Patents

Literature

929results about "Peroxy compound preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

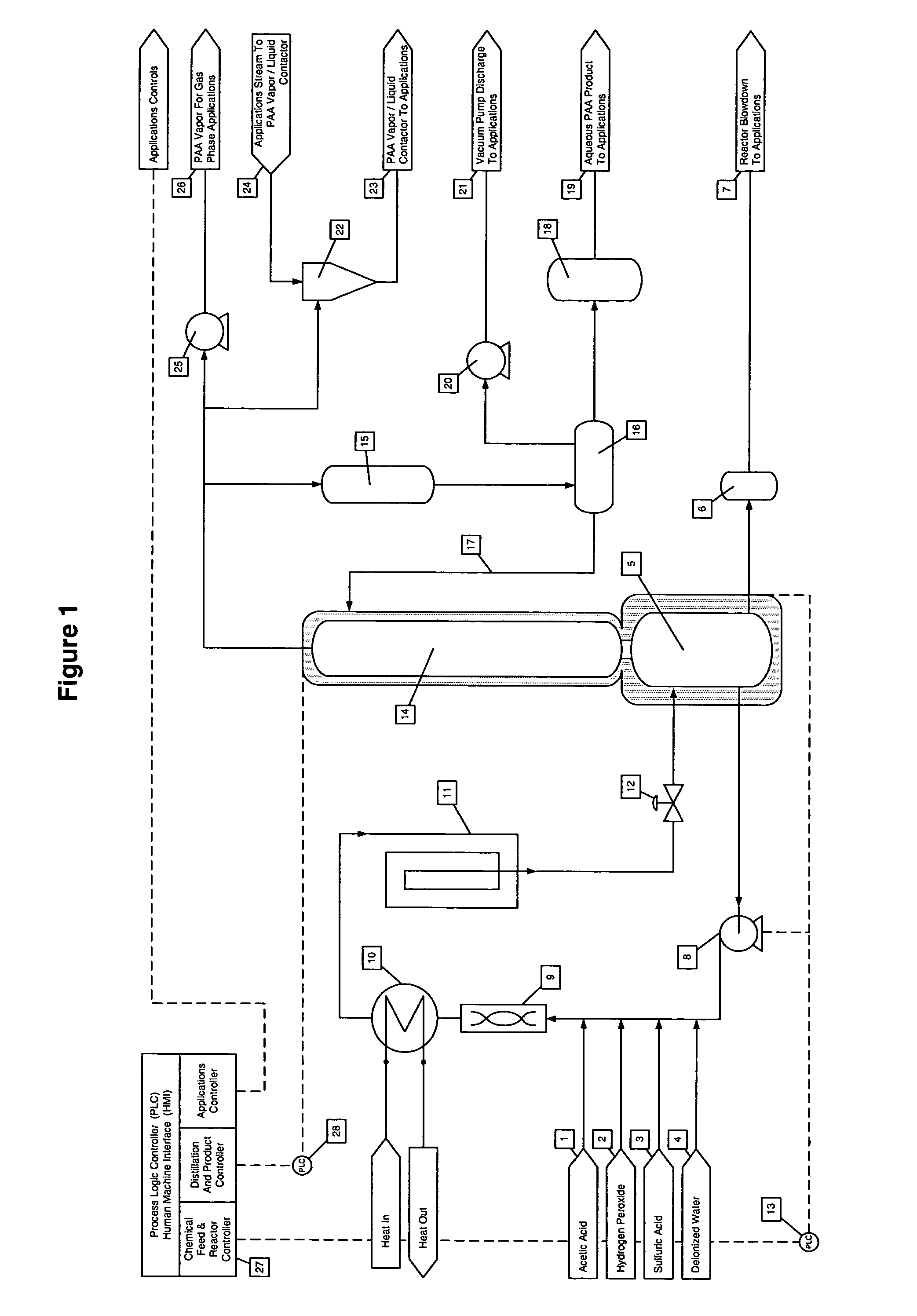

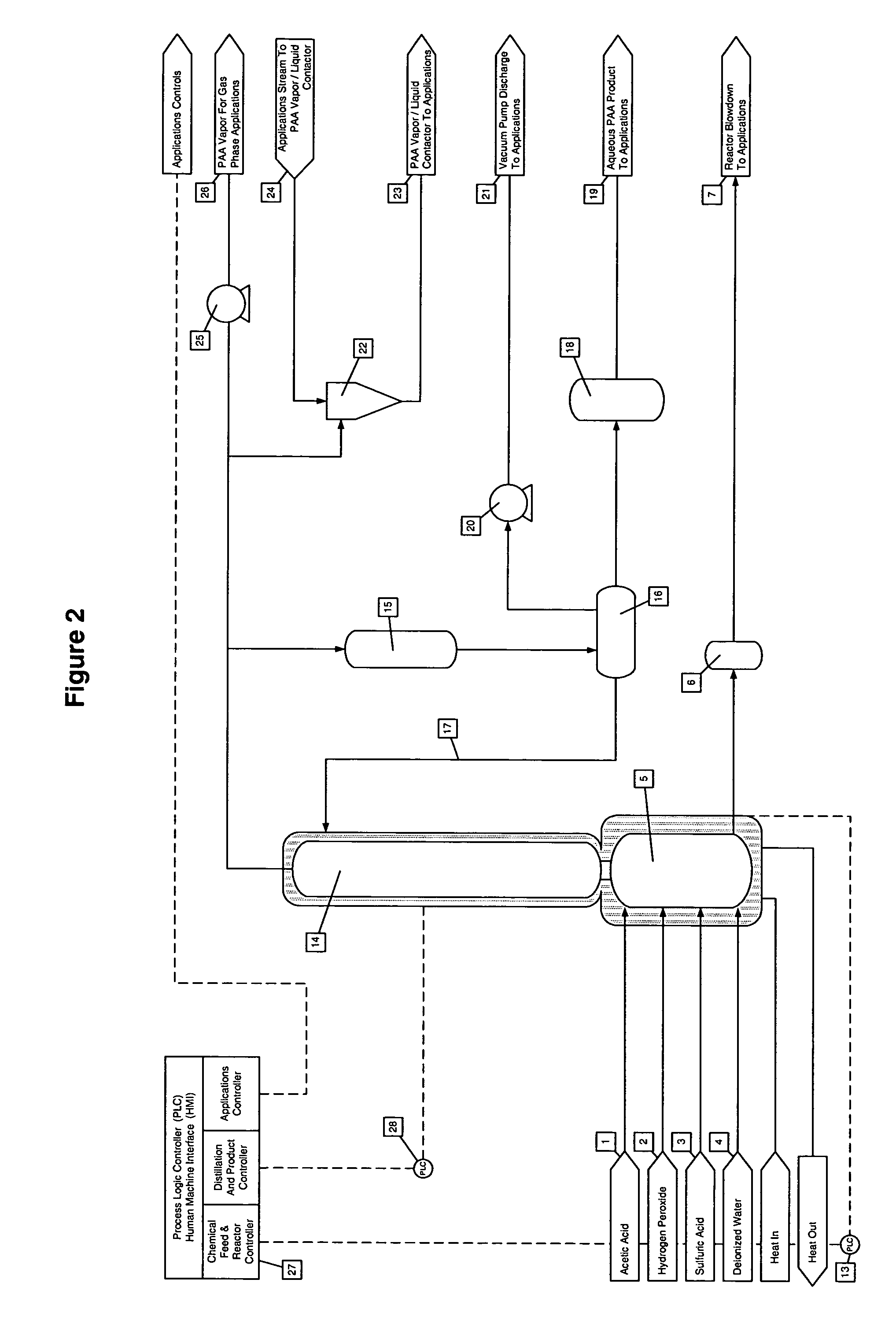

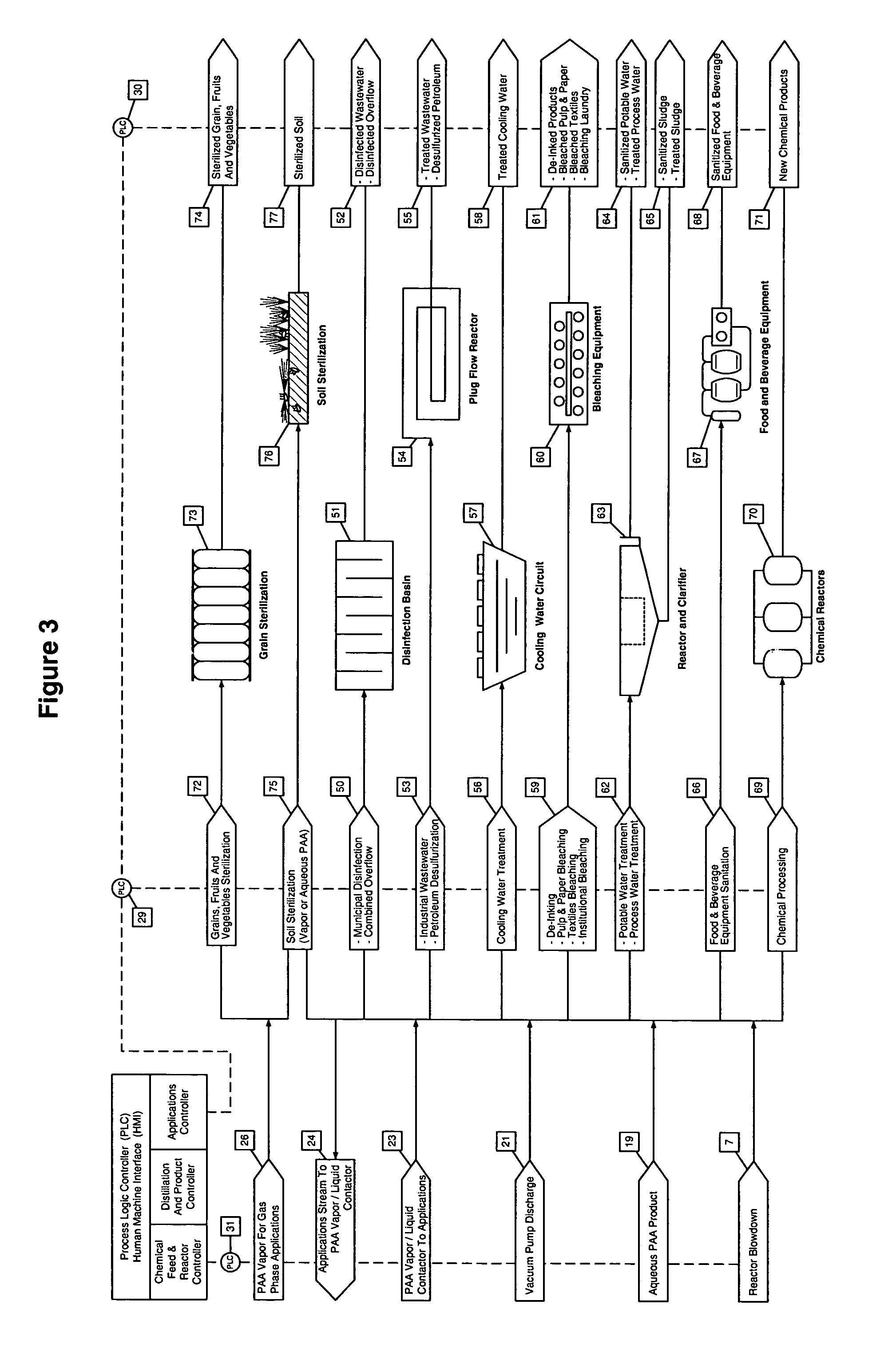

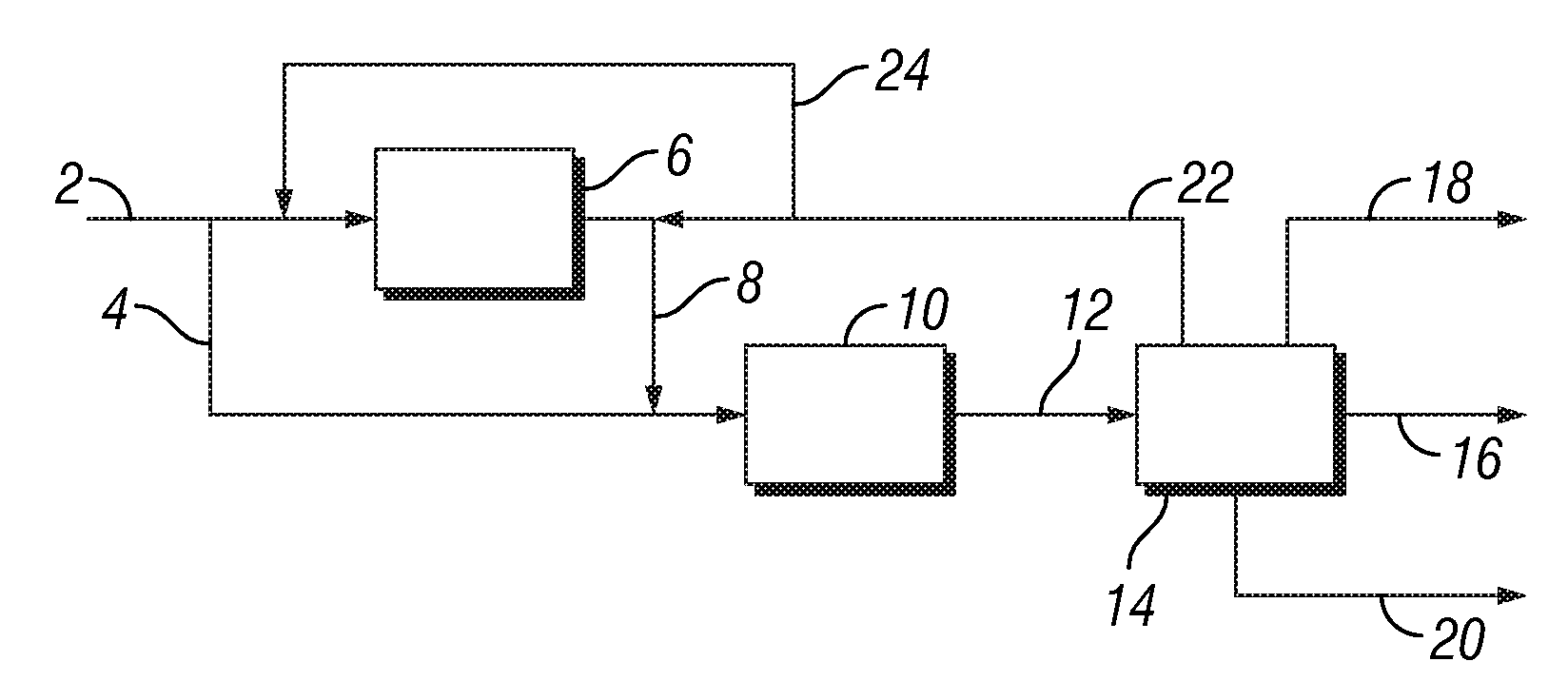

Continuous process for on-site and on-demand production of aqueous peracteic acid

ActiveUS7012154B2Low costSmall inventoryOrganic compound preparationOther chemical processesAcetic acidGas phase

Owner:ADVANCED PAA SOLUTIONS INC

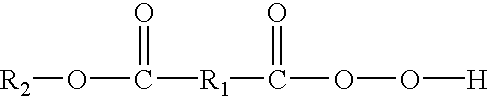

Stabilized ester peroxycarboxylic acid compositions

The present invention relates to stabilized compositions of an ester peroxycarboxylic acid, methods employing these stabilized compositions, and methods of making these compositions. Typically, the stabilized compositions also include a C.sub.2 or higher alcohol.

