Patents

Literature

200results about How to "Increase thrust density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic-concentrating-type consequent-pole cursor permanent magnet motor and application thereof

ActiveCN106374718AIncrease air gap flux densityImproved Air Gap Ability to Transfer Electromagnetic PowerPropulsion systemsPower factorElectric machine

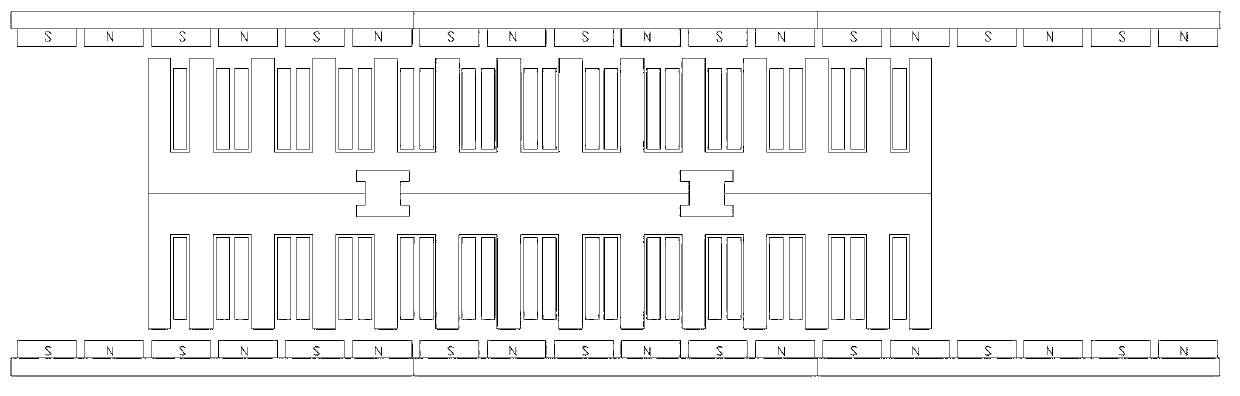

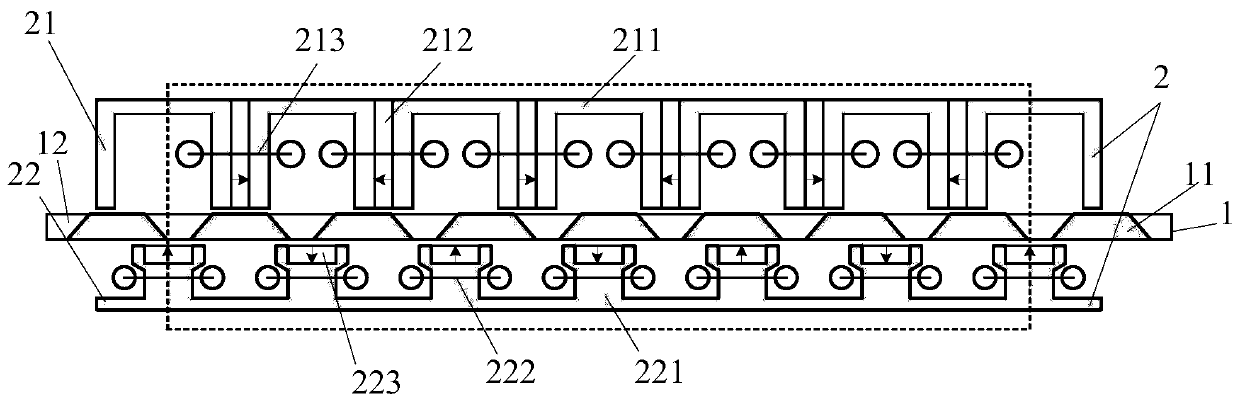

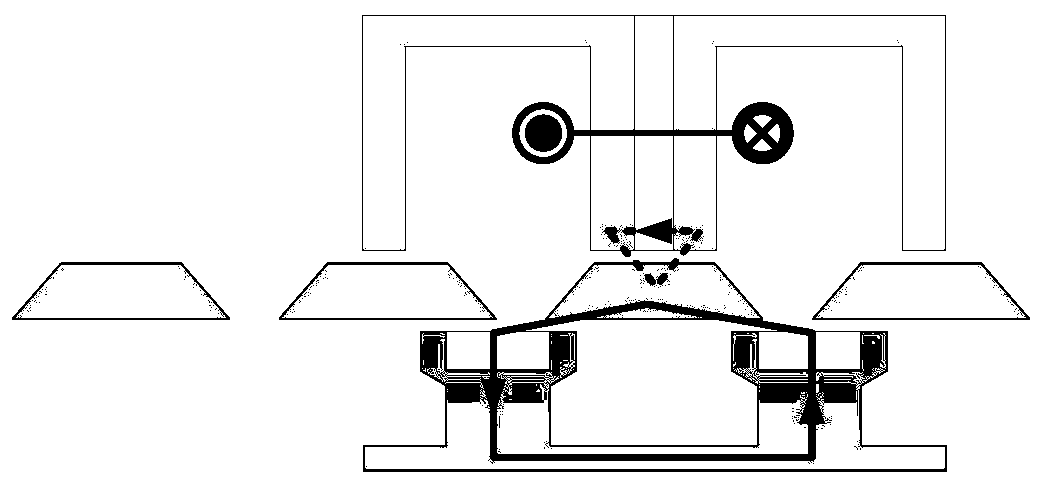

The invention discloses a magnetic-concentrating-type consequent-pole cursor permanent magnet motor, which comprises a primary core and a secondary core, wherein a plurality of open slots are formed in the primary core; armature windings are arranged in the open slots of the primary core; the secondary core and the primary core are arranged at an interval and can oppositely move; Halbach permanent magnets are arranged in notches of the open slots of the primary core, thereby forming a Halbach (Halbach) permanent magnet array; a plurality of open slots which are arranged at intervals are formed in the surface, relative to the primary core, of the secondary core and permanent magnets are arranged in the open slots, thereby forming an excitation permanent magnet array; and the magnetization direction of the Halbach permanent magnet array is matched with that of the excitation permanent magnet array. Through comprehensive application of a consequent-pole structure and a Halbach array, the air-gap flux density of the motor is significantly strengthened, the air-gap electromagnetic power transmission capacity of the motor is improved, the electromagnetic properties of the counter electromotive force, the thrust density, the power factor and the like of the motor are improved, and reduction of the volume of the motor, improvement of the acceleration performance of the motor and reduction of the capacity of a frequency converter are facilitated.

Owner:HUAZHONG UNIV OF SCI & TECH

Short-circuit fault-tolerant vector control method for embedded hybrid magnetic material fault-tolerant cylindrical linear motor

InactiveCN105245156ASimple structureImprove reliabilityElectronic commutation motor controlAC motor controlVoltage source inverterCompensation strategy

The invention discloses a short-circuit fault-tolerant vector control method for an embedded hybrid magnetic material fault-tolerant cylindrical linear motor. The short-circuit fault-tolerant vector control method comprises the following steps: building a five-phase embedded hybrid magnetic material fault-tolerant cylindrical linear motor model; compensating normal thrust missing caused by a short-circuit fault phase and suppressing a thrust ripple caused by phase short-circuit current with non-fault phase current of the motor; and obtaining expected phase voltage by adopting a series of coordinate conversion and voltage feed-forward compensation strategies, and achieving a fault-tolerant vector control after the phase short-circuit fault of the motor by a zero-sequence voltage harmonic injection-based CPWM modulation mode. According to the short-circuit fault-tolerant vector control method, the motor can suppress the thrust ripple of the motor under the condition of a phase short-circuit fault-tolerant operation; more importantly, the dynamic property, the steady-state performance and the properties in a normal state are consistent; the switching frequency of a voltage source inverter is constant; a CPU is low in overhead; and a natural coordinate system only needs to counterclockwise rotate a certain angle in any phase short-circuit fault, so that the motor fault-tolerant operation can be achieved.

Owner:JIANGSU UNIV

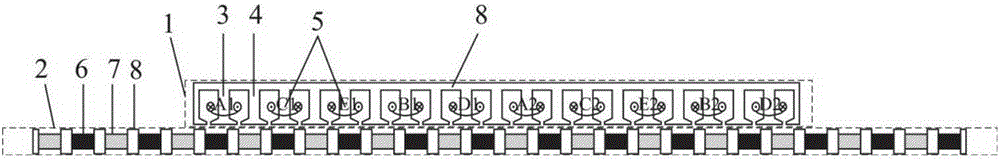

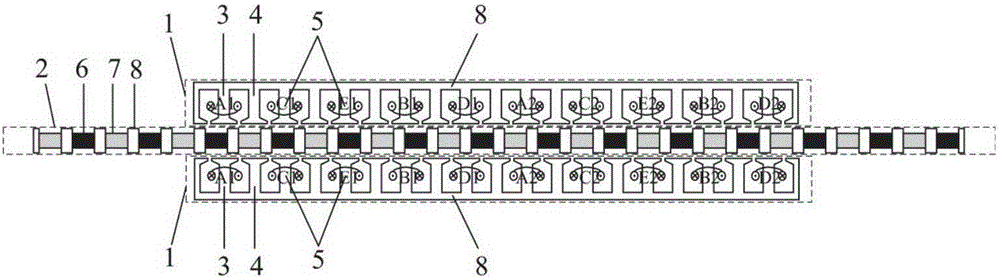

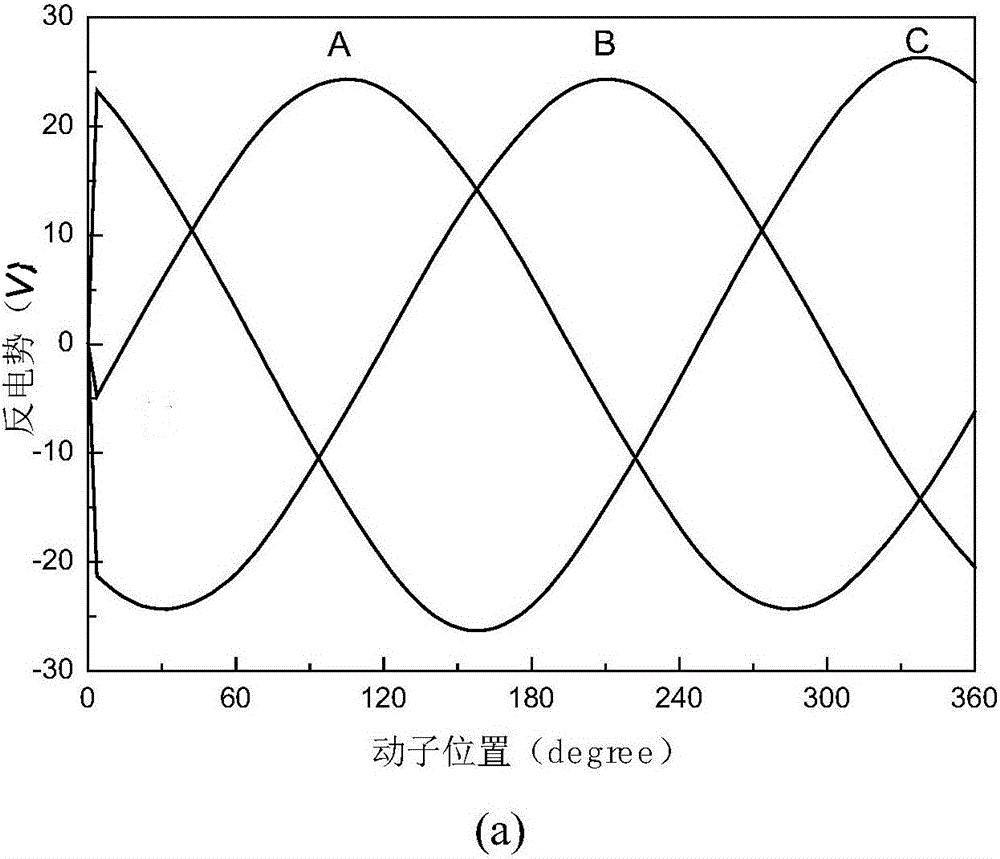

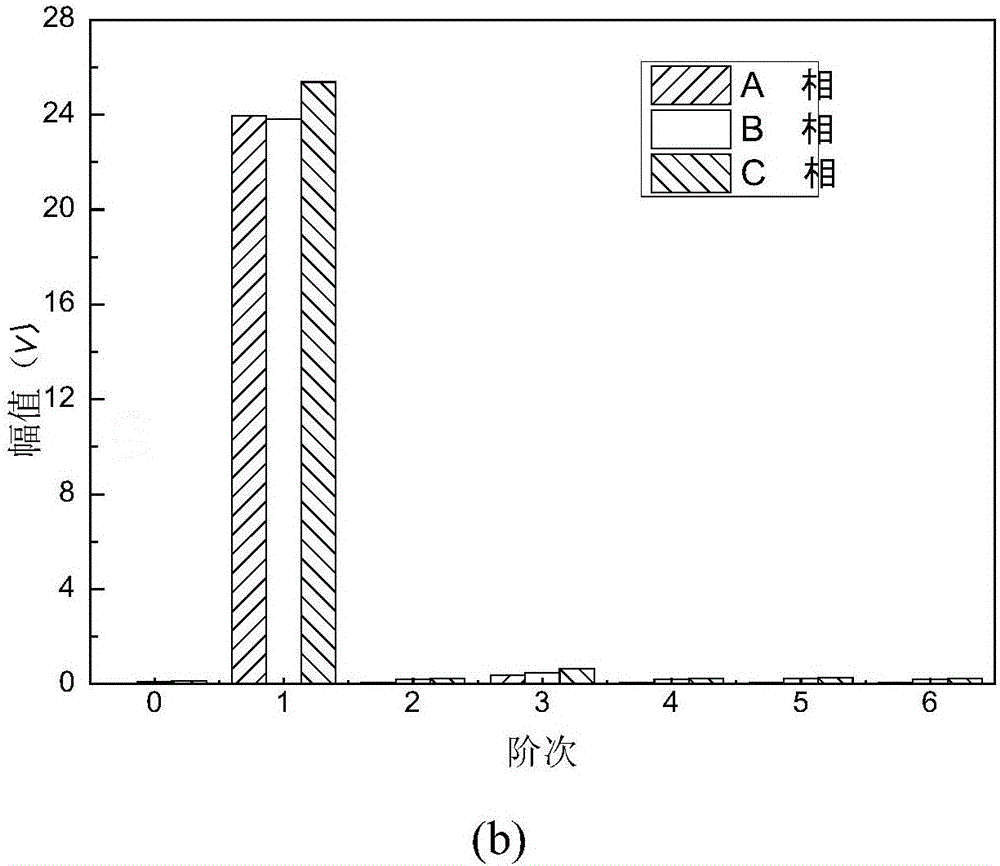

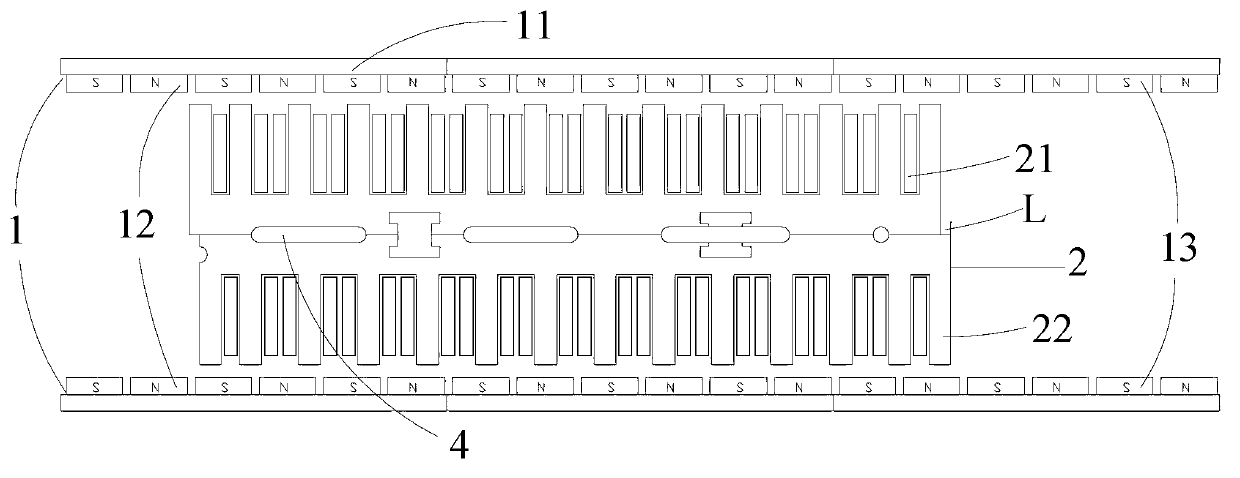

Modular vernier permanent magnetic linear motor based on Halbach permanent magnetic structure

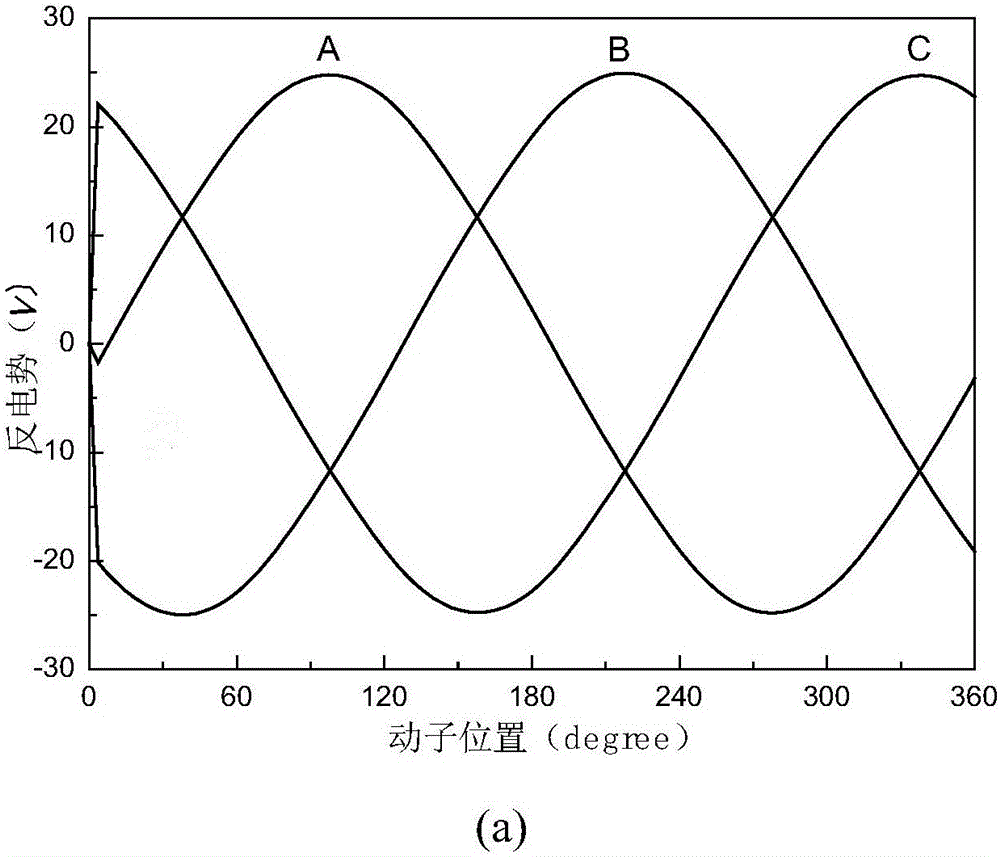

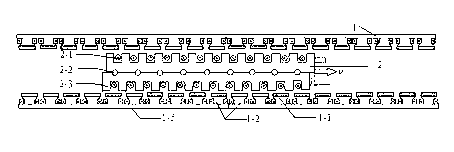

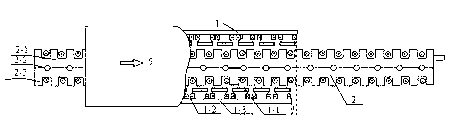

ActiveCN106411096AReduce thrust fluctuationImprove the unbalanced three-phase potential problemPropulsion systemsMagnetic barrierPhase difference

The invention discloses a modular vernier permanent magnetic linear motor based on a Halbach permanent magnetic structure. The modular vernier permanent magnetic linear motor comprises 3k mover modules and one stator, there are air gaps between the two, the stator comprises a permanent magnet which is provided with a stator core, is surface-mounted to the stator core and has a Halbach array structure, armature windings are arranged in grooves of the mover modules, positions of each phase of the armature windings in the different mover modules are different, positions of axles of the same phase of the armature windings in each module correspondingly relative to the stator permanent magnet are maintained consistent, each module can work as an individual complete vernier permanent magnetic linear motor, two adjacent mover modules are connected by use of a magnetic barrier made of a non-magnetic material, the different mover modules respectively generate push forces with certain phase differences with the stator, through modular combination of movers and variation of positions of the windings in the different modules, each phase of the windings is enabled to have a completely symmetric structure in an overall view, and thus the effect of offsetting and weakening thrust fluctuations is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

