Patents

Literature

31results about How to "Solve the problem of flux leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Permanent-magnetic rotor with non-magnetic-permeable distance sleeve and method for manufacturing permanent-magnet rotor

InactiveCN102761211AIncrease profitImprove electromagnetic compatibilityMagnetic circuit rotating partsManufacturing stator/rotor bodiesPermanent magnet rotorWork performance

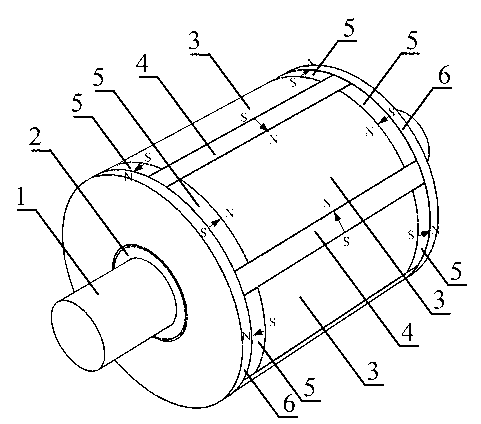

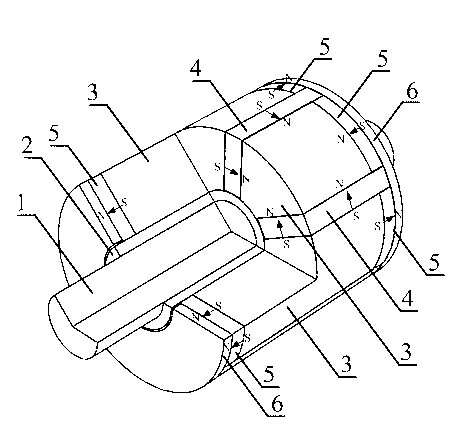

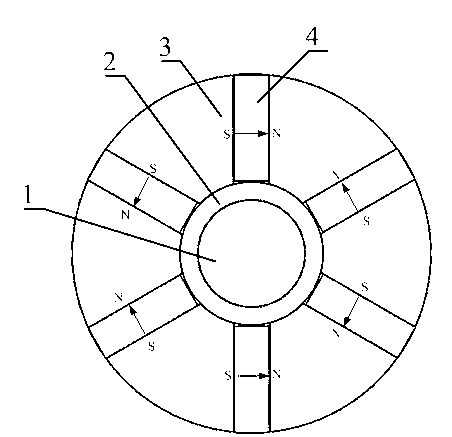

The invention discloses a permanent-magnetic rotor with a non-magnetic-permeable distance sleeve and a method for manufacturing the permanent-magnetic rotor. The method includes sleeving the non-magnetic-permeable distance sleeve made of a non-magnetic-permeable material on a rotor shaft at first when iron cores of the rotor are mounted on the rotor shaft; then manufacturing the iron cores of the rotor into fan-shaped iron cores; uniformly distributing and fixedly mounting the fan-shaped iron cores of the rotor on the non-magnetic-permeable distance sleeve; encircling four surfaces, except for the arc-shaped upper end surface and a contacting surface with the non-magnetic-permeable distance sleeve, of each fan-shaped iron core, which is fixedly mounted on the non-magnetic-permeable distance sleeve, of the rotor by permanent magnets made of permanent magnetic materials in an attached manner; and arranging attached surfaces of the permanent magnets and the fan-shaped iron cores of the rotor properly so that magnetic polarities of the attached surfaces of the permanent magnets and the fan-shaped iron cores are identical correspondingly. The permanent-magnetic rotor has the advantages that the permanent-magnetic rotor is compact in structure, high in interference resistance, stable in work performance and long in service life, flux leakage at axial ends and flux leakage interference of the rotor are low, magnetic efficiency and utilization rate of each permanent magnet are high, and the like.

Owner:LINQUAN AEROSPACE MOTOR CO LTD

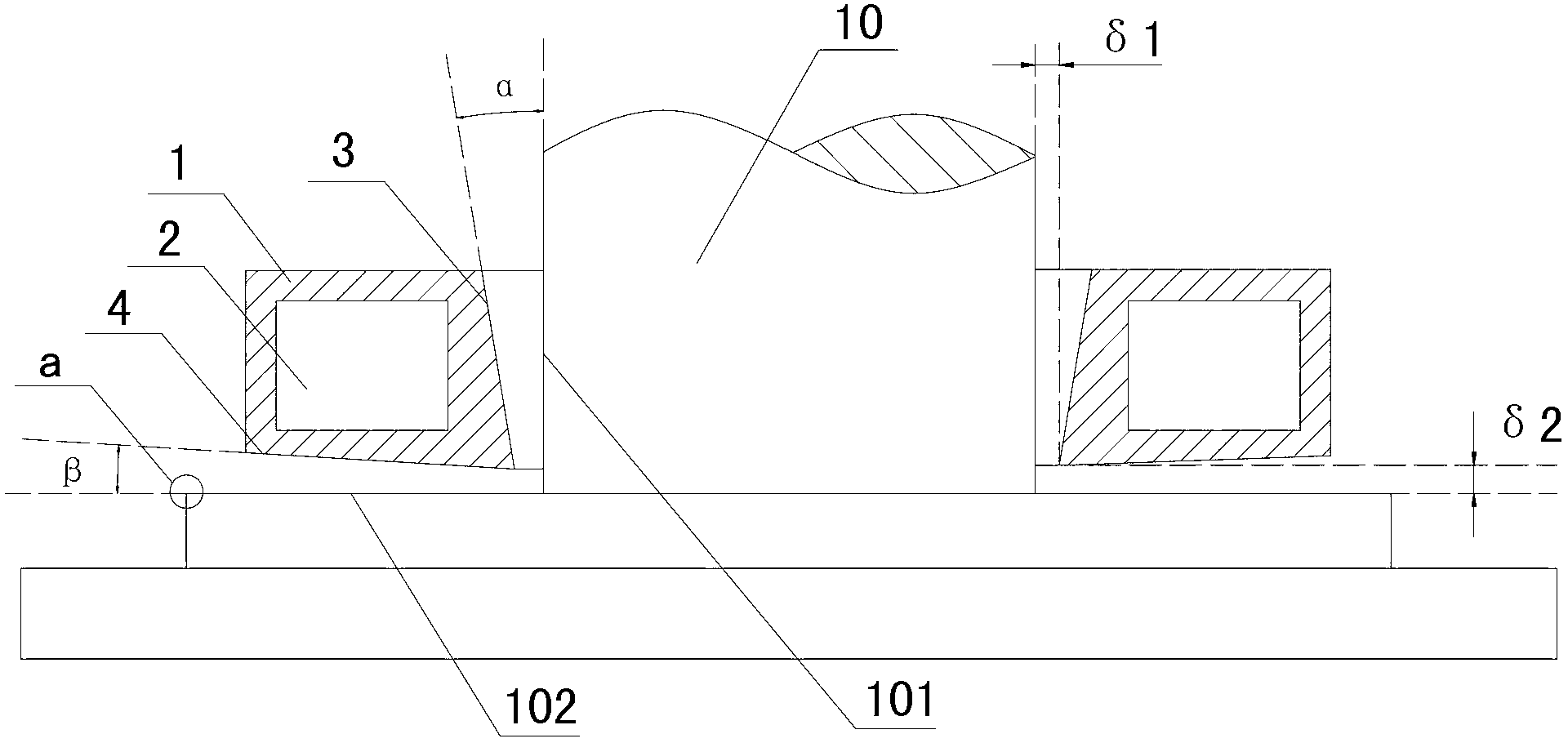

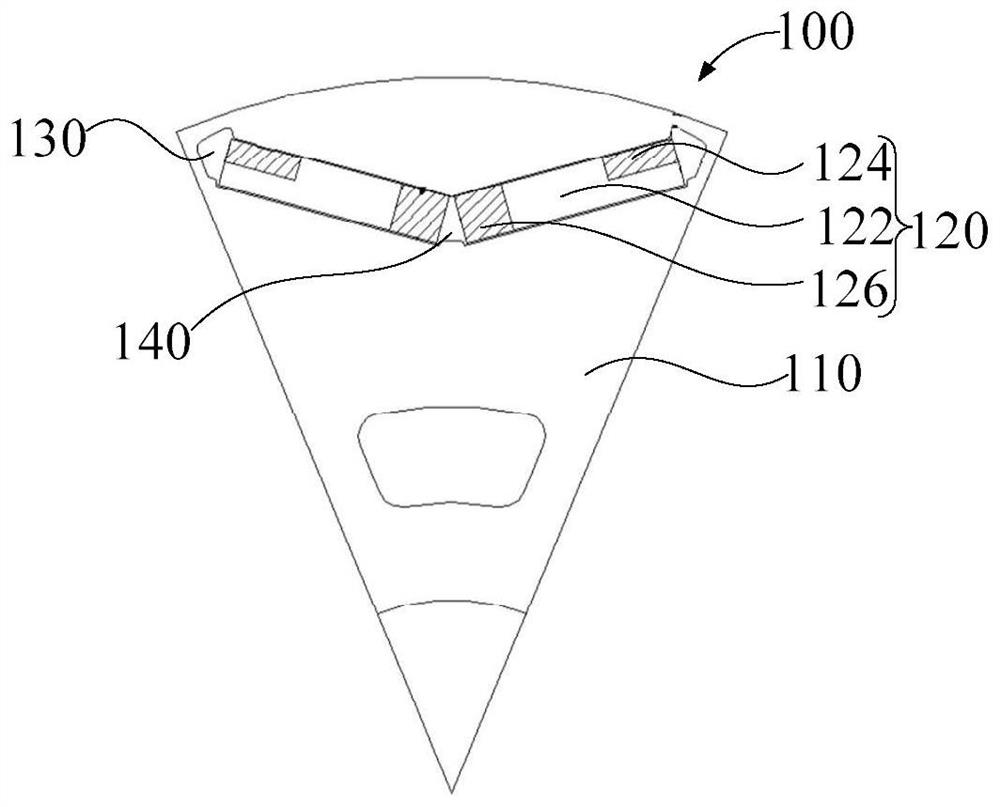

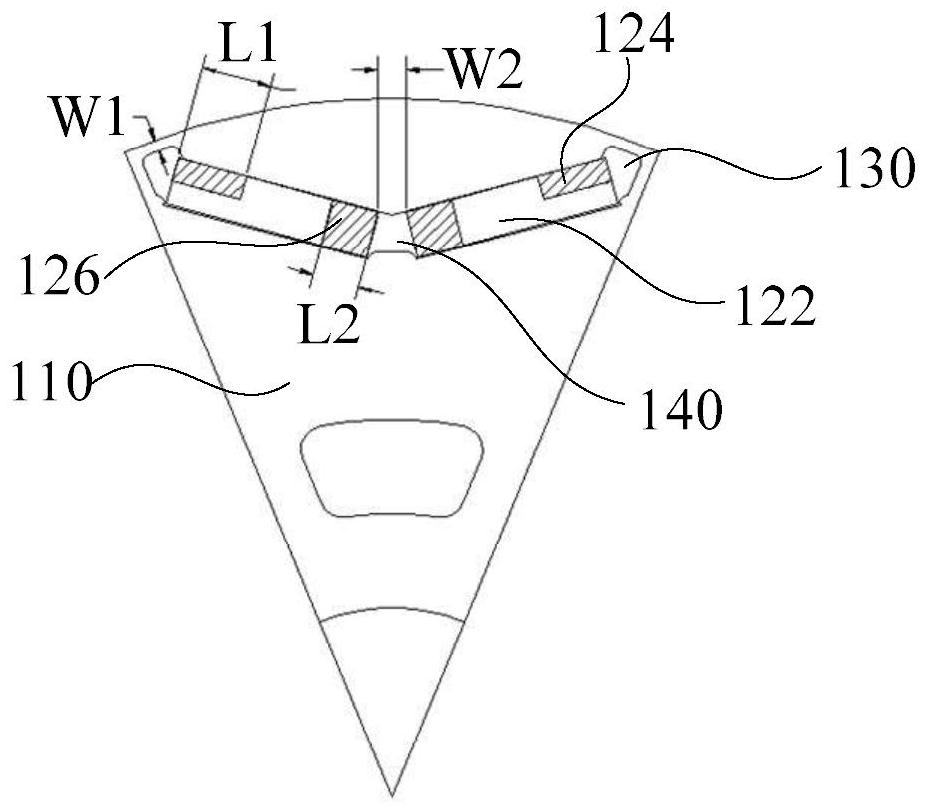

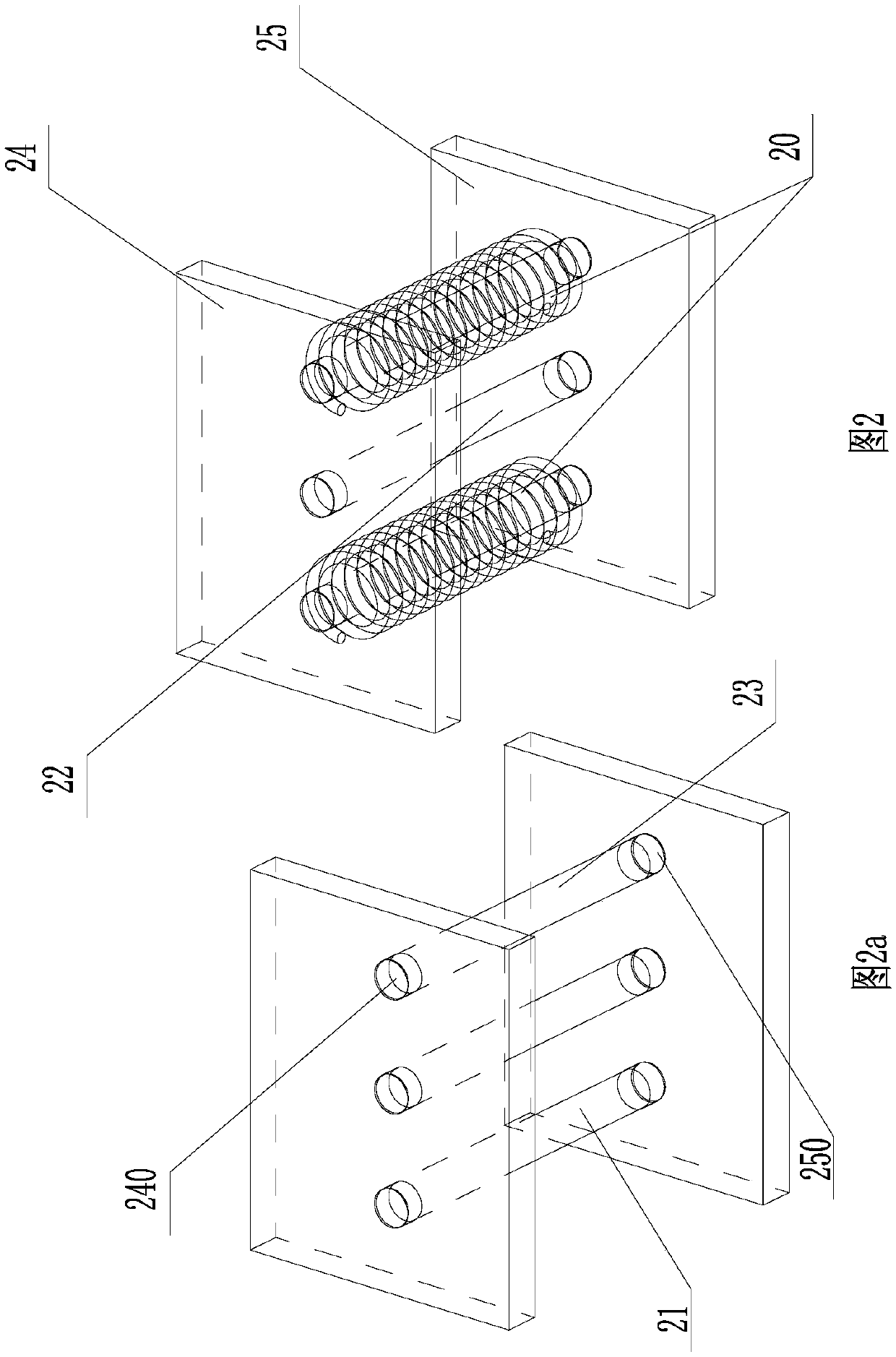

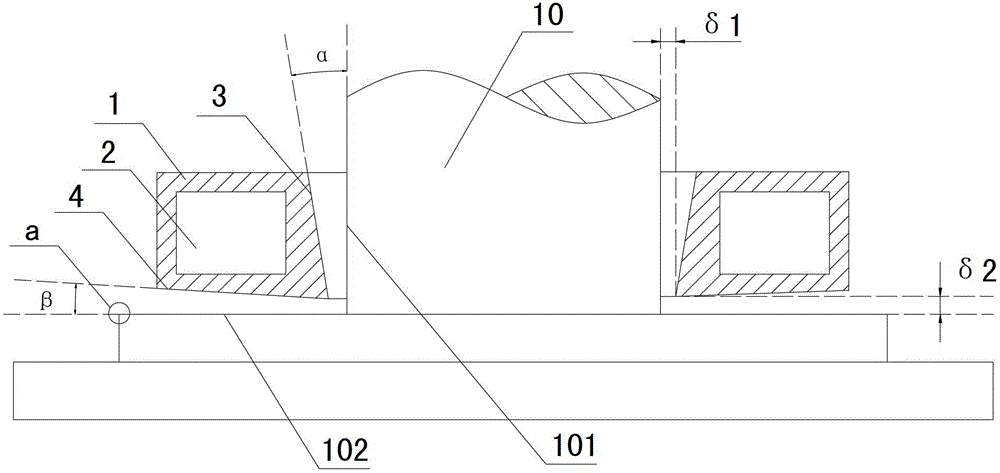

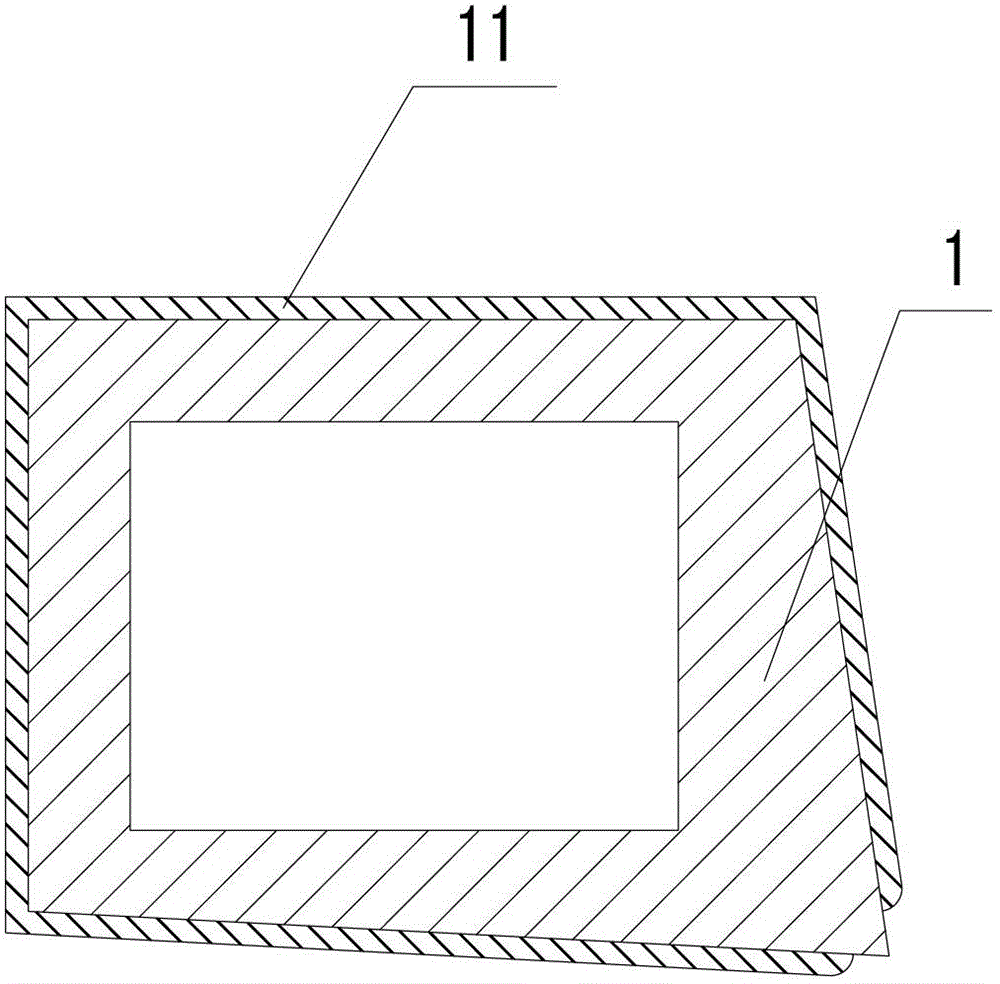

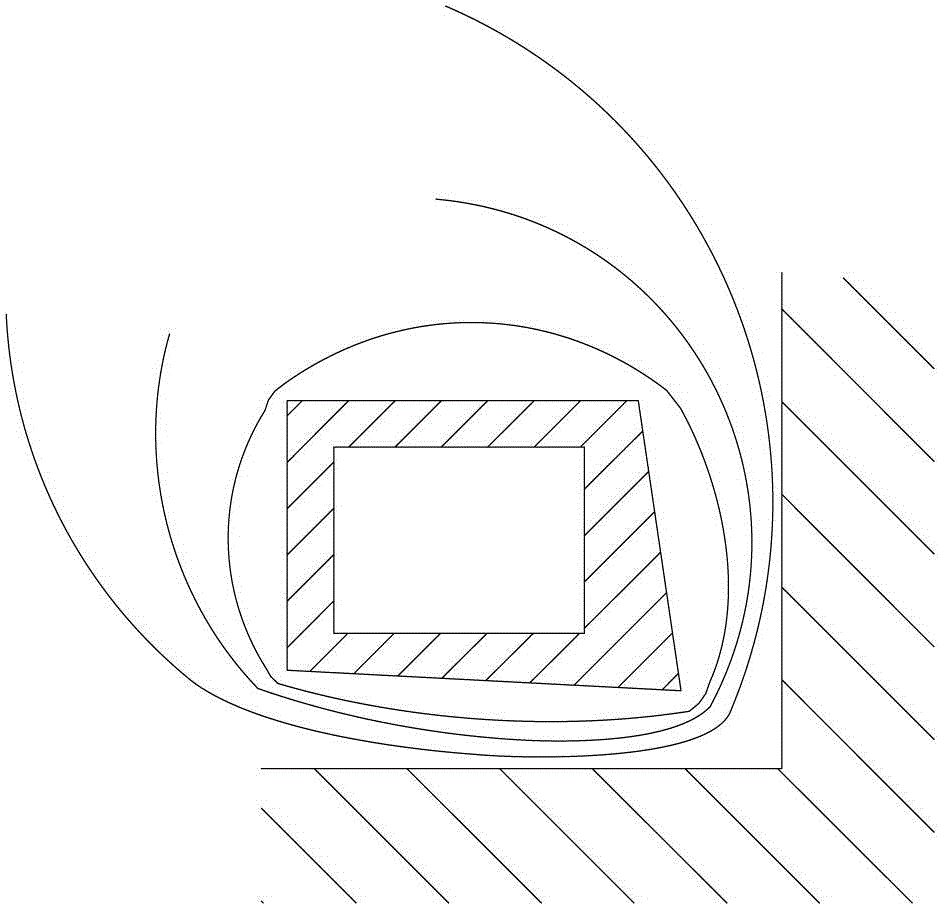

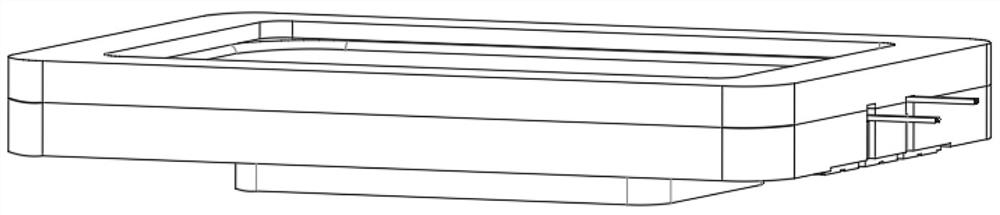

Quenching inductor for shaft parts and quenching method

InactiveCN103173595AMitigating the proximity effectImproved power loss and electrical efficiency performanceFurnace typesIncreasing energy efficiencyQuenchingThin walled

The invention discloses a quenching inductor for shaft parts and a quenching method, which are designed for solving the problem of poor quenching effect of shaft necks of existing shaft parts. The quenching inductor for the shaft parts is a ring-shaped body, wherein the inner surface of the quenching inductor is a conical surface, and the bottom surface of the quenching inductor is an inclined surface. A self-cooling water channel and a quenching liquid channel of the inductor are formed in a cavity. Magnet conduction layers are formed on the outer surface, the inner surface, the top surface and the bottom surface of the quenching inductor. A quenching system for the shaft parts comprises the shaft parts and the quenching inductor for the shaft parts. According to the quenching method, an included angle is formed between the inner surface and the cylindrical surface of the inductor, and an included angle is formed between the bottom surface and the lower end face of the inductor. The quenching inductor and system for the shaft parts are reasonable in structure, convenient to use and low in manufacture cost, and are suitable for the shaft parts including hollow shaft parts and thin-walled tubes. The quenching method is simple in procedure and has low requirements on hardware such as a device.

