Patents

Literature

133results about How to "Guaranteed filling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

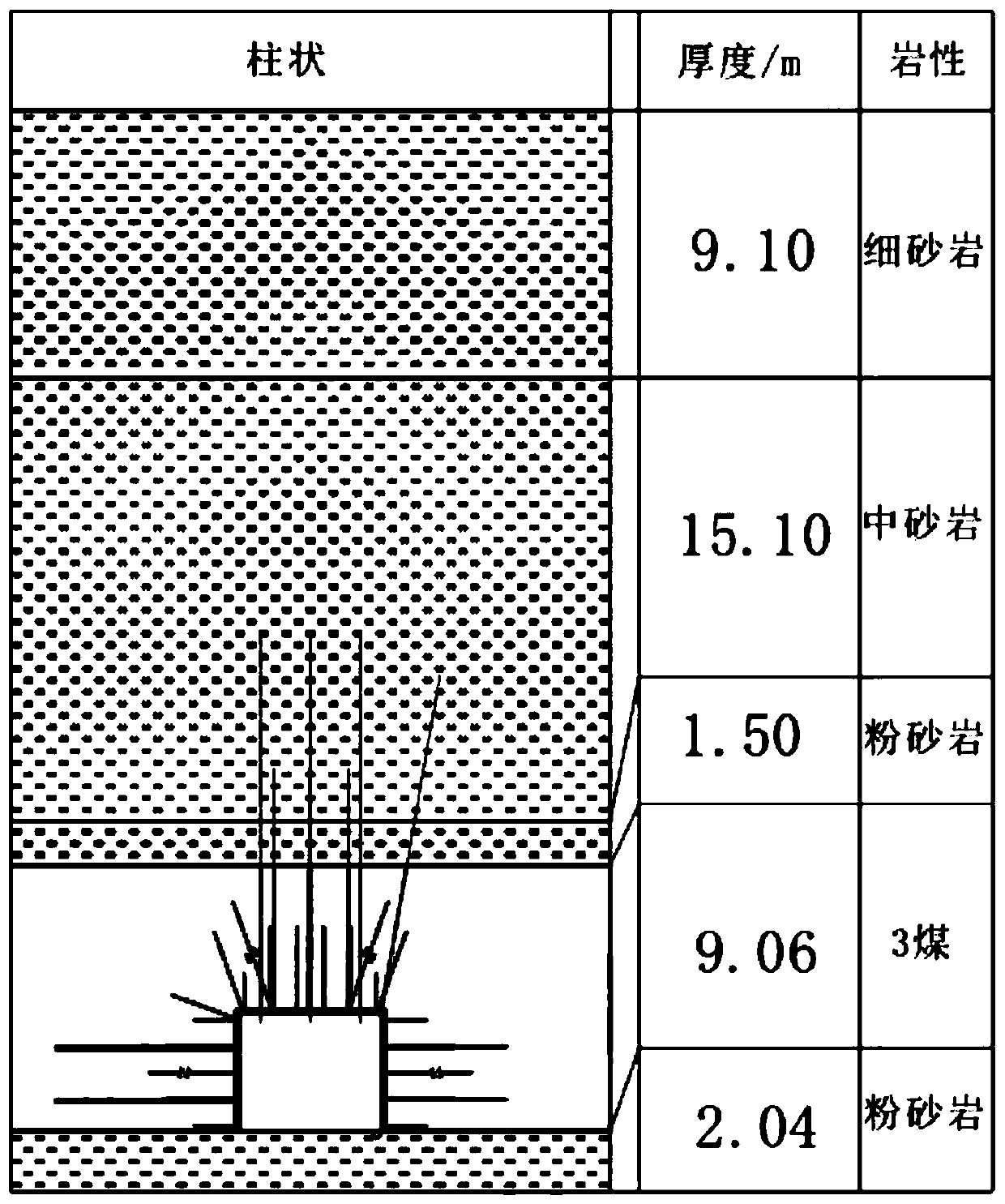

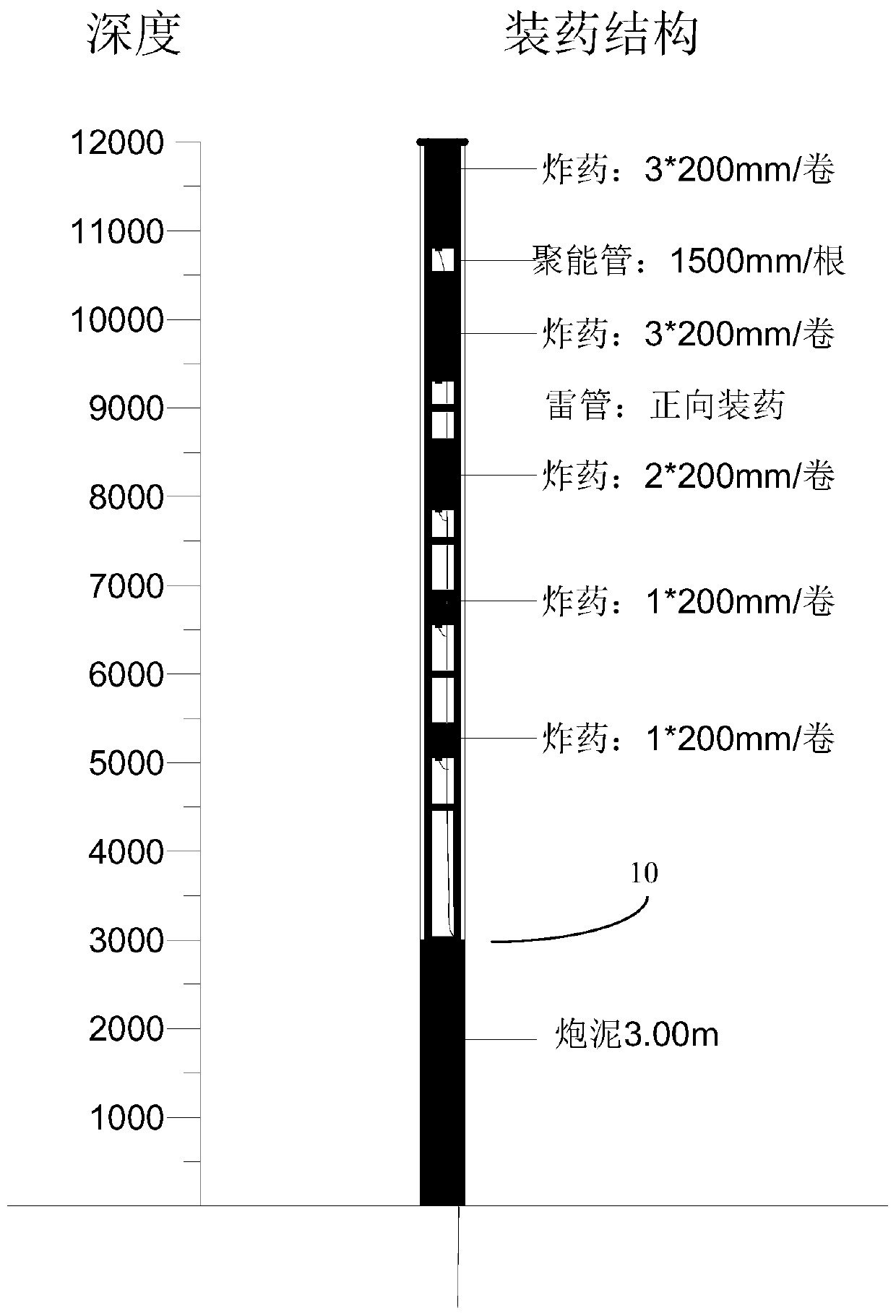

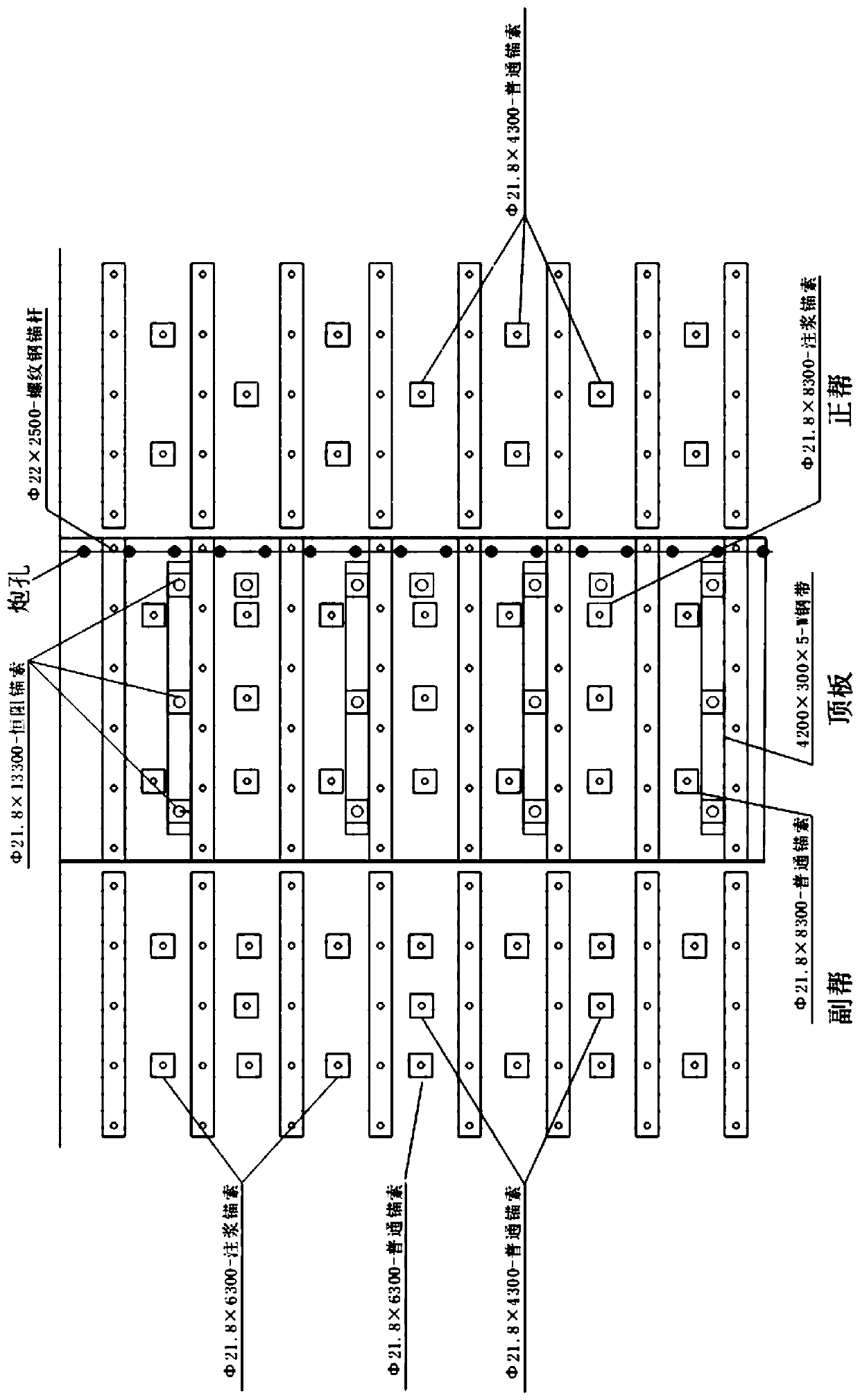

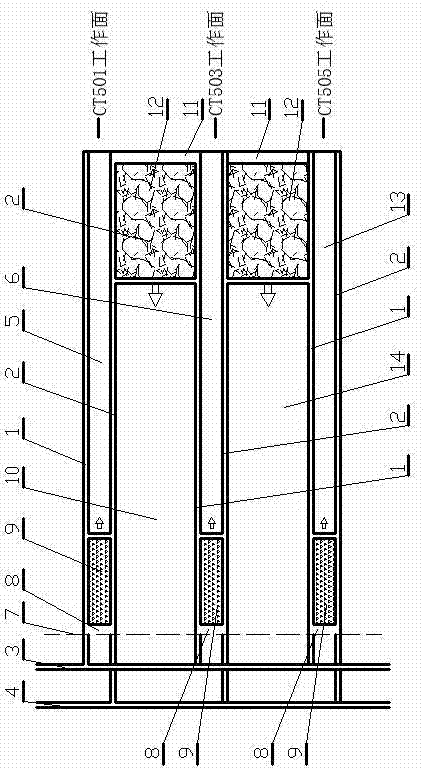

Non-coal-pillar auto-roadway-forming mining method suitable for thick-seam fully mechanized top coal caving

ActiveCN110206542AConducive to collapseIncrease stressDisloding machinesUnderground miningPre crackingCoal pillar

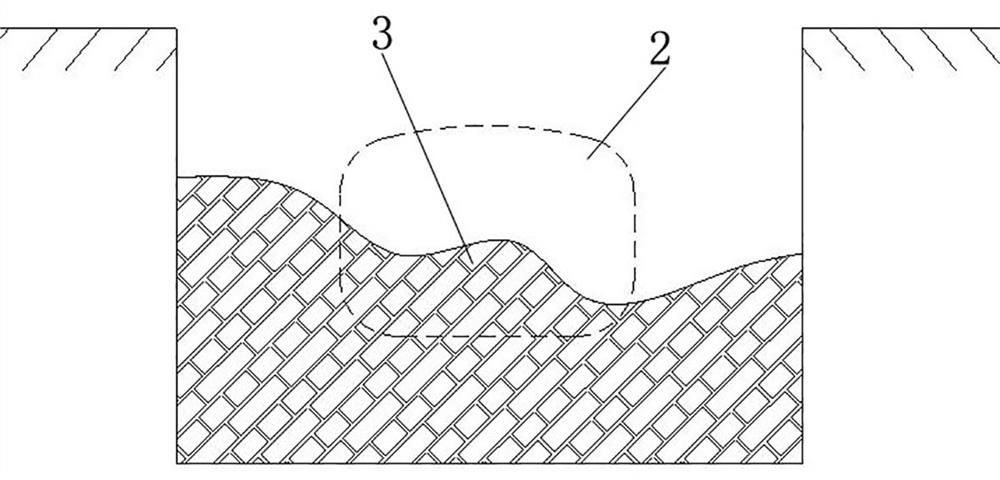

The invention relates to the technical field of coal mine mining, in particular to a non-coal-pillar auto-roadway-forming mining method suitable for thick-seam fully mechanized top coal caving. The method includes the following steps that reinforcing and supporting are carried out on a roof and two walls of a roadway; roof cutting explosion is carried out to form a pre-cracking seam; a temporary supporting device in the roadway and a gangue blocking device are erected along a retained entry; coal caving is not performed within a preset distance to the working face end close to the entry retaining side; after the roadway is stabilized, the temporary supporting device in the roadway is removed, a goaf is closed, and the entry retaining is completed. The roof cutting explosion better facilitates collapsing of the rock stratum in the goaf, the stoping space can be well filled after the rock stratum in the seam is collapsed, a short arm beam structure is formed in the lateral direction of the entry-retaining roof, a long suspended roof formed in the goaf is avoided, and the surrounding rock stress of the gob-side entry is improved; coal caving is not performed within a certain range ofthe working face end of the entry retaining side, the filling effect of the empty area of the entry retaining side is further guaranteed, rotary sinking of basic top block bodies is effectively limited, and the influence on the entry retaining stability is greatly reduced.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

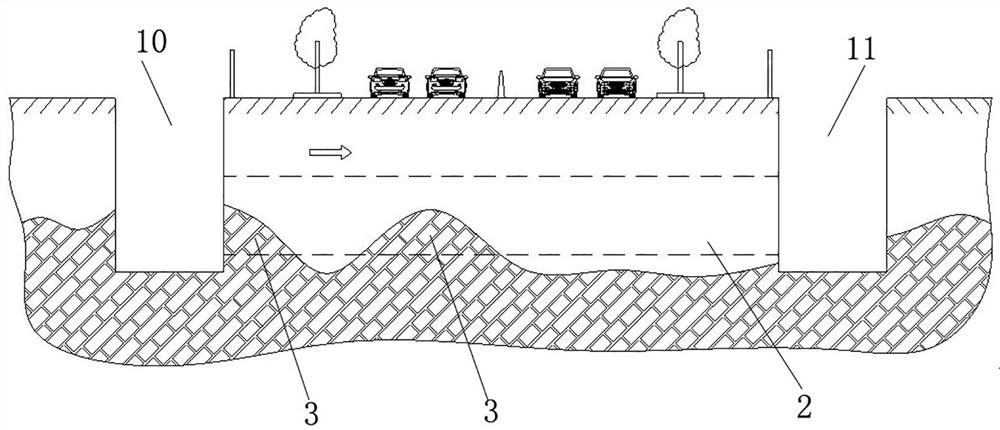

Deep inclined coal seam mining roadway mine pressure control mining method

InactiveCN104775819ASafe and efficient miningControl mine pressure displayUnderground miningSurface miningRetreat miningCoal pillar

The present invention relates to a deep inclined coal seam mining roadway mine pressure control mining method. According to the method, the filled mining strip and the fully mechanized mining work face are subjected to coordination arrangement, wherein the one fully mechanized mining work face is arranged between each two filled mining strips; and after the mining of the filled mining strip is completed, the mining roadway is adopted as the mining roadway of the middle fully mechanized mining work face by using the gob-side entry retaining method, the filled work face is arranged in a rising manner, the advancing mining is performed, the fully mechanized mining work face is arranged in a dip manner, the retreating mining is performed, the width of the filled mining strip is 35-45 m, and the width of the fully mechanized mining work face is 3-4 times the width of the filled strip. With the method of the present invention, the problem of the influence of the near goaf concentrated stress on the mining roadway is fundamentally solved, the mine pressure appearing of the gob-side entry retaining country rock is effectively controlled, the country rock deformation of the roadway is reduced, the safe mining of the mining area work face is ensured, the resource loss caused by the protection coal pillars between the work faces is reduced through the gob-side entry retaining technology, and the recovery rate of the mining area reduces is improved.

Owner:CHINA UNIV OF MINING & TECH

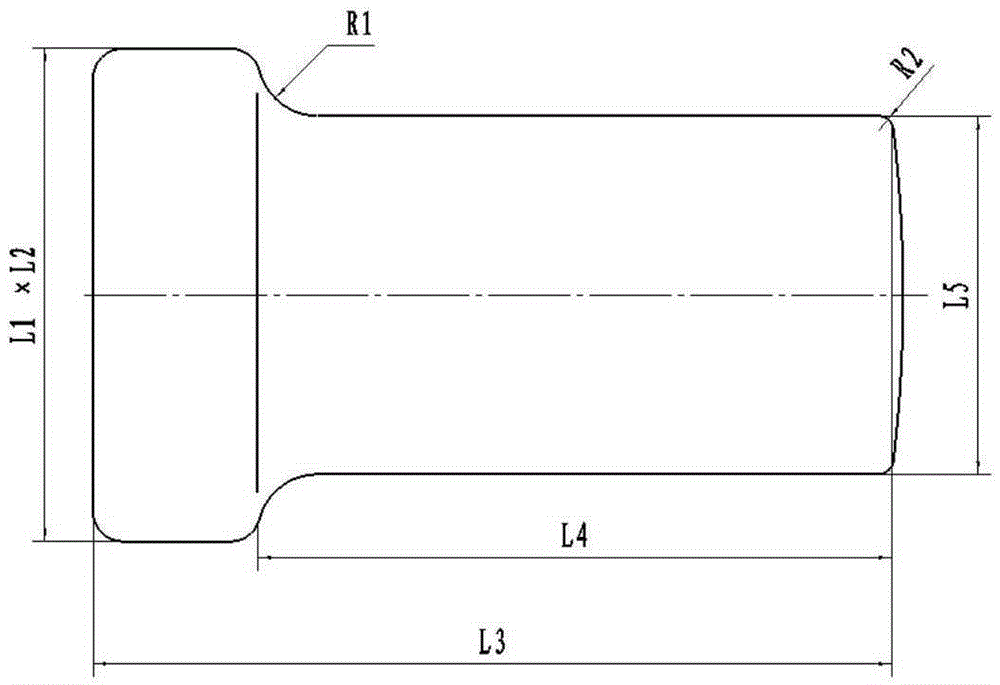

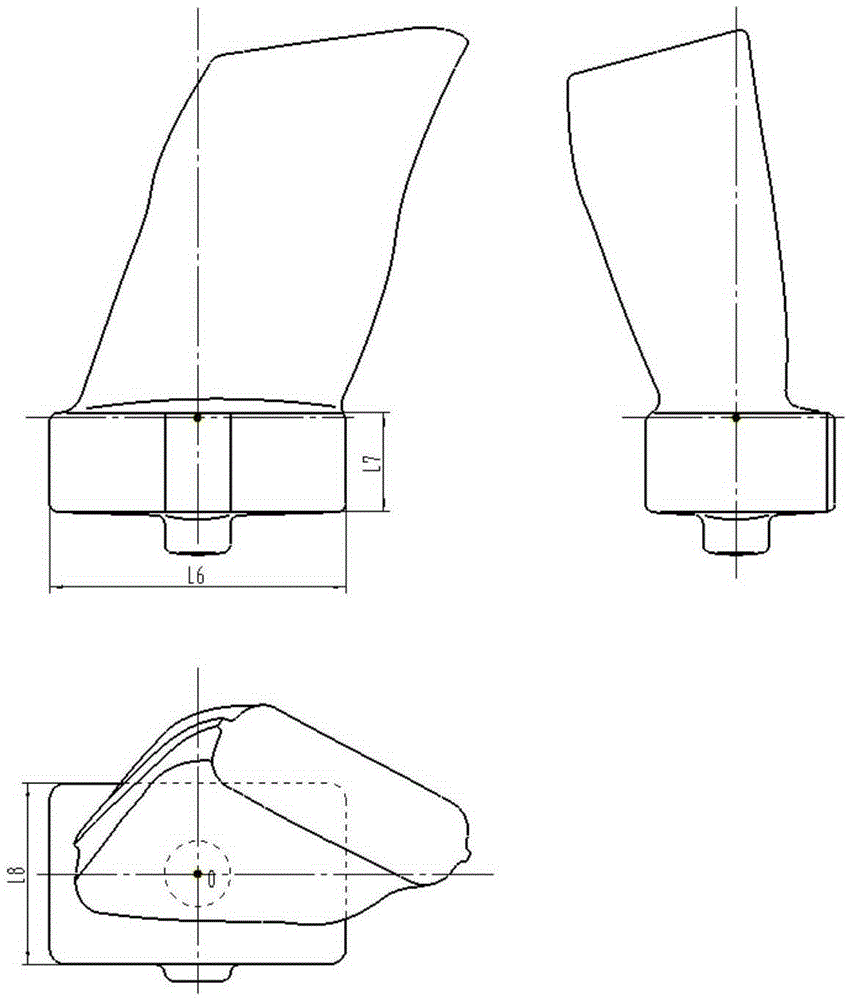

Isothermal beta forging method for TC17 titanium alloy blade

ActiveCN106607540AGuaranteed DimensionsReplaceableEngine componentsHeating/cooling devicesTitanium alloyMachining

The invention discloses an isothermal beta forging method for a TC17 titanium alloy blade, and the problem that the process requirement of existing TC17 blisk forging is high can be solved to a certain extent. The process requirement of TC17 blisk forging is high, and the machining requirement of forge pieces in the machining link is quite high. Machining errors in machining of the blade can cause scrapping of a whole blisk forge piece, time and labor are saved, and the economic cost is high. A wheel disc and the blade are forged separately, the identical isothermal beta forging method is adopted for the blade and a compressor blisk, and thus the forging forming difficulty is low, and subsequent machining is greatly facilitated.

Owner:SHAANXI HONGYUAN AVIATION FORGING

Production method of nano crystal-sand floor

ActiveCN101337366AStrong hardnessAnti-wear strengthPolishing machinesPretreated surfacesFloor slabWear resistant

The invention discloses a method for producing nanometer crystal sand surface floor slabs. The production method comprises the steps of slicing timber, selecting slabs and grooving according to conventional techniques, and further comprises the steps of conducting the polishing treatment for floor slab base materials, including seventeen-layer multiple permeation paint application technique, that is, applying two layers of water environmental protection primer, three layers of wear-resistant primer, nine layers of elastic primer, and three layers scraping-resistant finishing coat. The production method adopts the seventeen-layer multiple mutual-type permeation technique, that is, three plus two plus nine plus three, and utilizes the interactive permeation technique of nano-titanium paint molecules, so as to enable paint molecule layers to permeate into wood molecules. Through a plurality of layers of wear-resistant primer and hardening primer, and through leveling and a plurality of curing and sanding layers, the floor slab has high performance of super strong hardness, wear resistance, scraping resistance, oxidation and yellowing resistance. The paint surface adhesive force, the flexibility, and the scraping resistance of the floor slab greatly exceed those of the ordinary technical floor slab.

