Indexable milling cutter blade and milling cutter

A technology of milling inserts and inserts, which is applied in the field of indexable circular milling inserts and milling tools, can solve the problems of affecting cutting performance, insufficient chip space, high manufacturing cost, etc., and achieves convenient operation, accurate positioning, and simplified positioning structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

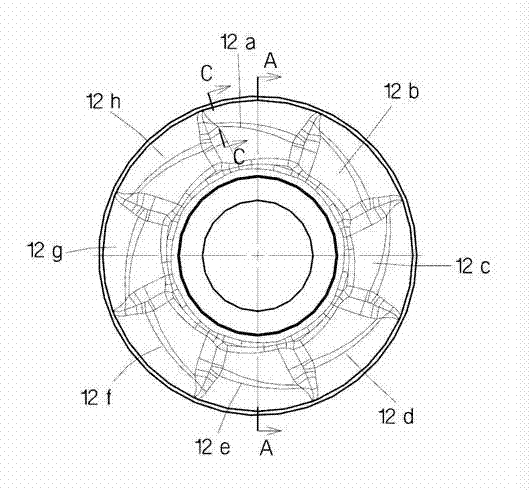

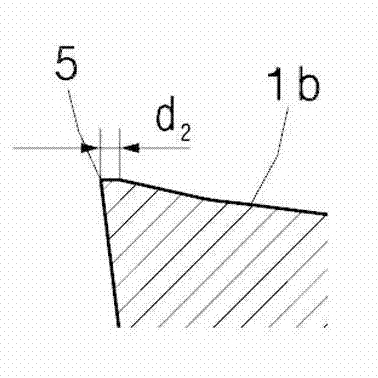

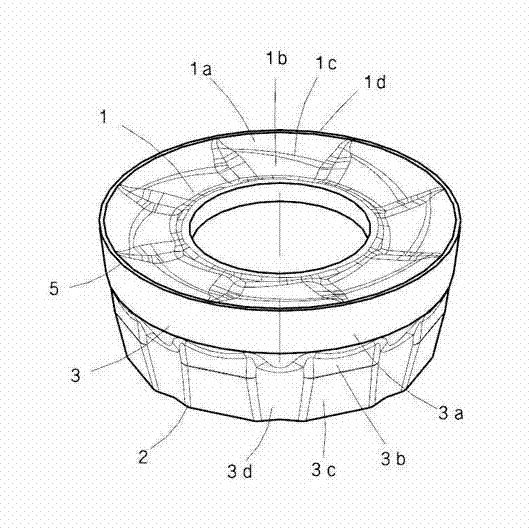

[0043] An indexable circular milling insert, as attached Figure 1-6 As shown, the blade body is conical, including an upper surface 1, a lower surface 2, and a side surface 3 connecting the upper surface and the lower surface. The geometric center of the blade body is provided with a blade positioning hole. The side surface 3 includes a flank surface 3a close to the upper surface 1 and a positioning surface close to the lower surface 2, a groove is arranged between the positioning surface and the flank surface 3a, and a plurality of uniform grooves are arranged on the positioning surface. Distributed positioning platform 13. The positioning platform 13 includes a positioning plane 3c protruding outward from the side surface 3 and a transition surface 3b connecting the groove and the positioning plane 3c, the positioning plane 3c extends from the transition surface 3b to the lower surface 2, and the lower Surface 2 is the reference plane for blade installation.

[0044] For ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com