Patents

Literature

118results about How to "Simple clamping process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

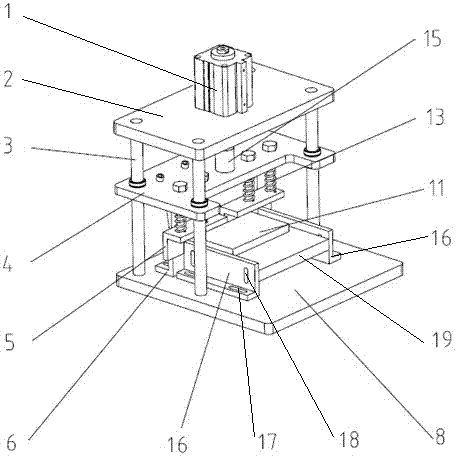

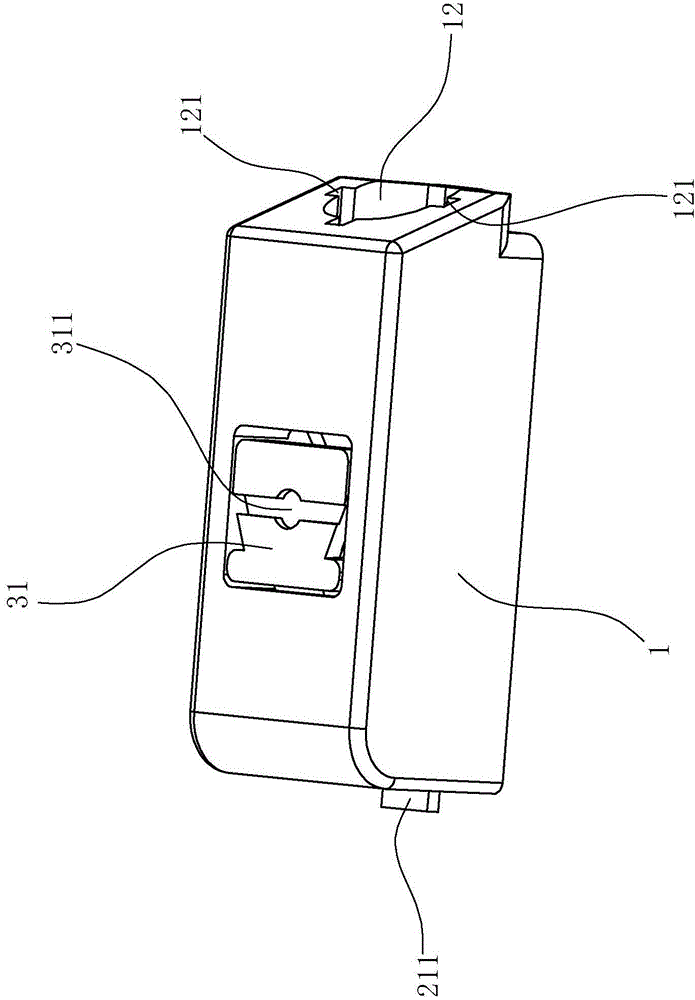

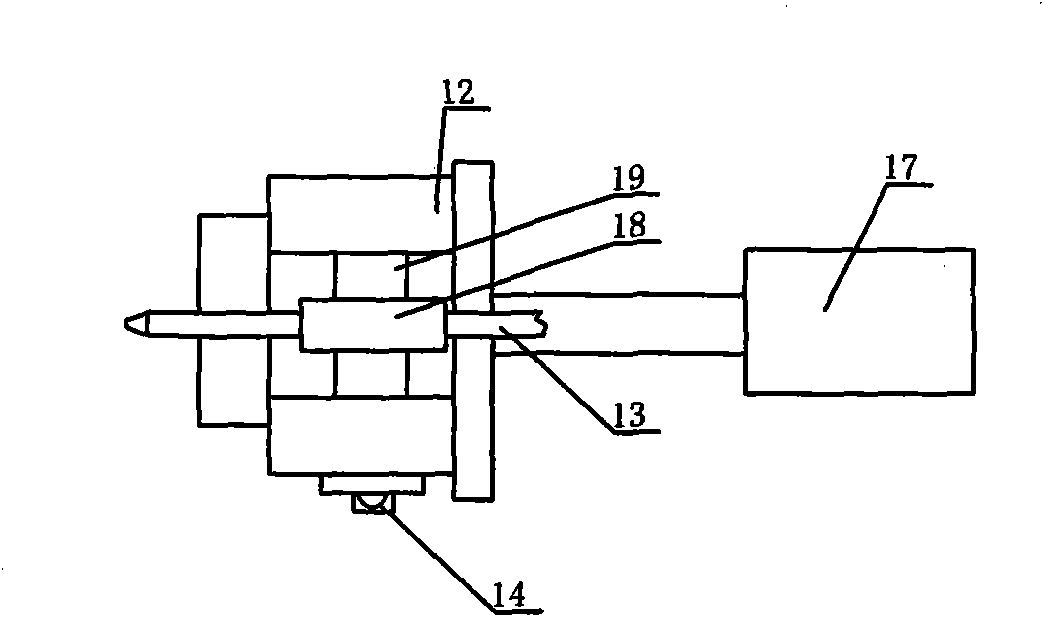

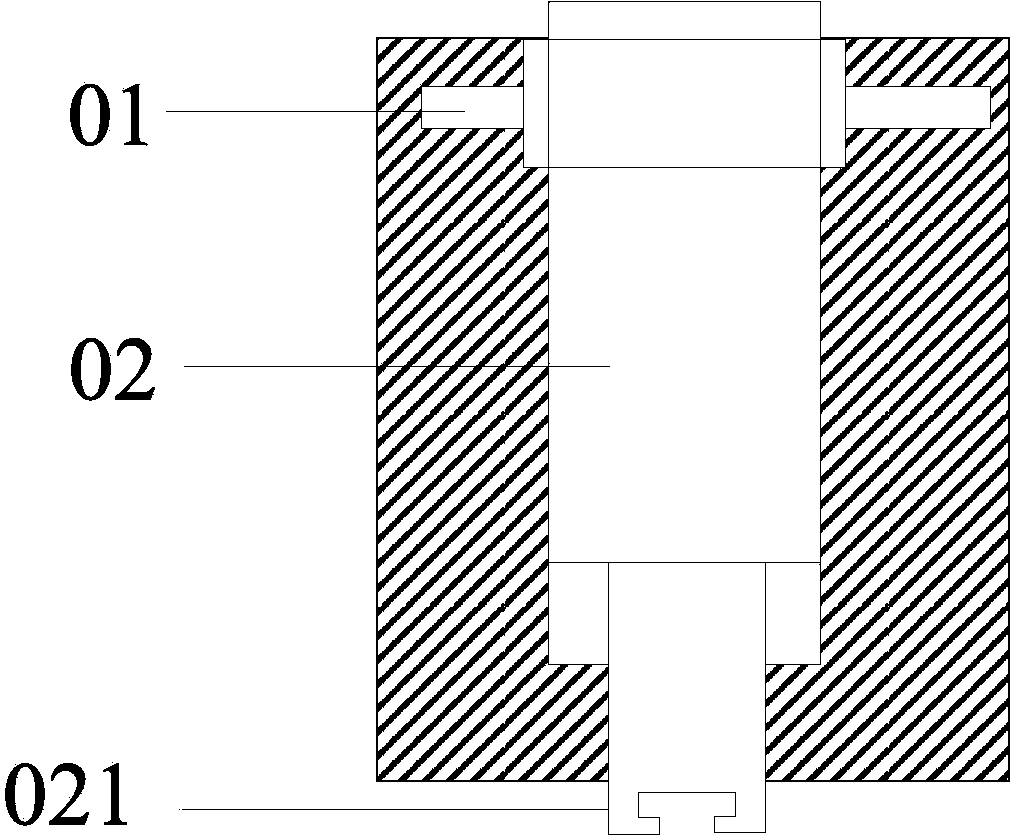

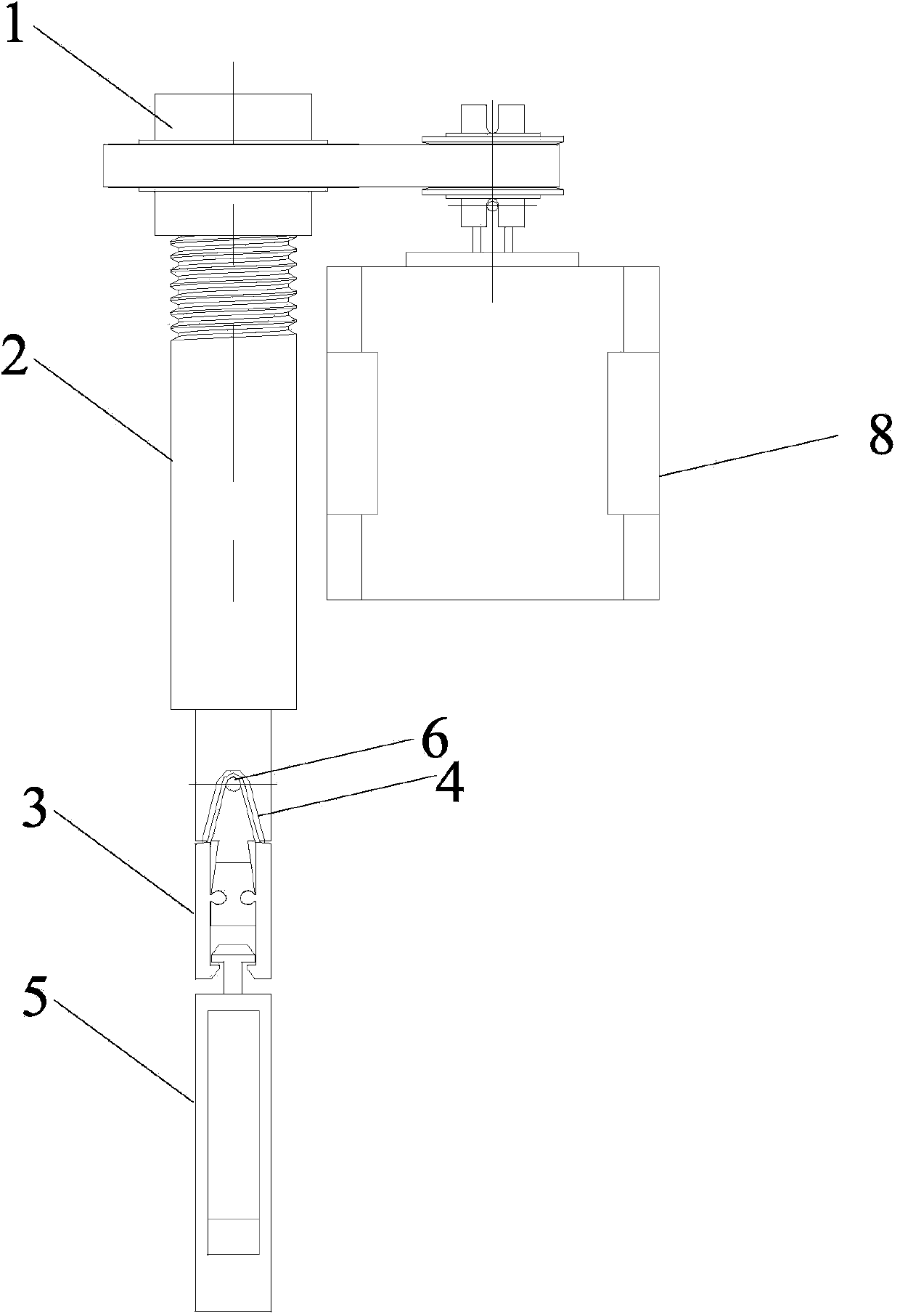

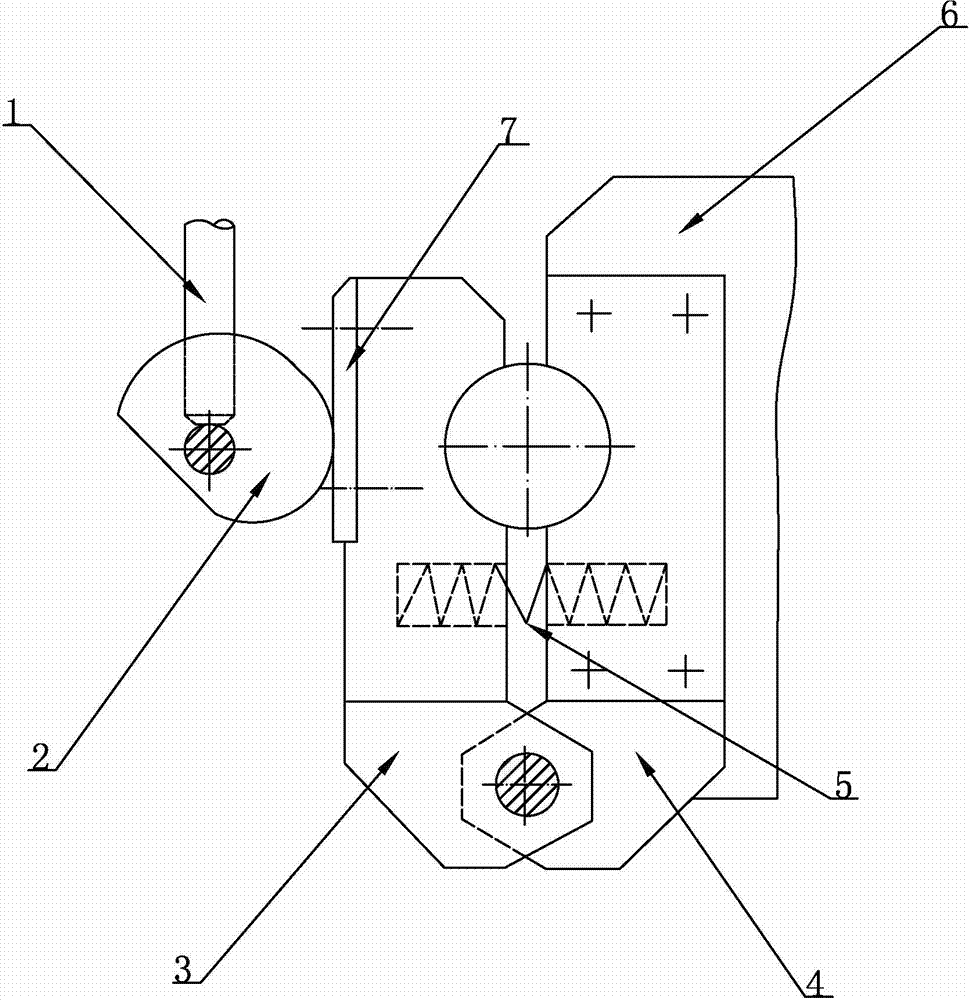

Tab cutting device of lithium battery core and tab cutting equipment using tab cutting device

ActiveCN102873390AIncrease profitHigh automation efficiencyShearing machinesShearing machine accessoriesPower batteryElectrical battery

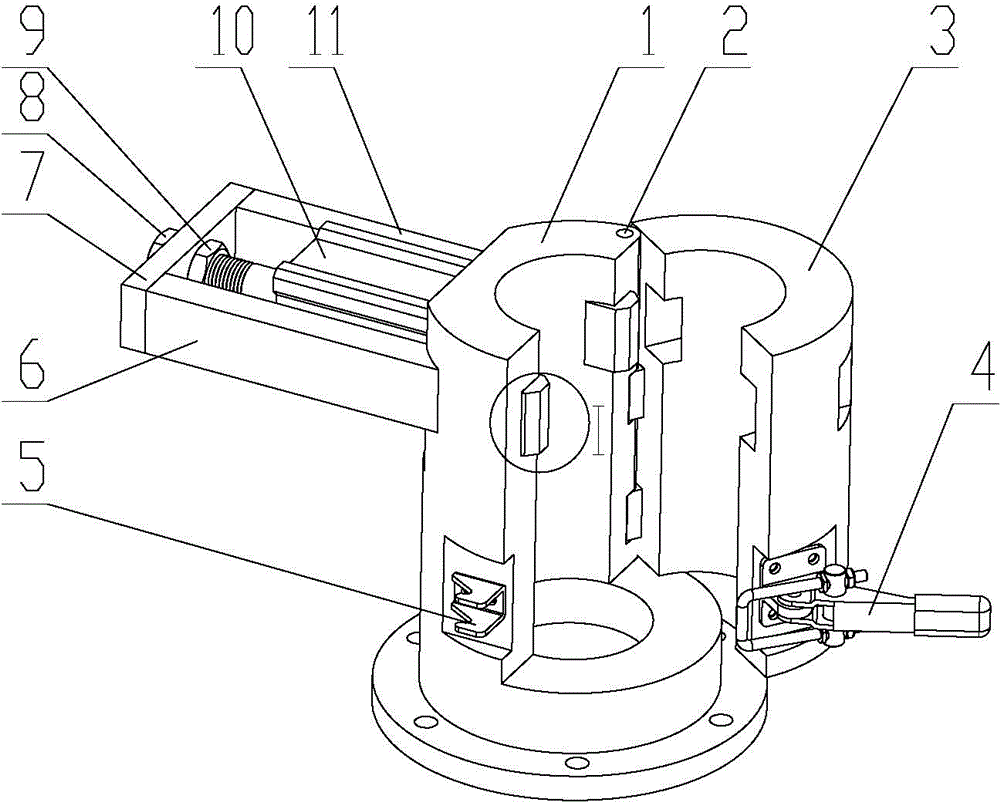

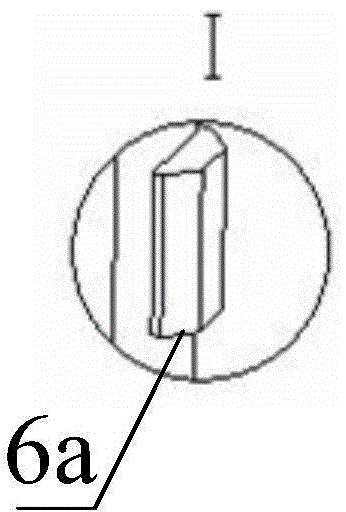

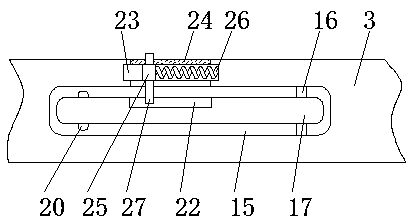

The invention relates to the field of manufacturing of lithium ion power batteries, in particular to a tab cutting device of a lithium battery core and tab cutting equipment using the tab cutting device. The tab cutting device of the lithium battery core comprises a driving mechanism and a tab compressing component, wherein the driving mechanism is used for driving an upper cutter to move up and down; the tab compressing component compressing component comprises a lower cushion block and an upper compressing block; the upper compressing block vertically corresponding to the lower cushion block is arranged on the driving mechanism; the upper compressing block and the upper cutter can move together up and down; a compressible elastic supporting device is arranged between the upper compressing block and the driving mechanism; or the tab cutting device of the lithium battery core is provided with a guide device, an elastic reset device, a jacking mechanism and an elastic supporting device; the guide device is used for guiding the upper compressing block to move up and down; the elastic reset device is used for providing upward elastic support for the upper compressing block; the jacking mechanism is arranged on the driving mechanism in a guide motion manner and can downwards jack the upper compressing block; and the elastic supporting device is arranged between the jacking mechanism and the driving mechanism. By adoption of the scheme, a tab can be automatically compressed in the downcutting process of the cutter.

