Patents

Literature

140results about How to "Control dose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

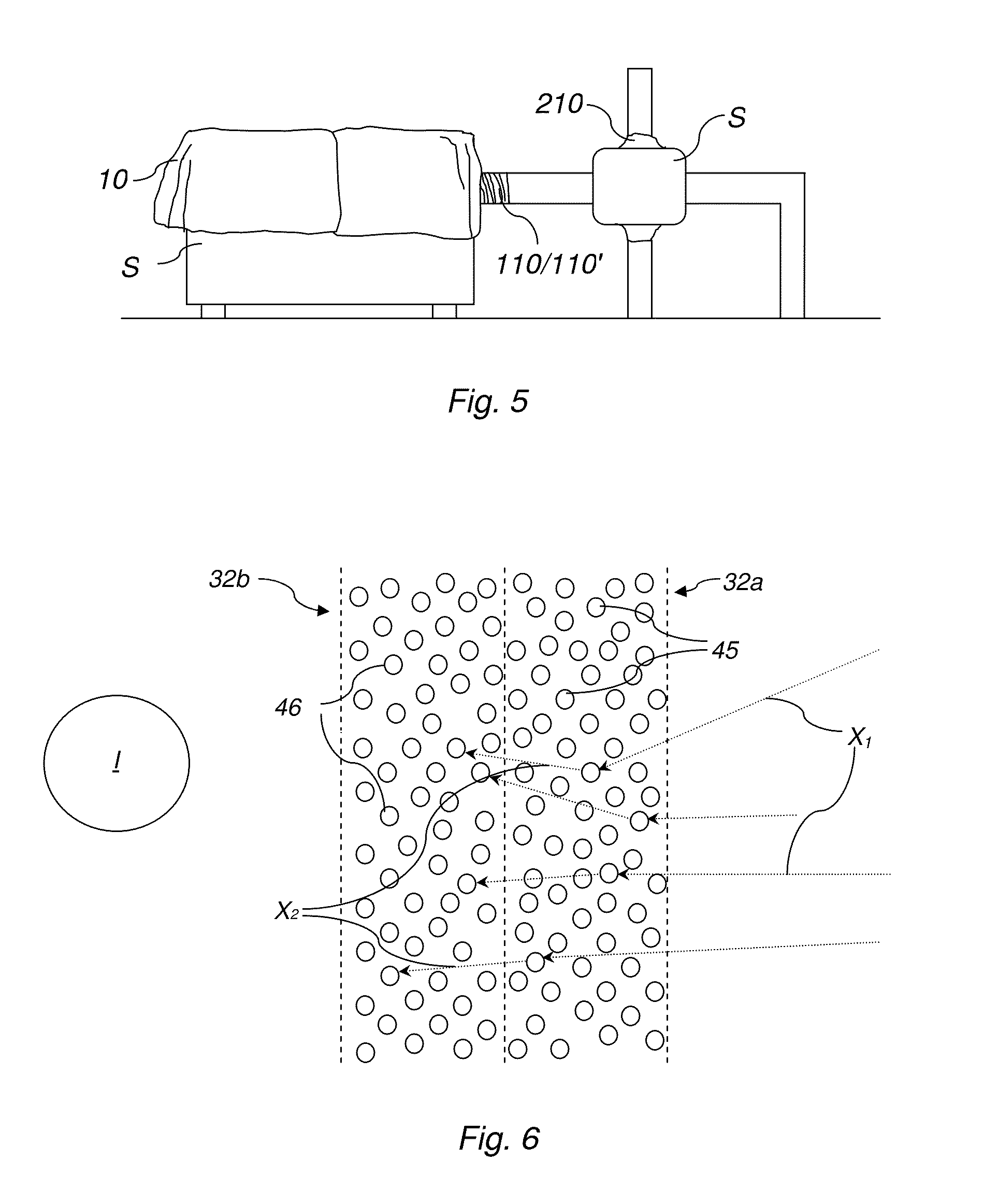

External addition of pulses to fluid channels of body to release or suppress endothelial mediators and to determine effectiveness of such intervention

InactiveUS7090648B2Easy to adjustHigh expressionElectrotherapyPneumatic massageShear stressReciprocating motion

Methods of medical treatment and diagnosis using mediators released by endothelial cells stimulated by external addition of pulses to the circulation are disclosed. The external pulses produce circumferential shear stress in body fluid channels that subsequently stimulates the endothelial cells to produce mediators that become available for therapeutic and diagnostic purposes. The preferred means of adding external pulses is the mechanical inducement of periodic acceleration of the body or parts of the body by a reciprocating motion platform.

Owner:NON INVASIVE MONITORING SYST INC

External addition of pulses to fluid channels of body to release or suppress endothelial mediators and to determine effectiveness of such intervention

ActiveUS20020103454A1Regulates the endothelial releaseImprove bioavailabilityElectrotherapyPneumatic massageShear stressReciprocating motion

Methods of medical treatment and diagnosis using mediators released by endothelial cells stimulated by external addition of pulses to the circulation are disclosed. The external pulses produce circumferential shear stress in body fluid channels that subsequently stimulates the endothelial cells to produce mediators that become available for therapeutic and diagnostic purposes. The preferred means of adding external pulses is the mechanical inducement of periodic acceleration of the body or parts of the body by a reciprocating motion platform.

Owner:NON INVASIVE MONITORING SYST INC

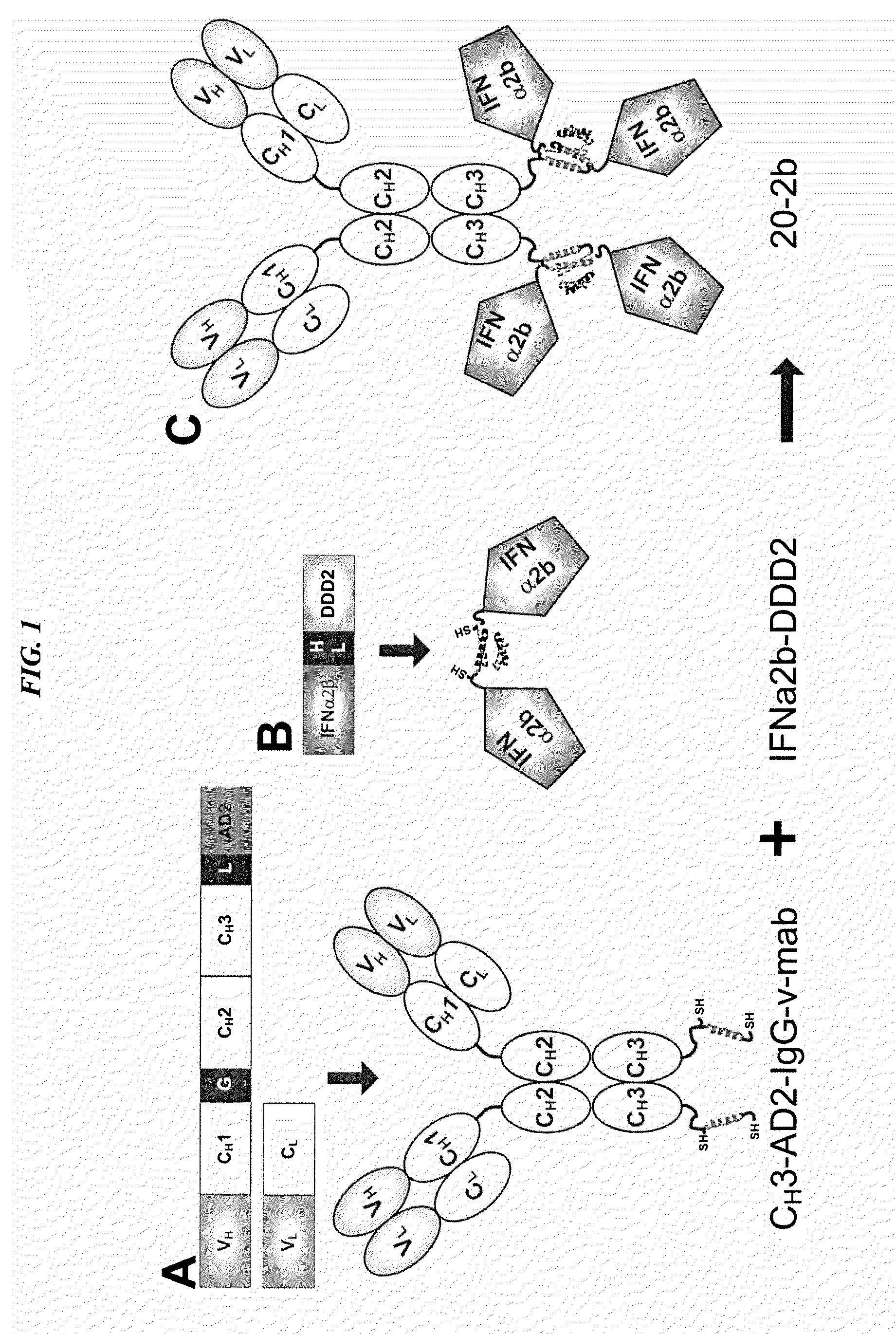

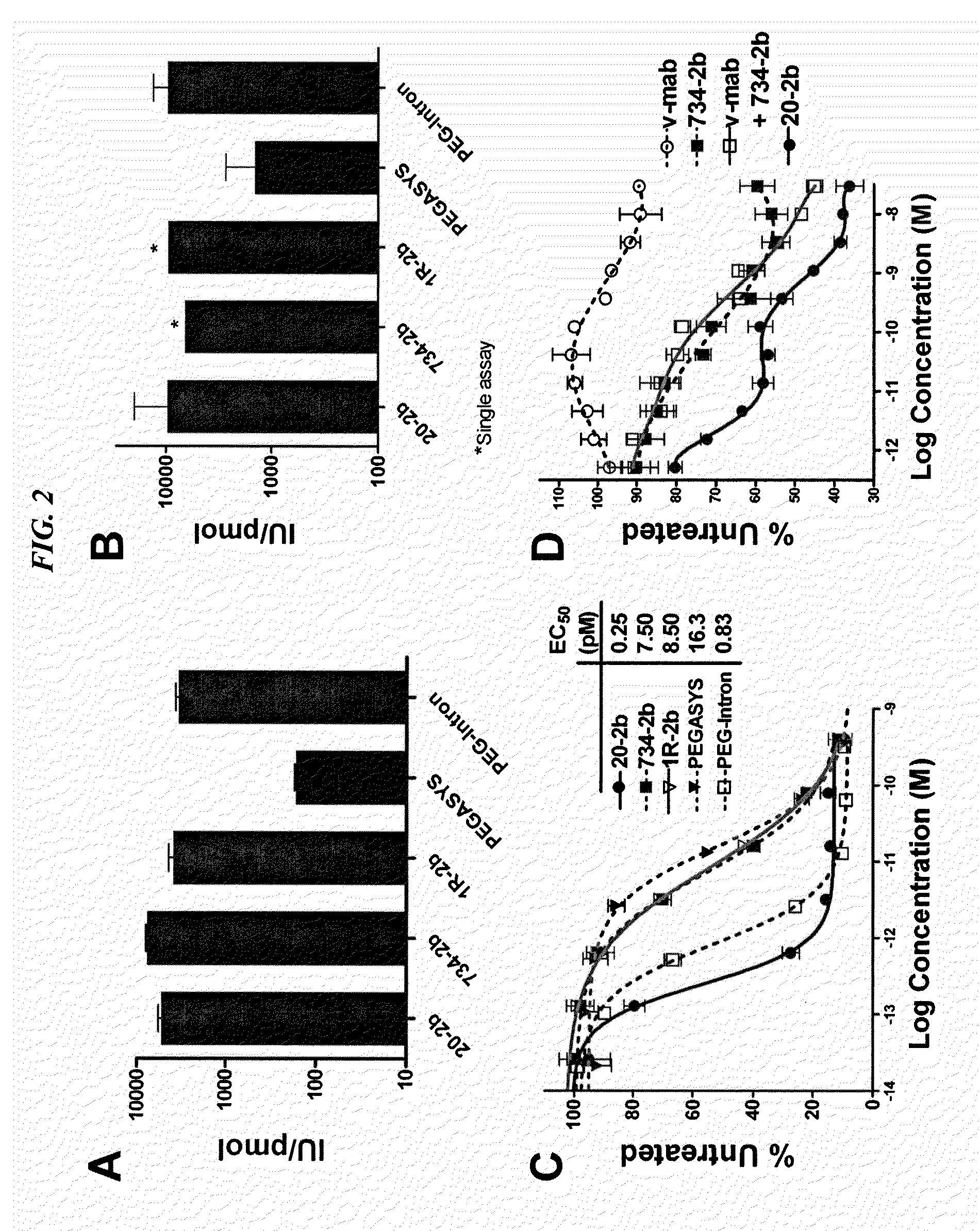

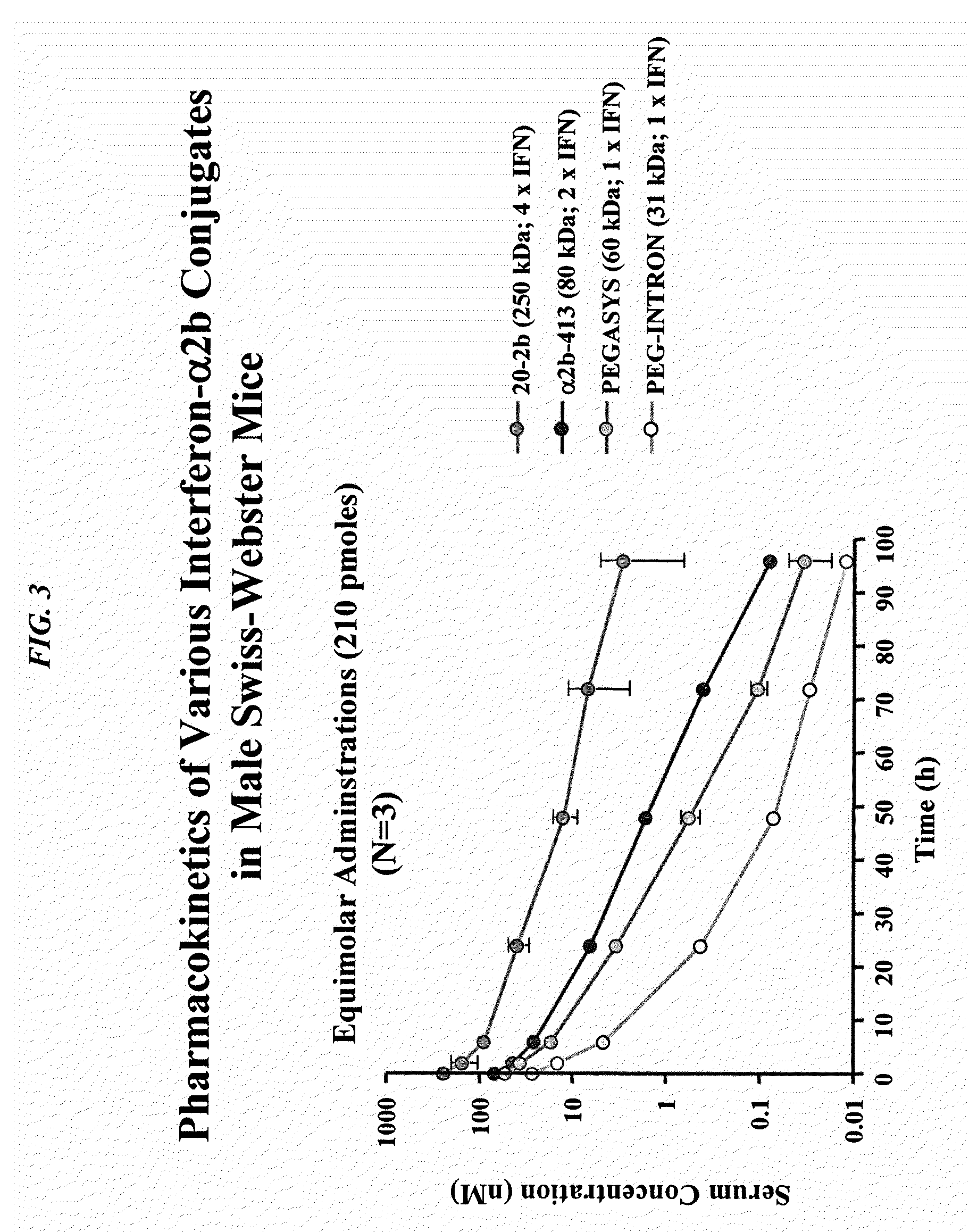

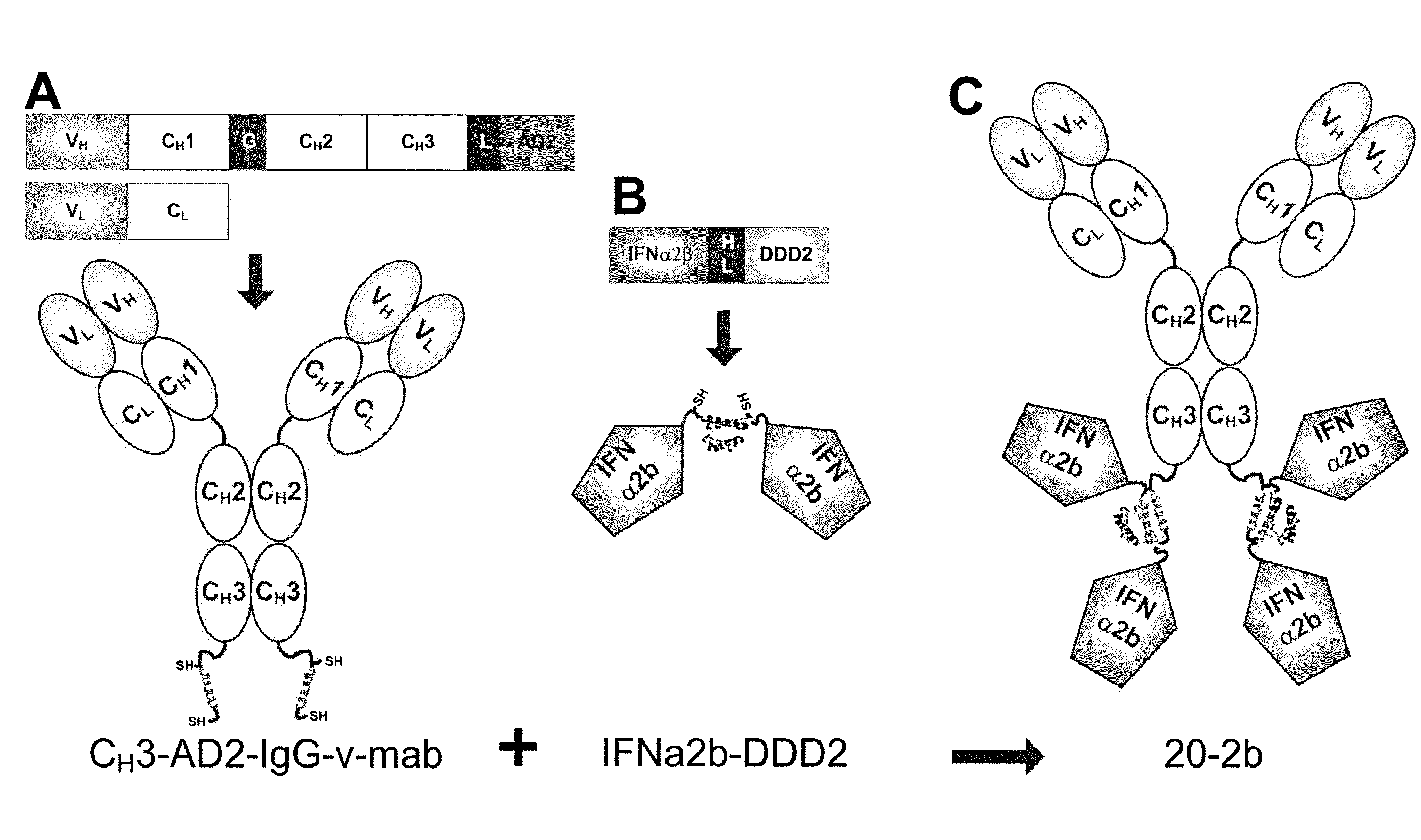

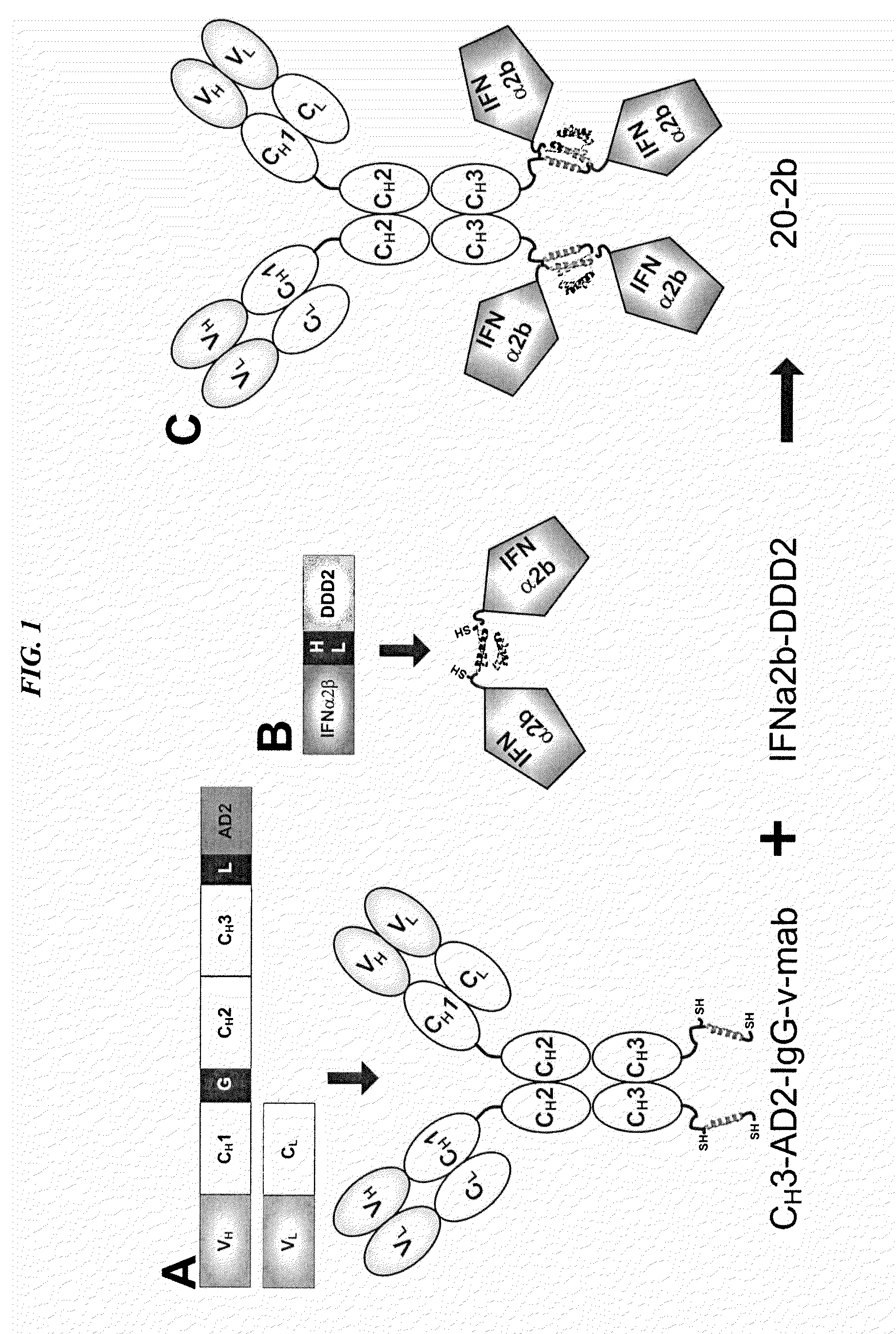

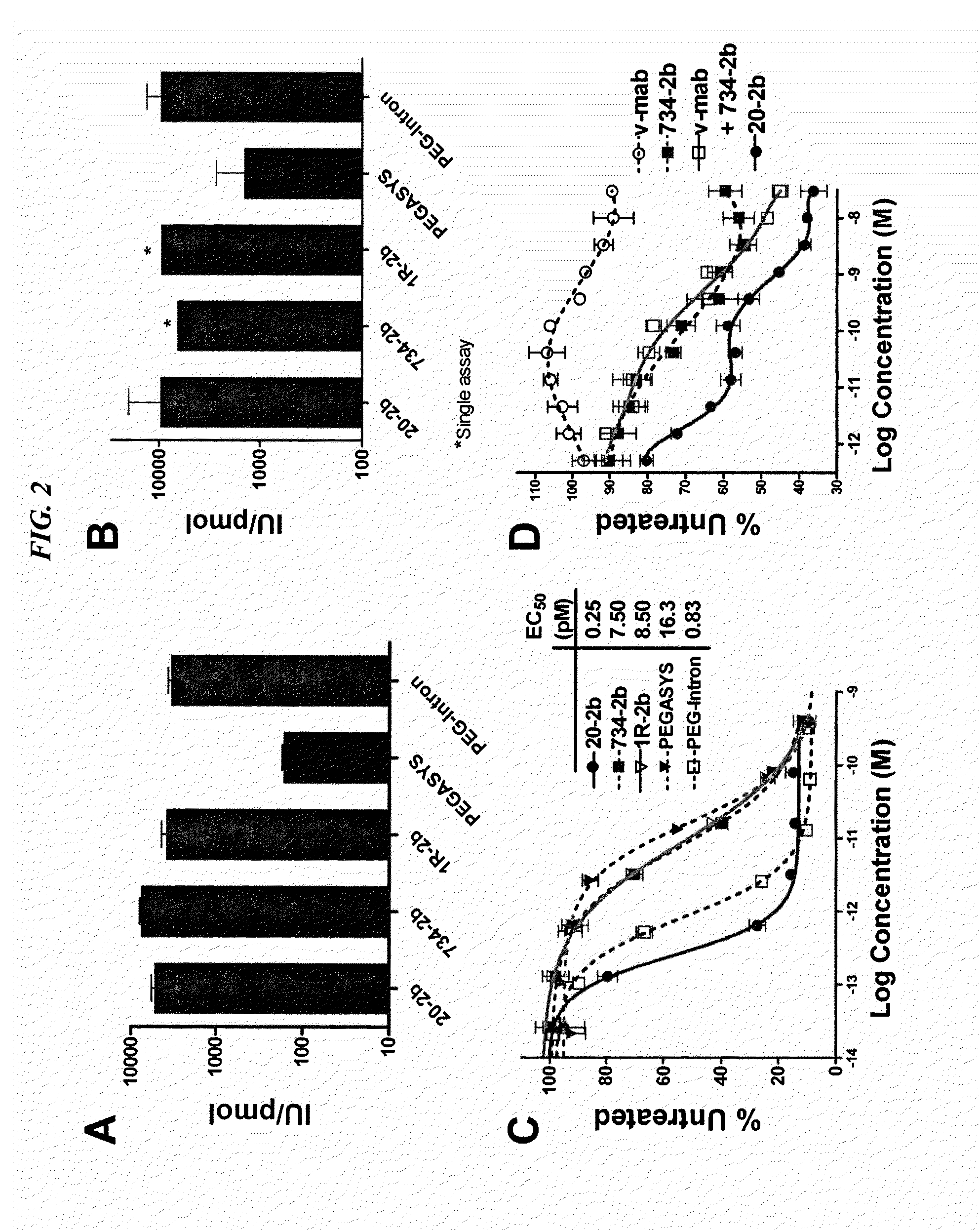

Tetrameric cytokines with improved biological activity

ActiveUS8034352B2Keep for a long timeLow toxicityMaterial nanotechnologyPeptide/protein ingredientsSerum igeHalf-life

The present invention concerns methods and compositions for forming cytokine-antibody complexes using dock-and-lock technology. In preferred embodiments, the cytokine-MAb DNL complex comprises an IgG antibody attached to two AD (anchor domain) moieties and four cytokines, each attached to a DDD (docking and dimerization domain) moiety. The DDD moieties form dimers that bind to the AD moieties, resulting in a 2:1 ratio of DDD to AD. The cytokine-MAb complex exhibits improved pharmacokinetics, with a significantly longer serum half-life than either naked cytokine or PEGylated cytokine. The cytokine-MAb complex also exhibits significantly improved in vitro and in vivo efficacy compared to cytokine alone, antibody alone, unconjugated cytokine plus antibody or cytokine-MAb DNL complexes incorporating an irrelevant antibody. In more preferred embodiment the cytokine is G-CSF, erythropoietin or INF-α2b.

Owner:IBC PHARMACEUTICALS INC

Tetrameric Cytokines with Improved Biological Activity

ActiveUS20100189689A1Low toxicityLong infusion timeMaterial nanotechnologyPeptide/protein ingredientsChemistryHalf-life

The present invention concerns methods and compositions for forming cytokine-antibody complexes using dock-and-lock technology. In preferred embodiments, the cytokine-MAb DNL complex comprises an IgG antibody attached to two AD (anchor domain) moieties and four cytokines, each attached to a DDD (docking and dimerization domain) moiety. The DDD moieties form dimers that bind to the AD moieties, resulting in a 2:1 ratio of DDD to AD. The cytokine-MAb complex exhibits improved pharmacokinetics, with a significantly longer serum half-life than either naked cytokine or PEGylated cytokine. The cytokine-MAb complex also exhibits significantly improved in vitro and in vivo efficacy compared to cytokine alone, antibody alone, unconjugated cytokine plus antibody or cytokine-MAb DNL complexes incorporating an irrelevant antibody. In more preferred embodiment the cytokine is G-CSF, erythropoietin or INF-α2b.