Owner:浙江永吉木业有限公司

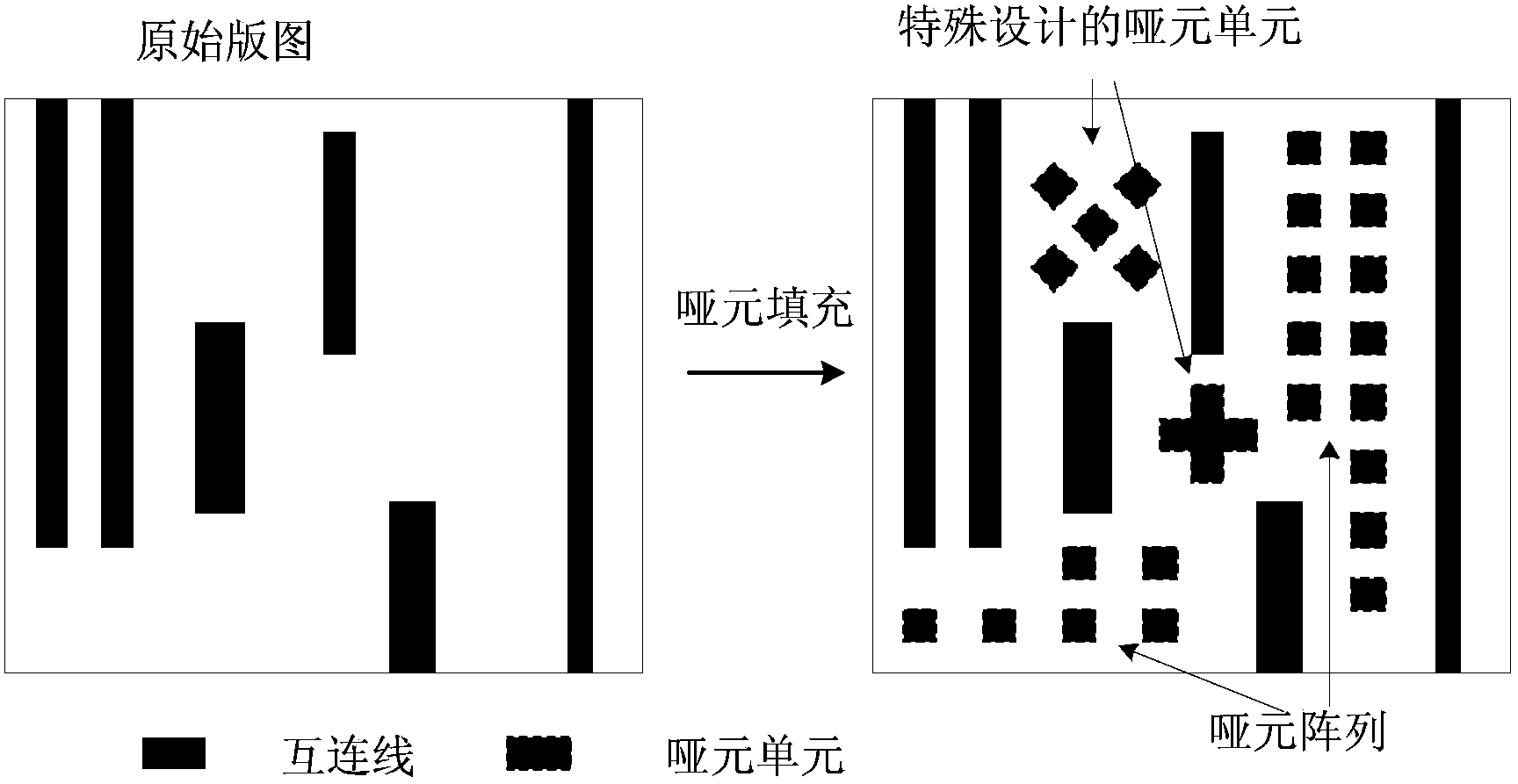

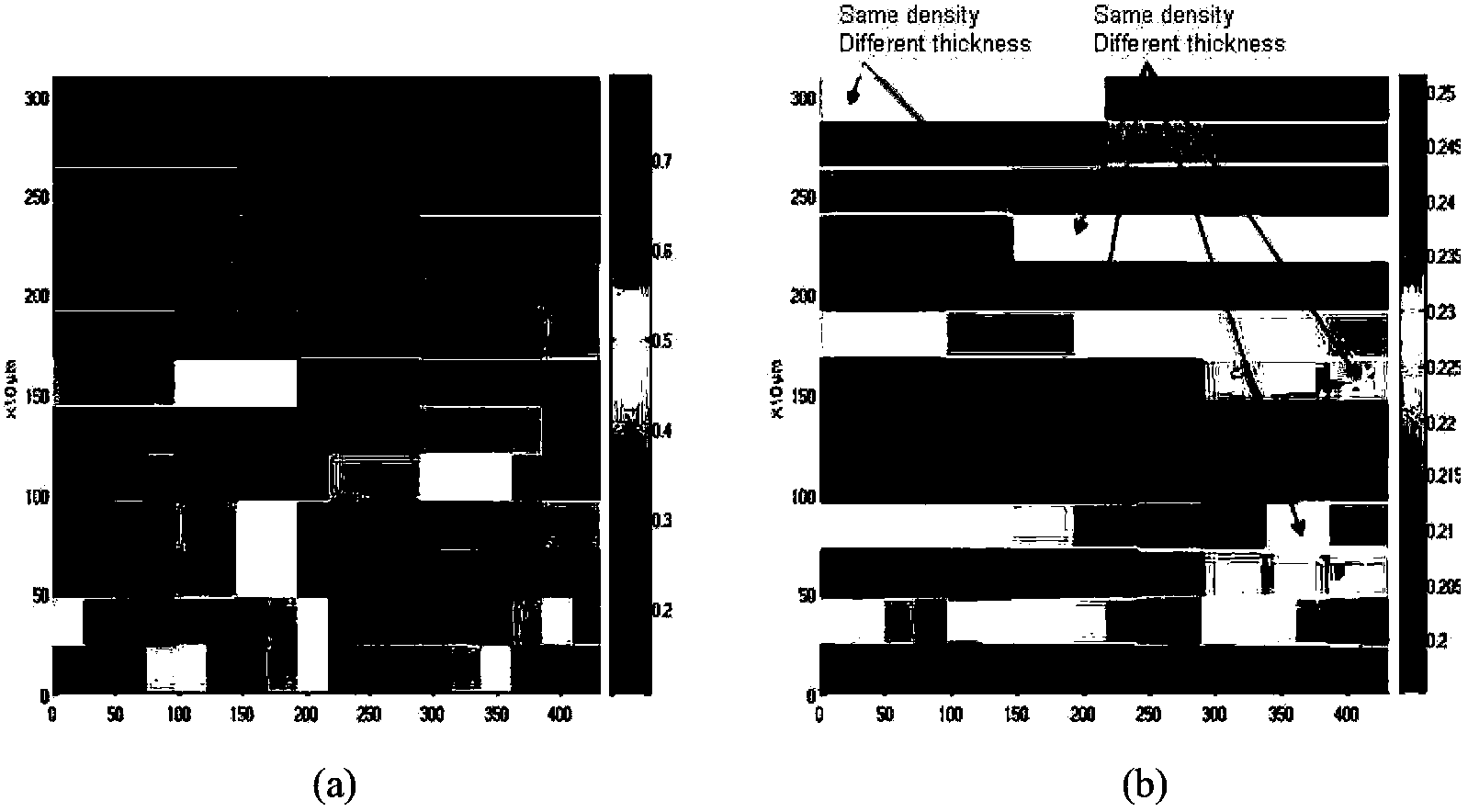

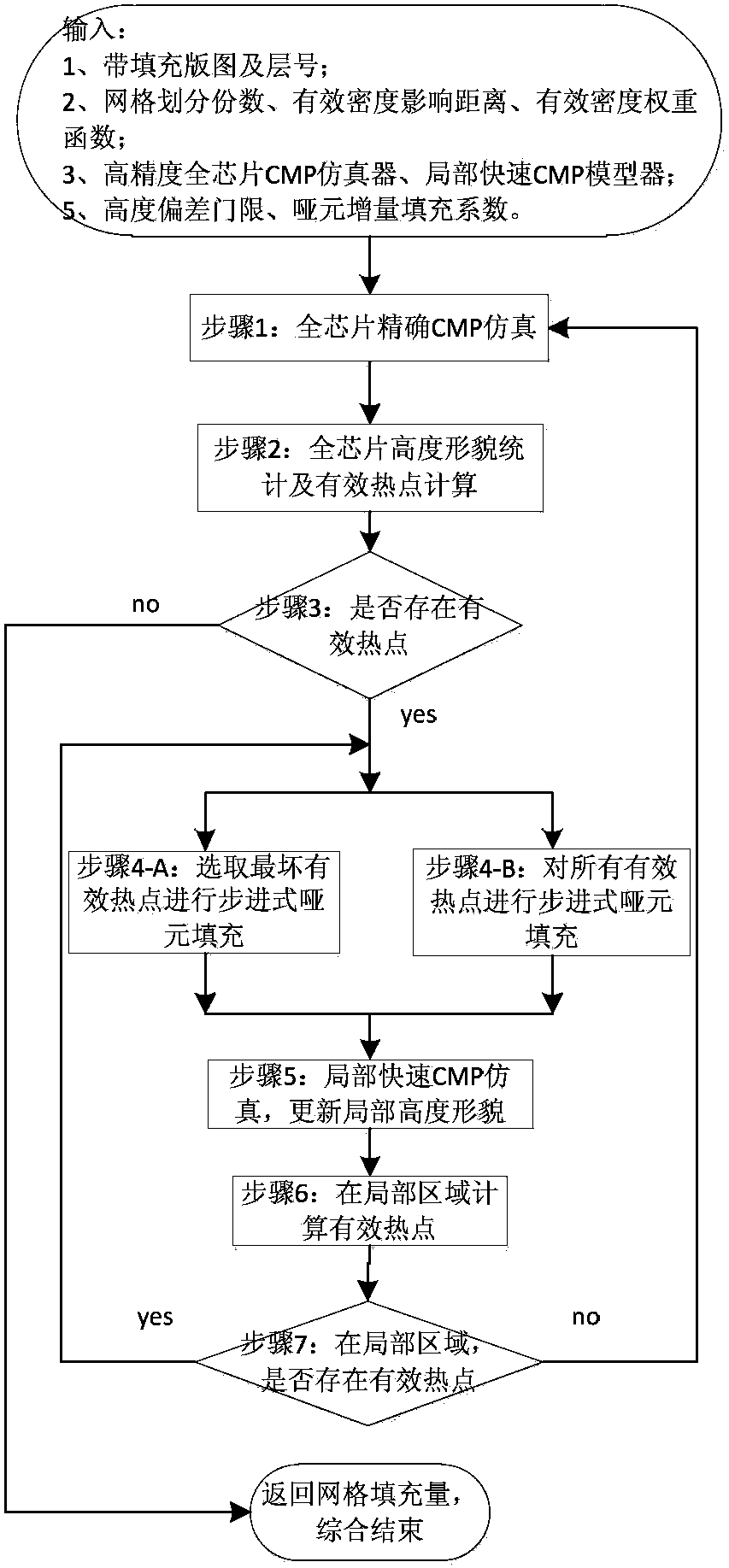

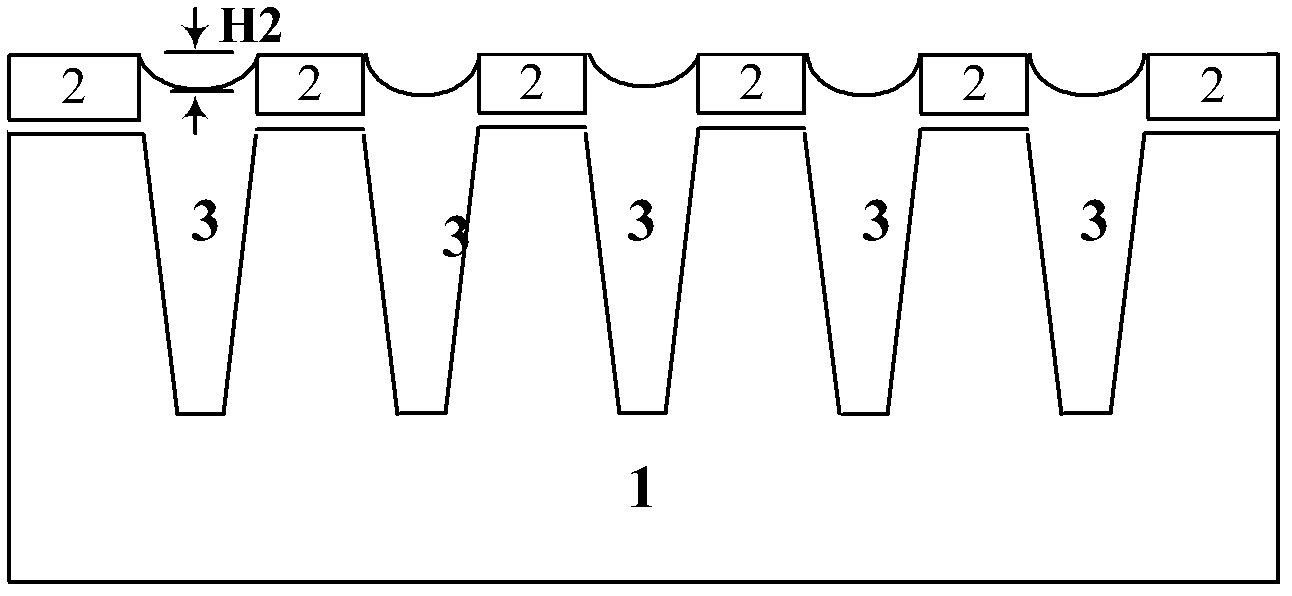

Dummy comprehensive optimization method based on CMP simulation model

ActiveCN103544331AGuaranteed flatnessGuaranteed height differenceSpecial data processing applicationsMean squareEngineering

The invention belongs to the field of manufacturability design of semiconductors and particularly relates to a dummy comprehensive optimization method based on a CMP simulation model for the copper-connection dummy metal filling technology. According to the method, the height morphology of the surface of a chip after undergoing CMP is obtained through full-chip CMP simulation, and an effective hot spot region with intense height changes is obtained; step-by-step dummy filling and fast CMP simulation of local regions are carried out iteratively in the effective hot spot region to gradually eliminate hot spots; finally, it is assured that no effective hot spot exists through the full-chip CMP simulation. Compared with a dummy comprehensive method based on rules, the dummy comprehensive optimization method based on the CMP simulation model can ensure that the height deviation of a layout after dummy filling and the CMP is within a given deviation threshold, and the dummy filling amount is small. Experiments show that in the same filling amount, the mean-square error ratio of the height morphology obtained respectively through the SMDF dummy filling method and the FMF dummy filling method is 58% smaller than that of the height morphology obtained through the dummy filling method driven by density, and the dummy comprehensive optimization method based on the CMP simulation model has obvious advantages.

Owner:FUDAN UNIV

Flexible assembly technology of low-voltage motor and assembly line thereof

ActiveCN101951082AEasy to assemblePlay a transitional roleManufacturing dynamo-electric machinesLow voltageEngineering

The invention discloses a flexible assembly technology of a low voltage motor and an assembly line thereof. The assembly process comprises the following steps in sequence: a stator enters an assembly area from the top line of a piece feeding area to start motor assembly, and then enters a pretreatment area from the underline of a primary underline area; the appearance of the motor is subjected to fine treatment in the pretreatment area; the motor enters a primary painting area to paint and dry an end cover from the top line of a primary top line area, and then a fan and an end shield are assembled on line; the motor enters an experimental area from the underline of a secondary underline area; a motor experiment is carried out in a test area, and then the motor enters a perfect area after test permission to be perfectly assembled in the perfect area; the motor enters a secondary painting area to be painted and dried from the top line of a secondary top line area, and then is packaged at the underline of a package area; and after packaging, the motor enters a finished motor storage area to be stored. The time and beat of each assembly link can be flexibly regulated and controlled so as to realize flexible assembly, thus not only reserving the advantage of the assembly line facilitating line production but also meeting the production requirements of various species, small batch and multiple specifications.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

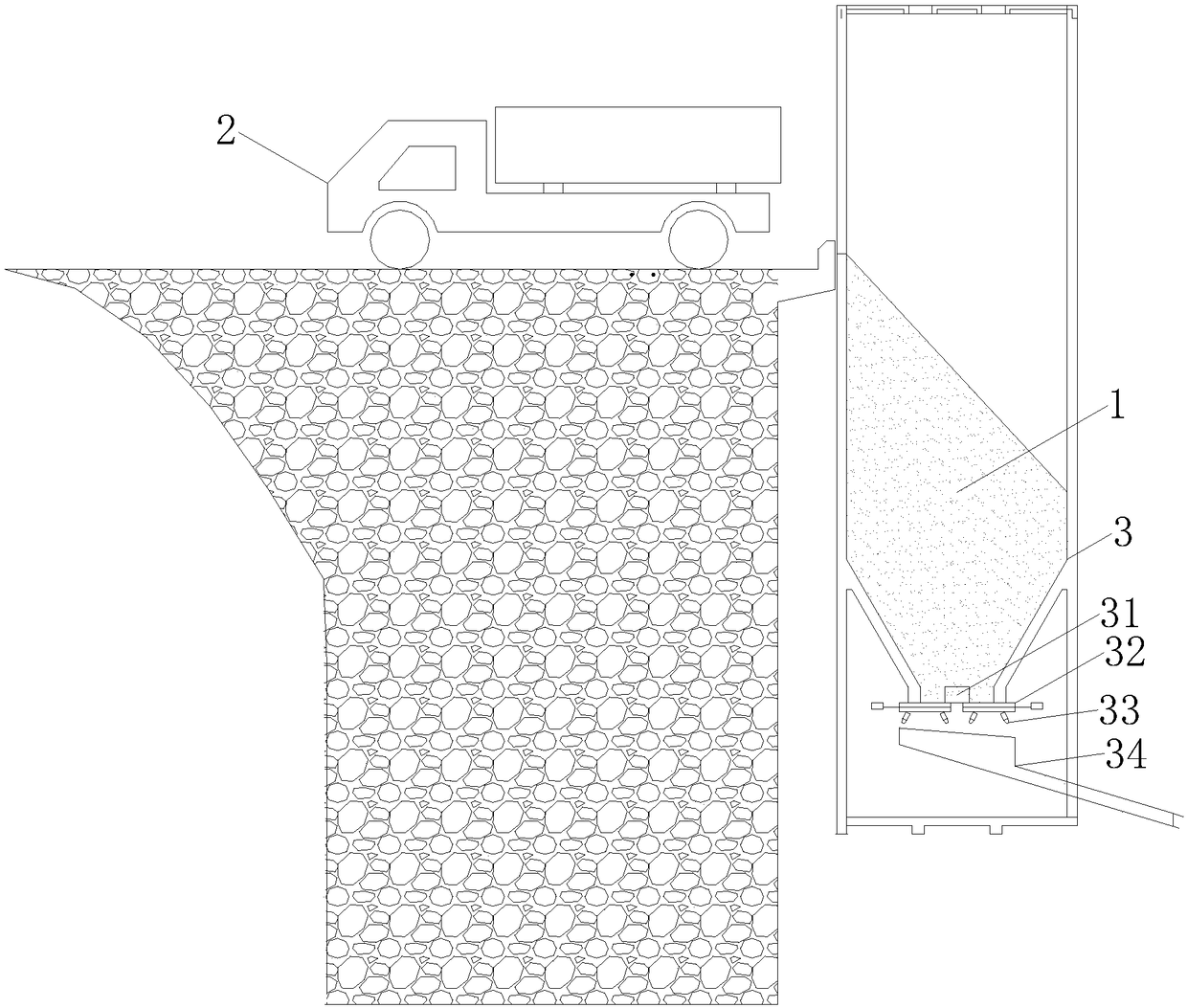

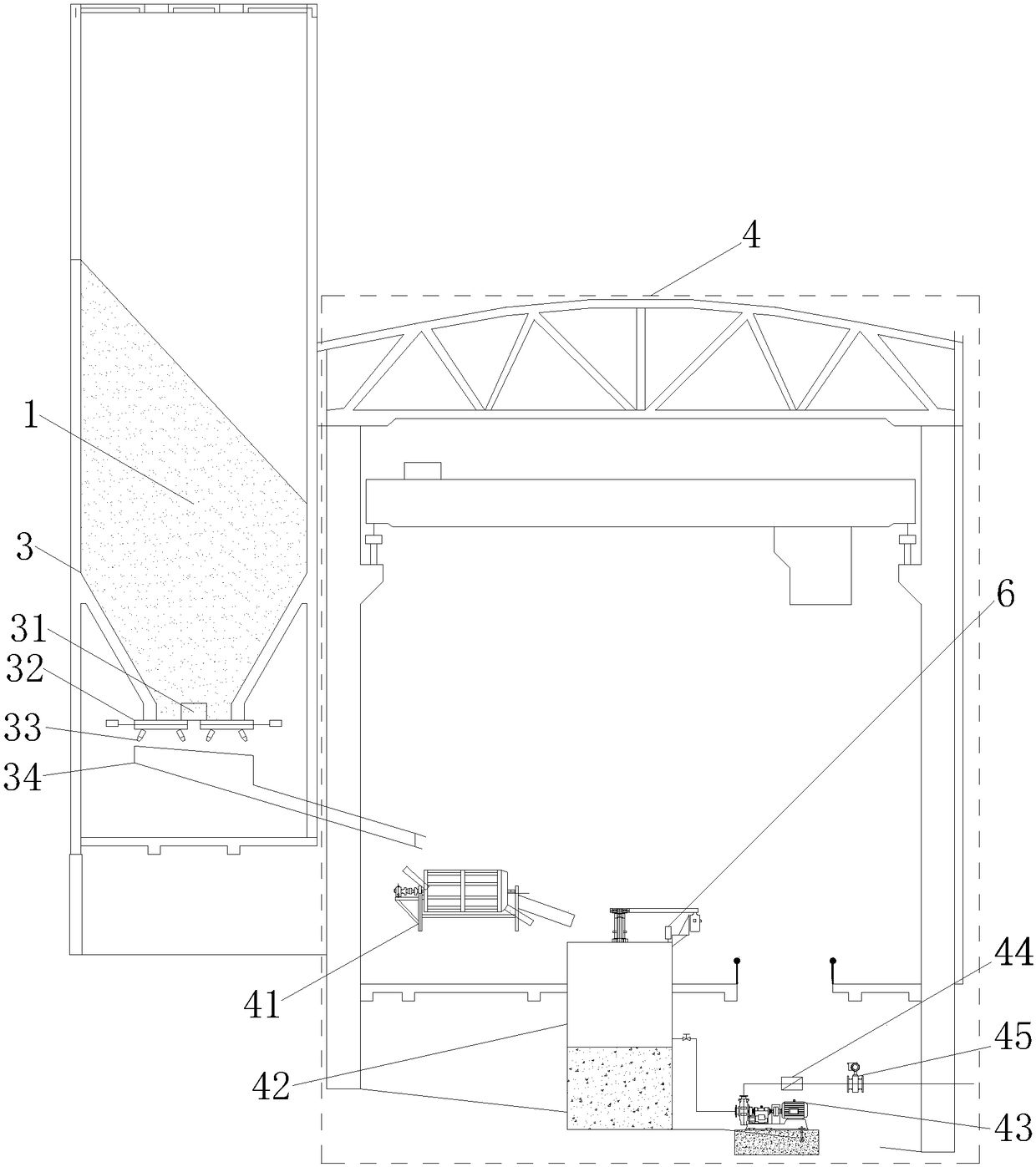

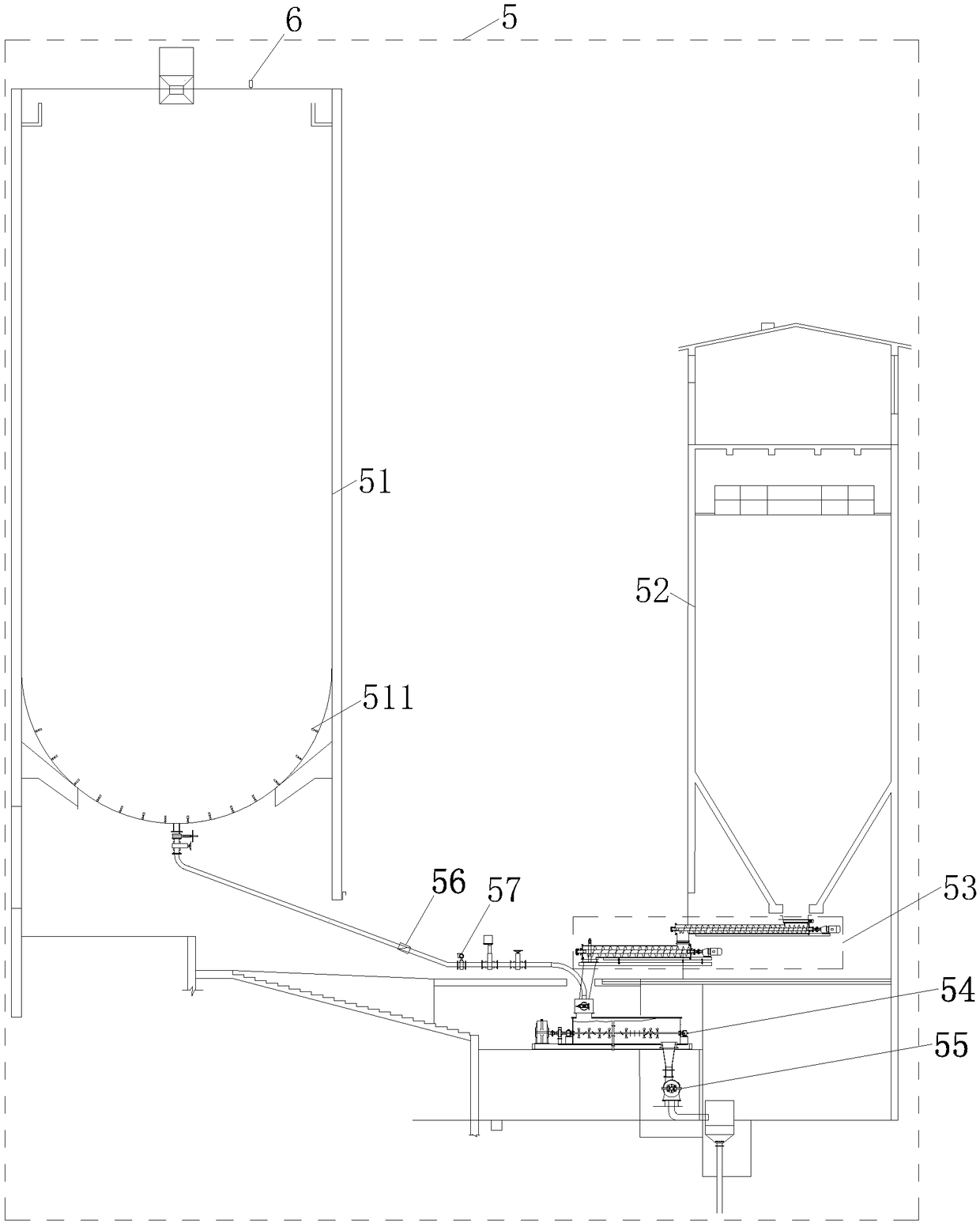

Tailing slurry recycling filling system and technology

PendingCN108590748AControl ratioControl concentrationMaterial fill-upIngredients weighing apparatusHigh concentrationSlurry

