Patents

Literature

184results about "Filling without pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

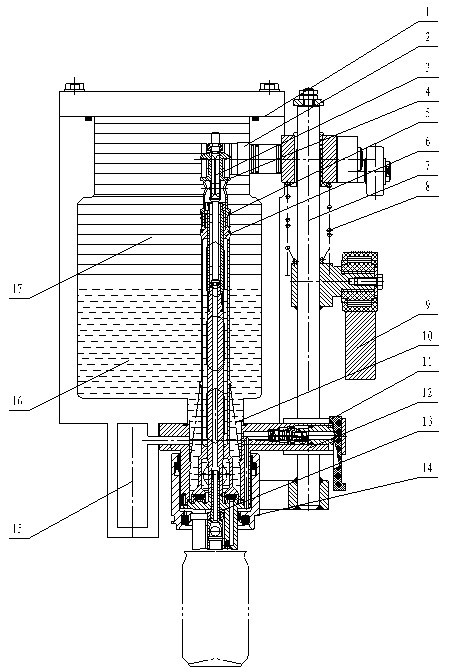

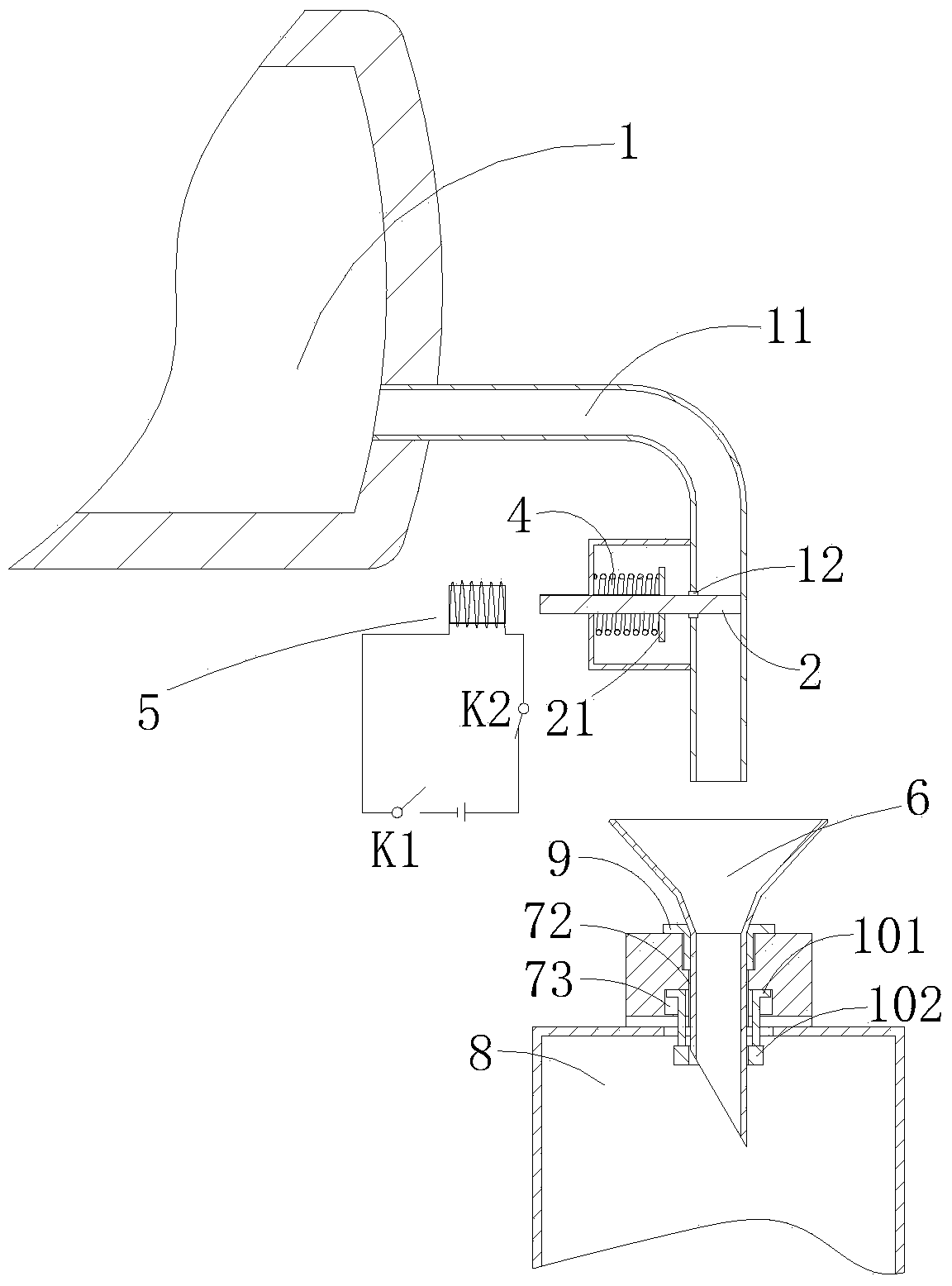

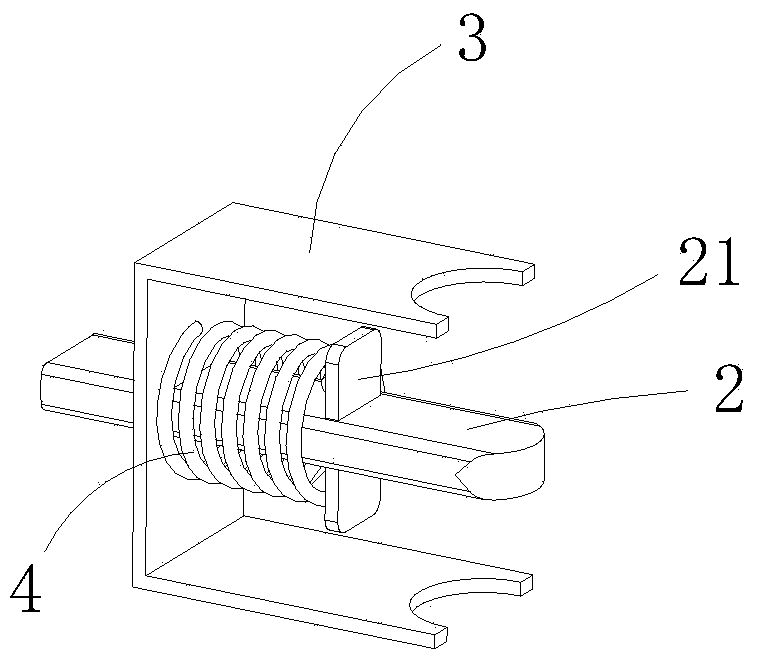

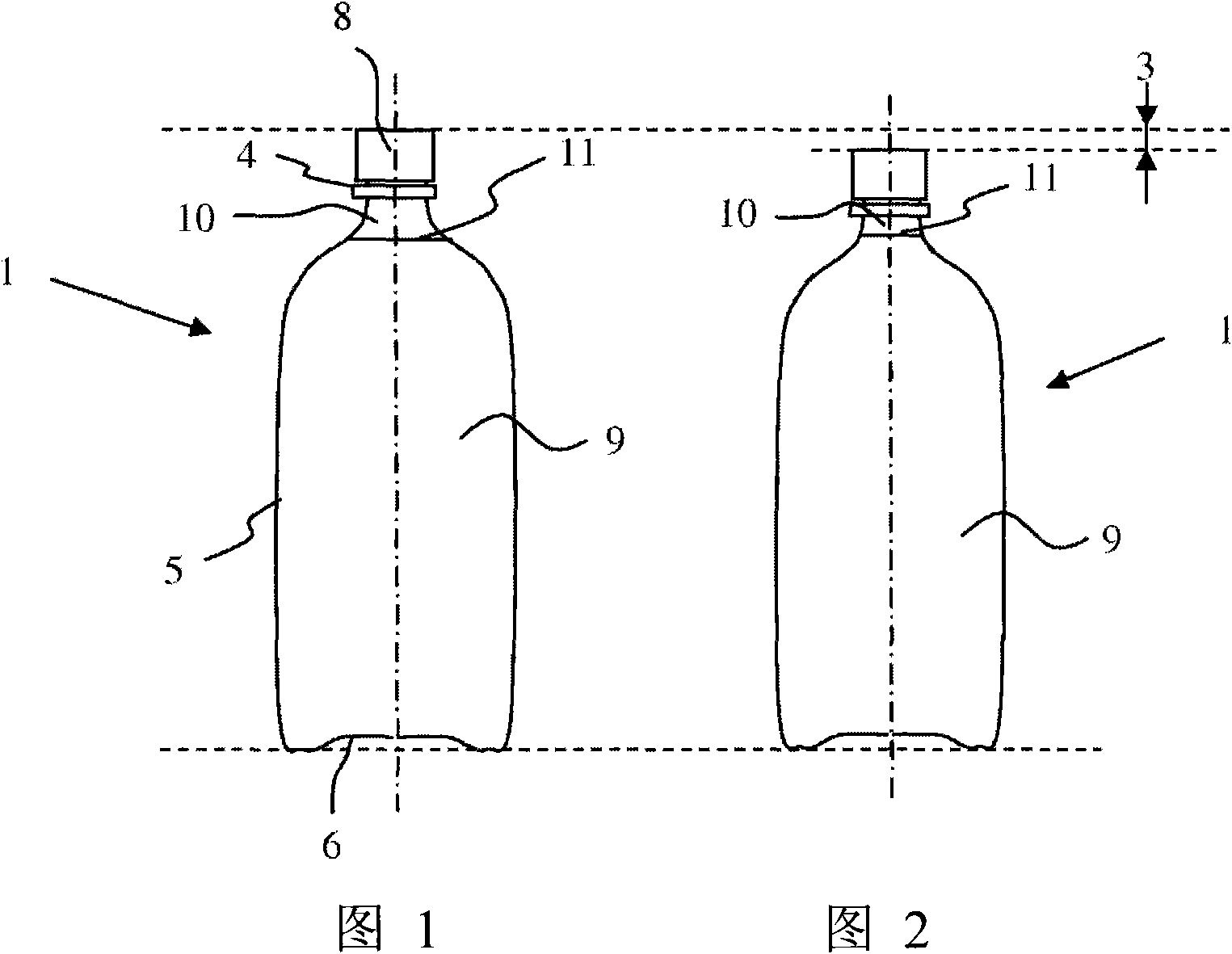

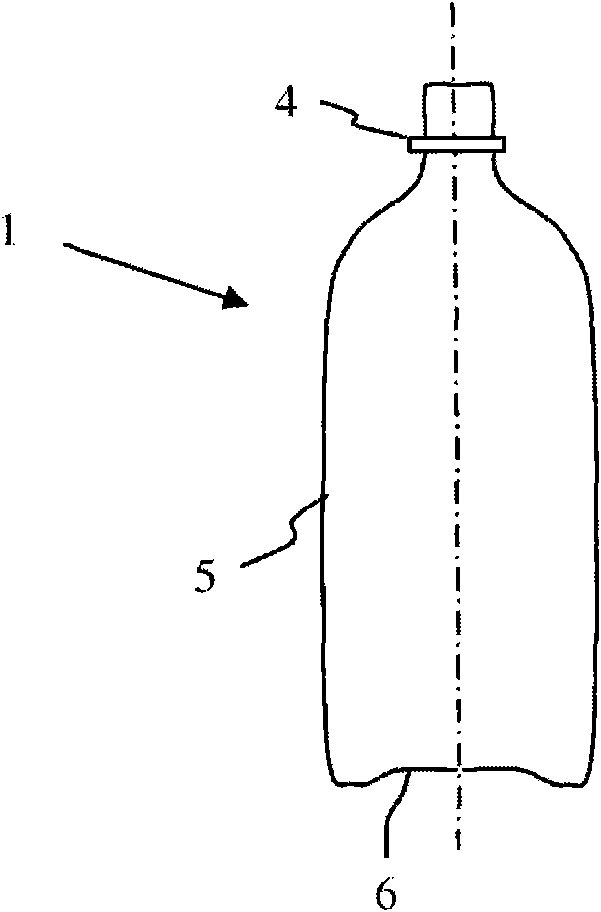

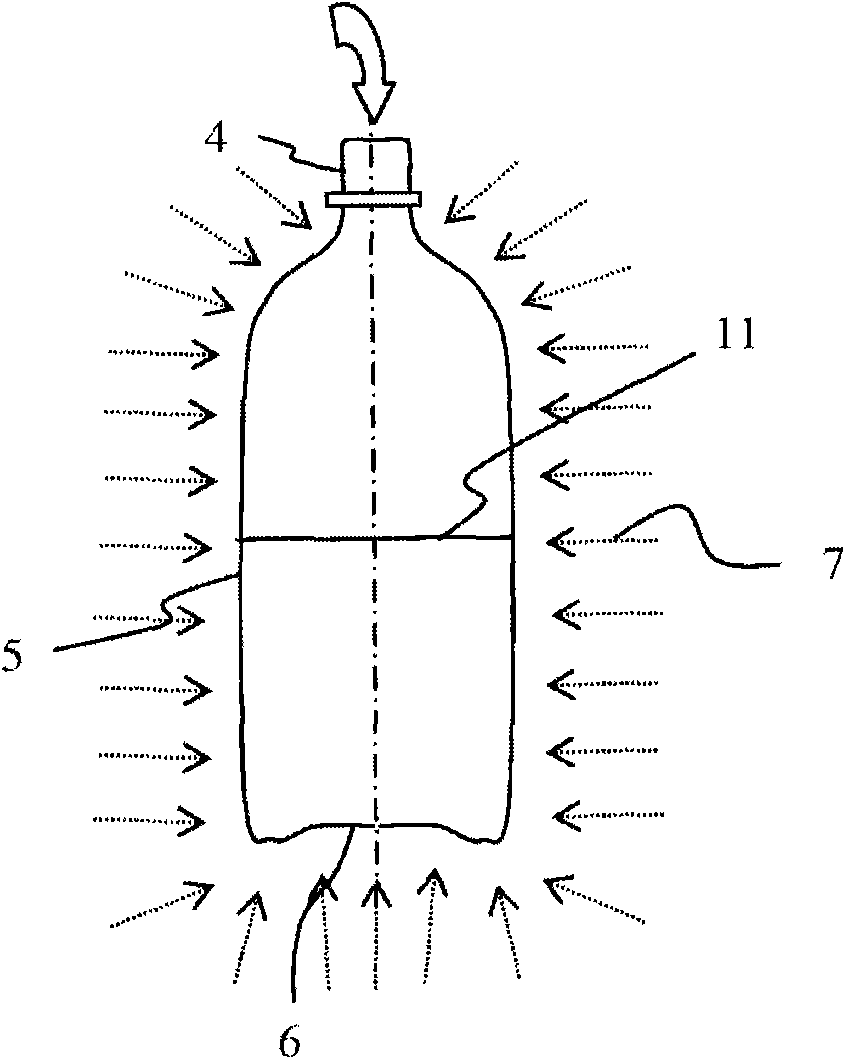

Method and Device for Producing Content Filling Bottle

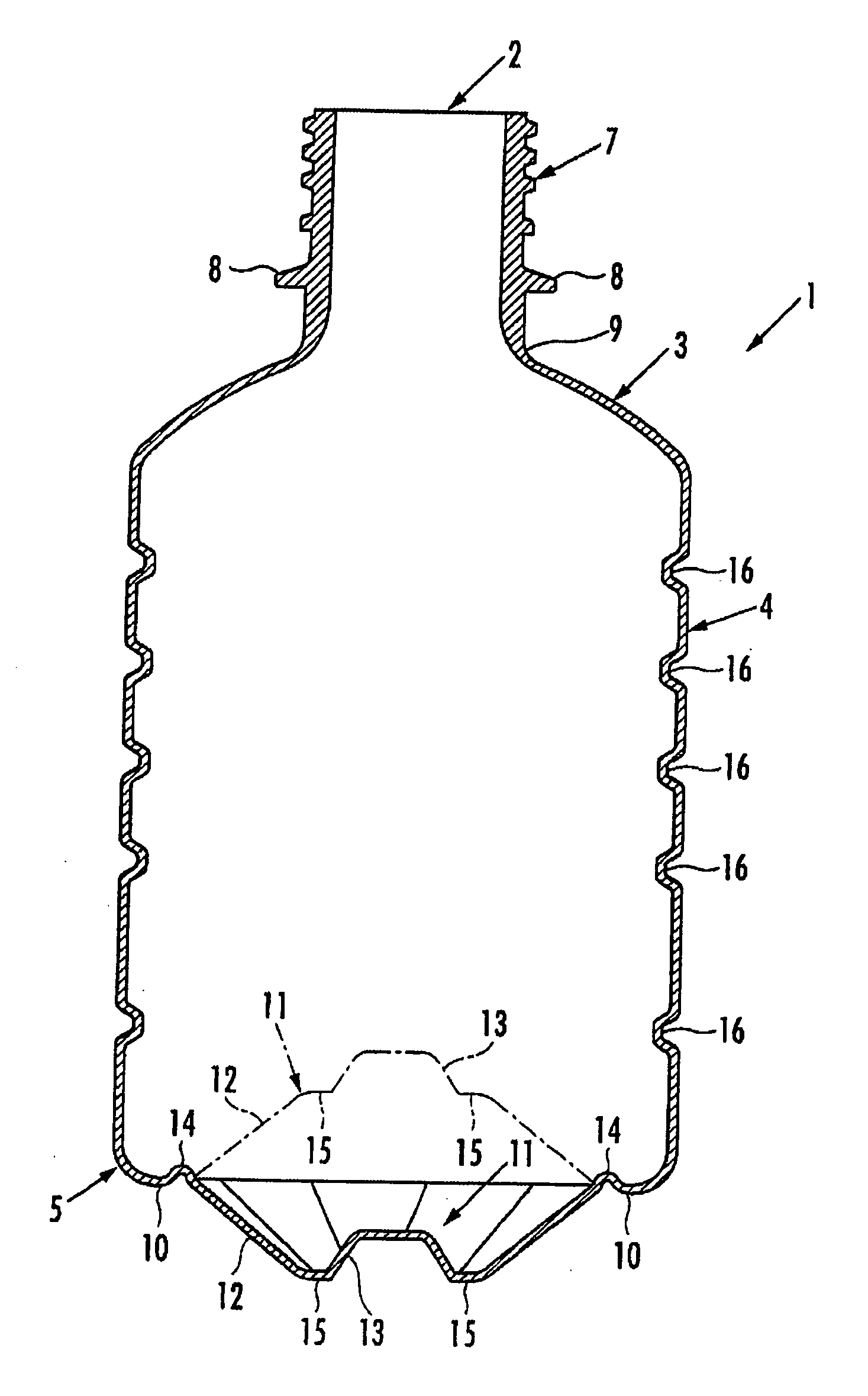

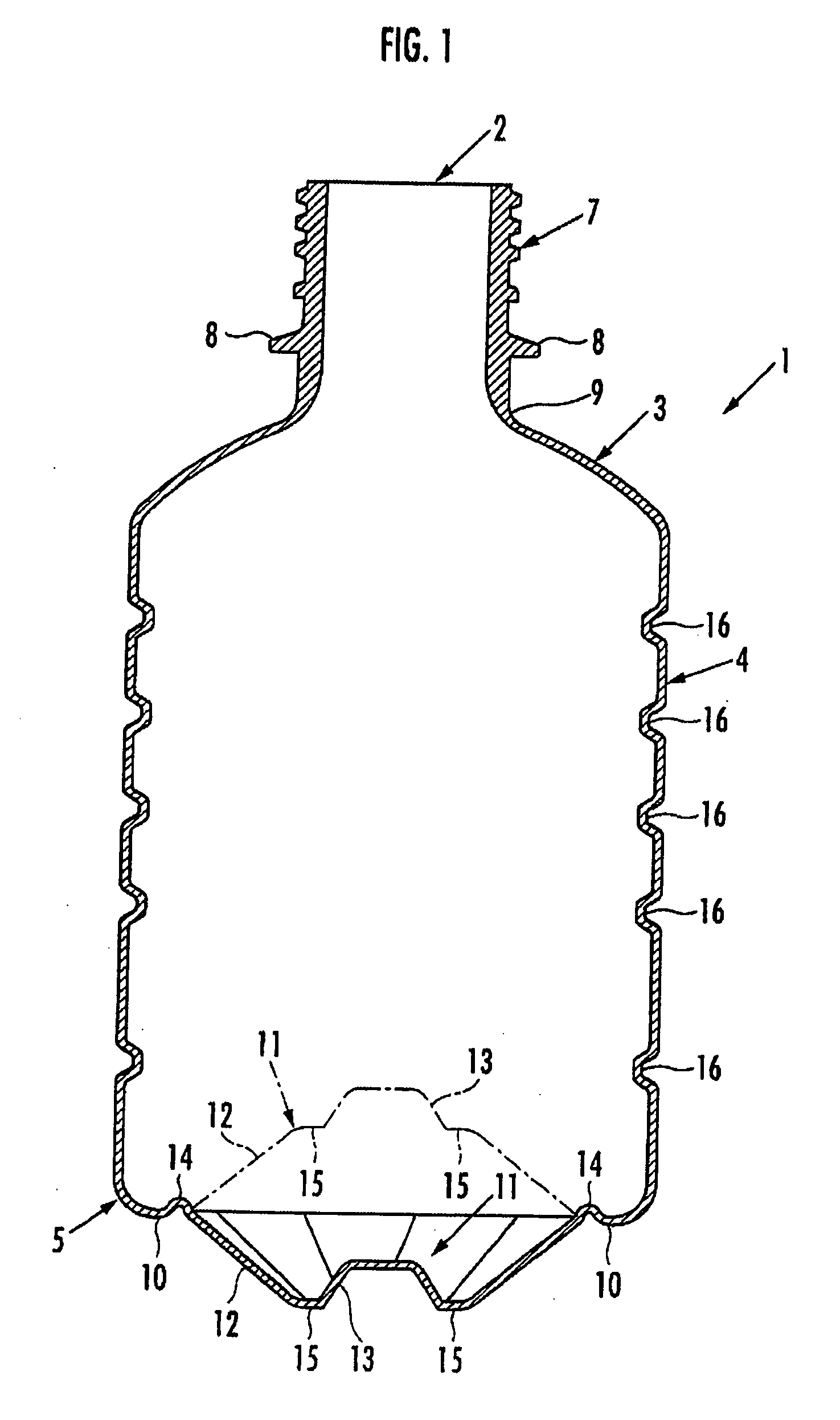

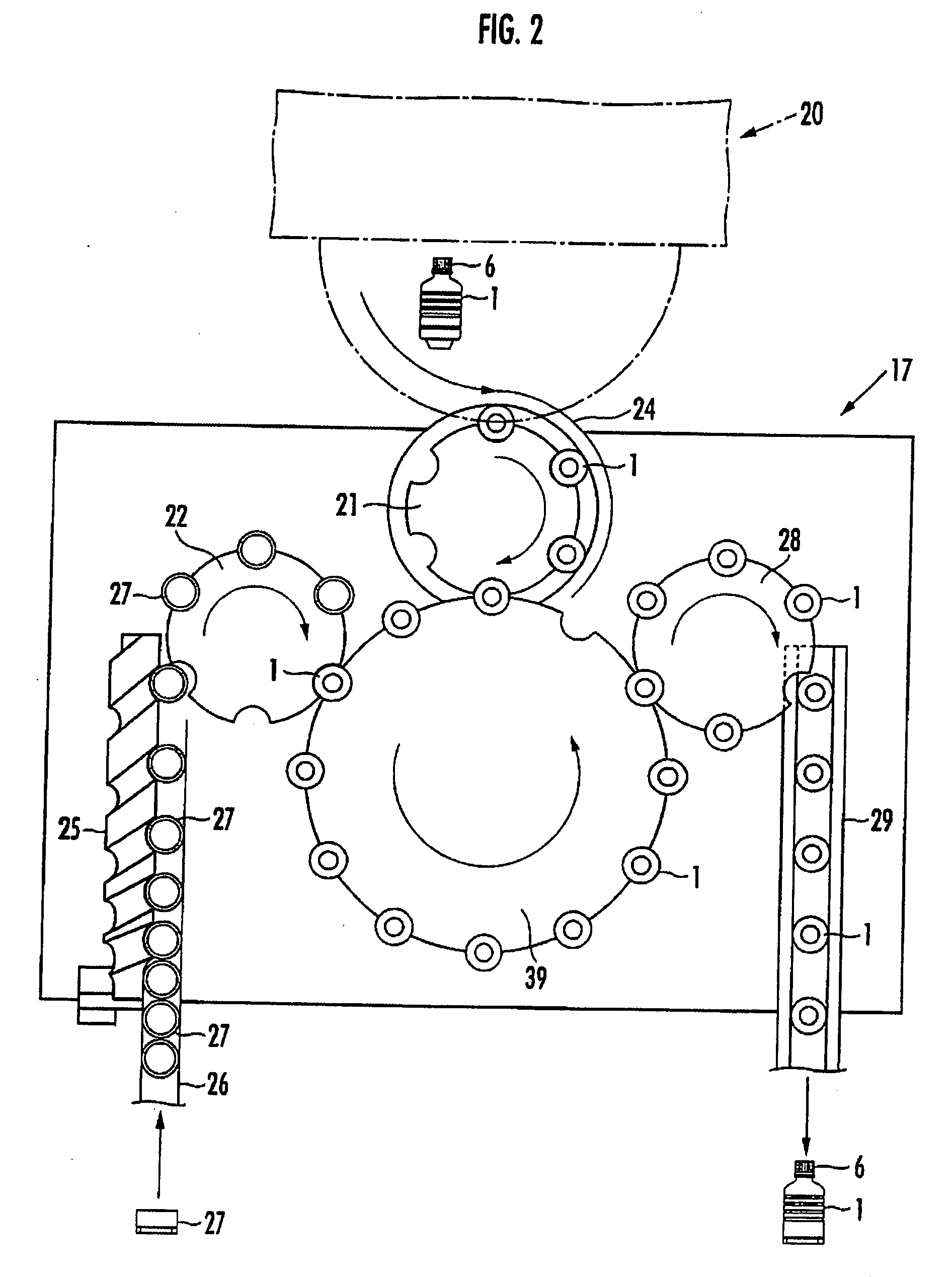

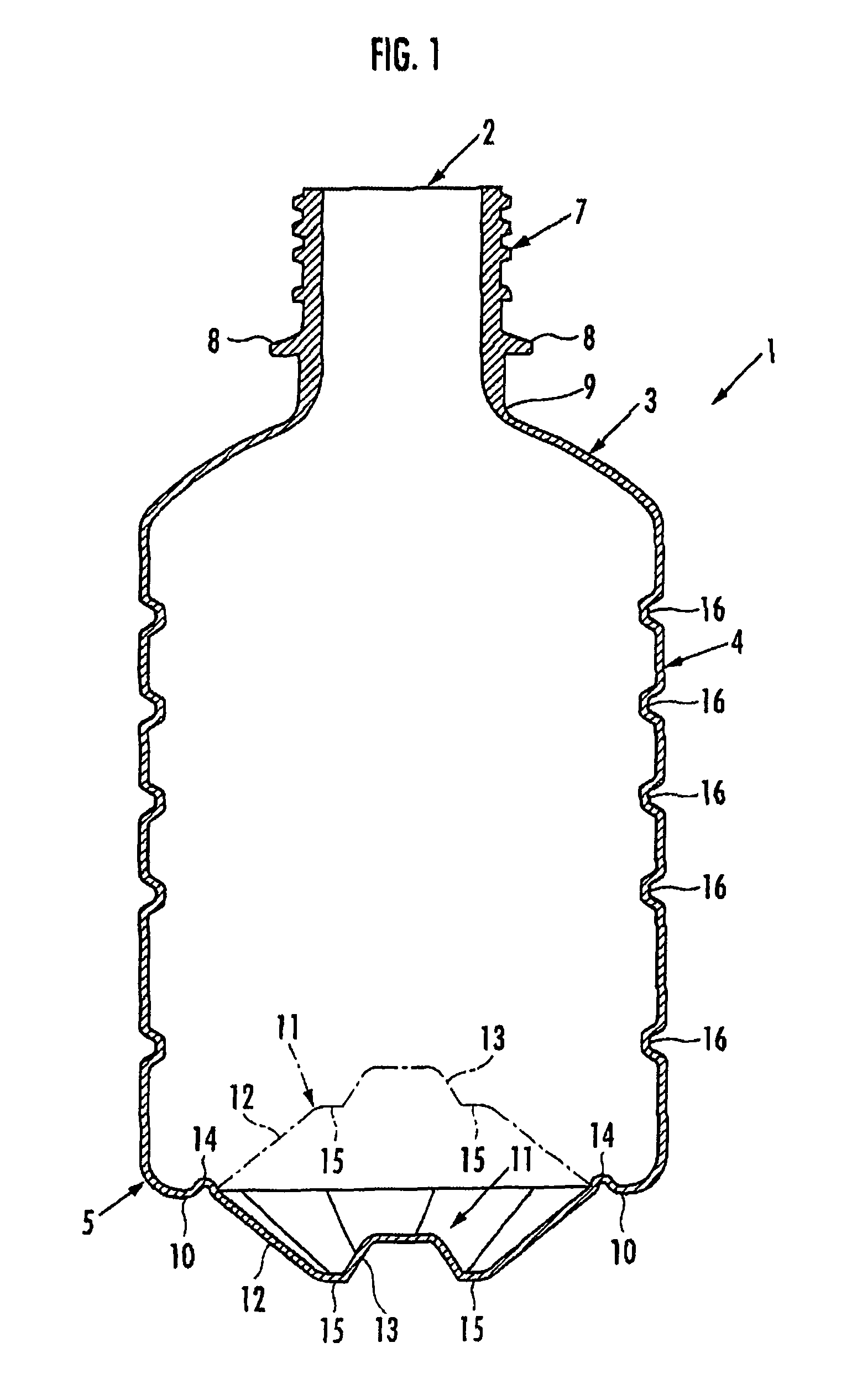

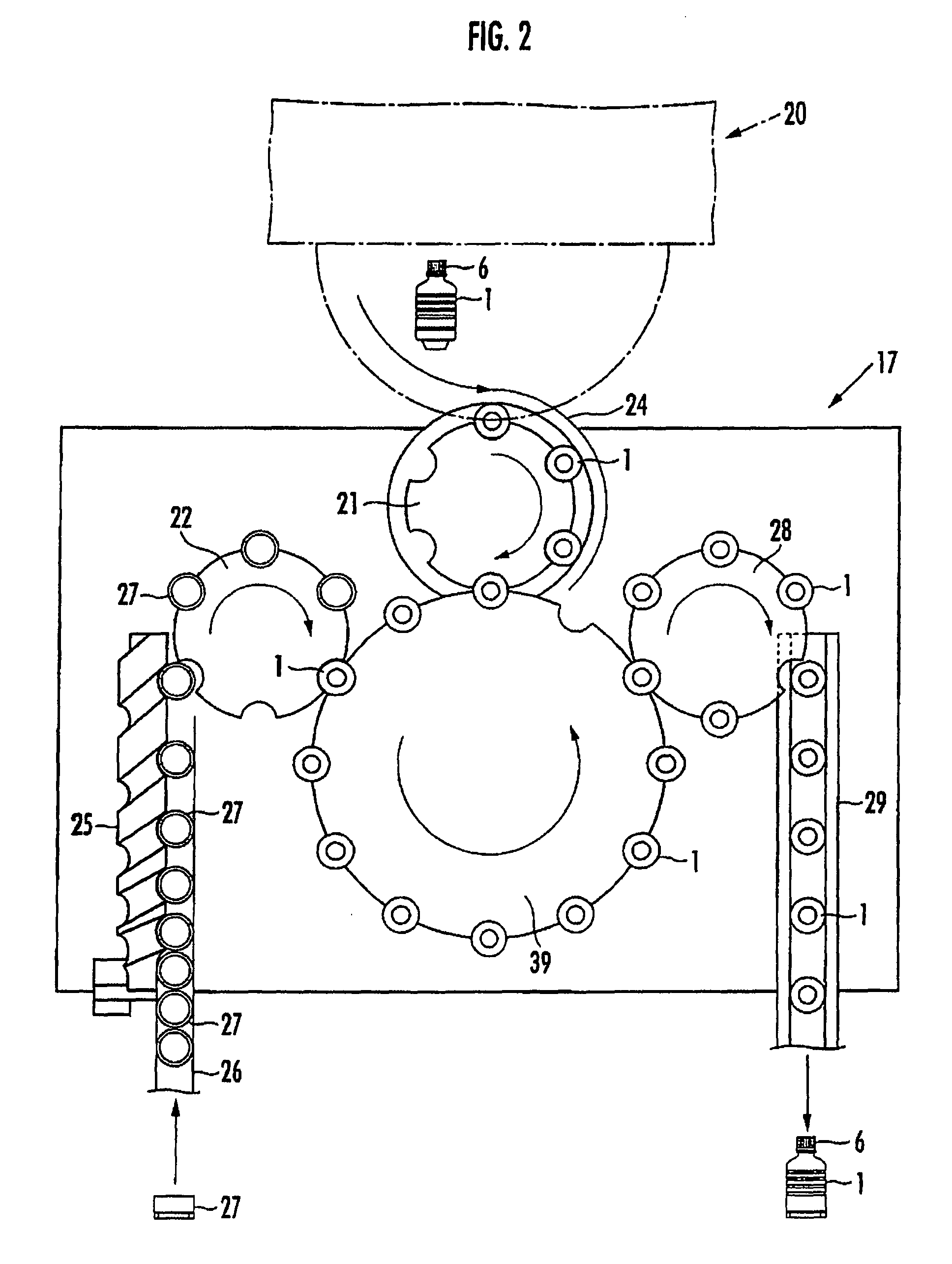

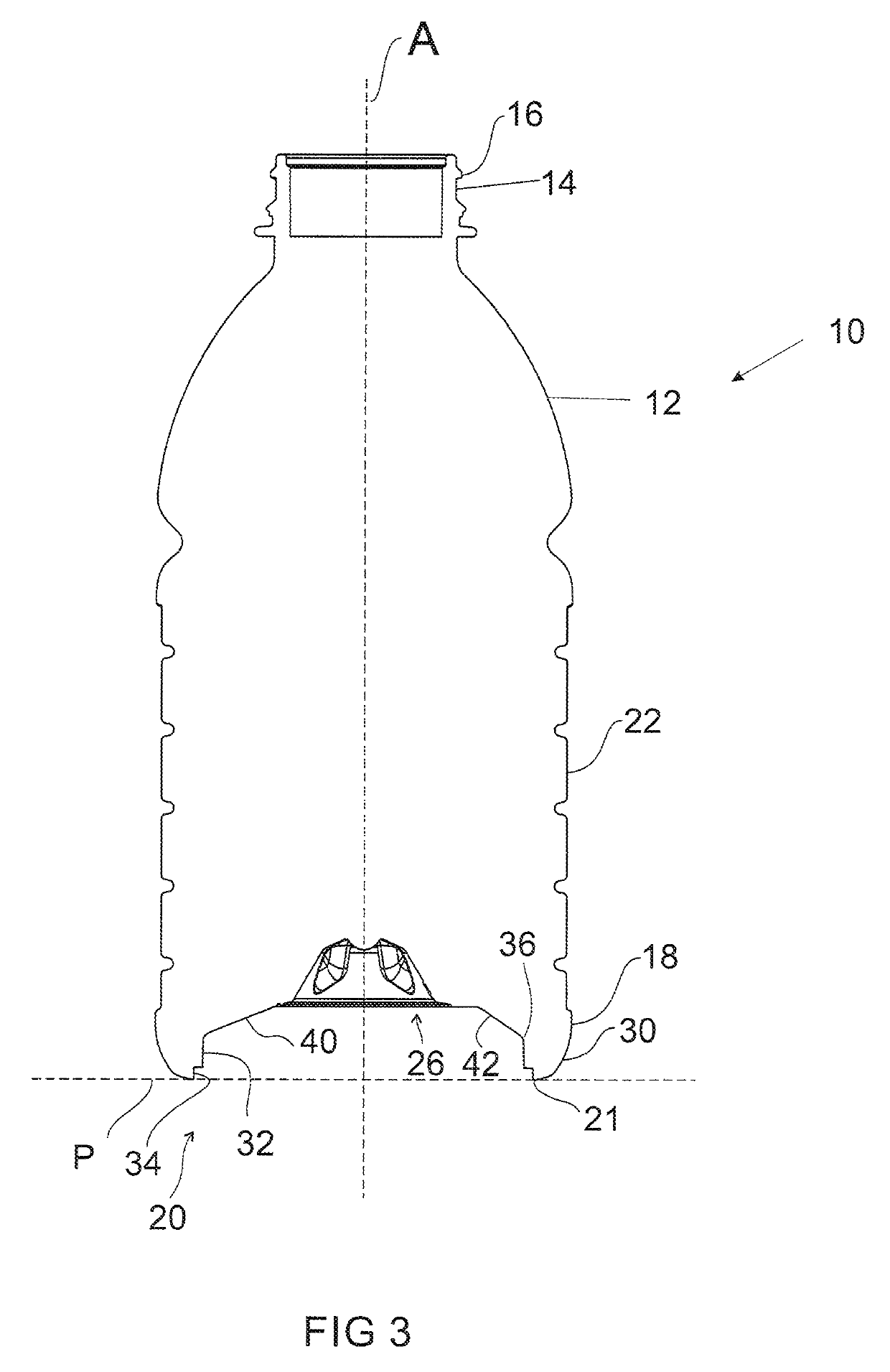

The present invention provides a method and device for producing a content filling bottle including a bottom part that is inverted between a concave shape and a convex shape to prevent a body part from being subjected to reduced pressure deformation, the method and device being capable of efficiently producing a sanitary and high-quality content filling bottle. Contents are filled into an empty bottle 1 with an inversion part 11 projecting outwardly from the body part. A cap 6 is fitted onto an opening of the bottle 1 to seal the bottle 1. An auxiliary tool 27 is then installed on the bottom part 5 of the bottle 1. Then, the bottom part of the bottle 1 with the auxiliary tool 27 installed thereon is supported via the auxiliary tool 27. The downwardly projecting inversion part 11 is pressed up so as to be inverted and recessed inwardly into the bottle 1. Subsequently, with the opening of the bottle 1 gripped, the auxiliary tool 27 is separated from the bottle 1.