Owner:IBC PHARMACEUTICALS INC

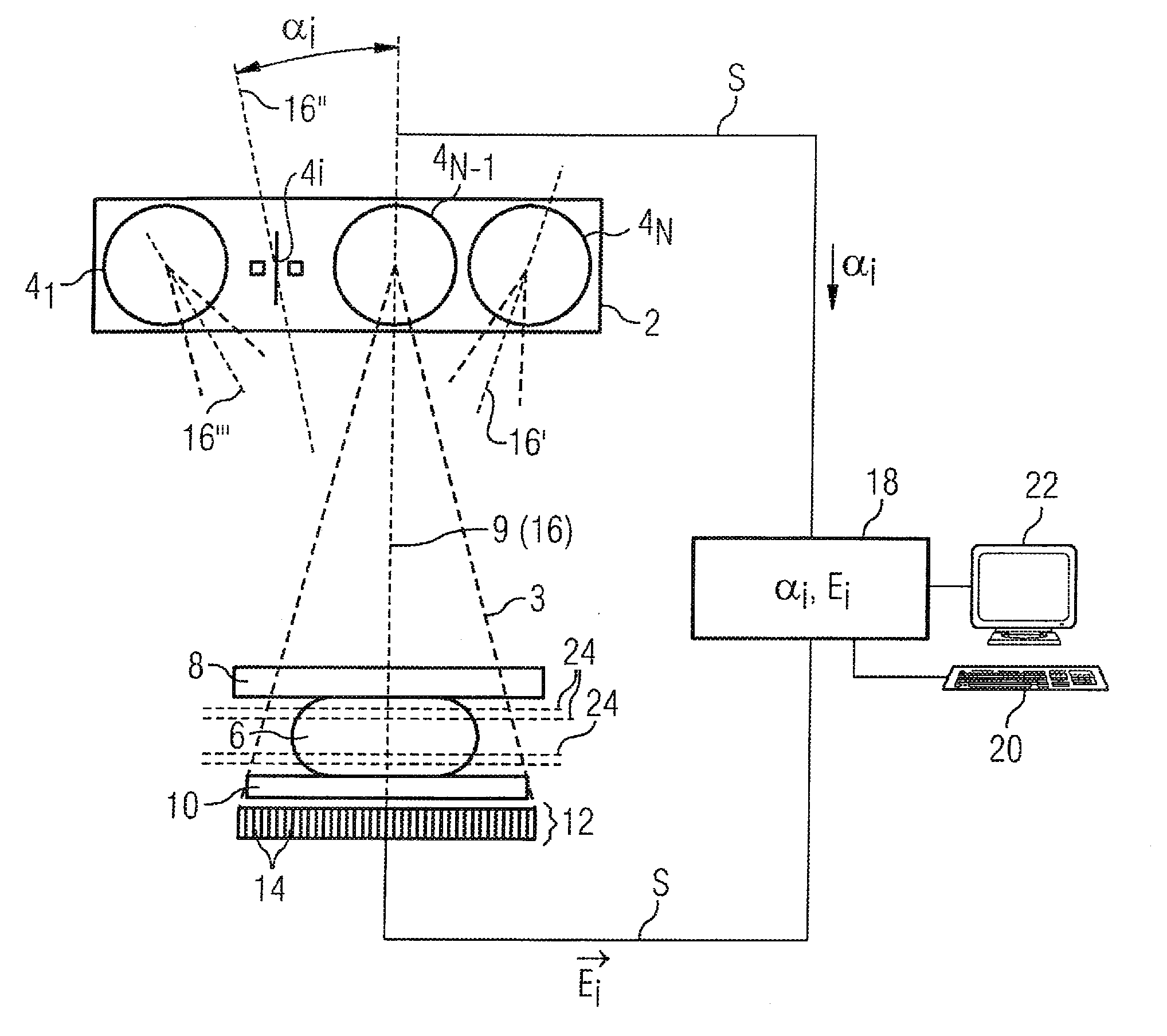

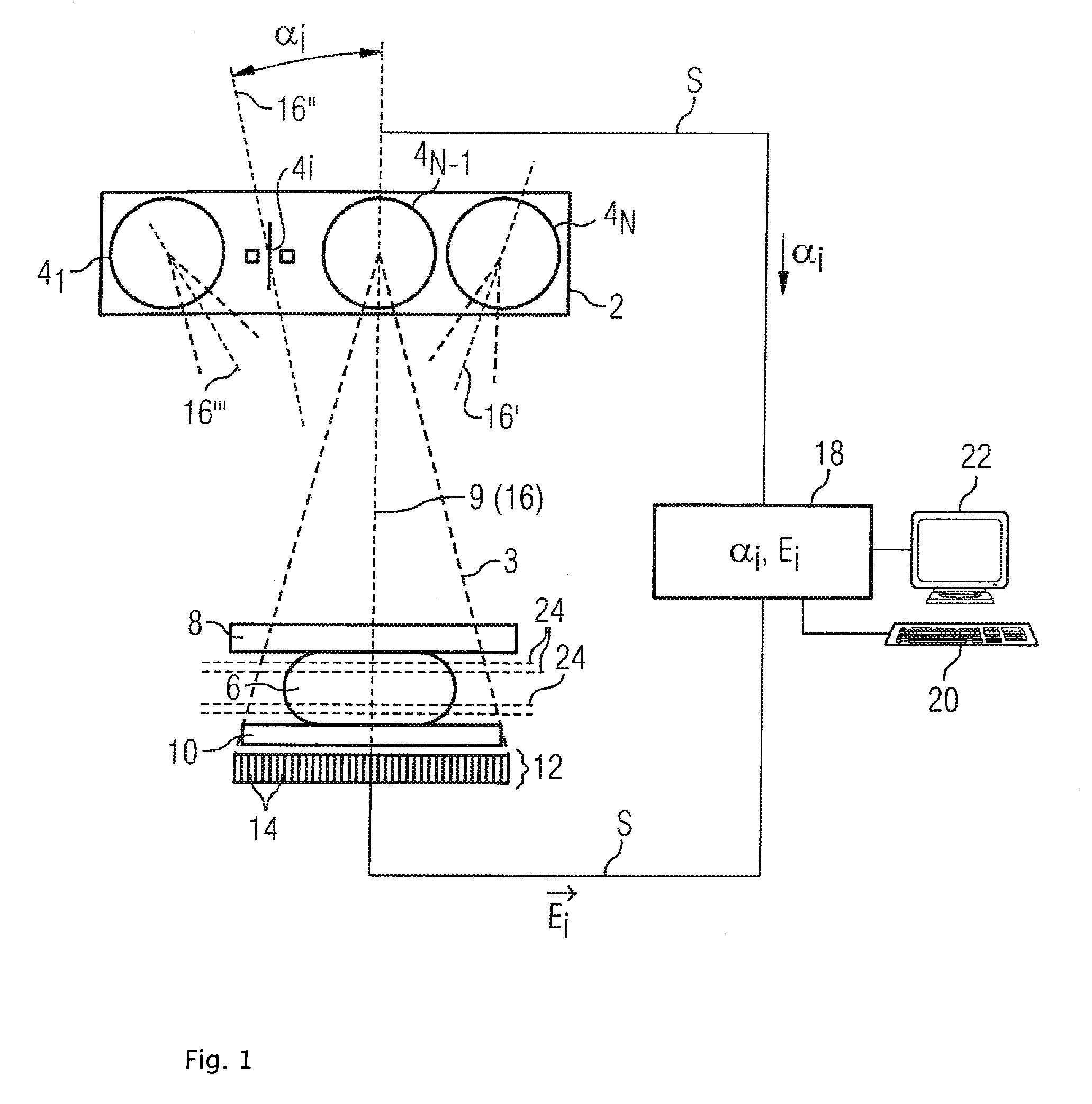

Method and device for producing a tomosynthetic 3D x-ray image

InactiveUS20100034450A1Increase doseLarge doseMaterial analysis using wave/particle radiationRadiation/particle handlingProjection image3d image

In a method and device for producing a tomosynthetic 3D x-ray image, a number of 2D projection images of an examination subject are acquired using a fixed x-ray source. The x-ray source has multiple, individually controllable emitters that respectively emit a single x-ray dose from various different directions. The tomosynthetic 3D image is reconstructed from the individual 2D projection images, and at least one 2D projection image is composed of multiple individual images.

Owner:SIEMENS AG

Percutaneous absorption preparation for treating ophthalmic disease, use thereof and method for migration of ophthalmic remedy into topical tissue in eye

InactiveUS20060036220A1Efficacy can be sustainedly developedCan be sustainedly developedSenses disorderAntipyreticDiseaseEyelid

A transdermal drug delivery system for treatment of ophthalmic diseases comprising a structure that a plaster layer containing a remedy for ophthalmic diseases is provided on a support, wherein the system is applied to a skin surface including a front surface of an eyelid to administer the remedy for ophthalmic diseases in the plaster layer to an ophthalmic topical tissue by percutaneous permeation substantially without being administered through a systemic blood flow. Use of the transdermal drug delivery system for treatment of ophthalmic diseases, comprising applying the transdermal drug delivery system to a skin surface including a front surface of an eyelid to transfer the remedy for ophthalmic diseases in the plaster layer to an ophthalmic topical tissue by percutaneous permeation substantially without being administered through a systemic blood flow, and a method for transferring the remedy for ophthalmic diseases to the ophthalmic topical tissue.

Owner:SENJU PHARMA CO LTD

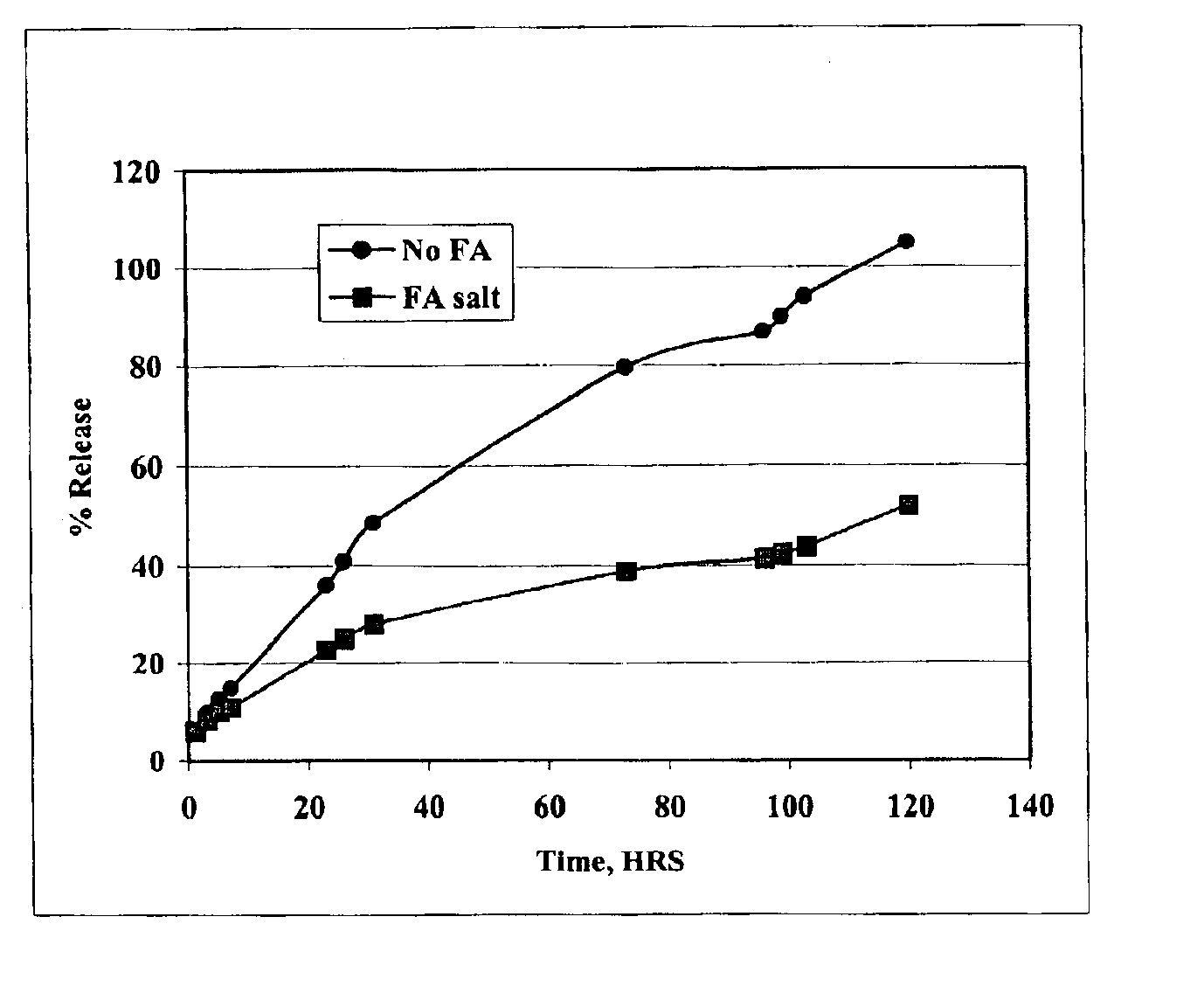

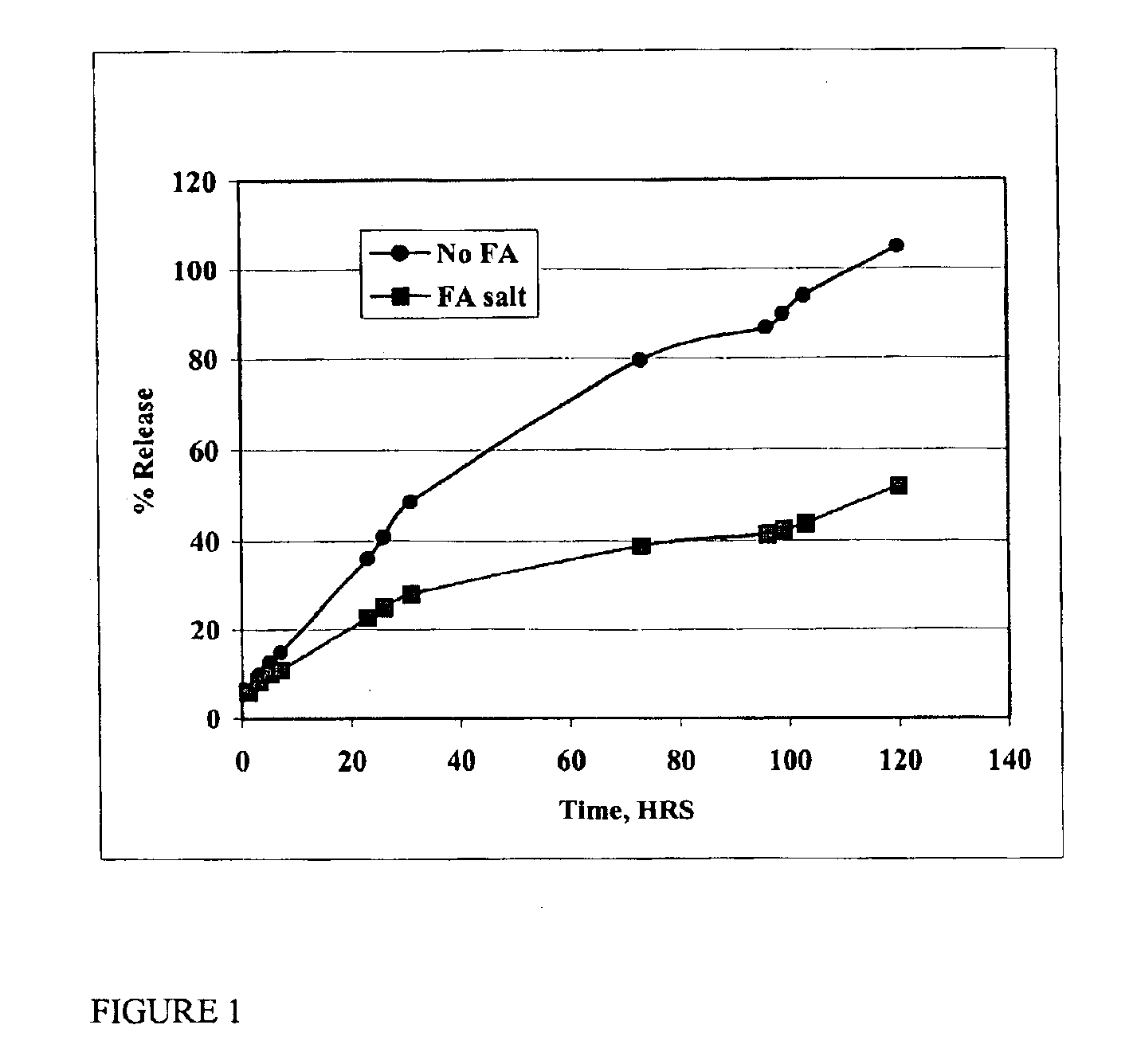

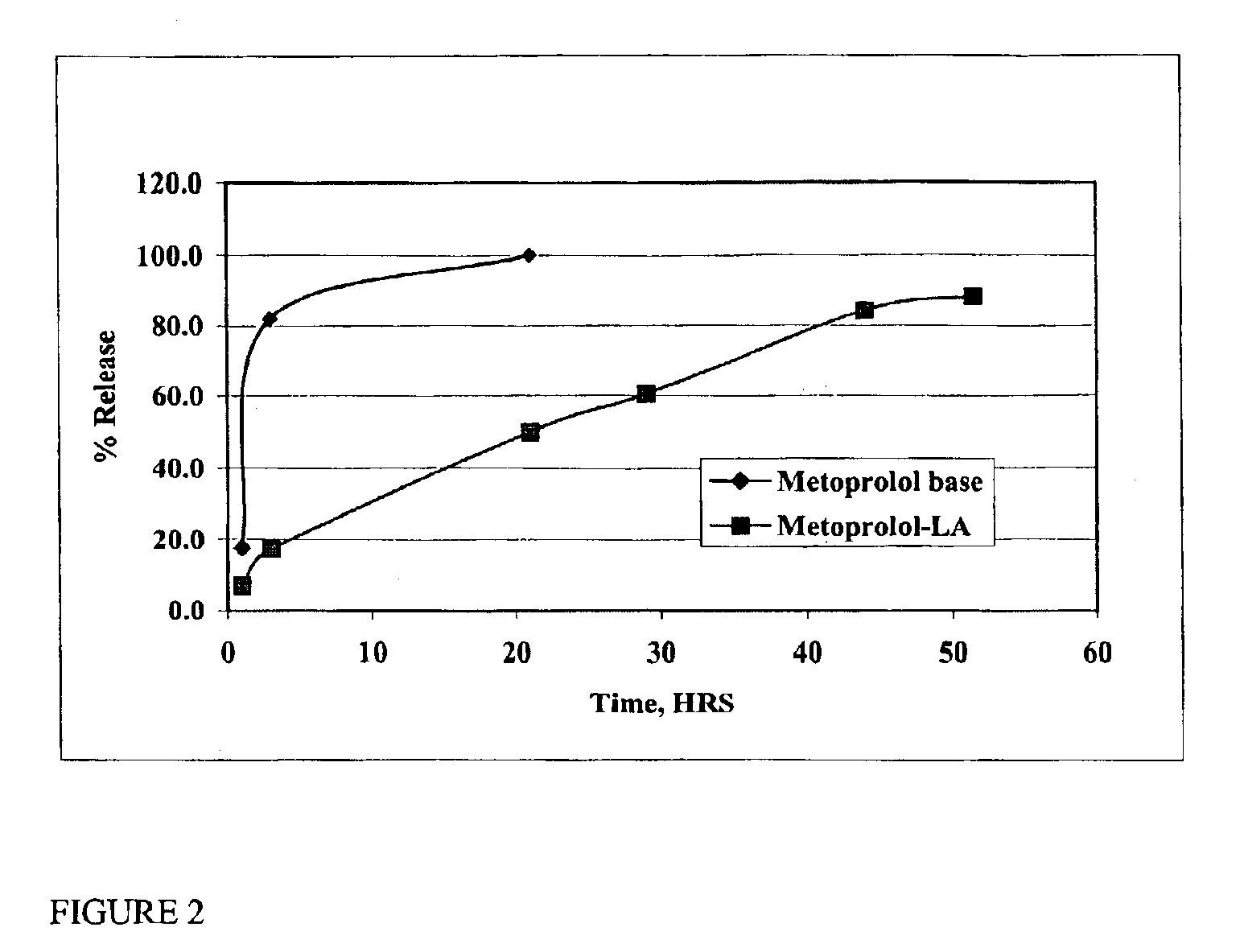

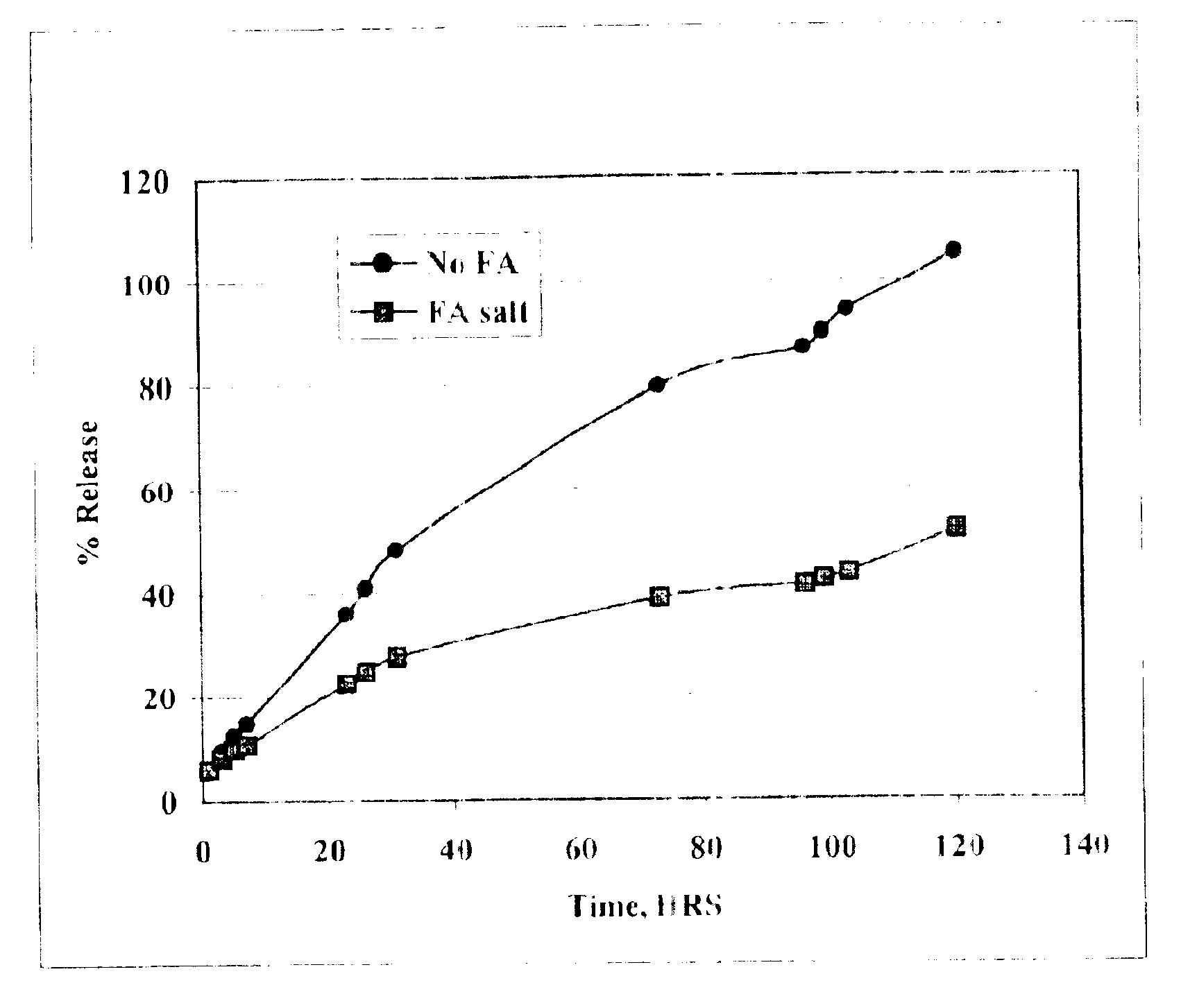

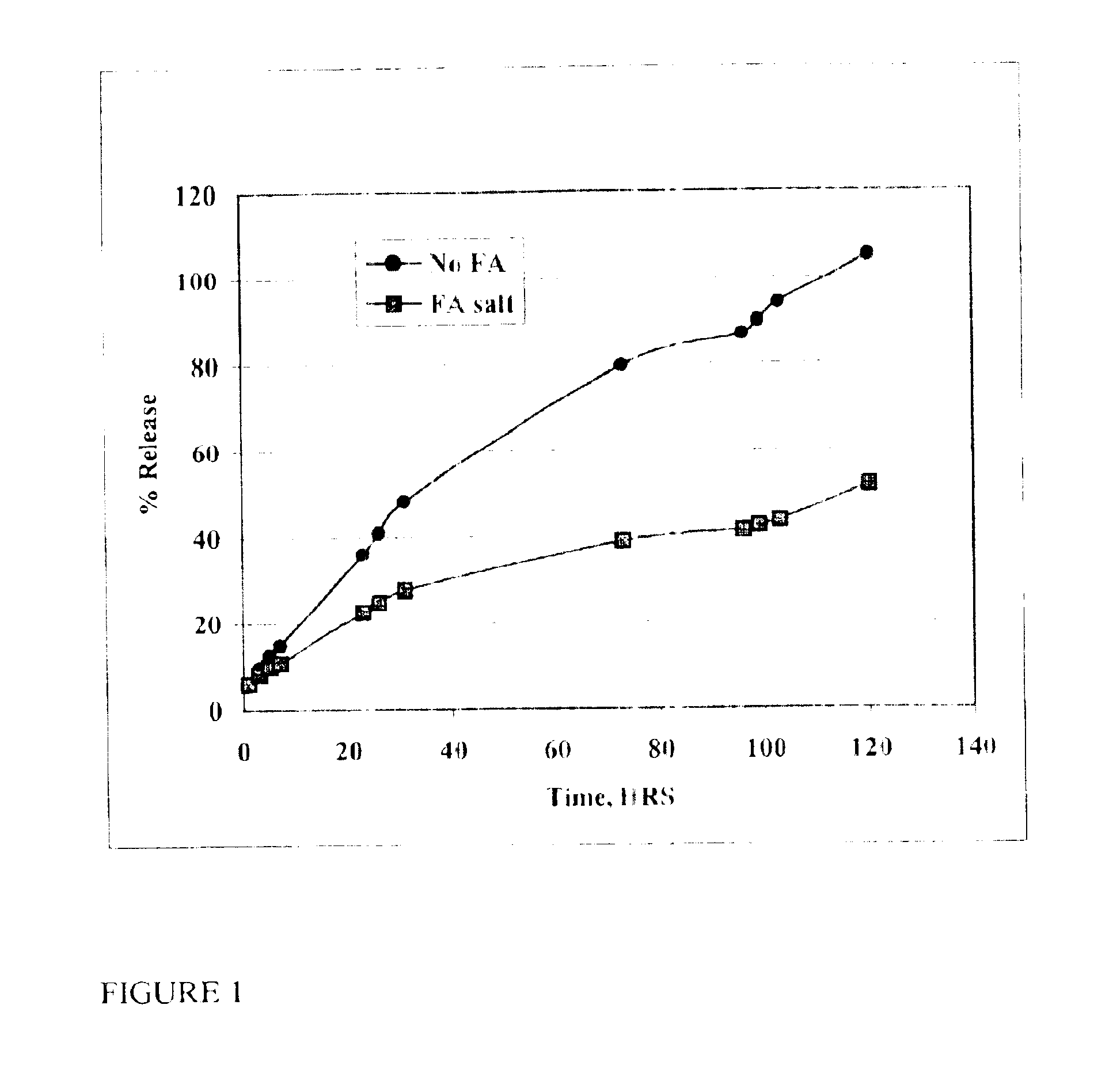

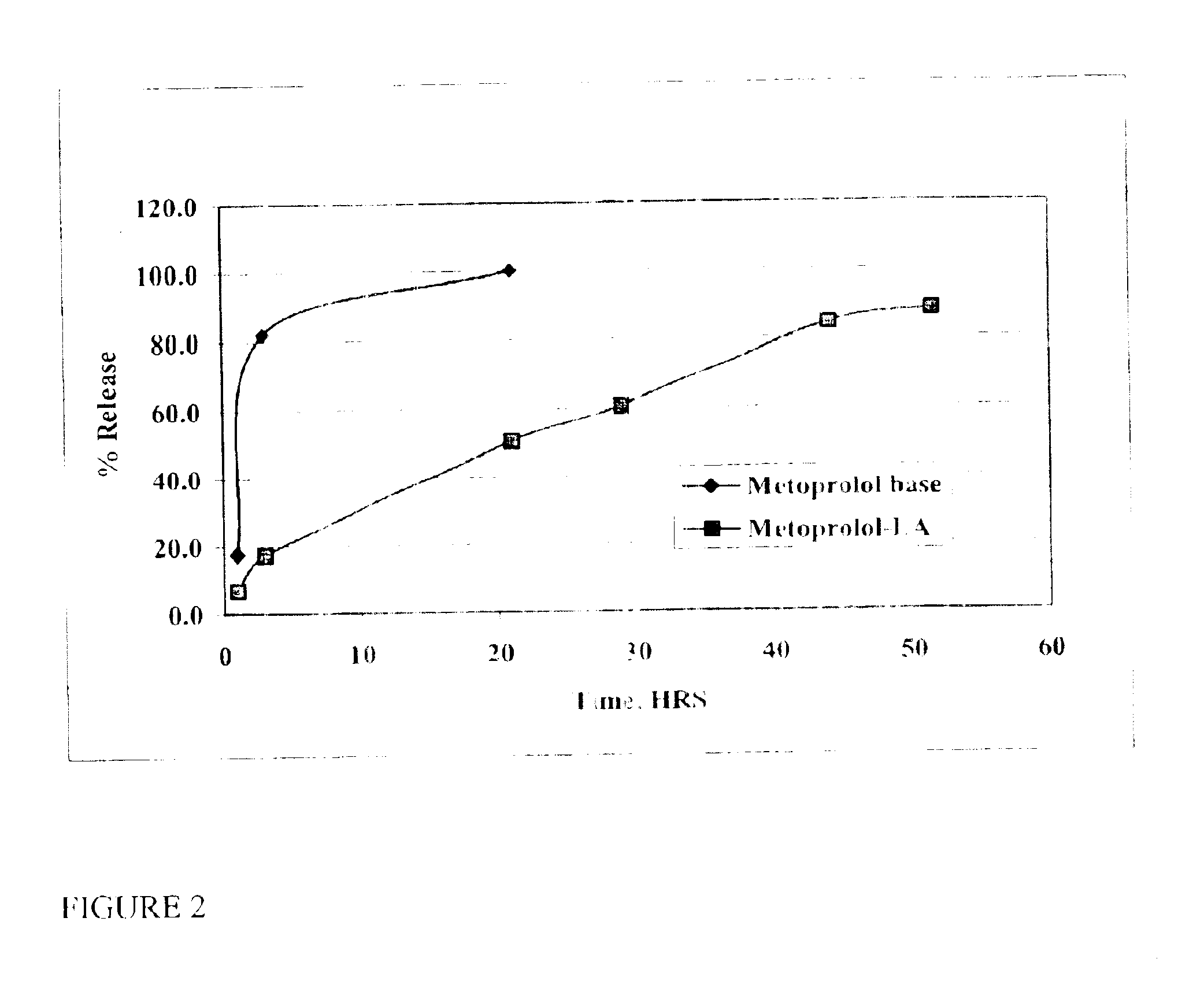

Injectable compositions for the controlled delivery of pharmacologically active compound

InactiveUS6887487B2Extend posting timeControl doseAntibacterial agentsBiocideRoxithromycinRelease time

The present invention provides compositions and methods for extending the release times and lowering the toxicity of pharmacologically active compounds. The compounds comprise a salt of the pharmacologically active compound with a lipophilic counterion and a pharmaceutically acceptable water soluble solvent combined together to form an injectable composition. The lipophilic counterion may be a saturated or unsaturated C8-C22 fatty acid, and preferably may be a saturated or unsaturated C10-C18 fatty acid. When injected into a mammal, at least a portion of the composition precipitates and releases the active compound over time. Thus, the composition forms a slowly releasing drug depot of the active compound in the mammal. Therefore, the present invention enables one to provide a controlled dose administration of the active compound for a periods of up to 15 days or even longer. Many compounds can be administered according to the present invention including, but not limited to, tilmicosin, oxytetracycline, metoprolol, fluoxetine, roxithromycin, and turbinafine.