Owner:中创新航科技(江苏)有限公司

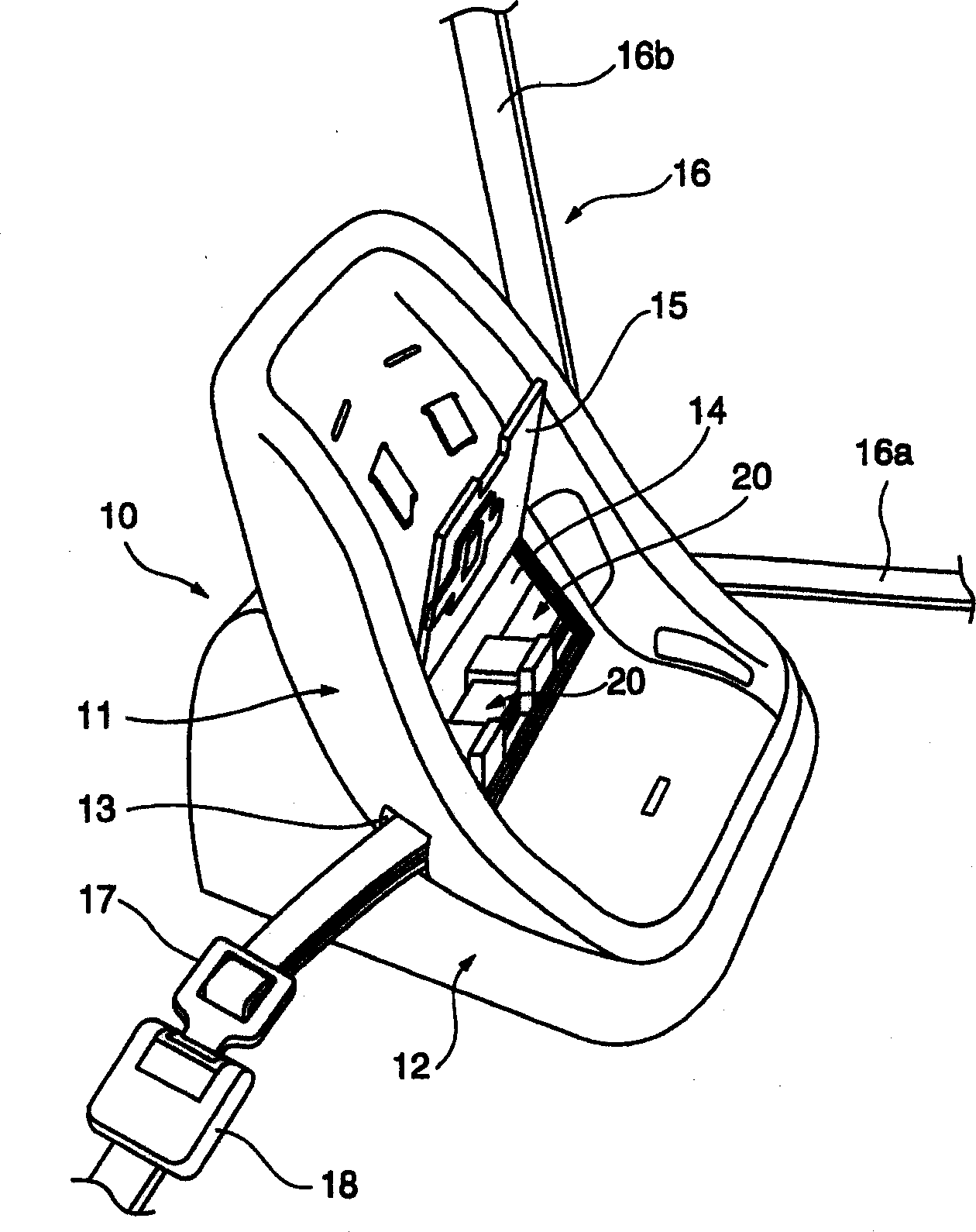

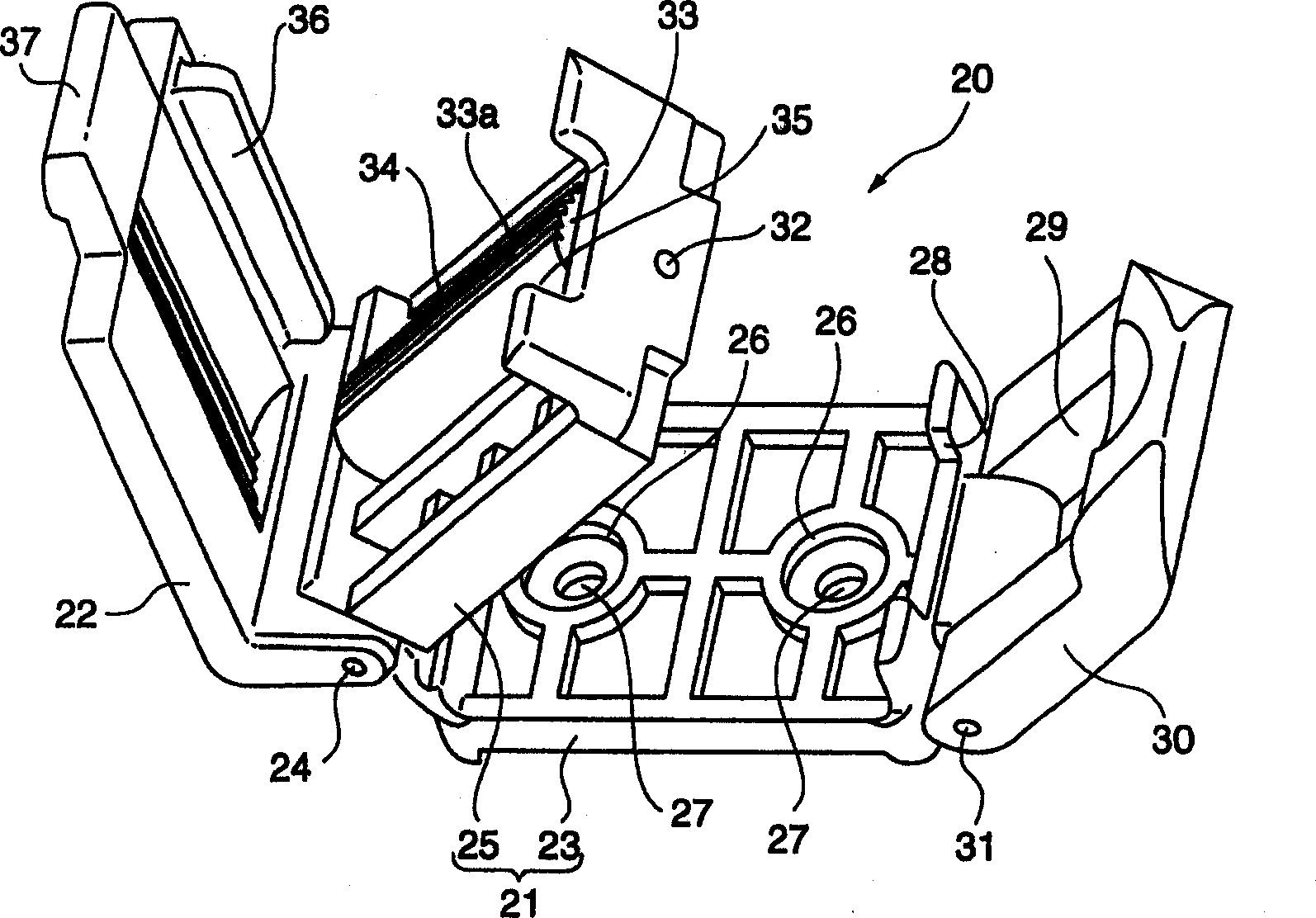

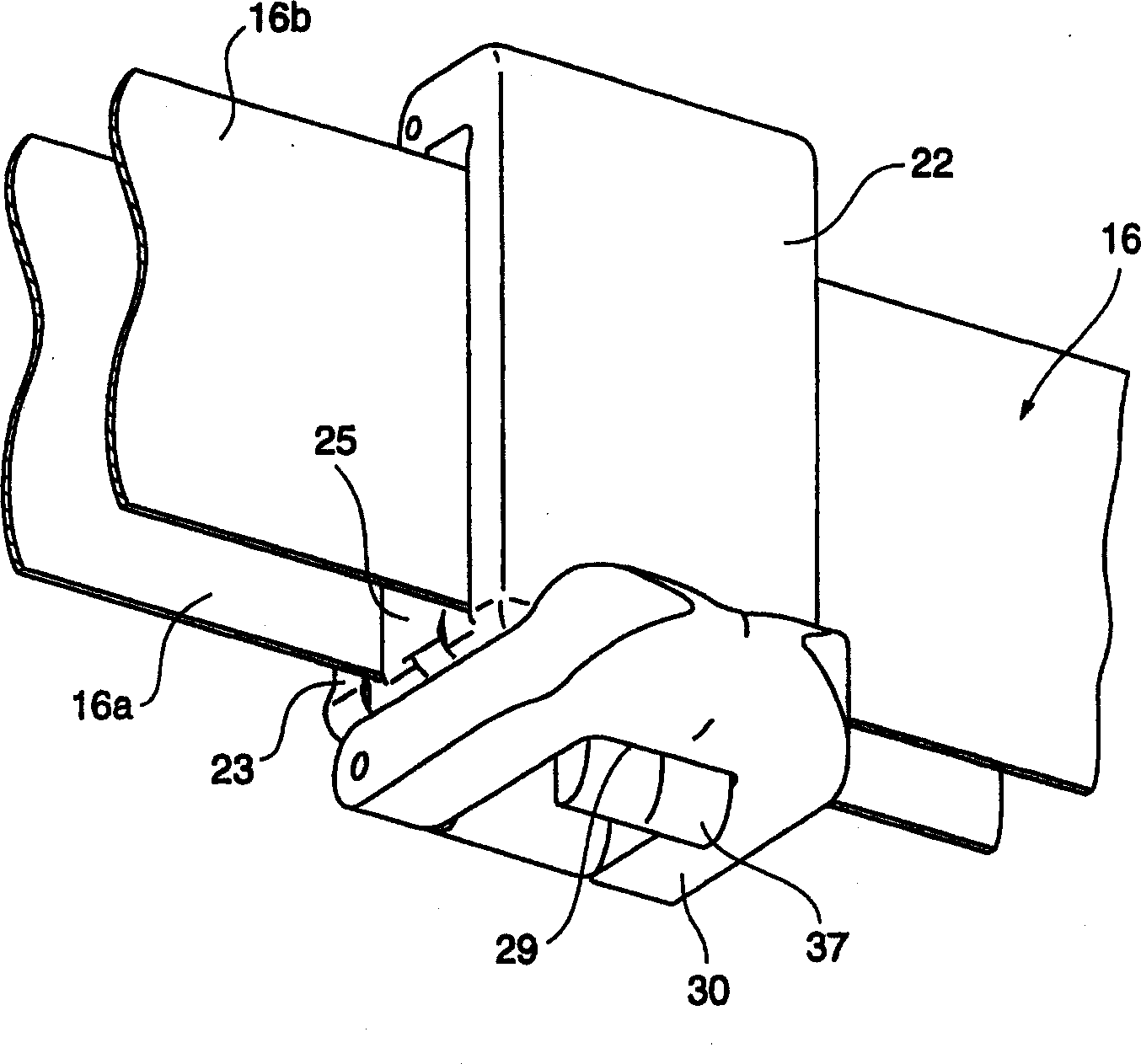

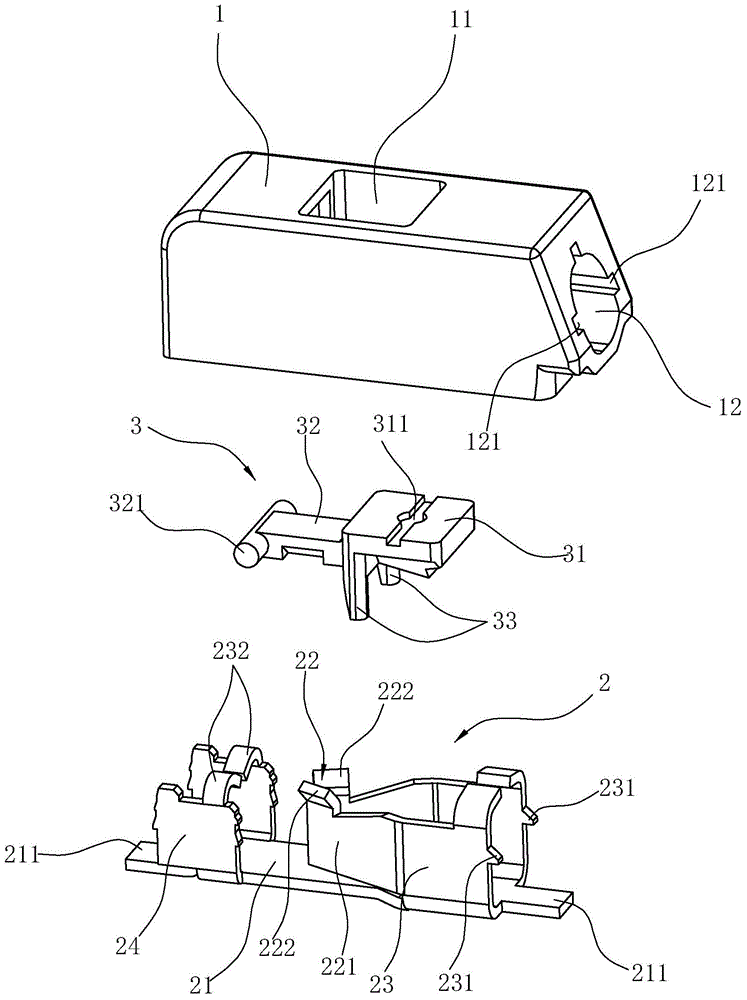

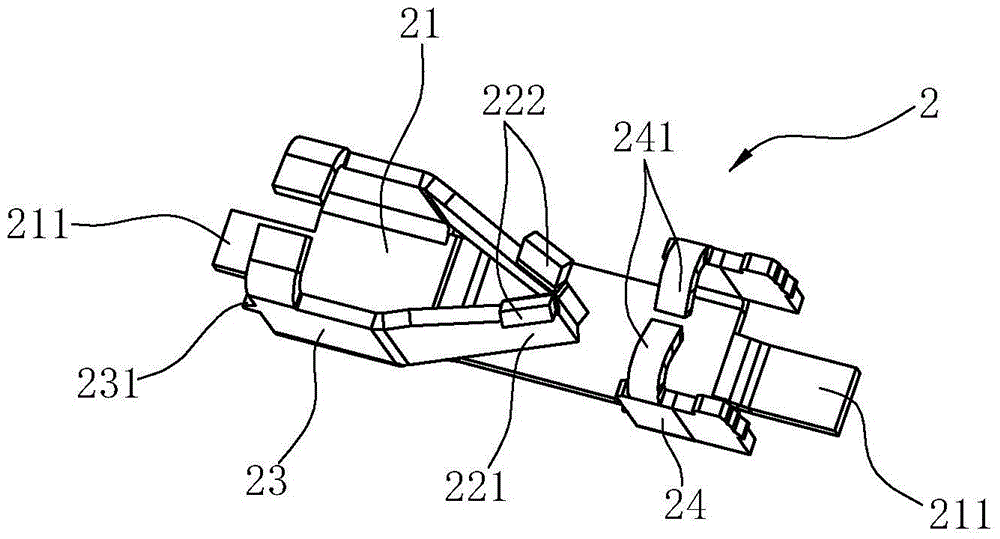

Child car seat and its locking belt device

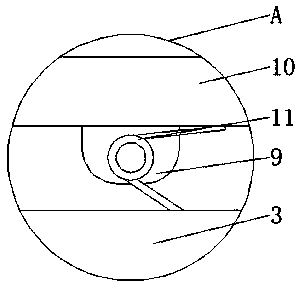

A child car seat (10) has a belt insertion opening (13) having inlets at opposite side surfaces thereof to receive a seat belt (16) inserted therethrough, and has an aperture (14) opening to the front surface thereof to provide access to the belt insertion opening (13). A belt locking apparatus (20) is disposed inside the belt insertion opening (13) to be handled through the aperture (14). The belt locking apparatus (20) includes a base (21) secured inside the belt insertion opening (13), and a lock arm (22) disposed for rotation relative to the base (21) to receive the seat belt (16) therein when the lock arm (22) is opened, and to clamp the seat belt (16) between the lock arm (22) and the base (21) when the lock arm (22) is closed.

Owner:COMBI CORP

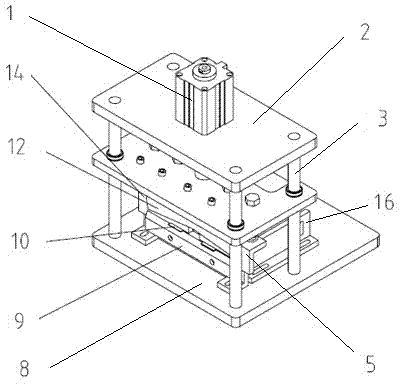

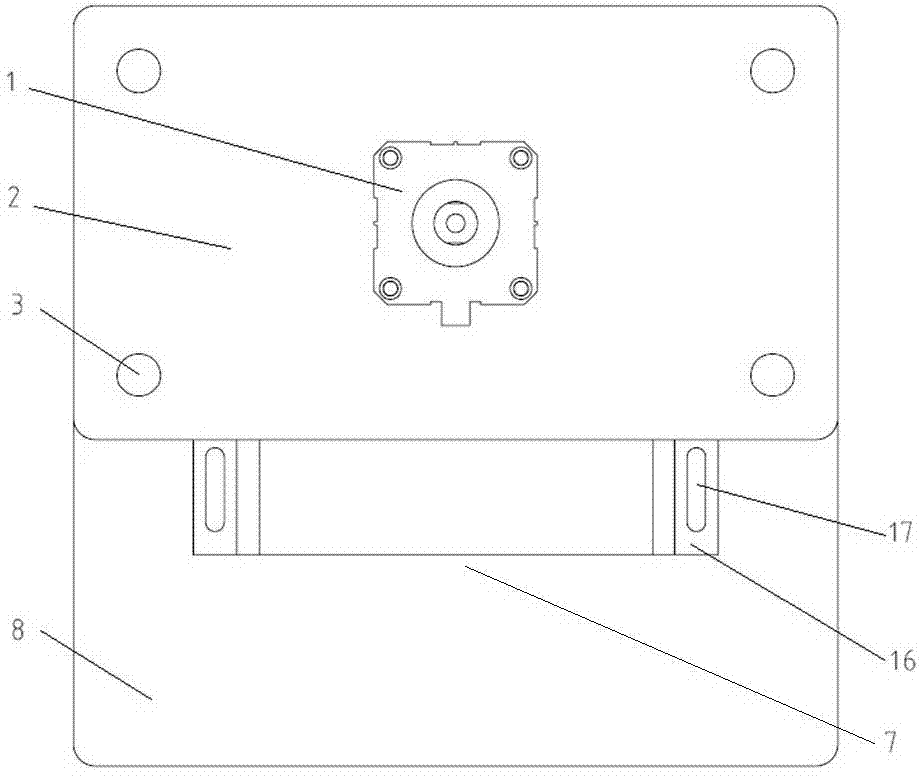

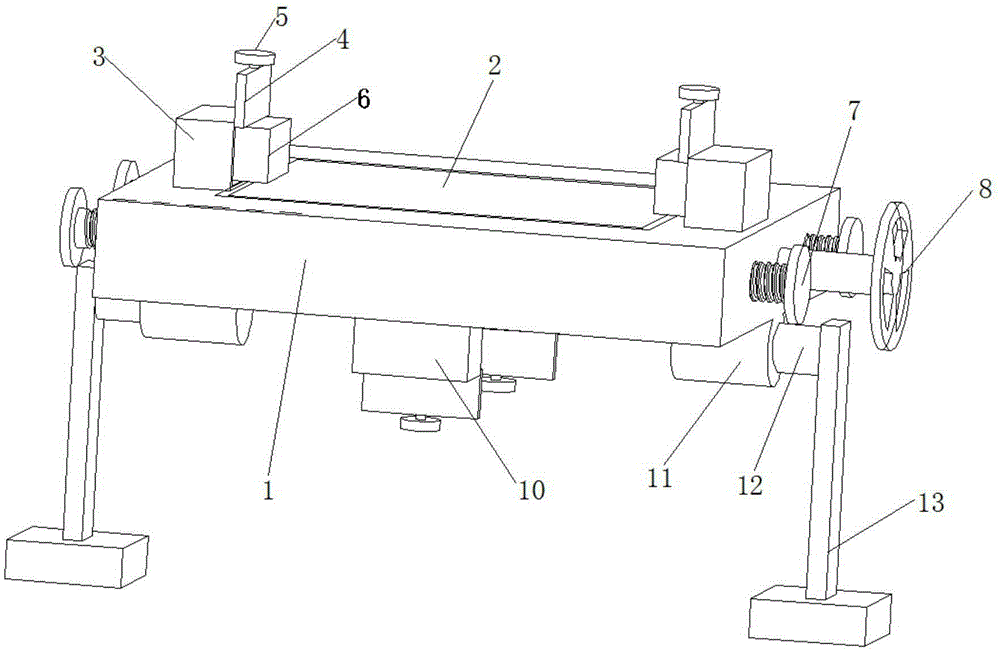

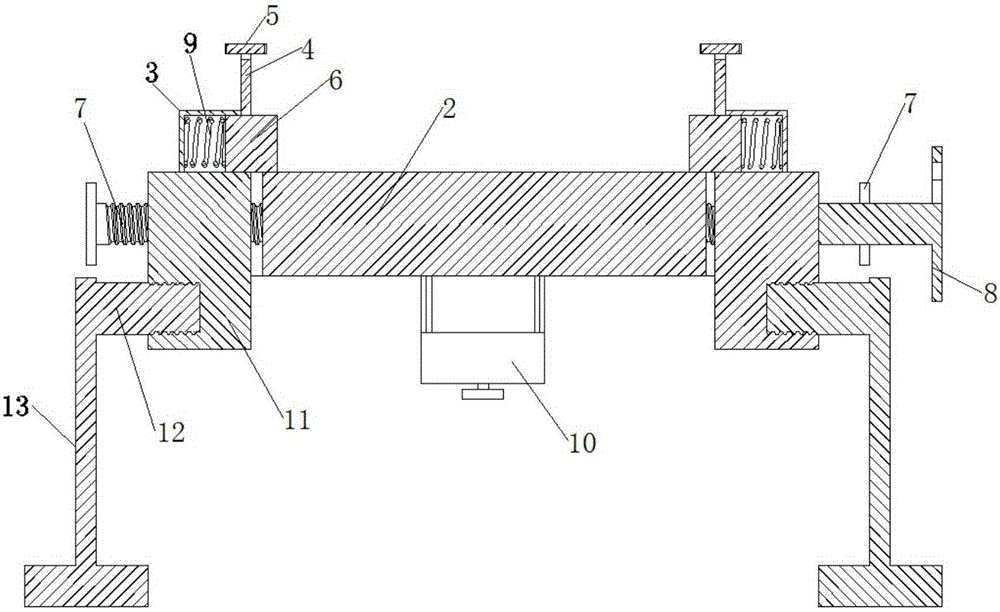

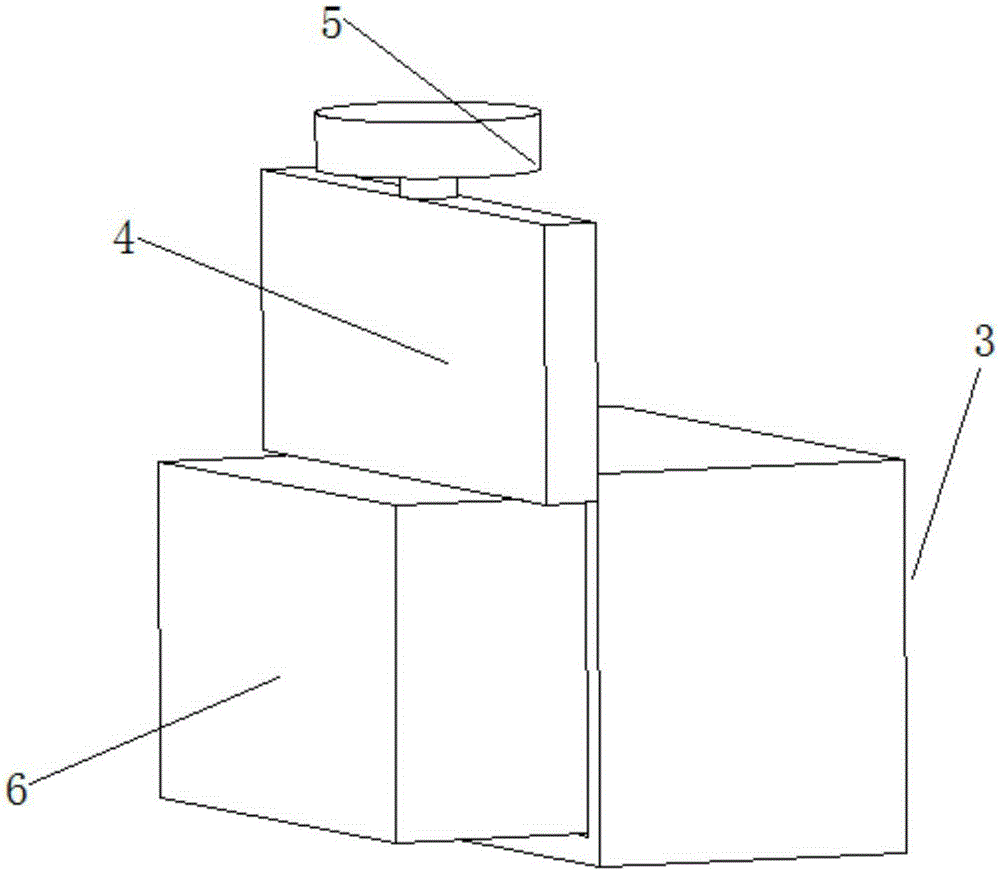

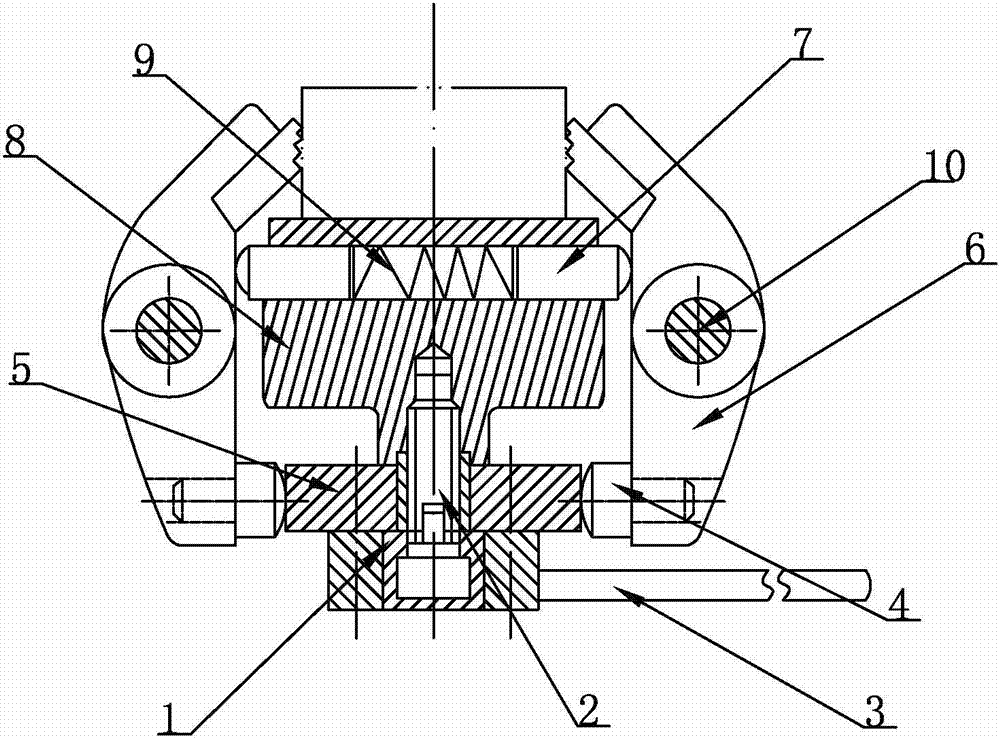

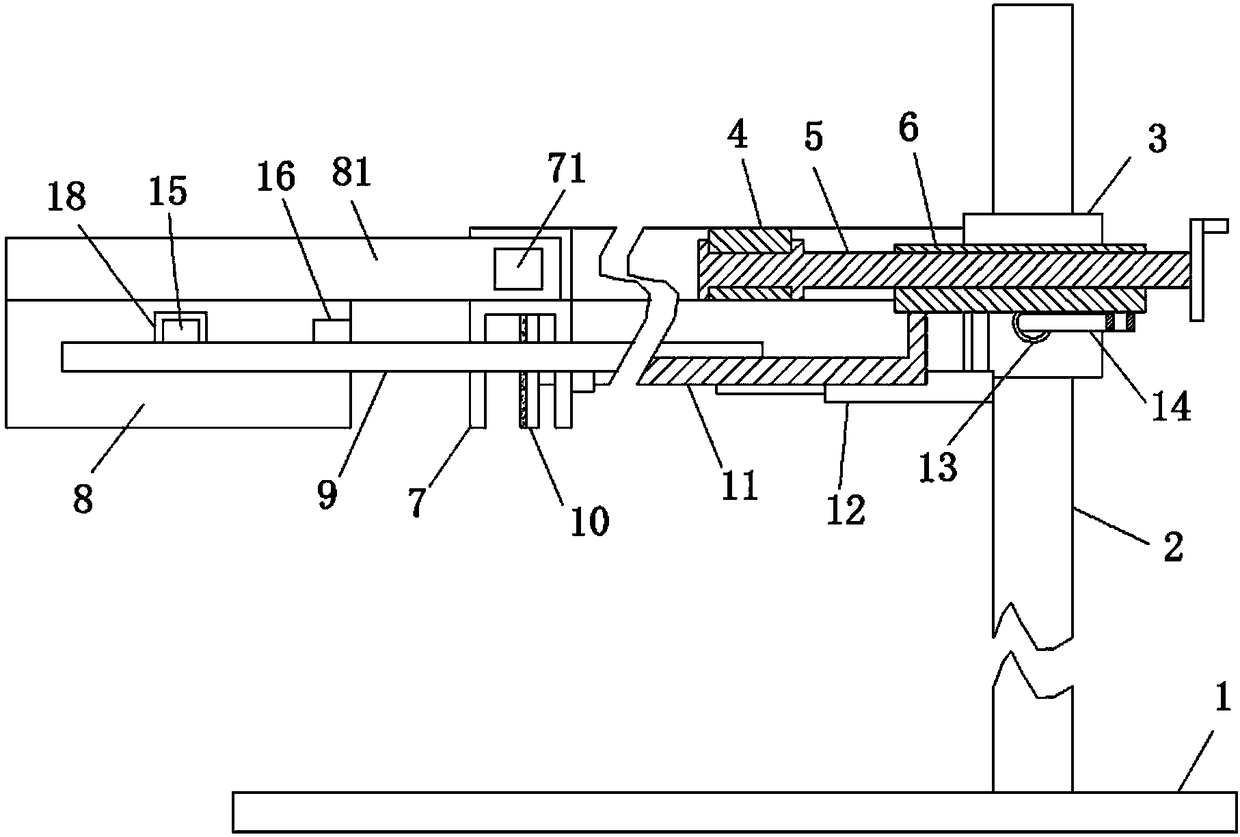

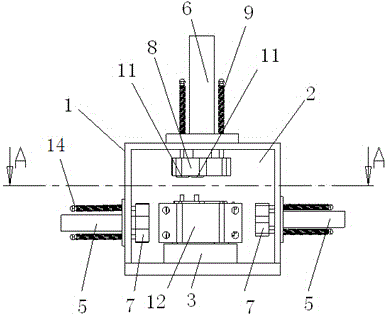

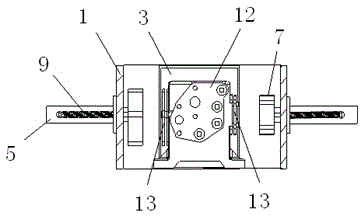

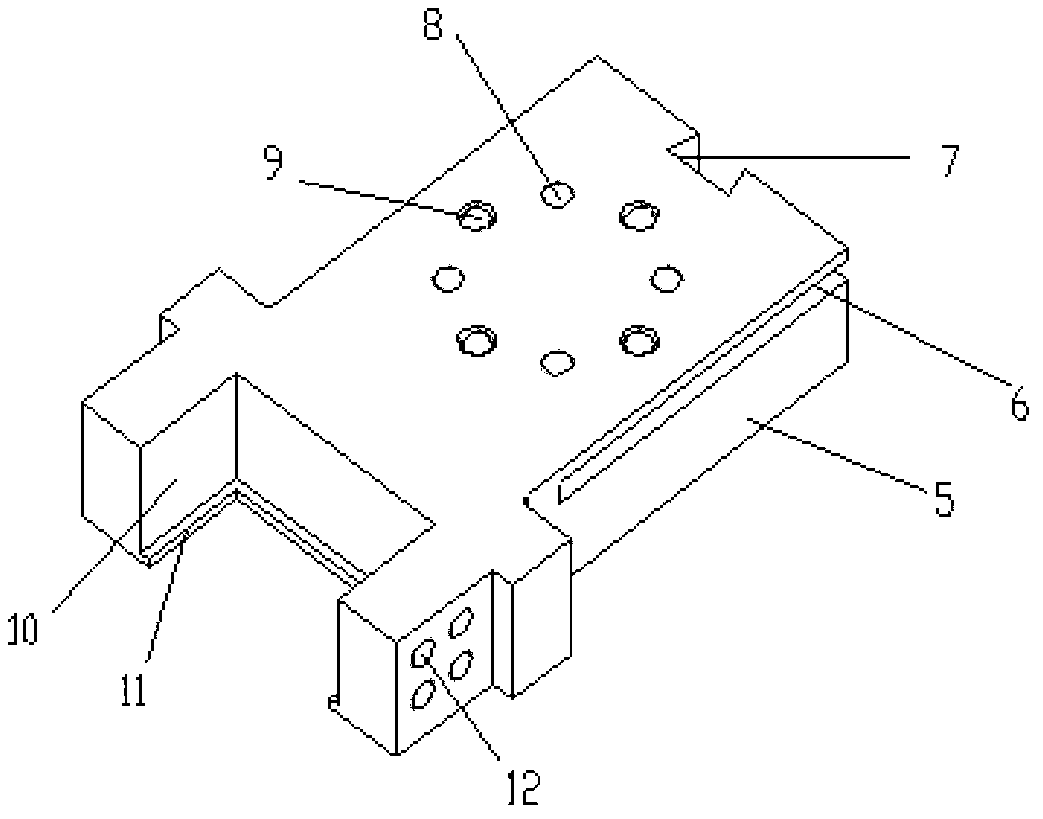

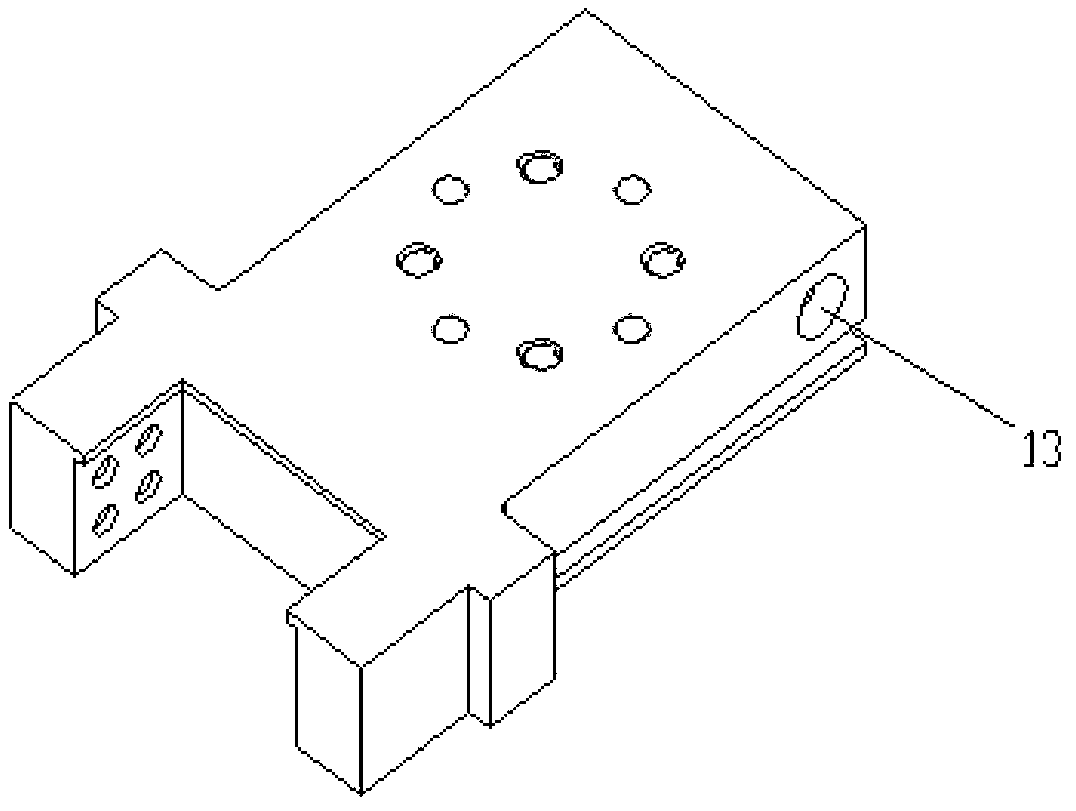

Fast fixture for two-sided flat shaft

InactiveCN104907844ALimited rotationSimple clamping processWork clamping meansWork holdersEngineeringMechanical engineering

The invention discloses a fast fixture for a two-sided flat shaft. The two-sided flat shaft is used for positioning and bearing torque in machining or assembling, a bench vice is usually adopted to manually fix the two-sided flat shaft by an enterprise and is difficult to be matched with industrial automation equipment, and therefore the production efficiency of the enterprise is limited. According to the fixture, a fixture body comprises a fixture fixing plate, a fixture cover plate and a fast clamp; the fixture fixing plate is hinged to the side portion of the fixture cover plate; a push rod is arranged on a piston rod of a driving air cylinder in a sleeving mode; an outer locking nut and an inner locking nut lock the push rod from the outer side and the inner side respectively; a first limit rod and a second limit rod form moving pairs with a first limit rod guide hole of the fixture fixing plate and a second limit rod guide hole of the fixture cover plate respectively; the fixing end of the fast clamp is fixed with the fixture fixing plate, and the movable end of the fast clamp is fixed with the fixture cover plate. The fast fixture is provided with a U-shaped plug pin type clamping jaw which can effectively limit the rotation of the two-sided flat shaft; the U-shaped plug pin type clamping jaw is driven by the driving air cylinder, and the automation level of the fixture is improved.