Owner:CO2 PAC

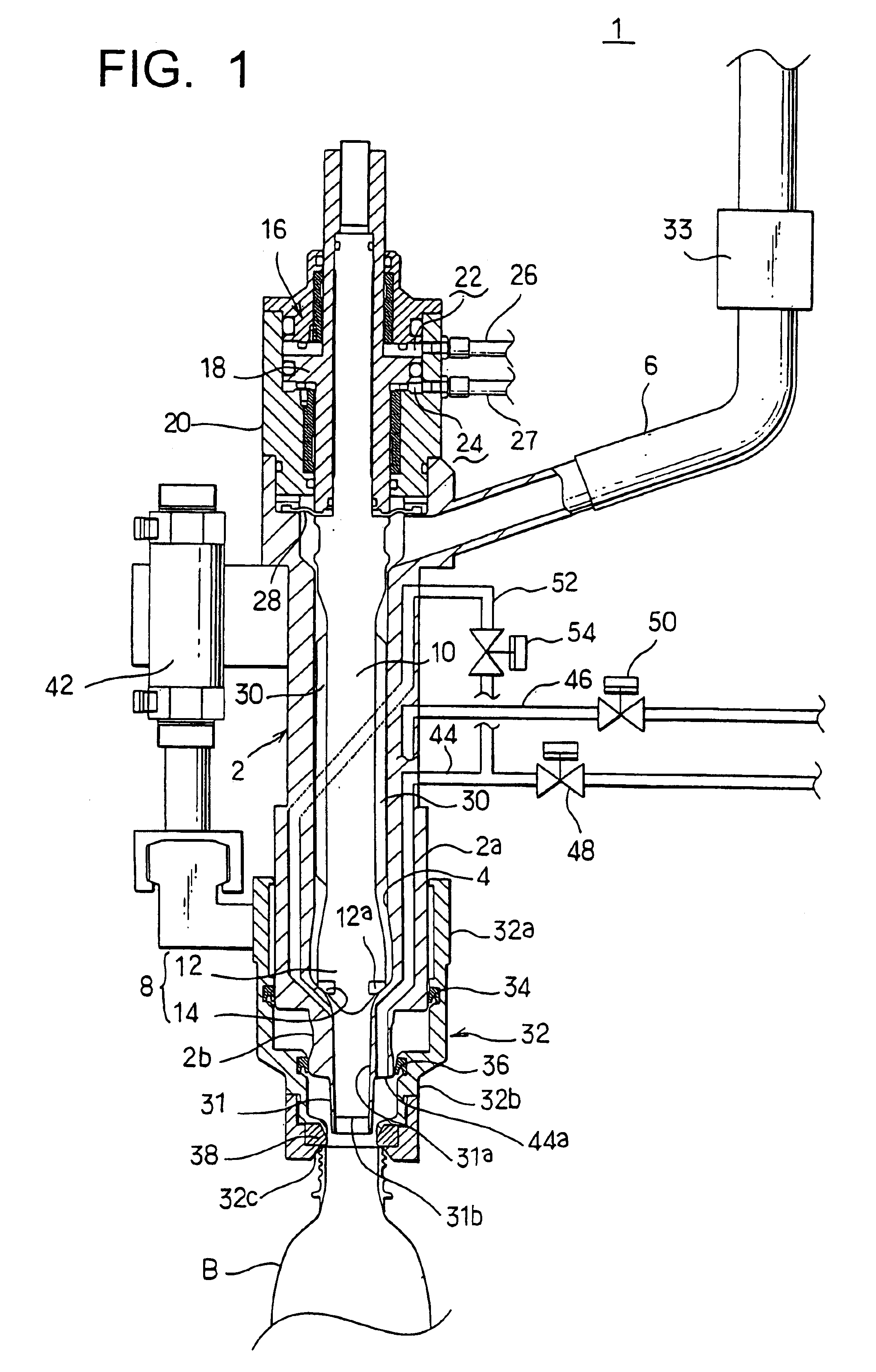

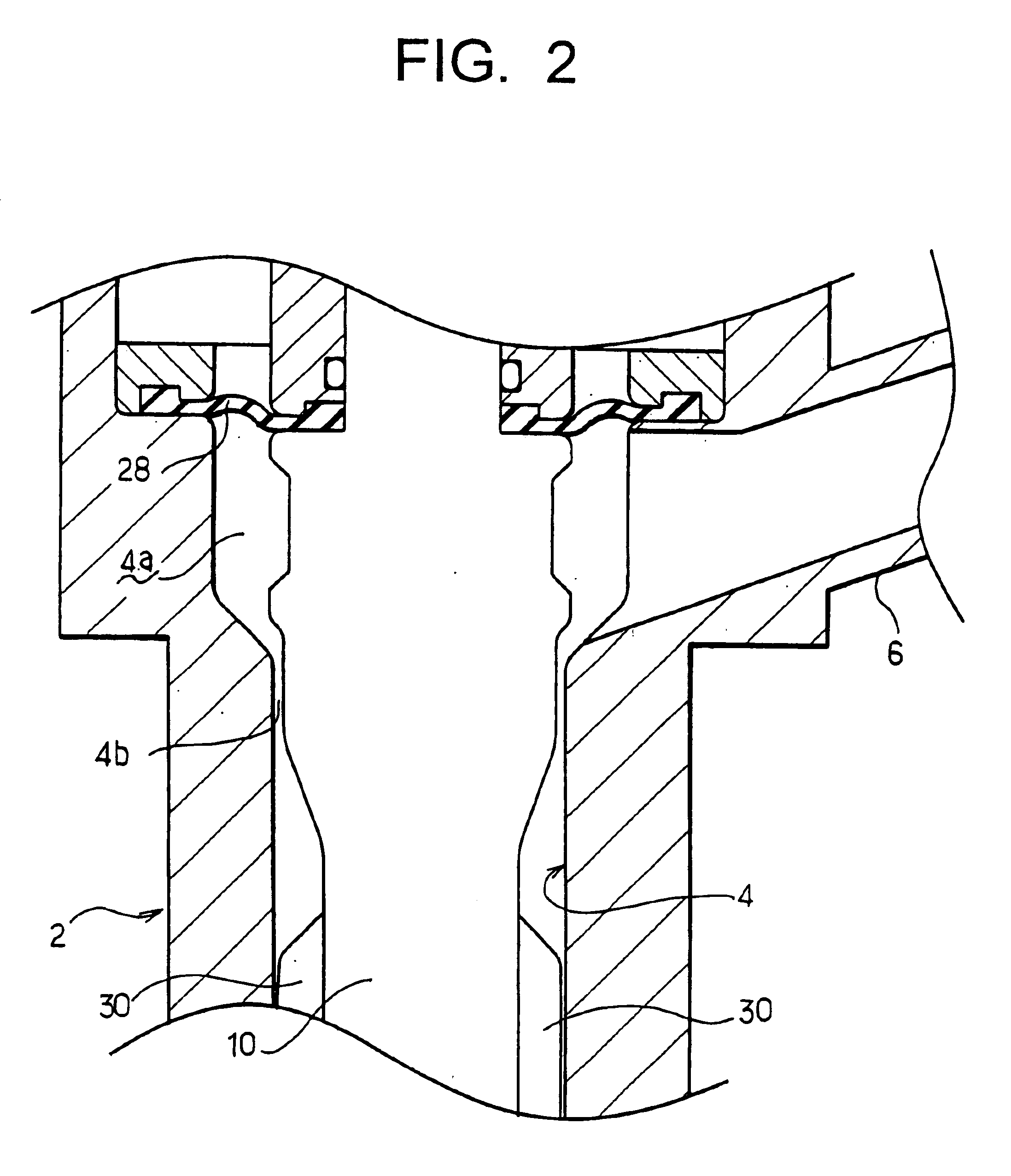

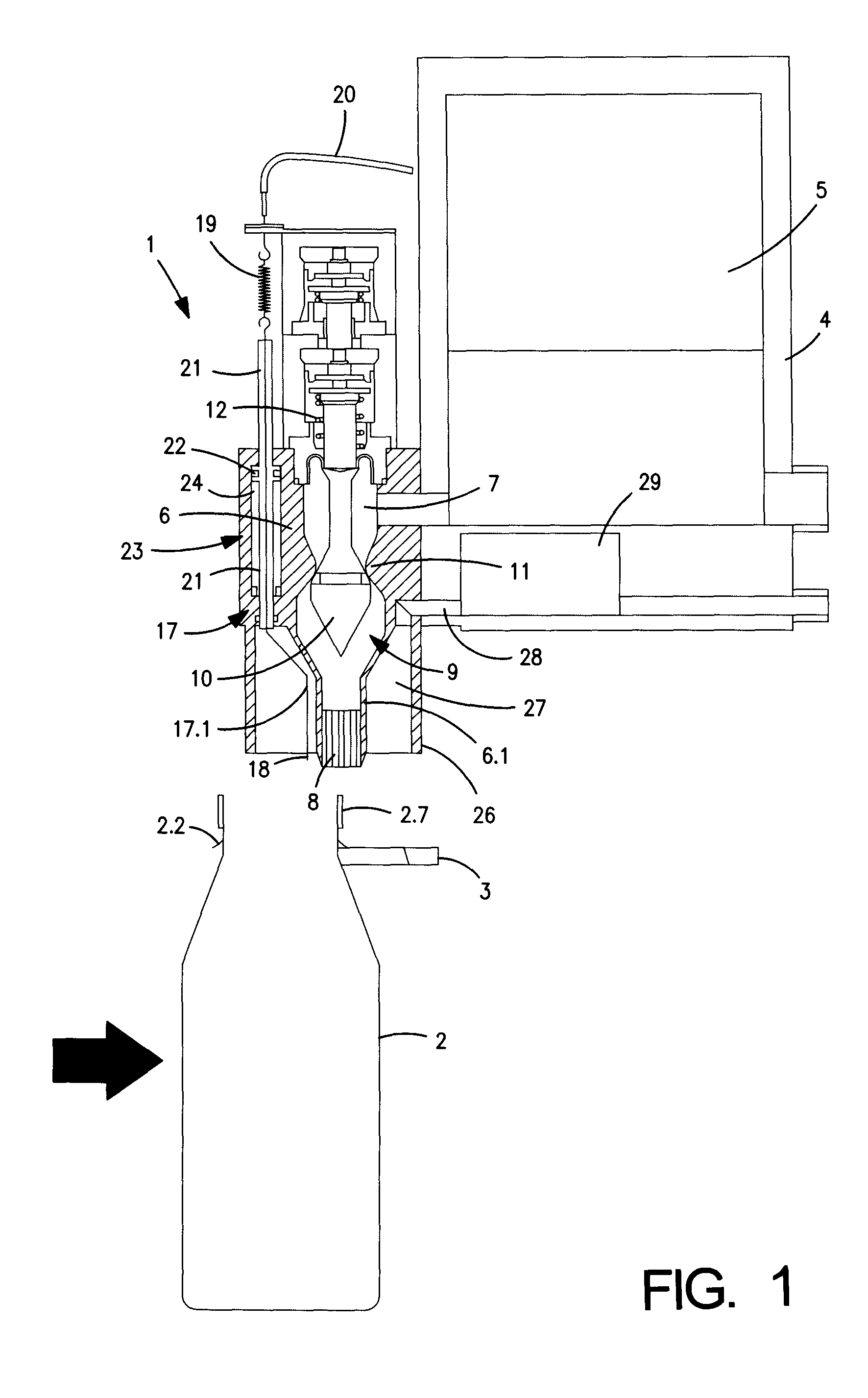

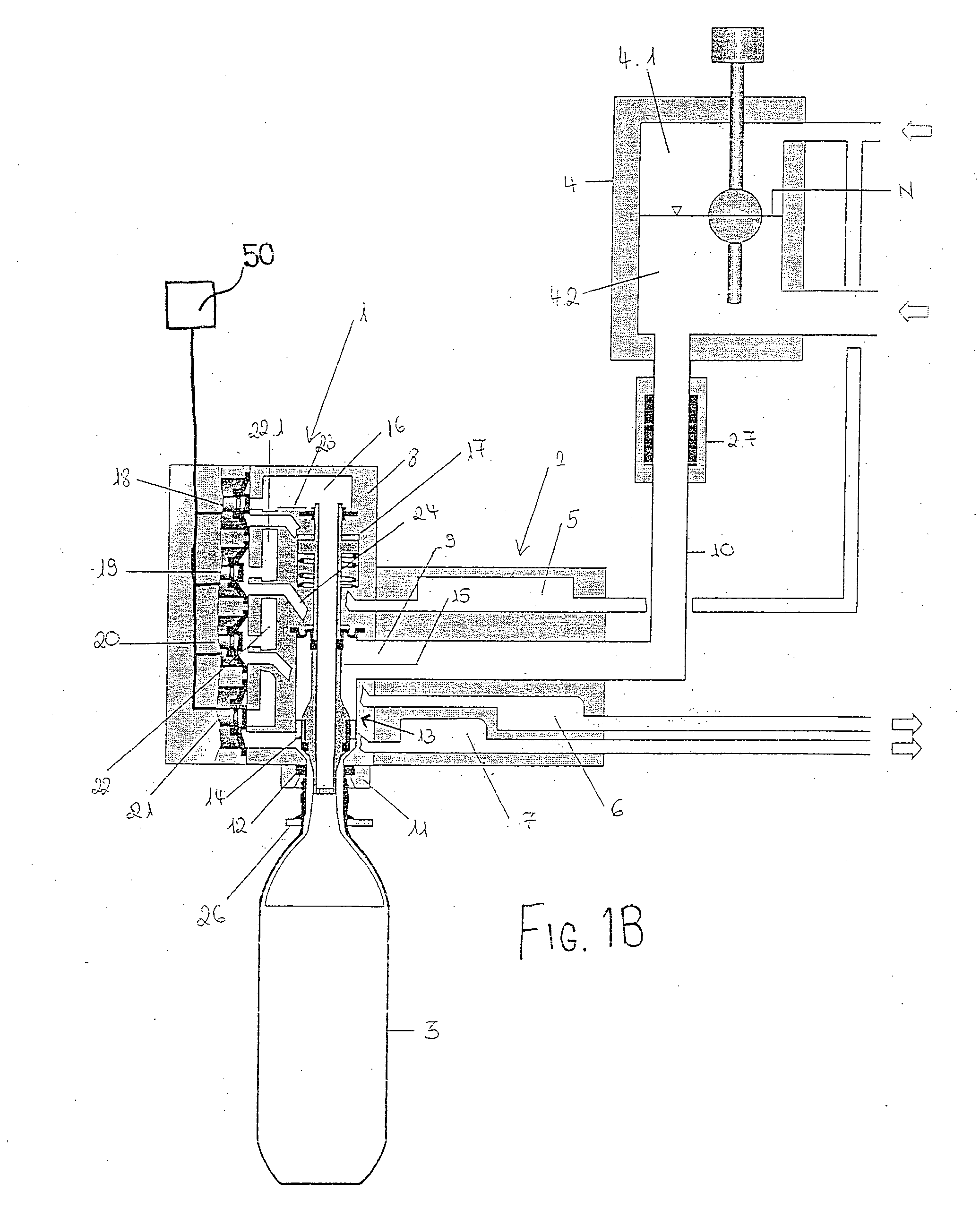

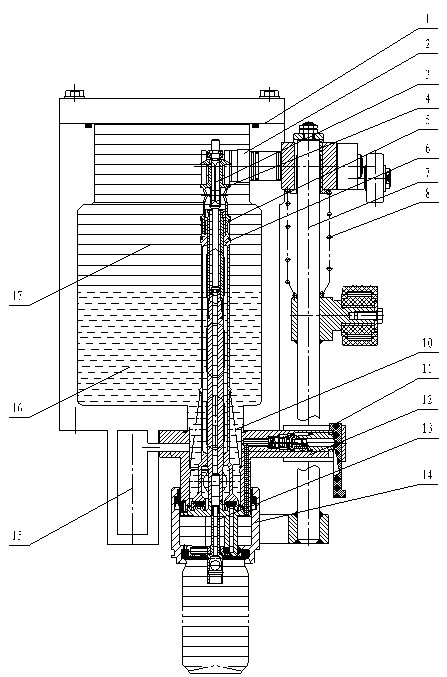

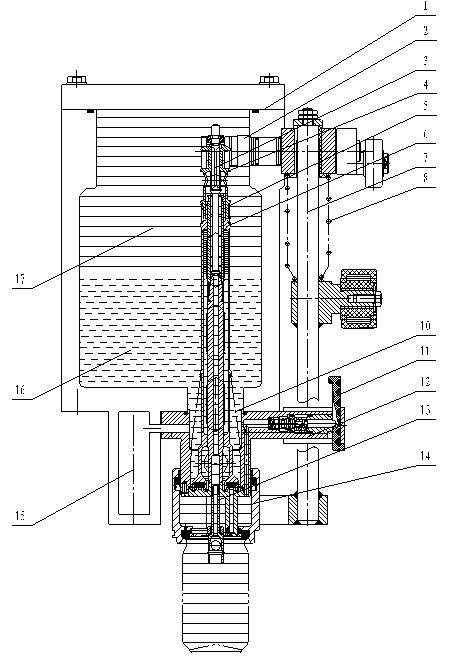

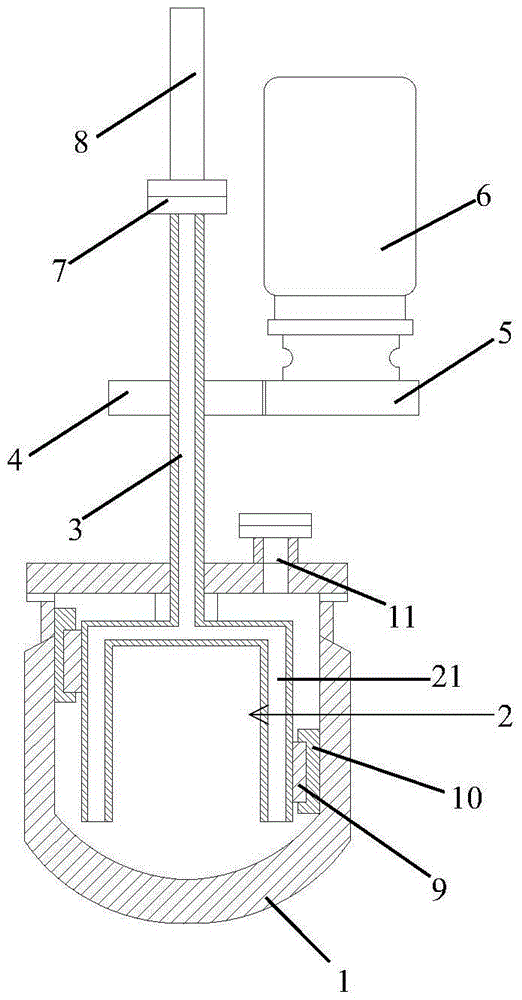

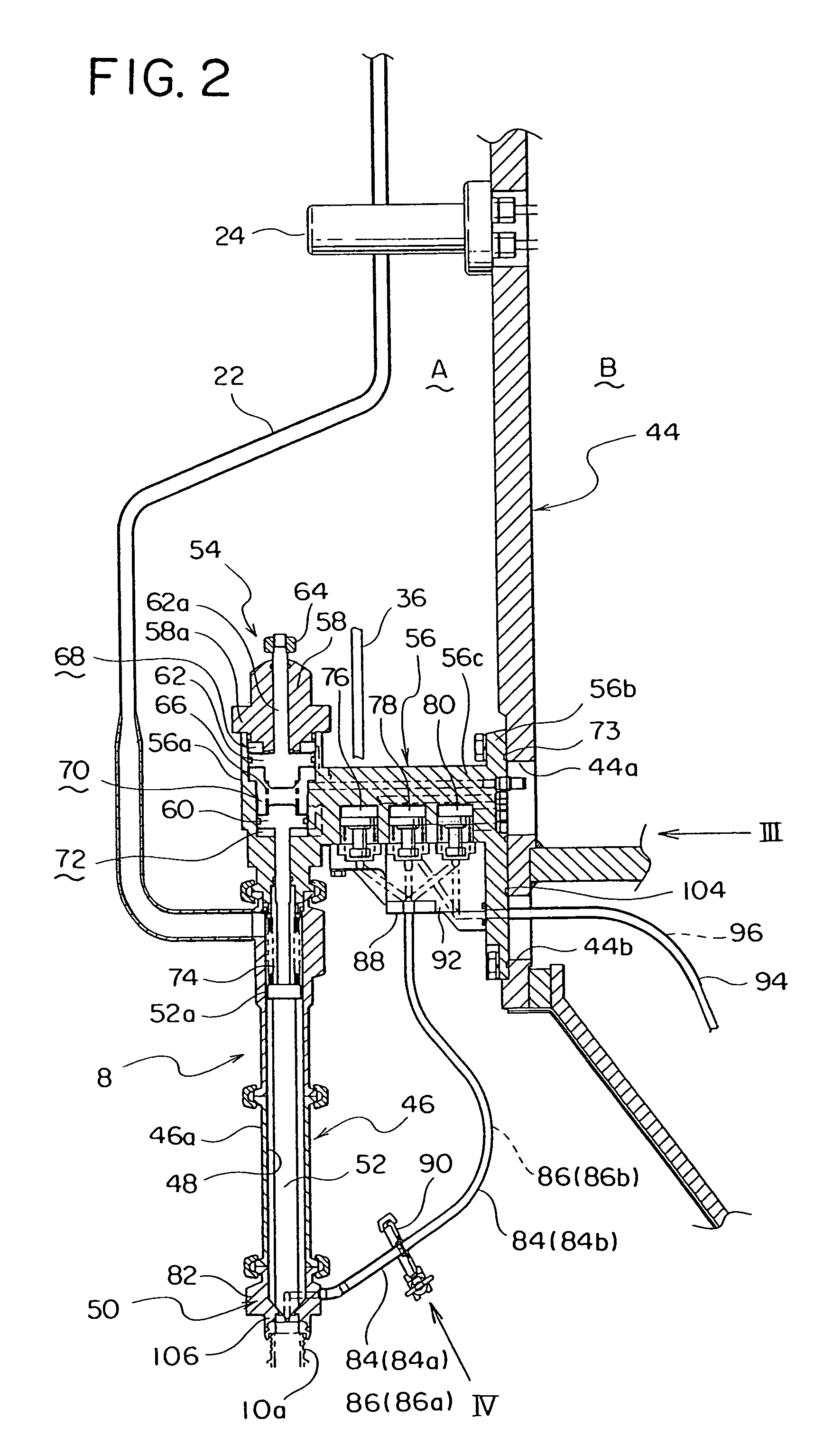

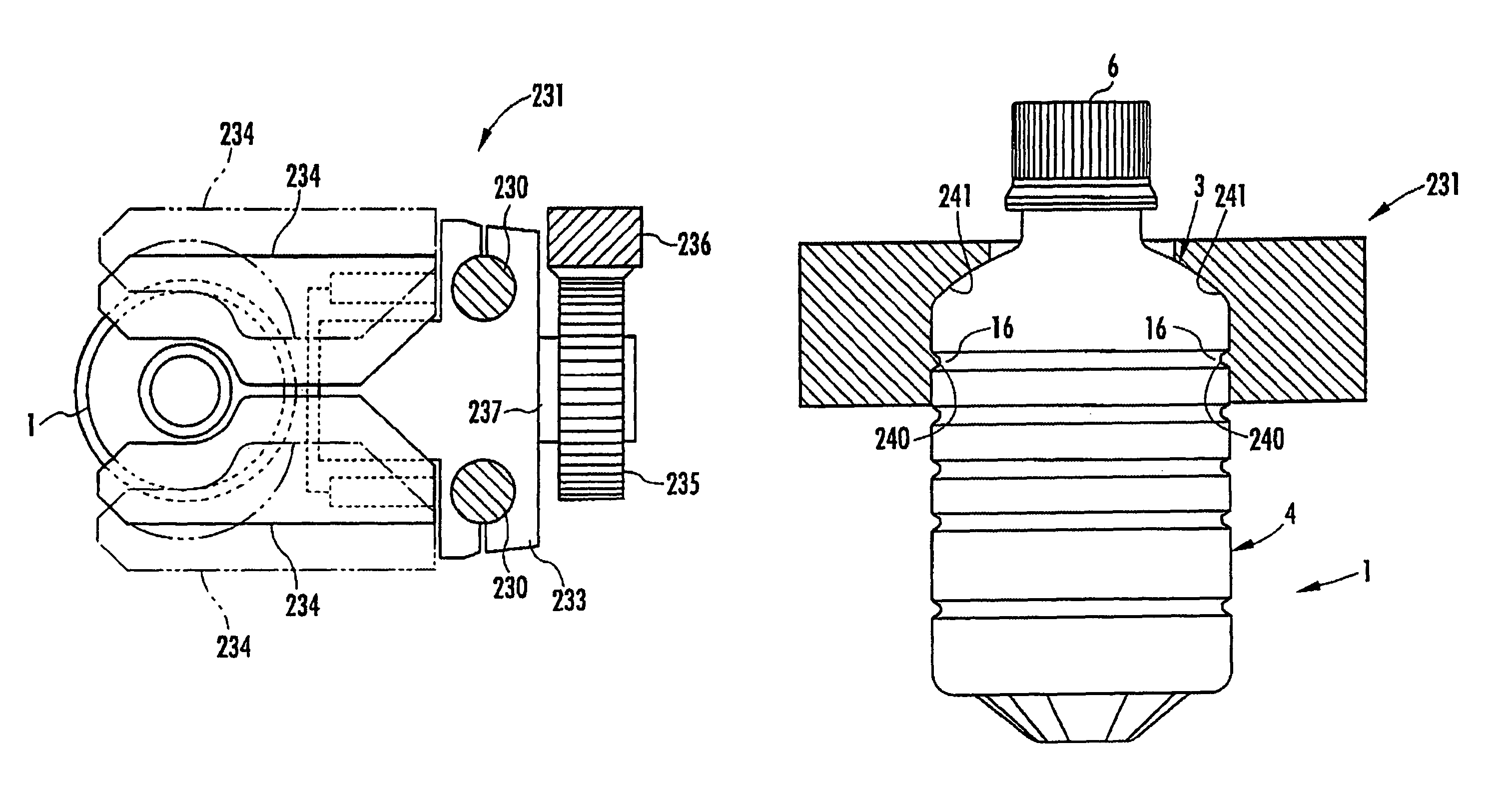

Filling valve

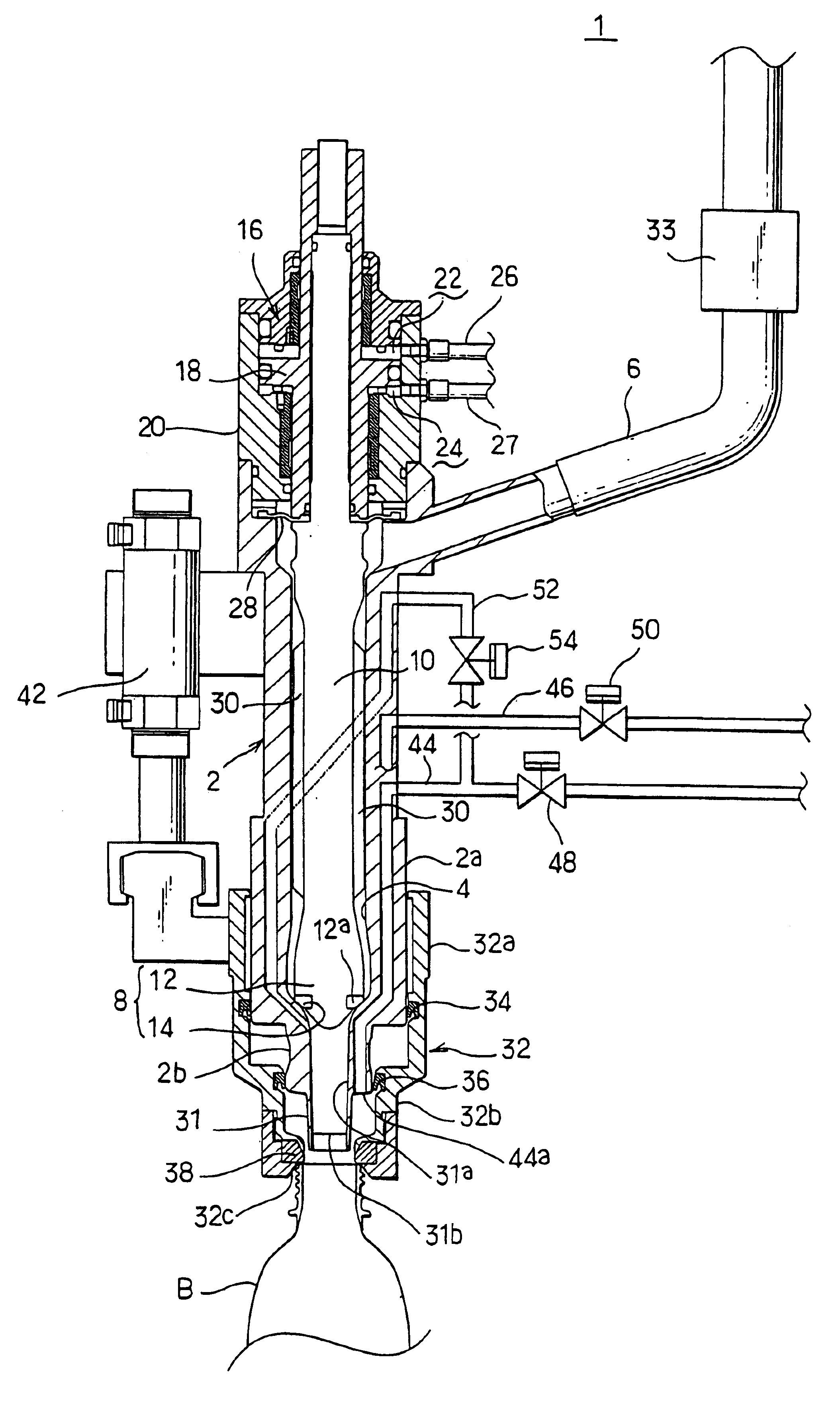

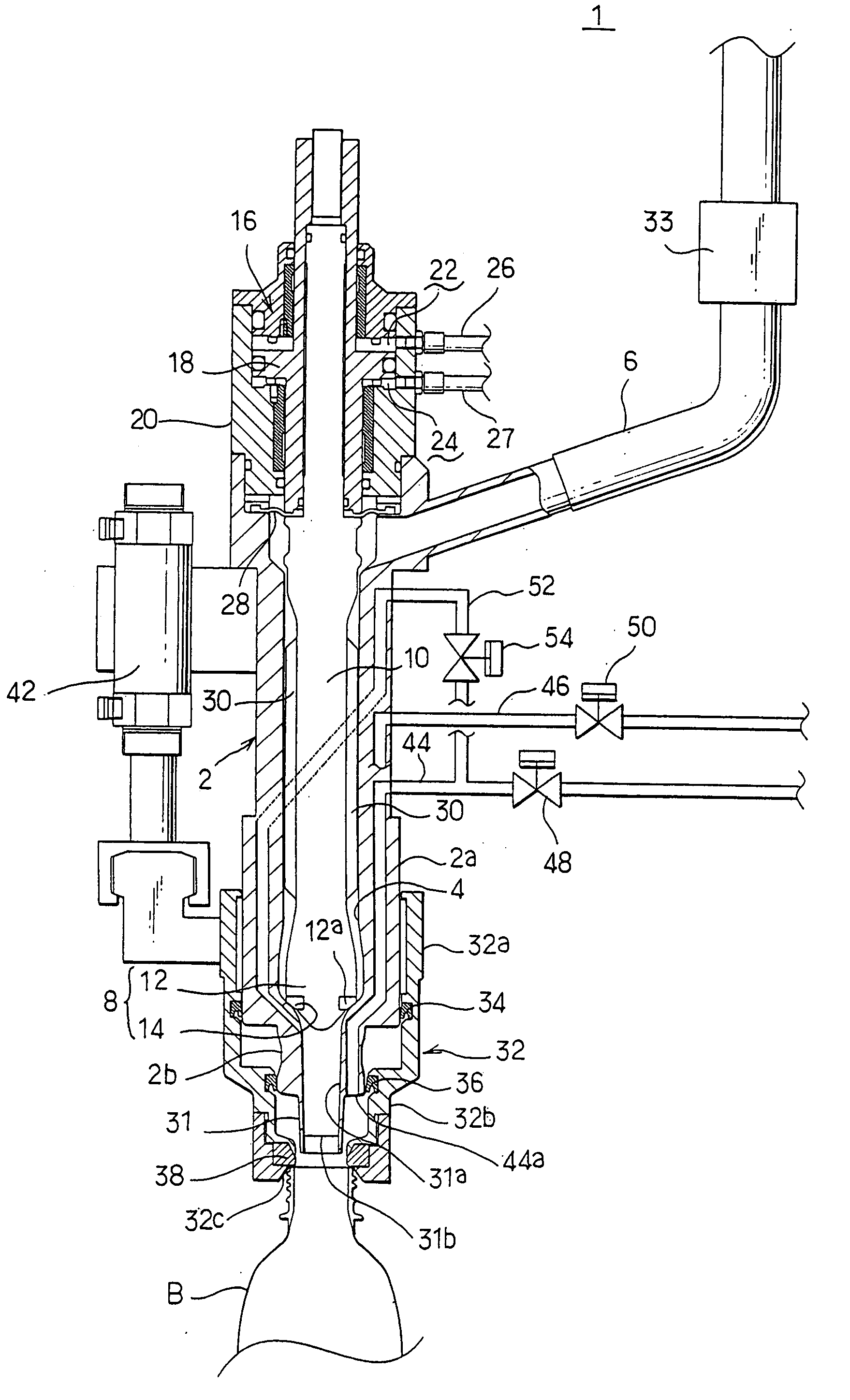

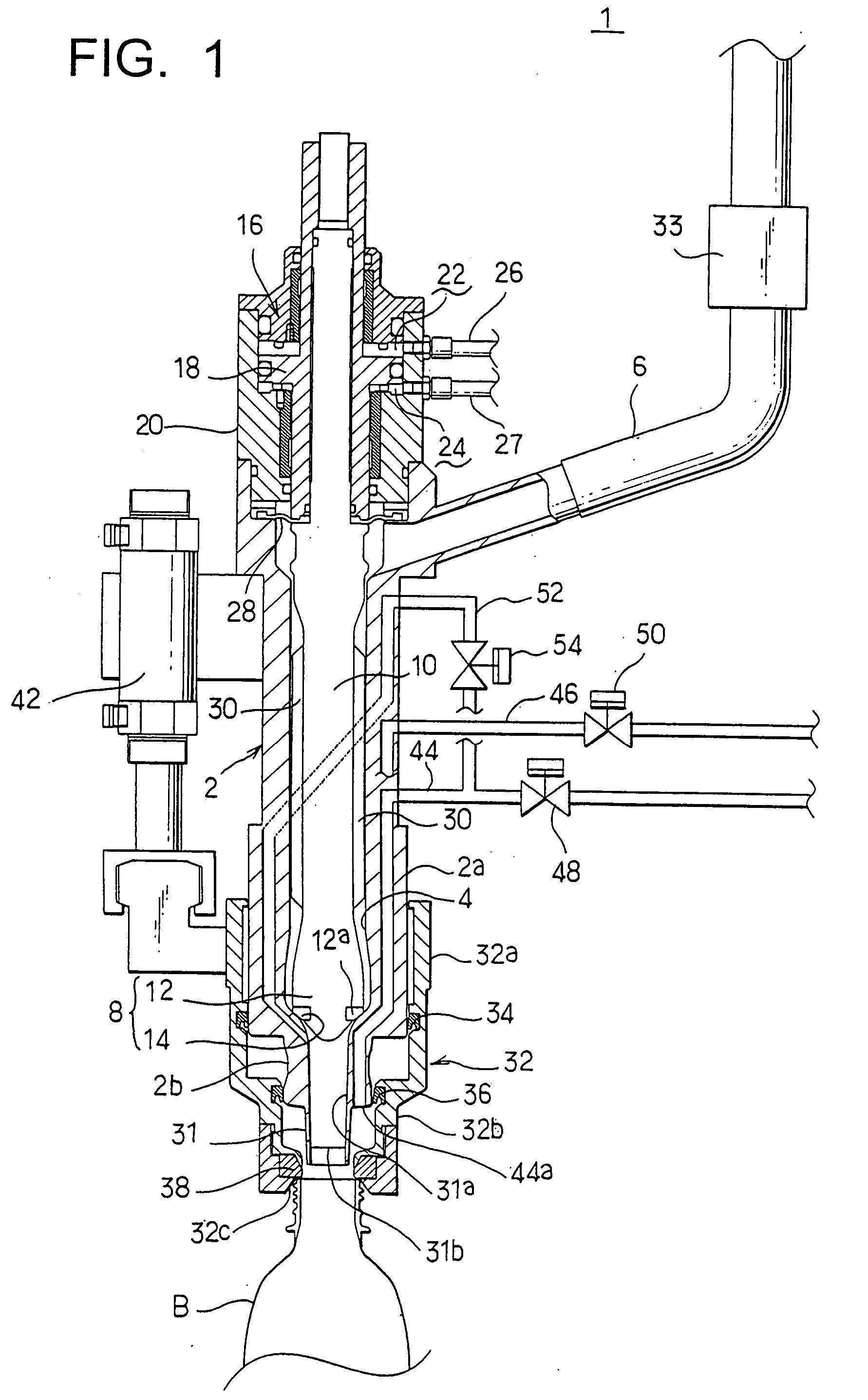

InactiveUS6817386B2Improve hygieneGuaranteed uptimeFilling using counterpressureFilling without pressureEngineeringMechanical engineering

A liquid passage 4 for filling which communicates with a liquid supply piping 6 for filling is formed within a valve housing 2 and carries a filling nozzle 31 at its lower end. The liquid passage 4 is opened or closed by a liquid valve. A packing 38 which seals the mouth of a vessel B, a cylinder 42 which elevates the packing 38, a flow meter 33 which detects a filled content of the liquid which is filled into the vessel B, and an exhaust passage 44 formed in the valve housing 2 are provided. The exhaust passage 44 has an opening disposed toward the vessel which is disposed outside an opening of the filling nozzle 31, and the opening of the filling nozzle 31 is maintained above the elevation of the liquid level which is filled into the vessel B during the filling operation. The filling valve assures a sanitary excellence and is usable with vessels B of differing sizes and shapes.