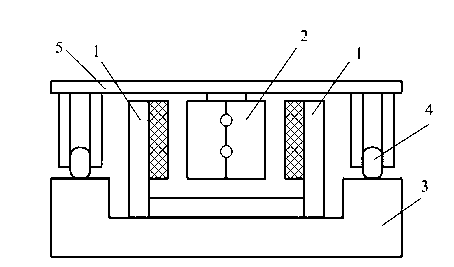

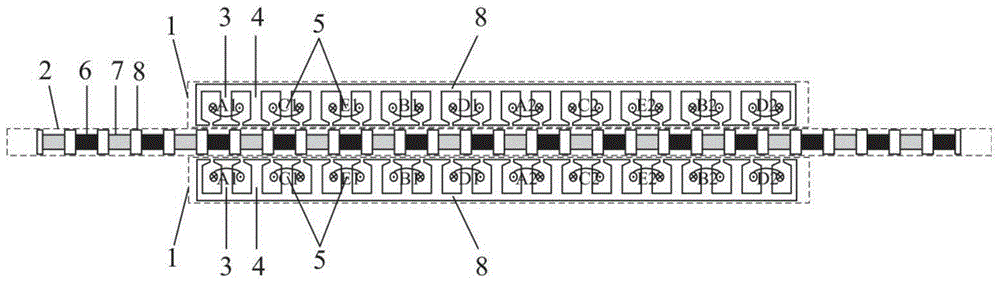

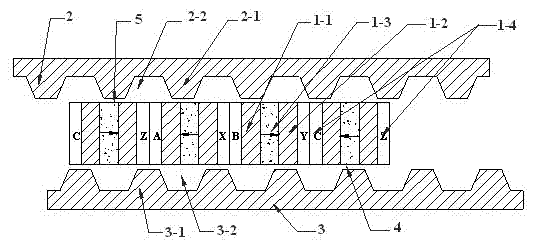

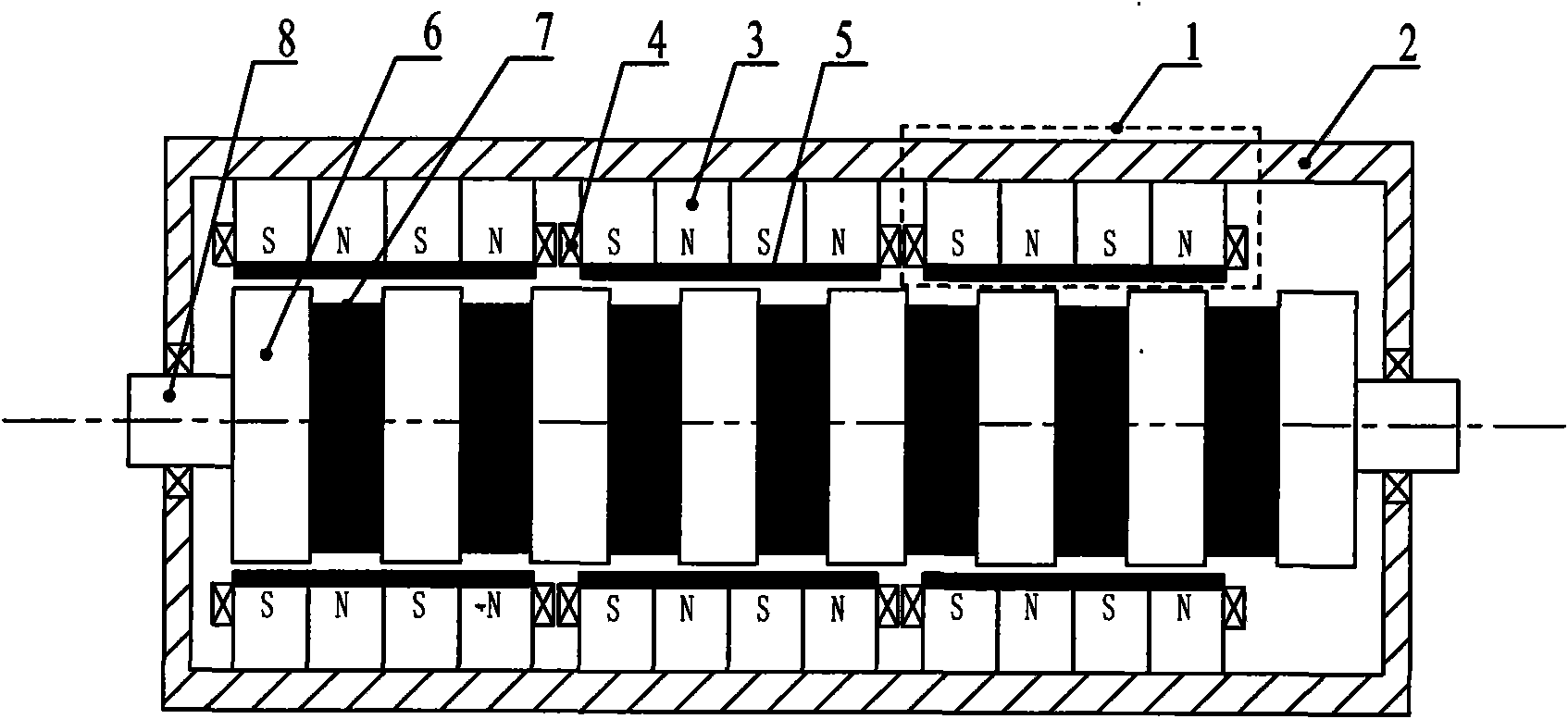

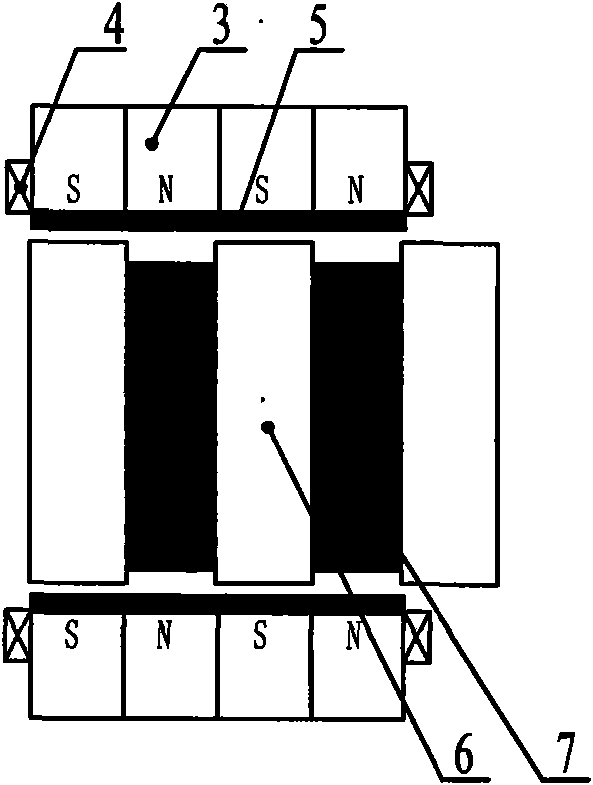

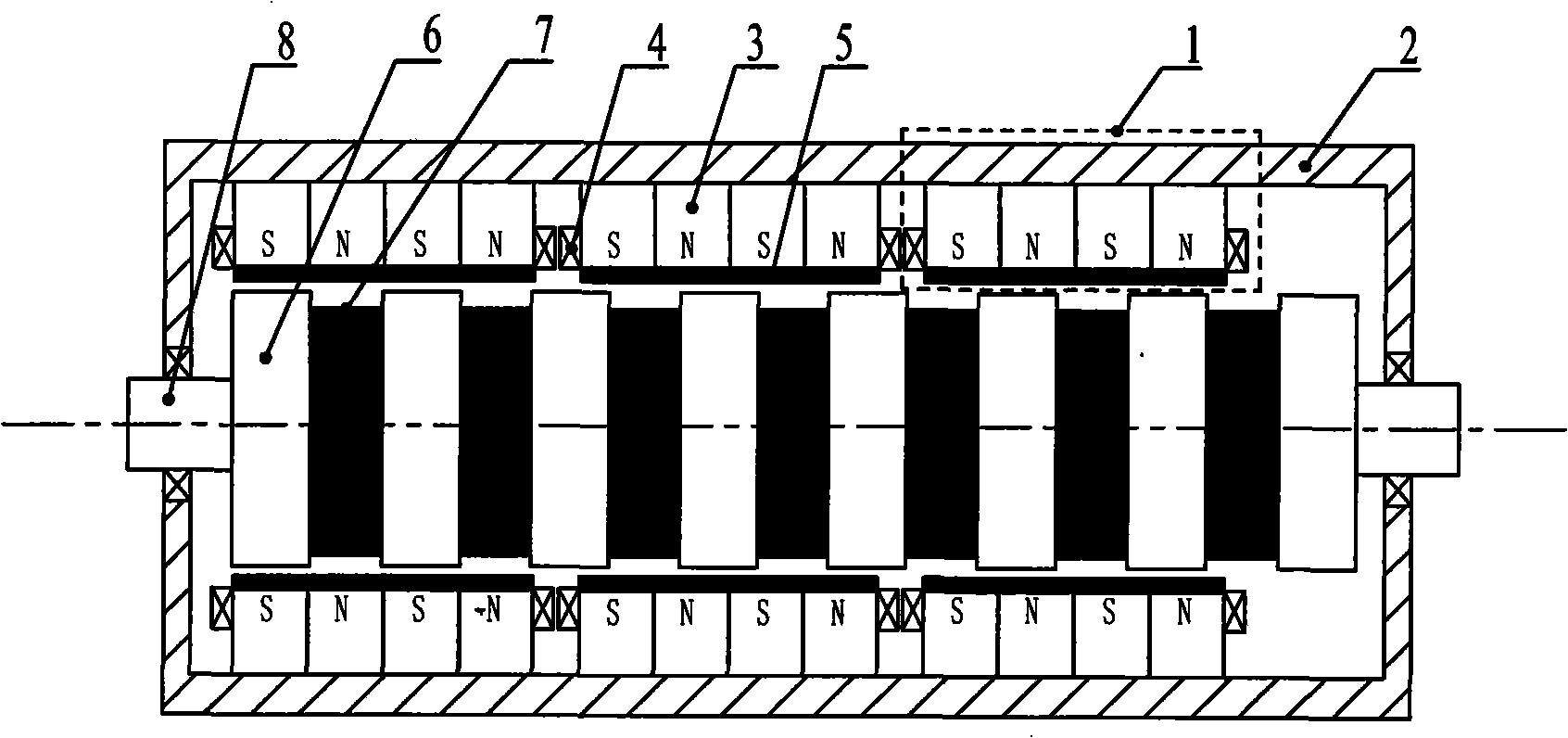

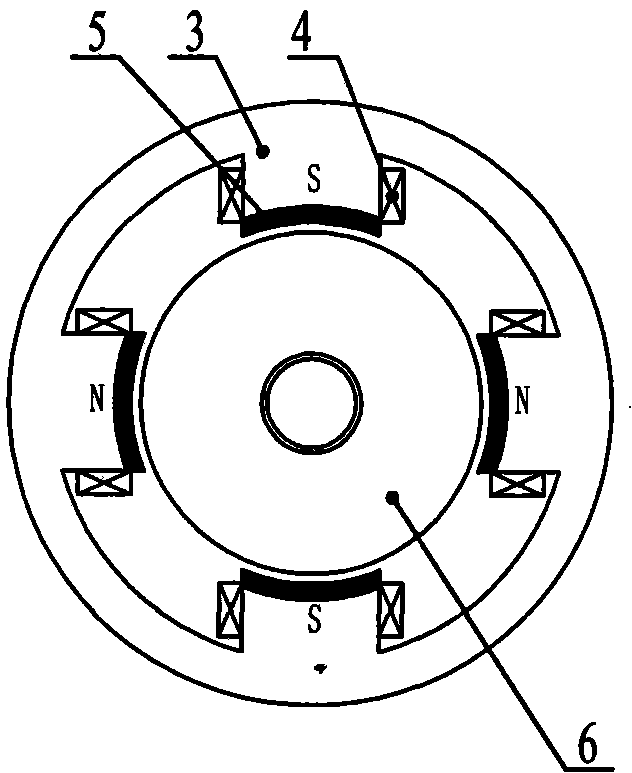

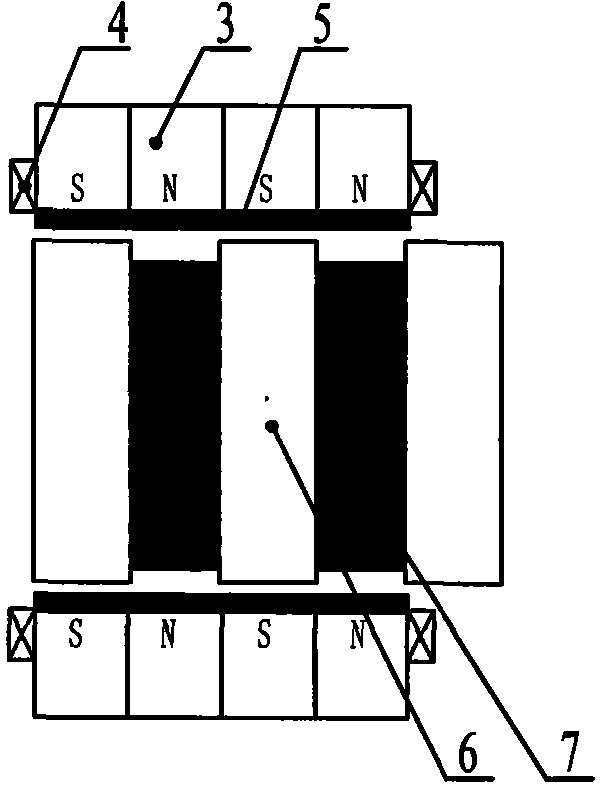

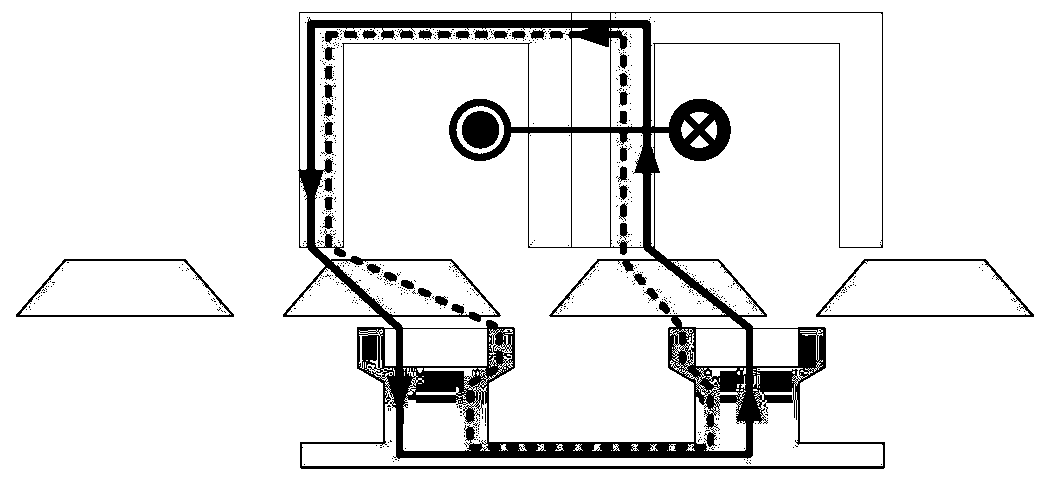

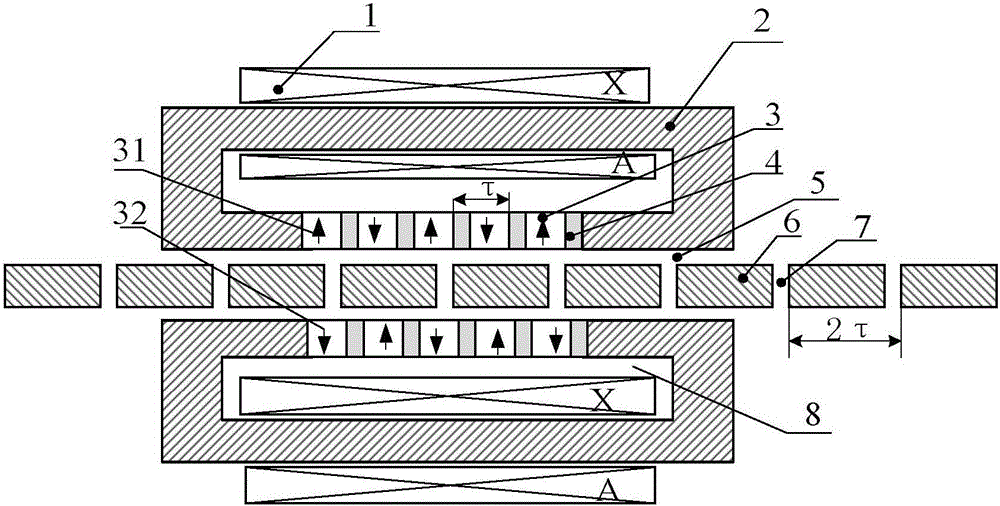

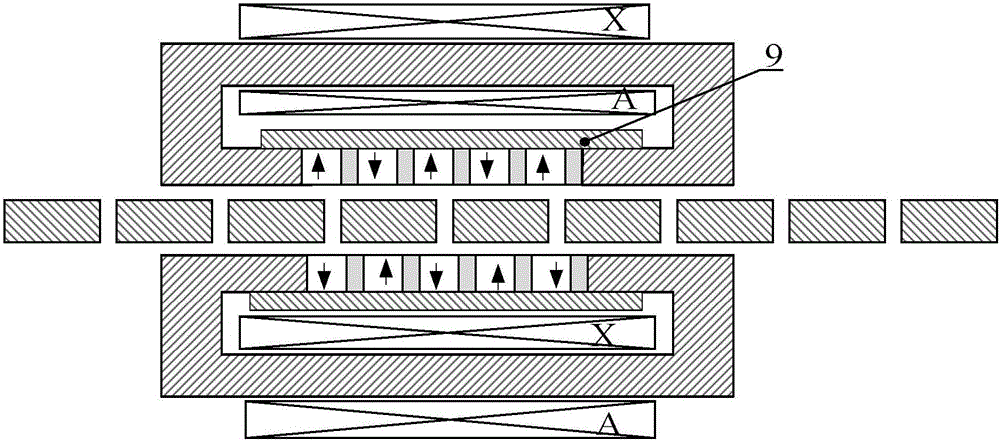

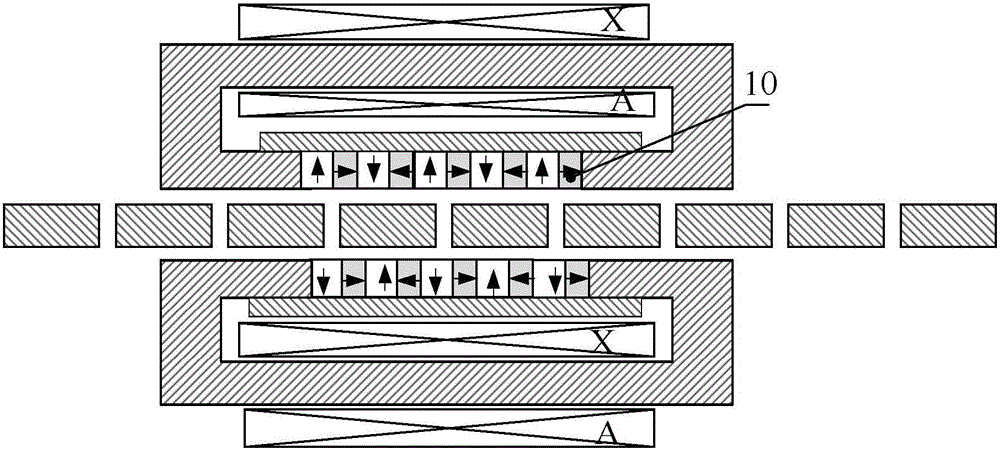

Bilateral mixed excitation type high-thrust linear synchronous motor

InactiveCN103178687AReduce edge effectsIncrease thrust densityPropulsion systemsSynchronous motorMagnetic poles

The invention discloses a bilateral mixed excitation type high-thrust linear synchronous motor. The bilateral mixed excitation type high-thrust linear synchronous motor comprises magnetic poles and armatures, wherein the armatures are arranged in two rows in a back-to-back manner; and the magnetic poles are arranged at two sides of the armatures. Each magnetic pole comprises a tooth-shaped back iron, an adjustable DC (Direct Current) exciting winding arranged between teeth of each back iron in an embedded manner, and a permanent magnet arranged on the teeth of each back iron. Each armature comprises two tooth-shaped armature iron cores which are arranged back to back; the back part of each armature iron core is provided with a cooling pipe groove; an armature winding is arranged between the teeth of the armature iron cores; the cooling pipe groove at the backside of each armature iron core is internally provided with a transverse cooling pipeline or a lengthways cooling pipeline. Each magnetic pole of the invention is provided with the permanent magnet and an electric exciting winding; an air-gap magnetic field is provided through the adoption of a mixed excitation way; and each armature is provided with an armature winding, the armature iron cores and cooling pipelines. As a double-row type staggered assembling structure is adopted by the armatures in the invention, the side end effect is reduced; as a built-in cooling structure is adopted by the armatures adopt, thrust density is improved; and as the mixed excitation structure is adopted by the magnetic poles, the air-gap magnetic field is flexible and adjustable.

Owner:TONGJI UNIV

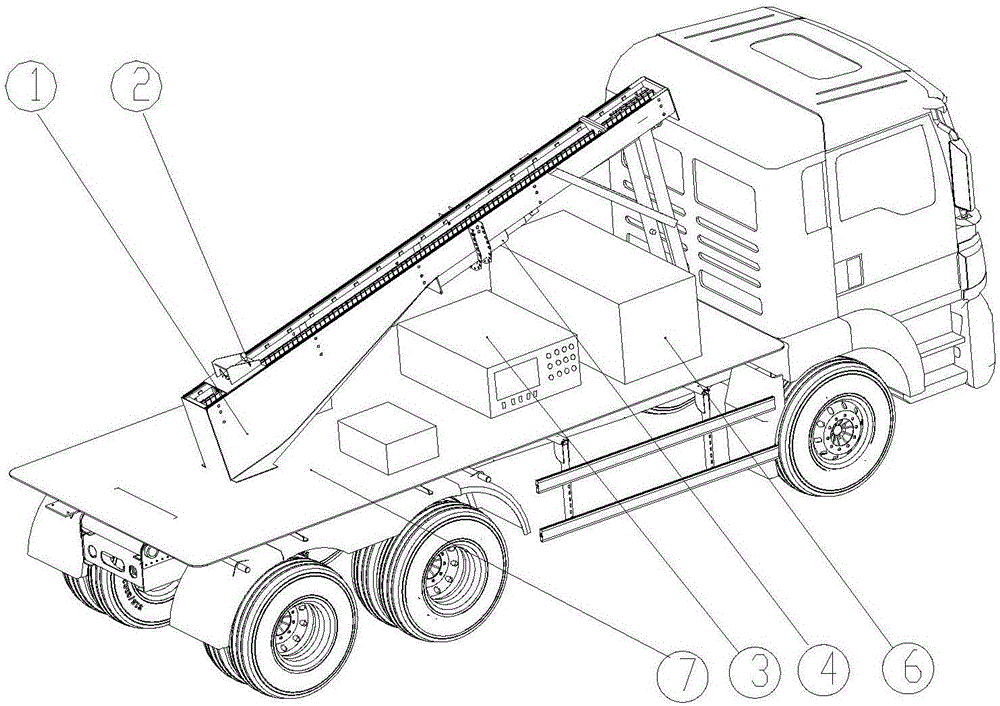

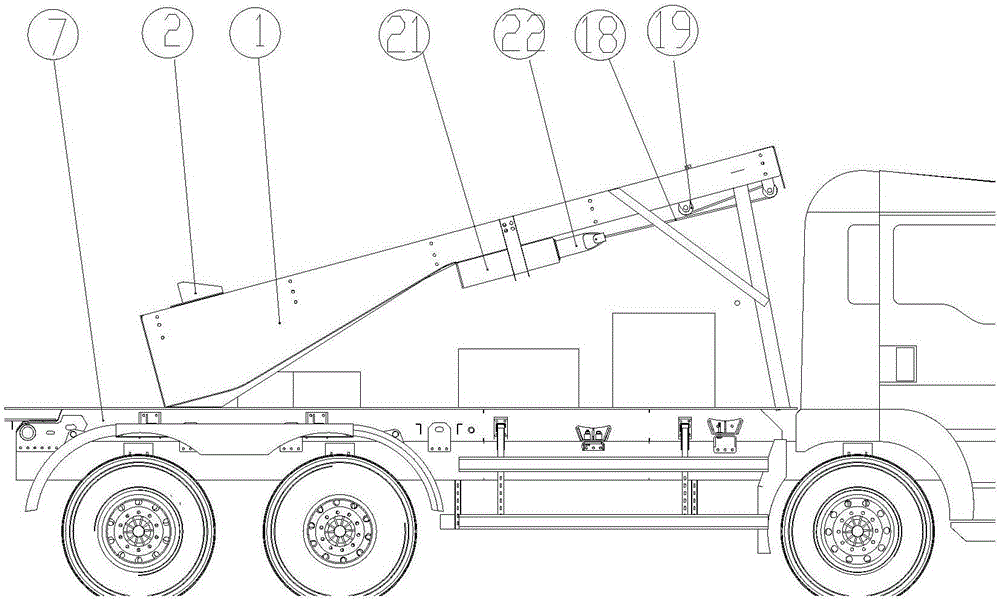

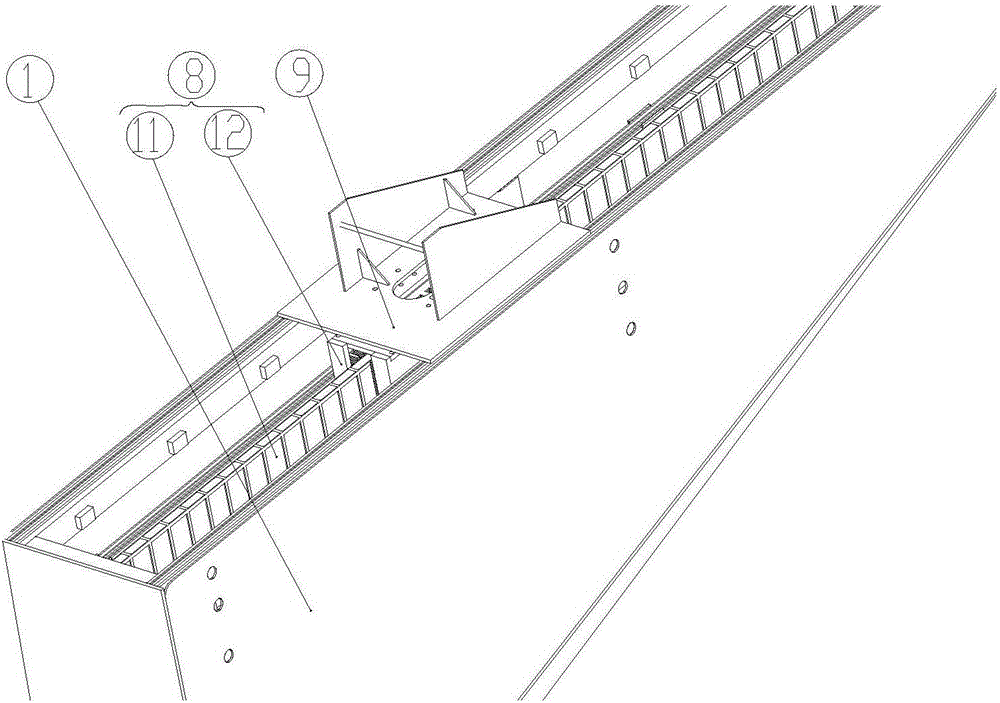

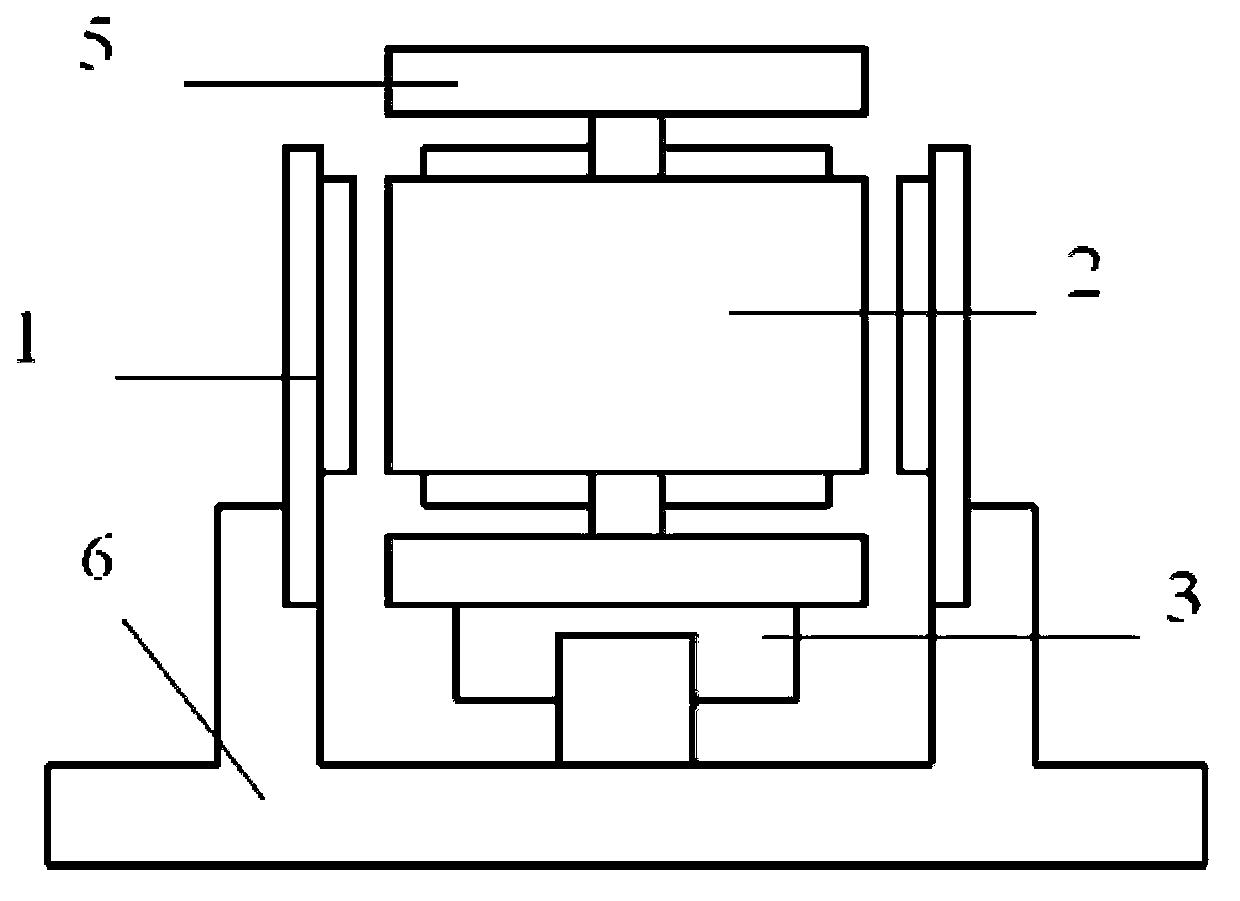

Permanent magnet linear motor type electromagnetic catapult for unmanned aerial vehicle

