Patents

Literature

40 results about "Bubble density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for treating synthetic silica powder and synthetic silica powder treated thereof

ActiveUS7452518B2Improve stabilityLow densitySilicaPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesBubble densityVolumetric Mass Density

A process for producing a synthetic quartz glass powder which is substantially free of carbon contaminant, for reduced bubble density and improved stability of articles made from the synthetic quartz glass during fusion molding by maintaining the synthetic silica powder in an oxidizing environment, e.g., an atmosphere comprising at least 3 vol. % ozone at a temperature of less than 1400° C., causing carbon containing compounds to be reduced to less than 10 ppm.

Owner:GENERAL ELECTRIC CO

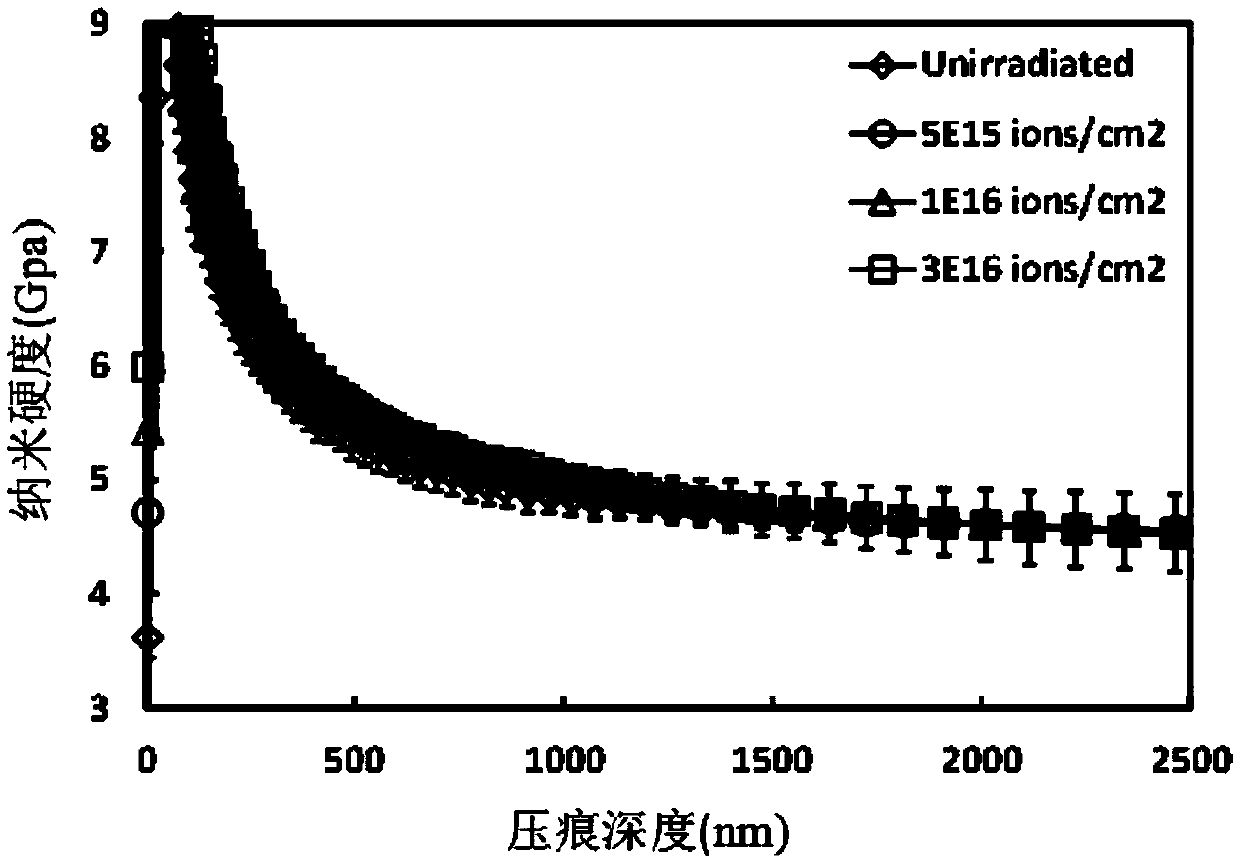

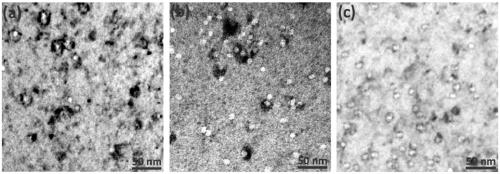

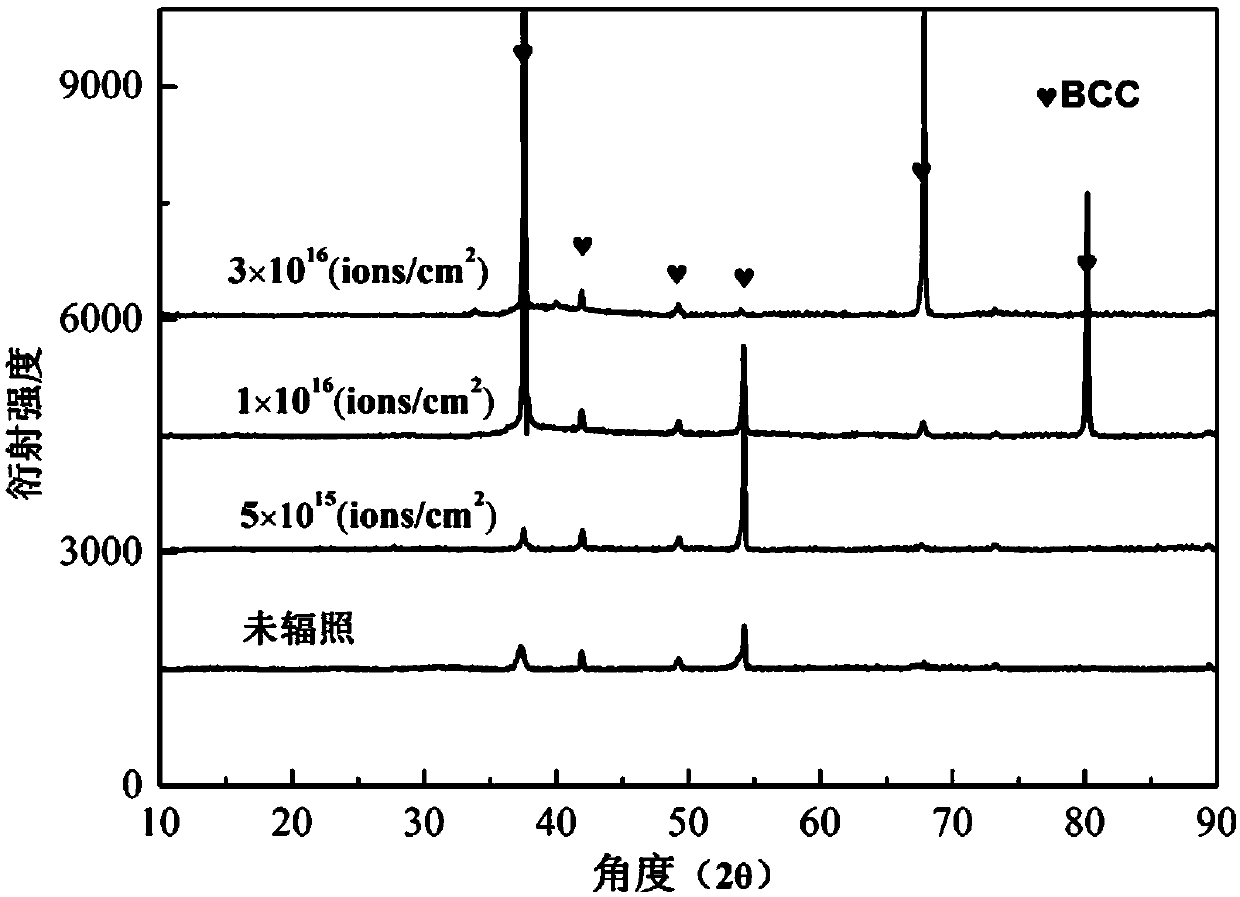

Irradiation-resistant high-entropy alloy and preparation method thereof

ActiveCN109666811AImprove high temperature performanceImprove corrosion resistanceOptical rangefindersNuclear energy generationHigh entropy alloysVolumetric Mass Density

The invention provides irradiation-resistant high-entropy alloy and a preparation method thereof. The general formula of the irradiation-resistant high-entropy alloy is TiZrHfVMoTaxNby, wherein X is no more than 0.25 and no less than 0.05, y is no more than 0.5 and no less than 0.05, and x and y are molar ratio. The preparation method of the irradiation-resistant high-entropy alloy comprises the following steps: sequentially mixing Ti, Zr, Hf, V, Mo, Ta and Nb, and then adopting vacuum electromagnetic suspension induction smelting or vacuum electric arc melting to obtain the irradiation-resistant high-entropy alloy. The irradiation-resistant high-entropy alloy is excellent in performance; helium ion simulated irradiation does not generate irradiation hardening damage; on the condition thatthe helium bubble size and traditional alloy size is equivalent, the bubble density is far lower than the density of the traditional alloy, and the lattice constant after irradiation is reduced abnormally; the irradiation resistance of the irradiation-resistant high-entropy alloy is far better than that of the traditional alloy; the irradiation-resistant high-entropy alloy has excellent strengthand plasticity; the compression yield strength of the irradiation-resistant high-entropy alloy under the cast condition is as high as 1.1 Gpa, and the compression ratio and elongation exceed 50%.

Owner:DALIAN UNIV OF TECH

Method for preparing micro-foaming poly lactic acid based wood-plastic composite with supercritical fluid

The invention discloses a method for preparing a micro-foaming poly lactic acid (PLA) based wood-plastic composite with a supercritical fluid, and relates to the method for preparing the micro-foaming PLA based wood-plastic composite. The method aims at solving the problem that a PLA based wood-plastic composite which is uniform in bubble distribution, high in bubble density, small in bubble size and high in foaming ratio is difficultly obtained by the existing preparation method. The method comprises the steps that PLA, wood flour, a flexibilizer, a chain extender, a lubricant and a nucleating agent are mixed in a high mixing machine; melt blending is performed by a twin-screw extruder; an extruded molten mixture is placed in a pressure forming machine to obtain the PLA based wood-plastic composite; clipping is performed; swelling and permeation are performed in the supercritical fluid; and then temperature reduction and foaming are performed to obtain the micro-foaming PLA based wood-plastic composite. The micro-foaming PLA based wood-plastic composite is uniform in bubble distribution, high in bubble density, small in bubble size and high in foaming ratio. The method is mainly used for preparing the micro-foaming PLA based wood-plastic composite with the supercritical fluid.

Owner:NORTHEAST FORESTRY UNIVERSITY

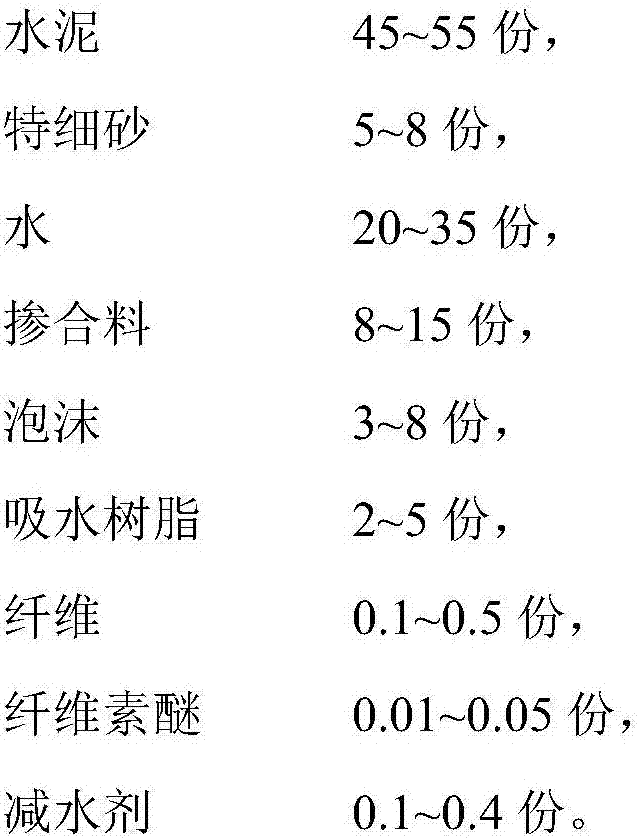

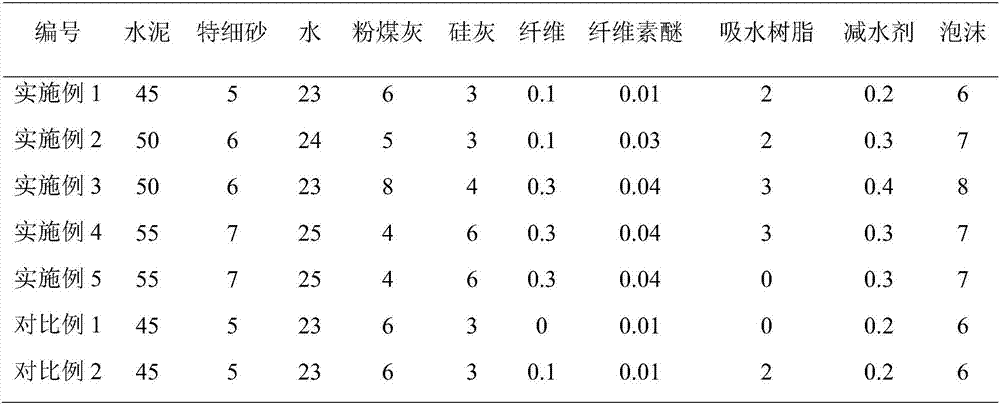

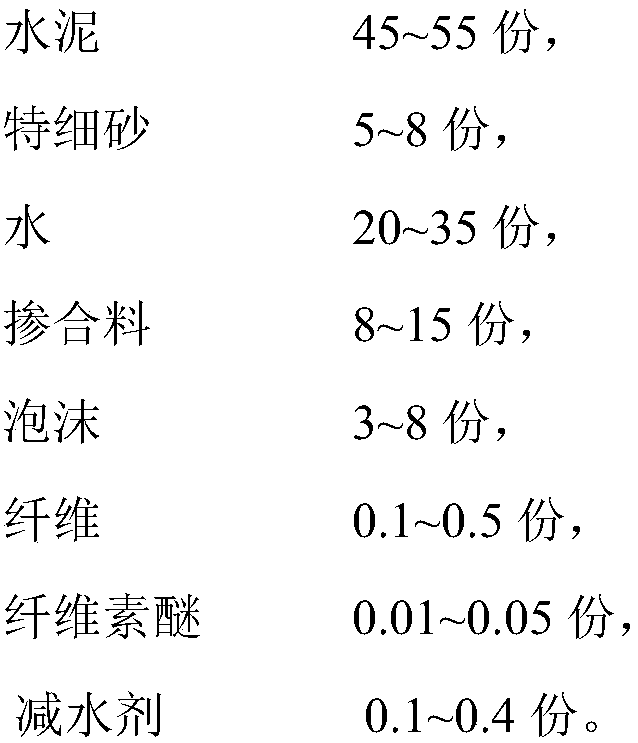

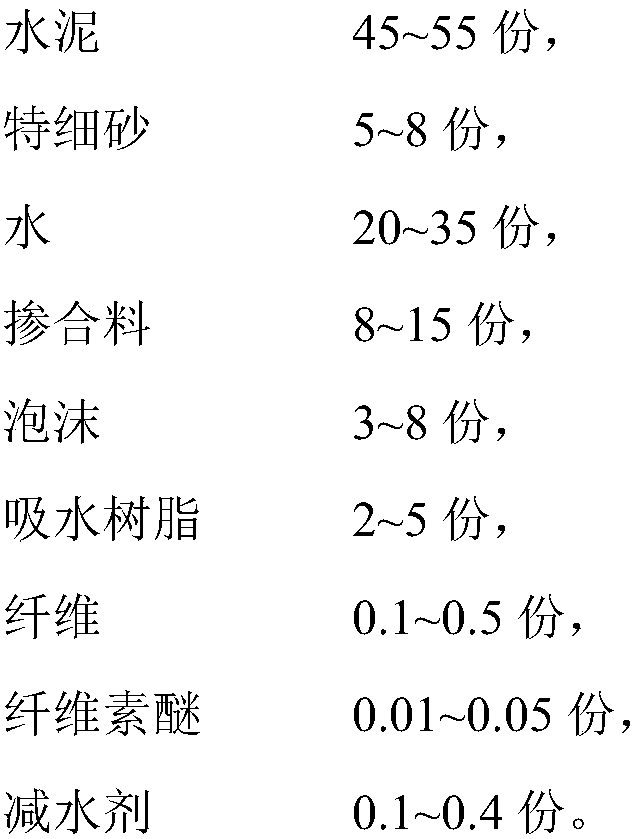

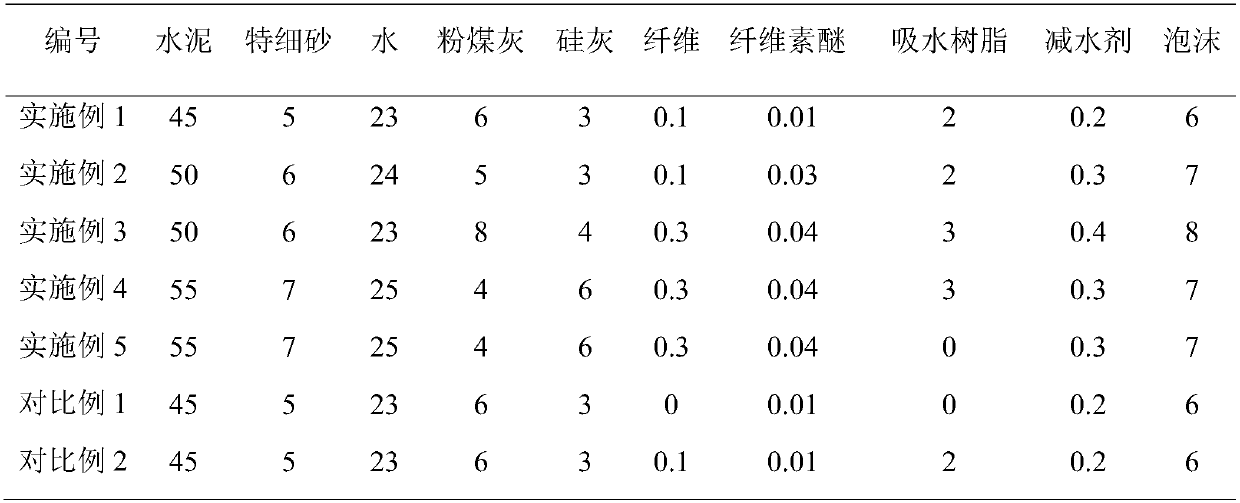

Water-permeable foam concrete and preparation method thereof

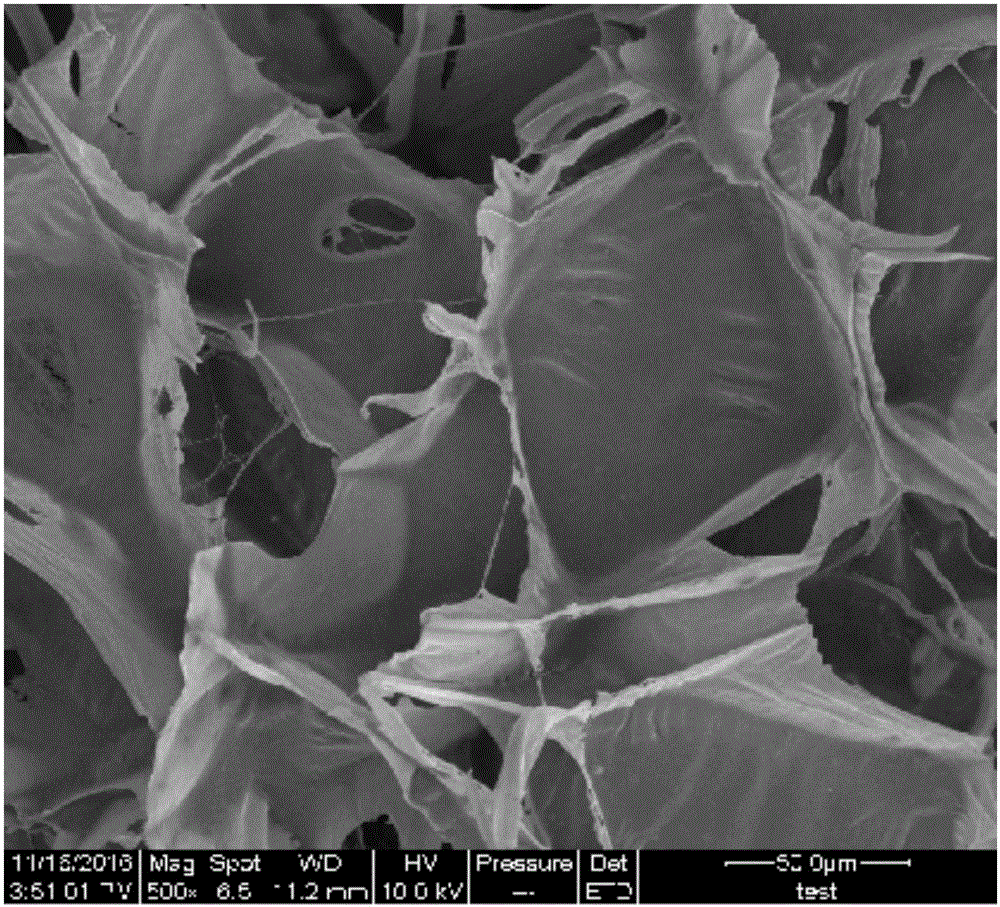

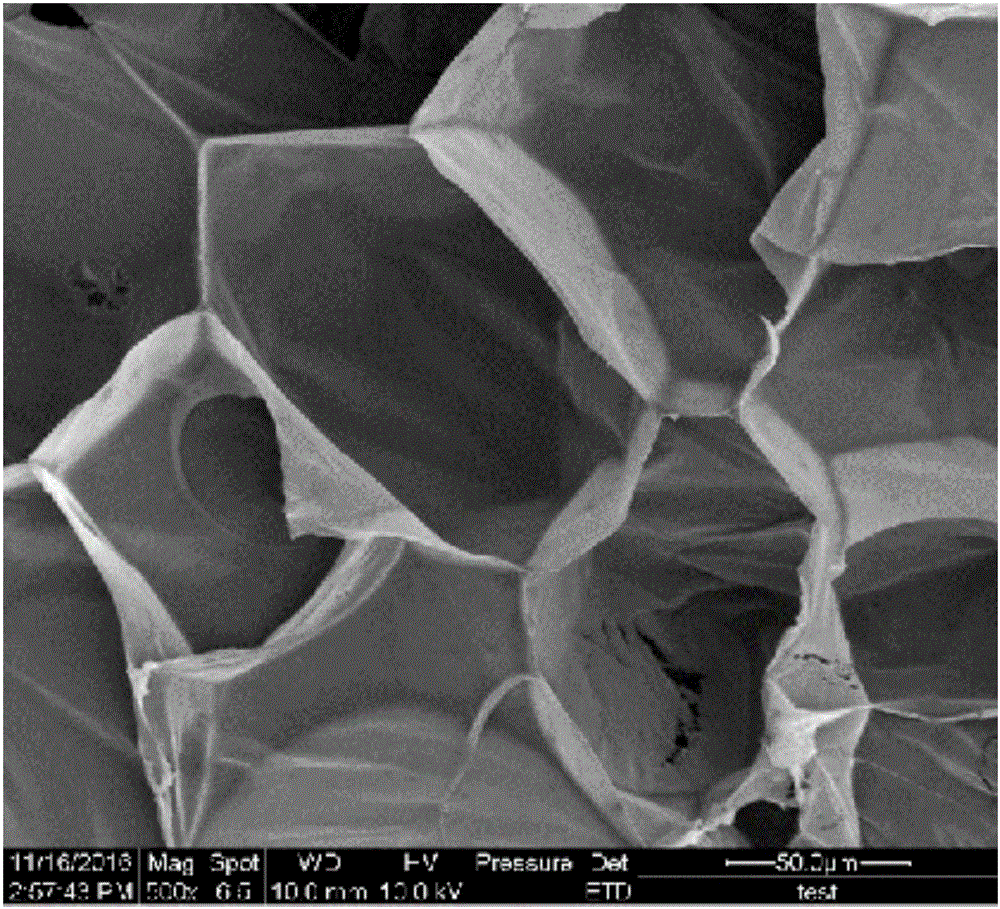

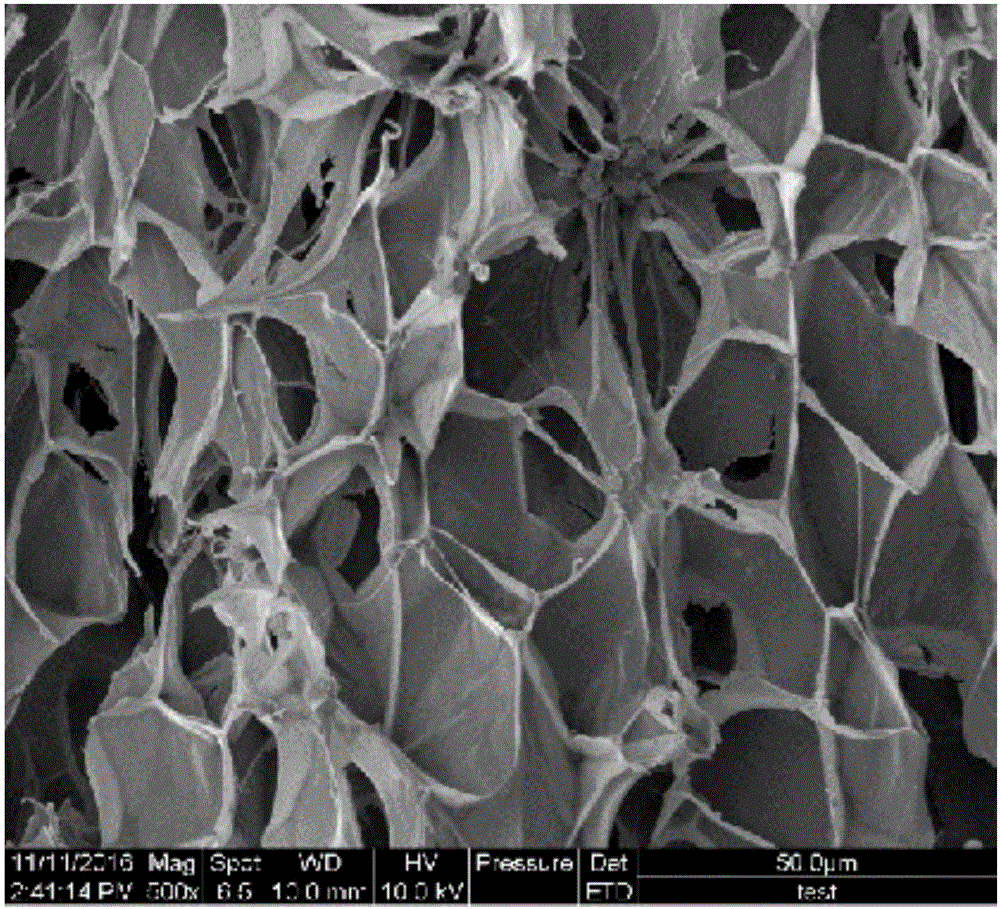

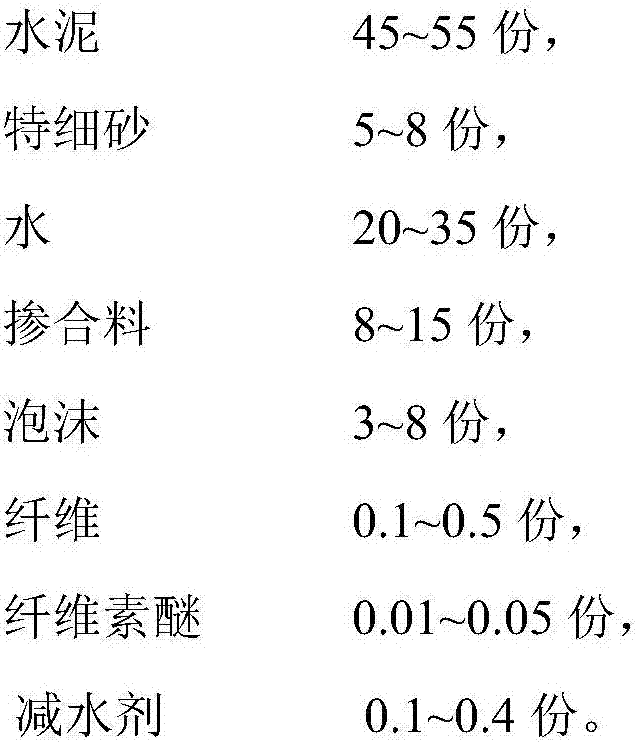

ActiveCN107140902AIncrease the average pore sizeGood water permeabilityCeramicwareFiberFoam concrete

The invention discloses water-permeable foam concrete which is prepared from the following main raw materials: cement, super-fine sand, water, admixtures, foams, fibers, cellulose ether and a water reducer. According to the water-permeable foam concrete, the crude fibers with larger size are doped into a foam concrete matrix, so that foam pores of foam concrete form a communication channel taking the fibers as guide pipes firstly; meanwhile, the average pore size of the foam concrete is increased by decreasing the bubble density in a blending process of the foam concrete, so that the foam pores and the crude fibers form better adaptability; the foam concrete shows better water permeability performance and use performance, so that the problem that the water permeable rate of the conventional foam concrete is low is solved; in addition, involved raw materials are low in cost, and a preparation method is simple, therefore, the water-permeable foam concrete is suitable for popularization and application.