The invention provides a tailing slurry recycling filling system. The tailing slurry recycling filling system comprises a conveying vehicle, a filter cake storage bin, a tailing slurry recycling device and a filling slurry preparing device; the conveying vehicle is used for conveying high-concentration tailing filter cakes generated in a dressing plant and formed through filter pressing to a filling station; the filter cake storage bin is used for storing the high-concentration tailings filter cakes in a concentrated mode and impacting and diluting the high-concentration tailings filter cakesthrough high-pressure water so as to output tailing slurry in a flowing mode; the tailing slurry recycling device is used for filtering and stirring the tailing slurry output by the filter cake storage bin to obtain the tailing slurry with the stable concentration; and the filling slurry preparing device is used for preparing and forming filling slurry through the tailing slurry, with the stable concentration, output by the tailing slurry recycling device and outputting the filling slurry to fill a goaf. The filter cake storage bin disperses the high-concentration tailing filter cakes throughthe high-pressure water, so that tailings and water are mixed and diluted to obtain the tailings slurry. The tailings slurry recycling device filters and stirs the tailing slurry output by the filtercake storage bin to remove coarse-particle impurities in the tailing slurry to enable the tailings and water to be mixed evenly so as to obtain the tailing slurry with the stable concentration.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

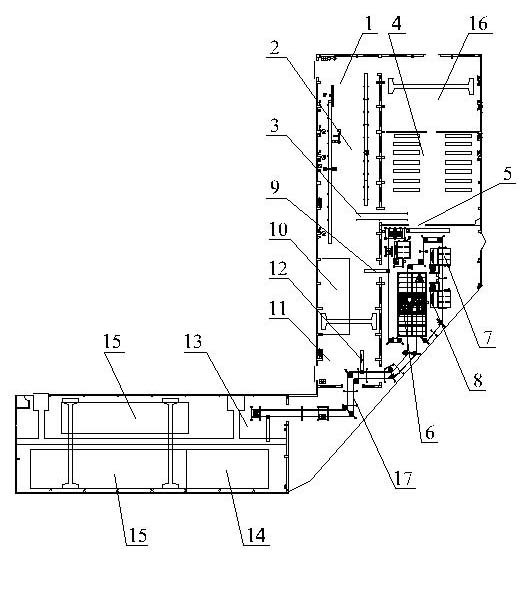

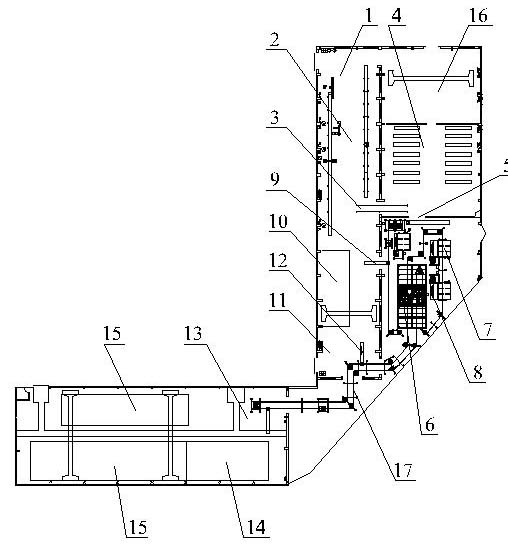

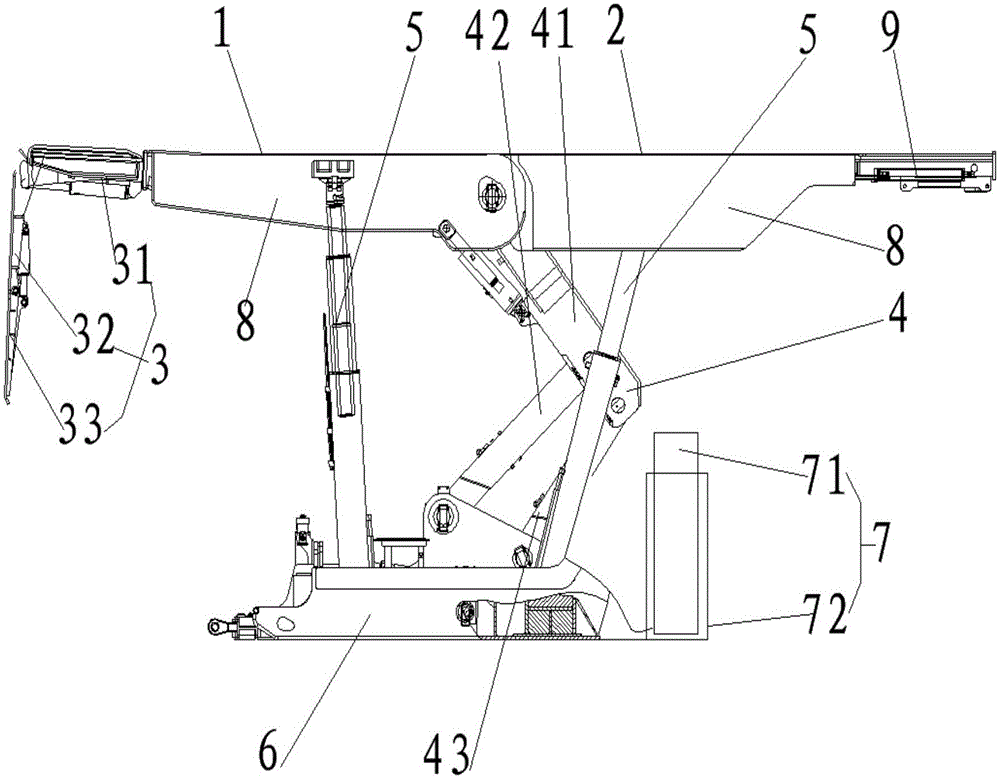

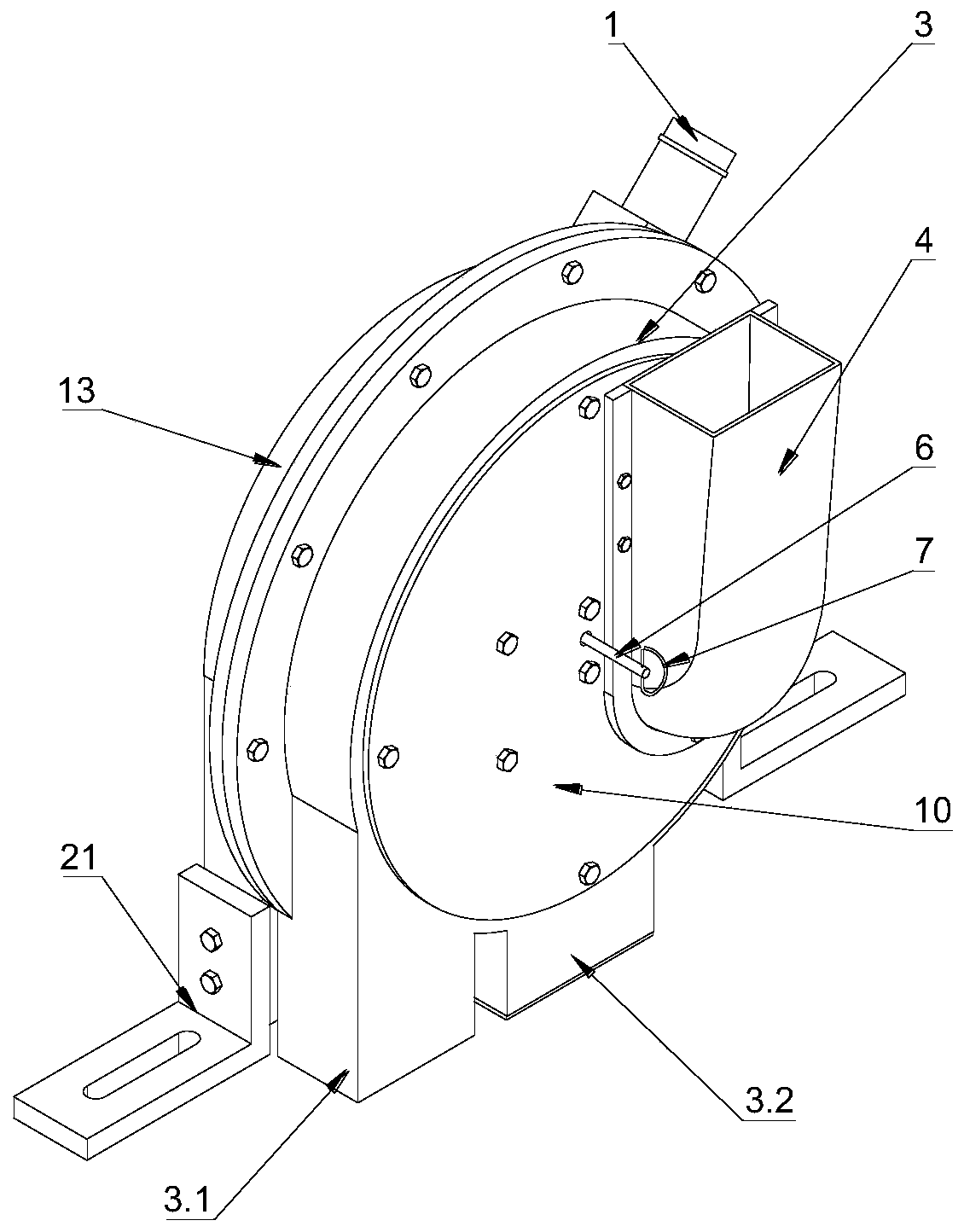

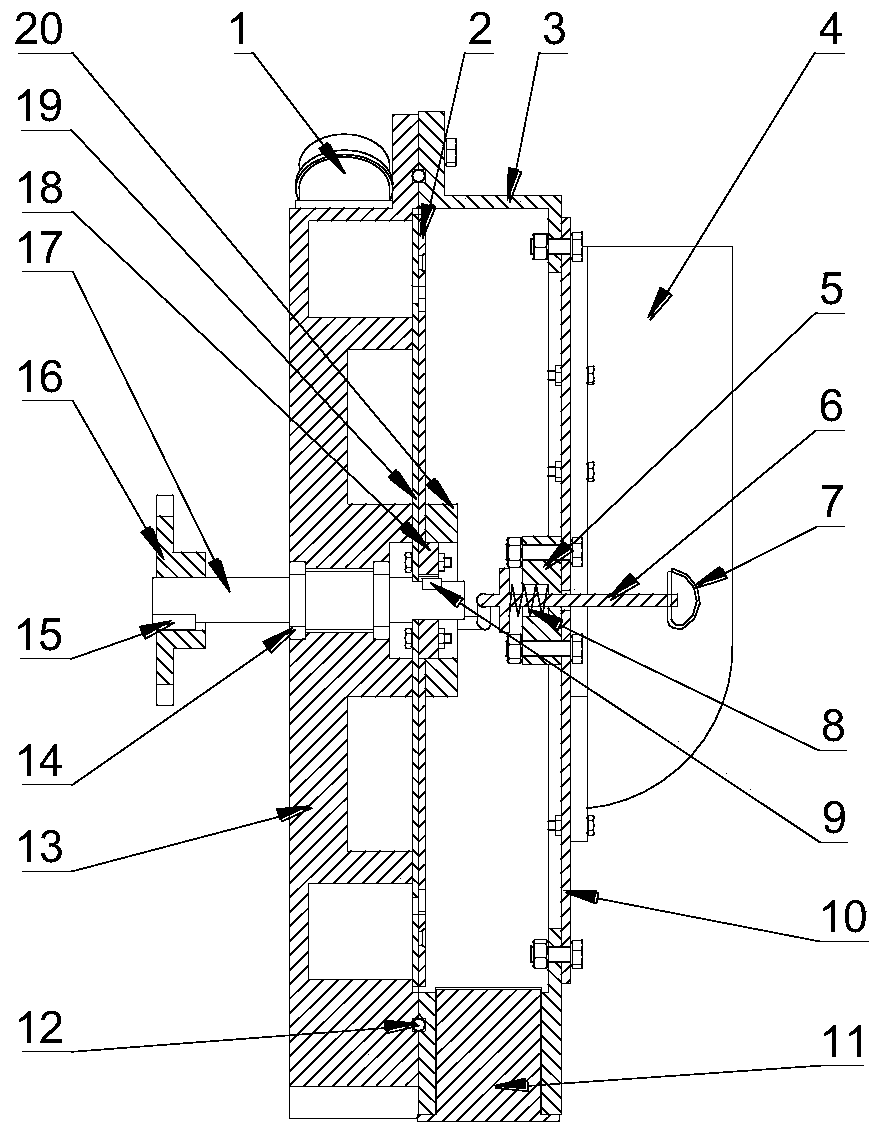

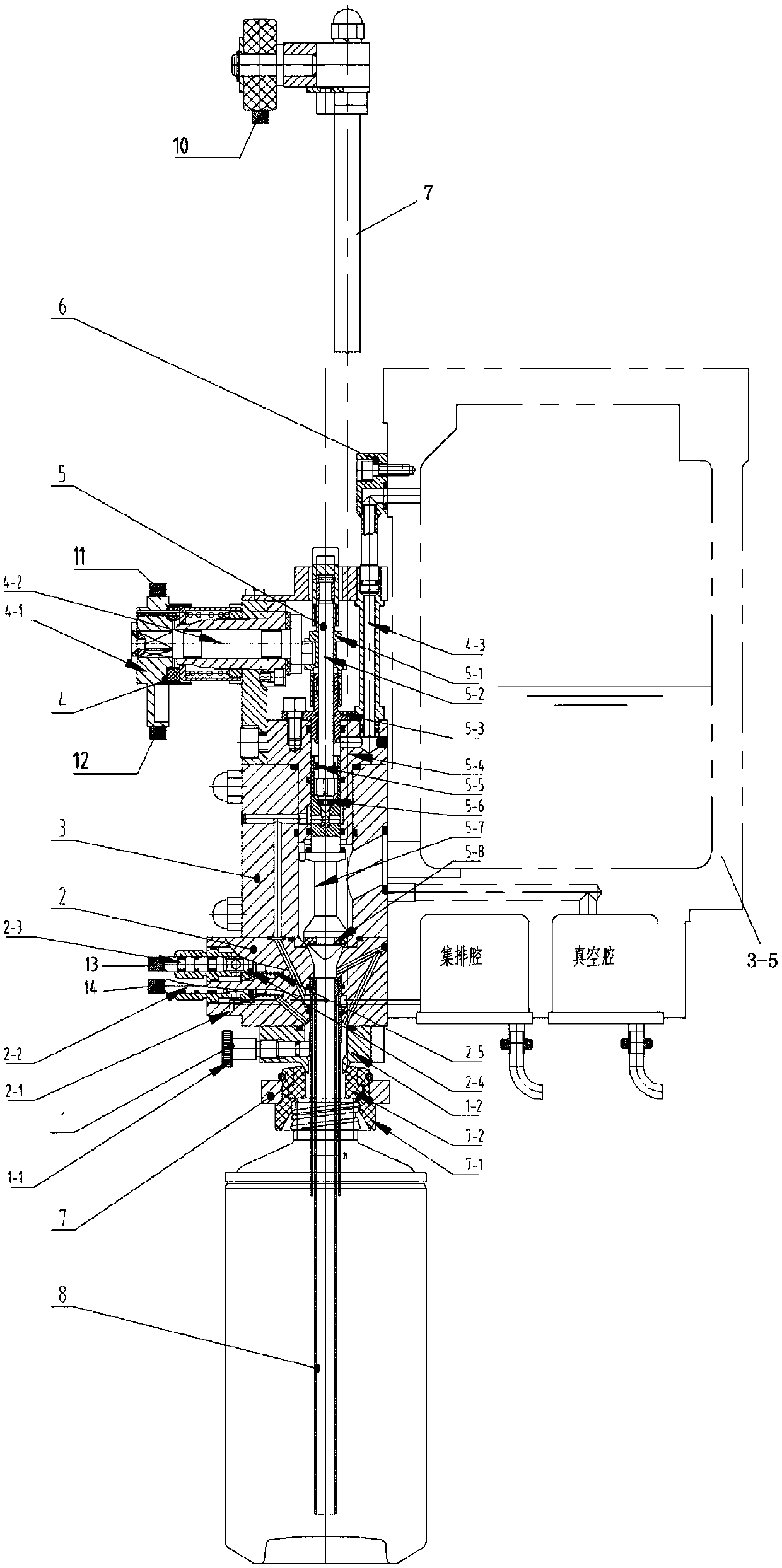

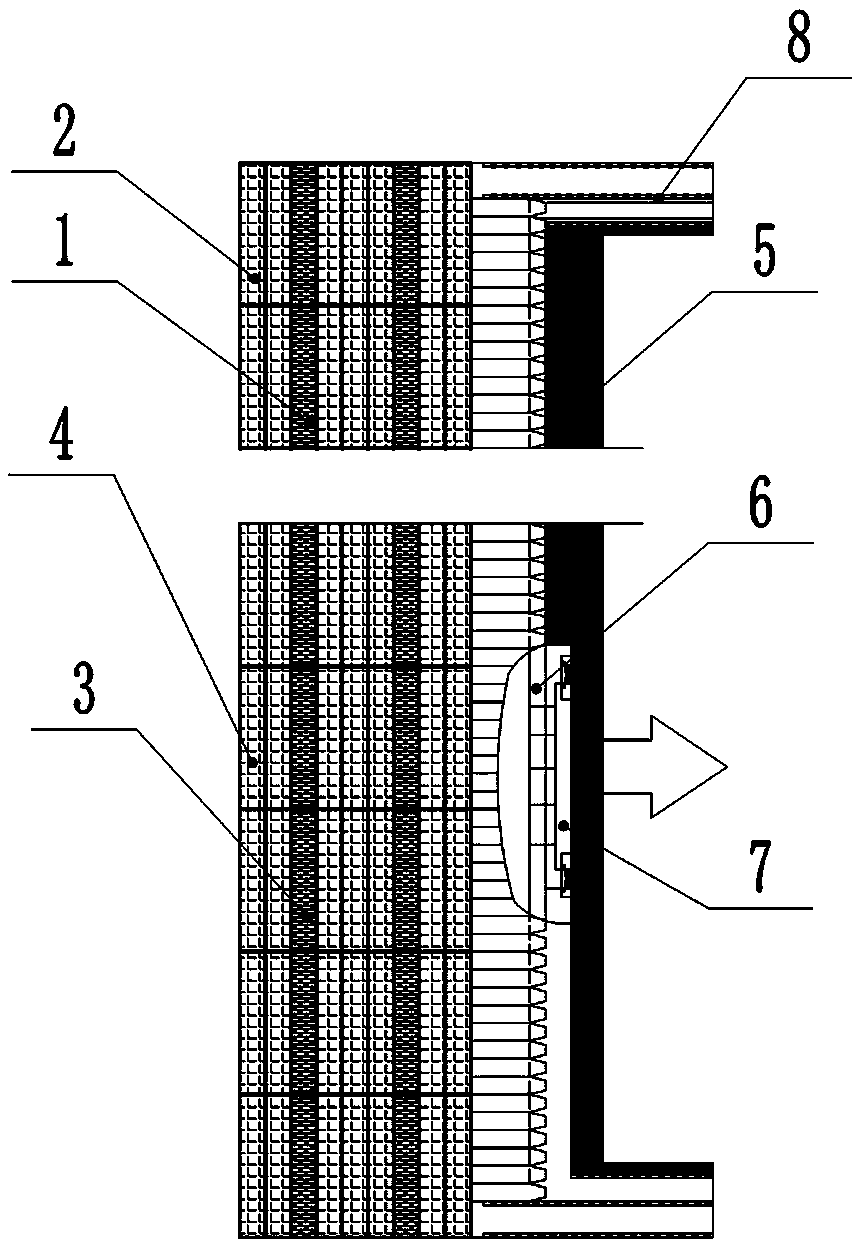

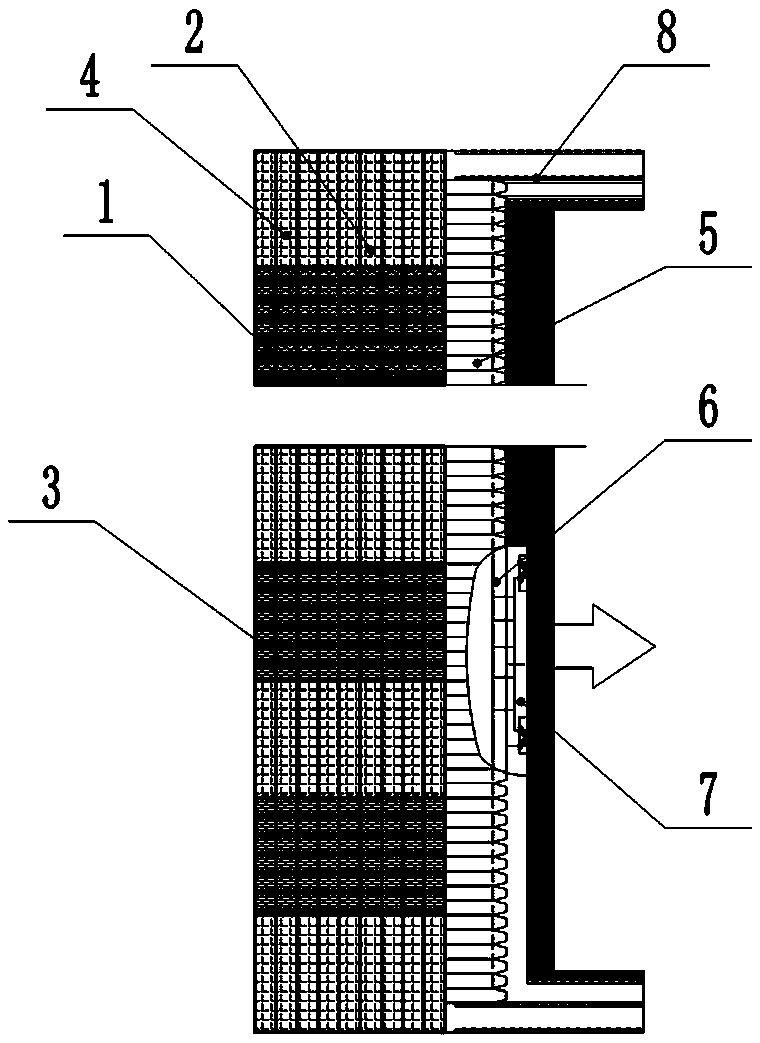

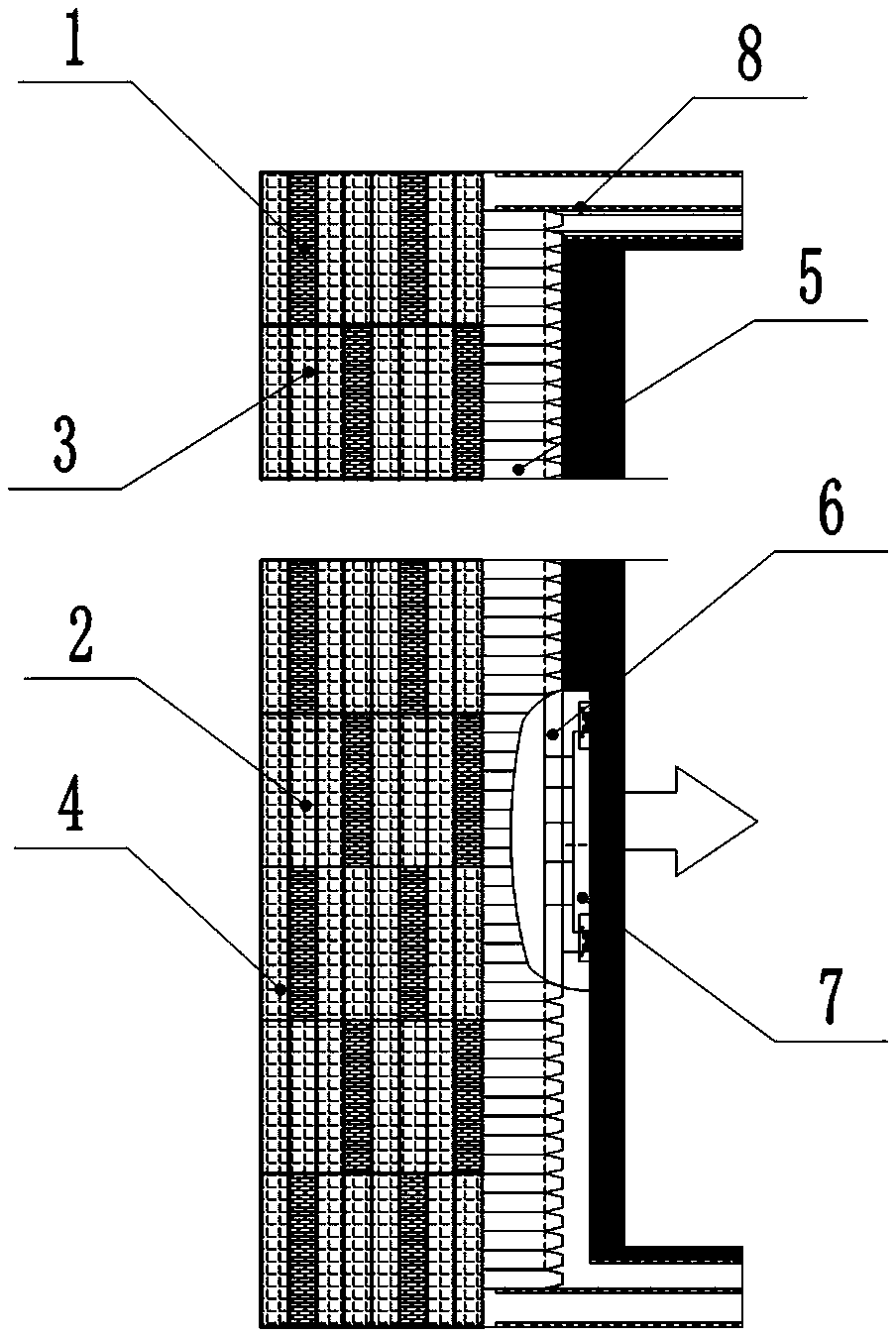

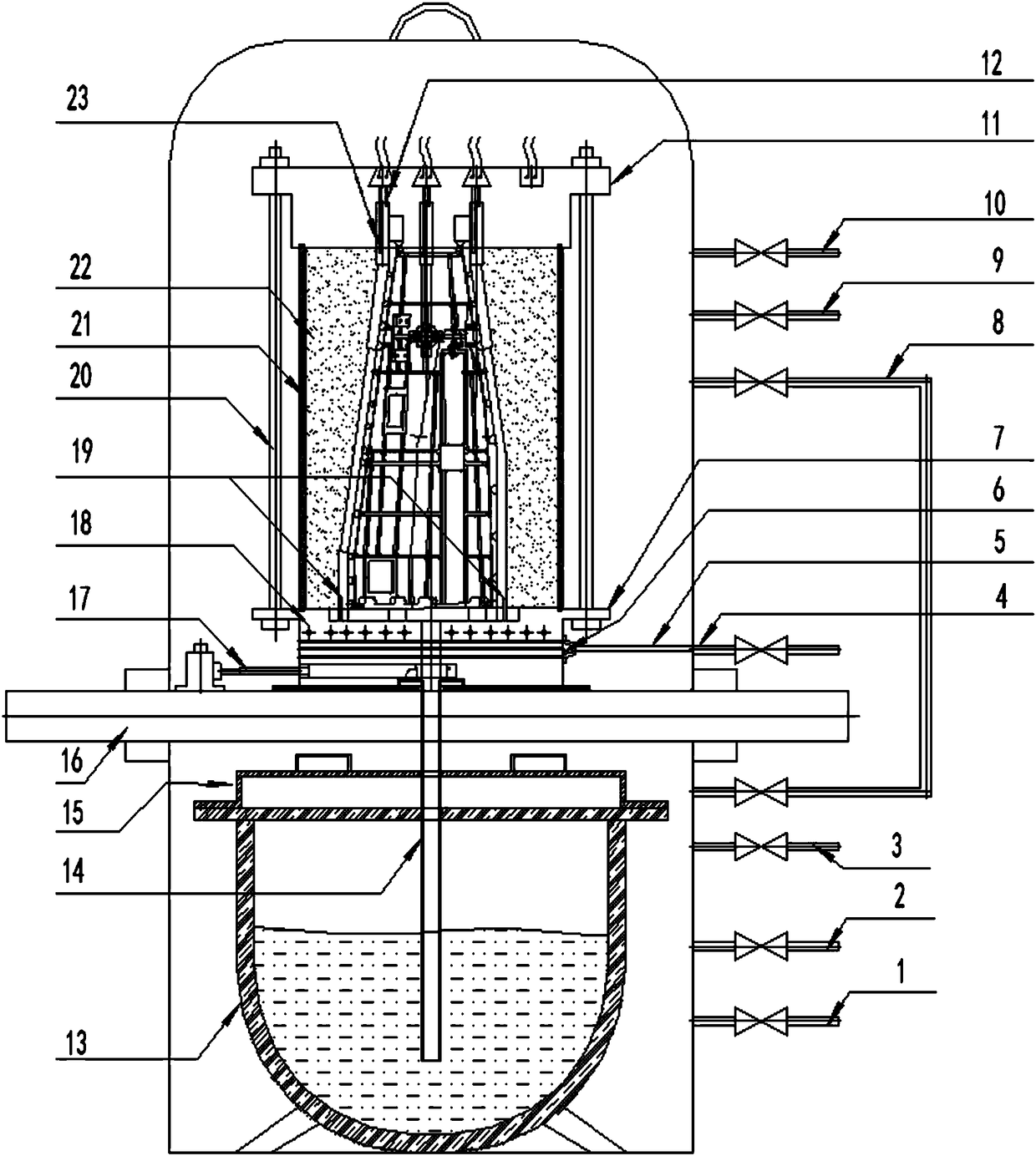

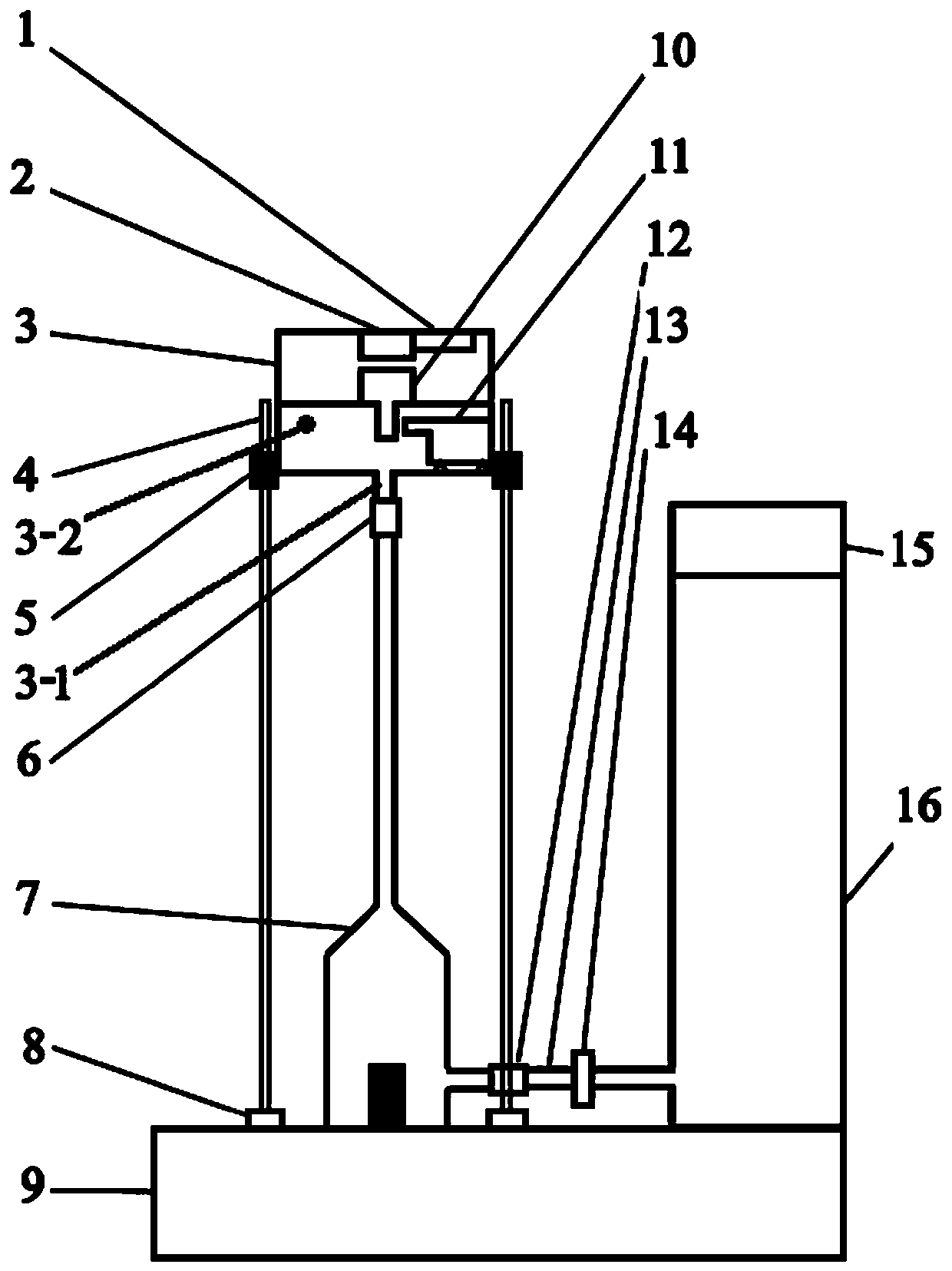

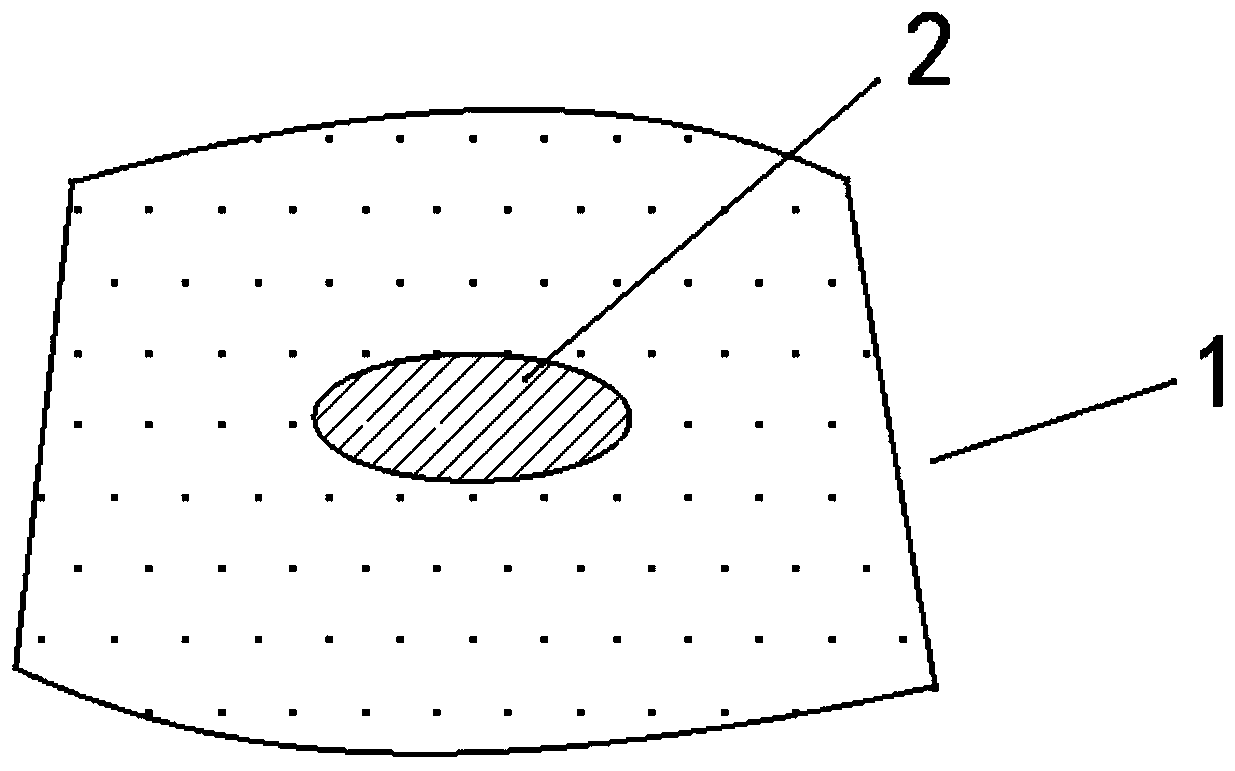

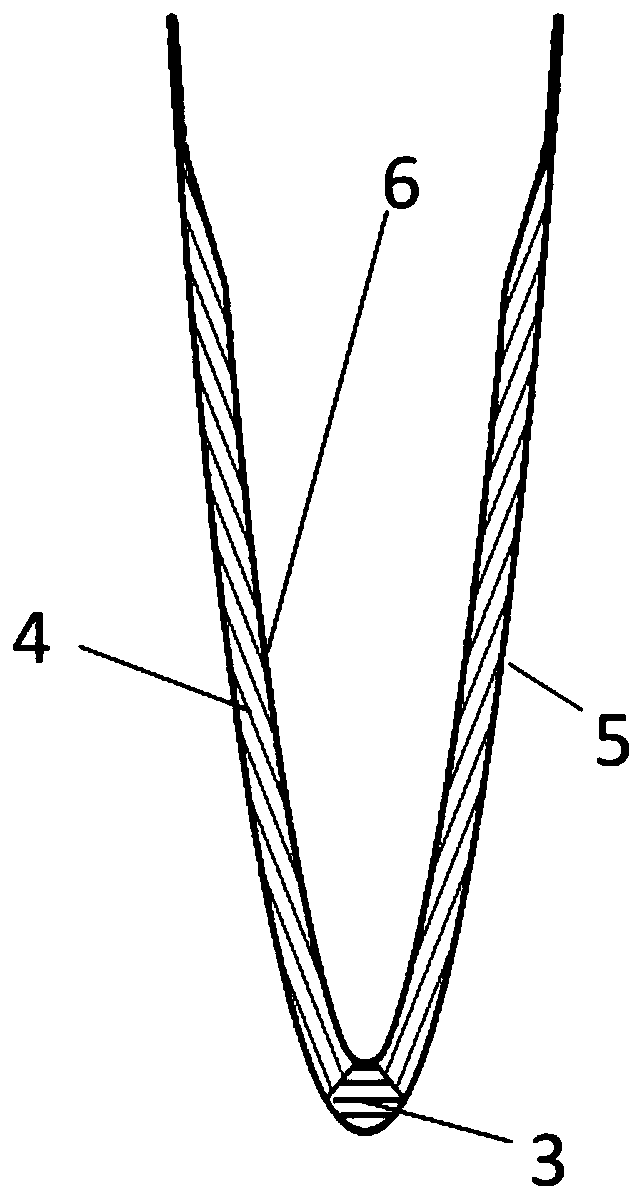

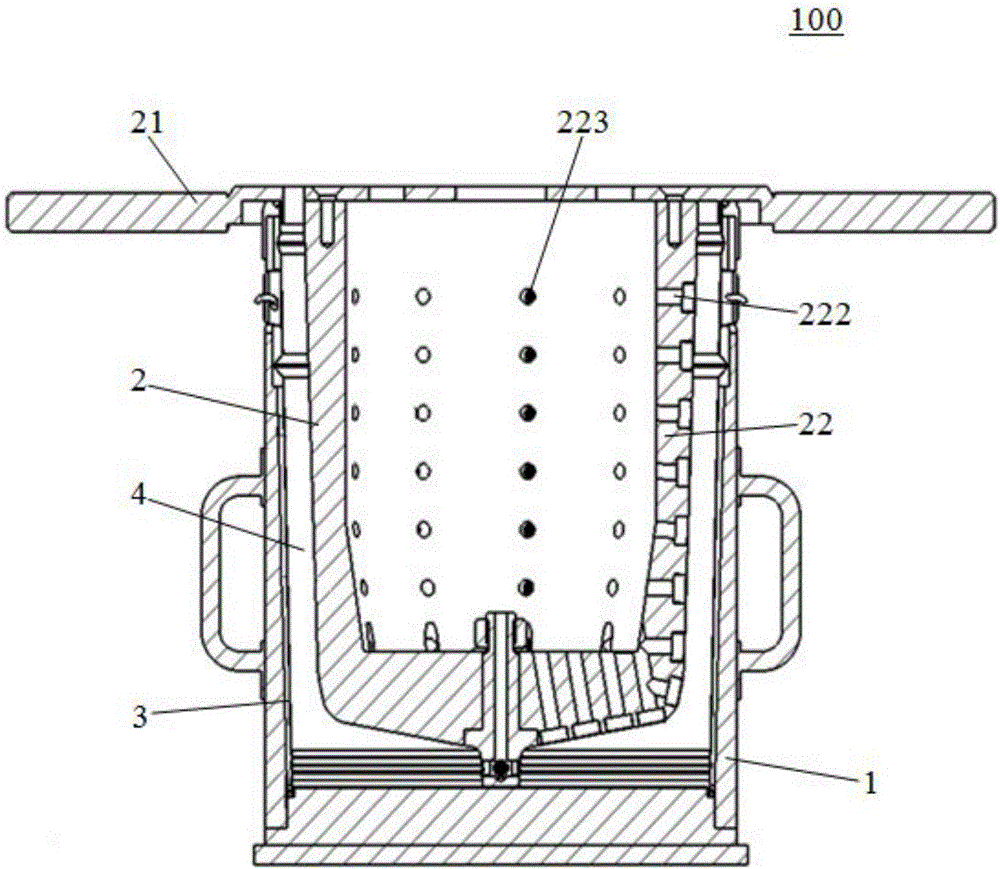

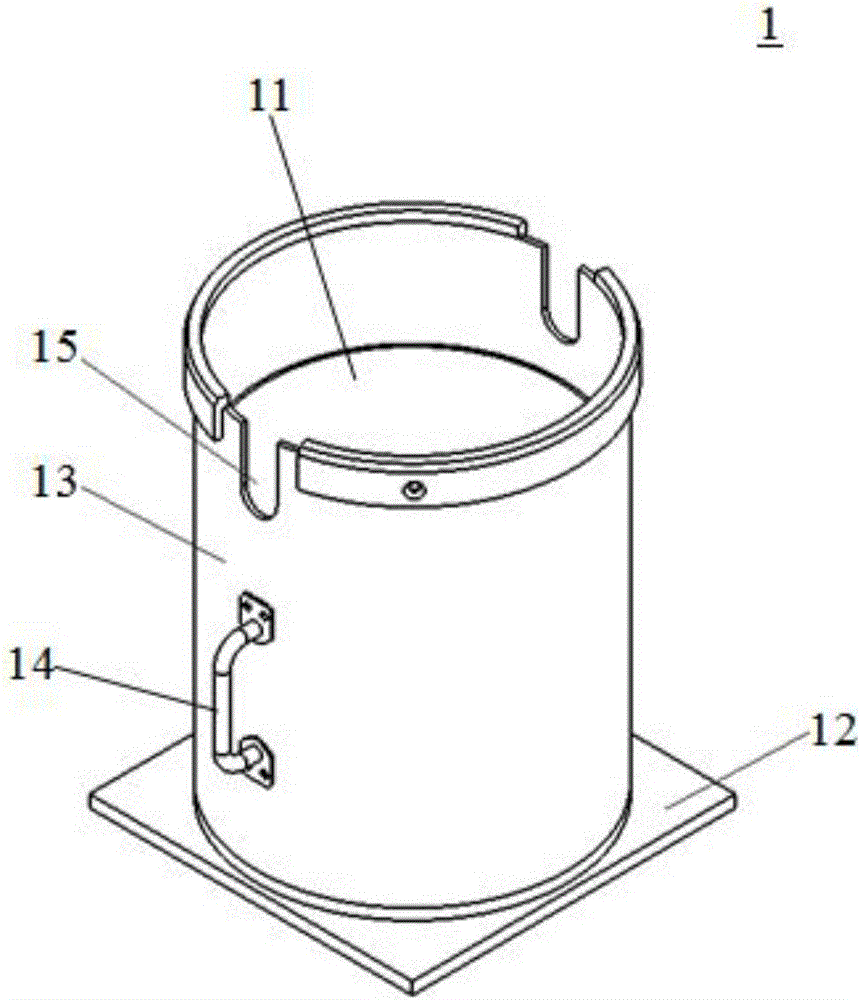

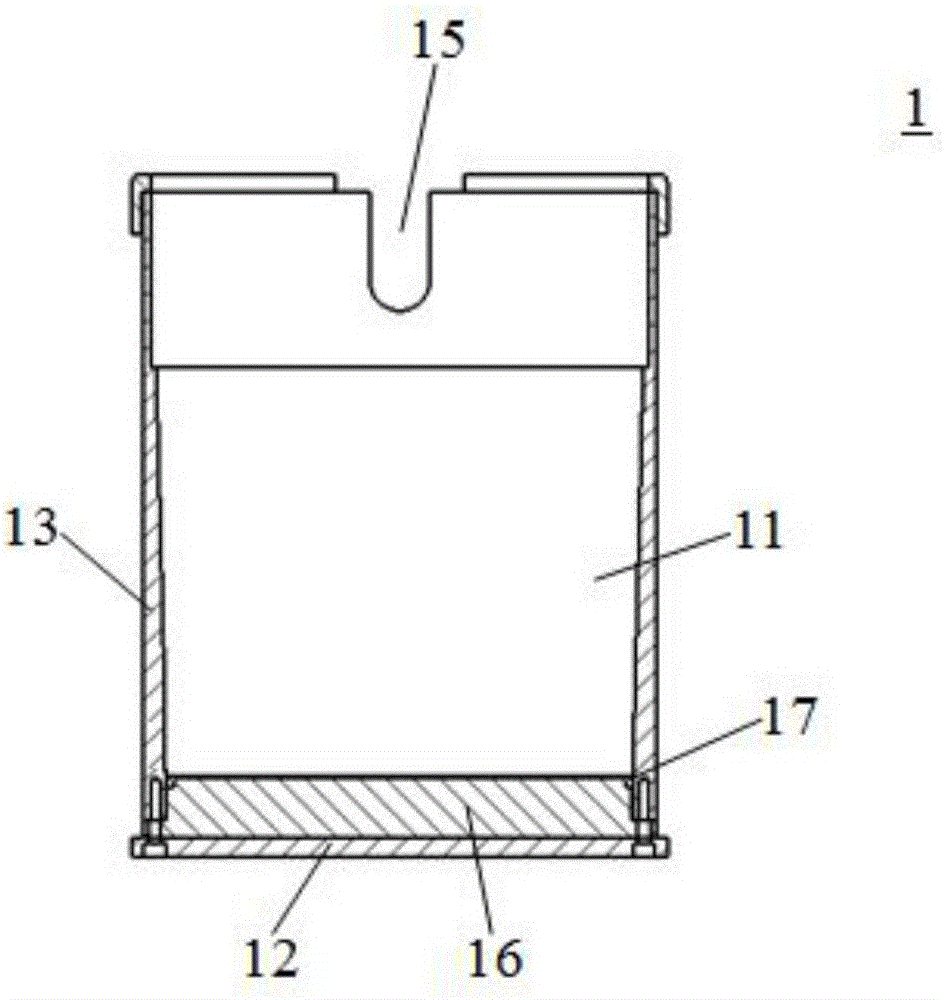

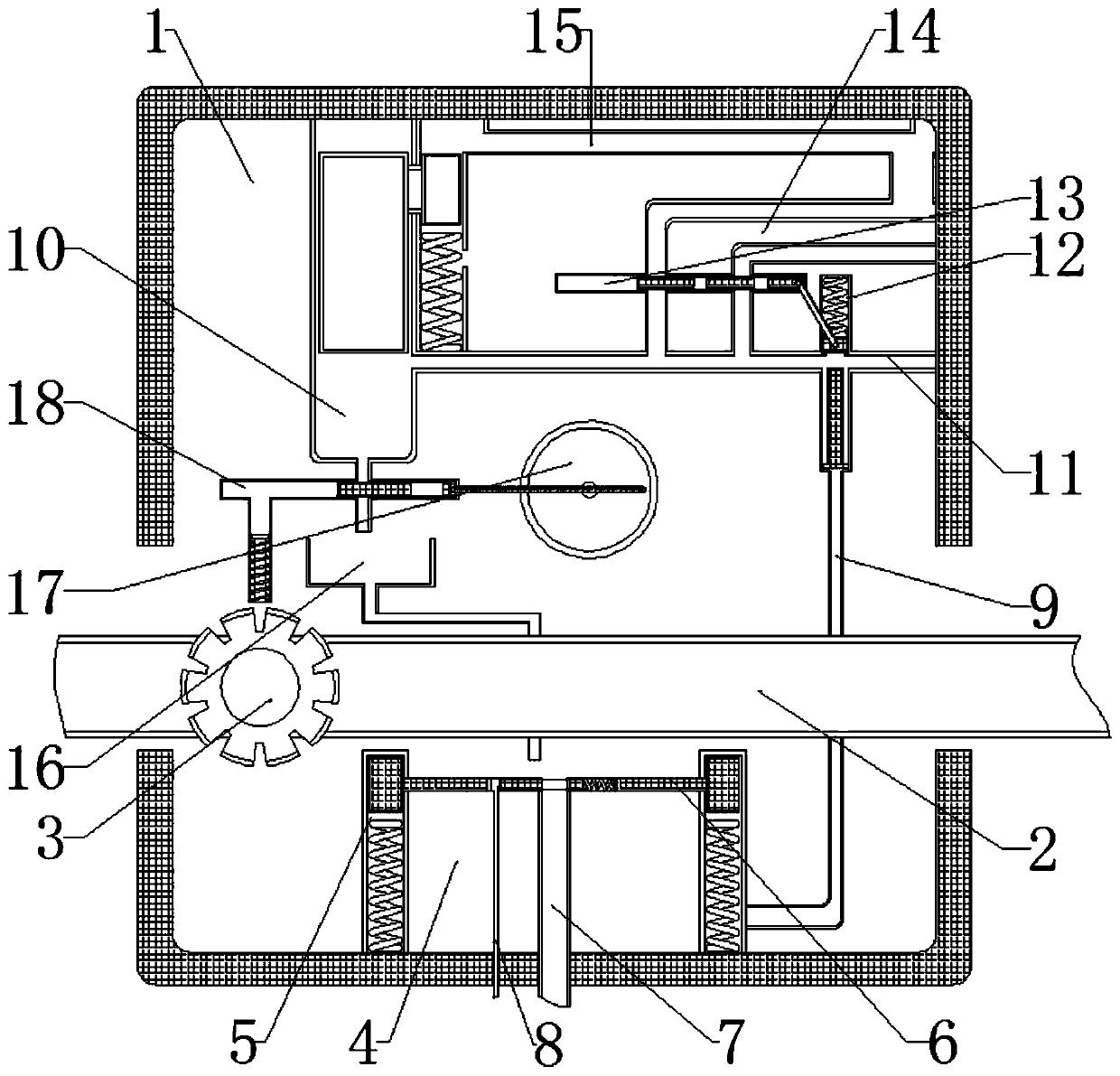

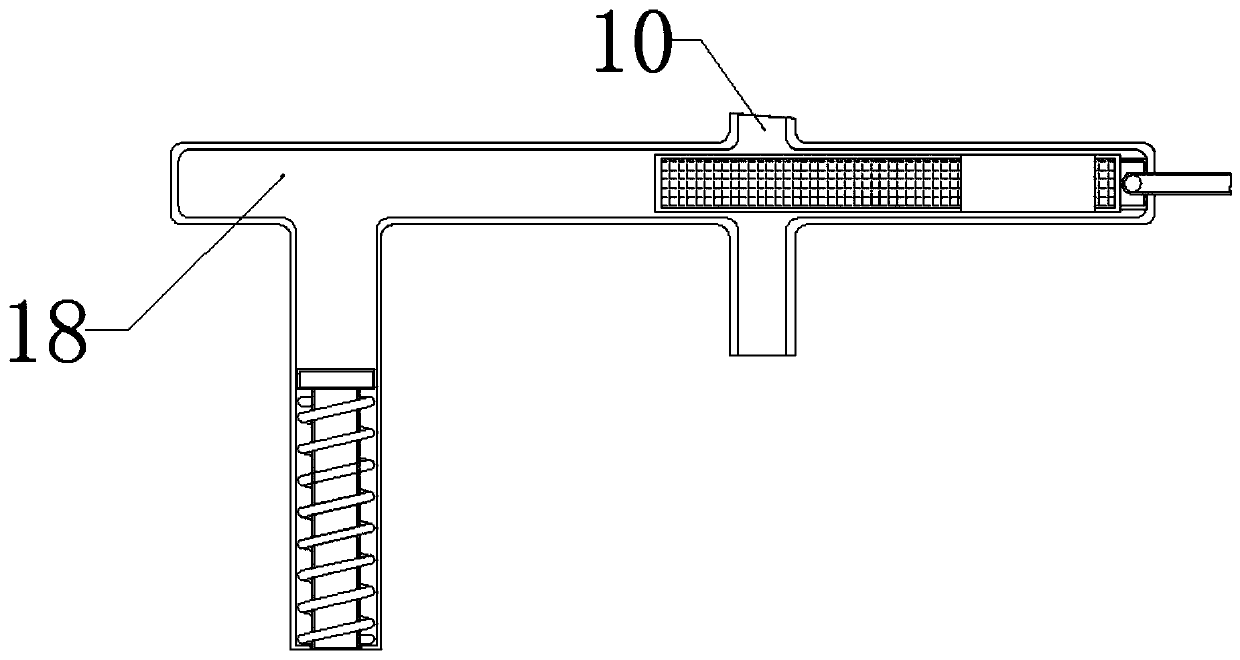

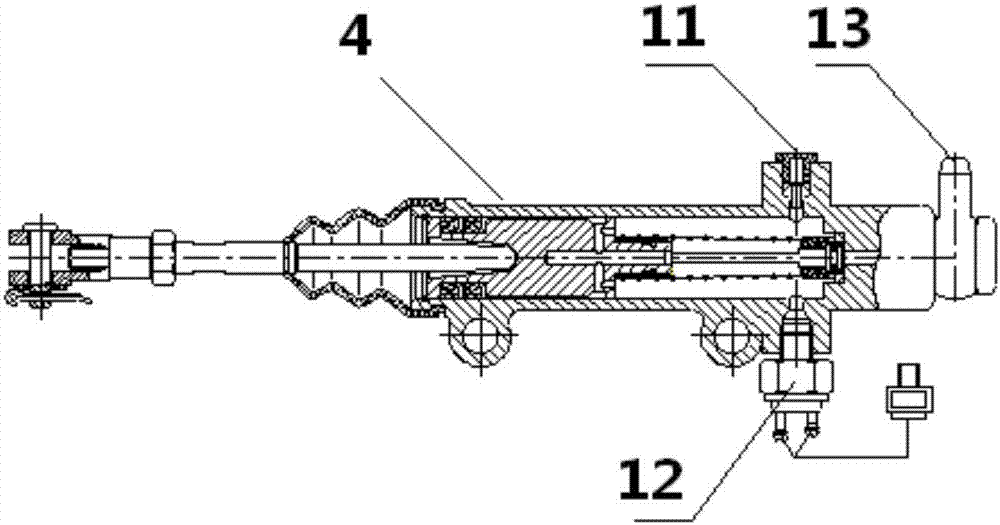

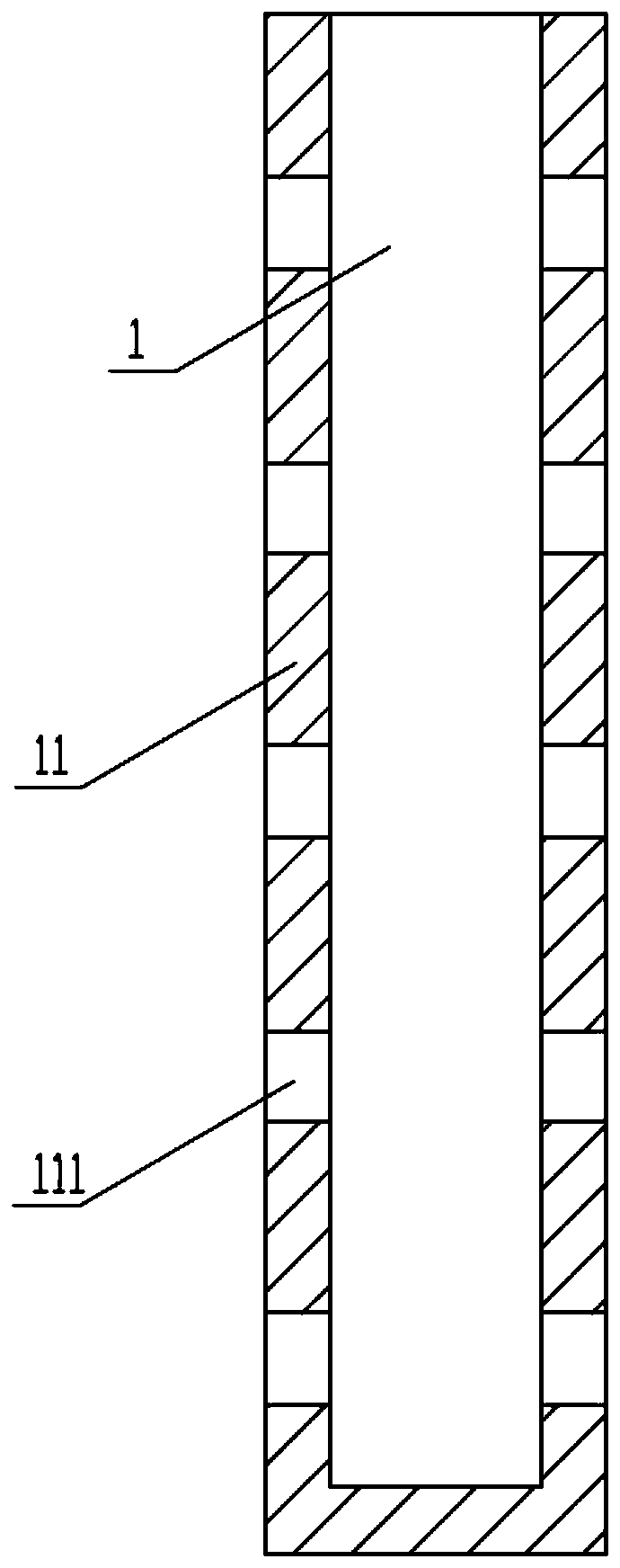

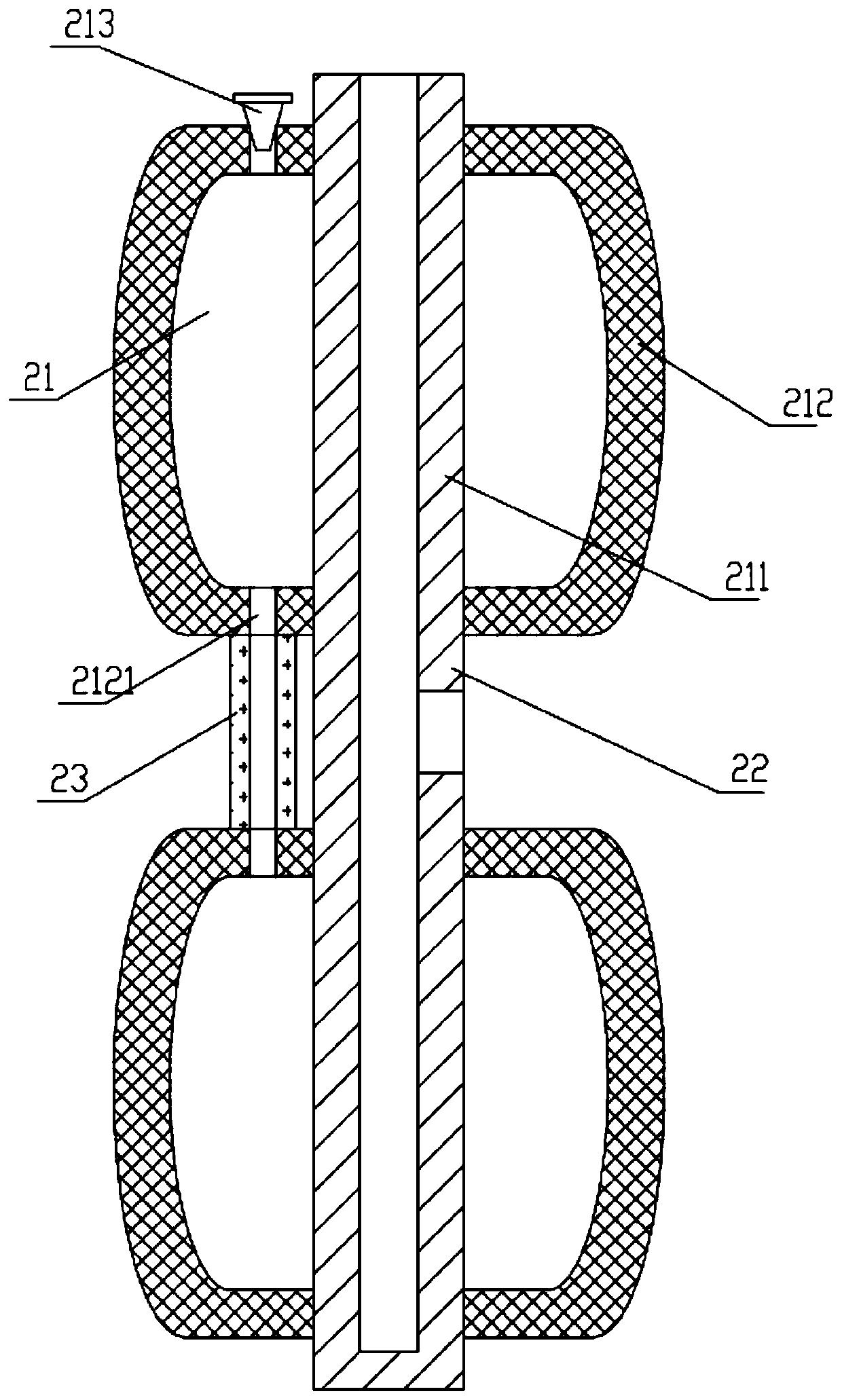

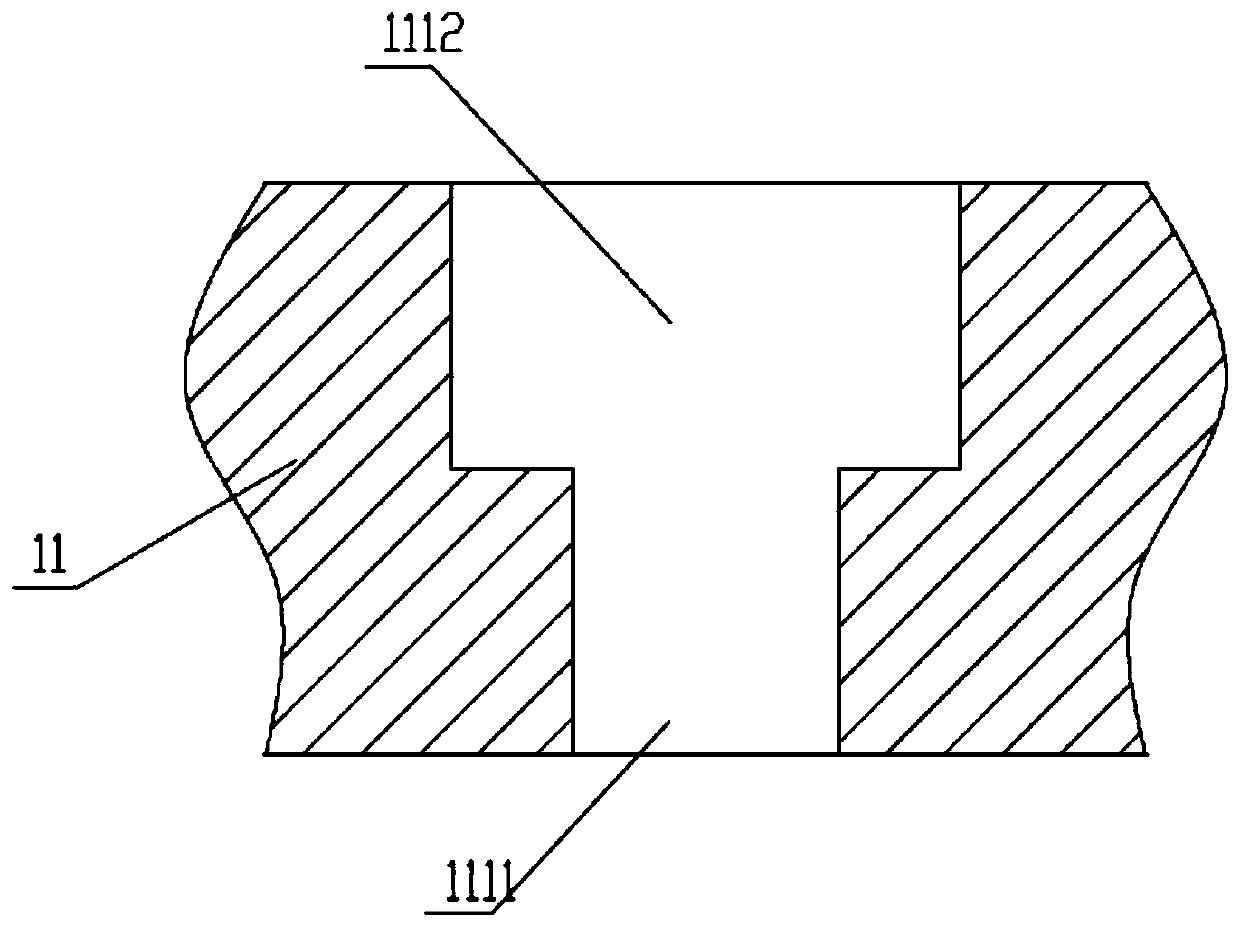

Hydraulic support for high-water cut and fill mining

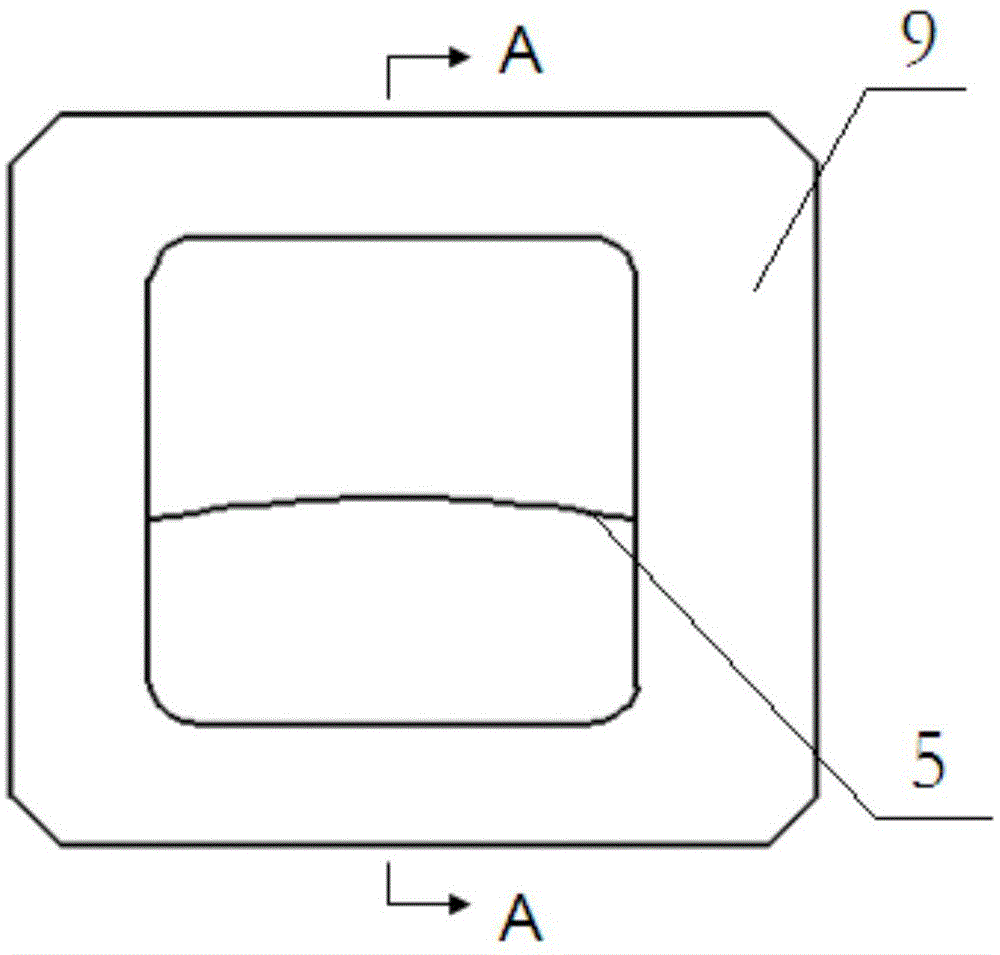

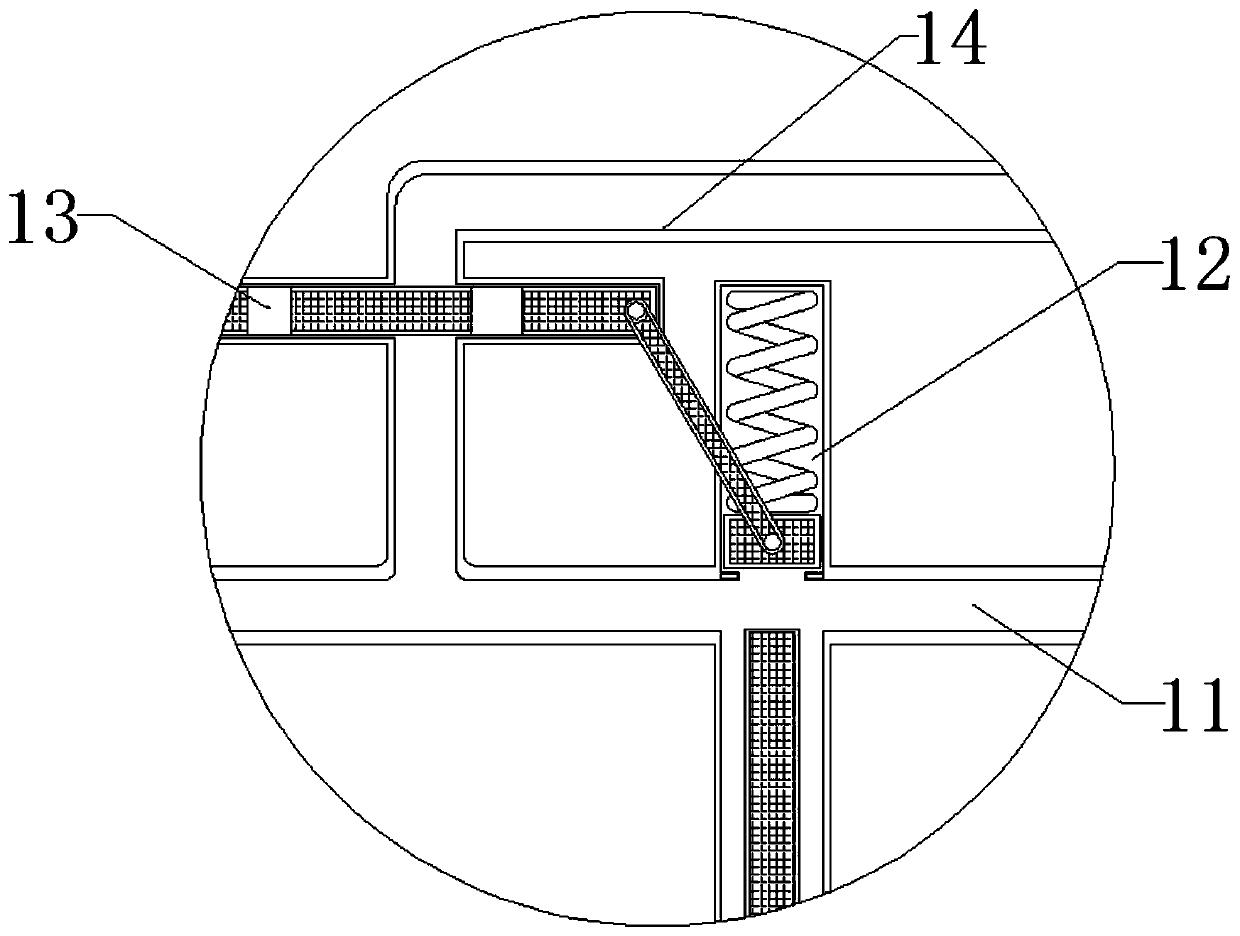

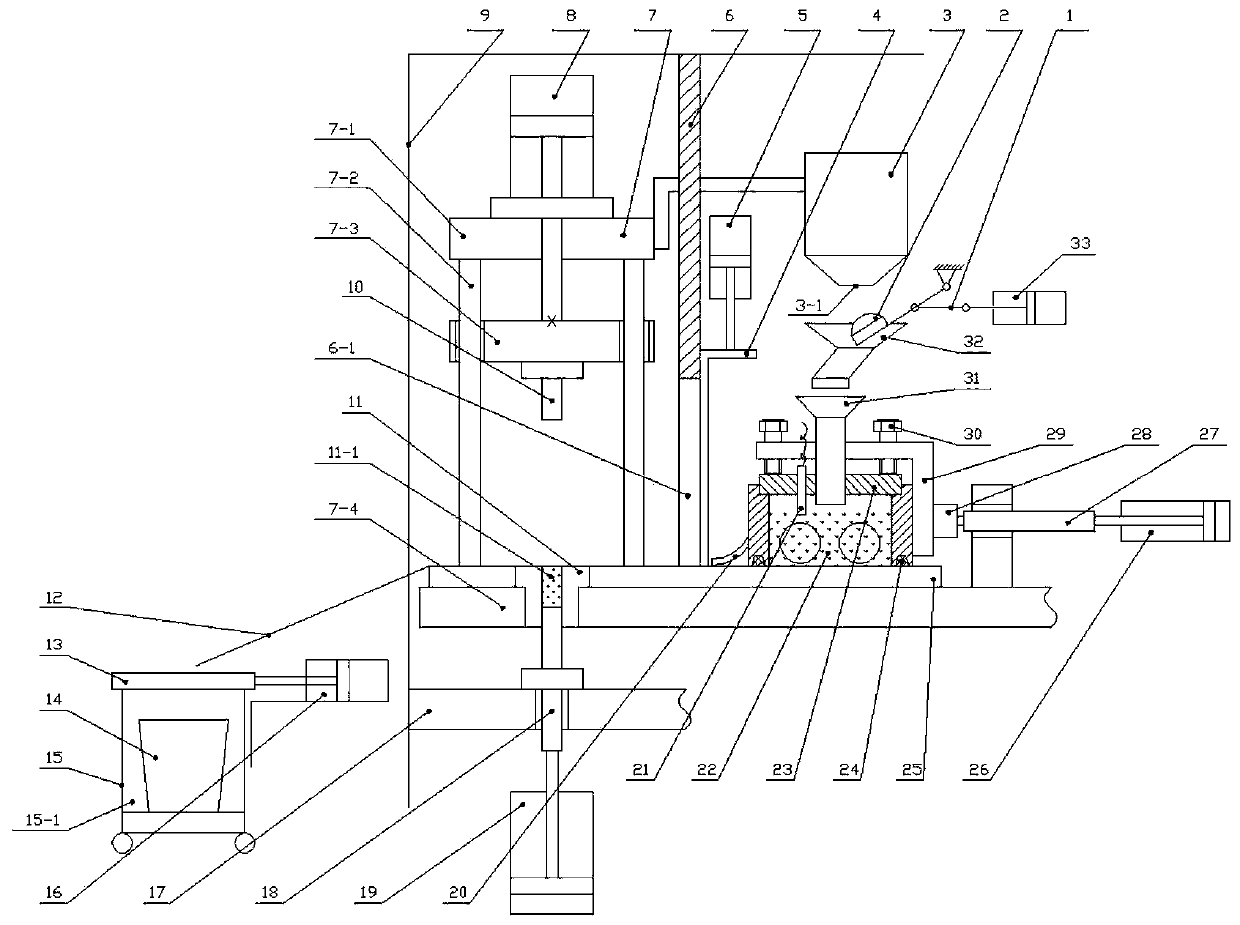

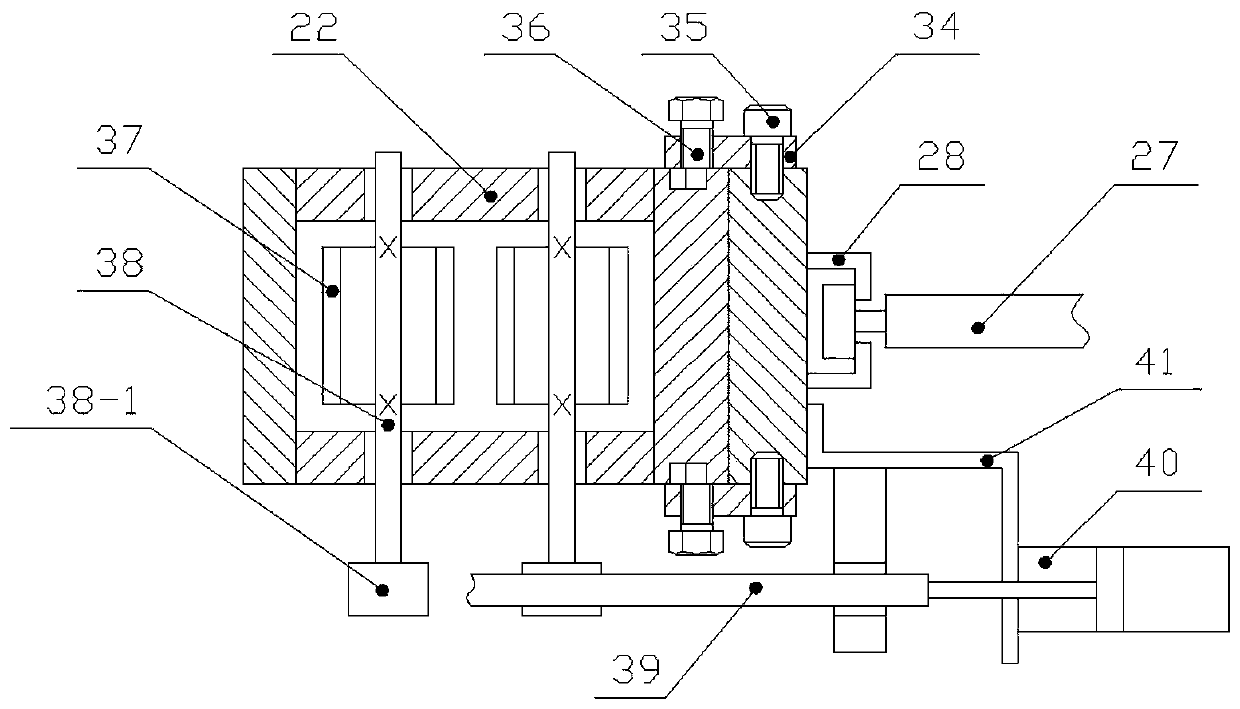

InactiveCN105065049AGuaranteed filling effectCoal mining works smoothlyMaterial fill-upMine roof supportsEngineeringCut and fill

The invention relates to the technical field of coal mining and discloses a hydraulic support for high-water cut and fill mining. The hydraulic support comprises a front top beam, a rear top beam, a length-changeable extension structure, a connection structure, a telescopic stand column, a base and a height-adjustable baffle structure. According to the hydraulic support, the front top beam and the rear top beam are integrated at the same base at the same time, the front top beam and the rear top beam are supported through the telescopic stand column, the front top beam can support a coal mining region and a coal wall, and smooth operation of the coal mining work is guaranteed; the rear top beam conducts supporting and cut and fill supporting on the top face of a goaf in the next process while conducting coal mining, and the baffle structure can isolate the goaf, so that high-water packing materials can achieve cut and fill forming in the goaf so as to form the thickness having the supporting function quickly, and the cut and fill effect is guaranteed; by means of the hydraulic support, the coal mining work and the cut and fill work are conducted at the same time, and the coal mining efficiency and the cut and fill efficiency are improved greatly.