ActiveCN106394924AImprove securityImprove concealmentLaunching/towing gearControl systemPermanent magnet linear motor

The invention provides a permanent magnet linear motor type electromagnetic catapult for an unmanned aerial vehicle. The permanent magnet linear motor type electromagnetic catapult comprises a catapulting rack, an unmanned aerial vehicle supporting and catapulting platform, a power supply system, a brake system and a control system. The permanent magnet linear motor type electromagnetic catapult is characterized in that the catapulting rack can be carried on transport equipment and is provided with linear slide rails, the unmanned aerial vehicle supporting and catapulting platform is supported on the linear slide rails of the catapulting rack through the two sides of the unmanned aerial vehicle supporting and catapulting platform, the catapulting rack is provided with the brake system, the unmanned aerial vehicle is carried on the unmanned aerial vehicle supporting and catapulting platform which can be driven by a catapulting motor to accelerate along the linear slide rails, the catapulting motor is a permanent magnetic linear motor, and when the unmanned aerial vehicle reaches the speed needed for taking-off, the unmanned aerial vehicle supporting and catapulting platform is braked under the damping effect of the brake system, and the unmanned aerial vehicle flies out inertially. The permanent magnet linear motor type electromagnetic catapult overcomes the problems that in the prior art, an unmanned aerial vehicle is poor in maneuverability, low in reliability, poor in concealment and low in efficiency during catapulting.

Owner:NAT UNIV OF DEFENSE TECH

Embedded type mixing magnetic material fault-tolerant cylindrical linear motor

The invention discloses an embedded type mixing magnetic material fault-tolerant cylindrical linear motor which comprises primary bodies and secondary bodies. The length of each primary body is smaller than that of each secondary body. An air gap is reserved between each primary body and the corresponding secondary body. Each primary body comprises armature teeth, fault-tolerant teeth and a coil winding. The 2*m armature teeth and the 2*m fault-tolerant teeth are uniformly distributed on each primary body, wherein m is the phase number of the motor and is larger than or equal to three; the armature teeth and the fault-tolerant teeth are arranged at intervals in a staggered mode. Only one set of disc-shaped coil windings are placed into an armature tooth groove of each primary body. No windings are arranged on the fault-tolerant teeth. The secondary bodies of the motor are made of mixing magnetic materials, a part of ferrite is used for replacing a part of rare earth permanent magnets to form four different mixing magnetic material structures, on one hand, the quantity of the adopted rare earth permanent magnets is greatly reduced, and the cost of the motor is reduced; on the other hand, as the magnetic energy product of the permanent magnets is reduced, the eddy-current loss of the motor is reduced greatly, and efficiency of the motor is improved.

Owner:JIANGSU UNIV

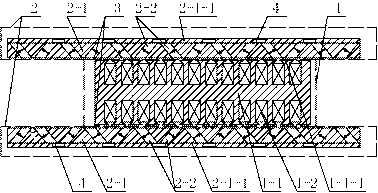

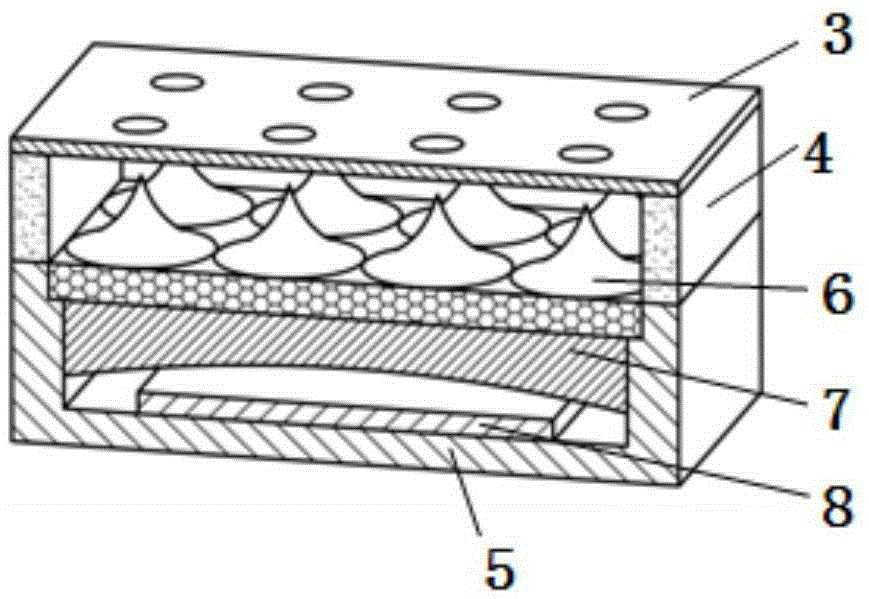

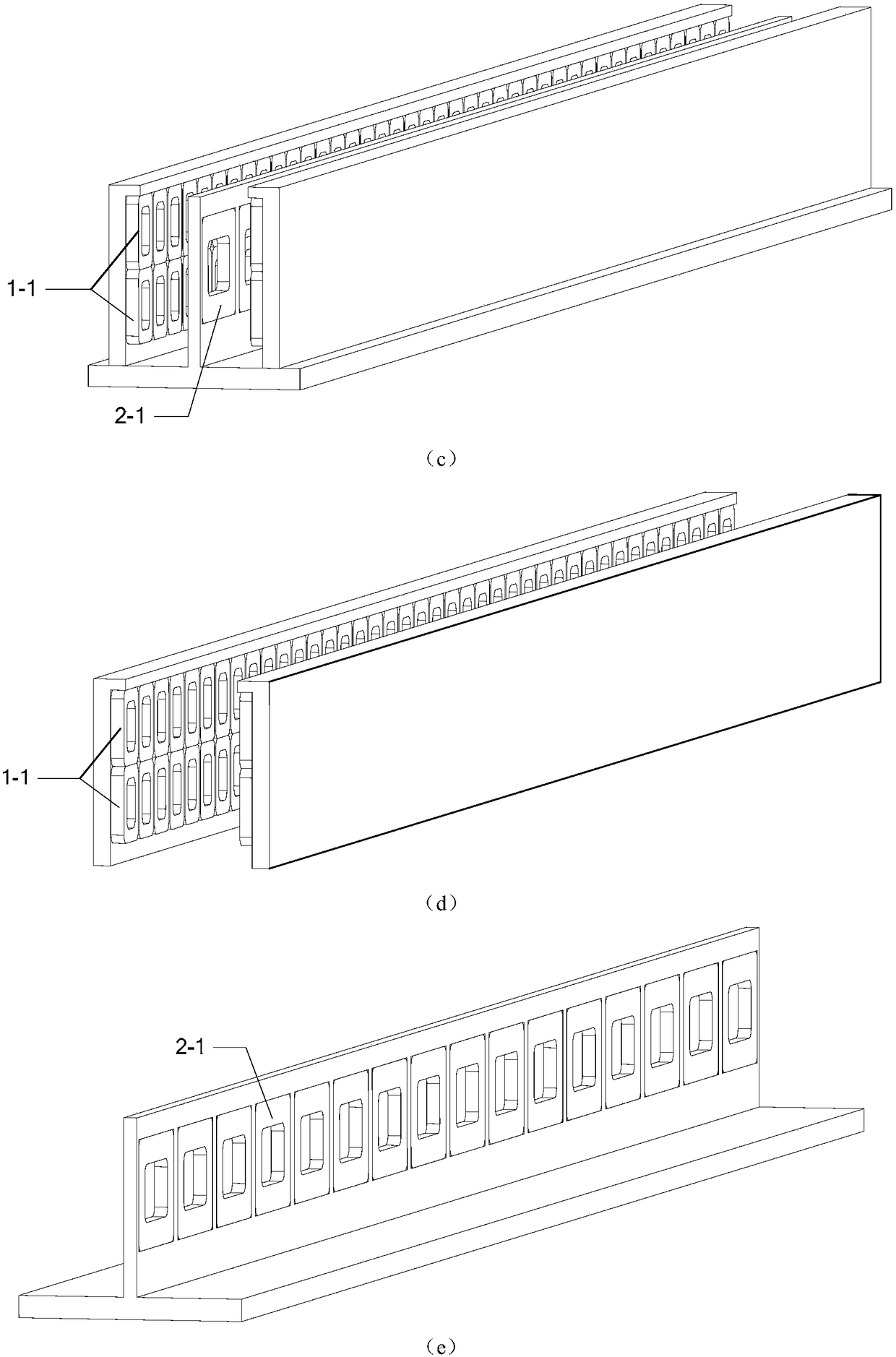

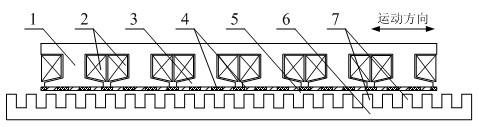

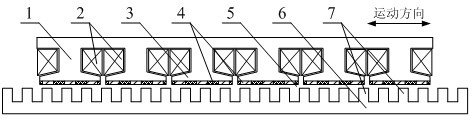

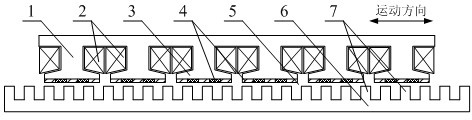

Concentrated-winding multi-segment permanent magnet synchronous linear motor

InactiveCN101777821AIncrease thrust densityReduce lossPropulsion systemsWindings conductor shape/form/constructionPermanent magnet synchronous motorPermanent magnet synchronous generator

The invention discloses a concentrated-winding multi-segment permanent magnet synchronous linear motor, which belongs to the technical field of liner motors and solves the problem of low system operation efficiency of the traditional primary dynamic magnetic steel type permanent magnet synchronous linear motor of which the rotor windings are electrified at the same time. In the concentrated-winding multi-segment permanent magnet synchronous linear motor, an armature is arranged in the middle of the upper surface of a machine seat; a pair of guide rails is arranged on two sides of the armature on the upper surface of the machine seat; the pair of the guide rails are in sliding fit connection with a pair of sliding blocks which are fixedly connected with a rotor body; a plurality of pairs of permanent magnets are arranged on the inner surface of the rotor body along a motion direction in one row and a plurality of columns; air gaps are reserved between the permanent magnets and the armature; a plurality of segments of armature cores are sequentially and closely connected in the motion direction of the rotor body; the armature cores adopt a tooth slot structure; a segment of armature winding is embedded in the tooth slot of each segment of armature core; each segment of armature winding is a concentrated winding; and two adjacent segments of armature windings are overlapped to be embedded on the end part of each segment of armature core, wherein the length of the overlapped area is equal to the pitch, which is 1, of the windings. The motor is applicable to heavy-load propulsion systems.

Owner:HARBIN INST OF TECH

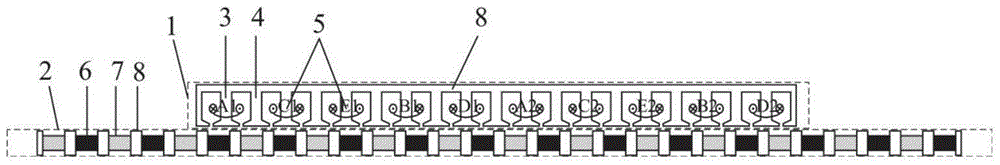

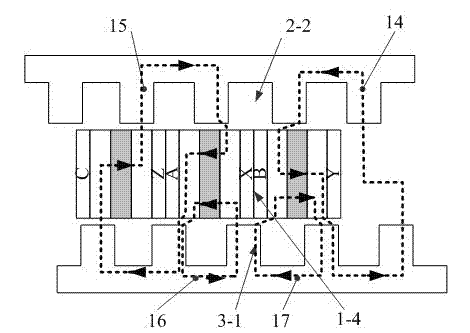

Double-edge staggered teeth flat type flux switching permanent magnet linear motor

InactiveCN103296857AIncrease thrust densityIncrease profitReciprocating/oscillating/vibrating magnetic circuit partsMagnetic circuit stationary partsSecondary toothMagnet

The invention provides a double-edge staggered teeth flat type flux switching permanent magnet linear motor and belongs to the technical field of motors. The double-edge staggered teeth flat type flux switching permanent magnet linear motor comprises a primary part and two secondary parts. In the primary part, a permanent magnet body is arranged between two magnet guiding primary iron core teeth to form a sandwich structure, magnetizing directions of the permanent magnet bodies on two adjacent sandwich structures are opposite, through grooves are formed between the sandwich structures, and armature windings are arranged in the through grooves. The two secondary parts are arranged on two sides of the primary part and are both magnet guiding iron cores of tooth socket structures. Secondary teeth on one side of the primary part and opposite secondary teeth on the other side of the primary part are staggered in position to form a structure with teeth of one secondary part corresponding to grooves of the other secondary part. During work of the double-edge staggered teeth flat type flux switching permanent magnet linear motor, along with changing of the relative positions of the primary part and the secondary parts on two sides, a flux changes the path, and the maximum flux with a winding turn chain in each groove is generated by three adjacent permanent magnets. The double-edge staggered teeth flat type flux switching permanent magnet linear motor can improve utilization rate of the permanent magnet bodies, improves thrust density and removes one-side magnetic pull.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Anode and cold air thruster combined air supply cusped magnetic field plasma thruster

The invention provides an anode and cold air thruster combined air supply cusped magnetic field plasma thruster and belongs to the field of the space technology and low-temperature plasma. The plasmathruster is provided for solving the problem that an existing cusped magnetic field thruster can hardly generate the thrust less than 100 micronewtons. The plasma thruster comprises a discharge channel, a magnetic conducting ring, a first permanent magnet, an anode, a magnetic conducting ring heat conducting plate, a second permanent magnet and a shell. The anode is arranged at the bottom of the discharge channel. The two permanent magnets are sequentially arranged between the outer sidewall of the discharge channel and the shell from the bottom of a discharge outlet. The magnetic conducting ring and the magnetic conducting ring heat conducting plate are arranged between the two permanent magnets. A gap is reserved between the two permanent magnets and the outer sidewall of the discharge channel. The plasma thruster further comprises a cold air thruster. The anode is of a hollow structure. The cold air thruster is arranged in an inner cavity of the anode. The cold air thruster can operate independently and is used for generating the micronewton-scale thrust. The discharge channel is a variable cross-section channel. The radium of the channel gradually decreases from the discharge outlet to the bottom. The longitudinal section of the sidewall of the discharge channel is a right trapezoid.

Owner:HARBIN INST OF TECH

Built-in permanent magnet dual-side flat plate type linear motor

ActiveCN101741214AIncrease effective lengthIncrease magnetic densityPropulsion systemsSurface mountingPermanent magnet linear motor

The invention relates to a built-in permanent magnet dual-side flat plate type linear motor, which belongs to the technical field of motors, and solves the problems of low air gap flux density and low thrust density of the conventional surface-mount permanent magnet dual-side flat plate type linear motor. A secondary pole of the built-in permanent magnet dual-side flat plate linear motor comprises two flat plate type excitation components, a primary pole is positioned between the two flat plate type excitation components of the secondary pole, each secondary iron core is provided with a plurality of pairs of grooves on the air gap side, each permanent magnet is closely matched with the groove in which the permanent magnet is positioned, and two permanent magnets of each pair of grooves and the iron core between the grooves form a magnetic pole; on the lognitudinal cross section of the flat plate type excitation components, the cross section of each groove is a parallelogram, the groove bottoms of the two grooves of each pair of grooves are close to each other and form a V-shape, and the range of the included angle Theta of two adjacent sides of the two grooves in each pair of grooves is not less than 30 degrees and not more than 150 degrees; and the magnetizing direction of each permanent magnet is vertical to the bevel edge of the parallelogram, the magnetizing directions of the two permanent magnet in each magnetic pole are in the same direction or in the opposite directions, and the polarities of the adjacent two magnetic poles are opposite. The invention is a linear motor.

Owner:HARBIN INST OF TECH

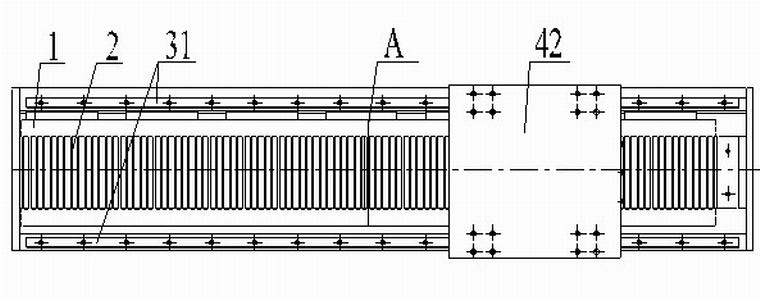

Liquid-cooling iron-coreless permanent-magnet linear motor

InactiveCN104967276AImprove cooling effectImprove output performanceCooling/ventillation arrangementPropulsion systemsFree coolingPermanent magnet synchronous motor

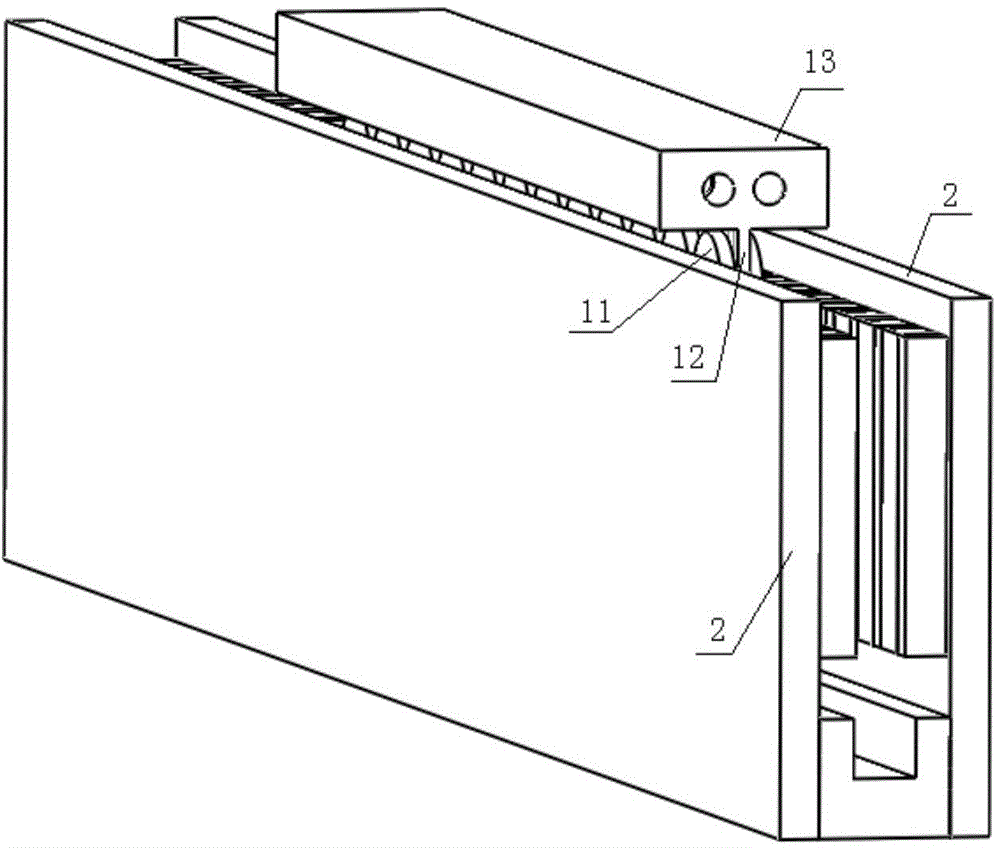

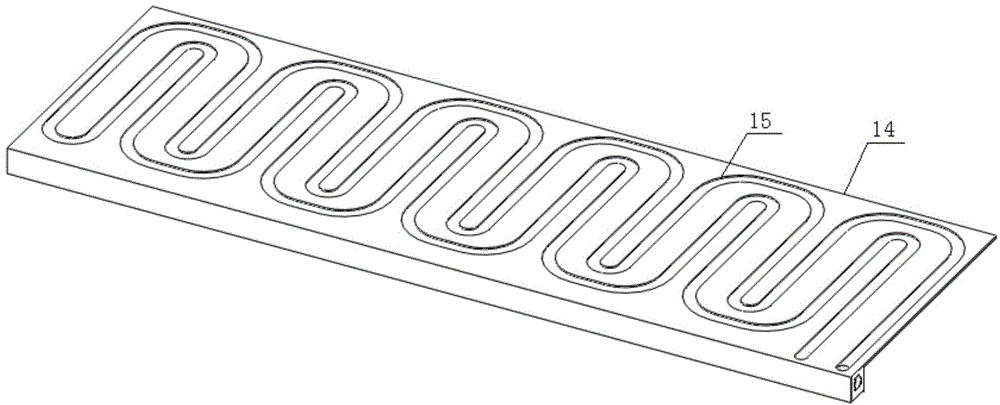

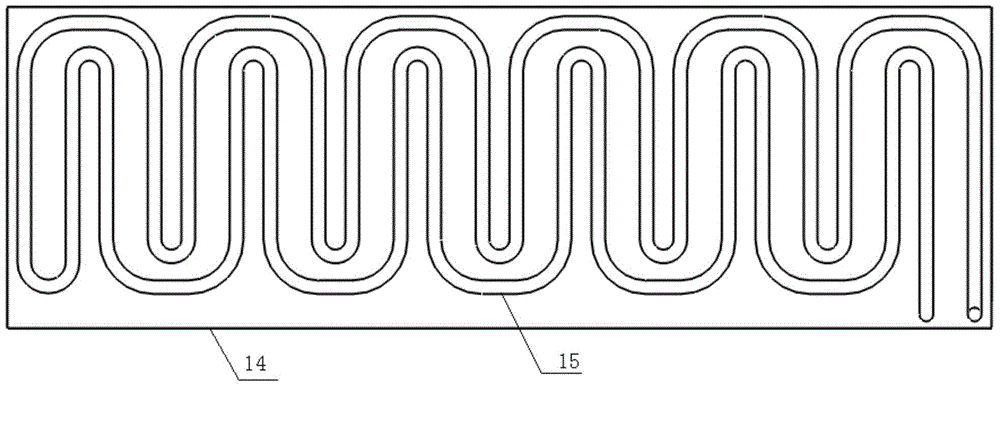

A liquid-cooling iron-coreless permanent-magnet linear motor belongs to the motor field. A traditional bilateral-iron-coreless-structure linear permanent-magnet synchronous motor adopts natural cooling so that a continuous output capability of the motor is poor; a rated thrust is small and a primary loss is large. By using the motor of the invention, the above problems are solved. A primary comprises a primary winding, a fixing plate and a thrust output plate. The primary winding is formed by 2km runway coils, wherein the k is a positive integer and the m is a phase number of the motor. The fixing plate is in a panel shape and a cooling fluid channel is arranged in the fixing plate. The 2km coils of the primary winding are symmetrically arranged on two sides of the fixing plate. The thrust output plate is fixedly connected to one end of the fixing plate along a motion direction. A secondary is a bilateral structure. Each edge secondary comprises a secondary iron core and a permanent magnet. The two edge secondaries are arranged on two sides of the primary and form a series magnetic circuit. Two air gaps form between the primary and the secondary. The continuous output capability of the motor is high, the rated thrust is large and the primary loss is less.

