Patents

Literature

134results about How to "Improve ignition reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

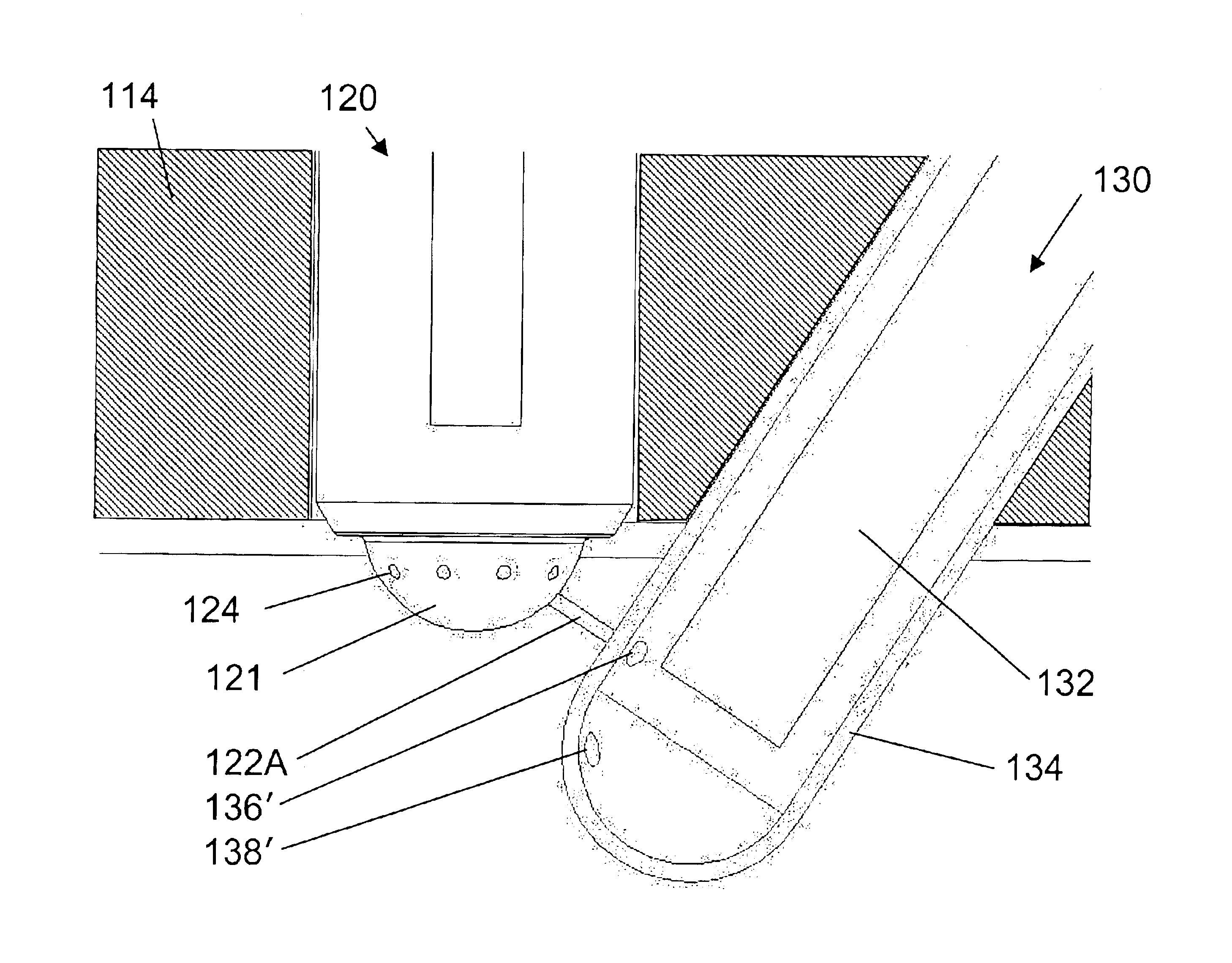

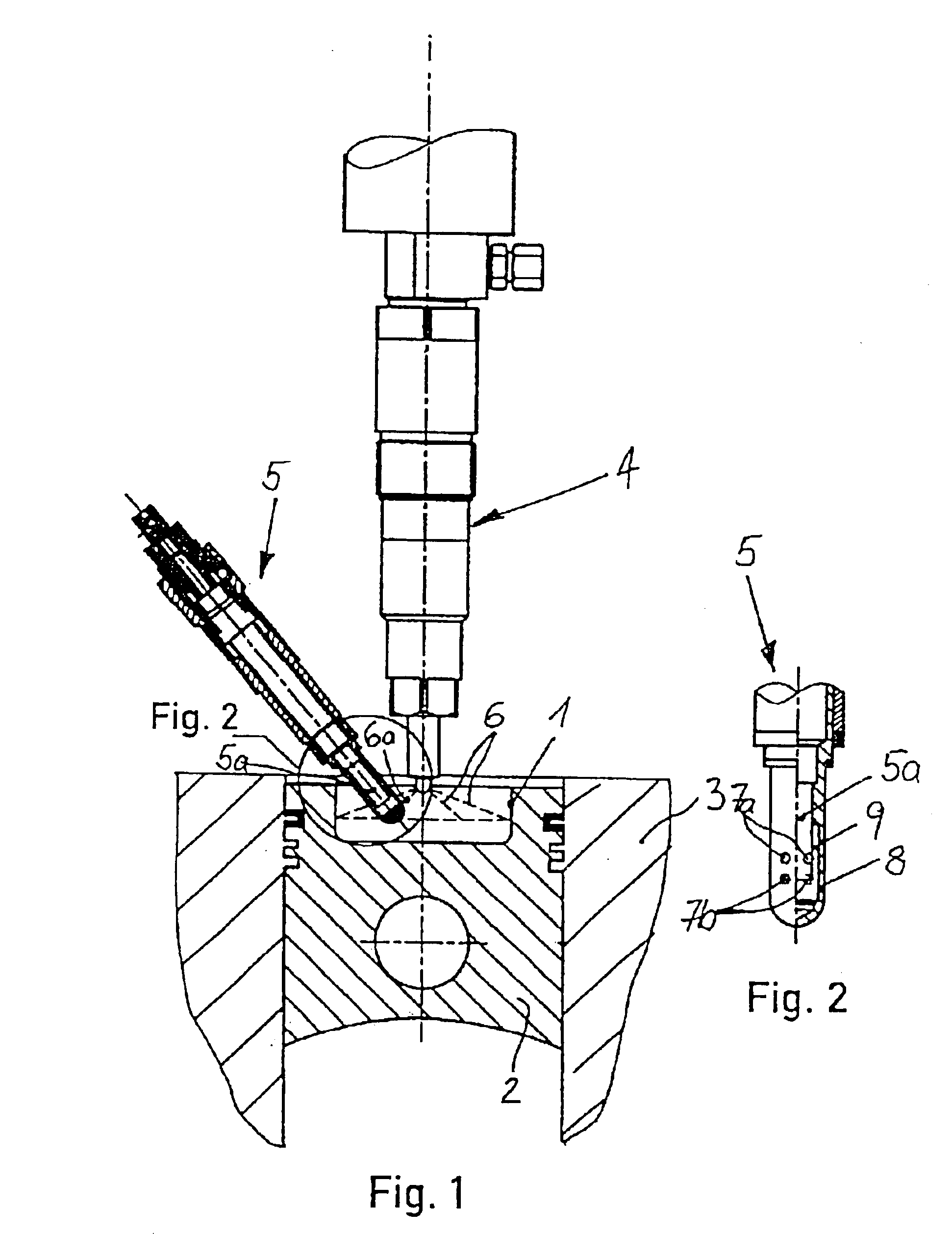

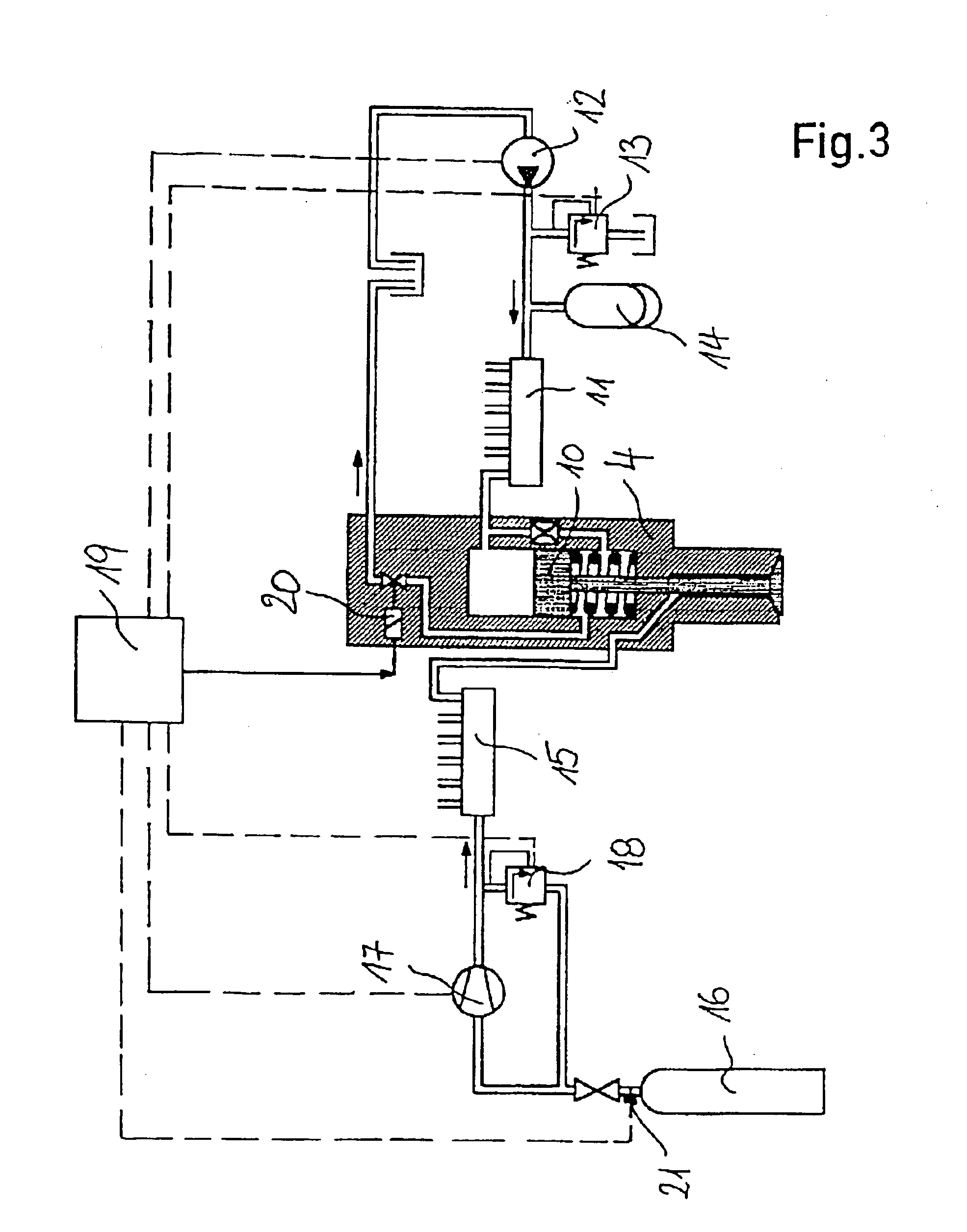

Internal combustion engine with injection of gaseous fuel

InactiveUS6854438B2Reduce modificationReduce manufacturing costIncandescent ignitionInternal combustion piston enginesInternal combustion engineFuel injection

An internal combustion engine comprises a fuel injection nozzle for injecting a gaseous fuel directly into the combustion chamber. shield, is installed in close proximity to the fuel injection nozzle, provides a shielded space around a hot surface igniter and restricts flow between the shielded space and the combustion chamber. The nozzle comprises a fuel injection port oriented to direct a fuel spray against a surface of the sleeve An inlet in the sleeve allows air and fuel to enter the shielded space to form a combustible mixture therein. The sleeve contains a substantial amount of the combustible mixture within the shielded space until it ignites and pressure builds within the shielded space to propel a combustion flame through at least one discharge opening and into contact with the fuel sprays emerging from the fuel injection nozzle.

