Patents

Literature

124results about How to "Simple positioning structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

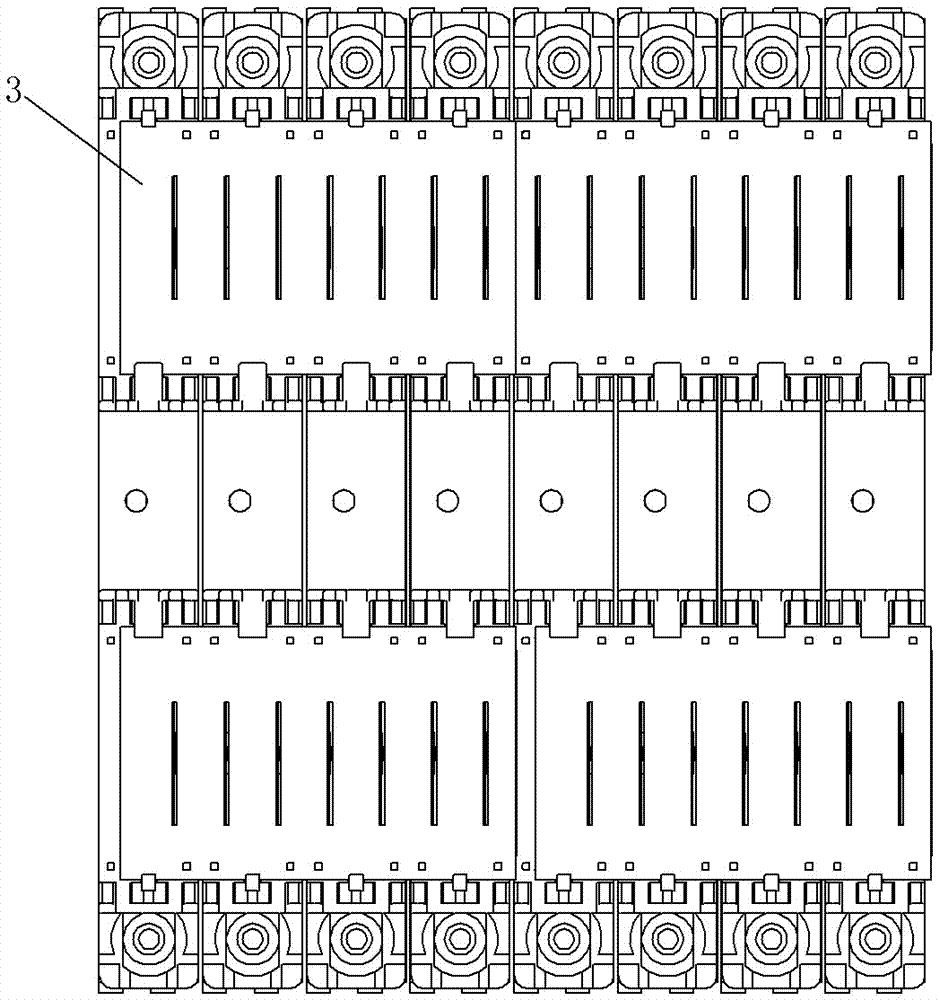

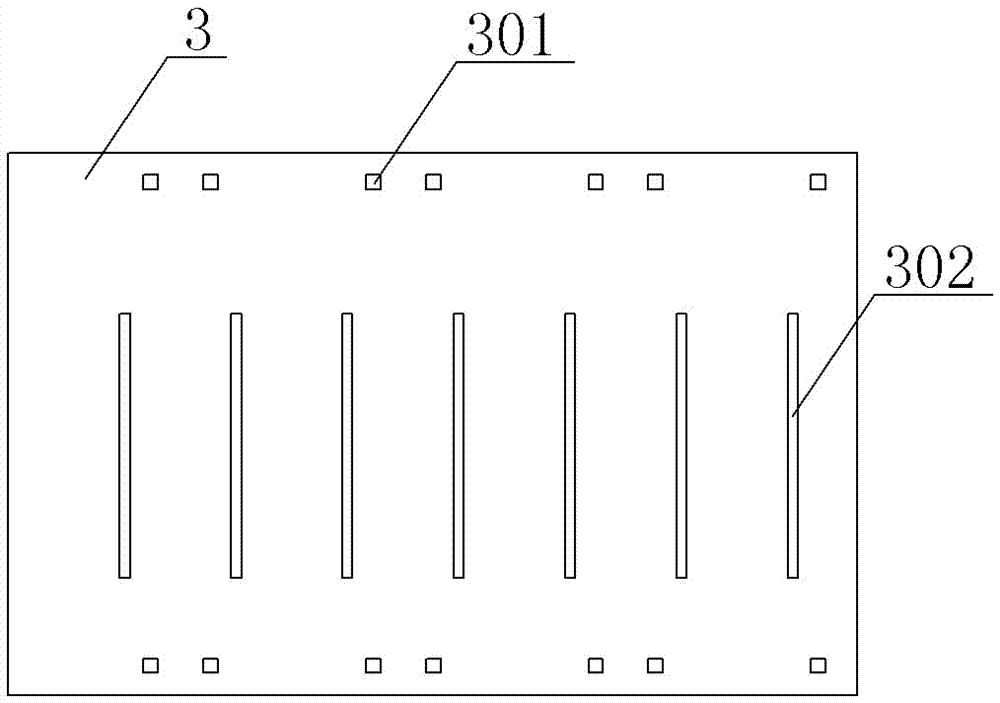

Connection structure of flexible-package lithium ion battery module

ActiveCN105070874ASimplify the assembly processTo achieve a conductive connectionCell component detailsBusbarElectrical battery

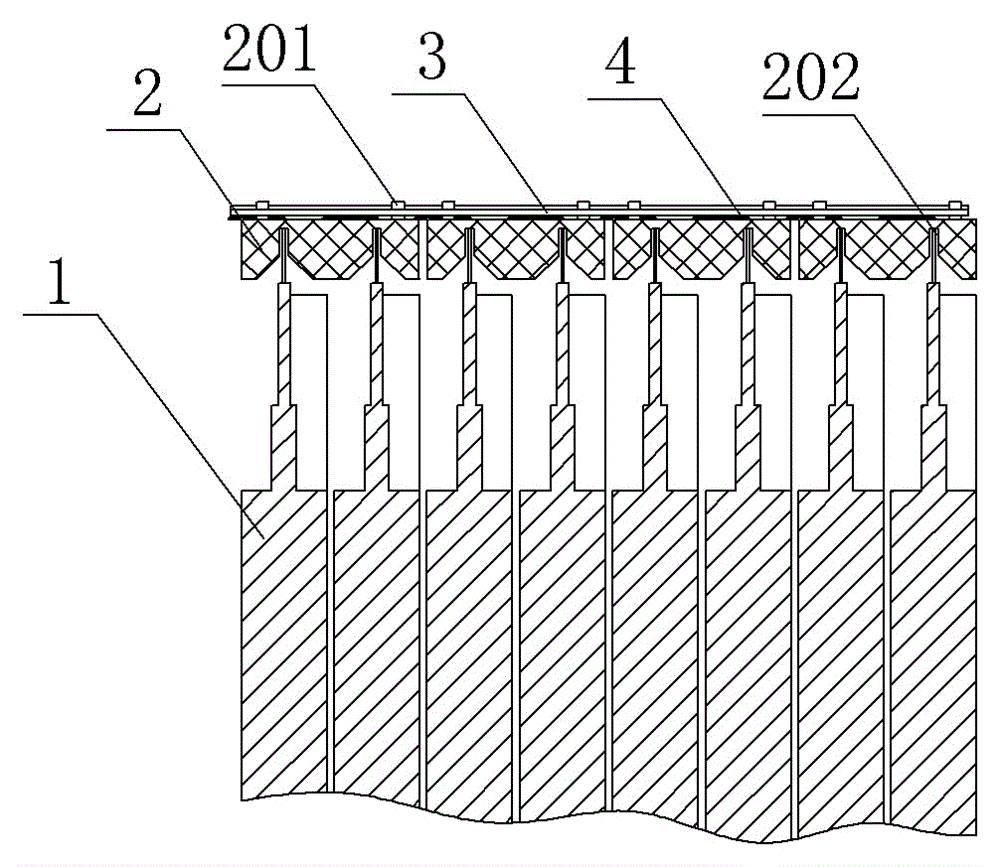

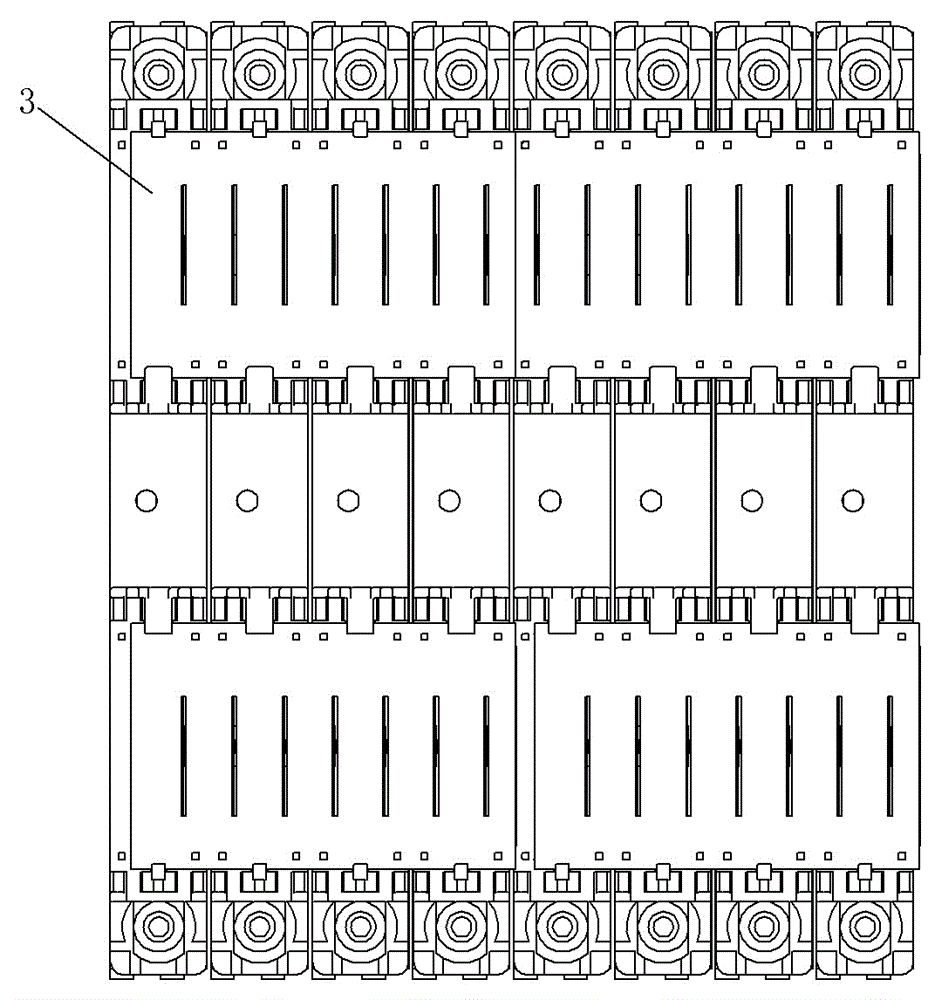

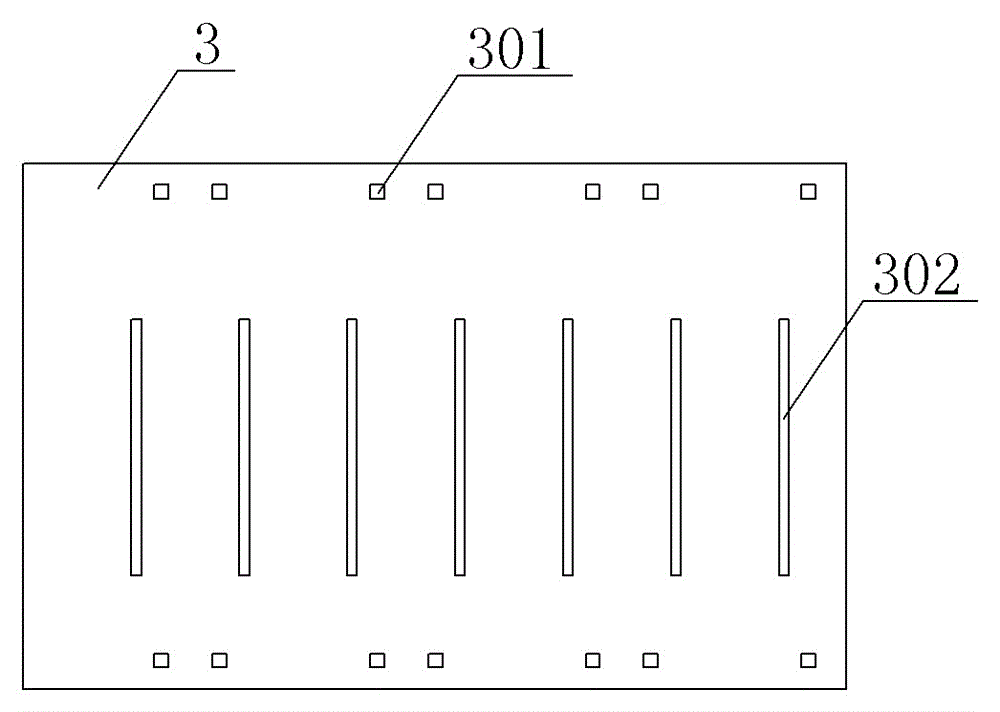

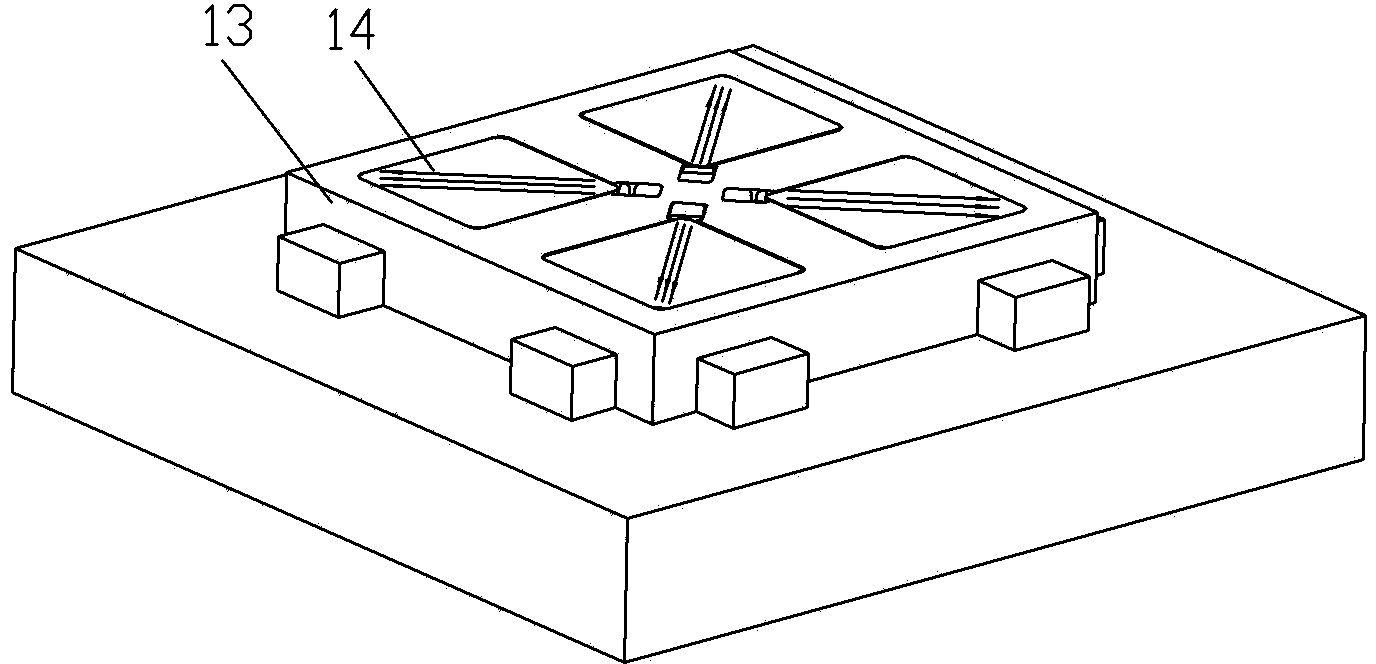

The invention provides a connection structure of a flexible-package lithium ion battery module. The connection structure comprises at least two battery cores and a busbar and also comprises an insulated grid plate, wherein the at least two battery cores are arranged in parallel; the busbar is arranged above the battery cores and electrically connected with tabs of the battery cores; the insulated grid plate is arranged below the busbar and fixedly assembled relative to the battery cores; tab via holes are formed in the insulated grid plate, are corresponding to the tabs of the battery cores and are used for the tabs to pass through; the tops, upwards passing through the tab via holes, of the tabs are provided with bent parts which are bent and are in tight contact with the upper side surface of the insulated grid plate; the busbar is provided with a lower side surface, and the lower side surface is connected onto the bent parts of the tabs in a pressed way and welded and fixedly connected with the bent parts of the tabs. Since the whole busbar is downwards connected onto the bent parts of the tabs in a pressed way, during actual welding and assembling, a corresponding crimping tool is only needed to downwards press the busbar, and the busbar downwards presses the bent parts of the tabs, thus, the problem that a tab crimping tool is required to be additionally arranged is solved, the assembly process of the battery module is effectively simplified, and product cost is reduced.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Printing template

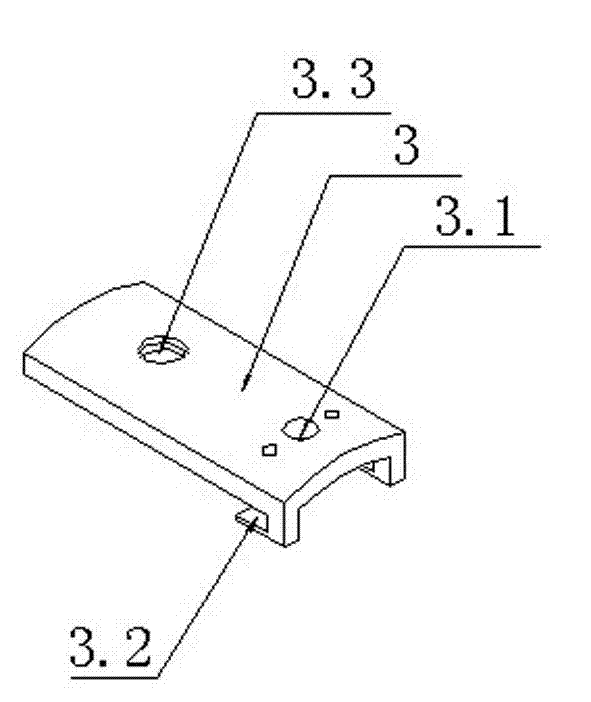

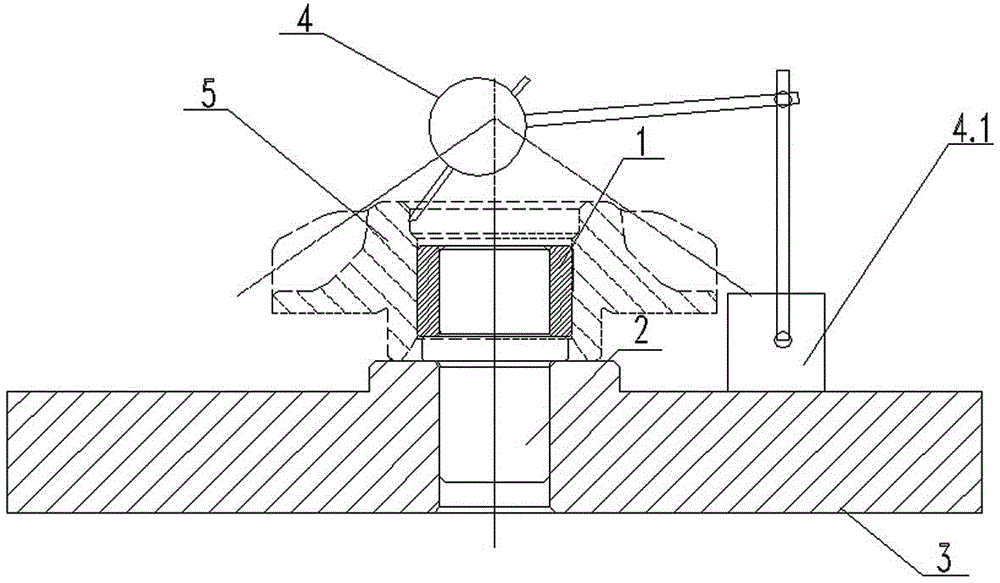

InactiveCN102632721ASimple fixed structureEasy to operateTypewritersOther printing apparatusEngineeringMechanical engineering

A printing template is a part for bearing a printing medium on a flat plate printing machine and comprises a body having a front side face, a rear side face, an upper surface, a lower surface, a left side face and a right side face, wherein the body is provided with a support face for supporting the printing medium; and a positioning part for fixing the printing medium on the support face extends perpendicularly to the support face. The printing template has the advantages of being simple in structure, easy to operate and capable of preventing other parts of the flat plate printing machine from being damaged.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

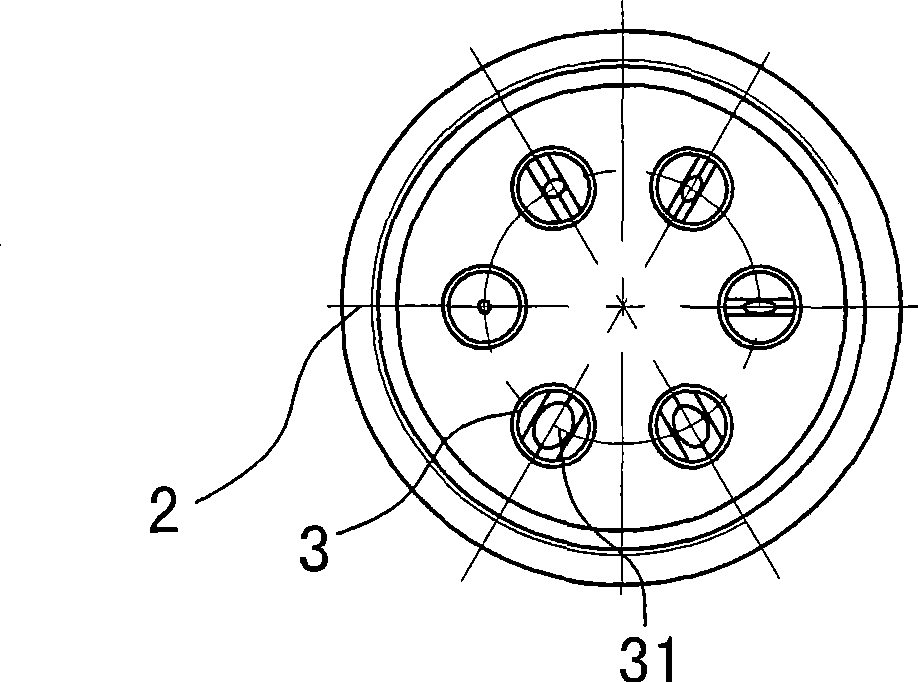

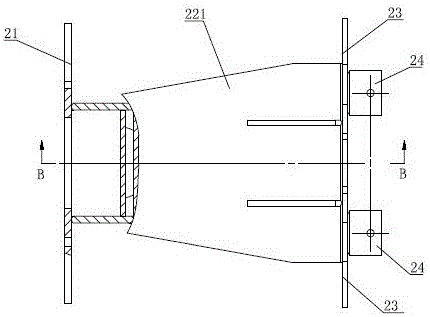

Multi-angle showerhead of washer

ActiveCN101428257AMeet the pressureFulfil requirementsSpray nozzlesCleaning using liquidsEngineeringWater spray

The invention relates to a multi-angle nozzle for a cleaner, which comprises a nozzle holder. Water inlets, flow passages, and water outlets are formed on the nozzle holder; the water inlet is connected with a spraying rod; the flow passage is connected with a water inlet and a water outlet; a nozzle cage is arranged outside the nozzle holder; nozzle cores are internally installed in the nozzle cage; water spraying holes are formed on the nozzle core; and the water spraying holes are communicated with the water outlets. The nozzle is characterized in that the nozzle holder is in clearance fit with the nozzle cage; a positioning device is arranged between the nozzle holder and the nozzle cage; two or more nozzle cores are arranged in the nozzle cage and uniformly distributed according to the circumference, wherein, the sparing hole of one of the spray cores corresponds with the water outlet, injection angles of all spraying holes are different, and the injection diffusion angle is between 0 degree to 90 degrees. The nozzle has the advantages that an injection angle can be arbitrarily chosen according to requirements, so that the requirements of different pressures and cleaning areas can be met, and the application range is wide.