Owner:HARBIN INST OF TECH

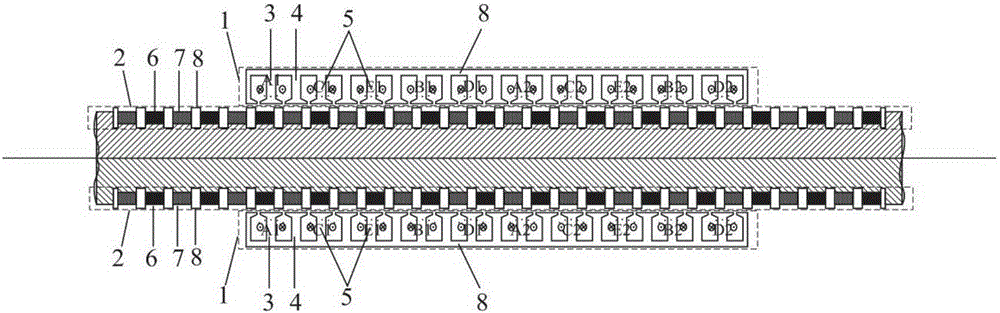

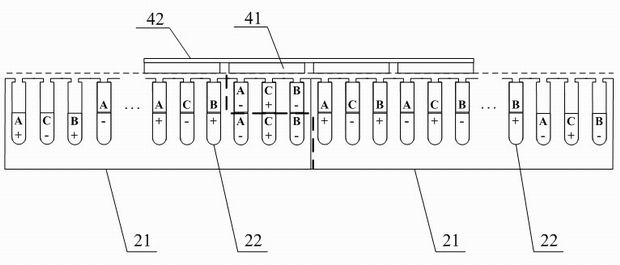

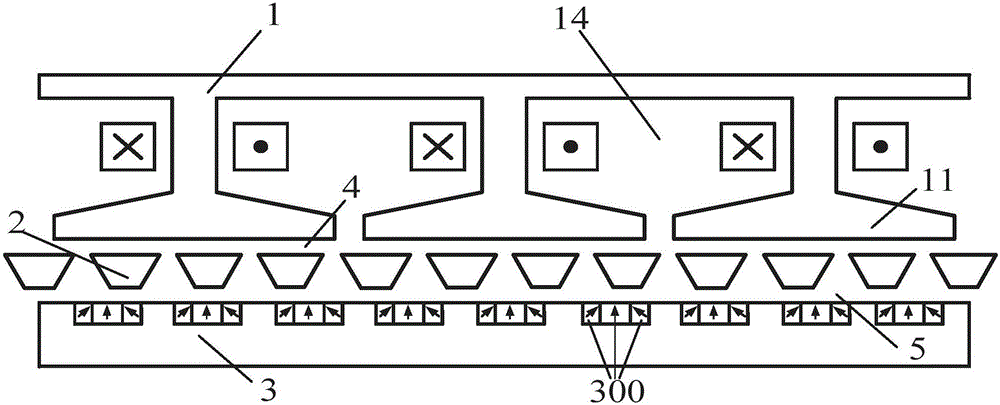

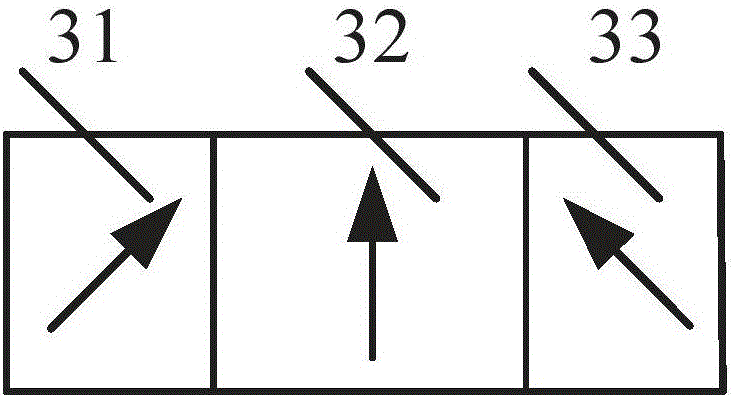

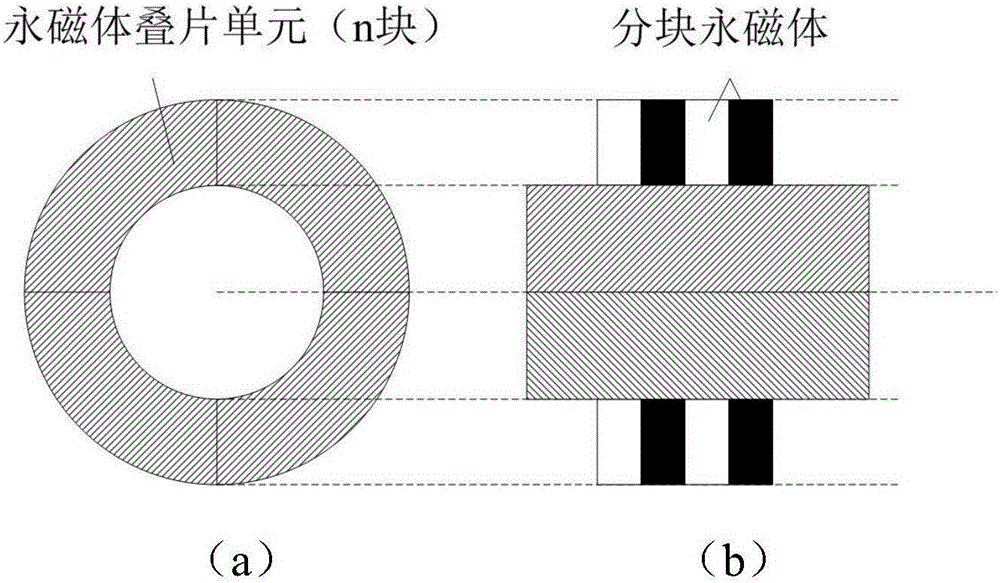

High-speed magnetic levitation linear electromagnetic propulsion system

ActiveCN108306477ARealize automatic suspensionImplementation orientationPropulsion systemsMagnetic holding devicesLevitationElectric machine

The invention relates to a high-speed magnetic levitation linear electromagnetic propulsion system and belongs to the electric motor field. The invention aims to solve the problem of serious magneticflux leakage due to the openness of a magnetic field and the problems of small levitation height, large levitation control difficulty and high requirements for lines of a normal conducting magnetic levitation technology due to large weight of vehicles. The high-speed magnetic levitation linear electromagnetic propulsion system of the invention a primary unit and a secondary unit; the primary unitis mounted on the ground, is of a bilateral structure and is arranged symmetrically on the left side and right side of the secondary unit; air gaps are left between the primary unit and secondary unit; the primary unit comprises a levitation guide primary unit and a propulsion primary unit; each primary structure at each side of the propulsion primary unit includes a primary coil and a primary substrate, wherein the primary coil is fixed at the inner side of the primary substrate; each primary structure at each side of the levitation guide primary unit includes an upper conductor plate and a lower conductor plate, wherein the upper conductor plate and the lower conductor plate are juxtaposed in a vertical direction; the propulsion primary unit is arranged between the upper conductor platesand the lower conductor plates; two columns of magnetic poles of the primary unit are respectively fixed at two sides of a skid; and each column of magnetic poles simultaneously serves as levitationguide magnetic poles and propulsion magnetic poles.

Owner:HARBIN INST OF TECH +1

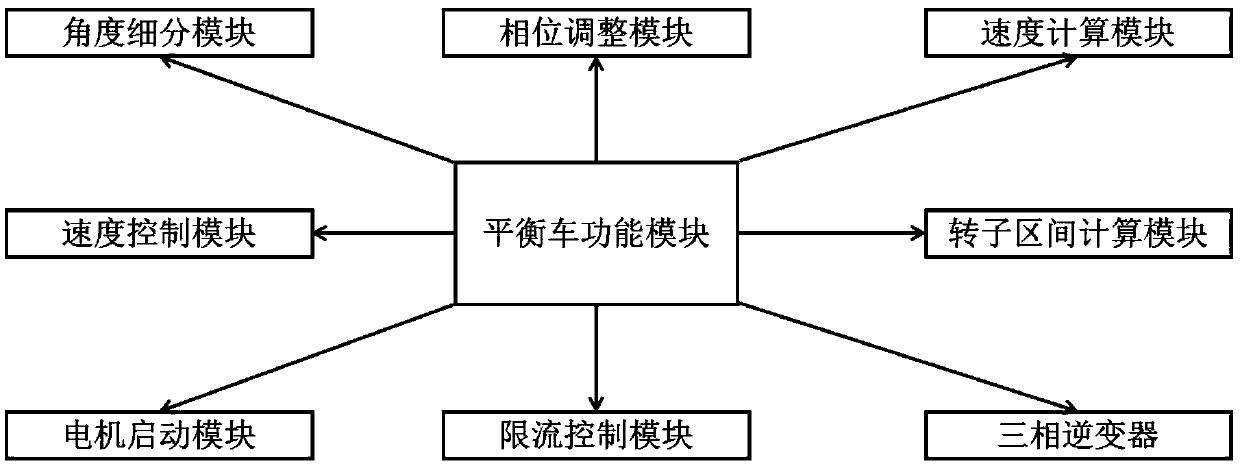

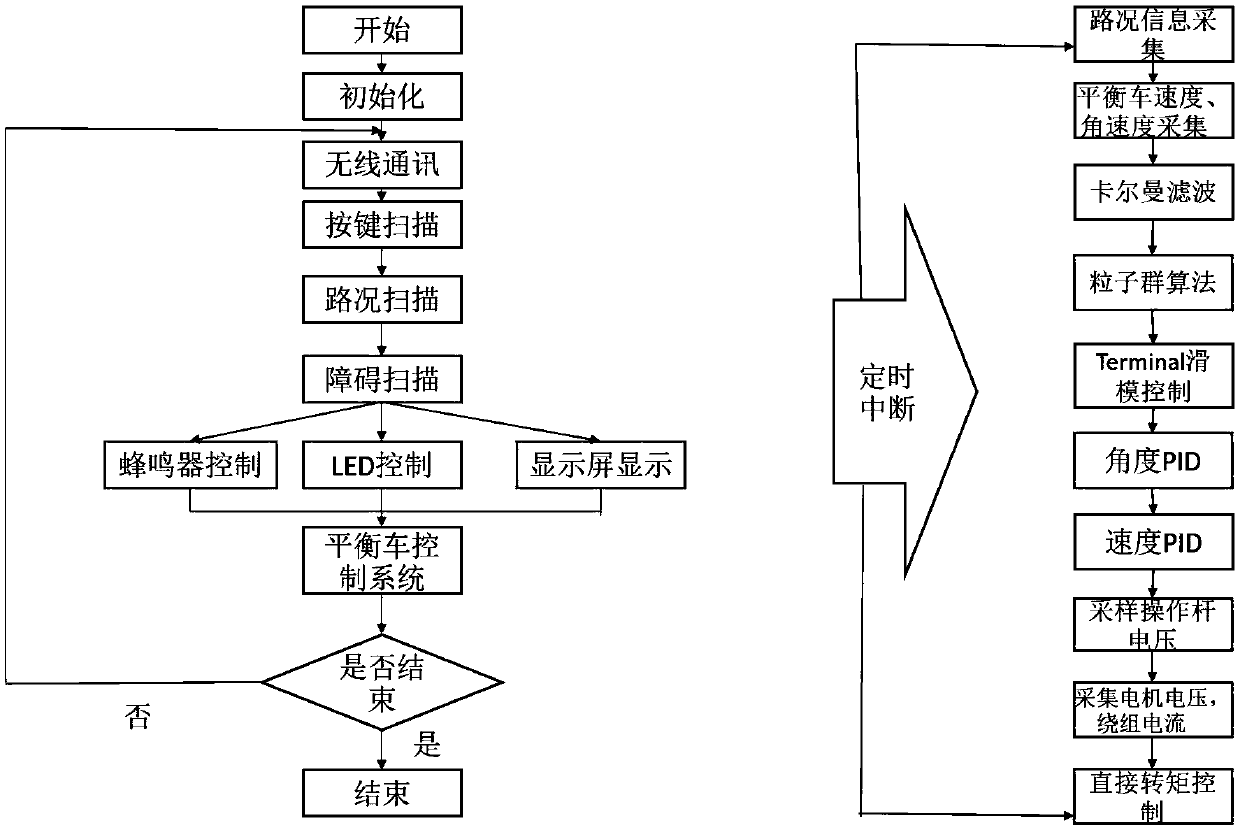

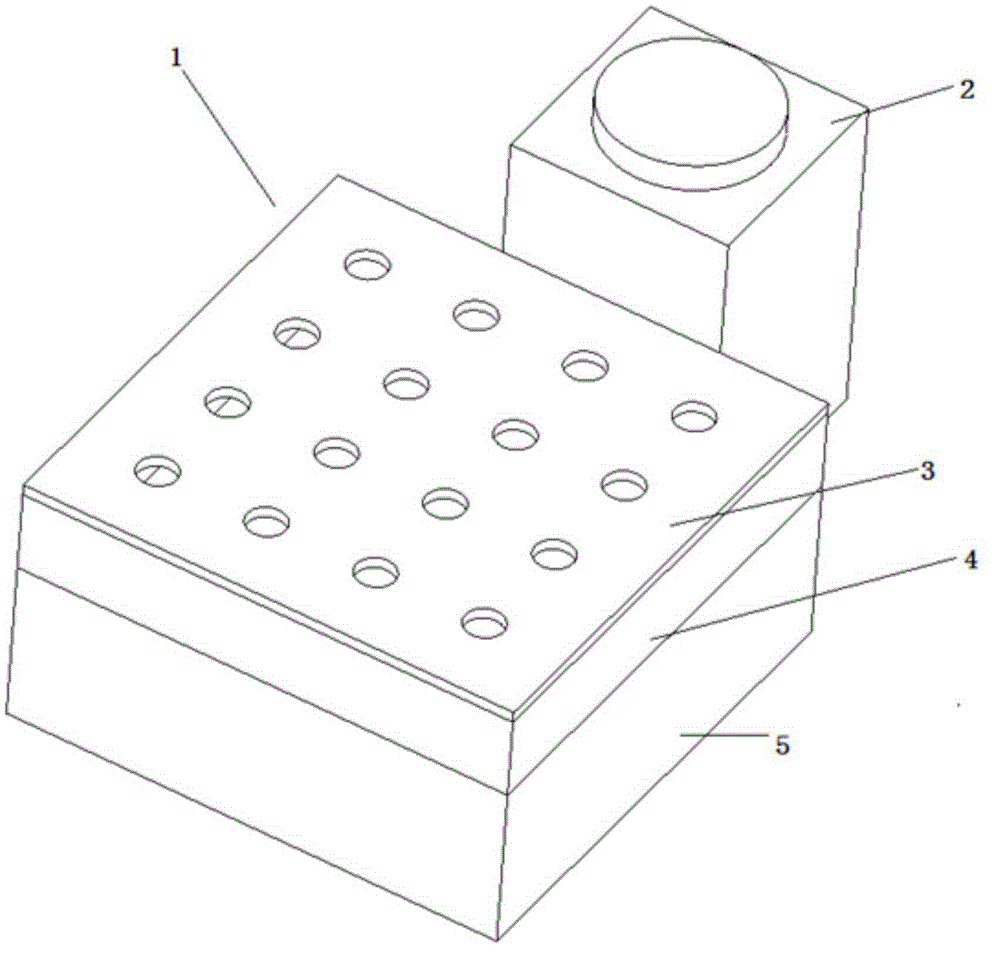

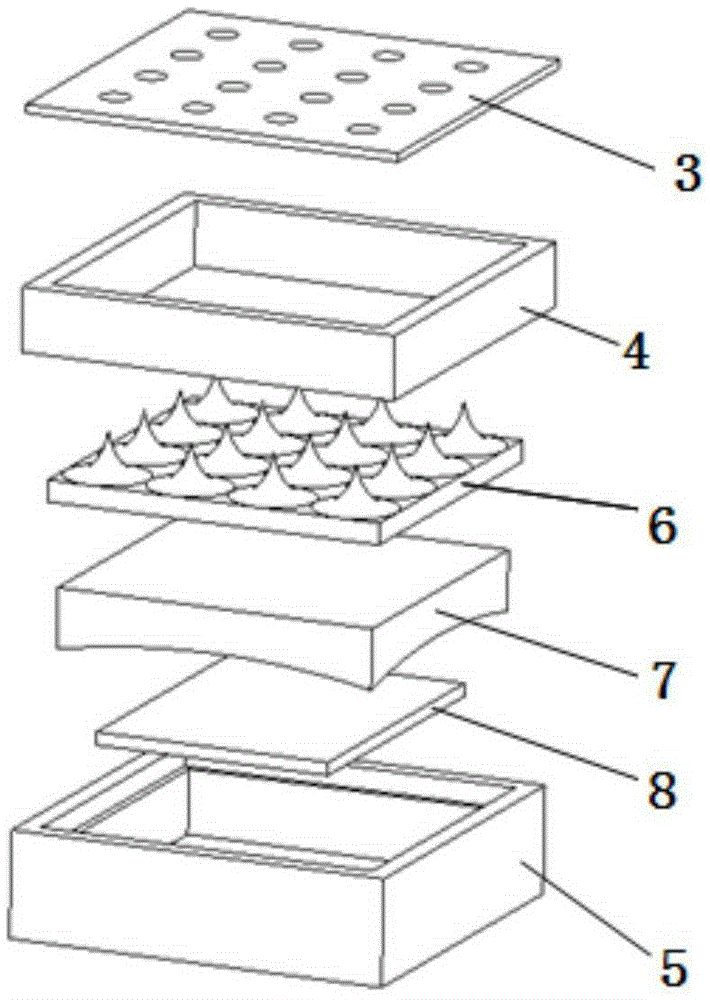

A system for balancing a vehicle and a control method thereof

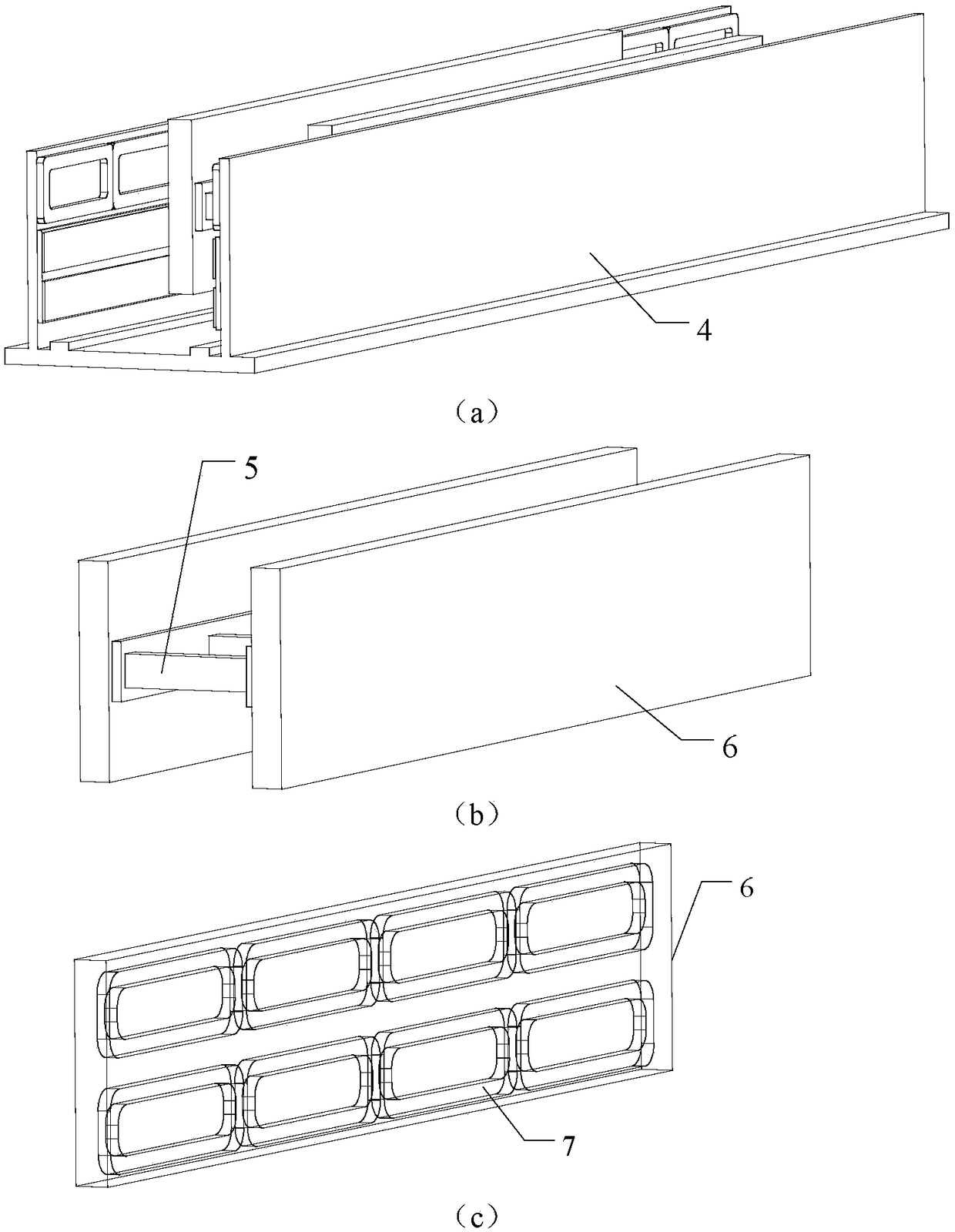

ActiveCN109067264AStrong battery lifeReduce loss rateTorque ripple controlMultiple motor speed/torque controlMathematical modelParticle swarm algorithm

The invention discloses a balancing vehicle system and a control method thereof. According to a difference equation model and a drift error model of attitude signals of the balancing vehicle system, astate equation of an extended Kalman filter and a mathematical model of a permanent magnet linear motor are established. A second-order dynamic Terminal sliding film is used to drive permanent magnetsynchronous motor. Particle Swarm Optimization (PSO) is used to optimize the parameters of tracking controller, synchronization controller, clearance elimination controller and switching function ina two-motor system. The invention realizes that the signal collected by the sensor of the balancing vehicle has large noise and zero drift error, and solves the problem of poor robustness and the problem that the Brush motor structure is complex, fault, maintenance workload, short life, commutation spark easy to produce electromagnetic interference, as well as in the balance of the car in the process of running jitter, deviation is too large, and low security.

Owner:汇佳网(天津)科技有限公司

Needle type porous material emitter array type mini-type field emission electric thruster

The invention discloses a needle type porous material emitter array type mini-type field emission electric thruster. The electric thruster comprises a neutralizer and a thruster main body which are connected with each other, wherein the thruster main body comprises a grid electrode, an insulating bracket and a propellant storage chamber which are sequentially matched and connected with one another from top to bottom; the insulating bracket is of a frame-type structure; an emitter array matched with the grid electrode is arranged inside the insulating bracket; a heater and the propellant which are matched with each other are arranged below the emitter array; the propellant and the heater are both positioned in the propellant storage chamber. The needle type porous material emitter array type mini-type field emission electric thruster disclosed by the invention is small in size, compact in structure, simple in structure, capable of being made into a chip-shaped mini-type thruster, applicable to mini-type satellites and especially applicable to mini-type satellites of which the weight is smaller than 10kg.

