Low-loss half-closed trough type fault-tolerant permanent magnet cylinder linear motor and machining method thereof

A semi-closed slot, linear motor technology, used in electrical components, electromechanical devices, electric components, etc., can solve problems such as increasing eddy current loss, and achieve the effect of reducing eddy current loss, compact structure, and reducing processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

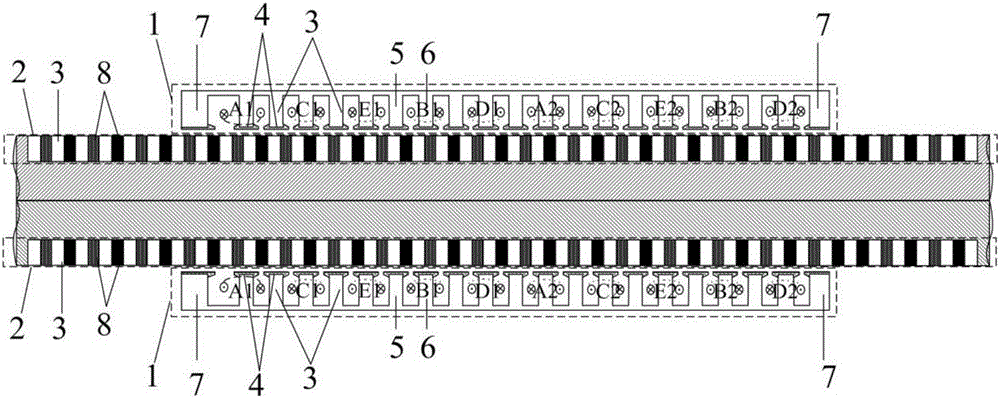

[0036] In order to explain the structural features and beneficial effects of the semi-closed slot fault-tolerant permanent magnet cylindrical linear motor of the present invention more simply and clearly, a detailed description will be given below in conjunction with a specific five-phase fault-tolerant permanent magnet cylindrical linear motor.

[0037] In order to illustrate the present invention more clearly, the pole-slot ratio of the semi-closed slot-type fault-tolerant permanent magnet cylindrical linear motor of the present invention is embodied, and m=5 is selected, which is a five-phase motor, and the corresponding number of slots and poles of the motor N respectively s =2*m*2=20,N p =18. And the cylindrical linear motor of this embodiment adopts the concentrated winding phase-splitting mode.

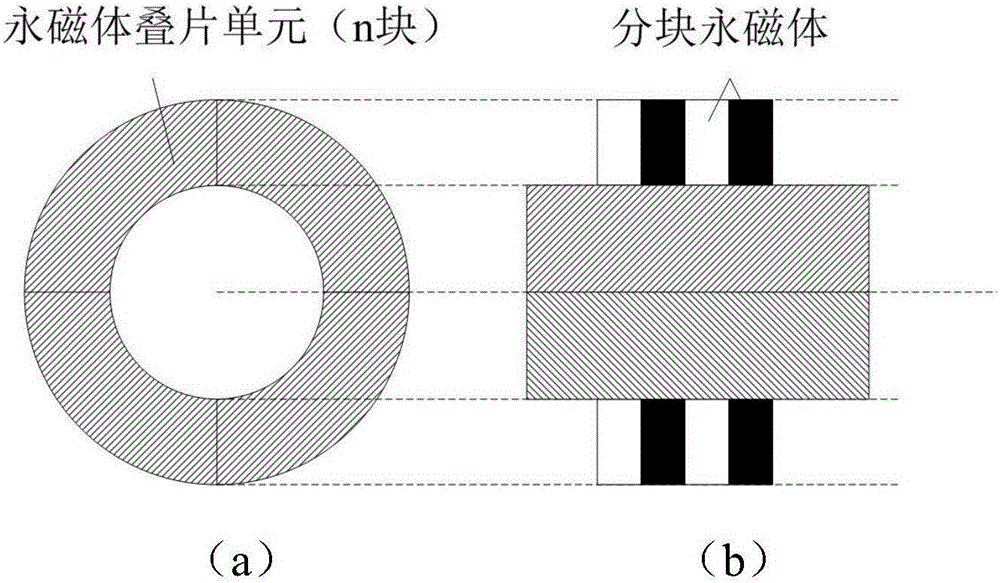

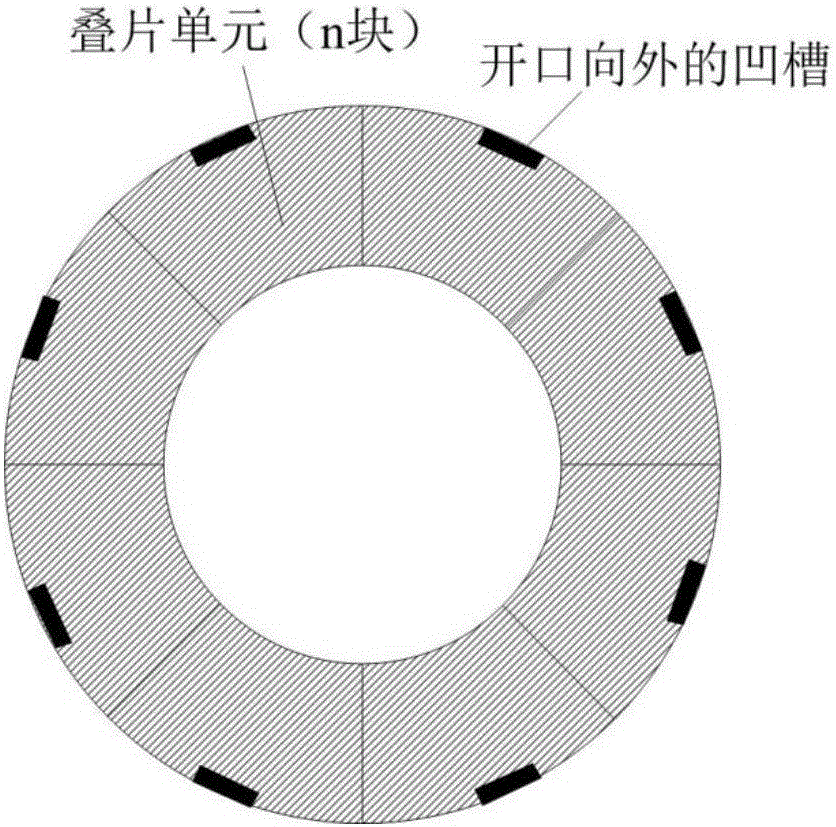

[0038] Such as figure 1 The shown st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com