Owner:CHINA NORTH IND NEW TECH PROMOTION INST +1

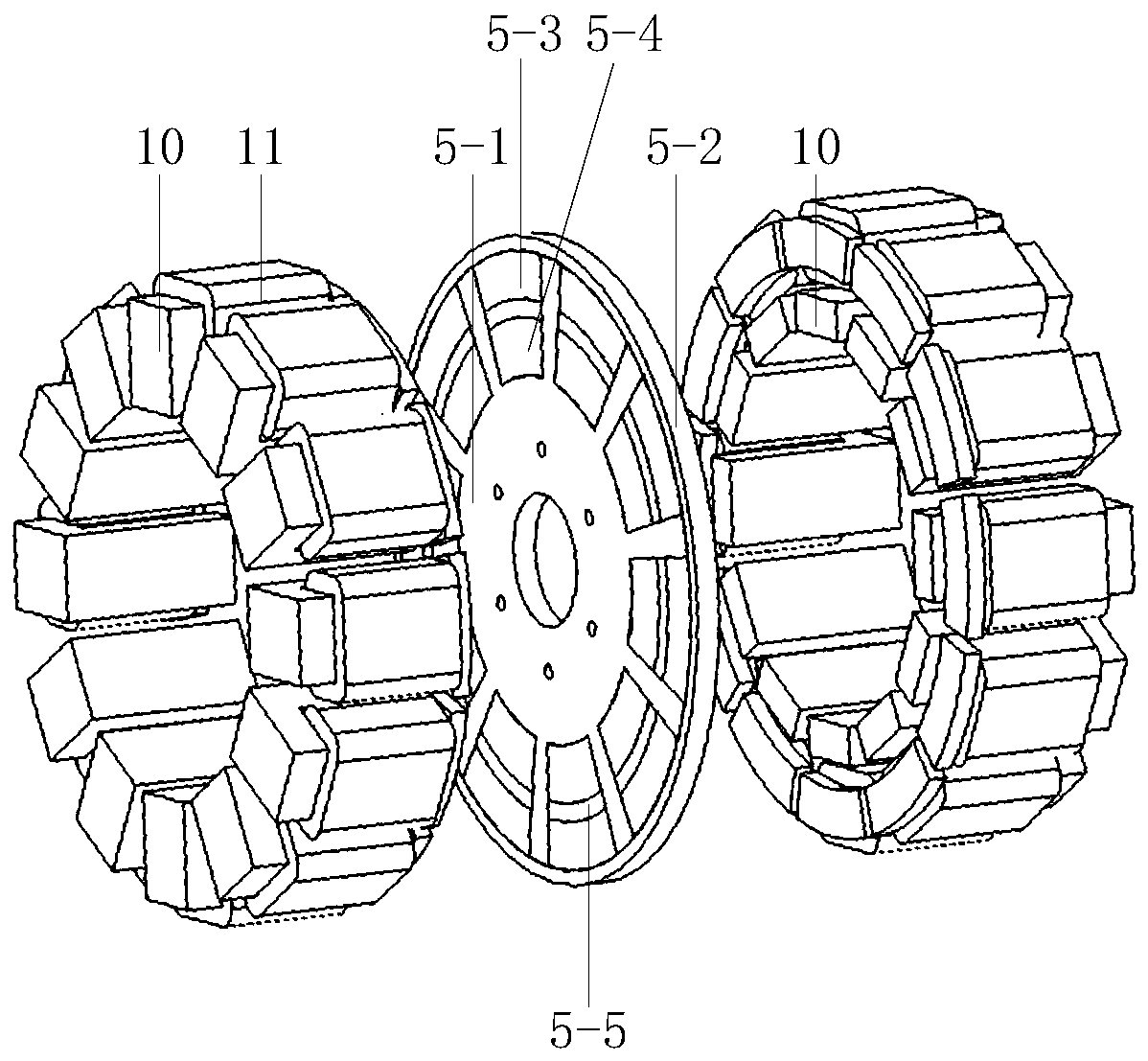

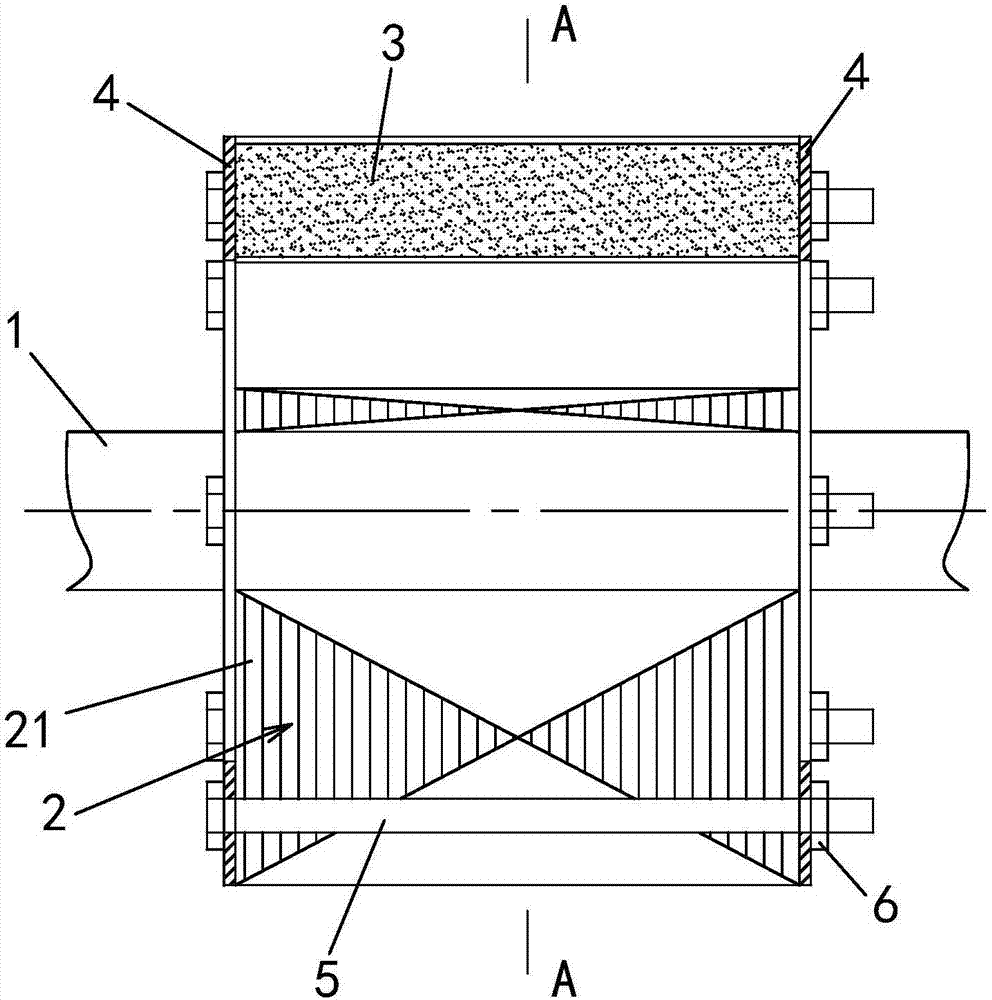

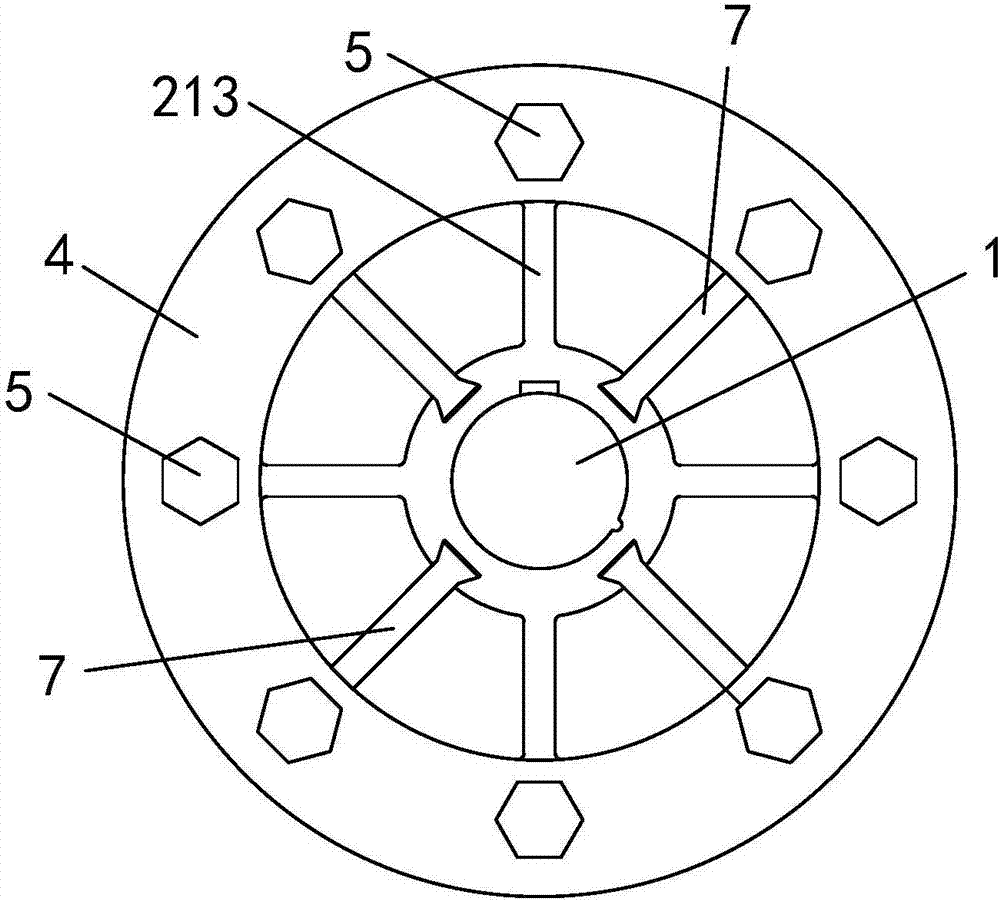

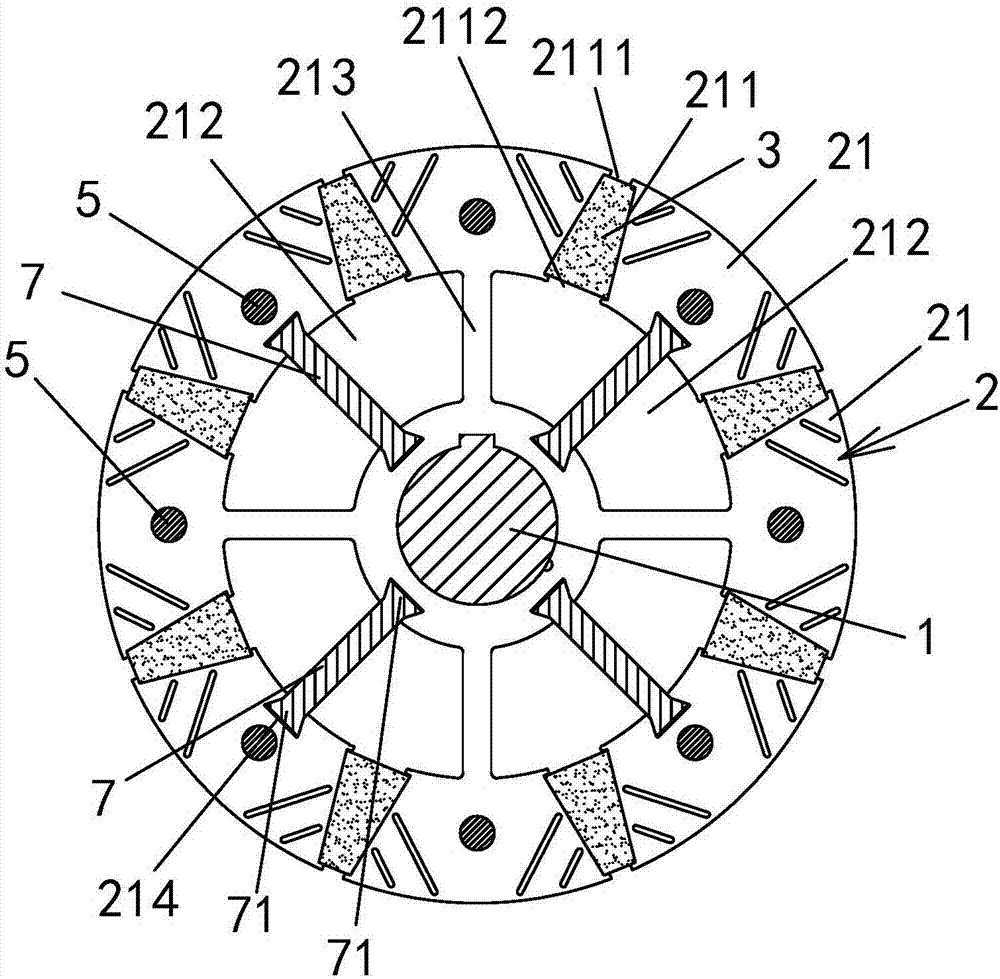

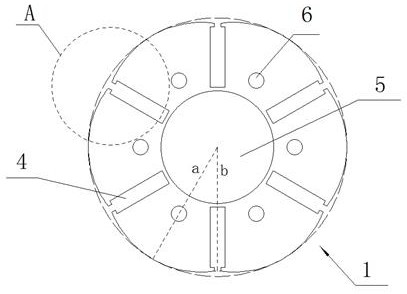

Disc type transverse flux permanent magnet brushless motor and method

ActiveCN110620449AIncreased torque densityShorten the axial lengthMagnetic circuit rotating partsMagnetic circuit stationary partsTransverse fluxBrushless motors

The invention provides a disc type transverse flux permanent magnet brushless motor and a method. The motor comprises two stator discs and a rotor disc, wherein the two stator discs are symmetricallydistributed on two sides of the rotor disc, the rotor disc is connected with a rotating shaft, two groups of permanent magnets distributed along the circumference are distributed on the rotor disc andare respectively called as an inner permanent magnet group and an outer permanent magnet group along the radial direction, each group comprises a plurality of permanent magnets with N poles and S poles arranged in a staggered manner along the circumferential direction, polarities of the upper and lower permanent magnets in the radial direction are opposite, each stator disc is composed of a plurality of stator iron cores which are uniformly distributed along the circumferential direction, each stator iron core comprises a C-shaped iron core pole body, a fan-shaped iron core pole shoe and an armature winding which is wound on a C-shaped iron core arm. The motor is advantaged in that industrial robot servo PMSM types are expanded, motor torque density is improved, the axial length of the motor is reduced, the motor can be flexibly applied to more occasions, the weight of a motor rotor part is greatly reduced, the rotational inertia of the motor is reduced, and a torque inertia ratio ofthe motor is improved.

