Clamping device convenient to adjust

A technology of a clamping device and a position adjustment hole, which is applied in the field of clamping devices that are easy to adjust, and can solve the problems of inconvenient adjustment and large volume of the clamping device of the pressure plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

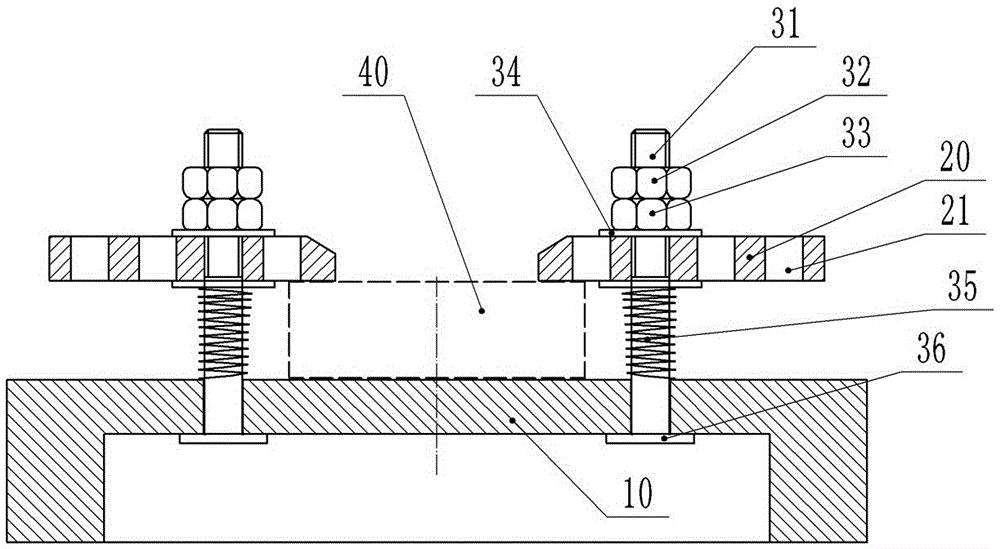

[0016] The reference numerals in the drawings of the specification include: support plate 10, pressure plate 20, adjustment hole 21, threaded shaft 31, upper nut 32, lower nut 33, washer 34, spring 35, baffle plate 36 and pressure plate 40.

[0017] Such as figure 1 As shown, the clamping device for easy adjustment includes a pressure plate 20, a threaded shaft 31, an upper nut 32, a lower nut 33, a spring 35 and a support plate 10; the pressure plate 20 is provided with a plurality of equidistant position adjustment holes 21, which is convenient for adjusting the pressure. The width of the disc 40 clamped. The threaded shaft 31 lower end is provided with the baffle plate 36 that prevents the threaded shaft from slipping, and the threaded shaft 31 is integrally connected with the baffle plate 36; The threaded shaft 31 passes through the support plate 10, the support pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com