Agricultural polyethylene resin composition

A technology of polyethylene resin and composition, which is applied in the field of modified linear low-density polyethylene resin composition, can solve the problems of affecting performance, many fish eyes in the film, and large amount of organic peroxide, so as to reduce the amount of use, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

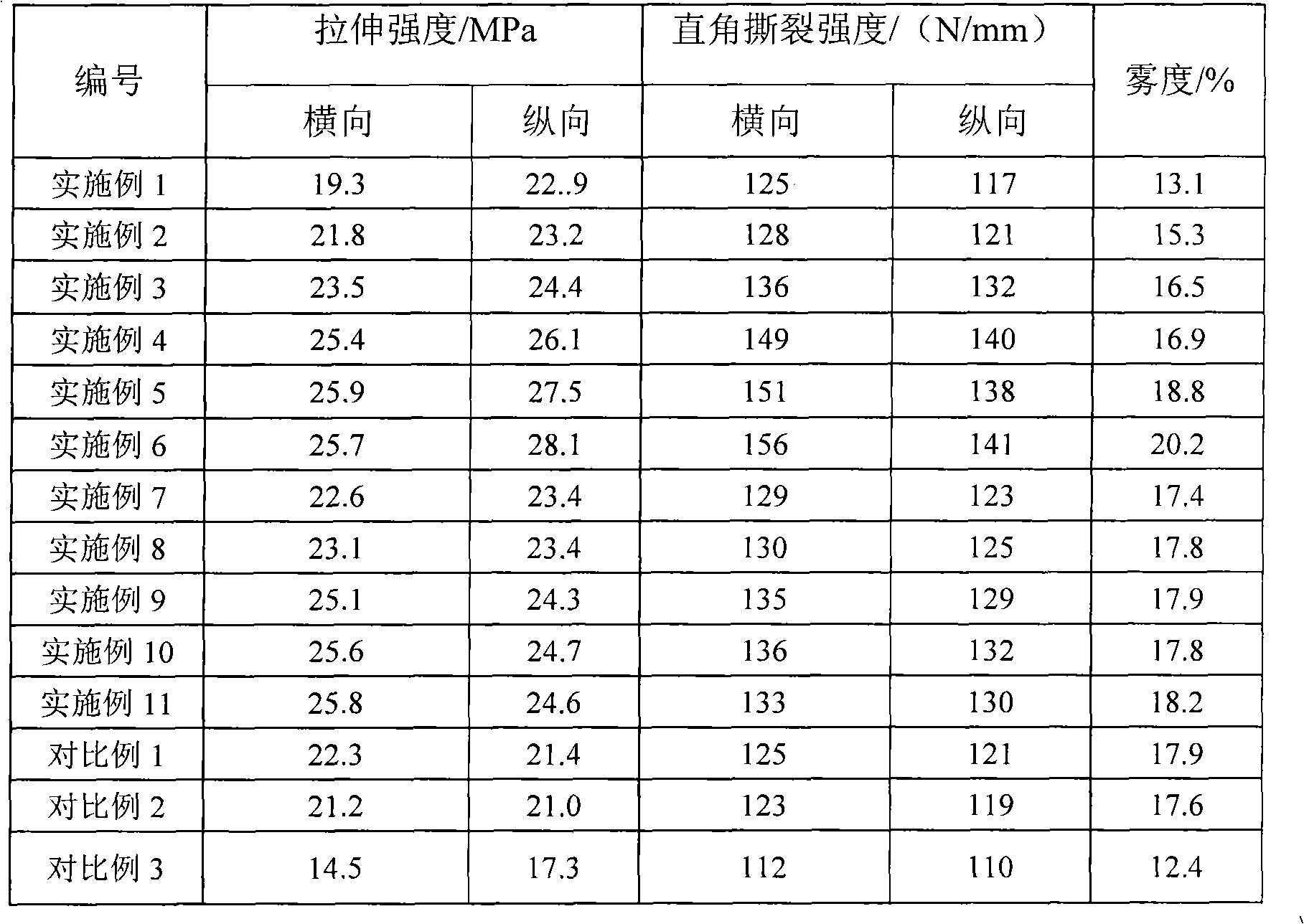

Examples

Embodiment Construction

[0007] Using the Φ34 twin-screw extruder produced by Germany Lestreiz Company as the reactor, LLDPE resin, peroxide and antioxidant are mixed evenly in a high mixer, and then extruded and granulated to obtain modified LLDPE resin. See Table 1 and Table 2 for the specific raw material formula and basic physical properties of modified LLDPE.

[0008] DFDA7042: product of Lanzhou Petrochemical Company, density 0.918g / cm 3 , melt flow rate 2.0g / 10min;

[0009] LL101AA: product of Lanzhou Petrochemical Company, density 0.918g / cm 3 , melt flow rate 1.0g / 10min;

[0010] Antioxidant: Composite antioxidant B561, product of Yingkou Fengguang Chemical Co., Ltd.;

[0011] Organic peroxides: di-tert-butyl peroxide (DTBP), tert-butyl hydroperoxide (TBHP) and benzoyl peroxide (BPO) are all products of Lanzhou Auxiliary Factory.

[0012] Table 1 raw material formula

[0013]

base resin

DTBP+TBHP

/ ppm

DTBP to TBHP mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com