Owner:山东艾克索仑电气有限公司

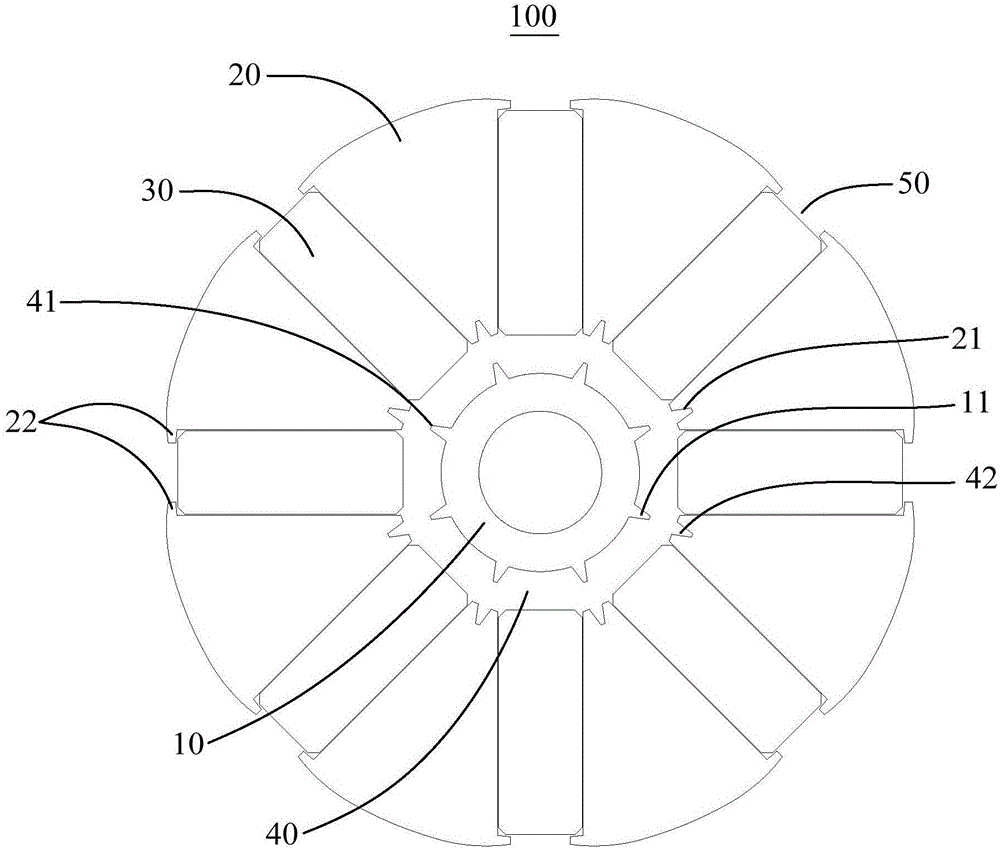

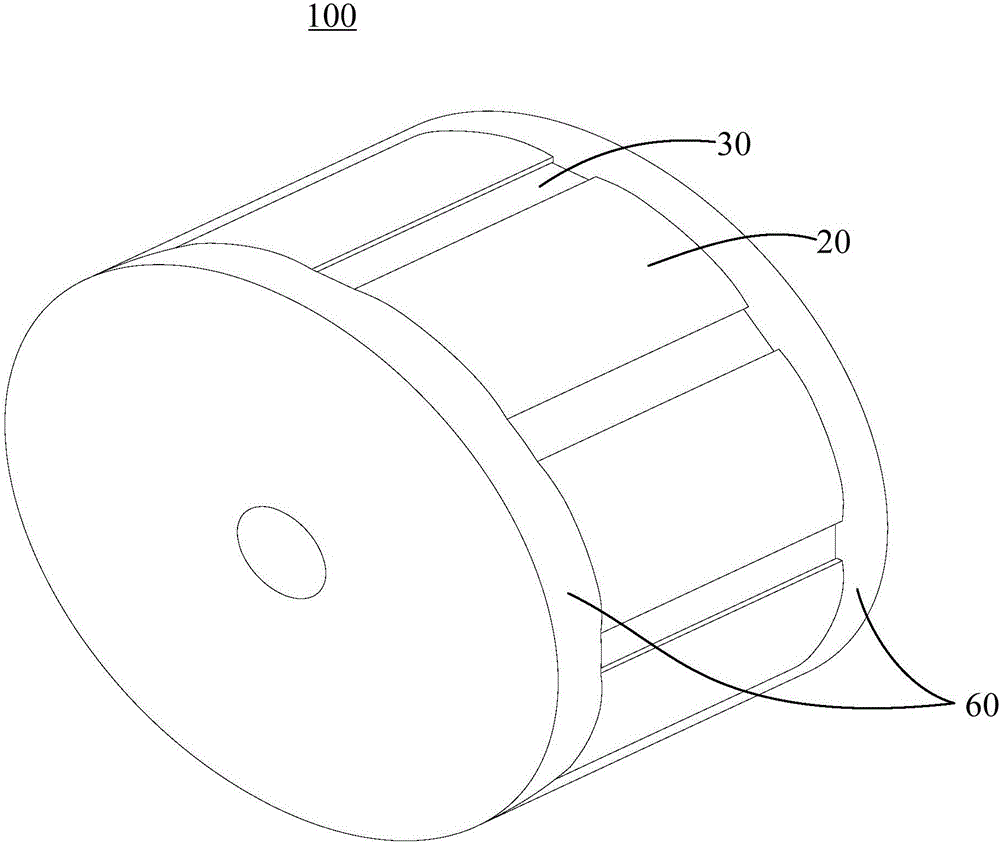

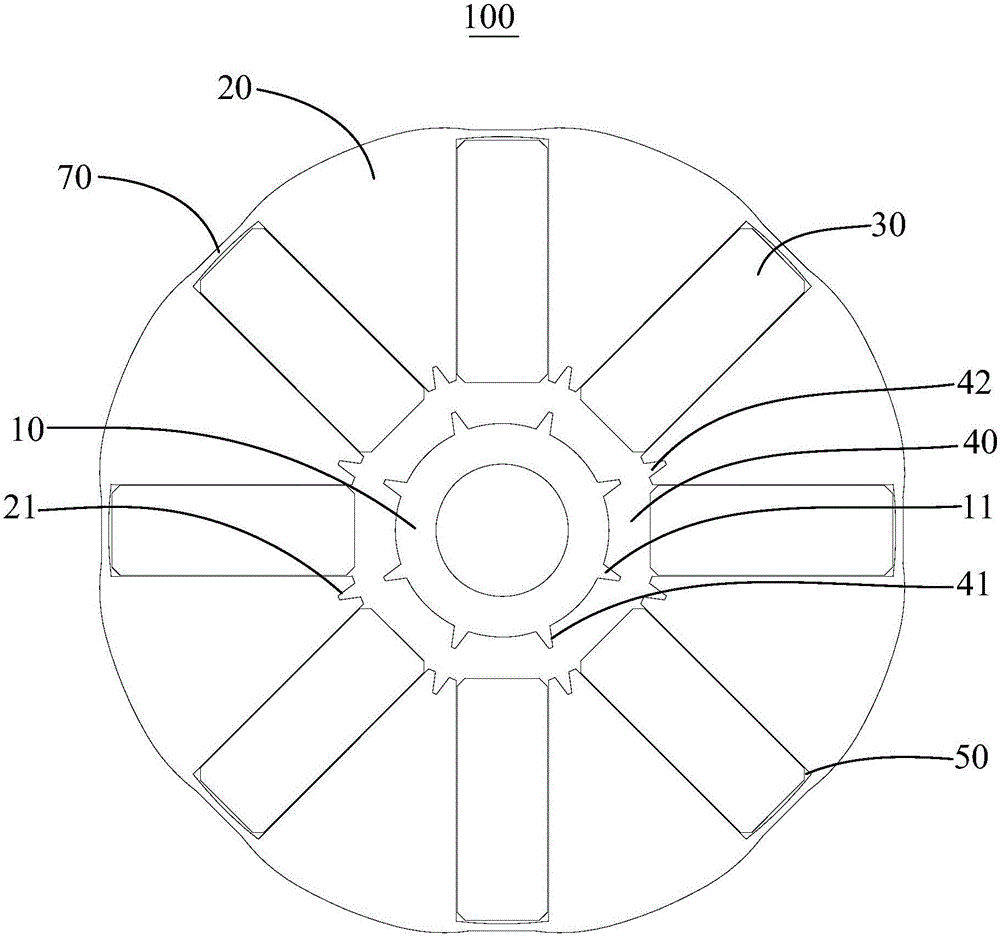

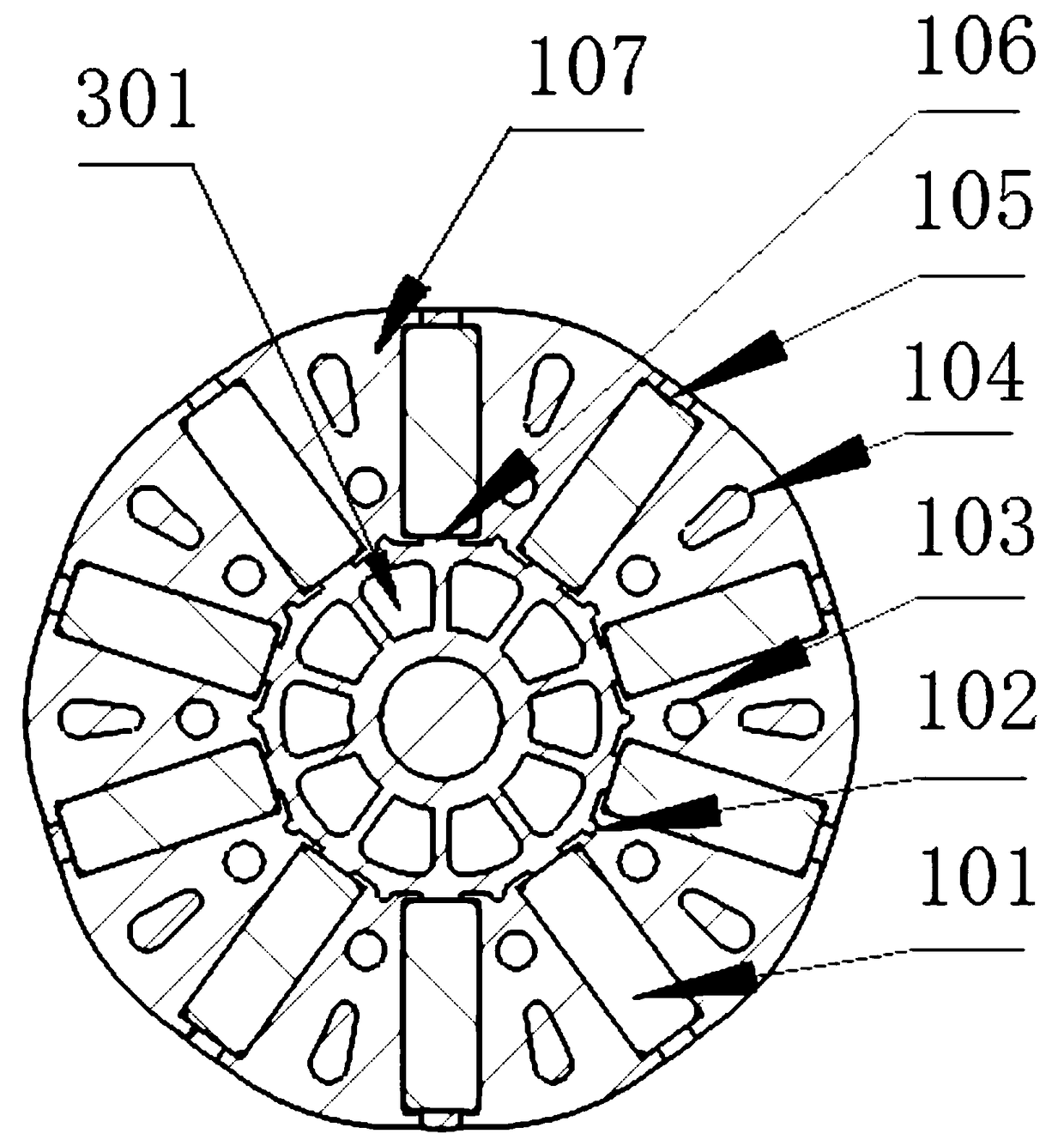

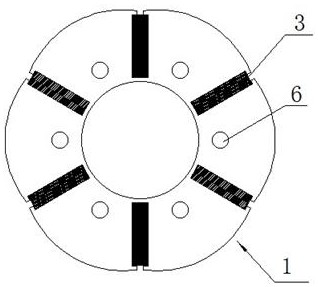

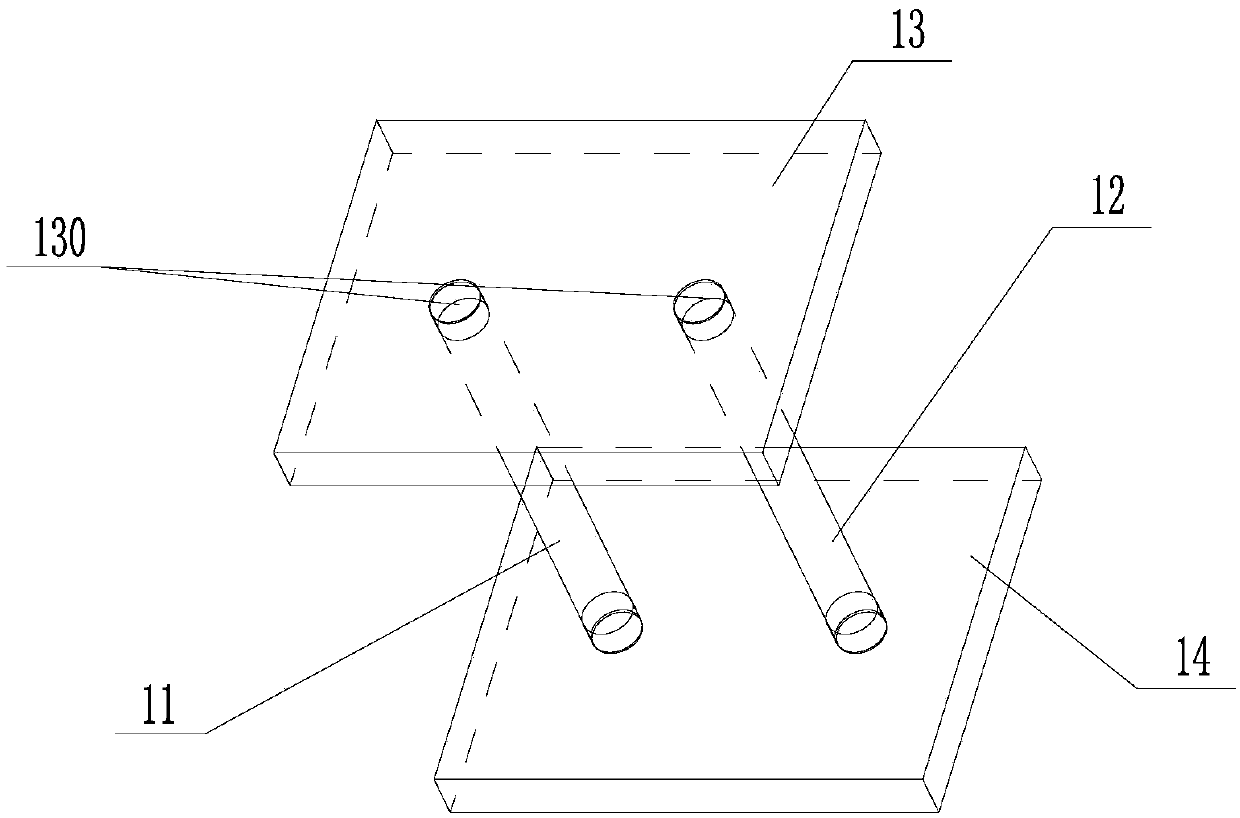

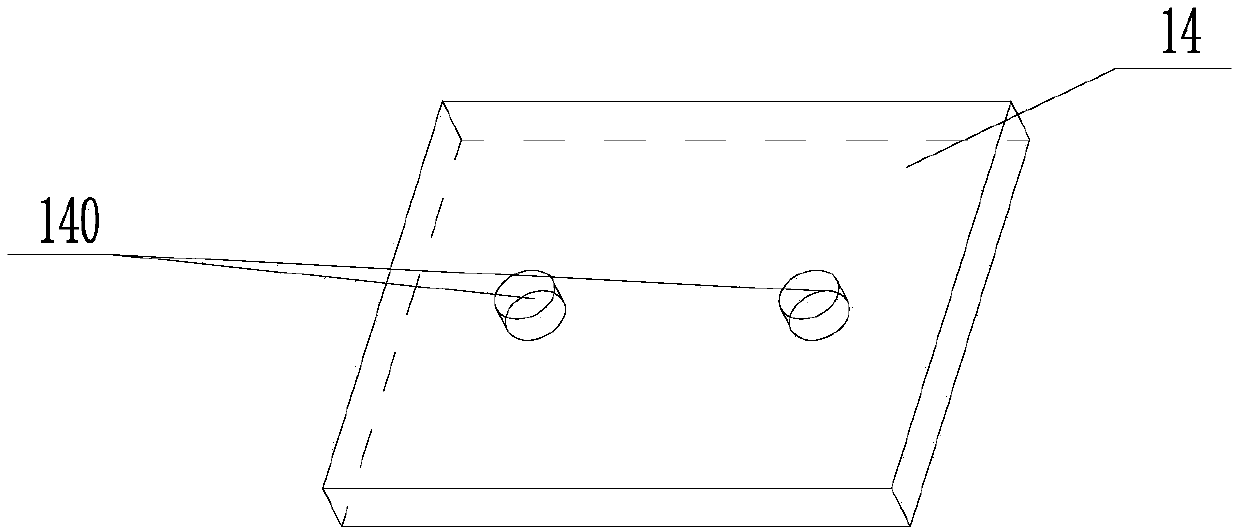

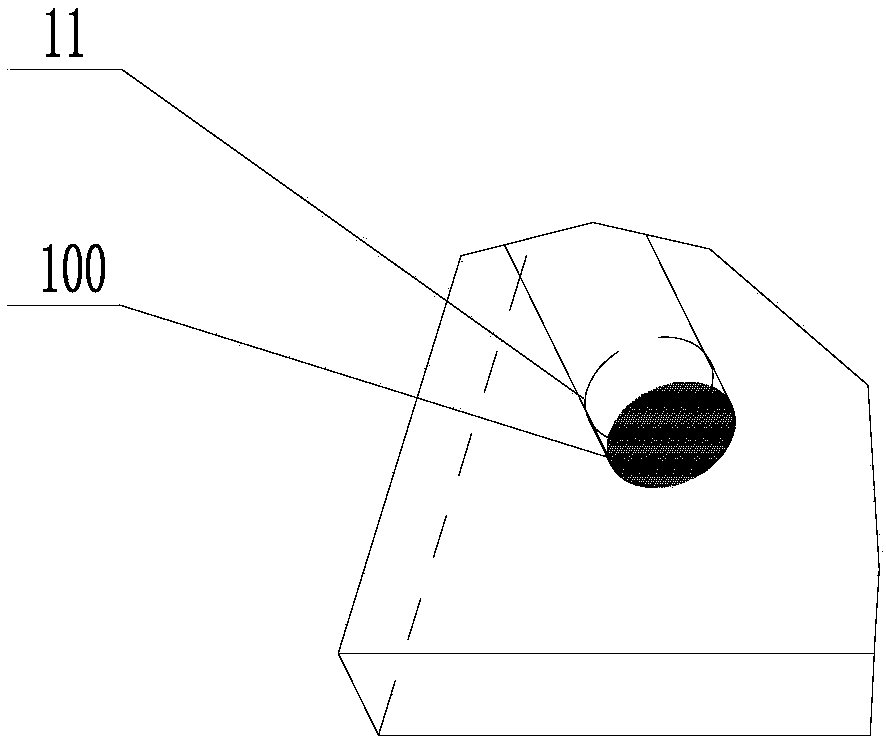

Permanent magnetism motor rotor and motor

ActiveCN106961174AIncrease profitReduce Flux LeakageMagnetic circuit rotating partsPunchingEngineering

A permanent magnetism motor rotor and a motor are provided; a rotor iron core is forming by stacking punching sheets; each punching sheet is provided with a central hole and a magnetic steel slot, and an air magnetic isolation slot; the features are that one side, facing the air slit, of the magnetic steel slot is broken and provided with a fracture; one side, facing the air magnetic isolation slot, of the magnetic steel slot is broken and provided with a fracture connecting with the air magnetic isolation slot; each the air magnetic isolation slot is connected with two adjacent magnetic steel slots; two axial ends of the rotor iron core are respectively stacked with a magnetic isolation fastening plate made of non-magnetic conductive material; the positions between adjacent magnetic steel slots of the rotor iron core are respectively penetrated by a fastening bolt along the rotor axial direction; the fastening bolt penetrates the magnetic isolation fastening plate on one end, passes the rotor iron core and reaches the magnetic isolation fastening plate on the other end, and is fastened and connected with a nut. The permanent magnetism motor rotor can greatly reduce magnetic flux leakage, can basically realize no magnetic flux leakage, thus greatly improving the permanent magnet utilization rate, ensuring the rotor intensity not to drop, and the motor is suitable for large power high rotating speed work occasions.

Owner:李致真

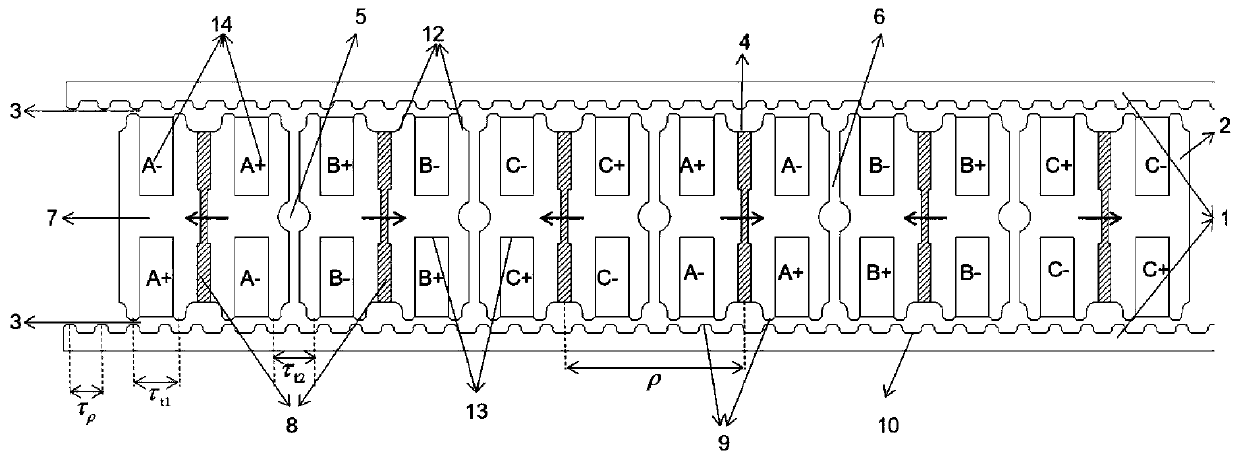

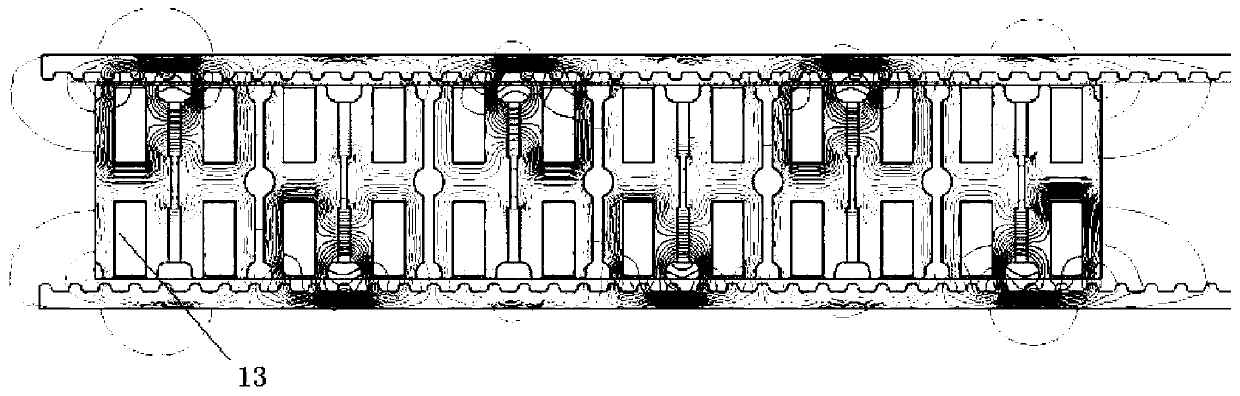

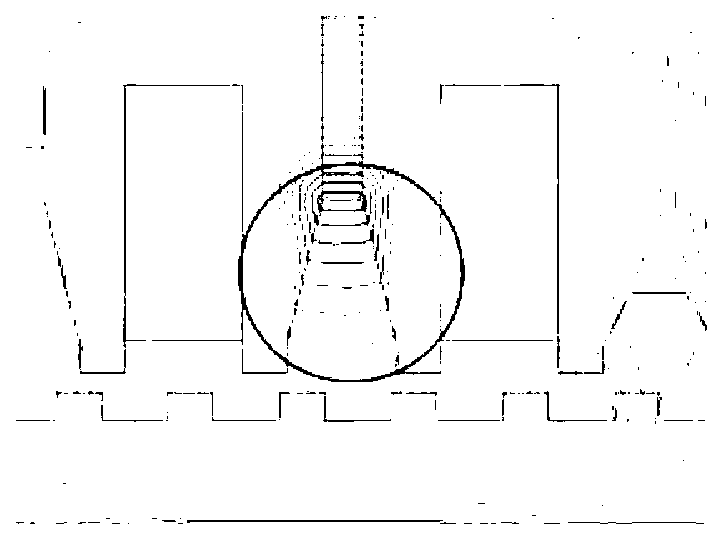

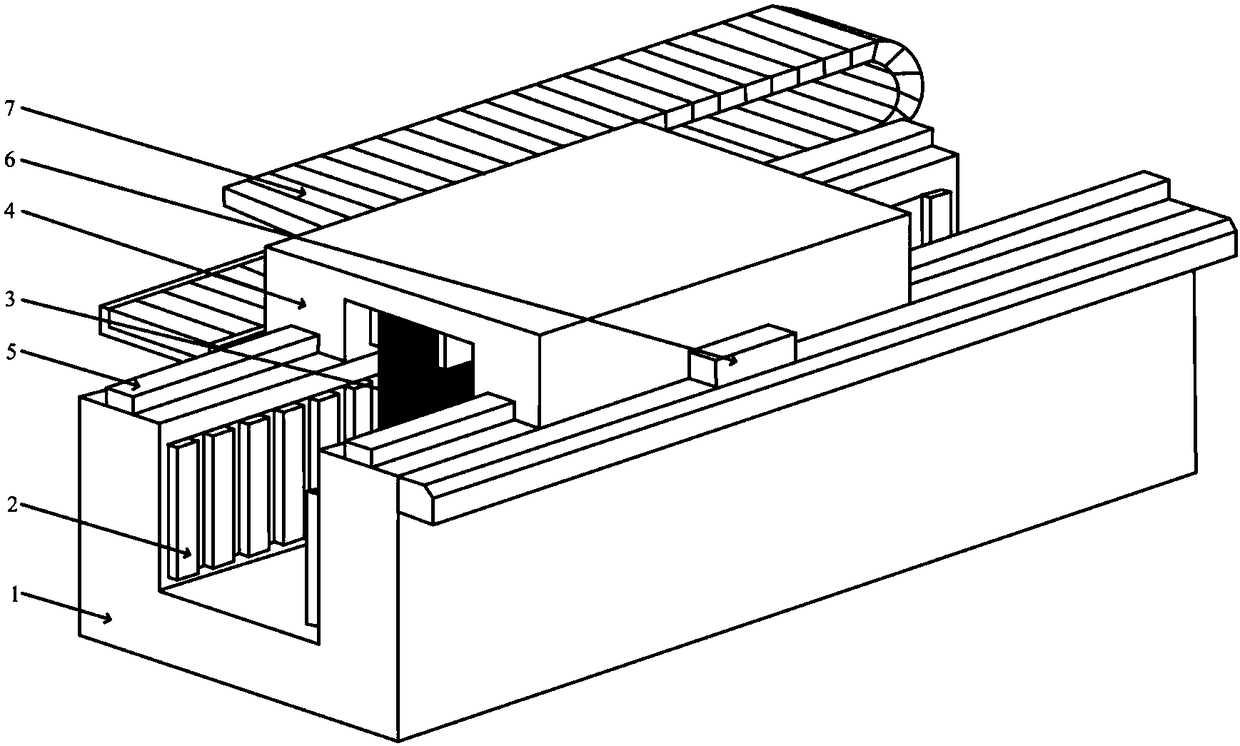

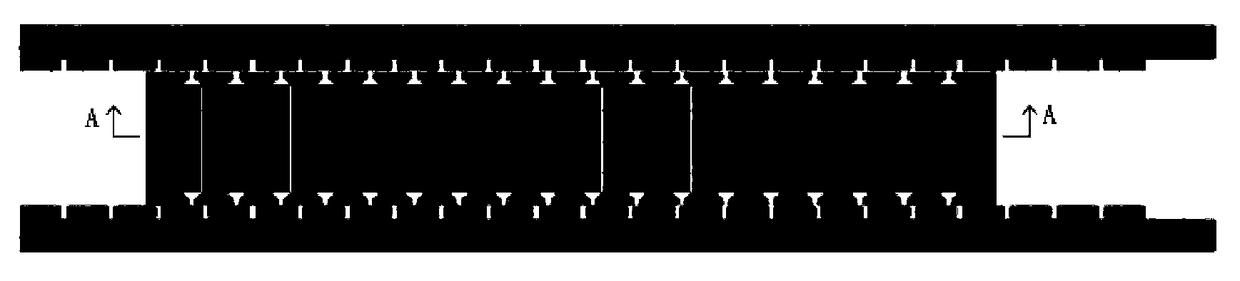

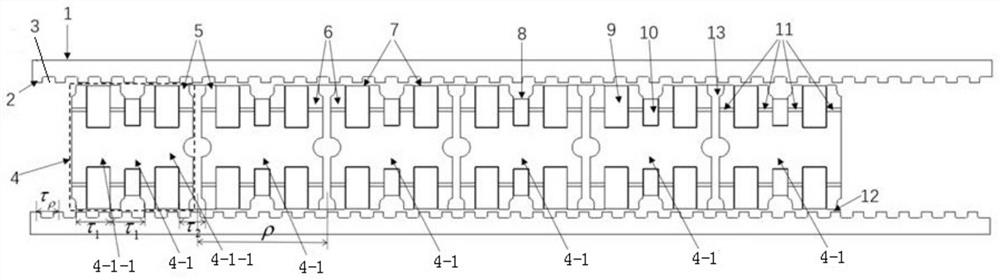

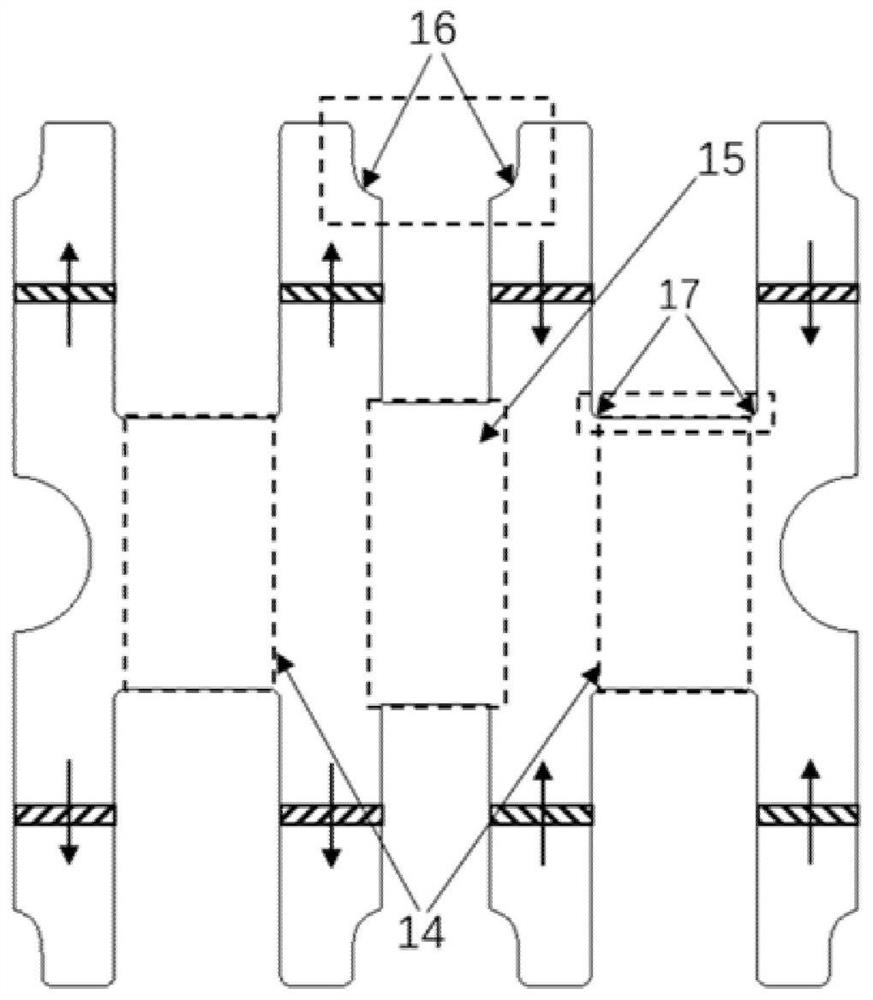

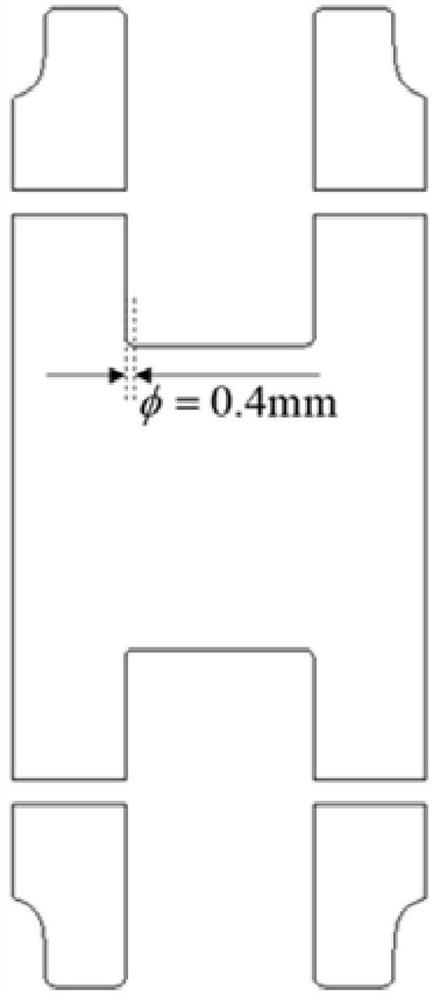

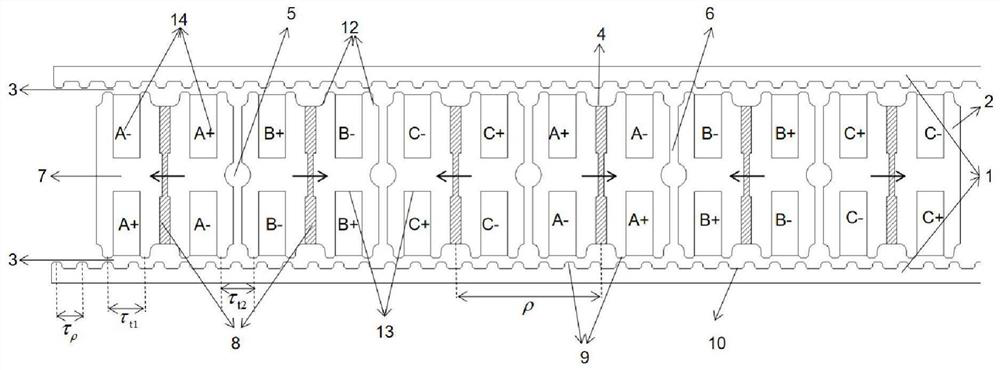

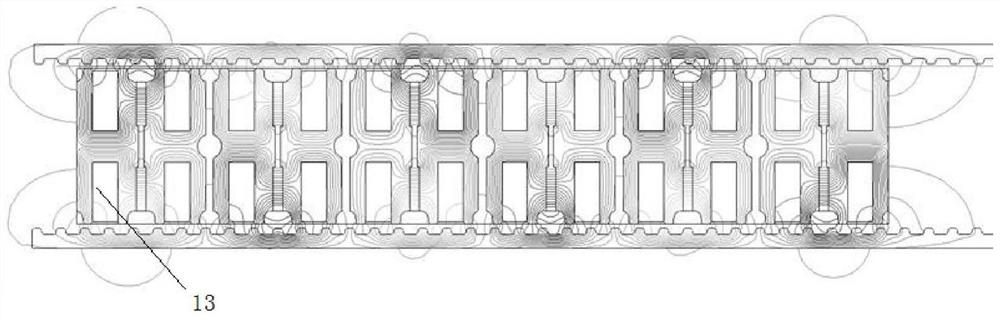

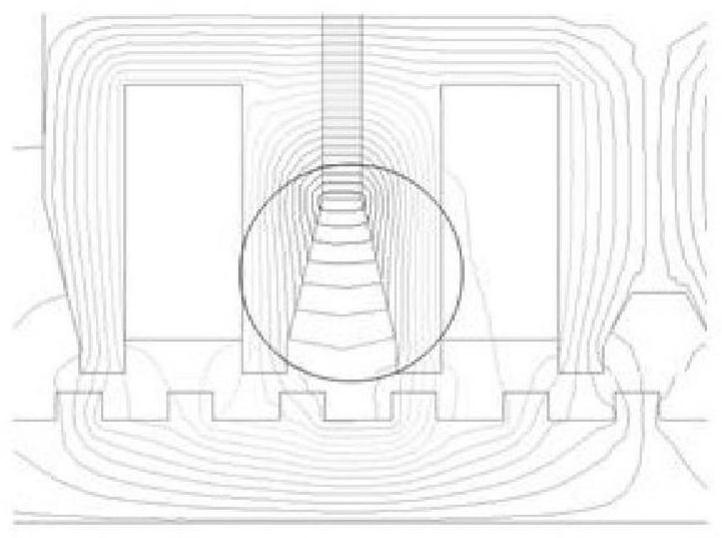

Bilateral magnetic flux switching permanent magnet linear motor

ActiveCN110957876AReduce weightWeight, reducing the cost of motor manufacturingMagnetic circuit rotating partsPropulsion systemsElectric machinePermanent magnet linear motor

The invention discloses a bilateral magnetic flux switching permanent magnet linear motor. The linear motor comprises bilateral secondary stators and a primary rotor arranged between the stators, theprimary rotor comprises six primary rotor units, connecting bridges exist between the primary rotor units, each primary rotor unit comprises two H-shaped magnetic conductive iron cores, and a permanent magnet is arranged between the two H-shaped magnetic conductive iron cores; a plurality of secondary teeth are formed on the secondary stators at intervals, secondary grooves are formed between thesecondary teeth, yoke parts are formed at the bottoms of the secondary grooves, magnetic conductive teeth are formed on the H-shaped magnetic conductive iron core opposite to the secondary teeth, andwinding mounting grooves are formed between the magnetic conductive teeth on the same side; the bilateral secondary stators are used as fixed parts, the primary rotor is used as a moving part, and theprimary rotor does linear motion in the middle of the bilateral secondary stators to form a motor with a bilateral flat plate structure. The linear motor has the advantages of the high utilization rate, the low magnetic flux leakage and the like.