Owner:WESTPORT POWER

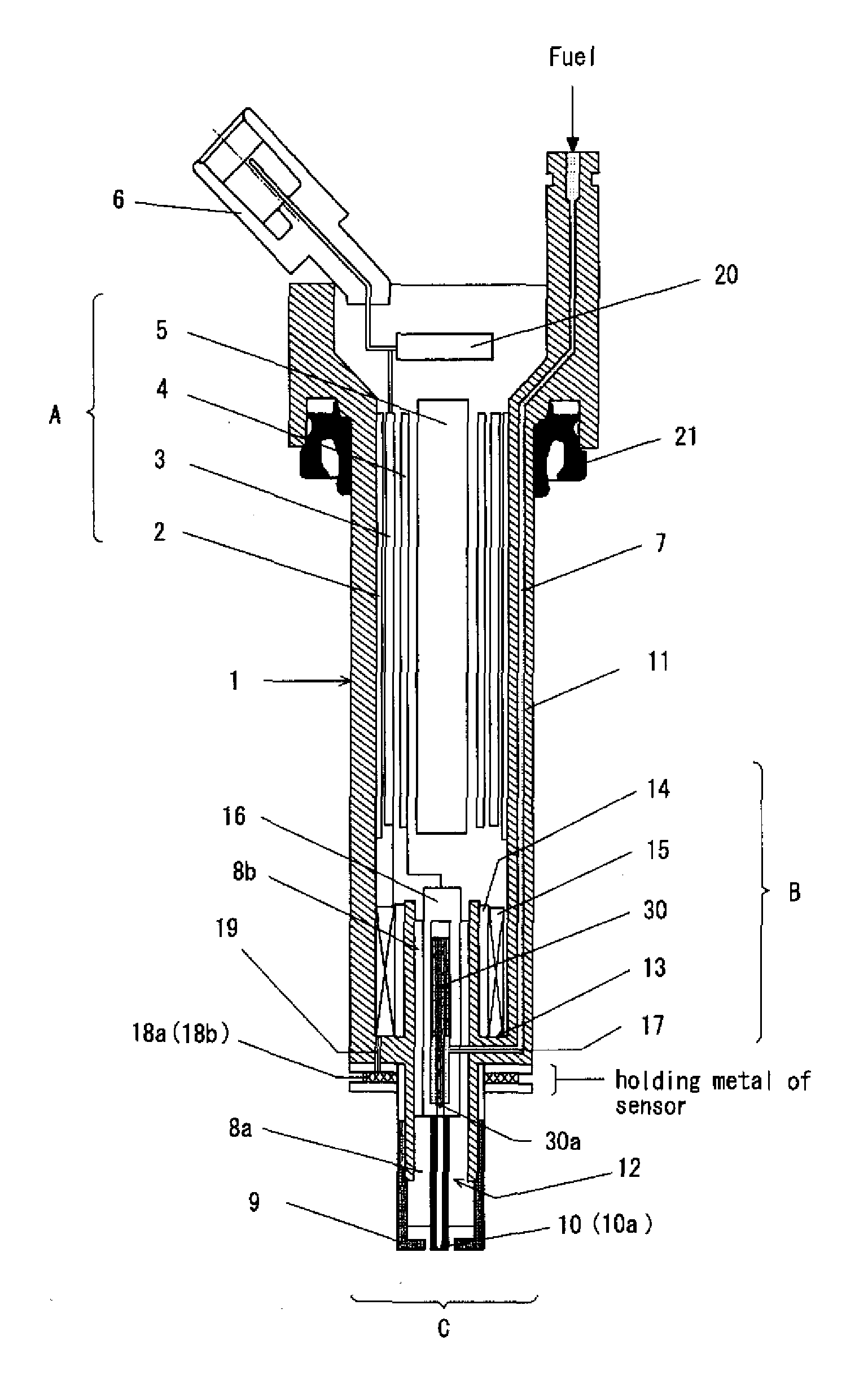

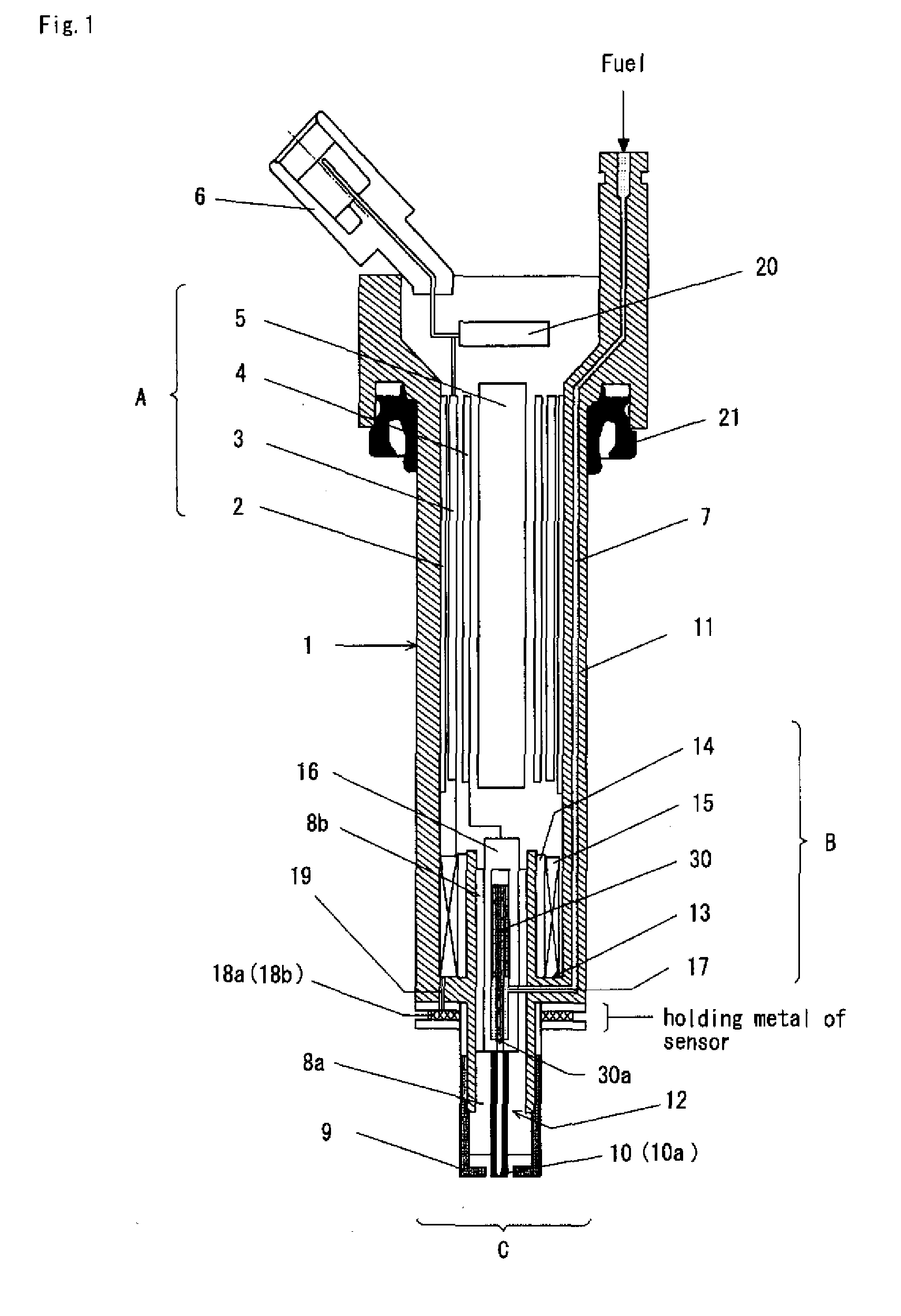

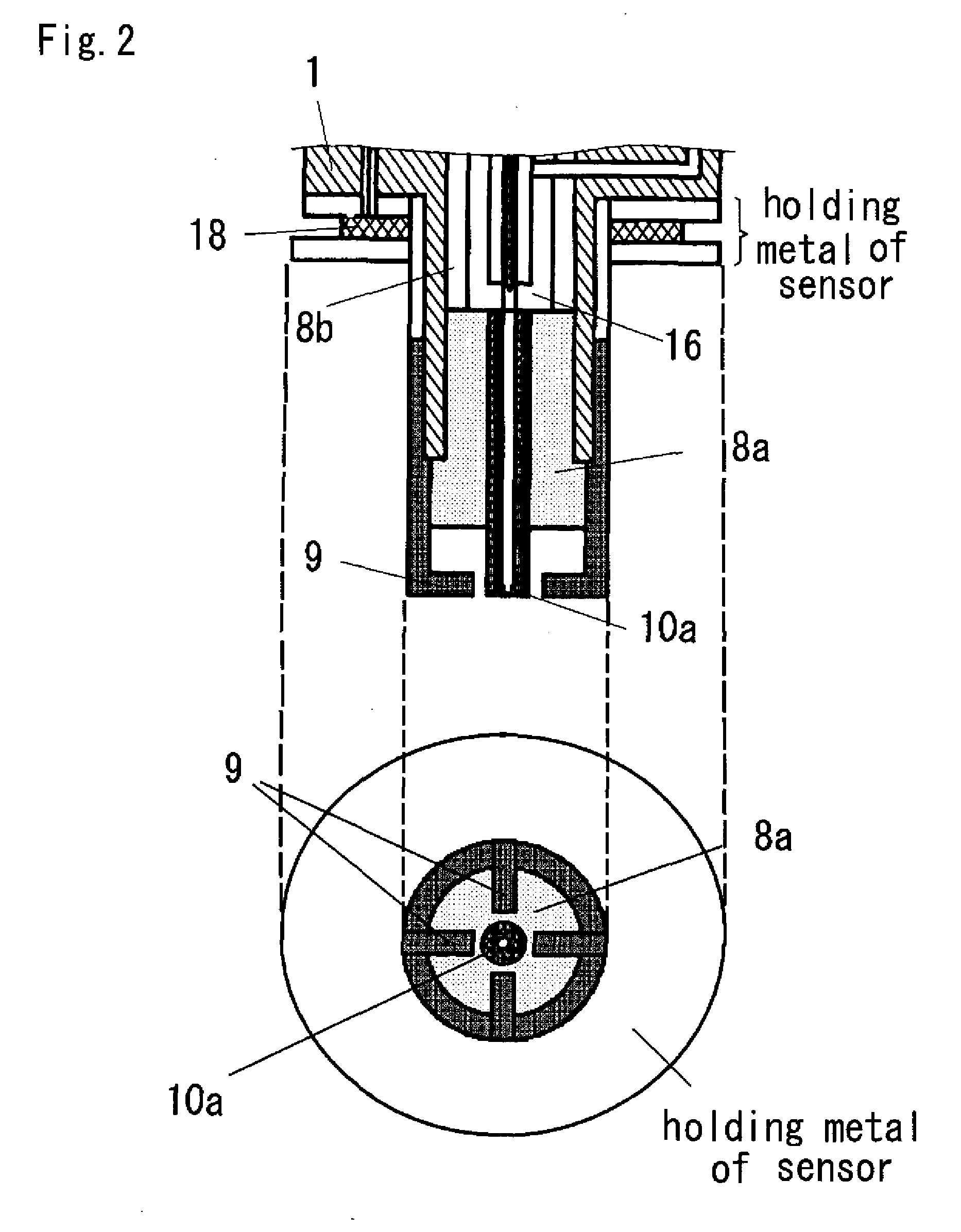

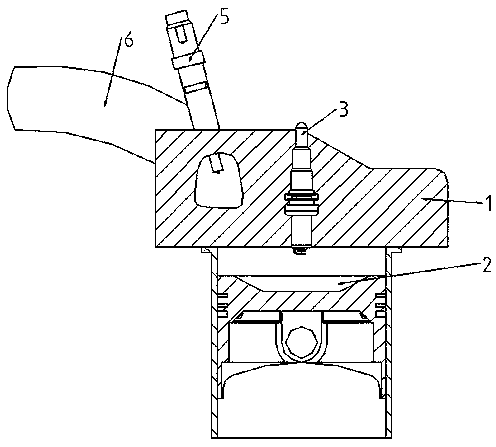

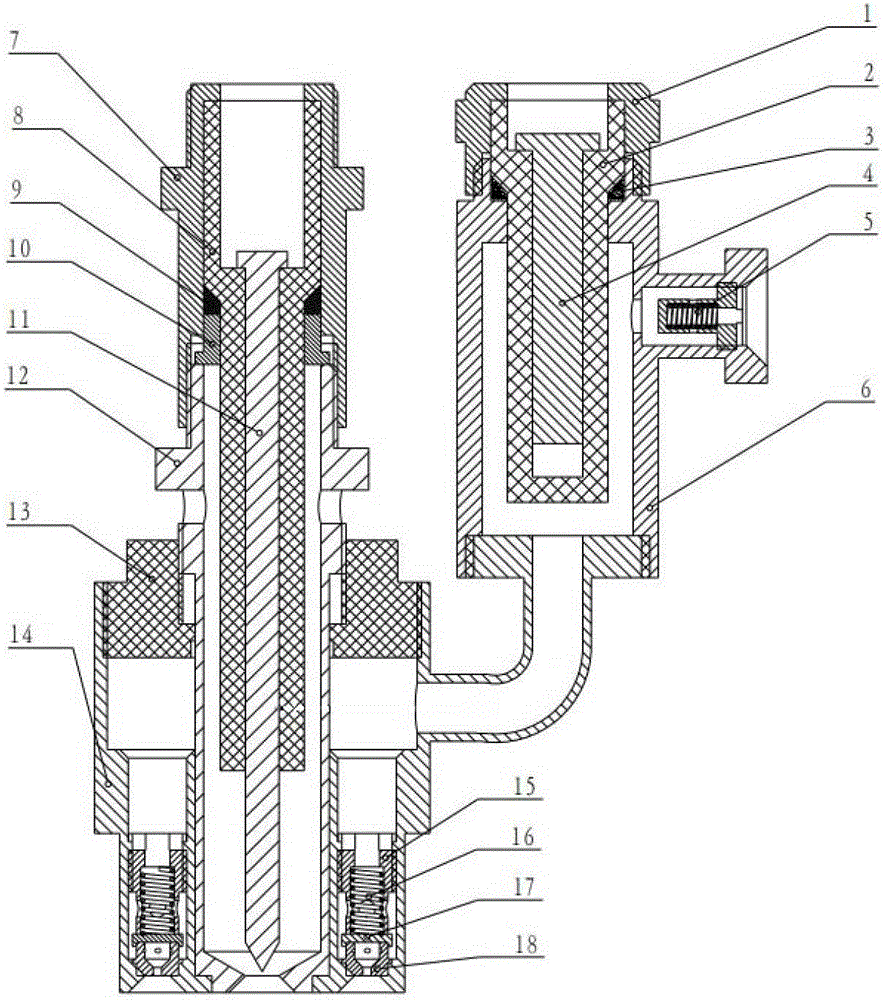

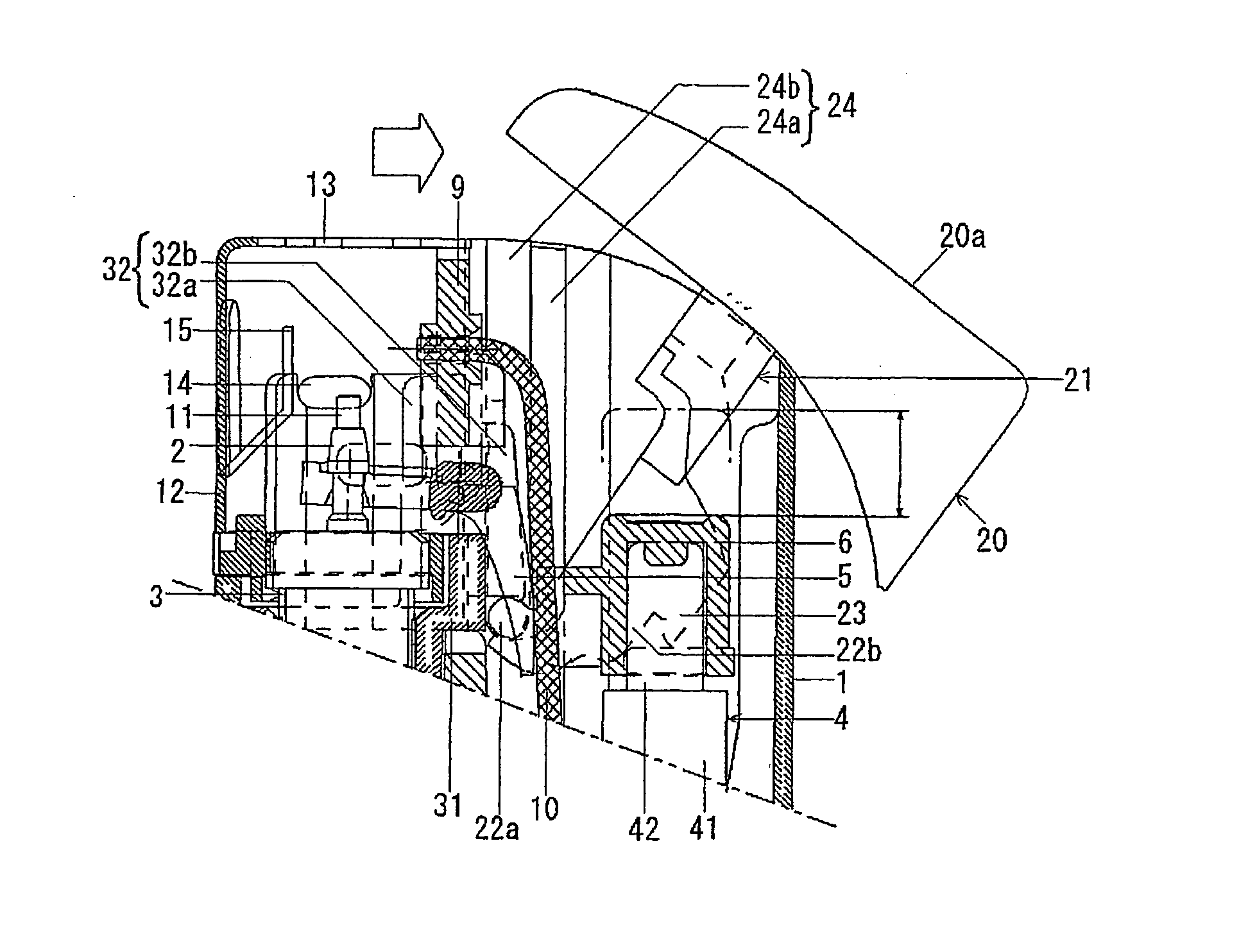

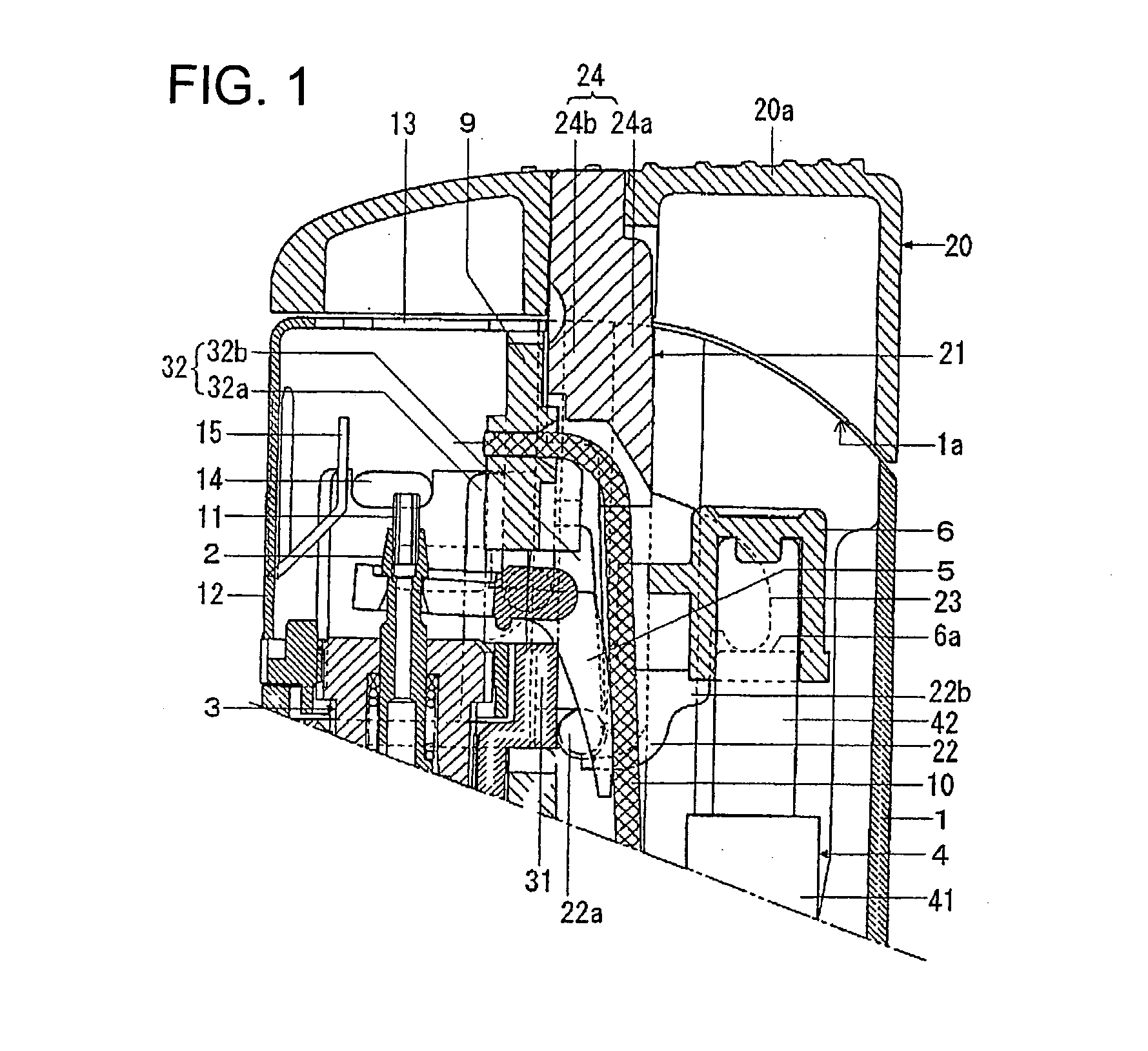

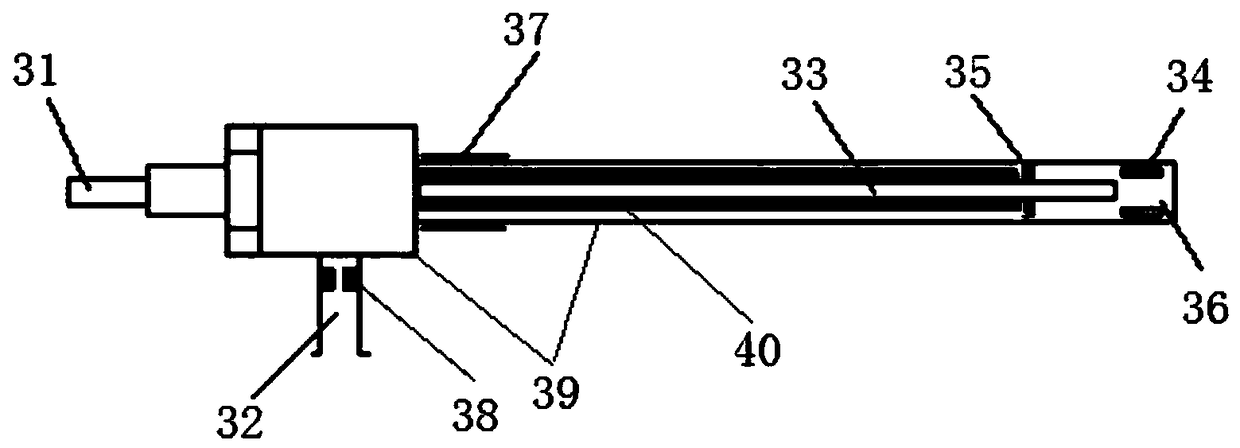

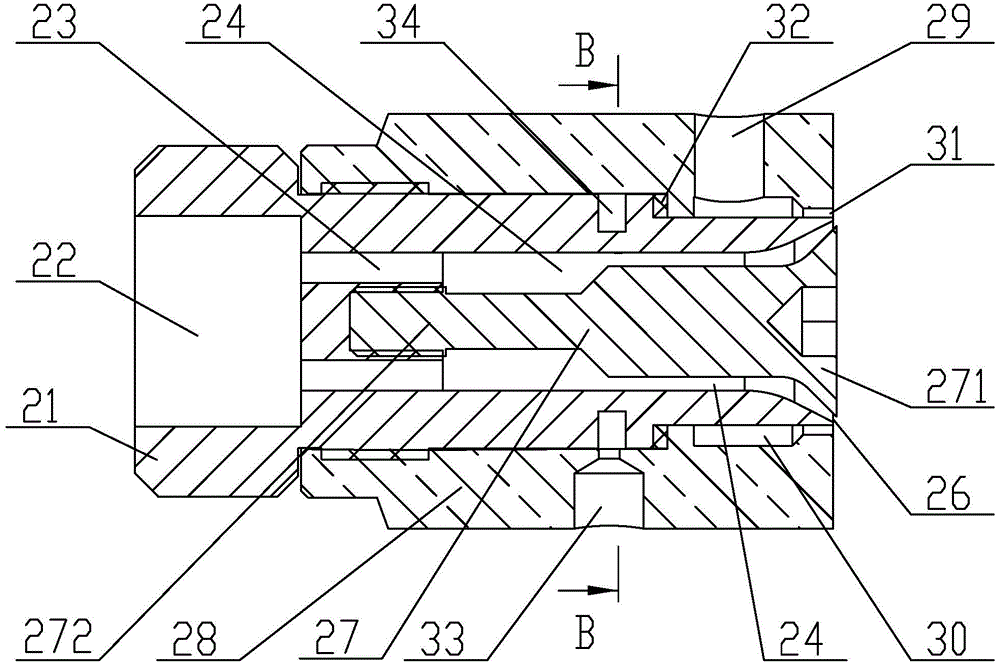

Multifunction ignition device integrated with spark plug

InactiveUS20080098984A1Improve ignition reliabilityIgnition is simplifiedTransformersMachines/enginesIgnition coilFuel efficiency

The object of the present invention is to provide a multifunction ignition device integrated with a spark plug for conserving space by integrating a spark plug, ignition coil, and fuel injection device in a single enclosure and for making a high fuel efficiency engine design possible and allowing spark plug electrode replacement, thereby reducing waste during plug maintenance. The multifunction ignition device of the present invention includes an ignition coil directly connected to a plug top of an internal combustion engine; the ignition coil, a fuel injection valve, and a fuel injection nozzle are housed in a single enclosure; and a center electrode and a ground electrode of the spark plug are removably mounted at the bottom end of the enclosure.

Owner:TOYO DENSO

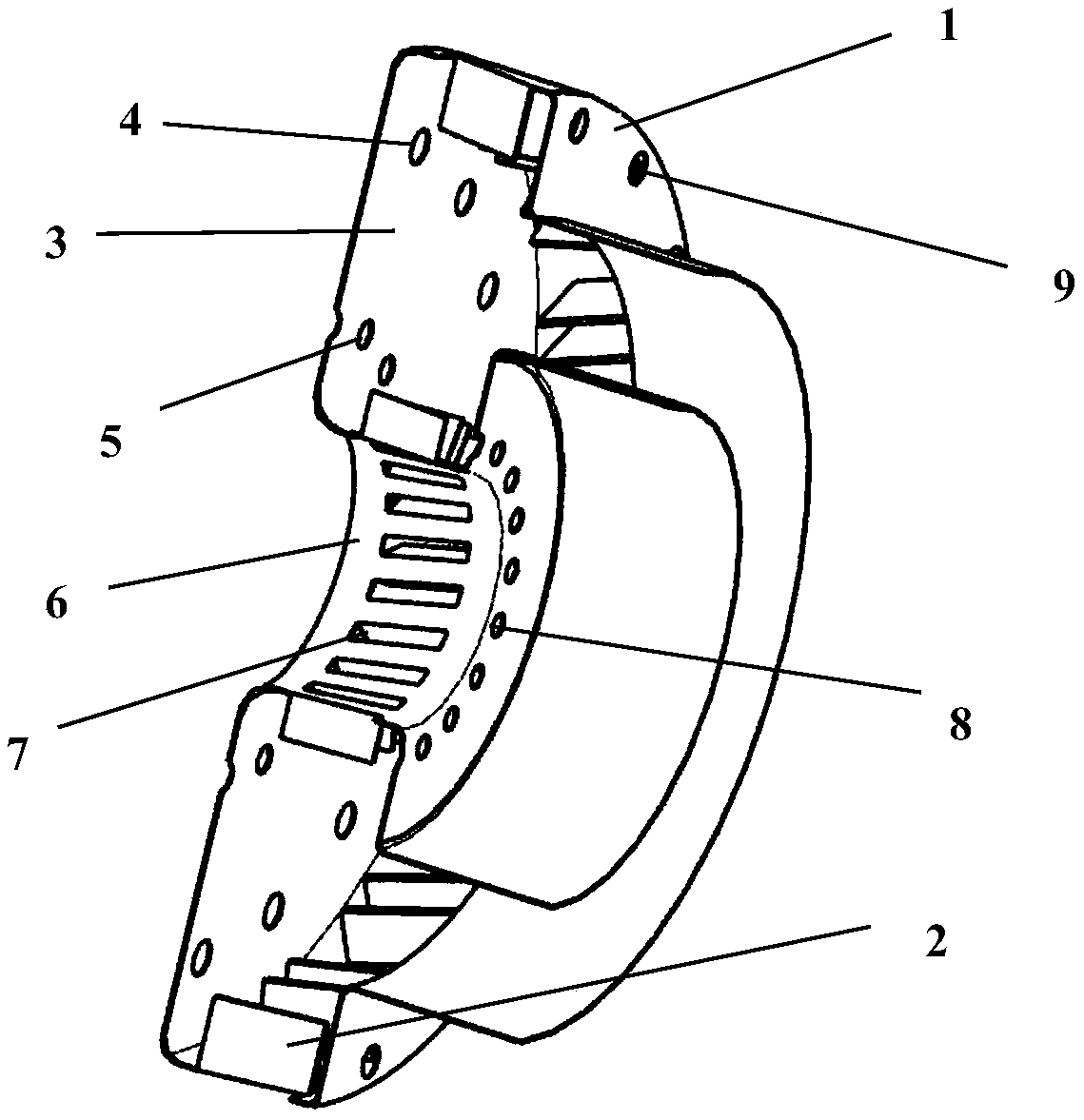

Wimble cap-shaped combusting device of oil heater

InactiveCN101280922AEasy to moveReduce flowLiquid fuel evaporation burnersCombustorCombustion chamber

The present invention provides a wimble cover shaped combustor of fuel heater comprising a combustion chamber cover, a oil suction wimble liner, a primary combustion barrel, a secondary combustion barrel, an air inlet guide barrel, an air inlet split stream slice, a fuel oil tube and a glow plug; the oil suction wimble liner is applied on the combustion chamber cover internal surface, an oil groove is arranged between the both; the primary combustion barrel is connected to the combustion chamber cover, and the air inlet guide barrel is arranged at outer portion of the primary combustion barrel, and air inlet holes are arranged circumferentially on the barrel wall of the primary combustion barrel; the primary combustion barrel is connected to the back end of the air inlet guide barrel to form a conical contraction hole; the front end of the air inlet guide barrel connects to the air inlet split stream slice which is provided with air split stream holes; the secondary combustion barrel connect is connected to the back end of the air inlet guide barrel; the combustion chamber cover has a conical shape, a fuel oil tube connected onto, a glow plug arranged on top, and tangential air holes are arranged circumferentially on the combustion chamber cover. The invention provides credible, rapid ignition start, uneasily generates carbon deposition, has high combustion efficiency and economical efficiency improved by more than 6%.

Owner:河北宏业永盛汽车加热器股份有限公司 +1

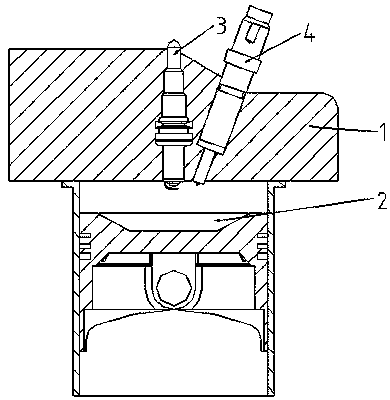

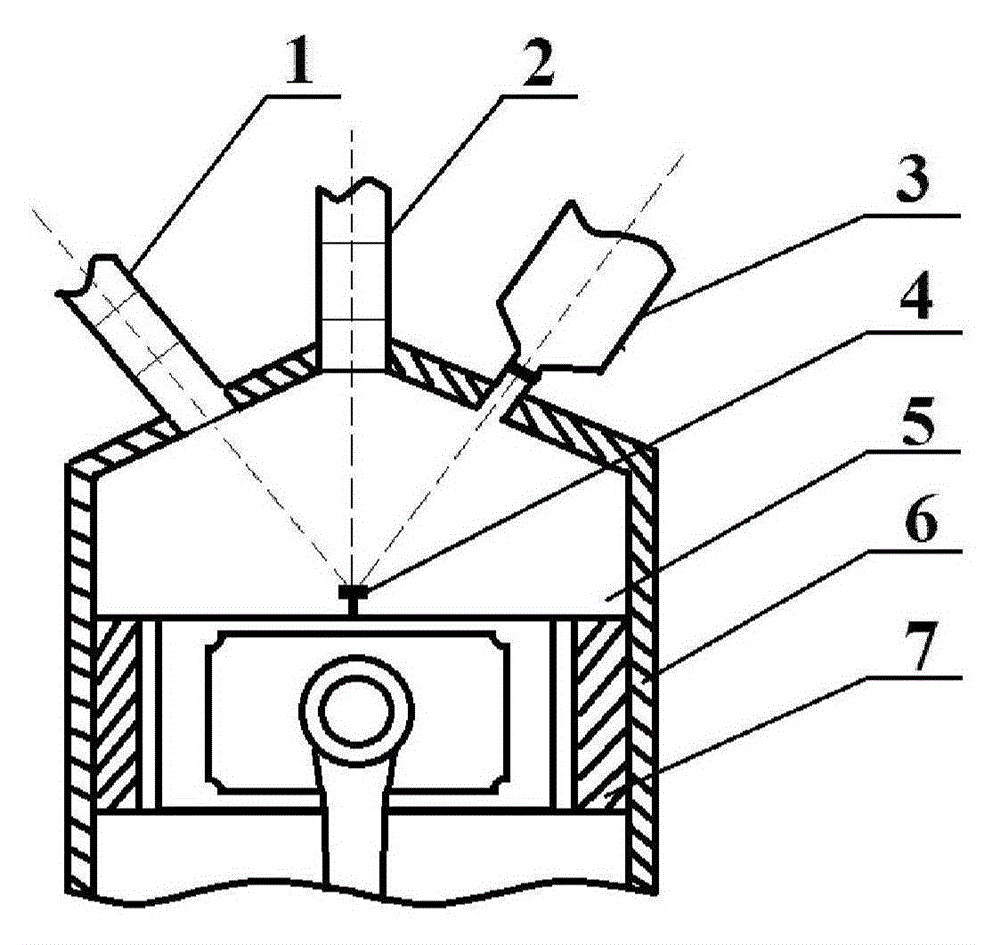

Sparking plug ignition-type premixing compression ignition system of internal combustion engine

ActiveCN107781026AReduce the effective compression ratioReduce the temperatureMechanical controlElectrical controlSpontaneous combustionExternal combustion engine

The invention discloses a sparking plug ignition-type premixing compression ignition system of an internal combustion engine, and belongs to the technical field of combustion of internal combustion engines. According to the premixing compression ignition system, a high-energy sparking plug is adopted for igniting diesel oil or igniting mixtures of the diesel oil and other fuels, wherein the dieseloil or the mixtures serve as the fuels for premixing and are jetted out in a gas feeding process or a compression process to generate premixing gas in a combustion chamber. By adopting an effective compression ratio under which the premixing gas cannot be ignited, the premixing gas in a cylinder cannot burn spontaneously; by using the high-energy sparking plug for ignition close to a compressionupper limit point, the mixed gas nearby the sparking plug is ignited to make the temperature and the pressure in the cylinder quickly rise, the other remaining premixing gas in the cylinder satisfiesthe conditions for spontaneous combustion, large-scale multi-point spontaneous combustion happens, and fast combustion of the premixing gas is achieved. By adopting a high expansion ratio, the heat efficiency is further improved.

Owner:DALIAN UNIV OF TECH

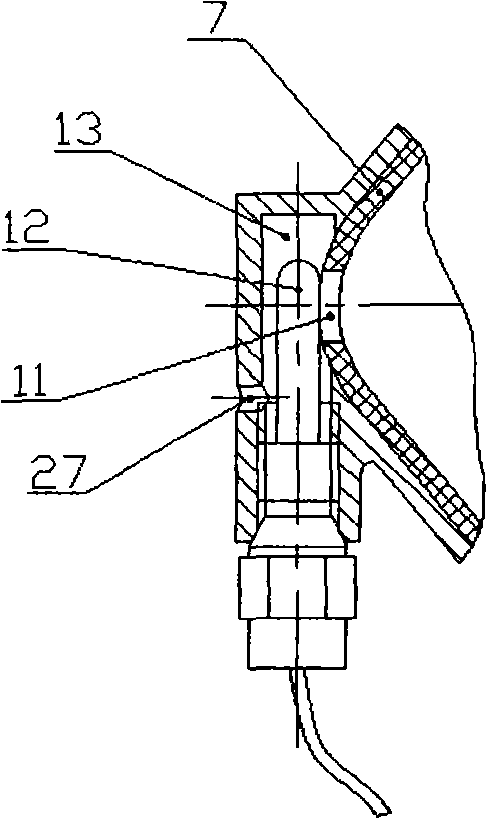

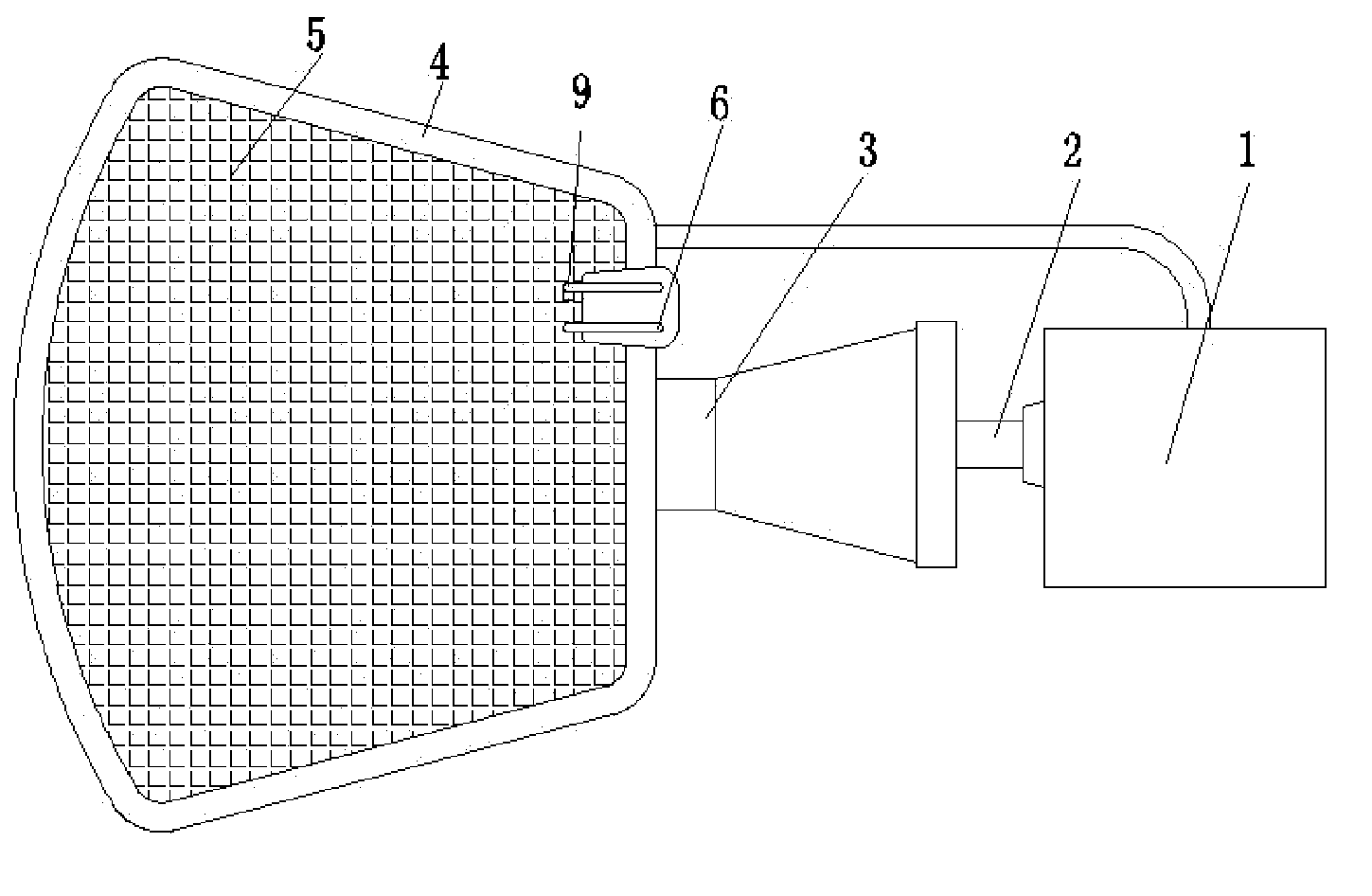

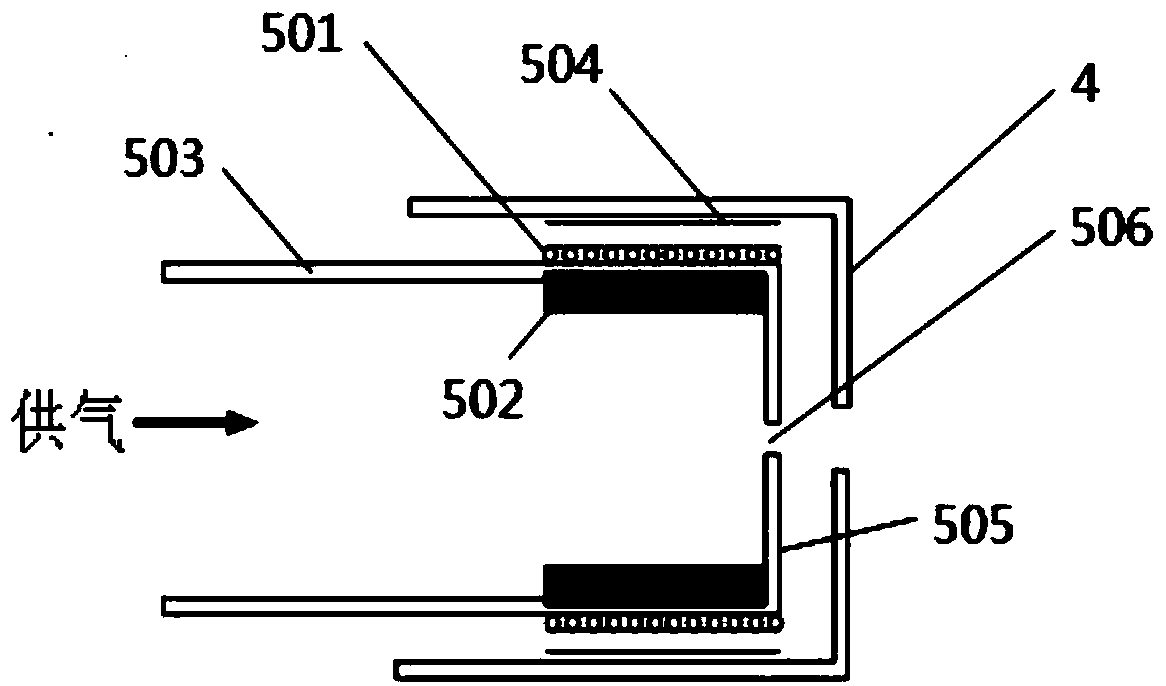

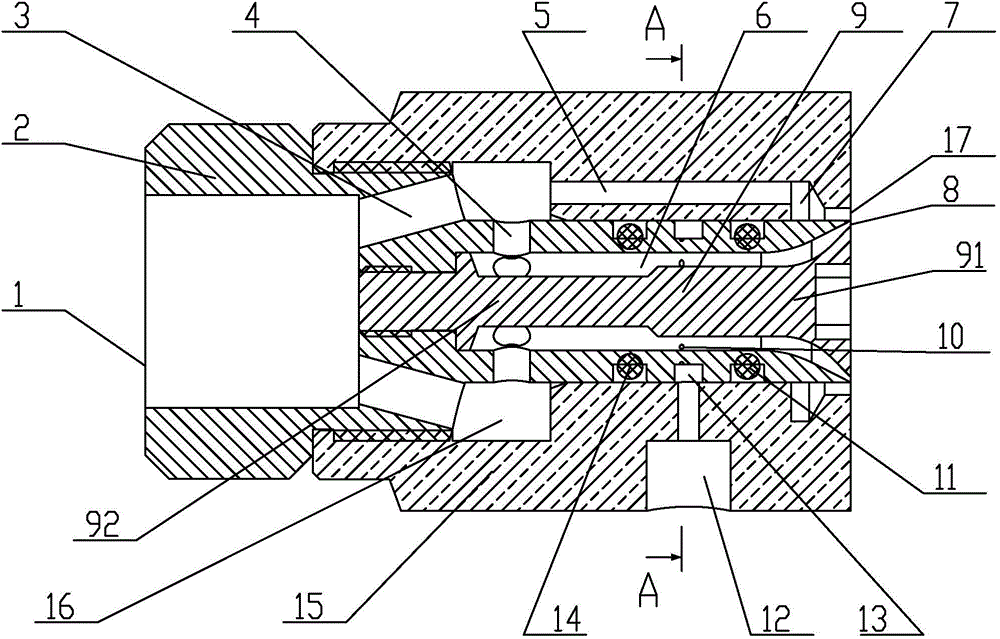

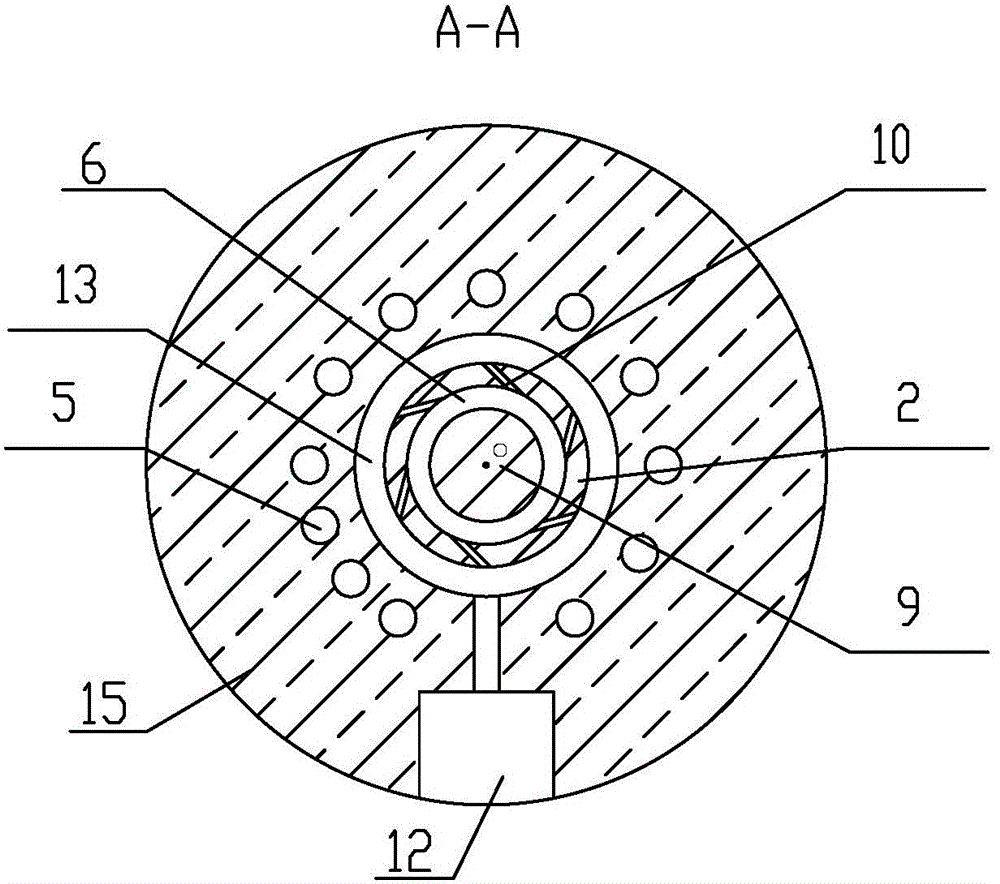

Plasma catalysis ignition integrated nozzle

InactiveCN102980209AGood drop spectrumLower activation energyContinuous combustion chamberPlasma jetCombustion chamber

The invention provides a plasma catalysis ignition integrated nozzle which is a plasma assisted atomization and plasma ignition integrated nozzle formed by a low-temperature plasma discharge assembly, a fuel pressure atomization nozzle assembly and a high-energy plasma ignition assembly. A barrier medium uniformly discharges to ensure that a liquid fuel partially pyrolyzes to generate a large quantity of gas activated components, so that a gas-liquid coexisting plasma microcell is formed, fuel activation energy and ignition energy are reduced, physical conditions of gas assisted atomization are formed, and atomization effect is improved. A plasma ignitor is arranged on the middle of a multi-point nozzle and is positioned in a combustion chamber low-pressure region, plasma and fuel atomized particles are well mixed to generate a chemical reaction, and a stable high-temperature ignition core is easily formed. Ignition is directly carried out by adopting a plasma jet, and because the plasma jet has special discharge characteristics and larger discharge energy and is highly concentrated in energy, the ignition reliability and the ignition concentration limit of a gas turbine are greatly improved. The plasma catalysis ignition integrated nozzle can be applied to a combustion chamber of the gas turbine.

Owner:三亚哈尔滨工程大学南海创新发展基地

Thermit and preparation method thereof

InactiveCN102925120AGood thermal stabilityLow mechanical sensitivityHeat-exchange elementsLiquid slagThermal stability

The invention discloses thermit and a preparation method thereof. The thermit comprises, by weight, 20-30 parts of Al powder, 70-80 parts of manganese dioxide and 5-10 parts of additives. The additives comprise one or combination of more of magnesium powder, nickel powder, nitrate barium and polytetrafluoroethene. The preparation method includes a series of steps of drying and dry-blending components and making grain and the like. The thermit is good in thermal stability, low in mechanical sensitivity and sensitivity of rifle bullet impact, good in integral security, high in ignition reliability, stable in burning process and appropriate in burning speed. Heat released by burning and produced high-temperature slag are concentrated in flame jet flow, and only a small amount of liquid slag is produced.

