Patents

Literature

609 results about "Tert-Butyl hydroperoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

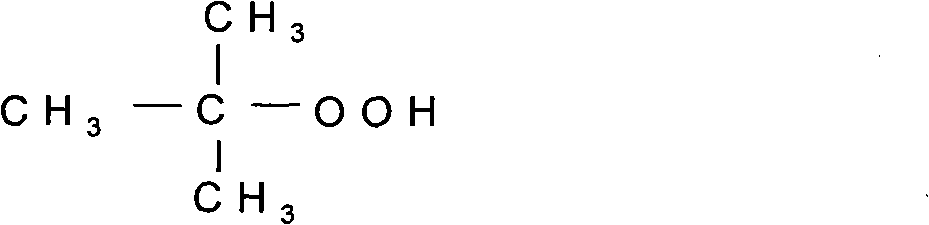

Tert-Butyl hydroperoxide (tBuOOH) is an organic peroxide widely used in a variety of oxidation processes, for example Sharpless epoxidation. It is normally supplied as a 69–70% aqueous solution.

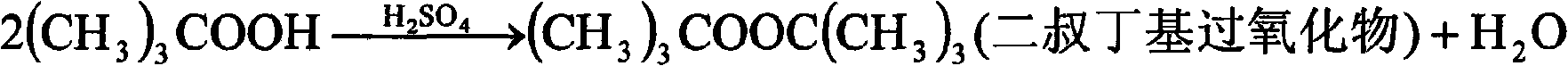

Preparation of tert-butyl hydrogen peroxide and di-tert-butyl peroxide

ActiveCN101298429AMild reaction conditionsHigh yieldOrganic chemistryDi-tert-butyl peroxideOil phase

The invention discloses a preparation method of tert-butyl hydroperoxide and di-t-butyl peroxide which includes the following steps: after mixing vitriol, oxyful and phosphotungstic acid with certain concentration, adding tertiary butyl alcohol into a mixed liquor or adding the mixed liquor into the tertiary butyl alcohol; reacting for 0.5 to 5 hours under 20 to 60 DEG C; obtaining an oil phase after carrying out liquid separation on the crude product of the reaction; obtaining the tert-butyl hydroperoxide and di-t-butyl peroxide products by carrying out decompressing and rectifying on the oil phase; the method has the advantages of simple and convenient operation, low manufacture cost, safety, high efficiency and high yield; in addition, the method of the invention can adjust the relative content of the two reaction products by changing the reaction conditions. The reaction products of tert-butyl hydroperoxide and di-t-butyl peroxide are separated by decompressing and rectifying, thus avoiding the working procedures of acid cleaning and caustic wash in the traditional technique, solving the defect of overlarge waste water amount in the traditional technique, being beneficial to protecting the environment, reducing the manufacture cost and being capable of greatly increasing the enterprise benefits.

Owner:ZHEJIANG JINKE CHEM

Method for refining catalytic liquefied petroleum gas

The present invention relates to a method for refining catalytic liquefied petroleum gas, in which catalyzed liquefied petroleum gas by alconol-amine method removing hydrogen sulfide process is operated by hydrolysis carbonyl sulfur process by passing through carbonyl sulfur hydrolysis activator bed layer, such that carbonyl sulfur hydrolysis generates sulfureted hydrogen and carbon dioxide; then it passes through the desulfurizer bed layer to operate hydrogen sulfide removing process, the preparation of reaction of the hydrogen sulfide and the desulfurizer is chemically absorbed on the desulfurizer; at last, liquid oxygen supplying agent having effective component of tert-butyl hydroperoxide is applied into the catalyzed liquefied petroleum gas, then it is processed by transformation mercaptan by passing through the double effects activator bed layer, under the effect of the double effects activator, the tert-butyl hydroperoxide is hydrogen peroxide decomposed to release fresh state oxygen, and the mercaptan is oxygenated to bisulfide; the activate component of the double effects activator is compound of manganic.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

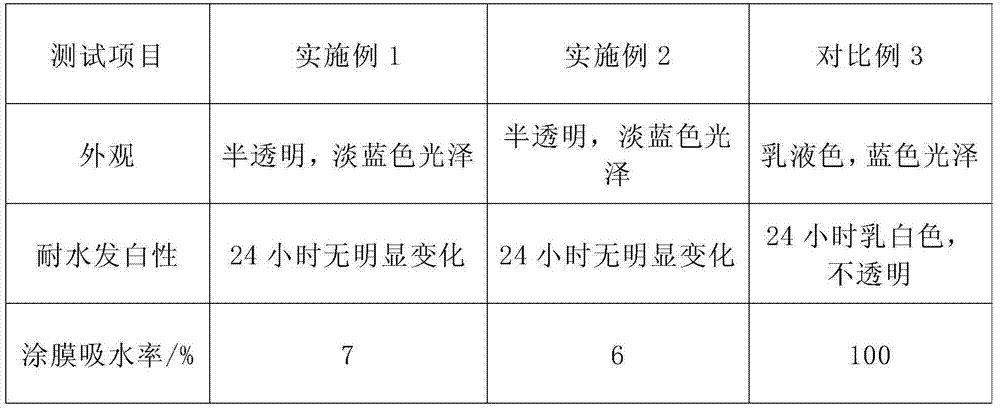

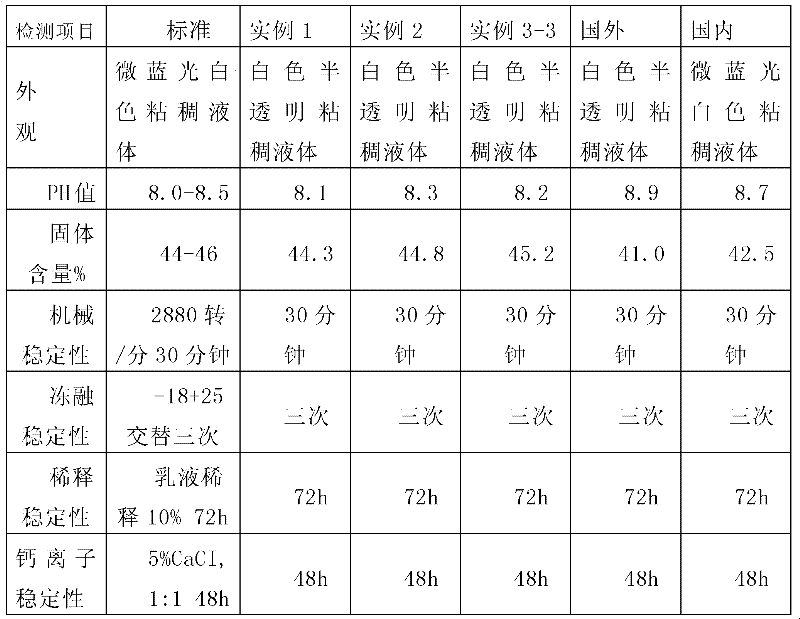

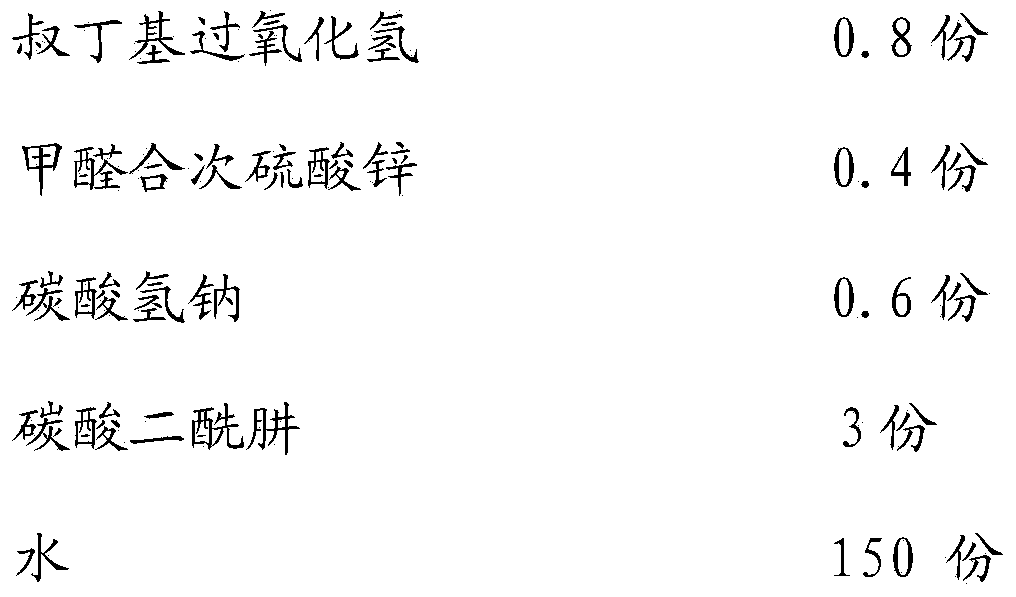

Water resistant whiting emulsion pressure sensitive adhesive synthesis method

The invention discloses a water resistant whiting emulsion pressure sensitive adhesive synthesis method, and a water resistant whiting emulsion pressure sensitive adhesive comprises the following components by weight: 20-60% of a soft monomer; 1-40% of a hard monomer; 1-5% of an emulsifier and the balance of water. The emulsifier is selected from allyloxy nonylphenol propanol polyoxyethylene ether ammonium sulfate, allyloxy nonylphenoxy propanol polyoxyethylene ether ammonium sulfate, allyloxy nonylphenoxy propanol polyoxyethylene ether, and a mixture of allyloxy nonylphenol propanol polyoxyethylene ether ammonium sulfate, allyloxy nonylphenoxy propanol polyoxyethylene ether ammonium sulfate and allyloxy nonylphenoxy propanol polyoxyethylene ether. The method comprises the following steps: (I) mixing the emulsifier and the monomer basically without stirring; (II) adding part of an initiator at 78 to 82 DEG C into a reaction kettle with water, adding dropwise the monomer mixture, after addition of the monomer mixture for 30 minutes, adding dropwise the remaining initiator solution for 2 to 5 hours, controlling the reaction temperature at 80-85 DEG C, and performing thermal insulation for 0.5 to 1 hour; and (III) after thermal insulation, reducing the temperature to 50 to 70 DEG C, adding tert-butyl hydroperoxide and methylsodium hydrosulfite aqueous solution, continuing to react for 0.2-1 hour, and adjusting the emulsion pH value to 6-8 when the temperature is reduced to 40 to 50 DEG C.

Owner:SHANGHAI HUAYI NEW MATERIAL

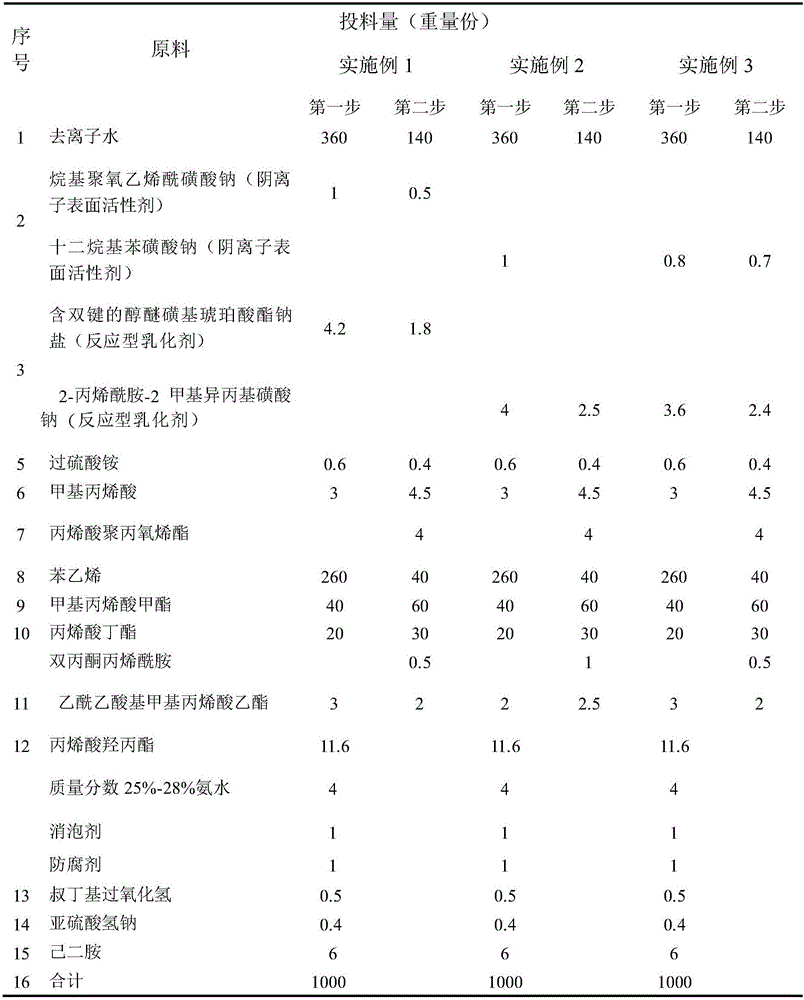

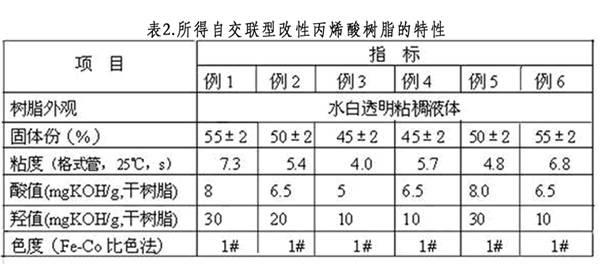

Normal temperature self-crosslinking acrylic emulsion and preparation method thereof