Owner:IDEXX LABORATORIES

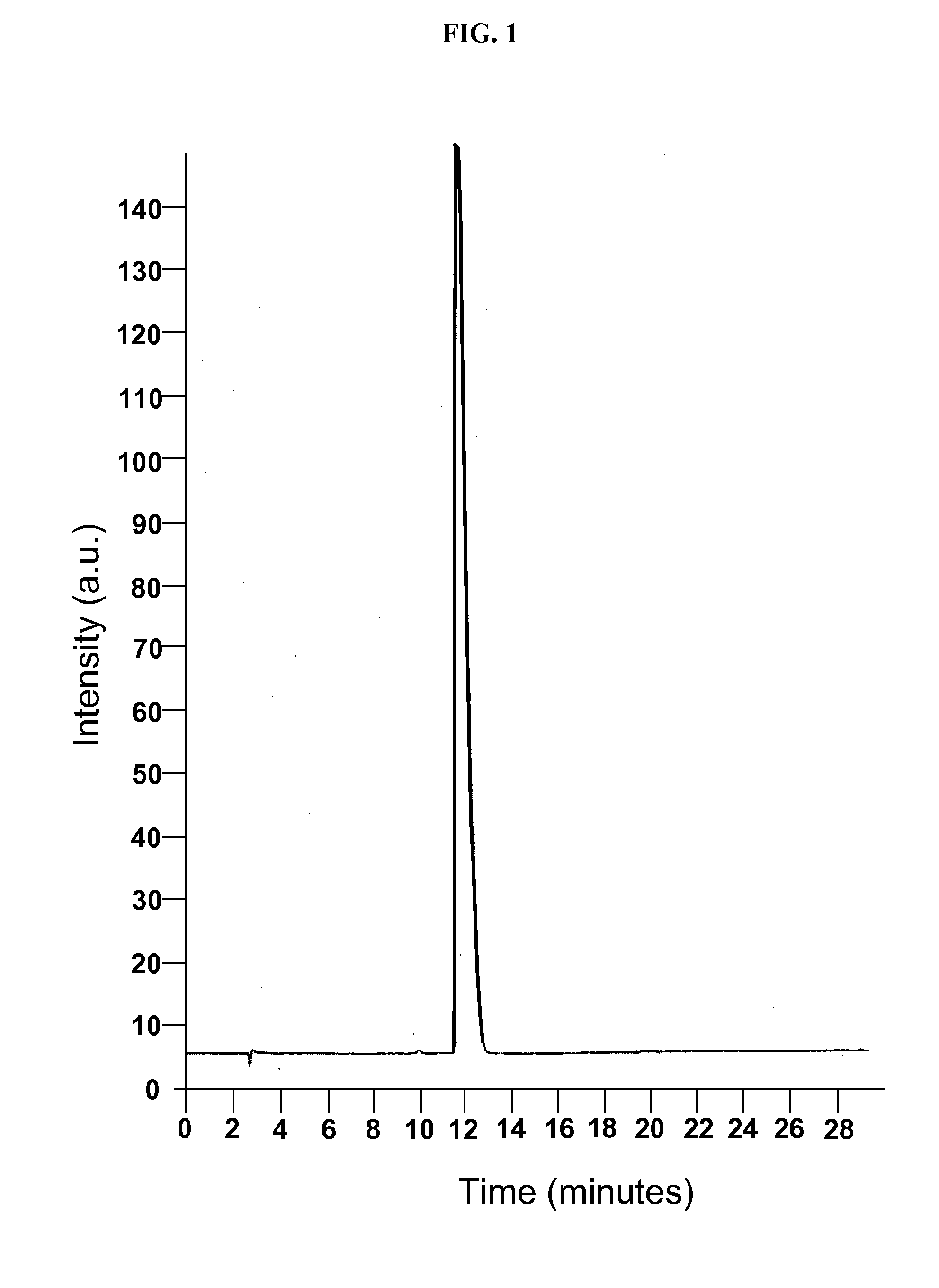

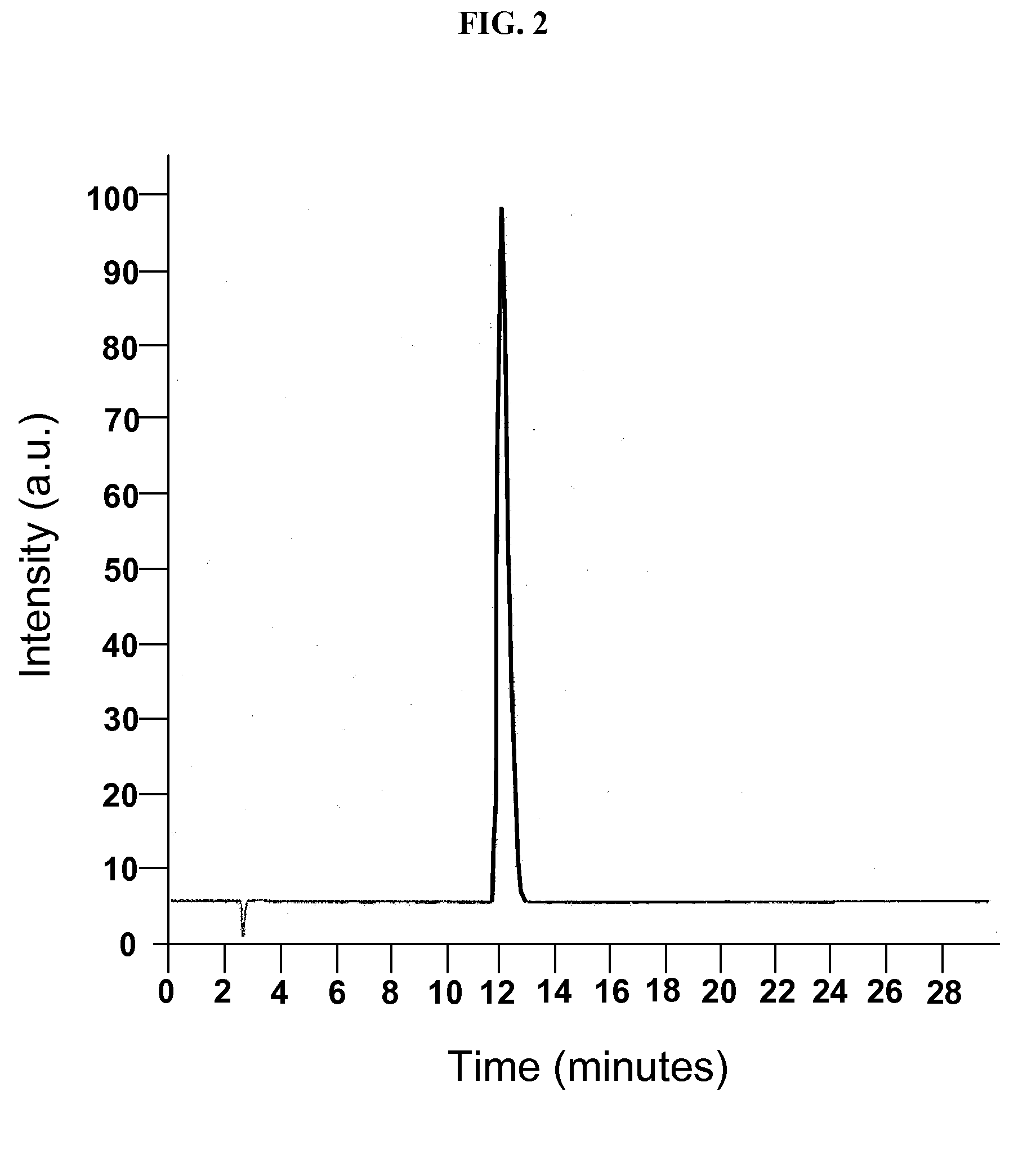

Topiramate Compositions and Methods of Making and Using the Same

The present invention is directed to compositions comprising topiramate and a sulfoalkyl ether cyclodextrin, and methods of making and using the same.

Owner:RGT UNIV OF MINNESOTA

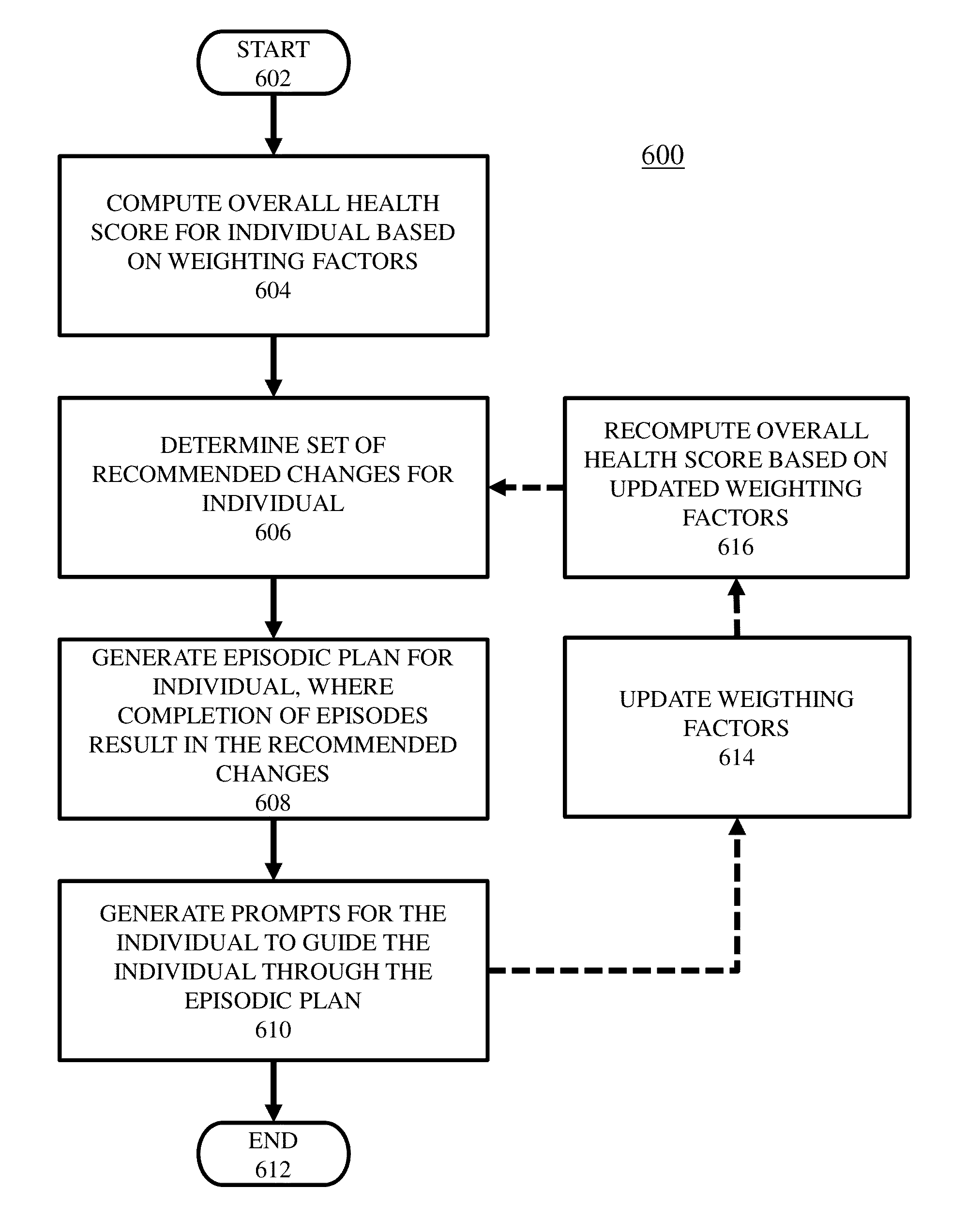

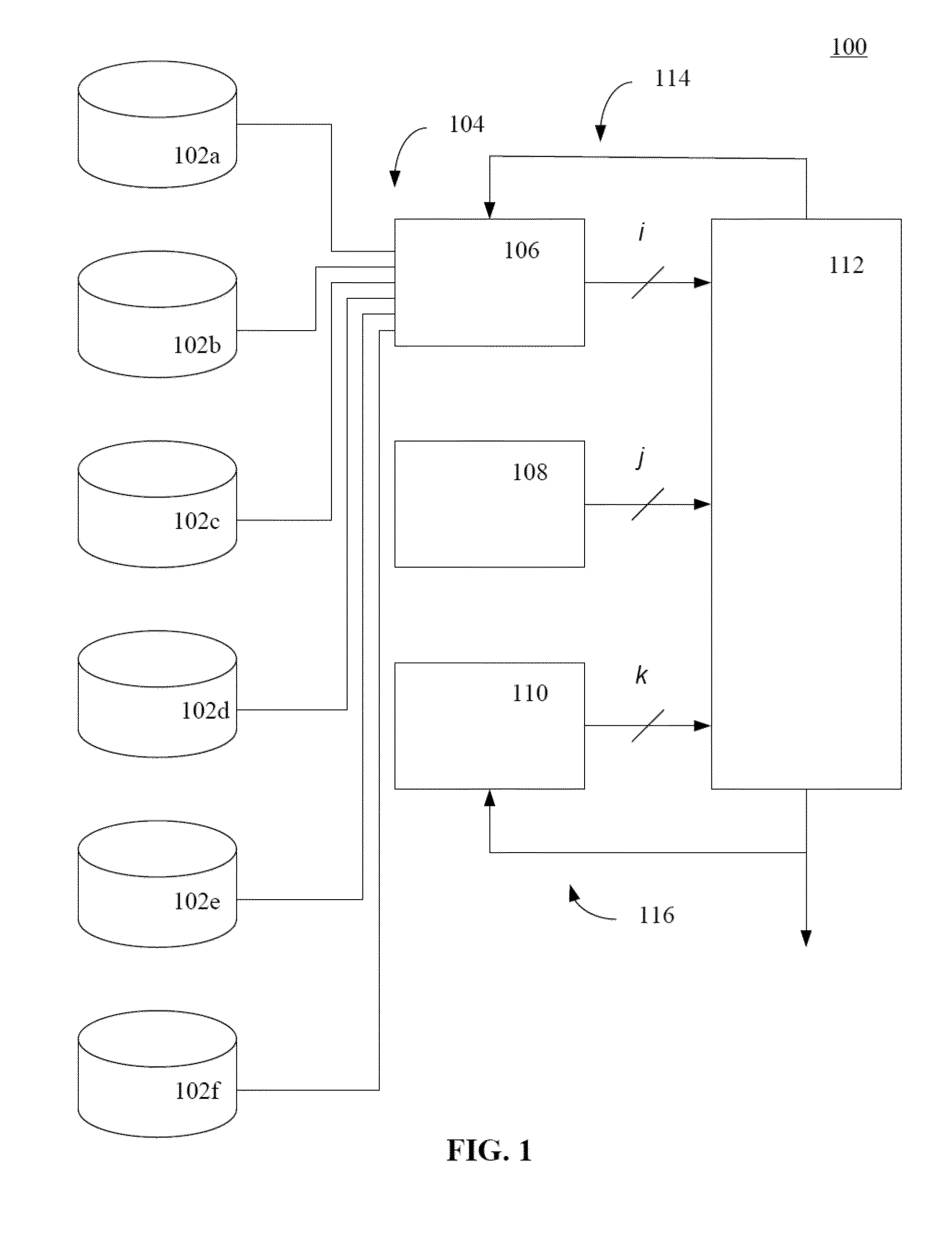

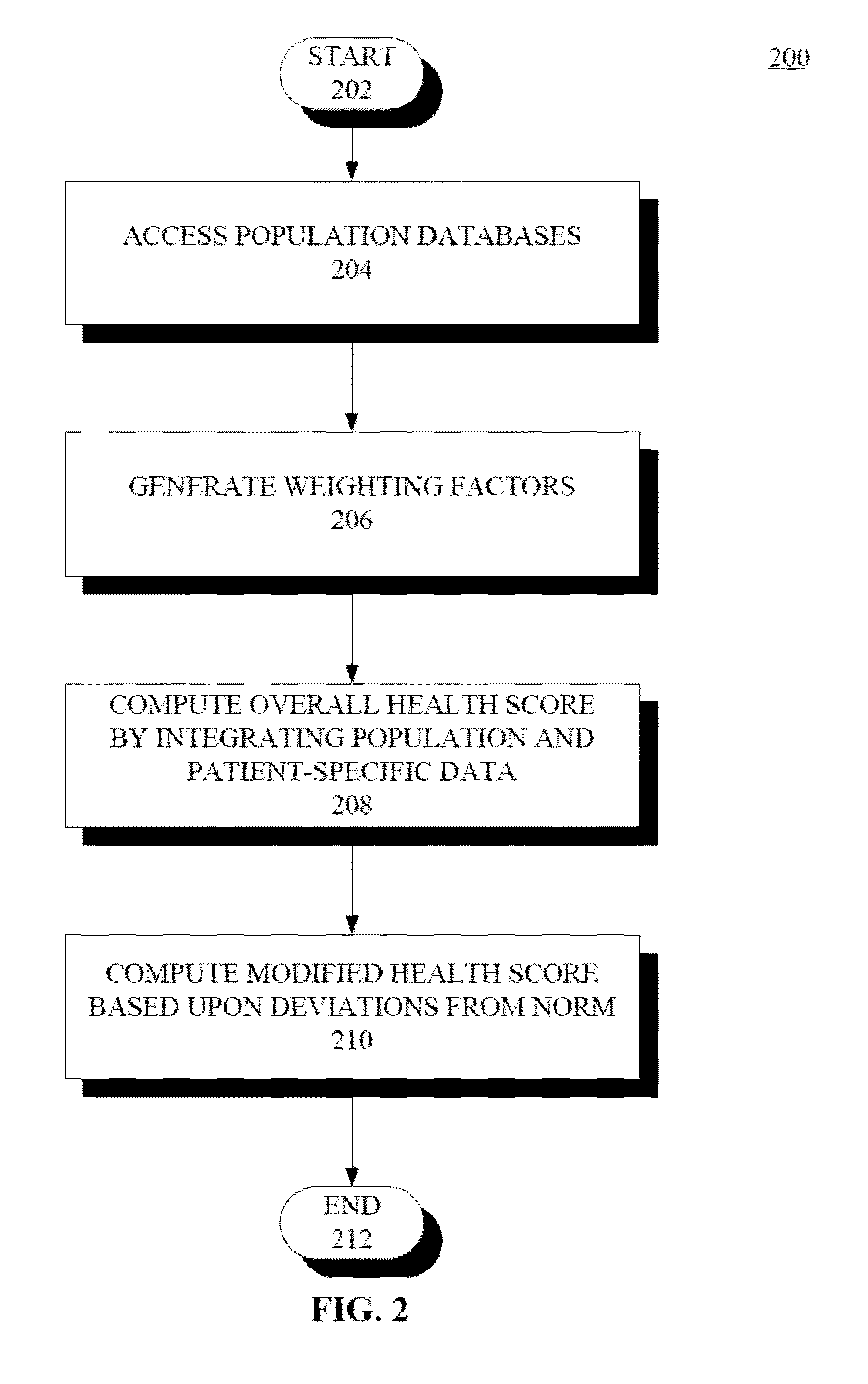

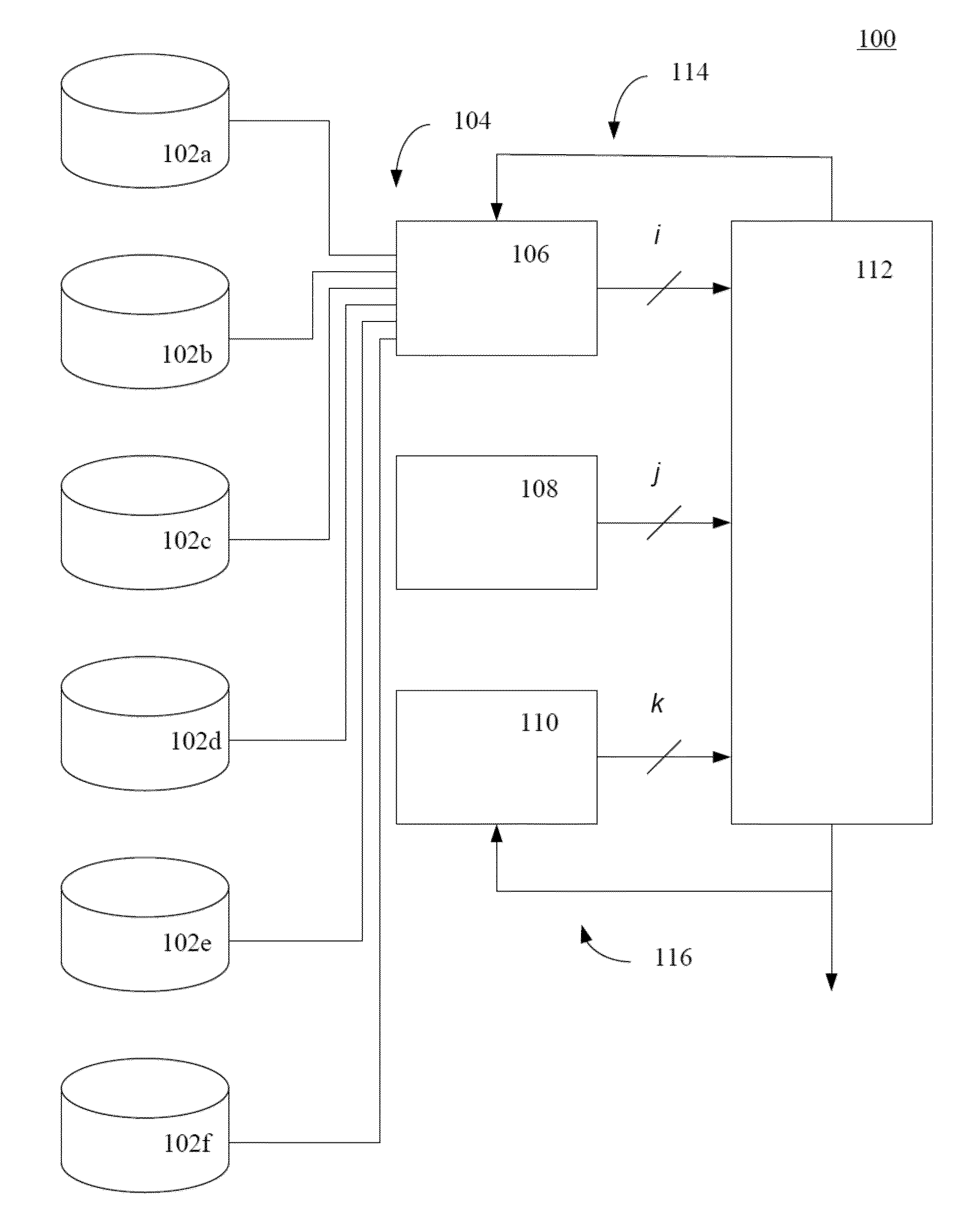

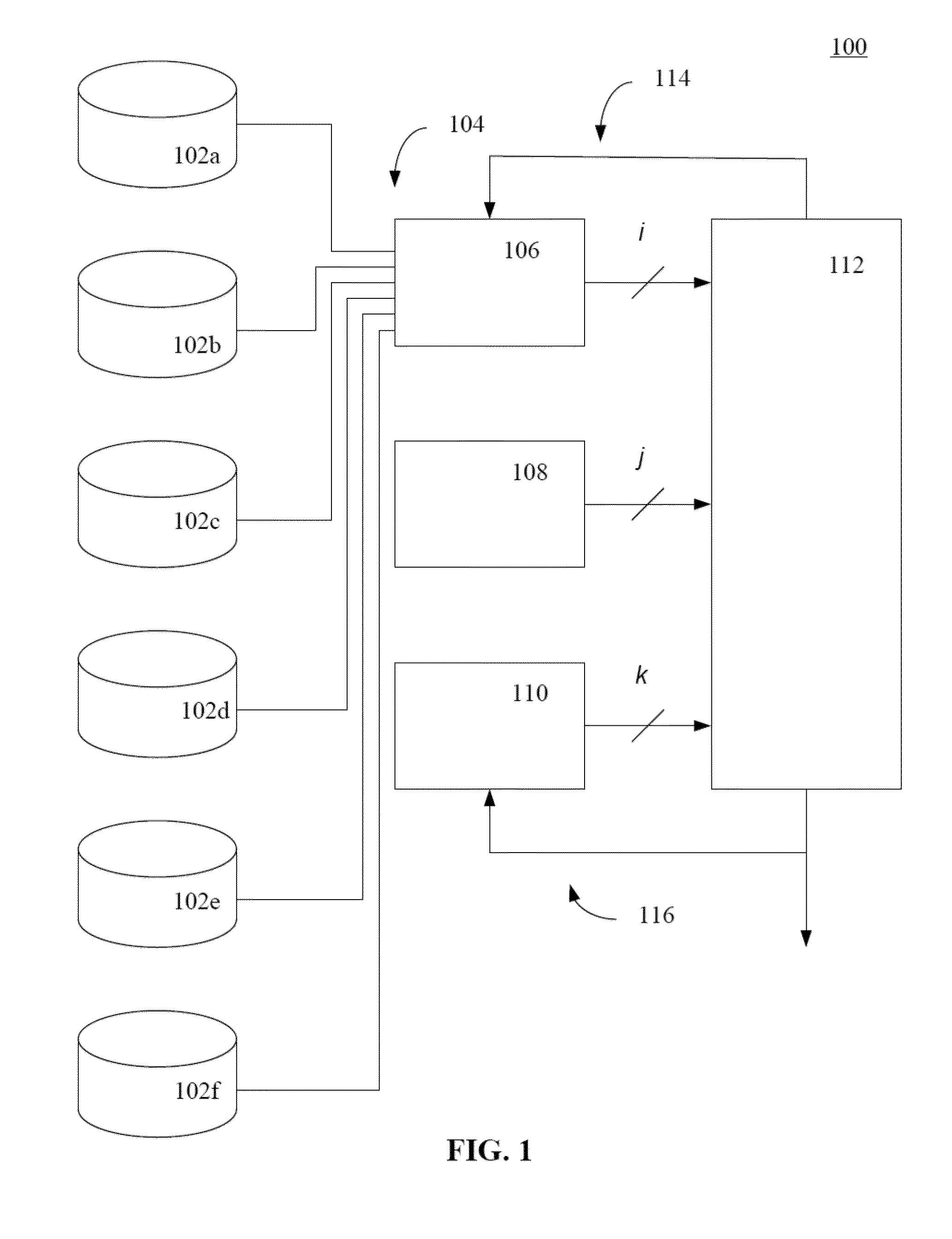

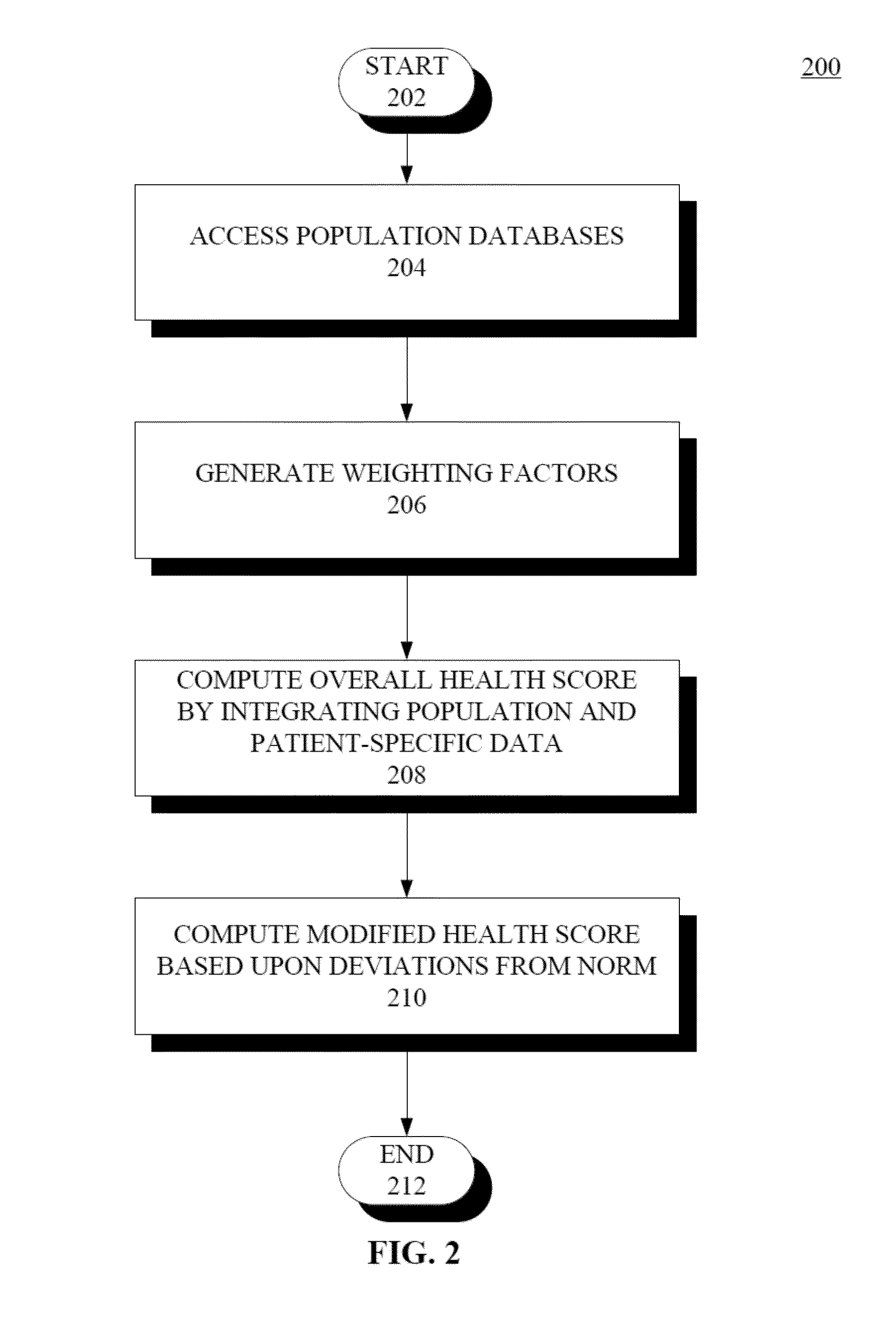

System and methods for providing dynamic integrated wellness assessment

ActiveUS9370689B2Expand the populationHigh indexMedical simulationHealth-index calculationFactor baseEngineering

Systems and methods for generating and using measurable indexes for providing a total wellness assessment of an individual are provided. A method includes computing an overall health score corresponding to the individual based on a plurality of weighting factors, the weighting factors based at least on health conditions associated with the individual. The method also includes determining a set of recommended changes for the individual based on the overall health score and generating an episodic plan for the individual, the episodic plan comprising a series of episodes for the individual that when completed will result in the individual having implemented the set of recommended changes. The method further includes generating a series of prompts for the individual, the series of prompts selected to guide the individual through the episodic plan.

