Mixed crystal degree automatic measurement and fine classification method for steel crystal grains, and system thereof

An automatic measurement and fine classification technology, applied in particle size analysis, measuring devices, particle and sedimentation analysis, etc., can solve the problems of uneven distribution of steel grain size, inability to perform quantitative characterization, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

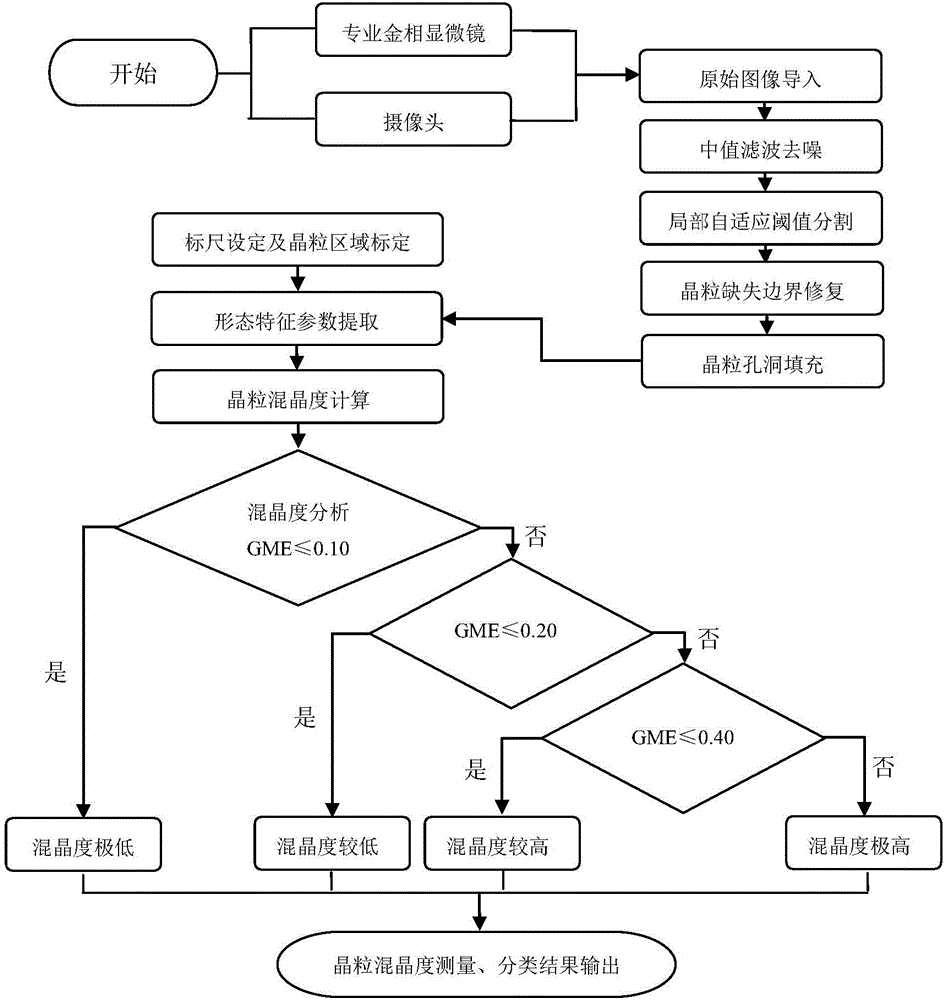

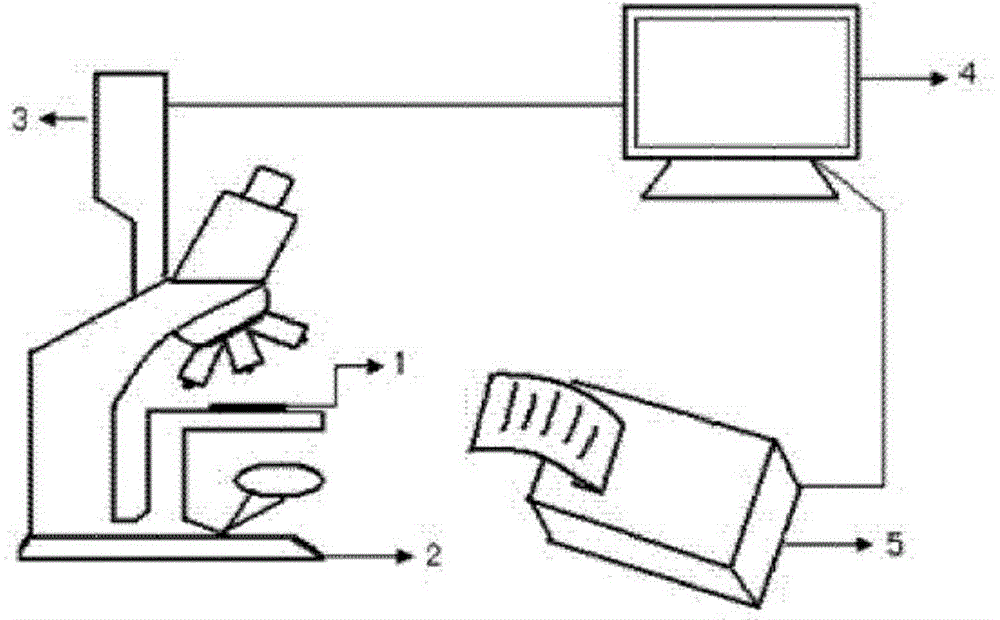

[0104] Use the image acquisition device to obtain the original image of the grain to be tested. The hardware of the image acquisition device is as follows: figure 2 As shown: it includes a steel sample 1, a professional metallographic microscope 2, a camera 3, a computer 4 and a printer 5, and the computer 4 is attached with an image acquisition card.

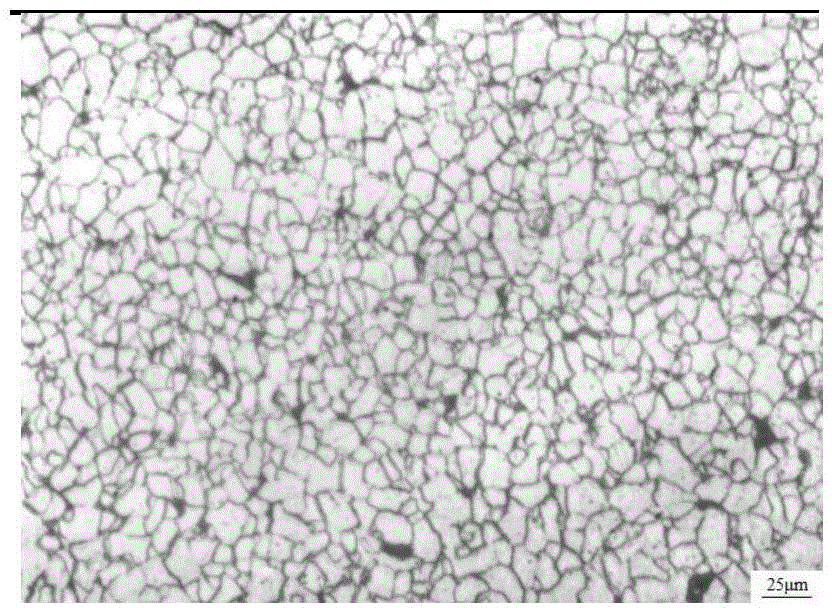

[0105] The specific steps of image acquisition are to use the professional metallographic microscope 2 to adjust the image to a suitable focal length, and use the camera 3 to take pictures and store the image in the computer 4 when the original image of the steel grain to be tested is the clearest In the acquisition card, the original image of the steel sample 1 steel grain to be measured (such as image 3 shown), followed by subsequent image preprocessing.

[0106] The image preprocessing process includes: median filter denoising, binary segmentation, grain missing boundary repair and grain hole filling.

[0107] The proces...

Embodiment 2

