Bilateral mixed excitation type high-thrust linear synchronous motor

A linear synchronous and hybrid excitation technology, applied in electrical components, electromechanical devices, propulsion systems, etc., can solve the problems of difficult magnetic adjustment of air-gap magnetic fields and low thrust density, and reduce edge effects, improve thrust density, gas density, etc. The effect of flexible and adjustable gap magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

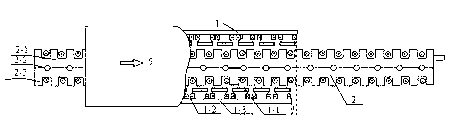

[0018] based on the following Figure 1 to Figure 4 , specifically explain the preferred embodiment of the present invention.

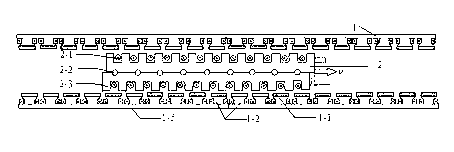

[0019] The present invention provides a double-sided hybrid excitation high-thrust linear synchronous motor, which includes a magnetic pole 1 and an armature 2. The armature is in the form of double-sided back-to-back, and the double-sided magnetic pole 1 is arranged on both sides of the armature 2.

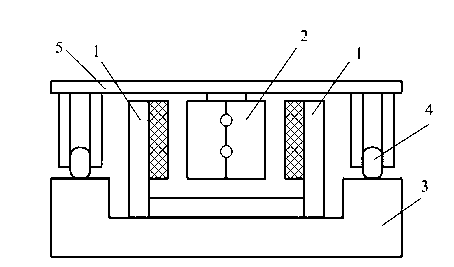

[0020] The magnetic pole 1 includes a toothed back iron 1-3, an adjustable DC field winding 1-2 embedded between the teeth of the back iron 1-3, and a permanent magnet 1-1 arranged on the teeth of the back iron 1-3 . Adjacent permanent magnets 1-1 have opposite polarities.

[0021] Such as Figure 4 As shown, the armature 2 includes two toothed armature cores 2-3 facing away from each other, and several cooling pipe slots are arranged on the back of the armature cores 2-3. The armature 2 also includes an armature winding 2-1 arranged between the teet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com