Owner:ECOLAB USA INC

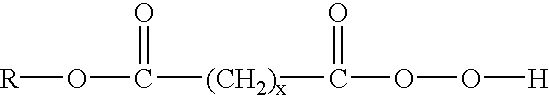

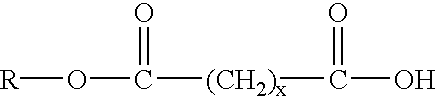

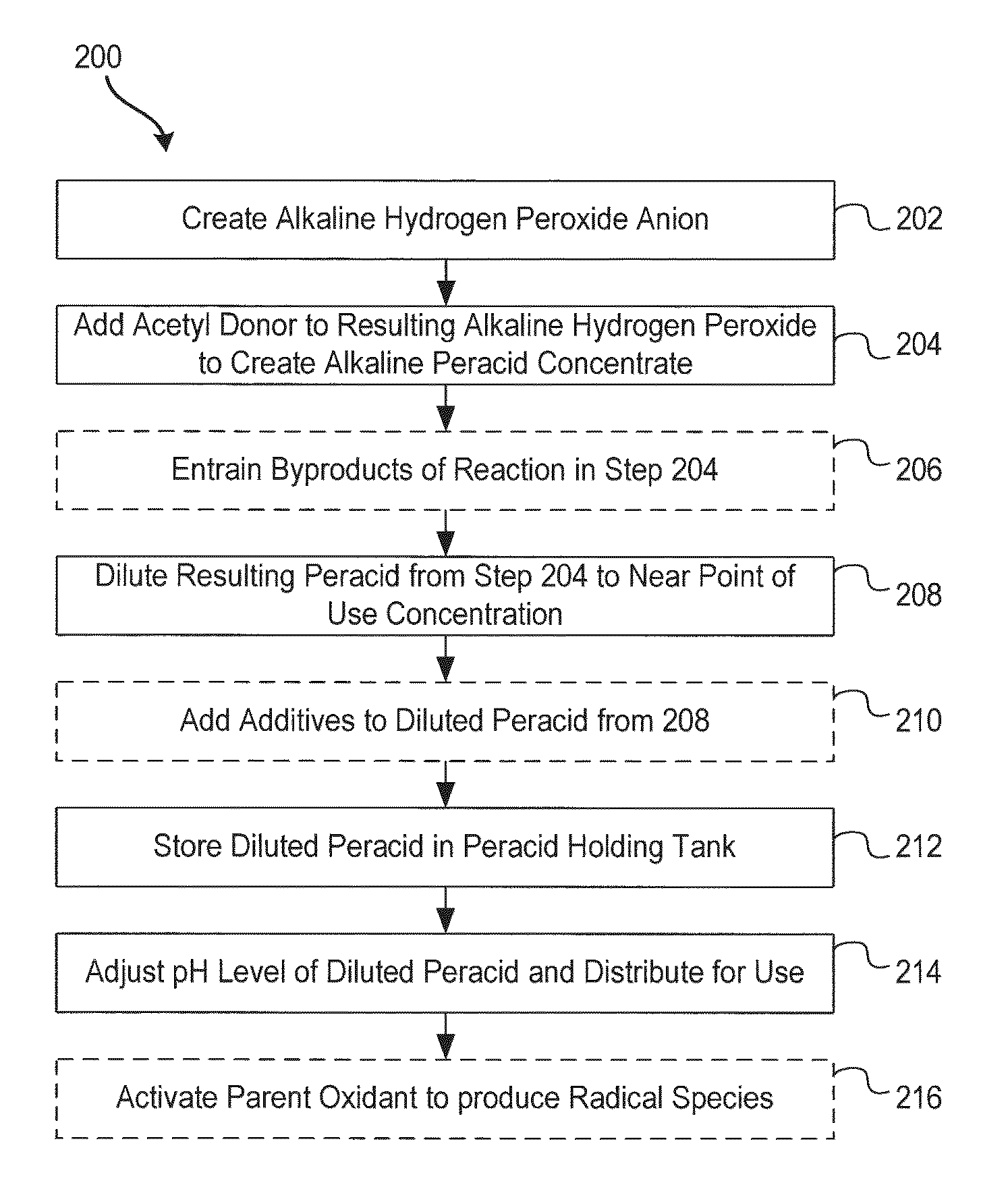

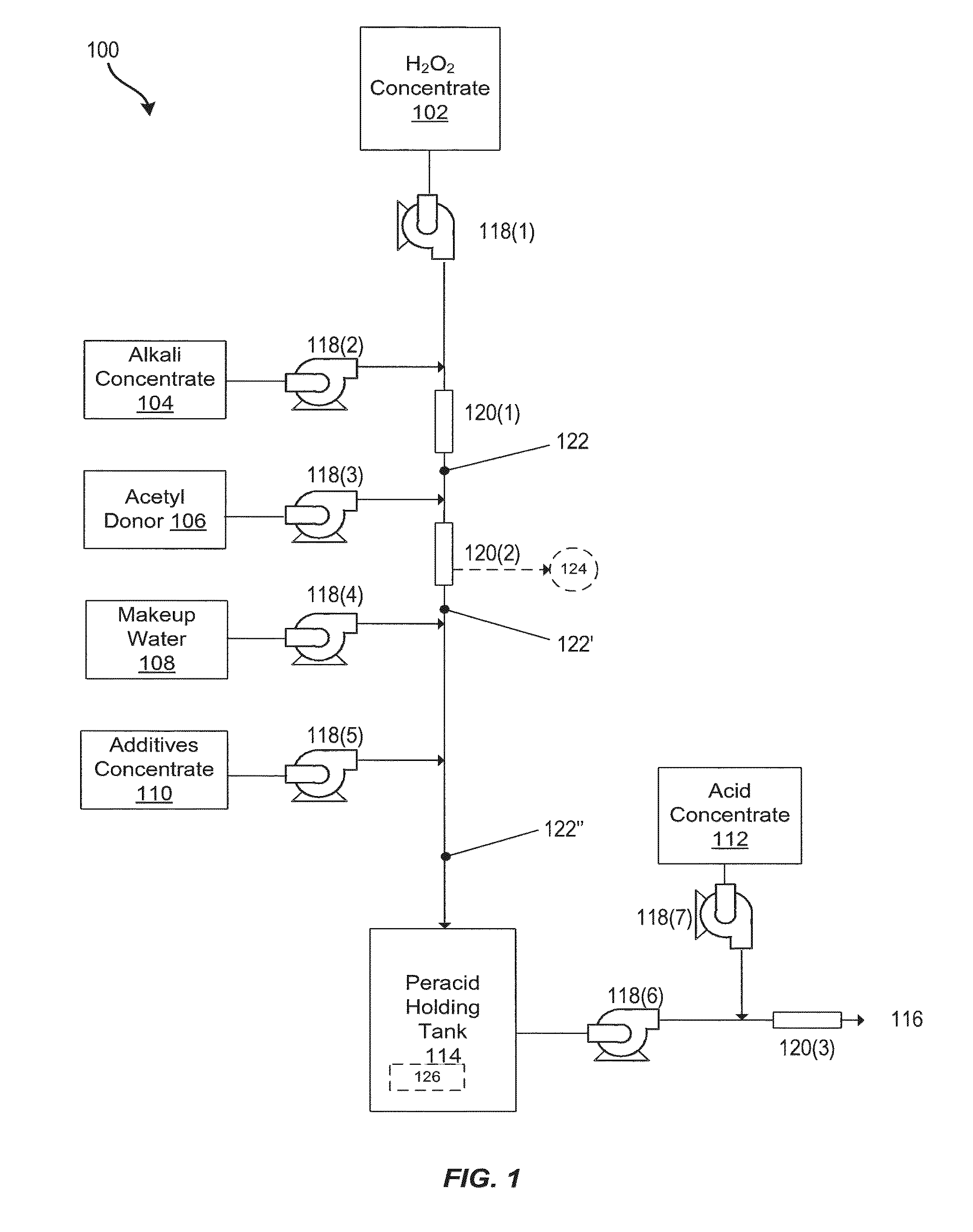

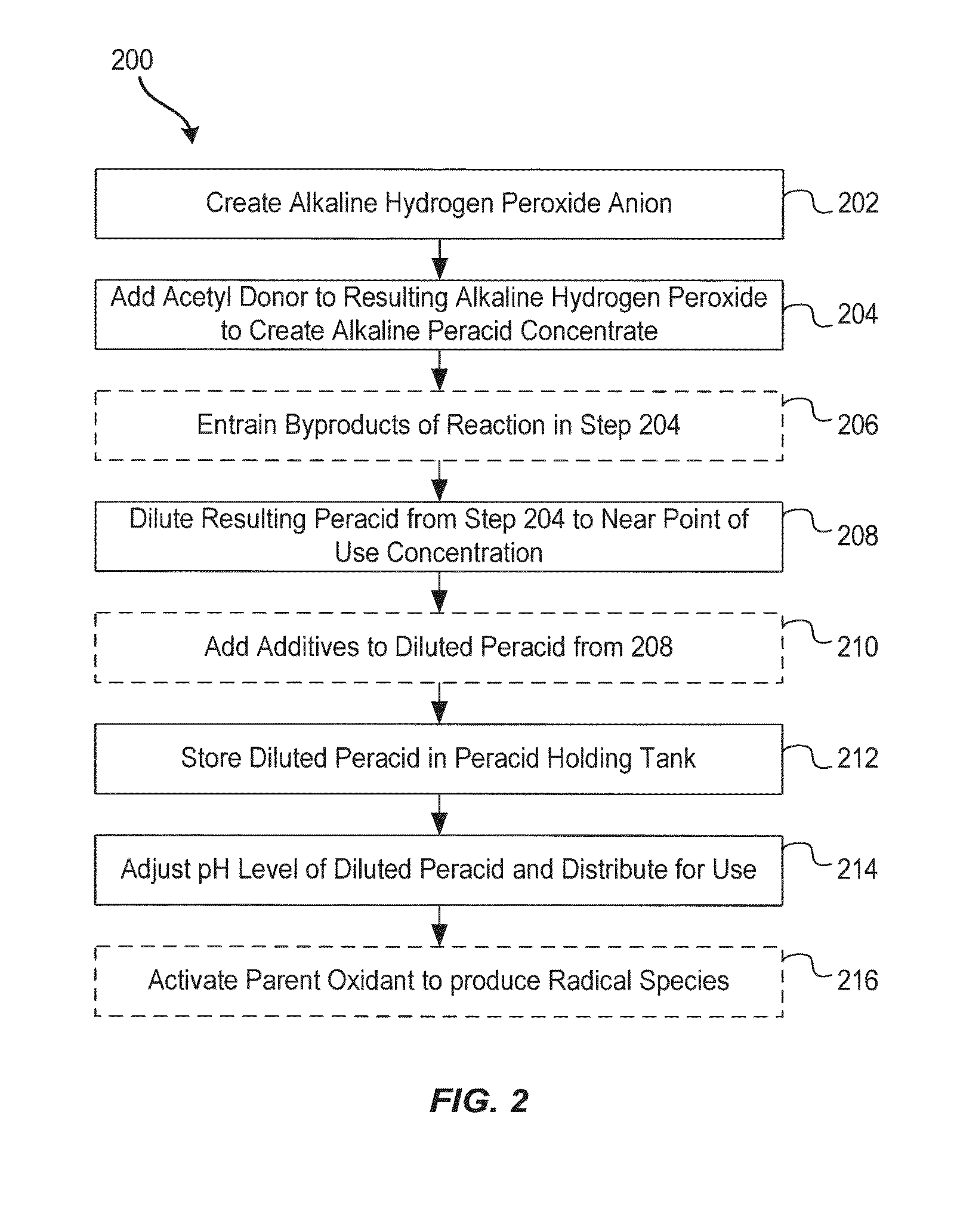

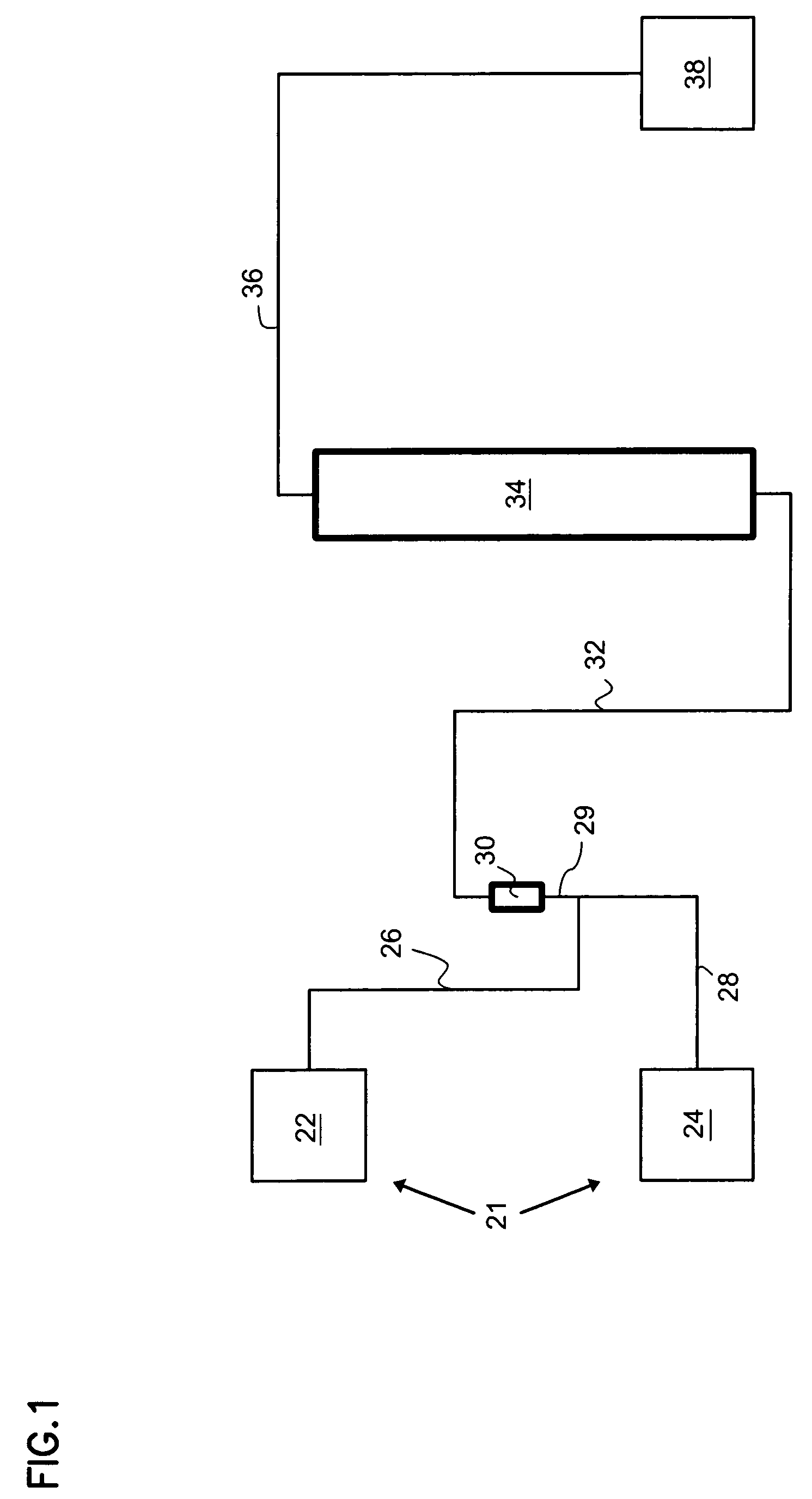

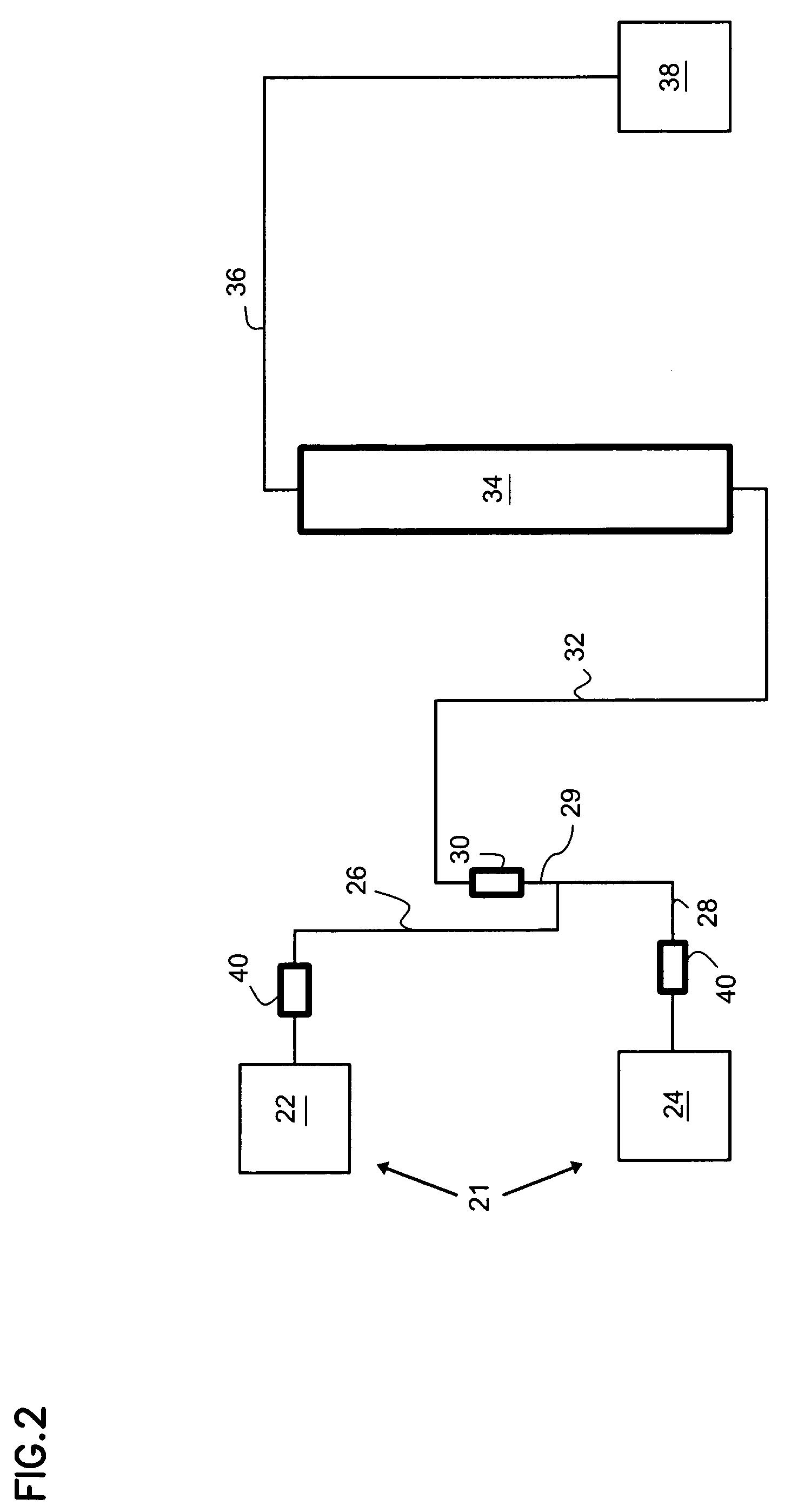

System and method for generation of point of use reactive oxygen species

Systems and methods for generating reactive oxygen species formulations useful in various oxidation applications. Exemplary formulations include singlet oxygen or superoxide and can also contain hydroxyl radicals or hydroperoxy radicals, among others. Formulations can contain other reactive species, including other radicals. Exemplary formulations containing peracids are activated to generate singlet oxygen. Exemplary formulations include those containing a mixture of superoxide and hydrogen peroxide. Exemplary formulations include those in which one or more components of the formulation are generated electrochemically. Formulations of the invention containing reactive oxygen species can be further activated to generate reactive oxygen species using activation chosen from a Fenton or Fenton-like catalyst, ultrasound, ultraviolet radiation or thermal activation. Exemplary applications of the formulations of the invention among others include: cleaning in place applications, water treatment, soil decontamination and flushing of well casings and water distribution pipes.

Owner:CLEAN CHEM

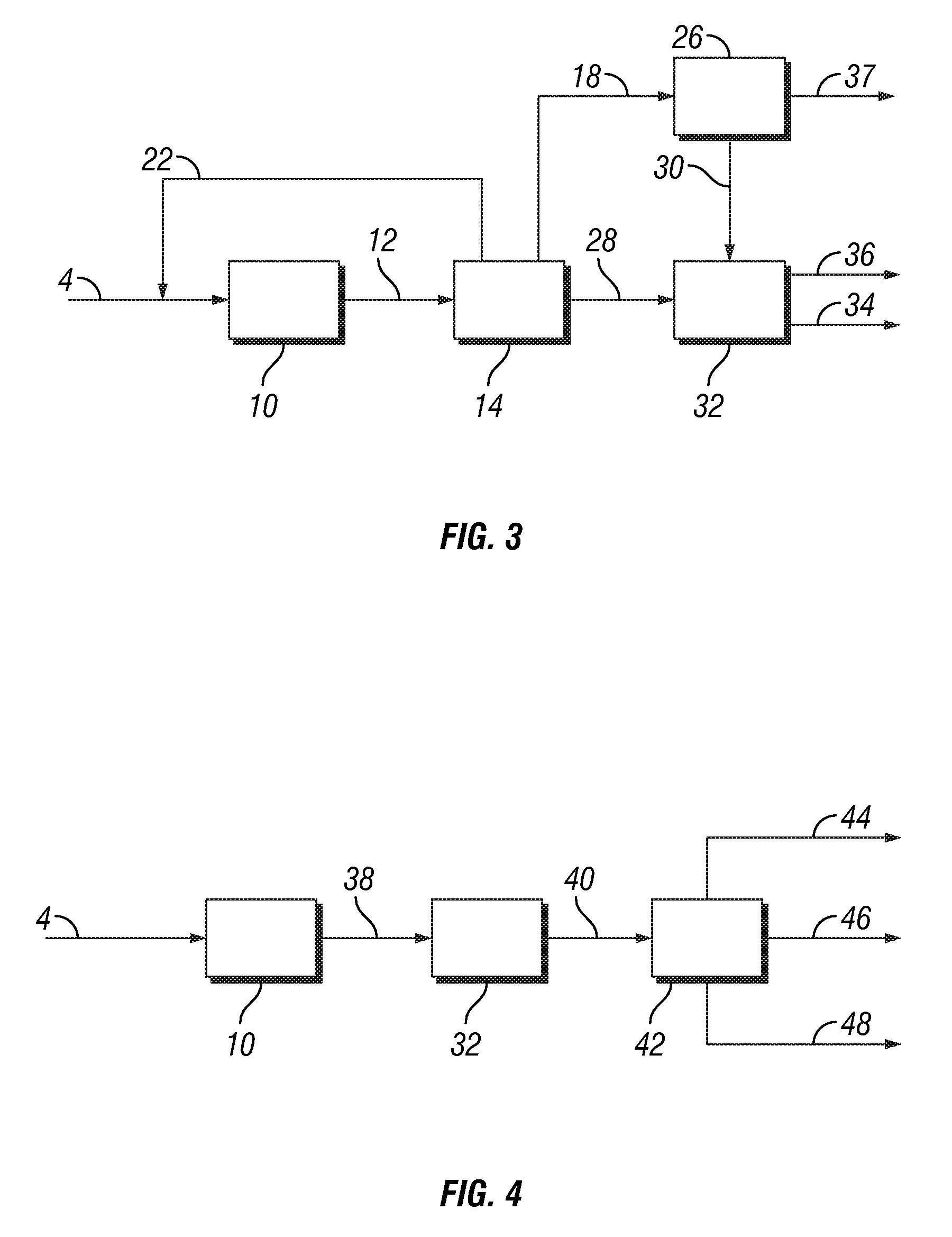

Process for the preparation of peroxy acids

ActiveUS20090221704A1Easy to controlIncrease powerBiocideOrganic compound preparationPeroxy acidCarboxylic acid

The present invention relates to a process for the preparation of a solution comprising a first peroxy acid comprising performic acid and a second peroxy acid, said process comprising forming a carboxylic acid solution comprising a first carboxylic acid comprising formic acid, a second carboxylic acid and hydrogen peroxide, wherein the amount of formic acid is from 0.5 to 20% by weight of the amount of the second carboxylic acid, and allowing the components to react to form a solution comprising performic acid and said second peroxy acid, the amount of peroxy acids being at least 5% by weight. The invention also relates to a storable solution comprising performic acid and said second peroxy acid. The solution can be used as a disinfecting agent for controlling micro-organisms.

Owner:KEMIRA OY

Composition for production of a sterilizer and a process for producing organic peracid

The invention provides a composition for production of a sterilizer having a water content of 1 to 25% by weight and comprising (A) an ester of a polyhydric alcohol and an organic acid having a hydrocarbon group which may have a hydroxyl group and (B1) hydrogen peroxide. From the composition, a sterilizer is obtained as an aqueous solution containing an organic peracid.

Owner:KAO CORP

Method and arrangement for the preparation of percarboxylic acid

InactiveUS7915445B2Easy to manufactureEasy to customizeOrganic compound preparationFractional distillationCarboxylic acid

Owner:KEMIRA OY

Process for preparation of hydroperoxides

Owner:REPSOL QUIMICA

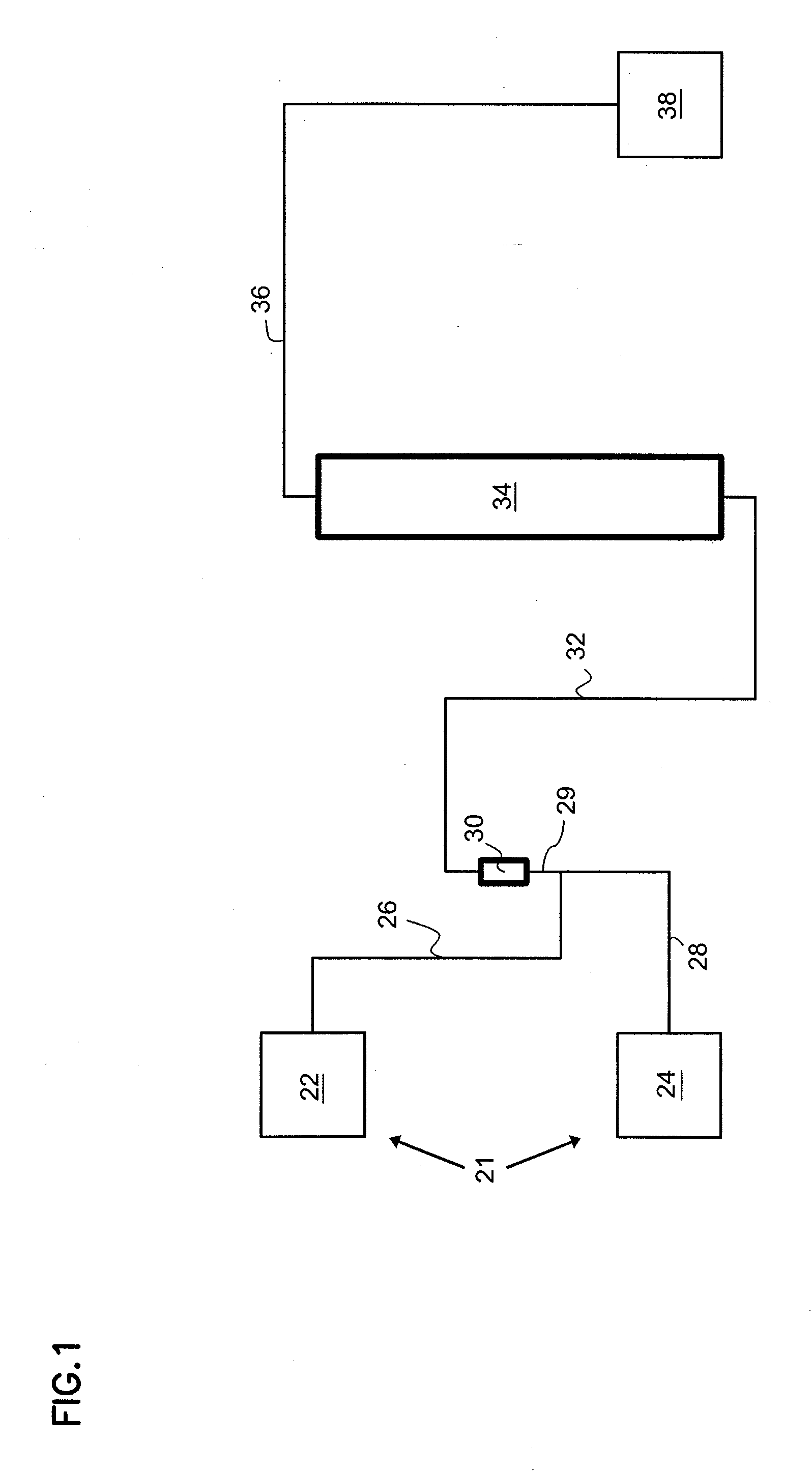

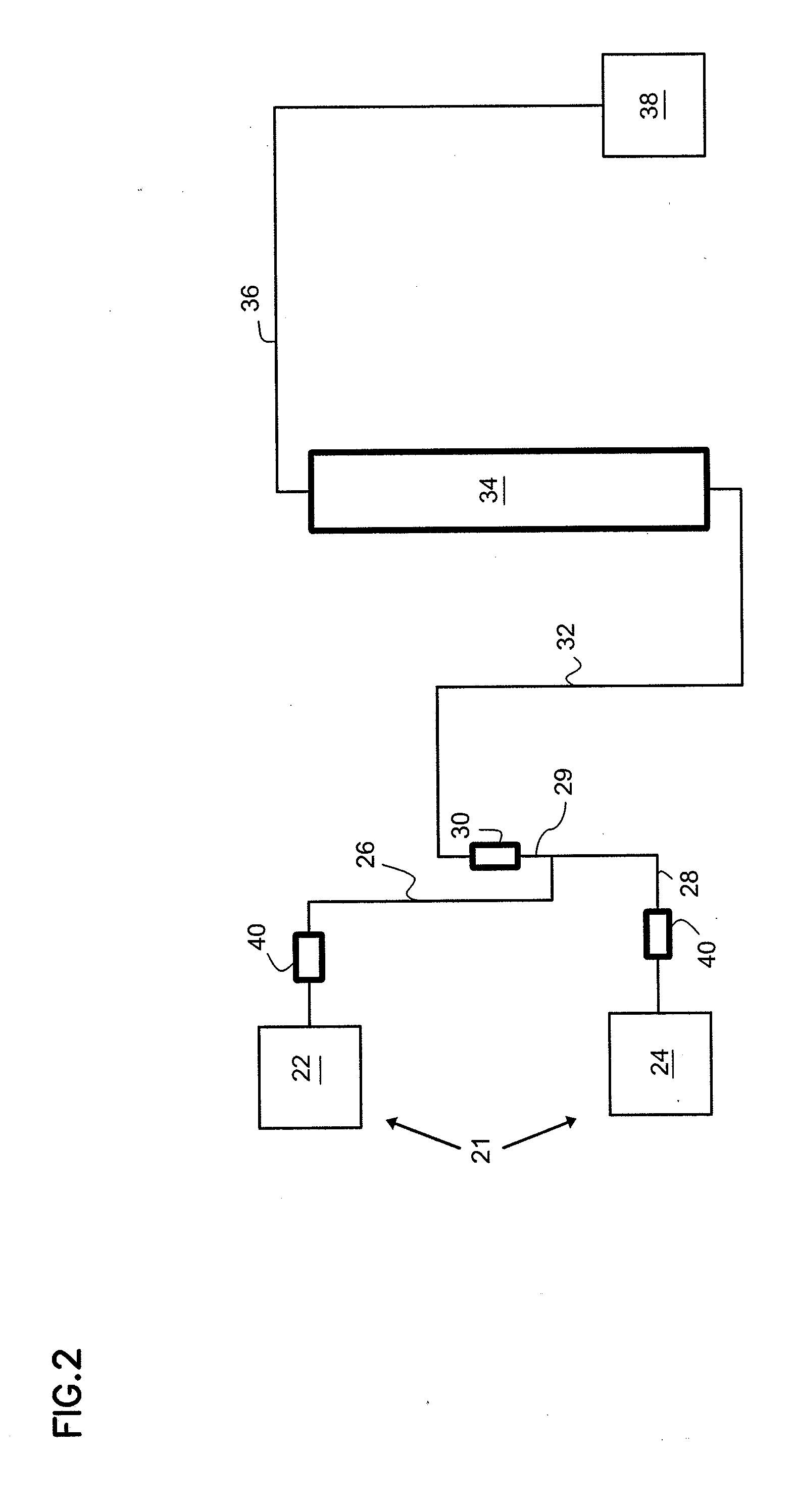

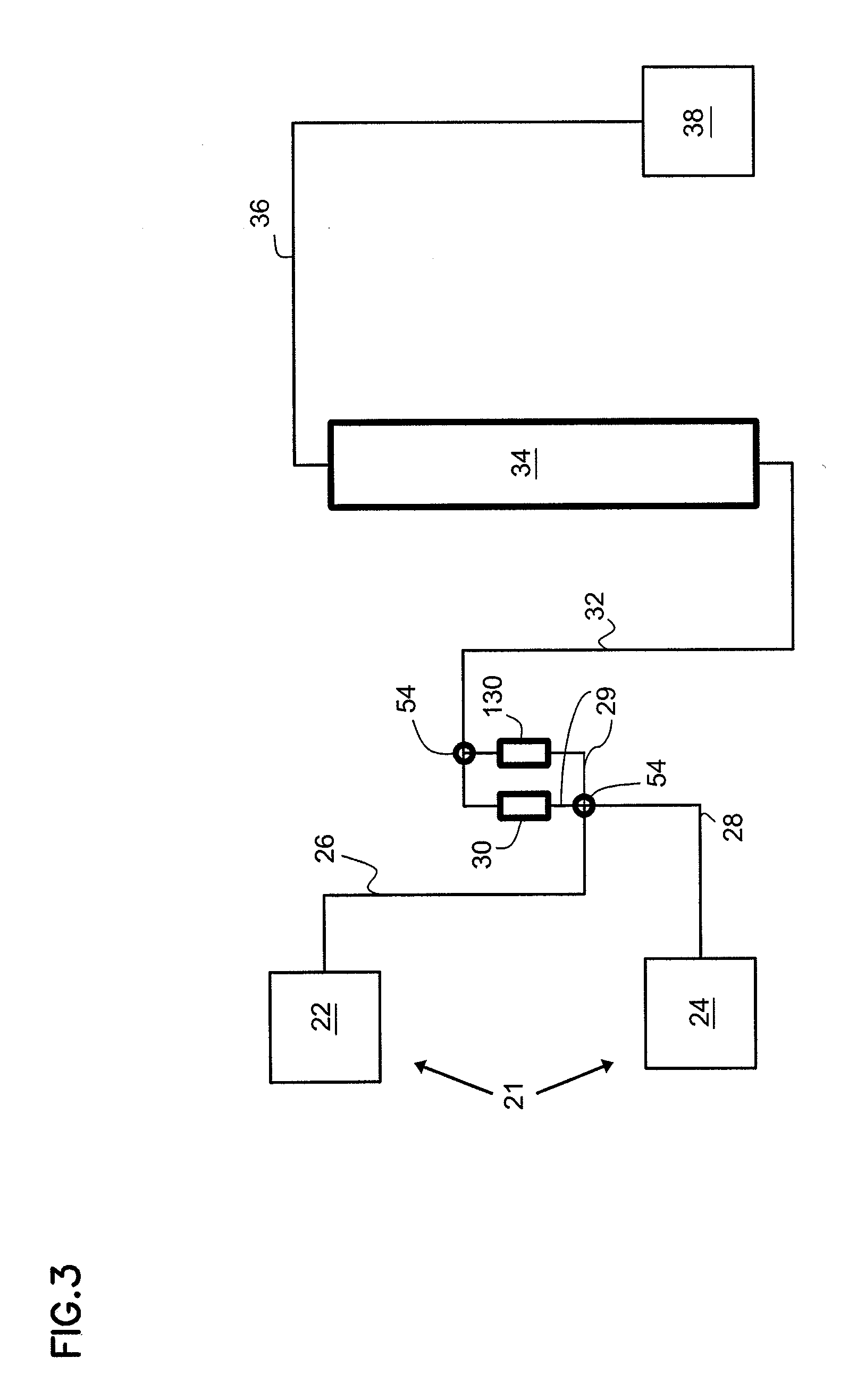

Apparatus and method for making a peroxycarboxylic acid

ActiveUS7547421B2Increase life and activity and safetyProcess control/regulationExhaust apparatusCarboxylic acidReagent

Owner:ECOLAB USA INC

Process for the conversion of ethane to mixed lower alkanes to aromatic hydrocarbons

A process for producing aromatic hydrocarbons which comprises a) contacting ethane or mixed lower alkanes with an aromatic hydrocarbon conversion catalyst to produce reaction products including benzene, b) separating methane, hydrogen, and C2-5 hydrocarbons from the reaction products of step a), and c) hydrodealkylating the remaining reaction products to produce benzene. In a preferred embodiment, the feed is split into two streams, one of which is catalytically or thermally cracked to produce ethylene which is then combined with the remaining ethane or lower alkanes and contacted with the aromatic hydrocarbon conversion catalyst.