Owner:HANGZHOU DIANZI UNIV

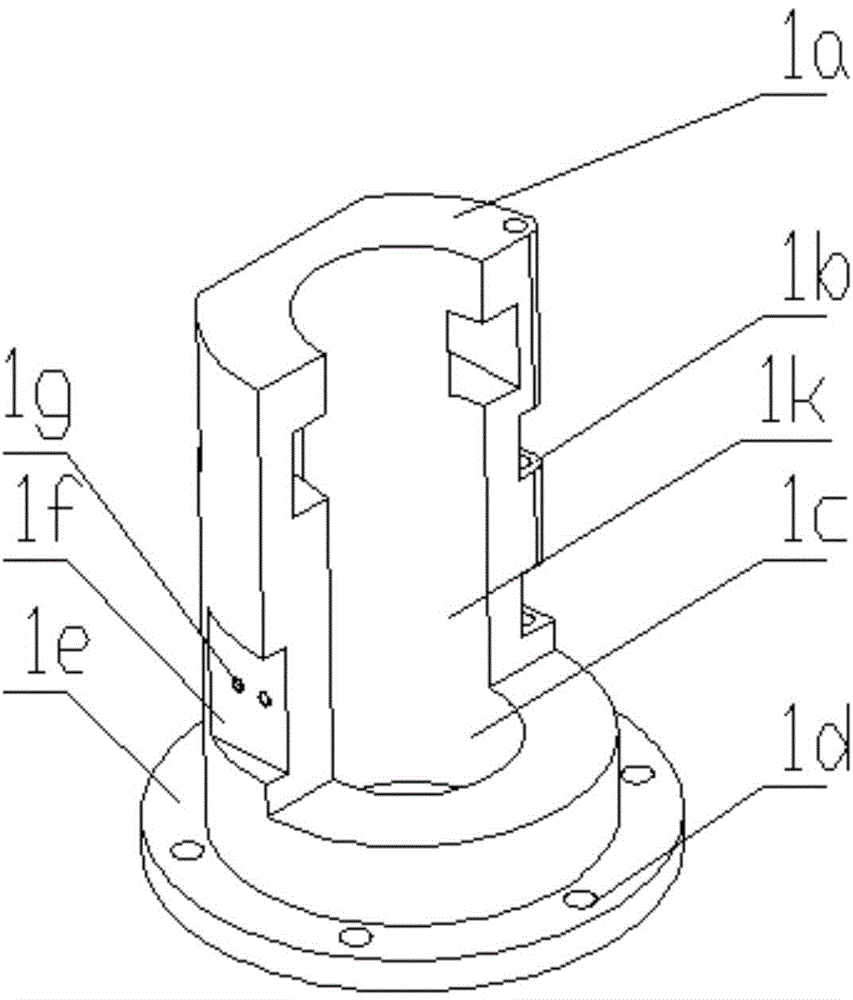

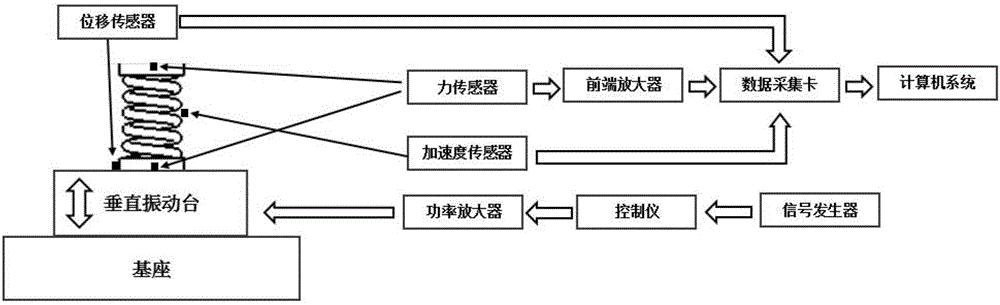

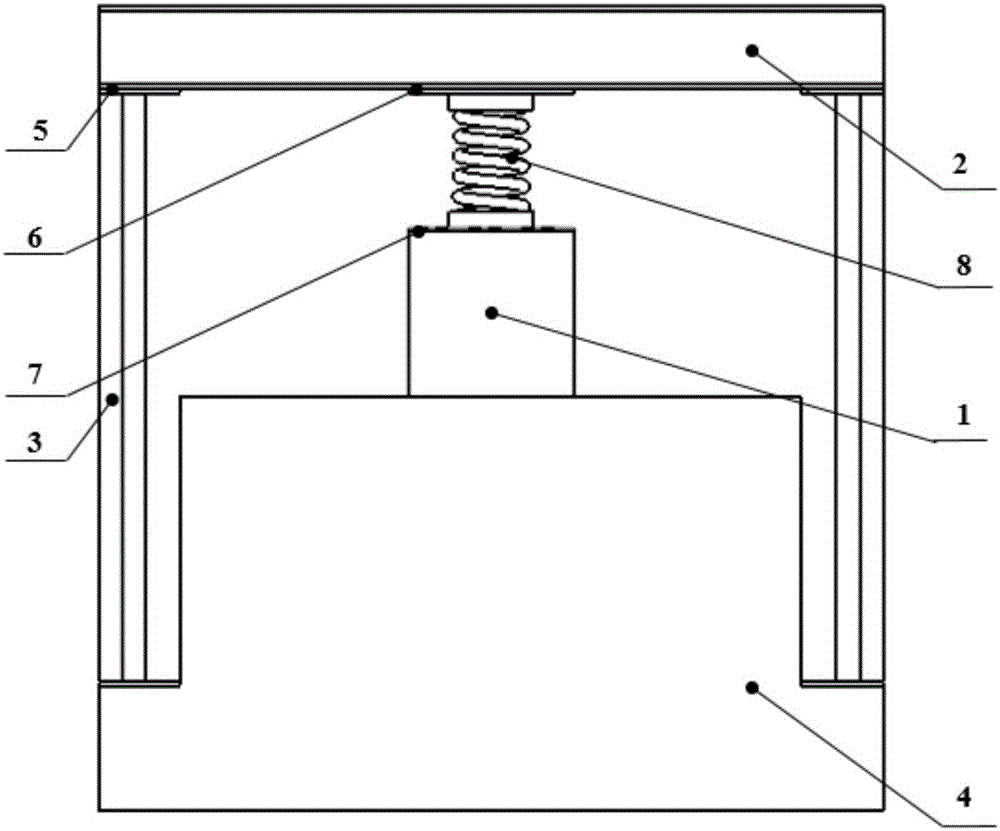

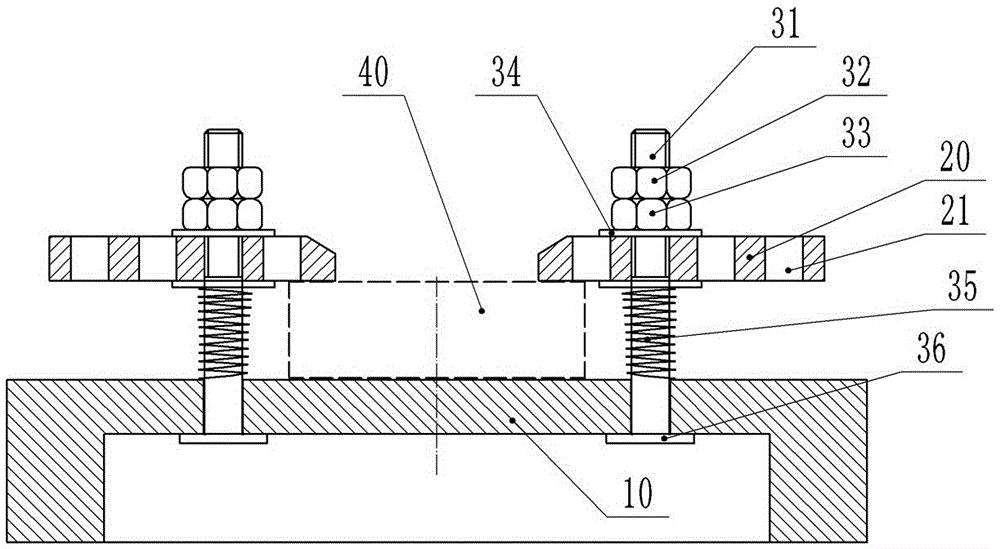

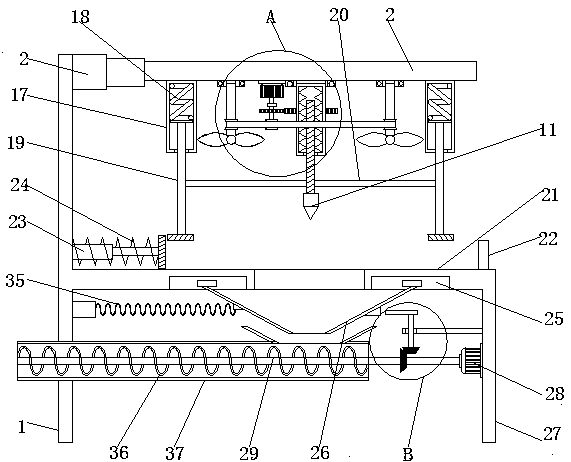

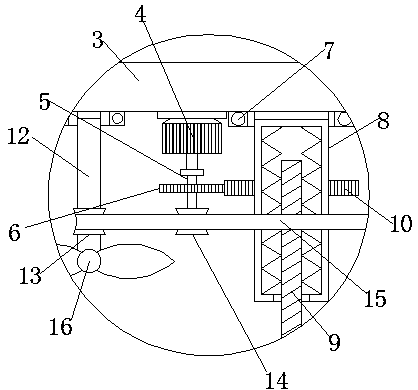

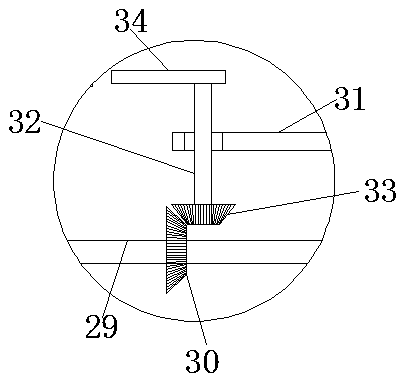

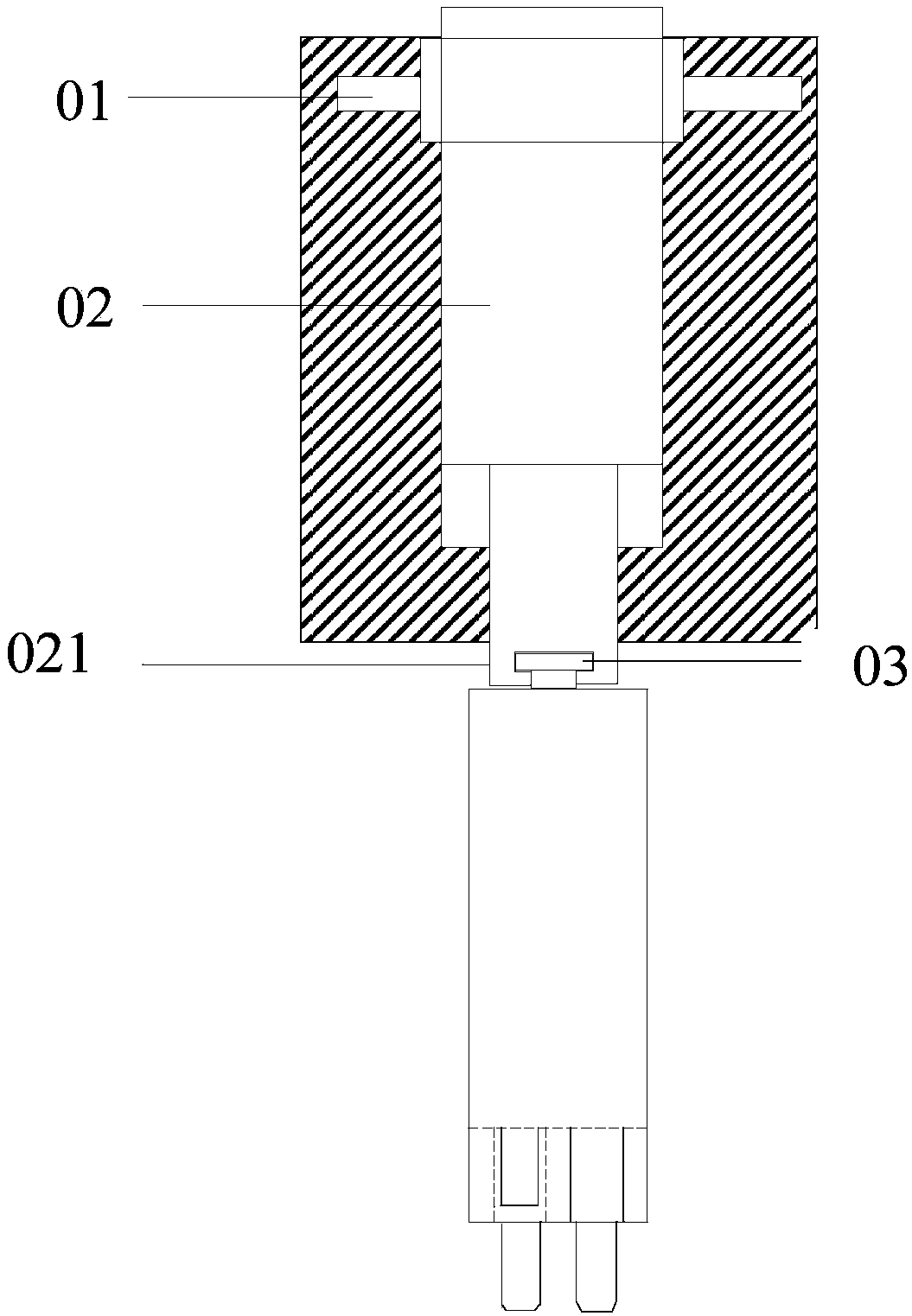

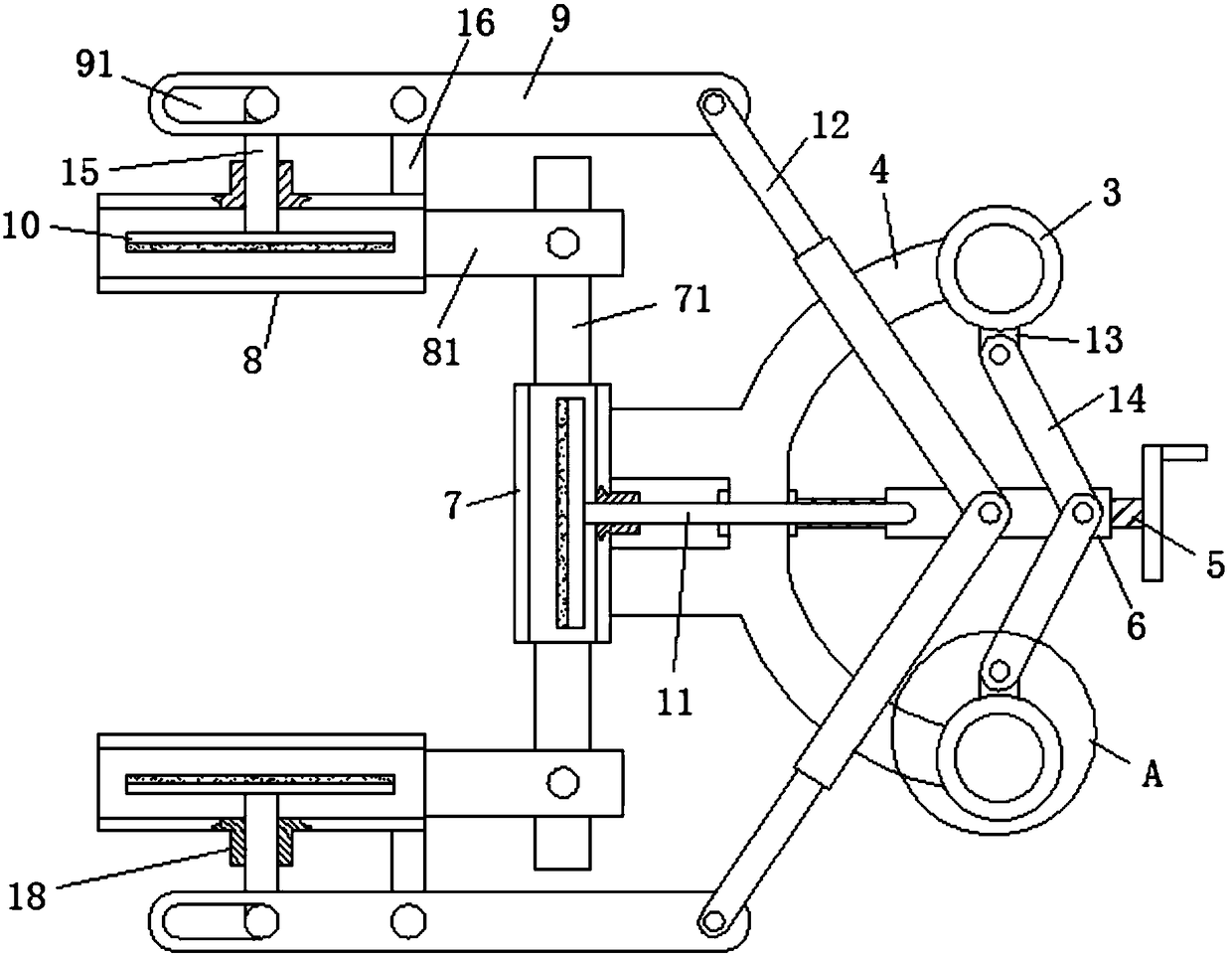

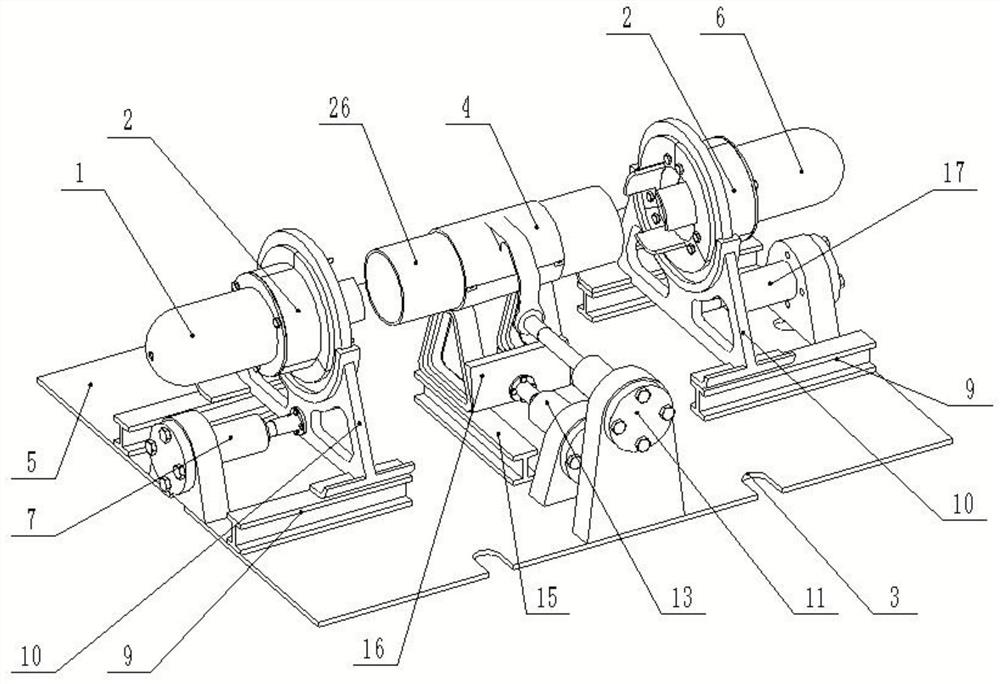

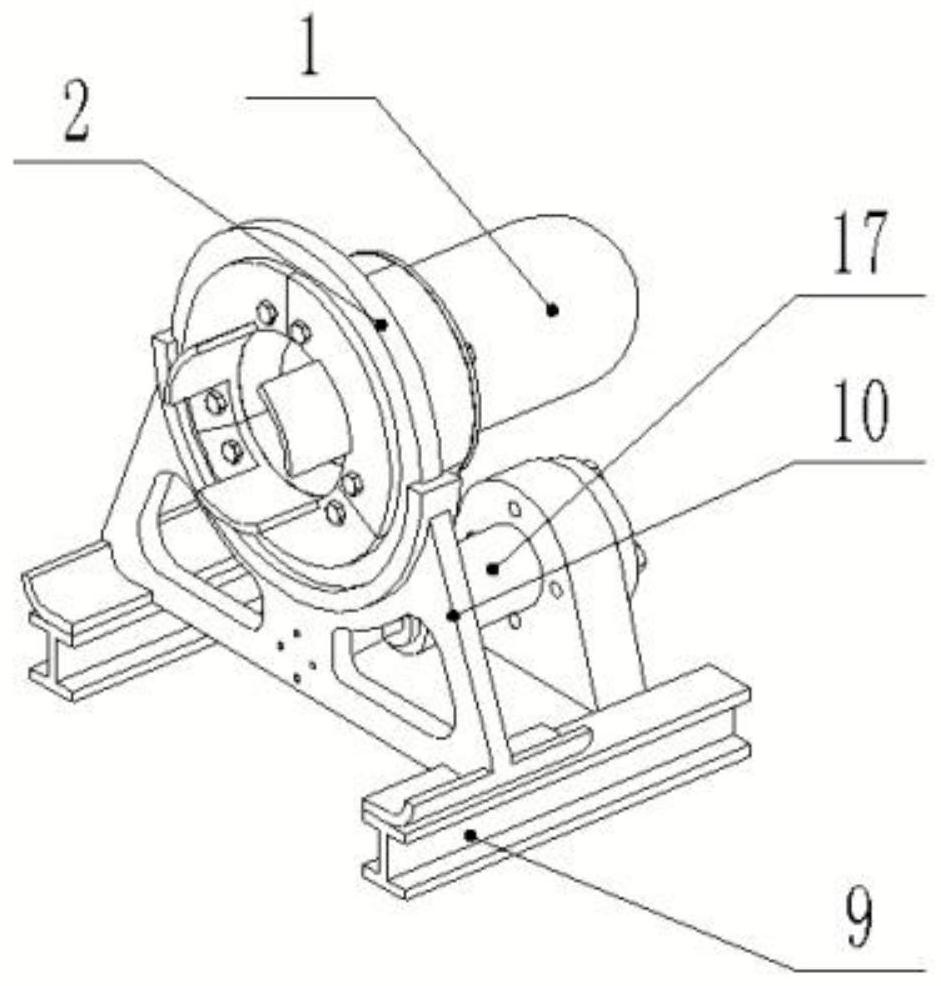

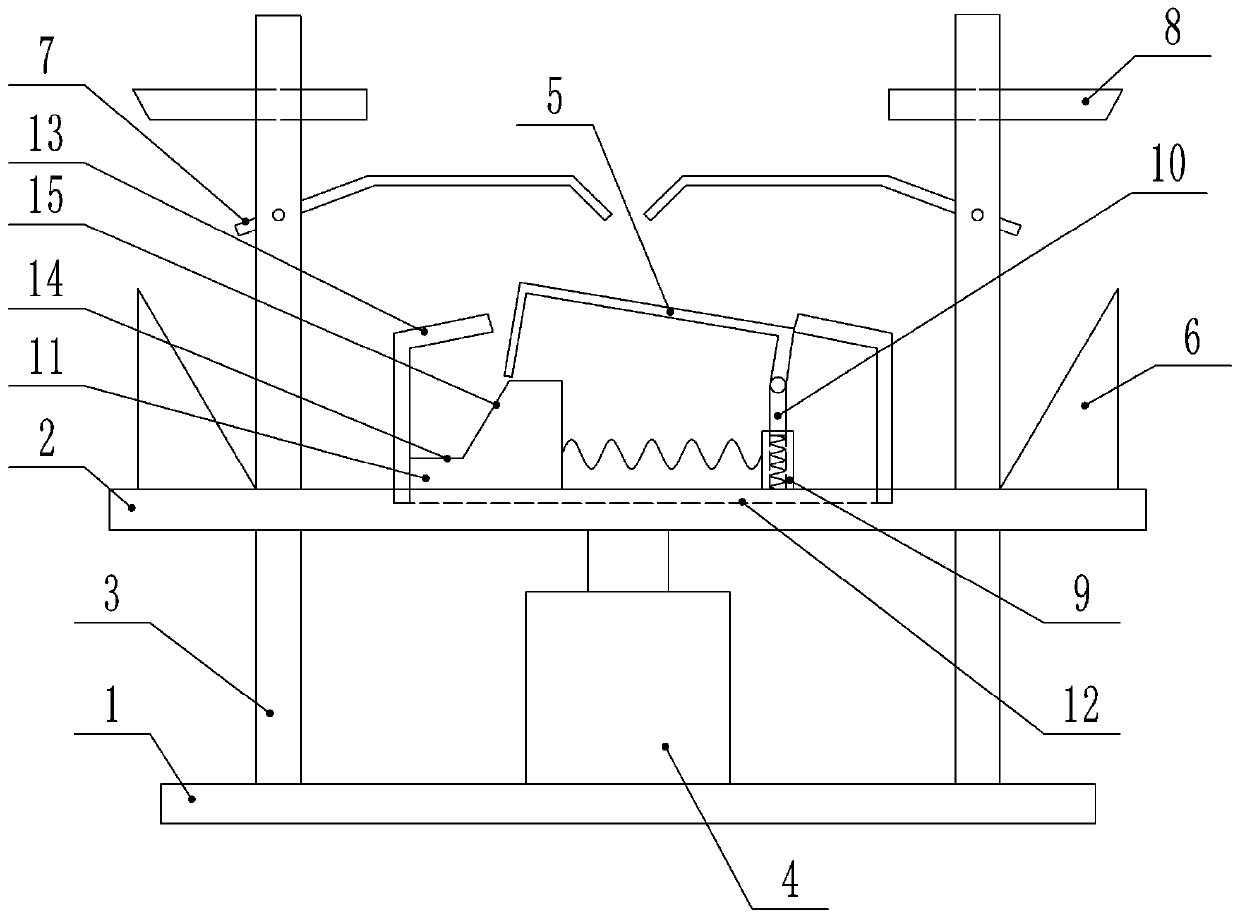

System and method for testing dynamic characteristics of helical spring

ActiveCN105784347AEasy to installReduce the clamping processMachine part testingVibration amplitudeVertical vibration

The invention relates to a system for testing the dynamic characteristics of a helical spring. The system comprises a pedestal, a vertical vibration bench, a displacement sensor, a spring clamp, two sets of force sensors contacted with two ends of the helical spring to be tested, accelerometers fixed to each wound spring of the helical spring to be tested, and signal acquisition and processing devices connected with each sensor, wherein the vertical vibration bench and the spring clamp are fixed on the pedestal, a first load-bearing platform and a second load-bearing platform are respectively arranged on the excitation end of the vertical vibration bench and the spring clamp, the helical spring to be tested is pre-compressed by adjusting the distance between the first load-bearing platform and the second load-bearing platform, the displacement sensor is arranged on the second load-bearing platform, and the two sets of force sensors are respectively arranged on the first load-bearing platform and the second load-bearing platform. Compared with the prior art, the system has the advantages of wide application scope, simple clamping procedure and wide excitation frequency band, and dynamic parameters of helical springs under different pre-compression amount and different vibration amplitude can be tested.