Owner:SHIBUYA IND CO LTD

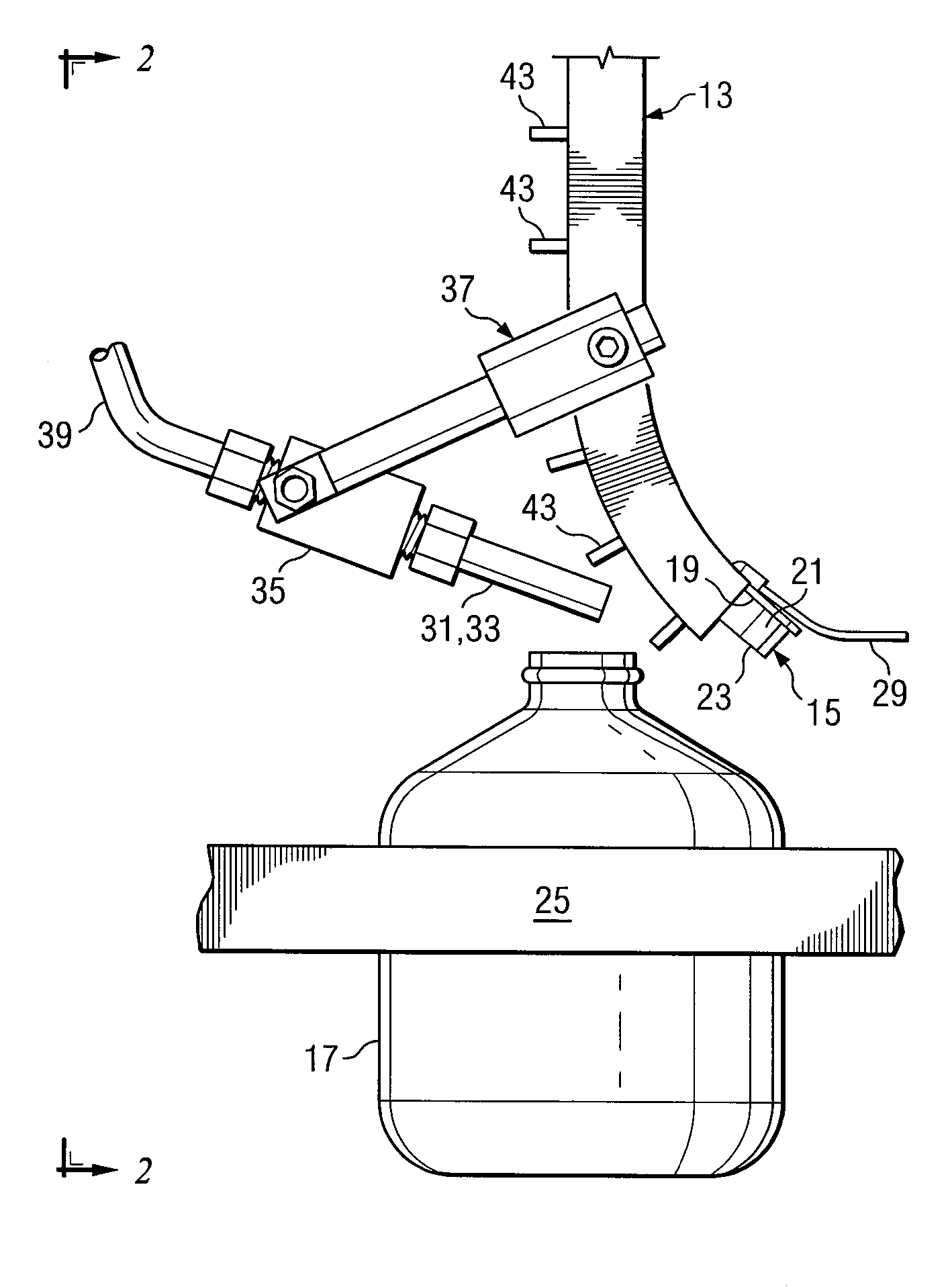

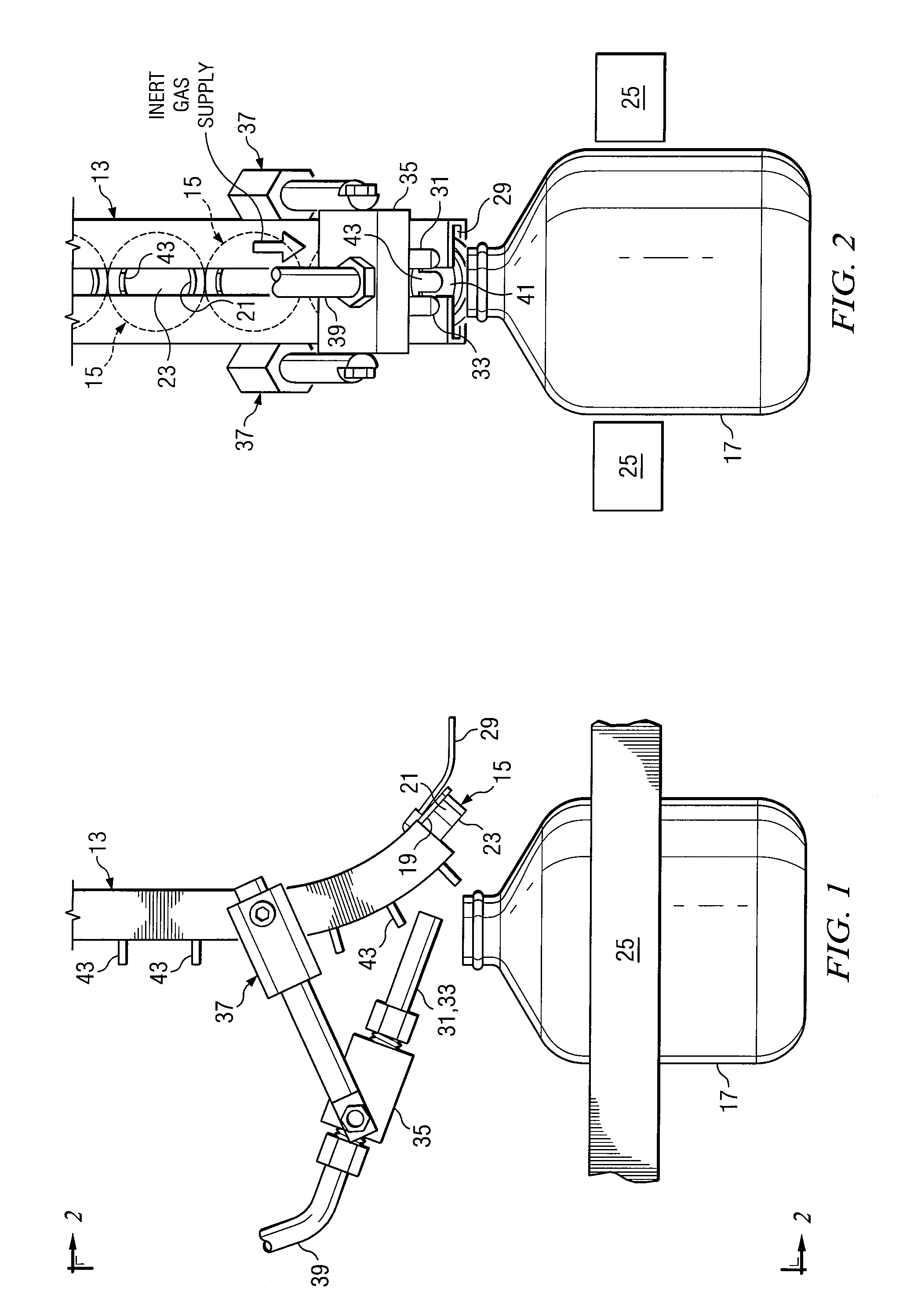

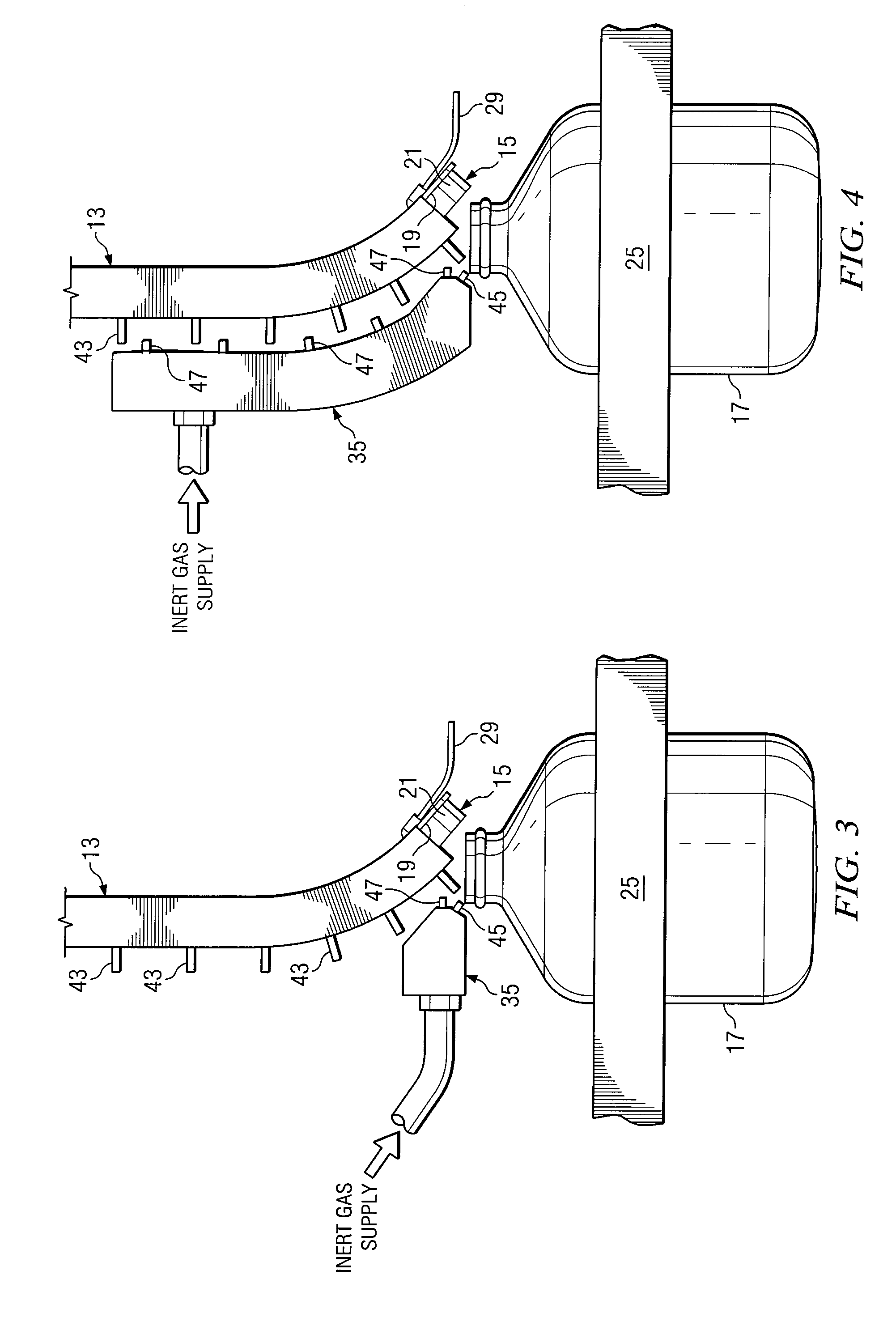

Method and Apparatus for Flushing a Container with an Inert Gas

InactiveUS20070056251A1Extended shelf lifeLower Level RequirementsSnap-on cap applicationFilling without pressureEngineeringOxygen

A process to reduce oxygen in the head space of containers includes introducing an inert gas into the container head space. This may be accomplished during a capping process. The process may further include flushing the container with an inert gas. The flushing step may be performed while the container is empty or prior to being completely filled.