Owner:SHELL OIL CO

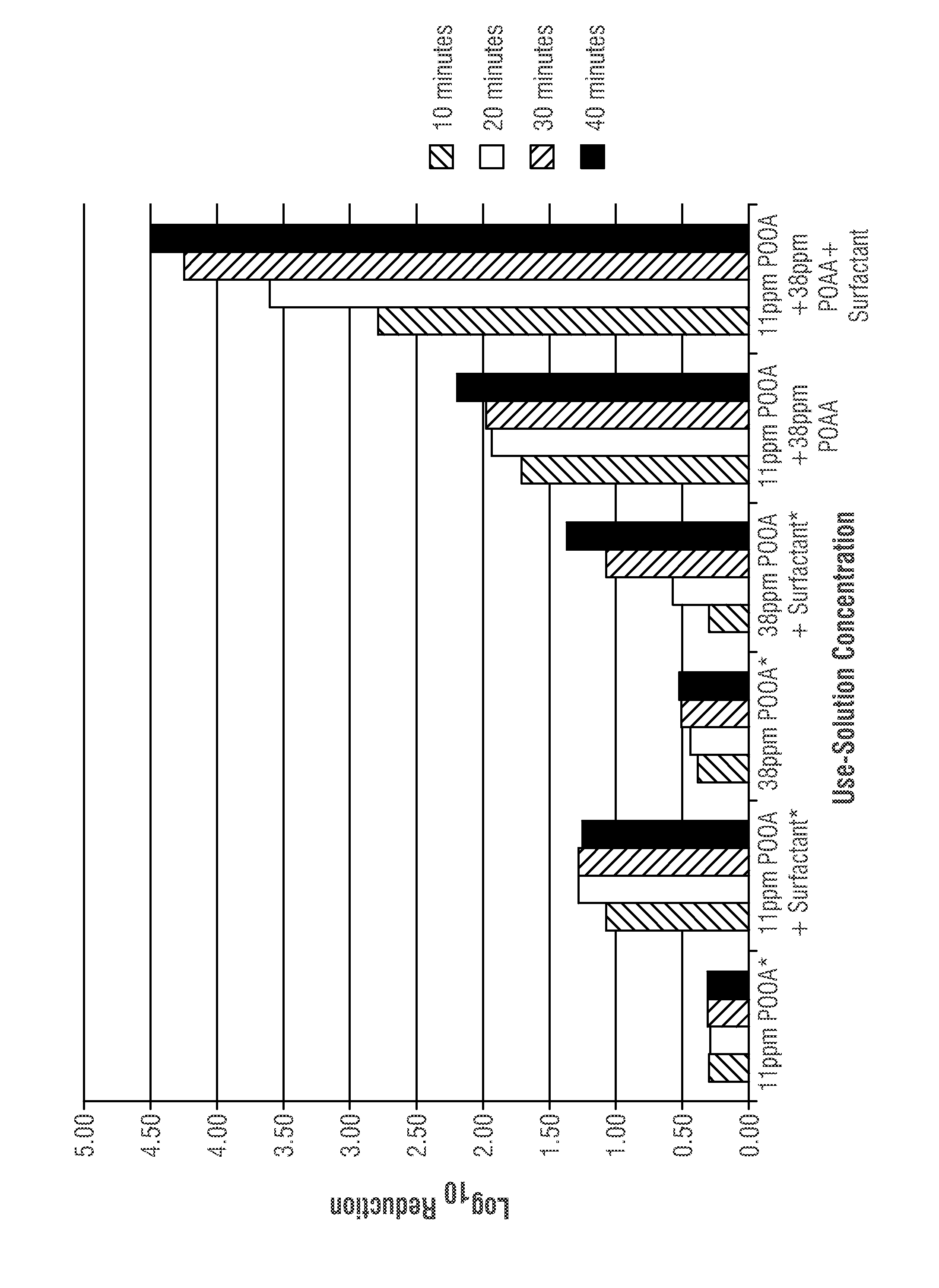

Methods for washing and processing fruits, vegetables, and other produce with medium chain peroxycarboxylic acid compositions

ActiveUS20050151117A1Reduce Microbial ContaminationReduce the burden onBiocideSurface-active detergent compositionsMicroorganismCarboxylic acid

The present invention relates to methods employing compositions including medium chain peroxycarboxylic acid for reducing microbial contamination on fruit, vegetable, or other produce; in waters used to transport or process fruit, vegetable, or other produce; or on surfaces employed in transporting or processing fruit, vegetable, or other produce. The present invention also relates to the medium chain peroxycarboxylic acid compositions. The methods include applying a medium chain peroxycarboxylic acid composition to fruit, vegetable, or other produce; into waters used to transport or process fruit, vegetable, or other produce; or to surfaces employed in transporting or processing fruit, vegetable, or other produce.

Owner:ECOLAB USA INC

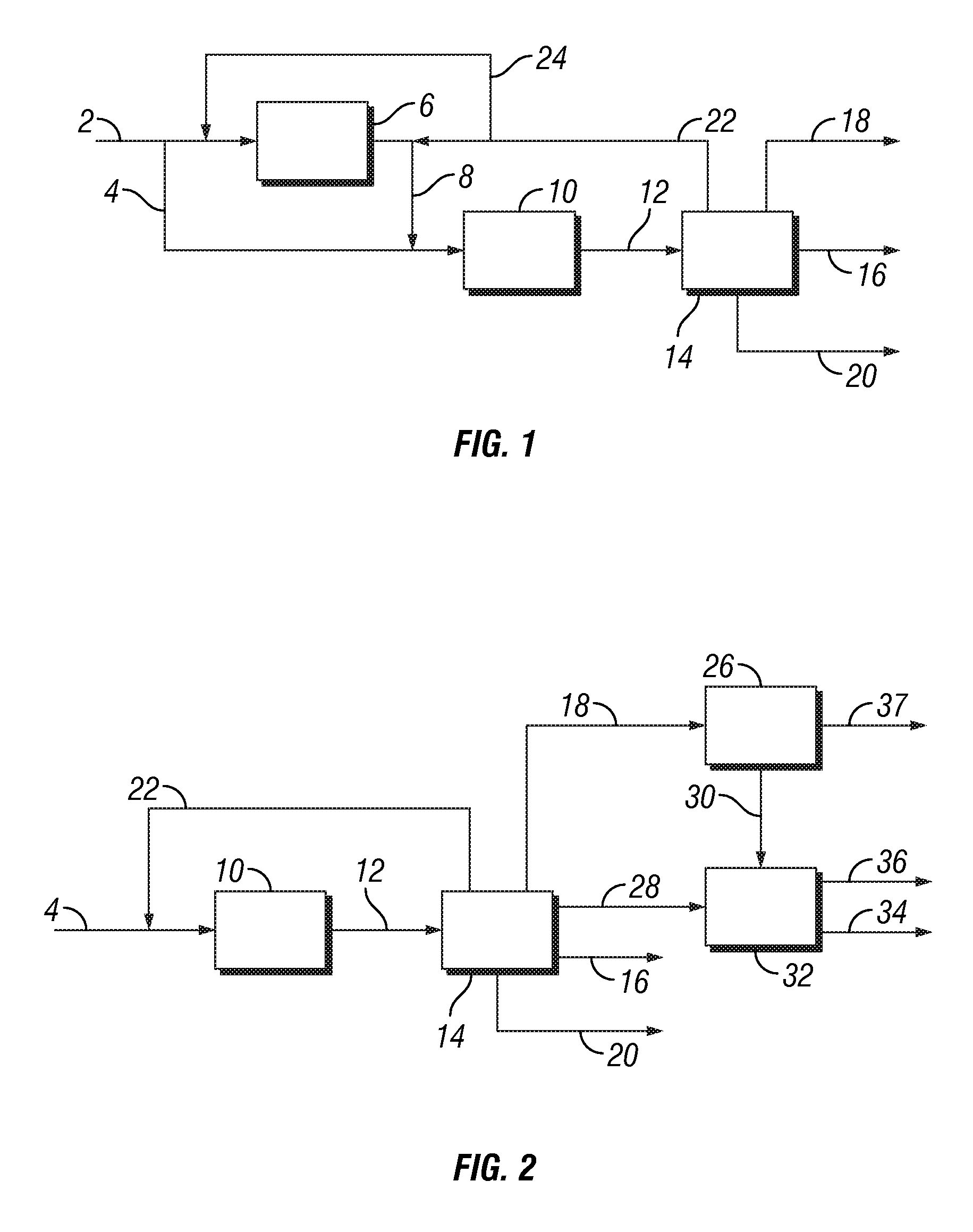

Process for the preparation of peroxy acids

ActiveUS8828910B2Easy to controlIncrease powerBiocideOrganic compound preparationCarboxylic acidPeroxy acid

The present invention relates to a process for the preparation of a solution comprising a first peroxy acid comprising performic acid and a second peroxy acid, said process comprising forming a carboxylic acid solution comprising a first carboxylic acid comprising formic acid, a second carboxylic acid and hydrogen peroxide, wherein the amount of formic acid is from 0.5 to 20% by weight of the amount of the second carboxylic acid, and allowing the components to react to form a solution comprising performic acid and said second peroxy acid, the amount of peroxy acids being at least 5% by weight. The invention also relates to a storable solution comprising performic acid and said second peroxy acid. The solution can be used as a disinfecting agent for controlling micro-organisms.

Owner:KEMIRA OY

Generation of peroxycarboxylic acids at alkaline pH, and their use as textile bleaching and antimicrobial agents

The present disclosure provides methods for generating percarboxylic acid compositions and / or peroxycarboxylic acid compositions formed external to a point of use in non-equilibrium reactions for use in certain bleaching and antimicrobial applications, in particular laundry applications. The compositions are generated external to a point of use, at alkaline pH levels, viz. greater than about pH 12, and optionally suitable for use with detergents and / or surfactants for synergistic bleaching efficacy. Methods of bleaching and / or disinfecting are further provided.

Owner:ECOLAB USA INC

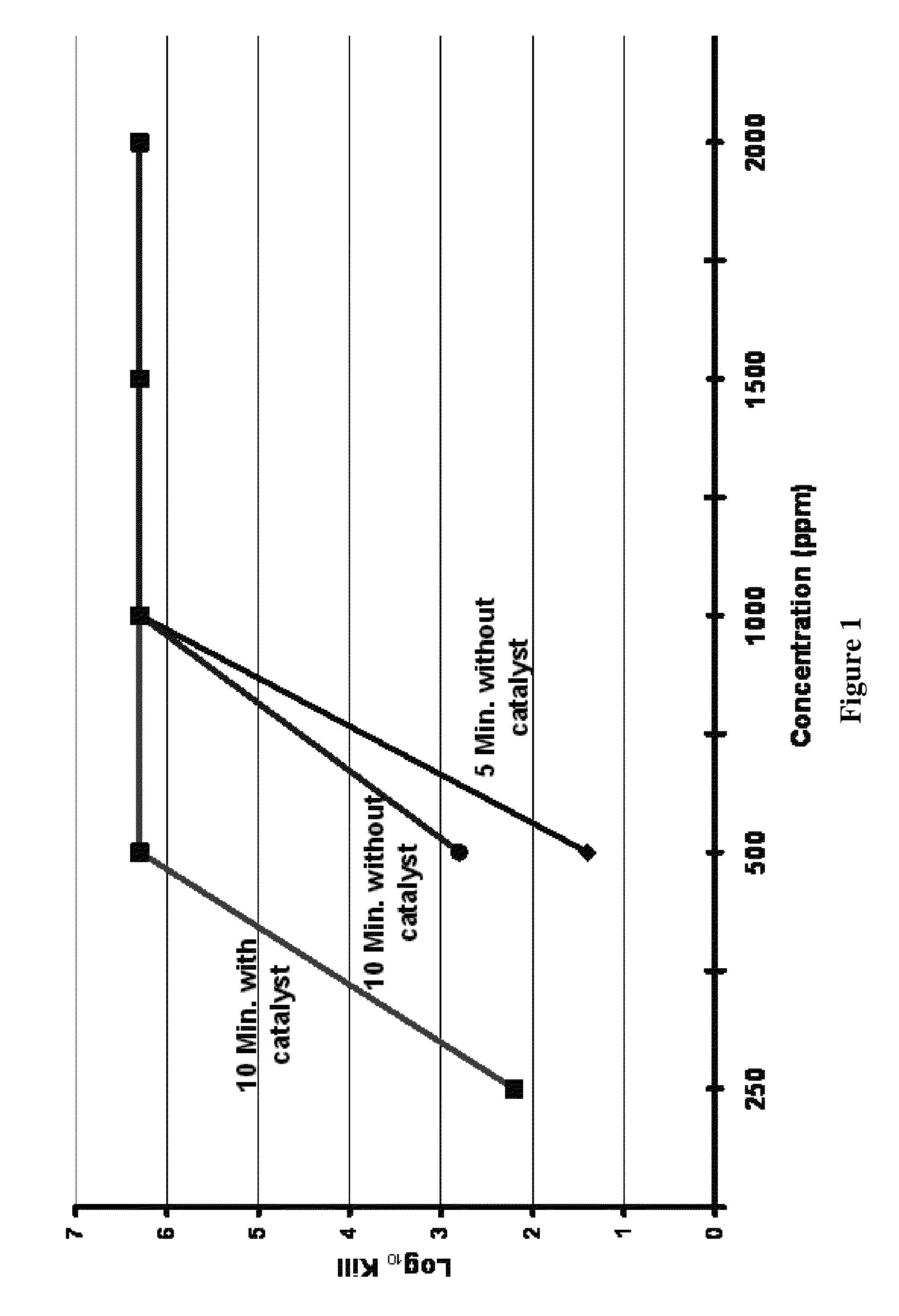

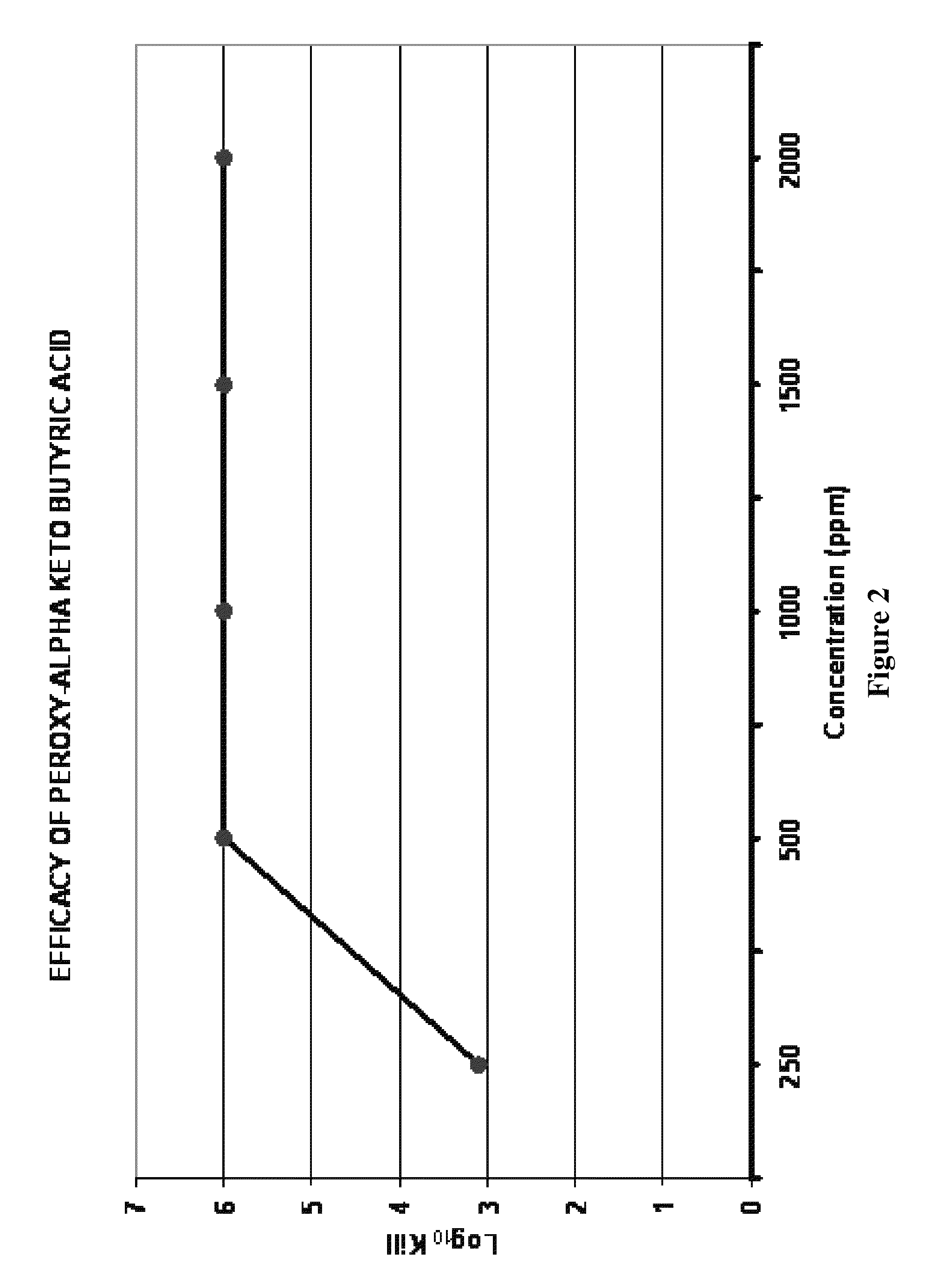

Alpha-keto peracids and methods for producing and using the same

The present invention provides α-keto peracids and methods for producing and using the same. In particular, α-keto peracids are useful as antimicrobial agents.

Owner:ARMIS BIOPHARMA INC

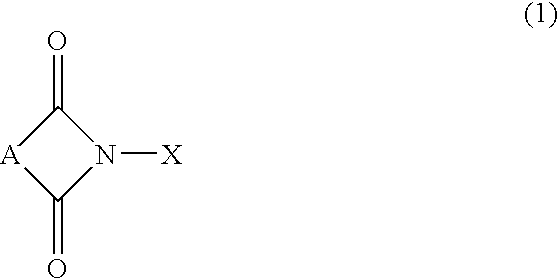

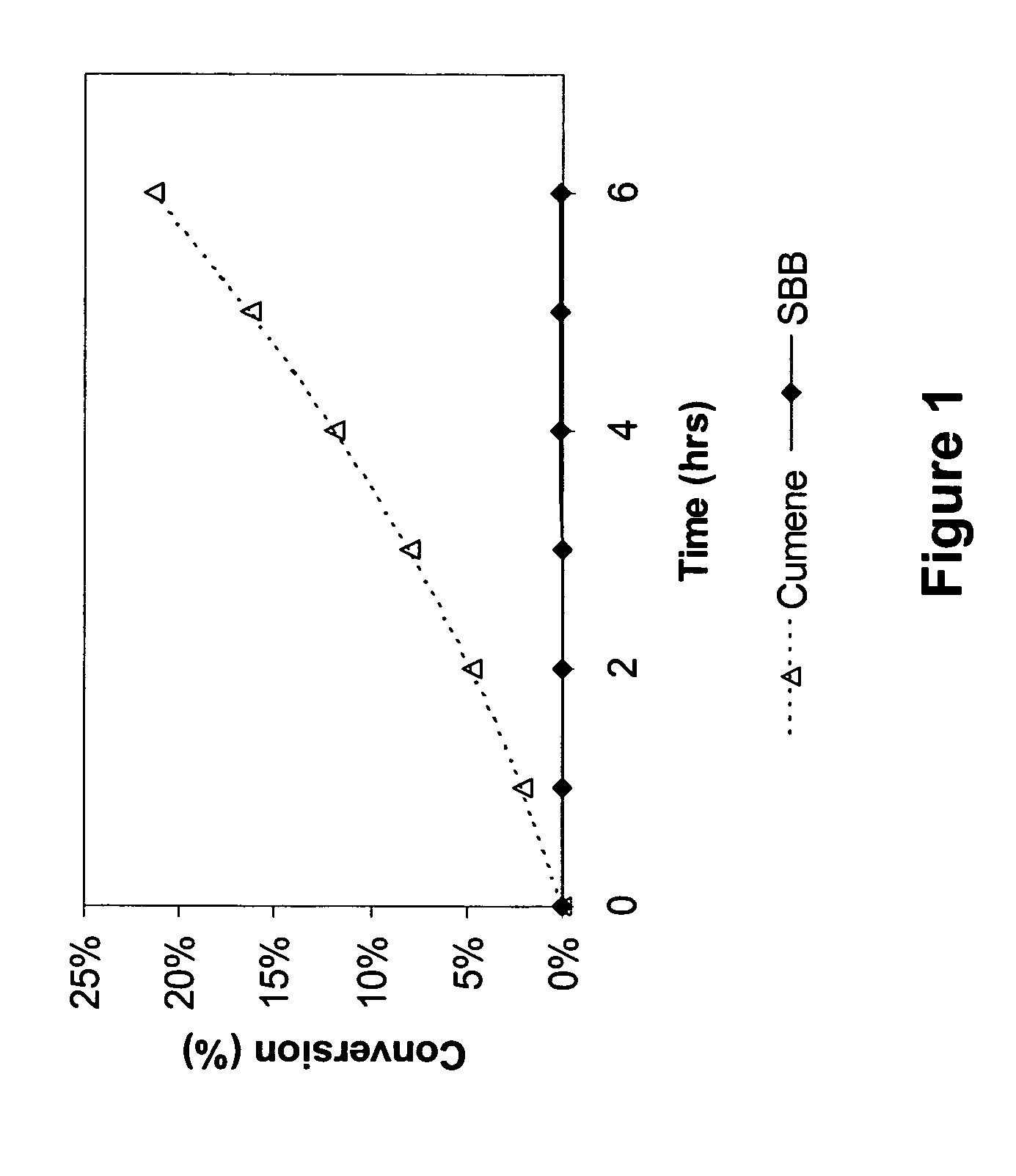

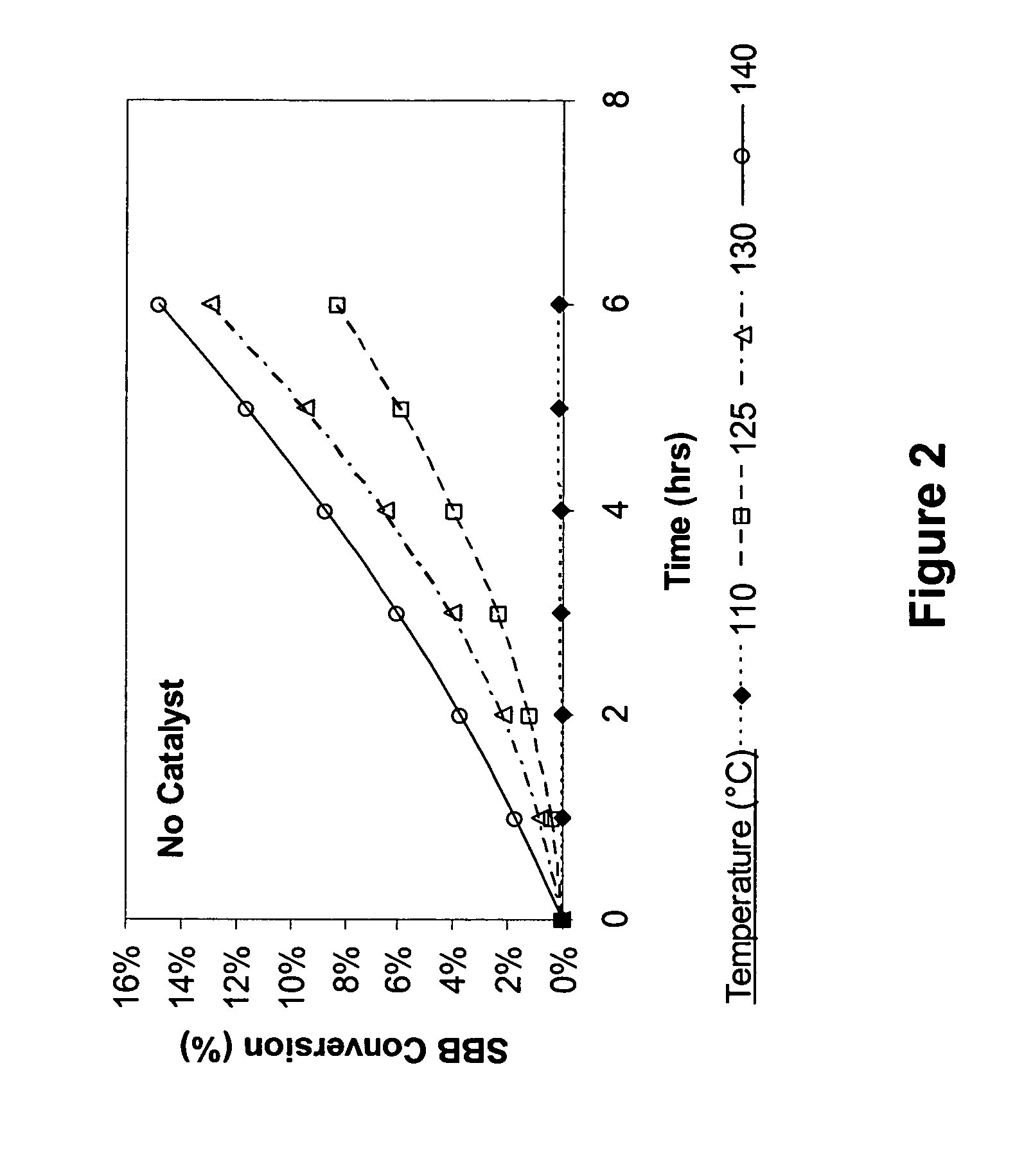

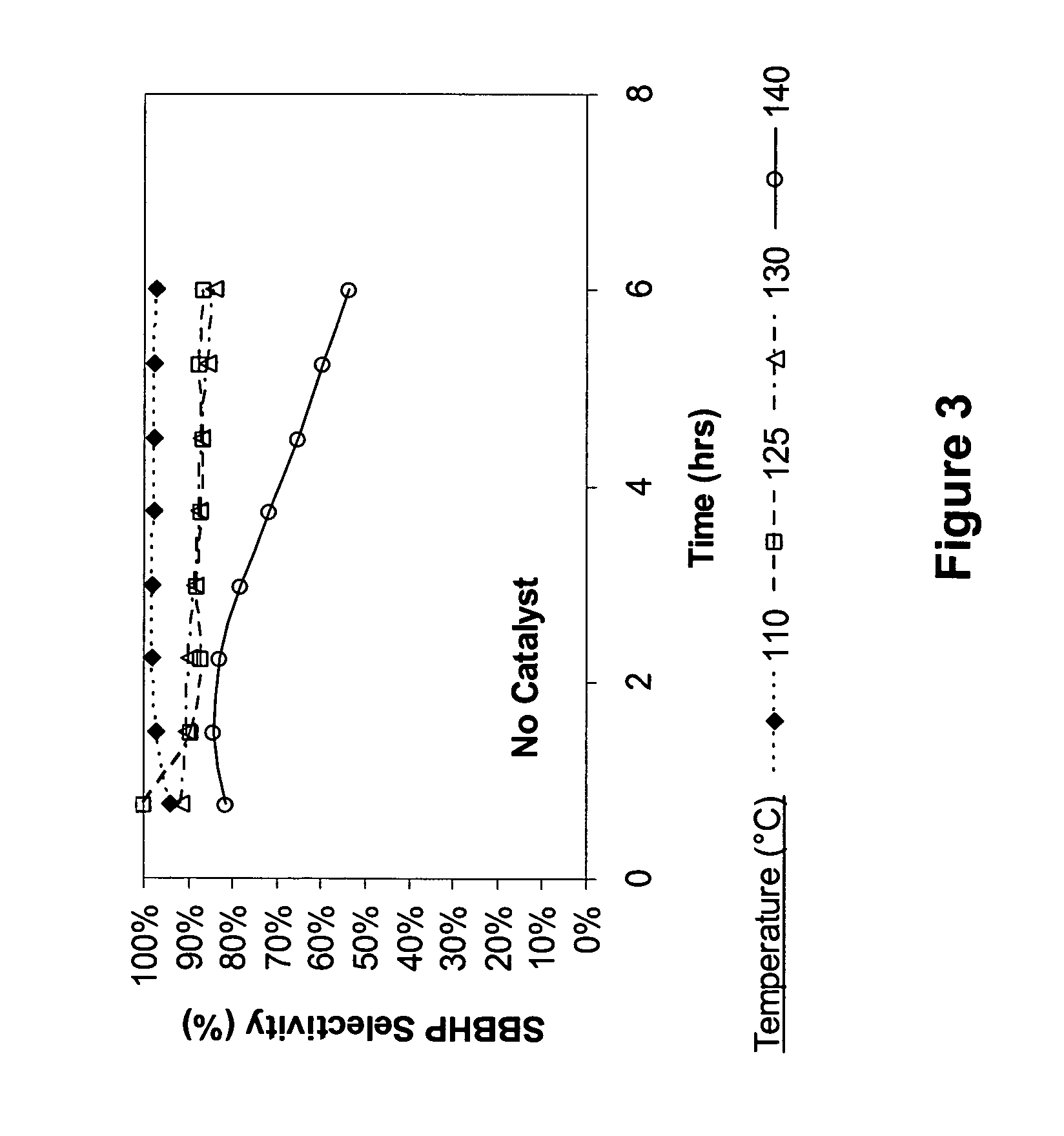

Selective oxidation of alkylbenzenes

InactiveUS20070265476A1Organic compound preparationOrganic chemistry methodsAlkaline earth metalStructural isomer