Owner:SHANGHAI INST OF SPACE PROPULSION

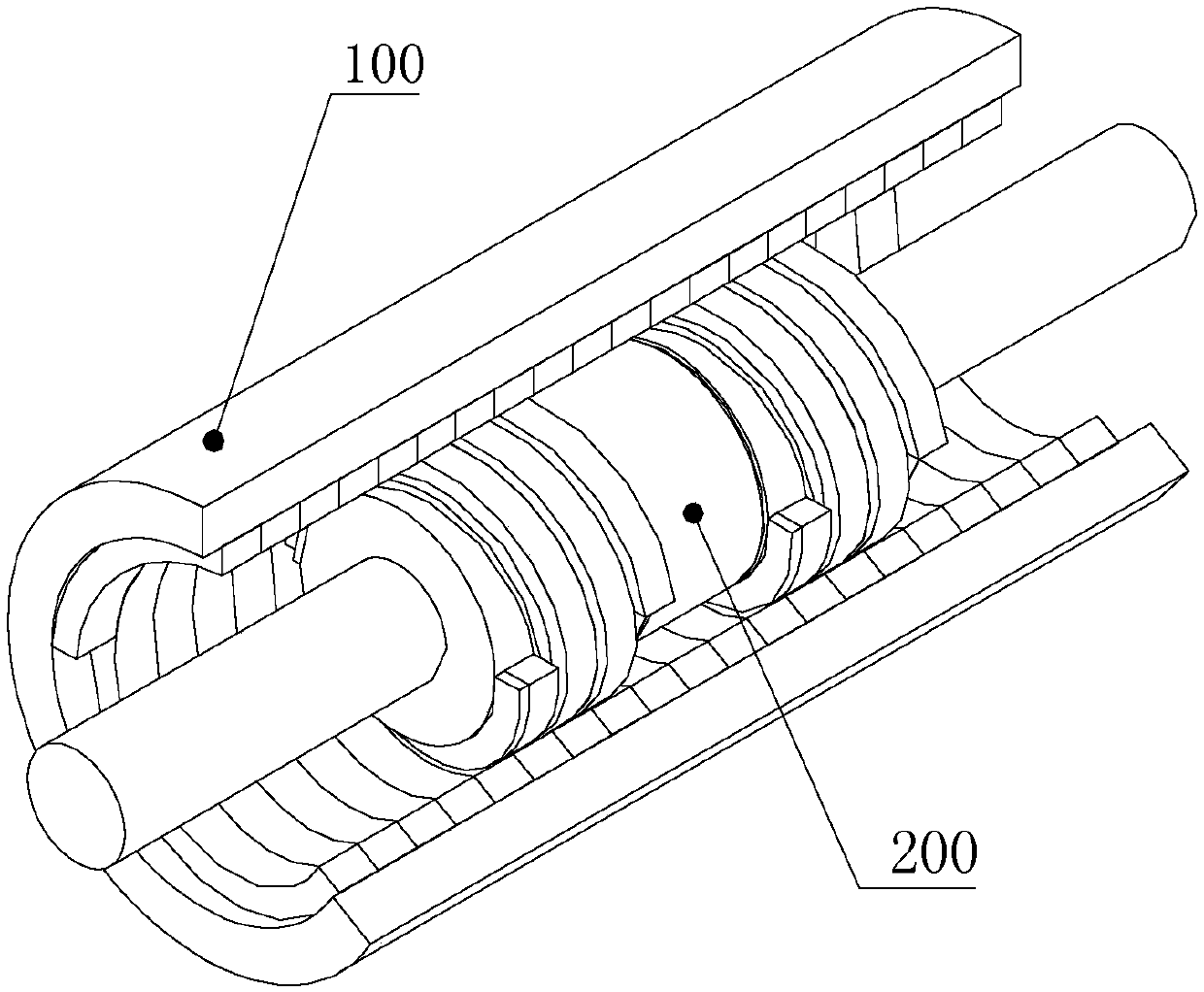

Single winding hybrid excitation magnetic lead screw

ActiveCN107896047AIncrease thrust densityQuantity halvedPermanent-magnet clutches/brakesEngineeringLinear motion

The invention discloses a single winding hybrid excitation magnetic lead screw and belongs to the field of electromechanical transmission. The invention solves the problems of low thrust density, complex structure, and low utilization of an excitation winding of an existing hybrid magnetic circuit magnetic lead screw. The single winding hybrid excitation magnetic lead screw includes a magnetic nutand a magnetic screw, both of which are provided with spiral permanent magnets, and also includes an annular excitation winding. The magnetic nut coaxially sleeves the outside of the magnetic screw and an air gap is left therebetween. The annular excitation winding is fixed on the magnetic nut or the magnetic screw, for adjusting a coupling magnetic field of the air gap so as to adjust the thrustacting on the magnetic nut and the magnetic screw and finally complete the mutual transformation of linear motion and rotary motion. The single winding hybrid excitation magnetic lead screw of the invention is mainly for use on the electromechanical transmission.

Owner:HARBIN INST OF TECH

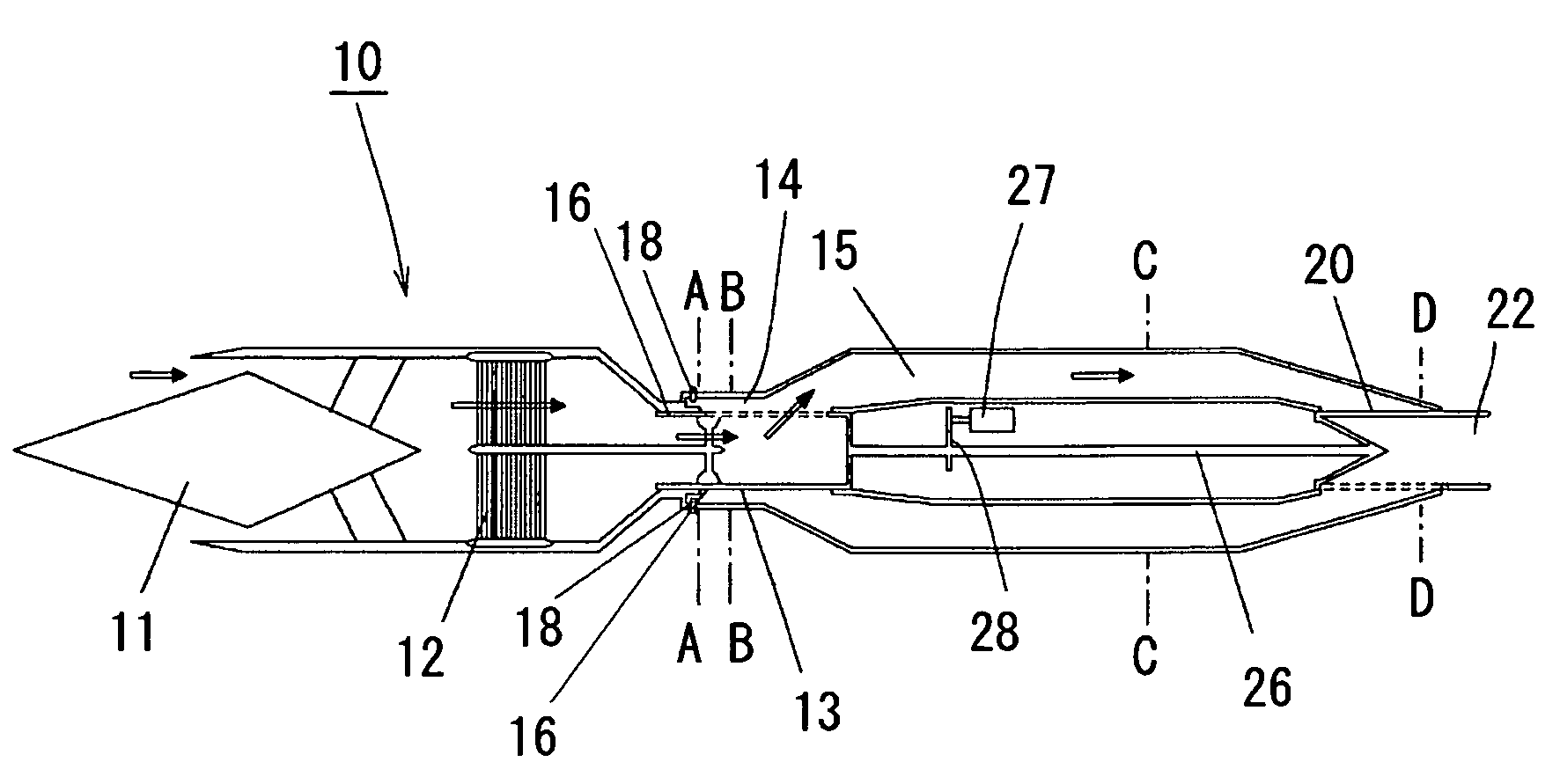

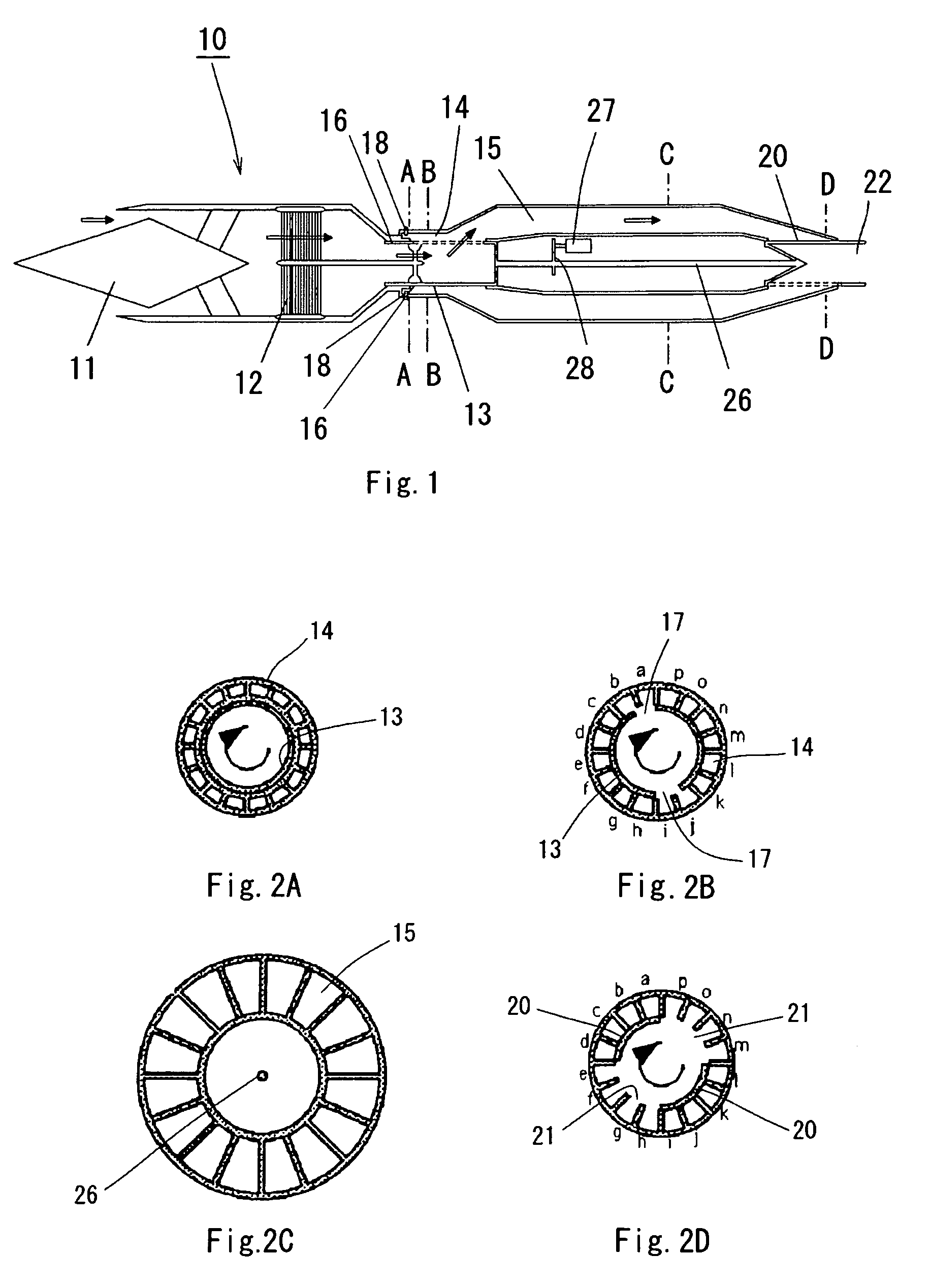

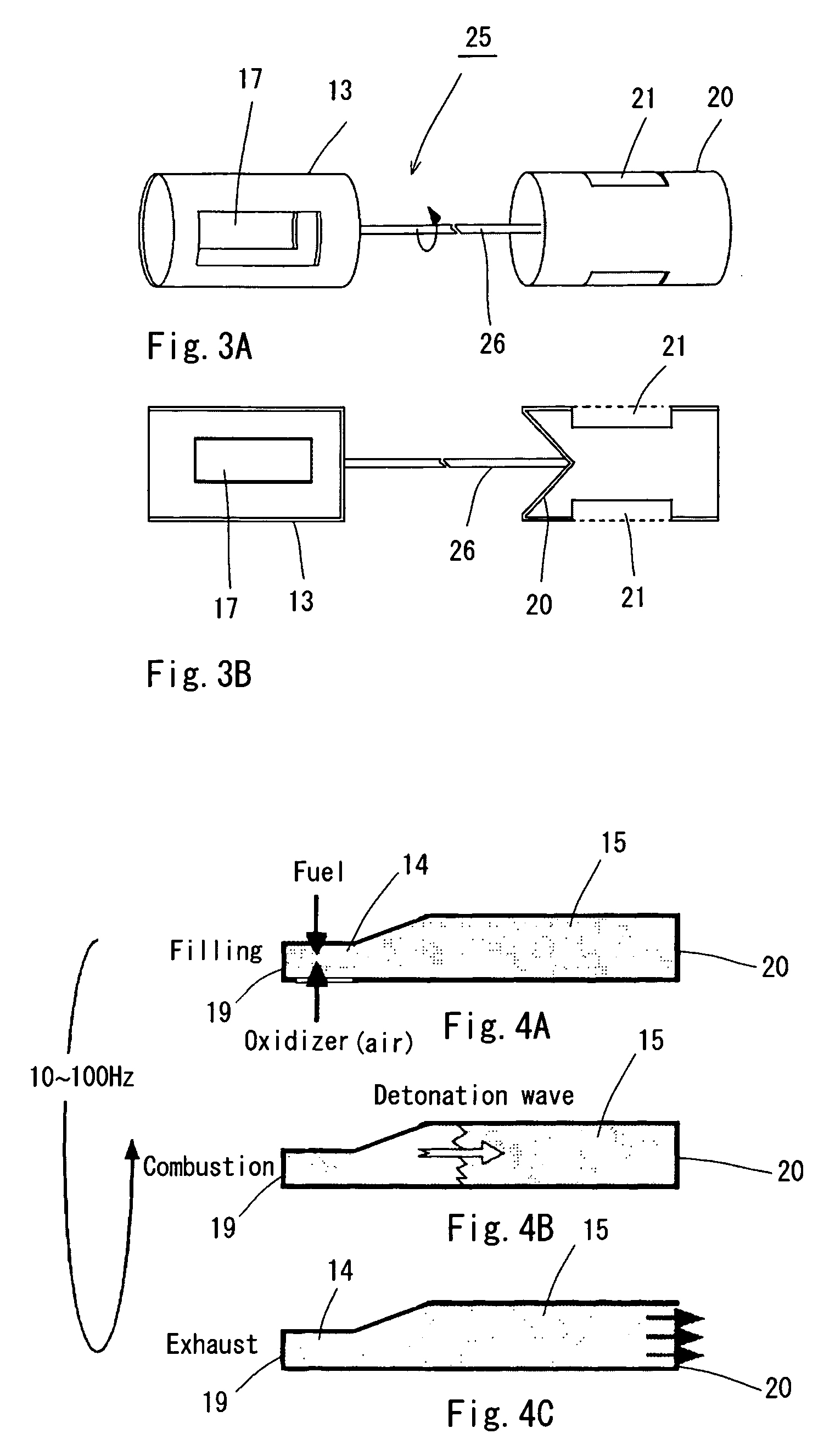

Pulse detonation engine and valve

InactiveUS7251928B2Increase thrust densitySuperior rapid opening and closing performancePulsating combustionTurbine/propulsion fuel heatingCombustorHigh density

Pressure and density of a gaseous mixture are increased in the process of introducing the gaseous mixture into the combustor of an air-breathing pulse detonation engine employing atmospheric oxygen as an oxidizer. The exit valve 20 able to be opened and closed is provided at the outlet of the combustor 15, an air cooler 12 is provided in the exit of the intake, and density is increased by exchange of heat of the air received at the intake with a coolant in the air cooler 12. Furthermore, by closing the exit valve 20 provided in the outlet of the combustor during the process of loading the gaseous mixture, transition to the detonation process is possible without expansion of the high-pressure high density air obtained by ram-compression at the intake.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

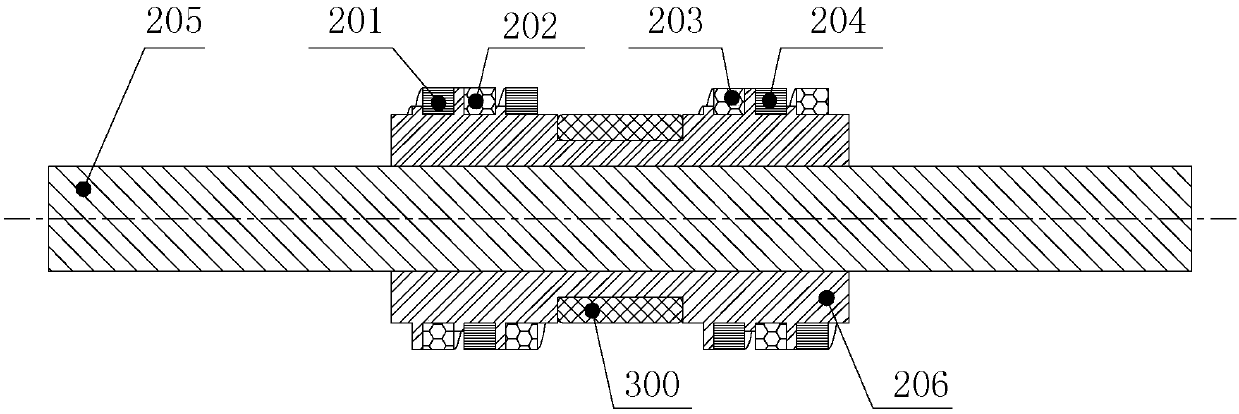

Double-sided permanent magnet linear synchronous motor

InactiveCN103107672ASmall edge effectLarge thrustPropulsion systemsPermanent magnet synchronous motorMagnetic poles

The invention discloses a double-sided permanent magnet linear synchronous motor which comprises two magnetic poles arranged respectively on two sides and an armature between the two magnetic poles, and two laminated iron cores are assembled together to form the armature. The two magnetic poles are mutually staggered in the horizontal direction and the two iron cores are flushed with other in the horizontal direction, or the two iron cores are mutually staggered in the horizontal direction and the two magnetic poles are flushed with other in the horizontal direction. According to the double-sided permanent magnet linear synchronous motor, the number of iron core slots is greater than the number of the magnetic poles, the magnetic poles of the left side and the right side are mutually staggered or the two iron cores are mutually staggered, and end force is basically counteracted, so that thrust ripple is greatly weakened. The double-sided permanent magnet linear synchronous motor has the advantages of being convenient to regulate, easy to achieve, large in regulating scope, and convenient to install and maintain and the like. The double-sided permanent magnet linear synchronous motor is suitable for situations of high speed, high accuracy, high efficiency, and high thrust.

Owner:ZHEJIANG UNIV

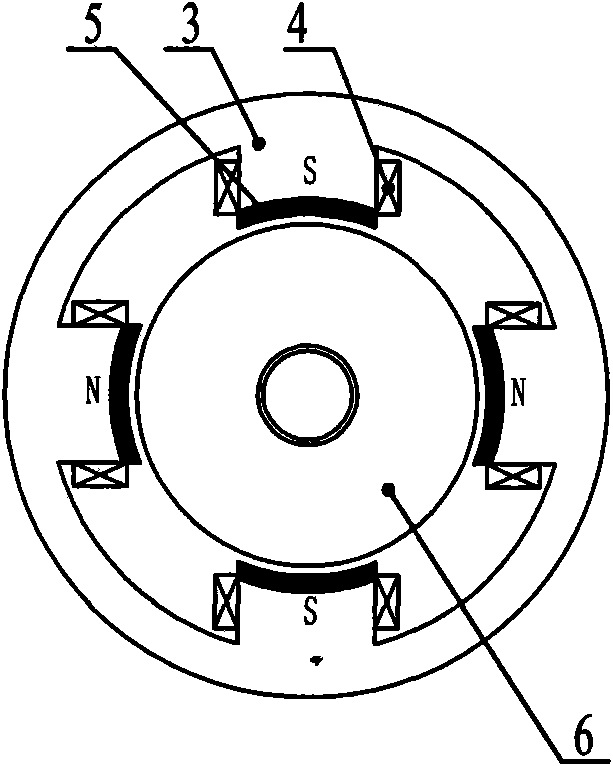

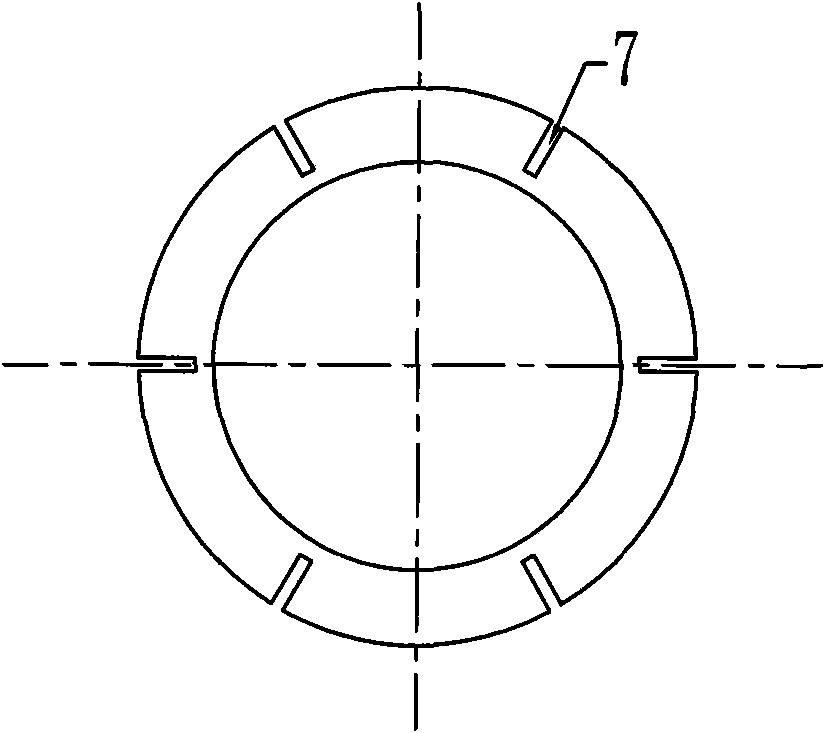

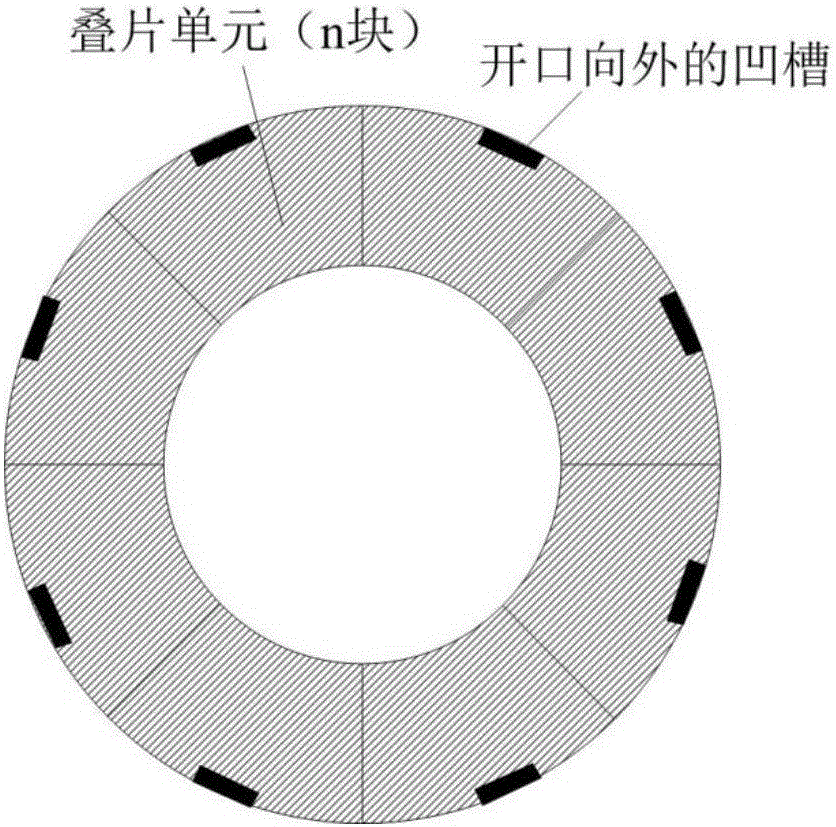

Cylinder type flux-reversal linear machine

InactiveCN101552535ASimple structureIncrease thrust densityPropulsion systemsElectric machineEddy current

The present invention relates to a cylinder type flux-reversal linear machine. The invention relates to the field of electric machine and settles the problems of low efficiency, large eddy current loss, complex technique and effect to control precision and dynamic characteristic in prior linear machine. The armature core of phase unit according to the nveition is an annular core which is uniformly installed with 2n teeth on the inner circumstance, wherein n is a natural number. The armature winding of phase unit is a concentrated winding. Each coil is corresponding winded on each tooth of armature core of phase unit. The winding directions of coils on adjacent teeth are opposite. All coils on the teeth of armature core of same phase unit are connected in series to a same phase unit armature winding. The phase unit armature windings are connected in series or in parallel to each phase armature winding. A permanent magnet is adhibited on the teeth of armature core of phase unit. The phase unit armature core center distance taut between two adjacent phase armature units in axial direction and the tooth pitch taup of secondary teeth along the axial direction satisfy a relationship: taut=ktaup+ / -(1 / m)taup, wherein k and m are natural numbers, and m is a phase number and is larger than or equal to 3. The cylinder type flux-reversal linear machine not only can be used as a motor, but also can be used as a generator.

