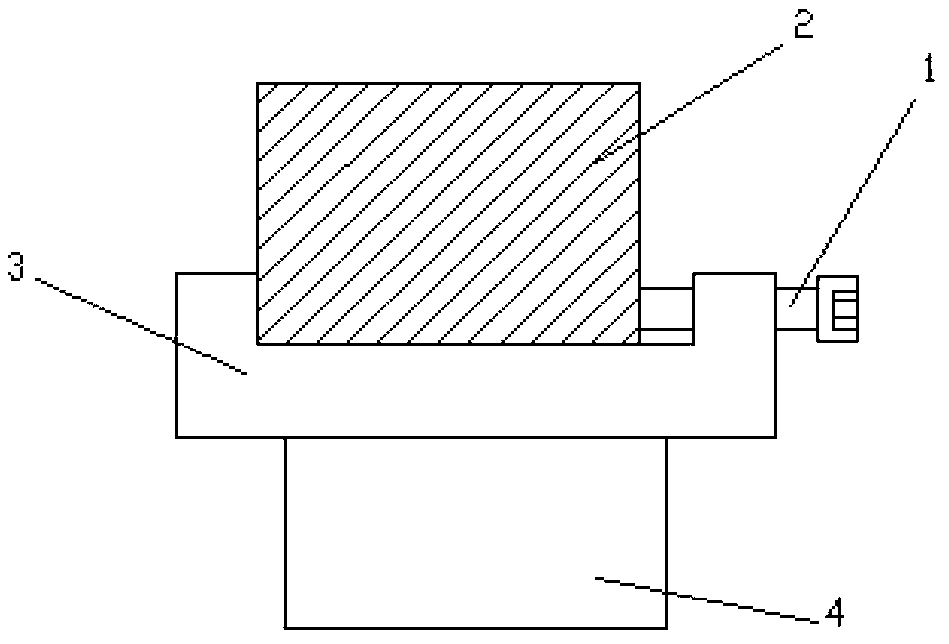

General T-shaped fixture used for die electrode machining

A technology for electrode processing and fixtures, which is applied in metal processing equipment, metal processing machinery parts, clamping, etc., can solve the problems of low repeat positioning accuracy of electrode clamping, inability to pass wire cutting wires, and increased clamping errors, etc. , to achieve the effect of improving clamping accuracy and repeat positioning accuracy, shortening working time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