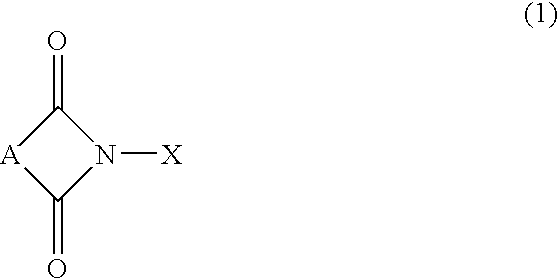

The present invention relates to a process for producing phenol and a ketone of general formula R1COCH2R2 (I), in which R1 and R2 each independently represent an alkyl group having from 1 to 4 carbon atoms, said process comprising: (a) providing an alkylbenzene feedstock comprising (i) an alkylbenzene of general formula (II) in which R1 and R2 have the same meaning as in formula (I) and (ii) at least one structural isomer of said alkylbenzene of formula (II) in an amount of at least 0.7% of the weight of alkylbenzene of formula (II), (b) submitting the alkylbenzene feedstock to oxidation conditions in the presence of oxygen and in the presence of a cyclic imide of formula (III): in which X represents a carbonyl (CO) group or a sulfonyl (SO2) group, n is 0, 1, 2, 3 or 4, R3 is one or several groups selected from a hydrogen atom, a halogen atom, an alkyl group, an alkoxy group, an amino group and R4 is a hydrogen atom, an alkaline metal cation or an alkaline earth metal cation, or in the presence of N,N′,N″-trihydroxyisocyanuric acid (THICA), to produce a product comprising a hydroperoxide of general formula (IV) in which R1 and R2 have the same meaning as in formula (I), and (c) converting the hydroperoxide of formula (IV) into phenol and a ketone of formula (I).

Owner:EXXONMOBIL CHEM PAT INC

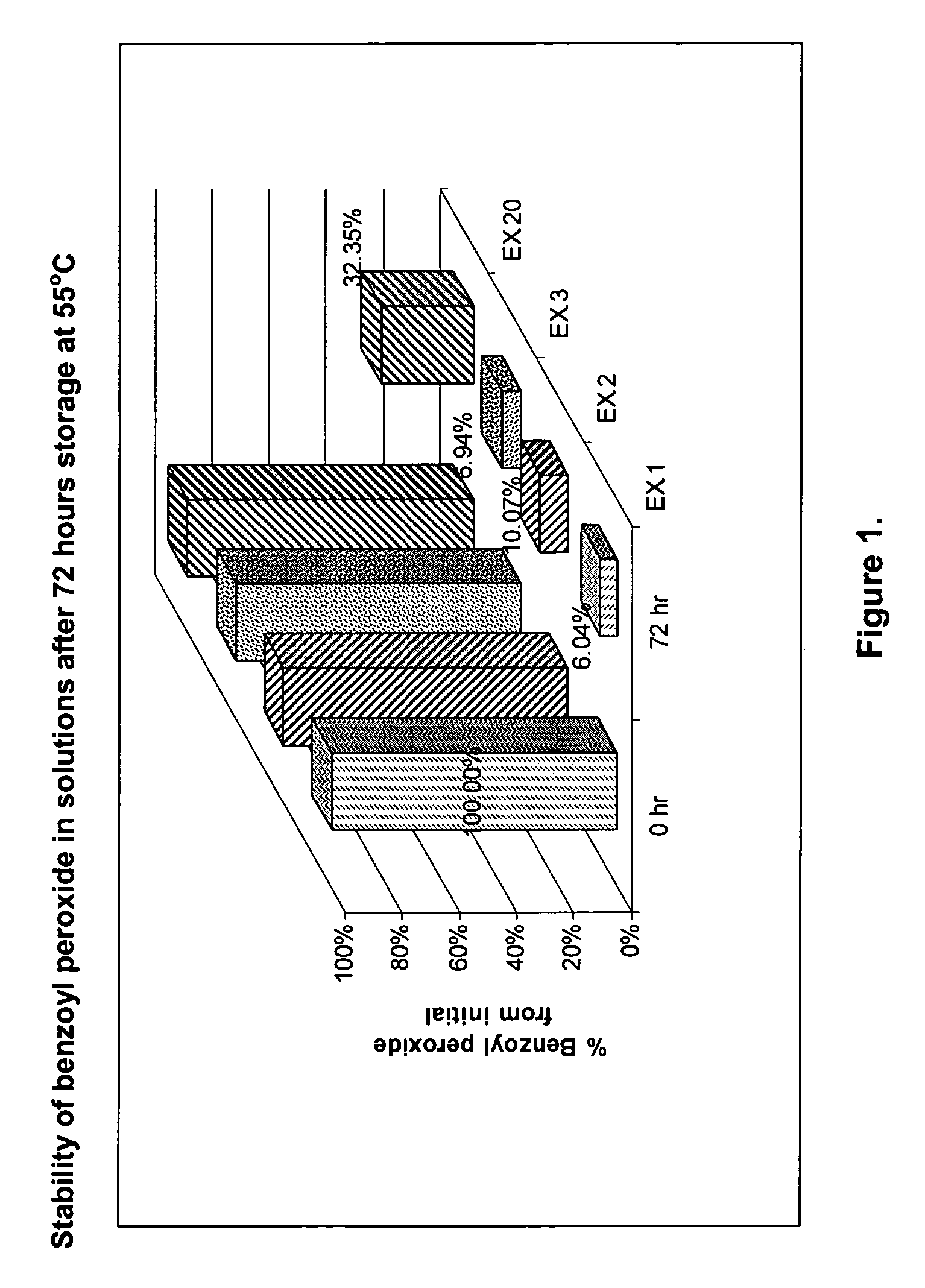

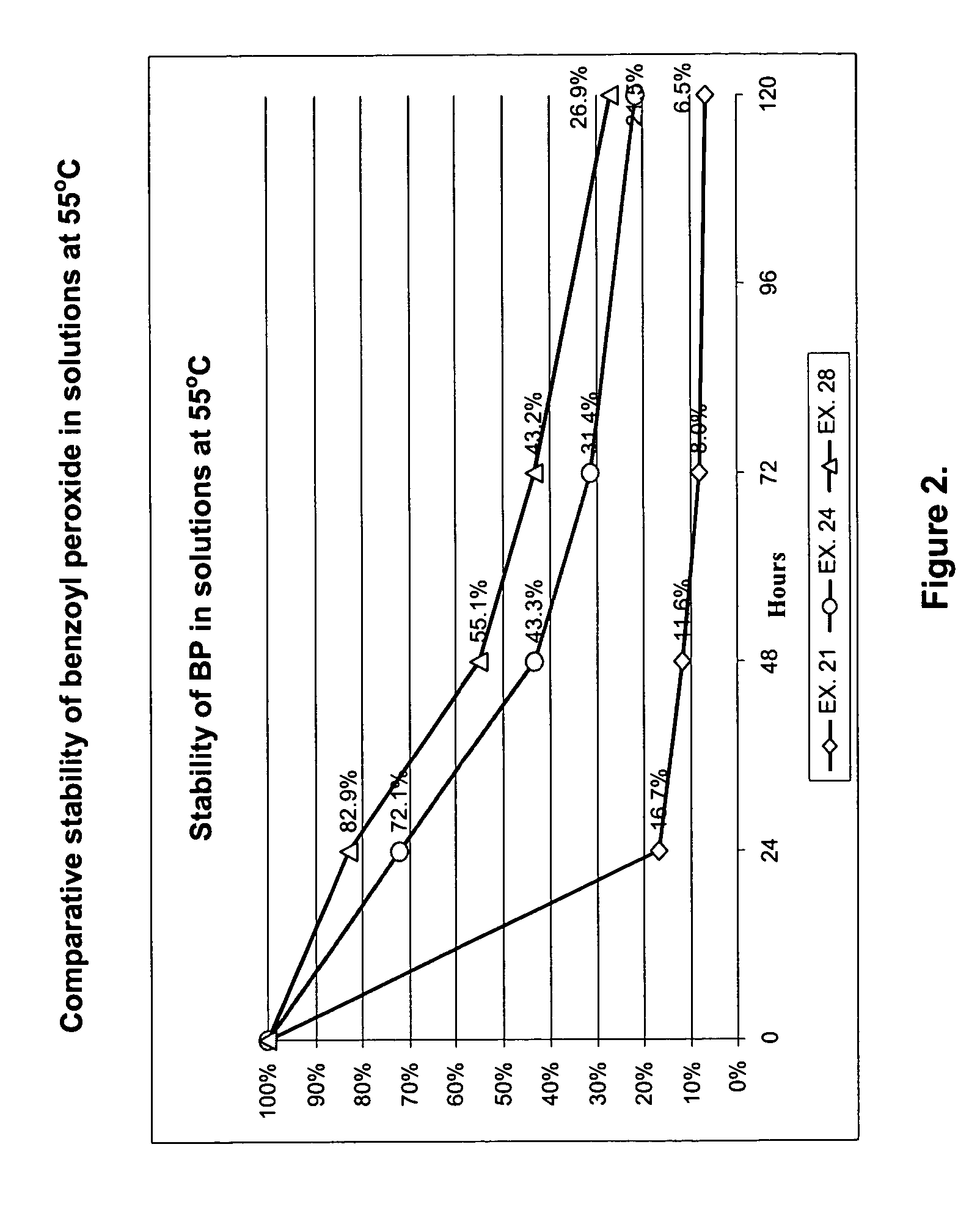

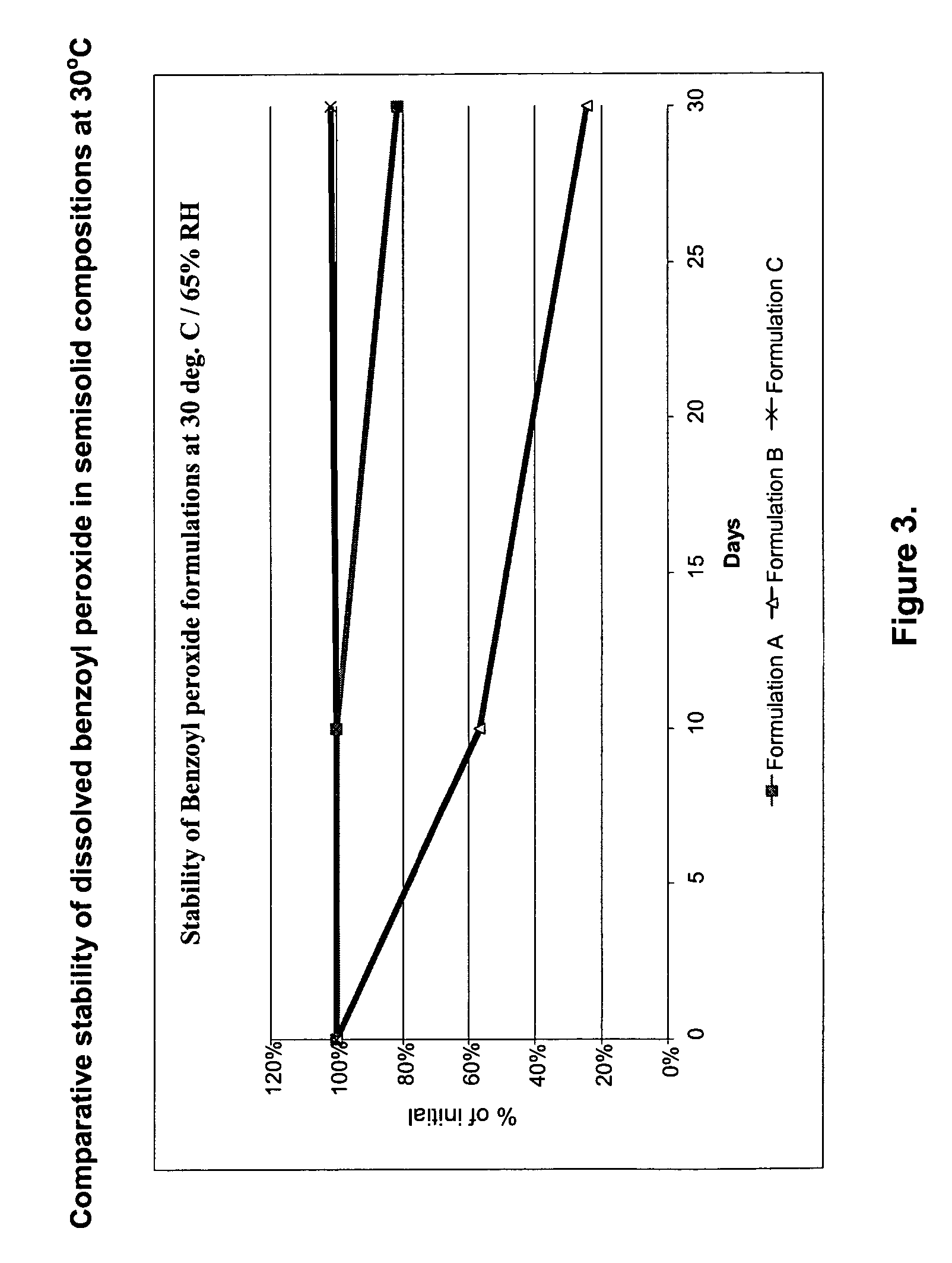

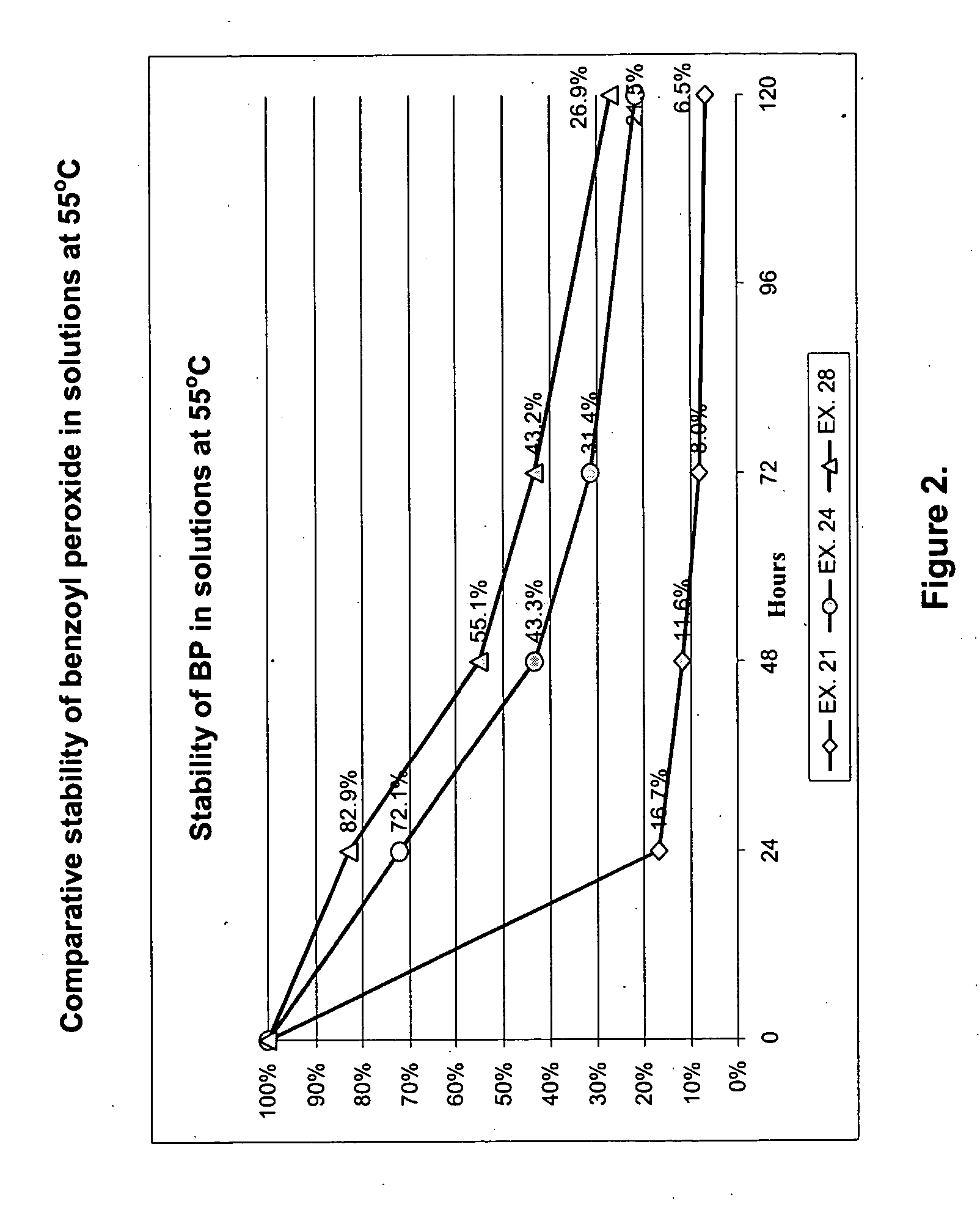

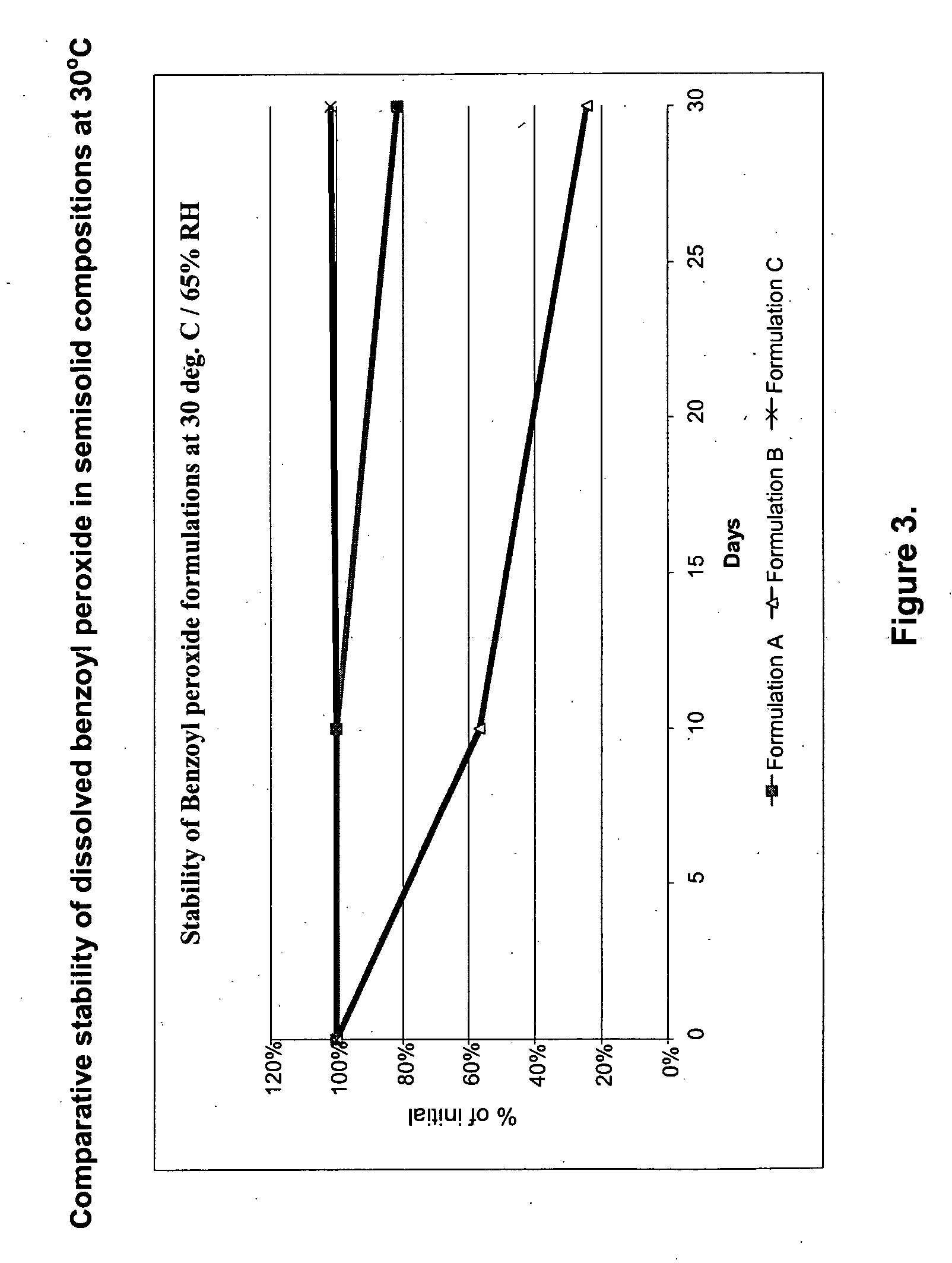

Stabilization of benzoyl peroxide in solution

InactiveUS7153888B2Minimal skin irritating propertiesPrevent degradationBiocideOrganic compound preparationBenzoyl peroxideDibenzoyl Peroxide

The stabilization of benzoyl peroxide for extended periods of time is disclosed. The stabilized solution contains from between 0.5% and 20% organic peroxide and a stabilizer for preventing degradation of said peroxide in the solution.