Owner:PLA UNIV OF SCI & TECH

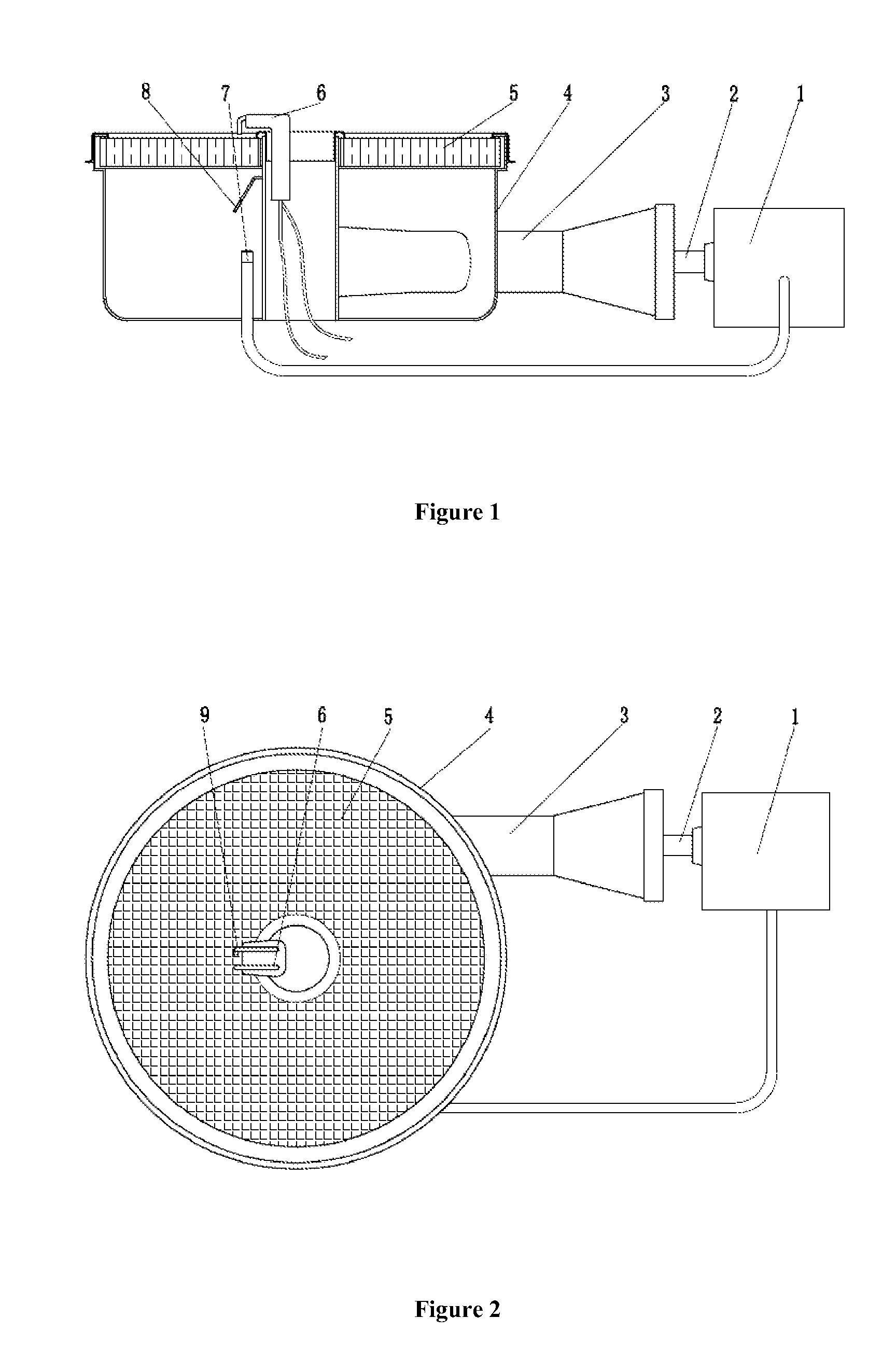

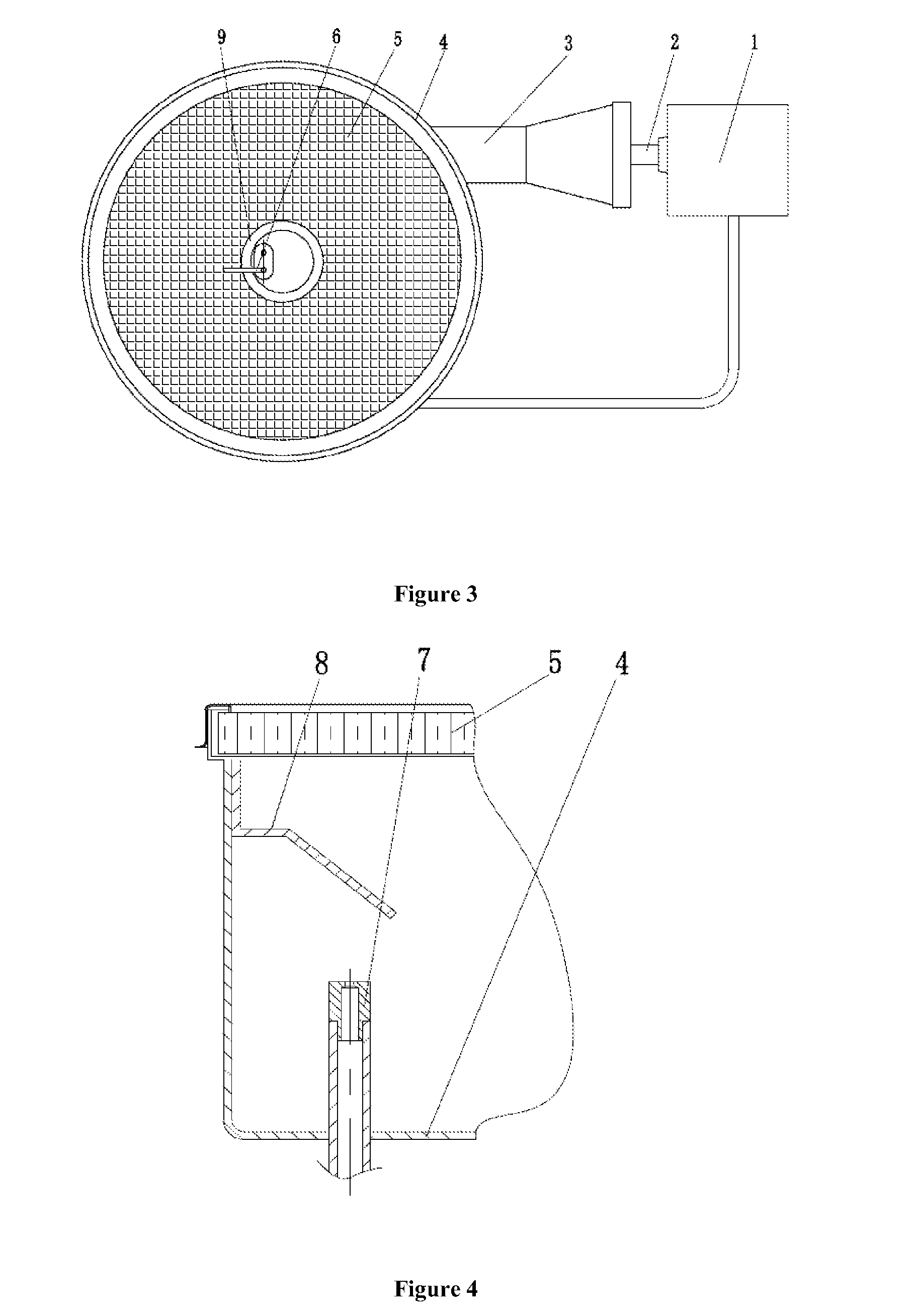

Combustion heater

ActiveCN110186069ASimple structureNovel way of head air intakeContinuous combustion chamberGas-turbine engine testingCombustionFuel oil

The invention provides a combustion heater and is used for the field of combustion tail gas reheating. The combustion heater comprises an outer casing, a flame barrel, a nozzle, a nozzle main air inlet, an auxiliary air channel inlet, a fuel oil inlet, an ignition electric nozzle and an inlet diffusion section, wherein the flame barrel is arranged inside the outer casing, the nozzle is arranged atthe inlet of the flame barrel, the nozzle main air inlet, the auxiliary gas channel inlet and the fuel oil inlet are formed in the side wall of the outer casing and communicate with the nozzle through pipelines, the ignition electric nozzle penetrates through the side wall of the outer casing and the barrel wall of the flame barrel so as to ignite the flame barrel, and the inlet diffusion sectionis close to the nozzle and is connected with one end of the outer casing. The combustion heater is simple in structure, novel in air inlet mode of the head, high in ignition reliability, and high incombustion efficiency; and the combustion heater can work stably under severe conditions, and is suitable for an aero-engine ground test bench.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

Infrared ray gas burner

InactiveUS20140248570A1High gas concentrationSuitable for ignitingDomestic stoves or rangesIncandescent ignitionInfraredCombustion

An infrared ray gas burner comprises an ignition valve, a nozzle, an ejector, a furnace chamber, a porous combustion radiant panel and an ignition needle. An ignition nozzle is placed in the furnace chamber, a sundries baffle is provided in the furnace chamber below the porous combustion radiant panel and above the ignition nozzle and the ignition needle is set above the porous combustion radiant panel, so the gas for ignition ejected from the ignition nozzle quickly mixes with the air inside the furnace chamber, and the gas-air mixture escapes from fire holes of the porous combustion radiant panel above the ignition nozzle. The gas concentration of the mixed gas is relatively high and suitable for igniting, the main burner can be quickly ignited, there is no black smoke, obviously incomplete combustion, and it brings a high ignition rate.

Owner:GUANGZHOU REDSUN GAS APPLIANCE

Natural gas engine combustion organization method with natural high-low pressure mixed jet and diesel oil micro jet ignition of pre-combustion chamber

ActiveCN109296446AImprove emission effectImprove powerInternal combustion piston enginesEngine controllersCombustion chamberProcess engineering

The invention aims to provides a natural gas engine combustion organization method with natural high-low pressure mixed jet and diesel oil micro jet ignition of a pre-combustion chamber. In a low loadworking condition, the amount of natural gas directly jetted under high pressure by a high-pressure natural gas jet valve accounts for more than 50% the total amount of natural gas jet by each circle, and the diesel oil jet timing is 15-25 degrees CA before the top center; in a medium load working condition, the amount of natural gas premixed through air intake of an air intake manifold accountsfor 60-70% the total amount of natural gas jet by each circle, and the diesel oil jet advance angle is 10-20 degrees CA before the top center; and in a high load working condition, the amount of natural gas premixed through air intake of the air intake manifold accounts for 80-90% the total amount of natural gas jet by each circle, and the diesel oil jet timing is 5-15 degrees CA before the top center. The method achieves control over the concentration layered gradient of mixed gas inside a cylinder, overcomes the defect that an engine cannot have the emission performance and dynamic propertyat the same time under different working conditions, and improves the emission performance of the natural gas engine under the different working conditions.

Owner:HARBIN ENG UNIV

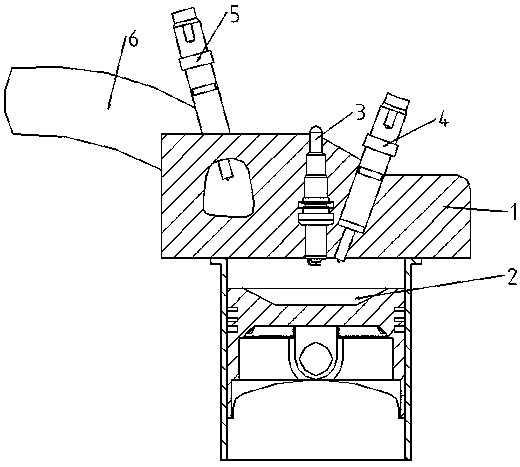

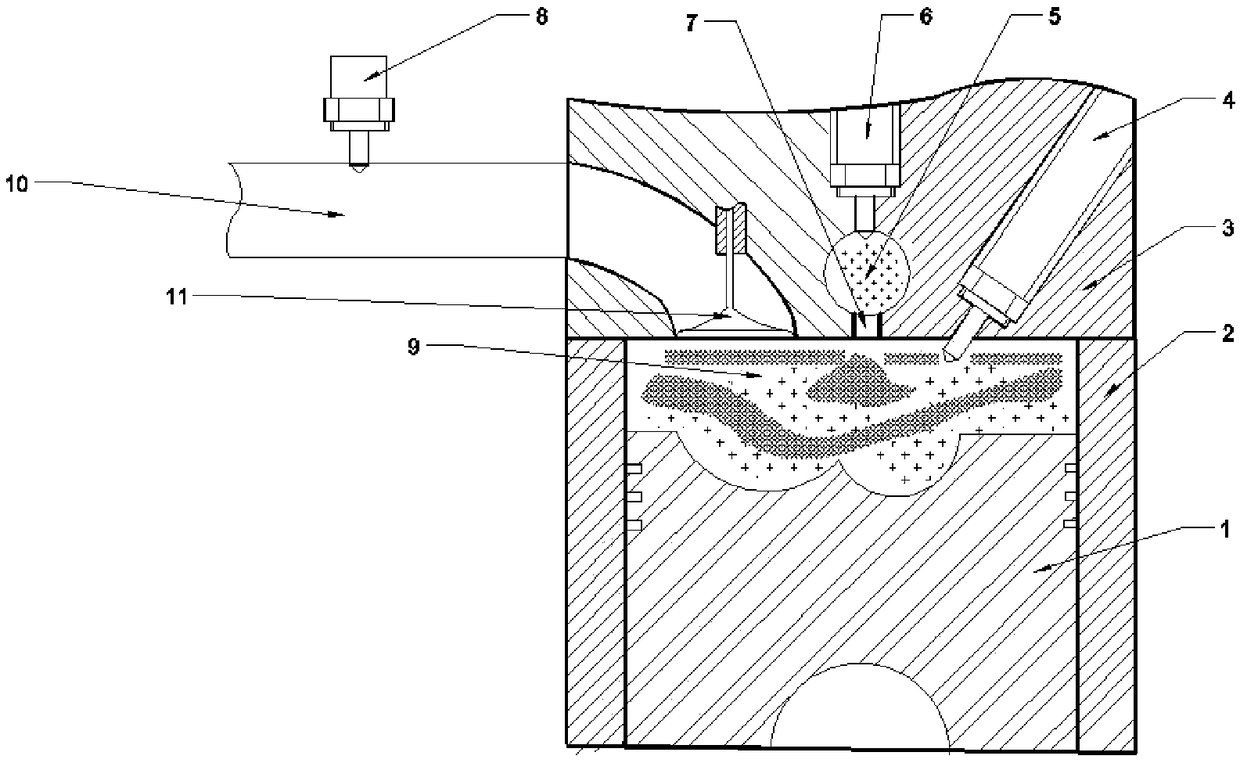

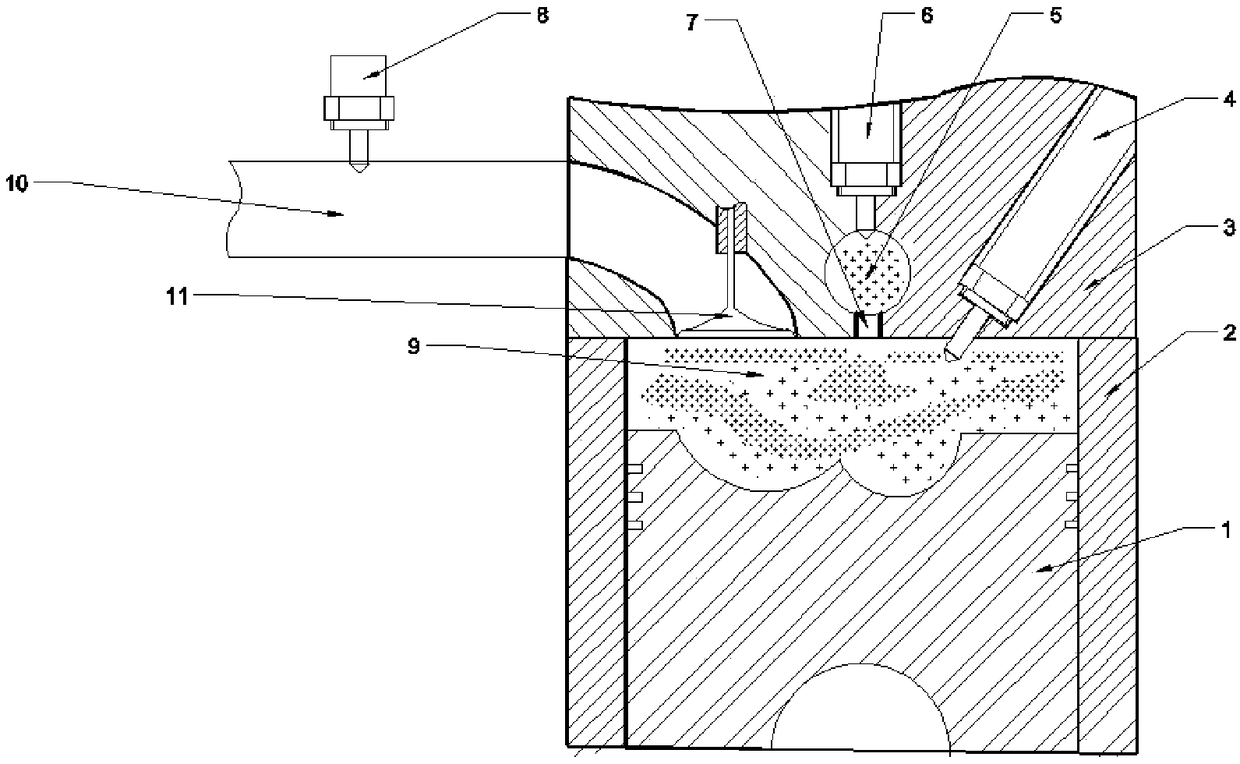

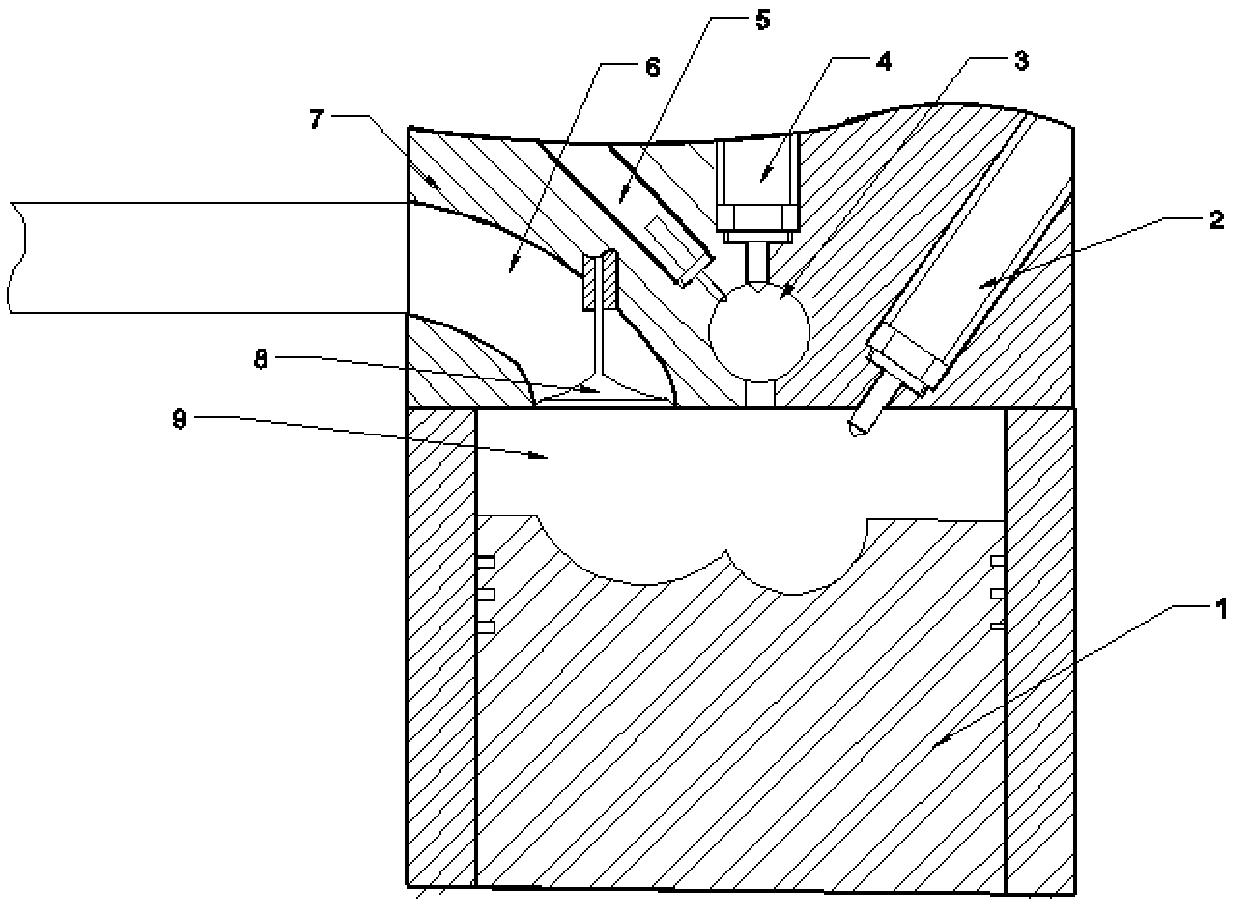

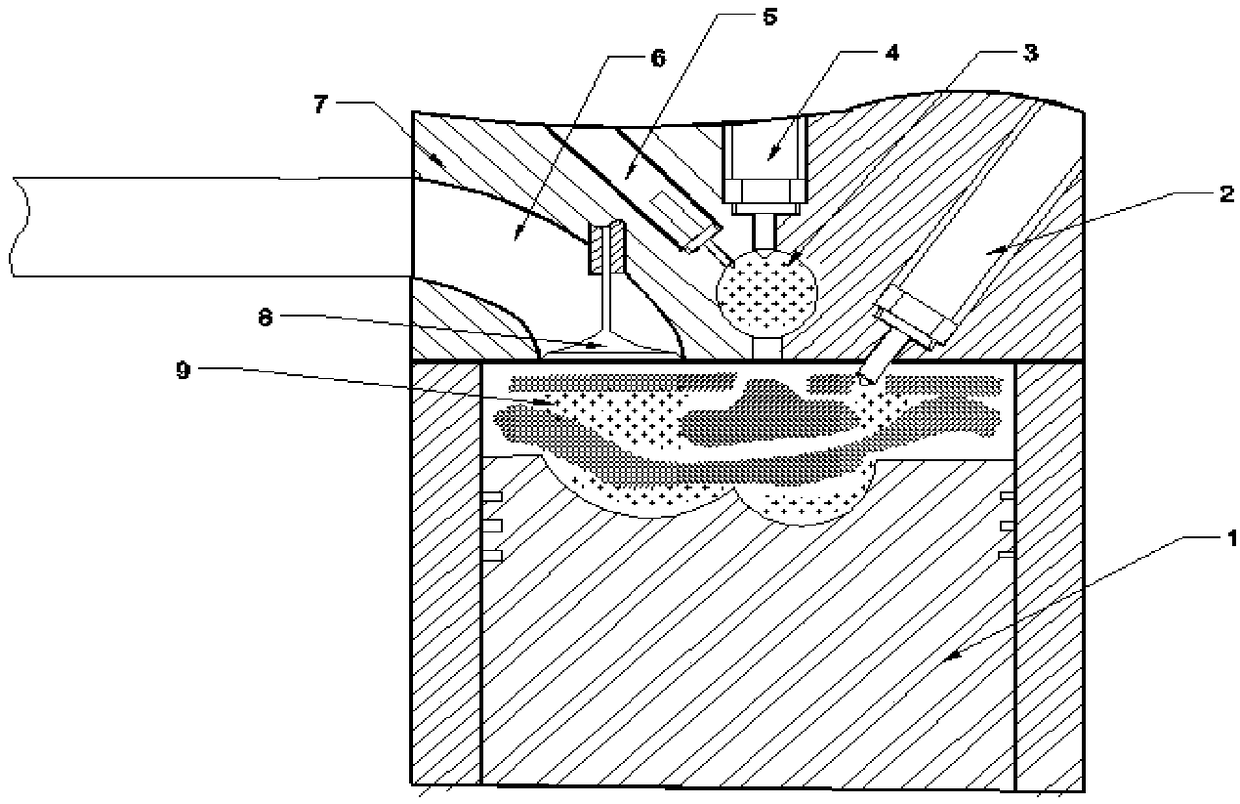

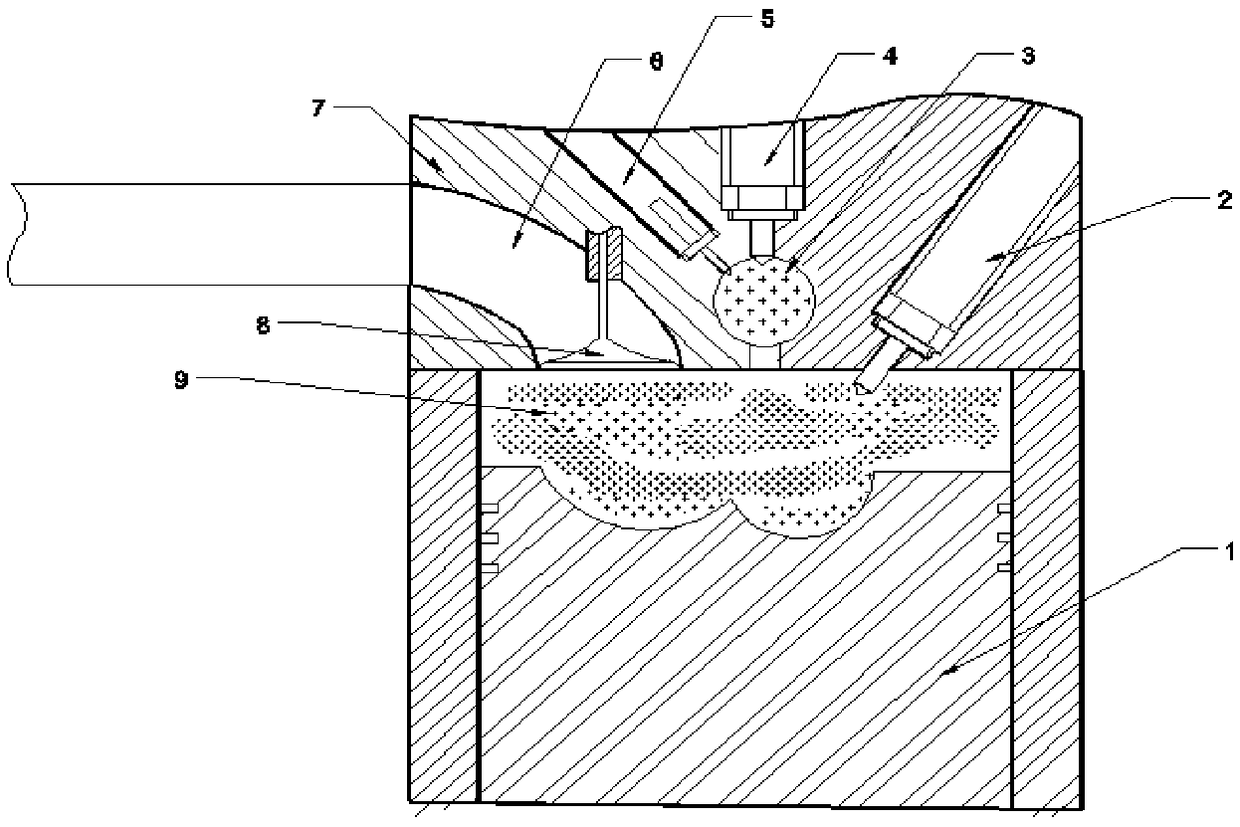

Combustion organization method with multiple injection, low pressure air feed in pre-combustion chamber and micro spray ignition of diesel oil for natural gas engine

ActiveCN109209656AImprove ignition reliabilityImprovement can not take into account its emissionsElectrical controlInternal combustion piston enginesMultiple injectionCombustion chamber

The invention aims at providing a combustion organization method with multiple injection, low pressure air feed in a pre-combustion chamber and micro spray ignition of diesel oil for a natural gas engine. A one-way air feed valve injects natural gas to the pre-combustion chamber in an air inlet stroke; a high pressure natural gas injection valve sprays natural gas into a cylinder directly for multiple times, and gas mixture layers in different concentration gradient are formed in the cylinder under different engine loads; and the pre-combustion chamber is positioned in the middle of a cylindercover, a fuel injector sprays a small amount of diesel oil into the pre-combustion chamber near a top dead center of compression, the diesel oil is self ignited and ignites a gas mixture in the pre-combustion chamber, and high-temperature combustion gas is injected out of the pre-combustion chamber and ignites the gas mixture in the cylinder. The pressure of the one-way air feed valve is regulated to control the concentration of natural gas in the pre-combustion chamber; the injection frequency and quantity of the high pressure natural gas injection valve are adjusted to control the concentration gradient of the gas mixture in the cylinder; and the injection quantity and correction injection time of the diesel oil in the pre-combustion chamber are adjusted to realize reliable ignition andhigh-efficiency low-discharge combustion of the natural gas engine in different conditions.

