Production instrument for electric arc coating quartz glass crucible and manufacturing technique thereof

A quartz glass crucible and production equipment technology, which is applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problems that the purity and bubble density cannot meet the quality requirements of electronic-grade single crystal products

Inactive Publication Date: 2007-12-12

上海新沪玻璃有限公司

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, its purity and bubble density cannot meet the quality requirements for pulling electronic-grade single crystal products.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0022] The above embodiment of the present invention is a 12-inch to 16-inch arc-coated quartz glass crucible, the manufacturing process is basically the same, and the coating thickness of 0.5-0.8mm can be produced on the inner wall of the glass.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

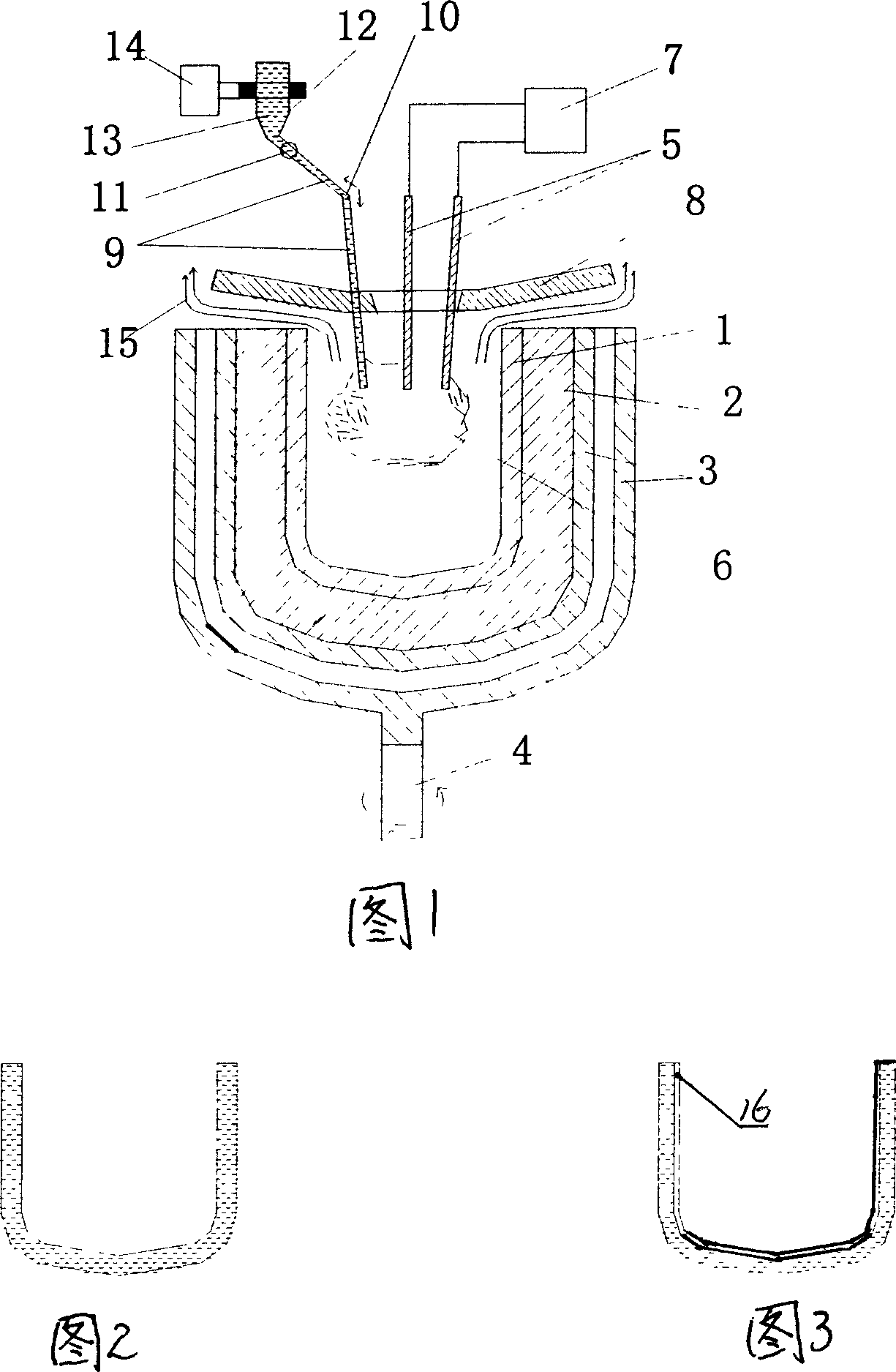

The invention discloses a device that can increase the inner wall purity and reduce inner wall bubble density for quartz pot, and the production process. It comprises graphite module, quartz feeding bar inside the graphite module, the quartz feeding bar is connected to feeding bottle, the middle part of quartz feeding bar is equipped with rotary joint, and the feeding bottle is provided with vibrating device. The invention employs adjustable electromagnetic vibration and moderates vibration by moderating current to ensure even distribution of high- purity crystal powder in pot, and makes crystal powder be sprayed to different positions in the internal wall of pot by adjusting the rotary joint.

Description

Technical field [0001] The invention relates to the production equipment and the production process of the arc-coated quartz glass crucible. Background technique [0002] At present, the general principle and method of arc quartz glass crucible production: add crystal powder into a high-speed rotating mold, rely on centrifugal force to make the crystal powder adhere to the inner wall of the mold, and make the shape of the crystal powder meet the process requirements after shaping. The crystal powder is then melted into glass by indirect heating with an electric arc. However, its purity and bubble density cannot meet the quality requirements for pulling electronic-grade single crystal products. Contents of the invention [0003] The purpose of the present invention is to provide the production equipment and the manufacturing process of the arc quartz glass crucible which can improve the purity of the inner wall of the quartz glass crucible and reduce the density of bubbles...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03B20/00C03B5/06C03B19/01

CPCC03B19/095

Inventor 王龙森朱锡剑赵庆良王和平

Owner 上海新沪玻璃有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com