Owner:THE QUANTUM GROUP +2

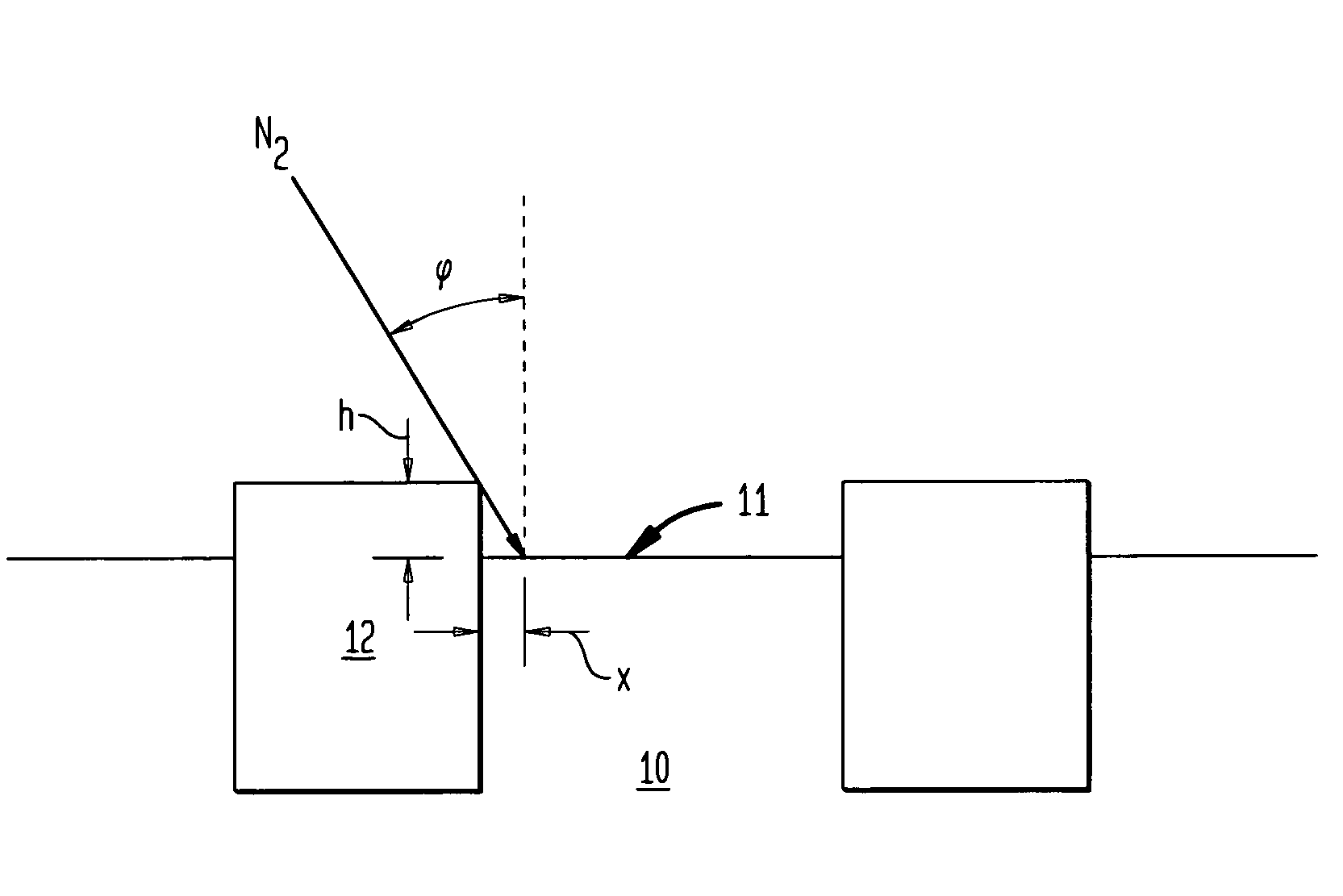

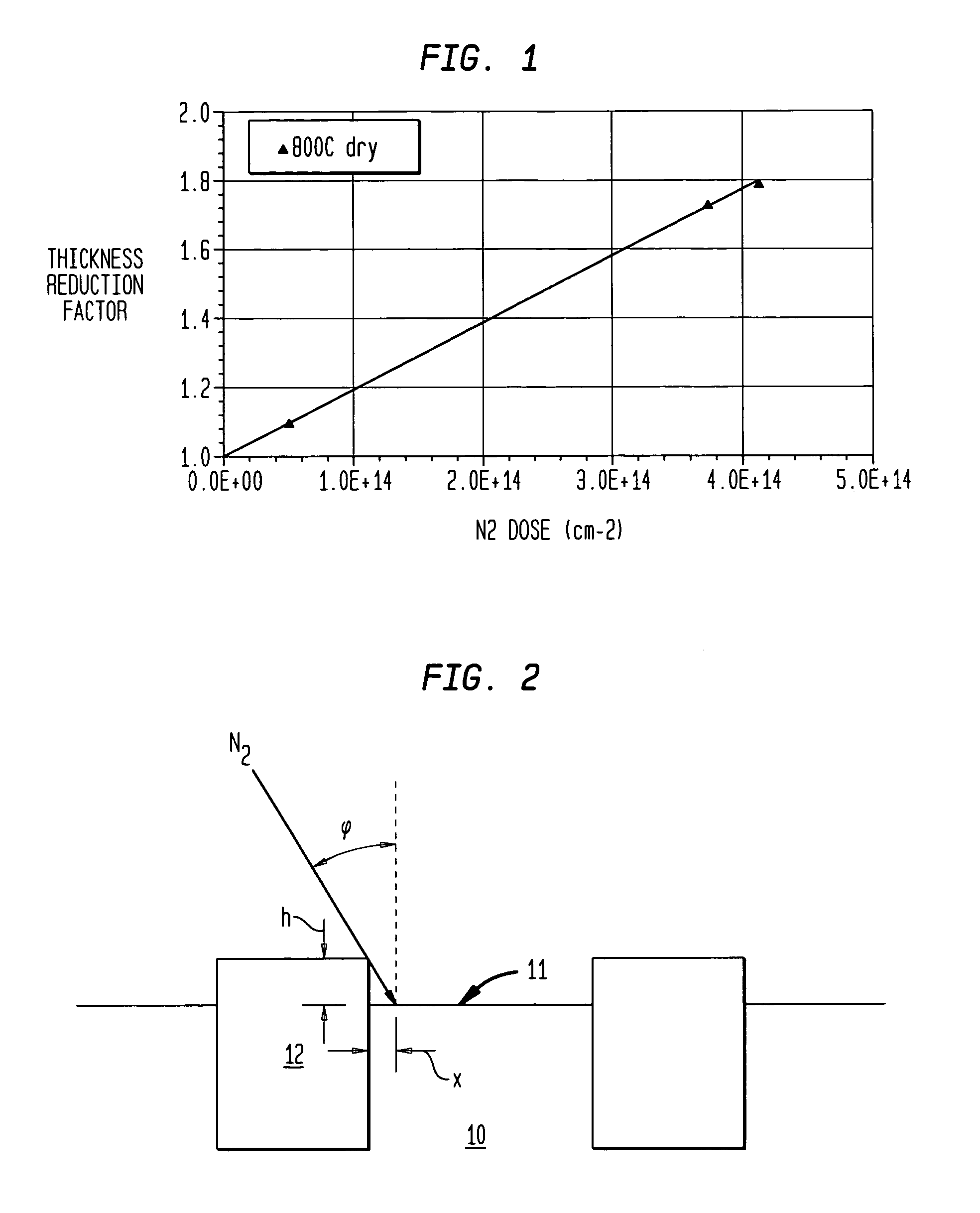

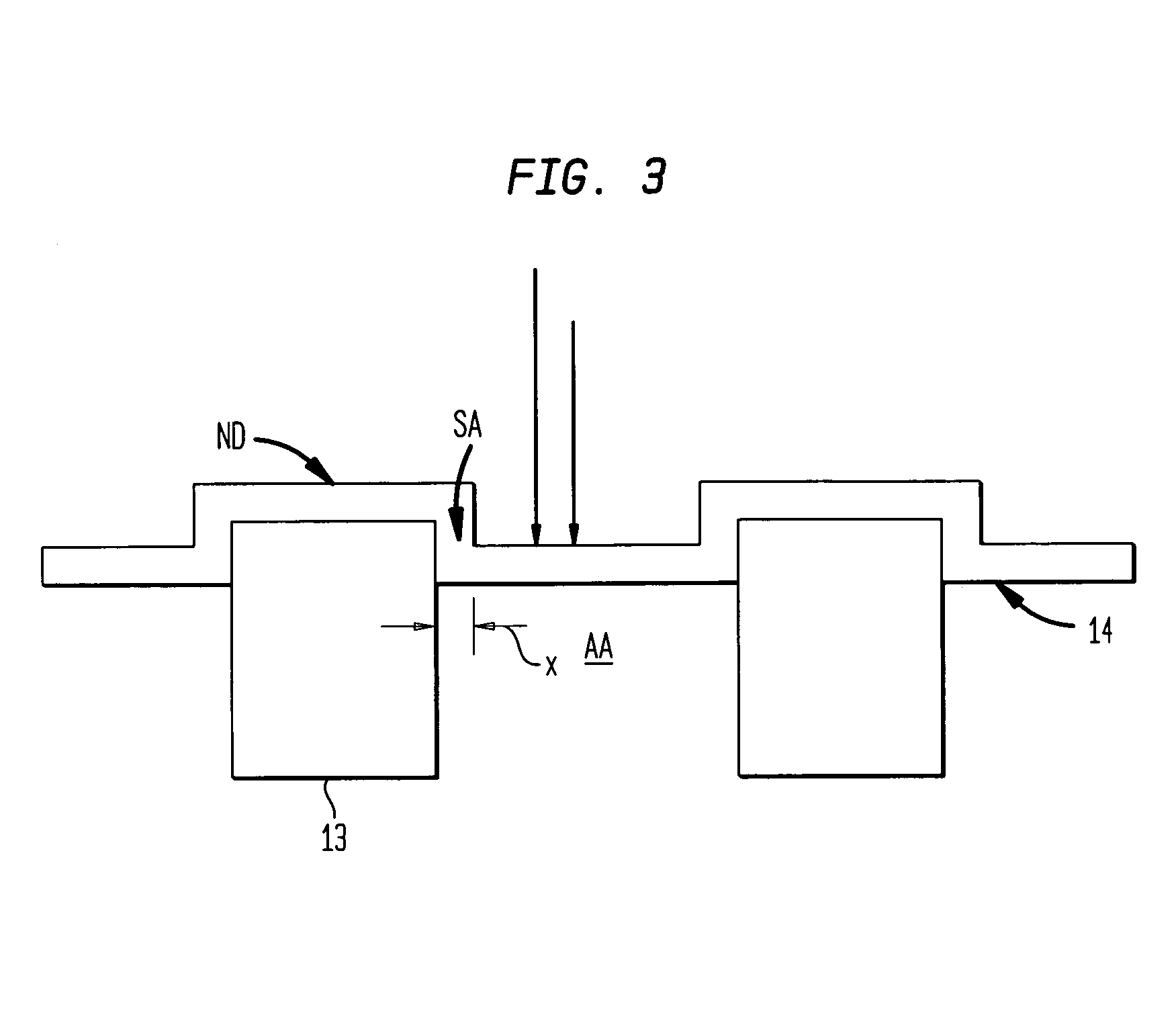

Nitrogen implantation using a shadow effect to control gate oxide thickness in DRAM semiconductor

Process for forming dual gate oxides for DRAMS by incorporating different thicknesses of gate oxides by using nitrogen implantation. Either angled nitrogen implantation or nitride spacers is used to create a “shadow effect” or area, which limits the nitrogen dose close to the edges of the active area. The reduction of nitrogen dose leads to an increased gate oxide thickness at the active area (AA) adjacent to the shallow trench, increases the threshold of the parasitic corner device and reduces sub Vt (threshold voltage) and junction leakage.

Owner:POLARIS INNOVATIONS LTD

Gum based chewing product and process for preparing the same

InactiveUS20040107971A1Increase capacityReduce intakeTobacco treatmentAerosol deliveryBiotechnologyBetel nuts

A gum based chewing product, particularly a chewing / bubble gum, contains a synthetic or natural betel nut source, an alkaloid-like composition such as nicotine or other such alkaloids like caffeine, theine etc. from natural or synthetic origin for its source. The product preferably has taste enhancers like lime and / or catechu. A process for preparing the gum based chewing product. The product has improved high smoothness, less saliva generation, excellent overall taste and chewing properties. The gum pieces deliver 1 to 12.6 mg of nicotine per piece.

Owner:DALMIA CENT FOR RES & DEV

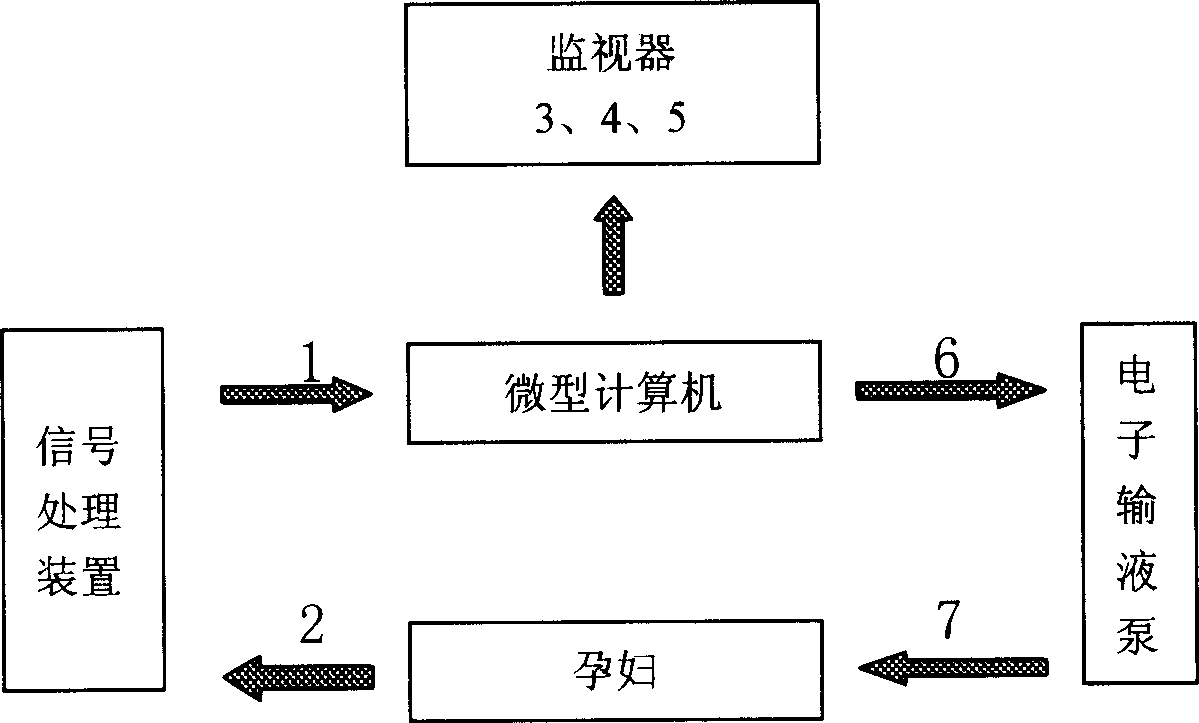

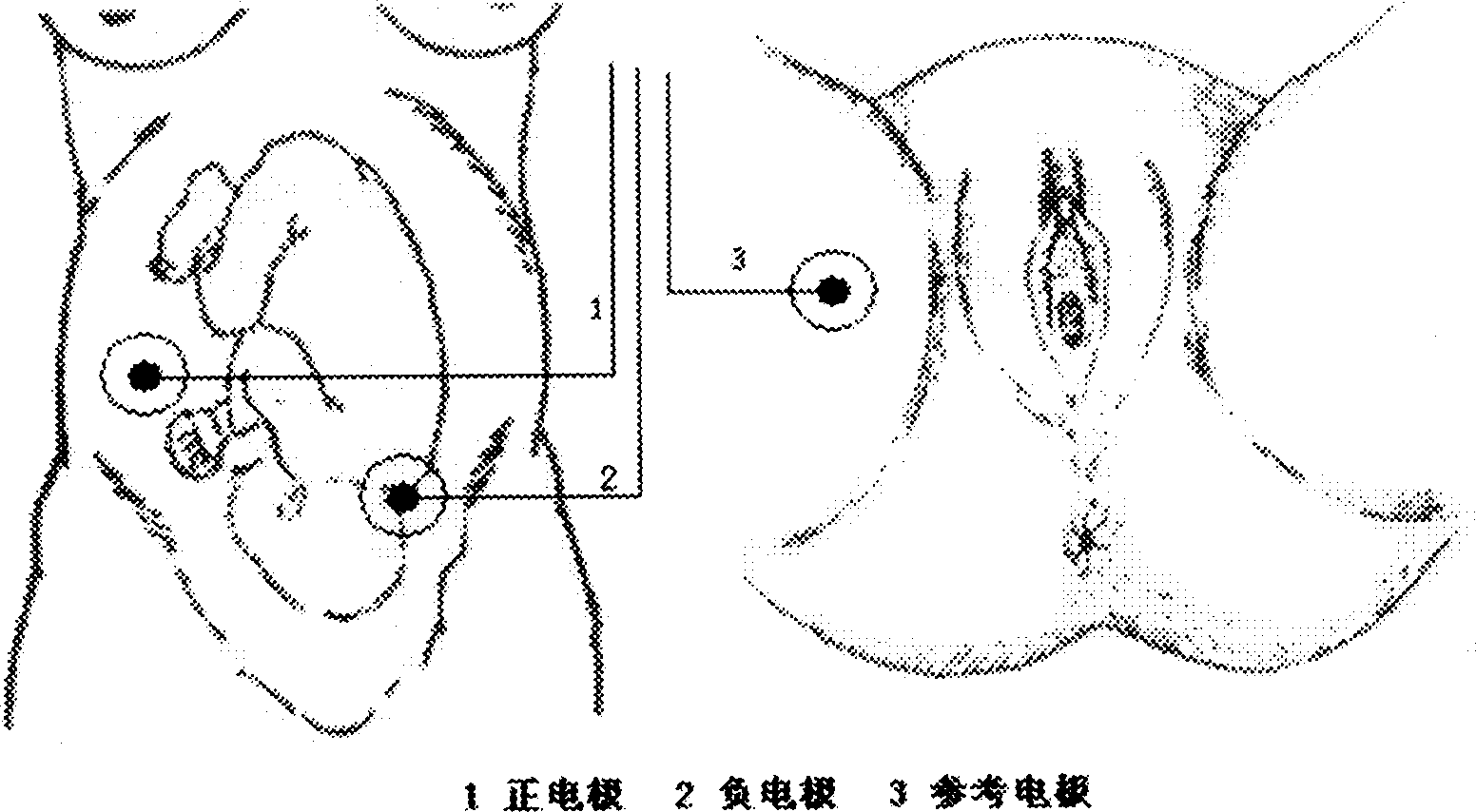

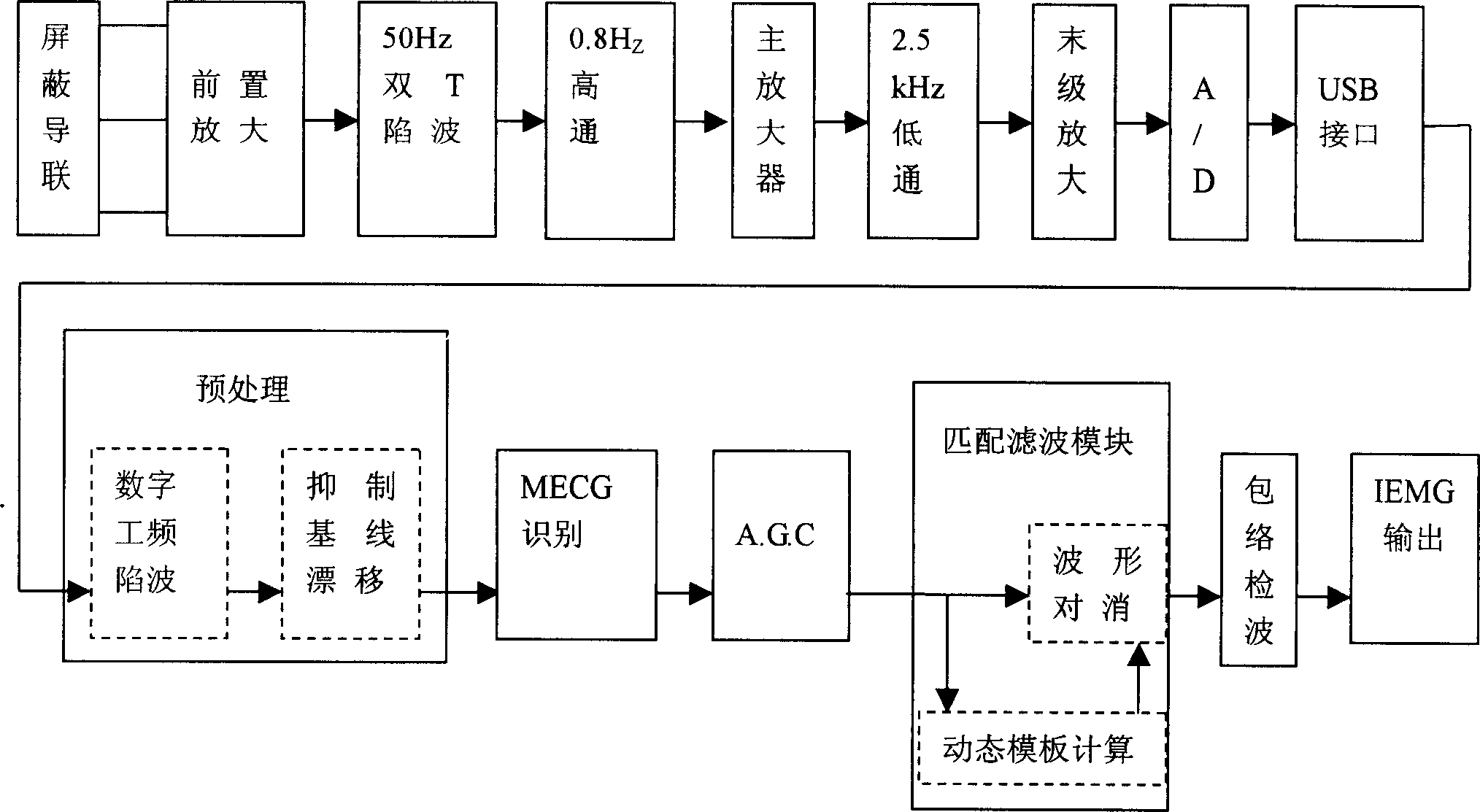

Method and device for monitoring contraction activities of mother womb and controlling childbirth process

InactiveCN1444905AConvenient and effective extractionEfficient extractionAnimal reproductionDiagnostic recording/measuringDigital signal processingWeighted average method

A method and equipment for monitoring the uterine contraction of mother and controlling the delivery process features that an abdominal electrode including method is used to sample all abdominal signals including the noisese, such as mother ECG, fetal ECG and electromagnetic interference, and AGC module is designed for suppressing said noises, and a digital signal processor is used as the core unit to eliminate mother ECG. Its advantages are high reliability, no damage, and less distortion.

Owner:GUANGZHOU SUNRAY MEDICAL APP +1

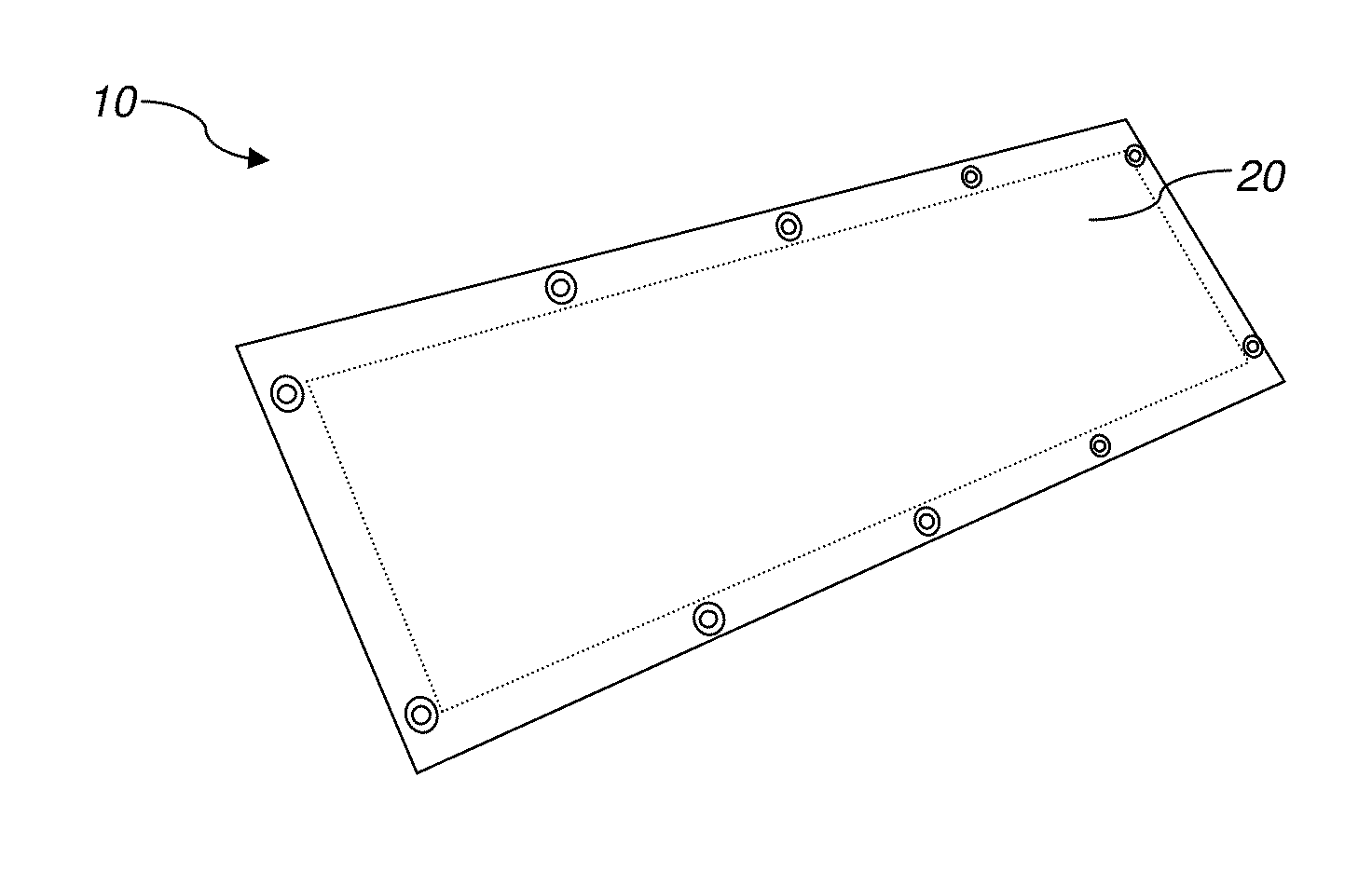

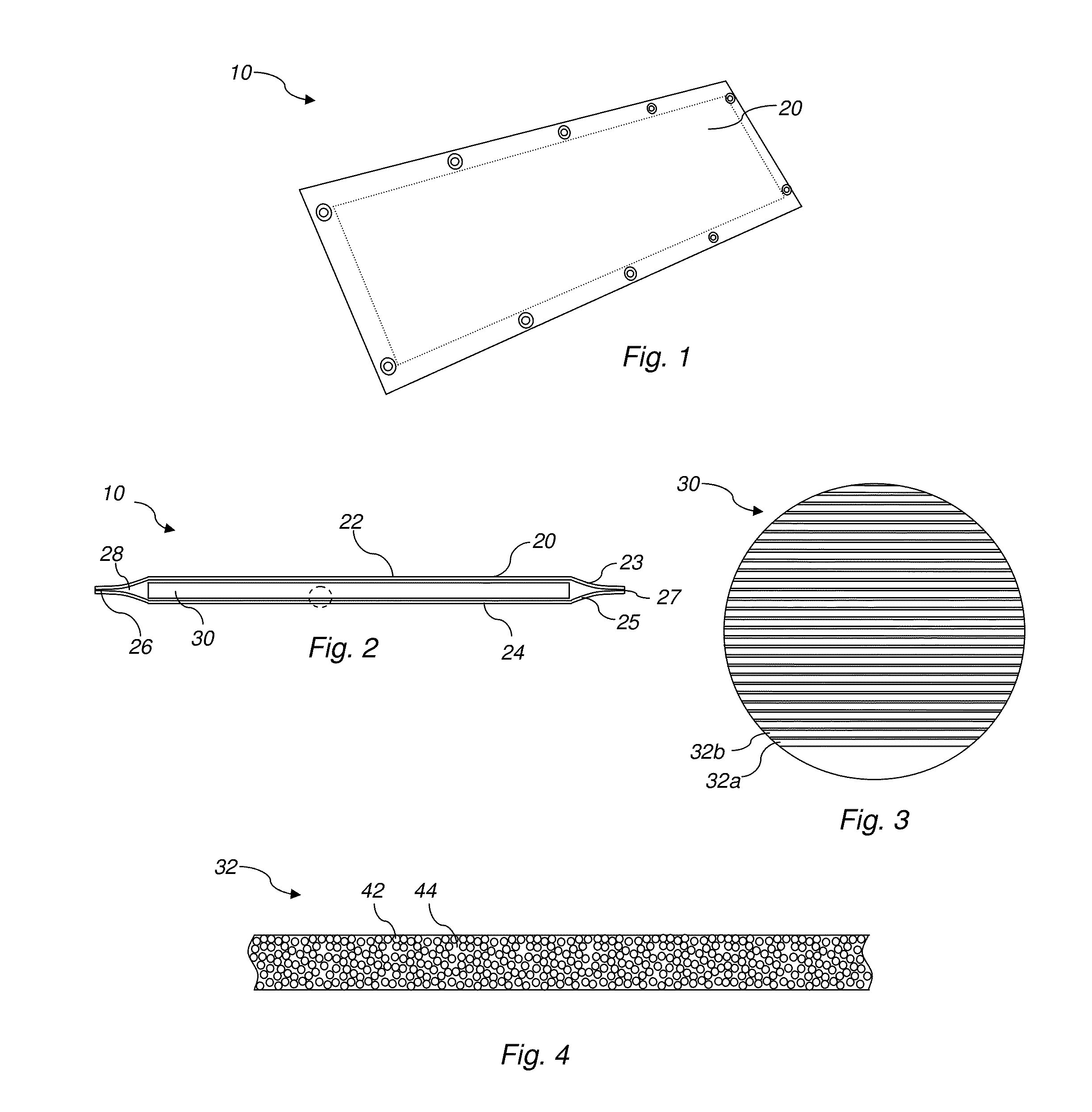

Nuclear radiation shields, shielding systems and associated methods

InactiveUS20140151584A1Resistance to crackingImpart radioactivity-limiting element with flexibilityShieldingPortable shielded containersNuclear radiationRadiation shield

A radiation shield, which may attenuate nuclear radiation or ionizing particles, may include a non-toxic, radioactivity-attenuating material based on an element or an elemental species having an atomic number of 56 or more. Examples of such materials include barium sulfate and bismuth oxide. A radiation shield may include two or more different radioactivity-attenuating materials, which may attenuate different types of nuclear radiation or ionizing particles, or attenuate different energy ranges of nuclear radiation or ionizing particles. Different radioactivity-attenuating materials may be carried by different layers of the radiation shield. Radiation shields with at least partially superimposed layers are also disclosed. Adjacent layers of such a radiation shield may be able to move longitudinally relative to one another, or slide somewhat relative to each other. Any of these features may be incorporated into a blanket, a protective suit or other protective garment, tape or any other configuration of radiation shield. Pliable radiation shields that attenuate nuclear radiation or ionizing particles are also disclosed, as are methods for limiting exposure to nuclear radiation or ionizing particles.