Owner:HARBIN ENG UNIV

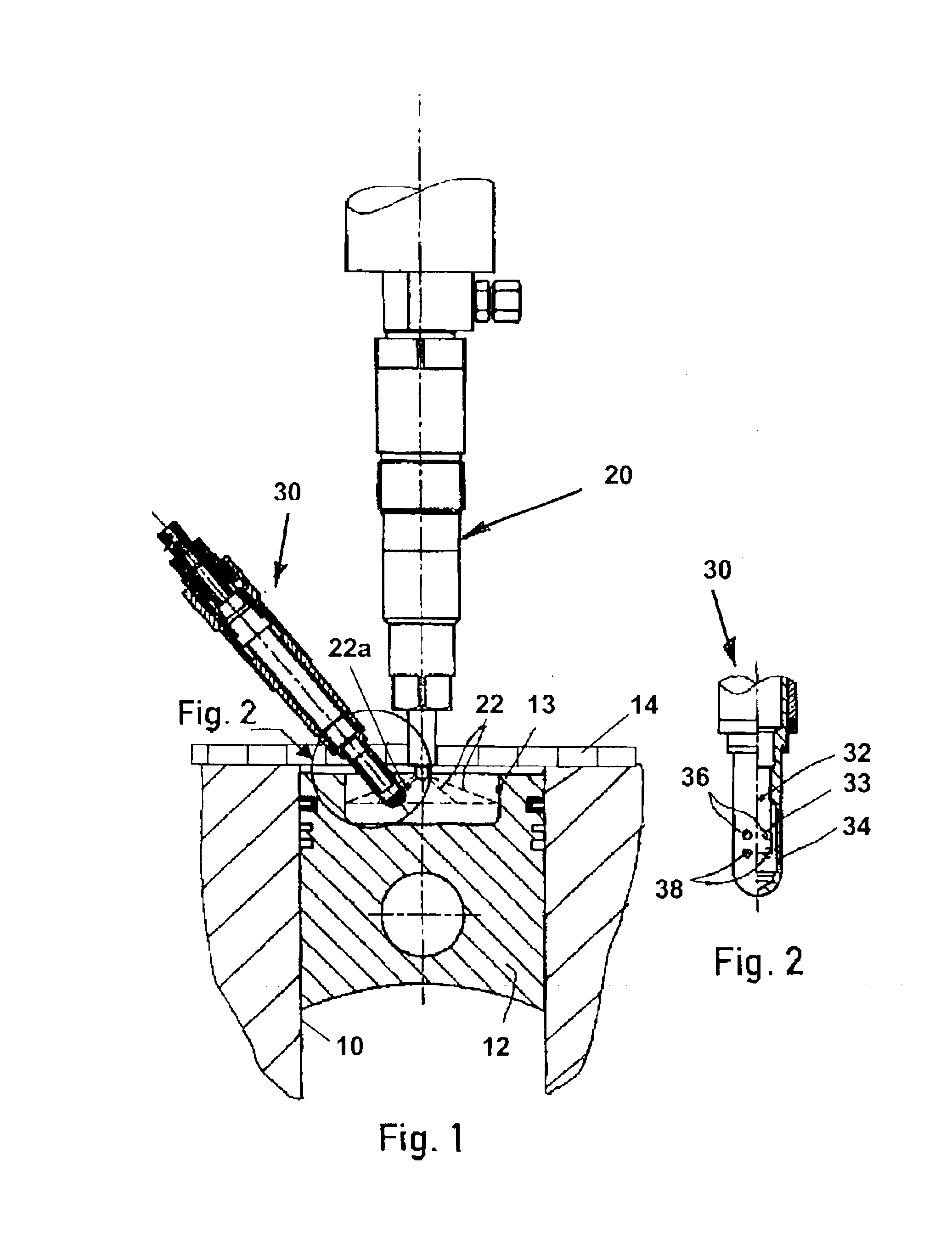

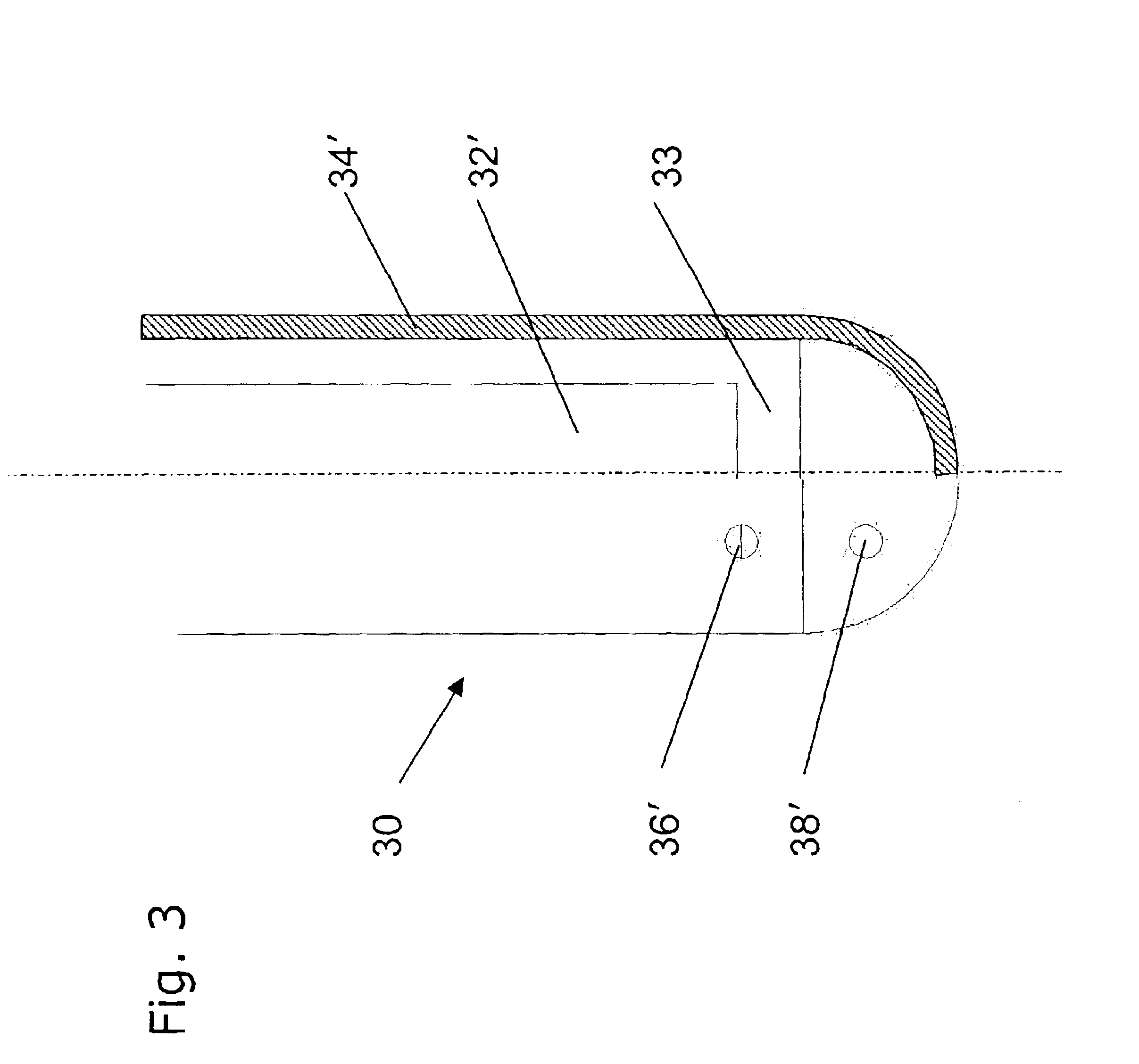

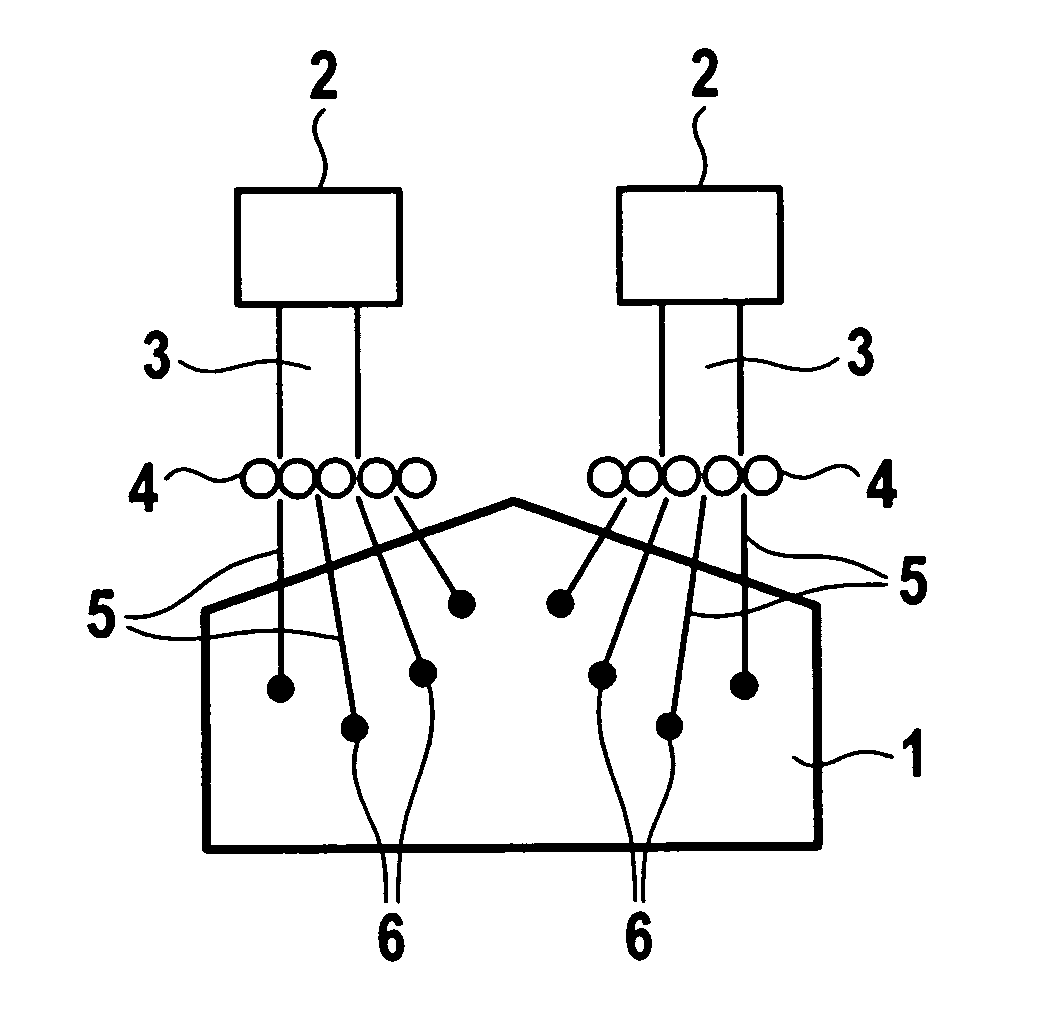

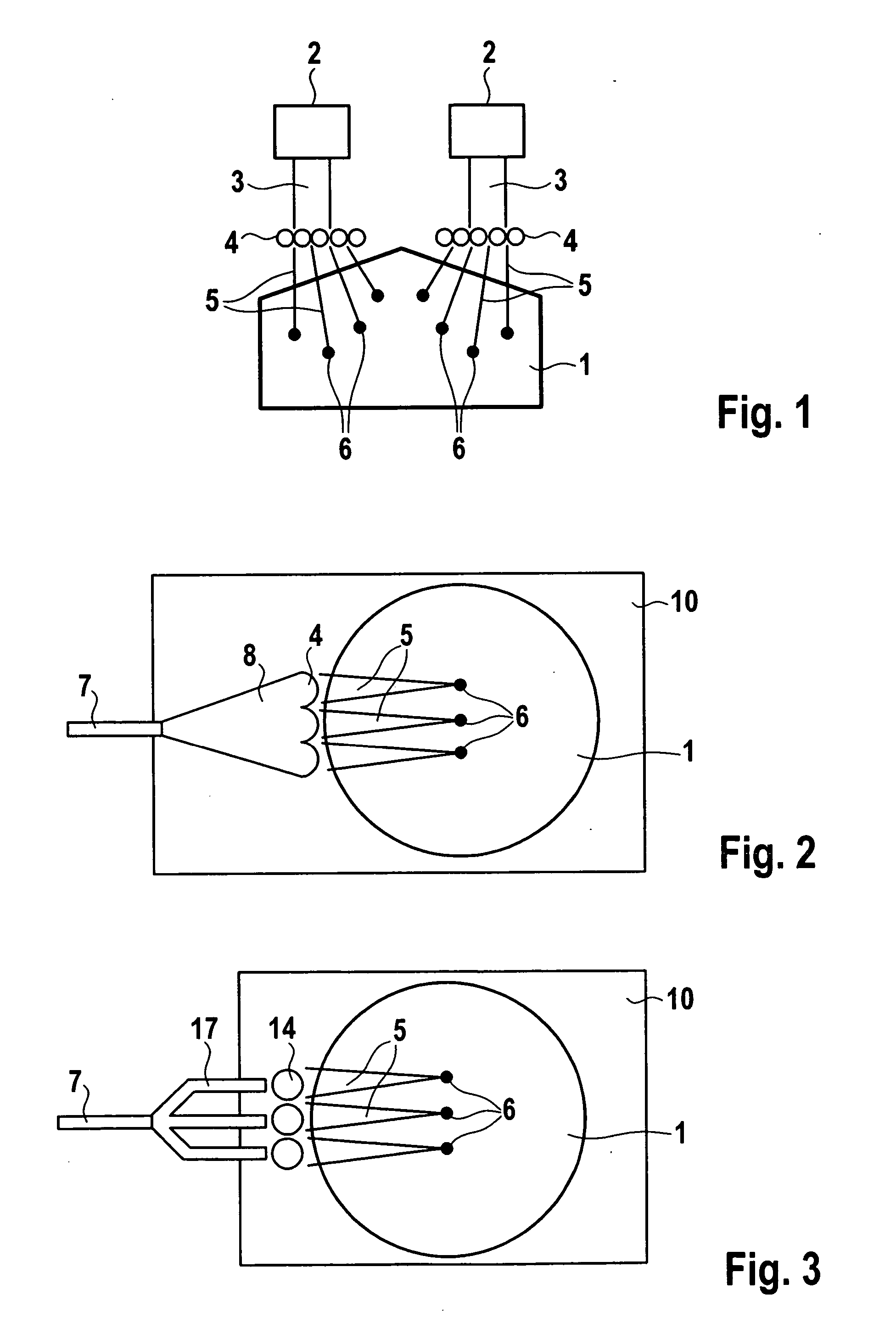

Device for igniting an internal combustion engine

InactiveUS20060032470A1Improve ignition reliabilityShorten the timeCombustion enginesEngine ignitionCombustion chamberLight beam

A device for ignition in an internal combustion engine using laser radiation. The laser radiation has a plurality of laser sub-beams that are focused at a plurality of different focus points in the combustion chamber.

Owner:ROBERT BOSCH GMBH

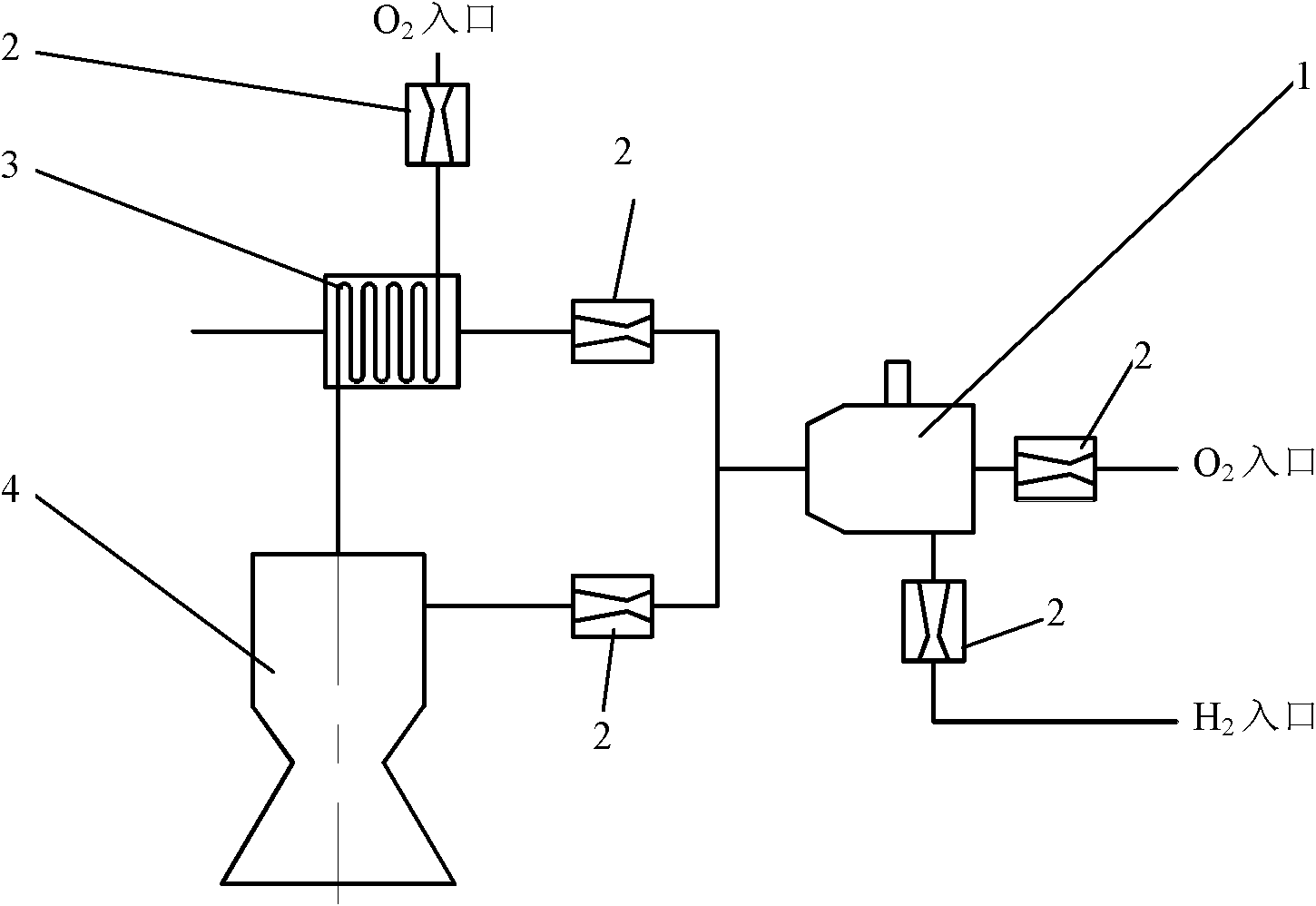

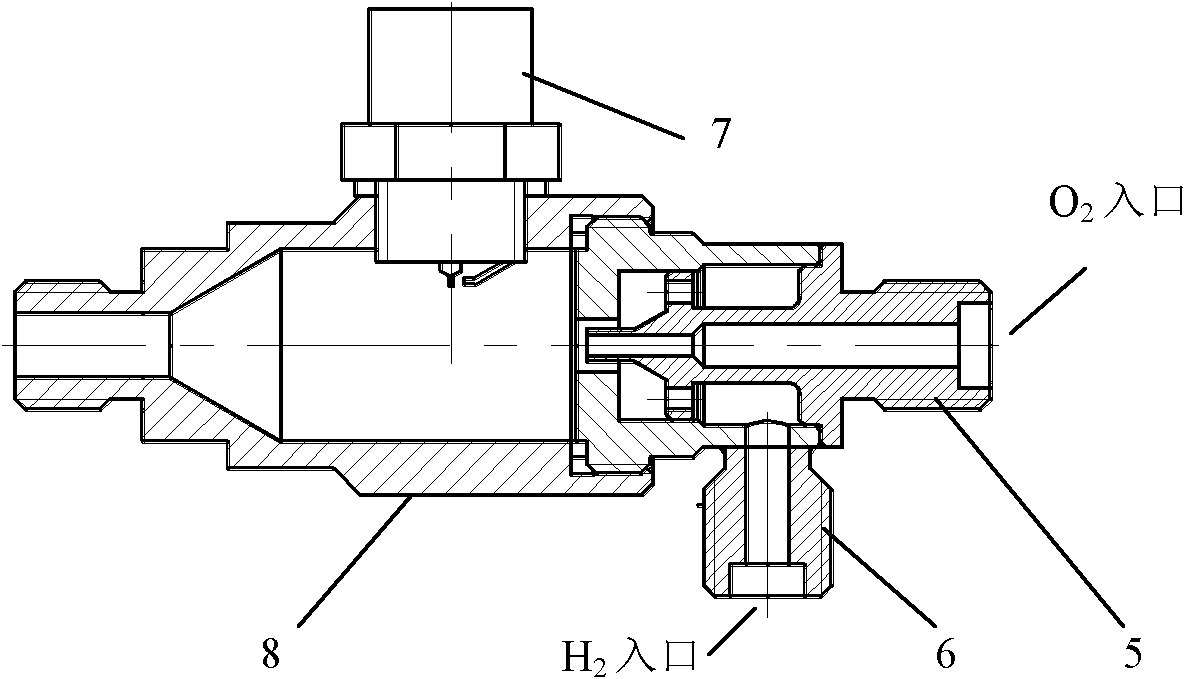

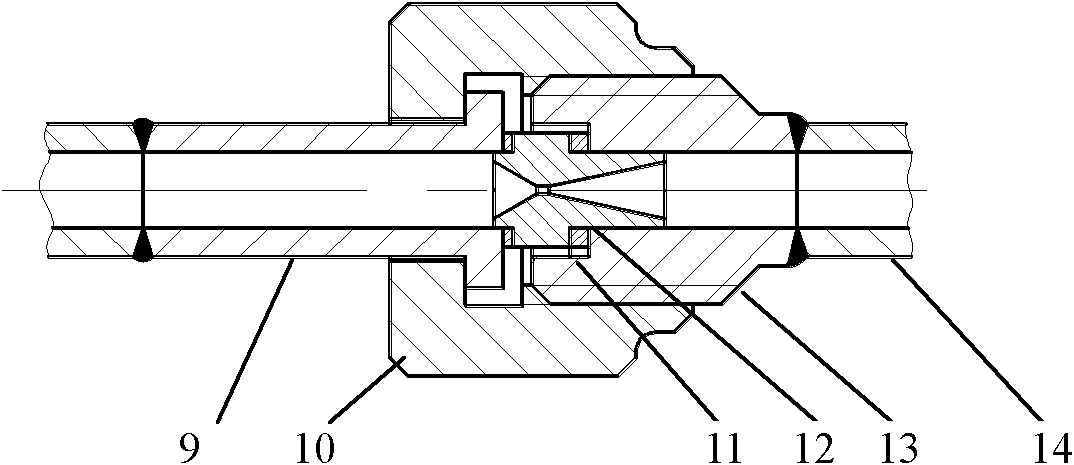

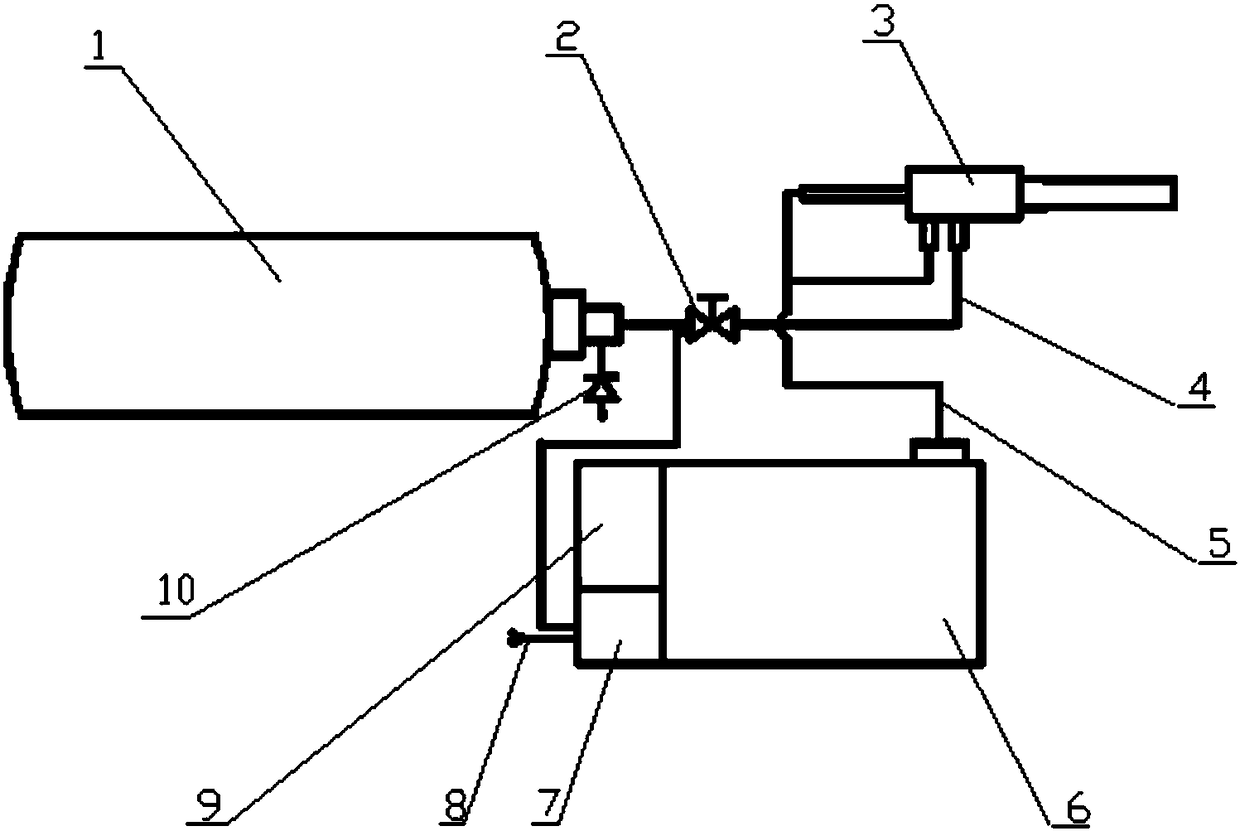

Supplying device of small-flow and high-temperature gas propellant

InactiveCN102094728AImprove ignition reliabilitySimple structureRocket engine plantsCombustion chamberOxygen

The invention discloses a supplying device of a small-flow and high-temperature gas propellant, which belongs to the field of a gas supply system of a rocket engine. The device disclosed by the invention comprises a small combustion room, a sound speed nozzle assembly, a heat exchanger and a gas nozzle testing fitting, wherein one part of hydrogen-enriched gas generated by the small combustion room is supplied to the gas nozzle testing fitting to meet testing requirements, and the other part of the hydrogen-enriched gas generated is supplied to the heat exchanger to be used for heating oxygen and meeting the testing requirements; and the two parts of flow are controlled by the sound speed nozzle assembly. Under a certain flow, the temperature of the hydrogen-enriched gas can be adjusted by adjusting the ratio of hydrogen to oxygen, thereby realizing the purpose of adjusting the temperature. Under a certain mixing ratio condition, the flow adjustment is realized by enhancing or reducing the flows of the hydrogen and the oxygen. The temperature of the oxygen is controlled by adjusting the flow of the heated hydrogen-enriched gas.

Owner:BEIHANG UNIV

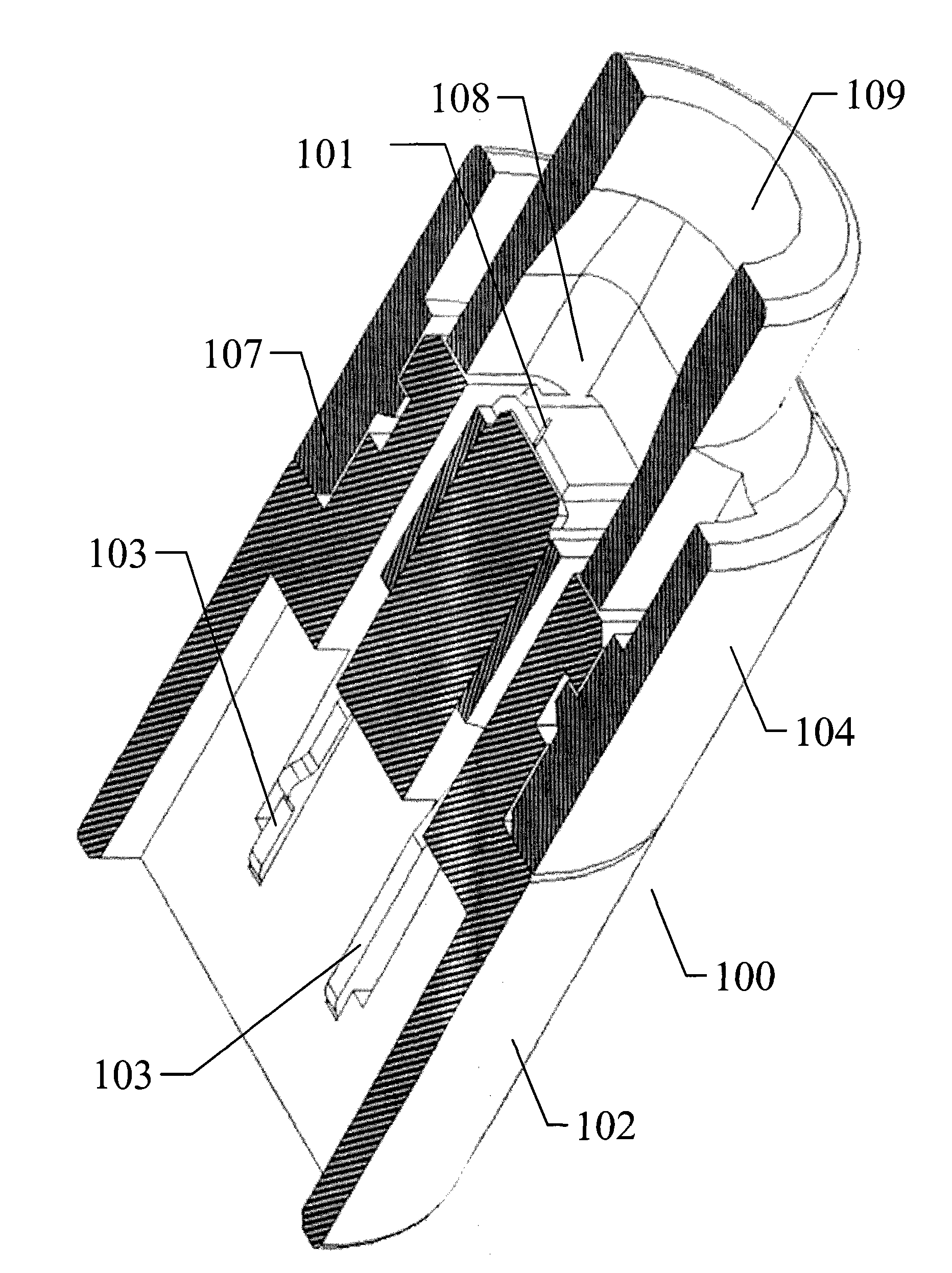

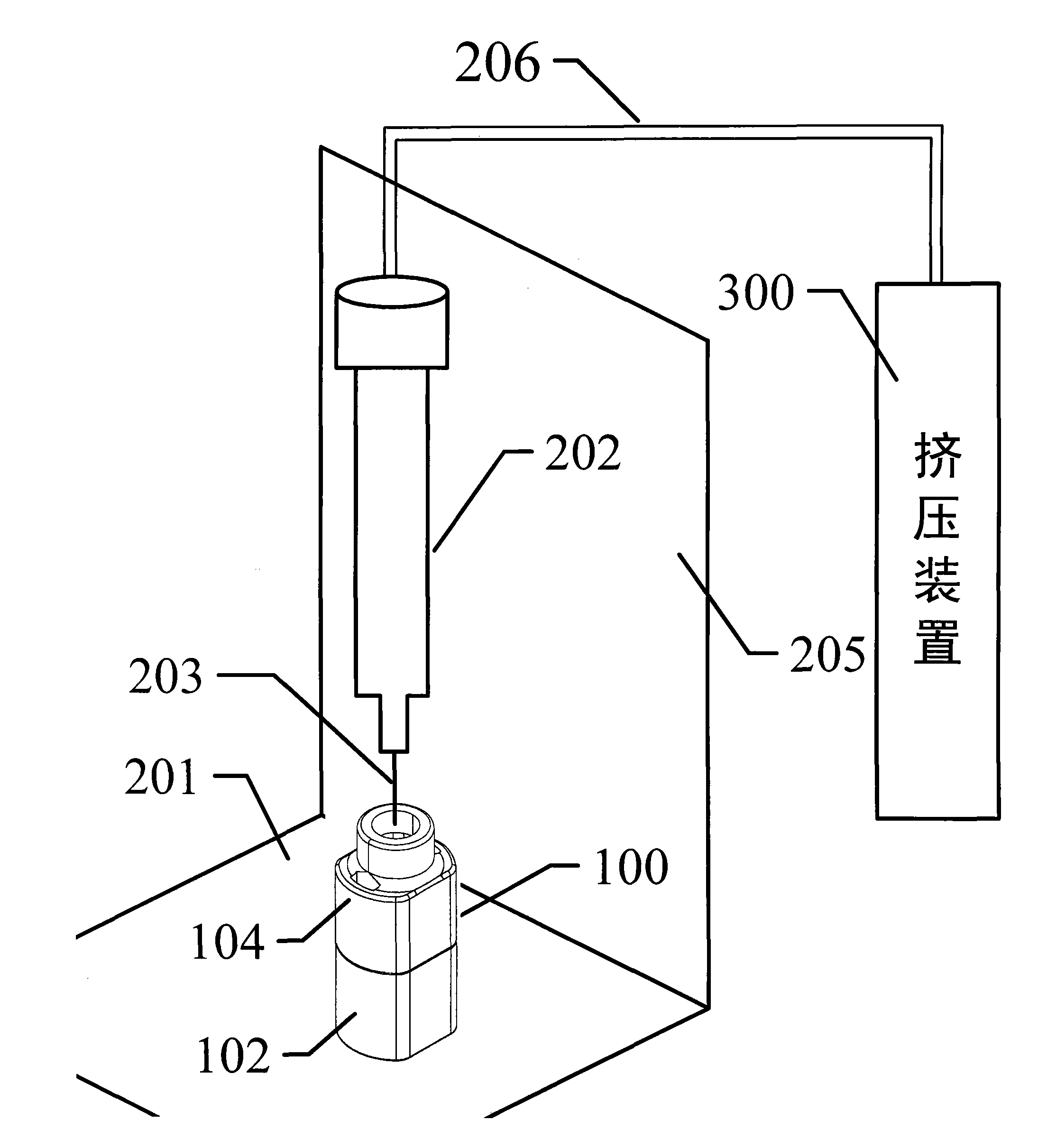

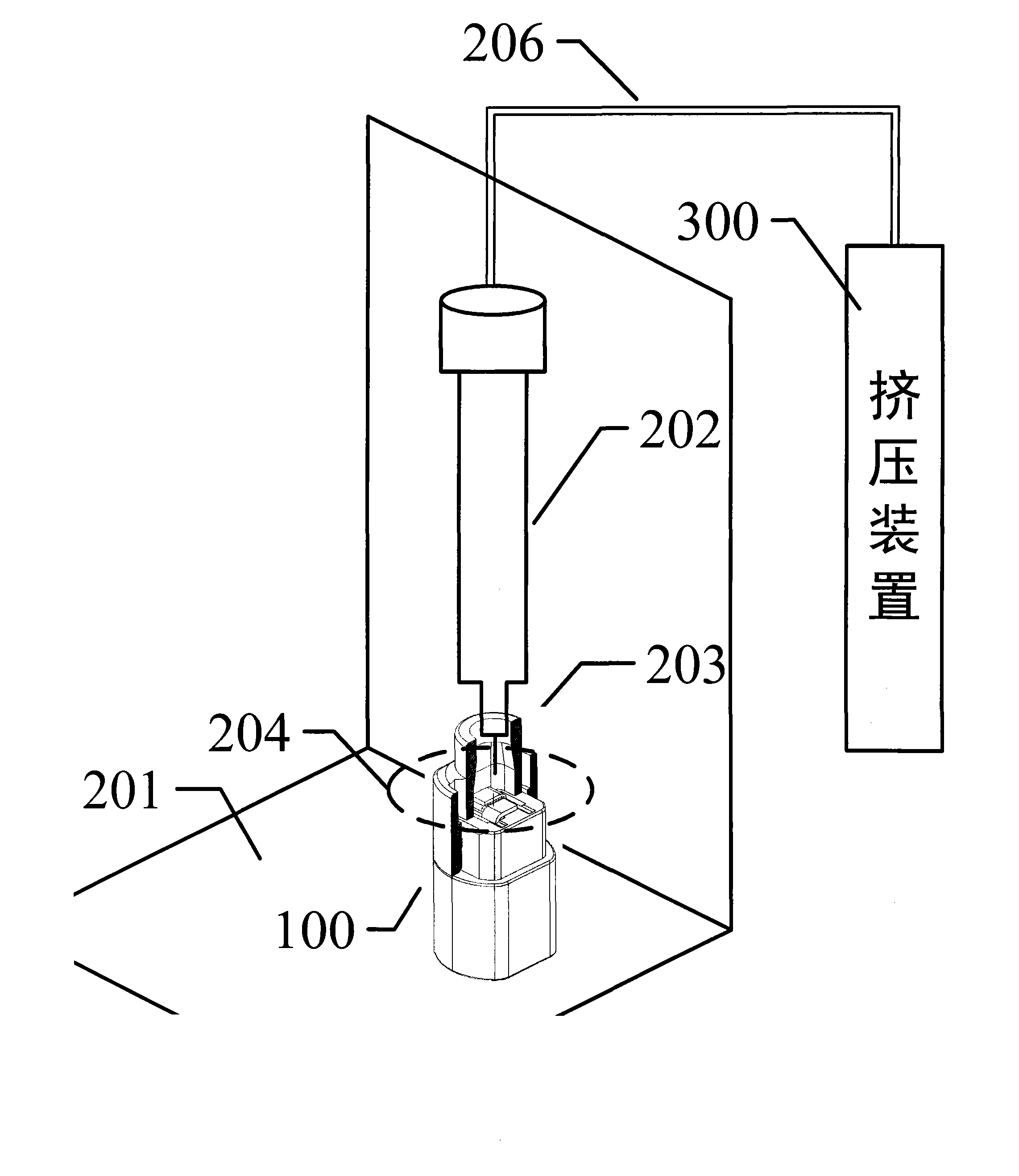

Method for producing explosive ignition head in detonator production and special explosive ignition device thereof

The invention provides a method for producing a detonator explosive ignition head. The method comprises the following processes of: 1, upwards fixedly placing an ignition head explosive cavity on an operating table; 2, adjusting an explosive injection cartridge or the operating table so that the cartridge is positioned right above a cavity shell and aims at an ignition bridge wire; 3, adjusting an explosive injection head or the operating table so that the explosive injection head descends to the explosive cavity; and 4, starting an extrusion device to extrude an ignition agent, and injecting the agent into the explosive cavity so that the agent fully wraps the ignition bridge wire; and finally, extracting the explosive injection head to complete the production. The invention also provides an explosive ignition device for implementing the method, which comprises the operating table, the explosive injection cartridge, the explosive injection head, the extrusion device and an explosion-proof device for isolating a person and the operating table. A fixer on the operating table fixes the ignition head on the operating table, the extrusion device can hermetically connected with the explosive injection cartridge through an air pipe, and the explosive injection cartridge is hermetically connected with the explosive injection head. According to the technical scheme, automatic production of the explosive ignition head can be realized.