Owner:THE FIRST SINCERITY CONSTR TECH CO LTD

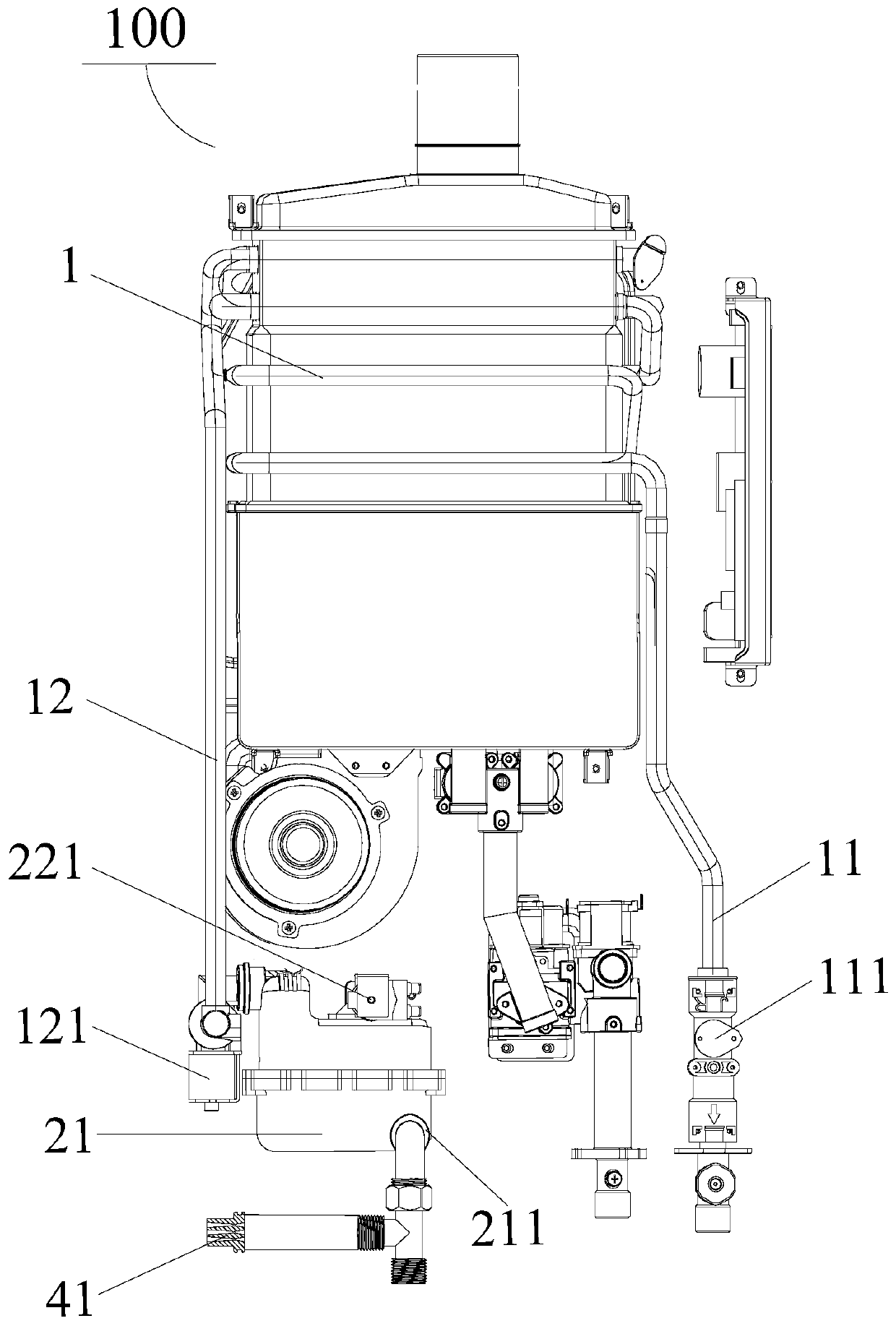

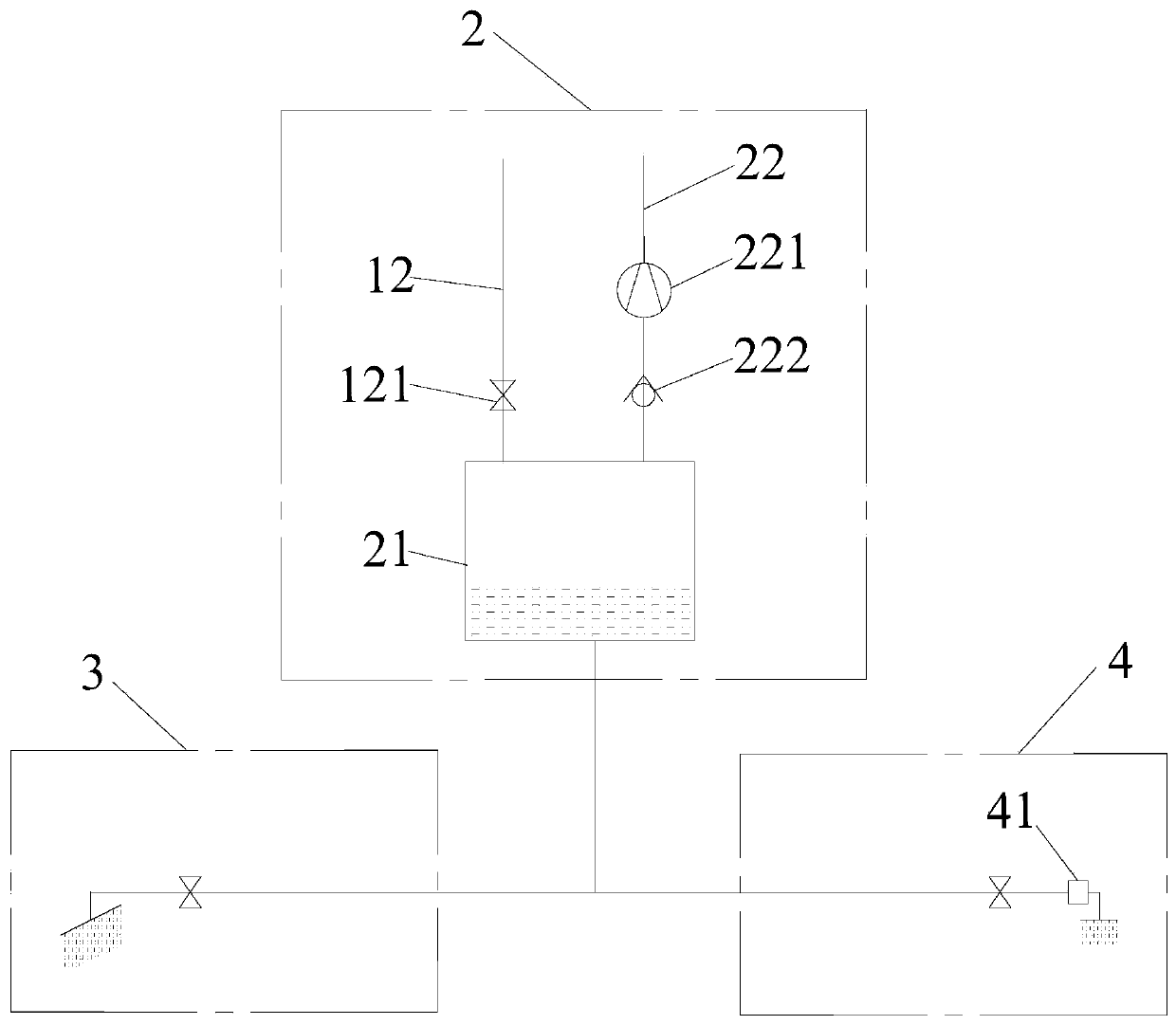

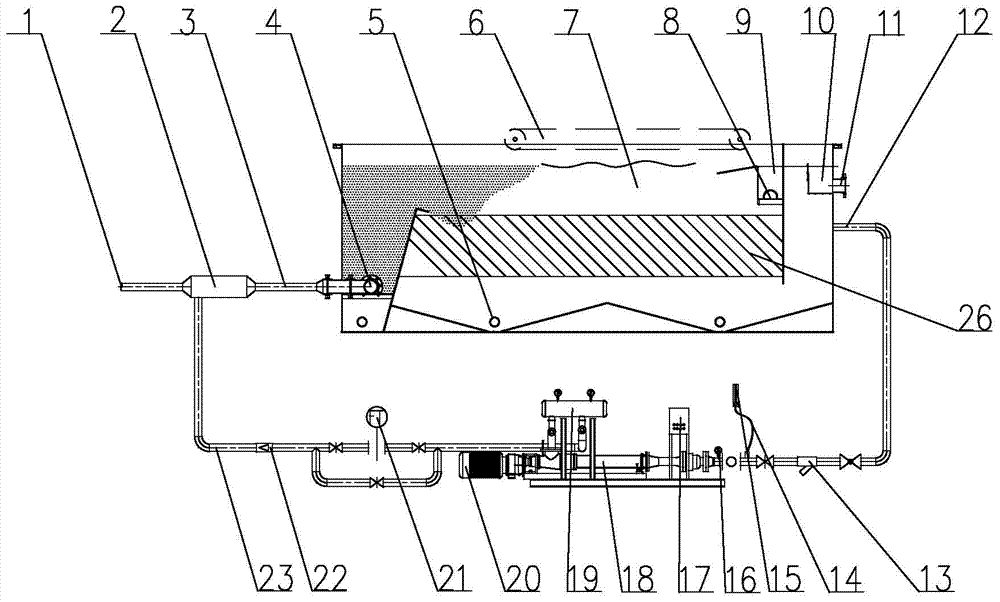

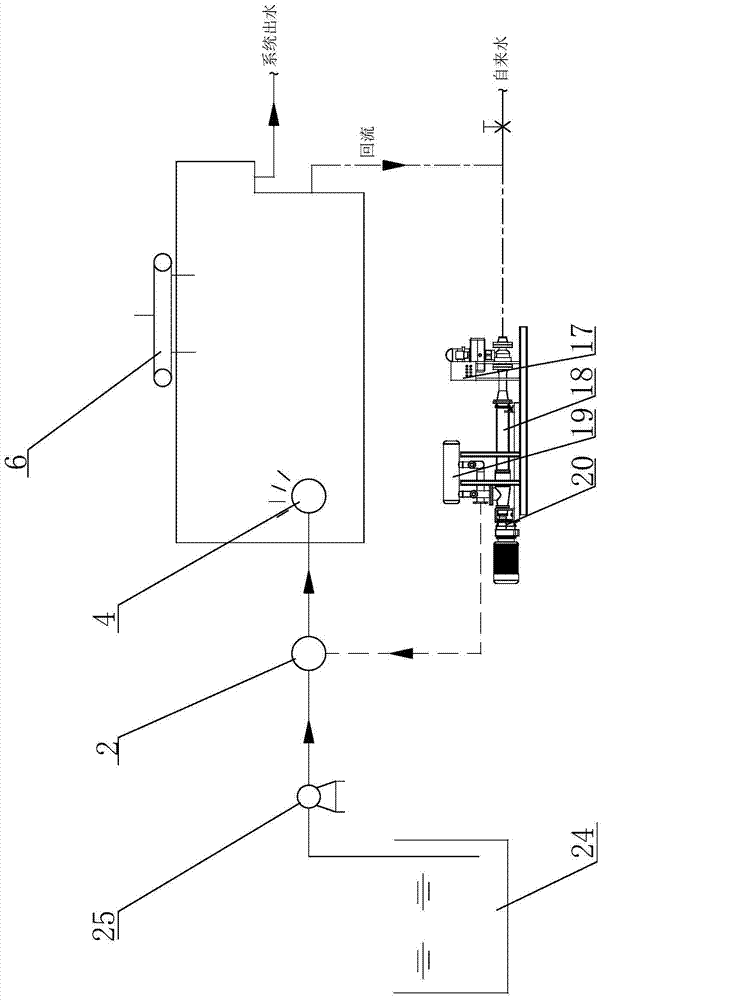

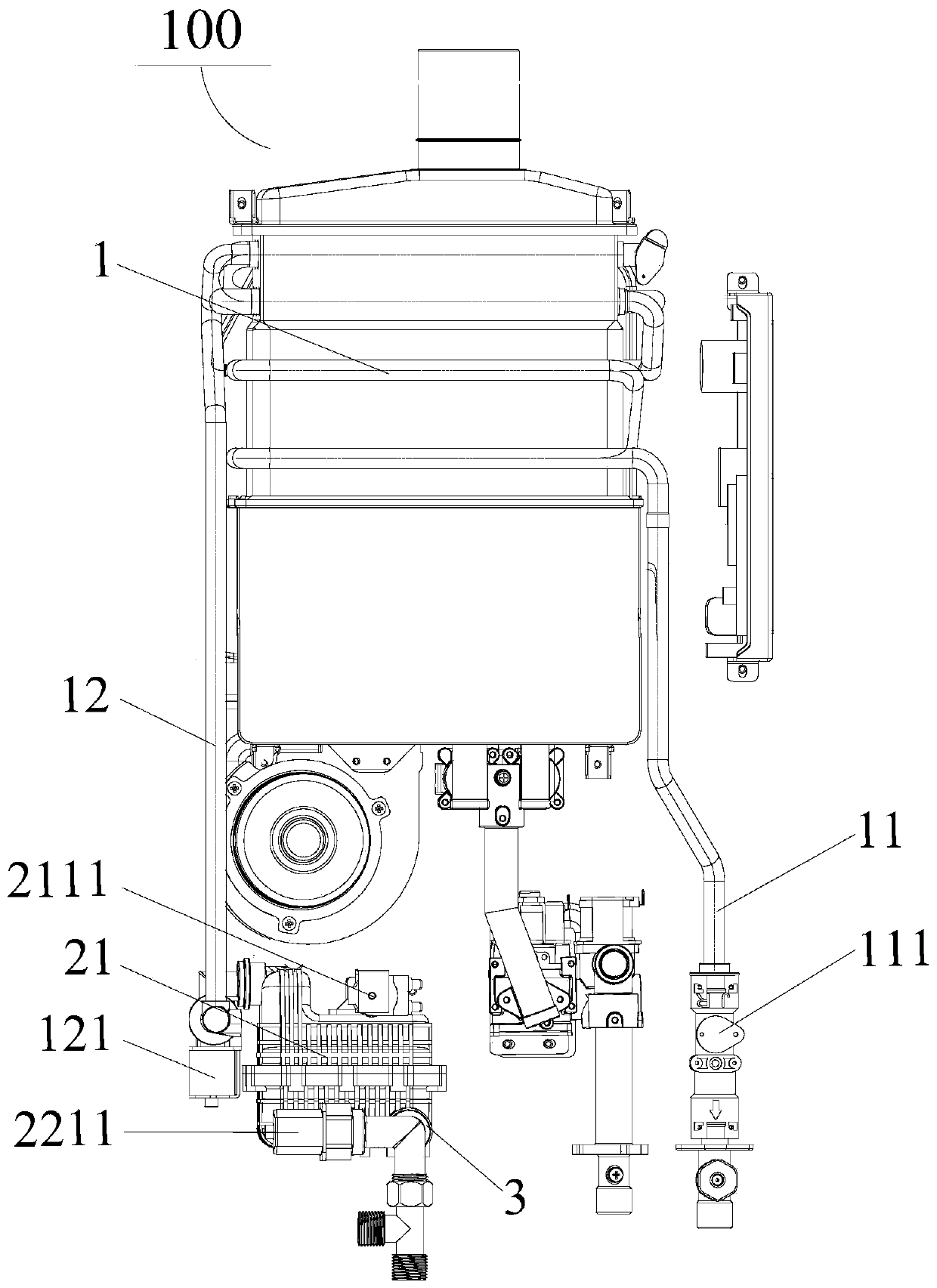

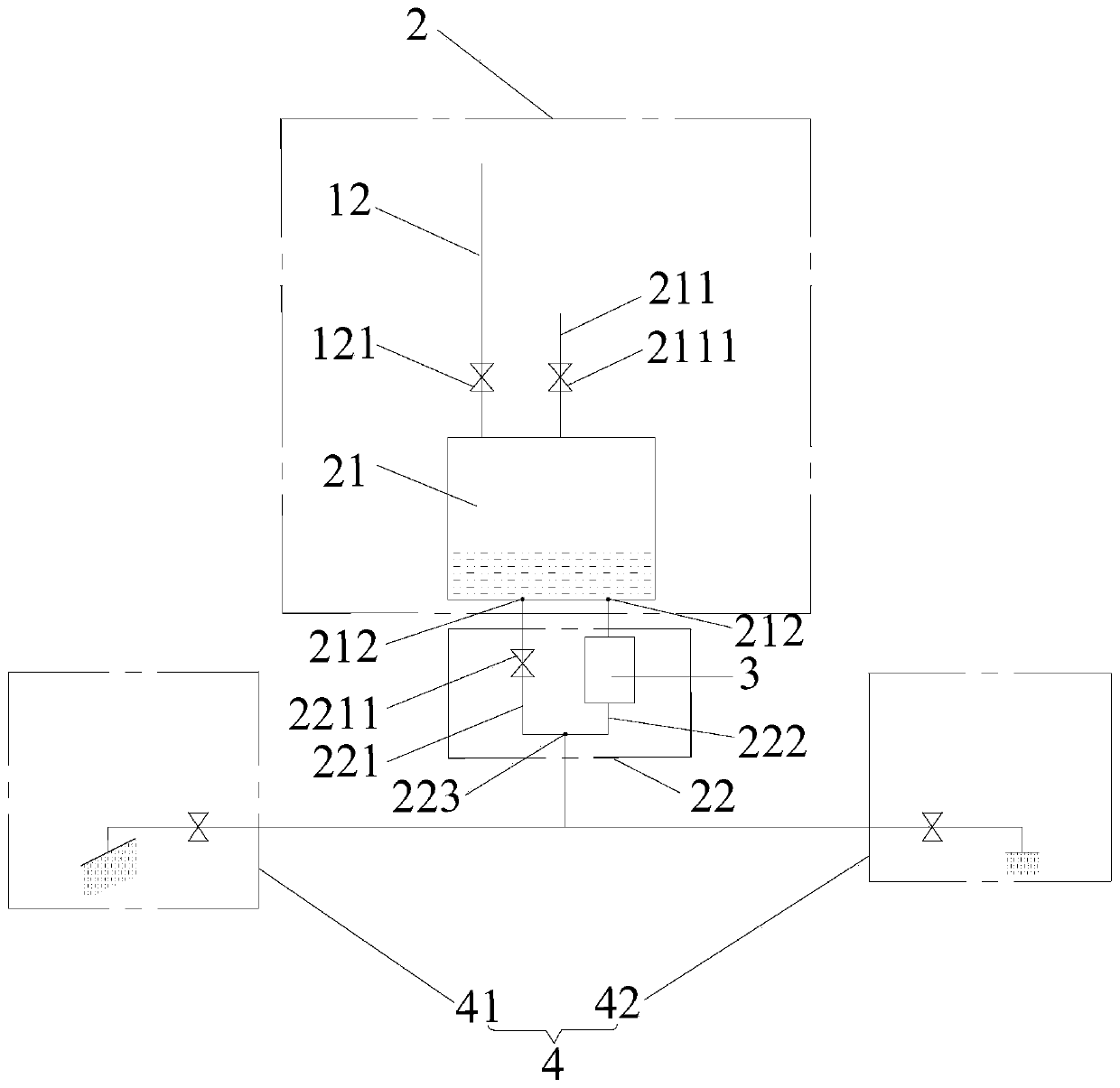

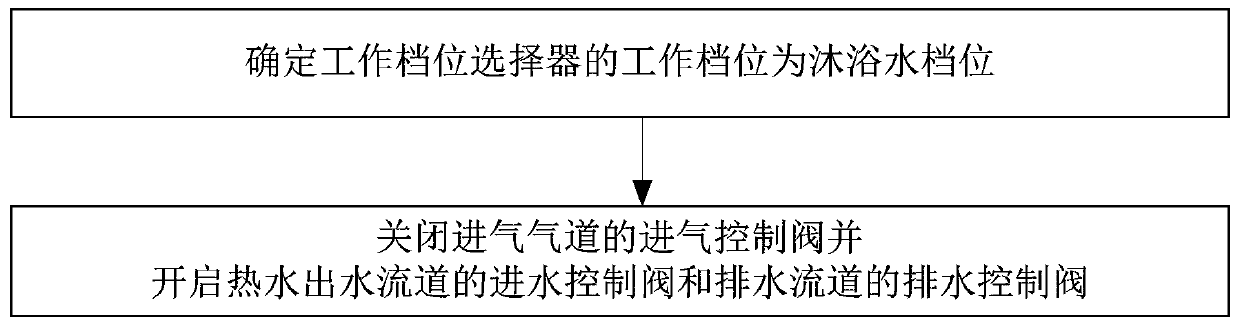

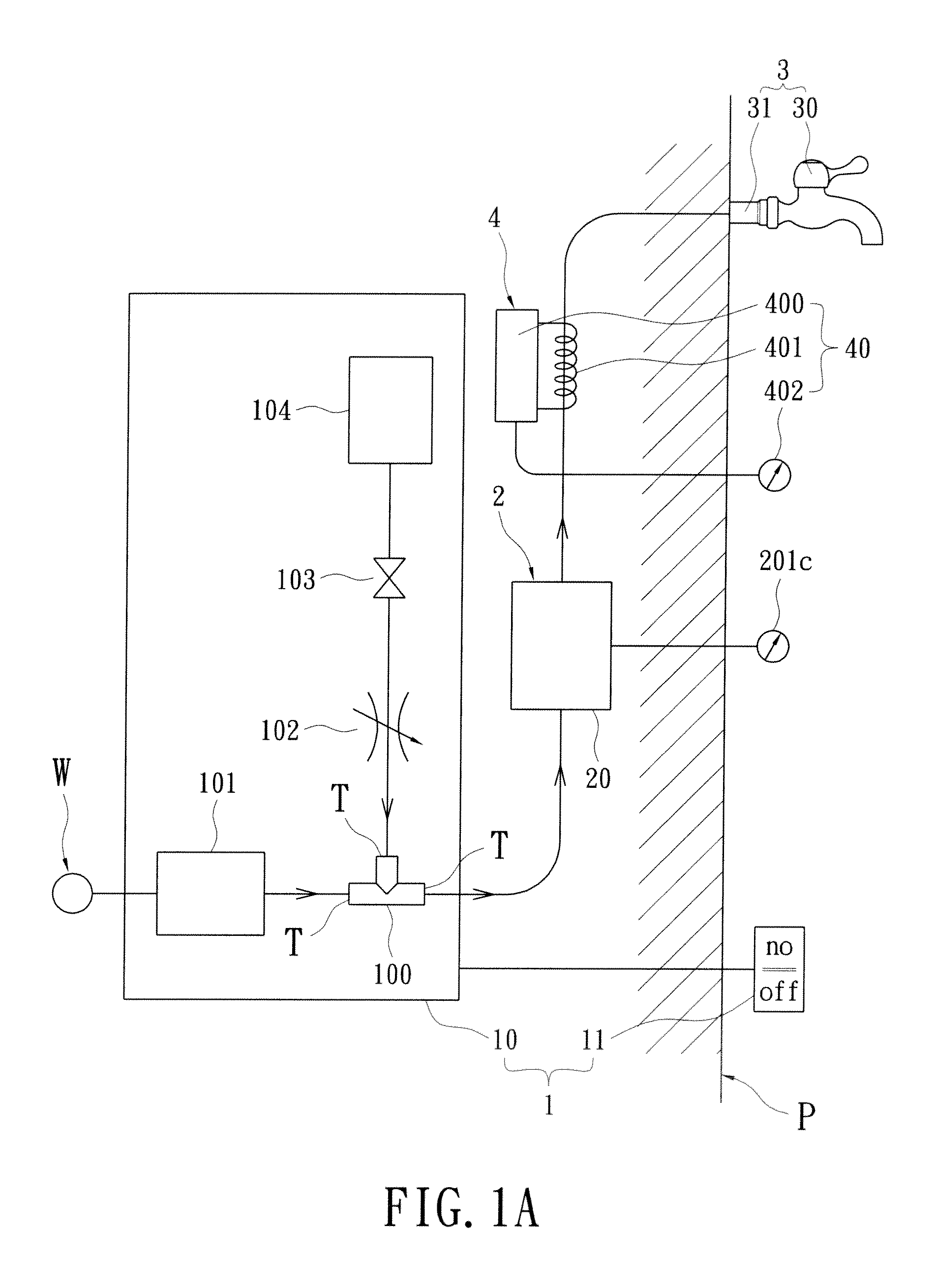

Water heater

The invention discloses a water heater. The water heater comprises a heat exchange device, a dissolved air control device, a bathing water pipeline assembly and a bubble water pipeline assembly. The heat exchange device is connected with a cold water inlet flow channel and a hot water outlet flow channel. The dissolved air control device comprises an air and liquid mixing cavity which comprises anair inlet channel. The hot water outlet flow channel is connected to the air and liquid mixing cavity. The bathing water pipeline assembly and the bubble water pipeline assembly are connected to a cavity water outlet of the dissolved air control device through pipelines in parallel. The bubble water pipeline assembly comprises a micro-nano bubble water generation device. The micro-nano bubble water generation device is arranged in the bubble water pipeline assembly, and bubble water micro flow channels are arranged in the micro-nano bubble water generation device. The dissolved air water in the cavity water outlet passes through the bubble water micro flow channels to form micro-nano bubble water, and the micro-nano bubble water is discharged. The water heater can discharge the micro-nanobubble water which is high in micro-nano bubble density, and is easy to control, mute and small in size.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD

High-efficiency dissolved air flotation system

InactiveCN103936093AImprove stabilitySmall footprintWater/sewage treatment by flotationMicrobubblesSlag

The invention relates to a high-efficiency dissolved air flotation system which comprises an air flotation tank, a slag scraper, a slag discharge device, a water outlet device and an air-liquid mixing pump water inlet pipe, wherein the slag scraper, the slag discharge device and the water outlet device are arranged in the air flotation tank; the air-liquid mixing pump water inlet pipe is led out from the tail end of the air flotation tank, the air-liquid mixing pump water inlet pipe is provided with an air inlet pipe and connected with an air-liquid mixing pump and a microbubble generator through an air-liquid mixing pipe; a high-pressure saturated dissolved air water pipe led out from the microbubble generator and an external sewage inlet pipe are communicated with a dissolved air releaser positioned on the tail end of the water inlet pipe of the air floatation tank through a T-shaped mixer. Compared with the prior art, the high-efficiency dissolved air flotation system has the beneficial effects that dissolved air generated through the system is good in water stability and high in bubble density, microbubbles with grain diameters of about 5 micrometers and generated through the system are more easily adhered to suspended substances and oil droplets which are contained in sewage and a better removing effect can be achieved because the dissolved air ratio of dissolved air water inside the system can achieve 30%-35% and is simple in structure, easy to debug, stable in operation, stable and reliable in operation, conserved in energy, reduced in consumption and high in automation degree.

Owner:辽宁华霆环保科技有限公司

Process for treating synthetic silica powder and synthetic silica powder treated thereof

ActiveUS20060137400A1Reduced bubble densityImprove stabilitySilicaPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesShell moldingBubble density

A process for producing a synthetic quartz glass powder which is substantially free of carbon contaminant, for reduced bubble density and improved stability of articles made from the synthetic quartz glass during fusion molding by maintaining the synthetic silica powder in an oxidizing environment, e.g., an atmosphere comprising at least 3 vol. % ozone at a temperature of less than 1400° C., causing carbon containing compounds to be reduced to less than 10 ppm.

Owner:GENERAL ELECTRIC CO

Method for producing high foaming EPE pearl wool by using carbon dioxide foaming agent

The invention belongs to the technical field of high molecular material processing, in particular to a method for producing high foaming EPE pearl wool by using a carbon dioxide foaming agent. The method for producing high foaming EPE pearl wool by using the carbon dioxide foaming agent comprises the following steps: S1, taking materials; S2, mixing raw materials: putting expandable polyethylene in a mixer for mixing for 3-5 min and then adding talc powder, a silicon dioxide aerogel and filler and further mixing for 16-18 min to obtain a mixture; and S3, heating and extruding. According to themethod for producing high foaming EPE pearl wool by using the carbon dioxide foaming agent, the pearl wool has good elasticity, heat stability and mechanical properties, and the tensile and tear strength of the pearl wool are improved. By taking carbon dioxide as a foaming agent, the pearl wool is low in cost and good in flame retardance. The method can be used for obtaining a relatively high bubble density. The foamed abscess is more stable. The method is simple in process and convenient for scaled production.

Owner:安徽荣茂塑胶包装材料有限公司

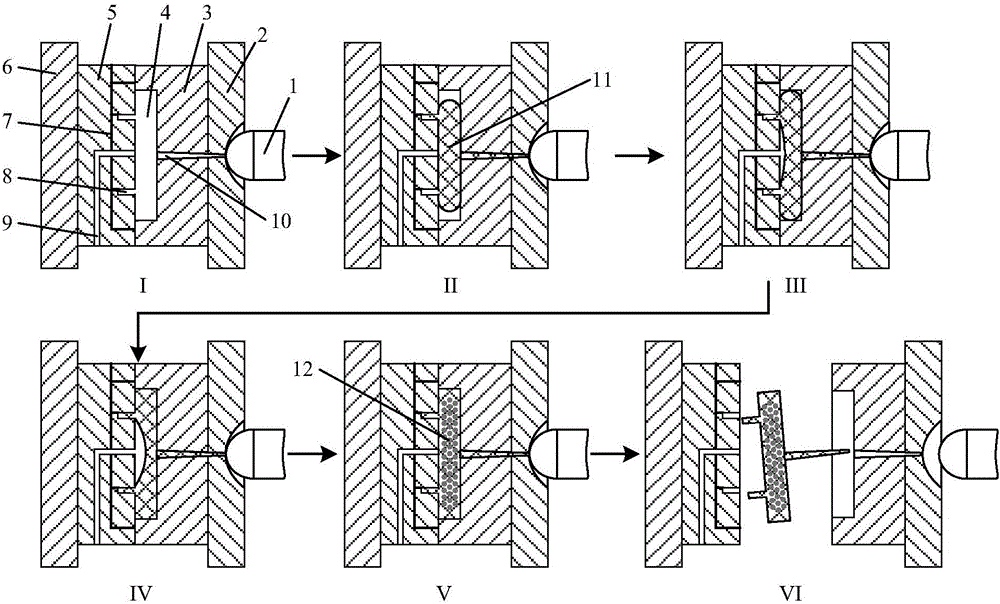

Microcellular foaming injection molding technology capable of realizing high surface glossiness and high bubble density as well as mold

ActiveCN105835299ASolve bottlenecksRequirements for lower measurement accuracyFoaming agentPolymer science

The invention discloses a microcellular foaming injection molding technology capable of realizing high surface glossiness and high bubble density as well as a mold. The technology comprises steps as follows: a physical foaming agent or a chemical foaming agent is evenly mixed with polymer melt in a high-pressure environment by the aid of a microcellular foaming injection molding machine; the temperature of a mold is increased, high-pressure gas is introduced into a cavity of the mold, the polymer melt smaller than the total volume of the cavity of the mold is injected into the cavity of the mold, and foaming space is reserved; the high-temperature state of the wall surface of the cavity of the mold is kept, gas channels located on a moving mold side wall surface of the cavity of the mold and a parting surface of the mold are opened in a matched manner, a gas is controlled to enter and leave the cavity of the mold, and the polymer melt is controlled to flow, so that the reserved foaming space is transferred to the moving mold side of the cavity of the mold; the mold is cooled, when the temperature of the melt is decreased to the foaming temperature, all gas channels of the mold are opened, gas inside the reserved space is exhausted, and a polymer foams and fills rest space of the cavity of the moving mold. The technology can prevent dynamic foaming and promote static foaming and can be used for producing plastic products with the high surface glossiness and the high inside bubble density.

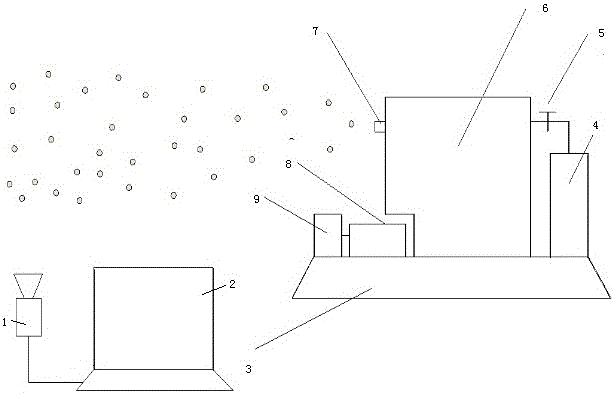

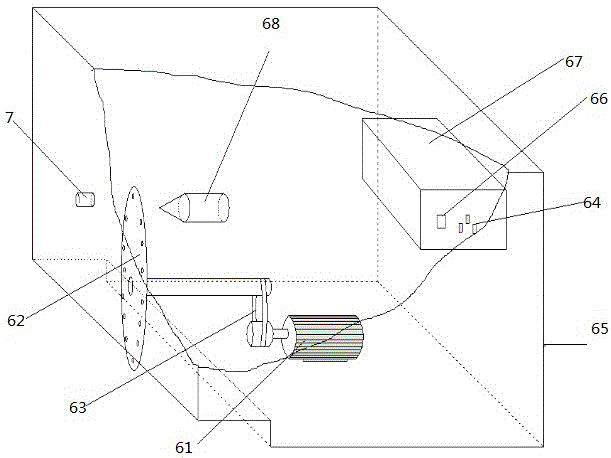

Electric field measuring device

The invention discloses an electric field measuring device. The electric field measuring device comprises a bubble generator, an insulation reservoir, an electrostatic generator, a hydrogen cylinder, a pressure regulating valve, a camera and an image processing computer, wherein the bubble generator is composed of a film forming device, a motor driving the film forming device to rotate and a gas nozzle, and the gas sprayed by the gas nozzle is sprayed to the film forming device to form bubbles; the insulation reservoir provides bubble liquid for the film forming device, and the bubble liquid is insulated from metal pieces in the bubble generator and the ground; the electrostatic generator is connected with the insulation reservoir through a wire, voltage of the bubble liquid in the insulated reservoir produces voltage for the electrostatic generator, and the electrostatic generator has charges; the hydrogen cylinder and pressure regulating valve are connected with the bubble generator through a gas pipe, the flow of hydrogen can be controlled by regulating the pressure regulating valve, the sizes of the bubbles are further controlled, bubble density and air density are equalized, and the bubble gravity is equal to buoyancy; the camera is used for shooting movement of the bubbles in an external electric field; the image processing computer receives videos shot by the camera, processes the videos into movement trails of the bubbles, and calculates the field intensity distribution of the external electric field.

Owner:XIHUA UNIV

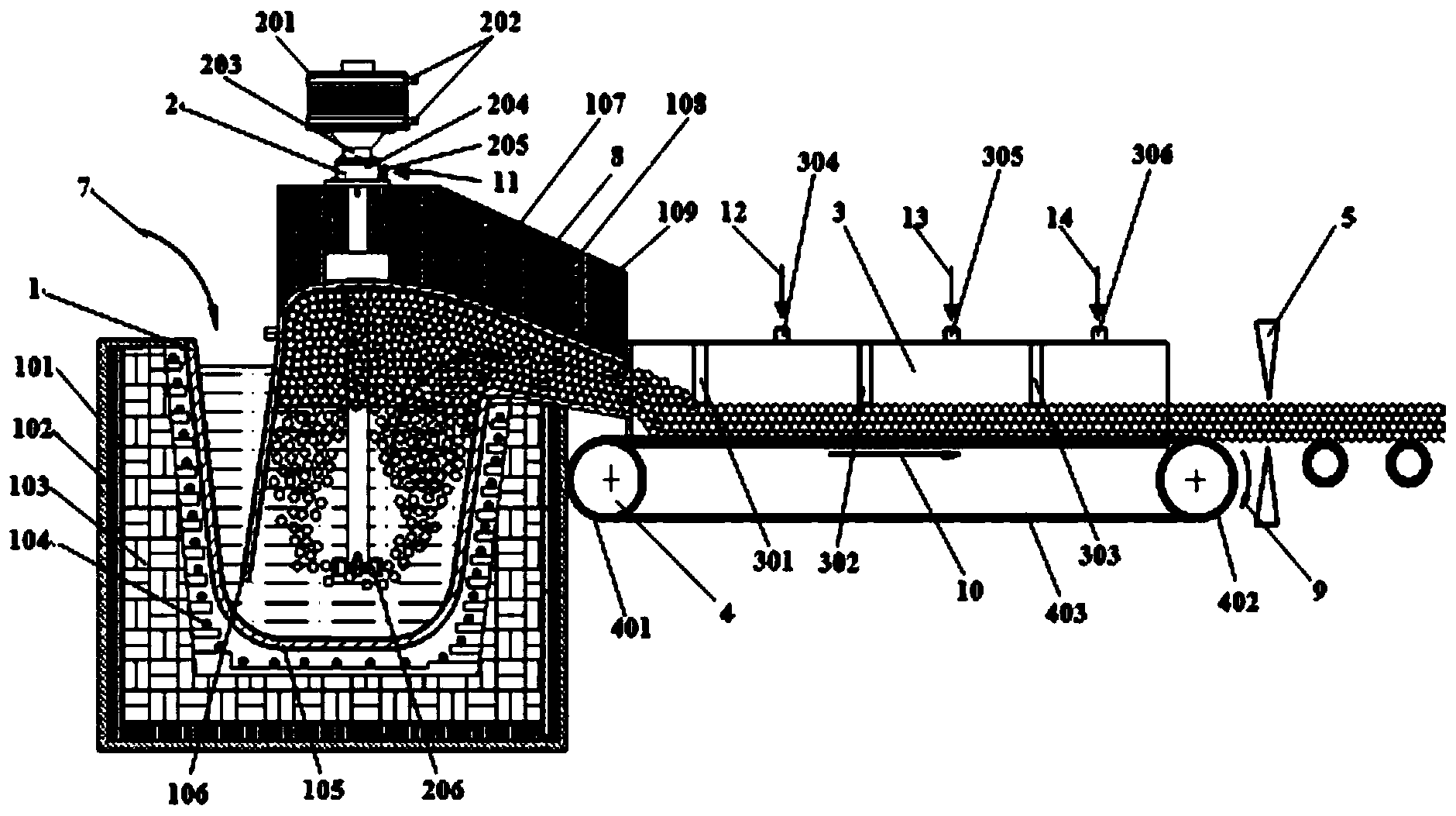

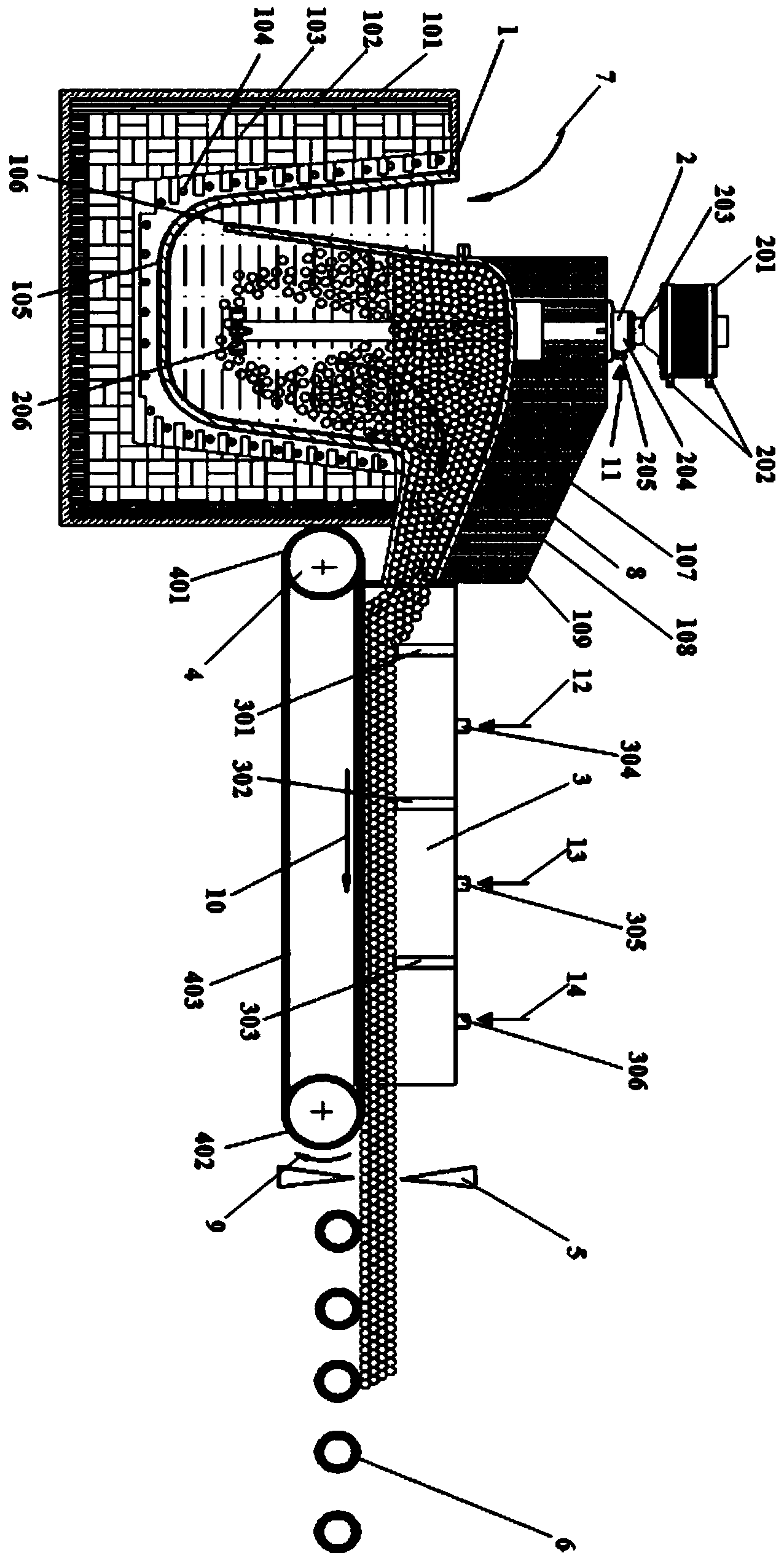

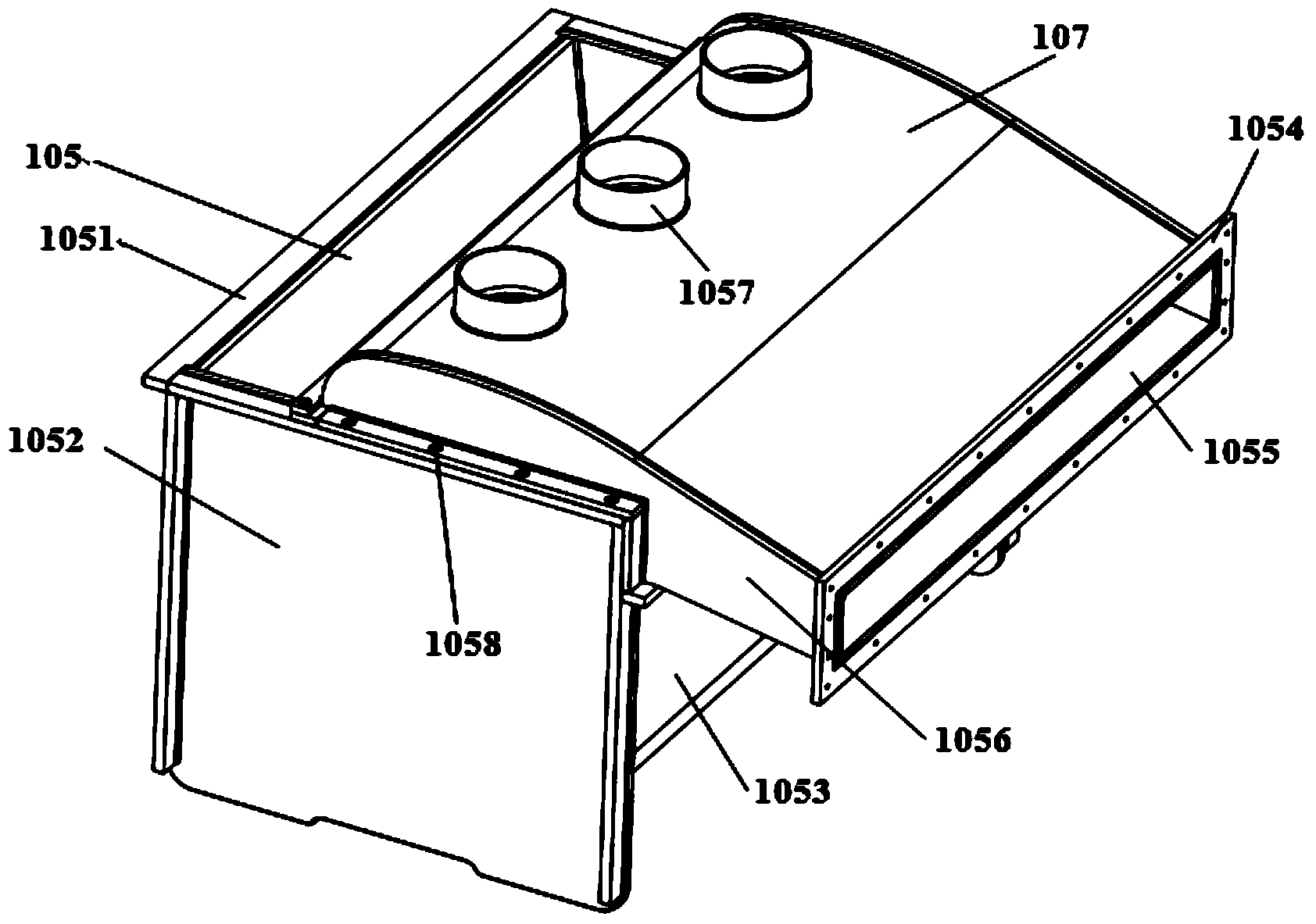

Casting equipment and method for continuous production of controllable-density oxidation-free foamed aluminum sheets

InactiveCN104259411ADensity controllableEvenly inflatedElectrical resistance and conductanceNitrogen

The invention discloses casting equipment and method for continuous production of controllable-density oxidation-free foamed aluminum sheets. The equipment comprises a resistive heating continuous foaming furnace, a blower stirrer, a nitrogen cooling tank, a strip steel conveyor, flying shears and a conveying roller bed; the blower stirrer is mounted on a foamed molten aluminum guide hood; the devices above allow sufficient guiding, full stirring and uniform filling of air in blow holes; the molten aluminum and bubbles are fully mixed to obtain controllable-density uniform foamed aluminum; the strip steel conveyor drives the foamed molten aluminum into a terminal cooling space at a constant traction speed, not a press roller manner but a graphite baffle manner is adopted to scrape-thin the foamed molten aluminum (not increasing surface bubble density but ensuring uniform density of the foamed molten aluminum), the foamed molten aluminum is fed to the following cooling space to allow the internal of the foamed aluminum to harden; finally, high-quality foamed aluminum sheets free of oxidization and internal cracking and having uniform and controllable foam density can be produced; low-cost production is achieved.

