Model testing device for studying, explosion, energy gathering, cutting and destroying of underwater unexploded projectile

A technology of model testing device and cutting device, which is applied in ammunition testing, warheads, blasting, etc. It can solve problems such as fuze assembly errors, high difficulty in discovery, and threats to life and property safety, so as to prevent detonators from entering water and have high ignition reliability. , The effect of firing time controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

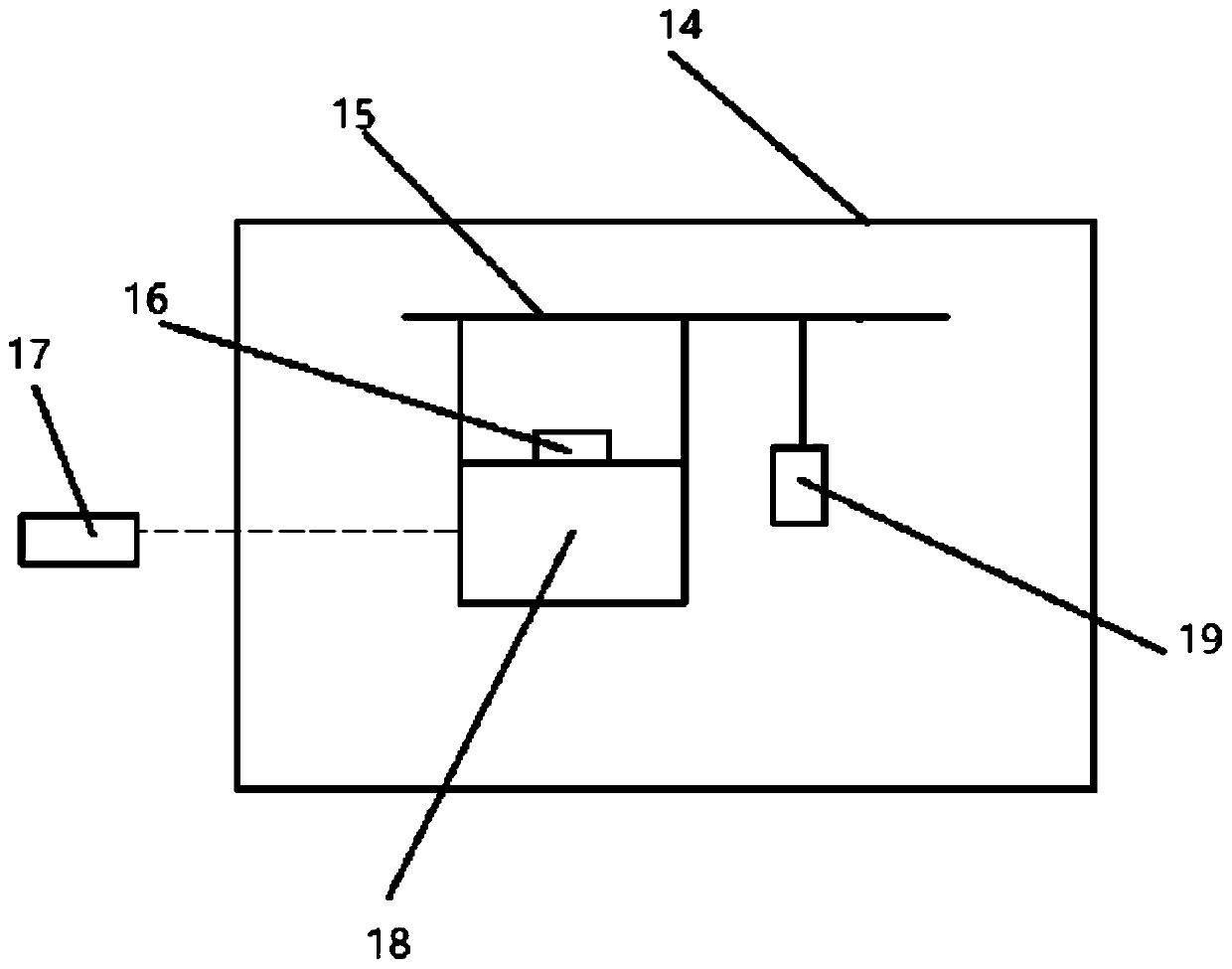

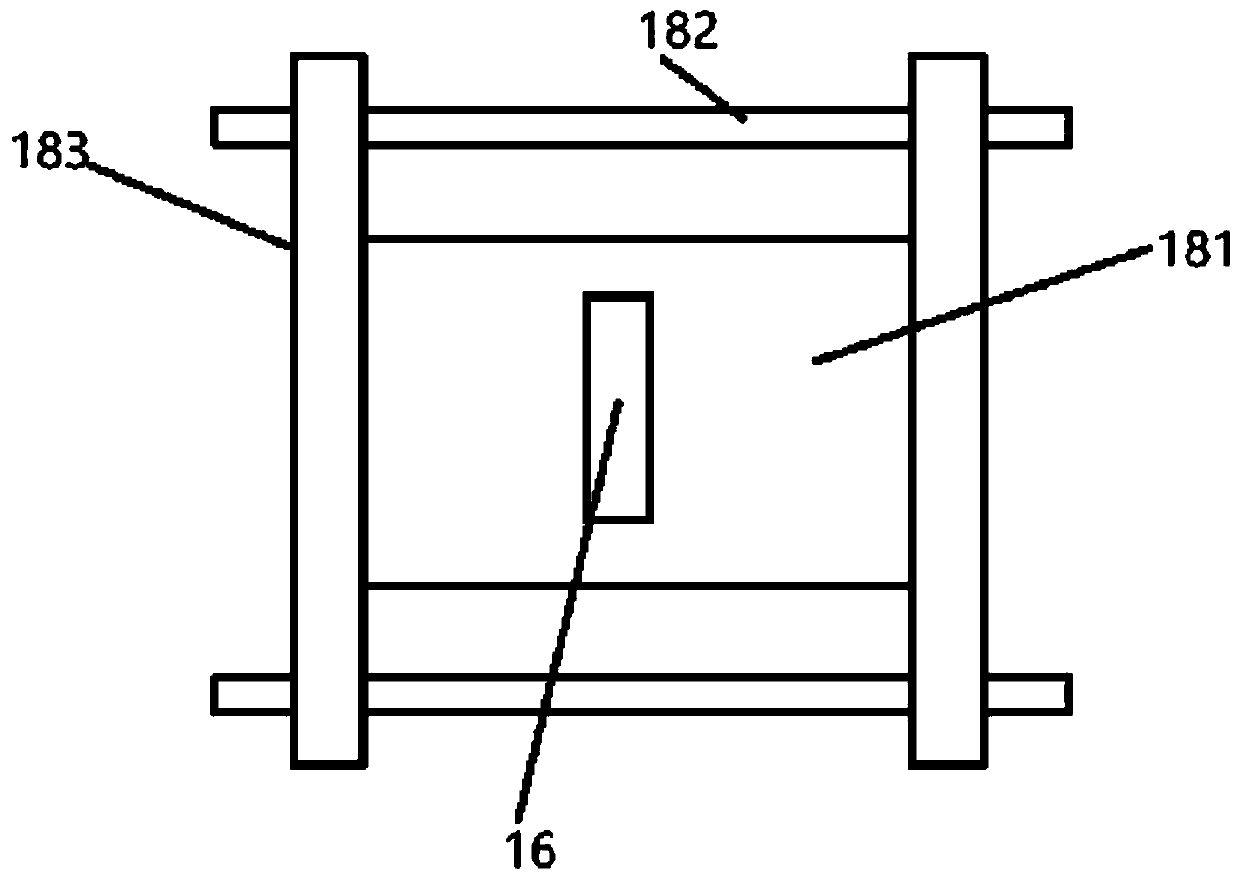

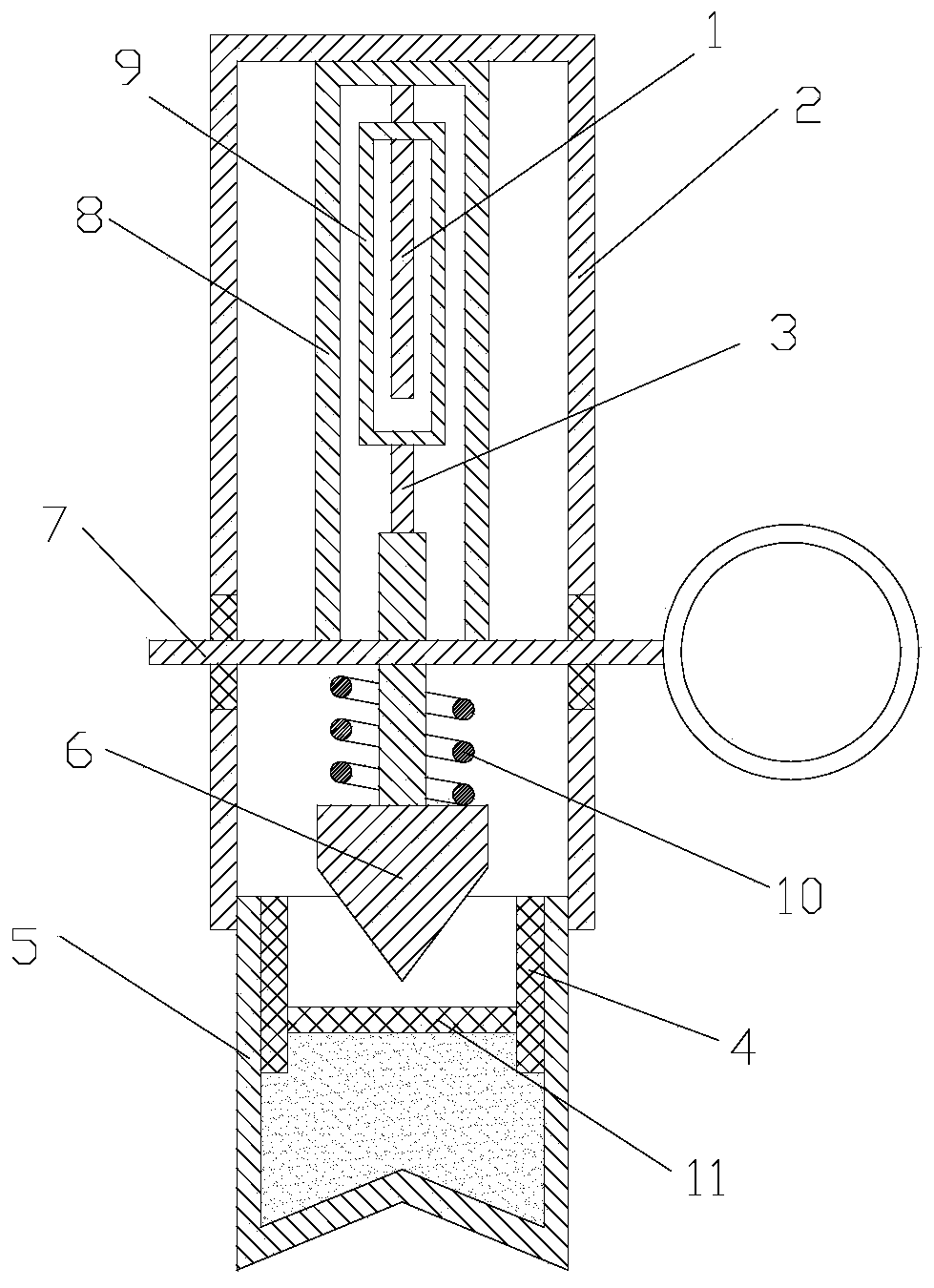

[0020] Such as Figure 1 to Figure 5 As shown, a kind of model test device of the present invention that is used for researching explosive energy-gathering cutting and destroying underwater unexploded bombs includes an explosive water tank 14, a simulated bomb body 18, a data acquisition and analysis unit and a synchronous control unit, and the explosive water tank There are transparent windows on the four sides of 14, and the explosion water tank 14 has a specification of 2m×2m×2m, and is resistant to micro-charge explosion. A bracket 15 is installed in the explosion water tank, and a simulated projectile 18 is suspended on the bracket 15. The explosion water tank 14 is equipped with Test medium, put the simulated projectile 18, the cutting device and the pressure sensor 19 for sensing pressure changes in the test medium. At the same time, there is a high-speed photog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com