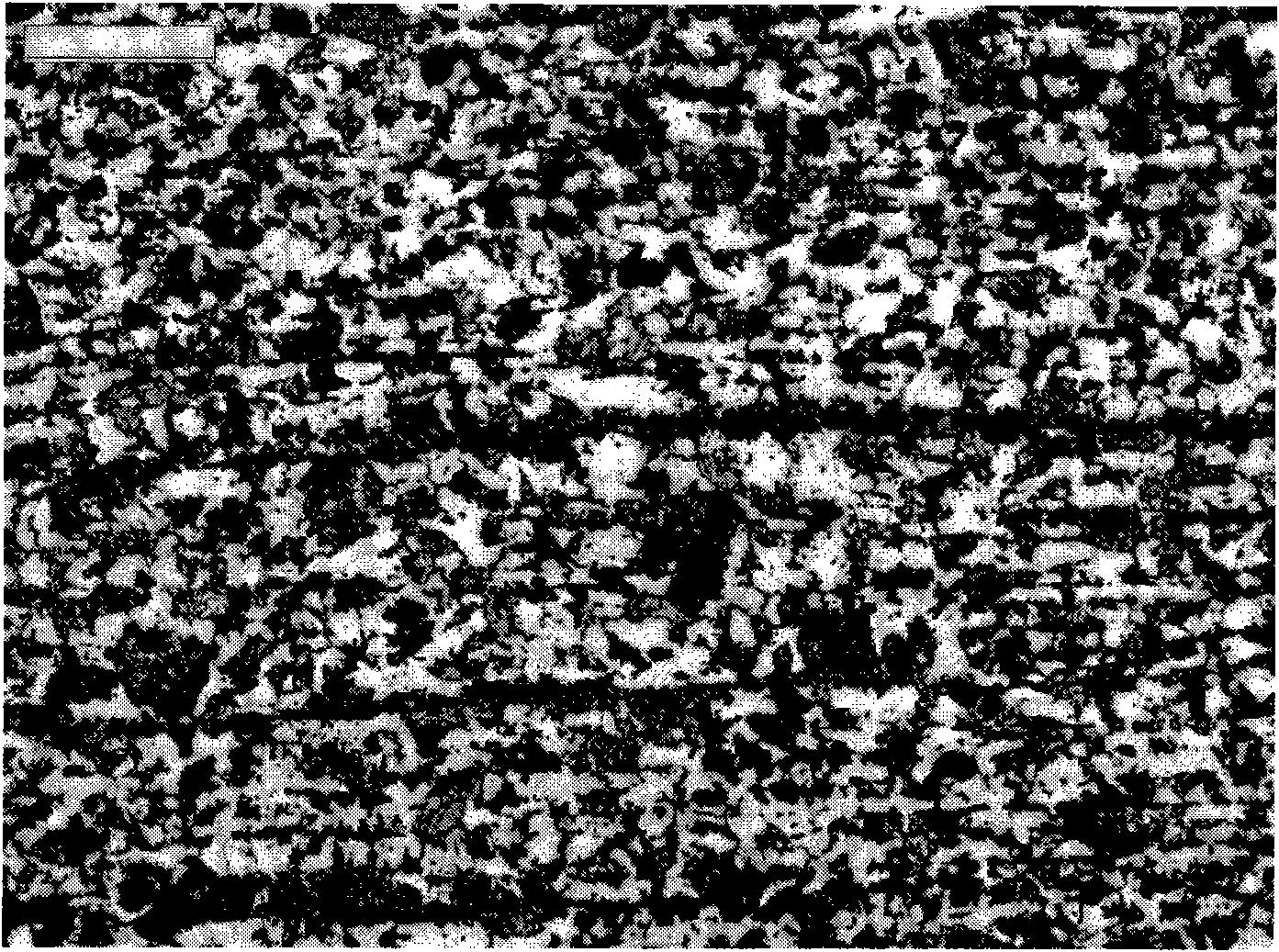

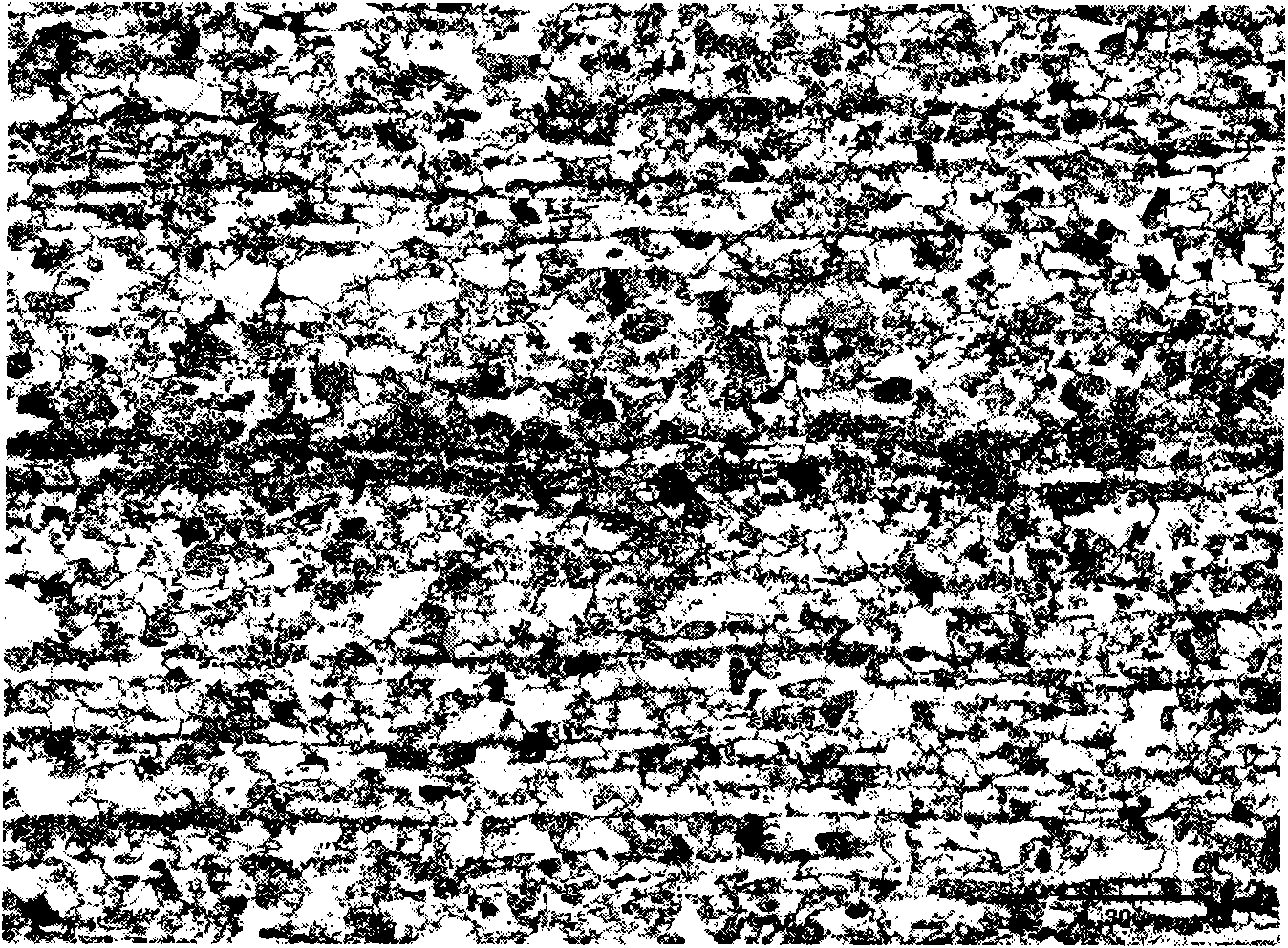

[0021] The present invention is a continuous annealing production method for cold-rolled sheet 45 steel. The mass percentage of the chemical composition of the steel is: C, 0.47%; Mn, 0.60%; Si, 0.31%; P, ≤0.035%; S, ≤0.035 %; Cr≤0.25; Ni≤0.25; Cu≤0.25, the balance is Fe. The hot rolling process of its steel controls the heating temperature: 1250±30°C; the final rolling temperature: 900±20°C; the coiling temperature: 730±20°C; the cold rolling process controls the cold rolling reduction rate at 50%-70%. It is characterized in that the following process steps are passed through the continuous annealing process:

[0022] Invention Process 1:

[0023] A. Strip steel enters the medium from room temperature as H 2 And N 2 The composition is heated to 240℃ in 37 seconds in a non-oxidizing atmosphere;

[0024] B. Then in H 2 And N 2 The composition was further heated to 750°C in 607 seconds in a non-oxidizing atmosphere;

[0025] C. The subsequent H at 750℃ 2 And N 2 Insulation in a non-ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com