Owner:SHIJIAZHUANG TIEDAO UNIV

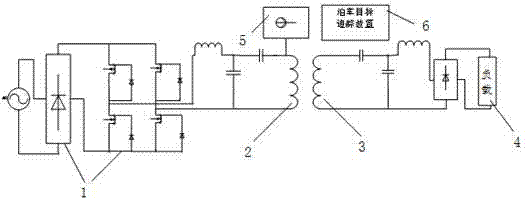

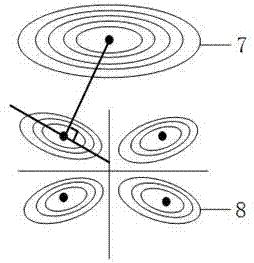

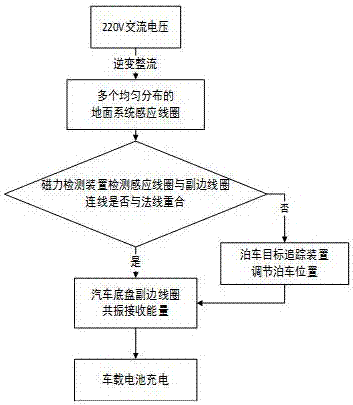

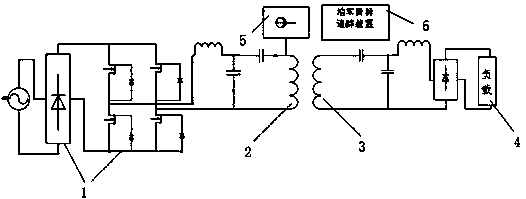

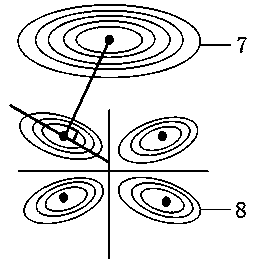

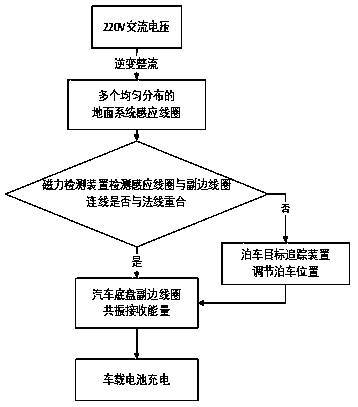

Normal form multi-coil magnetic gathering type wireless charging device for electric automobiles

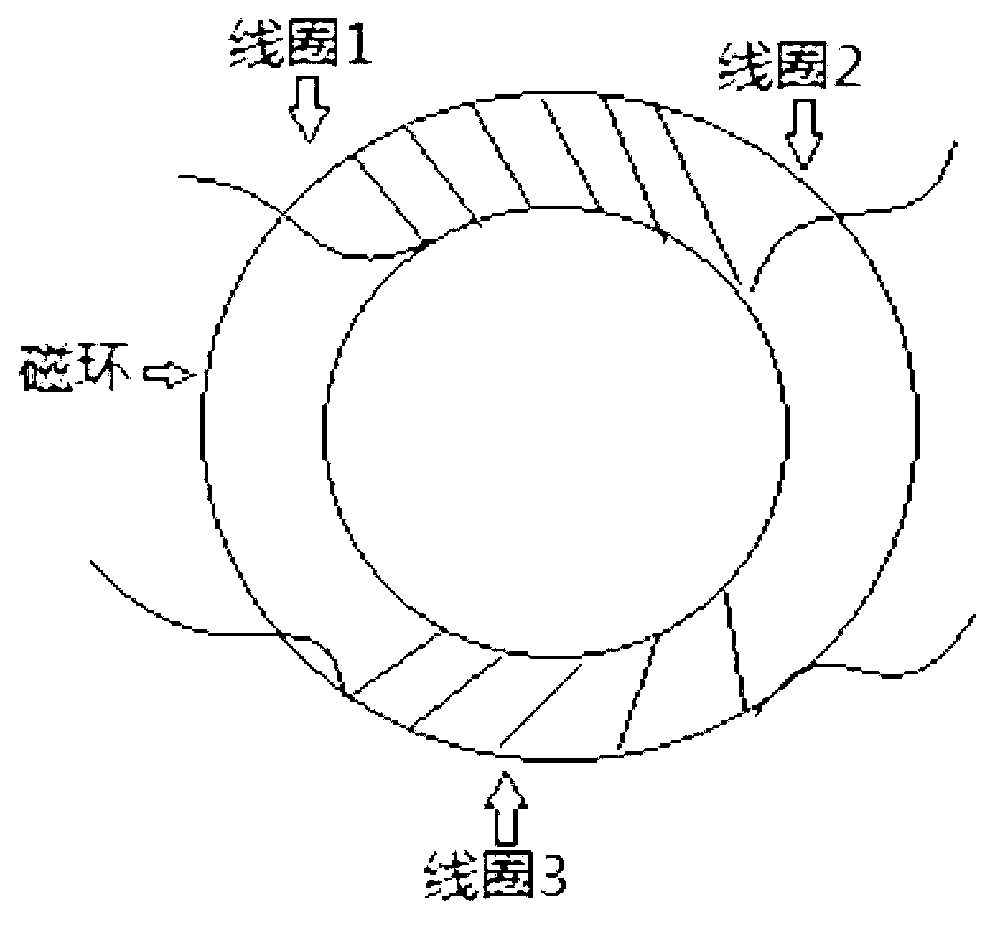

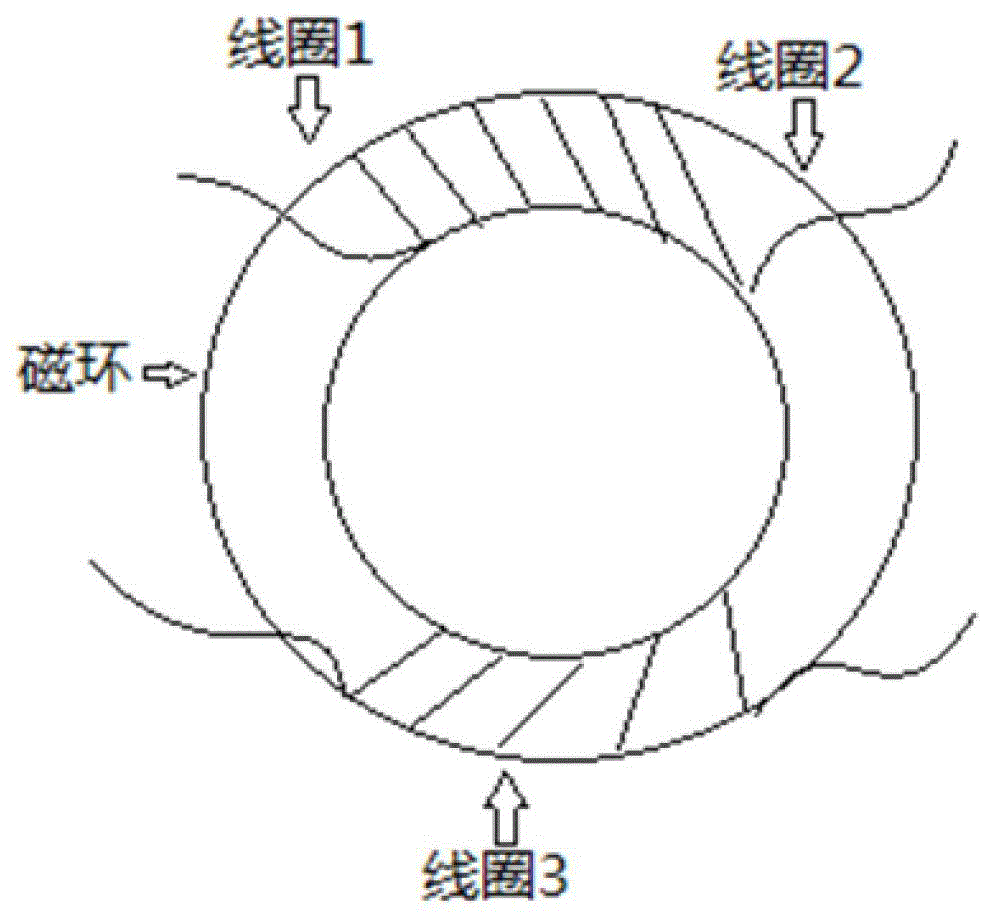

InactiveCN107199901ASolve the problem of flux leakageCharging stationsElectric vehicle charging technologyCoincidenceInductive coupling

The invention discloses a normal form multi-coil magnetic gathering type wireless charging device for electric automobiles. The wireless charging device comprises an inverter, a ground system induction coil, an automobile chassis secondary coil, vehicular battery equipment, a magnetism detection sensor and a parking target tracking device. The wireless charging device is characterized in that the ground system induction coil controls the parking target tracking device according to the magnetism detection sensor to adjust a parking position in order to realize coincidence of a line between a small coil and the automobile chassis secondary coil with the normal line, induction electromotive force is acquired close to a primary winding space through inductive coupling of high-frequency alternating flux, flux leakage is reduced, wireless transmission efficiency is improved, and electric energy is provided for a vehicular battery.

Owner:NANJING AGRICULTURAL UNIVERSITY

Motor rotor, motor and air conditioner

InactiveCN106208460AImprove the utilization rate of magnetic steelSolve the problem of flux leakageMagnetic circuit rotating partsMechanical engineeringMagnetic leakage

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

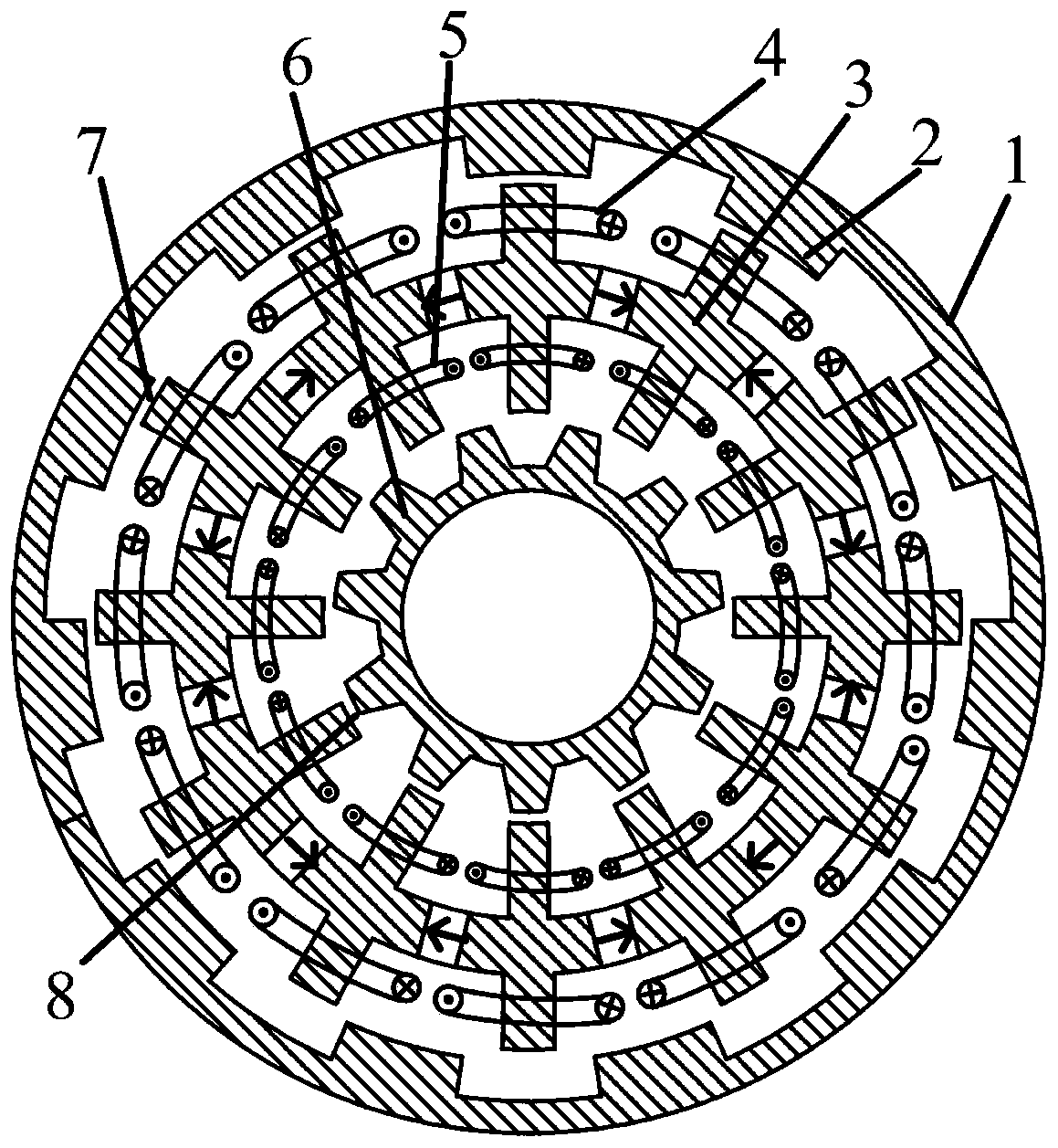

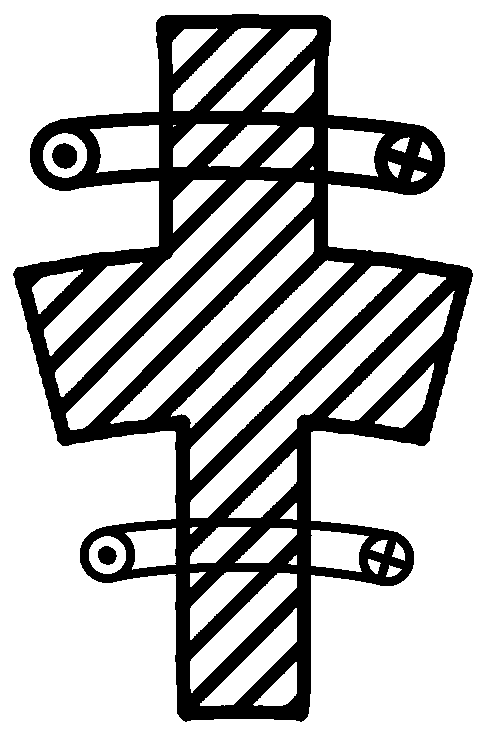

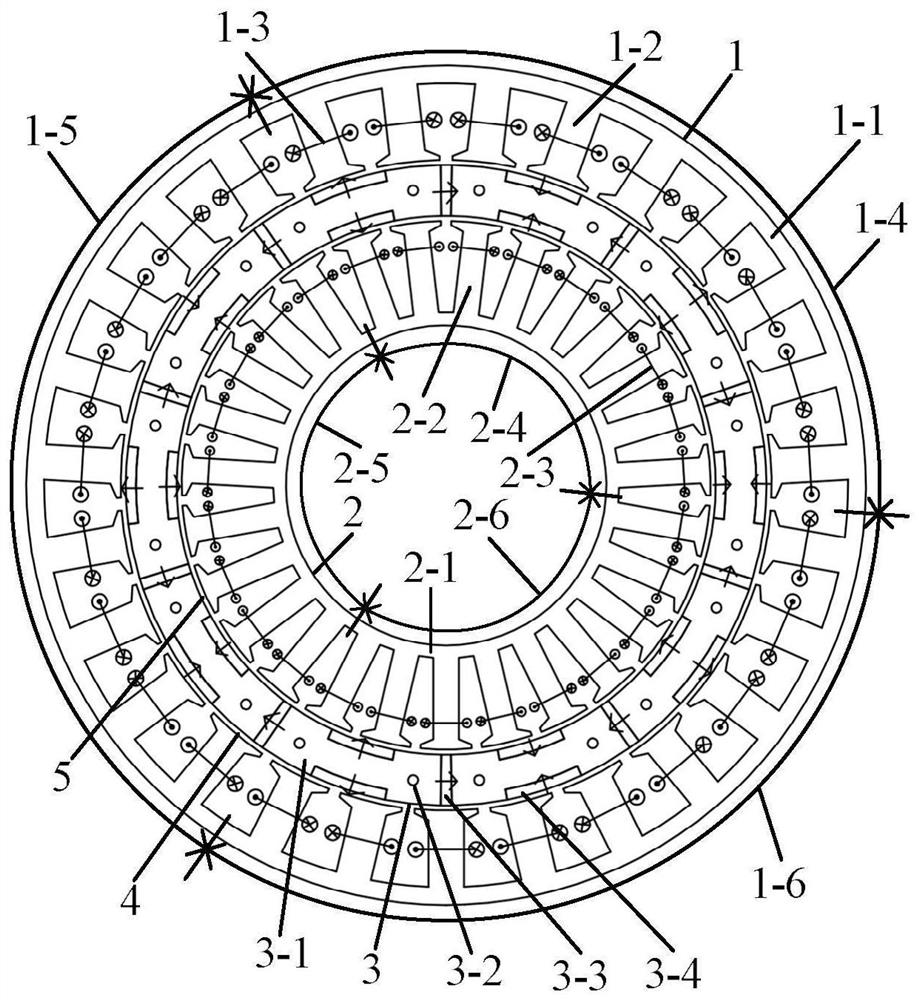

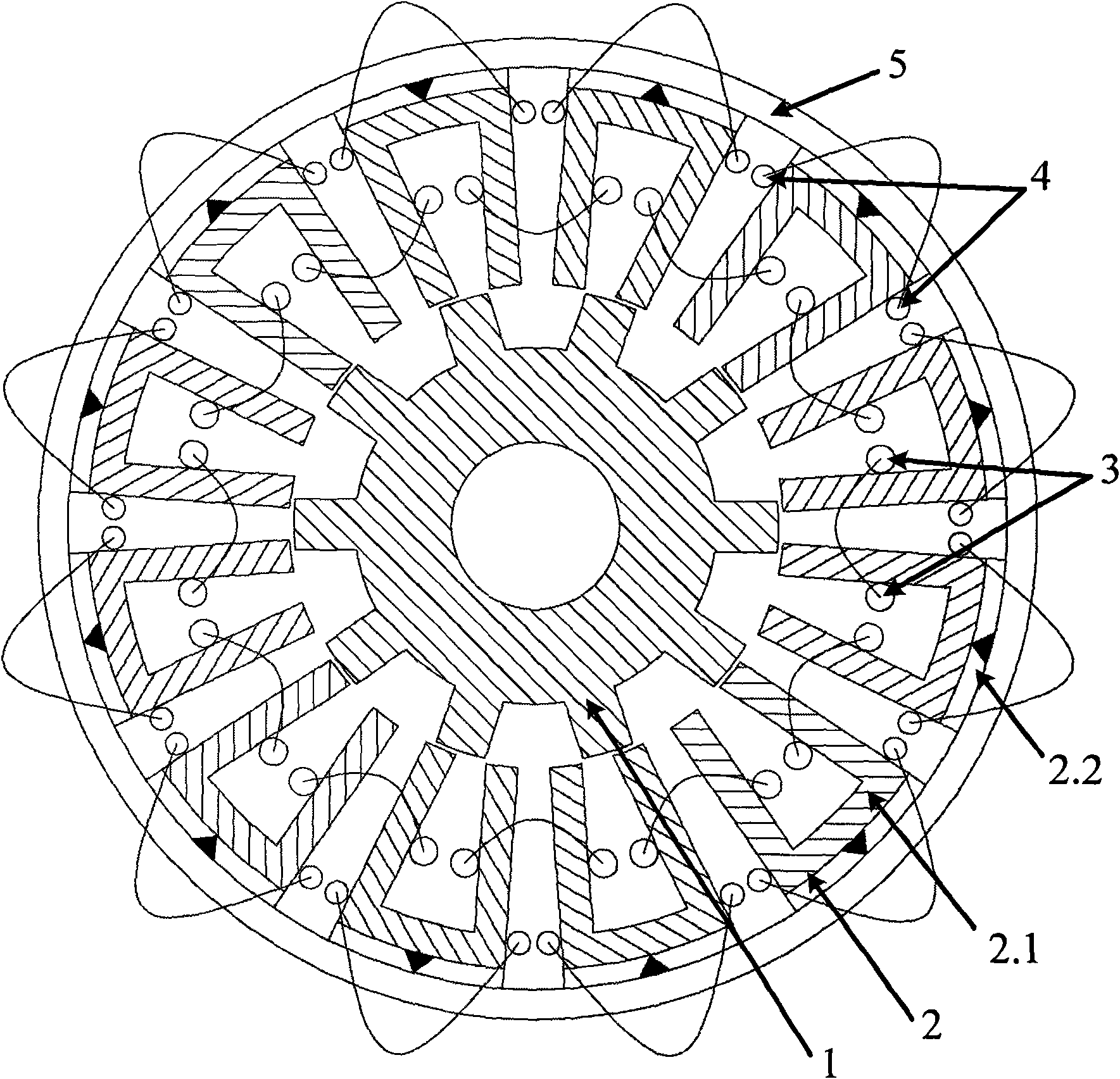

Stator modular double-rotor doubly salient permanent magnet motor

InactiveCN111181339AAvoid Flux Leakage ProblemsIncrease utilization and motor torque densityDynamo-electric machinesMagnetoDoubly salient

The invention discloses a stator modular double-rotor doubly salient permanent magnet motor, which comprises an inner salient pole rotor, an outer salient pole rotor and a stator located between the inner salient pole rotor and the outer salient pole rotor, wherein independent air gaps are formed between the inner salient pole rotor and the stator and between the outer salient pole rotor and the stator respectively; the stator comprises a plurality of stator modules, each stator module comprises a stator yoke part, outer stator teeth and inner stator teeth, the outer stator teeth and the innerstator teeth are connected with the outer side and the inner side of the middle position of the stator yoke part respectively, and the stator yoke parts of the stator modules are connected through permanent magnets to form a complete stator; armature windings are wound on the outer stator teeth and the inner stator teeth of each stator module; and positive and negative alternating counter electromotive forces are induced in armature windings of the inner and outer stators of the motor along with synchronous rotation of the inner and outer rotors and change of relative positions of the stators. The problem of serious stator side flux leakage of the traditional single-rotor doubly salient permanent magnet motor is solved, and the permanent magnet utilization rate and the motor torque density are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