Owner:TONGJI UNIV

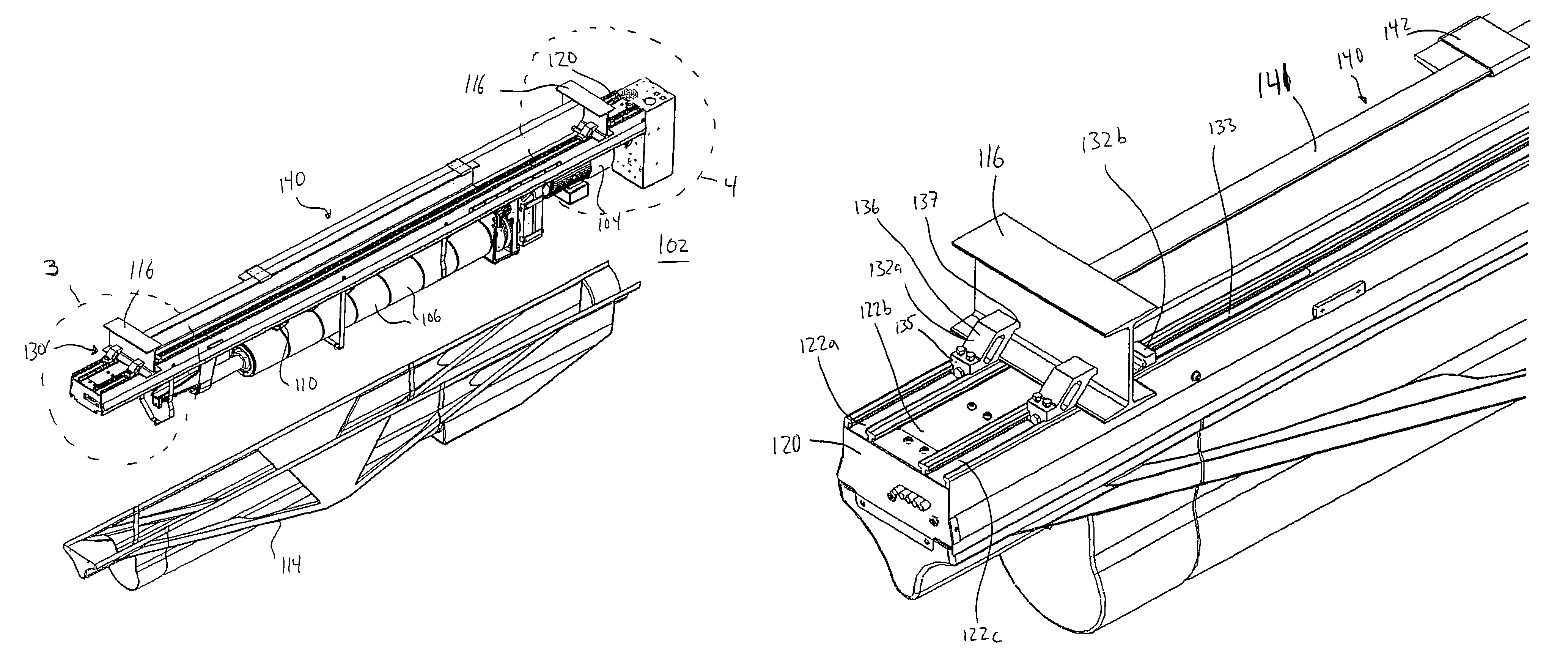

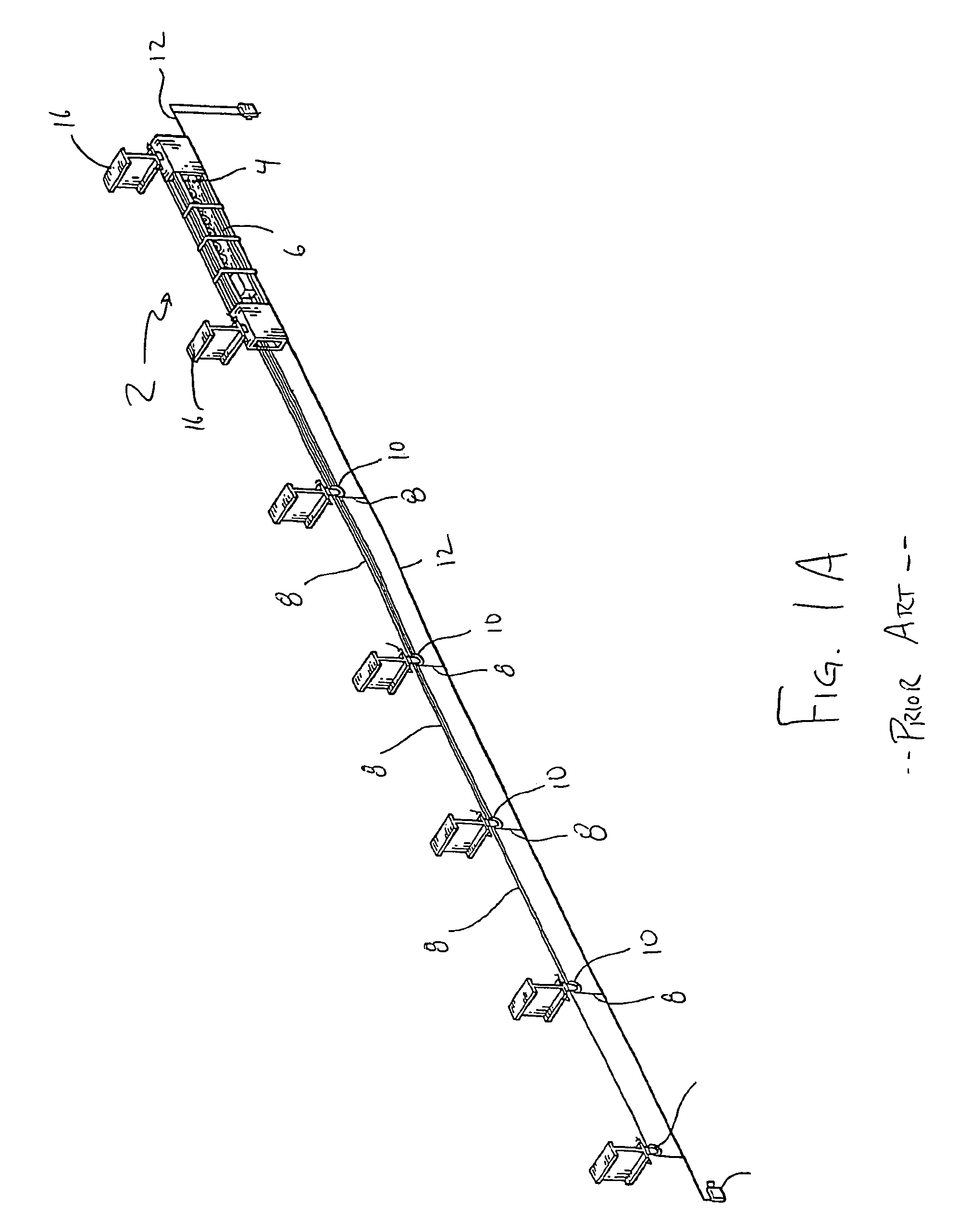

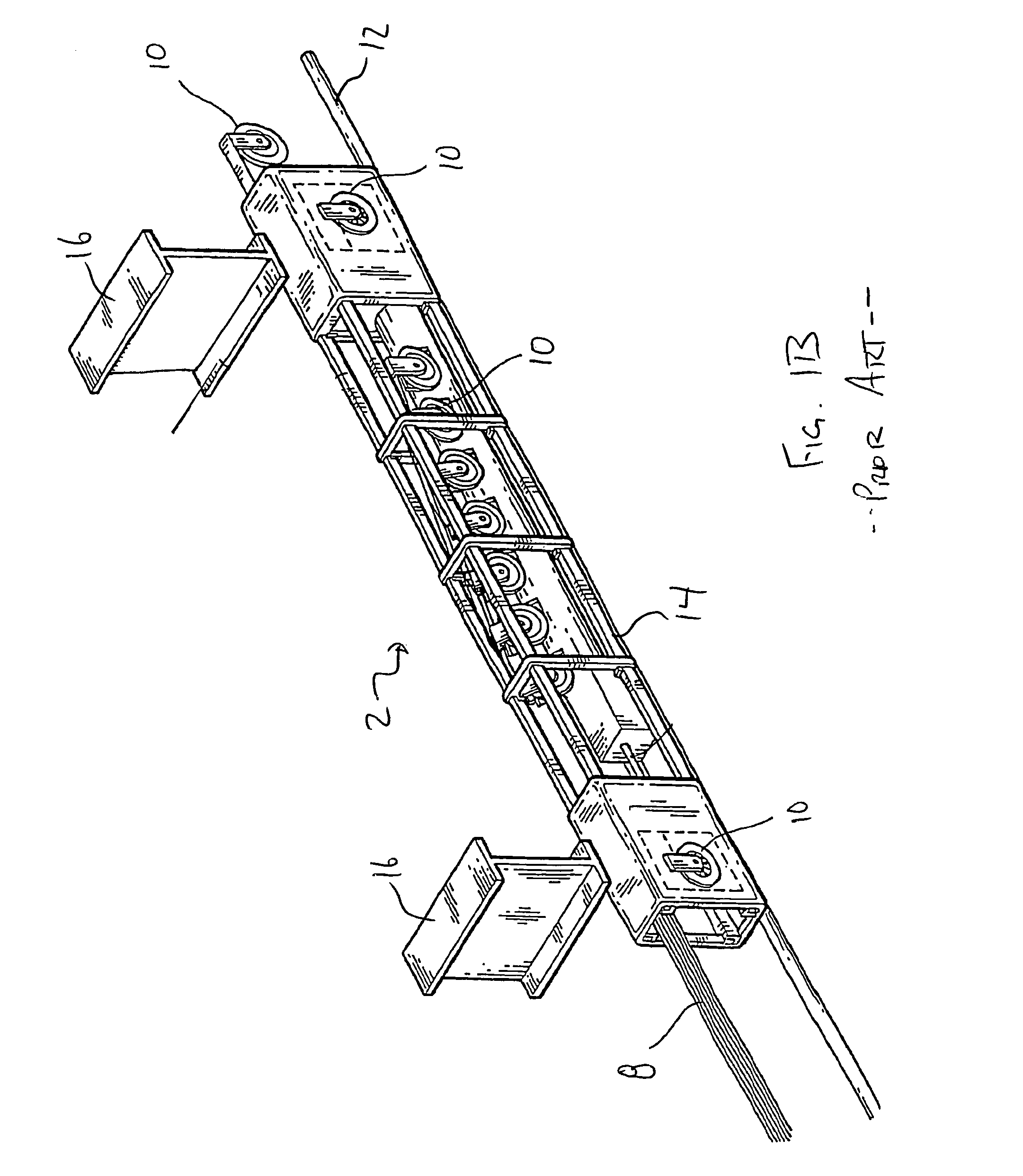

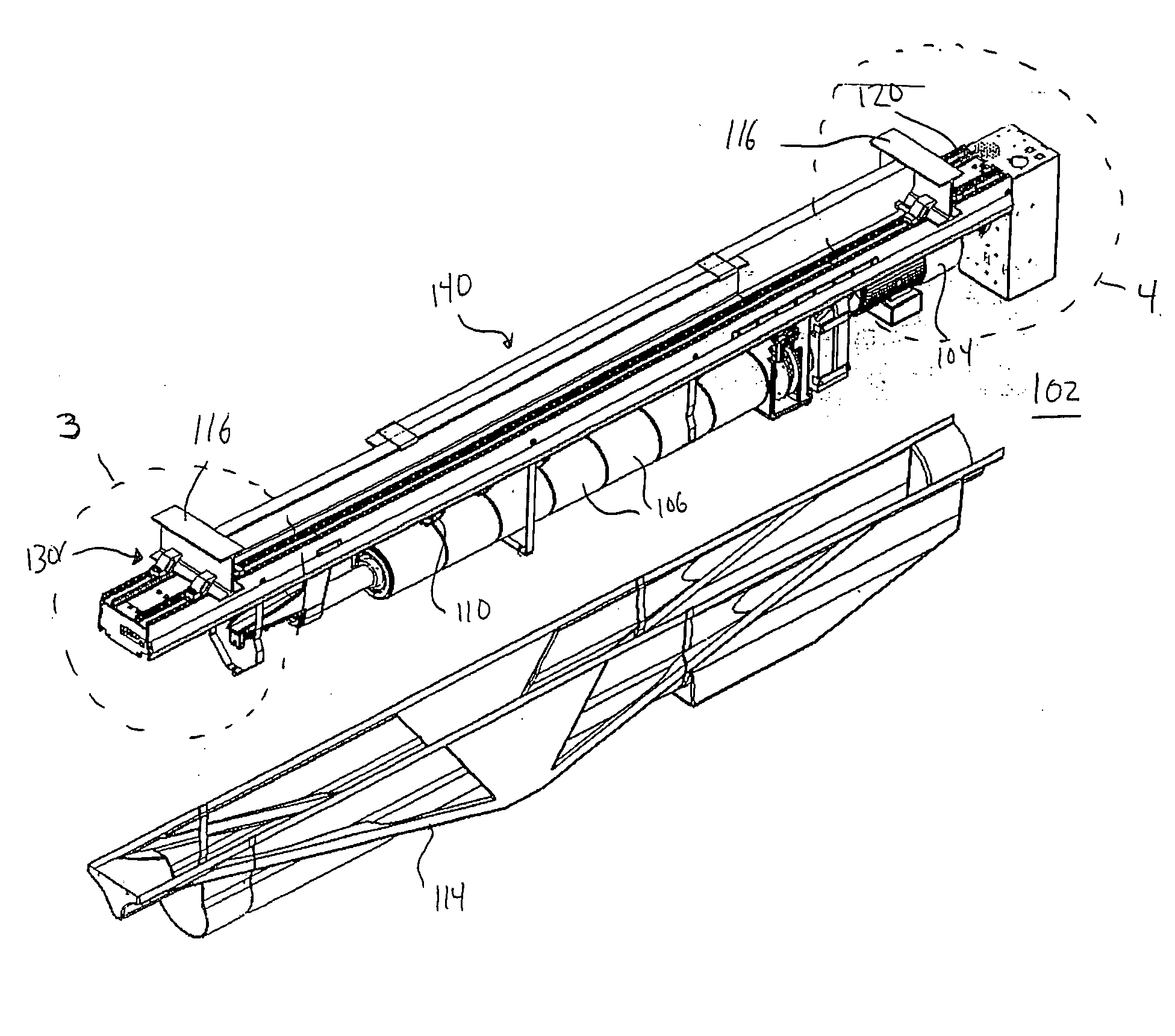

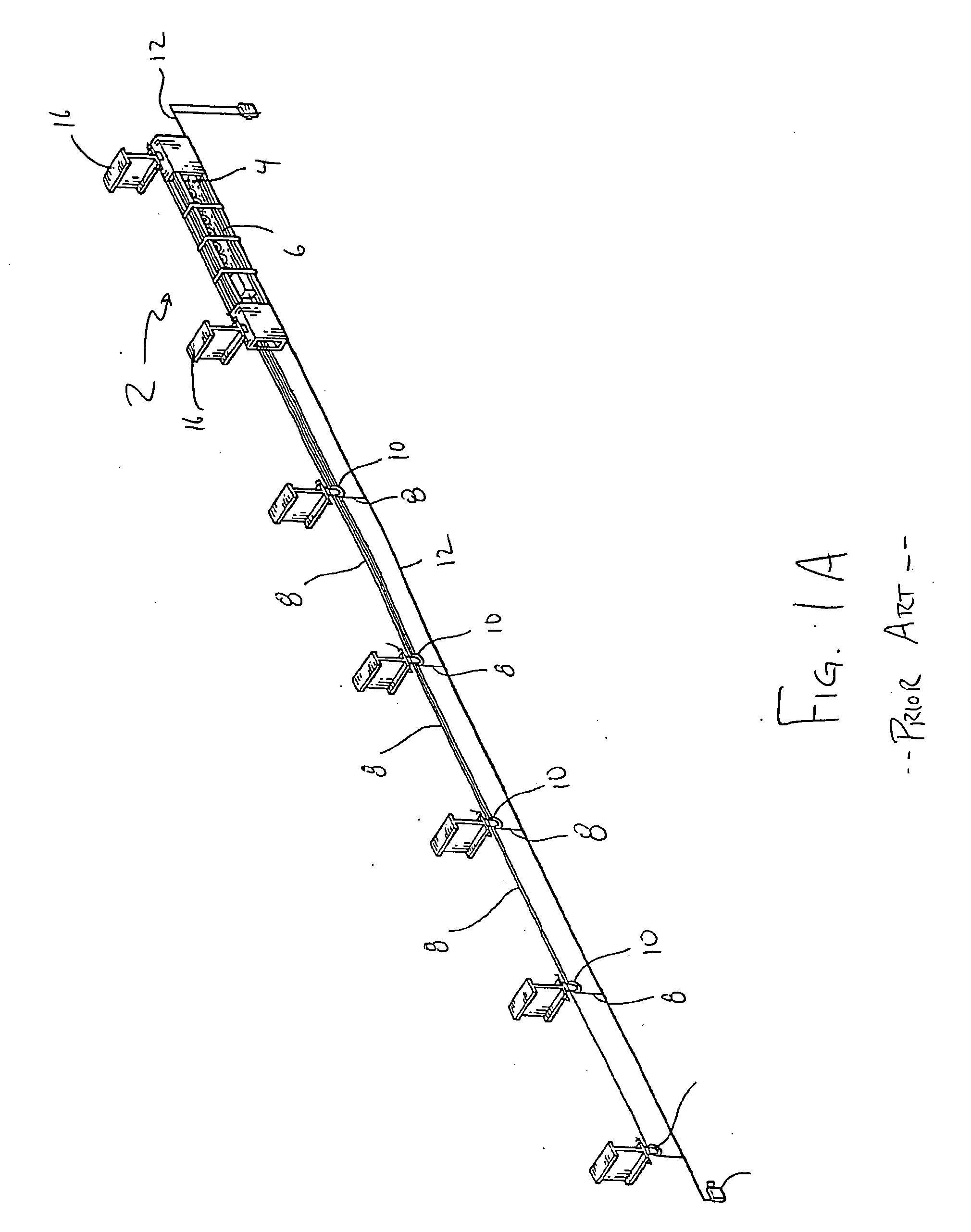

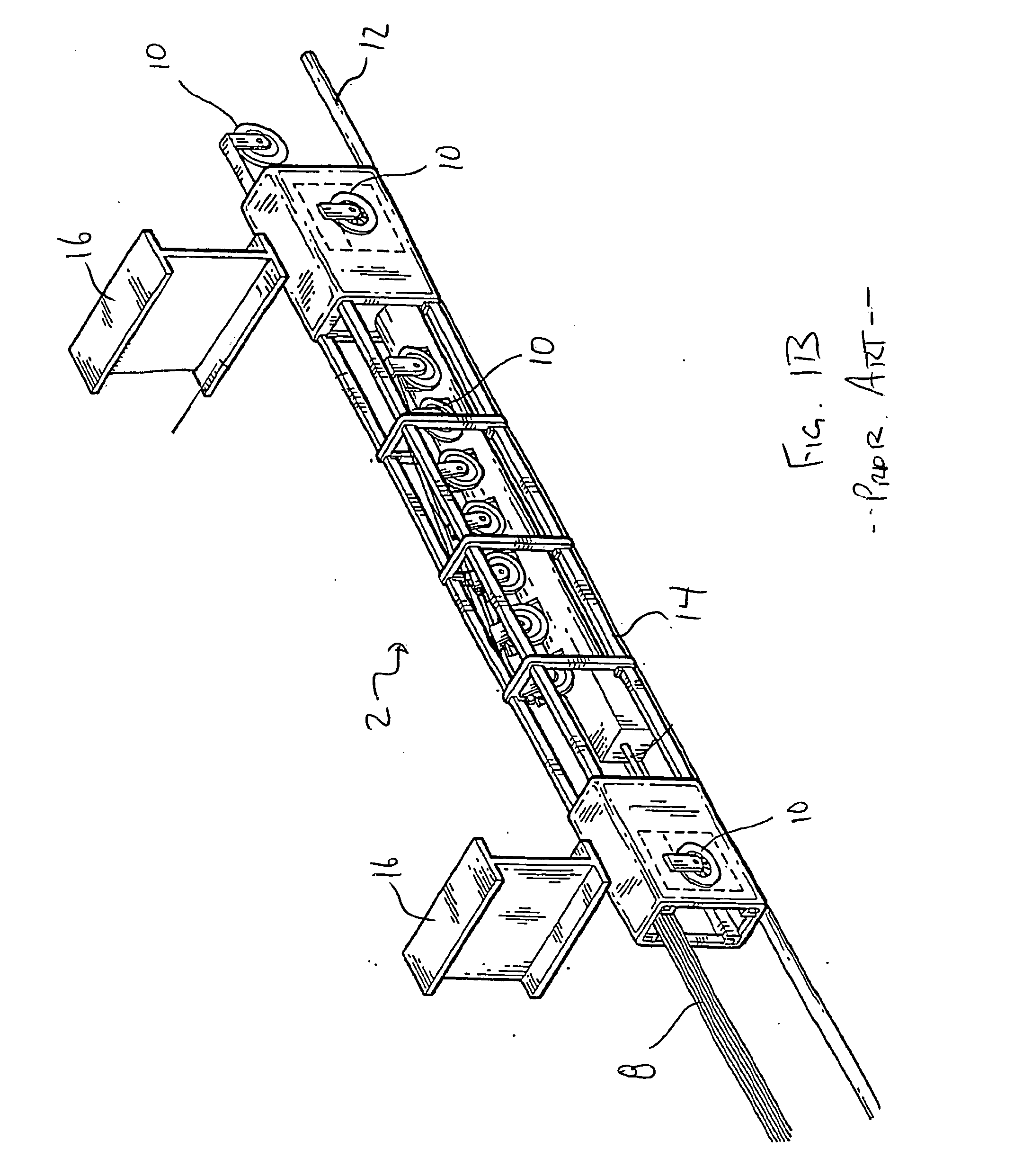

Modular lift assembly having telescoping member

ActiveUS7484715B2Easy to installSimple clamping processCeilingsScaffold connectionsIndustrial engineeringRolling chassis

Owner:ELECTRONIC THEATRE CONTROLS

Clamping device convenient to adjust

InactiveCN105458775AEasy to adjustEasy to fixPositioning apparatusMetal-working holdersEngineeringScrew thread

