Preparation method of supercritical micro-foaming high-light plastic and plastic-based composite material and supercritical micro-foaming high-light plastic or plastic-based composite material prepared through preparation method

A composite material and plastic-based technology, applied in the field of polymer material preparation, can solve problems such as difficult control, reduced bubble density and uniformity, roughness, etc., and achieve simple operation and process control, controllable density, and small cells Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

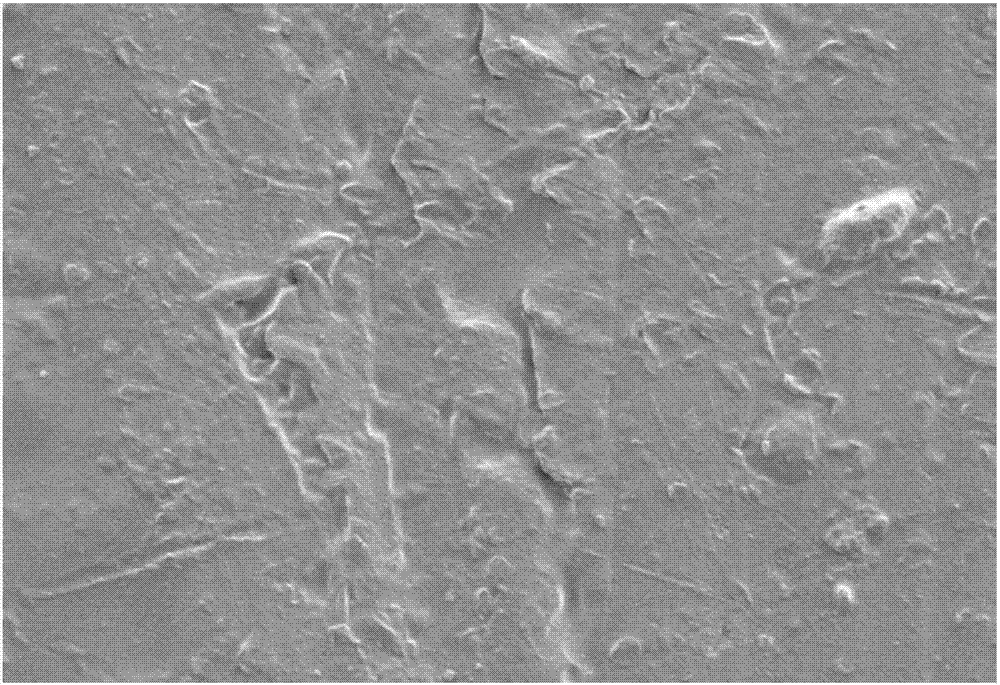

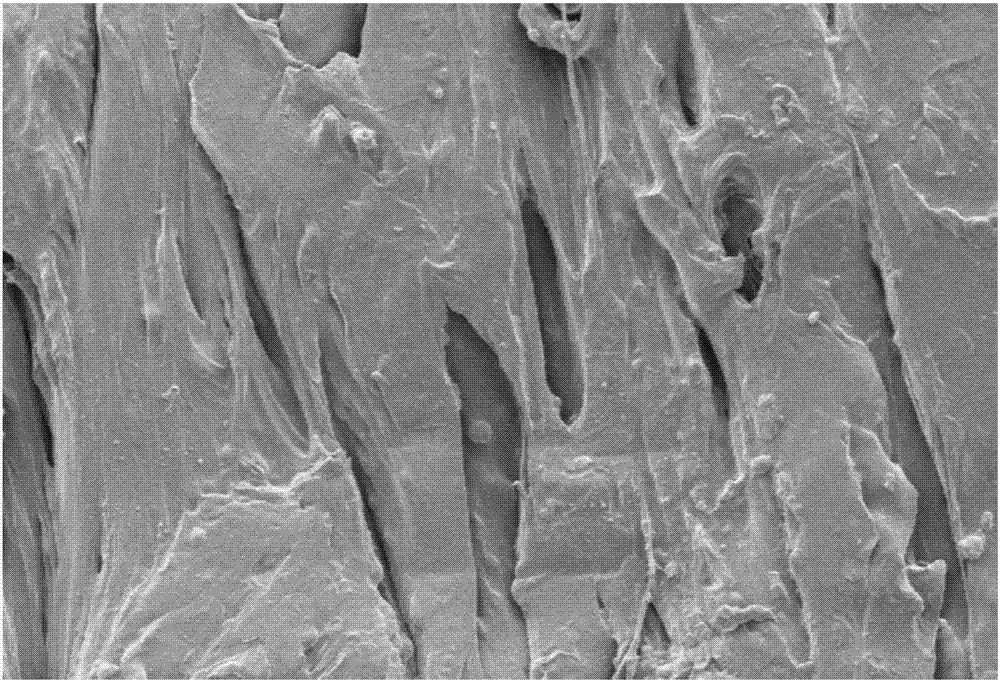

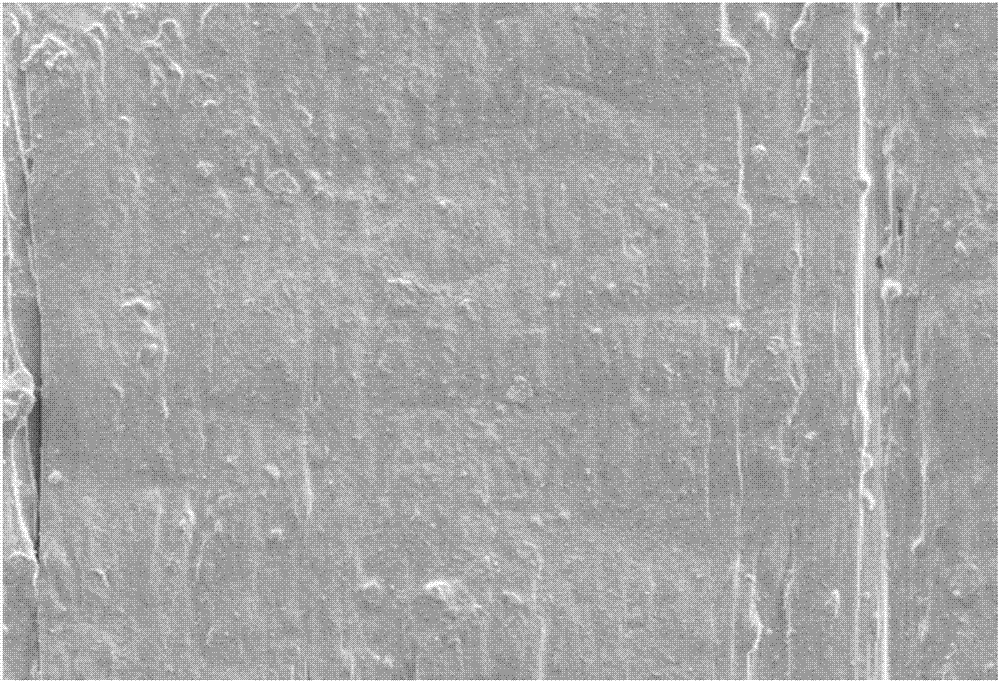

Image

Examples

Embodiment 1

[0039] A method for preparing supercritical micro-foaming high-gloss plastics and plastic-based composite materials, comprising the following steps:

[0040] (1) Preparation of hot-melt adhesive: Polypropylene is heated to melt, and under the action of screw shear, the hot-melt adhesive is formed through plasticization, melting and homogenization;

[0041] (2) Preparation of a single-phase melt: at the end of the screw, inject supercritical foaming gas nitrogen to dissolve it into the hot melt adhesive obtained in step (1) to form a single-phase melt;

[0042] (3) Injection molding: quickly inject the single-phase melt obtained in step (2) into the injection mold with high-temperature steam, the temperature of the high-temperature steam is 30°C higher than that of the single-phase melt obtained in step (2), and the injection The temperature of model is identical with the temperature of the single-phase melt that step (2) obtains;

[0043] (4) Cooling molding: After the inject...

Embodiment 2

[0047] A method for preparing supercritical micro-foaming high-gloss plastics and plastic-based composite materials, comprising the following steps:

