Method for producing explosive ignition head in detonator production and special explosive ignition device thereof

A production method and ignition head technology, applied in the field of pyrotechnics manufacturing, can solve the problems of lowering the qualified rate of the charge head production process, unfavorable batch automation production, and poor performance uniformity of the ignition charge head, so as to avoid excessive charge of the charge head Too much or too little, avoiding major safety accidents and improving ignition reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

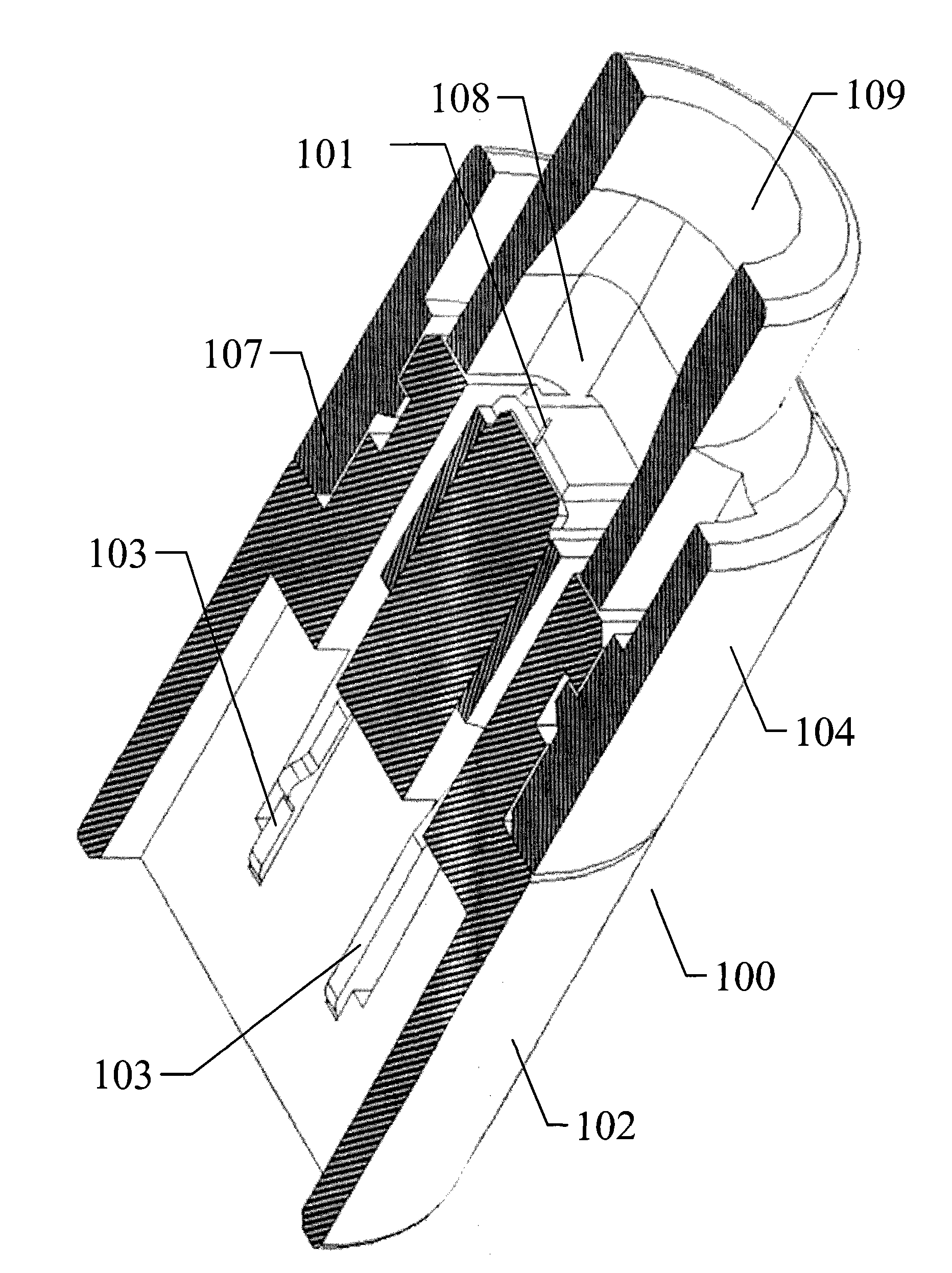

[0033] The ignition charge production method of the present invention is based on the ignition head technical solution disclosed in the patent application document 200910078238.5, such as figure 1 The schematic cross-section is shown. The ignition head 100 includes an ignition bridge wire 101 , a pair of metal sheets 103 , a metal sheet base 102 , and a chamber shell 104 . Wherein, the cavity housing 104 is composed of an assembly cavity 107 , a drug cavity 108 , and an ignition cavity 109 , and the ignition bridge wire 101 welded on a pair of metal sheets 103 is assembled into the drug cavity 108 through the assembly cavity 107 . The sectional view of ignition head 100 after assembly is as follows figure 1 shown.

[0034] The present invention is further designed on the basis of the structure of the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com