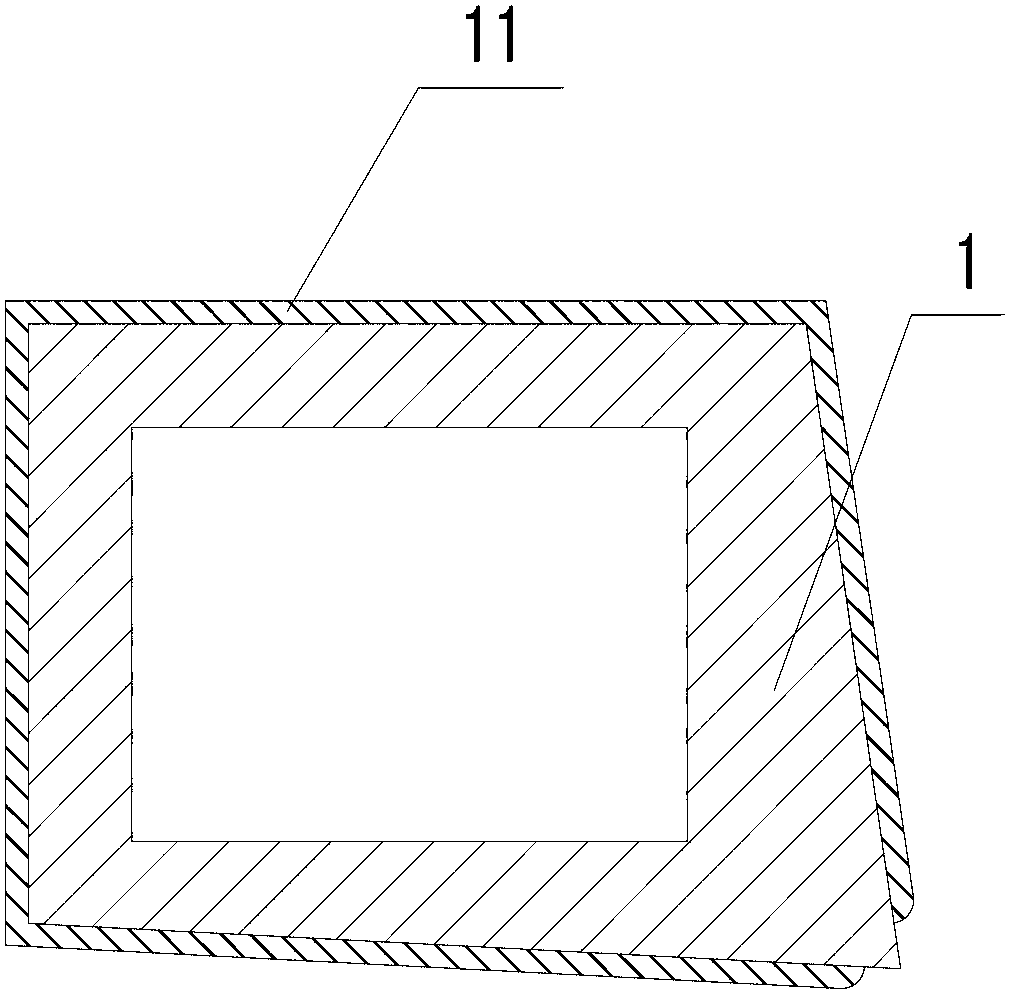

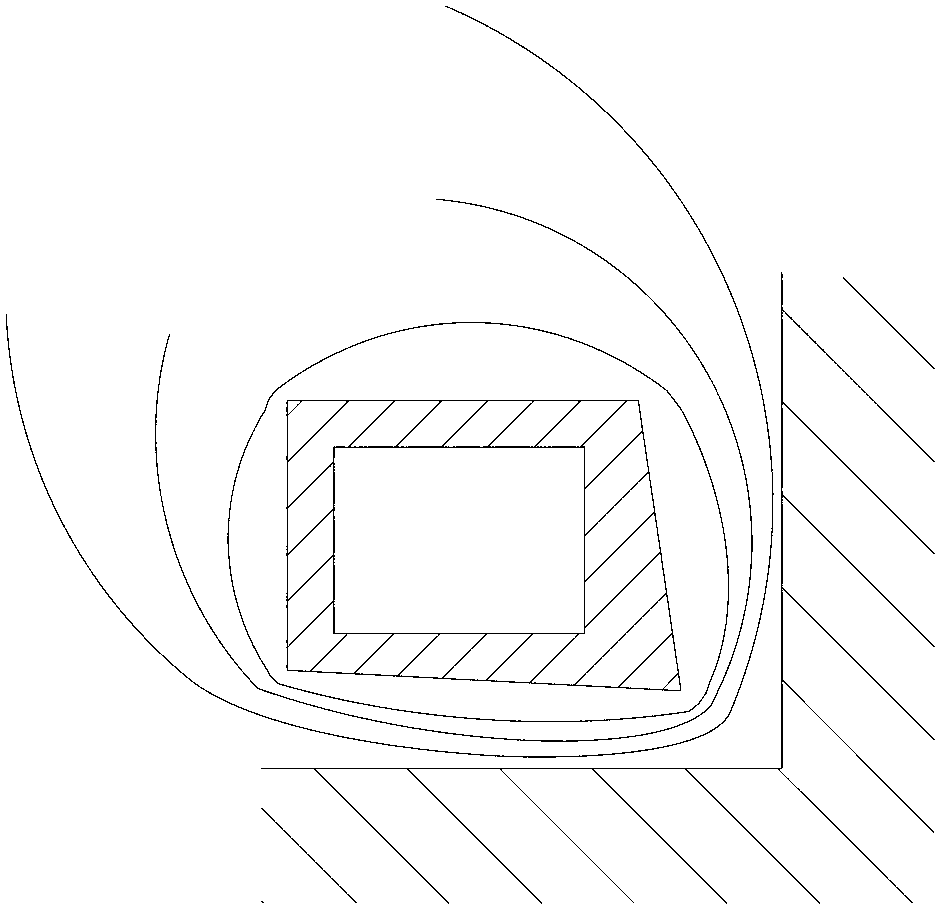

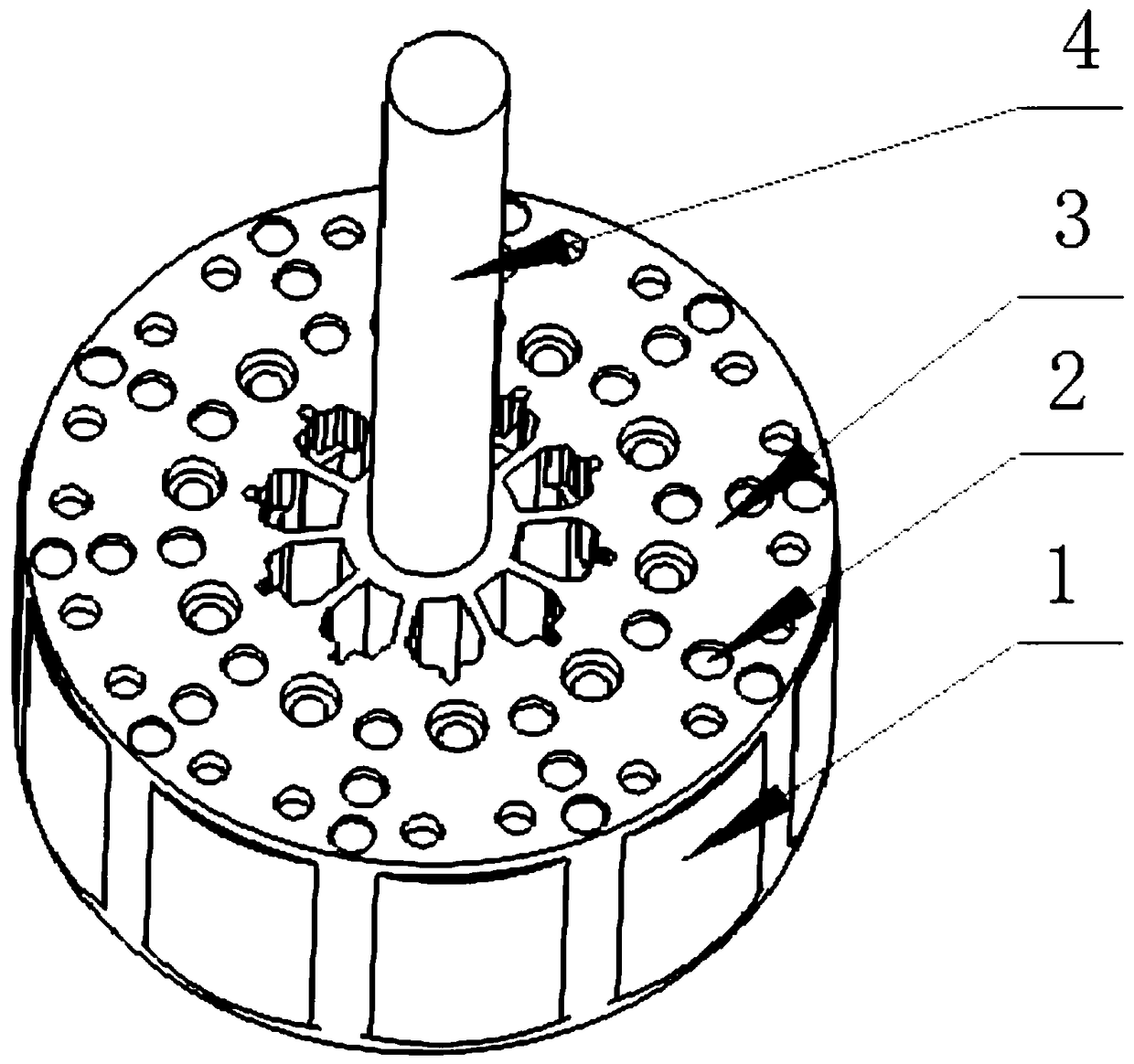

Segmented iron core IPM plastic package forming rotor

PendingCN108711980ASolve the problem of flux leakageImprove power densityMagnetic circuit rotating partsWhole bodyEngineering

The invention discloses a segmented iron core IPM plastic package forming rotor, and relates to the field of motors. An existing IPM rotor is designed into an integral punch forming rotor iron core ofa magnetism isolating bridge structure, and greater leakage flux exists. The segmented iron core IPM plastic package forming rotor comprises a rotor iron core, magnetic shoes, a PBT and a shaft, wherein the rotor iron core consists of a plurality of same iron core segments in an encircling manner; a magnetic shoe groove and an anti-leakage flux groove for reducing leakage flux are arranged between every two adjacent iron core segments respectively; every two adjacent iron core segments are separated from each other through the corresponding anti-leakage flux groove and the corresponding magnetic shoe groove; each iron core segment is provided with a positioning structure for realizing the positioning of the corresponding iron core segment respectively; each magnetic shoe is inserted intothe corresponding magnetic shoe groove; the magnetic shoes are fixed on the rotor iron core through the PBT; and the shaft is connected with the magnetic shoes and the rotor iron core into a whole body through the PBT. Through the technical scheme, the rotor iron core is segmented into the same iron core segments, so that the magnetism isolating bridge leakage flux problem of a traditional integral rotor iron core is solved, the utilization rate of the rotor magnetic shoes is improved, and the power density of the motor is improved.

Owner:WOLONG ELECTRIC GRP CO LTD

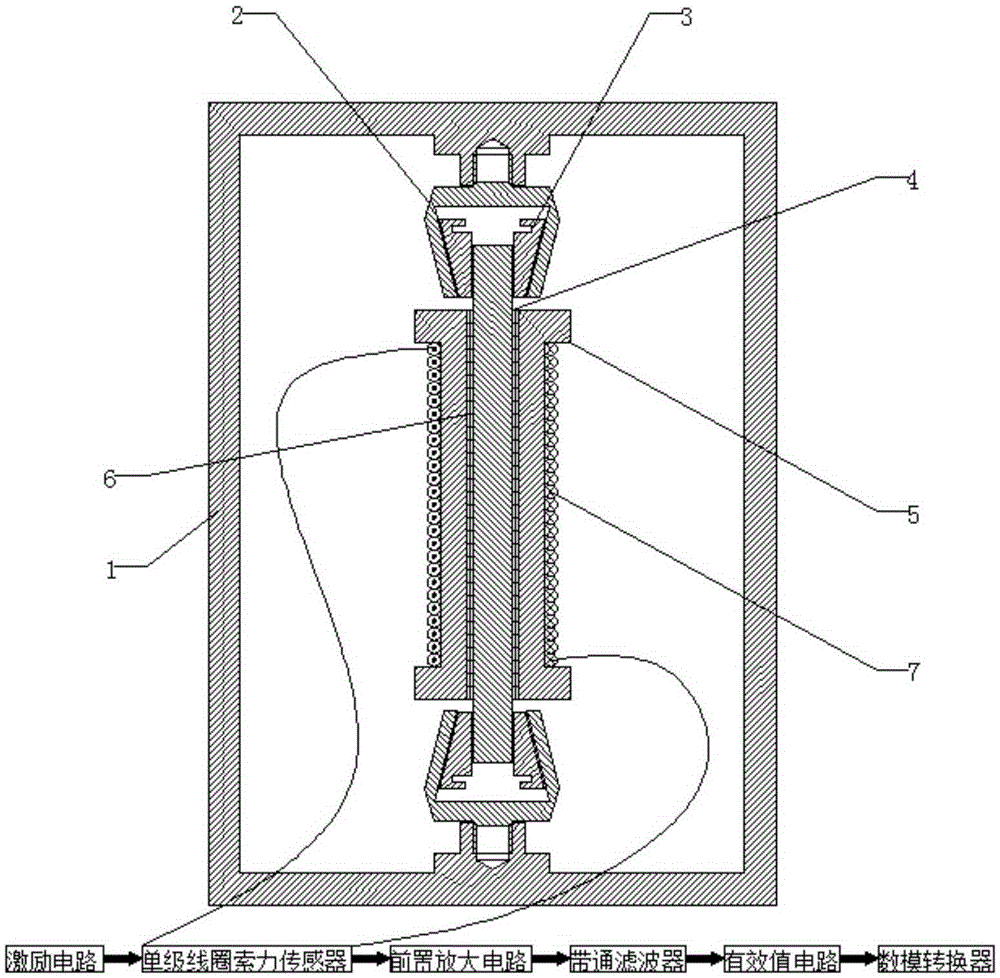

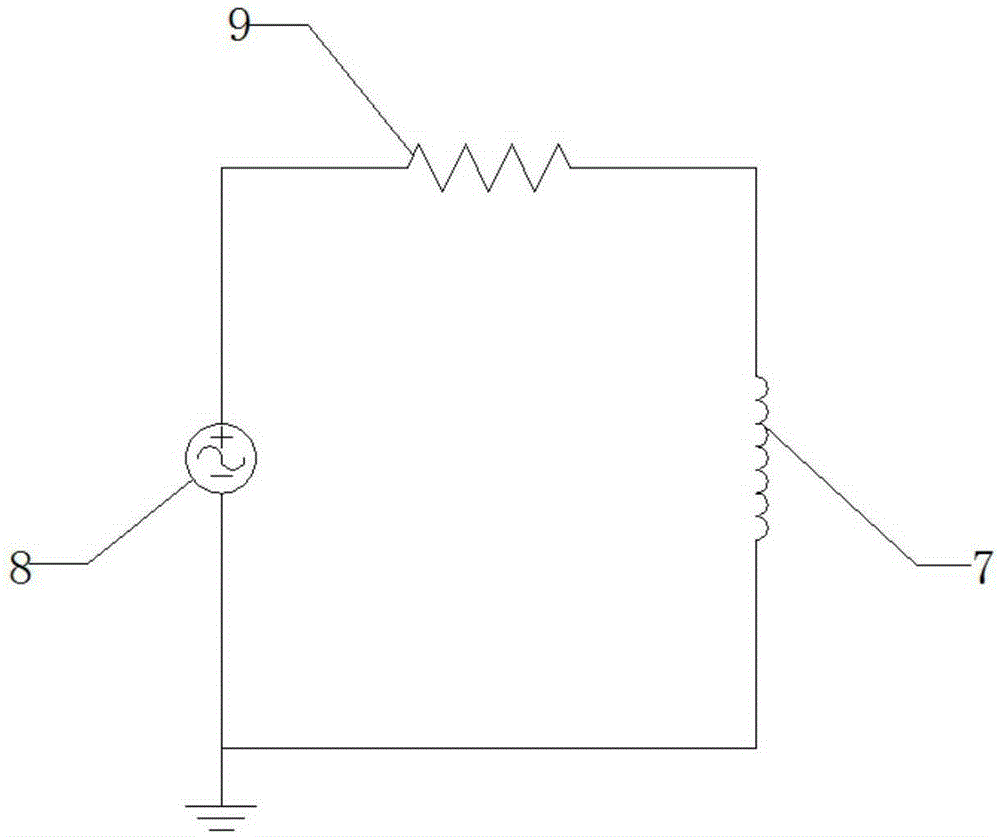

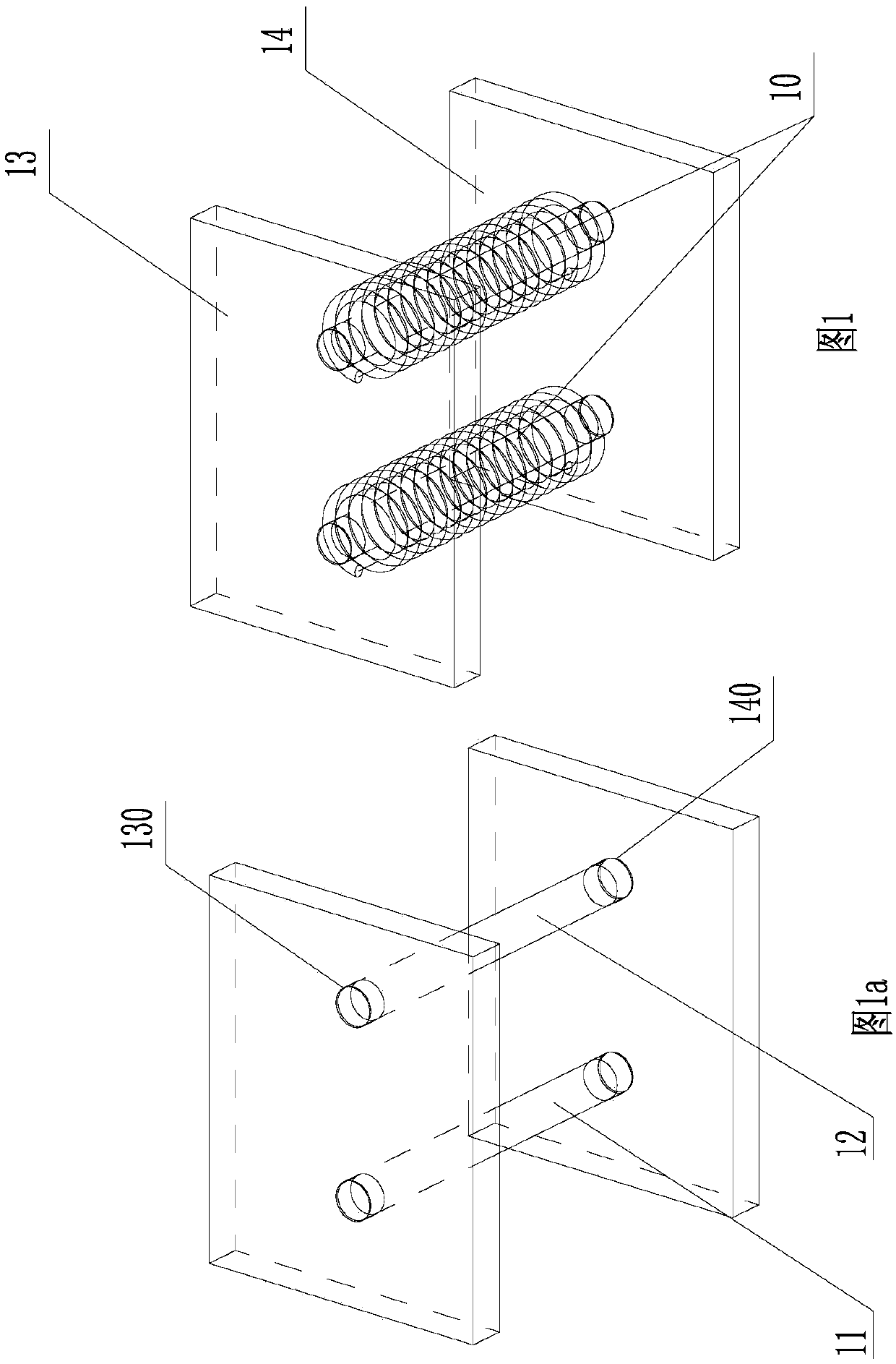

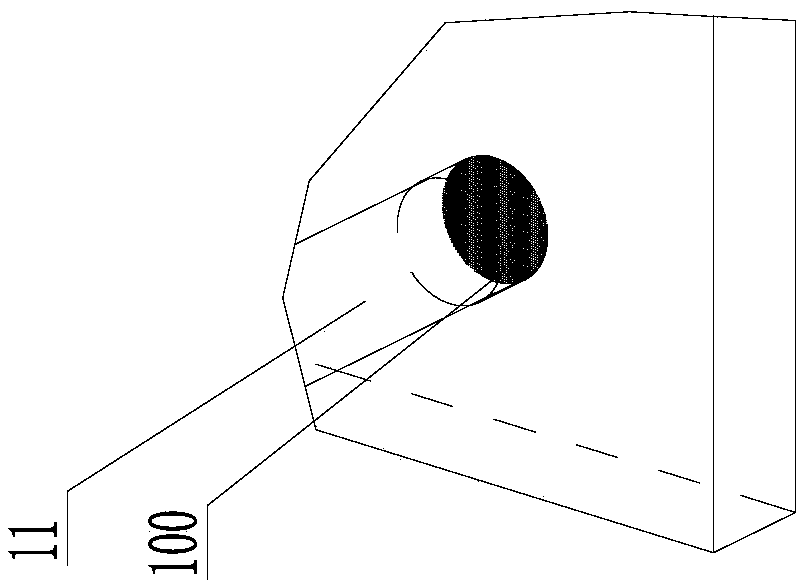

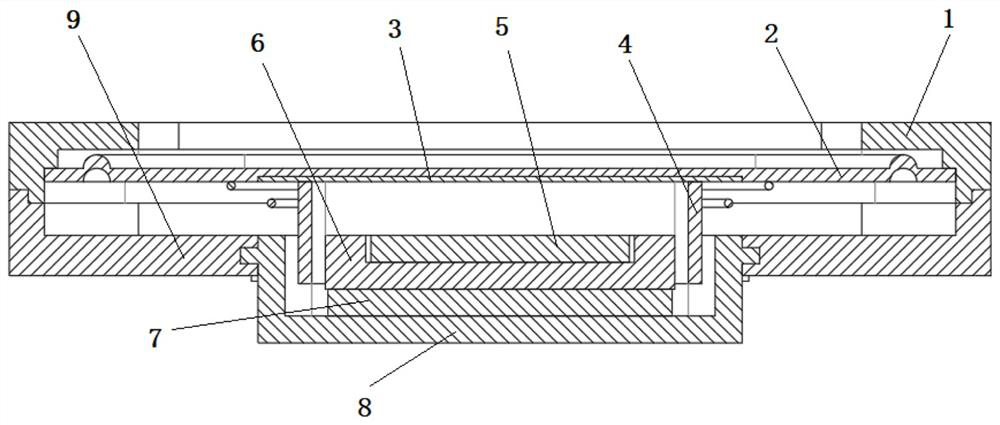

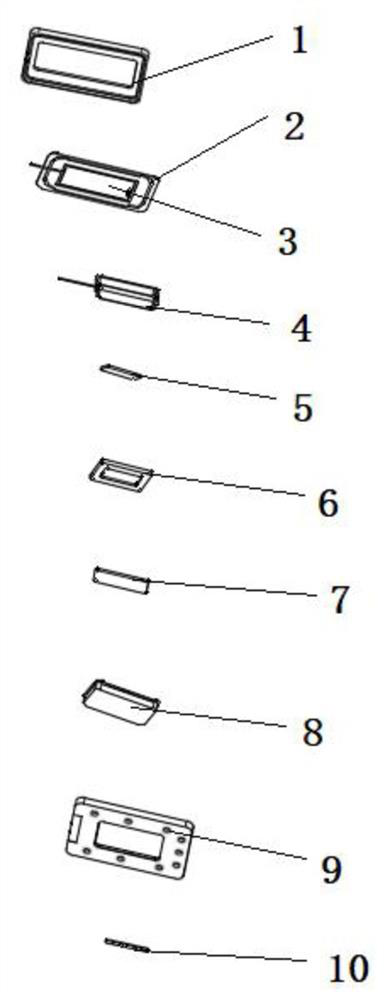

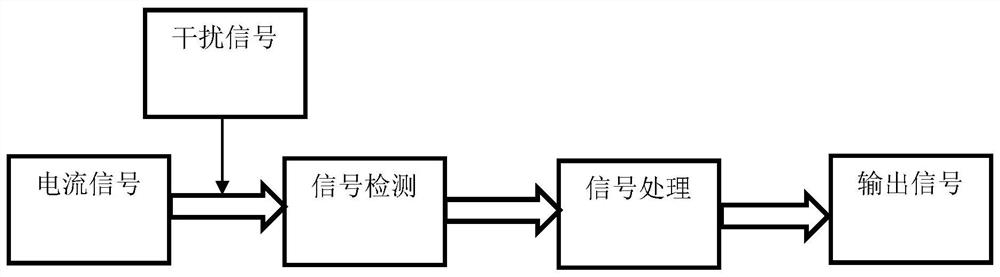

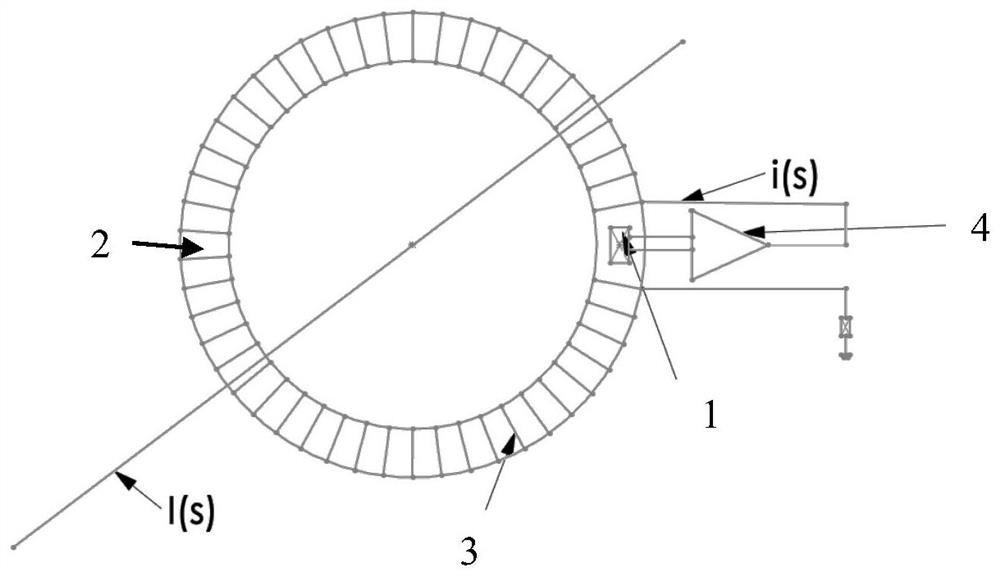

Single-stage coil cable tension sensor based on self-inductance principle and test method thereof

ActiveCN105333986ALow costReduce volumeTension measurementSignal-to-noise ratio (imaging)Cable tension

The invention provides a single-stage coil cable tension sensor based on a self-inductance principle and a test method thereof, and belongs to the technical field of structural health monitoring. The single-stage coil cable tension sensor comprises a magnetic conductive steel cable test piece, a single-stage coil cable tension sensor for cable tension measurement, a coil skeleton for winding the sensor, a loading device, a test piece fixing and clamping device, a generation circuit for generating a self-inductance coil sensor excitation signal, an amplification circuit, a filtering circuit, an effective value circuit and a digital analog conversion circuit and other circuits for analyzing and processing each signal. The steel cable test piece magnetic permeability variance is used as the intermediate quantity, and a linear relation between the cable tension value and the self-inductance variance is established so that the cable tension value can be measured. The single-stage coil cable tension sensor based on a self-inductance principle and the test method thereof can solve the problems that a traditional magnetic flux cable tension sensor has more coils and is large in volume, and is low in anti-interference capability, and have the advantages of being simple in manufacturing process, being small in volume, and being able to improve the signal to noise ratio of the sensor.