[0048] (1) Preparation of hot-melt adhesive: heat polyvinyl chloride to melt, and under the shear action of the screw, form hot-melt adhesive through plasticization, melting and homogenization reactions;

[0049] (2) Preparation of a single-phase melt: at the end of the screw, inject supercritical foaming gas carbon dioxide gas to dissolve it into the hot melt adhesive obtained in step (1) to form a single-phase melt;

[0050] (3) Injection molding: quickly inject the single-phase melt obtained in step (2) into the injection mold with high-temperature steam, the temperature of the high-temperature steam is 15°C higher than that of the single-phase melt obtained in step (2), and the injection The temperature of model is identical with the temperature of the single-phase melt that step (2) obtains;

[0051] (4) Cooling molding: A...

Embodiment 3

[0055] A method for preparing supercritical micro-foaming high-gloss plastics and plastic-based composite materials, comprising the following steps:

[0056] (1) Preparation of hot melt adhesive: the composite material of polyphenylene sulfide and titanium dioxide is heated to melting, and under the shearing action of the screw, the hot melt adhesive is formed through plasticization, melting and homogenization;

[0057] (2) Preparation of single-phase melt: At the end of the screw, inject a mixture of supercritical foaming gas nitrogen and carbon dioxide gas to dissolve it into the hot melt adhesive obtained in step (1) to form a single-phase melt ;

[0058] (3) Injection molding: quickly inject the single-phase melt obtained in step (2) into the injection mold with high-temperature steam, the temperature of the high-temperature steam is 45°C higher than that of the single-phase melt obtained in step (2), and the injection The temperature of model is identical with the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com