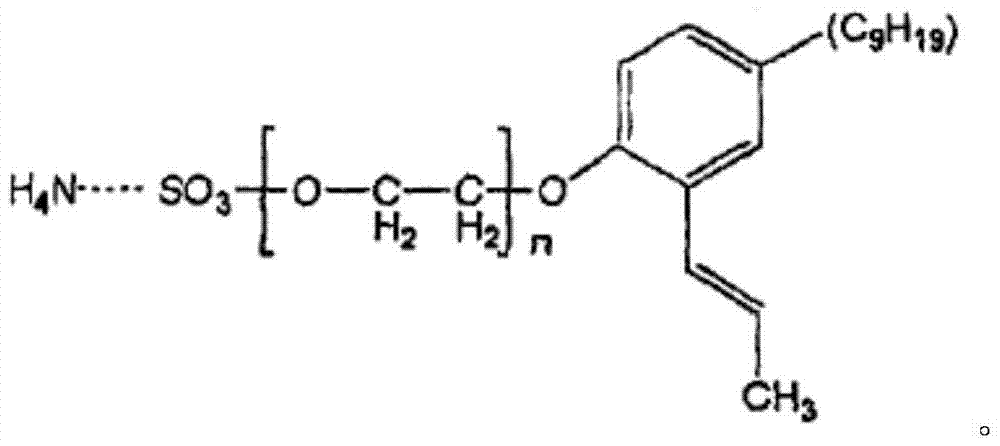

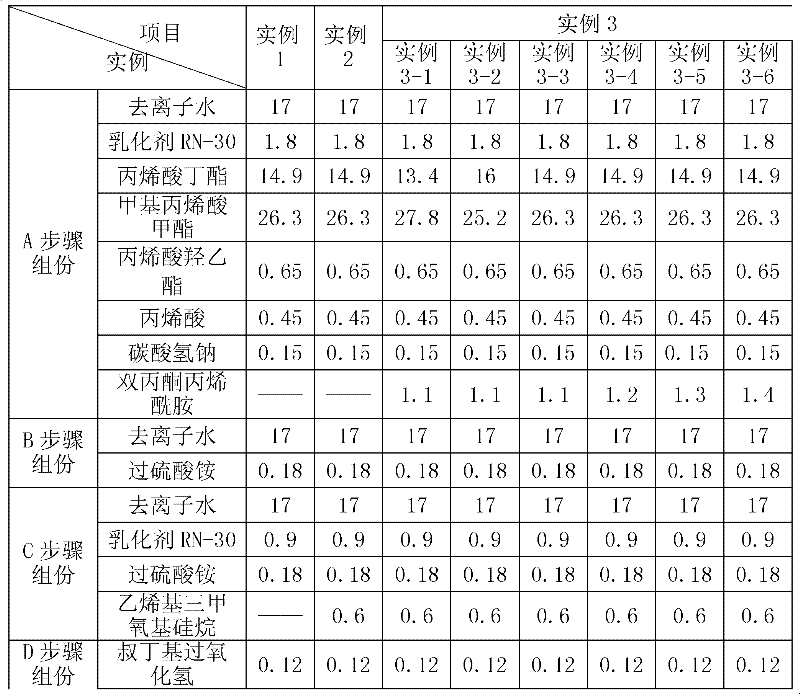

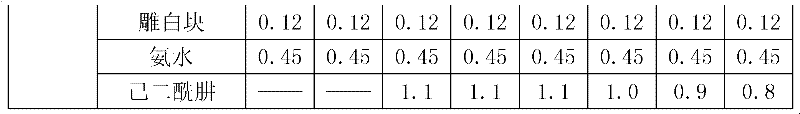

The invention discloses a normal temperature self-crosslinking acrylic emulsion and a preparation method thereof. The acrylic emulsion is obtained by radical-initiated polymerization of the following raw materials by weight: 50 to 52 parts of deionized water, 2 to 3 parts of emulsifier RN-30, 12 to 16 parts of butyl acrylate, 22 to 28 parts of methyl methacrylate, 0.5 to 1 part of hydroxyethyl acrylate, 0.3 to 0.6 part of acrylic acid, 0.4 to 0.8 part of vinyltrimethoxy silane, 0.1 to 0.3 part of sodium bicarbonate, 0.2 to 0.4 part of ammonium persulfate, 1 part to 2 parts of diacetone-acryloamide, 0.5 part to 1.5 parts of adipic dihydrazide, 0.1 to 0.14 part of the oxidizing agent tert-butyl hydroperoxide, 0.1 to 0.14 part of the reducing agent rongalite and 0.3 to 0.6 part of ammoniacalliquor. The normal temperature self-crosslinking acrylic emulsion provided in the invention has better water resistance and oil resistance and greatly enhances the problems of after tack at high temperature and embrittlement at low temperature under the condition that the quality of a final product is guaranteed to be no worse than the quality of products of a same kind.

Owner:山东奔腾漆业股份有限公司

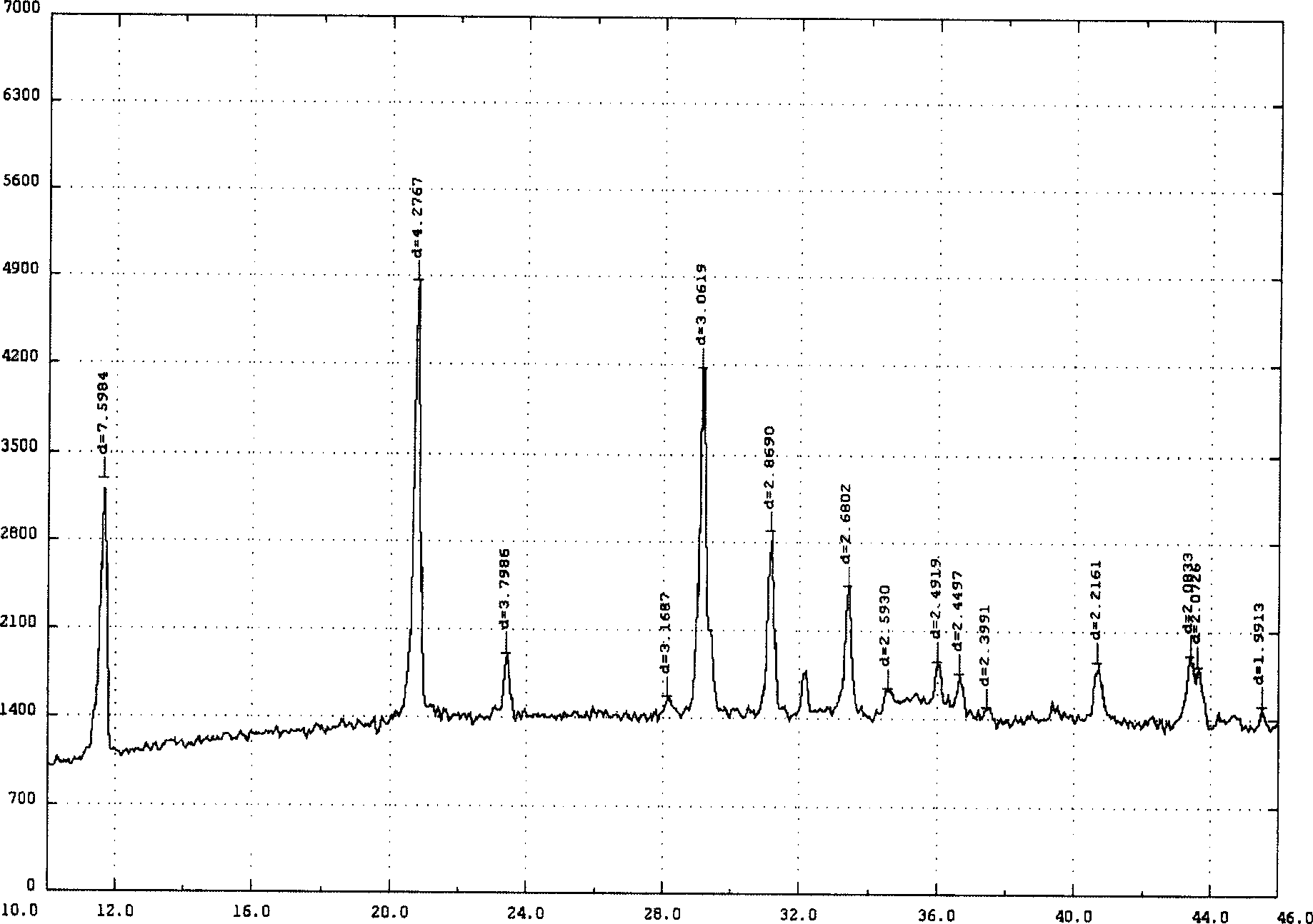

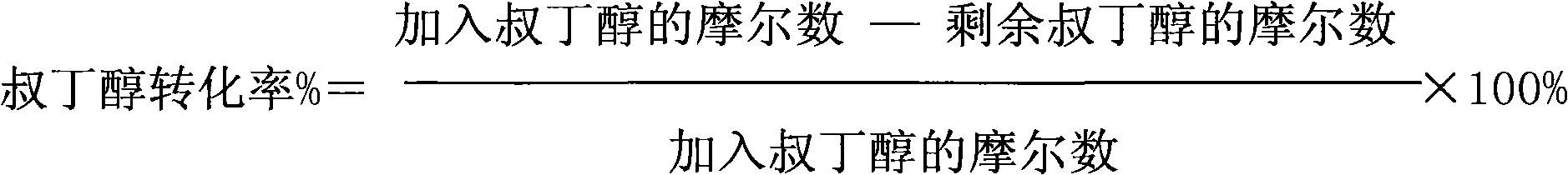

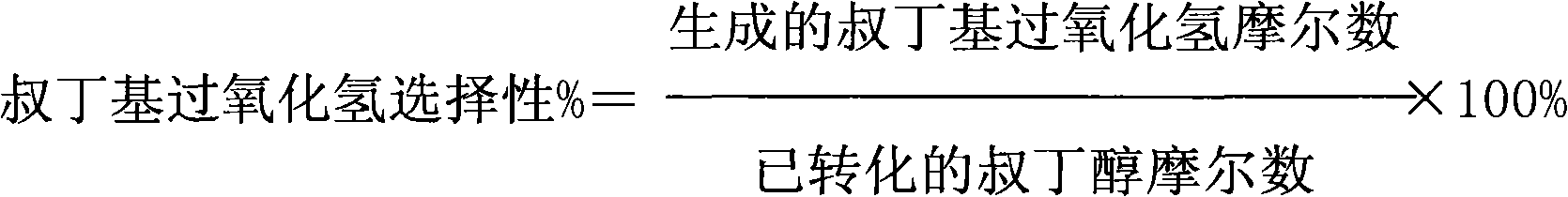

Preparation method of tert-butyl hydroperoxide

ActiveCN103204792AHigh hydrogen peroxide yieldHigh yieldOrganic compound preparationPeroxy compound preparationMolecular sieveHeteroatom

The invention discloses a preparation method of tert-butyl hydroperoxide. Under oxidation reaction conditions, tert-butyl alcohol, an oxidant, a solvent and a catalyst are subjected to mixed contact. The method is characterized in that the catalyst is a soluble zinc salt modified heteroatom molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing epoxy styrene by direct oxidation of phenylethylene

InactiveCN101463020ASimple production processGood repeatabilityPhysical/chemical process catalystsOrganic chemistryEpoxyNitrogen atmosphere

The invention relates to a method for synthesizing epoxyphenylethane by directly oxidizing styrene. The method is characterized by taking Ag-gamma-ZrP as a catalyst, taking tert-butyl hydroperoxide as an oxygen source, taking acetonitrile as a solvent, and directly epoxidizing the styrene to synthesize the epoxyphenylethane in a nitrogen atmosphere at the temperature of 70-90 DEG C. The maximum conversation rate of the styrene is up to 92%, and selectivity of the epoxyphenylethane is up to 96%.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

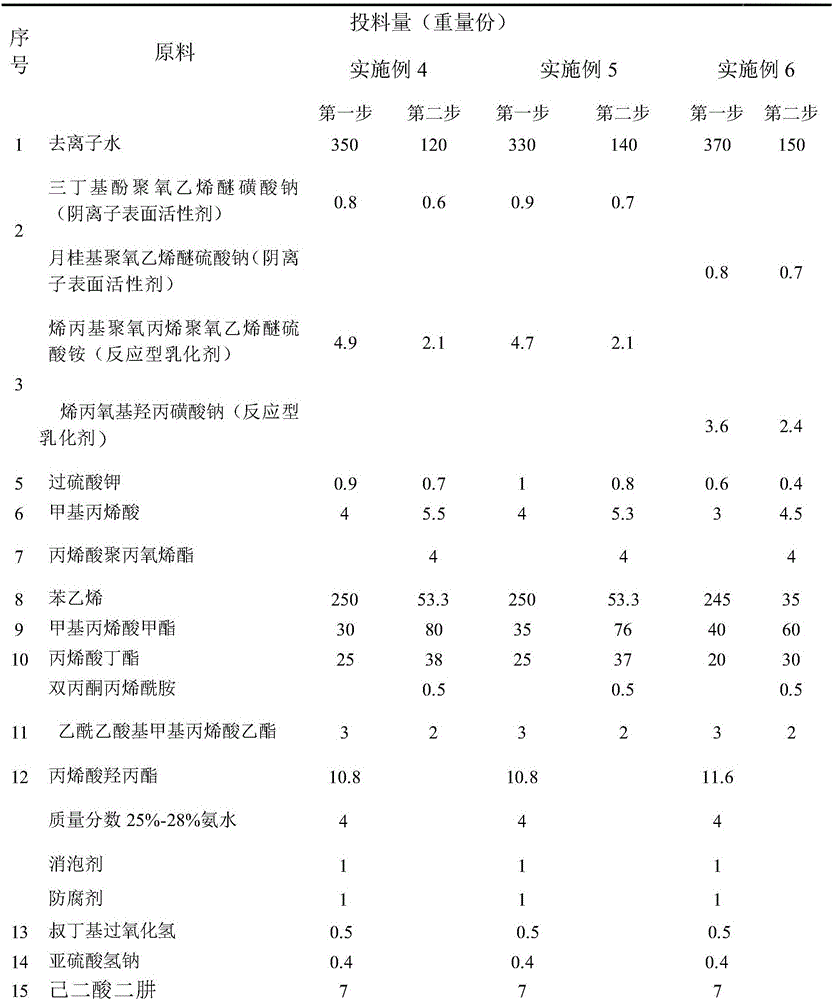

Acrylate copolymer emulsion, and aqueous industrial anticorrosive paint adopting acrylate copolymer emulsion as film forming substance

ActiveCN105859936AReduce the temperatureGuaranteed compactnessAnti-corrosive paintsCross-linkSodium bisulfate

The invention discloses an acrylate copolymer emulsion, and belongs to the technical field of aqueous coatings. The acrylate copolymer emulsion comprises, by weight, 450-550 parts of deionized water, 1-2 parts of an anionic surfactant, 5-8 parts of a reactive emulsifier, 3-15 parts of hydroxypropyl acrylate, 50-160 parts of methyl methacrylate, 20-75 parts of butyl acrylate, 200-410 parts of styrene, 5-10 parts of methacrylic acid, 3-10 parts of an adhesion function monomer, 2-9 parts of a cross-linking monomer, 3-10 parts of a cross-linking agent, 0.1-3 parts of an antifoaming agent, 0.8-2 parts of an initiator, 3-5 parts of ammonia water, 0.8-2 parts of an antiseptic, 0.1-1 part of tert-butyl hydroperoxide and 0.1-0.8 parts of sodium bisulfate. The invention also discloses an aqueous industrial anticorrosive coating adopting the acrylate copolymer emulsion as a film forming substance. The coating has the advantages of high adhesion to a substrate, high water resistance and high salt spray resistance.