Owner:DALIAN UNIV OF TECH

Rotor assembly, permanent magnet motor and compressor

PendingCN114709952AReduce Flux LeakageSimple structureMagnetic circuit rotating partsElectric machineryPermanent magnet motor

The invention provides a rotor assembly, a permanent magnet motor and a compressor, and the rotor assembly comprises a rotor iron core which comprises a through hole; the permanent magnet is arranged in the through hole, the permanent magnet is cut out through a surface perpendicular to the axis of the rotor iron core to obtain a first section, the included angle between the extension direction of the permanent magnet and the radial direction of the rotor iron core is larger than 0 degree and smaller than 90 degrees on the first section, the permanent magnet comprises a non-diffusion part, and the non-diffusion part comprises a first end and a second end in the extension direction, the first end is close to the circumferential side of the rotor core, and the second end is close to the axis of the rotor core; the first diffusion part is connected with the first end of the non-diffusion part; the first magnetic isolation bridge is connected with the first diffusion part and is positioned between the first diffusion part and the circumferential side surface of the rotor iron core; wherein the mass ratio of the heavy metal elements in the first diffusion part is greater than the mass ratio of the heavy metal elements in the non-diffusion part. According to the invention, the technical problems that the anti-demagnetization capability of the permanent magnet motor is weak and irreversible demagnetization is easy to occur are solved.

Owner:ANHUI MEIZHI PRECISION MFG

Novel integrated inductor

PendingCN107705957ASolve the problem of flux leakageImprove inductor space utilizationInductance with magnetic coreCores/yokesCoil inductanceEngineering

The invention provides a novel integrated inductor. The novel integrated inductor comprises a coil, a first magnetic core, a second magnetic core and a columnar magnetic core, wherein the columnar magnetic core is connected between the first magnetic core and the second magnetic core, the first magnetic core, the second magnetic core and the columnar magnetic core are connected integratedly, the coil is wound around the columnar magnetic core to form a winding column, at connection positions of the first magnetic core, the second magnetic core and the columnar magnetic core, the first magneticcore and the second magnetic core are provided with positioning holes, an end part of the columnar magnetic core is embedded into the positioning holes, gaps are arranged in the connection positions,and the hardness of an inductor is conveniently changed. Holes are formed in an upper magnetic core and a lower magnetic core, and the problem of positioning of winding column installation can be solved; the winding column is embedded into the positioning holes of the first magnetic core and the second magnetic core, and the problem of magnetic leakage of the inductor is solved; certain gaps exist between the upper strip-shaped magnetic core and the lower strip-shaped magnetic core of the inductor and the winding column, and relative balance is formed between inductor volume and inductance value of the inductor; and the hardness of the inductor is adjusted by adjusting the gaps, meanwhile, the space utilization rate of the inductor is improved, and installation and automatic winding operation are facilitated.

Owner:HANGZHOU ZHONGHEN ELECTRIC CO LTD

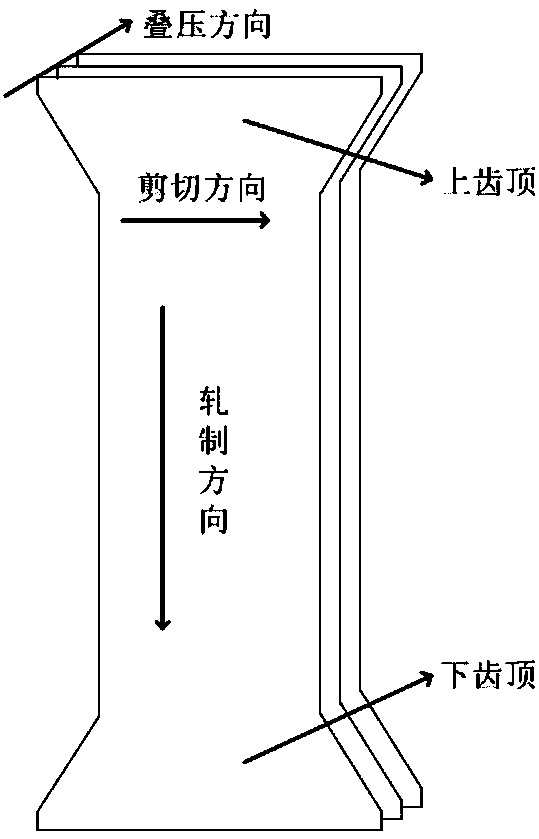

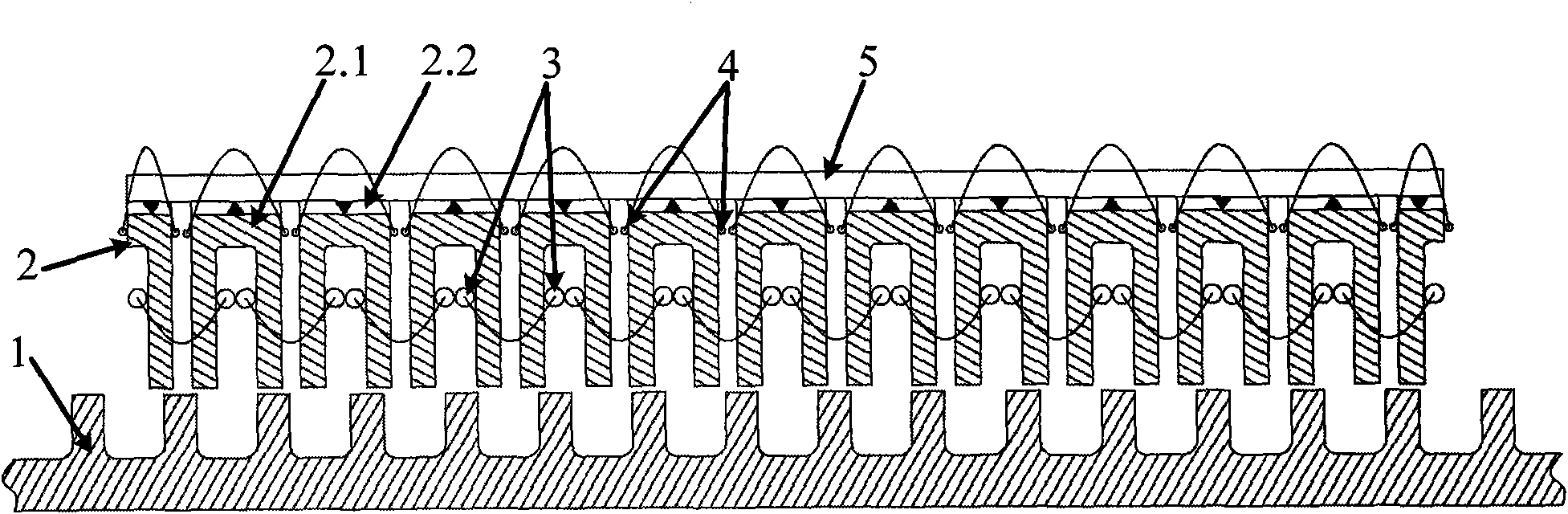

Double-stator rotor-yoke-free oriented silicon steel sheet permanent magnet linear motor

PendingCN108110987AIncrease thrust densityHigh magnetic flux densityPropulsion systemsEngineeringMagnetic circuit

The invention provides a double-stator rotor-yoke-free oriented silicon steel sheet permanent magnet linear motor. The permanent magnet linear motor comprises U-shaped double stators, a rotor iron core and a rotor bearing plate. The U-shaped double stators have a U-shaped structure formed by two vertical plates and one transverse plate. Two rows of permanent magnets are installed on the internal walls of the two side vertical plates of the U-shaped structure. A guide rail is installed on the top part of each side vertical plate. The double-stator double-air-gap structure is used, and the rotoruses the iron core structure so that the air gap magnetic co-nergy can be enhanced and the thrust density of the motor can be effectively increased. Besides, the anisotropic magnetic performance of the oriented silicon steel sheets and the magnetic circuit characteristics of the motor are combined, and the magnetic line direction of the rotor teeth and the high magnetic performance direction of the rolling direction of the oriented silicon steel sheets are consistent; and the characteristic of great magnetic performance of the rolling direction of the oriented silicon steel sheets is utilized, the saturation working point can be enhanced and the magnetomotive force produced by the stator current can be increased so that the stator tooth magnetic flux density and the air gap magnetic fluxdensity can be enhanced and the objective of enhancing the thrust density under the unit volume of the linear motor can be achieved.

Owner:SHENYANG POLYTECHNIC UNIV

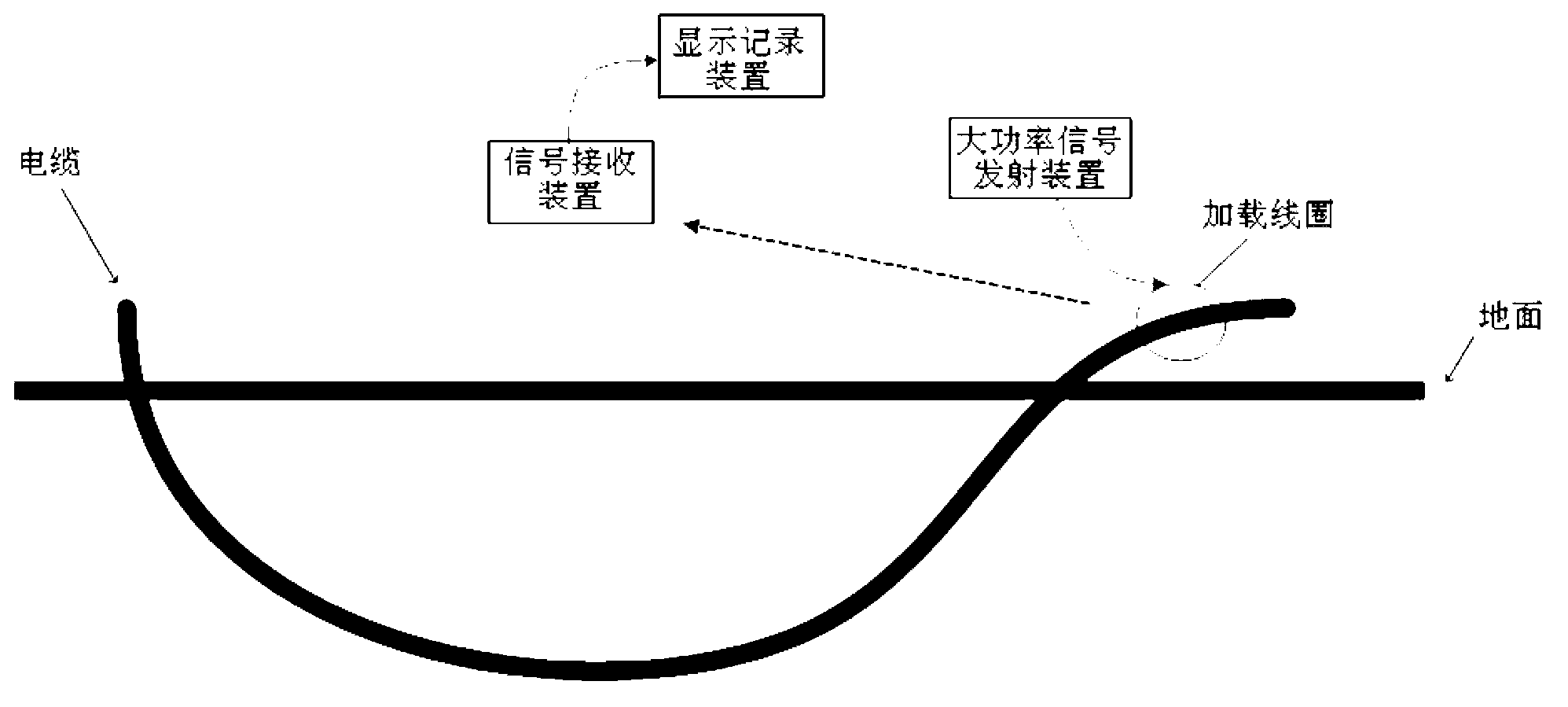

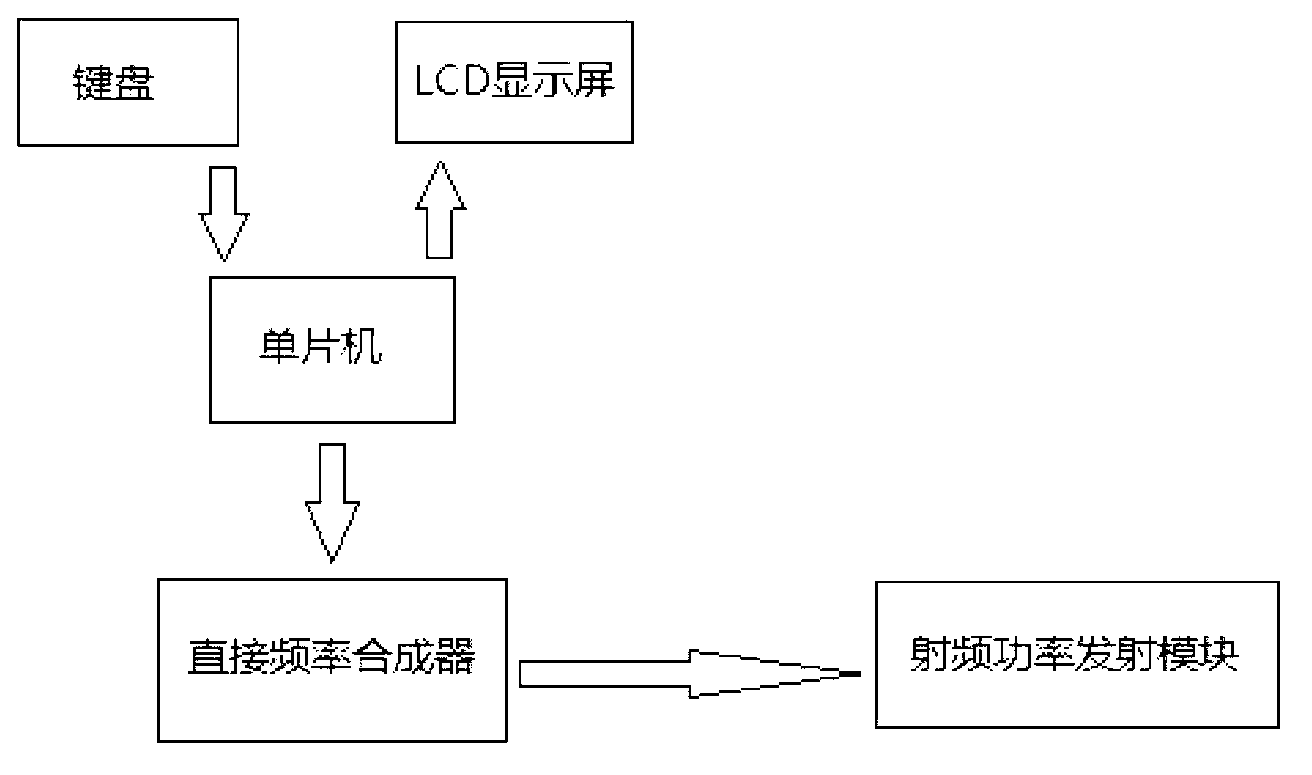

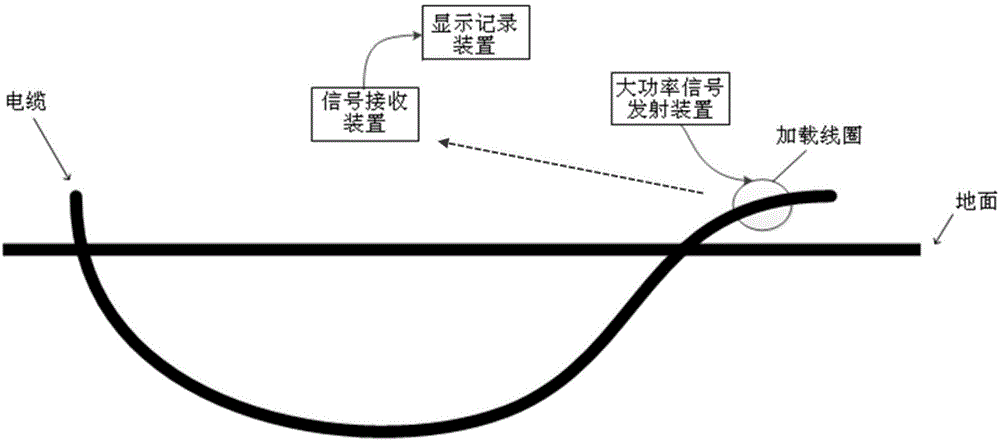

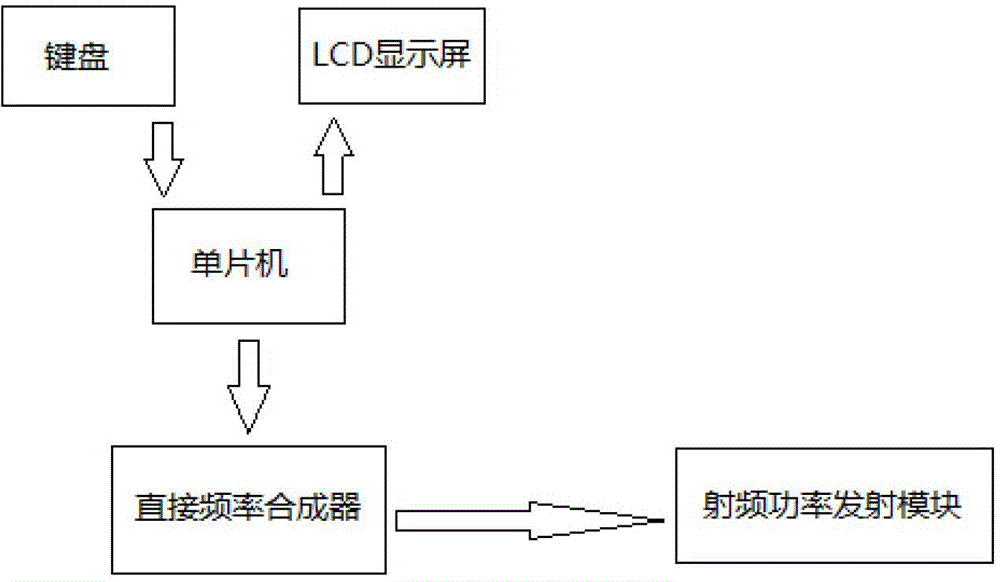

Underground cable comprehensive detection system

ActiveCN103278856AHigh control precisionFrequency stabilityElectric/magnetic detectionAcoustic wave reradiationRadio frequency signalEngineering

The invention relates to an underground cable comprehensive detection system which is technically characterized by comprising a high-power signal emission device, a loading coil, a signal receiving device and a display recording device, wherein an output end of the high-power signal emission device is connected with the loading coil, the loading coil is installed on a cable to be detected in a sleeved mode and produces radio-frequency signals under control of the high-power signal emission device, voltage displaying is carried out and voltage is outputted to the display recorder device after the signal receiving device receives the radio-frequency signals, and the display recording device carries out calculation on the received voltage and then outputs detection results. According to the underground cable comprehensive detection system, design is reasonable, the direct digital frequency synthesis technology is utilized, the high-power radio-frequency power emission technology is combined, control precision of frequency is higher, the frequency is more stable, meanwhile double receiving antennas are utilized to be matched with a receiving circuit, display is carried out on the display recording device, detecting difficulty is reduced, accuracy of detection is improved, and labor intensity of detecting staff is lightened.