Owner:BEIJING BANGIUNION TECH DEV

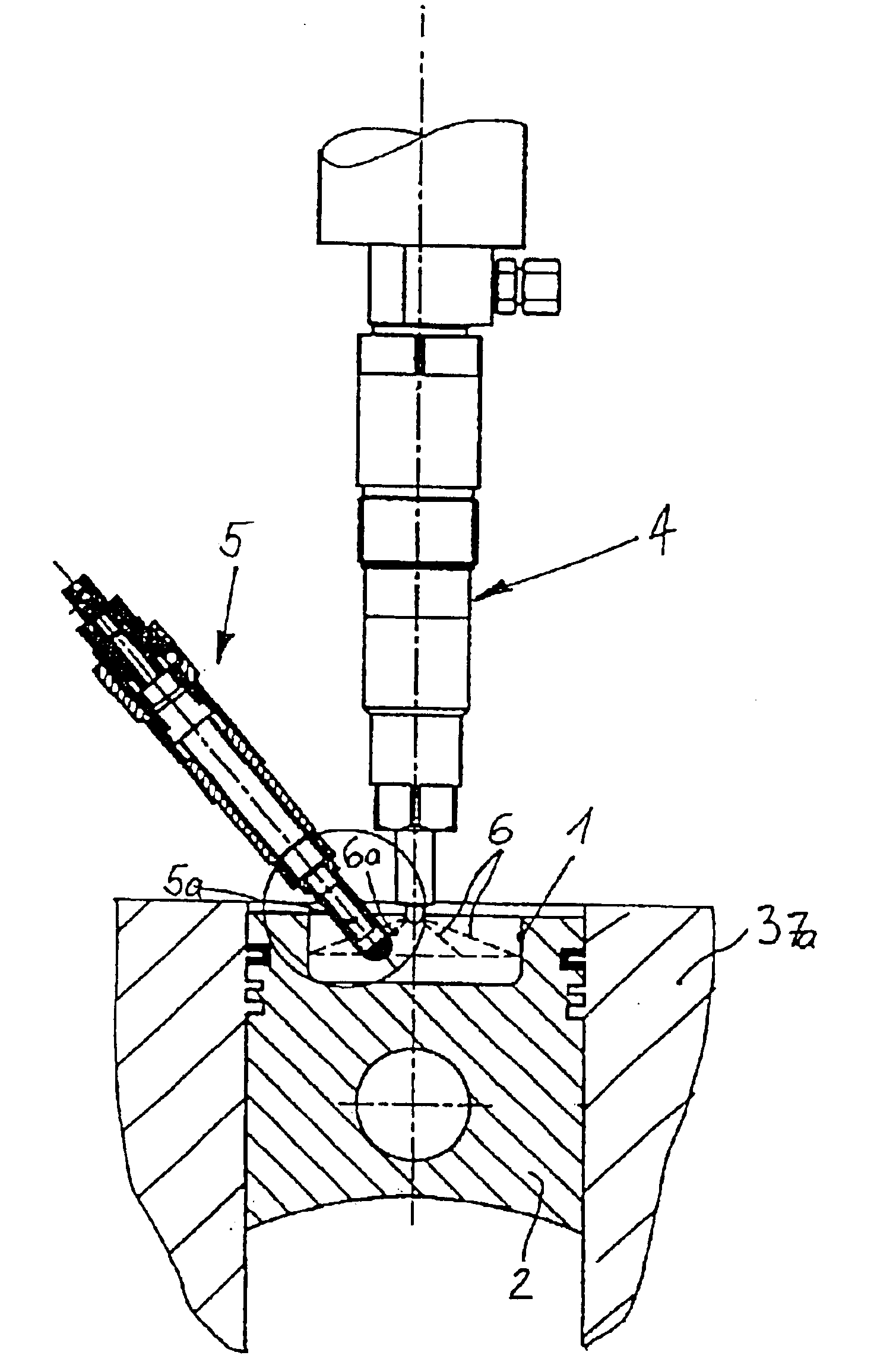

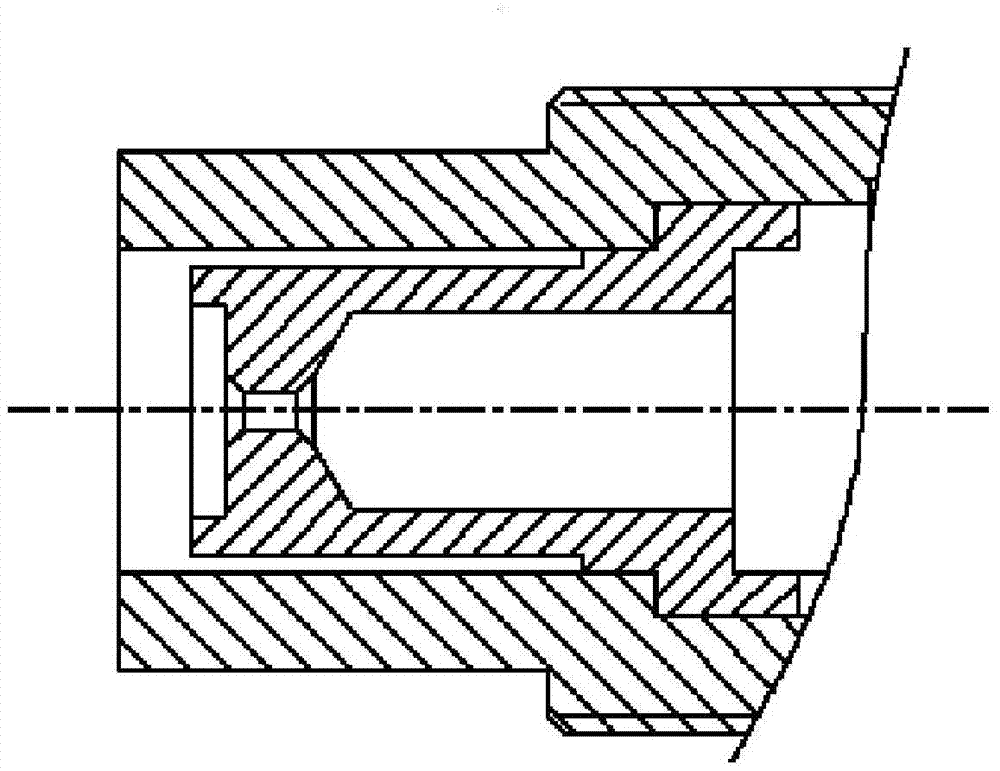

Internal combustion engine with injection of gaseous fuel

InactiveUS6845746B2Improve ignition reliabilityReduce nitrogen oxide emissionsIncandescent ignitionInternal combustion piston enginesInternal combustion engineFuel injection

An internal combustion engine comprises a fuel injection nozzle for injecting a gaseous fuel directly into the combustion chamber. Installed in close proximity to the fuel injection nozzle is an ignition device, comprising a sleeve that provides a shielded space around a hot surface igniter. The sleeve restricts flow between the shielded space and the combustion chamber. An inlet opening in the sleeve allows air and fuel to enter the shielded space to form a combustible mixture therein. The sleeve contains a substantial amount of the combustible mixture within the shielded space until it ignites and pressure builds within the shielded space to propel a combustion flame through at least one discharge opening that is oriented to direct the combustion flame into contact with the fuel spray roots emerging from the fuel injection nozzle.

Owner:WESTPORT POWER

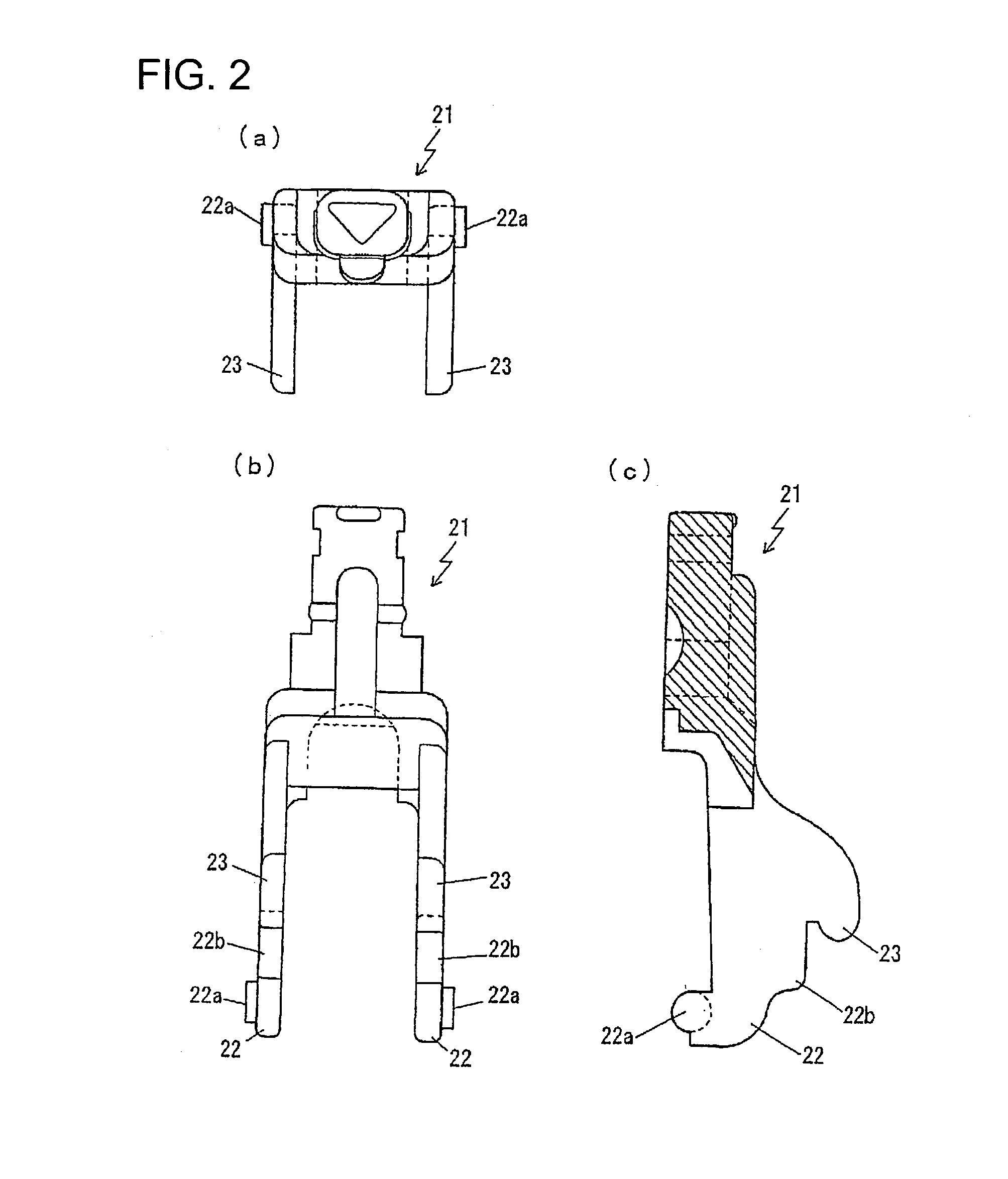

Ignition operating mechanism for slide type lighters

InactiveUS20030157449A1Prevent careless ignition and ignitionReduce the burden onBurnersIncandescent ignitionSpring forceEngineering

An ignition operation mechanism for slide type lighters that is capable of preventing accidental ignition or ignition due to erroneous use or the like while maintaining good operability, wherein pivots 22a, 22a for an operating cap 20 are made substantially circular in cross section and so sized as to form a vertically movable clearance as they are locked to a support section in the lighter main body, the pivots 22a, 22a for the operating cap 20 are normally urged to be positioned in the upper region of the interior of a support section by the spring force of a return spring for a piezoelectric mechanism 4, the operating cap 20 is slid until a lever member 21 strikes the lighter main body 1 and no longer moves in the slide direction, from which state (a), the operating cap is pressed downward, whereby the pivots 22a, 22a move downward (b) within the support section, whereupon pressing levers 23, 23 reach the operation stroke that overcomes the piezoelectric mechanism 4, producing a discharge voltage to enable ignition.

Owner:TOKAI

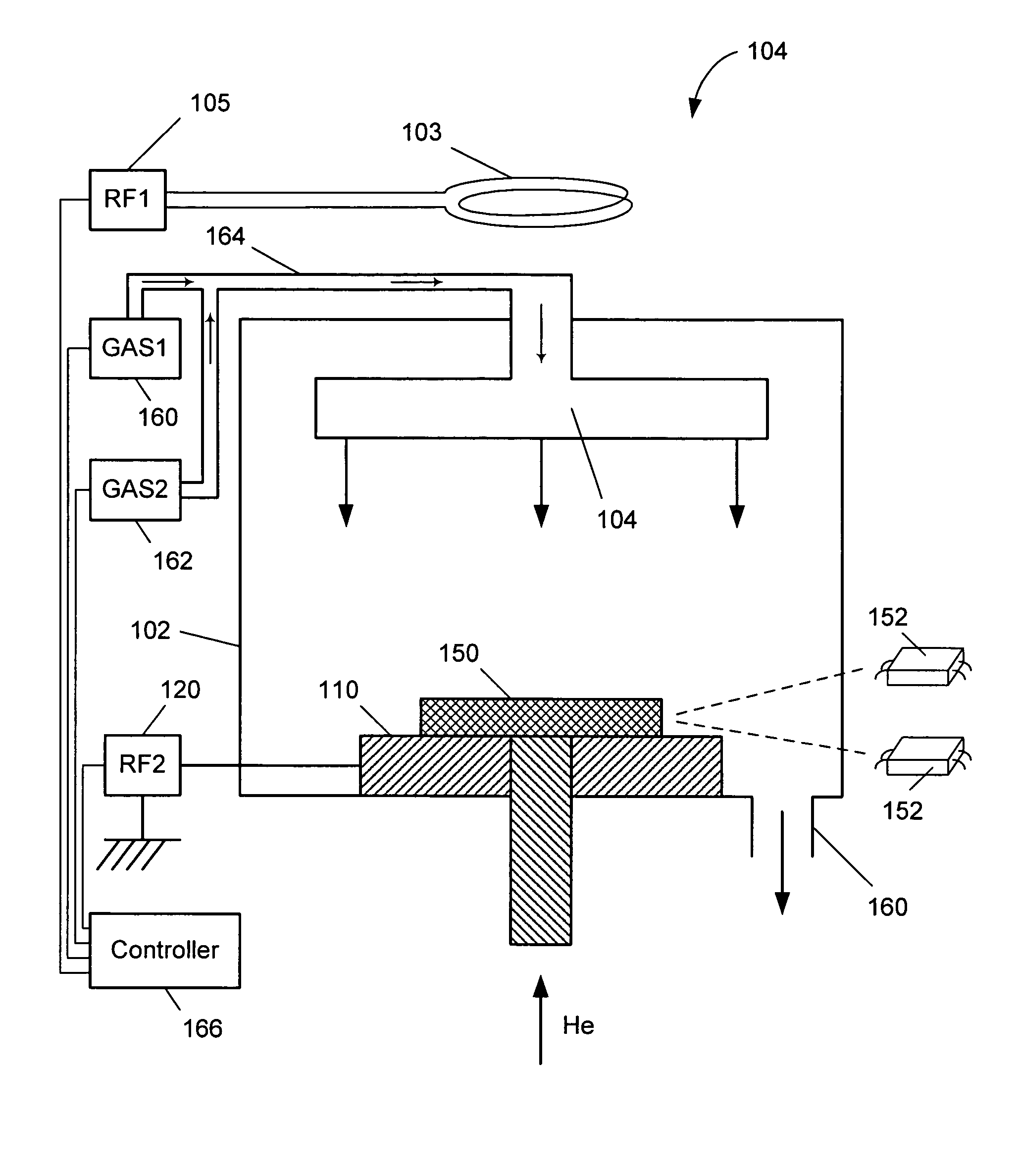

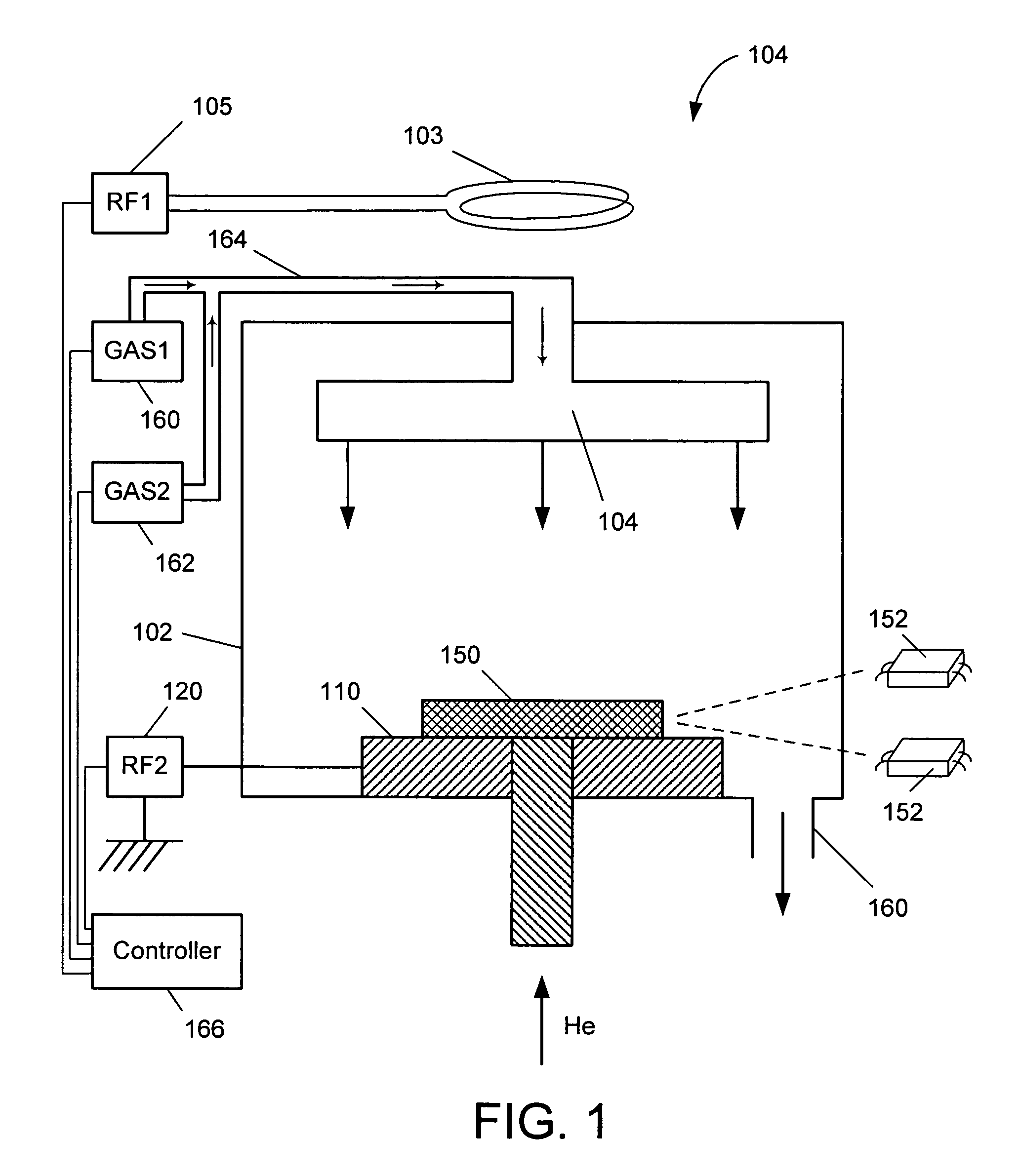

Method to improve ignition in plasma etching or plasma deposition steps

InactiveUS7279429B1Improve flammabilityImprove ignition reliabilityElectric discharge tubesDecorative surface effectsPlasma depositionEngineering

In one embodiment, the present invention relates to a method for increasing the ignition reliability of a plasma in a plasma reactor, the method comprising: supplying a source gas to the plasma reactor, the source gas comprising: (a) at least one reactive compound; and (b) at least one ignition gas, wherein the at least one ignition gas increases the ignitability of the source gas as compared to the ignitability of the source gas lacking the at least one ignition gas.

Owner:ADVANCED MICRO DEVICES INC

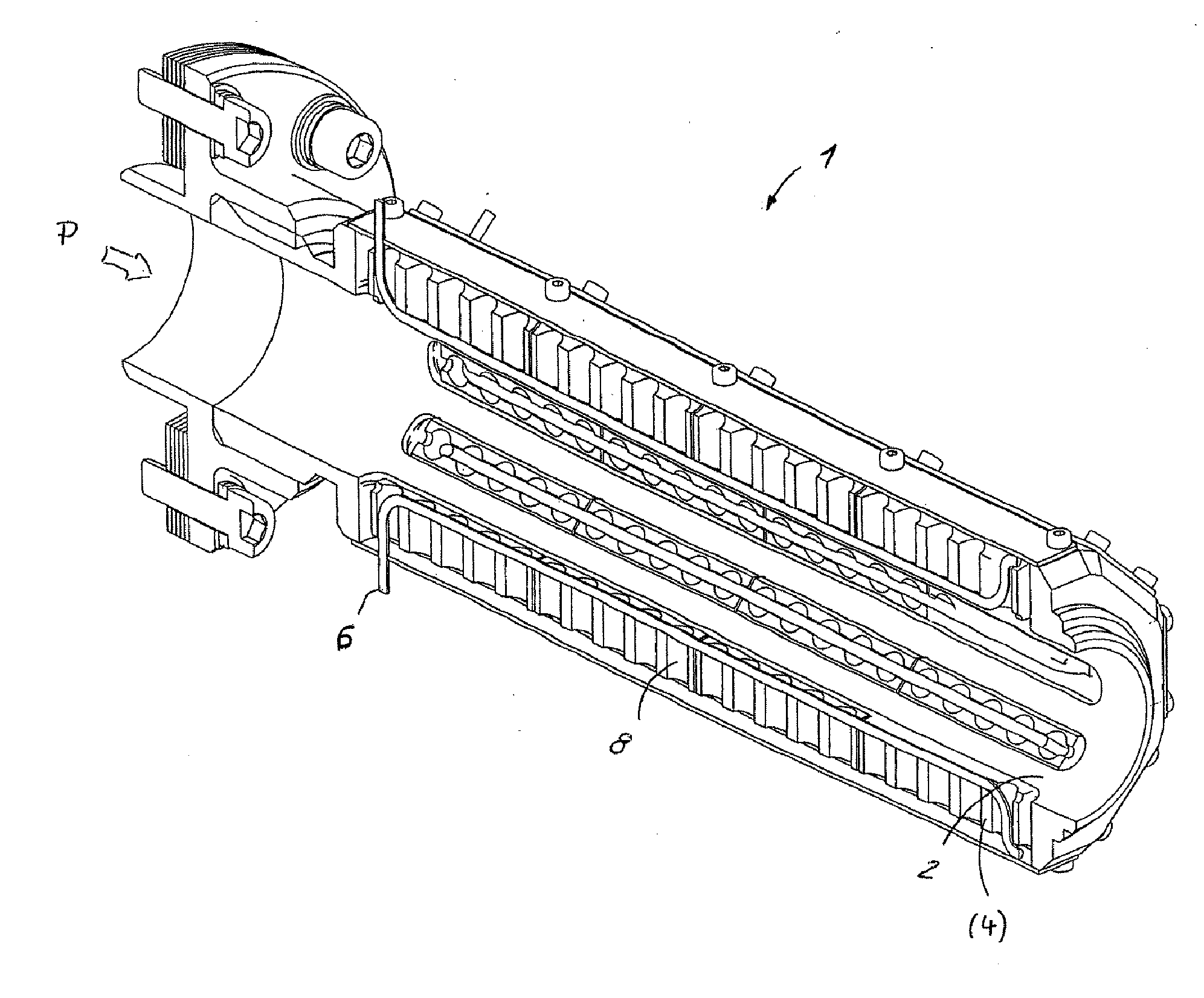

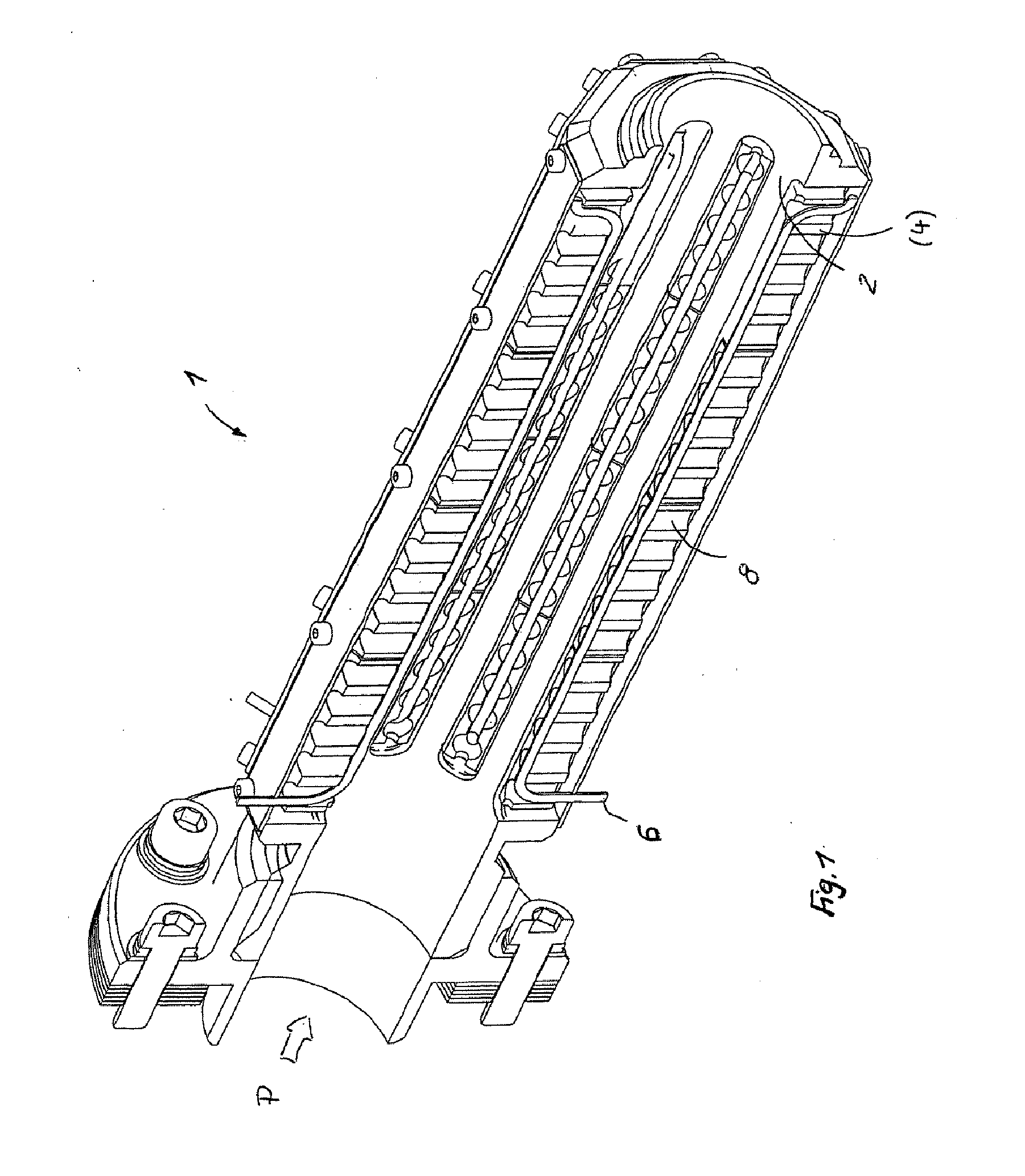

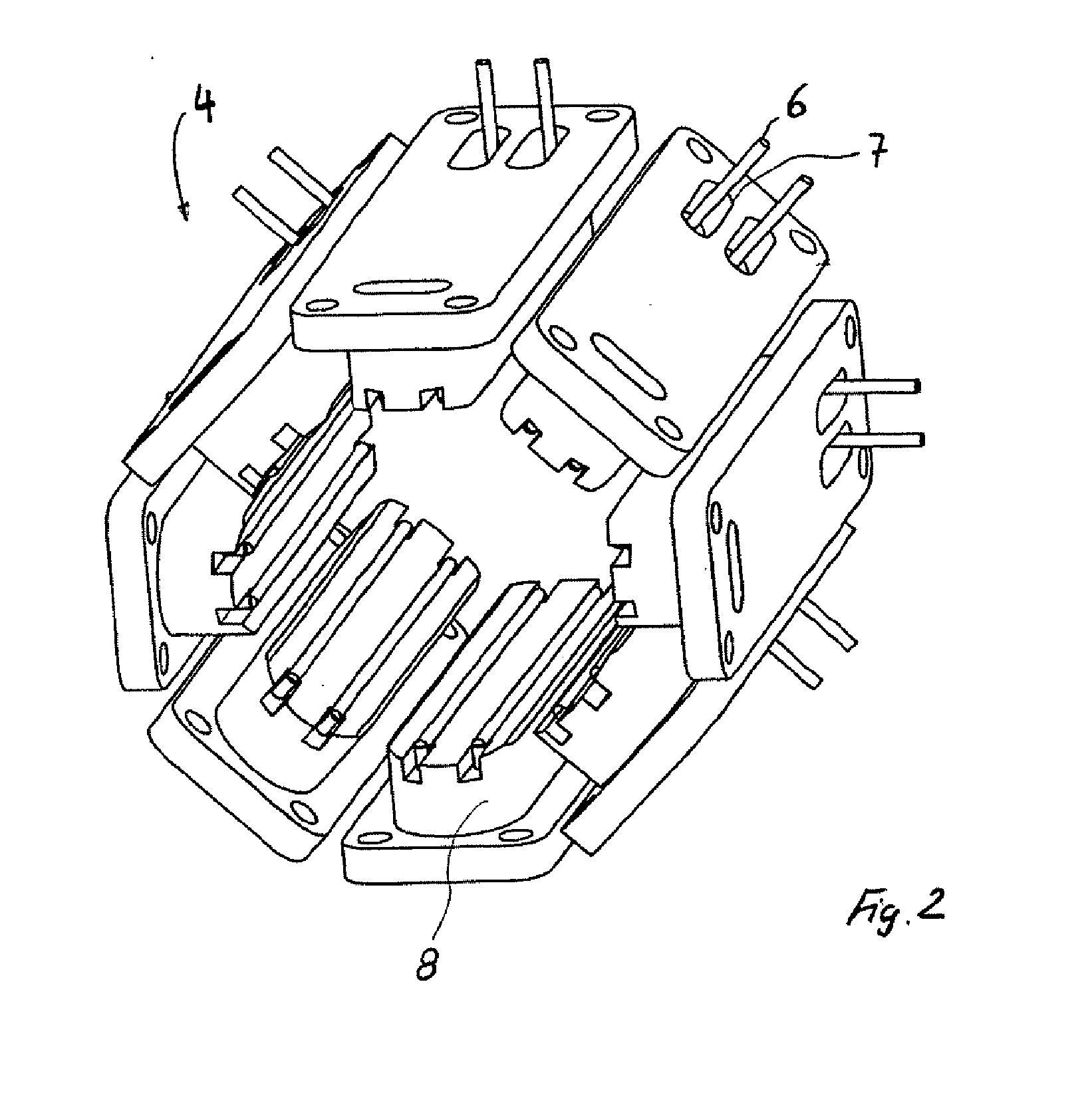

Activation unit for munition-free decoys

InactiveUS20110174182A1Increased functional reliabilityImprove efficiencyDefence devicesFirework flares/torchesThermal energyDecoy

An activation unit (1, 10) for munitions-free decoys, active masses or active bodies (3) is characterized by an ejector tube (2) and a high-powered heater element (4) arranged around the ejector tube (2, 12), wherein the heater element is made up of at least one heating wire (6), provided with electrical current by a regulator unit. Each heating wire (6) is enclosed in a sleeve (7) and embedded in at least one heat-loss minimizing material. The active body (3) passing through the activation unit (1,10) directly or indirectly contacts with the individual elements (4) of the activation unit (1, 10). Thermal energy is transmitted to the active body (3) from the heating wires (6), which ignites at the touching or contact point.