Owner:HENGSHUI XINGUANG CHEM

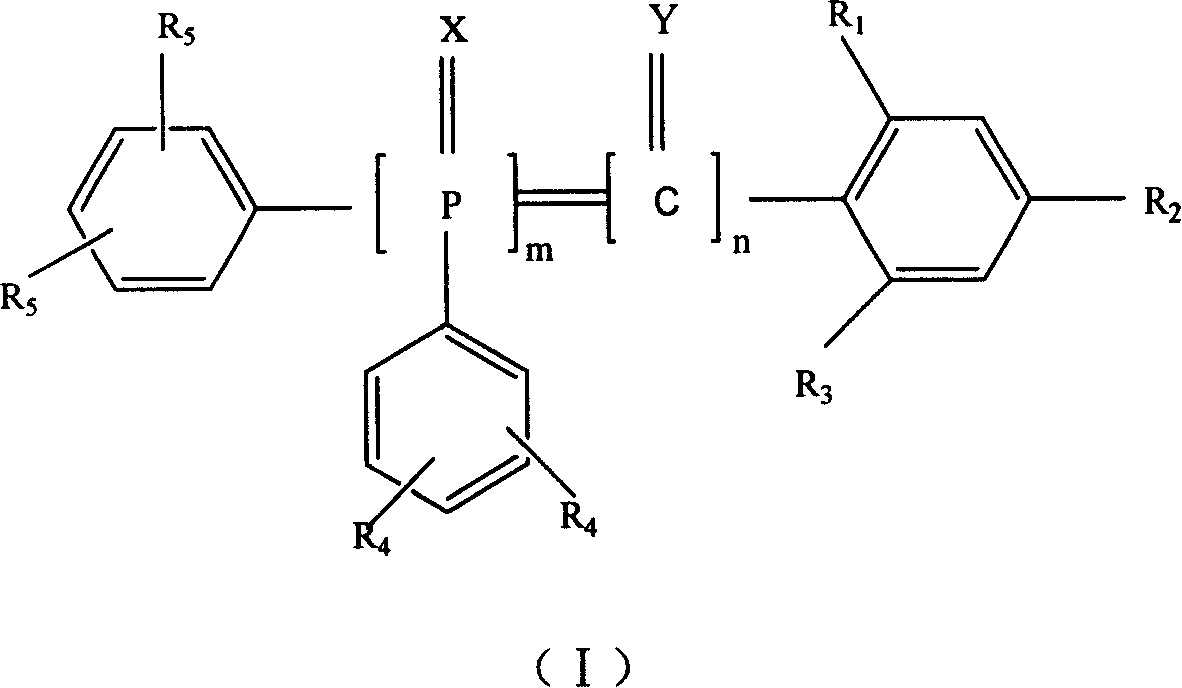

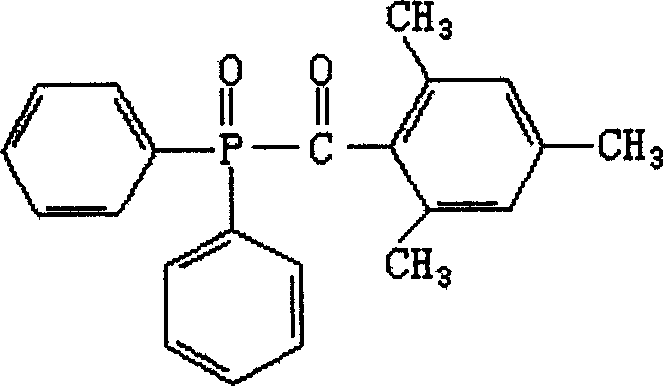

Method for preparing acyl and bisacyl phosphine oxide or acyl and bisacyl sulfur phosphines

InactiveCN101200475AReduce manufacturing stepsReduce decreaseGroup 5/15 element organic compoundsCoatingsBenzaldehydePhosphine oxide

The invention relates to a preparation method of single acyl or two acyl phosphine oxide and single acyl or two acyl sulfur phosphine compound, in particular to a preparation method of the 2,4,6-trimethylbenzene formacyl-diphenyl phosphine oxide of the photoinitiator. The addition reaction is carried out between Trimethyl benzaldehyde and diphenyl phosphorus chloride and then the mixture is oxidized by tert-butyl alcohol peroxide. The invention adopts the addition reaction of aldehyde and halogenated phosphorus and replaces the original process of acyl chloride and halogenated phosphorus, and has the advantages of greatly shortening the preparation procedures, low cost, easy operation and quick production. The compound prepared by the invention has more than 98 percent of the 2,4,6-trimethylbenzene formacyl-diphenyl phosphine oxide and can be served as the photoinitiator for solid for producing the solidification product with the performance of paint, varnish, porcelain glaze, paint, pigment or ink, and can better satisfy the increasing market demand.

Owner:TIANJIN JIURI NEW MATERIALS CO LTD

Wood lacquer water-borne flat self-crosslinking acrylic emulsion and synthesizing method thereof

ActiveCN109439124AReduce manufacturing costReduce energy consumptionCoatingsIsooctyl acrylateSodium bicarbonate

The invention discloses a wood lacquer water-borne flat self-crosslinking acrylic emulsion and a synthesizing method thereof. The wood lacquer water-borne flat self-crosslinking acrylic emulsion is composed of raw materials of monomers, functional monomers, solvent, neutralizer, buffer agent, initiator, emulsifier and flatting agent, wherein the monomers are composed of, by weight part, 3-12 partsof methacrylic acid, 120-300 parts of methyl methacrylate, 2-20 parts of butyl acrylate, 10-50 parts of styrene and 40-120 parts of ethylhexyl acrylate; the functional monomers are composed of 4-14 parts of diacetone acrylamide, 3-10 parts of adipic dihydrazide and 1-10 parts of vinyl trimethoxysilane; the solvent is 500-800 parts of deionized water; the neutralizer is 2-10 parts of ammonia hydroxide; the buffer agent is 0.2-1 part of sodium bicarbonate; the initiator is composed of 0.5-3 parts of ammonium persulfate, 0.1-2 parts of tert-butyl hydroperoxide and 0.1-2 parts of ascorbic acid; the emulsifier is 0.5-8rts of lauryl sodium sulfate; the flatting agent is 5-35 parts of fumed silica. The wood lacquer water-borne flat self-crosslinking acrylic emulsion has the advantages of excellent transparency, excellent water resistance, excellent alcohol resistance and flatness and can be combined to manufacture water-borne wood lacquers of different glossiness.

Owner:HUBEI JIADE PUAN PAINT

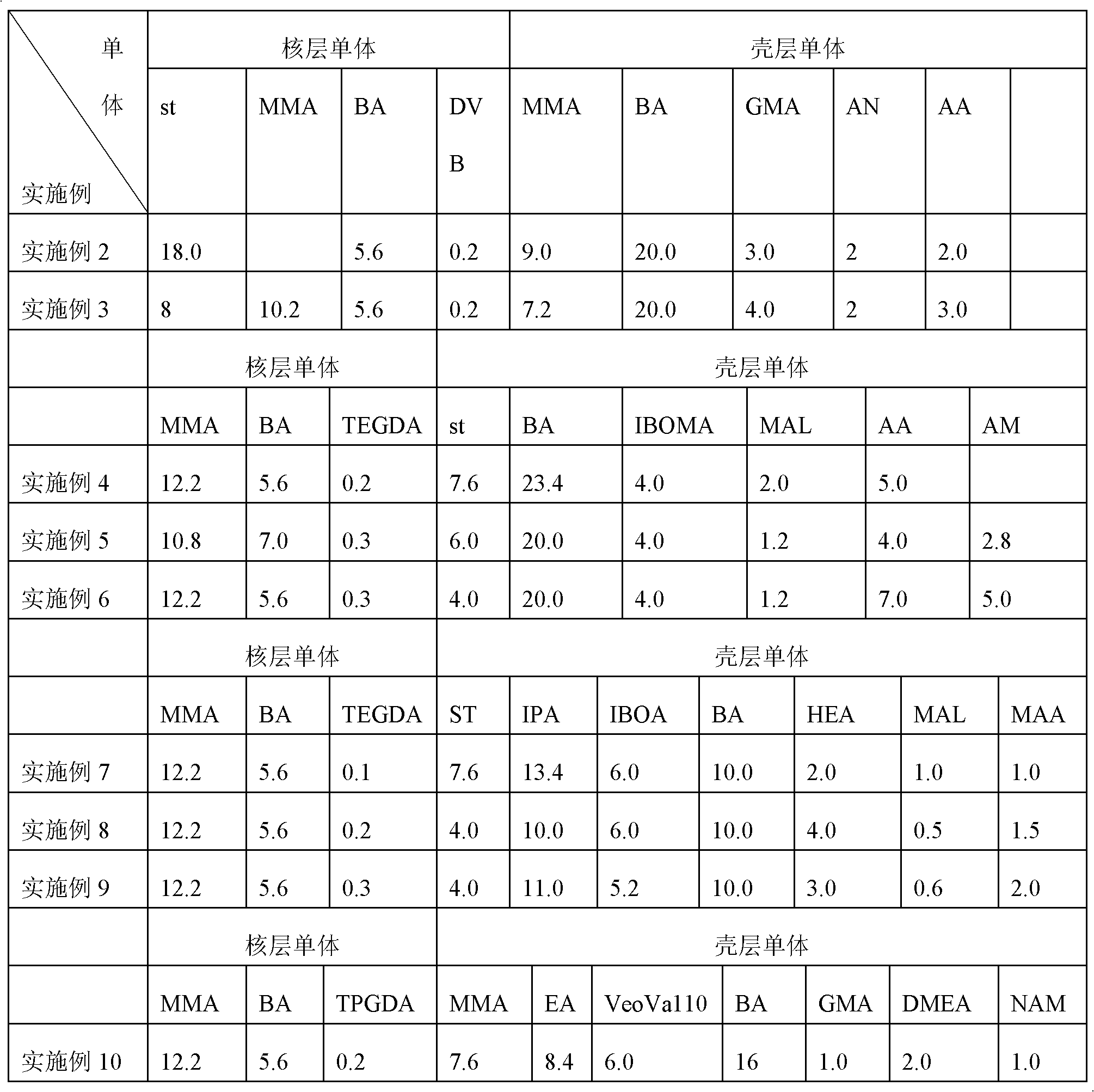

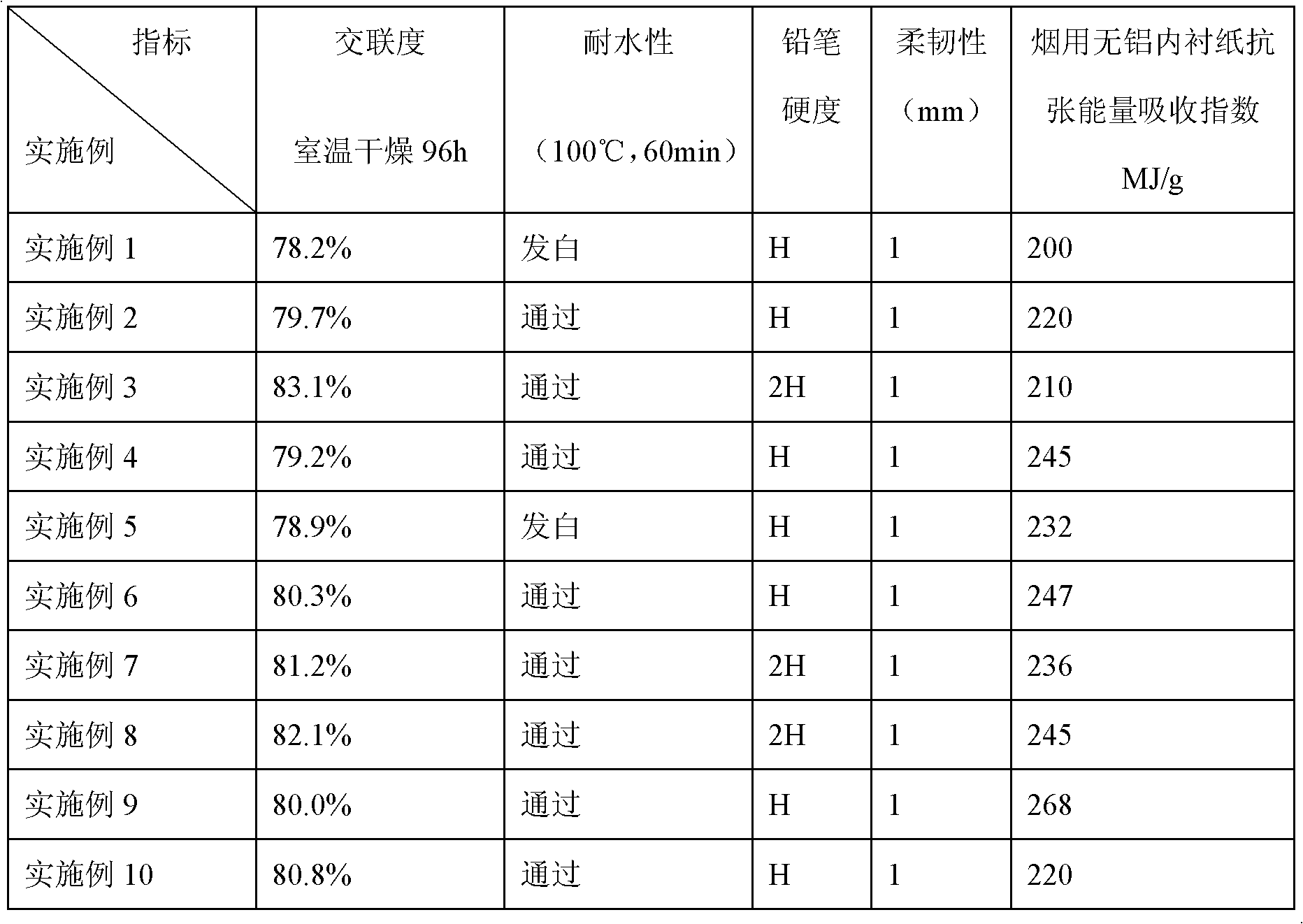

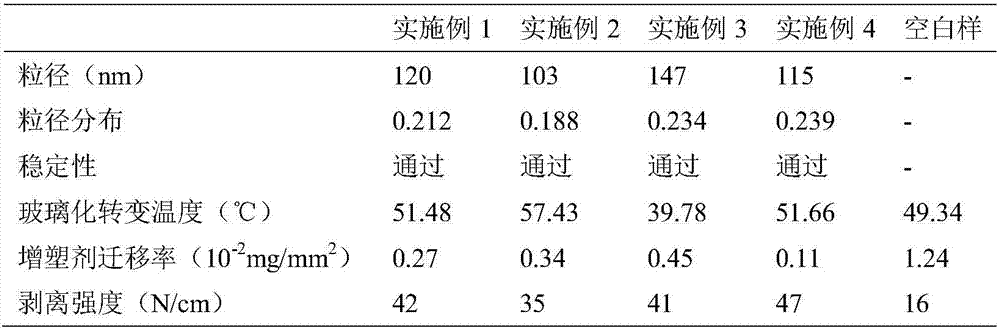

Novel aluminum-free lining paper coating for cigarette package and preparation method thereof

InactiveCN102619135AIncrease crosslink densityHigh hardnessDefoamers additionPaper coatingEmulsionAluminum foil

The invention discloses a novel aluminum-free lining paper coating for cigarette package and a preparation method thereof. The method includes preparation of core-shell structure cross-linking type polyacrylate emulsion and preparation of a novel cigarette aluminum-free lining paper coating. The method includes: adding deionized water, an emulsifying agent and a core layer monomer in a reaction kettle, stirring and emulsifying, heating to 75-80 DEG C, adding water solution of an initiating agent dropwise, leading polymerization reaction, and manufacturing core layer particles; simultaneously adding a core layer olefin monomer and the water solution of the initiating agent which are mixed well in a core layer particle reaction system dropwise, and adding tert-butyl hydroperoxide water solution after reaction; cooling, filtering, and discharging to obtain the core-shell structure cross-linking type polyacrylate emulsion. The obtained novel cigarette aluminum-free lining paper coating is suitable for being coated on aluminum-free paper, the paper can replace aluminum foil composite paper to be applied to the cigarette package after being dried, and the novel aluminum-free lining paper coating has the advantages of being high in strength, good in tightness and water resistance and the like.