Owner:CHONGQING QINGYING MOTORCYCLE PARTS CO LTD

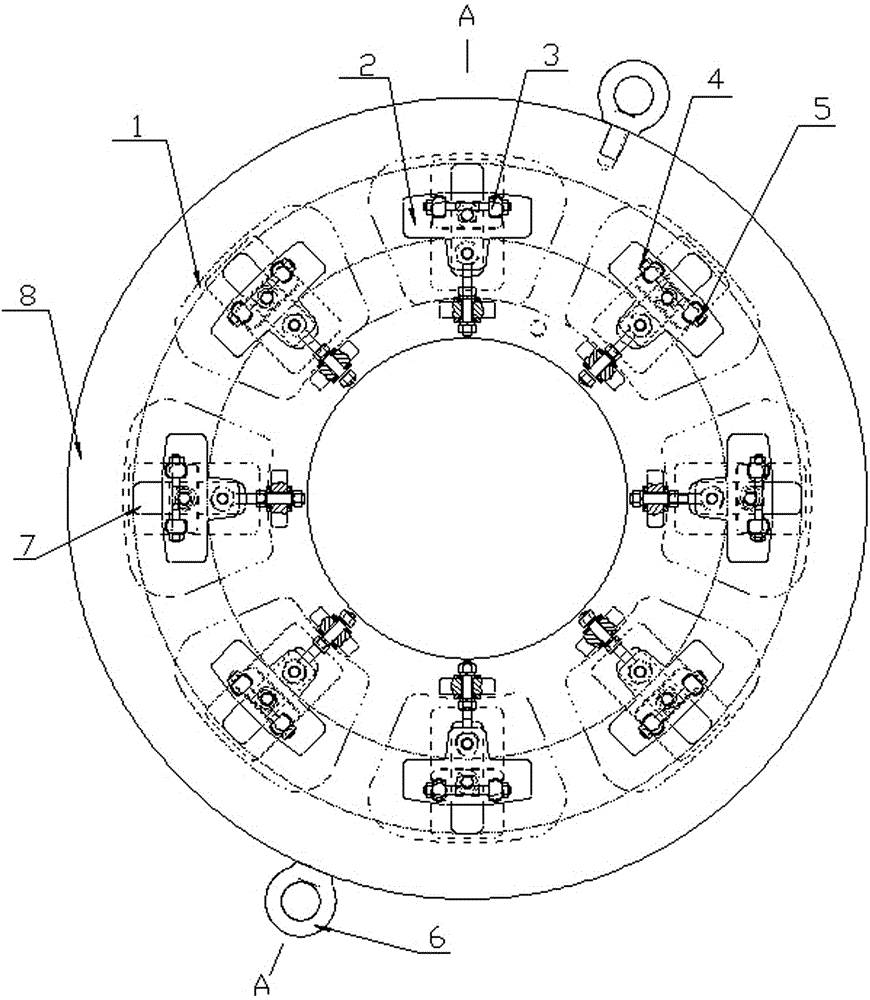

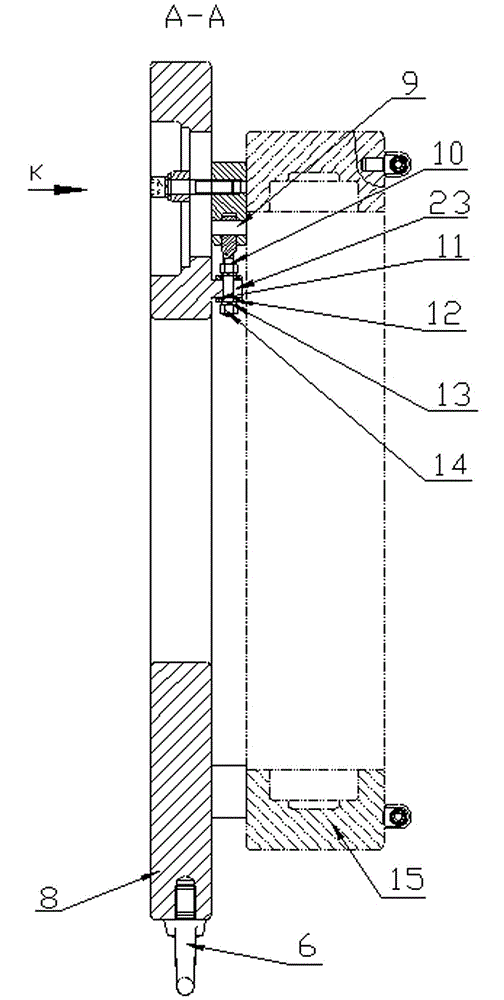

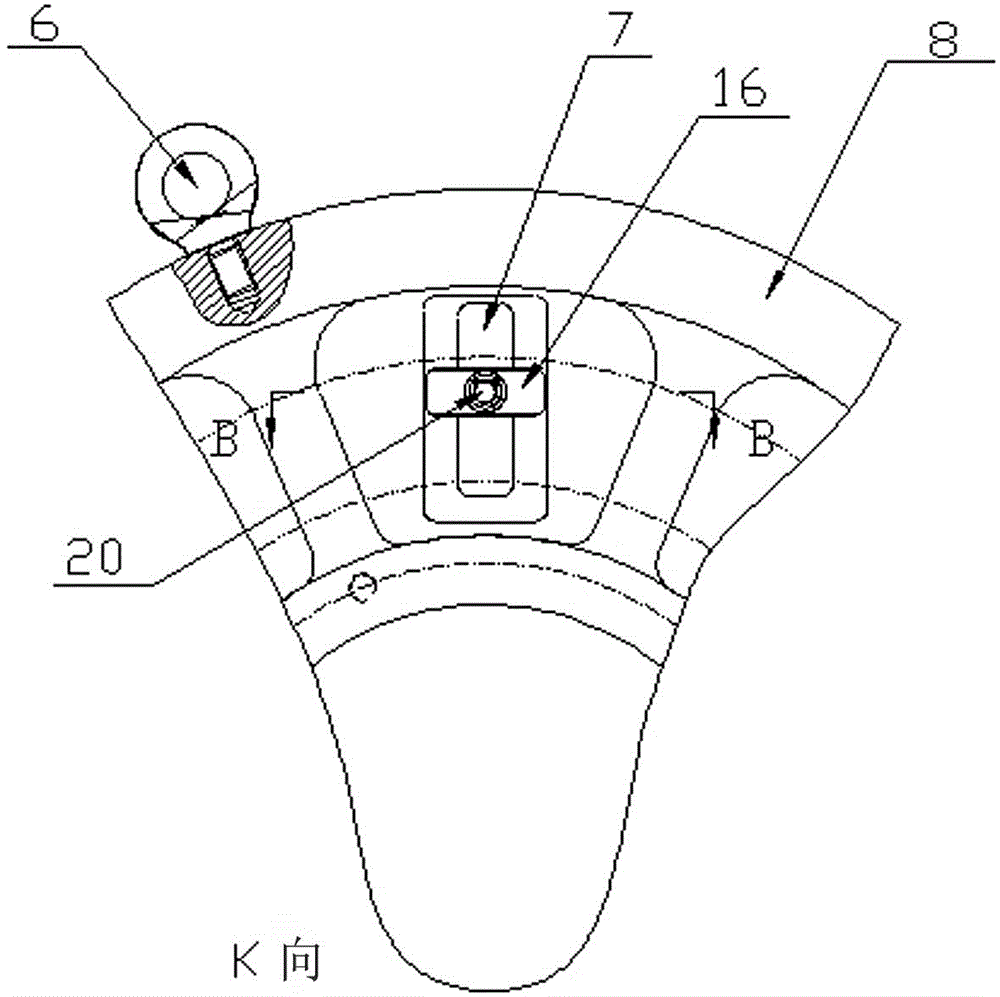

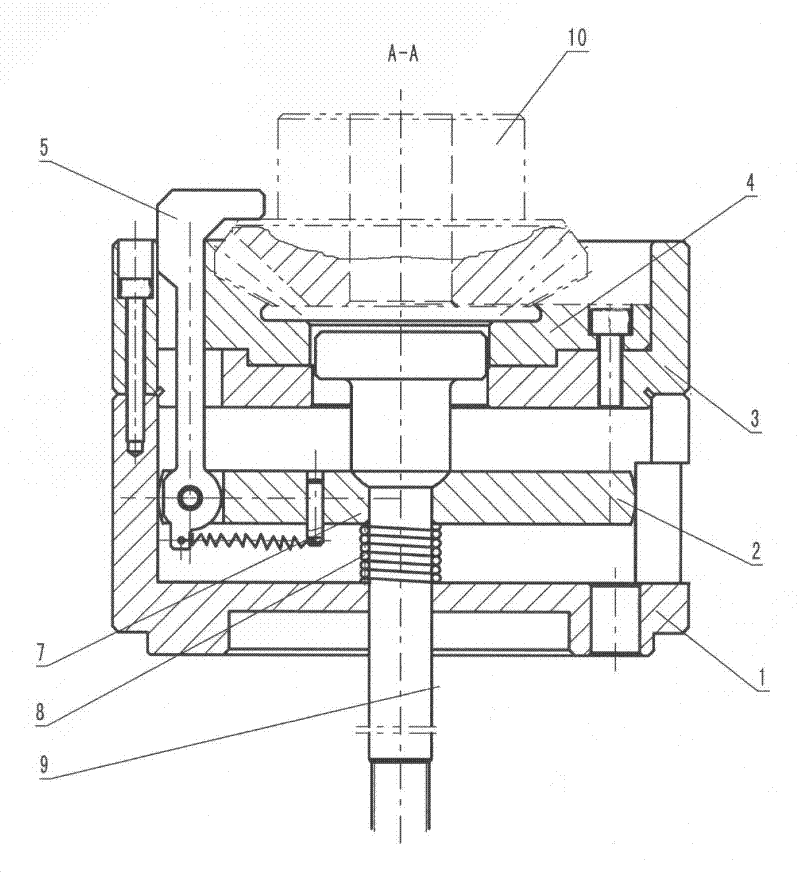

Universal fixture device and method for machining fan-shaped workpiece combinations

ActiveCN104889758ASimple designShort lead time for productionPositioning apparatusMetal-working holdersEngineeringMachining

The invention relates to a universal fixture device and a method for machining fan-shaped workpiece combinations. The universal fixture device and the method have the advantages that slide grooves are formed in fixture bodies of the fixture device according to the numbers of fan-shaped workpieces, the lengths of the slide grooves are designed according to the limit sizes of the workpieces, and accordingly the fixture device is high in universality; designs of fixtures are simplified, and accordingly labor, the time and the cost can be saved; tools with different specifications do not need to be selected according to the different workpieces, accordingly, the production preparation time is short, wastage of a large quantity of time for pre-machining preparation work can be prevented, the preparation time can be shortened by one week to half a month at least as compared with the prior art, the integral machining periods can be shortened, and the machining efficiency can be improved; the fan-shaped workpieces with different specifications can be machined by the same tools and the same fixtures, and accordingly the tools and the fixtures are high in utilization rate and long in service life; the service life of the fixture device can reach 7-8 years at least, accordingly, the total input for the tools and the fixtures can be reduced, and the universal fixture device is low in cost, simple in clamping process and high in machining efficiency.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

Fixture for positioning and broaching bevel gear tooth surface

InactiveCN102335827ASimple positioning structureSimple clamping processPositioning apparatusMetal-working holdersGear wheelEngineering

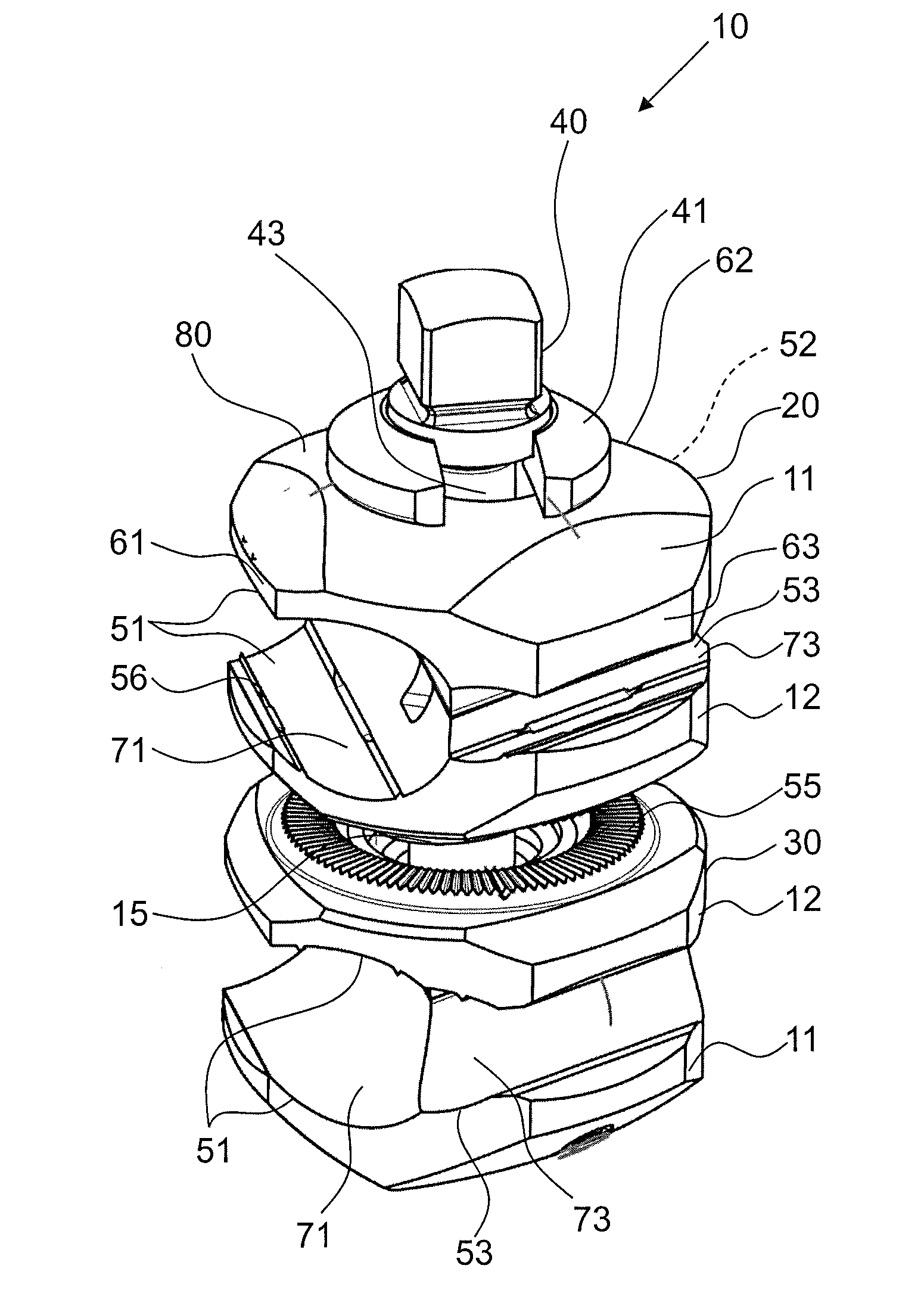

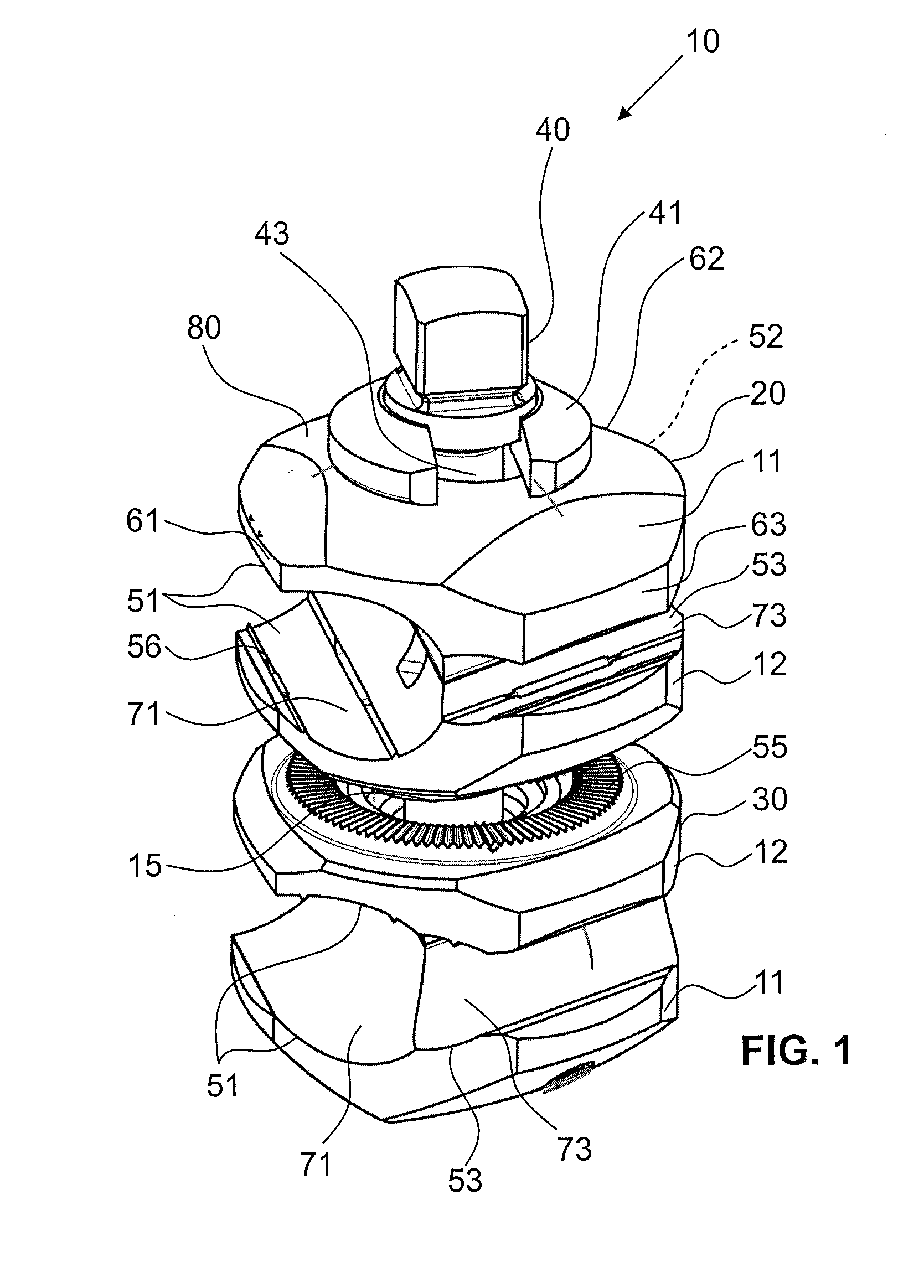

The invention discloses a fixture for positioning and broaching a bevel gear tooth surface, comprising a positioning structure and a clamping structure, wherein the positioning structure comprises a chassis, a positioning seat and a tooth die which are successively overlaid and connected from bottom to top; the clamping structure comprises a sliding block, an angle buckle, a tension spring, a pin, a pressure spring and a draw bar; the sliding block is built in an inner cavity between the chassis and the positioning seat; the outer outlines of the sliding block and the positioning seat are provided with two opening slots with symmetrical structure; the opening slot in the sliding block is hinged with the angle buckle; two ends of the tension spring are respectively connected with the lower end of the angle buckle and the pin to form an elastic tension structure; and the draw bar is penetrated from the inner hole of the tooth die to be connected with the positioning seat, the sliding block, the pressure spring and the chassis in series in sequence to form the structure that the draw bar and the pressure spring guide the sliding block to drag the angle buckle to axially slide. In the fixture, the tooth die positioning structure is adopted, and therefore the fixture is accurate and reliable to position. After a workpiece is installed, the workpiece is directly meshed with the teeth of the tooth die, the pitch cercle of the tooth die serves as the positioning reference which is same with a design reference, and therefore positioning errors can be prevented from generating.