Owner:四川金岳新型材料有限公司

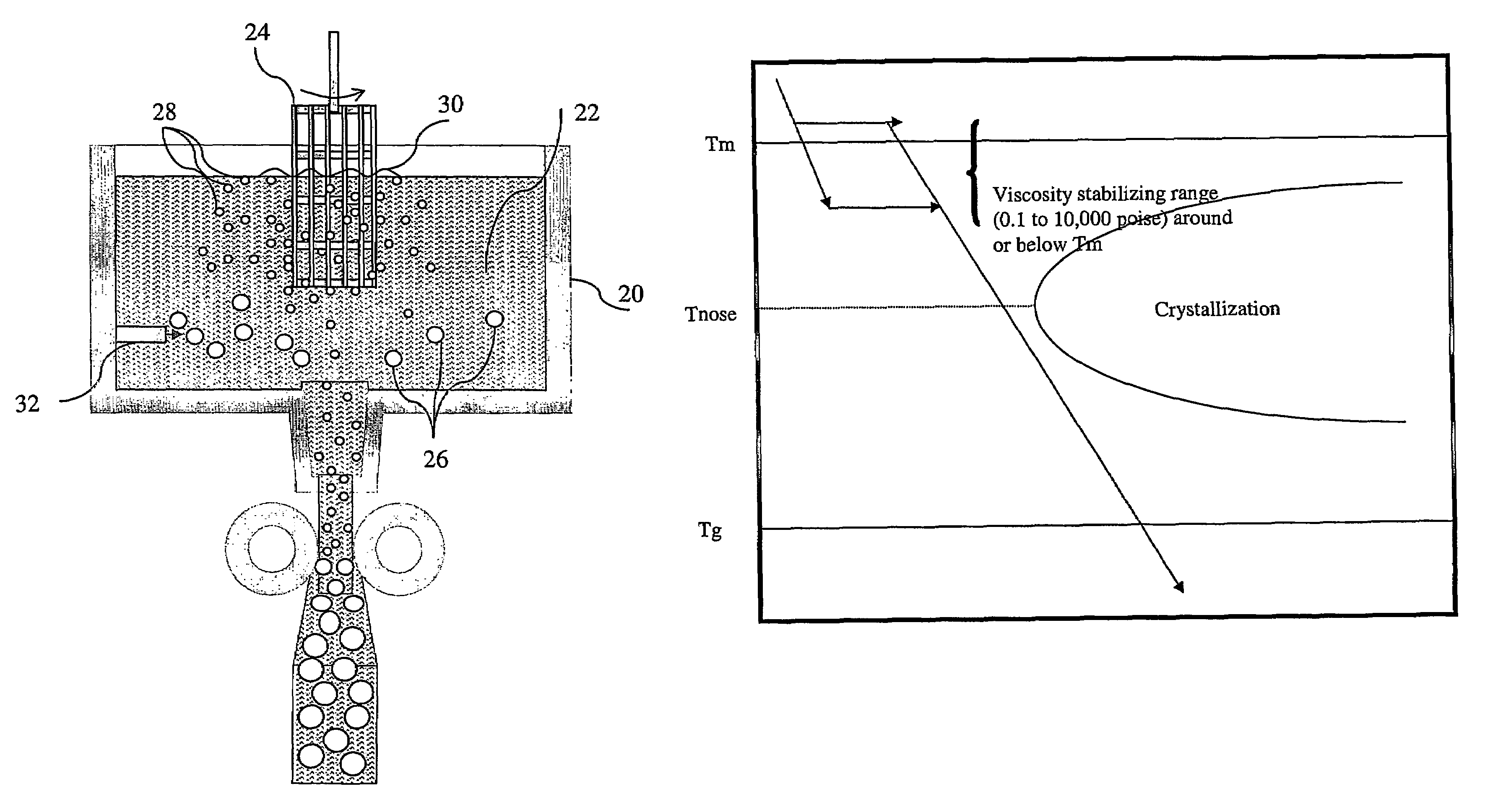

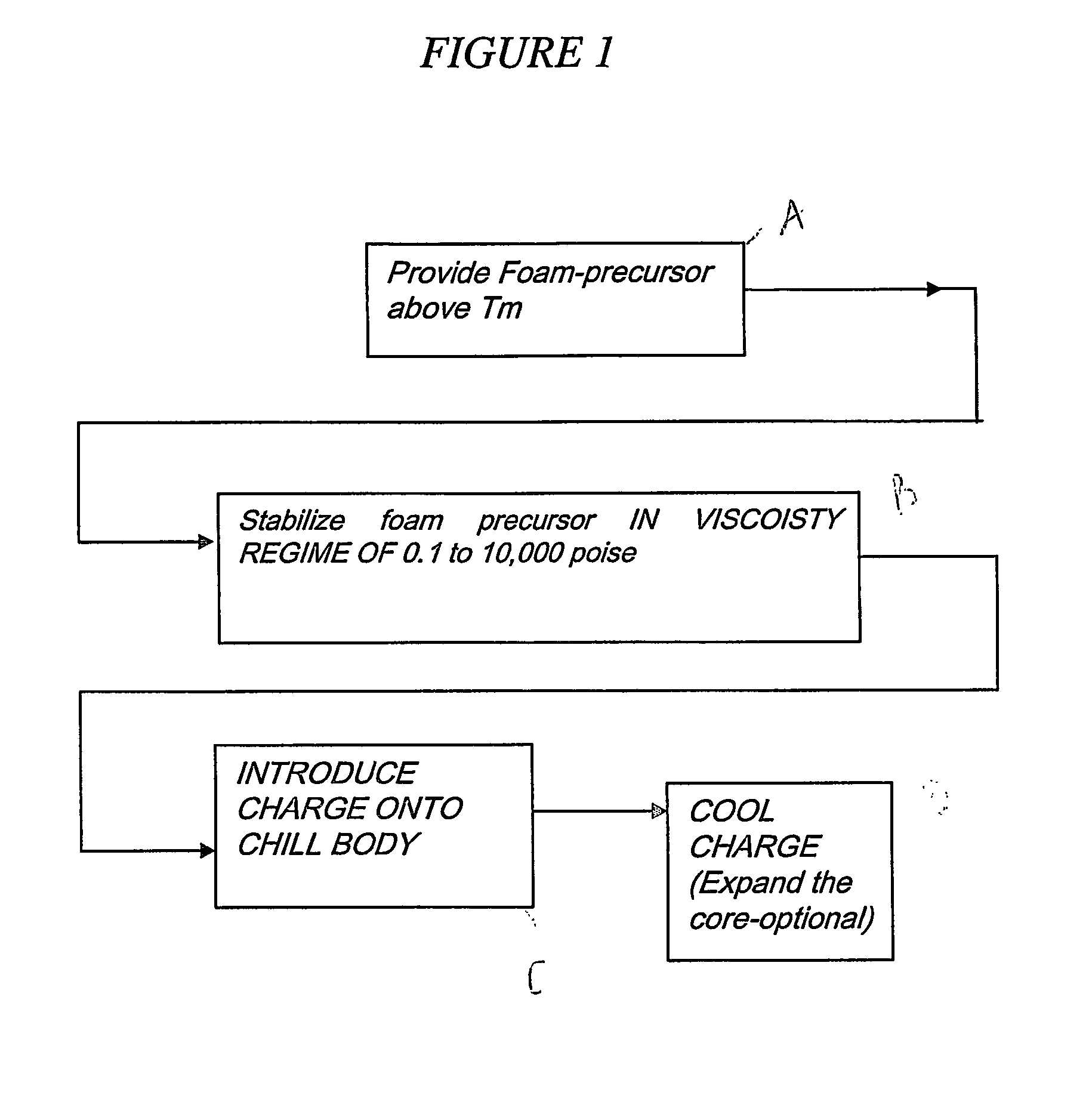

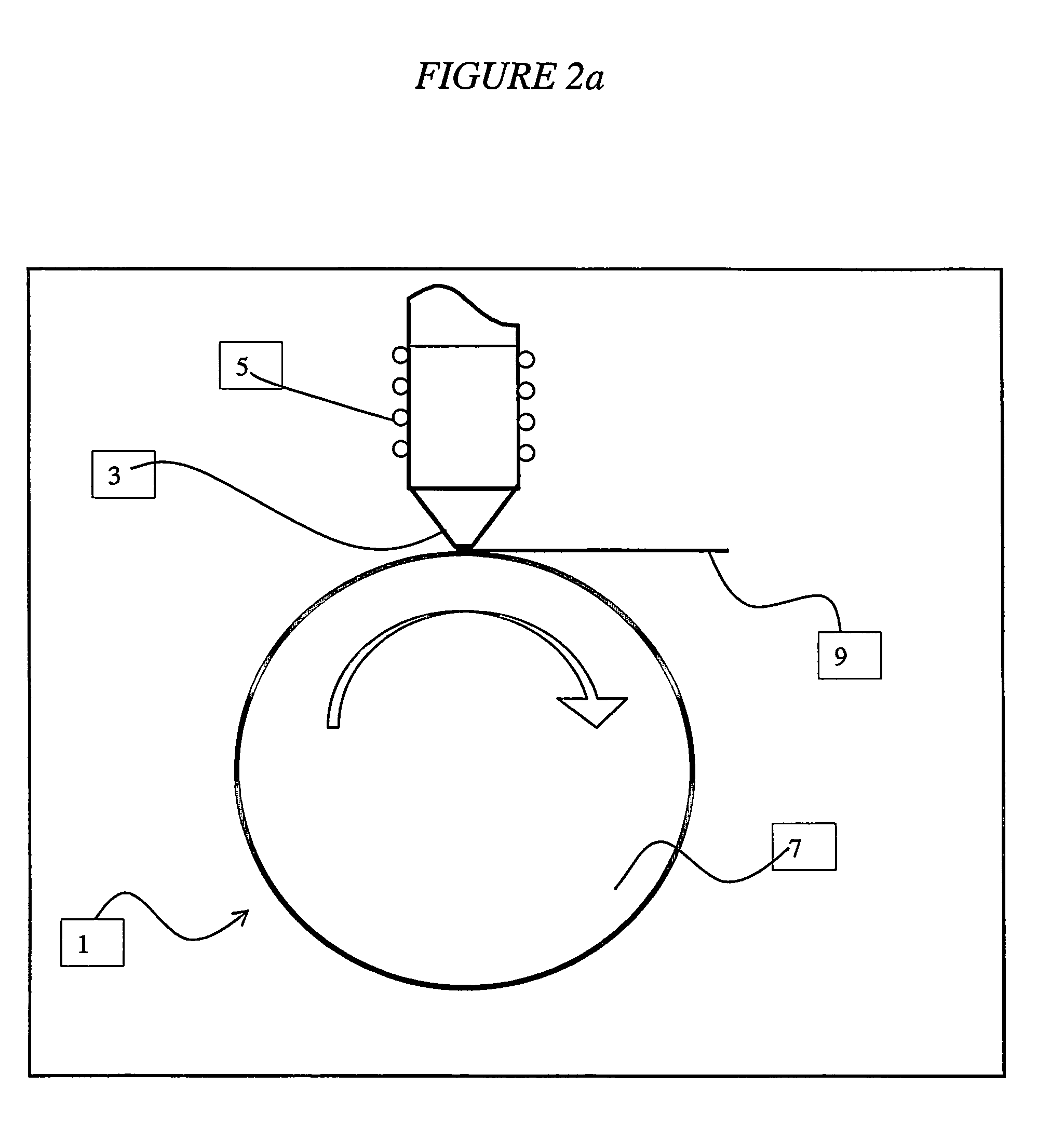

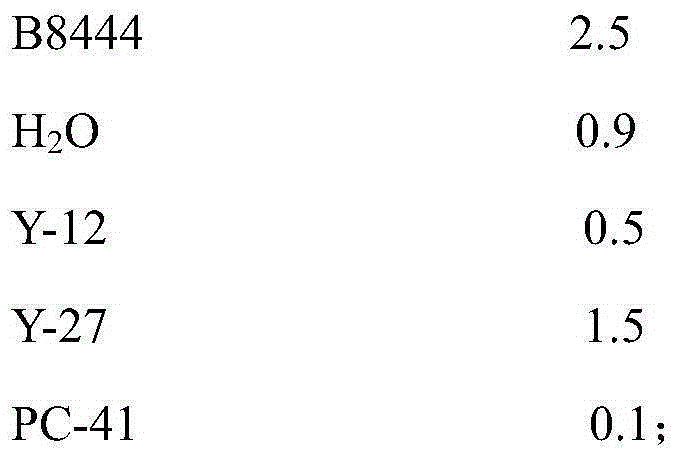

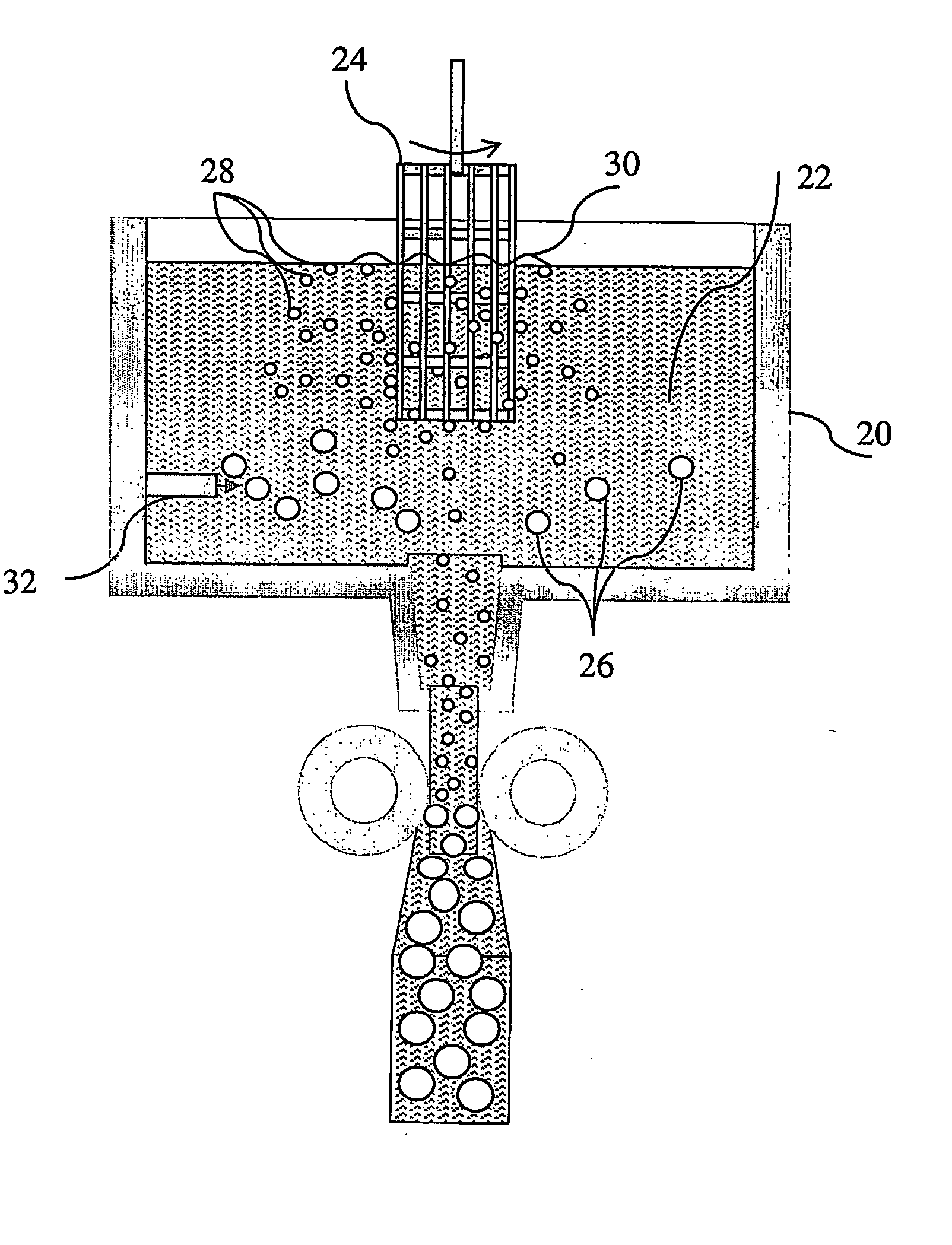

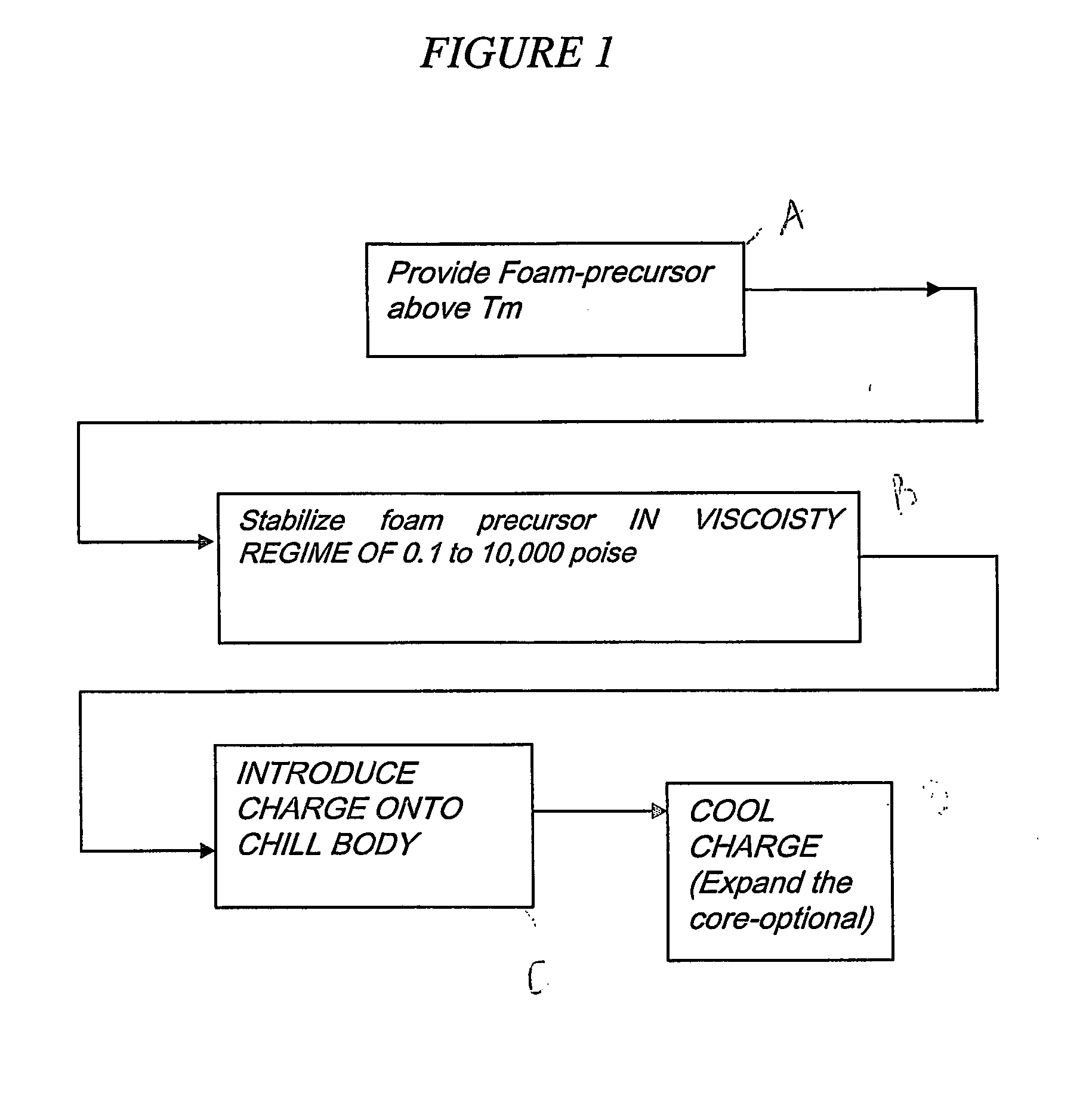

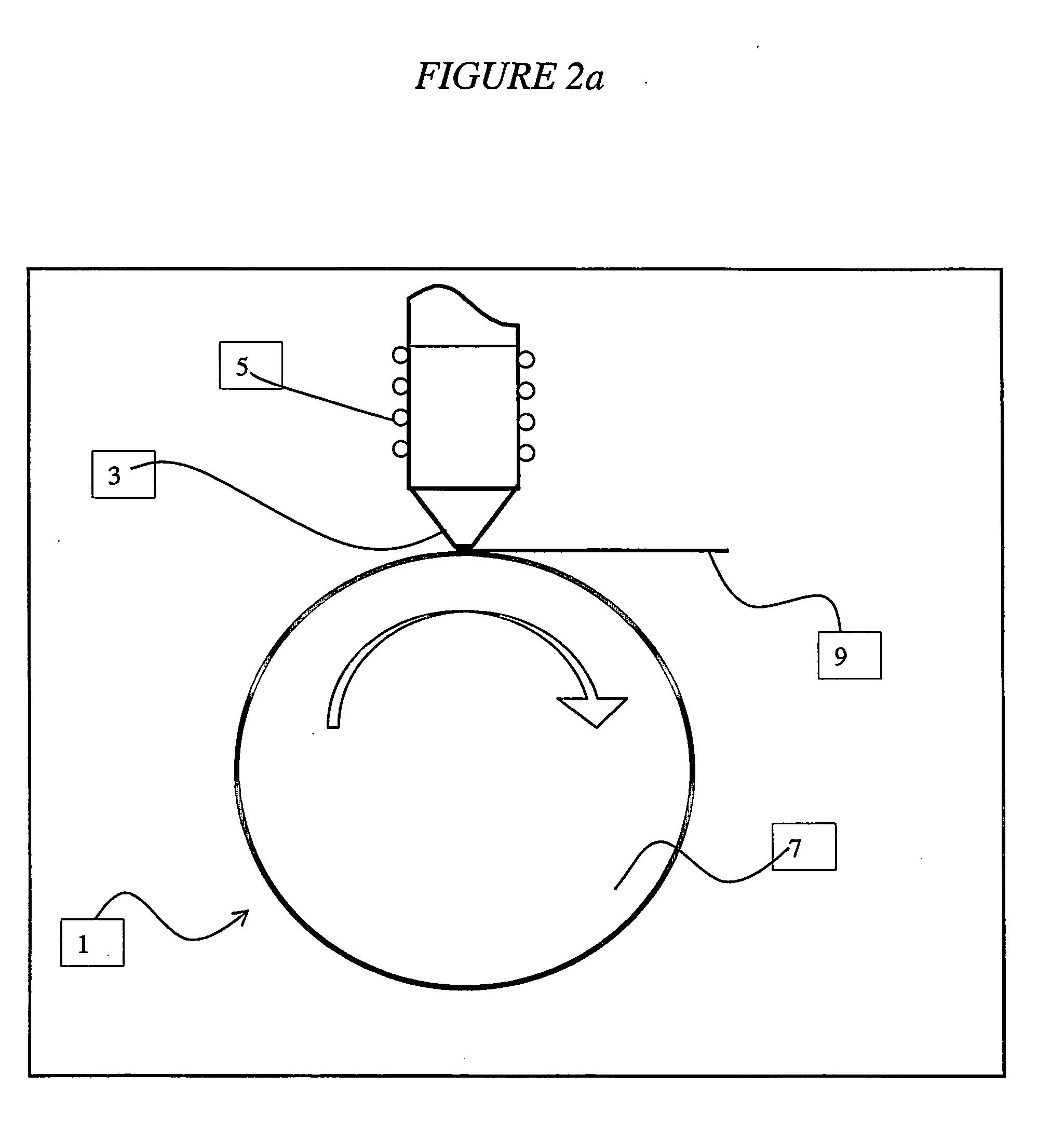

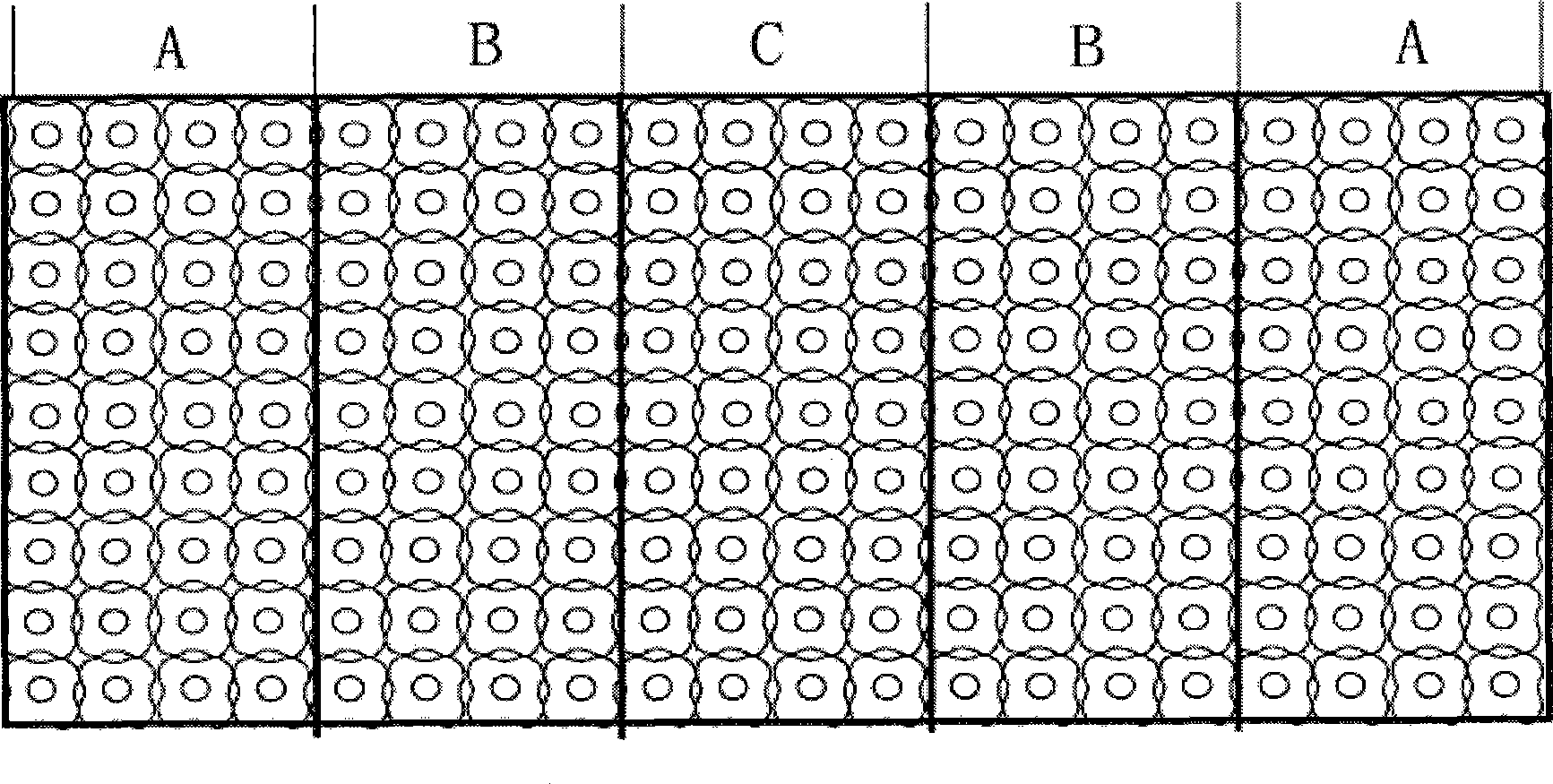

Continuous casting of foamed bulk amorphous alloys

Methods and apparatuses for the continuous casting of solid foam structures with varying bubble density from bulk solidifying amorphous alloys are provided. Continuously cast solid foam structures having bubble densities in the range of from 50 percent up to 95% by volume are also provided.