Owner:ALPHARX

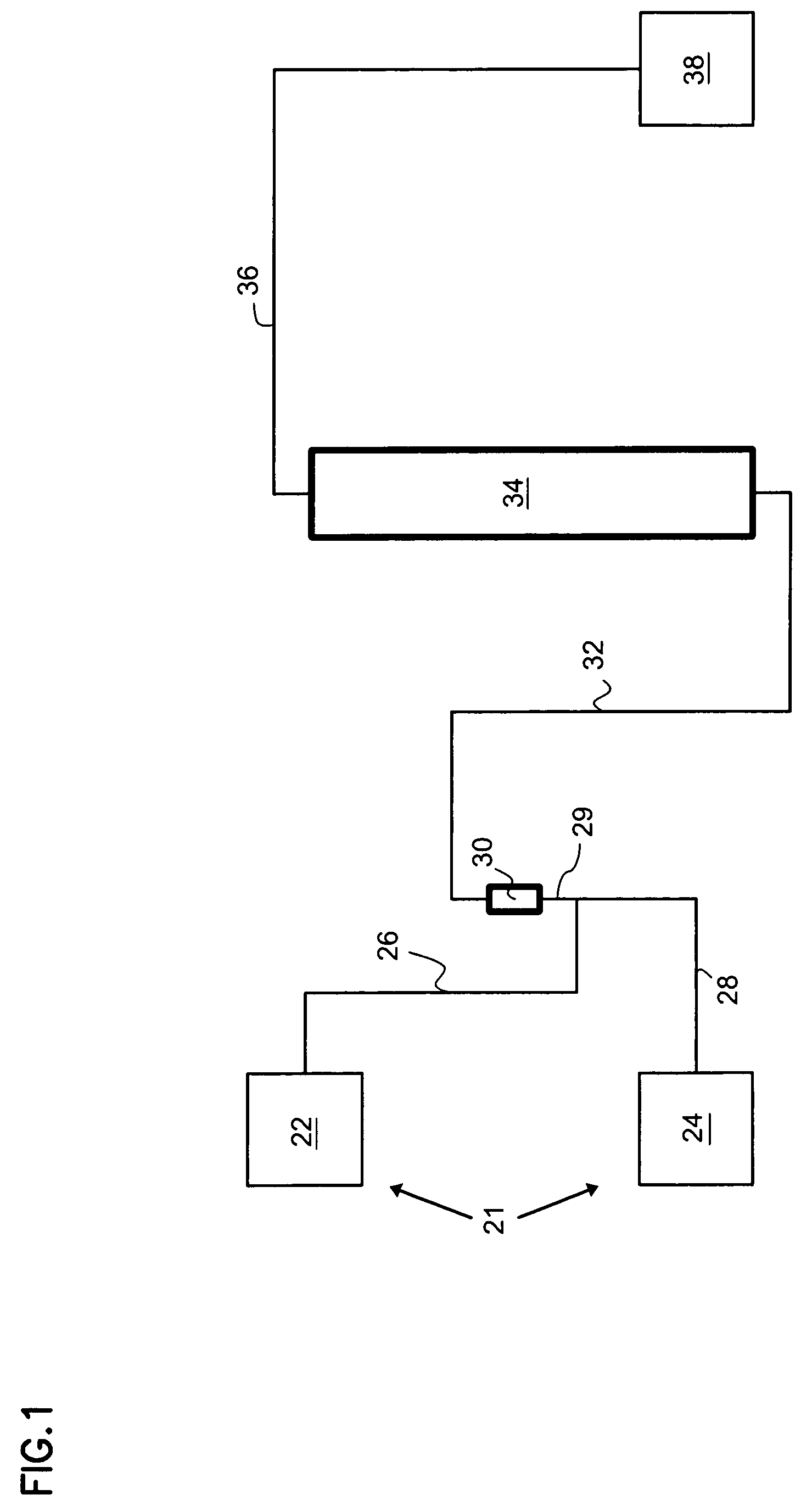

Apparatus and method for making a peroxycarboxylic acid

Owner:ECOLAB USA INC

Apparatus and method for making a peroxycarboxylic acid

ActiveUS8075857B2Increase life and activity and safetyBiocideExhaust apparatusCarboxylic acidPre treatment

Owner:ECOLAB USA INC

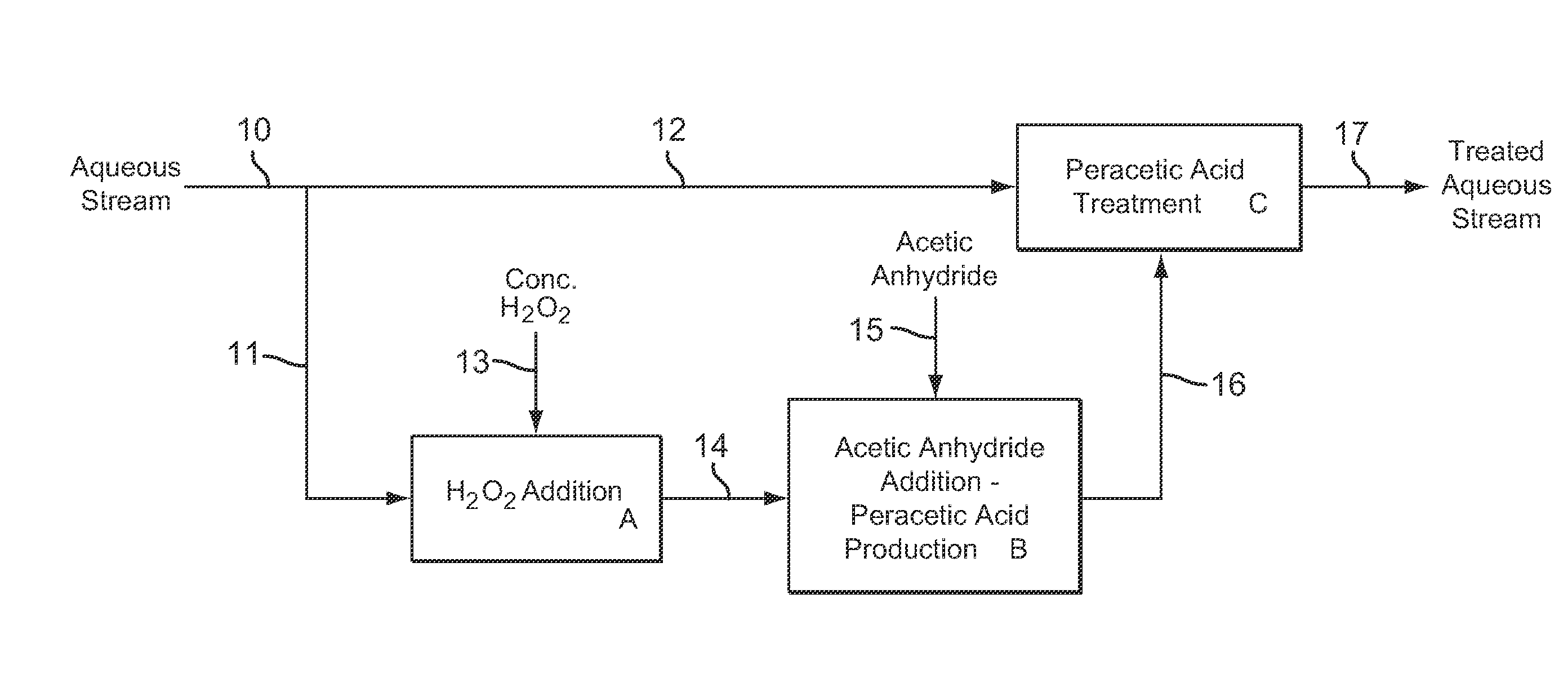

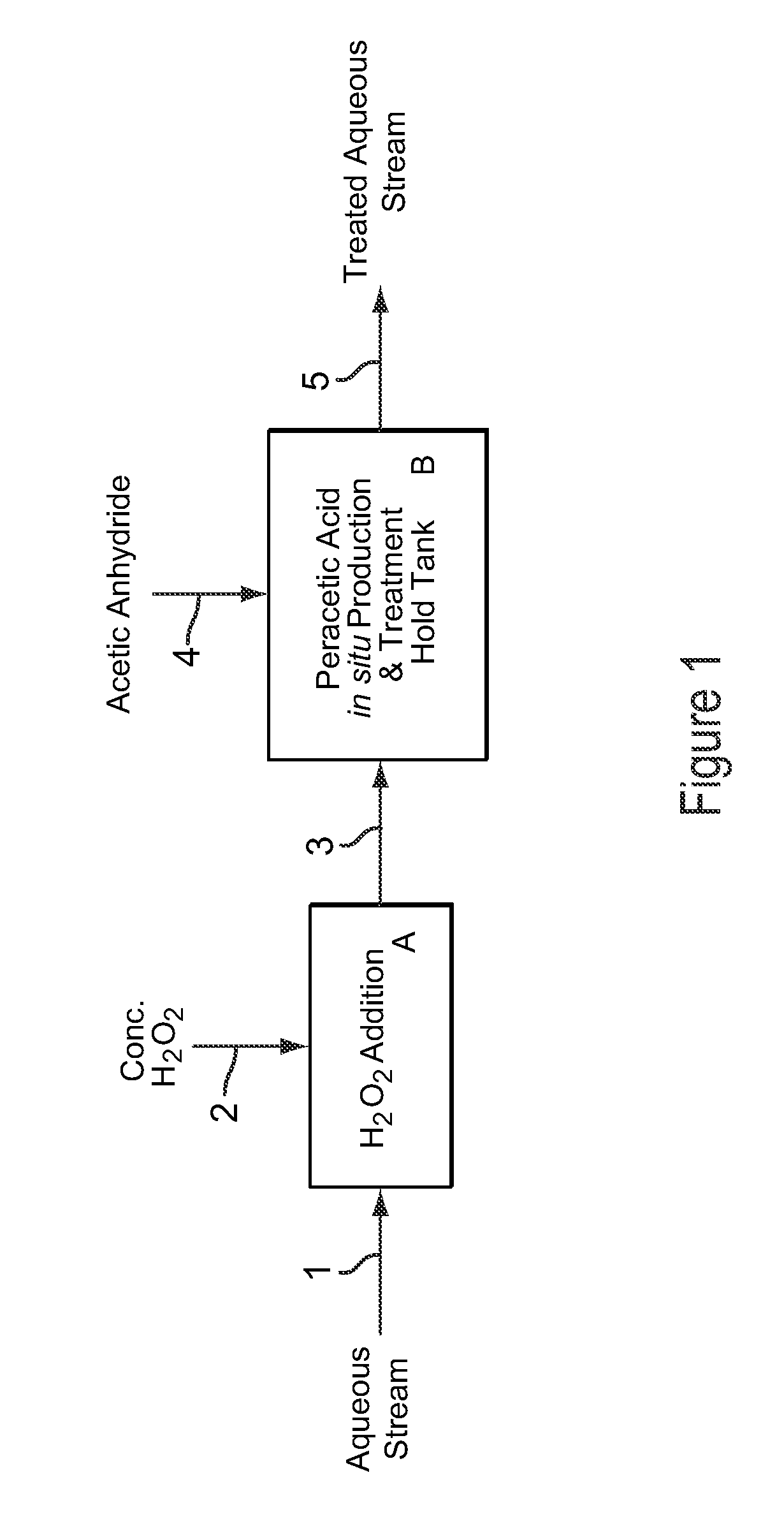

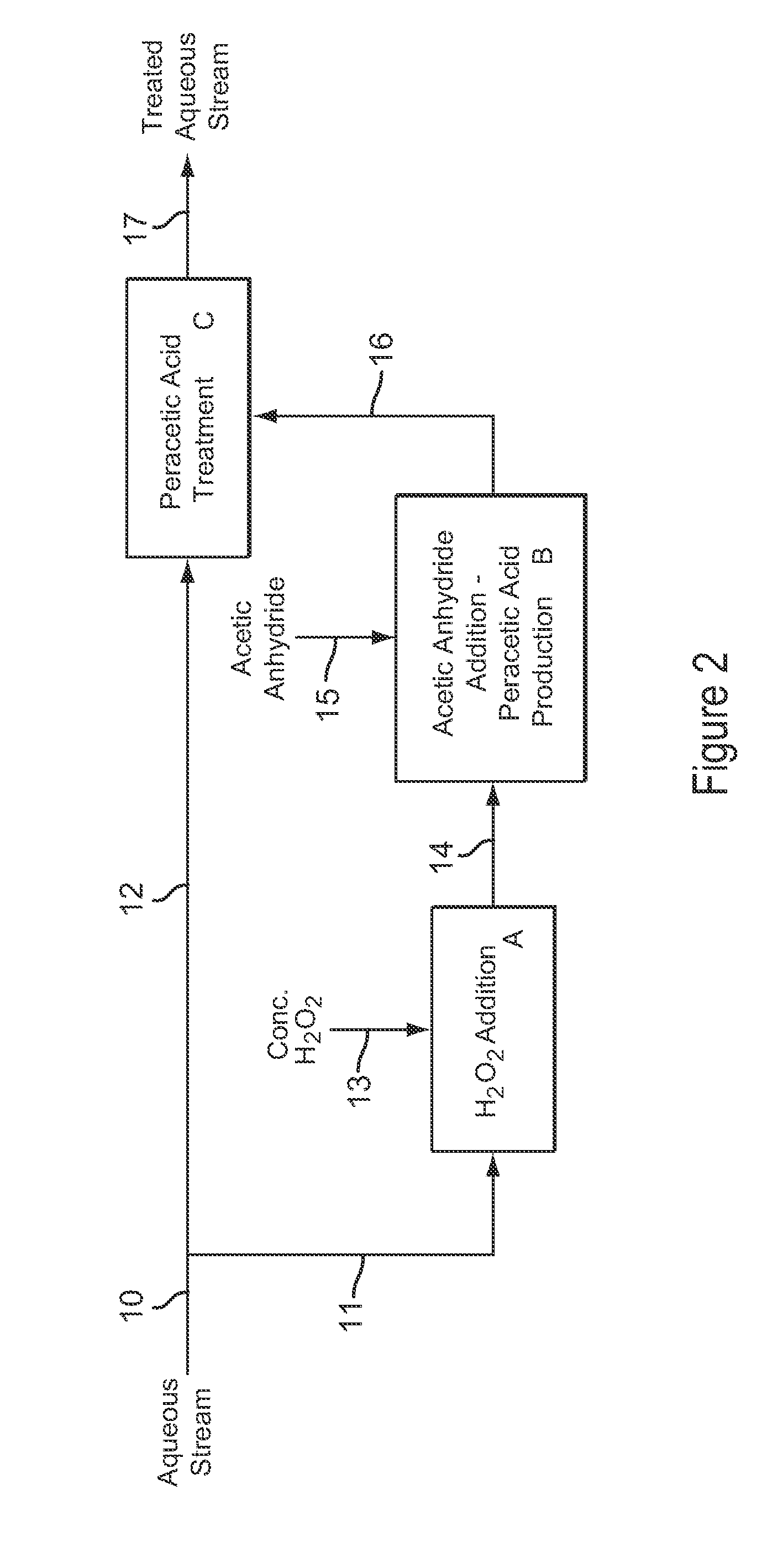

Dilute Stabilized Peracetic Acid Production and Treatment Process

InactiveUS20090043123A1Improve stabilityMinimizes decompositionBiocideOrganic compound preparationAcetic acidAcetic anhydride

A process for the rapid production and stabilization of dilute aqueous peracetic acid in which acetic anhydride and hydrogen peroxide are reacted in an aqueous medium with a stoichiometric excess of hydrogen peroxide and the aqueous medium containing the peracetic acid reaction product is adjusted, as necessary, to a pH of less than about 8 to provide a stabilized dilute peracetic acid solution. The dilute peracetic acid may be produced on site or in situ for treatment of an aqueous medium requiring disinfecting, biocidal, antimicrobial or bleaching treatment.

Owner:FMC CORP

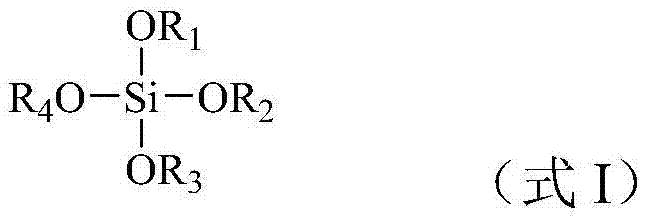

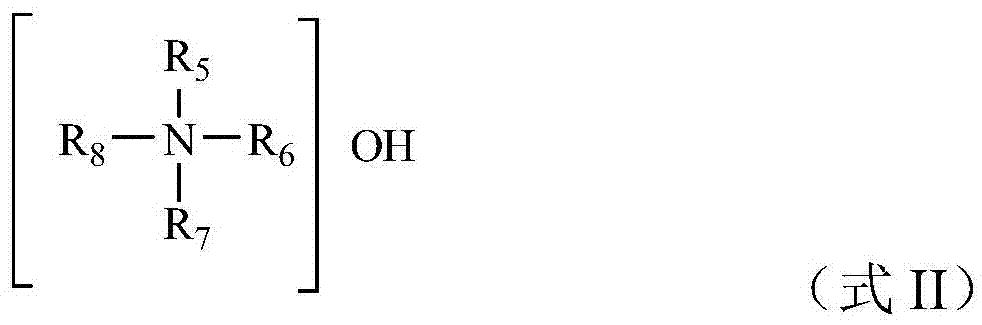

Peroxyacetic acid generator and preparation method thereof

InactiveCN102964285APromote effectivenessSystem stabilityBiocideOrganic compound preparationTetraacetylethylenediamineSURFACTANT BLEND

The invention provides a peroxyacetic acid generator which consists of acetylsalicylic acid, tetraacetylethylenediamine, sodium percarbonate, a surfactant, a corrosion inhibitor and a pH regulator at a mass ratio of 1:(1.5-2.0):(3.5-5):(0.02-0.05):(0.1-0.3):(3-6). Meanwhile, the invention also discloses a preparation method of the peroxyacetic acid. Through the invention, by adding the pH regulator, the pH value of the mixed solution is stabilized at about 7-8, and then the prepared peroxyacetic acid solution has higher stability and lower corrosivity.

Owner:北京红辉力上科技有限公司

Noble metal modified mesoporous titanium silicalite molecular sieve, compounding method and application thereof and method for oxidizing cyclic ketone

ActiveCN106904633AHigh crystallinityReduce dosageMolecular sieve catalystsOrganic compound preparationMolecular sieveMaterial synthesis

The invention relates to the field of catalytic material synthesis and specifically provides a noble metal modified mesoporous titanium silicalite molecular sieve and a compounding method thereof. The method comprises the following steps: (1) hydrolyzing an organic silicon source, a titanium source, a noble metal source, an alkali source and a surface active agent, so as to obtain a mixture A, and then performing first crystallization on the obtained mixture A; and (2) mixing the material after the first crystallization with the inorganic silicon source, so as to obtain a mixture B, and then performing second crystallization on the obtained mixture B. The invention provides the noble metal modified mesoporous titanium silicalite molecular sieve compounded according to the method provided by the invention. The invention provides an application of the noble metal modified mesoporous titanium silicalite molecular sieve provided by the invention in oxidizing reaction. The invention provides a method for oxidizing cyclic ketone. According to the compounding method for the noble metal modified mesoporous titanium silicalite molecular sieve, provided by the invention, the relative low-cost inorganic silicon source, such as, silica gel or silica sol, can be used as a part and even main silicon source, so that the dosage of organic silicone can be reduced and the compounding benefit can be greatly increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

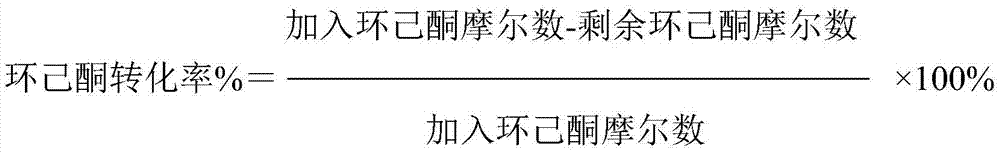

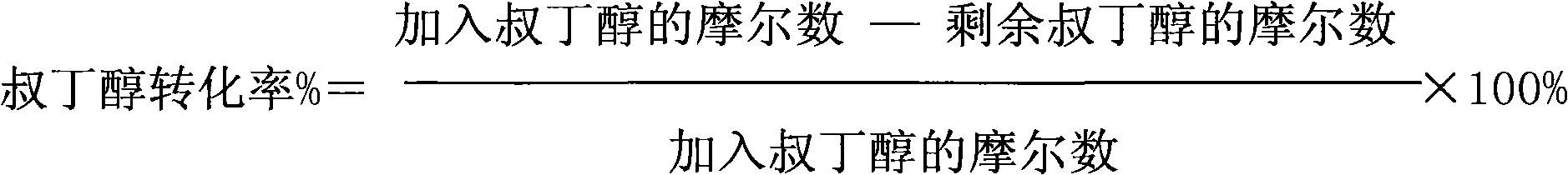

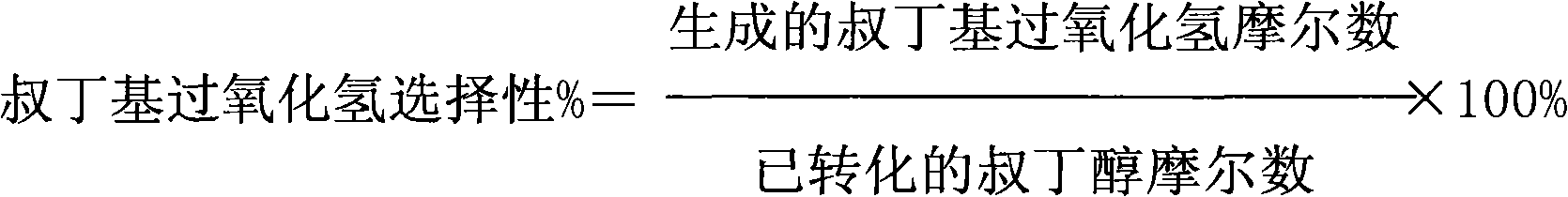

Preparation method of tert-butyl hydroperoxide

ActiveCN103204792AHigh hydrogen peroxide yieldHigh yieldOrganic compound preparationPeroxy compound preparationMolecular sieveHeteroatom

The invention discloses a preparation method of tert-butyl hydroperoxide. Under oxidation reaction conditions, tert-butyl alcohol, an oxidant, a solvent and a catalyst are subjected to mixed contact. The method is characterized in that the catalyst is a soluble zinc salt modified heteroatom molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