Owner:JIANGSU AIRSHIP GEAR

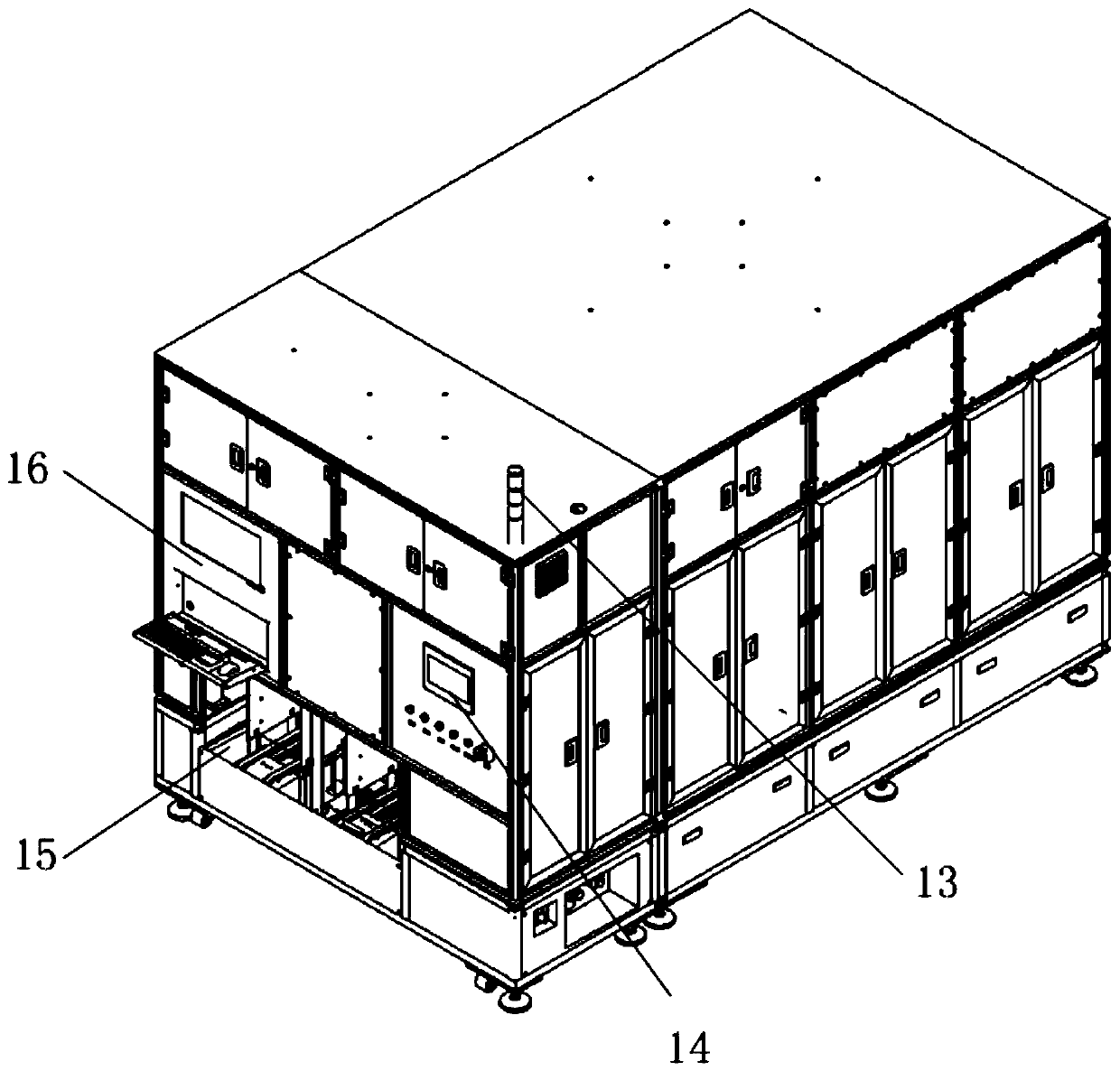

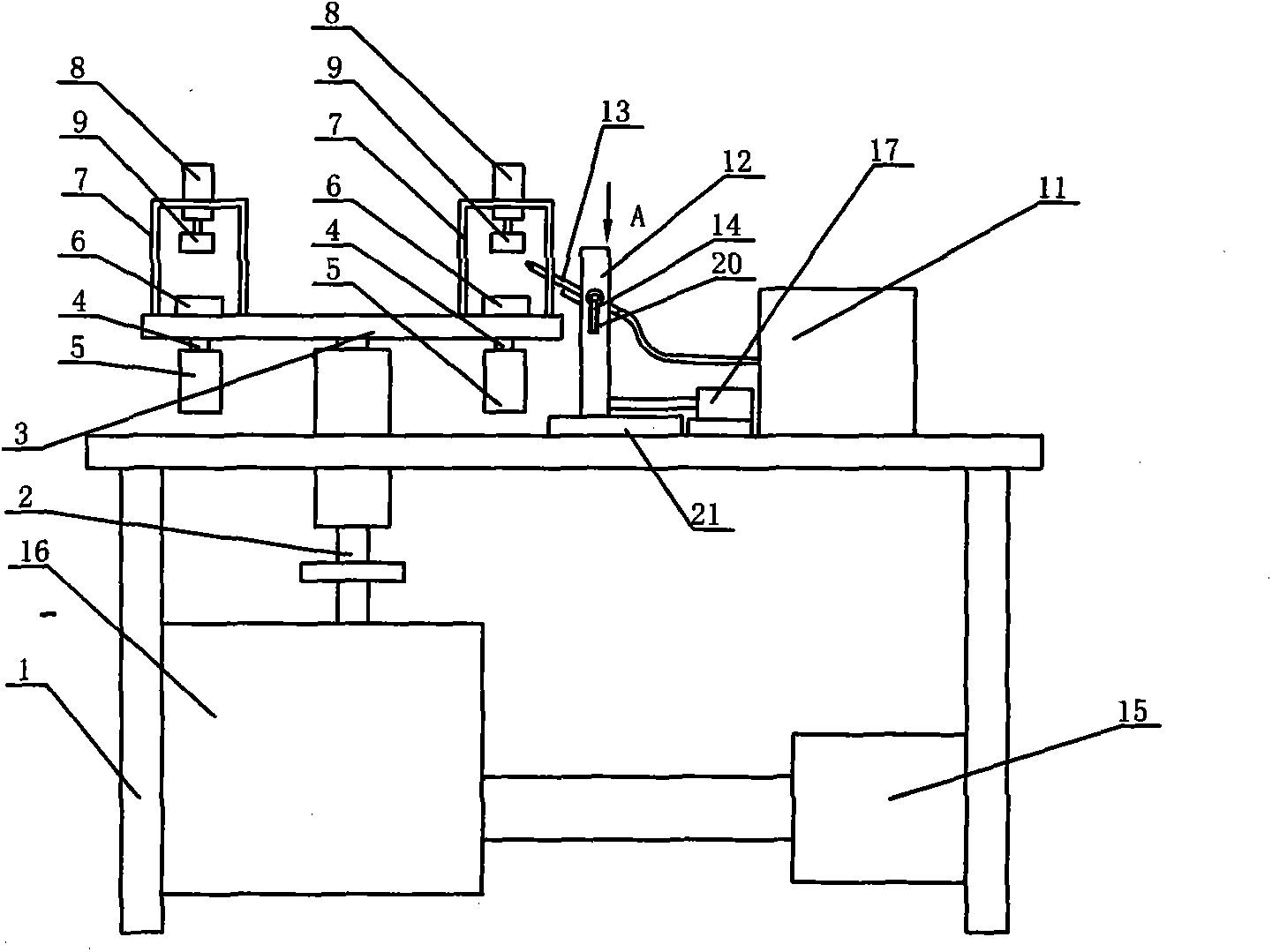

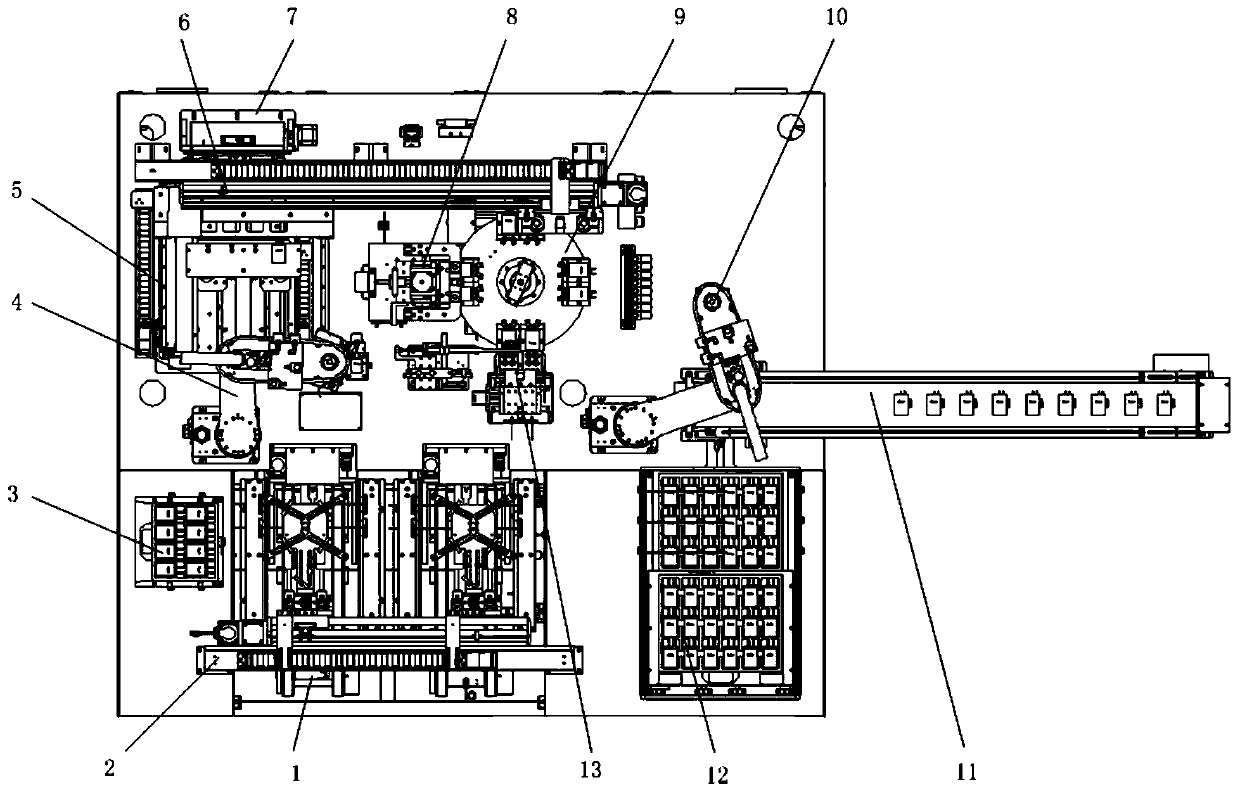

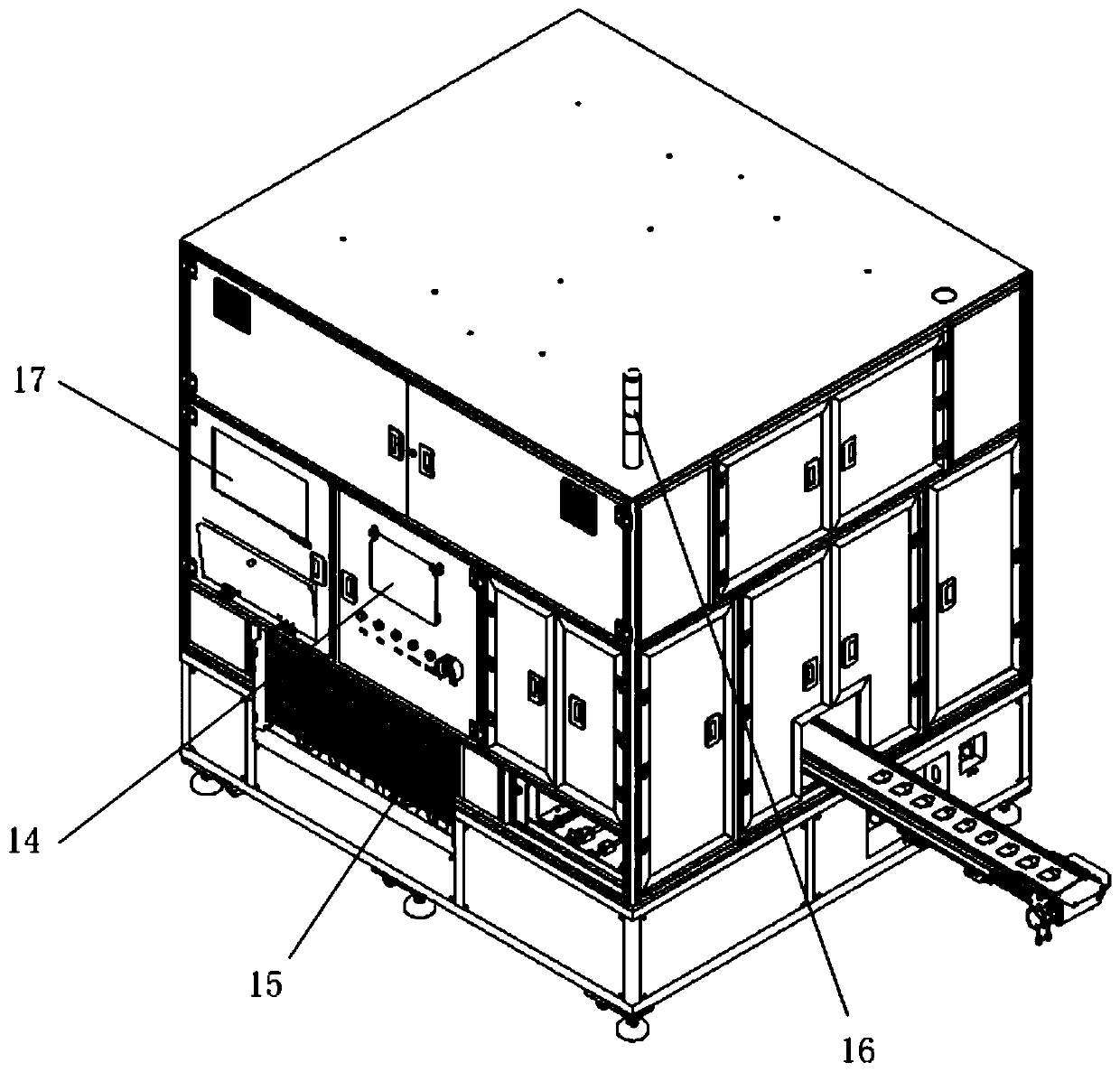

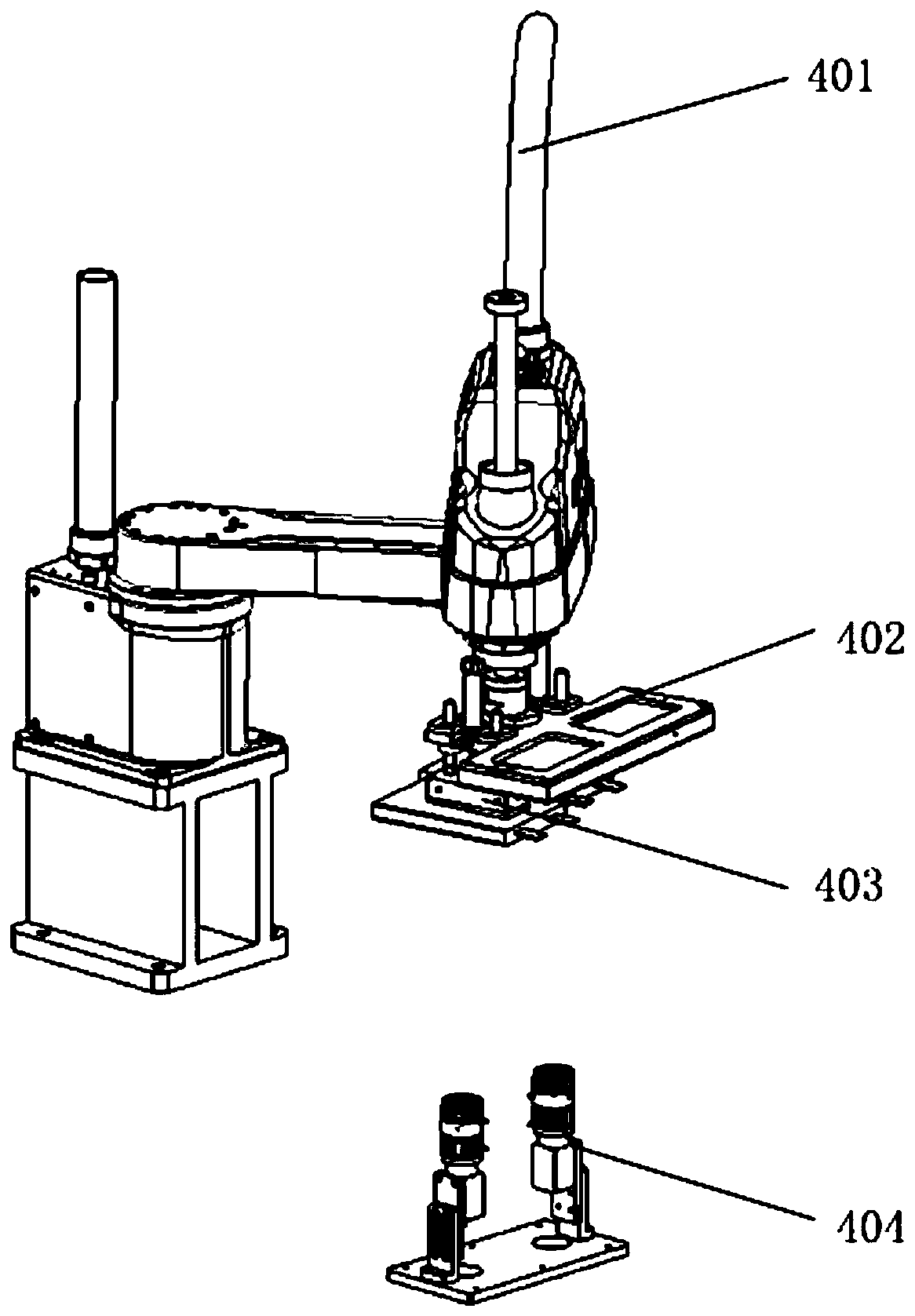

Full-automatic voltage internal resistance testing system

PendingCN110794320AImprove efficiencyNot affected by human factorsResistance/reactance/impedenceElectrical testingInternal resistanceControl engineering

The invention discloses a full-automatic voltage internal resistance testing system. The full-automatic voltage internal resistance testing system comprises a material frame cart, a transfer platformwith a plurality of material storage positions, a turntable mechanism with a plurality of working positions and a discharging platform. The full-automatic voltage internal resistance testing system further comprises: a multi-connected clamping jaw manipulator used for transferring battery cells in a cart material frame to the transfer platform; a feeding, sorting, visual positioning and monitoringrobot used for grabbing the battery cells on the transfer platform, carrying out visual positioning and detection on the battery cells and placing the qualified battery cells on the working station of the turntable mechanism; a tab shaping mechanism, a battery cell body temperature testing mechanism, a code scanning mechanism and a battery cell voltage internal resistance testing mechanism whichare arranged at each working position of the turntable mechanism and are respectively used for carrying out tab shaping, battery cell body temperature testing, code scanning and battery cell voltage internal resistance testing; and a discharging and sorting robot used for discharging the battery cells which are tested to be qualified from the turntable mechanism to the discharging platform. According to the test system, the voltage and internal resistance test efficiency of a large square cell is improved, and test data is stable.

Owner:GUANGDONG ZHENGYE TECH

Perforating equipment for machining special sensors for agricultural machinery

InactiveCN109396887ASimplify the clamping processImprove work efficiencyPositioning apparatusMaintainance and safety accessoriesElectric machineryAgricultural engineering

The invention discloses perforating equipment for machining special sensors for agricultural machinery. The equipment comprises a supporting plate, the right side wall of the supporting plate is fixedly connected with an air cylinder, the telescopic end of the air cylinder is fixedly connected with a mounting plate, a drilling motor is fixedly connected to the lower surface of the mounting plate,the output end of the drilling motor is fixedly connected with a rotating shaft, the outer surface of the rotating shaft is fixedly connected with a gear ring, a bearing is fixedly connected to the lower surface of the mounting plate, and a threaded sleeve is fixedly connected to the interior of the bearing. According to the equipment, a driving motor is arranged, when the equipment is used, the driving motor drives a rotating rod to rotate, the rotating rod drives a bevel gear rod to rotate through a first bevel gear and a second bevel gear, the bevel gear rod drives a cam to rotate, when thecam is rotated to be connected with a funnel, the funnel is extruded to move leftwards, when the cam rotates to be staggered with the funnel, the funnel moves rightwards under the action of a tensionspring, so that the effect that the funnel is shaken leftwards and rightwards to shake off scraps is realized, and therefore the purpose of preventing blockage is achieved.

Owner:柳州国福科技有限公司

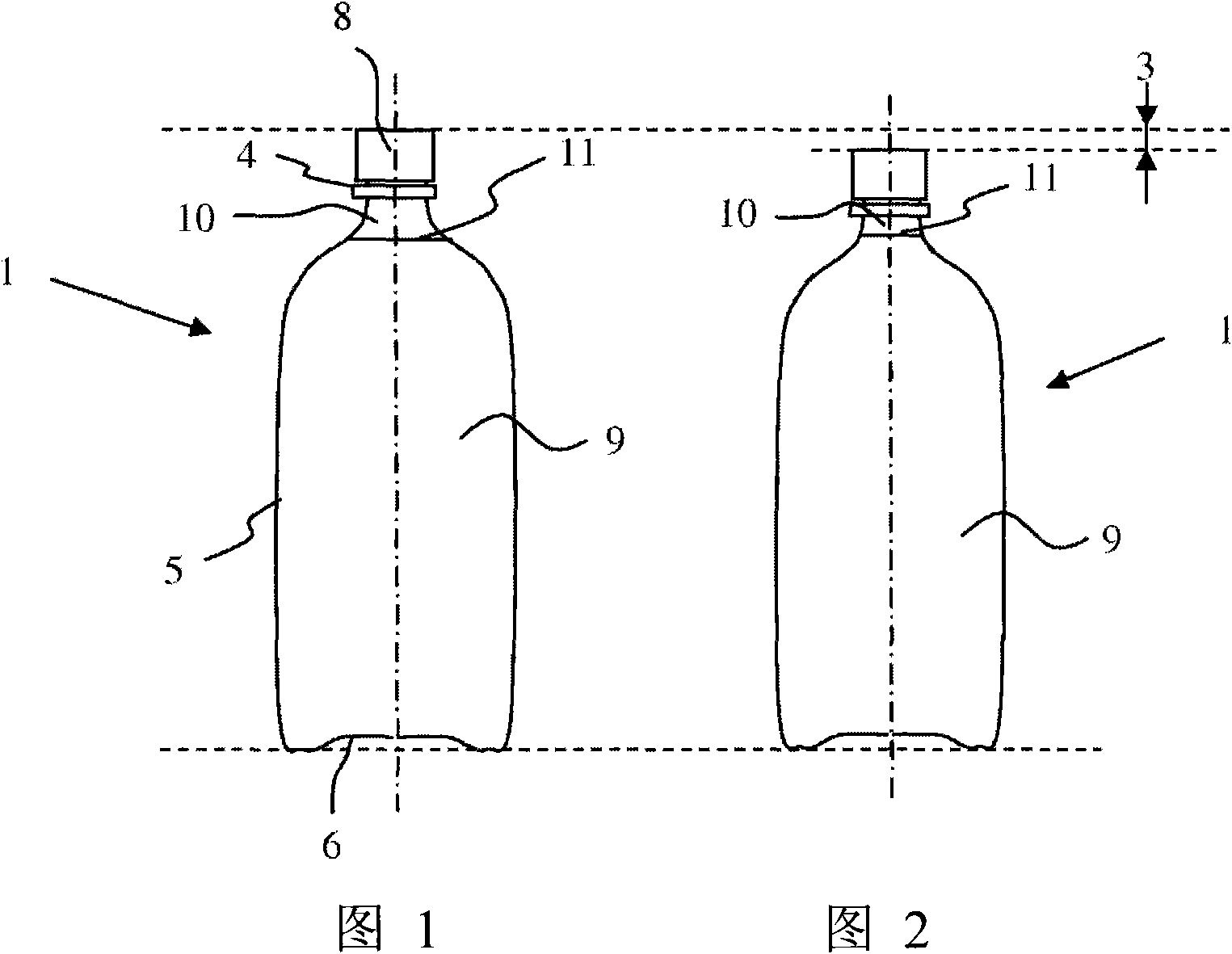

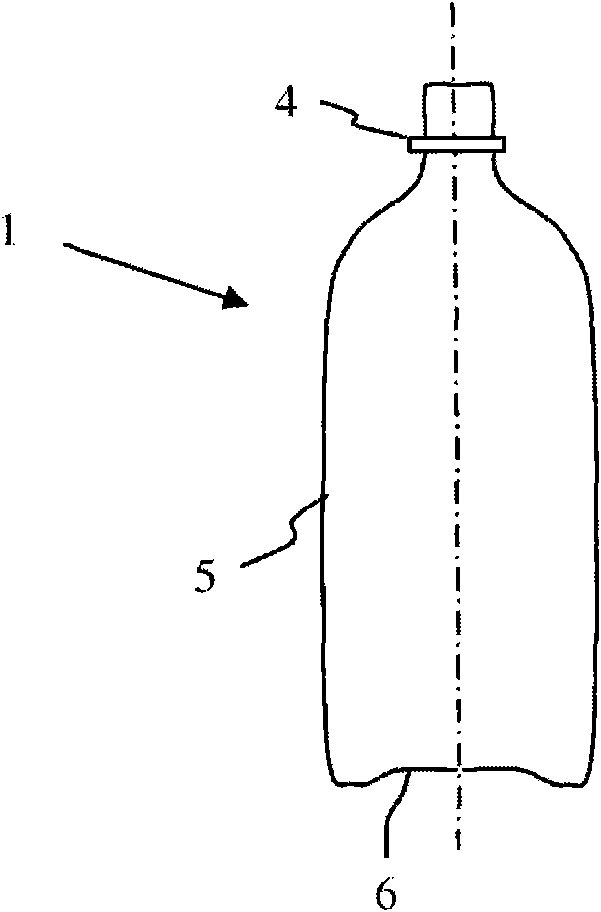

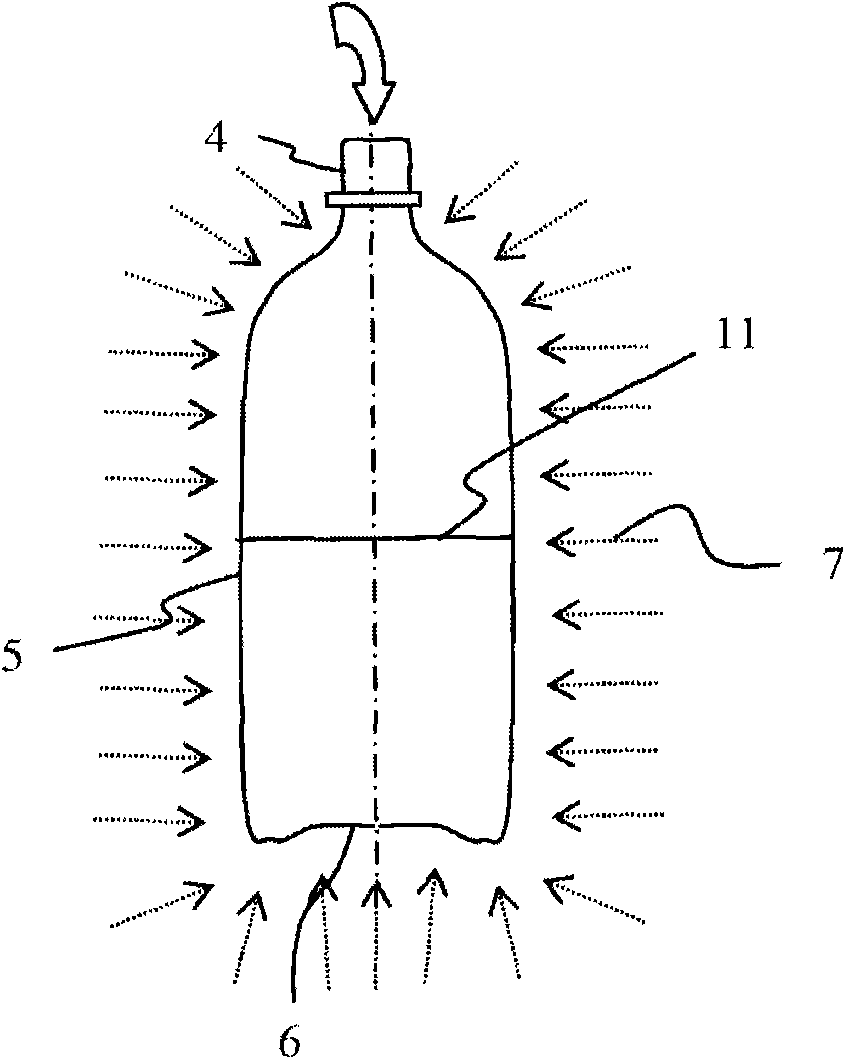

Method for filling shrink packaging

InactiveCN101652314ASimple clamping processIncrease vertical pressureFilling using counterpressureFilling without pressureEngineeringMechanical engineering

Owner:AISAPACK HLDG SA

SMT wiring terminal convenient to operate

ActiveCN104916929AEasy clamping and looseningExtended Life and ReusabilityElectric connection basesClamped/spring connectionsEngineeringElectrical conductor

The invention relates to an SMT wiring terminal convenient to operate, which comprises an insulating shell body and an electric conductor arranged inside the insulating shell body, and is characterized in that a body of the electric conductor is provided with a clamping part for clamping a lead wire, a through hole is formed in the top part of the shell body, and a button which can make the clamping part of the electric conductor open and can reset elastically is arranged inside the through hole. Compared with the prior art, the SMT wiring terminal has the advantages that the single button which can be pressed downward for operation is additionally arranged, so that the clamping and loosening of the lead wire is more convenient and simpler, the SMT wiring terminal can realize the assembly and disassembly of the lead wire quickly when compared with the traditional wiring terminal without the button structure; in addition, the button is an independent part and can be replaced separately in case of damage after repeated use, the situation that the entire wiring terminal is scrapped due to the integral structure of the button and the shell body is avoided, the service life of the entire terminal is prolonged, the repeated utilization rate of the entire terminal is increased, and the SMT wiring terminal has higher practicality.

Owner:NINGBO DEGSON ELECTRICAL CO LTD

Modular lift assembly having telescoping member

ActiveUS20070246695A1Easily mountedEasy and effective clampingCeilingsScaffold connectionsModularityEngineering

A modular lift assembly configured for attachment between two substantially parallel support beams includes a chassis, at least one lift component attached to the chassis, a telescoping stiffener, and at least one attachment assembly. The chassis has a plurality of grooves formed in one surface thereof. The telescoping stiffener is disposed in at least one of the grooves and engages facing surfaces of adjacent parallel support beams. The attachment assembly is disposed in another of the grooves formed in the chassis for engaging at least one of the adjacent support beams.

Owner:ELECTRONIC THEATRE CONTROLS

Steel tube butt welding machine

InactiveCN103639638AReduce labor intensityEasy clampingWelding/cutting auxillary devicesAuxillary welding devicesWeld seamSteel tube

The invention relates to a steel tube butt welding machine. The butt welding machine comprises a rack, and a main shaft which is driven by a drive unit to rotate at intervals and is arranged vertically is in rotary connection onto the rack. A rotary disc is arranged at the top of the main shaft, at least three rotary shafts distributed circularly at intervals are in rotary connection onto the rotary disc, and drive motors for driving the rotary shafts to rotate respectively are further installed on the rotary disc. Lower steel tube clamps are arranged at the tops of the rotary shafts, supporting frames corresponding to the rotary shafts are further arranged on the rotary disc, and upper location air cylinders are arranged on the supporting frames. Upper steel tube clamps are mounted on downward stretching piston rods of the upper location air cylinders. A welder and a welding gun fixing seat are arranged on the rack, and a welding gun of the welder is in rotary connection onto the welding gun fixing seat which is in sliding connection onto the rack and is driven by a drive air cylinder. By means of the butt welding machine, clamping processes of product can be simplified, the welding efficiency and the welding quality are improved, the weld appearance quality of product produced through the butt welding machine is good, the labor intensity of workers is greatly reduced, and the product welding time is shortened.

Owner:GAOMI WANHE AXLE

Turnover clamping device for woods

InactiveCN105196362AFlip helpsSimple clamping processMulti-purpose machinesWear resistantSlide plate

The invention discloses a turnover clamping device for woods, and relates to the field of machining. The turnover clamping device for the woods comprises a worktable, a first clamping mechanism, a second clamping mechanism, a turnover hand wheel, a threaded column and a support, wherein the turnover hand wheel is fixedly connected with the worktable; a sleeve is in threaded connection with a roller; overturning of the worktable is facilitated; when not overturning, the worktable cannot easily roll voluntarily; the woods can be clamped by rotating the threaded column; meanwhile, the woods with different sizes can be clamped; each clamping mechanism is provided with a sliding plate and a spring; when the woods are clamped, the sliding plates are opened, and clamping blocks are popped out by the springs; when the woods are released, the sliding plates are closed, the clamping blocks tightly press the springs in the clamping mechanisms, and clamping and releasing of the woods are realized; each sliding plate is provided with a lifting column, so that the sliding plate is convenient to open and close; and the turnover hand wheel is made of high-chromium iron which is a wear-resistant material, and cannot slip easily when used.