Owner:STATE GRID CORP OF CHINA +1

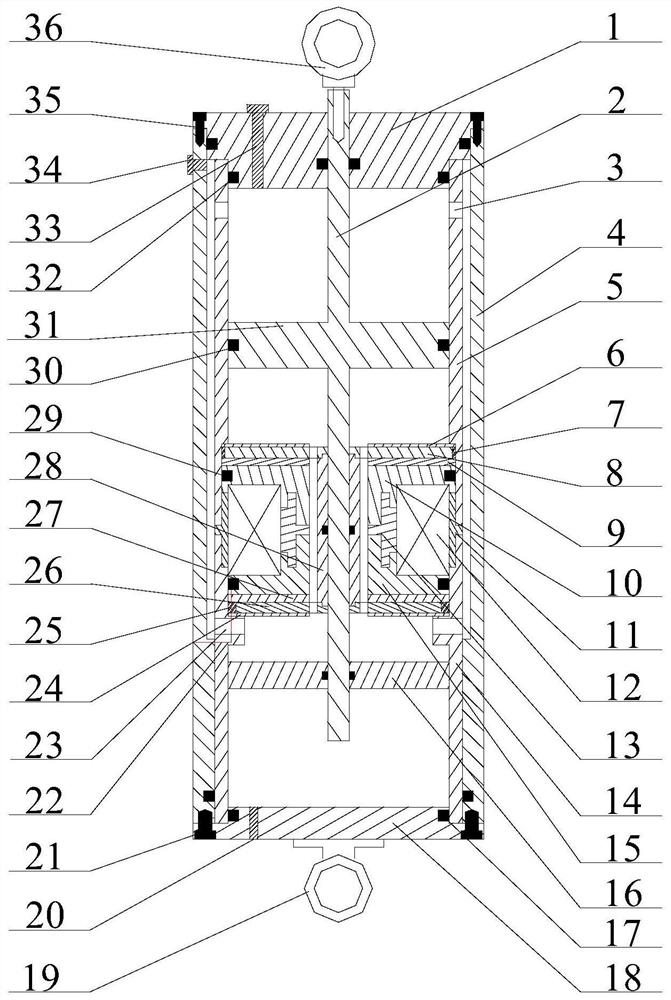

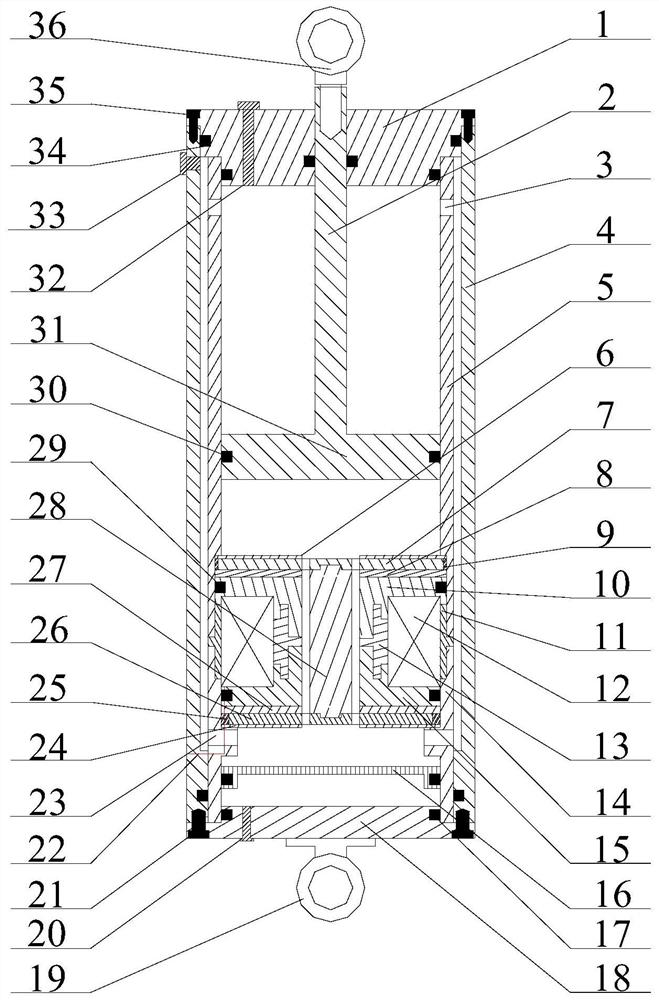

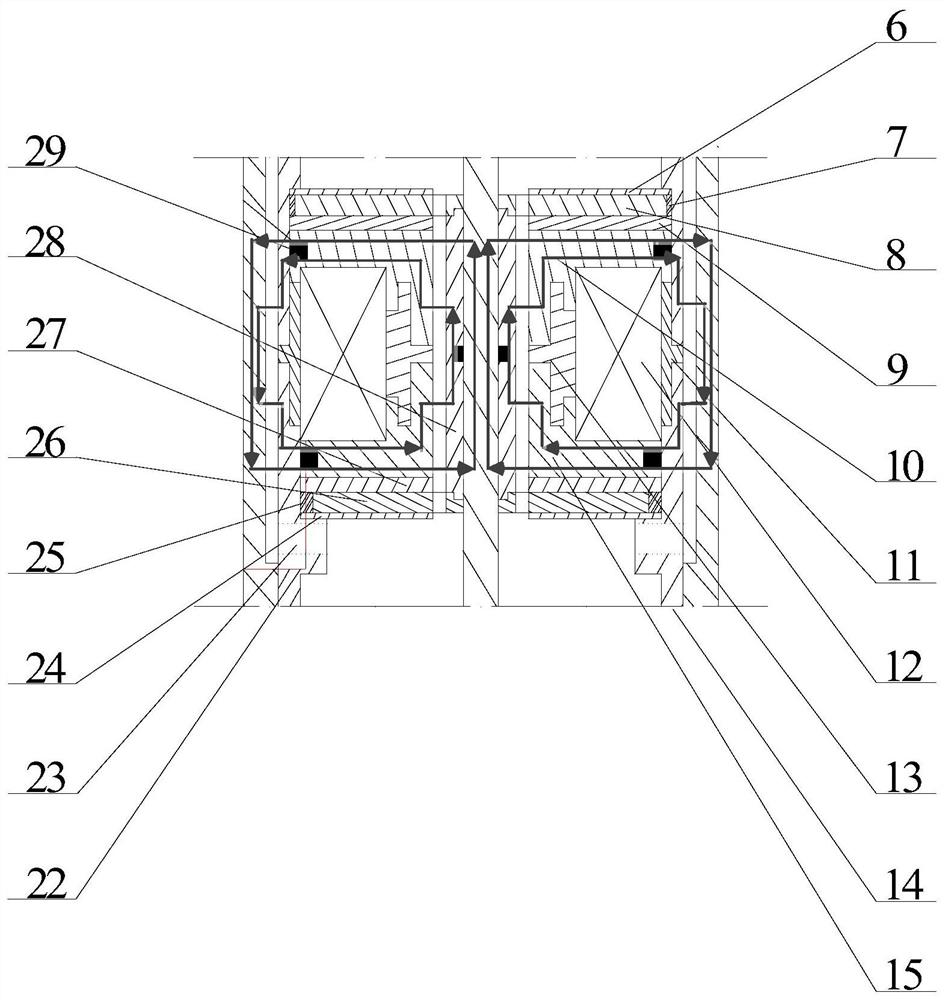

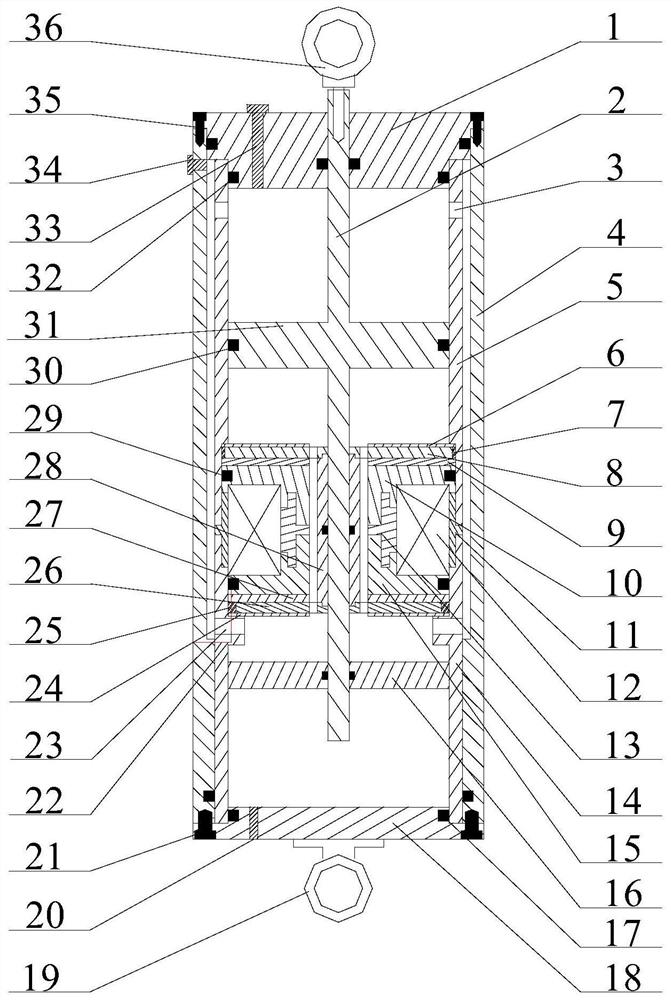

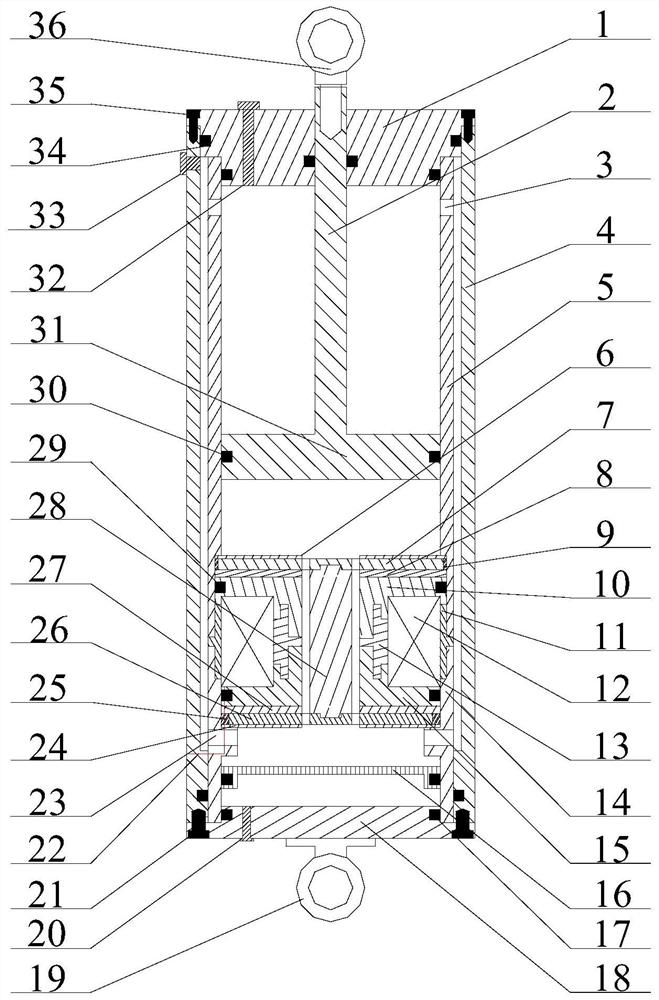

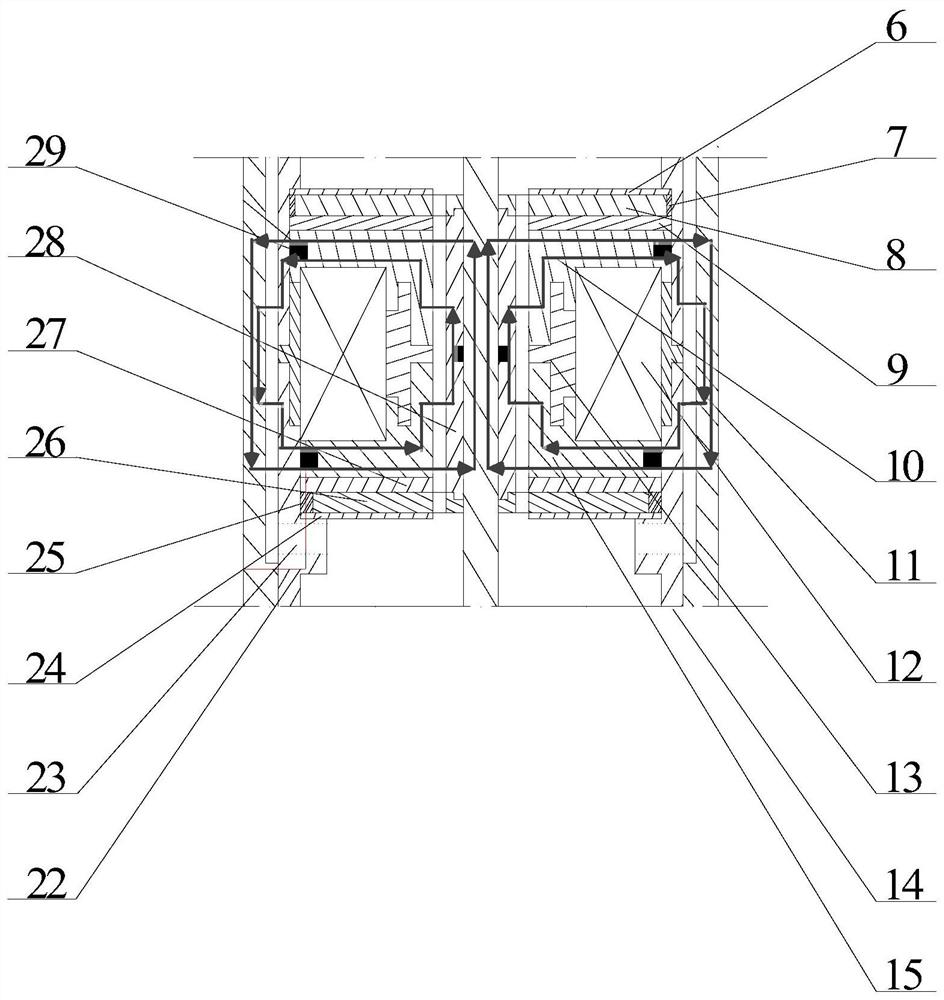

Magneto-rheological damper with double annular damping gaps

ActiveCN112555326AImprove the utilization of magnetic fieldExpand the scope ofSpringsNon-rotating vibration suppressionCircular discMagneto

The invention discloses a magneto-rheological damper with double annular damping gaps. The damper is characterized in that an inner cylinder barrel is arranged inside an outer cylinder barrel, and theinner cylinder barrel sequentially comprises an inner cylinder barrel upper section, an inner cylinder barrel middle section and an inner cylinder barrel lower section from top to bottom; the outer cylinder barrel, the inner cylinder barrel upper section and the inner cylinder barrel lower section are made of high-magnetic-conductive materials, and the inner cylinder barrel middle section is madeof a non-magnetic-conductive material; cylinder barrel upper covers are arranged at the upper ends of the outer cylinder barrel and the inner cylinder barrel, cylinder barrel lower covers are arranged at the lower ends, a piston rod is arranged inside the inner cylinder barrel, one end of the piston rod extends out of the cylinder barrel upper cover, and the other end of the piston rod penetratesthrough a low-carbon steel disc; a piston head is arranged on the piston rod, a damping generator is arranged between the piston head and the low-carbon steel disc, and the upper end and the lower end of the damping generator are each provided with a non-magnetic-conductive material used for isolating a magnetic field; and a high-magnetic-conductivity material and a non-magnetic-conductivity material for changing magnetic field distribution are arranged in the middle of the damping generator. According to the damper, the magnetic field utilization rate is improved, and the damping force rangeand the dynamic range are remarkably improved.

Owner:XI AN JIAOTONG UNIV

Quenching sensor and quenching method for shaft parts

InactiveCN103173595BIncreased power lossImprove power efficiencyIncreasing energy efficiencyFurnace typesWater channelInductor

Owner:CHINA NORTH IND NEW TECH PROMOTION INST +1

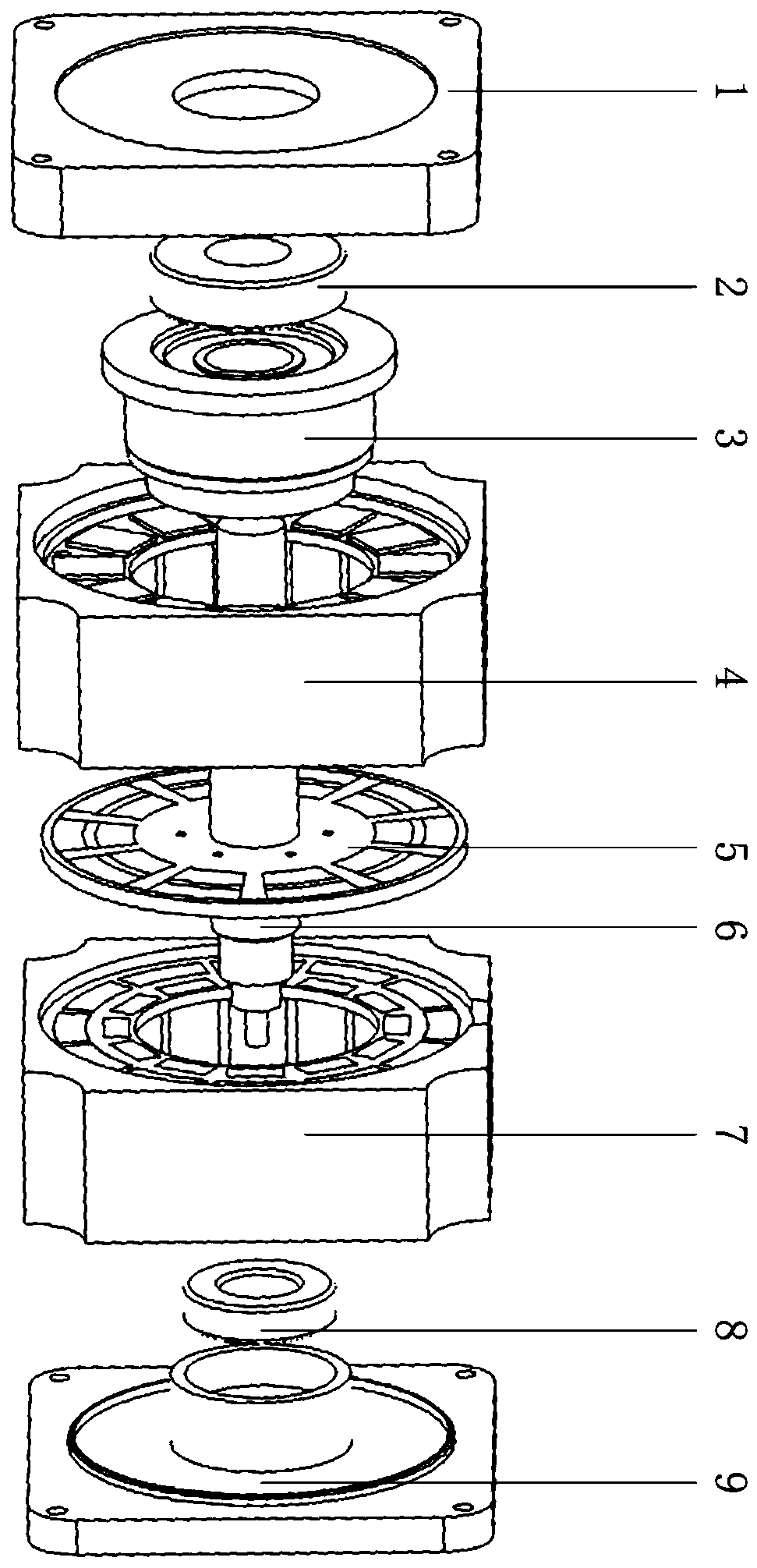

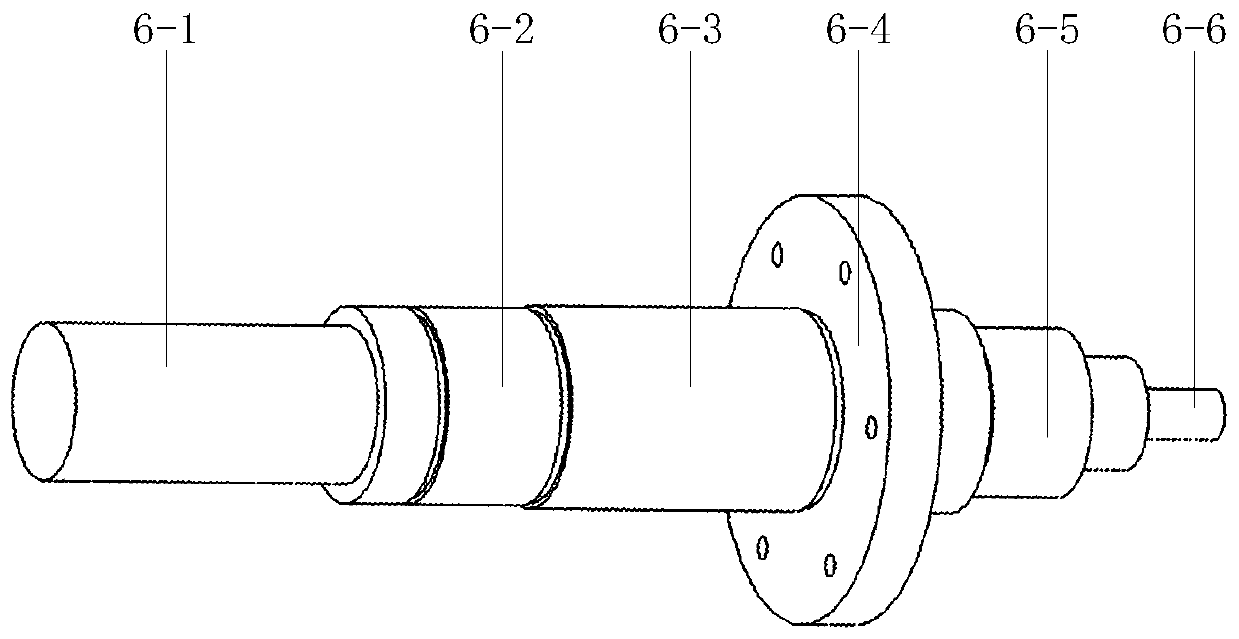

a speaker

ActiveCN112261559BExtend the effective frequency rangeHigh frequencyElectrical transducersNonlinear distortionSound film

The invention relates to a loudspeaker and belongs to the technical field of loudspeakers. Including a mesh cover, a bracket and a U cup, the mesh cover and the bracket are matched and connected to each other to form a whole, the U cup is clamped at the bottom of the bracket, a sound membrane is installed in the mesh cover, and the bottom surface of the sound membrane is provided with A rectangular piezoelectric ceramic sheet, the bottom of the piezoelectric ceramic sheet is cemented with a grooved voice coil that runs through up and down, and a rectangular U-cup mounting port is also opened on the bottom surface of the bracket, and the U-cup mounting port is snap-fitted and installed. U cup, the top surface of the U cup is also provided with a magnetic slot for installing the washer, the top surface of the washer is provided with a secondary magnetic slot, and a secondary magnet is glued and installed inside the secondary magnetic slot. There is also a main magnet glued to the bottom surface of the company, and the bottom surface of the main magnet is glued in the magnetic groove of the U cup. The loudspeaker of the invention solves the problem of difficult assembly of the loudspeaker, simultaneously solves the technical problems of magnetic flux leakage and nonlinear distortion, and has low production cost, high production efficiency, high finished product qualification rate and excellent acoustic performance.

Owner:常州诚铭电子科技有限公司

A single-stage coil cable force sensor based on self-inductance principle and its testing method

The invention provides a single-stage coil cable tension sensor based on a self-inductance principle and a test method thereof, and belongs to the technical field of structural health monitoring. The single-stage coil cable tension sensor comprises a magnetic conductive steel cable test piece, a single-stage coil cable tension sensor for cable tension measurement, a coil skeleton for winding the sensor, a loading device, a test piece fixing and clamping device, a generation circuit for generating a self-inductance coil sensor excitation signal, an amplification circuit, a filtering circuit, an effective value circuit and a digital analog conversion circuit and other circuits for analyzing and processing each signal. The steel cable test piece magnetic permeability variance is used as the intermediate quantity, and a linear relation between the cable tension value and the self-inductance variance is established so that the cable tension value can be measured. The single-stage coil cable tension sensor based on a self-inductance principle and the test method thereof can solve the problems that a traditional magnetic flux cable tension sensor has more coils and is large in volume, and is low in anti-interference capability, and have the advantages of being simple in manufacturing process, being small in volume, and being able to improve the signal to noise ratio of the sensor.

Owner:DALIAN UNIV OF TECH

Comprehensive detection system for underground cables

ActiveCN103278856BHigh control precisionFrequency stabilityElectric/magnetic detectionAcoustic wave reradiationRadio frequency signalEngineering

The invention relates to an underground cable comprehensive detection system which is technically characterized by comprising a high-power signal emission device, a loading coil, a signal receiving device and a display recording device, wherein an output end of the high-power signal emission device is connected with the loading coil, the loading coil is installed on a cable to be detected in a sleeved mode and produces radio-frequency signals under control of the high-power signal emission device, voltage displaying is carried out and voltage is outputted to the display recorder device after the signal receiving device receives the radio-frequency signals, and the display recording device carries out calculation on the received voltage and then outputs detection results. According to the underground cable comprehensive detection system, design is reasonable, the direct digital frequency synthesis technology is utilized, the high-power radio-frequency power emission technology is combined, control precision of frequency is higher, the frequency is more stable, meanwhile double receiving antennas are utilized to be matched with a receiving circuit, display is carried out on the display recording device, detecting difficulty is reduced, accuracy of detection is improved, and labor intensity of detecting staff is lightened.