Owner:RHEINMETALL WAFFE MUNITION GMBH

Device and method for ignition through dual-mode lasers in target portion breakdown manner

ActiveCN105134452AFast ignitionImprove combustion efficiencyMachines/enginesEngine ignitionCombustion chamberDual mode

The invention provides a device and method for ignition by plasma sparks generated through continuous and pulsed dual-mode lasers in a target portion breakdown manner. The device is mainly provided with a pulsed laser transmitting end, a continuous laser transmitting end, a fuel injection device, a target portion, a combustion chamber, a cylinder cover, a piston and the like. The laser transmitting end does not stretch into the combustion chamber. According to the device and method for ignition through the continuous and pulsed dual-mode lasers in the target portion breakdown manner, the plasma sparks can always be reliably generated to ignite a fuel-air mixture in the combustion chamber; and the ignition speed can be effectively increased, the ignition adjusting difficulty is lowered, ignition reliability is improved, the combustion area is increased, combustion efficiency can be improved, and fuel can be saved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

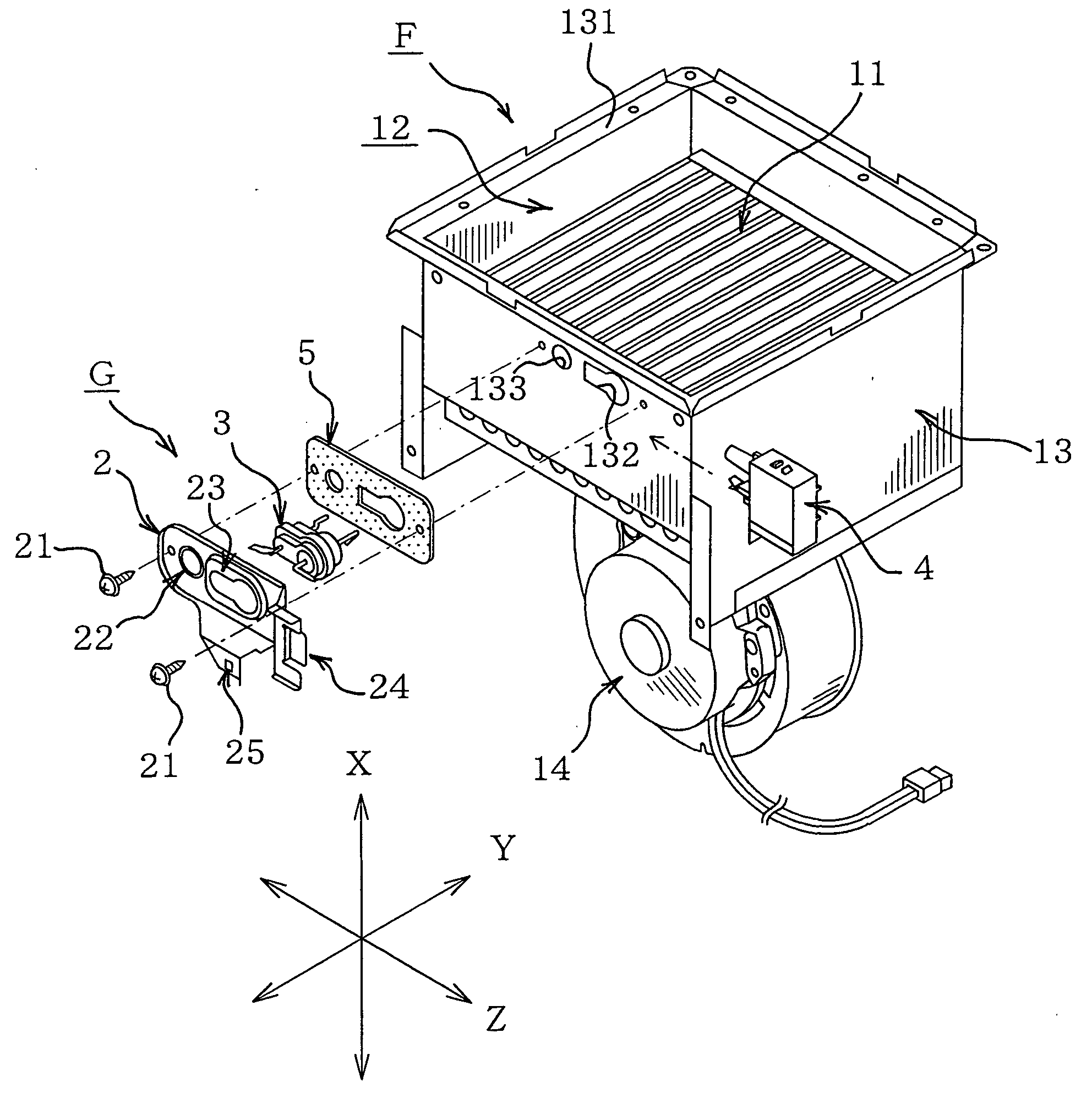

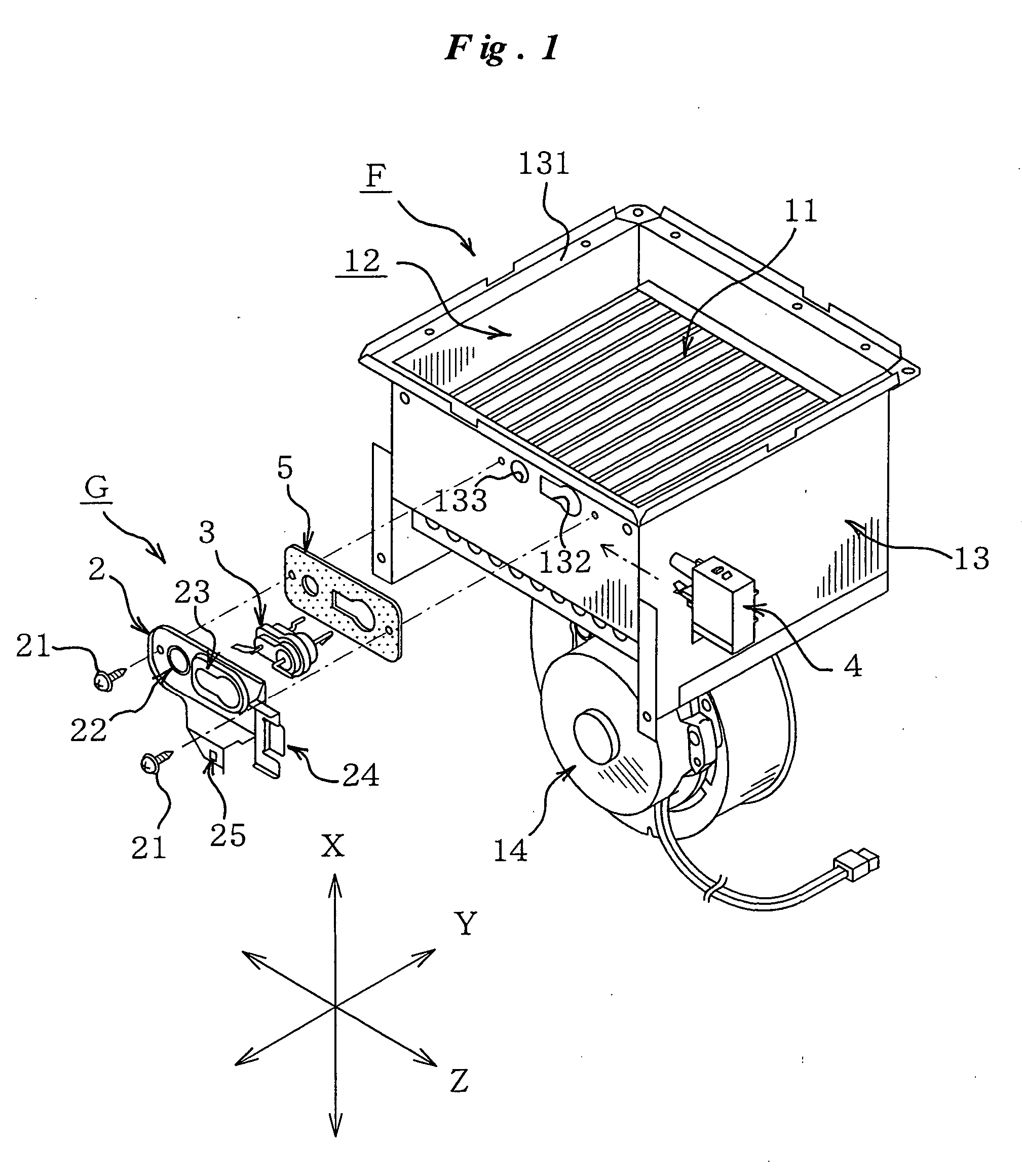

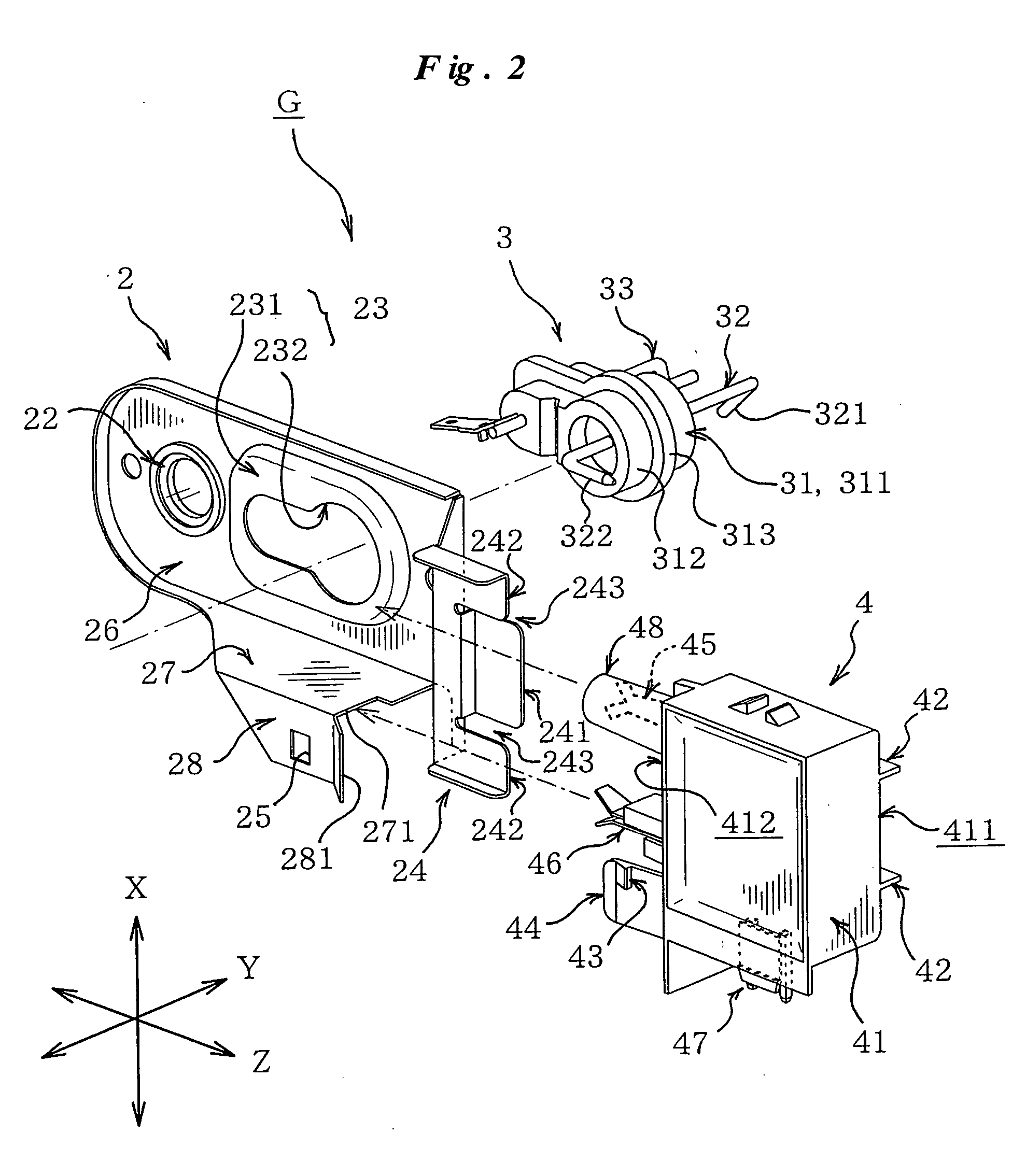

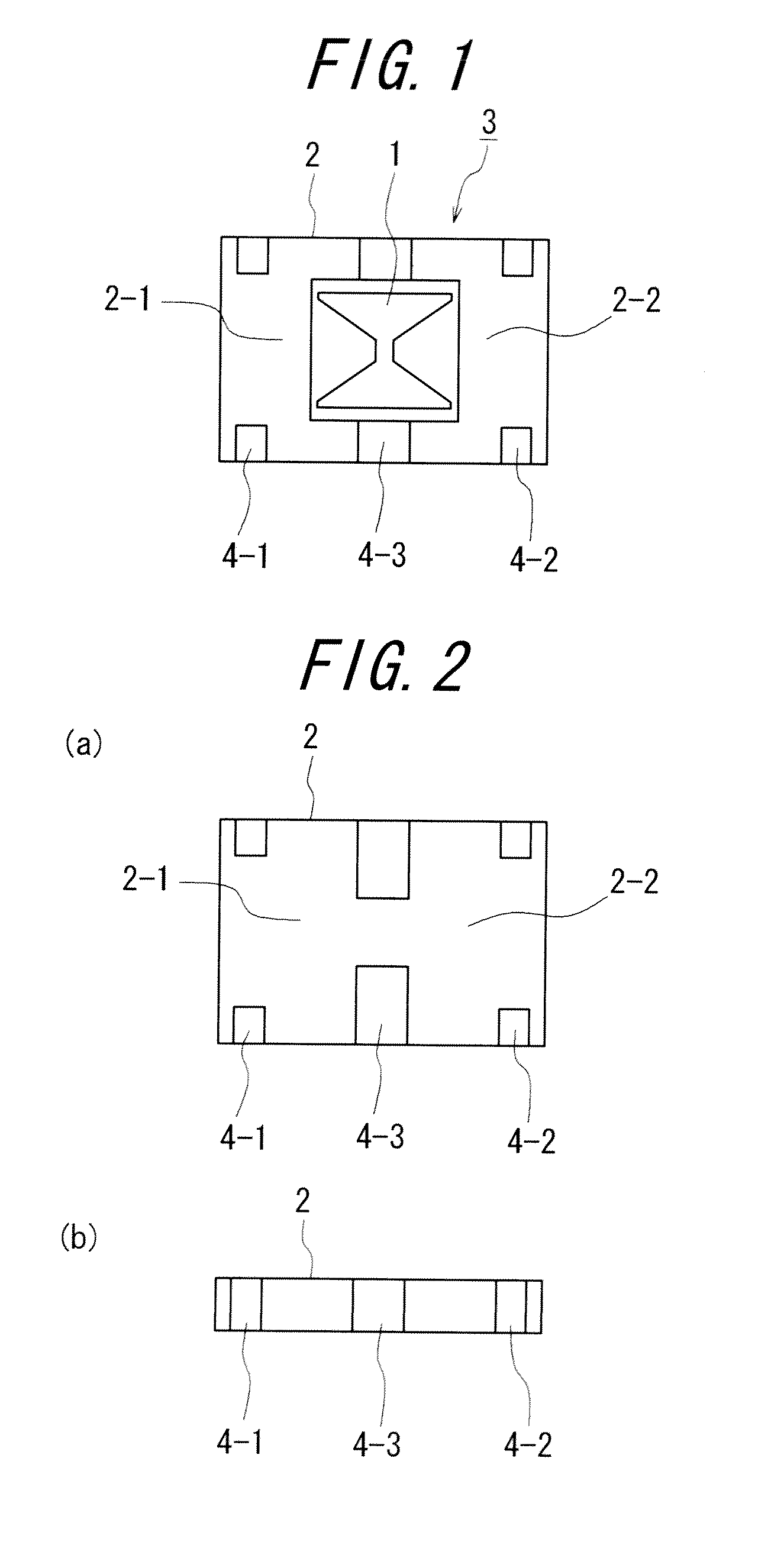

Ignition unit

InactiveUS20050042564A1Inhibit the influence of heatImprove ignition reliabilityIncandescent ignitionElectric spark ignitersHigh pressureHigh voltage

An ignition unit promotes the efficiency of assembly because connections on the high voltage output side and the ground side are completed by a single operation, when an ignition electrode part and a main unit are connected together directly. A guide rail of the main unit is insertion-engaged into a slit between clamp pieces of a bracket so that the main unit is mounted onto the bracket. With the insertion engagement, a high voltage output terminal receives therein a high voltage input terminal of a spark plug supported by the bracket, a plate terminal which is a part of the bracket is driven into a ground-side connection terminal, and a convex portion of a projected piece is engaged into an engagement hole, for positioning and slipping-off prevention.

Owner:NORITZ CORP

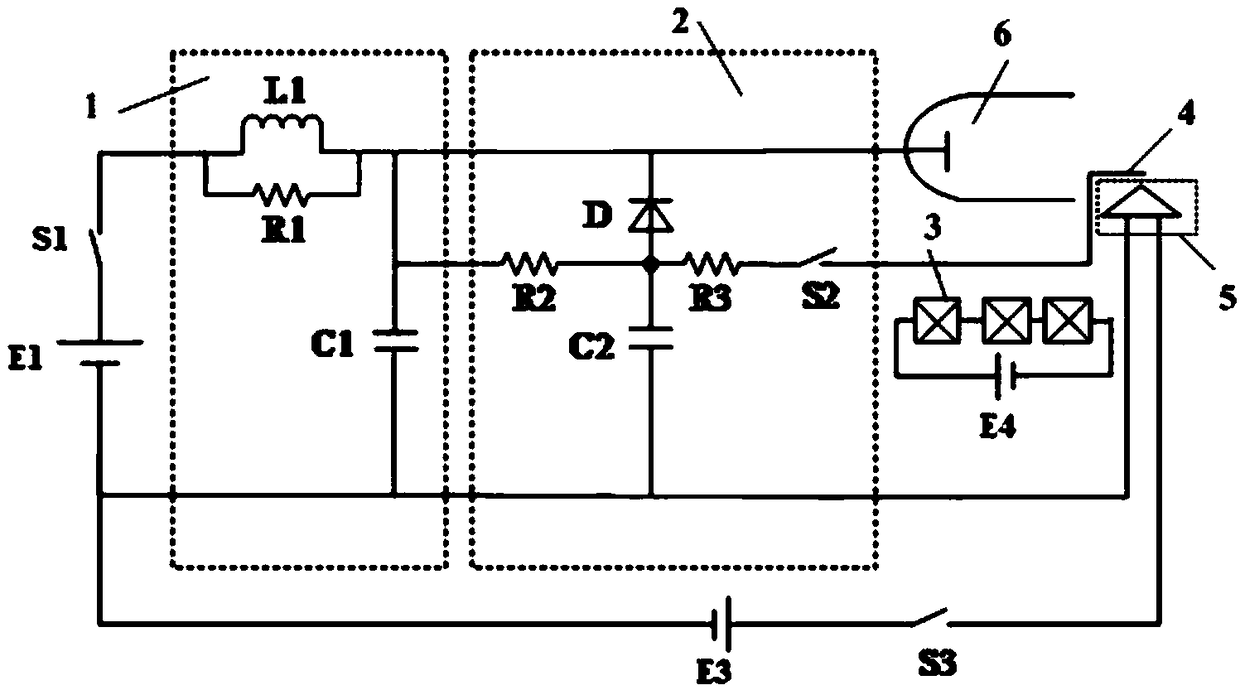

High-pressure intensity and mass-flow liquid oxygen kerosene engine plasma ignition device

ActiveCN108194943AEasy to integrateHigh degree of automationIncandescent ignitionKeroseneEngineering

The invention relates to non-hypergolic propellant rocket engine ignition devices, in particular to a high-pressure intensity and mass-flow liquid oxygen kerosene engine plasma ignition device. The high-pressure intensity and mass-flow liquid oxygen kerosene engine plasma ignition device comprises an air source, a plasma torch, a power module and a control unit. An outlet of the air source communicates with an air inlet of the plasma torch through a high-pressure electromagnet and an air supply pipeline. The control unit comprises a drive module and a measuring and controlling module. The output end of the drive module is connected with an electrical signal input end of the plasma torch through a cable and is used for providing electrical signals for driving the plasma torch. The measuringand controlling module is connected with the high-pressure electromagnetic valve, the drive module and the power module and used for controlling opening and closing of the high-pressure electromagnetic valve and the drive module according to an external control instruction and feeding back the temperature of the power module and output electrical signal parameters of the drive module. The power module is used for supplying power to the electromagnetic valve.

Owner:XIAN AEROSPACE PROPULSION INST

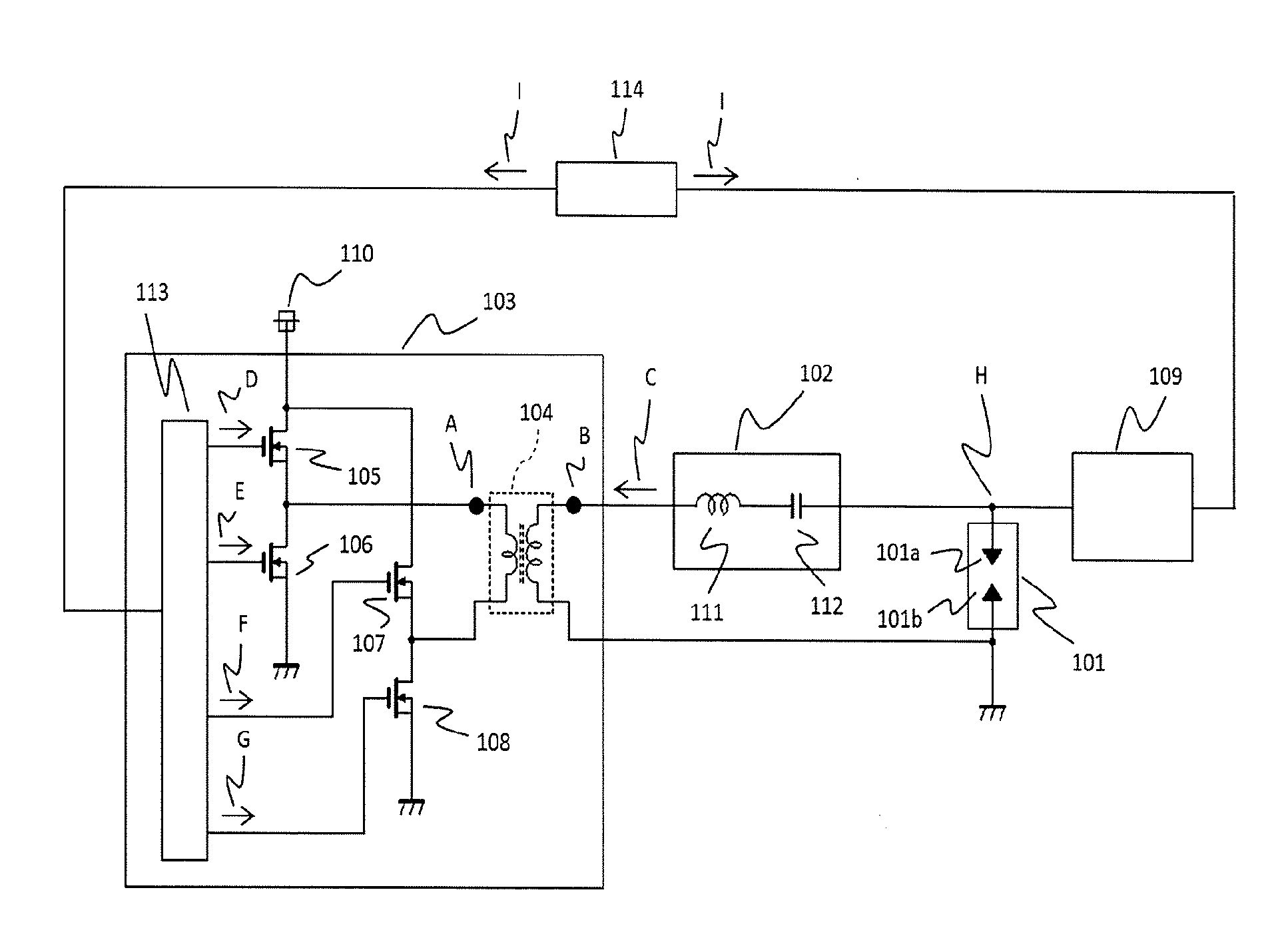

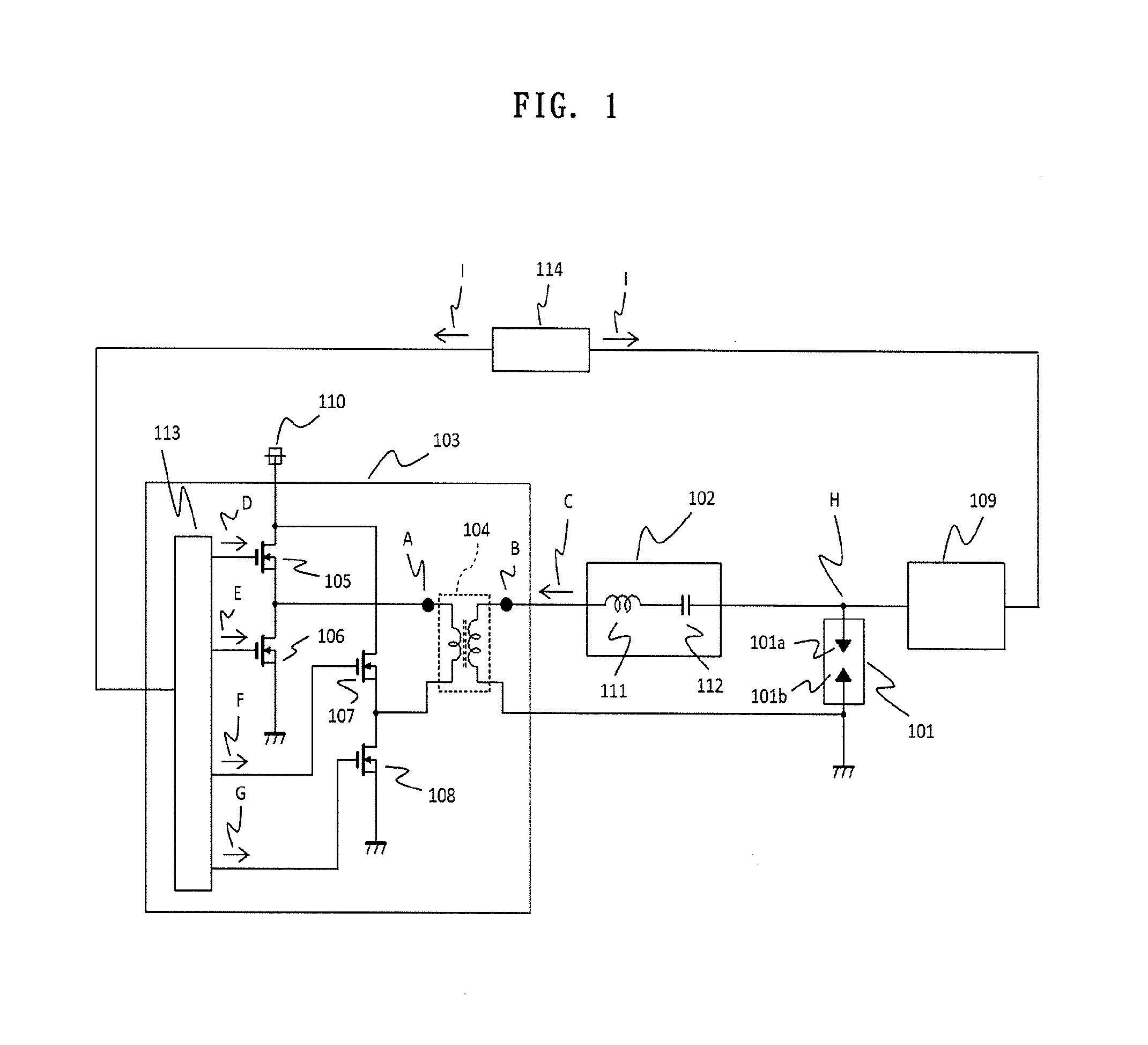

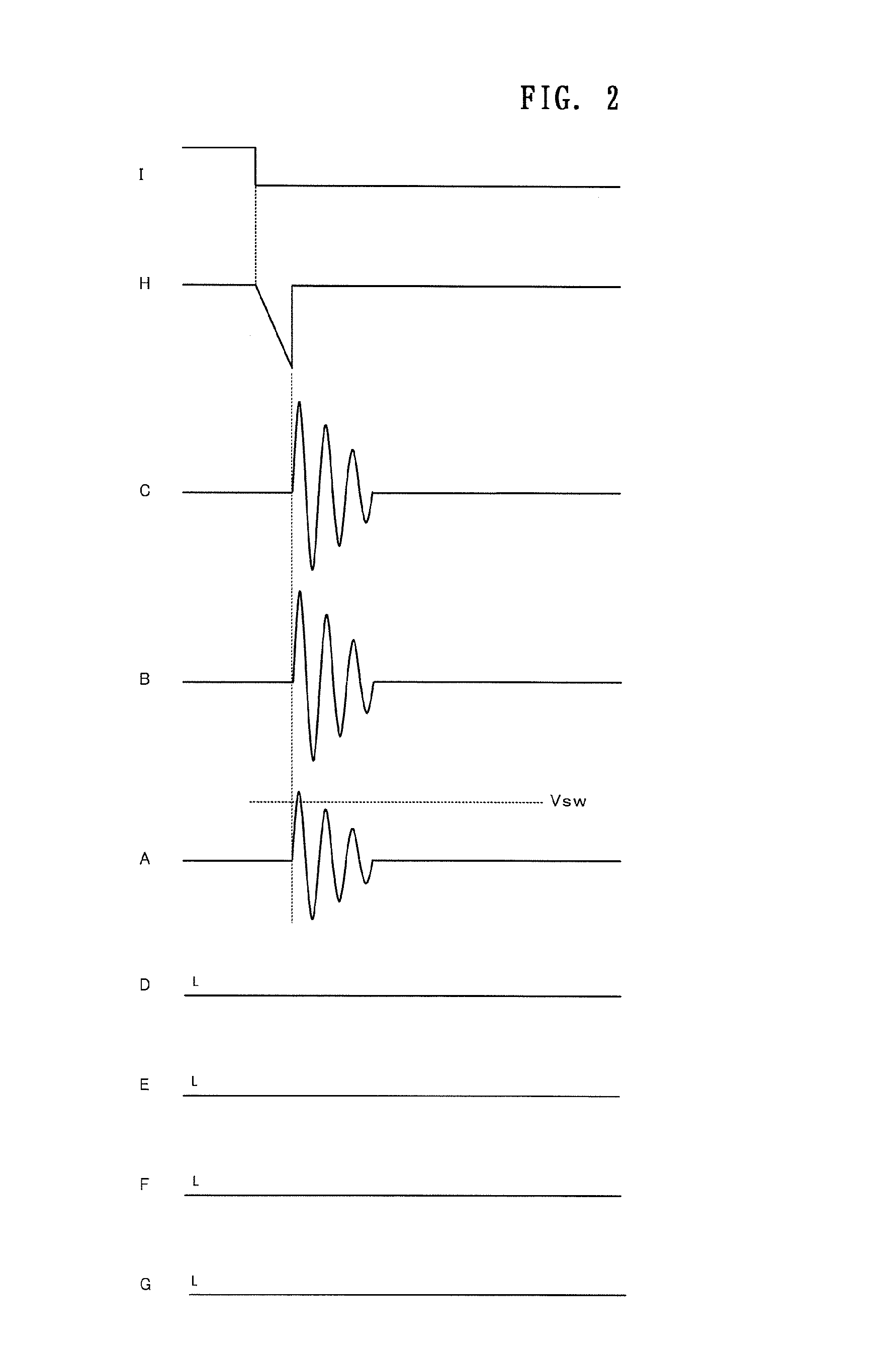

Ignition device

ActiveUS20160164263A1Improve ignition reliabilityAvoid it happening againElectric lighting sourcesMachines/enginesCapacitanceControl signal

In an ignition device, at a timing of a control signal provided by a control device to control an ignition coil device or at a timing prior to the control signal in order that a high voltage is applied to an ignition plug to initiate a spark discharge, a control circuit of an AC power source unit in response to the control signal controls switching elements composing a bridge circuit in the AC power source unit for a DC-AC inversion to thereby short-circuit a winding of a transformer device on the side of the AC power source unit, connected between a boosting device including a capacitor device and the bridge circuit for the circulation of a capacitance discharging current from the boosting device to the transformer device.