Owner:LUTIAN MASCH CO LTD

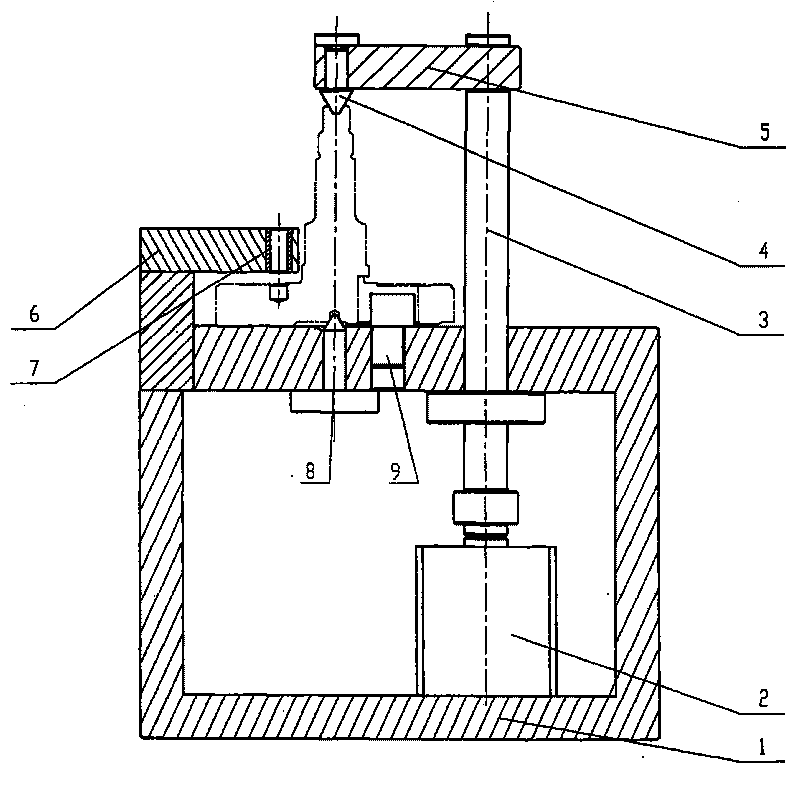

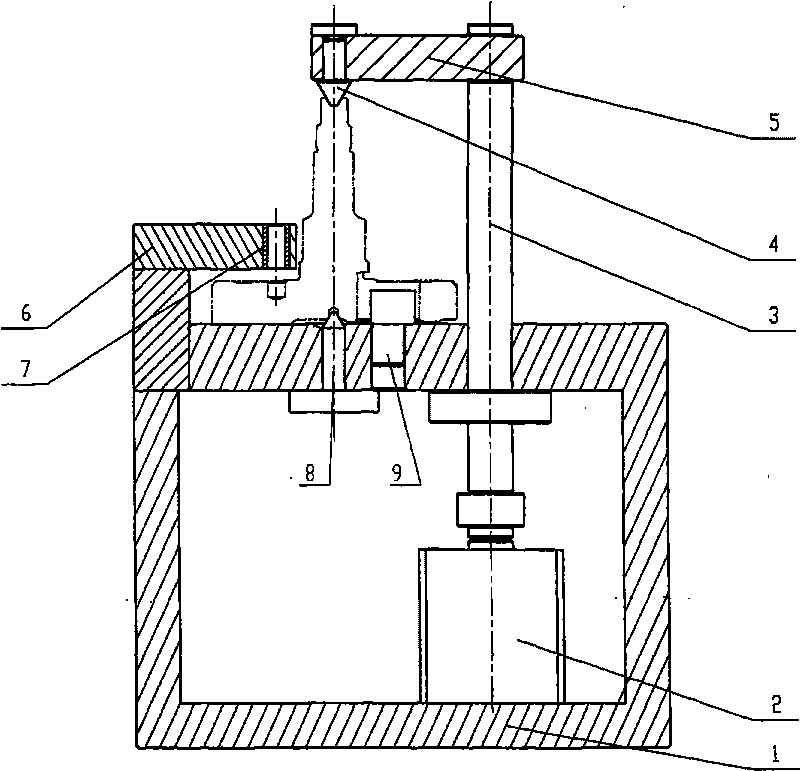

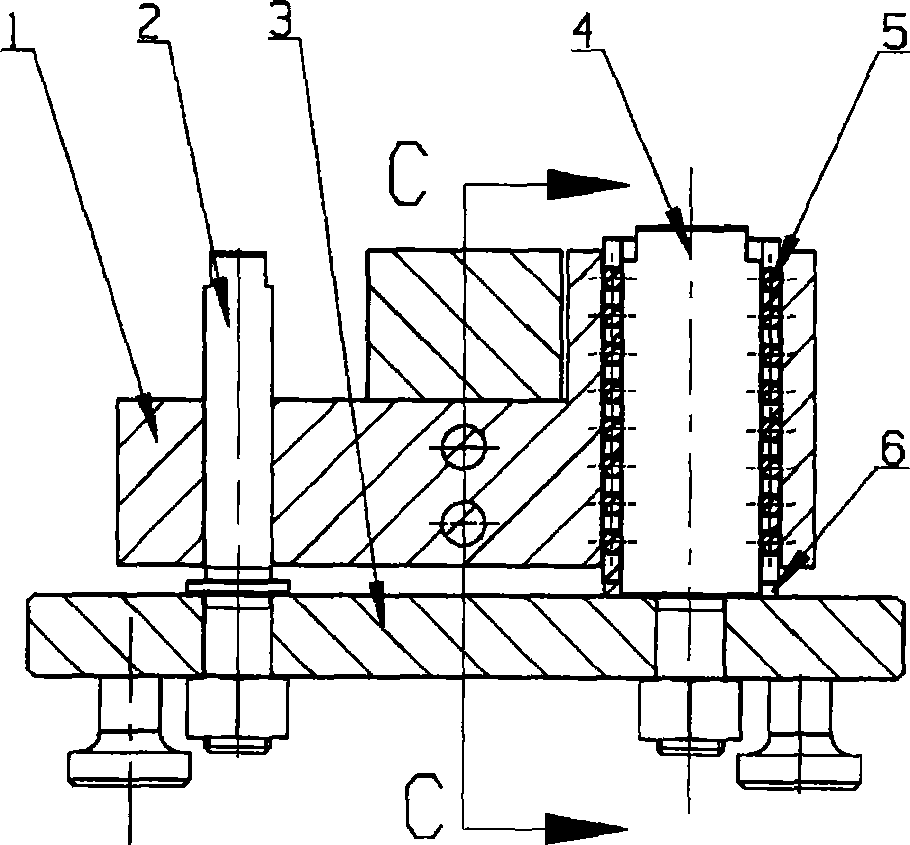

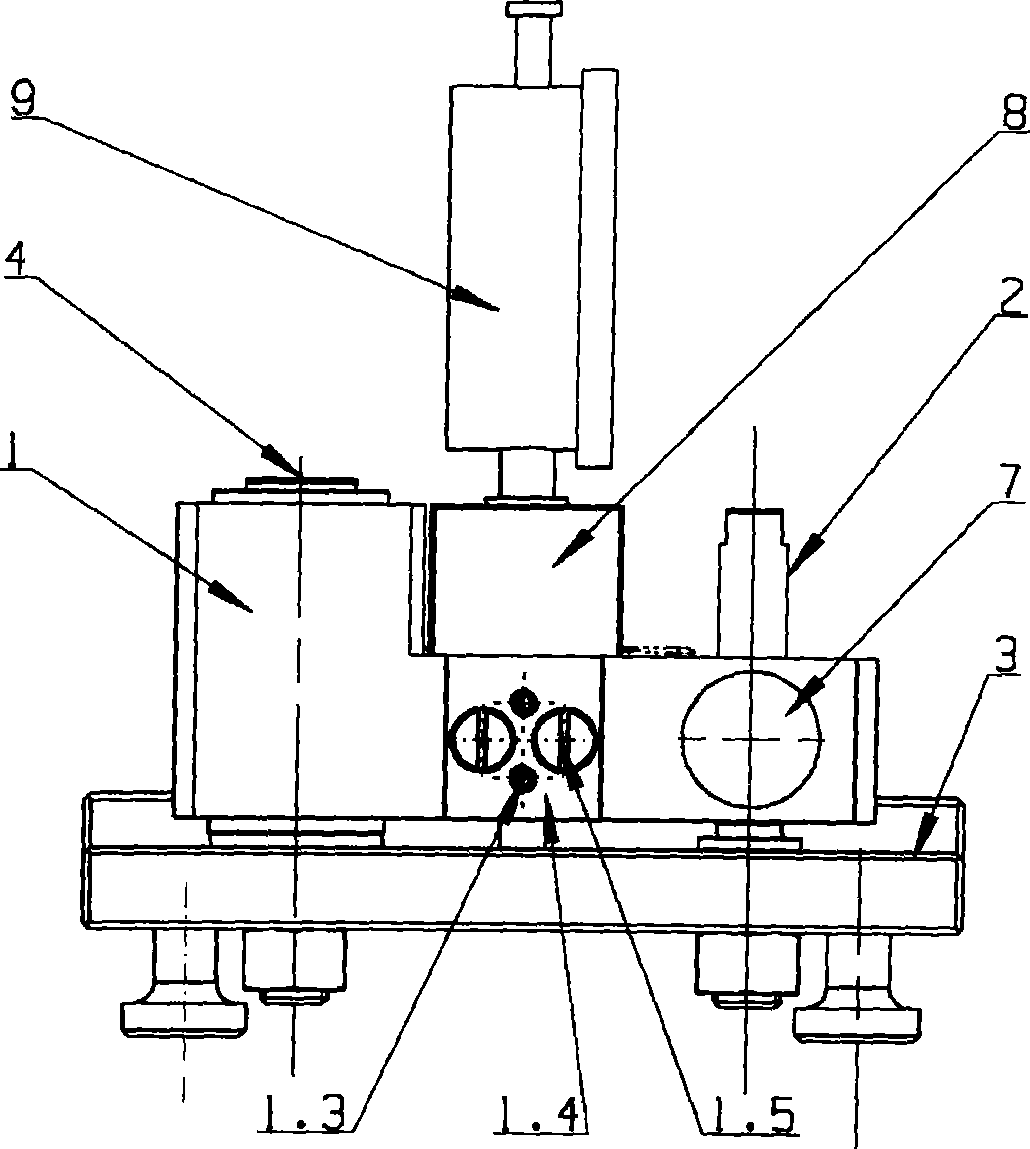

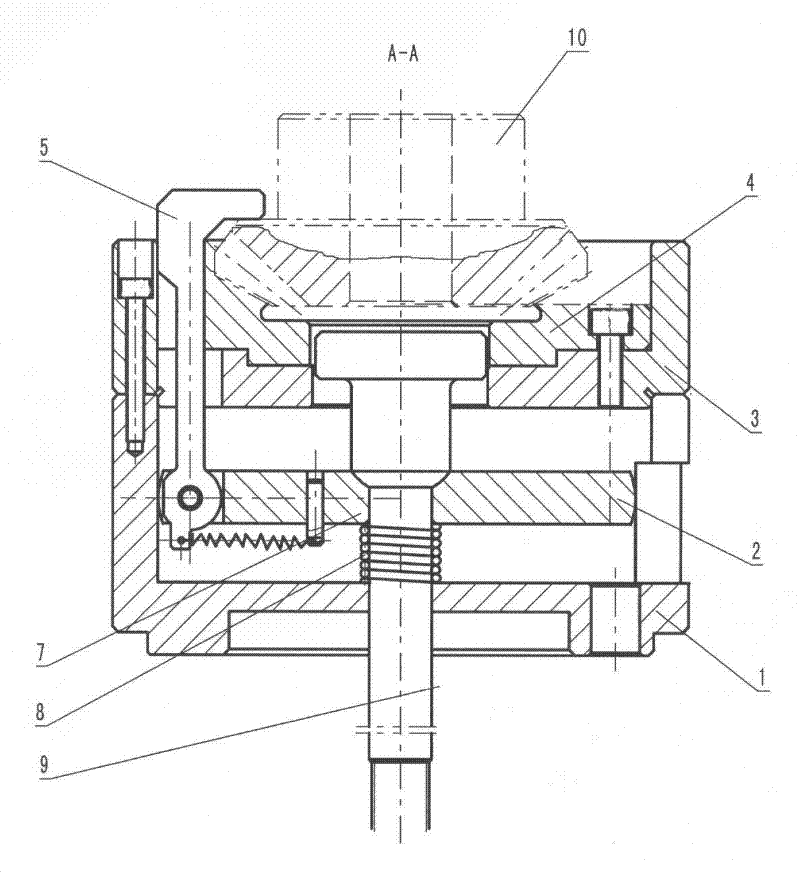

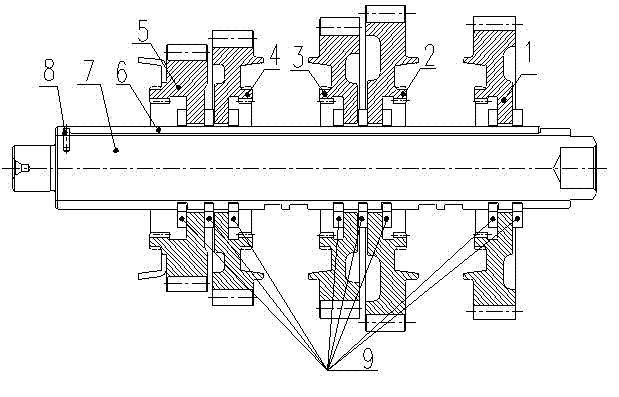

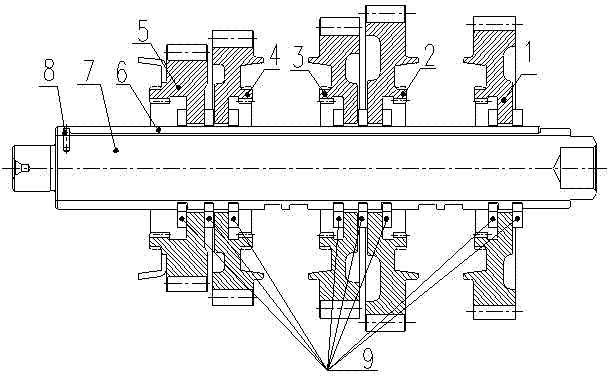

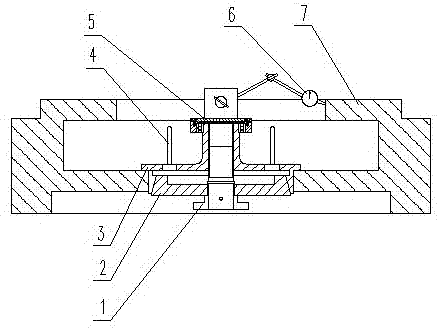

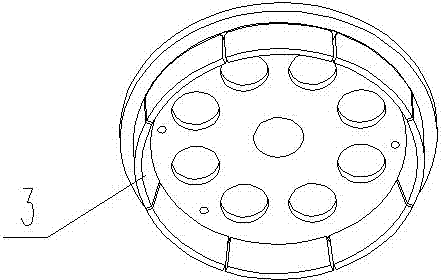

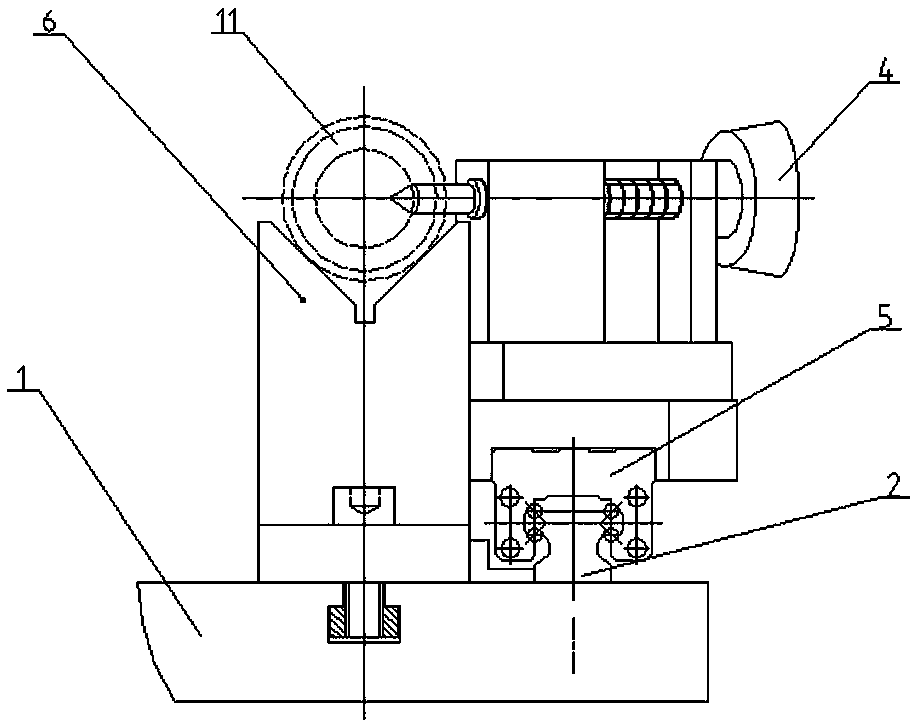

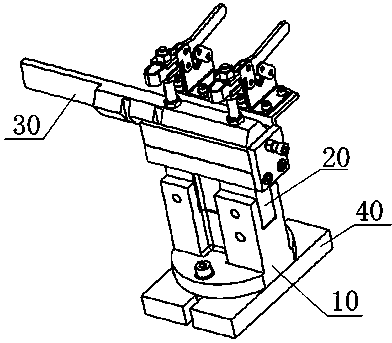

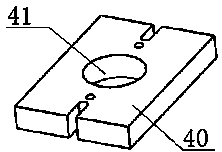

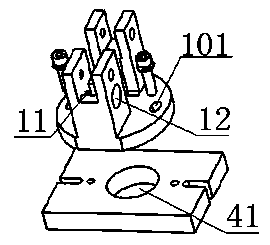

Drilling fixture for crank positioning pin hole

ActiveCN101758399ASimple positioning structureHigh positioning accuracyPositioning apparatusBoring/drilling componentsEngineeringMechanical engineering

The invention discloses a drilling fixture for a crank positioning pin hole, which comprises a fixture body, a cylinder, an upright post, an upper tip, a positioning plate, a template, a drilling sleeve, a floating tip and a positioning pin. The drilling fixture realizes initial positioning by utilizing the matching between the outer end surface of a crank and the floating tip at the top end of the fixture body as well as the positioning pin; the cylinder in the fixture body is started to pull the upright post so as to realize the matching between the downward upper tip at the top end of the upright post and an upward central hole of the crank, thereby realizing axial positioning and clamping of the crank; and the crank positioning pin hole is accurately drilled according to the drilling sleeve on the template. With synchronous installing and positioning, synchronous positioning and compacting, good drilling quality, short auxiliary working hours and high production efficiency, the drilling fixture is particularly suitable for mass production and application.

Owner:JIANGSU GANGYANG

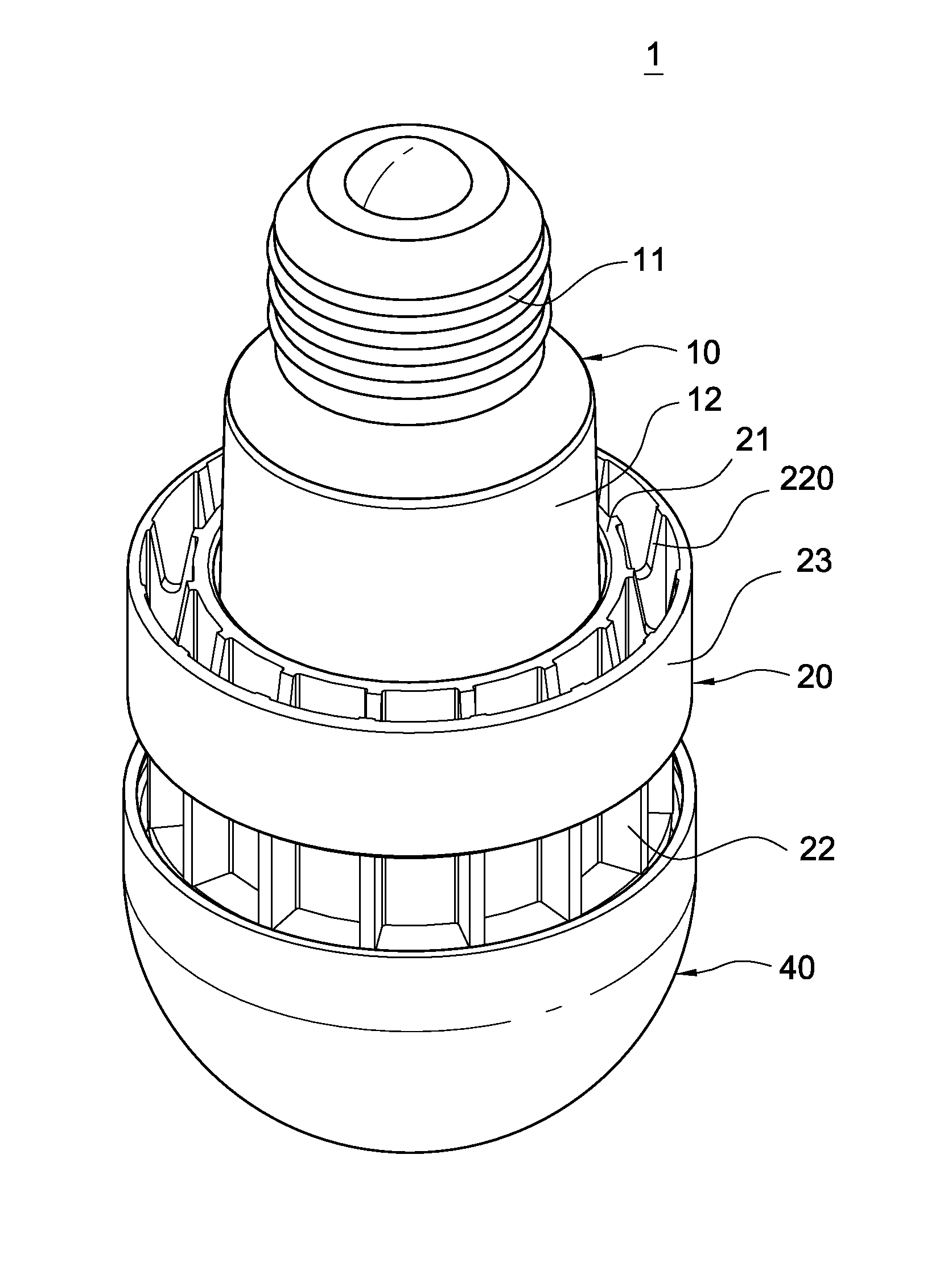

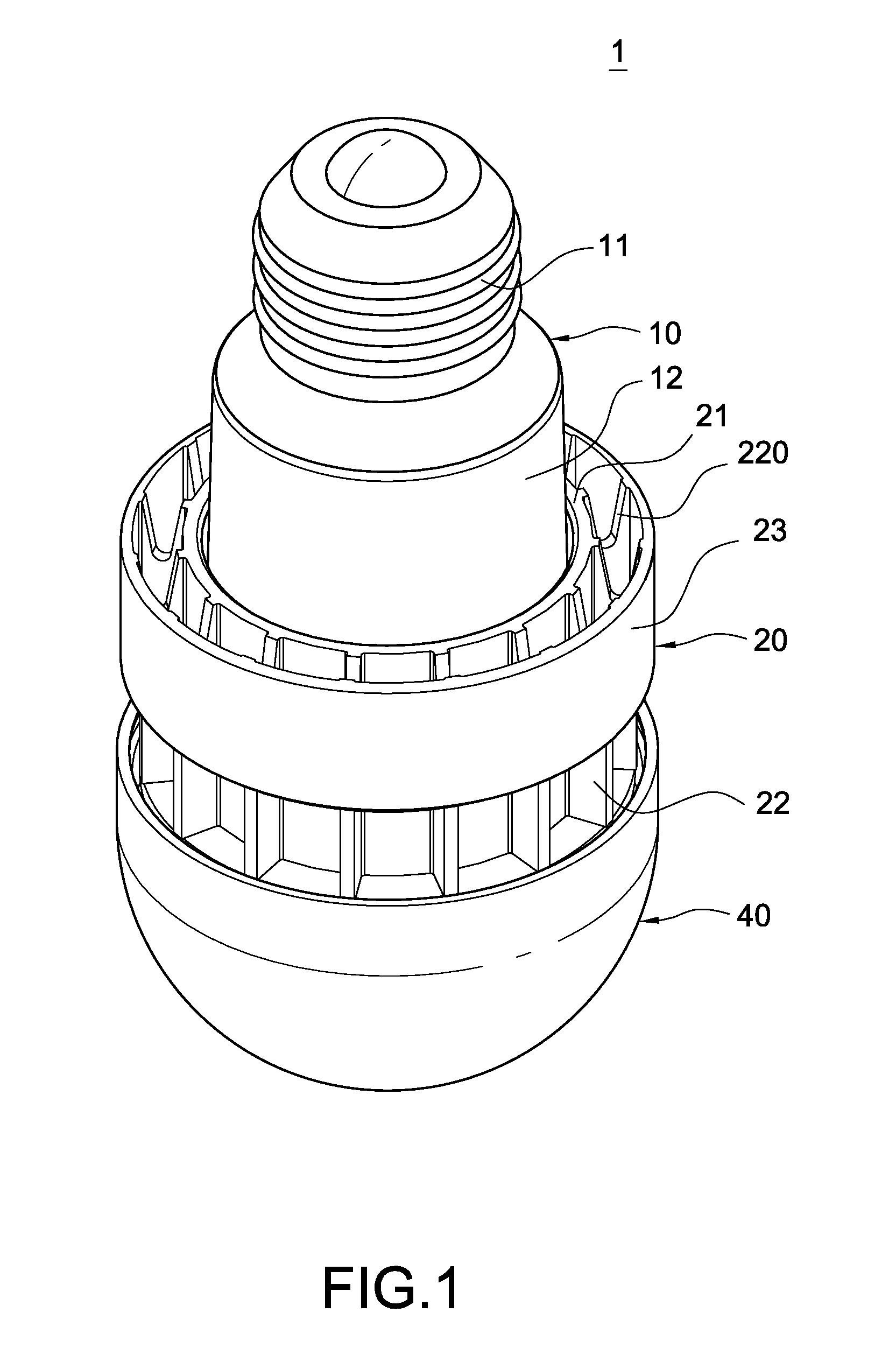

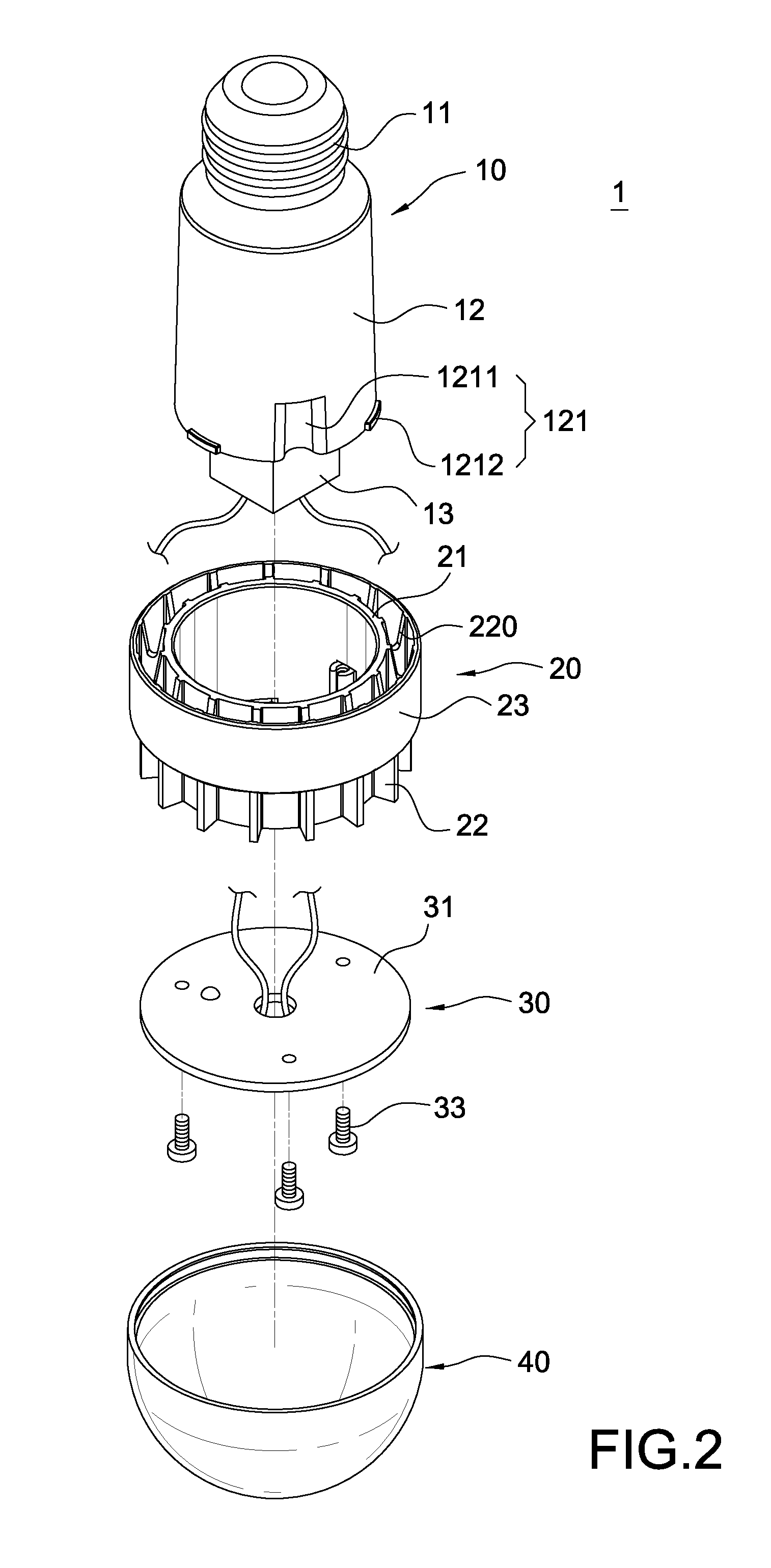

LED bulb with heat dissipater

InactiveUS20120248961A1Duration of manufacturing can be shortenedReduce manufacturing costPlanar light sourcesPoint-like light sourceEngineeringLED lamp

A LED bulb has a heat dissipater. The LED bulb includes a base, a heat dissipater, a LED module and a cap. The base has a conducting portion and an isolation tube positioned at a bottom portion of the conducting portion. The heat dissipater is assembled to the isolation tube. The heat dissipater has a hollow tunnel and a plurality of fins extending perpendicularly and positioned with an interval from one another in a radial fashion. The fins have an outer flange connected to a heat dissipation ring, and the heat dispensing ring is circularly connected to the fins. The LED module has a circuit board fixed to the heat dissipater and a plurality of LED scattered on the circuit board. The cap is assembled to the heat dissipater to house the LED module. The LED bulb increases the air circulation and accordingly promotes the heat dissipation effect.

