Preparation method of tert-butyl hydroperoxide

A technology of tert-butyl hydroperoxide and tert-butanol, which is applied in the direction of preparation of peroxy compounds, preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of harmful emissions and high yield of tert-butyl hydroperoxide, etc. Achieve the effect of simple production process, high yield, and overcome the complex production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0010] In the preparation method provided by the present invention, it can be realized under solvent-free conditions. The inventors found that the reaction performance can be improved when a certain solvent is introduced during the implementation process. Therefore, in the preparation method provided by the present invention, a solvent can also be introduced as required, and the solvent is preferably introduced. Described solvent is selected from the ketones such as methanol, ethanol or acetone, methyl ethyl ketone or the nitriles such as acetonitrile, propionitrile, benzyl nitrile or their mixture, preferably acetonitrile, acetone, methanol or their mixture, more preferably acetone, methanol and / or acetonitrile.

[0011] In the method provided by the present invention, the preferred ratio of raw materials is as follows: the molar ratio of tert-butanol to oxidant is preferably 1:1-5, and the mass ratio of solvent to catalyst is preferably 0-150:1. The amount between the raw m...

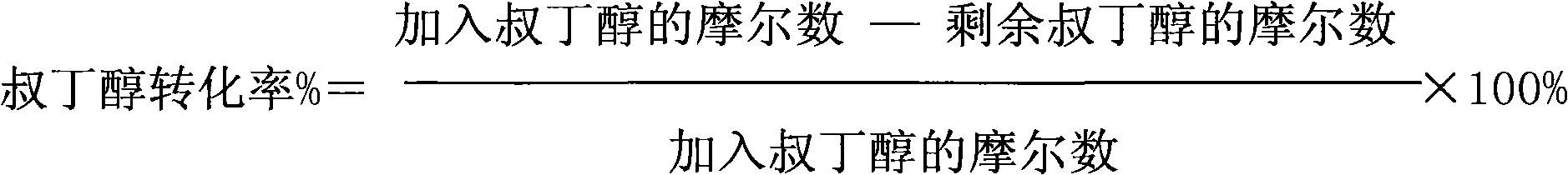

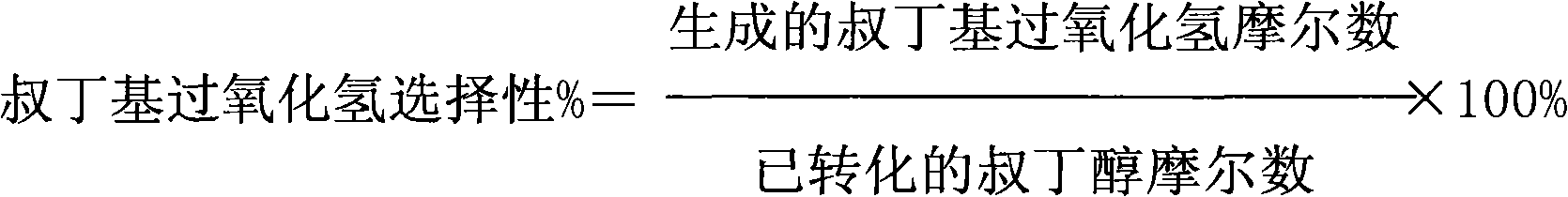

Embodiment 1

[0030] The mol ratio of tert-butanol, hydrogen peroxide, solvent and catalyst (molar ratio 0.2: 1 of titanium silicon molecular sieve and zinc nitrate) is 1: 2 according to the mol ratio of tert-butanol and hydrogen peroxide, and the mass ratio of solvent acetonitrile and catalyzer is 20:1, the mass ratio of tert-butanol to catalyst is 10:1, and the reaction is carried out at a temperature of 50° C. and a pressure of 1.5 MPa. The results of the reaction for 2 hours were as follows: the conversion rate of tert-butyl alcohol was 34%; the selectivity of tert-butyl hydroperoxide was 94%.

Embodiment 2

[0032] The mol ratio of tert-butanol, hydrogen peroxide, solvent and catalyst (molar ratio 1: 1 of titanium silicon molecular sieve and zinc phosphate) is 1: 3 according to the mol ratio of tert-butanol and hydrogen peroxide, and the mass ratio of solvent acetone and catalyzer is 50:1, the mass ratio of tert-butanol to catalyst is 20:1, and the reaction is carried out at a temperature of 60° C. and a pressure of 2.5 MPa. The results of the reaction for 2 hours were as follows: the conversion rate of tert-butyl alcohol was 45%; the selectivity of tert-butyl hydroperoxide was 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com