Owner:冀中能源股份有限公司邢东矿

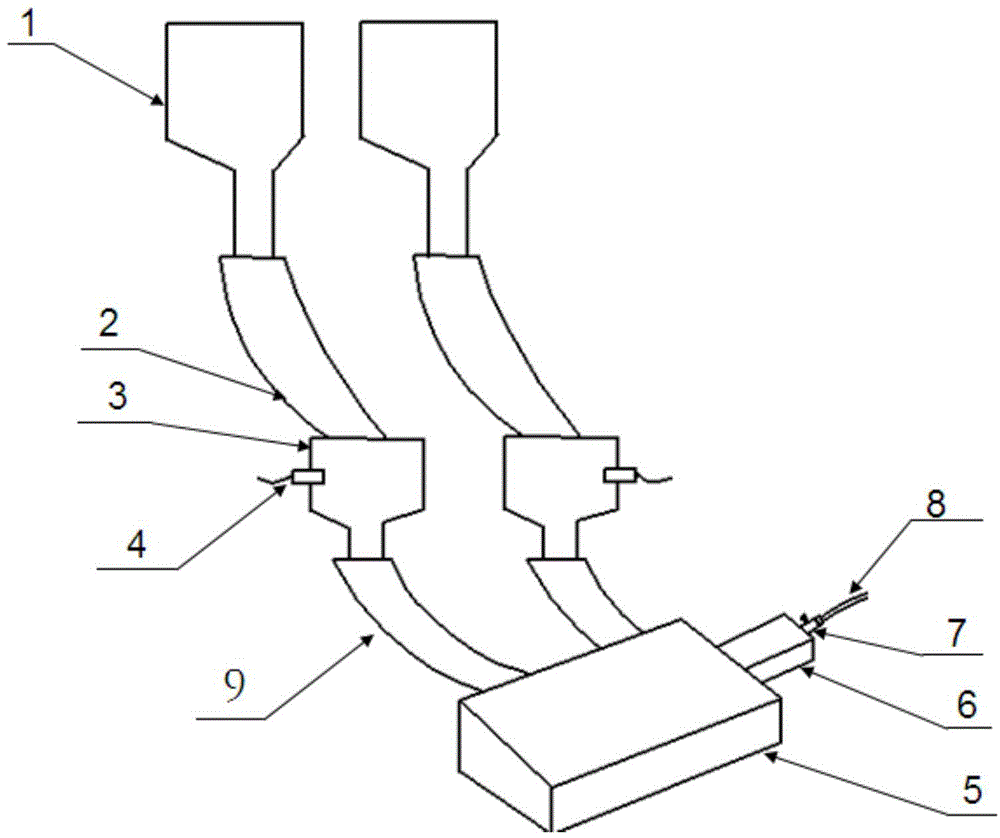

Powder metallurgy compression molding powder filling device and control method thereof

The invention discloses a powder metallurgy compression molding powder filling device and a control method thereof. The device comprises a material feeding box and at least one path of material conveying pipeline. Each material conveying pipeline comprises a first-stage hopper and a second-stage hopper which is communicated with the first-stage hopper via a material discharging pipe. The second-stage hopper is communicated with the material inlet of the material feeding box via a conveying pipe. The second-stage hopper is internally provided with a height detection sensor. The material feeding box is connected with a pneumatic vibrator. The height detection sensor and the material feeding box are connected with a control system. The height detection sensor can detect height of powder in real time and feed back to the control system so that material tainting and reduction of precision caused by oversized speed of material discharging and excessive accumulate of powder can be avoided; the material feeding box has vibration in two mutually perpendicular directions of the material feeding plane so that filling performance of powder and uniformity of material discharging can be guaranteed; and a great solving scheme is provided to automatic compression of powder which is poor in fluidity and difficult to fill so that the device is widely suitable for the powder metallurgy compression molding technology.

Owner:WUHAN WAN BANG LASER DIAMOND TOOLS

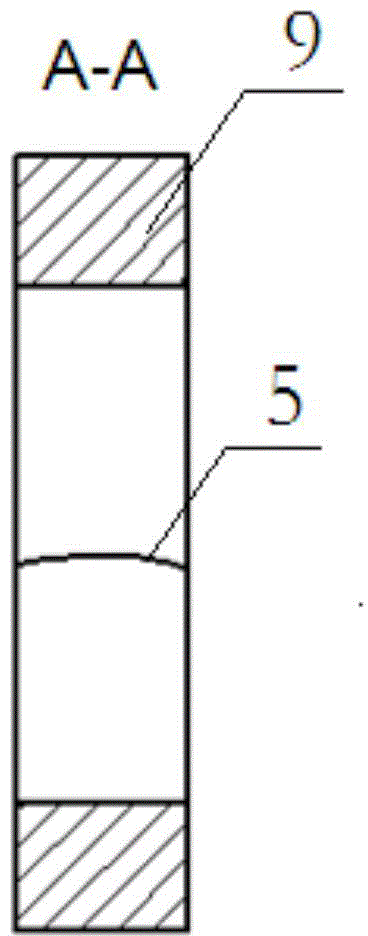

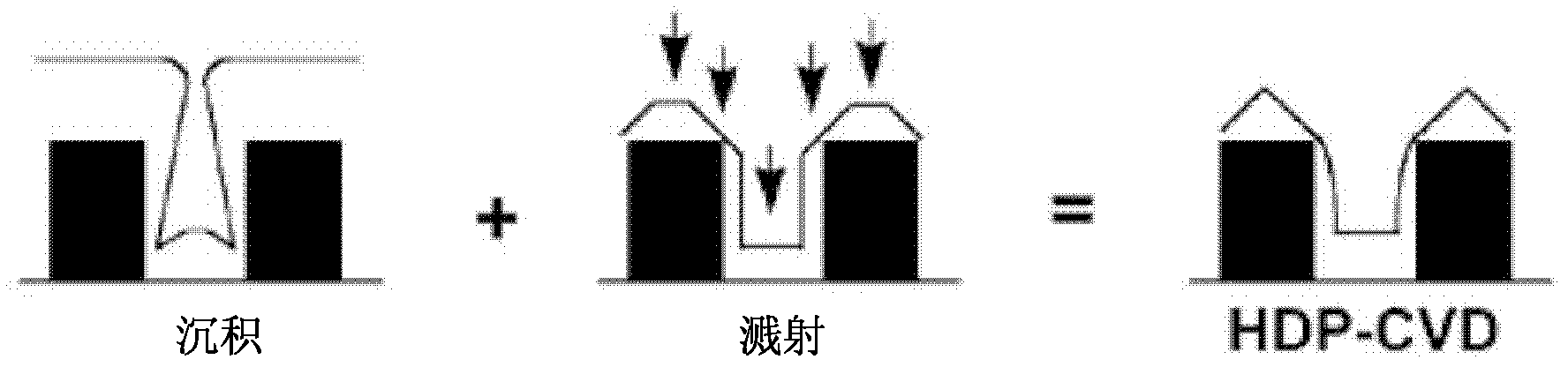

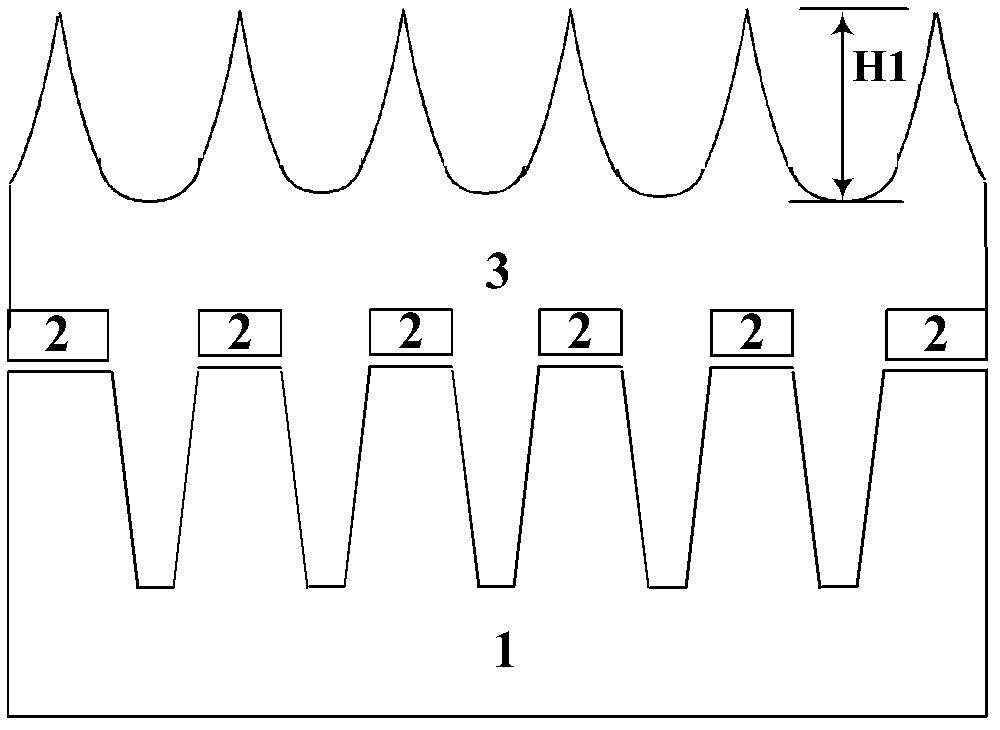

Process for improving isolating oxide chemical mechanical planarization (CMP) uniformity

ActiveCN102969238AImprove planarization uniformityImprove uniformitySemiconductor/solid-state device manufacturingHigh densityEngineering

The invention discloses a process for improving isolating oxide CMP uniformity. The process comprises the steps of forming a cushion layer on a substrate, and forming isolating oxide layers on the cushion layer and in the substrate; forming first covering layers on isolating oxide layers, wherein the height difference between tops of first covering layers is equal to or lager than that between tops of isolating oxide layers; forming second covering layers on first covering layers, wherein the height difference between tops of second covering layers is smaller than that between tops of first covering layers and / or that between tops of isolating oxide layers; and conducting CMP treatment on second covering layers, first covering layers and isolating oxide layers sequentially till the cushion layer is exposed. According to the process, integration is conducted in a process chamber of high-density plasma (HDP) depositions, no additional process step is required, the filling effect can be guaranteed at the same time when height differences are effectively reduced, and dishing defects in the CMP process can be reduced or avoided, so that the planarization uniformity of the CMP process can be improved, and the window of the CMP process can be expanded.

Owner:BEIJING YANDONG MICROELECTRONICS

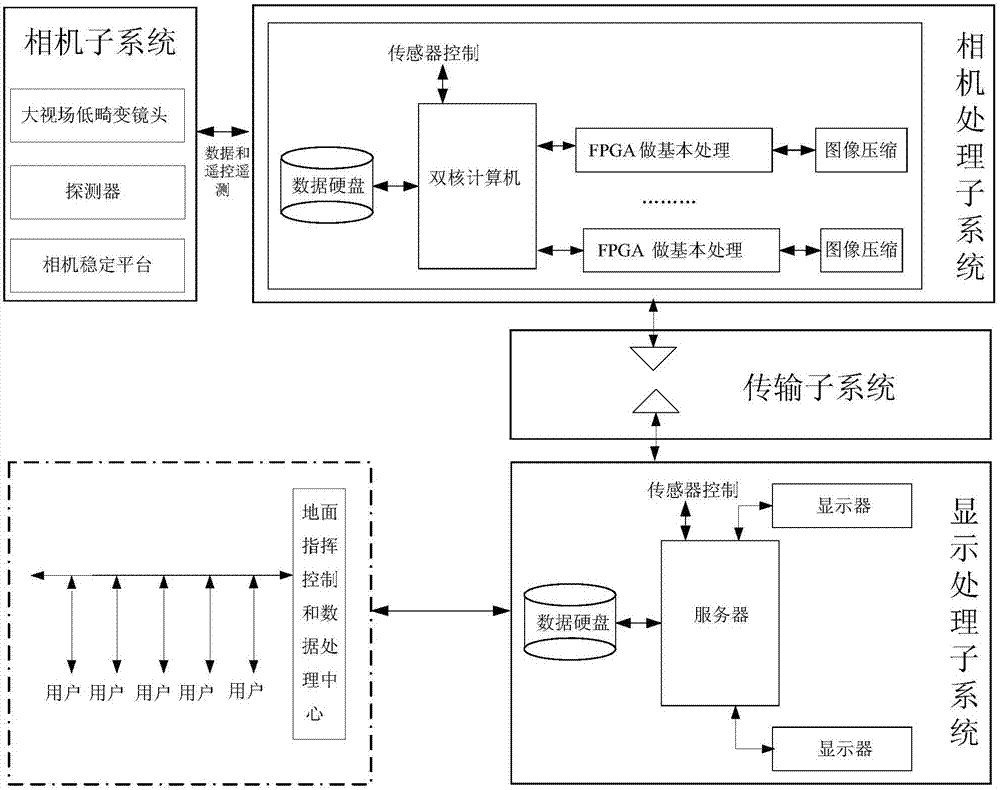

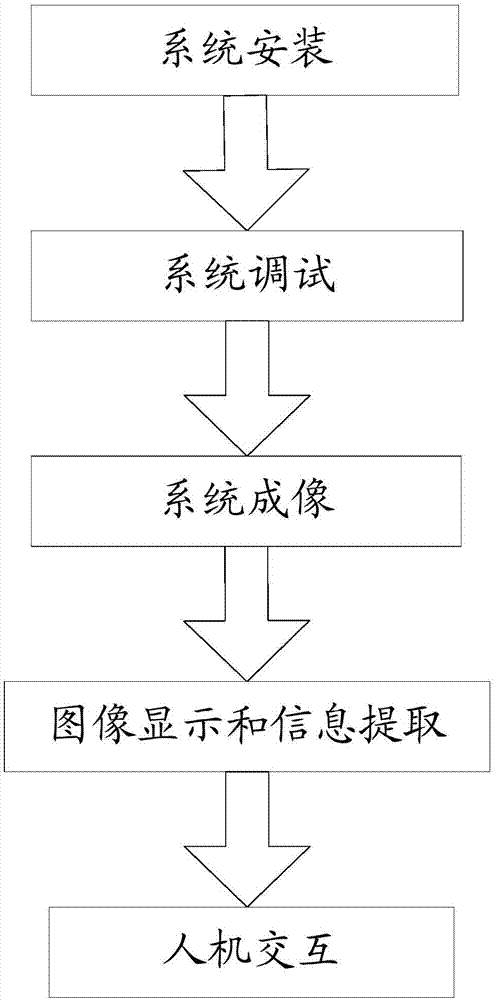

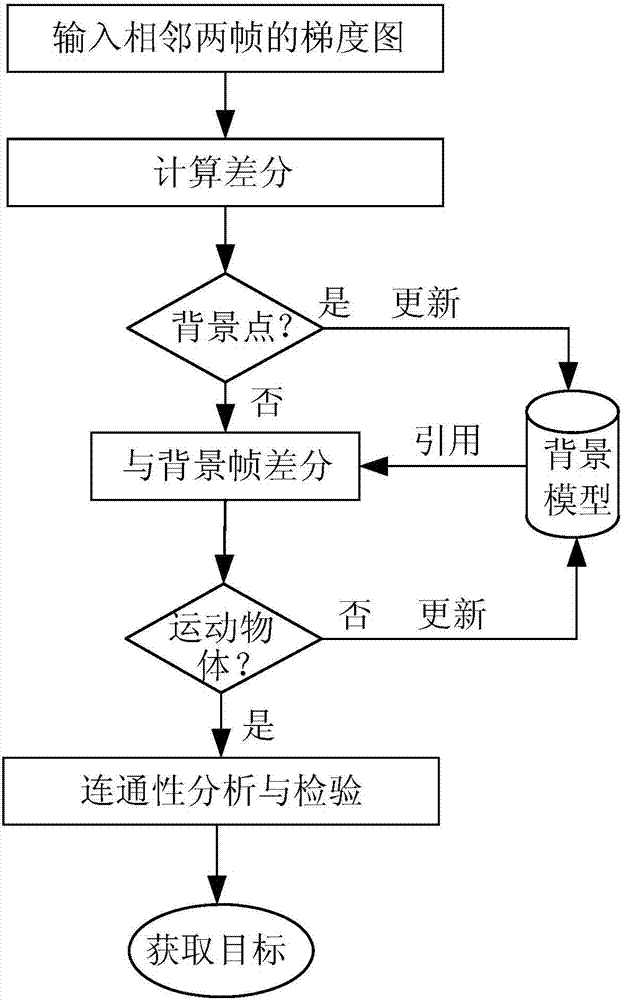

Intelligent reconnaissance monitoring optoelectronic system

ActiveCN106878611AExpand the scope of surveillanceGuaranteed filling effectImage enhancementTelevision system detailsUser needsInter frame

Provided is an intelligent reconnaissance optoelectronic system which can download the pictures of the needed area according users' needs without increasing the communication bandwidth. The system has the advantages of intelligentization, networking, and digitlization, and a camera subsystem, a camera processing subsystem, a transmission subsystem, and a display processing subsystem. A user can transfer the information of the needed area or target through the display processing subsystem to the camera processing subsystem through the transmission subsystem, the camera processing subsystem cuts or tracks the user interested area or target by software, the camera processing subsystem automatically locks the tracking target by means of inter-frame differential detection. The system can download the needed information according to the user's needs, so that the difficulty that the reconnaissance monitoring cannot acquire the key information in real time due to the limitation of transmission bandwidth.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Fabric with cotton filling stereoscopic effect and weaving method thereof

ActiveCN108360121AUnique application effectFeel comfortableSwivel-woven fabricsLappet-woven fabricsYarnEngineering

Owner:上海奕姜新材料科技有限公司

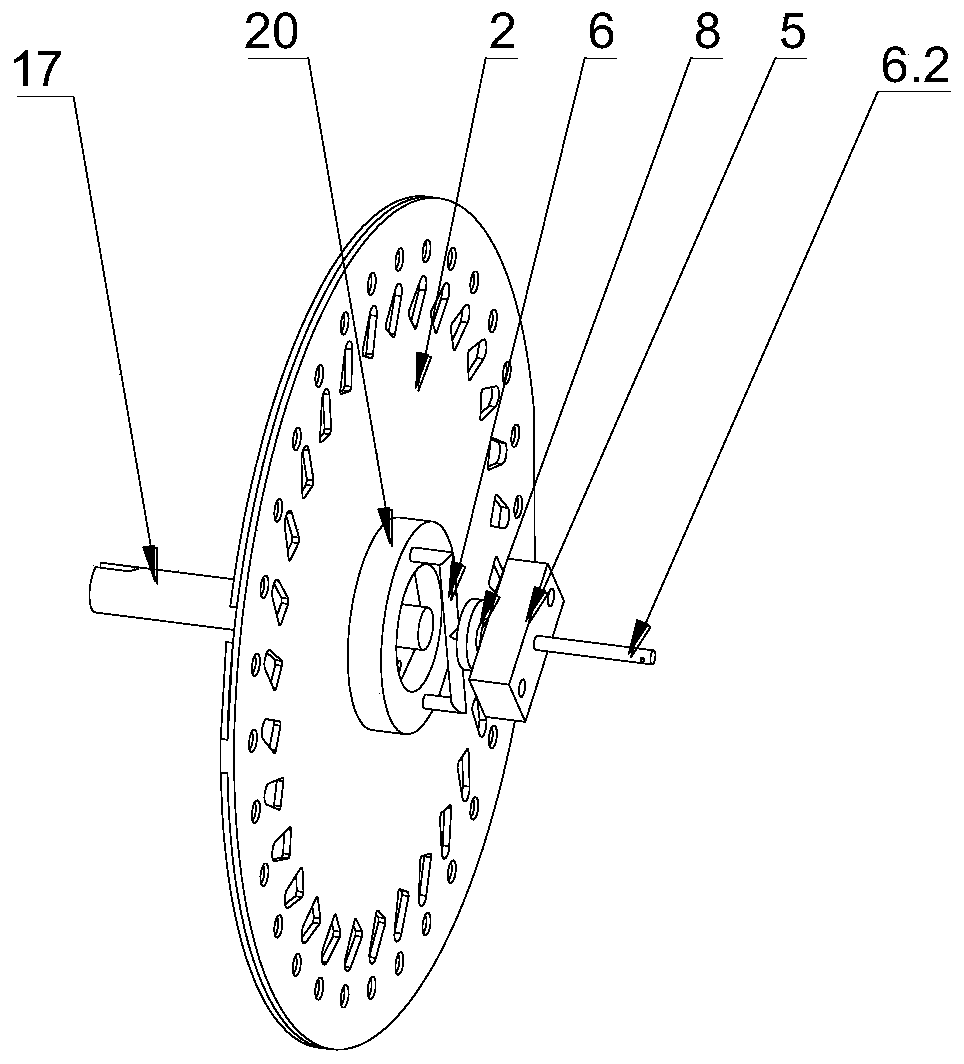

Variable-suction-hole dual-disc air-aspiration type precise seeding device

PendingCN110583176AImprove filling performanceSimple structureSeed depositing seeder partsRegular seed deposition machinesAgricultural engineeringGravity effect

The invention discloses a variable-suction-hole dual-disc air-aspiration type precise seeding device. The device comprises a seed conveying pipe, a front panel, a front shell body, an air chamber shell body, a seeding plate and an adjusting plate; the seed conveying pipe is installed on the front panel, and seeds flow into a seed filling chamber along the seed conveying pipe under the gravity effect; the front panel is installed on the front shell body and made from a transparent material through cutting, and the seed filling quality is conveniently observed; the front shell body is provided with a seed partition plate, a seed throwing port and a seed discharging port, the seed partition plate partitions a seed filling area and a seed throwing area, the seed throwing port is connected witha seed guiding pipe, and the seed discharging port is used for removing remaining seeds; a negative pressure area with the three quarter arc surface is arranged on an air chamber shell body; an adjustable-seed-hole dual-disc mechanism comprises the seeding plate, an adjustment plate and an adjustment rod, and seed holes are uniformly formed in the seeding plate and the adjustment plate. The variable-suction-hole dual-disc air-aspiration type precise seeding device adopts the superposition combination principle, is simple in structure, meets the universal seed sowing demands of soybeans and corn, and effectively avoids the situation that a seed suction component is detached and assembled many times, so that gas tightness is influenced.

