Patents

Literature

342 results about "Electromagnetic suspension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electromagnetic suspension (EMS) is the magnetic levitation of an object achieved by constantly altering the strength of a magnetic field produced by electromagnets using a feedback loop. In most cases the levitation effect is mostly due to permanent magnets as they don't have any power dissipation, with electromagnets only used to stabilize the effect.

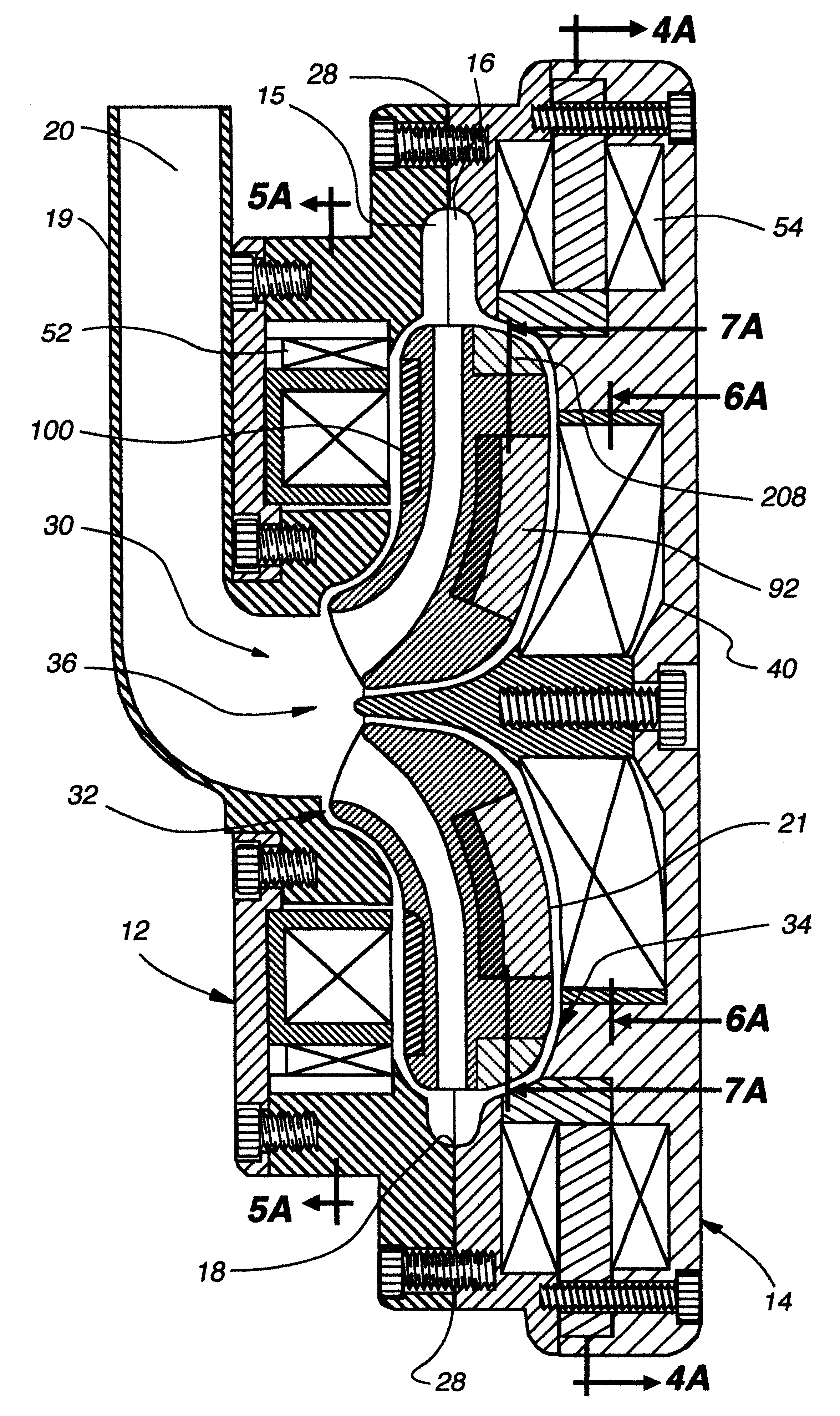

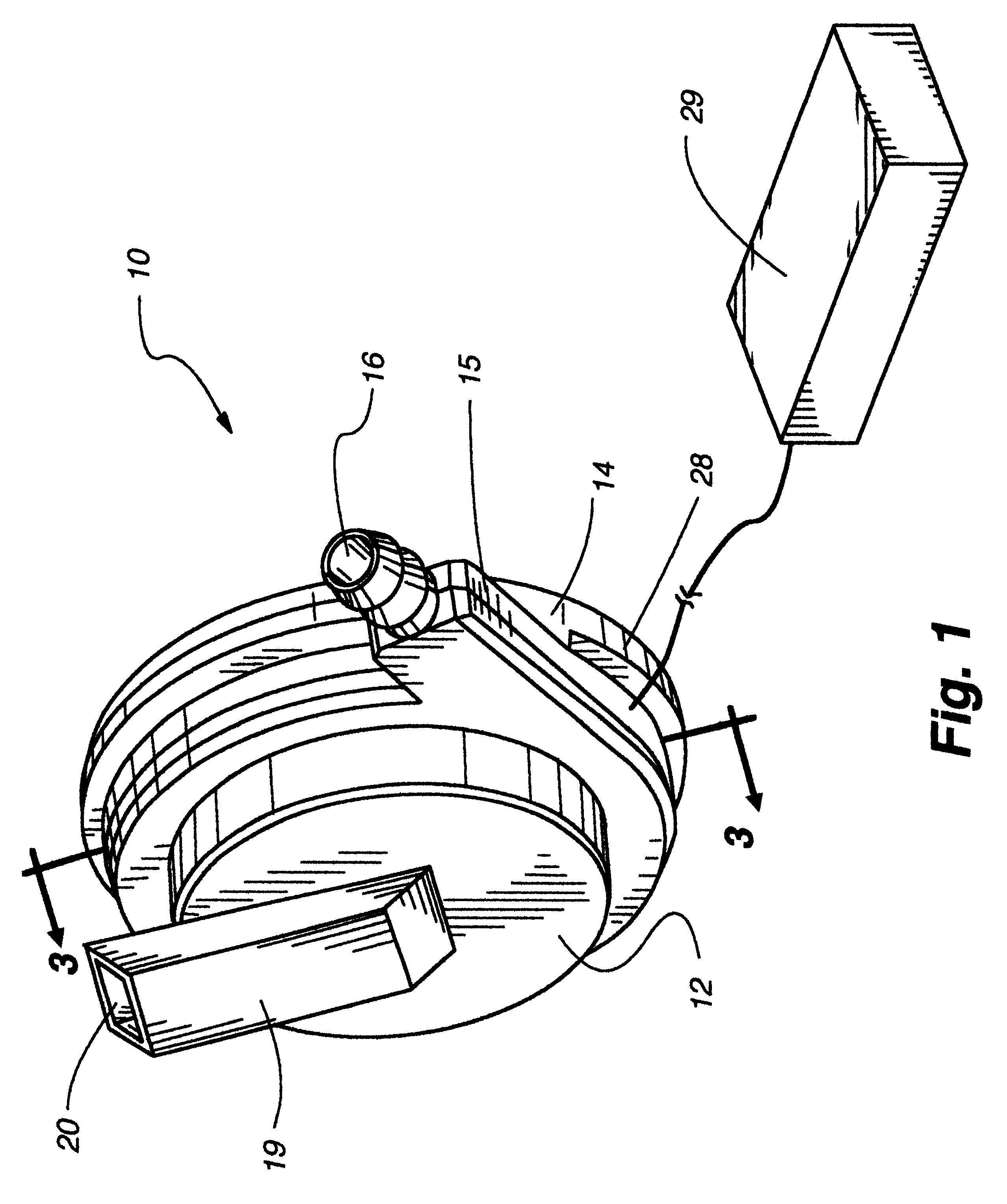

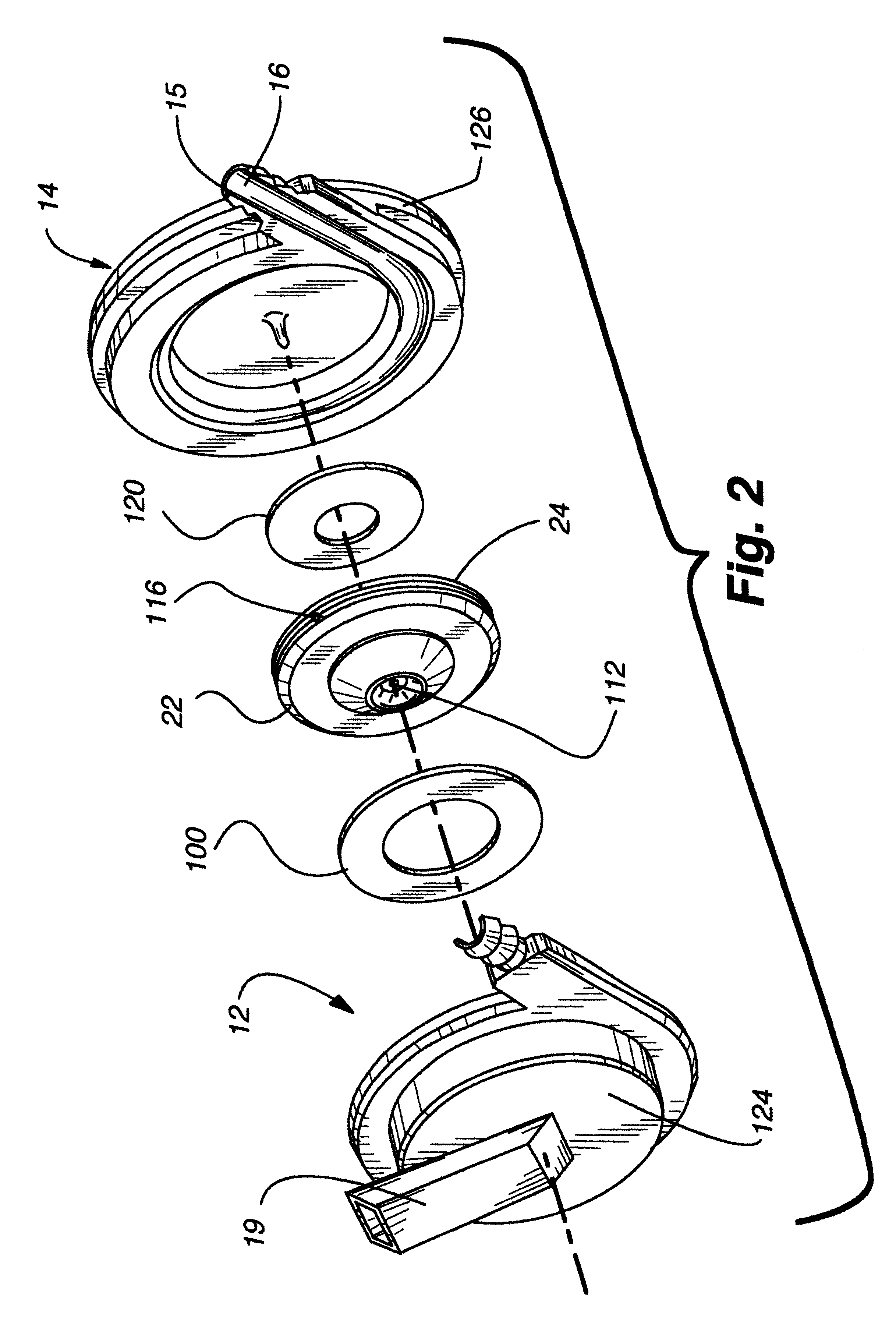

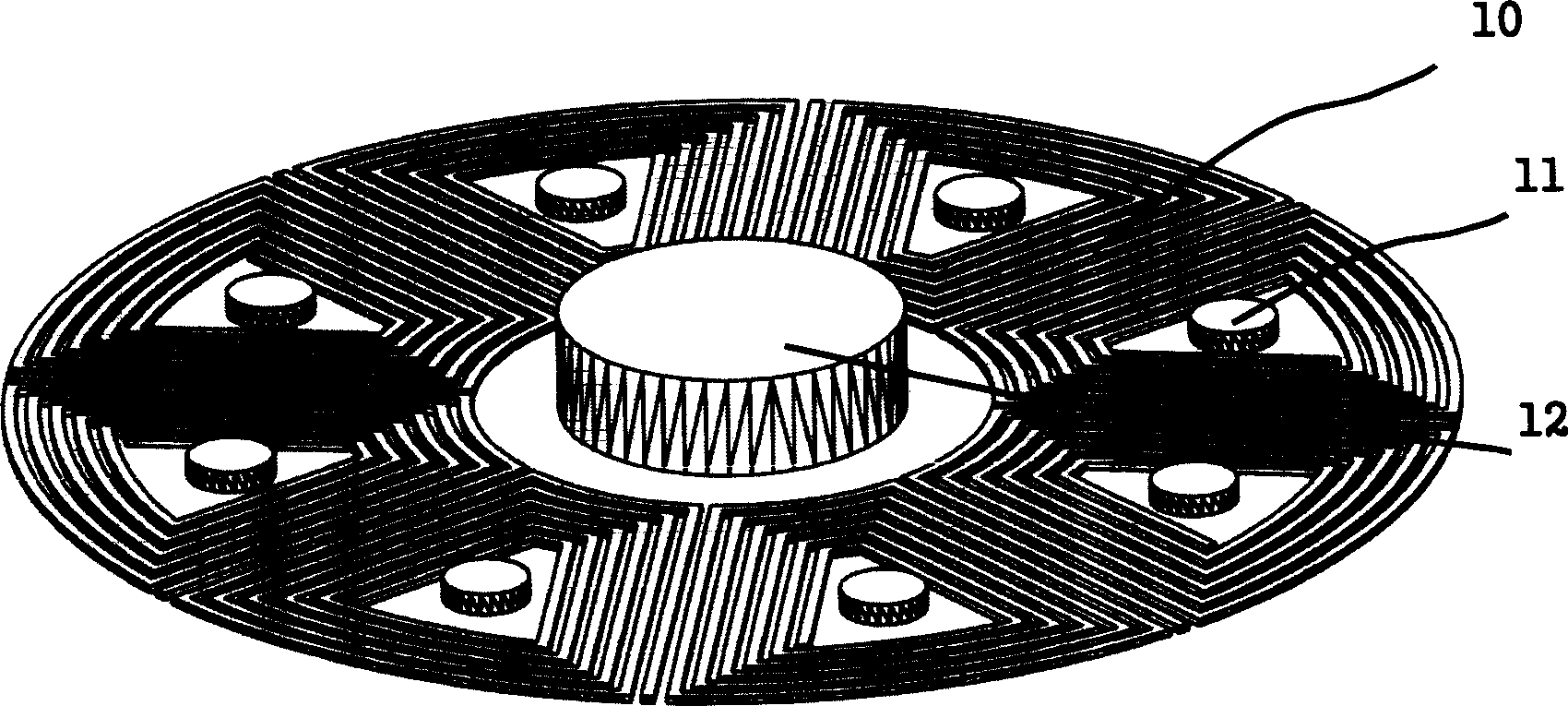

Electromagnetically suspended and rotated centrifugal pumping apparatus and method

InactiveUS6302661B1Increase energy lossIncrease frictionSpecific fluid pumpsPump componentsElectric machineryEngineering

An apparatus and method for a centrifugal pump for pumping sensitive biological fluids which includes (i) an integral impeller and rotor which is electromagnetically supported and rotated, (ii) a pump housing and arcuate passages for fluid flow and containment, (iii) a brushless driving motor embedded and integral with the pump housing, (iv) a power supply, and (v) specific electronic sensing and control algorithms-all fitly joined together to provide efficient, durable and low maintenance pump operation. A specially designed impeller and pump housing provide the mechanism for transport and delivery of fluid through the pump to a pump output port with reduced fluid turbulence.

