Patents

Literature

106results about How to "Guaranteed film quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

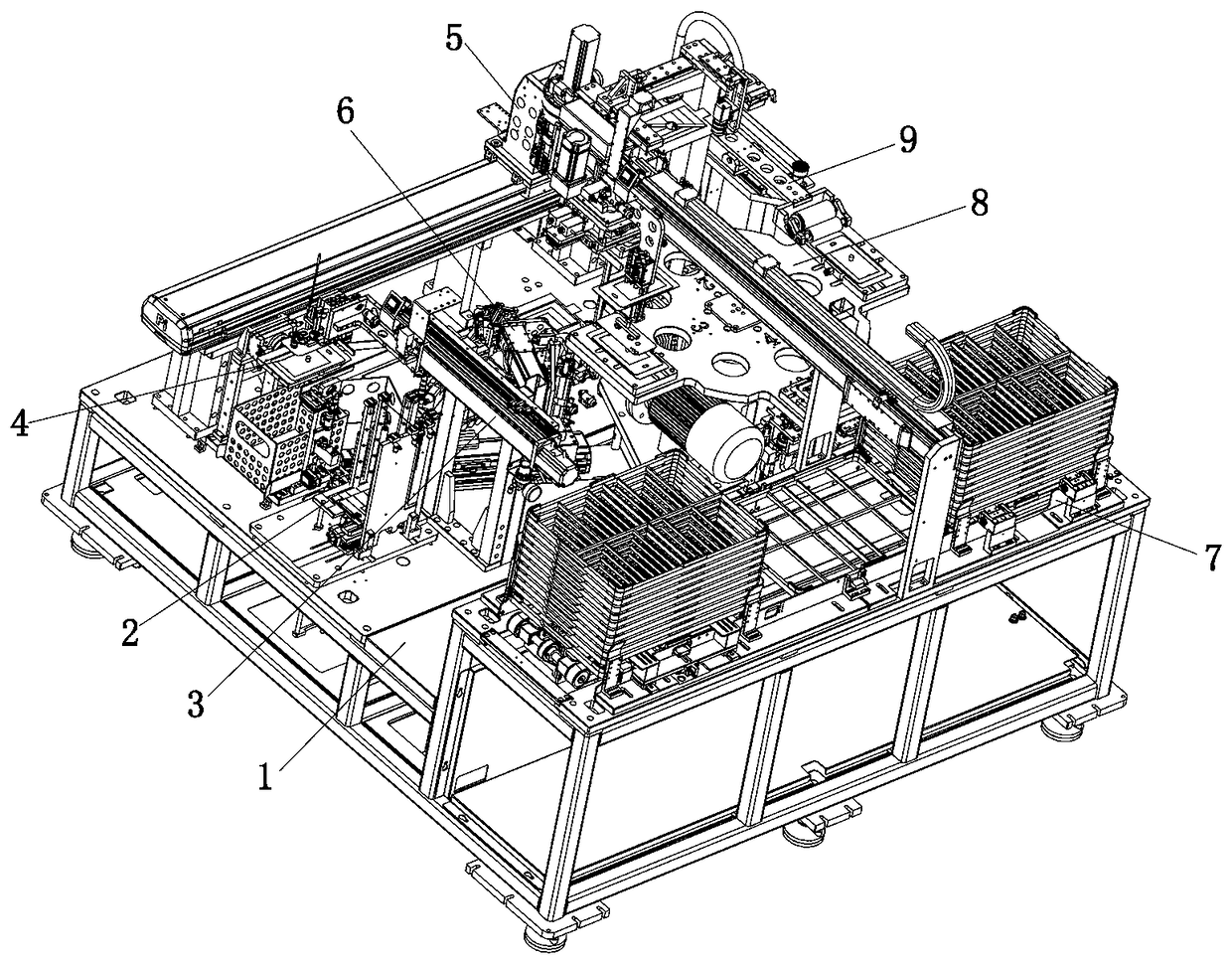

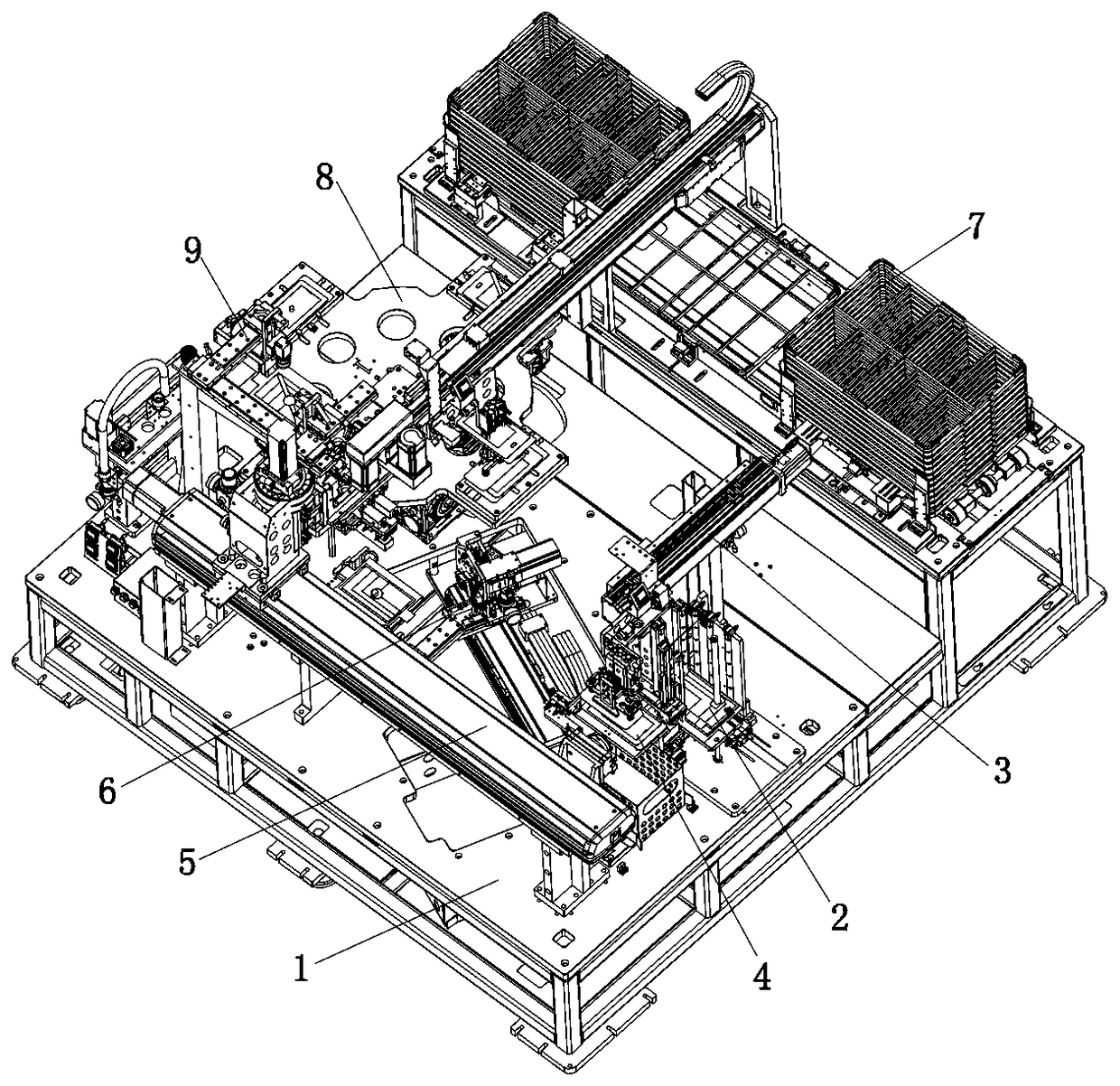

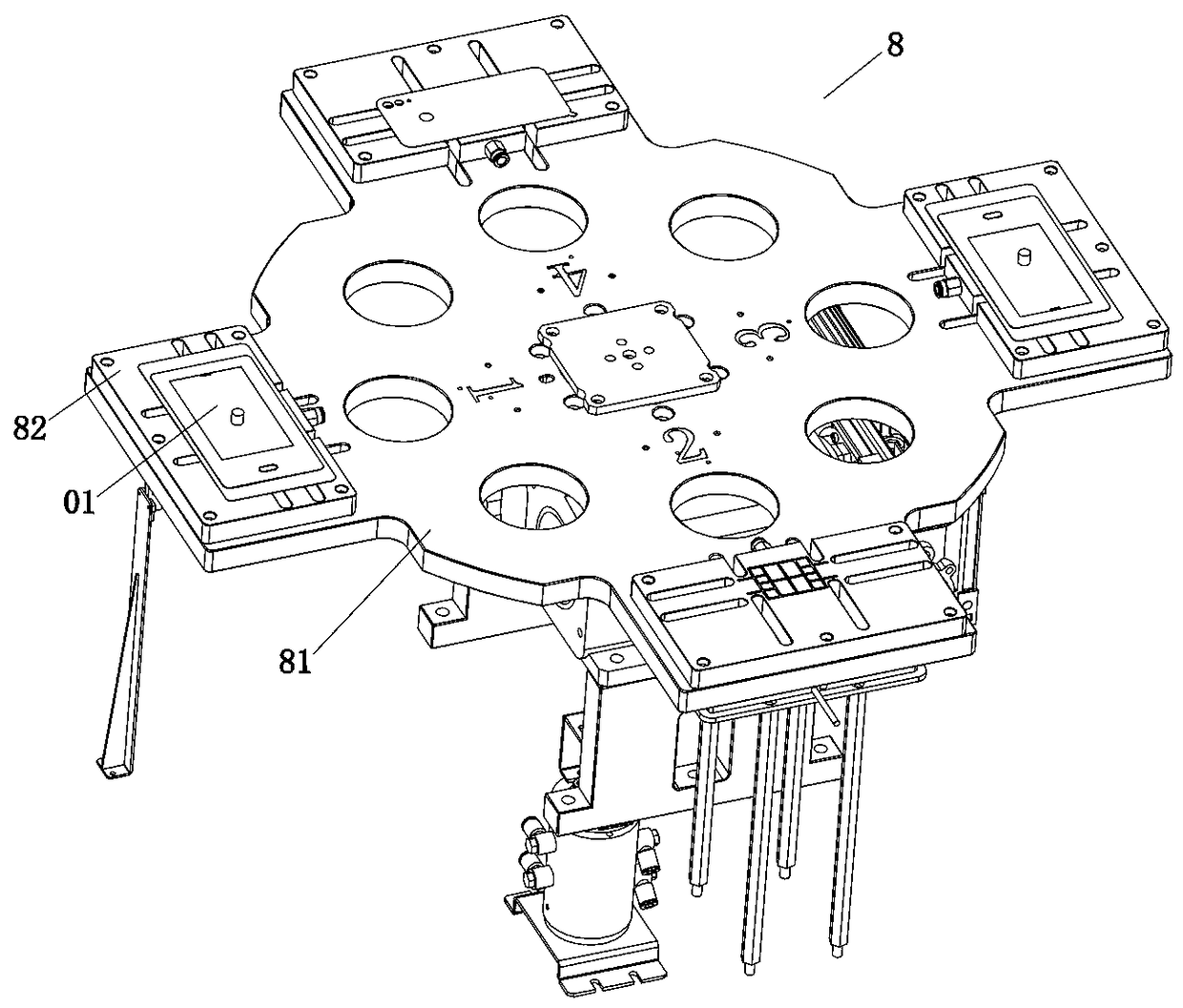

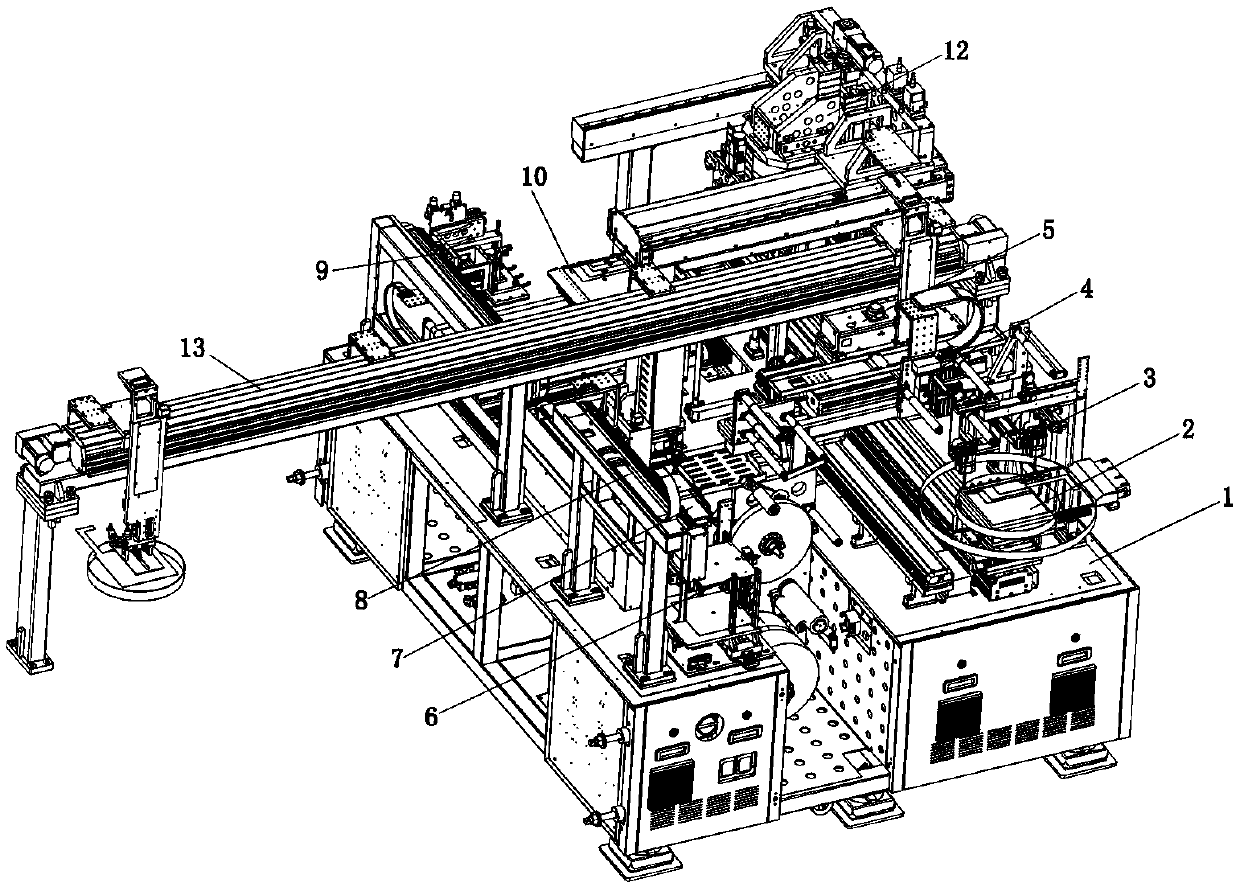

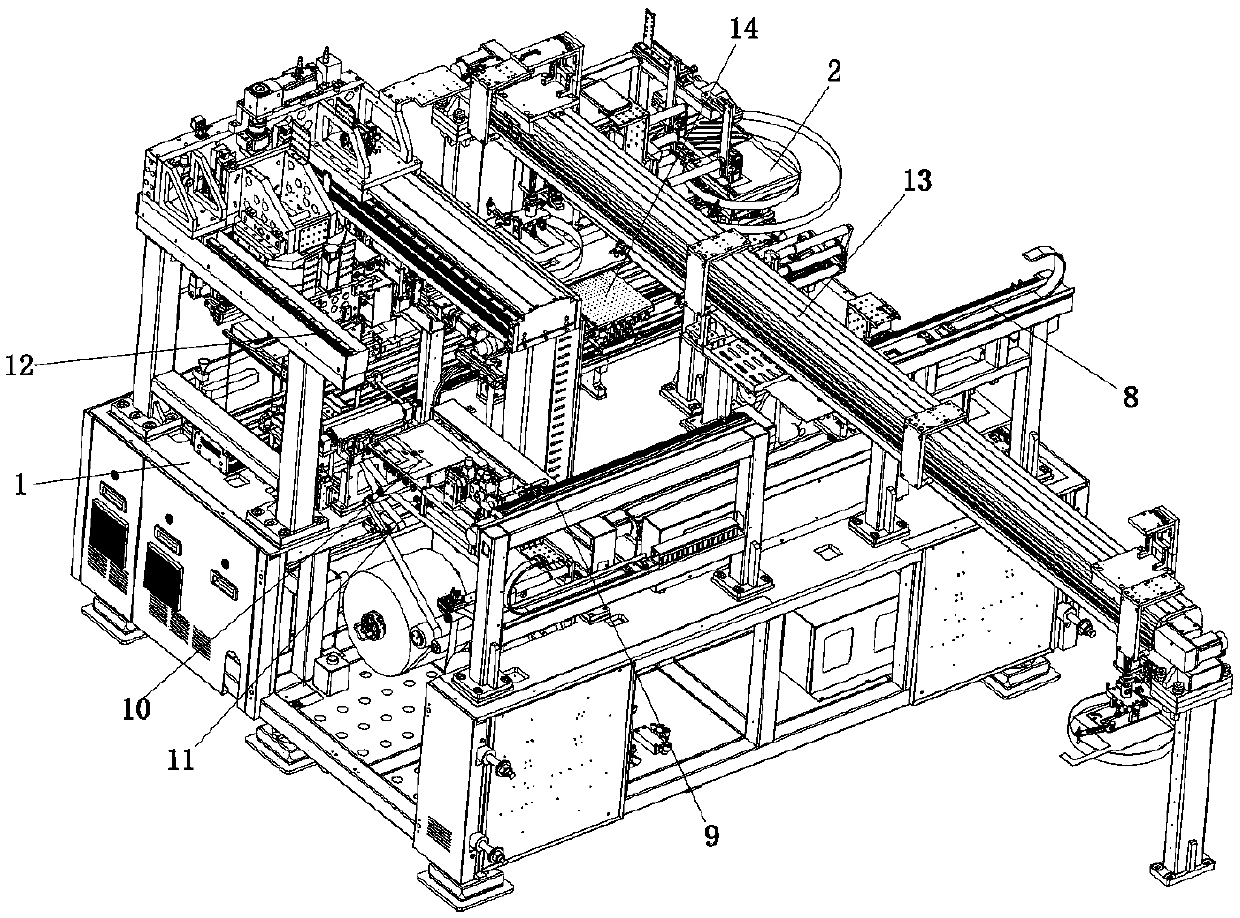

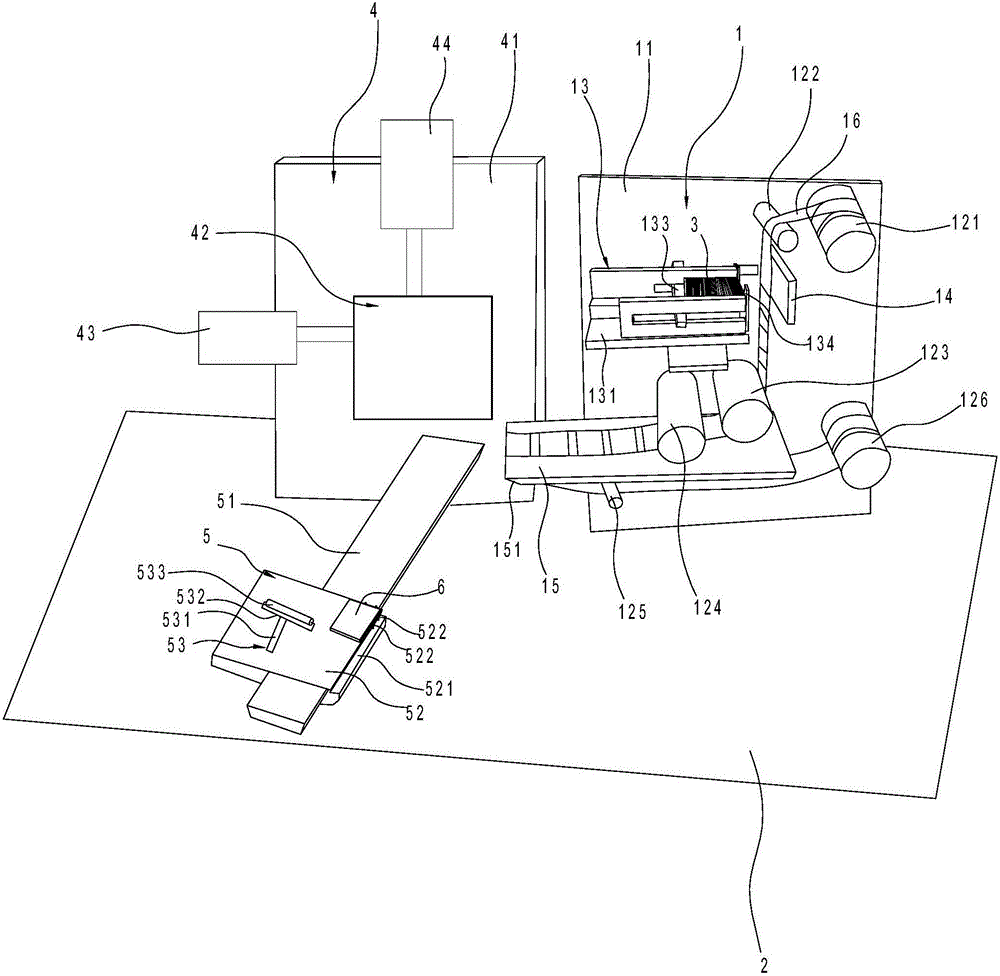

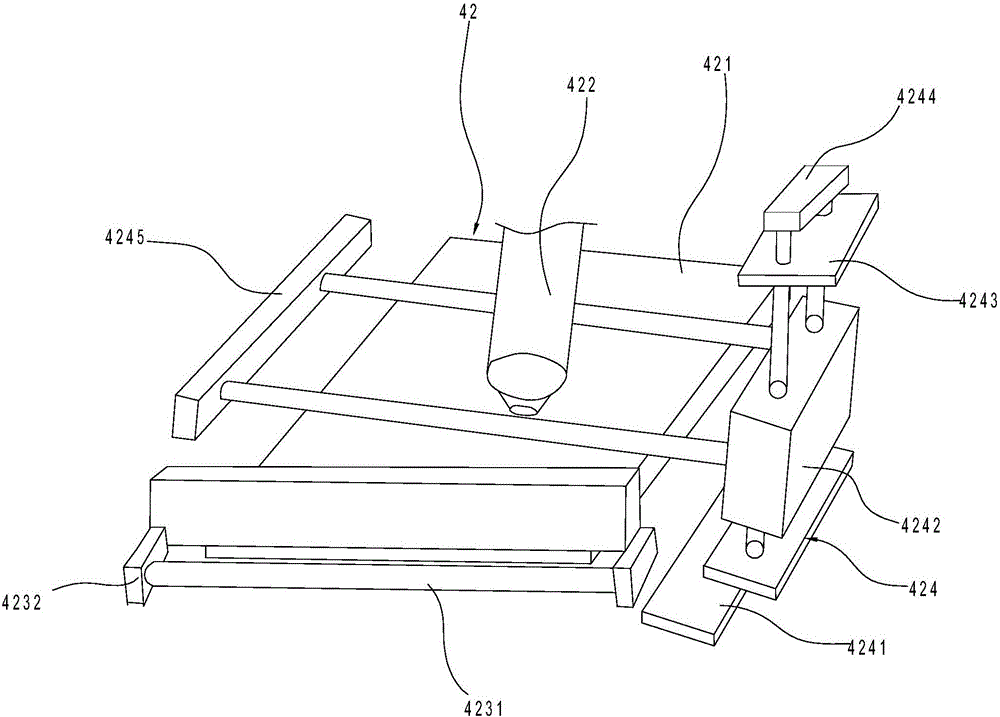

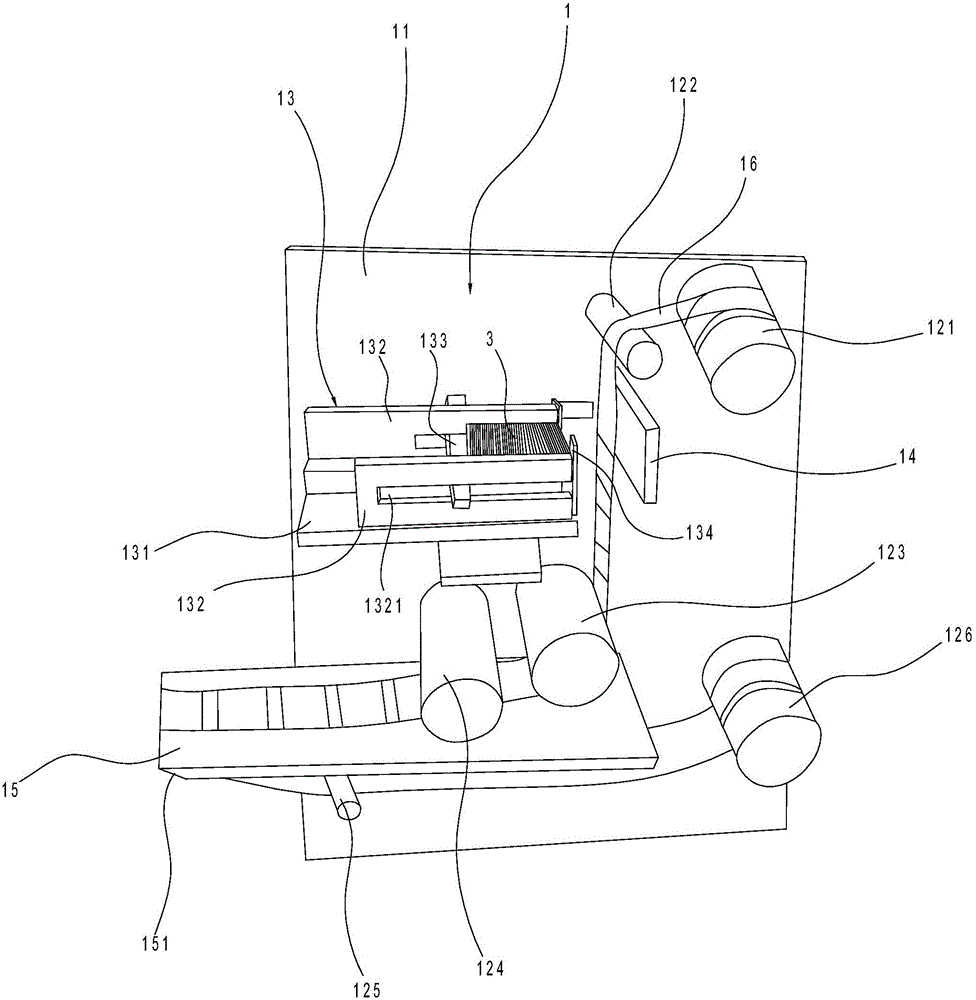

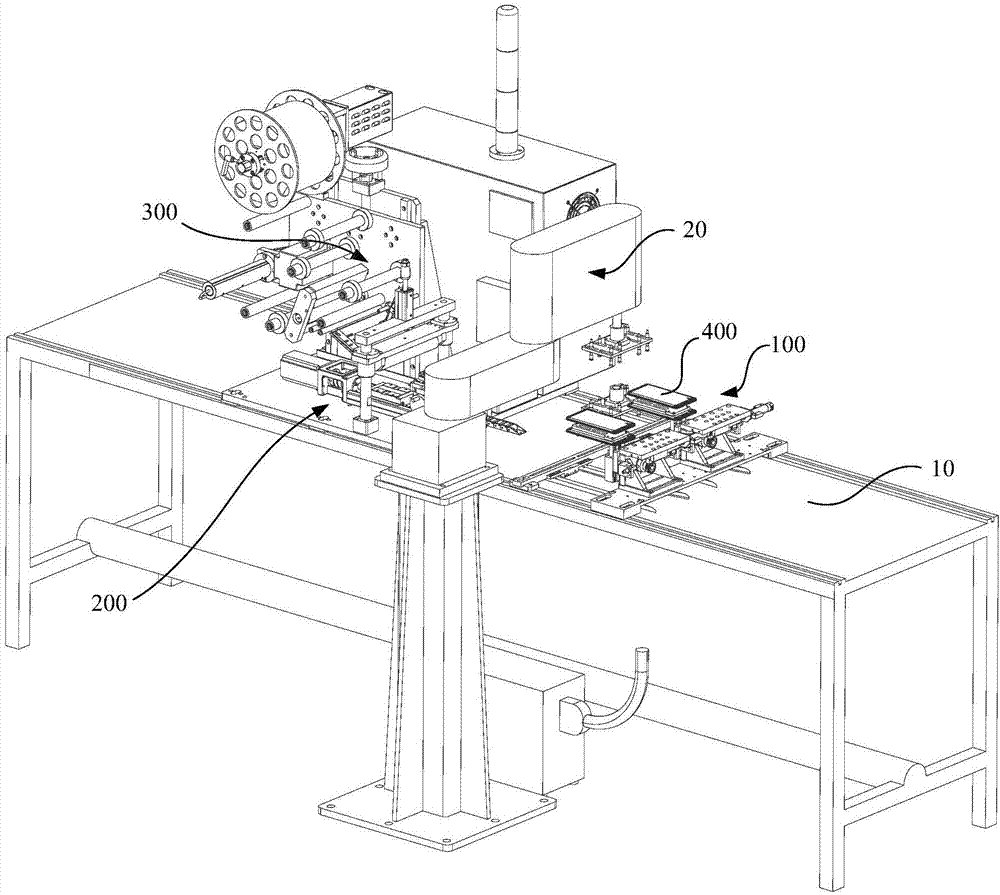

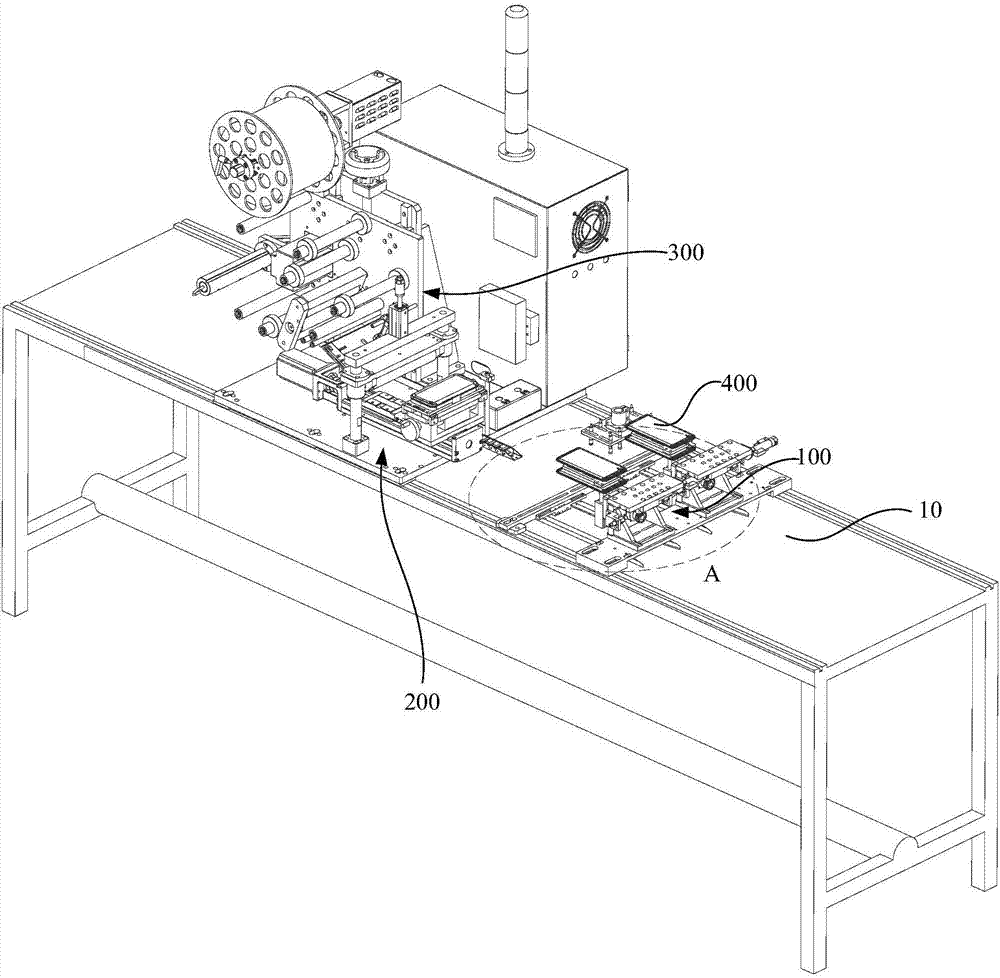

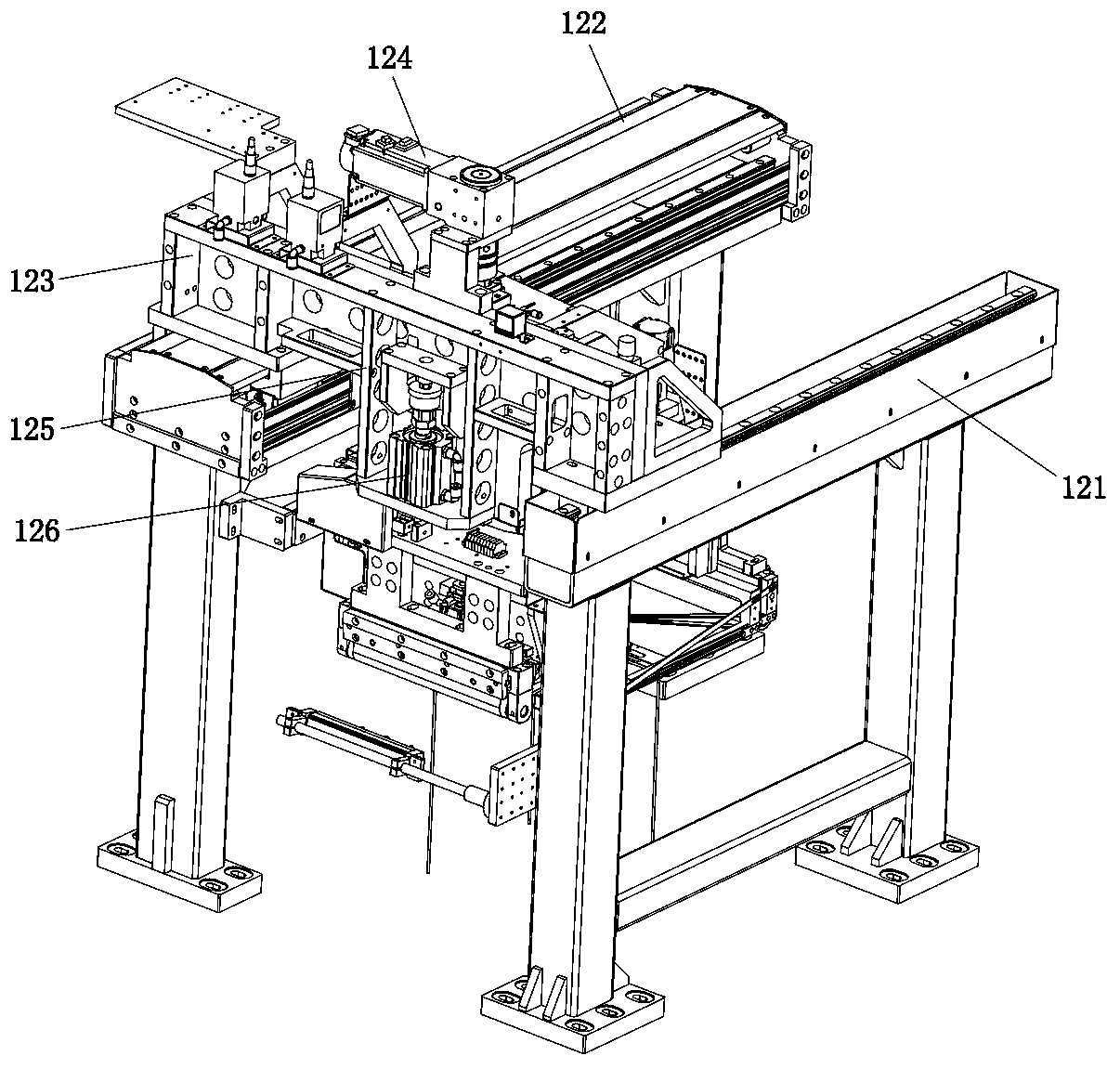

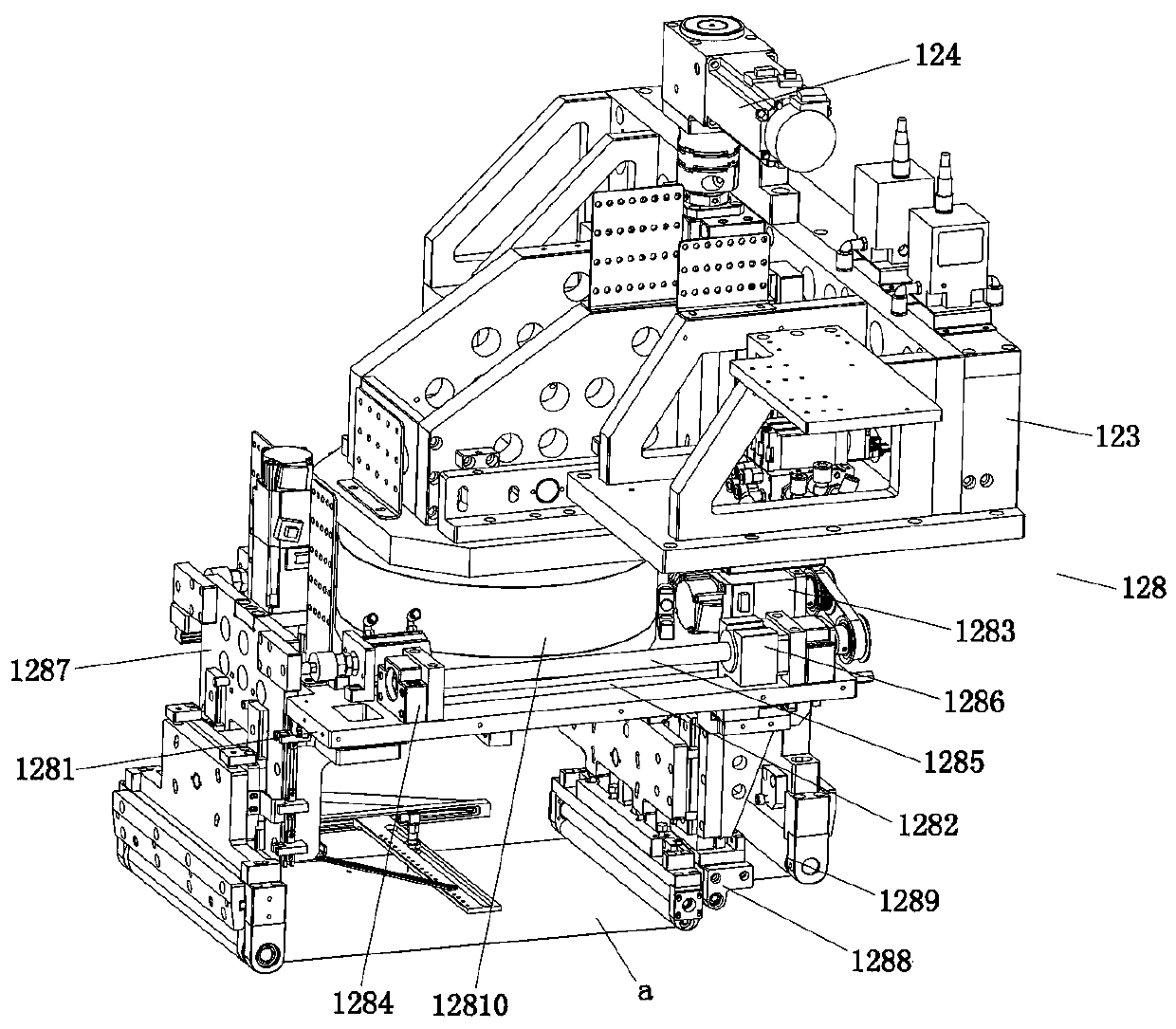

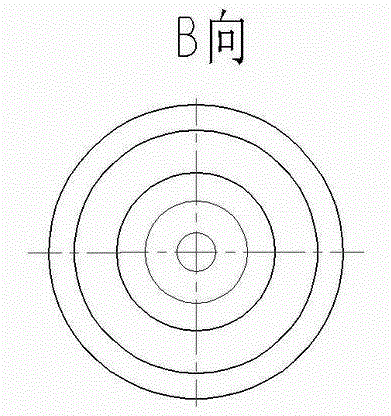

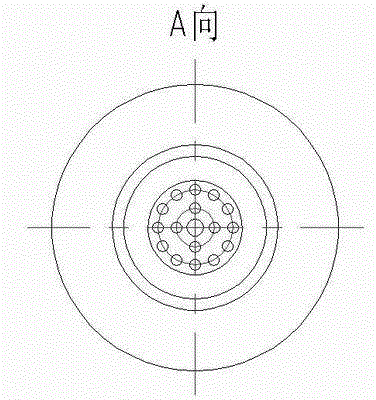

Full-automatic film detecting and pasting production line and film pasting process thereof

ActiveCN109318474AReduce bendingGuaranteed accuracyFinal product manufactureProduction lineGlass sheet

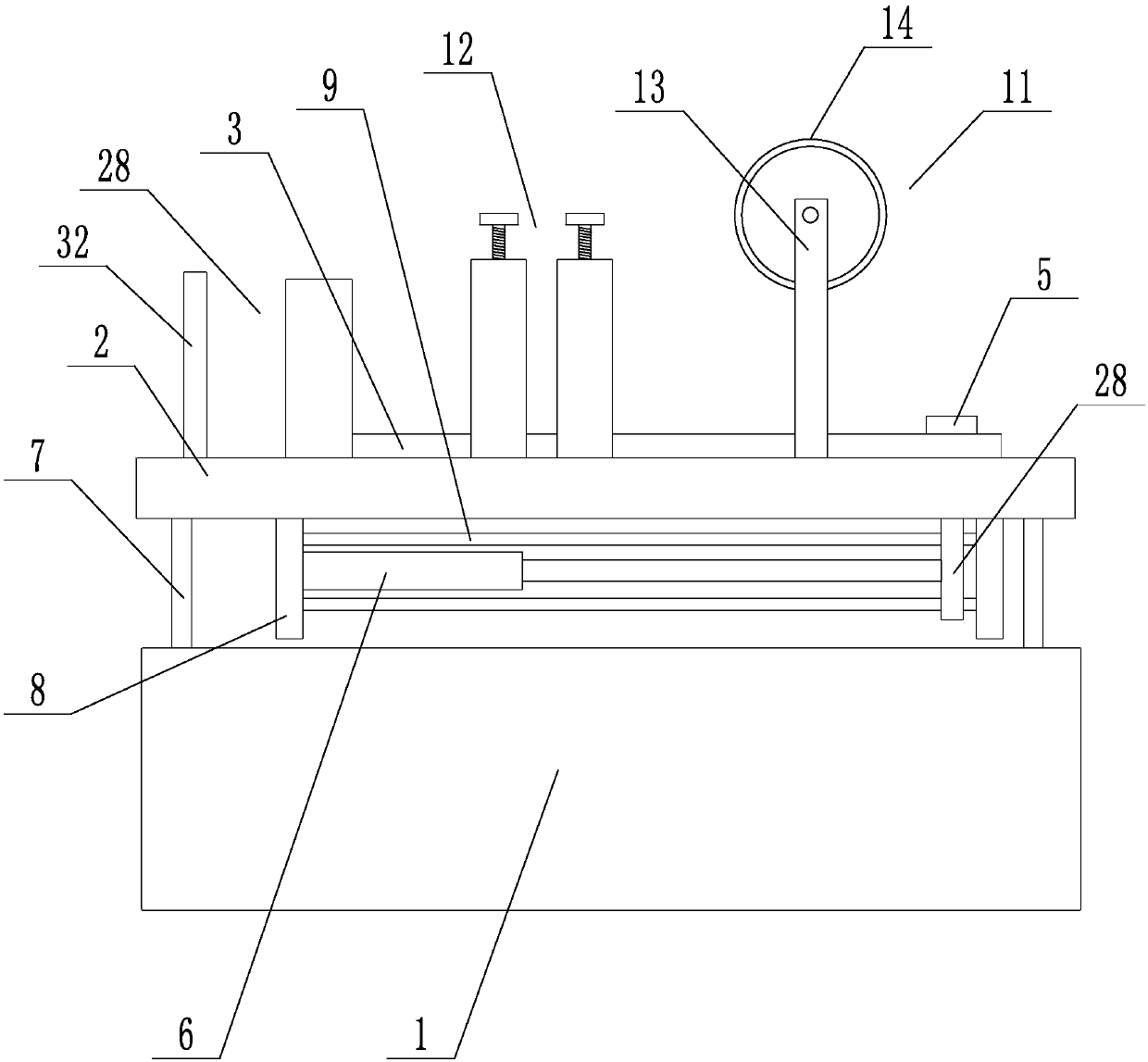

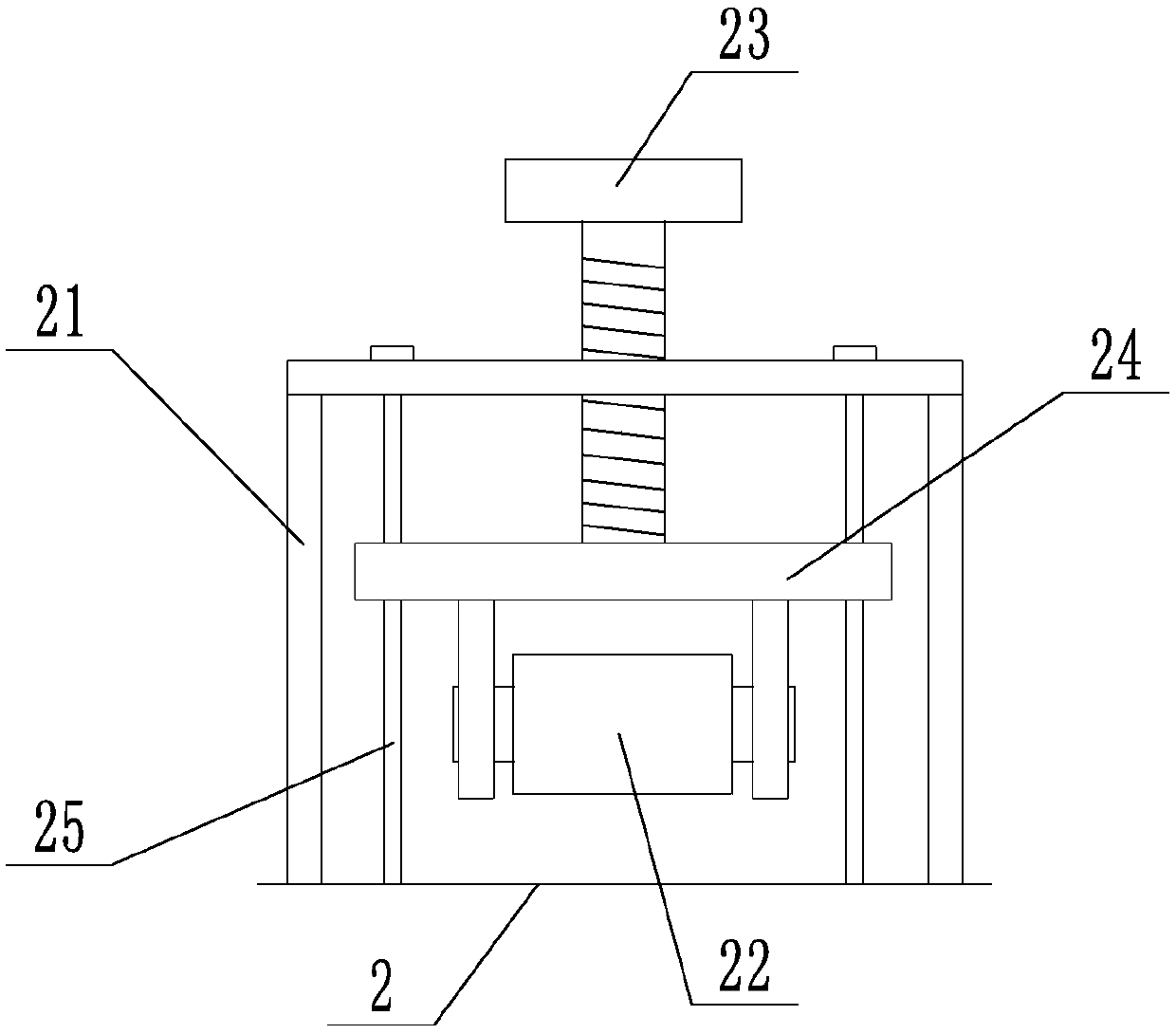

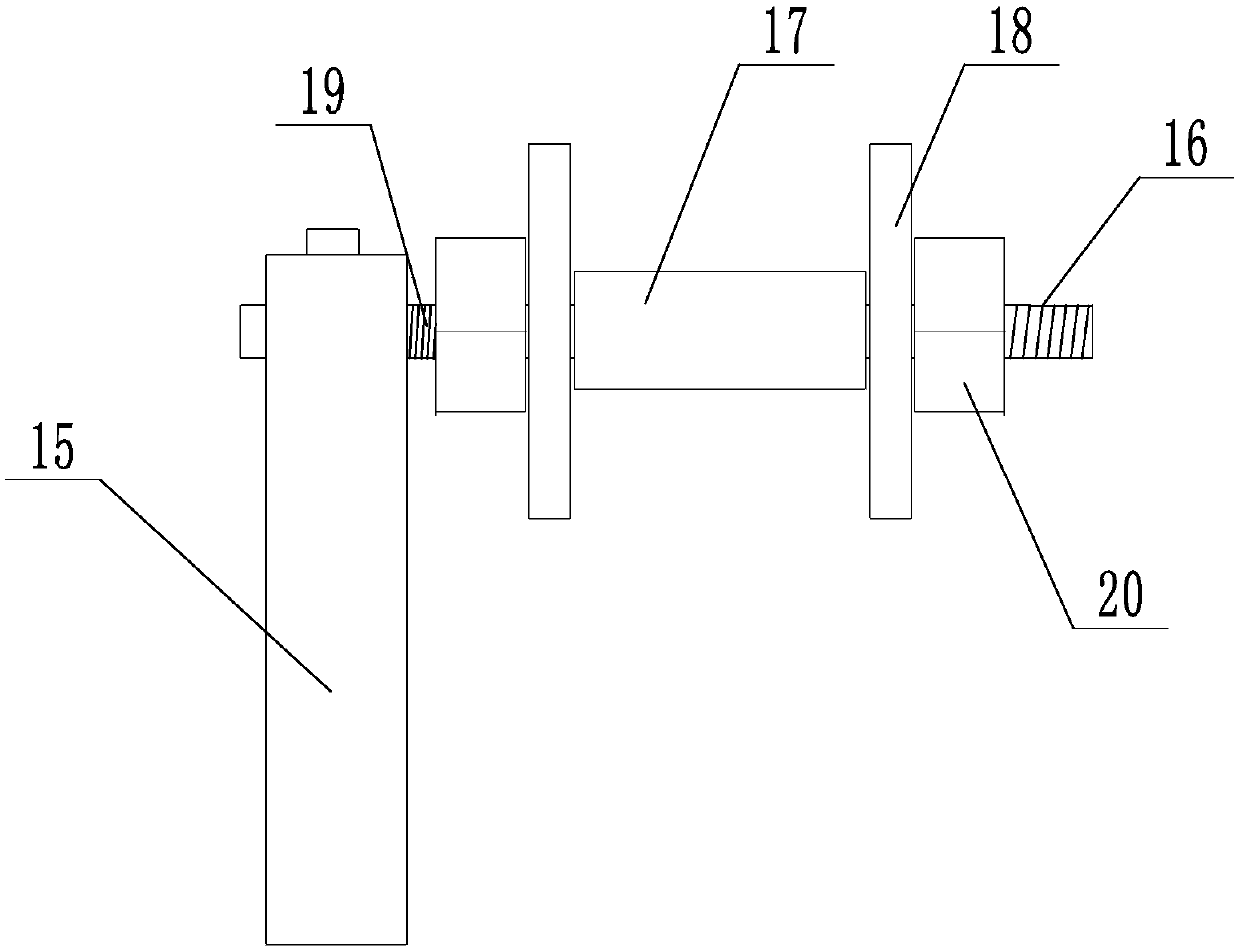

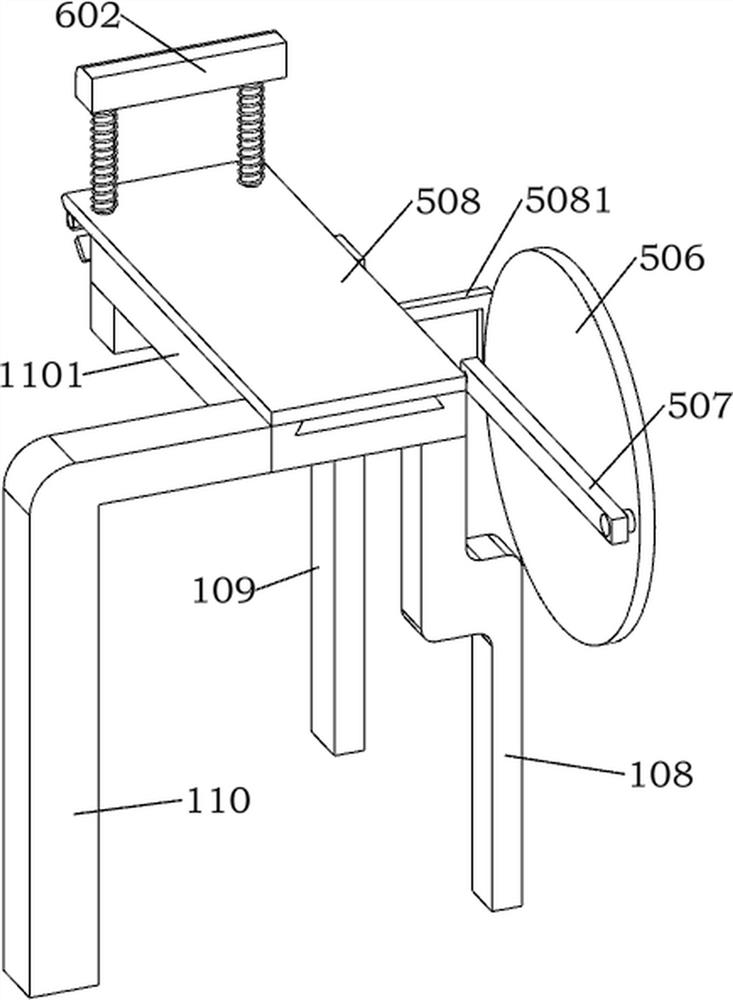

The invention discloses a full-automatic film detecting and pasting production line and a film pasting process thereof. The production line comprises a film feeding assembly, a film taking and detecting mechanical arm, a film transfer table, a correcting and mounting mechanical arm, a film tearing assembly, a glass loading assembly and a turntable; the film pasting process comprises the followingprocess steps of transferring a material frame, picking up the glass sheets and laminating the empty material frames, removing dust of the glass and photographing, film feeding, double-piece detectingand correcting, film recovering and primary correction, film taking and film tearing, membrane position correcting and film pasting. According to the film detecting and pasting production line and afilm pasting process, automatic centralized feeding of the diaphragm and the glass sheet is realized, the production line has a film suction quantity detection function and an automatic film tearing function on the surface of the film, the situation of sticking the double films is effectively avoided, the accuracy of the position of the film pieces in the film tearing process is guaranteed, the bending situation of the film sheet during film tearing is reduced, a sticking head which integrates the functions of film collecting sheet correction and pasting and mounting is adopted, in the film pasting process, the film is in contact rolling with the edge of the glass sheet, so that the situation of film sticking bubbles and crease marks can be effectively reduced, and the film sticking quality can be improved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