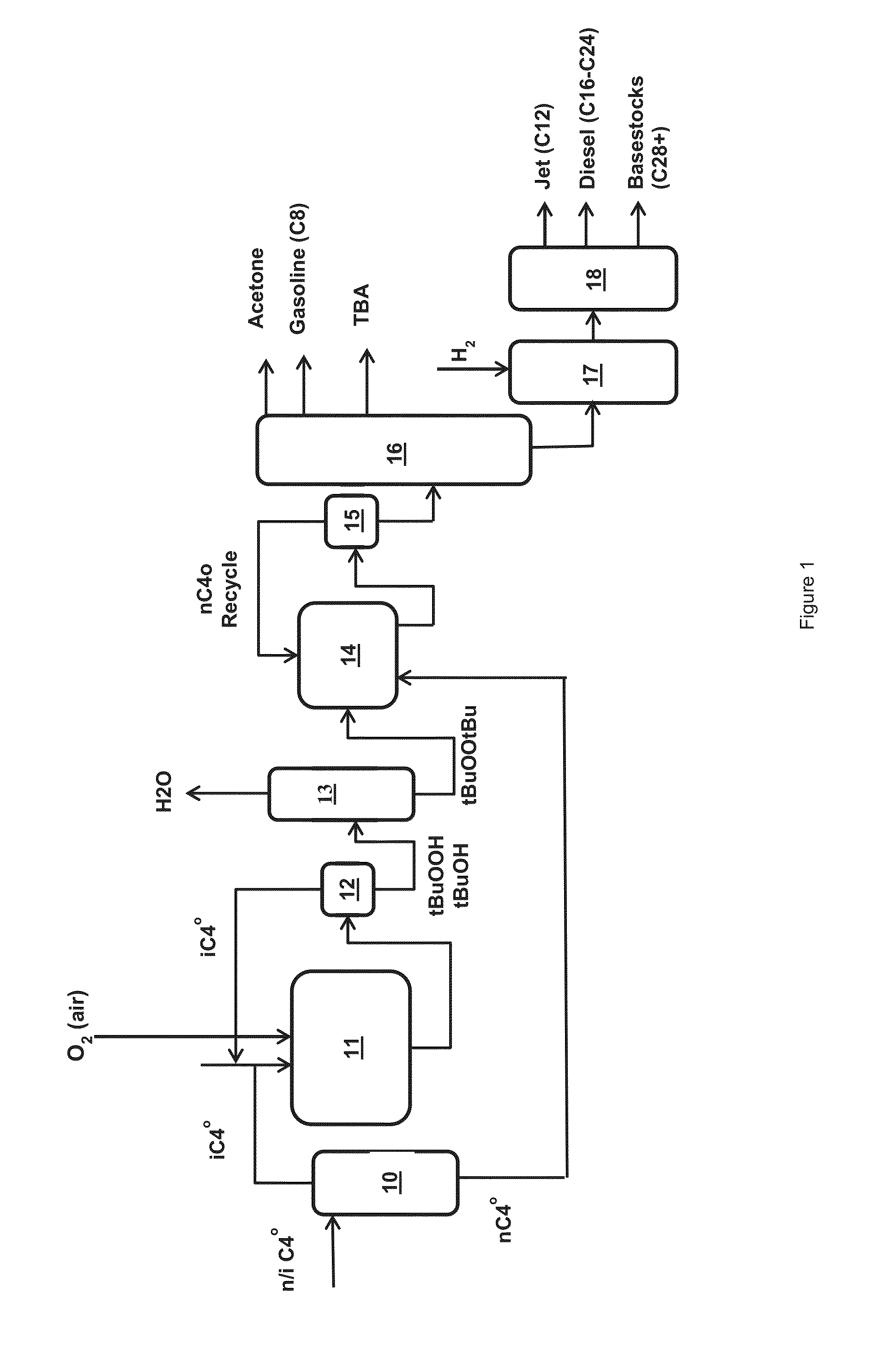

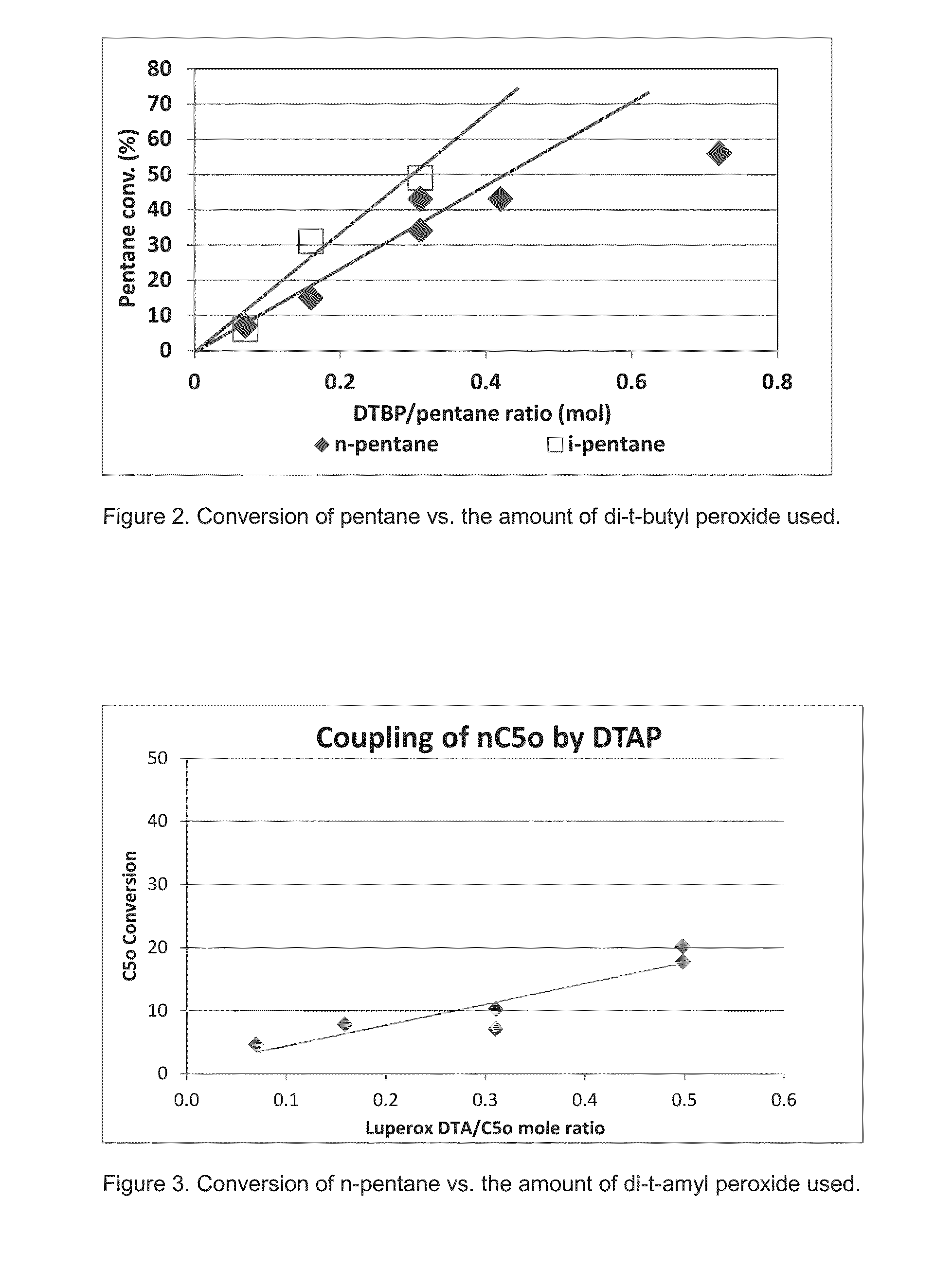

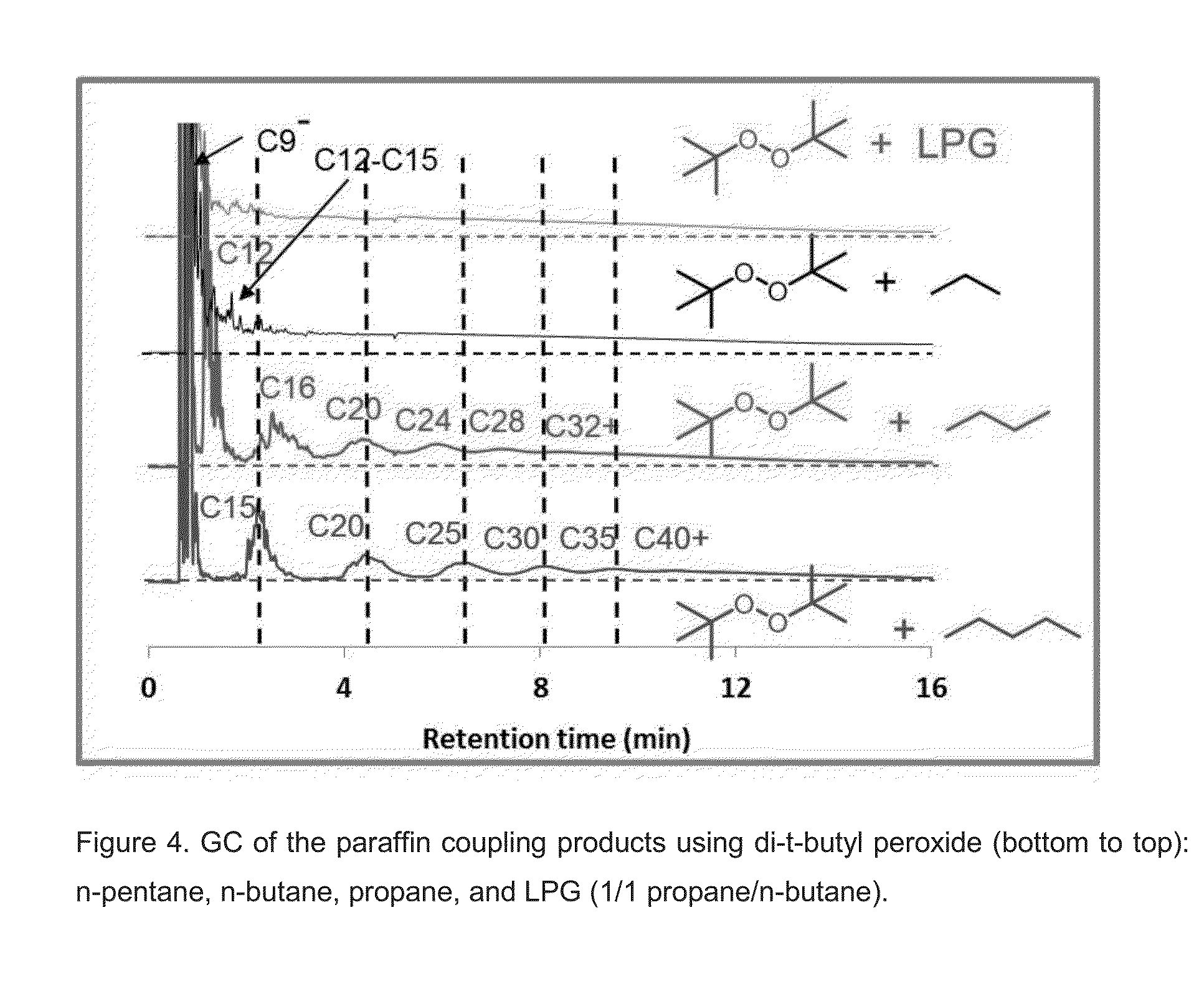

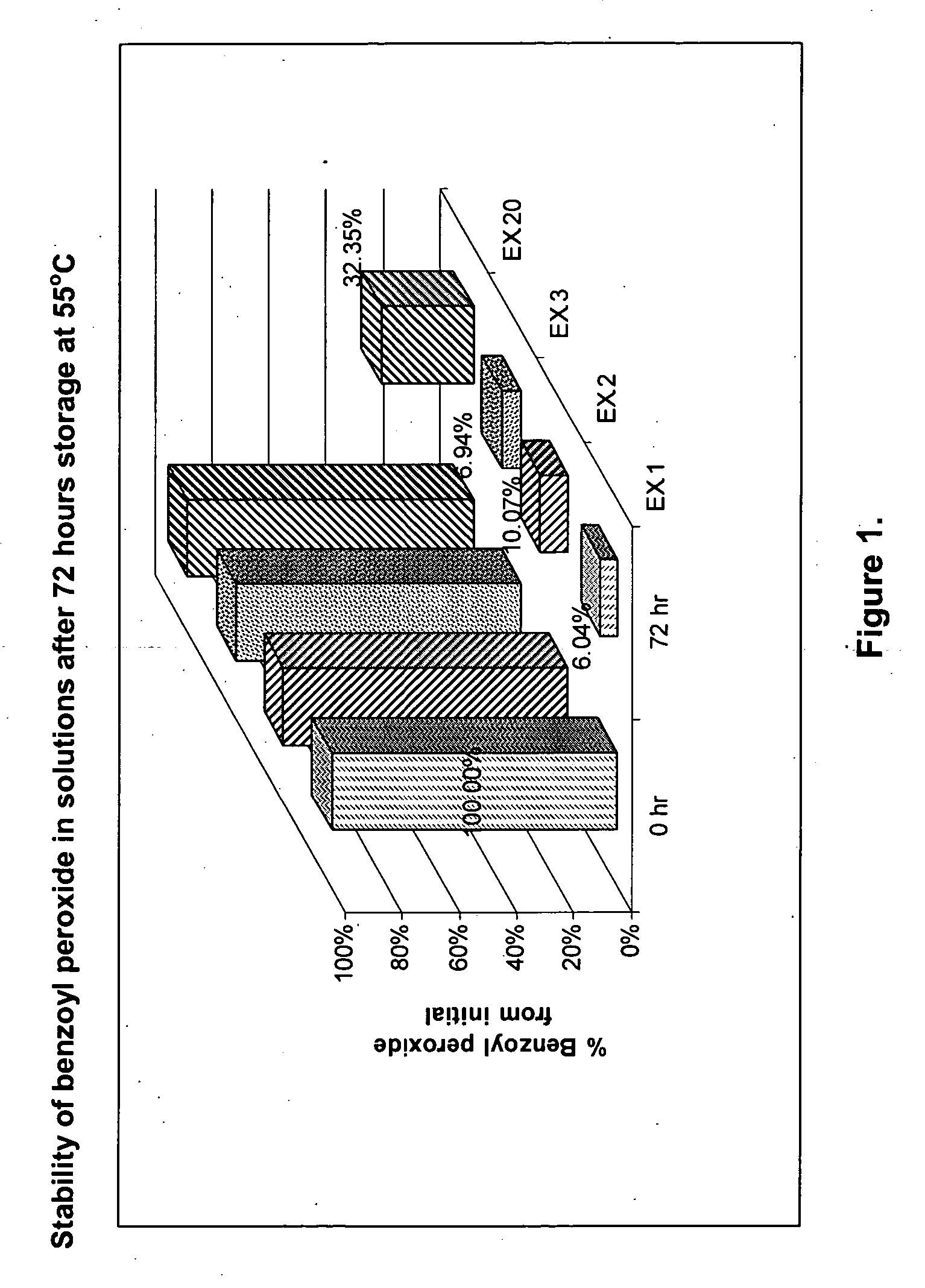

Upgrading paraffins to distillates and lubricant basestocks

ActiveUS20160168048A1Treatment with hydrotreatment processesHydrocarbon by hydrocarbon condensationParaffin waxAlkane

A process for converting light paraffins (especially C3-C5) to middle distillate and higher boiling range liquid hydrocarbons by (1) oxygen or air oxidation of iso-paraffins to alkyl hydroperoxides; (2) conversion of alkyl hydroperoxides to dialkyl peroxides; (3) radical coupling of paraffins using the dialkyl peroxides as radical initiators forming heavier hydrocarbon products; and (4) fractionation of the heavy hydrocarbon products. The net reaction is catalytically converting light paraffins to heavier hydrocarbons using oxygen or air to effect the conversion.

Owner:EXXON RES & ENG CO

Stabilization of benzoyl peroxide in solution

InactiveUS20060135822A1Minimal skin irritating propertiesPrevent degradationBiocideOrganic compound preparationBenzoyl peroxideDibenzoyl Peroxide

The stabilization of benzoyl peroxide for extended periods of time is disclosed. The stabilized solution contains from between 0.5% and 20% organic peroxide and a stabilizer for preventing degradation of said peroxide in the solution.

Owner:ALPHARX

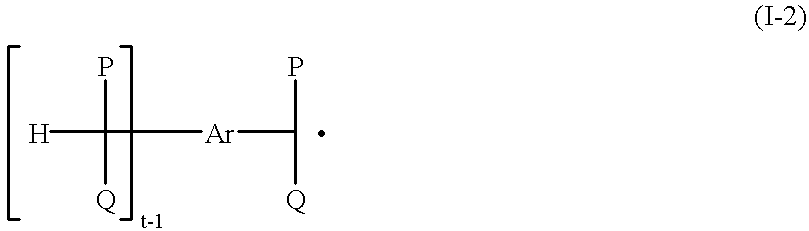

Process for preparing hydroperoxides

InactiveUS6291718B1Organic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSulfurNitrogen

A process for preparing hydroperoxides which comprises oxidizing hydrocarbon by a gas containing oxygen in the presence of a specific compound and converting them selectively to corresponding hydroperoxides. The specific compound is the compound that can capture radicals. The preferable example may be a compound selected from radicals of oxygen, nitrogen, phosphorus, sulfur, carbon or silicon or a compound that forms radicals of these in the reaction system. The present invention can be applied to oxidation of hydrocarbons including arylalkylhydrocarbons such as cumene, m-diisopropylbenzene, p-diisopropylbenzene, 1,3,5-triisopropylbenzene, isopropylnaphthalene, diisopropylnaphthalene, isopropylbiphenyl, diisopropylbiphenyl, etc.

Owner:MITSUI CHEM INC

Preparation method of tert-butyl peroxide

InactiveCN104557652AStrong acidPore structure highOrganic compound preparationPeroxy compound preparationPtru catalystDi-tert-butyl peroxide

The invention provides a method for preparing tert-butyl peroxide by using a heterogeneous catalyst. The method comprises the following steps: by using tert-butyl alcohol and oxydol as raw materials and an acidic ion exchange resin as a catalyst, reacting under reflux, cooling, standing, and separating to obtain an oil phase and a water phase; and washing the oil phase with alkali and water to obtain a di-tert-butyl peroxide solution (DTBP), wherein the oil phase water washing solution and water phase are the tert-butyl hydroperoxide water solution (TBHP). Since the ion exchange resin has the advantages of large pore structure, high acidity and high catalysis efficiency and the large pore structure can not be destroyed in reaction, the catalyst can be easily separated from the reaction product and can be recycled repeatedly, thereby having higher economic value. Besides, no sulfuric acid or any other strong acid is used in the production process, so the method has the advantages of low corrosion to equipment and no environment pollution, and has higher environmental benefit.

Owner:NORTHWEST NORMAL UNIVERSITY

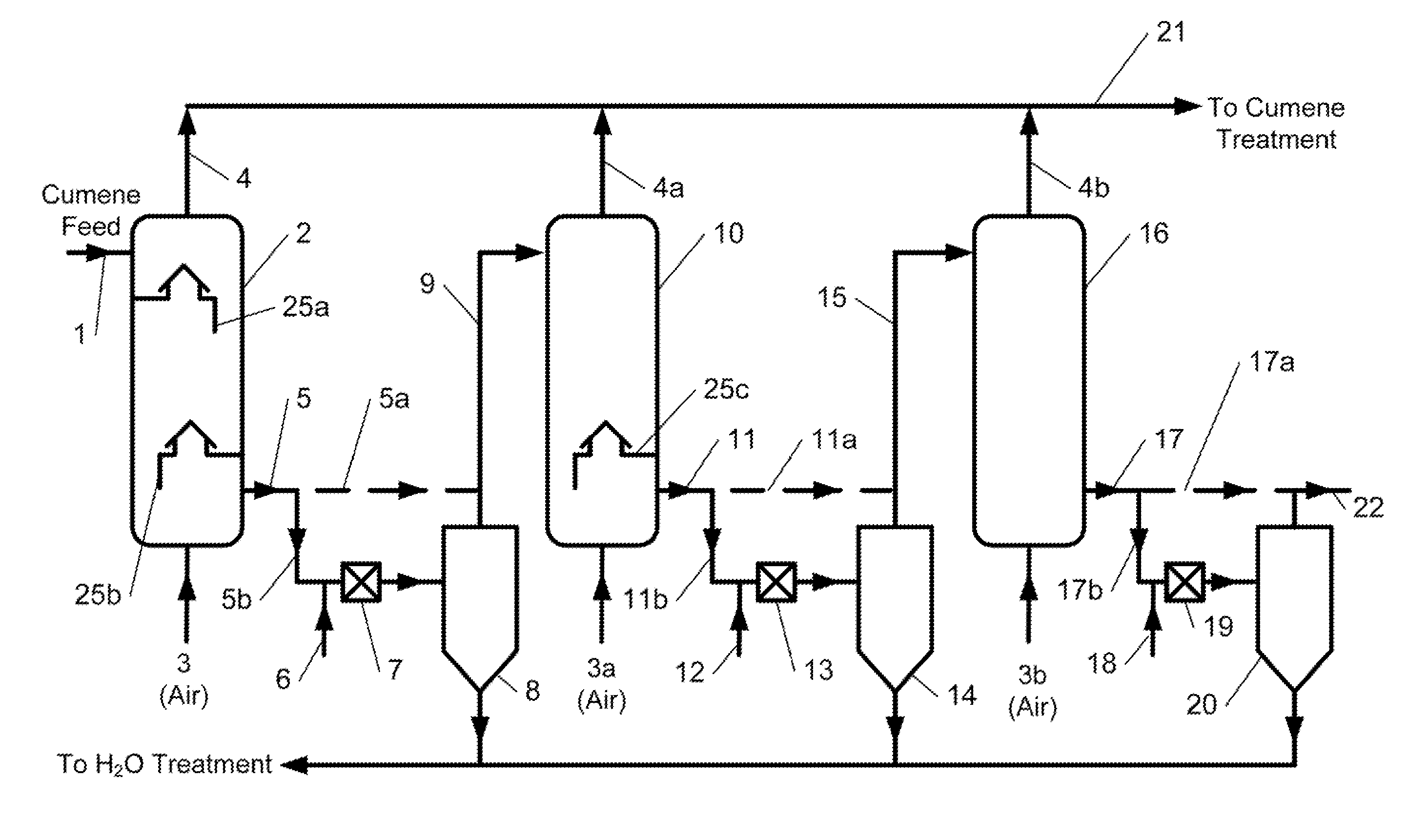

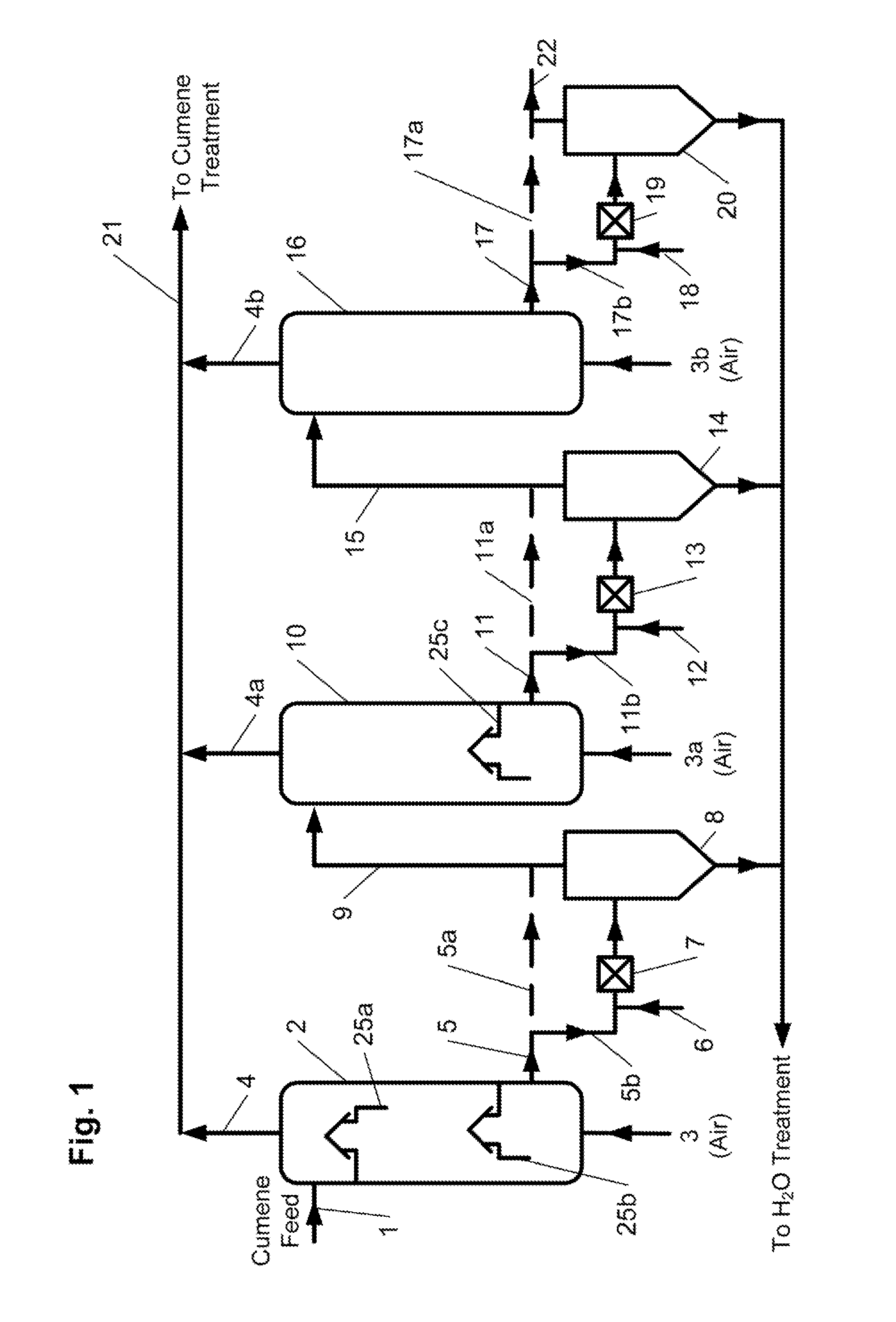

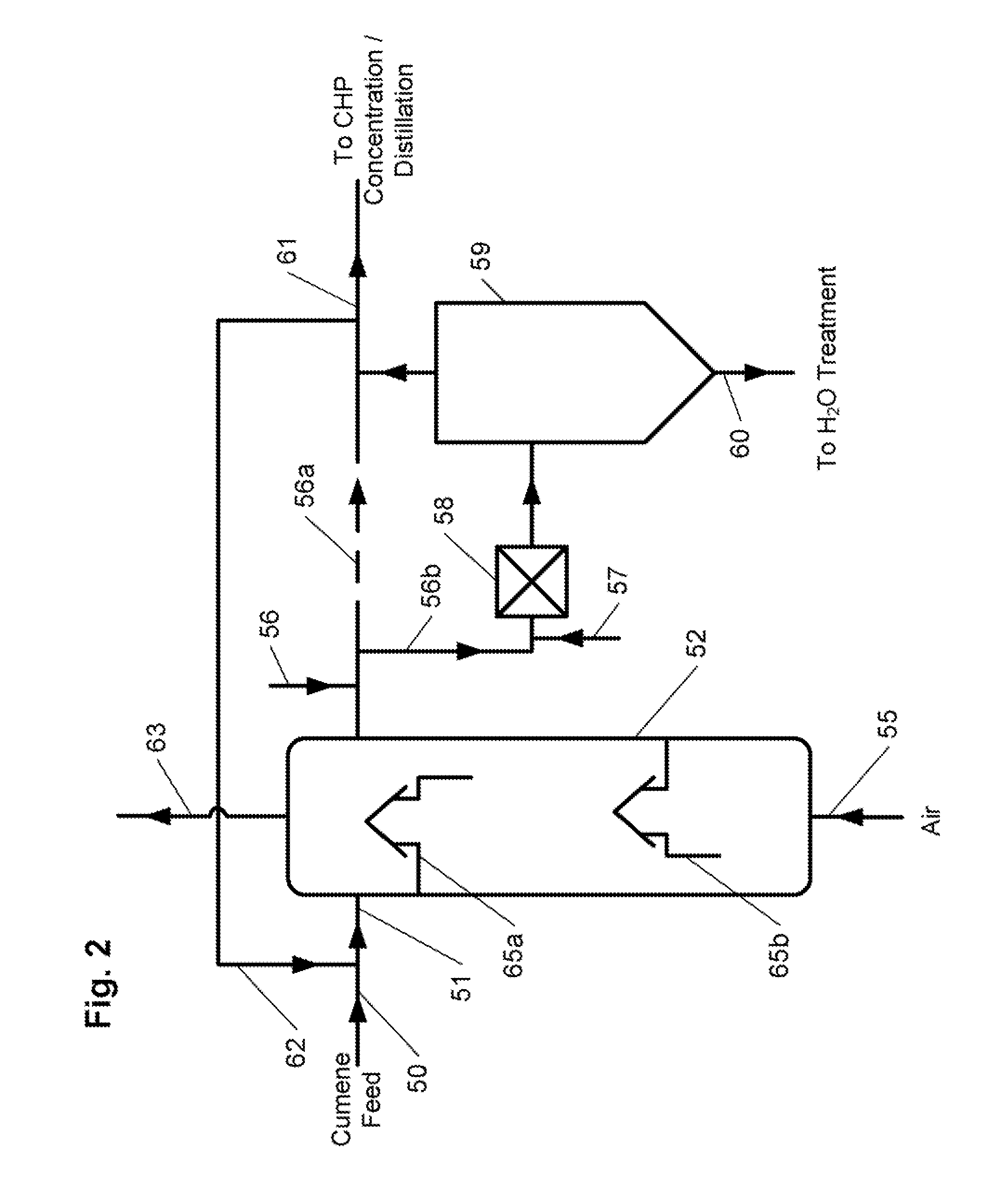

Method for production of cumene hydroperoxide

ActiveUS7393984B1Improve productivityRemoving and reducing formation of undesirableOrganic compound preparationPeroxy compound preparationBenzoic acidGas phase

A continuous method of cumene oxidation in a gas-liquid system is provided, where the liquid phase is represented by cumene and its oxidation products and the gas phase is represented by air. The oxidation process can be carried out either in a reactor series or in a single reactor at least one of which is preferably equipped with at least two airlift-type trays. When specific CHP concentration is achieved, the oxidation products are discharged from the to reaction zone and treated in a mixing device with aqueous ammonia or water to remove organic acids such as formic acid, benzoic acid, etc. and to remove phenol, which is an inhibitor of oxidation reaction. The cumene oxidation product stream, free of organic acids and phenol is recycled to the same reactor in the case of single reactor, or is passed to the next reactor of the series in the case of reactor series. In all cases, the oxidation products treated with water or aqueous ammonia is first directed to a unit for separation of aqueous phase from organic products and then anhydrous organic product stream is forwarded to the next reactor of the series, or recycled to the single reactor for the continued cumene oxidation until the required CHP concentration is achieved. The airlift-type trays in at least one process reactor accelerate the cumene oxidation reaction therein while increasing the process selectivity and enabling the process to be conducted at lower temperature, improving safety thereof. Advantageously, lower quality cumene having impurities such as sulfur-containing trace elements, can be used in the inventive process while maintaining a high process selectivity.