Owner:MITSUBISHI ELECTRIC CORP

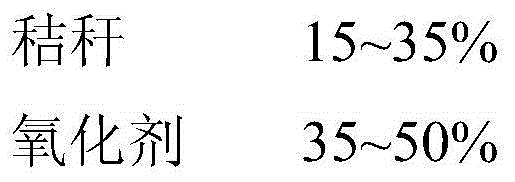

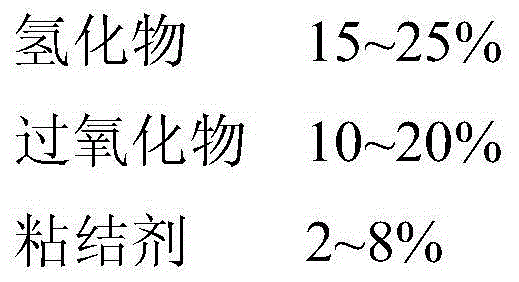

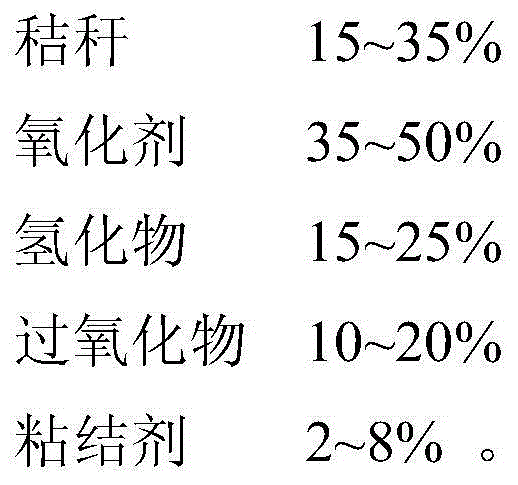

High-energy-point gunpowder and preparation method

The invention relates to high-energy-point gunpowder and a preparation method and belongs to the field of energetic materials. The high-energy-point gunpowder comprises 15-35 percent of straw, 35-50 percent of an oxidizing agent, 15-25 percent of hydride, 10-20 percent of peroxide and 2-8 percent of a binder. A preparation process for the gunpowder comprises the following steps: weighing all components according to the ratio; preparing the binder into liquid glue through an anhydrous solvent, respectively wrapping the hydride, oxide and peroxide, uniformly mixing the wrapped matters with the straw, dropwise adding the liquid gel on the mixture, stirring uniformly, screening, drying and screening again so as to obtain the high-energy-point gunpowder. The high-energy-point gunpowder is high in safety; since the surface of each of the hydride, the oxide and the peroxide is wrapped with a layer of protective film with good performance, the sensitivity is reduced and transportation and use safety is improved; the high-energy hydride and high-oxidbillity peroxide are used for gunpowder ignition, so that a large amount of energy and gas are released in the reaction process, stable pressure is formed and firing reliability is high.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

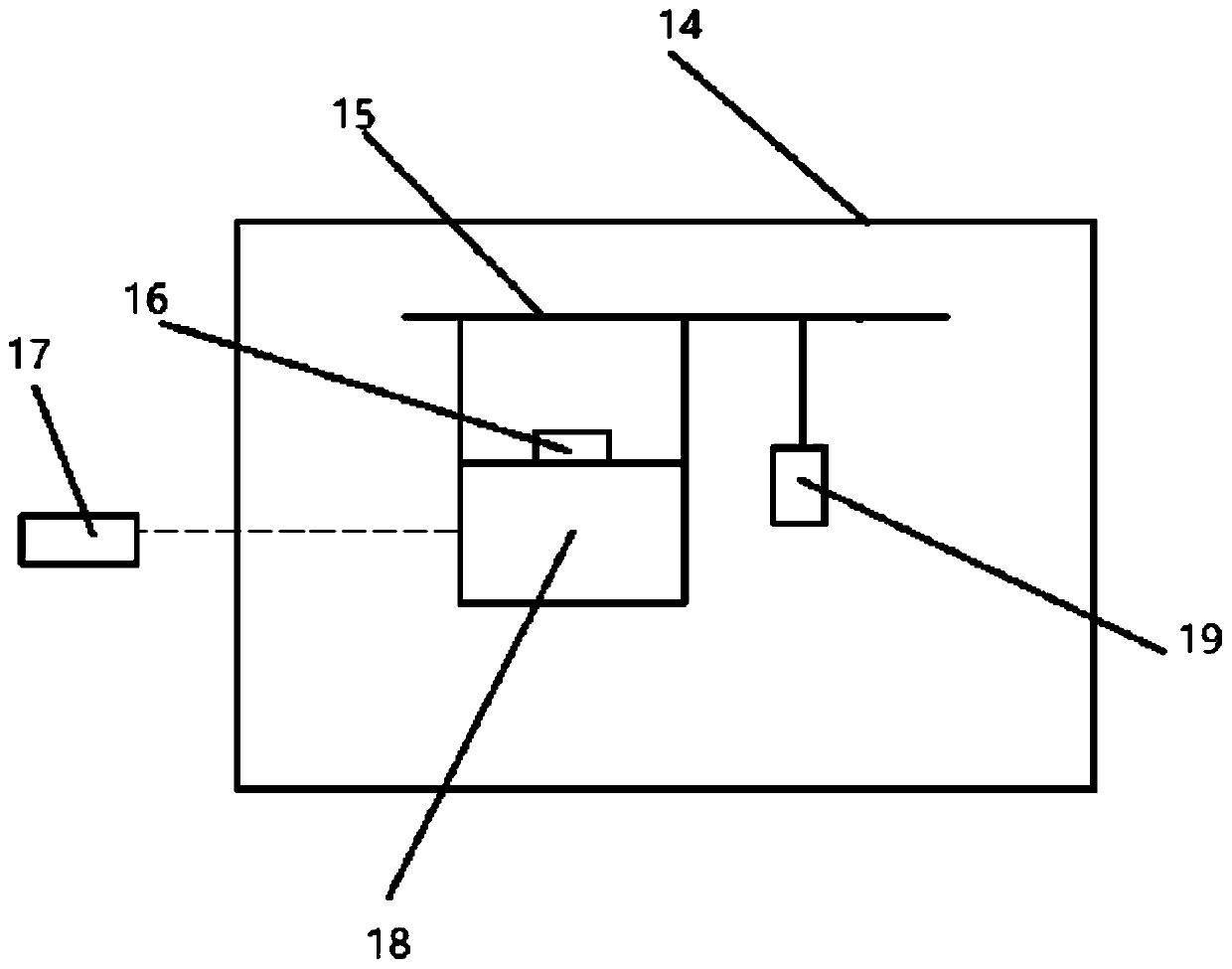

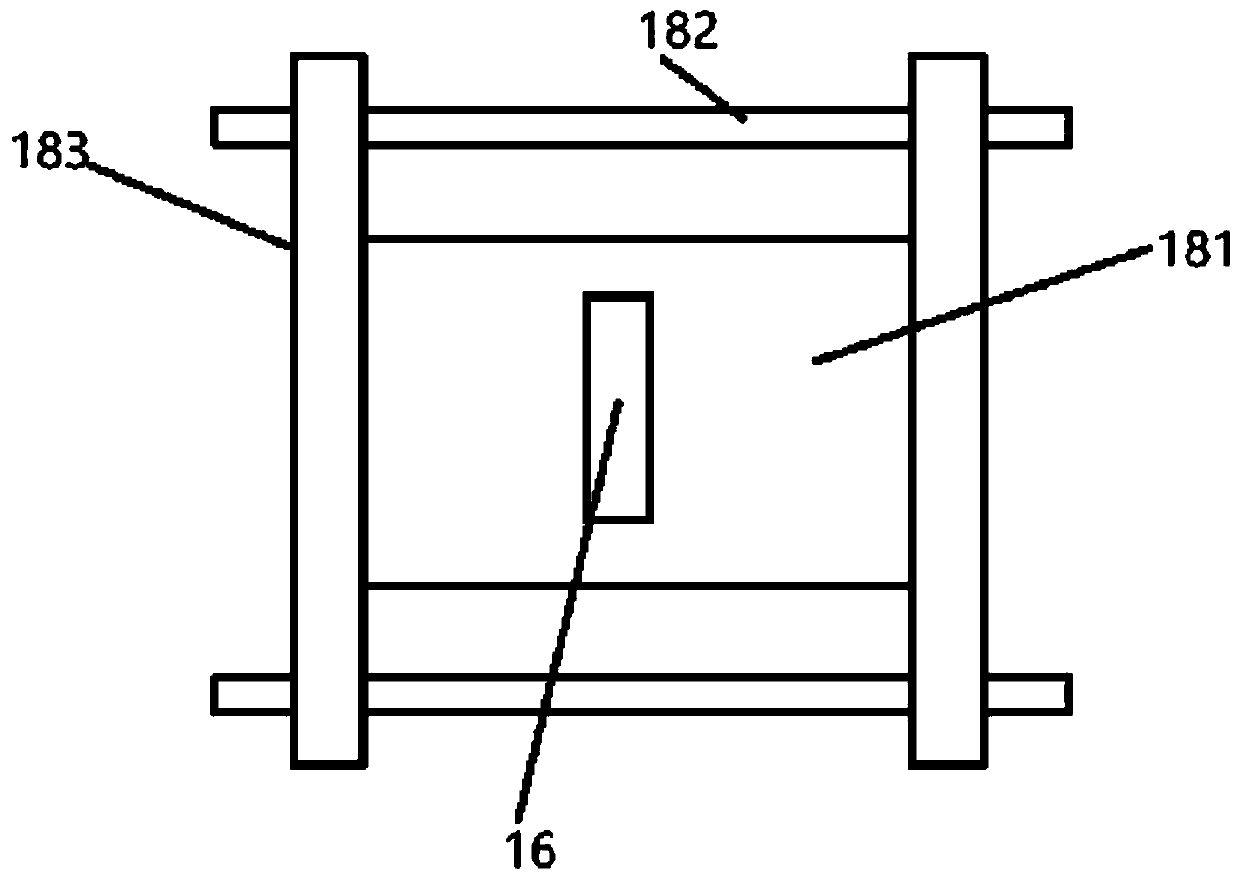

Model testing device for studying, explosion, energy gathering, cutting and destroying of underwater unexploded projectile

ActiveCN109916246AExcellent rangeGuaranteed integrityAmmunition projectilesAmmunition testingDetonationUnderwater

The invention discloses a model testing device for studying, explosion, energy gathering, cutting and destroying of an underwater unexploded projectile. The device comprises an explosion water tank; asupport is installed inside the explosion water tank; a simulation projectile body is suspended on the support; a pressure sensor is installed around the simulation projectile body; a cutting deviceis installed on the simulation projectile body; an observation window is arranged on the explosion water tank; a high-speed camera device is arranged outside the observation window; the cutting devicecuts the projectile body and detonates the projectile body; and the pressure sensor and the high-speed camera device collects the explosion signal. The model testing device for studying, explosion, energy gathering, cutting and destroying of the underwater unexploded projectile can accurately simulate the state of the underwater unexploded projectile and the problems of destroying, so that testing data are more close to the real data, and accurate and safe detonation of an explosion device in underwater test and synchronous acquisition and transmission of types are achieved.

Owner:ARMY ENG UNIV OF PLA

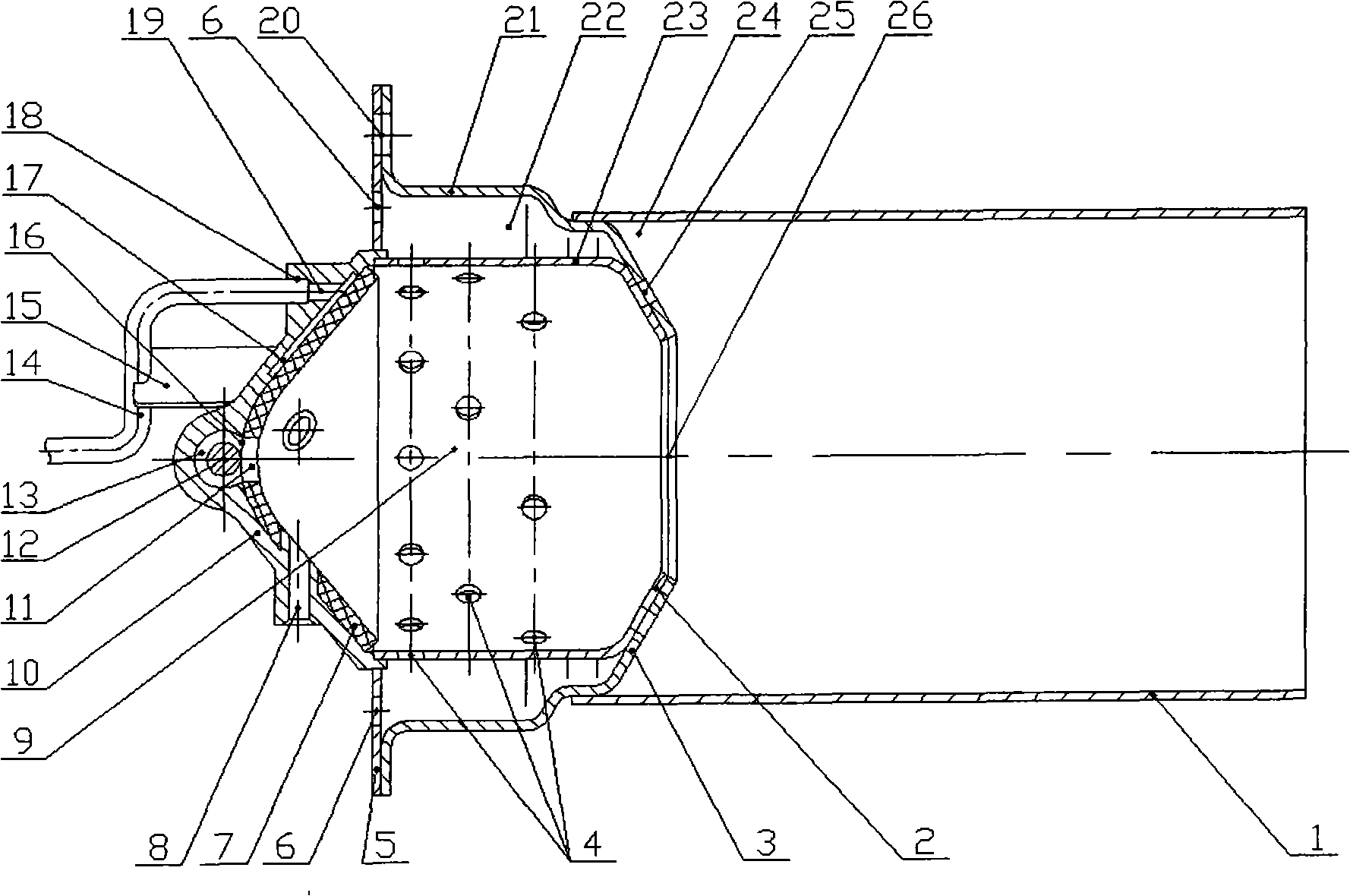

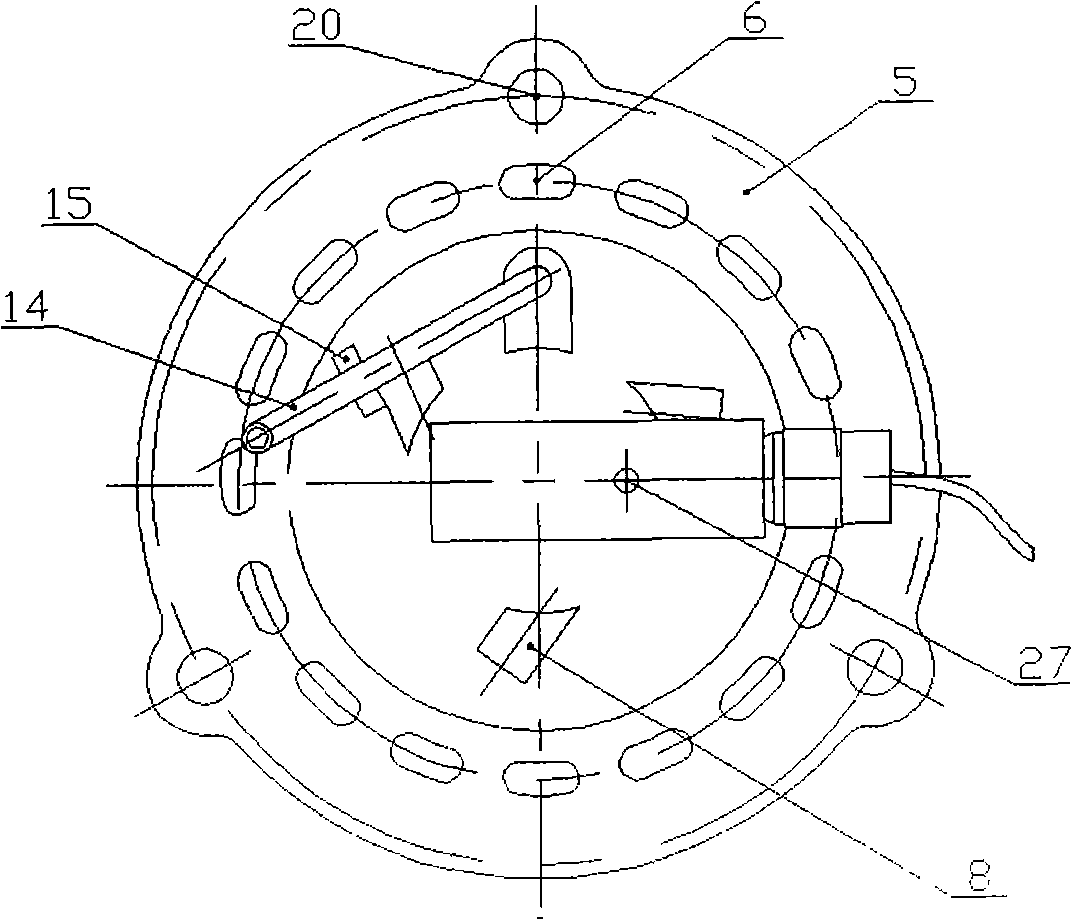

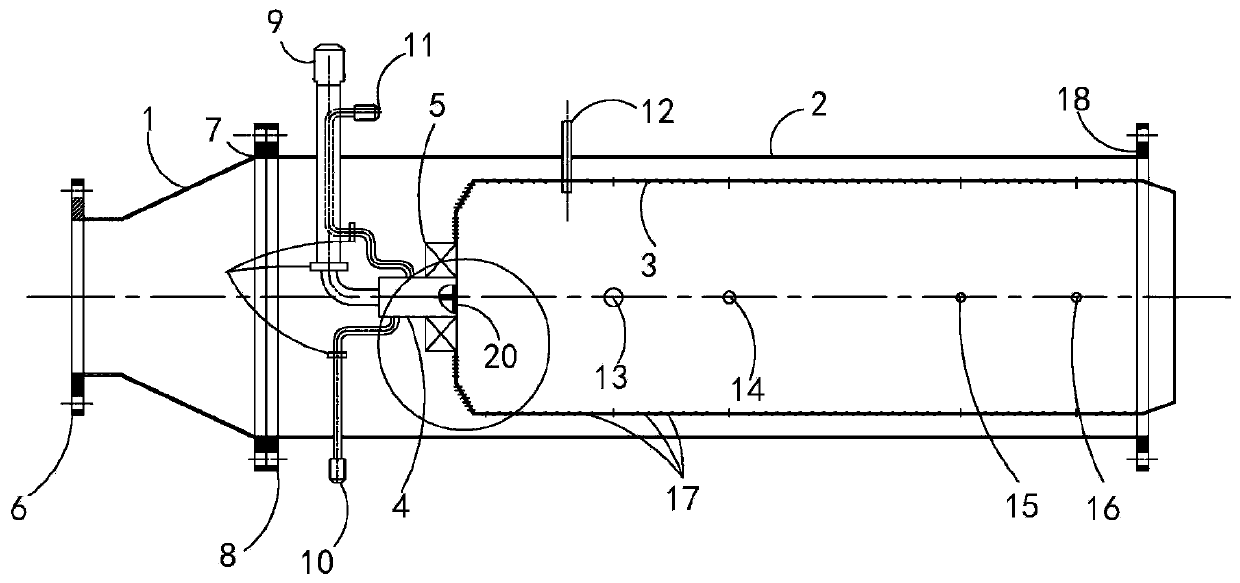

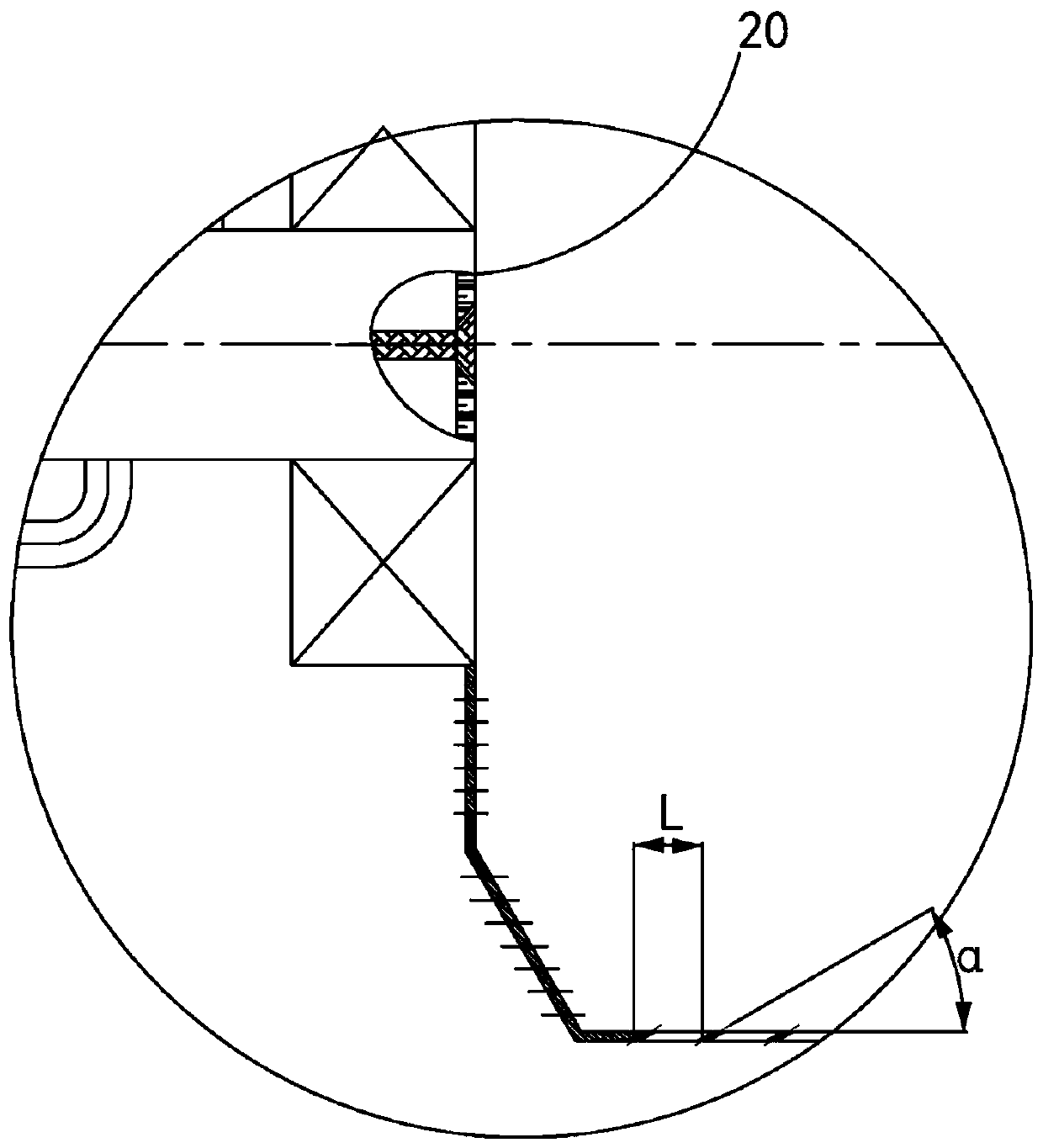

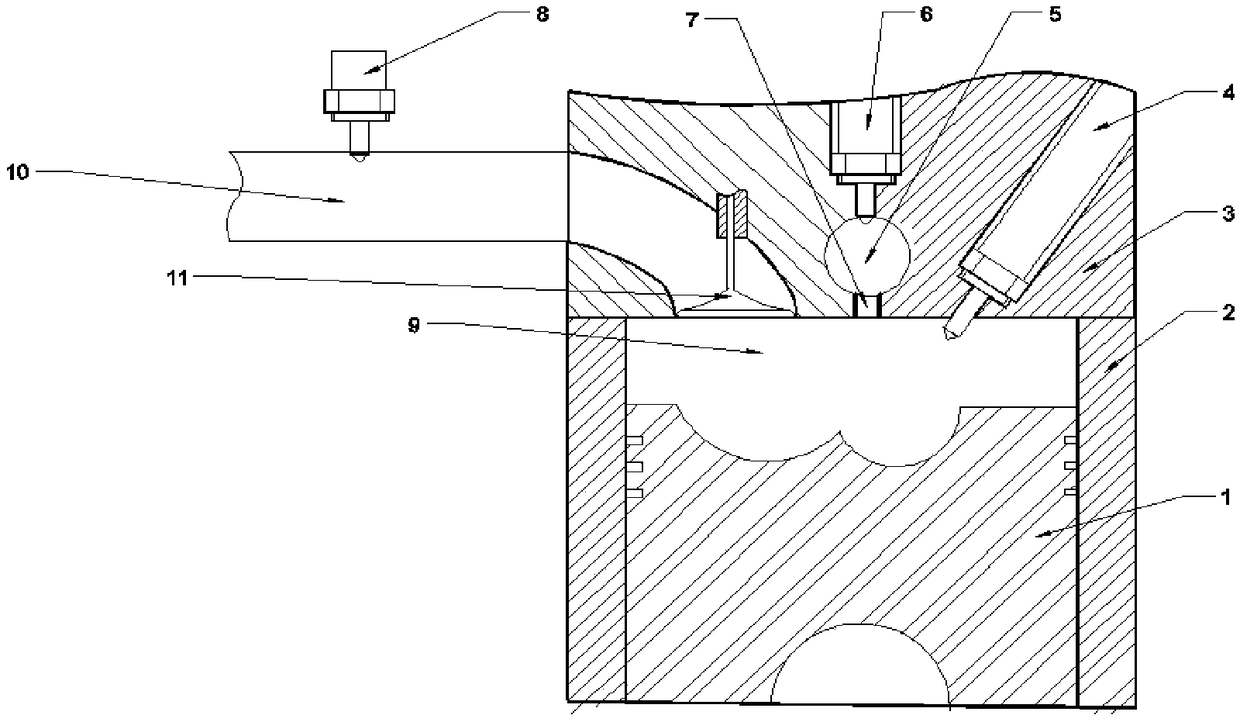

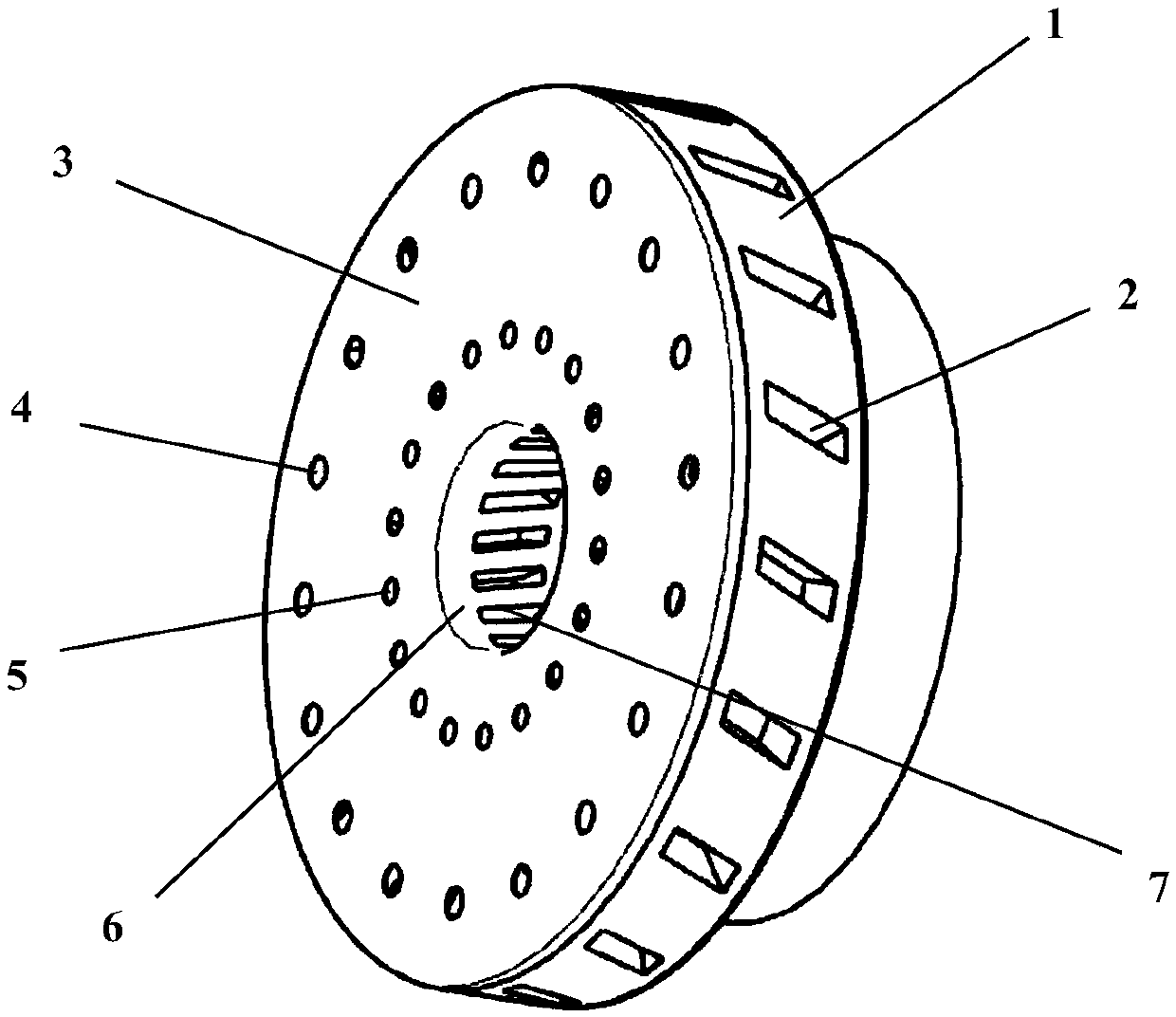

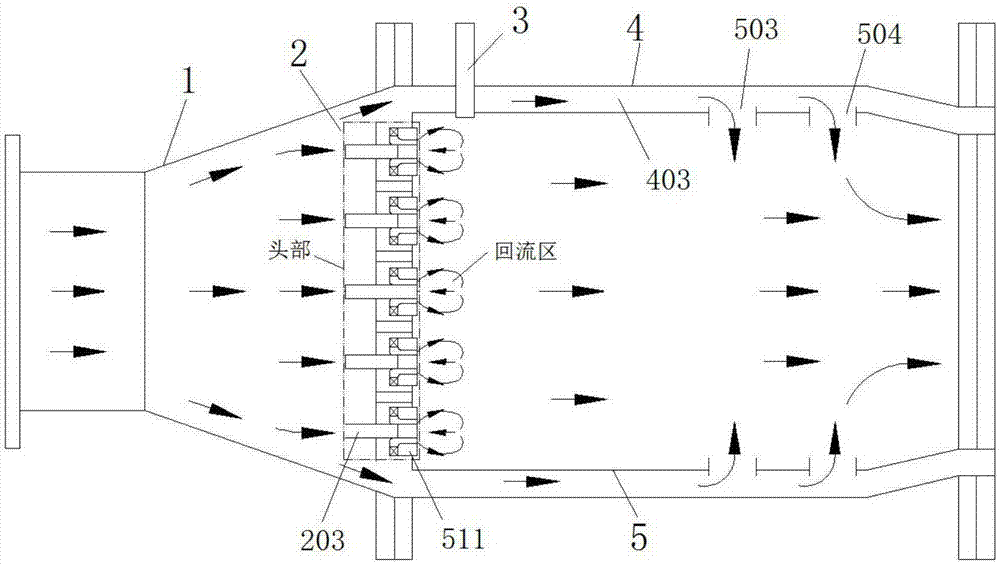

Swirl trapped vortex type combustion chamber of micro-turbine engine

InactiveCN108679644AExtended dwell timeExtended burn timeContinuous combustion chamberCombustion chamberCombustor