Owner:CRUCIBLE INTPROP LLC

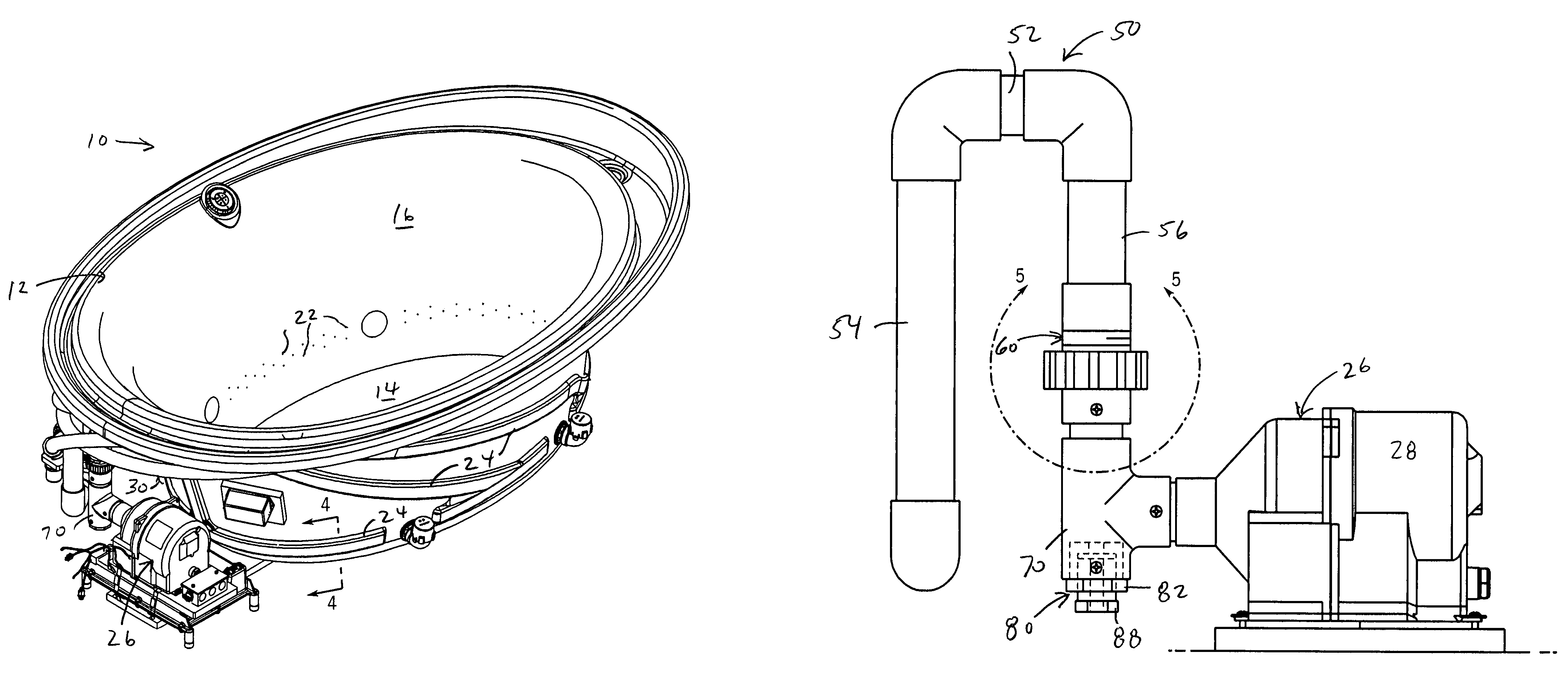

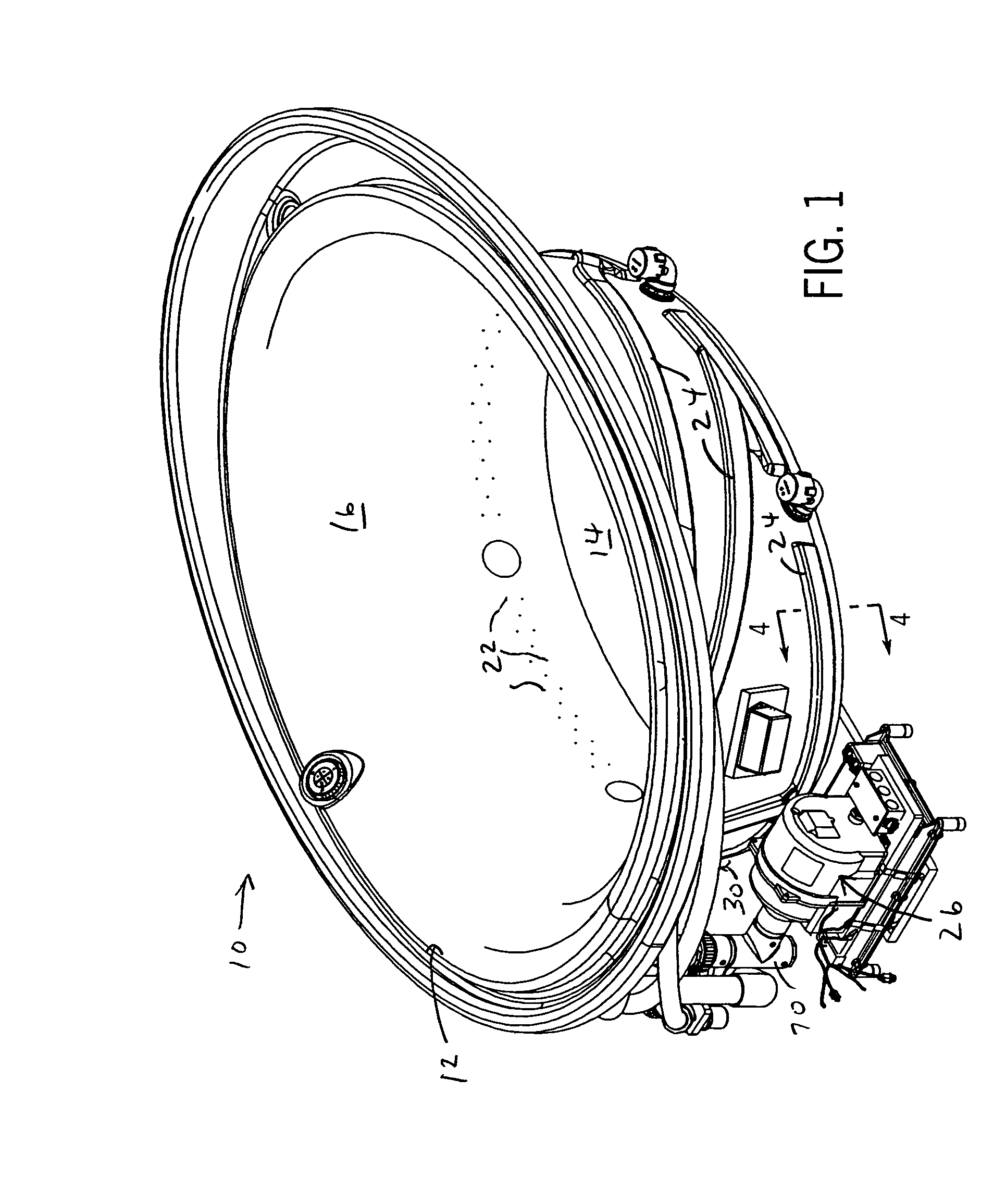

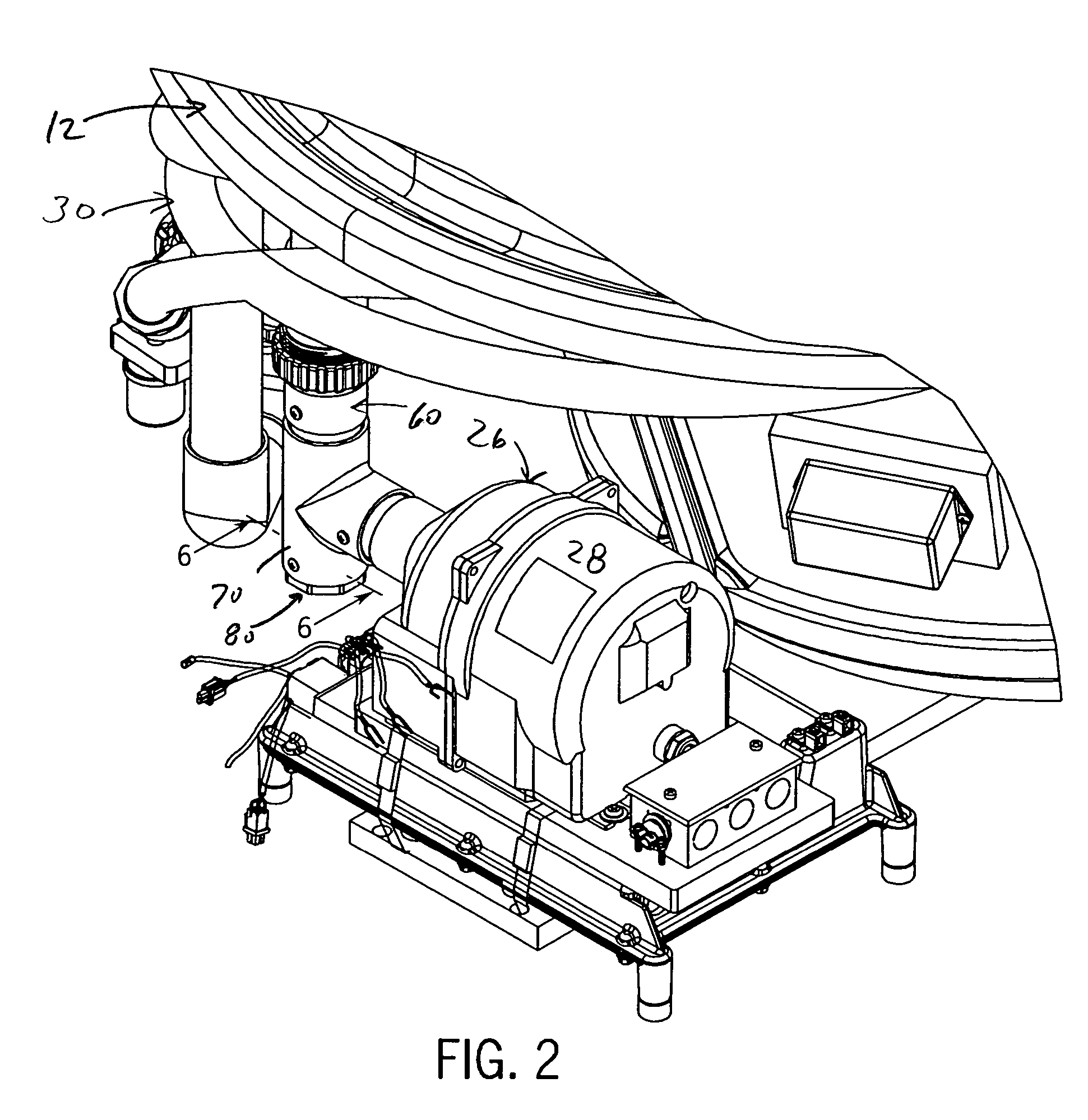

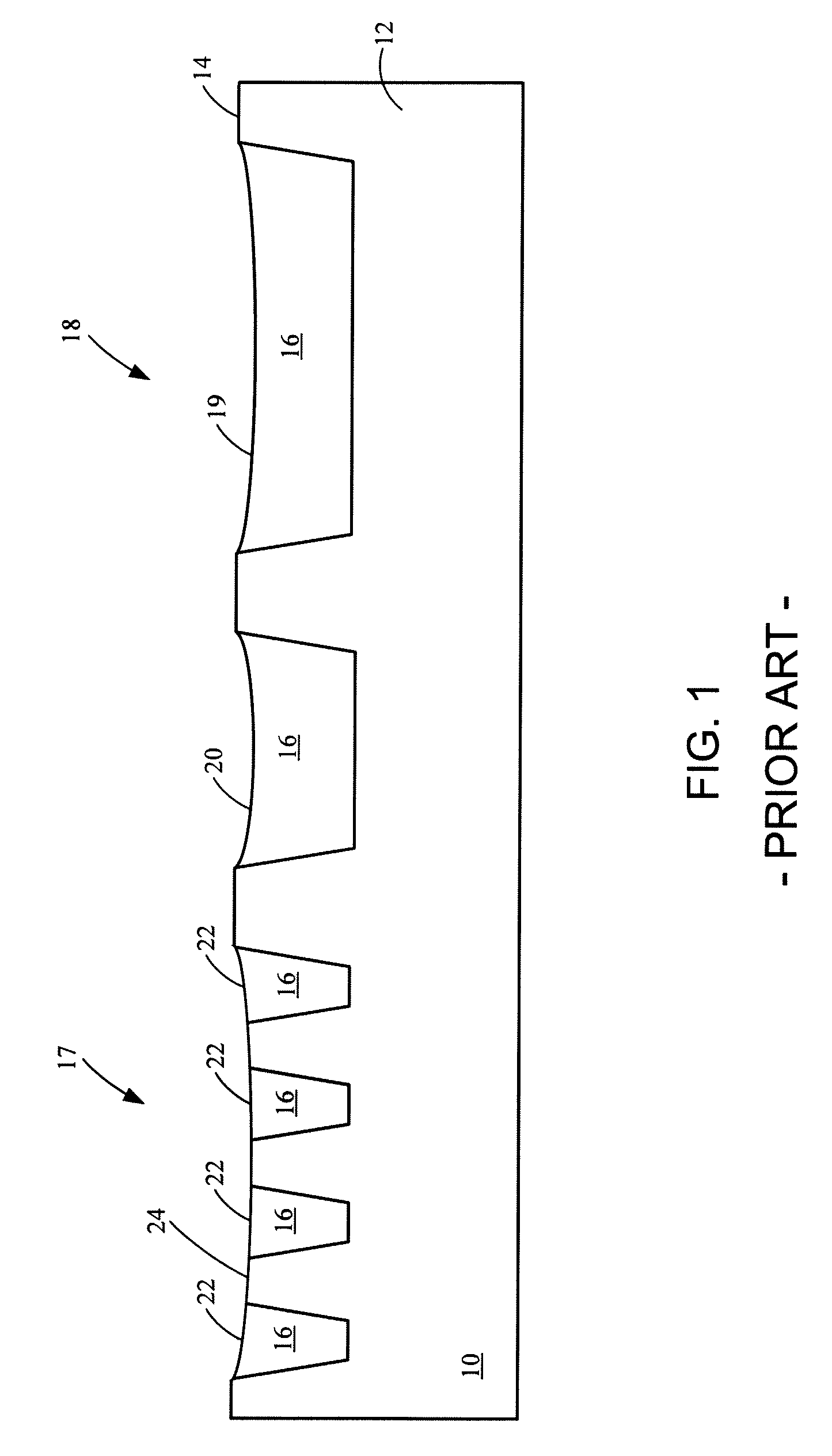

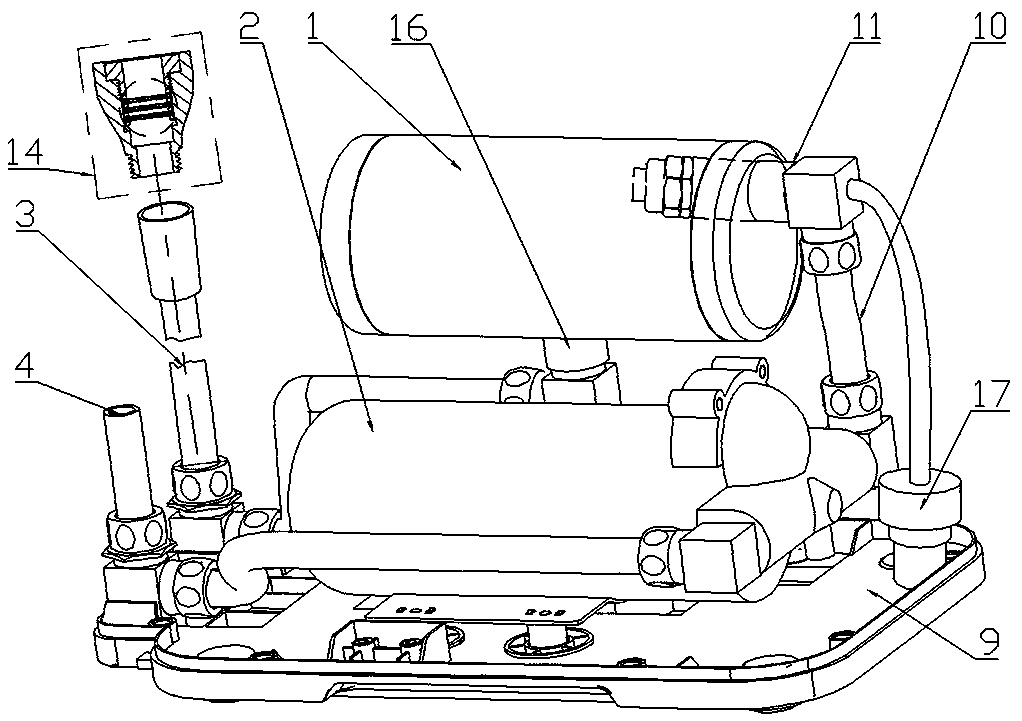

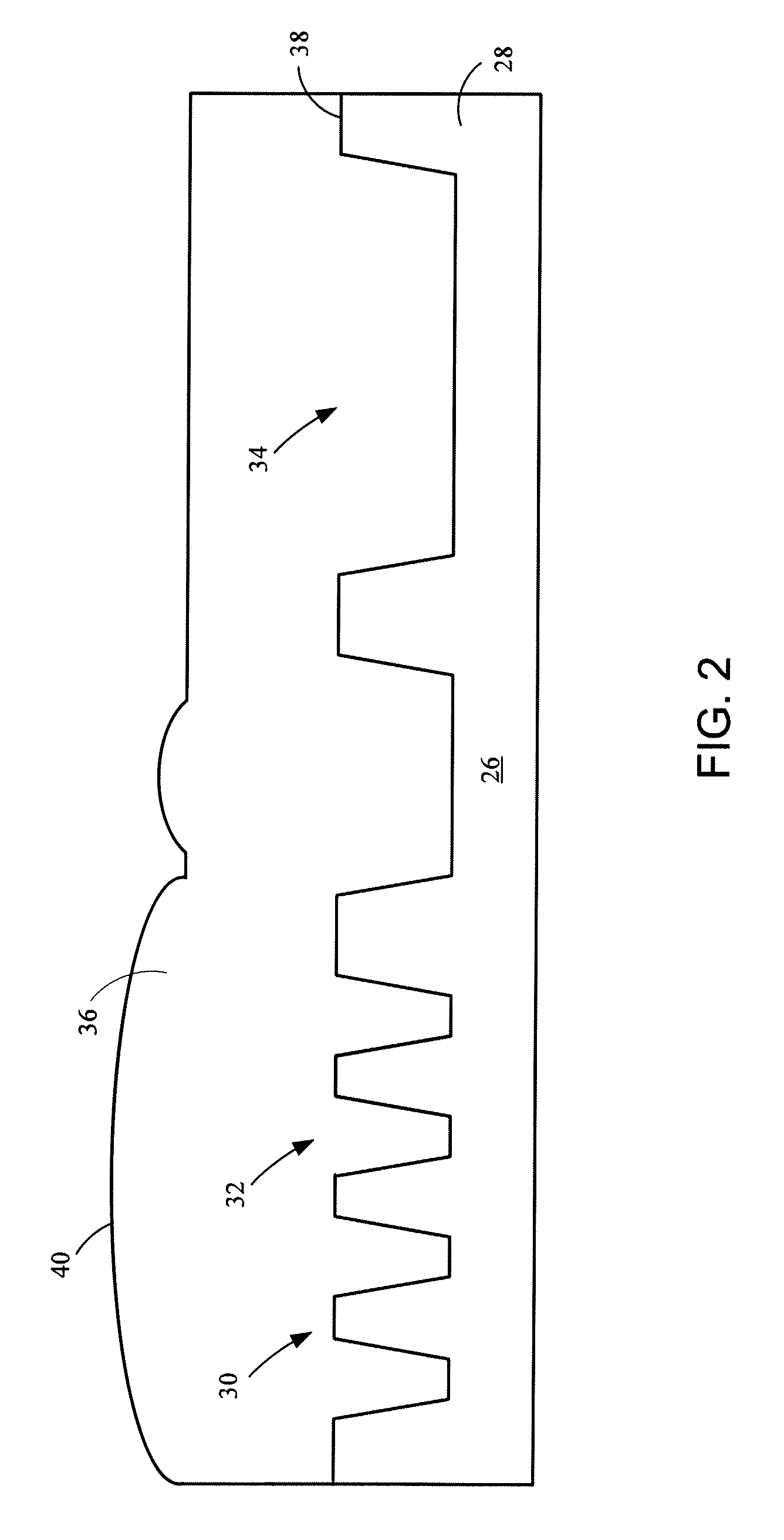

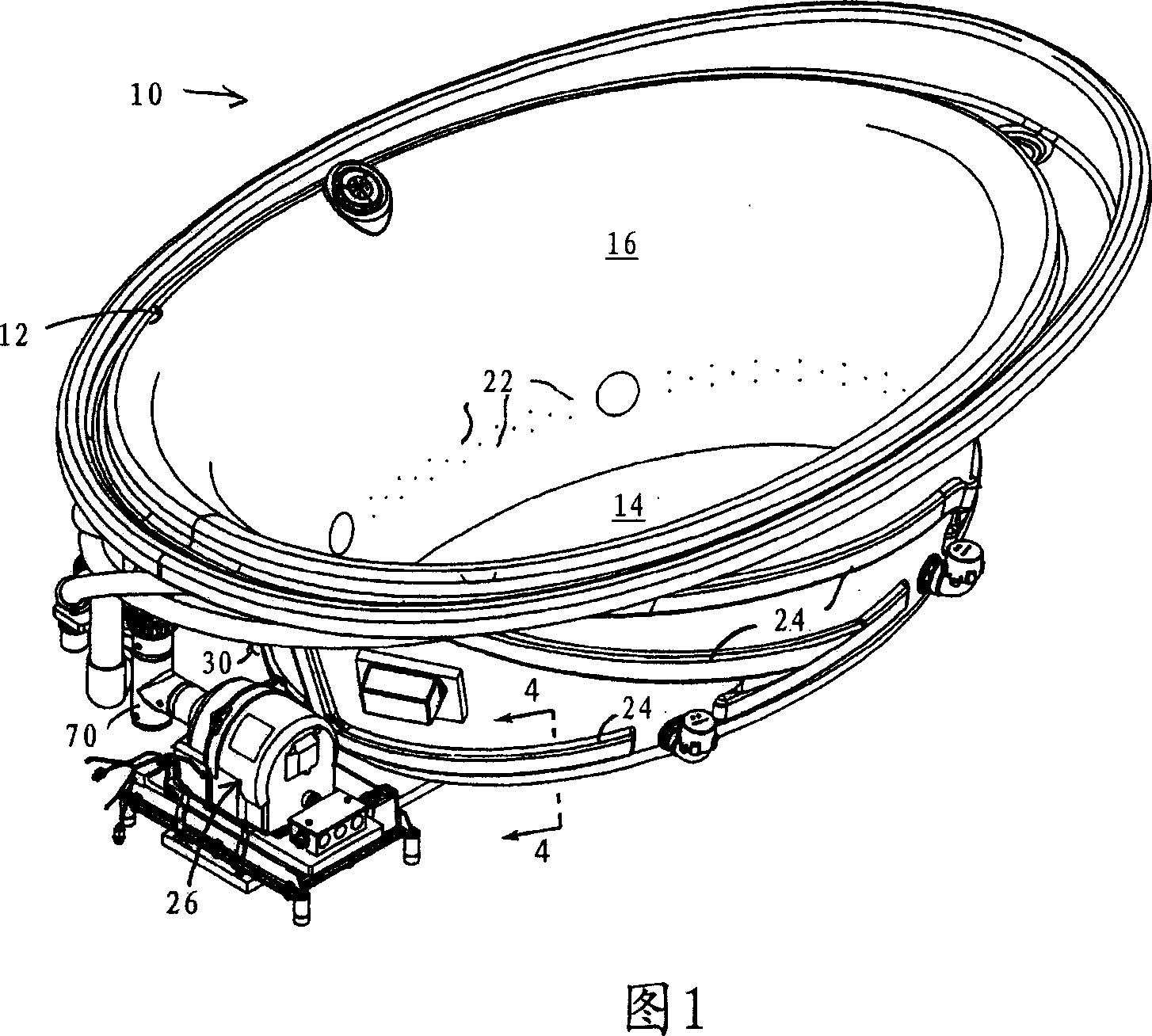

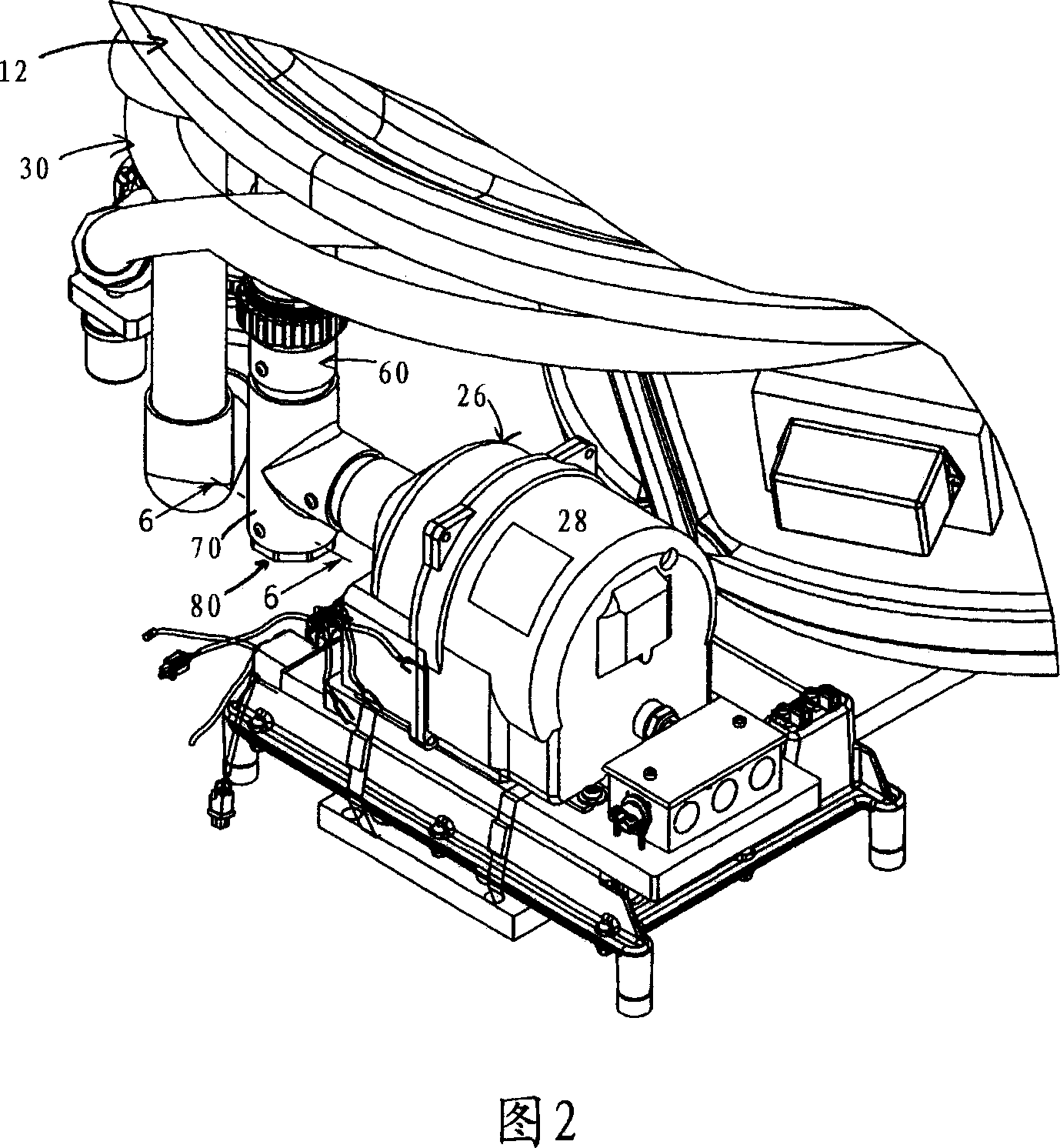

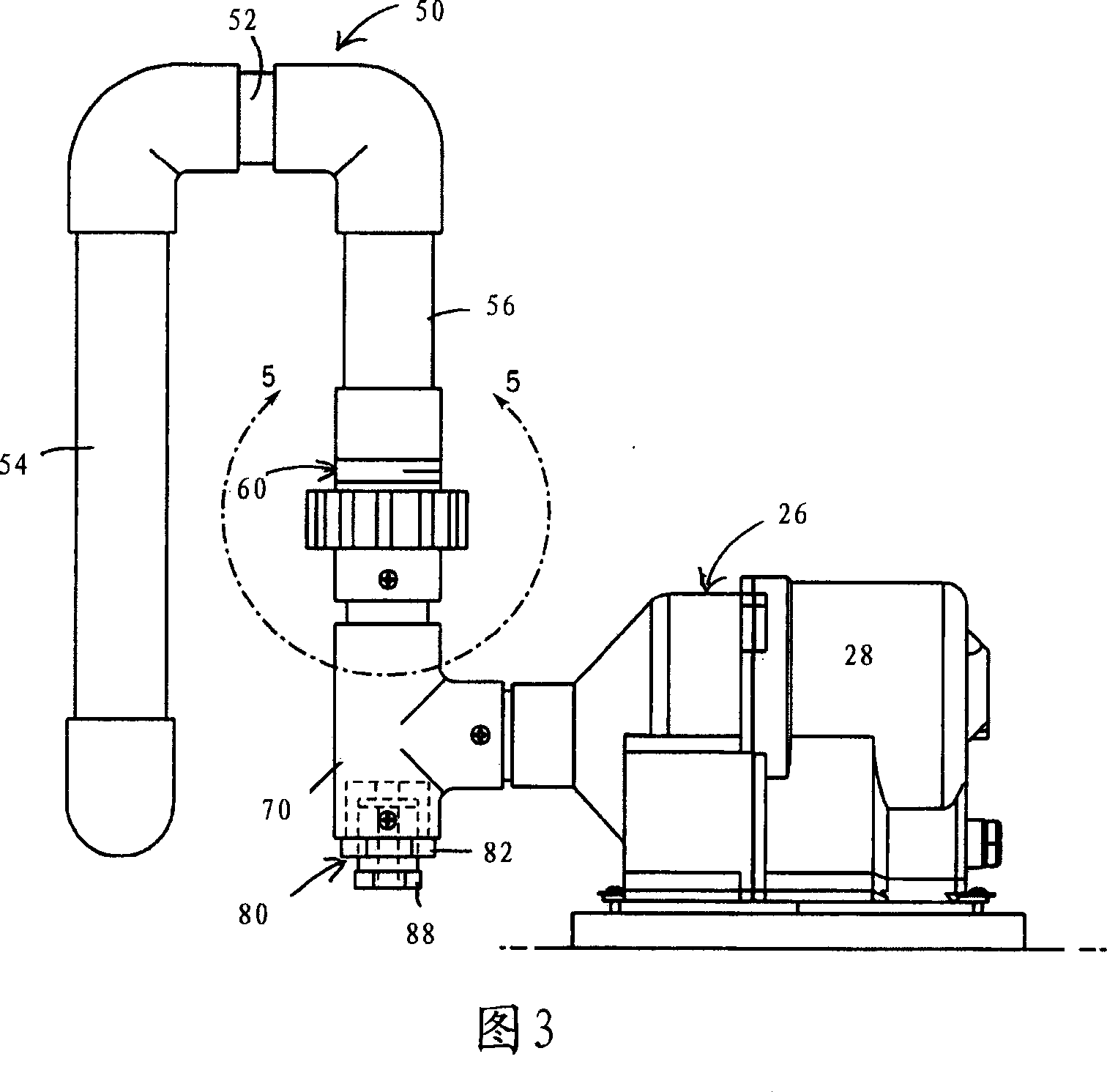

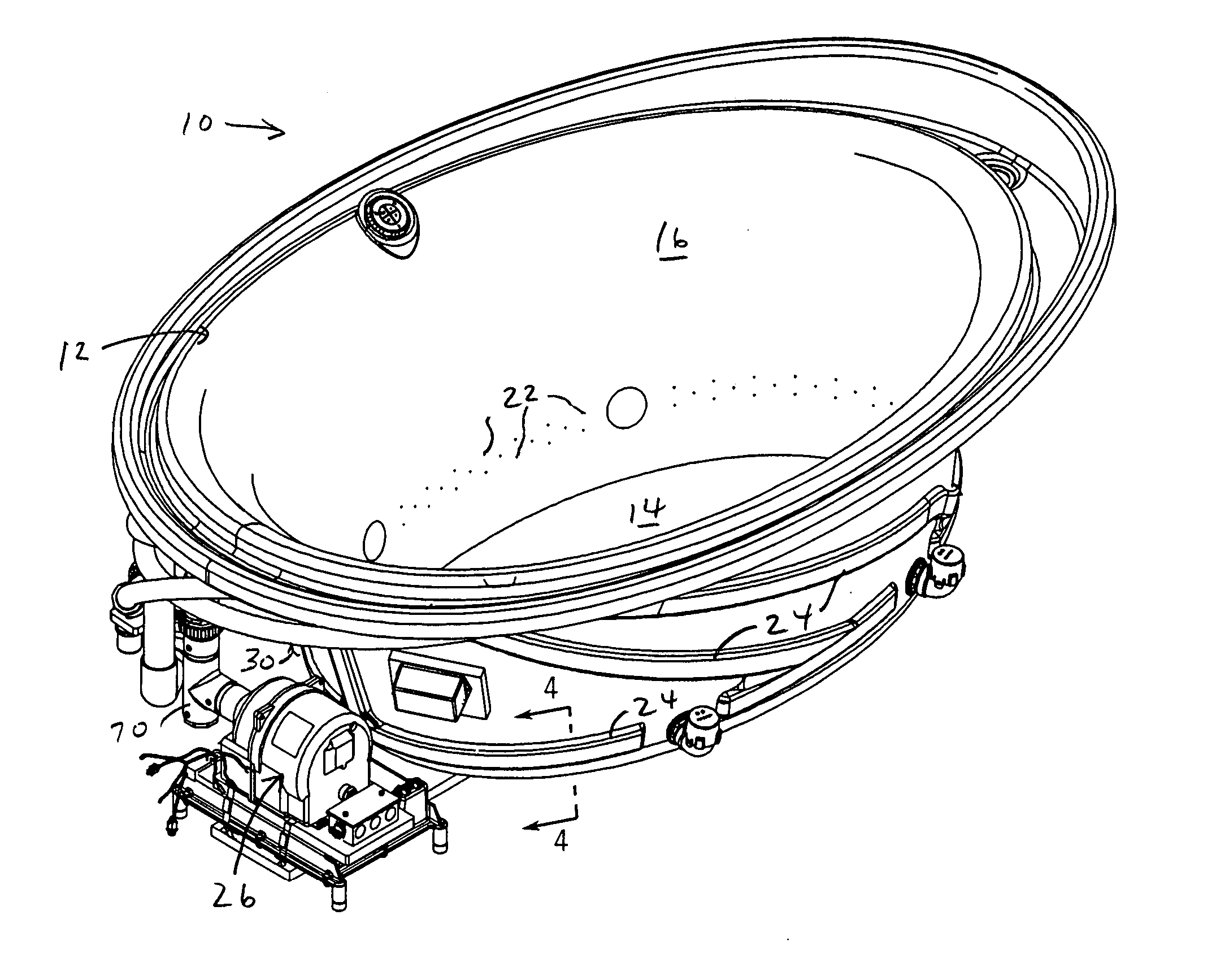

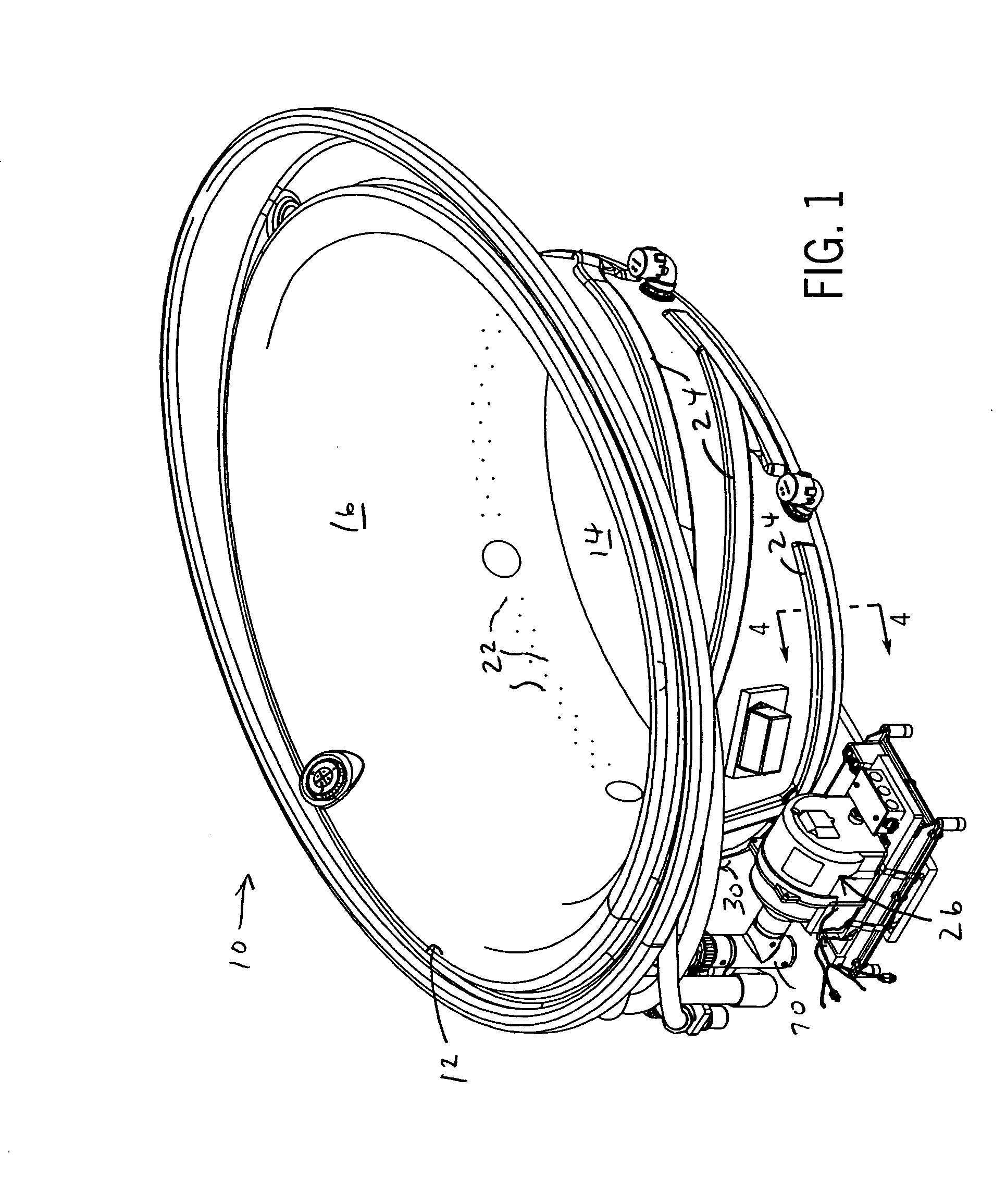

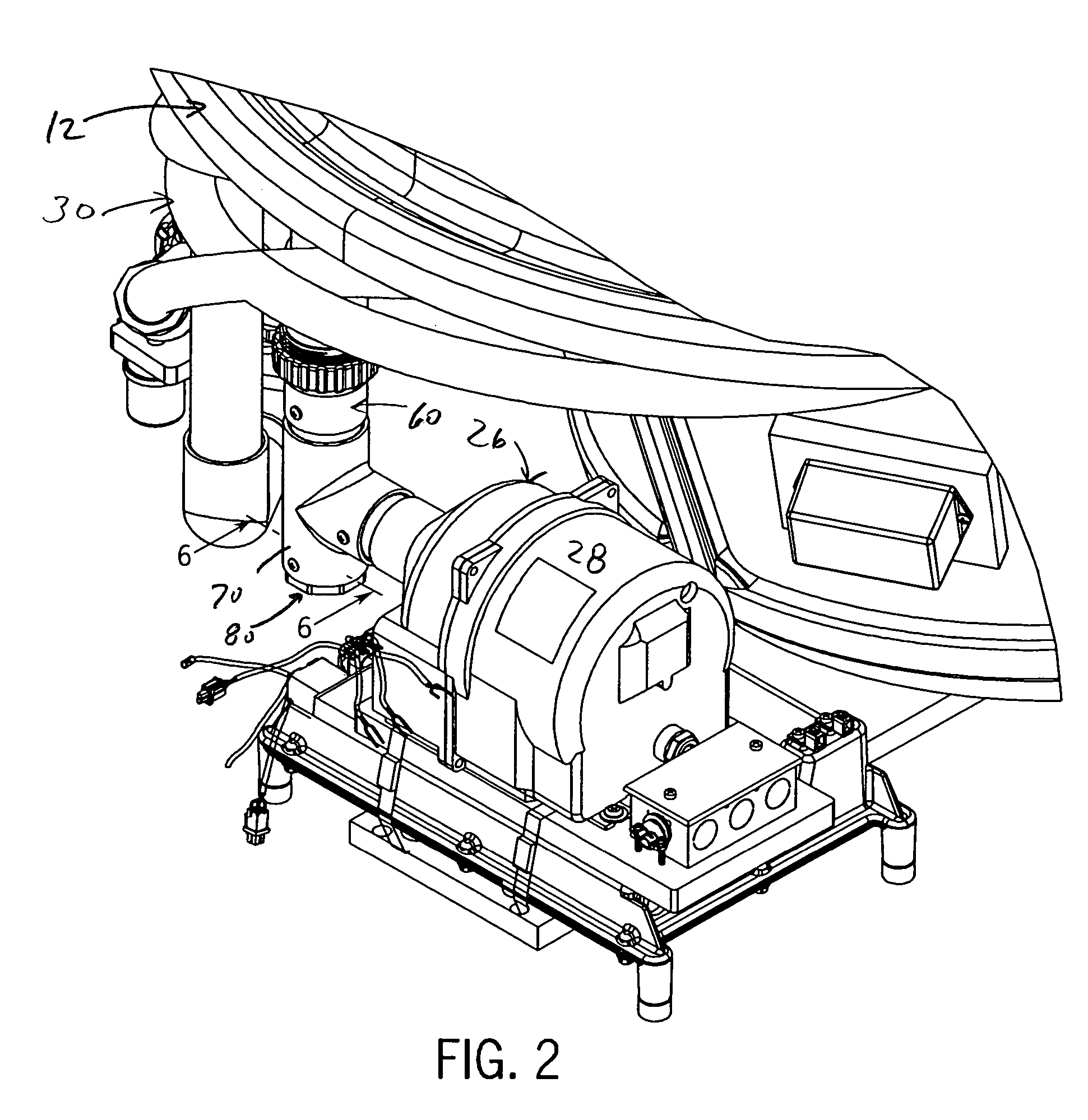

Air bath with bypass vent

ActiveUS7614095B2Enhance bathing experienceReduce deliveryBathing devicesLight therapyLow speedBubble density

An air bath has air outlets extending around the side walls of the water basin. Air is delivered to the air outlets through a ring-like air manifold coupled to a blower by conduit. The conduit has a bypass vent that siphons off a portion of the air flow otherwise passing to the air outlets and maintains the blower in communication with ambient air. The air delivery system provides a wider range of bubble densities by allowing the blower to operate at lower speeds without overheating or stalling from back pressure arising from the pressure head of the water in the basin.