Owner:WORLD HEART

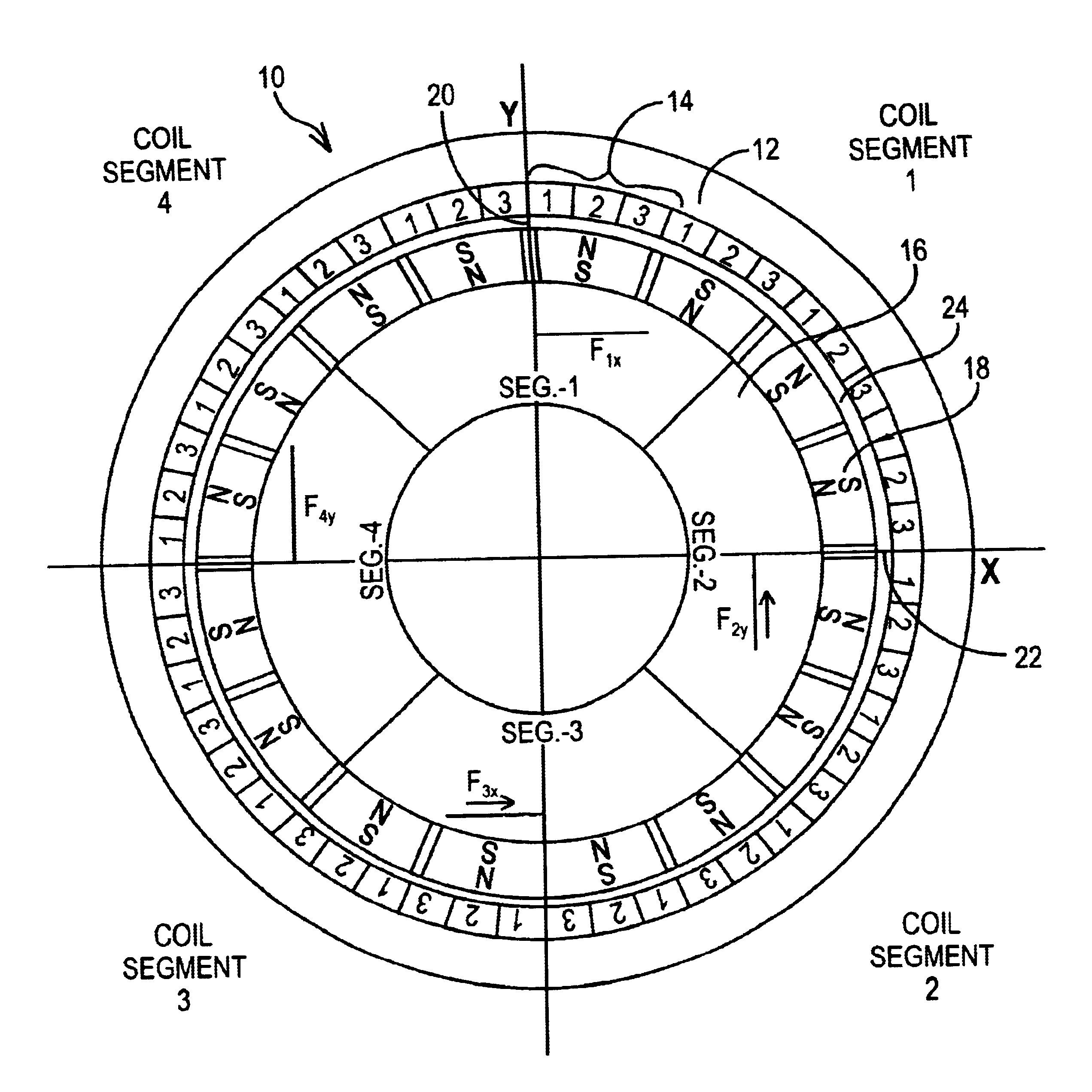

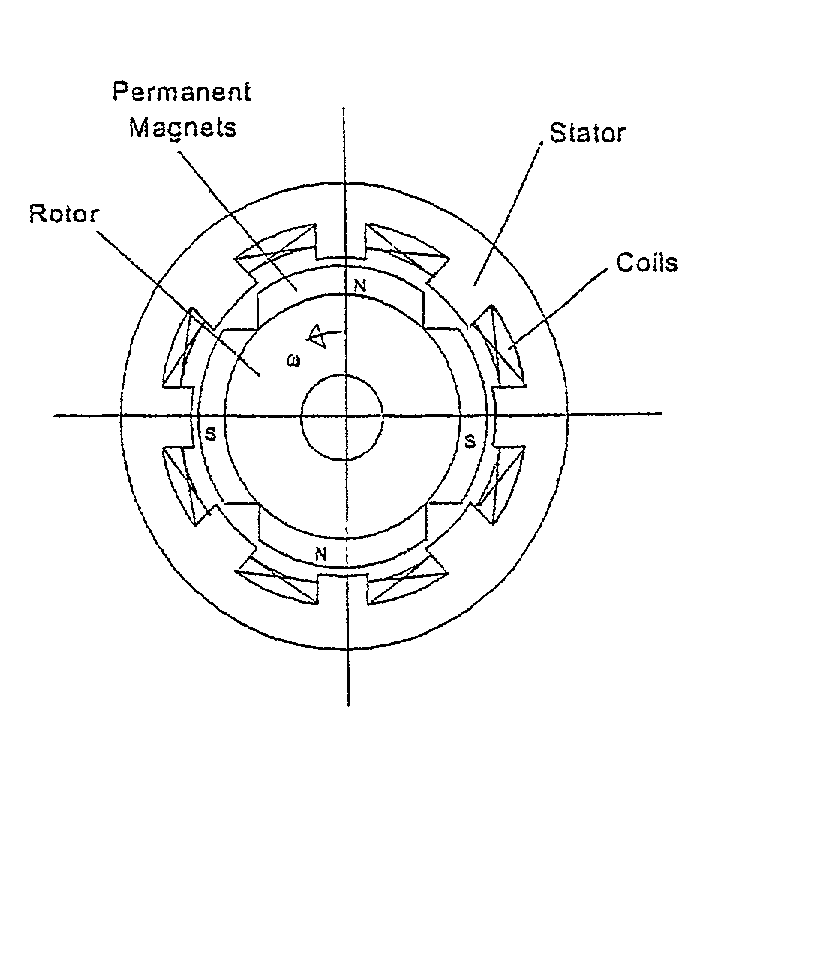

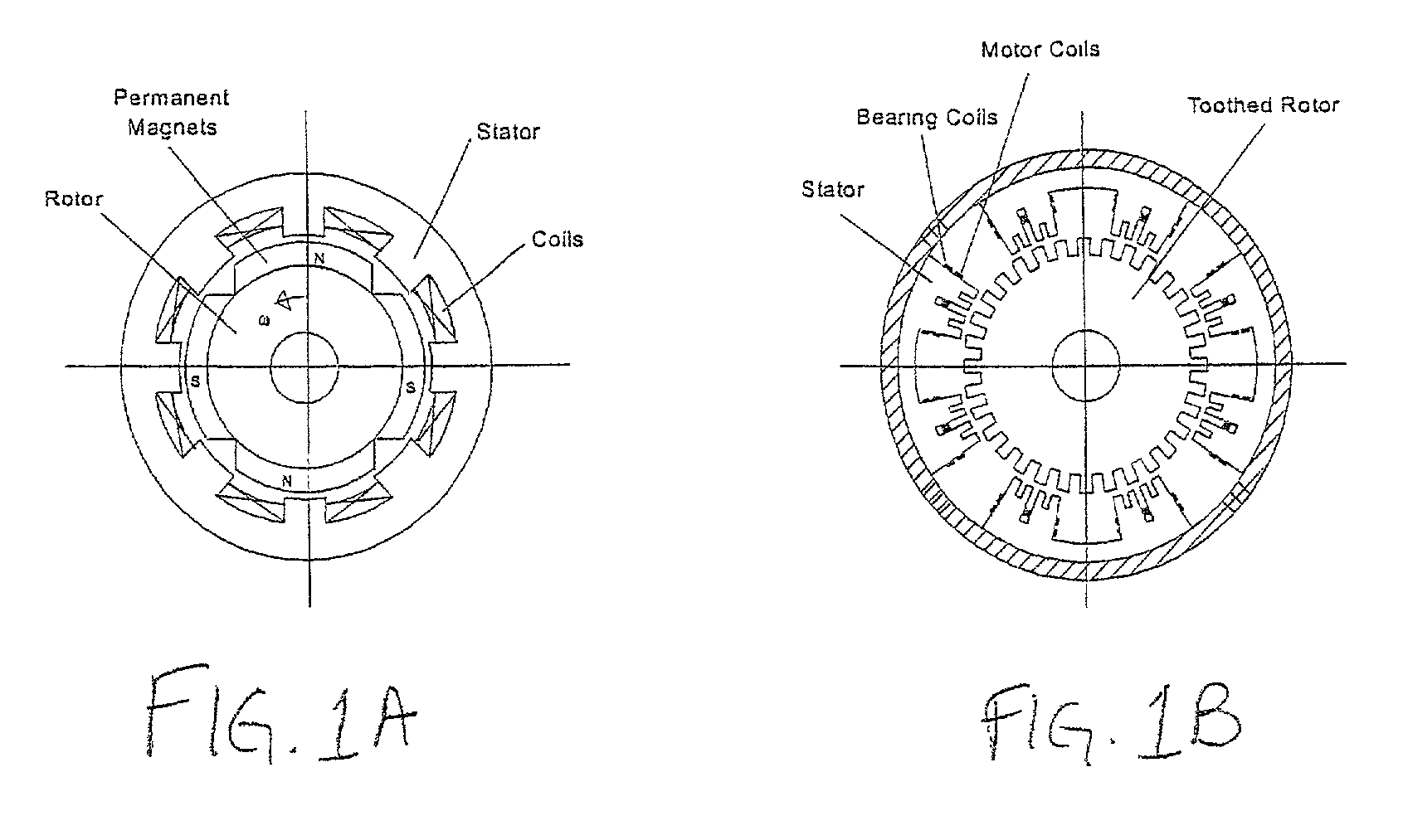

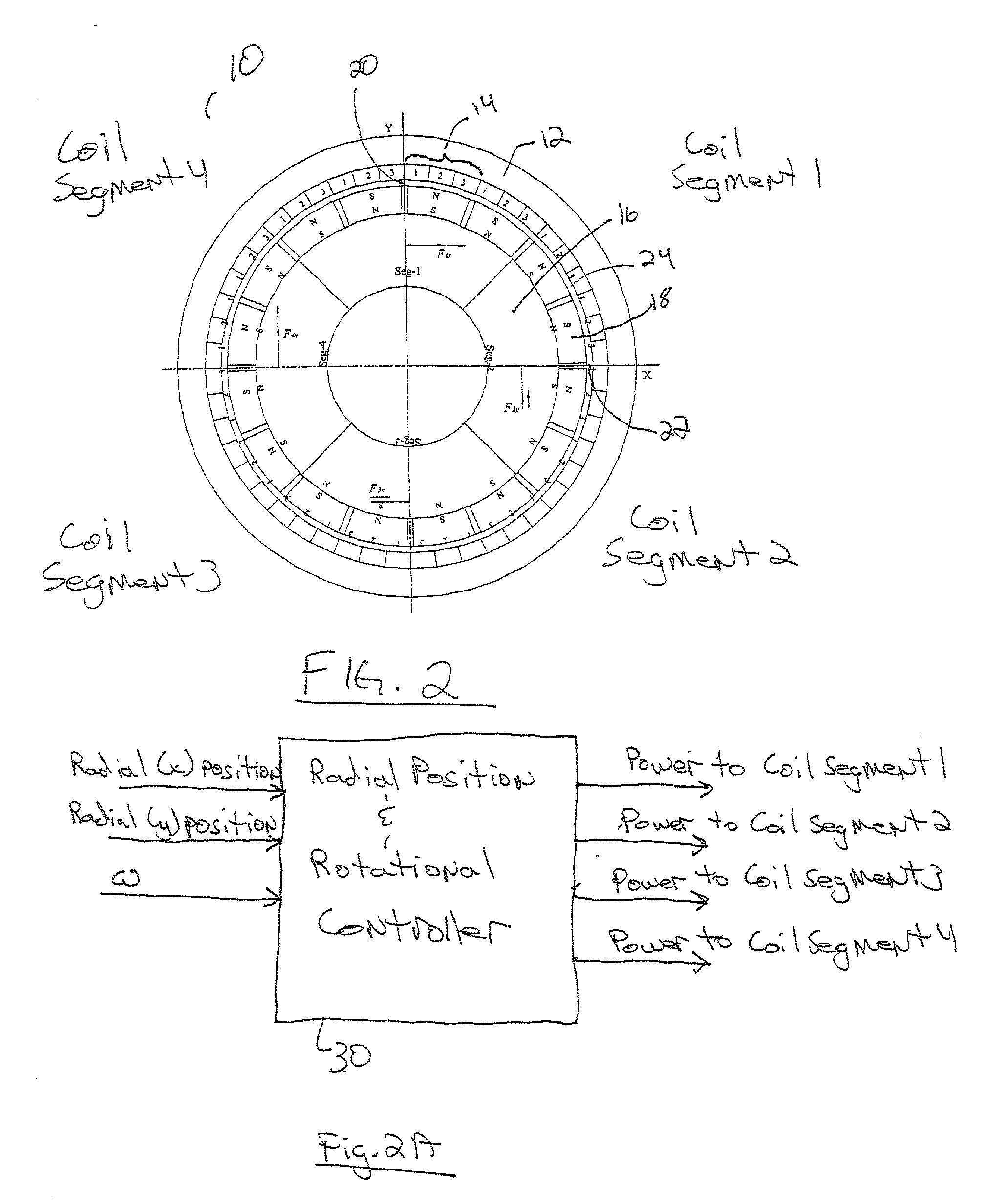

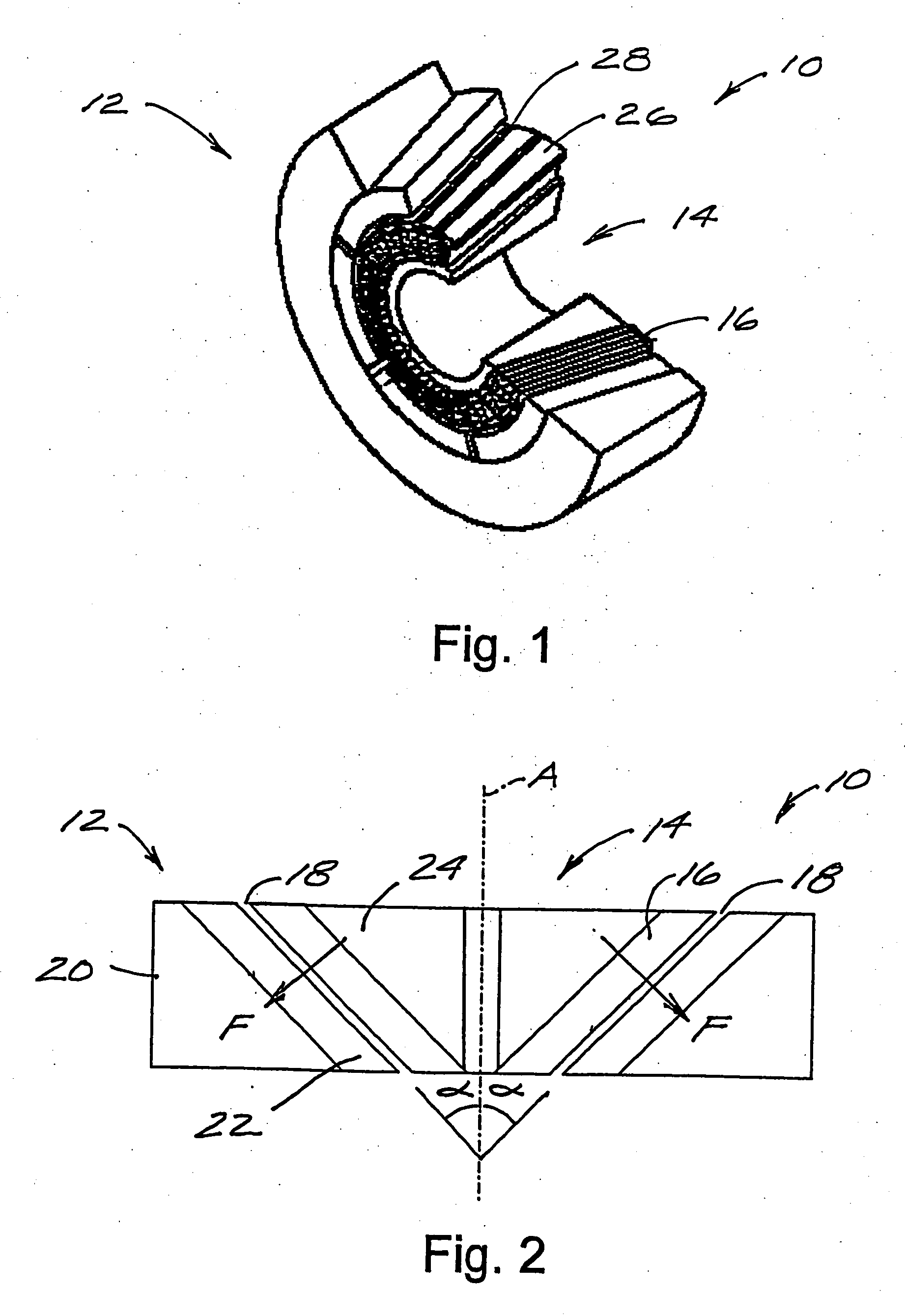

Integrated magnetic bearing

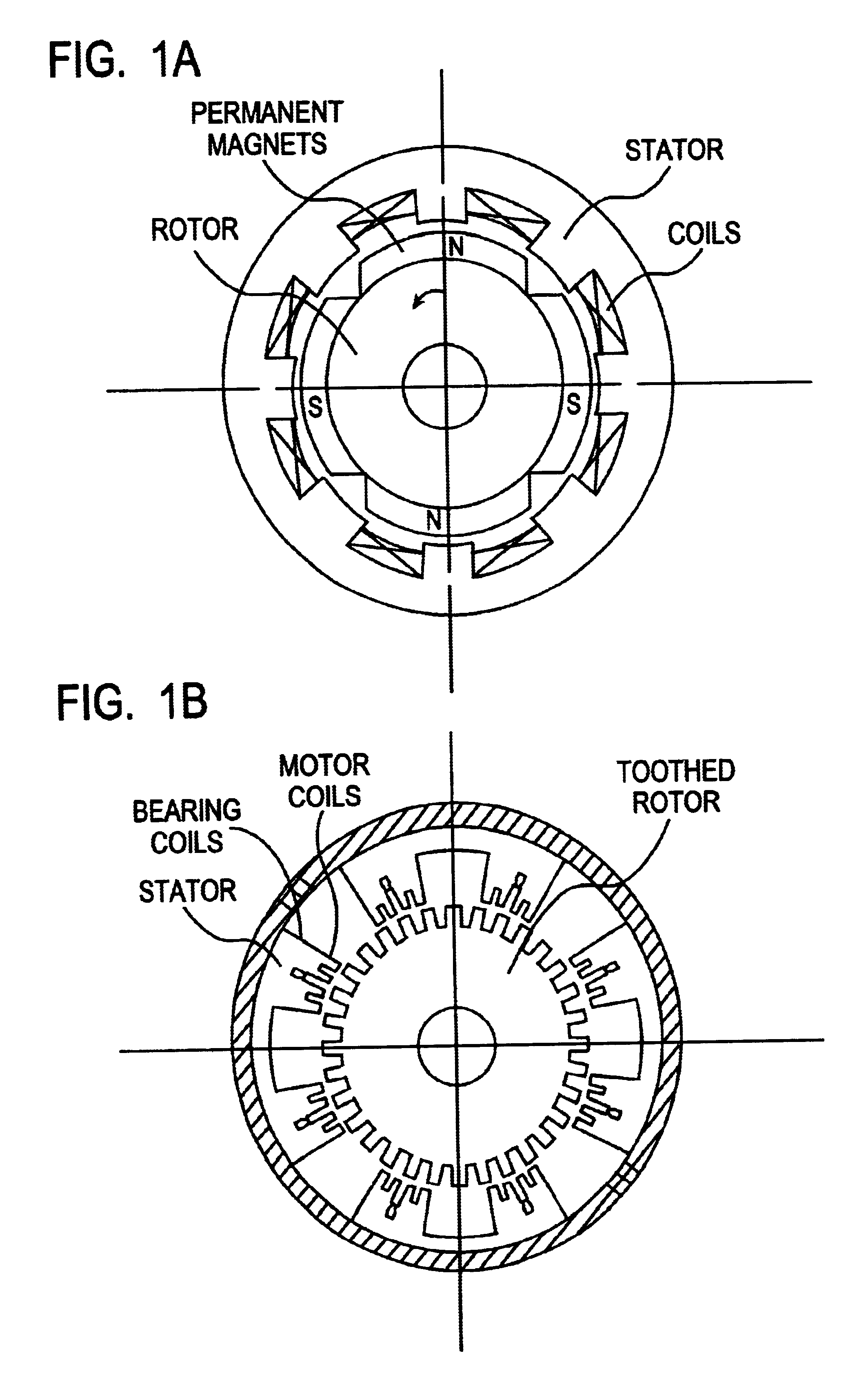

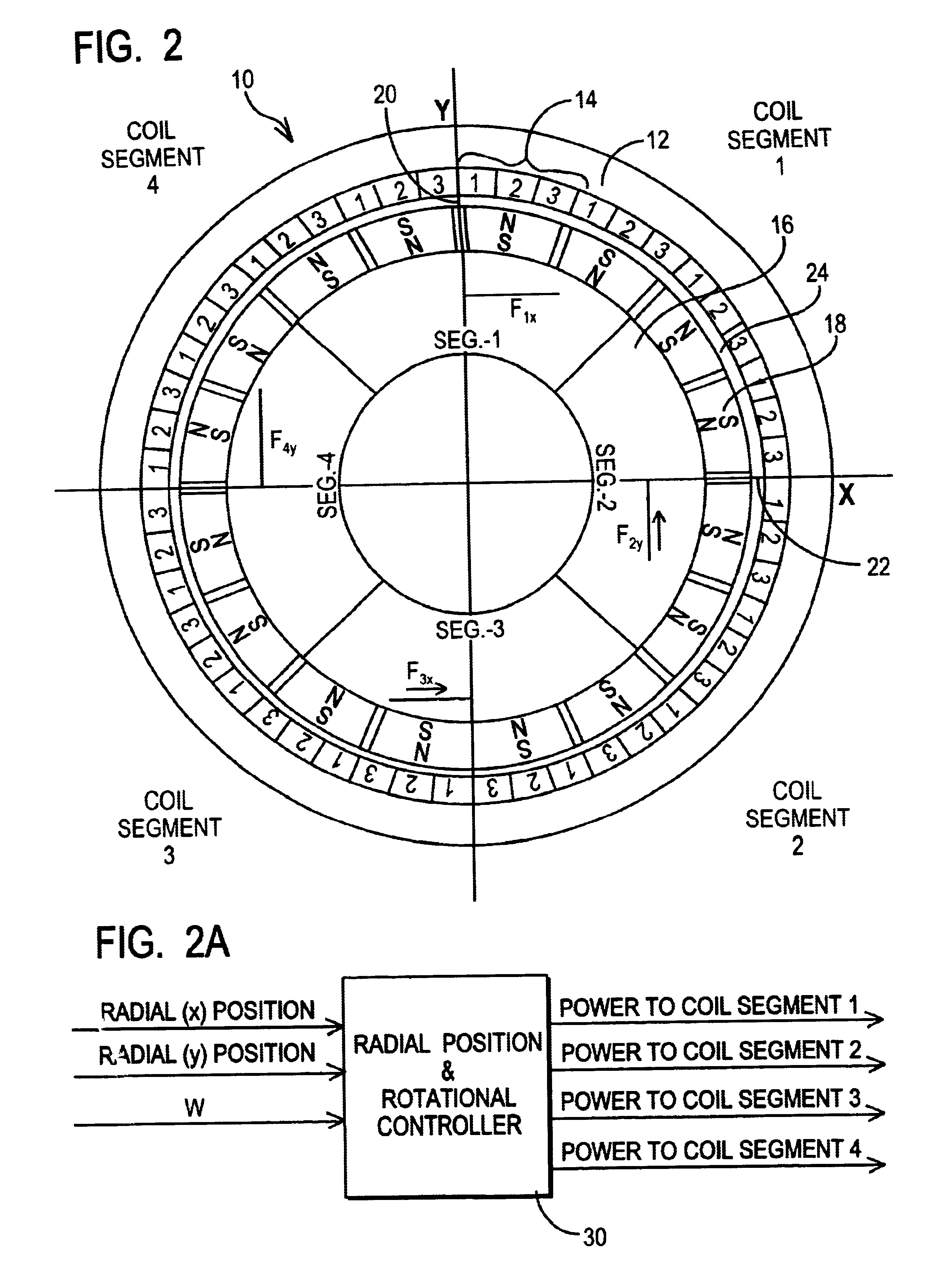

The present invention provides a rotational magnetic gimbal with an integral magnetic bearing. Brushless DC motor technology provides electromagnetic suspension, using a single electromagnetic actuator to perform both the radial bearing and rotary torque (motoring) functions. An integrated motor and magnetic bearing consistent with the invention comprises a rotor comprising a plurality of permanent magnets and a stator comprising a plurality of independently controlled coil segments magnetically coupled to the permanent magnets. Embodiments may further comprise first and second radial position sensors, the first radial position sensor disposed in or adjacent to a clearance gap between the rotor and the stator for sensing the position of the rotor with respect to the stator along a first axis, and a second radial position sensor disposed in or adjacent to the clearance gap between the rotor and the stator for sensing the position of the rotor with respect to the stator along a second axis. In method form, a method for providing integral electromagnetic motor and bearing functions comprises sensing a first radial position of a rotor, the rotor comprising a plurality of permanent magnets, with respect to a stator along a first axis, the stator comprising a plurality of independently controlled coil segments magnetically coupled to the permanent magnets; and sensing a second radial position of the rotor with respect to the stator along a second axis; and delivering current to at least one coil segment, the amount of current based on at least one sensed position.

Owner:AIREX CORP

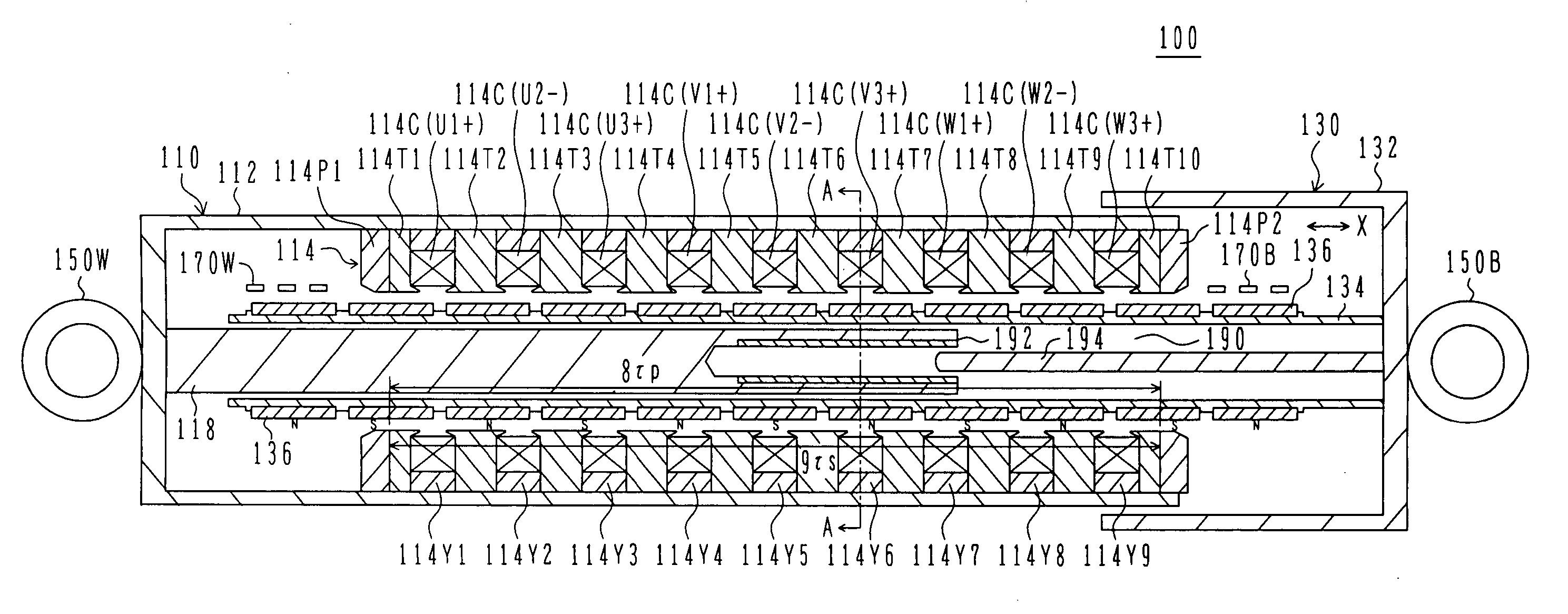

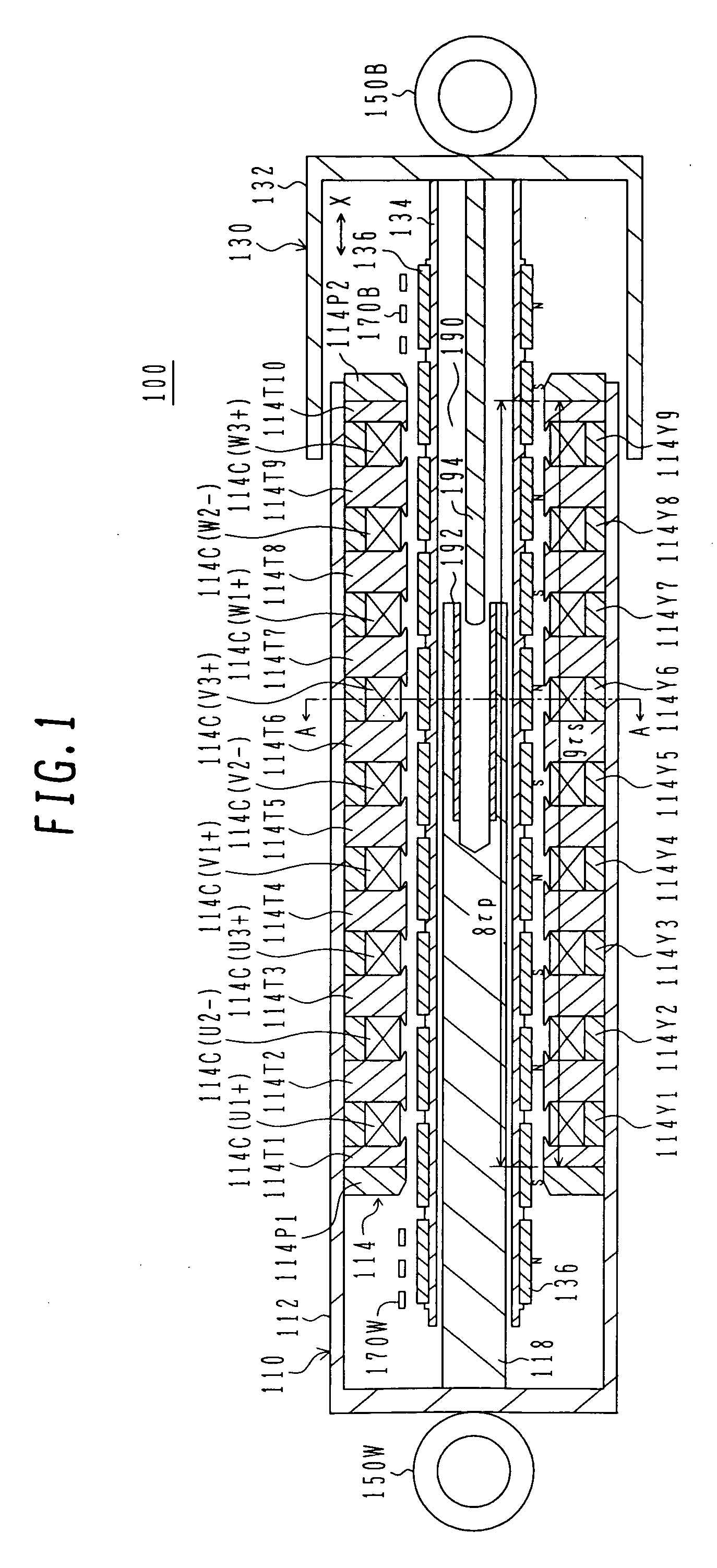

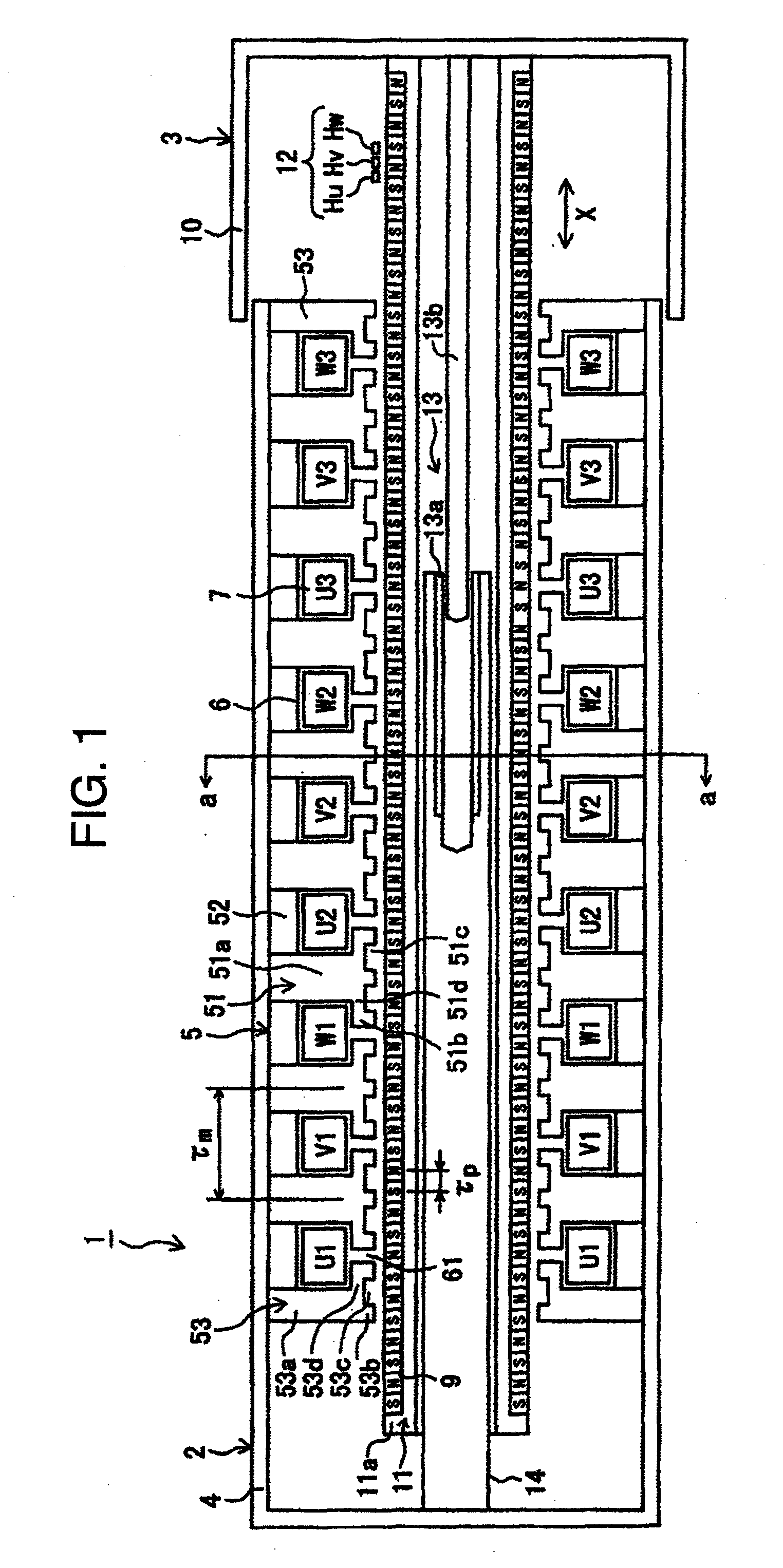

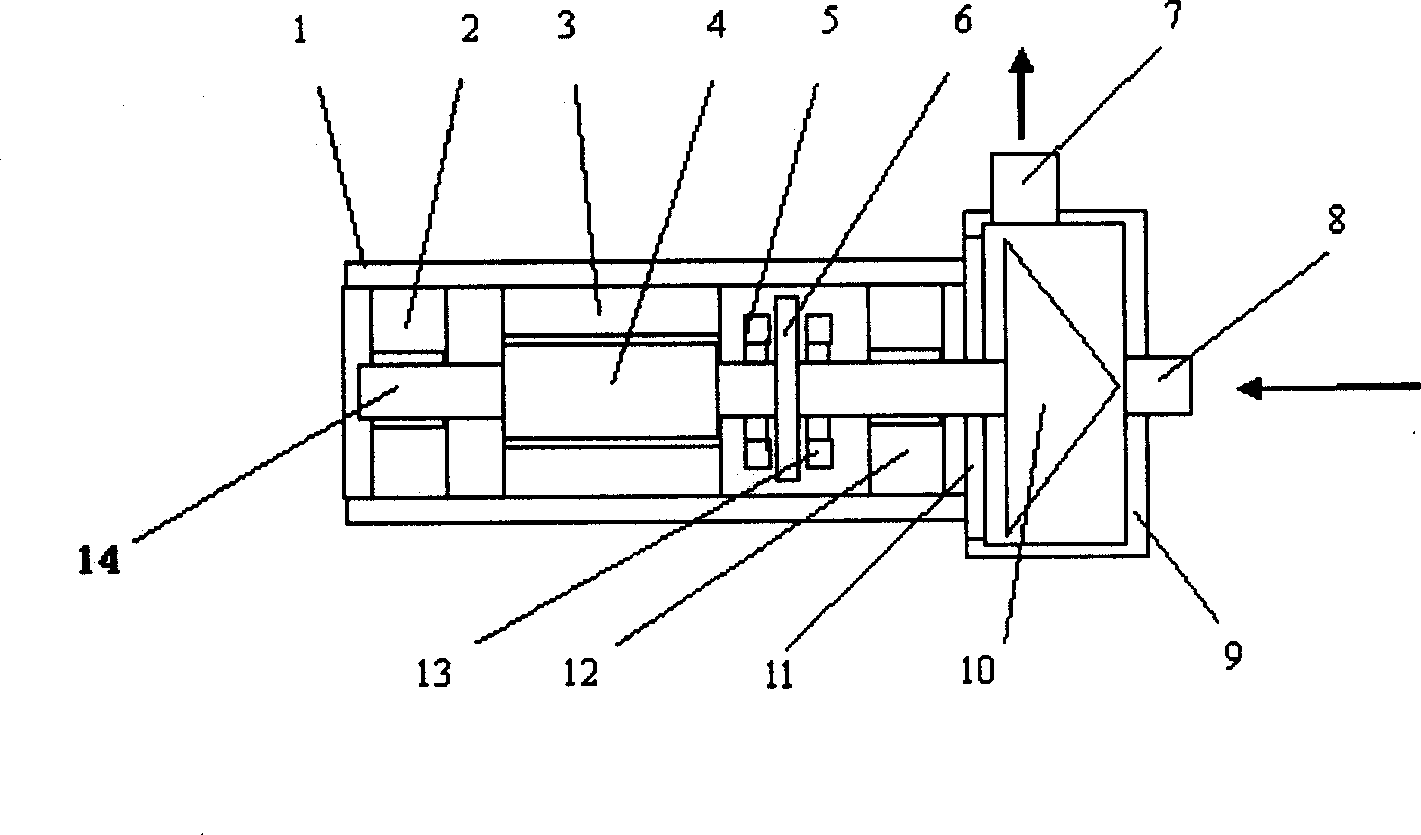

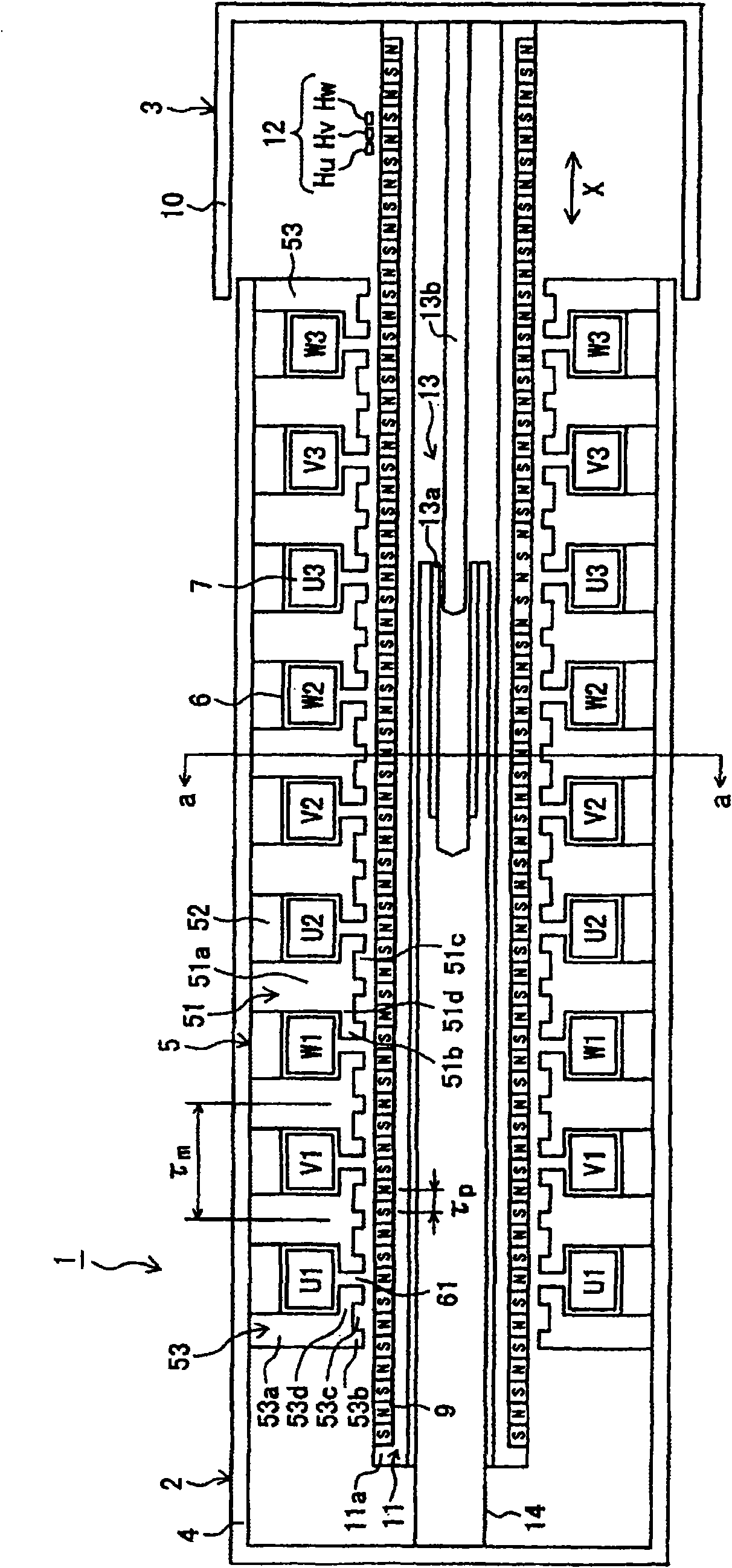

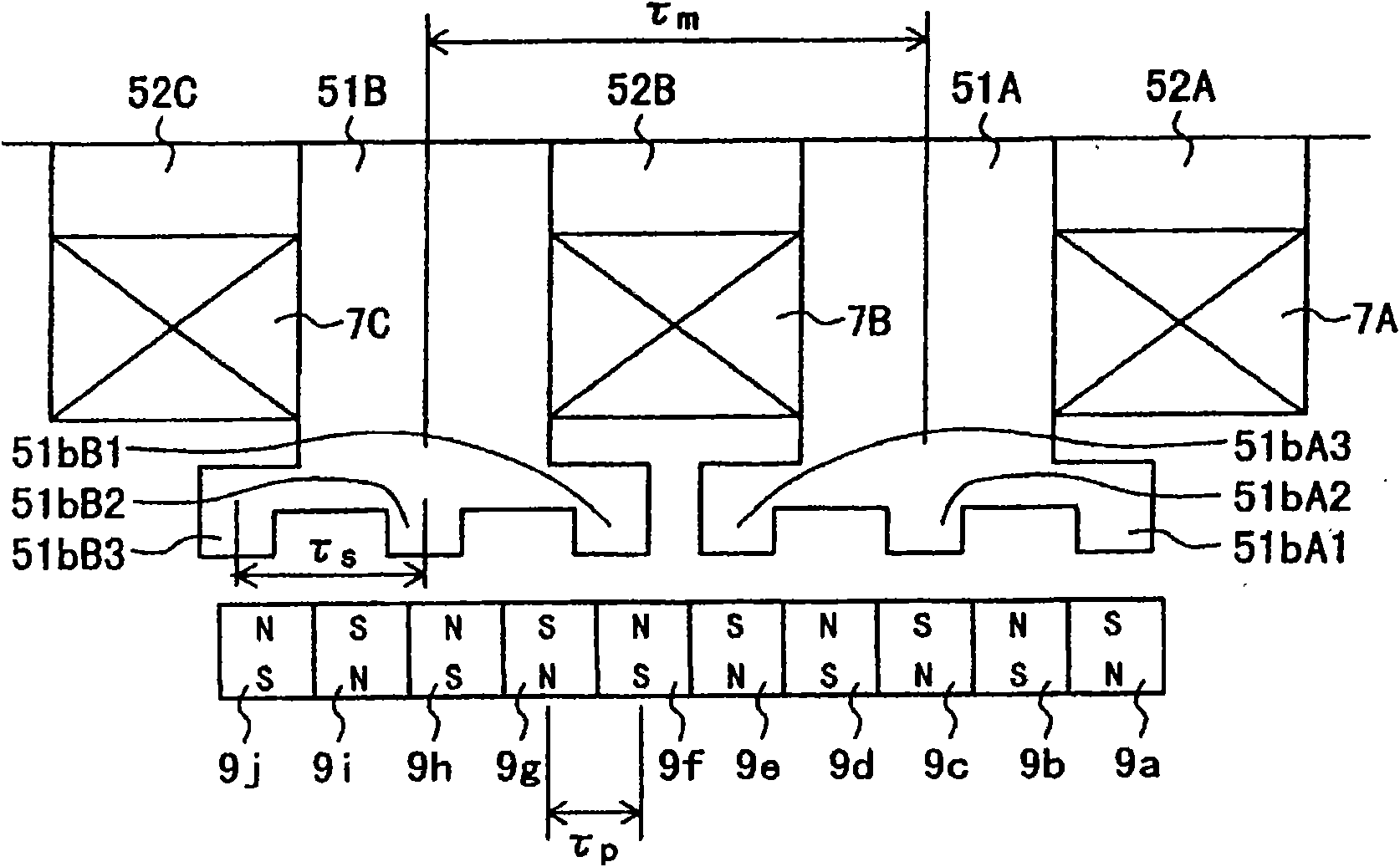

Cylindrical linear motor, electromagnetic suspension, and vehicle using the same

InactiveUS20060181158A1Reduce torque pulsation torqueReduce torque cogging torqueResilient suspensionsPropulsion systemsElectric machineEngineering

A cylindrical linear motor, an electromagnetic suspension, and a vehicle using the same, which can generate a large thrust and reduce torque pulsations and cogging torque. The cylindrical linear motor comprises a stator and a slider disposed with a gap left relative to the stator and being linearly movable relative to the stator. The stator comprises a stator core having stator salient poles, and 3-phase stator windings inserted in slots formed in the stator core. The slider comprises a plurality of permanent magnets fixed to a slider core. The motor satisfies τp:τs=9:9±1 where τs is a pitch of the stator salient poles and τp is a pitch of the permanent magnets.

