Digital tube film pasting and cutting equipment

A technology of cutting equipment and digital tubes, which is applied in metal processing, packaging, instruments, etc., can solve the problems of lower production efficiency, poor operation, and film sticking work changes, and achieve the effects of improving production efficiency, ensuring film quality, and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

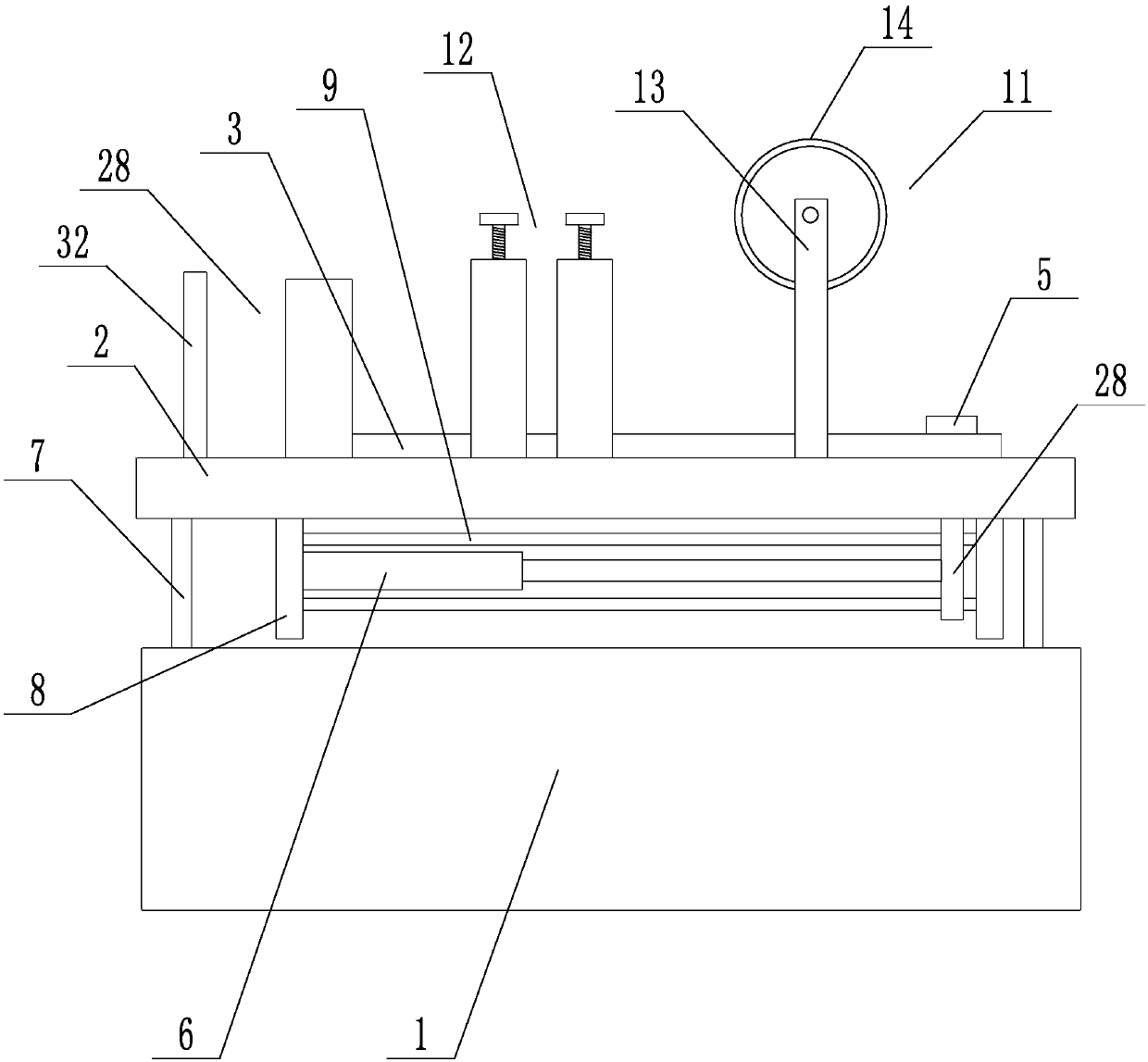

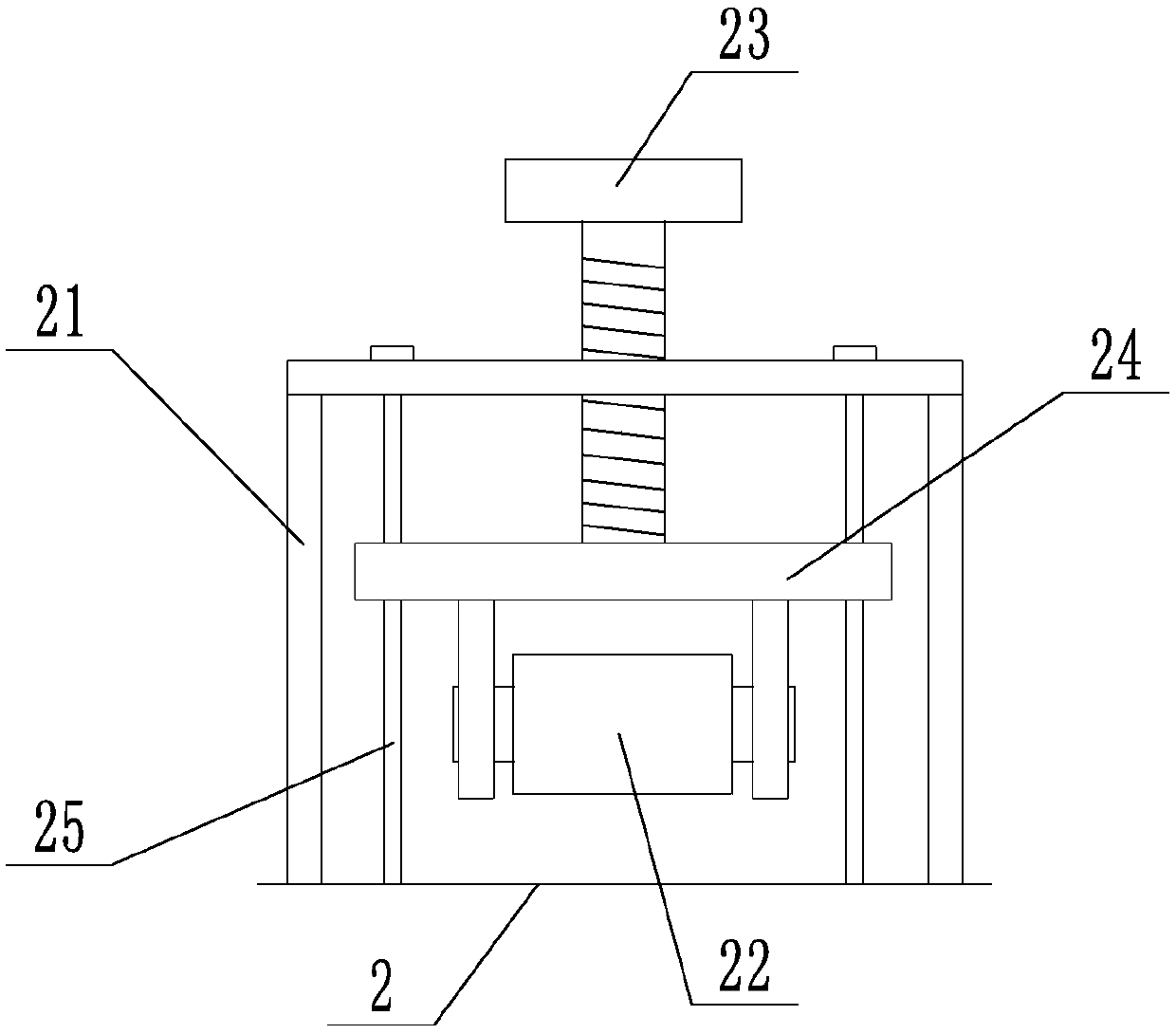

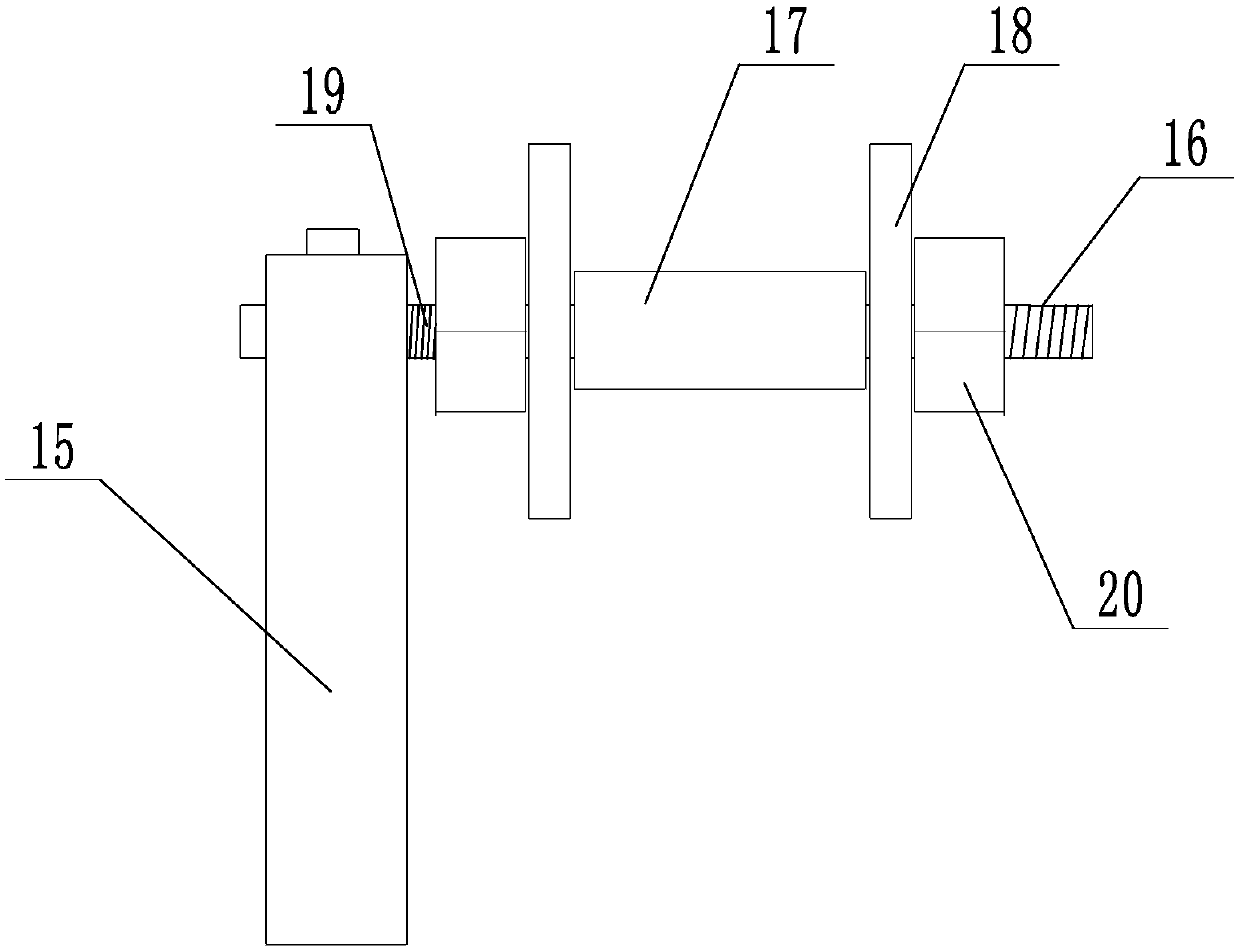

[0022] like Figure 1 to Figure 5 As shown, a nixie tube film sticking cutting equipment includes a base 1, a film sticking platform 2 is arranged on the base 1, and two parallel limit bars 3 are set in the middle of the film sticking platform 2 along its length direction, and the two limit bars 3 There is a limit groove 4 between them. A push block 5 is movable in the limit groove 4. The push block 5 is connected to the first cylinder 6 and driven by the first cylinder 6 to slide in the limit groove 4. Above the chute Along the conveying direction of the nixie tube, there are successively arranged a film feeding mechanism 11 for providing a film, a rolling mechanism 12 for flattening the film and covering it on the surface of the nixie tube, a cutting mechanism 28, and a film set at the end of the limit groove 4. Limiting plate 32, cutting mechanism 28 comprises the knife rest 29 that is arranged on the limit groove 4 tops and the blade 30 that is arranged on the knife rest 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com