Fixture for positioning and broaching bevel gear tooth surface

A bevel gear and tooth surface technology, which is applied in the field of bevel gear tooth surface positioning broaching fixtures, can solve the problems of being unsuitable for mass production, consuming a lot of man-hours, and low work efficiency, and achieving easy clamping, high production efficiency, and positioning. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

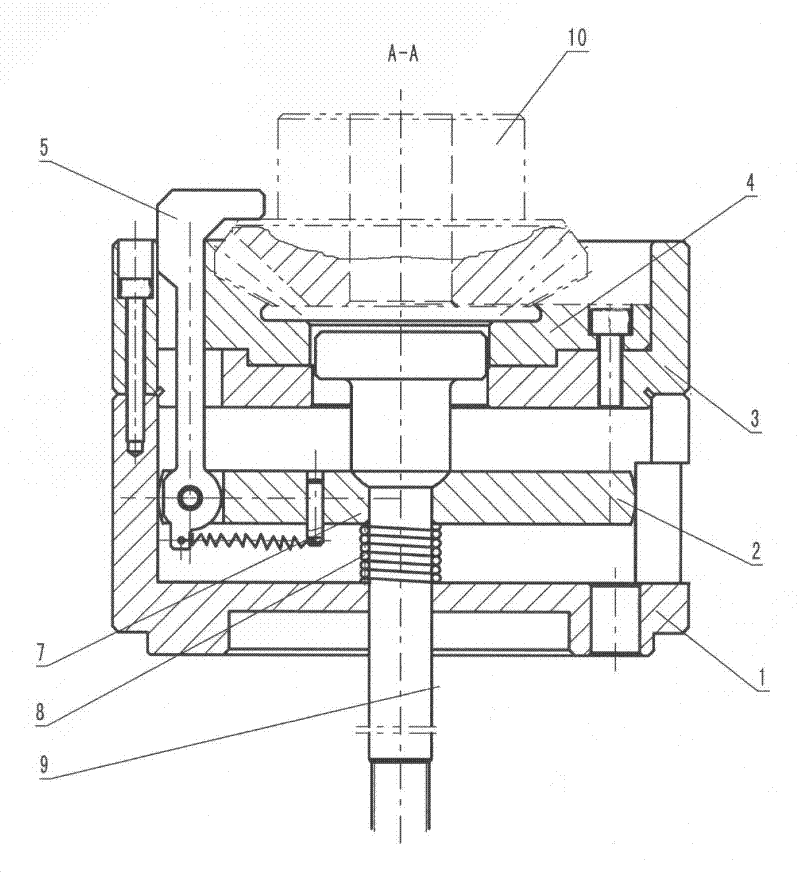

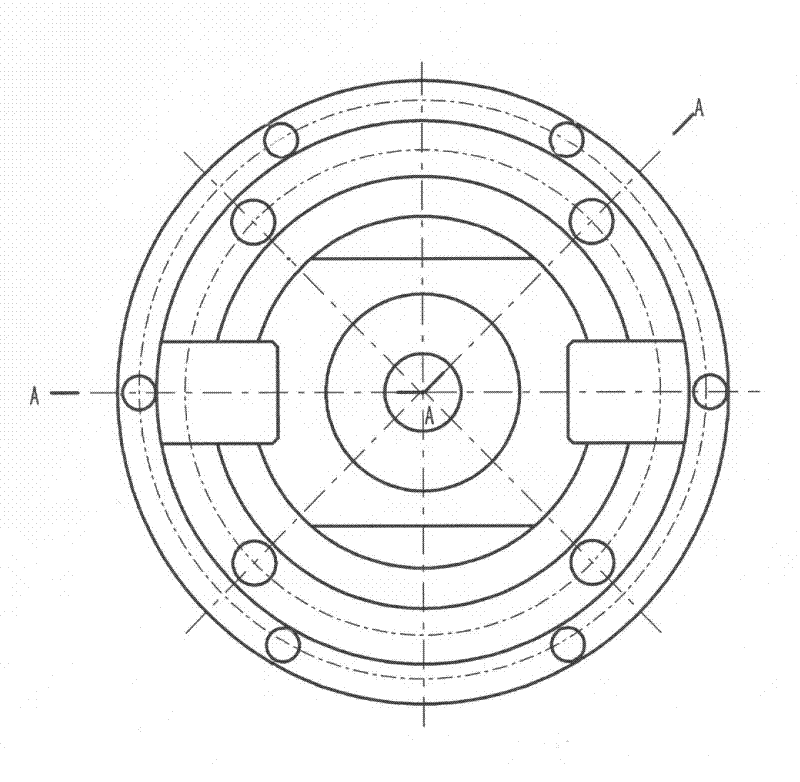

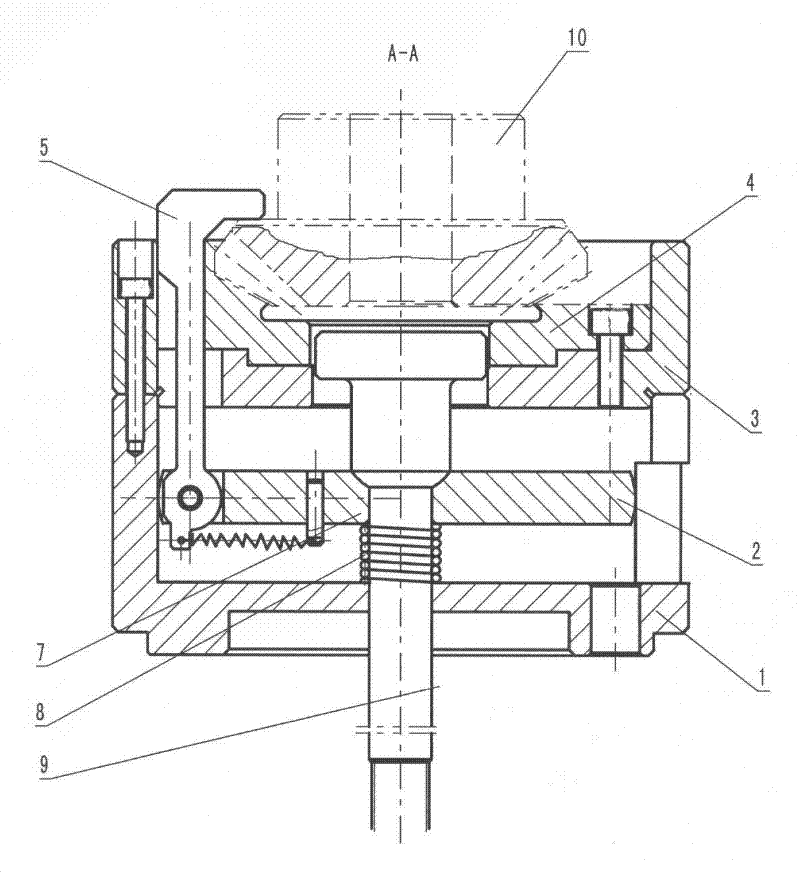

[0015] figure 1 Shown is the embodiment of the bevel gear tooth surface positioning broaching jig, and the elongated boss on the back of the broaching gear. The fixture is composed of two parts: a positioning structure and a clamping structure. The positioning structure includes a chassis 1, a positioning seat 3 and a tooth mold 4 that are coaxially stacked and connected in sequence from bottom to top. The chassis 1 at the bottom is positioned on the workbench with a seam, and the tooth mold 4 is placed on the positioning seat. 3. Position with seam. The clamping structure is built in the positioning structure, and it includes a slide block 2, an angle buckle 5, a tension spring 6, a pin 7, a compression spring 8 and a pull rod 9. The slider 2 is placed between the chassis 1 and the positioning seat 3, and the outer contours of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com