Owner:RUPPMAN KURT H SR +1

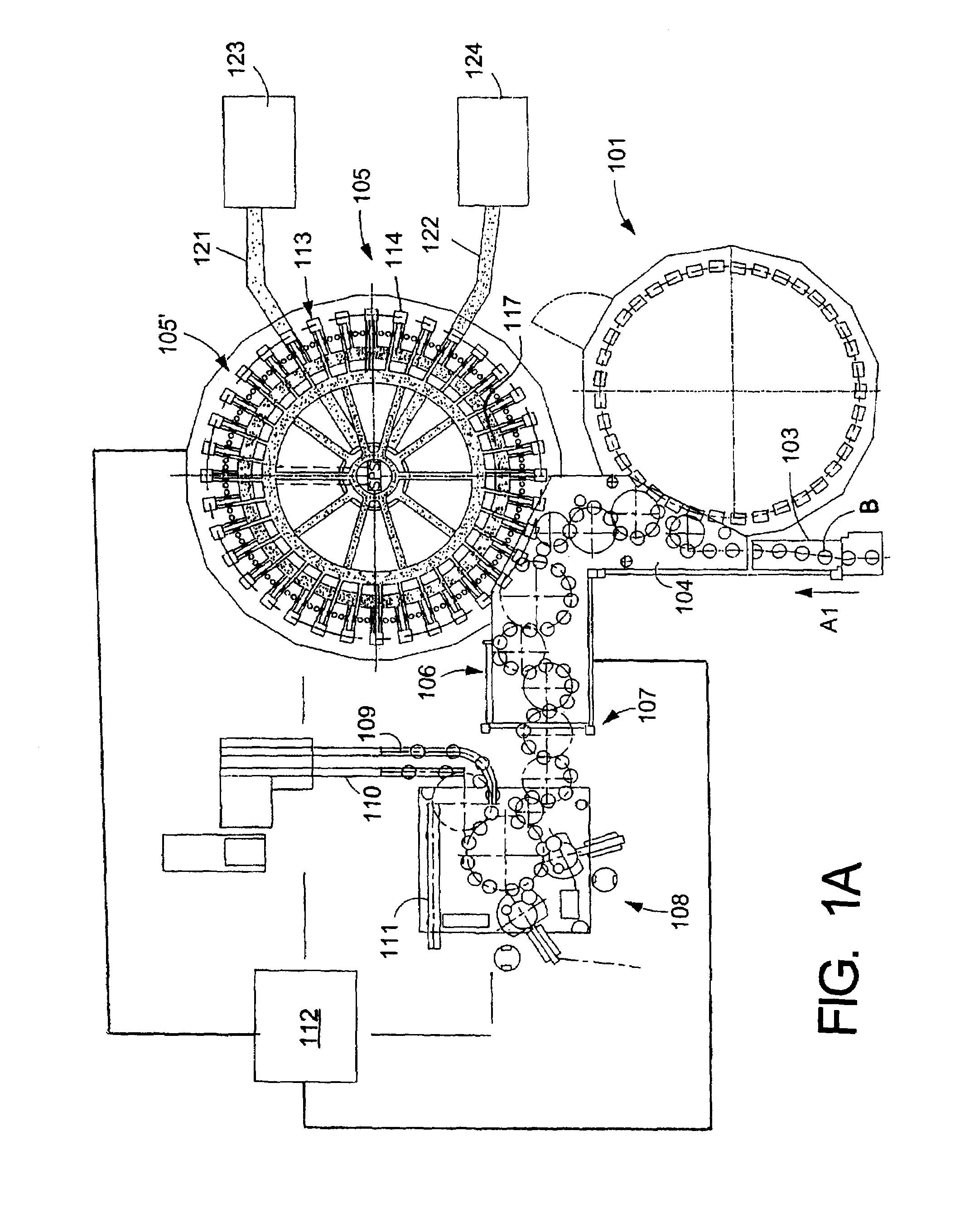

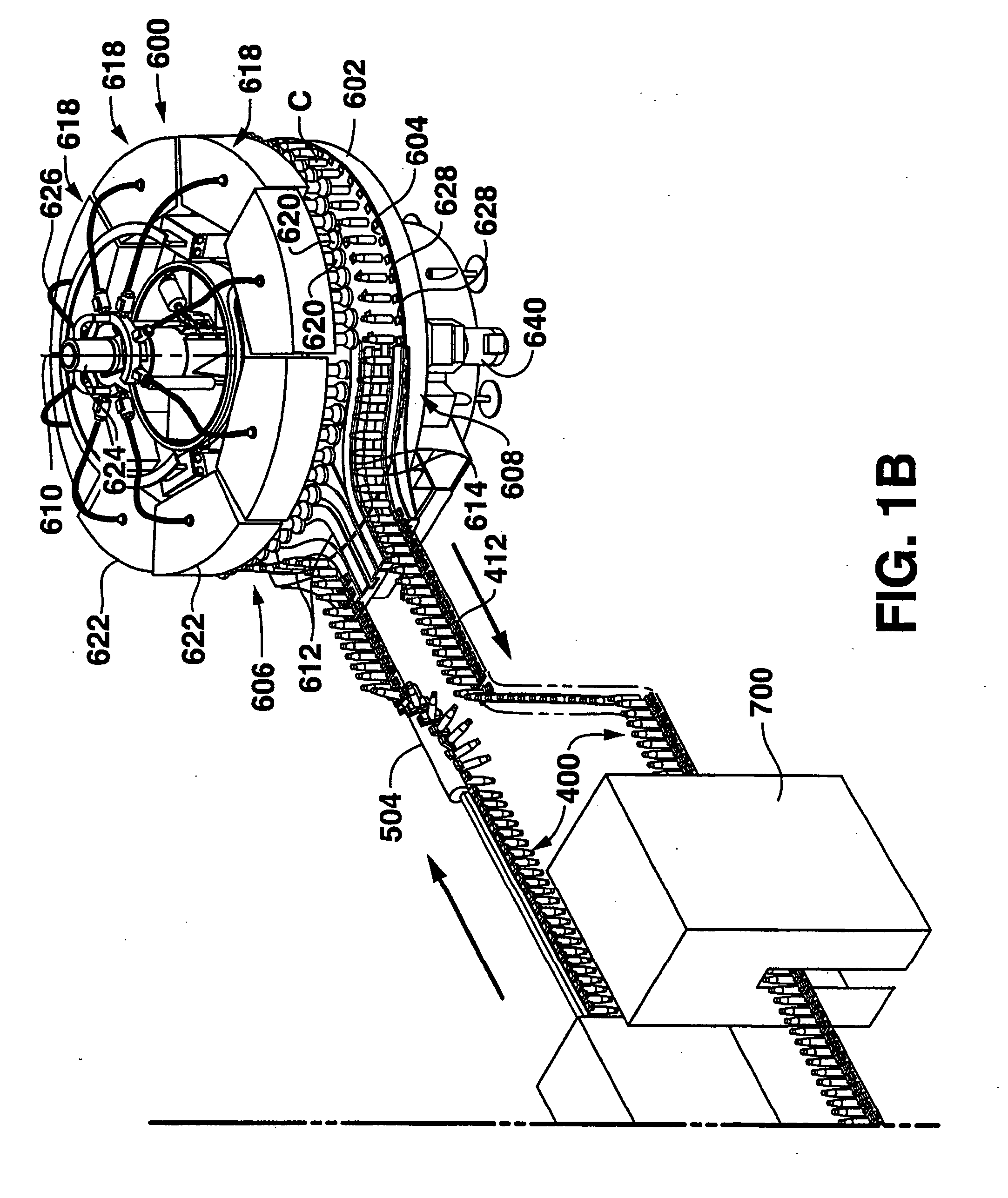

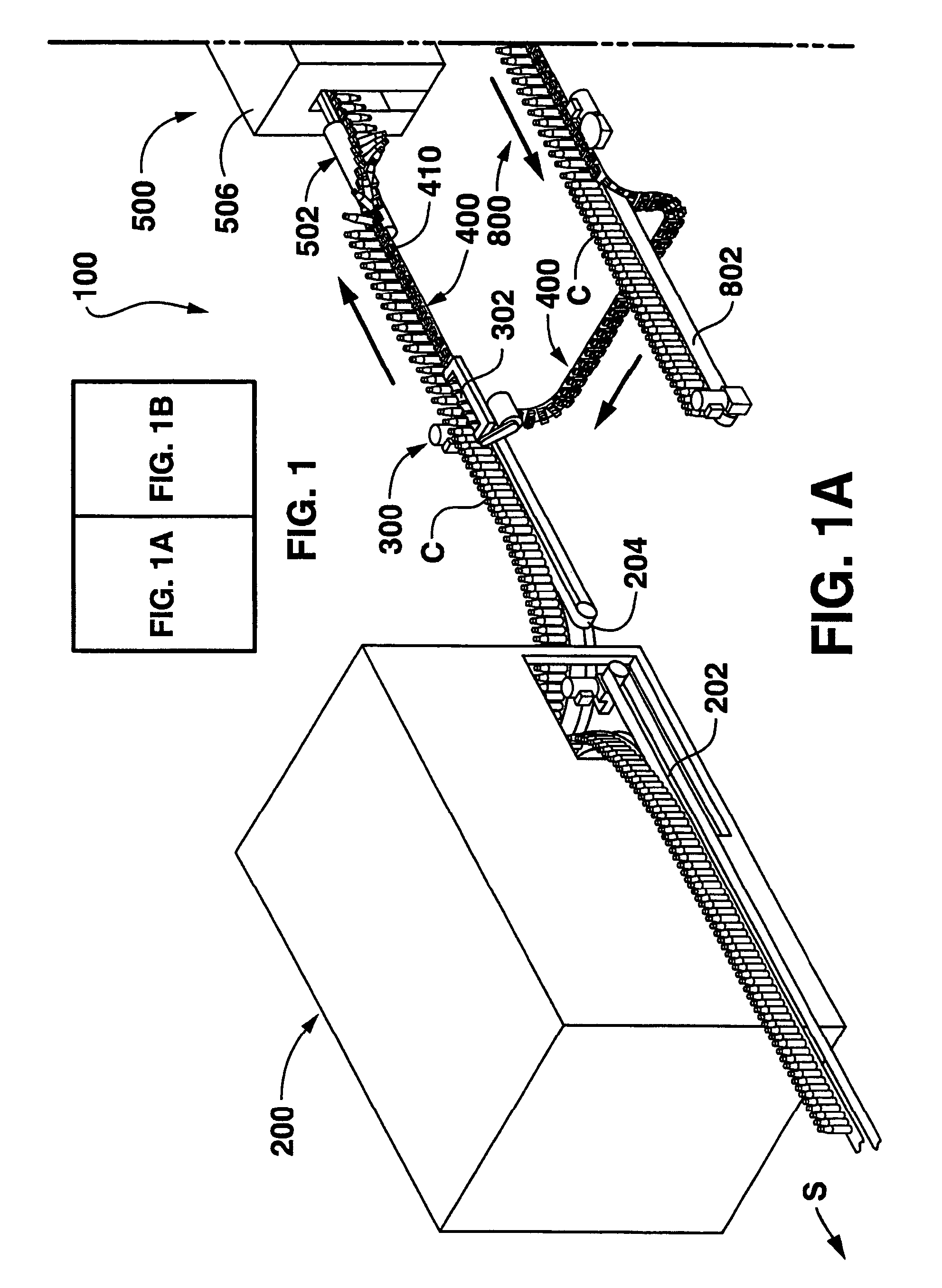

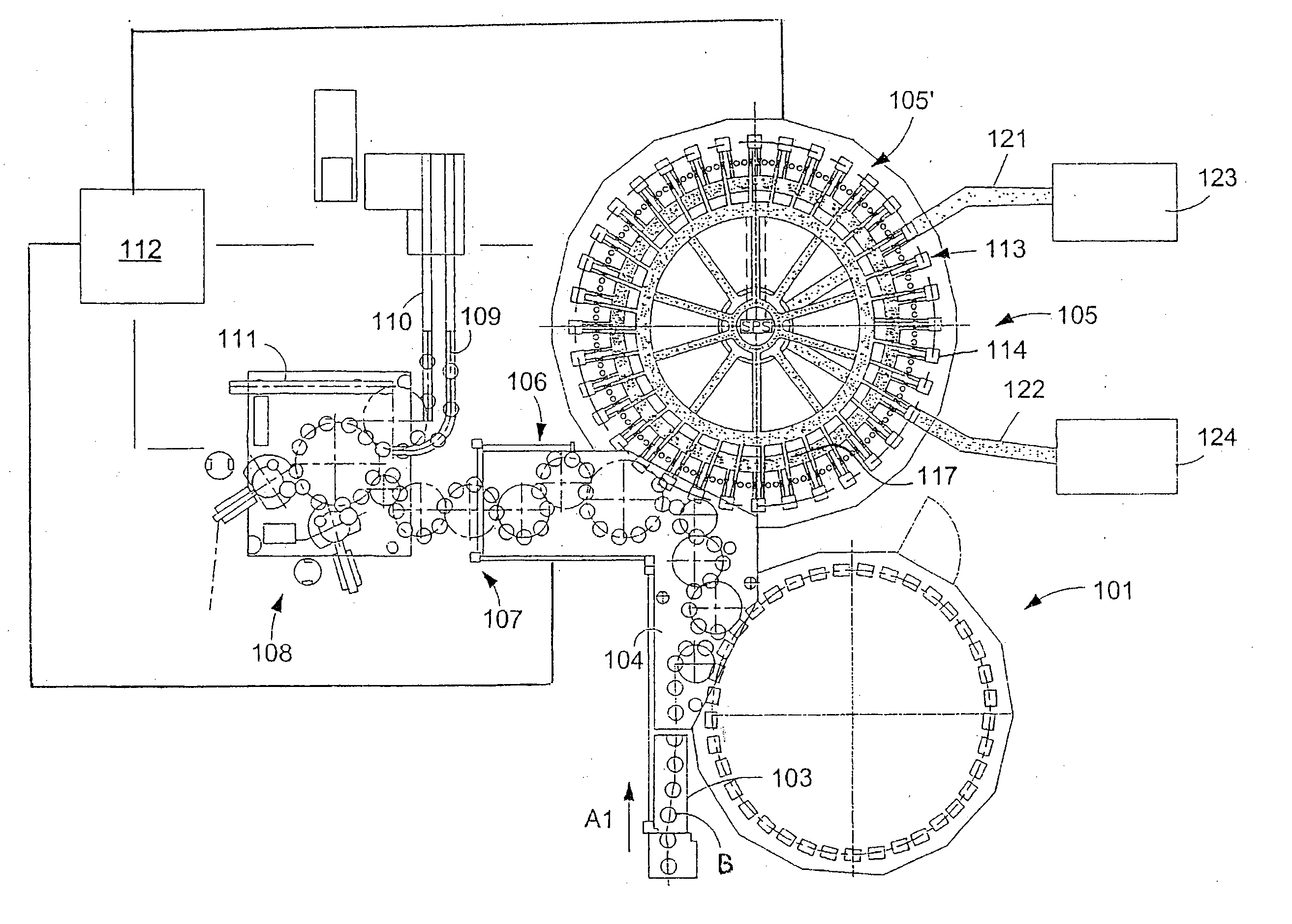

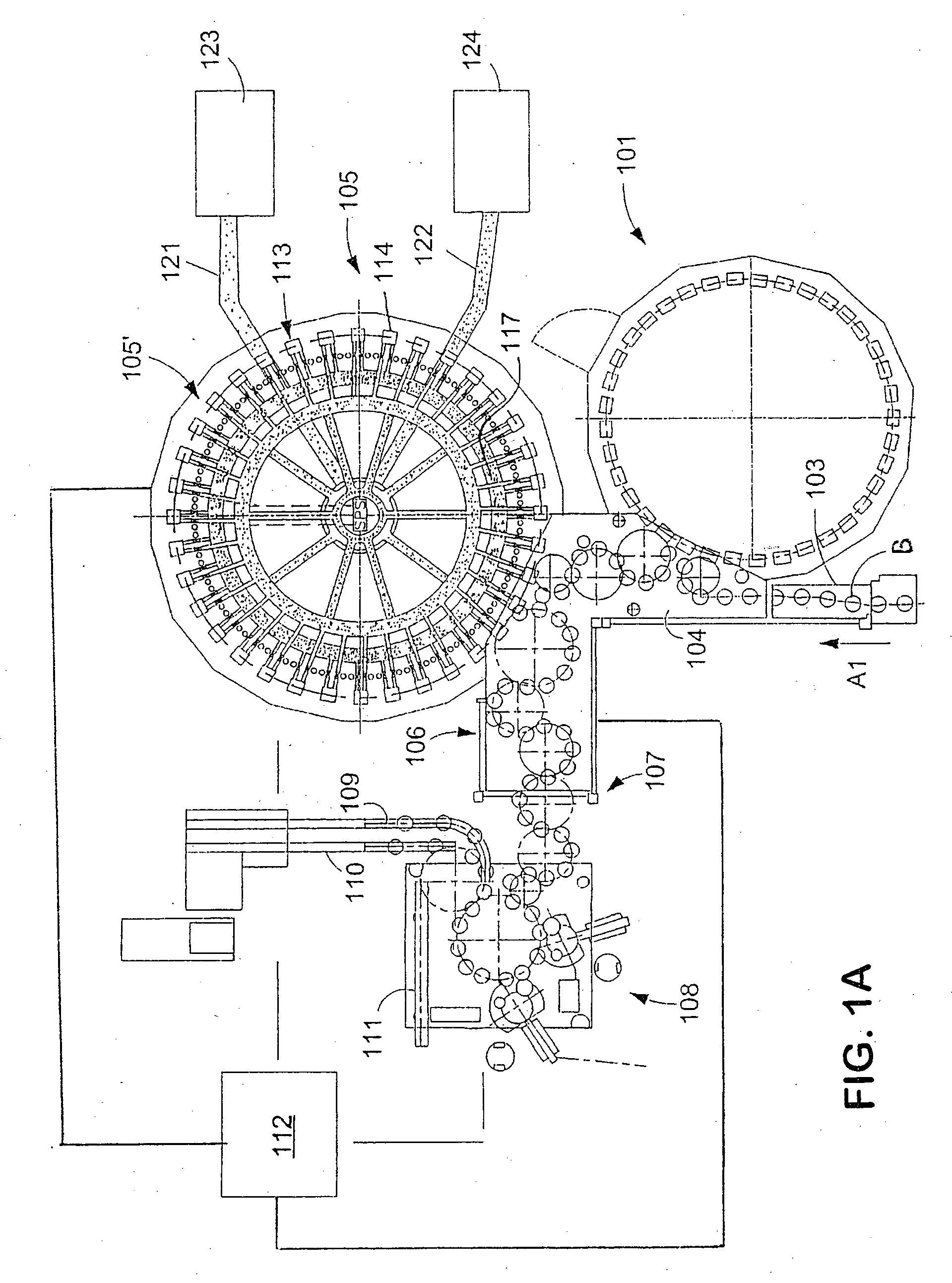

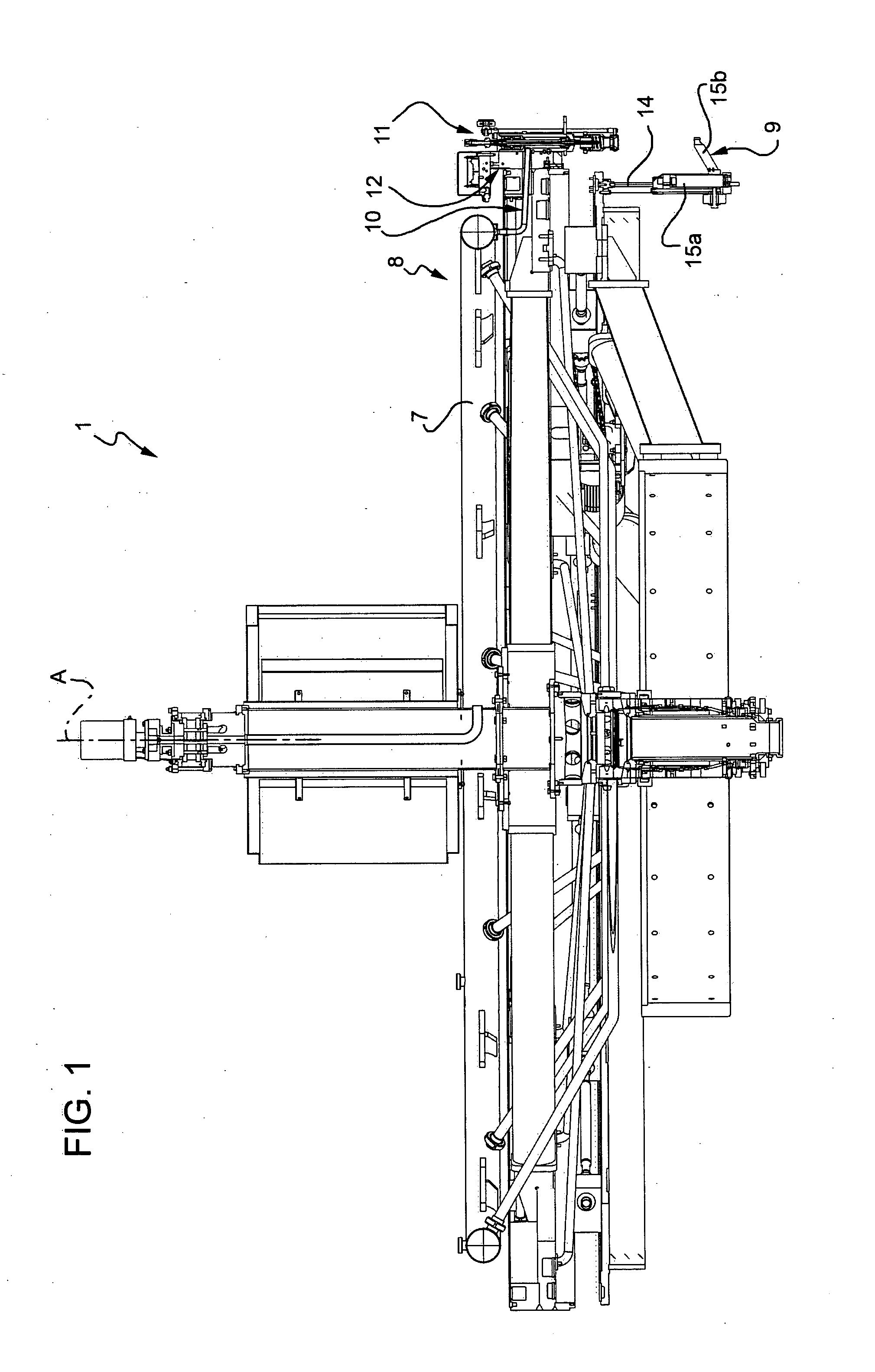

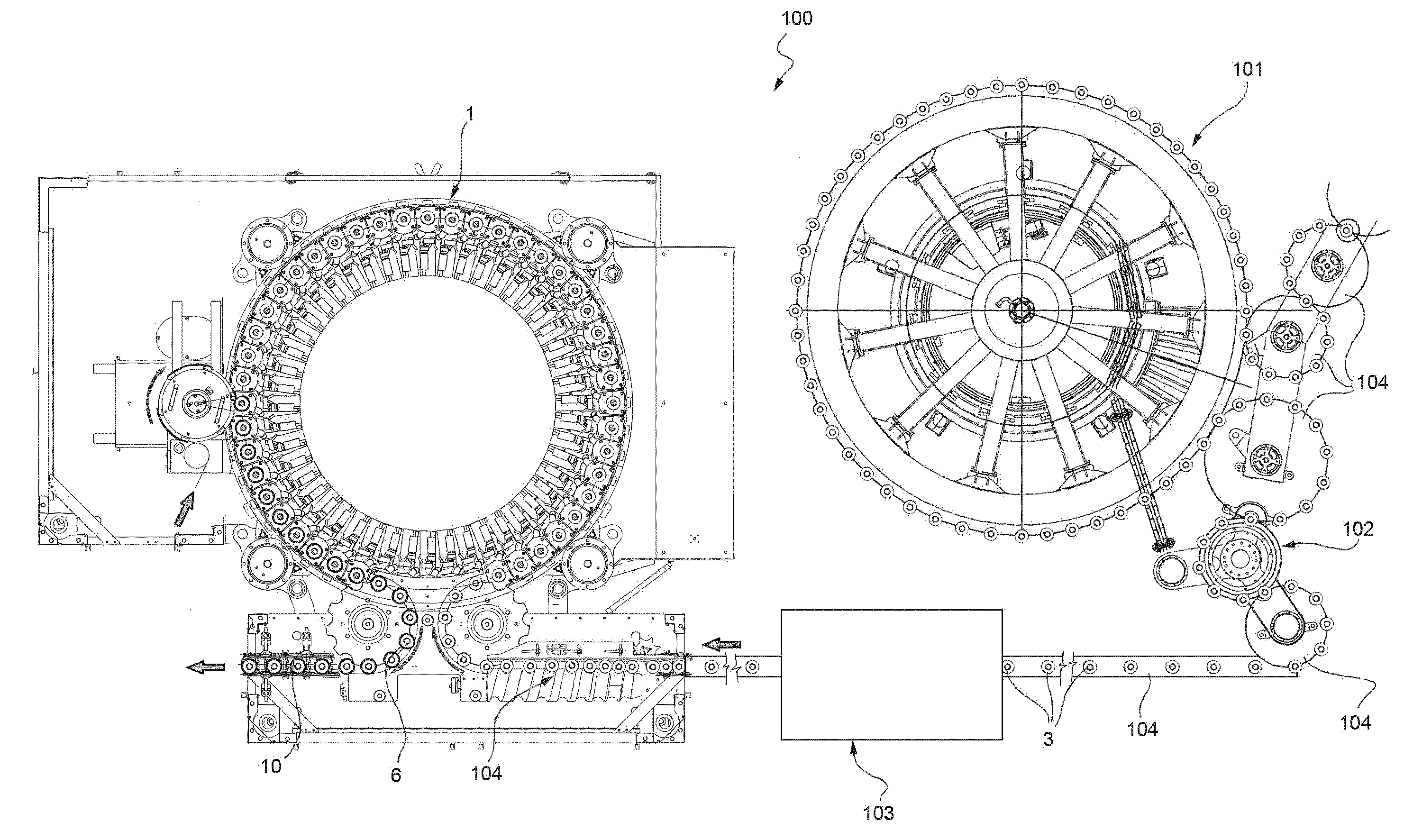

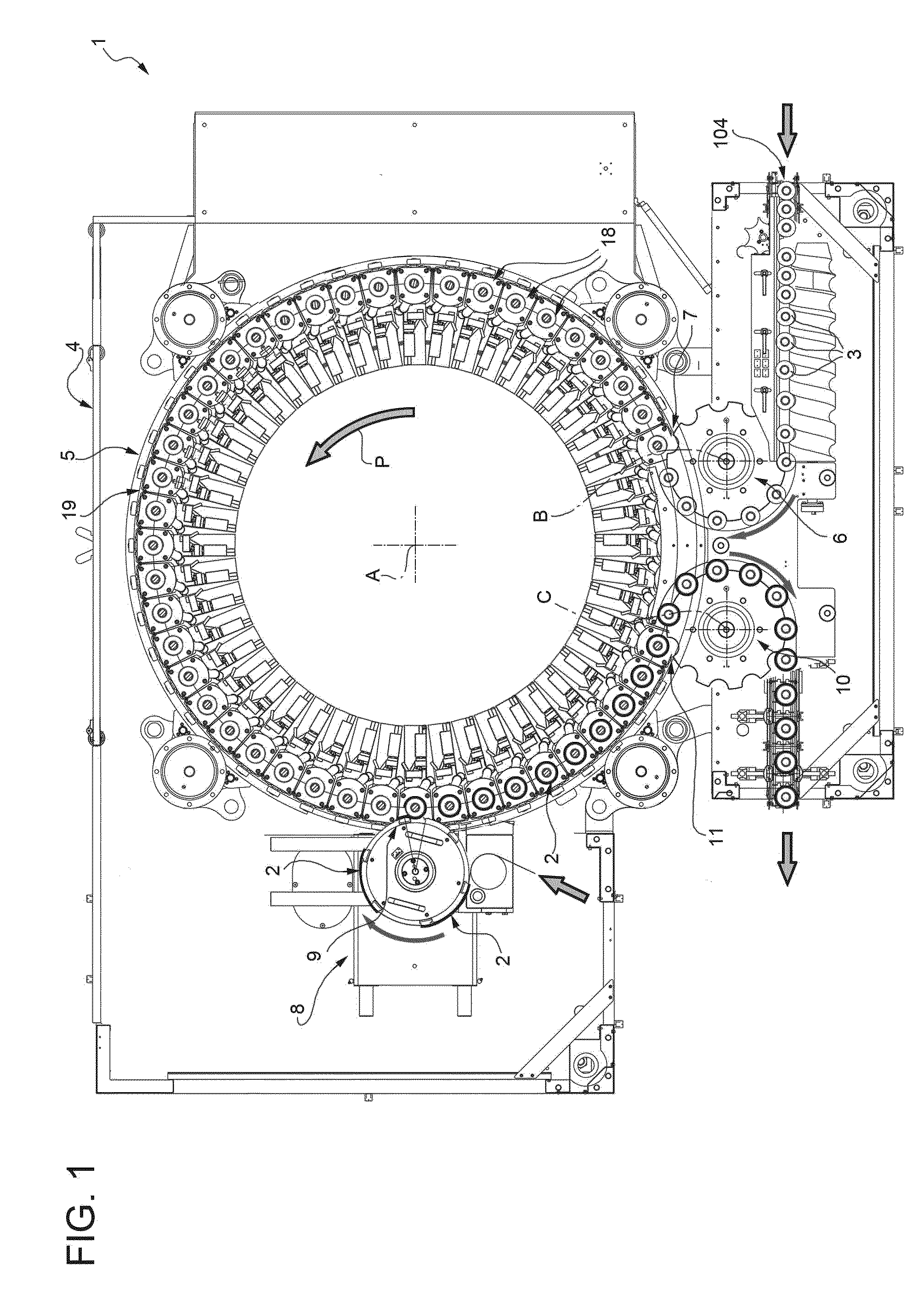

Rotary filling machine and related components, and related method

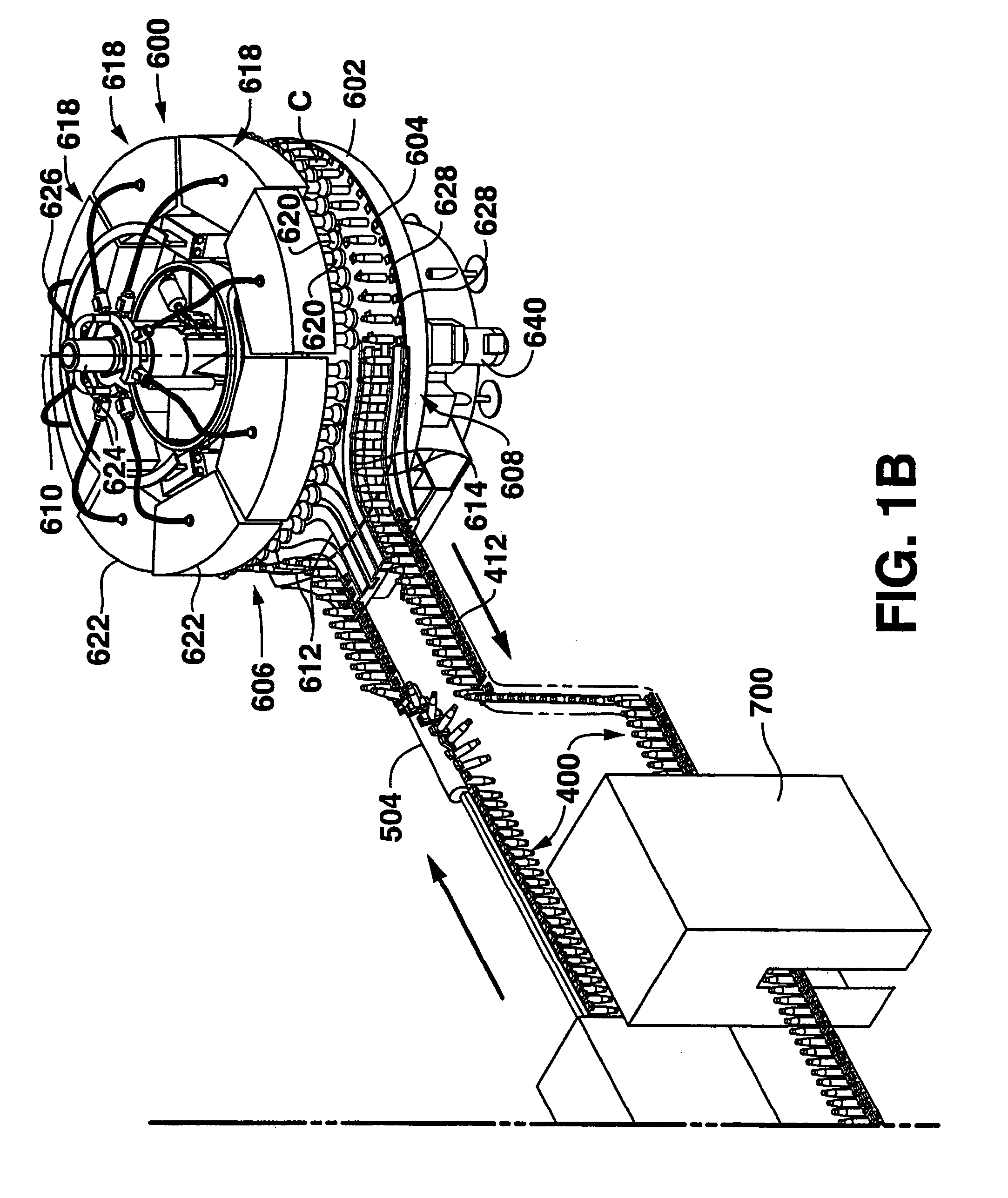

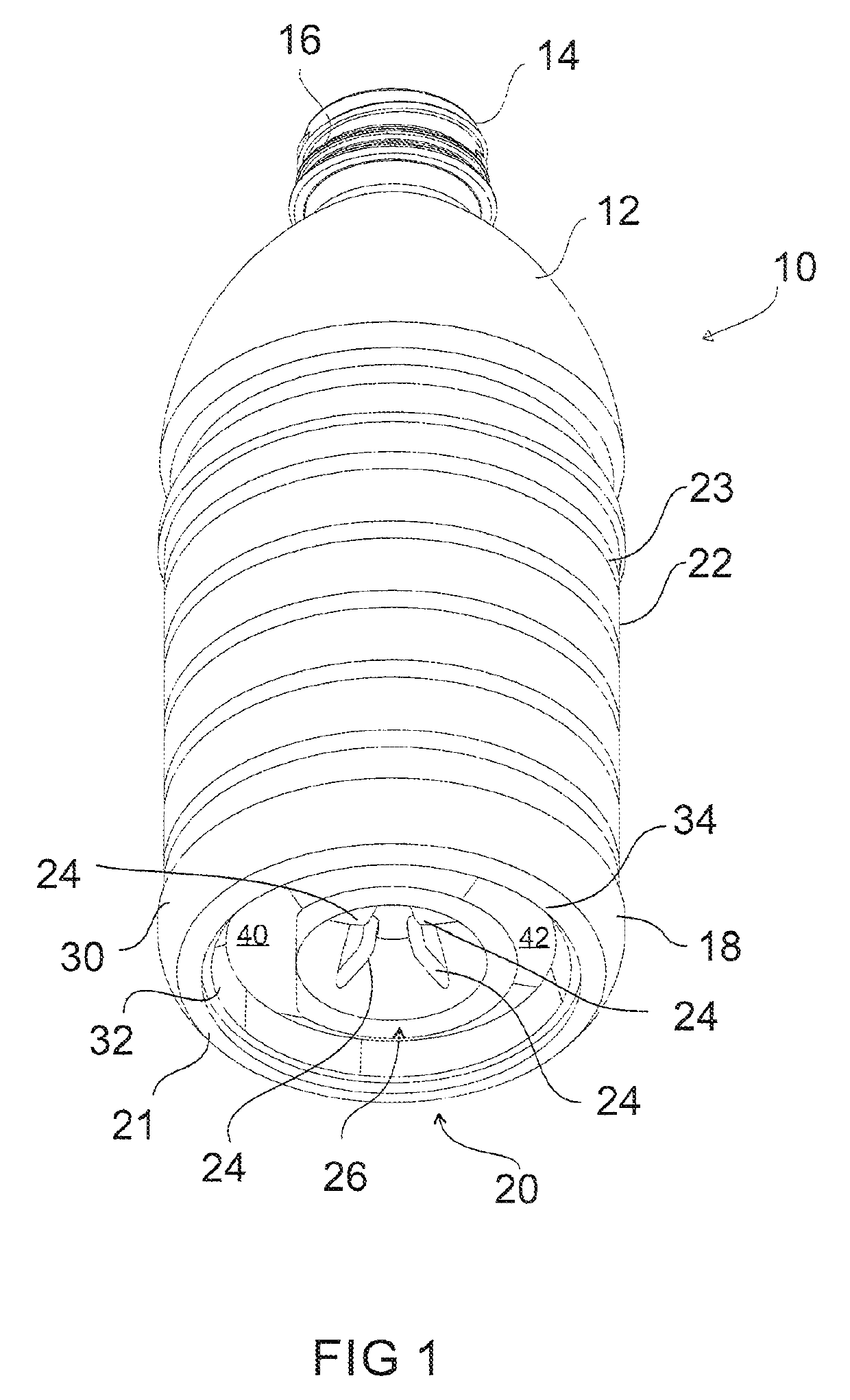

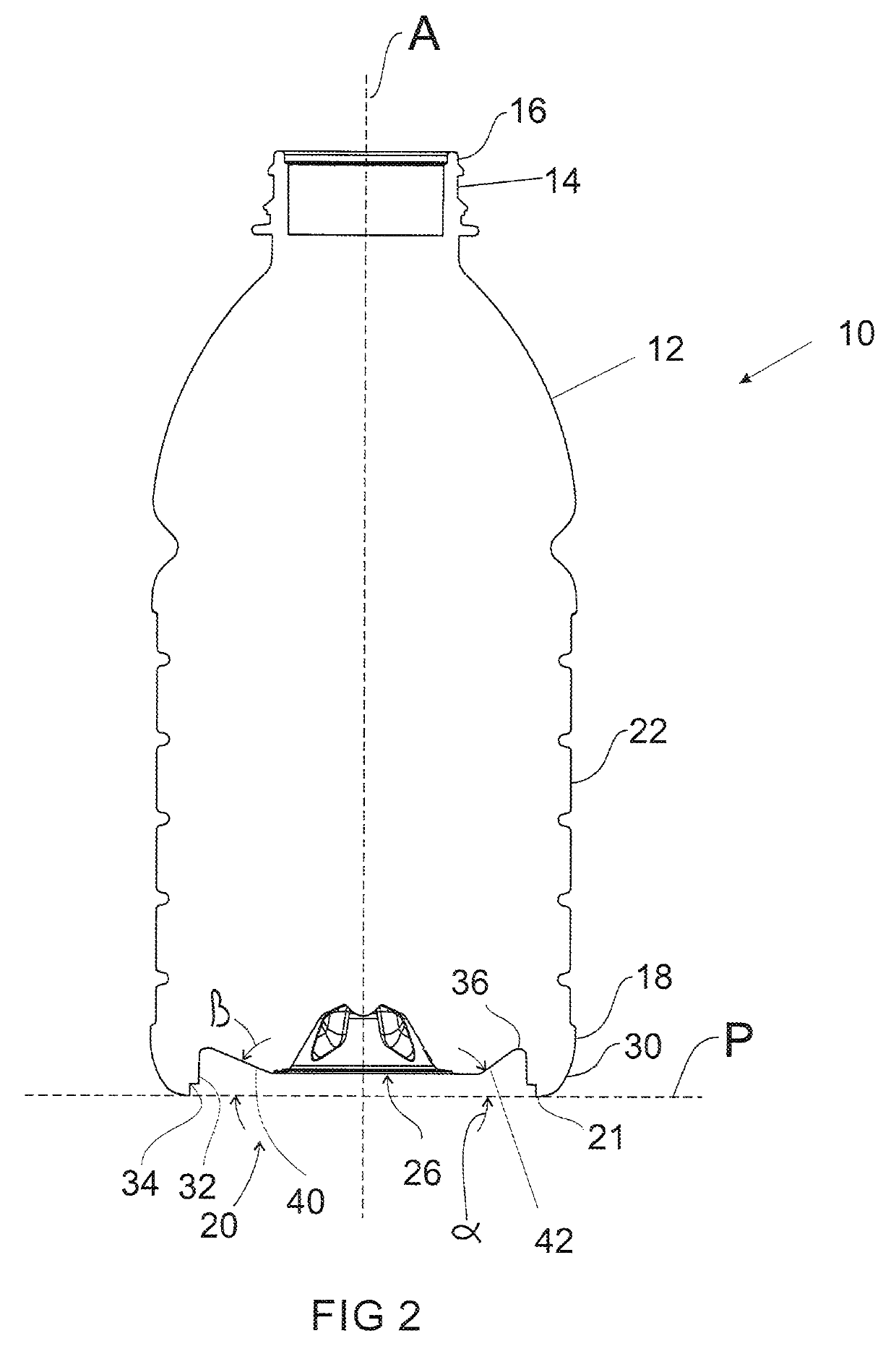

A rotary filling machine is disclosed for filling containers, the machine including a rotating platform rotatable relative to a vertical rotating axis through a filling zone, and a conveyor configured to convey empty containers to be filled to the rotating platform for filling and to convey filled containers from the rotating platform. Various aspects and designs of the above elements are disclosed, as well as a related method.

Owner:ILLINOIS TOOL WORKS INC

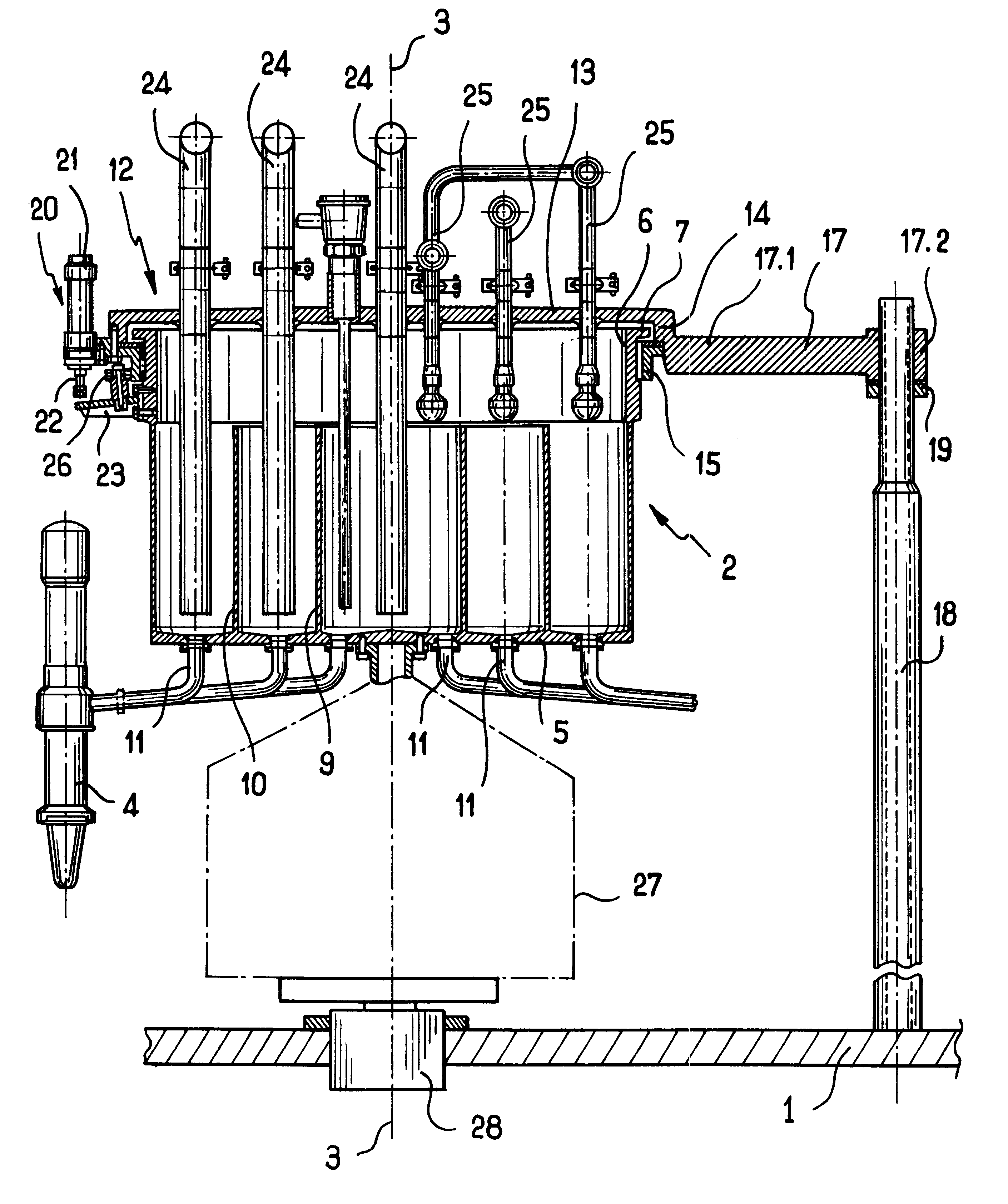

Installation for filling containers

InactiveUS6334473B1Keep the distancePrevent rotationFilling without pressureSolid materialFixed frameEngineering

A filling installation comprising a fixed frame, a tank mounted on the fixed frame so as to rotate about an axis, and a lid associated with the tank and provided with a feed pipe, positioning means being fixed to the lid, and being mounted on the fixed frame to slide parallel to the axis of rotation between a position in which the lid is applied against an edge of the tank so as to close off said tank and a position in which the lid is spaced apart from the edge of the tank.

Owner:SERAC GROUP

Container filling element for open-filling of containers

A beverage bottling plant for filling bottles with a liquid beverage material having a filling element and a filling machine having such filling elements. The filling elements each have a movable probe which may be moved into a bottle or container to be filled in order to detect the level of liquid, such as a beverage, in the bottle or container.