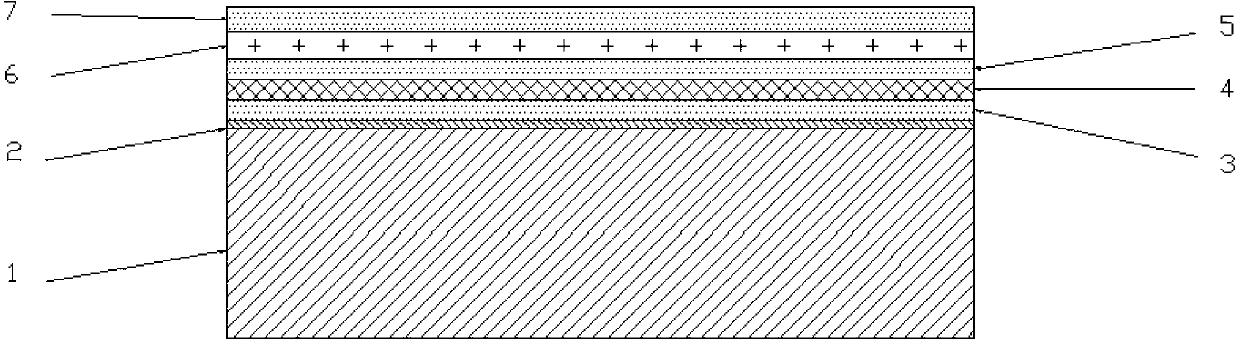

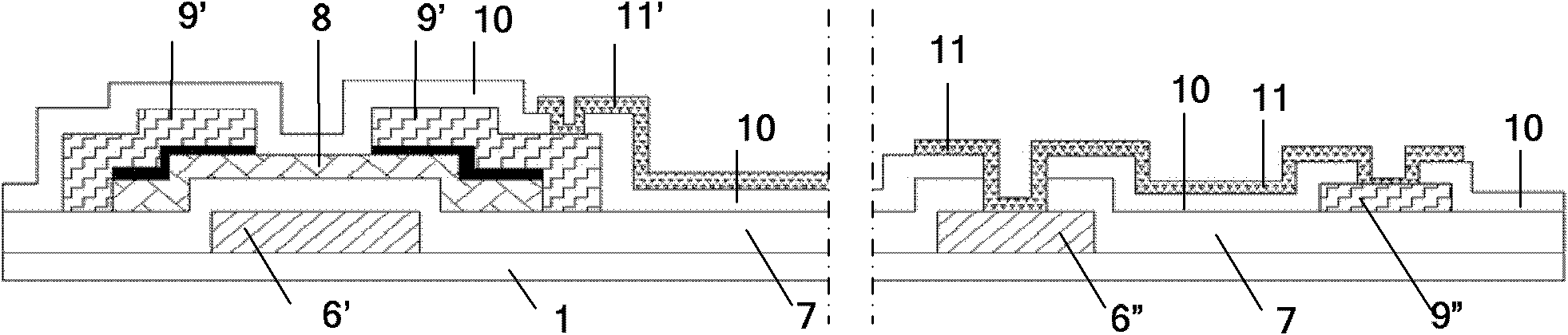

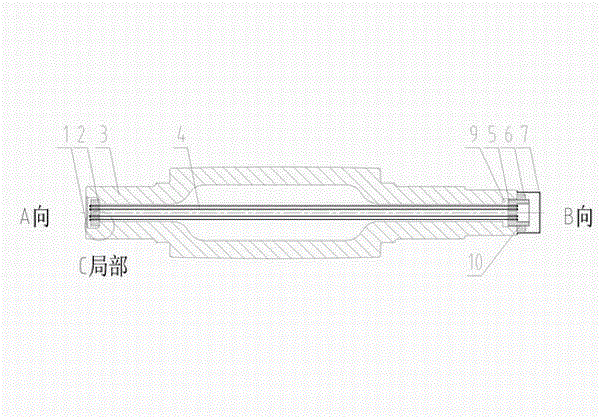

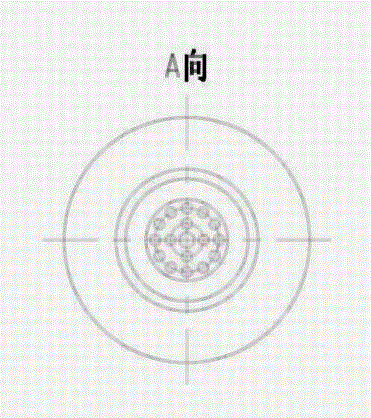

High-temperature ceramic base film thermocouple and manufacturing method thereof

ActiveCN103344350ALattice Mismatch ReliefImprove bindingThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThin film thermocouplesManufacturing technology

The invention discloses a high-temperature ceramic base film thermocouple and a manufacturing method of the high-temperature ceramic base film thermocouple, and belongs to the field of sensor manufacturing technologies and high temperature measurement technologies. The high-temperature ceramic base film thermocouple sequentially comprises a ceramic base 1, a SiO2 layer 2, a first A12O3 layer 3, an interlayer 4, a second A12O3 layer 5, a thermocouple layer 6 and a third A12O3 layer 7. The high-temperature ceramic base film thermocouple has the advantages that (1) the SiO2 transition layer is adopted, so that binding force on the interface between an insulating layer and the ceramic base is enhanced; (2) the A12O3-Si3N4 / A1N-A12O3 composite insulating layer is adopted, the excellent insulating performance is possessed, oxygen can be prevented from entering the high-temperature ceramic base film thermocouple, oxidization of a film on an inner layer is eliminated, and good dynamic response of a sensor is guaranteed; (3) thermal stress of the film caused by thermal loads is effectively reduced, and film forming quality and stability of the film are guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

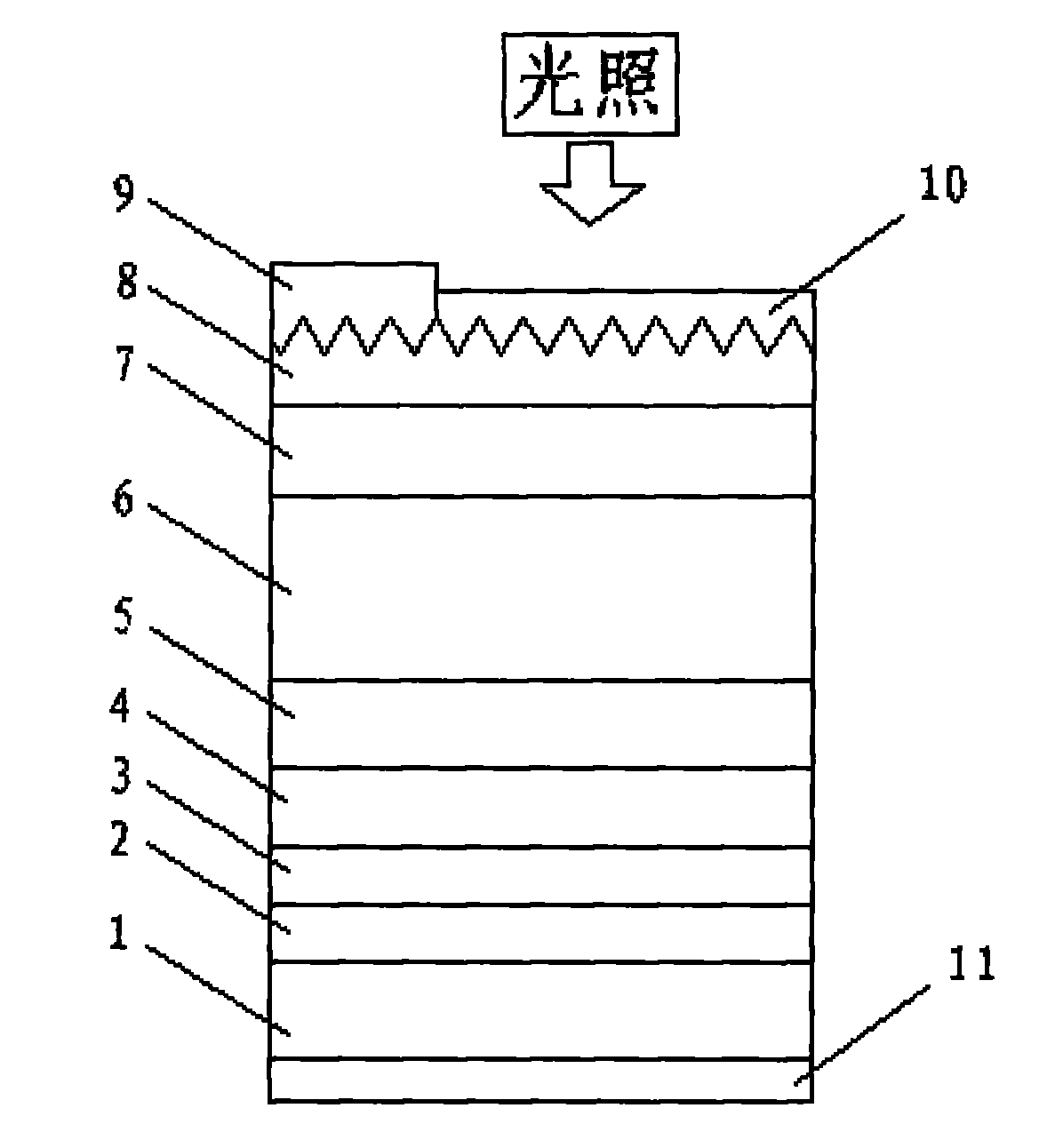

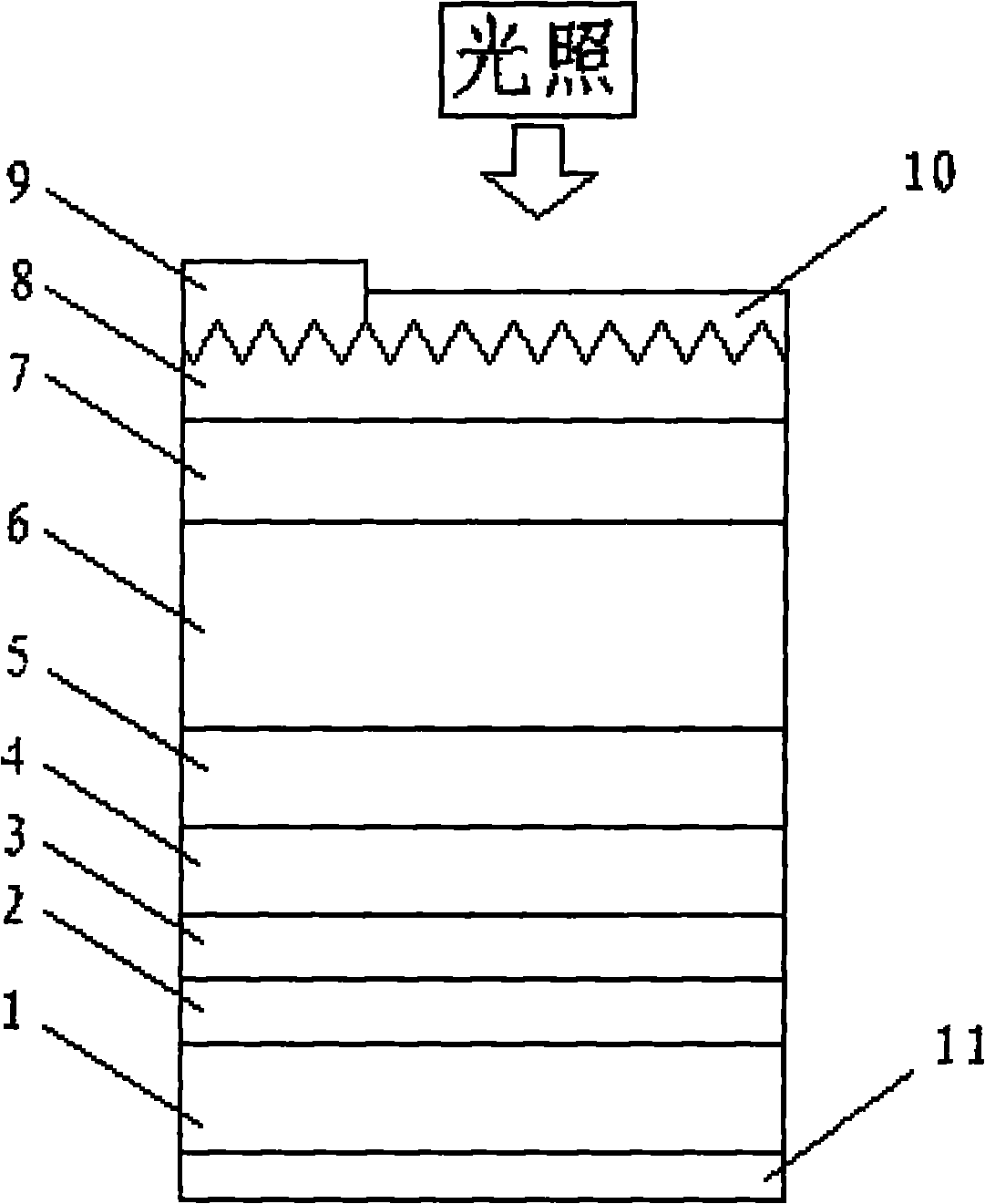

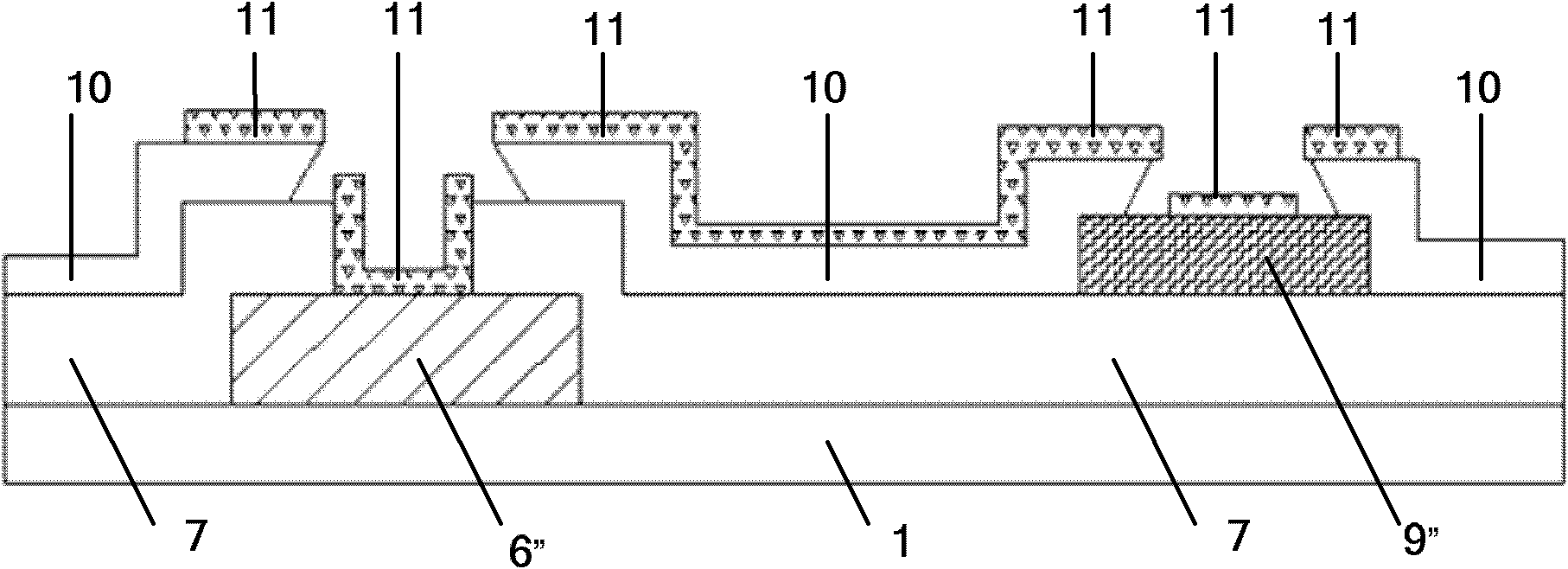

Solar cell

InactiveCN101866967AReduce manufacturing costImprove conductivityFinal product manufacturePhotovoltaic energy generationThermal expansionSolar cell

The invention relates to a silicon-based single-junction gallium indium nitride solar cell which comprises a back electrode (11), a silicon substrate (1), a seed crystal layer (2), a buffer layer (3), an n-type doped GaN buffer layer (4), an InaGal-aN layer (5), an unintentional doped InbGal-bN layer (6), a p-type doped IncGal-cN layer (7), a window layer (8), a positive electrode (9) and an anti-reflection conductive film (10) which are arranged from bottom to top, wherein the silicon substrate and the InaGal-aN layer is are an n-type doped structure, the seed crystal layer and the buffer layer are made of ZnO material, the window layer is made of p-type heavily doped GaN, and the anti-reflection conductive film covers areas of the window layer other than the positive electrode. The solar cell can quite effectively solve the problems of lattice matching, thermal expansion coefficient matching and the like encountered when a GaN film extends from the silicon substrate, and has the advantages of low manufacturing cost, high sunlight absorbability and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

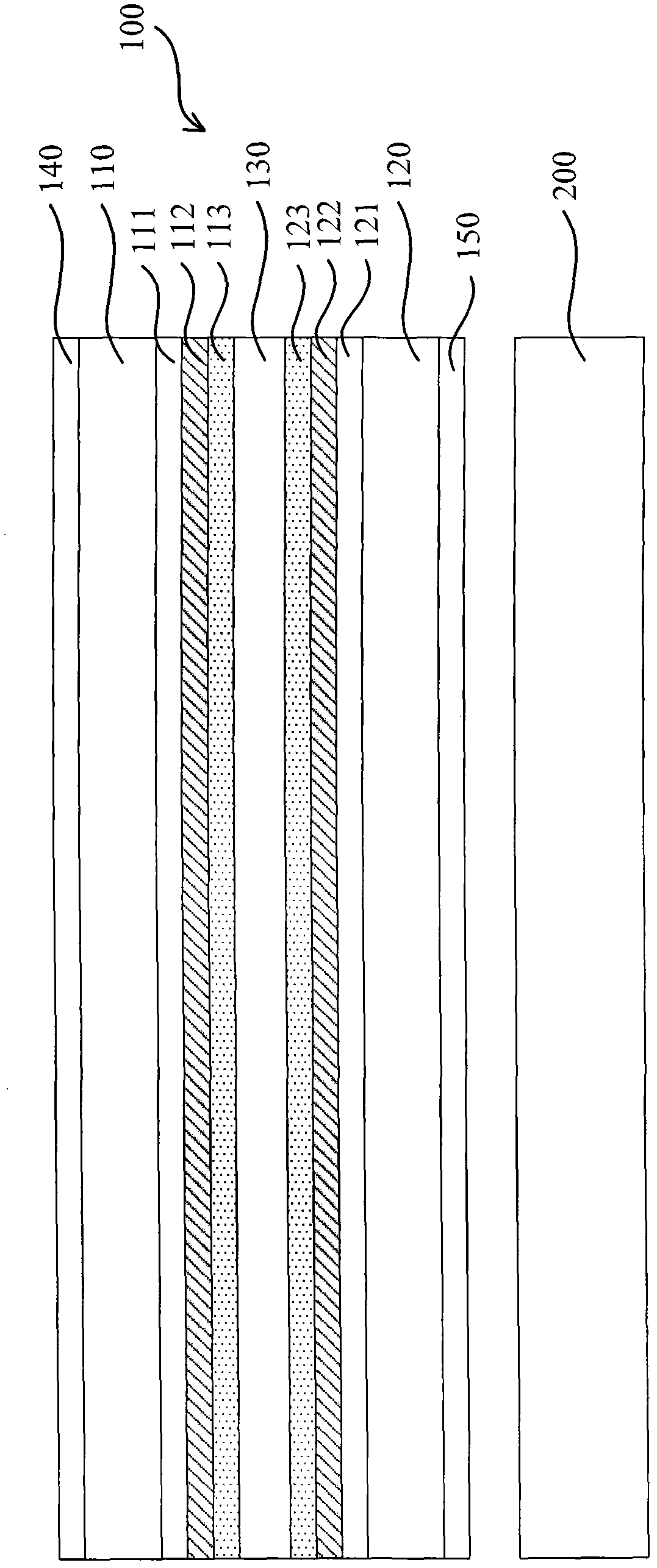

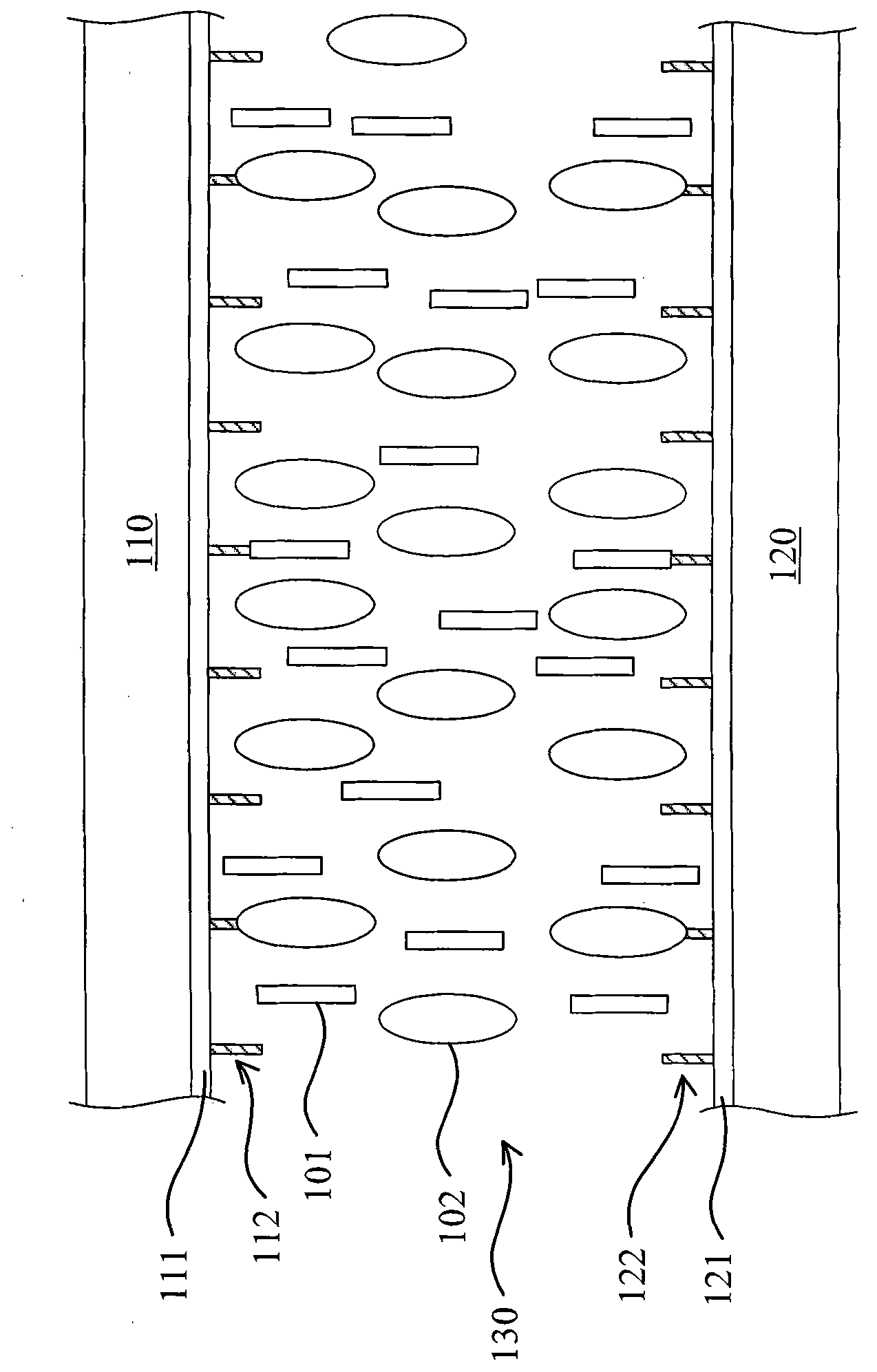

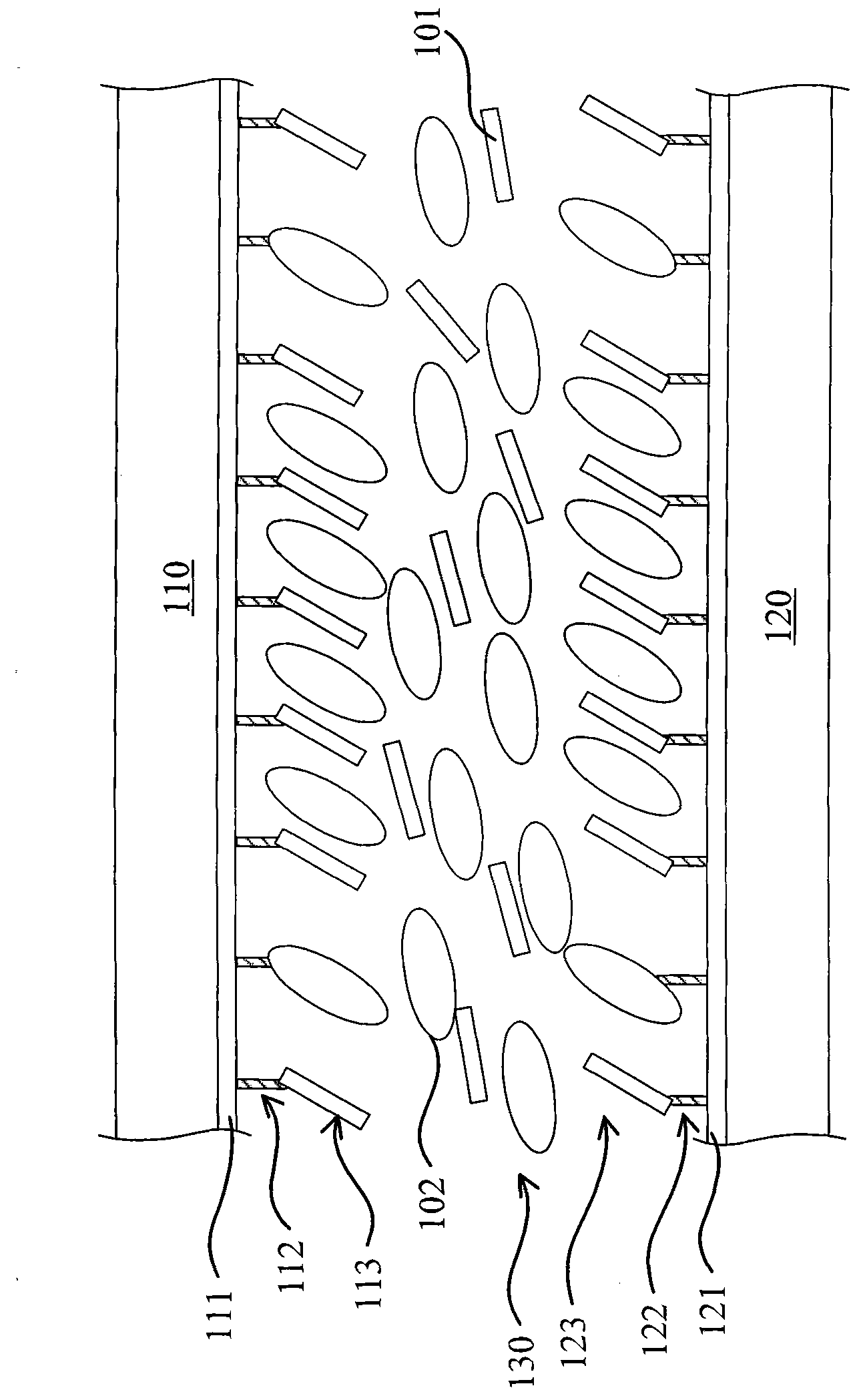

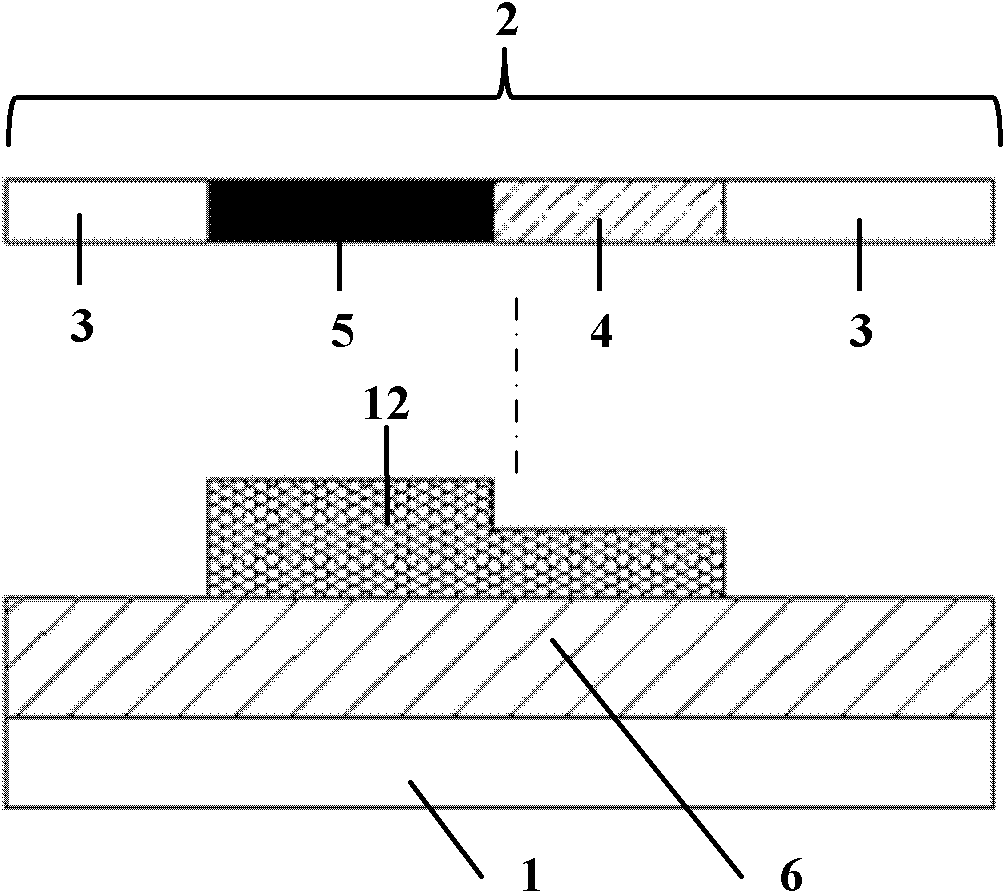

Manufacturing method of display panel and display device

InactiveCN102081250AGuaranteed film qualityQuality improvementNon-linear opticsSputteringUltraviolet lights