Owner:HARBIN INST OF TECH

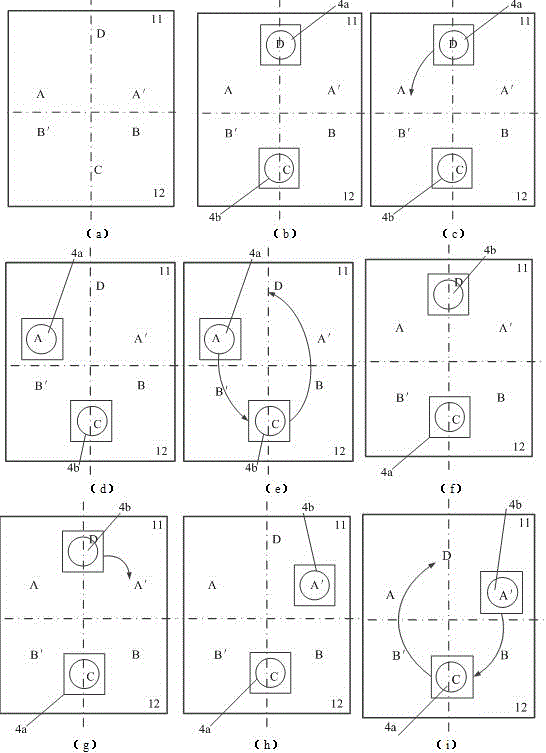

Vector arc stage switching method and device for double rotary balance mass-based dynamic magnetic steel type magnetic levitation workpiece stages

InactiveCN105629676AFewer starts and stopsFew stable linksSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLithographic artistMeasurement device

The invention provides a vector arc stage switching method and device for double rotary balance mass-based dynamic magnetic steel type magnetic levitation workpiece stages, and belongs to a semiconductor manufacturing equipment technology. The device comprises a support frame, a balance mass block, a rotating shaft, magnetic levitation workpiece stages, a workpiece stage measurement device and a workpiece stage drive device, wherein the two workpiece stages work between a measurement station and an exposure station; the positions of the workpiece stages are measured by plane gratings; the workpiece stages are driven by magnetic levitation planar motors; and the two workpiece stages are driven by the planar motors to achieve single-beat arc fast stage switching in the double workpiece stage switching process. According to the vector arc stage switching method and device, the problems that an existing stage switching scheme has multiple beats, a long track, multiple starting and stopping beats, long stabilization time and the like are solved; the stage switching link is reduced; the stage switching time is shortened; and the productivity of a lithography machine is improved.

Owner:HARBIN INST OF TECH

Cylinder type flux-reversal linear machine

InactiveCN101552535BSimple structureIncrease thrust densityPropulsion systemsElectric machineLinear machine

Owner:HARBIN INST OF TECH

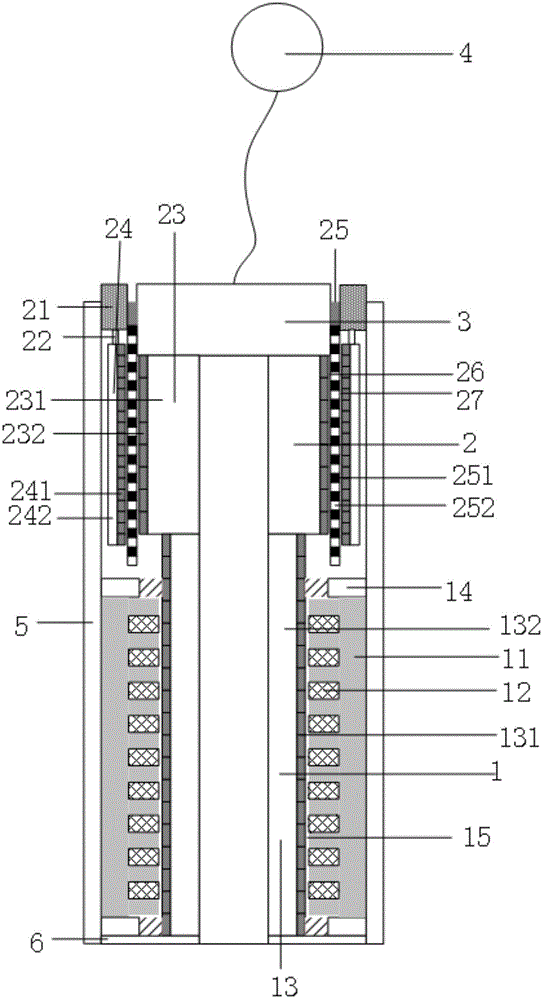

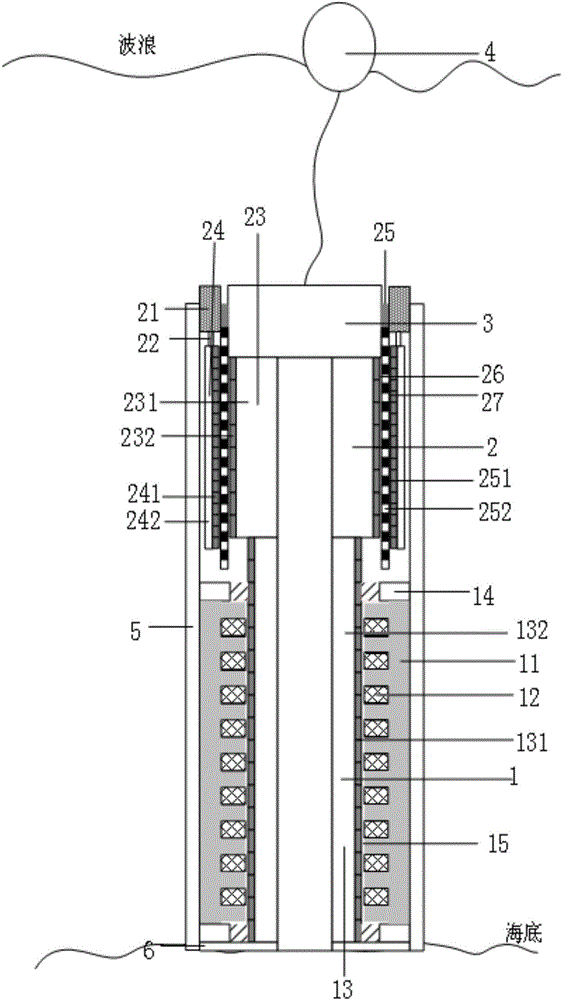

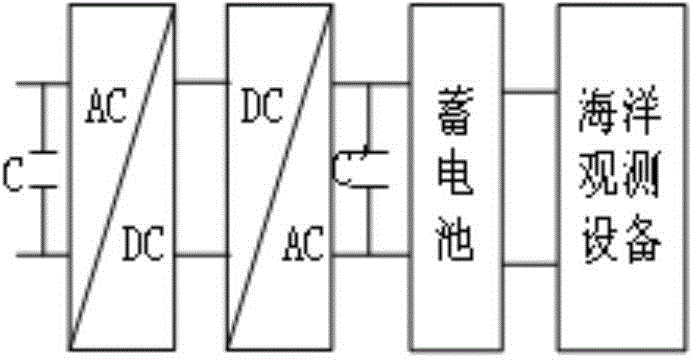

Wave energy power generating device based on serial connection linear magnetic gear motor

InactiveCN104061116AImprove power generation efficiencySimple structureDynamo-electric gearsMachines/enginesElectric machinePermanent magnet linear motor

The invention discloses a wave energy power generating device based on a serial connection linear magnetic gear motor, and belongs to a power generating device combining a linear magnetic gear and a permanent-magnet linear motor through serial connection. The wave energy power generating device comprises a permanent-magnet linear motor part, a linear magnetic gear part, a floating tube, a floater, an external encapsulation device and a base, wherein an outer rotor is driven by a driving motor and a mechanical transmission part to move in a certain moving range, the goal of variable transmission ratio is achieved, and the whole set of device has the advantages that the additional arrangement of a huge accelerator is not needed, the size is smaller, the energy capturing and power generating efficiency is high, no terminal winding is adopted, no radial force is exerted on a bearing, and the like.

Owner:SOUTHEAST UNIV

An asymmetric double permanent magnet hybrid excitation switch flux linkage linear motor

ActiveCN108155775BIncrease thrust densityIncrease the areaPropulsion systemsConstant powerElectric machine

Owner:ZHEJIANG UNIV

Super-conduction magnetic suspension linear electromagnetic propelling system

ActiveCN108448873ARealize independent designImplementation orientationDynamo-electric machinesMagnetic holding devicesElectromagnetic propulsionEngineering

The invention discloses a super-conduction magnetic suspension linear electromagnetic propelling system, relates to the field of a motor, and aims to solve the problems as follows: the magnetic fieldformed by a super-conduction magnet of the existing magnetic suspension propelling system is open on a vehicle, which causes severe magnetic leakage and high magnetic field shielding difficulty; the vehicle is high in weight and the conventional conduction magnetic suspension technology is relatively low in suspension height, which causes high suspension control difficulty, and relatively high requirements on circuit flatness, roadbed sinkage and turnout junction structure. The invention provides the super-conduction magnetic suspension linear electromagnetic propelling system; and by adoptionintegrated suspension, guiding winding and series magnetic path super-conductor excitation, automatic suspension and guiding of the high-speed linear propelling system mover is realized, and independent design of the propelling winding is achieved.

Owner:HARBIN INST OF TECH +1

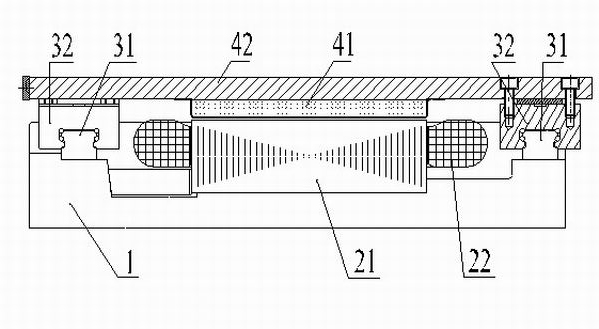

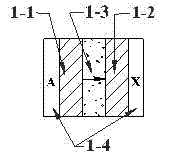

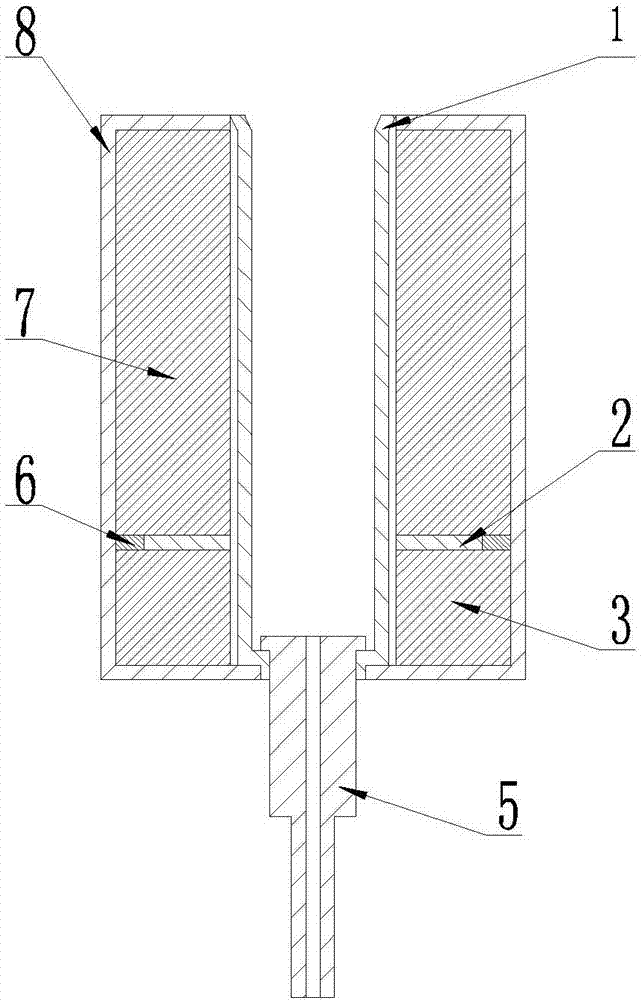

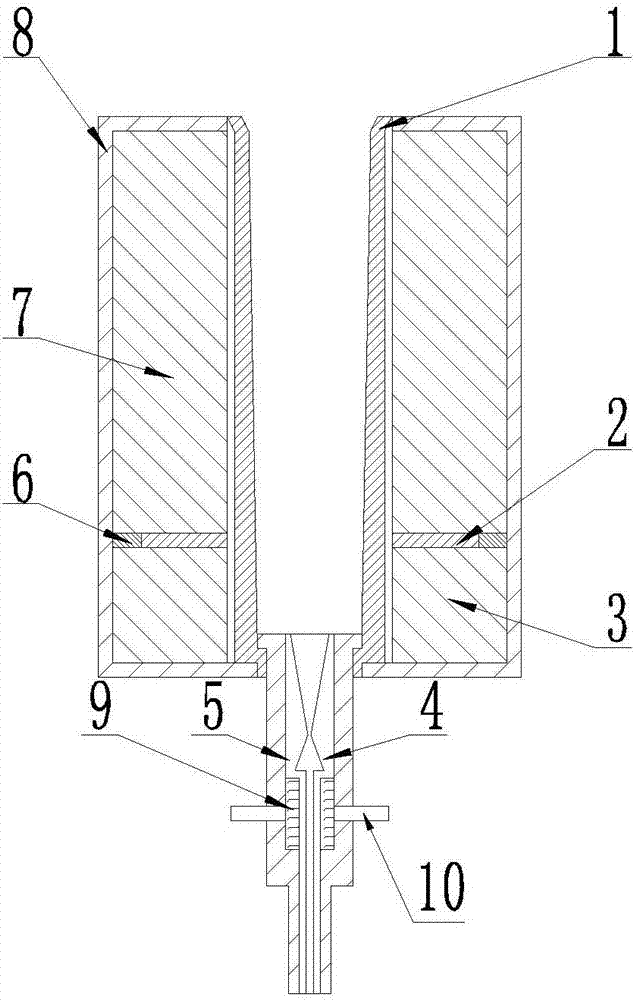

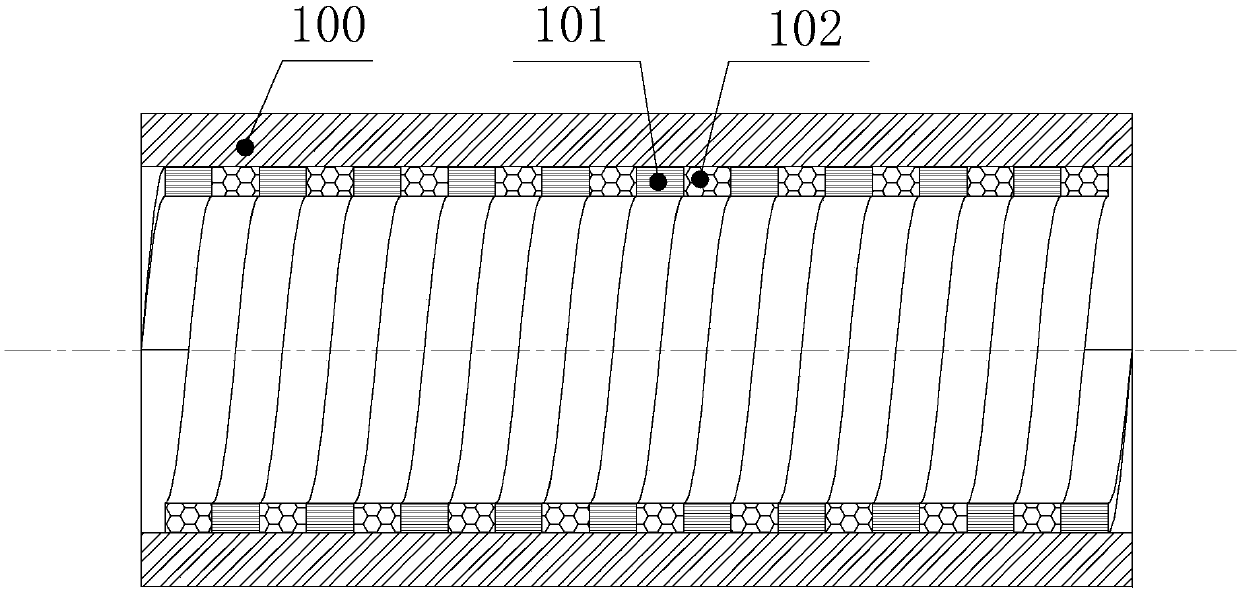

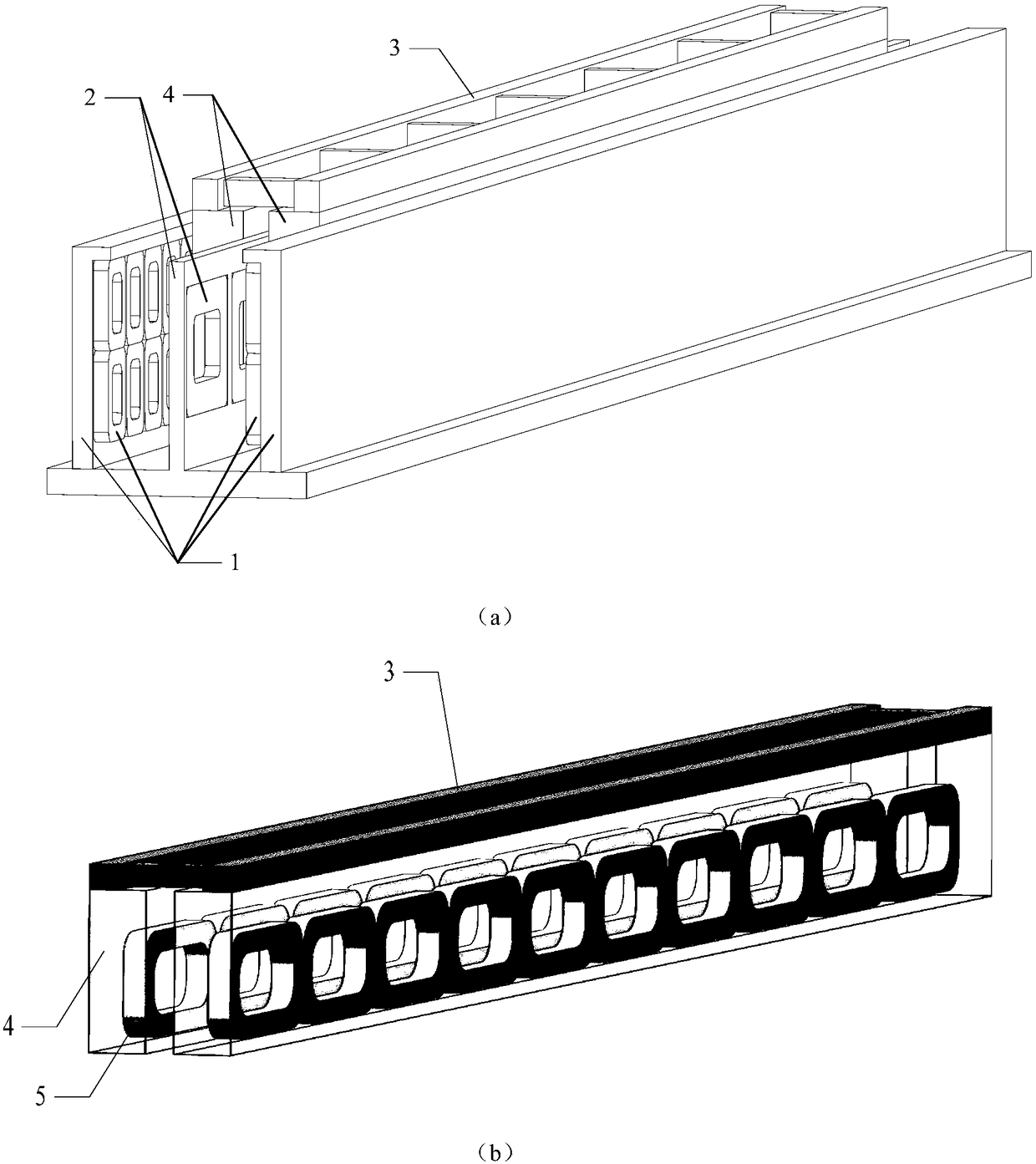

High-thrust permanent magnet direct drive linear electric motor

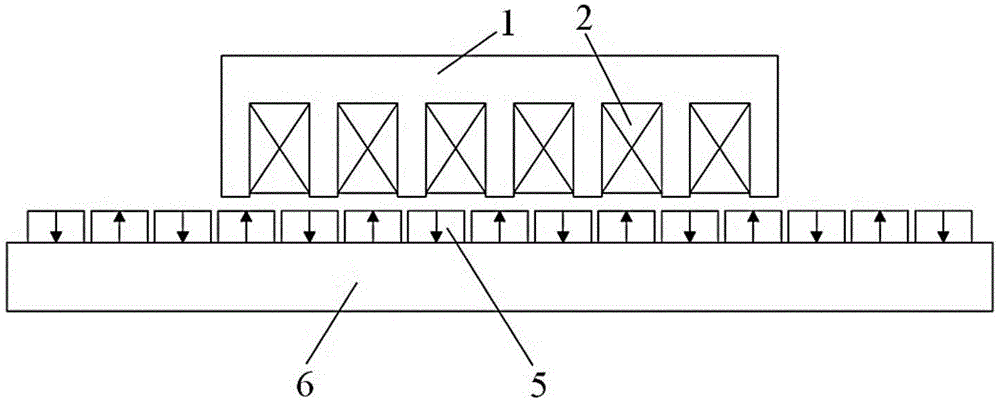

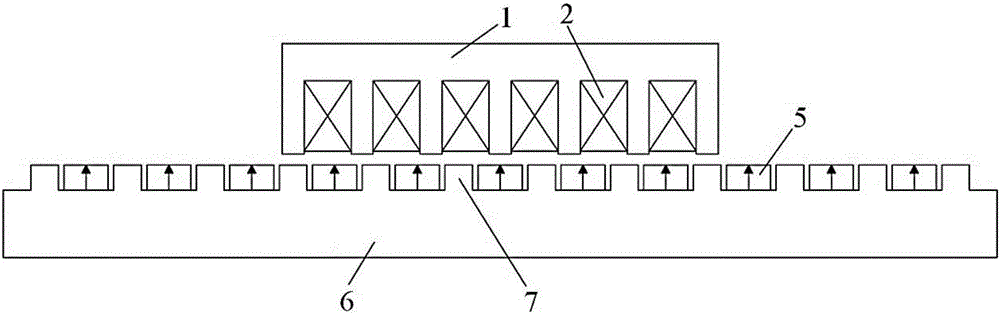

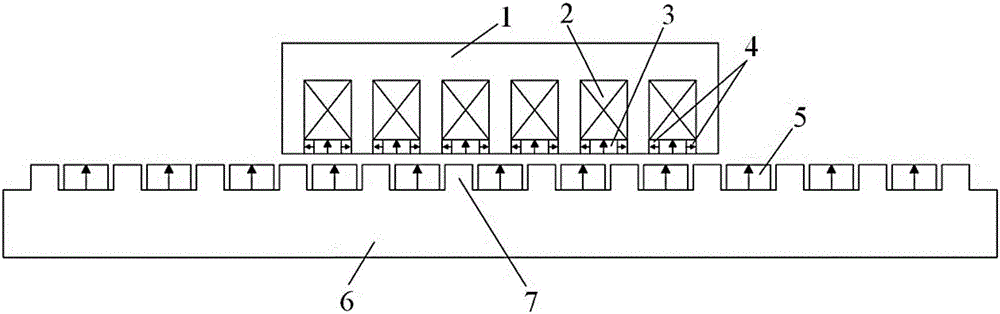

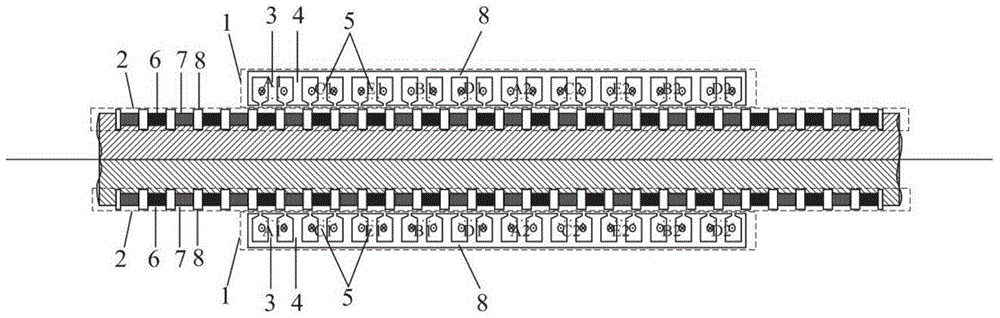

InactiveCN102082490ARealize the effect of speed-upIncrease thrust densityPropulsion systemsElectric machineMagnetic reluctance