Owner:GUANGDONG RONGYU INDAL

Water-based ink resin for PVC furniture membranes and preparation method of water-based ink resin

The invention provides water-based ink resin for PVC furniture membranes and a preparation method of the water-based ink resin. Raw materials of the water-based ink resin for the PVC furniture membranes comprise an anionic emulsifier, a nonionic emulsifier, a pH buffering agent, an initiator, a chain transfer agent, a methyl methacrylate monomer, a methyl acrylate monomer, a glycidyl methacrylate monomer, tert-butyl hydroperoxide, rongalite, a preservative, and deionized water; based on a design concept of ''polymer welding'', an emulsion-type resin which is well compatible to PVC and of which glass transition temperature is similar to that of the PVC is prepared and designed, wherein the main body of the emulsion-type resin is poly(methyl methacrylate-methyl acrylate), and the high peeling strength of the water-based ink resin and the PVC furniture membranes is guaranteed; and meanwhile, a characteristic that the PVC furniture membranes have a large number of plasticizers is combined, a proper amount of the glycidyl methacrylate monomer with epoxy groups is introduced to a copolymerization monomer system, and therefore the plasticizer migration resistant ability of the water-based ink resin is improved.

Owner:HANGZHOU HIWETECH CHEM TECH CO LTD

Process for preparing tert-butyl hydroperoxide

ActiveCN1699339AIncrease profitHigh activityOrganic compound preparationPeroxy compound preparationCatalytic oxidationTitanium

The invention provides a process for preparing tert-butyl hydroperoxide, which comprises contacting tert-butanol and hydrogen dioxide by the mol ratio of 0.5-10 for 0.5-10hours at 40-100 deg. C at the presence of titanium-silicon molecular screen, the content of titanium-silicon molecular screen is 0.005-0.1g molecular screen in each one ml of reaction liquid.

Owner:CHINA PETROLEUM & CHEM CORP +1

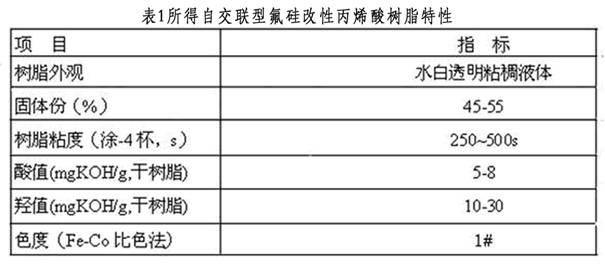

Self-crosslinked fluorosilicate acrylic resin and preparation method thereof

The invention discloses self-crosslinked fluorosilicate acrylic resin and a preparation method thereof. The self-crosslinked fluorosilicate modified acrylic resin has the structural formula shown in the specifications, wherein n=4, 6 and 8, and the molecular weight is 60,000-80,000; X refers to a (meth)acryloxy functional group or an alkenyl-containing silane coupling agent; and X has the structural formula shown in the specifications, wherein R is -CH3 or -CH2CH3. The preparation method comprises the following steps of: adding a solvent into a reaction container, and heating to the temperature of between 90 and 100DEG C; uniformly mixing methyl methacrylate, acrylic acid, ethyl acrylate, hydroxyethyl acrylate, a silane coupling agent, perfluoroalkylethyl acrylate and tert-butyl hydroperoxide, and dripping for 2 to 3 hours; keeping the temperature for 3 to 4 hours; and reducing the temperature to 40-60DEG C and discharging. The prepared resin has high weatherability, high chemical resistance, high-temperature resistance, good mechanical properties and glossiness, and high insulativity; and the preparation method has simple process steps and is easy to implement.

Owner:JINZHOU DPF TH CHEM CO LTD

Graphene oxide melamine resin and preparation method thereof

InactiveCN104804159AImprove dispersion uniformityImprove mechanical propertiesCarbon nanotubePhosphoric acid

The invention discloses graphene oxide melamine resin. The graphene oxide melamine resin is prepared from the following raw materials in parts by weight: 0.5-0.8 part of carbon nanotubes, 0.2-0.3 parts of aluminum phosphate, 20-25 parts of melamine, 40-45 parts of a 37% formalin, 1.8-2.1 parts of graphene oxide, 0.7-0.9 part of trifluoroethyl methacrylate, 0.7-0.9 part of polyacrylonitrile, an appropriate amount of dimethylformamide, 0.2-0.3 parts of polyoxyethylene, an appropriate amount of a composite solvent which comprises dimethylformamide and dichloromethane according to the volume ratio of 1:1, 0.3-0.5 part of tert-butyl hydroperoxide, an appropriate amount of citric acid, an appropriate amount of an alkaline pH value modifier AMP-95, and an appropriate amount of ethanol. According to the graphene oxide melamine resin disclosed by the invention, graphene oxide, the carbon nanotubes and aluminum phosphate are added, so that the mechanical properties of the material are improved, and the conductivity and the bending strength are improved.

Owner:WUHU BAOYI AMUSEMENT EQUIP

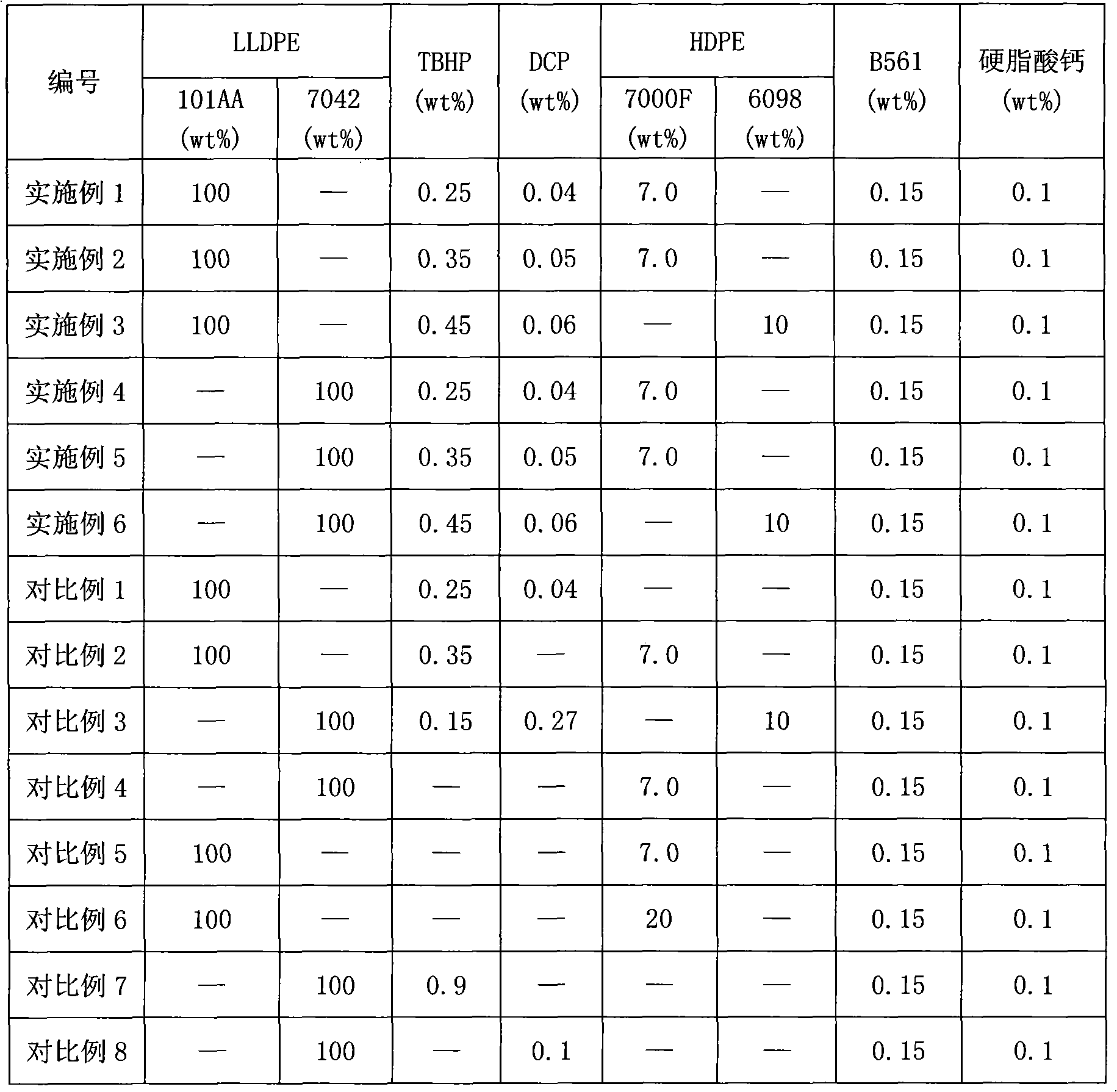

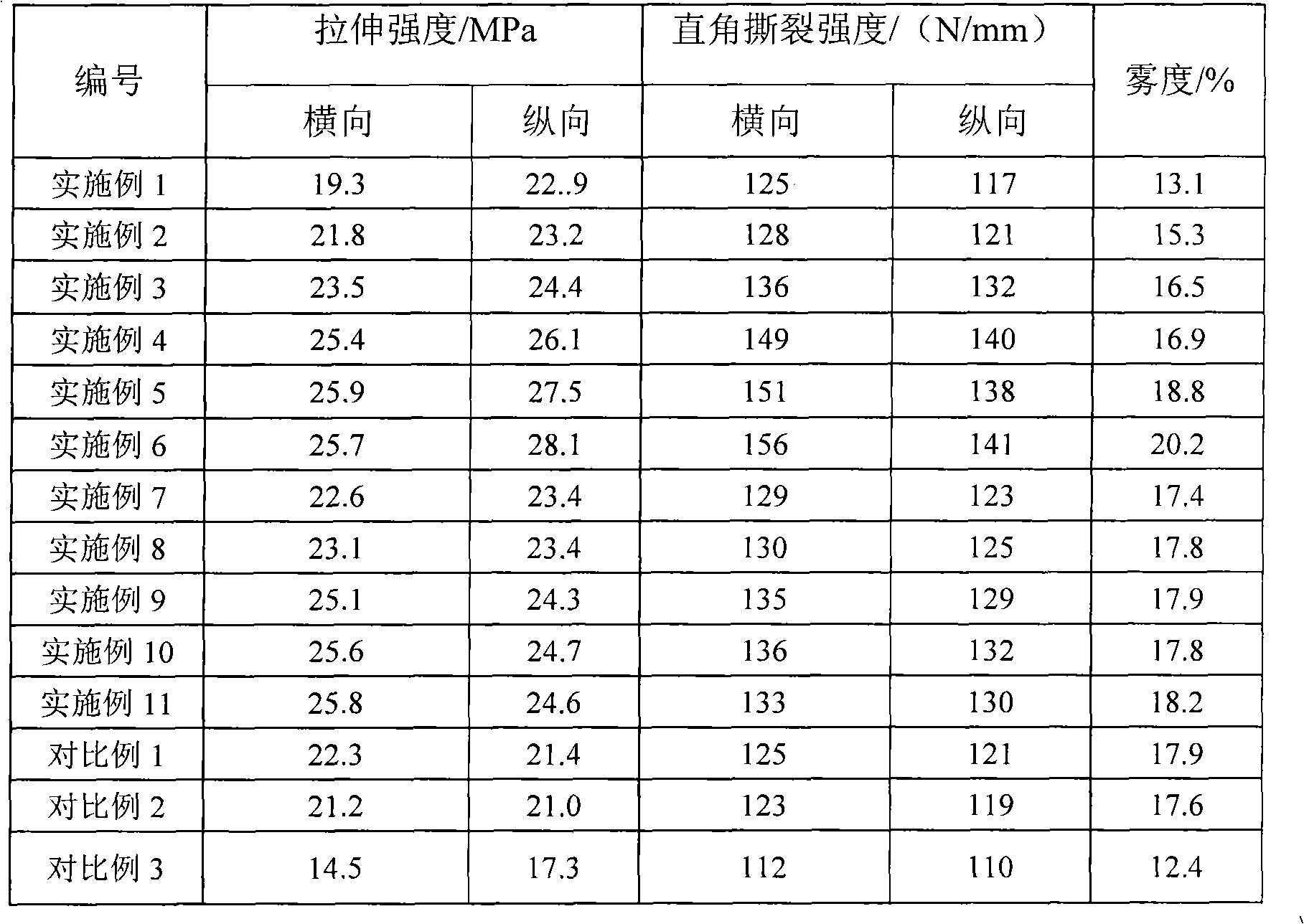

Polyethylene greenhouse film resin composition and preparation method thereof

The invention discloses a polyethylene greenhouse film resin composition, which is calculated by linear low density polyethylene in weight percent, and comprises the following components: 1) linear low density polyethylene the melt flow rate of which is 0.7-3.0g / 10min; 2) 5-15% of low-pressure polyethylene the melt flow rate of which is 0.01-0.1g / 10min; 3) 0.1-0.5% of tert-butyl hydroperoxide; and 4) 0.03-0.07% of dicumyl peroxide. The composition can stably blow a wide greenhouse film on a common film blowing unit which is not transformed, wherein, the thickness of the wide greenhouse film is more than or equal to 80 mu m, and the width of the wide greenhouse film is more than or equal to 8m; the product has no crystallization point on the appearance, has high tearing strength, and can resist 7-8 grade sand wind, wherein, the wind power is 17.2-20.7m / s, and is especially suitable for the laying of the central and western regions in which the sandstorm occurs frequently. The invention also further discloses a preparation method of the composition.

