Method for filling shrink packaging

A container and hot filling technology, applied in liquid filling, using back pressure filling, packaging, etc., can solve the problems of increasing container cost, bottle wall deformation, and bottle productivity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

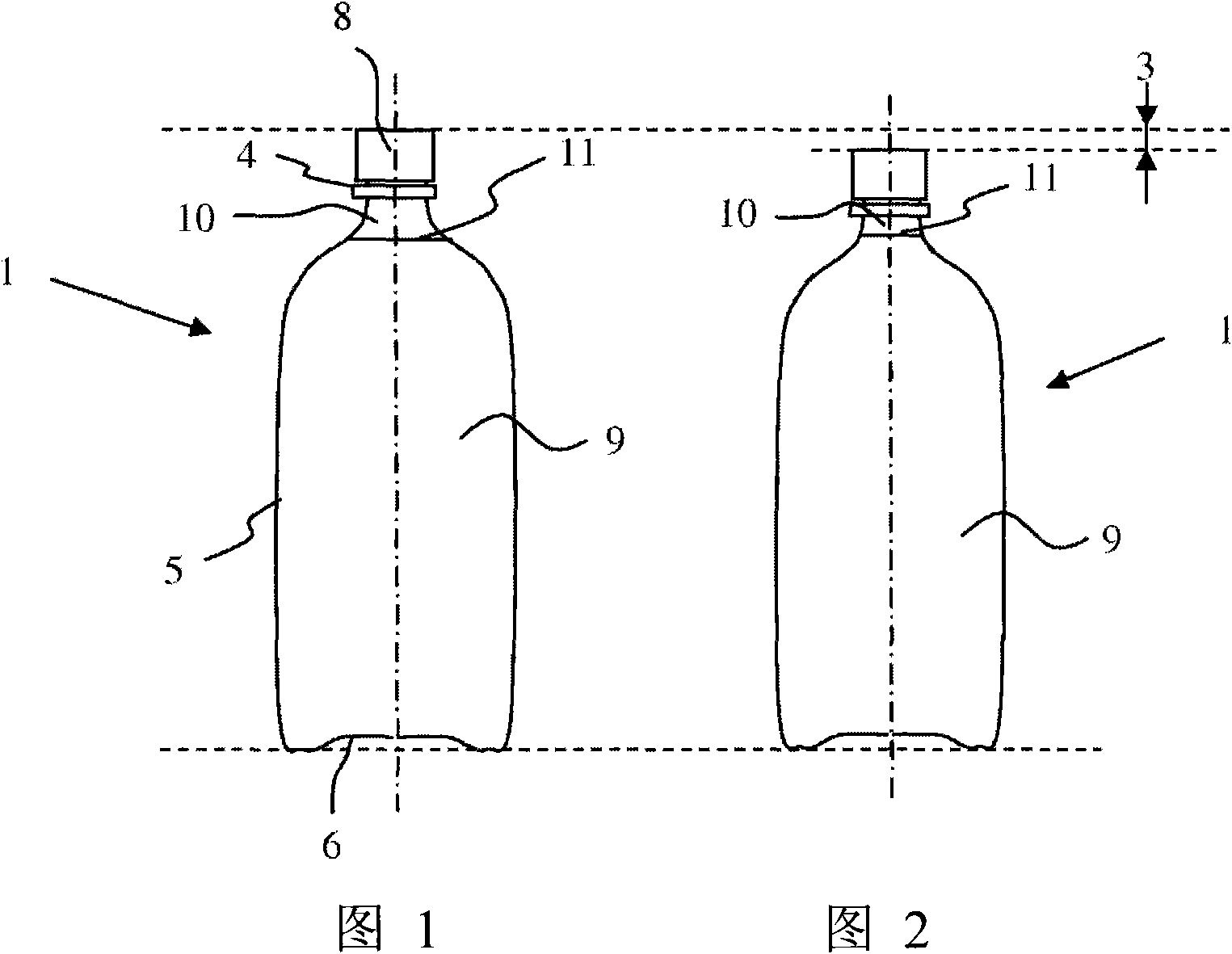

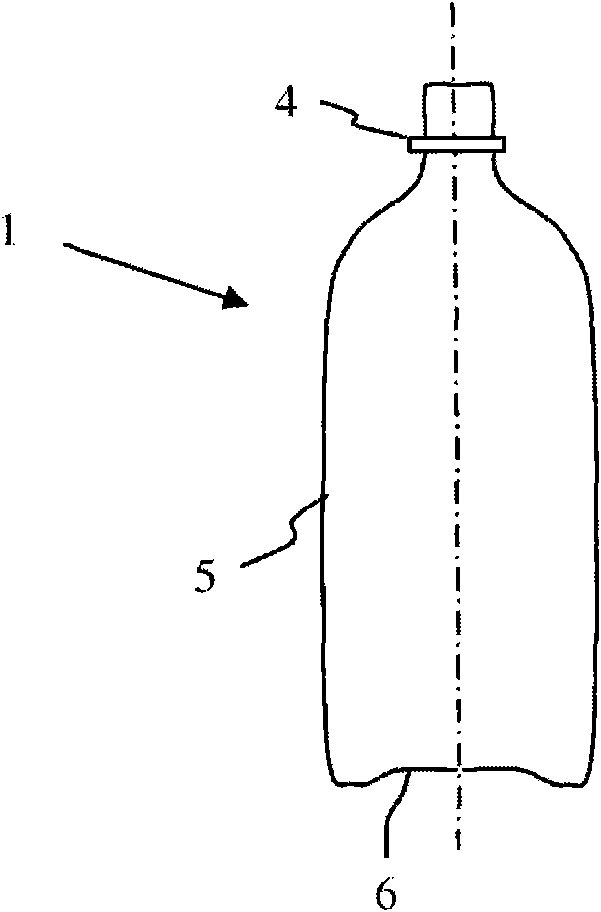

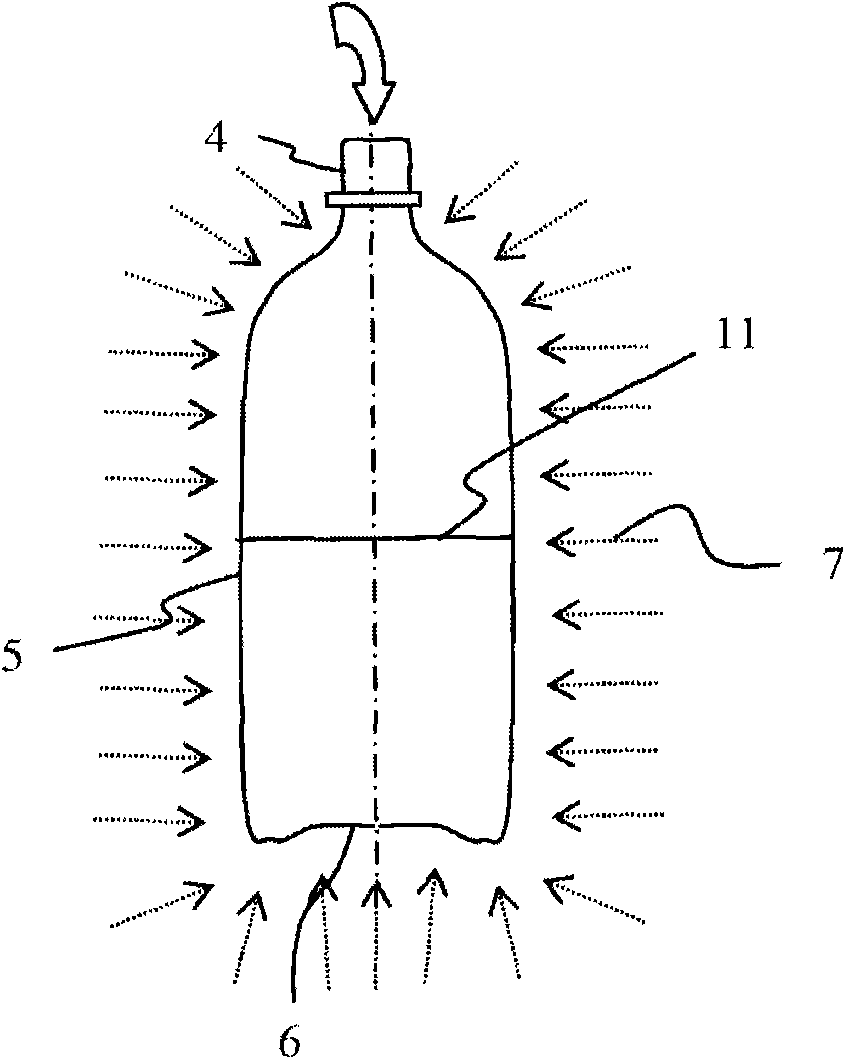

[0080] The weight of the bottle is 24 grams and its base is petal-shaped. Its initial volume is 543.2 ml. After filling at 90°C using the following procedure, its volume became 508.7 ml. The bottle thus shrinks by 6.35% during filling. After cooling, the relative pressure inside the bottle is slightly positive.

[0081] Fill the bottle using the following how-to:

[0082] 1. Provide empty bottles

[0083] 2. Rinse the bottle

[0084] 3. Conveying the bottles to the supply station

[0085] 4. Start cooling the outer wall of the bottle by spraying water at 15°C

[0086] a. Fill the bottle with 90°C water

[0087] i. Filling time: 4 seconds

[0088] ii. Fill volume: 92% of the initial volume, which is 499.7 ml