Owner:HITACHI LTD

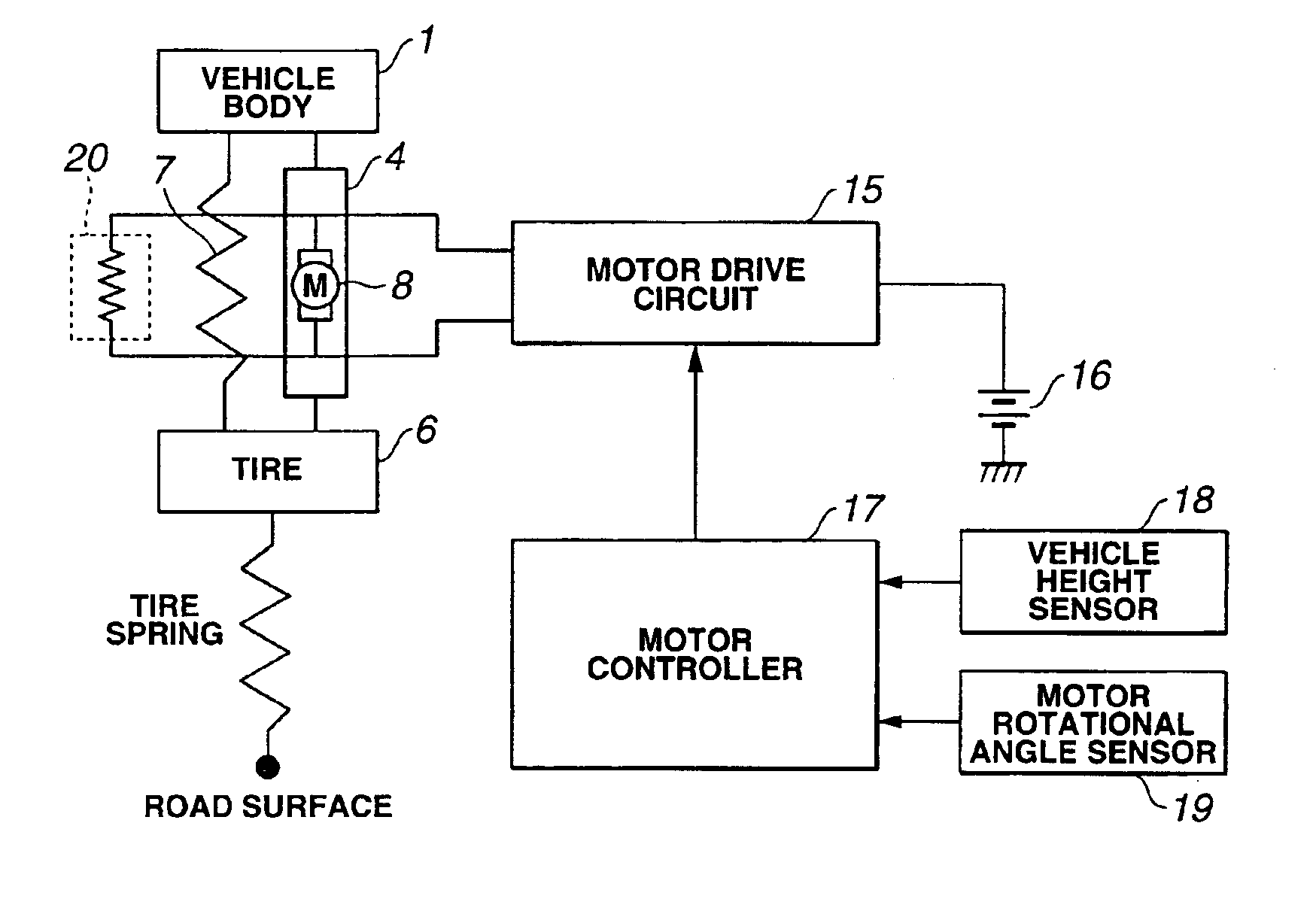

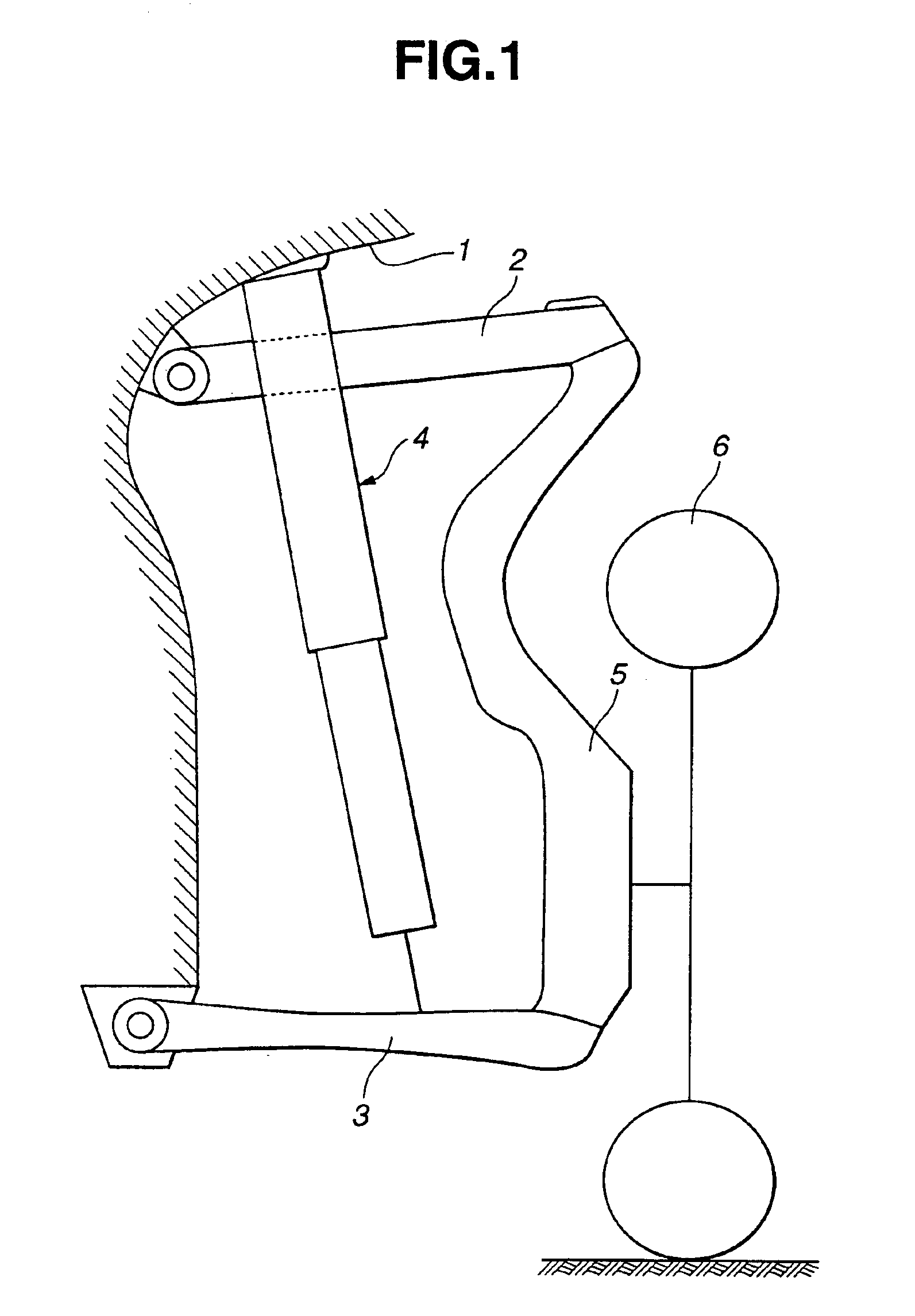

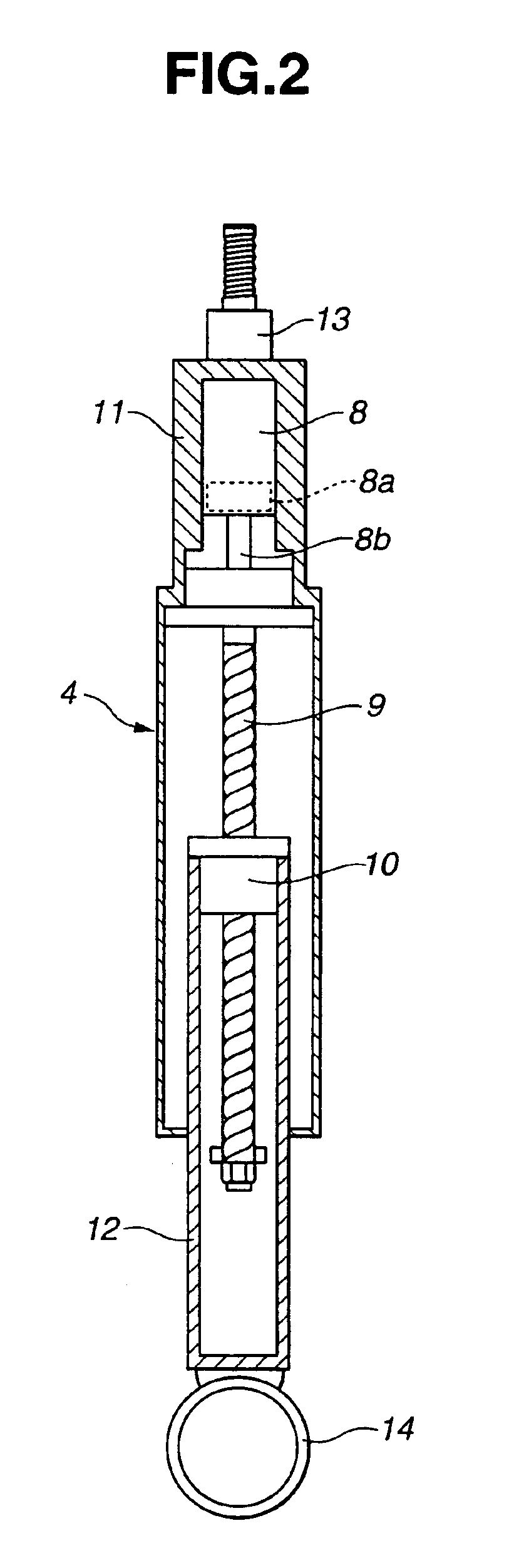

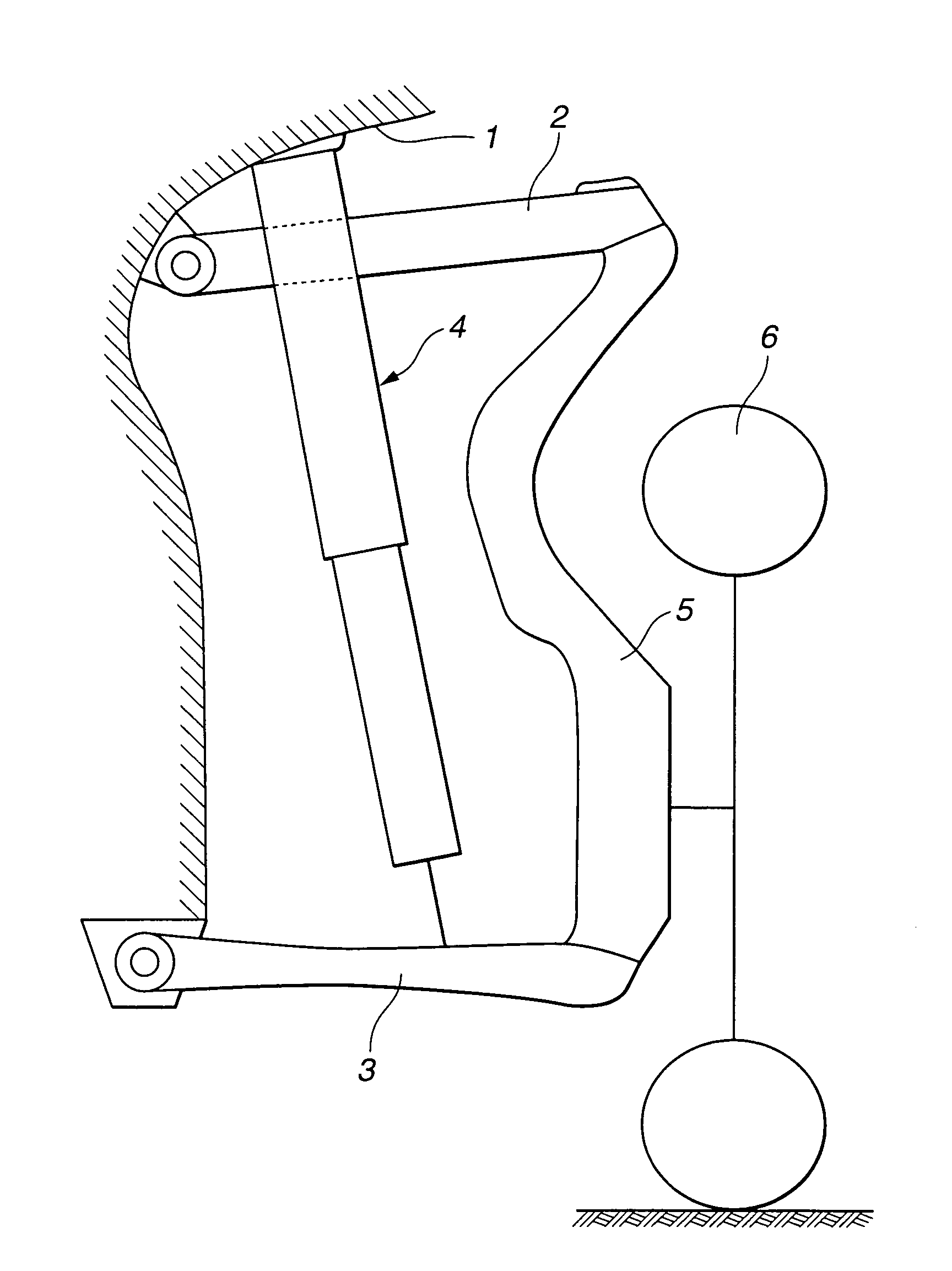

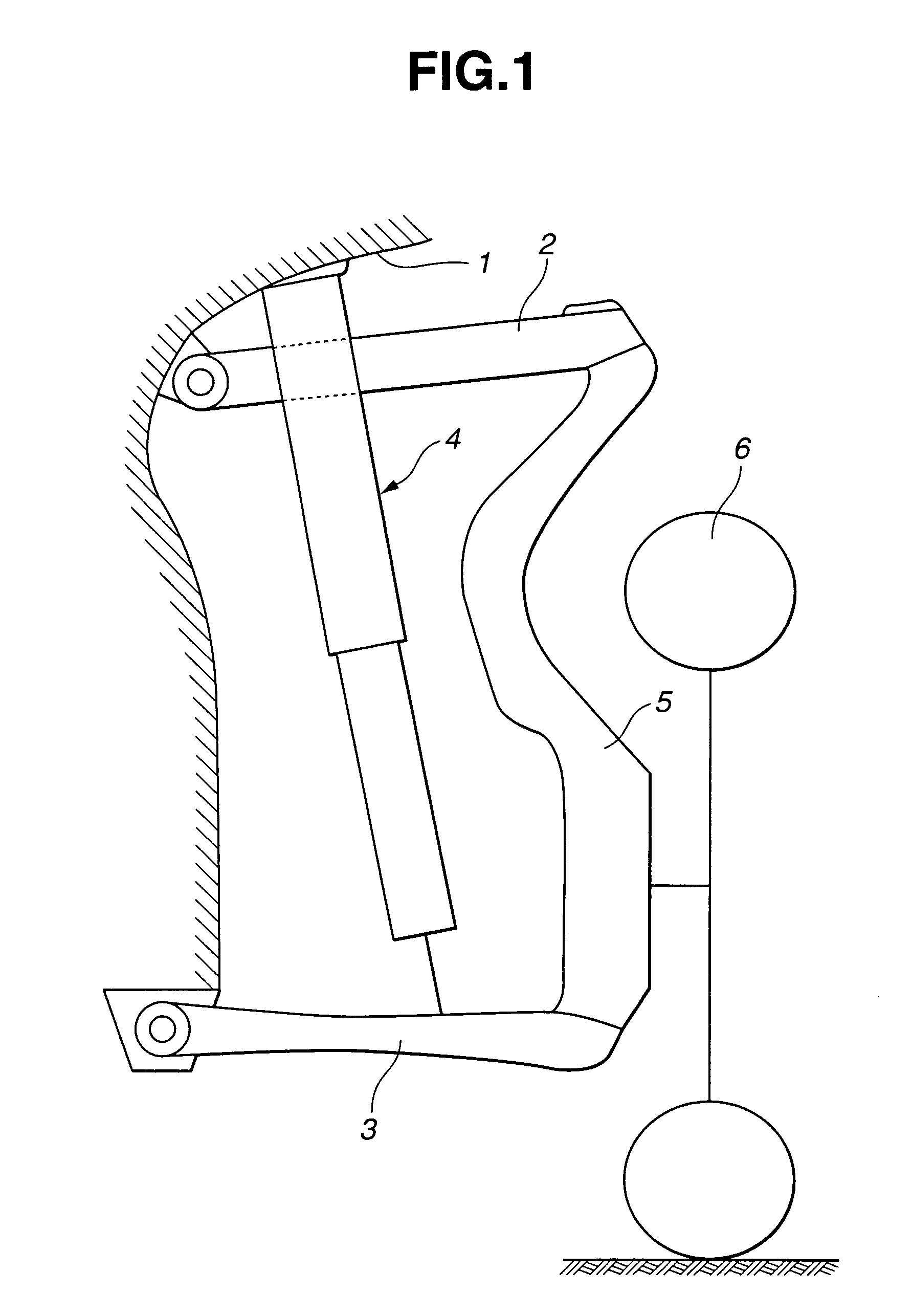

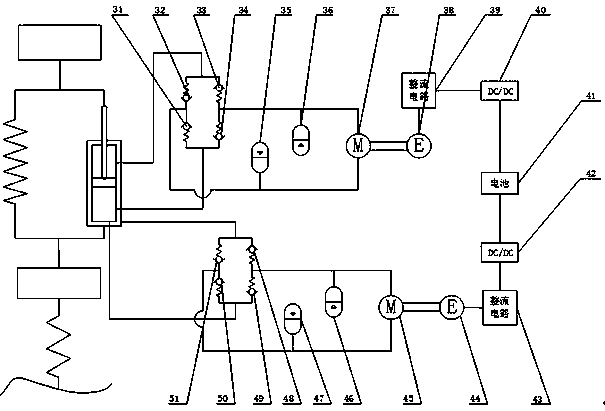

Electromagnetic suspension system for vehicle

ActiveUS7005816B2Effectively overcome drawbacksEasy to controlAuxillary drivesLiquid resistance brakesElectricityMotor control

An electromagnetic suspension system for a vehicle, comprises an electromagnetic actuator interposed between a sprung mass and an unsprung mass and disposed substantially in parallel with an spring element. An electric motor is provided for driving the electromagnetic actuator. A motor controller is configured to calculate a displacement input applied to the electromagnetic actuator and to control the electric motor in a manner that the electromagnetic actuator generates an optimum damping force corresponding to the displacement input. A motor control circuit is provided for the electric motor, through which the electric motor is connected to the motor controller. Additionally, an electrical damping element is electrically connected to the motor control circuit and in parallel with the electric motor to generate a damping force in a passive manner under a dynamic braking of the electric motor in response to the displacement input to the electromagnetic actuator from the unsprung mass.

Owner:NISSAN MOTOR CO LTD

Electromagnetic suspension apparatus for automotive vehicles and method for controlling electric motor of the same

InactiveUS7270335B2Lower performance requirementsLowering drivabilityAuxillary drivesLiquid resistance brakesEngineeringControl theory

An electromagnetic suspension apparatus for an automotive vehicle, employs an electromagnetic actuator interleaved between a sprung mass and an unsprung mass and arranged in parallel with a suspension spring element, and an electric motor built in the electromagnetic actuator for driving the electromagnetic actuator. A motor controller calculates a displacement input, such as a suspension stroke acceleration and a suspension velocity, transmitted to the electromagnetic actuator, and controls the motor to bring a suspension damping force closer to a desired damping force suited for the displacement input. The motor controller calculates an internal inertia force of the electromagnetic actuator, and corrects or compensates for a motor output by the internal inertia force of the electromagnetic actuator.

Owner:NISSAN MOTOR CO LTD

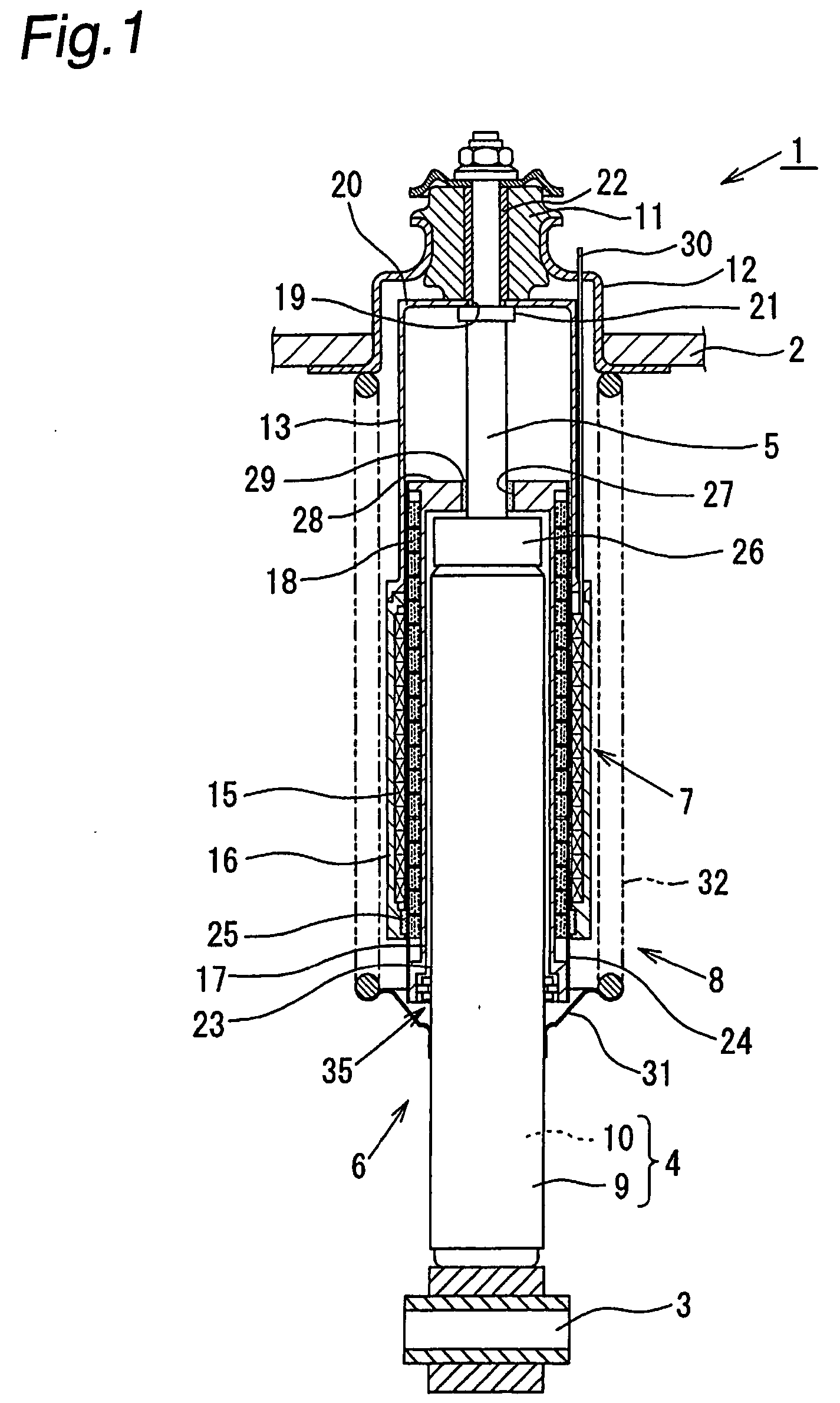

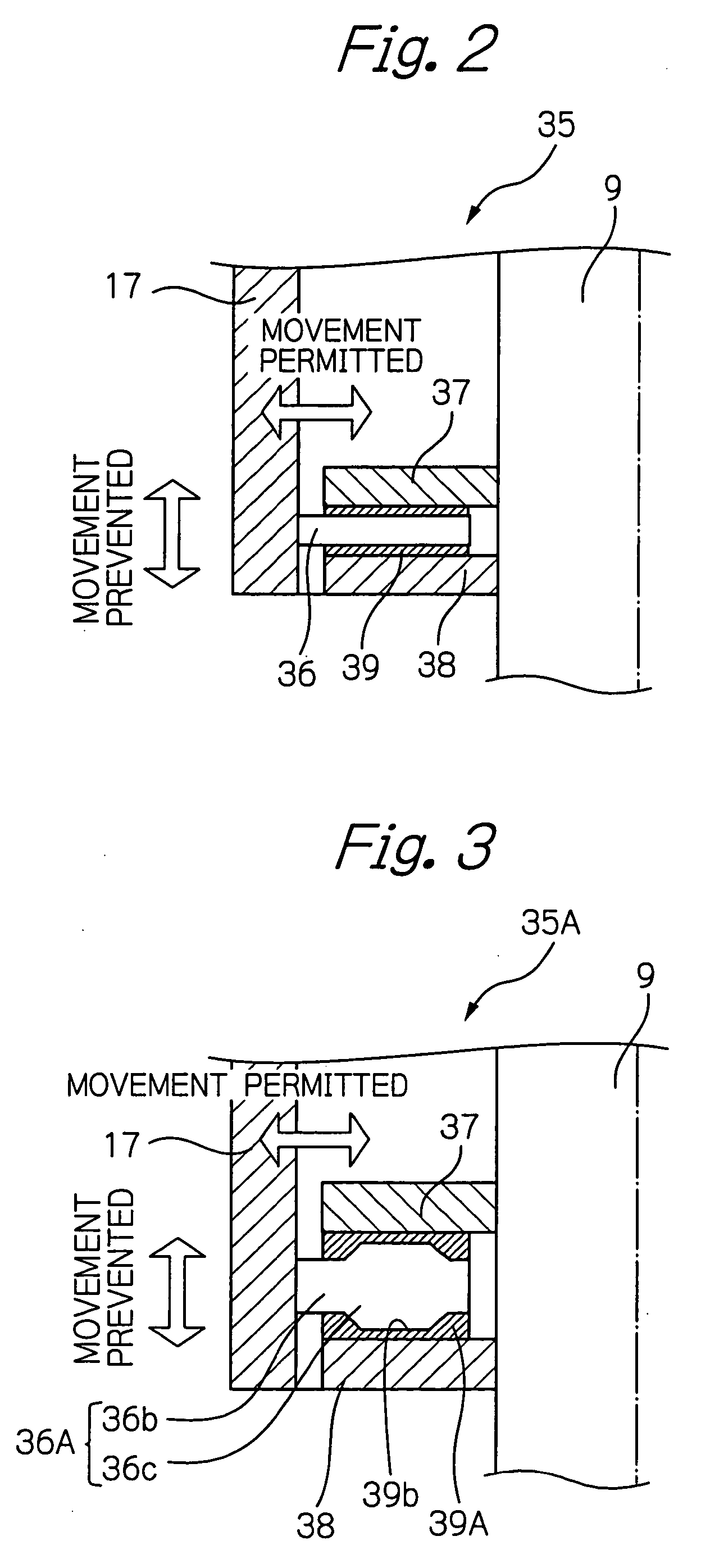

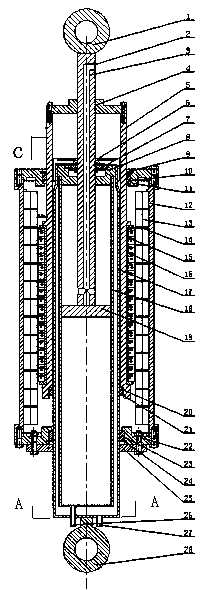

Electromagnetic suspension system

ActiveUS20050016802A1Displacement stabilityPrevent movementSpringsNon-rotating vibration suppressionRelative displacementUniversal joint

An electromagnetic suspension system comprises a universal joint mechanism for permitting radial movement of a cylinder relative to a center yoke while preventing axial movement of the cylinder relative to the center yoke. Since the cylinder is capable of radial movement relative to the center yoke, if a lateral force acts on the cylinder, the lateral force acting on a hydraulic damper does not have any significant effect on the center yoke 17, with respect to radial movement or rocking movement thereof. Therefore, excessive sliding friction does not occur in a center-yoke dry metal and a piston-rod dry metal, thereby ensuring smooth axial relative displacement between the center yoke and an outer yoke.