Owner:PETROCHINA CO LTD

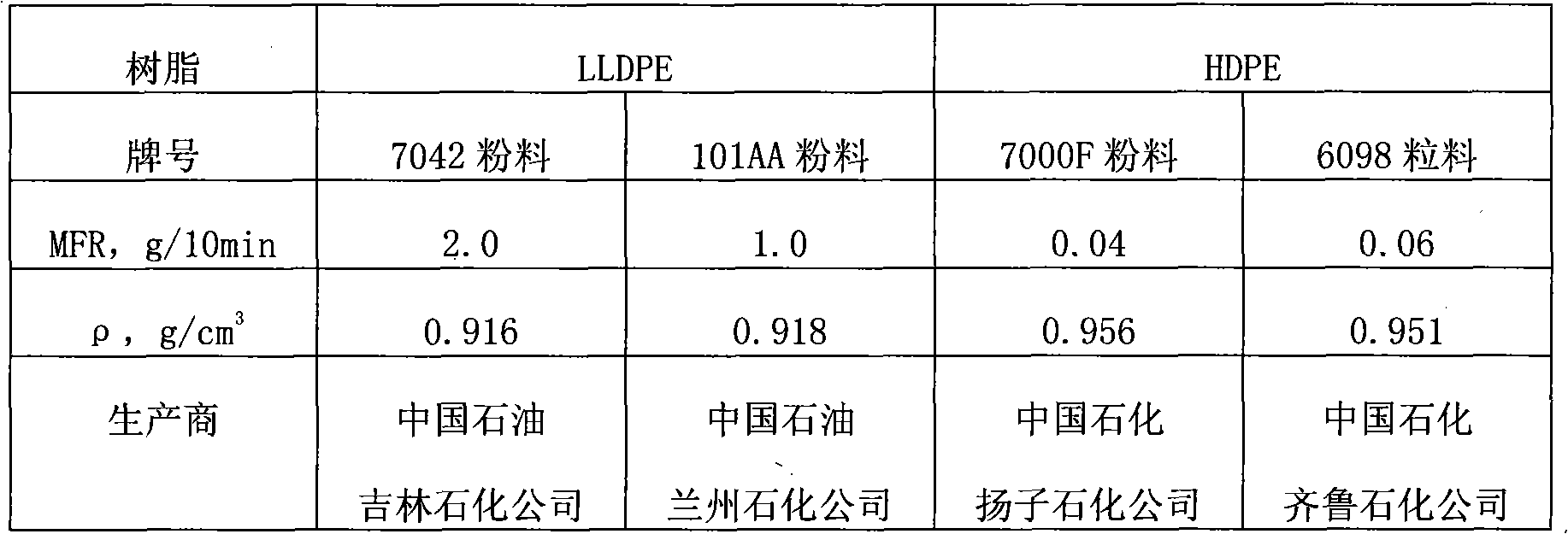

Agricultural polyethylene resin composition

ActiveCN101538386AReduce dosageGuaranteed stabilityClimate change adaptationGreenhouse cultivationLow-density polyethyleneCross-link

The invention discloses an agricultural polyethylene resin composition. The composition mainly consists of linear low-density polyethylene LLDPE and organic peroxide, wherein the organic peroxide is combined by di-tert-butyl peroxide DTBP and tert-butyl hydroperoxide TBHP according to the combination ratio of between 1:1 and 6:1, and the consumption of the organic peroxide is between 500 and 2,500ppm (based on each gram of linear low-density polyethylene). In the composition, the linear low-density polyethylene LLDPE is cross-linked by compounding the peroxide, and when the obtained modified high-bath strength LLDPE resin is used for blowing a 80 mum agricultural green house membrane, and under the condition of ensuring the membrane blowing stability and the quality of the membrane, the consumption of the peroxide is lowered, so that the production cost is also lowered.

Owner:PETROCHINA CO LTD

Copper catalyst system for decarboxylation coupling reaction

InactiveCN102614927ANon-toxicLow costOrganic compound preparationOrganic chemistry methodsDi-tert-butyl peroxideIodide

The invention discloses a copper catalyst system for decarboxylation coupling reaction, which comprises a copper-containing compound and an oxidant in a mol ratio of 1:(10-40), wherein the copper-containing compound is one or mixture of cuprous iodide, cupric acetylacetonate, cuprous bromide, cupric sulfate and copper powder; and the oxidant is tert-butyl hydroperoxide, di-tert-butyl peroxide or dicumyl peroxide. The catalyst system can catalyze the decarboxylation coupling reaction of cinnamic acid and methylbenzene compounds to prepare olefin compounds. Compared with the existing noble-metal-containing catalyst system, the catalyst system disclosed by the invention uses the cheap copper-containing compound instead of noble metal, thereby lowering the cost; and the byproduct is only carbon dioxide, thereby being beneficial to environment protection and cost saving, and satisfying the requirement for green chemistry.

Owner:SUZHOU UNIV

High-fire resistance modified polyethylene tube material

The invention discloses a high-fire resistance modified polyethylene tube material. The high-fire resistance modified polyethylene tube material comprises high density polyethylene, silicone resin, polypropylene, an ethylene-propylene-diene monomer, maleic anhydride-grafted polyphenyl ether, tert-butyl hydroperoxide, ferriferrous oxide, barium sulfate, nanometer calcium carbonate, calcium silicate whisker, polyacrylonitrile fibers, an antistatic agent, a lubricant, an anti-oxidant and a fire retardant. The fire retardant is prepared by adding polyethylene, silicone rubber, maleic anhydride and benzoyl peroxide into a mixture, carrying out mixing to obtain a uniform mixture, adding the mixture into an extruder, carrying out primary granulation to obtain a modifier, adding aluminum hydroxide nanometer fibers, carbon nanotubes, zinc borate, magnesium hydroxide, powdered steatile and the modifier into the extruder, carrying out secondary granulation and mixing the granules, triphenyl phosphate, hydroquinol bis(diphenylphosphate) and polysulfonyldiphenylene phenyl phosphonate to obtain a uniform mixture. The high-fire resistance modified polyethylene tube material has the advantages of high strength, good pressure resistance, heat resistance, flame resistance and long service life.

Owner:安徽宁国市高新管业有限公司

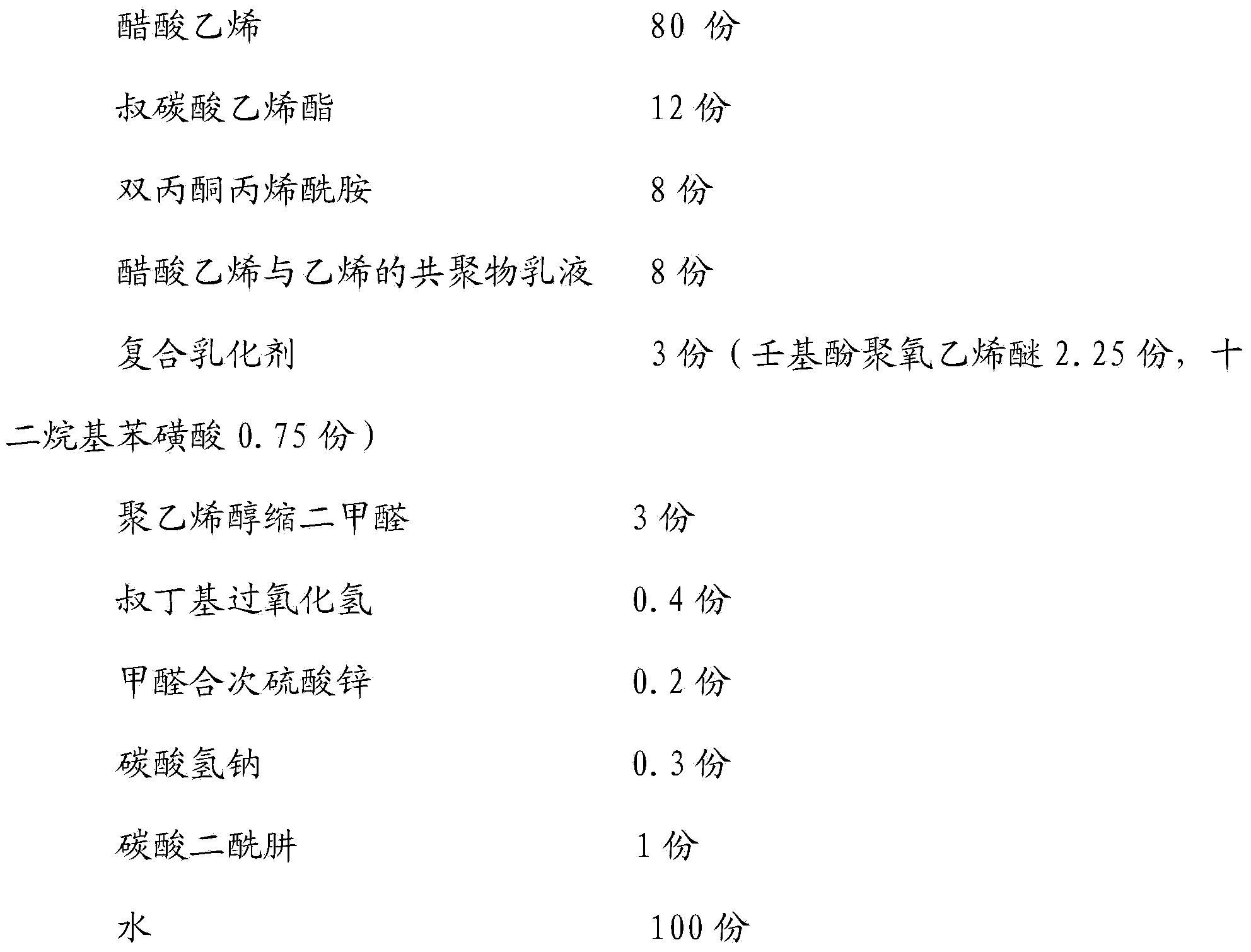

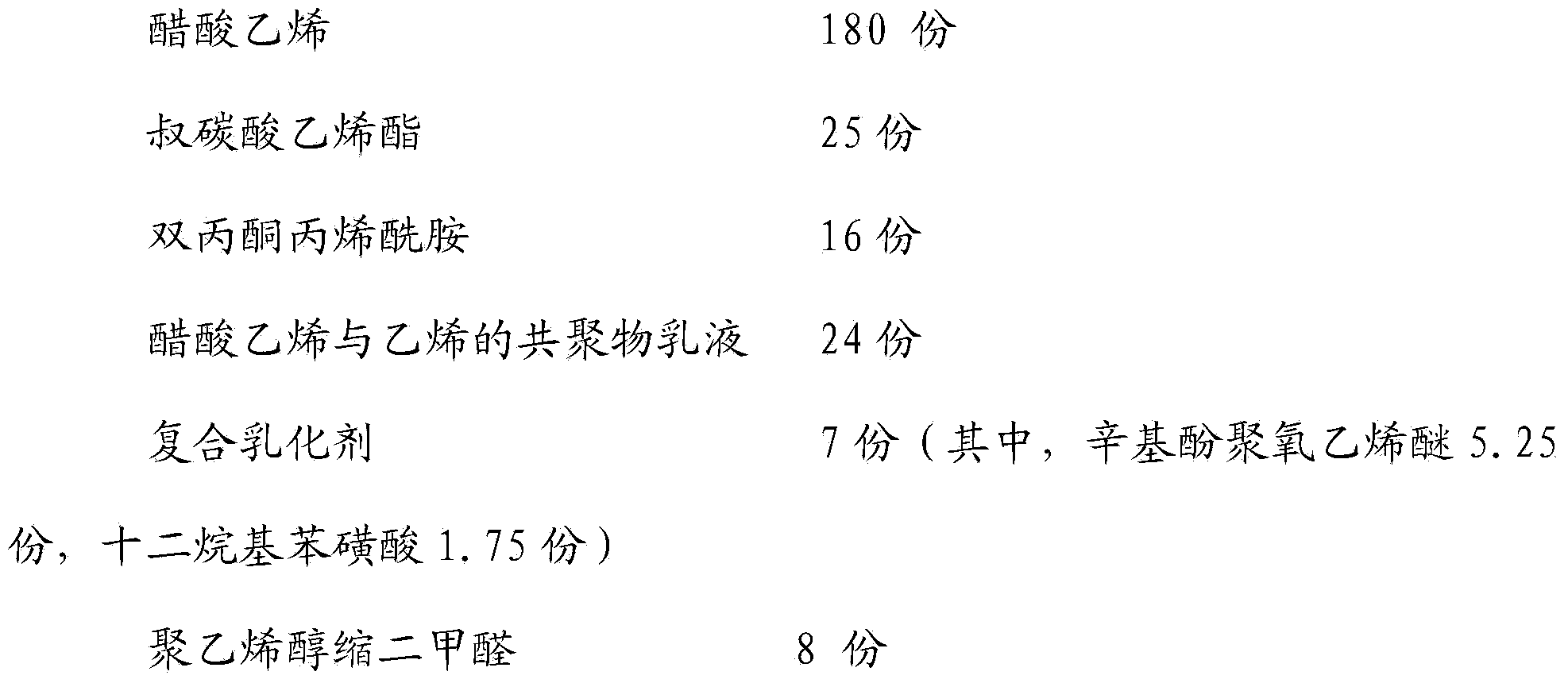

Water-based superspeed cigarette lap adhesive and preparation method thereof

ActiveCN102181247AGood adhesionFast dryingNon-macromolecular adhesive additivesGraft polymer adhesivesWater basedPolymer science

The invention discloses a water-based superspeed cigarette lap adhesive and a preparation method thereof. In the product, ethylene-vinyl acetate copolymer emulsion and polyvinyl alcohol are used as main raw materials; under the action of tert-butyl hydroperoxide-ferrous sulfate, a part of residual vinylacetate is reacted; then the content of the vinylacetate is controlled to be less than 1,000mg / kg by vacuum pumping; the viscosity of an adhesive and the solid content technical index are adjusted by adding lemon butyl acetate plasticizer and water; and the lap adhesive is lacte fluid and has fine and smooth texture, the particles are uniform, the viscosity is 200 to 1,000mPa.S, the solid content is 45 to 55 percent, the pH value is 4 to 6, the content of vinyl acetate is less than 1,000mg / kg, phthalic acid esters are less than 500mg / kg, and the formaldehyde content is less than 50mg / kg. The product is the water-based, safe and environment-friendly, is high in drying speed, and used for lapping and bonding cigarette paper of a superspeed cigarette making machine of a cigarette making factory, and has strong bonding capacity; and the engine speed reaches 12,000 to 17,000 cigarettes / min.

