Surface coiling device for automatically adjusting weight of coil

A technology of automatic adjustment and winding device, which is applied in the direction of winding strips, transportation and packaging, and thin material processing, etc. It can solve the problems affecting the quality of the film, stretching deformation, easy pleating, etc., and achieve the effect of ensuring the quality of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

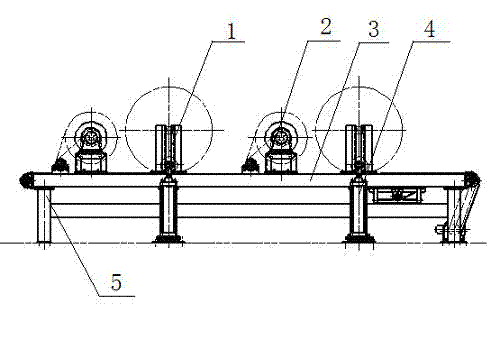

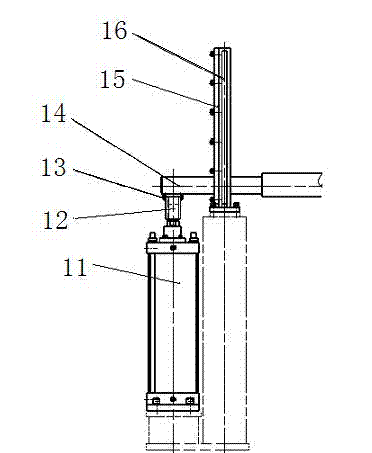

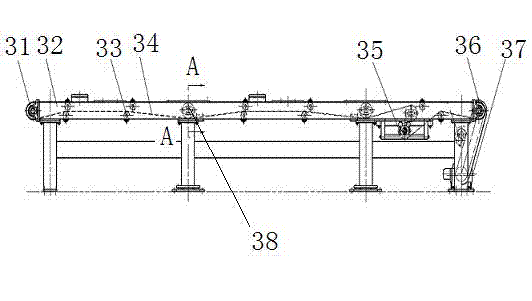

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the surface coiling device for automatically adjusting the coil weight is mainly composed of a coiling part 1, an interlining guide part 2, a belt transport part 3, an air control part 4 and a frame body 5. The coiling part 1, the interlining guide part 2 and the belt transport part 3 are installed on the frame body 5, the air control part 4 is installed on the bottom end of the frame body 5, and the coiling part 1 includes a cylinder 11, a connector 12, a square steel 14, a lining plate 15 and a bracket 16, and the cylinder 11 is connected to the square steel 14 through the connector 12, the square steel 14 is connected to the bracket 16, the liner 15 is installed on the bracket 16, a pad 13 is provided between the connector 12 and the square steel 14, and the lining cloth guiding part 2 includes the left and right brackets , base, safety chuck, magnetic powder brake and deviation correcti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com