[0171] like Figure 8 The original image shown is the metallographic structure and grain image of steel sample 2. The processing process of the present invention is as follows: firstly, the target image is subjected to median filter denoising and an improved local adaptive threshold segmentation algorithm is used to perform binary segmentation processing, and the image after median filter denoising and binary segmentation is as follows: Figure 9 As shown; and then use the new modified watershed segmentation algorithm based on extreme corrosion and the improved seed filling algorithm to repair grain missing boundaries and fill intragranular holes. The image after defect repair is as follows Figure 10 Shown; set the scale and calibrate the area of each grain, the image after area calibration is as follows Figure 11 Shown; Measure and calculate characteristic parameters such as grain area, grain size, grain mixed crystal degree GME; Completed the automatic measurement and f...

Embodiment 3

[0173] like Figure 13 The original image shown is the metallographic structure and grain image of steel sample 3. The processing process of the present invention is as follows: firstly, the target image is subjected to median filter denoising and an improved local adaptive threshold segmentation algorithm is used to perform binary segmentation processing, and the image after median filter denoising and binary segmentation is as follows: Figure 14 As shown; and then use the new modified watershed segmentation algorithm based on extreme corrosion and the improved seed filling algorithm to repair grain missing boundaries and fill intragranular holes. The image after defect repair is as follows Figure 15 Shown; set the scale and calibrate the area of each grain, the image after area calibration is as follows Figure 16 Shown; Measure and calculate characteristic parameters such as grain area, grain size, grain mixed crystal degree GME; Completed the automatic measurement and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com