The invention provides a manufacturing method of a display panel and a display device. The method comprises the following steps of: sputtering alignment layers on a substrate; forming a liquid crystal layer between the alignment layers to form a liquid crystal box; applying a voltage to the liquid crystal box; irradiating ultraviolet light on the liquid crystal box; and arranging the display panel on a backlight module. The quality of an alignment film of the display panel can be improved with the method.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Agricultural polyethylene resin composition

ActiveCN101538386AReduce dosageGuaranteed stabilityClimate change adaptationGreenhouse cultivationLow-density polyethyleneCross-link

The invention discloses an agricultural polyethylene resin composition. The composition mainly consists of linear low-density polyethylene LLDPE and organic peroxide, wherein the organic peroxide is combined by di-tert-butyl peroxide DTBP and tert-butyl hydroperoxide TBHP according to the combination ratio of between 1:1 and 6:1, and the consumption of the organic peroxide is between 500 and 2,500ppm (based on each gram of linear low-density polyethylene). In the composition, the linear low-density polyethylene LLDPE is cross-linked by compounding the peroxide, and when the obtained modified high-bath strength LLDPE resin is used for blowing a 80 mum agricultural green house membrane, and under the condition of ensuring the membrane blowing stability and the quality of the membrane, the consumption of the peroxide is lowered, so that the production cost is also lowered.

Owner:PETROCHINA CO LTD

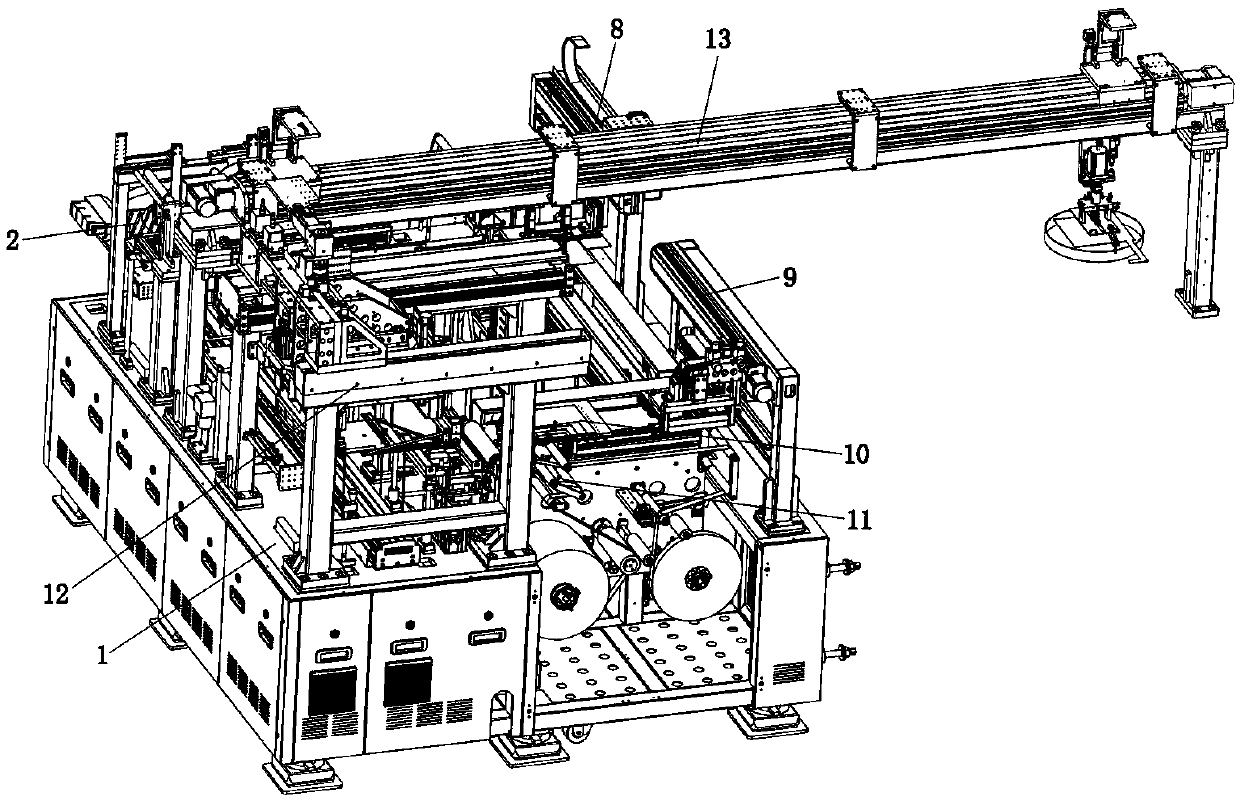

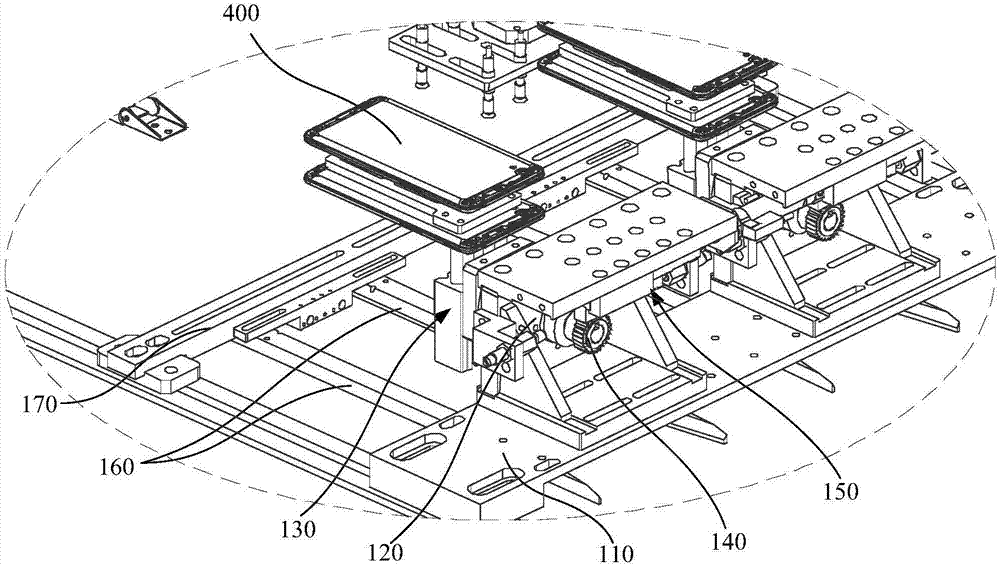

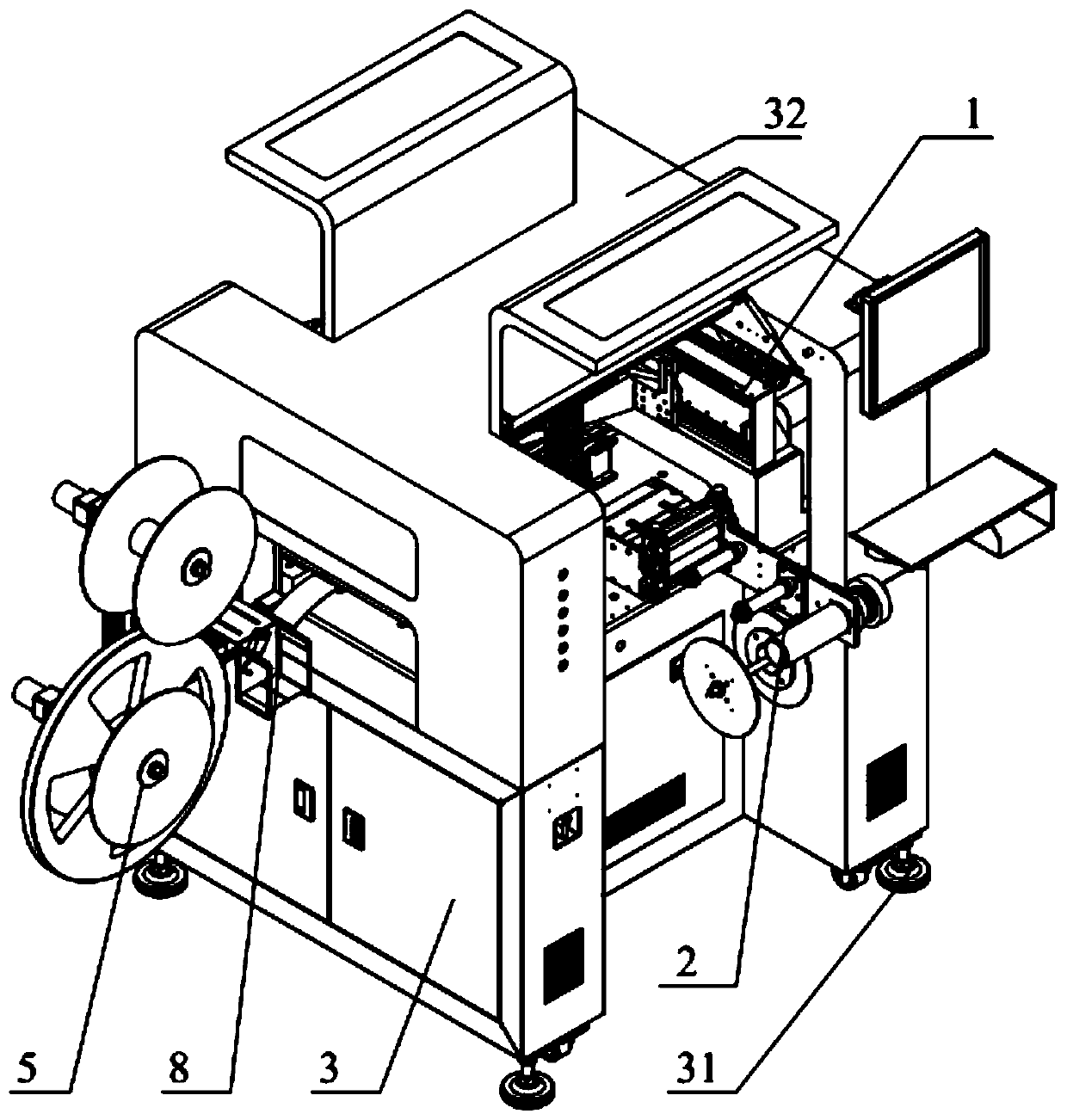

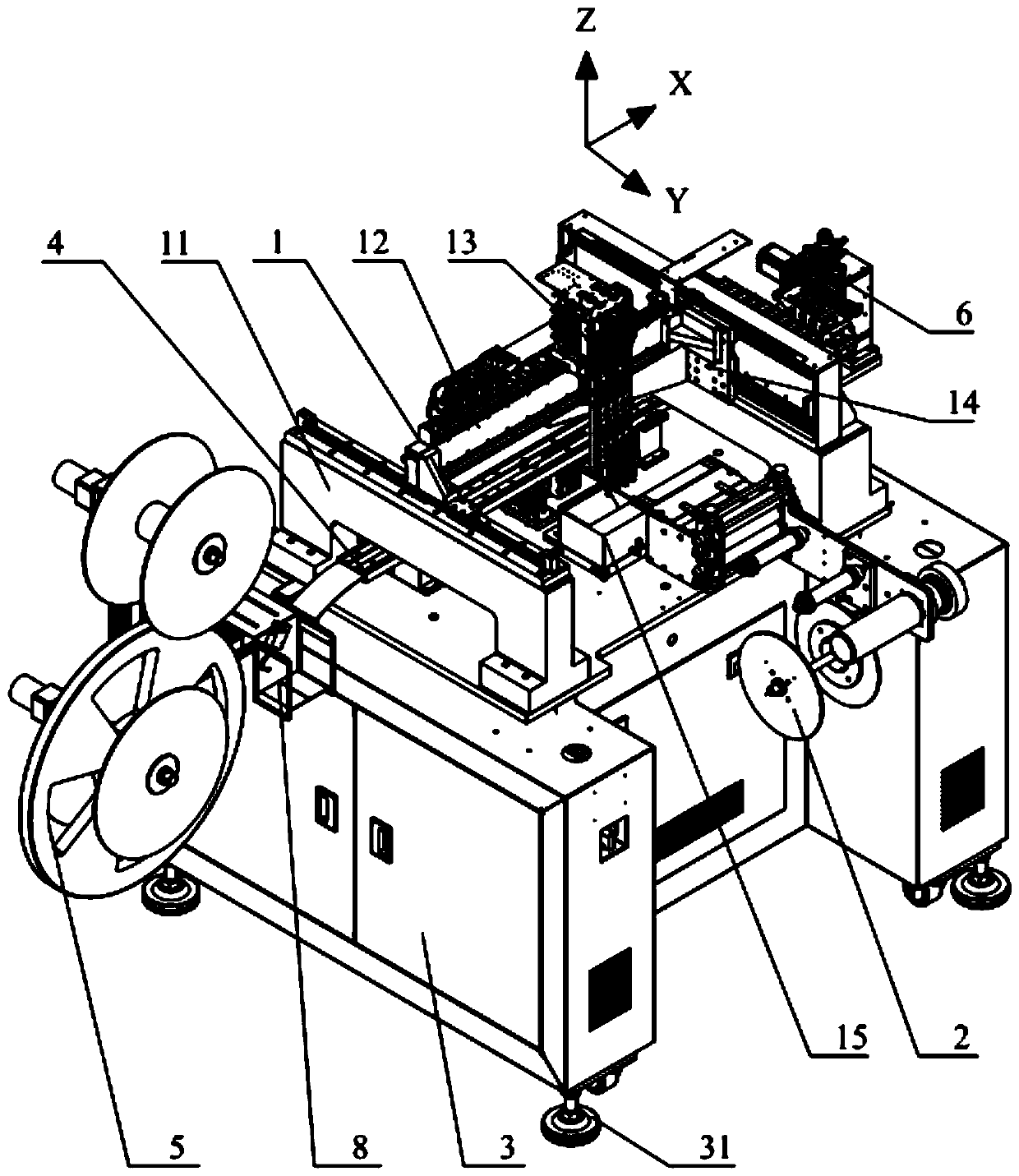

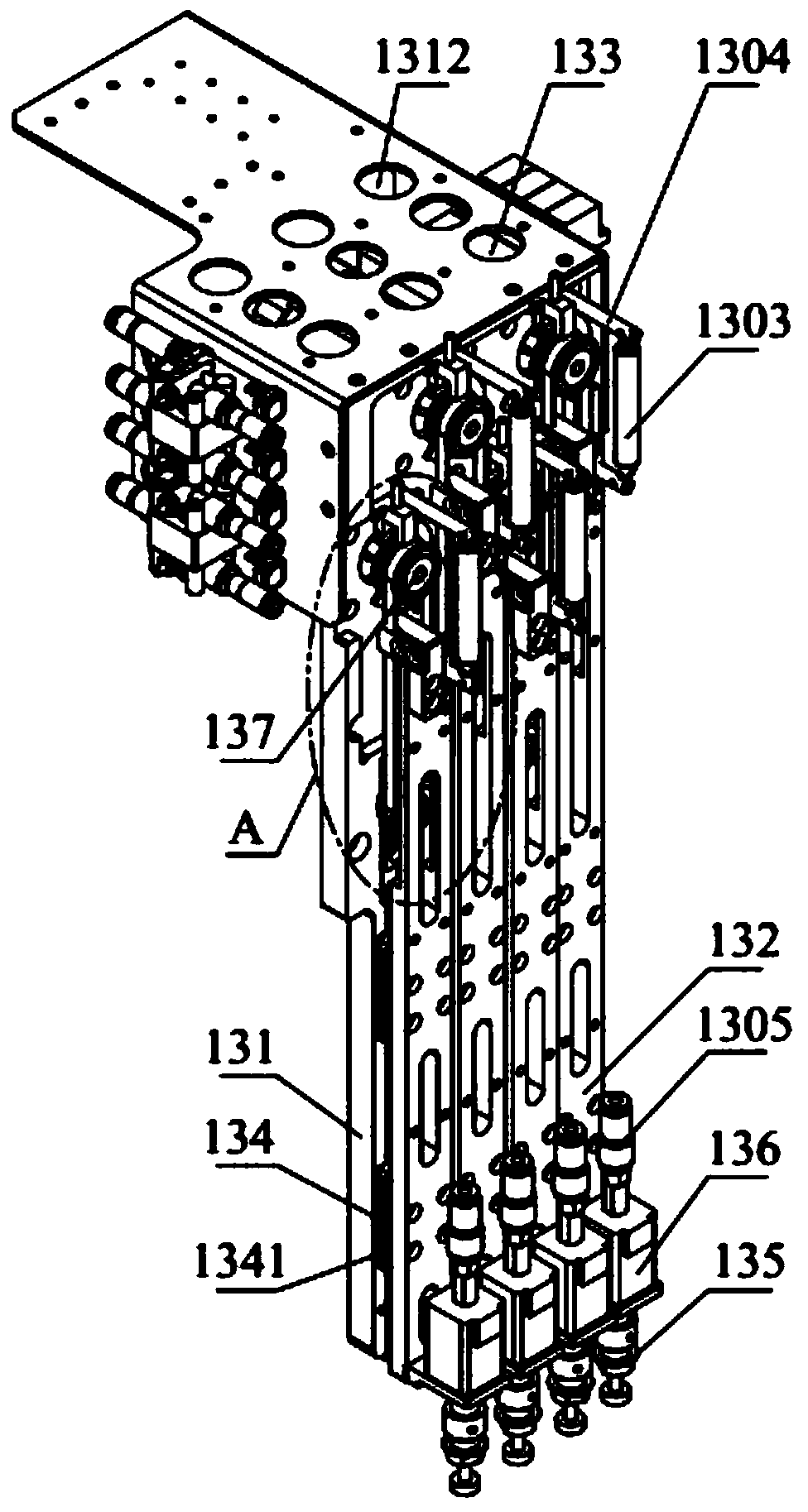

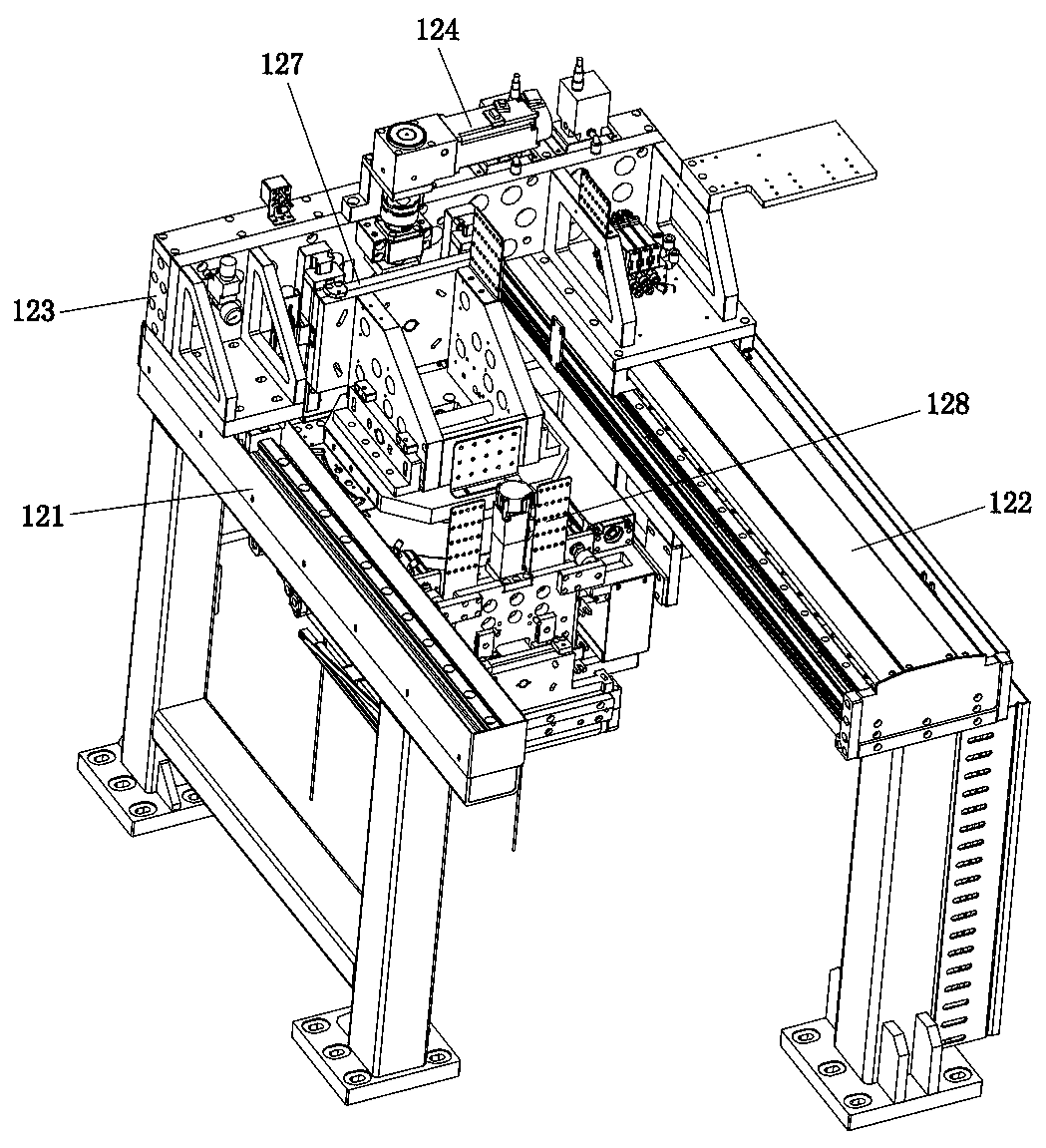

Automatic soft-to-soft flexible attaching machine and attaching process thereof

PendingCN109514969AControl tensionReduces fit bubblesLamination ancillary operationsLaminationArm movingEngineering

The invention discloses an automatic soft-to-soft flexible attaching machine and an attaching process thereof. The automatic soft-to-soft flexible attaching machine comprises an OLED adsorption and transfer platform, an OLED film tearing mechanism, a FILM feeding mechanism, a FILM transferring platform, a first carrying arm, a second carrying arm, a FILM tearing mechanism and an attaching mechanism. The OLED adsorption and transfer platform and the FILM transferring platform are horizontally arranged on a machine frame in the same direction at intervals, an OLED film is placed on the OLED adsorption and transfer platform, after initial positioning, the OLED film sequentially moves to the OLED film tearing mechanism and the attaching mechanism and the like to perform the film tearing action; and after a FILM is exported by the FILM feeding mechanism, the FILM is transported by the first carrying arm to the FILM transferring platform, the second carrying arm moves the FILM to the FILM tearing mechanism, the FILM tearing mechanism tears a film body at the bottom of the FILM, and the attaching mechanism attaches the FILM to the OLED film. The automatic soft-to-soft flexible attaching machine and the attaching process thereof solve the problems of bottom and surface film tearing of a flexible film, the adsorption stability during attaching and film tearing, the control over the angle change of the film or the film body during attaching and film tearing and the like.