Owner:HITACHI ASTEMO LTD

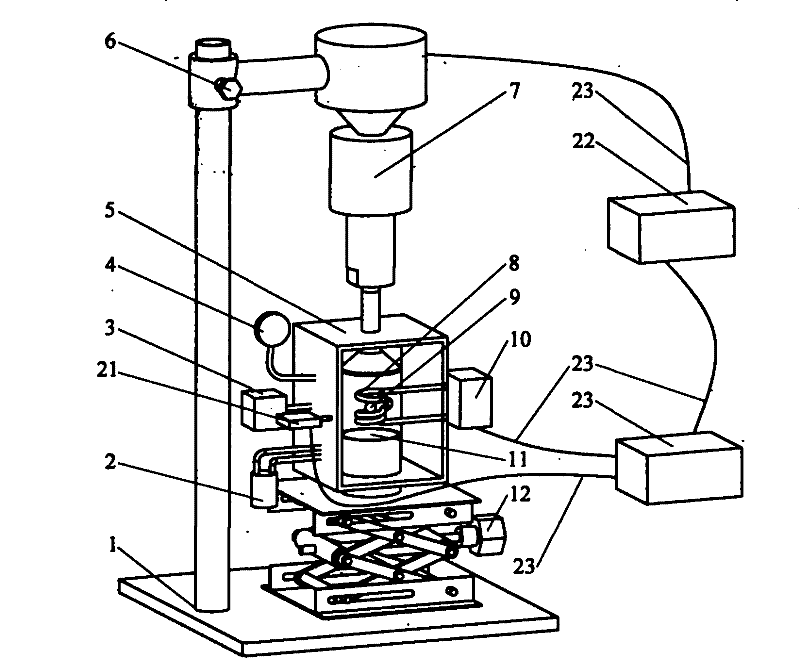

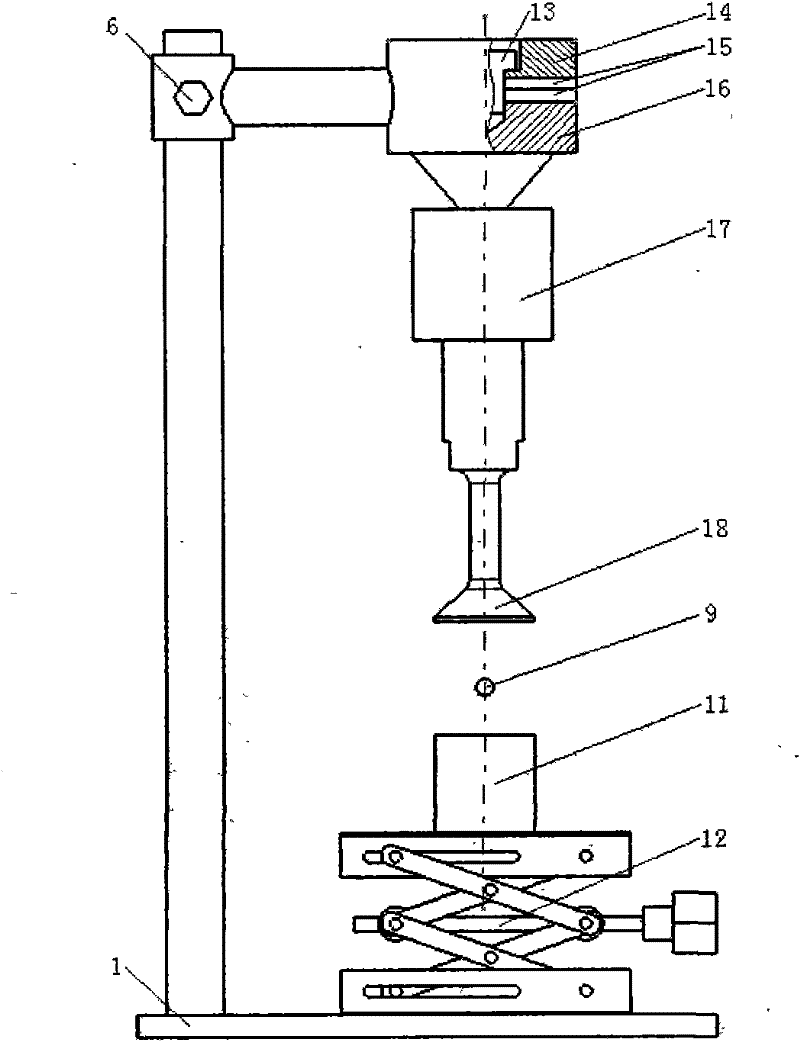

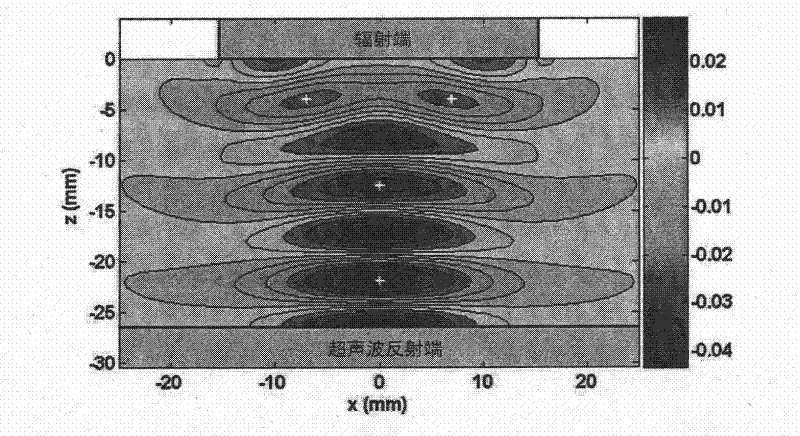

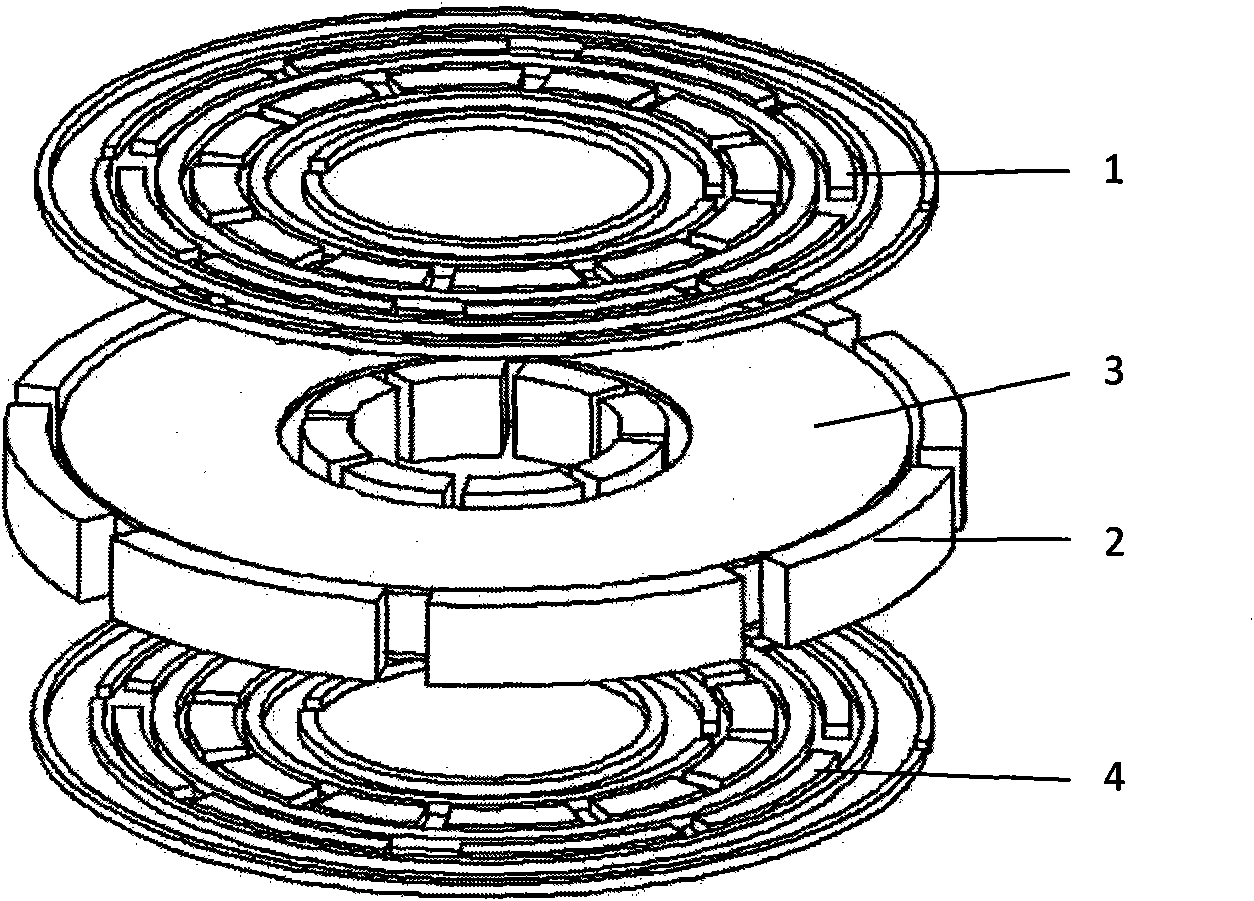

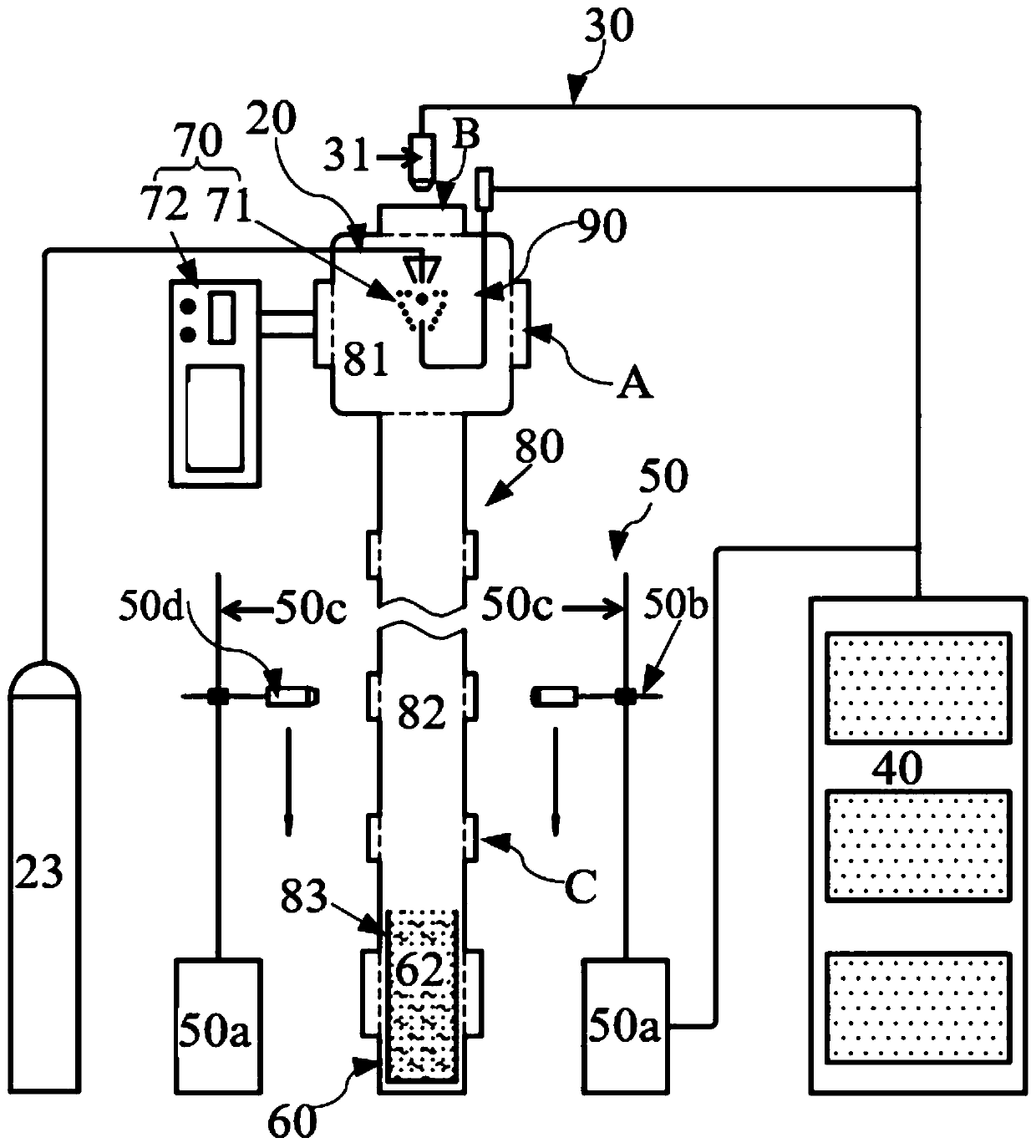

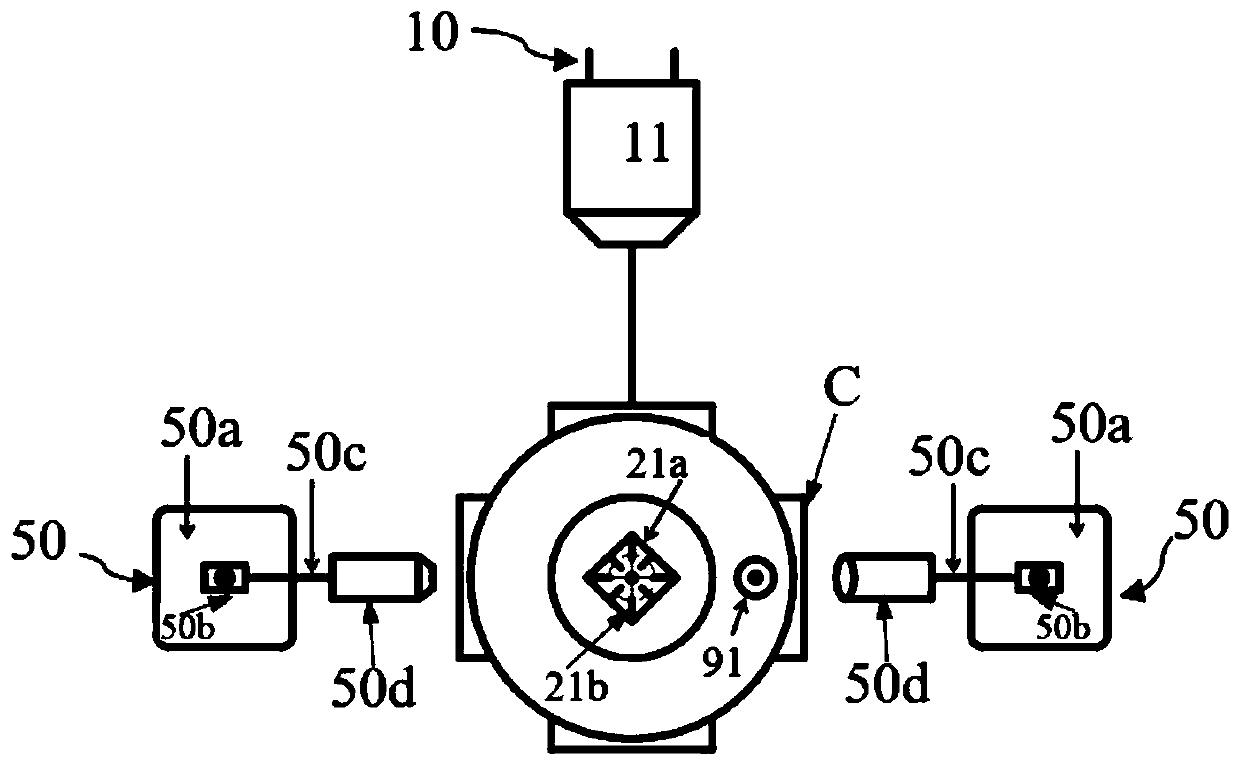

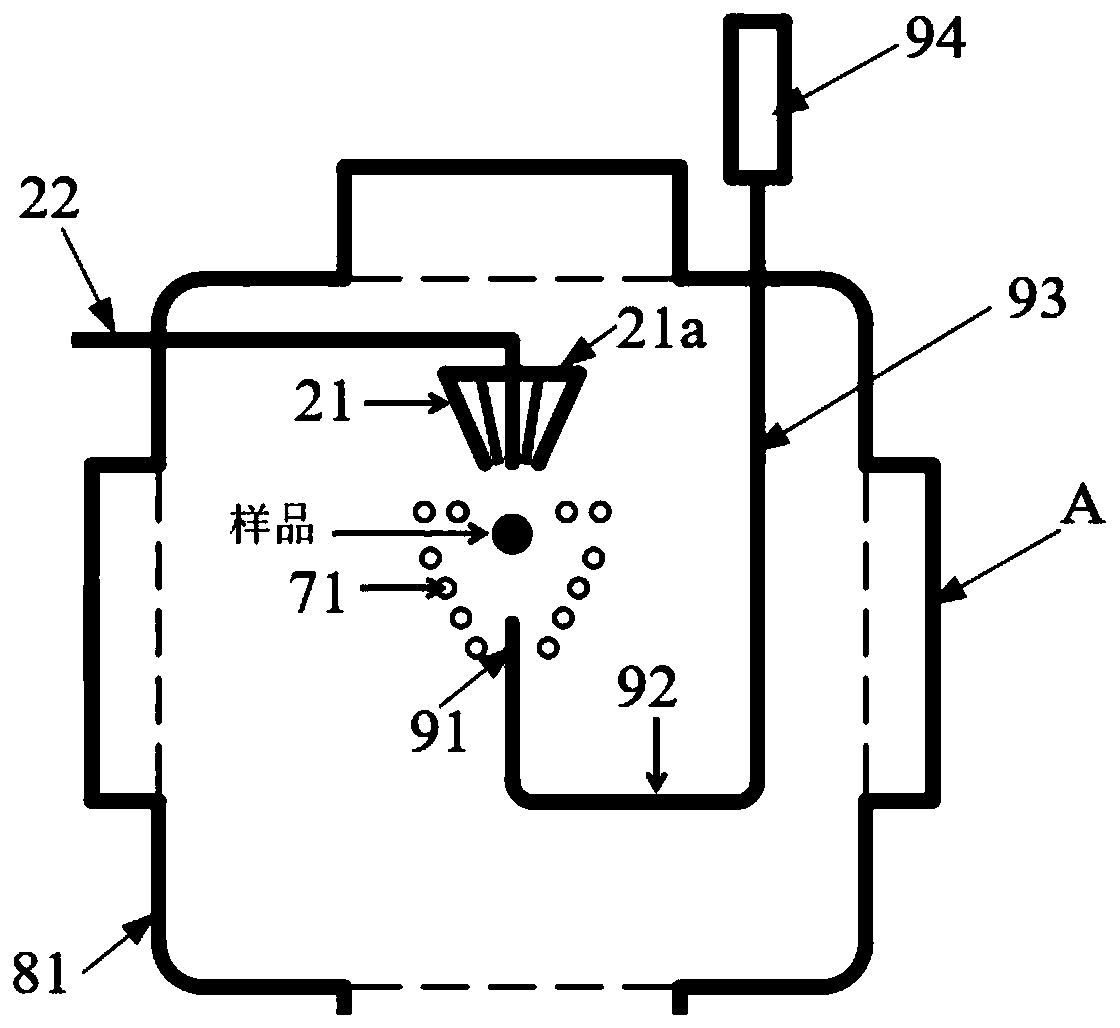

Piezoelectric ultrasonic/high-frequency electromagnetic hybrid suspension non-contact smelting method and device

InactiveCN102519249ARealize non-contact meltingSimple structureFluidised-bed furnacesSuspended particlesMolten state

The invention relate to a piezoelectric ultrasonic / high-frequency electromagnetic hybrid suspension non-contact smelting method and a device, which belong to the technical field of non-contact material smelting. The device comprises a sealing box, an ultrasonic generator, an ultrasonic transducer, a high-frequency inductive power source, a high-frequency inductor, a base, deflating and inflating equipment, an infrared temperature measurer, a pressure gauge, an ultrasonic wave reflecting end and an adjusting device of the ultrasonic wave reflecting end. Ultrasonic suspension force and electromagnetic suspension force jointly act on suspended particles (metal), or the electromagnetic suspension force independently acts on the suspended particles, and the suspended particles generate electromagnetic induction in a high-frequency magnetic field generated by the high-frequency inductor, and are heated until the suspended particles are melted. The output power of the high-frequency power source is reduced, a melted article independently acts under the effect of the ultrasonic wave suspension force, and is cooled to form solid in a suspension state. Smelting of materials is completed in a state without a container, high-purity alloy without impurities can be prepared, and non-contact smelting of metal with active chemical properties can be carried out.

Owner:JILIN UNIV

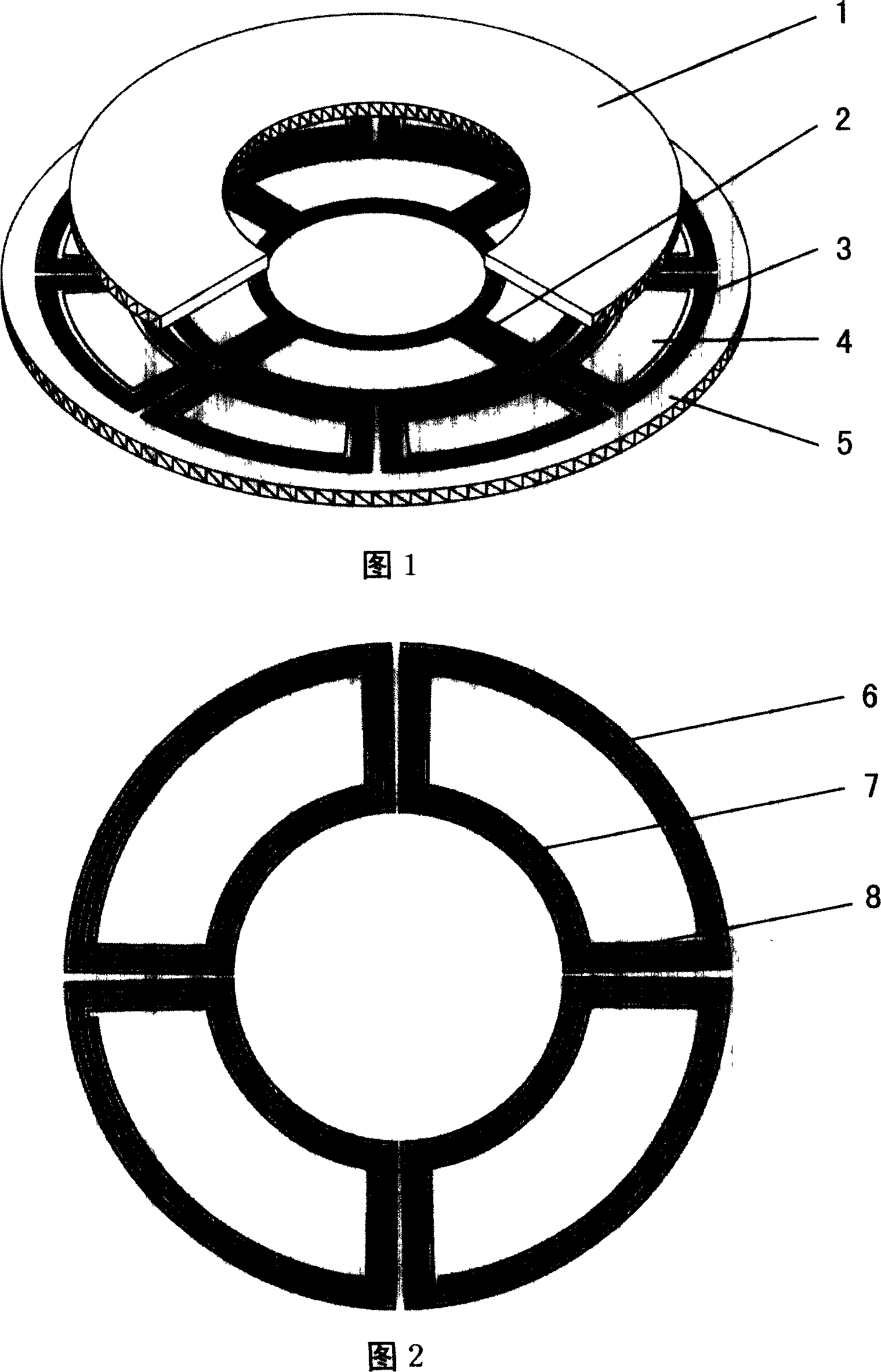

Suspension rotor micro gyro by utilizing electromagnetism and charge relaxation to work

InactiveCN101561275AIncrease stiffnessGood effectTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesLocation detectionEngineering

The invention relates to a suspension rotor micro gyro by utilizing electromagnetism and charge relaxation to work, which is used in the field of navigation control of satellites, automobiles, and the like. The suspension rotor micro gyro consists of upper and lower stators, a micro rotor and a peripheral structure which form a cage structure. The stators comprise rotary driving electrodes, axial suspension detection electrodes, first suspension stabilization coils and second suspension stabilization coils, and are fixedly connected to a substrate; and under the action of electromagnetic force, the micro rotor suspends between the stators and has an annular shape, the inside and outside of the annulus are provided with surrounding structures which are mainly radial suspension electrodes and radial suspension detection electrodes. The micro gyro has simple structure, provides an electromagnetic suspension charge relaxation rotary structure, and can realize the self-stable suspension of the rotor by axially arranging inner and outer suspension stabilization coils. The axial and radial suspension detection electrodes can further enhance the suspension rigidity and realize position detection. The suspension rotor micro gyro has the characteristics of small size, light weight, low cost, high precision and low power consumption.