Owner:KHS GMBH

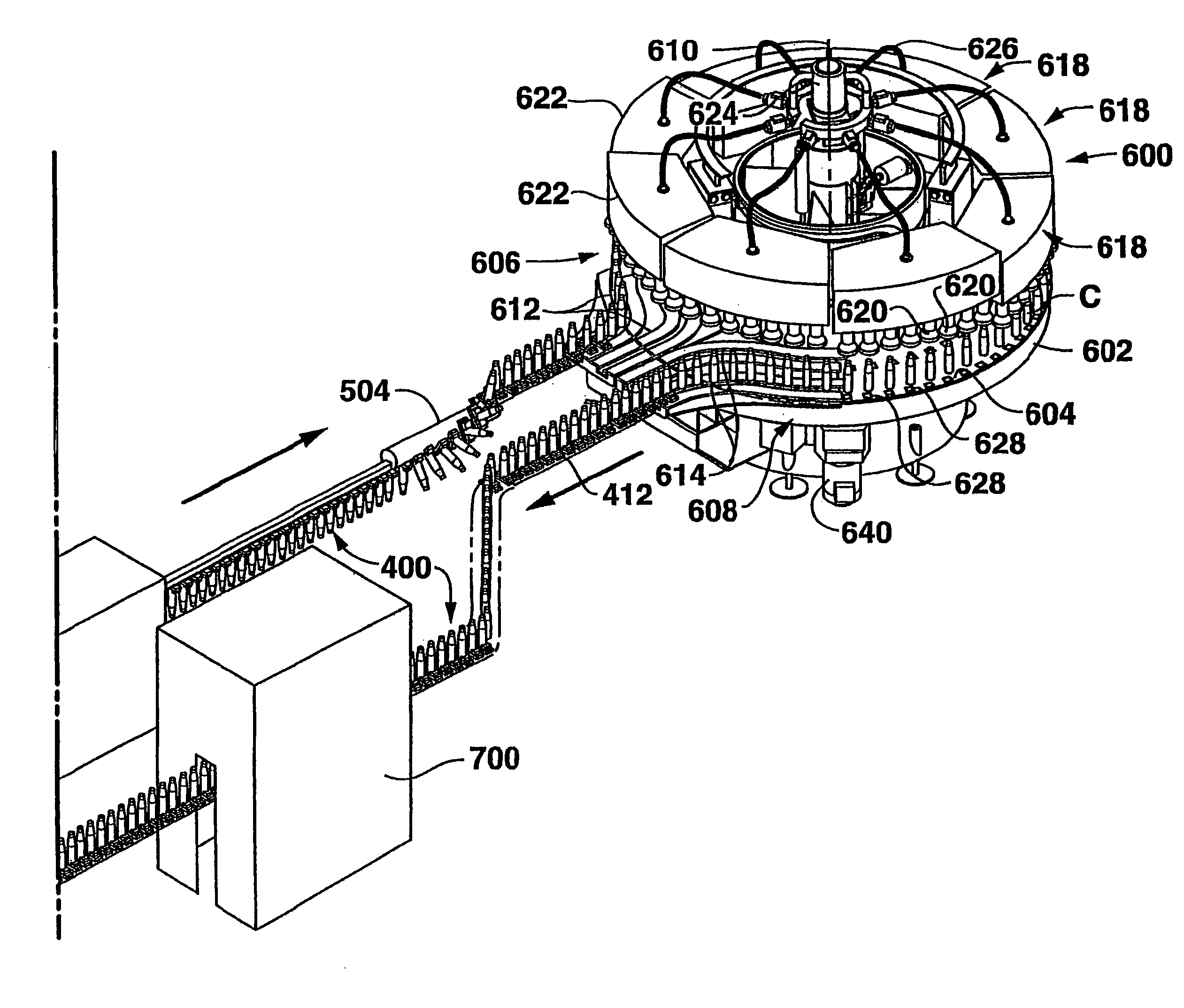

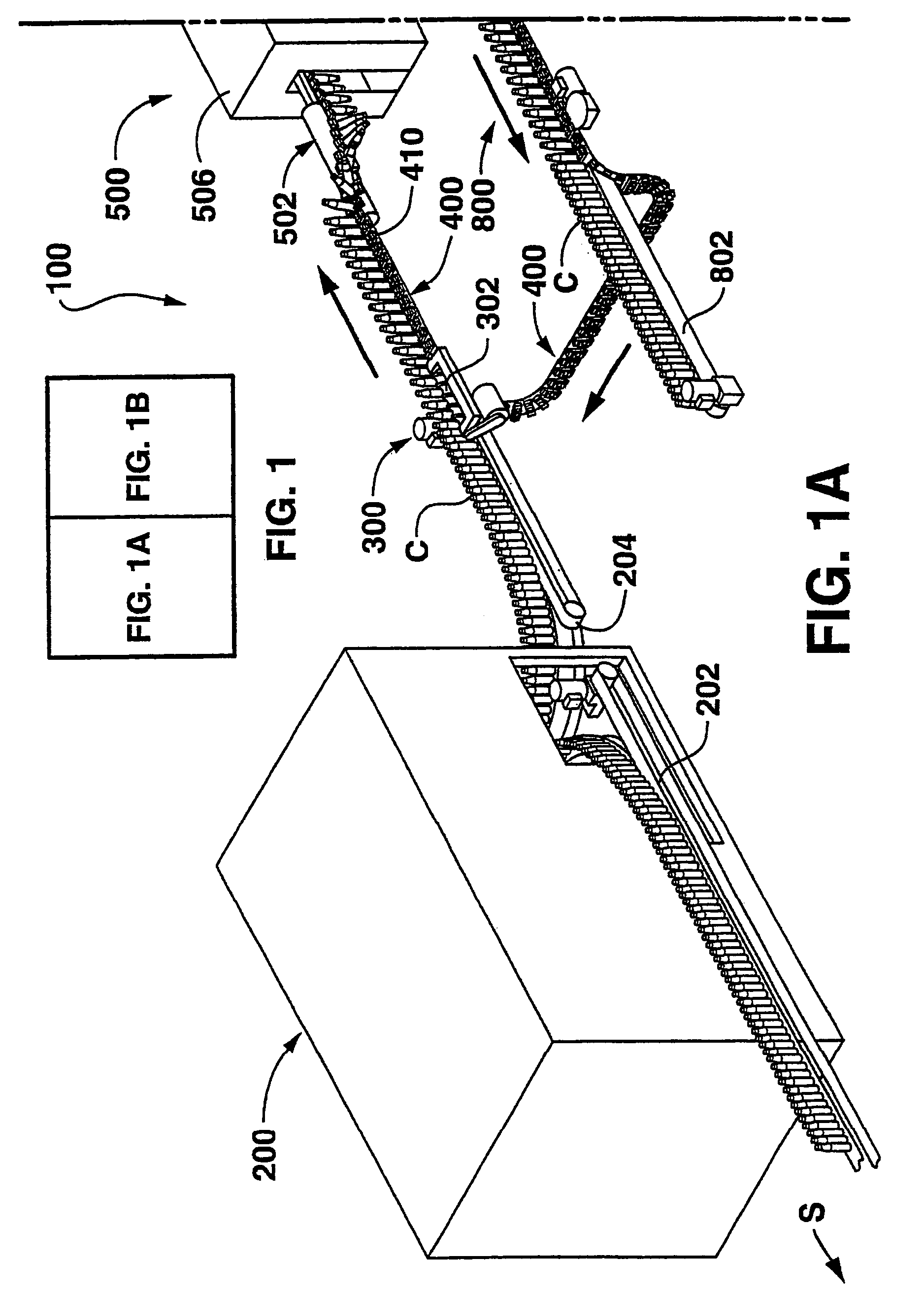

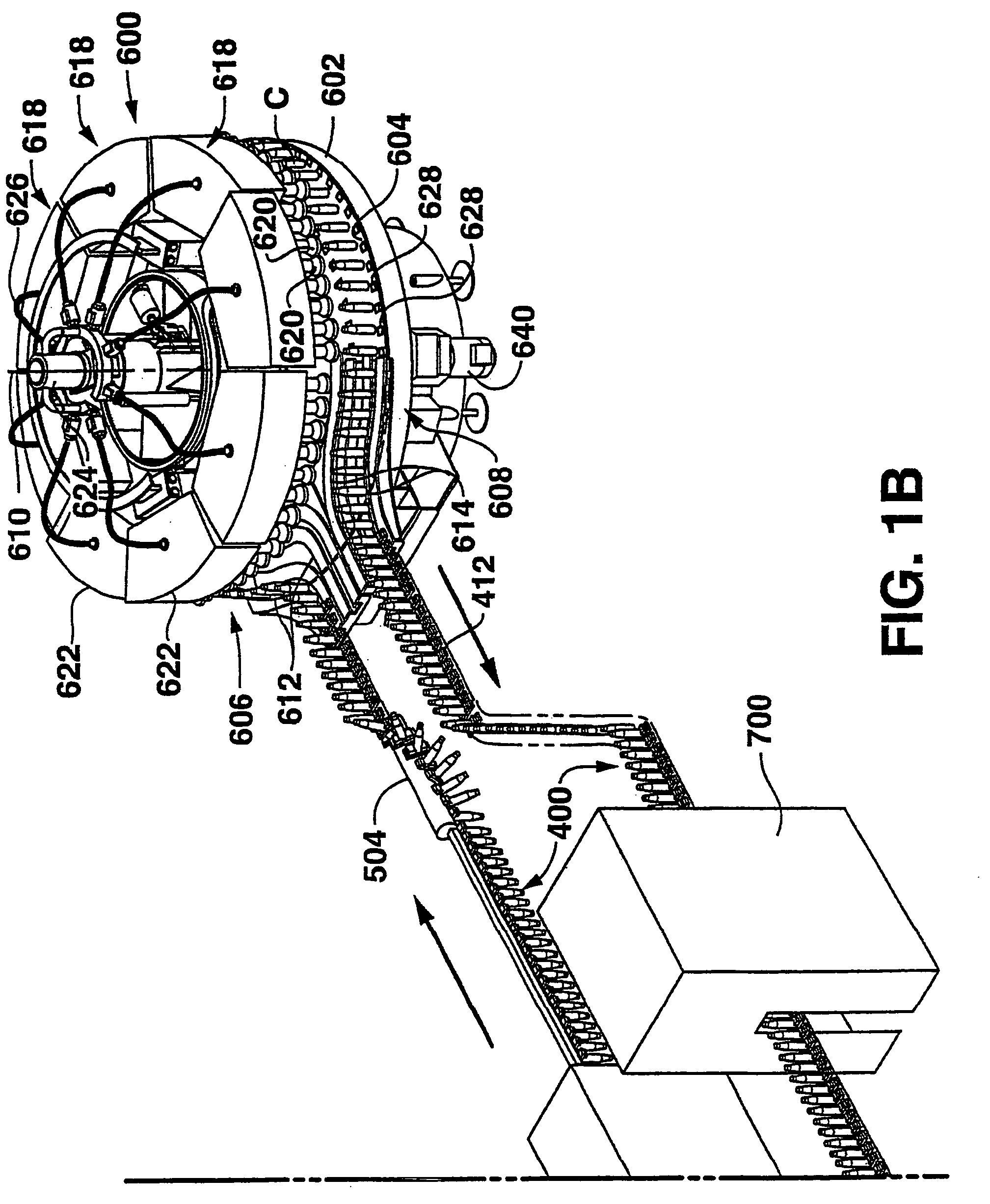

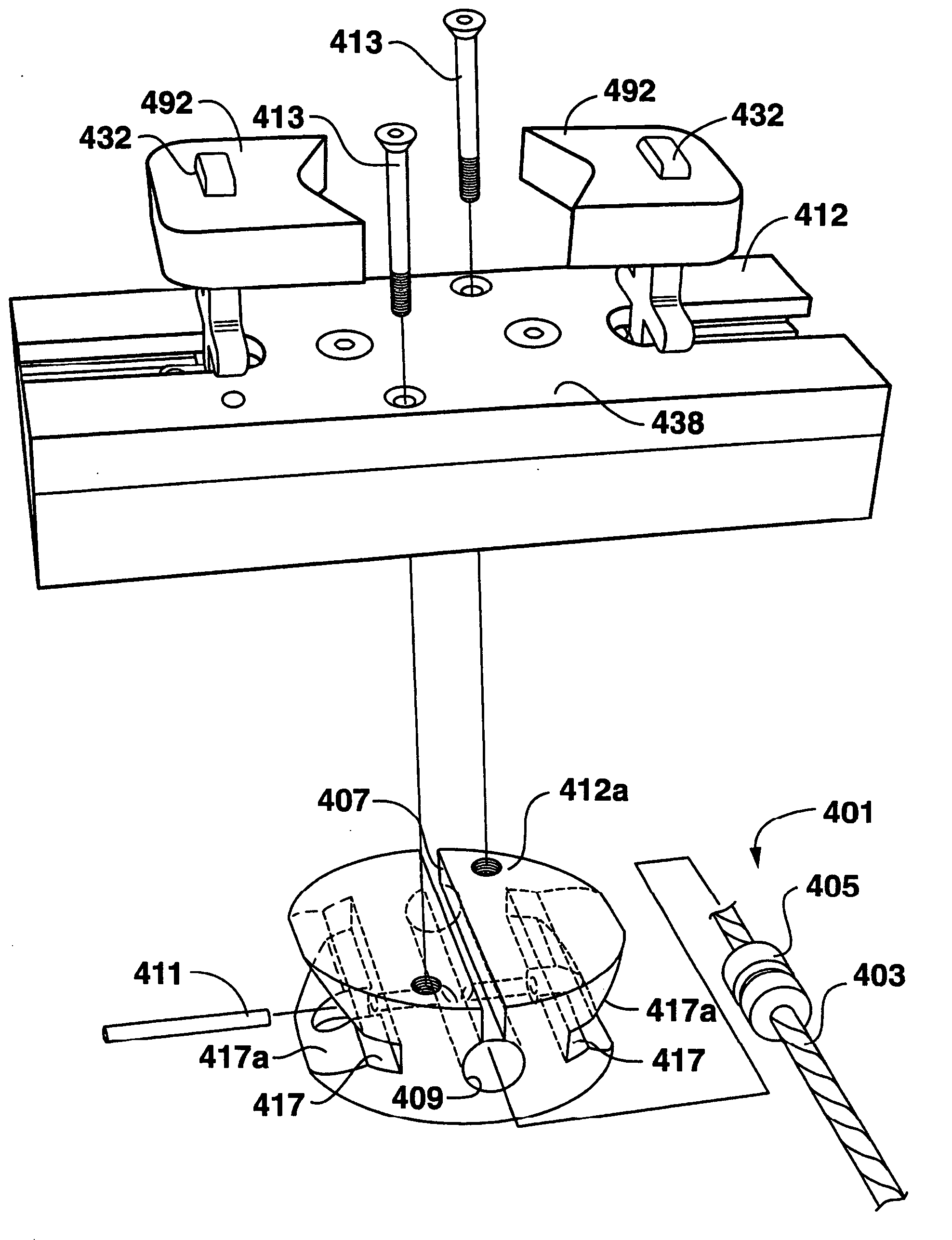

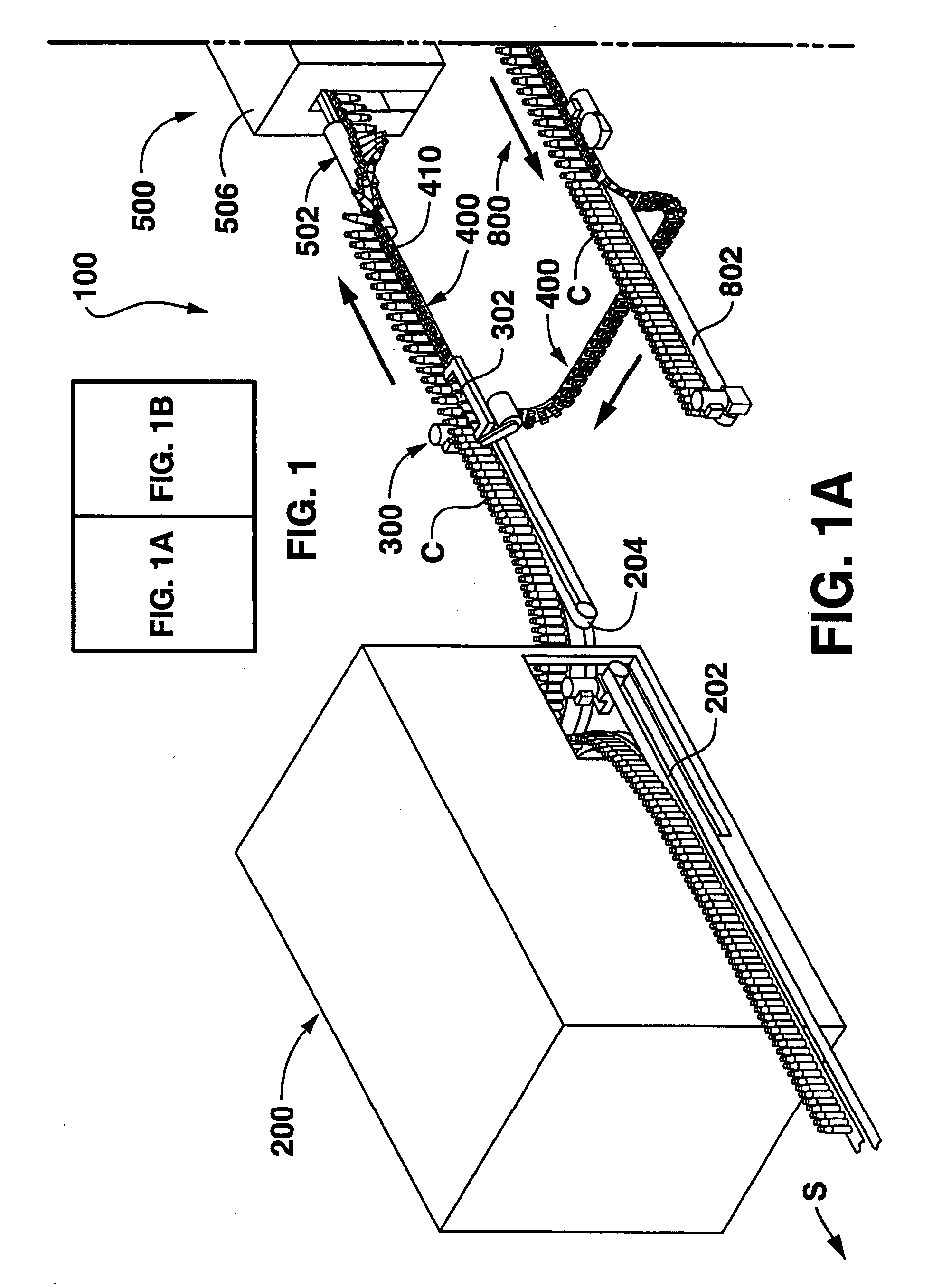

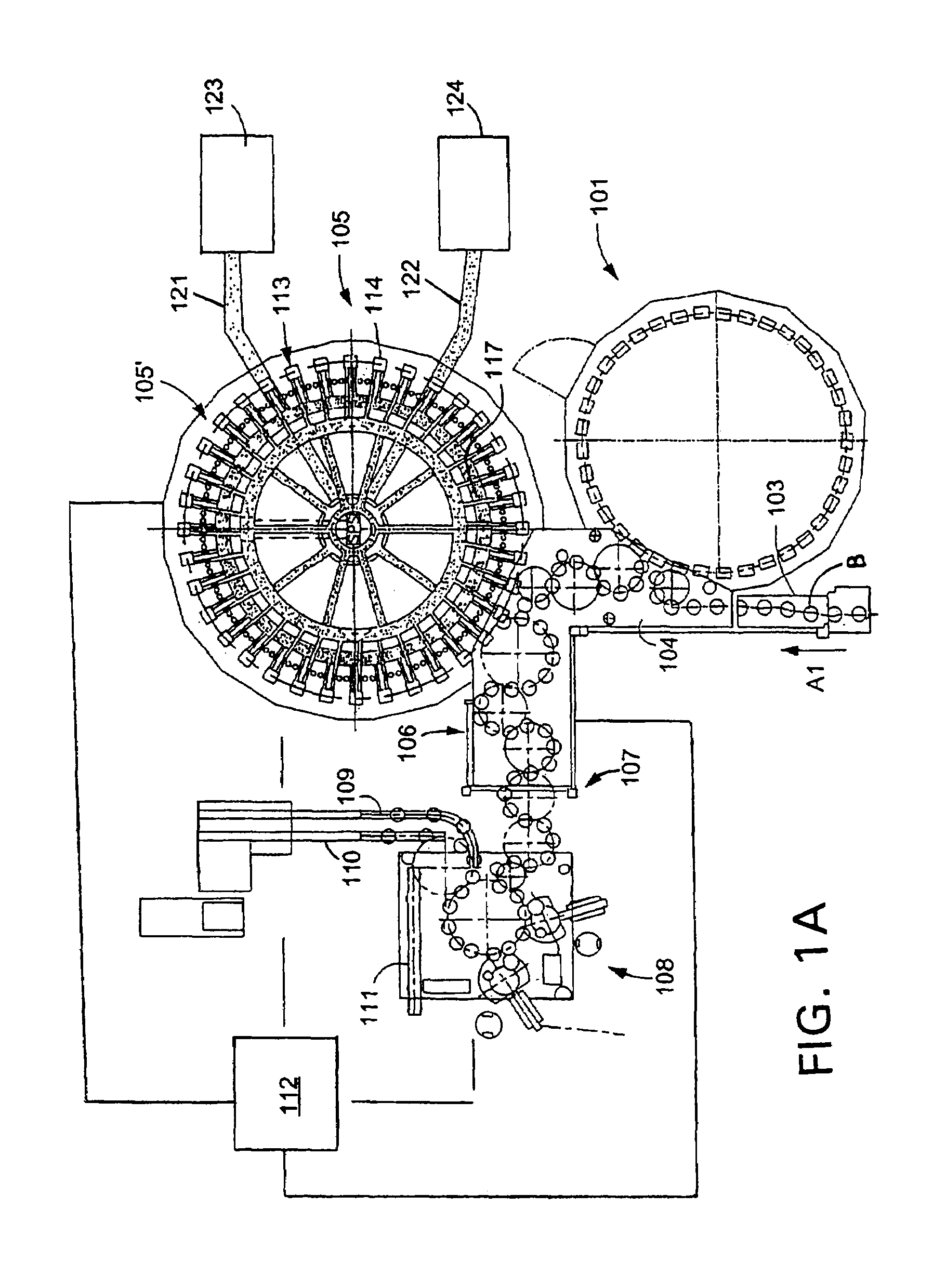

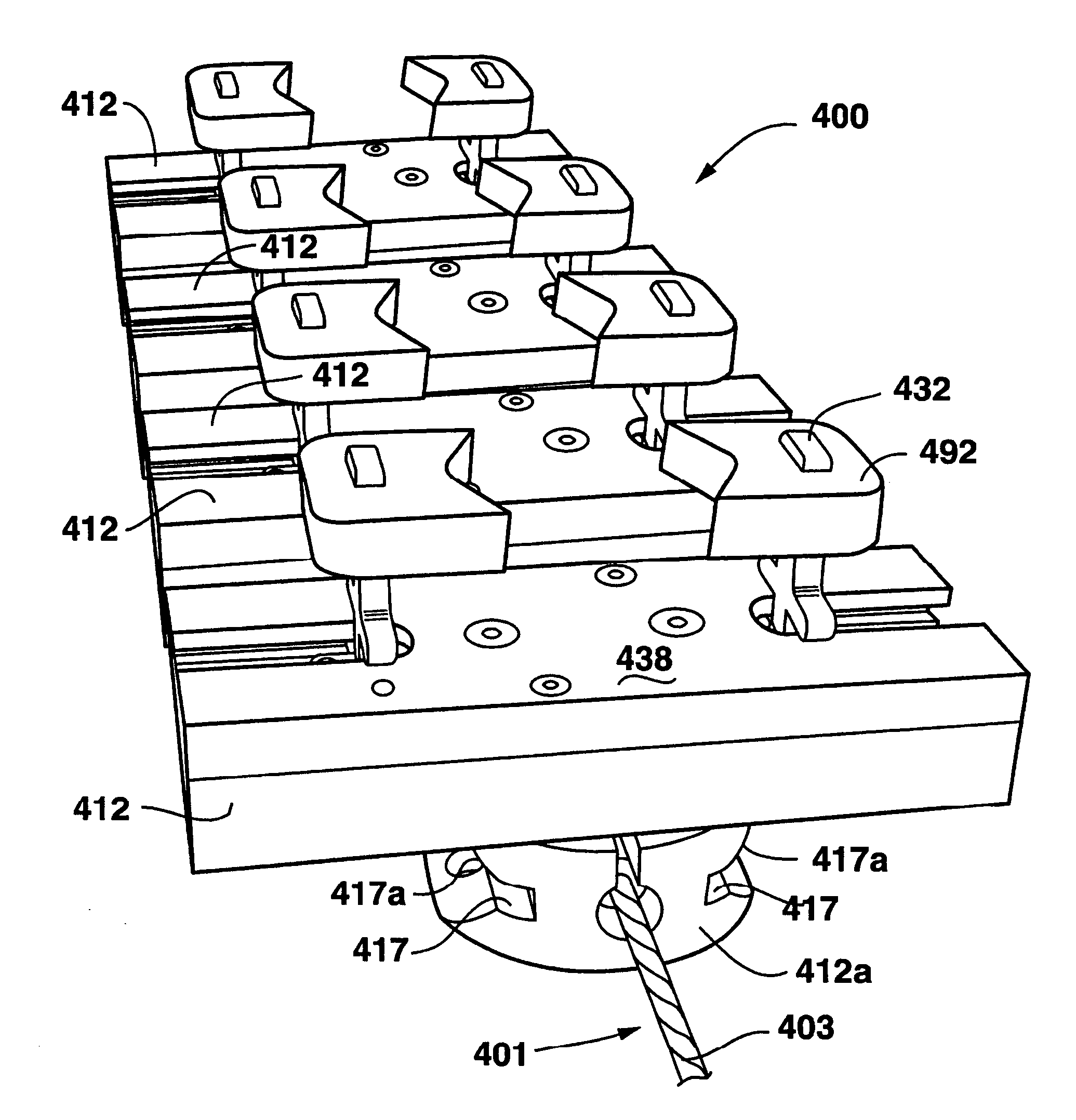

Neck gripping conveyor and link, and related rotary filler and system

InactiveUS20050284731A1Synchronising machinesFilling using counterpressureMechanical engineeringDelivery system

A conveyor is disclosed suitable for conveying objects such as containers to a processing station. The conveyor includes a plurality of connected links, and at least one gripping member extending from each of the links. Each gripping member is movable relative to its respective link for gripping a container by the neck of the container. A guide structure is disposed on the link for mating a component of the processing station to the neck of the container for processing the container. The processing station may be a filler such as a rotary filler, a capper, or a rinser. Related individual links, conveying systems, and filler components are also disclosed.

Owner:ILLINOIS TOOL WORKS INC

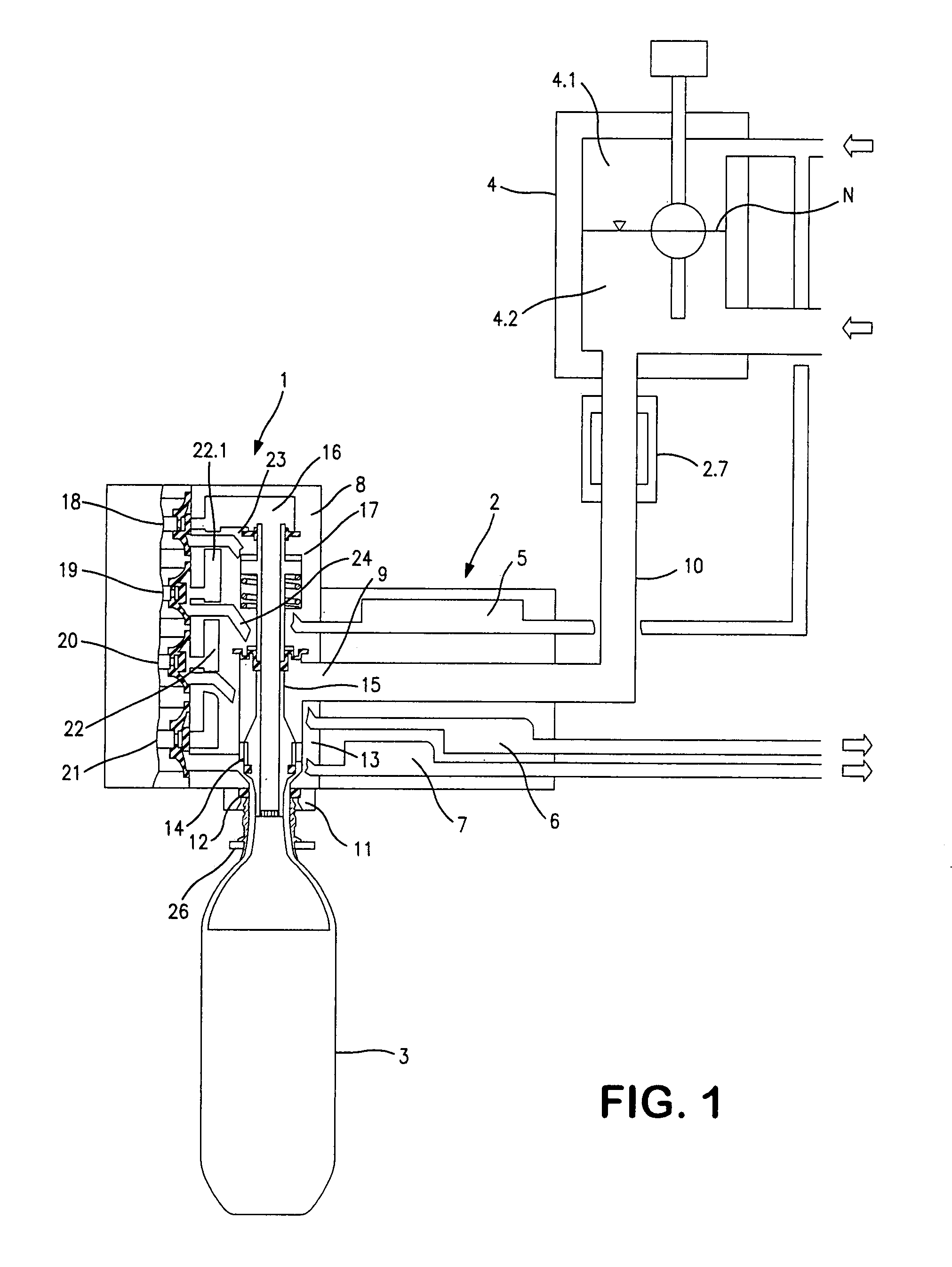

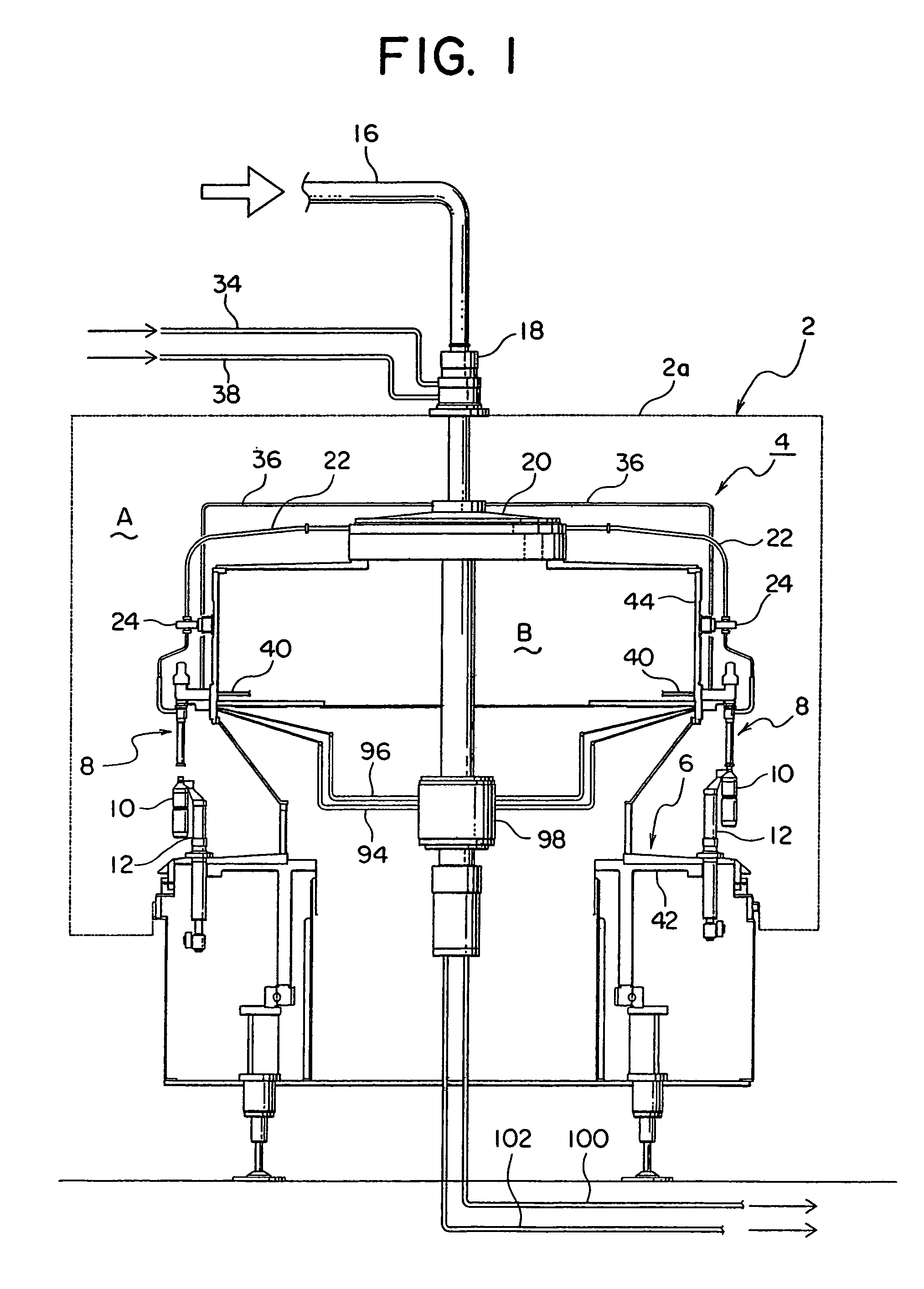

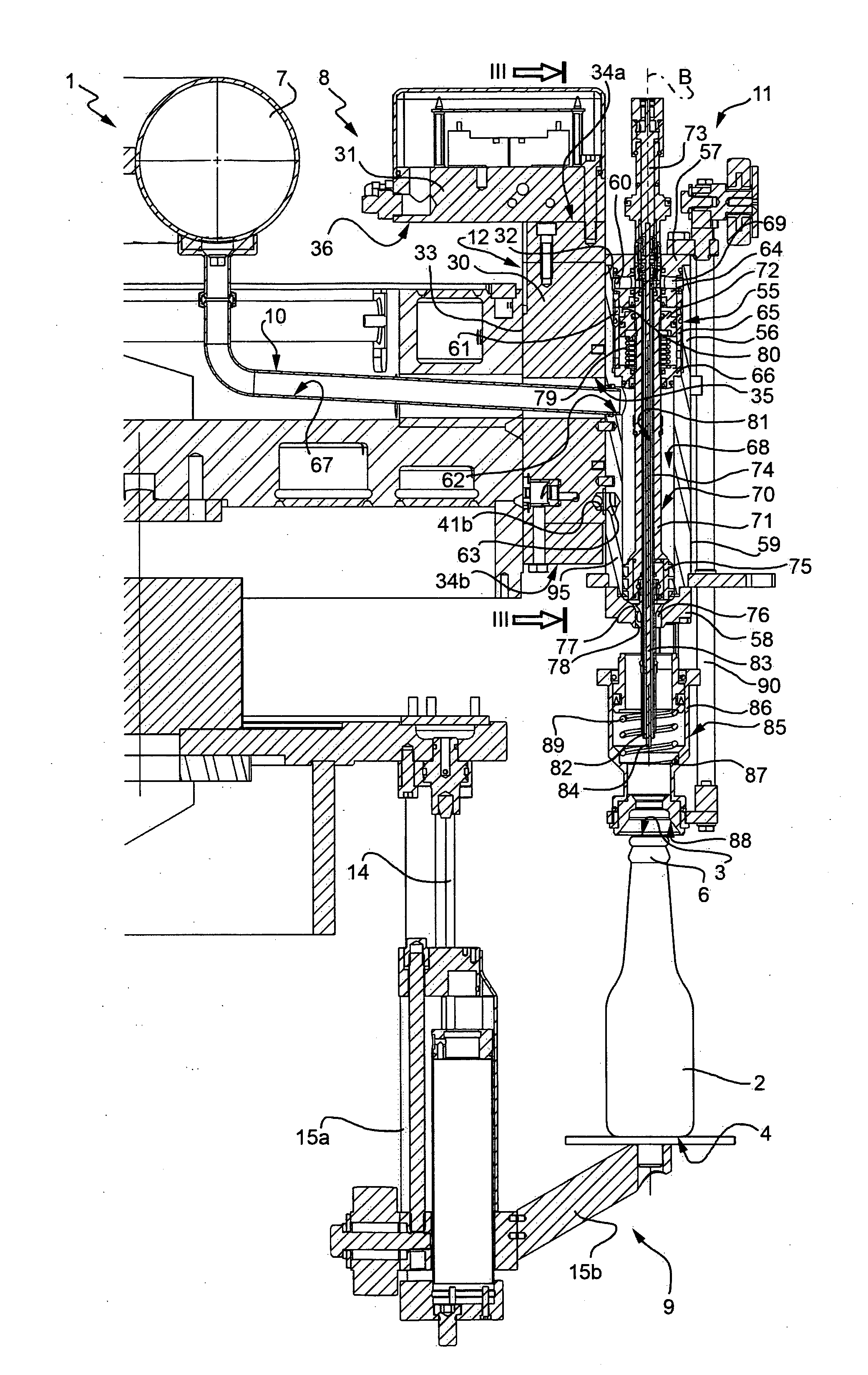

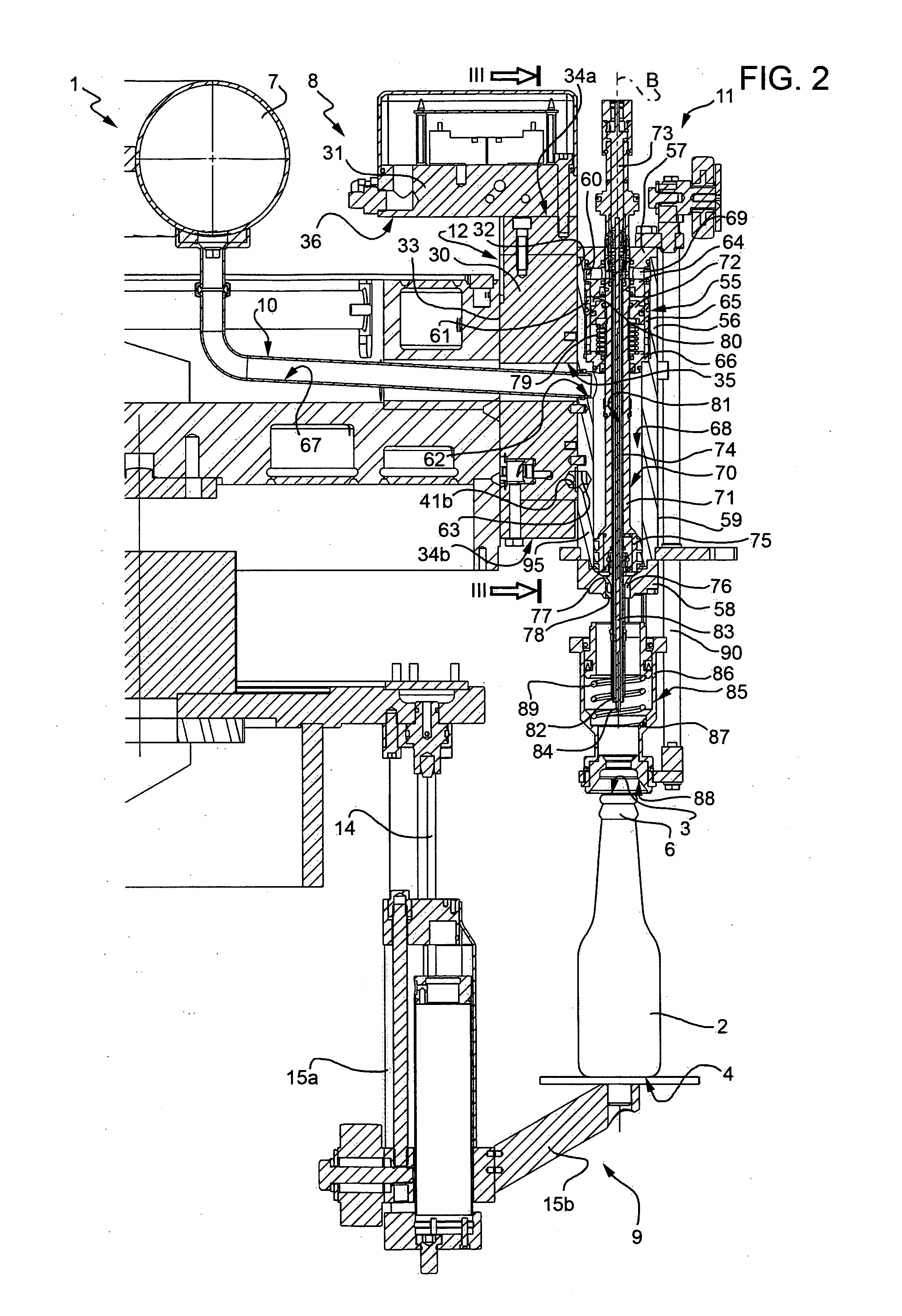

Beverage bottling plant for filling bottles with a liquid beverage filling material having a filling device and a filling machine having such a filling device

ActiveUS7353848B2Reduce manufacturing costFilling using counterpressureFilling without pressureFilling materialsTrademark

A beverage bottling plant for filling bottles with a liquid beverage filling material having a filling device and a filling machine having such a filling device. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