[0089] b. Conveying the bottles to the sealing station

[0090] i. Duration: 1 second

[0091] c. Airtight bottle

[0092] i. Duration of stopper: 1 second

[0093] 5. End the cooling of the outer wall of the bottle

[0094] 6. Shrinkage of bottles in the op...

example 2

[0101] The bottle weighs 37.4 grams and has a petal-shaped base. Its initial volume is 1064.2 ml. After filling at 88°C using the following procedure, its volume became 1012.1 ml. The bottle therefore shrank by 4.9% during filling. After cooling, the relative pressure inside the bottle is slightly positive.

[0102] Fill the bottle using the following how-to:

[0103] 1. Provide empty bottles

[0104] 2. Rinse the bottle

[0105] 3. Conveying the bottles to the supply station

[0106] 4. Start cooling the outer wall of the bottle by spraying water at 15°C

[0107] a. Fill the bottle with water at 88°C

[0108] i. Filling time: 8 seconds

[0109] ii. Filling volume: 92% of the initial volume, ie 979.1 ml

[0110] b. Conveying the bottles to the sealing station

[0111] i. Duration: 1 second

[0112] c. Airtight bottle

[0113] i. Duration of stopper: 1 second

[0114] 5. End the cooling of the outer wall of the bottle

[0115] 6. Shrinkage of bottles in the open a...

example 3

[0122] The weight of the bottle is 24 grams and its base is petal-shaped. Its initial volume is 543.2 ml. After filling at 95°C using the following procedure, its volume became 489.5 ml. So the bottle shrinks by 9.89% during filling. After cooling, the relative pressure inside the bottle is slightly positive.

[0123] Fill the bottle using the following how-to:

[0124] 1. Provide empty bottles

[0125] 2. Rinse the bottle

[0126] 3. Conveying the bottles to the supply station

[0127] 4. Start cooling the outer wall of the bottle by spraying water at 5°C

[0128] a. Fill the bottle with water at 95°C

[0129] i. Filling time: 4 seconds

[0130] ii. Fill volume: 92% of the initial volume, which is 499.7 ml

[0131] b. Conveying the bottles to the sealing station

[0132] i. Duration: 1 second

[0133] c. Airtight bottle

[0134] i. Duration of stopper: 1 second

[0135] 5. End the cooling of the outer wall of the bottle

[0136] 6. Shrinkage of bottles in the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com