Owner:涟水县中林木制品厂

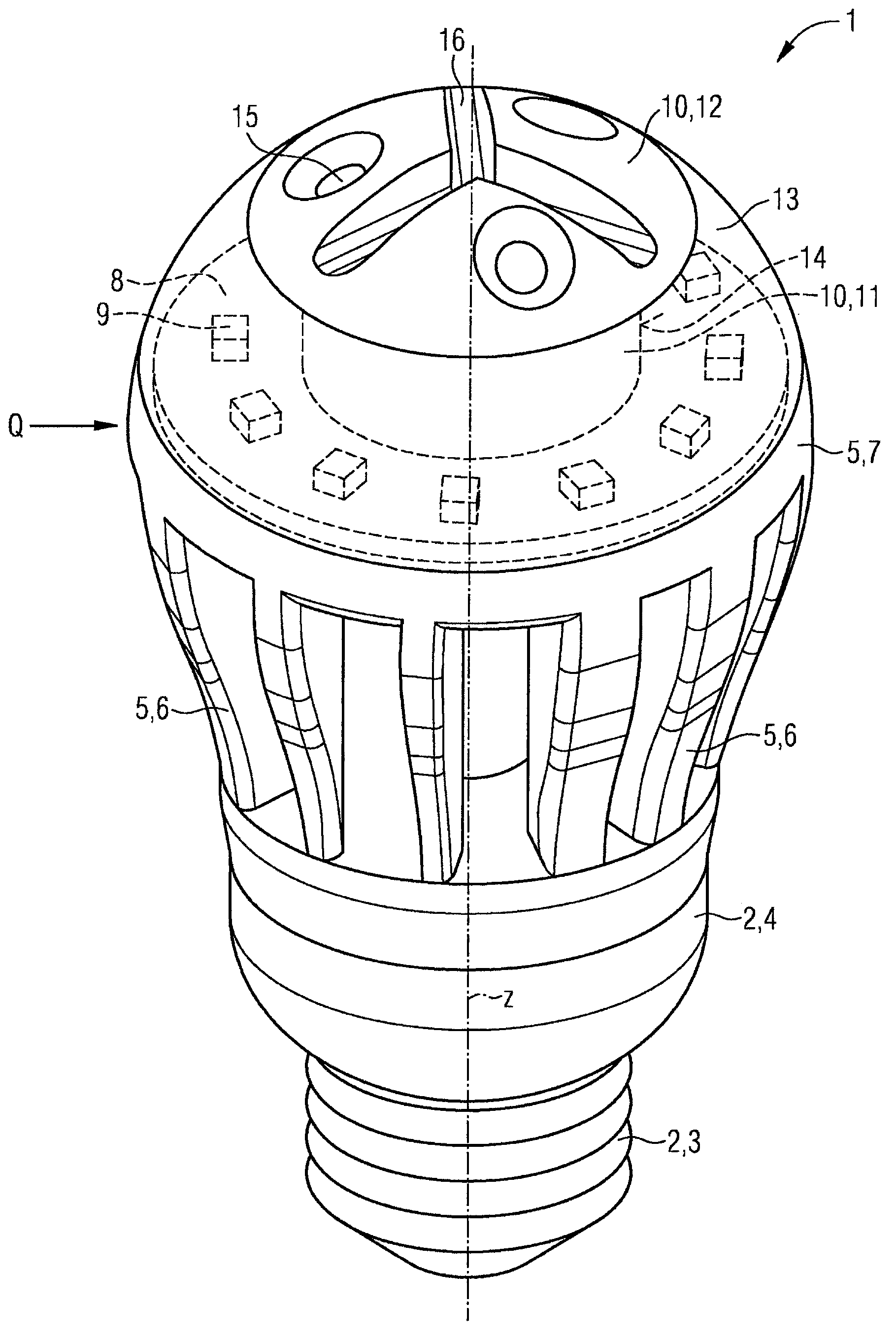

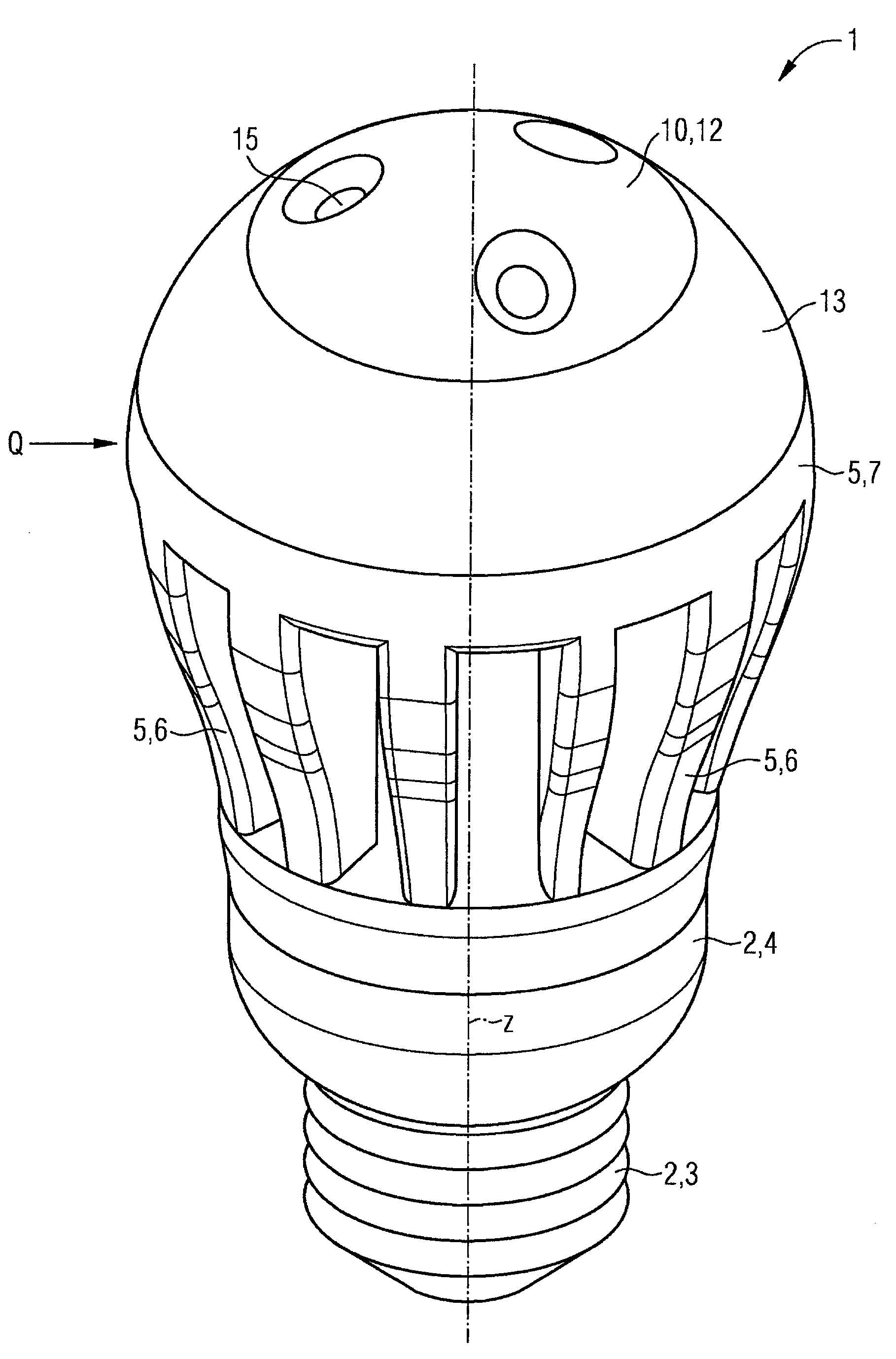

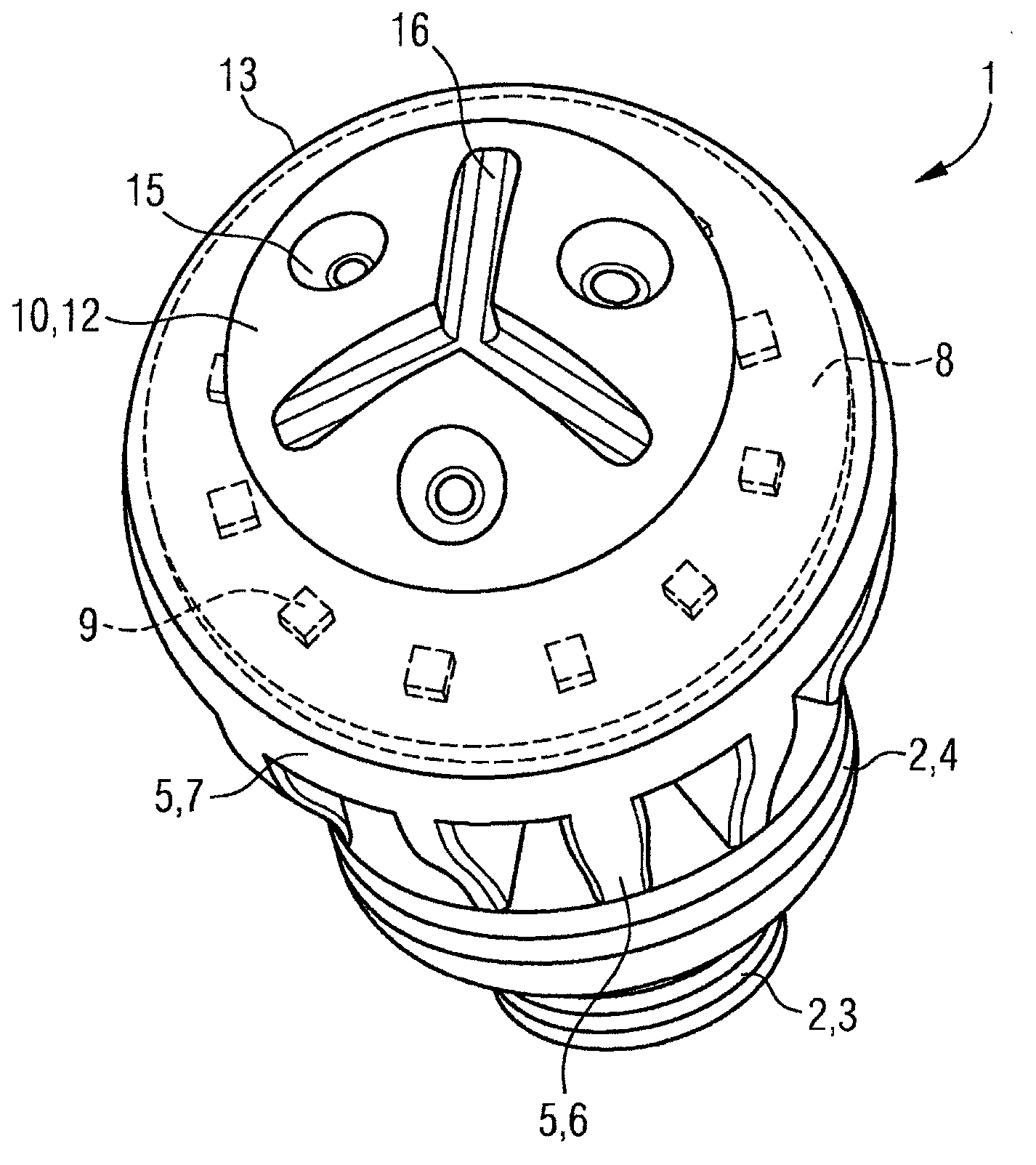

Illumination device

InactiveCN102713409ALow priceHigh proximityPoint-like light sourceElongate light sourcesEngineeringHeat sink

The invention relates to an illumination device (1) comprising a first heat sink (5), a carrier substrate (8) populated on the front side thereof by at least one light source (9), in particular a light-emitting diode, and the back side thereof being attached to the first heat sink (5), and comprising a second heat sink (10) disposed substantially in front of the carrier substrate (8), wherein the at least one light source (9) is disposed outside of the second heat sink (10; 32).

Owner:OSRAM GMBH

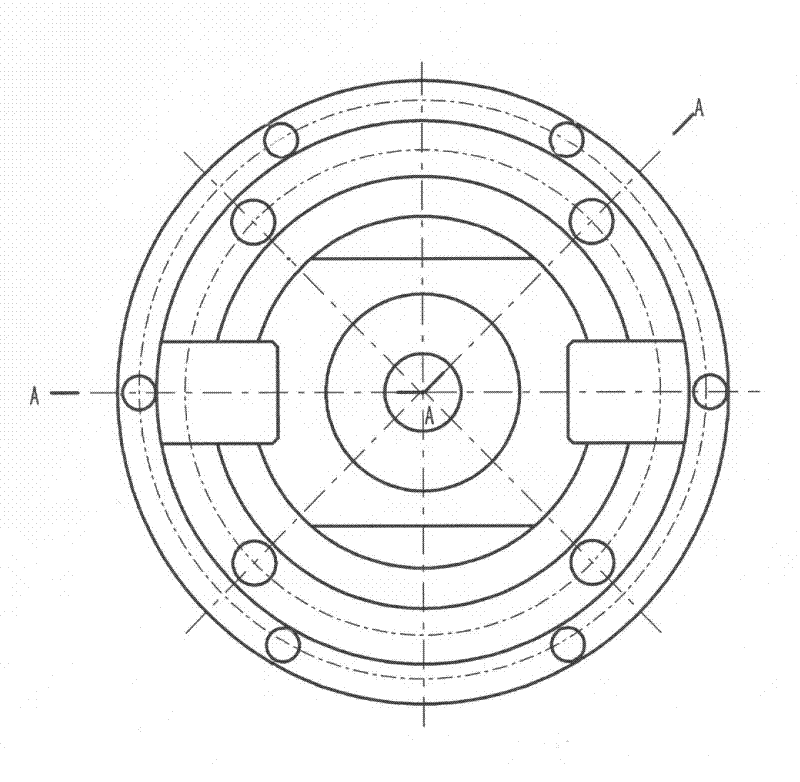

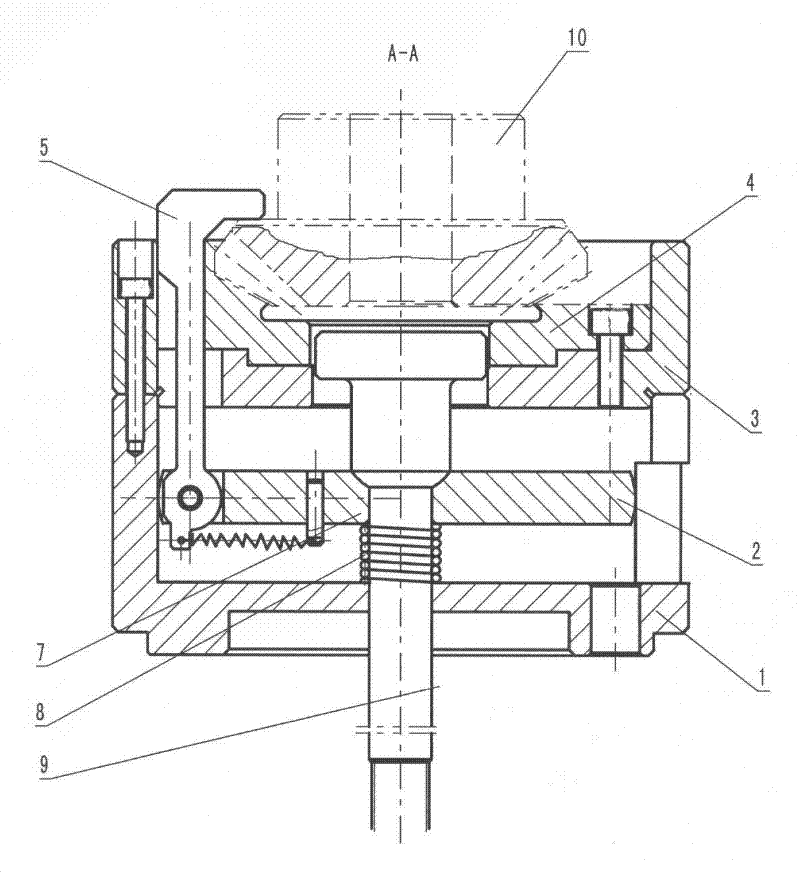

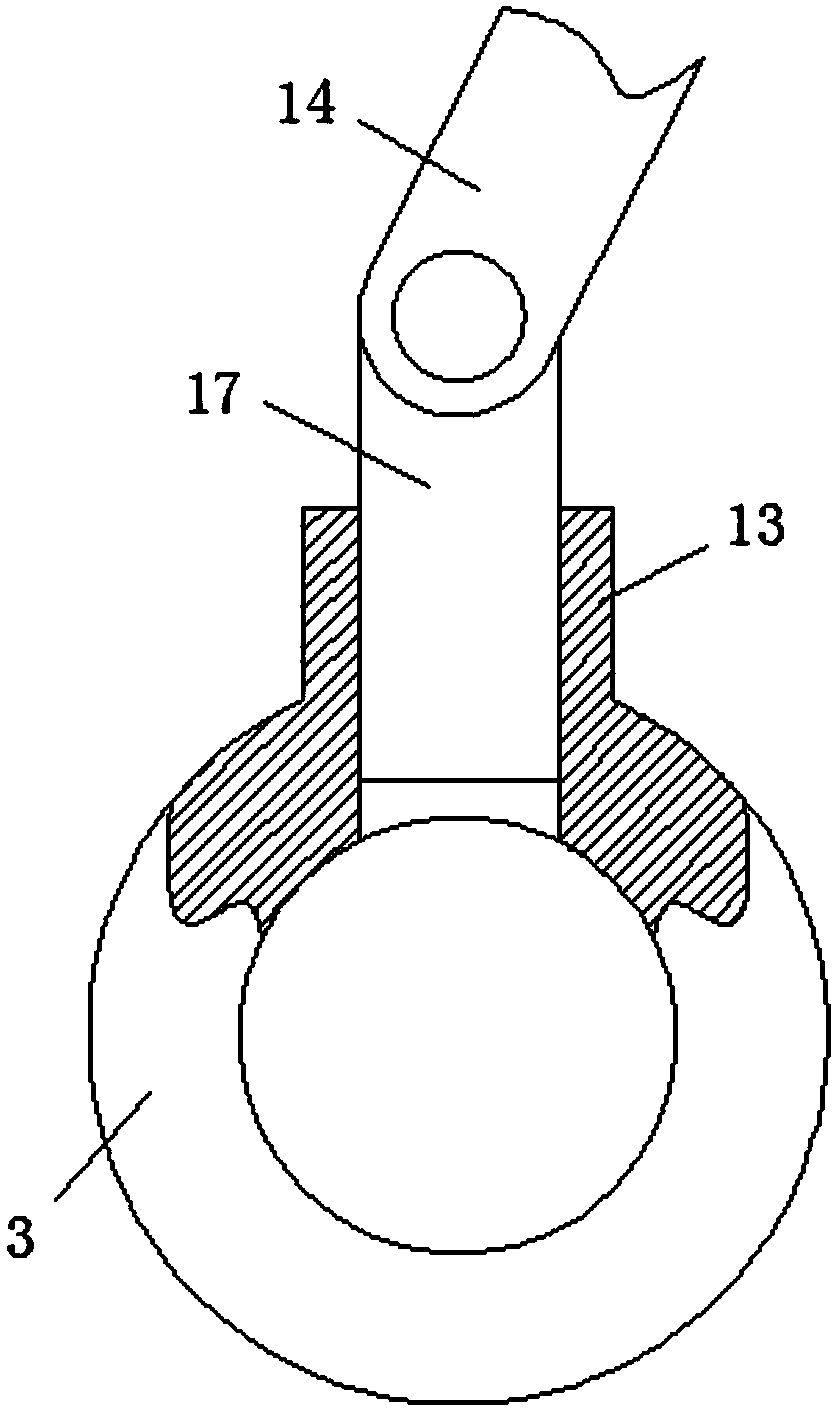

Transmission centering clamping device with rotation axes

InactiveCN103111865ASimple clamping processClamp firmlyPositioning apparatusMetal-working holdersEngineeringBolt connection

The invention discloses a transmission centering clamping device with a rotation axes and relates to a centering clamping device. The transmission centering clamping device with the rotation axes comprises a machine frame, an upper die block, a middle die block, a lower die block, a rotation handle, two clamping claws and two ejecting blocks. The upper die block, the middle block and the lower die block are connected through bolts. Nuts of the bolts are embedded in the lower die block which is connected with the rotation handle in a welded mode. The two clamping claws are respectively hinged with the machine frame. Screws are respectively arranged at the lower ends of the two clamping claws. Nuts of the screws are respectively attached with two ends of the middle die block. A through hole is formed in the top of the upper die block. The two ejecting blocks are arranged in the through hole. A reset spring is arranged between the two ejecting blocks which are respectively attached with the two clamping claws. The transmission centering clamping device with the rotation axes overcomes the defects that centering claming for a work pieces is difficult to achieve or clamping is not firm, and improves machining efficiency.

Owner:CHONGQING MING SHIELD ELECTROMAGNETIC VALVE

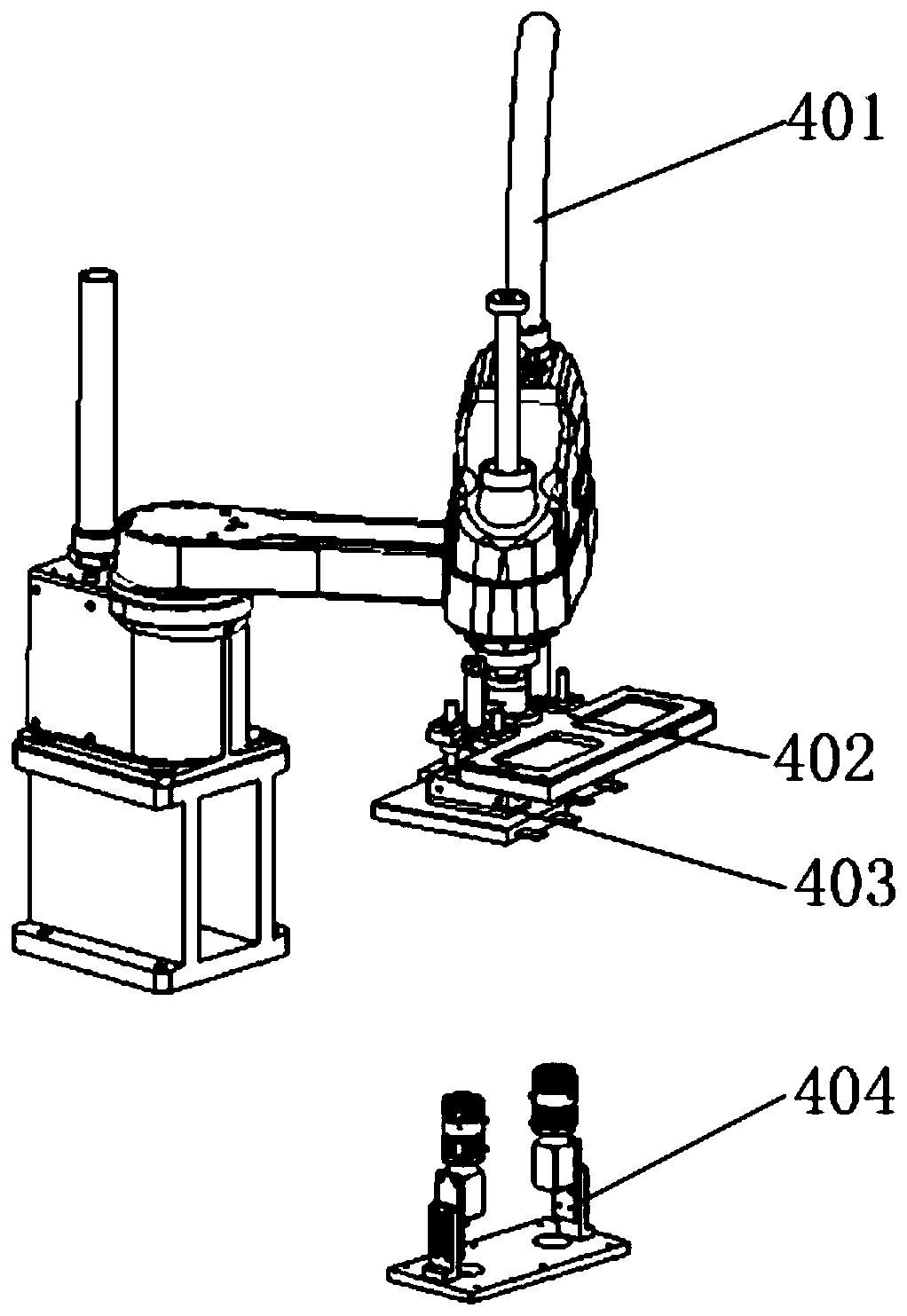

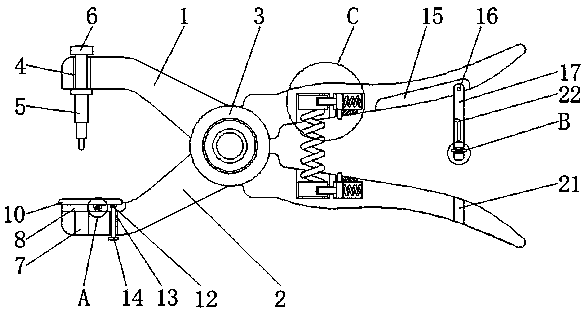

Manipulator

ActiveCN103698859ASimplify the clamping processImprove convenienceGripping headsCoupling light guidesFiberManipulator

The embodiment of the invention discloses a manipulator, comprising a transmission device, a first structure part, a second structure part and an elastic structure, wherein the cross section of a second connection part in the first structure part is gradually increased along the direction from a first connection part to the second connection part; the second structure part is hinged to the second connection part, so under the action of the elastic structure, a first state in which the distance between a first clamping angle and a second clamping angle is smaller than the distance between a first clamping arm and a second clamping arm is recovered from a second state in which the distance between the first clamping angle and the second clamping angle is larger than the distance between the first clamping arm and the second clamping arm, and the first state can become the second state under the action of an external force, so when the manipulator is used for clamping a fiber core connector, only the second structure part needs to be moved in the vertical direction, the process for clamping the fiber core connector by using the manipulator is simplified and the portability for clamping the fiber core connector by the manipulator is improved.

Owner:NINGBO YINGMING ELECTRIC TECH

Multi-face synchronous bonding device for paving tiles

ActiveCN108277966AAchieve simultaneous fitSave the trouble of pastingBuilding constructionsEngineeringElectrical and Electronics engineering

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

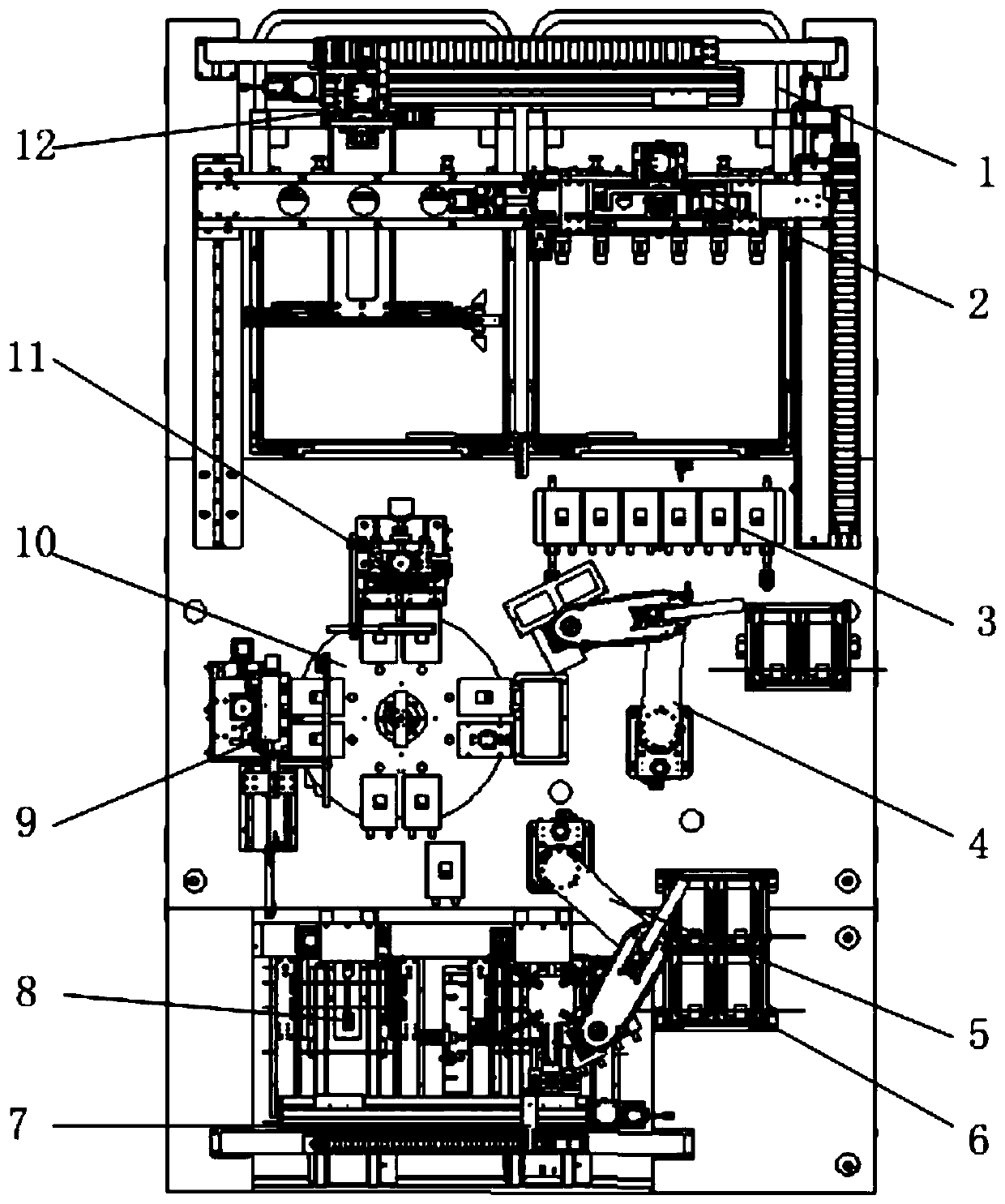

Full-automatic voltage internal resistance testing system

PendingCN110927603ATest data is stableSimplify the clamping processResistance/reactance/impedenceElectrical testingElectrical and Electronics engineeringMechanical engineering

The invention discloses a full-automatic voltage internal resistance testing system which comprises a feeding platform, an advancing and retreating working platform, a turntable mechanism and a discharging conveying belt. A feeding, sorting, visual positioning and monitoring robot is used for grabbing the battery cells on the feeding platform, carrying out visual positioning and detection on the battery cells and placing the battery cells on the advancing and retreating working platform, a side voltage testing mechanism is used for carrying out side voltage testing on the battery cells on theadvancing and retreating working platform, and an upper turntable transfer manipulator is used for transferring the qualified battery cells to the turntable mechanism. A tab shaping mechanism, a battery cell body temperature testing mechanism, a code scanning mechanism and a battery cell voltage internal resistance testing mechanism which are arranged at each working position of the turntable mechanism are respectively used for the tab shaping, a battery cell body temperature test, the code scanning and a battery cell voltage internal resistance test, and a discharging sorting robot is used for discharging the battery cells from the turntable mechanism to the discharging conveying belt. According to the test system, the voltage and internal resistance test efficiency of the small square battery cells is improved, and the test data is more stable.

Owner:GUANGDONG ZHENGYE TECH

Rotary type clamping device

InactiveCN103111858AHigh hardnessReduce coefficient of frictionPositioning apparatusMetal-working holdersProcess efficiencyEngineering

The invention discloses a rotary type clamping device and relates to a clamping device. The rotary type clamping device comprises a base seat, a rotary handle, a cam, two clamping jaws and a harden friction pad. A movable clamping jaw is hinged with a fixed camping jaw. A spring is arranged between the movable clamping jaw and the fixed clamping jaw. The fixed clamping jaw is fixed on the base seat through a bolt. The movable clamping jaw is fit with the cam. The harden friction pad is arranged on the cam, wherein the harden friction pad is fit with the movable clamping jaw in a contact mode. The cam is hinged with the base seat. The cam is in welded with the rotary handle. The rotary type clamping device overcomes the defect that a workpiece cannot be clamped or the workpiece cannot be fastened when clamped. So processing efficiency is improved and service life is prolonged.

