Coating method and preparation method of wall finish for underground space decoration

A technology of underground space and wall paint, which is applied in the direction of antifouling/underwater paint, coating, paint containing biocide, etc. It can solve the problems of 801 glue pollution, great harm to construction personnel, and long residual time of formaldehyde, etc., to achieve Improve film quality, antibacterial spectrum light, and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for coating a wall paint for underground space decoration, comprising the following steps,

[0039] Step 1: Remove all the original wall paint layer, and then paint the interface agent on the wall;

[0040] Step 2: Paste white glue stickers on the cracks on the wall, then lay grid cloth on the entire wall, and then brush cement mortar until the wall is flat;

[0041] Step 3: First apply a layer of putty on the base layer, then brush the putty on the surface layer twice, and then polish;

[0042] Step 4: First apply a layer of anti-alkali primer, then brush the wall paint twice;

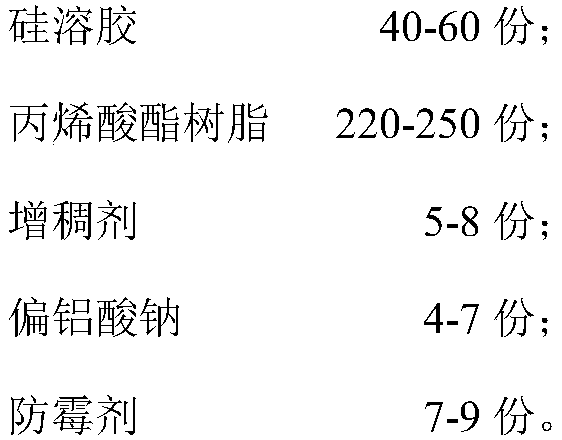

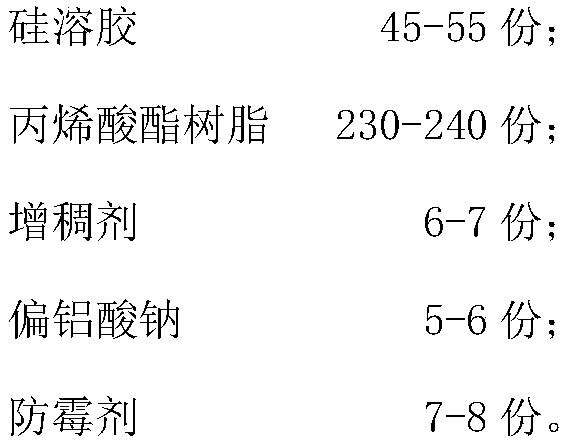

[0043] In parts by weight, the raw material components of the wall paint are shown in Table 1.

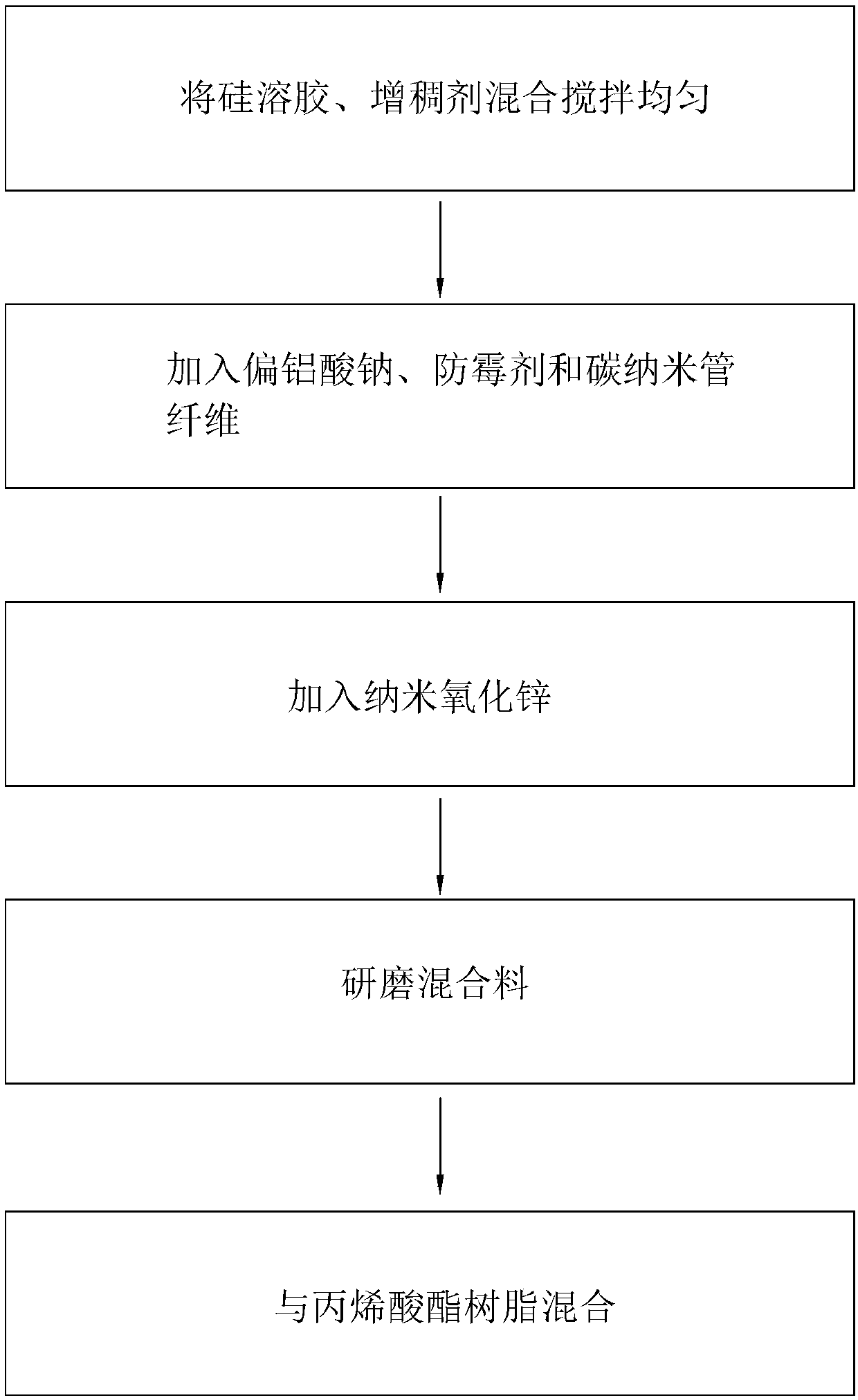

[0044] Wherein, the preparation method of this wall paint comprises the following steps:

[0045] Step 1, add silica sol and thickener to the mixer, mix and stir until uniform, and obtain the compound glue;

[0046] Step 2, continue to put sodium metaaluminate into the agitator, continu...

Embodiment 2

[0052] The difference from Example 1 is that, in parts by weight, the raw material components of the wall paint are shown in Table 1.

Embodiment 3

[0054] The difference from Example 1 is that, in parts by weight, the raw material components of the wall paint are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com