Owner:SHANGHAI JIAO TONG UNIV

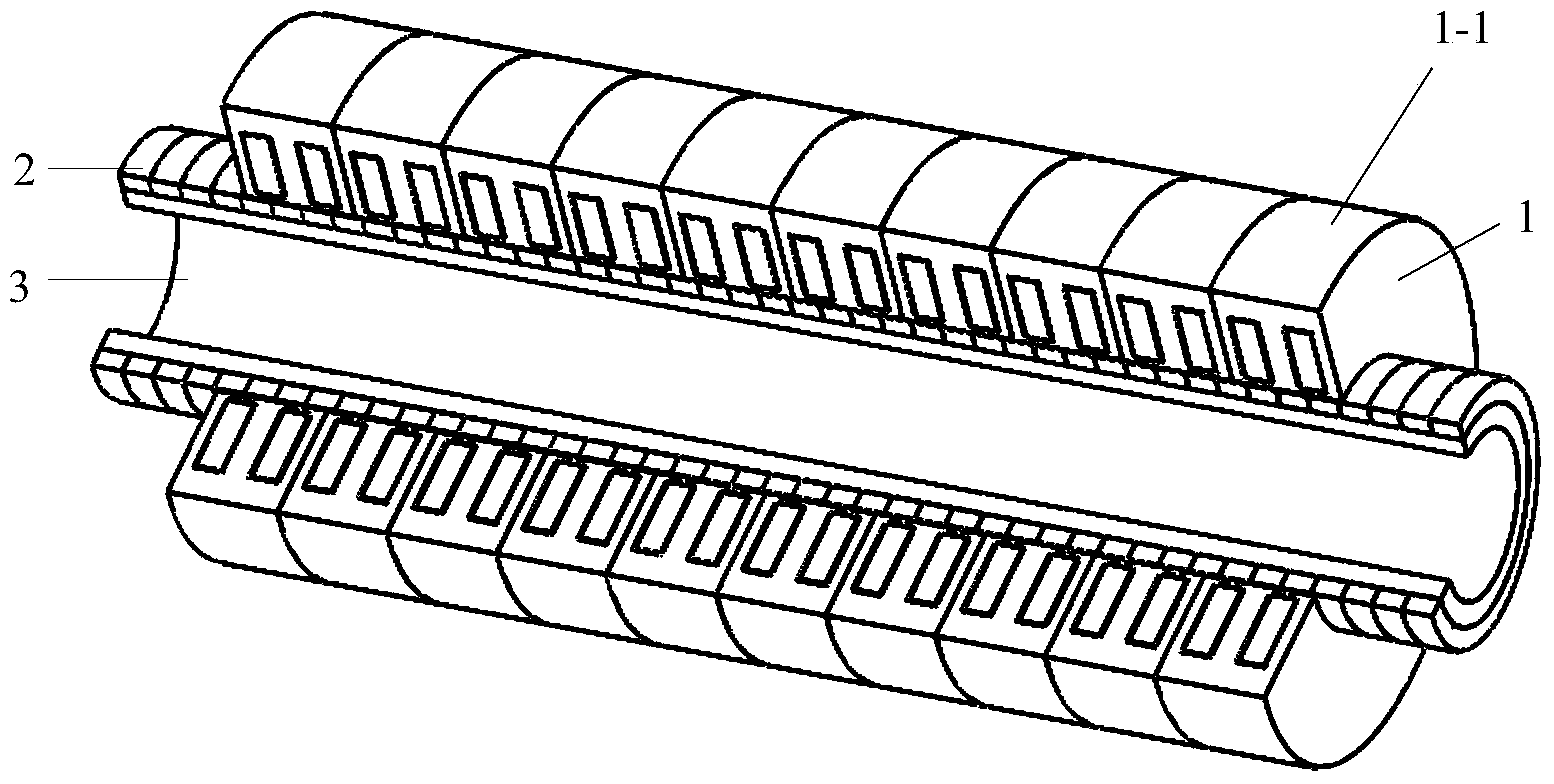

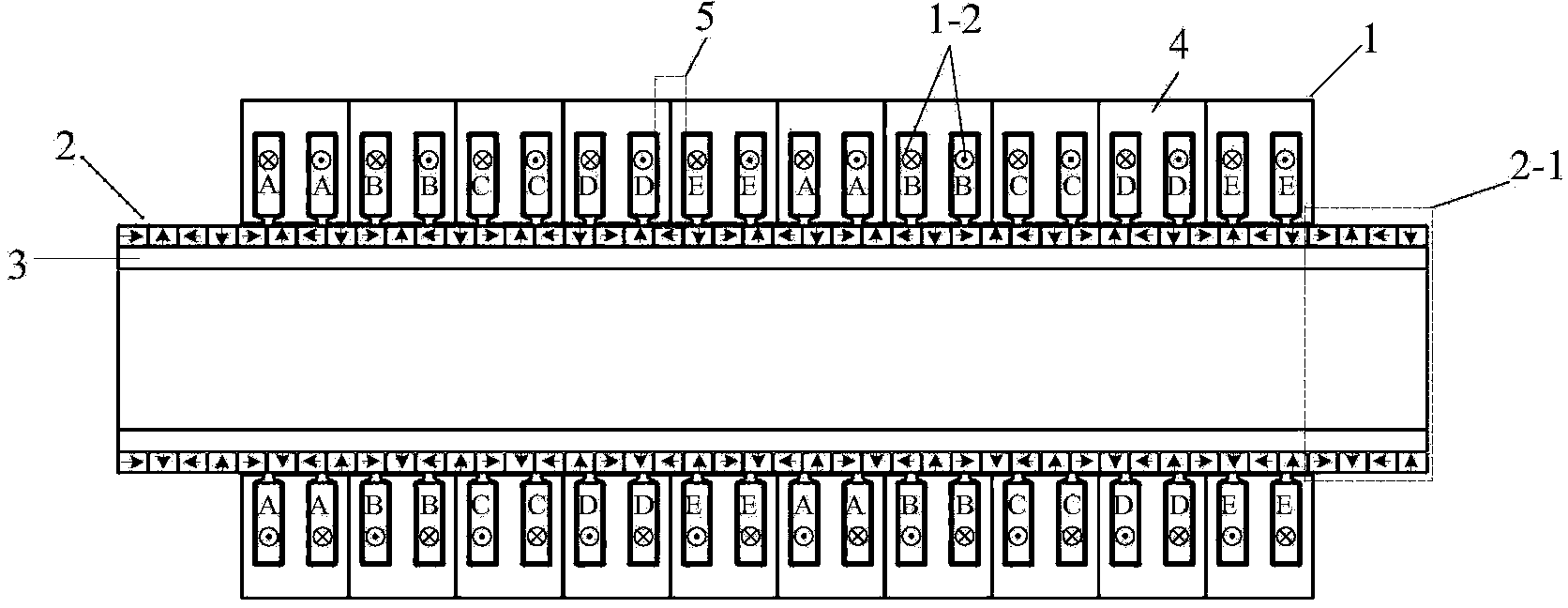

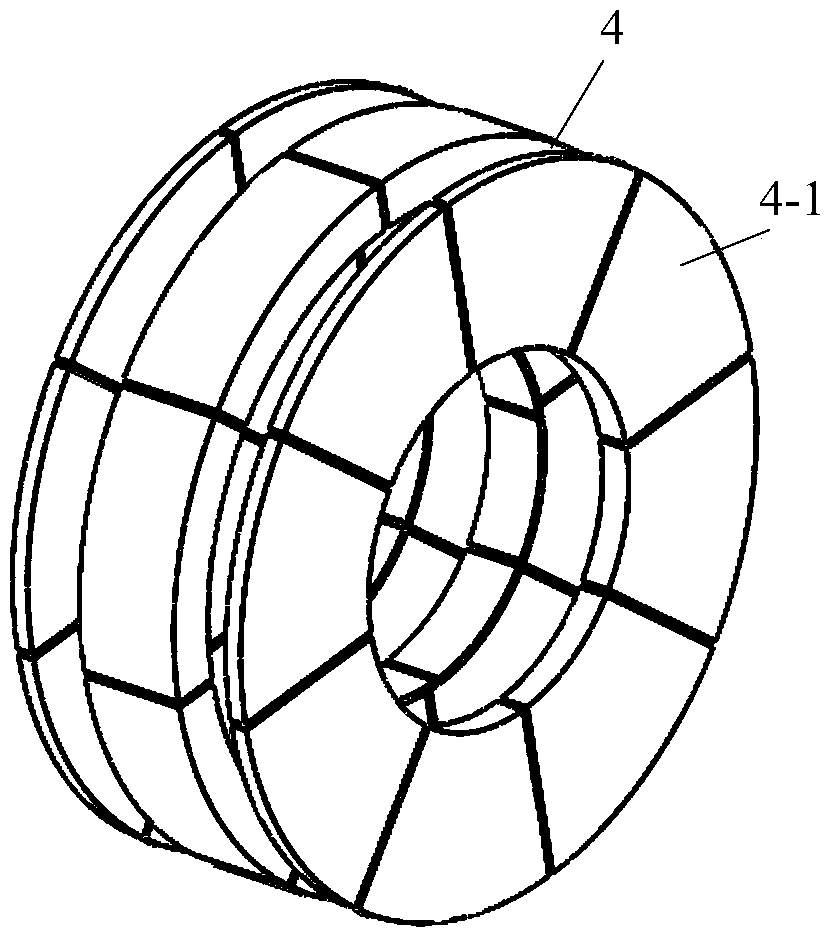

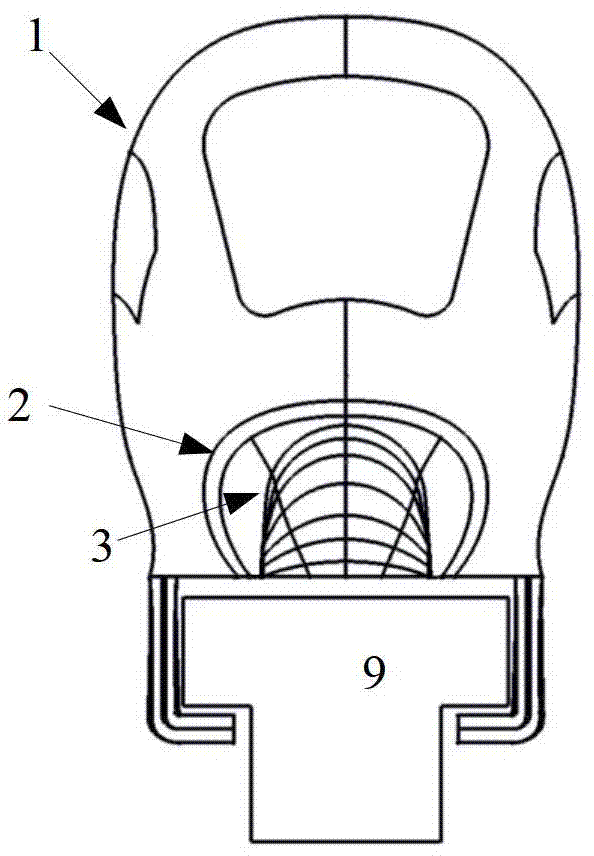

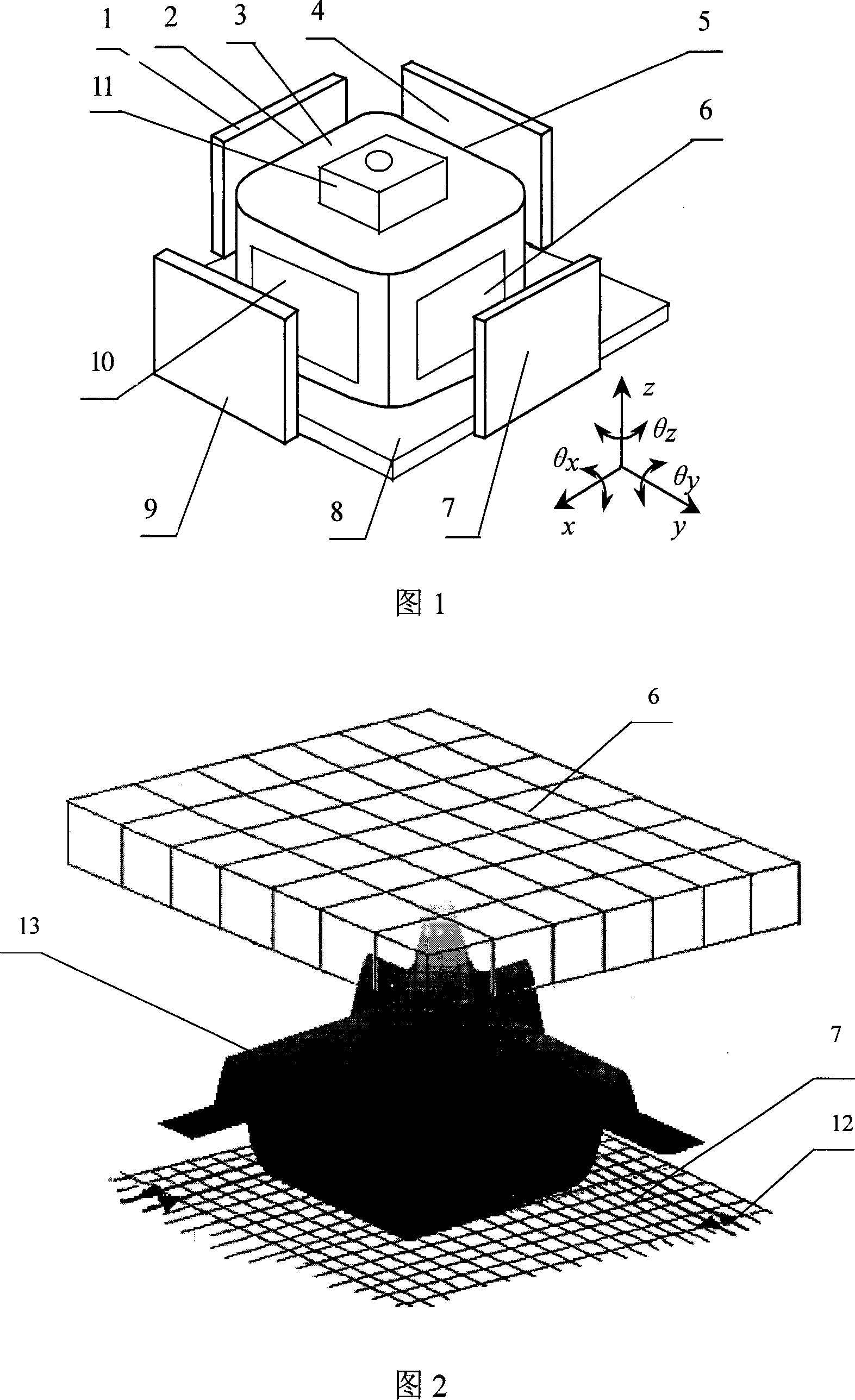

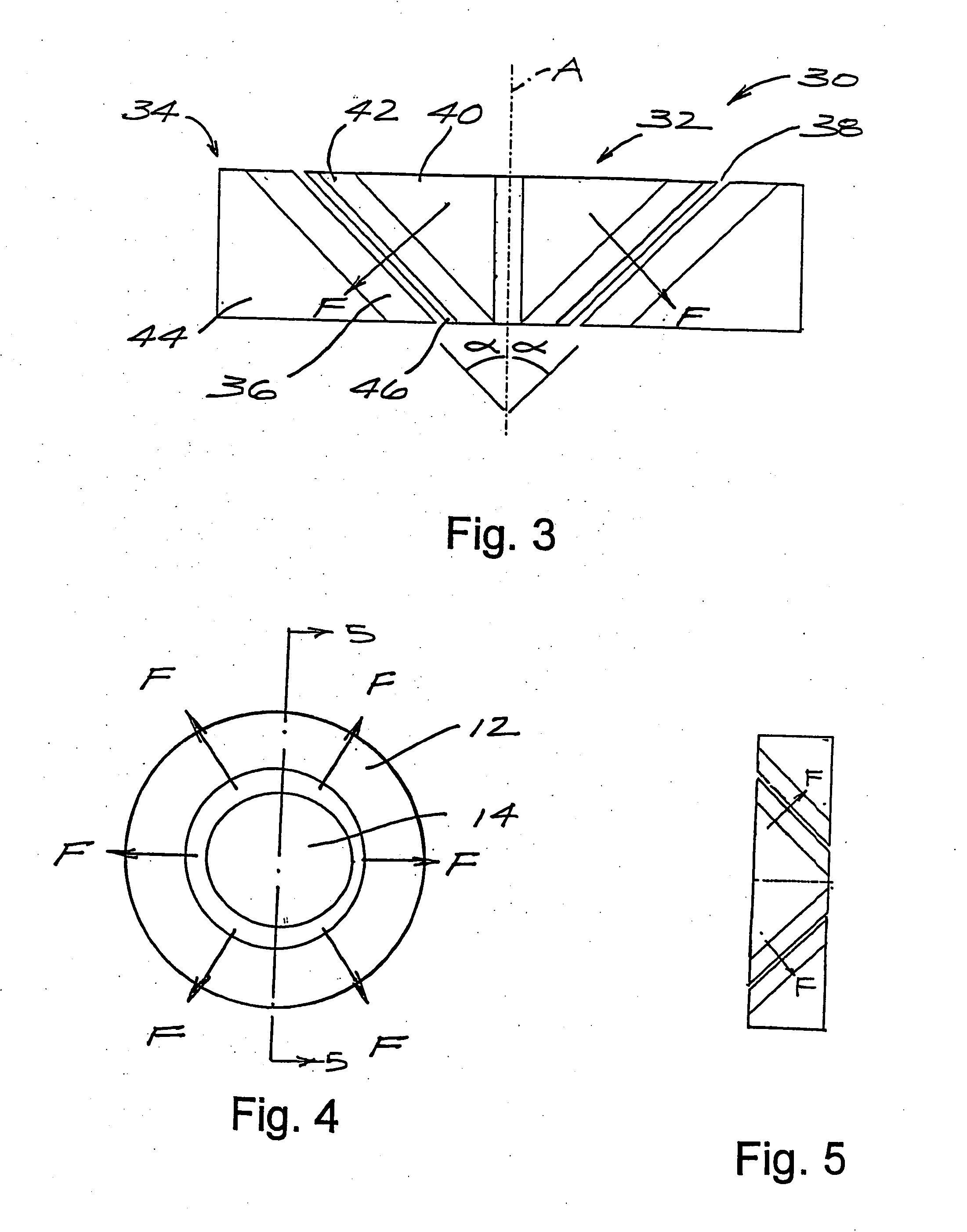

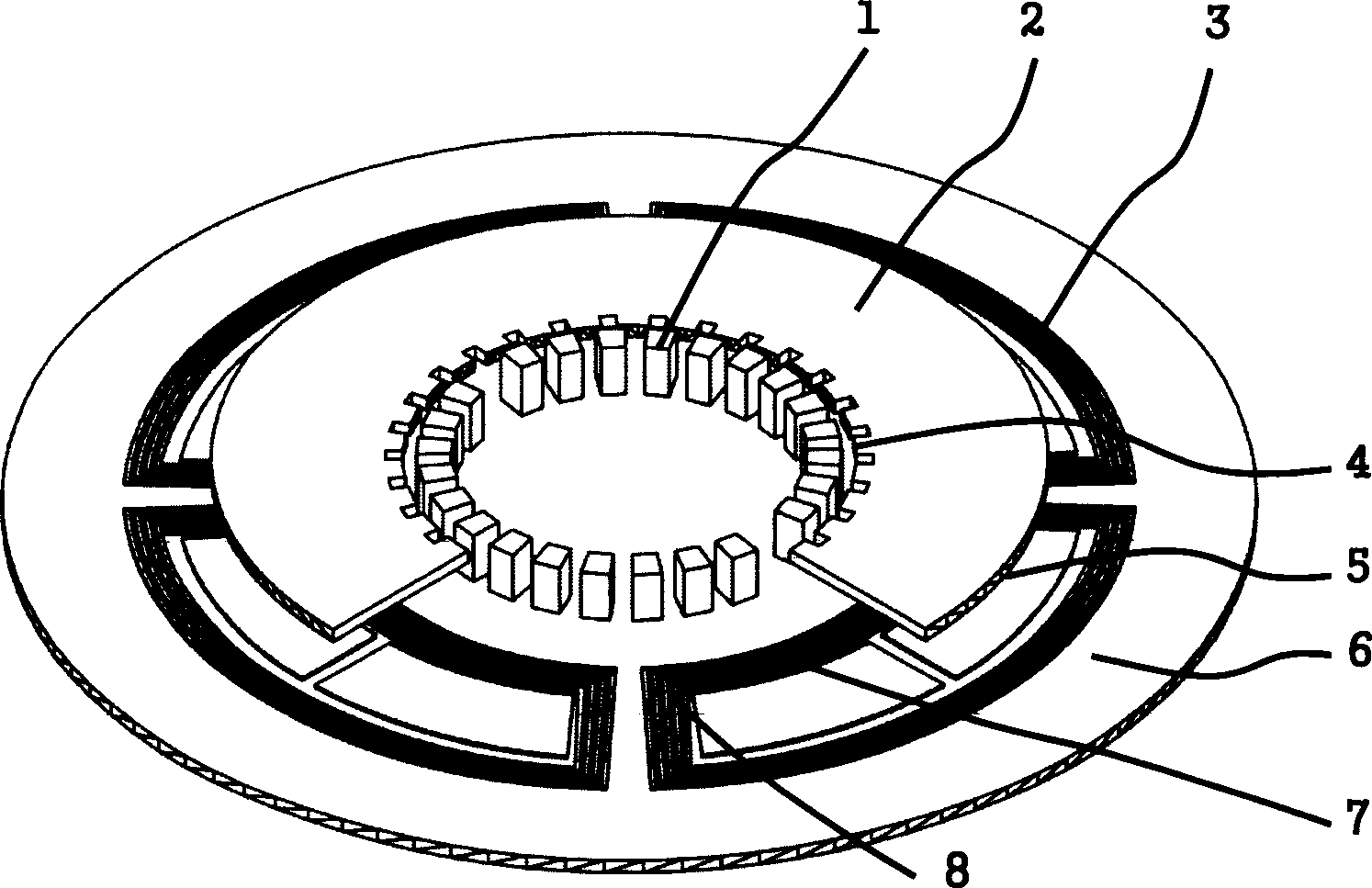

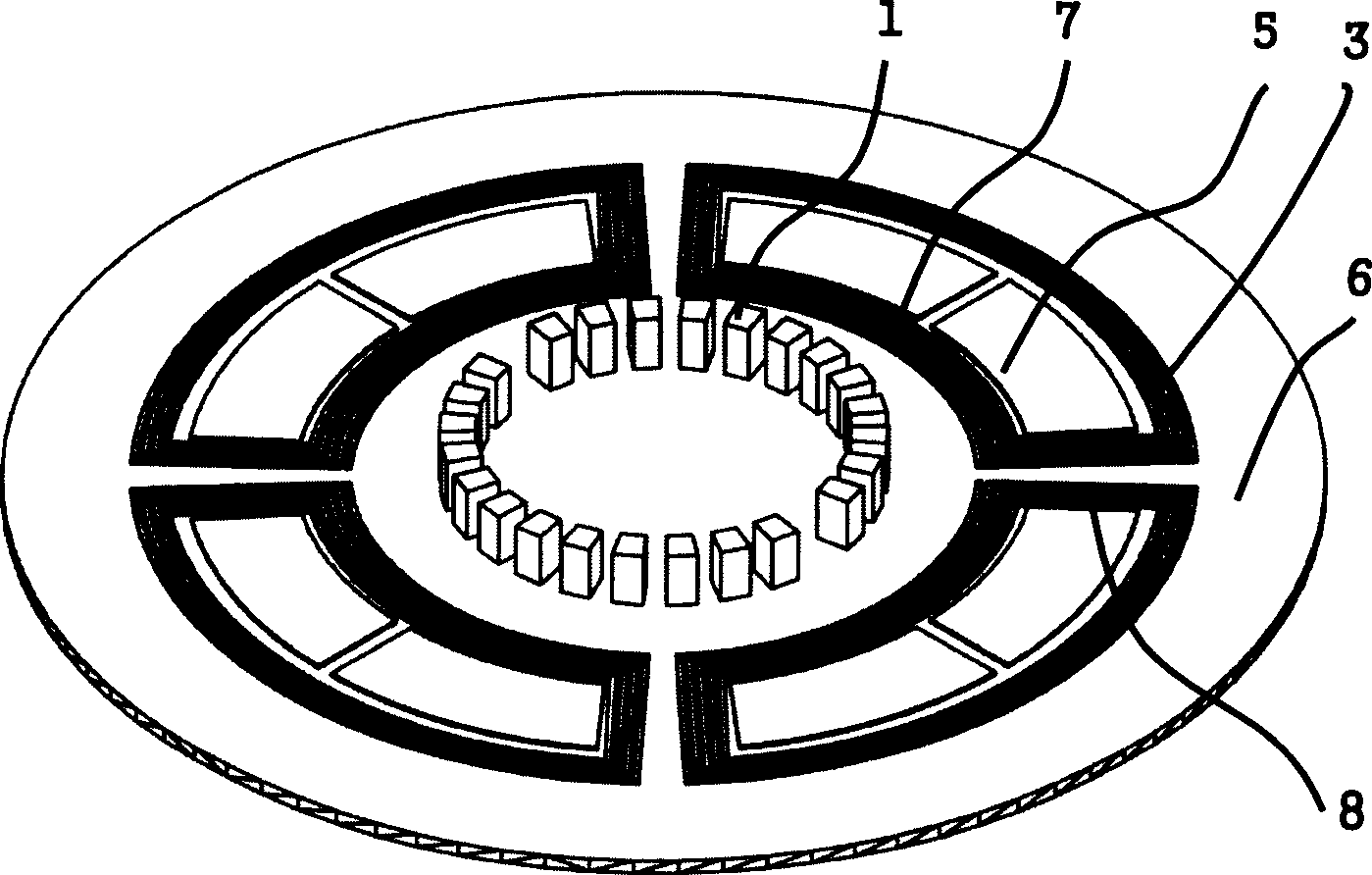

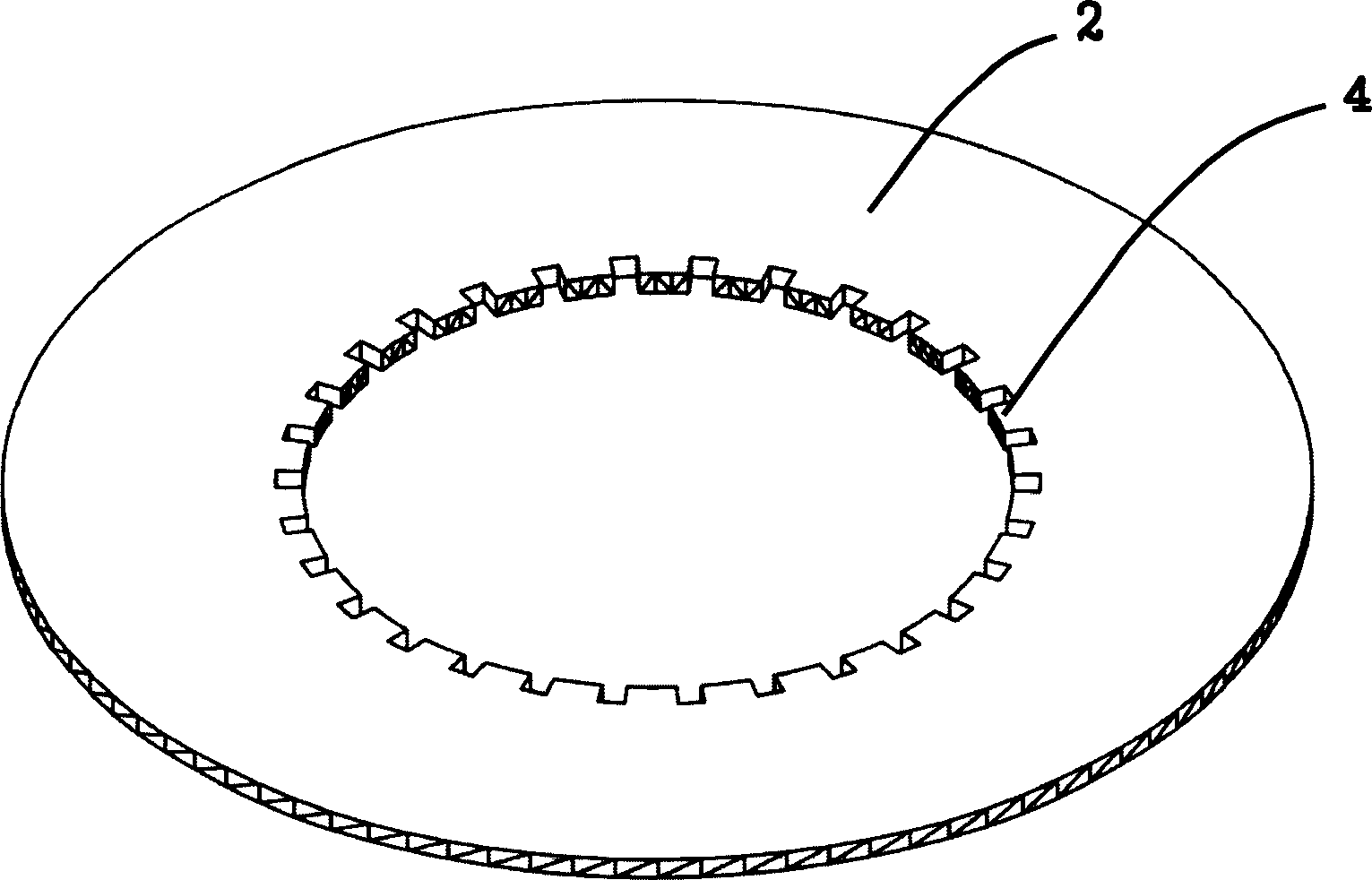

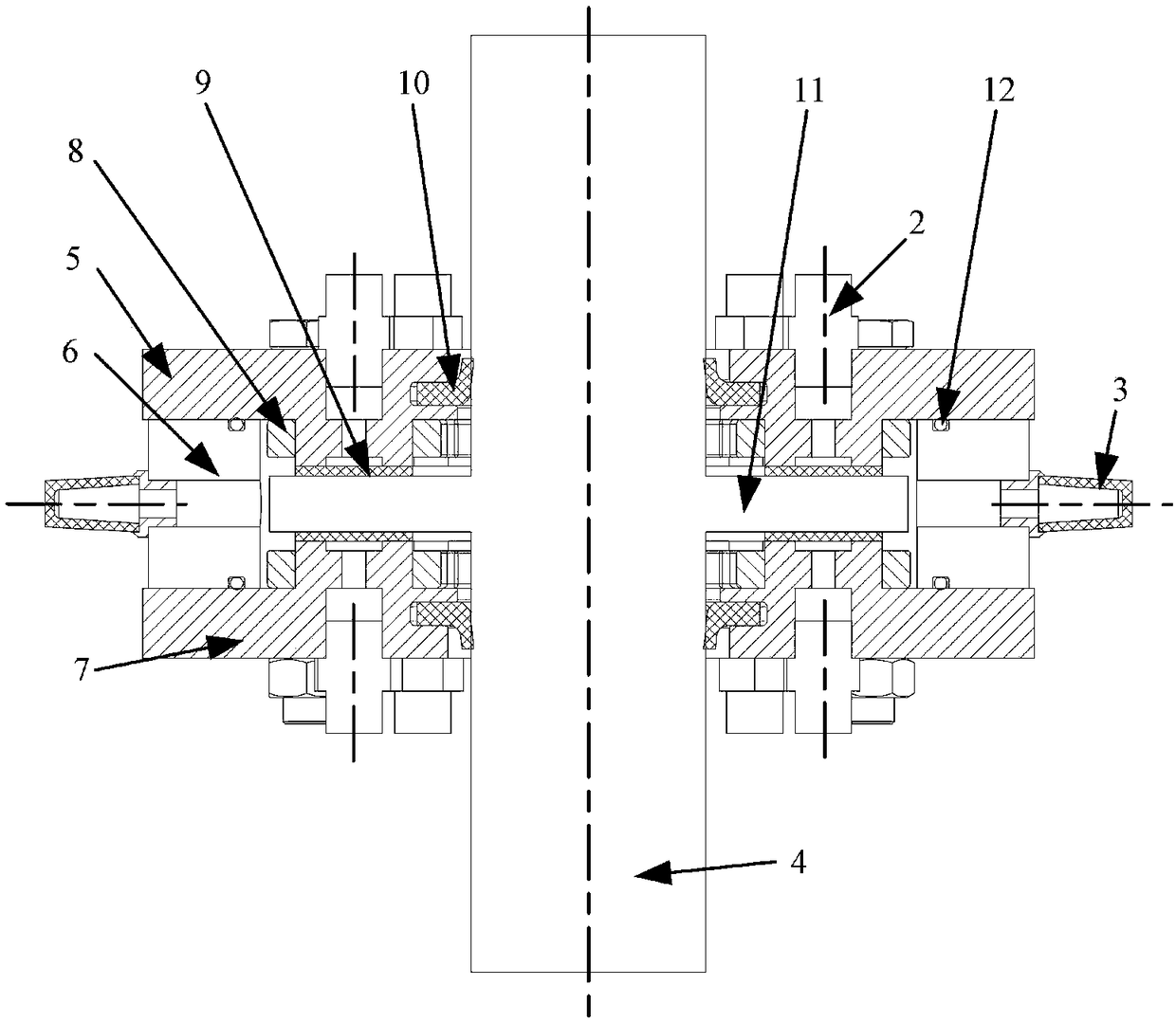

Five-phase cylindrical fault-tolerant permanent magnet linear actuator for driving vehicle electromagnetic suspension

InactiveCN104052234AImprove reliabilityAchieve decouplingPropulsion systemsEddy currentConductor Coil

The invention discloses a five-phase cylindrical fault-tolerant permanent magnet linear actuator for driving a vehicle electromagnetic suspension. The fiver-phase cylindrical fault-tolerant permanent magnet linear actuator comprises a stator ring, a rotor ring and a supporting shaft. The stator ring is composed of a disc-shaped primary iron core and a disc-shaped winding, the primary iron core is formed by arranging identical standard-E-shaped iron core bodies in the axial direction, teeth, leaning together, of the adjacent standard-E-shaped iron core bodies form fault-tolerant teeth, a concentrated winding is adopted as the winding, the winding is wound into a disc shape to be embedded into an E-shaped iron core groove, and the rotor ring comprises a permanent magnet and is arranged on the supporting shaft. The reliability and the capability of operation with faults of the fiver-phase cylindrical fault-tolerant permanent magnet linear actuator are improved, and physical isolation and magnetic path decoupling among phases are achieved. The fiver-phase cylindrical fault-tolerant permanent magnet linear actuator can operate in a fault-tolerant mode, and the heat dispersion performance of the winding is improved. Eddy-current losses on the iron core are lowered.

Owner:JIANGSU UNIV

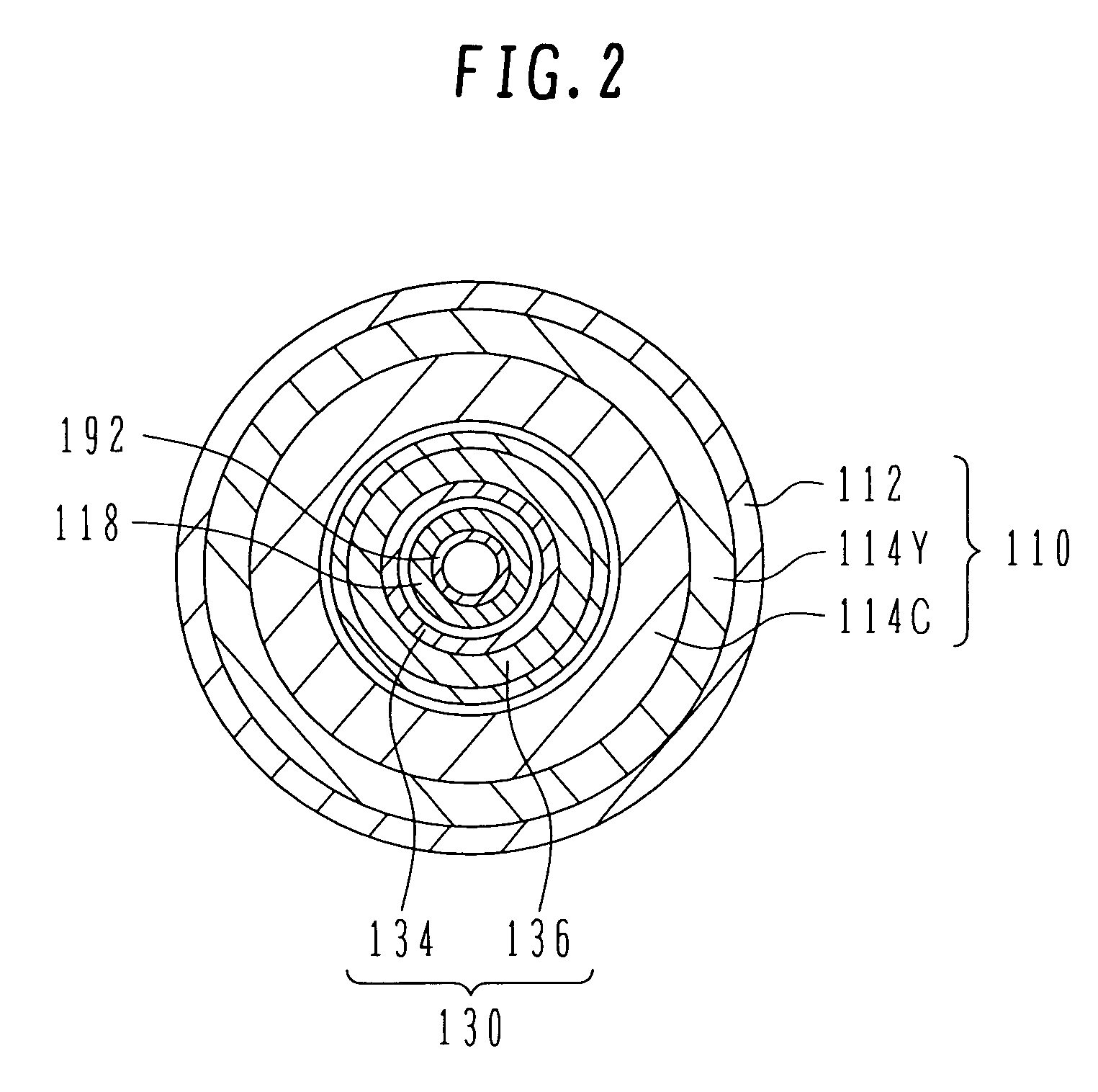

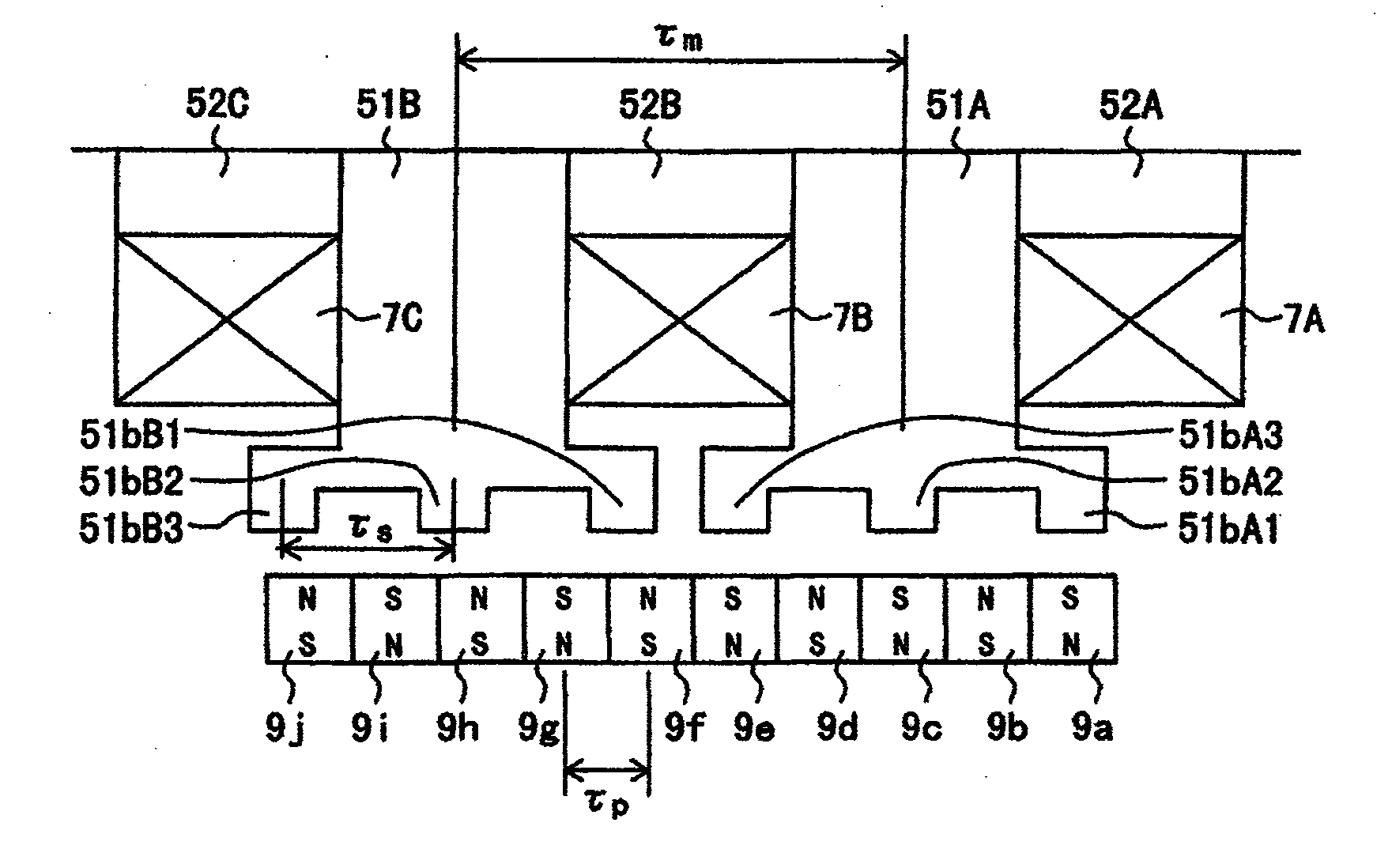

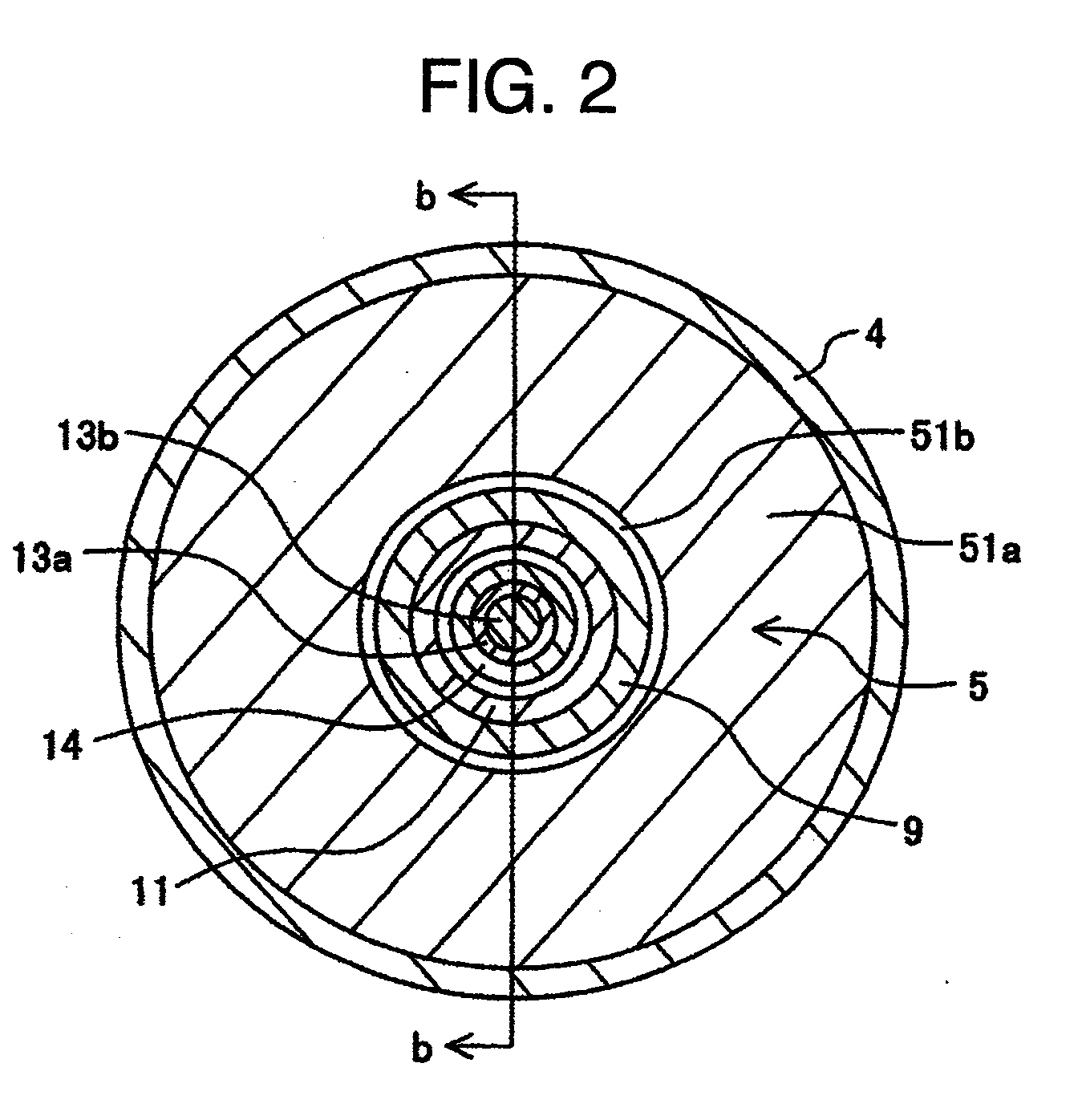

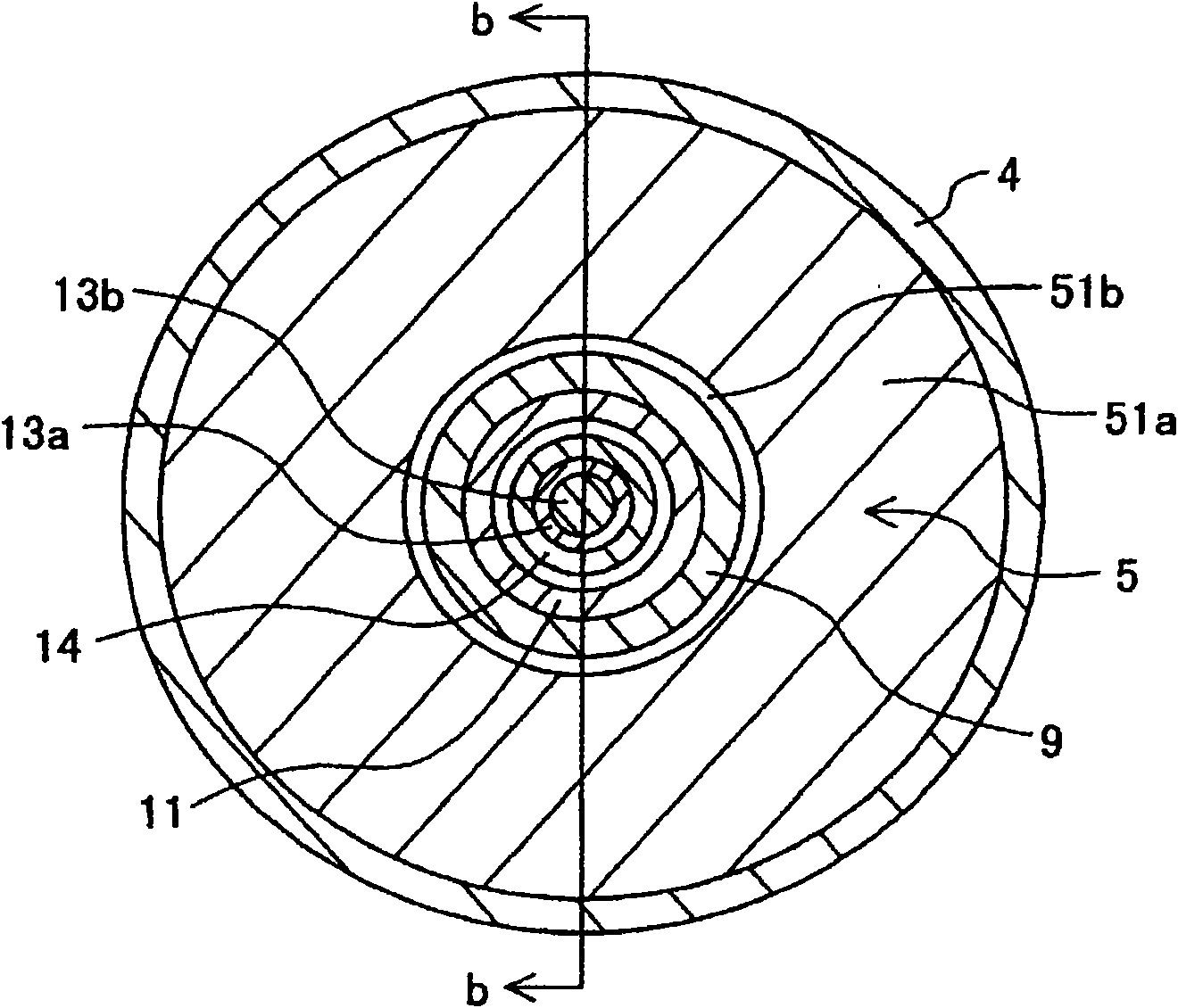

Circular-Shaped Linear Synchronous Motor, Electromagnetic Suspension and Motor-Driven Steering Device Using the Same

InactiveUS20100044144A1High-damping and high-thrust performanceIncrease slot areaMotor/generator/converter stoppersDC motor speed/torque controlElectric power steeringSynchronous motor

Disclosed are a high-damping and high-thrust cylindrical linear motor and a motor-driven power steering device. A stator includes three-phase stator and a stator core. A slider includes a slider core and permanent magnets. The stator core includes stator-core salient poles, two auxiliary poles and yoke units with a small poles on its surface of the side of the slider, the auxiliary poles being deployed at both ends of the stator-core salient poles, the yoke units configuring a magnetic circuit in cooperation with the stator core and the auxiliary poles. The magnetic circuit is shared among the three phases. Polarities of magnets of the slider become an identical polarity, each of the plurality of permanent magnets being positioned at a position which is opposed to each of the plurality of small poles included in one stator-core salient pole out of the plurality of stator-core salient poles.