Owner:HUAZHONG AGRI UNIV

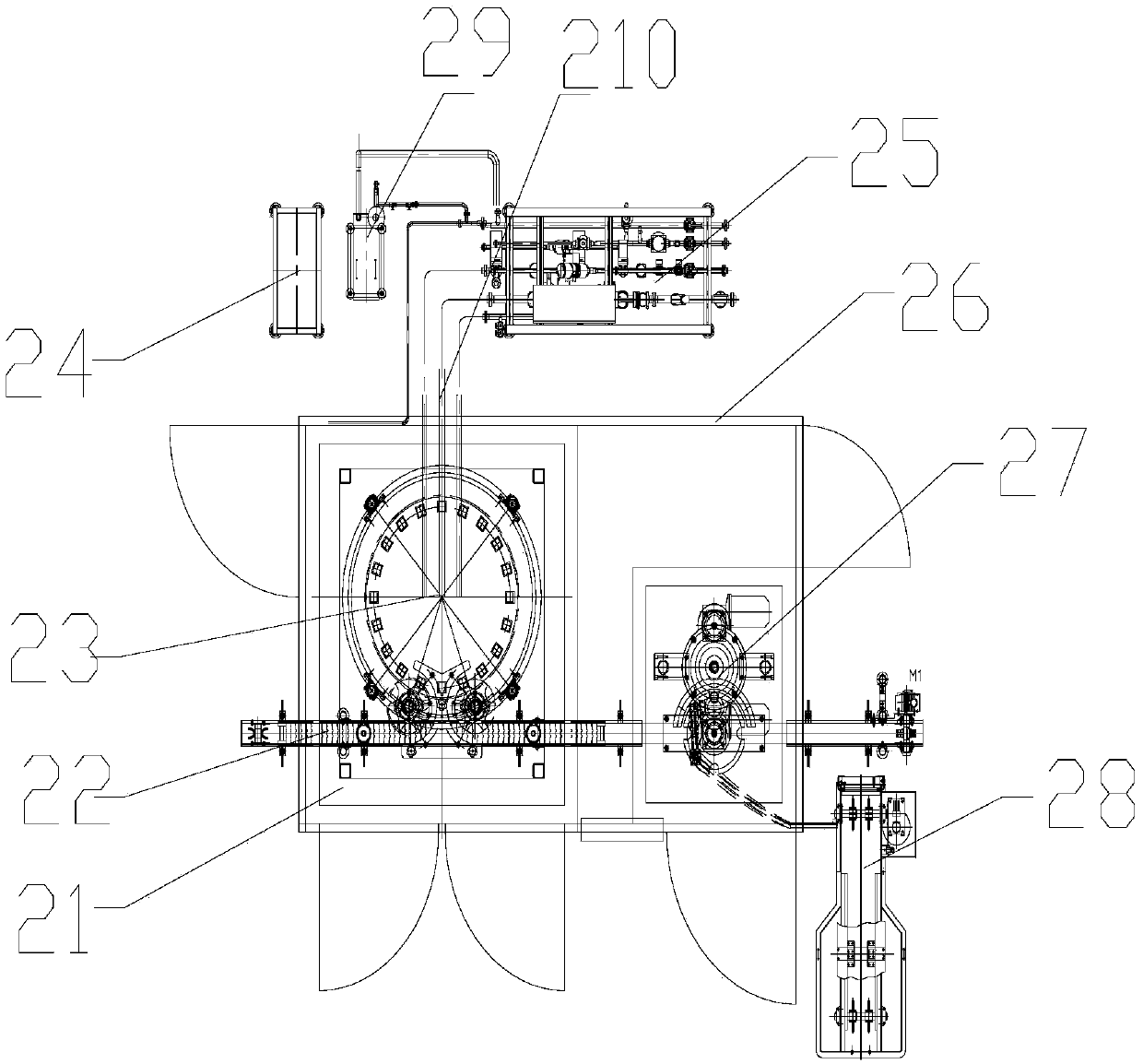

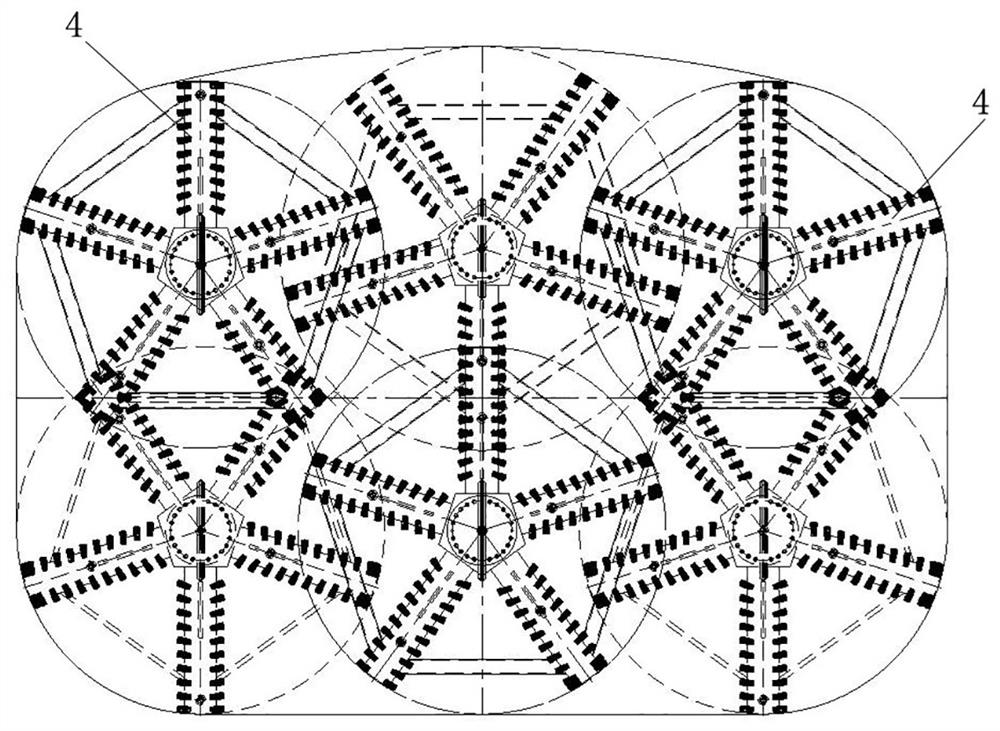

Craft beer filling and capping machine

PendingCN110734024AGuaranteed uptimeTake up a reasonable amount of spaceThreaded caps applicationSynchronising machinesRotary stageWine bottle

The invention relates to the technical field of packaging beverage conveying equipment, in particular to a craft beer filling and capping machine. The machine comprises a workbench, wherein the workbench is provided with a filling mechanism and a cap screwing mechanism, the workbench is provided with a conveying mechanism for conveying empty wine bottles to the filling mechanism and conveying thewine bottles finishing filling to the cap screwing mechanism, the filling mechanism comprises a mounting frame rotated relative to the workbench, a plurality of long tube filling valves are fixed on the mounting frame in the circumferential direction, a rotating table used for bearing the beer bottles is rotatably arranged below the mounting frame, a guide plate mechanism, a bottle feeding shifting wheel and a bottle discharging shifting wheel are arranged between the conveying mechanism and the rotating table, wherein the bottle feeding shifting wheel is used for guiding the beer bottles fromthe conveying mechanism to the rotating table, the bottle discharging shifting wheel is used for exporting the beer bottles from the rotating table to the conveying mechanism, the bottle feeding shifting wheel and the bottle discharging shifting wheel are in a chain gear structure, and the side faces, facing the bottle feeding shifting wheel and the bottle discharging shifting wheel, of the guideplate mechanism are in arc shapes. According to the machine, the liquid level is changed from bottom to top until filling is finished, and the filling process is stable.

Owner:南京恒昌包装机械有限公司

Method for filling goaf with different materials alternately

ActiveCN110486082AGuaranteed filling effectIncrease production capacityMaterial fill-upEngineeringMechanical engineering

Owner:河北充填采矿技术有限公司

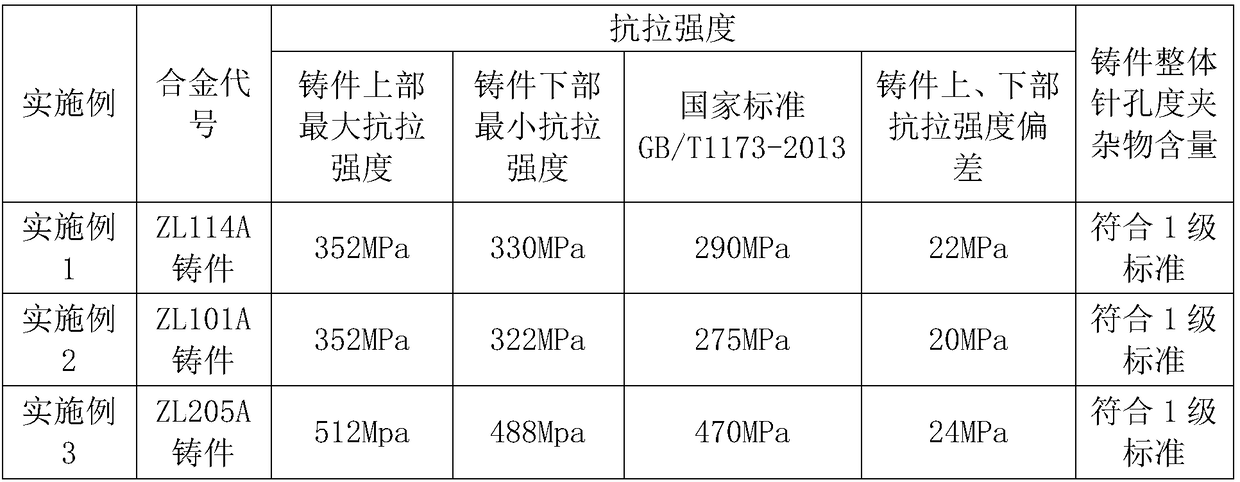

Gypsum casting method for large-sized thin-walled aluminum alloy castings

ActiveCN108127101ATensile strength deviation reducedQuality improvementTemperature controlMold filling

The invention provides a gypsum casting method for large-sized thin-wall aluminum alloy castings. The method comprises the steps of refining treatment, melt mold filling and pressurization solidification; in the melt mold filling process, the temperature of a lower mold plate is always controlled within 650-720 DEG C, and the temperature of an upper mold plate is always controlled within 750-780 DEG C. By means of the method, through the temperature control over the mold plates, the temperature fields of a casting mold and aluminum alloy melt of the casting mold are well optimized to make thedeviation of the tensile strength of the aluminum alloy castings greatly reduced, and the quality of the aluminum alloy castings is improved.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

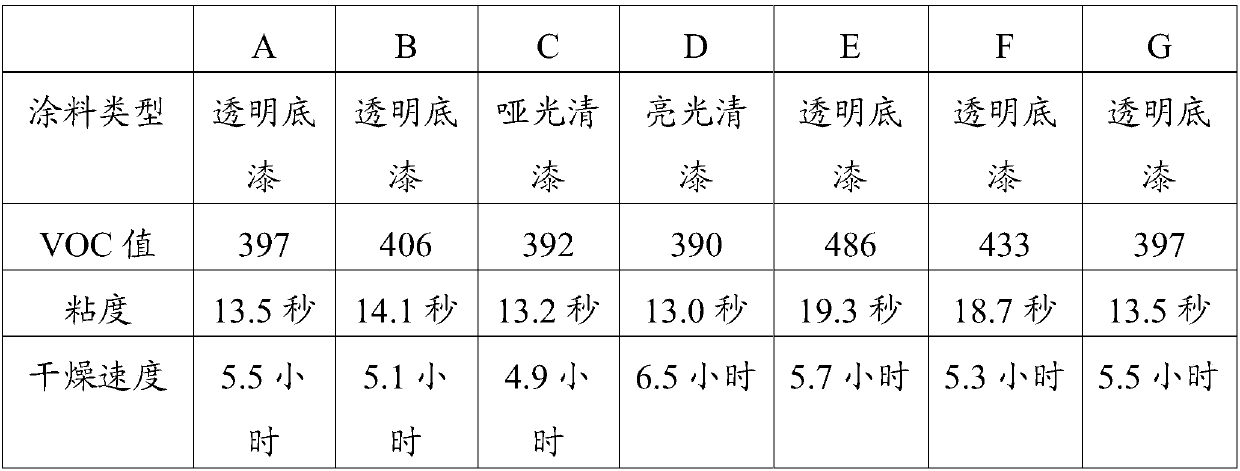

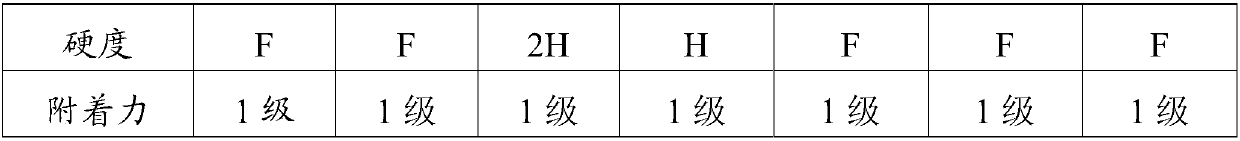

Two-component polyurethane coating with low emission of volatile organic compounds (VOC), and preparation method of polyurethane coating

InactiveCN107674575ALow viscosityReduce usagePolyurea/polyurethane coatingsDefoaming AgentsDiphenylmethane diisocyanate

The invention relates to a two-component polyurethane coating with low emission of volatile organic compounds (VOC). The polyurethane coating is prepared from a component A, a component B and a component C, wherein the weight ratio of the component A to the component B to the component C is equal to 1 to (2 to 3) to (0.5 to 1); the component A is prepared from 10-30 parts of a diisocyanate prepolymer and 70-90 parts of diphenylmethane diisocyanate; the component B is prepared from 50-80 parts of short-oil alkyd resin, 5-25 parts of an organic solvent, 0-0.5 part of a dispersing agent, 0-5 parts of extinction powder, 0-1.0 part of wax powder, 0-15 parts of talcum powder, 0-3.0 parts of an anti-settling agent, 0-0.5 part of a leveling agent, 0.1-0.5 part of a defoaming agent and 0.1-0.3 partof a drying catalyst; the component C is prepared from 70-90 parts of butyl acetate and 10-30 parts of propylene glycol methyl ether acetate. The two-component polyurethane coating provided by the invention is prepared from the high solid content raw materials, so that the consumption of the solvent is effectively reduced; the VOC emission of the polyurethane coating is about 400g / L, so that thepolyurethane coating is especially suitable for being applied and popularized to finishing and painting of wood furniture.

Owner:CARPOLY CHEM GRP

Imbibition bottle fluid adding device and method for imbibition experiment

PendingCN110987766AGuaranteed filling effectEasy to operate manuallyPermeability/surface area analysisPressure generationRock core

The invention discloses an imbibition bottle fluid adding device and method for an imbibition experiment. The imbibition bottle fluid adding device comprises a negative pressure generation system, animbibition bottle and a fluid supply system. The top of a capillary metering tube of the imbibition bottle is connected with the negative pressure generation system, and an inlet of a glass wide-mouthbottle of the imbibition bottle is connected with the fluid supply system. A rock core sample is arranged in the glass wide-mouth bottle, and the capillary metering tube is connected with the glass wide-mouth bottle; and the glass wide-mouth bottle inlet of the imbibition bottle is connected with the fluid supply system. Imbibition liquid in the fluid supply system is pumped into the imbibition bottle by utilizing the negative pressure generation system; the negative pressure generation system stops working when the imbibition bottle is full of the imbibition liquid. The glass wide-mouth bottle inlet and the fluid supply system are separated from a connection portion, a rubber plug is inserted into the glass wide-mouth bottle inlet, and the top of the capillary metering tube and the negative pressure generation system are separated from the connection portion. The experimental result accuracy is improved, the operation difficulty of an imbibition liquid adding link is reduced, the time consumed by the imbibition liquid adding link is shortened, and the experimental efficiency is greatly improved.

Owner:XI'AN PETROLEUM UNIVERSITY

Method for crushing and solidifying cohesive soil by spraying high-pressure liquid-gas mixed fluid

ActiveCN112227127AWell mixedMoisture content is easy to controlRoadwaysSoil preservationLand acquisitionSoil science

The invention discloses a method for crushing and solidifying cohesive soil by spraying a high-pressure liquid-gas mixed fluid. The method comprises the following steps: detecting the characteristicsof cohesive soil on a construction site, including detection of the water content and the clay particle content, then pre-burying a pipeline into the cohesive soil, and starting to prepare liquid-gasmixed fluid; then, applying the pressure on the liquid-gas mixed fluid, after pressing is finished, conveying the high-pressure liquid-gas mixed fluid into the cohesive soil at a certain burial depththrough a pipeline and spraying the fluid into the cohesive soil through spraying devices such as a spraying head, applying the shearing force to a soil body, cutting and crushing the soil body, and in the cutting and crushing process of the soil body through the high-pressure spraying mixed fluid, fully mixing a curing agent solution in the mixed fluid with the soil body broken particles to ensure that the soil body broken particles react with the soil body, so that the soil body is cured. According to the method, the soil body can be maintained in situ, land occupation or land acquisition isnot needed, and the method is efficient and environment-friendly.

Owner:HEBEI ROAD & BRIDGE GROUP +1

Composite honeycomb sandwich structure and styrofoam filling method for structure

ActiveCN110744872AGuaranteed filling effectReduce internal stressLayered productsThermal dilatationHoneycomb

The invention relates to the technical field of composite material manufacture, in particular to a composite honeycomb sandwich structure and a styrofoam filling method for the structure. The sandwichstructure includes a composite inner skinning, a composite outer skinning, a honeycomb core material, styrofoam and shrinkage inhibiting members, wherein a filling cavity is formed between the composite inner skinning and the composite outer skinning, the filling cavity includes a honeycomb core material filling cavity and a styrofoam filling cavity, and the honeycomb core material is filled intothe honeycomb core material filling cavity; and the styrofoam is filled into the styrofoam filling cavity, and the shrinkage suppression members are bundled and put into the styrofoam. The prepreg unidirectional tape and the styrofoam are cured together, so that the problem of deformation caused by the internal stress which is brought by thermal expansion of the styrofoam is solved.

Owner:AVIC BASIC TECH RES INST

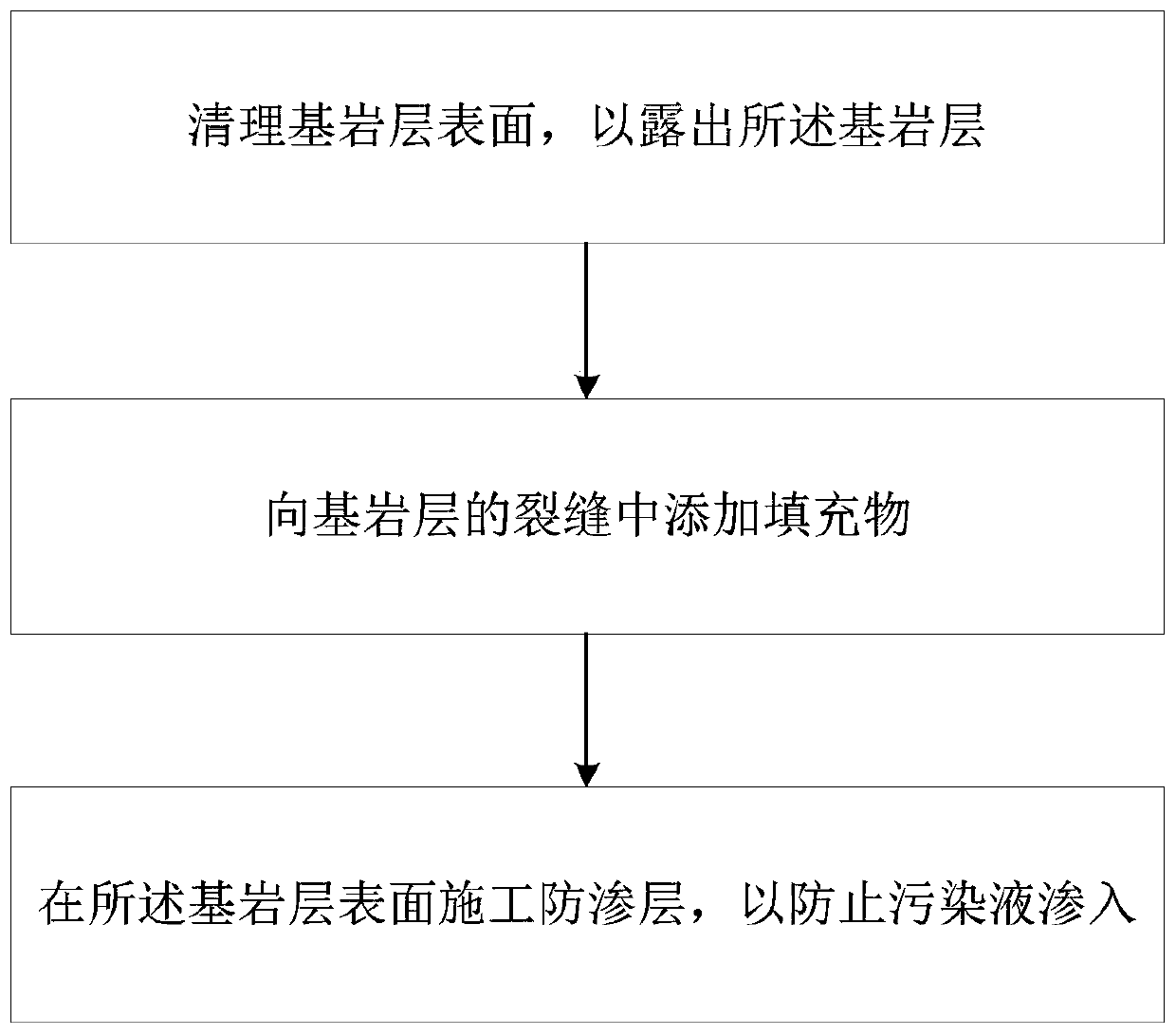

Method for repairing anti-seepage weathering bedrock at bottom of waste slag or tailings storage yard

InactiveCN110258652AImprove bearing strengthSolve pollutionProtective foundationSlagIndustrial waste

The invention discloses a method for repairing anti-seepage weathering bedrock at the bottom of a waste slag or tailings storage yard. The method comprises the following steps that S1, the surface of a bedrock layer is cleaned to expose the bedrock layer; S2, filler is added to cracks of the bedrock layer; and S3, an anti-seepage layer is constructed on the surface of the bedrock layer to prevent infiltration of polluted liquid. The cracks of the bedrock layer are filled with the filler, the problem of insufficient strength in the prior art due to the existence of a large number of cracks in the bedrock can be effectively solved, and the problem of serious environmental pollution caused by the infiltration of industrial waste liquid, chemical products, slag and the like into the bedrock layer is solved.

Owner:中节能大地环境修复有限公司 +1

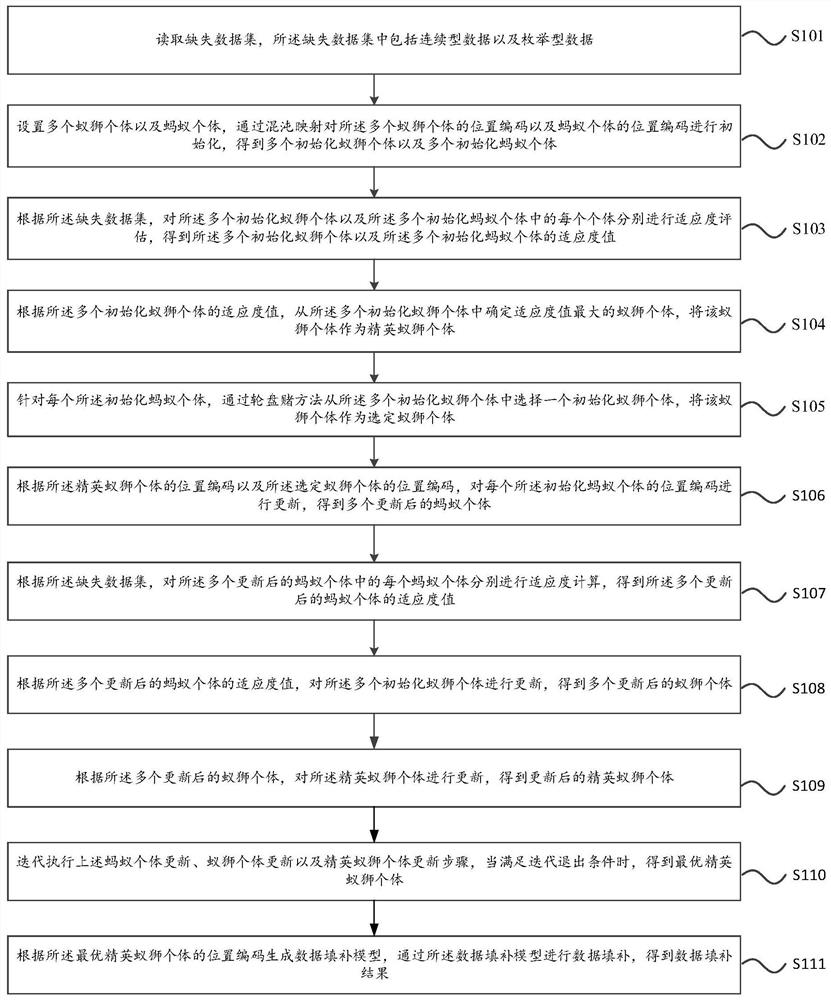

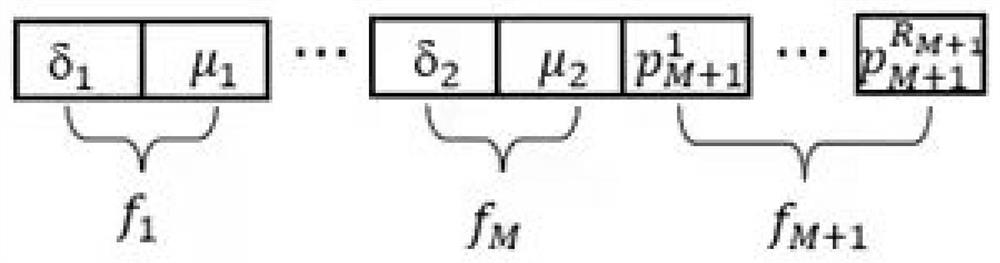

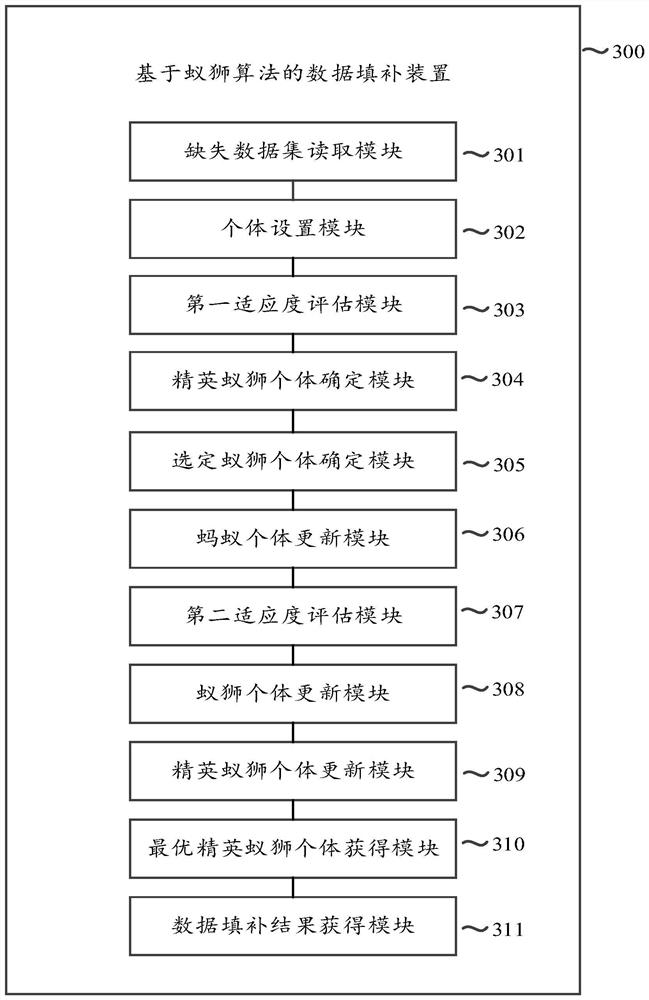

Data filling method and device based on ant lion algorithm, equipment and storage medium

ActiveCN114490618AGuaranteed filling effectImprove filling qualityArtificial lifeData miningData classMissing data

The embodiment of the invention relates to the technical field of data processing, in particular to a data filling method and device based on an ant lion algorithm, equipment and a storage medium, and aims to improve the data filling quality in a missing data filling task. The method comprises the following steps: receiving a missing data set, setting a plurality of ant individuals and ant lion individuals according to missing data types, calculating fitness values of each ant individual and each ant lion individual, selecting the ant lion individual with the maximum fitness value as an elite ant lion individual, selecting one selected ant lion individual for each ant individual, and selecting the selected ant lion individual as the elite ant lion individual; updating the position codes of the ant individuals according to the position codes of the selected ant lion individuals and the position codes of the elite ant lion individuals, updating the selected ant lion individuals according to the updated ant individuals so as to determine new elite ant lion individuals, iteratively executing the steps, generating a data filling model according to the finally obtained elite ant lion individuals, and completing the data filling. And executing the data filling task.