Owner:ILLA INT

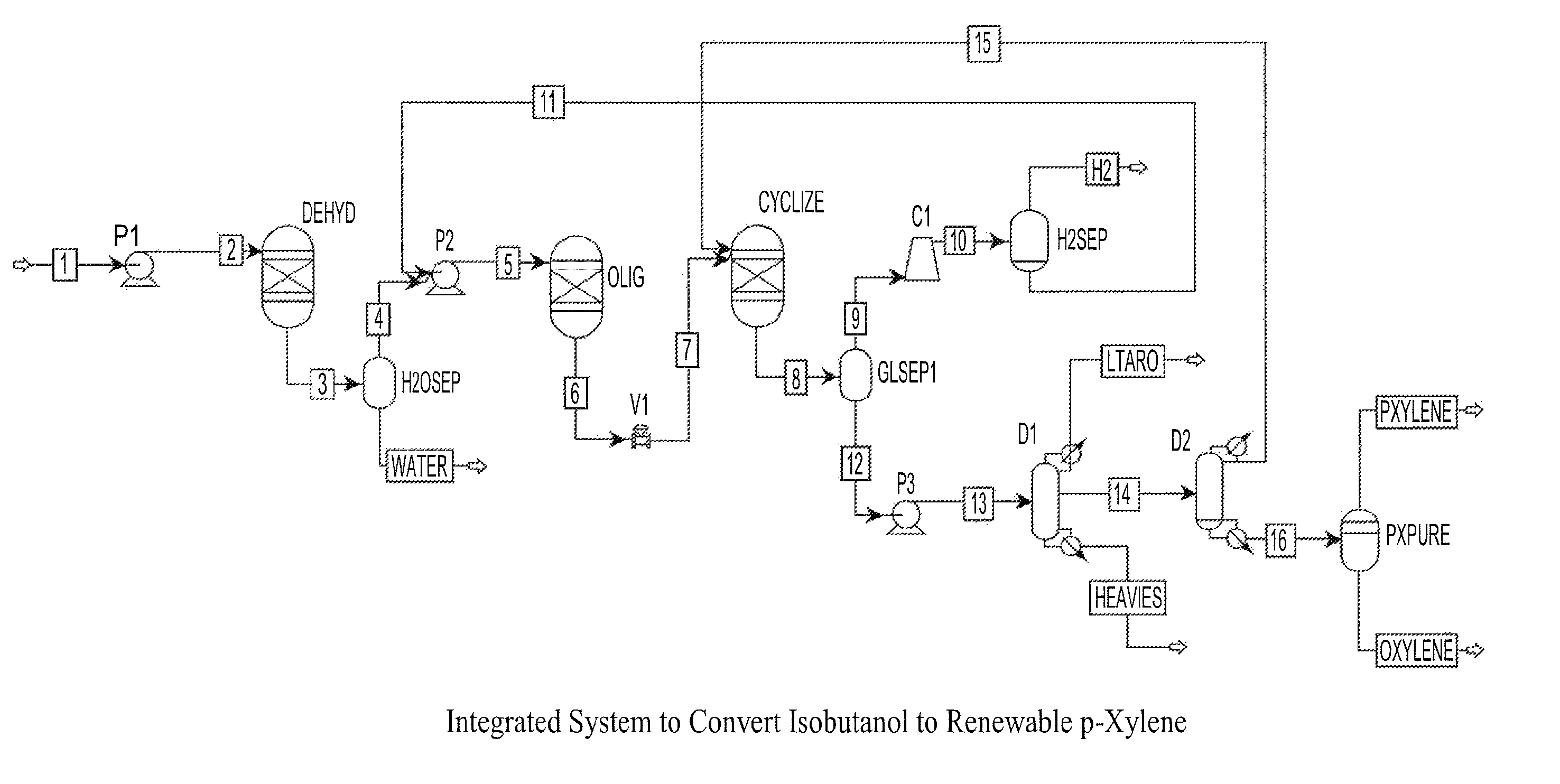

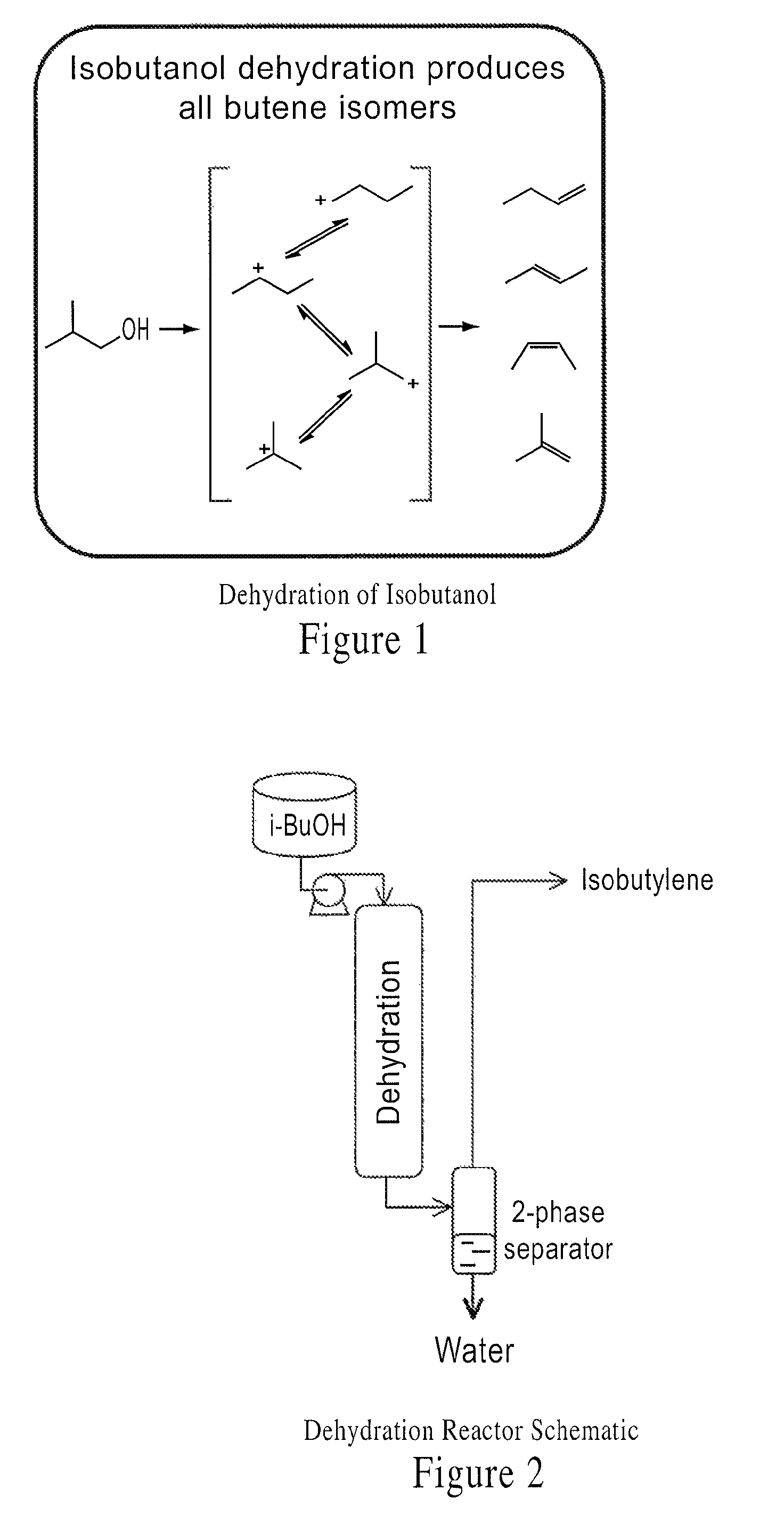

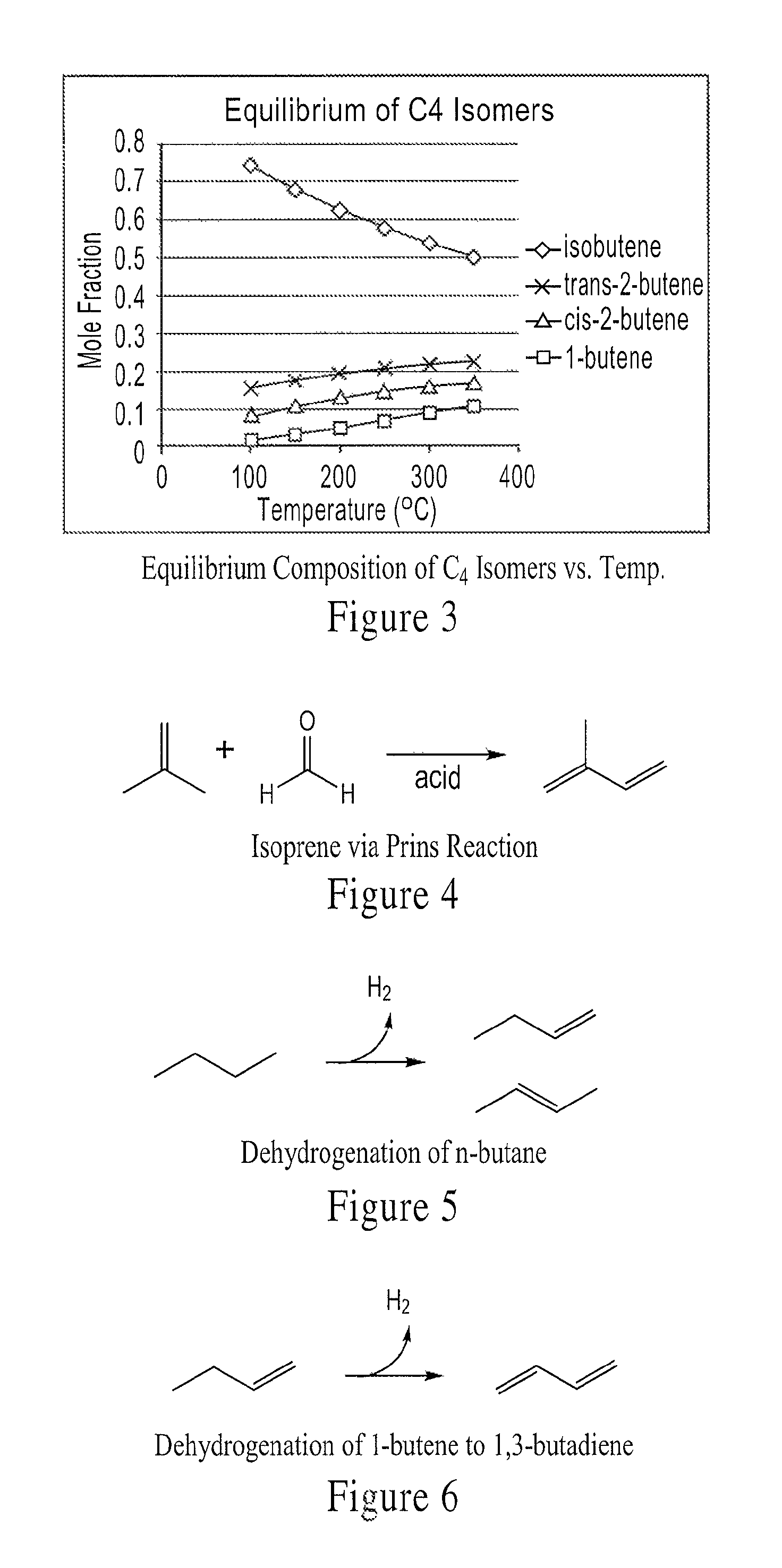

Integrated methods of preparing renewable chemicals

ActiveUS8450543B2Readily and flexibly adaptHydrocarbon by dehydrogenationHydrocarbon by hydrogenationPolyesterPolymer science

Isobutene, isoprene, and butadiene are obtained from mixtures of C4 and / or C5 olefins by dehydrogenation. The C4 and / or C5 olefins can be obtained by dehydration of C4 and C5 alcohols, for example, renewable C4 and C5 alcohols prepared from biomass by thermochemical or fermentation processes. Isoprene or butadiene can be polymerized to form polymers such as polyisoprene, polybutadiene, synthetic rubbers such as butyl rubber, etc. in addition, butadiene can be converted to monomers such as methyl methacrylate, adipic acid, adiponitrile, 1,4-butadiene, etc. which can then be polymerized to form nylons, polyesters, polymethylmethacrylate etc.