Owner:HITACHI AUTOMOTIVE SYST LTD

Method for preparing contact material having high performance and low mixed copper-chromium alloy content

The invention discloses a method for preparing a contact material having high performance and low mixed copper-chromium alloy content. The method comprises the following steps of: (1) mixing a metal copper material and a metal chromium material according to a proportion of 10-75 weight percent of the weight content of the chromium to prepare a sample according to alloy components required by a process; (2) pressing the prepared mixed material powder into blocks, or preparing the prepared mixed material powder into alloy prefabricating ingots through vacuum induction smelting or vacuum non-consumable arc smelting; (3) under the protection of inert gas, heating and smelting the alloy prefabricating ingots in a vacuum electromagnetic suspension stove or a cold crucible stove through high-frequency induction; and (4) cooling and solidifying by adopting high-purity inert gas or a water-cooling copper crucible to obtain copper-chromium alloy ingots. The preparation method has uniform alloy components, low content of gas such as oxygen, nitrogen, and the like, dense texture, uniform component, high purity and fewer impurities, greatly improves the performance of the copper-chromium alloy contact material, can avoid pollution of crucible materials to the alloy at high temperature and ensures that the microscopic structure of the alloy is more uniform.

Owner:CHONGQING UNIV OF TECH

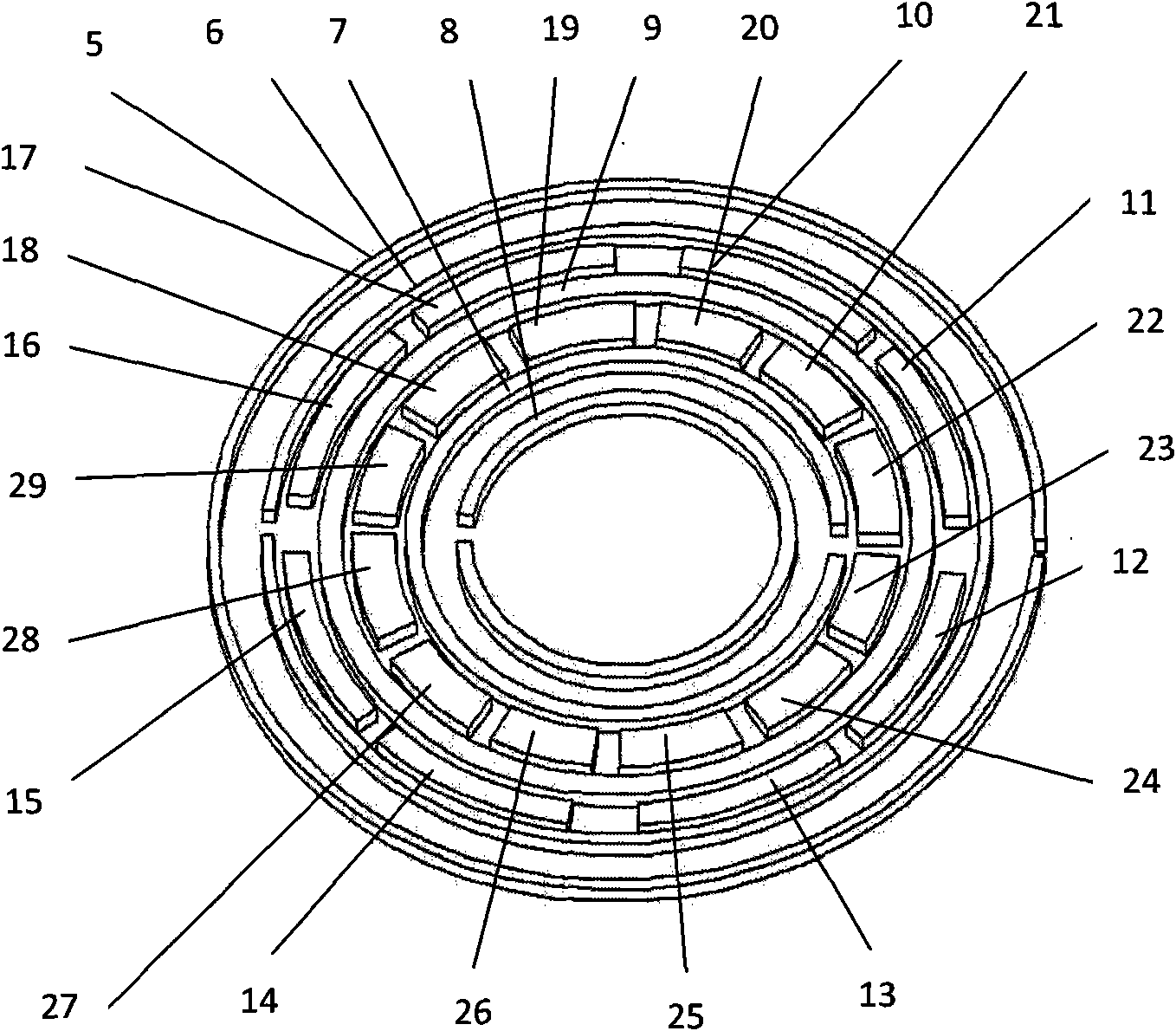

Micro-rotation top with double-stator electromagnetic suspension rotor

InactiveCN1818552AImprove impact resistanceRestricted degrees of freedomSpeed measurement using gyroscopic effectsRotary gyroscopesGyroscopeLaser

A micro rotation gyroscope with double stator and electromagnetic suspension rotator consists of top base body, top stator, micro rotator, bottom stator, bottom base body and seal ring .It features that micro rotator is a conductive ring; rotary coil sensing electrode and suspension-stabilizing coil prepared by photo etching-plating are applied on top and bottom base bodies; the structure of top stator is completely the same as the structure of bottom stator except spacing column of micro rotator is set on bottom stator.

Owner:SHANGHAI JIAO TONG UNIV

Integrated magnetic bearing

The present invention provides a rotational magnetic gimbal with an integral magnetic bearing. Brushless DC motor technology provides electromagnetic suspension, using a single electromagnetic actuator to perform both the radial bearing and rotary torque (motoring) functions. An integrated motor and magnetic bearing consistent with the invention comprises a rotor comprising a plurality of permanent magnets and a stator comprising a plurality of independently controlled coil segments magnetically coupled to the permanent magnets. Embodiments may further comprise first and second radial position sensors, the first radial position sensor disposed in or adjacent to a clearance gap between the rotor and the stator for sensing the position of the rotor with respect to the stator along a first axis, and a second radial position sensor disposed in or adjacent to the clearance gap between the rotor and the stator for sensing the position of the rotor with respect to the stator along a second axis. In method form, a method for providing integral electromagnetic motor and bearing functions comprises sensing a first radial position of a rotor, the rotor comprising a plurality of permanent magnets, with respect to a stator along a first axis, the stator comprising a plurality of independently controlled coil segments magnetically coupled to the permanent magnets; and sensing a second radial position of the rotor with respect to the stator along a second axis; and delivering current to at least one coil segment, the amount of current based on at least one sensed position.

Owner:AIREX CORP

High speed power driven magnetic suspension centrifugal blower

This invention discloses a magnetically levitated centrifugal fan of high electro motion, which includes: the shell of the electric motor in which there is the first radial axletree, the stator of the motor, the second radial axletree, the first thrust axletree and the second thrust axletree; the shell is connected with a turbine through back tray, a main axis is set on the central axes in the space of the shell, on the main axis there is orderly the rotor of the motor matched with the motor stator, the thrust disk and the impeller; the impeller is in the eddy shell on which the axes-directed air input and the radial directed air output are equipped. This invention use the design of coaxal motor rotor and the thrust disk, the radial axletree and the thrust axletree adopt magnetic levitated axletree or air axletree. This invention has high speed, small cubage, light weight, large flux, high efficiency, convenient charge adjustment and non-pollution.

Owner:XI AN JIAOTONG UNIV

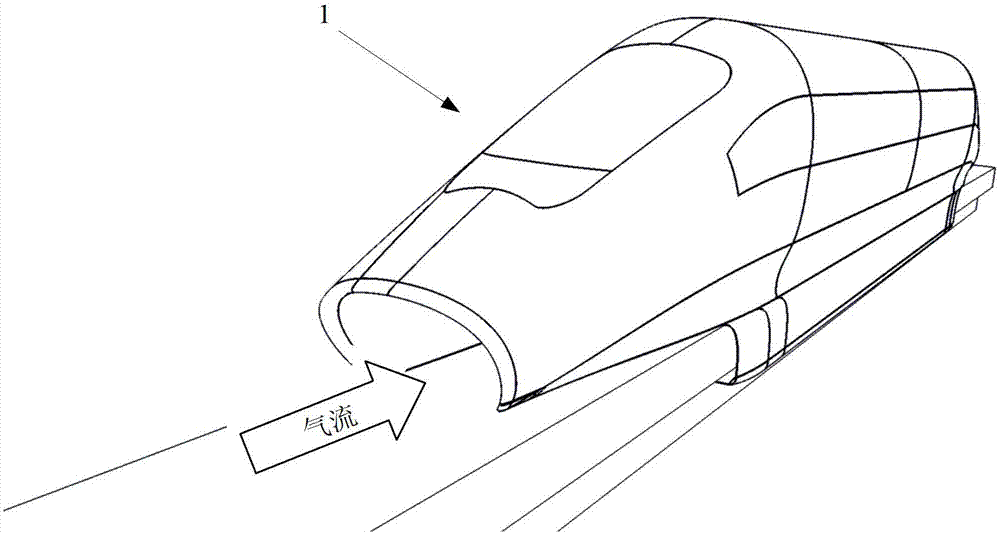

Novel superfast train by utilizing ground effect pneumatic suspension and electromagnetic propulsion

ActiveCN103085805AReduce energy consumptionReduce resistanceRoad vehiclesGround effect (aerodynamics)Electromagnetic propulsion

The invention discloses a novel superfast train by utilizing ground effect pneumatic suspension and electromagnetic propulsion, and belongs to the field of ground effect aerodynamics and superfast trains. According to the novel superfast train, pneumatic modification is conducted to the train bottom of an existing magnetic suspension train, the train bottom forms a continuous smooth contracted type curved surface, and a contracted air passage is formed by the contracted curved surface and the surface of a rail. The sectional surface of the train head in an entrance portion is the largest, and the sectional surface of the train tail in an exit is the smallest. Electromagnetic force is replaced by pneumatic lifting force generated by the ground effect so as to suspend the train, the advantages that the existing magnetic suspension train is low in resistance and slow in speed are reserved, the problem of power energy consumption of magnetic suspension is improved, the weight of vehicle-mounted superconduction relative devices is reduced at the same time, energy consumption of the train in the process of superfast running is reduced and efficiency of transporting is improved.

Owner:BEIHANG UNIV

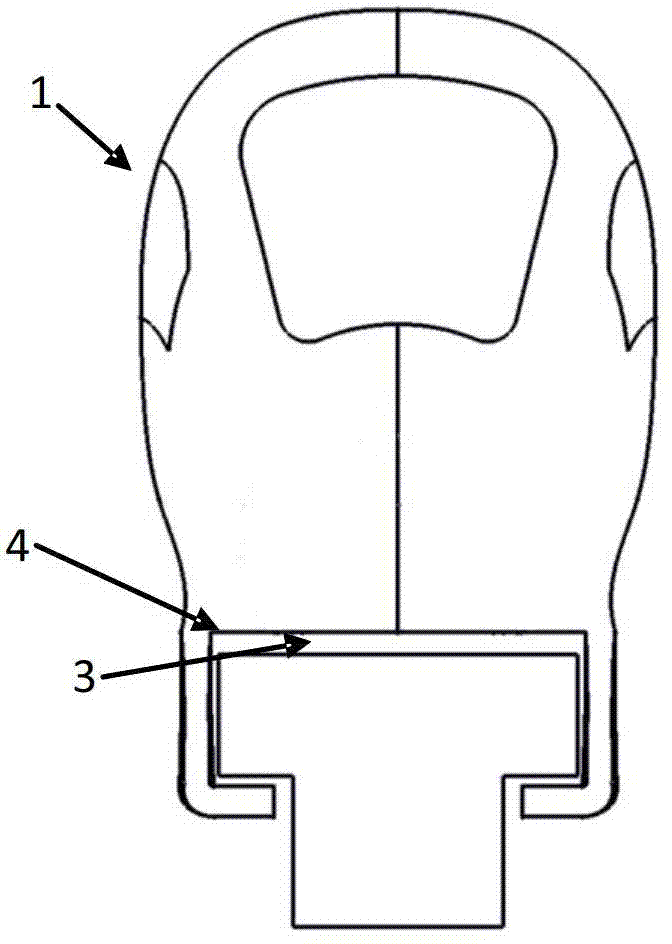

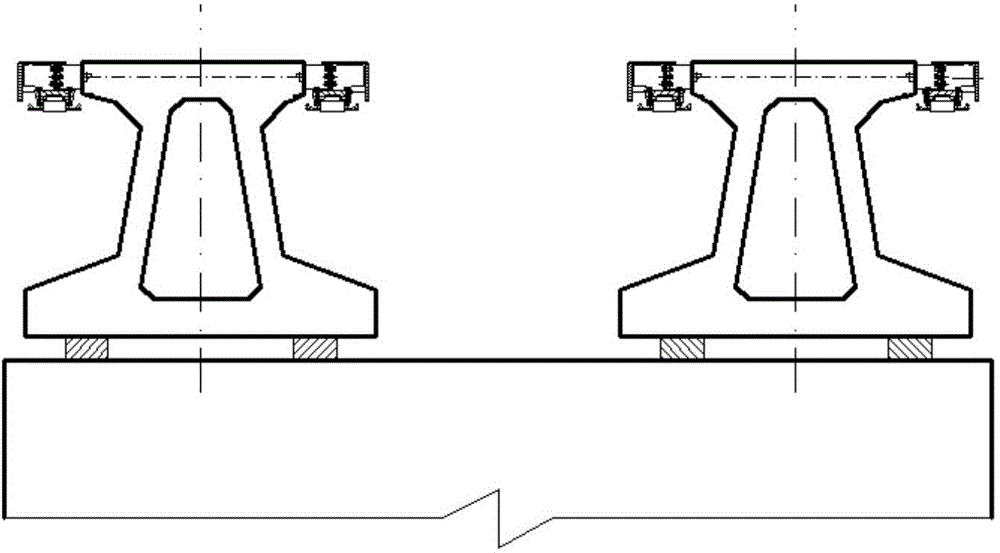

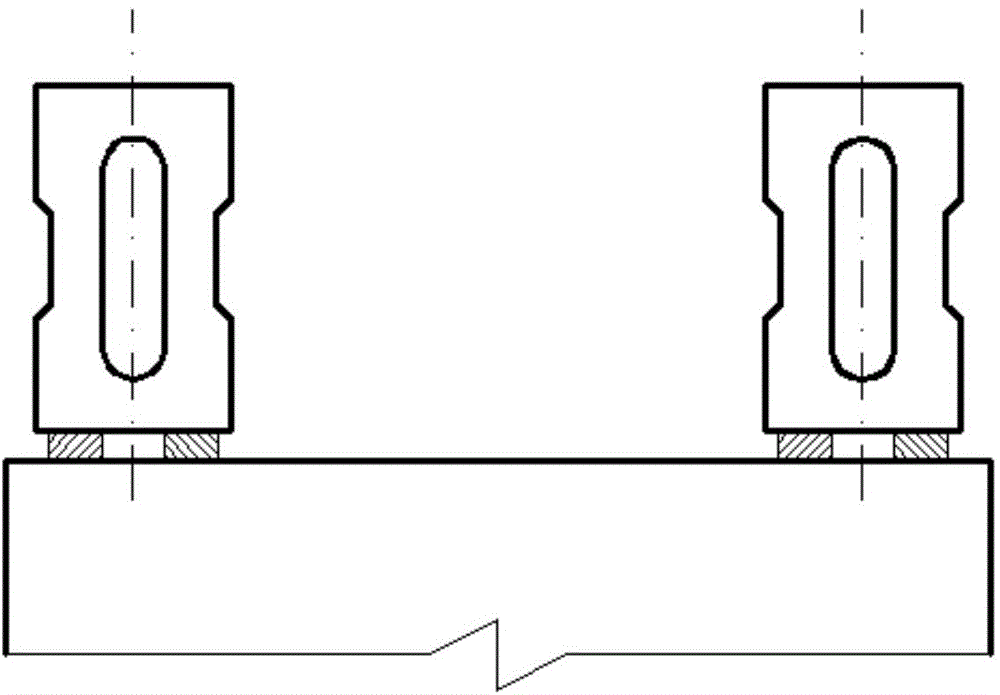

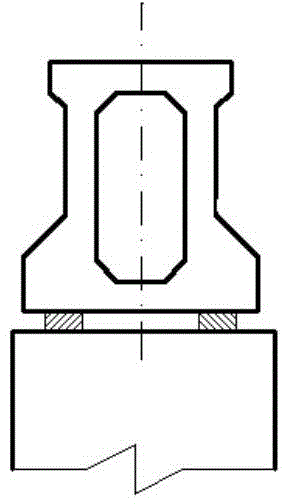

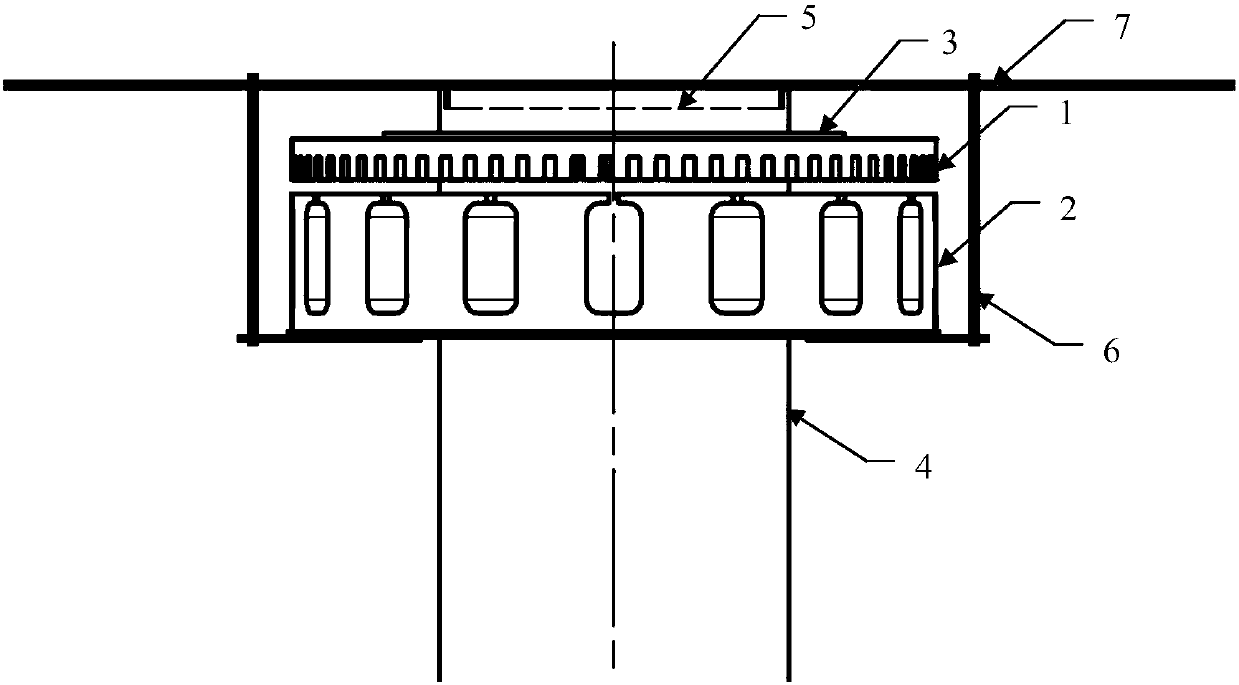

Rail holding type electromagnetic suspension track traffic box girder

ActiveCN104594173AImprove the ability to respond to emergenciesEasy for daily maintenanceRailway tracksBridge structural detailsReinforced concreteNoise barrier

The invention discloses a rail holding type electromagnetic suspension track traffic box girder. The box girder comprises a top plate, a bottom plate and a web plate located between the top plate and the bottom plate. The top plate, the bottom plate and the web plate are of a reinforced concrete structure formed by overall pouring, an outer protrusion and a boss allowing an electromagnetic suspension track to be mounted are arranged at the two side ends of the top plate, and wing plates which stretch out towards the upper inclined portion are arranged on the two sides of the bottom plate. A mounting platform is arranged at the top ends of the wing plates, the mounting platform is of a boss structure which stretches out towards the outer side in the horizontal direction, can be used for arranging a pedestrian footpath and an evacuation exit and also can be used for arranging track traffic accessory facilities such as an inspection gallery, guardrails, a noise barrier, a signal machine and an AP antenna, and daily maintenance of a line is facilitated. The wing plates of the box girder shield on-bridge tracks, trackside equipment, cables and the like, and the landscape effect is obviously improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

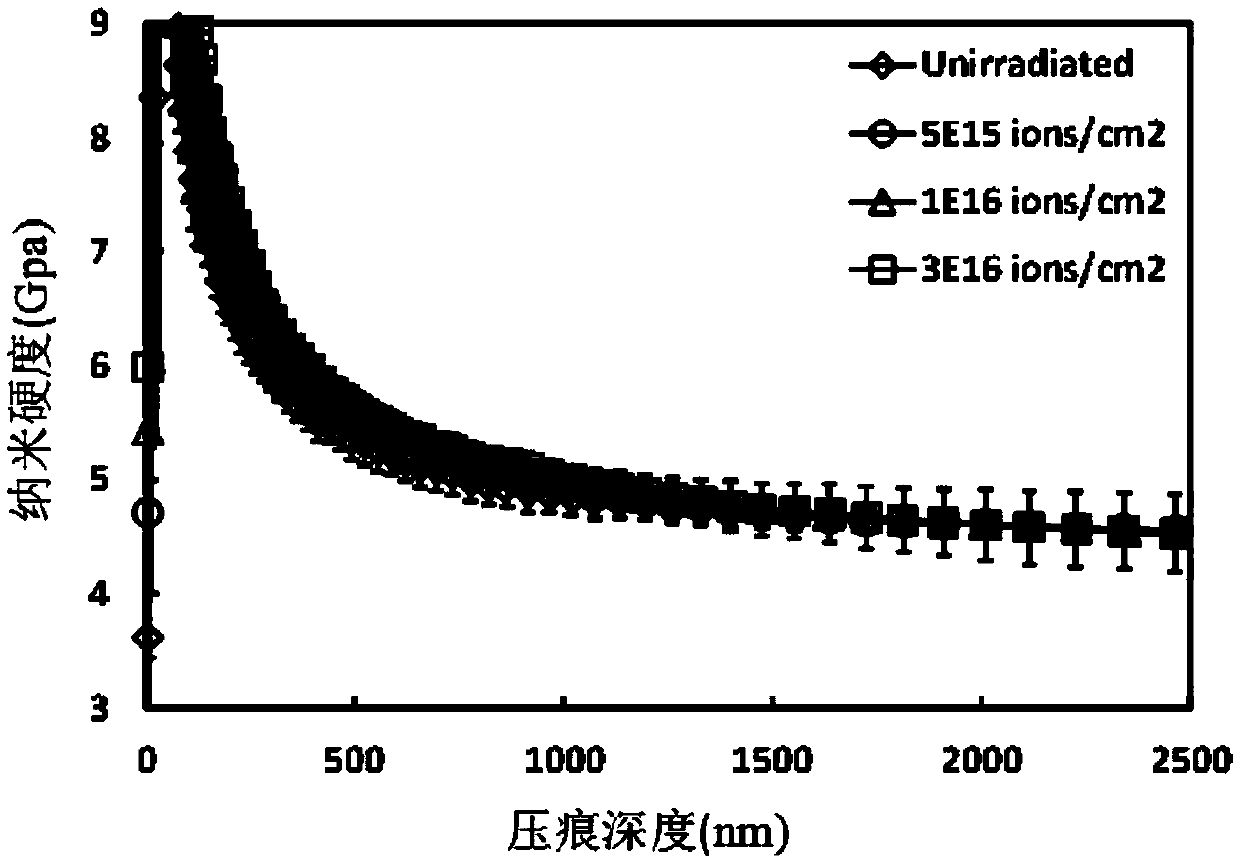

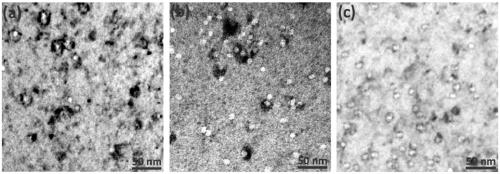

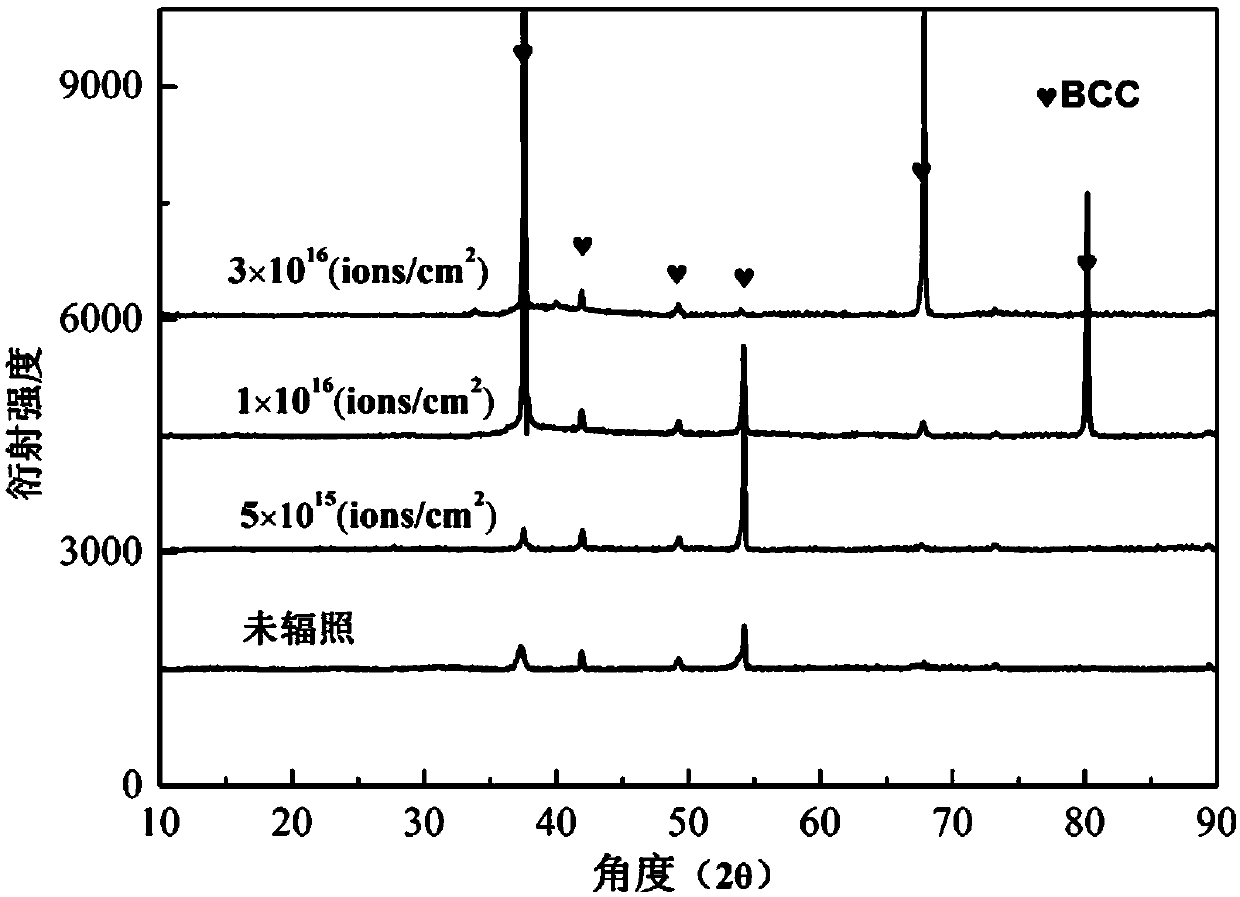

Irradiation-resistant high-entropy alloy and preparation method thereof

ActiveCN109666811AImprove high temperature performanceImprove corrosion resistanceOptical rangefindersNuclear energy generationHigh entropy alloysVolumetric Mass Density

The invention provides irradiation-resistant high-entropy alloy and a preparation method thereof. The general formula of the irradiation-resistant high-entropy alloy is TiZrHfVMoTaxNby, wherein X is no more than 0.25 and no less than 0.05, y is no more than 0.5 and no less than 0.05, and x and y are molar ratio. The preparation method of the irradiation-resistant high-entropy alloy comprises the following steps: sequentially mixing Ti, Zr, Hf, V, Mo, Ta and Nb, and then adopting vacuum electromagnetic suspension induction smelting or vacuum electric arc melting to obtain the irradiation-resistant high-entropy alloy. The irradiation-resistant high-entropy alloy is excellent in performance; helium ion simulated irradiation does not generate irradiation hardening damage; on the condition thatthe helium bubble size and traditional alloy size is equivalent, the bubble density is far lower than the density of the traditional alloy, and the lattice constant after irradiation is reduced abnormally; the irradiation resistance of the irradiation-resistant high-entropy alloy is far better than that of the traditional alloy; the irradiation-resistant high-entropy alloy has excellent strengthand plasticity; the compression yield strength of the irradiation-resistant high-entropy alloy under the cast condition is as high as 1.1 Gpa, and the compression ratio and elongation exceed 50%.

Owner:DALIAN UNIV OF TECH

Circular-shaped linear synchronous motor, electromagnetic suspension and motor-driven steering device using the same

InactiveCN101635499AIncrease dampingIncrease thrustElectrical steeringResilient suspensionsMotor driveSynchronous motor

The invention provides a high-damping and high-thrust cylindrical linear motor and an electromagnetic suspension and a metor-driven steering device using the same. A stator includes a stator winding and a stator core. A slider includes a slider core and a plurality of permanent magnets. The stator core includes a plurality of stator core magnets comprising a plurality of small magnets on surface of the slider side; two auxiliary poles deployed at both ends of the stator-core salient poles; a yoke units configured to compose a magnetic circuit with the auxiliary pole. The magnetic circuit composed by using the stator core is shared among the three phases. Polarities of magnets of the slider become an identical polarity, each of the plurality of permanent magnets being positioned at a position which is opposed to each of the plurality of small poles included in one stator-core salient pole out of the plurality of stator-core salient poles.

Owner:HITACHI AUTOMOTIVE SYST LTD

Rapid solidification system and method for suspension large-dimension metal liquid drops under micro-gravity condition

The invention relates to a rapid solidification system for suspension large-dimension metal liquid drops under a micro-gravity condition. The rapid solidification system comprises a vacuum cavity, a suspension induction heating device, a motion detecting device and a rapid liquid quenching device, wherein the vacuum cavity comprises an electromagnetic suspension cavity, a micro-gravity cavity anda rapid liquid quenching cavity which are connected from top to bottom; the suspension induction heating device is provided with a tapered suspension induction coil which is formed by spiral winding,and the coil is arranged on the center of the electromagnetic suspension cavity for melting and suspending an alloy sample; the micro-gravity cavity is a hollow tube body, so that the alloy sample obtains micro-gravity; the motion detecting device is used for continuously and dynamically acquiring a temperature and a form of the alloy sample in dropping motion; and the rapid liquid cooling deviceis provided with a quenching cooling medium for realizing rapid liquid quenching solidification for the alloy sample. The rapid solidification system avoids heterogeneous nucleation generated by wallcontact while the sample is molten, so that the sample is deeply super-cooled, and therefore, tissue segregation caused by gravity effect is eliminated, and rapid solidification from millimeter-grademetal liquid drops to the centimeter-grade metal liquid drops is realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

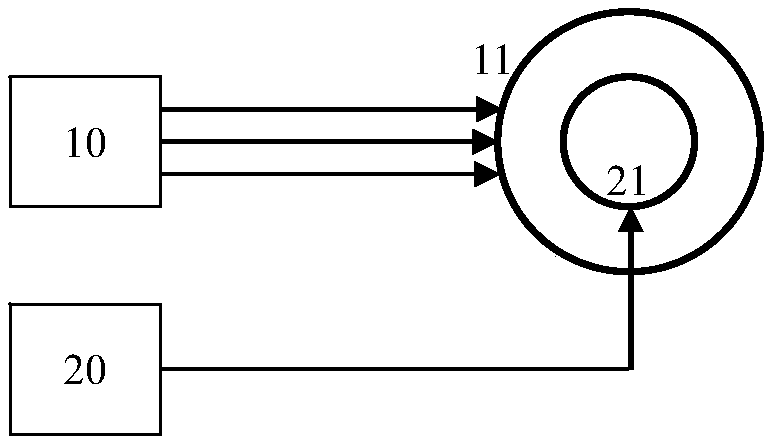

Wind power magnetic suspension yaw motor control method based on model predictive control

ActiveCN108183650AEnhanced Multiple InputImprove steady state performanceElectronic commutation motor controlVector control systemsElectrical engineering technologyOptimal control

The invention relates to a wind power magnetic suspension yaw motor control method based on model predictive control and belongs to the technical field of electrical engineering. According to the method, the model predictive control technology is used, and the suspension and yaw rotation processes of a magnetic suspension yaw motor is smoothly controlled in real time. When a wind direction changesand yaw is needed, firstly a rotor current converter finds an optimal control law through a cost function to control the current of a rotor, thus the rotor is suspended upwards and is maintained at asuspension equilibrium point, secondly a stator converter finds an optimal control law through a cost function to control the current of a stator, thus the yaw motor rotates to a wind position according to a specified rotation speed, at the same time the rotor converter finds an optimal control law through a cost function to control the current of a rotor, thus the rotor is maintained at the suspension equilibrium point, the coordinated control of the stator and the rotor can be realized without decoupling, the fast tracking ability and stability of a system are ensured, at the same time, theinfluence of external disturbance on system operation can be effectively suppressed, and the system performance in an entire suspension yaw rotation process is optimal in real time.

