RJ connector assembling structure and assembling method thereof

A technology for assembling structures and connectors, which is applied in the assembly/disassembly and connection of parts and contacts of connection devices, and can solve problems such as increased production costs, cumbersome manufacturing processes, and complex mold structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

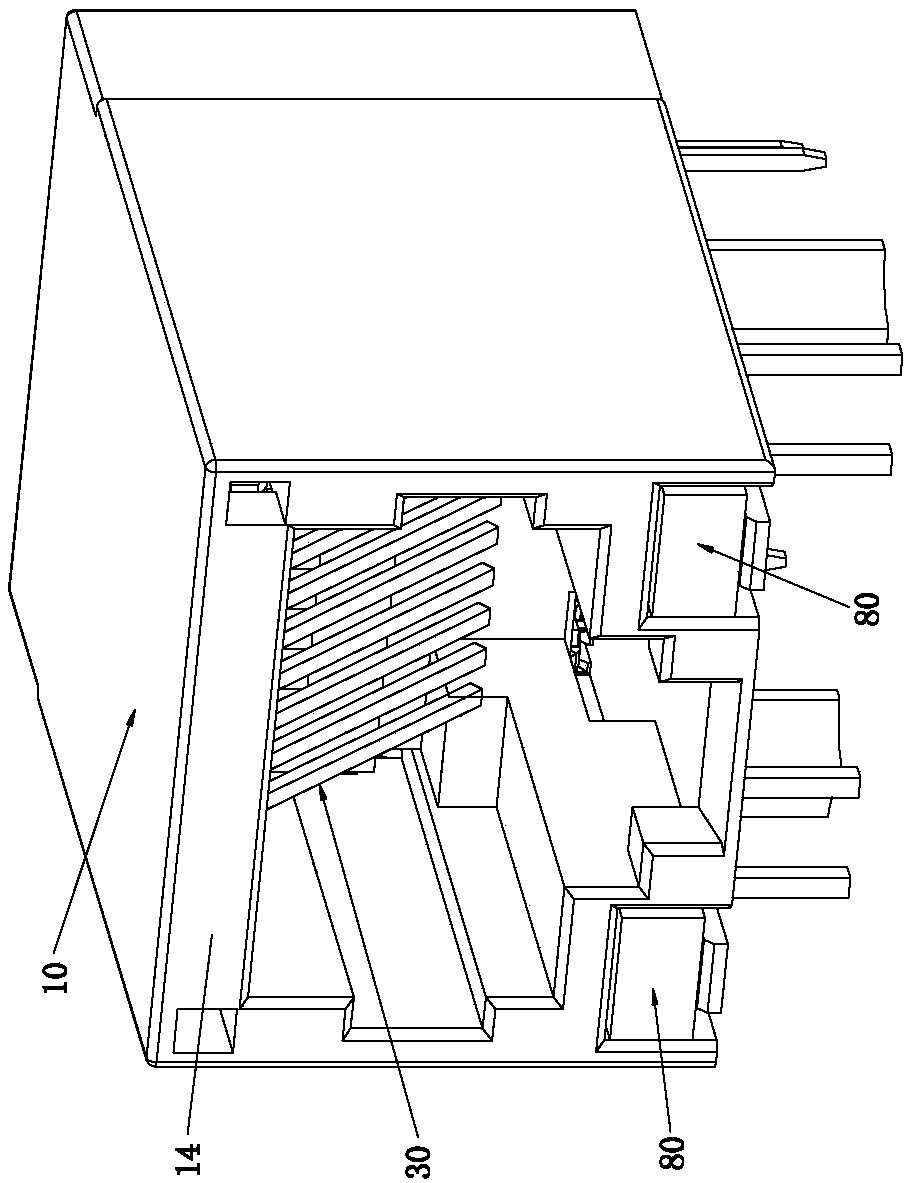

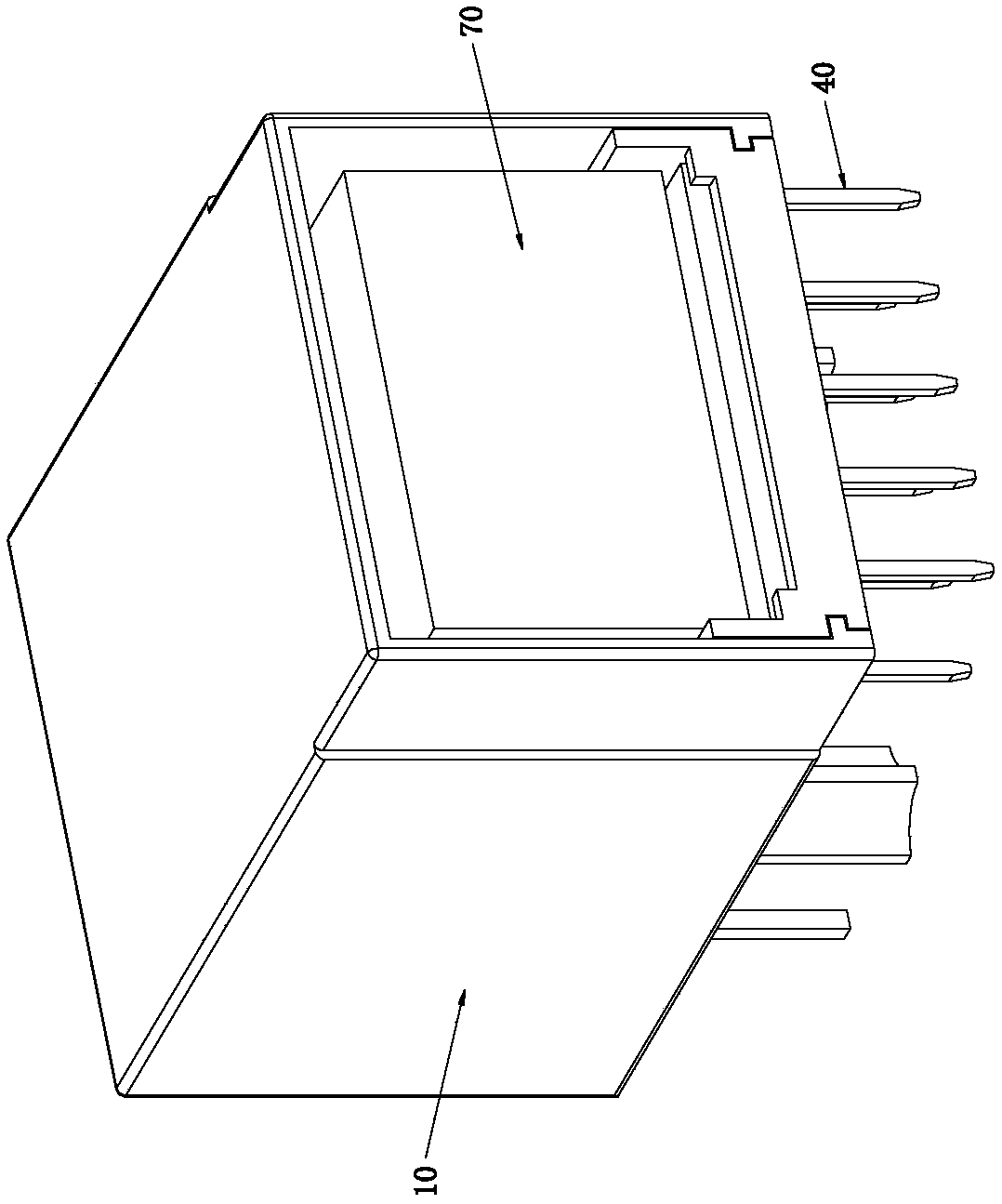

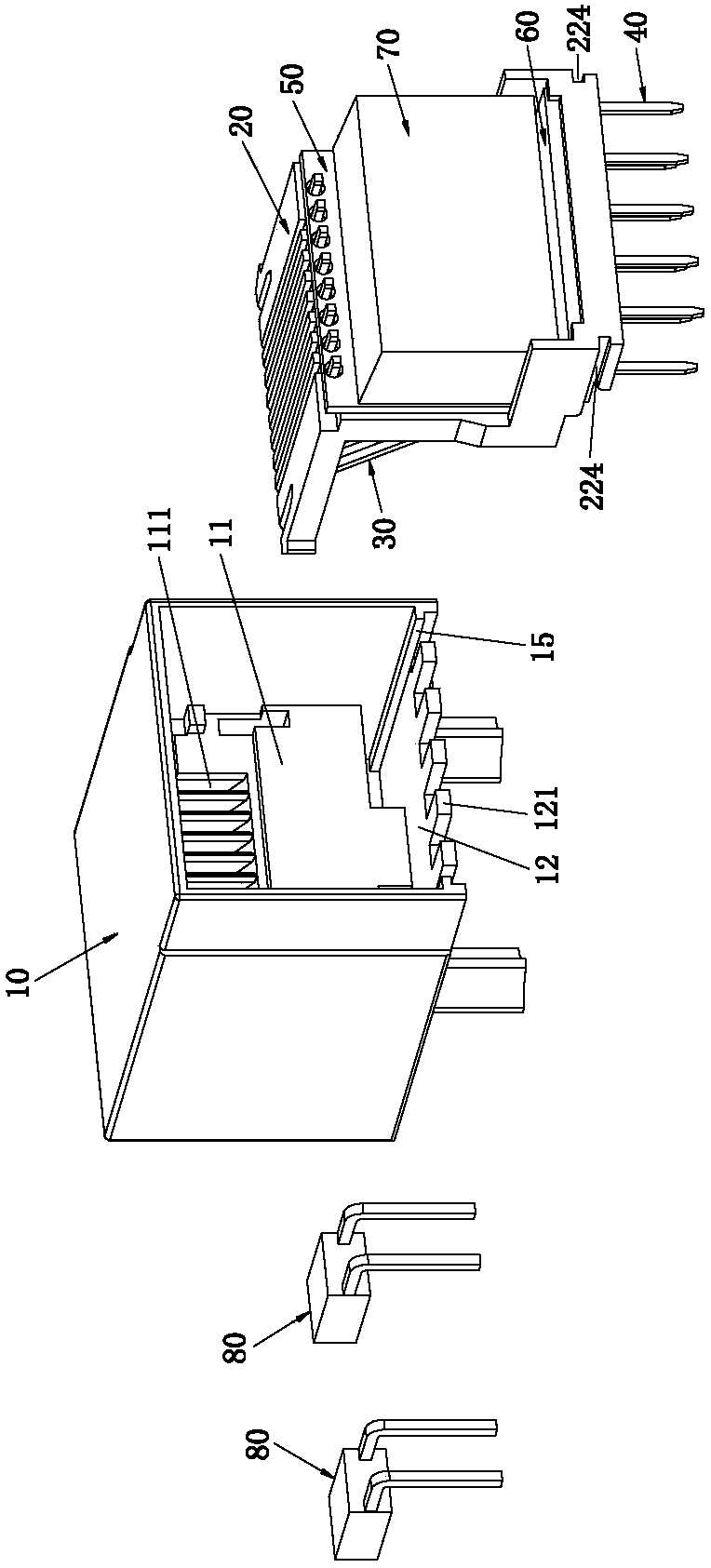

[0071] Please refer to Figure 1 to Figure 12 As shown, it shows the specific structure of the embodiment of the present invention; it includes: the shell 10 and the RJ connector ferrule 20 installed in the shell 10, the RJ terminal 30, the PIN terminal 40, the first PCB board 50, the second Two PCB board 60 , network filter 70 and indicator light 80 .

[0072] Specifically, the RJ connector ferrule 20 is inserted and installed in the housing cavity of the housing 10, the RJ terminal 30 and the PIN terminal 40 are installed on the upper and lower ends of the RJ connector ferrule 20 respectively, and the welding part of the RJ terminal 30 ( This article refers to the first welding part 33) passing through and connected to the upper end of the first PCB board 50, the first PCB board 50 is connected to the second PCB board 60, the welding part of the PIN terminal 40 (herein referred to as the second The welding part 41 ) is connected to the bottom of the second PCB 60 , the netw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com