Owner:SHENZHEN ETMADE AUTOMATION EQUIP

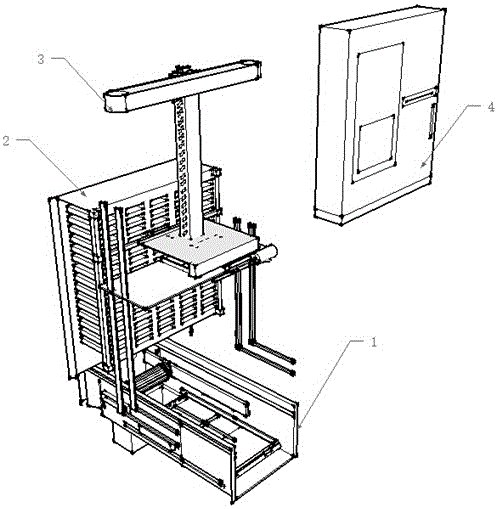

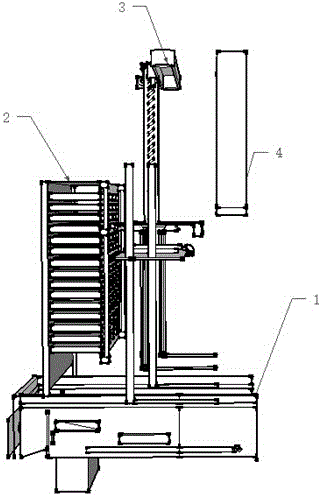

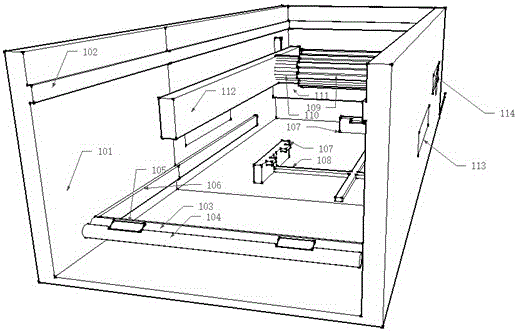

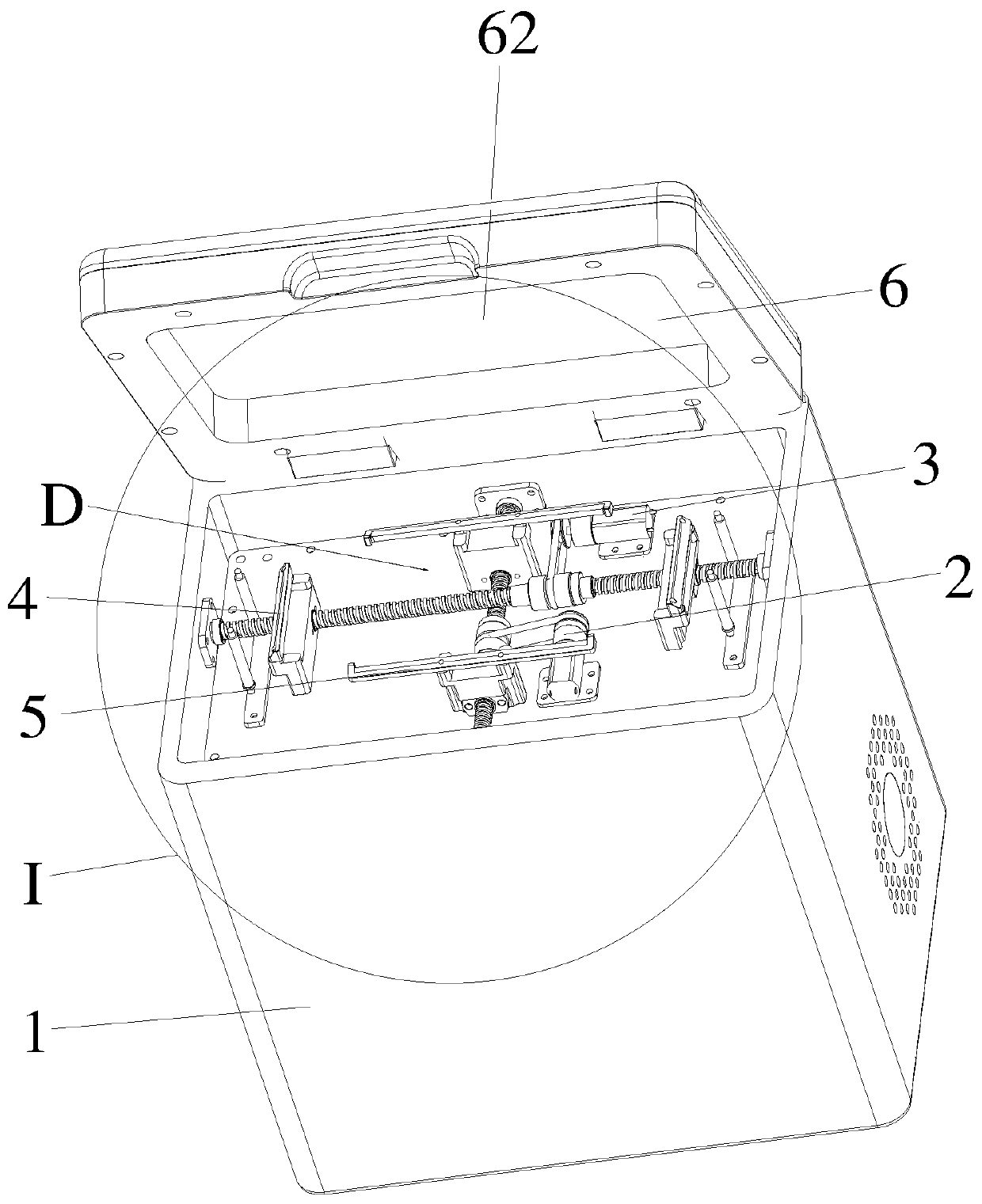

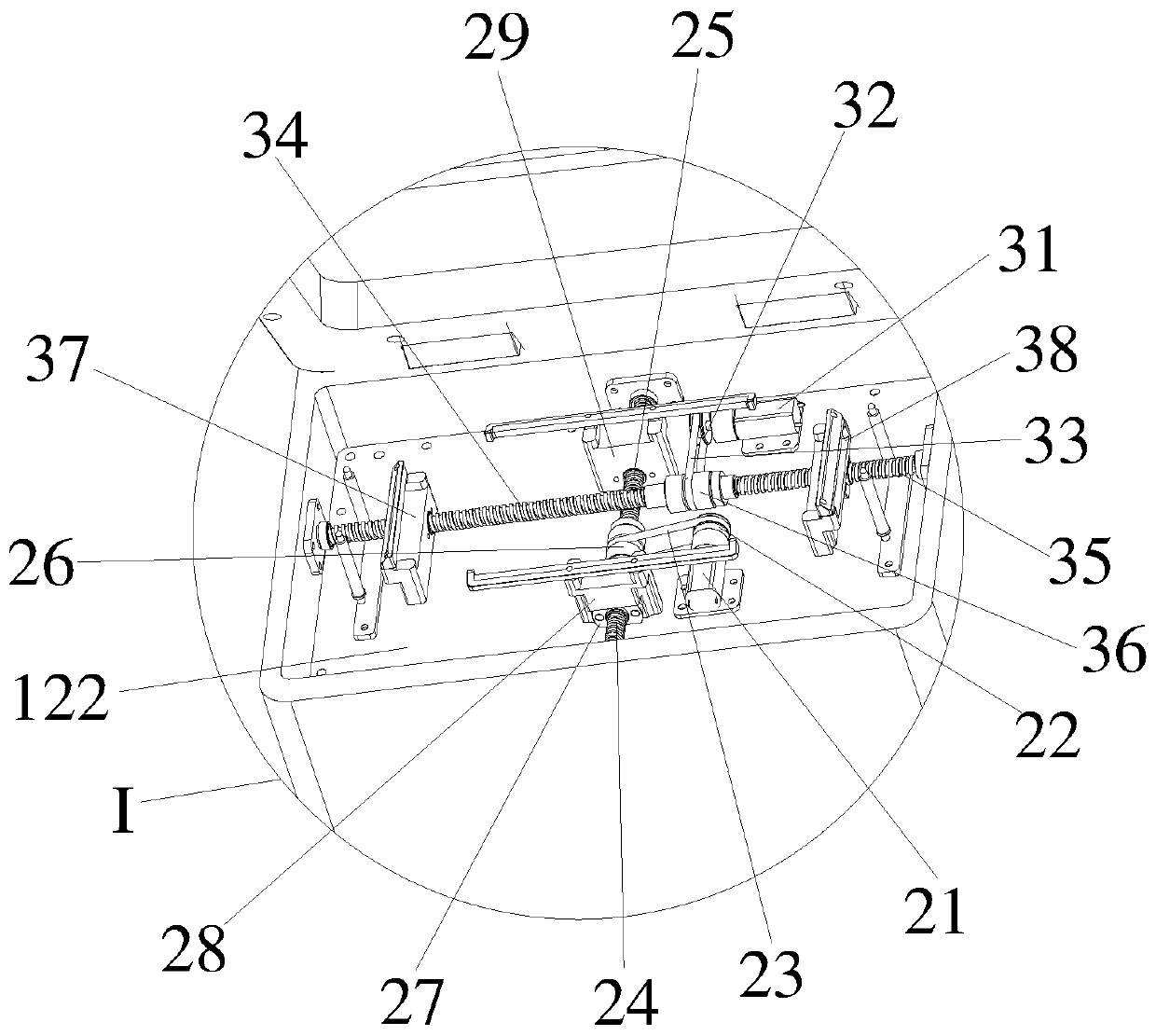

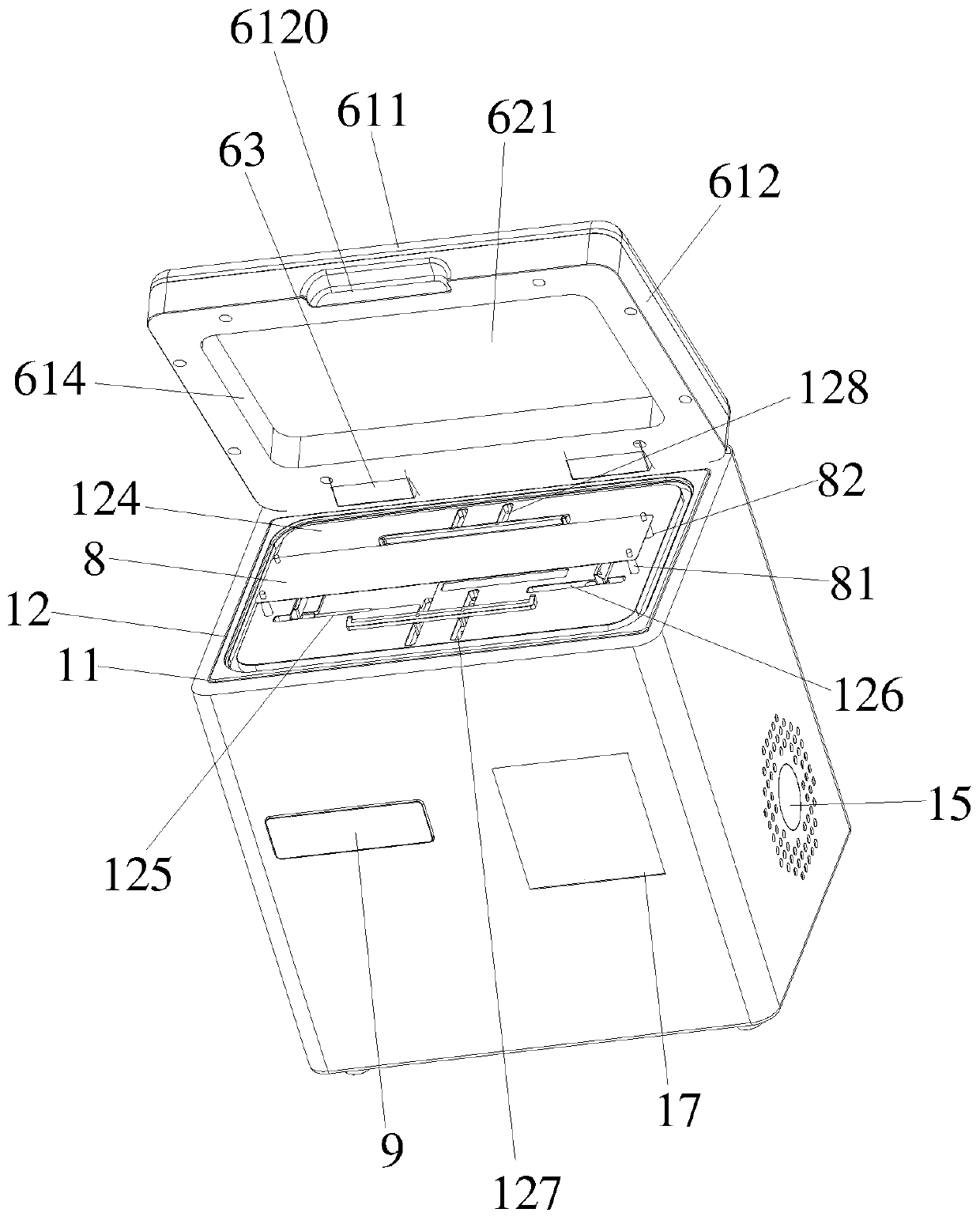

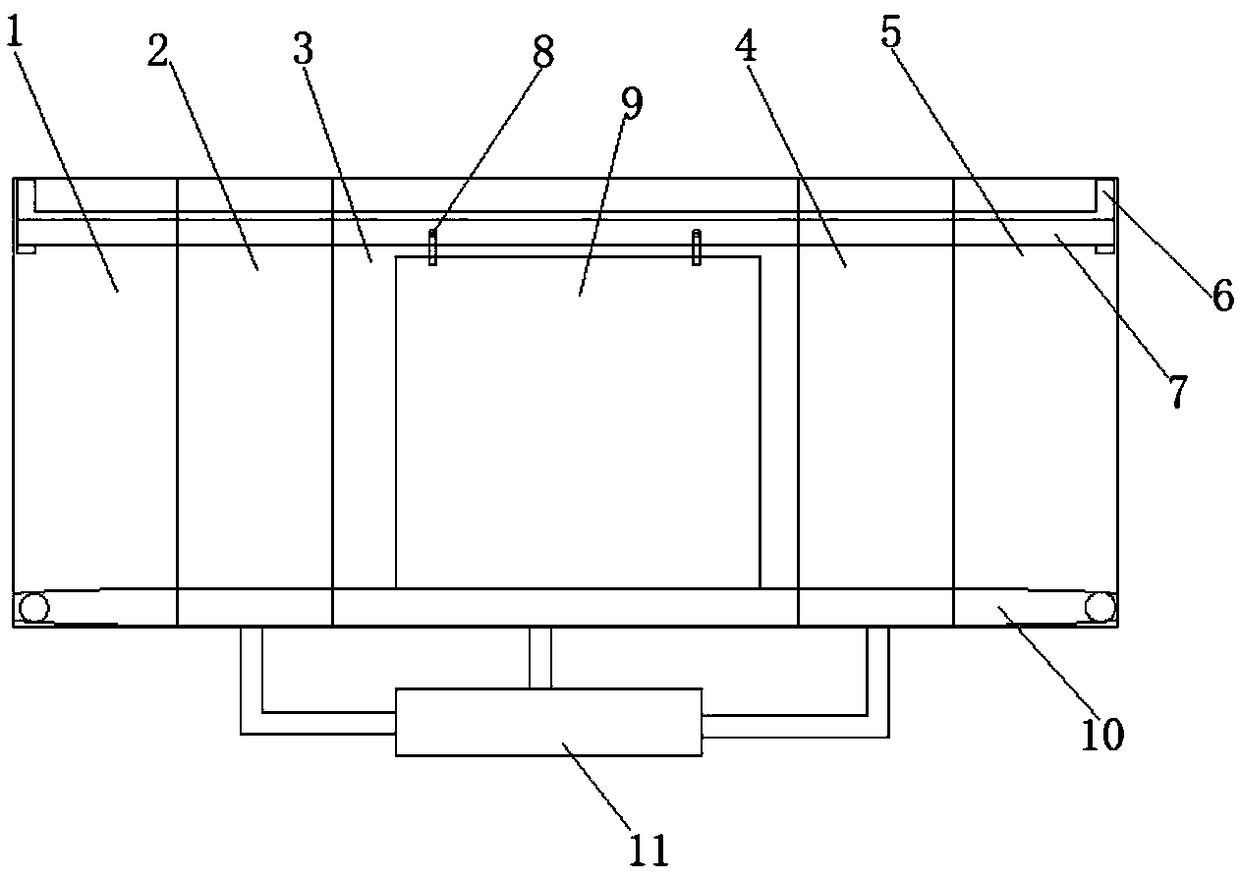

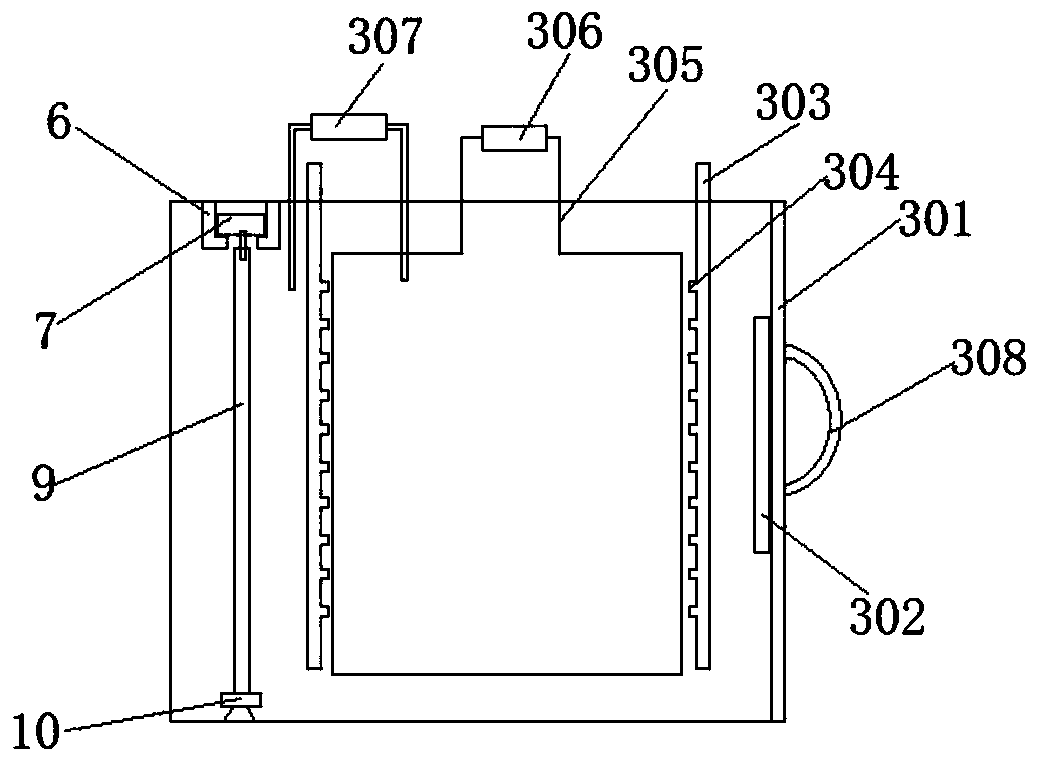

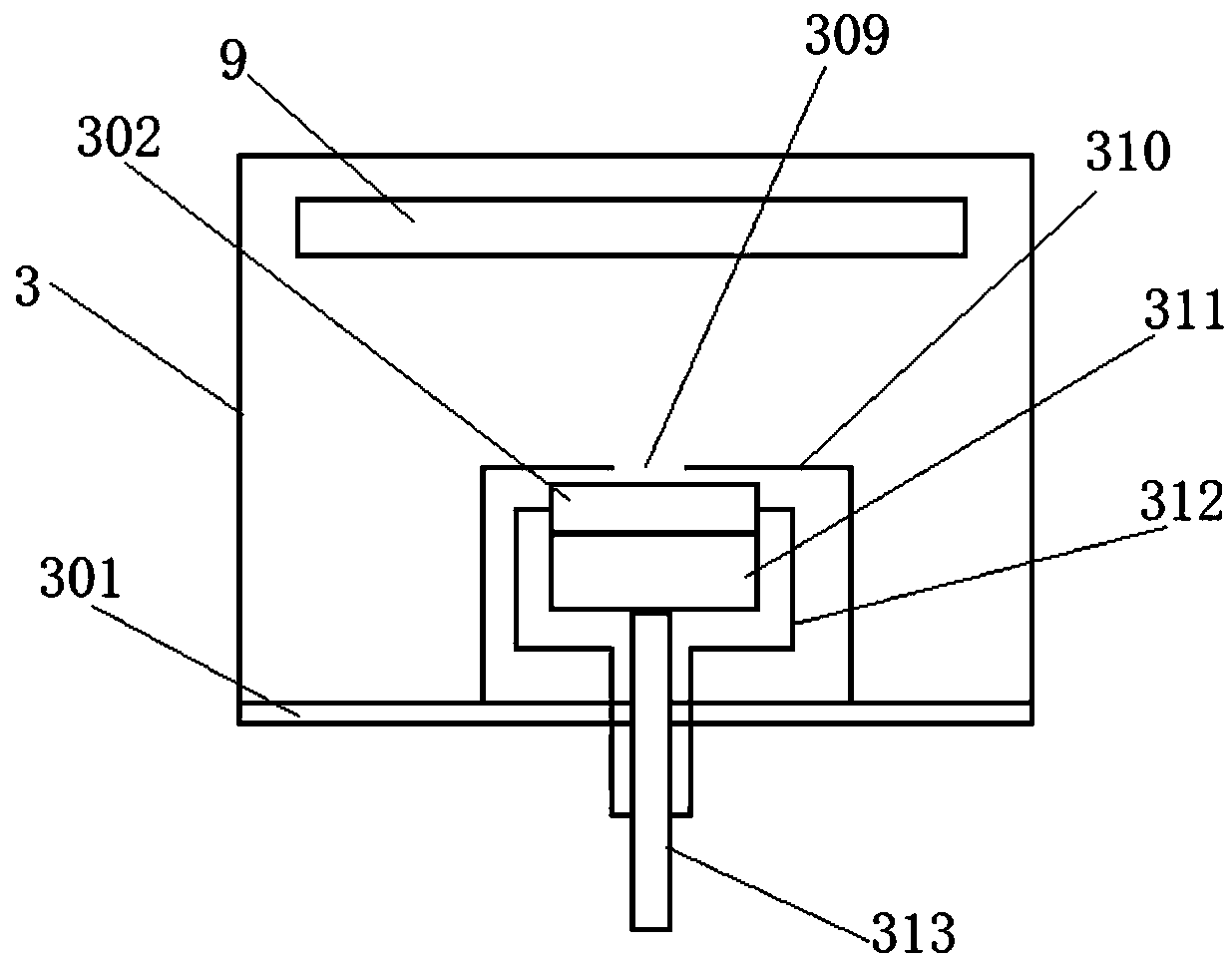

Full-automatic mobile phone film pasting cabinet

ActiveCN105083618AReduce work intensityImprove the film effectPackage sterilisationMobile phoneElectrical and Electronics engineering

The invention provides a full-automatic mobile phone film pasting cabinet which comprises a film pasting chamber, a film storage chamber, a flat plate, a mechanical movement structure and a control box. The control box is connected with the film pasting chamber, the film storage chamber, the flat plate and the mechanical movement structure through connection lines. The full-automatic mobile phone film pasting cabinet can be used for achieving full-automatic film pasting according to actual conditions of mobile phones, the whole film pasting process is conducted full automatically in a dust-free space, and the film pasting effect is good, and full-automatic film pasting can be achieved under an unmanned condition. Accordingly, film pasting quality can be guaranteed, and the labor intensity of film pasting work is lowered.

Owner:徐州博创建设发展集团有限公司

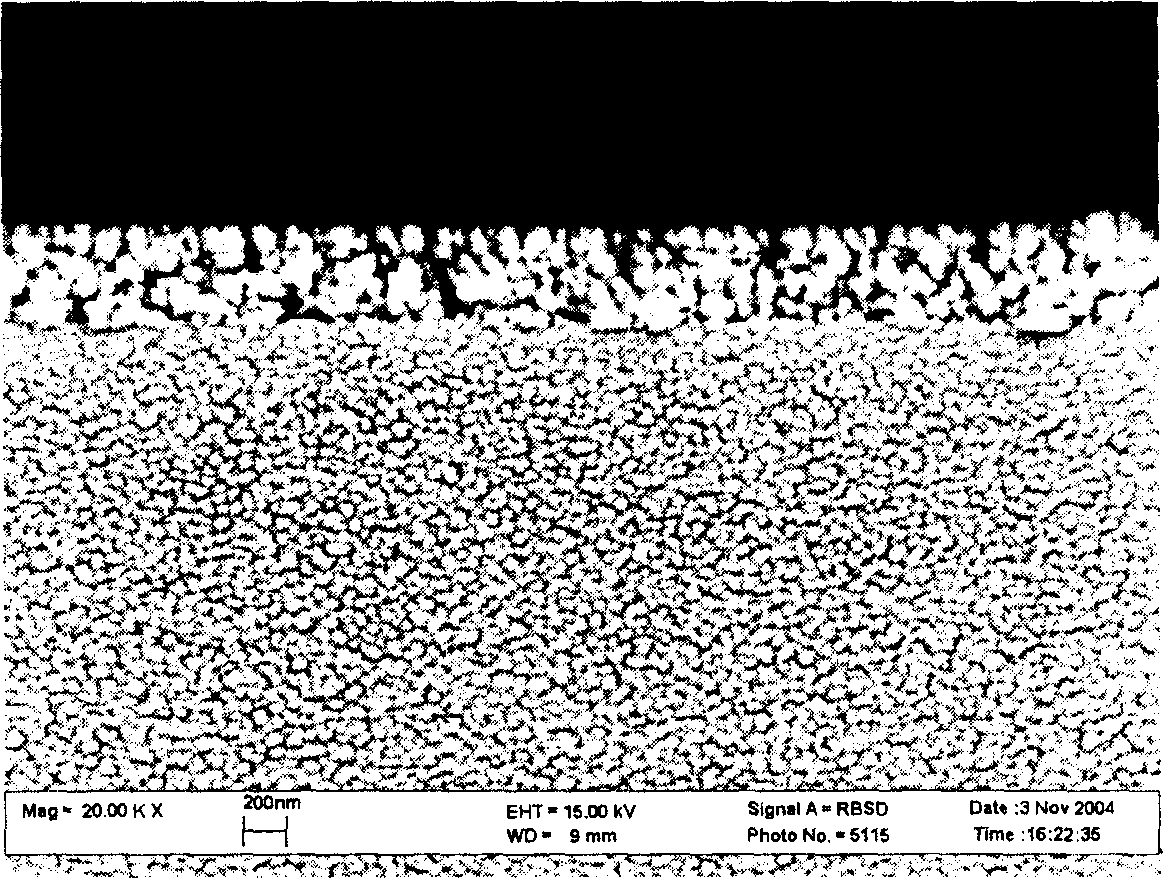

Preparation method of TiO2 photocatalyst for loading on ceramic surface

The invention relates to the process for preparing TiO2 photo-catalyst carrier on ceramic surface, wherein the compact ceramic carrier material is supported with TiO2 colloidal sol through sol-gal process, the TiO2 colloidal sol is prepared through dissolving butyl titanate or propyl titanate into acids, alcohols and water, washing and drying the finished ceramic carrier into TiO2 colloidal sol for 2-40 minutes, seasoning, sintering the carrying agent with carried colloidal sol in the furnace, elevating the temperature from room temperature to 80-250 deg. C, heat preserving for 10-80 minutes, elevating temperature again to 250-400 deg. C, heat preserving for 20-80 minutes, elevating the temperature to 450-550 deg. C, heat preserving for 40-90 minutes, furnace cooling to room temperature. A stabilized catalytic activity can be achieved by the invention.

Owner:NANJING UNIV

Device for peeling red skins of peanut kernels

ActiveCN103892419ANo pollution in the processIncrease frictional adhesionHuskingHullingLow speedCircular cone

The invention discloses a device for peeling the red skins of peanut kernels. The device comprises a vibrating feeder, an inflatable plastic circular cone table and an inflatable plastic circular ring, wherein the surface of the circular cone table and the surface of the circular ring are provided with a large number of micro protrusions, an adjustable balance weight ring is arranged on the circular ring, the circular ring is positioned by a circular ring rod and hung above the circular cone table through a spring hanger, and the height from the circular ring to the circular cone table can be adjusted by the spring hanger; a rotating shaft is connected to the circular cone table, and the face of the circular cone table can be driven to rotate by the rotating shaft; the circular cone table is arranged in a machine case, a discharging hopper at the lower end of the machine case is connected with a vibrating screen, a draught hood is arranged above the vibrating screen and connected with a draught fan, and an outlet of the draught fan is connected with a cyclone separator. With the device, the skin peeling and separation quality can be guaranteed, the complete particles can reach more than 80 percent, the working efficiency is high, low-speed flexible kneading skin peeling is achieved, and dust pollution is avoided.