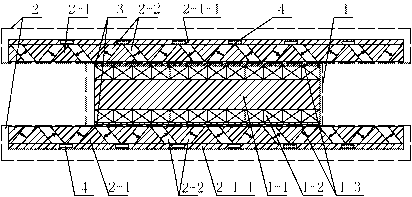

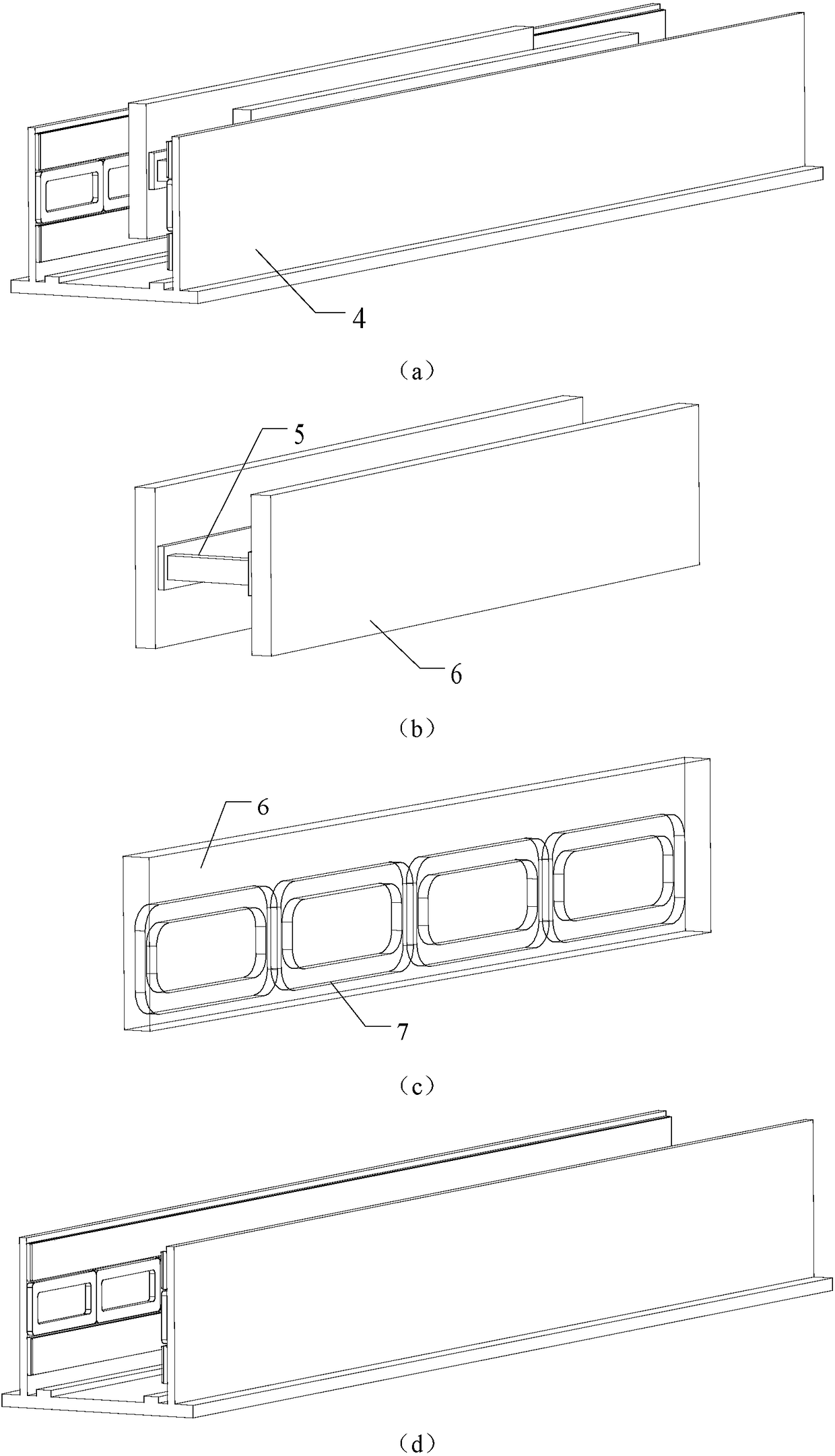

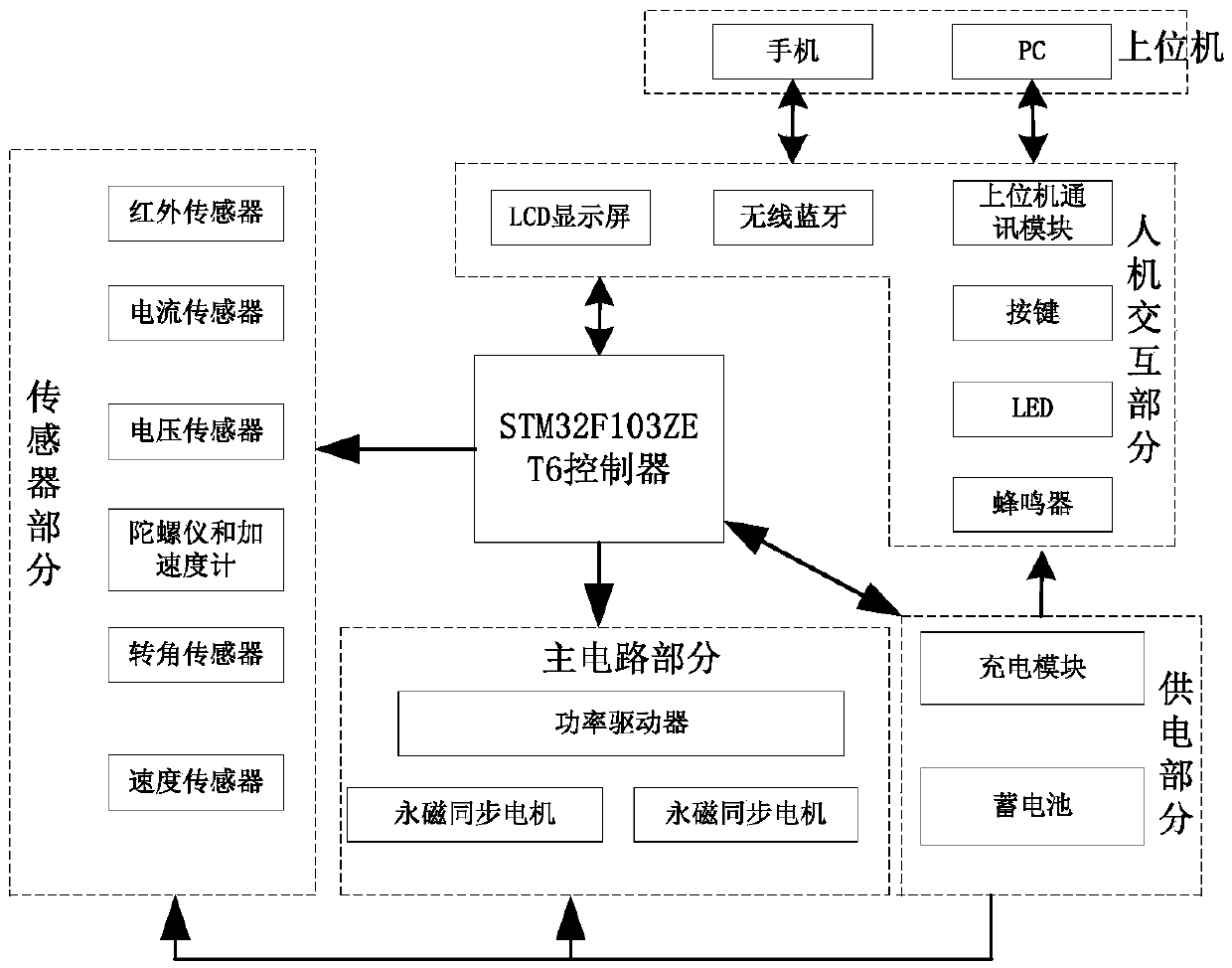

The invention relates to a high-thrust permanent magnet direct drive linear electric motor, comprising a motor primary and a motor secondary, wherein the motor primary comprises a primary iron core (1) with a slot, an armature winding (2), primary pole shoes (3) and permanent magnets (4), wherein the armature winding (2) is embedded into the slot of the primary iron core (1); the permanent magnets (4) are arranged on the surfaces of the primary pole shoes (3); the motor secondary comprises a secondary iron core (6) and secondary salient poles (7); an air gap (5) exists between the motor primary and the motor secondary; and the motor primary is fixed, and the motor secondary linearly moves along with the motion direction of a motor. The motor comprises a unilateral flat-plate structure, a bilateral flat-plate structure, and a cylindrical structure. In the high-thrust permanent magnet direct drive linear electric motor, the special structures of the motor are utilized to modulate the air gap reluctance distribution of the motor. When the motor is in operation, the movement velocity of a permanent magnetic flux in the motor primary is multiplied of that of a permanent magnetic flux in the motor secondary, thus realizing the speed-raising effect. The high-thrust permanent magnet direct drive linear electric motor is applied to low-speed direct drive application occasions, and has the characteristics of high power density, large rated thrust and the like.

Owner:SOUTHEAST UNIV

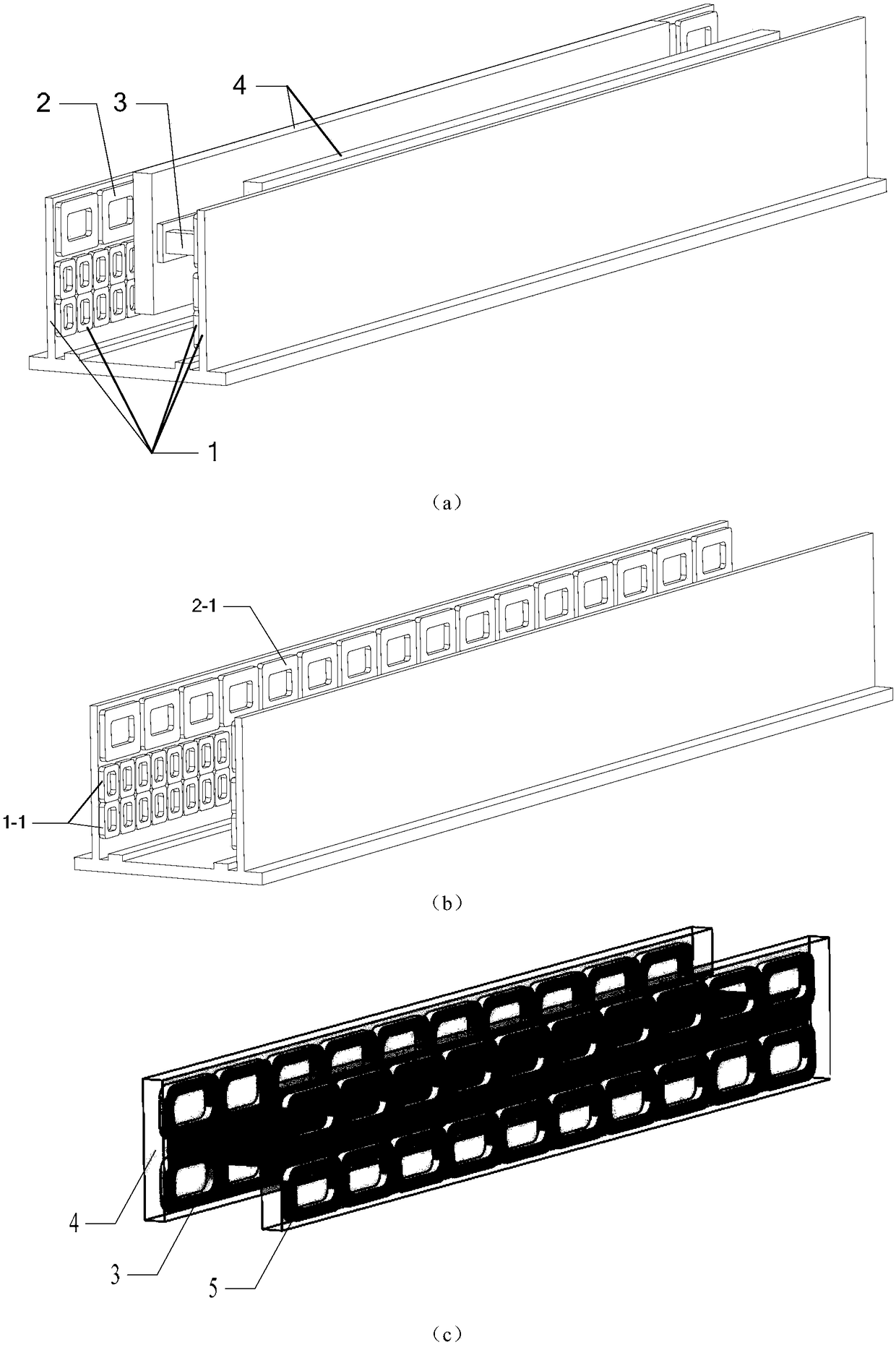

Independent-winding double-side plate permanent magnet linear motor

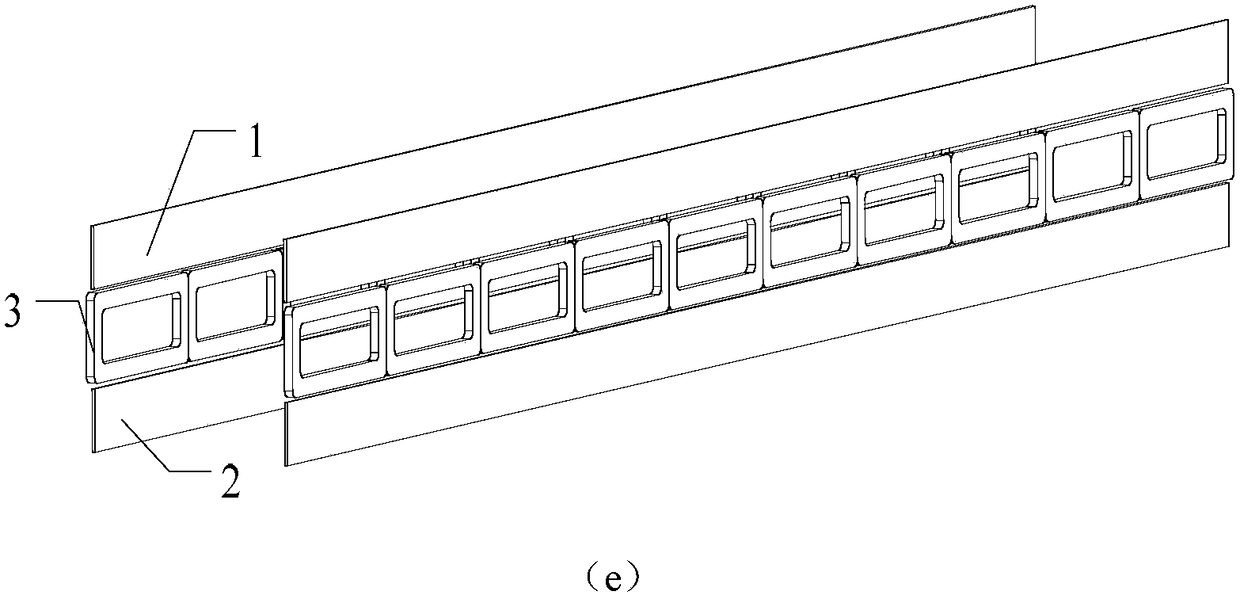

ActiveCN106100283ASimple winding processEasy to achieve coolingPropulsion systemsModular compositionElectricity

The invention discloses an independent-winding double-side plate permanent magnet linear motor, which comprises primary sides, a secondary side and air gaps. Each primary side comprises an armature winding, a primary magnetic-conductive iron core and a permanent magnet array. The two primary side assemblies are arranged at the two sides of the secondary side respectively to form a double-side structure. The primary magnetic-conductive iron core forms a big open slot structure, and the permanent magnet array is arranged in the slot mouth. One side, opposite to the corresponding open slot, of each primary magnetic-conductive iron core is provided with the armature winding; and the armature windings of the two primary sides at the two sides of the secondary side are same-phase windings, but electrical angle difference is 180 degrees. The secondary side is formed by magnetic-conductive iron cores having a salient pole structure, and gaps. The two air gaps are formed between the two primary sides and the secondary side respectively. The motor is a single-phase motor or a multi-phase motor, wherein the multi-phase motor is modular combination of the single-phase motors. Permanent magnets and the armature windings of the permanent magnet linear motor are arranged at the primary sides; through the big open slot structure design, winding heat dissipation is realized helpfully, and through the design of a large electrical load, thrust is improved; and meanwhile, the secondary side is simple in structure and light in weight.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

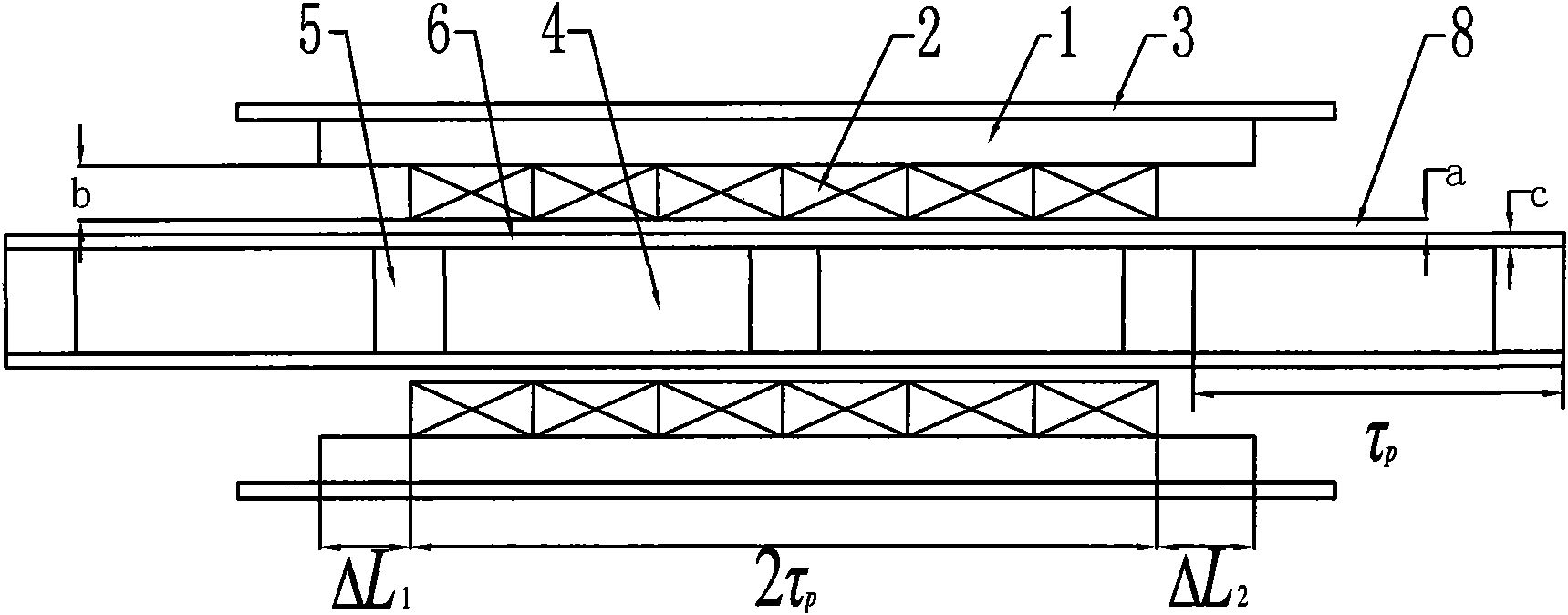

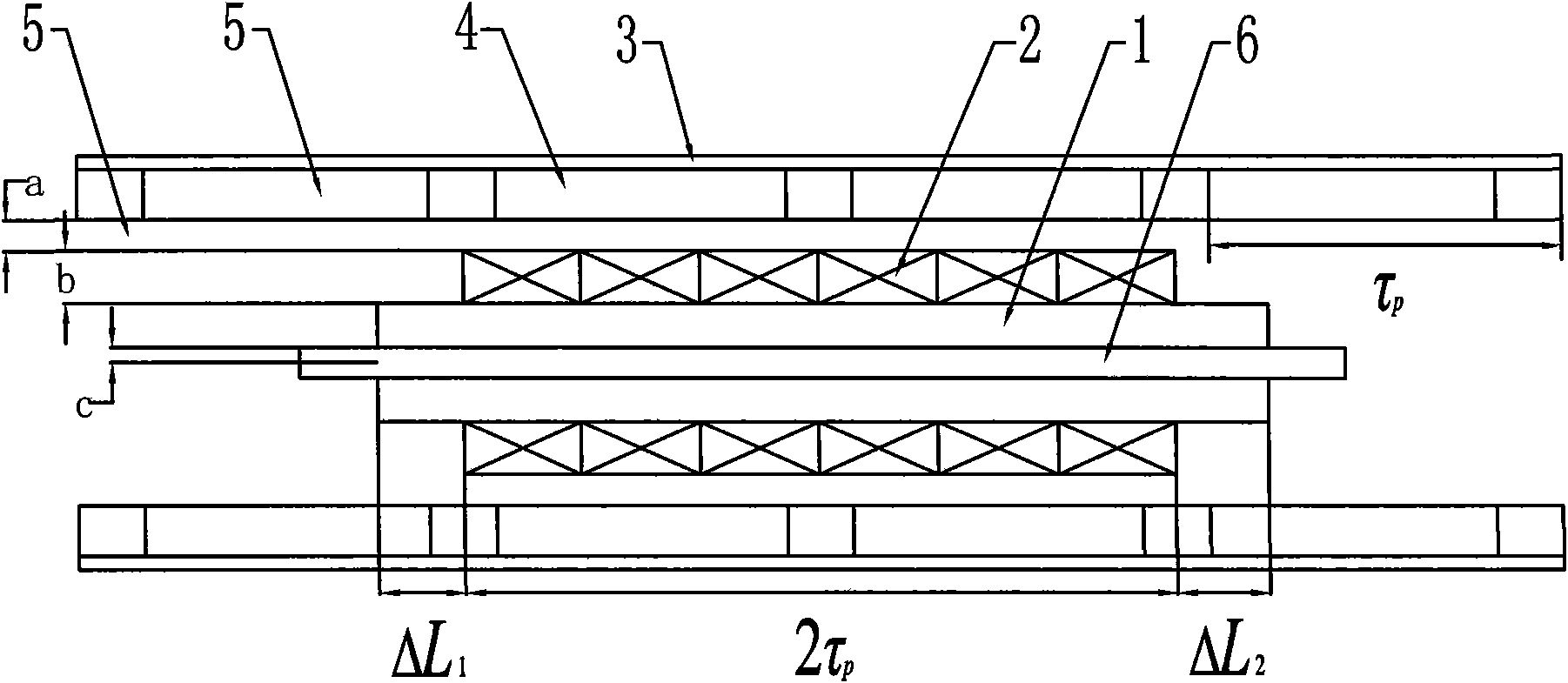

High thrust density cylinder type linear electric motor

InactiveCN101552523ASimple manufacturing processImprove overload capacitySynchronous machine detailsWindings conductor shape/form/constructionElectric machineLinear motor

A high thrust density cylinder type linear electric motor of the invention relates to motor technology. The invention settles the problems of high positioning force, low overload capacity and thrust density and complex fabrication technique of prior linear motor. A permanent magnet and a magnetic yoke are cylindrical and are arranged separately. An armature core is cylindrical, and the outer wall of armature core is uniformly distributed with radiation-shaped grooves with outwards openings. The widths of grooves are 0.1-2mm. The armature core is fixed in the casing or outside the fixing component. The coils of armature winding are sequentially arranged on the inner wall or outer wall of armature core. An air gas is installed between a primary step and a secondary step. The axial length of permanent magnet is larger than the summation of axial thickness b of coil, radial length a of air gap 8 and the wall thickness c of fixing component 6. The axial length of magnetic yoke is 1 / 3-1 / 6 of axial length of permanent magnet. The length La of armature core and the secondary pole distance taup satisfy the following relationships: La=ntaup+deltaL, deltaL=deltaL1+delta2=1 / 2taup. The high thrust density cylinder type linear electric motor of the invention has the advantages of simple manufacturing technique, eliminated positioning force caused by core grooving, and increased overload capacity and thrust density of electric motor.