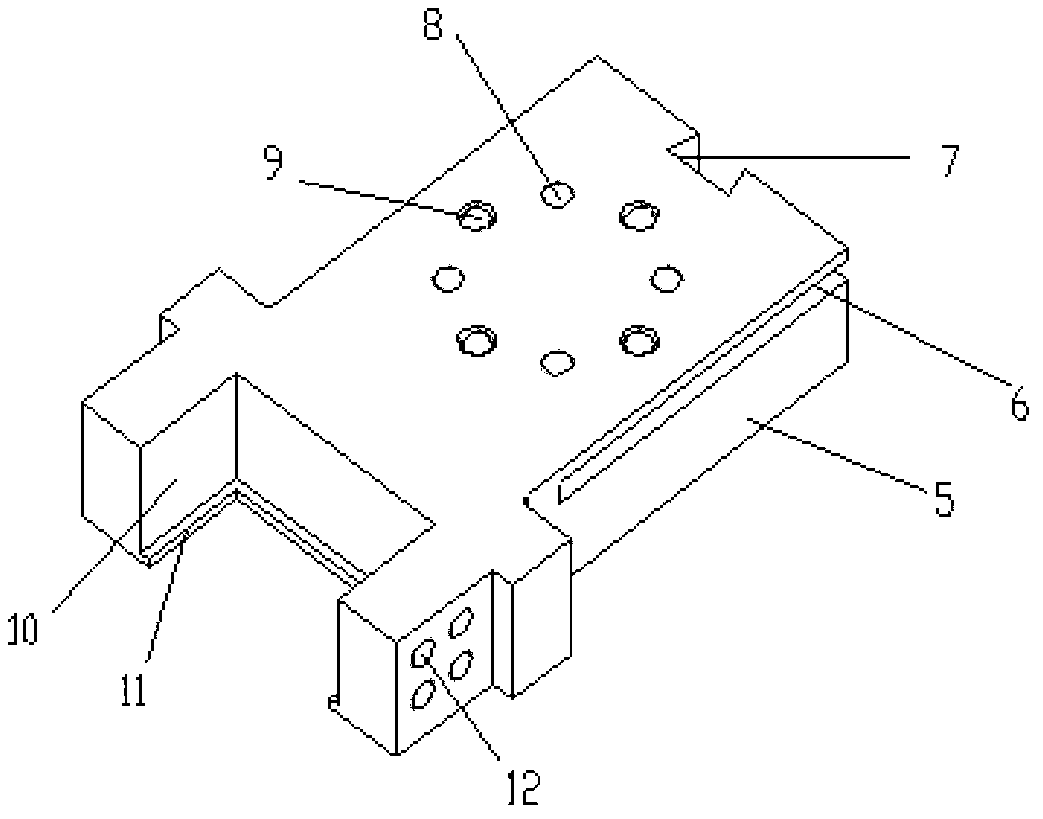

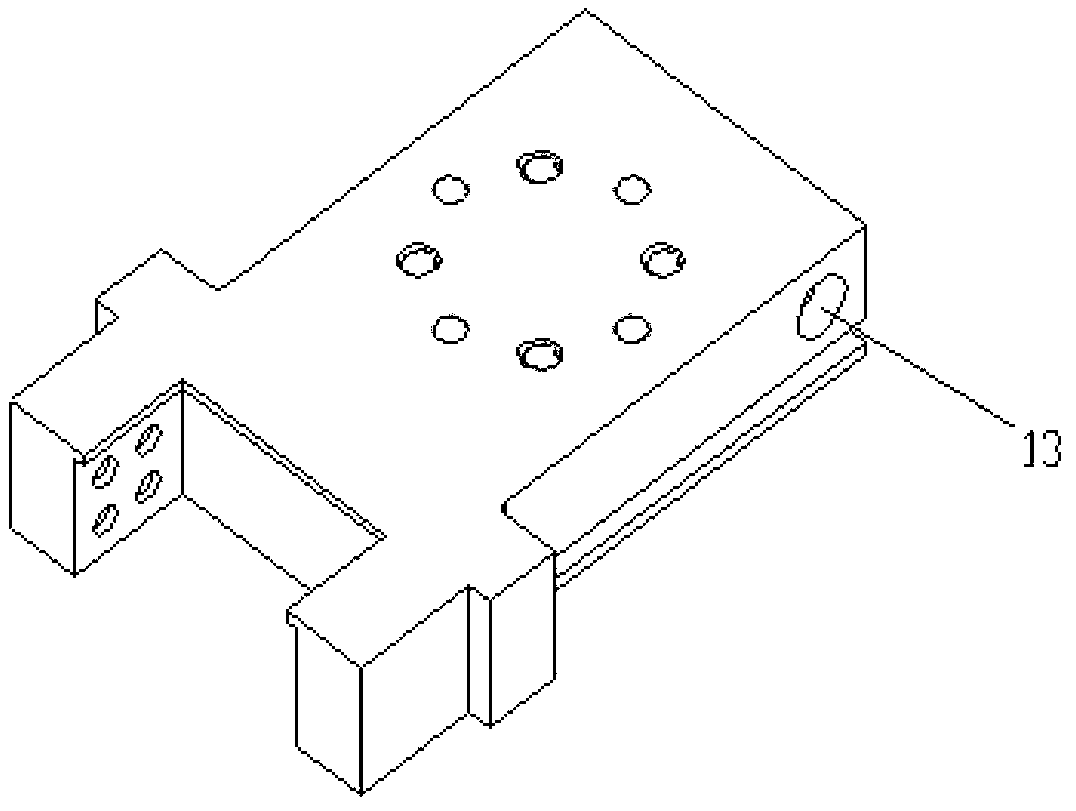

[0025] Such as figure 2 As shown, a universal T-shaped fixture for mold electrode processing includes a T-shaped body 5, a square fixture clamping groove 10, a manipulator chute 6, and a trapezoidal groove 7. The square fixture clamping groove 10 is located on the T-shaped body 5, the trapezoidal groove 7 is located on the right side of the T-shaped body 5, and the manipulator chute 6 is symmetrically arranged on the top of the front and rear sides of the T-shaped body 5.

[0026] The length and width of the clamping groove 10 of the square clamp are determined according to the size of the electrodes used.

[0027] The size of the manipulator chute 6 matches the size of the used manipulator chuck of the CNC machining center.

[0028] The depth of the trapezoidal groove 7 is smaller than the height of the T-shaped body 5, generally set to 1 / 2-2 / 3 of the height of the T-shaped body, and the height of the T-shaped body is the distance from the bottom to the top. The trapezoida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com