Owner:CHICONY POWER TECH CO LTD

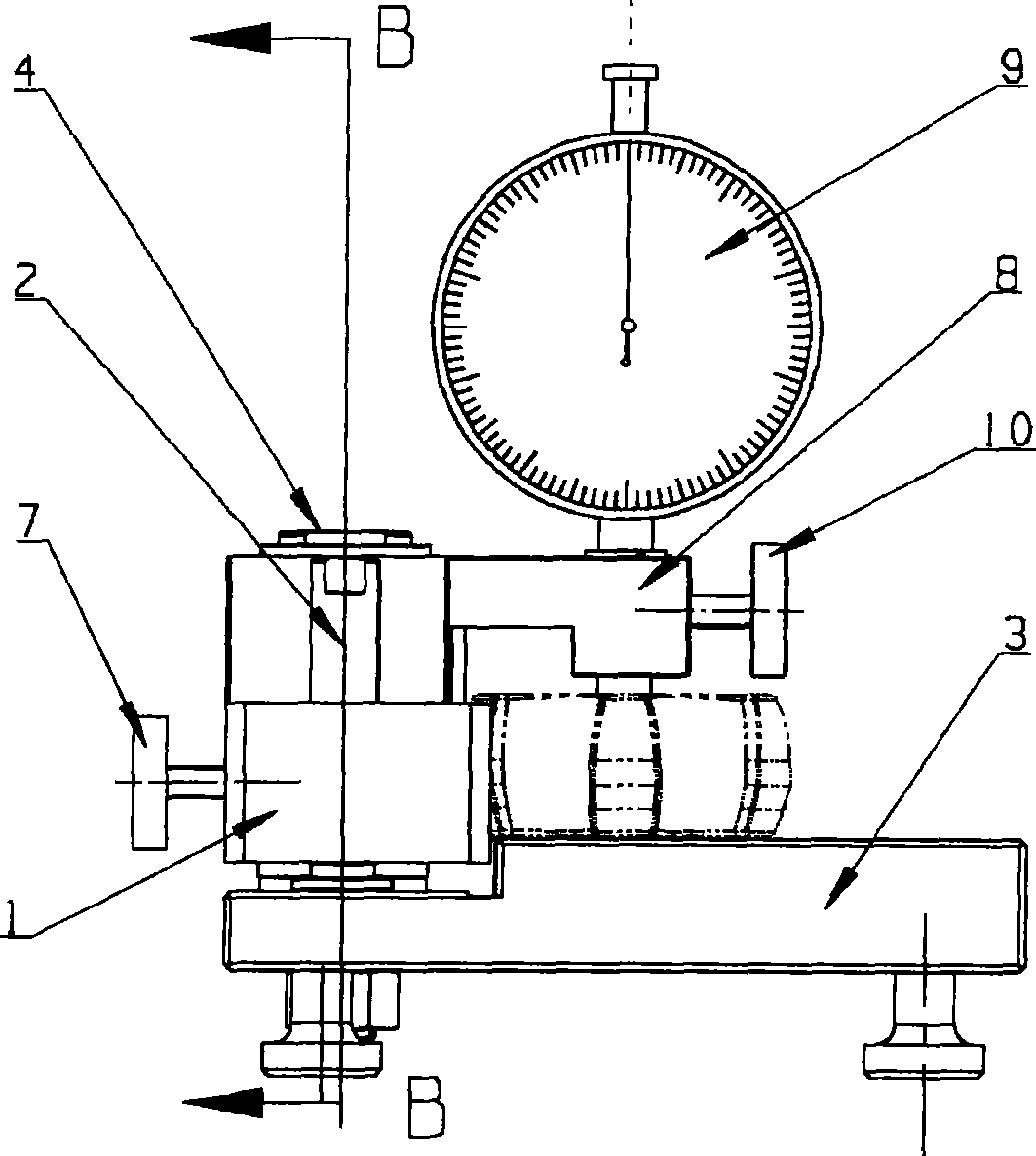

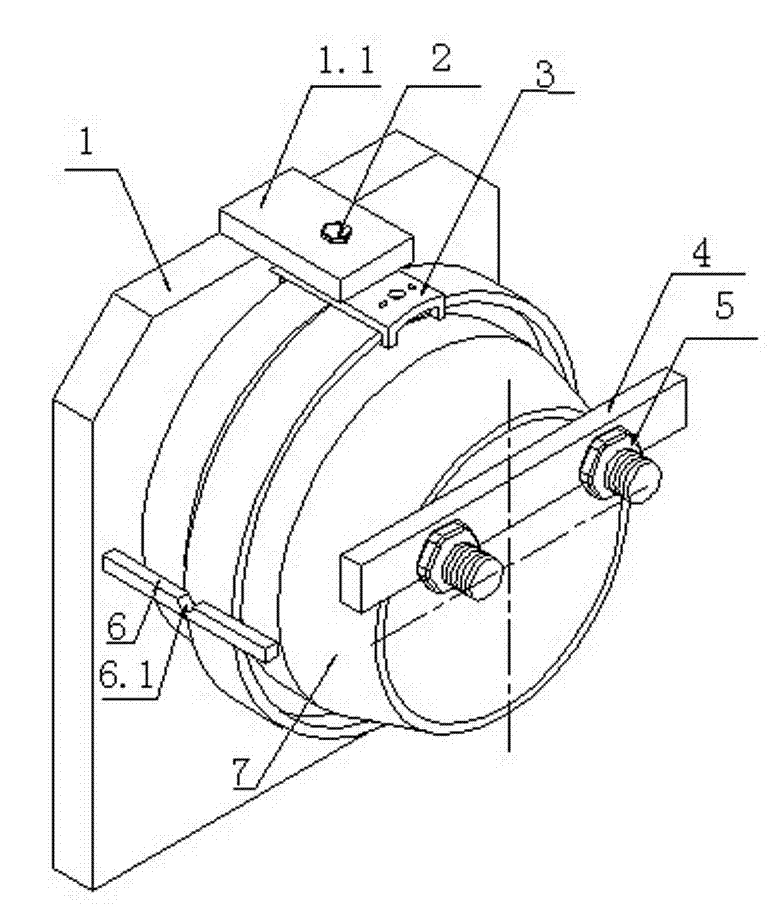

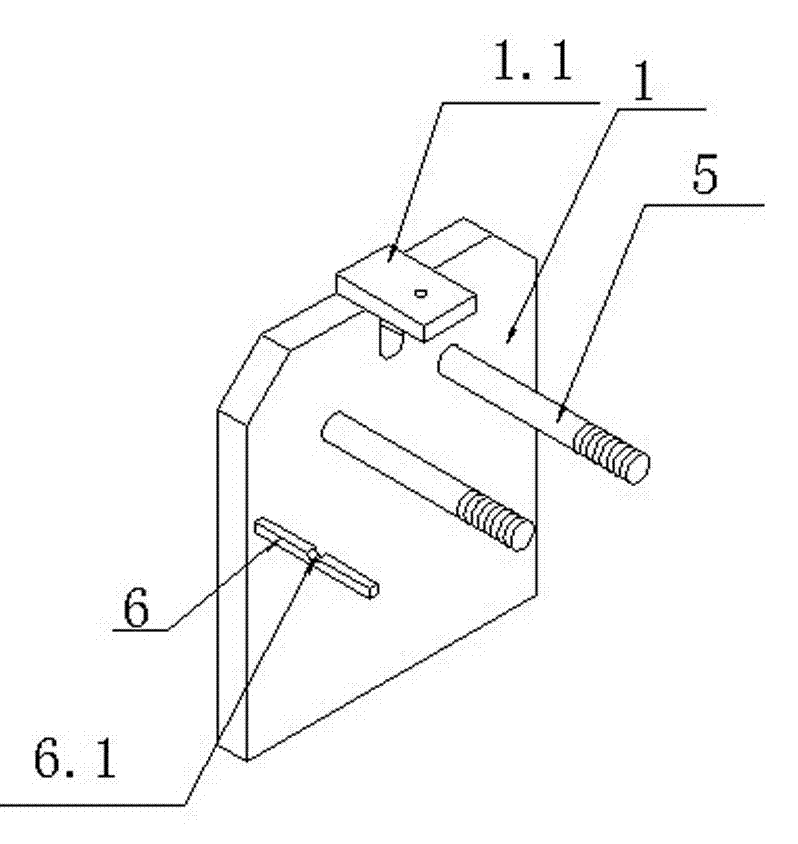

Sphere center position detection apparatus for inner spider alley

InactiveCN101430183ASimple positioning structureEasy to manufactureMechanical measuring arrangementsEngineeringSet screw

The invention discloses a device for detecting an inner star wheel padded wall center of sphere position, which comprises a positioning seat, an auxiliary axis, a base, a principle axis, a washer, a cage, a holding screw, a gauge stand, a dial test indicator, and a locking screw. The base is connected with the auxiliary axis and the principle axis. The cage and the washer are sheathed on the principle axis together. The positioning seat is provided with two parallel through holes which are matched with the auxiliary axis and the cage in a transitional way. The positioning seat can move up and down corresponding to the base. The middle part of the upper plane of the positioning seat is connected with the gauge stand used for fixing the dial test indicator and the side surface of the positioning seat is provided with a padded wall center of sphere positioning benchmark setting structure which comprises a pin roll, steel ball, a bolt and a cover board. The plane of the base is set as zero position in actual measurement. The deviation value between the actual value and the theoretical value of the detected surface of the inner star wheel away from the center of sphere of the inner star wheel can be detected by moving the positioning seat up and down. The device is especially suitable for being used as the production field witnessed inspections.

Owner:JIANGSU PACIFIC PRECISION FORGING

Fixture for positioning and broaching bevel gear tooth surface

InactiveCN102335827ASimple positioning structureSimple clamping processPositioning apparatusMetal-working holdersGear wheelEngineering

The invention discloses a fixture for positioning and broaching a bevel gear tooth surface, comprising a positioning structure and a clamping structure, wherein the positioning structure comprises a chassis, a positioning seat and a tooth die which are successively overlaid and connected from bottom to top; the clamping structure comprises a sliding block, an angle buckle, a tension spring, a pin, a pressure spring and a draw bar; the sliding block is built in an inner cavity between the chassis and the positioning seat; the outer outlines of the sliding block and the positioning seat are provided with two opening slots with symmetrical structure; the opening slot in the sliding block is hinged with the angle buckle; two ends of the tension spring are respectively connected with the lower end of the angle buckle and the pin to form an elastic tension structure; and the draw bar is penetrated from the inner hole of the tooth die to be connected with the positioning seat, the sliding block, the pressure spring and the chassis in series in sequence to form the structure that the draw bar and the pressure spring guide the sliding block to drag the angle buckle to axially slide. In the fixture, the tooth die positioning structure is adopted, and therefore the fixture is accurate and reliable to position. After a workpiece is installed, the workpiece is directly meshed with the teeth of the tooth die, the pitch cercle of the tooth die serves as the positioning reference which is same with a design reference, and therefore positioning errors can be prevented from generating.

Owner:JIANGSU AIRSHIP GEAR

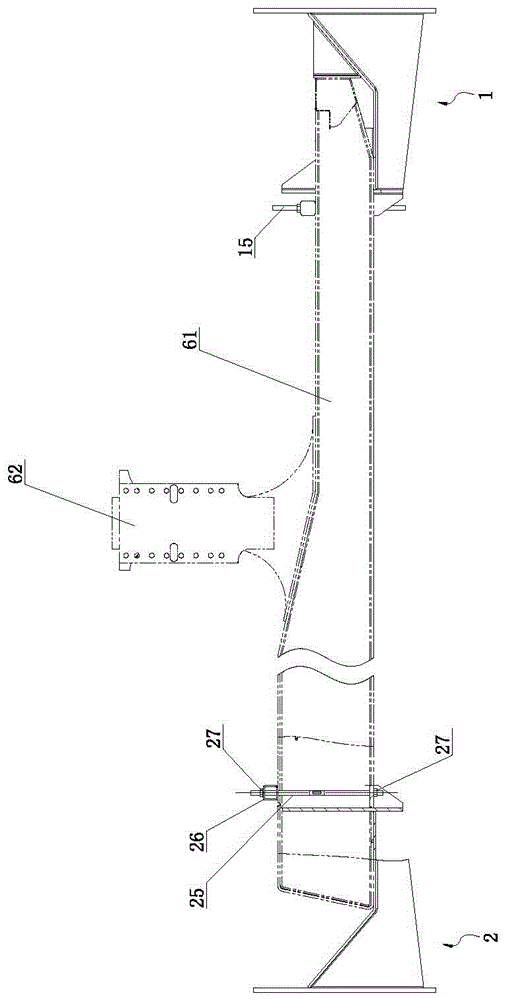

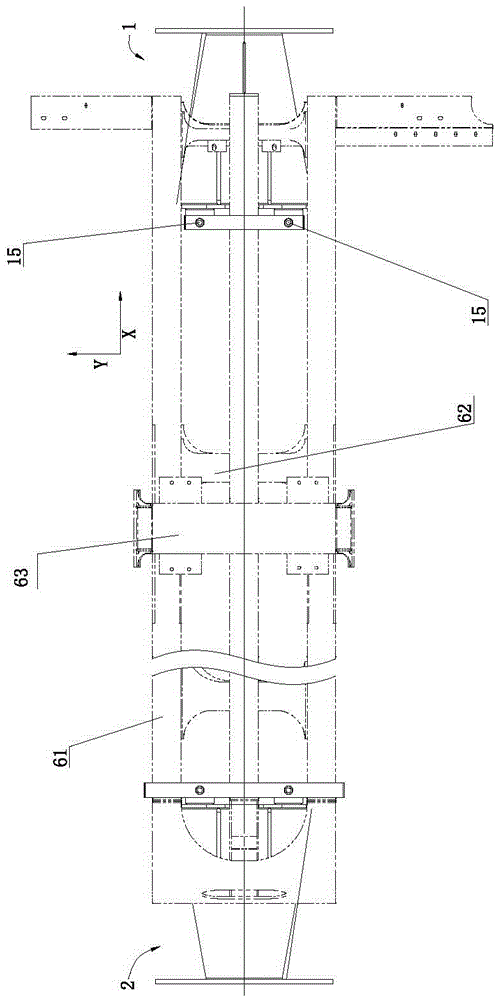

Welding fixture of frame and welding method

ActiveCN106736136AReliable clampingHigh positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesWelding

The invention discloses a welding fixture of a frame and a welding method. The welding fixture comprises a first rotational positioning device and a second rotational positioning device. The first rotational positioning device comprises a first connecting disc, a first bearing seat, a first limiting plate, a first connecting lug, a first screw, a first pressing block and a first nut. The second rotational positioning device comprises a second connecting disc, a second bearing seat, a second limiting plate, a second connecting lug, a second screw, a second pressing block and a second nut. The welding method includes the step that the fixture is used for welding a single longitudinal beam and the frame. The welding fixture and the welding method can be suitable for welding of the single longitudinal beam and suitable for welding of the frame.

Owner:GUANGZHOU ELECTRICAL LOCOMOTIVE

Spindle assembly for double-intermediate-shaft transmission

Provided is a spindle assembly for a double-intermediate-shaft transmission. The technical scheme of the spindle assembly is that axial positioning of a gear on a spindle is achieved through eight spindle adjusting gaskets, radial positioning of the gear on the spindle is achieved through mutual mesh between the spindle gear and a countershaft gear, and the spindle assembly is simple in structure, strong in bearing capacity, short in axial length and low in noise. For the double-intermediate-shaft transmission, gears at all gear positions of the spindle float on the spindle in the radial direction, and axes of the spindle and a countershaft are located in the same plane, so that radial force generated by meshing of the gears offsets mutually, namely the spindle only transmits torque and resultant force of the spindle stressed by the radial force is zero. The spindle assembly is simple in positioning structure, strong in bearing capacity and high in durability, and prolongs service life of the double-intermediate-shaft transmission under the premise of not increasing cost.

Owner:SINO TRUK JINAN POWER

Detection device of inner hole coaxiality of large disc type workpiece

ActiveCN103528486ASimple positioning structureEasy to operateMechanical measuring arrangementsEngineeringMechanical engineering

The invention relates to the technical filed of detection devices, in particular to a detection device of inner hole coaxiality of a large disc type workpiece. The detection device of the inner hole coaxiality of the large disc type workpiece comprises a hand wheel, an inner conical piece, an outer conical piece, a handle, a rotary table and a dial indicator, wherein the inner conical piece is assembled in an inner conical hole of the outer conical piece; the rotary table provided with a bearing is arranged at the top of the outer conical piece; the dial indicator is arranged on the rotary table; and the hand wheel is connected with the inner conical piece and the outer conical piece. The detection device of the inner hole coaxiality of the large disc type workpiece is simple in structure, easy to operate, high in measurement accuracy and low in measurement technical requirement, and can realize real-time detection.

Owner:CRRC QISHUYAN CO LTD

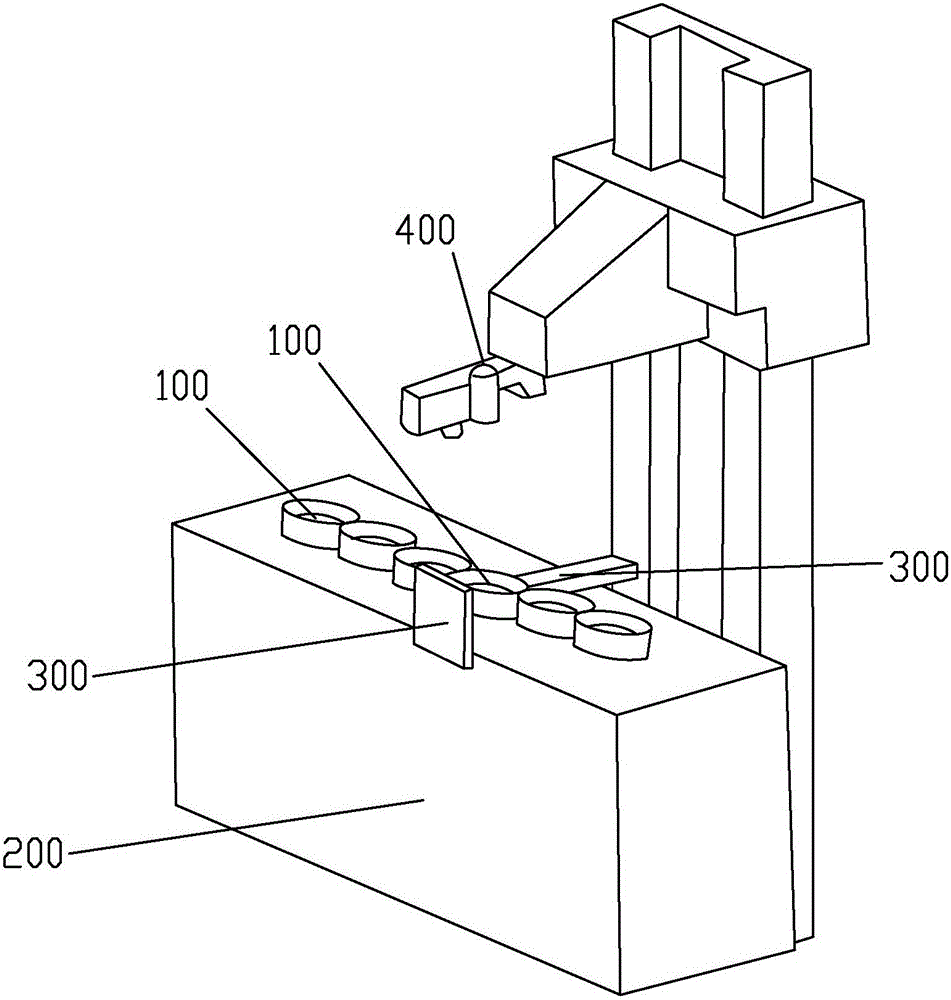

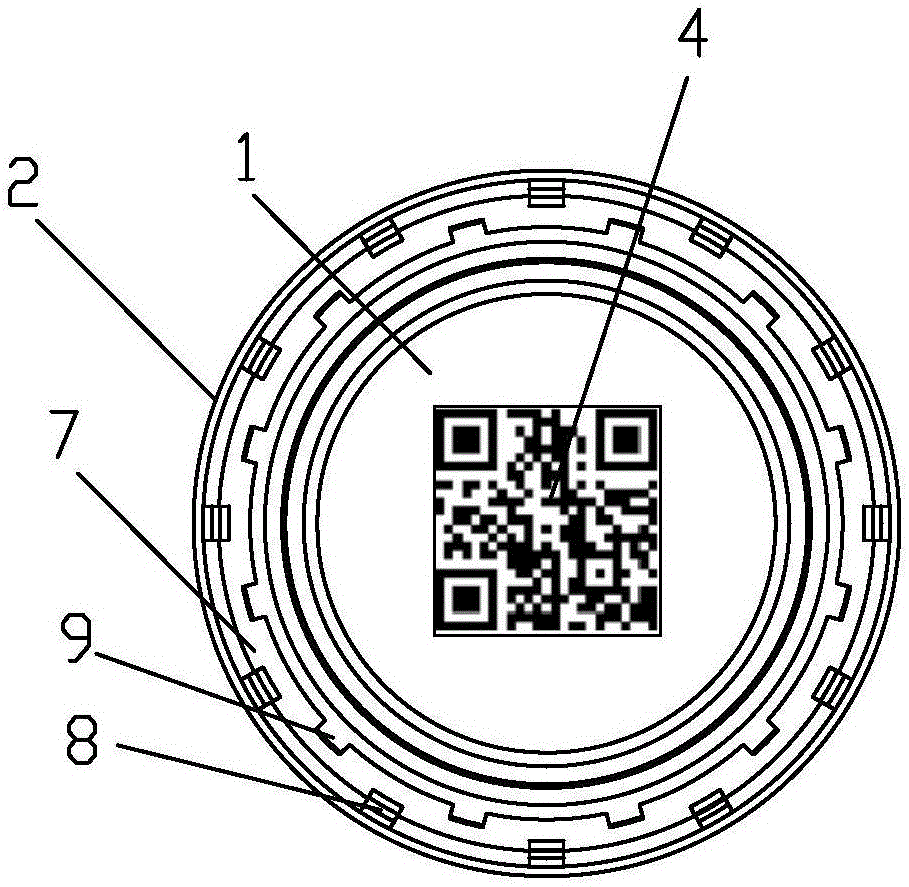

Laser marking method for plastic bottle caps

ActiveCN105855713ASimple positioning structureCause damageMetal working apparatusLaser beam welding apparatusEngineeringManufacturing line

The invention discloses a laser marking method for plastic bottle caps. The laser marking method comprises the following steps that 1, the plastic bottle caps are placed on a production line and conveyed onto a laser marking platform through a conveying device, and a mechanical clamping jaw on the laser marking platform and a positioning part on each plastic bottle cap are matched so that the plastic bottle caps can be positioned; 2, laser beams sent from a laser marking machine near the laser marking platform are directly irradiated on top pieces of the plastic bottle caps, laser etching layers which can store product information are directly etched on the top pieces, and the laser etching layers are uneven two-dimensional code patterns formed on the top pieces which are subjected to laser beam etching; and 3, laser beam etching and marking are completed through the laser marking machine, the mechanical clamping jaw on the laser marking platform and the positioning part on each plastic bottle cap are separated, and the plastic bottle caps are sent to a material receiving device through the conveying device, so that material receiving is completed. The laser marking method for the plastic bottle caps is simple in process, healthy, safe and low in cost.

Owner:ZHONGSHAN HUIWEI PLASTIC METAL IND

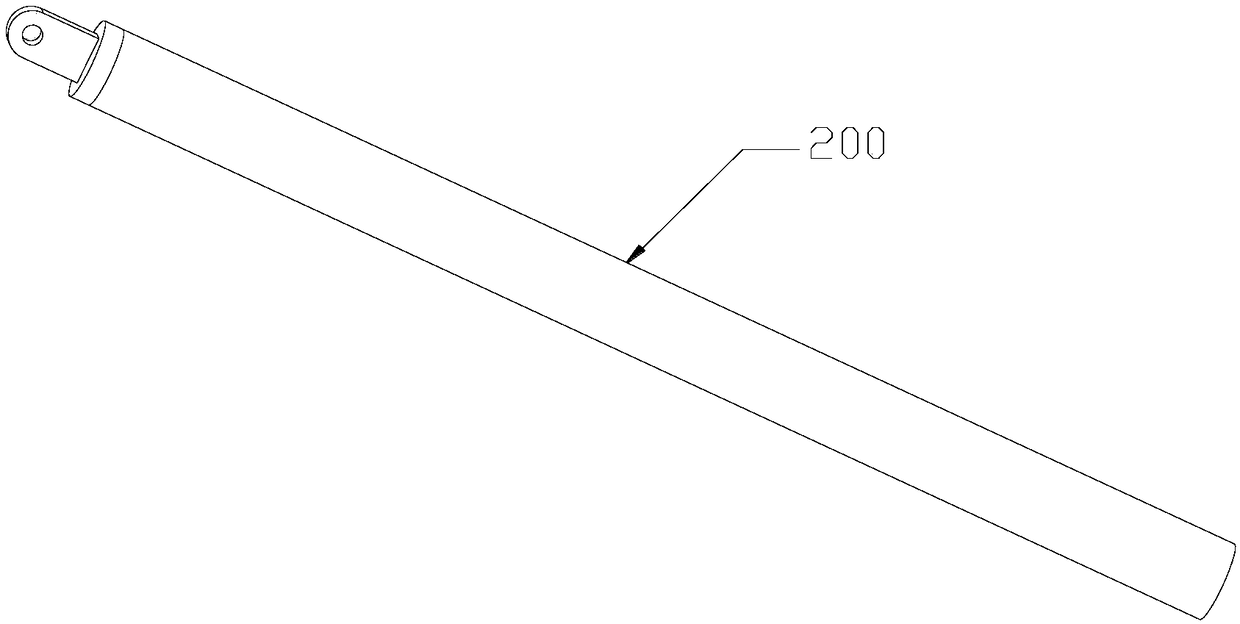

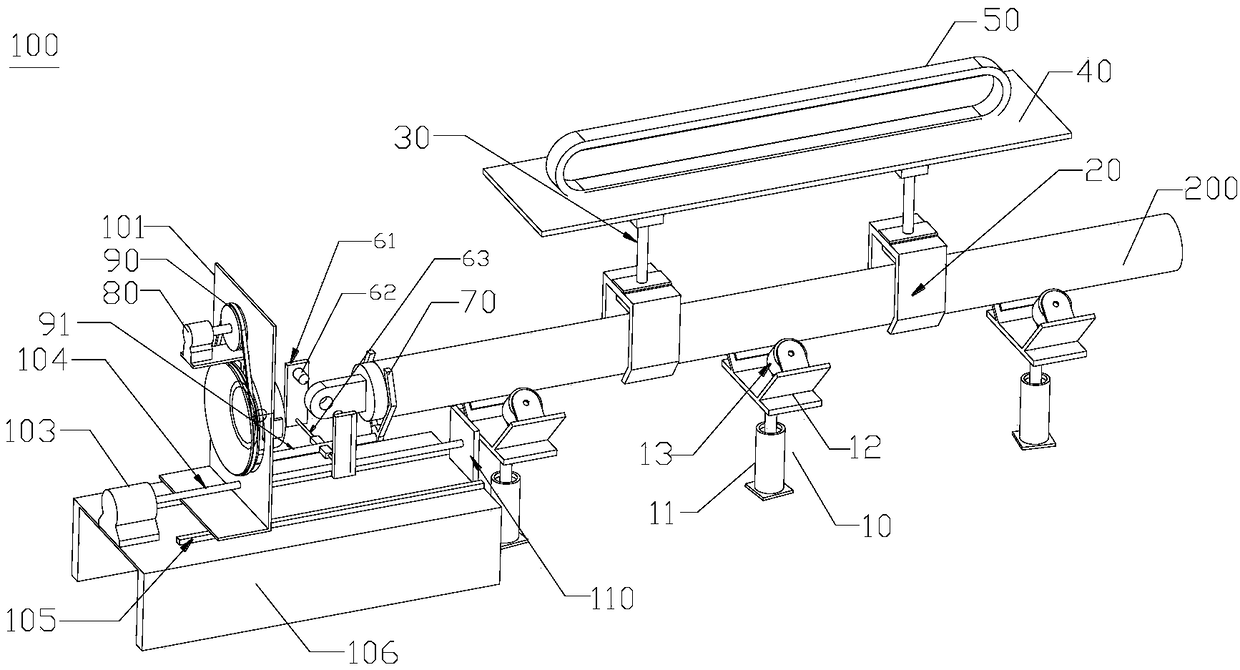

Oblique cantilever mounting hole automatic hole searching device

PendingCN108859871AEasy to fine-tune the rotationPrecise positioningTrolley linesNuclear energy generationCantileverPosition sensor

The invention relates to an oblique cantilever mounting hole automatic hole searching device. The oblique cantilever mounting hole automatic hole searching device comprises a supporting device, wherein the supporting device is arranged under an oblique cantilever, an upper platform is arranged above the oblique cantilever, a linear transmission mechanism is arranged on the upper platform, a secondautomatic telescopic mechanism is fixed to the linear transmission mechanism, the second automatic telescopic mechanism is fixed to a first automatic clamping jaw, a hole searching mechanism is fixedat an output end of a retarding mechanism, an output shaft of a first driving piece is fixedly connected with an input end of the retarding mechanism, an output end of the retarding mechanism is fixedly connected with an automatic clamping jaw, and a position sensor is fixed to the retarding mechanism and is opposite to the oblique cantilever. The oblique cantilever mounting hole automatic hole searching device has the advantages that the oblique cantilever is automatically transferred to an accurate position forward, thereby saving the time and labor; when a mounting hole end of the obliquecantilever moves to the hole searching mechanism, a controller immediately commands the linear transmission mechanism to stop moving, thereby providing convenience for controlling the oblique cantilever to be transferred to the accurate position forward; and the retarding mechanism is utilized to rotate the second automatic clamping jaw and the hole searching mechanism, thereby providing convenience for fine-tuning rotation and axial positioning of the oblique cantilever.

Owner:中铁武汉电气化局集团第一工程有限公司

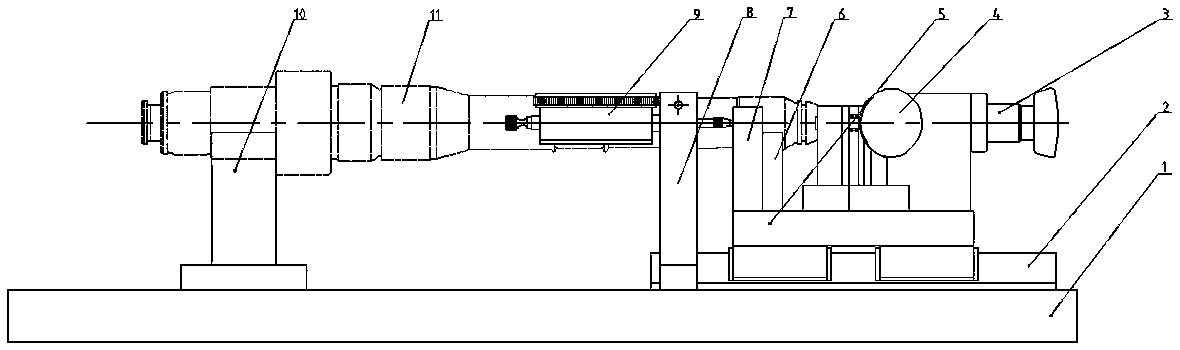

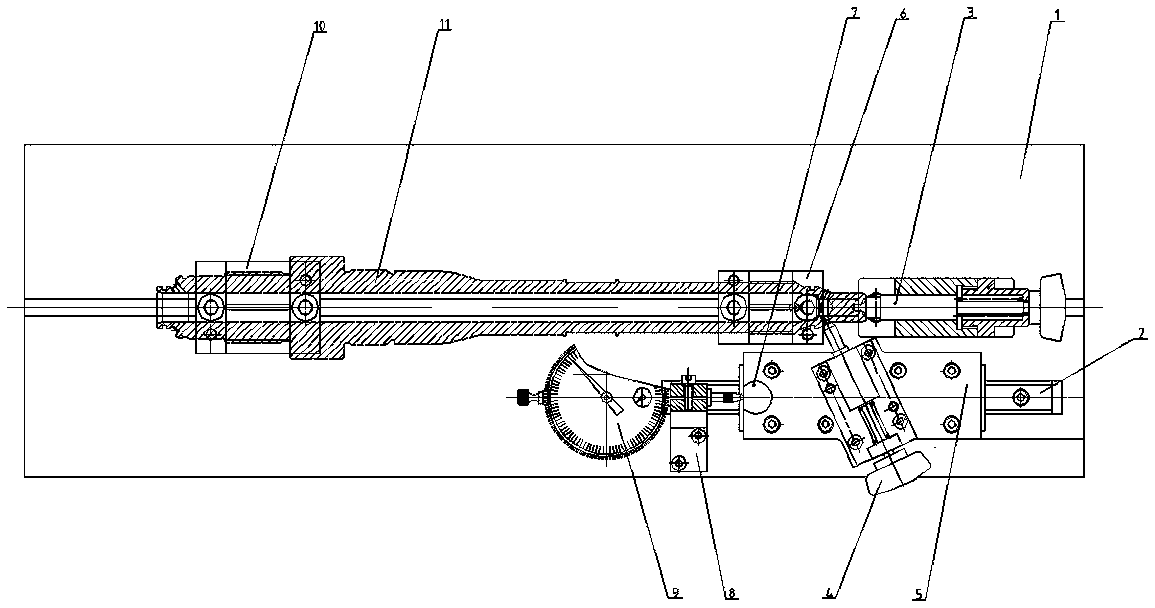

Detection tool for measuring position accuracy of shaft outer wall oblique hole

PendingCN110220436ASimple positioning structureEasy to installMechanical measuring arrangementsVertical edgeEngineering

The invention discloses a detection tool for measuring position accuracy of a shaft outer wall oblique hole. The detection tool comprises a base, a linear rail, a tail base, a pin base, a sliding plate, a right bearing, an edge cutting pin, a gauge frame, a clock gauge and a left bearing, wherein the sliding plate is matched with the oblique pin base to move left and right along the linear rail, so that an oblique hole in a conical shaft section of a workpiece can be aligned; the edge cutting pin is fixedly connected with the left end surface of the sliding plate; the vertical edge cutting pinis mounted in a manner of enabling the cut edge to be arranged outwards; the gauge frame is arranged on one side of the linear rail; the upper end of the gauge frame is used for clamping the clock gauge with an upward gauge disc; a gauge head end of the clock gauge faces rightwards and is in contact with the plane of the edge cutting pin to form a positioning and measuring mechanism. The detection tool is simple in structure and high in detection accuracy, is capable of efficiently detecting the position accuracy of the shaft outer wall oblique hole, and is especially applied to on-line detection of production site.