Owner:CHONGQING MING SHIELD ELECTROMAGNETIC VALVE

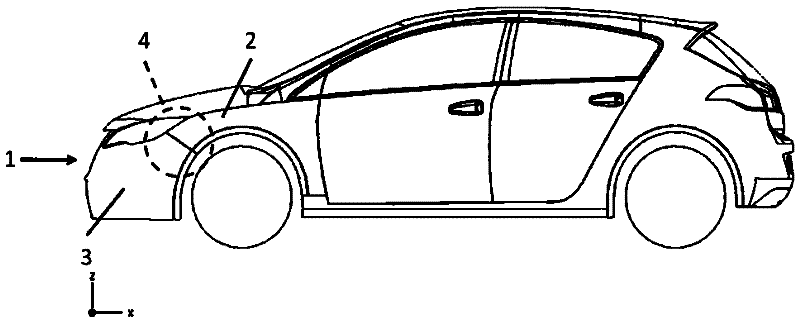

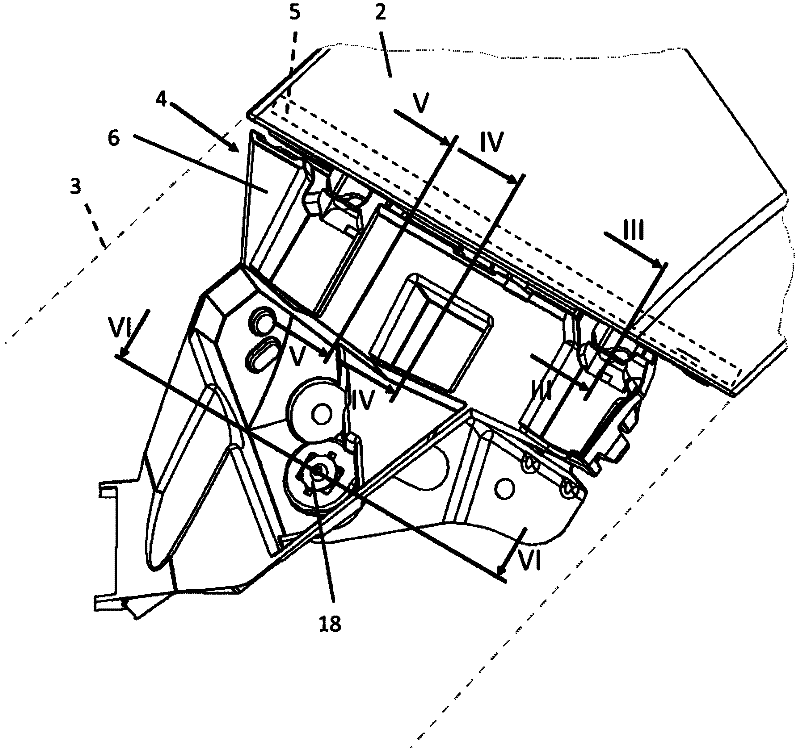

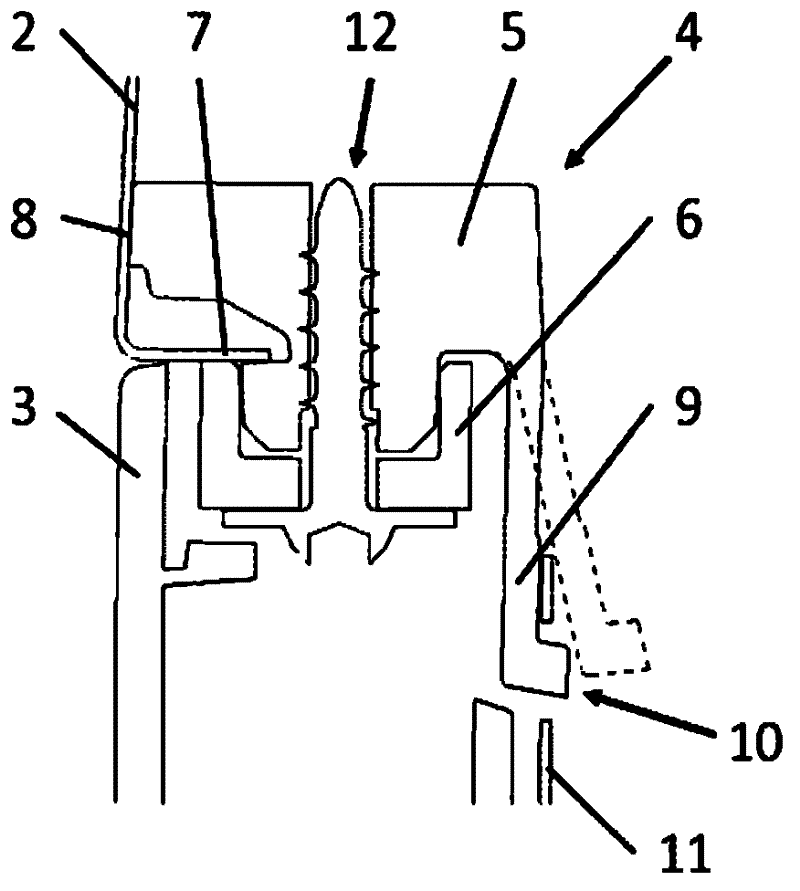

Front structure for a motor vehicle

InactiveCN102371958AAvoid position changesAvoid changeSuperstructure subunitsBumpersAerospace engineering

A front structure 1 for a motor vehicle has holding means 4 for connecting a bumper 3 to a wing or fender 2 comprising a fastening strip 5 and a guide rail 6. The fastening strip 5 spring-elastically supports itself on the wing or fender 2 and is screwed to the guide rail 6. The bumper 3 is latched to the guide rail 6. Because of this an even joined course between the bumper 3 and the wing or fender 2 can be ensured.

Owner:GM GLOBAL TECH OPERATIONS LLC

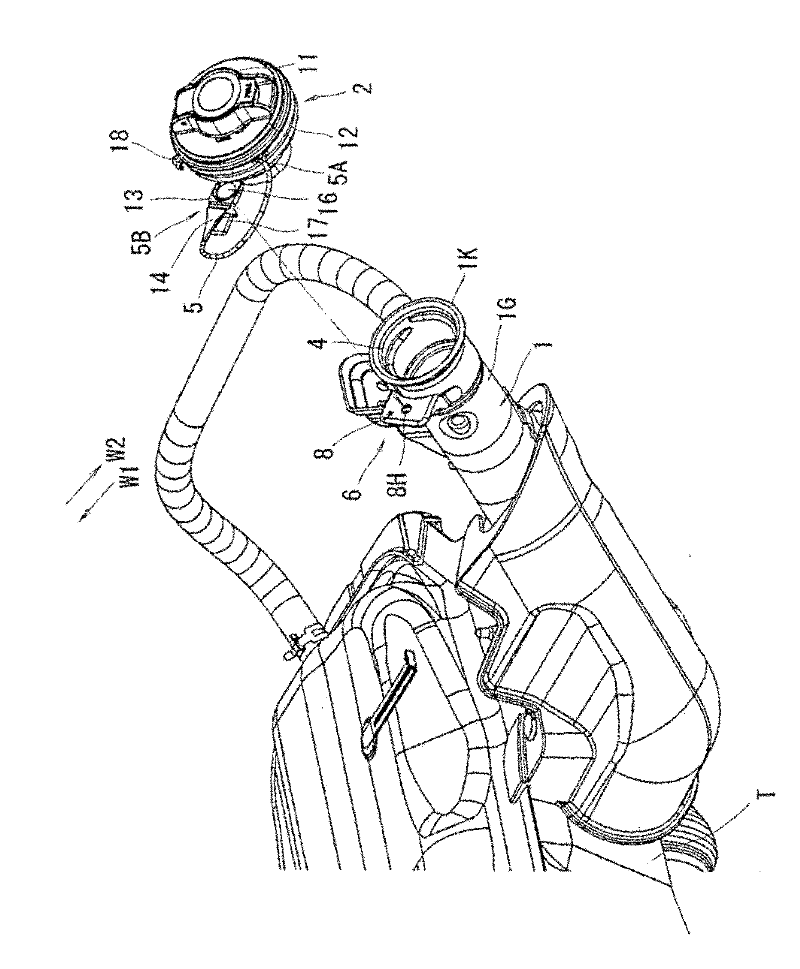

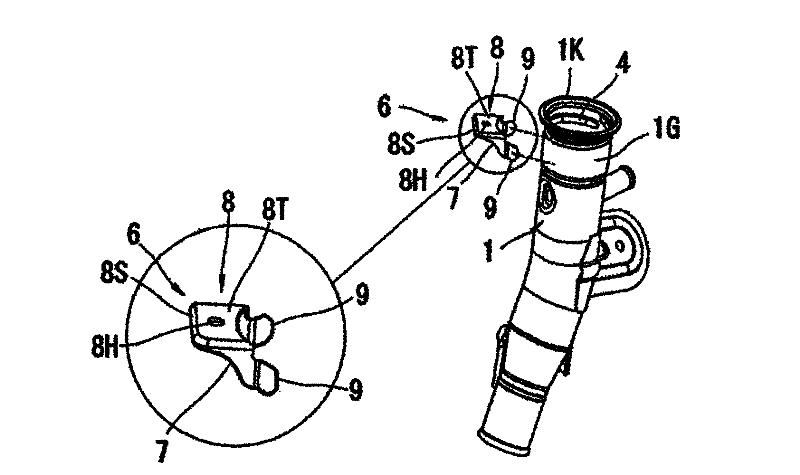

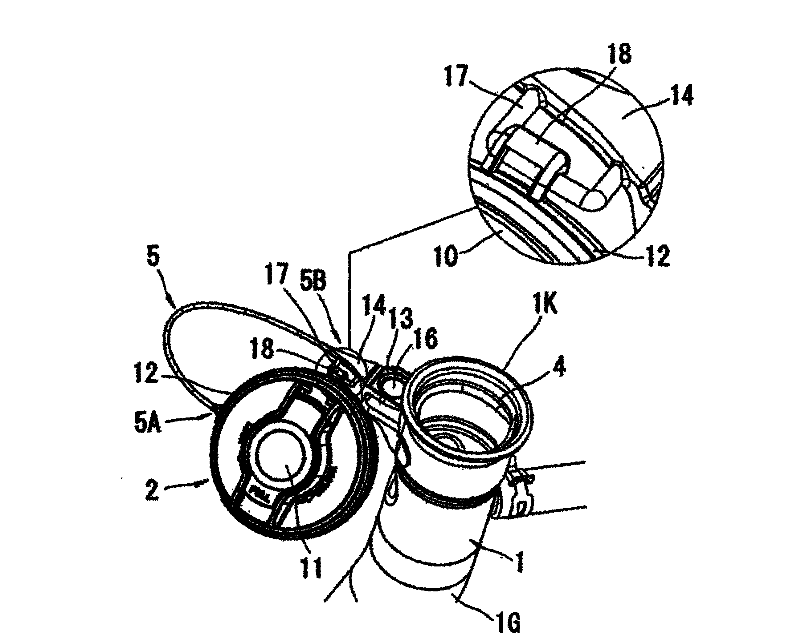

Fuel supply part structure of vehicle

Provided is a fuel supply part structure of a vehicle. The fuel supply part structure comprises a fuel charging port (1) connected with a fuel tank (T) and connected with a vehicle body when a part near a charging opening (1K) is exposed to the outside; and a fuel discharging port cover (2) installed on the charging opening (1K) of the fuel charging port (1) and connected with one end (5A) of a tightening rope (5). A support (6) is connected to the external surface (1G) of the fuel charging port (1) at a place near the charging opening (1K), and the other end (5B) of the tightening rope (5) is attached to the support (6).

Owner:SUZUKI MOTOR CORP

Clamp for cleaning cavity of air brake control valve middle body

The invention discloses a clamp for a cleaning cavity of an air brake control valve middle body. The clamp comprises a cleaning chamber shell and a cleaning chamber formed in the cleaning chamber shell, wherein a foundation is arranged at the bottom of the cleaning chamber; a placing hole corresponding to a bolt on the air brake control valve middle body is formed in the foundation; side hydraulic oil cylinders and a top hydraulic oil cylinder are respectively arranged on the left side, the right side and the top of the cleaning chamber shell; side sealing covers and a top sealing cover are respectively arranged at one end of piston rods of each of the side hydraulic oil cylinders and the top hydraulic oil cylinder; a reset spring is arranged on each of the side sealing covers and the top sealing cover; a conical positioning hole is formed in each of the side sealing covers and the top sealing cover. The clamp has the advantages of simple structure and convenience in operation, is capable of eliminating size error, and satisfies the cleaning requirement of middle bodies from different factories, the sealing property is stable, and a clamping process is simple, quick and safe.

Owner:CRRC GUIYANG CO LTD

Water tank welding device

PendingCN112453820ACoaxiality error is smallReduce setup timeWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringPipe

The invention relates to a water tank welding device. The water tank welding device comprises a middle clamping mechanism and two side clamping mechanisms with a same structure. The two side clampingmechanisms are used for clamping the upper half section and the lower half section of a water tank to be welded correspondingly and symmetrically arranged at the left end and the right end of a bottomplate. Each side clamping mechanism comprises an outer ring and a spring clamping device capable of transversely moving and pushing along with a first pushing air cylinder, wherein the outer ring isfixed to a first support, a spring sliding groove is formed in the inner wall of the outer ring, and the middle of the lower end of the first support is connected with an output shaft of the first pushing air cylinder. The middle clamping mechanism is used for clamping the middle section of the water tank to be welded and comprises an arc clamping device. The arc clamping device comprises an upperhalf ring and a lower half ring, wherein one end of the upper half ring and one end of the lower half ring are hinged through a hinge, the upper half ring and the lower half ring are in a round pipeshape after being closed, the inner diameter of the round pipe is matched with the outer diameter of the middle section, and the central axis of the round pipe is flush with the circle center of eachclosed arc plate of the two side clamping mechanisms. The coaxiality error of the three sections of the water tank is reduced, and the clamping time is saved.

Owner:HUBEI JIANGSHAN SPECIAL PURPOSE VEHICLE

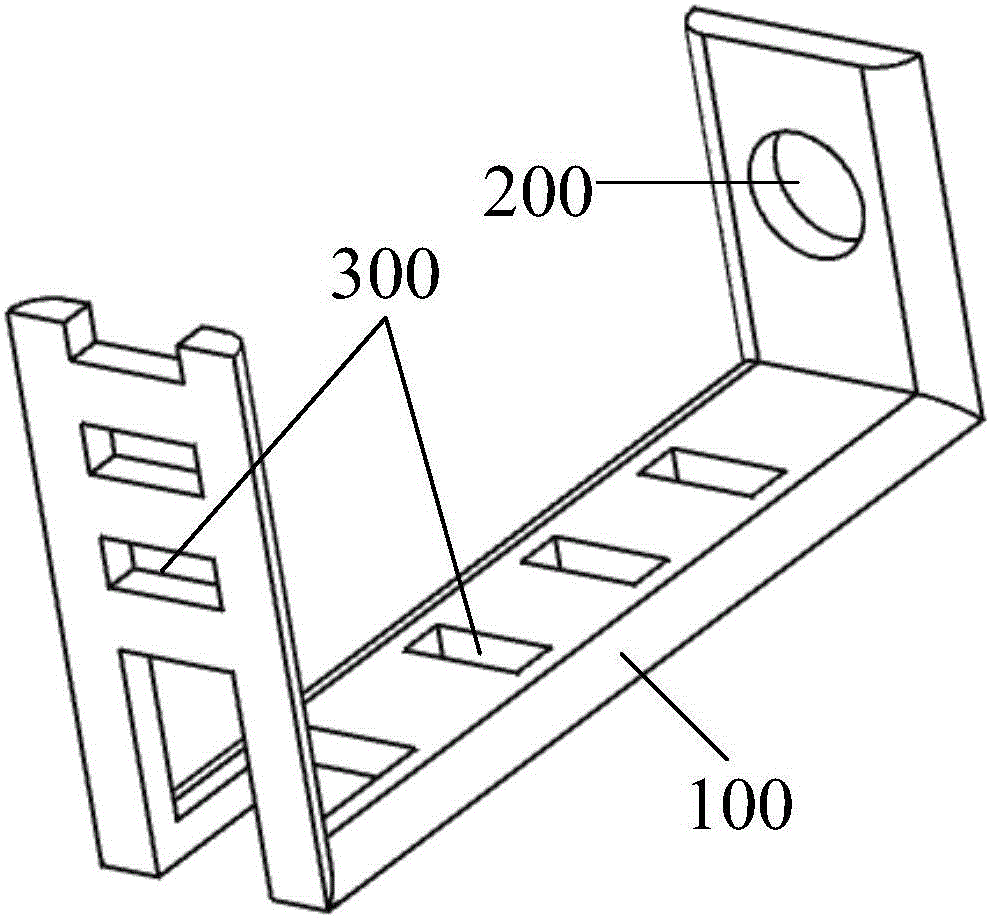

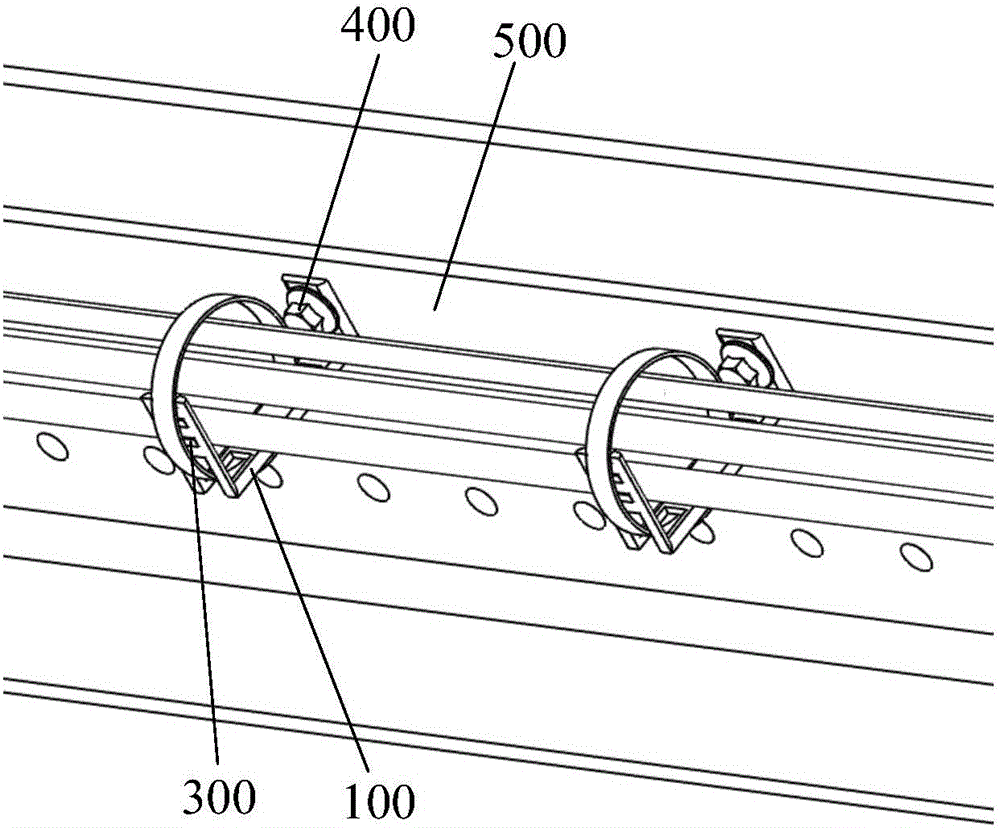

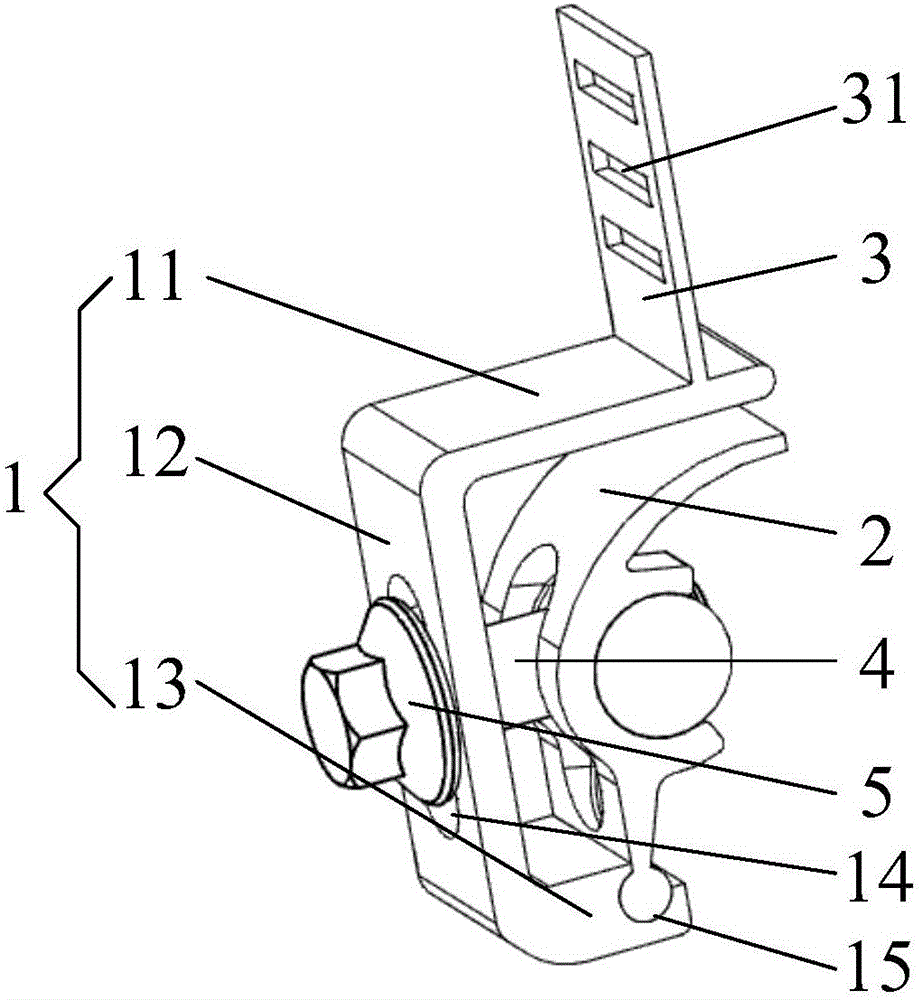

Clamping type fixed support

InactiveCN106347343ADoes not affect strengthSolve the problem of easy breakage from the openingPiping arrangementsVehicle frameEngineering

The invention discloses a clip-type fixed bracket, which comprises a fixed bracket (1), a movable bracket (2), a cable tie installation plate (3) and a connecting rod mechanism (4), and the fixed bracket (1) includes a top plate ( 11), a riser (12) and a bottom plate (13), the riser (11) is provided with a first waist-shaped hole (14), and the bottom plate (13) is provided with a connecting groove (15) with an opening The cable tie installation plate (3) is arranged on the top of the top plate (11), and the cable tie installation plate (3) is provided with a cable tie installation hole (31); the bottom of the movable support (2) Rotationally installed in the connecting groove (15), the end of the connecting rod mechanism (4) passes through the first waist-shaped hole (14) and connects with the riser (12) through a nut (5) . The invention does not need to be fixed by bolts, does not affect the strength of the vehicle frame, and can adjust the installation position of the bracket, and is suitable for various vehicle frames with different thicknesses.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

General T-shaped fixture used for die electrode machining

InactiveCN103231259AGuaranteed positioning accuracyHigh clamping precisionPositioning apparatusMetal-working holdersNumerical controlElectric discharge

The invention discloses a general T-shaped fixture used for die electrode machining. The general T-shaped fixture comprises a T-shaped body, a fixture clamping groove, mechanical hand sliding grooves and a ladder-shaped groove, wherein the square fixture clamping groove is formed in the left side of the T-shaped body; the ladder-shaped groove is formed in the right side of the T-shaped body; and the mechanical hand sliding grooves are symmetrically distributed in the front side surface and the rear side surface of the T-shaped body. According to the general T-shaped fixture, an electrode blank to be machined only needs to be clamped once by the general fixture without repeated replacement of the fixture in the CNC (computer numerical control) machining, EDM (electric discharge machining) electric spark forming machining and wire cutting machining processes, so that the clamping precision and the repeated positioning precision of a die electrode can be improved, the machining efficiency of die manufacture can be improved, and the convenience is provided for flow line production of die manufacture.

Owner:SOUTH CHINA UNIV OF TECH

Auto parts clamping device

Owner:全椒蓝图铸业有限公司

Livestock record detection marking equipment

The invention relates to the technical field of livestock breeding equipment and discloses livestock record detection marking equipment which comprises upper forceps, wherein a connecting part is fixedly mounted in the middle of the upper forceps; the outer surface of the connecting part is moveably sleeved by lower forceps; a connecting hole is formed in the head of the upper forceps; the head ofthe upper forceps is moveably sleeved by a hole drilling needle through the connecting hole; the top end of the hole drilling needle extends to the outer side of the head of the upper forceps throughthe connecting hole and is in threaded sleeve with a screw nut; the bottom of the screw nut is moveably connected with the outer surface of the upper forceps. According to the livestock record detection marking equipment, a positioning plate is connected with a connection groove through a fixed rotating shaft, a torsional spring acts upon the positioning plate, then one end of the positioning plate contacts the bottom of the connection groove, and a tag can be clamped; a moveable rotating shaft is matched, so that a moving rod can be connected with the positioning plate; one end of the positioning plate can be raised through the moving rod, then the tag can be mounted, and functions of security and simple clamping process can be achieved.

Owner:诸暨市开翎工业设计有限公司

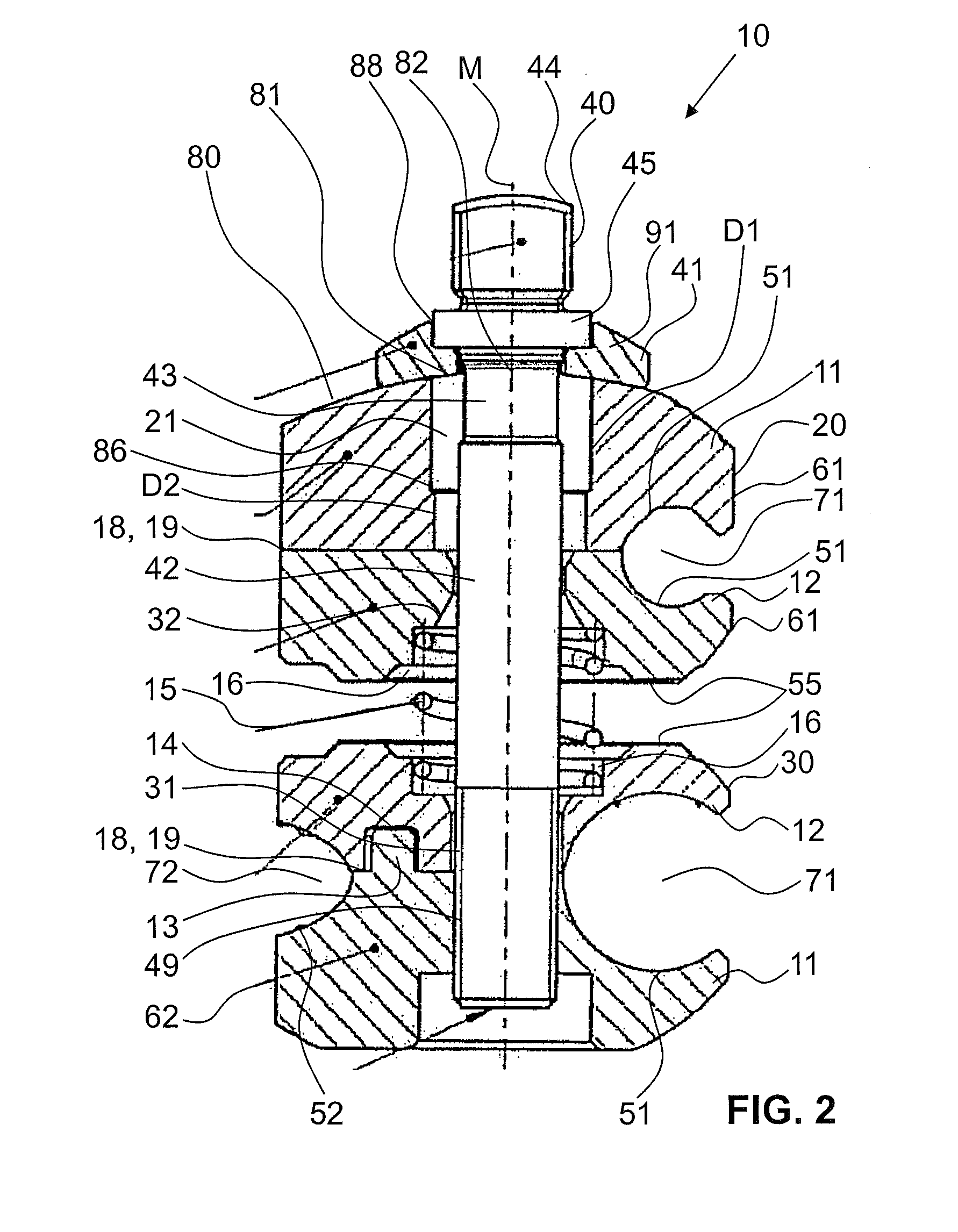

Fixation clamp with thumbwheel

A fixation clamp, more particularly for use in an external fixation system for holding bone fragments adjacent to each other with the help of fixation elements, has at least one clamping assembly having at least one reception opening to accommodate a fixation element along the longitudinal axis of the reception opening. At least one locking element extends through the clamping assembly which locking element provides a clamping force to clamp the fixation element upon tensioning the locking element. The fixation clamp further comprises an actuation element which is in connection with the locking element such that the locking element is actuateable by means of the actuation element, and the actuation element is designed such that it is detachable from the locking element after use and that remounting onto the locking element is prevented after having detached the actuation element from the locking element.

Owner:STRYKER EURO OPERATIONS HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com