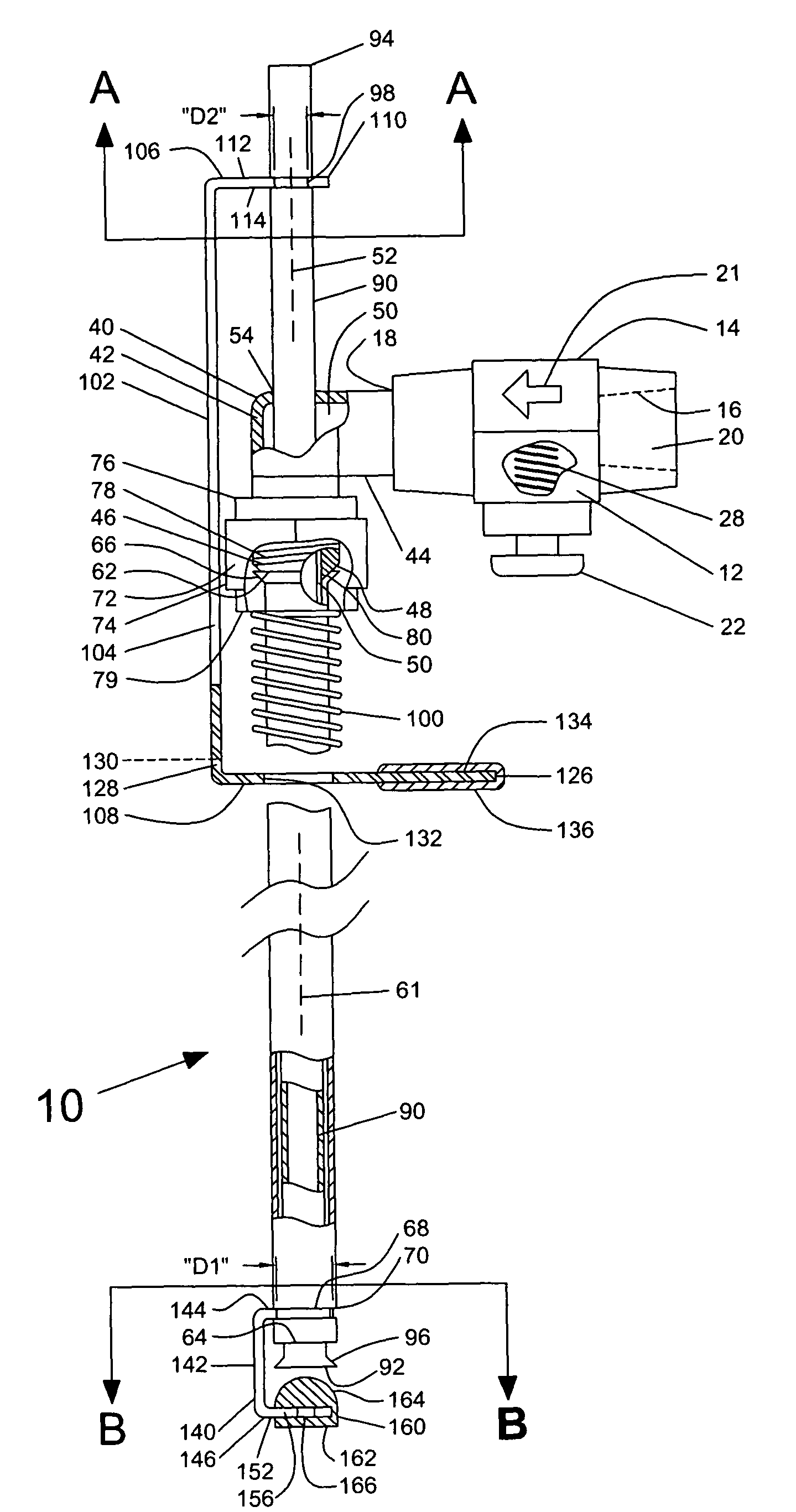

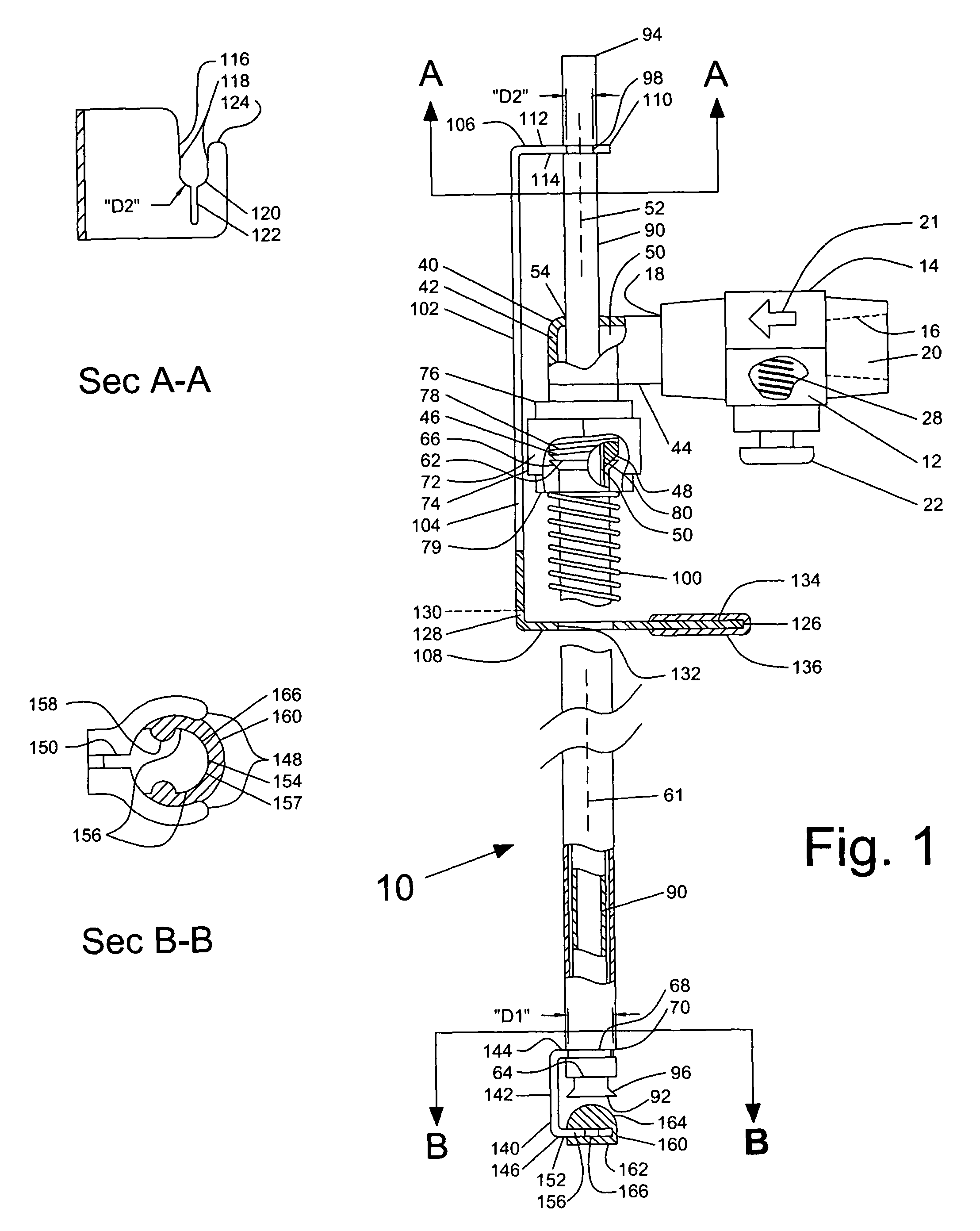

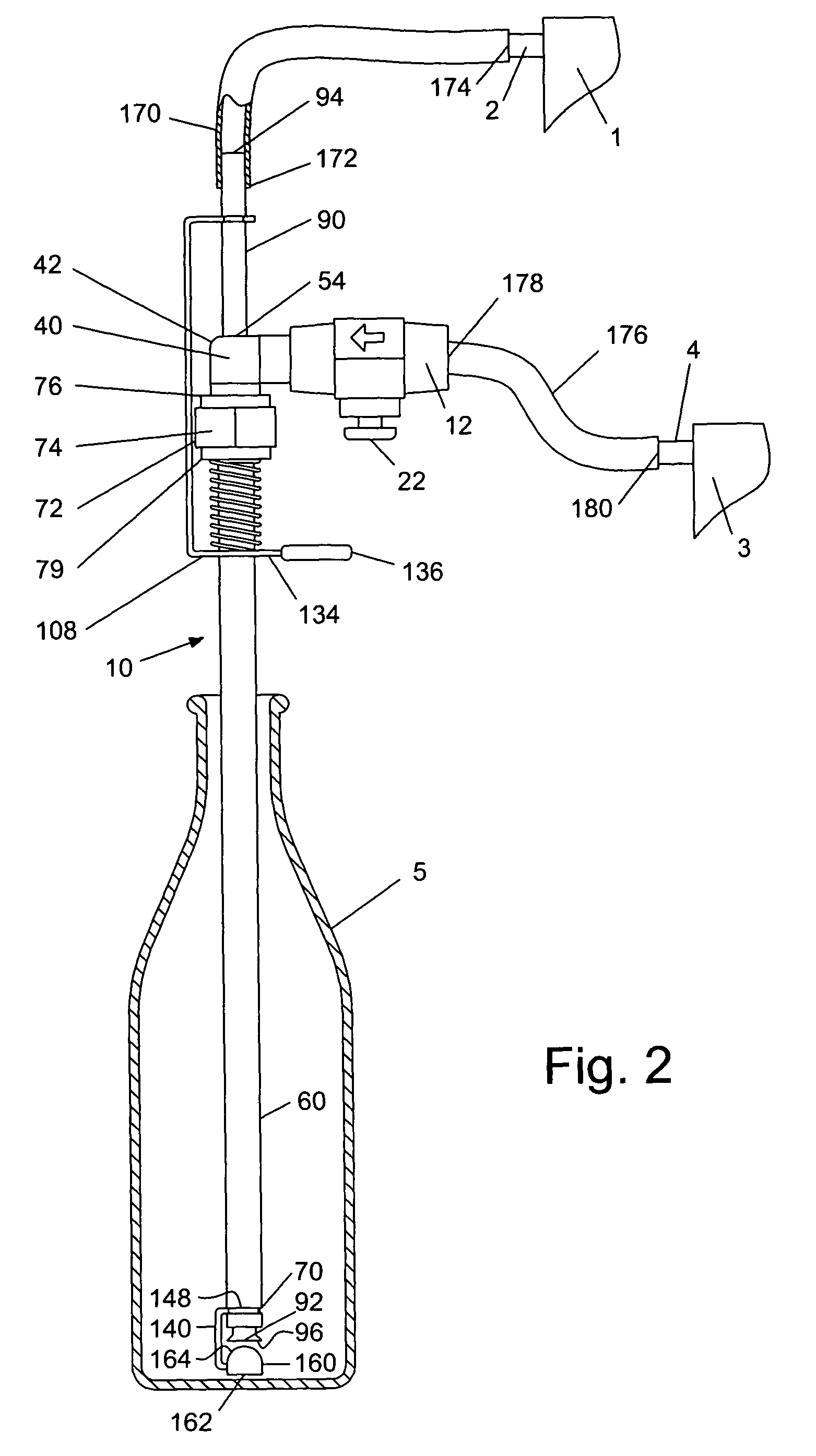

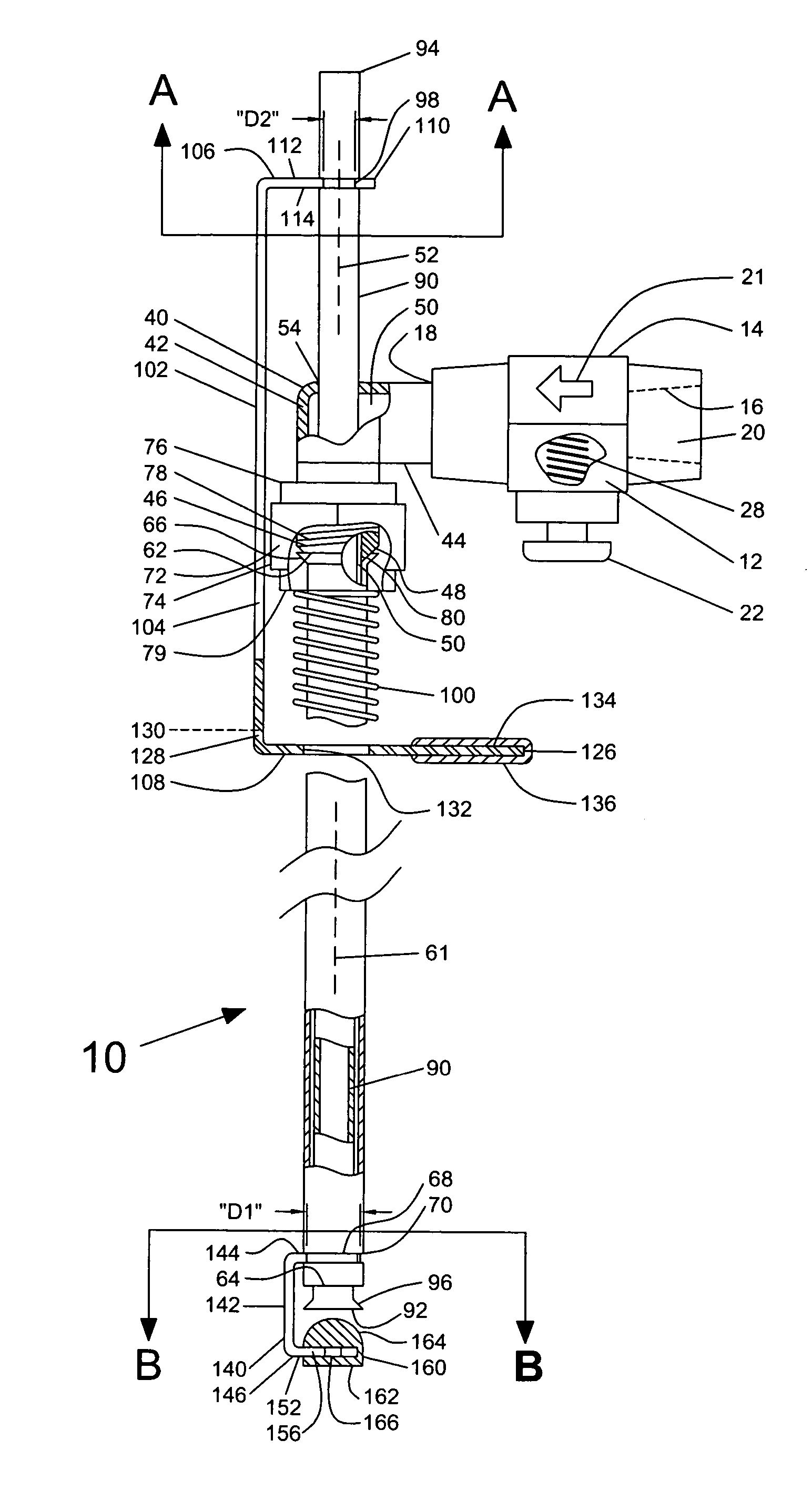

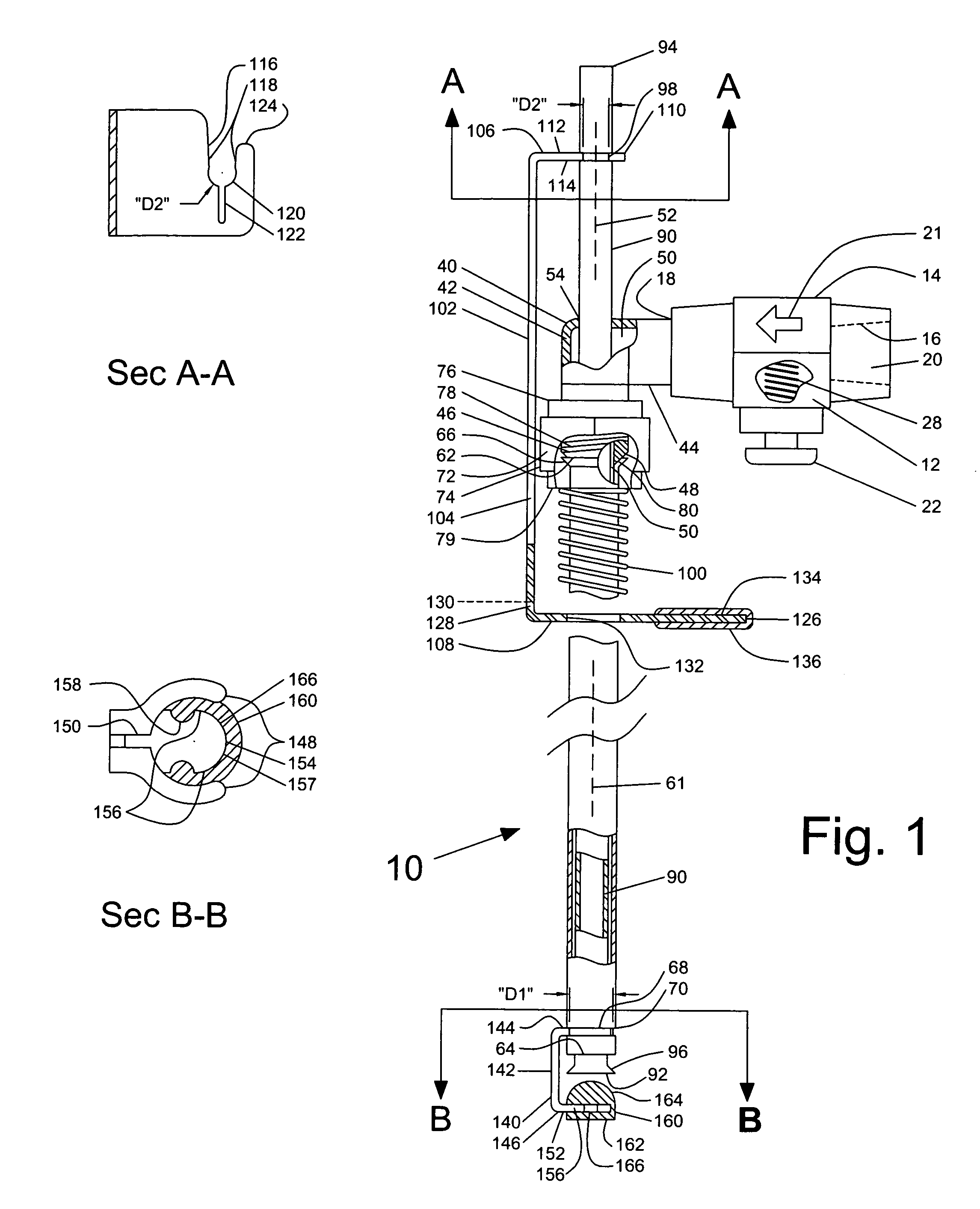

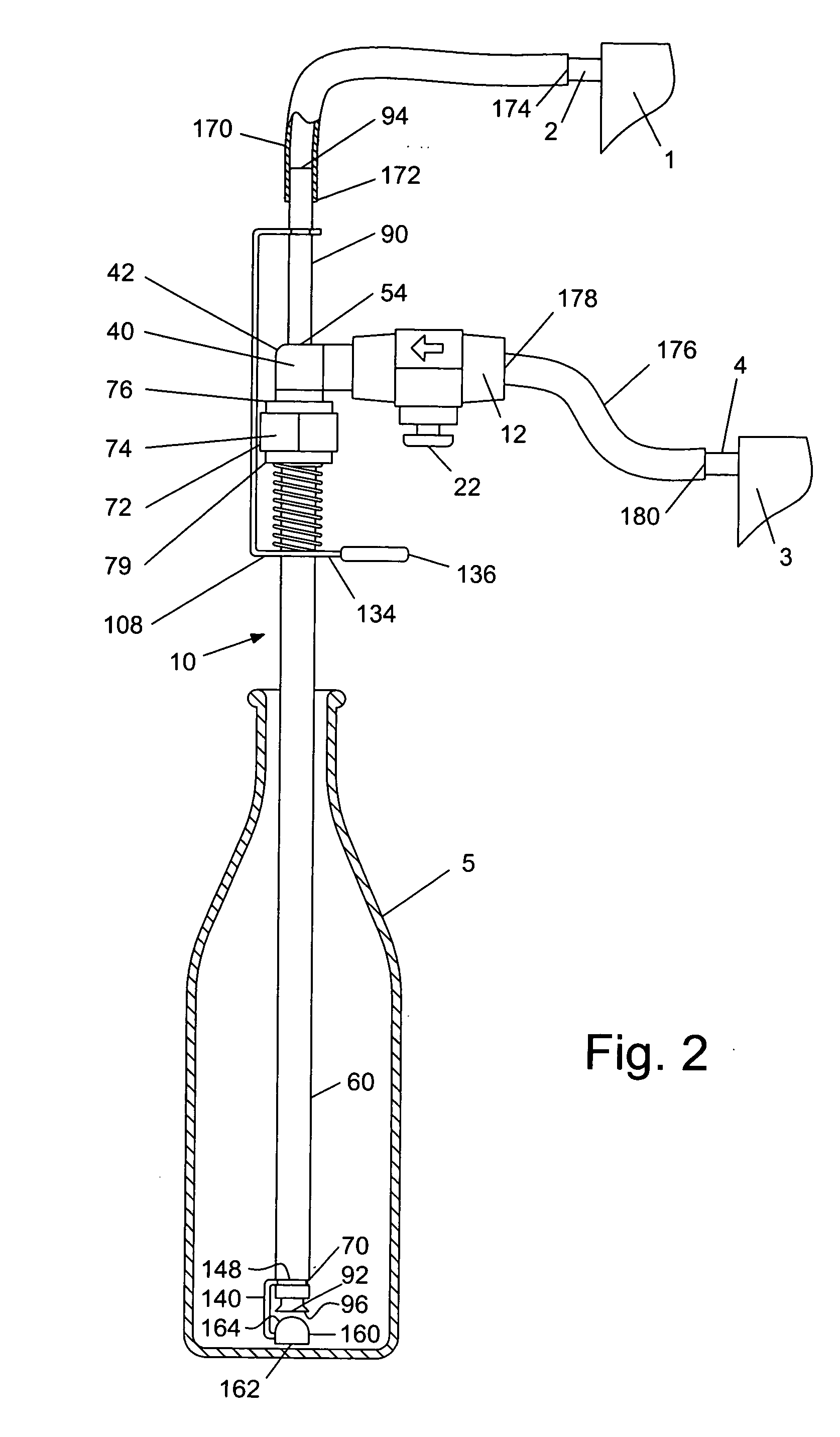

Bottle filler

An improved bottle filler assembly for filling bottles from kegged carbonated or non carbonated beverages without carbonation loss or oxidation that is intuitive to use, sanitize, and keep free of bacteria. In the preferred embodiment, a long hose gradually reduces the pressure of the beverage on the way to the filler. Two tubes are placed inside each other forming an annulus where CO2 can be forced to the bottom of the bottle via a CO2 valve thereby purging the bottle of air (O2). A valve seat placed on the bottom of the tubes allows the beverage to flow into the bottle from the bottom by depressing a trigger.

Owner:BLICHMANN JOHN RICHARD

Neck gripping conveyor and link, and related rotary filler and system

InactiveUS7261199B2Synchronising machinesFilling using counterpressureEngineeringMechanical engineering

A conveyor is disclosed suitable for conveying objects such as containers to a processing station. The conveyor includes a plurality of connected links, and at least one gripping member extending from each of the links. Each gripping member is movable relative to its respective link for gripping a container by the neck of the container. A guide structure is disposed on the link for mating a component of the processing station to the neck of the container for processing the container. The processing station may be a filler such as a rotary filler, a capper, or a rinser. Related individual links, conveying systems, and filler components are also disclosed.

Owner:ILLINOIS TOOL WORKS INC

Bottle filler

An improved bottle filler assembly for filling bottles from kegged carbonated or non carbonated beverages without carbonation loss or oxidation that is intuitive to use, sanitize, and keep free of bacteria. In the preferred embodiment, a long hose gradually reduces the pressure of the beverage on the way to the filler. Two tubes are placed inside each other forming an annulus where CO2 can be forced to the bottom of the bottle via a CO2 valve thereby purging the bottle of air (O2). A valve seat placed on the bottom of the tubes allows the beverage to flow into the bottle from the bottom by depressing a trigger.

Owner:BLICHMANN JOHN RICHARD

Beverage bottling plant for filling bottles with a liquid beverage filling material having a filling device and a filling machine having such a filling device

ActiveUS20050217753A1Reduce manufacturing costFilling using counterpressureFilling without pressureTrademarkEngineering

A beverage bottling plant for filling bottles with a liquid beverage filling material having a filling device and a filling machine having such a filling device. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

Carbon dioxide beverage and beer pop can filling valve

ActiveCN102190263AEliminate level fluctuationsGood filling effectFilling without pressureStable stateDifferential pressure

Owner:NANJING LEHUI LIGHT IND EQUIP

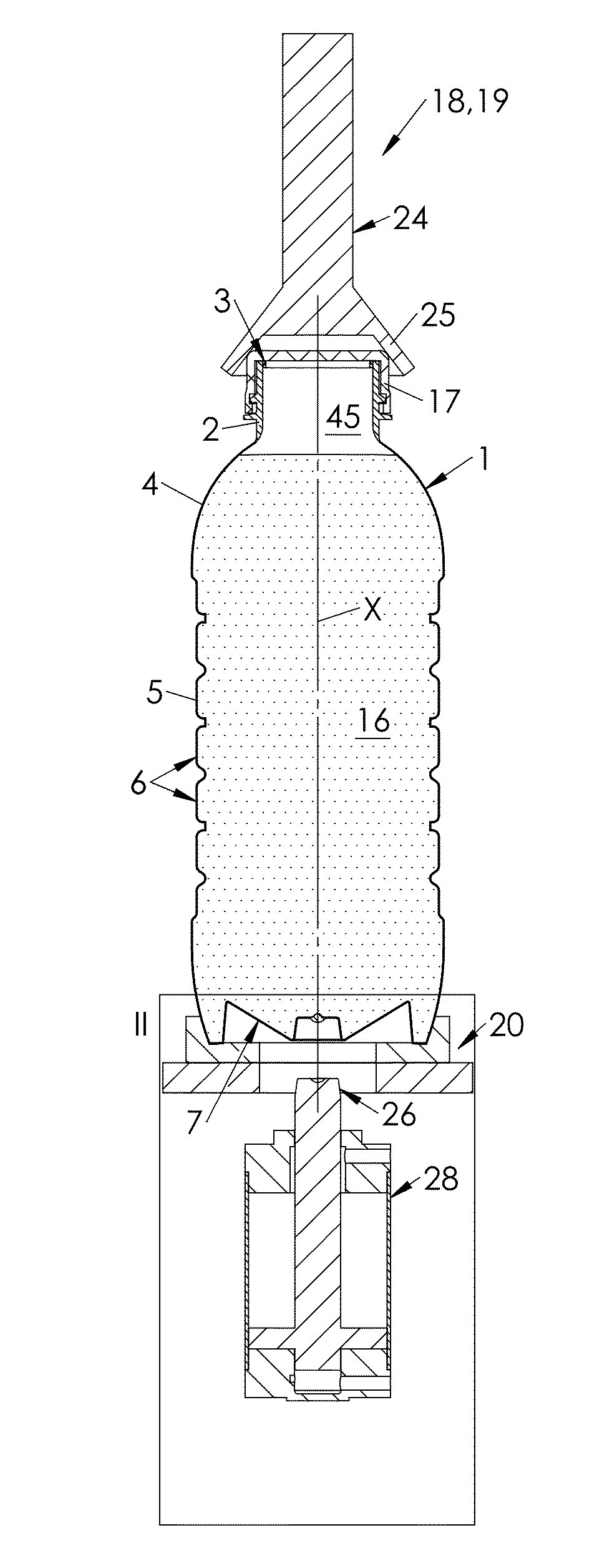

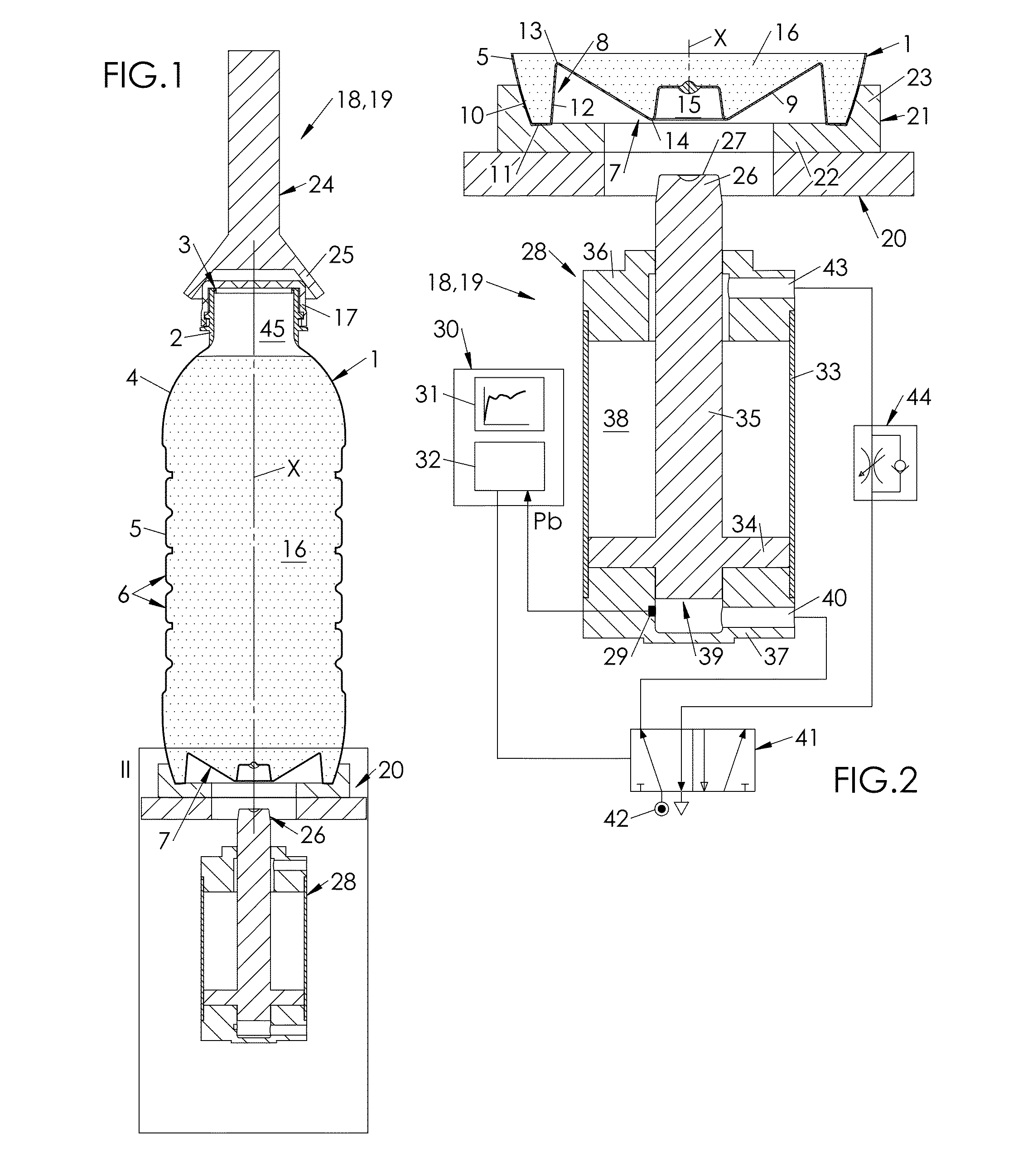

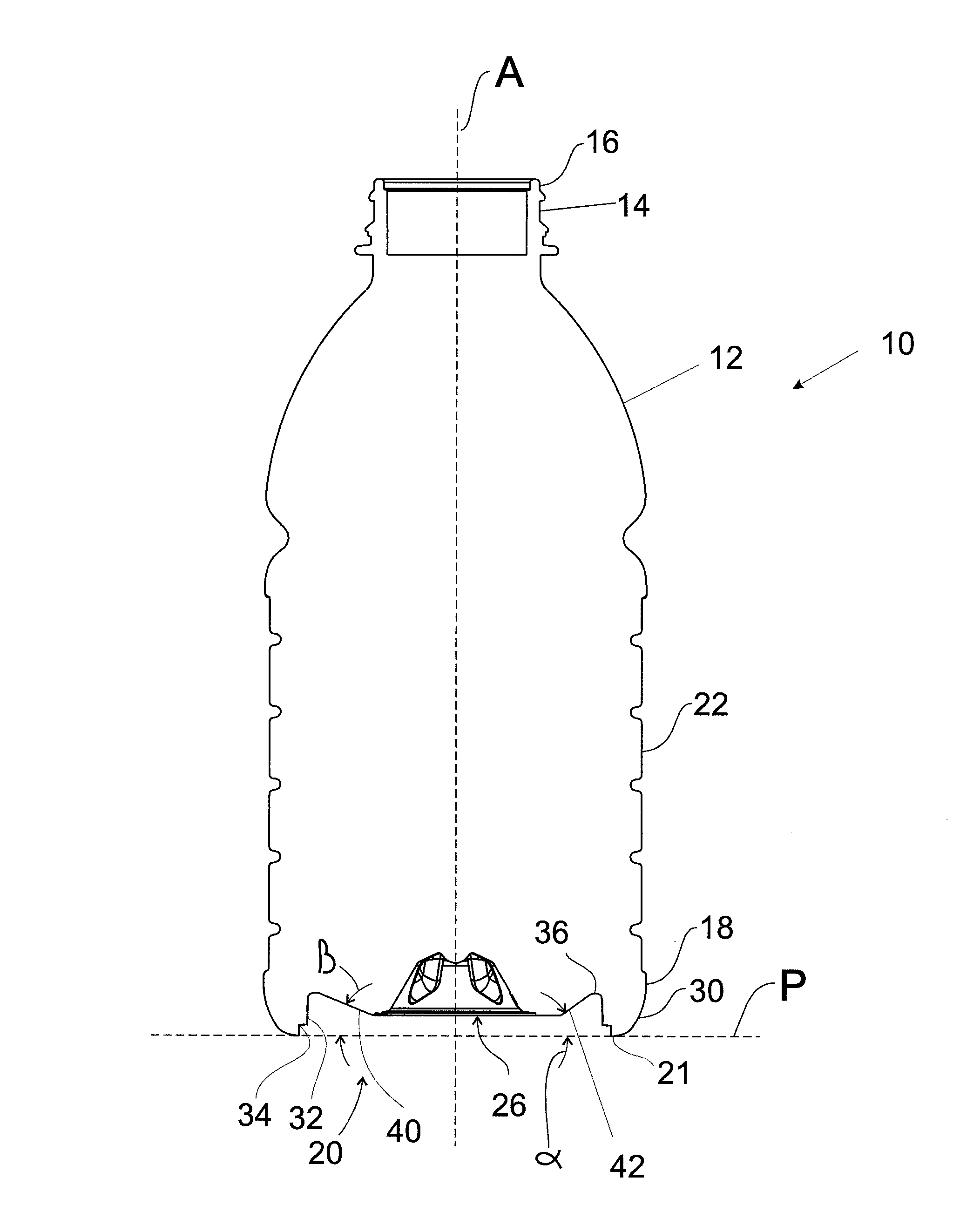

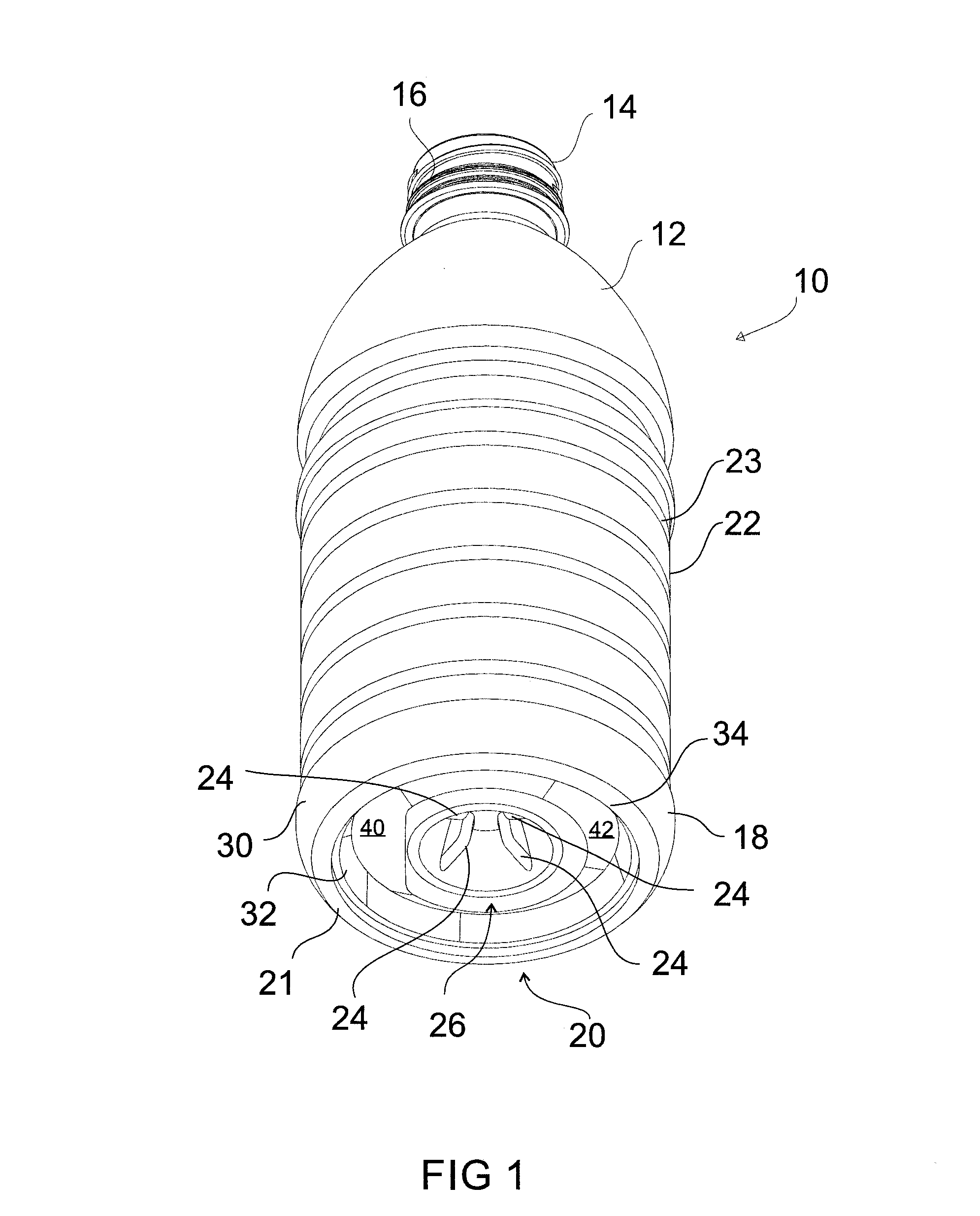

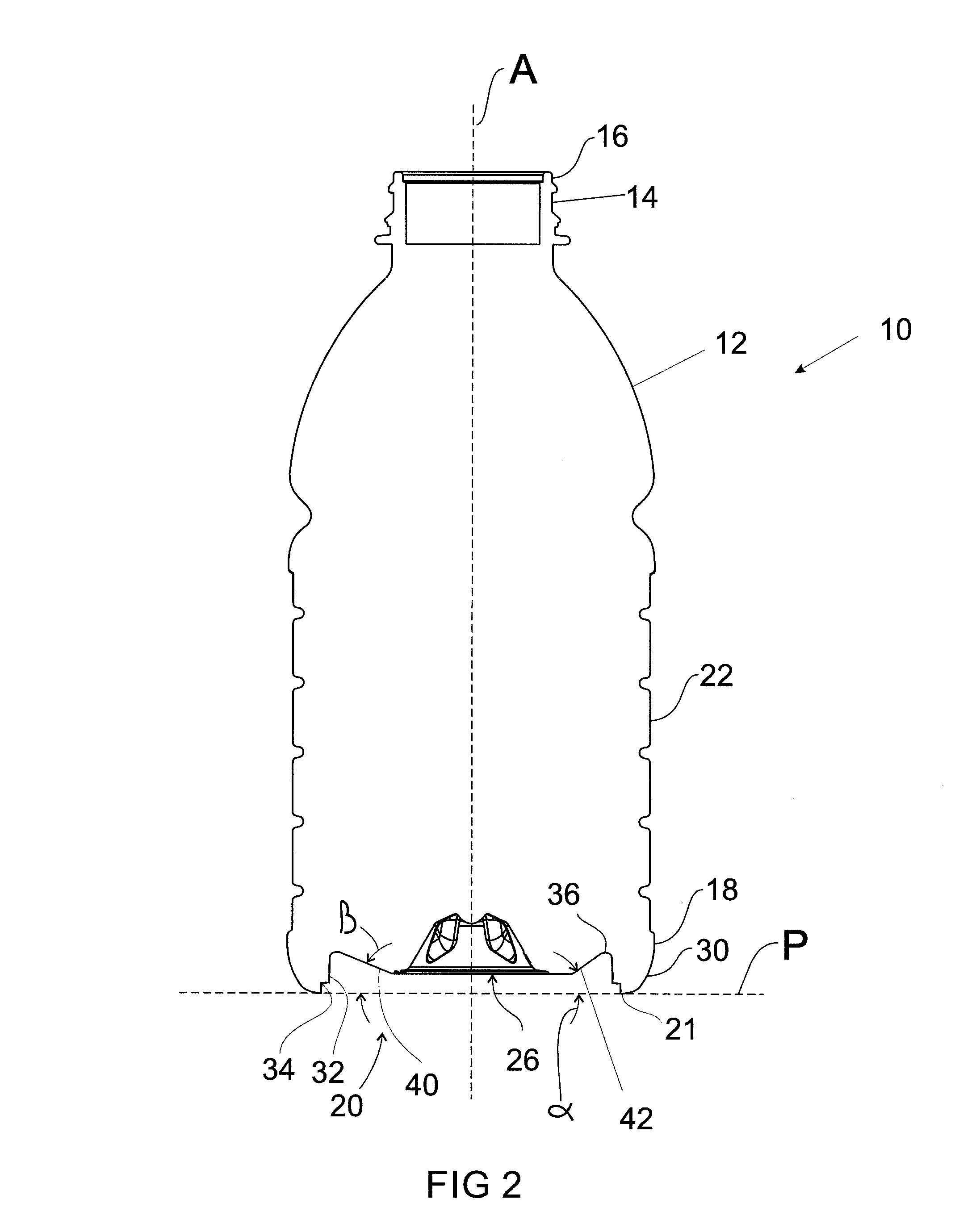

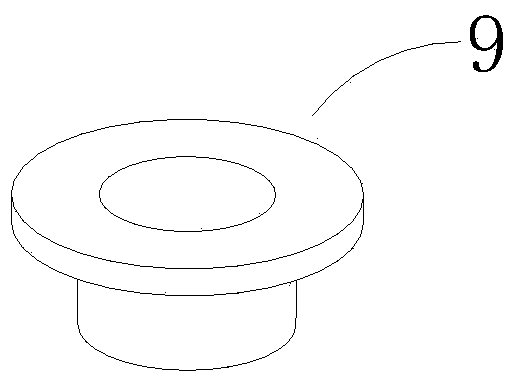

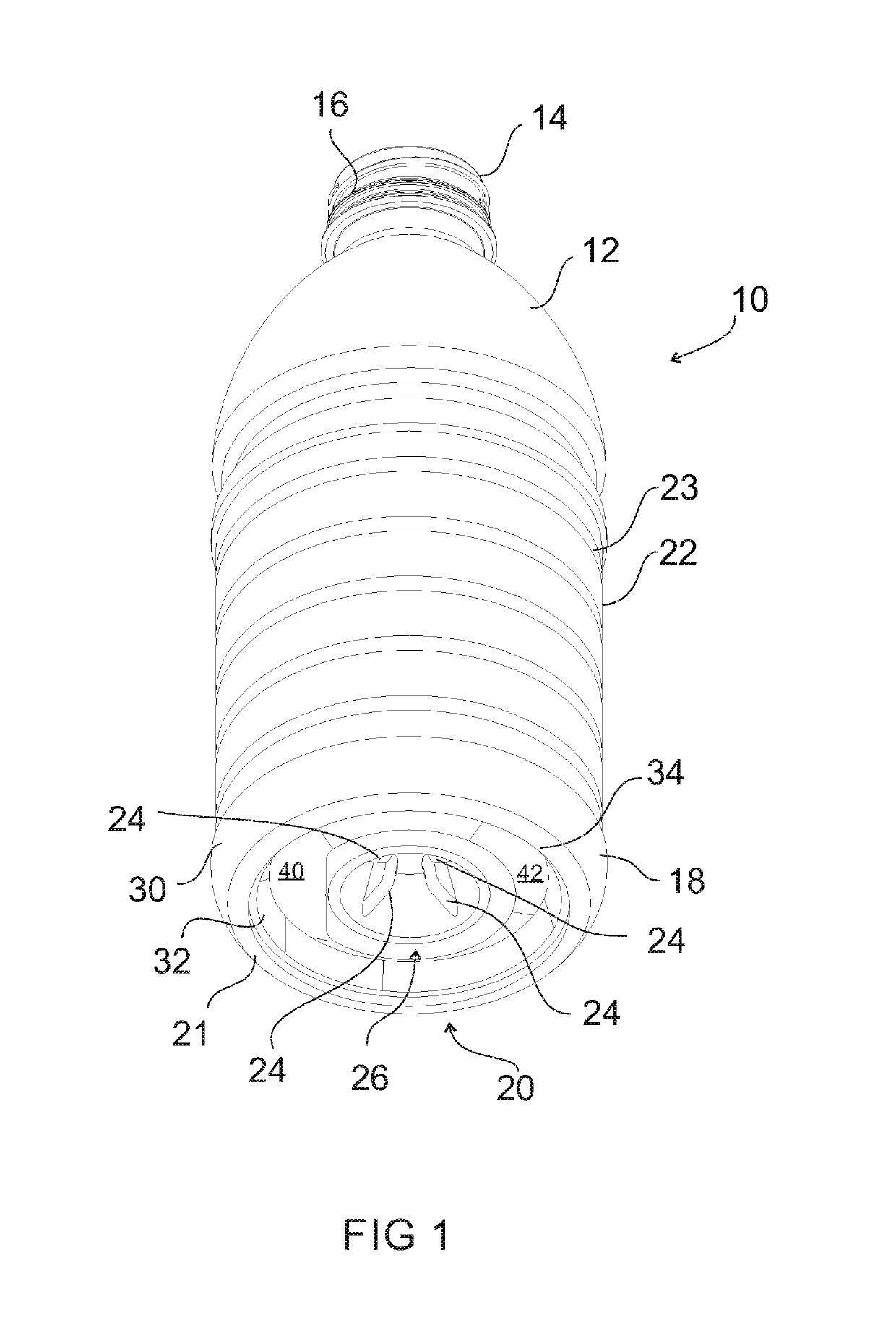

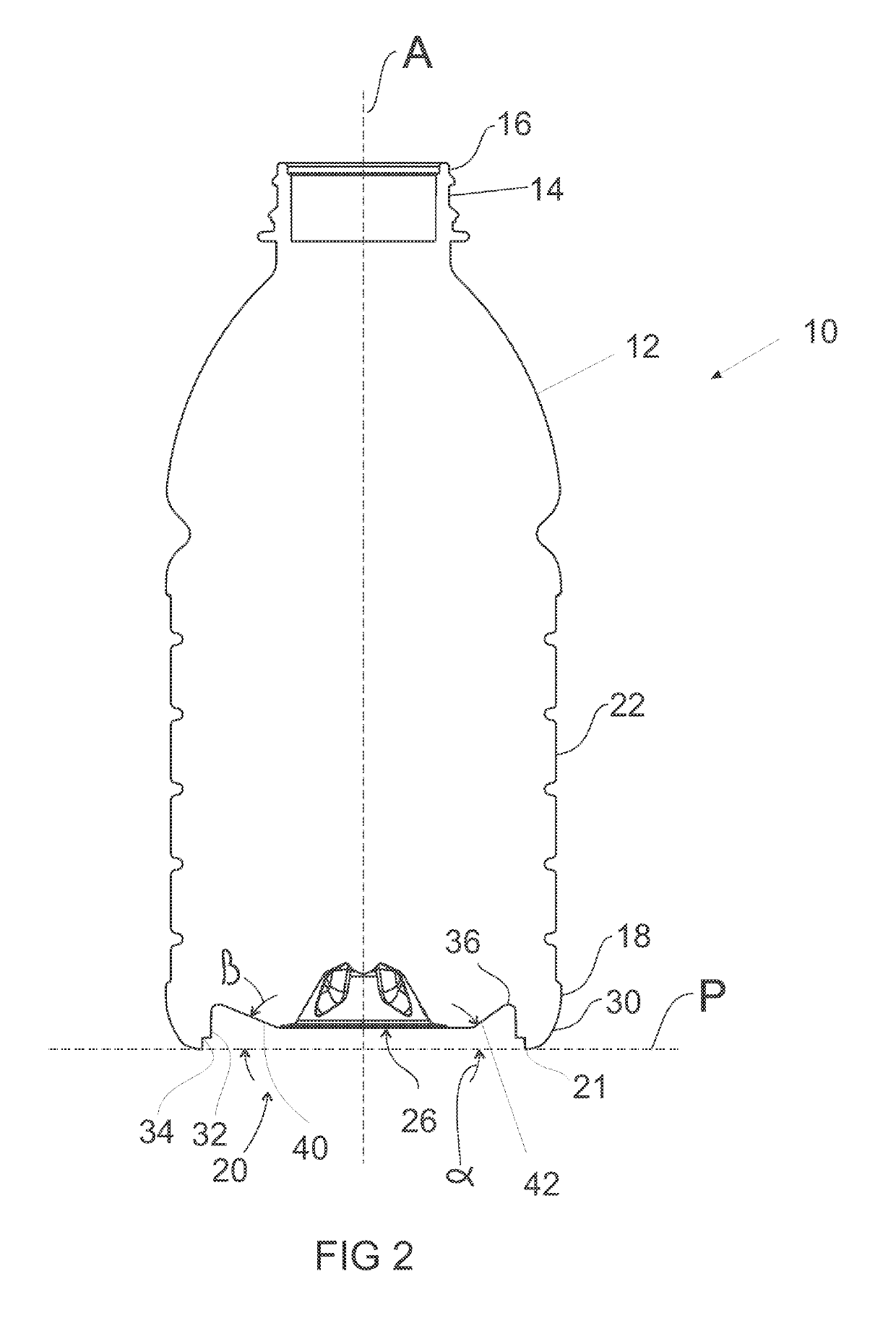

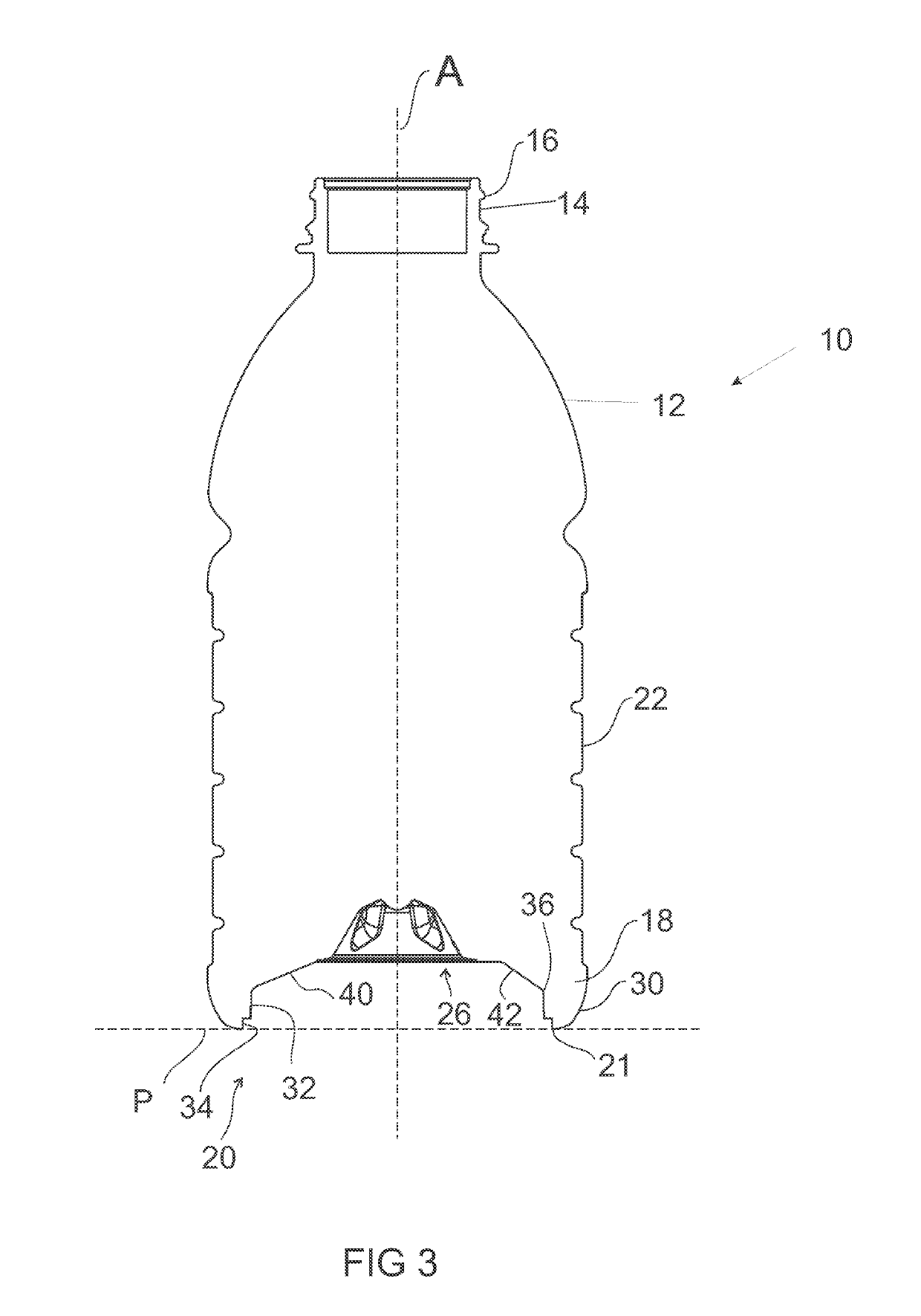

Machine and method for processing filled containers having an invertible diaphragm

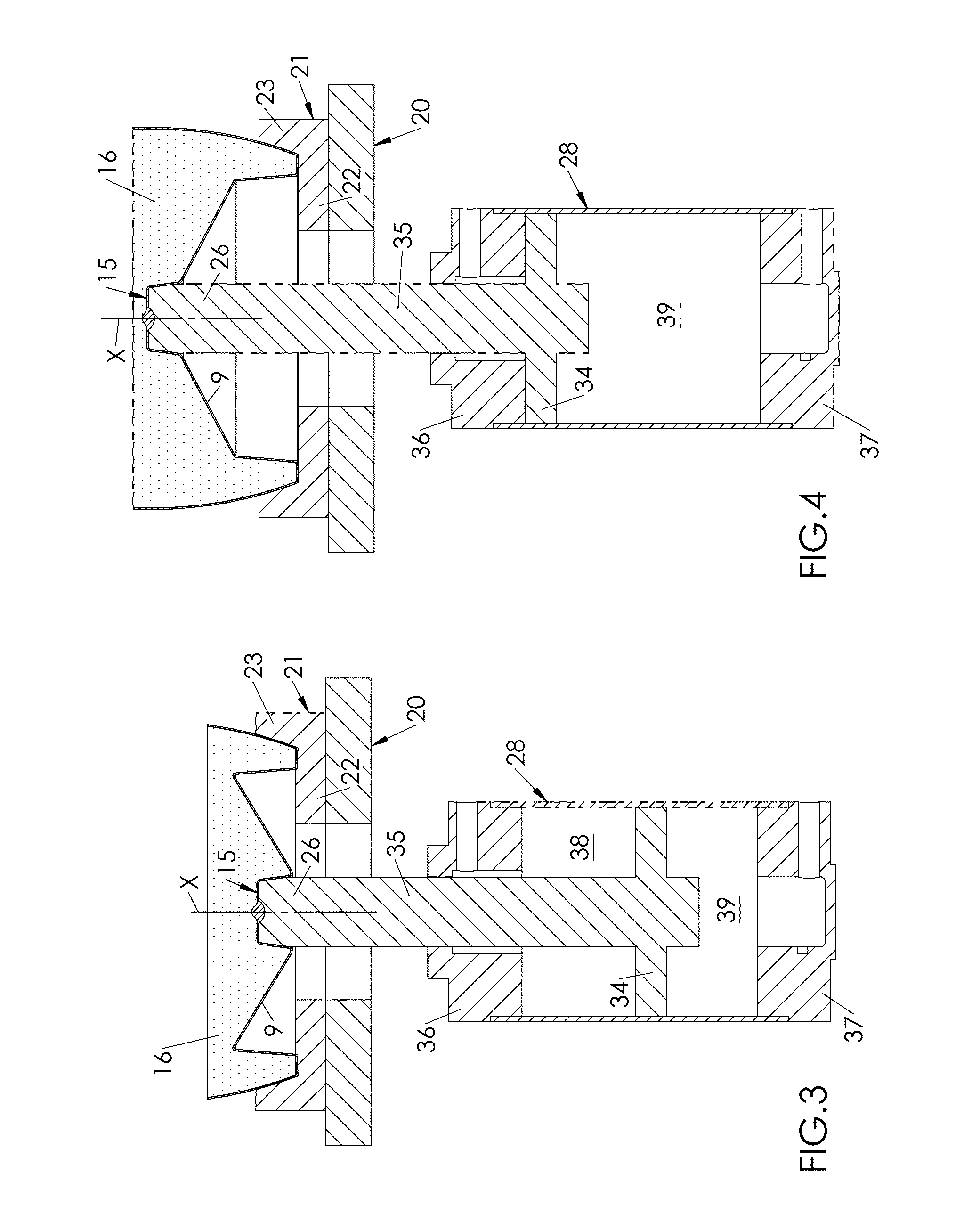

Machine (18, 19) for processing containers (1) including a base (7) having a high standing ring (8) and a central invertible diaphragm (9), the machine (18, 19) including:a container supporting frame (20) including a hollow support ring (21) for engaging a container base (7),a pusher (26) movable with respect of the container supporting frame (20), capable of coming into abutment with the container base (7) through the supporting frame (20),an actuator (28) for slidingly moving the pusher (26) frontwards towards the container base (7) through the supporting frame (20), and backwards,a strain gauge (29) coupled to the actuator (28) for gauging a strain applied by the actuator (28) to the pusher (26),a control unit (30) including a processor (32) connected to the strain gauge (29) and programmed for comparing a gauged strain value to a memorized strain reference value.

