Full-automatic forming unit for dry powder of pyrotechnic composition

A technology of forming unit and pyrotechnic powder, which is applied to explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of serious safety hazards, consumption of land and resources, poor sanitary conditions, etc., and achieves reliable performance, good economy, and fluidity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the drawings and specific embodiments.

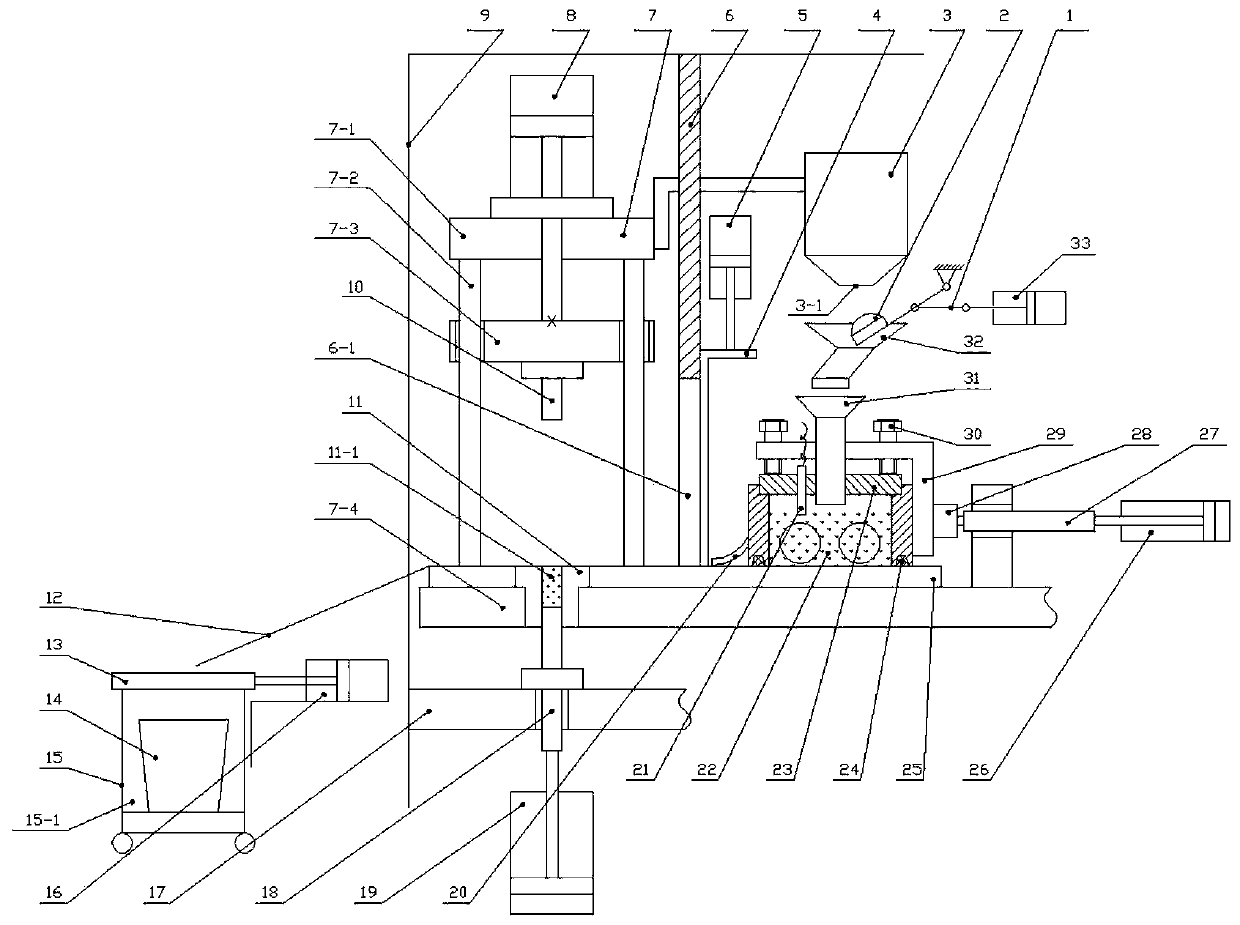

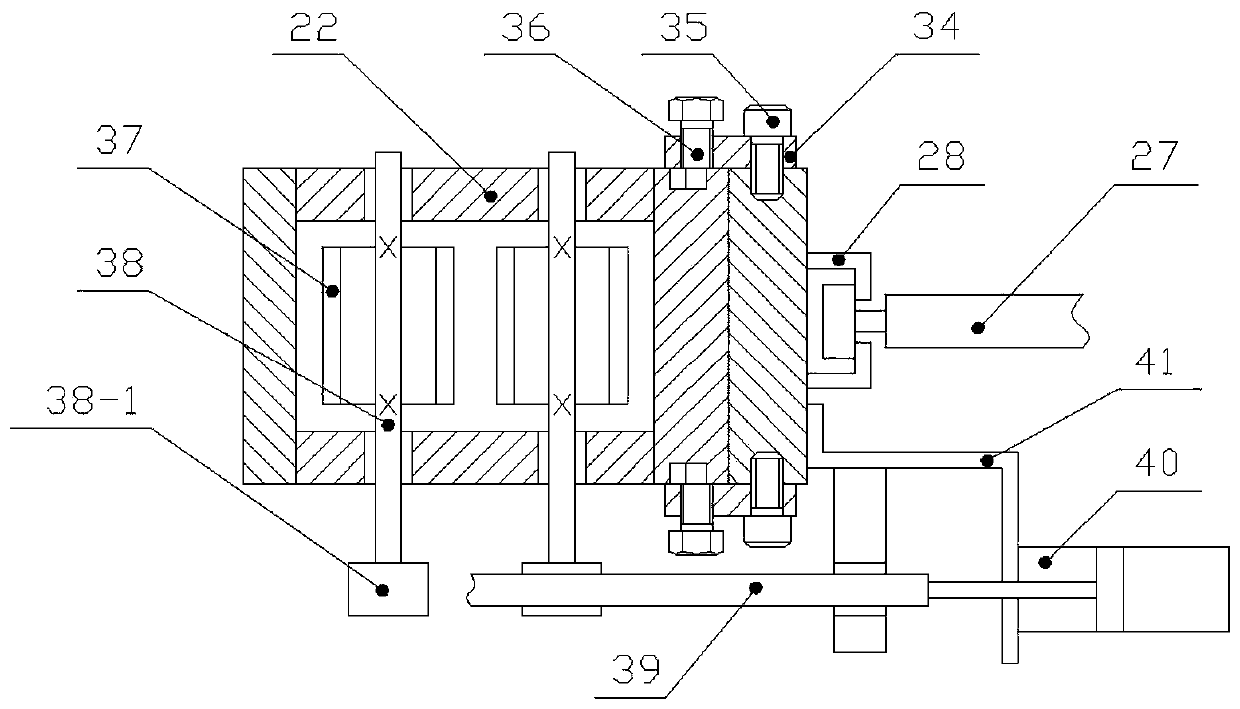

[0019] See attached figure 1 , A partition 6 is provided on the base 17, and a mold base 7 is provided on one side of the partition 6. The mold base 7 is composed of an upper beam 7-1, a slider 7-3, a bottom plate 7-4 and a column 7-2 , The upper cross beam 7-1 and the bottom plate 7-4 are fixedly connected with the column 7-2, the sliding block 7-3 is slidingly connected with the column 7-2, the bottom plate 7-4 is fixed on the base 17, and the upper cross beam 7-1 is set There is an upper cylinder 8, the sliding block 7-3 and the upper cylinder 8 are movably connected, the sliding block is provided with an upper die punch 10, the bottom plate 7-4 is provided with a concave mold 11, and the concave mold has a cavity hole 11-1 and a cavity The hole is provided with a lower die punch 18, which is slidably connected with the cavity hole. The upper die punch 10, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com