Owner:山东省华礼海洋科技有限公司

Electromagnetic shielding material of coverage compound carbon base and its making method and purpose

InactiveCN101080161AEasy to prepareLow costMagnetic/electric field screeningScreening apparatusElectromagnetic shieldingCarbonylation

This invention relates to a covered compound carbon-base inorganic electromagnetic shield material, its preparation method and usage, which mixes carbonyl iron, carbonyl nickel or a mixture of carbonyl iron and nickel with carbon base powder in the weight percentage of 50-90 : 10-50 and suspends them fully with an electromagnetic suspension blender under inert gas atmosphere and 35-103dge.C to get powder, which is heated under 100-450deg.C inert gas atmosphere to become a covered compound carbon base electromagnetic shield material.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Turbocharger

InactiveCN101429878AImprove efficiencyNot vulnerableCombustion enginesGas turbine plantsImpellerTurbocharger

The invention discloses a turbocharger. The invention adopts a technical proposal that the turbocharger comprises a turbine rotor shaft assembly, an intermediate, a pressure housing, a diffusion plate fixedly connected with or integrally formed with the pressure housing, wherein the turbine rotor shaft assembly is at least provided with a set of permanent magnet rings matched with each other between a turbine and a compressor impeller. The permanent magnet rings comprise at least one permanent magnet dynamic ring and at least one permanent magnet static ring which are matched with each other to suspend a rotor shaft of the turbine rotor shaft assembly. The invention provides a friction-free turbocharger which uses permanent magnet rings to suspend the rotor shaft of the turbine. The turbocharger can solve the problems of susceptibility to damage, oil leakage and pollution, reduce response lags, and does not cause serious influence on the engine except for reduction in power when damaged. The turbocharger solves the problems of susceptibility to damage, oil leakage and pollution of the prior turbocharger and overcomes the drawbacks such as high price, large volume and complex structure of electromagnetic suspension bearing exhaust turbocharger.

Owner:南通通州江华纺织有限公司

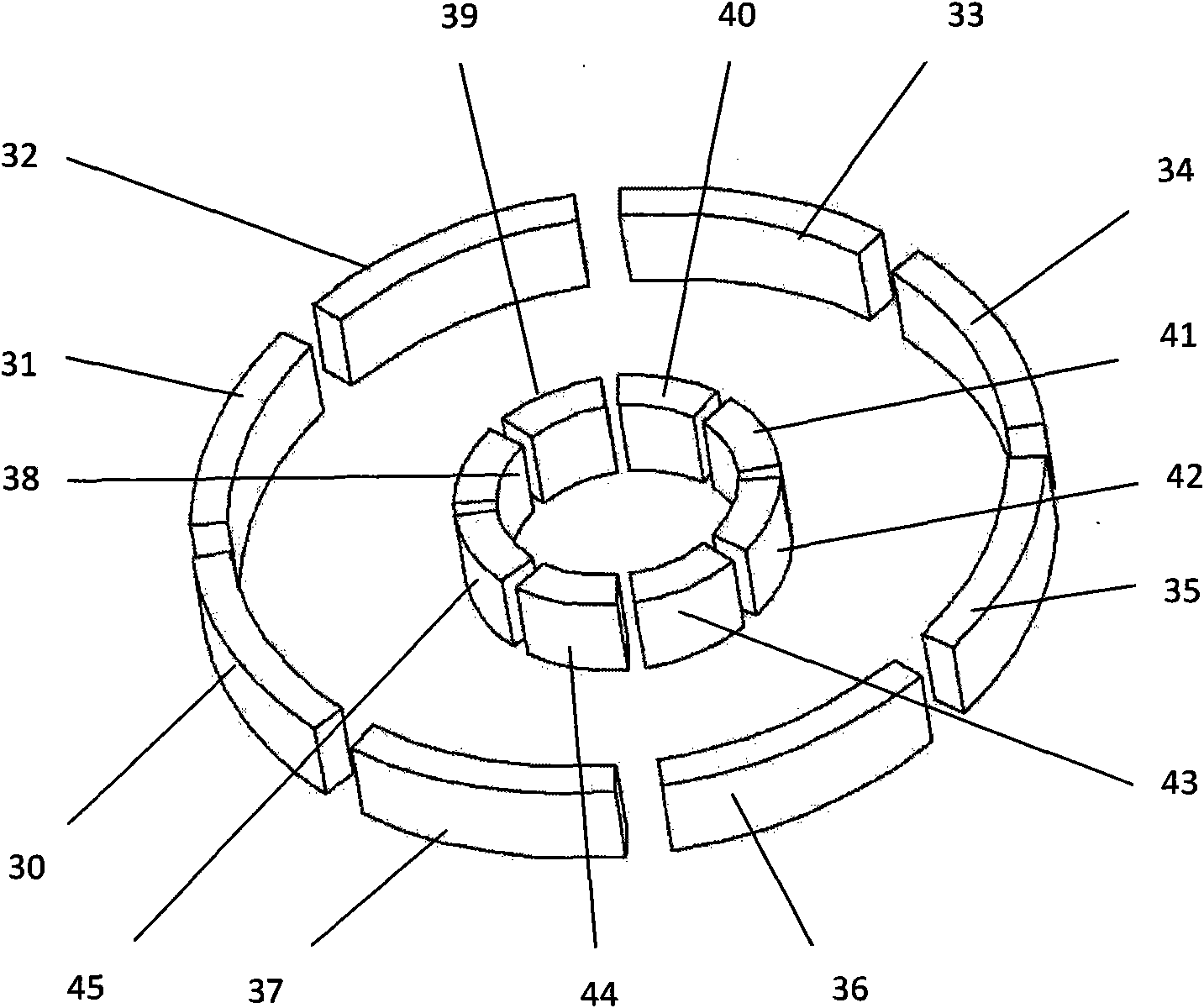

Internal stabilized electromagnetic suspension ring-shaped micro-rotating gyroscope

InactiveCN101017088AIncrease rotational torqueRotary gyroscopesMechanical energy handlingGyroscopeEngineering

This invention relates to one inner stable hanging ring rotor micro rotation top in micro machine system technique field, wherein, setting the stable float coil, rotation coil and sensor electrode onto base to form fix connection and base; micro rotor is floating one the base under electronic magnetic force and the ring rotor is under function of hanging coil force to get stable hanging outside rotation coil to generate rotation magnetic field; micro rotor is under rotation magnetic field to generate rotation torque for high speed rotation through sensor electrode.

Owner:SHANGHAI JIAO TONG UNIV

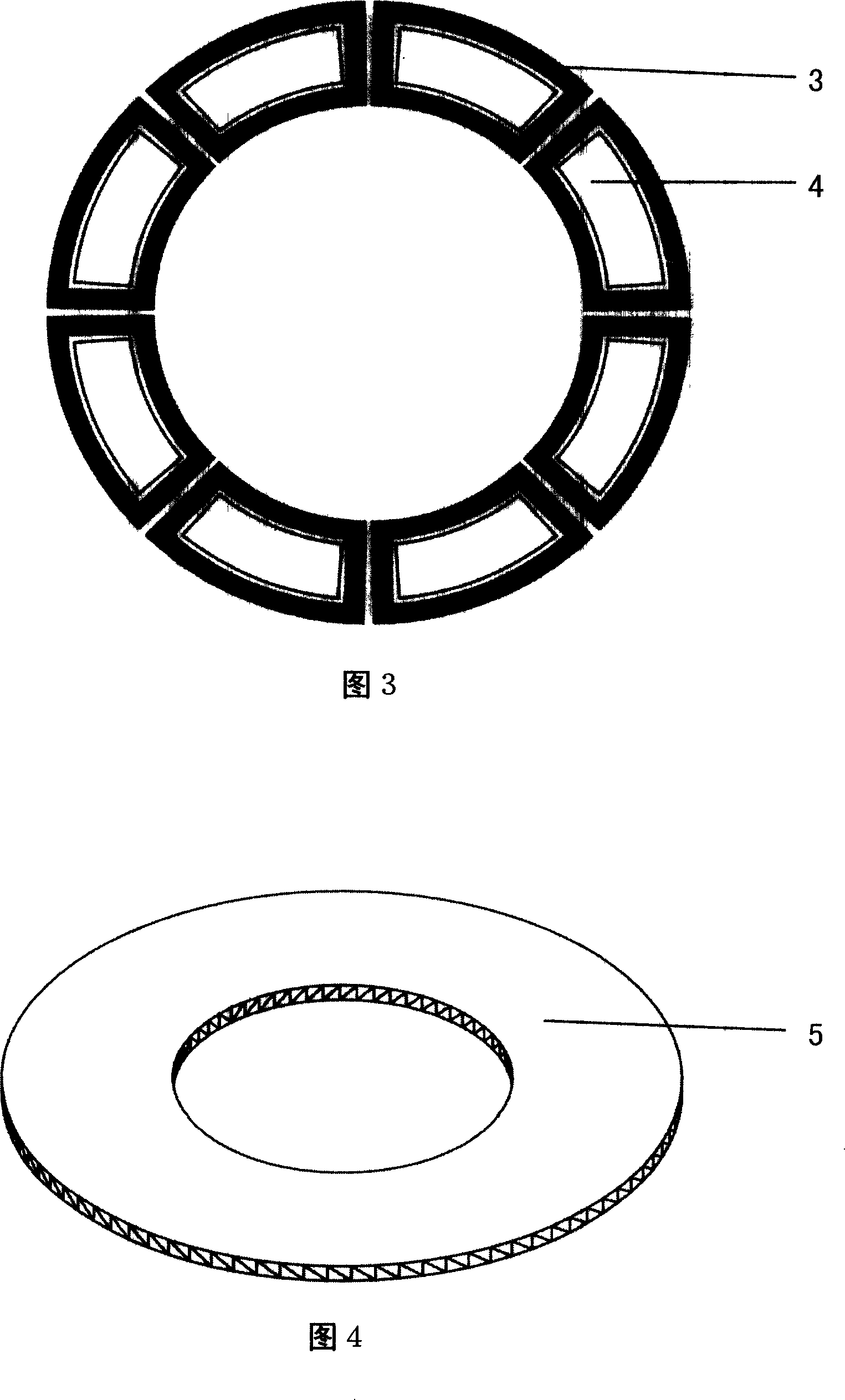

Electromagnetic suspension and driving space micro motion method and mechanical device

InactiveCN1937391ALarge range of motionHigh movement precisionMagnetic holding devicesManufacturing technologyRange of motion

The micro-operator is fixed on the moving object. A group of permanent magnet arrays (PMA) are buried into the bottom and four sides of the object. A group of wire arrays are set corresponding to each group of PMA. Whenever the electric current flows through the wire arrays under the moving object, the electric-magnetic field produced by the wire arrays interacts with the magnetic field produced by the PMA. It causes the moving object floating. By means of changing the direction and magnitude of the current in each group of the wire arrays, the 6-dimension space micro-movement needed by the micro-operator can be realized. This is such a Nano-lever movement, which has advantages of great working range, high precision and fast response time. This apparatus suits mainly for fields as the micro mechanical-electric system, the biology engineering, IC chip manufacture technique, the molecule and atom control, etc.

Owner:ZHEJIANG SCI-TECH UNIV

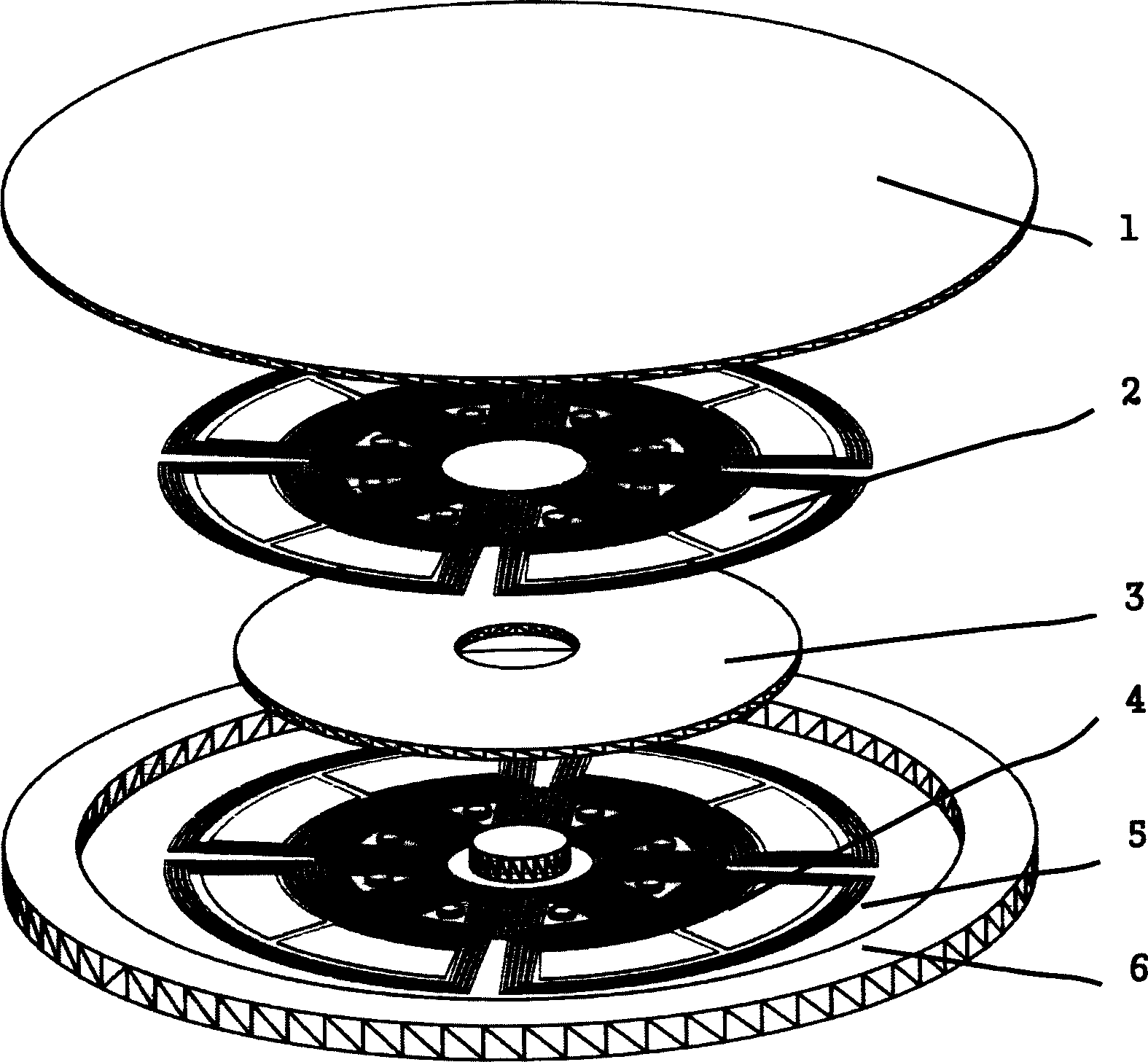

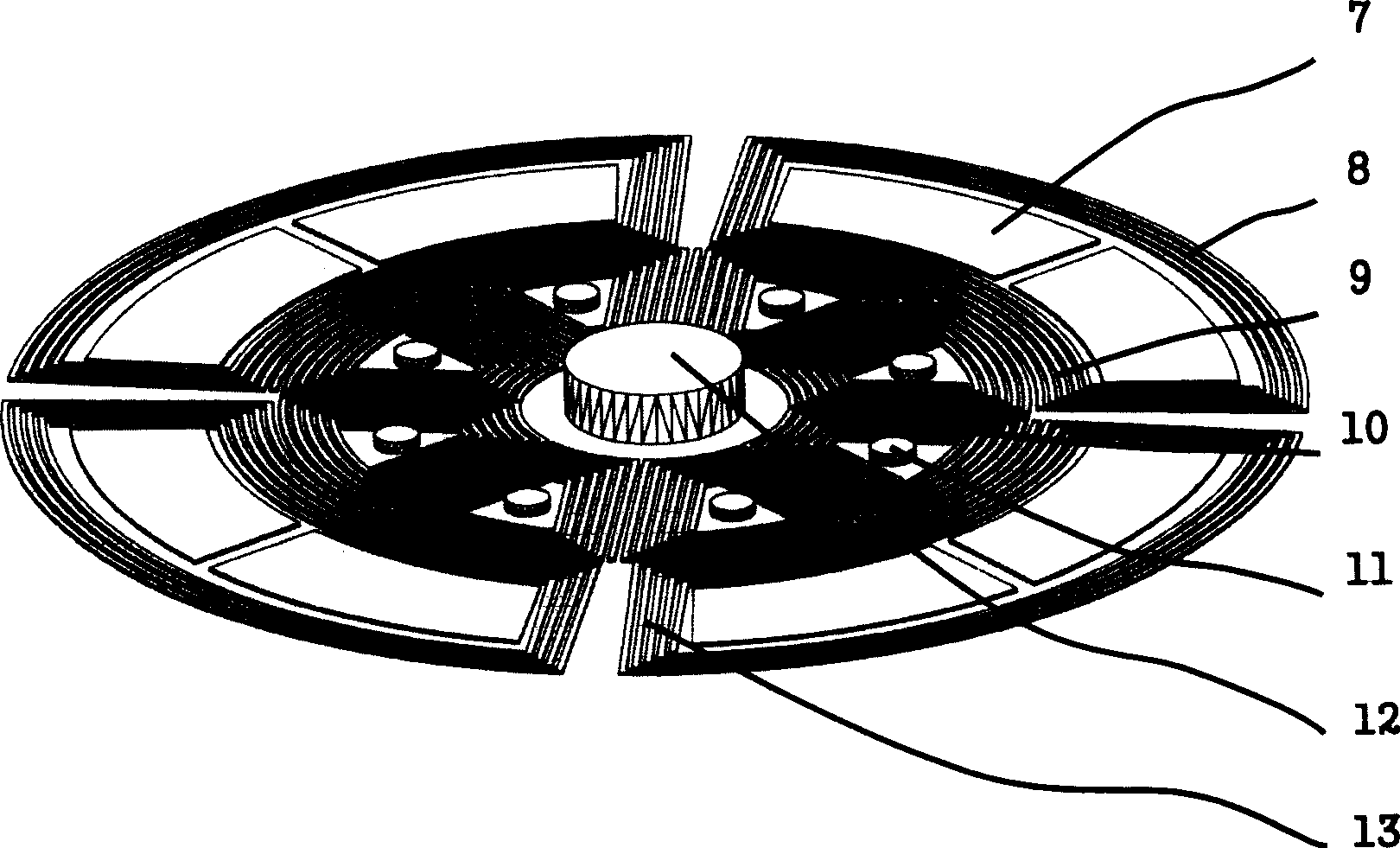

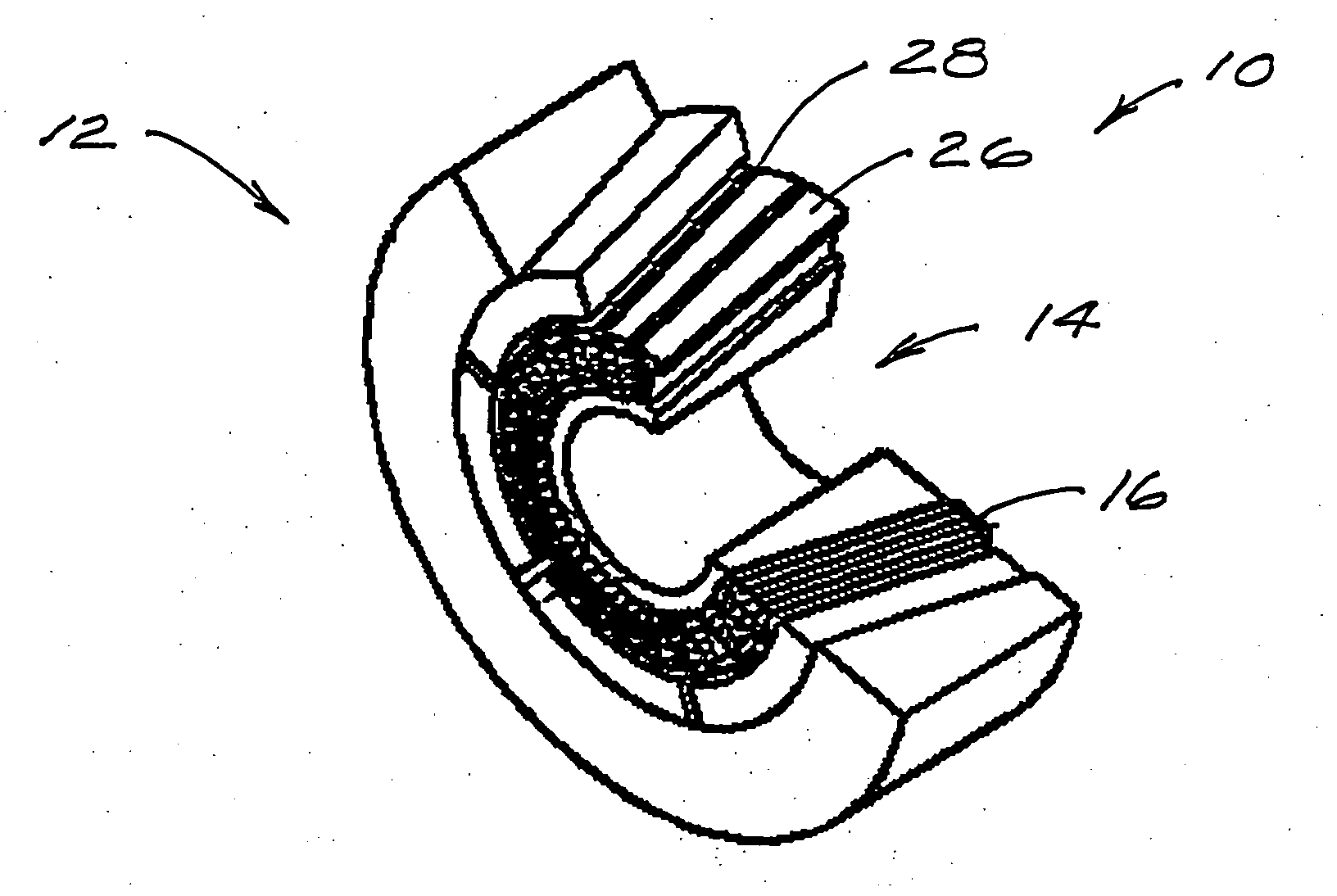

Magnetic suspension and drive system for rotating equipment

An electromagnetic suspension and rotary drive system comprises at least one conical bearingless motor / generator. Each conical bearingless motor / generator comprises a rotatable part and a stationary part. The rotatable part has an axis of rotation with respect to the stationary part. The stationary part has one or more windings for producing a drive field and a control field. The drive field is provided for exerting a torque on the rotatable part to transfer energy between the rotatable part and the stationary part. The control field is provided for exerting a force on the rotatable part to levitate the rotatable part. The force exerted by the conical bearingless motor / generator is adapted to be directed at an angle greater than 0° and less than 90° relative to the axis of rotation of the rotatable part.

Owner:UNIVERSITY OF TOLEDO

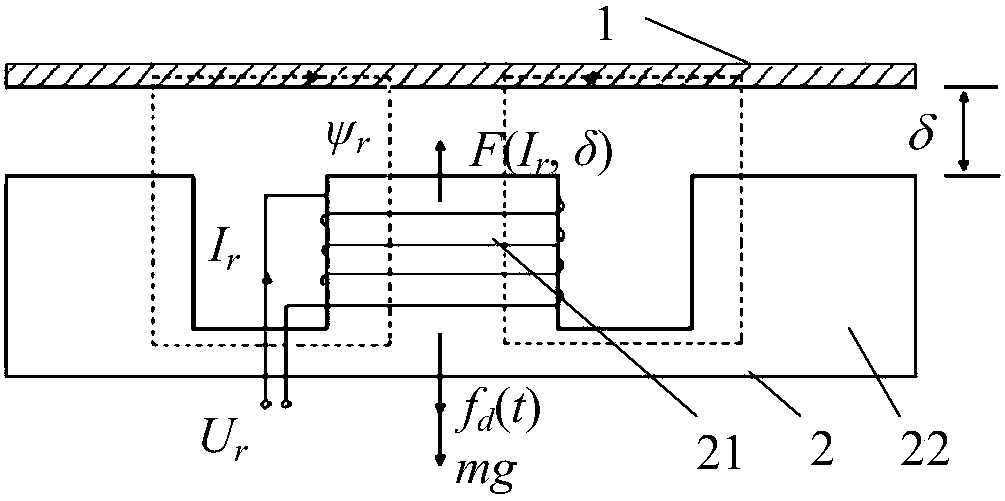

A hybrid electromagnetic suspension capable of realizing self-power supply and a control method thereof

ActiveCN109080399ASolve the problem of high energy consumptionImprove performanceResilient suspensionsVehicle springsSemi activeRoad surface

Owner:JIANGSU UNIV

Electromagnetic levitation static driven micro-rotation gyro

The invention relates to an electromagnetic suspension static electricity driving micro-rotating gyrostat in the field of Micro Electro-Me-chanical Systems technique. It comprises: a rotation driving electrode, a micro-rotor, a stabilizing floating coil collar, a tooth outline electrode, a sensing electrode, a base body, a stabilizing floating coil inner ring and a connecting line, wherein the stabilizing floating coil collar, the stabilizing floating coil inner ring, the sensing electrode and the rotation driving electrode are fixed on the base body and forms to the fixed connection; the micro-rotor is positioned on the upper of the base body on the electromagnetic force effect; the micro-rotor is loop type with the tooth outline electrode, the rotation driving electrode and the tooth outline electrode distributed on the inner side of the loop to form the variable capacity; the stabilizing floating coil inner ring is connected with the stabilizing floating coil collar by connecting wire.