Owner:广西诚杨食品有限公司

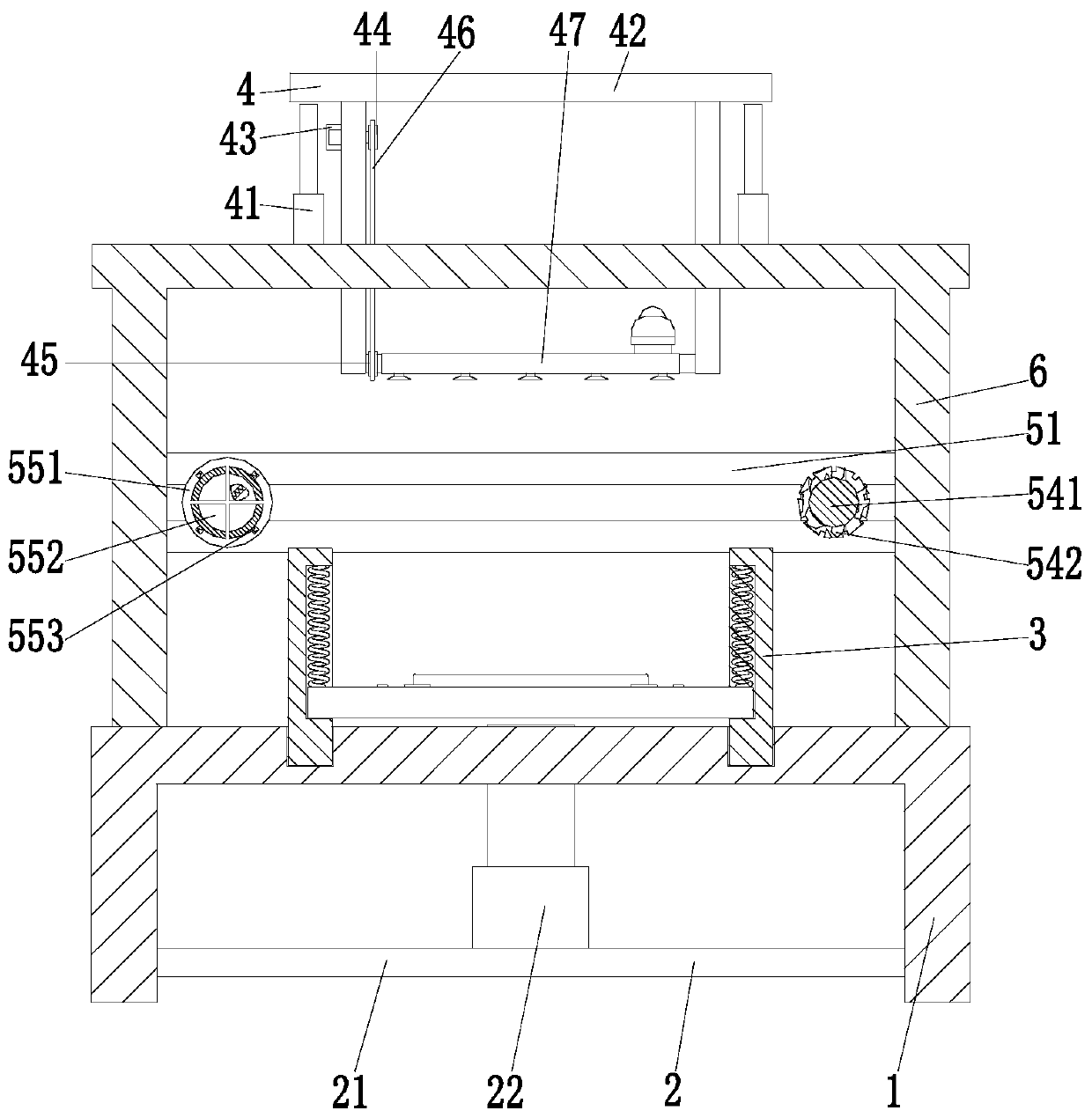

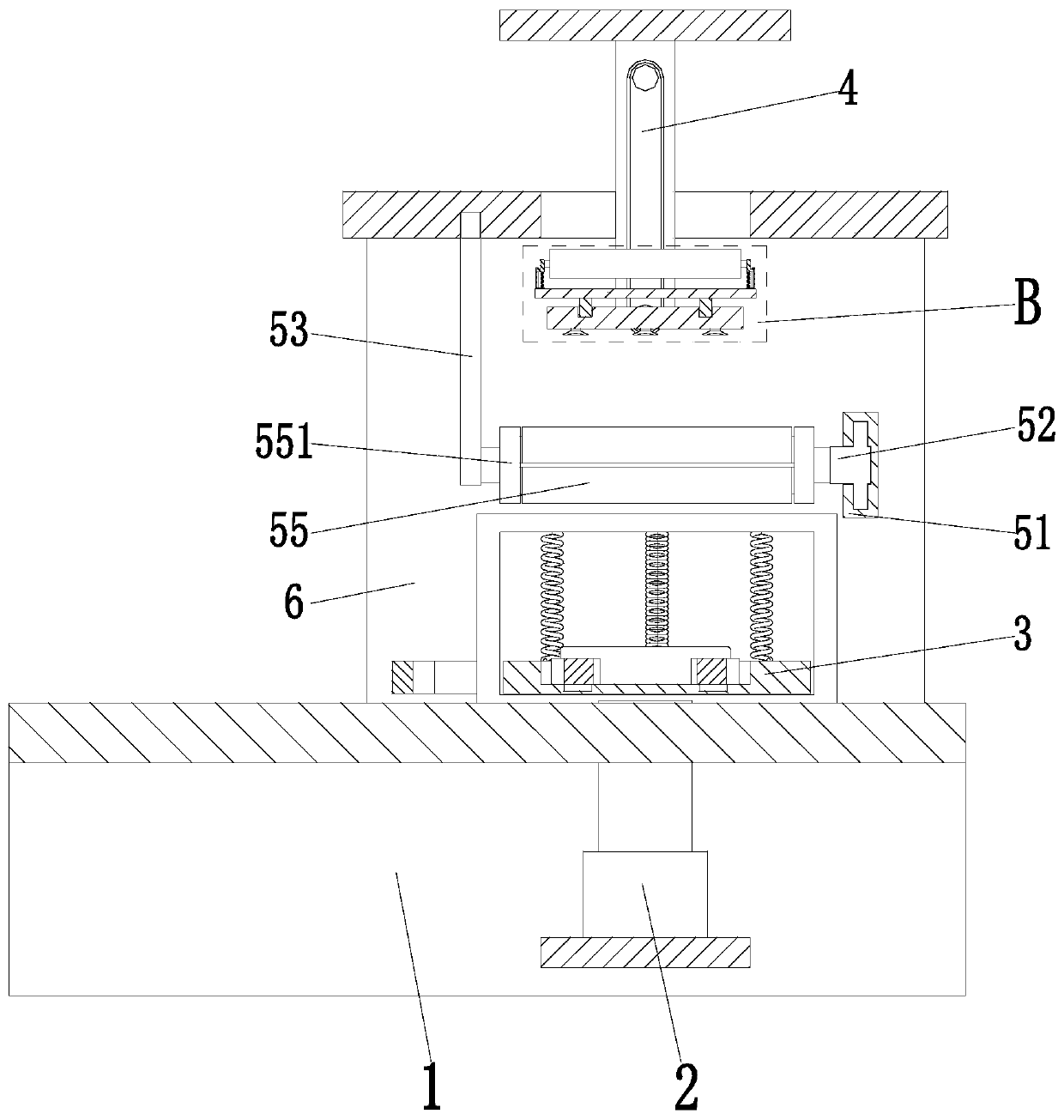

Film mounter and film mounting method thereof

InactiveCN105947280AQuality improvementAchieve regulationPackagingOptical elementsTectorial membraneSemi automatic

The invention discloses a film mounter and a film mounting method thereof. The film mounter comprises a film tearing device, a film mounting device and a plate feeding device. When the film mounter is used, plastic adhesive tape is wound on the film tearing device and moves at intervals, the sides, provided with protecting membranes, of films are attached to the plastic adhesive tape at intervals through a film feeding mechanism, vacuum is formed in a vacuum suction nozzle, and negative pressure is formed at the bottom of a film mounting bottom plate so as to adsorb the film on a film tearing plate onto the position under the film mounting bottom plate; under the cooperation of two correction assemblies, the position of the film is adjusted, people only need to place an LCD plate on a sliding block of the feeding device to achieve limiting, a wiping part is used for wiping the surface of the LCD plate, under the control of a fourth air cylinder, the sliding block automatically moves to the position under the film mounting bottom plate, high pressure is formed in the vacuum suction nozzle, and the LCD plate is covered with the film on the film mounting bottom plate; and in the resetting process of the fourth air cylinder, a first rubber sleeve on a rolling rod rolls the film, and the semi-automatic film mounting process of the LCD plate is achieved.

Owner:江苏华东文化科技融资租赁有限公司

Atomization assisting CVD thin film deposition method

ActiveCN109440083AAdjust gas atmosphereAdjust the atmosphereLiquid/solution decomposition chemical coatingChemical vapor deposition coatingGas phaseRoom temperature

The invention discloses an atomization assisting CVD thin film deposition method. The atomization assisting CVD thin film deposition method is characterized by comprising the following steps that a, an atomization assisting CVD thin film deposition device is designed; b, a plane substrate being about to form a film is placed in an installing hole in a substrate template, then the substrate template is horizontally placed on the upper plate face of a lower lifting plate, and the position of the lower lifting plate is adjusted; d, after a temperature of a reaction area reaches a preset temperature, firstly an atomization source is opened, and is used for atomizing liquid precursors into aerosol precursors, the aerosol precursors are input into a buffering mixing chamber through carrier gas sent out of the atomization source; and e, after the temperature of the reaction area is close to a room temperature or is 45 DEG C or below, the operation that the precursors are input into the buffering mixing chamber through a gas phase matter inflow pipe and an aerosol inflow pipe firstly stops, then a gas sucking pump is closed, finally, a sealing cover is opened, the substrate template is taken out, and finally a substrate is taken down from the substrate template. The thin film deposition method is high in deposition efficiency, reasonable in process arrangement and high in thin film quality.

Owner:CHONGQING UNIV OF TECH +1

Magnetron sputtering pulse power supply with high starting voltage

InactiveCN101824602AIncrease the starting voltageEliminate load voltage oscillationsVacuum evaporation coatingSputtering coatingSputteringAnomaly detection

The invention discloses a magnetron sputtering pulse power supply with high starting voltage, which comprises a DC input, a high-voltage starting module, a pulse generating module and a follow current module which are connected in turn, wherein the follow current module is connected with a substrate and a target in a magnetron sputtering device; the high-voltage starting module is connected with an abnormal detection module, and is used for providing a starting voltage of 1,500V for a magnetron sputtering process; the pulse generating module is used for generating pulse bias voltage; the follow current module is used for solving the problem that the output voltage produces large oscillation due to the special property of a plasma load during pulse magnetron sputtering; and the abnormal detection module is used for detecting the change of plasma load current and performing secondary high-voltage startup on the magnetron sputtering process according to the change of the load current when an abnormal condition happens. The power supply structure of the invention has the advantages of improving the ionization rate of plasma in the magnetron sputtering engineering, enhancing the combination strength of a film and a matrix and ensuring a deposition process.

Owner:XIAN UNIV OF TECH

Tempered glass screen protector pasting machine for touch screen surface

The invention provides a tempered glass screen protector pasting machine for a touch screen surface. The machine comprises a U-shaped frame, an auxiliary unit, a fixing device, a screen protector pasting device, an executing device and a limiting frame. The machine can solve the problems mainly existing during manual screen protector pasting that the position of a screen protector does not corresponds to the position on a mobile phone in the manual screen protector pasting process, deviation exists, and attractiveness and application are influenced; the pasted tempered glass screen protector easily generates bubbles, and utilization is affected; the screen protector is likely to fall off in the using process; in the manual screen protector pasting process, a screen of the mobile phone needs to be subjected to dust removal, cleaning is always not thorough, and fingerprints are easily left in the cleaning process.

Owner:广州市帝麦思电子科技有限公司

Film laminating machine

ActiveCN107380519ASimple structureImprove film application efficiencyPackagingEngineeringTransfer mechanism

The invention relates to a film laminating machine which is used for laminating protective films onto workpieces and further corresponds to a conveying belt and a material collecting mechanical arm. The film laminating machine comprises an overturning mechanism, a transfer mechanism and a film laminating mechanism. The overturning mechanism comprises a first base, a rotating shaft installed on the first base, an adsorption assembly which is connected with one end of the rotating shaft and used for adsorbing the workpieces, a gear which is connected with the other end of the rotating shaft and a first driving assembly used for driving the gear to rotate. The transfer mechanism comprises a second base, a linear guide rail installed on the second base, a carrier which is in sliding fit with the linear guide rail and used for bearing the workpieces, and a second driving assembly used for driving the carrier to slide. The adsorption assembly adsorbs the workpieces from the conveying belt, the rotating shaft drives the adsorption assembly to be overturned, a robot carries the workpieces on the adsorption assembly onto the carrier, and the workpieces with the films being laminated are taken from the carrier onto the conveying belt. The film laminating efficiency is improved on the basis that film laminating quality is guaranteed.

Owner:GUANGDONG EVERWIN PRECISION TECH

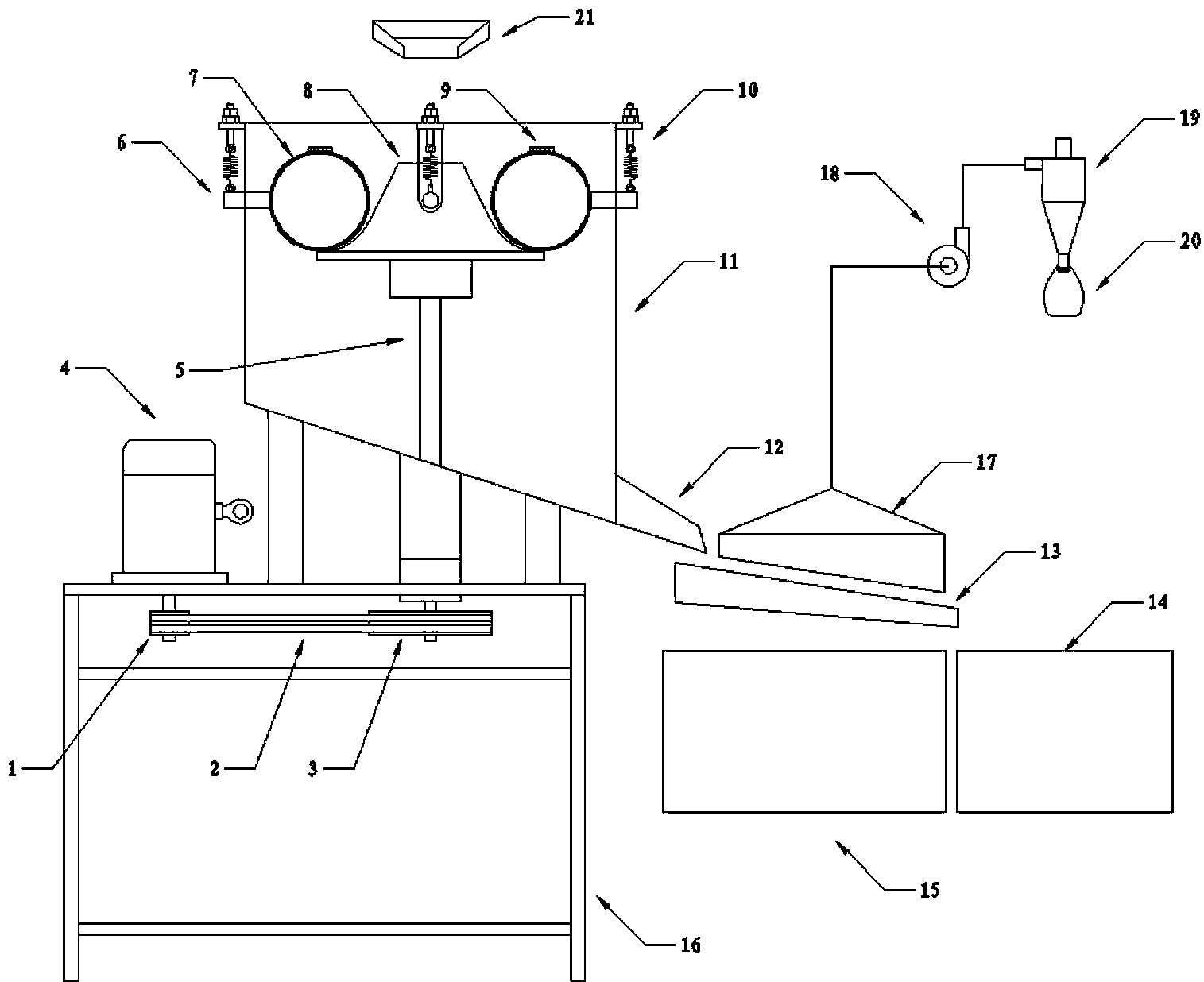

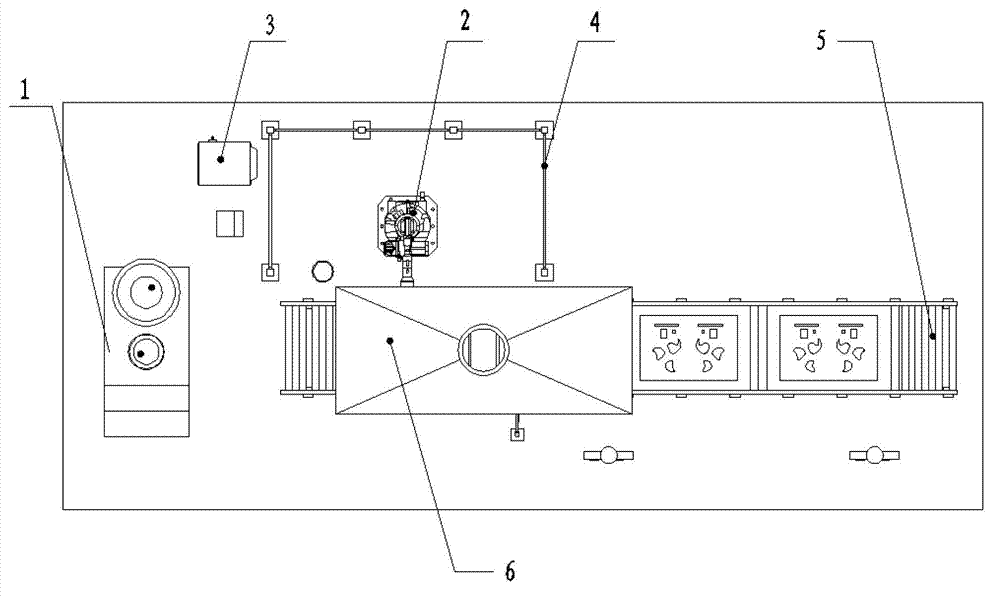

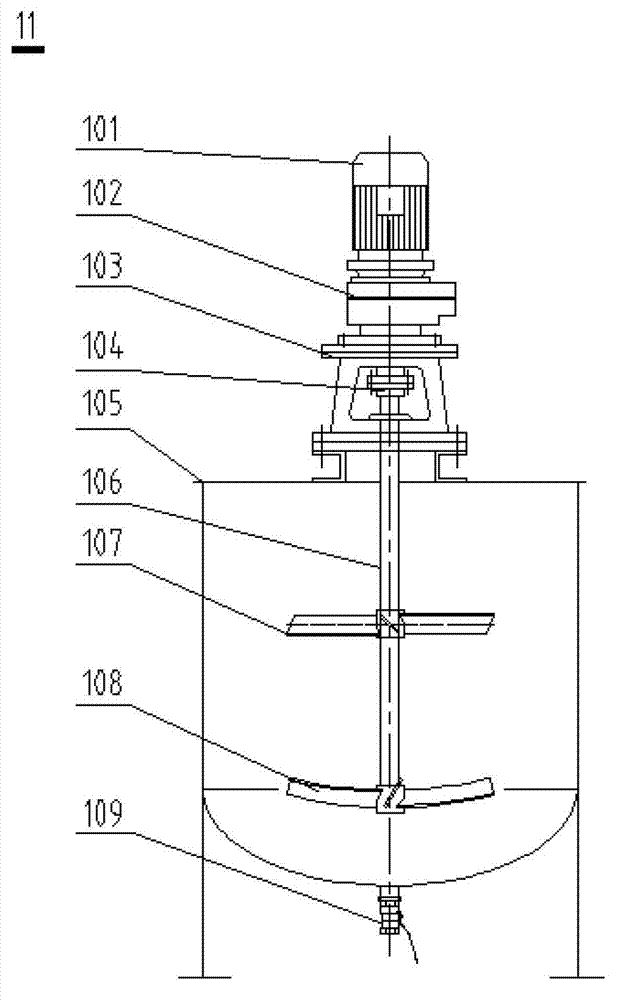

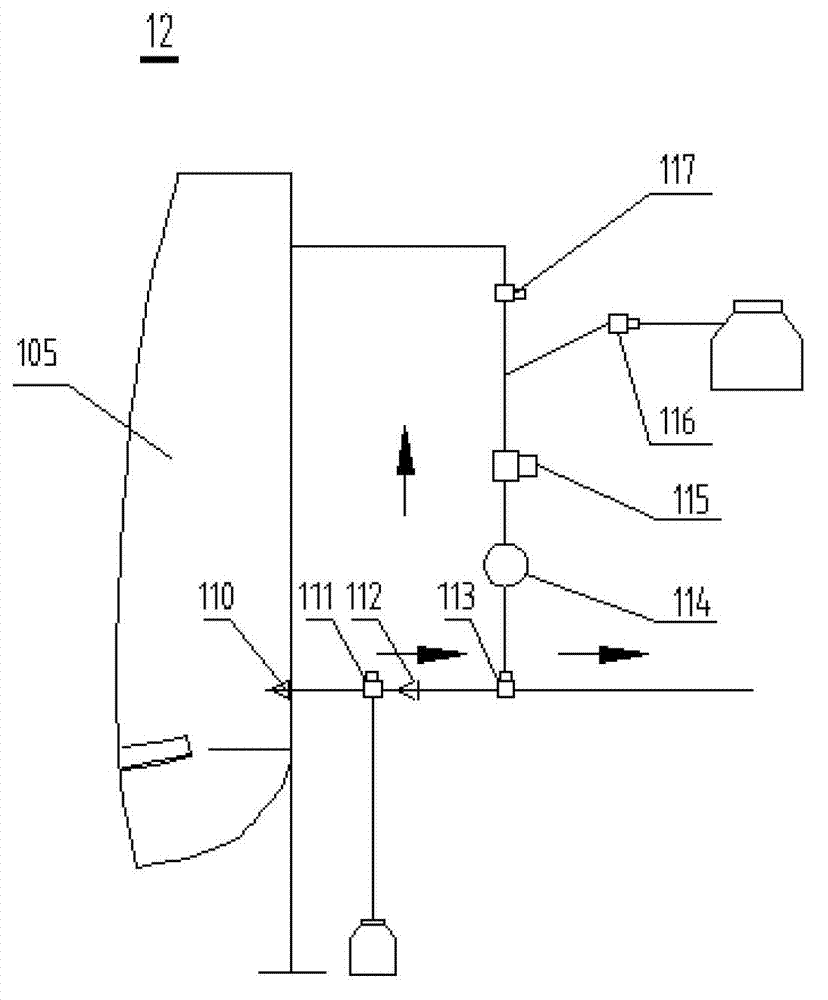

Robot automatic spray system used for quick drying mould coating

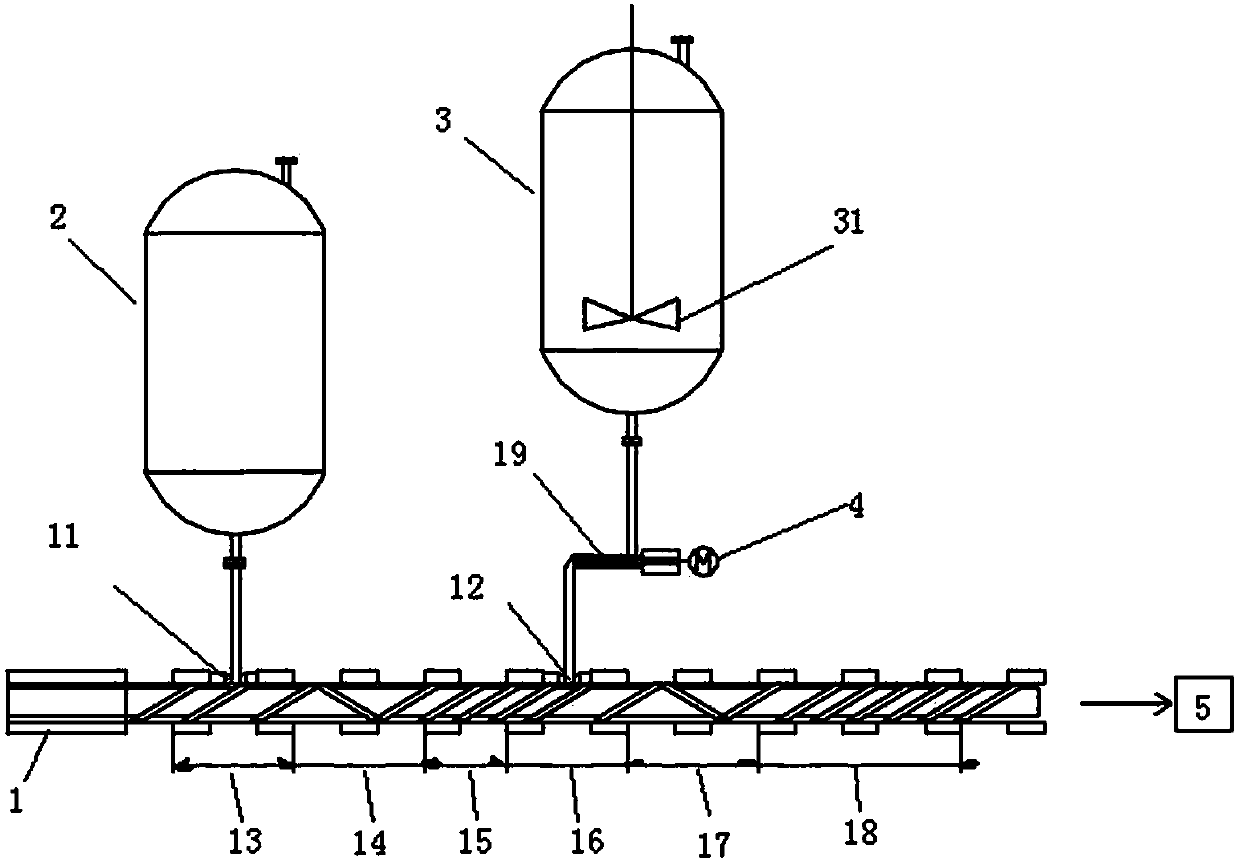

ActiveCN103240209AGuaranteed film qualityAccurate angleLiquid spraying apparatusFiltrationRobot control

The invention discloses a robot automatic spray system used for quick drying mould coating. The robot automatic spray system comprises a robot, a robot control cabinet, a mould conveying roller way and an automatic spray system. The robot is arranged beside the mould conveying roller way. Commands of the robot control cabinet are received by the robot to start the automatic spray system working. The automatic spray system comprises a coating stirring module, a cycling filtration module, a spraying module and a cleaning module. By the aid of industrial robot spraying, automation of spraying operation is improved, and the technical defects such as easiness in floating coating depositing and caking are overcome; alarm processing functions are provided when spraying jams or flow is insufficient, and rejection rate is reduced; and different teaching paths are remembered by the robot, different moulds can fit with the spraying system, and flexibility and use ration are improved.

