Culture medium split charging device for test tubes

A culture medium and test tube technology, applied in the field of tools, can solve the problems of complicated operation and low efficiency of medium packing, and achieve the effects of high filling efficiency, convenient hand-held operation, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

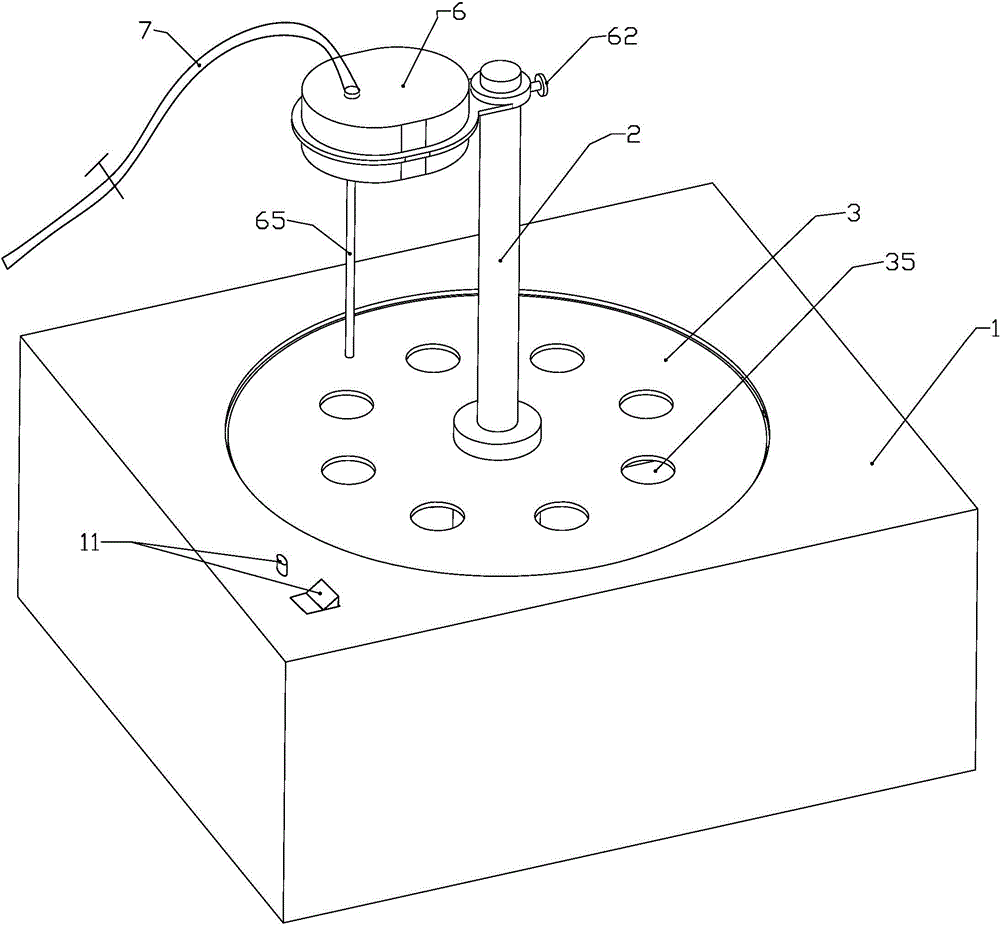

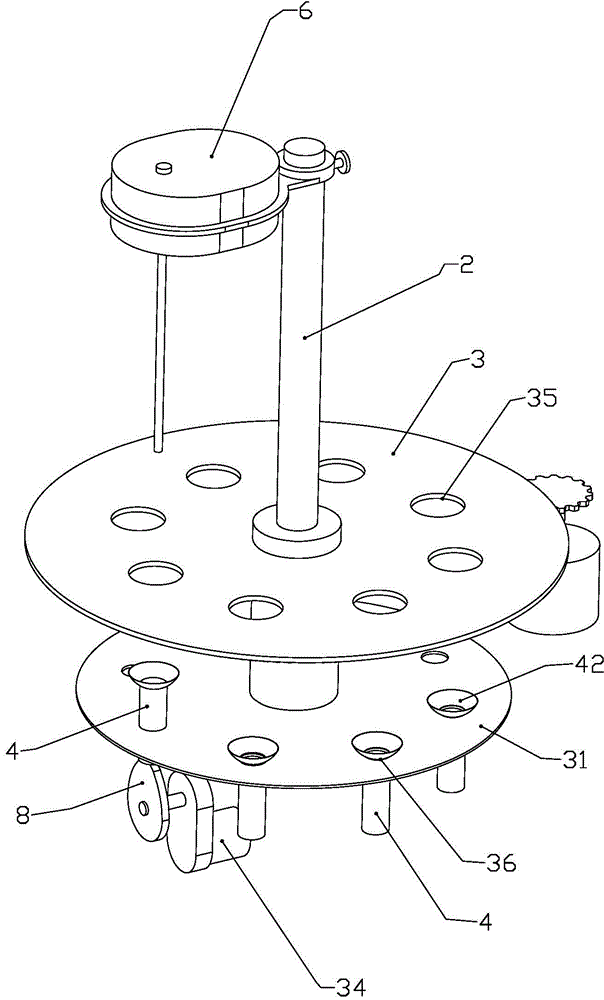

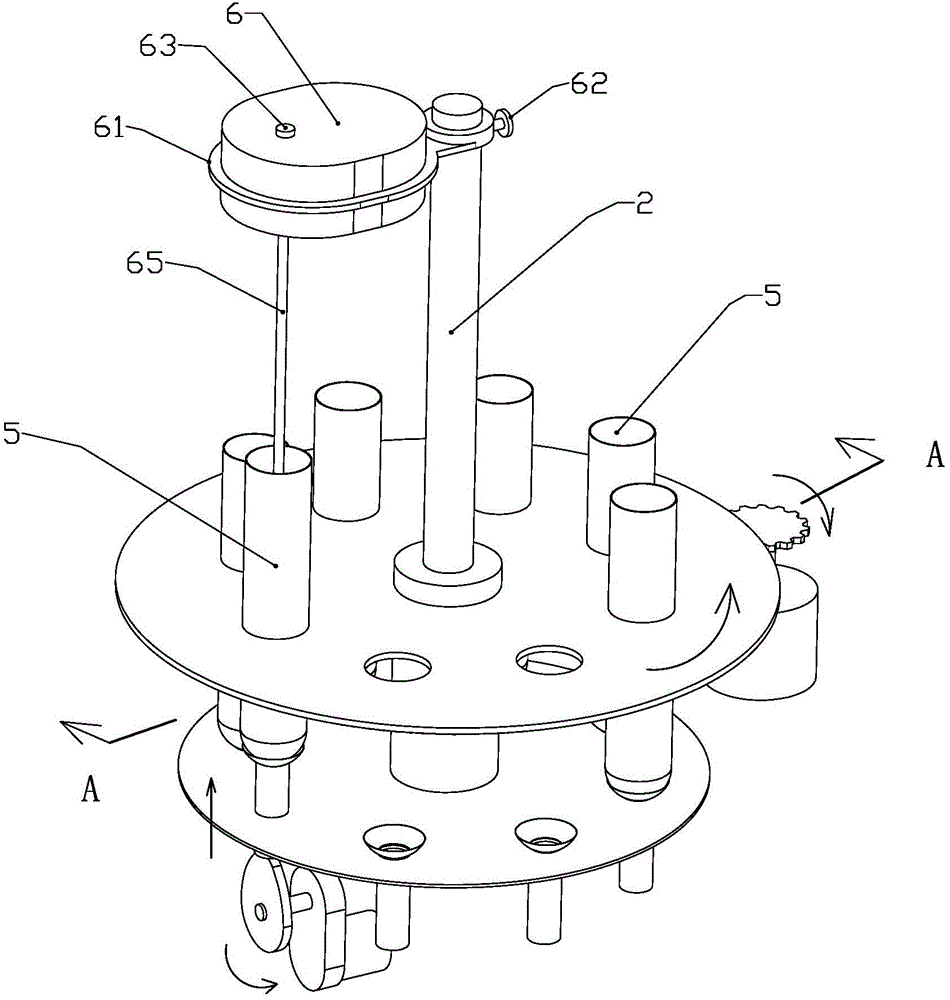

[0028] like Figure 1 to Figure 5 As shown, a medium packing device for test tubes consists of the following parts.

[0029] The base 1 providing support and installation space is made of stainless steel plate. The whole is in the shape of a cube and can be placed on a workbench, and switches and buttons 11 are arranged on the upper surface of the base.

[0030] A column 2 extending upwards, the lower end of the column is fixed at the center of the base, and the upper end is used to fix the container. An annular first groove is arranged on the base around the column.

[0031] A turntable 3, and a coaxial tray 31 is arranged on the lower side of the turntable 3, and the turntable and the tray are connected by a sleeve 32 to form an integrated structure. A coaxial large ring gear is fixed on the lower surface of the turntable 3, a small gear and a first motor 33 are installed in the base inner wall on one side of the turntable, the output shaft of the first motor directly dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com