Owner:KOHLER CO

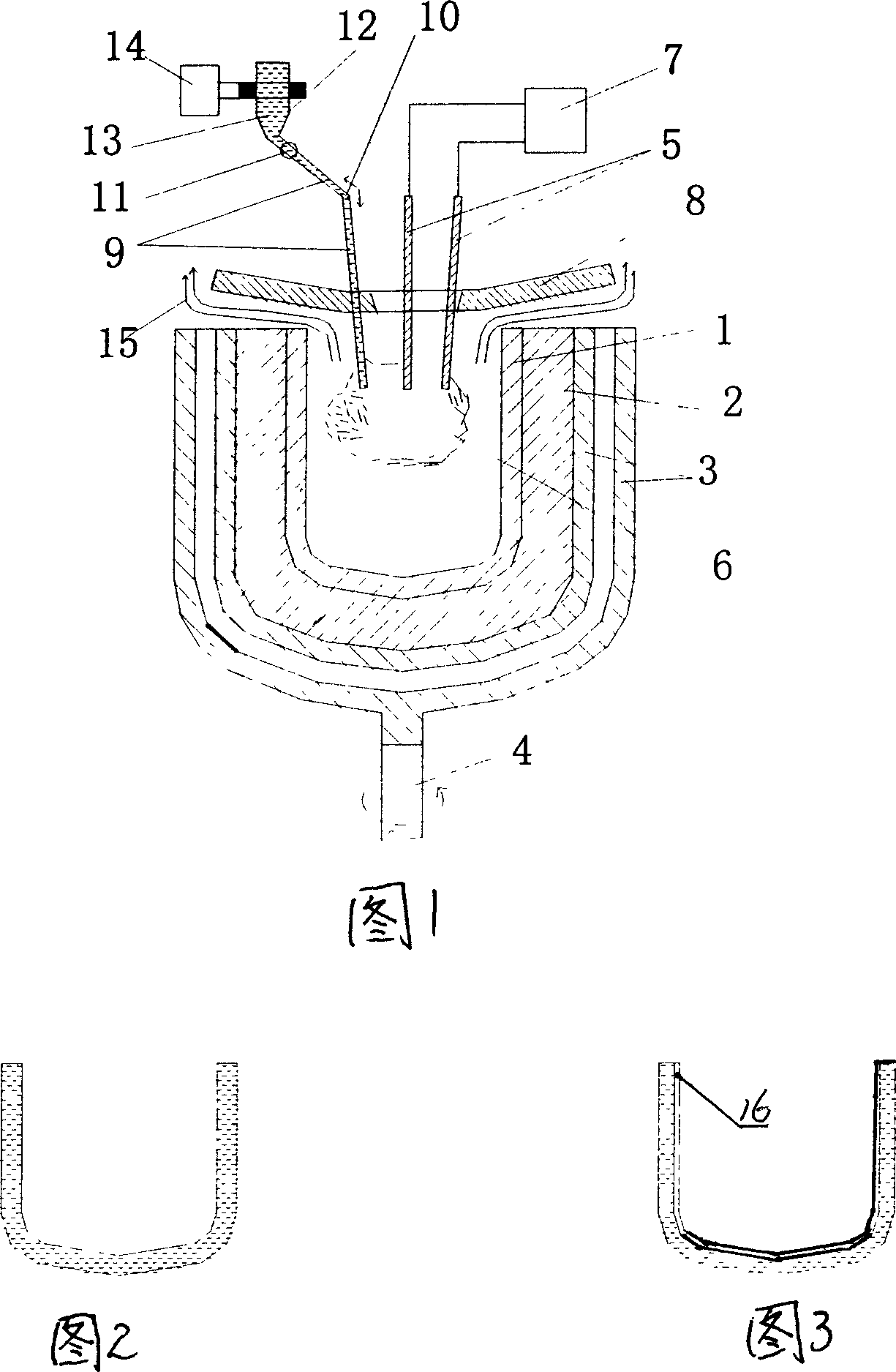

Production instrument for electric arc coating quartz glass crucible and manufacturing technique thereof

InactiveCN101085696AAnti-devitrification abilityHave mechanical strengthPot furnacesGlass shaping apparatusPower flowCrucible

The invention discloses a device that can increase the inner wall purity and reduce inner wall bubble density for quartz pot, and the production process. It comprises graphite module, quartz feeding bar inside the graphite module, the quartz feeding bar is connected to feeding bottle, the middle part of quartz feeding bar is equipped with rotary joint, and the feeding bottle is provided with vibrating device. The invention employs adjustable electromagnetic vibration and moderates vibration by moderating current to ensure even distribution of high- purity crystal powder in pot, and makes crystal powder be sprayed to different positions in the internal wall of pot by adjusting the rotary joint.

