Rotary type clamping device

A clamping device, rotary technology, applied in the direction of positioning device, clamping, support, etc., can solve the problems of reduced processing efficiency, insufficient clamping, difficult workpieces, etc., to achieve low friction coefficient, firm clamping, high durability abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

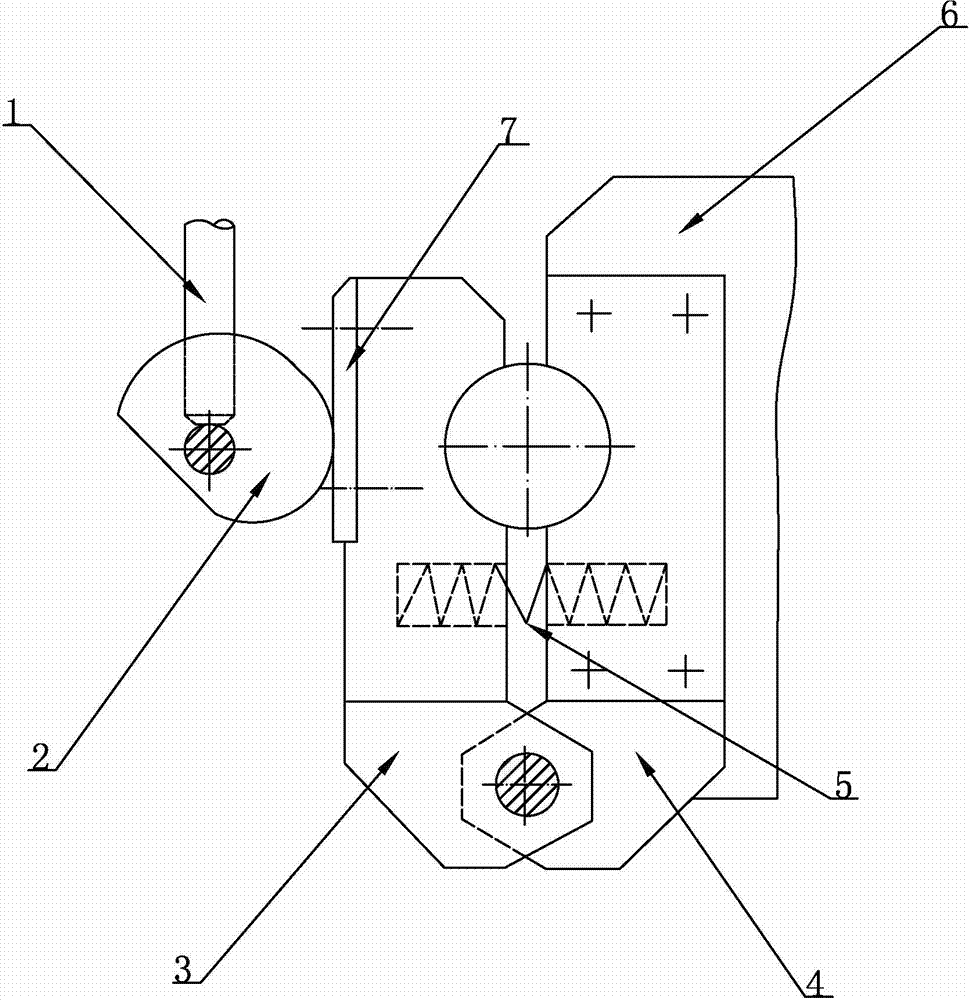

[0008] As shown in Figure 1, the rotary clamping device of the present invention comprises a rotating handle 1, a cam 2, a movable jaw 3, a fixed jaw 4, a spring 5, a base 6, a hardened friction pad 7, a movable jaw 3 and a fixed The lower end of the jaw 4 is hinged, a spring 5 is provided between the movable jaw 3 and the fixed jaw 4, the fixed jaw 4 is fixed on the base 6 by bolts, the upper end of the movable jaw 3 fits with the cam 2, and the upper end of the cam 2 There is a hardened friction pad 7 in contact with the movable jaw 3 , the cam 2 is hinged to the base 6 , and the cam 2 is welded with a rotating handle 1 . When the workpiece is placed between the movable jaw 3 and the fixed jaw 4, the cam 2 is rotated clockwise by turning the handle 1. Under the transmission of the rotating cam 2, the movable jaw 3 is drawn towards the fixed jaw 4, and the workpiece is clamped. Tight; when the cam 2 is loosened, since the spring 5 is compressed when the workpiece is clamped,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com