Owner:常德市金芙蓉精细化工有限责任公司

Compound plug removal technological method for offshore oil field injection well

The invention discloses a compound plug removal technological method for an offshore oil field injection well. The compound plug removal technological method for the offshore oil field injection well is characterized by comprising the following steps of forwards extruding stratum pretreating agent, closing the well for 24 hours, forwards extruding prepad fluid, forwards extruding spacer fluid, forwards extruding oxidative plug removable agent, closing the well for 24 hours, forwards extruding processing agent, forwards extruding postpad fluid, forwards extruding displacing liquid, and finishing construction. The stratum pretreating agent comprises cocoamidopropyl betaine, coconut diethanol amine and sodium lignin sulfonate, the mass ratio among cocoamidopropyl betaine, coconut diethanol amine and sodium lignin sulfonate is 1:1:1, and the use mass concentration is 15%. The prepad fluid is hydrochloric acid, and the mass concentration is 10%. The spacer fluid comprises a compound of tartaric acid, fatty alcohol ether sulfosuccinic acid solution, the mass ratio between tartaric acid and fatty alcohol ether sulfosuccinic acid solution is 2:1, and the mass concentration is 45%. The oxidative plug removal agent comprises a compound of calcium oxide and tert-Butyl hydroperoxide, the mass ratio of calcium oxide and tert-Butyl hydroperoxide is 3:1, and the mass concentration is 35%. The processing agent comprises fluoboric acid, wherein the mass concentration is 13%. The postpad fluid comprises hydrochloric acid, wherein the mass concentration is 10%. The displacing liquid is water injected and allocated on site.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Method for preparing tert-butyl hydroperoxide

InactiveCN105523982AShort processReduce corrosionOrganic compound preparationPeroxy compound preparationDi-tert-butyl peroxideDistillation

The invention relates to a method for preparing tert-butyl hydroperoxide. According to the invention, the raw materials are isobutane and di-tert-butyl peroxide, and steps of catalysis, underpressure distillation and crystallization are carried out on the raw materials according to a certain proportion under high temperature and high pressure. According to the invention, the raw materials are isobutane and the di-tert-butyl peroxide with mass ratio being 1:1-3; the high temperature and high pressure condition are 140-160 DEG C and 1.5-2.5 atmospheric pressure; a catalyst is ferric potassium oxalate; the underpressure distillation condition is 0.1-0.3 atmospheric pressure, and temperature is 30-40 DEG C; the crystallization step is characterized in that the collected liquid is dissolved by distilled water at temperature of 20-40 DEG C, then is cooled to the temperature of 1-5 DEG C, is slightly stirred, and is stood for crystallization. The process flow is short, reaction byproduct is less, environment pollution and corrosion degree on production equipment are low, and product purity is high.

Owner:茅海强

Vinyl acetate wood adhesive and preparation method thereof

InactiveCN104293245AImprove water resistanceHigh bonding strengthMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesSodium bicarbonateCross-link

Owner:GUANGXI UNIV

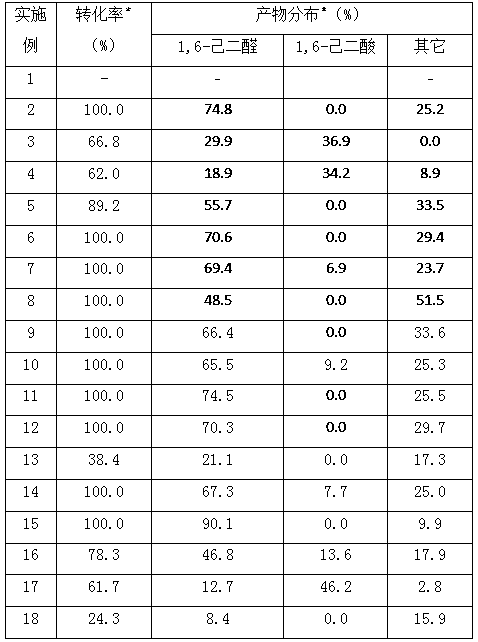

Method for preparing 1,6-adipaldehyde through selective oxidation of cyclohexene

ActiveCN109369356AHigh reactivityHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDecompositionCyclohexene

The invention discloses a method for preparing 1,6-adipaldehyde through selective oxidation of cyclohexene. A catalyst is a cobalt complex of an isosteviol derivative. The method comprises the steps as follows: adding a solvent, cyclohexene, a catalyst and a cocatalyst to a reaction kettle, introducing oxygen, keeping the pressure of the reaction kettle at 0.2-0.6 MPa, and conducting a reaction atthe temperature of 120-170 DEG C for 60-300 min to obtain 1,6-adipaldehyde. Compared with existing methods, the method has the advantages that free radicals produced through decomposition of the cocatalyst tert-butyl hydroperoxide act with oxygen to produce oxygen radicals, the catalyst cobalt complex of the isosteviol derivative acts with double bonds in cyclohexene, so that the reaction activity is higher, and activated double bonds and free radicals react to produce 1,6-adipaldehyde. The method is environmentally friendly, and 1,6-adipaldehyde is good in selectivity and high in yield.

Owner:ZHENGZHOU UNIV

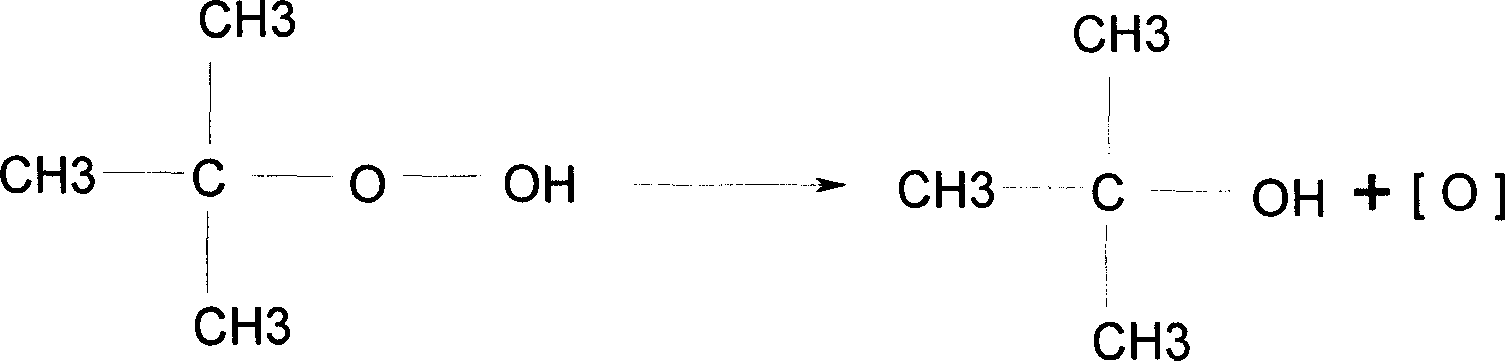

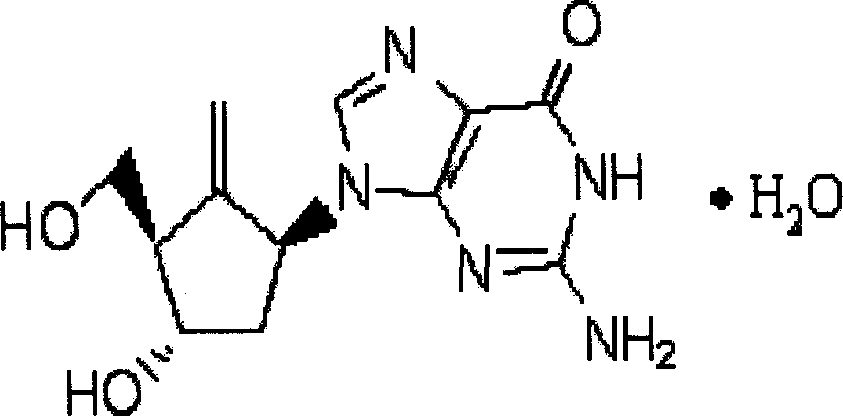

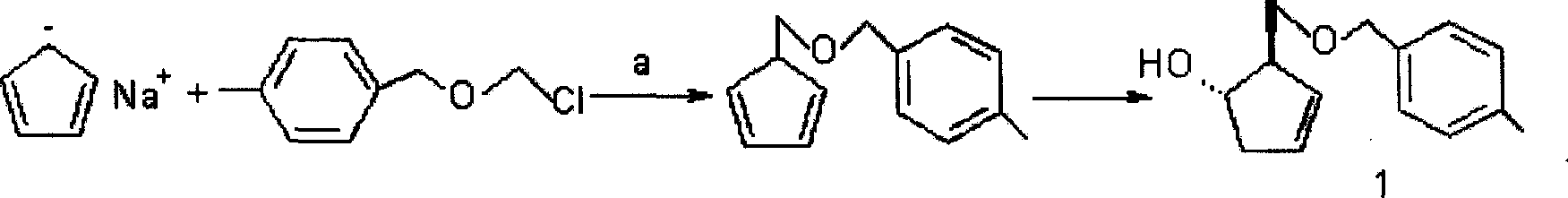

Method of preparing antivirotic entecavir hydrate

InactiveCN101012228AHigh yieldInhibitionOrganic chemistryBulk chemical productionPurification methodsKetone

The invention discloses a making technique of entikawei monohydrate as antiviral drug, which comprises the following steps: reacting cyclopentadiene monomer and sodium hydride protected by inert gas to make sodium cyclopentadiene; oxidizing through tert-butyl hydroperoxide; reacting with benzyl halogen under alkaline to obtain compound 3 to react with 6-benzyloxy guanine acted by alkaline to obtain compound 4; reacting with amino protective group to prepare compound 5; oxidizing through DMP tert-butanol oxidizing system to obtain ketone compound 6 to generate methylene compound 7 acted by Zn / TiCl4 / CH2Br2; stripping protective product under acid condition to produce compound 8; recrystallizing to obtain the product.

Owner:SHANGHAI SUN SAIL PHARMA SCI & TECH CO LTD +1

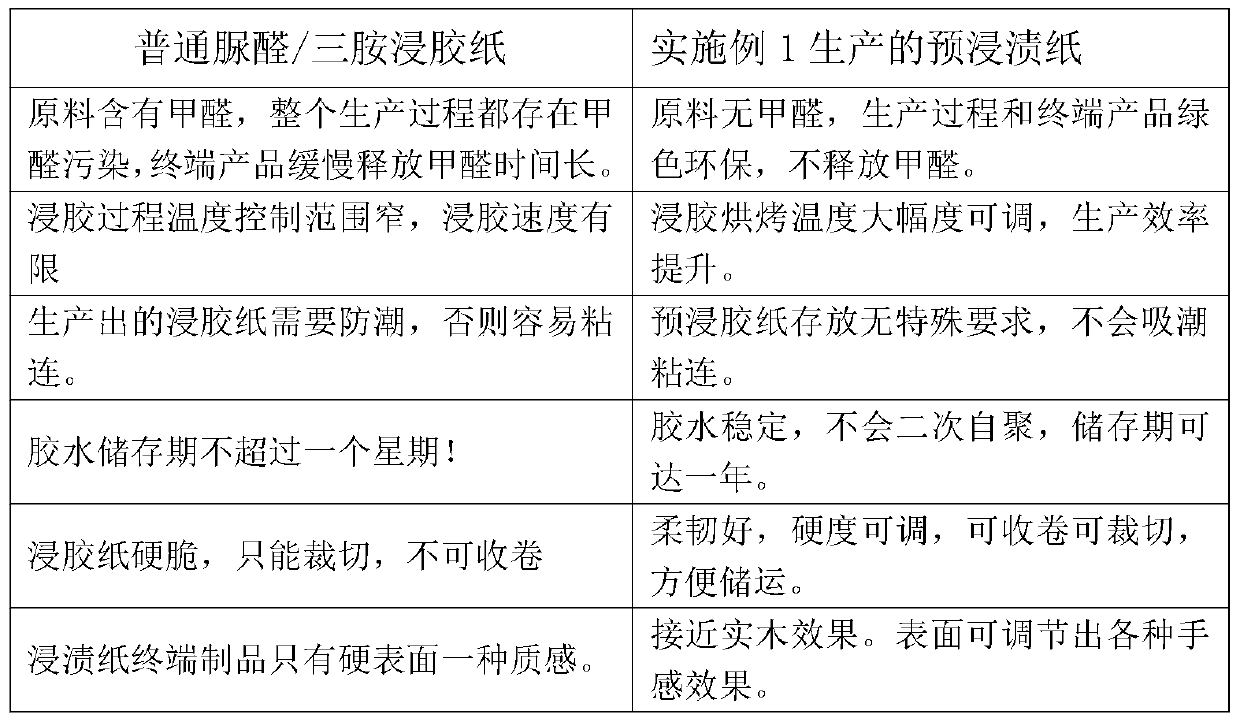

Formaldehyde-free preimpregnation glue and synthetic process thereof

InactiveCN109776717AStable storageStable in natureNon-fibrous pulp additionPaper/cardboardDefoamerAldehyde

Formaldehyde-free preimpregnation glue is provided. The glue is characterized by comprising following raw materials by weight: 0.713 parts of ammonium bicarbonate, 4.65 parts of ammonia water having aconcentration of 25%, 2.558 parts of ammonium persulfate, 0.775 part of tert-butyl hydroperoxide the concentration of which is 70%, 4.2 parts of an emulsifier CO436, 0.775 part of sodium hydroxymethanesulfinate the concentration of which is 95%, 0.9 part of a defoamer, 1.24 parts of a surfactant OT-75, 5.6 parts of acrylic acid, 12.5 parts of methyl acrylate, 200 parts of styrene and 340 parts ofbutyl acrylate. Beneficial effects of the glue are that 1) raw materials are formaldehyde-free, a production process is formaldehyde-free, and the glue is formaldehyde-free; 2) preimpregnated decorative paper and veneer prepared by utilizing the glue are formaldehyde-free; 3) decorative paper prepared by utilizing the glue is soft and can be rolled and cut; 4) decorative paper prepared by utilizing the glue, when compared with traditional melamine-urea-formaldehyde impregnated bond paper, is not sticky due to damp, and can be stably stored for 1 year or longer; and 5) the glue has stable properties and can be stored at room temperature for 1 year or longer.