Owner:BLOXR SOLUTIONS

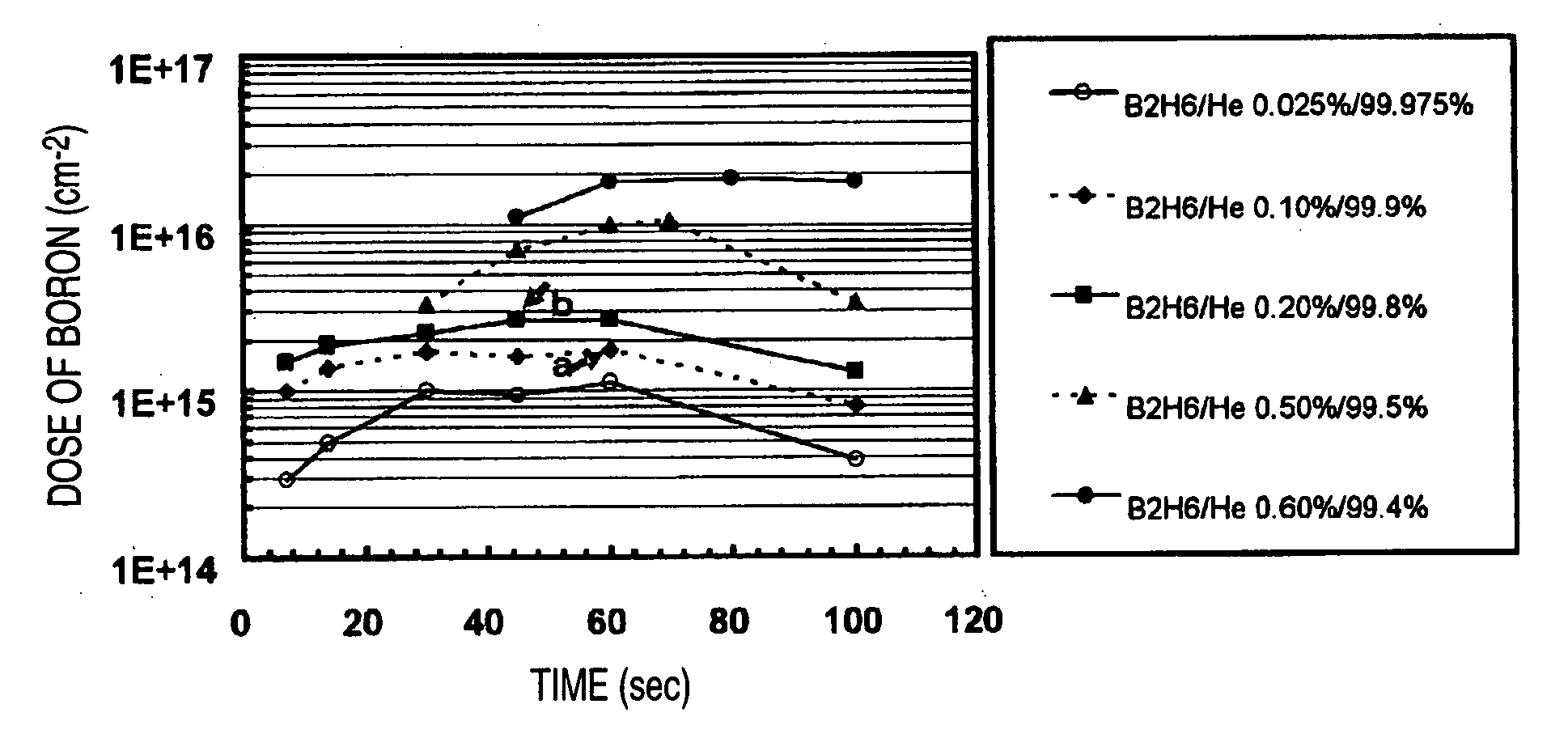

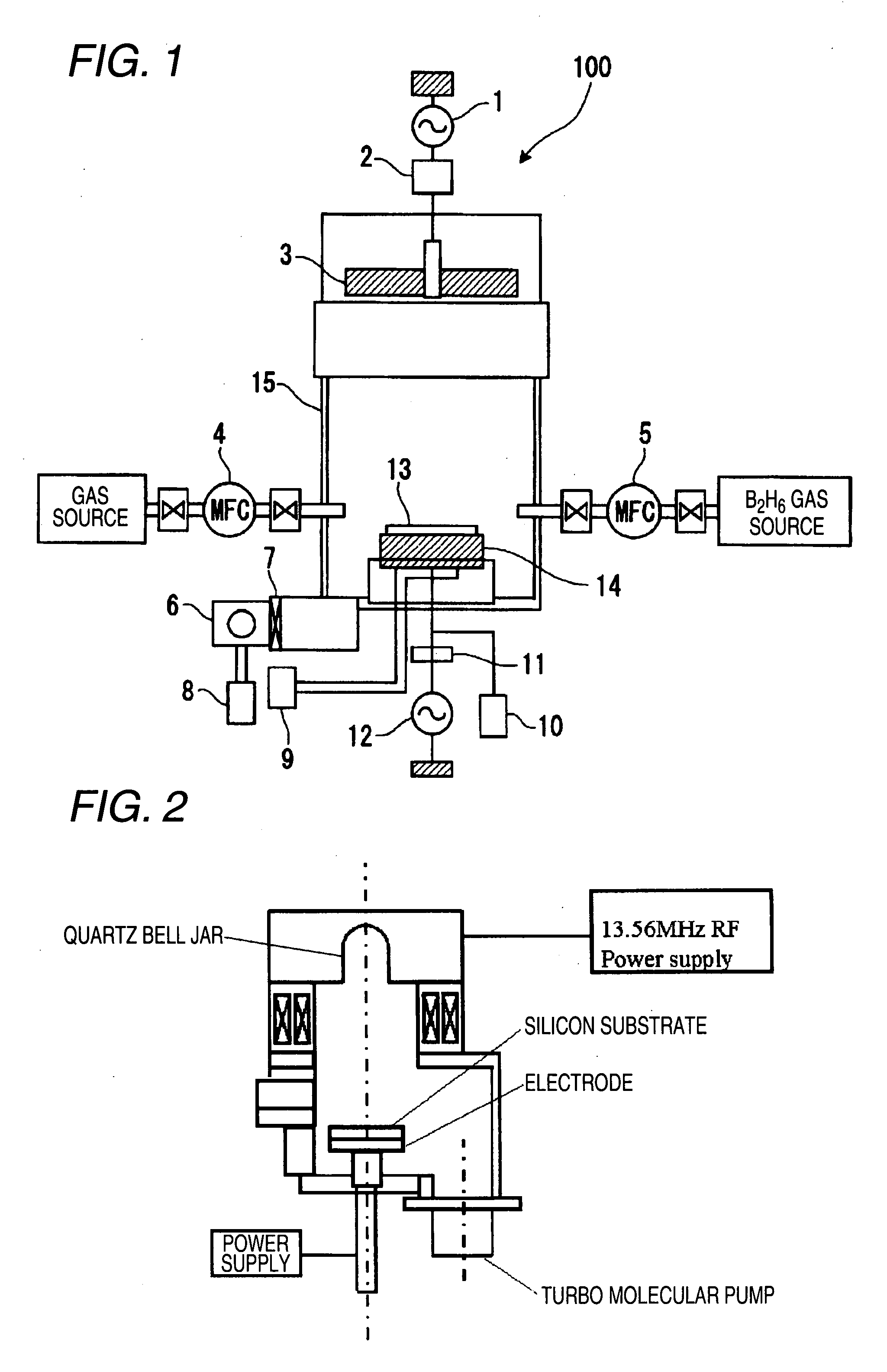

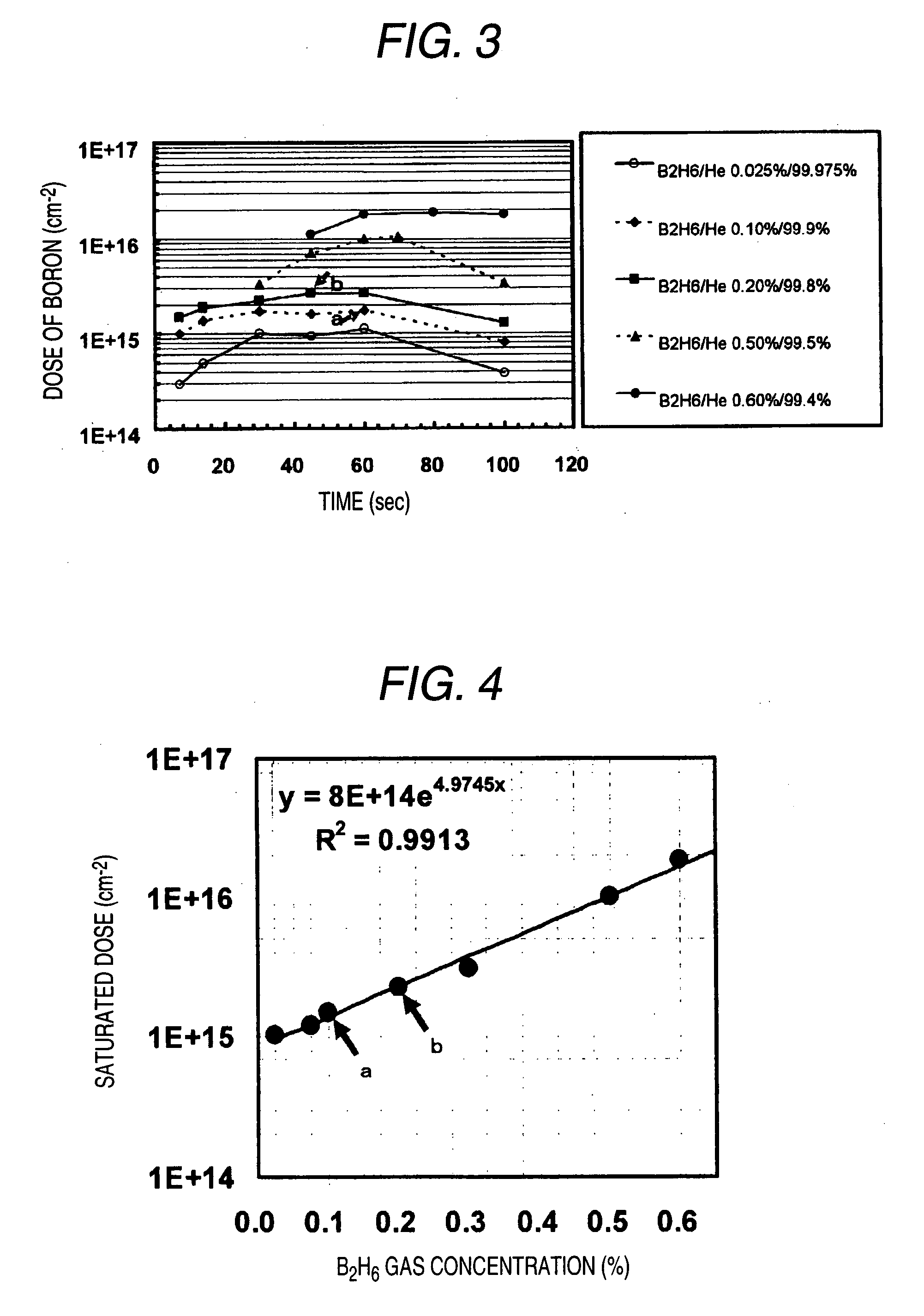

Plasma doping method

InactiveUS20070166846A1Improve uniformityControl doseSemiconductor/solid-state device testing/measurementElectric discharge tubesIn planeMedicine

A plasma doping method that can control a dose precisely is realized. In-plane uniformity of the dose is improved. It has been found that, if a bias is applied by irradiating B2H6 / He plasma onto a silicon substrate, there is a time at which a dose of boron is made substantially uniform, and the saturation time is comparatively long and ease to stably use, compared with a time at which repeatability of an apparatus control can be secured. The invention has been finalized focusing on the result. That is, if plasma irradiation starts, a dose is initially increased, but a time at which the dose is made substantially uniform without depending on a time variation is continued. In addition, if the time is further increased, the dose is decreased. The dose can be accurately controlled through a process window of the time at which the dose is made substantially uniform without depending on the time variation.

Owner:PANASONIC CORP

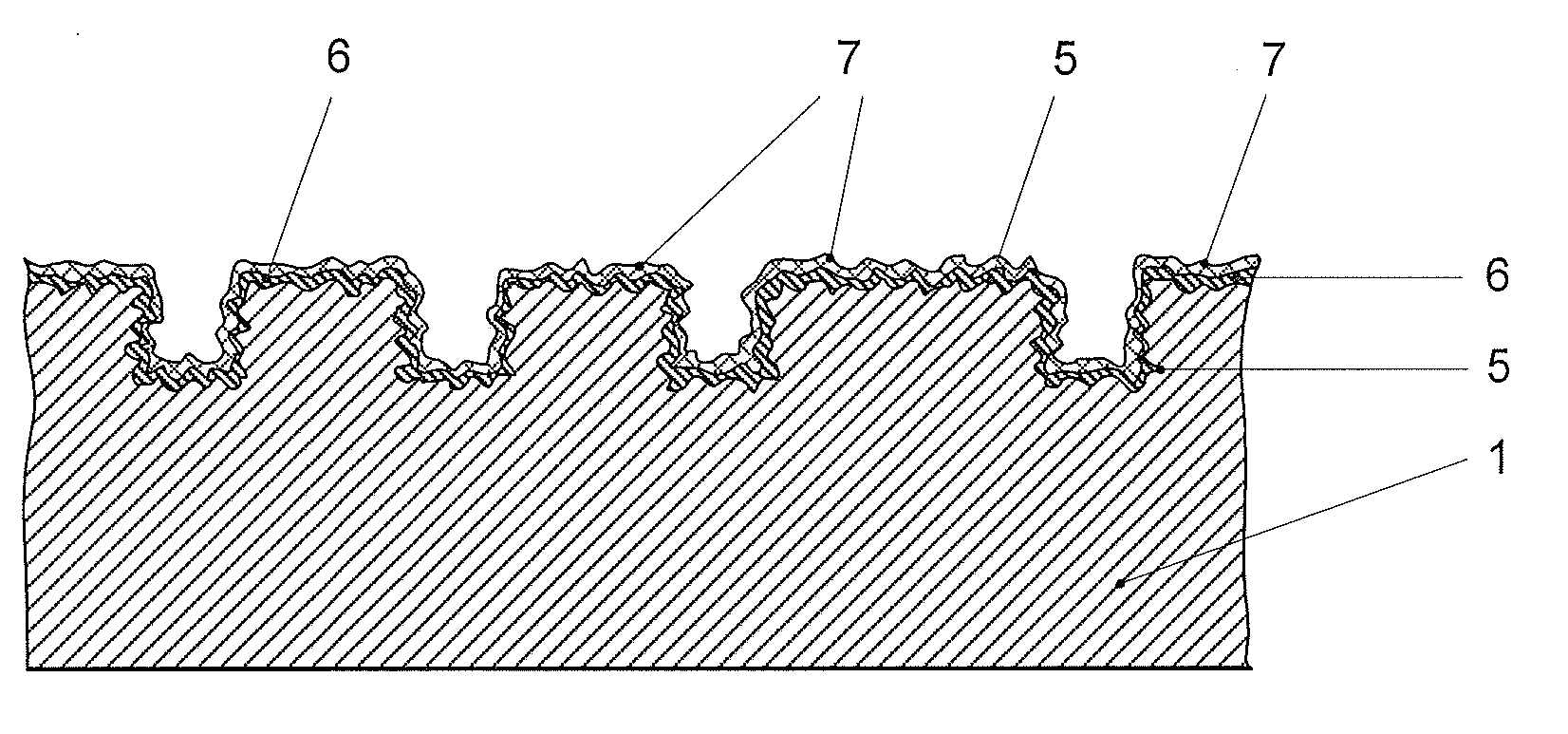

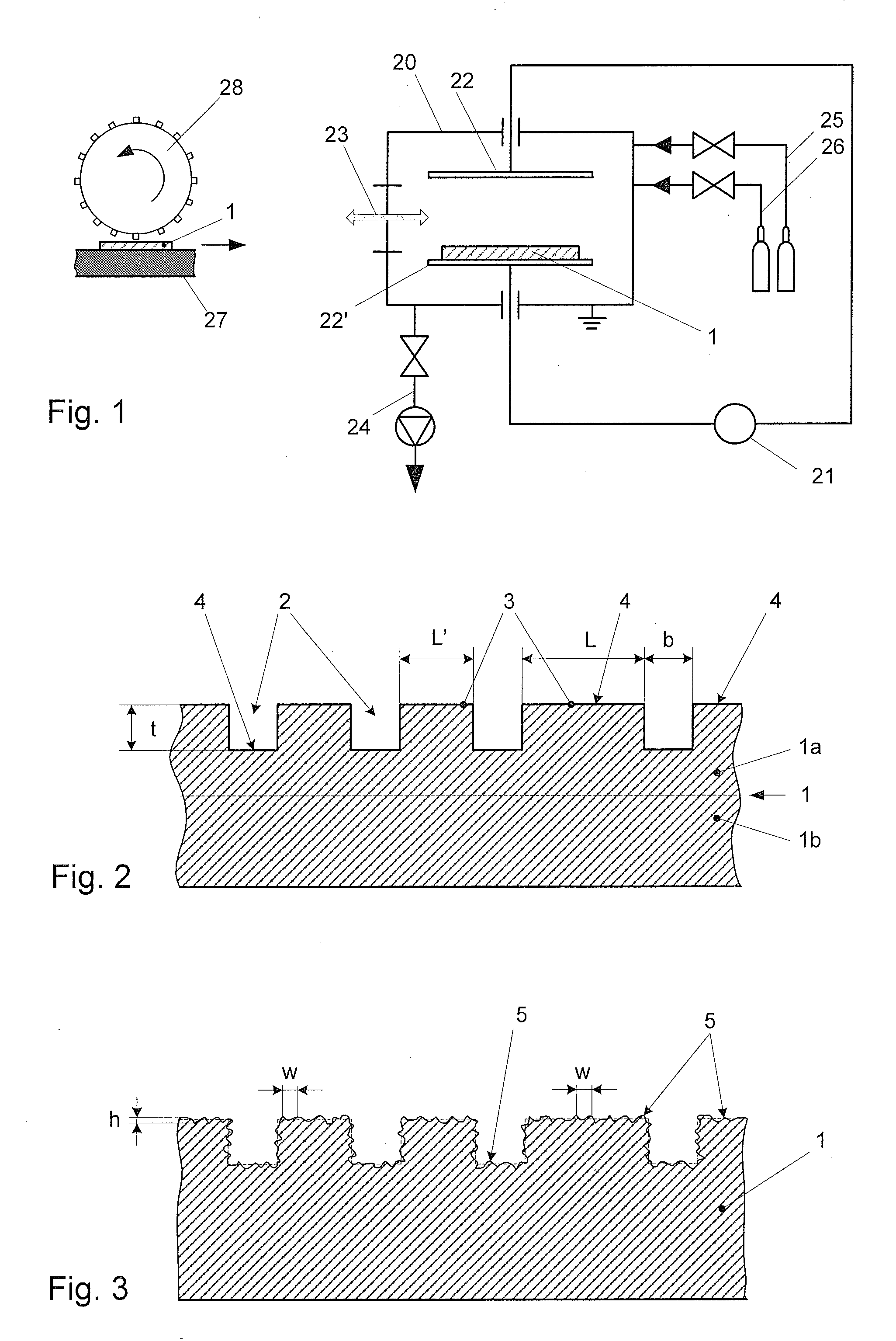

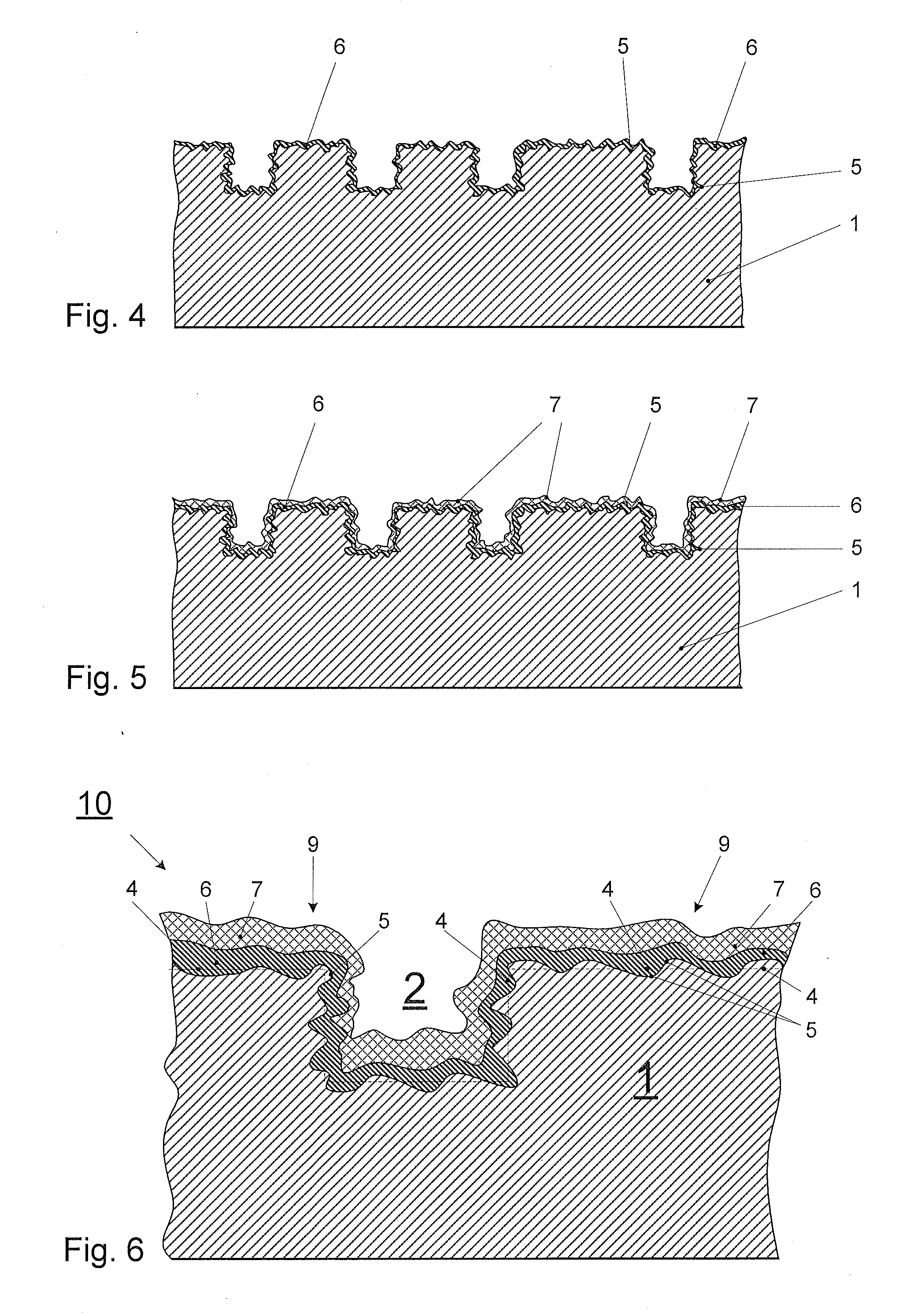

Method for producing a metal-oxide-coated workpiece surface with predeterminable hydrophobic behaviour

InactiveUS20110287227A1Improve adhesionSurface stabilizationMaterial nanotechnologyDecorative surface effectsCoated surfaceNanoparticle