Owner:上海新沪玻璃有限公司

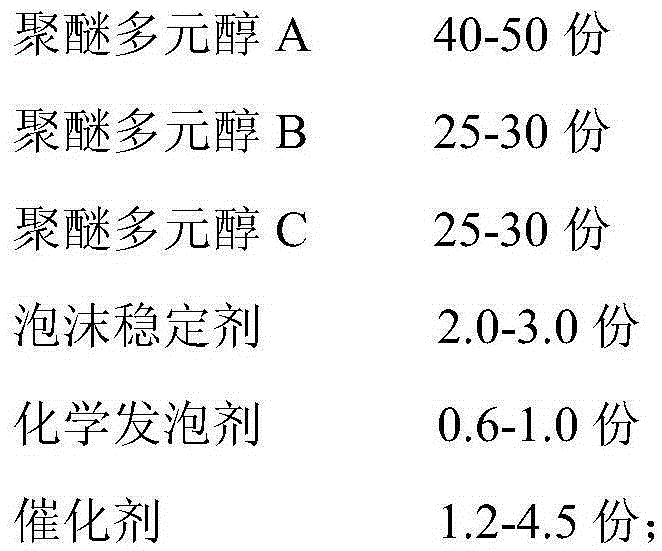

Degradable polyurethane wood-imitation material and preparing method thereof

InactiveCN105384910AMeet performance index requirementsDimensional stability Small shrinkageFoaming agentCompound (substance)

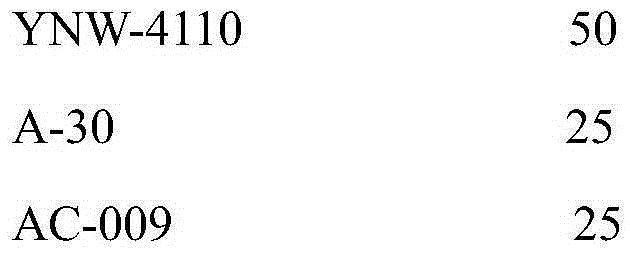

The invention belongs to the technical field of polyurethane, and particularly relates to a degradable polyurethane wood-imitation material and a preparing method thereof. The degradable polyurethane wood-imitation material is prepared from a component A and a component B, wherein the component A is prepared from polyether polyol A, polyether polyol B, polyether polyol C, a foam stabilizer, a chemical foaming agent and a catalyst, and the component B is prepared from polymethylene polyphenyl isocyanate. The multiple kinds of degradable biology-base polyether polyol are matched, and environment-friendly water is selected as the chemical foaming agent to prepare the environment-friendly degradable polyurethane wood-imitation product. The Shore hardness can be D 40 or above when the free bubble density of the product is 120-150 kg / m<3>, the dimensional stability shrinking percentage is smaller than 0.5%, the performance index requirement of the polyurethane wood-imitation material is met, and the degradable polyurethane wood-imitation material can be used for preparing wood-imitation products in complex styles.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

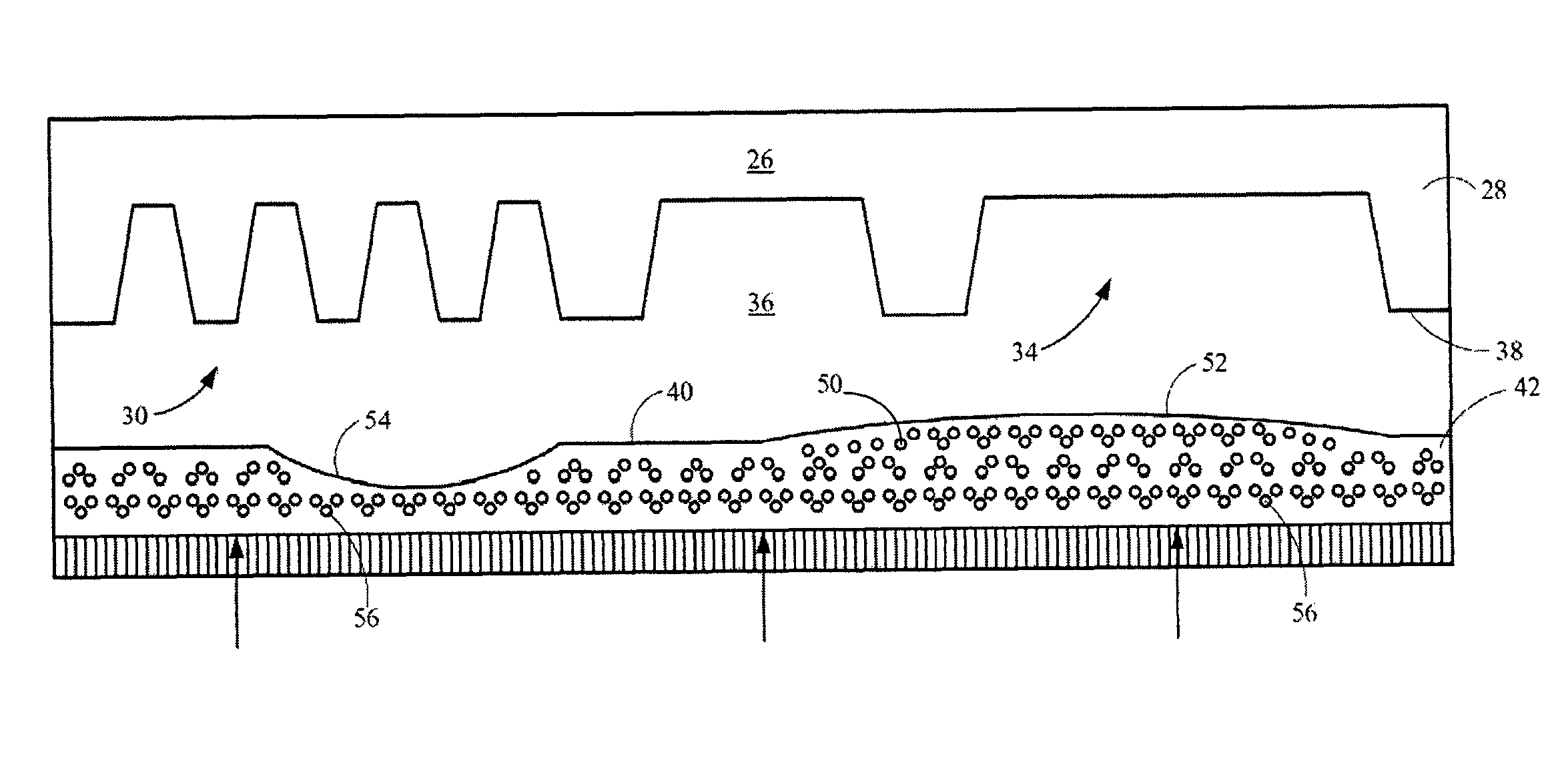

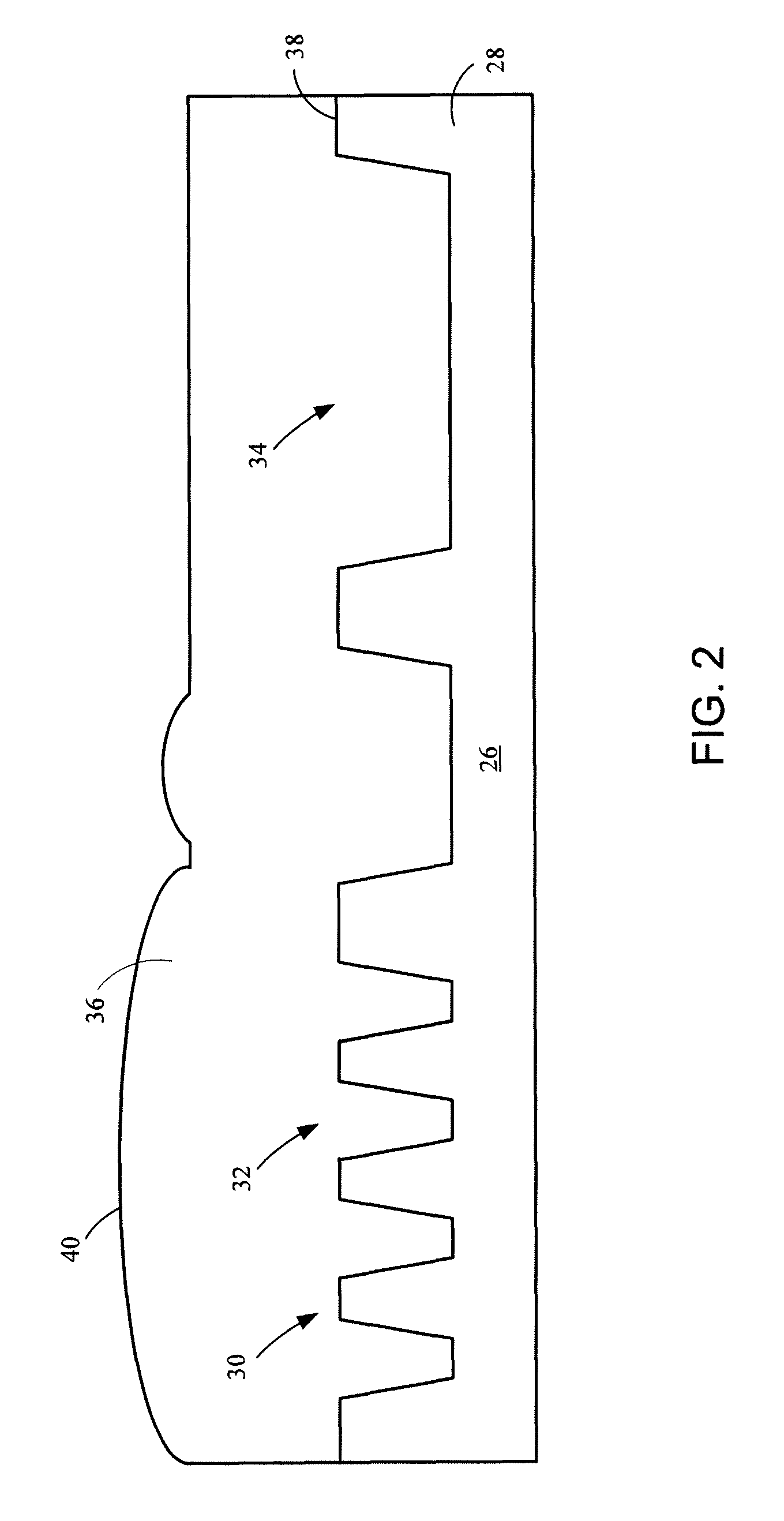

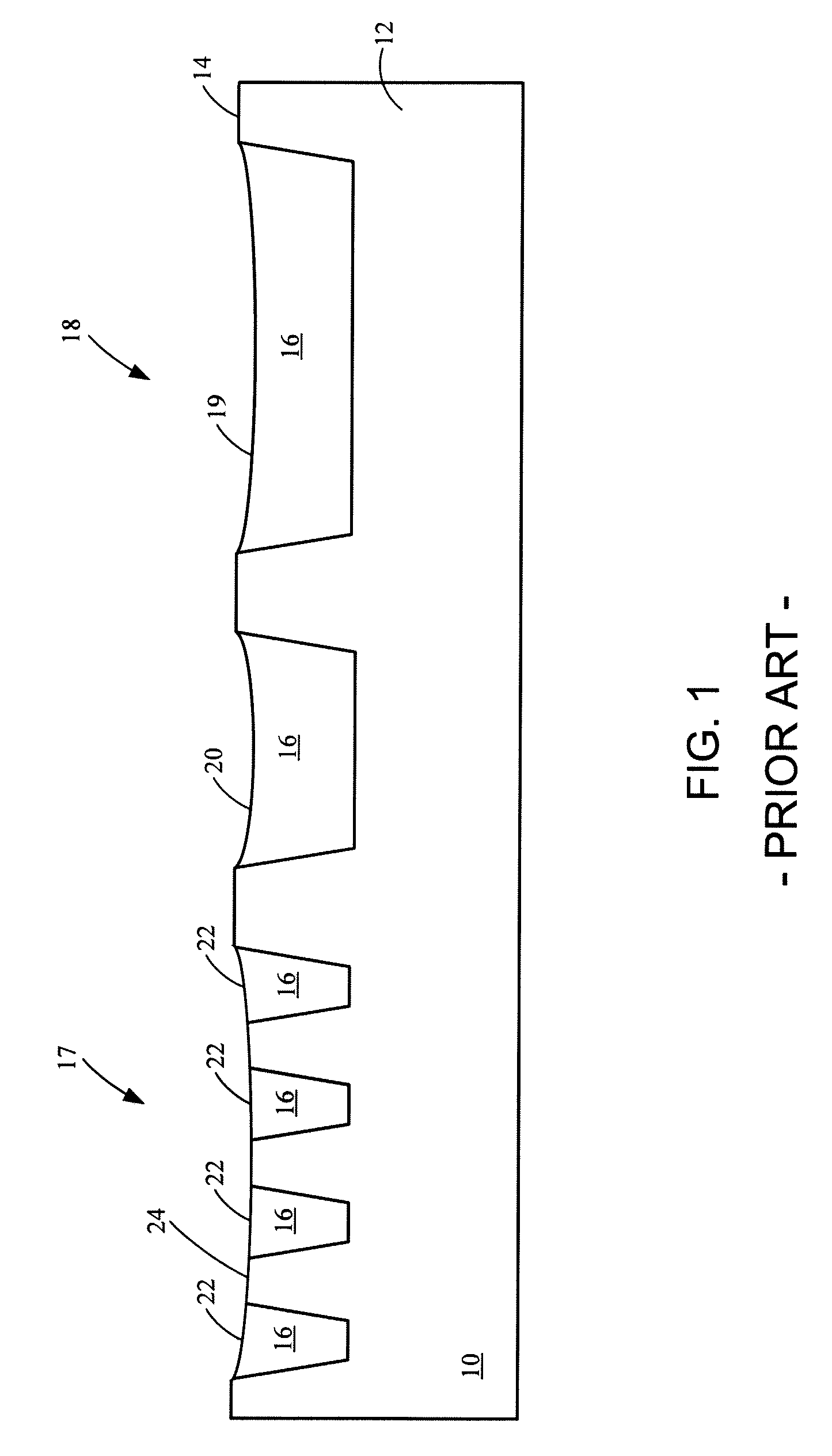

Polishing method with inert gas injection

InactiveUS8143166B2Semiconductor/solid-state device manufacturingPlane surface grinding machinesGas phaseBubble density

A polishing process in a semiconductor device fabrication process employs a polishing composition in which a gaseous phase is created within the polishing composition. During a polishing process, the gaseous phase dynamically responds to changes in the surface profile of the material undergoing removal by chemical and abrasive action during polishing. The inert gas bubble density dynamically increases in proximity to surface region of the substrate being polished that are prone to dishing and erosion. The increased inert gas bubble density operates to reduce the polish removal rate relative to other regions of the substrate. The dynamic action of the gaseous phase within the polishing composition functions to selectively reduce the localized polish removal rate such that a uniformly smooth and flat polished surface is obtained that is independent of the influence of pattern density during the polishing process.

Owner:GLOBALFOUNDRIES SINGAPORE PTE LTD +1

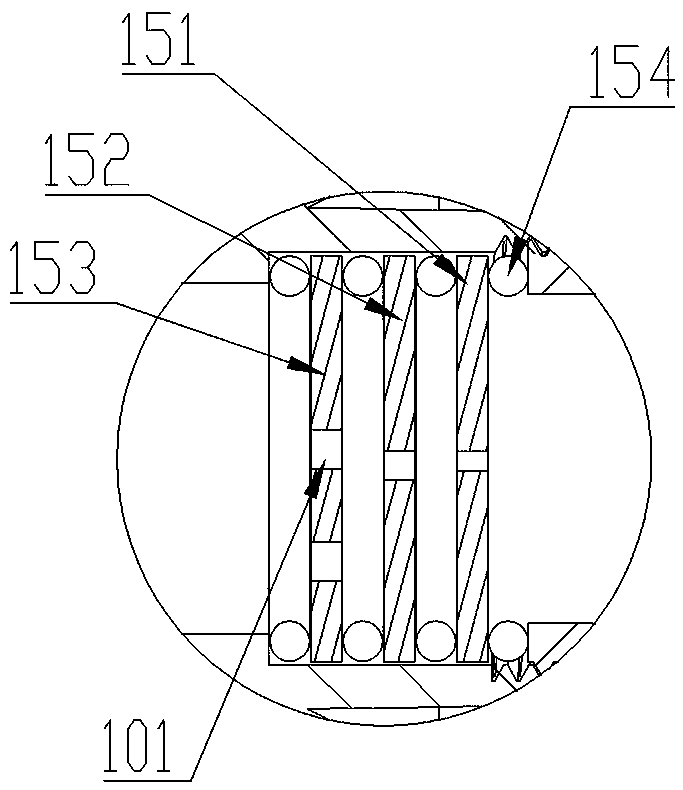

Micro-nano-bubble generation device

PendingCN110102196AFast foamingHigh bubble densityFlow mixersTransportation and packagingMicro nanoEngineering

The invention discloses a micro-nano-bubble generation device. The device comprises a base, a water inlet pipe, a booster pump, an inflation pump, a pressure tank, a water outlet pipe and an emulsifying spraying head, the water inlet pipe is connected to the booster pump, and the booster pump is installed on the base; a connection pipe is arranged at an outlet of the booster pump, a flow control pressurizing device is arranged on the pressure tank, and the flow control pressurizing device is separately connected with the connection pipe and the inflation pump; a water outlet is formed in the bottom of the pressure tank and communicated with the water outlet pipe, and the emulsifying spraying head is connected with the other end of the water outlet pipe. According to the micro-nano-bubble generation device, through a mode that liquid feeding, mixing, atomization and emulsifying are conducted, bubbles are generated, and the device has the advantages that water can be recycled, the bubblegeneration speed is high, the bubble density is high, and the sustainable capacity is high and is suitable for multiple occasions of beautifying, skin care, sterilization and the like.

Owner:叶忠达

Continuous Casting of Foamed Bulk Amorphous Alloys

Methods and apparatuses for the continuous casting of solid foam structures with varying bubble density from bulk solidifying amorphous alloys are provided. Continuously cast solid foam structures having bubble densities in the range of from 50 percent up to 95% by volume are also provided.

Owner:CRUCIBLE INTPROP LLC

Latex mattress capable of adjusting partial hardness thereof

The invention relates to the technical field of bedding products, particularly to a bed mattress, more particularly a latex bed mattress with adjustable local hardness. The latex bed mattress with adjustable local hardness comprises an elastic mesh and a plurality of latex column units, wherein the latex column units are respectively arranged in each grid of the mesh and the bubble densities of the latex column units are the same or different. The latex bed mattress has good air permeability, is matched with the human physiological curve, ensures comfortable sleep, and has no damage to the human spine. Additionally, the hardness of each latex column unit is different from one another, so that the whole bed mattress can provide zones with different hardness to meet the requirements for sleepers with different body shapes.

Owner:SHANGHAI LATEX INDAL

Polishing method with inert gas injection

A polishing process in a semiconductor device fabrication process employs a polishing composition in which a gaseous phase is created within the polishing composition. During a polishing process, the gaseous phase dynamically responds to changes in the surface profile of the material undergoing removal by chemical and abrasive action during polishing. The inert gas bubble density dynamically increases in proximity to surface region of the substrate being polished that are prone to dishing and erosion. The increased inert gas bubble density operates to reduce the polish removal rate relative to other regions of the substrate. The dynamic action of the gaseous phase within the polishing composition functions to selectively reduce the localized polish removal rate such that a uniformly smooth and flat polished surface is obtained that is independent of the influence of pattern density during the polishing process.

Owner:GLOBALFOUNDRIES SINGAPORE PTE LTD +1

Water heater

The invention discloses a water heater. The water heater comprises a heat exchange device, a gas dissolving control device and a water outlet pipeline assembly, wherein the heat exchange device is connected with a cold water inlet flow passage and a hot water outlet flow passage; the gas dissolving control device comprises a gas-liquid mixing cavity, a water outlet module and a water outlet pipeline assembly; a cavity water inlet of the gas-liquid mixing cavity is connected with the hot water outlet flow channel, and the gas-liquid mixing cavity is provided with an air inlet air channel and acavity water outlet; the water outlet module comprises a drainage flow channel and a bubble water flow channel which are arranged between the module water outlet of the water outlet module and the cavity water outlet in parallel; a micro-nano bubble water generating device for forming micro-nano bubble water is arranged in the bubble water flow channel; and the water outlet pipeline component is connected to the module water outlet and comprises a bath water pipeline and a bubble water pipeline which are arranged in parallel. The water heater is capable of draining micro-nano bubble water withhigh micro-nano bubble density, and is shock-absorbing and noise-reducing, simple in structure and good in user experience.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD

Preparation method of supercritical micro-foaming high-light plastic and plastic-based composite material and supercritical micro-foaming high-light plastic or plastic-based composite material prepared through preparation method

The invention relates to the technical field of preparation of high polymer materials and provides a preparation method of supercritical micro-foaming high-light plastic and a plastic-based composite material and the supercritical micro-foaming high-light plastic or the plastic-based composite material prepared through the preparation method for solving the problem that the bubble hole size and bubble density of plastic and a plastic-based composite material thereof are difficult to control. The method comprises the following steps that 1, a hot melt adhesive is prepared, particularly, the plastic or the plastic-based composite material is heated to be molten, and the hot melt adhesive is formed under the shearing effect of a screw rod; 2, a single-phase melt is prepared, particularly, supercritical foaming gas is injected into the end of the screw rod to be mixed into the hot melt adhesive obtained in the step 1, and the single-phase melt is formed; 3, injection molding is carried out, and particularly high-temperature steam is adopted for rapidly injecting the single-phase melt obtained in the step 2 into an injection model; and 4, cooling molding is carried out, particularly, a condensing agent is adopted for rapidly reducing the temperature of the injection model in the step 3, and therefore the high-light plastic or the plastic-based composite material with high-density micro holes inside is obtained.

Owner:段辉

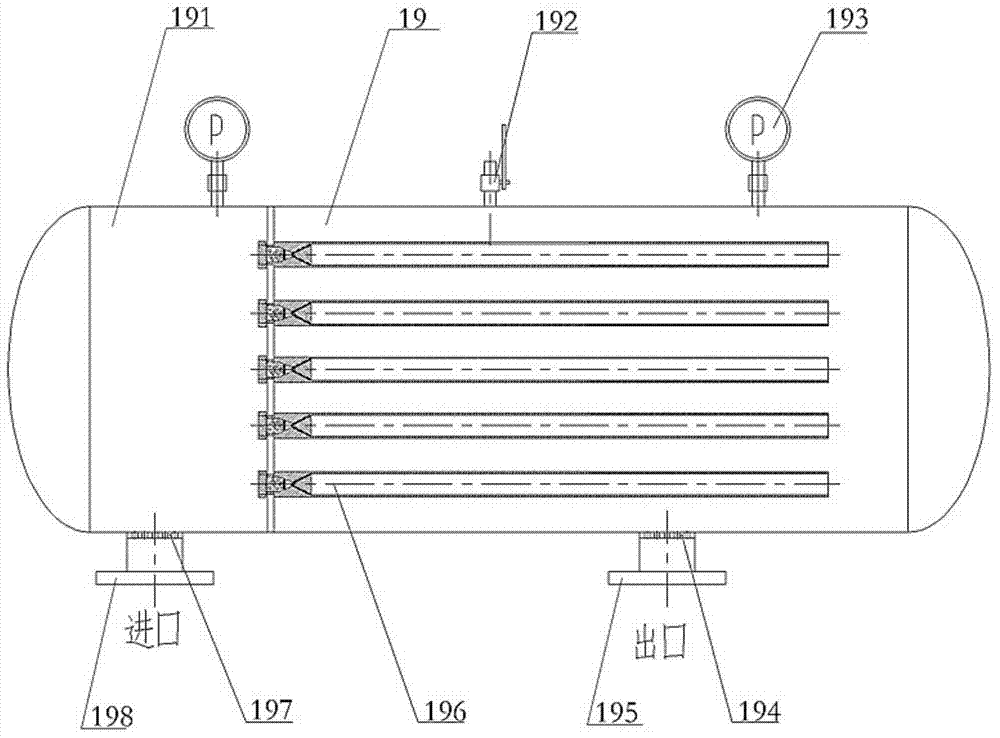

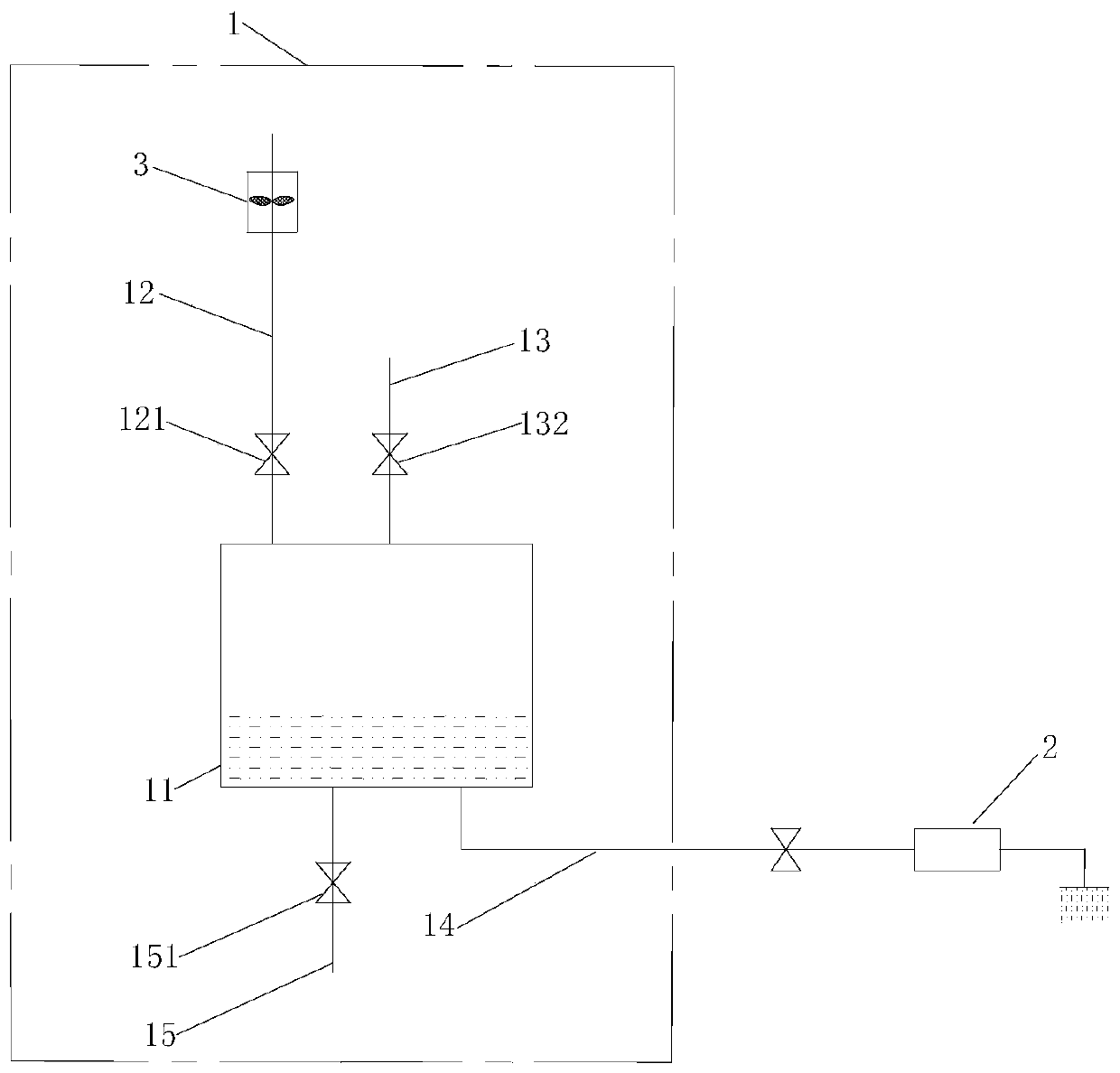

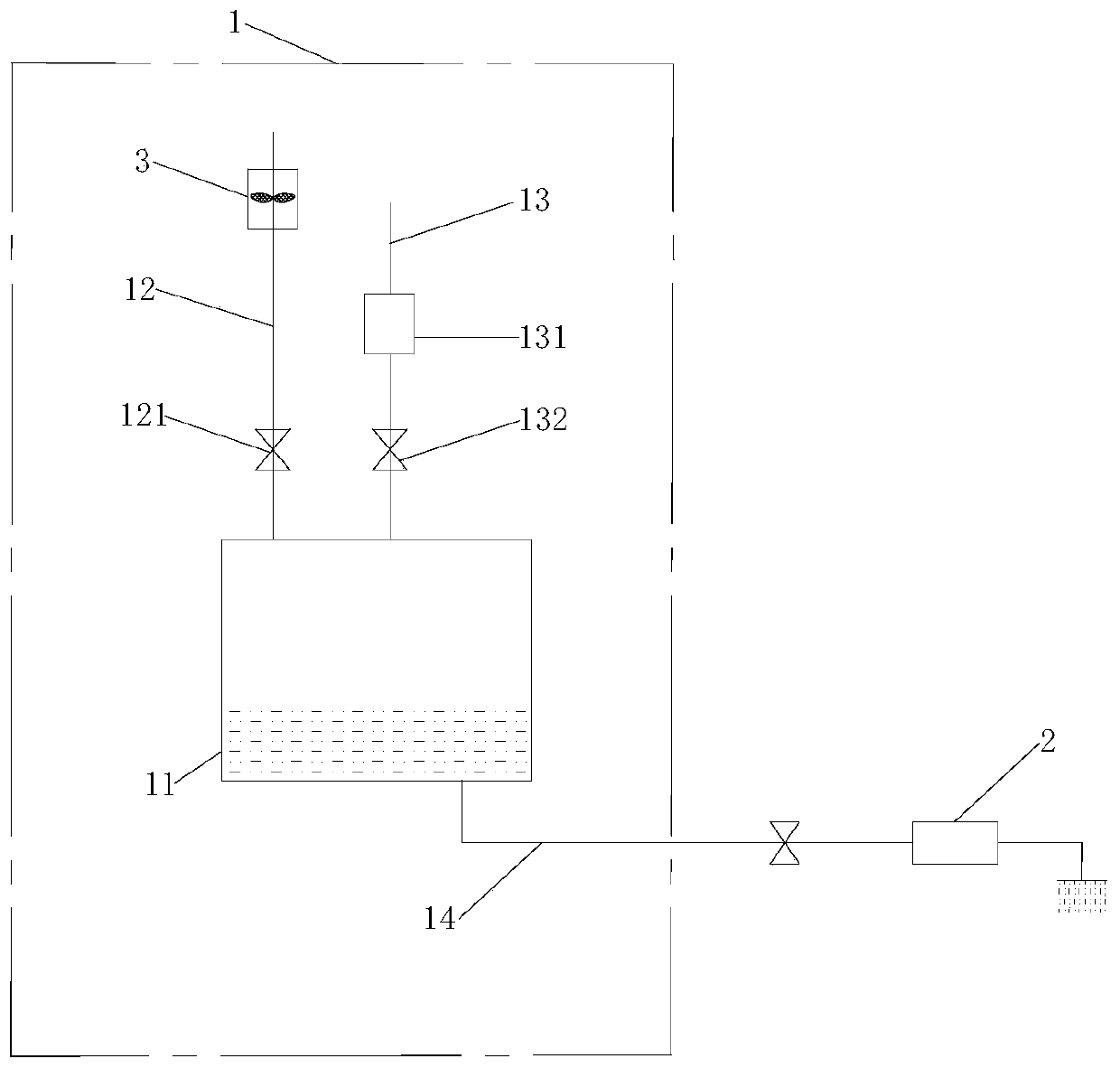

Hot micro-nano bubble liquid generation system

ActiveCN110614042AHigh densityMeet water requirementsFlow mixersTransportation and packagingMicro nanoBubble density