Owner:JIANGSU PACIFIC PRECISION FORGING +1

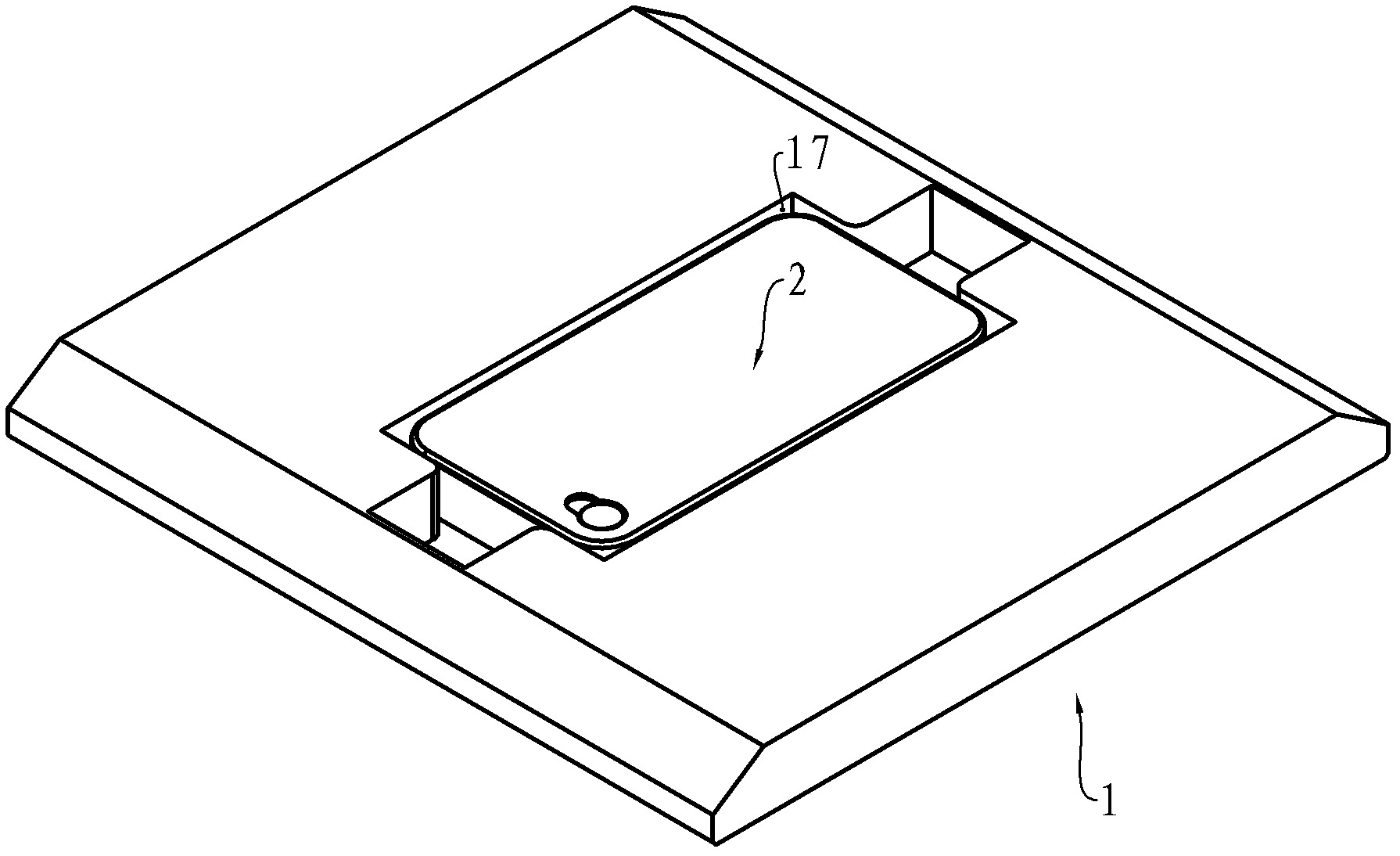

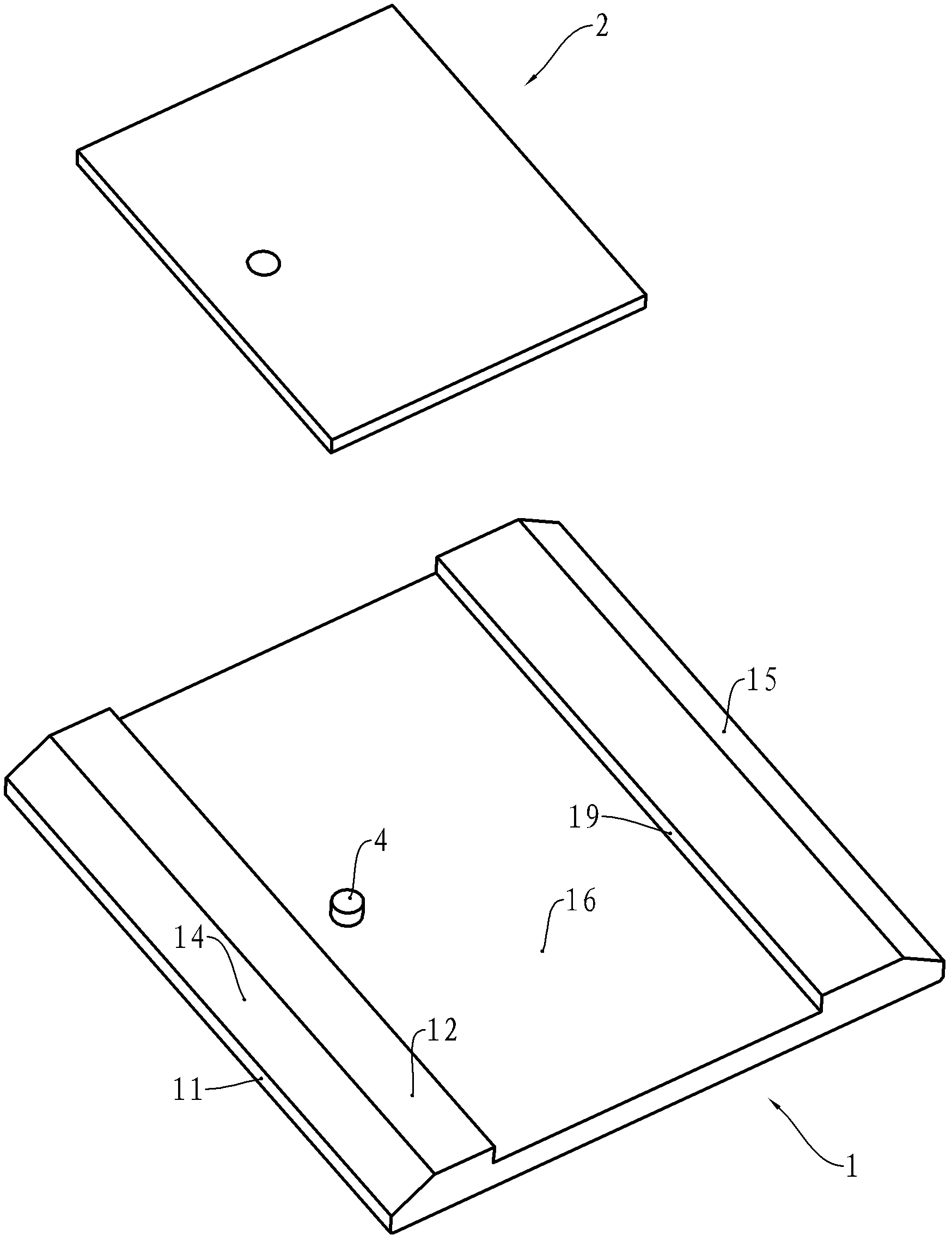

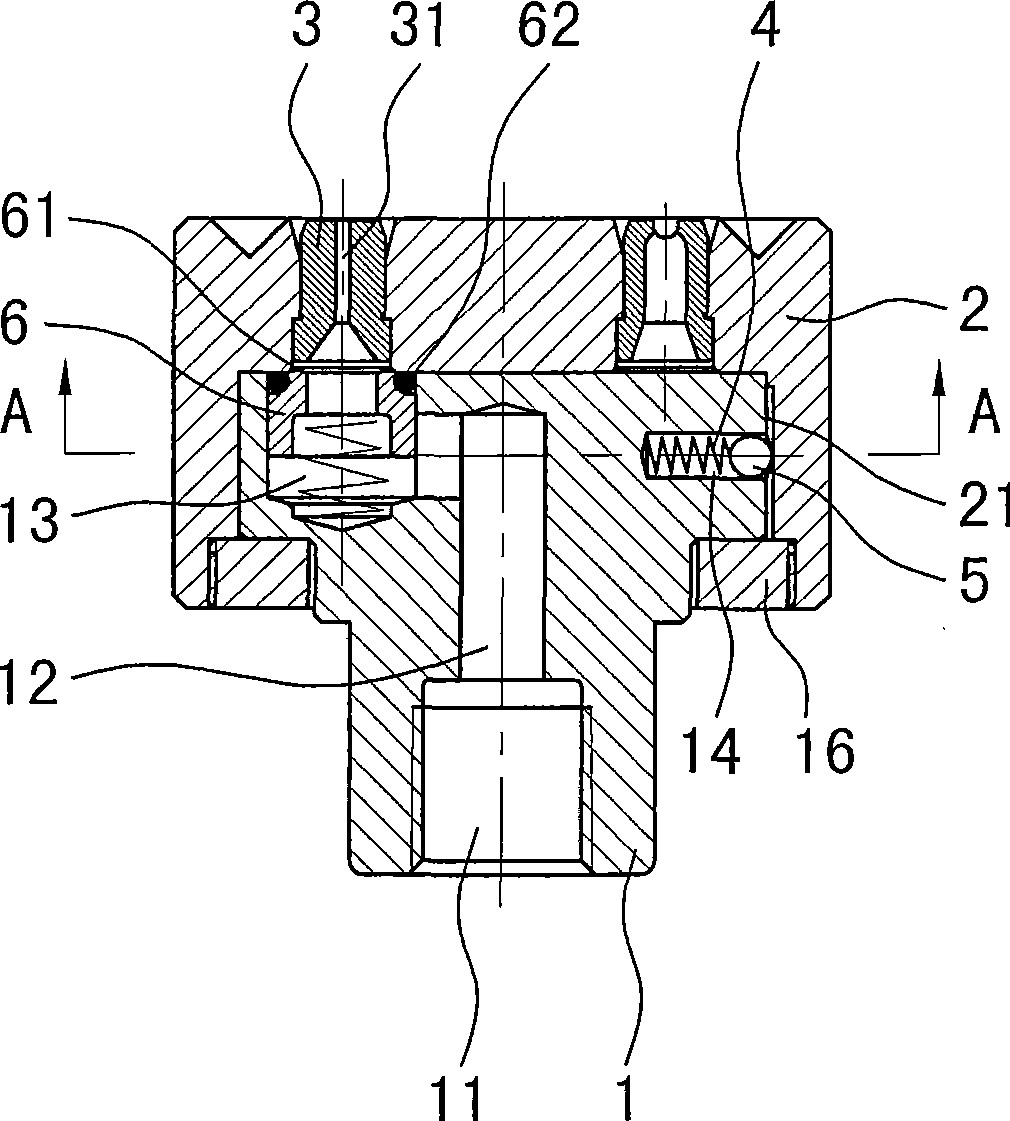

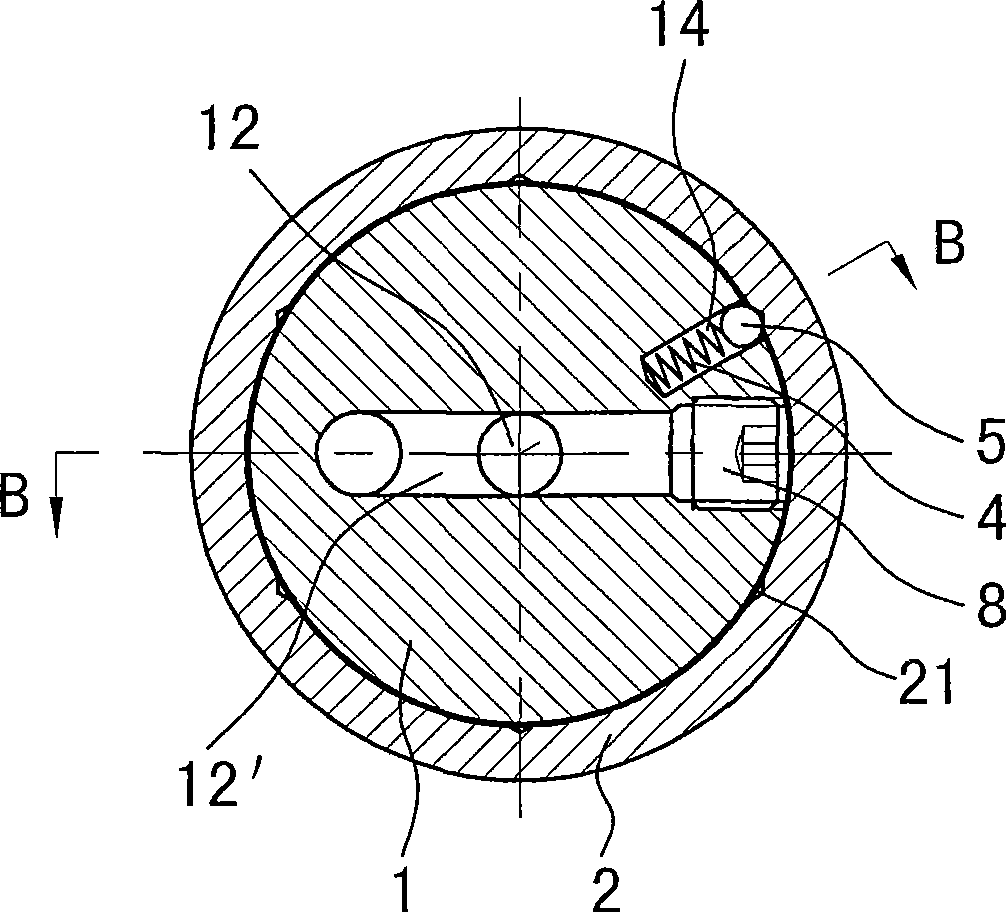

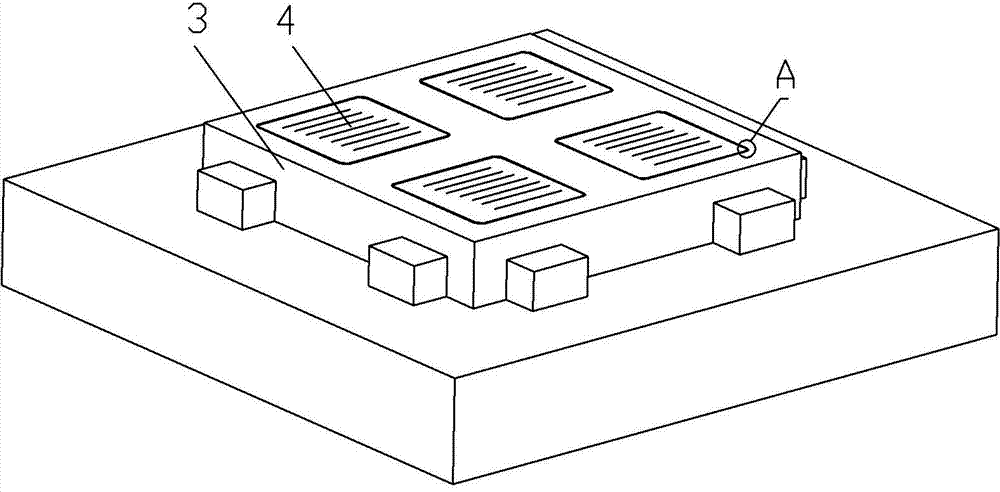

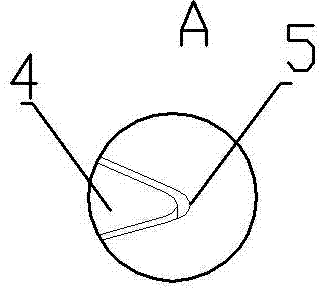

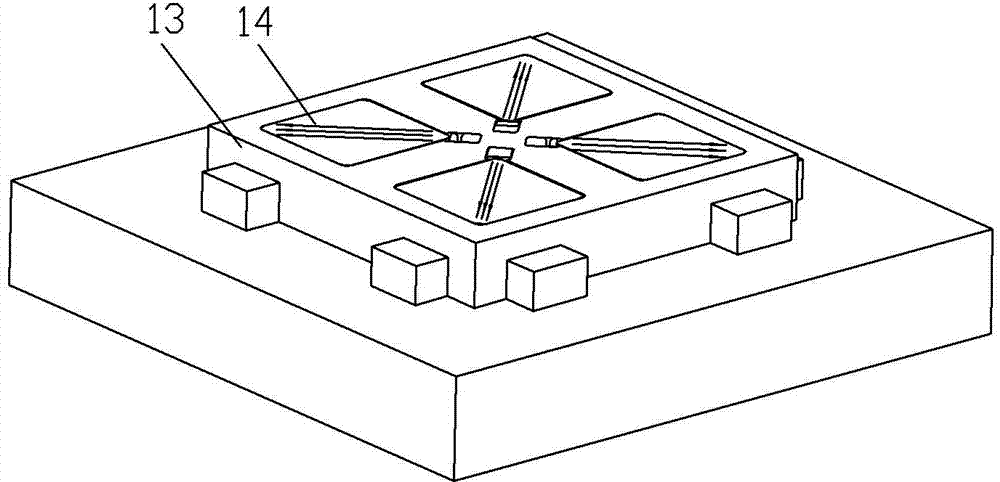

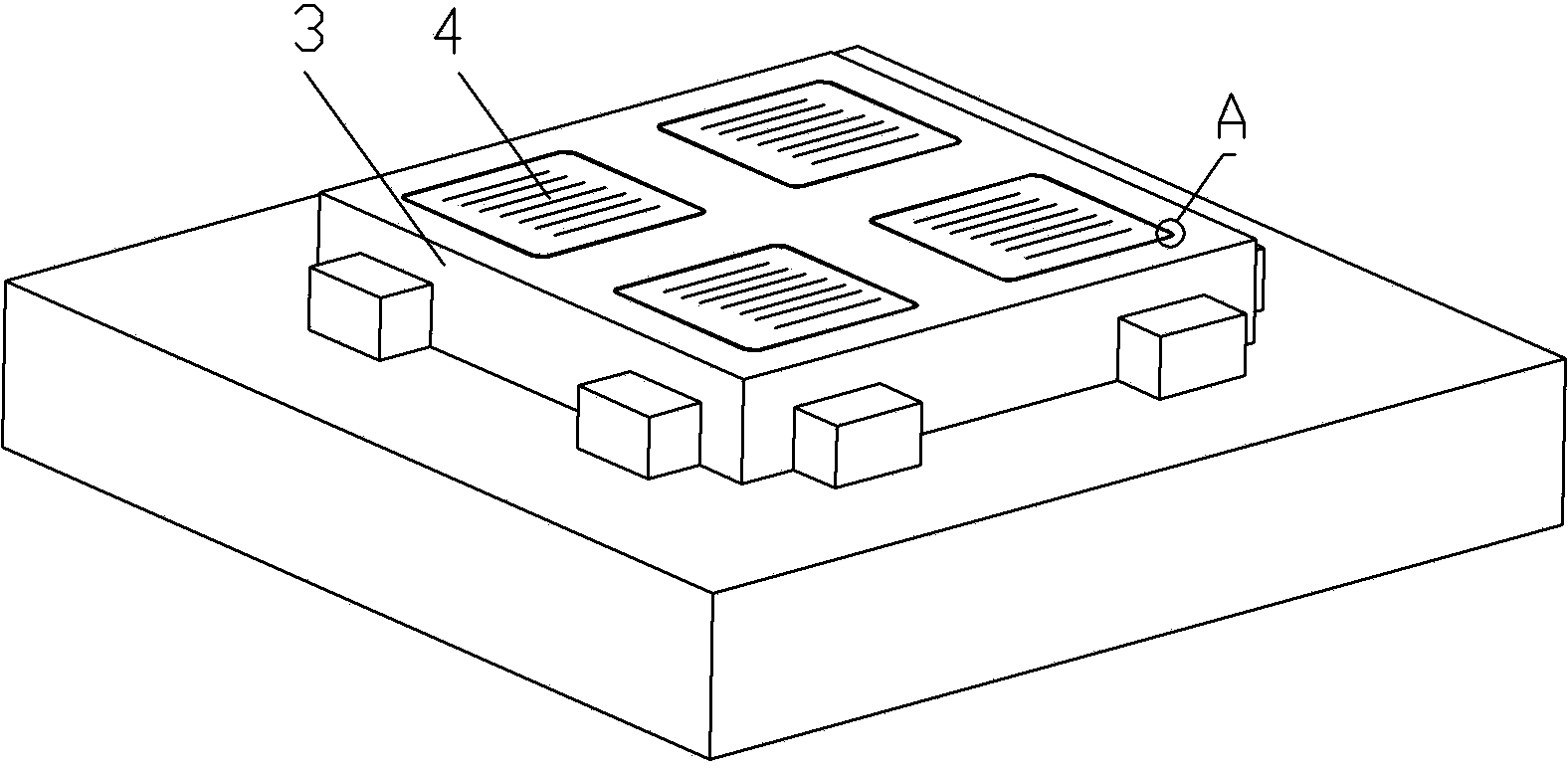

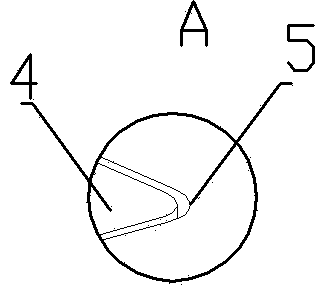

Workpeice positioning structure and silk-screen printing positioning tool for display protection screen

InactiveCN102848705AAchieve precise positioningGuaranteed positioning accuracyScreen printersScreen printingEngineering

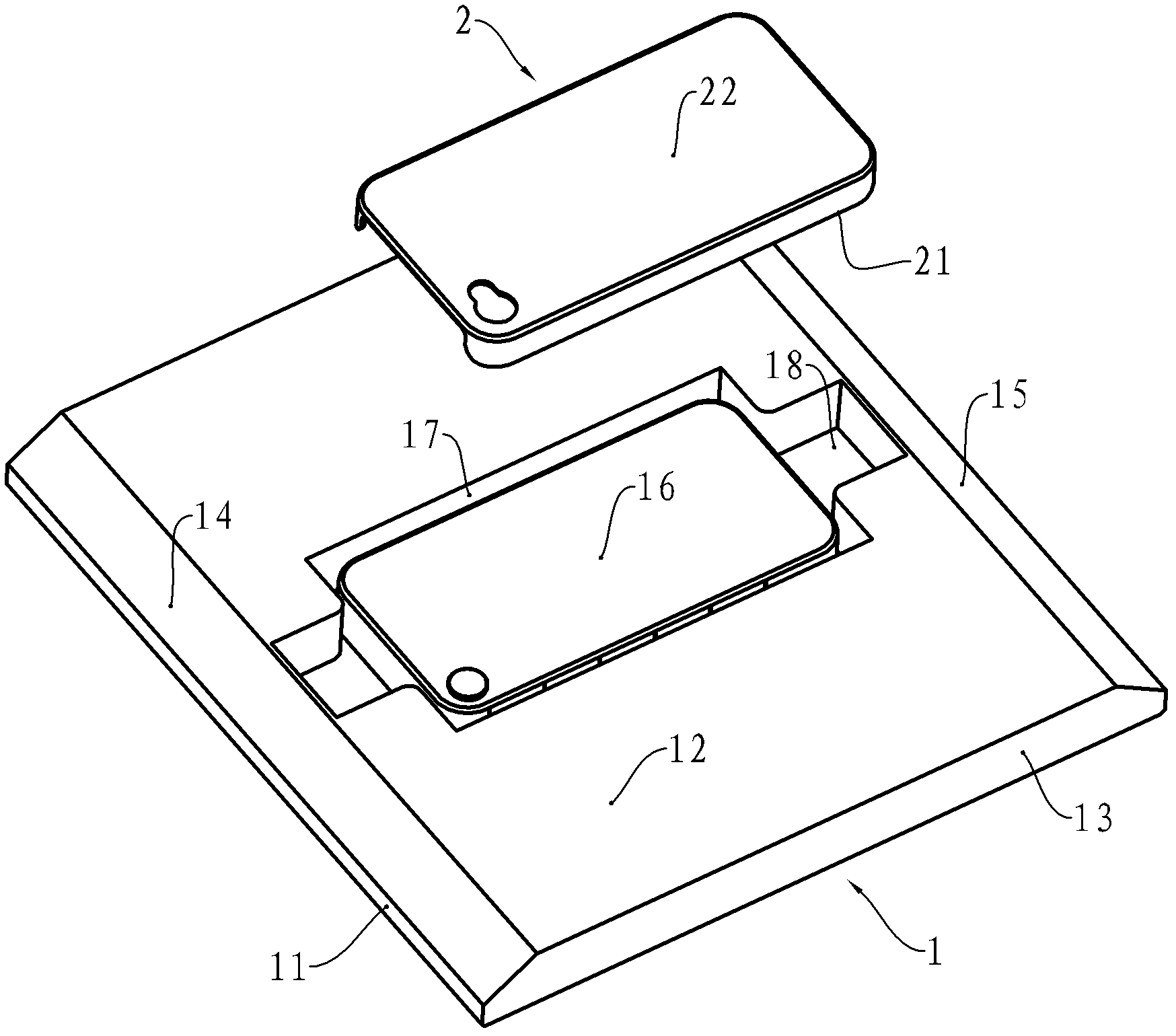

The invention discloses a workpeice positioning structure and a silk-screen printing positioning tool for a display protecting screen. The positioning tool comprises a positioning plate, wherein at least one positioning groove for accommodating the display protecting screen is concavely formed in the positioning plate; at least two positioning groove walls and accommodating groove walls are formed in the positioning grooves; the at least two positioning groove walls are intersected or in extending intersection and are used as positioning references so as to contact and support against the display protecting screen; and the accommodation groove walls are in clearance fit with the display protecting screen. The positioning structure further comprises an elastic member, wherein during use, the elastic element is supported against and matched with the display protecting screen and applies a force on the display protecting screen so as to enable the display protecting screen to be supported against and contacted with the positioning groove walls, then the display protecting screen can be fixed in the positioning grooves. During use, the positioning grooves which are intersected or in extending intersection are used as the positioning reference sides, so that accurate positioning for the display protecting screen on a plane is effectively realized; and in addition, under the action of the elastic element, the display protecting screen is supported against the positioning groove walls used as the positioning reference sides and the positioning precision of the positioning mode can be further ensured.

