Magnetic-air suspension axial bearing with porous medium

A technology of porous media and axial bearings, applied in the direction of magnetic bearings, shafts and bearings, bearings, etc., can solve the problems of unsuitable high power, heavy load operation, aerostatic bearing support stiffness and low bearing capacity, etc., to achieve saving Effect of material, reduction of friction and wear, improvement of bearing capacity and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described in detail:

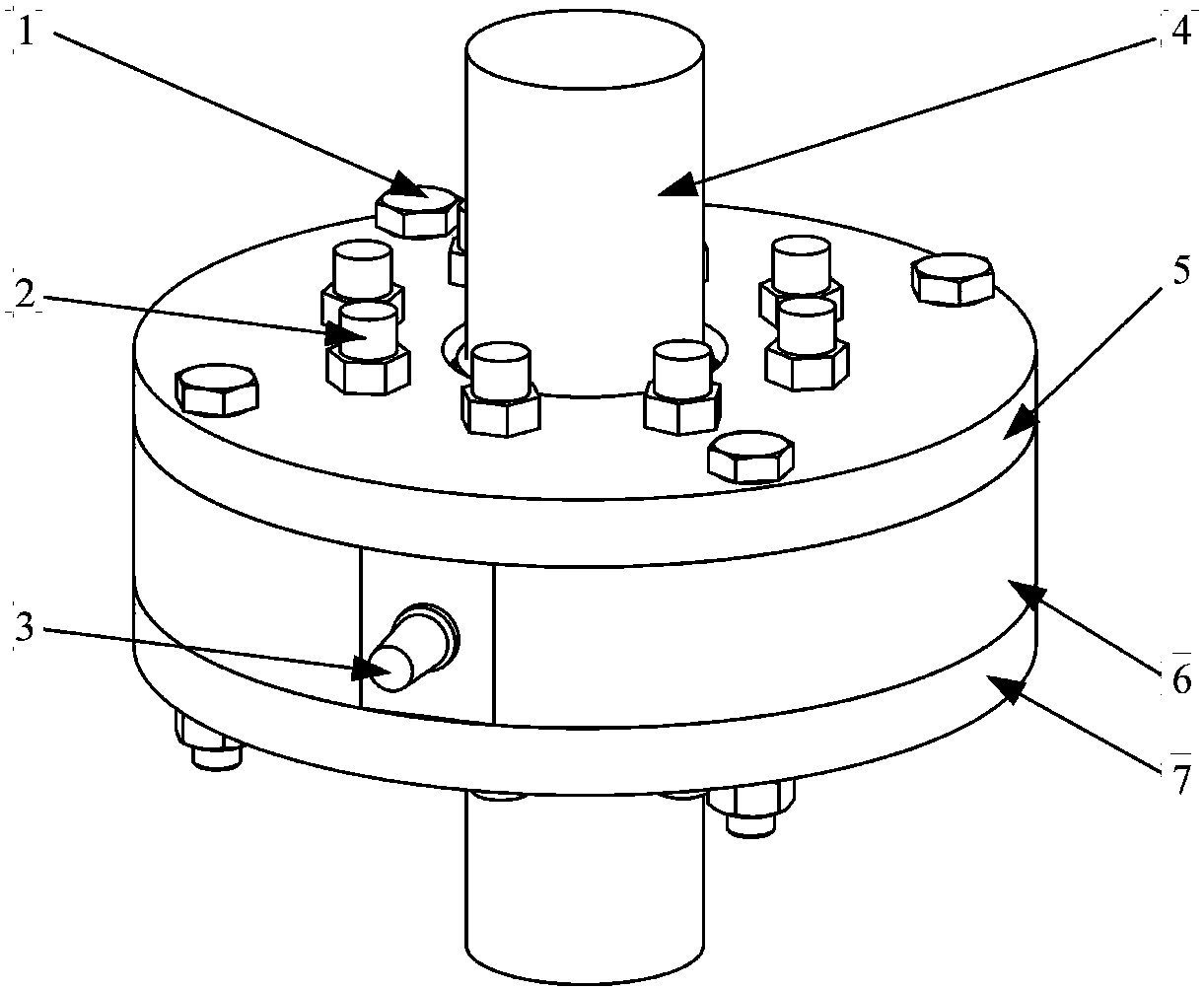

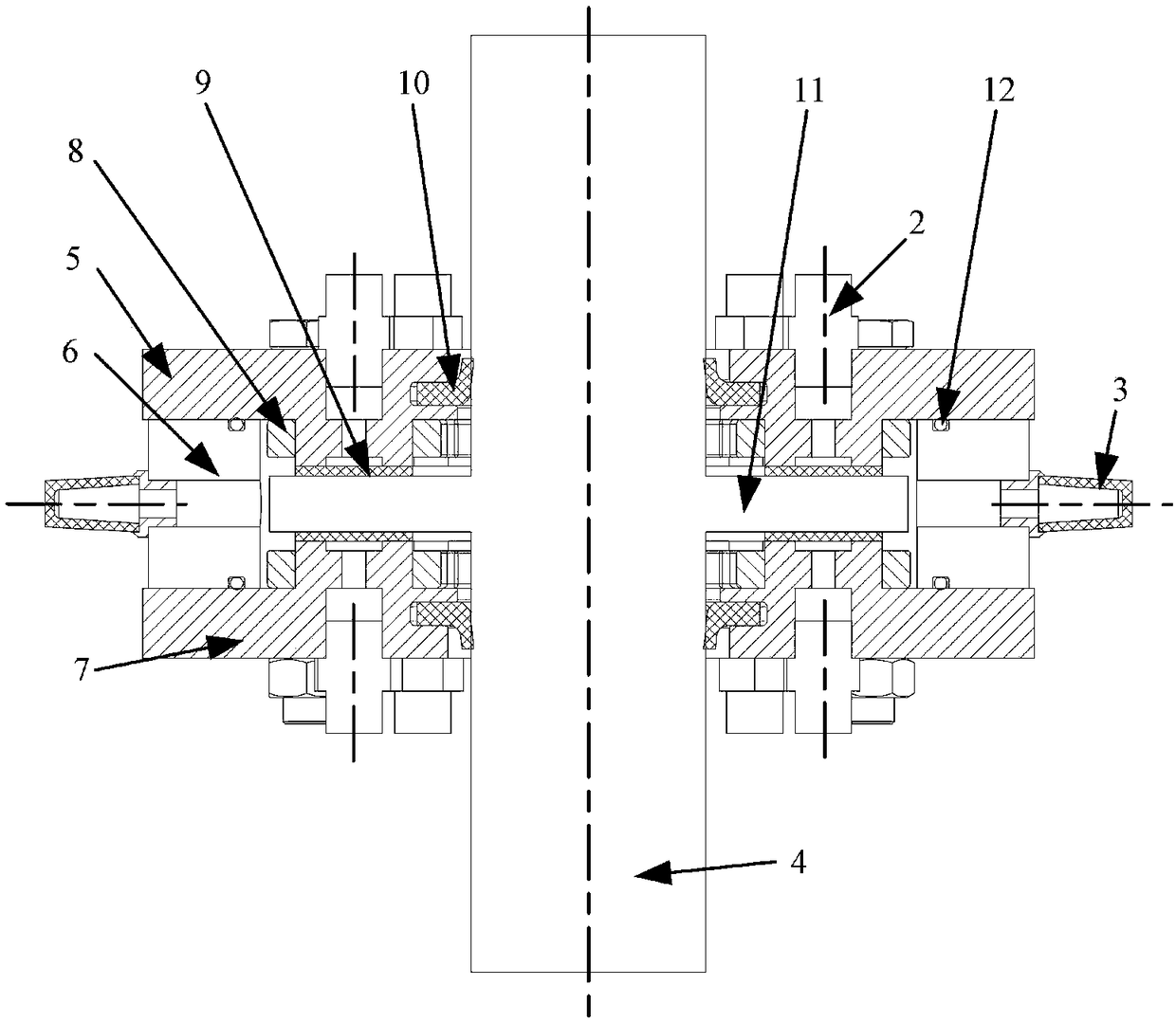

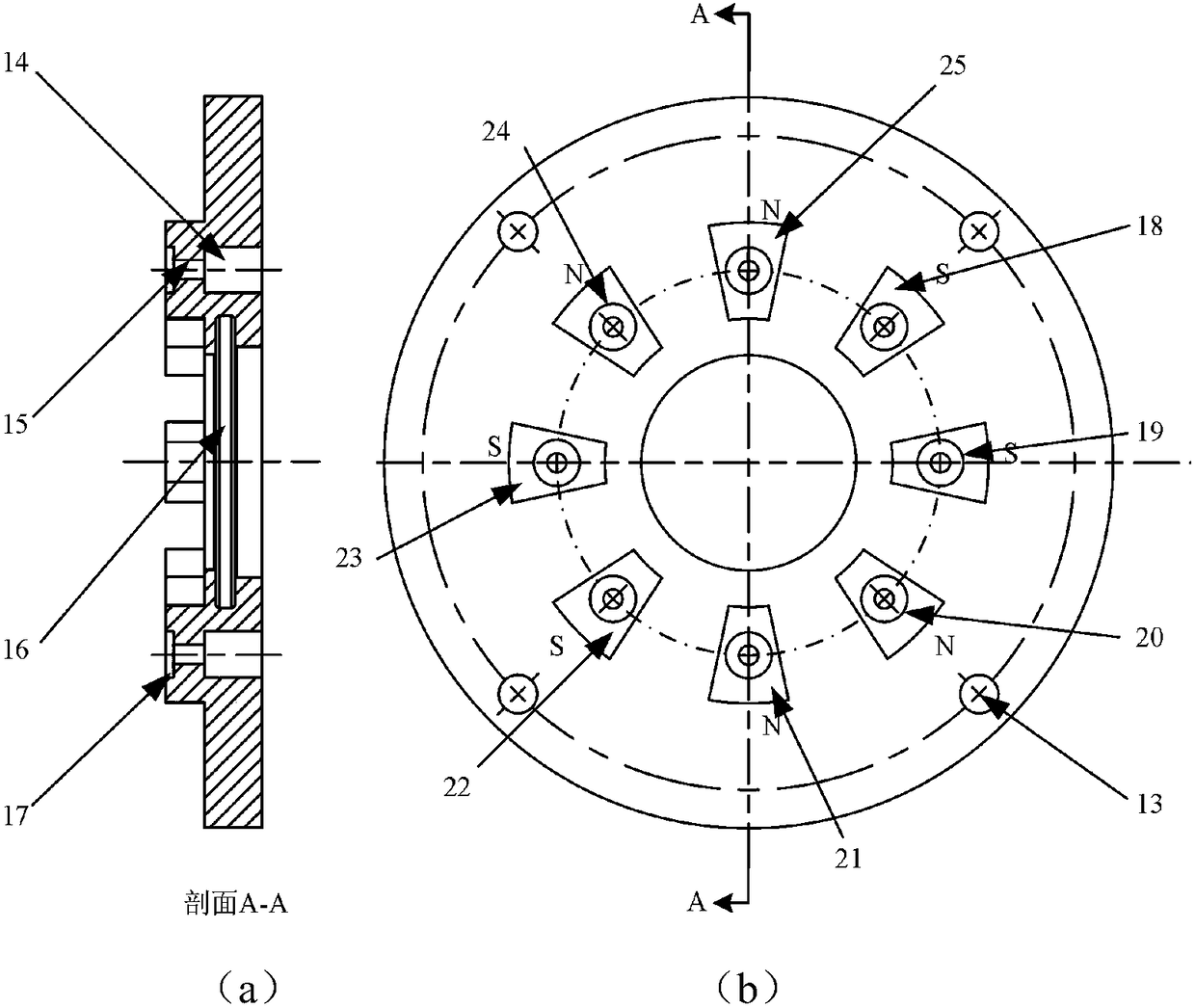

[0021] A magnetic double-suspended axial bearing with a porous medium of the present invention, such as figure 1 , figure 2 As shown, as a preferred solution, the bearing includes an aerostatic pressure system and an electromagnetic suspension system; the bearing structure includes a shaft 4, a thrust plate 11, a first stator 5, a second stator 7 and an adjustment pad 6, The diameter of the shaft 4 is 50mm, the diameter of the thrust plate 11 is 130mm, and the thickness is 12mm; the first stator 5 is a disc-shaped structure, its diameter is 190mm, and the thickness is 15mm; figure 2 As shown, eight magnetic poles 18, 19, 20, 21, 22, 23, 24 and 25 are evenly arranged along the circumference of the stator on one end face of the disc. The thickness of the magnetic poles is 10 mm. The magnetic poles are arranged in the manner of NSSNNSSN. Two magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com