Owner:INCOAT

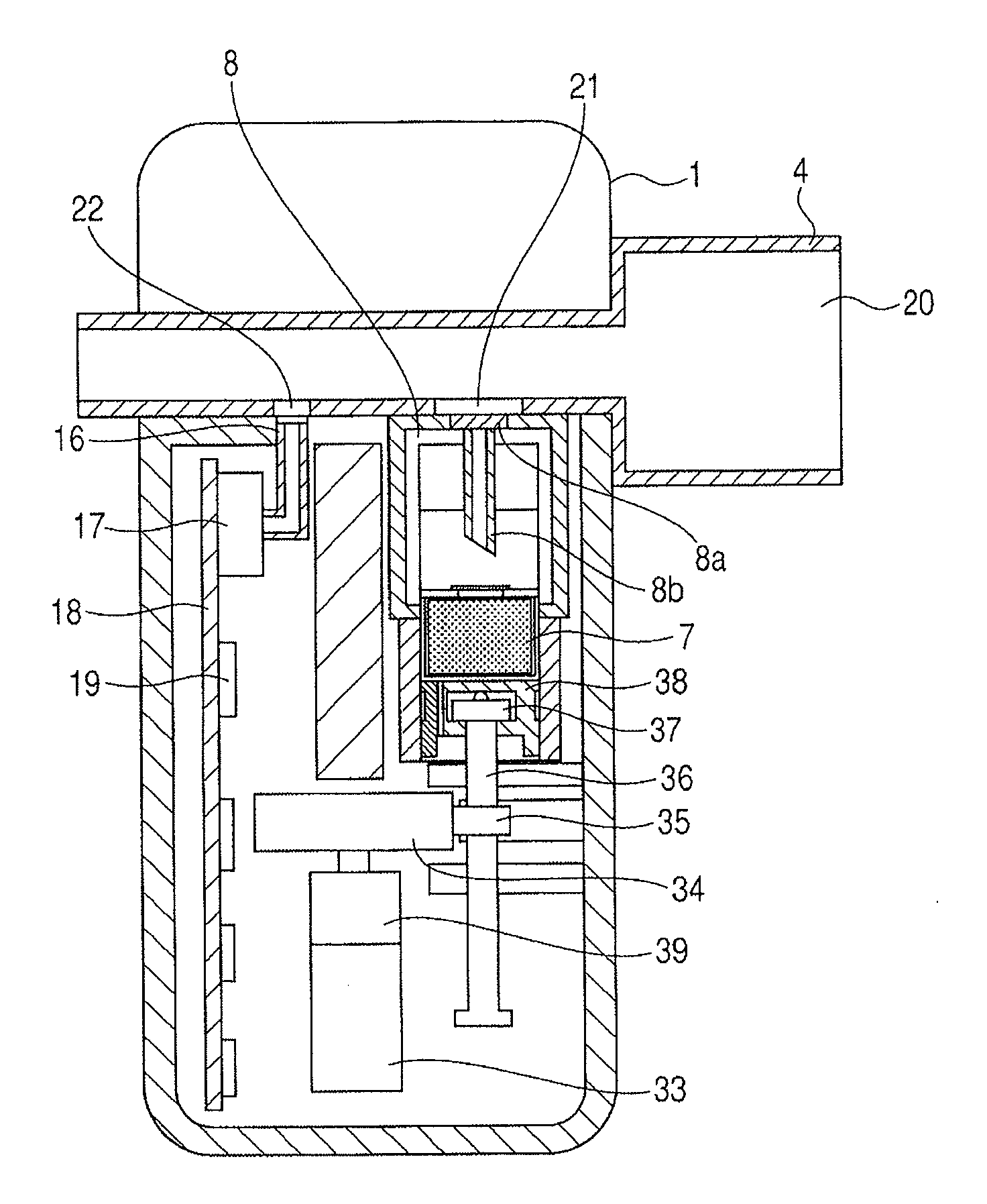

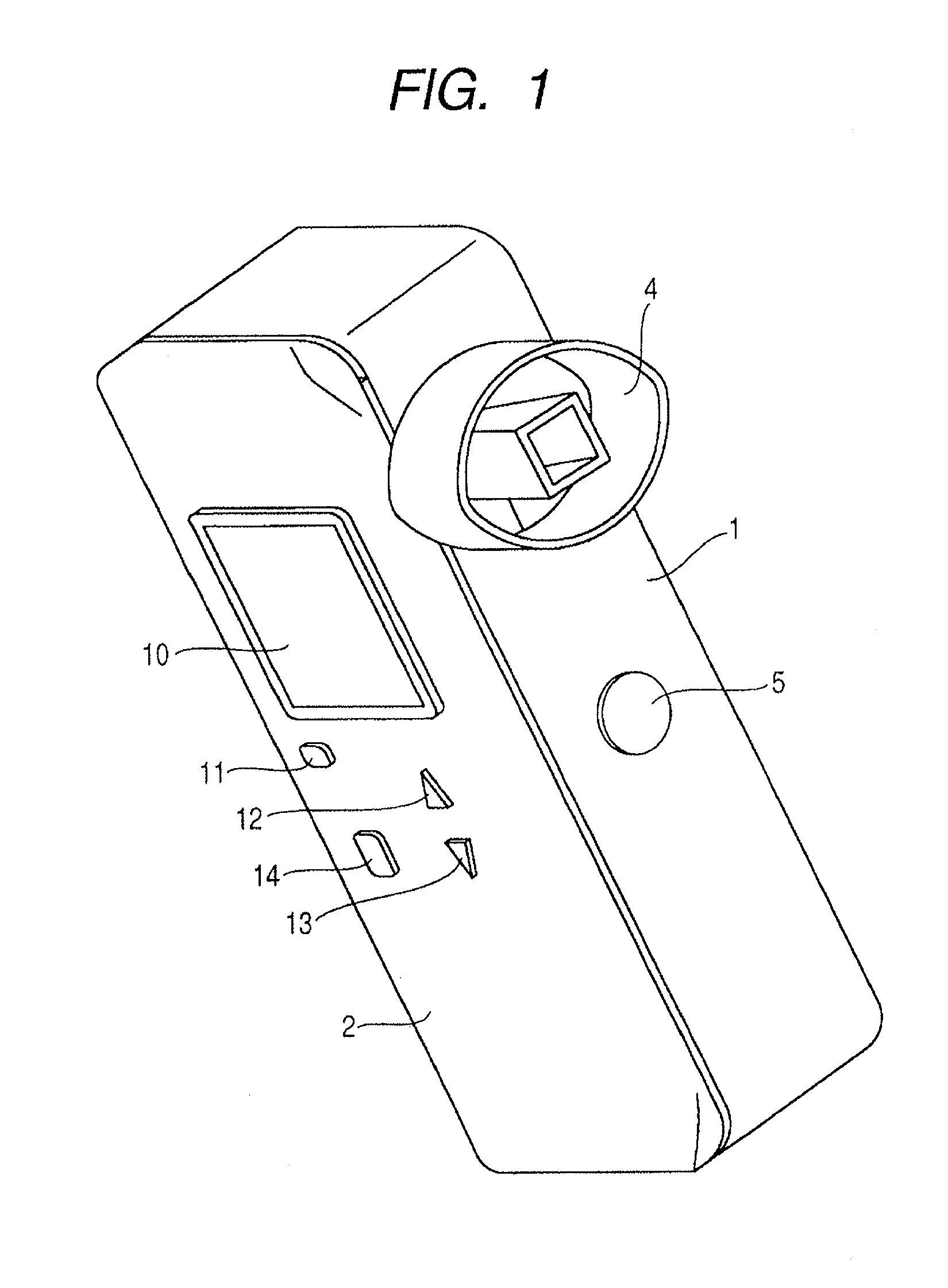

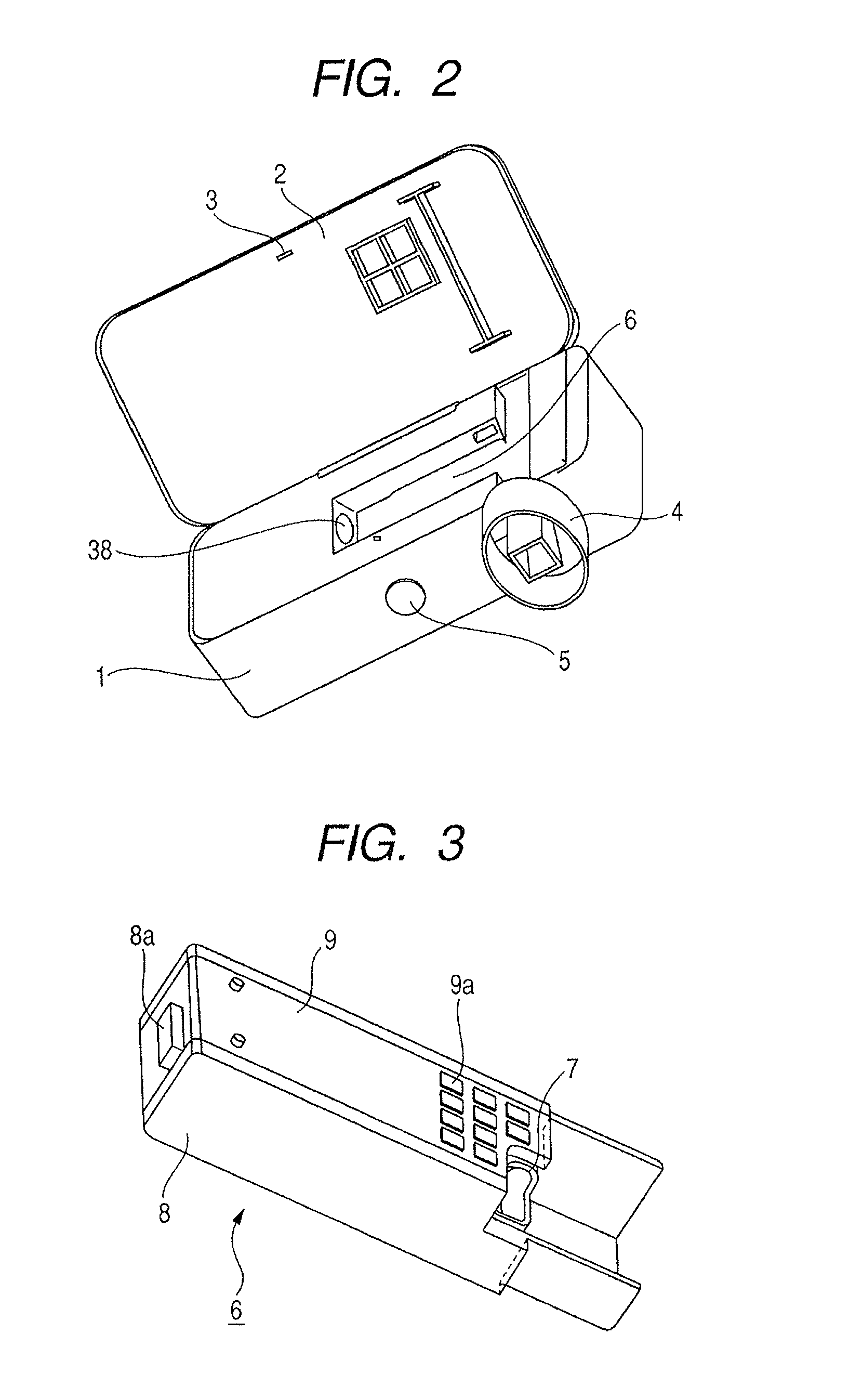

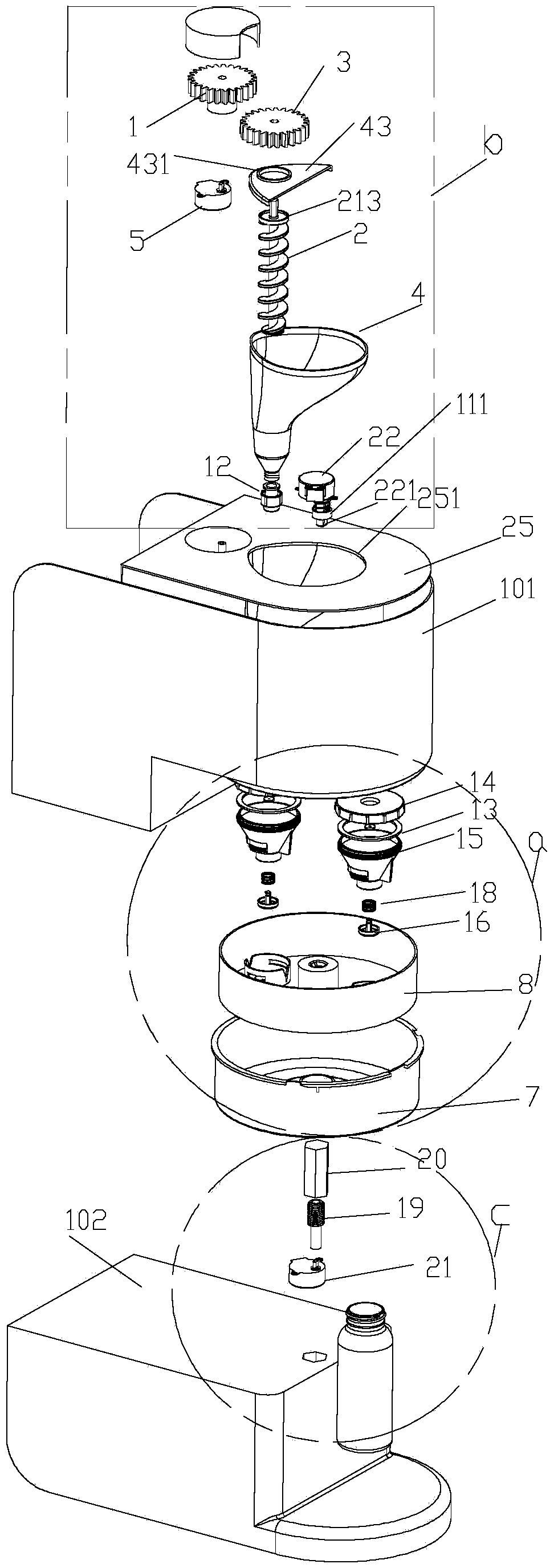

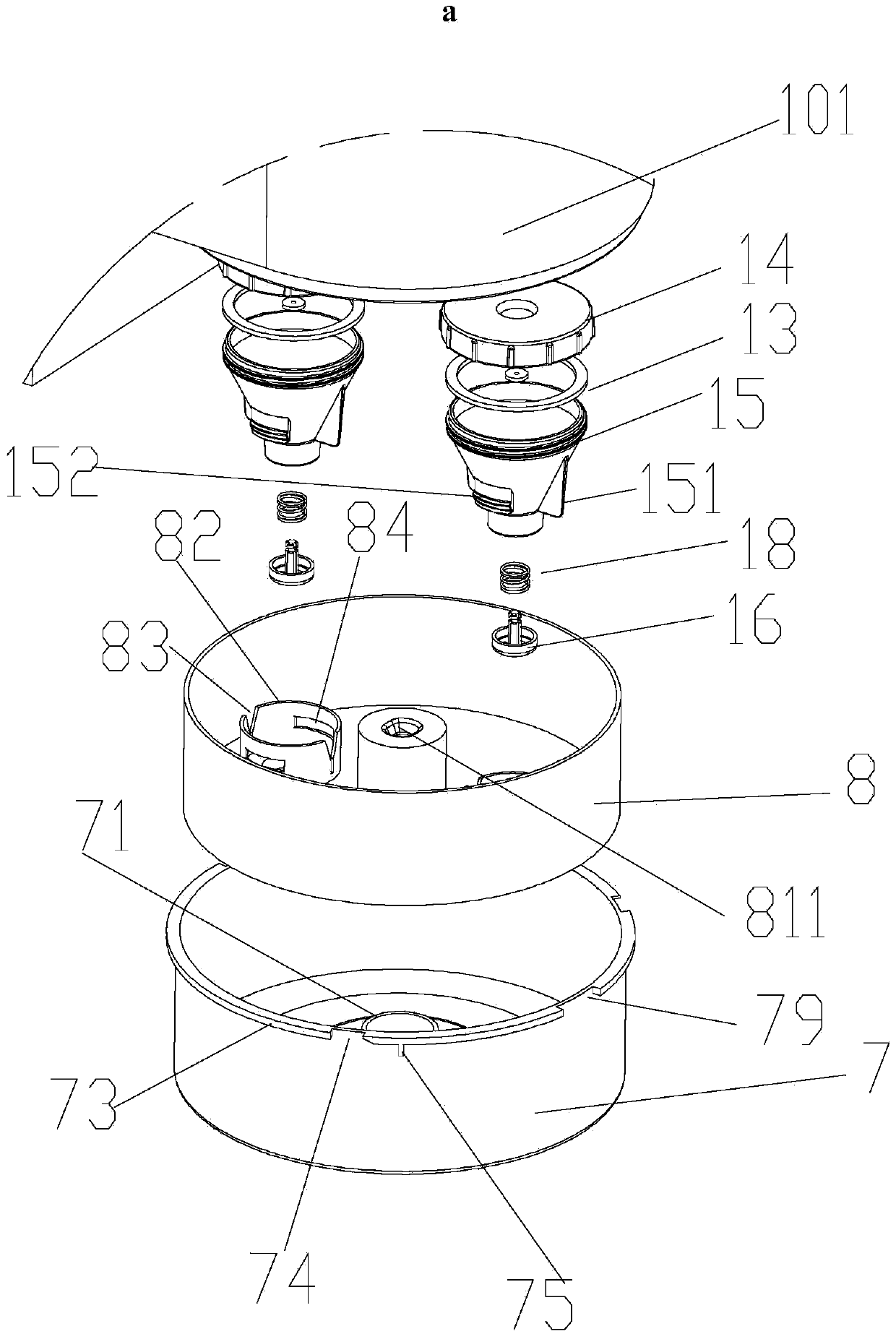

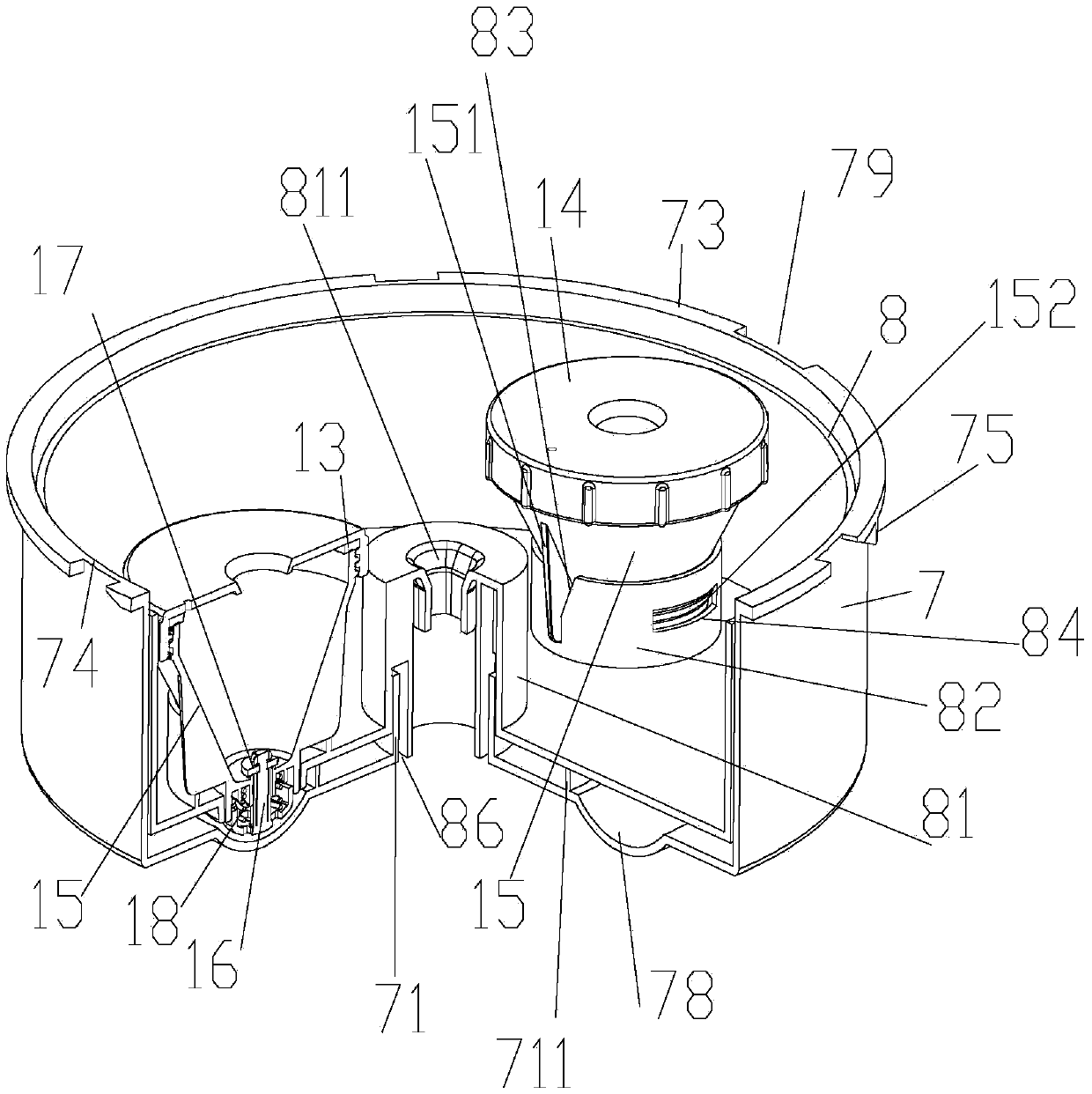

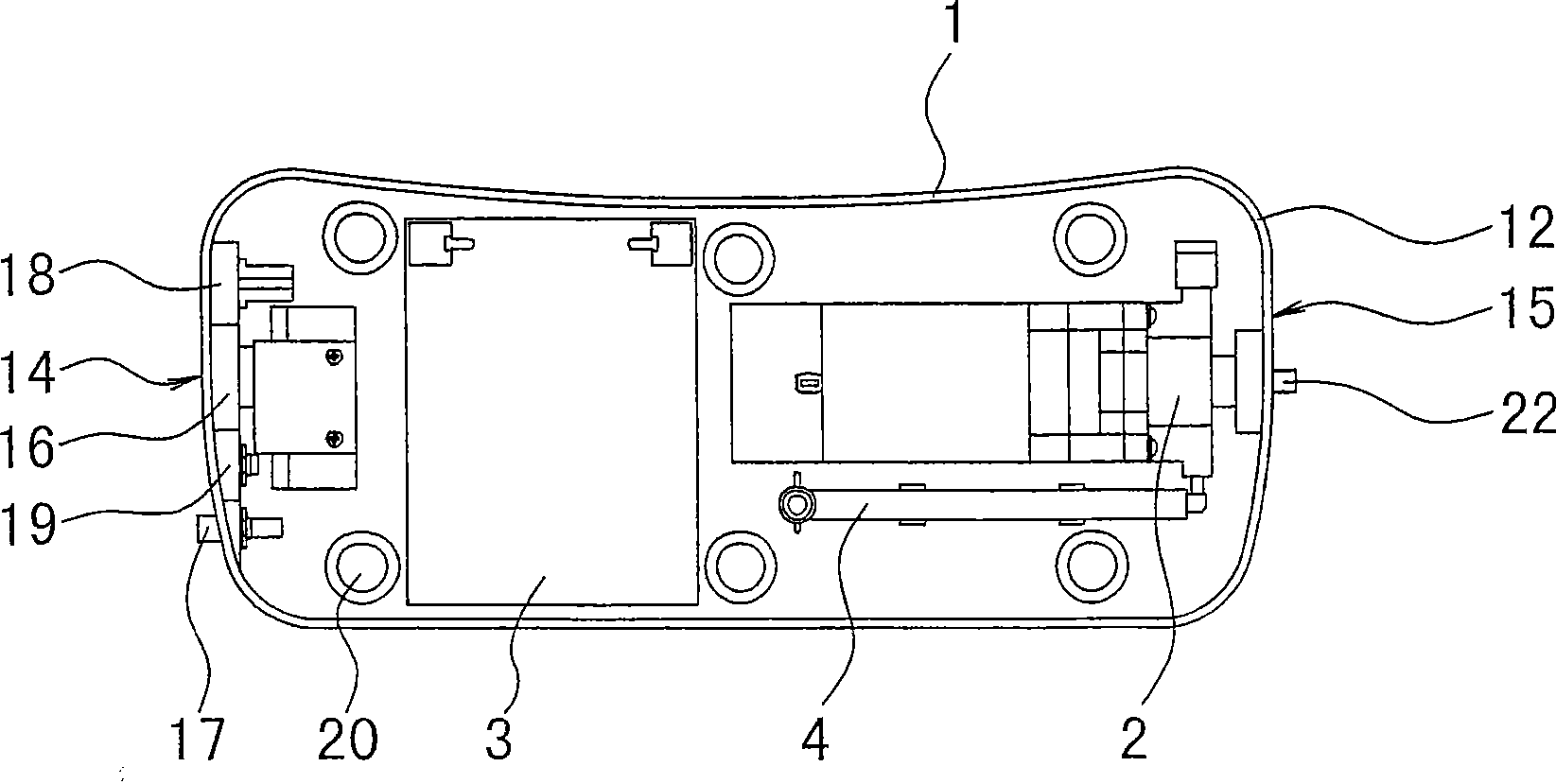

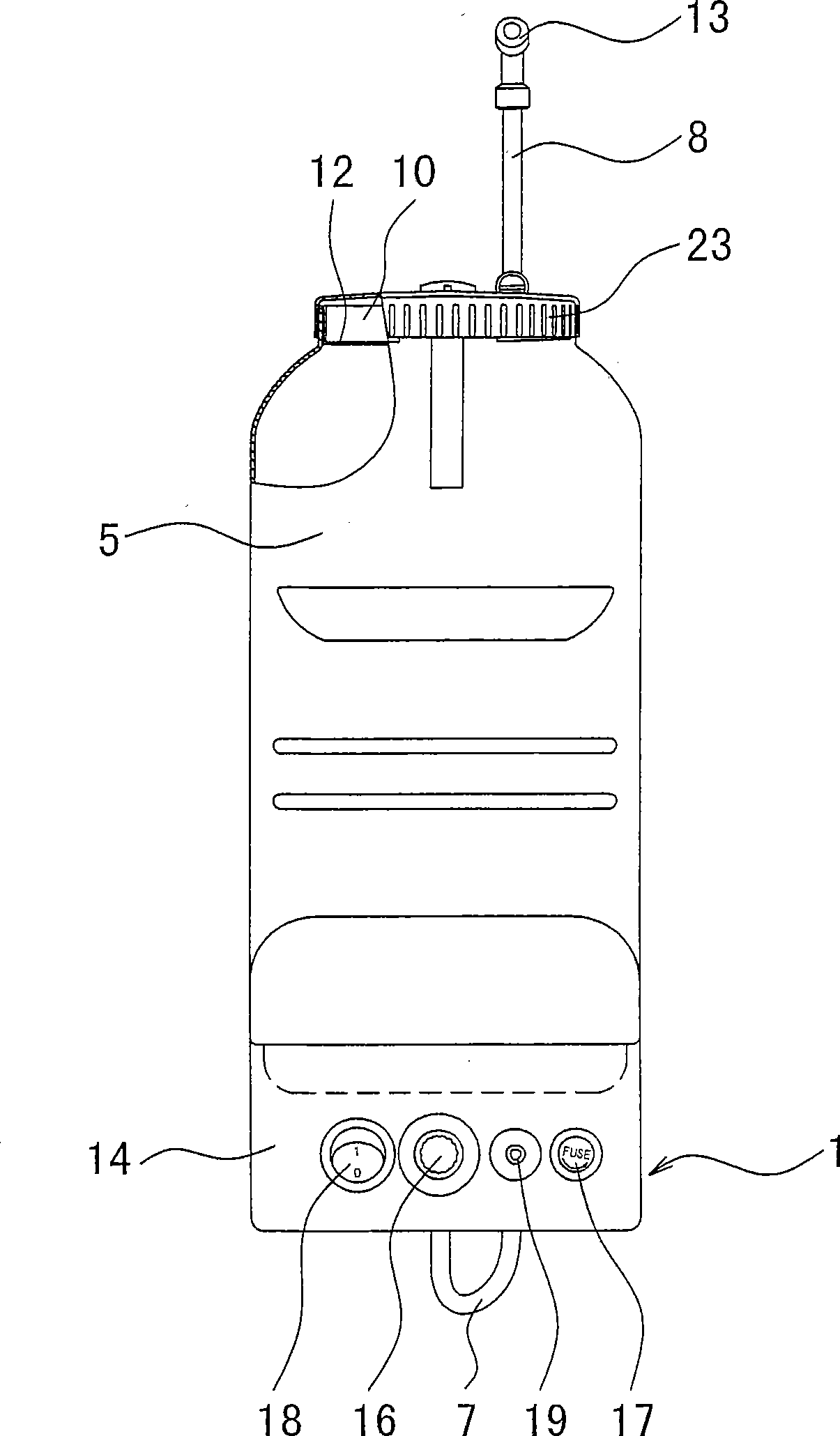

Medicine ejection device

This medicine ejection device is directed at uniformizing an amount of a medicine inhaled by a user through a mouthpiece: and ejects a predetermined constant amount of the medicine by measuring a remaining amount of the medicine in a reservoir 7 at every inhalation time with the use of a strain gauge 37, which supplies the medicine through a connection tube 8b to an ejection head 8a for ejecting a medicine into a flow path 20 of a mouthpiece 4, so as to compensate for a decrease of an amount to be inhaled due to the deposition of the medicine in a nozzle (orifice) of the ejection head 8a, and by adjusting an ejecting operation duration of the ejection head 8a when the user inhales the medicine next time.

Owner:CANON KK

Methods for the controlled delivery of pharmacologically active compounds

InactiveUS6946137B2Low toxicitySmall investmentBiocideTetracycline active ingredientsRoxithromycinRelease time

The present invention provides compositions and methods for extending the release times and lowering the toxicity of pharmacologically active compounds. The compounds comprise a salt of the pharmacologically active compound with a lipophilic counterion and a pharmaceutically acceptable water soluble solvent combined together to form an injectable composition. The lipophilic counterion may be a saturated or unsaturated C8-C22 fatty acid, and preferably may be a saturated or unsaturated C10-C18 fatty acid. The compounds precipitate in aqueous environments. When injected into a mammal, at least a portion of the composition precipitates and releases the active compound over time. Thus, the composition forms a slowly releasing drug depot of the active compound in the mammal. Therefore, the present invention enables one to provide a controlled dose administration of the active compound for a period of up to 15 days or even longer. Many compounds can be administered according to the present invention including, but not limited to, tilmicosin, oxytetracycline, metoprolol, fluoxetine, roxithromycin, and turbinafine.

Owner:IDEXX LABORATORIES

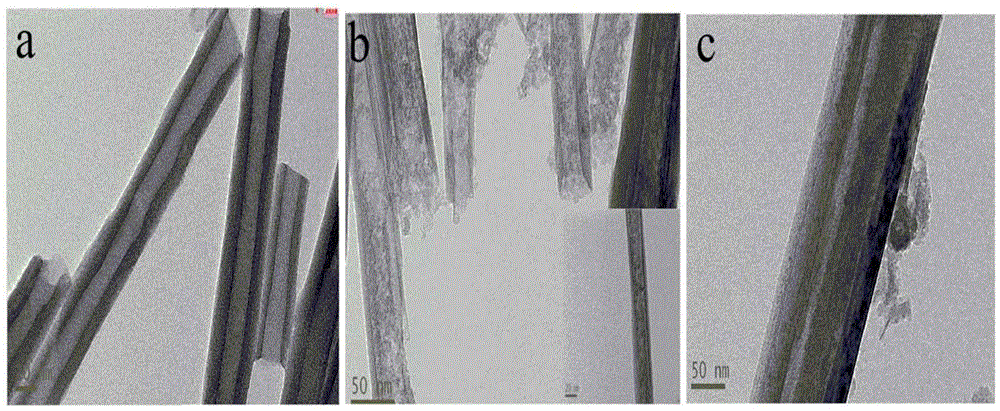

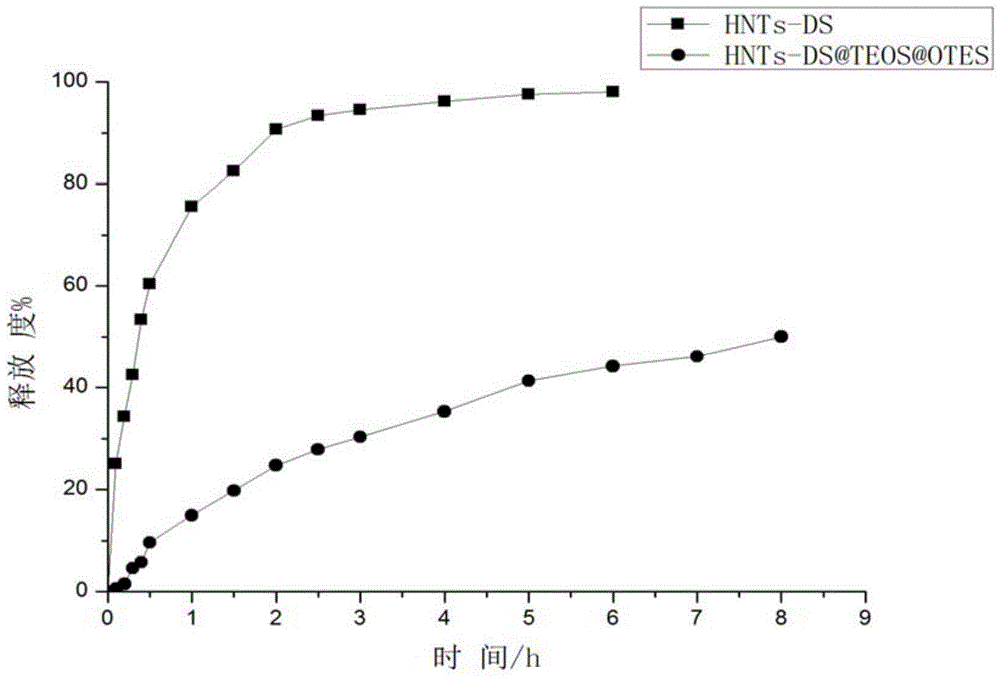

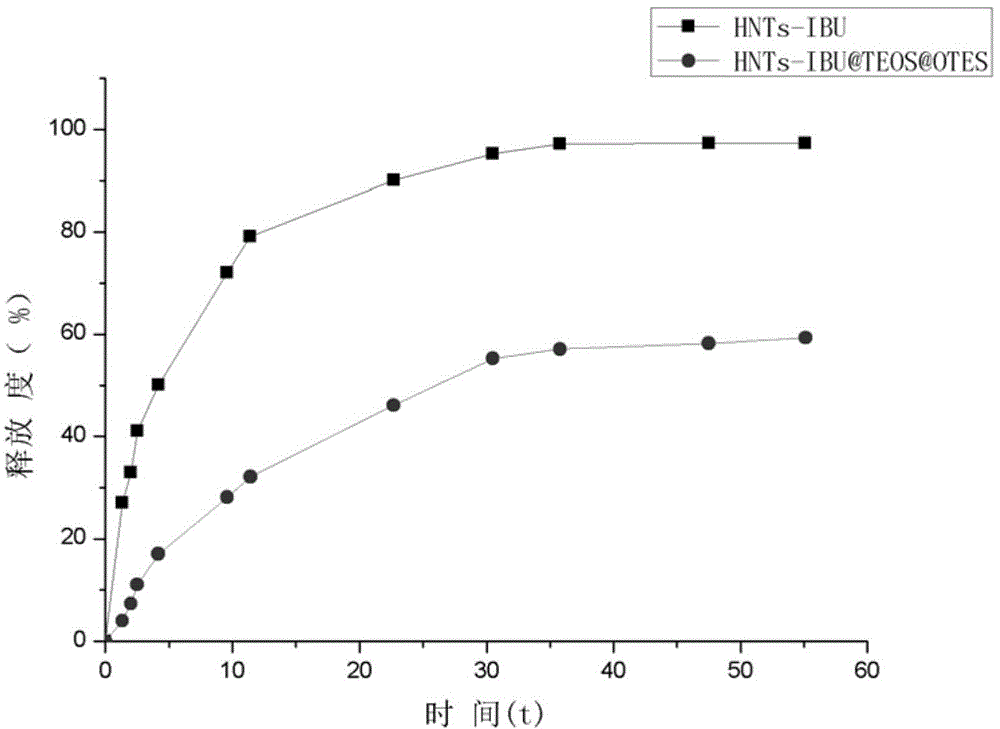

Halloysite nanotube drug sustained-release material and preparation method thereof

InactiveCN104587489AHigh encapsulation efficiencyGood slow releaseOrganic active ingredientsPharmaceutical non-active ingredientsHalloysiteMedicine

The invention relates to a halloysite nanotube drug sustained-release material and a preparation method thereof. The drug sustained-release material is prepared by the following steps: performing acid corrosion to a halloysite nanotube to obtain a dilated nanotube, loading the drug into an inner cavity of the halloysite nanotube, and coating an organosilane polymerized hydrophobic layer onto the surface of the drug-carried halloysite nanotube, wherein the during the coating of the organosilane polymerized hydrophobic layer, organosilane I is firstly used for modifying the outer surface of the halloysite nanotube, and then organosilane II is added to form the organosilane polymerized hydrophobic layer on the surface of the nanotube. Compared with the prior art, the sustained release material has universality on a hydrophobic drug and a hydrophile drug, the drug release time can be effectively prolonged, the encapsulation efficiency is high, and the administration safety of the drug can be improved.