Owner:新乡市天光科技有限公司

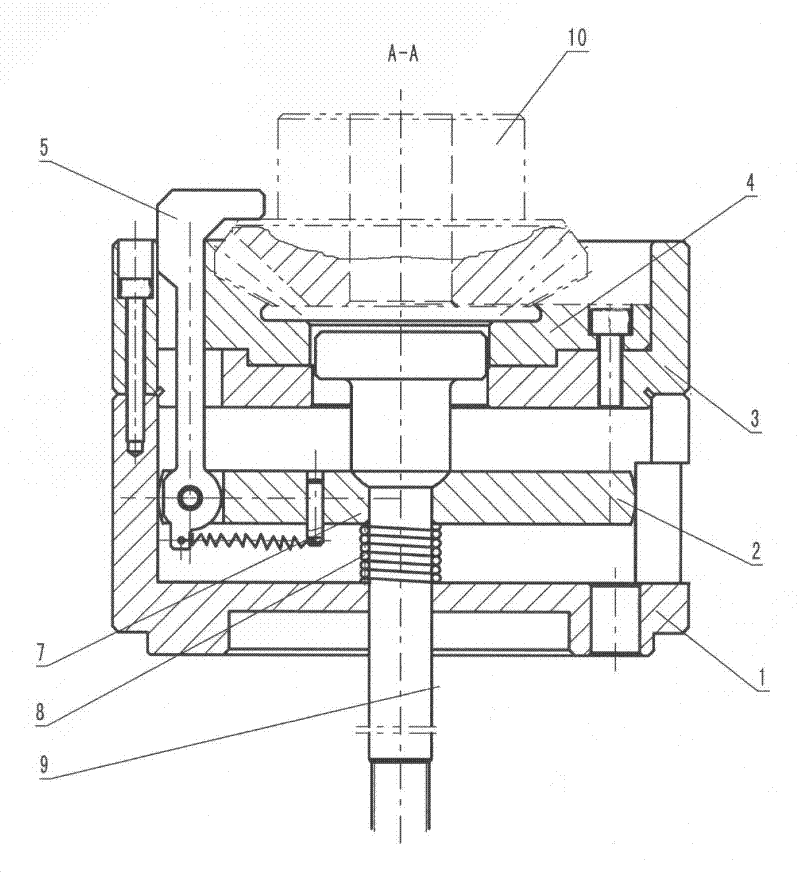

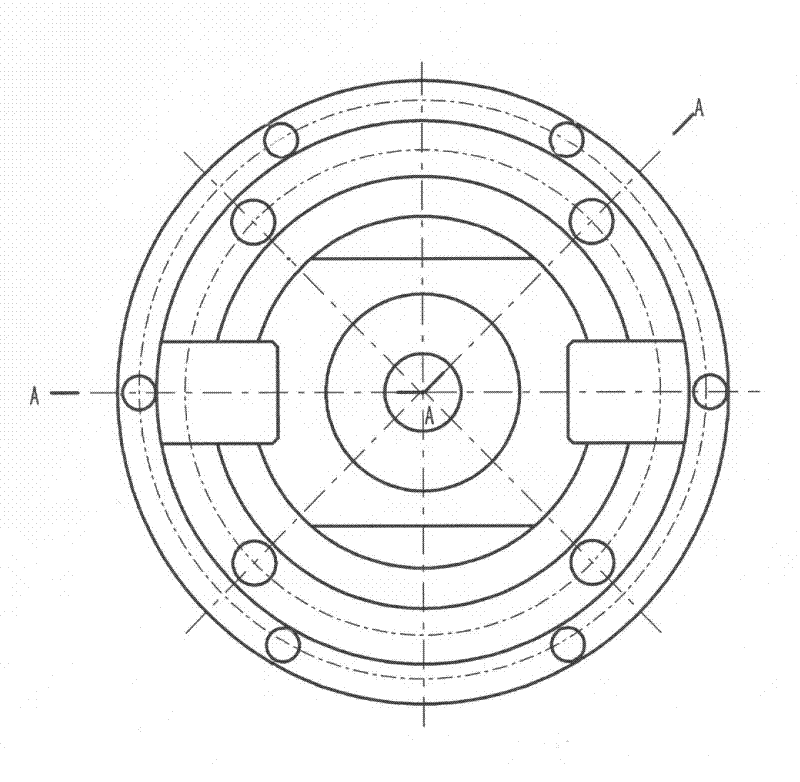

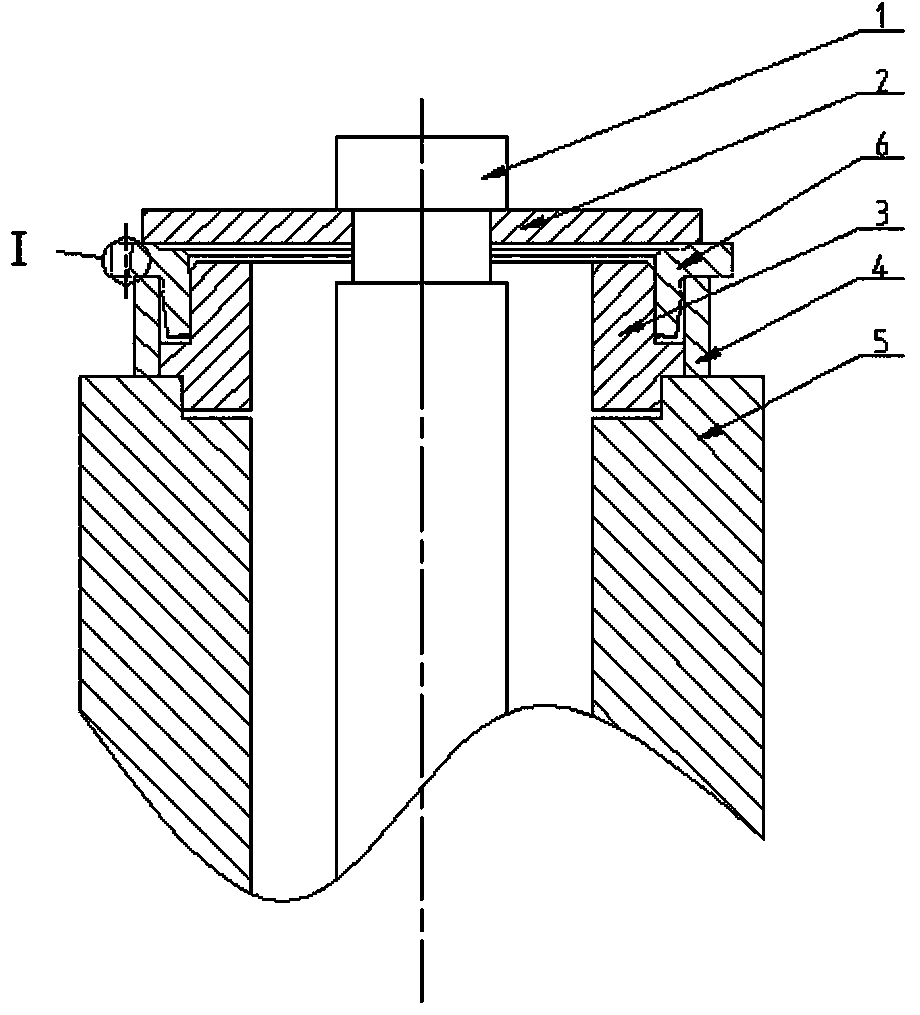

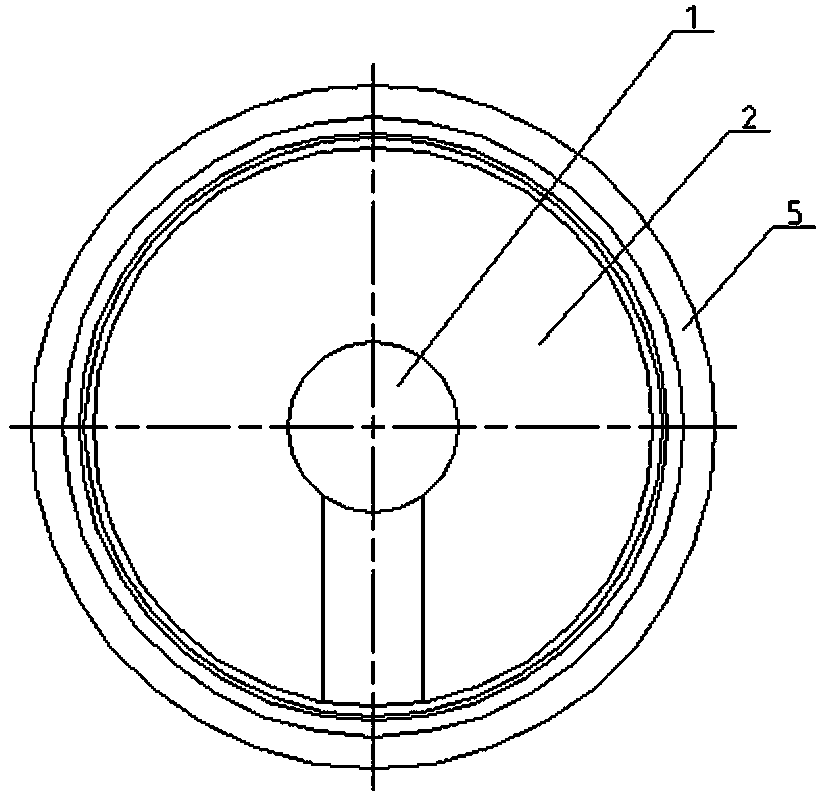

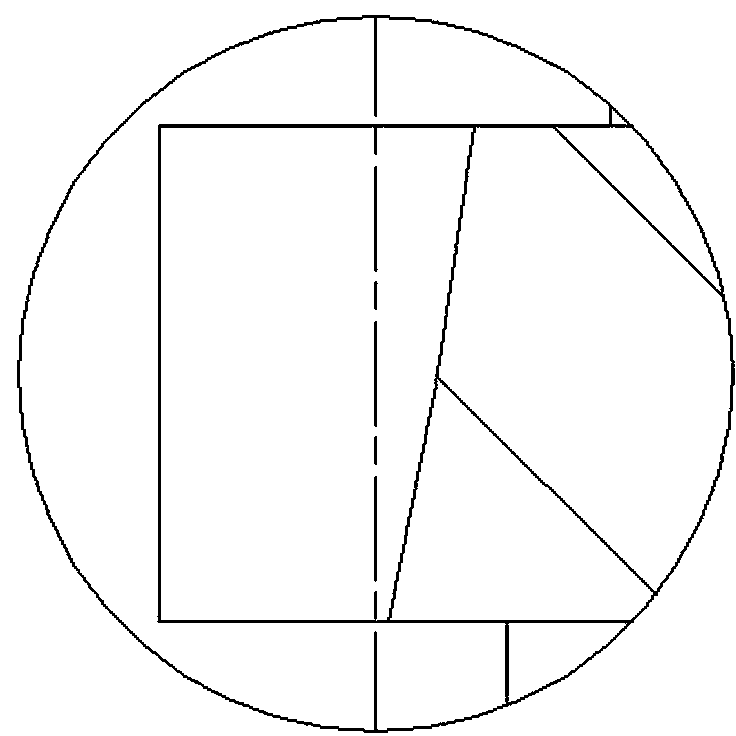

Fixture for gear shaping on thin-wall outer gear ring

InactiveCN104325200ANo radial forceSimple positioning structureGear-cutting machinesGear teethMachining deformationAxial force

The invention discloses a fixture for gear shaping on a thin-wall outer gear ring. The fixture jointly consists of a pull rod, a gasket, a shaft seat, a shaft sleeve and a substrate, wherein the end face facing upwards of the substrate is provided with a concave spigot for installing the shaft seat in a positioning manner; the pull rod penetrates the inner bore of the substrate, and an annular groove is formed in the outer wall of the upper exposed rod end; the gasket is assembled in the groove to form a linkage structure; the shaft seat of the fixture disclosed by the invention is a multi-section shaft component, two sections of shaft segments located above and below a convex circular bead are coaxial, and the external diameter of the previous section of shaft segment is in clearance fit with the inner bore of a workpiece to form a positioning structure; the shaft sleeve directly covers the shaft sleeve, the shaft sleeve is located between the opposite end faces of the substrate and the workpiece, the workpiece is axially supported by the shaft sleeve, and the workpiece is axially locked by the gasket moving down along with the pull rod. According to the fixture disclosed by the invention, aiming at the problems that the rigidity of the thin-wall gear ring is insufficient and the deformation of the thin wall can be easily caused by the gear shaping, the radial positioning and axial locking structure is adopted, so that the thin wall of the workpiece is neither subjected to the action of the radial force nor subjected to the action of the axial force, and therefore the goals that machining deformation is reduced and the machining accuracy is improved are achieved.

Owner:JIANGSU PACIFIC PRECISION FORGING +1

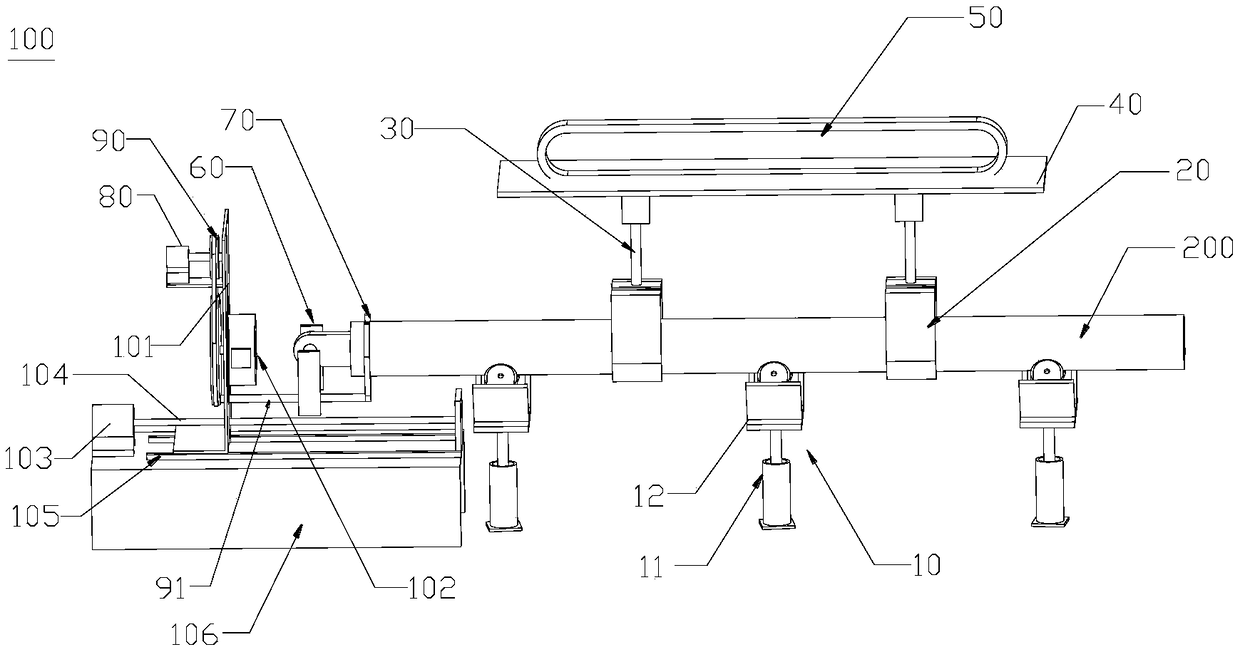

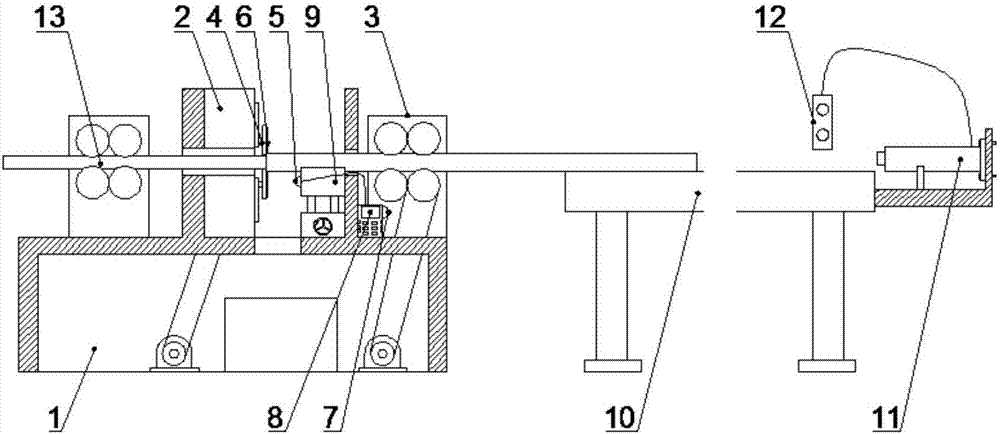

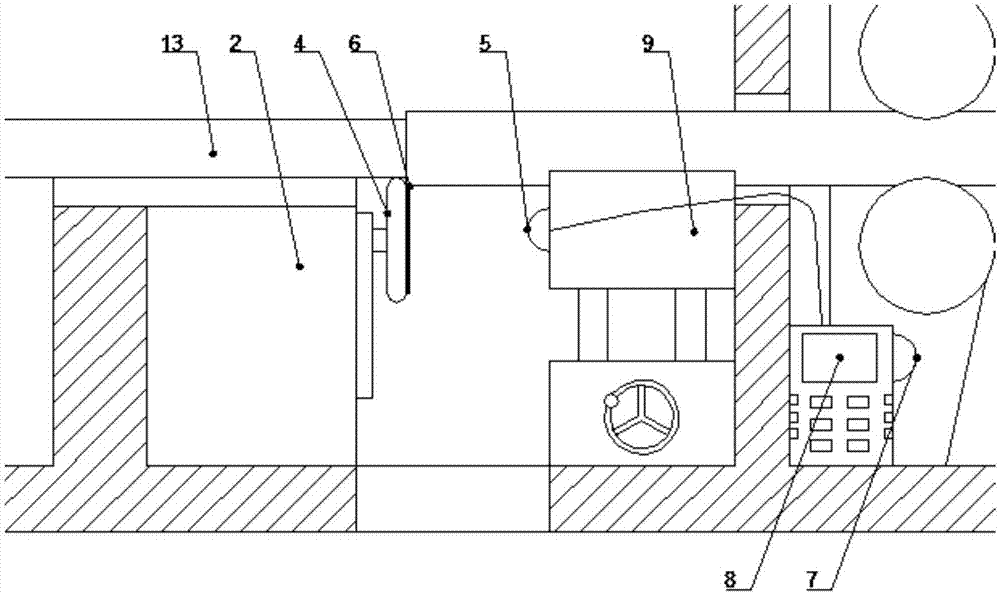

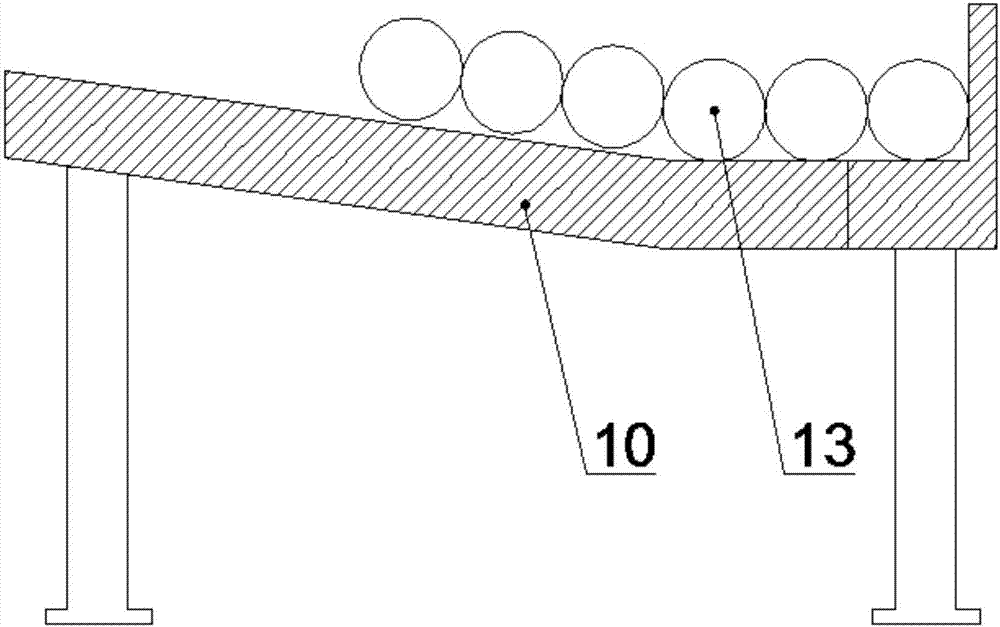

Grinding type stripping machine capable of monitoring grinding disc and working method for grinding type stripping machine

InactiveCN107443229AMonitor wearAvoid the phenomenon of large depth of cutGrinding drivesGrinding machinesPulp and paper industryVision sensor

The invention discloses a grinding type stripping machine capable of monitoring a grinding disc. The grinding type stripping machine comprises a machine frame, a stripping mechanism, a positioning mechanism, feeding and supporting mechanisms, a conveying mechanism and a monitoring mechanism, wherein the stripping mechanism is arranged on the machine frame, the positioning mechanism is arranged on one side of the stripping mechanism, and the monitoring mechanism is arranged on the positioning mechanism; the grinding disc is arranged on the stripping mechanism; and the monitoring mechanism comprises a visual sensor, a marking patch, a buzzer and a PLC, wherein the visual sensor is opposite to the grinding disc, the marking patch is arranged on the grinding disc and covers the side surface of the grinding disc, and the buzzer is arranged on the PLC. The invention further discloses a working method and a monitoring method for the grinding type stripping machine. According to the grinding type stripping machine and the working method and the monitoring method for the grinding type stripping machine, the phenomenon of the large cutting depth can be effectively avoided, and a tool can be protected; the grinding degree of the grinding disc can be automatically monitored, and an alarm can be given; and by means of mechanical feeding, time and manpower resources can be saved.

Owner:TAICANG BEST MECHANICAL EQUIP

Offshore oil pipe joint outer wall drilling fixture

InactiveCN103084621ASimple positioning structureFast workpiece loading and unloadingDrill jigsPetroleumHigh volume manufacturing

The invention discloses an offshore oil pipe joint outer wall drilling fixture comprising a fixture body, bolts, a drilling jig, a pressing plate, a screw unit and a limiting rod. An extending connecting plate, perpendicular to a working surface and parallel to an axis, is arranged on a top surface of the fixture body. The pressing plate and the screw unit form a two-rod supporting-locking structure. The drilling jig is inserted between a workpiece and the connecting plate, positioned at a limiting bayonet and is connected by the bolts. The limiting rod is arranged on the working surface of the fixture body and located on the out wall of the workpiece, and a positioning groove displaced to a drilling-jig hole by 90 degrees is arranged on the limiting rod. Under the condition of positioning and clamping, the offshore oil pipe joint outer wall drilling fixture drills a rotate-resisting hole and auxiliary holes machined on both sides of the outer wall of the offshore oil pipe joint along the drilling-jig hole, and thus, drilling quality is stable, producing efficiency is high and the fixture is adaptable to mass production and utilization.

Owner:JIANGSU SHUGUANG OIL DRILLING EQUIP CO LTD

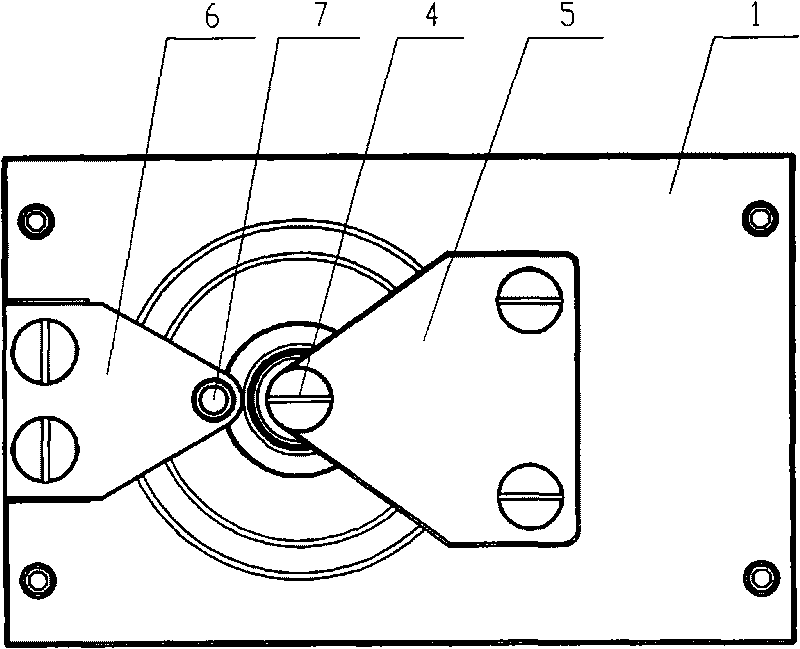

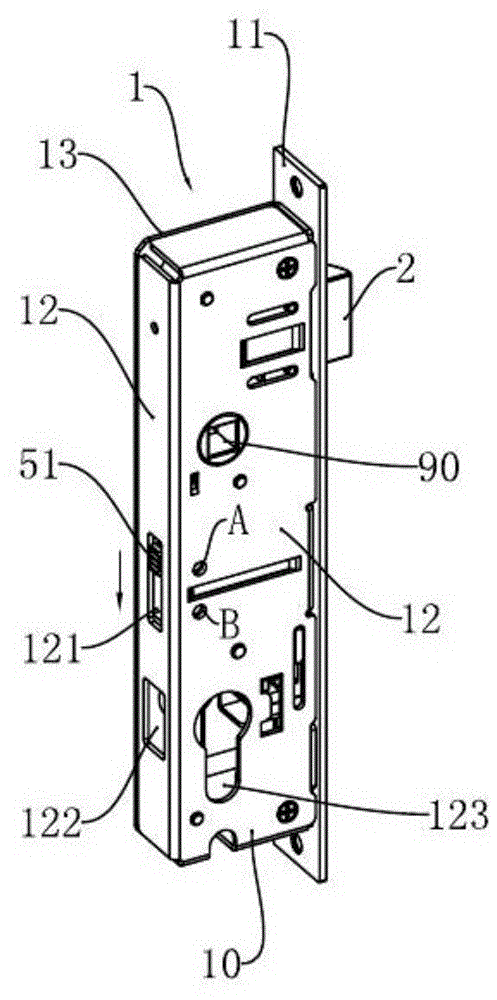

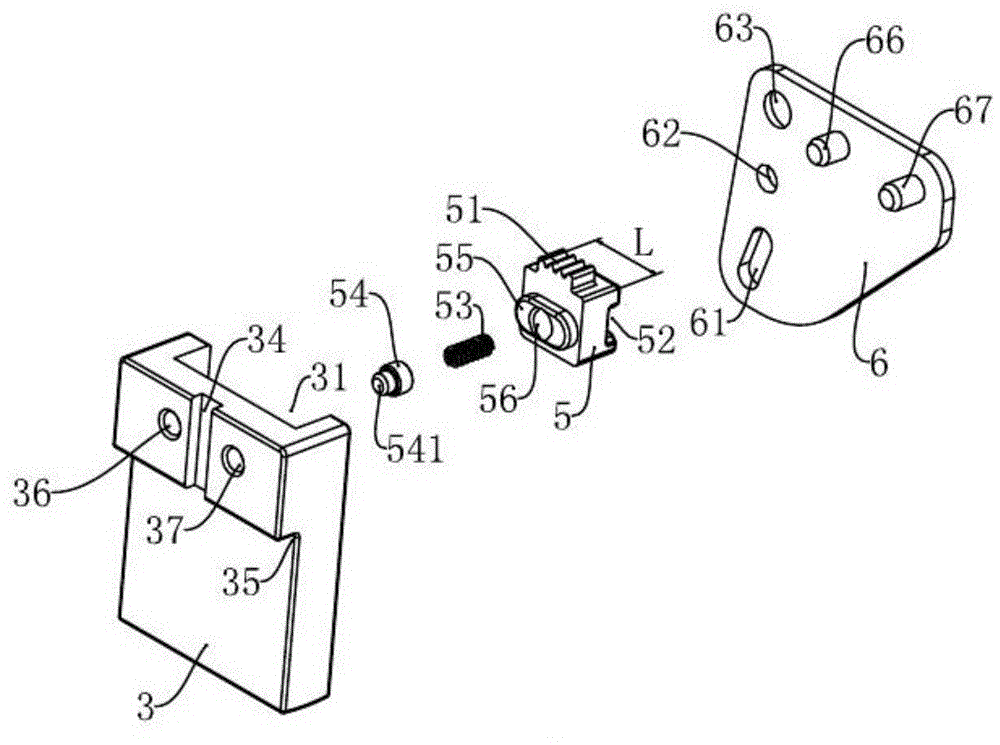

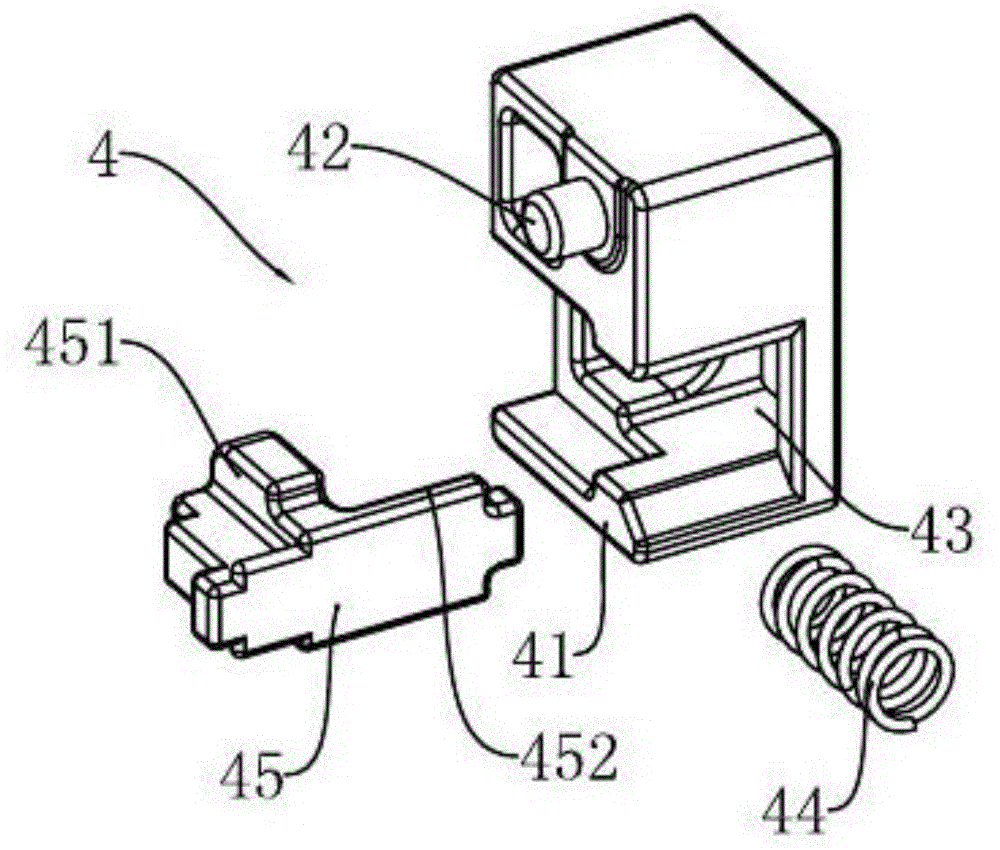

Lock with bolt adjusting mechanism

ActiveCN104100147AChange the extension strokeIncrease the stick out lengthBuilding locksUltimate tensile strengthControl theory

A lock with a bolt adjusting mechanism comprises a lock shell and a first bolt. The bolt adjusting mechanism comprises a stirring part and a slider, a rotating pivot is arranged on the stirring part, the slider is arranged at the tail end of the first bolt and can move in the horizontal direction, and the stirring part and the slider are arranged up and down. A first joint point and a second joint point are further arranged on the stirring part, and the distance between the second joint point and the rotating pivot is larger than that between the first joint point and the rotating pivot. When the slider moves to the position corresponding to the first joint point, the slider leaves the position of the second joint position, and the stirring part is jointed with the slider at the first joint point to form first drive fit; when the slider moves to the position corresponding to the second joint point, the slider already leaves the position of the first joint point, and the stirring part is jointed with the slider at the second joint point to form second drive fit. Therefore, the length of the bolt can be flexibly set according to gap sizes of different door crack gaps or according to the size of antitheft strength needing to be provided.

