Production device and preparation method of glass fiber reinforced polyimide film

A technology of polyimide film and production equipment, which is applied in the direction of flat products, household utensils, and other household utensils, etc. It can solve the problem that the self-supporting strength of film products cannot meet the actual application requirements, poor strength and heat resistance, and film warping and deformation and other issues, to achieve excellent mechanical properties, stable product quality, and reduce warping and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

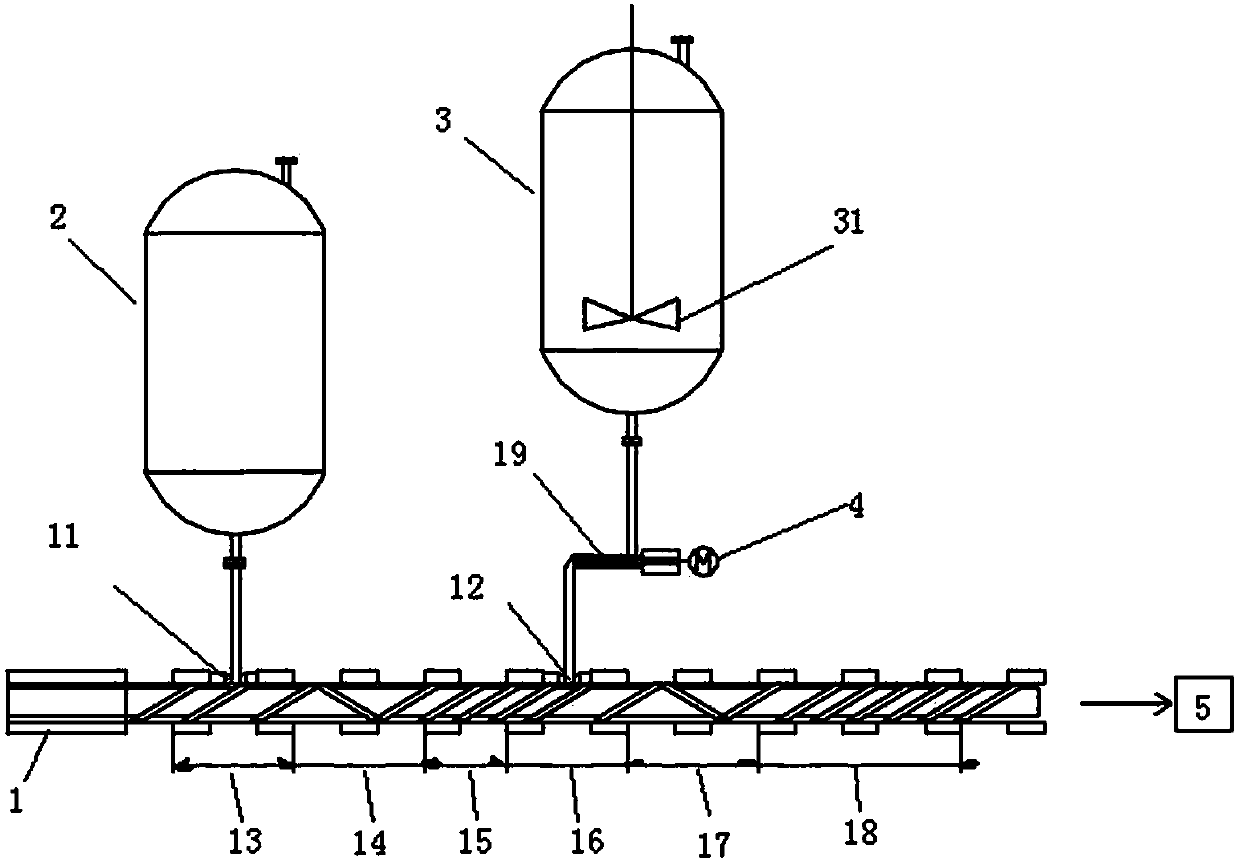

[0027] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

[0028] Such as figure 1 As shown, a production device for glass fiber reinforced polyimide film, comprising a twin-screw extruder 1, a PAA solution storage tank 2 at the front, and a glass fiber storage tank 3 at the rear, the glass fiber storage tank 3 is equipped with There is a low-speed mixer 31, and the twin-screw extruder 1 is provided with a front side feeding port 11 connected with a PAA solution storage tank, and a rear side feeding port 12 connected with a glass fiber or powder storage tank, and the twin-screw extruder The extruder is provided with a front feeding section 13 and a rear feeding section 16, the front side feeding port 11 is located at the front feeding section 13, and the rear part of the front feeding section 13 is successively the front mixing section 14, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com