Owner:临沂江源装饰材料有限公司

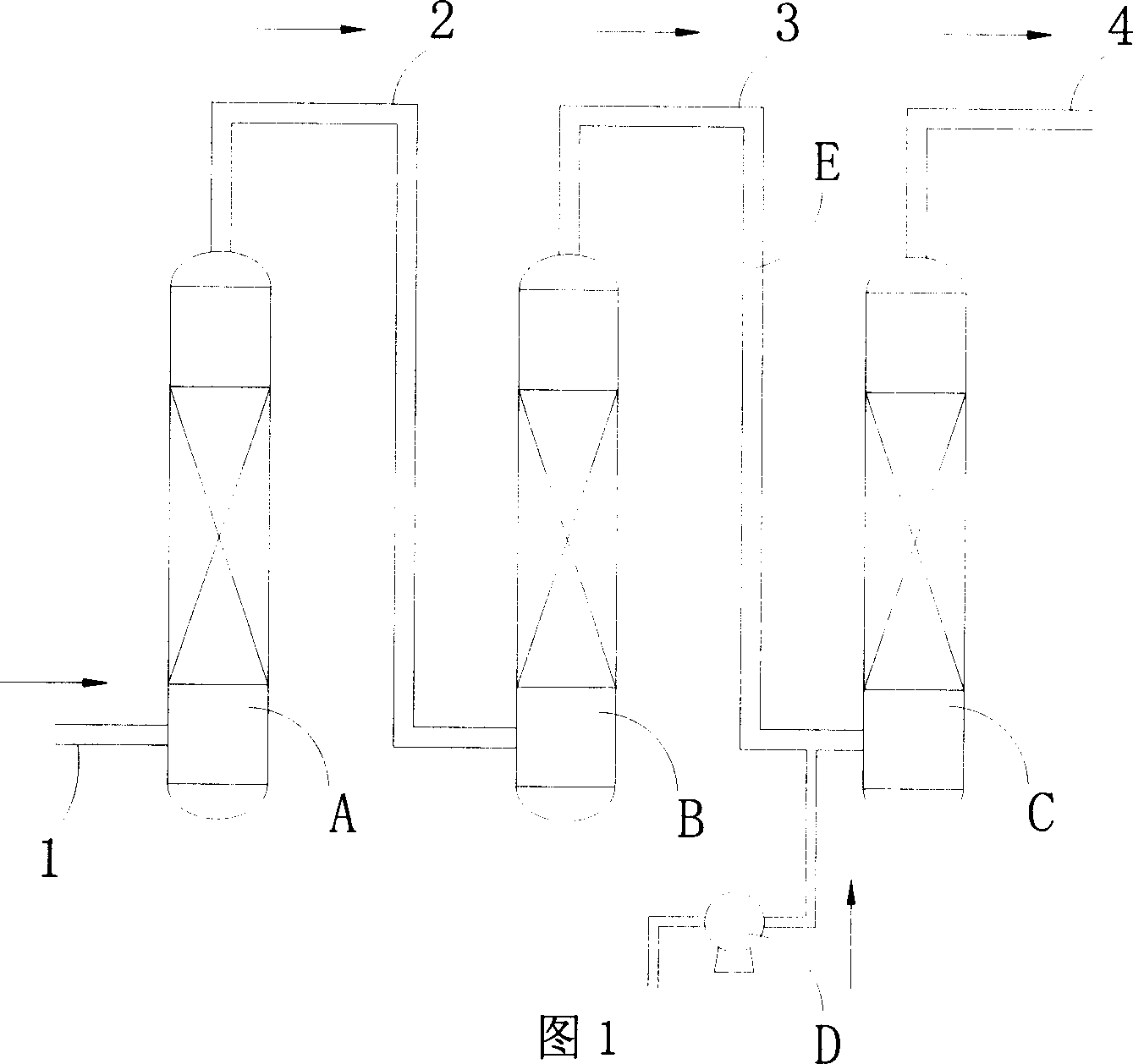

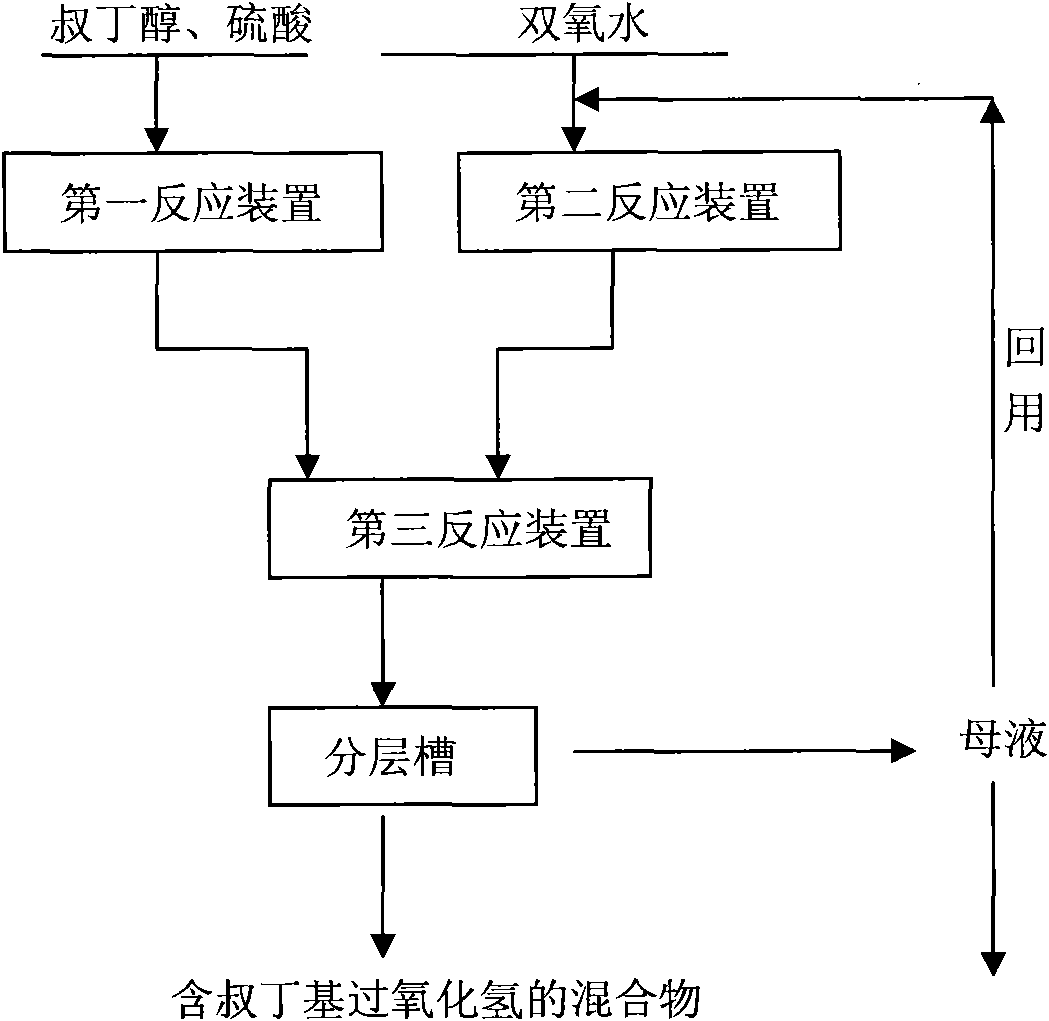

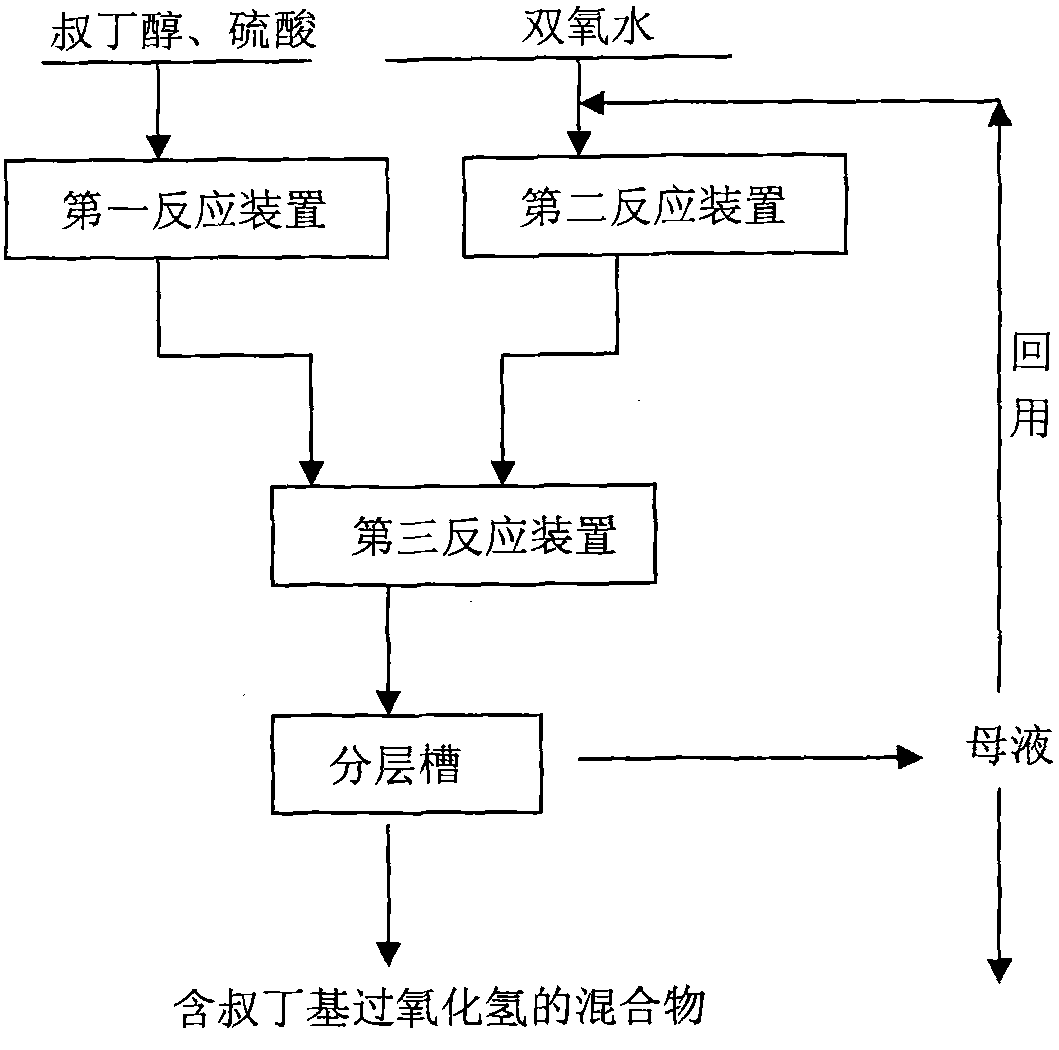

Preparation method for mixture containing tert-butyl hydroperoxide

ActiveCN101857563AAvoid emissionsImprove protectionOrganic compound preparationPeroxy compound preparationHydrogen SulfateReaction temperature

The invention relates to a preparation method for a mixture containing tert-butyl hydroperoxide, which belongs to the technical field of organic peroxide preparation. The method includes the following steps that: (A) tert-butyl alcohol and sulfuric acid are added into a first reactor and stirred for reaction and the reaction temperature is controlled, so that tert-butyl hydrogen sulfate esterified solution is obtained; (B) hydrogen peroxide and recycled mother solution are added into a second reactor and stirred and the stirring temperature is controlled, so that mixed solution is obtained; (C) the tert-butyl hydrogen sulfate esterified solution and the mixed solution are added into a third reactor and stirred for reaction and the reaction temperature is controlled, so that reaction product is obtained; (D) the reaction product is led into a liquid-separating tank to separate liquid, so that upper oleic-phase mixture containing the tert-butyl hydroperoxide and lower aqueous-phase mother solution containing sulfuric acid and hydrogen peroxide are obtained, moreover, the lower aqueous-phase mother solution containing the sulfuric acid and the hydrogen peroxide returns to the step B and is mixed with the hydrogen peroxide, and the upper oleic phase is the mixture containing the tert-butyl hydroperoxide. The invention prevents the discharge of industrial sewage, so that the environment is protected, and energy and materials are saved, so that the preparation cost is reduced.

Owner:常熟市滨江化工有限公司

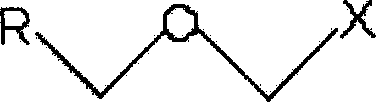

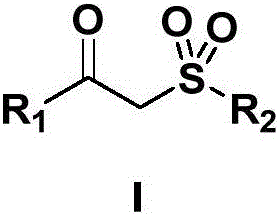

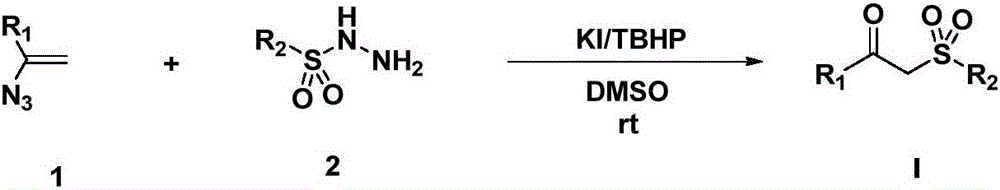

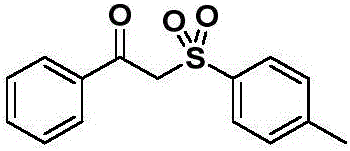

Preparation method of beta-arone substituted sulfone compounds

InactiveCN105777593AReasonable designRaw materials are easy to getOrganic chemistryOrganic compound preparationReaction temperaturePotassium iodine

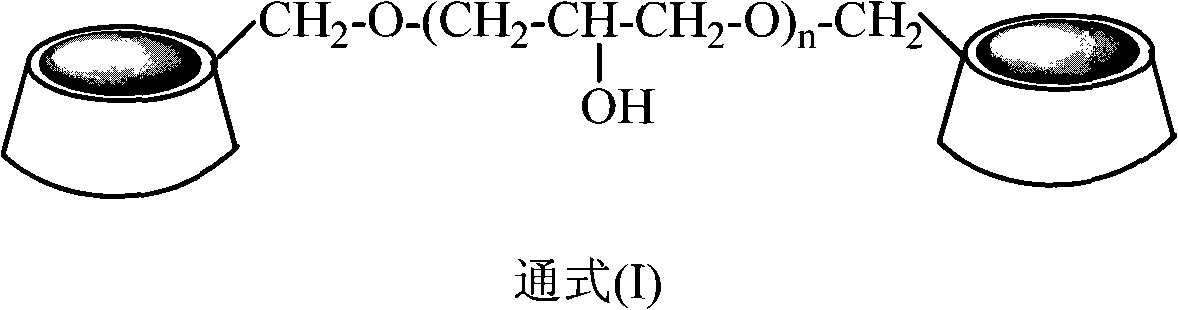

The invention provides a preparation method of beta-arone substituted sulfone compounds. In the method, olefin azide and sulfonyl hydrazide are used as start raw materials; and in an organic solvent, potassium iodide serves as a catalyst while tert-butyl hydroperoxide serves as an oxidizing agent, and the beta-arone substituted sulfone compounds are generated by reactions, wherein the reaction temperature is room temperature, and the reaction time is 2-4 hours. The preparation method provided by the invention has the advantages that the design is reasonable, the raw materials are easily available, no metal catalyst is involved, the reaction conditions are mild, high-temperature backflow is not required, the method is safe and convenient, the yield is high, and the yield of most products is over 70%. The preparation method provided by the invention is an easy-to-operate method for quickly establishing beta-arone substituted sulfone compounds in a mild and diversified manner, wherein the two start raw materials can be obtained by a one-step method, and the reaction raw materials are cheap and easily available. The general formula I of the beta-arone substituted sulfone compounds is shown in the specification.