Owner:GUANGDONG ARCHIE HARDWARE

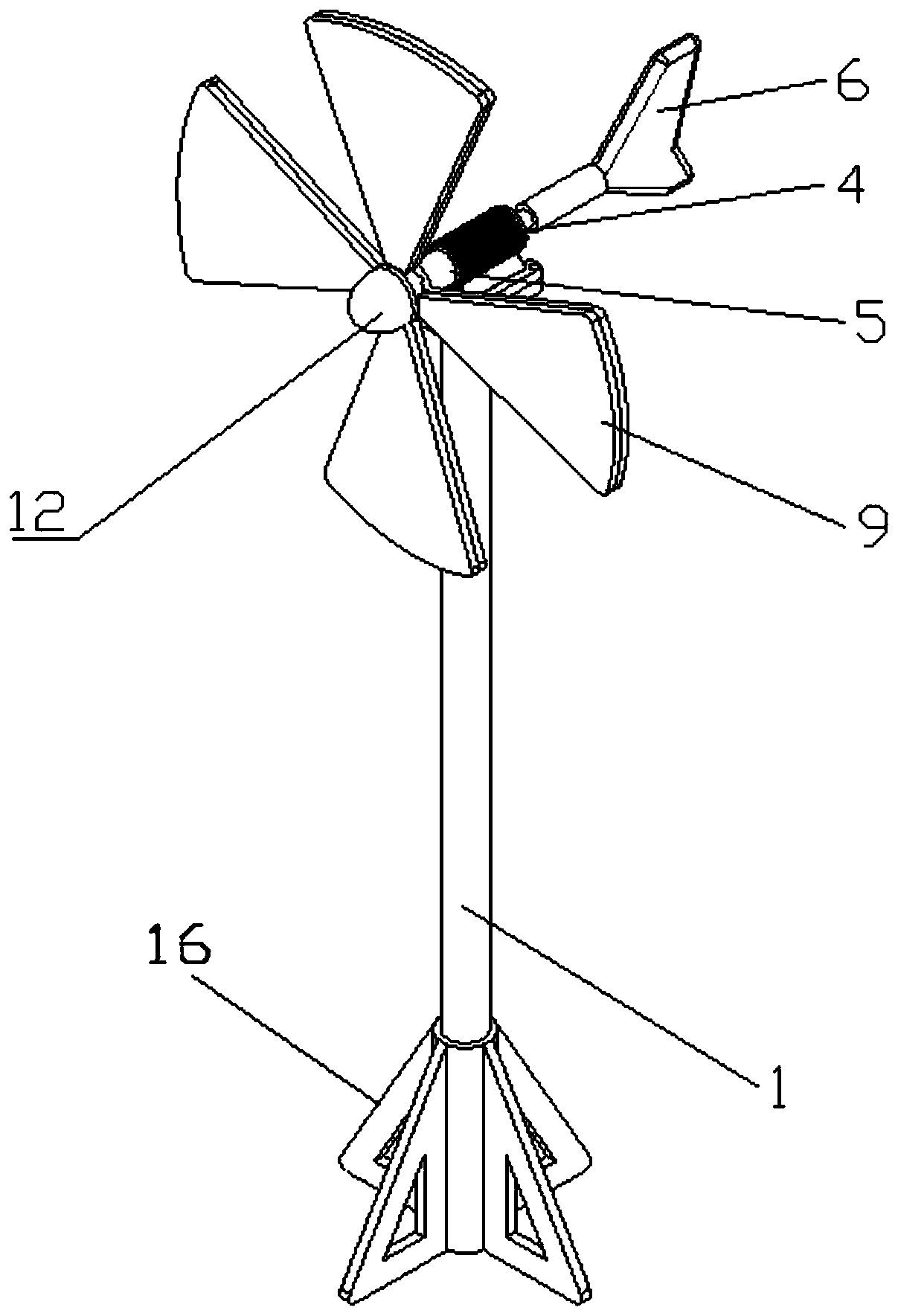

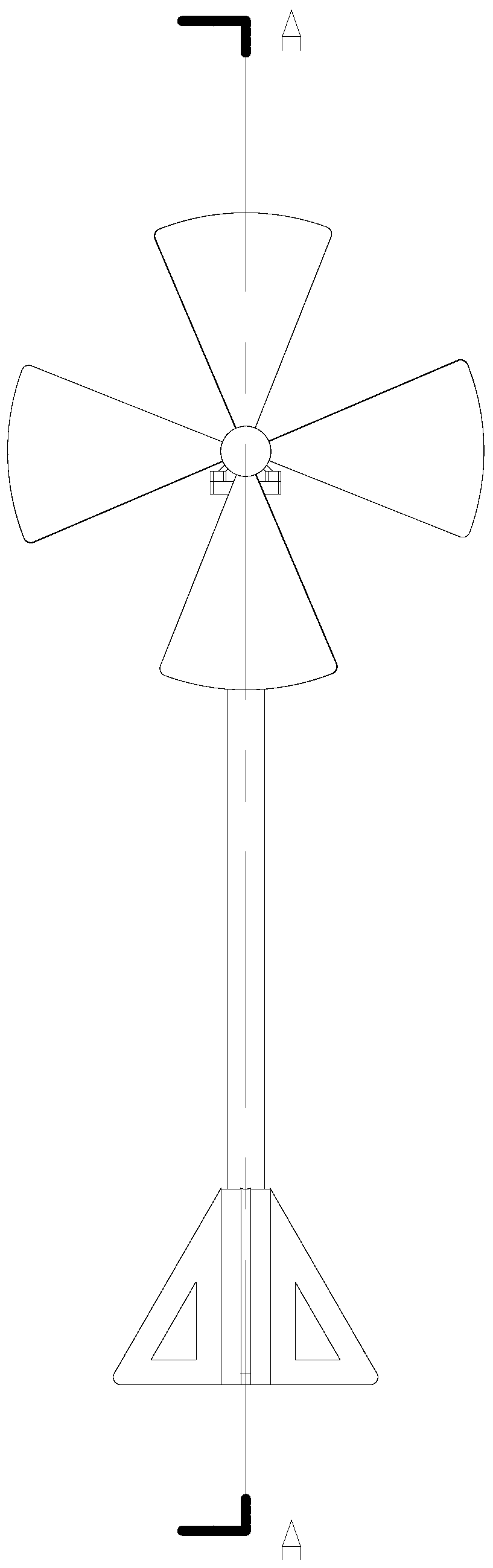

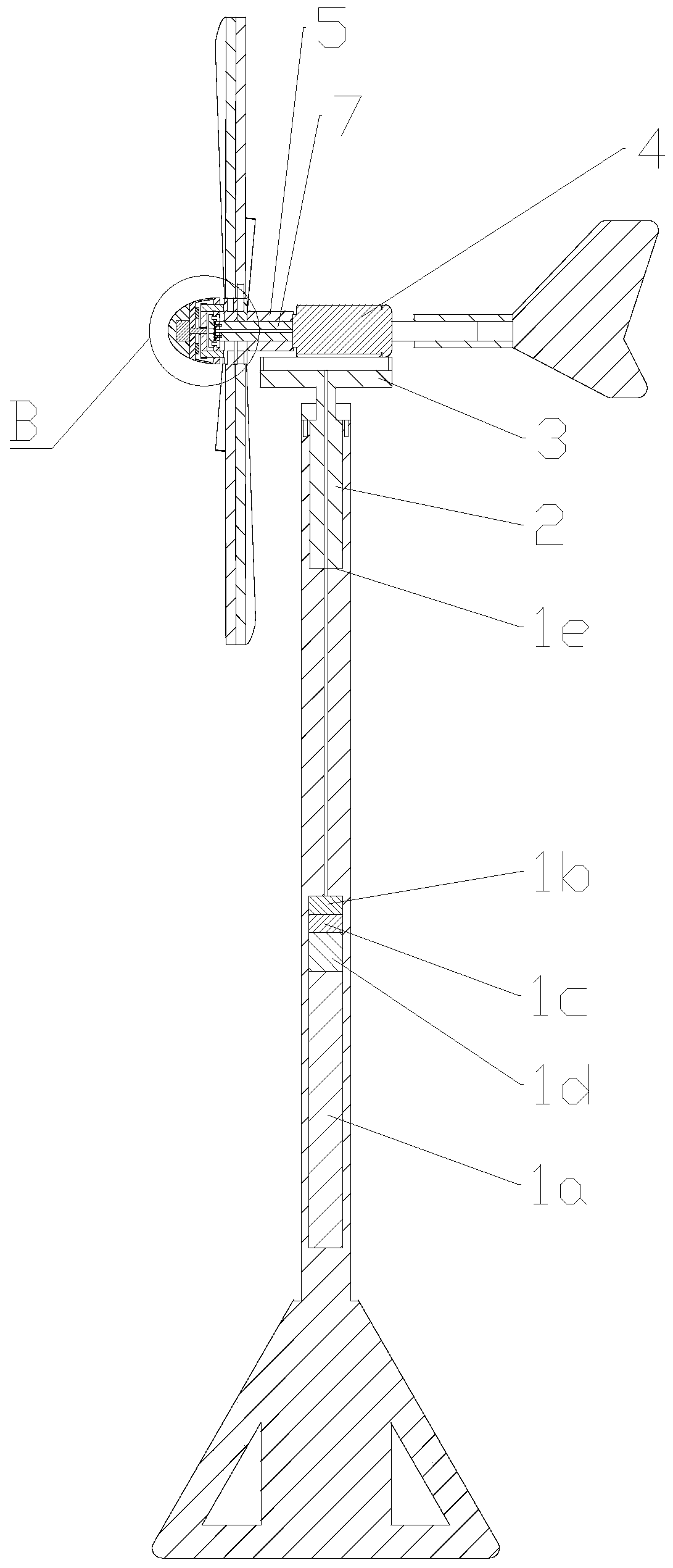

Intelligent solar and wind power generation device

PendingCN111404450ALow costSimple positioning structurePV power plantsPhotovoltaic energy generationPhysicsElectric generator

The invention discloses an intelligent solar and wind power generation device. A rotating groove is formed in the axis of the upper end of a supporting rod body; the mounting platform is arranged above the supporting rod body, and the center of the lower end of the mounting platform is fixedly connected with a wind direction rotating shaft rotationally arranged in the rotating groove; a wind driven generator is mounted on the mounting plate; the output end of the wind driven generator is fixedly connected with the transmission shaft through a transmission device, and the other end of the winddriven generator is provided with a guide empennage; a form conversion mechanism is arranged at one end of the transmission shaft, and fixed and movable rotating flanges are sleeved outside the form conversion mechanism respectively; four rotating blades are evenly and fixedly connected to each of the fixed rotating flange and the movable rotating flange in the circumferential direction, and a solar cell panel is installed on the surface of each rotating blade. A photovoltaic control converter is arranged in the fixed rotating flange; the form conversion mechanism comprises a conversion shell,an end plate, an angle servo motor and an angle conversion plate, the end plate is fixedly connected with the transmission shaft, and two kidney-shaped holes are formed in the end plate; the two endsof the conversion connecting rod located in each kidney-shaped hole are fixedly connected with the movable rotating flange and the angle conversion plate respectively. The device can realize efficient power generation.

Owner:XUZHOU INSTITUTE OF TECHNOLOGY

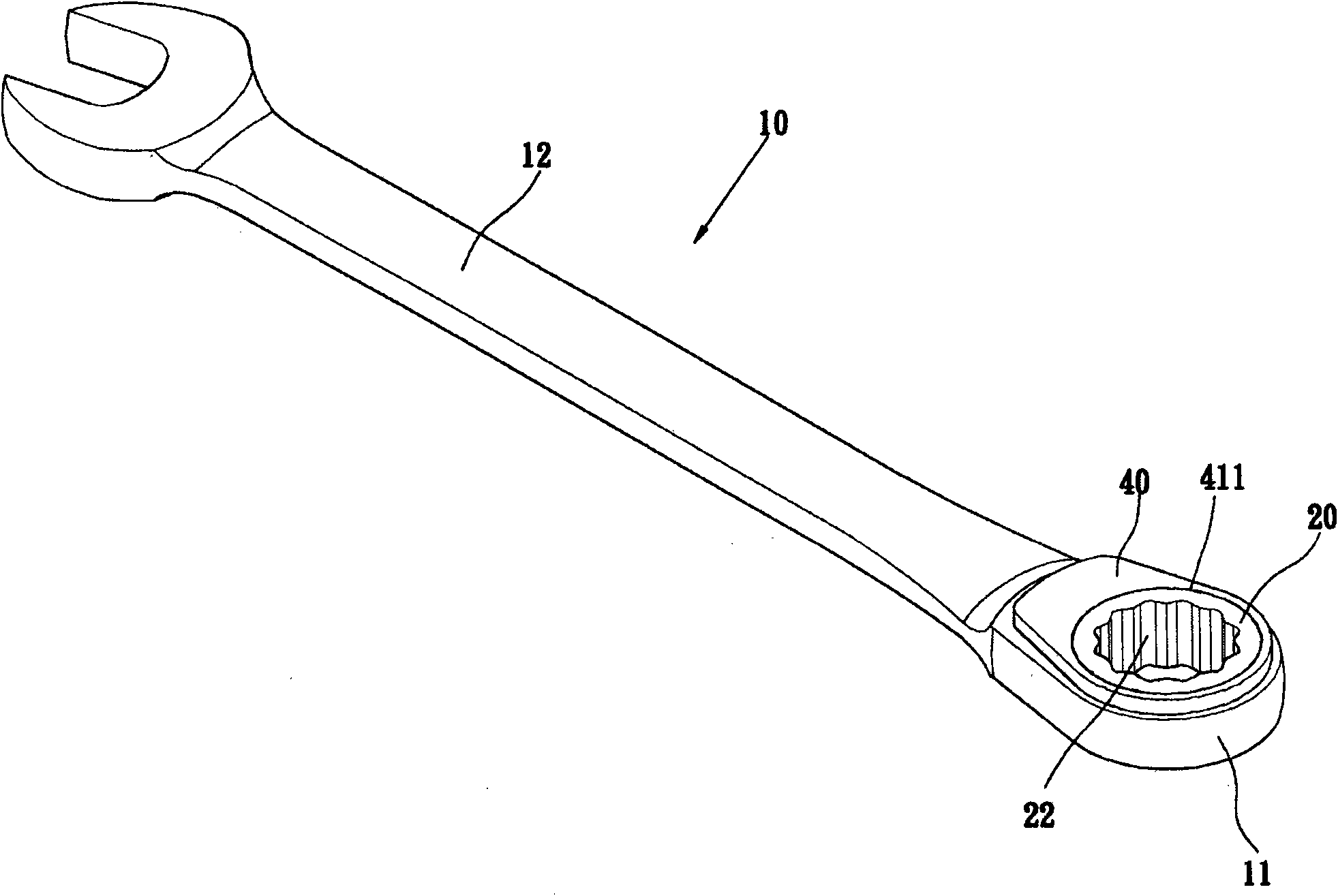

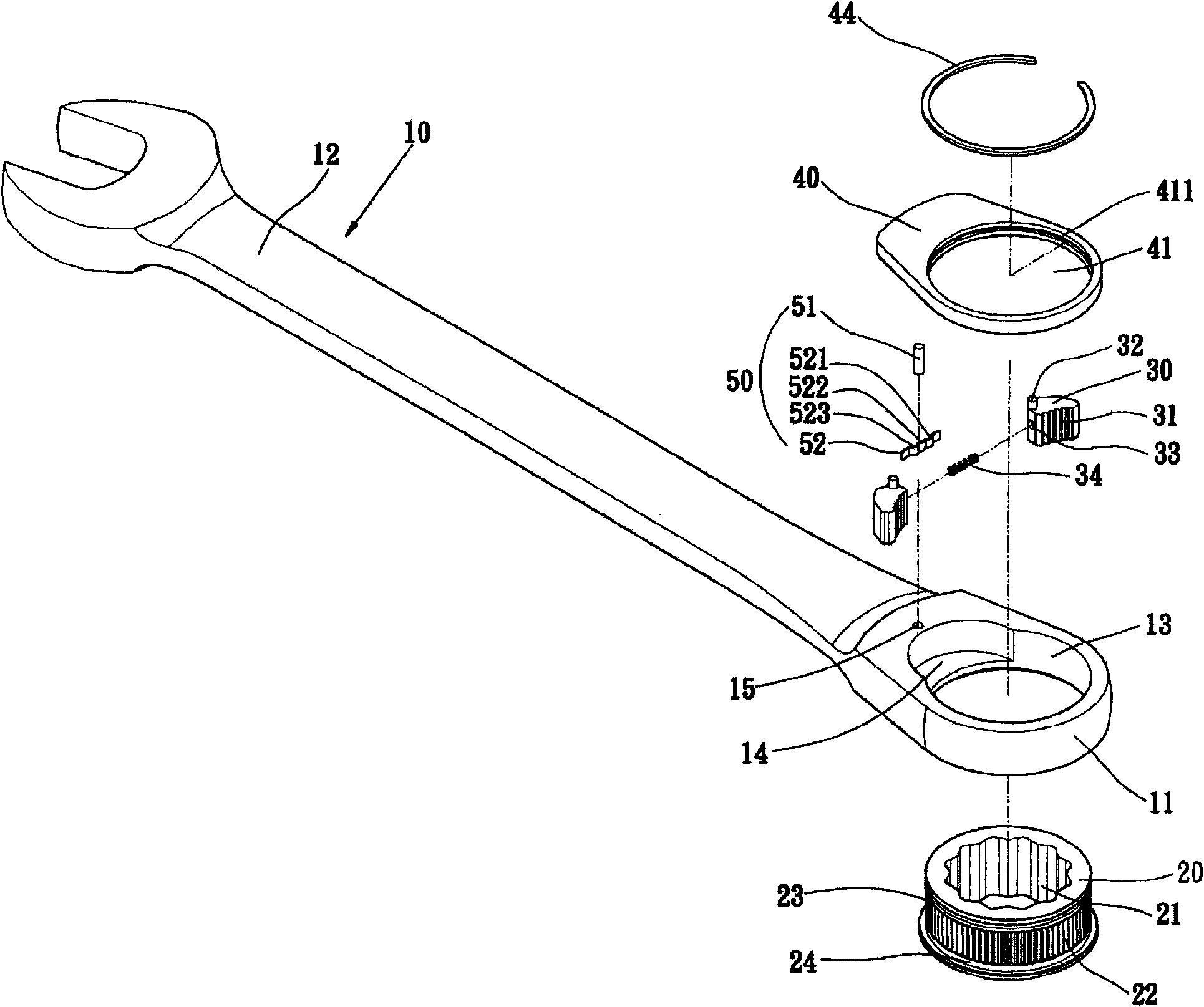

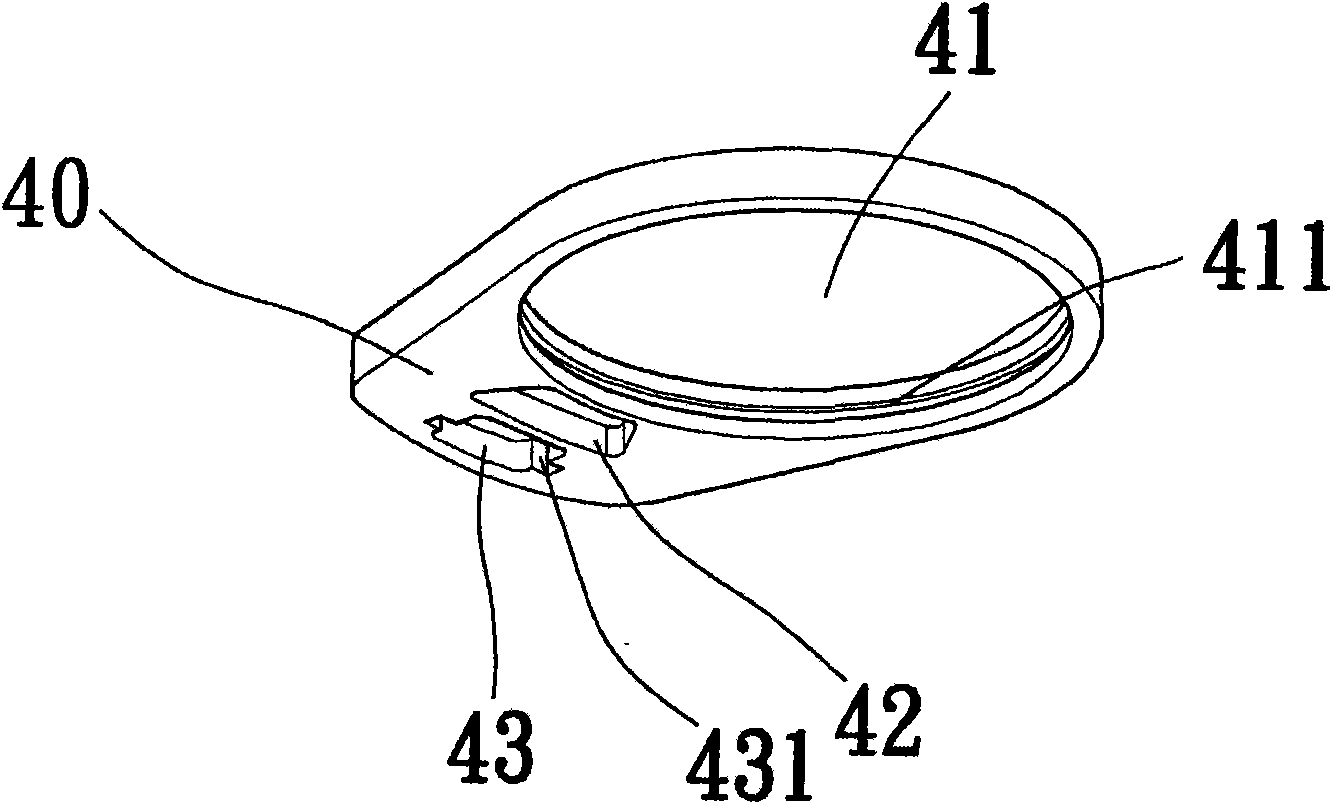

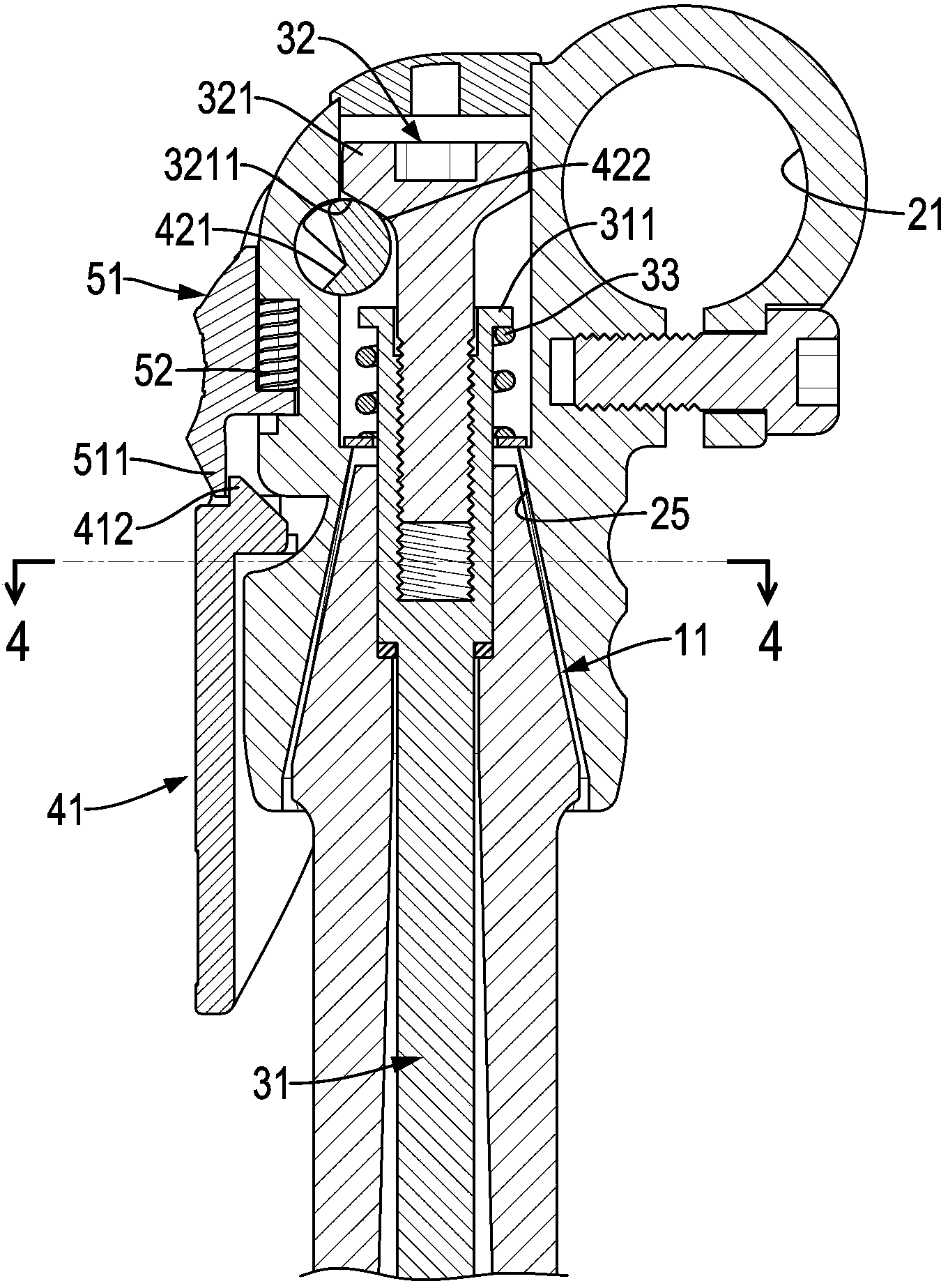

Toggle reversing ratchet wrench

The invention provides a reversing ratchet wrench which comprises a body, a ratchet piece, two clamping pieces and a reversing piece, wherein one end of the body is provided with a drive part, the drive part is connected with a holding part and is provided with a first accommodation part and a second accommodation part tangent with the first accommodation part; the ratchet piece is rotatably arranged in the first accommodation part of the body, teeth are circularly arranged on the side wall surface of the outer edge of the ratchet piece; the two clamping pieces are respectively arranged at twoends in the accommodation part of the body in a slip way, one side of each clamping piece opposite to the ratchet piece is provided with teeth, the top surfaces of the opposite ends of the two clamping pieces are respectively provided with a guide part, an elastic body is arranged between the two clamping pieces; one end of the reversing piece is pivoted at one end of the ratchet piece and the inner edge of the other end of the reversing piece is provided with a direction control part corresponding to the two guide parts of the two clamping pieces, and the direction control part can extend into the second accommodation part through the cut of the slip part and can selectively stir the guide parts of the clamping pieces to enable the teeth of the clamping pieces to be separated from the teeth of the ratchet piece. Therefore, the invention simplifies the positioning of a clamp ring and relatively lowers the manufacture cost of the wrench.