Owner:CHANGSHA CTR ROBOTICS

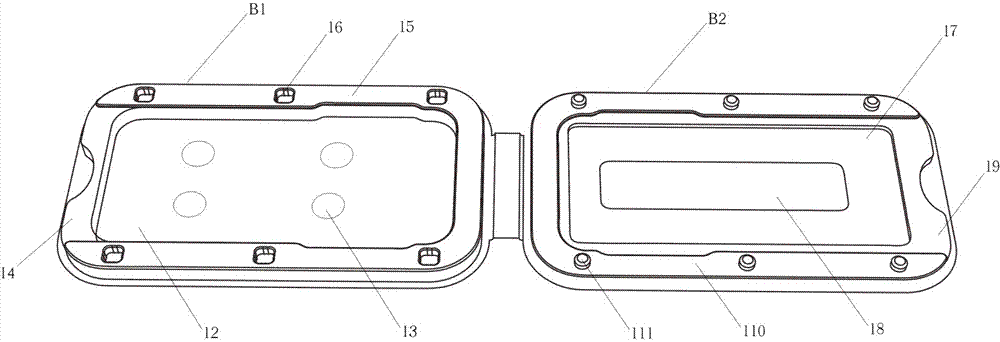

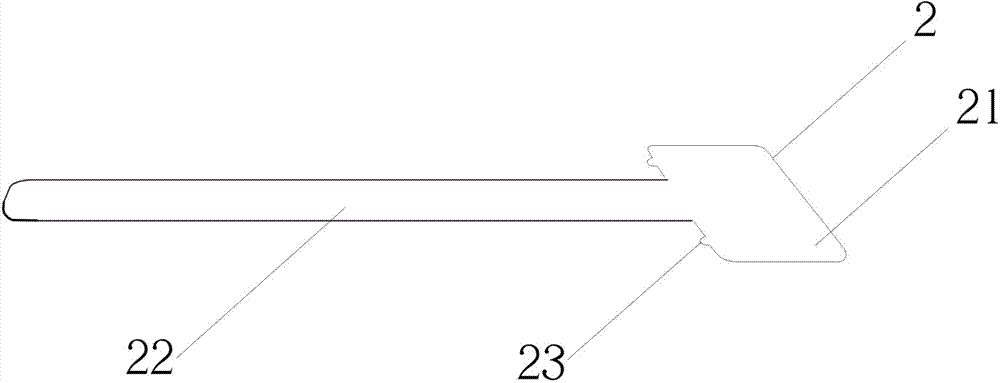

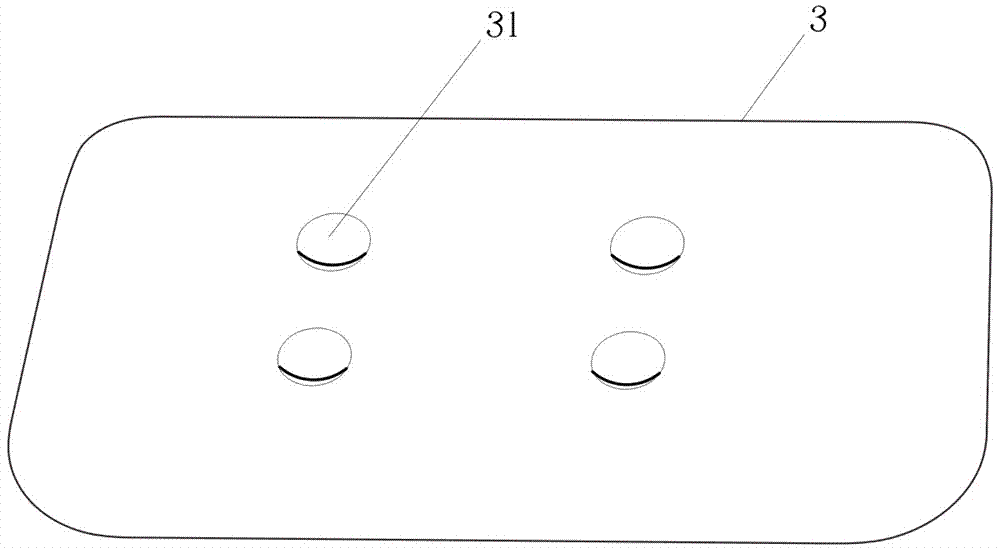

Closed type pasting method and device of screen protection film

The invention discloses a closed type pasting method and device of a screen protection film. The device comprises a base B1, a base B2, a T-shaped drawing pull rod and a cushion which are connected through hinges. The front face of the base B1 is provided with a screen device locating cavity. The front face of the base B1 is provided with a protection film locating cavity. When a screen device and the protection film are located in the cavities respectively and the two bases are closed, a protection film release layer and a dustproof paster are completely pulled out of the closed pasting device by pulling the T-shaped drawing pull rod. The pasting device is arranged on the cushion, the screen device is flatly lifted up and is attached to the protection film, and the protection film is pressed to be pasted to the screen. The two bases are opened, the screen device is taken out, and a scraper is used for scraping the protection film until the protection film is completely pasted to the screen. Locating is accurate in the pasting process, bubbles can not be generated between a product layer and a panel screen, dust and other impurities can not be clamped between the product layer and the panel screen, the pasting operation is simple and convenient, time and effort are saved, and the pasting quality can be guaranteed no matter the closed type pasting device is operated by a green hand or an experienced person.

Owner:王旭辉

Vacuum automatic film pasting all-in-one machine and film pasting method using same

PendingCN111497210AIncrease the scope of applicationEasy to inflateMechanical engineeringMobile phone

The invention discloses a vacuum automatic film pasting all-in-one machine and a film pasting method using the same. The film pasting all-in-one machine is simple in structure and can adapt to mobiledevices (such as mobile phones and tablet computers) with different sizes, so that the application range of the film pasting all-in-one machine is widened; the film pasting method is simple and reliable, and part of manpower is replaced with a machine, so that the film pasting efficiency and the film pasting quality are improved; in the film pasting process, a film pasting mechanism is inflated while a clamping space is vacuumized, so that the air pressure in the film pasting mechanism is larger than the air pressure in the clamping space, inflation is easier, the film pasting mechanism can more easily and more accurately paste a film onto mobile equipment, and the film pasting quality is guaranteed; and besides, in the film pasting all-in-one machine and the film pasting method using thesame, by arranging fixing piece positioning columns used for hanging a film fixing piece and the film fixing piece used for fixing the film, it can be guaranteed that the film does not make contact with the mobile equipment to be pasted with the film firstly before film pasting, and therefore the film pasting quality is guaranteed.

Owner:东莞市博亦德科技实业有限公司

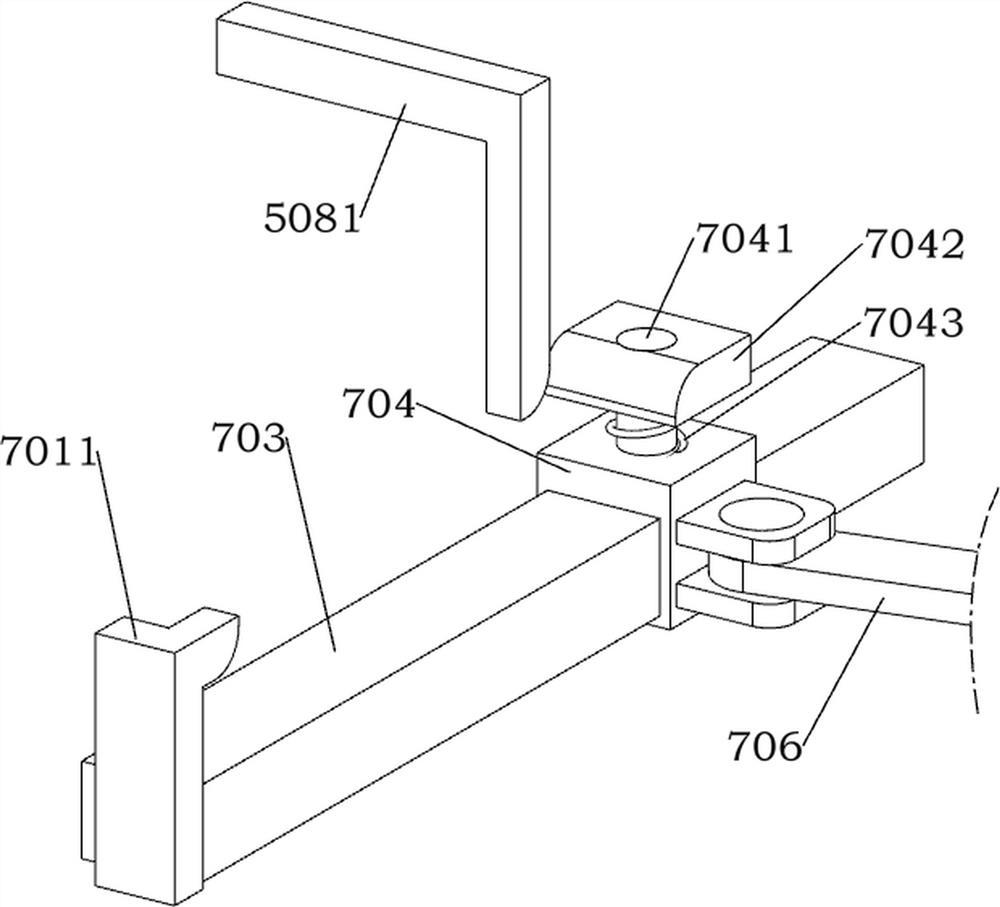

Wireless charging accessory film coating equipment

PendingCN110615136AEasy to operateReduce labor intensityWrapping material feeding apparatusEngineeringFilm coating

The invention provides wireless charging accessory film coating equipment. The wireless charging accessory film coating equipment comprises a rack. A material suction and coating device, a stripping device, a carrier table assembly, a first discharge assembly, a material pulling mechanism and a debubbling assembly are arranged on the rack. The material suction and coating device comprises a material suction assembly, a first rectilinear module for driving the material suction material to move in the X-direction, a second rectilinear module for driving the first rectilinear module to move in the Y-direction and a detection assembly matched with the material suction assembly. The wireless charging accessory film coating equipment disclosed by the invention realizes automatic film coating onwireless charging accessories, is easy and convenient to operate, low in labor intensity, high in film coating precision, good in quality and high in stability and reliability, is not likely to causedefects such as contamination to products, improves the production efficiency and the product yield, effectively saves manpower and time and reduces the cost.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

Array substrate and preparation method thereof

ActiveCN102637698AImprove conductivityShorten the production cycleSolid-state devicesSemiconductor/solid-state device manufacturingSiliconNanotechnology

The invention discloses an array substrate and a preparation method thereof. The array substrate comprises a substrate, gate electrodes, a gate insulating layer, a silicon island, source drain electrodes, a passivation layer and pixel electrodes, wherein two layers of conductive structures separated from each other through insulating media are connected by virtue of a connecting part, and the conductive structure below the connecting part and the insulating media is formed through a primary composition technology with a halftone or grey tone. According to the invention, the preparation technology of the array substrate is simplified.

Owner:BOE TECH GRP CO LTD +1

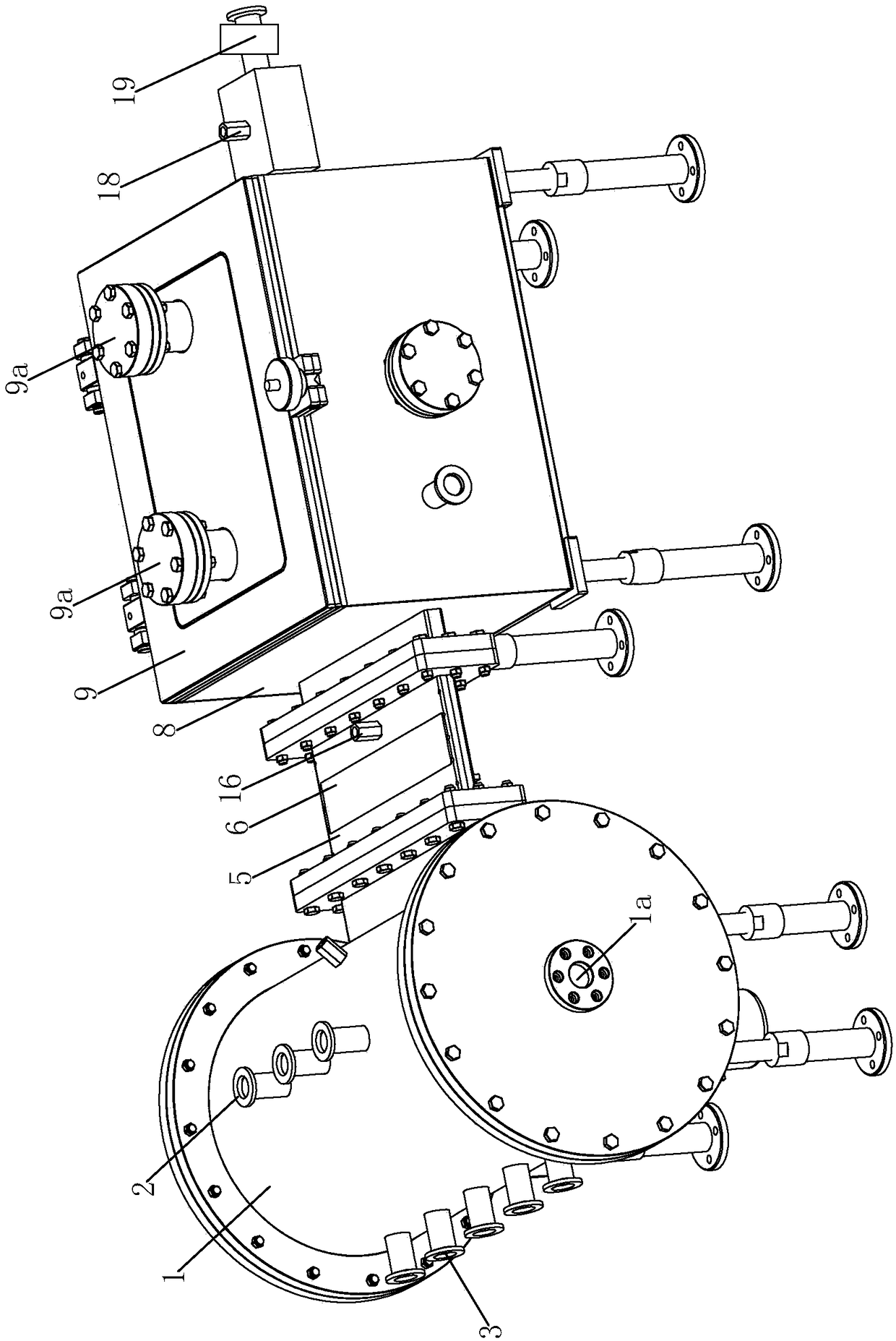

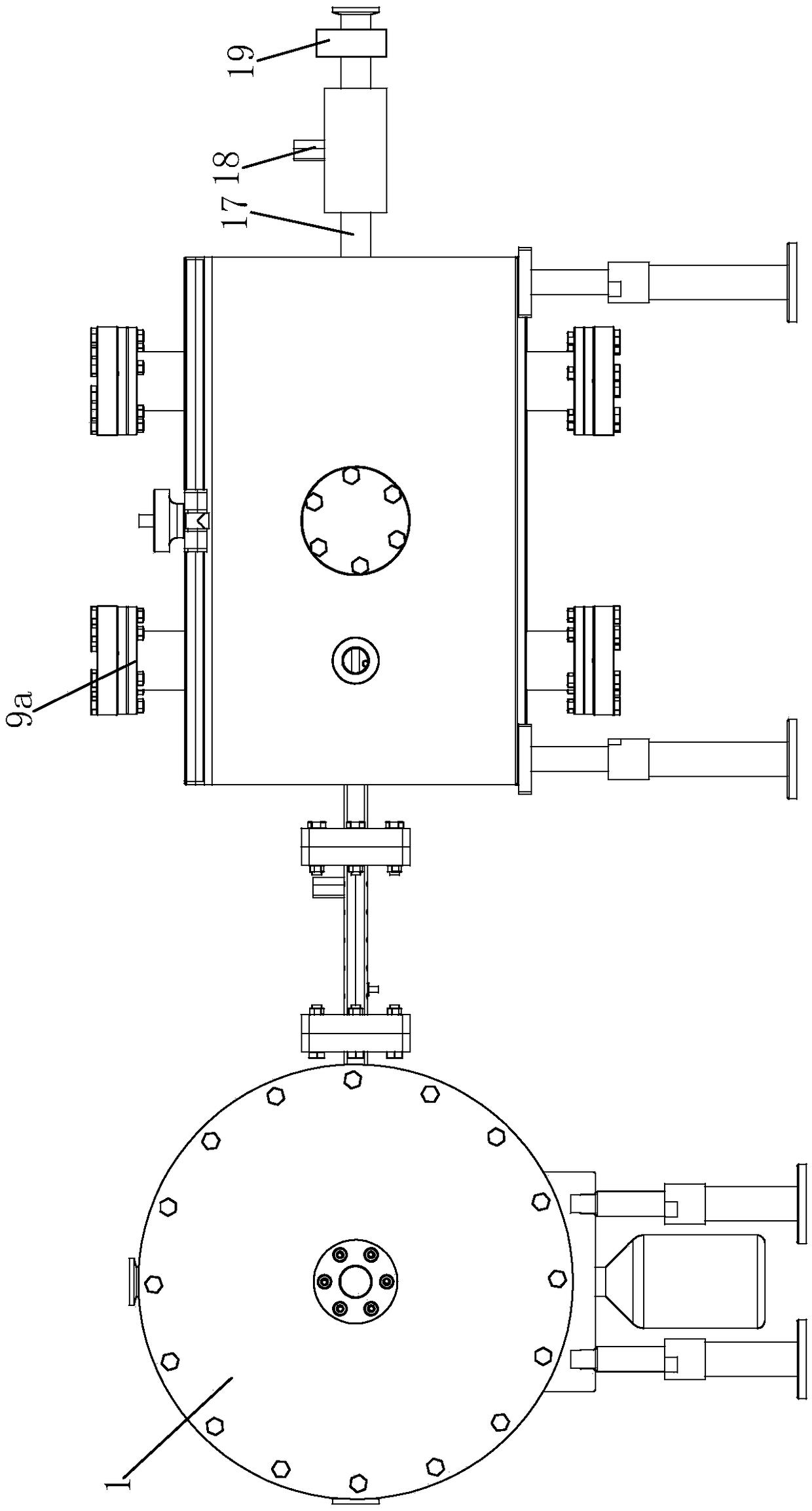

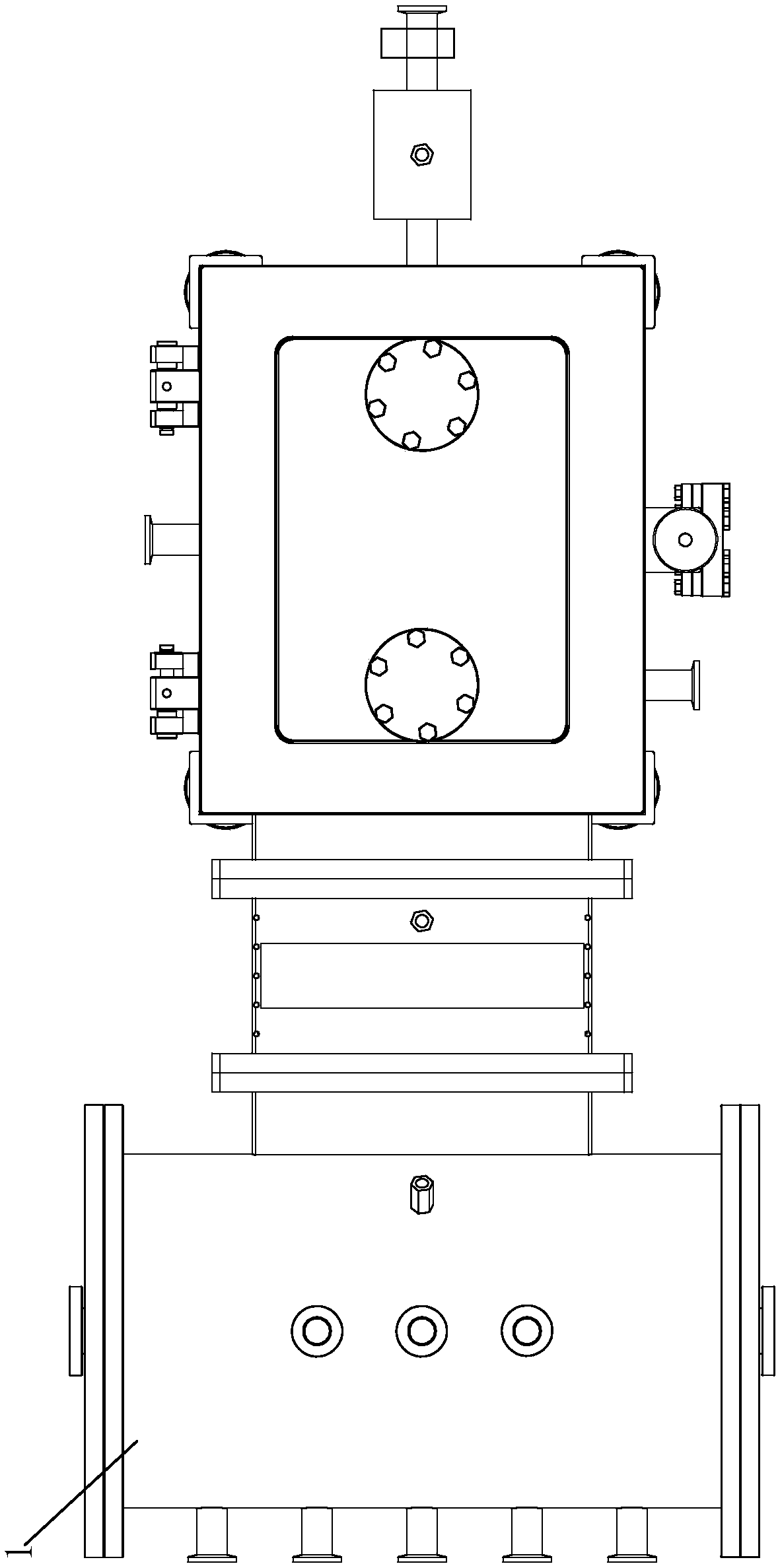

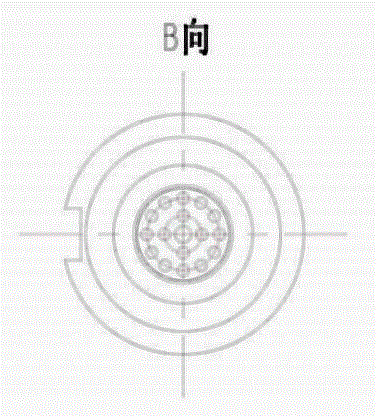

Vertical PECVD compound PVD vacuum coating system

PendingCN109055911AGuaranteed Film QualityRealize industrializationVacuum evaporation coatingSputtering coatingIonizationVacuum pumping

The invention discloses a vertical PECVD compound PVD vacuum coating system. The vertical PECVD compound PVD vacuum coating system comprises a feeding cavity, a preheating cavity, a coating cavity, abuffer cavity and a discharge cavity, wherein the feeding cavity, the preheating cavity, the coating cavity, the buffer cavity and the discharge cavity are tightly connected with one another in sequence, the feeding cavity and the discharge cavity are in atmospheric environment. The preheating cavity, the coating cavity and the buffer cavity are connected with a vacuum pumping system. A rail is welded to the top of the coating cavity, and a base material frame is connected in the rail in a sleeving mode. A base plat is hung on the base material frame through hooks, the bottom of the base plateis located on a conveying belt, and the conveying belt is connected to the bottom of the coating cavity through drive rollers. The existing problem that poor uniformity and low ionization rate of thin film coated by a coating device in the prior art is solved.

Owner:苏州善柔真空科技有限公司

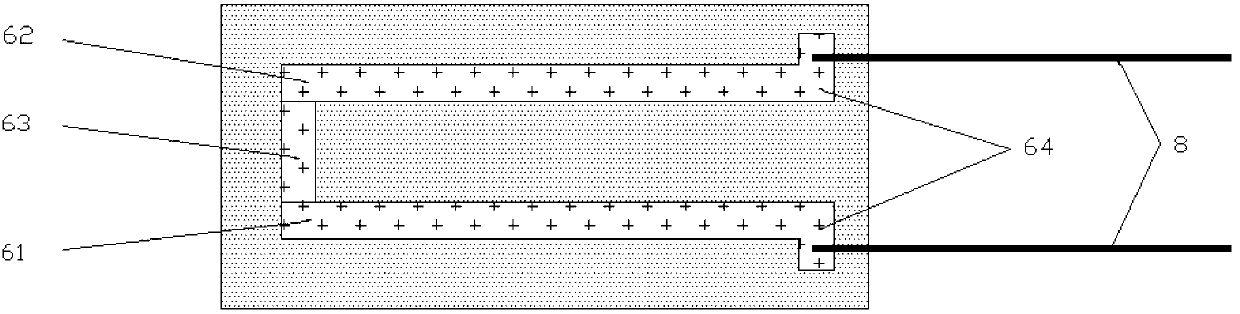

OLED flexible laminating device and laminating process thereof

PendingCN109755419AReduces fit bubblesImprove fit qualitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringHeight difference

The invention discloses an OLED flexible laminating device and a laminating process thereof. The device comprises a laminating bracket, a laminating linear module, a laminating linear sliding seat, alaminating lifting motor, a laminating mounting seat, a laminating weight elimination cylinder, a laminating lifting seat and a laminating head, wherein the laminating bracket is arranged at the rearend of a frame; the laminating linear module is arranged on the upper part of the laminating bracket; the laminating linear sliding seat is arranged on the laminating linear module along the directionperpendicular to the laminating linear module; the laminating lifting motor is arranged on the upper part of the laminating linear sliding seat; the laminating mounting seat is arranged on the otherside of the laminating linear sliding seat, the laminating weight elimination cylinder is arranged in the laminating mounting seat, and the output end is connected with the laminating head; and the laminating lifting seat is slidably arranged on the side wall at one side of the laminating linear sliding seat. According to the scheme of the invention, the height difference forms at the two ends ofan adhesive film strip, so that the FILM membrane and an OLED membrane are in linear contact, laminating bubbles are effectively reduced, and the angle change during lamination of the FILM membrane iscontrolled through the up-down adjustable film pressing roller, so that the separation of the FILM membrane can be prevented.