Owner:ZHEJIANG UNIV

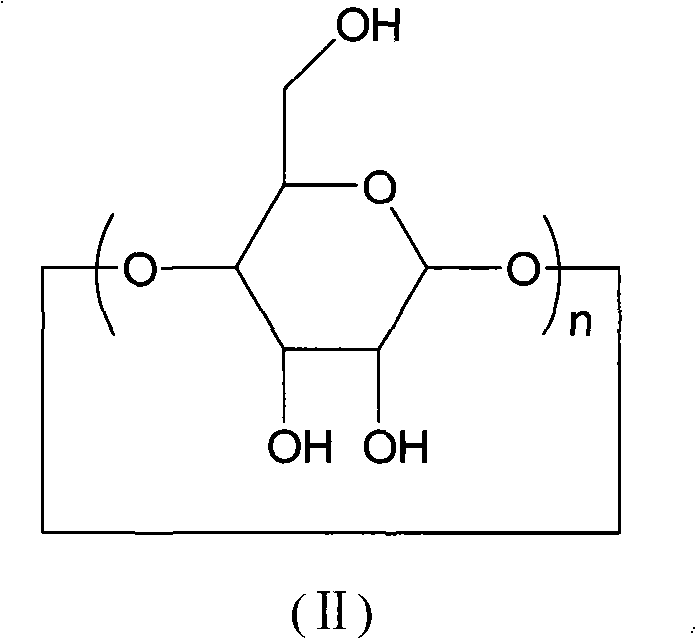

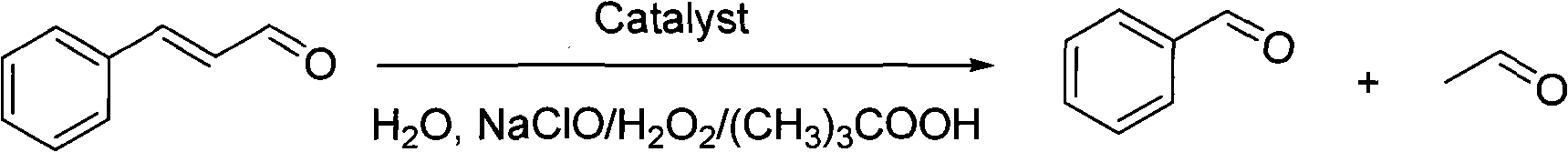

Method for preparing benzaldehyde by using cyclodextrin polymer to catalyze oxidation of cinnamic aldehyde or cinnamon oil

InactiveCN101838187AAvoid low naturalnessAvoid pollutionCarbonyl compound preparation by oxidationBenzaldehydeReaction temperature

The invention discloses a method for preparing benzaldehyde by using cyclodextrin polymer to catalyze the oxidation of cinnamic aldehyde or cinnamon oil. The method comprises the following steps: taking the cinnamic aldehyde or the cinnamon oil as raw materials, adopting the cyclodextrin polymer as a catalyst, taking one of hydrogen peroxide, sodium hypochlorite or tert-butyl hydroperoxide as an oxidizing agent, taking water as a solvent, controlling the reaction temperature to be 30-90 DEG C, after finishing the reaction, using an ester solvent, methyl alcohol, acetone or acetonitrile to conduct extraction, and obtaining the benzaldehyde by decompression and concentration. The method has the advantages of simple technique, mild reaction condition, low cost, high yield, high natural levelof the benzaldehyde, environment friendliness, easily-separable catalyst with reusability and the like.

Owner:SUN YAT SEN UNIV +1

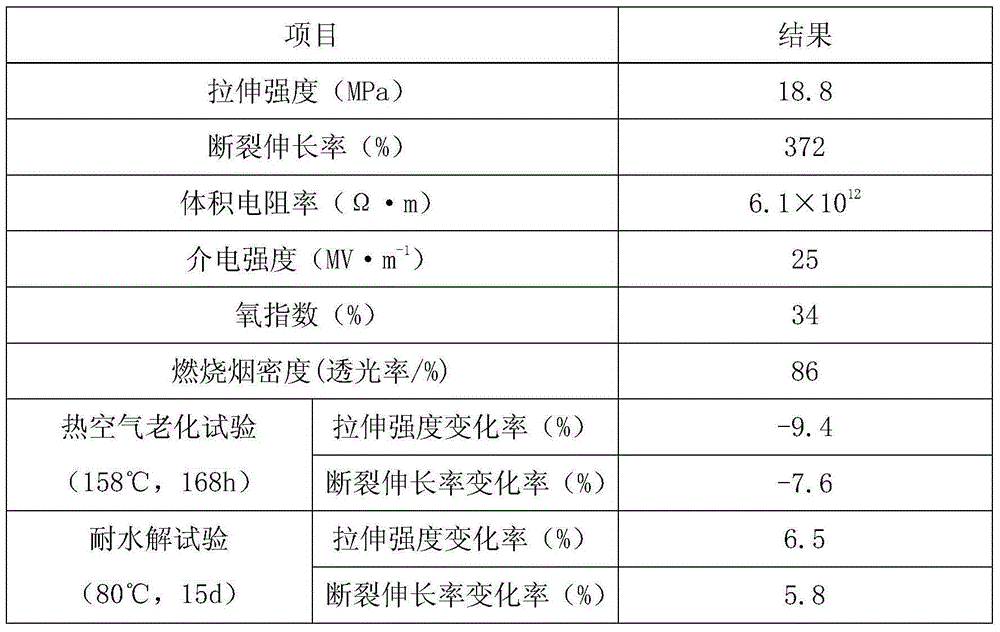

Hydrolysis-resistant cable material for automobile and preparation method of hydrolysis-resistant cable material

InactiveCN105037960AImprove hydrolysis resistanceAvoid hydrolysisRubber insulatorsFire retardantTert butyl

The invention discloses a hydrolysis-resistant cable material for an automobile and a preparation method of the hydrolysis-resistant cable material. The hydrolysis-resistant cable material is prepared from the following raw materials, by weight part: 45-60 of ethylene propylene diene monomer rubber, 22-34 of tetrafluoroethylene-propylene rubber, 9-14 of rectorite powder, 5-10 of C5 hydrogenated petroleum resin, 2-3 of tert-butyl-hydroperoxide, 1.5-2.5 of basic lead carbonate, 3-5 of polyparadinitrosobenzene, 4-8 of dibutyl sebacate, 2-3 of magnesium oxide, 1-2 of zinc stearate, 3-6 of disproportionated rosin, 2.5-4.5 of N-ethyl-p-toluenesulfonamide, 12-17 of a composite flame retardant agent, 5-10 of spherical silicon powder, 1-2 of an accelerant PPD, 1-2 of an accelerant ZBPD, and 1-2 of an antioxidant 2246. The prepared cable material has excellent hydrolysis resistance, so that the electric wires and cables of the automobile can be effectively prevented against hydrolysis. The cable material can maintain excellent properties after continuously used in high pressure and high temperature, and has good electrical insulation property, mechanical strength, corrosion resistance, abrasive resistance, and thermal resistance.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

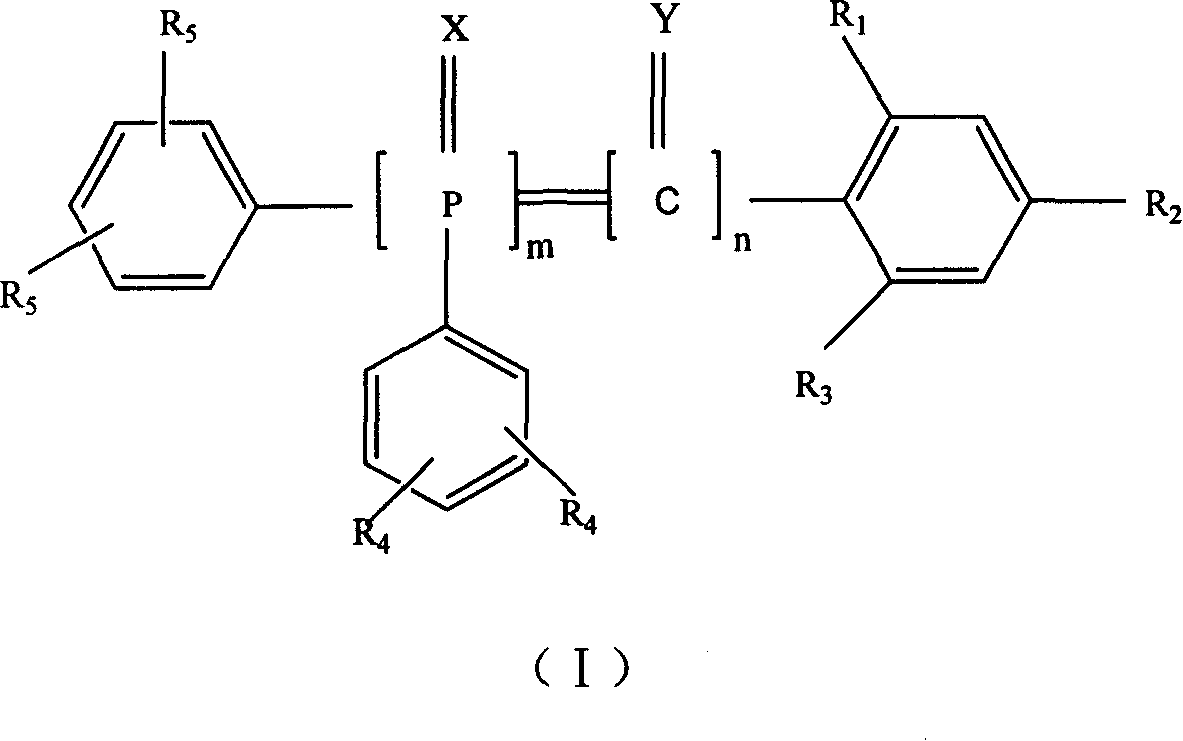

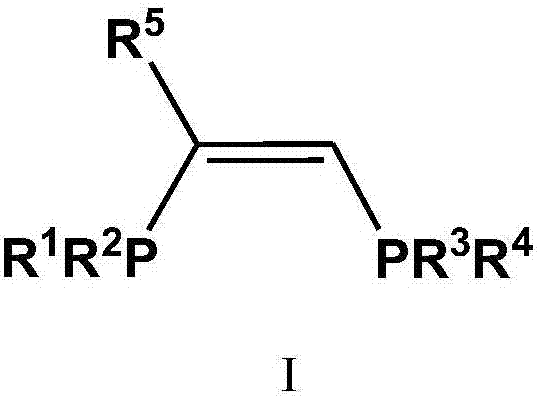

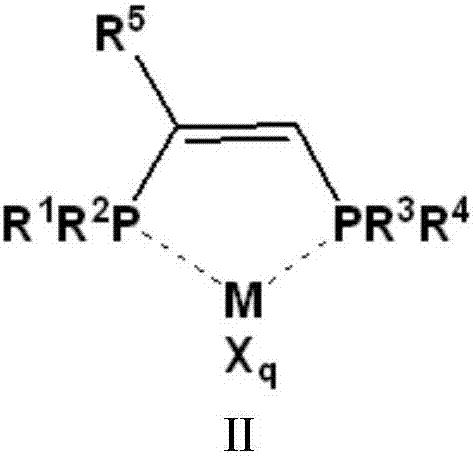

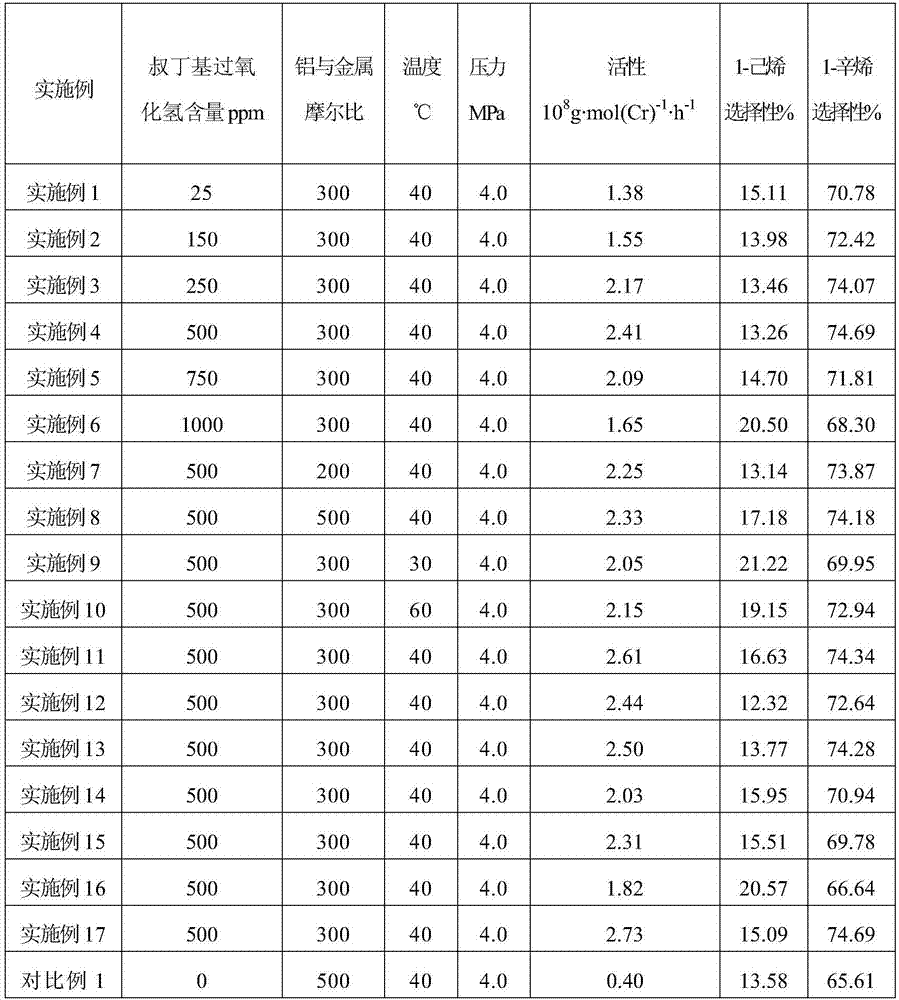

Ethylene tetramerization catalyst composition and application thereof

ActiveCN107282126ARapid responseImprove responseOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsDiphosphorusMetal

The invention relates to an ethylene tetramerization catalyst composition which comprises diphosphorus ligand shown in formula I, a transition metal compound, an aluminum-containing promoter and tert-butyl hydroperoxide. The invention further provides an ethylene tetramerization method. The catalyst composition provided by the invention is applied to ethylene tetramerization, is high in reaction activity, is capable of producing 1-octylene with high selectivity, and the selectivity of 1-octylene is 74% or higher.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com