Owner:CENT SOUTH UNIV

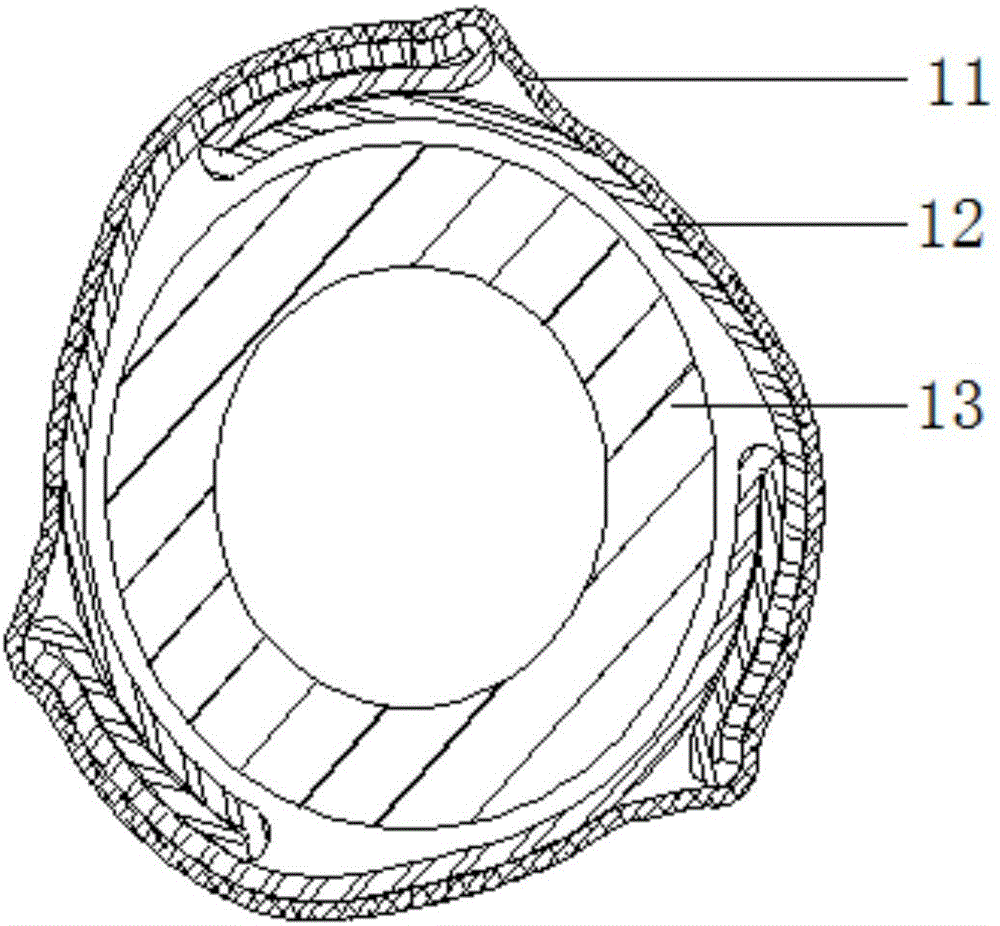

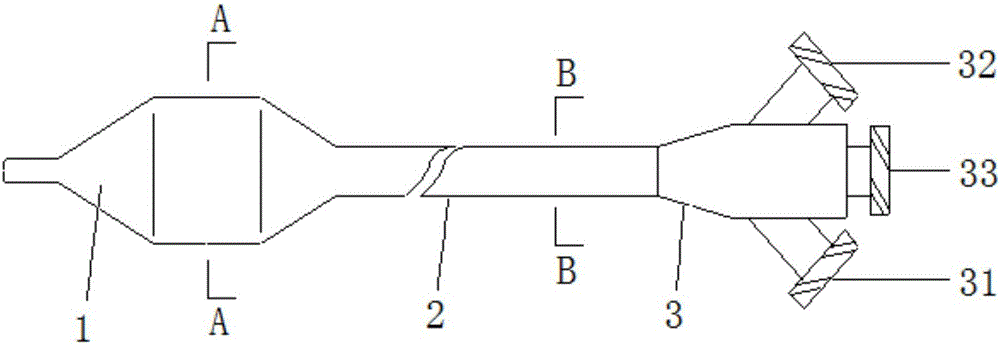

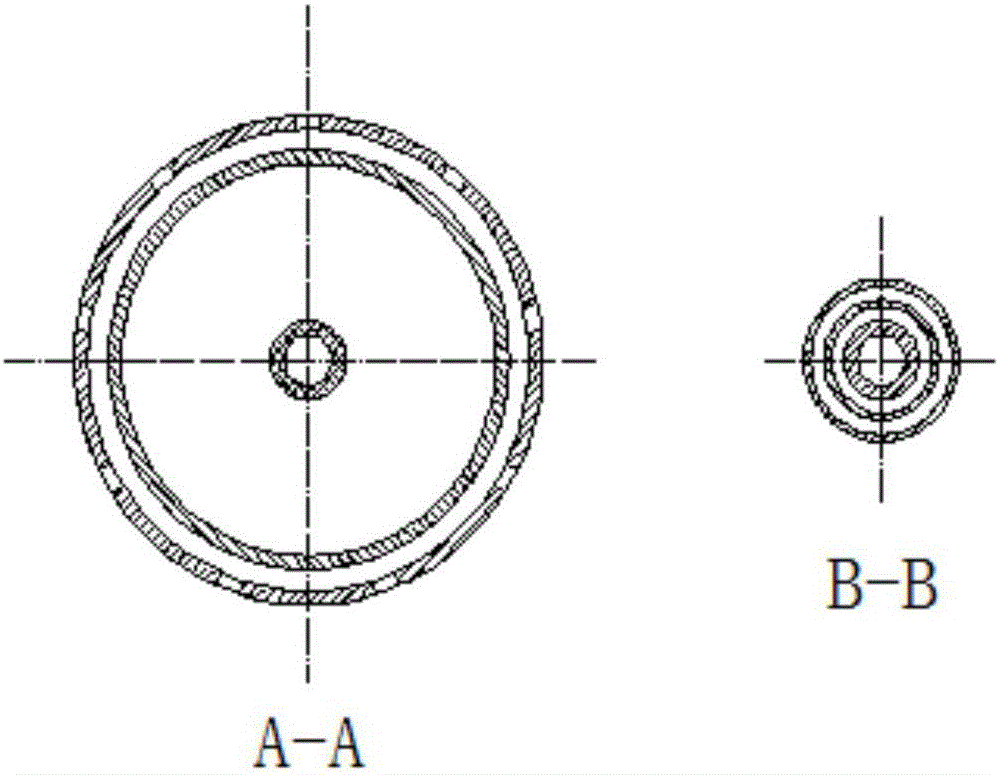

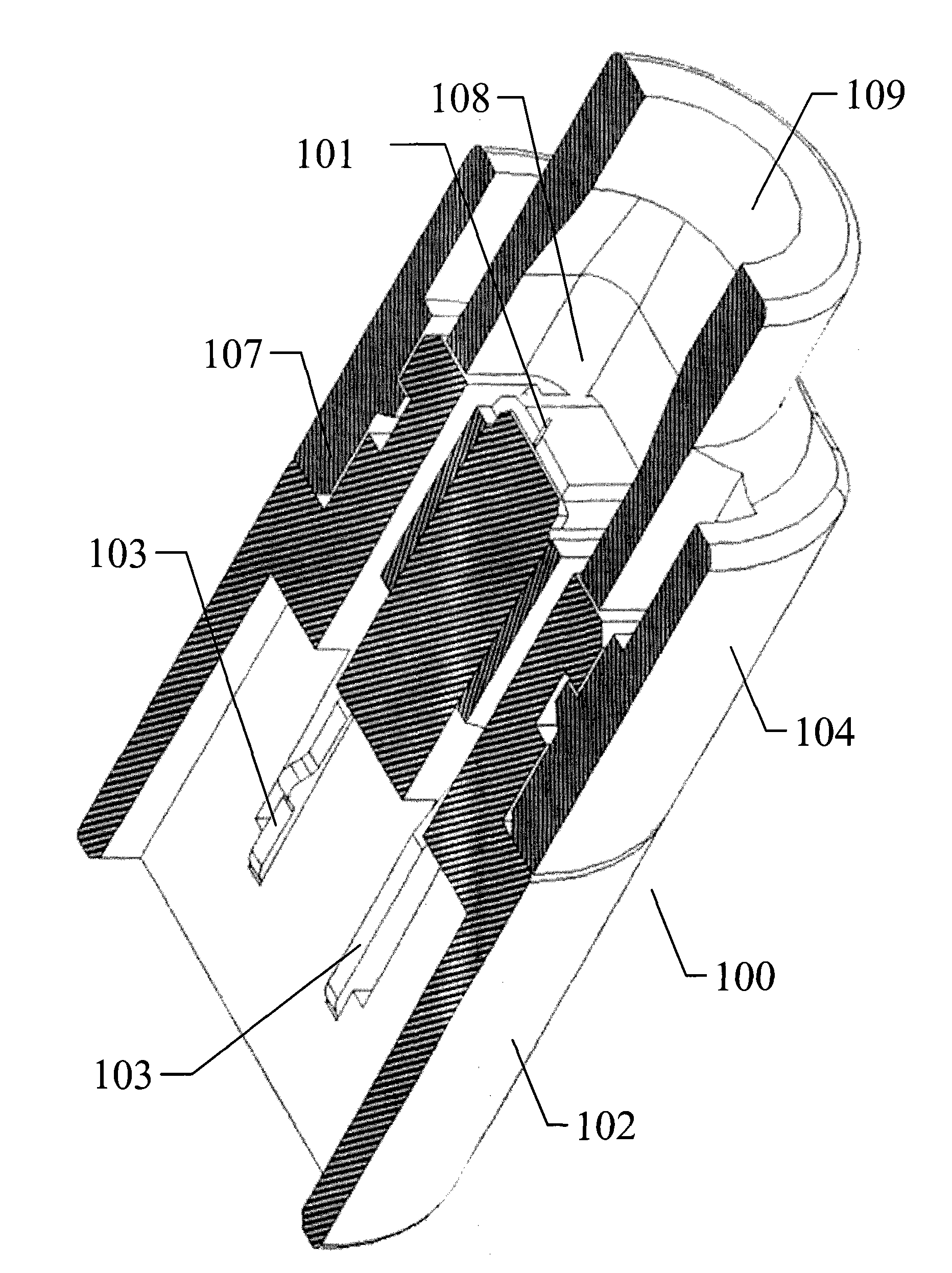

Expansible and infusable balloon catheter

InactiveCN106390268AControl doseLow costBalloon catheterMulti-lumen catheterHuman bodyNon compliance

The invention discloses a balloon catheter capable of expanding lesion and capable of infusing a location of lesion. A balloon portion of the catheter is of a double-layer structure, an inner layer is a semi-compliance or non-compliance expansible balloon, and an outer layer is a high-resilience compliance balloon; the outer-layer balloon covers on the inner-layer balloon, and a certain quantity of micro-pores penetrating the balloon wall are distributed in the high-resilience compliance balloon. When the balloon is independently filled and expanded, the high-resilience compliance balloon is passively expanded so as to expand the location of the lesion; and after the balloon is filled and expanded, when the high-resilience balloon is filled with a perfusion solution, medicine can be infused to a lumen of the human body by virtue of the micro-pores in the balloon wall. Compared with the medicine balloon, the dosage of the medicine can be more precisely controlled; the dosage of the medicine and the type of the dosage can be changed according to requirements; and due to the pressure of the filled outer-layer balloon, the infused medicine can enter deeper blood vessel wall tissue, and a better treatment effect can be achieved. The balloon catheter can also be used for infusing stem cells and other substances at a fixed point.

Owner:ZHONGSHAN HOSPITAL FUDAN UNIV

Milk making machine

PendingCN105361703ACause health problemsProblems in preventing moisture deteriorationBeverage vesselsInjection portTorque transmission

The invention discloses a milk making machine, which comprises a machine shell, a water supply unit, a milk supply unit and mixing containers, and further comprises a container fixing base and a rotation driving mechanism, wherein the water supply unit is arranged on the machine shell and is used for controlling water temperature and a water supply amount; the milk supply unit is used for controlling a milk amount; and the mixing containers are used for mixing milk powder with warm boiled water, so that milk liquid is formed, and is exported to a milk bottle; the mixing containers are centrifugally installed on the container fixing base; the rotation driving mechanism is arranged on the machine shell and is connected to the container fixing base by virtue of a torque transmission structure; the rotation driving mechanism is used for driving the container fixing seat to rotate for rotating the mixing container to various stations; an injection port for injecting water and milk powder is arranged in the top surface of the mixing container, and a milk liquid outlet, which is controlled by a valve, is additionally arranged at the bottom of the mixing container; the milk outlet of the milk supply unit and the water outlet of the water supply unit are respectively aligned with the injection ports of the mixing containers on different stations; and a milk outlet station of the milk making machine is located below the water outlet. The milk making machine disclosed by the invention can be used for effectively protecting the milk powder from being affected with damp.

Owner:GUANGDONG SHUNDE CHINNO IND DESIGN

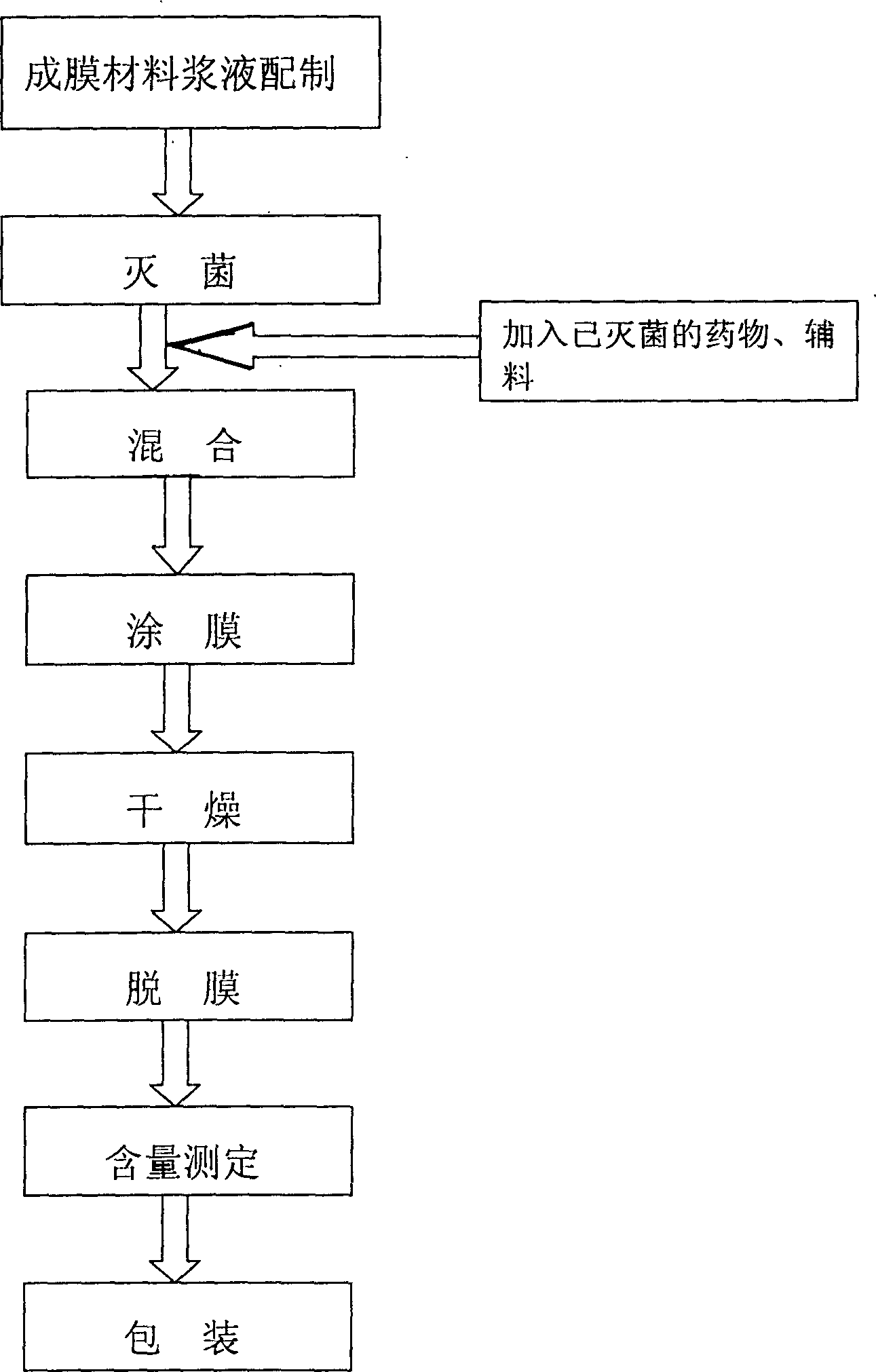

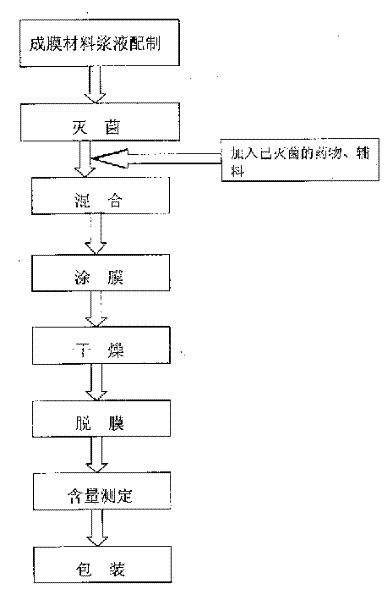

Alkaline fibroblast growth factor pellicle and its production method

InactiveCN1524577AGood treatment effectMeet needsPeptide/protein ingredientsDigestive systemDistilled waterFilm-coated tablet

An alkaline desmocyte growth factor film agent comprising, (1) alkaline desmocyte growth factor (bFGF) 0%-1% (W / W) of effective wound treatment dose, (2) medicinal film forming material 10%-90% (W / W), (3) medicinal findings 0%-50% (W / W), and the process of preparation comprises the steps of, dispersing the medicinal film forming material into distilled water, after sufficient swelling, heat pressing sterilization, dissolving the bFGF stock solution and medical dressing in distilled water, asepsis filtering, charging the filter liquor into disinfected film matrix, stirring slowly and evenly, the bFGF film agent can be obtained through film coating, drying and demoulding.

Owner:ZHUHAI ESSEX BIO PHARMA

Nano composite foaming agent and preparation method and foamed product thereof

The invention relates to a nano composite foaming agent and a preparation method and a foamed product thereof. The foaming agent is compounded from layered montmorillonite and 4,4-oxo-bis hydrazide, wherein the mass ratio of the 4,4-oxo-bis hydrazide to the montmorillonite is 1:(4-16). The composite foaming agent is obtained by a method of recombining and compounding the layered montmorillonite with the 4,4-oxo-bis hydrazide after stripping in preparation of the foaming agent. The foaming agent has the advantages that an organic foaming agent is embedded between nanoscale montmorillonite layers, so that the foaming agent is refined, the dosage of the foaming agent is effectively controlled, a nucleating point is increased, the foaming efficiency is improved, formed bubbles are even and small in holes, and meanwhile, the property of the obtained foamed product is also improved to a certain extent by adding of an inorganic material.

Owner:BEIJING UNIV OF CHEM TECH

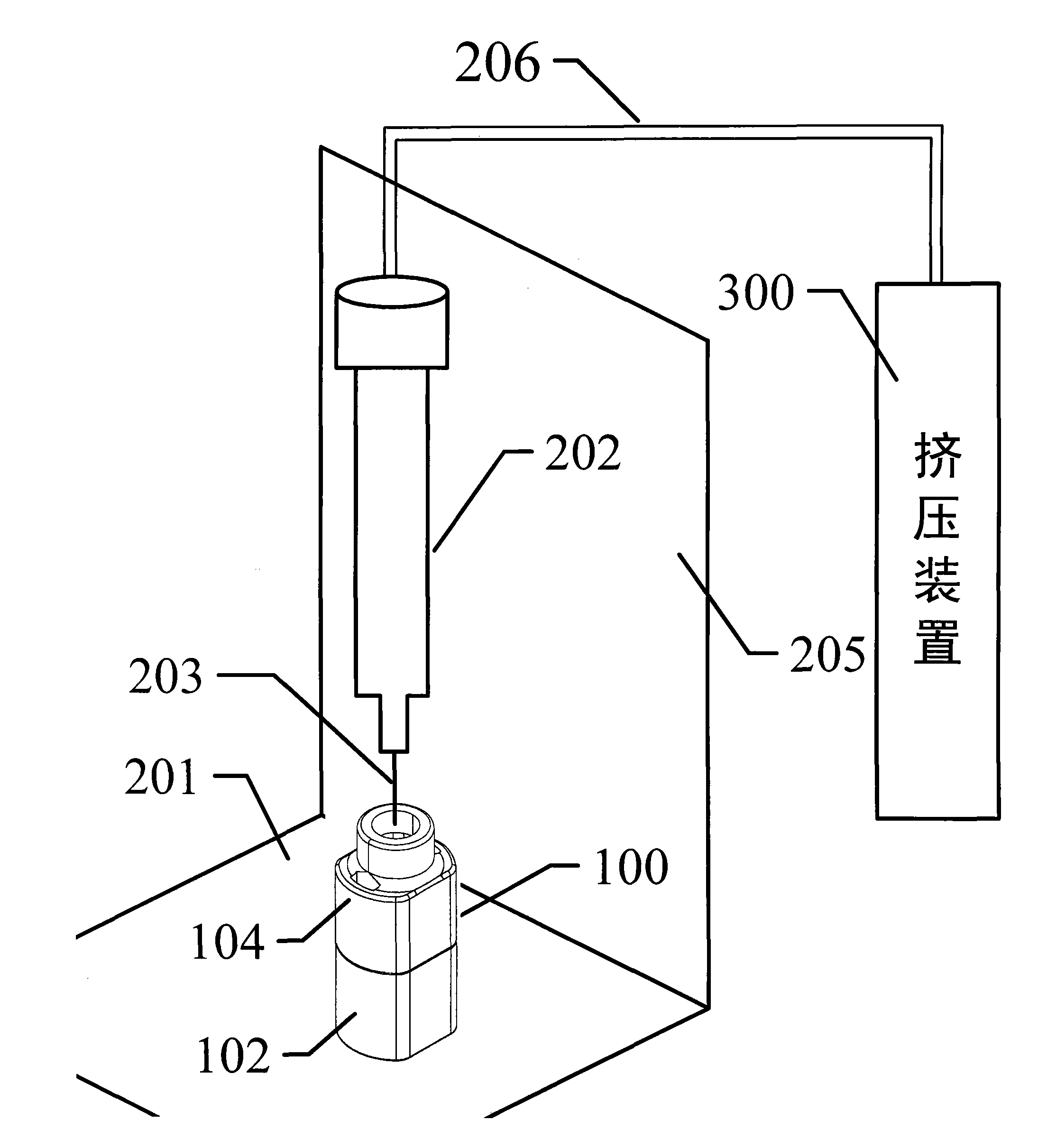

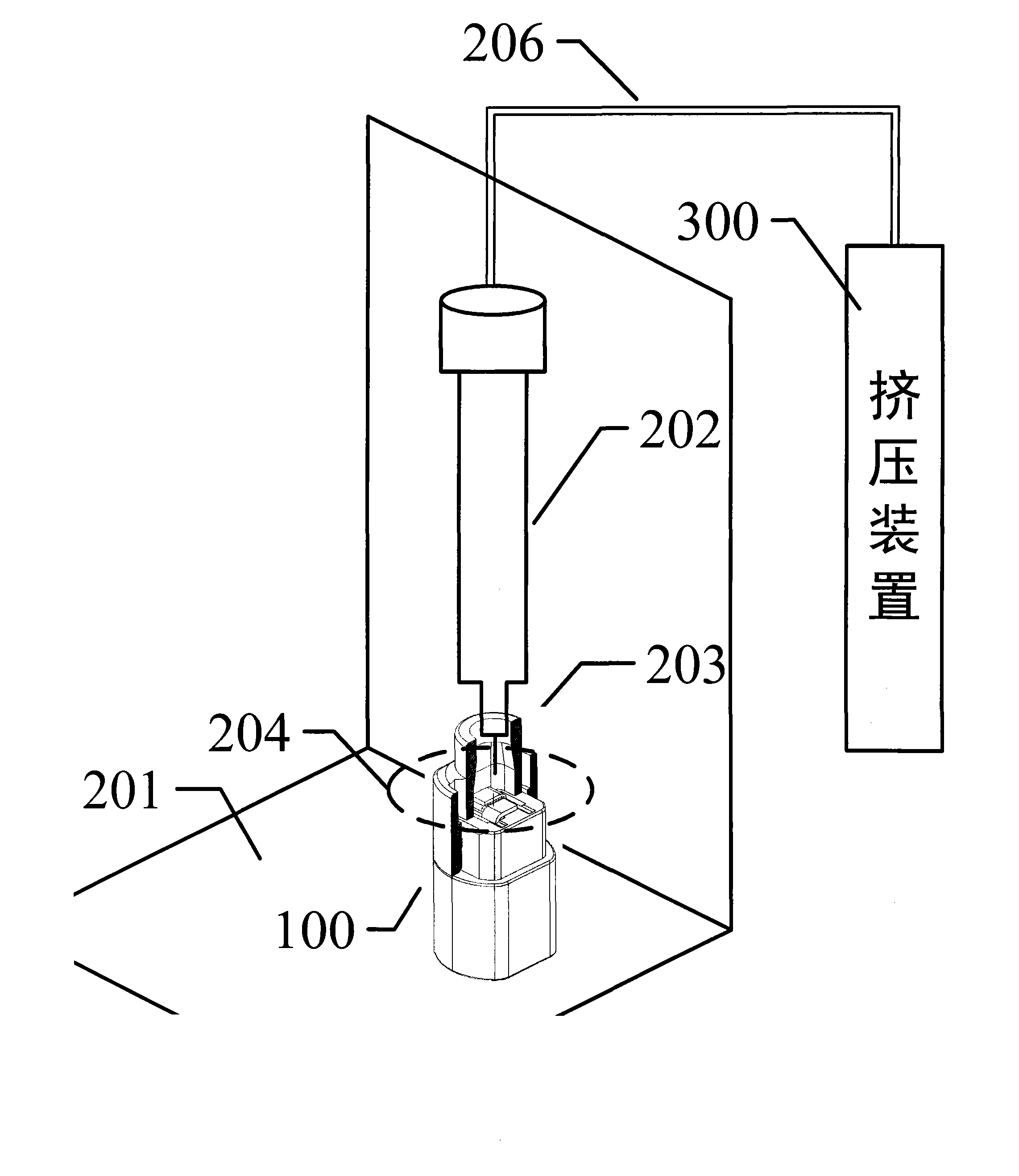

Method for producing explosive ignition head in detonator production and special explosive ignition device thereof

The invention provides a method for producing a detonator explosive ignition head. The method comprises the following processes of: 1, upwards fixedly placing an ignition head explosive cavity on an operating table; 2, adjusting an explosive injection cartridge or the operating table so that the cartridge is positioned right above a cavity shell and aims at an ignition bridge wire; 3, adjusting an explosive injection head or the operating table so that the explosive injection head descends to the explosive cavity; and 4, starting an extrusion device to extrude an ignition agent, and injecting the agent into the explosive cavity so that the agent fully wraps the ignition bridge wire; and finally, extracting the explosive injection head to complete the production. The invention also provides an explosive ignition device for implementing the method, which comprises the operating table, the explosive injection cartridge, the explosive injection head, the extrusion device and an explosion-proof device for isolating a person and the operating table. A fixer on the operating table fixes the ignition head on the operating table, the extrusion device can hermetically connected with the explosive injection cartridge through an air pipe, and the explosive injection cartridge is hermetically connected with the explosive injection head. According to the technical scheme, automatic production of the explosive ignition head can be realized.