Owner:SHENZHEN ETMADE AUTOMATION EQUIP

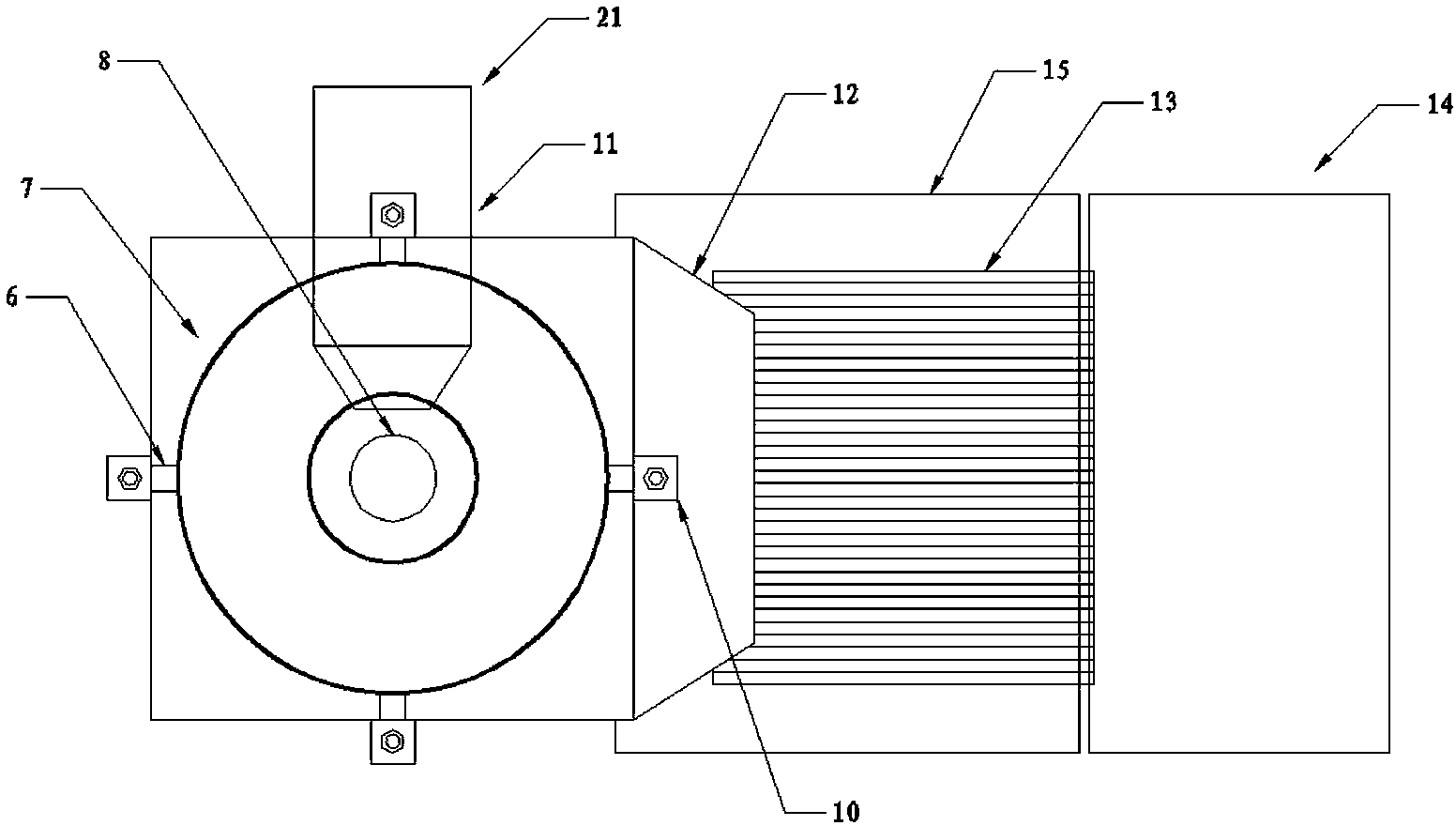

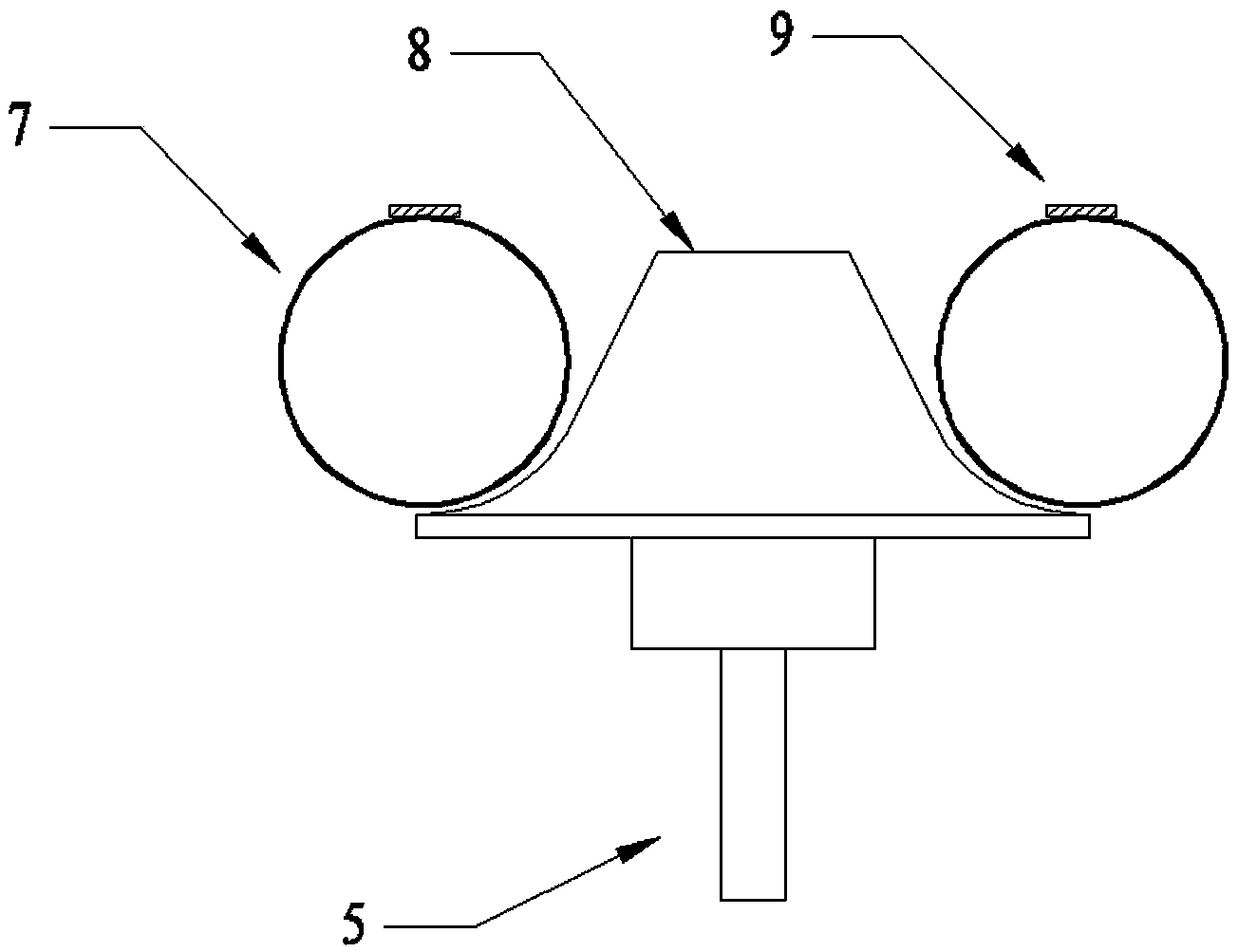

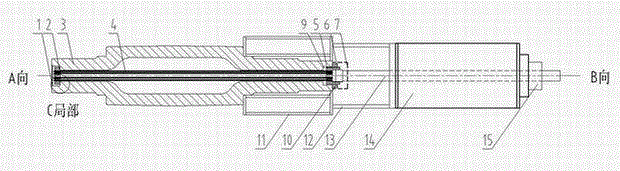

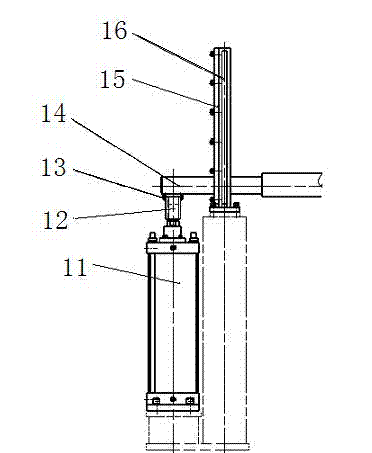

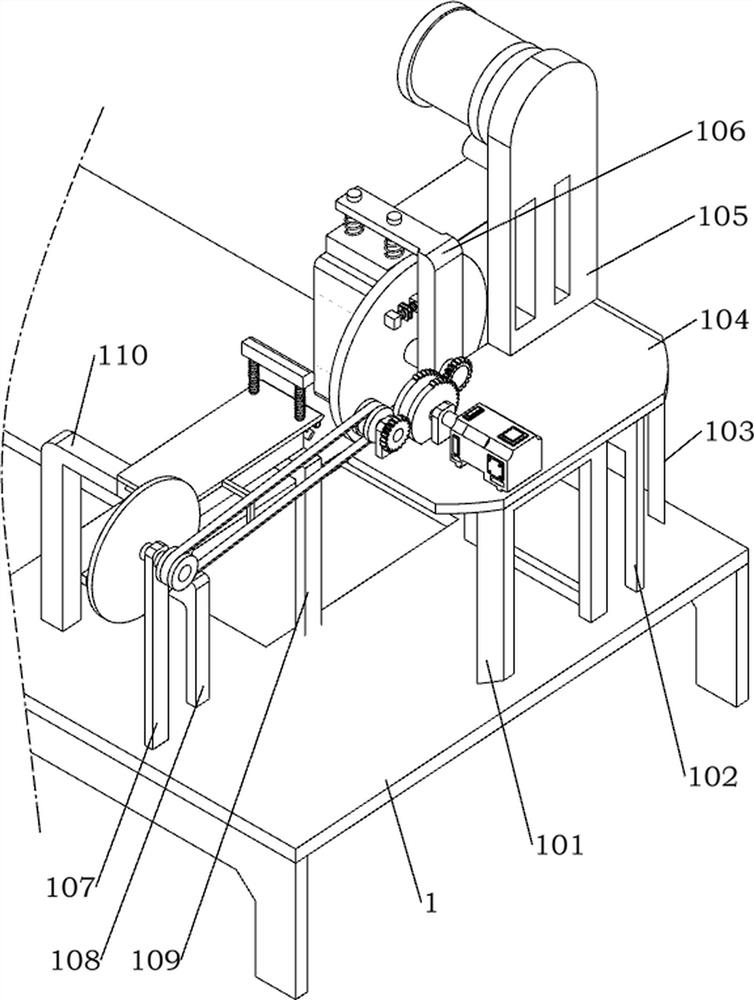

Manufacturing method for prestressed chilled cast iron roll

The invention relates to the field of rubber-plastic machinery, specifically to a manufacturing method for a prestressed chilled cast iron roll used for rubber-plastic mastication and mixing. The manufacturing method for the prestressed chilled cast iron roll comprises the working flow of manufacturing a prestressed upset-head anchorage-cable assembly and tensioning the prestressed upset-head anchorage-cable assembly by using a center hole jack assembly so as to exert prestress on the chilled cast iron roll. According to the invention, since prestress is exerted on the chilled cast iron roll, the structure of the chilled cast iron roll no long bears radial force caused by rubber-plastic mastication and mixing, so the risk of roll breakage is reduced or eliminated; addition of more rare metals for improvement of the structure of the chilled cast iron roll is not need, so manufacturing cost is reduced; meanwhile, a common model casting method can be adopted, so manufacturing difficulty and cost are reduced. Moreover, since the prestress is exerted on the chilled cast iron roll and can be adjusted according to the rubber variety, formula and process for mastication, bending moment suffered by the chilled cast iron roll is balanced, and a roll surface is guaranteed to be parallel at the same time, so yielding quality of the rubber-plastic mastication is reliably guaranteed.

Owner:SUZHOU SHIHAO BUILDING MATERIAL NEW TECH ENG

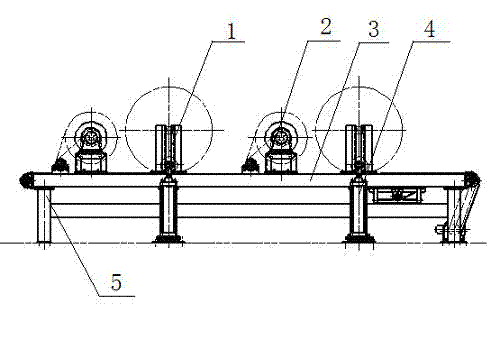

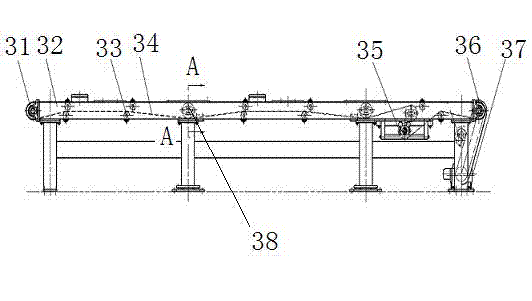

Surface coiling device for automatically adjusting weight of coil

ActiveCN102502296AGuaranteed film qualityRealize automatic adjustmentWebs handlingSurface coilMechanical engineering

Owner:大连橡胶塑料机械有限公司

Preparation technique of nanoparticle composite material film for welding

The invention relates to the technical field of preforming welding material, and particularly discloses a preparation technique of a nanoparticle composite material film for welding; the technique includes steps of material mixing-vacuum defoamation- curtain coating and film formation-drying and curing-after-treatment. The preparation technique is featured by simple and feasible practice, strong controllability, high efficiency, and low cost; the technique can effectively guarantee the component of the prepared nanoparticle composite material film, uniform and stable dimension, excellent processing performance and high reliability of low-temperature sintering and welding; the preparation technique can be widely applied to the field of preforming welding material.

Owner:SOLDERWELL MICROELECTRONIC PACKAGING MATERIALS CO LTD

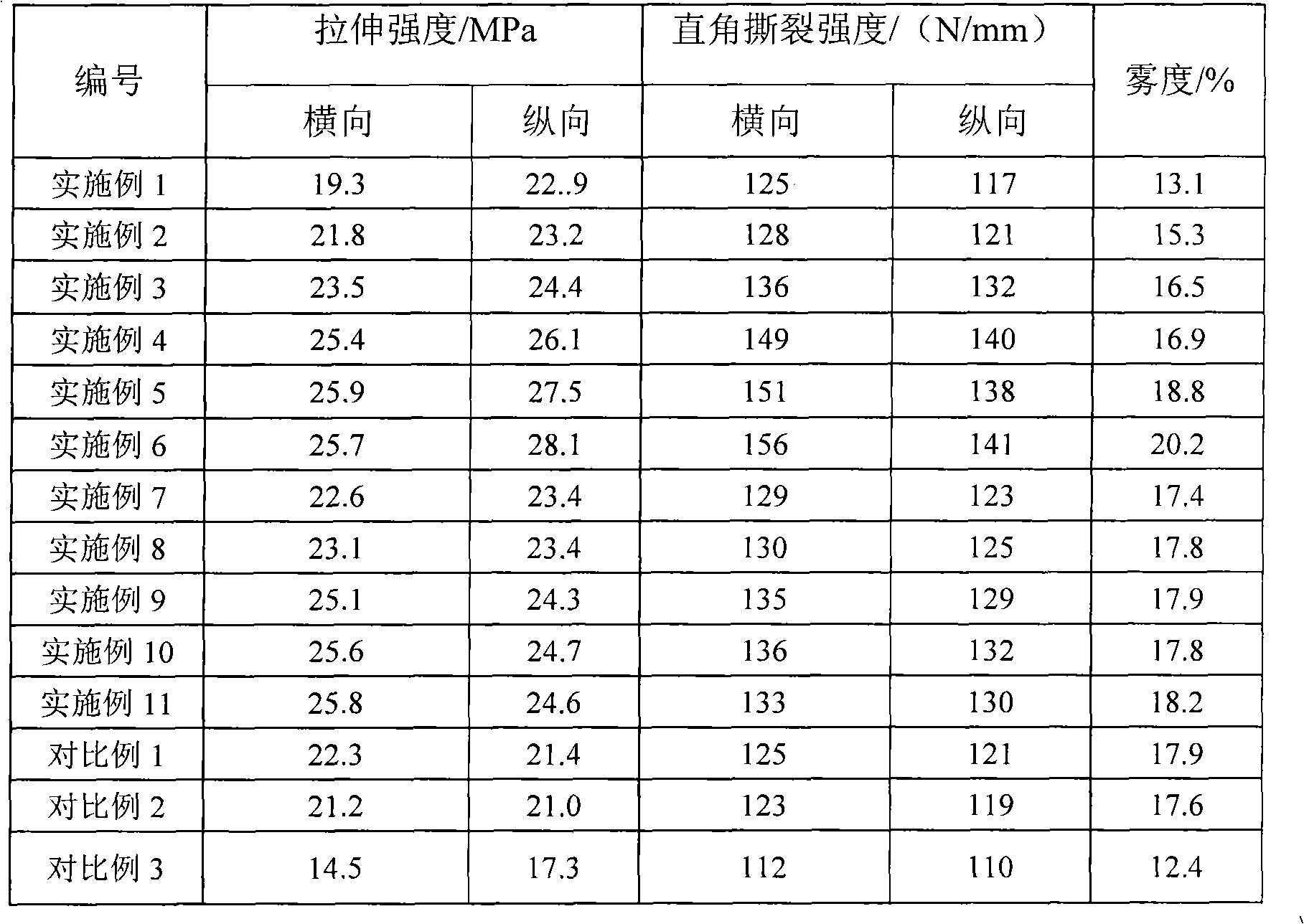

Production device and preparation method of glass fiber reinforced polyimide film

InactiveCN104191627AImprove product qualityImprove mechanical propertiesFlat articlesCoatingsProduction lineGlass fiber

The invention discloses a production device and a preparation method of a glass fiber reinforced polyimide film. The production device comprises a double-screw extruder, a PAA (polyamic acid) solution storage tank at the front part and a glass fiber storage tank at the rear part, wherein the double-screw extruder is provided with a front side feeding port connected with the PAA solution storage tank and a rear side feeding port connected with the glass fiber or powder storage tank; the double-screw extruder is provided with a front feeding section and a rear feeding section; the front side feeding port is formed in the front feeding section; a front mixing section and a front conveying section are sequentially arranged at the rear part of the front feeding section; the rear side feeding port is formed in the rear feeding section; a rear mixing section and a rear conveying section are sequentially arranged at the rear feeding section; and the front conveying section is located at the front part of the rear feeding section. With the adoption of the double-screw extruder structure, mounting space of a production line is compact, diversity of a resin formula is improved, and product production efficiency and product quality are improved.

Owner:LAIWU ZHONGTIAN INSULATING MATERIAL

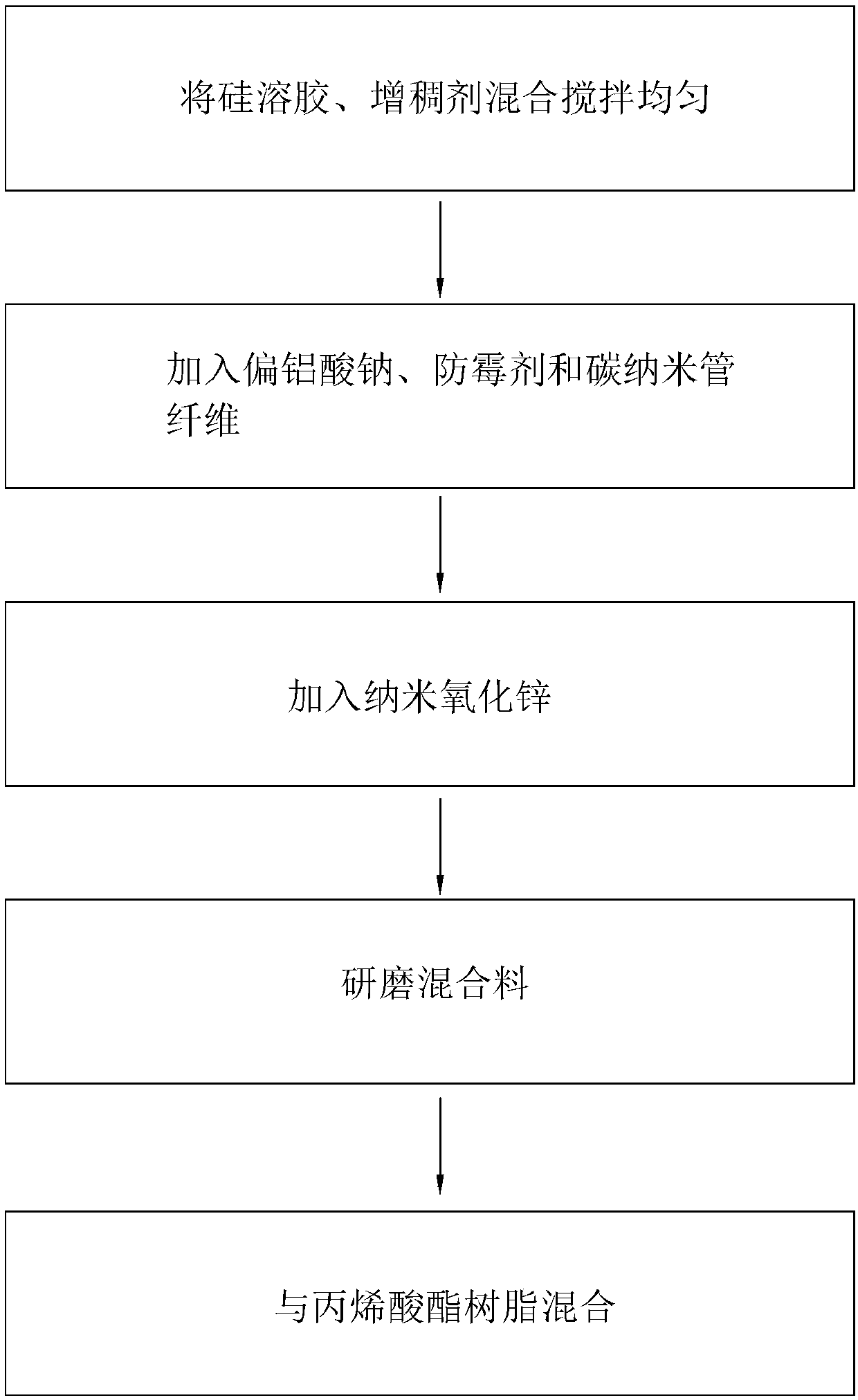

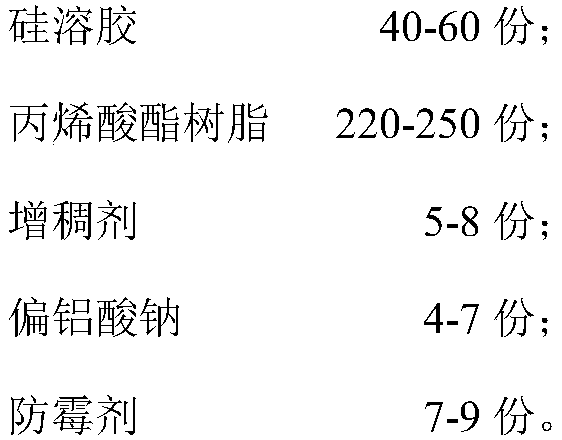

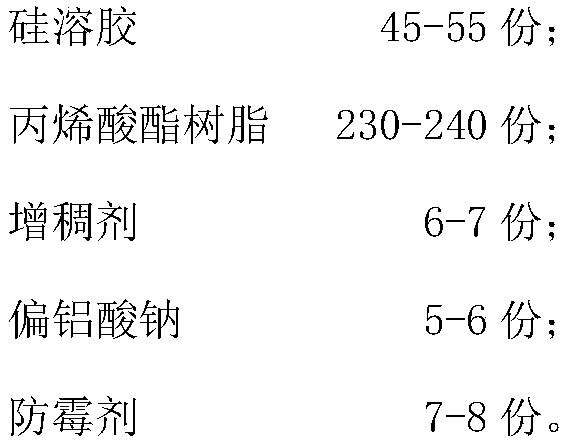

Coating method and preparation method of wall finish for underground space decoration

InactiveCN109679424AImprove adhesionImprove performanceAntifouling/underwater paintsPaints with biocidesCalcium silicateAcrylic resin

The invention discloses wall finish for underground space decoration. The wall finish is prepared from the following raw materials in parts by weight: 40-60 parts of silica sol, 220-250 parts of acrylate resin, 5-8 parts of a thickening agent, 4-7 parts of sodium metaaluminate and 7-9 parts of a mildewproof agent. Silica sol particles are ultrafine, can penetrate into a base layer through the capillary action of the wall surface and can react with calcium hydroxide in the concrete base layer to generate calcium silicate, and thus coating has high bonding force. When moisture in the silica solevaporates, colloidal ions firmly adhere to the surface of an object, and silica-oxygen bonded reticular membrane structures are formed between the particles. The silica sol can be mutually complemented with the characteristics of the acrylic resin, and thus the composite coating with excellent properties can be prepared. The sodium metaaluminate reacts with the silica sol in a silica sol system,thus a layer of zeolite film is formed on the surface of a paint film, the zeolite film is provided with a porous structure and has high catalytic activity, and the effect of the mildewproof agent oninhibiting and killing mold can be improved. The wall finish has the characteristic of good environmental protection while having a mildewproof effect.

Owner:温州市东日建筑装饰工程有限公司

Digital tube film pasting and cutting equipment

PendingCN107756531AGuaranteed film qualityNo manual cuttingPackagingMetal working apparatusEngineeringKnife blades

The invention discloses digital tube film pasting and cutting equipment which comprises a base. The base is provided with a film pasting platform, the middle of the film pasting platform is provided with two parallel limiting strips in the length direction, a limiting groove is formed between the two limiting strips, a push block is movably arranged in the limiting groove, the push block is connected with a first air cylinder and driven by the first air cylinder to slide in the limiting groove, a film supply mechanism, a rolling mechanism, a cutting mechanism and a limiting plate arranged at the end of the limiting groove are sequentially arranged above the sliding groove in the conveying direction of digital tubes, the cutting mechanism comprises a tool rest straddling the limiting grooveand a blade arranged on the tool rest, the tool rest is provided with a tool slot, the two sides of the blade are in sliding fit with the tool slot, and the blade is driven by a second air cylinder to move up and down along the tool slot. The digital tube film pasting and cutting equipment has the advantages that accurate cutting can be automatically achieved after film pasting, and digital tubefilm pasting efficiency is improved.

Owner:JIANGMEN PENGJIANG AREA JINGHUI ELECTRONICS SCI & TECH CO LTD

Heat insulation material for interior and exterior walls, and preparation method thereof

InactiveCN108359374AGood adhesionIncrease stickinessPolyurea/polyurethane coatingsReflecting/signal paintsSlurrySilicon dioxide

The invention belongs to the technical field of heat insulation coatings, and concretely relates to a heat insulation material for interior and exterior walls, and a preparation method thereof. A nano-slurry is innovatively added to a heat insulation coating based on the prior art, the nano-slurry adopts a silica nano-slurry, the silica has a good film-forming property and a low heat conductivity,and can assist heat conduction obstruction, and the nano-slurry has a good adhesion and a good viscosity, so the heat insulation material for interior and exterior walls has the advantages of easiness in dyeing and decorating and good heat insulation effect when applied indoors.

Owner:江苏翔鹭节能科技有限公司

Mobile phone charger film wrapping device with positioning function

ActiveCN113264211AInhibit sheddingPrecise positioningWeb rotation wrappingCircular discMobile charge

The invention relates to a film wrapping device, in particular to a mobile phone charger film wrapping device with a positioning function. The mobile phone charger film wrapping device with the positioning function comprises a bottom frame, a first supporting leg, a second supporting leg, a third supporting leg, a transverse supporting plate and the like, wherein the first supporting leg, the second supporting leg and the third supporting leg are fixedly arranged on the upper end face of the bottom frame, and the first supporting leg, the second supporting leg and the third supporting leg support the transverse supporting plate. A first gear is intermittently driven by a second missing gear to rotate, and a clamping disc is indirectly driven to intermittently rotate. A plug hole in the clamping disc is matched with a mobile phone charger plug so that the mobile phone charger plug can be accurately positioned. A charger can be prevented from falling off during film wrapping due to the arrangement of a clamp assembly. The clamping disc can be matched with a cutting device to complete film wrapping of the charger in the rotating process. Compared with manual film wrapping, the mobile phone charger film wrapping device is more stable in film pasting and accurate in film pasting positioning.

Owner:深圳市吉奥科技有限公司

Pre-stress chilled cast iron roll

ActiveCN104589533AEliminates the risk of broken rollsImproving the Structure of Chilled Cast Iron RollsBending momentCast iron

The invention relates to the field of rubber and plastic machinery and concretely relates to a pre-stress chilled cast iron roll for rubber and plastic plastication and mixing. The pre-stress chilled cast iron roll comprises a pre-stress upset head anchorage cable assembly and a chilled cast iron roll. Pre-stress is applied to the chilled cast iron roll and thus the chilled cast iron roll structure does not bear radial load produced by rubber and plastic plastication and mixing so that roll breaking risk is reduced or eliminated, more rare metals for improving the chilled cast iron roll structure are avoided and a manufacturing cost is reduced. A common model casting method is adopted so that manufacturing difficulty and cost are reduced. The pre-stress is applied to the chilled cast iron roll and can be adjusted according to types, formulas and technology of rubber and plastic plastication so that bending moments on the chilled cast iron roll are balanced and roll surface parallelism is guaranteed and thus quality of the produced rubber and plastic sheets is guaranteed.

Owner:新绛县祥和机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com