Owner:HARBIN INST OF TECH

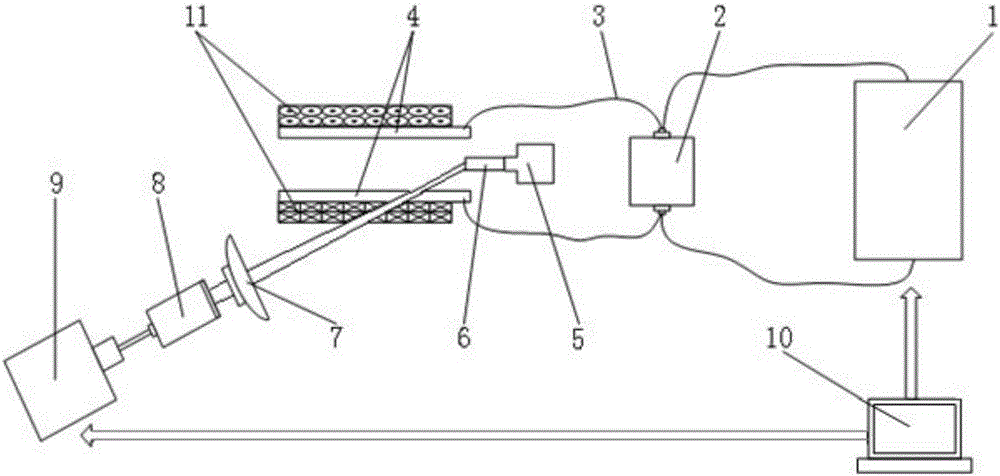

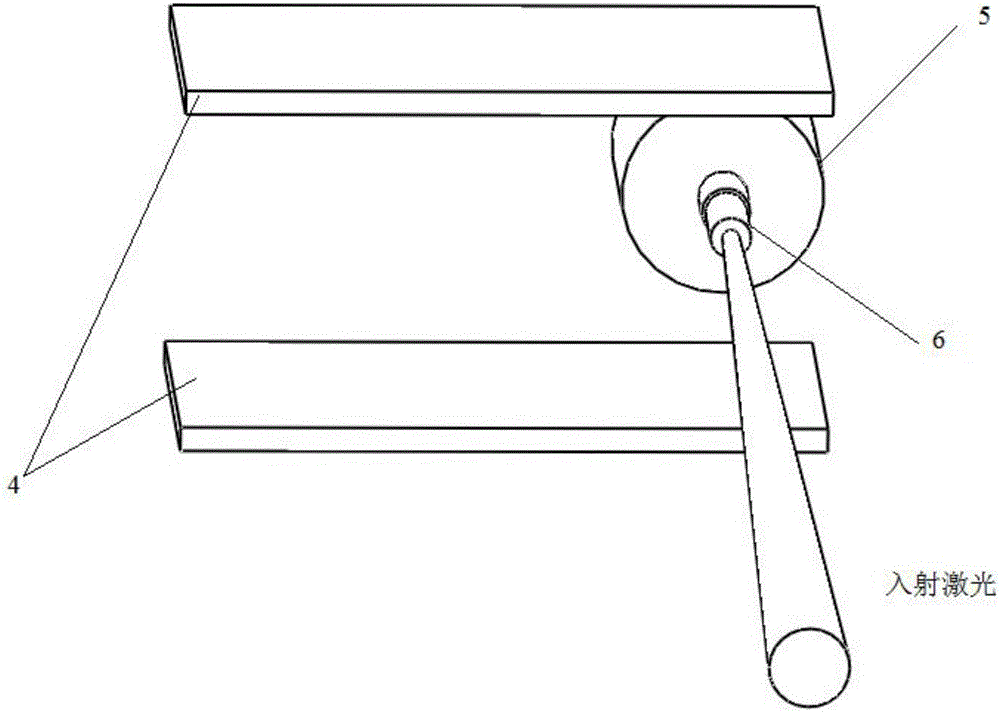

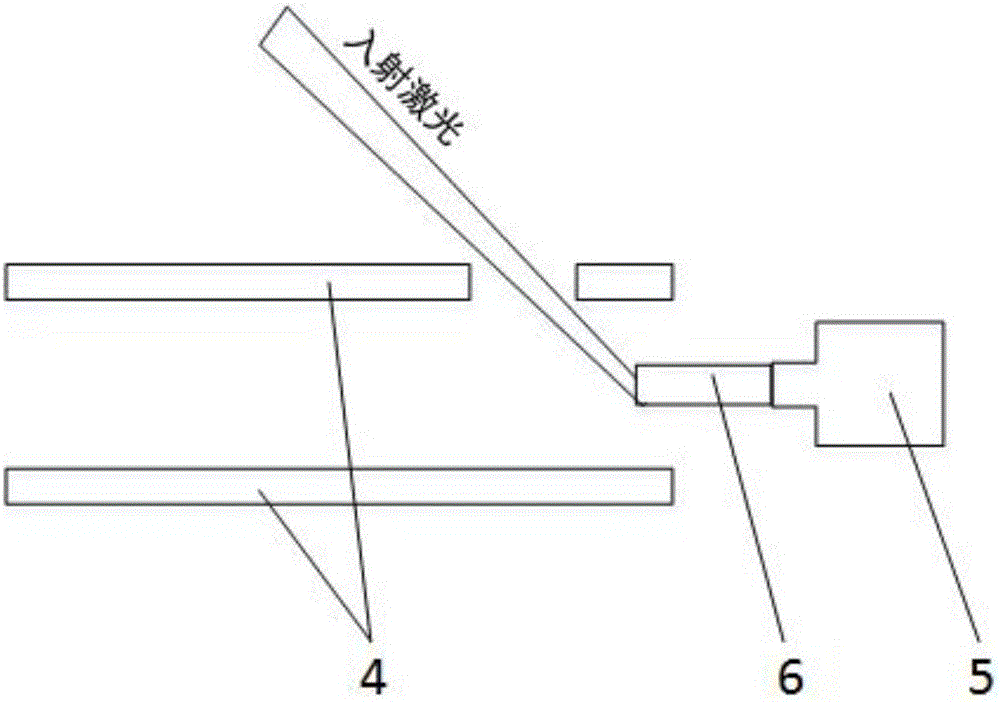

Laser ablation pulsed plasma thruster

ActiveCN105952603AWide range of optionsNo carbon depositsMachines/enginesUsing plasmaPlasma jetParticulates

The invention provides a laser ablation pulsed plasma thruster. The laser ablation pulsed plasma thruster comprises a power processing unit, a capacitor unit, a working medium, a working medium supply device, a cathode, an anode and a laser generating mechanism. The power processing unit is connected with the capacitor unit through a transmission line. The positive output end and the negative output end of the capacitor unit are connected to the cathode and the anode through transmission lines correspondingly. The capacitor unit, the transmission lines, the cathode and the anode form a discharging loop, and gas between the cathode and the anode can be ionized and accelerated. A discharging channel is formed between the cathode and the anode. The working medium supply device for fixing and conveying the working medium is arranged at one end of the discharging channel, and the working medium stretches into the discharging channel from the end. Gaps exist between the working medium and the cathode as well as between the working medium and the anode. The laser generating mechanism emits laser beams into the discharging channel to ablate the working medium, the laser beams continuously ablate the working medium to generate part of ionized gas and particulate matters, the ionized gas and the particulate matters enter the discharging channel to form plasma jets moving along the discharging channel, and thrust is generated. The laser ablation pulsed plasma thruster is high in specific impulse, total impulse, working medium utilization rate and control precision.

Owner:NAT UNIV OF DEFENSE TECH

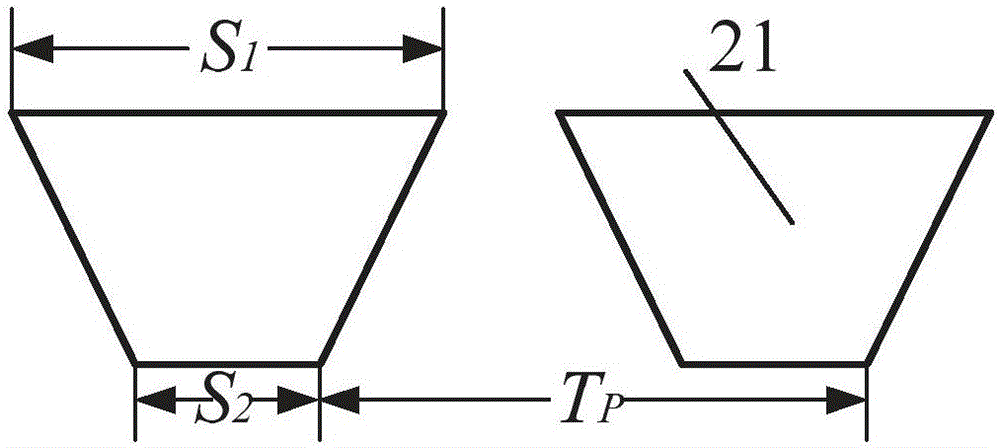

Primary permanent-magnet vernier linear motor and segmenting method therefor

InactiveCN106505821AReduce performanceIncrease thrust densityManufacturing dynamo-electric machinesPropulsion systemsPrimary permanentLinear motor

The invention discloses a primary permanent-magnet vernier linear motor and a segmenting method therefor, and belongs to the field of vernier linear motors. A primary side which is provided with a permanent magnet in an embedded manner and a winding is segmented to form an upper primary side and a lower primary side, wherein the upper primary side and the lower primary side are respectively provided with the winding and the permanent magnet in an independent manner, the winding is a centralized or distributed winding, and the permanent magnet is disposed at the lower primary side in a surface-embedded or built-in manner, and also can be embedded at the lower primary side in the surface-embedded if a magnetism gathering module is employed. The magnetism gathering module consists of the following parts: one permanent magnet with the magnetizing direction being in a radial direction, and two smaller permanent magnets which are distributed at two sides of the radial magnetizing permanent magnet, wherein the magnetizing directions of the permanent magnets at two sides are symmetric. A secondary side is a cut-off inverted trapezoidal iron core, and is disposed between the upper primary side and the lower primary side. The linear motor is advantageous in that the primary side is segmented, thereby effectively avoiding the space conflict between the permanent magnet and the winding, facilitating the adjustment of an electric load so as to improve the push density; in addition, a long secondary side has no winding and permanent magnet, thereby greatly reducing the cost; the linear motor can be used in the field of long-distance rail transit.

Owner:JIANGSU UNIV

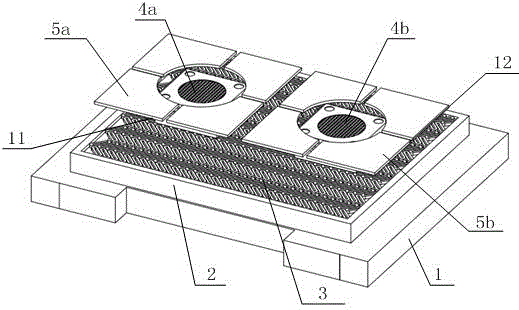

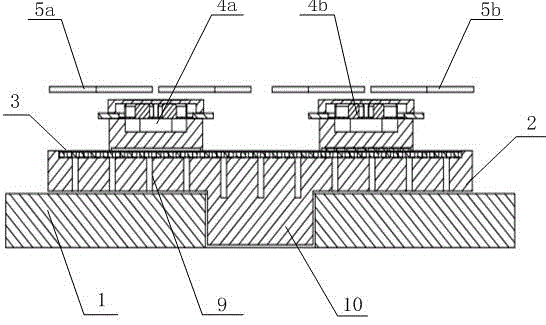

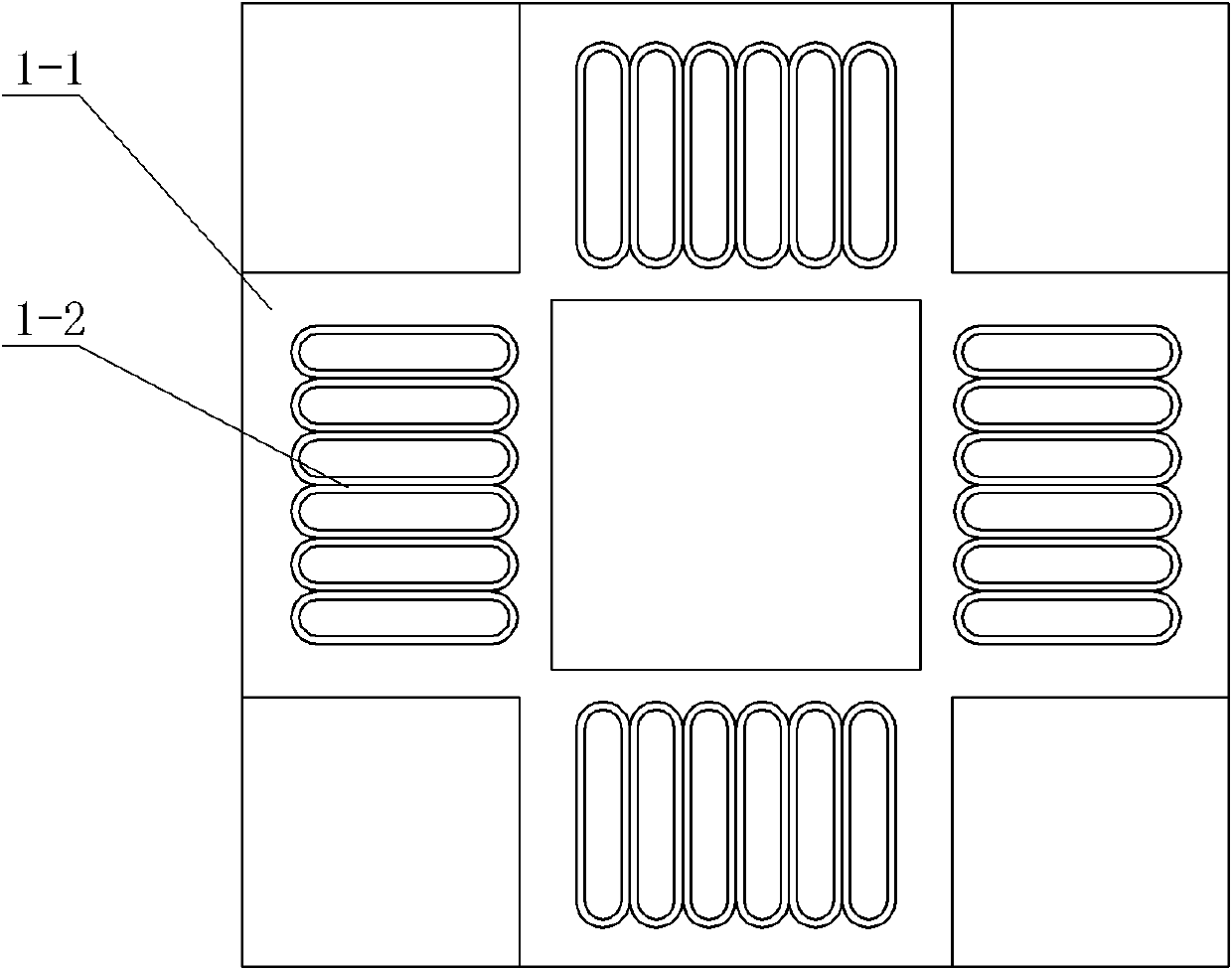

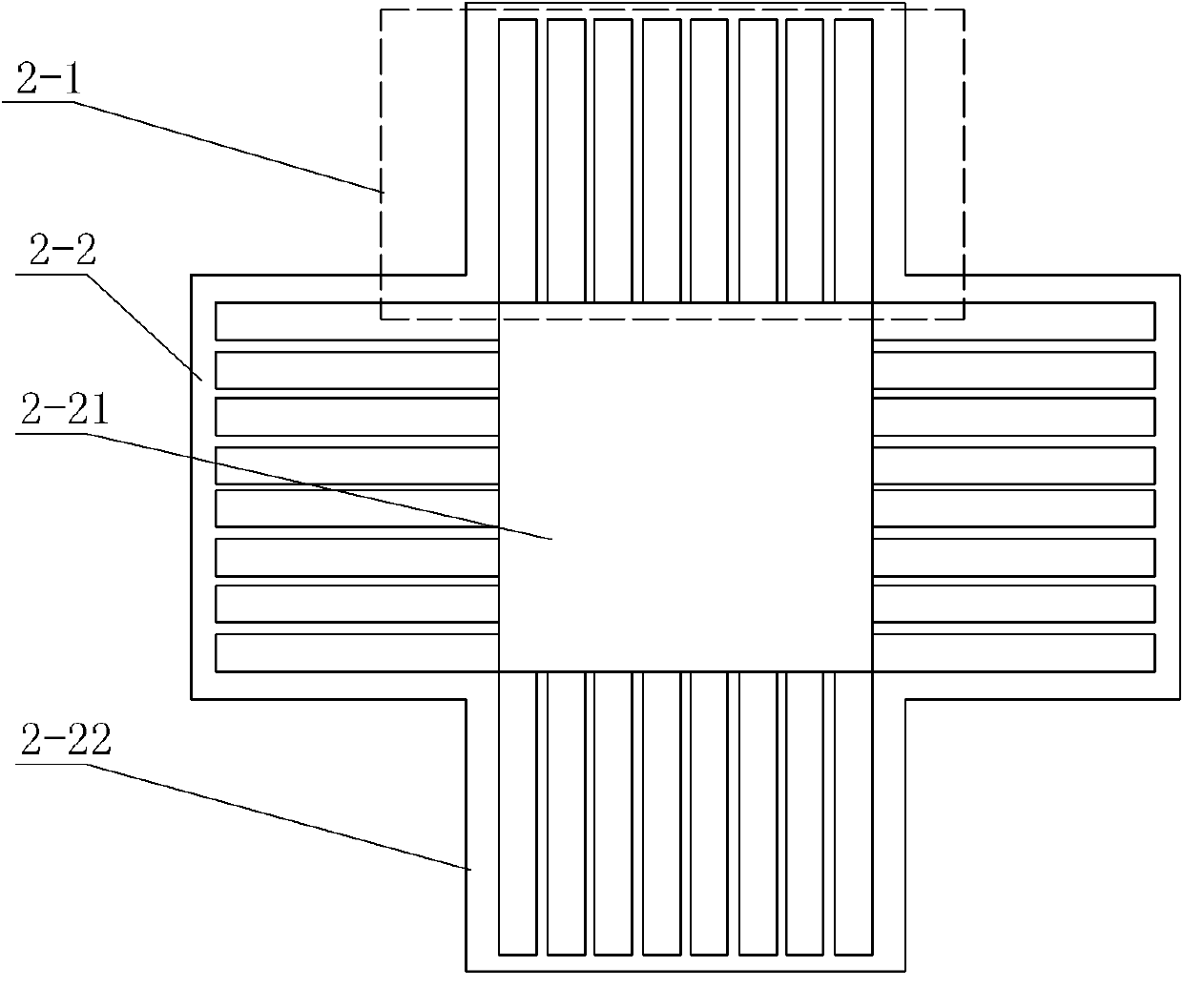

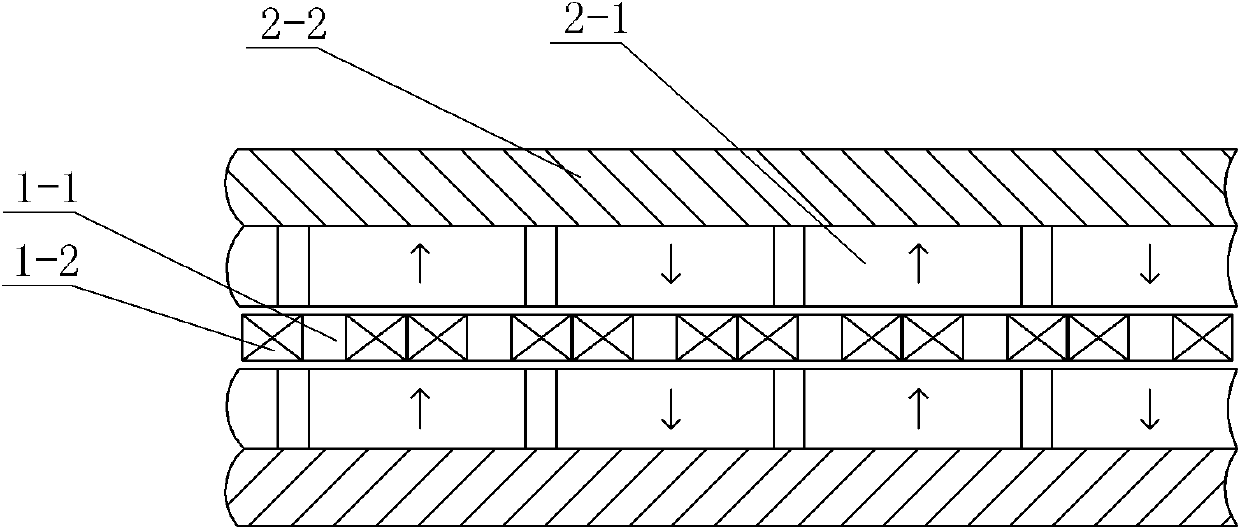

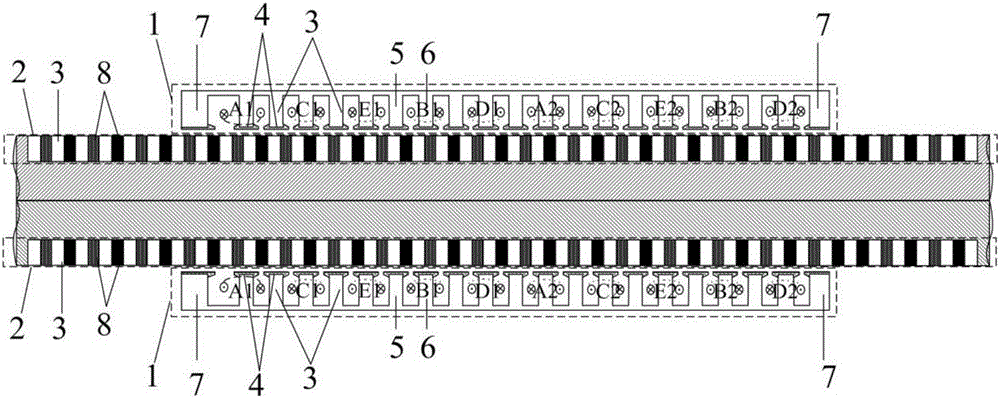

Limited stroke high-dynamic plane motor

ActiveCN102185443AIncrease output thrustIncrease the itineraryDynamo-electric machinesMotor unitControl theory

The invention relates to a limited stroke high-dynamic plane motor which belongs to the technical field of motors. The invention solves the problems of small stroke and small output thrust of the traditional synchronous short-stroke plane motor. The limited stroke high-dynamic plane motor comprises a motor unit and a rotor support mechanism, wherein the motor unit comprises a motor primary class and a motor secondary class; the motor unit has a short motor primary class and long motor secondary class structure; an air gap is arranged between the motor primary class and the motor secondary class; the motor primary class has an iron core-free structure and comprises a winding fixed support plate and four armature windings; the winding fixed support plate has a lip-rounding structure; each armature winding is correspondingly and centrally fixed on a lip-rounding frame of the fixed support plate, the four armature windings are positioned on the same plane, each armature winding is a symmetrical multiphase winding formed by a group of coils; the effective edge of the coil of each armature winding is perpendicular to the lip-rounding frame of the fixed support plate; and the motor secondary class has a double-edge structure and is symmetrically arranged at both sides of the motor primary class. The limited stroke high-dynamic plane motor is used as a plane motor.

Owner:HARBIN INST OF TECH

Low-loss half-closed trough type fault-tolerant permanent magnet cylinder linear motor and machining method thereof

InactiveCN106067720ASolve processing difficultiesImprove efficiencyMagnetic circuit stationary partsPropulsion systemsElectric machineSecondary stage

The invention discloses a low-loss half-closed trough type fault-tolerant permanent magnet cylinder linear motor and a machining method thereof. The system comprises a primary stage and a secondary stage. The length of the primary stage is smaller than the length of the secondary stage. An air gap is formed between the primary stage and the secondary stage. The primary stage is composed of a yoke part and teeth, wherein the teeth are composed of armature teeth and fault-tolerant teeth. The end portions of the teeth are provided with pole shoes. A coil winding is arranged in a tooth space. The armature teeth and the fault-tolerant teeth are the same in number and are arranged in a staggered manner. The primary stage is composed of a primary stator iron core and the primary stator iron core is composed of silicon steel sheets and an electrical pure iron. The secondary stage is composed of a permanent magnet and a secondary iron core. The permanent magnet is embedded in the secondary iron core. The secondary iron core is composed of axially laminated silicon steel sheets. Each silicon steel laminated sheet is divided into a plurality of fan-shaped laminated pieces. The inner diameter of each secondary silicon steel sheet is smaller than the inner diameter of the secondary permanent magnet. According to the invention, the low-loss half-closed trough type fault-tolerant permanent magnet cylinder linear motor is convenient to machine and manufacture, and the designing and machining cost of the motor is reduced. Meanwhile, the efficiency of the motor is improved on the basis that the performance of an original permanent magnet embedded cylindrical linear motor is ensured.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com