Owner:胡厚飞

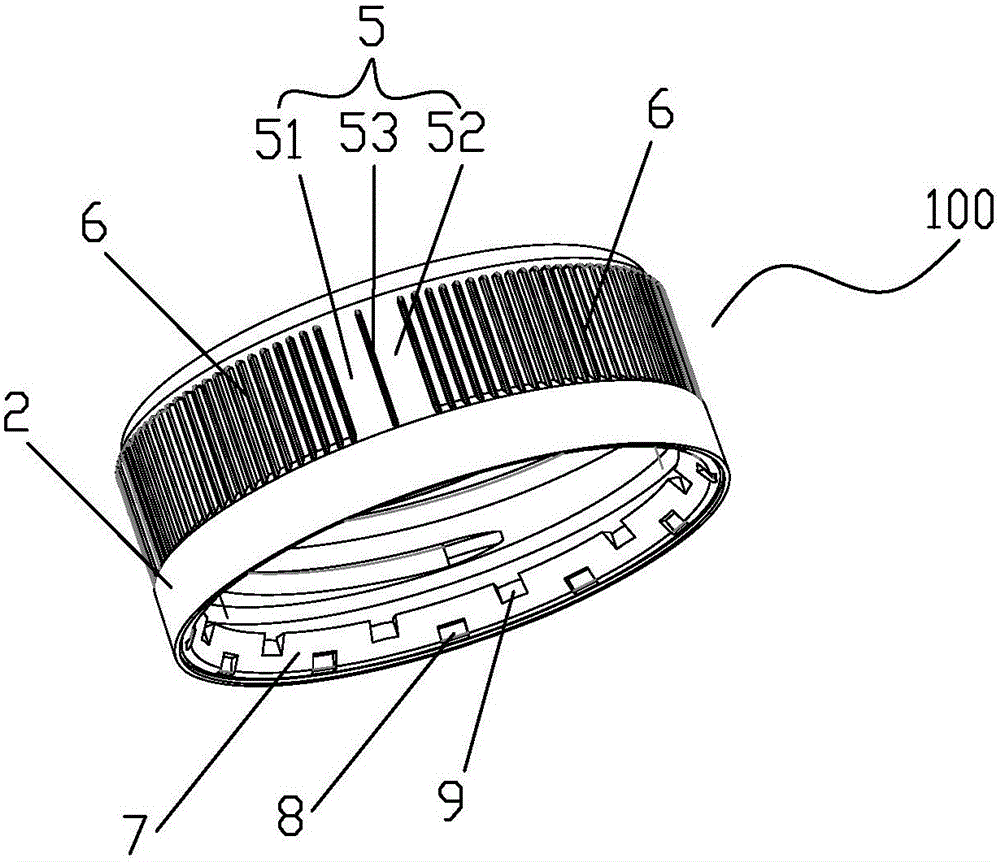

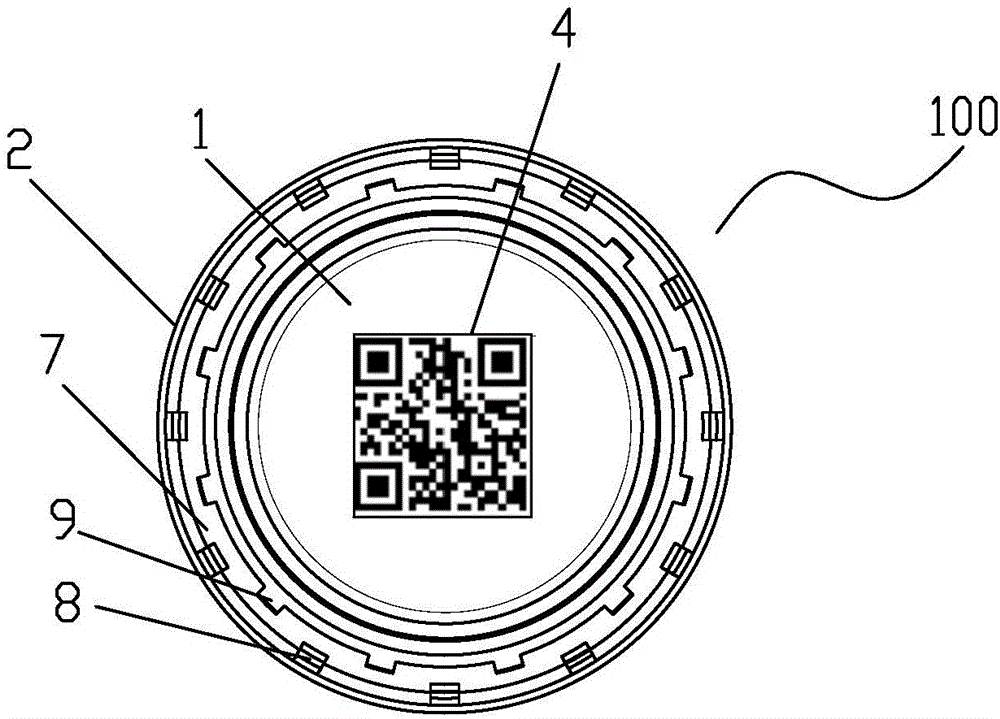

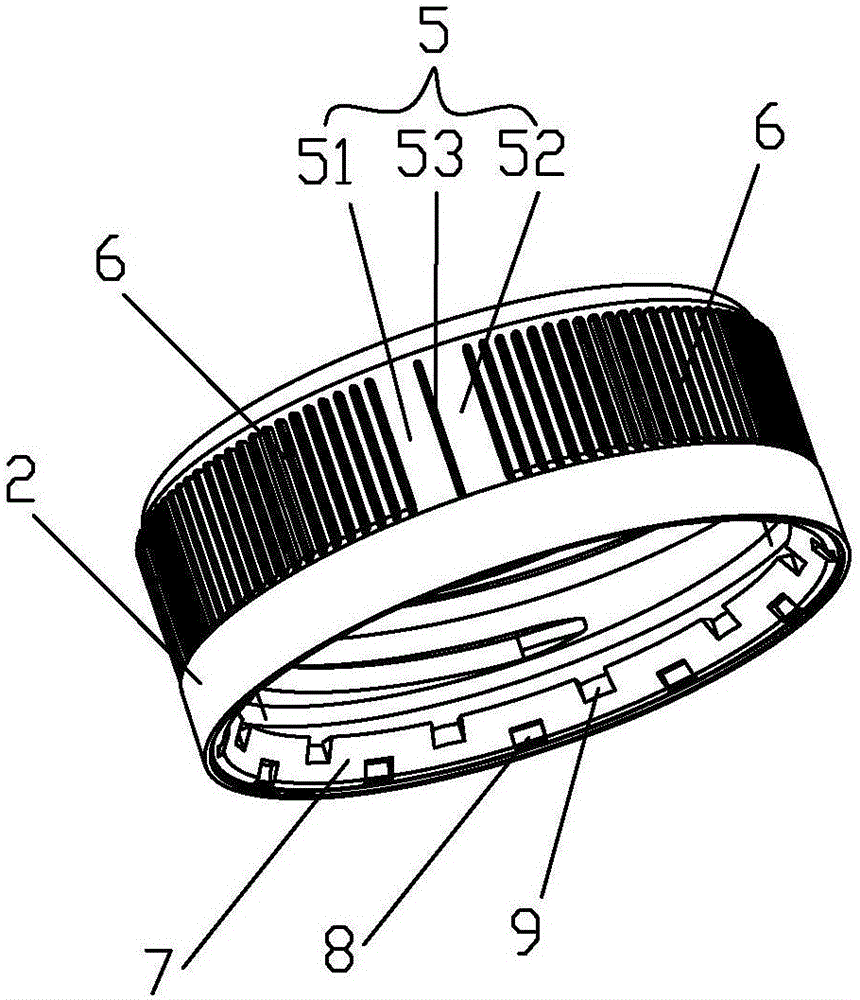

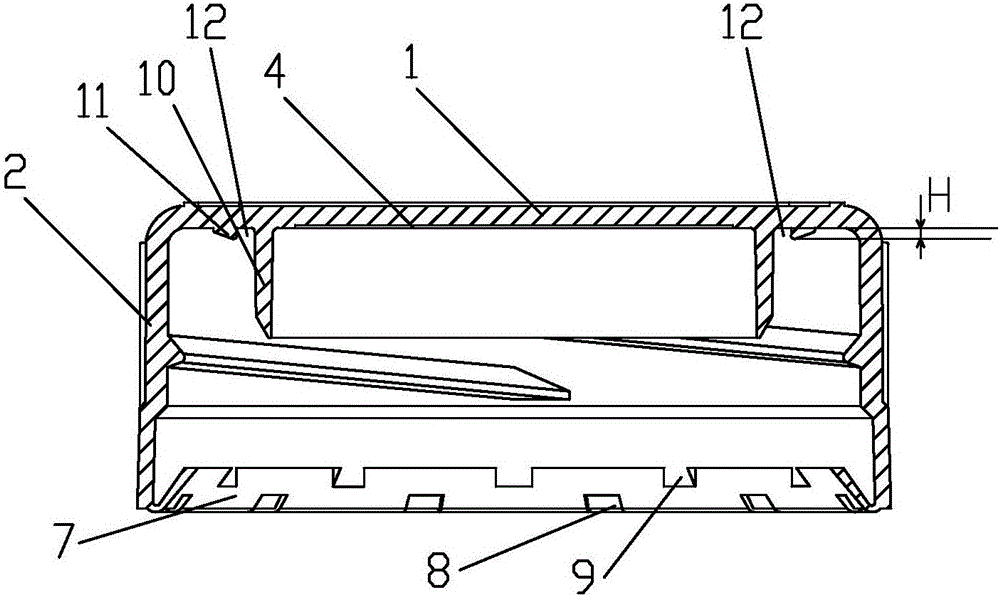

Novel plastic bottle cap

The invention discloses a novel plastic bottle cap. The novel plastic bottle cap comprises a top sheet (1). An annular side sheet (2) is arranged on the outer edge of the top sheet (1) and extends to one side of the top sheet (1), wherein the top sheet (1) and the annular side sheet (2) are integrally formed. The inner wall of the side sheet (2) is provided with threads matched with threads of a bottle neck (3). The top sheet (1) is provided with an ultraviolet laser etched layer (4) which is formed through etching of an ultraviolet laser beam and can store product information. The novel plastic bottle cap is simple in structure, healthful, safe and low in cost.

Owner:ZHONGSHAN HUIWEI PLASTIC METAL IND

Bar adjusting mechanism

The invention provides a bar adjusting mechanism which comprises a lower support and an upper support. The lower support is fixed on the workbench of an internal circle slicer. A bar is fixed on the upper support. A pitching adjusting device and a non-return positioning device are disposed on the lower support. The pitching adjusting device is used for driving the upper support to rotate relative to the lower support so as to adjust the pitching angles of the bar. The non-return positioning device is used for stopping the upper support from continuing rotating and positioning the upper support when the upper support stops rotating. The bar adjusting mechanism has the advantages that by the non-return positioning device, the upper support can keep still after manual adjusting, fixing is facilitated, and high fixing efficiency is achieved; the positions of the upper support need not to be kept by hands during fixing, manual errors can be avoided, and high adjusting precision of the perpendicularity between the bar and a blade can be guaranteed.

Owner:三环永磁(北京)科技有限公司

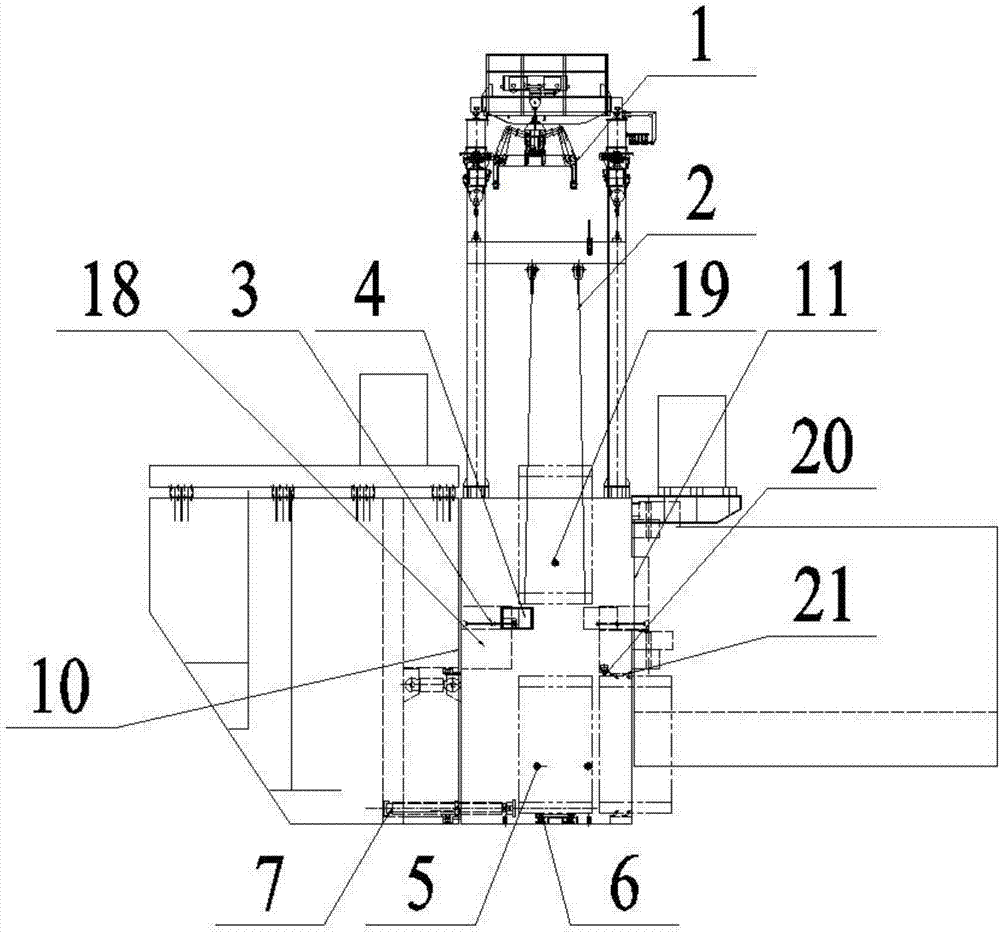

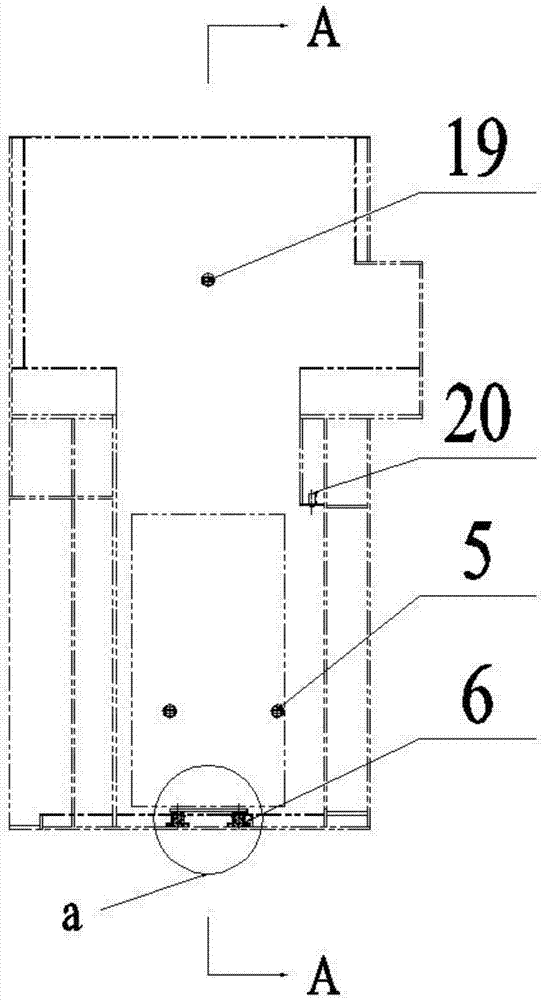

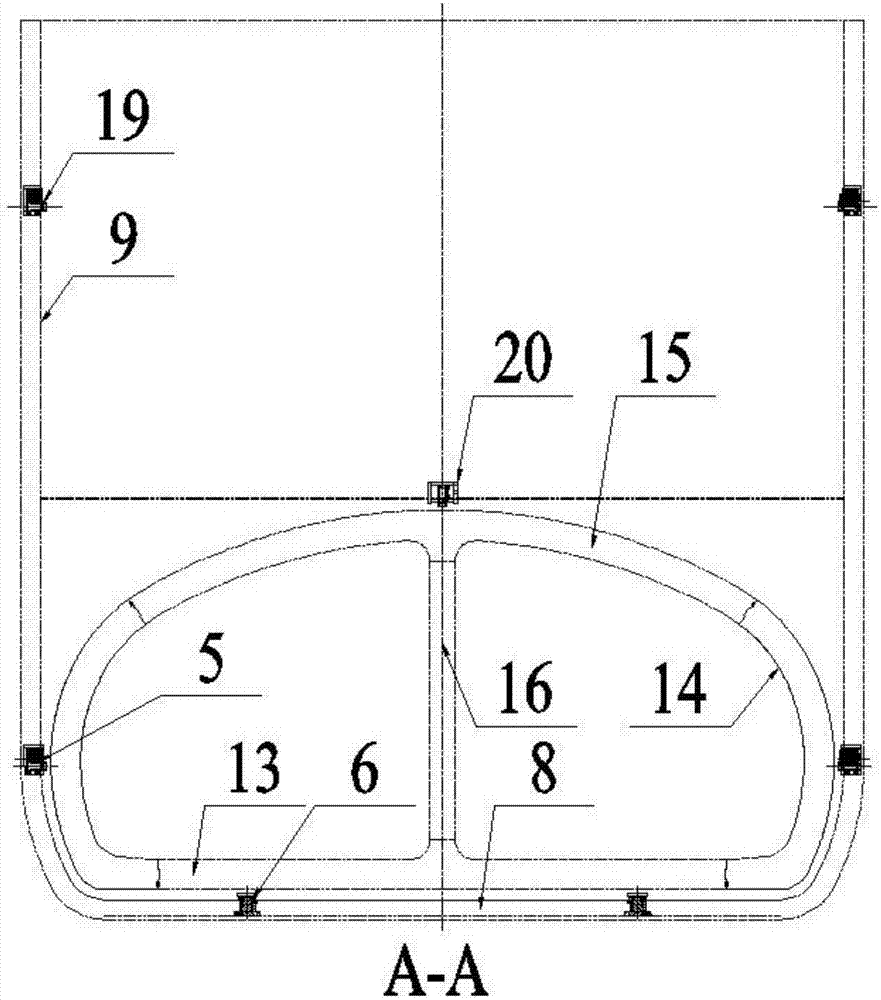

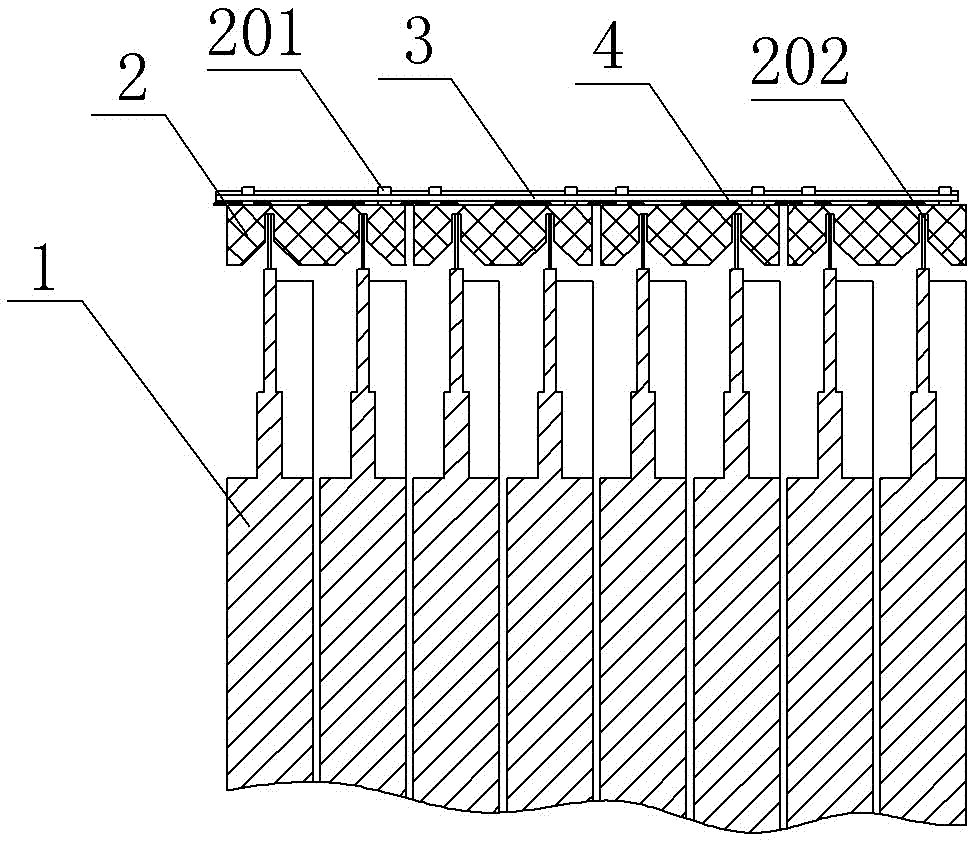

Pipe segment splicing method for segmental prefabricated underground pipe gallery

ActiveCN107035384AImprove assembly efficiencyReduce difficultyUnderground chambersTunnel liningBuilding constructionCivil engineering

The invention relates to the technical field of underground pipe gallery building construction, in particular to a pipe segment splicing method for a segmental prefabricated underground pipe gallery. The pipe segment splicing method comprises the steps that pipe segment parts are conveyed into pipe segment splicing equipment; the pipe segment parts are spliced into an annular pipe segment in the pipe segment splicing equipment; squeezing and pushing acting force is applied to the pipe segment to force the adjacent pipe segment parts to be tightly connected into a whole; then the pipe segment is jacked and pushed to a designed position to be connected with an adjacent pipe segment against the pipe gallery building direction; and the splicing working procedure is completed. The pipe segment splicing mode is convenient to operate, can be widely applied to various open cutting pipe gallery building construction, lowers the pipe segment conveying difficulty, reduces pipe segment conveying cost, improves the pipe segment splicing precision and has great popularization value.

Owner:CCCC SECOND HARBOR ENG +2

A connection structure of soft pack lithium-ion battery modules

ActiveCN105070874BSimplify the assembly processTo achieve a conductive connectionCell component detailsBusbarLithium-ion battery

The invention provides a soft-pack lithium-ion battery module connection structure, which includes at least two battery cells arranged in parallel and a bus bar located above the battery cells and electrically connected to the tabs of the battery cells, and also includes a bus bar arranged below the bus bar and connected to the tabs of the battery cells. The electric core is relatively fixedly assembled with an insulating grid, and the insulating grid is provided with tab perforations corresponding to the tabs of the battery for the tabs to pass through, and the tabs go upward through the top of the tab perforations It has a bent portion that is bent close to the upper side of the insulating grid, and the bus bar has a lower side that is crimped on the bent portion of the tab and welded and fixed to the bent portion of the tab. Since the entire busbar is crimped downwards on the bending part of the tab, in the actual welding assembly, it is only necessary to press down the busbar through the corresponding crimping tool, and the busbar will press down on the bend of the tab part, eliminating the need to configure additional lug press-fitting tooling, effectively simplifying the assembly process of the battery module and reducing production costs.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

A workpiece positioning structure and a screen printing positioning tool for a display protection screen

InactiveCN102848705BAchieve precise positioningGuaranteed positioning accuracyScreen printersScreen printingEngineering

The invention discloses a workpeice positioning structure and a silk-screen printing positioning tool for a display protecting screen. The positioning tool comprises a positioning plate, wherein at least one positioning groove for accommodating the display protecting screen is concavely formed in the positioning plate; at least two positioning groove walls and accommodating groove walls are formed in the positioning grooves; the at least two positioning groove walls are intersected or in extending intersection and are used as positioning references so as to contact and support against the display protecting screen; and the accommodation groove walls are in clearance fit with the display protecting screen. The positioning structure further comprises an elastic member, wherein during use, the elastic element is supported against and matched with the display protecting screen and applies a force on the display protecting screen so as to enable the display protecting screen to be supported against and contacted with the positioning groove walls, then the display protecting screen can be fixed in the positioning grooves. During use, the positioning grooves which are intersected or in extending intersection are used as the positioning reference sides, so that accurate positioning for the display protecting screen on a plane is effectively realized; and in addition, under the action of the elastic element, the display protecting screen is supported against the positioning groove walls used as the positioning reference sides and the positioning precision of the positioning mode can be further ensured.

Owner:新乡市天光科技有限公司

Bouncing detector for end-surface counter bore of bevel gear

InactiveCN105928435ASimple positioning structurePrecise positioningMechanical measuring arrangementsEngineeringBevel gear

The invention discloses a bouncing detector for an end-surface counter bore of a bevel gear. The detector is composed of a lining, a core shaft, a pedestal and a dial indicator. A downward shaft segment of the core shaft is inserted into a through hole of the pedestal, a middle shoulder is used for axial limiting, and an upward shaft segment is left to positioning and installing the lining. The cooperative length of the lining and the core shaft does not exceed the cooperative shaft-hole length of the bevel gear to be detected. The dial indicator is supported by an indicator frame on the pedestal, a pointer of the dial indicator in a cantilever shape abuts against to the wall of the end-surface counter bore of the bevel gear to be detected, and thus, a measuring structure which rotates, by taking the shaft hole as the reference, to measure the radial bouncing of the end-surface counter bore of the bevel gear to be detected is formed. Measuring reference is consistent with design reference, a measuring result is accurate therefore, the deflection direction of the point of the dial indicator is used to determine the bounding size and direction of a product, convenience is provided for improvements in subsequent processing, and basis is provided for improvement of the product quality.

