Array substrate and preparation method thereof

An array substrate and substrate technology, applied in the field of array substrate and its preparation, can solve problems such as unstable electrical conductivity of contact holes, damage to the surface of the medium, complex patterning process, etc., achieve reliable and stable electrical conductivity, ensure film quality, and simplify preparation The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

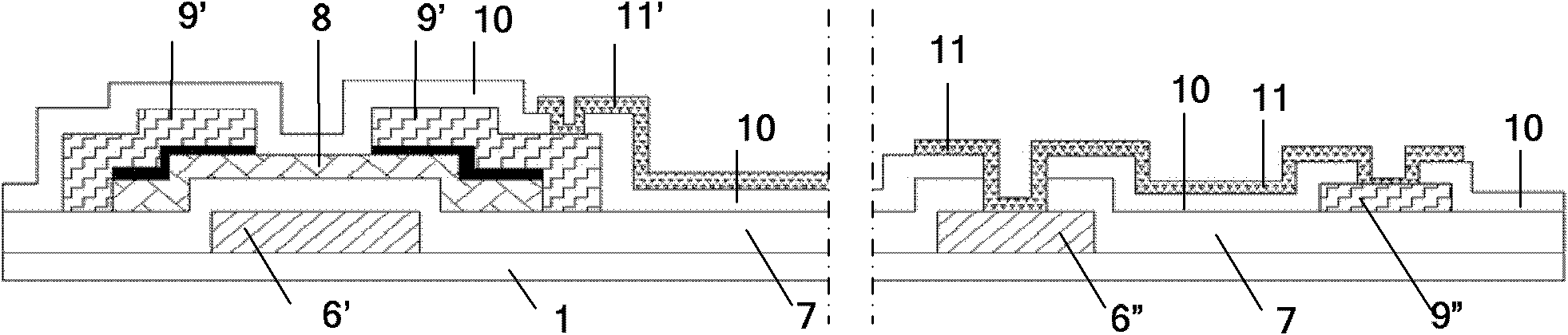

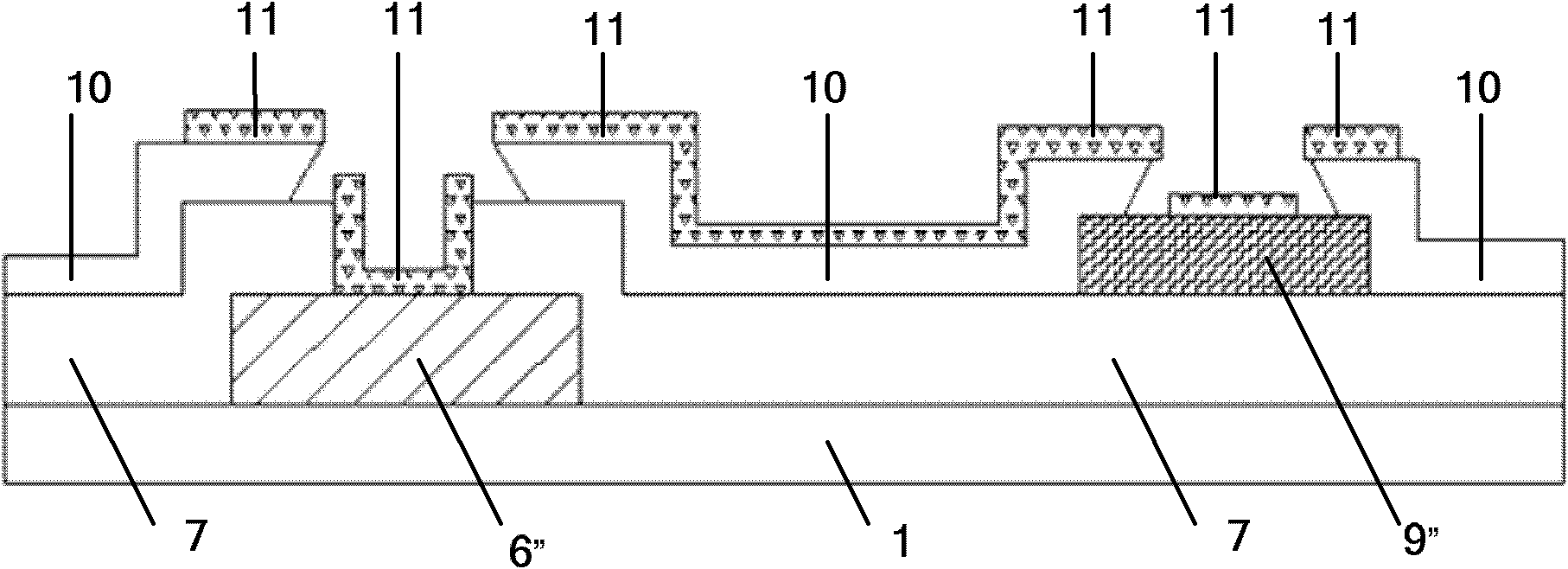

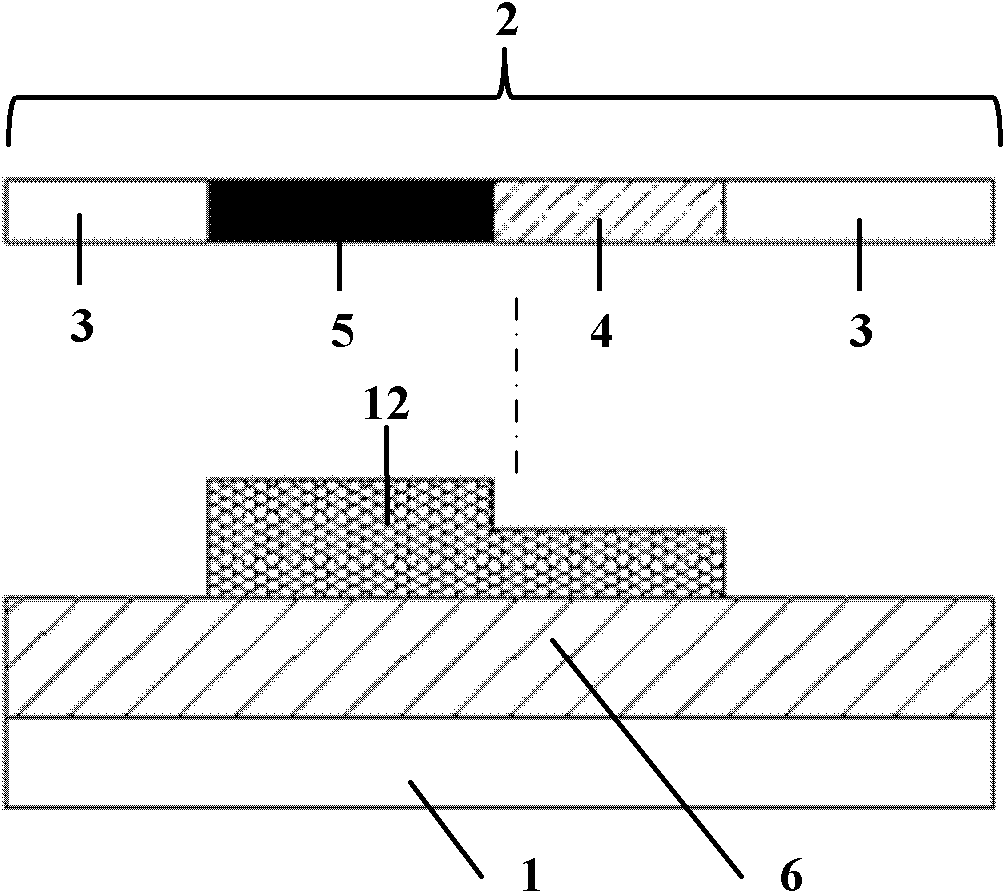

[0041]Those skilled in the art know that in the process of manufacturing a TFT-LCD, it is necessary to perform a patterning process on the film layer according to product design requirements to obtain the required film morphology. That is, apply photoresist on the substrate after film formation, and expose the substrate with a mask plate with the target pattern. The light on the part without pattern on the mask plate can completely pass through, and the properties of the photoresist after being irradiated by light Changes occur, and in subsequent development, the photoresist that is irradiated by light (referring to positive photoresist) is dissolved in the developer solution or the photoresist that is not irradiated by light (referring to negative photoresist) is dissolved in the developer solution , and then etch away the film layer without photoresist protection, and finally peel off the photoresist to form a film layer on the substrate with the same shape as the target patt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com