The present invention solves the technical problem that a swirl trapped vortex type combustion chamber of micro-turbine engine is provided. A main combustion region of the head of the flame tube adopts the form of a trapped vortex, which is a protruding structure, and the position and size of the jet holes are reasonably arranged. In addition, a radial swirler is disposed on the inner and outer walls of the micro-combustor flame tube. The airflow action of the jet holes is stable between blades of the radial swirler and has a certain strength axial backflow region, so that the residence time of the head airflow in the head region of the flame barrel is increased, and the combustion time of the fuel oil in the head region is increased. Besides, in addition to the axial backflow region generated by the jet holes, the radial swirler generates a circumferential backflow region in the head region, so that heat and mass exchange of each axial backflow interval can be carried out, and the ignition reliability and stability of the combustion chamber are improved. The high-temperature region of the combustion chamber is close to the head region, the temperature distribution uniformity of the outlet of the combustion chamber is good, and the overall combustion chamber performance of the combustion chamber is greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

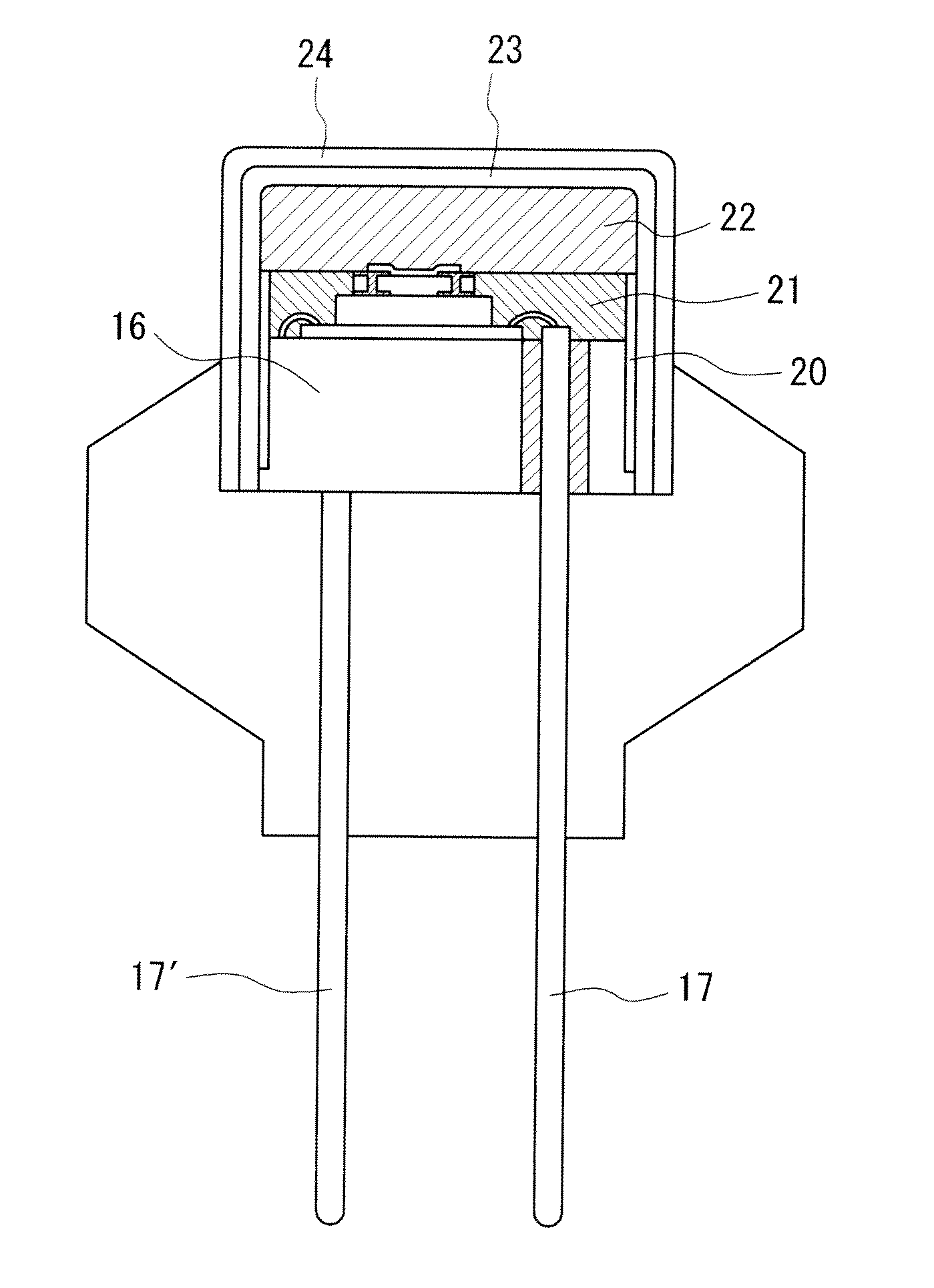

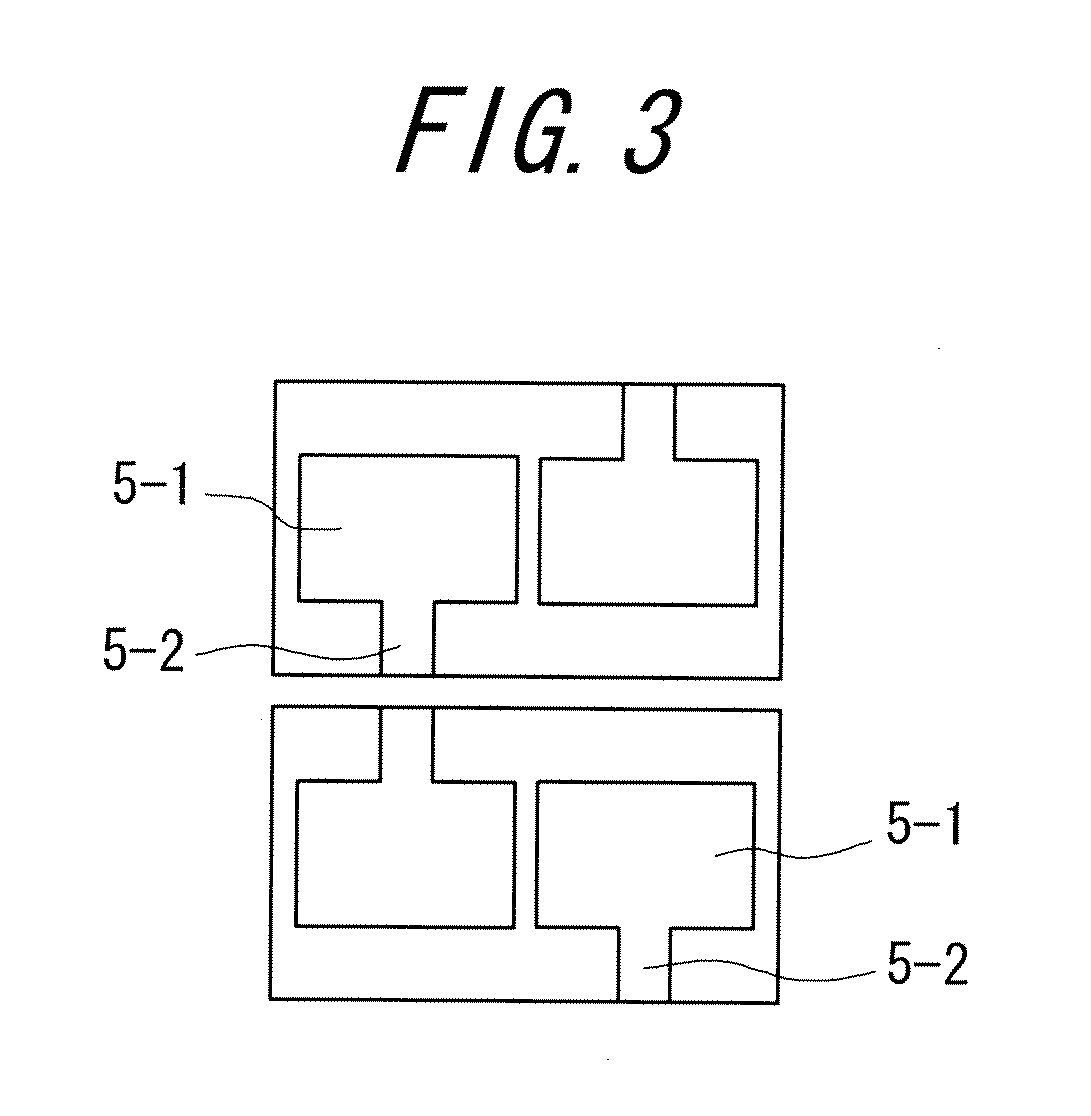

Ignition Element Mounting Capacitor, Header Assembly, Squib and Gas Generator for Air Bag and Gas Generator for Seat Belt Pretensioner

ActiveUS20100072736A1MiniaturizationImprove ignition reliabilityIncandescent ignitionBelt retractorsElectricitySeat belt

An ignition element mounting capacitor having an ignition element mounted on a capacitor, includes therein a first capacitor section and a second capacitor section, and first external terminal electrodes electrically connected to the first capacitor section and second external terminal electrodes electrically connected to the second capacitor section. The first capacitor section has a capacity for igniting ignition powder, and the second capacitor section has a function for removing noise which affects external circuits. Further, provided on the surface of the capacitor are third external terminal electrodes electrically connected to the ignition element. In this manner, the invention provides a squib enabling its size to be miniaturized and its quality to be improved, while keeping a high productivity, and hence provides a header assembly and a ignition element mounting capacitor as components of the squib and further provides a gas generator having such a squib installed therein for an air bag and a gas generator having the squib for a seat belt pretensioner.

Owner:NIPPON KAYAKU CO LTD +2

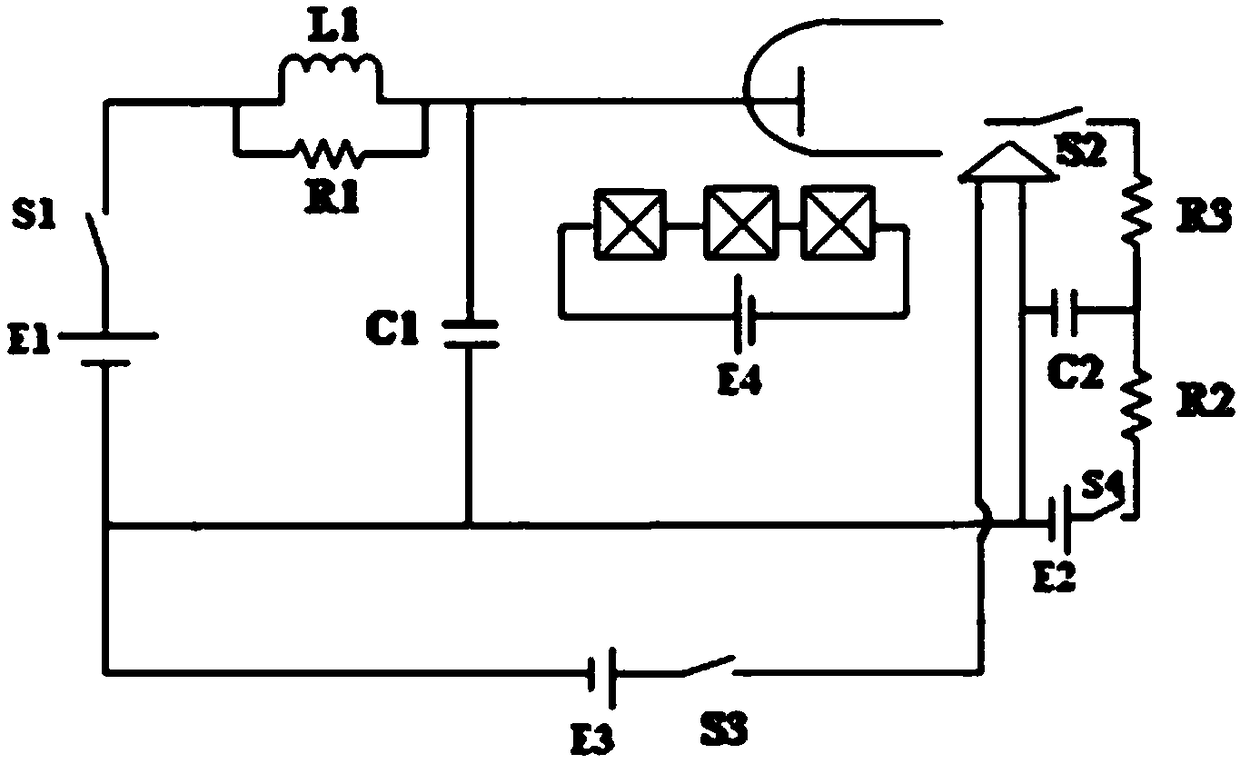

Hall thruster ignition device and method

ActiveCN108561283ASimplify Design ComplexityReduce quality problemsMachines/enginesUsing plasmaCapacitanceLow voltage

The invention discloses a Hall thruster ignition device and method. The high-voltage side of a discharge unit in the device is connected with a first input end of a filtering unit, and the low-voltageside of the discharge unit is connected with a second input end of the filtering unit. A first output end of the filtering unit is connected with one end of a charge resistor, a cathode of a diode and an anode of a Hall thruster, and a second output end of the filtering unit is connected with one end of a charge capacitor and a cathode of the Hall thruster. The other end of the charge resistor, the other end of the charge capacitor, one end of a current-limiting resistor and an anode of the diode are connected together. The other end of a current-limiting resistor R3 is connected with one endof an ignition switch in series, and the other end of the ignition switch is connected with a cathode touch pole of the Hall thruster. The low-voltage side of a heating unit is connected with the low-voltage side of the discharge unit, and the high-voltage side of the heating unit is connected with a cathode of the Hall thruster. The design complexity of the ignition power source technology can be simplified, the effective load mass and volume of a power source space occupation device are reduced, and the ignition reliability is improved.

Owner:HARBIN INST OF TECH

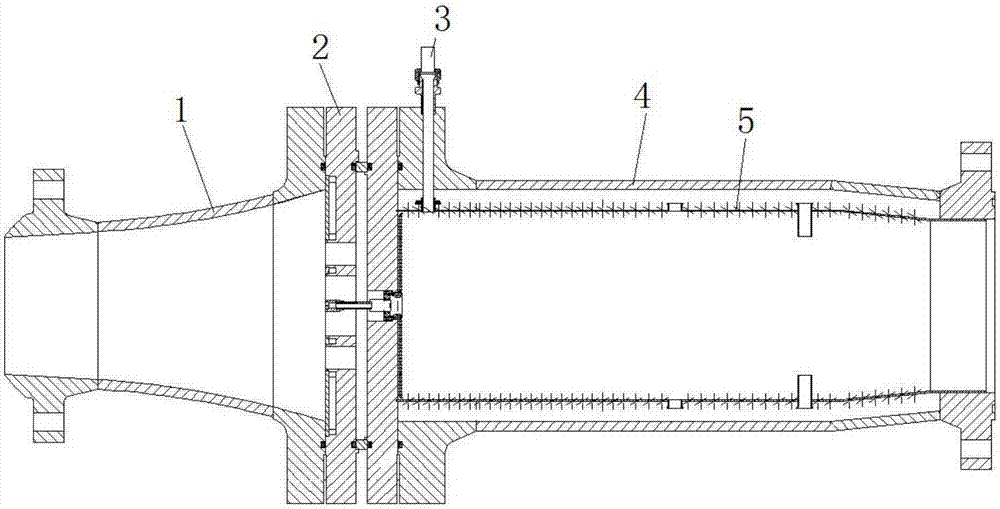

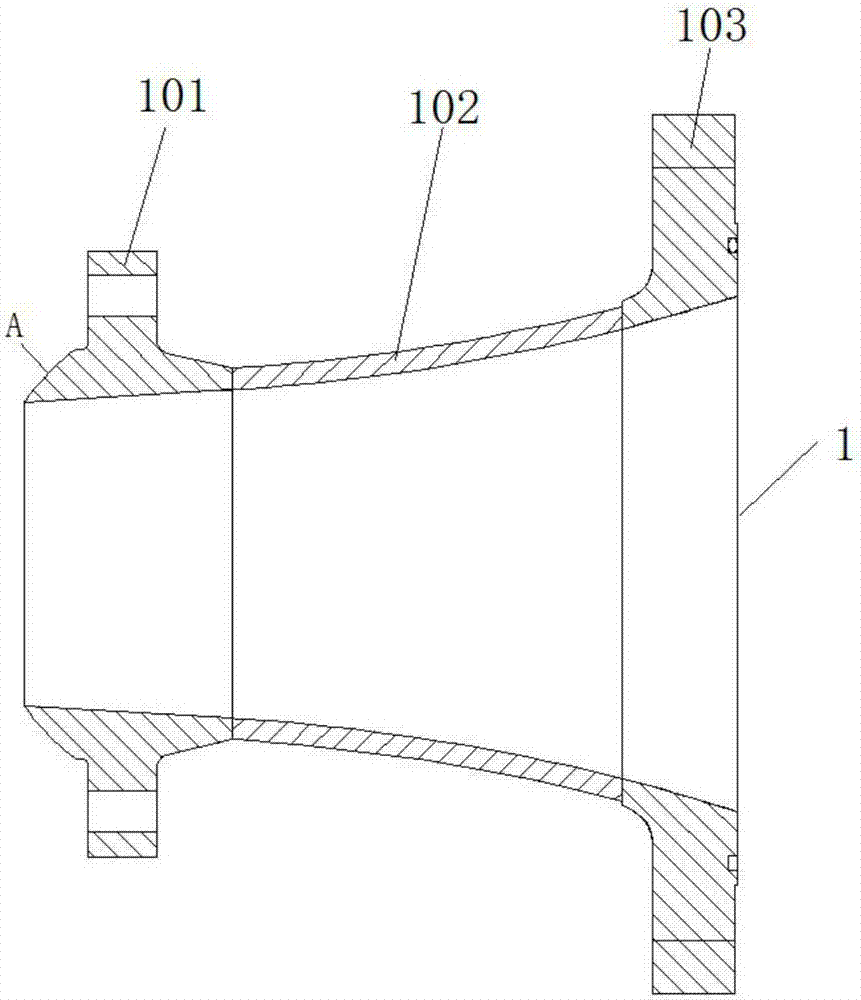

Multi-point injection fuel gas generator using ethanol as fuel

The invention provides a multi-point injection fuel gas generator using ethanol as a fuel. The generator comprises a diffuser, a fuel split atomizing device, a high-energy plasma ignition electric nozzle, a shell and a flame tube, the fuel split atomizing device and a head adapter section are fixed between a rear flange and a shell front flange, the high-energy plasma ignition electric nozzle 3 is fixed on the shell and a barrel body, an annular channel is arranged between the shell and the barrel body, a floating ring installation seat is arranged at the position, 20 mm -50 mm away from the head transferring section, of the barrel body, a clamping ring is arranged on the floating ring installation seat, a floating ring is fixed on the clamping ring, the end part of the high-energy plasma ignition power nozzle is fixed on the floating ring, and fuel supplementing holes and mixing holes are sequentially formed in an axial direction of the barrel body. The generator solves many problems existing in the existing fuel gas generator with the ethanol as the fuel, and has the advantages that the gas enthalpy value is high, the reliability of an ignition system is improved, the geometrical size under the large-volume flow is relatively small, weight is light, a cooling water system does not need to be arranged, running cost is low, combustion efficiency is high, and the service life is long.

Owner:四川艾蒙特航空器材有限公司

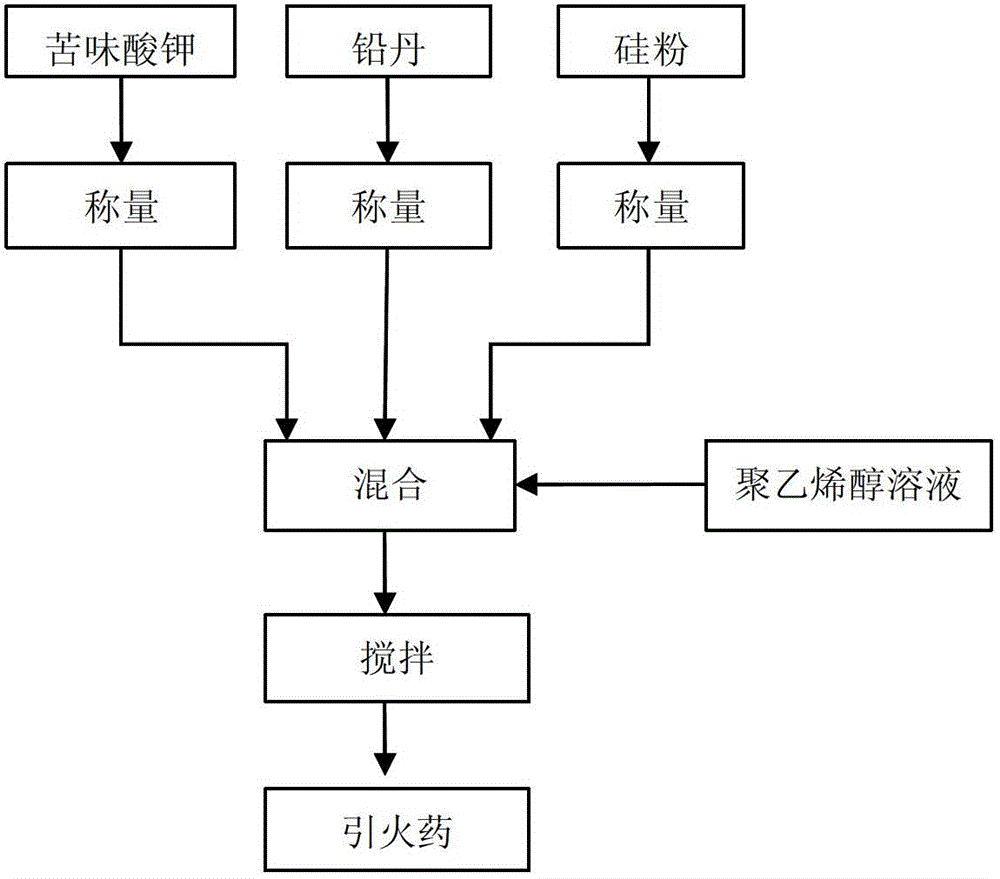

Manufacturing method of potassium picrate-red lead silicon series electric ignition charge

InactiveCN102875268AImprove ignition abilityGood flame sensitivityNitrated metallo-organic explosive compositionsIntrinsic safetyElectricity

The invention aims to provide a manufacturing method of a potassium picrate-red lead silicon series electric ignition charge. The manufacturing method comprises the steps of: weighing, mixing, smearing the ignition charge and the like, so that the ignition charge has better flame sensitivity and lower mechanical strength; and thus, the ignition capacity of the electric ignition charge is high, and the intrinsic safety and reliability during production and use can be effectively improved.

Owner:FUJIAN CIVILIAN BLASTING CHEM

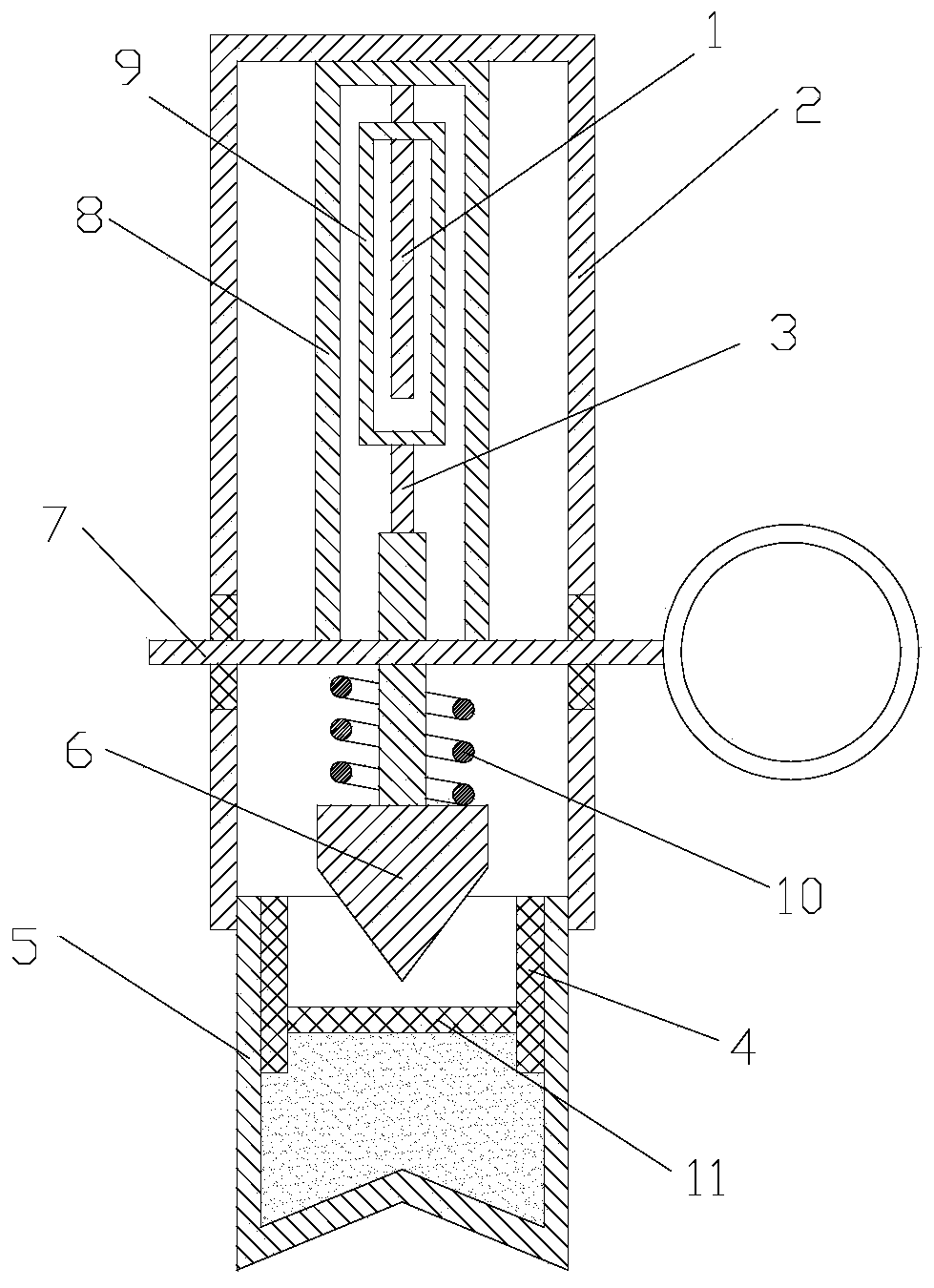

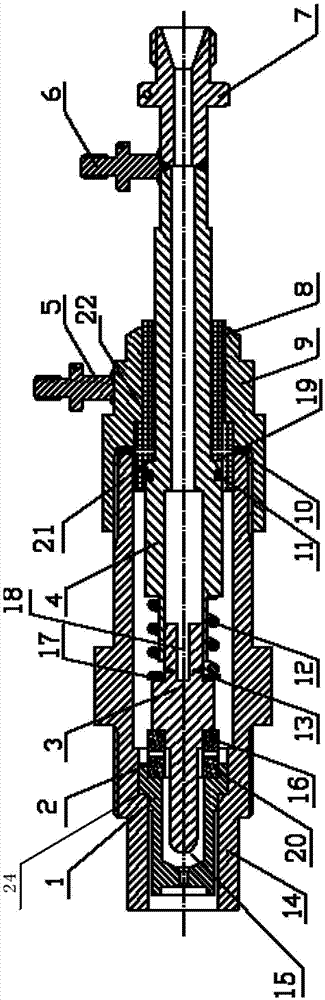

Mini-type non-cooling plasma jet igniter

The invention provides a mini-type non-cooling plasma jet igniter which mainly comprises an anode, a cathode, a whirlcone, ceramic parts, a shell, a spring, and an air supply pipeline (cathode connection pipe), wherein parts such as the anode, the cathode and the ceramic parts are pressed and fixed via the shell and the spring; and the cathode is in plug-in connection with the cathode connection pipe. The mini-type non-cooling plasma jet igniter has the advantages that the size is small; the weight is light; the use is convenient; the mounting and the maintenance are simple; the ignition capability is high; and repeated ignition can be realized. The mini-type non-cooling plasma jet igniter can serve as an ignition device for various heaters, combustion chambers, aero-engines and ATR combined engines.

Owner:XIAN AEROSPACE PROPULSION INST

High-speed fuel oil atomizing spray nozzle for thermally spraying fuel gas

ActiveCN104674156AImprove uniformityCompact structureMolten spray coatingLiquid spraying apparatusSpray nozzleFuel oil

The invention discloses a high-speed fuel oil atomizing spray nozzle for a thermally spraying fuel gas. The high-speed fuel oil atomizing spray nozzle comprises a primary cavity, wherein a secondary cavity is assembled on the outer wall of the primary cavity; a gas inlet is formed in the inlet end of the primary cavity, an inner cavity is formed in the outlet end of the primary cavity, a similar cone is mounted in the inner cavity, a ring-shaped primary chamber which is gradually expanded towards the peripheral side in the shape of horn from the inside to the outside is formed between the outer wall of the similar cone and the inner wall of the inner cavity, a ring-shaped primary spray nozzle is formed in an opening in the outlet end of the primary cavity, a gas inlet is communicated with the end part, which is arranged on the inner part of the primary cavity, of the primary cavity through a gas conveying channel, an oil injection hole is formed in the secondary cavity, the oil injection hole is communicated with the middle part of the primary chamber through an oil conveying channel, a ring-shaped secondary chamber for conveying secondary gas flow is formed in the secondary cavity, the secondary chamber is communicated with the outer part through a ring-shaped secondary spray nozzle, the secondary spray nozzle is positioned at the peripheral side of the primary spray nozzle, so that secondary gas flow sprayed out by the secondary spray nozzle and mixed gas flow sprayed out by the primary spray nozzle are crossed at a set included angle and collide. The high-speed fuel oil atomizing spray nozzle is used for atomizing the fuel oil through gas power, so that the gas and the fuel oil are uniformly mixed and atomized, and stably combusted.

Owner:ACADEMY OF ARMORED FORCES ENG PLA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com