The invention discloses a micro-nano bubble liquid generation system. The micro-nano bubble liquid generation system comprises a gas dissolving control device and a micro-nano bubble liquid generationdevice, wherein the gas dissolving control device comprises a gas-liquid mixing cavity; the gas-liquid mixing cavity is connected with a liquid inlet flow channel; a gas inlet gas channel and a liquid outlet flow channel used for discharging gas-dissolved liquid; the micro-nano bubble liquid generation device is arranged in the liquid outlet flow channel and is internally provided with a bubble liquid micro-channel; the gas-dissolved liquid forms micro-nano bubble liquid through the bubble liquid micro-channel to be discharged. The liquid inlet flow channel can be a normal-pressure liquid inlet flow channel, the air inlet air channel can be a normal-pressure air inlet air channel, and the bottom end of the air-liquid mixing cavity can be connected with an emptying flow channel or the airinlet air channel can be provided with an air pump. The micro-nano bubble liquid generation system is simple and reasonable in structure, high in micro-nano bubble density, low in cost and suitable for being applied to miniaturized equipment.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD

Air bath with bypass vent

An air bath has air outlets extending around the side walls of the water basin. Air is delivered to the air outlets through a ring-like air manifold coupled to a blower by conduit. The conduit has a bypass vent that siphons off a portion of the air flow otherwise passing to the air outlets and maintains the blower in communication with ambient air. The air delivery system provides a wider range of bubble densities by allowing the blower to operate at lower speeds without overheating or stalling from back pressure arising from the pressure head of the water in the basin.

Owner:KOHLER CO

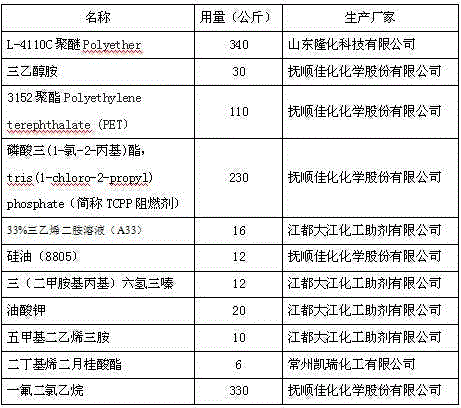

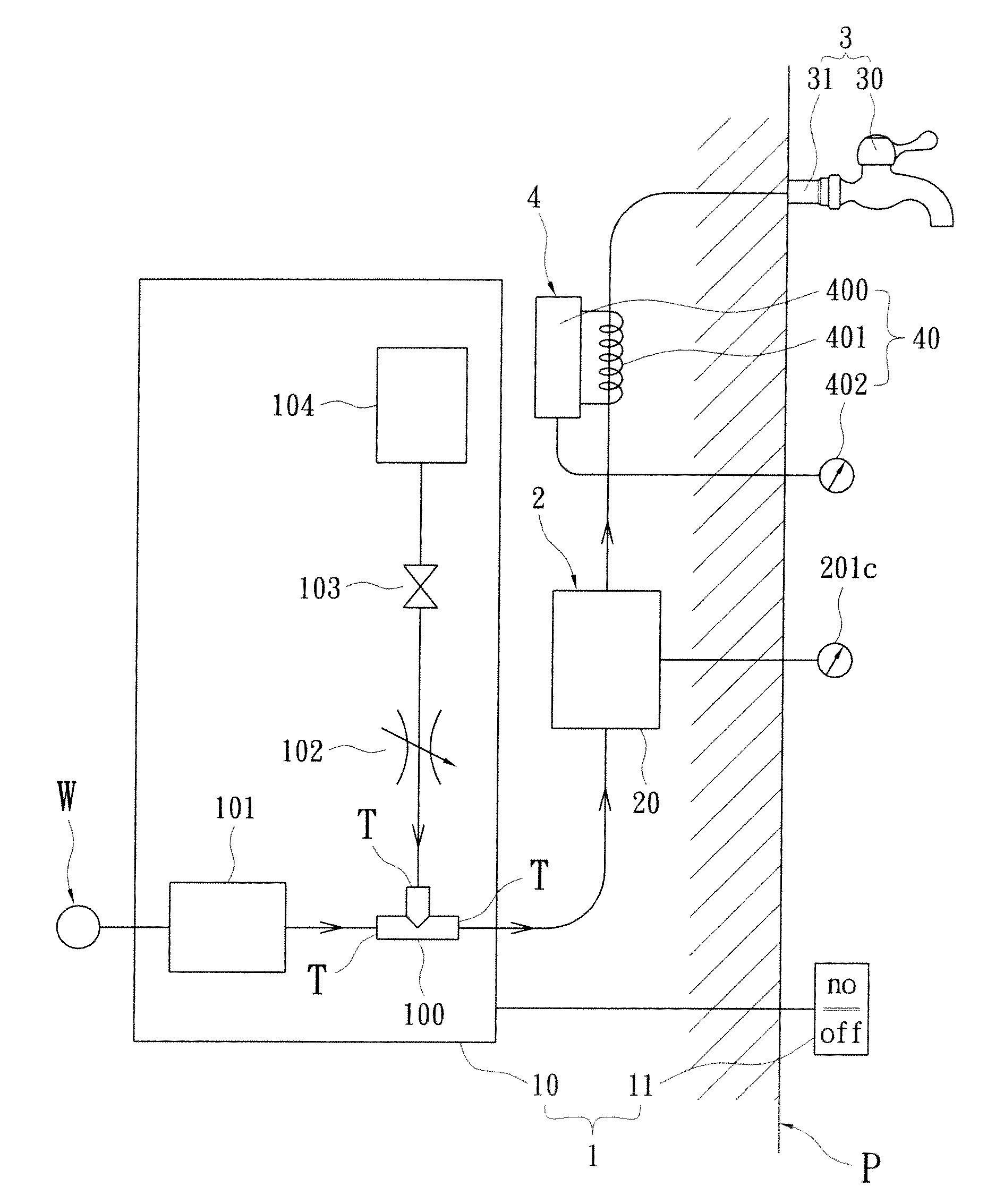

Flame-retardant composite polyether for on-site spraying

The invention belongs to a main raw material for rigid polyurethane foam, and provides flame-retardant composite polyether for on-site spraying. The composite polyether is prepared from following raw materials according to a ratio: L-4110C polyether, triethanolamine, 3152 polyester, tris(1-chloro-2-propyl)phosphate, A33, silicone oil (8805), 1,3,5-tris[3-(dimethylamino)propyl]hexahydro-1,3,5-triazine, potassium oleate, pentamethyldiethylenetriamine, dibutyltin dilaurate and dichlorofluoroethane. Compared with products of the same type, the composite polyether has obvious advantages and is advantageous in that: a polyether cost is low; a formula is simple; during using, products of the composite polyether are milky white, short in wire drawing and debonding time and good in adhesion force; the oxygen index can reach 30; the free bubble density can reach about 40, and flame retardant effects are ensured.

Owner:DALIAN YIXING ENERGY TECH

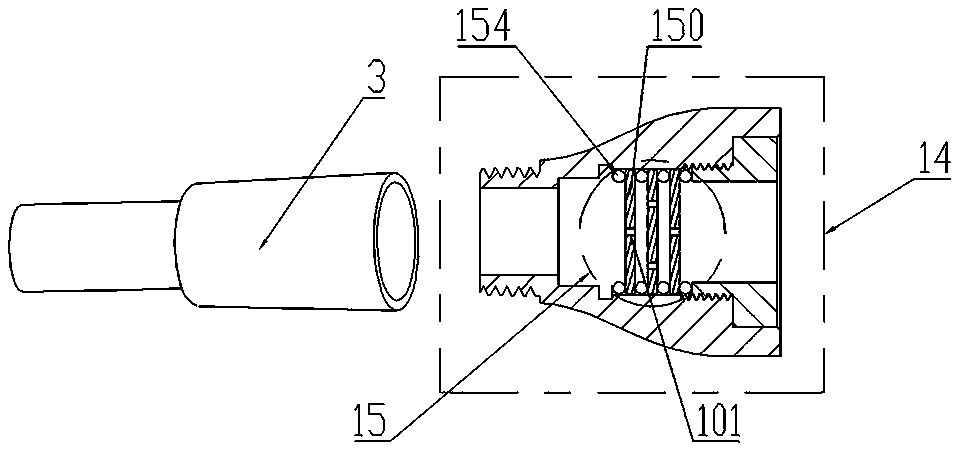

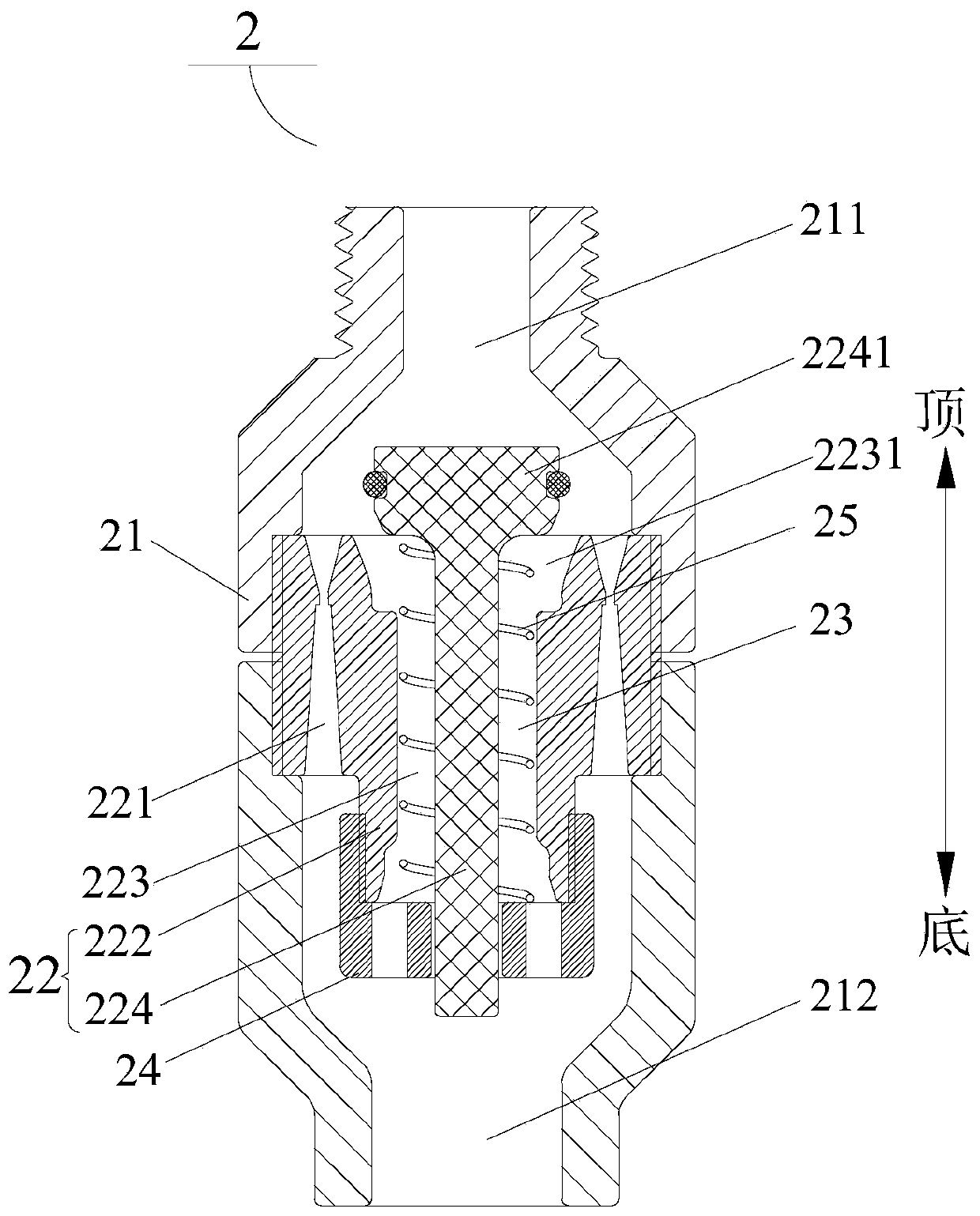

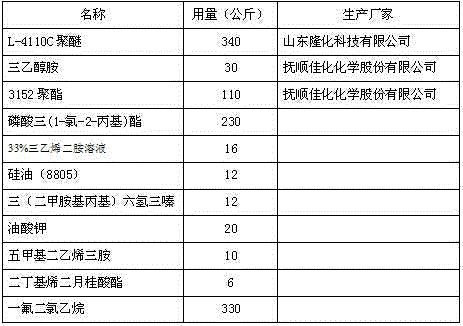

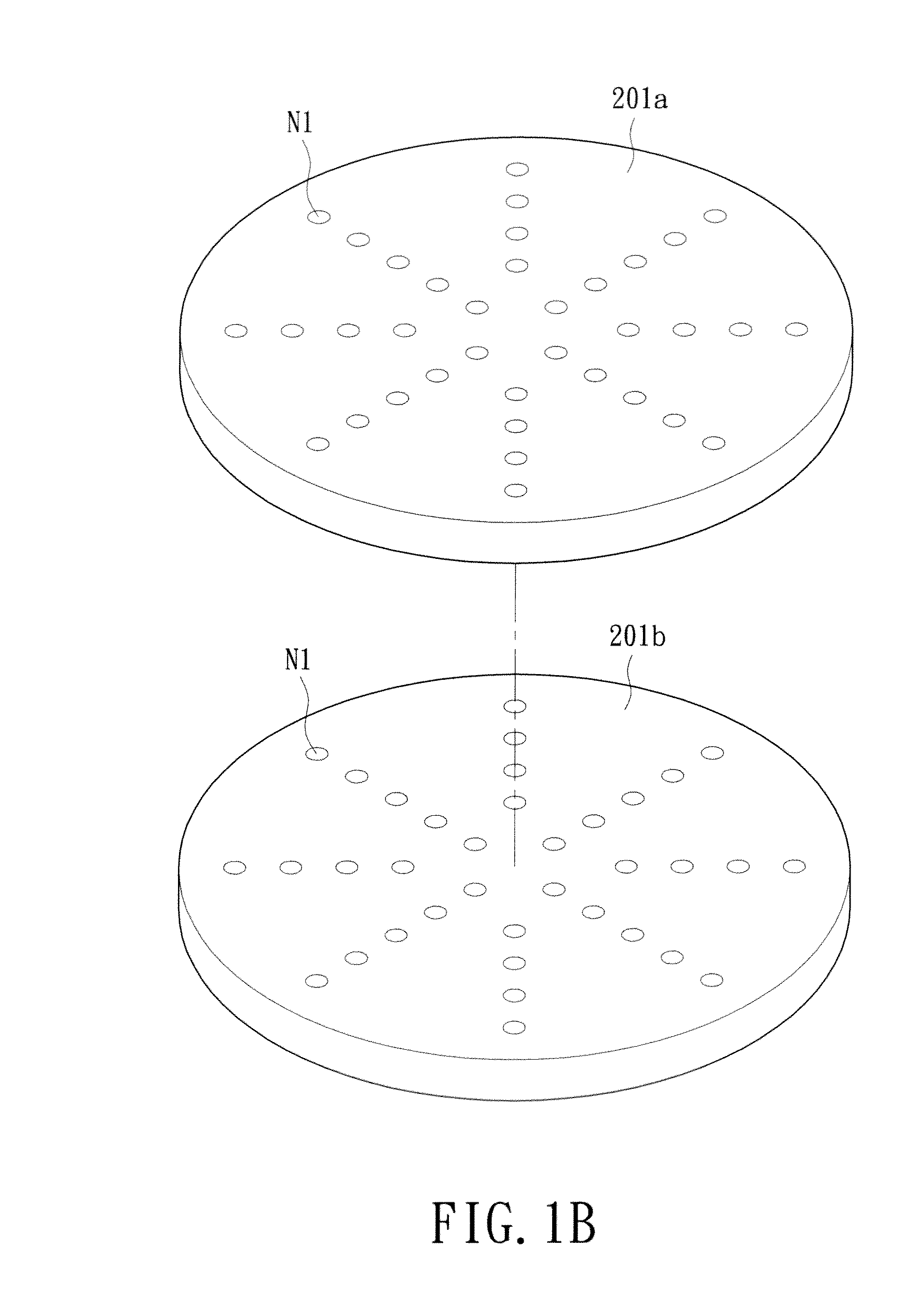

Integrated aerated bubble generating device

InactiveUS20110114761A1Reducing chance of unwanted damageMaintaining overall aesthetic unityDomestic plumbingElectricityEngineering

An aerated bubble generating device, integrated into water-supply means and creating fine bubbles, includes a bubble generation unit, a bubble density-adjustment unit and a water discharge unit. The bubble generation unit has a bubble generation device arranged in the predetermined object and a switch electrically connecting to the bubble generation device and exposed out of the predetermined object. The bubble density-adjustment unit has a bubble density-adjustment device arranged in the predetermined object, for controlling the size of each bubble. The bubble density-adjustment device defines a distal end linking the bubble generation device. The water discharge unit has a water-supply device exposed out of the predetermined object and a communicating pipe linking both of the bubble density-adjustment and the water-supply devices.

Owner:CASHIDO

A kind of permeable foam concrete and preparation method thereof

ActiveCN107140902BIncrease the average pore sizeGood water permeabilityCeramicwareFiberFoam concrete

The invention discloses water-permeable foam concrete which is prepared from the following main raw materials: cement, super-fine sand, water, admixtures, foams, fibers, cellulose ether and a water reducer. According to the water-permeable foam concrete, the crude fibers with larger size are doped into a foam concrete matrix, so that foam pores of foam concrete form a communication channel taking the fibers as guide pipes firstly; meanwhile, the average pore size of the foam concrete is increased by decreasing the bubble density in a blending process of the foam concrete, so that the foam pores and the crude fibers form better adaptability; the foam concrete shows better water permeability performance and use performance, so that the problem that the water permeable rate of the conventional foam concrete is low is solved; in addition, involved raw materials are low in cost, and a preparation method is simple, therefore, the water-permeable foam concrete is suitable for popularization and application.

Owner:THE FIRST SINCERITY CONSTR TECH CO LTD

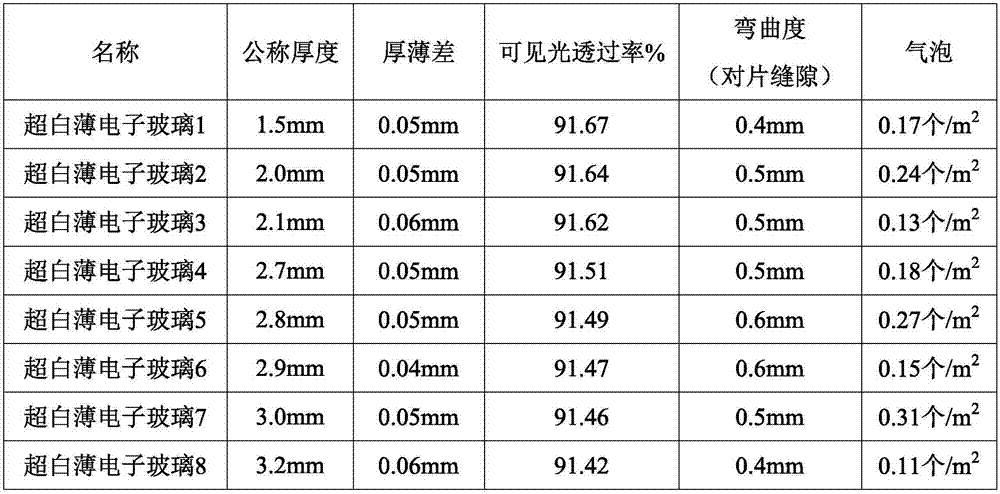

Ultra white thin electronic glass and production method thereof

The invention discloses ultra white thin electronic glass and a production method thereof, the ultra white thin electronic glass is made by a float glass production technology, the thickness is 1.5-3.2mm, the visible light transmittance is 91.3-91.8%, bubble density is 0.1-0.32 / m<2>, raw materials comprises a base component, a clarifying agent and a decoloring agent, the base component comprises 71.0-72.0 parts by weight of SiO2, 12-15 parts by weigh of Na2O+K2O, 8.5-10.5 parts by weigh of CaO, 1.5-3 parts by weigh of MgO, 0.2-0.8 part by weigh of Al2O3 and 0.01-0.015 part by weigh of Fe2O3, the clarifying agent comprises CeO2 and KNO3, the weight of the KNO3 is 11-15% of the total amount of Na2O +K2O, the weight of the CeO2 is 0.32-0.45% of the total weight of the base component, the KNO3 and the decoloring agent, the decoloring agent is Co2O3, and the dosage of the decoloring agent is 0.000005 to 0.00004 part by weight. The clarification process of the ultra white and thin electronic glass can be controlled by combination of the clarifying agent, glass liquid viscosity and the melting process atmosphere, and bubbles of the ultra white thin electronic glass can be reduced.

Owner:漳州旗滨光伏新能源科技有限公司

Air bath with bypass vent

ActiveUS20050273922A1Enhance bathing experienceReduce deliveryBathing devicesLight therapyLow speedBubble density

An air bath has air outlets extending around the side walls of the water basin. Air is delivered to the air outlets through a ring-like air manifold coupled to a blower by conduit. The conduit has a bypass vent that siphons off a portion of the air flow otherwise passing to the air outlets and maintains the blower in communication with ambient air. The air delivery system provides a wider range of bubble densities by allowing the blower to operate at lower speeds without overheating or stalling from back pressure arising from the pressure head of the water in the basin.

Owner:KOHLER CO

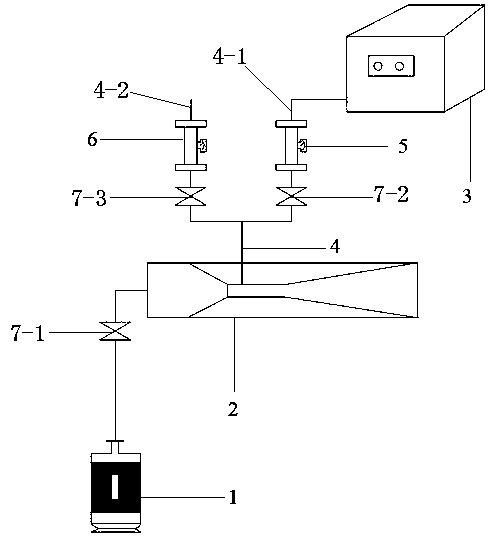

Dynamic adjustable river-lake oxygenation flow-pushing method and device

PendingCN109734204AQuick functionChange the black and smelly situationWater aerationSustainable biological treatmentMicro nanoThroat

The invention discloses a dynamic adjustable river-lake oxygenation flow-pushing method and device, and relates to the technical field of the river control. The device comprises a submersible sewage pump, an ejector, a micro-nano bubble generator, a throat hose, a fluid flowmeter, a gas flowmeter and solenoid valves. The submersible sewage pump is connected with the ejector through the first solenoid valve. The ejector is connected with the throat hose. The throat hose is further provided with a first branch pipe and a second branch pipe. The first branch pipe is connected with the micro-nanobubble generator. The second branch pipe is communicated with air. The first branch pipe is provided with the second solenoid valve and the fluid flowmeter which are successively connected. The fluidflowmeter is connected with the micro-nano bubble generator. The second branch pipe is provided with the third solenoid valve and the gas flowmeter which are successively connected. The gas flowmeteris communicated with the air. The device is capable of, according to dissolved oxygen concentration of rivers and lakes, dynamically adjusting a bubble density and a bubble size, changing the flow pushing effect of the device, thereby more effectively realizing an application in the river and lake treatment.

Owner:北京环域生态环保技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com