Owner:JIANGSU AIRSHIP GEAR

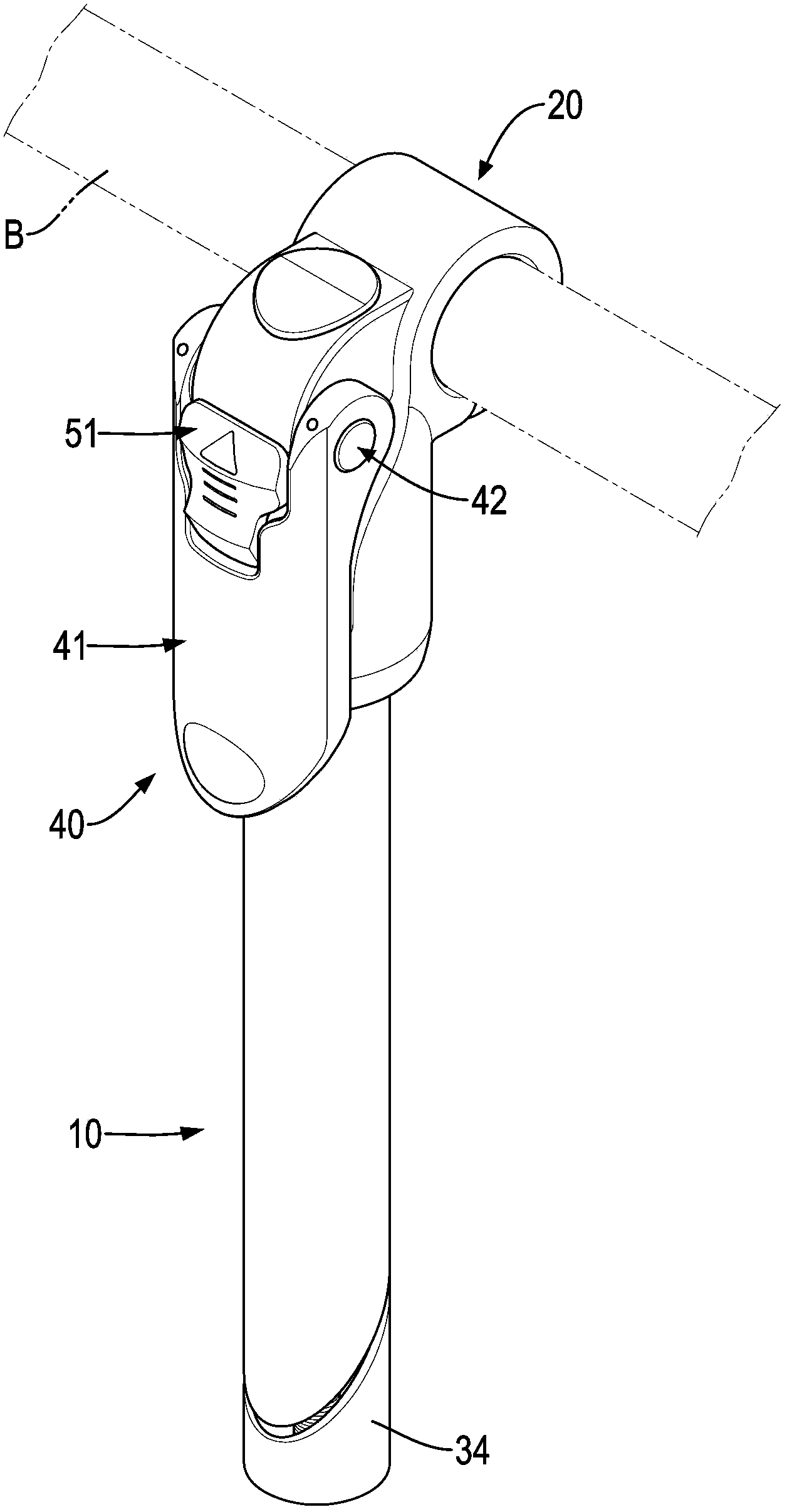

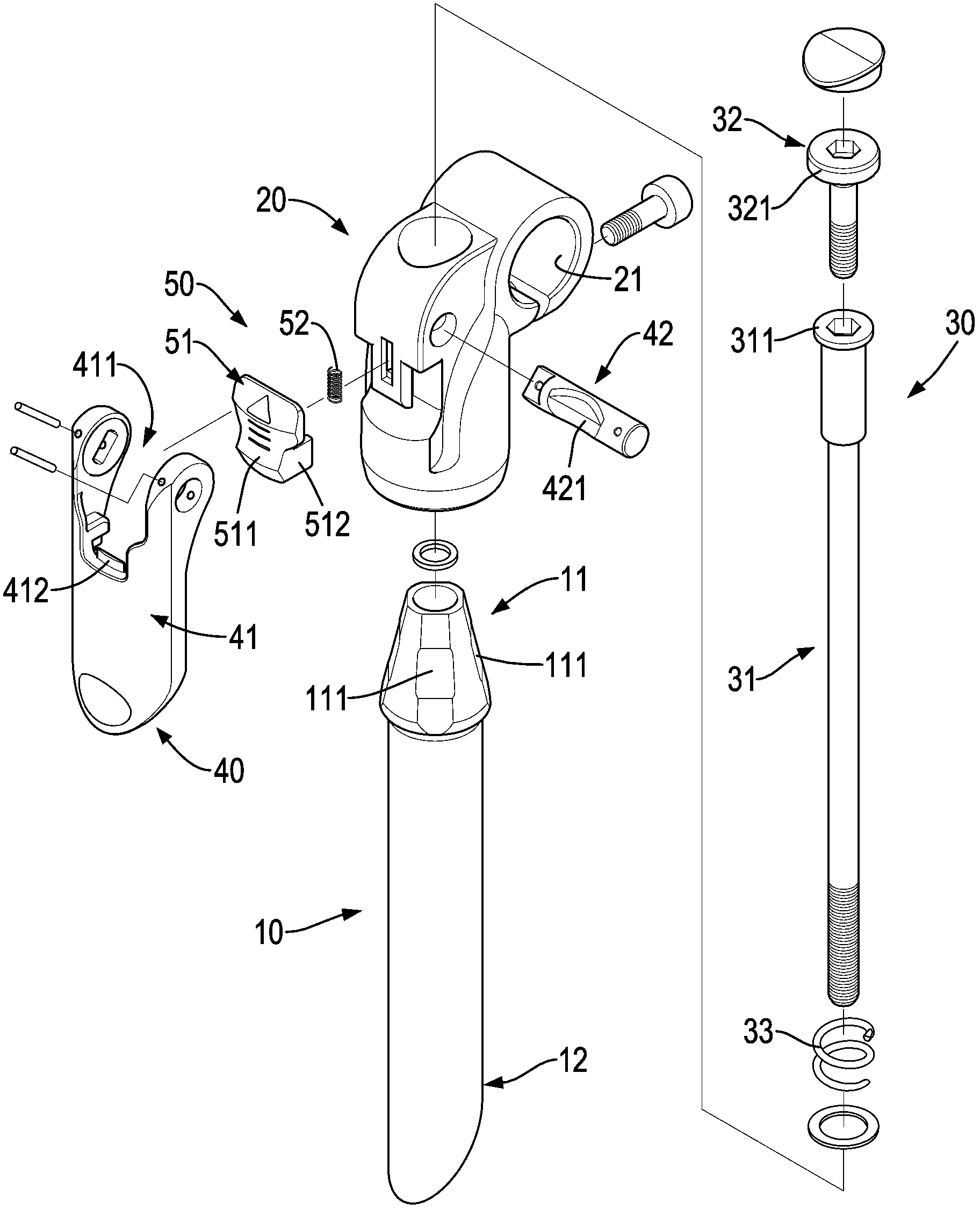

Bicycle vertical tube device capable of rotationally folded

InactiveCN104085486AImprove efficacySimple positioning structureSteering deviceElectrical and Electronics engineeringVertical tube

The invention relates to a bicycle vertical tube device capable of being rotationally folded. The bicycle vertical tube device comprises a vertical tube, a connecting base, a rod piece unit and a quick release unit, wherein the top of the vertical tube is tapered and forms a plurality of propping surfaces; the inner wall surface of the groove of the connecting base is propped against the propping surfaces; rod piece unit axially penetrates through and is fixed in the vertical tube; the quick release unit is arranged on the connecting base; the rotation of the pivot of the quick lease unit is adopted to ensure that the connecting base is quickly clamped with or released from the rod piece unit, so that the bicycle vertical tube has functions of stable positioning, quick rotating folding and the like. The bicycle vertical tube device is simple in the integral structure and quick and convenient in the positioning mode.

Owner:YUAN LIANG MACHINE

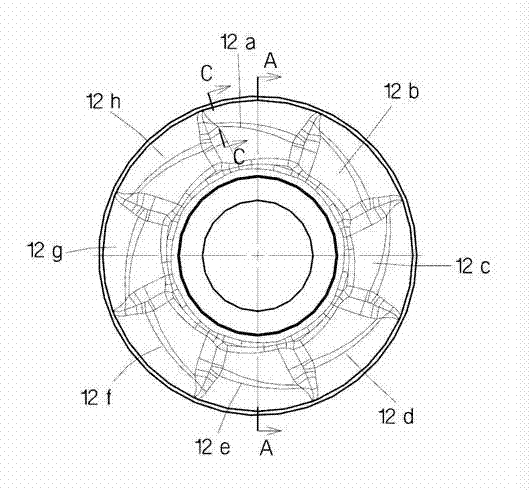

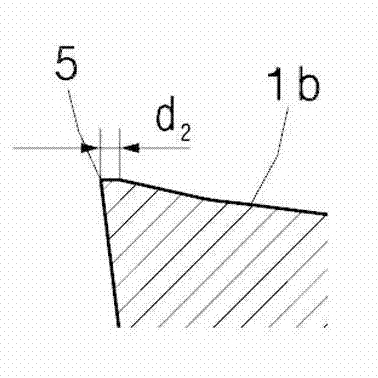

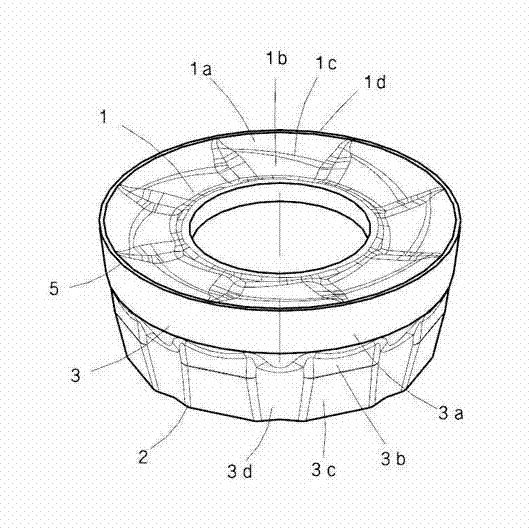

Indexable milling cutter blade and milling cutter

The invention discloses an indexable milling cutter blade and a milling cutter. A cutter blade body is in the shape of a cone and comprises an upper surface, a lower surface and a side surface connecting the upper surface with the lower surface. The geometric center of the cutter blade body is provided with a cutter blade positioning hole. The side surface comprises a rear cutter surface near the upper surface, and a positioning surface near the lower surface; a groove is arranged between the positioning surface and the rear cutter surface; the positioning surface is provided with a plurality of positioning tables which are distributed uniformly; each positioning table comprises a positioning plane protruding outwards from the side surface, and a transition surface for connecting the groove with the positioning plane; each positioning plane extends to the lower surface from the transition surface; and the lower surface 2 is a cutter blade installation reference plane. Each protruding positioning plane clings to a positioning side surface of a cutter groove to restrict the radial rotation of the blade, then the rear cutter surface of the blade clings to the positioning side surface of the cutter groove, therefore the blade is positioned correctly and prevented from rotating and sliding under the actions of cutting force and friction force in processing.

Owner:株洲欧科亿切削工具有限公司

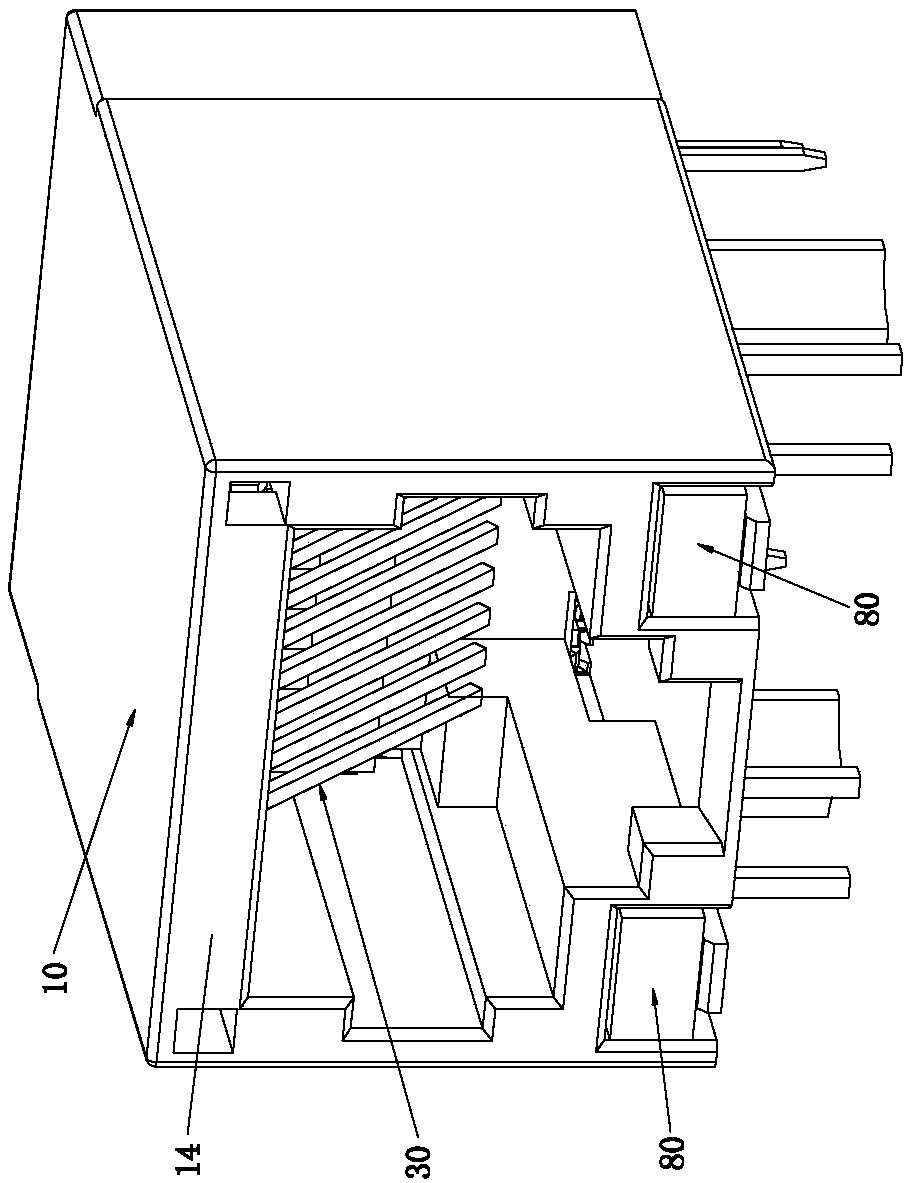

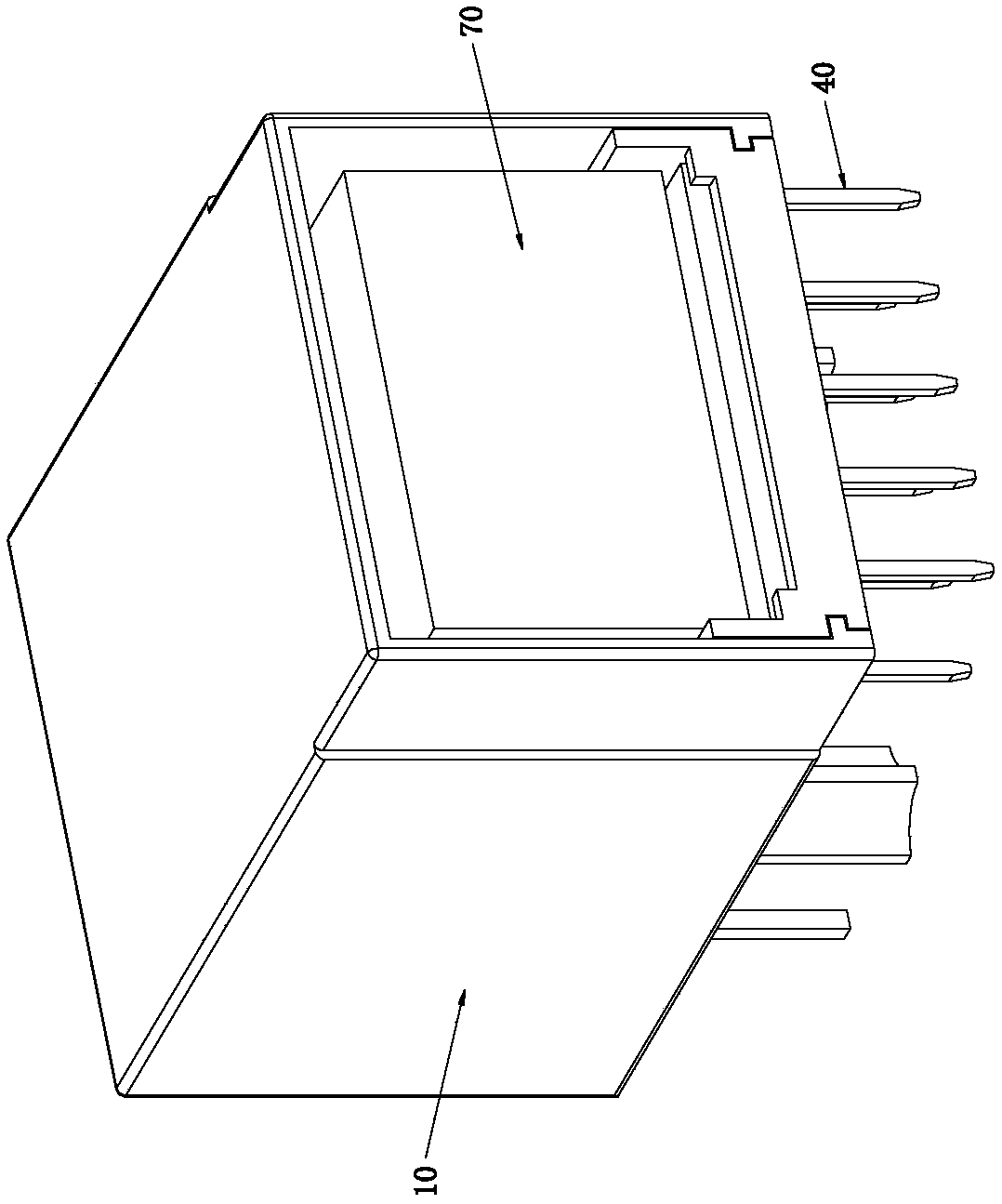

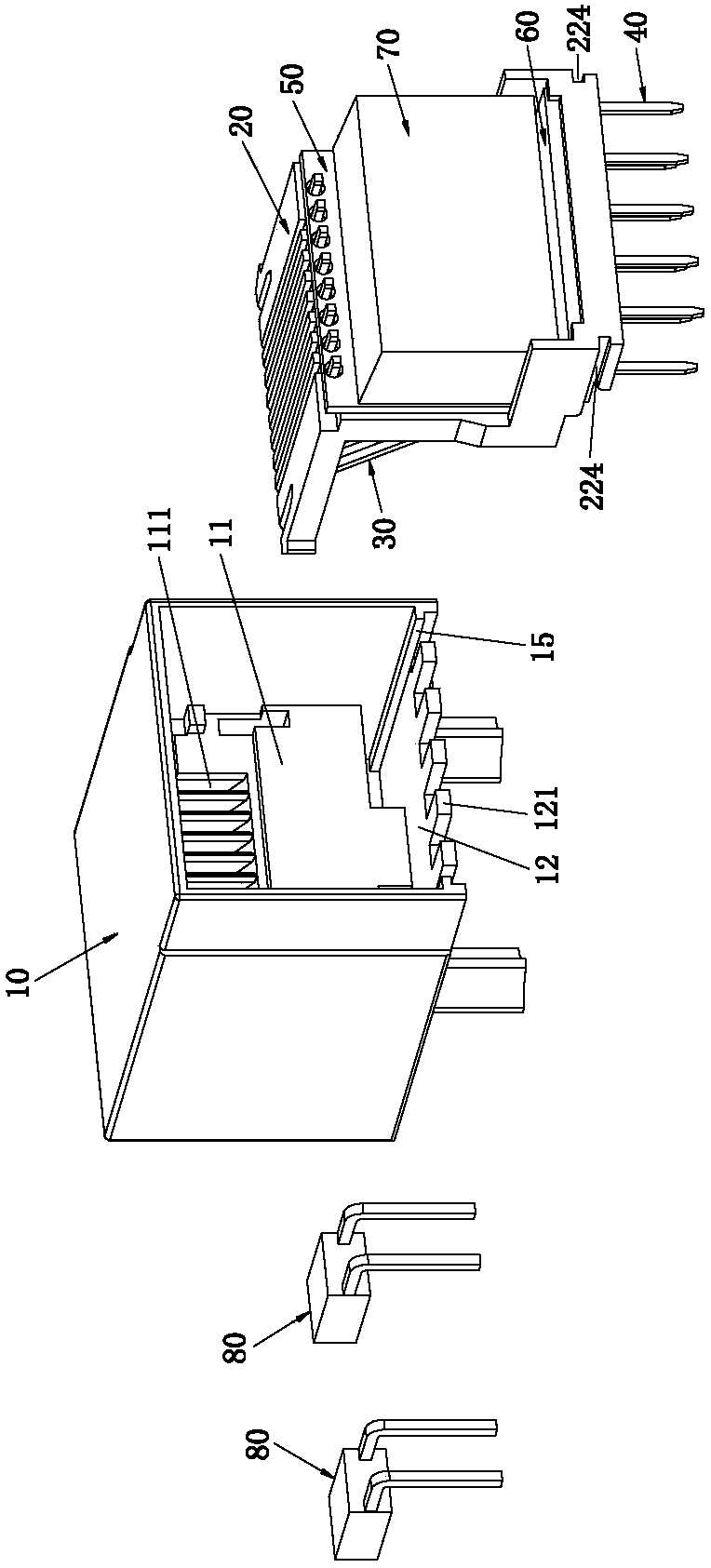

RJ connector assembling structure and assembling method thereof

InactiveCN107834246ASimple positioning structureReasonable and ingenious structural designContact member assembly/disassemblyCoupling contact membersEngineeringElectrical and Electronics engineering

The invention discloses an RJ connector assembling structure and an assembling method thereof. The RJ connector assembling structure comprises a housing, an RJ connector insertion core, an RJ terminal, a PIN terminal, a first PCB, a second PCB, a network filter and an indicating lamp, wherein the RJ connector insertion core, the RJ terminal, the PIN terminal, the first PCB, the second PCB, the network filter and the indicating lamp are mounted in the housing. The RJ connector insertion core is inserted into an accommodating chamber which is mounted on the housing. The RJ terminal and the PIN terminal are respectively mounted at the upper end and the lower end of the RJ connector insertion core. The welding part of the RJ terminal is connected with the upper end of the first PCB. The firstPCB is connected with the second PCB. The welding part of the PIN terminal is connected with the second PCB. The network filter is inserted into and mounted on the first PCB. The indicating lamp is inserted into and mounted in the housing. Therefore the RJ terminal is connected with the PIN terminal through the first PCB and the second PCB, and positioning structures of the RJ connector insertioncore and the PCBs on the housing are simplified. The RJ connector assembling structure and the assembling method thereof have advantages of realizing ingenious and reasonable structure design and easyforming and manufacture, simplifying the positioning structure of each component and a forming and manufacturing mold, reducing production cost and improving machining efficiency.

Owner:文山意德电子科技有限公司

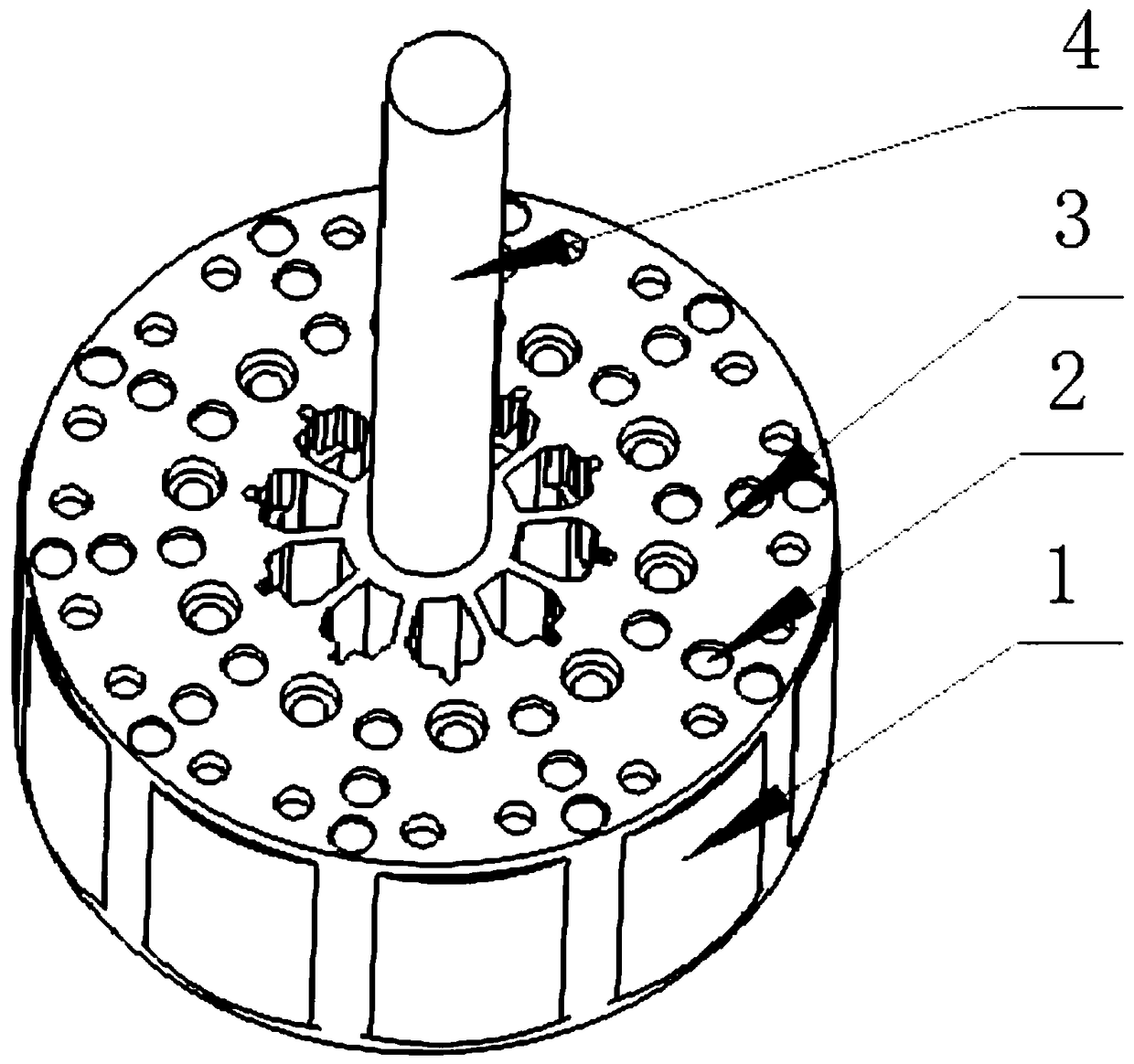

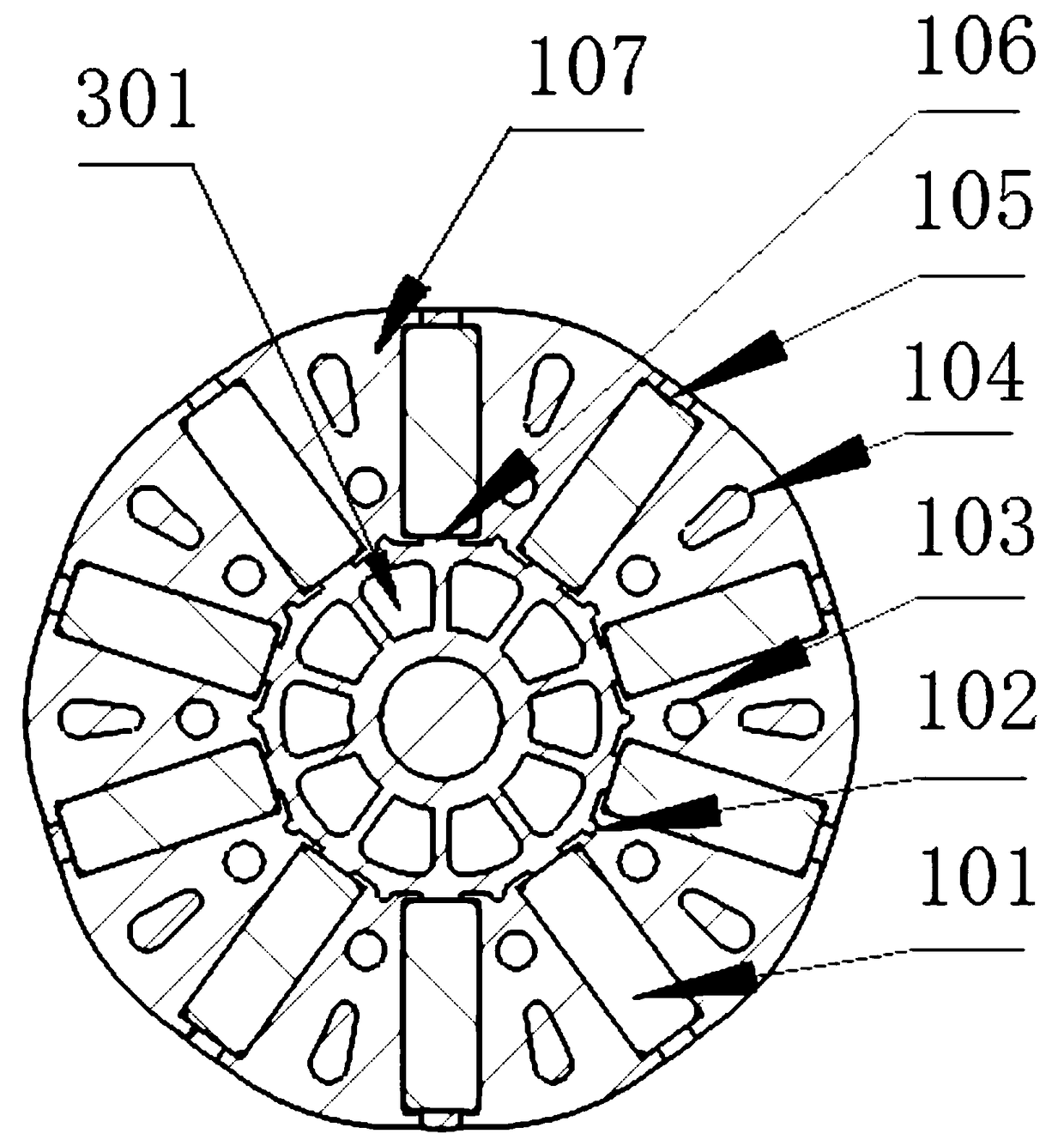

Segmented iron core IPM plastic package forming rotor

PendingCN108711980ASolve the problem of flux leakageImprove power densityMagnetic circuit rotating partsWhole bodyEngineering

The invention discloses a segmented iron core IPM plastic package forming rotor, and relates to the field of motors. An existing IPM rotor is designed into an integral punch forming rotor iron core ofa magnetism isolating bridge structure, and greater leakage flux exists. The segmented iron core IPM plastic package forming rotor comprises a rotor iron core, magnetic shoes, a PBT and a shaft, wherein the rotor iron core consists of a plurality of same iron core segments in an encircling manner; a magnetic shoe groove and an anti-leakage flux groove for reducing leakage flux are arranged between every two adjacent iron core segments respectively; every two adjacent iron core segments are separated from each other through the corresponding anti-leakage flux groove and the corresponding magnetic shoe groove; each iron core segment is provided with a positioning structure for realizing the positioning of the corresponding iron core segment respectively; each magnetic shoe is inserted intothe corresponding magnetic shoe groove; the magnetic shoes are fixed on the rotor iron core through the PBT; and the shaft is connected with the magnetic shoes and the rotor iron core into a whole body through the PBT. Through the technical scheme, the rotor iron core is segmented into the same iron core segments, so that the magnetism isolating bridge leakage flux problem of a traditional integral rotor iron core is solved, the utilization rate of the rotor magnetic shoes is improved, and the power density of the motor is improved.

Owner:WOLONG ELECTRIC GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com