Owner:STATE GRID CORP OF CHINA +1

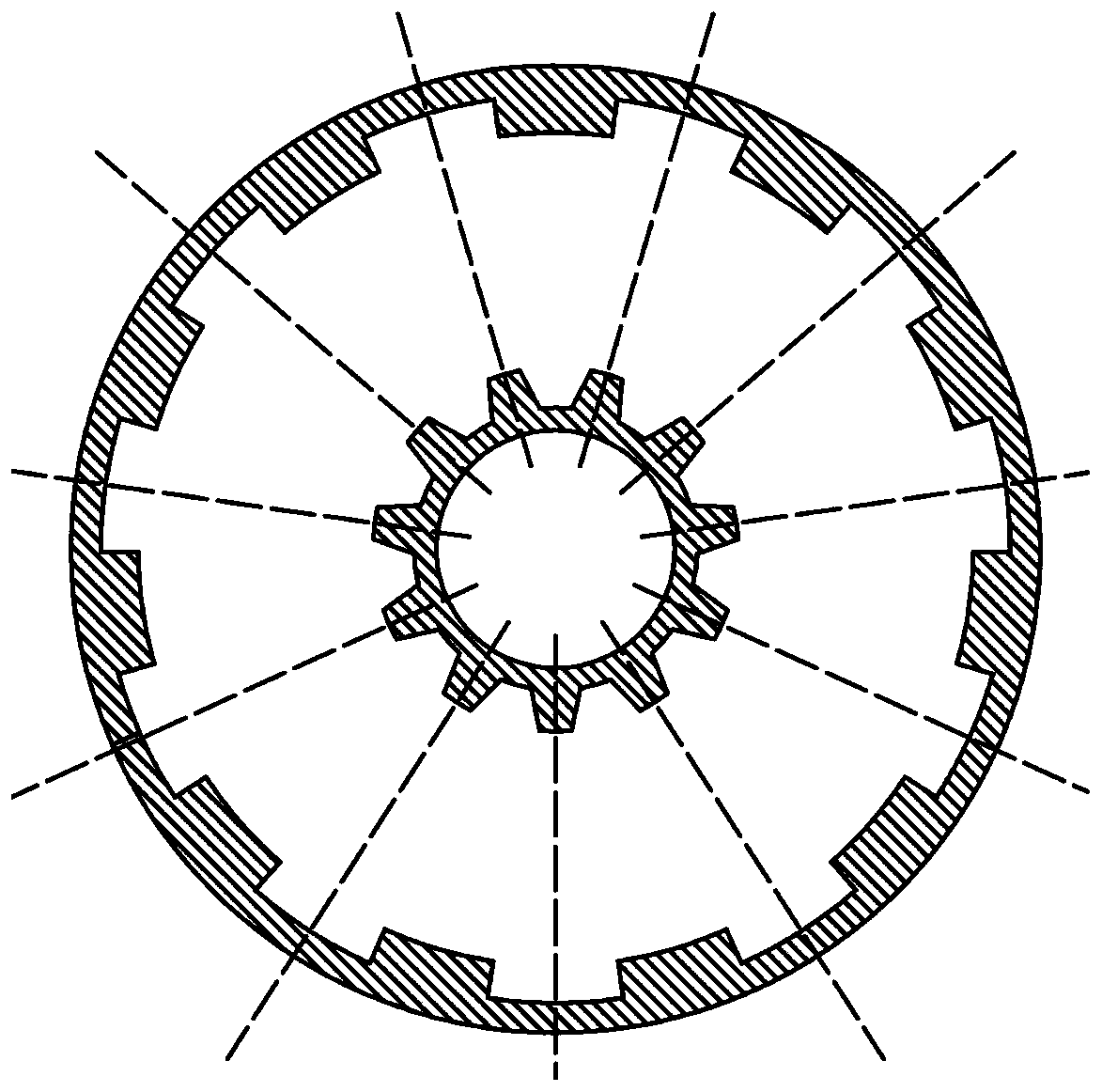

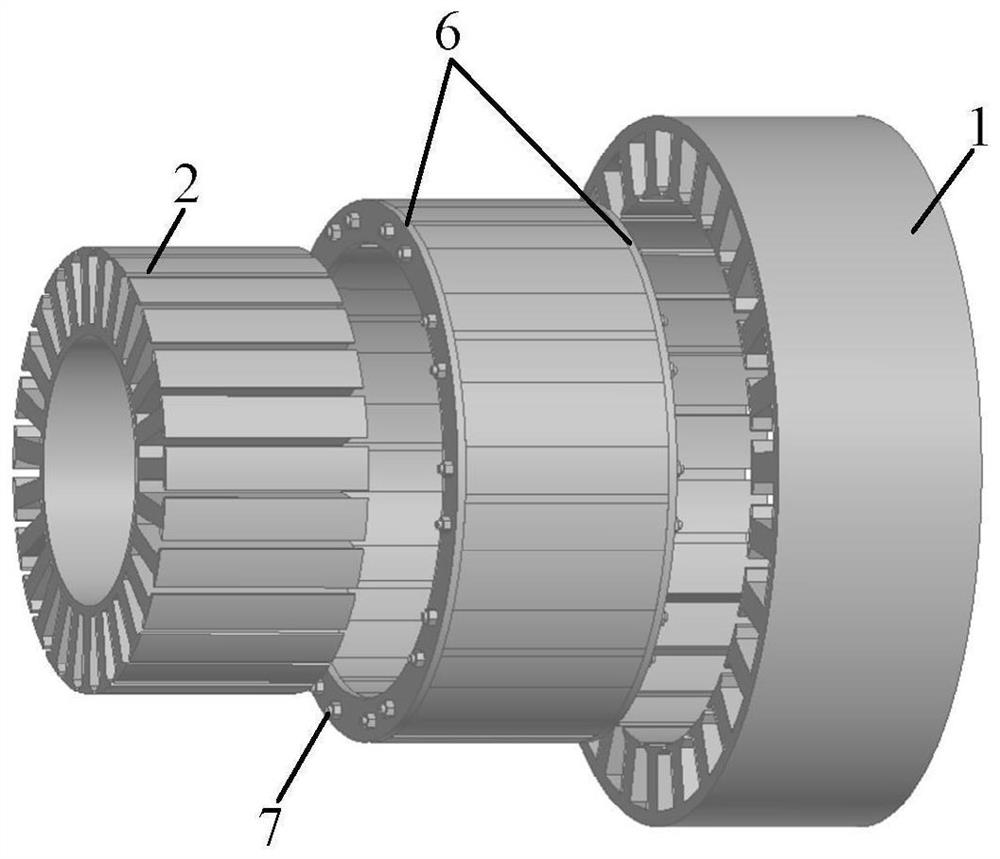

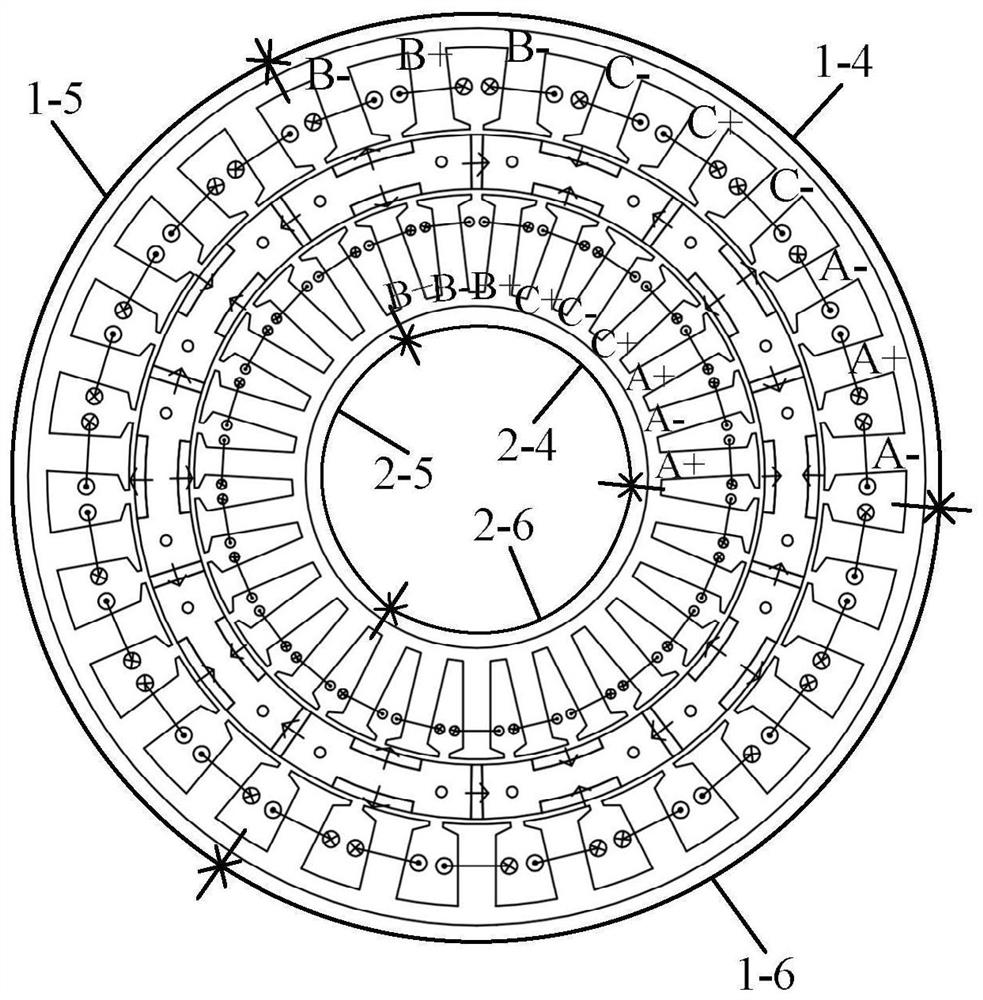

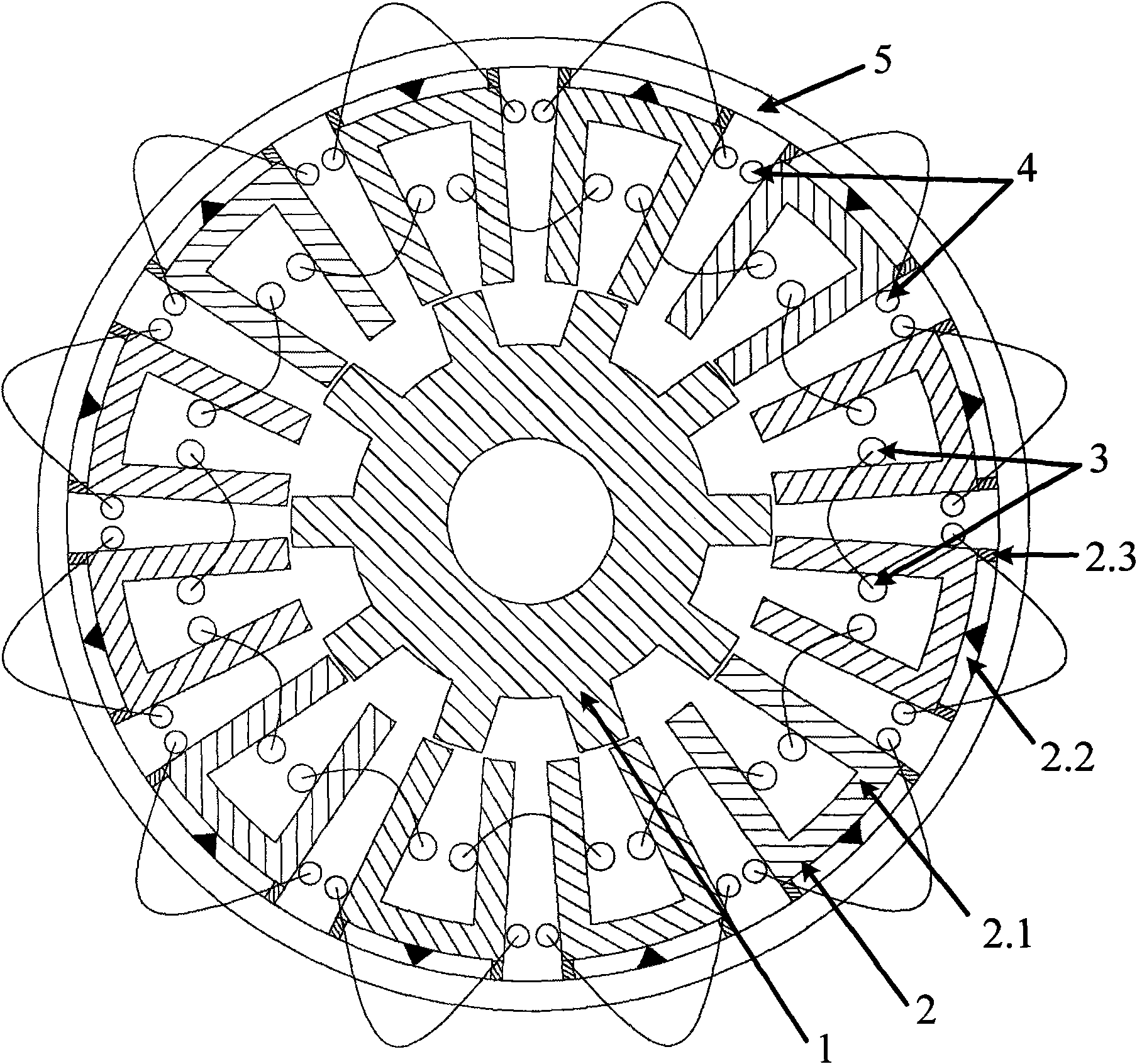

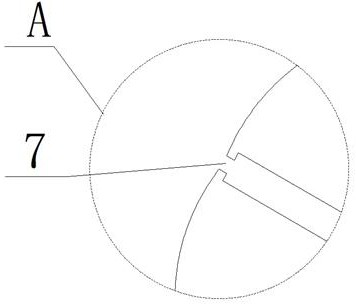

Direct-drive consequent-pole permanent magnet hub motor

ActiveCN114006489AReduce electromagnetic torque rippleLow costElectric machinesMagnetic circuit stationary partsElectric machinePermanent magnet motor

The invention discloses a direct-drive consequent-pole permanent magnet hub motor. The direct-drive consequent-pole permanent magnet hub motor comprises an inner stator, an outer stator and a consequent-pole rotor located between the inner stator and the outer stator; the inner stator and the outer stator are each formed by combining a plurality of stator modules; the consequent-pole rotor comprises a plurality of modularized iron cores, Spoke permanent magnets and surface-mounted permanent magnets, wherein the Spoke permanent magnets and the surface-mounted permanent magnets are alternately arranged, the Spoke permanent magnets are magnetized in the annular direction, and the surface-mounted permanent magnets are magnetized in the radial direction; positioning holes are formed in the modularized iron cores; non-magnetic pressing plates are arranged on the inner side and the outer side of the consequent-pole rotor; and the non-magnetic pressing plates are fixed with the positioning holes in the modularized iron cores through positioning bolts. According to the direct-drive consequent-pole permanent magnet hub motor of the invention, the problem of counter electromotive force even harmonic caused by asymmetric air gap flux density of the consequent-pole permanent magnet motor is solved, the counter electromotive force waveform quality of the motor is improved, the electromagnetic torque characteristic of the motor is improved, the problem of single-side magnetic leakage of a single-stator Spoke rotor structure is solved, and the permanent magnet utilization rate is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Built-in hybrid excitation bilateral magnetic channel linear motor

ActiveCN113629973BReduce manufacturing costReduce DC componentPropulsion systemsMagnetic barrierElectric machine

Owner:SHIJIAZHUANG TIEDAO UNIV

Bilateral Flux Switching Permanent Magnet Linear Motor

ActiveCN110957876BReduce weightLow costMagnetic circuit rotating partsPropulsion systemsElectric machinePermanent magnet linear motor

The invention discloses a bilateral magnetic flux switching permanent magnet linear motor, which comprises a bilateral secondary stator and a primary mover arranged between the stators, the primary mover includes six primary mover units, and the primary mover There is a connecting bridge between the subunit and the primary mover unit, each primary mover unit includes two H-shaped magnetic cores, and permanent magnets are arranged between the two H-shaped magnetic cores; the spaced on the secondary stator A number of secondary teeth are formed, a secondary slot is formed between the secondary teeth, a yoke is formed at the bottom of the secondary slot, and the H-shaped magnetic permeable core opposite to the secondary tooth Magnetic teeth are formed on the top, and winding installation slots are formed between the magnetic teeth on the same side; the bilateral secondary stator is used as a fixed part, the primary mover is a moving part, and the primary mover is used to make a straight line between the bilateral secondary stators. Movement, the motor that constitutes the bilateral flat plate structure. The linear motor has the advantages of high utilization rate and low flux leakage.

Owner:SHIJIAZHUANG TIEDAO UNIV

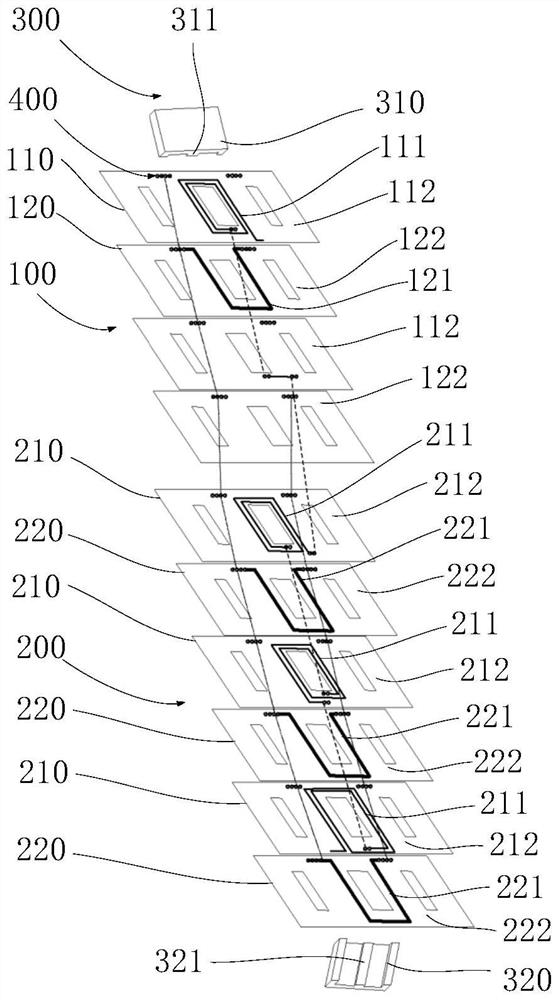

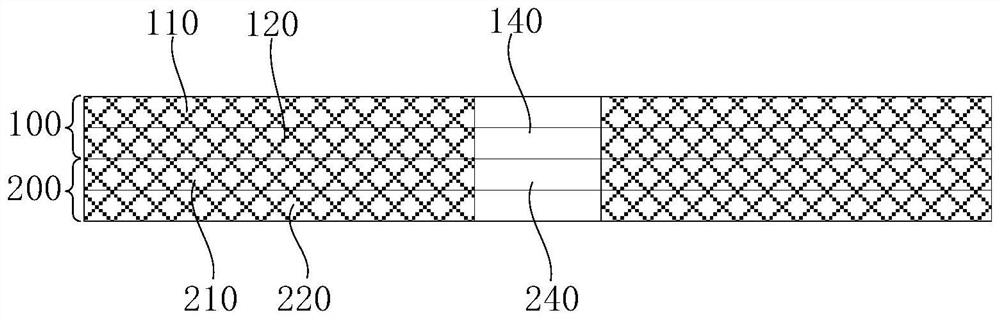

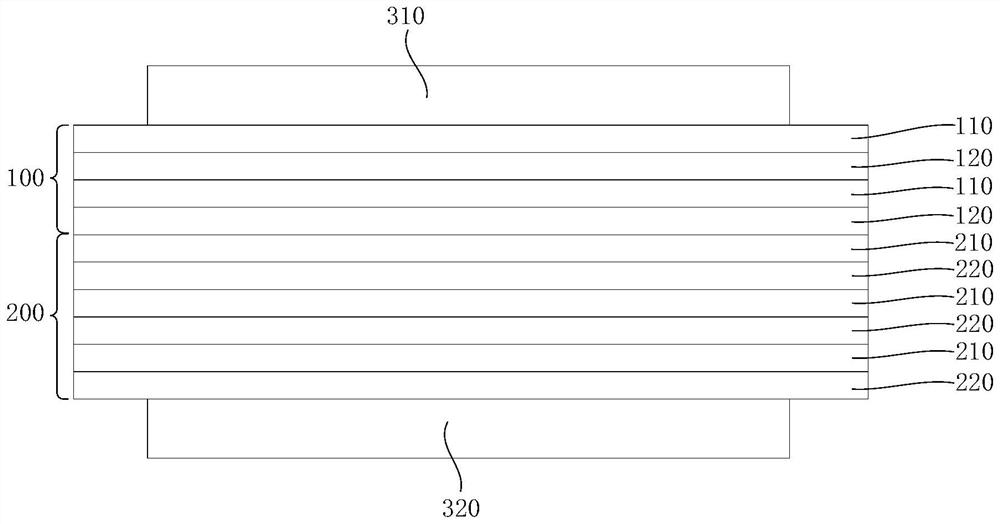

Planar transformer

PendingCN114864239AImprove performanceIncrease the cross-sectional areaTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresMechanical engineeringElectrical element

The invention discloses a planar transformer, and relates to the field of electrical elements. The planar transformer comprises a first PCB, a second PCB and a planar magnetic core, wherein the first PCB and the second PCB are stacked, and the planar magnetic core is used for fixing the first PCB and the second PCB. The first PCB and the second PCB respectively comprise a plurality of circuit layers, each circuit layer is provided with a winding, the winding is a primary winding or a secondary winding, in all the circuit layers, the circuit layers provided with the primary windings and the circuit layers provided with the secondary windings are alternately arranged, and the circuit layers provided with the primary windings and the circuit layers provided with the secondary windings are alternately arranged. And the windings of all the circuit layers are combined in series and in parallel to form a primary coil and a secondary coil of the planar transformer. The PCB planar transformer at least can solve the problem that a current PCB planar transformer is prone to a magnetic leakage phenomenon.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

A mixed excitation biconvex pole motor T

InactiveCN101552497BEasy to adjustImprove controllabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineElectromagnetic interference

he invention discloses a mixed excitation biconvex pole motor, including rotors, stators, three-phase armature windings and a case, wherein, the case is in magnetic conduction material, the rotor is composed of alveolar type core lamination, the stator fixed in the case includes 'U'-shaped cores arranged with interval between each other and permanent magnets provided between the 'U'-shaped cores and the case, the first permanent magnet charges magnetism tangentially along the circumference, N pole and S pole are arranged alternately, a second permanent magnet is provided between the 'U'-shapedcore base and the case, the second permanent magnet charges magnetism along the radius direction, N pole and S pole are arranged alternately, the three phase armature winding is a concentrated winding, winding on the armature teeth, the armature teeth are composed of adjacent two edges of two 'U'-shaped cores, the single-phase excitation is a concentrated winding, winding on the 'U'-shaped coreand the permanent magnet. In the inventive mixed excitation biconvex pole motor, the permanent magnet excitation and exciter winding electric excitation jointly combine an air-gap field to realize theadjustability of air-gap field, and simultaneously adopts magnetic conduction material as the case so that it can avoid the leakage of case outer edge, improves the motor anti-electromagnetic interference and electromagnetic compatibility, and improves utilization of permanent magnets.

Owner:ZHEJIANG UNIV

A normal-line multi-coil magnetic gathering wireless charging device for electric vehicles

InactiveCN107199901BSolve the problem of flux leakageCharging stationsElectric vehicle charging technologyWireless transmissionElectrical battery

Owner:NANJING AGRICULTURAL UNIVERSITY

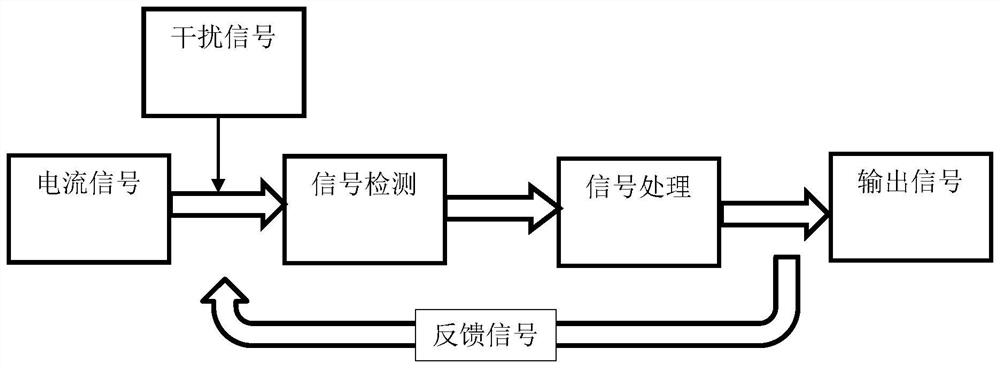

Design method of a closed-loop current sensor

ActiveCN112147393BReduce power consumptionLow costCurrent measurements onlySignal processing circuitsCurrent sensor

A design method of a closed-loop current sensor, the closed-loop current sensor includes a magnetically sensitive chip, a magnetic circuit, a feedback coil and a signal processing circuit, the magnetic circuit consists of iron core segments arranged at intervals along the circumferential direction or is a full hollow magnetic circuit, The design method of the current sensor includes the following steps: determine the structure of the sensor; determine the size of the secondary current; determine the standard feedback amount of the sensor according to the secondary current and the number of coil turns, and then determine the design feedback amount of the sensor; calculate the conversion of the current to the magnetic field The value of the function; calculate the magnification K of the signal processing circuit, and determine the signal processing circuit after determining the magnification of the signal processing circuit, thereby completing the overall design of the closed-loop current sensor. The invention can effectively reduce the power consumption of the sensor, reduce the cost, balance the problems of accuracy and power consumption encountered in the current sensor, and is especially suitable for the design of a closed-loop current sensor with high precision, large range and low power consumption.

Owner:珠海多创科技有限公司

A magneto-rheological damper with double annular damping gap

ActiveCN112555326BImprove the utilization of magnetic fieldEffective isolationSpringsNon-rotating vibration suppressionCircular discConductive materials

The invention discloses a magneto-rheological damper with a double annular damping gap. An inner cylinder is arranged inside an outer cylinder, and the inner cylinder includes an upper section of the inner cylinder, a middle section of the inner cylinder and a lower section of the inner cylinder from top to bottom. ;The outer cylinder, the upper part of the inner cylinder and the lower part of the inner cylinder are made of high magnetic permeability material, and the middle part of the inner cylinder is made of non-magnetic material; the upper end of the outer cylinder and the inner cylinder is provided with a cylinder upper cover , the lower end is provided with the lower cover of the cylinder, and the inside of the inner cylinder is provided with a piston rod, one end of the piston rod protrudes to the outside of the upper cover of the cylinder, and the other end is set through a low carbon steel disc; the piston rod is provided with a piston head , a damping generator is set between the piston head and the low-carbon steel disc, and the upper and lower ends of the damping generator are respectively provided with non-magnetic materials for isolating the magnetic field; the middle of the damping generator is provided with a high-permeability material for changing the magnetic field distribution materials and non-magnetic materials. The utilization rate of the magnetic field is improved, and the damping force range and dynamic range are significantly improved.

Owner:XI AN JIAOTONG UNIV

Rotor punching sheet group, rotor iron core, rotor and motor

InactiveCN113659746AGuaranteed mechanical strengthSolve the problem of flux leakageMagnetic circuit rotating partsPhysicsEngineering

The invention discloses a rotor punching sheet group, a rotor iron core, a rotor and a motor. The rotor punching sheet group comprises a first rotor punching sheet and a second rotor punching sheet, a plurality of permanent magnet grooves are formed in the first rotor punching sheet and the second rotor punching sheet, and the permanent magnet grooves extend along the radial direction of the rotor punching sheets and are distributed on the rotor punching sheets in a central symmetry manner; an outer diameter magnetic isolation notch is formed between the outer end of the permanent magnet groove on the first rotor punching sheet and the outer diameter of the first rotor punching sheet; and an inner diameter magnetic isolation notch is formed between the inner end of the permanent magnet groove on the second rotor punching sheet and the inner diameter of the second rotor punching sheet. The rotor iron core is formed by laminating a plurality of the first rotor punching sheets and the second rotor punching sheets. The rotor comprises the rotor iron core and a permanent magnet, and the permanent magnet is arranged in the rotor iron core. The motor comprises the rotor. Two rotor punching sheets are laminated, so that the problem of magnetic leakage of rotor magnetic steel is effectively solved on the basis of ensuring the mechanical strength of the rotor, the magnetic leakage amount is reduced, and the use amount of the magnetic steel is saved.

Owner:天津众科科技发展有限公司

Novel inductor magnetic core

PendingCN107705969ASimple utilizationSimple winding processTransformers/inductances magnetic coresInductor windingsEngineering

The invention provides a novel inductor magnetic core. The novel inductor magnetic core comprises a first magnetic core, a second magnetic core and a columnar magnetic core, wherein the columnar magnetic core is connected between the first magnetic core and the second magnetic core, the first magnetic core, the second magnetic core and the columnar magnetic core are connected integratedly, at connection positions of the first magnetic core, the second magnetic core and the columnar magnetic core, the first magnetic core and the second magnetic core are provided with positioning holes, an end part of the columnar magnetic core is embedded into the positioning holes, gaps are arranged in the connection positions, and the hardness of an inductor is conveniently changed. The high-frequency inductor magnetic core integrates the advantages of space utilization rate and simple winding of a traditional combination inductor, the problems of magnetic leakage and difficulty in assembly and positioning also can be solved, meanwhile, the gaps are also convenient to adjust, and the hardness of the inductor is adjusted by adjusting the gaps.

Owner:HANGZHOU ZHONGHEN ELECTRIC CO LTD

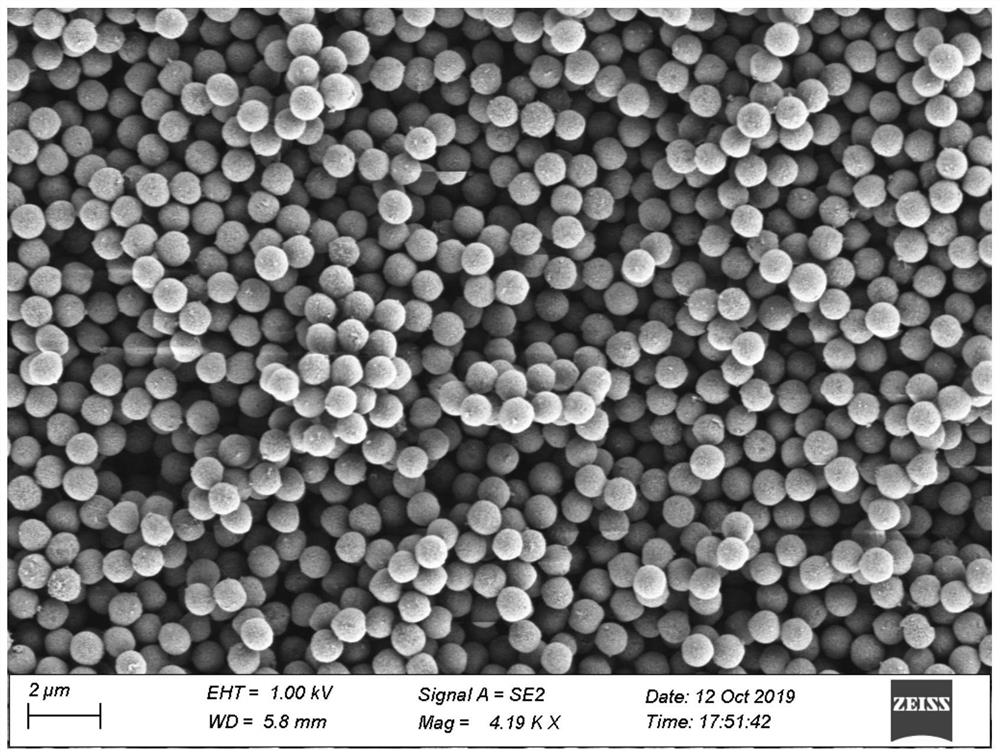

A magnetic microsphere with functional groups on its surface, its preparation method and application

ActiveCN111393574BUniform particle sizeHigh magnetic contentPeptide preparation methodsTissue cultureFunctional monomerMicrosphere

The present invention relates to a magnetic microsphere with functional groups on the surface and its preparation method and application. The method comprises surface modification of polymer microspheres to obtain modified microspheres, and preparation of magnetic microspheres with functional groups on the surface. The magnetic nanoparticles are dispersed and mixed in the solvent, and the pH of the solution is adjusted so that the surface of the modified microsphere and the magnetic nanoparticle are oppositely charged, and the magnetic nanoparticle is adsorbed on the surface of the modified microsphere to form a composite microsphere, and then composite The microsphere is the nucleus. In the presence of the surfactant, the functional monomer forms a polymer layer with functional groups on the surface of the composite microsphere to obtain the magnetic microsphere. The method of the present invention effectively solves the problem of traditional magnetic microspheres. Due to the problems of magnetic flux leakage and uneven surface hydrophilicity and hydrophobicity in the preparation process, the obtained magnetic microspheres have uniform particle size, high magnetic content and good consistency, and rich surface functional groups.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com