Owner:SHANGHAI JIAO TONG UNIV

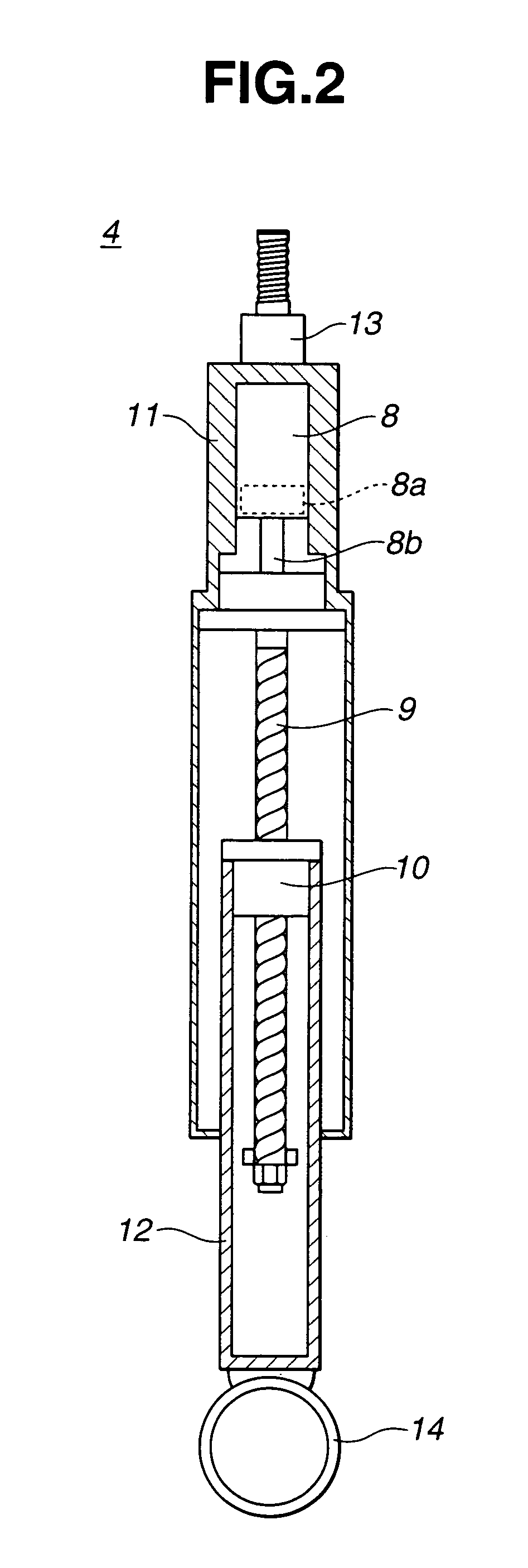

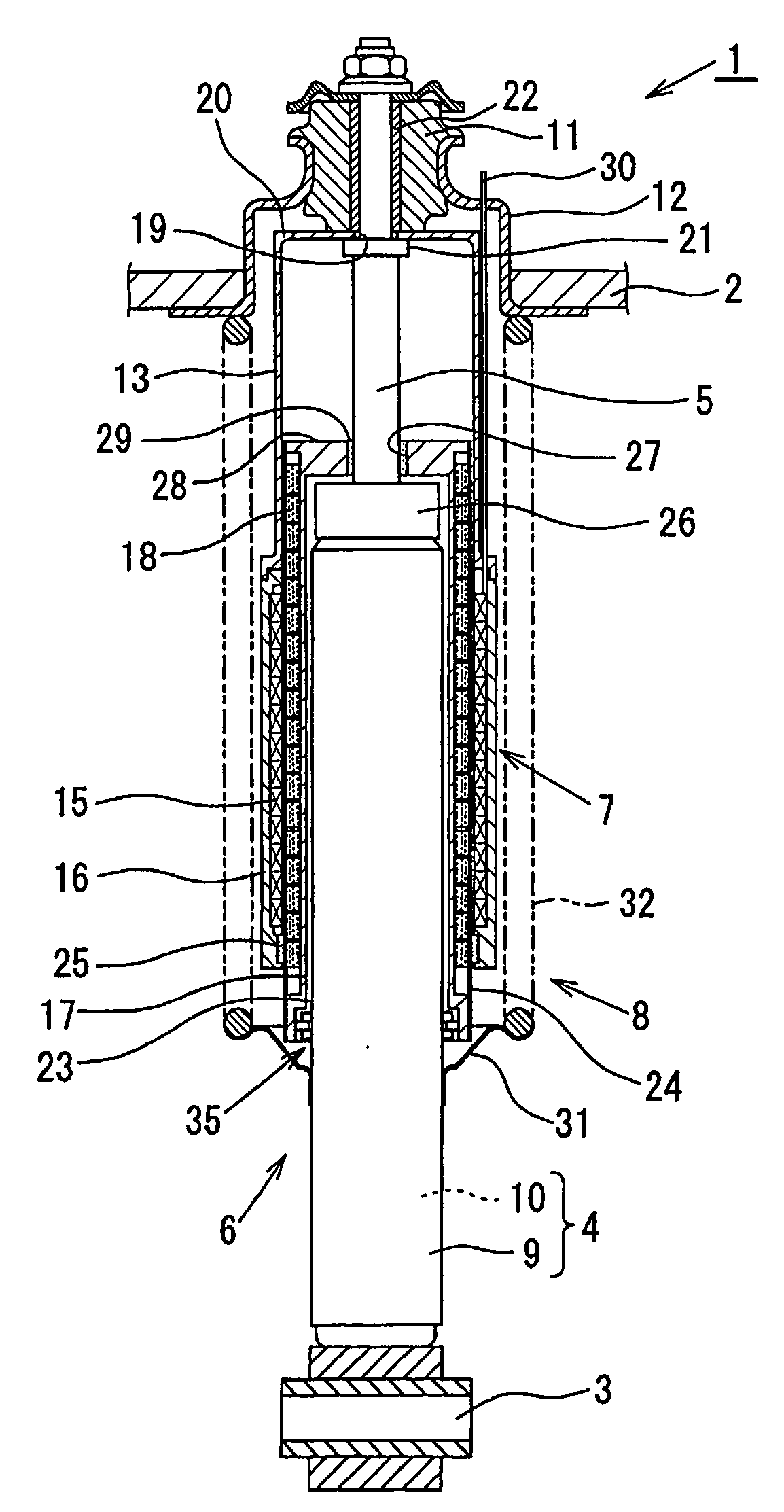

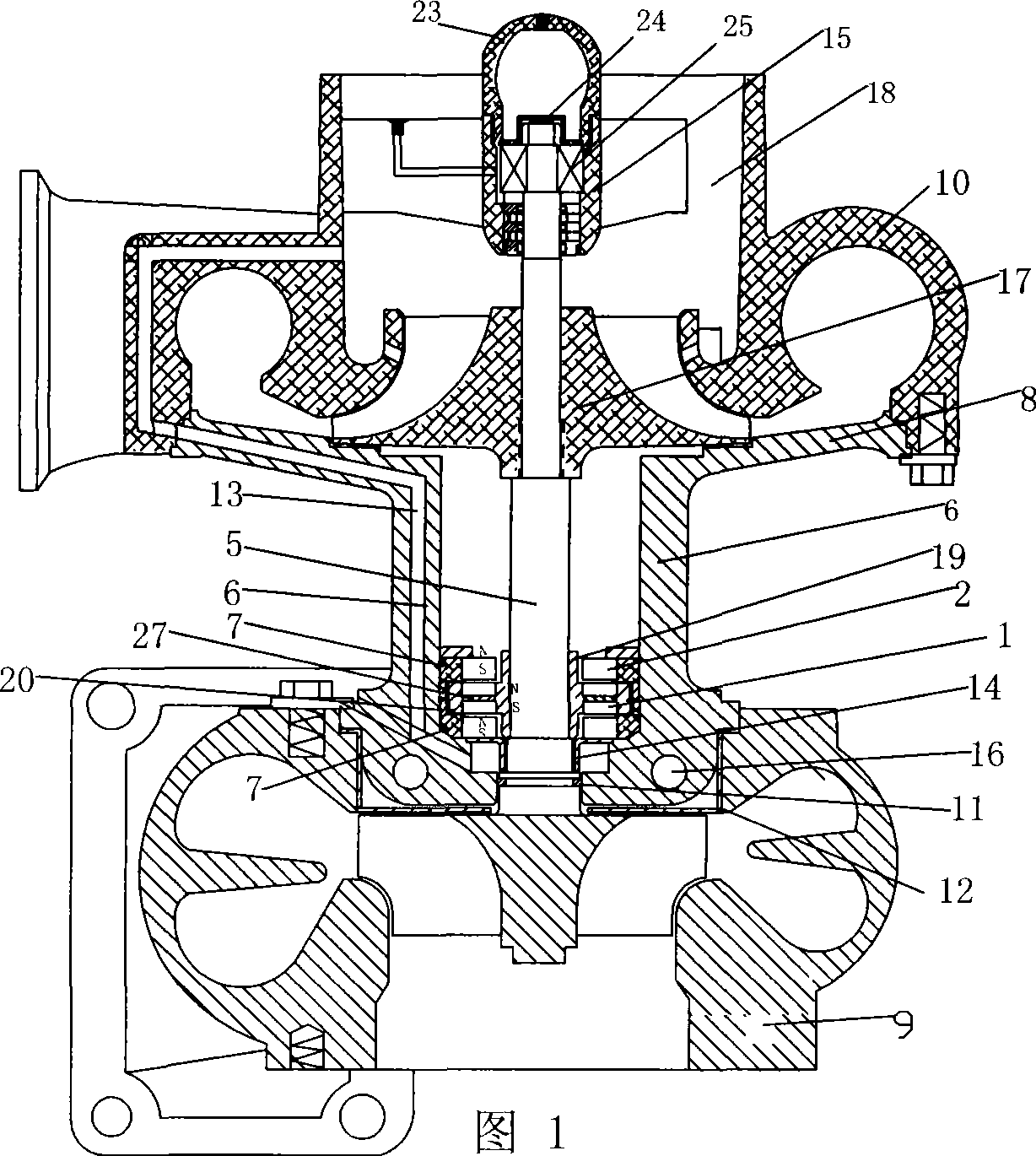

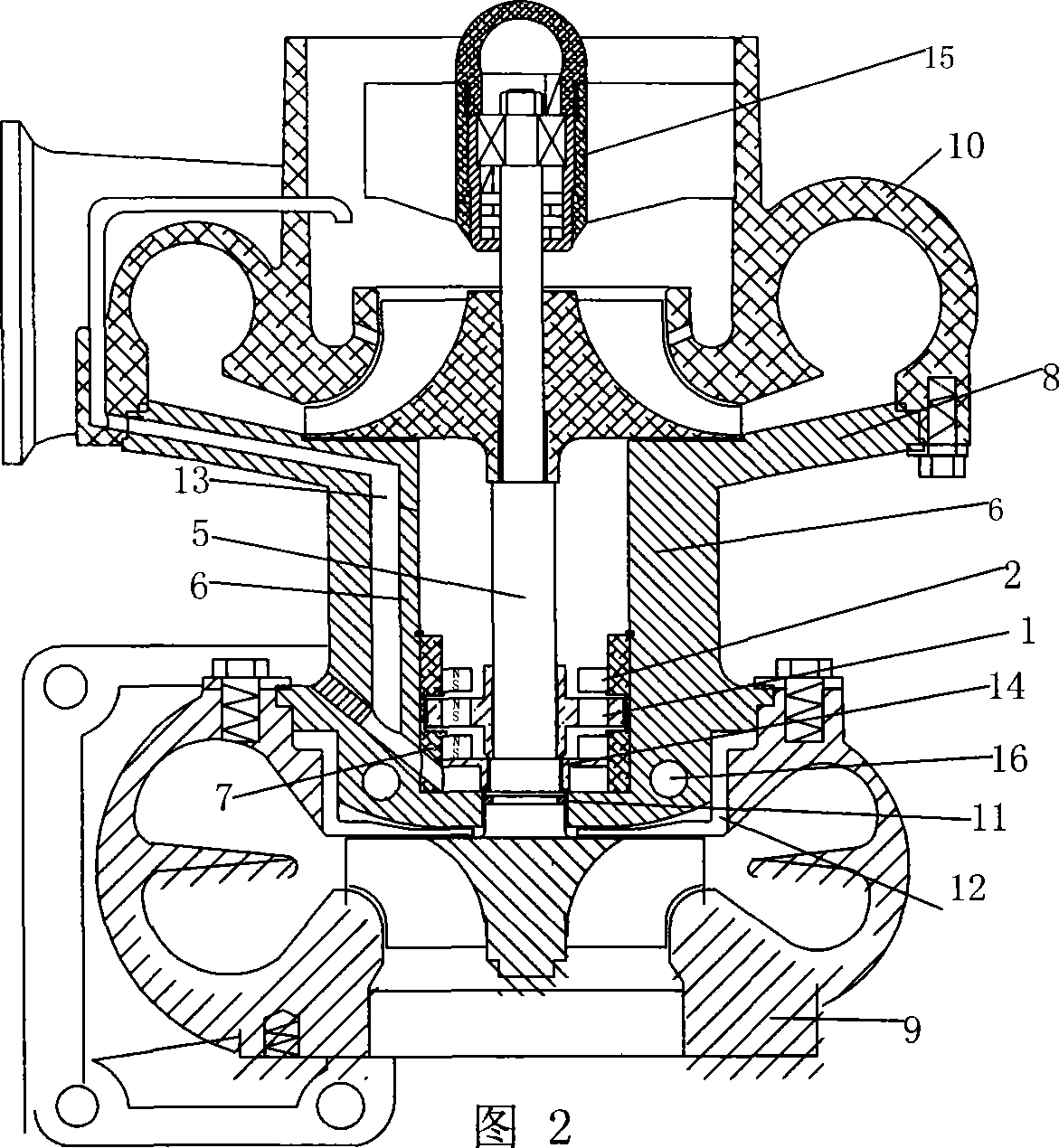

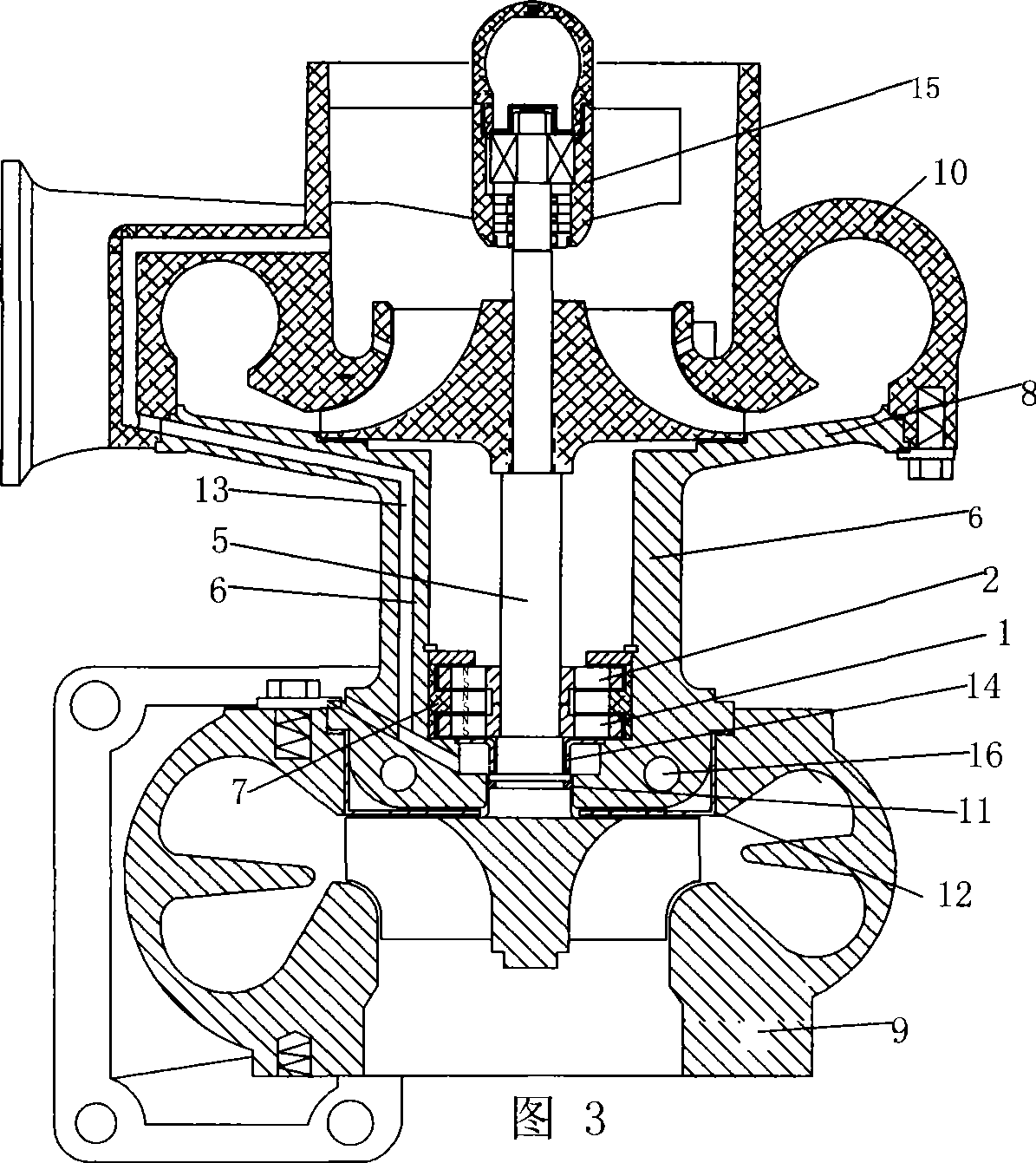

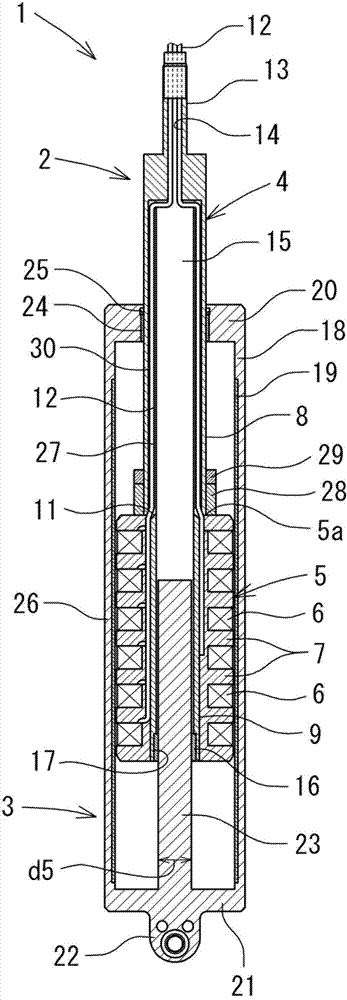

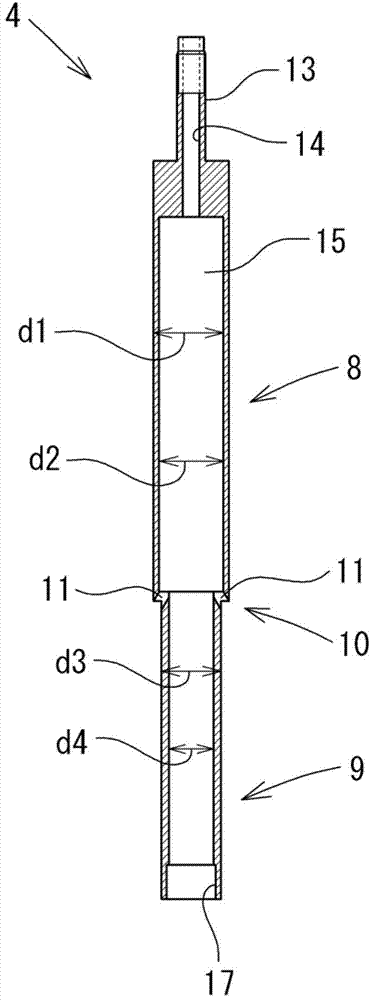

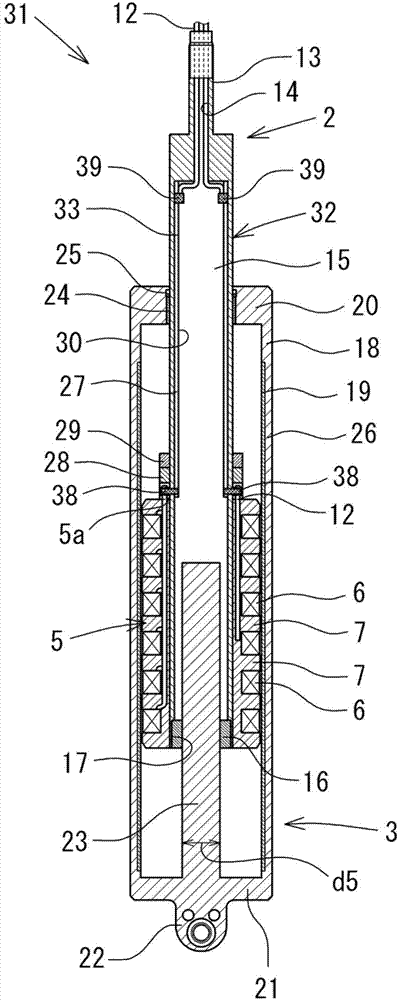

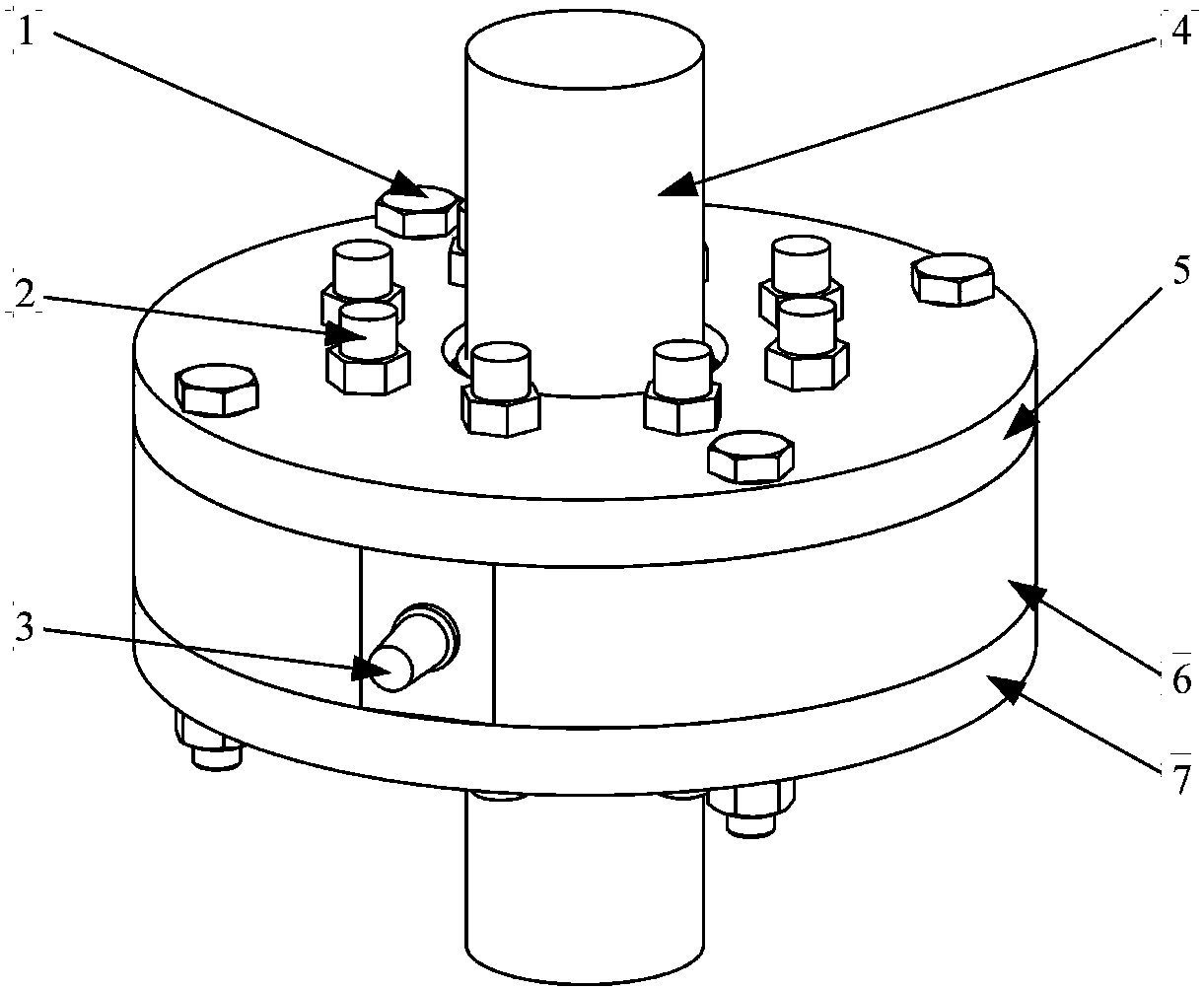

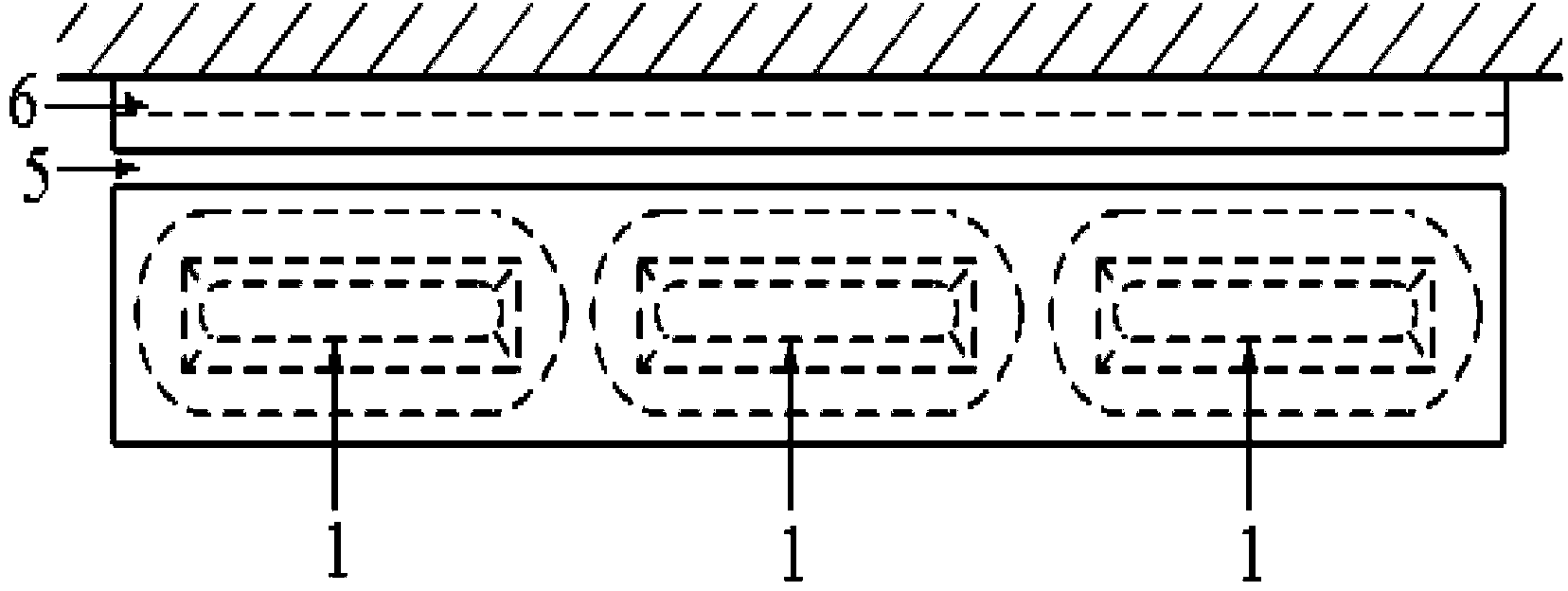

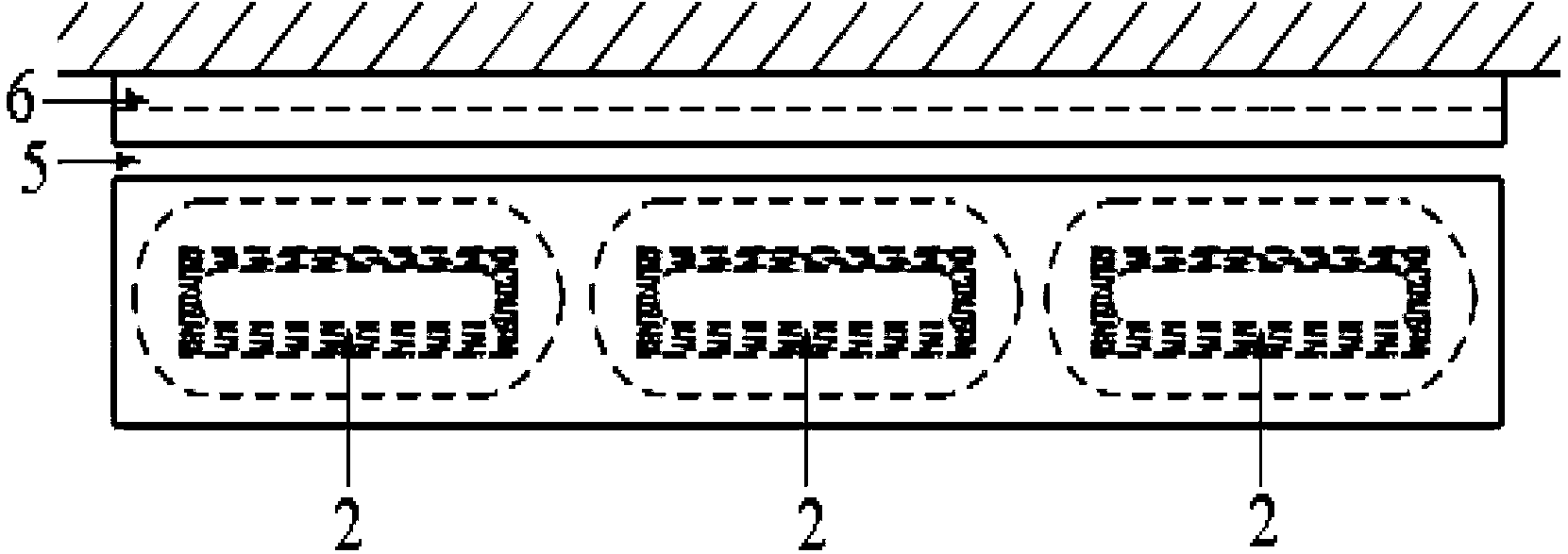

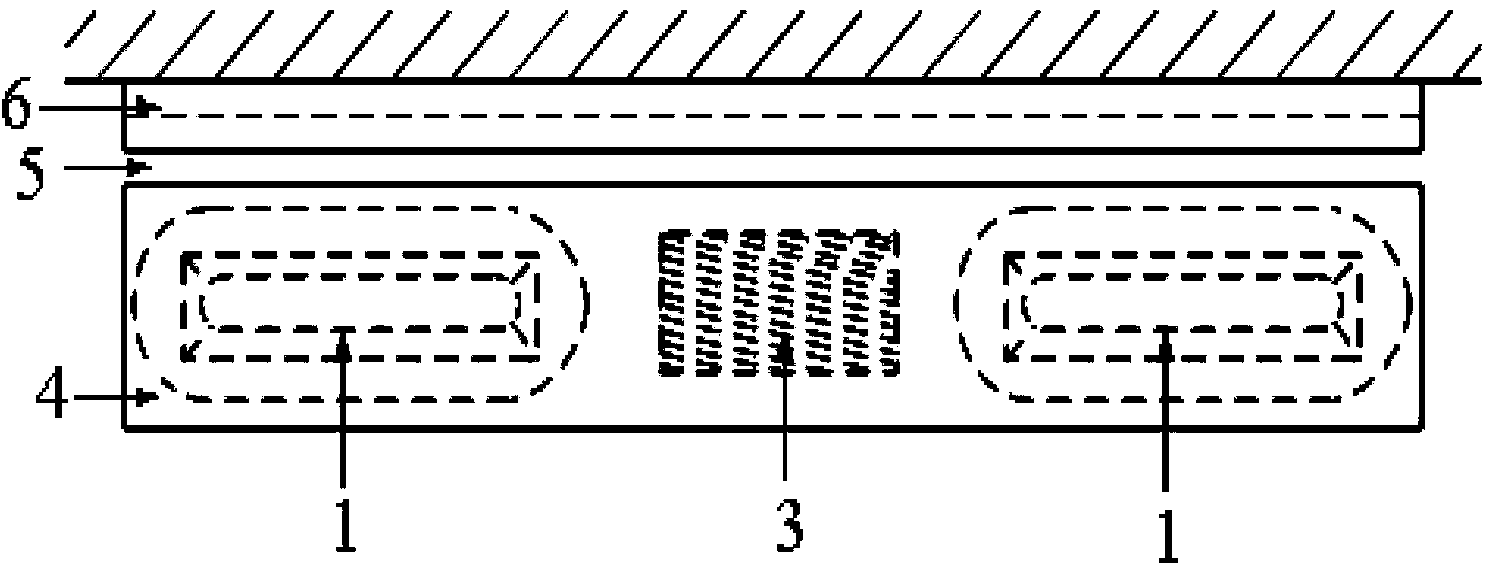

Electromagnetic suspension

An electromagnetic suspension system uses a linear motor having coils (6) disposed around the outer periphery of a stator (2) and permanent magnets (19) disposed along the inner periphery of a mover (3). Wiring (12) is routed through a gap (27) between a first rod (4) and a second rod (23). Thus, contact between the wiring (12) and the second rod (23) is avoided, and the wiring (12) is protected. Consequently, it is possible to ensure reliability for the electric system of the electromagnetic suspension system.

Owner:HITACHI ASTEMO LTD

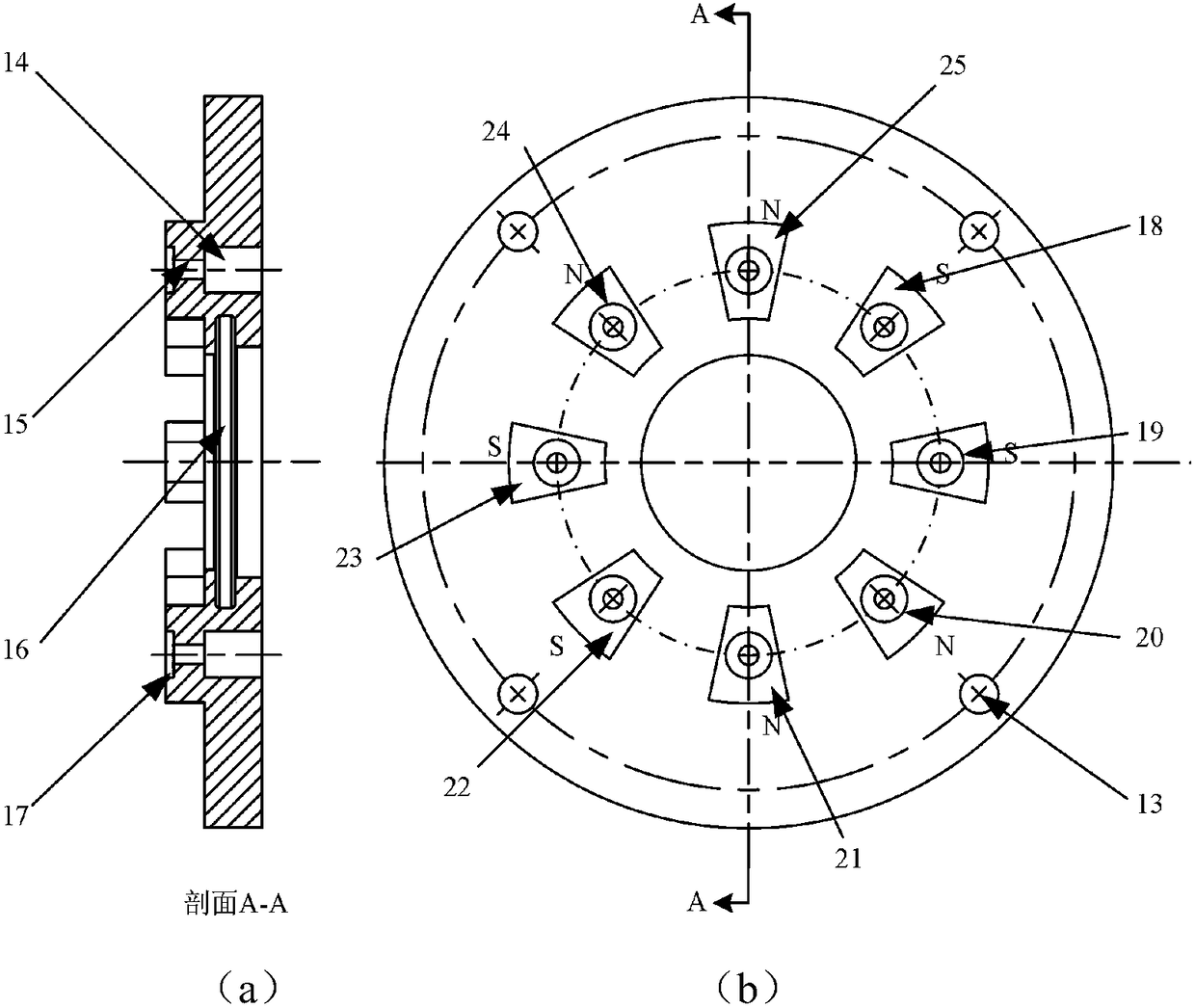

Magnetic-air suspension axial bearing with porous medium

InactiveCN108488233AReduce frictionReduce wearShaftsMagnetic bearingsPressure systemCarrying capacity

The invention discloses a magnetic-air suspension axial bearing with a porous medium, which comprises a static air pressure system and an electromagnetic suspension system. The bearing comprises a shaft, a thrust disc, a first stator, a second stator and an adjustment pad, wherein eight magnetic poles are arranged on the first stator and arrayed according to an NSSNNSSN manner; every two adjacentmagnetic poles are a pair; and the second stator and the first stator have the same structure. An assembly relationship is as follows: the external circumference of the thrust disc is sleeved with theadjustment pad; the first stator and the second stator are oppositely mounted on the two sides of the thrust disc; and the magnetic poles of the first stator and the second stator face towards the inner side. The bearing can integrate the static air pressure system and the electromagnetic suspension system; an auxiliary support and circulatory cooling system is not required to be adopted independently; the friction and abrasion of the bearing can be greatly reduced; and the carrying capacity and rigidity are improved.

Owner:YANSHAN UNIV

Combined-type suspension electromagnet for medium-low-speed maglev train and manufacturing method of combined-type suspension electromagnet

ActiveCN103481794AEliminate potential safety hazardsReduce suspension forceElectromagnetsElectric propulsionLow speedEnergy consumption

Disclosed are a combined-type suspension electromagnet for a medium-low-speed maglev train and a manufacturing method of the combined-type suspension electromagnet. The combined-type suspension electromagnet structurally comprises at least one permanent-magnetic suspension component and more than one electromagnetic suspension component and / or hybrid suspension component, and the permanent-magnetic suspension components and the electromagnetic suspension components and / or hybrid suspension components are combined and mounted together through a shared iron core electrode plate. The method includes the following steps: (1), determining structure sizes of permanent magnets in the permanent-magnetic suspension components; (2), designing and determining number of turns of excitation coils and the structure sizes of permanent magnets in the electromagnetic suspension components and / or the hybrid suspension components according to big gap working conditions of normal suspension and fluctuation of the train. The combined-type suspension electromagnet has the advantages of simple structure, low cost, high reliability, convenience for maintaining, low suspension energy consumption and good suspension controlling and adjusting performance.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com