Owner:BEIJING BANGIUNION TECH DEV

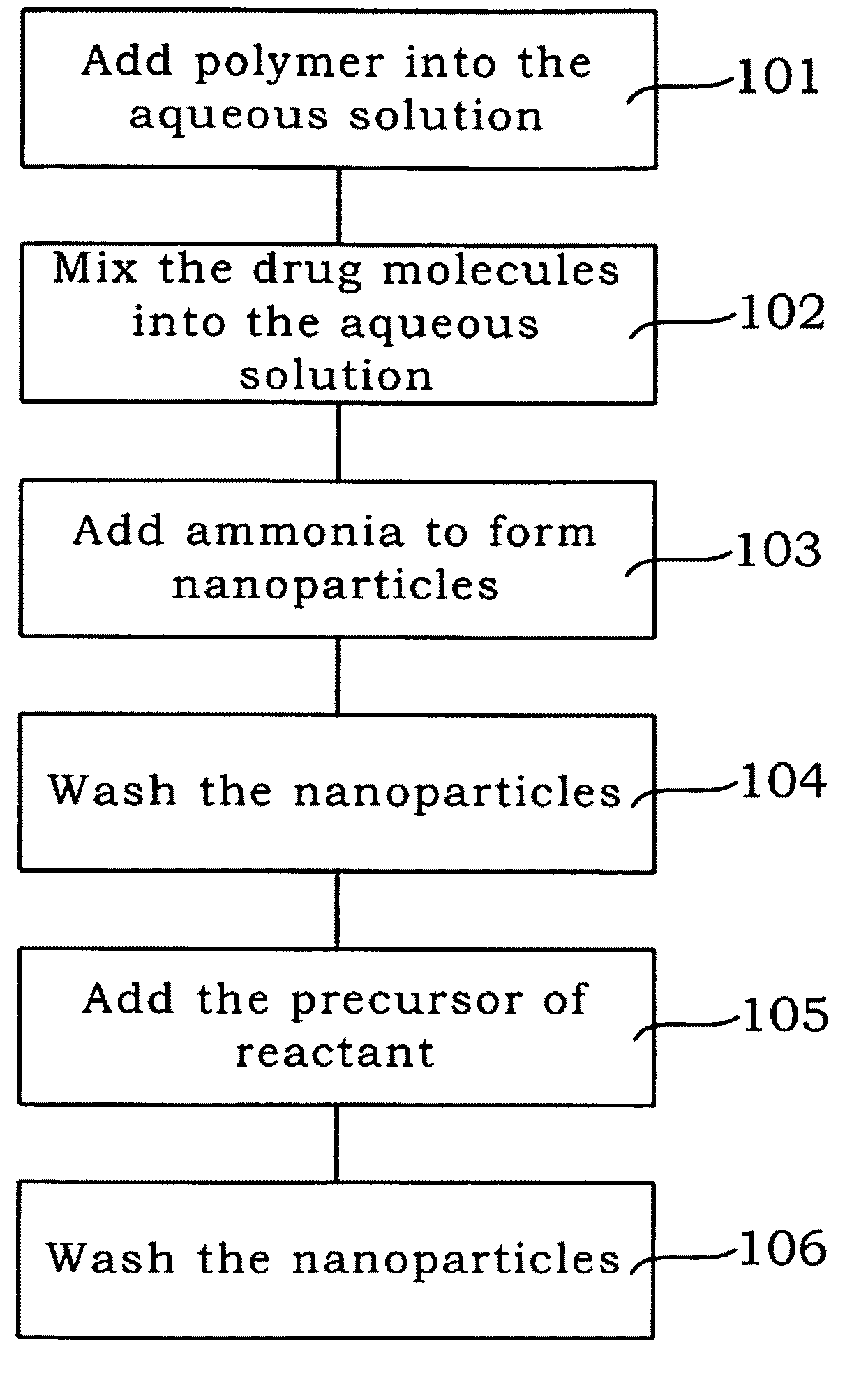

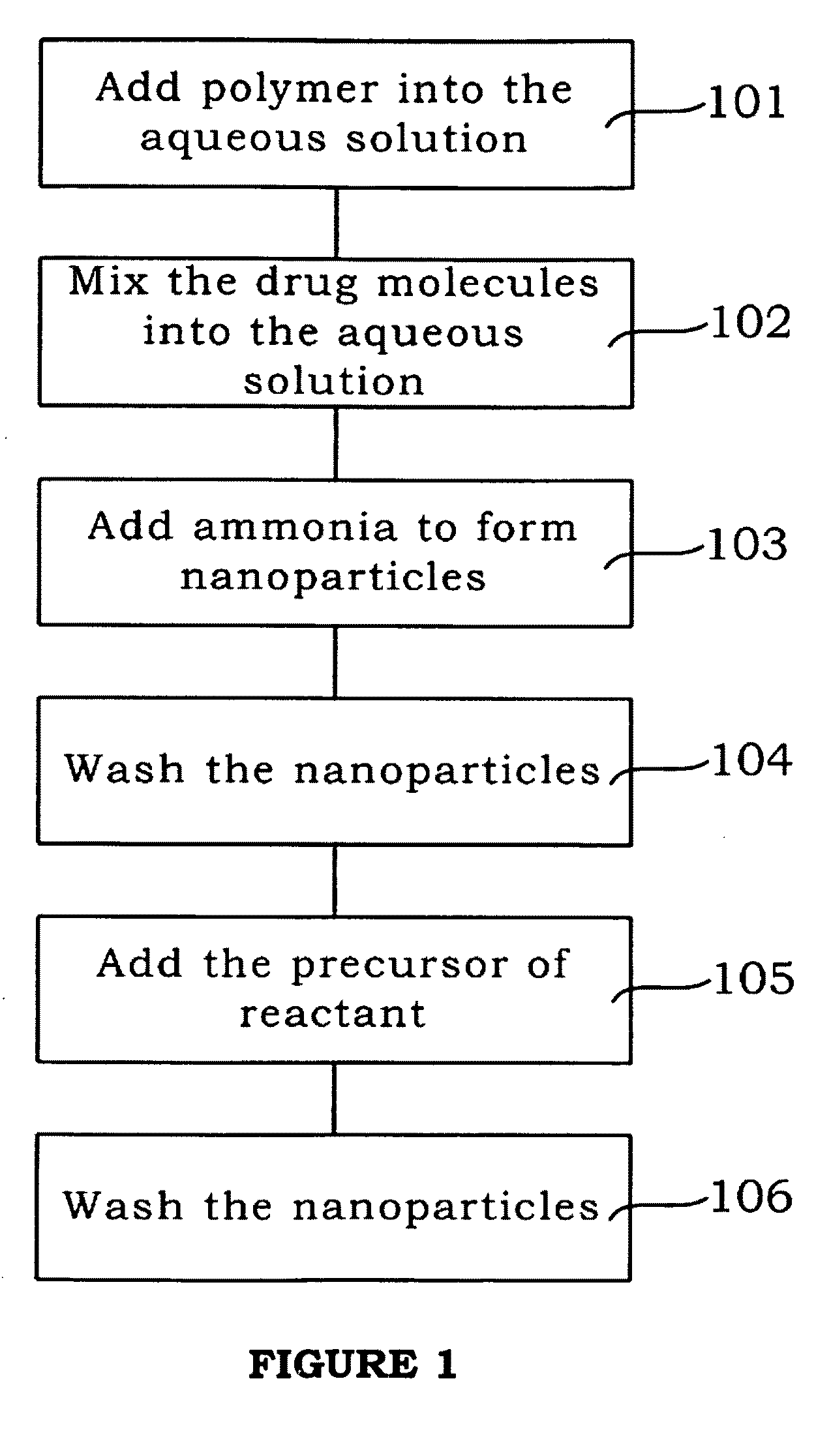

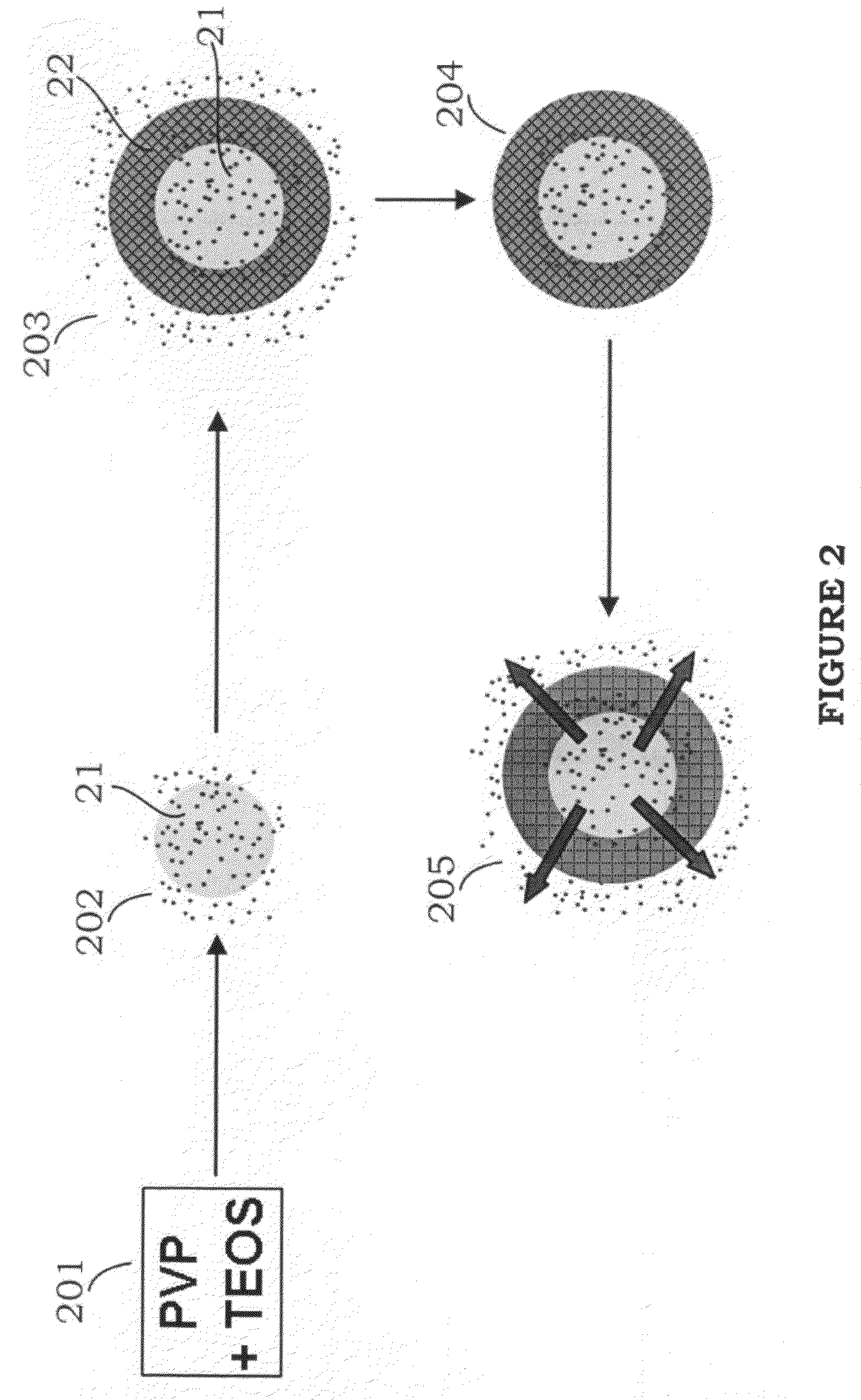

Method of forming a drug nanocarrier having a magnetic shell

InactiveUS20090285885A1Increased magnetic sensitivityHigh sensitivityBiocideInorganic non-active ingredientsNanocarriersMedicine

The invention discloses the synthesis and manufacturing of a novel core-shell nano-carrier with a drug-containing nanocomposite core surrounding with a single crystalline magnetic iron oxide shell. With a unique core-shell configuration, active agents such as drugs and biomolecules encapsulated in the core with an outer single-crystalline thin iron oxide shell can be perfectly protected from environmental damages and in the meantime, eliminating un-desirable release due to un-controllable diffusion of the active molecules from the nanocapsules during the course of delivery in patient's body, before reaching the disease sites.

Owner:NAT CHIAO TUNG UNIV

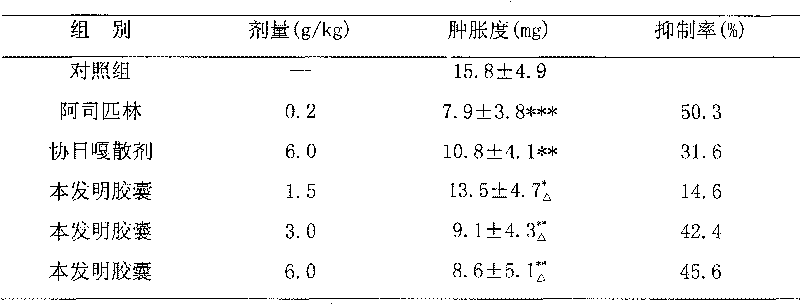

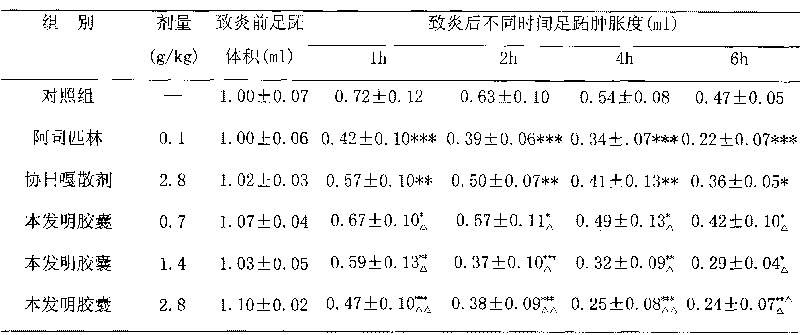

Preparation method of Chinese medicinal composition for treating urinary system infection

ActiveCN101732668AActive ingredients reservedActive ingredients fully retainedAntiinfectivesPill deliveryTribulus terrestrisActive ingredient

The invention provides a novel preparation method of a Chinese medicinal composition for treating urinary system infection, and particularly relates to the novel preparation method of the Chinese medicinal composition prepared from the following raw material medicaments: curcuma longa, gardenia jasminoides, puncturevine caltrop fruit and the like. The method has a simple process, is suitable for industrialized production, improves medicinal effect and greatly reduces production cost.

Owner:HUNAN JIUDIAN PHARMA

System and methods for providing dynamic integrated wellness assessment

ActiveUS20130122476A1Expand the populationHigh indexMedical simulationCosmonautic condition simulationsFactor baseEngineering

Systems and methods for generating and using measurable indexes for providing a total wellness assessment of an individual are provided. A method includes computing an overall health score corresponding to the individual based on a plurality of weighting factors, the weighting factors based at least on health conditions associated with the individual. The method also includes determining a set of recommended changes for the individual based on the overall health score and generating an episodic plan for the individual, the episodic plan comprising a series of episodes for the individual that when completed will result in the individual having implemented the set of recommended changes. The method further includes generating a series of prompts for the individual, the series of prompts selected to guide the individual through the episodic plan.

Owner:THE QUANTUM GROUP +2

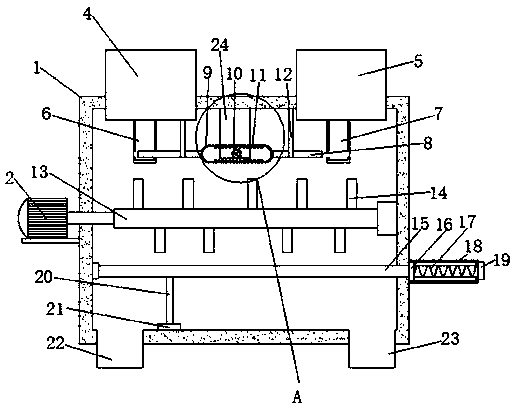

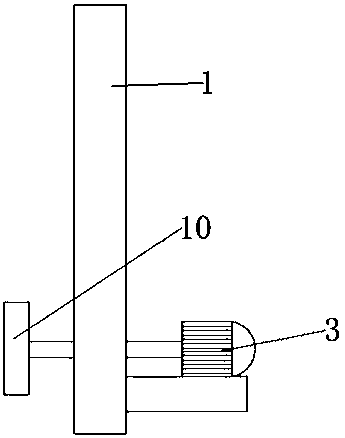

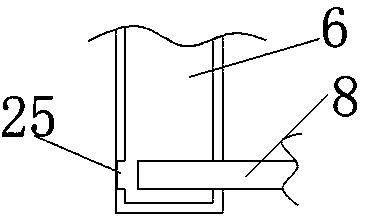

Push-pull decorative material unloading mechanism

InactiveCN108114663AAchieving stirringAchieve clearingRotary stirring mixersTransportation and packagingPush pullAgricultural engineering

The invention relates to the technical field of decorative materials and particularly relates to a push-pull decorative material unloading mechanism. The push-pull decorative material unloading mechanism comprises a tank body, wherein a decorative material storage tank is arranged on the left side of the upper end of the tank body, and an auxiliary material storage tank is arranged on the right side of the upper end of the tank body; an output shaft of a second motor penetrates through a fixed plate and is connected with a rotating shaft, and an incomplete gear is connected to one end, far from a second motor, of the rotating shaft; a frame body is arranged on opposite sides of two transverse rods, and racks meshed with the incomplete gear are symmetrically arranged on the inner wall of the frame body; and a support plate is arranged on one side of the tank body, a first motor is mounted at the upper end of the support plate, an output shaft of the first motor penetrates through the tank body and is connected with a rotating rod, a first discharging hole is formed in the left side of the lower end of the tank body, and the first motor and the second motor are connected with an external control switch. According to the push-pull decorative material unloading mechanism, a subsequent manual cleaning process is omitted, so the labor intensity of workers is reduced, and the workingefficiency is improved.

Owner:CHENGDU YALIAN TECH CO LTD

Methods for Treatment of Ophthalmic Disease of an External Ophthalmic Tissue

InactiveUS20100150992A1Efficacy can be sustainedly developedCan be sustainedly developedBiocideSenses disorderDiseaseEyelid

A transdermal drug delivery system for treatment of ophthalmic diseases comprising a structure that a plaster layer containing a remedy for ophthalmic diseases is provided on a support, wherein the system is applied to a skin surface including a front surface of an eyelid to administer the remedy for ophthalmic diseases in the plaster layer to an ophthalmic topical tissue by percutaneous permeation substantially without being administered through a systemic blood flow. Use of the transdermal drug delivery system for treatment of ophthalmic diseases, comprising applying the transdermal drug delivery system to a skin surface including a front surface of an eyelid to transfer the remedy for ophthalmic diseases in the plaster layer to an ophthalmic topical tissue by percutaneous permeation substantially without being administered through a systemic blood flow, and a method for transferring the remedy for ophthalmic diseases to the ophthalmic topical tissue.

Owner:SENJU PHARMA CO LTD

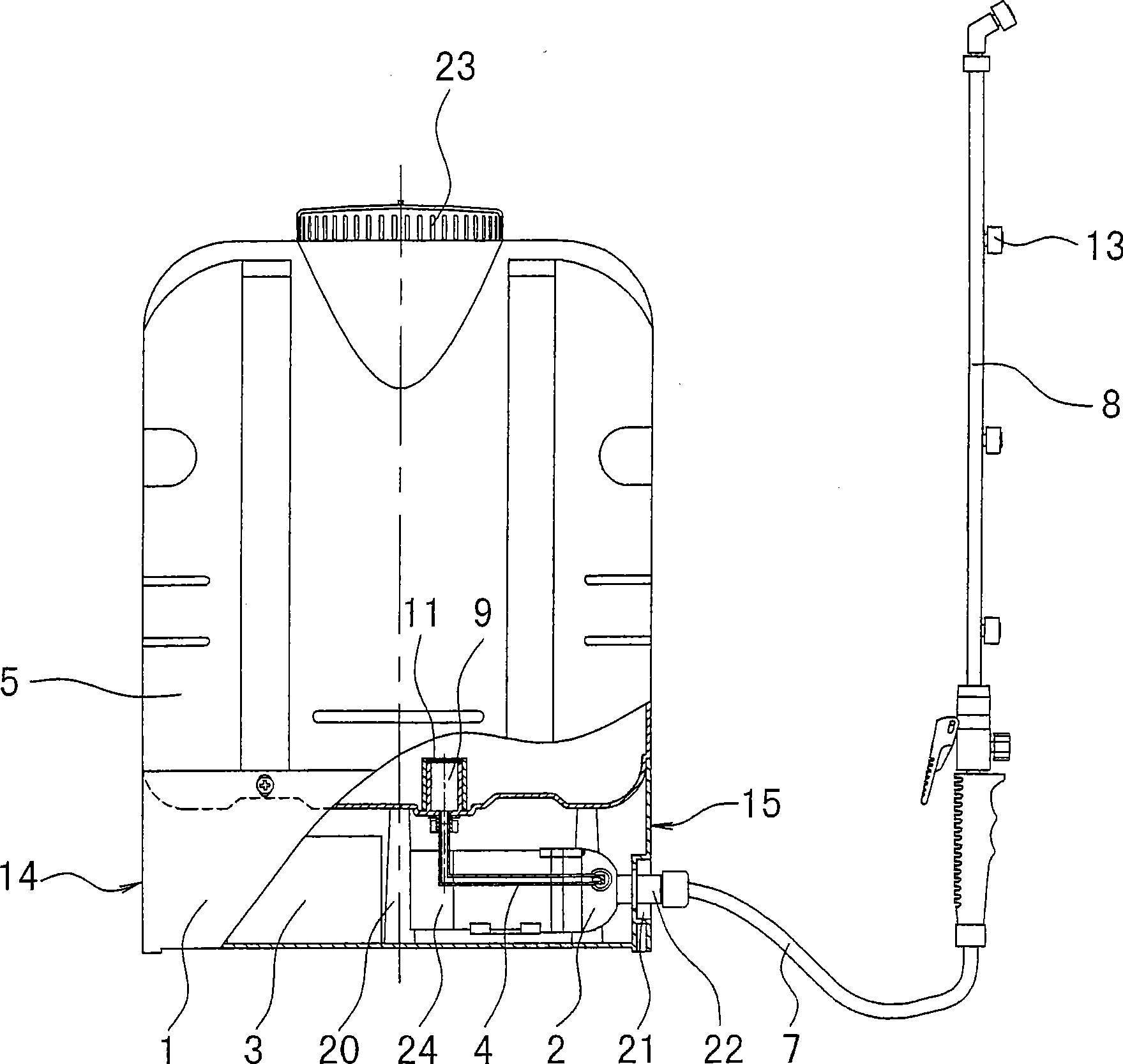

Backpack high-pressure electric sprayer

InactiveCN101439327AAvoid damageSimple structureDC motor speed/torque controlLiquid spraying apparatusDiaphragm pumpElectric machine

A backpack high pressure power sprayer comprises a base, an electrical pump component installed in the base and a storage battery; wherein, the electrical pump component is a membrane pump driven by a DC electric machine, a water inlet pipe of the membrane pump is connected with a water tank, and a water outlet thereof is connected with a spray rod by a water outlet pipe; the water tank is installed on the base, a liquid feeding hole is opened on the top of the water tank and is provided with a cover, and a strap is arranged on the wall of the water tank; the backpack high pressure power sprayer is characterized in that the base is internally provided with a support pillar, the top surface of the support pillar is contacted with the bottom surface of the water tank and is higher than the mounting planes of the storage battery and the membrane pump, a left side plate of the base is equipped and connected with a speed control switch of the storage battery, a fuse, a power switch and a charging socket, and a right side plate of the base is provided with a mounting groove which is internally provided with a water outlet connector of the membrane pump, so that the assembly and disassembly, the maintenance and the operation are considerably convenient.

Owner:任正志 +1

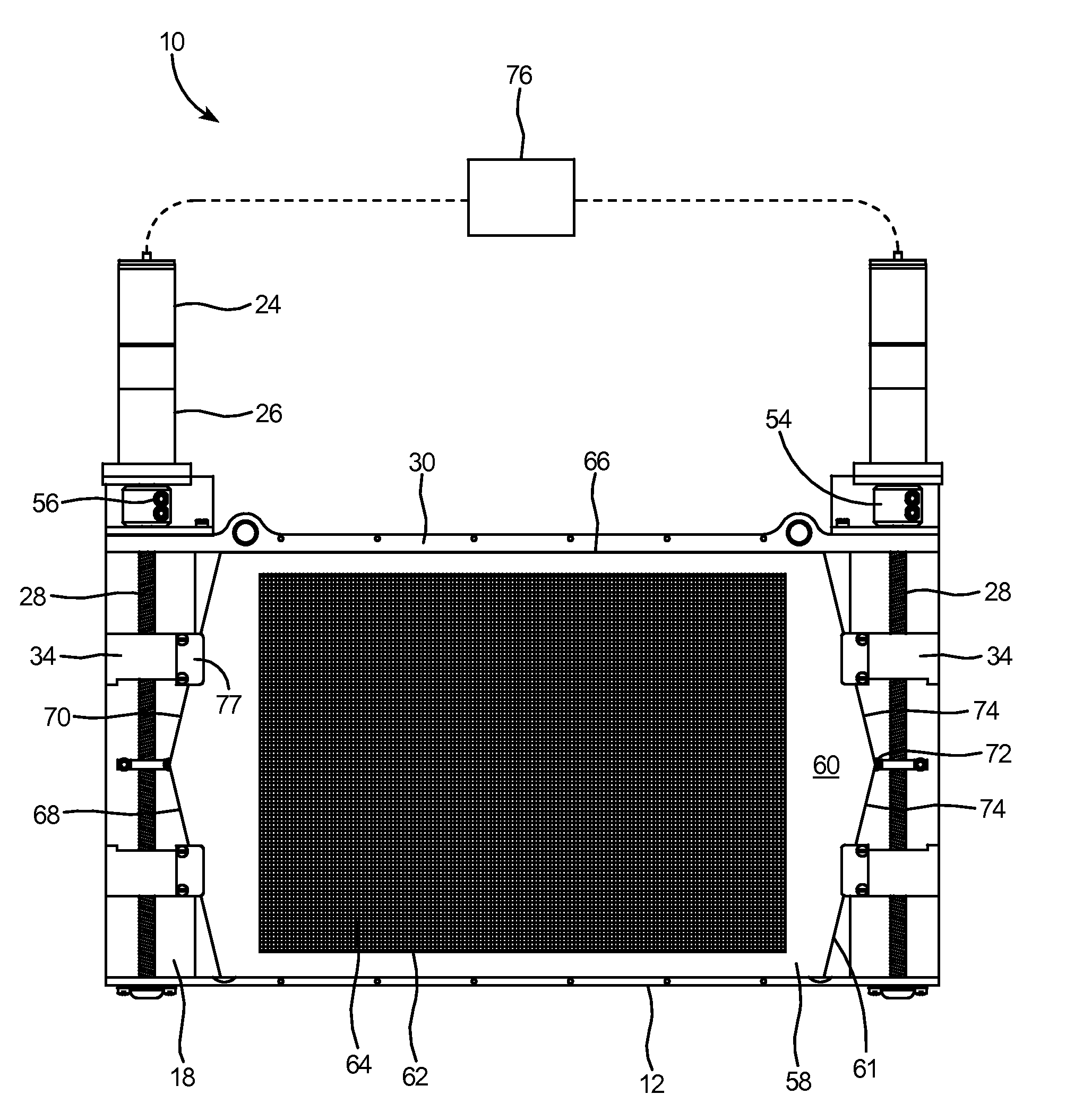

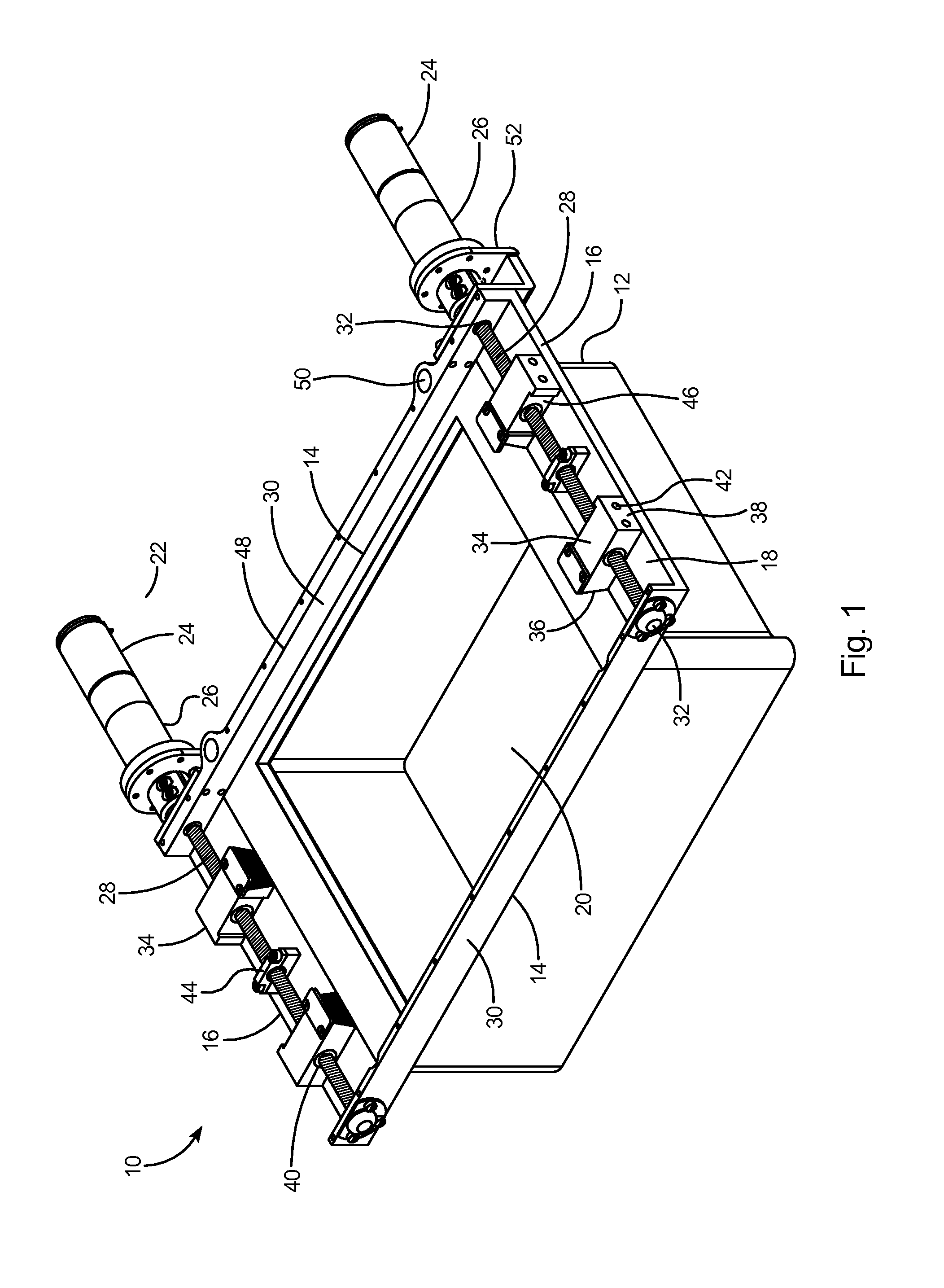

Apparatus and method for variable angle slant hole collimator

ActiveUS20170040077A1High precisionEasy to adjustHandling using diaphragms/collimetersTwin-leadHigh energy

A variable angle slant hole (VASH) collimator for providing collimation of high energy photons such as gamma rays during radiological imaging of humans. The VASH collimator includes a stack of multiple collimator leaves and a means of quickly aligning each leaf to provide various projection angles. Rather than rotate the detector around the subject, the VASH collimator enables the detector to remain stationary while the projection angle of the collimator is varied for tomographic acquisition. High collimator efficiency is achieved by maintaining the leaves in accurate alignment through the various projection angles. Individual leaves include unique angled cuts to maintain a precise target collimation angle. Matching wedge blocks driven by two actuators with twin-lead screws accurately position each leaf in the stack resulting in the precise target collimation angle. A computer interface with the actuators enables precise control of the projection angle of the collimator.

Owner:JEFFERSON SCI ASSOCS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com