Owner:SIDEL PARTICIPATIONS SAS

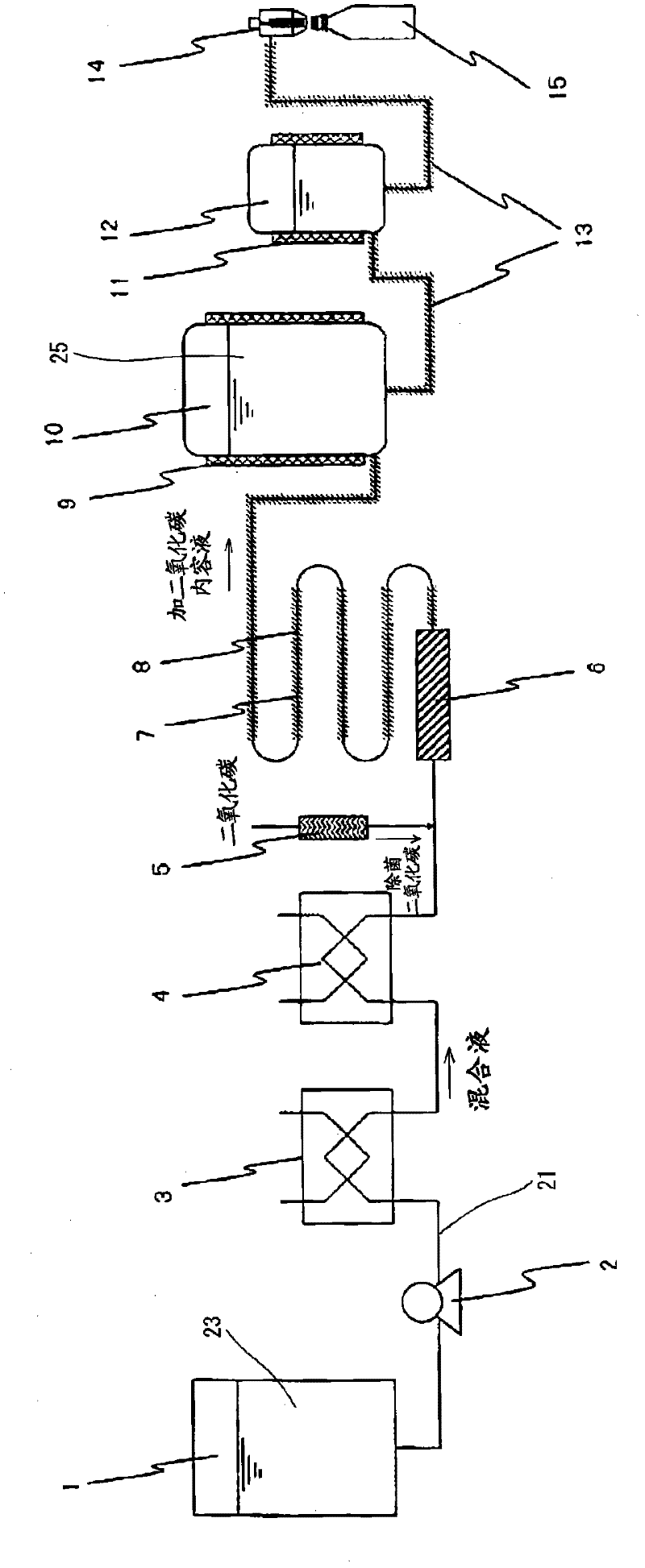

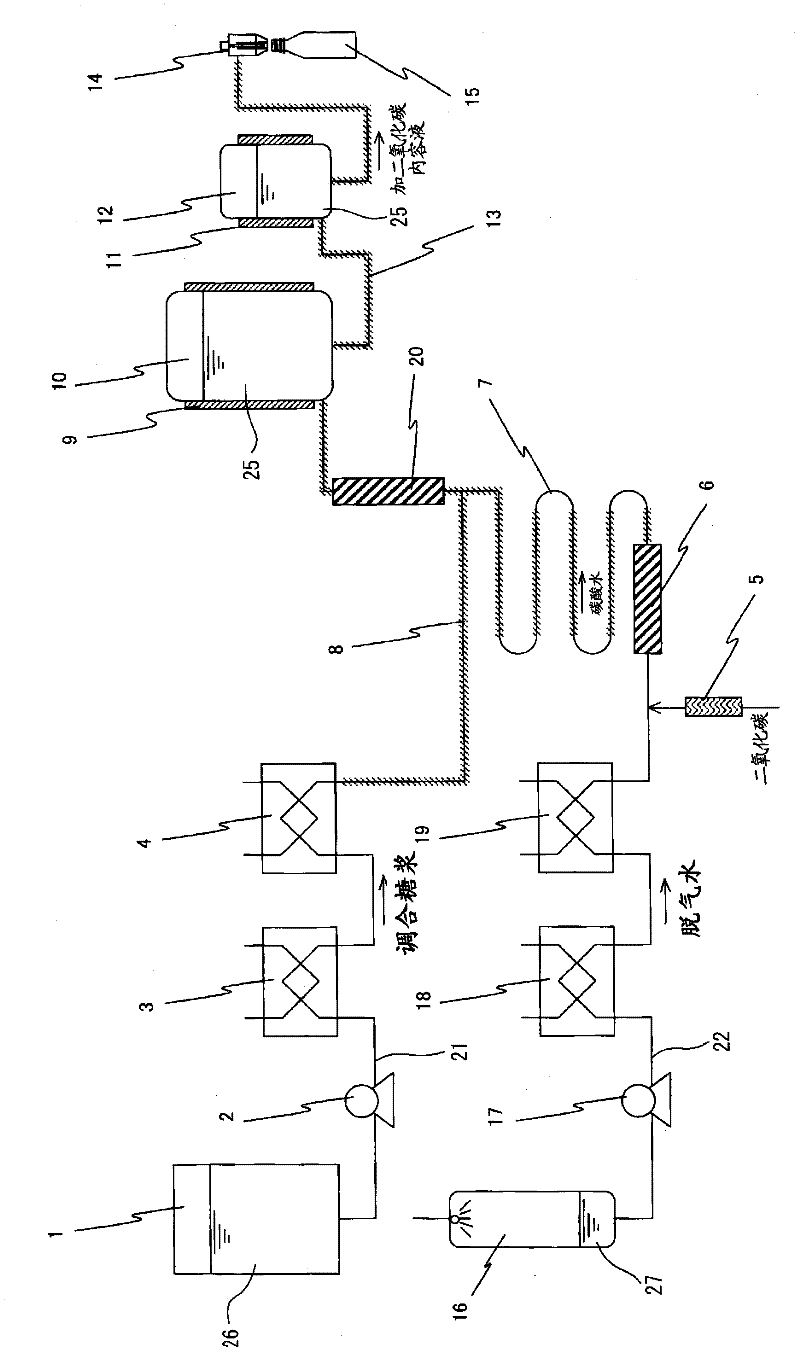

Method for aseptic filling with carbon dioxide-containing liquid contents

Provided is a method for aseptic filling with carbon dioxide-containing liquid contents wherein a container can be filled contact-free with a carbonated beverage and highly aseptic filling using an existing aseptic filling device is possible. The container, liquid contents, and carbon dioxide are individually sterilized; sterilized carbon dioxide-containing liquid contents are prepared by introducing bacteria-free carbon dioxide under pressure to the sterilized liquid contents such that the carbon dioxide volume is 15 to 25% greater than the target value; and the sterilized container is filled with the carbon dioxide-containing liquid contents under an aseptic atmosphere without contacting the filling valve.

Owner:TOYO SEIKAN KAISHA LTD

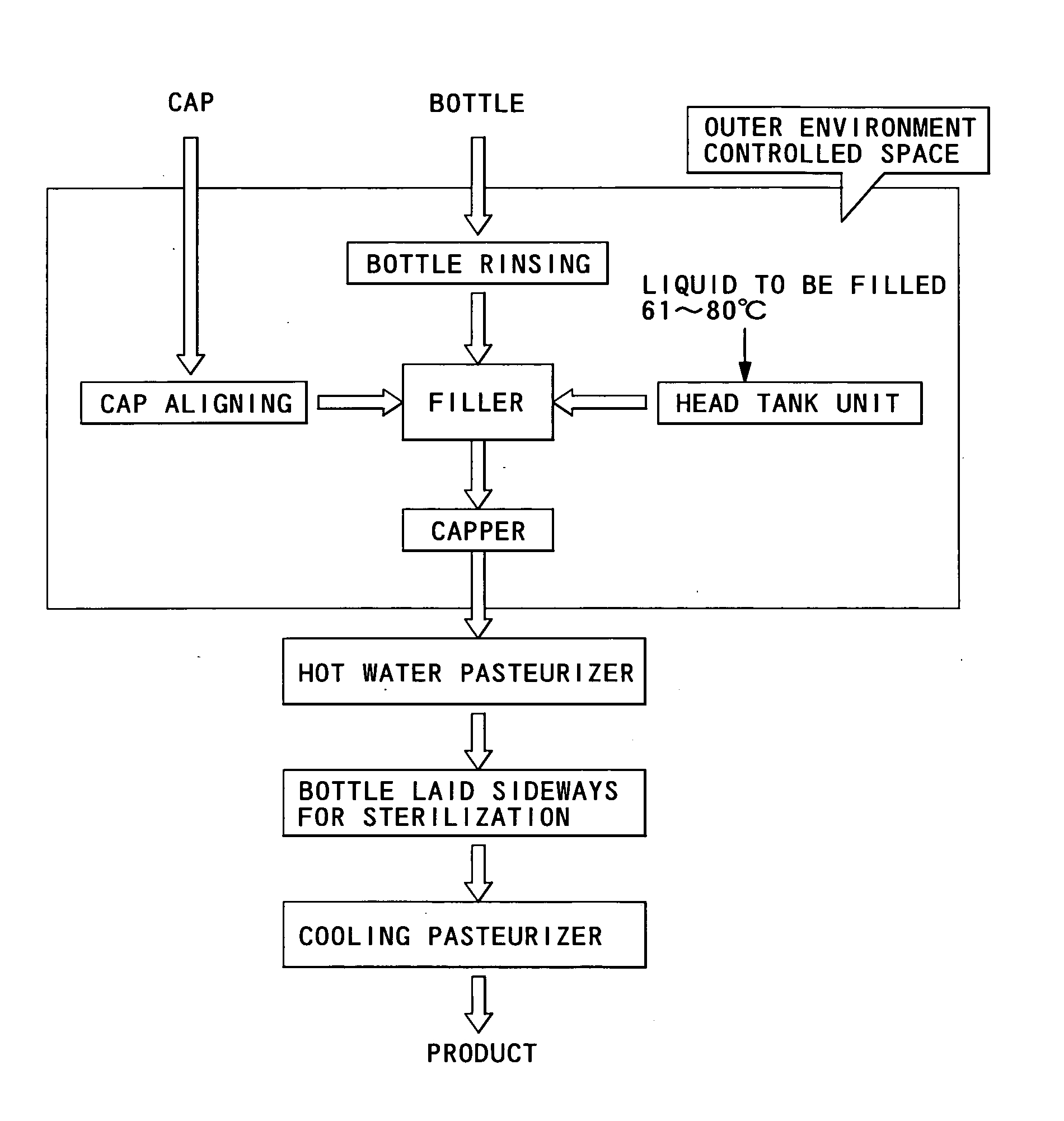

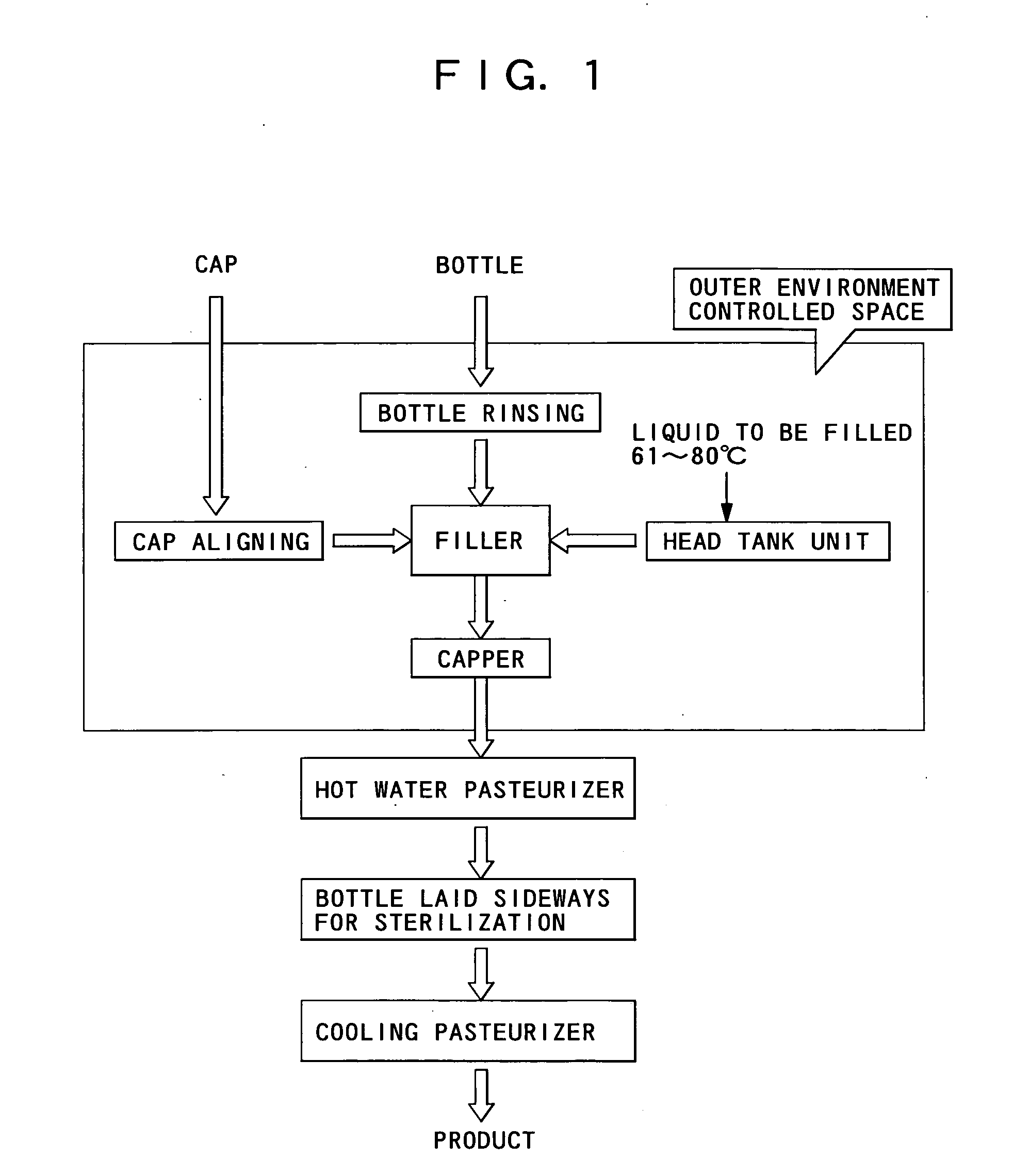

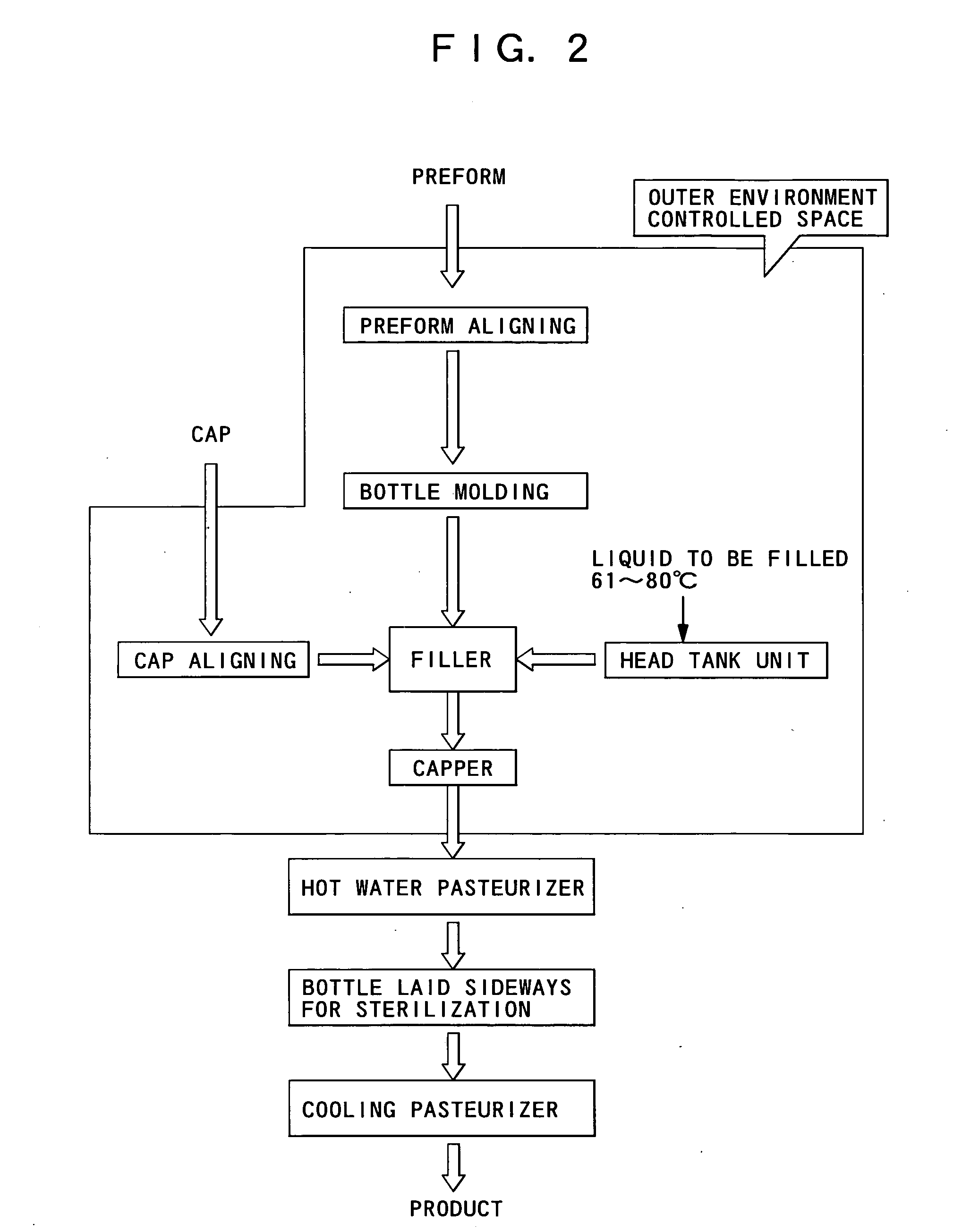

Method for manufacturing contents contained in a container

InactiveUS20070101681A1Reduce internal pressureMaintain temperatureCapsDecorative coversPolyesterVitrification

A method for manufacturing contents such as a drink contained in a container such as a PET bottle by filling the contents in the container, sealing the container and sterilizing the container includes steps of: filling the contents in a polyester container having a non-crystallized neck portion; sealing the container; and sterilizing the container in such a manner that temperature of the neck portion of the container during sterilization is maintained within a temperature range which is 61° C. or over and less than a glass transition temperature determined by moisture content of the container.

Owner:TOYO SEIKAN KAISHA LTD

Shampoo production line

ActiveCN105169992AEasy to operateLow costMixing methodsRotary stirring mixersRotational axisProduction line

The invention discloses a shampoo production line which comprises a shampoo dilution tank and a shampoo filling machine which are sequentially arranged. The shampoo dilution tank comprises a tank body. A stirring fin is arranged in the tank body and connected with a rotating shaft. A driven gear is fixed to the rotating shaft and meshed with a drive gear, and the drive gear is connected to the power output end of a motor. The rotating shaft is provided with a hollow structure, the upper end of the rotating shaft is provided with a connection flange, and the rotating shaft is connected with a water inlet pipe through the connection flange. The stirring fin comprises a plurality of hollow vertical pipes which are evenly distributed in the peripheral direction of the rotating shaft, and lower end openings of the vertical pipes are arranged to be open. By the adoption of the technical scheme, the shampoo production line is convenient to install, low in cost, easy to operate and capable of effectively lowering the cost, fast operation is achieved, and production efficiency is improved.

Owner:贵州省工程复合材料中心有限公司 +1

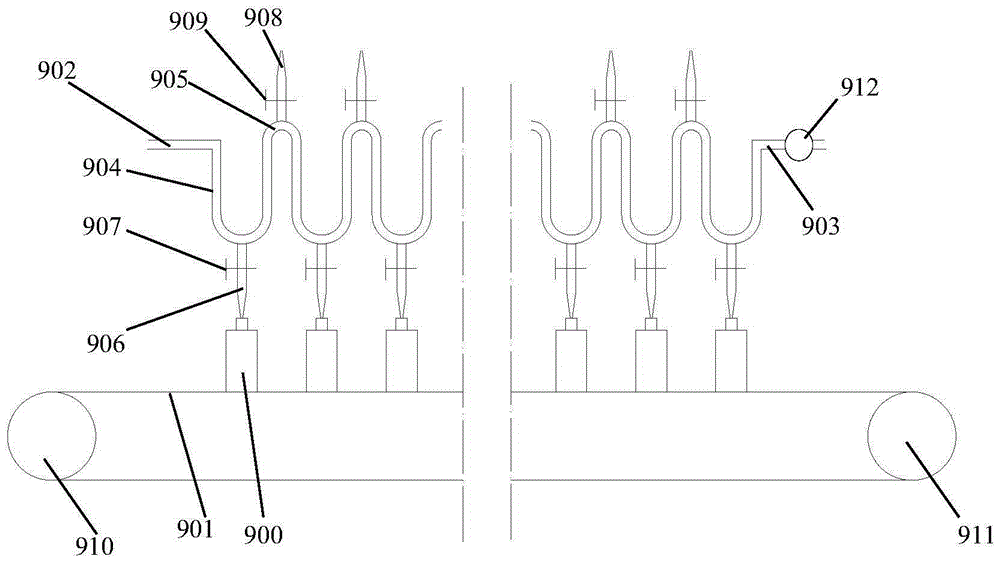

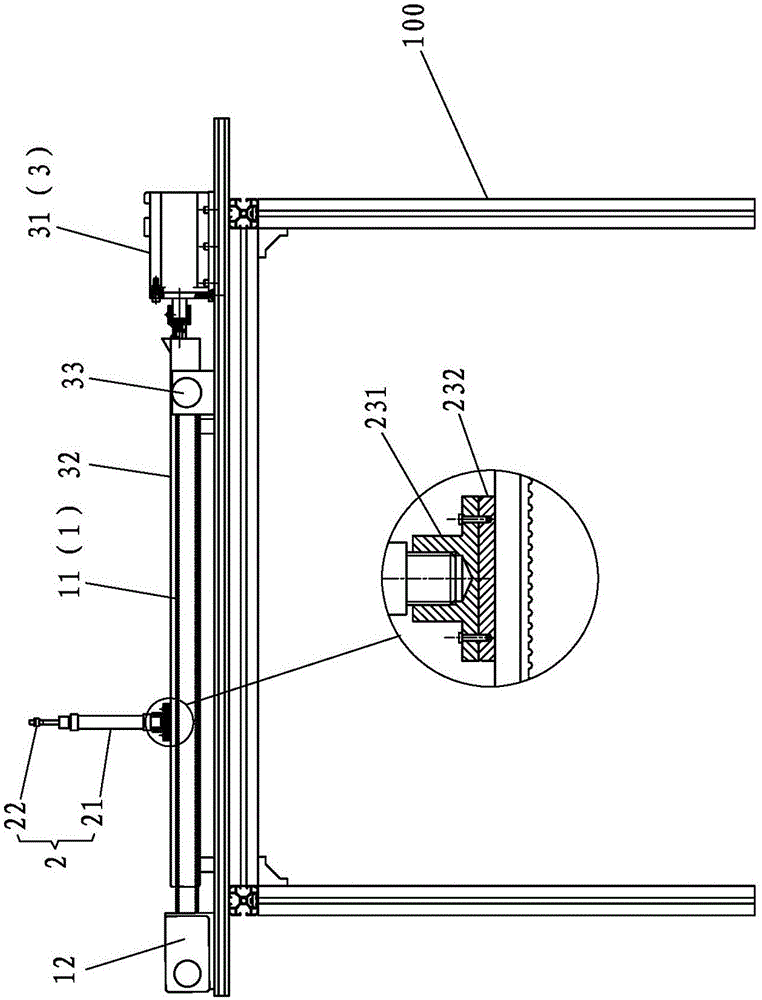

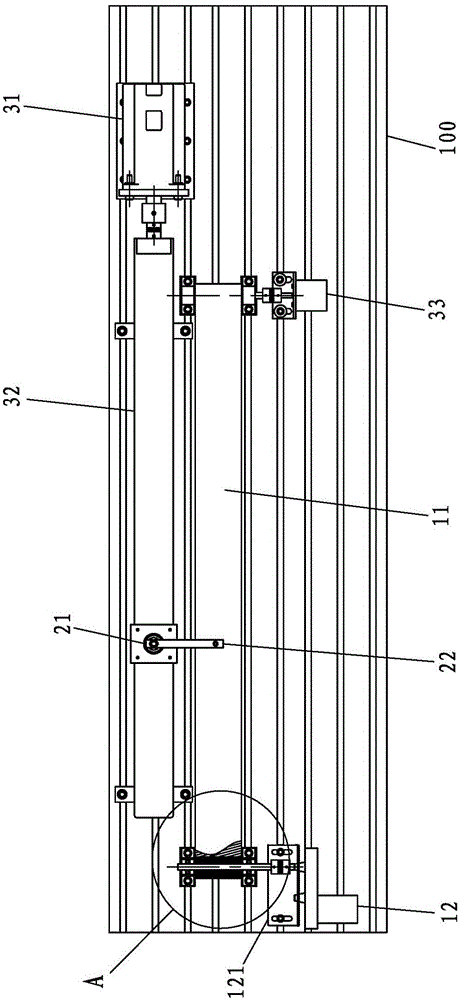

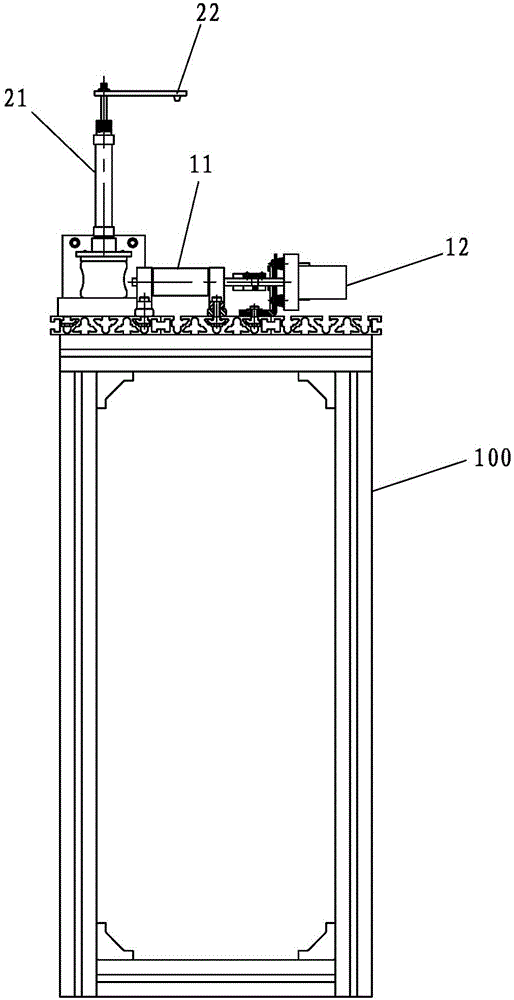

Tracking type self-filling machine and method thereof

InactiveCN105084276AImprove filling efficiencyHigh filling accuracyFilling without pressureEngineeringAssembly line

The invention discloses a tracking type self-filling machine and a method thereof. The self-filling machine comprises an assembly line and a filling mechanism. The assembly line is used for conveying filled bottles. The filling mechanism is arranged on a following mechanism. The filling mechanism is driven by the following mechanism to track the filled bottles on the assembly line and fill the filled bottles in a tracking mode. The tracking type self-filling method comprises the steps that the assembly line carries the filled bottles to run constantly, and the filling mechanism tracks the filled bottles on the assembly line and fills the filled bottles in the tracking mode. According to the tracking type self-filling machine and the method thereof, the filled bottles run on the assembly line constantly and the filling mechanism conducting filling operations is movably installed in a tracking mode, so that tracking filling is achieved when the assembly line keeps running; the filling system is capable of achieving synchronous filling to the filled bottles, so that the filling efficiency and filling precision of the filling system are greatly improved; in addition, the assembly line running constantly is capable of operating stably so that the stability and safety of the system can be ensured.

Owner:XIAMEN UNIV OF TECH

Filling valve

A valve housing which is internally formed with a filled liquid passage and a liquid valve which allows or interrupts a communication of the filled liquid passage are provided, and a liquid valve opening / closing air cylinder opens or closes the liquid valve to perform a filling operation of a filled liquid. An outlet portion located at the bottom end of the valve housing is formed by a separate liquid outlet member. A first liquid outlet member which is connected with a gas exhaust passage and used for a carbonated filling operation and a second liquid outlet member which carries a screen on its bottom end and used for a non-carbonated filling operation are interchangeably used. A filling valve which permits a combined use with a carbonated filling operation and a non-carbonated filling operation enables an accommodation for a filling operation which should take place in a clean environment.

Owner:SHIBUYA IND CO LTD

Liquid filling device

ActiveCN104129749AImprove stabilityMonitor filling statusFilling without pressureFunnelsEngineeringMaterial storage

The invention discloses a liquid filling device. The liquid filling device comprises a material storage tank, a material receiving tank, and a tunnel arranged above the material receiving tank. A material discharge pipe, which is communicated with the material storage tank, is arranged on the lower part of the material storage tank and extends outwardly. A material baffle plate is arranged to be perpendicular to the direction of the material discharge pipe, one end of the material baffle plate is inserted into any position of the material discharge pipe, the other end of the material baffle plate is provided with an electromagnet mechanism and a return spring, the electromagnet mechanism switches the on / off of a circuit, and the elastic return of the return spring changes the relative position between the material baffle plate and the material discharge pipe. The liquid filling device can solve the problem of overflowing during the filling process, can automatically detect whether the filling is complete or not, and improves the filling accuracy and work efficiency.

Owner:HUZHOU RONGSHENG BIOLOGICAL TECH

Method for filling shrink packaging

InactiveCN101652314ASimple clamping processIncrease vertical pressureFilling using counterpressureFilling without pressureEngineeringMechanical engineering

Owner:AISAPACK HLDG SA

Open Jet Filling System

InactiveUS20090314385A1Continuous fillingMeasuring the filling level reliably and easilyFilling without pressureSolid materialMechanical engineering

An open-jet filling system, a method of filling containers by means of such an open-jet filling system used for contactless filling a container, and a corresponding filling machine, with the open-jet filling system provided with a filling level probe. For always obtaining the same filling height in the containers and for simultaneously realizing hygienic filling, a centering unit is arranged below the open-jet filling element in a vertically movable manner such that it can be moved onto a container mouth, the filling level probe being arranged on the centering unit.