Owner:GEVO INC

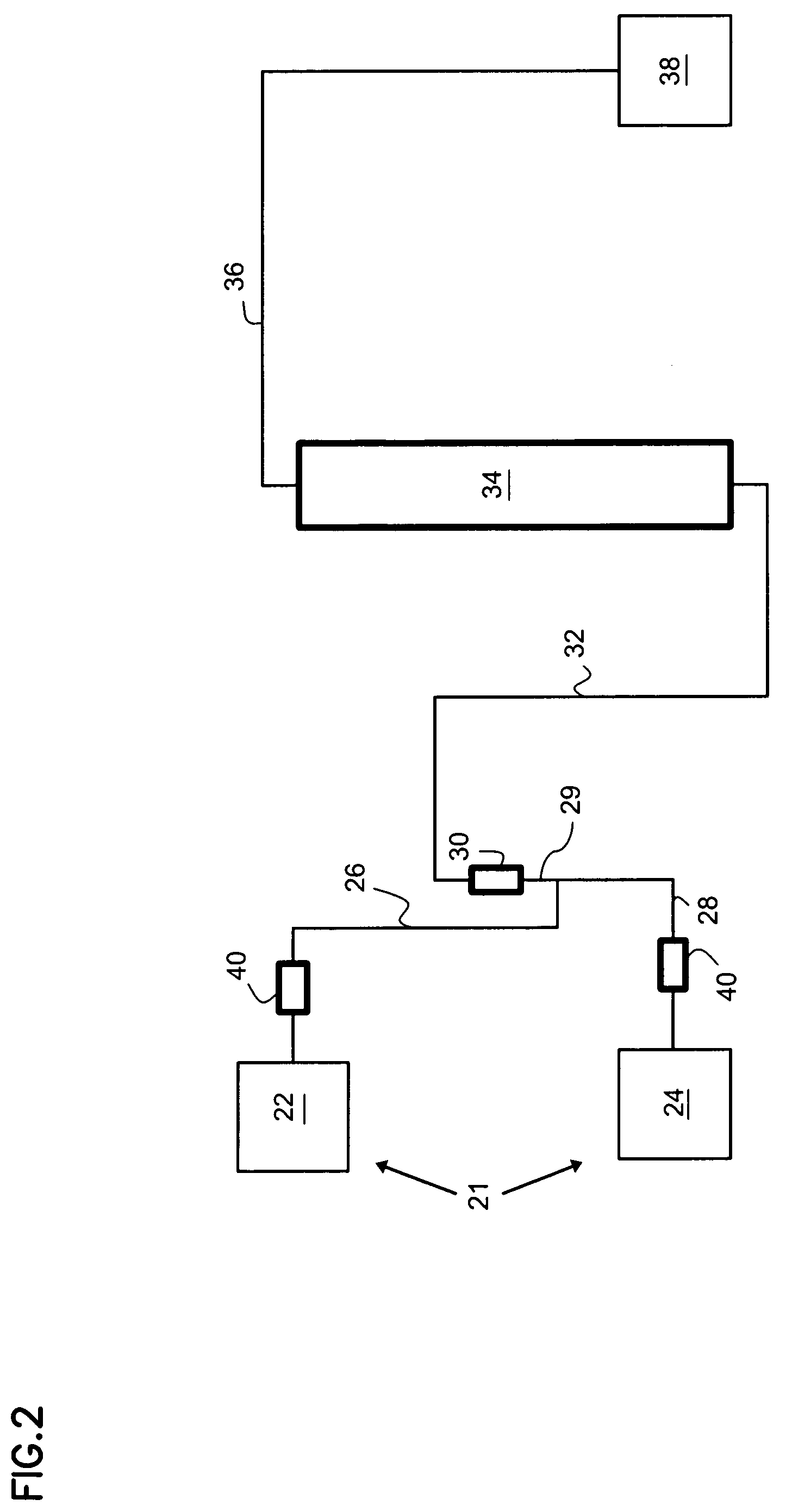

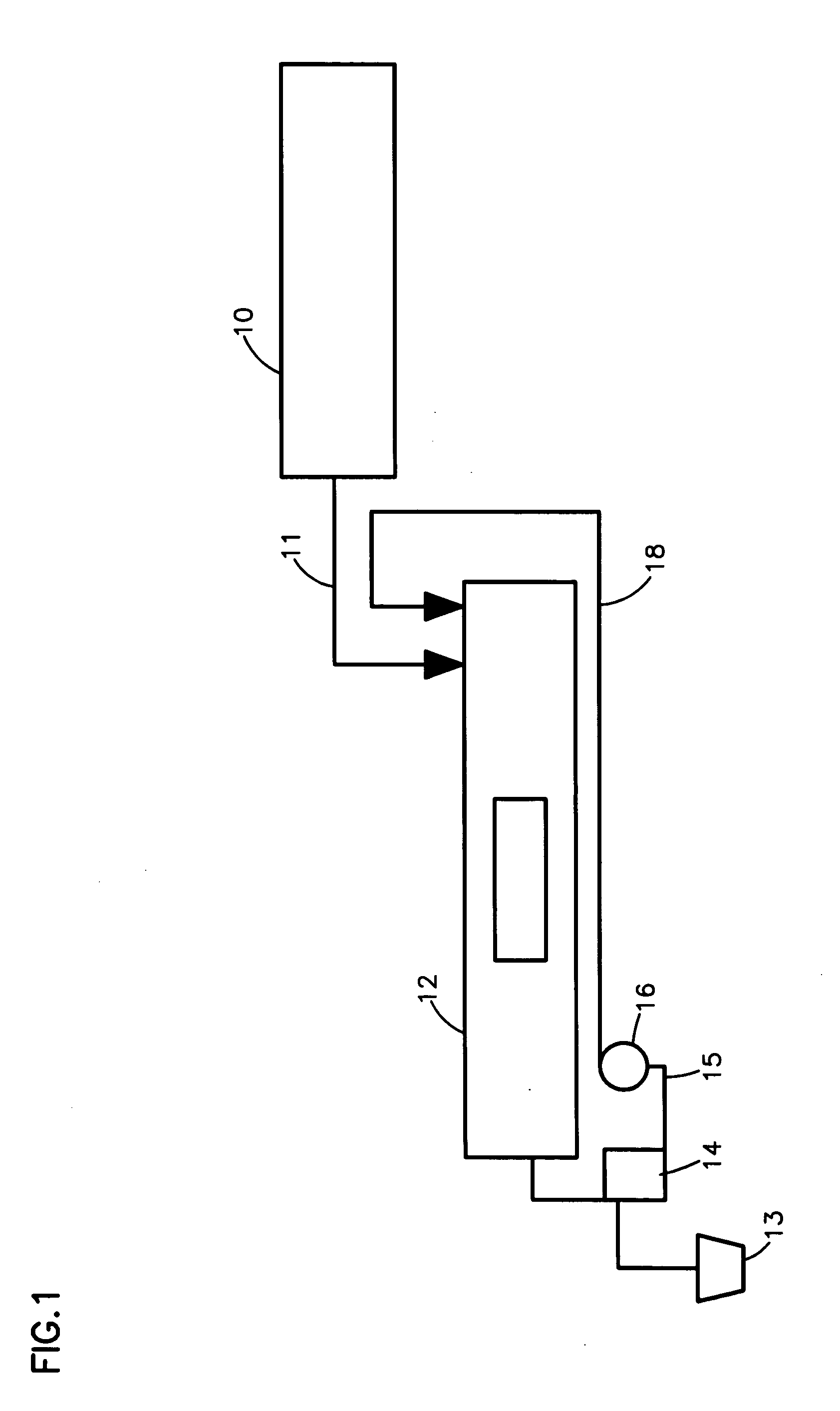

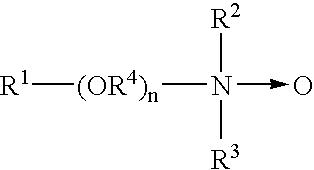

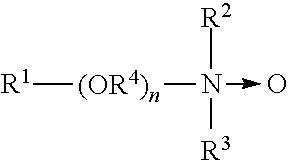

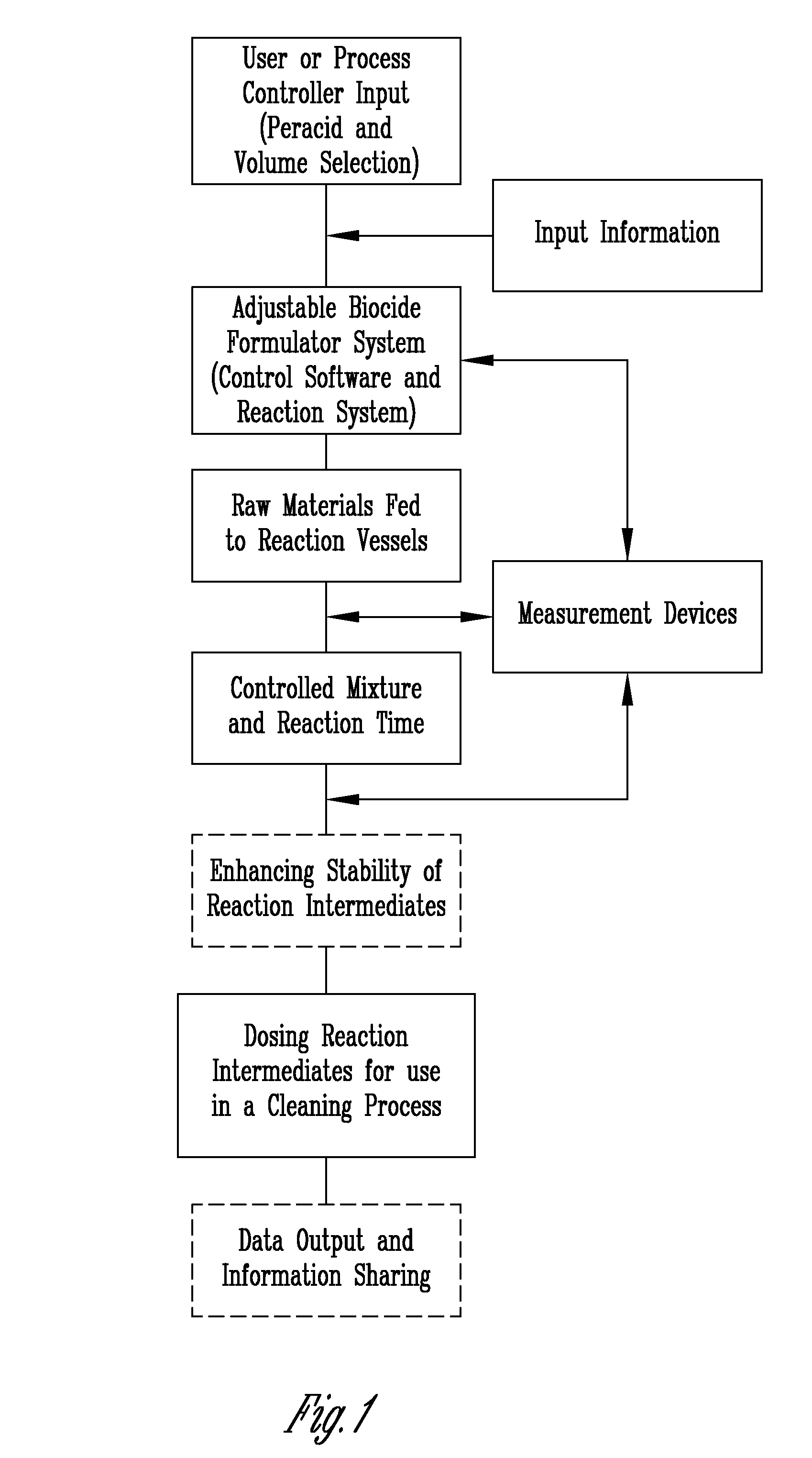

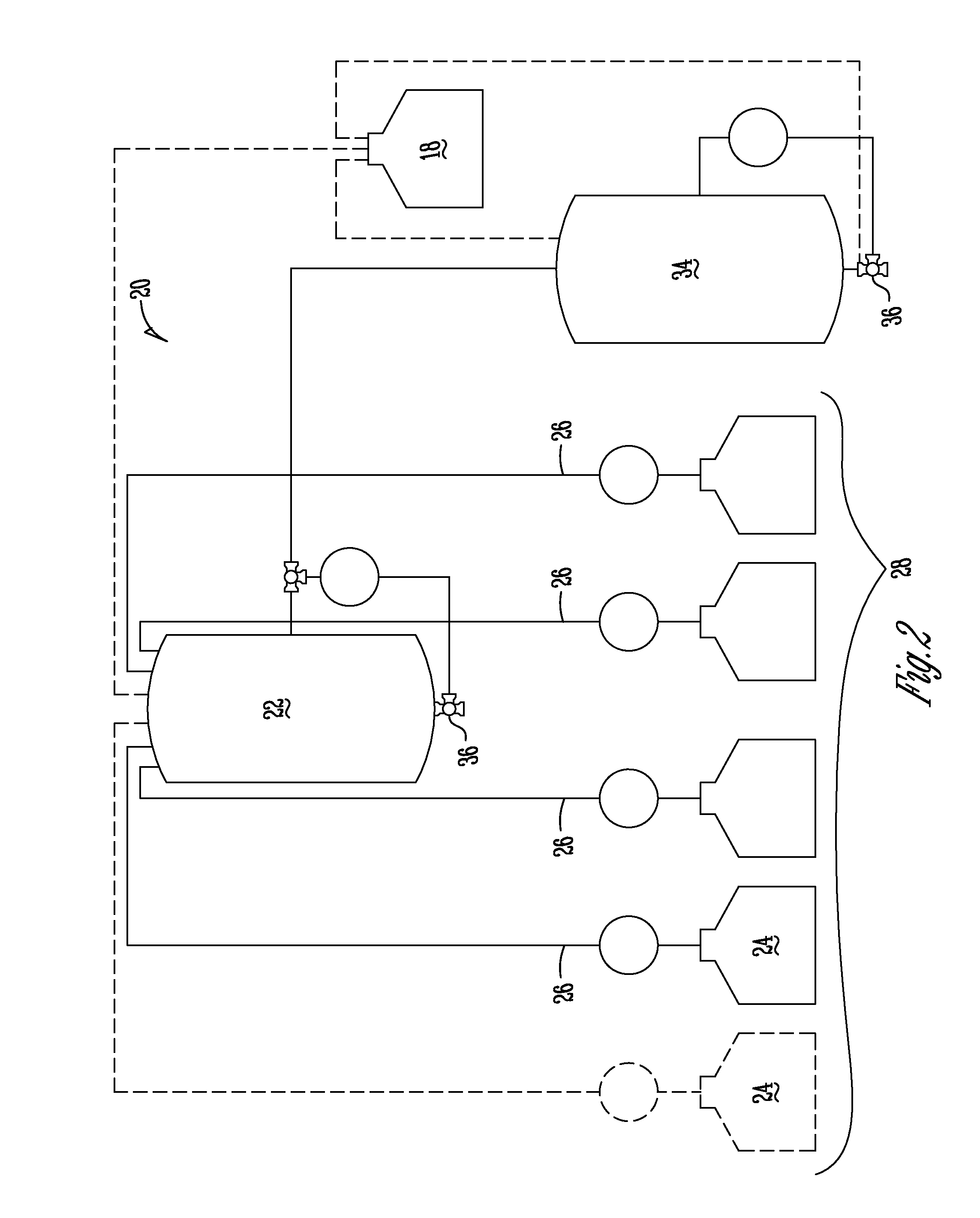

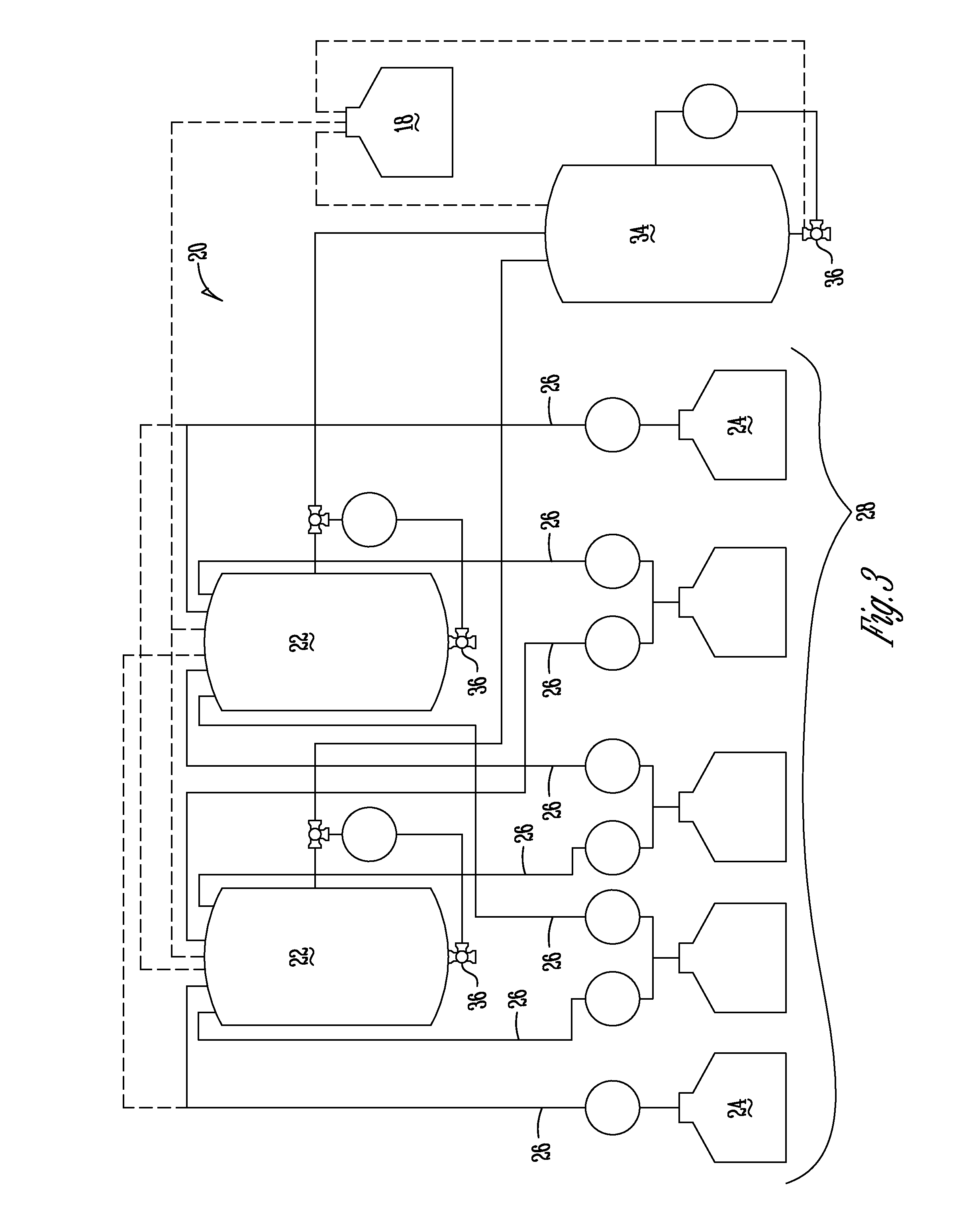

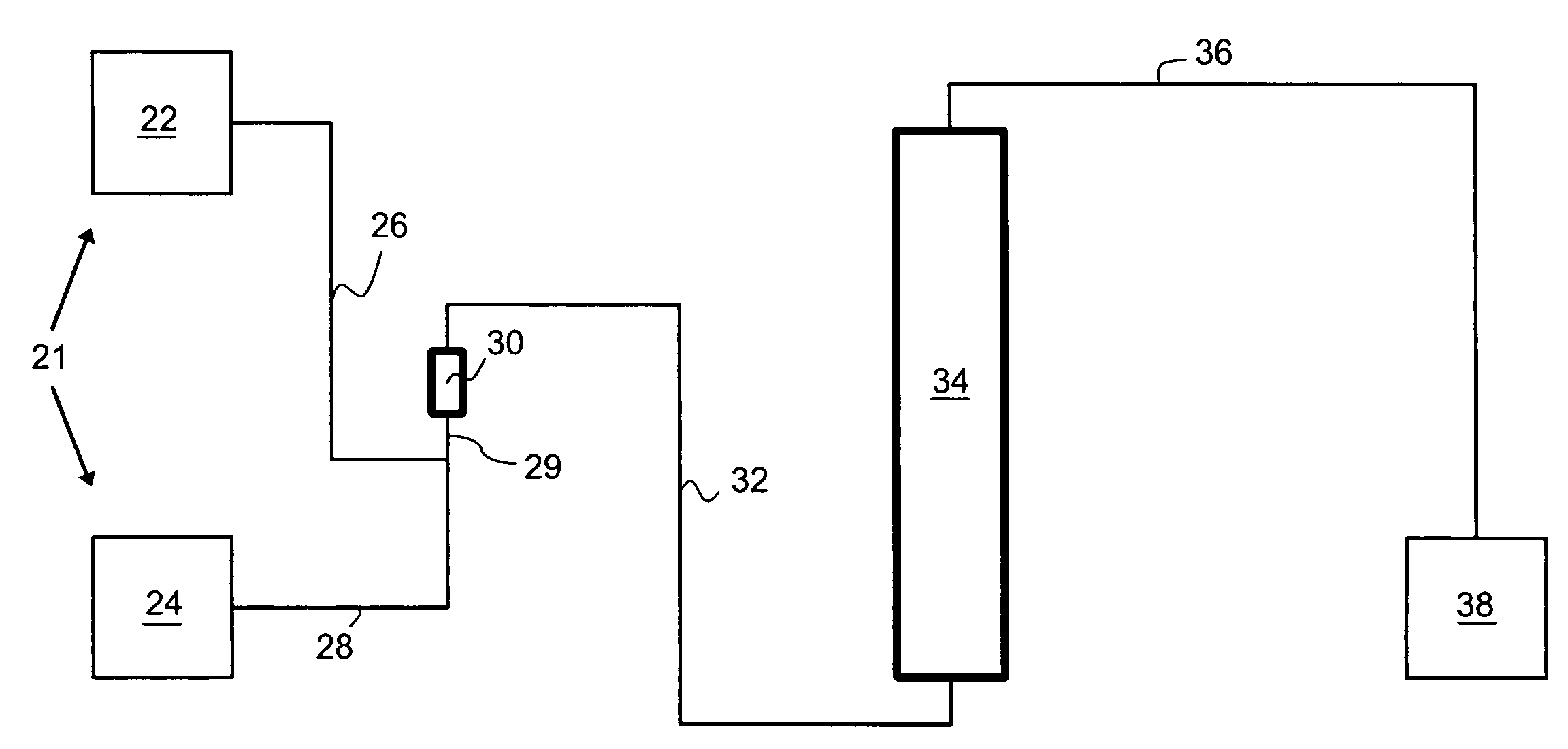

Sugar ester peracid on site generator and formulator

ActiveUS8889900B2Eliminate needReduced stabilityProcess control/regulationBiocideSugarMedicinal chemistry

Methods and systems for on-site generation of peracid chemistry, namely peroxycarboxylic acids and peroxycarboxylic acid forming compositions, are disclosed. In particular, an adjustable biocide formulator or generator system is designed for on-site generation of peroxycarboxylic acids and peroxycarboxylic acid forming compositions from sugar esters. Methods of using the in situ generated peroxycarboxylic acids and peroxycarboxylic acid forming compositions are also disclosed.

Owner:ECOLAB USA INC

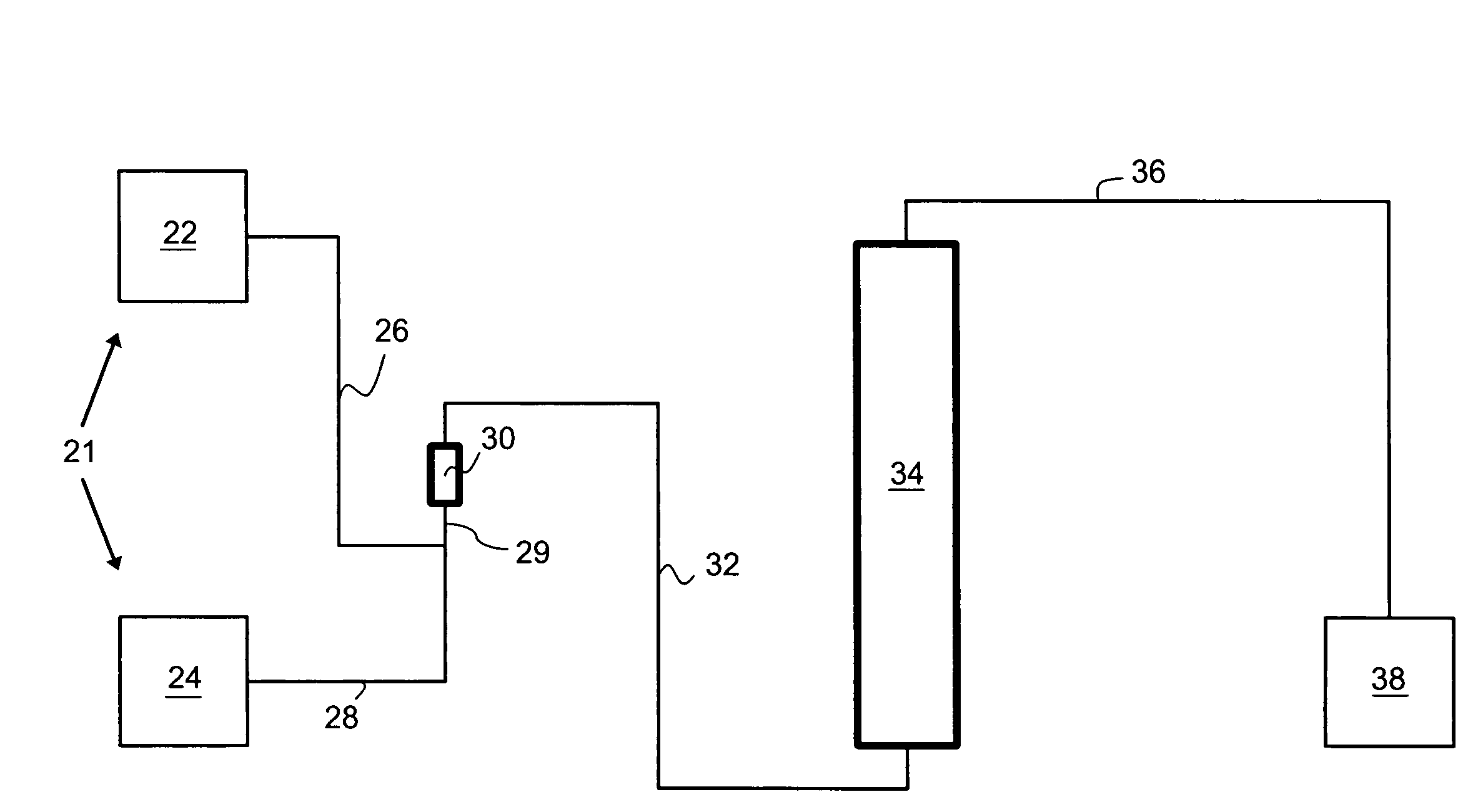

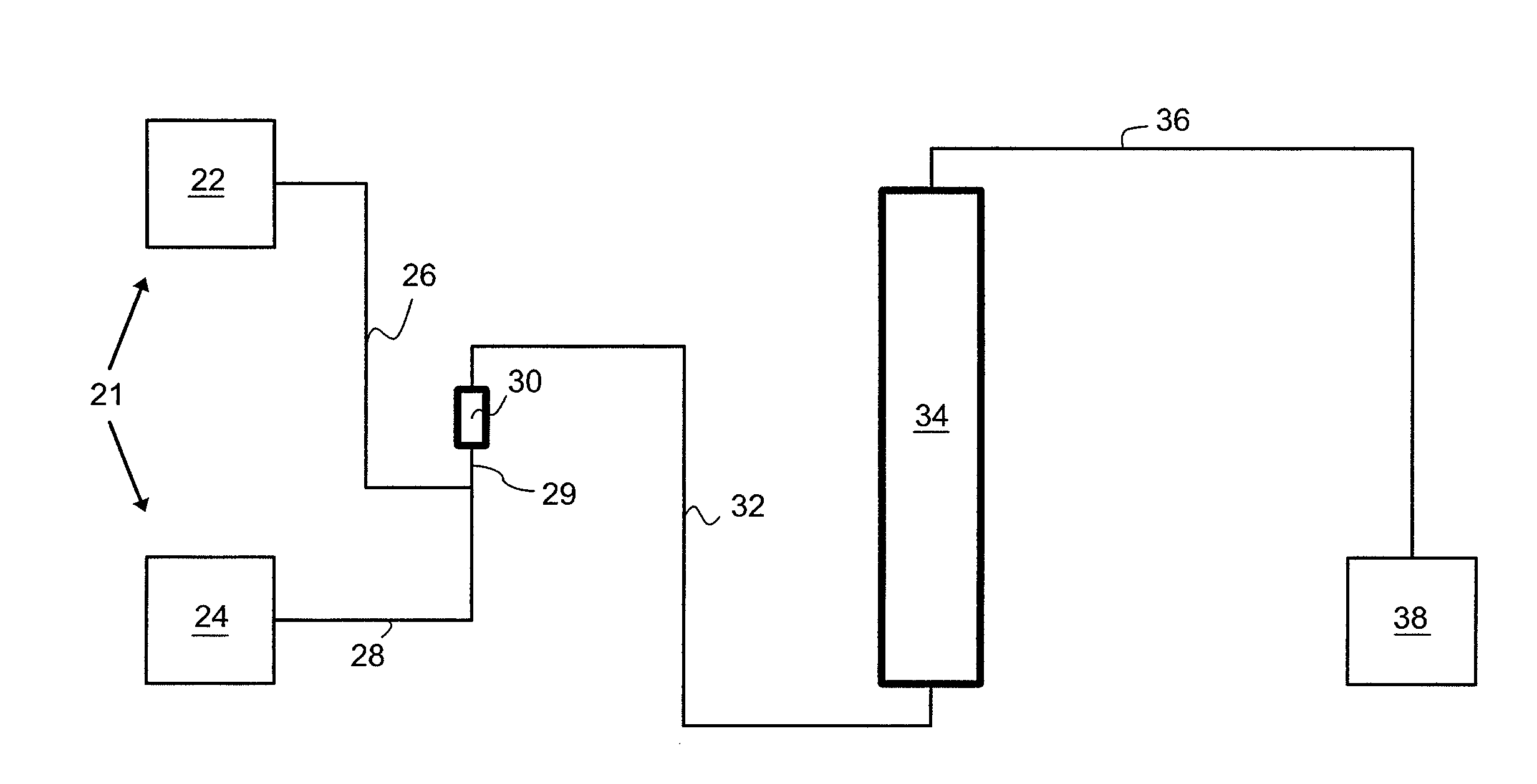

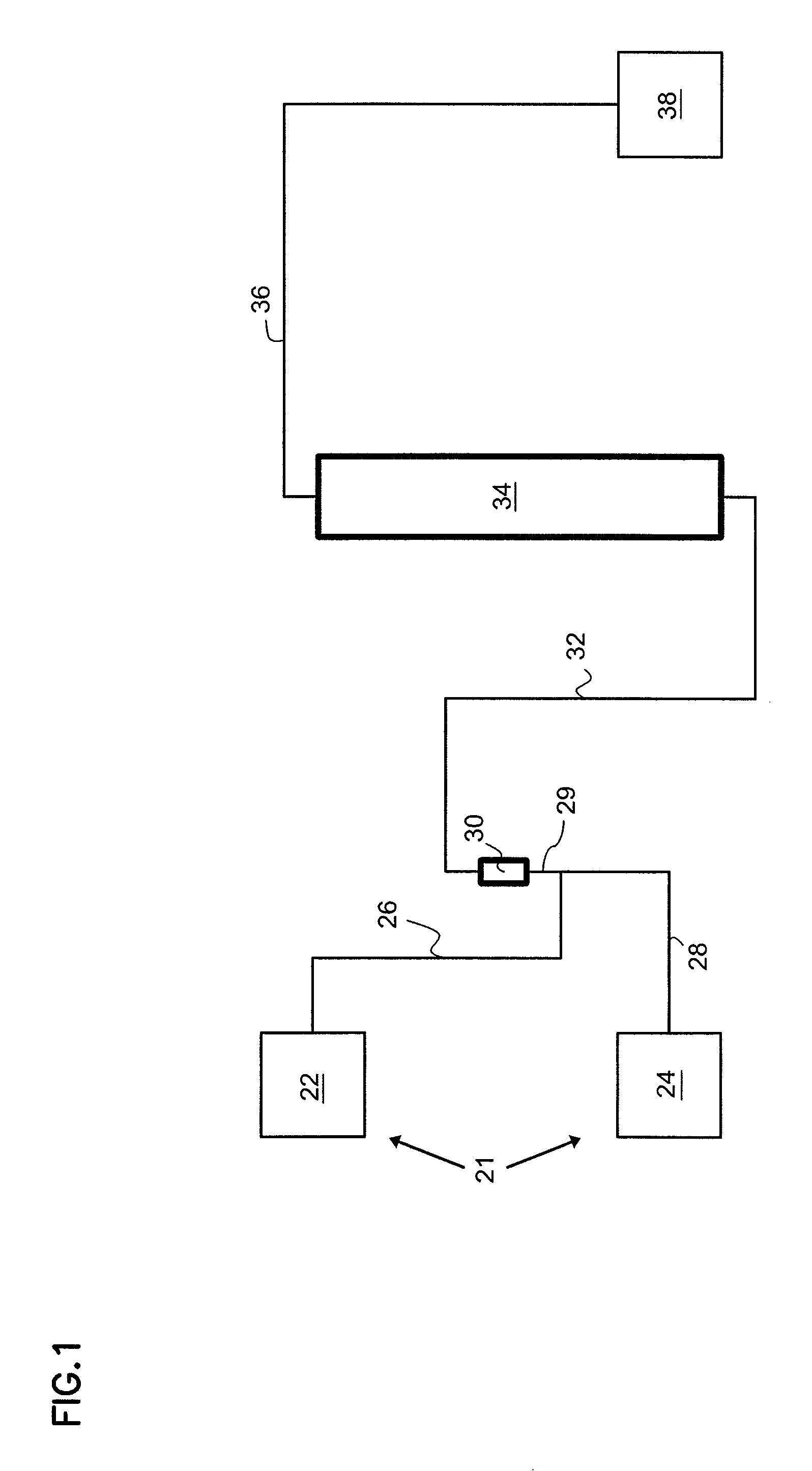

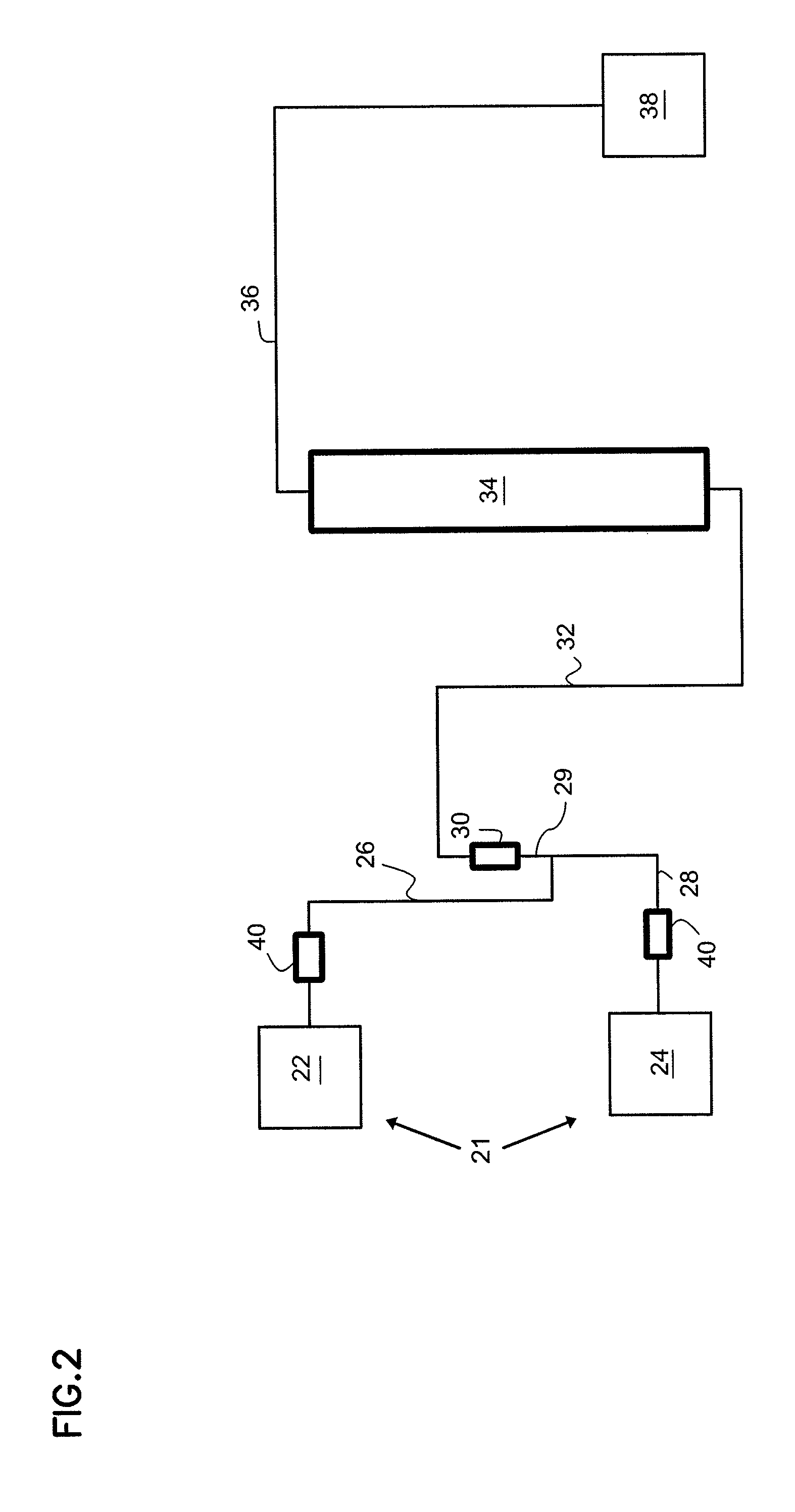

Apparatus and method for making a peroxycarboxylic acid

ActiveUS20080095677A1Prolong lifeHigh activityProcess control/regulationAnalysis using chemical indicatorsCarboxylic acidReagent

Owner:ECOLAB USA INC

Method of preparing organic peroxyacids

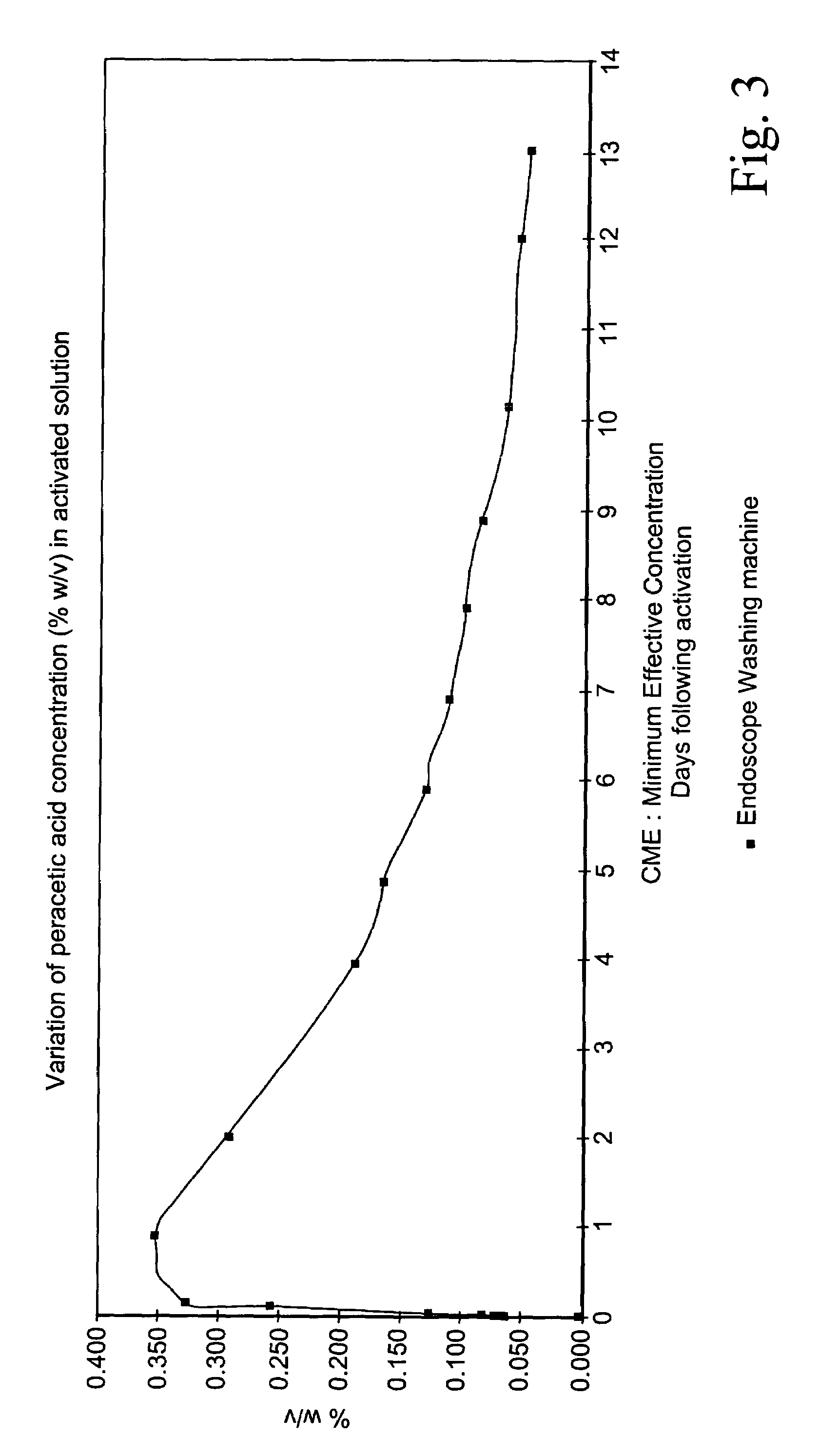

InactiveUS7235252B2Good dispersionResistance to effectBiocideOther chemical processesLiquid stateAcyl group

A system for a fast-rate preparation just before use of organic peroxyacids, in a hydroalcoholic environment, by mixing at temperatures lower than 40° C., preferably lower than 25° C., a first reactant and a second reactant, kept separate from each other during storage, to obtain an activated solution, the first reactant is in the solid or liquid state at a temperature from 5 to 45° C. and includes at least one acyl donating group, and the second reactant is in the solid state, at least in the temperature range from 5° C. and 40° C., and comprises a peroxide anion source in a concentration such as to provide at least 10-fold molar excess of peroxide with respect to the stoichiometric amount of the acyl-donor, a biocidal agent including at least one C1–C18 linear or branched aliphatic and / or aromatic alcohol, and a stabilizing buffer component suitable for keeping the second reactant at a desired pH value.

Owner:PRETO ANDREA +1

Popular searches

Peroxides/peroxyhydrates/peroxyacids/superoxides/ozonides Organic/inorganic per-compounds compounding agents Fire extinguisher Dead animal preservation Animal repellants Plant growth regulators Peroxide active ingredients Contaminated soil reclamation Water/sewage treatment by neutralisation Drilling composition

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com