Owner:BEIJING BIG DATA ADVANCED TECH RES INST

Exothermic welding crucible forming die

ActiveCN106003389AMade efficientlySuccessfully madeMouldsMould auxillary partsExothermic weldingCrucible

The invention discloses an exothermic welding crucible forming die. The exothermic welding crucible forming die comprises an outer die body with a first cavity formed inside and an inner die body partly contained in the first cavity. The inner die body comprises an inner die core contained in the first cavity. A plurality of exhaust holes arranged in order are formed in the surface of the inner die core. Exhaust plugs are arranged in the exhaust holes. By means of the exothermic welding crucible forming die, an exothermic welding single-use crucible with a protection layer can be efficiently and smoothly manufactured, and the functions of damp proofing, pressure resisting and breakage preventing are achieved for the crucible; the sand shooting forming effect is good, carrying is convenient, and the production problem that the crucible is not easy to form is solved; and the sand flow filling capability is guaranteed, and the production efficiency and forming effect are improved.

Owner:施密特钢轨技术(昆山)有限公司

Excavation blind area pretreatment method and tunnel excavation construction method

The invention relates to an excavation blind area pretreatment method and a tunnel excavation construction method. The tunnel excavation construction method specifically comprises the steps that firstly, an excavation blind area of a special-shaped section tunneling machine is pretreated through the excavation blind area pretreatment method, and then special-shaped section tunneling construction is conducted; and the pretreatment method specifically comprises the steps that the position where bed rock invades in the excavation blind area is determined, and then the bed rock at the position is pretreated, wherein pretreatment comprises the step that the bed rock at the position is crushed. In the abovementioned way, before special-shaped section tunneling construction, the bed rock which has adverse effects on tunneling of the special-shaped section tunneling machine in the excavation blind area is crushed, invasion of the bed rock in the excavation blind area is eliminated, and normal tunneling construction is guaranteed.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Device for rapidly cleaning and disinfecting interior of beverage packaging mechanism

InactiveCN111591483ARapid cleaning and disinfectionQuick washLiquid materialPackaging machinesPhysicsPackaging machine

The invention relates to the technical field of packaging, and discloses a device for rapidly cleaning and disinfecting the interior of a beverage packaging mechanism. The device comprises a filling machine, a conveying belt is movably connected to the interior of the filling machine, a control wheel is movably connected to the left side of the conveying belt, and an air pressure bin is movably connected to the bottom of the interior of the filling machine; and fixed rails are movably connected to the bottom of the interior of the filling machine, a partition plate is movably connected betweenthe two fixed rails, a blow-off pipe is movably connected to the lower portion of the partition plate, and an oil inlet pipe is movably connected to the left side of the blow-off pipe. The oil inletpipe starts to introduce hydraulic oil into the partition plate, a partition sliding block is pushed to move rightwards to compress a partition spring, the partition sliding block blocks the positionof a pipe opening of the blow-off pipe, along with increase of cleaning liquid above the partition plate, the effect of rapidly cleaning the filling machine after filling is completed is achieved, andthe filling effect is guaranteed.

Owner:胡礼文

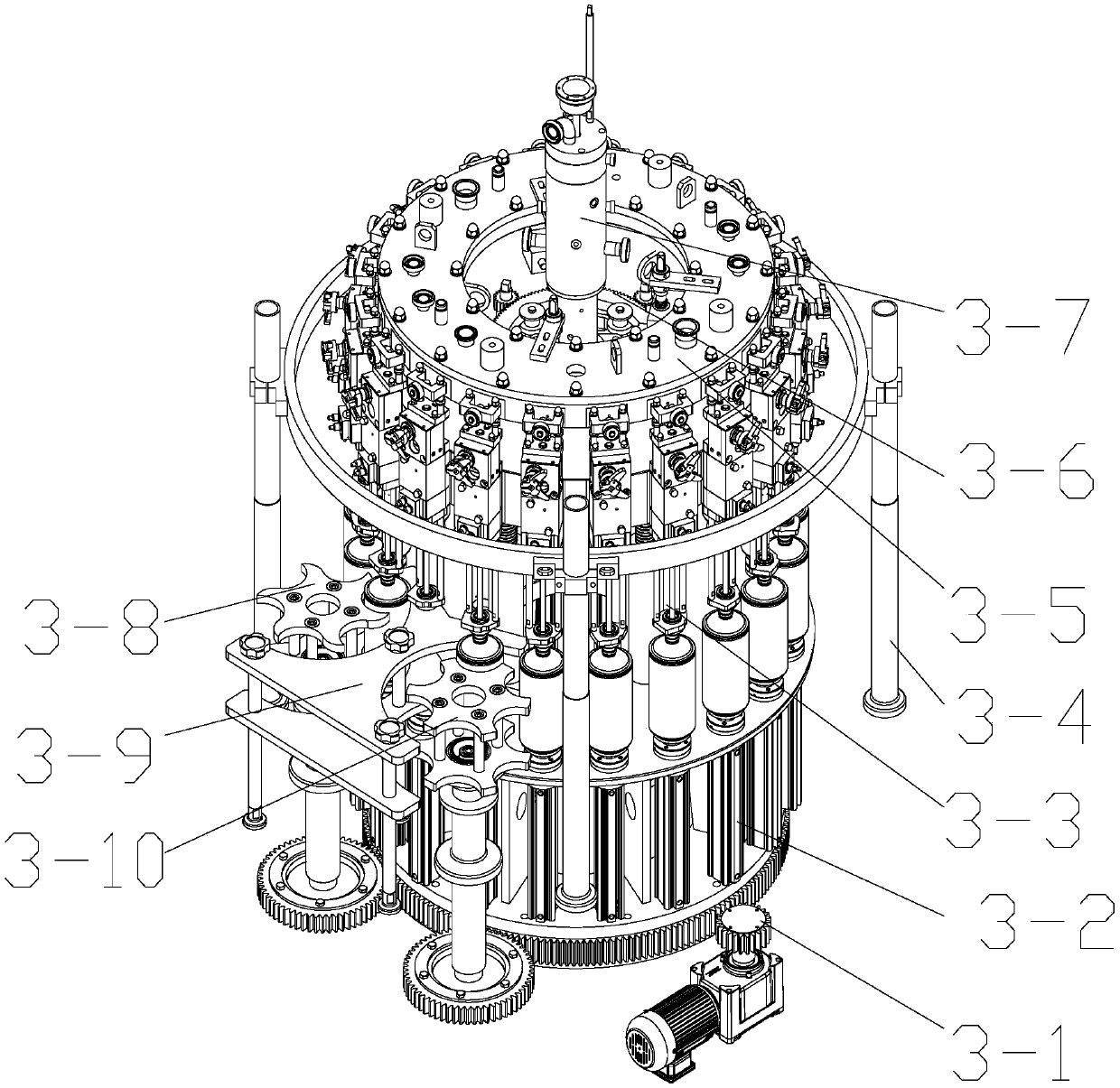

Full-automatic forming unit for dry powder of pyrotechnic composition

InactiveCN110642660AGood liquidityGuaranteed filling effectExplosive working-up apparatusBall valveMan machine

The invention discloses a full-automatic forming unit for dry powder of a pyrotechnic composition. According to the invention, a partition plate 6 is arranged on a main machine base 17; a die frame 7,an upper punch 10, a female die 11, a lower punch 18, a shuttle groove 12, a trolley 15 and a second shielding door 13 are arranged at one side of the partition plate; and a first shielding door 4, astorage hopper 3, a ball valve 2, a material box 22 and angle iron 29 are arranged at the other side of the partition plate 6. Wet powder obtained after slurrying of pyrotechnic composition powder isproperly dried into dry powder; the characteristics of good fluidity and no mold sticking of the dry powder are utilized; automatic compression molding is carried out in a hydraulic mode in a die; formed particles do not need to be baked any more and can be directly wrapped with powder for use; the automation degree of equipment is high; complete man-machine separation is achieved; safety and reliability are achieved; sanitary conditions are good; high economical performance is obtained; and the setting-off effect of a prepared pyrotechnic composition is good; and conditions are created for realizing workshop production of the pyrotechnic composition and saving land occupation area.

Owner:陈锐

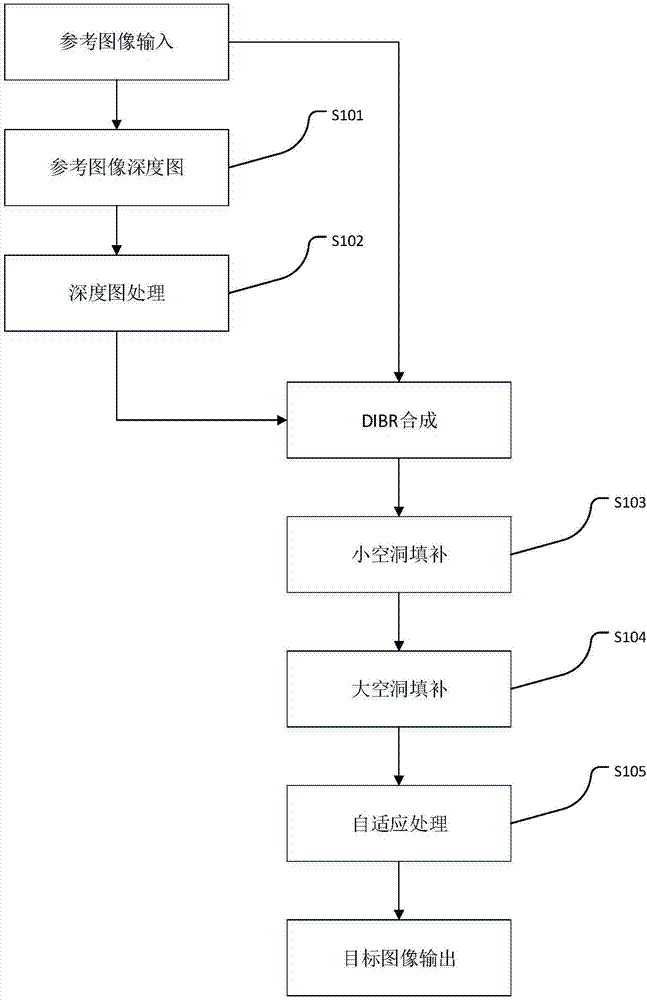

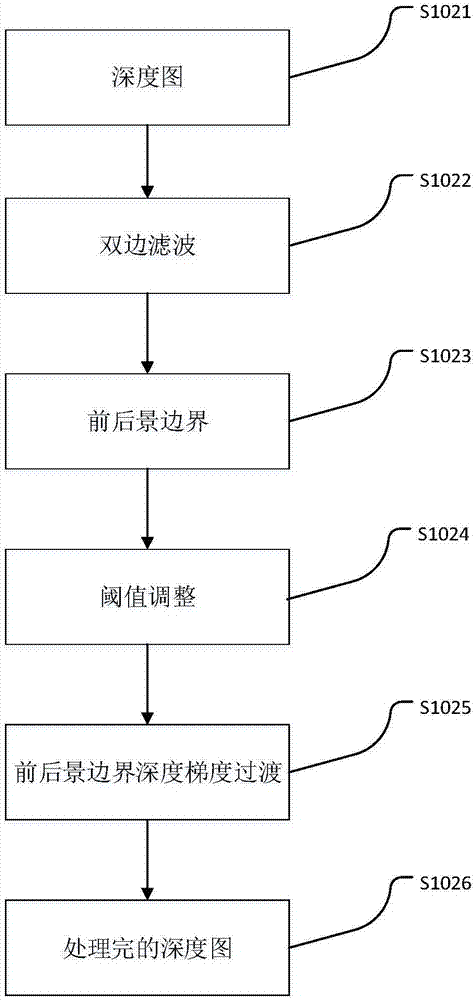

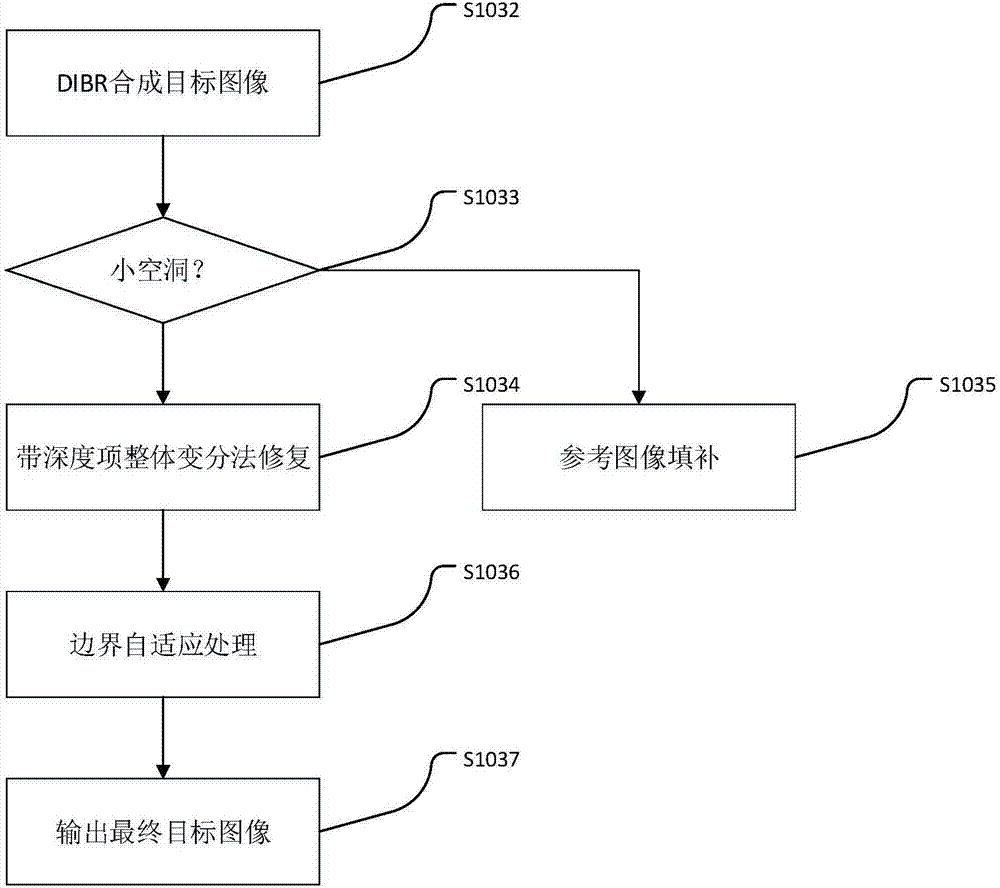

Hole filling algorithm based on depth transition and overall depth item variability

ActiveCN106998460AReduce or even eliminate areas with drastic changes in depth valuesEliminate areas with drastic changes in depth valuesImage enhancementImage analysisSignal-to-noise ratio (imaging)Reference image

Image drawing using a depth map is a commonly used algorithm in 2D to 3D, but holes occurs in a final image drawn by using this method, resulting in undesirable visual effects. To solve this problem, the invention provides a hole filling algorithm based on depth transition and overall depth item variability for filing the holes, and thus a high-quality target image can be obtained. Firstly, the depth map is filtered in a preprocessing phase, and then transition is carried out on front and back scene boundary depths of the depth map. Therefore, the occurrence of front and back scene boundary holes can be reduced. The small hole points occurring in the target image are processed by an overall variability restoration algorithm with depth items. Large hole points are generally hole points occurring on the boundary continuously, variability restoration cannot be carried out on these hole points, and these hole points are filled by pixels of corresponding positions of a reference image. Experiments show that the algorithm has an excellent visual effect and a relatively high peak signal to noise ratio.

Owner:HEFEI UNIV OF TECH

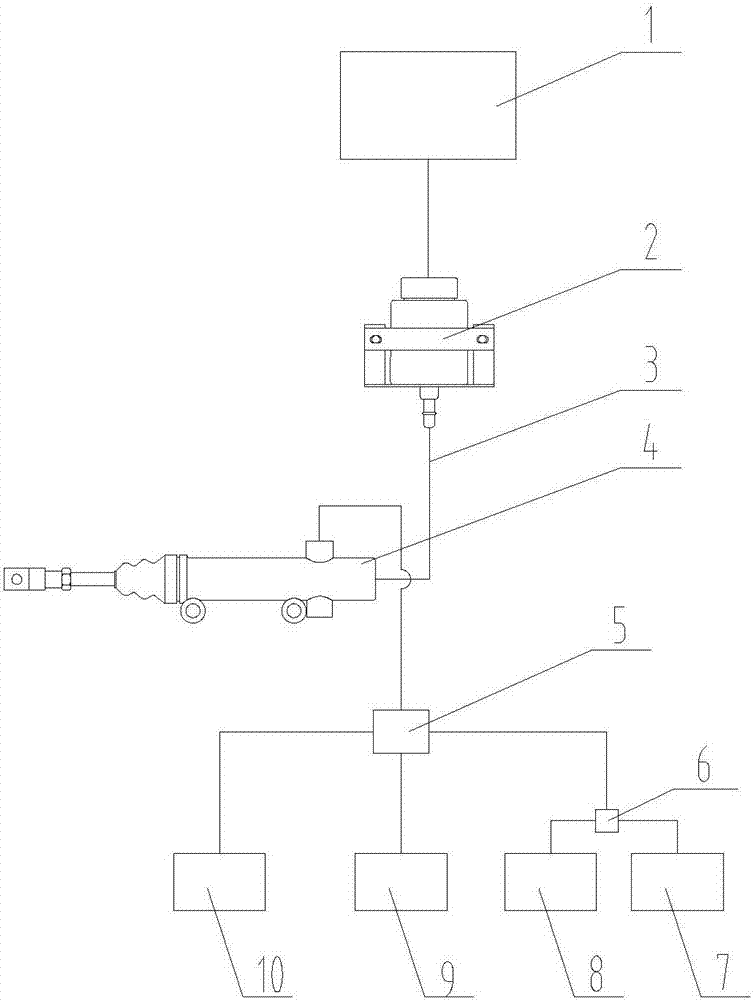

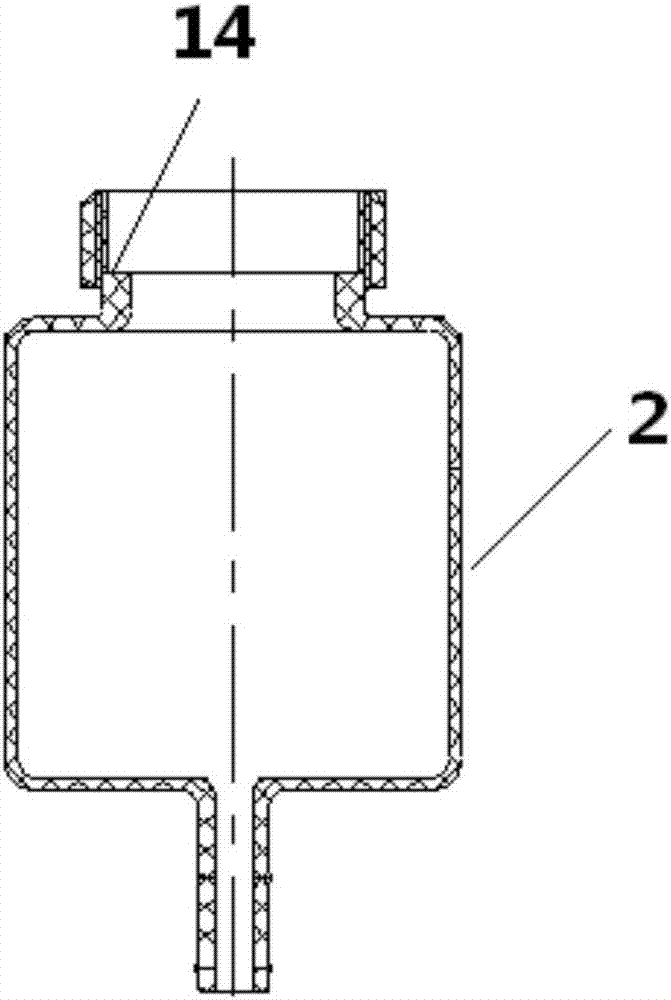

Harvester brake fluid vacuum filling system and method

InactiveCN107235464AEasy to operateRefill time shortenedLiquid transferring devicesVacuum pumpingClamp connection

The invention relates to a harvester brake fluid vacuum filling system and method. The system comprises a brake oil can and a brake main pump; an oil outlet of the brake oil can is connected with an oil inlet of the brake main pump through a brake pipeline, and the system is characterized by further comprising a vacuum filling machine; a filling gun head of the vacuum filling machine is in clamped connection with an oil filling opening of the brake oil can in a seal manner; the filling gun head of the vacuum filling machine is clamped on the oil adding opening of the brake oil can, gas in the brake oil can, the brake pipeline, the brake main pump and an output pipeline of the brake main pump is subject to vacuum pumping through the filling gun head, brake liquid is injected in to the brake oil can in a pressured manner through the filling gun head, and oil in the brake oil can is sucked through the filling gun head until the height of the liquid level in the brake oil can reaches the set value. A hydraulic execution element does not need to loosened and fastened, the vacuum gun head is directly clamped on the filling opening of the brake oil can, vacuum pumping and filling can be finished, operation is more convenient, filling time is shortened, and the filling efficiency is effectively improved.

Owner:HENAN RICHUANG GENERAL MACHINERY MFR

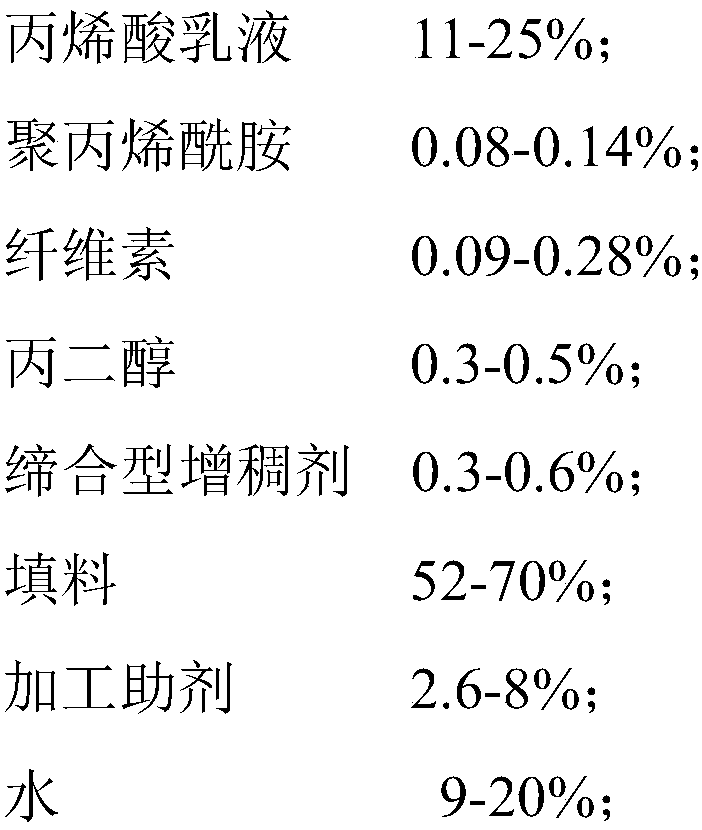

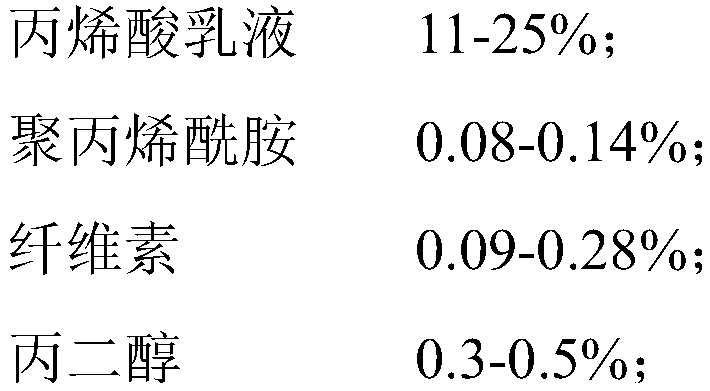

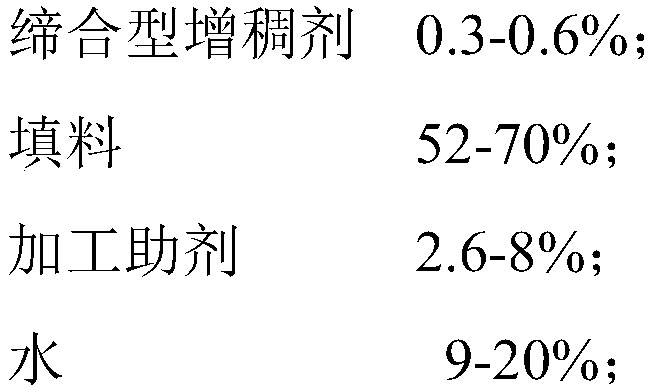

Texture coating and preparation method thereof

The invention relates to a texture coating. The texture coating comprises the following raw materials in percentage by weight: 11 to 25% of an acrylic emulsion, 0.08 to 0.14% of polyacrylamide, 0.09 to 0.28% of cellulose, 0.3 to 0.5% of propylene glycol, 0.3 to 0.6% of an associative thickening agent, 52-70% of a filler, 2.6-8% of other processing aids and 9-20% of water, wherein the polyacrylamide is non-ionic polyacrylamide, and has a molecular weight of no greater than 3 million; and the solid content of the acrylic emulsion is 45%-60%. The texture coating is good in moisture retention, convenient to construct, energy-saving and environment-friendly.

Owner:广东自然涂化工有限公司

Novel grout supplementing method and device for micro pile

The invention relates to the technical field of micro-pile grout supplementing construction, and in particular to a novel grout supplementing method and device for a micro pile. The method comprises the steps of: 1) pre-burying a grout supplementing pipe in a pouring pile; (2) after the pouring pile is poured and solidified, inserting a positioning grout supplementing device into the grout supplementing pipe pre-buried in the pouring pile, and grouting is conducted; and 3) moving the positioning grout supplementing device, and repeating the step 2) until the grout supplementing is completed. The method has the beneficial effects that only the part with the cavity is supplemented with grout; the periphery of a cap plug is supplemented with grout, and grout supplementation is more uniform; anon-return device is arranged to prevent grout from flowing back, and long-term pressure maintaining is not needed; an expanded polytetrafluoroethylene material is adopted, so that exhaust can be realized; grout supplementing can be positioned, and the grout supplementing part and the grout supplementing amount can be known conveniently; for the part close to the edge, grout can be prevented fromoverflowing under the action of pressure, and the grout supplementing effect is guaranteed.

Owner:中隧隧盾国际建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com