Owner:KRONES AG

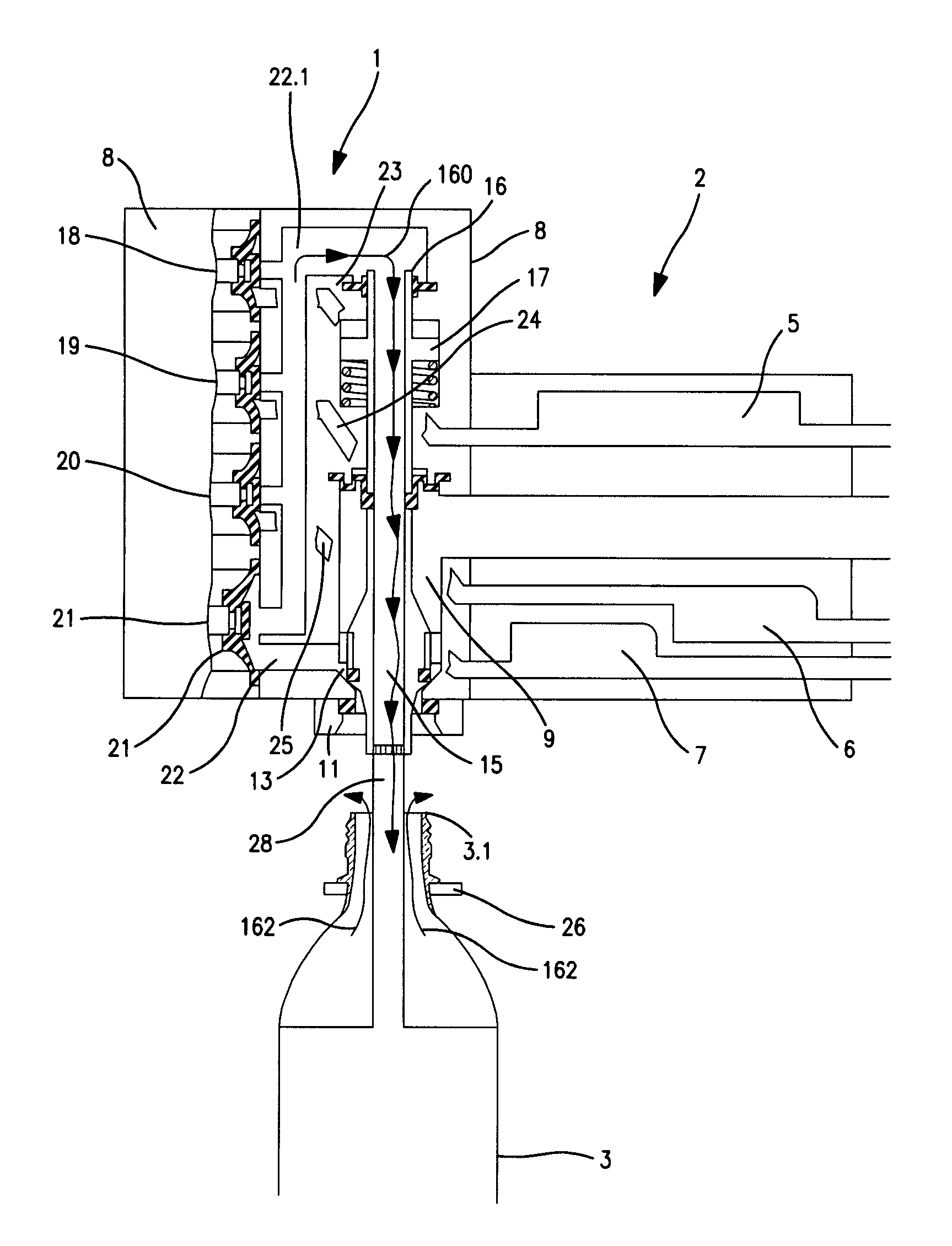

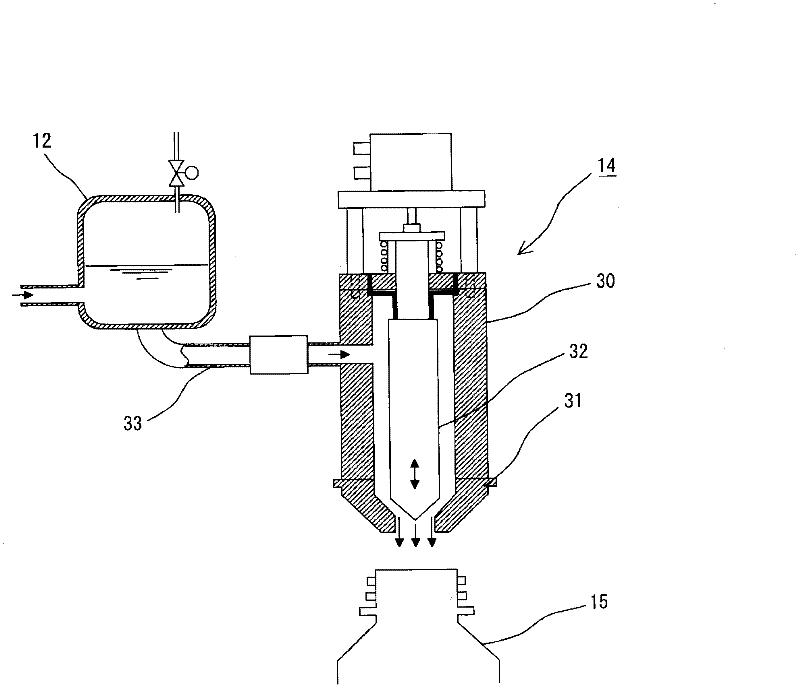

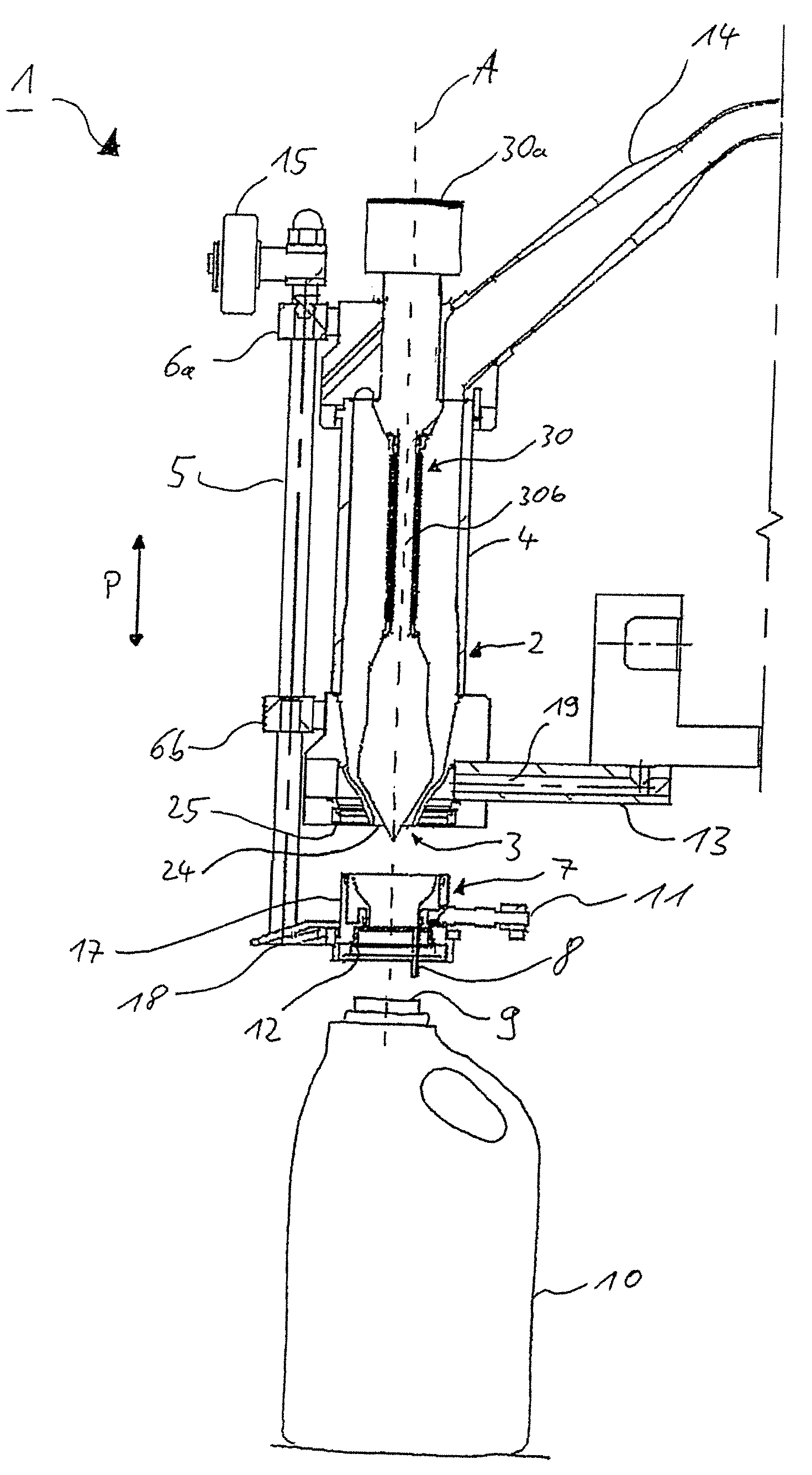

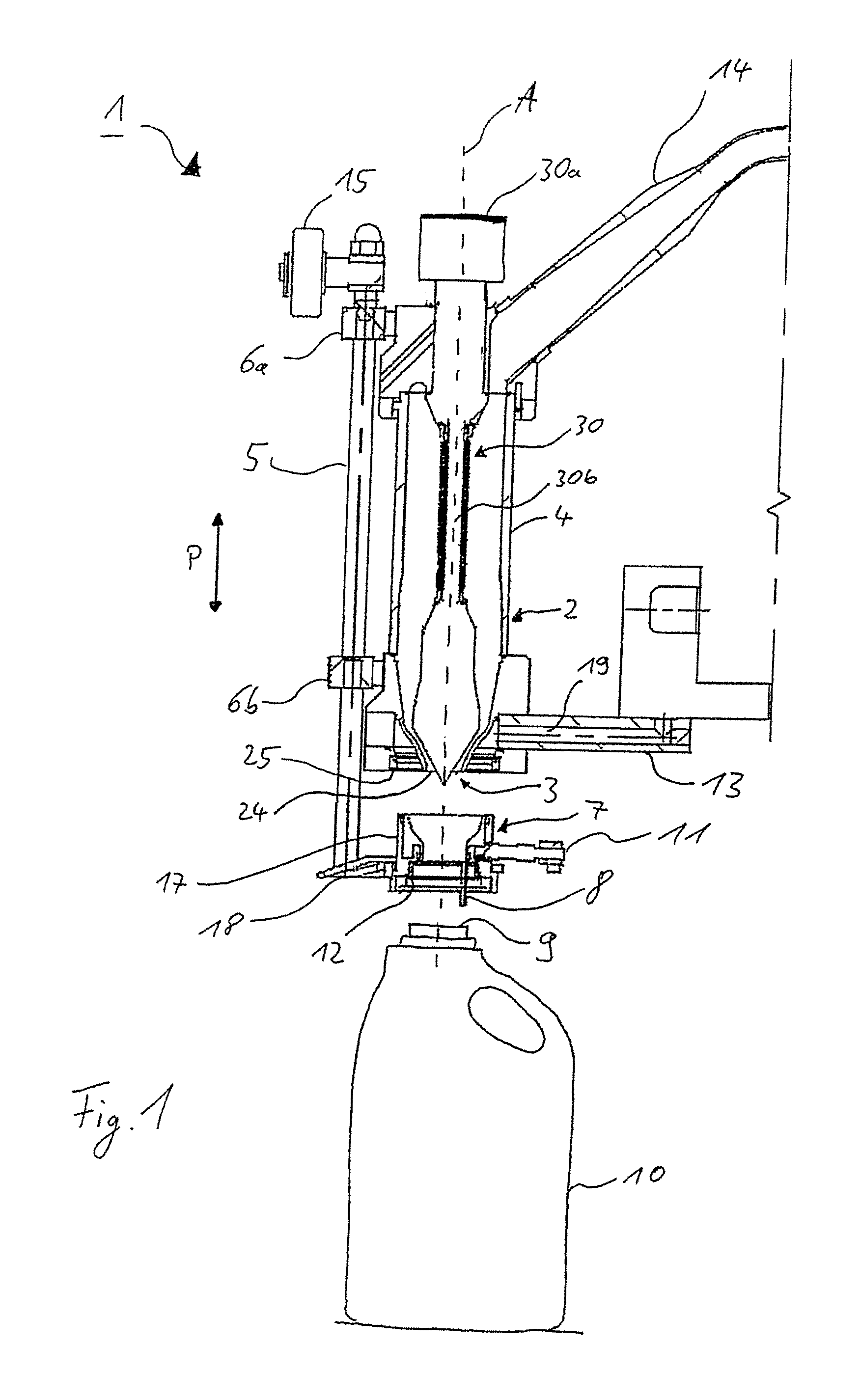

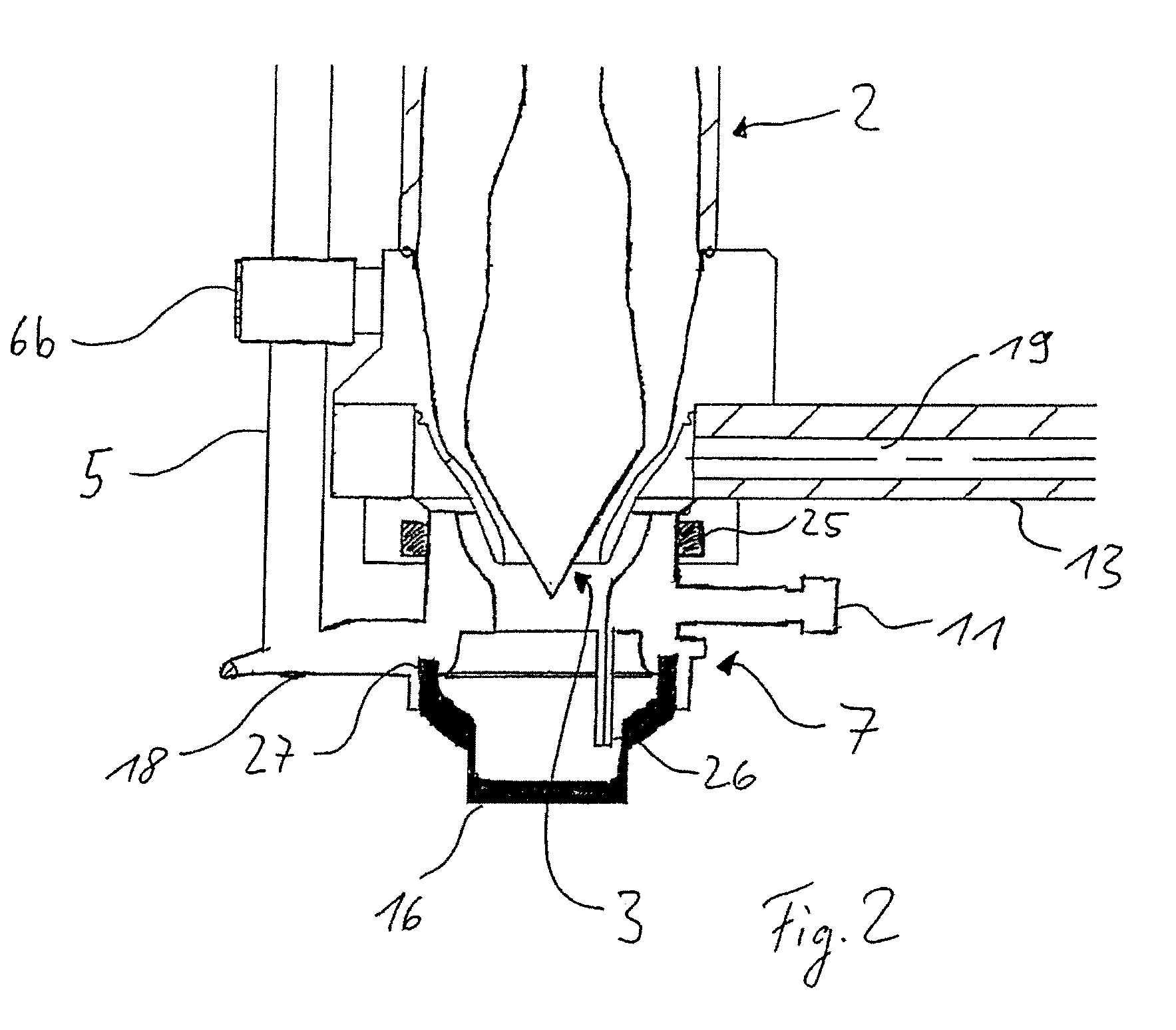

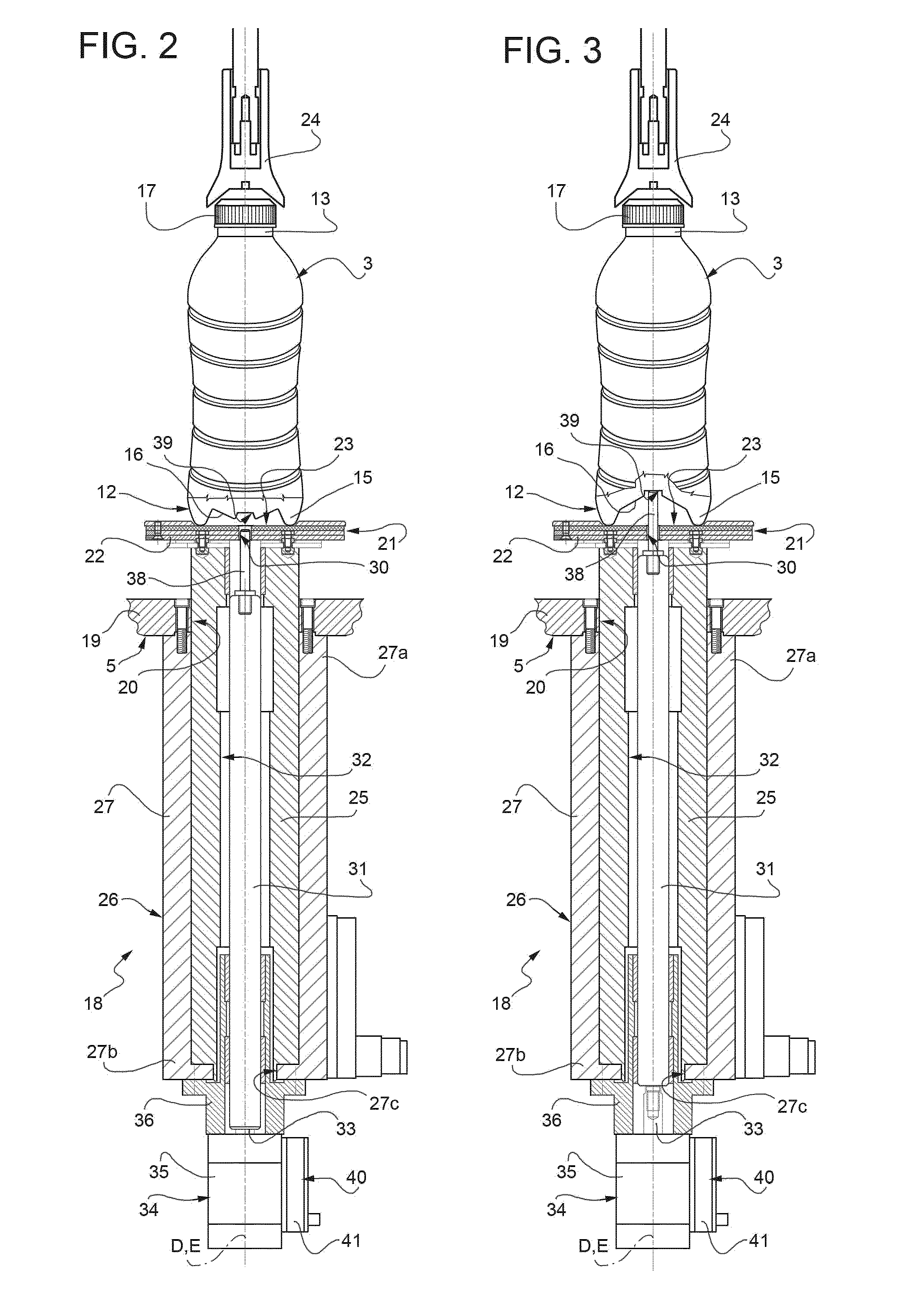

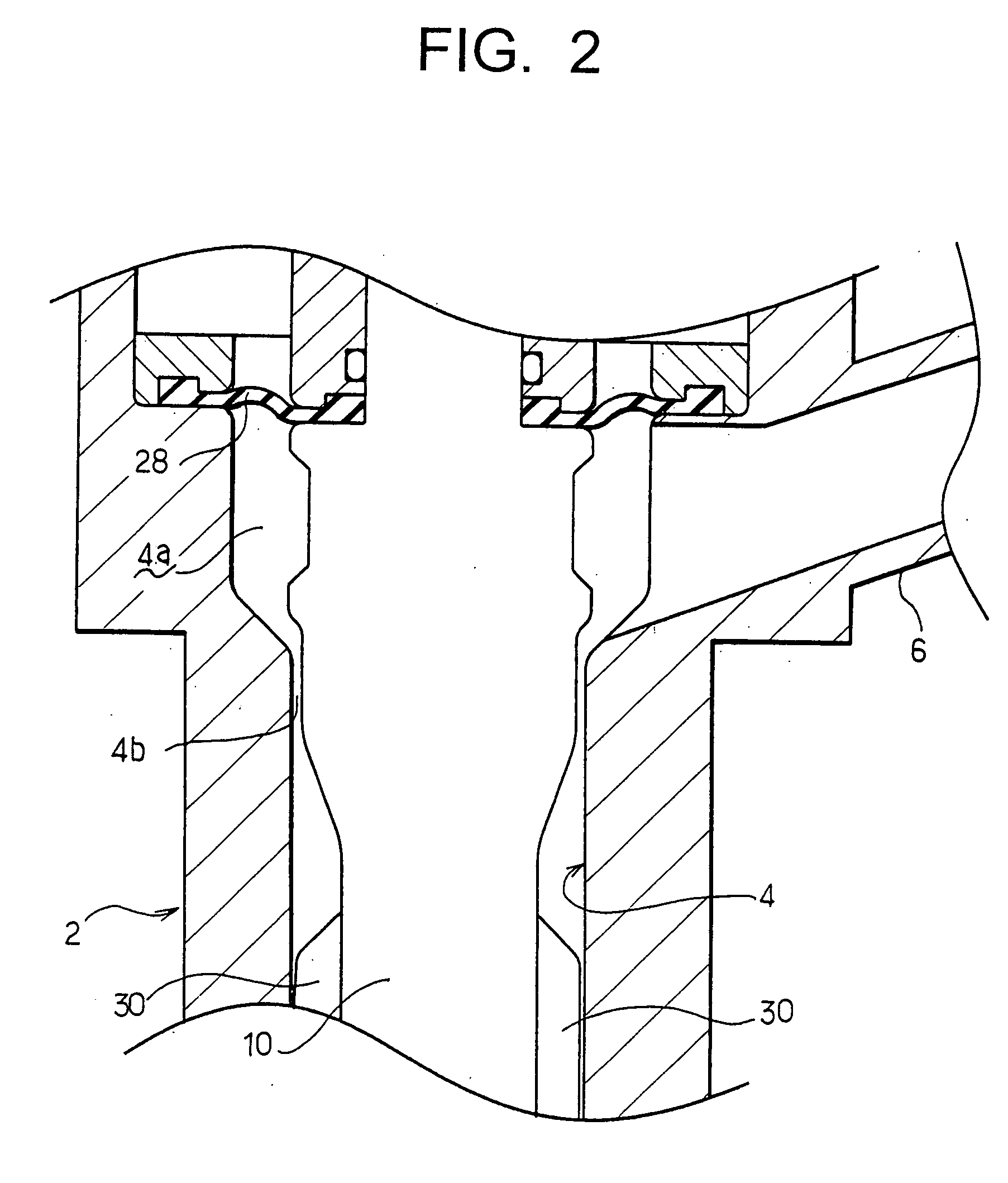

Method and device for producing content filling bottle

The present invention provides a method and device for producing a content filling bottle including a bottom part that is inverted between a concave shape and a convex shape to prevent a body part from being subjected to reduced pressure deformation, the method and device being capable of efficiently producing a sanitary and high-quality content filling bottle. Contents are filled into an empty bottle 1 with an inversion part 11 projecting outwardly from the body part. A cap 6 is fitted onto an opening of the bottle 1 to seal the bottle 1. An auxiliary tool 27 is then installed on the bottom part 5 of the bottle 1. Then, the bottom part of the bottle 1 with the auxiliary tool 27 installed thereon is supported via the auxiliary tool 27. The downwardly projecting inversion part 11 is pressed up so as to be inverted and recessed inwardly into the bottle 1. Subsequently, with the opening of the bottle 1 gripped, the auxiliary tool 27 is separated from the bottle 1.

Owner:CO2 PAC

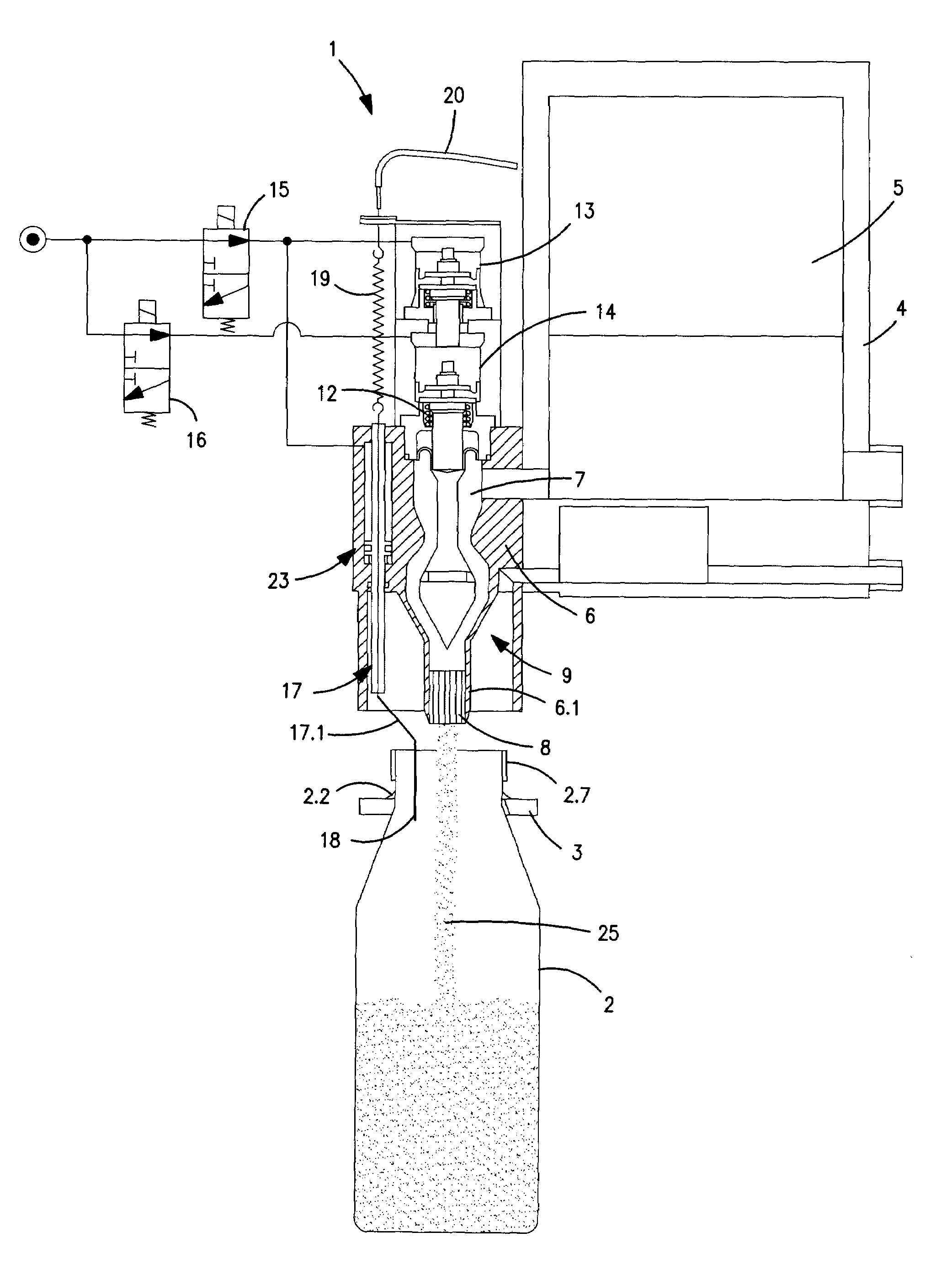

Filling machine and method of filling a container

InactiveUS20120138192A1Drawback can be obviatedFilling using counterpressureMulti-purpose machinesEngineeringControl valves

A filling machine for filling a container with a pourable food product, comprising a tank, a support structure, a first fluidic line through which food product may flow, connected with the tank and connectable with the inner volume of the container a filling valve and a distributor comprising at least two ducts defining, with a cavity of filling valve, at least partially a second fluidic line along which a fluid may flow; distributor element comprising a first and a second control valve may either be left open in respective first configuration over the whole operation of filling machine or be displaced between open and closed configuration during a step of the operation of filling machine on the basis of one parameter between the nature of container and the nature of pourable food product.

Owner:SIDEL SPA

Precise kiwi fruit juice constant-pressure dripping equipment

InactiveCN109650312ASolve uneven distributionSpray evenlyFilling without pressureSafety device in filling machineryActinidiaKiwi fruit

The invention relates to the technical field of kiwi fruit, and discloses precise kiwi fruit juice constant-pressure dripping equipment. The precise kiwi fruit juice constant-pressure dripping equipment comprises a box body I and a constant-pressure dripping mechanism; the constant-pressure dripping mechanism comprises a motor, a fixing block, a moving rod, a screw rod, a connection rod, a pressing plate, a sealing sleeve, a material inlet shield, a material inlet pipe, a material outlet pipe I, a box body II and a material outlet pipe III; and the motor is arranged on the top of the box bodyI. according to the precise kiwi fruit juice constant-pressure dripping equipment, through arrangement of the motor, the screw rod, the fixing block, the moving rod, the connection rod, the pressing plate and the sealing sleeve, the motor starts to drive the screw rod to rotate; the screw rod rotates to drive the connection rod to lift so as to drive the pressing plate to lift; the pressing platepresses liquid in the box body I; the pressing plate descends at constant speed, so that liquid which is sprinkled through a dripping head is uniformly outlet; the aim that kiwi fruit juice can be uniformly sprinkled from the bottom of the dripping head; and the problem in the prior art that during canning of the kiwi fruit juice, the flowing speed is unstable, so that the distribution of the kiwifruit juice in the bottom of a can is not uniform is solved.

Owner:NANJING LVHANG ECOLOGICAL AGRI

Labelling machine

InactiveUS20150040515A1Simple and cost-effectiveReduce in quantityMechanical working/deformationControlling laminationEngineeringActuator

A labelling machine for applying labels on respective containers is disclosed. The labelling machine is provided with at least one operative unit, adapted to receive a relative container to be labelled and having a support element for supporting a base portion of the container, with a conveyor device for transferring the operative unit from a feeding station of the containers to an outlet station, and with feeding means for providing at least one label to be applied on the container borne by the operative unit The operative unit also comprises an actuator element borne by the conveyor device on the opposite side of the support element with respect to the receiving position of the container.

Owner:SIDEL SPA

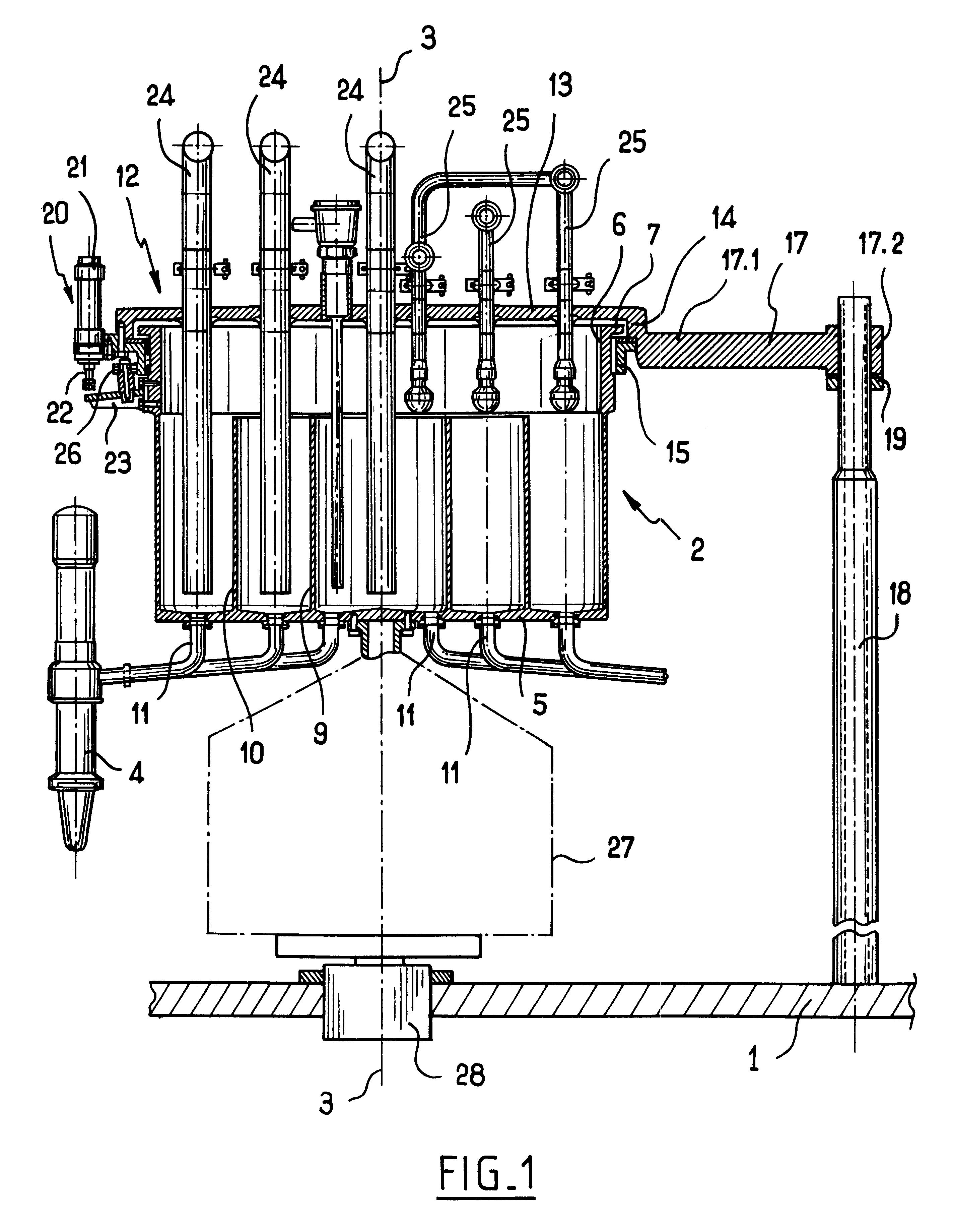

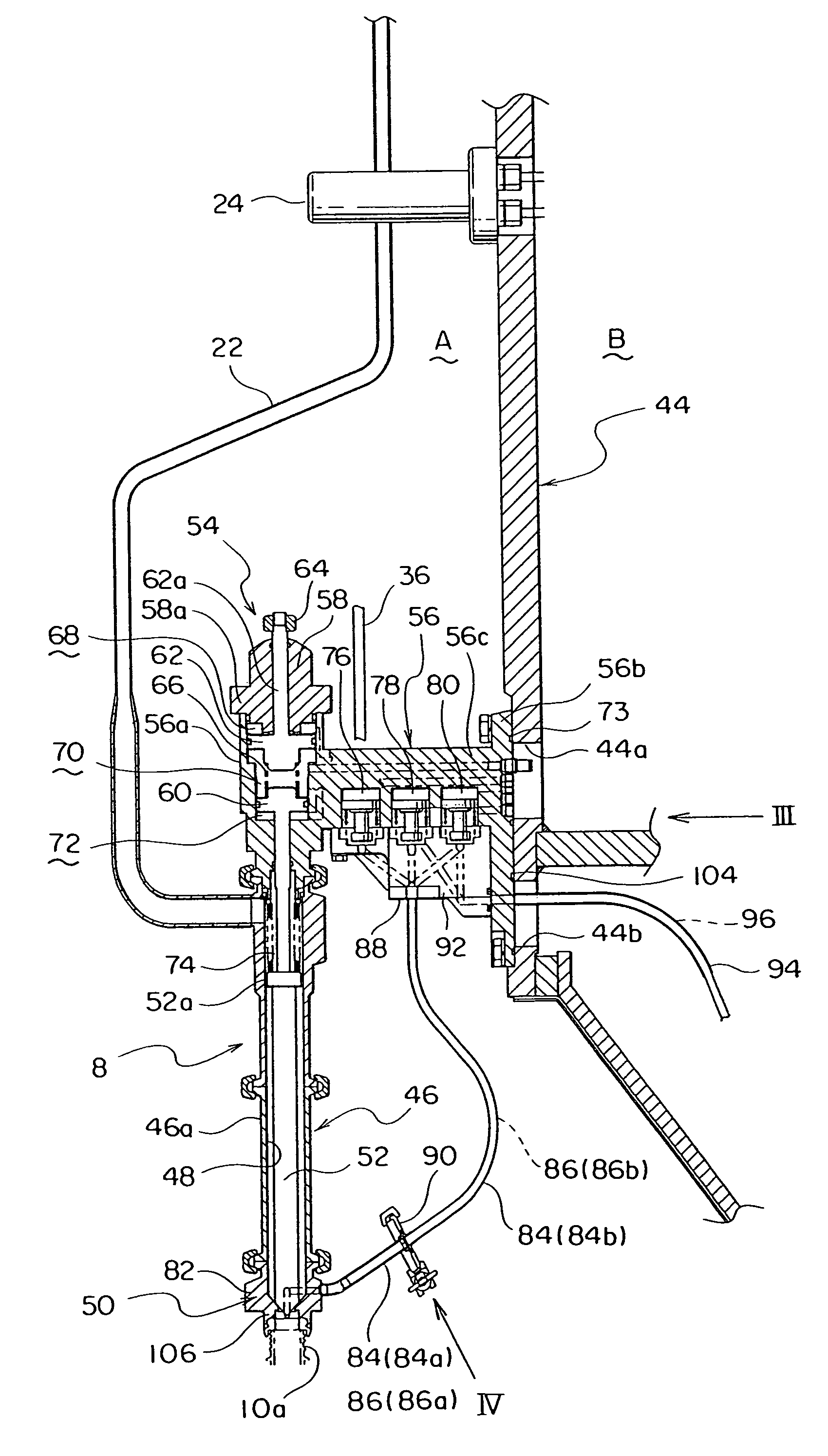

Filling valve

ActiveUS20040118479A1Improve hygieneStable filling operationFilling using counterpressureFilling without pressureEngineeringNozzle

A liquid passage 4 for filling which communicates with a liquid supply piping 6 for filling is formed within a valve housing 2 and carries a filling nozzle 31 at its lower end. The liquid passage 4 is opened or closed by a liquid valve. A packing 38 which seals the mouth of a vessel B, a cylinder 42 which elevates the packing 38, a flow meter 33 which detects a filled content of the liquid which is filled into the vessel B, and an exhaust passage 44 formed in the valve housing 2 are provided. The exhaust passage 44 has an opening disposed toward the vessel which is disposed outside an opening of the filling nozzle 31, and the opening of the filling nozzle 31 is maintained above the elevation of the liquid level which is filled into the vessel B during the filling operation. The filling valve assures a sanitary excellence and is usable with vessels B of differing sizes and shapes.

Owner:SHIBUYA IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com